Lamination equipment

A lamination and equipment technology, applied in sustainable manufacturing/processing, electrochemical generators, electrical components, etc., can solve problems such as complex equipment, high cost, and low production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

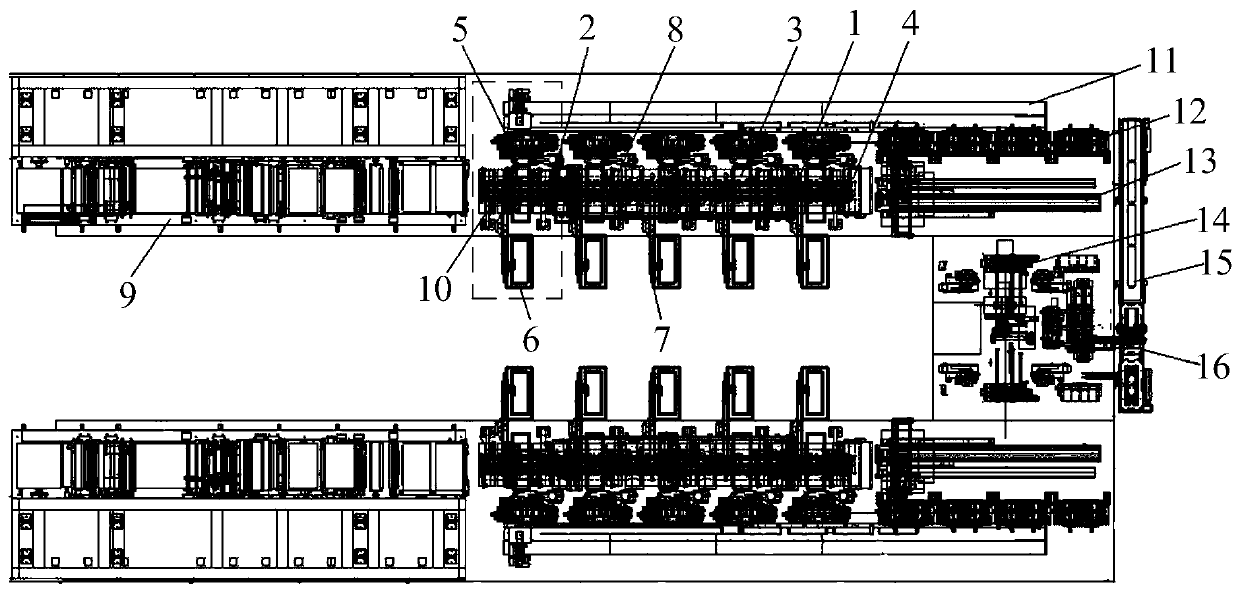

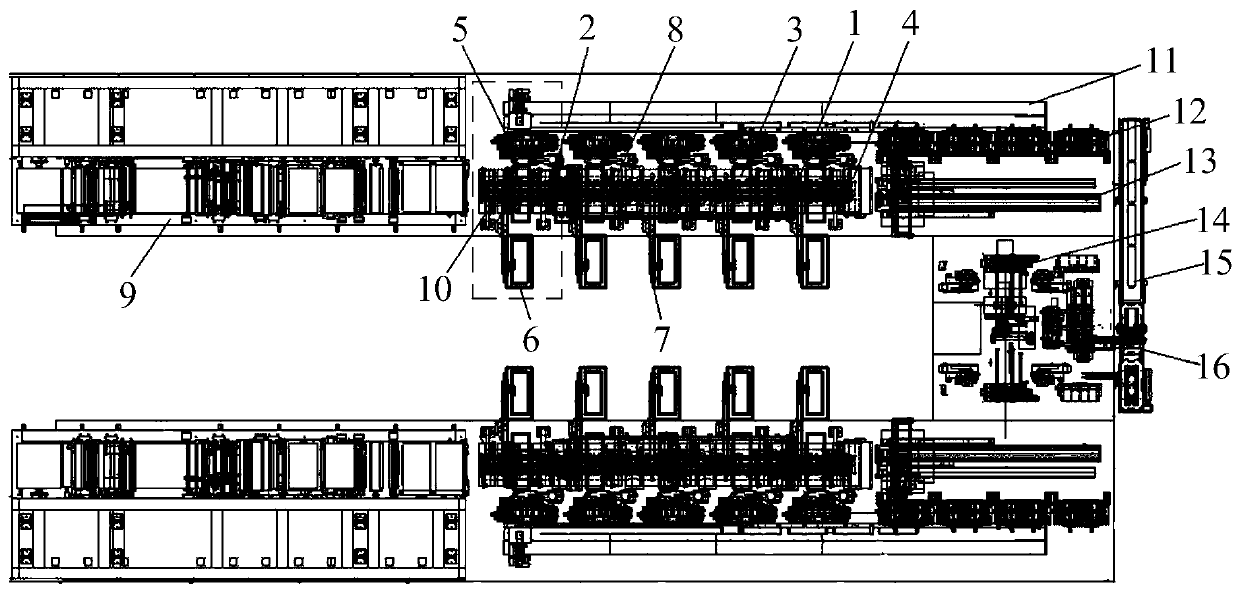

[0020] The present application will be further described in detail below through specific embodiments in conjunction with the accompanying drawings.

[0021] see figure 1 As shown, the present embodiment provides a kind of lamination equipment, including: at least one conveying line 1 and a plurality of laminating stations arranged on each conveying line 1, the laminating stations such as figure 1 As shown in the dotted line box in , the conveying line 1 is used to convey a plurality of first laminated units, and the plurality of first laminated units are conveyed to each laminated station sequentially on the conveying line, and each laminated station is used for The positive single-sided pole piece with the coating facing up, multiple first laminated units, the second laminated unit, and the positive single-sided pole piece with the coating facing down are sequentially stacked to form a laminated battery cell. The sheet station works at the same time to stack the pole pieces...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com