Automatic cover plate pressing machine

An automatic pressing and cover plate technology, which is applied in the direction of manufacturing tools, metal processing, metal processing equipment, etc., can solve the problems of low automation of cover plates and shaft sleeves, and achieve high automation, displacement prevention, and high position accuracy. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The following are specific embodiments of the present invention and the accompanying drawings to further describe the technical solutions of the present invention, but the present invention is not limited to these embodiments.

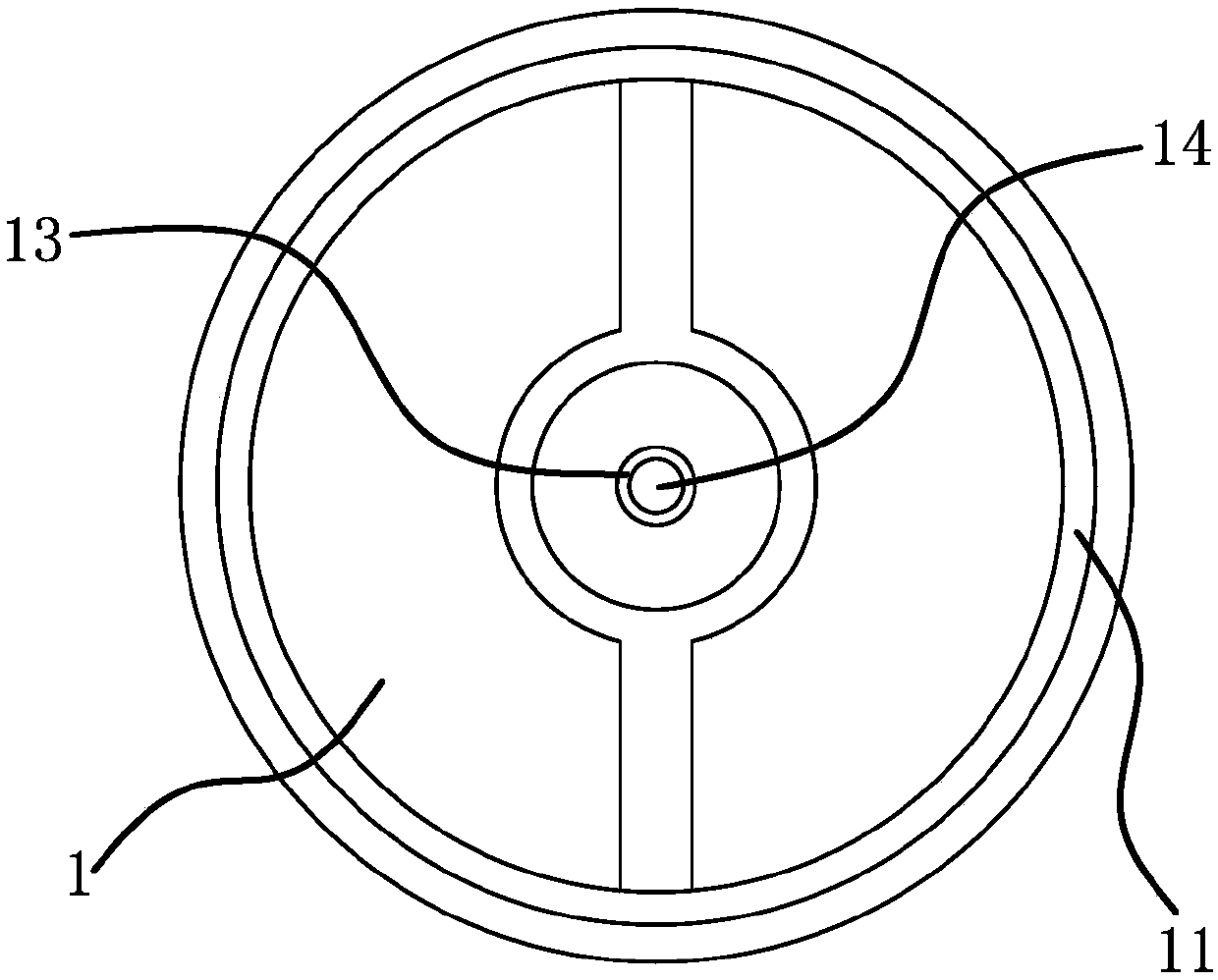

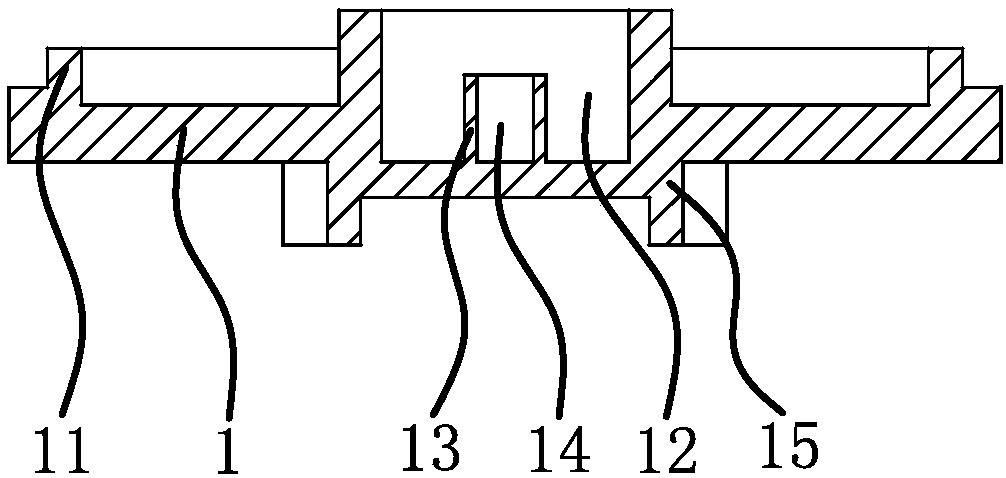

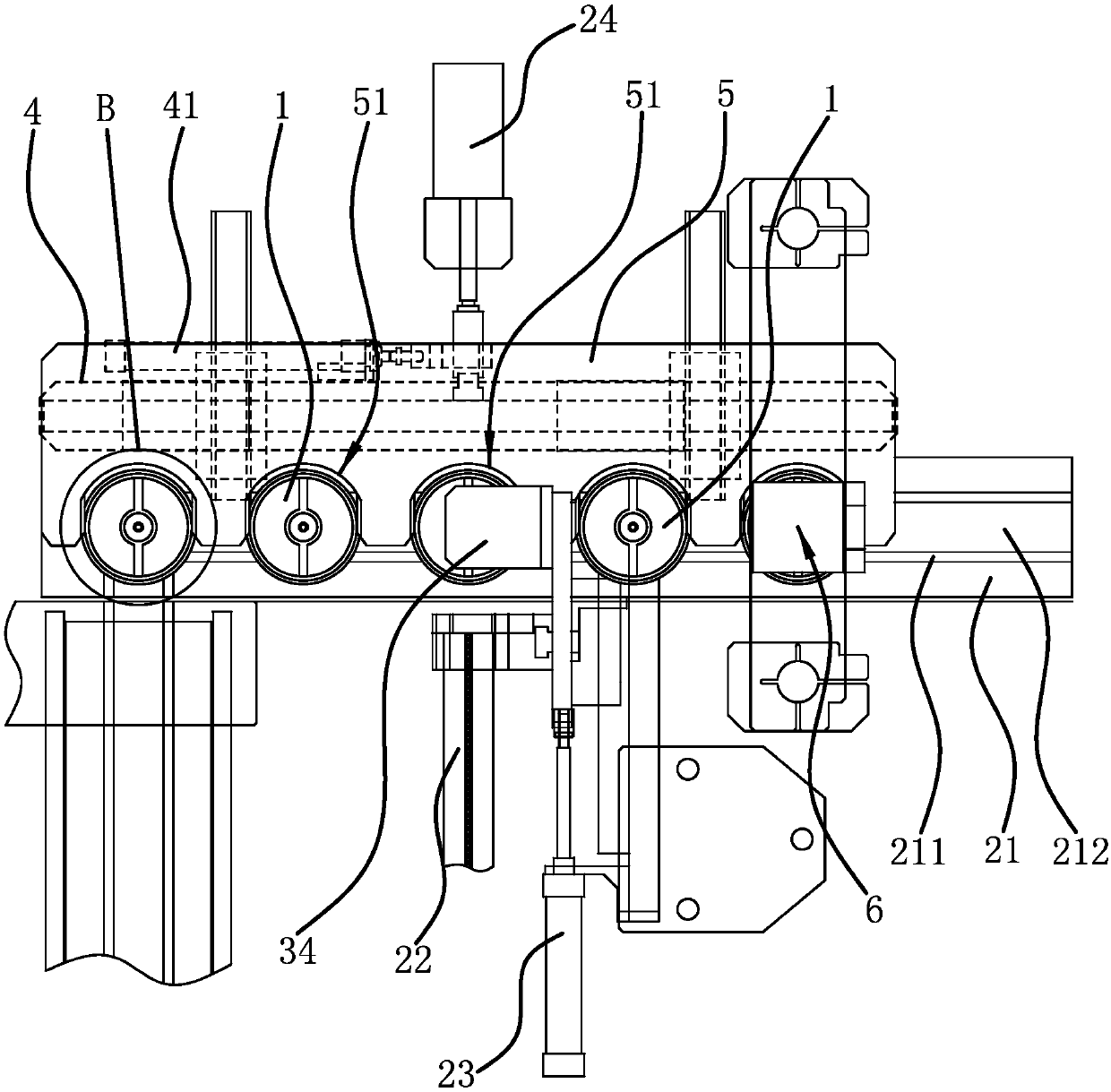

[0029] like image 3 , Figure 4As shown, an automatic cover plate pressing machine includes a frame 2. The frame 2 is provided with a feeding guide 21 and a feeding guide 22 respectively. The feeding guide 21 is used for horizontally conveying the cover 1, and the feeding guide 22 is used for horizontal In the conveying sleeve 7, a feeding slot 211 is opened on the upper side of the feeding guide 21 along the length direction, and the bottom surface of the feeding slot 211 is provided with a limiting slot 212 along the length direction, and the limiting slot 212 is located in the middle of the width of the feeding slot 211. When the cover plate 1 is conveyed, it is laid flat in the feeding slot 211, and the outer peripheral wall is transitiona...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com