Primary formation lamination machine of battery cell of lithium battery

A lamination machine, lithium battery technology, applied in the direction of secondary batteries, circuits, electrical components, etc., can solve the problems of bad pole pieces, impossible pole piece one-time lamination, easy to scratch pole pieces, etc., to achieve easy storage and take, improve lamination efficiency, increase the effect of adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0049] Specific examples of the present invention are given below. The specific embodiments are only used to further describe the present invention in detail, and do not limit the protection scope of the claims of the present application.

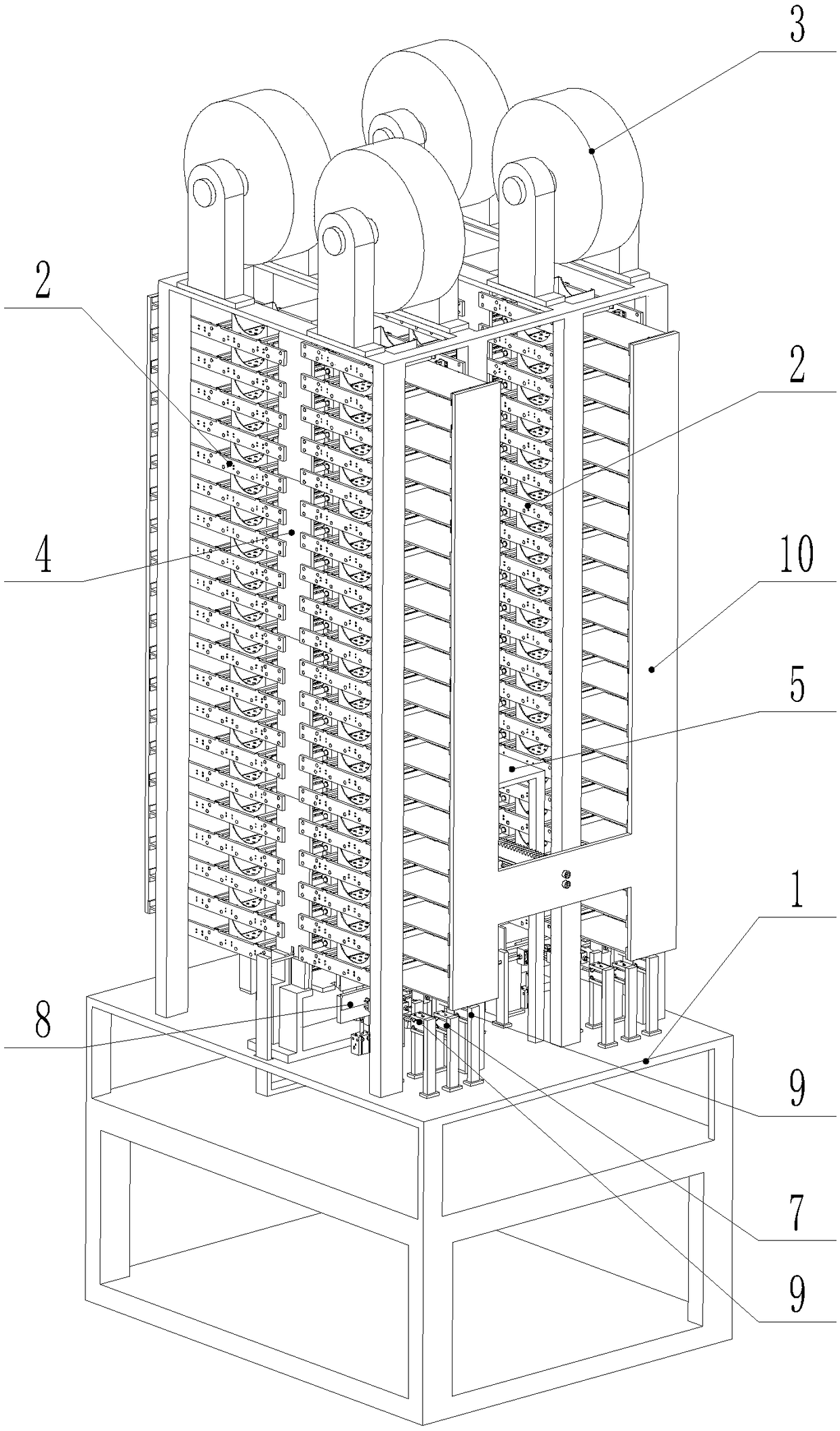

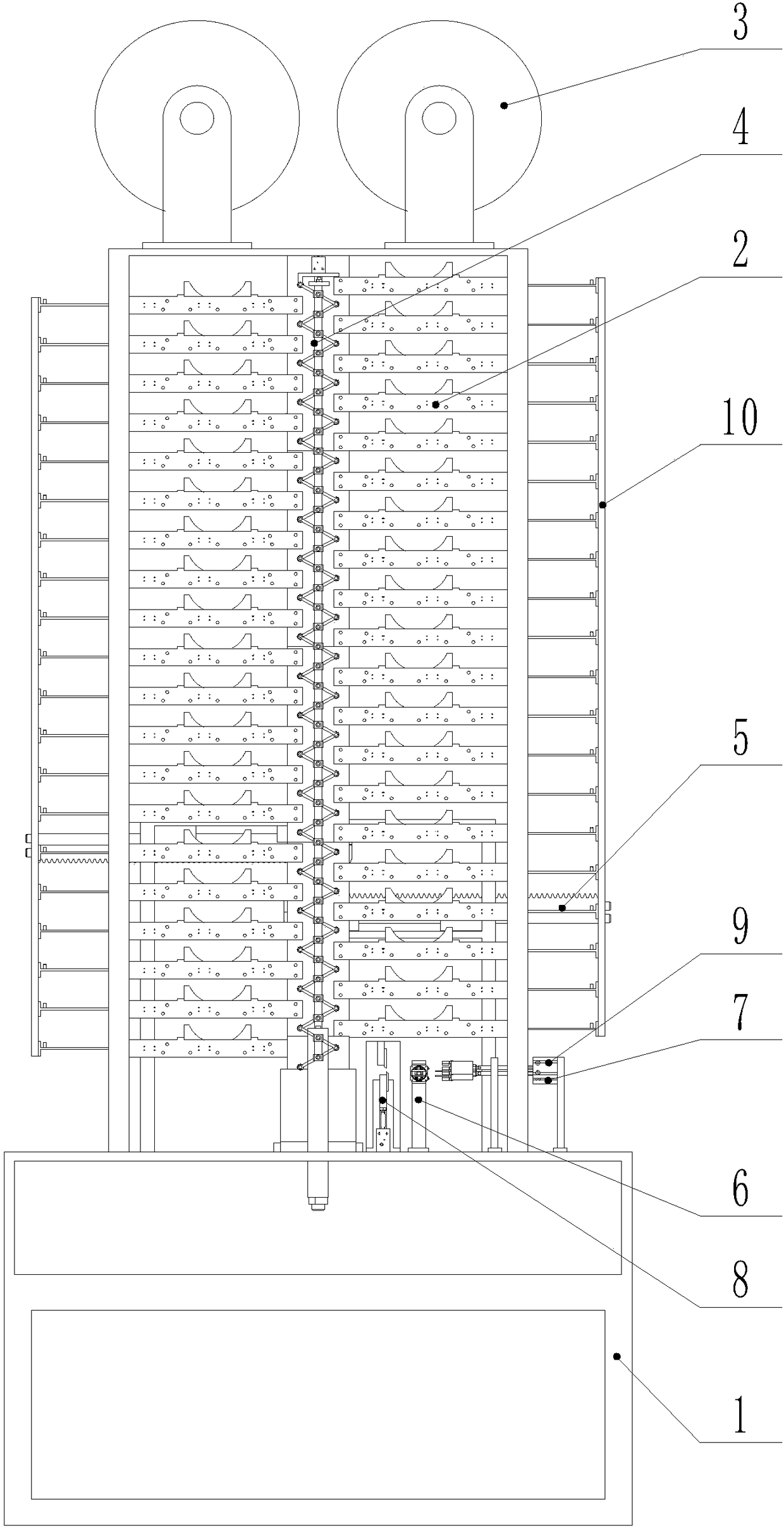

[0050] The invention provides a lithium battery cell one-time forming stacking machine (see Figure 1-9 , referred to as stacking machine), including frame 1, diaphragm unwinding mechanism 3, diaphragm winding mechanism 6, cell clamping mechanism 7, diaphragm clamping mechanism 9 and connecting plate 10; it is characterized in that the stacking machine also includes Electrode conveying mechanism 2, stacking mechanism 4, transmission mechanism 5 and diaphragm cutting mechanism 8;

[0051] The stacking mechanism 4 is installed in the middle of the frame 1, and is used for one-time stacking assembly of the positive and negative pole pieces and the diaphragm to form a battery cell;

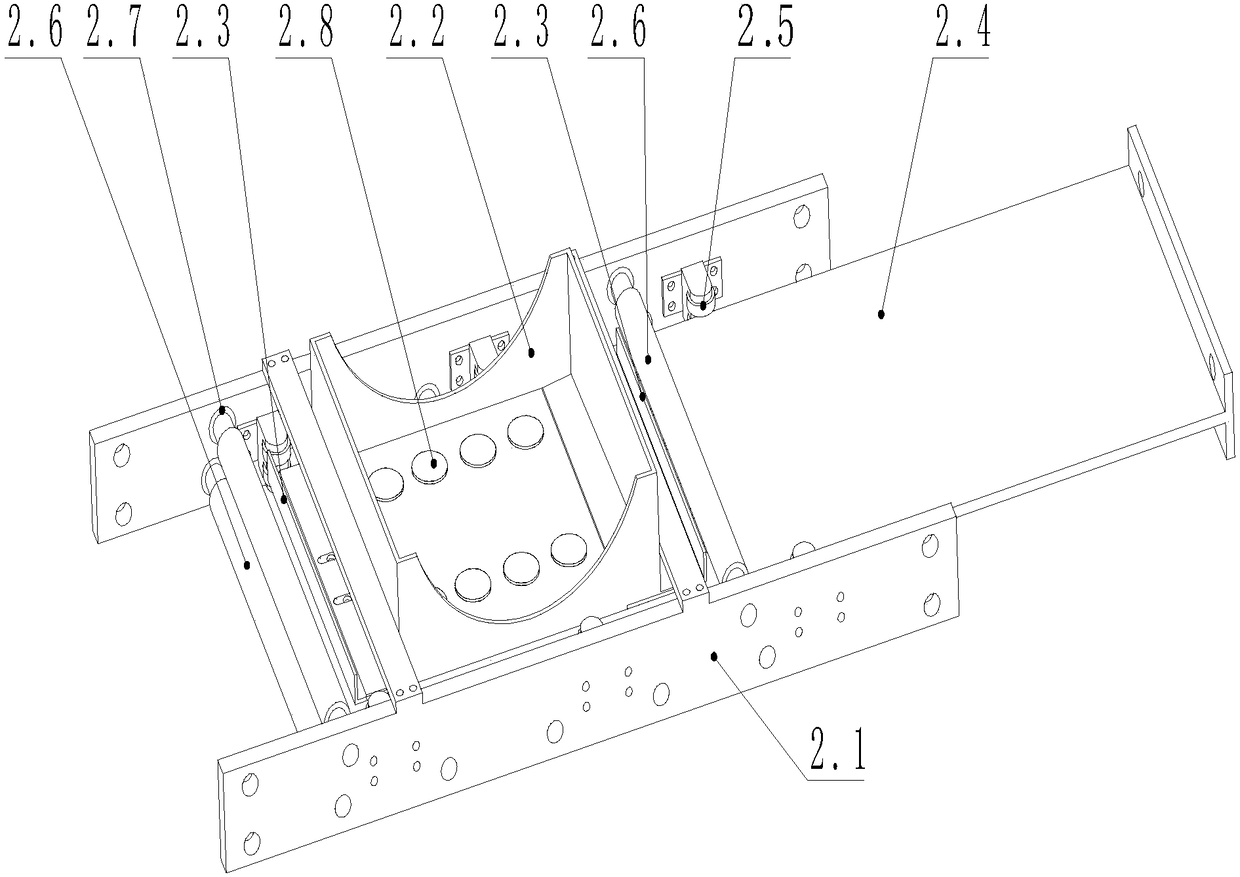

[0052] The pole piece conveying mechanism 2 is two groups w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com