Patents

Literature

46results about How to "Realize reclaiming" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

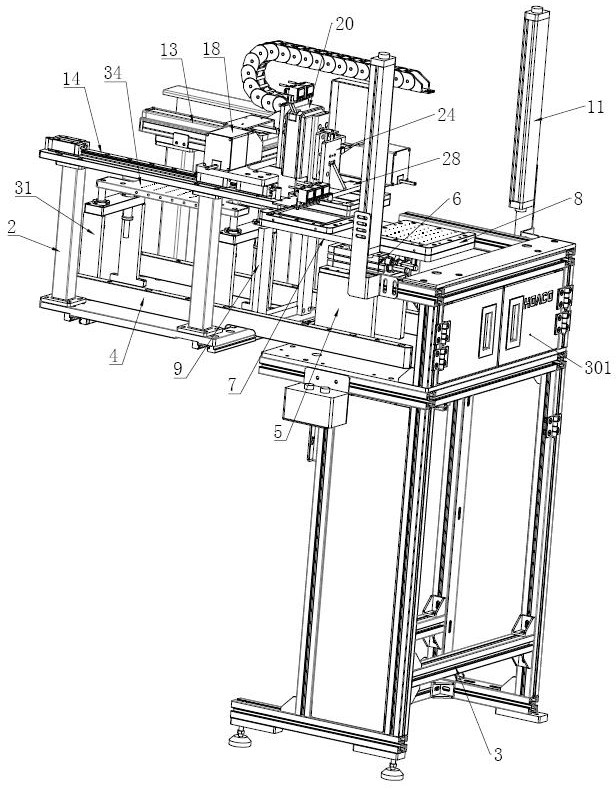

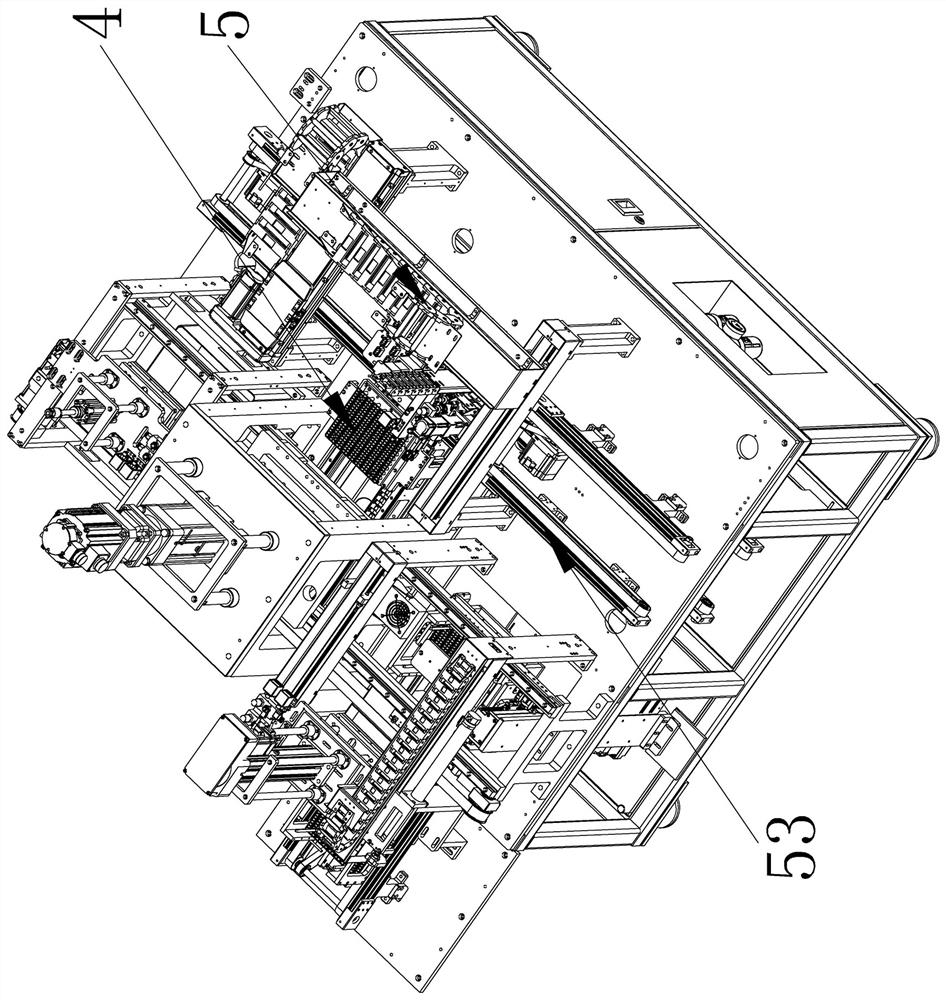

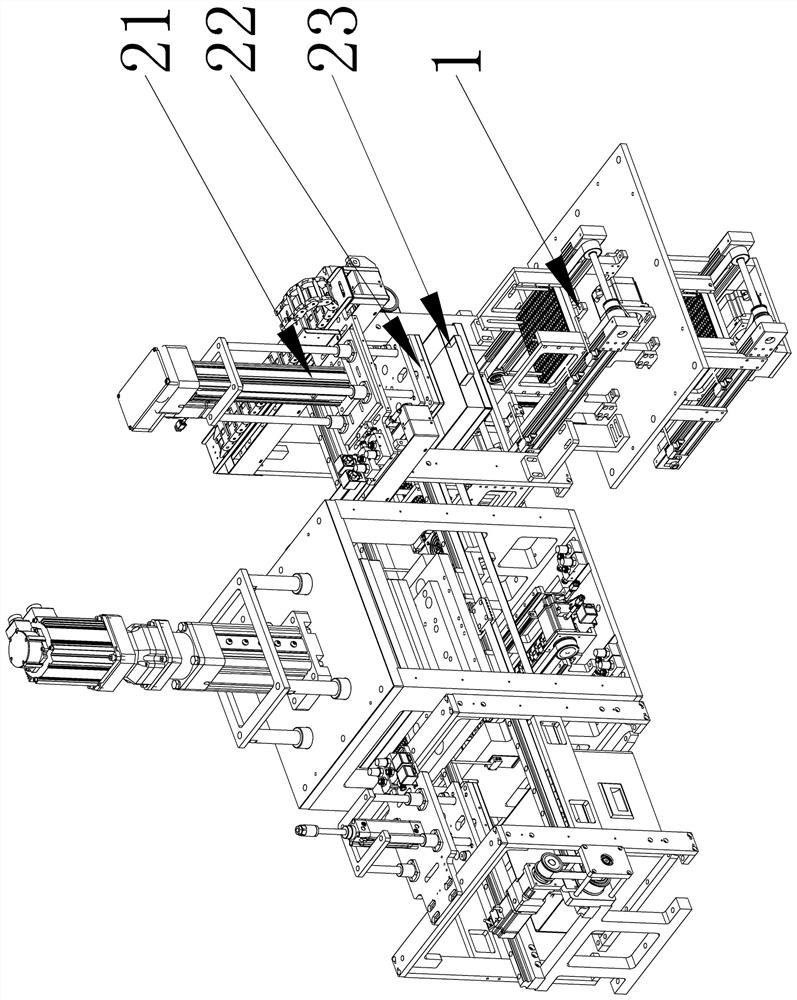

Laminating machine capable of driving film discharging by rotary loading

ActiveCN102709583ARealize reclaimingImprove lamination efficiencyFinal product manufactureSecondary cells manufactureSmall footprintEngineering

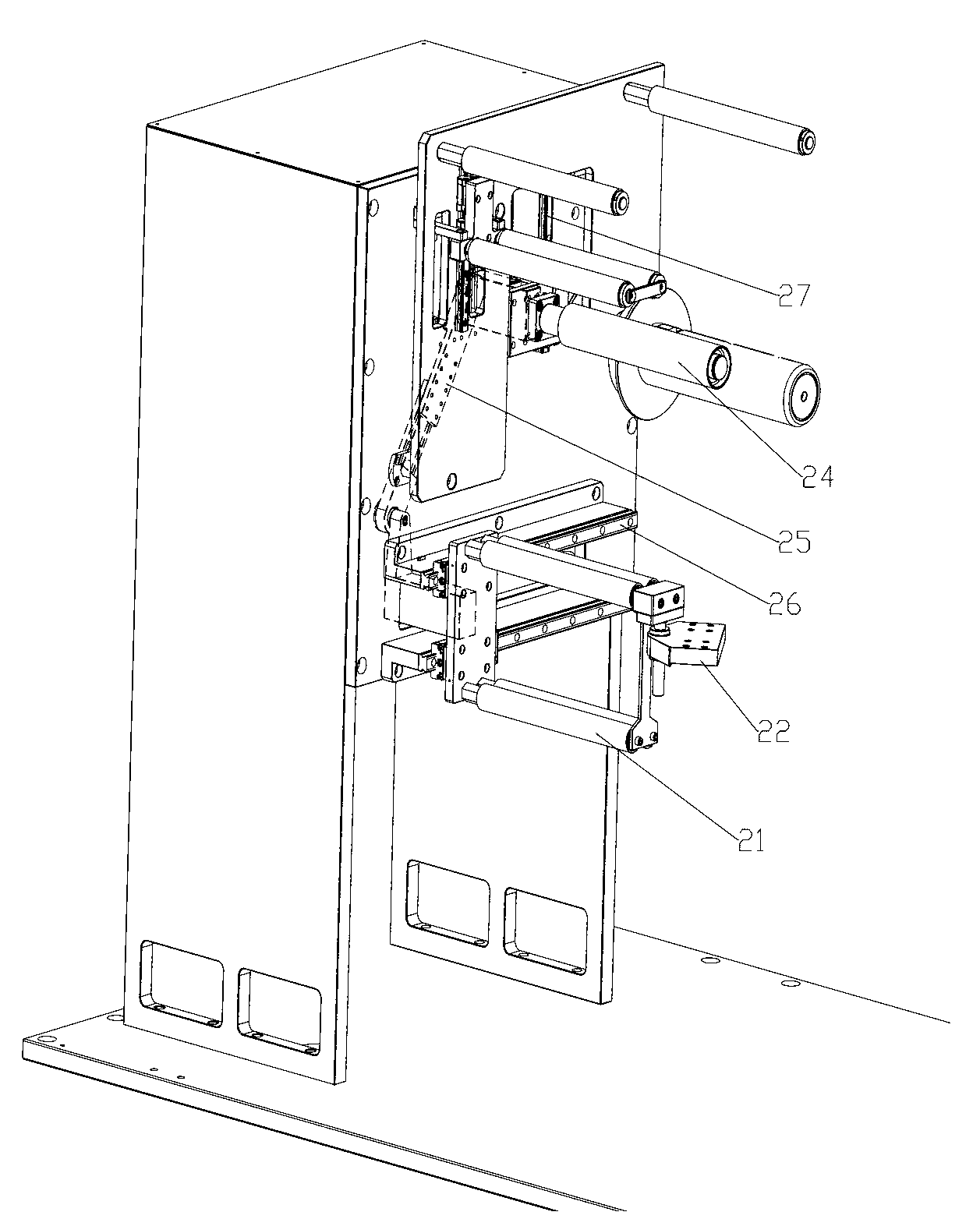

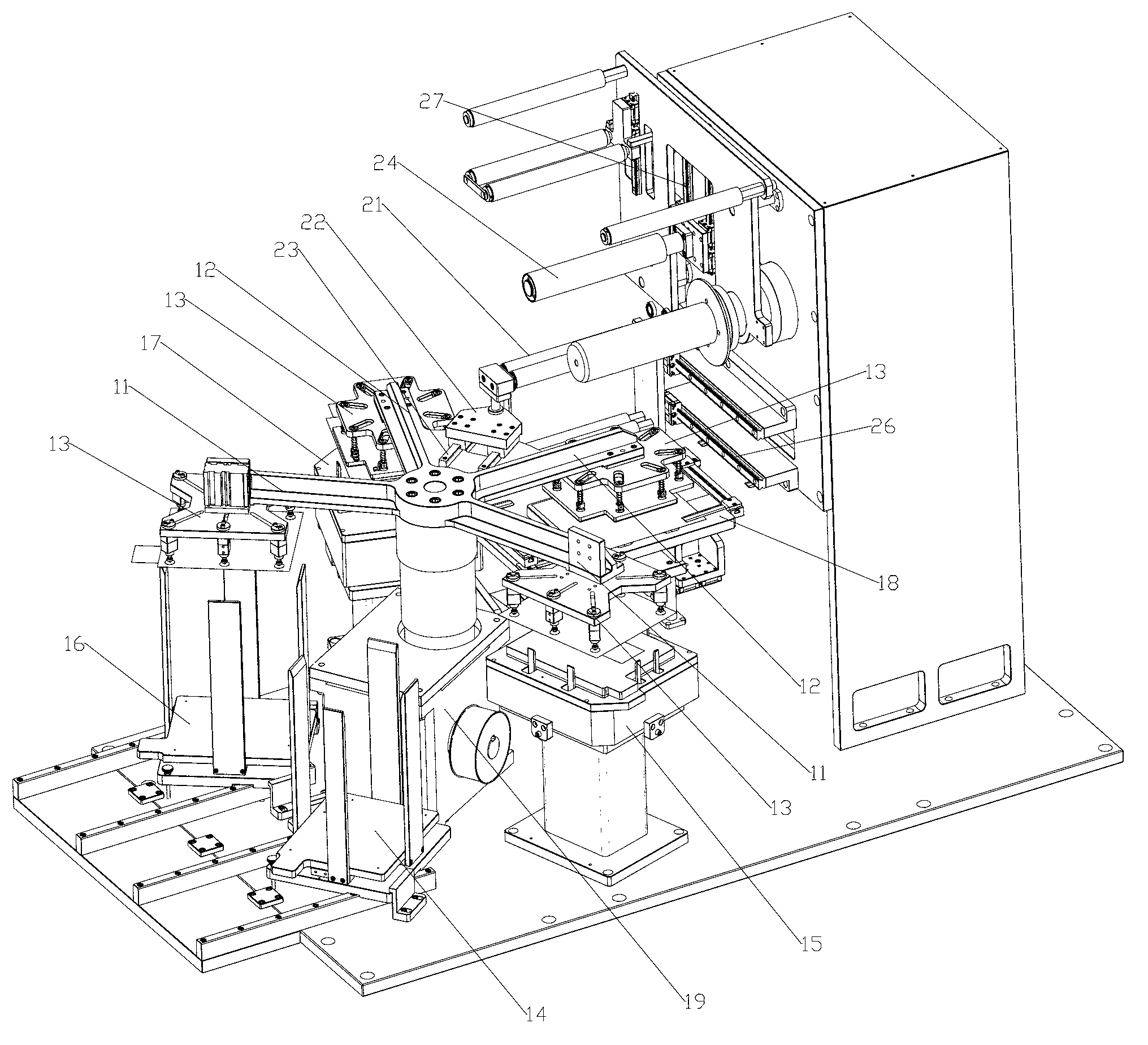

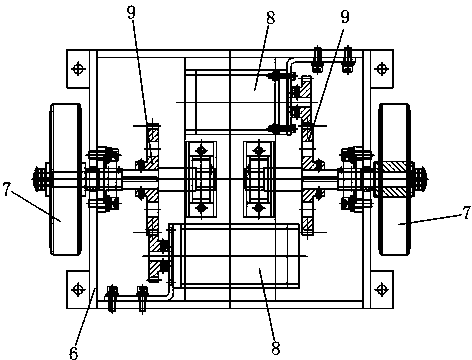

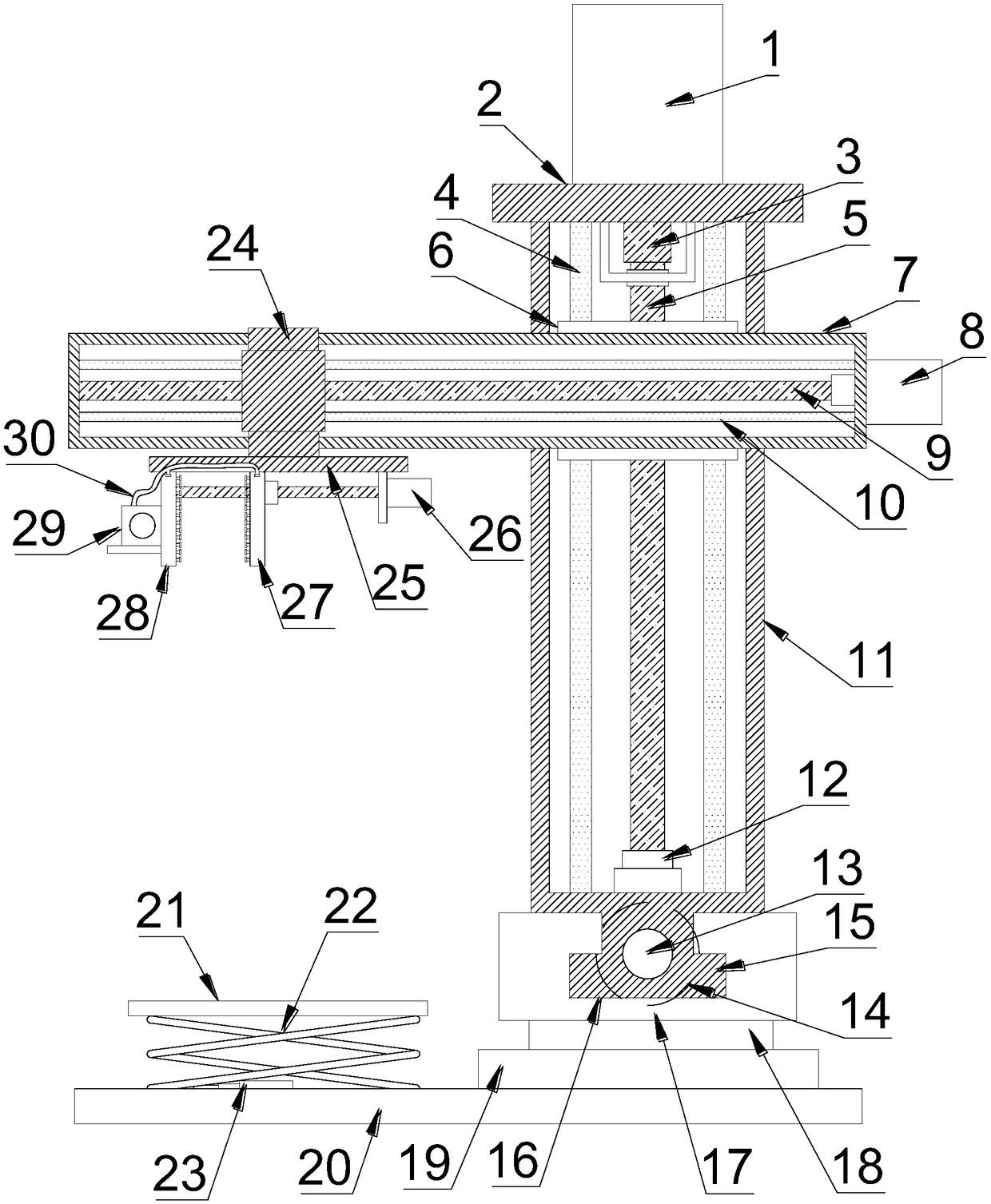

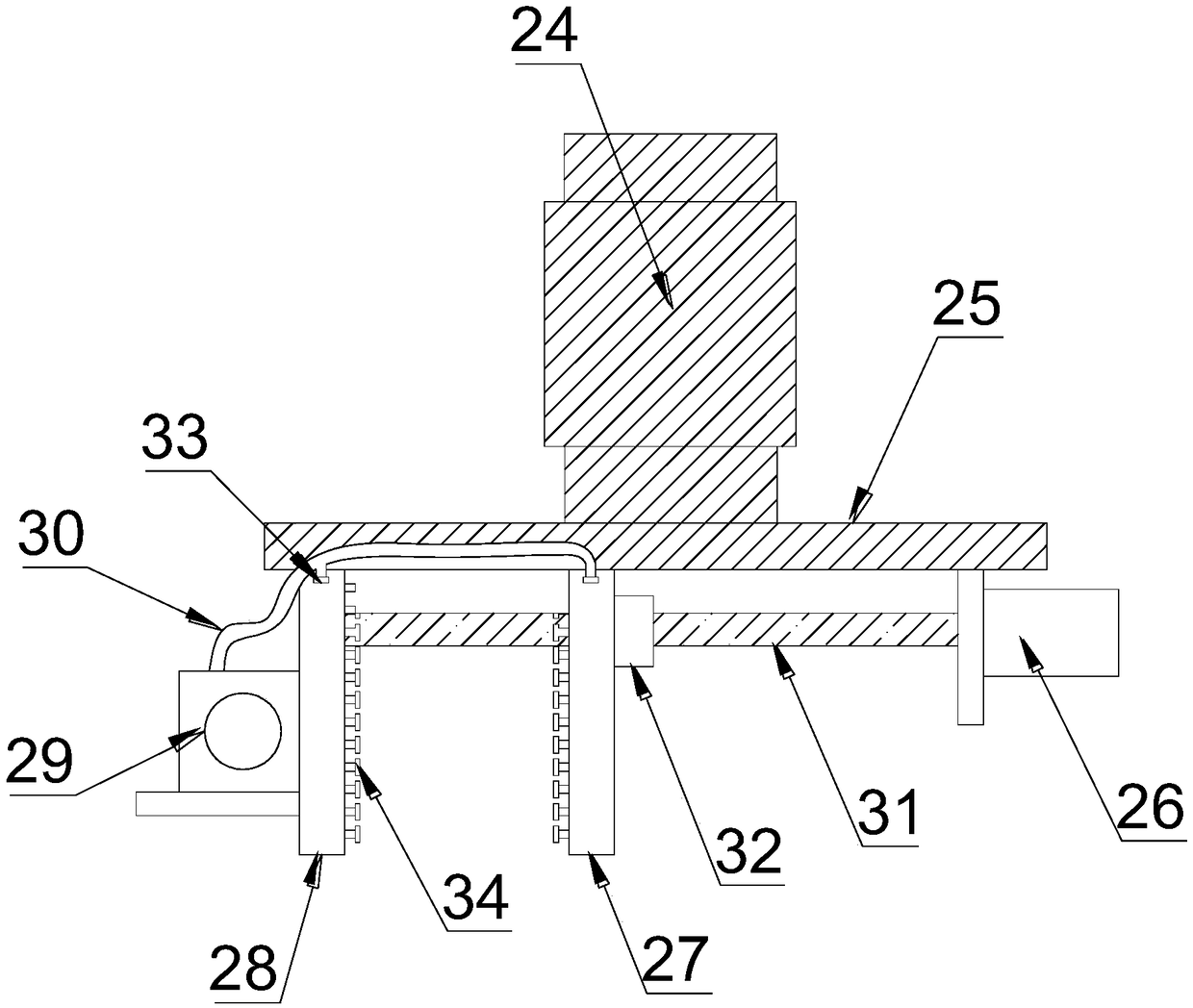

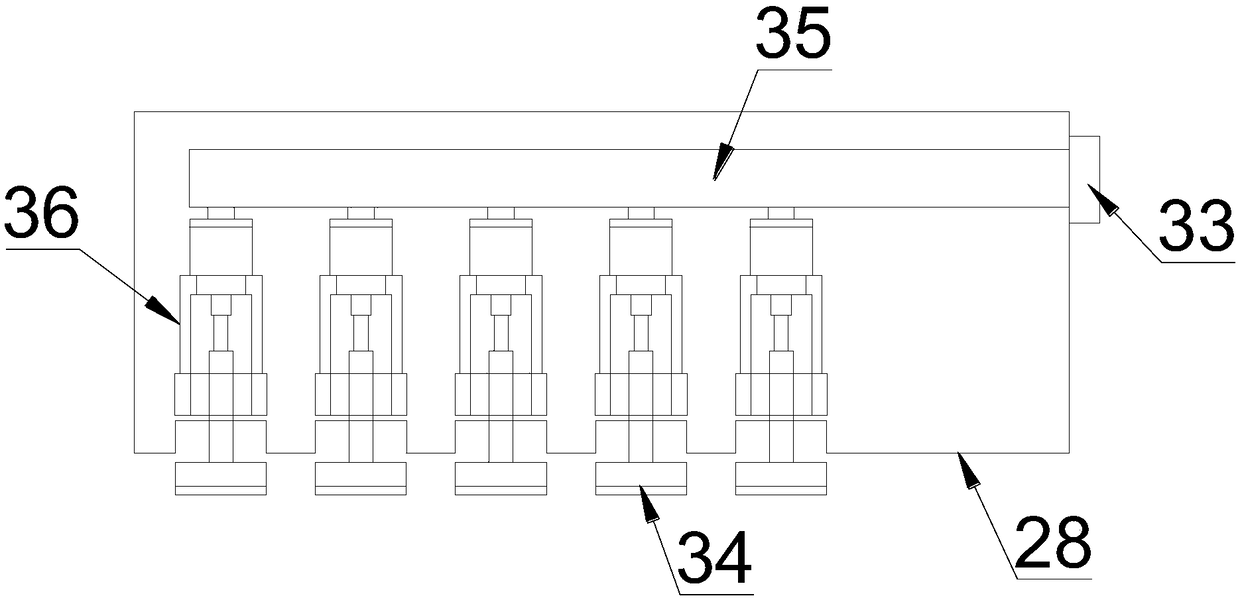

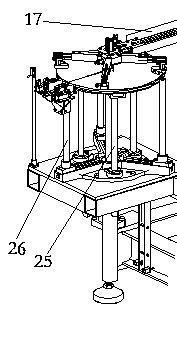

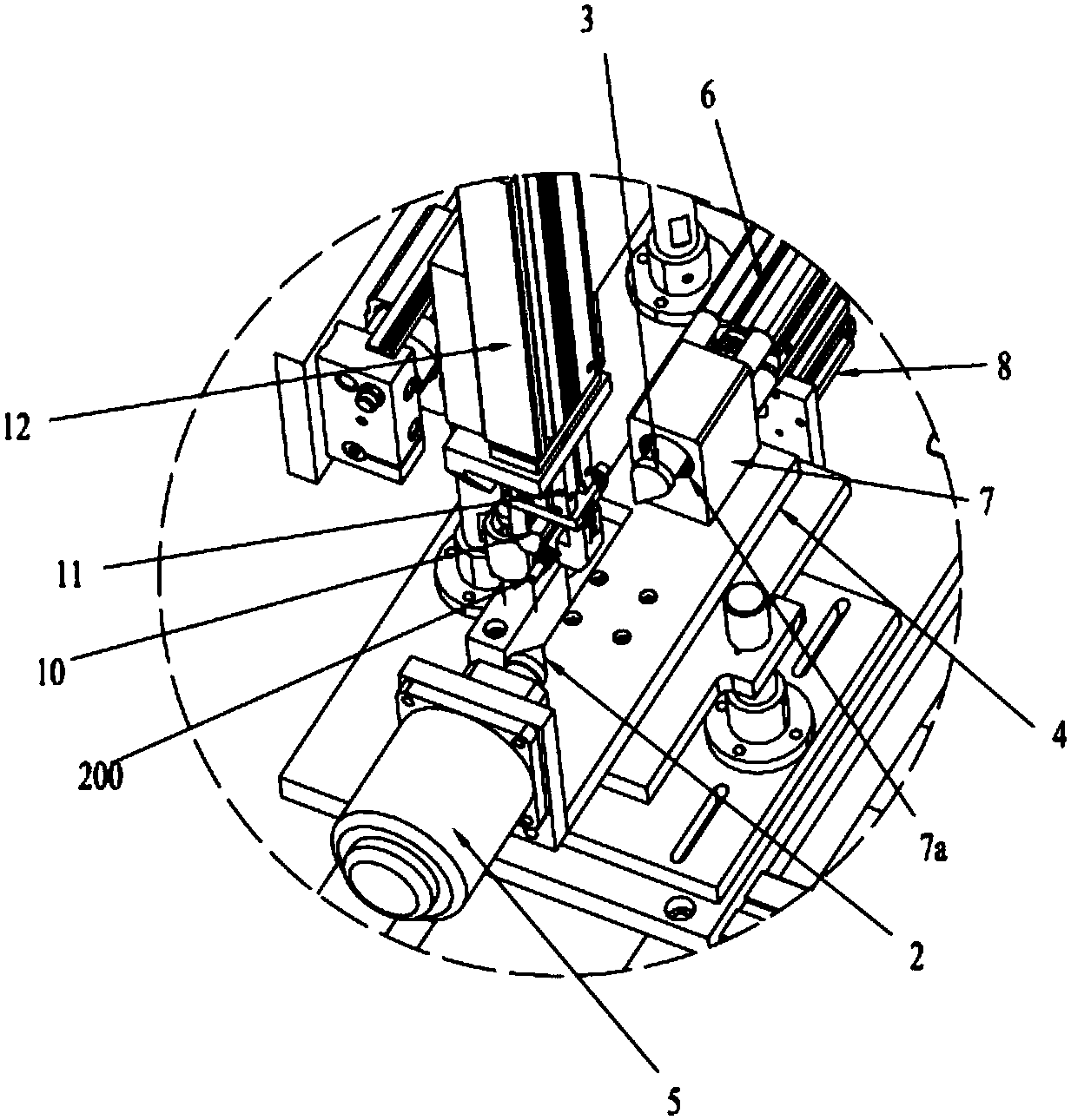

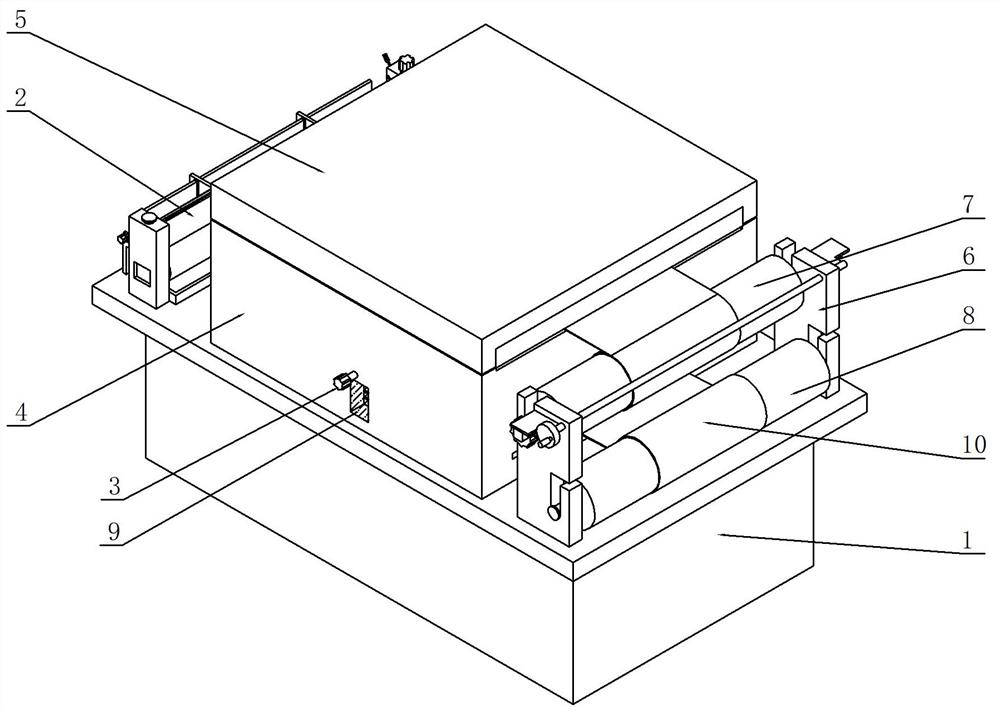

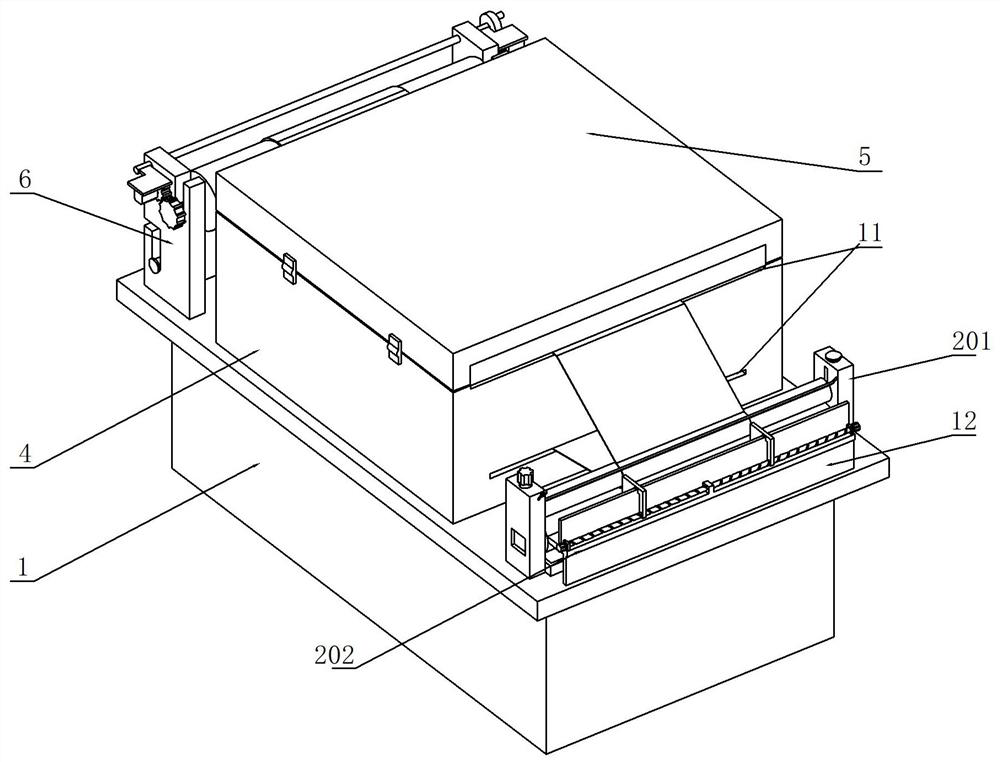

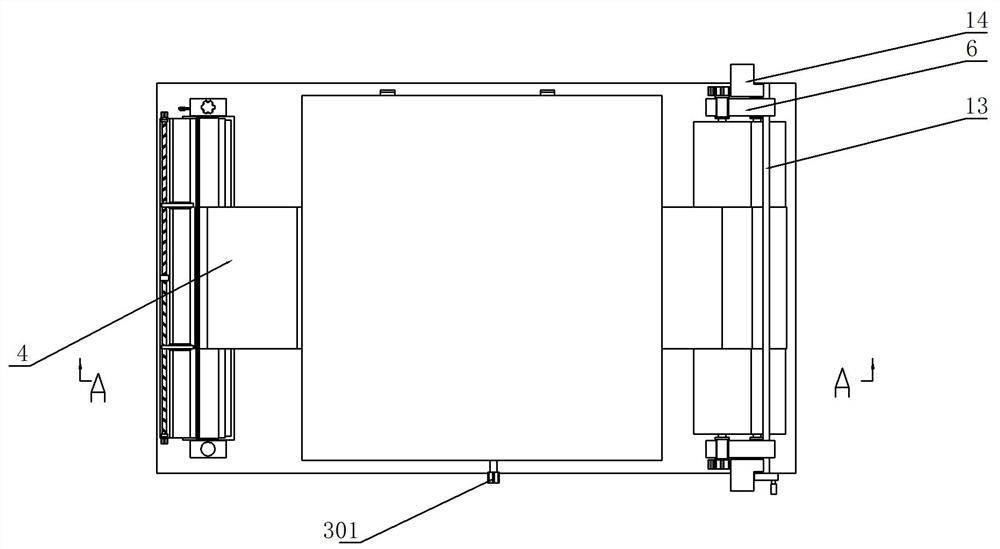

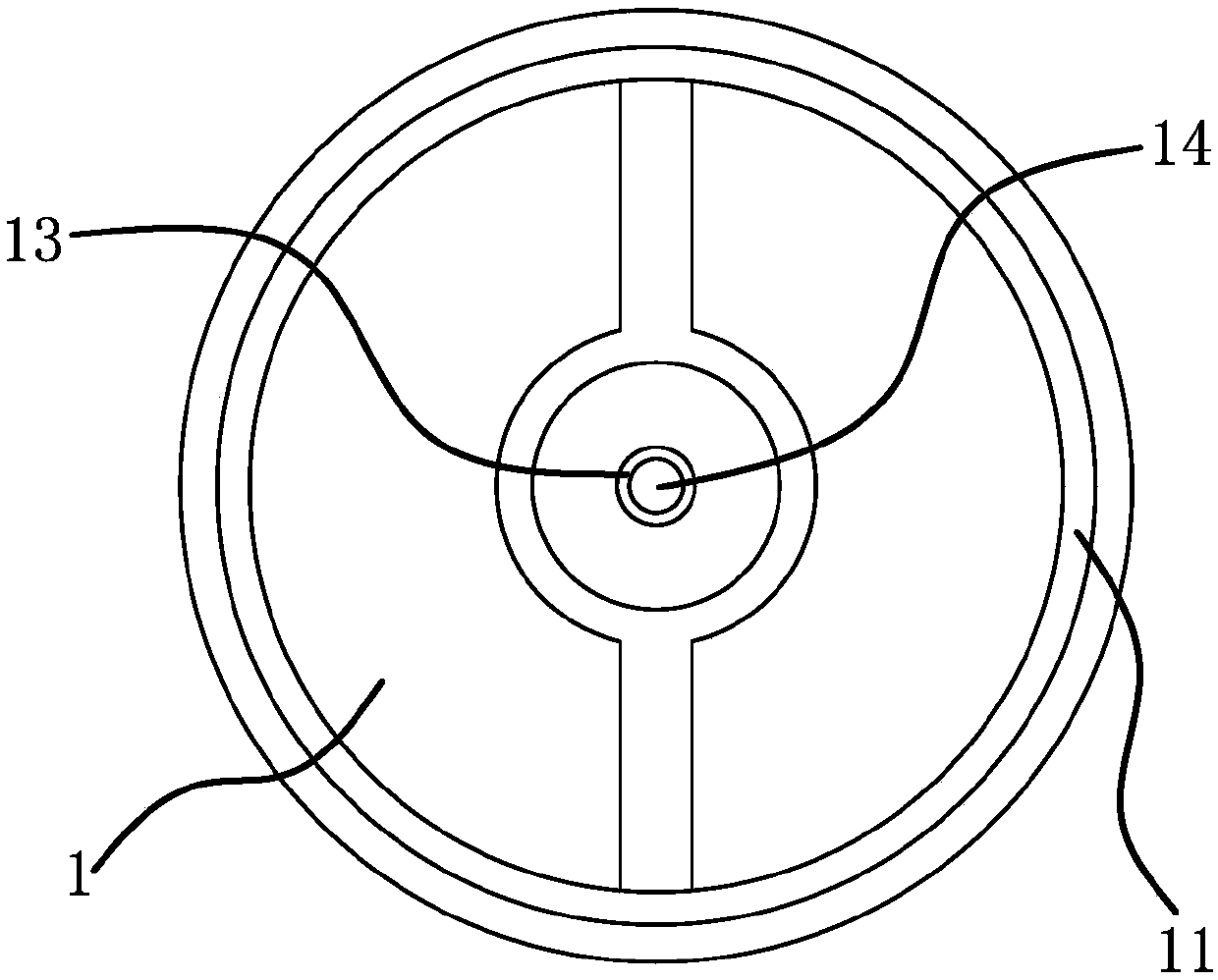

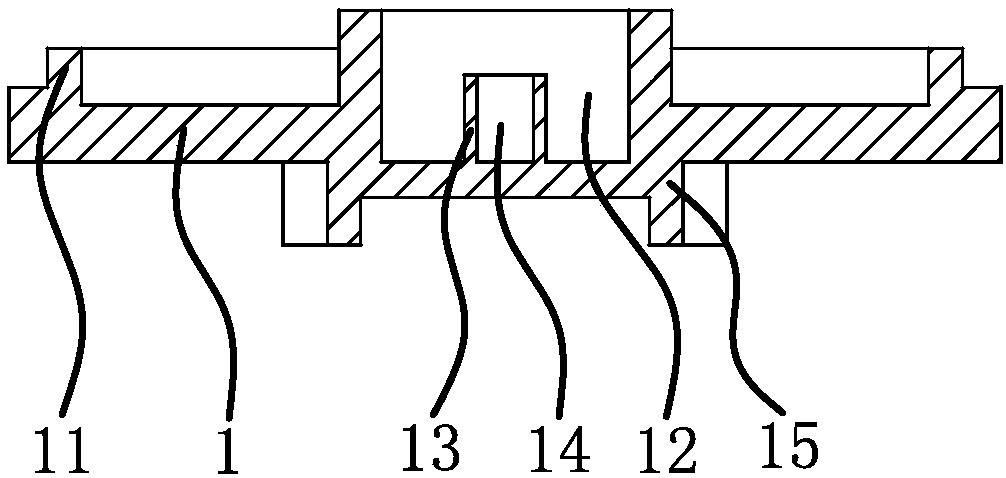

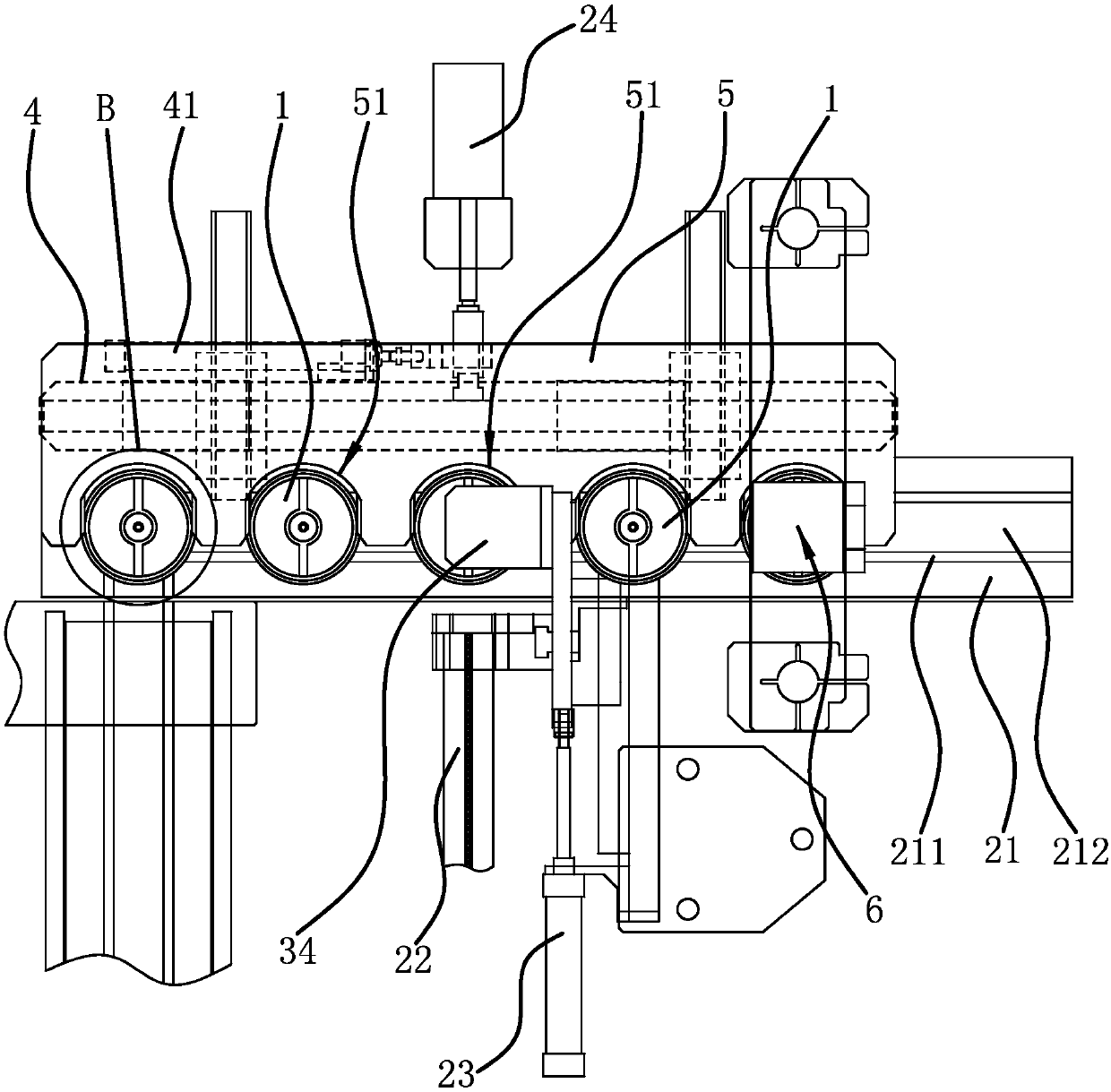

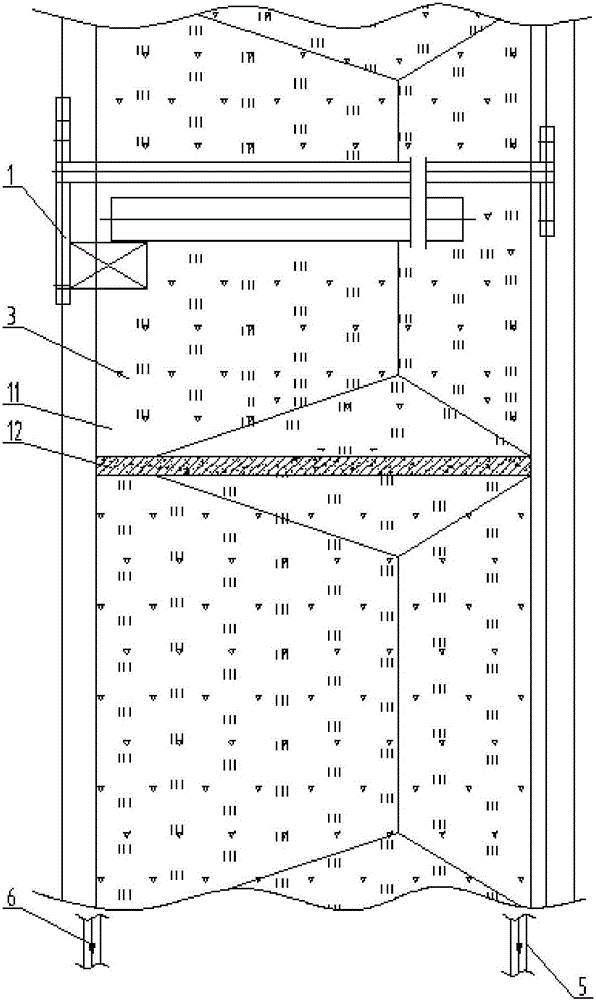

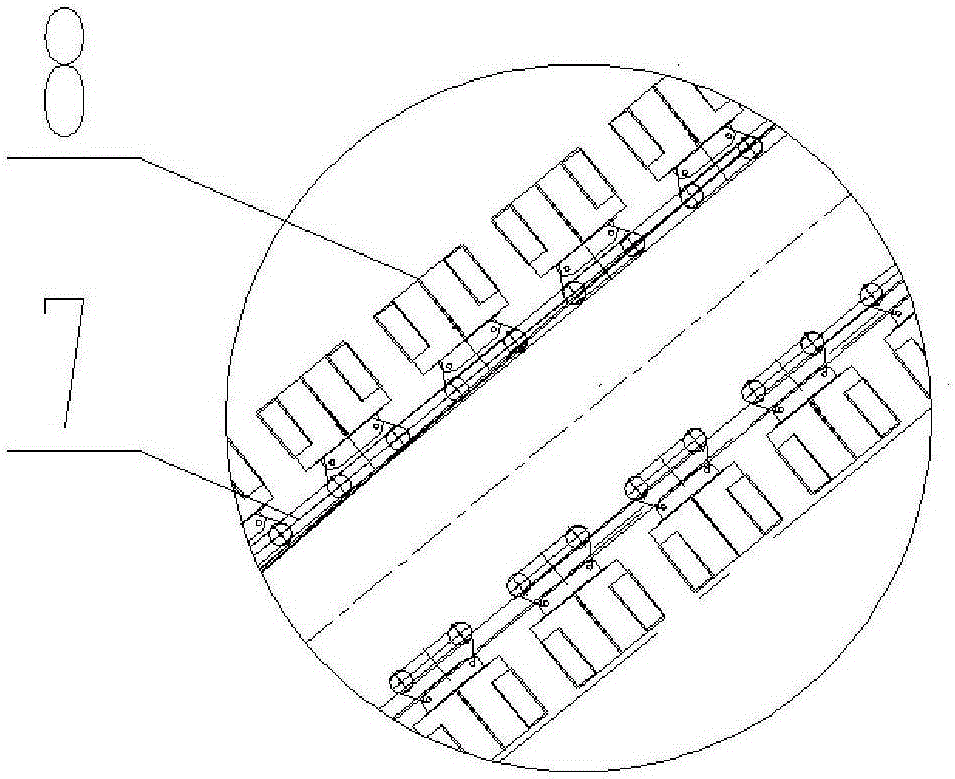

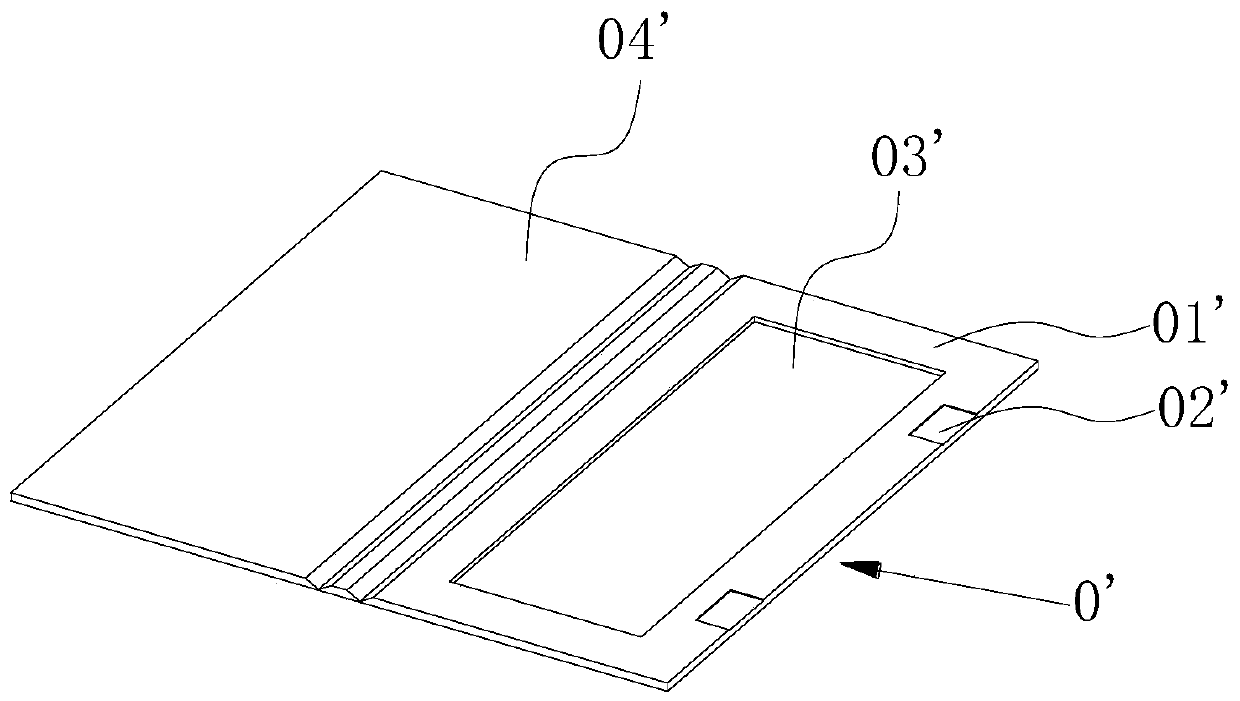

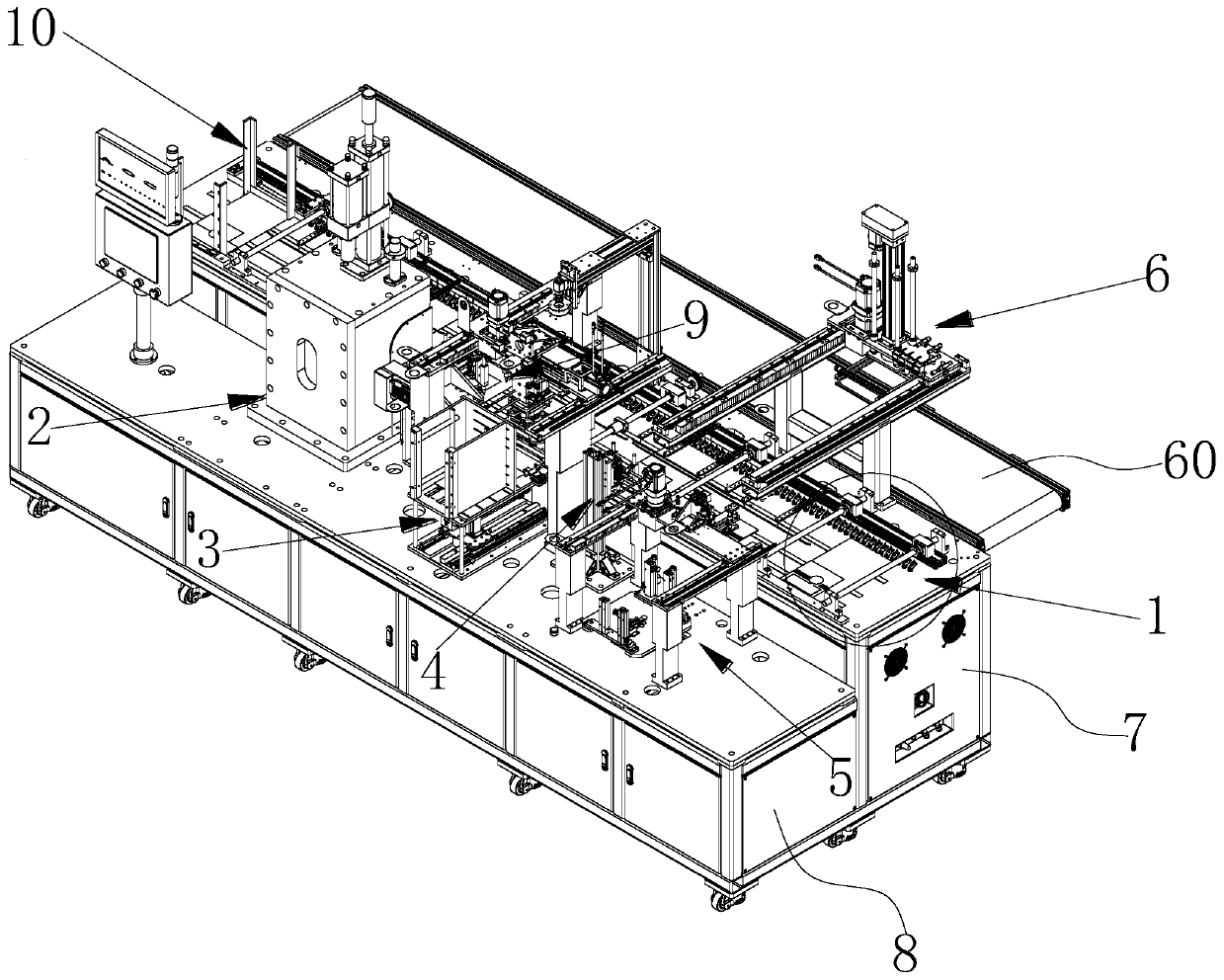

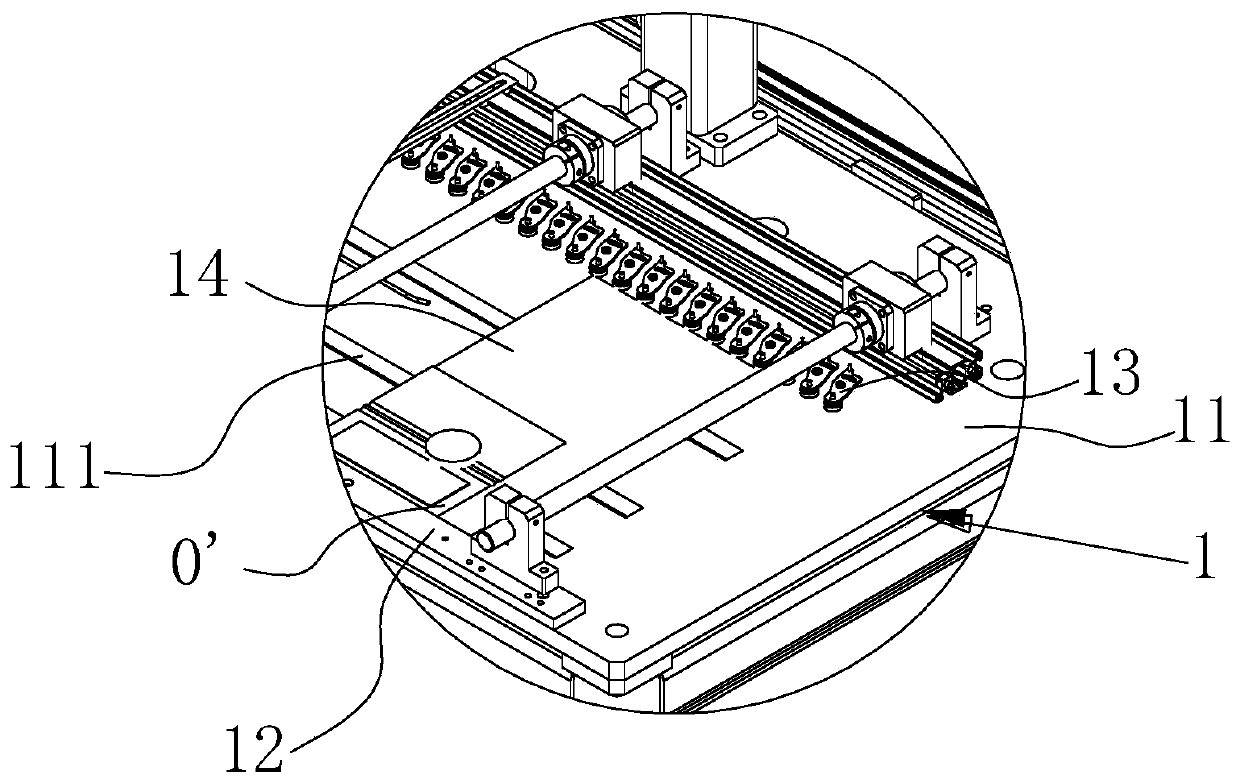

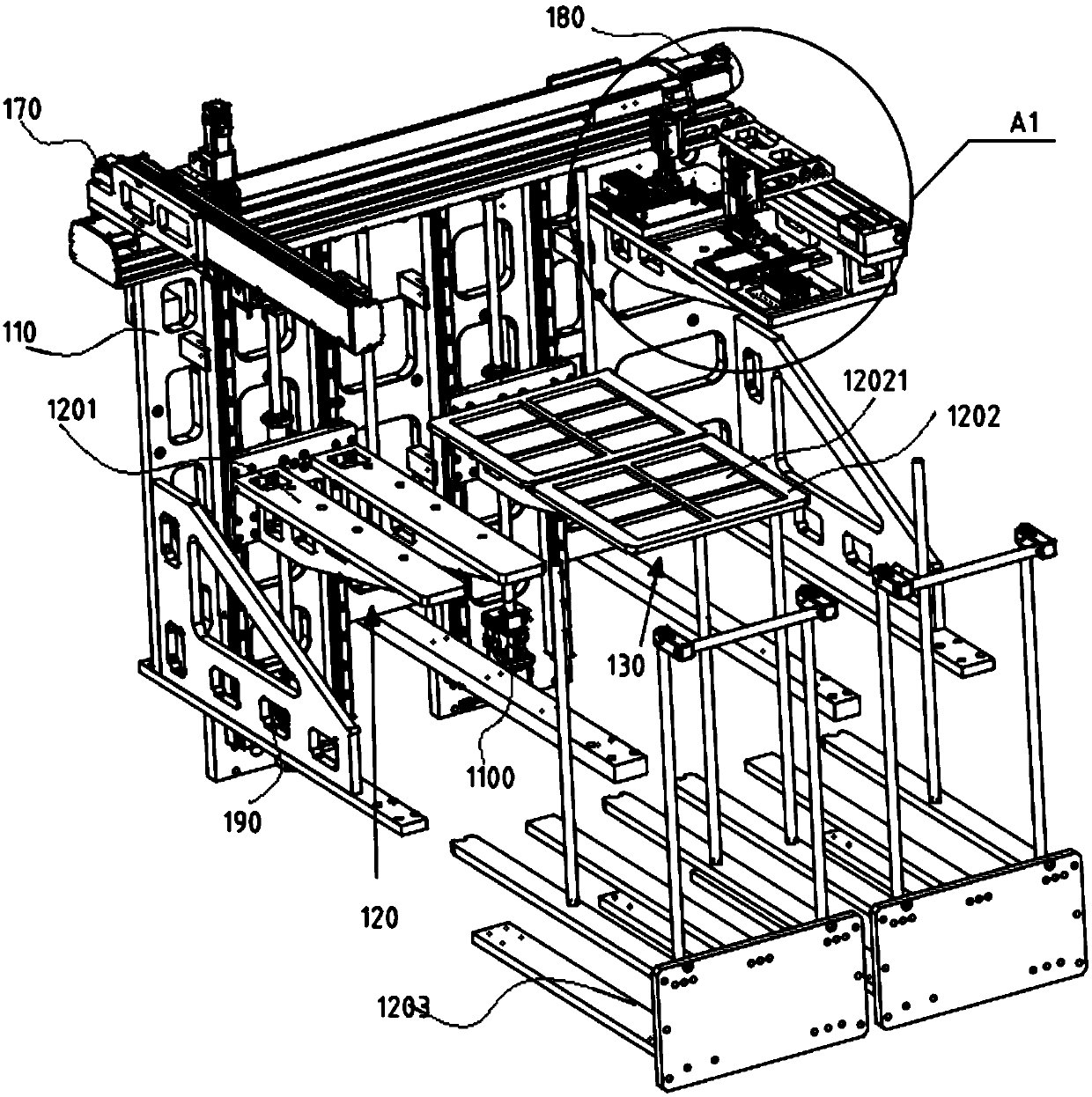

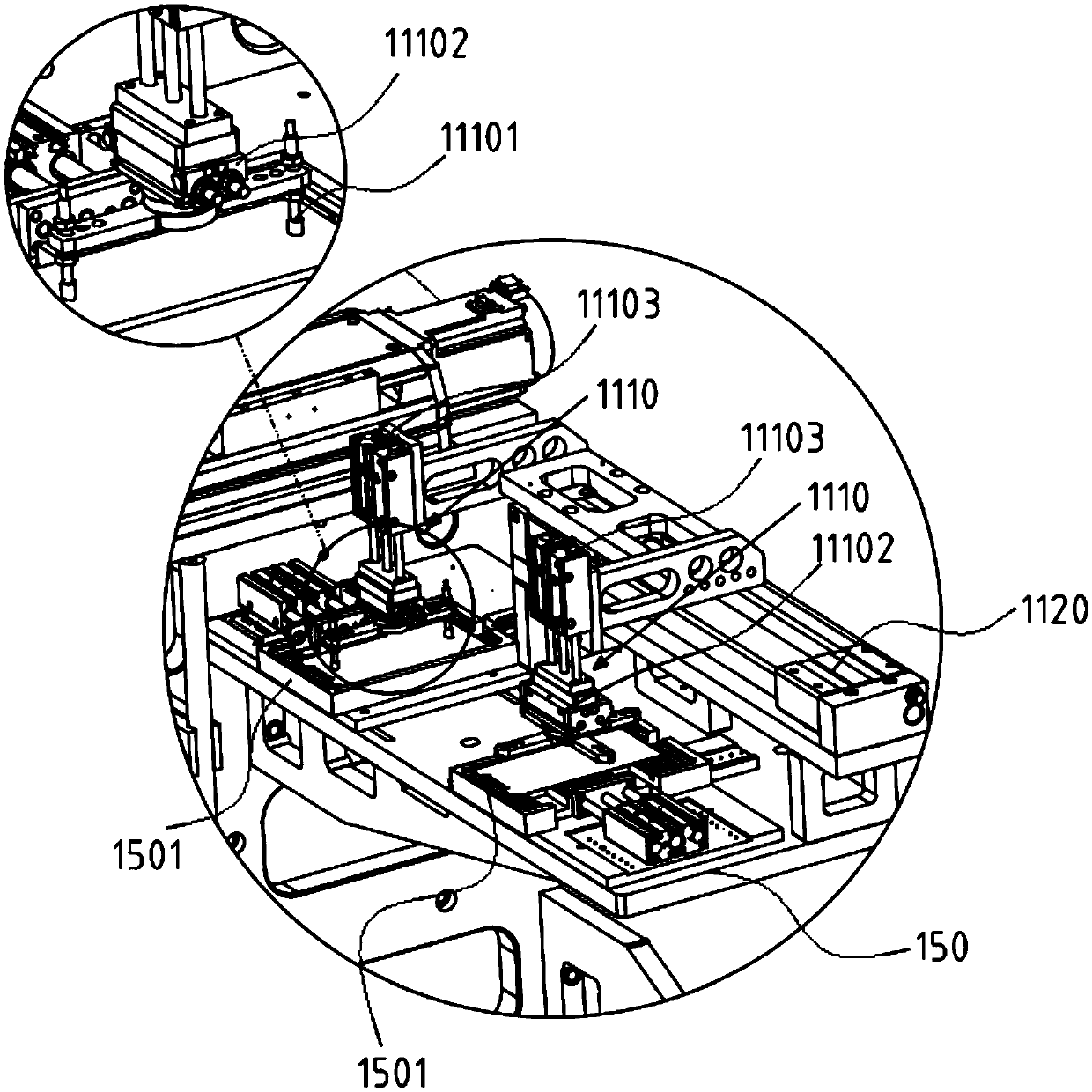

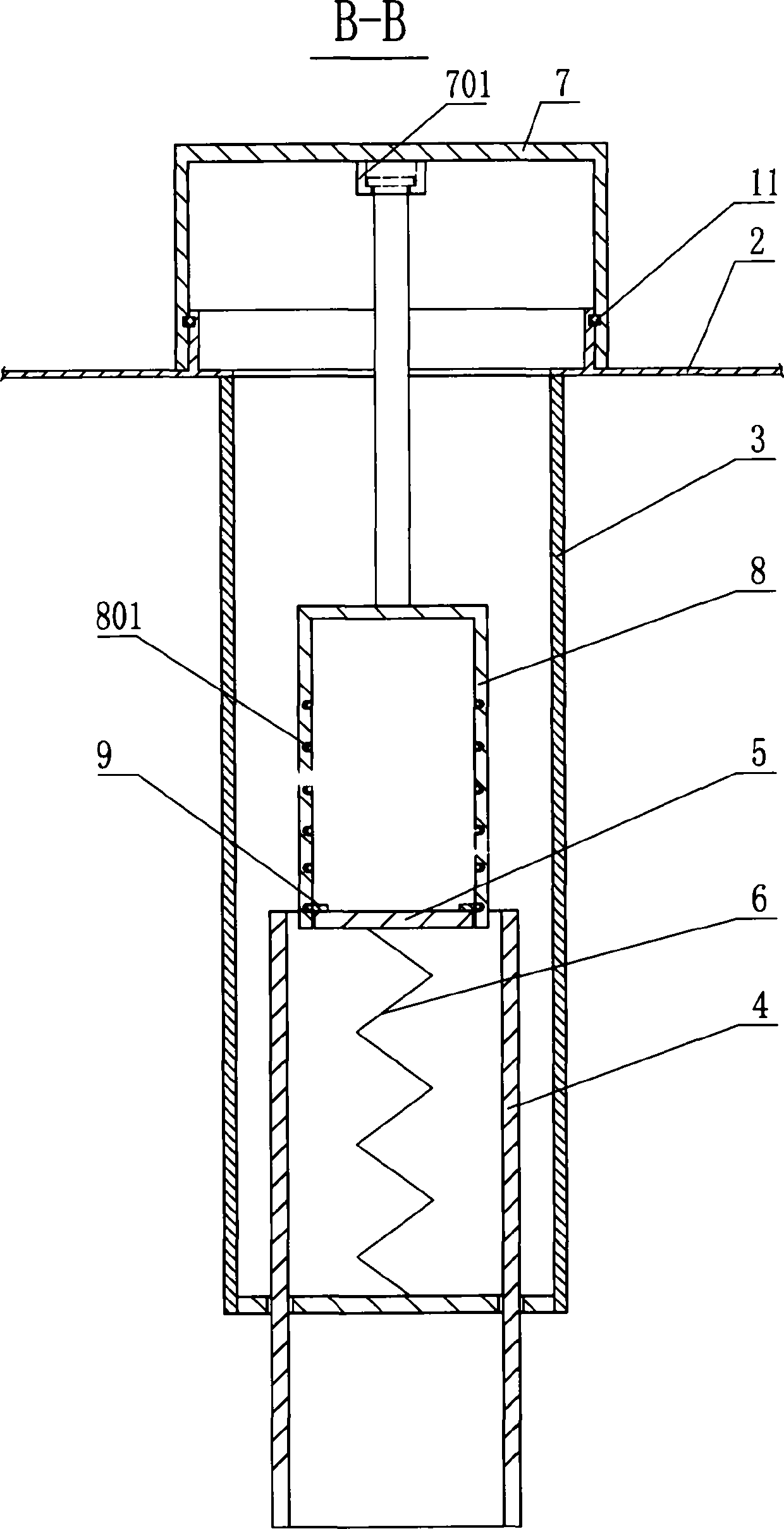

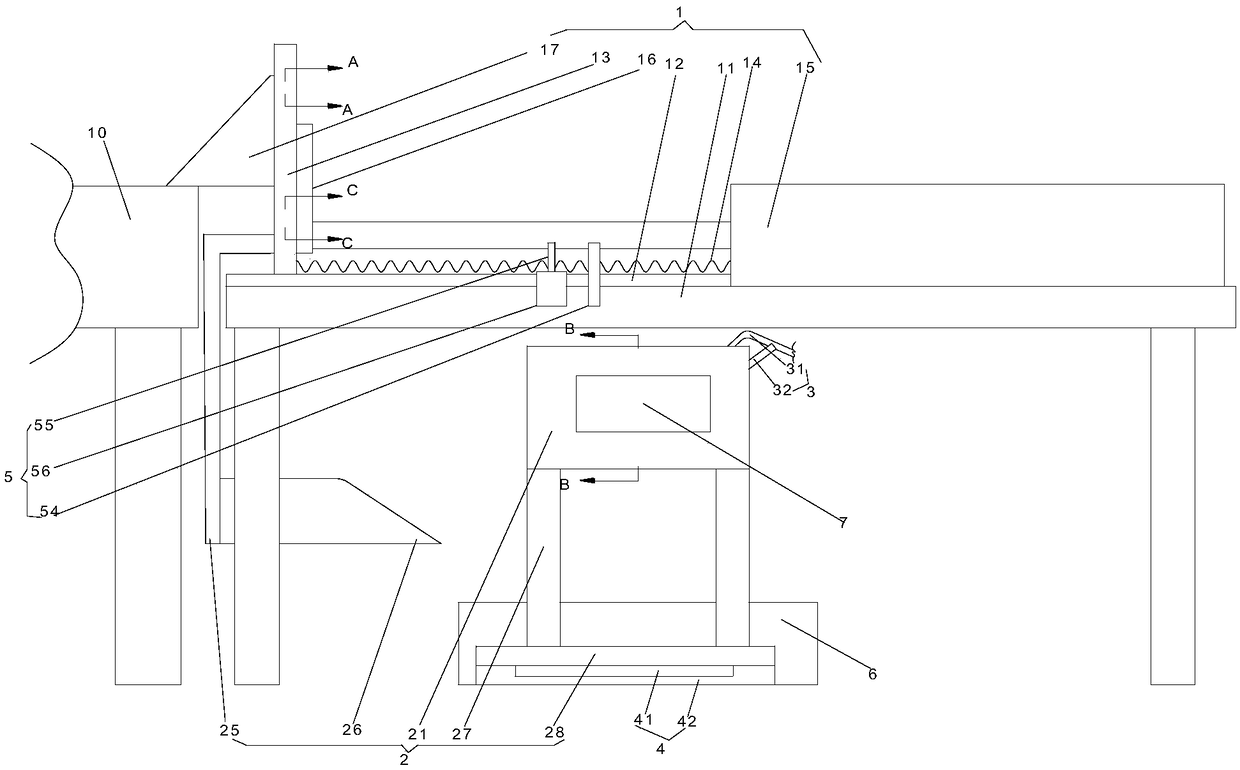

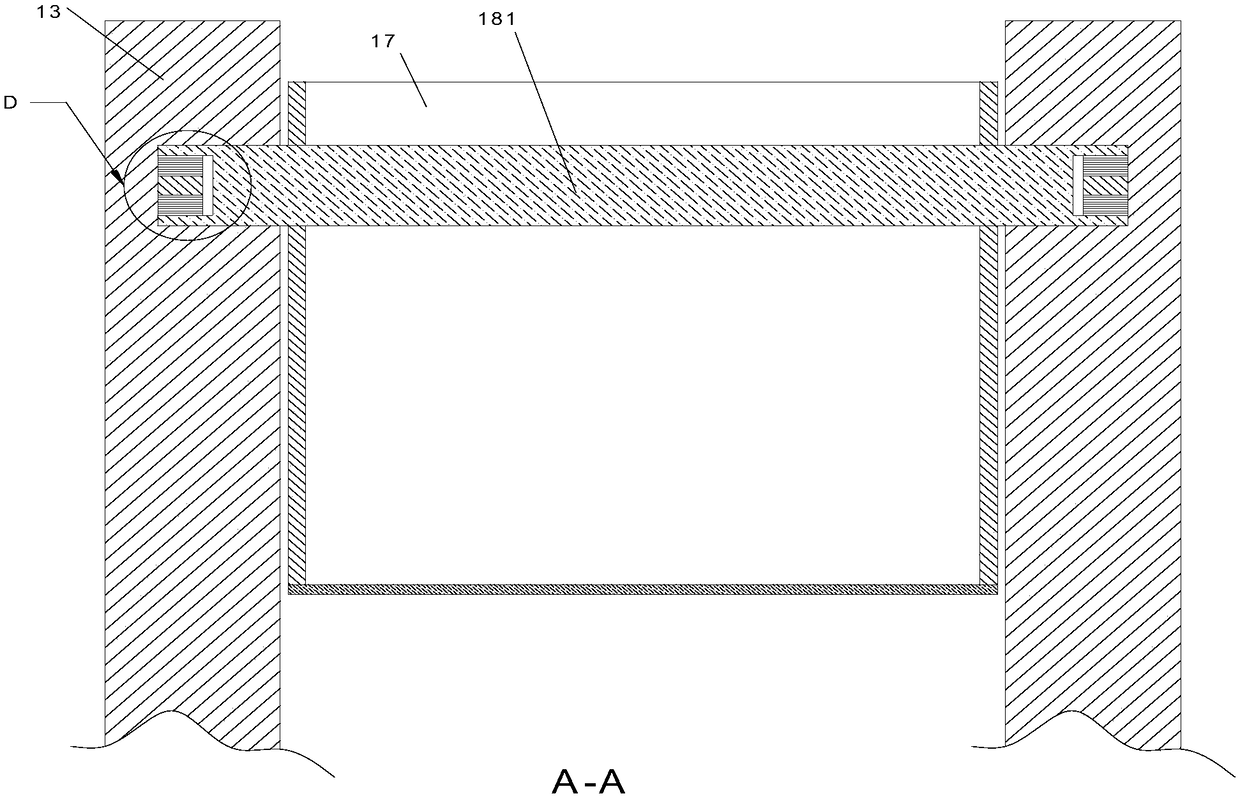

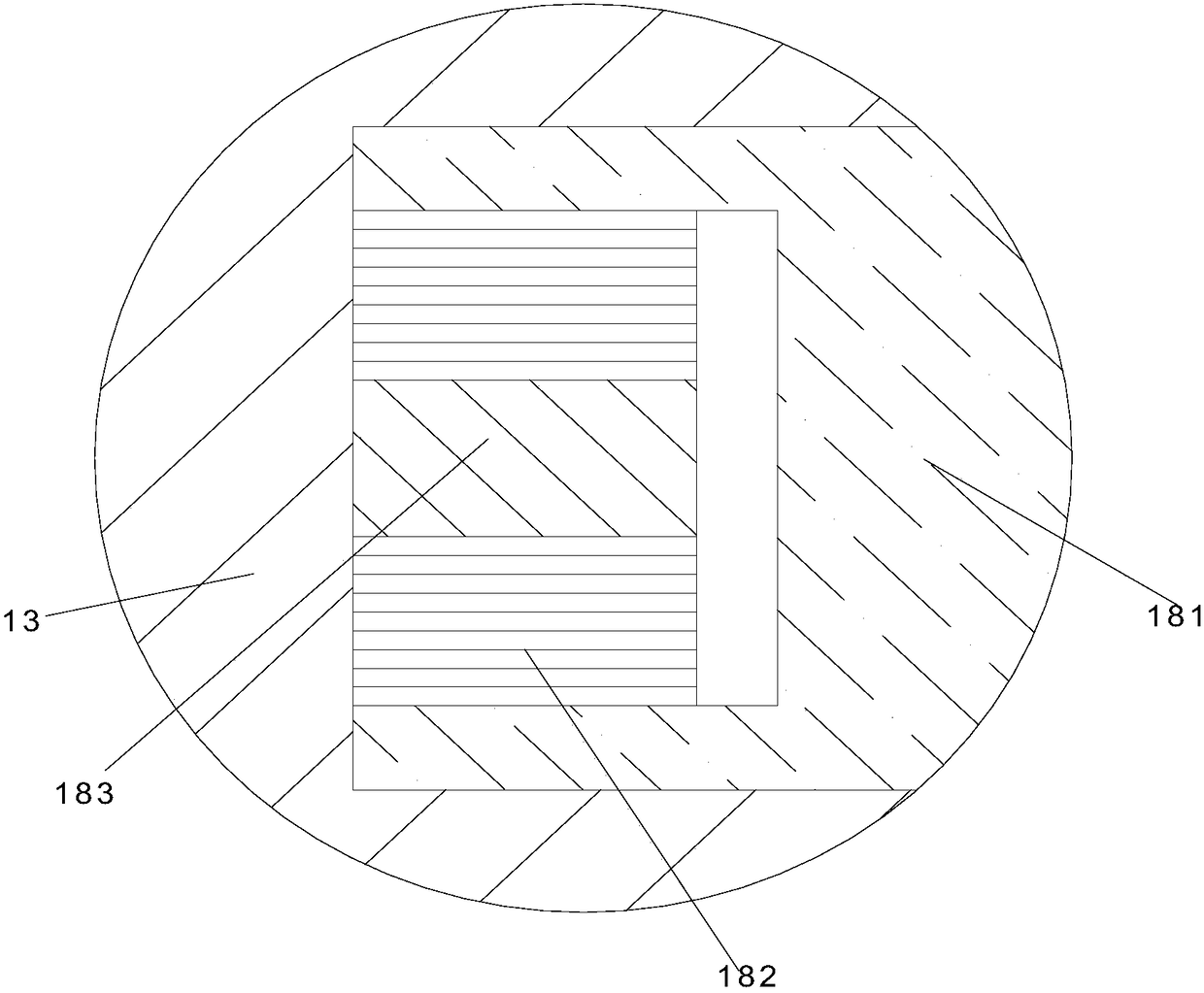

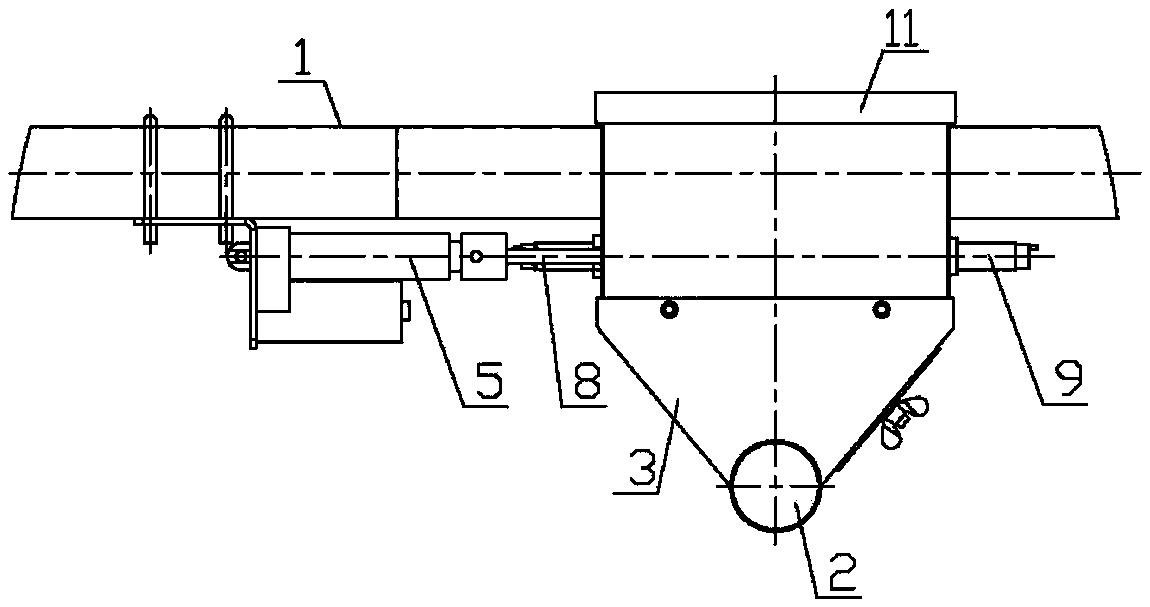

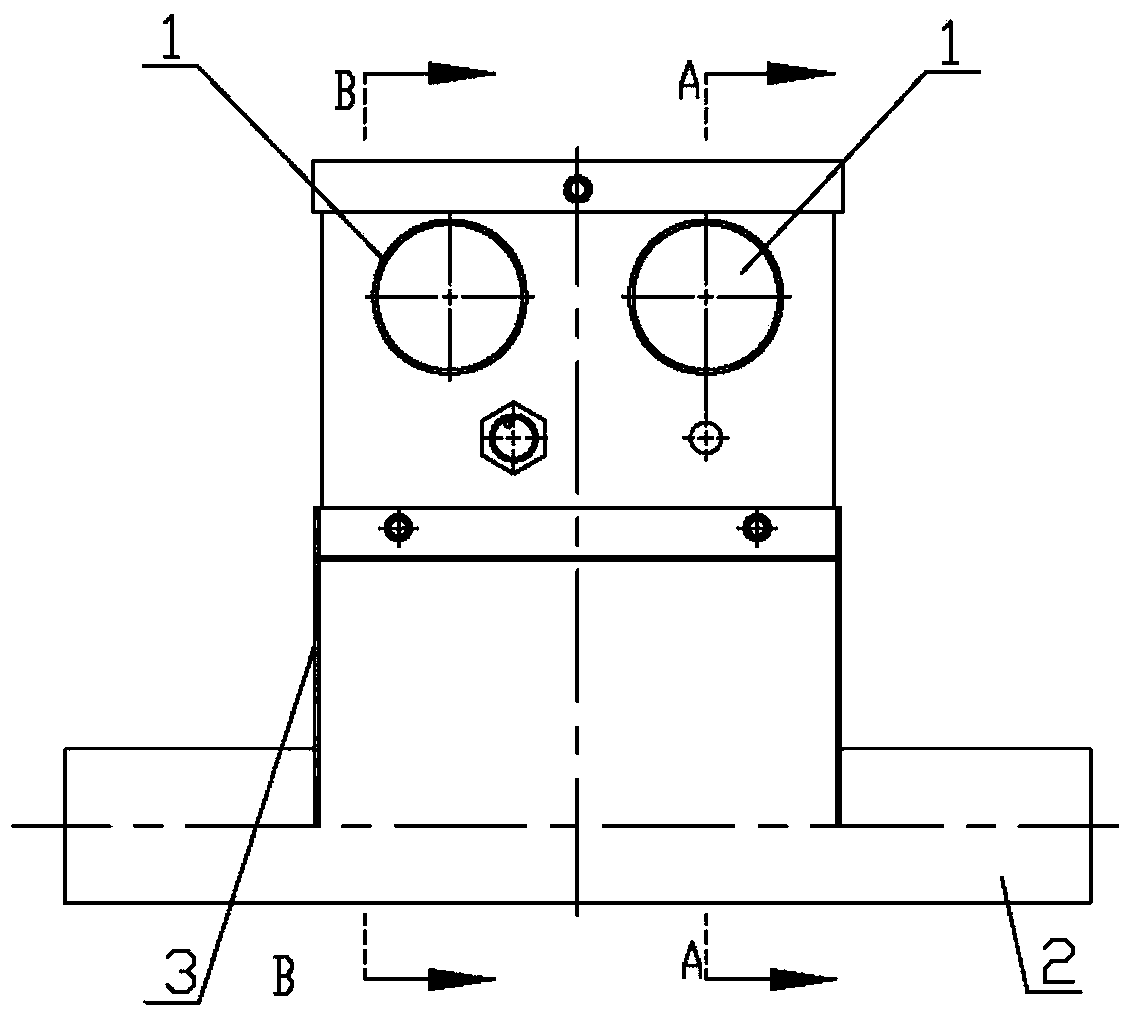

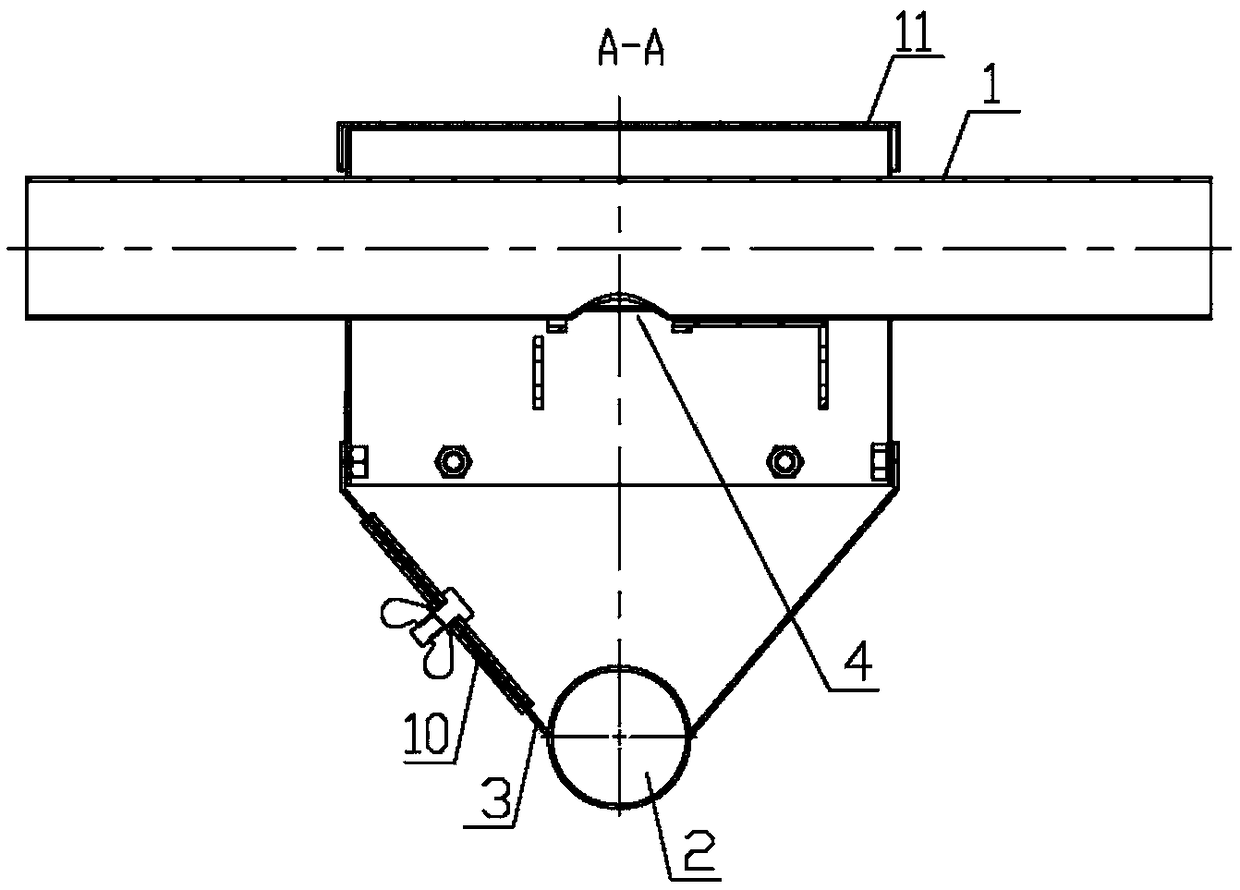

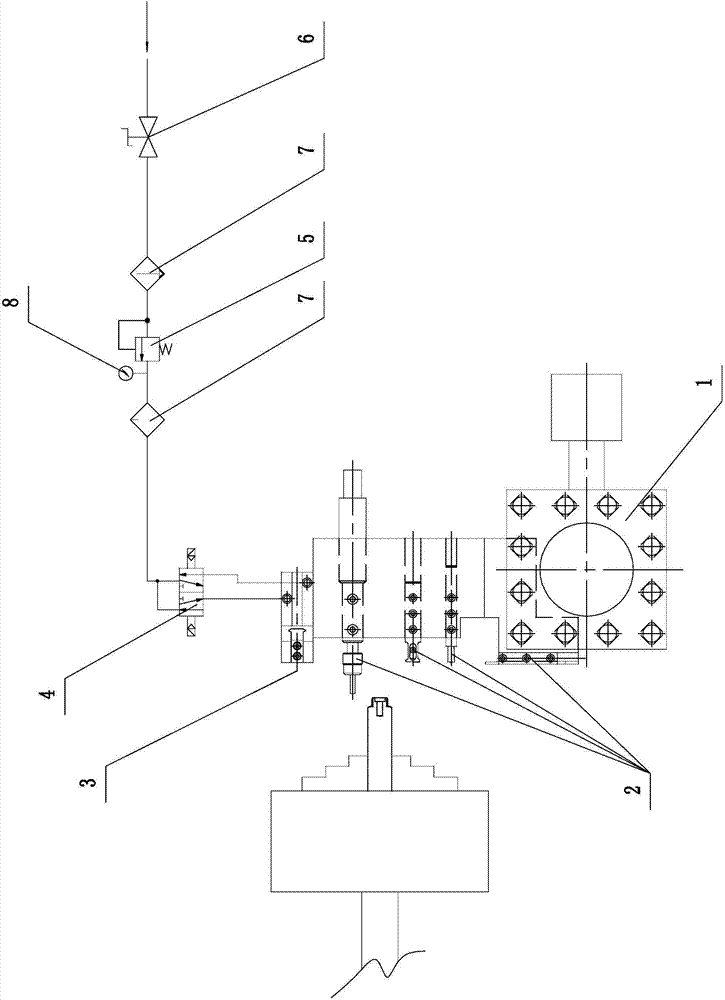

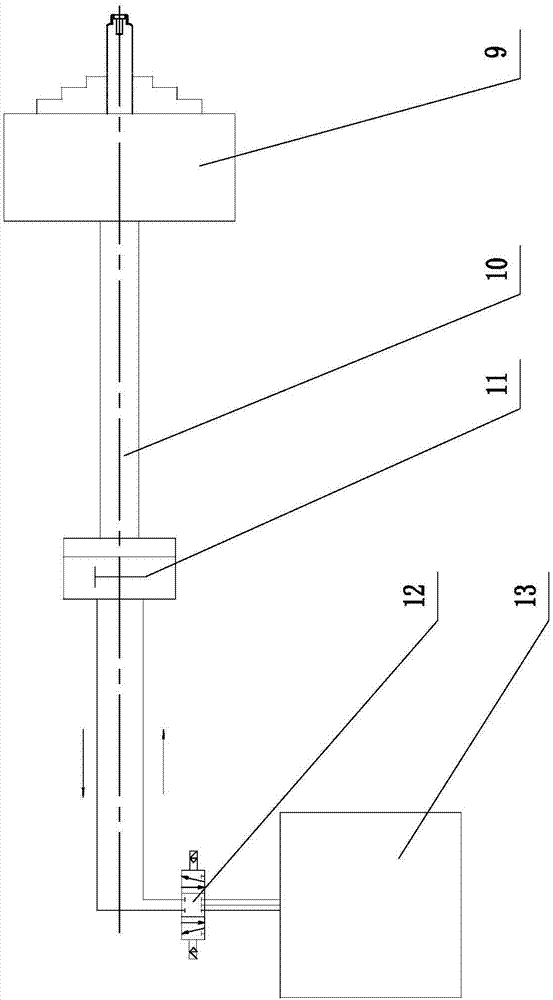

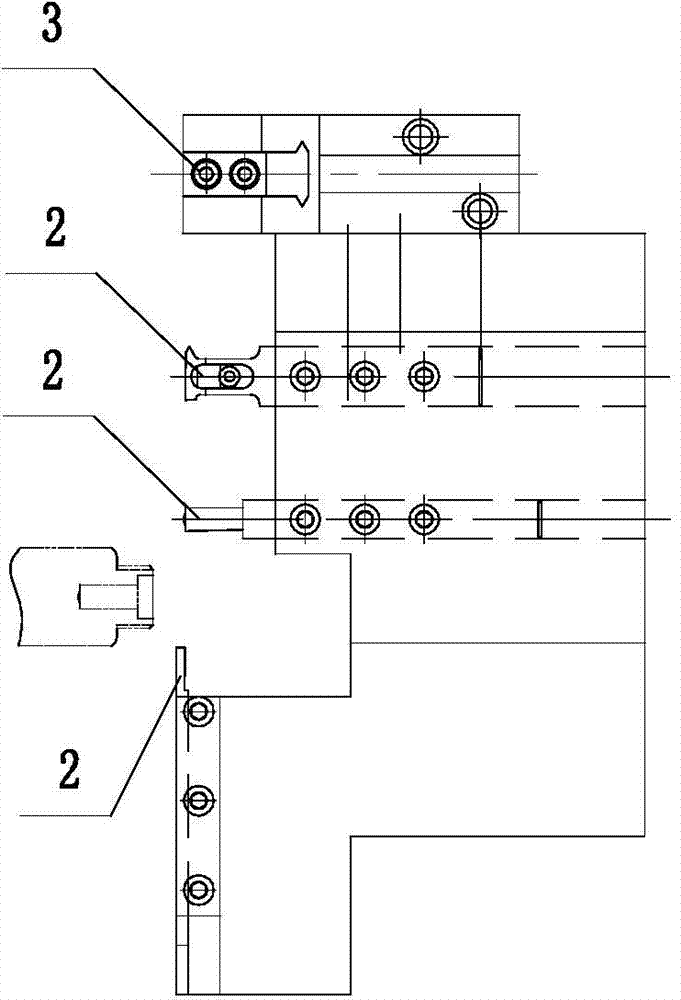

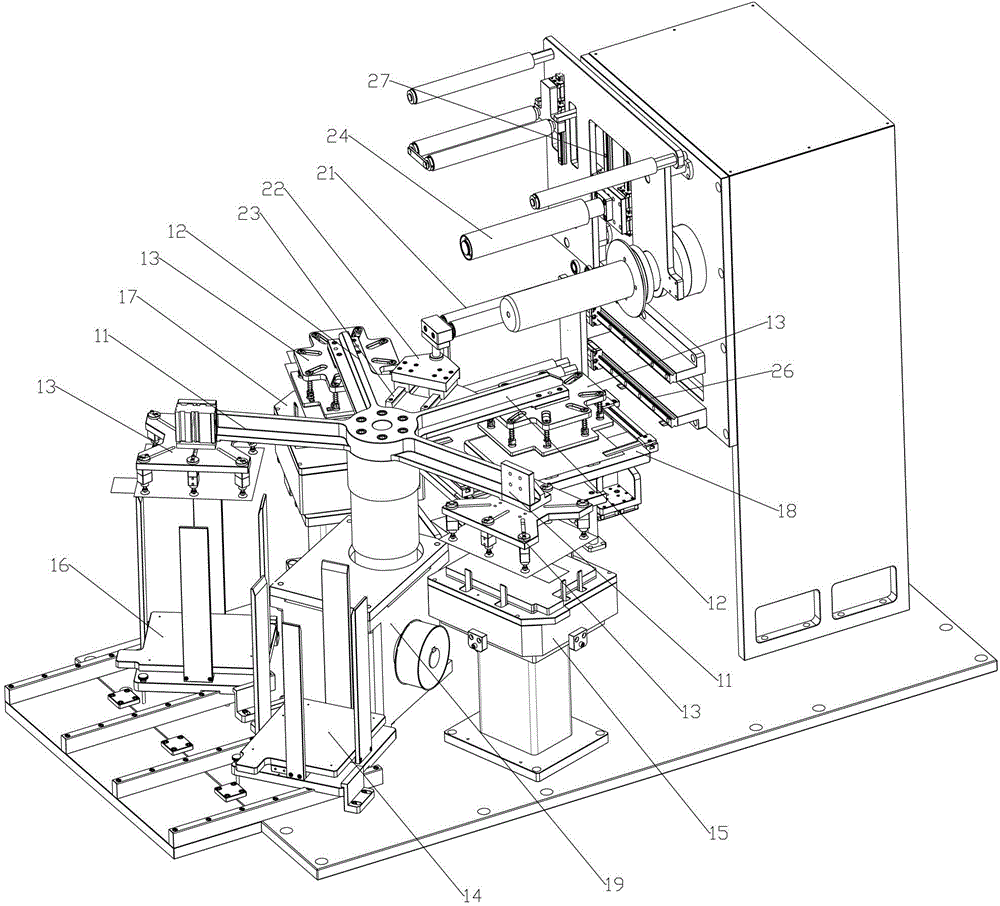

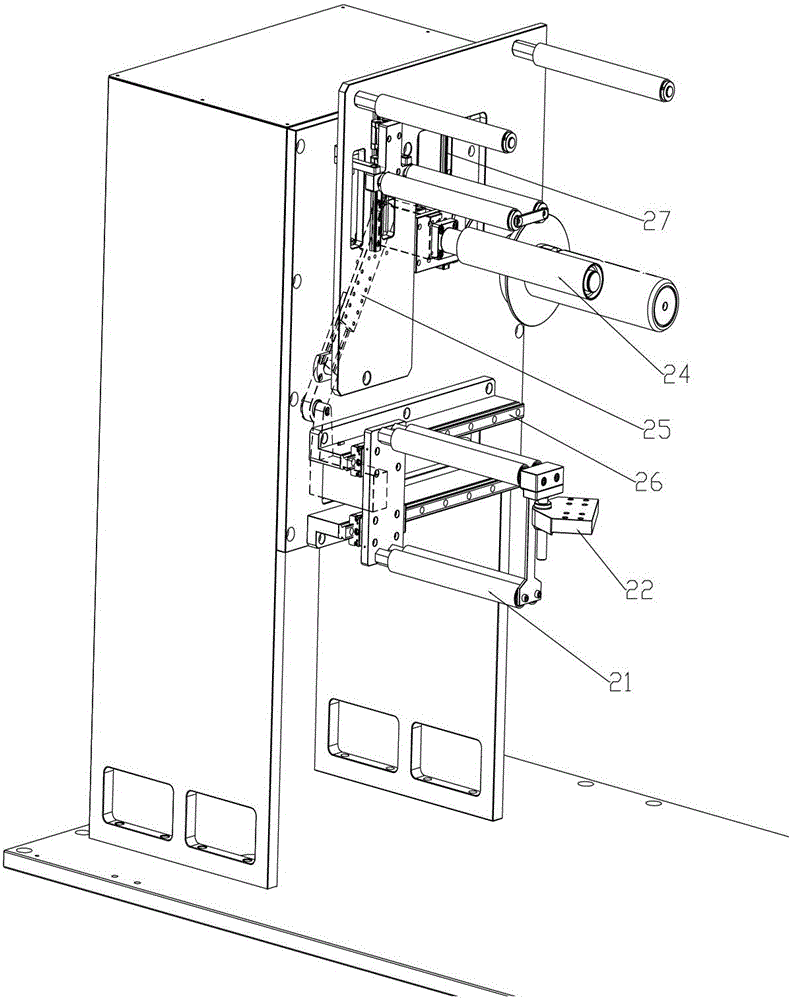

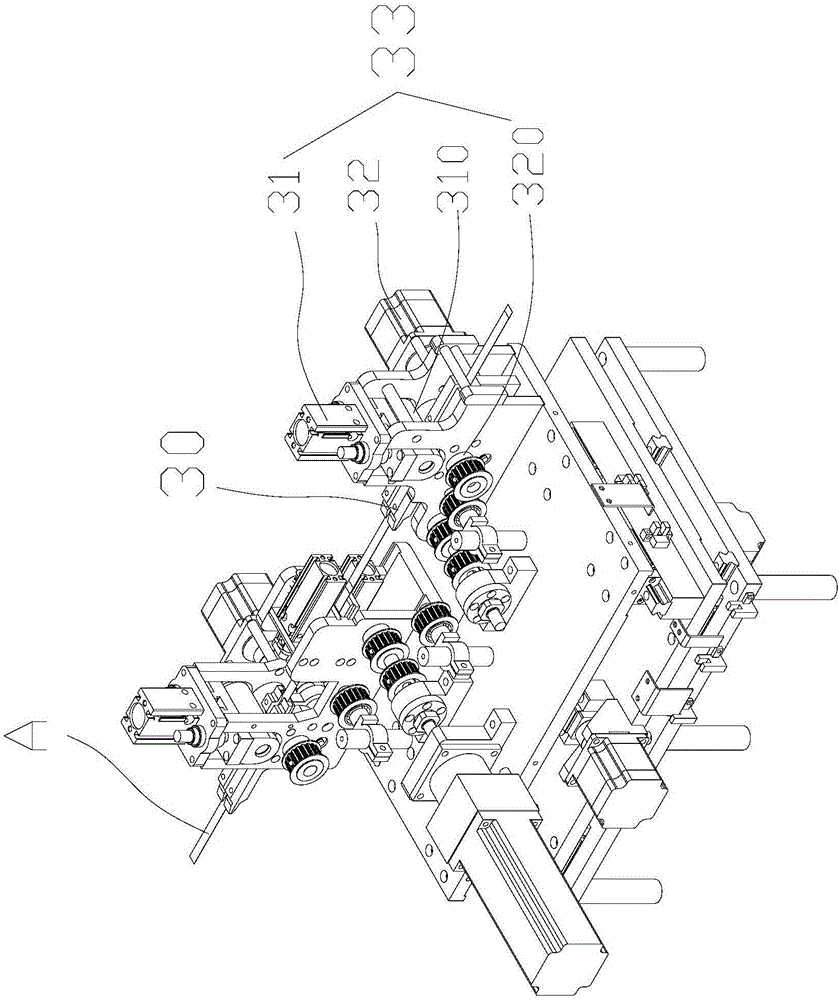

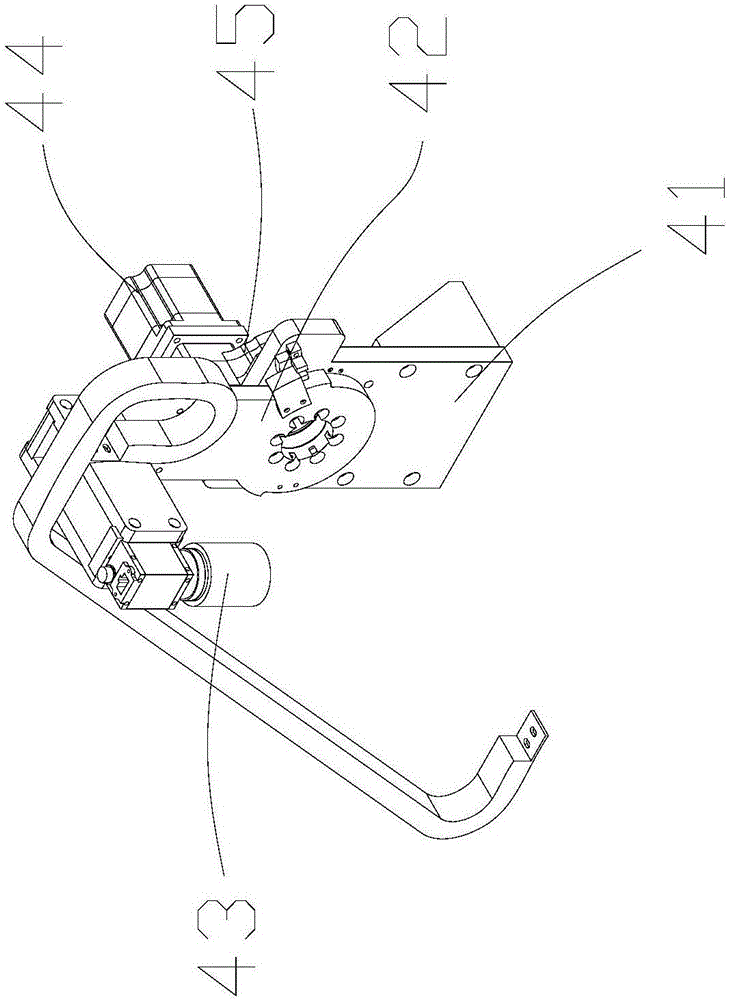

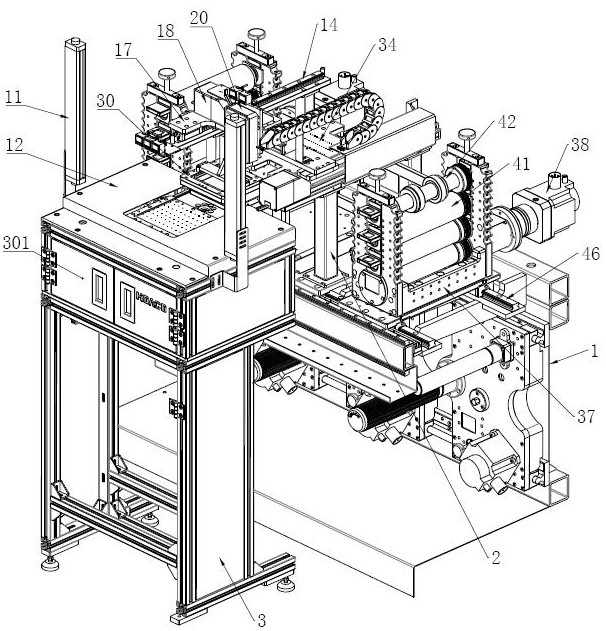

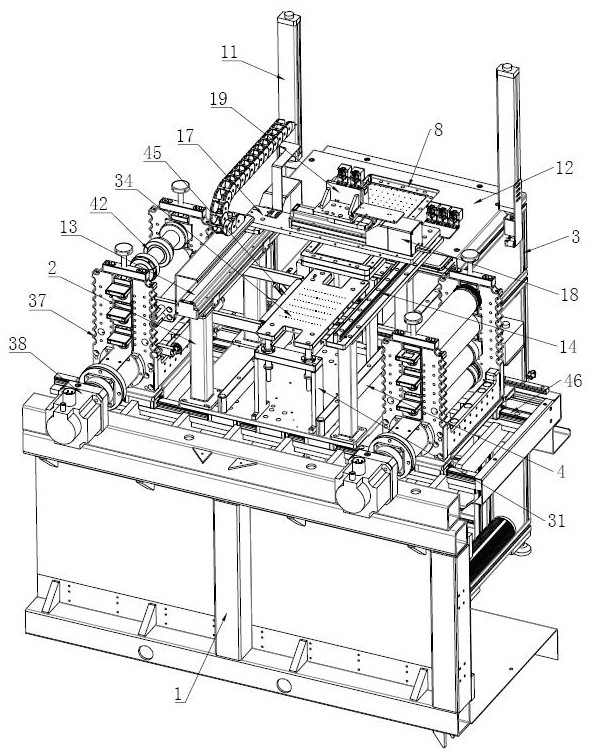

The invention relates to a laminating machine capable of driving film discharging by rotary loading. The laminating machine comprises a rotary loading mechanism, a positive pole piece trough, a positive pole piece calibration console, a negative pole piece trough, a negative pole piece calibration console, a lamination table and a film discharging mechanism, wherein the rotary loading mechanism is used for transferring pole pieces, and a big turntable which rotates in a reciprocating manner and is provided with four feeding arms is arranged at the upper part of the rotary loading mechanism; the positive pole piece trough, the positive pole piece calibration console, the negative pole piece trough, the negative pole piece calibration console and the lamination table are distributed along the periphery of the rotary loading mechanism; and the film discharging mechanism is arranged above the lamination table and driven by the big turntable which rotates in a reciprocating manner. When the big turntable rotates in a reciprocating manner, the two front feeding arms are used for respectively transferring positive pole pieces in the positive pole piece trough and negative pole pieces in the negative pole piece trough into the positive pole piece calibration console and the negative pole piece calibration console to be positioned; and the two rear feeding arms are used for respectively transferring the positioned positive pole pieces in the positive pole piece calibration console and the positioned negative pole pieces in the negative pole piece calibration console onto the lamination table and enabling the positive pole pieces and the negative pole pieces to be sequentially and alternately laminated with repeated Z-shaped films intermittently discharged by the film discharging mechanism. The laminating machine disclosed by the invention is simple in mechanisms for loading, transferring and laminating the positive pole pieces and the negative pole pieces in the circumferential direction, small in motion inertia, more stable in operation, small in occupied area and low in manufacturing cost.

Owner:DONGGUAN ARECONN PRECISION MACHINERY

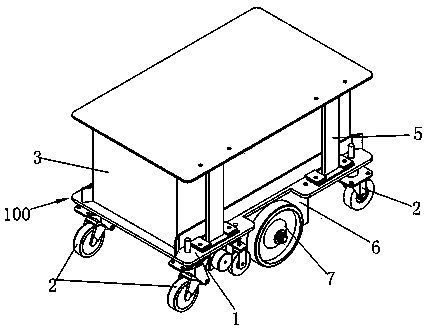

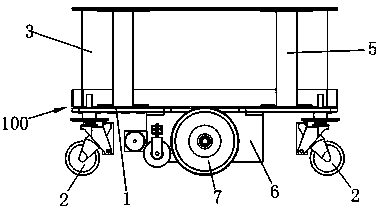

Pivot steering AGV self-walking carrier vehicle

The invention relates to a pivot steering AGV self-walking carrier vehicle, comprising a vehicle body, and is characterized in that the vehicle body comprises a chassis and a frame, wherein a control box is arranged at the inner side of the frame above the chassis, the front end and the rear end of the chassis are provided with two universal wheels respectively, a driving wheel box is arranged below the middle part of the chassis, two coaxial driving wheels are arranged at the two sides of the driving wheel box respectively, and the two driving wheels are connected with respective independent driving mechanisms. The pivot steering AGV self-walking carrier vehicle is simple and compact in structure, the two independently driven driving wheels are arranged between driven wheels at the front end and the rear end of the vehicle body and are enabled to rotate in reverse at the same rotating speed, so that pivot steering of the carrier vehicle is realized, the vehicle body is fast steered, and the occupied space is reduced, therefore operation of steering, pick-up and unloading of the AGV self-walking carrier vehicle in a narrow channel is realized.

Owner:WUXI HONGYE AUTOMATION ENG

Stacking transferring mechanical device with flexible clamping gripper

InactiveCN109019004AEasy to moveSimple structureStacking articlesDe-stacking articlesEngineeringStack effect

Owner:霸州市辉月网络技术有限公司

Detection device for material picking of mechanical arm

ActiveCN104002178AImprove loading and unloading efficiencyGuaranteed linear motionProgramme-controlled manipulatorMeasurement/indication equipmentsEngineeringManipulator

Owner:GUANGZHOU DAZHENG ADVANCED MATERIAL TECH CO LTD

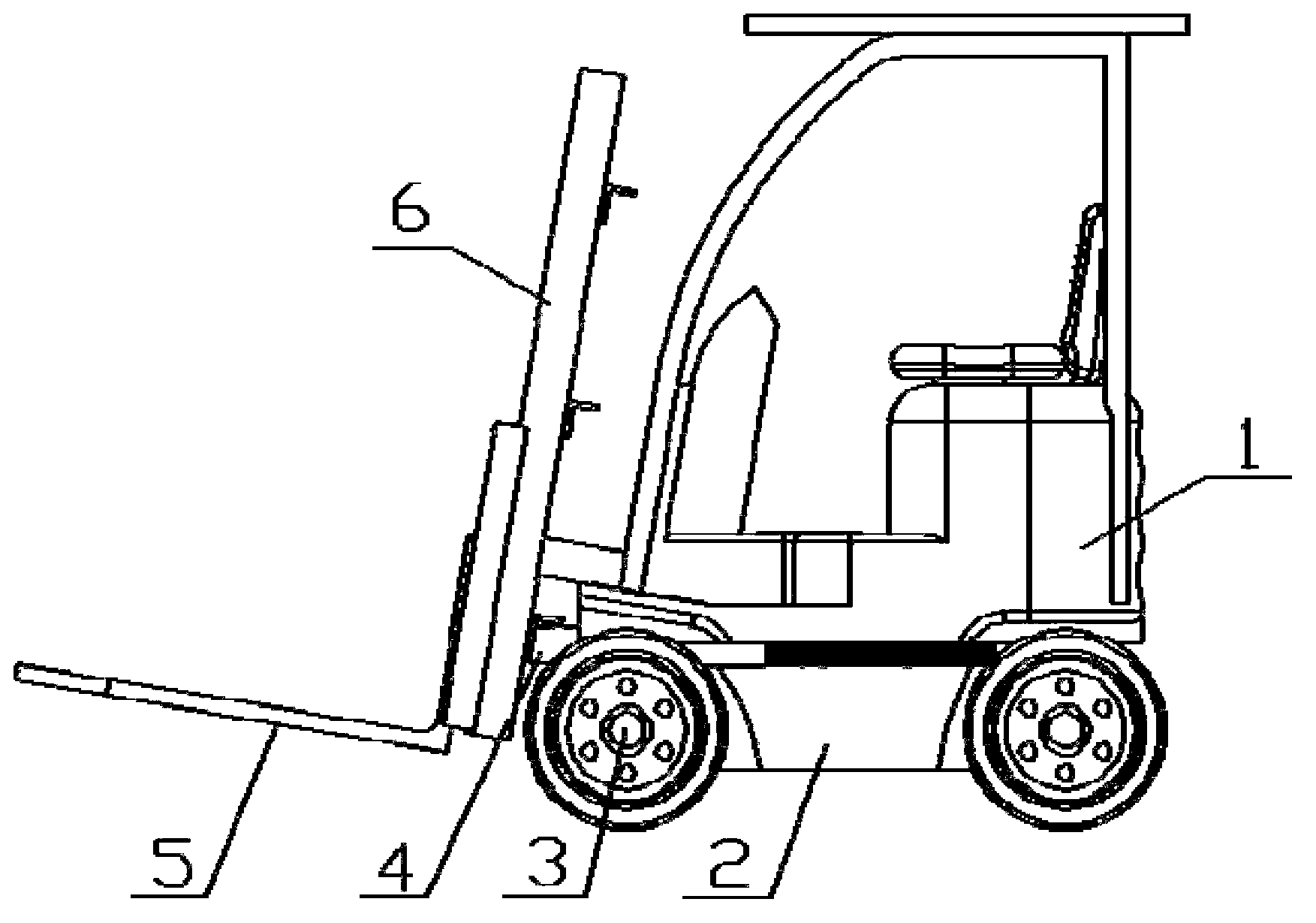

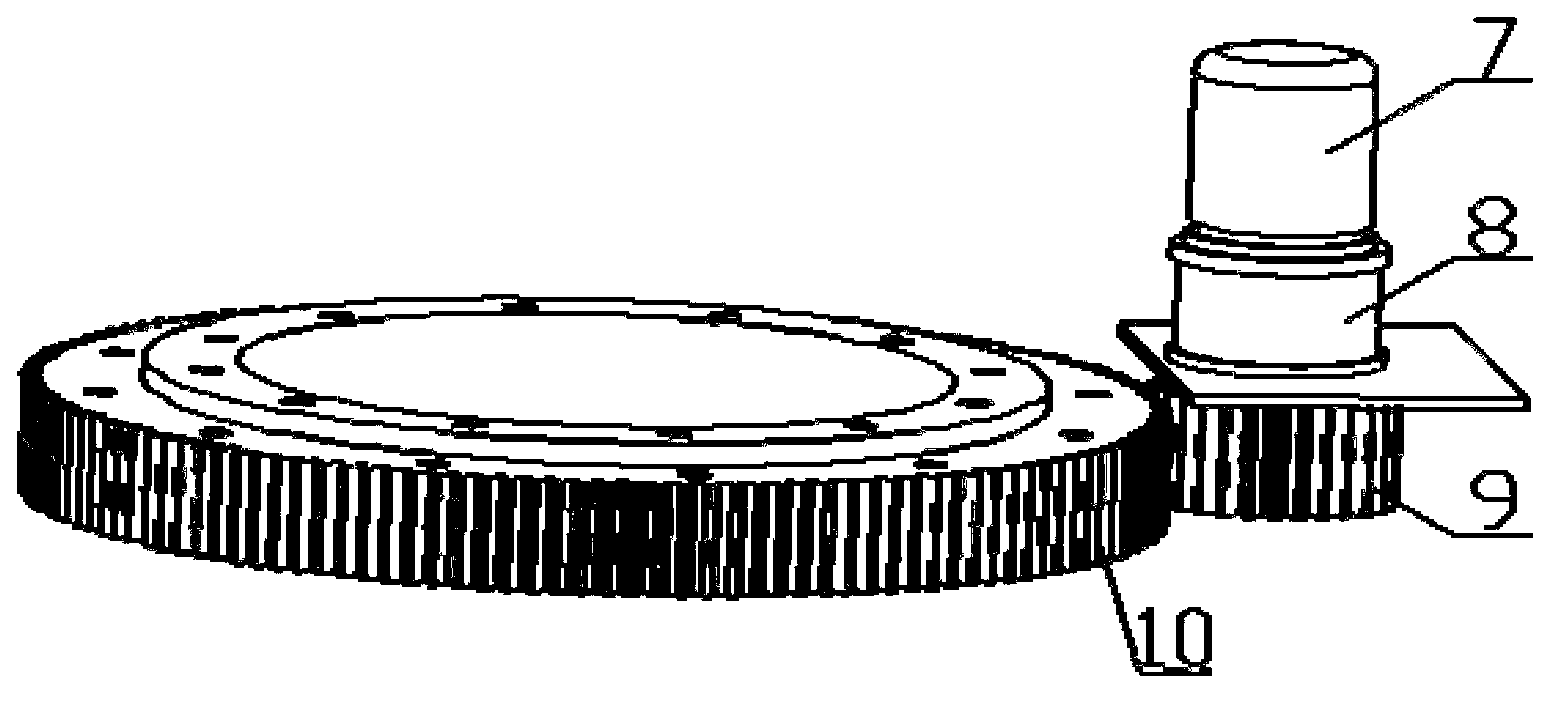

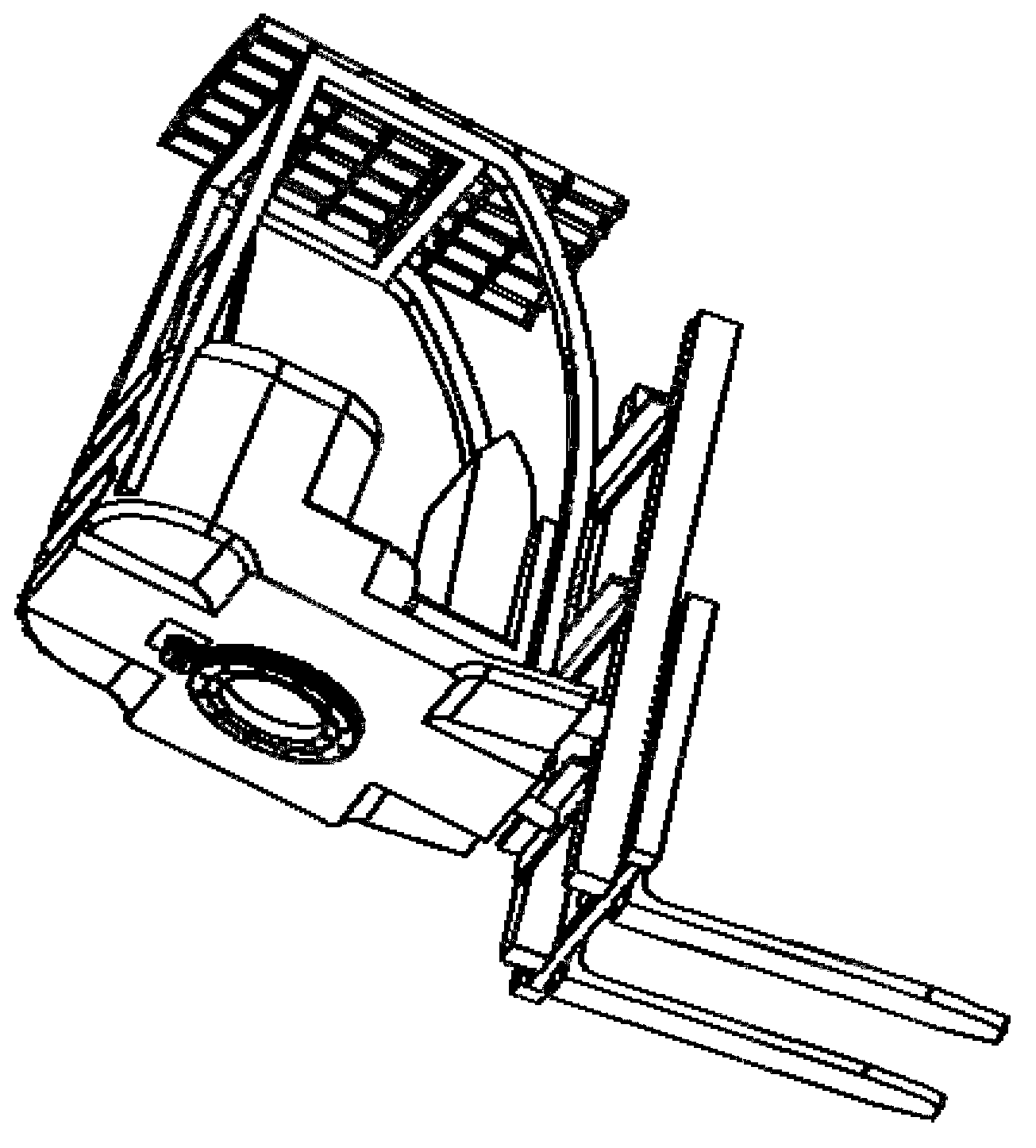

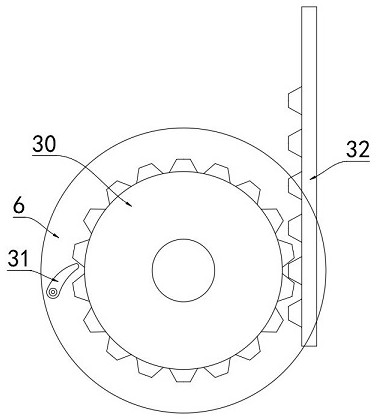

Revolving forklift

The invention discloses a revolving forklift which structurally comprises an upper forklift chassis, a lower forklift chassis, a gantry, a pallet fork, a gantry inclination mechanism, a forklift revolving support, a revolving pinion, a revolving driving motor, a speed reducer and a forklift tire, wherein the upper forklift chassis is connected with the lower forklift chassis through the forklift revolving support; the lower forklift chassis is connected with the forklift tire; the gantry inclination mechanism is connected with the upper forklift chassis; the gantry and the pallet fork are fixed in front of the upper forklift chassis; the revolving driving motor and the speed reducer are fixed below the upper forklift chassis; and the revolving pinion is connected with the speed reducer. The revolving forklift has the beneficial effects of easily revolving and taking materials in a special working space.

Owner:杜桂林

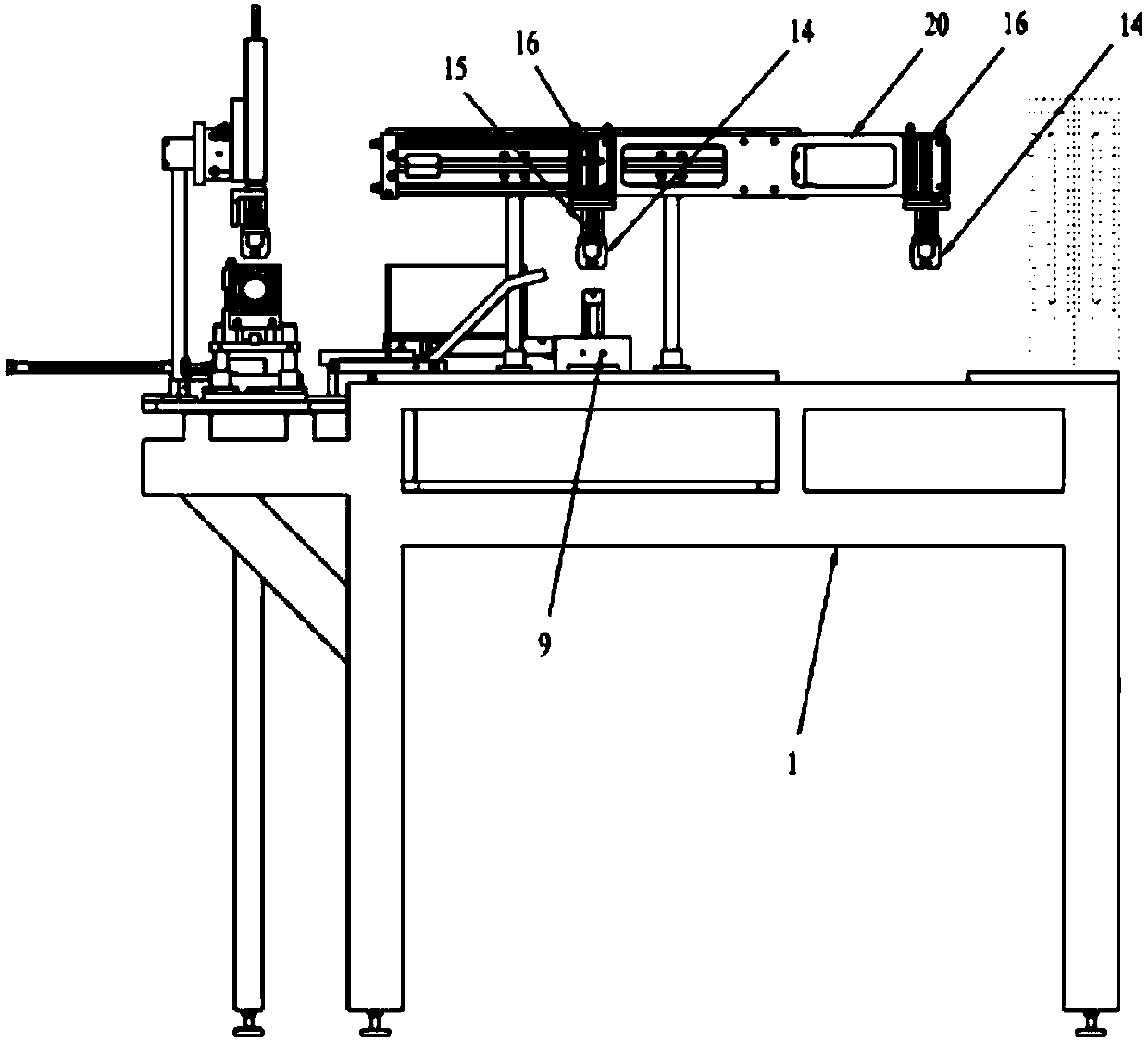

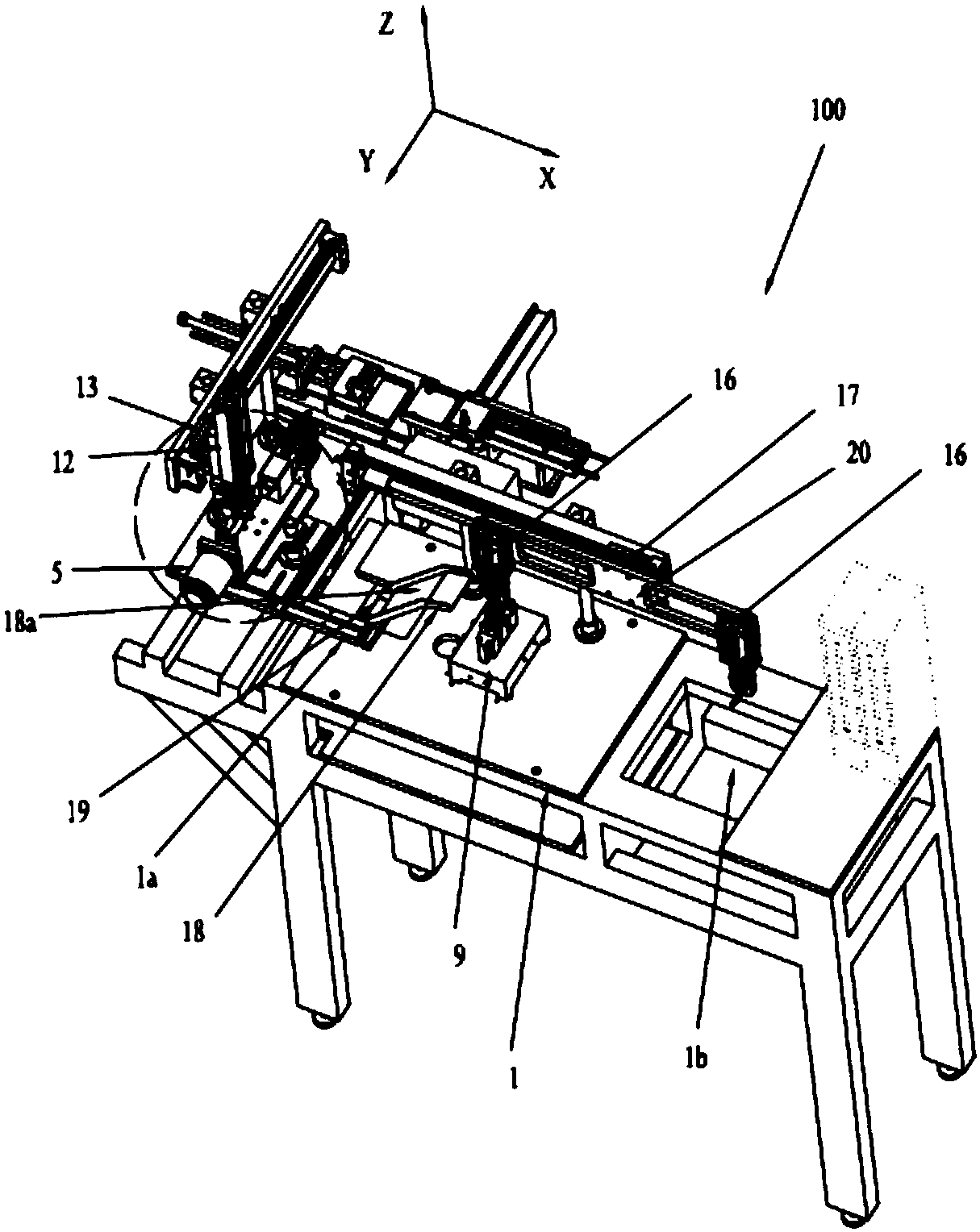

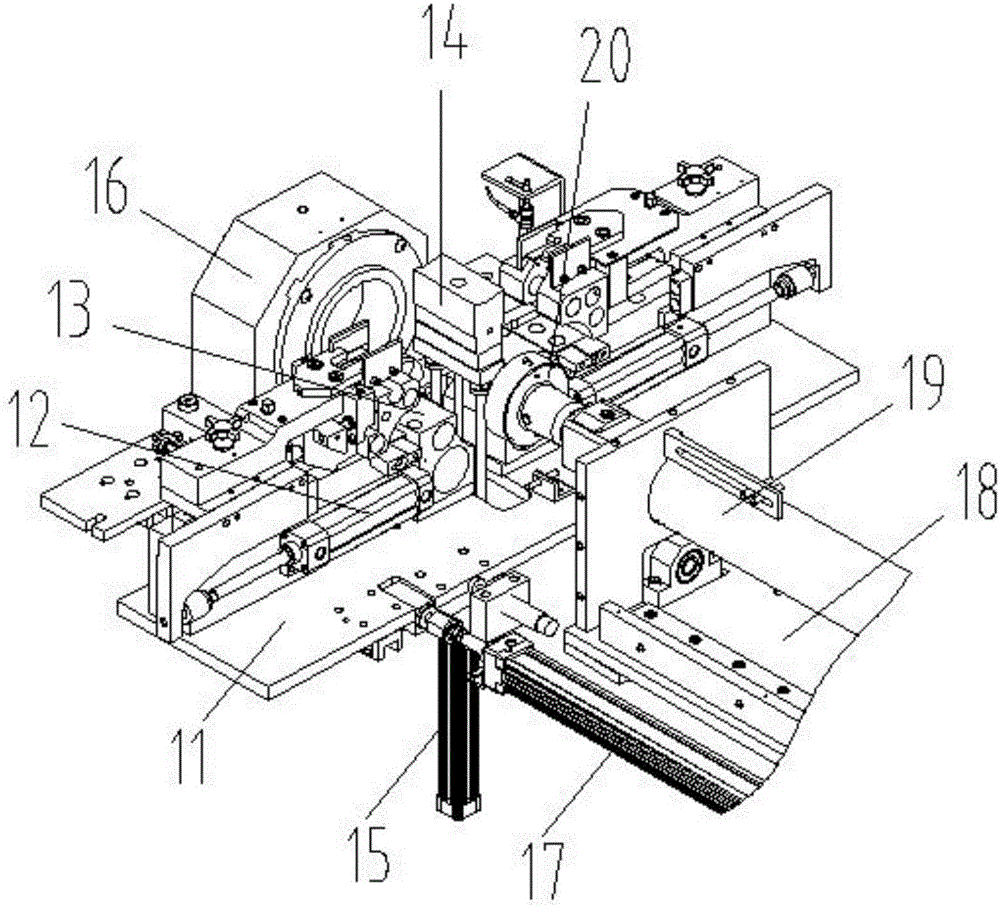

Detection device applicable to axis part

PendingCN107755284AImprove efficiencyImprove detection accuracyCleaning using gasesSortingMoving frameFeed drive

The invention discloses a detection device applicable to an axis part. A thimble driving cylinder drives a second thimble to slide relative to a thimble seat; a first thimble and the second thimble clamp the axis part from the two sides of the axis part; a movable frame movement driving cylinder drives a movable frame to move relative to a rack; a supporting platform is fixed onto the rack; an airblowing exit is formed between the thimble seat and the second thimble; a feeding manipulator driving cylinder drives a feeding gripper to move; a feeding vertical movement cylinder drives the feeding manipulator driving cylinder to move along the Z axis; a feeding longitudinal movement cylinder drives the feeding vertical movement cylinder to move along the Y axis; a discharging gripper drivingcylinder drives a discharging gripper to move; a discharging vertical movement cylinder drives the discharging gripper driving cylinder to move along the Z axis; and a discharging horizontal movementcylinder drives the discharging vertical movement cylinder to move along the X axis. The detection device applicable to the axis part has the advantages that detection on the axis part can be rapidlycompleted, and efficiency is high.

Owner:NANJING CHERVON AUTOMOBILE PRECISION TECH CO LTD

Macromolecular adhesive coating device for waterproof coiled material processing

ActiveCN113877761ARealize coating functionImprove adaptabilityPretreated surfacesCoatingsAdhesiveMaterials processing

The invention provides a macromolecular adhesive coating device for waterproof coiled material processing, and relates to the technical field of waterproof coiled material processing. The macromolecular adhesive coating device comprises a workbench, a heating shell is fixedly installed in the middle of the upper surface of the workbench, and penetrating through holes are formed in the surfaces of the two sides of the heating shell in a penetrating mode correspondingly; and an overturning upper cover is rotationally mounted at the upper end of the heating shell through a hinge. According to the device, the position of a second coating roller can be adjusted through a first coating assembly, and meanwhile, the contact area between coiled material bodies and an adhesive can be adjusted; so that compared with the prior art, the problems that different sizes of waterproof coiled materials need to be produced during production, the adhesive cannot be matched with the waterproof coiled materials during coating operation, the range of the adhesive cannot be controlled during coating, the problems that materials are wasted and follow-up machining is affected are solved, waste of the materials is greatly reduced, and the strength of later cleaning is reduced are solved.

Owner:WEIFANG HUAGUANG WATERPROOF MATERIALS

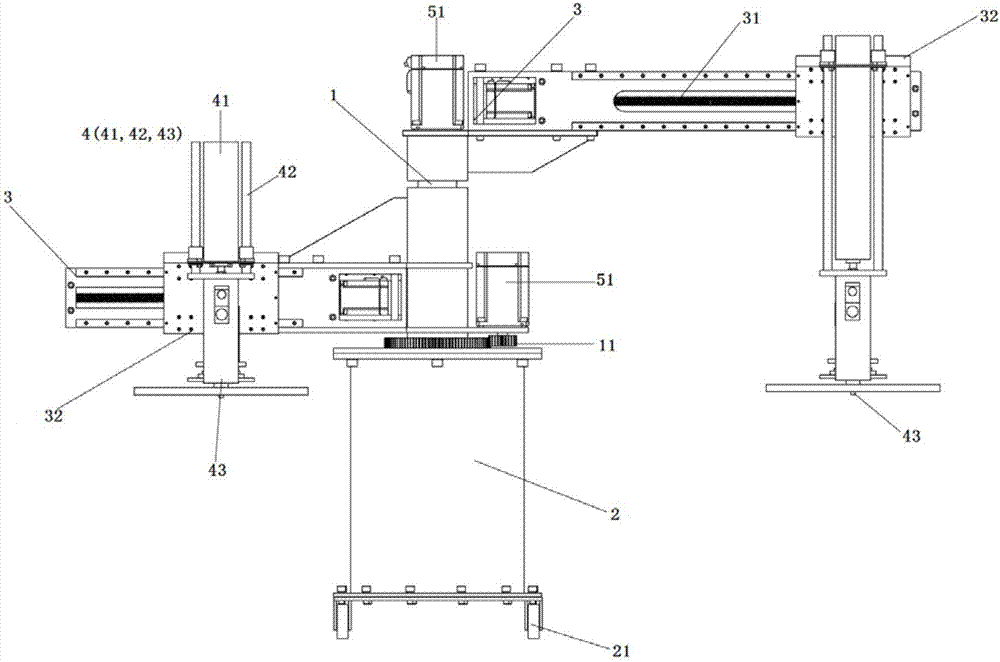

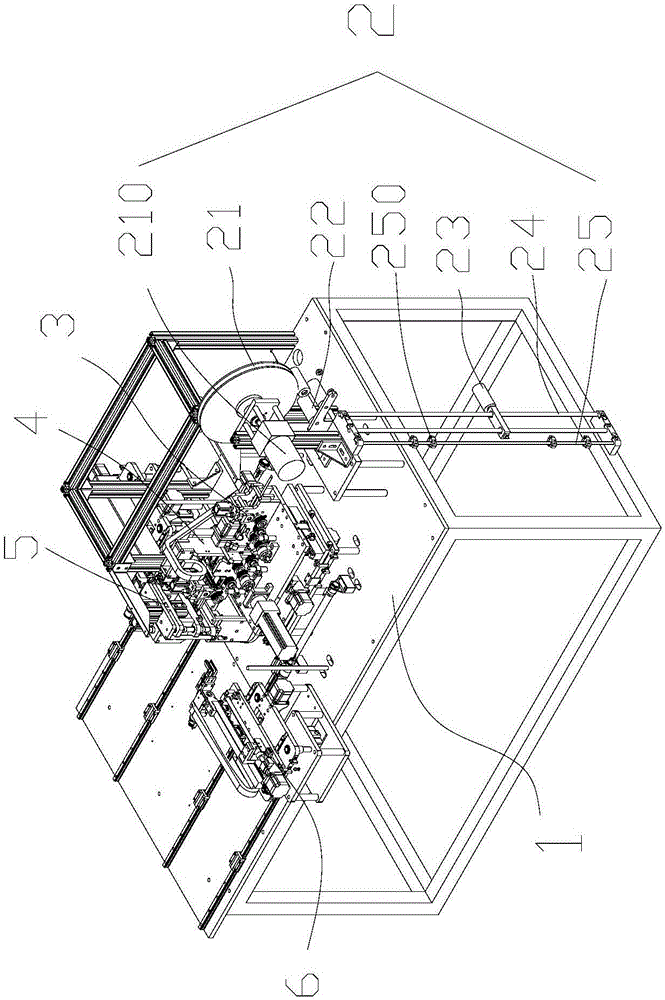

Feeding and discharging device

PendingCN108002031ARealize reclaimingRealize the discharge processConveyor partsAutomationEngineering

The invention relates to the technical field of PCB production and processing, and discloses a feeding and discharging device and method. The feeding and discharging device comprises a spindle, at least one rotating arm, liftable adsorption assemblies and a control assembly, wherein the spindle is fixed to a pedestal; one end of the at least one rotating arm is fixedly connected to the spindle, and the other end of the at least one rotating arm is suspended; the liftable adsorption assemblies are connected to the corresponding rotating arms in a sliding mode and are used for adsorbing materials; and the control assembly is used for controlling the rotating arms to rotate around the spindle and further controlling the liftable adsorption assemblies to slide along the corresponding rotatingarms. The feeding and discharging device is integrated on the same spindle, the materials can be collected and placed through the cooperative relation among the control assembly, the rotating arms andthe liftable adsorption assemblies, and the automation degree of the feeding and discharging working procedures is increased; and moreover, the structure is simple, and the installation cost and subsequent maintenance cost are both low.

Owner:福丰科技(连云港)有限公司

Red calcined material processing system

ActiveCN106800165ARealize transmissionRealize reclaimingConveyorsConveyor partsProcess engineeringMaterials processing

The invention discloses a red calcined material processing system. The red calcined material processing system solves the problems that the machining efficiency is low and meanwhile the safety is low. According to the technical scheme, the red calcined material processing system is characterized by comprising a red calcined material conveying mechanism for receiving and conveying red calcined materials conveyed from the last process, a material conveying limiting grid-blocking mechanism for grid-blocking the red calcined materials on the red calcined material conveying mechanism and conveying the red calcined materials to the tail end one by one, a material conveying grid-blocking mechanism for limiting the red calcined materials to the tail end of the red calcined material conveying mechanism and a grabbing mechanism for grabbing the red calcined materials from the tail end of the red calcined material conveying mechanism and putting the red calcined materials to the next process. The red calcined material processing system achieves automatic conveying, material taking and material putting, and the whole process is more efficient and safer.

Owner:宁波今日自动化科技有限公司

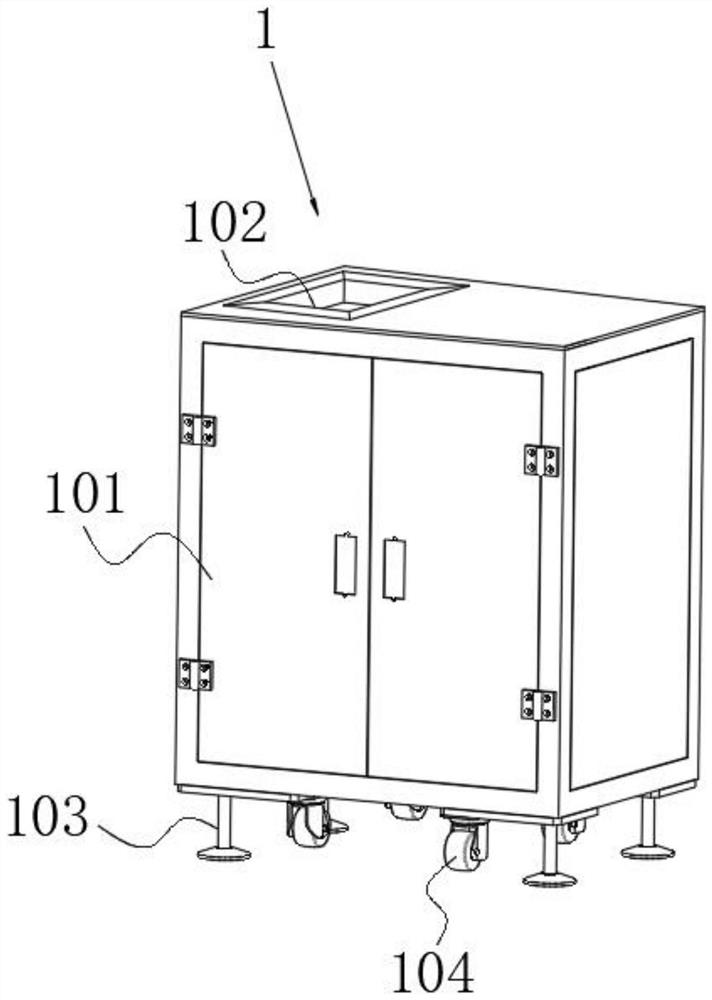

Automatic cover plate pressing machine

ActiveCN107825110ARealize fixed distance transportationRealize reclaimingMetal working apparatusEngineeringMachine

The invention provides an automatic cover plate pressing machine and belongs to the technical field of machining equipment. According to the automatic cover plate pressing machine, the problem that the automation degree of assembling of an existing cover plate and shaft sleeve is low is solved. The automatic cover plate pressing machine comprises a rack. A conveying guide rail and a feeding guiderail are arranged on the rack; a moving seat is slidably connected to the rack; a downward inserting pin is slidably connected to the moving seat in the vertical direction; a driving piece which can drive the moving seat to move and enables the inserting pin to move back and forth between the feeding guide rail and the conveying guide rail is arranged on the rack; and a lifting mechanism which candrive the inserting pin to rise and fall is further arranged on the moving seat. The automatic cover plate pressing machine is higher in automation degree.

Owner:WENLING YOUNIO WATER METER

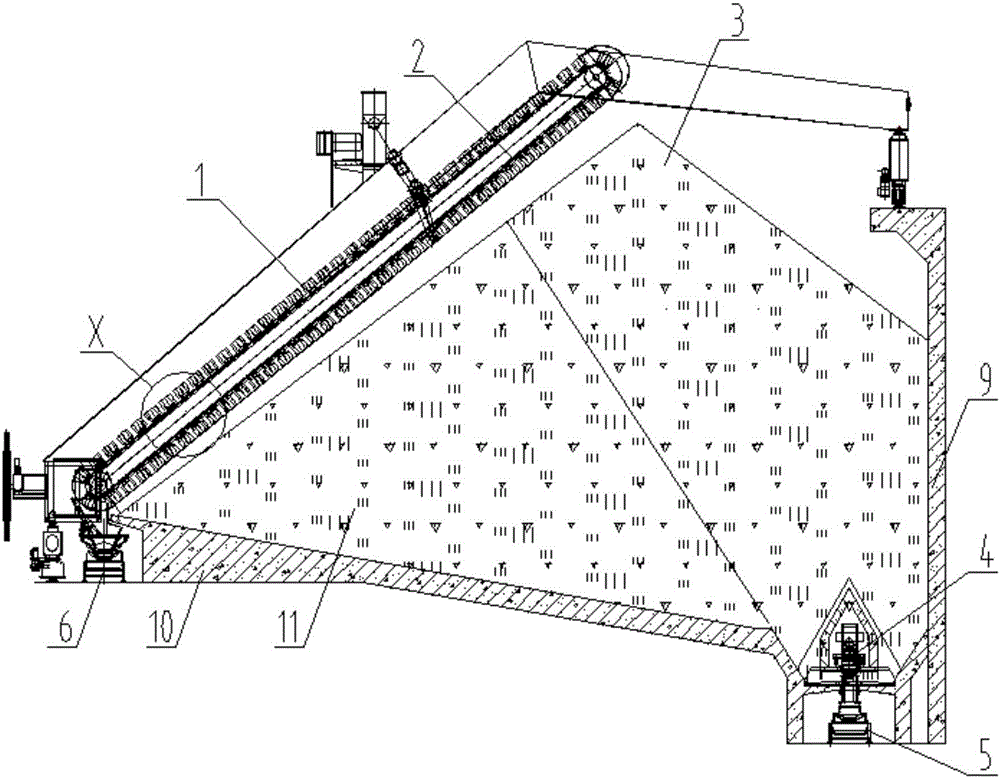

United material taking system and method for material yard

ActiveCN106829519AFlexible feeding methodAvoid useless workConveyorsLoading/unloadingEngineeringYard

The invention provides a united material taking system for a material yard. The united material taking system comprises an outer side output conveyer and a scraper blade material taking machine, wherein the scraper blade material taking machine is provided with a scraper blade mechanism; the united material taking system further comprises an inner side material feeder and an inner side output conveyer which are arranged below a material pile; the scraper blade mechanism comprises a chain and a scraper blade mounted on the chain; the chain clockwise or anticlockwise moves under the action of a driving device to drive the scraper blade to push a material to a corresponding material unloading opening. According to the united material taking system for the material yard, clockwise and anticlockwise motion of the chain of the scraper blade mechanism drives the scraper blade to move and push the material to the output conveyers on the inner and outer sides, and a material taking route can be selected according to a requirement, so that the material taking mode is more flexible, and more output routes are provided. The material level of stored materials is relatively low; when the material level is lower than a horizontal position, the chain anticlockwise moves to drive the scraper blade to move to push the material to the upper side of the inner side material feeder, thus realizing material taking; therefore, unnecessary energy consumption is reduced, and the material taking capacity of the scraper blade material taking machine is effectively guaranteed.

Owner:CISDI ENG CO LTD

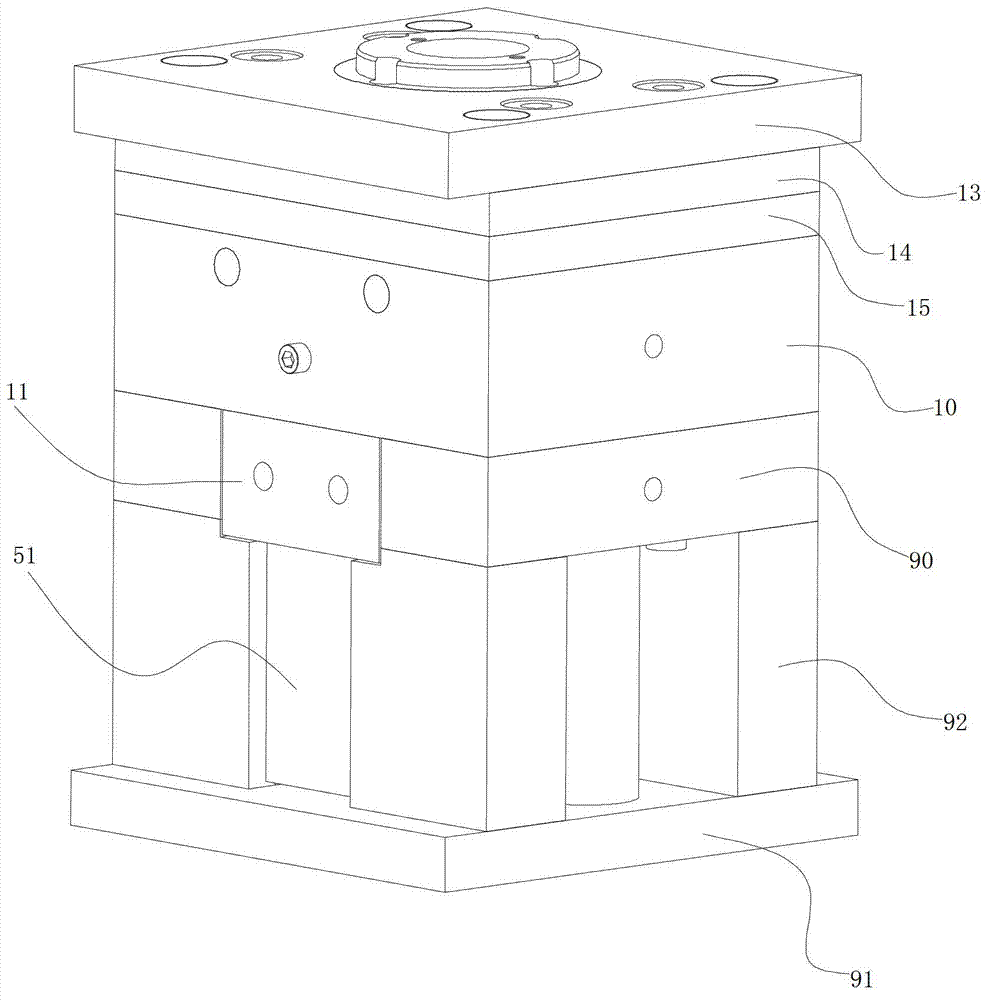

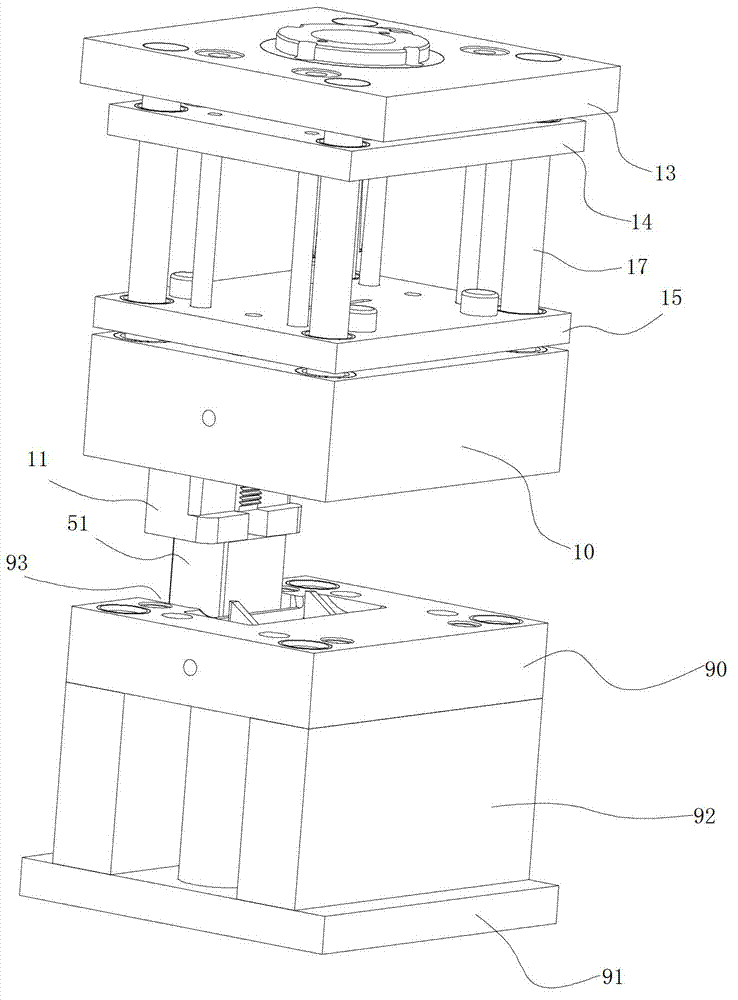

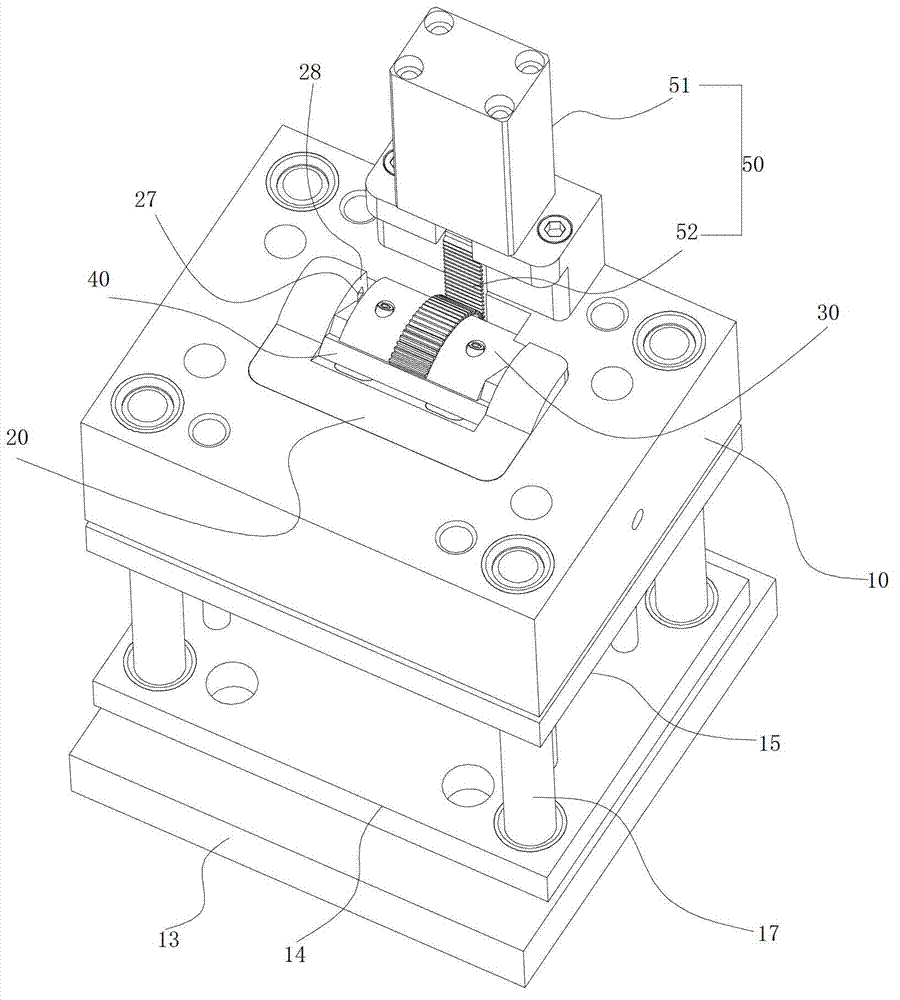

Rotating demolding type mold structure

The invention discloses a rotating demolding type mold structure which comprises a front mold and a back mold, wherein the front mold is provided with a front mold core, and the front mold core is provided with a front mold cavity; a gear board and a position clamping board, which are rotatably connected with each other, and a rectilinear power component used for driving the gear board and the position clamping board, are arranged on the front mold core, and a positioning component is arranged between the front mold core and the position clamping board; the position clamping board is provided with a bent mold cavity, and a bent mold core is arranged on the gear board; the gear board and the position clamping board are closed with the front mold core under the status of mold assembly, and a sealed forming mold cavity is formed by the bend mold core, the bent mold cavity and the front mold cavity; and the rectilinear power component drives the gear board and the position clamping board to rotate under the demolding status, the position clamping board is rotated to the position of the positioning component to be fixedly connected with the front mold core, and the gear board is driven by the rectilinear power component to withdraw the bent mold core out of the formed bent product. After the rotating demolding type mold structure is used, two rotating driving can be completed at the same time, the core withdrawing and the material withdrawing of the bent product can be realized, and the rotating demolding type mold structure has the characteristics of being simple in structure, low in manufacture cost, and easy to maintain; and the rotating demolding type mold structure is applicable to the injection process of various bent products.

Owner:乔丰科技实业(深圳)有限公司

Salt covering treatment method for salting smelly mandarin fish

The invention discloses a salt covering treatment method for salting smelly mandarin fish, which comprises the steps of fish cleaning, fishy smell removal, salt frying and salt covering. The method has the beneficial effects that the mandarin fish is transferred by using a moving frame, so that automatic feeding and taking of mandarin fish salt covering operation are realized, manual pushing operation is not needed, and the operation is simple and convenient. The use efficiency of the device is further improved, manpower and time are saved, fatigue of operators is relieved, and meanwhile, manual pushing operation is reduced, so that pollution of hands to mandarin fishes is reduced, the sanitary condition of the whole salt covering operation is improved, deterioration of the mandarin fishes is reduced, and economic benefits are improved. A clamping net is driven by a third motor, the mandarin fish can be rotationally adjusted, so that the mandarin fish can be more comprehensively coated with salt, the situation that the mandarin fish goes bad due to the fact that the mandarin fish is not locally coated with salt is avoided, the mandarin fish salt coating uniformity is improved, and the mandarin fish salt coating effect of the device is improved.

Owner:黄山市鑫黄山特产有限公司

Cosmetic box assembling machine having mirror mounting function

InactiveCN111546055ASuccessful realization of reclaimingSuccessful installationMaterial gluingAssembly machinesAdhesiveSlide plate

The invention relates to a cosmetic box assembling machine having the mirror mounting function. The cosmetic box assembling machine comprises a material box conveying station, an air-blowing cleaningstation, an indenting station, a first adhesive dispensing station, a mirror mounting station, a second adhesive dispensing station, a metal piece mounting station and a discharging station; the mirror mounting station is mounted on an operating platform, is located in the downstream position of the first adhesive dispensing station and is used for transferring mirrors discharged one by one into material boxes; and the mirror mounting station comprises two first supporting pieces mounted on the operating platform and arranged in a spaced manner, first supporting sliding plates glidingly mounted on the two first supporting pieces through first translation mechanisms, a mirror suction cup assembly which is glidingly mounted on the first supporting sliding plates and can rise and fall as wellas a mirror supply assembly mounted on the operating platform and matched with the mirror suction cup assembly. By the aid of the cosmetic box assembling machine, the mirrors can be taken and mountedsuccessfully, and the automation degree of the cosmetic box assembling machine can be guaranteed.

Owner:赵龙英

Automatic loading device for sheet materials

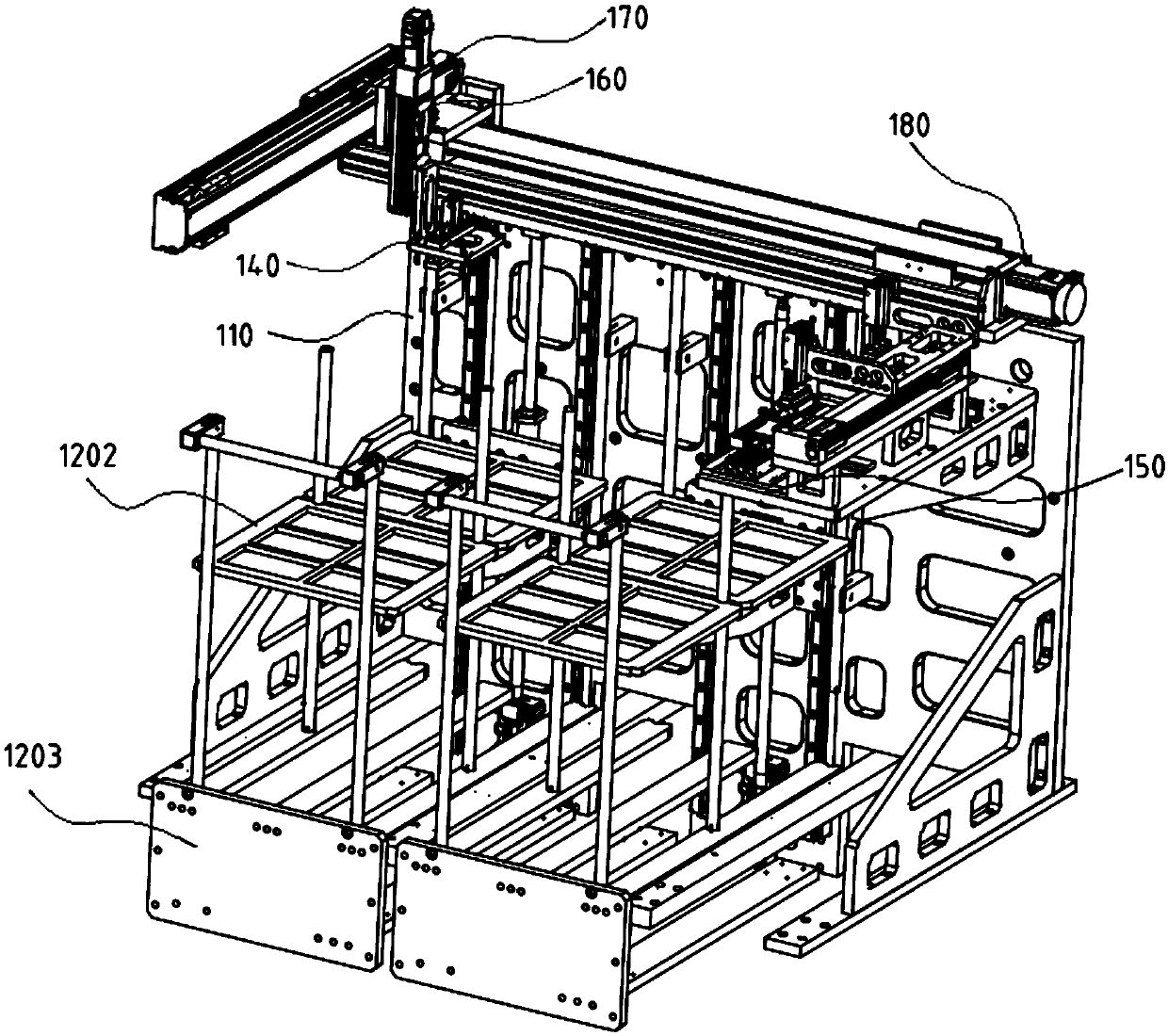

PendingCN109573619AFully automatedFacilitate follow-up work processCharge manipulationConveyor partsControl systemData acquisition

The invention discloses an automatic loading device for sheet materials. The device comprises a rack and a transporting and fetching mechanism arranged on the rack, a tray placing mechanism, a fetching mechanism and a discharging platform, wherein the rack is further provided with a second Z-direction driving mechanism capable of driving the transporting and feeding mechanism to translate in a Z direction a third Z-direction driving mechanism capable of driving the tray placing mechanism to translate in the Z direction; an adjusting mechanism is arranged at the discharging platform of the rackfor adjusting the position of the sheet materials, and a second X-direction driving mechanism capable of driving the adjusting mechanism to translate in an X direction is arranged on the dischargingplatform of the rack; a data collector capable of collecting the position information of the sheet materials is arranged at the discharging mechanism; and the automatic loading device further includesa control system. By means of the device, the continuous automatic loading of the sheet materials is achieved by the design of the loading mechanism, the tray placing mechanism, the fetching mechanism and the adjusting mechanism, so that the production efficiency is improved and one person using multiple machines is achieved; and the device is particularly suitable for loading during a glass plate grinding process of the mobile phone, the fully automated and continuous production of mobile glass panels is accelerated.

Owner:KUNSHAN HENGDA PRECISION MACHINERY IND CO LTD

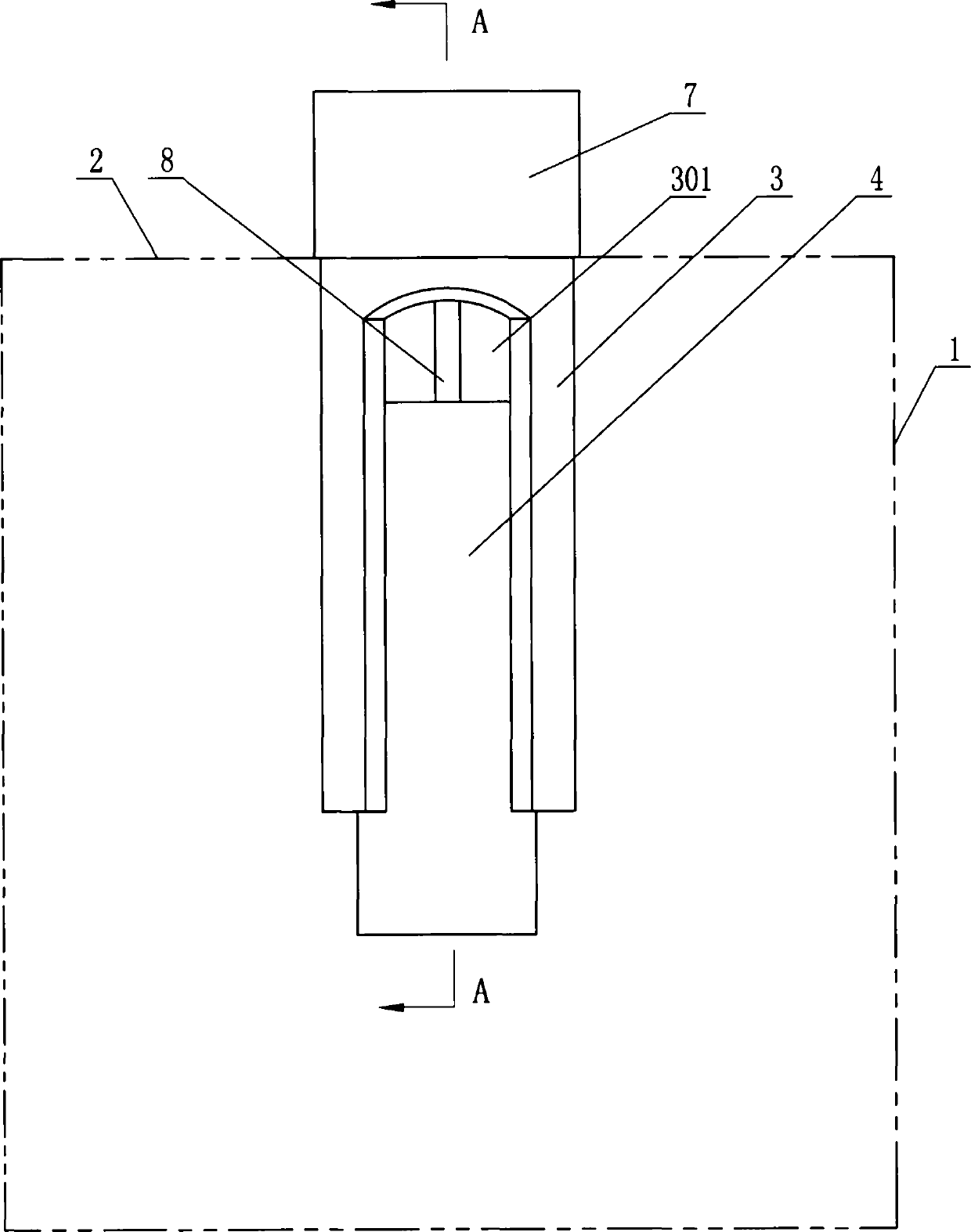

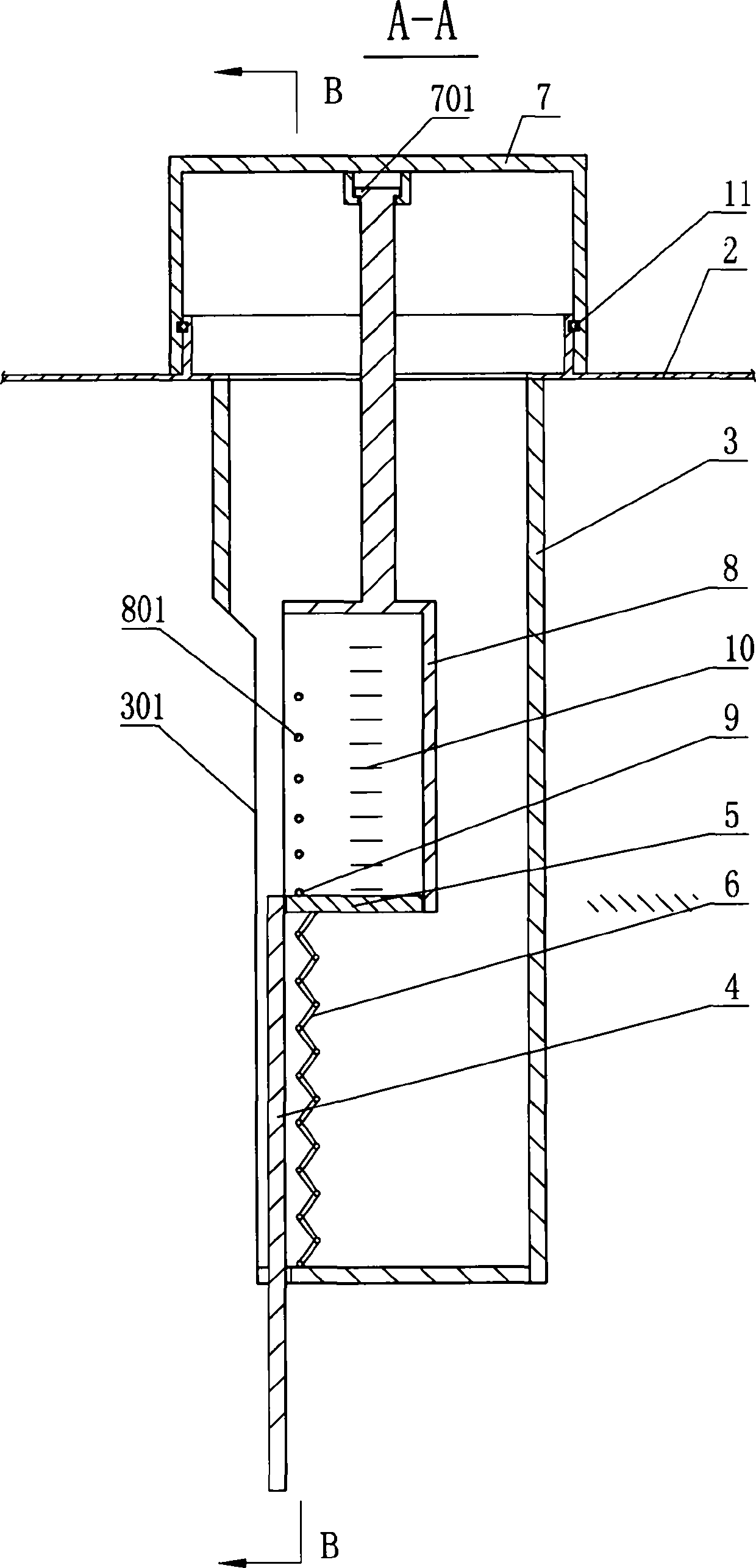

Gaugeable container

InactiveCN104176379AReduce the risk of contaminationUse clean and hygienicPowdered material dispensingEngineeringBottle cap

A gaugeable container comprises a tank body and a tank cover, wherein an axial opening runs through the tank cover; a measuring bottle body and the tank cover are integrally formed, and the measuring bottle body is communicated with the axial opening; the measuring bottle body is positioned in the tank body; a material inlet / outlet extending in the axial direction is formed in the bottle wall of the measuring bottle body and communicated with the interior of the tank body; a sliding cover is connected onto the material inlet / outlet in a sliding manner and used for opening or closing the material inlet / outlet; a baffle is arranged at the upper end of the sliding cover; a spring is arranged between the baffle and the bottom of the measuring bottle body; the periphery of the axial opening of the tank cover is in hermetical threaded connection with a bottle cap; the inner side of the cover cap is connected with a measuring spoon capable of rotating relatively; the spoon body of the measuring spoon is communicated with the material inlet / outlet and extends in the axial direction of the measuring bottle body; a pushing part is fixedly connected with the inner side of the spoon body of the measuring spoon; the pushing part is propped against the upper end face of the baffle; the baffle extends into the measuring spoon in the radial direction; the wall surface of the outer circumference of the baffle is propped against the wall surface of the inner circumference of the spoon body of the measuring spoon. The gaugeable container is convenient to meter, clean and sanitary, and has a measuring function.

Owner:两化(宁波)科技有限公司

System for automatic detection of moisture content of concrete aggregate

PendingCN108225971ASolve the problem that the aggregate in the middle of the conveyor belt cannot be removedPrevent normal transmissionWeighing by removing componentSolid waste managementEngineeringControl circuit

The invention provides a system for automatic detection of moisture content of concrete aggregate. The system comprises a material taking assembly, a material container, a drying assembly, a weighingassembly and a control circuit, wherein the material taking assembly comprises a mounting frame, two slide rails, two mounting rods, a first spring, a first cylinder, a push plate, a shovel and a mounting mechanism, wherein the mounting frame is erected on the ground, the two slide rails which are mutually parallel are mounted on the mounting frame, one mounting rod capable of sliding under the guide of each slide rail is mounted on each slide rail, the two mounting rods are positioned in a vertical direction, and the shovel is arranged between the two mounting rods; the material container ispositioned below the shovel close to the first cylinder; the drying assembly is used for drying aggregate in the material container; the weighing assembly is used for supporting the material container; and both the first cylinder and the weighing assembly are connected with the control circuit. The system for automatic detection of the moisture content of the concrete aggregate solves the problemin the prior art that the aggregate at the middle part of a conveying belt can not be taken because only the aggregate at the discharge end of a feeding belt can be taken.

Owner:重庆富沛新型建材有限公司

Secondary transferring hopper device convenient to change feeds

The invention discloses a secondary transferring hopper device convenient to change feeds. The secondary transferring hopper device convenient to change the feeds comprises primary feeding pipes, secondary feeding pipes, hoppers and valve assemblies, wherein at least two primary feeding pipes are arranged; primary discharge holes with corresponding positions are arranged on the lower parts of theprimary feeding pipes; the hoppers are fixedly arranged on the primary feeding pipes corresponding to the primary discharge holes; secondary discharge holes located under the primary discharge holes are formed in the lower parts of the hoppers; secondary feeding pipes communicating with the secondary discharge holes are fixedly arranged on the secondary discharging holes; and the valve assembliescapable of closing and opening the primary discharge holes are arranged on the hoppers. According to the secondary transferring hopper device convenient to change the feeds provided by the invention,the two primary feeding pipes can be arranged, different feeds can be conveyed through different feed lines according the demands of a hog house, and the hoppers can control blanking ports to open andclose according to the needs, so that the feeds can be taken separately through the feed lines according to the needs.

Owner:INST OF ANIMAL SCI OF CHINESE ACAD OF AGRI SCI

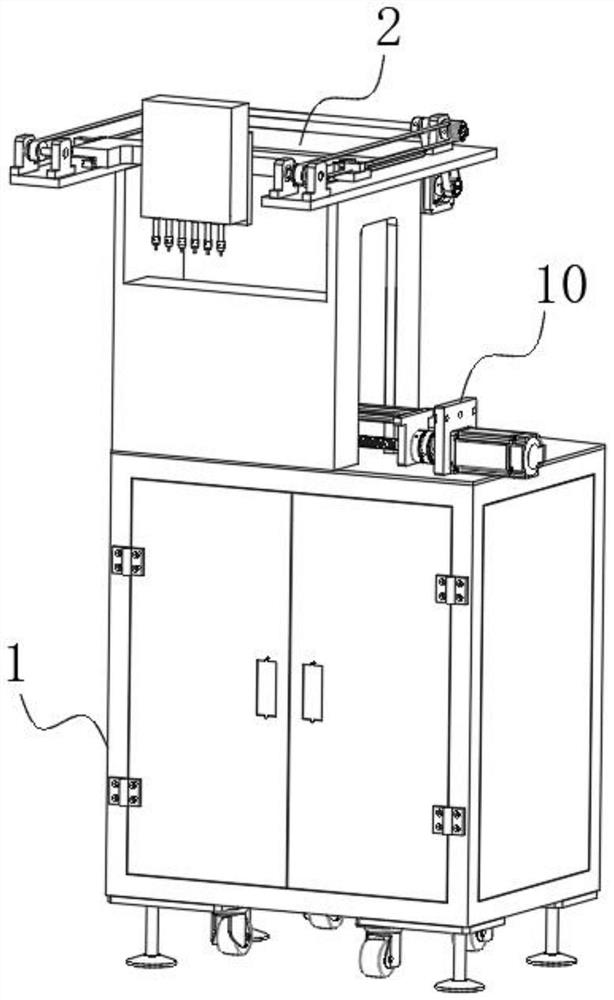

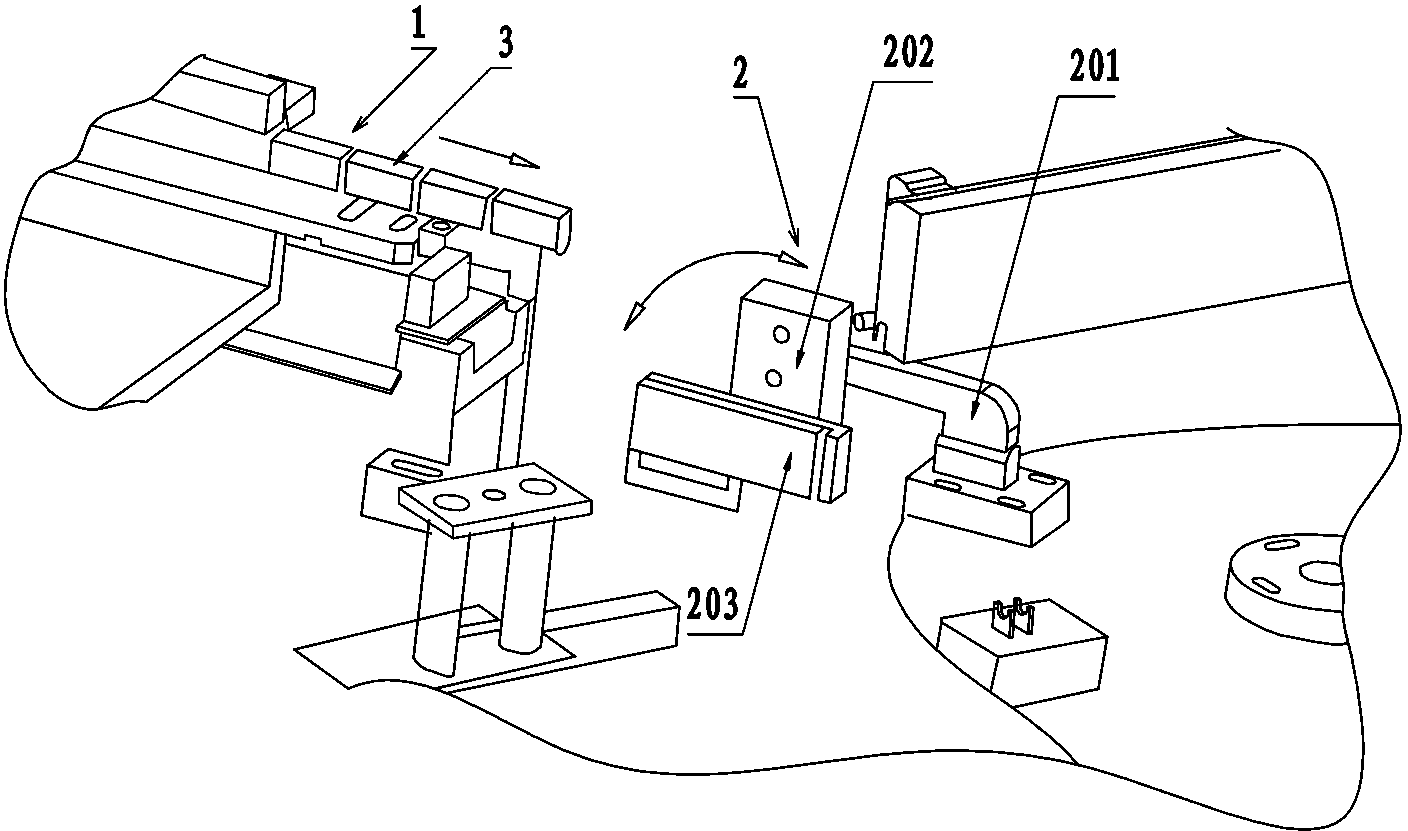

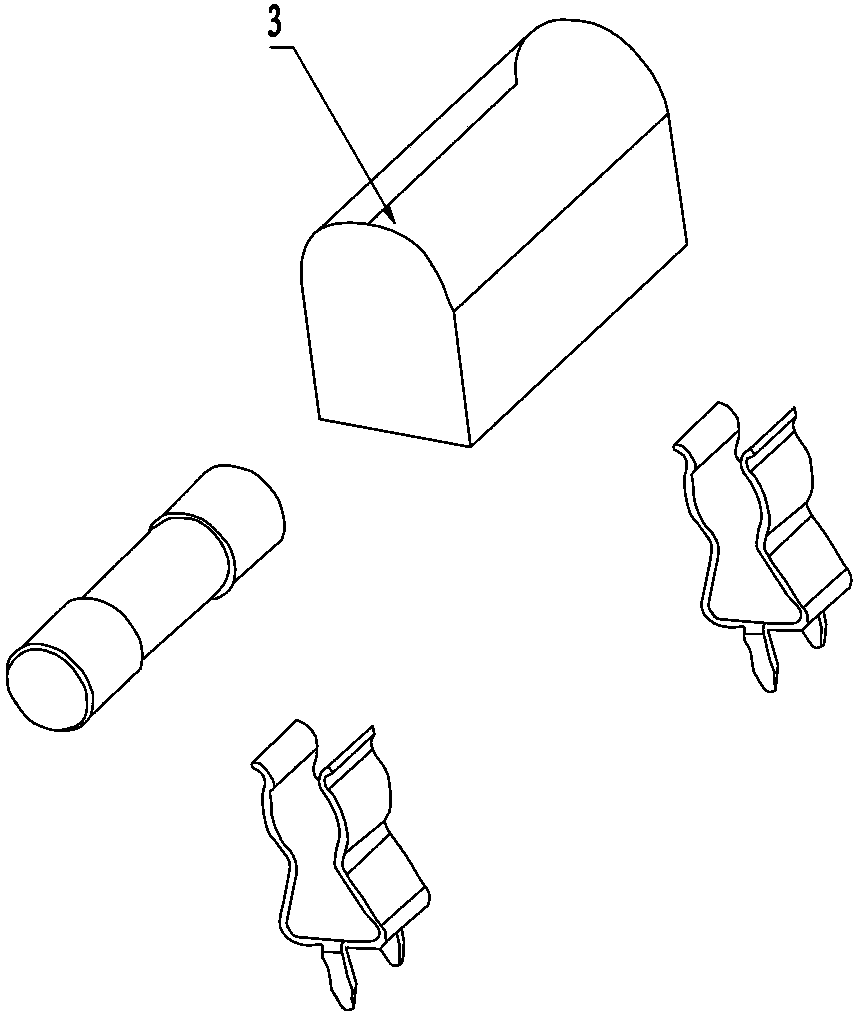

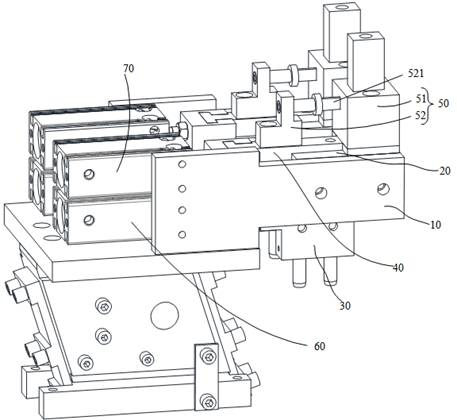

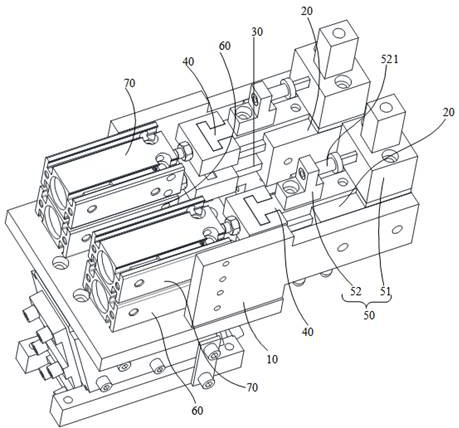

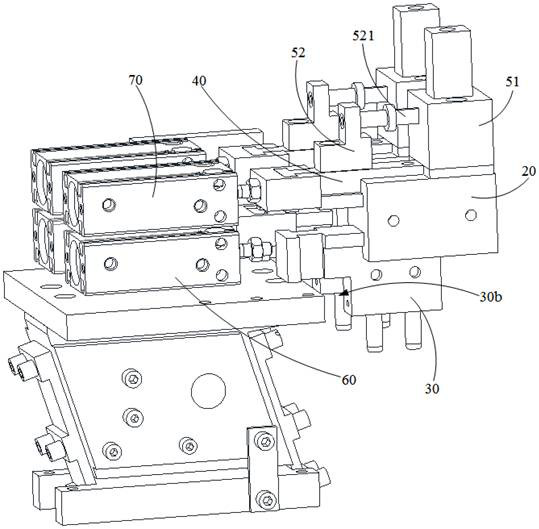

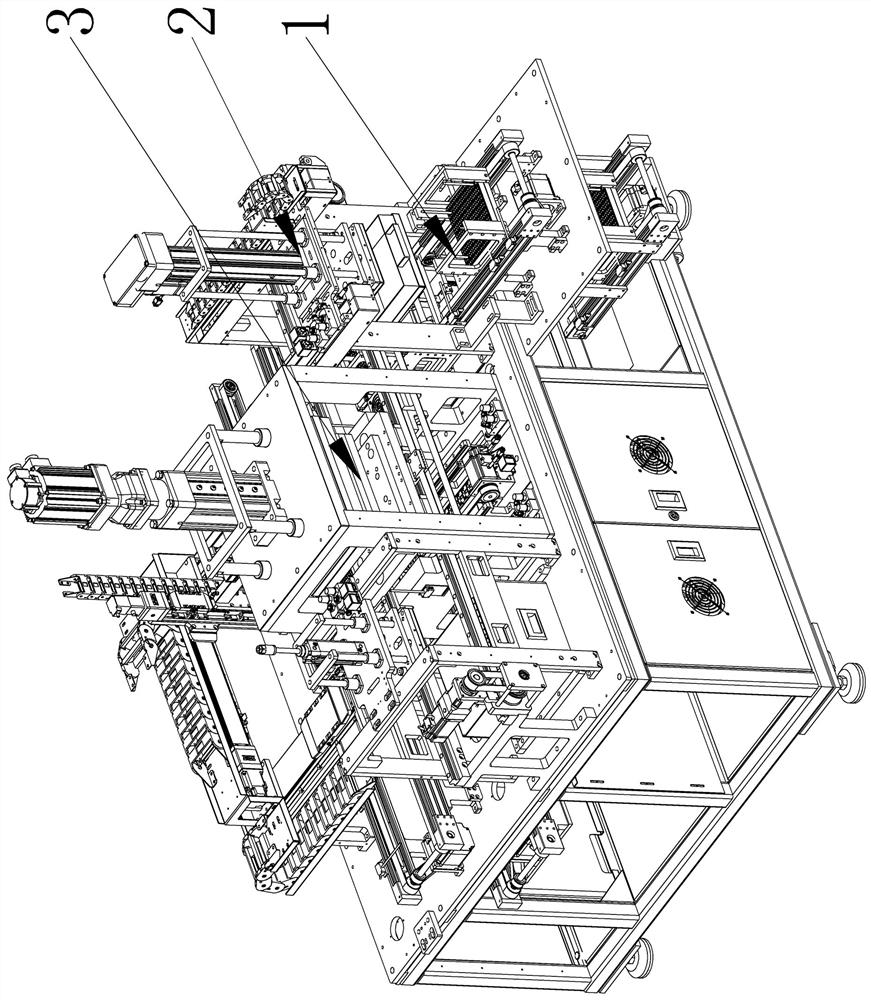

Plastic cement sleeve assembling mechanism for protective tube automatic assembling machine

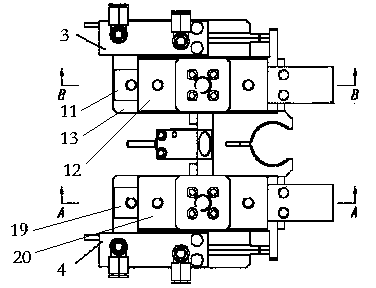

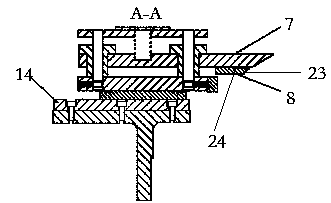

InactiveCN103962820ARealize reclaimingRealize the installation and assembly actionMetal working apparatusReciprocating motionPlastic cement

The invention relates to a plastic cement sleeve assembling mechanism for a protective tube automatic assembling machine. The plastic cement sleeve assembling mechanism comprises a vibrating disk used for vibration feeding, a conveying piece used for conveying plastic cement sleeves and a plastic cement sleeve grabbing assembly. One end of the conveying piece is matched with the discharging end of the vibrating disk for receiving the plastic cement sleeves, and the other end of the conveying piece is matched with the plastic cement sleeve grabbing assembly for fetching the plastic cement sleeves. The plastic cement sleeve grabbing assembly comprises a vacuum suction nozzle, a rotating cylinder and an adjusting cylinder. The vacuum suction nozzle is driven by the rotating cylinder to make rotating motion, the rotating cylinder further drives the vacuum suction nozzle to make straight reciprocating motion through the adjusting cylinder which is fixedly connected to a workbench, and accordingly grabbing and mounting assembly of the plastic cement sleeves can be matched respectively. According to the scheme, the plastic cement sleeve grabbing assembly in the plastic cement sleeve assembling mechanism is used for grabbing and fetching the plastic cement sleeves which are placed at the tail end of the plastic cement sleeve conveying piece on the upstream portion, and therefore the single mechanism can make continuous fetching and mounting assembly movement to the plastic cement sleeves.

Owner:FOSHAN ZHONGGEWEI ELECTRONICS

Stainless steel continuous bending device

PendingCN113510171ARealize deliveryStable clampingMetal-working feeding devicesPositioning devicesHydraulic cylinderStructural engineering

The invention discloses a stainless steel continuous bending device which comprises a base. Four supporting rods are fixedly connected to the base, the upper ends of the four supporting rods are jointly and fixedly connected with a top plate, a plurality of first supports are installed on a machining table, a plurality of first transmission wheels are installed on the multiple first supports, a transmission mechanism is arranged among the multiple first transmission wheels, multiple second transmission wheels which are matched with the multiple first transmission wheels and can move are arranged above the multiple first transmission wheels, two hydraulic cylinders are installed on the top plate, and the output ends of the two hydraulic cylinders are jointly and fixedly connected with a moving plate; and a driving mechanism is arranged between the moving plate and the adjacent first transmission wheel. According to the stainless steel continuous bending device, by means of the hydraulic cylinders, a cutting machine moves downwards to cut and bend stainless steel pipes, the stainless steel pipes can be conveyed in an equal-length manner, meanwhile, the bent stainless steel pipes can be taken out, manual taking out is not needed, and meanwhile, the stainless steel pipes can be continuously machined.

Owner:曹明燕

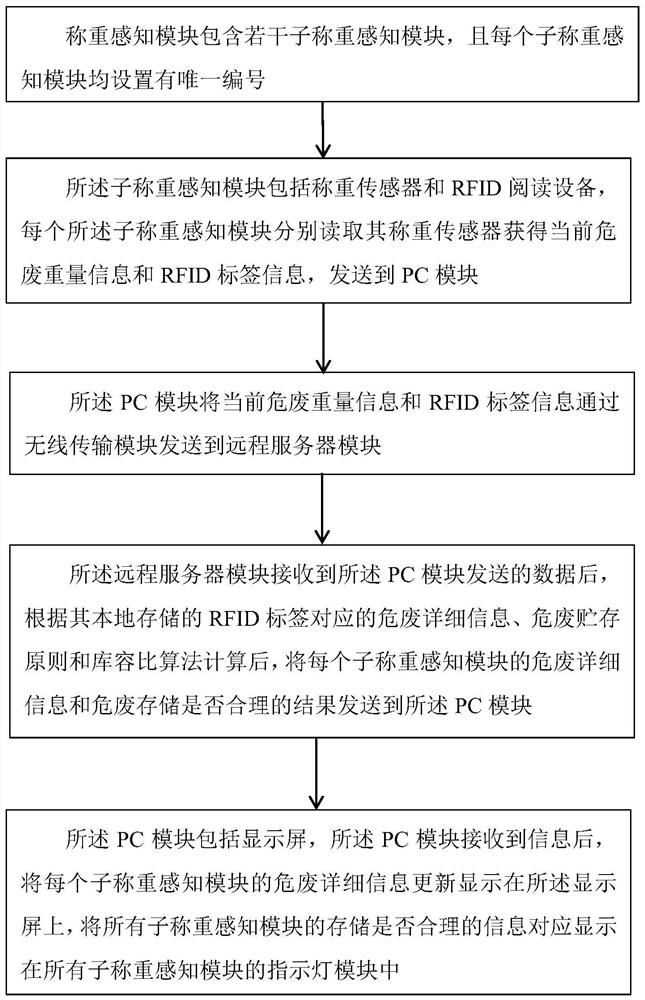

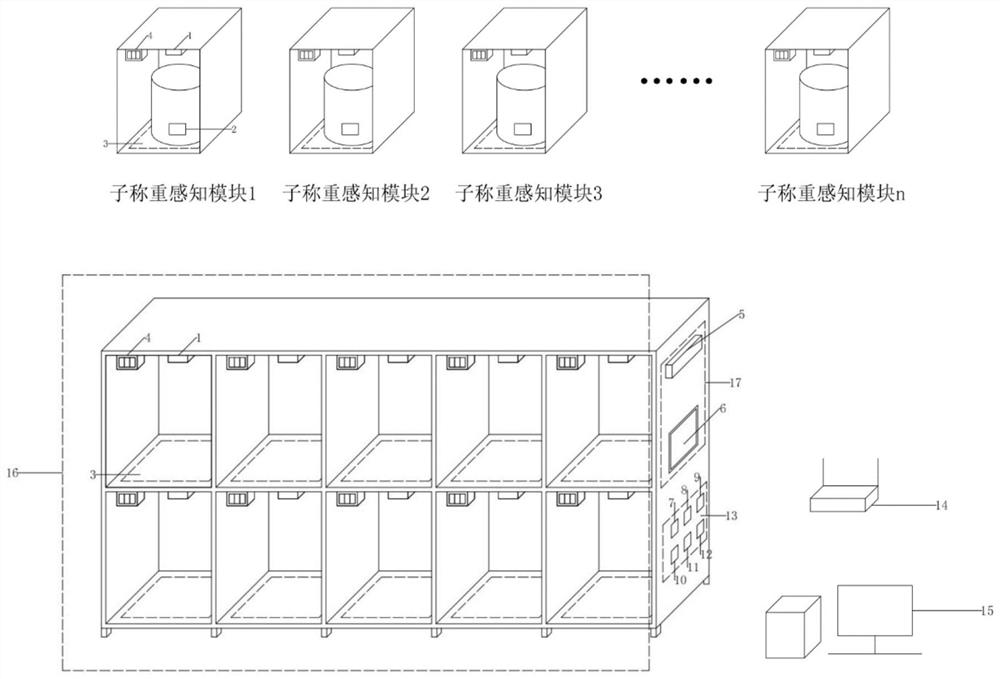

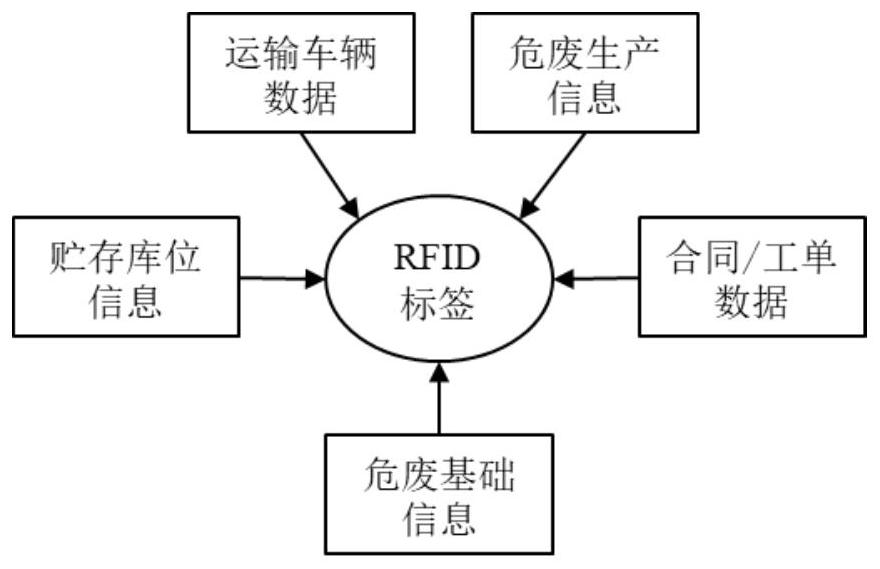

RFID-based dangerous and waste real-time risk early warning method and device

ActiveCN112862032AReal-time monitoring searchRealize automatic incineration compatibility calculationInterprogram communicationCo-operative working arrangementsWireless transmissionHazardous waste

The invention discloses an RFID-based hazardous waste real-time risk early warning method and device, and the method and device are based on an RFID technology, and are combined with a weighing sensing module, a remote server module, a PC module, a wireless transmission module, a hazardous waste storage monitoring module and a risk sensing module to carry out hazardous waste information scanning, hazardous waste storage classification, calculation and updating. The RFID technology is adopted, batch reading and writing can be achieved, hazardous waste information can be monitored in real time, hazardous waste searching and risk early warning are facilitated, accidents caused by improper storage are avoided. Meanwhile, automatic incineration compatibility calculation and material taking can be achieved, the process is simple and convenient, and safety is high.

Owner:NANJING UNIV

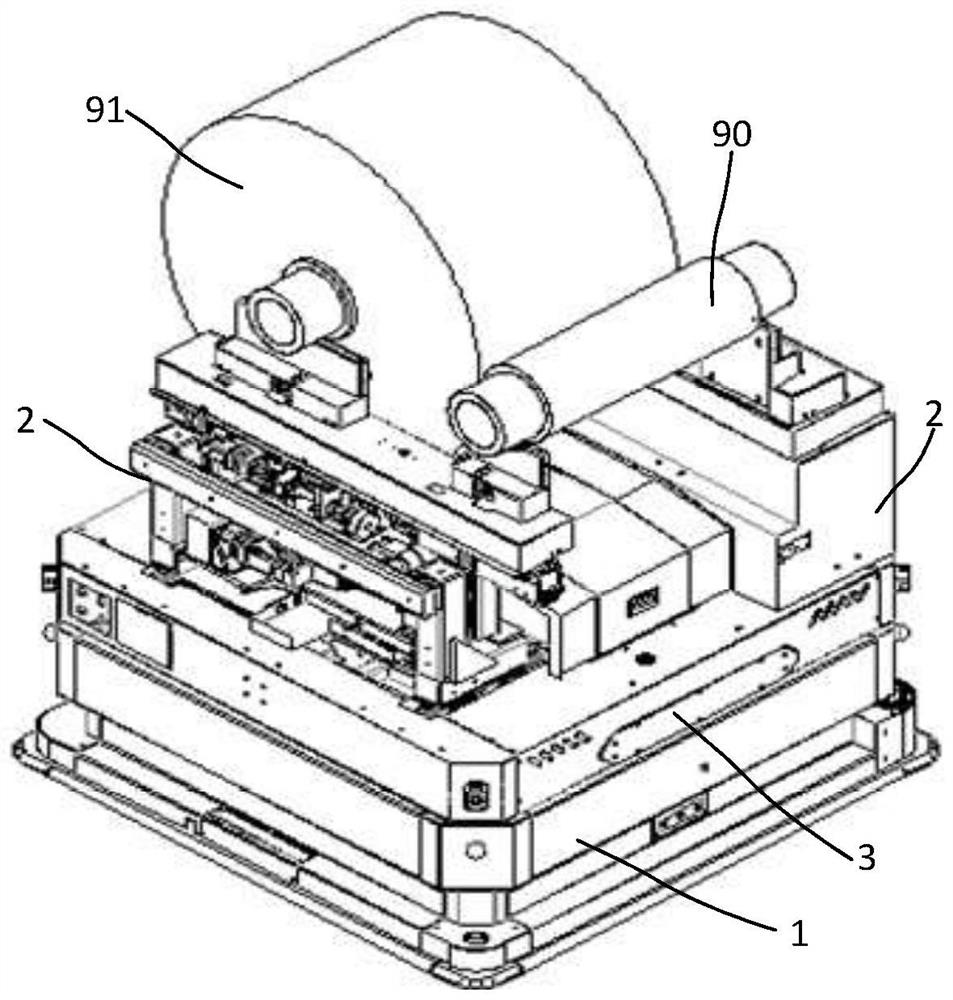

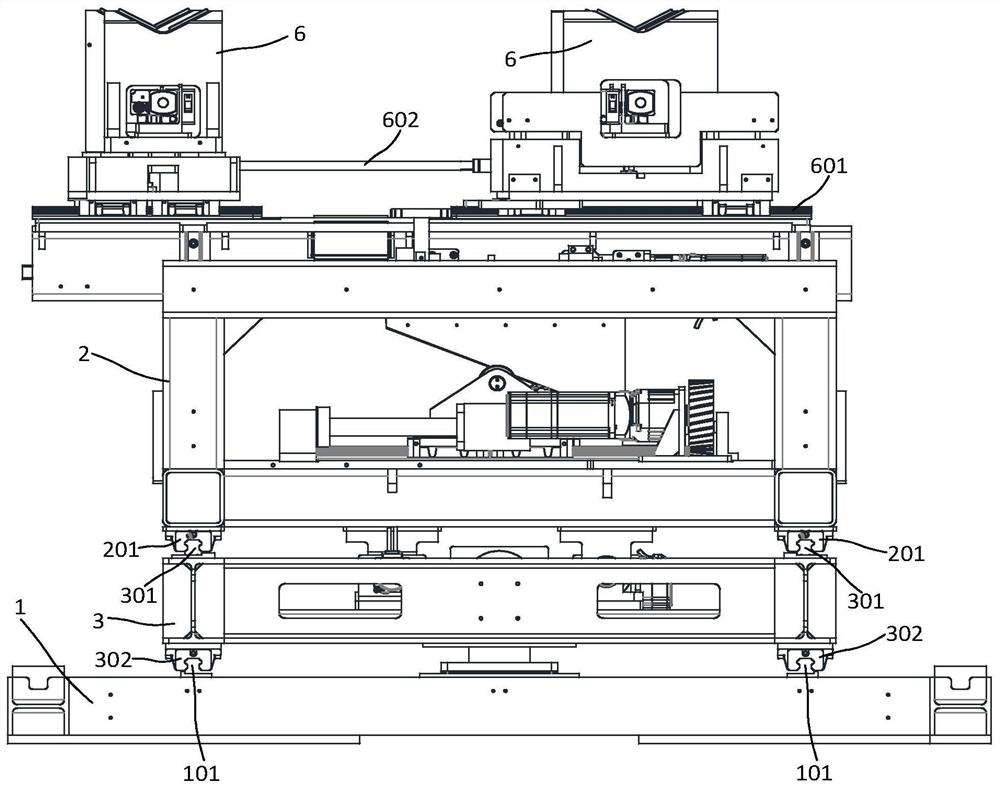

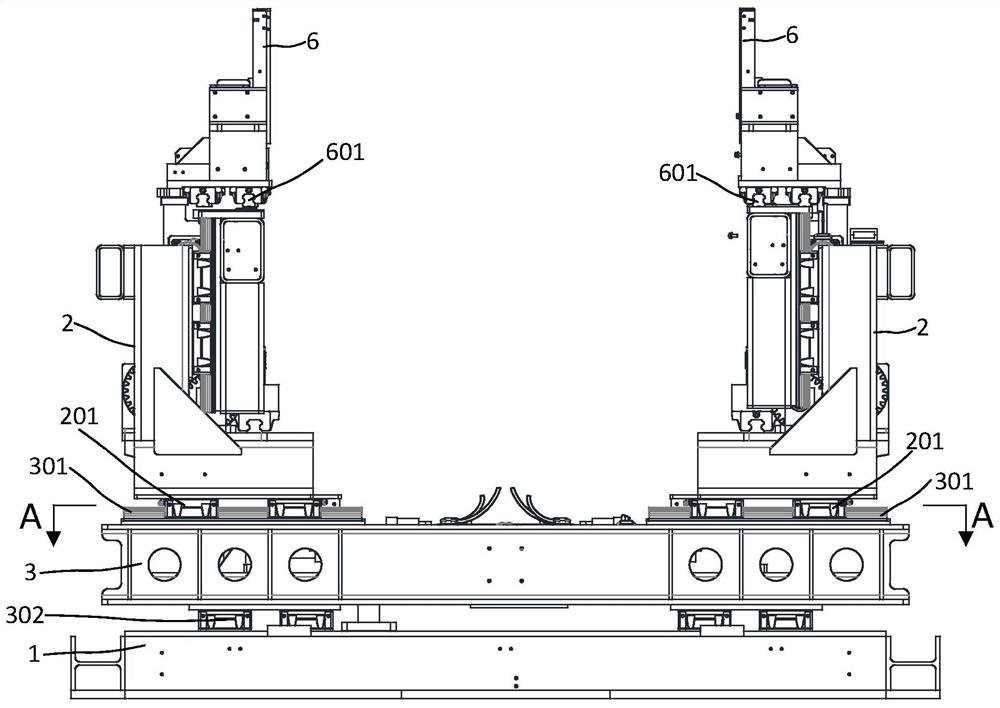

Double-lifting AGV

PendingCN112830178AImprove stabilityCompact structureLifting devicesMechanical conveyorsGravity centerIndustrial engineering

The invention provides a double-lifting AGV. The double-lifting AGV comprises a bottom layer fixing structure, a middle layer platform and two lifting mechanisms, wherein the bottom layer fixing structure is used for being installed on the AGV; the middle layer platform is slidably arranged at the top of the bottom layer fixing structure; the two lifting mechanisms are slidably arranged on the two sides of the top of the middle layer platform correspondingly, and at least two bearing structures are arranged at the tops of the lifting mechanisms; the bearing structures on the two opposite lifting mechanisms are in one-to-one correspondence; and the corresponding bearing structures form a set of stations. The four bearing structures form the two lifting stations, two reel type goods can be lifted simultaneously, and material taking and discharging can be achieved at a time; the distance between the two lifting mechanisms can be adjusted so as to adapt to the reel type goods with different lengths, the takt is saved, and the productivity is improved; and the lifting structures are compact in structure, horizontal movement can be converted into vertical movement, the space occupancy ratio is decreased, the gravity center is lowered, and the stability of the AGV is improved.

Owner:铽罗(上海)机器人科技有限公司

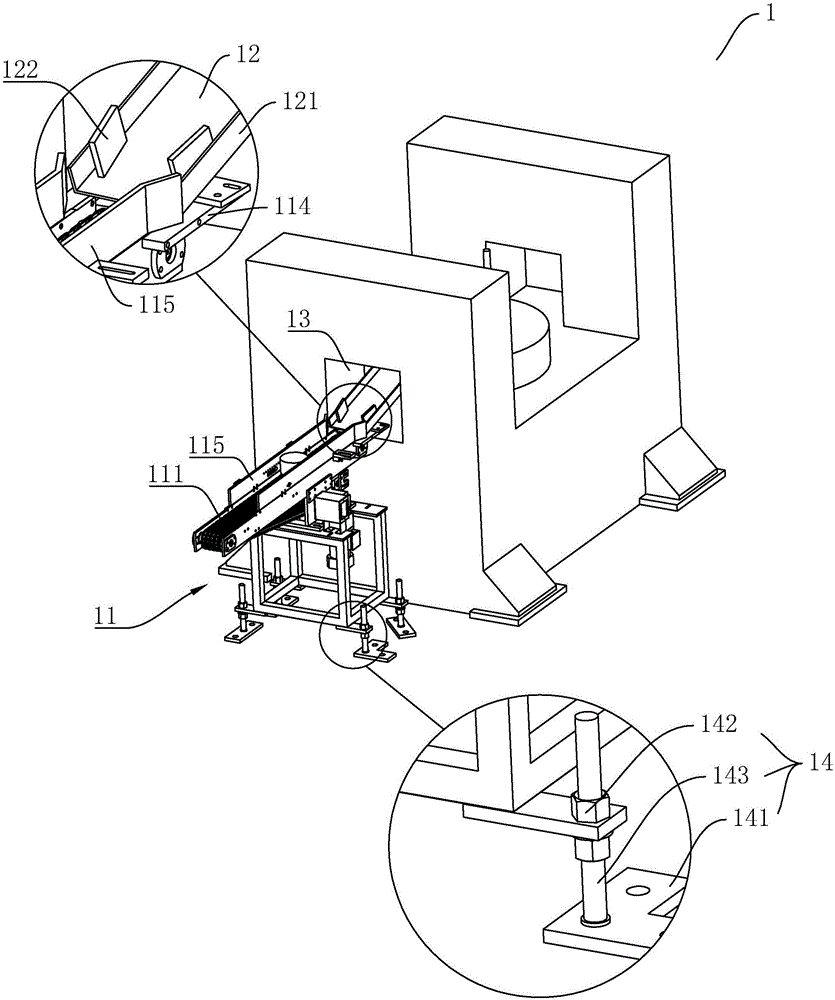

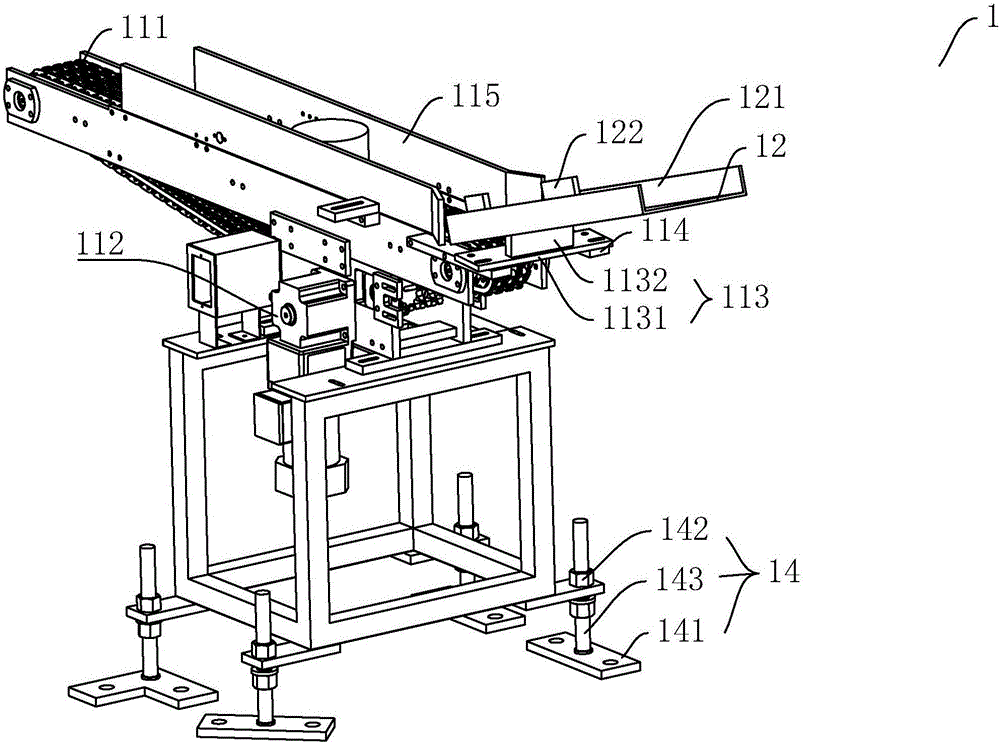

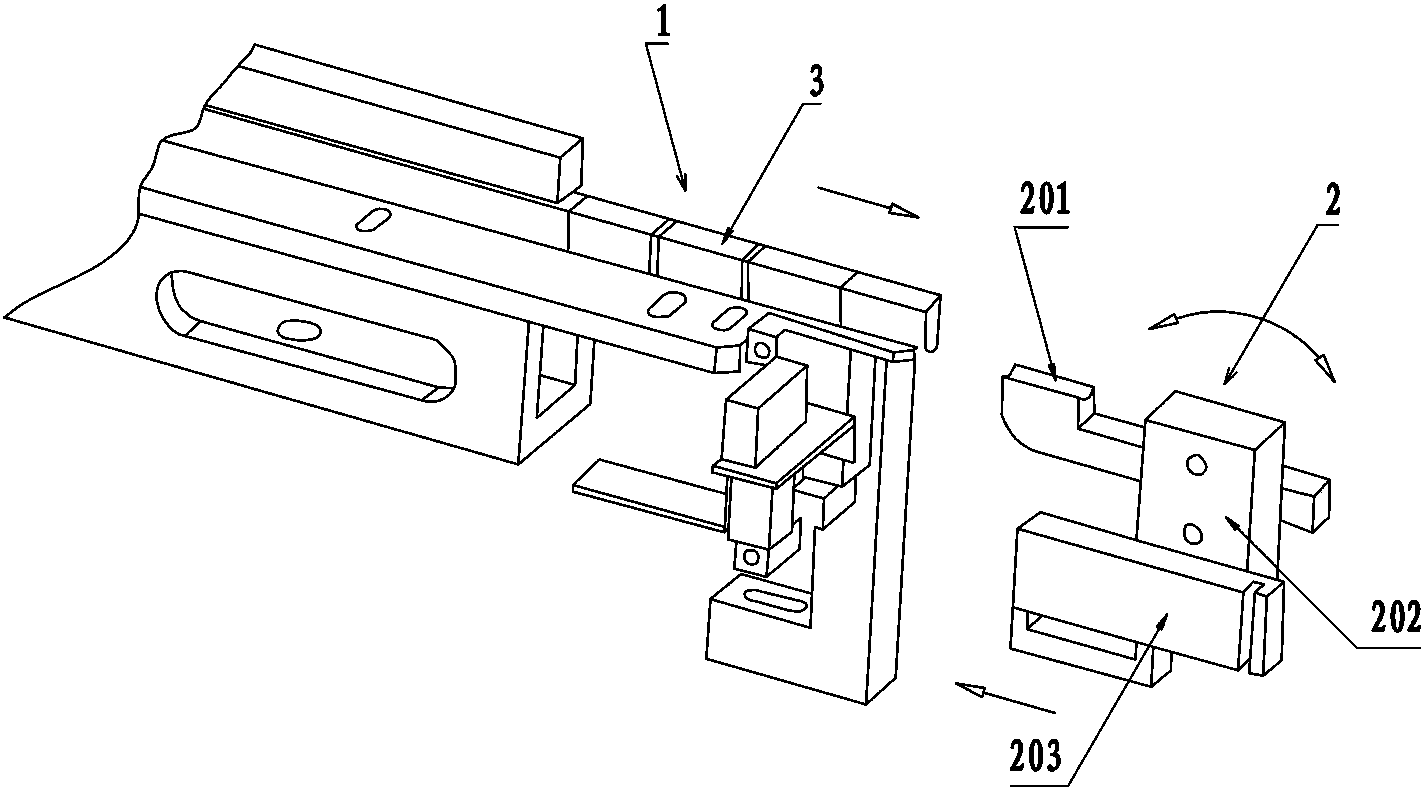

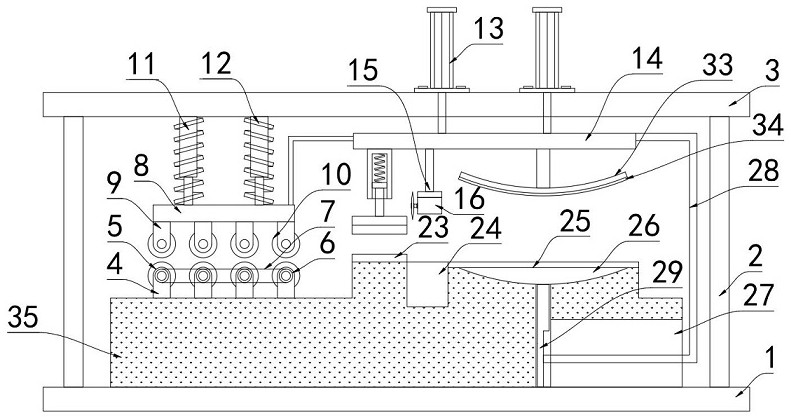

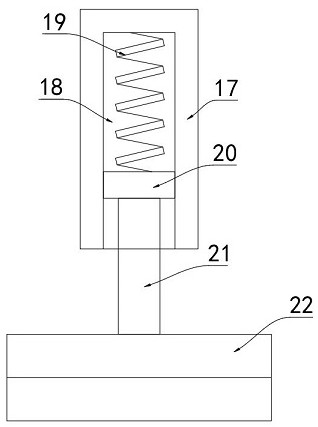

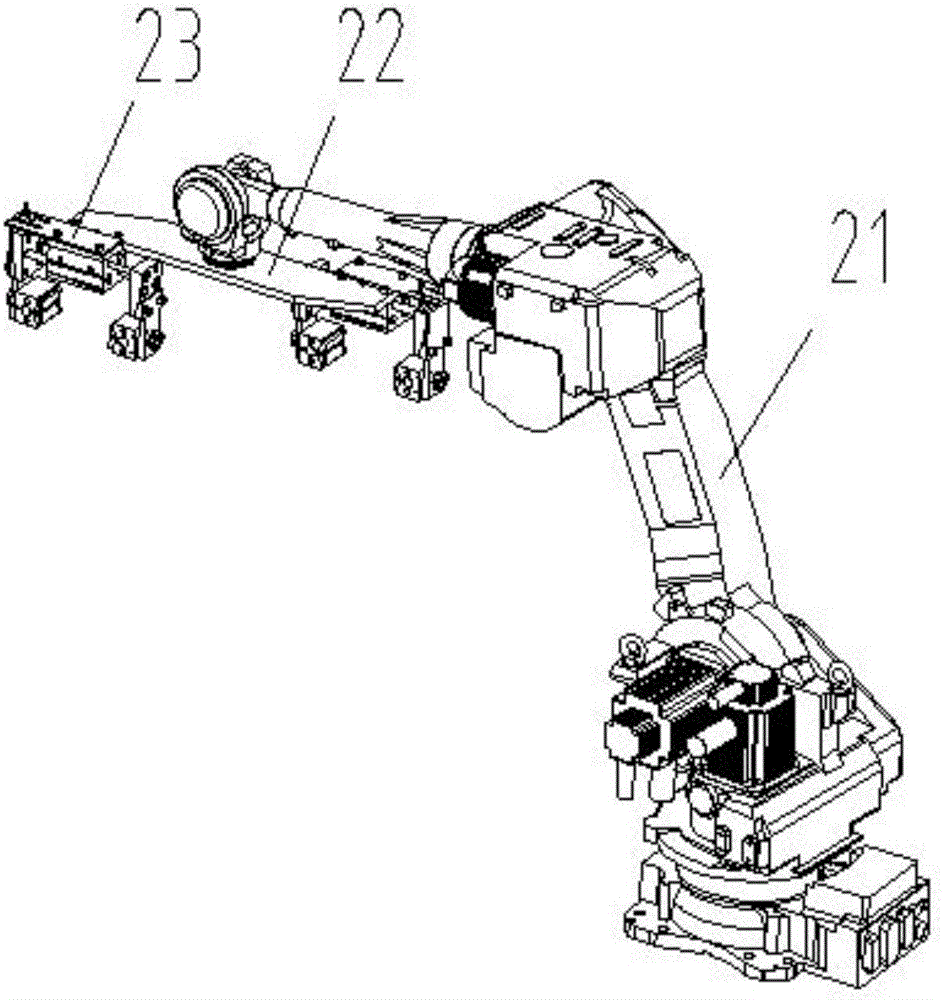

Automated bar part machining system and automated bar part machining method by numerical control lathe

InactiveCN104493205AShorten processing timeAvoid wasting time and effortAutomatic/semiautomatic turning machinesAutomatic conveying/guiding stockManipulatorEngineering

The invention relates to an automated bar part machining system and an automated bar part machining method by a numerical control lathe. The automated bar part machining system comprises a chuck portion and a tool array portion, and is characterized in that the tool array portion comprises a tool rest capable of moving in the X-axis direction and the Y-axis direction, the tool rest is provided with a plurality of tool positions side by side, and a manipulator is mounted at one end of the tool rest; the chuck portion is positioned on one side of the X-axis direction and comprises a power chuck for clamping a bar stock. The automated bar part machining method includes the steps of (1), mounting and clamping the bar stock on the power chuck, and clamping the bar stock to pull the same by a certain distance by the manipulator; (2), moving tools to required positions by the tool rest, enabling the power chuck to rotate and using the tools for cutting the bar stock; (3), machining a next part or enabling a spindle to stop rotating, loosening the power chuck and enabling the manipulator to feed. The automated bar part machining system and the automated bar part machining method have the advantages that automated production of the numerical control lathe is achieved truly, so that production efficiency is improved to a greater degree, and labor intensity of workers is reduced.

Owner:WUXI TUOFA AUTOMATIC CONTROL EQUIP

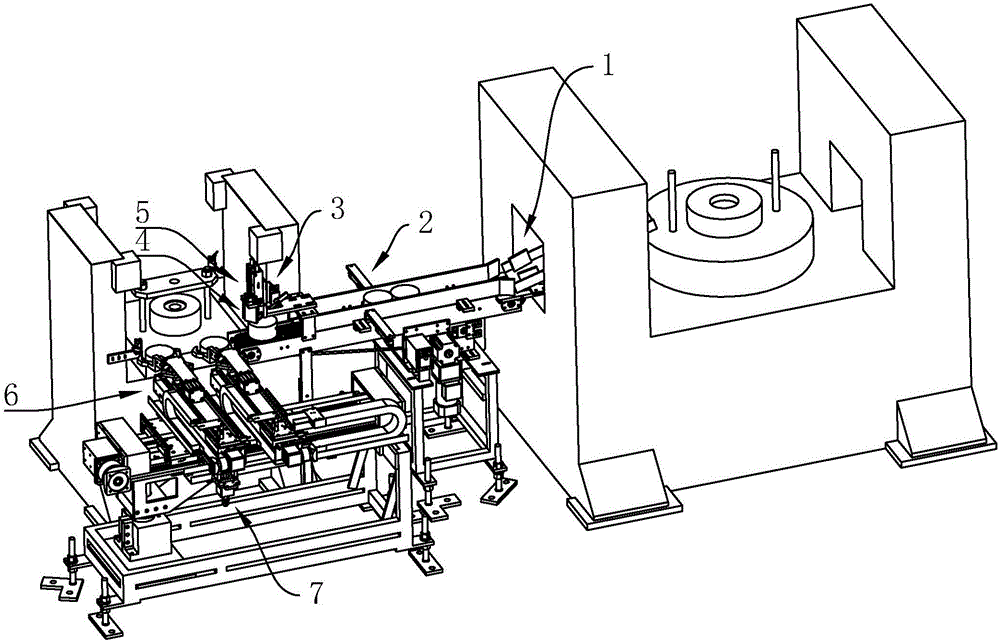

Laminating machine capable of driving film discharging by rotary loading

ActiveCN102709583BRealize reclaimingImprove lamination efficiencyFinal product manufactureSecondary cells manufactureSmall footprintPole piece

The invention relates to a laminating machine capable of driving film discharging by rotary loading. The laminating machine comprises a rotary loading mechanism, a positive pole piece trough, a positive pole piece calibration console, a negative pole piece trough, a negative pole piece calibration console, a lamination table and a film discharging mechanism, wherein the rotary loading mechanism is used for transferring pole pieces, and a big turntable which rotates in a reciprocating manner and is provided with four feeding arms is arranged at the upper part of the rotary loading mechanism; the positive pole piece trough, the positive pole piece calibration console, the negative pole piece trough, the negative pole piece calibration console and the lamination table are distributed along the periphery of the rotary loading mechanism; and the film discharging mechanism is arranged above the lamination table and driven by the big turntable which rotates in a reciprocating manner. When the big turntable rotates in a reciprocating manner, the two front feeding arms are used for respectively transferring positive pole pieces in the positive pole piece trough and negative pole pieces in the negative pole piece trough into the positive pole piece calibration console and the negative pole piece calibration console to be positioned; and the two rear feeding arms are used for respectively transferring the positioned positive pole pieces in the positive pole piece calibration console and the positioned negative pole pieces in the negative pole piece calibration console onto the lamination table and enabling the positive pole pieces and the negative pole pieces to be sequentially and alternately laminated with repeated Z-shaped films intermittently discharged by the film discharging mechanism. The laminating machine disclosed by the invention is simple in mechanisms for loading, transferring and laminating the positive pole pieces and the negative pole pieces in the circumferential direction, small in motion inertia, more stable in operation, small in occupied area and low in manufacturing cost.

Owner:DONGGUAN ARECONN PRECISION MACHINERY

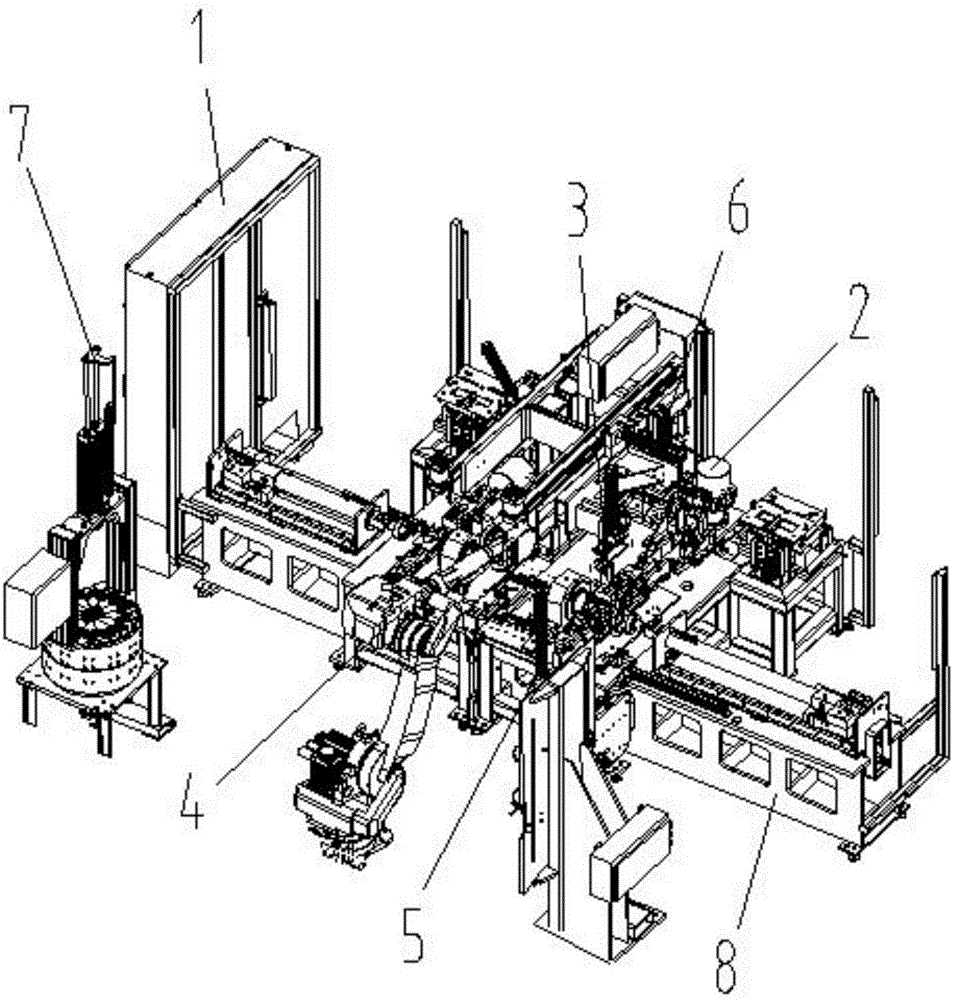

Automatic assembling machine for magnetic tile stator

ActiveCN106712403ARealize integrated automatic operationReduce manpower consumptionManufacturing stator/rotor bodiesPunchingDistribution control

The invention relates to an automatic assembling machine for a magnetic tile stator, and the machine comprises a rack and a distribution control box. The rack is provided with a punching device, and two sides of a front part are respectively provided with a detection device and a magnetizing device. Moreover, the front side is provided with a material rotating device, and the material rotating device comprises a fixed automatic universal arm. The automatic universal arm is connected with a material rotating connection plate, and a clamping device cooperating with a product is disposed below the material rotating connection plate. The clamping device comprises a clamping cylinder below the material rotating connection plate, and two sides of the clamping cylinder are connected with clamping movable blocks. Clamping blocks which cooperate with each other are disposed below the clamping movable blocks. The objective of the invention lies in providing the automatic assembling machine for the magnetic tile stator. The machine is provided with the material rotating device, and the material rotating device consists of the automatic universal arm and the clamping device, so the material rotating device can achieve the ingenious butt joint with the punching device, the detection device and the magnetizing device, thereby achieving the integrated automatic operation of a plurality of processes, reducing the manpower consumption, improving the assembling efficiency, and effectively improving the yield of products.

Owner:ANHUI DALAI MOTOR CO LTD

FFC (flexible flat cable) bending machine

ActiveCN106825330AAchieve bendingRealize reclaimingMetal working apparatusPulp and paper industryVisual detection

The invention relates to an FFC (flexible flat cable) bending machine. An FFC is bent and taken by arranging the structural layout including a release mechanism, a track mechanism, a bending and cutting mechanism and a finished product grabbing mechanism; meanwhile, a visual detection mechanism is further arranged on the track mechanism to perform visual detection on connectors of the FFC, detected defective products are classified and discharged by the finished product grabbing mechanism, automatic quality control of a bending process is realized, and the problem that the conventional FFC bending machine has no FFC quality control function is solved.

Owner:XIAMEN JUNFENG ELECTRONICS

A microneedle patch transfer device

ActiveCN113247675BAvoid it happening againRepost efficiency improvedArticle feedersArticle deliveryStructural engineeringMechanical engineering

Owner:SHANDONG HOACO AUTOMATION TECH

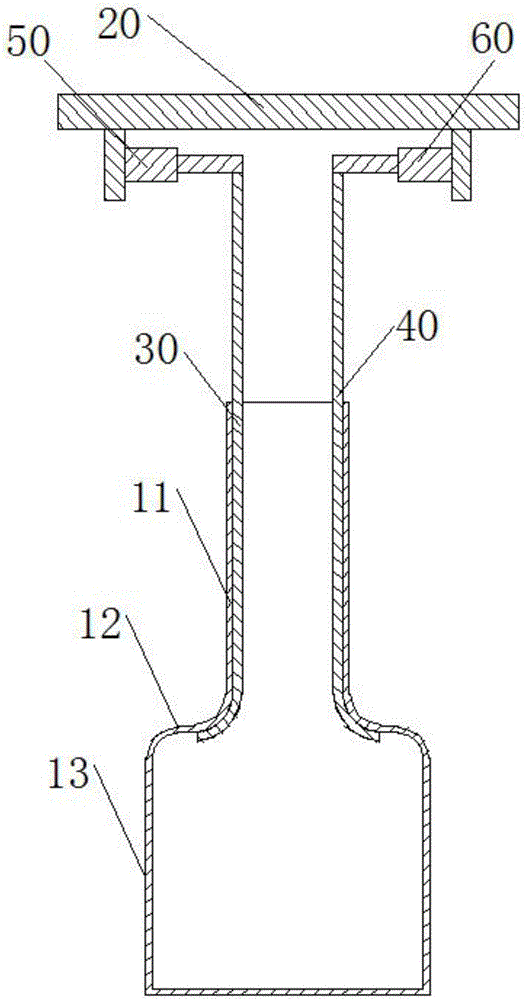

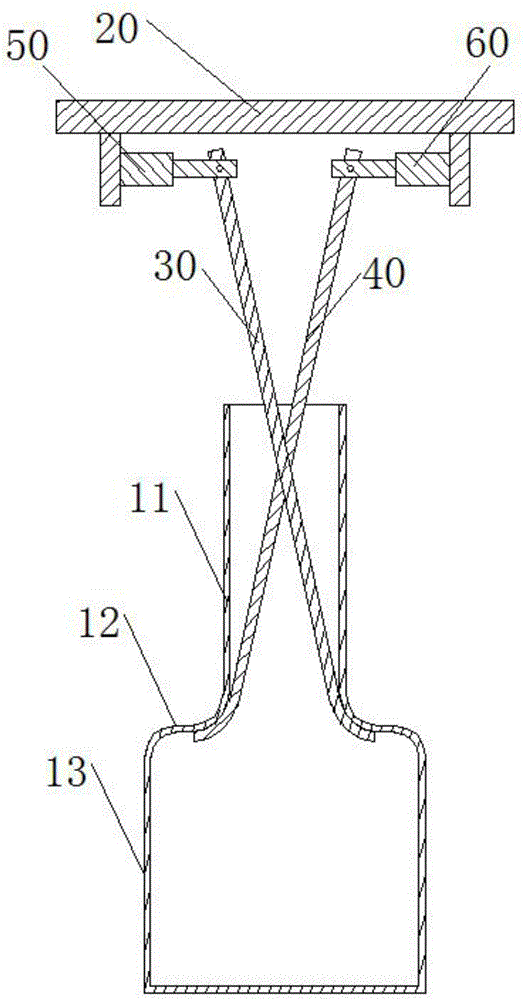

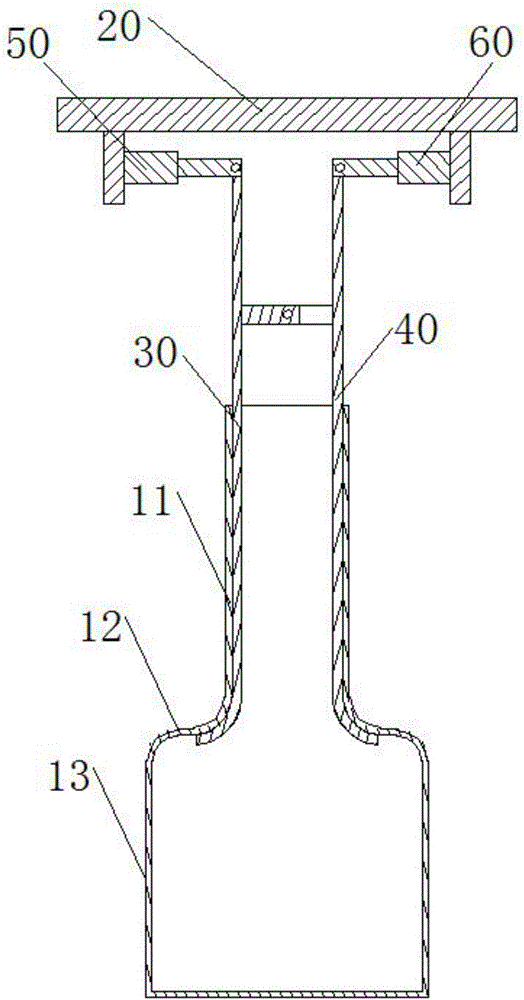

Material taking gripper for bottle

InactiveCN106218975ARealize reclaimingThe grab handle is firm in structurePackagingEngineeringBottle neck

The invention discloses a material taking gripper for a bottle. The material taking gripper comprises a top plate, a first clamping rod and a second clamping rod, wherein a first drive component and a second drive component are symmetrically installed at the bottom of the top plate; the upper end of the first clamping rod and the upper end of the second clamping rod are opposite in position and are connected to the first drive component and the second drive component respectively; the lower end of the first clamping rod and the lower end of the second clamping rod are opposite in position and are oppositely bent respectively to form gripping hooks matched with the inner wall of a bottle shoulder; and the first drive component and the second drive component drive the first clamping rod and the second clamping rod respectively to enable a distance between the free end of the gripping hook of the first clamping rod and the free end of the gripping hook of the second clamping rod to be greater than the inner-diameter dimension of a bottle neck. The material taking gripper disclosed by the invention realizes material taking for the bottle through the arrangement of the first clamping rod, the second clamping rod, the first drive component and the second drive component, and through adjustment for the distance between the first clamping rod and the second clamping rod.

Owner:TAICANG GOLDENMA METAL STRUCTURE

Material taking mechanism and switch socket assembling machine

InactiveCN113547308AImprove reclaiming efficiencyRealize reclaimingContact member assembly/disassemblyElectric switchesReclaimerAssembly machine

The invention relates to the technical field of production equipment, and particularly discloses a material taking mechanism and a switch socket assembling machine. The material taking mechanism comprises a support, a mounting seat and a first sliding piece, wherein the mounting seat is arranged on the support, and a first channel is formed in the mounting seat; the first sliding piece is slidably connected to one side of the mounting seat, and two second channels arranged at intervals are formed in the first sliding piece and used for communicating with an air pipe of vacuum equipment so as to temporarily store workpieces; and the first sliding piece slides on the mounting seat until the first channel is aligned and communicated with the two second channels in sequence, so that the two workpieces slide into the two second channels from the first channel in sequence. According to the technical scheme, the material taking efficiency of the material taking mechanism is improved.

Owner:GUANGDONG SHUNDE WEASI ROBOT CO LTD

Automatic sealing gasket punching and assembling equipment

ActiveCN112123797AEasy to take outContinuous switchingFinal product manufacturePunchingStructural engineering

The invention aims to provide automatic sealing gasket punching and assembling equipment which is suitable for online production, high in working efficiency, compact in structure, safe, reliable and good in assembling effect. The equipment comprises a feeding module, a material taking module, a punching module, a material receiving module and an inserting module which are matched in sequence, wherein the punching module comprises an upper punching die module and a lower conveying die module, the material taking module and the material receiving module are both matched with the lower conveyingdie module, the lower conveying die module comprises a first linear moving mechanism and a lower die plate, the lower die plate is fixed to the movable end of the first linear moving mechanism, a plurality of punching holes are formed in the lower die plate, the upper punching die module comprises an upper die plate and a pressing mechanism, a plurality of punching columns matched with the plurality of punching holes in a one-to-one correspondence mode are arranged on the upper die plate, the material receiving module comprises a second linear moving mechanism and a material receiving plate, the material receiving plate is connected with the movable end of the second linear moving mechanism, and a plurality of material receiving columns matched with the punching holes in a one-to-one correspondence mode are arranged on the material receiving plate. The automatic sealing gasket punching and assembling equipment is applied to the technical field of punching and assembling equipment.

Owner:深圳市芬能自动化设备有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com