Automatic sealing gasket punching and assembling equipment

A gasket and automatic flushing technology, applied in sustainable manufacturing/processing, climate sustainability, final product manufacturing, etc., can solve the problems of frequent handling, high labor intensity, easy to increase errors, etc., to avoid mutual interference , Improve the effect of linear movement accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

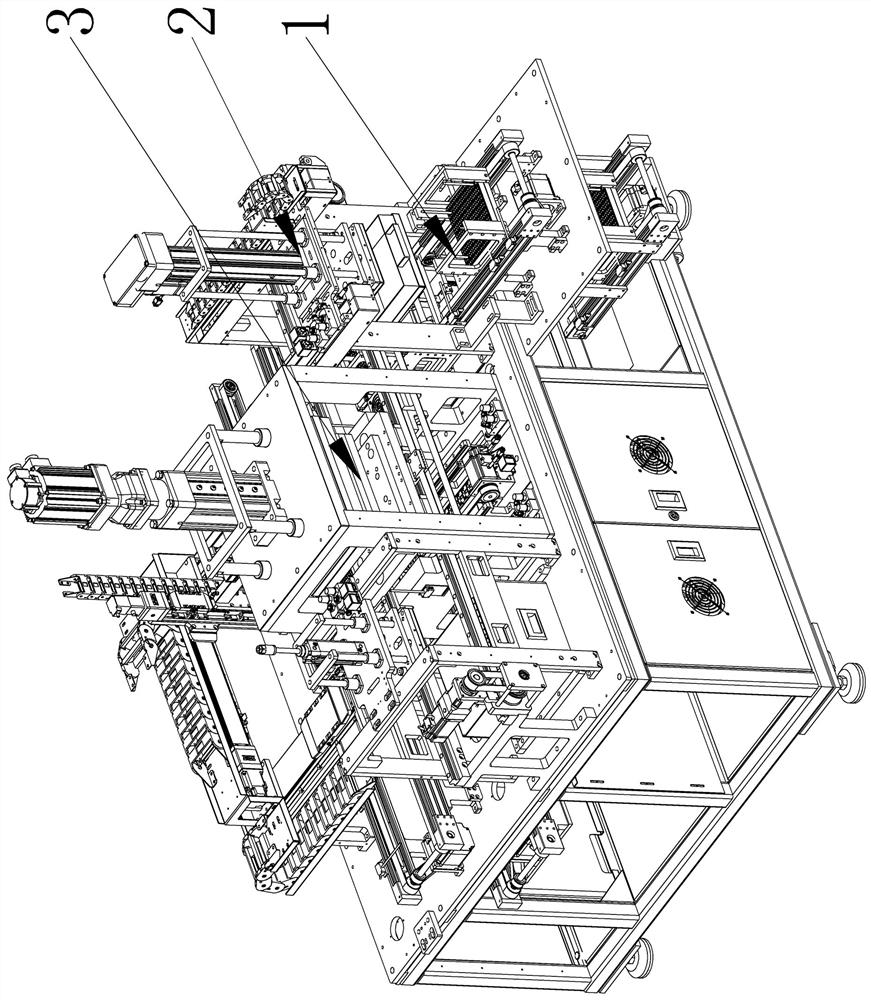

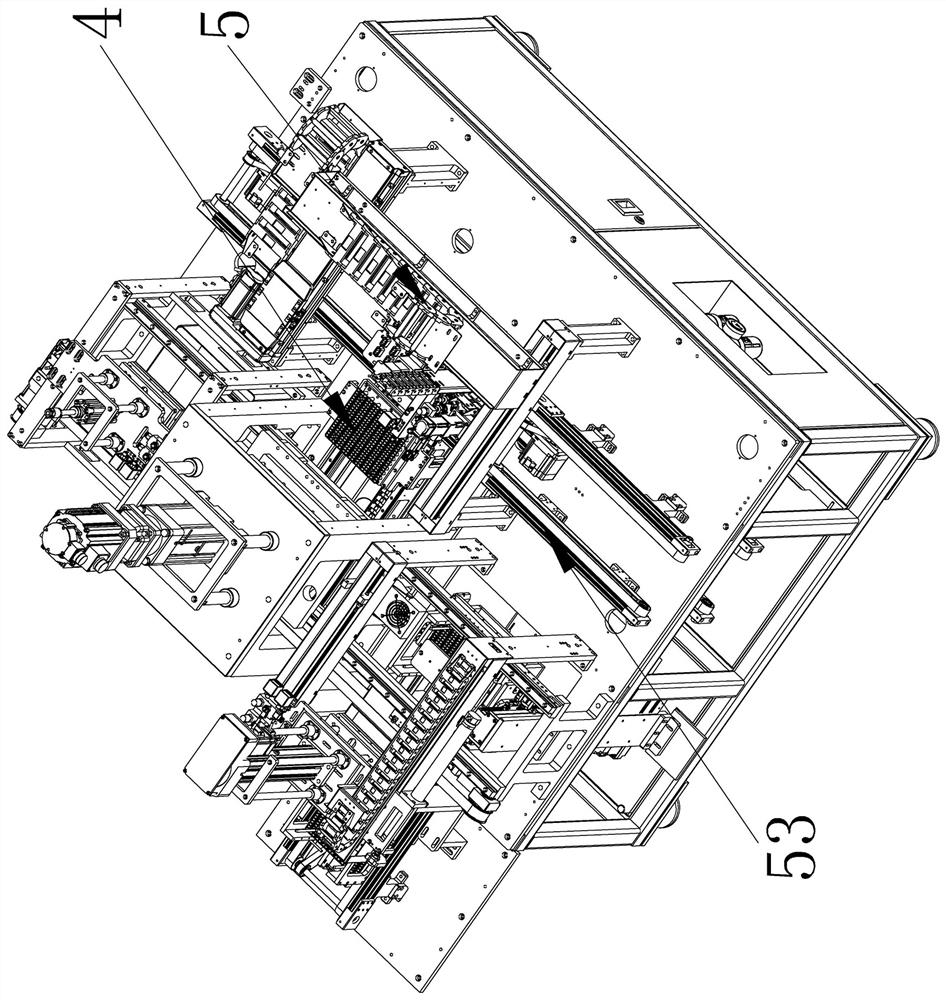

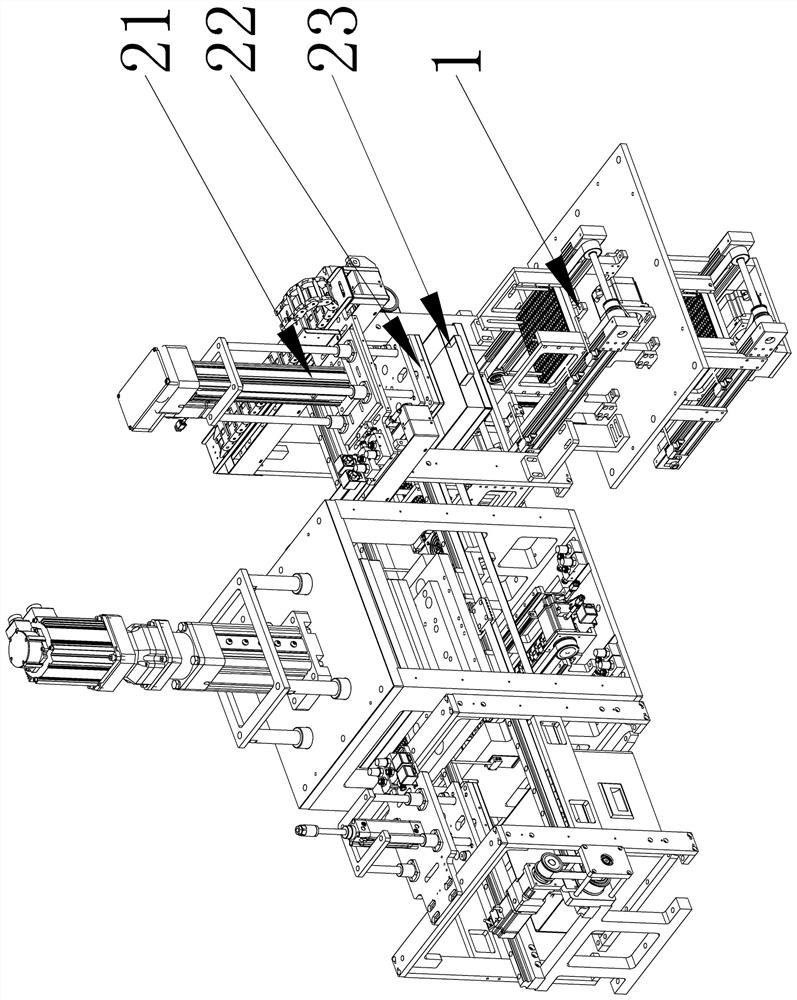

[0034] like Figure 1 to Figure 3 As shown, in this embodiment, the present invention includes a feeding module 1, a reclaiming module 2, a punching module 3, a receiving module 4 and a plug-in module 5 that are sequentially matched. Group 3 includes a punching upper die module and a lower transport die module, the reclaiming module 2 and the receiving module 4 are both matched with the lower transport die module, and the lower transport die module includes a first straight line Moving mechanism 31 and lower template 32, described lower template 32 is fixed on the movable end of described first linear moving mechanism 31, and described lower template 32 is provided with some punching holes, and described punching upper mold module comprises An upper template 33 and a lower pressing mechanism 34, the upper template 33 is provided with a number of punching columns corresponding to the punching holes one by one, and the material receiving module 4 includes a second linear moving ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com