Patents

Literature

238results about How to "Stop precise" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

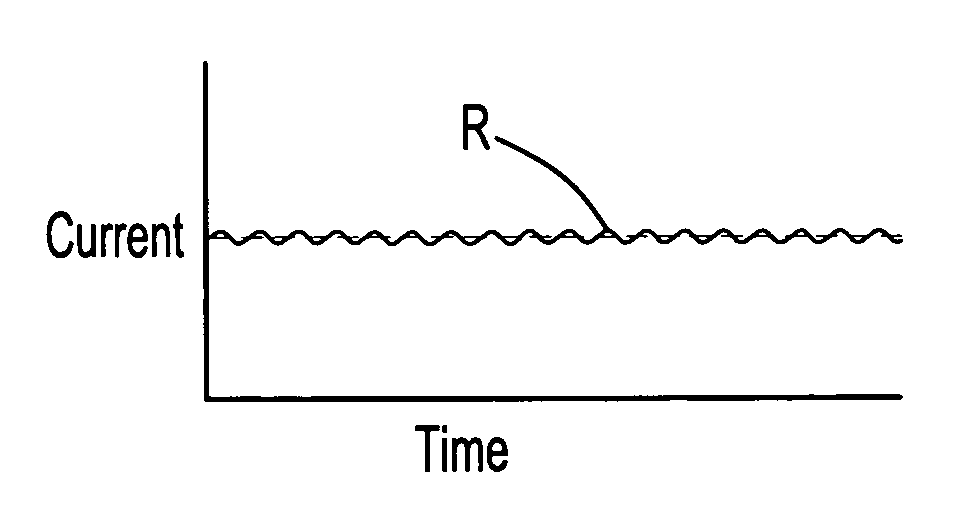

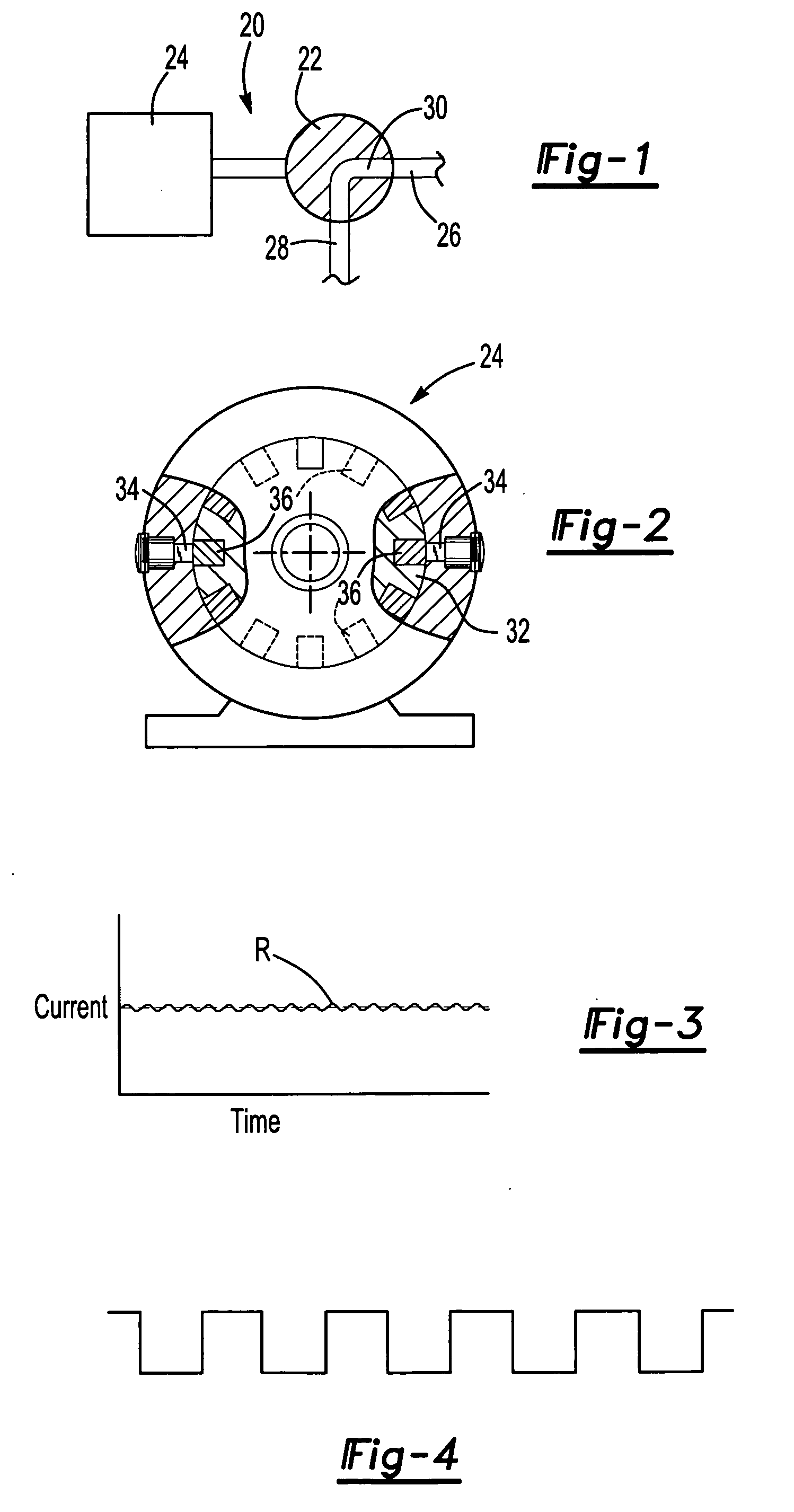

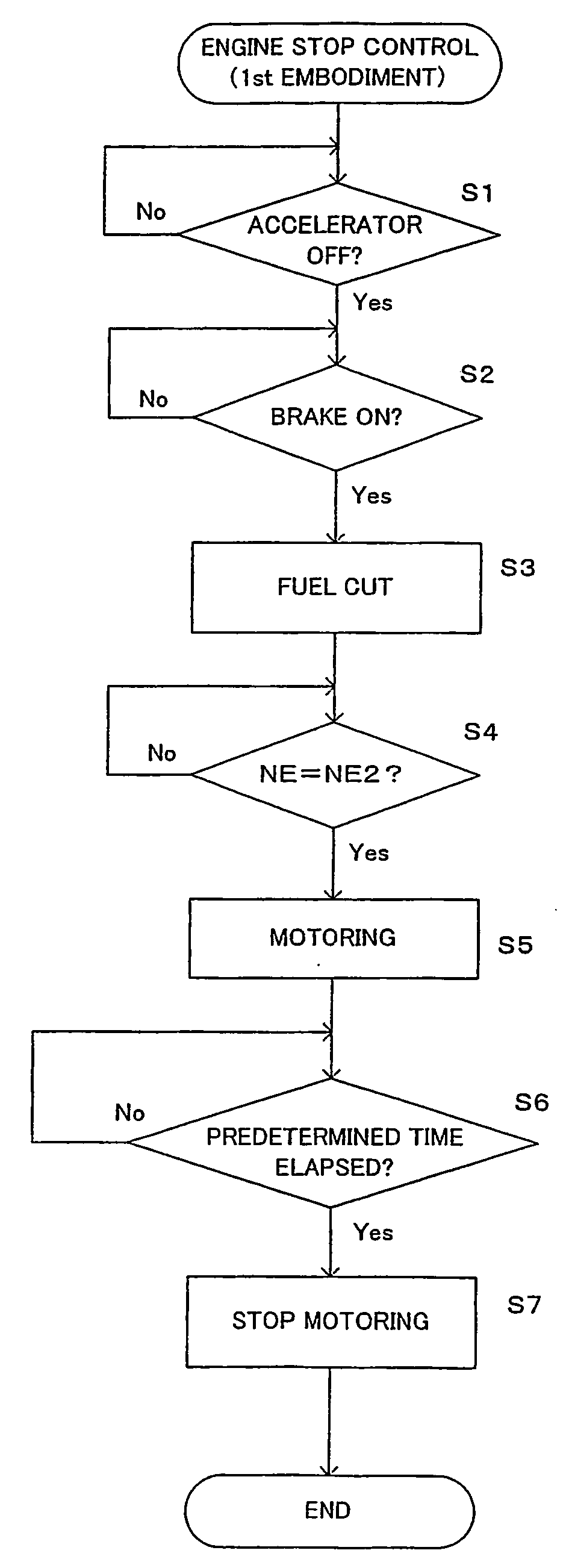

Brushed motor position control based upon back current detection

InactiveUS20060261763A1Exact numberStop preciseElectronic commutation motor controlMotor/generator/converter stoppersReverse currentEngineering

Owner:MASCO CORP

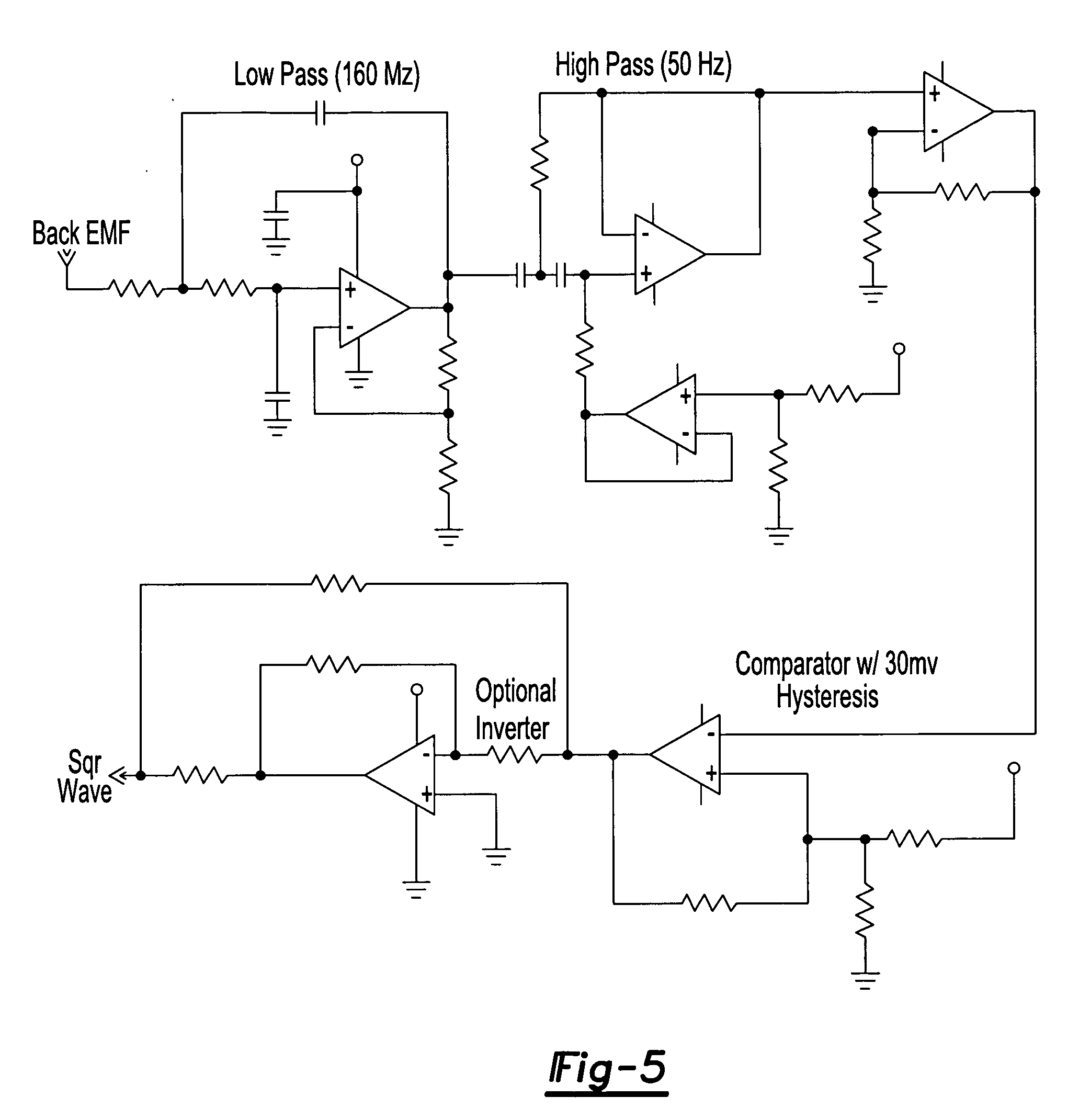

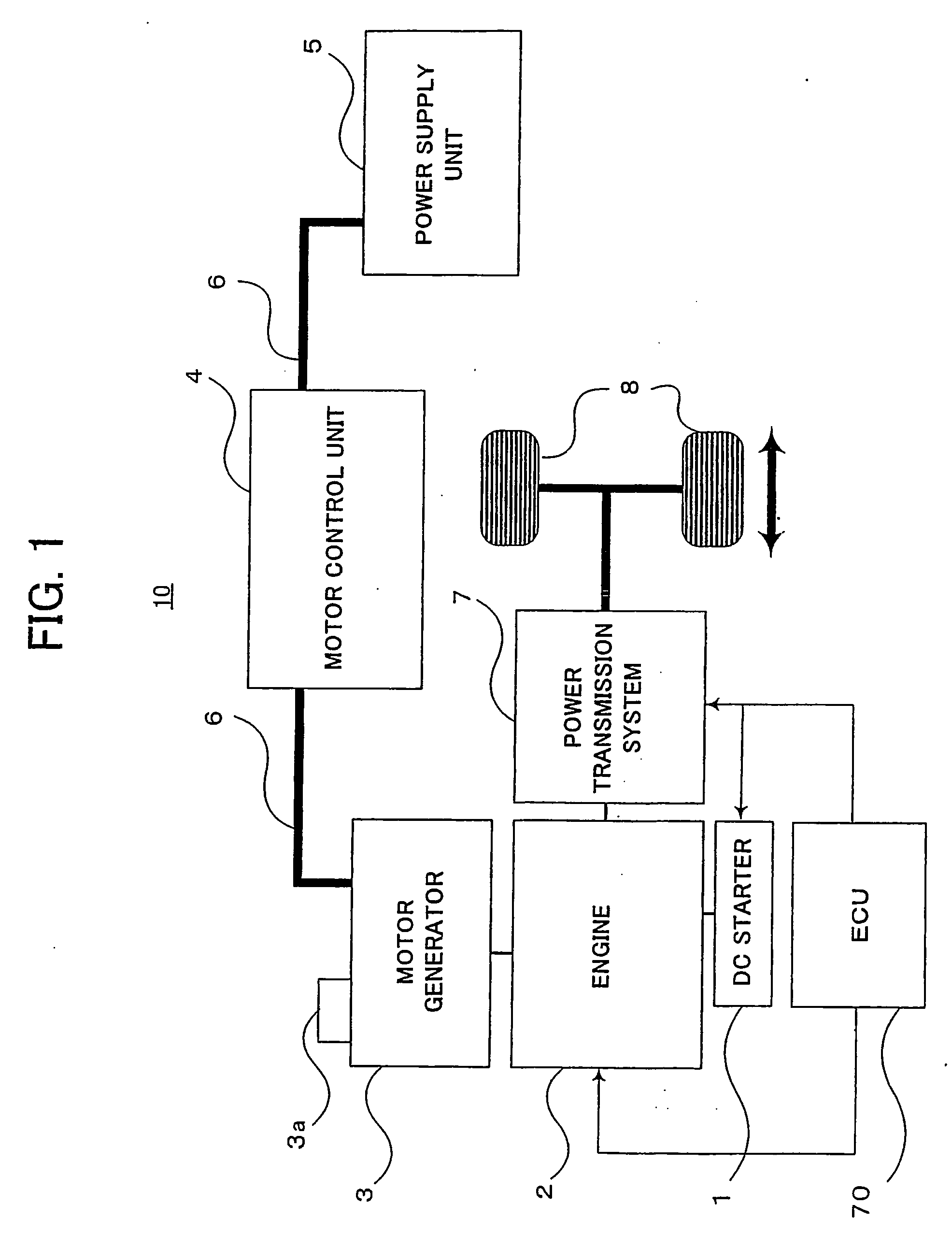

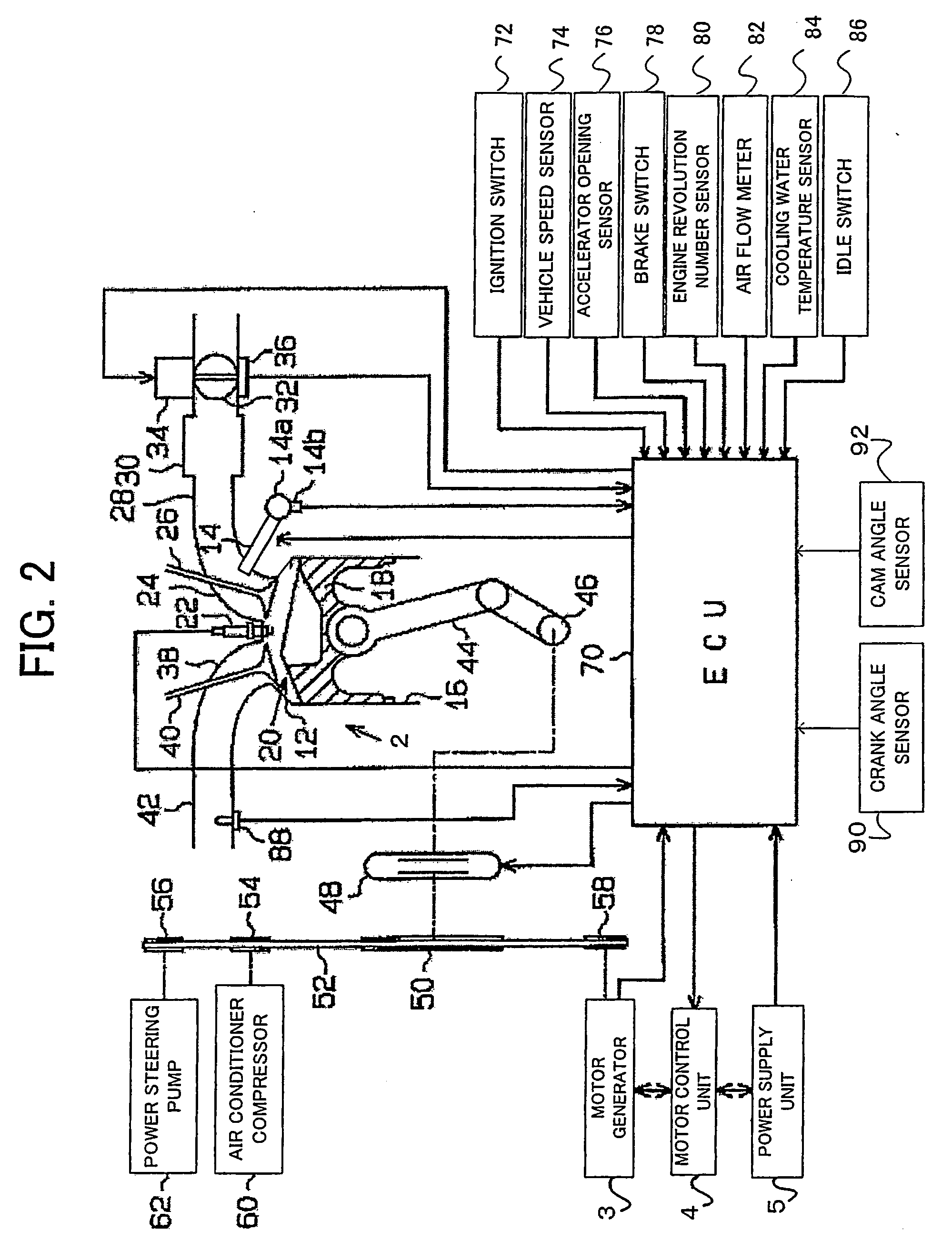

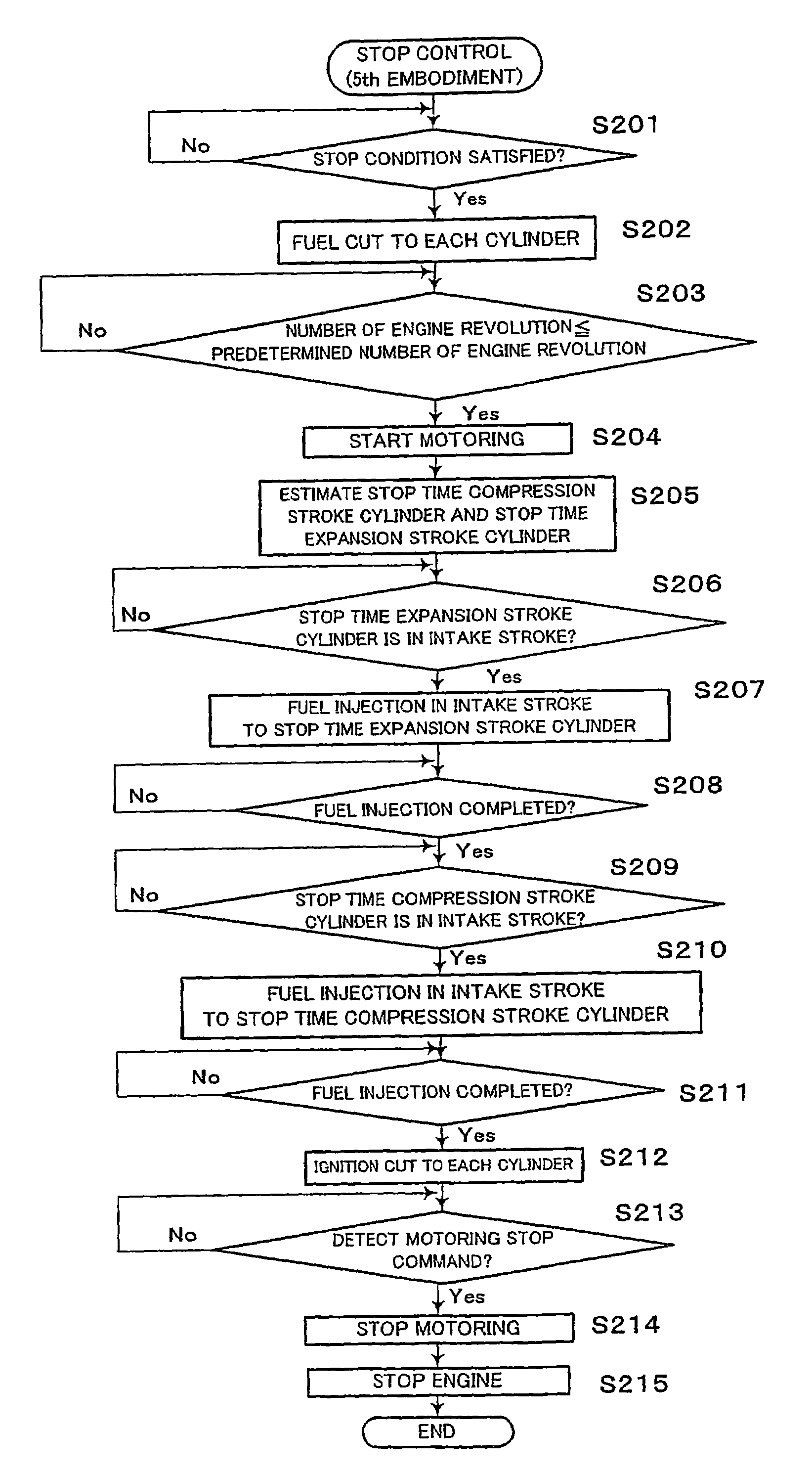

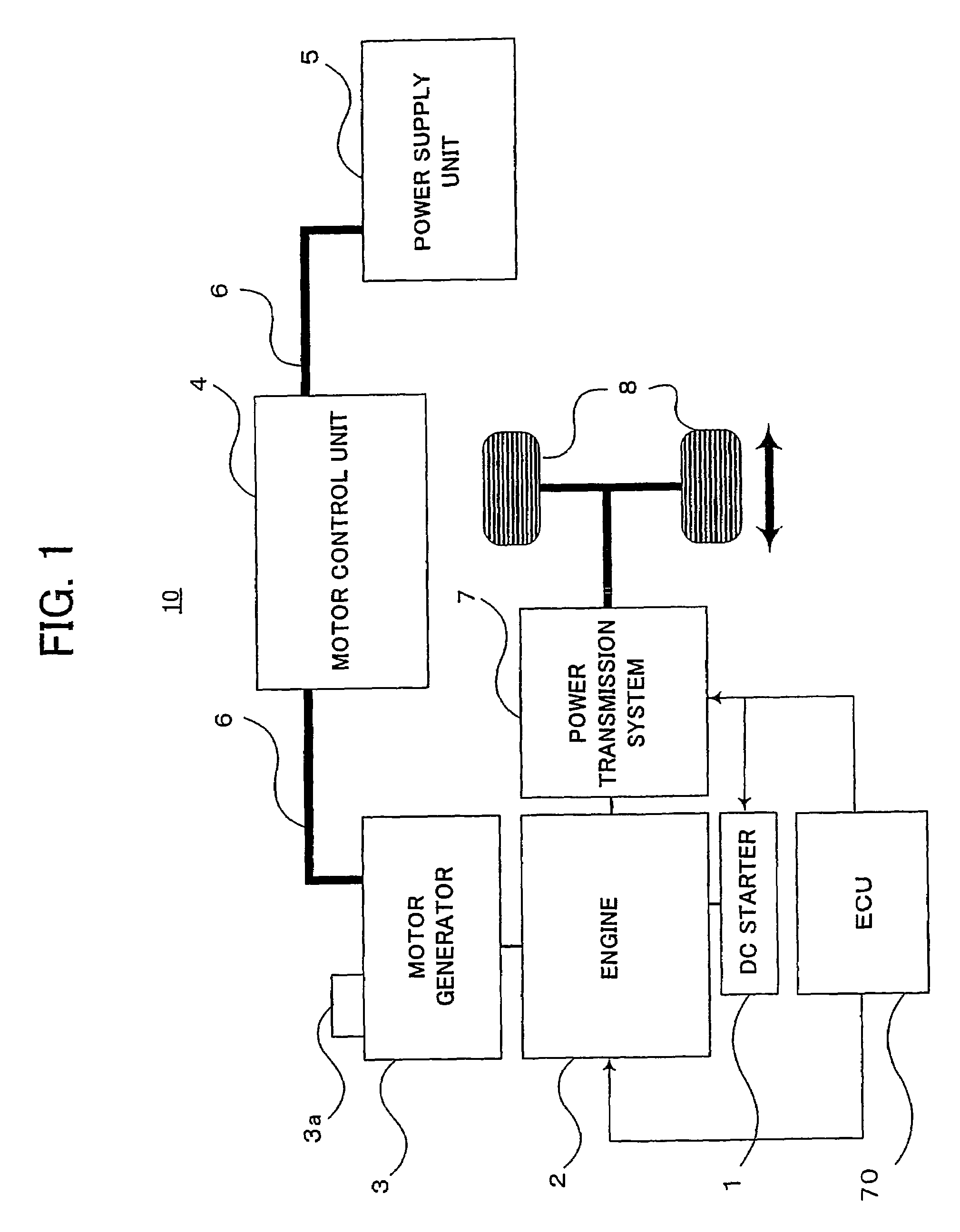

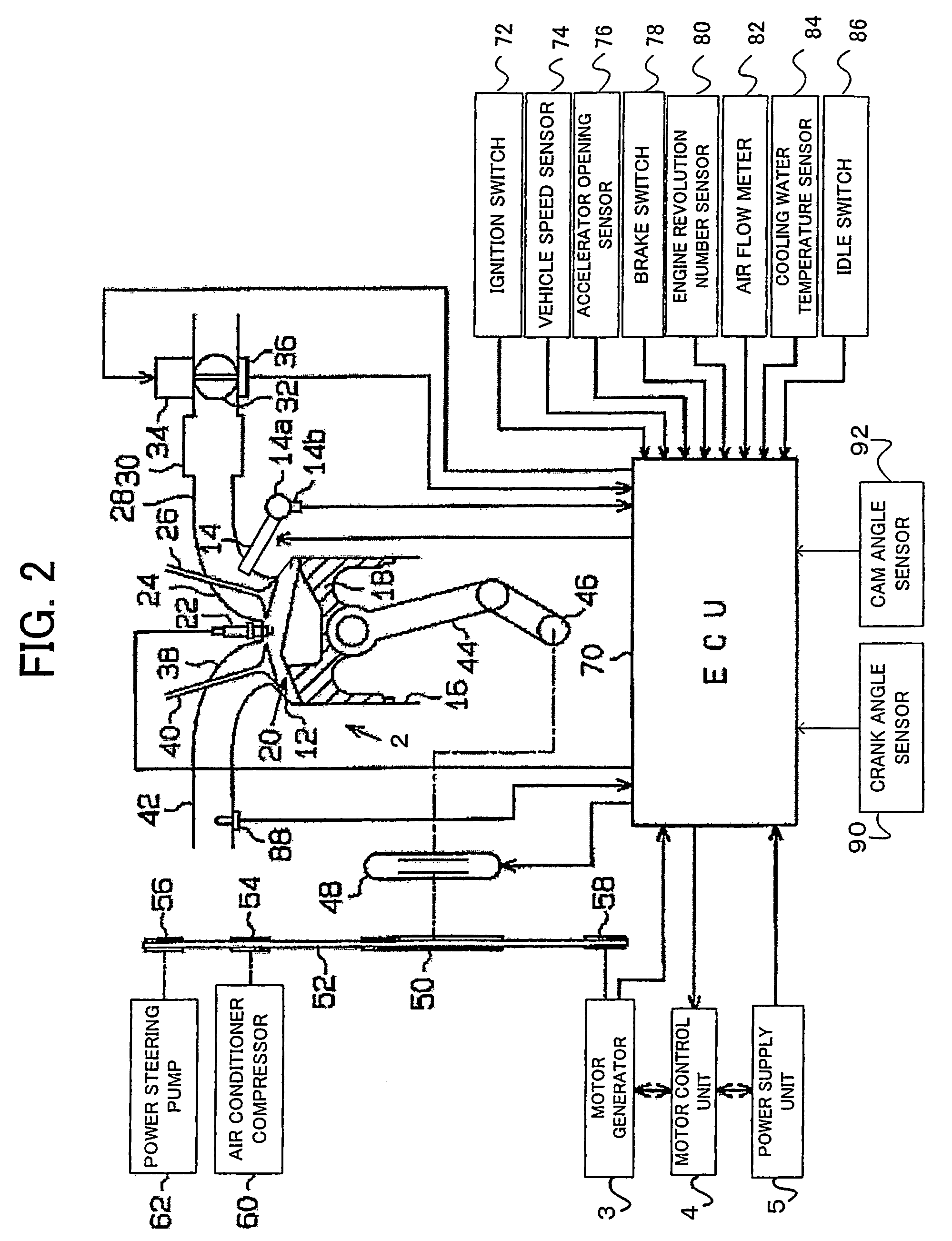

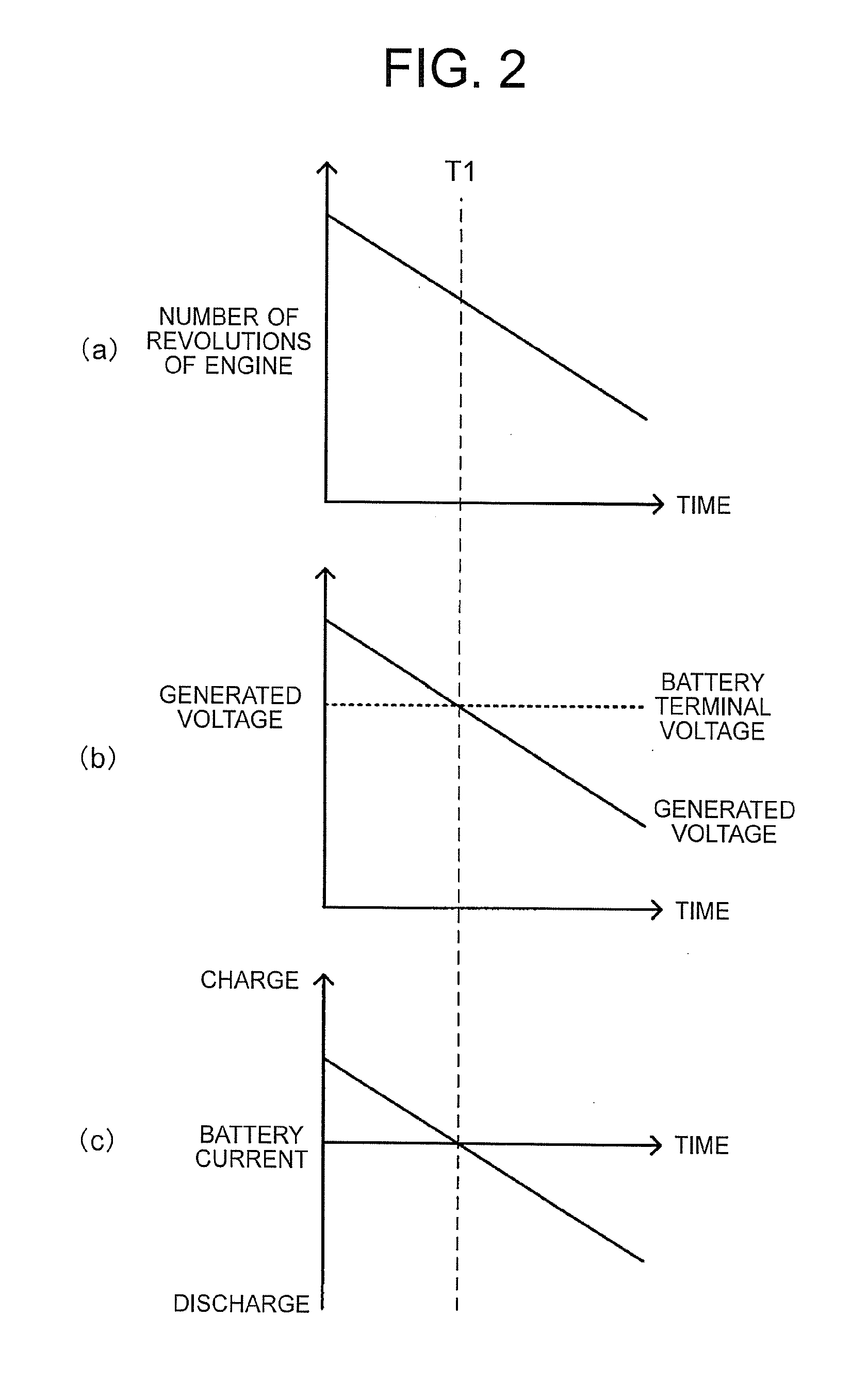

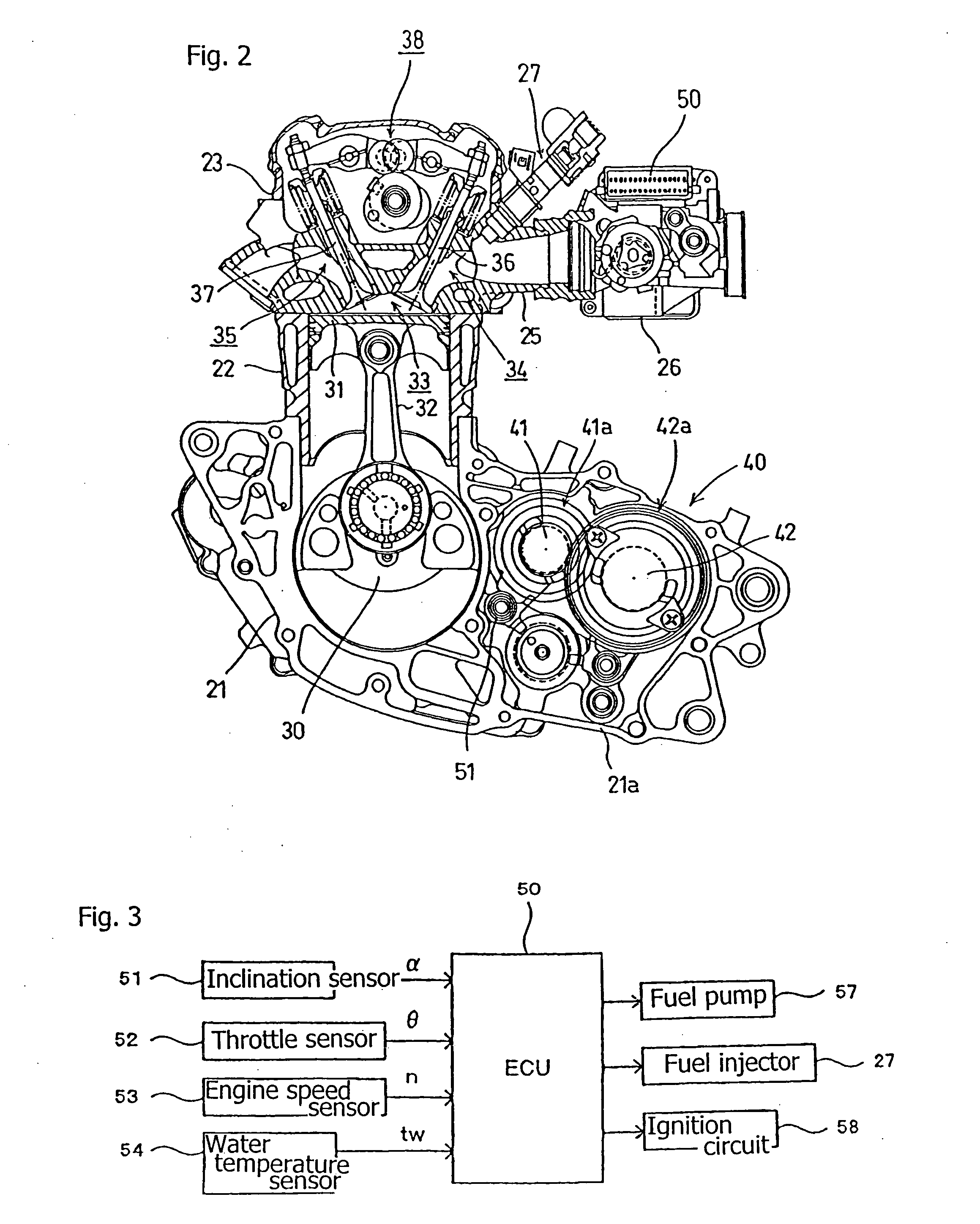

Control apparatus of internal combustion engine

ActiveUS20060048734A1Accurate stopLittle energyAnalogue computers for vehiclesPower operated startersCrankshaftCombustion

At a time of stopping an internal combustion engine, inertia energy of the engine is kept constant, for example, by controlling a number of engine revolution constant, while controlling combustion of the engine. By utilizing the controlled inertia energy, the engine is stopped at a predetermined crank angle position. Since the engine is stopped at the predetermined crank angle position by utilizing the controlled inertia energy, a large amount of energy for controlling the stop position of the energy is not needed, and the energy needed for the stop control can be reduced. Since the inertia energy utilized for the stop control is always controlled in a predetermined state, the engine can be stopped at a proper position reliably each time.

Owner:TOYOTA JIDOSHA KK

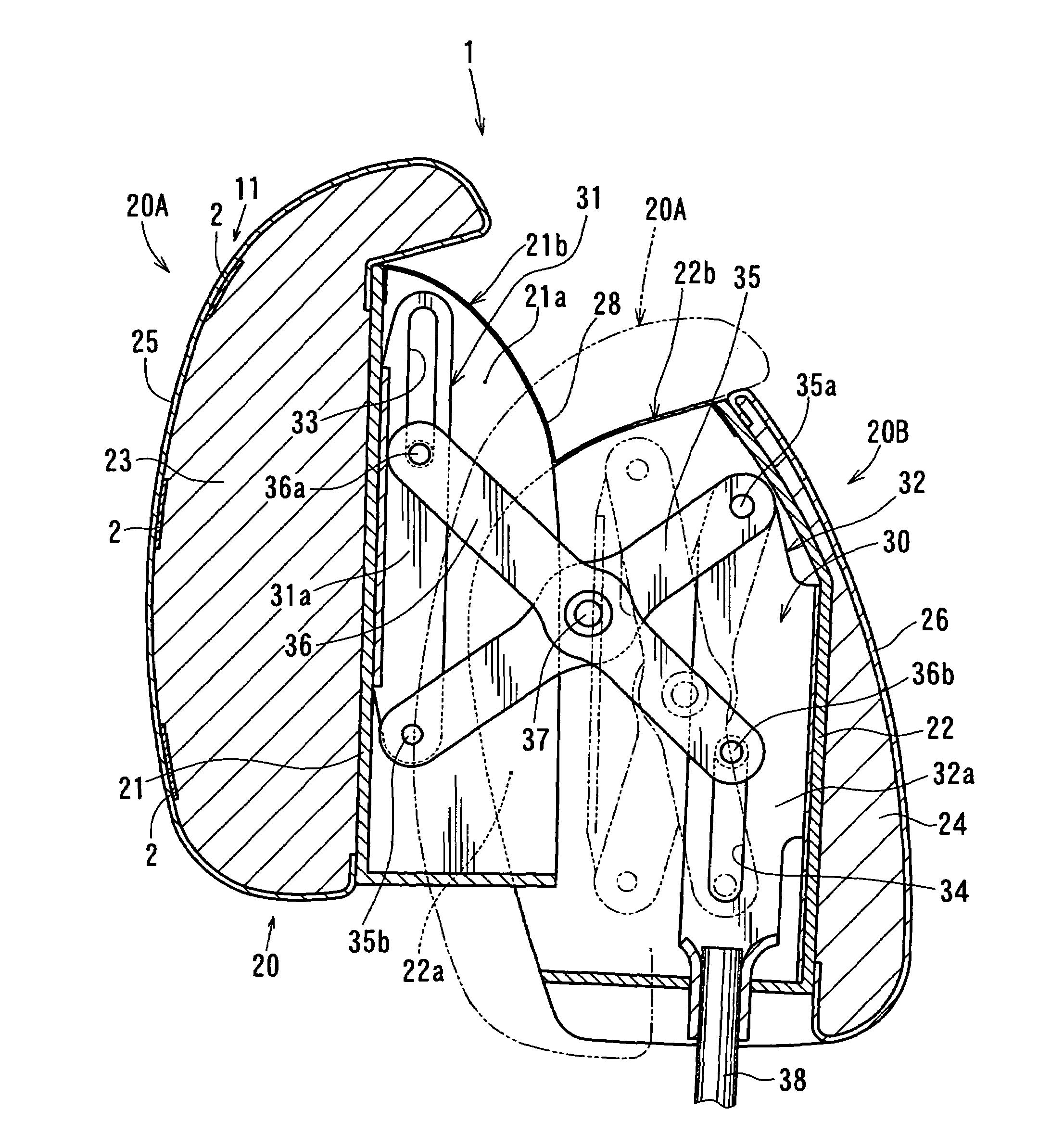

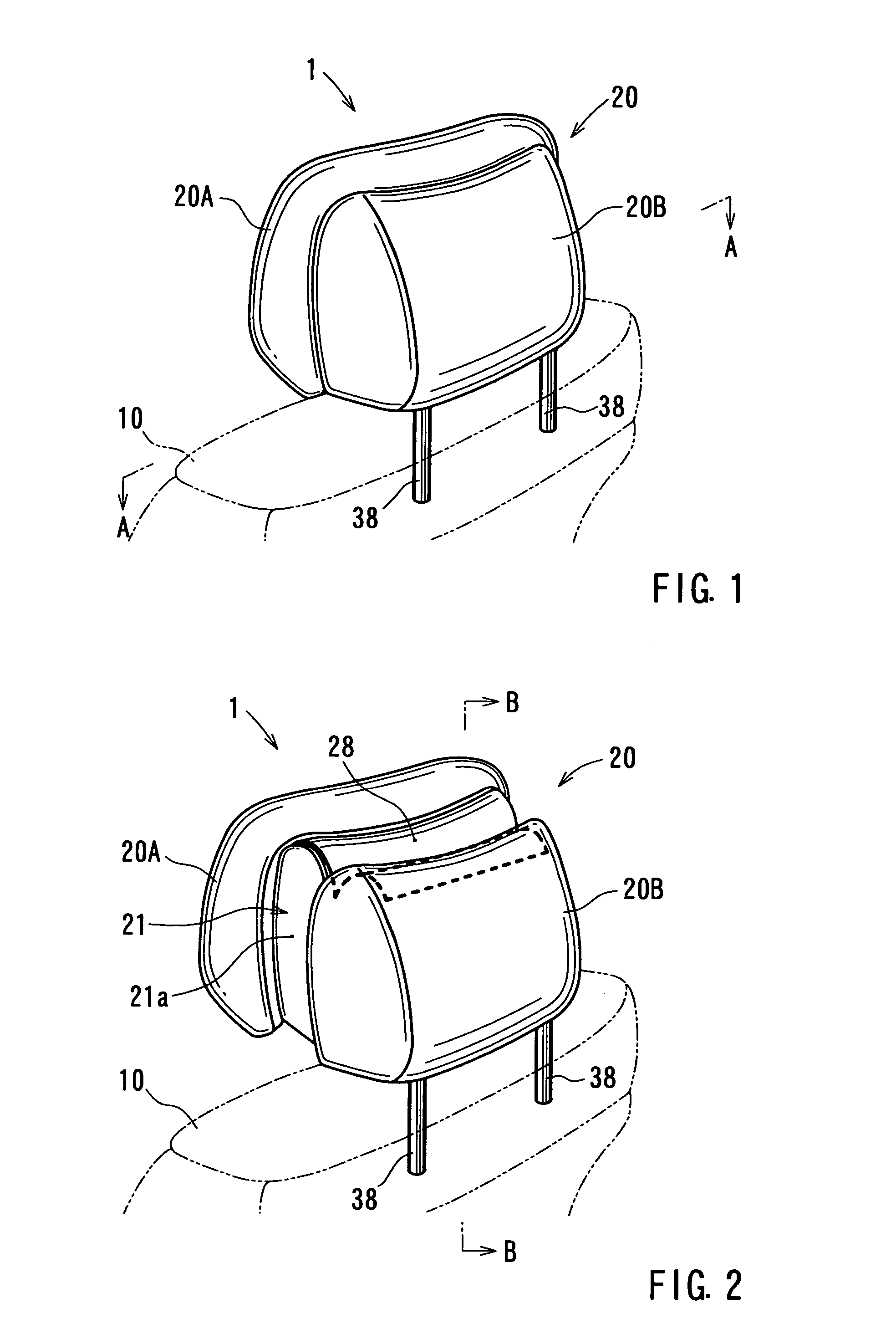

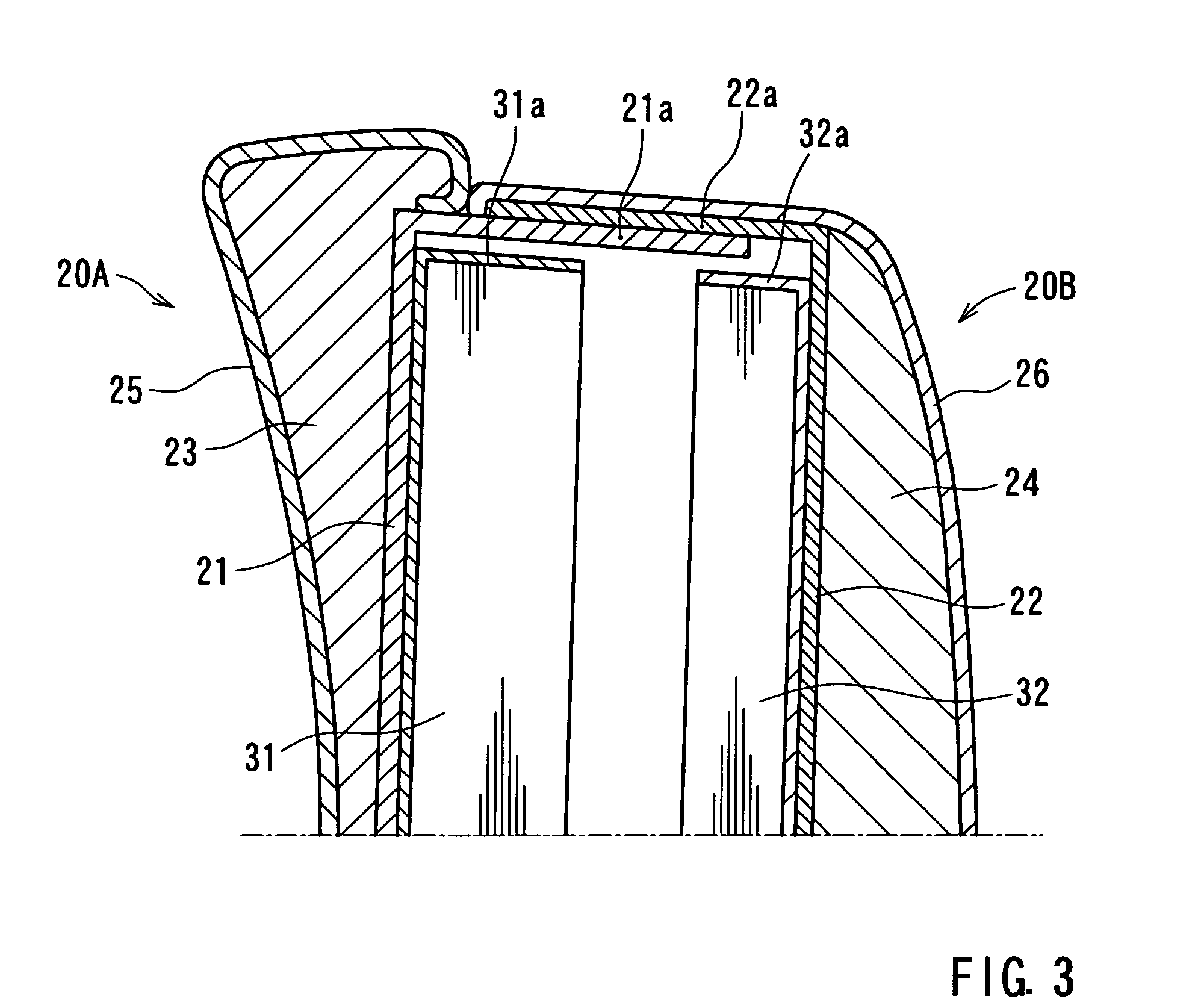

Head rest control device and active head rest

It is an object of this invention to provide an active headrest which will not over-push the head of a passenger. For this purpose, the invention provides a headrest controller for moving a part (20A) or whole of a headrest (20) of a vehicle seat toward a head of the passenger to reduce the distance between the headrest (20) and the head in the horizontal direction by predicting or detecting a crash to the rear of the vehicle, including a head position detecting unit (11) for detecting a predetermined state of approach or state of contact of the headrest (20) to or with the head during the movement of the headrest (20) and a control circuit for stopping the headrest based on a detection signal from the head position detecting unit (11).

Owner:TOYOTA BOSHOKU KK +1

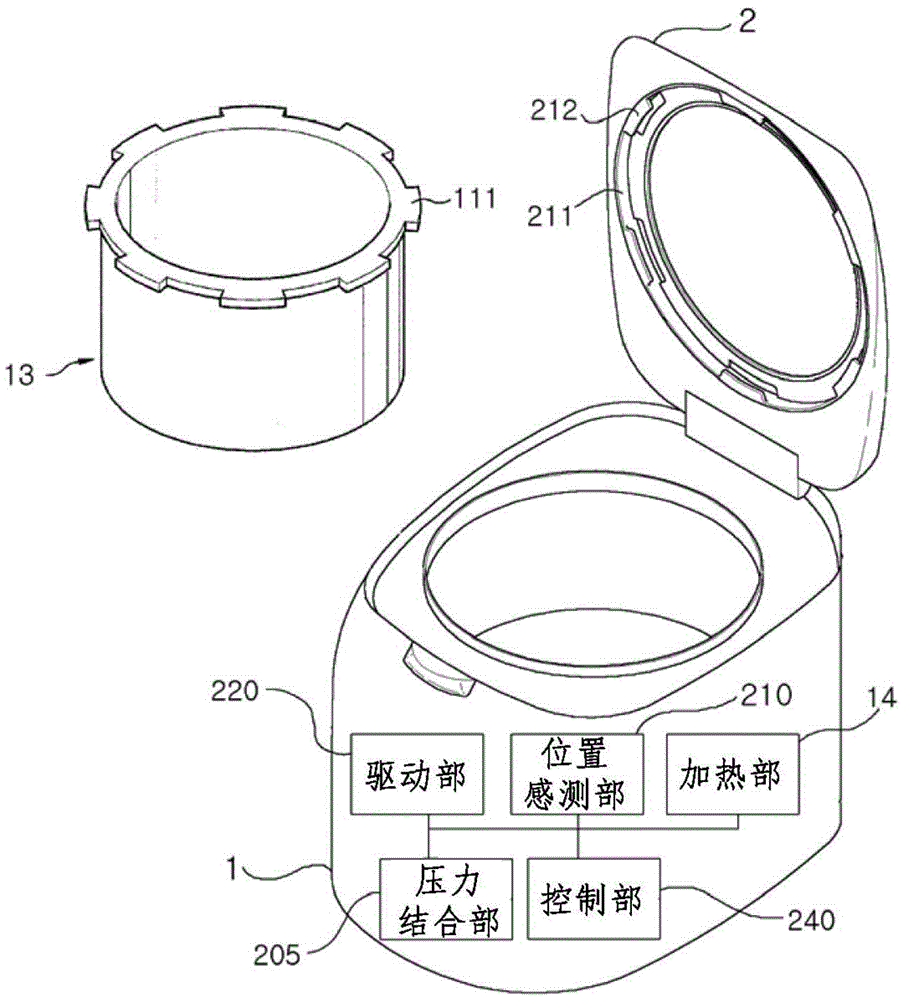

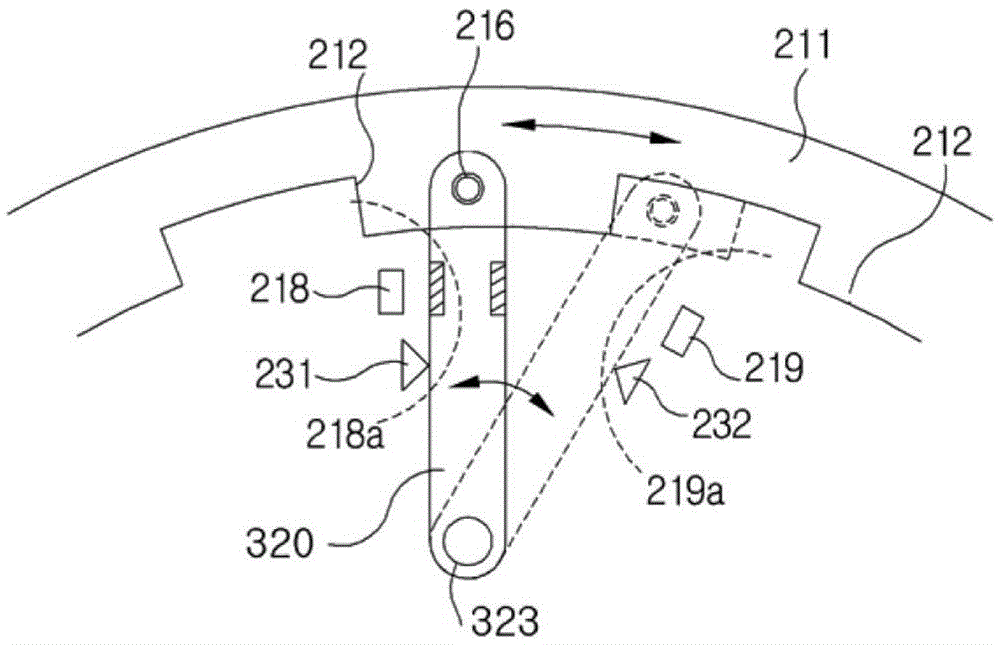

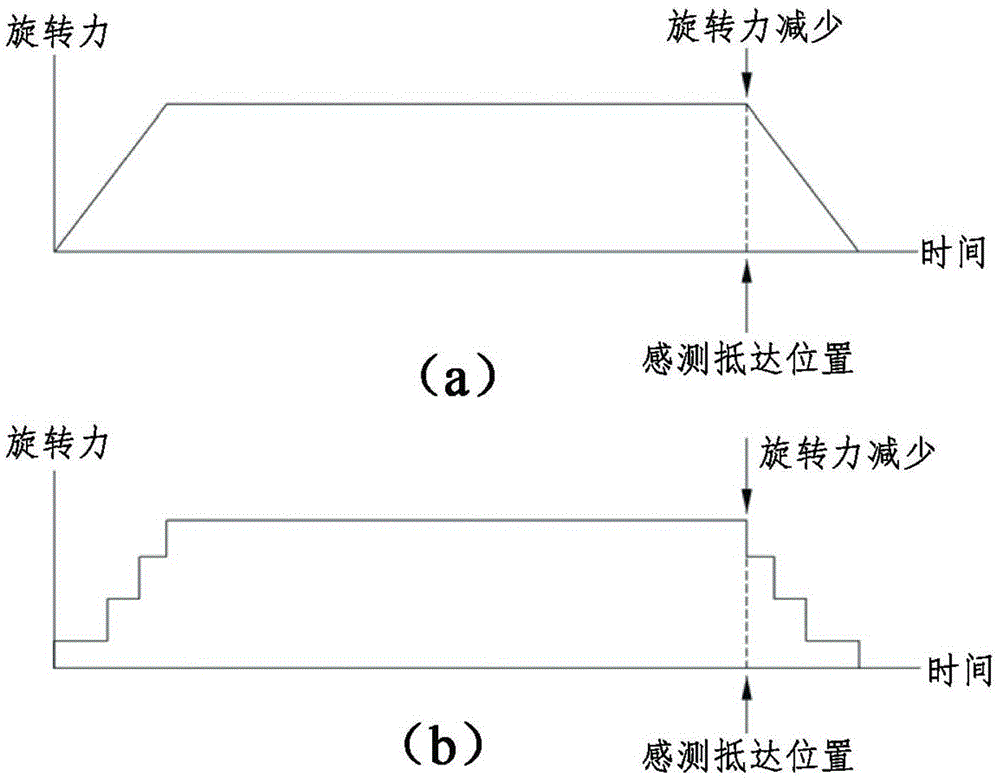

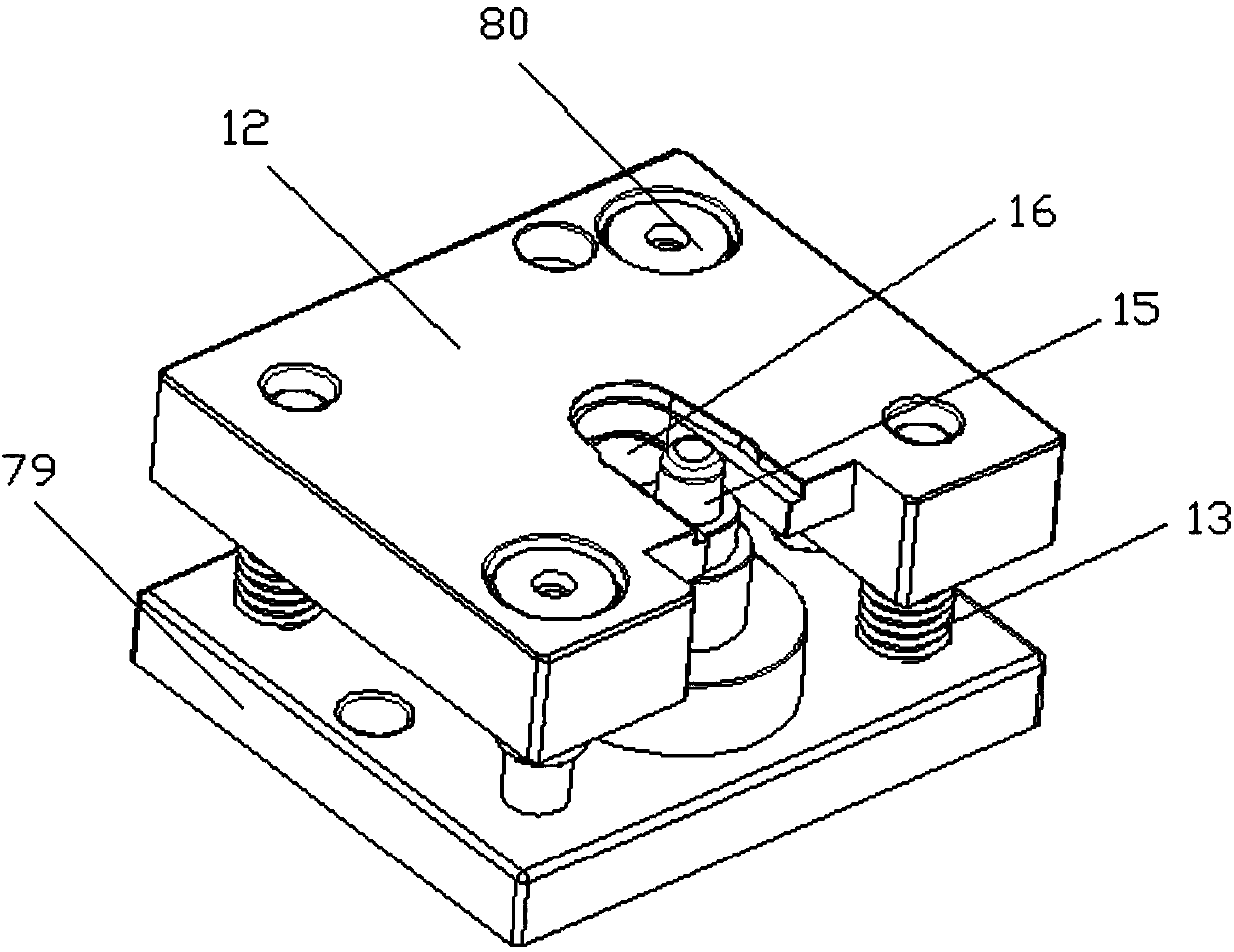

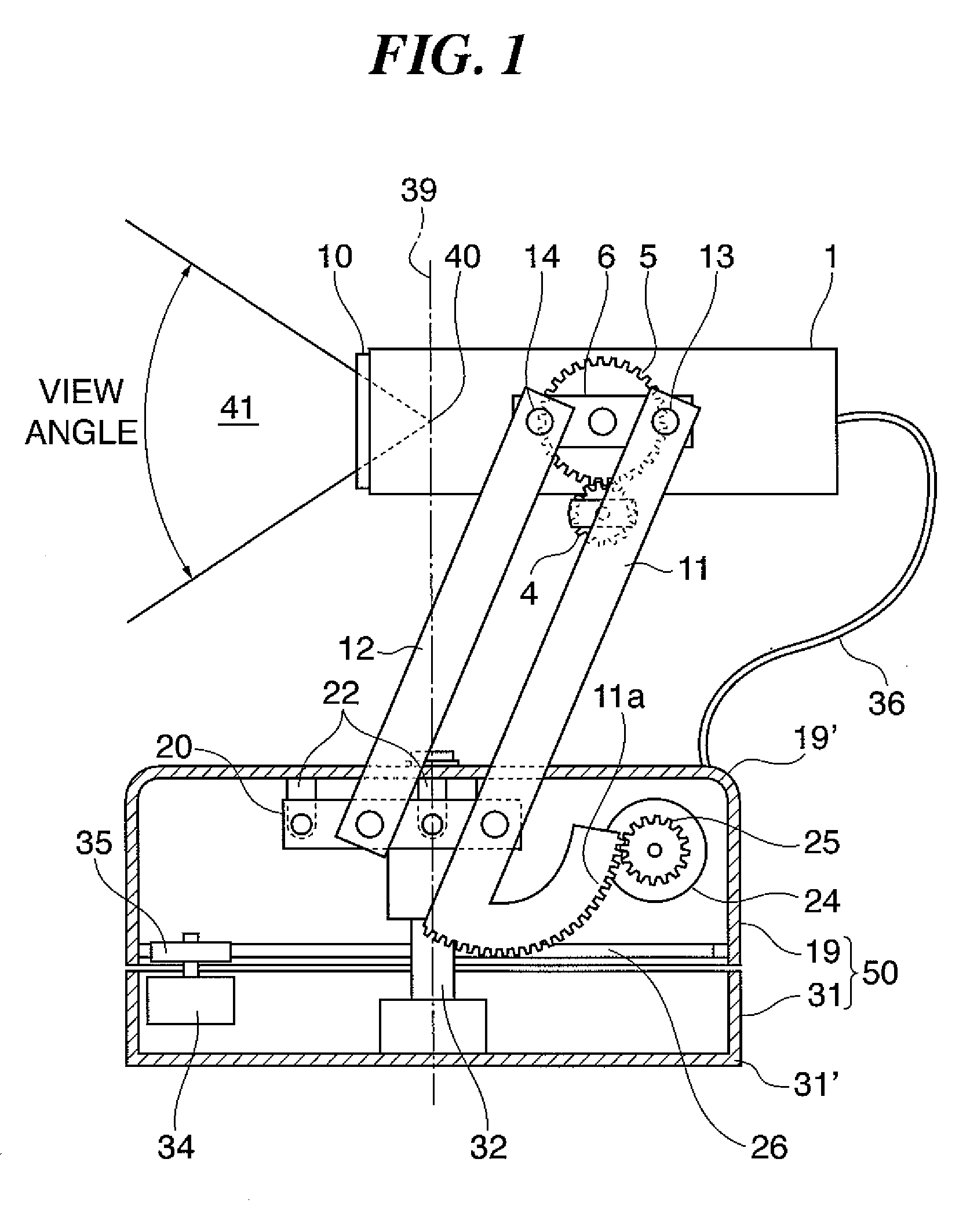

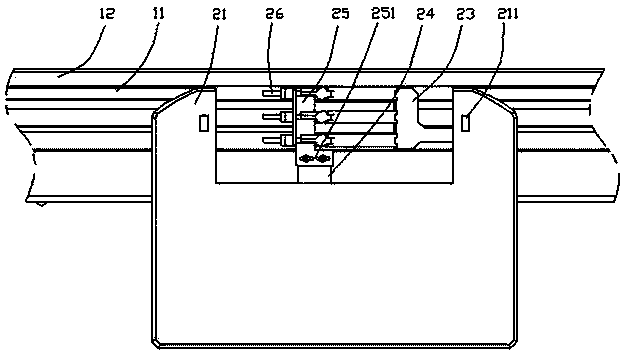

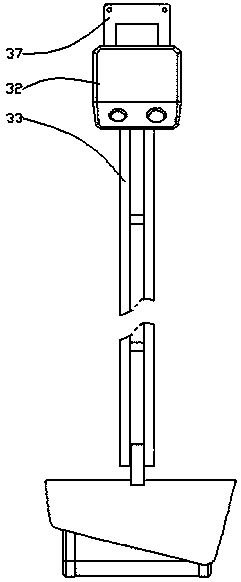

ELECTRIC PRESSURE RICE COOKER, AUTO LOCKING DEVICE, automatic pressure locking function control method

ActiveCN105662127AWith automatic pressure lock functionStop precisePressure-cookersCookerReduction ratio

The invention provides an electric pressure rice cooker with an automatic pressure locking function, an automatic pressure locking function control method for the electric pressure rice cooker, and an auto looking device for the electric pressure rice cooker. The auto looking device includes an inner cooker forming hanging projections, an outer cooker, a cover and a pressure combination part including a locking wheel provided with a plurality of hanging grooves; in the state that the cover covers the outer cooler. The hanging grooves are joint with the hanging projections at a second position (i.e., a pressure locking state), and the hanging grooves releases the hanging projections at a first position (i.e., a pressure locking releasing state); a position sensing portion is used for sensing the locking wheel; the driving portion is used for providing a rotary force for allowing the locking wheel to rotate; and a control portion is used for controlling cooking actions and reducing the rotary force of the driving portion at a certain reduction ratio and finally allowing the locking wheel to stop rotation completely when it is sensed that the locking wheel rotates near the first position or the second position.

Owner:(株)酷晨

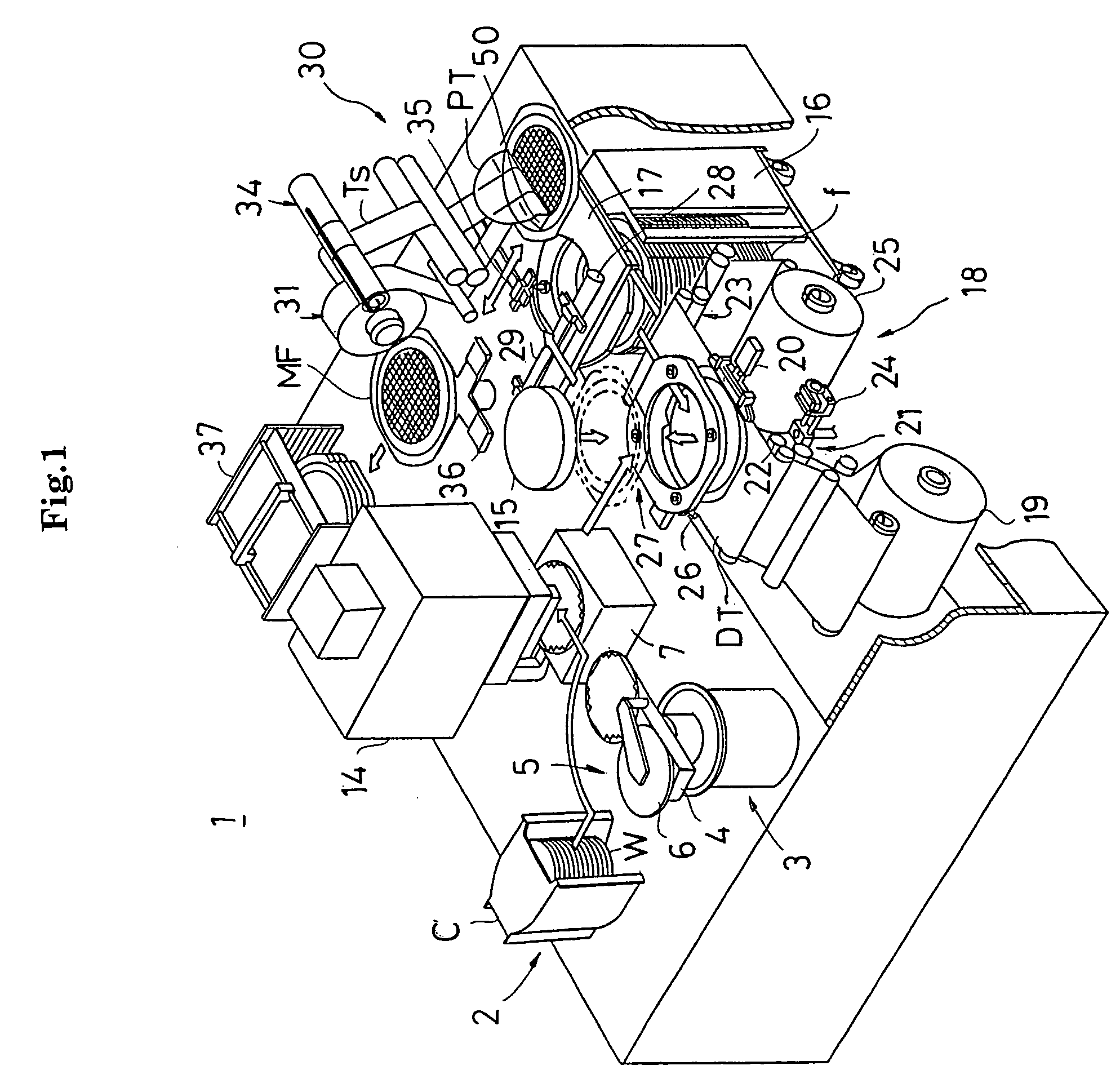

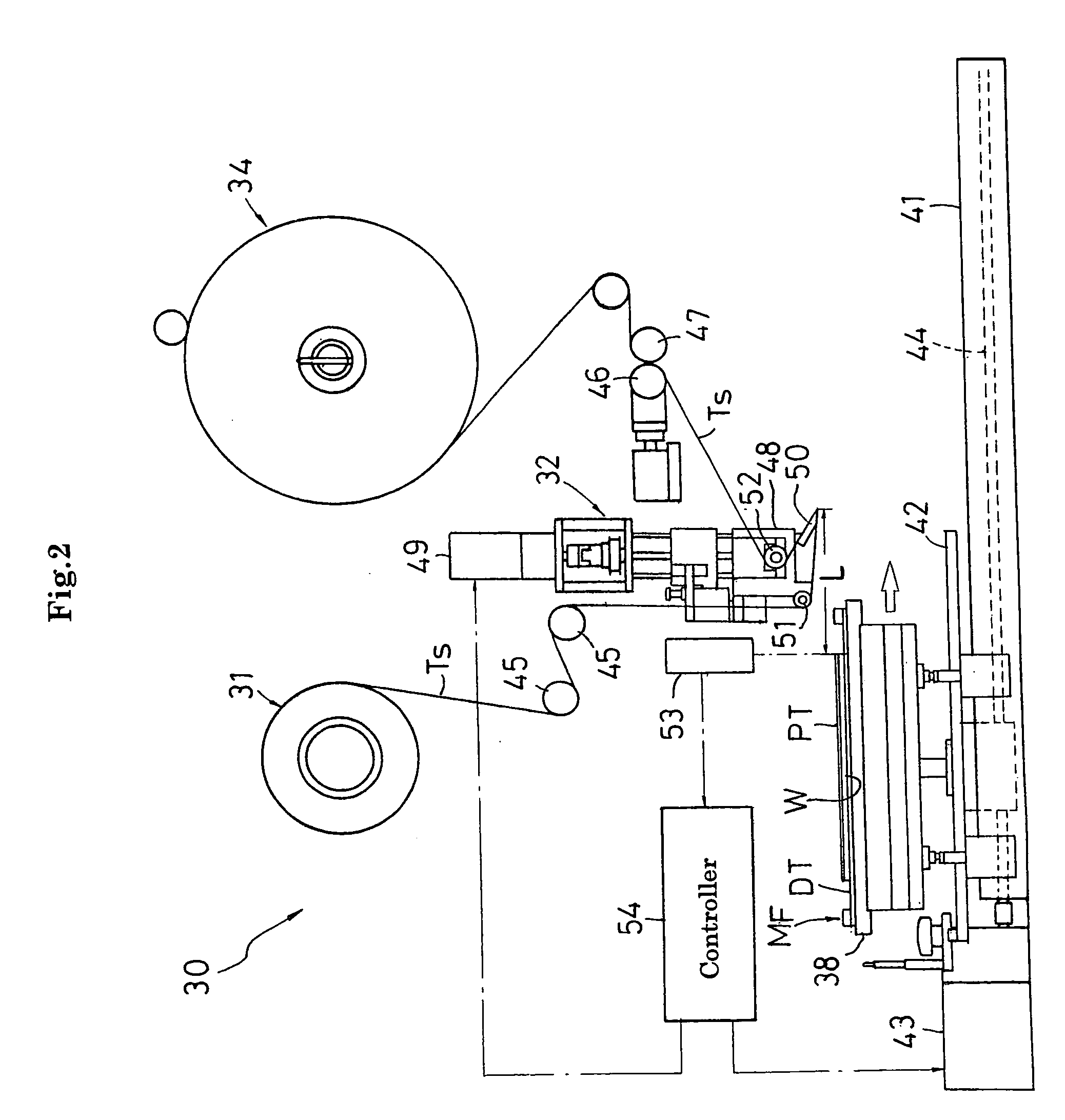

Protective tape separating method and apparatus using the same

InactiveUS20060219359A1Accurate separationReliable separationMechanical working/deformationSolid-state devicesEngineeringSemiconductor

During relative and horizontal movement of a mount frame, in which a semiconductor wafer with a protective tape is supported on a ring frame through a supporting adhesive tape, and a joining member, a position of an end edge of the protective tape is detected in a non-contact manner. Based on the detection result, a joining member is stopped in the position of the end edge of the protective tape and is moved close to the semiconductor wafer to press and bring a separation tape against and into contact with an end of the protective tape. In this state, the mount frame and the joining member are relatively and horizontally moved to join the separation tape onto the protective tape. Then, the mount frame and the joining member are relatively and horizontally moved to separate the separation tape together with the protective tape from a surface of the semiconductor wafer.

Owner:NITTO DENKO CORP

Control apparatus of internal combustion engine

ActiveUS7263959B2Stop preciseKeep energy smallAnalogue computers for vehiclesPower operated startersCombustionExternal combustion engine

At a time of stopping an internal combustion engine, inertia energy of the engine is kept constant, for example, by controlling a number of engine revolution constant, while controlling combustion of the engine. By utilizing the controlled inertia energy, the engine is stopped at a predetermined crank angle position. Since the engine is stopped at the predetermined crank angle position by utilizing the controlled inertia energy, a large amount of energy for controlling the stop position of the energy is not needed, and the energy needed for the stop control can be reduced. Since the inertia energy utilized for the stop control is always controlled in a predetermined state, the engine can be stopped at a proper position reliably each time.

Owner:TOYOTA JIDOSHA KK

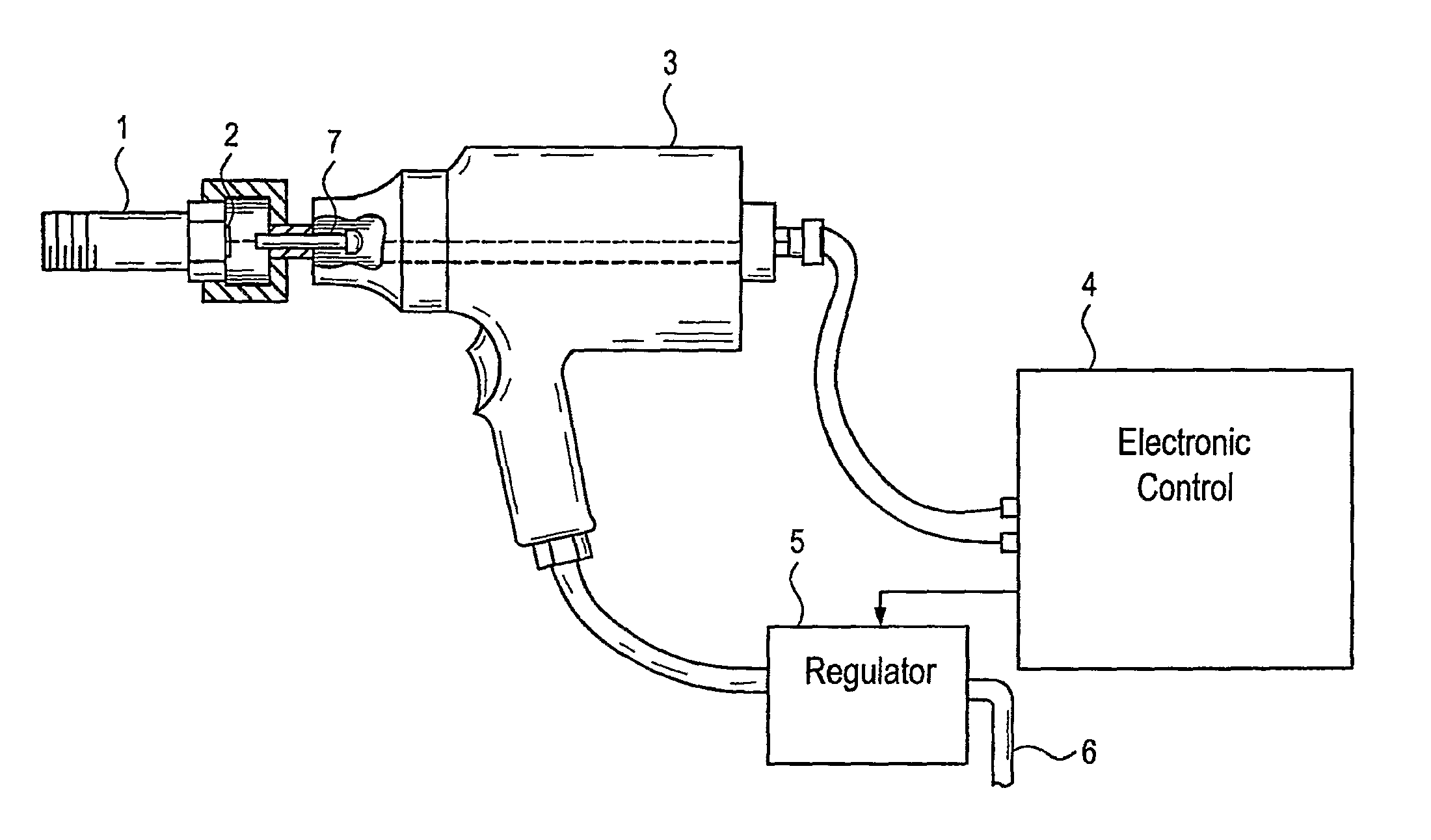

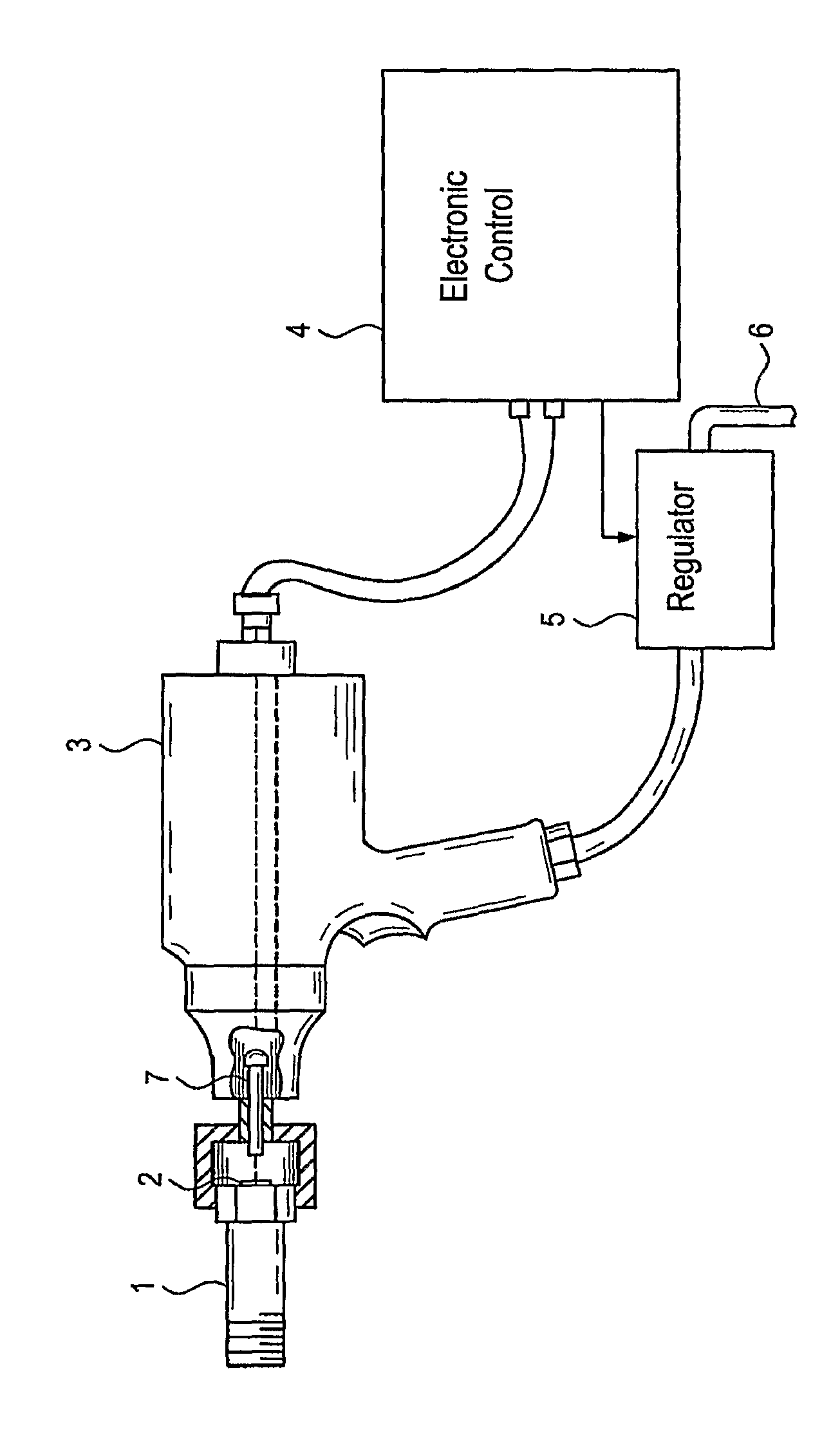

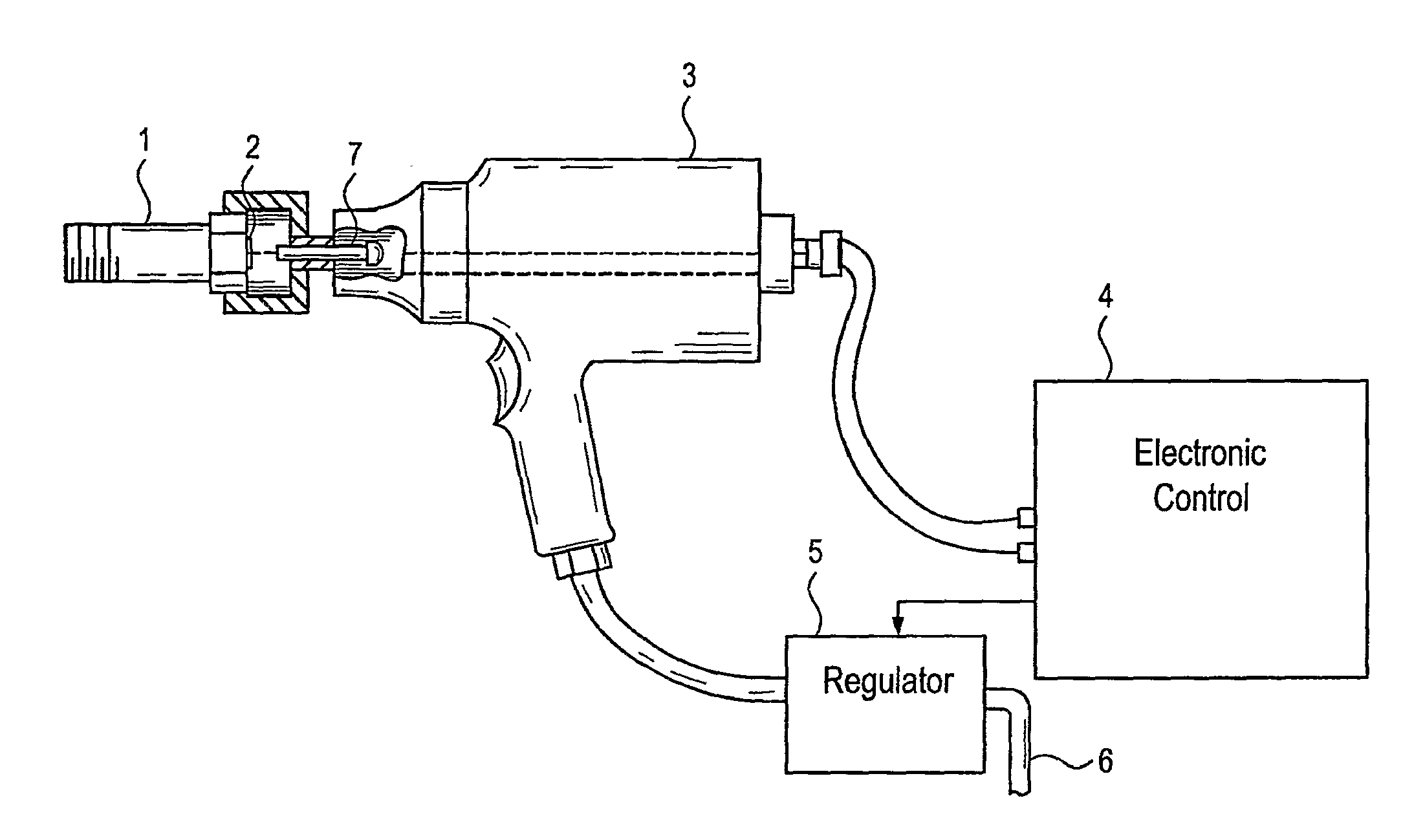

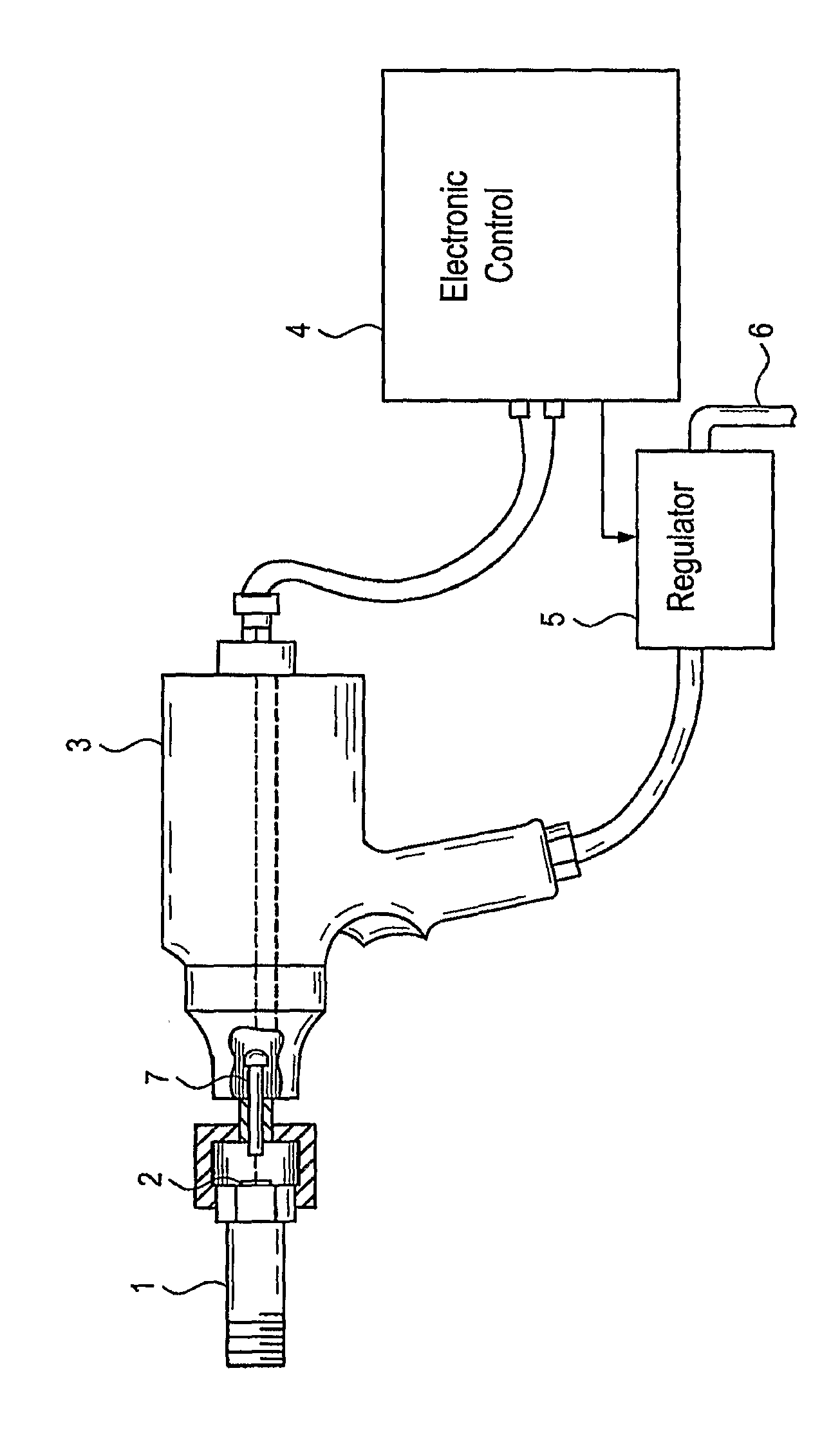

System for dynamically controlling the torque output of a pneumatic tool

ActiveUS7823458B2Reduce probabilityStop preciseDerricks/mastsTemperatue controlRotation velocityHeating effect

Pneumatic tightening tools can be used for high speed assembly of critical bolts to precise loads by dynamically controlling the output power of the pneumatic tool during a tightening cycle using an electronically controlled air pressure regulator to reduce the tightening rate, or the load increase per impact for impact or impulse tools, to enable the tool to be stopped precisely at a specified stopping load or torque. For prevailing torque fasteners, the output power of the pneumatic tool is dynamically controlled to minimize the speed of rotation during rundown, to minimize the heating effects associated with such torque fasteners, and to then increase the power from the tool, as required, to provide the torque to reach the specified stopping load or torque. The maximum air pressure supplied to the pneumatic tool can be limited, depending on the expected torque required to tighten the fastener to the specified load or torque.

Owner:INNOVATION PLUS LLC

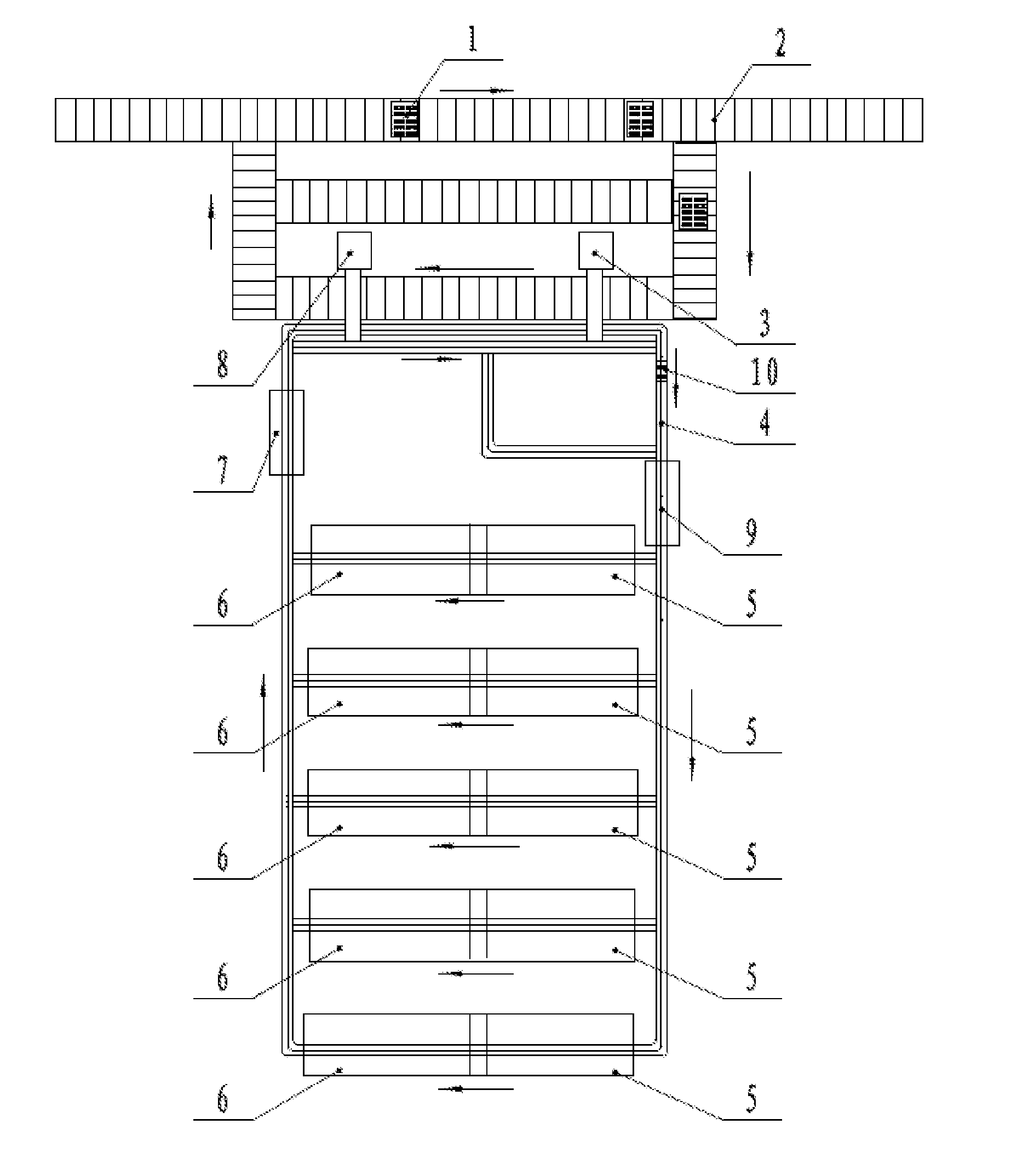

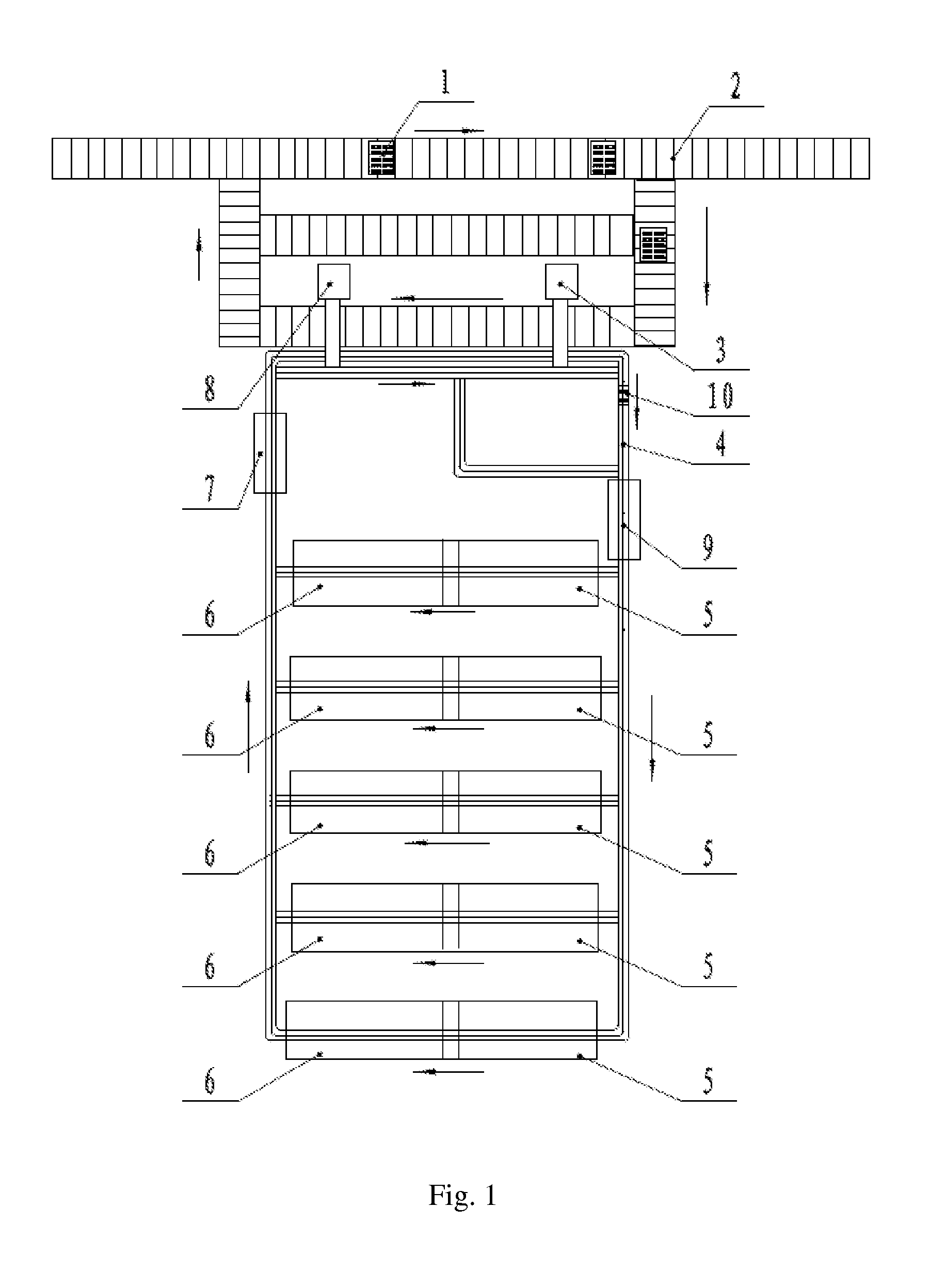

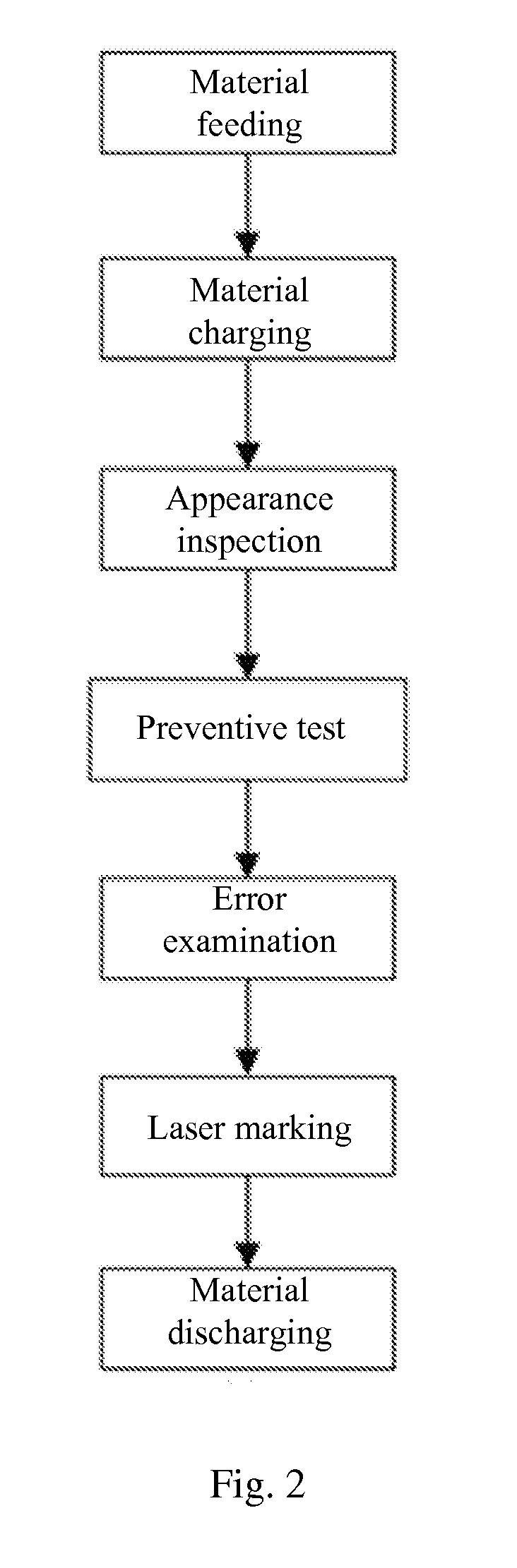

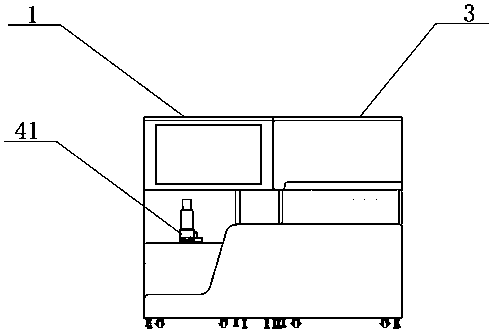

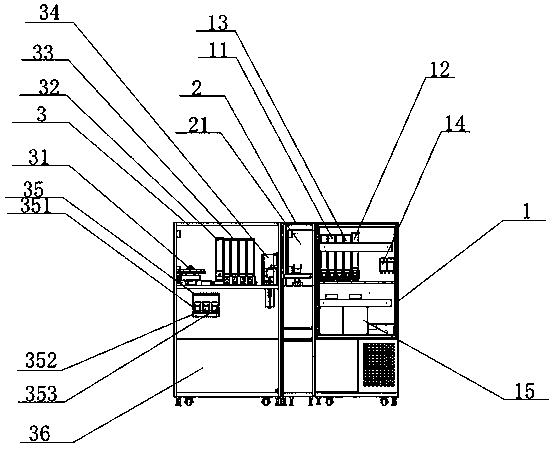

Full-automatic detecting system and method for transformer

ActiveUS20130297245A1Extended service lifeStability and accuracyTransformers testingInductances/transformers/magnets manufactureManagement systemEngineering

A full-automatic detecting system and method for a transformer. The system comprises a material delivery line; a feed device; a detection delivery line; insulating test devices; error detecting devices; a laser marking device; a discharge device; and a detection management system. The insulating test devices, the error detecting devices, and the laser marking device are sequentially arranged beside the detection delivery line. The material delivery line, the detection delivery line, and the devices work in coordination, to realize full-automatic detection of the transformer, avoid manual detection errors and improve the sorting accuracy.

Owner:STATE GRID ZHEJIANG ELECTRIC POWER

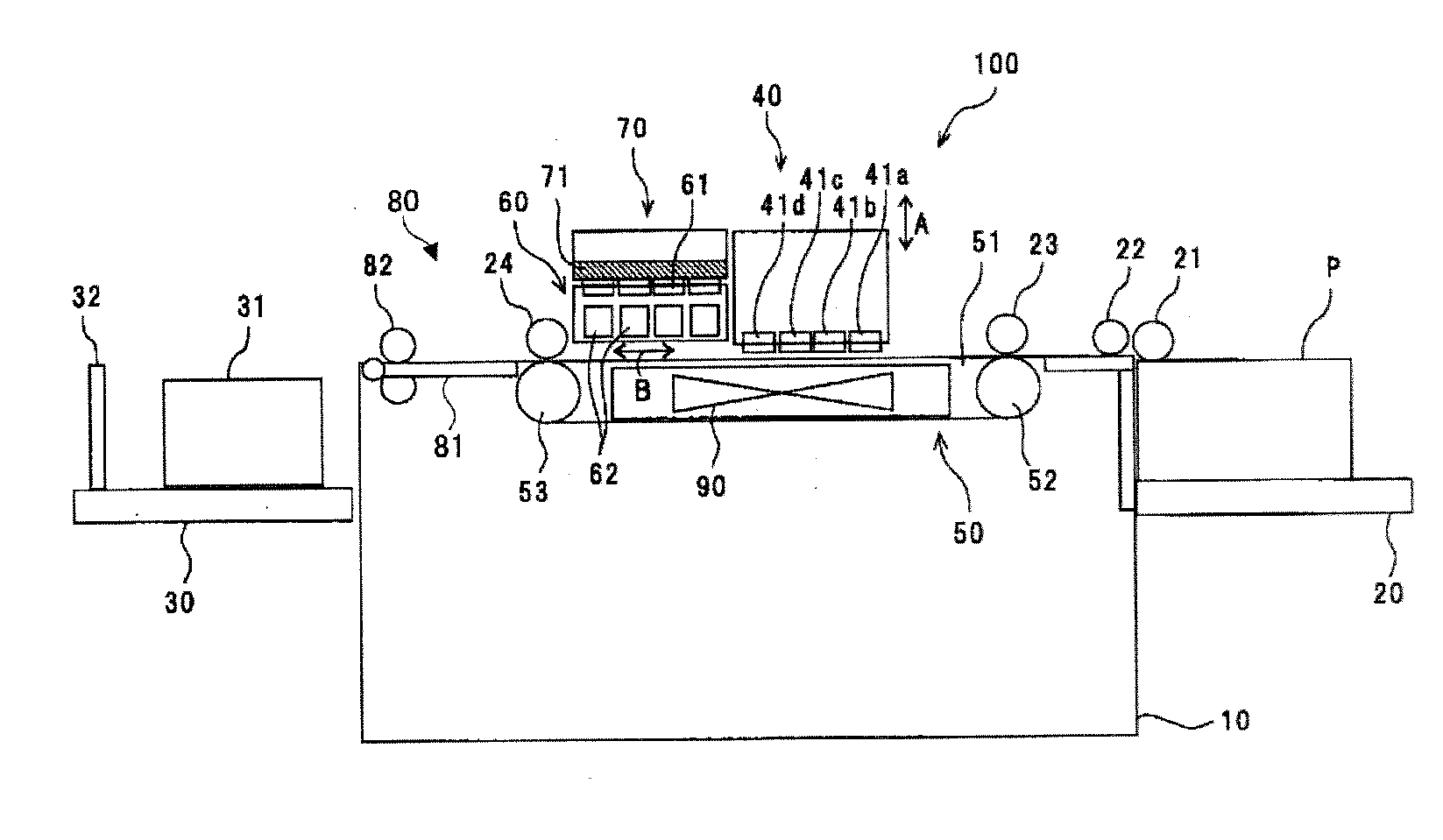

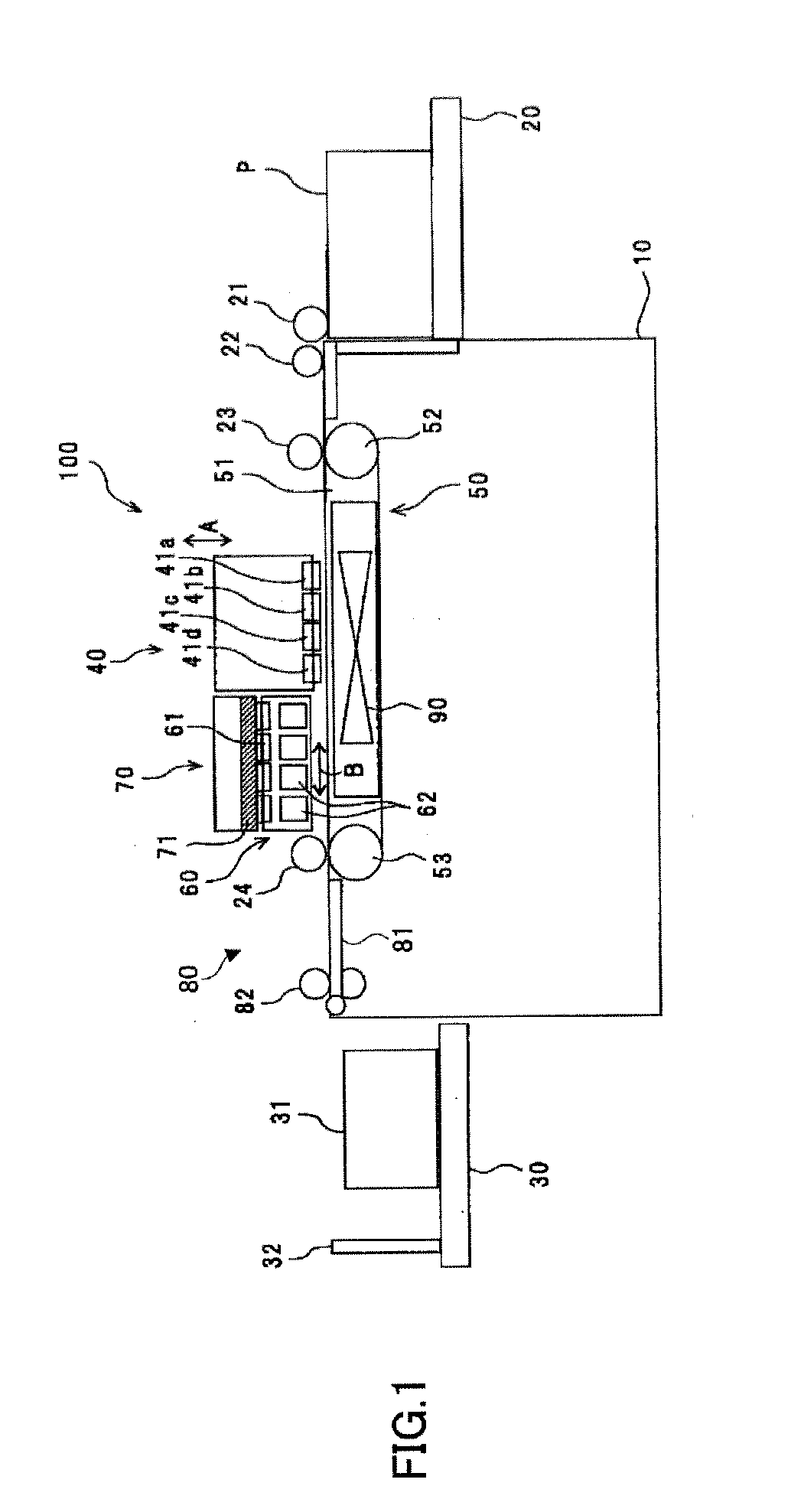

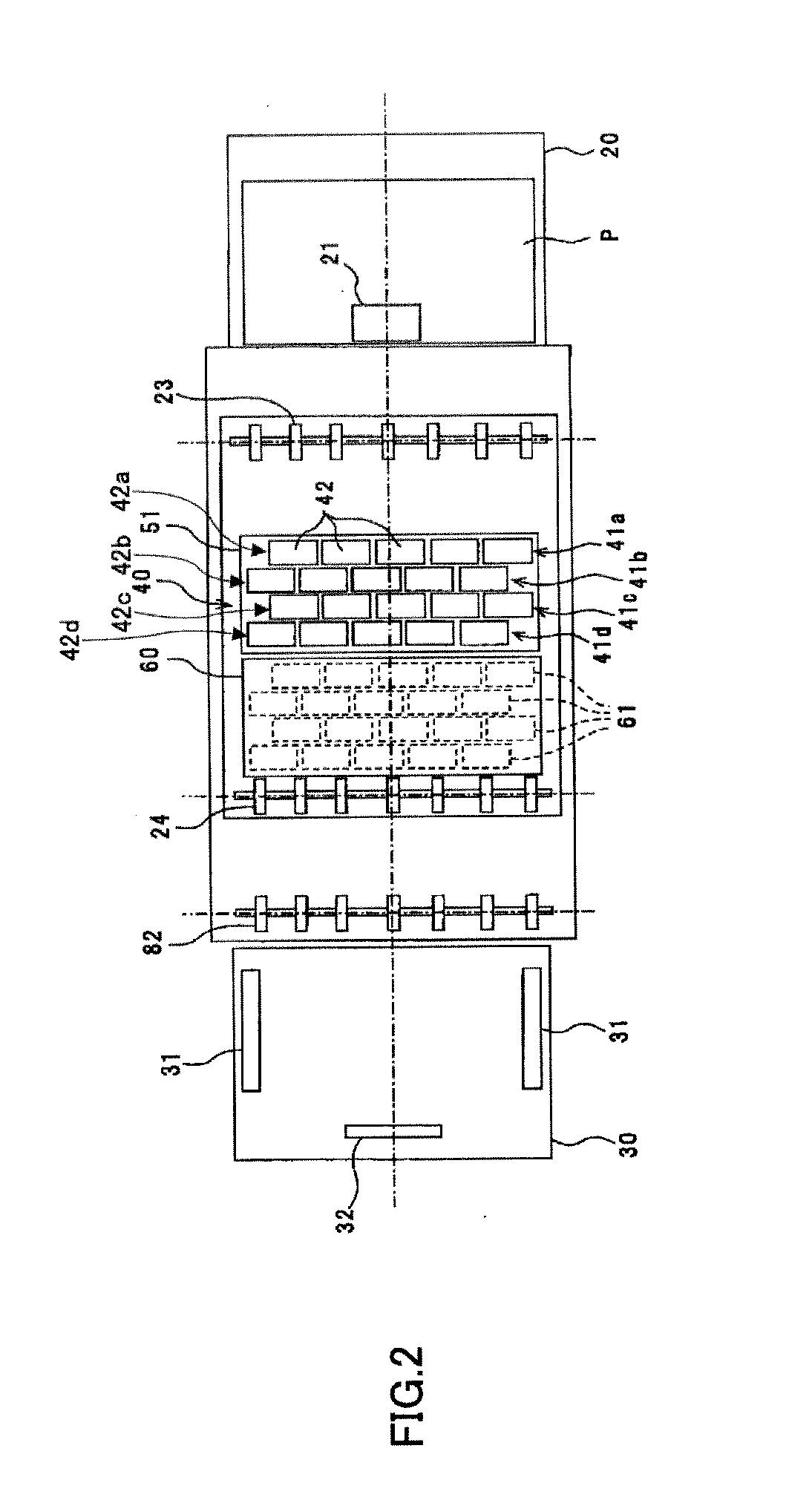

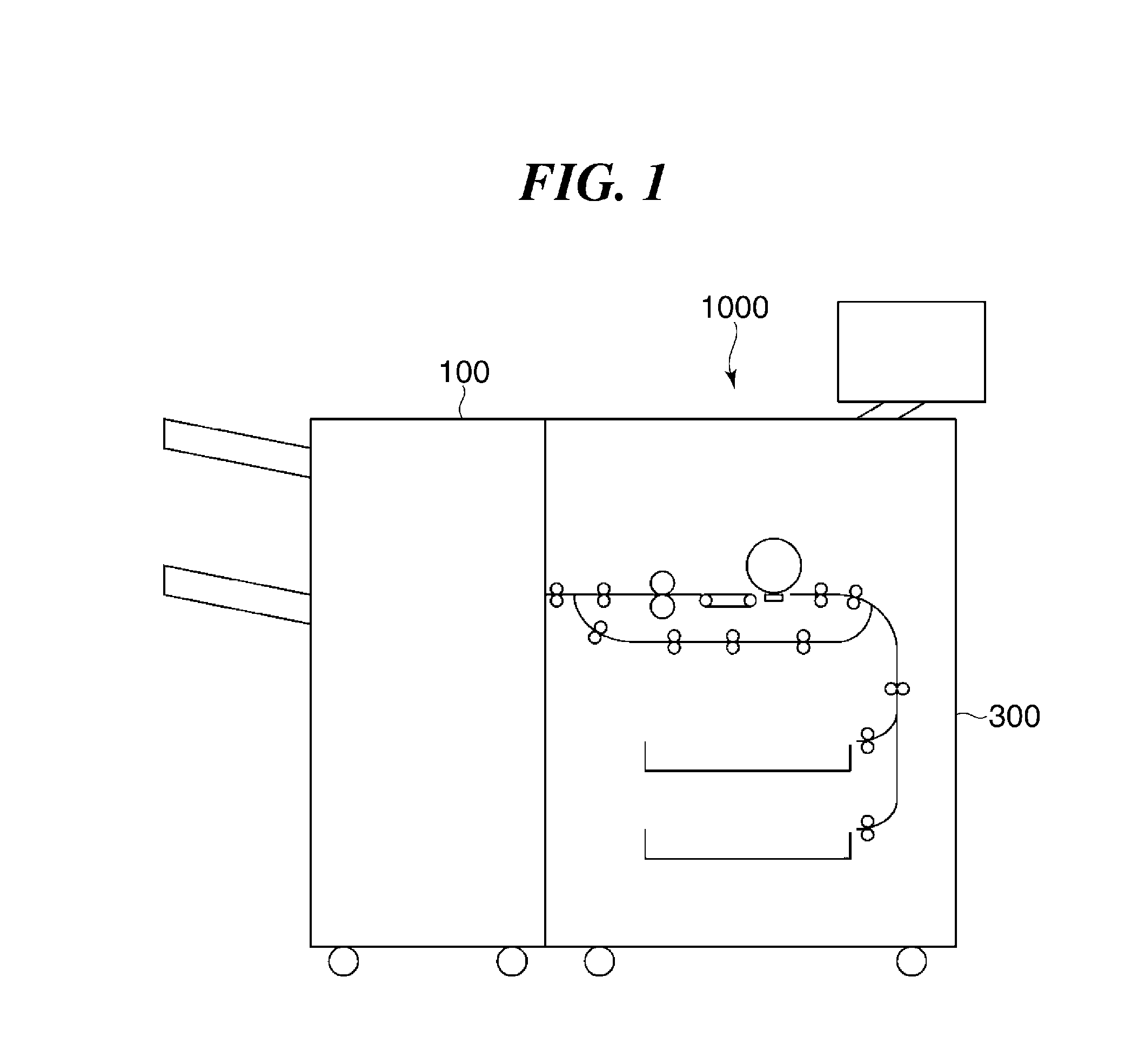

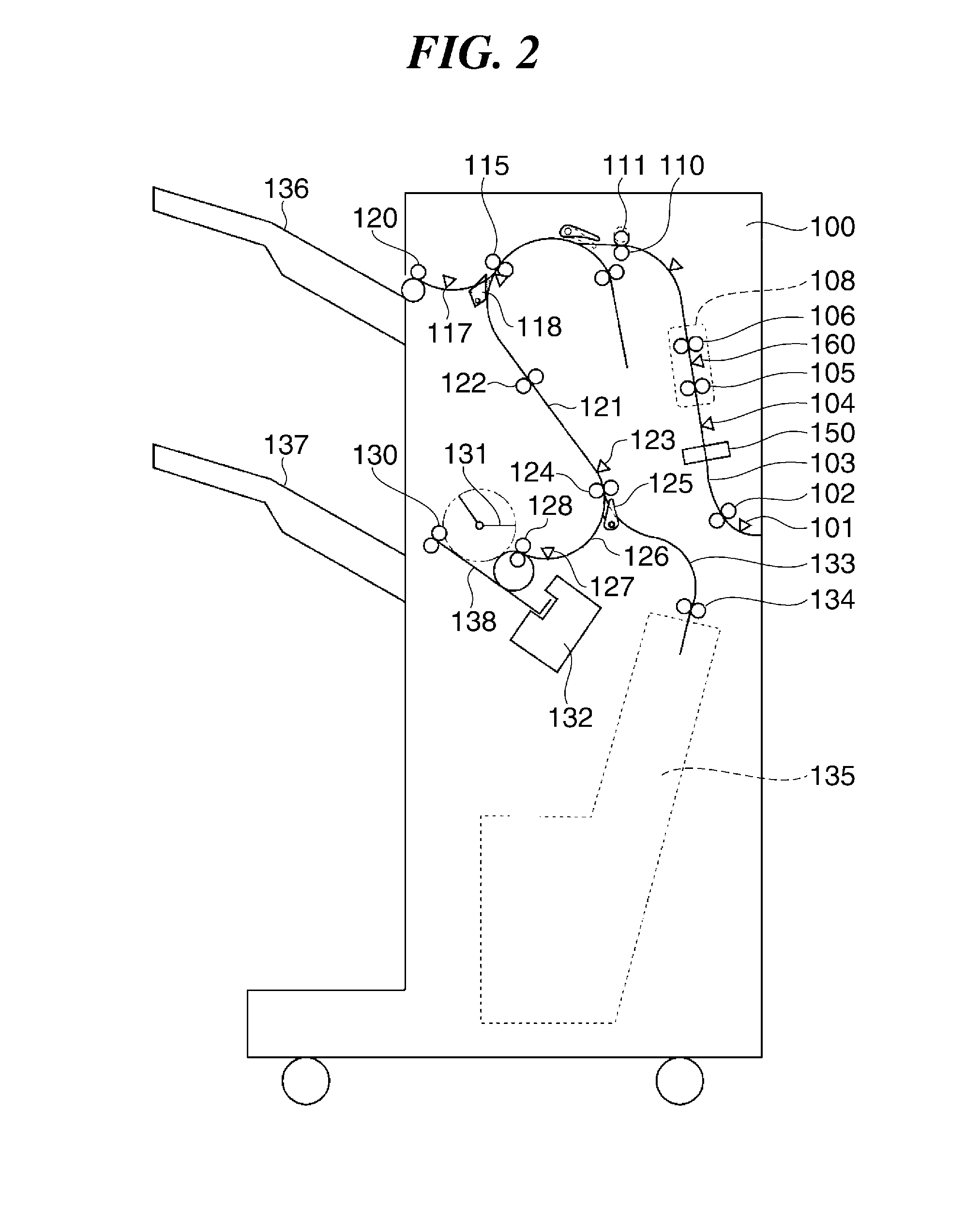

Image forming apparatus

InactiveUS20130162707A1Eliminate disadvantagesReduce equipment costsPower drive mechanismsOther printing apparatusImage formationCam

An image forming apparatus includes a liquid jetting head for jetting liquid onto a recording medium and a movement mechanism for moving the liquid jetting head orthogonal to the recording medium. The movement mechanism includes translation cams movable in a direction orthogonal to the movement of the liquid jetting head, each of the translation cams including a cam gap into which a protruding part of the liquid jetting head is inserted. Each cam gap includes a parallel part and a slope part. The cap gaps of the translation cams are configured so as to constantly maintain a relationship in which when the protruding part is positioned in the slope part of the cap gap of one of the translation cams, the protruding part is positioned in the parallel part of the cap gap of the other translation cam.

Owner:RICOH KK

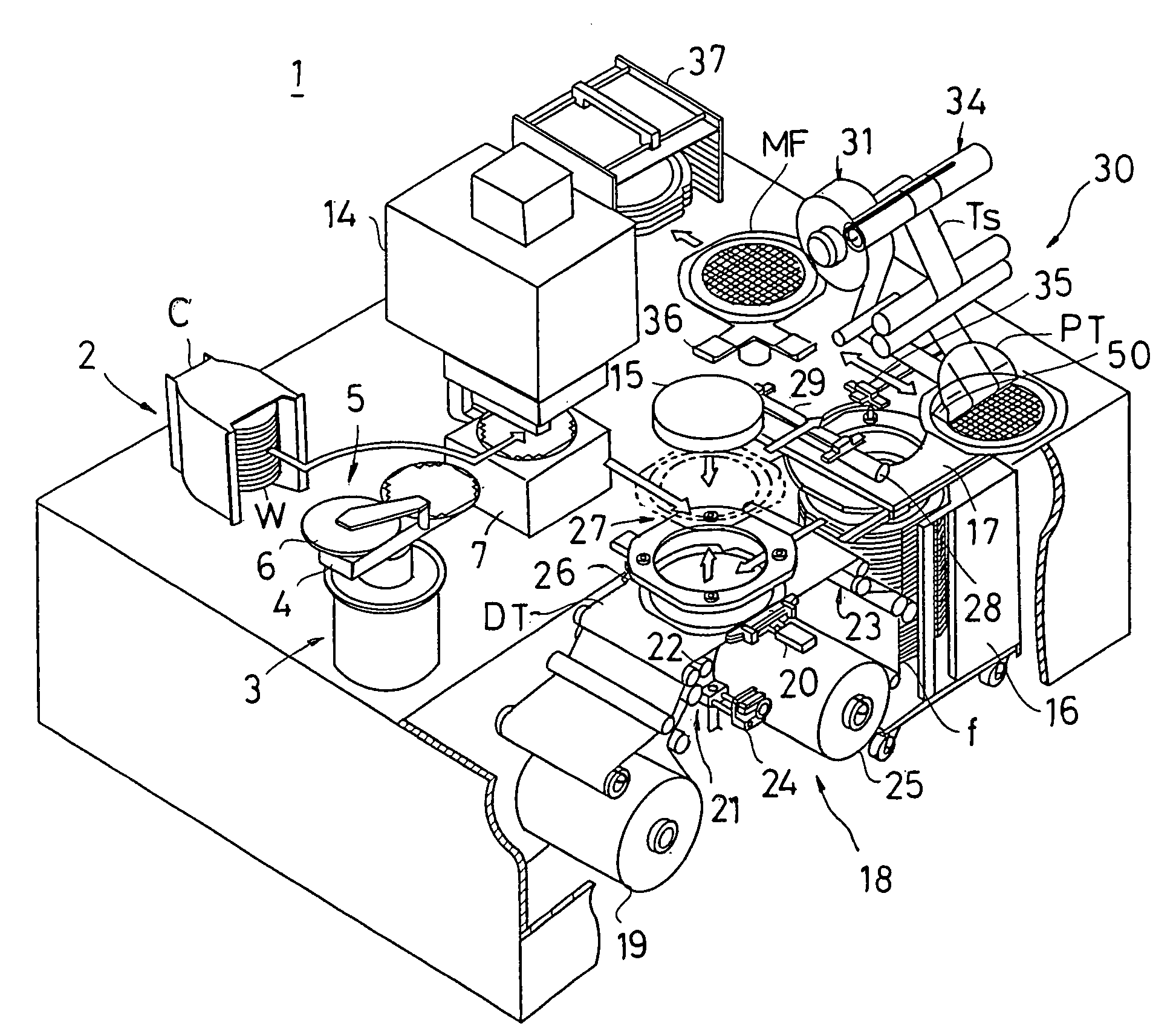

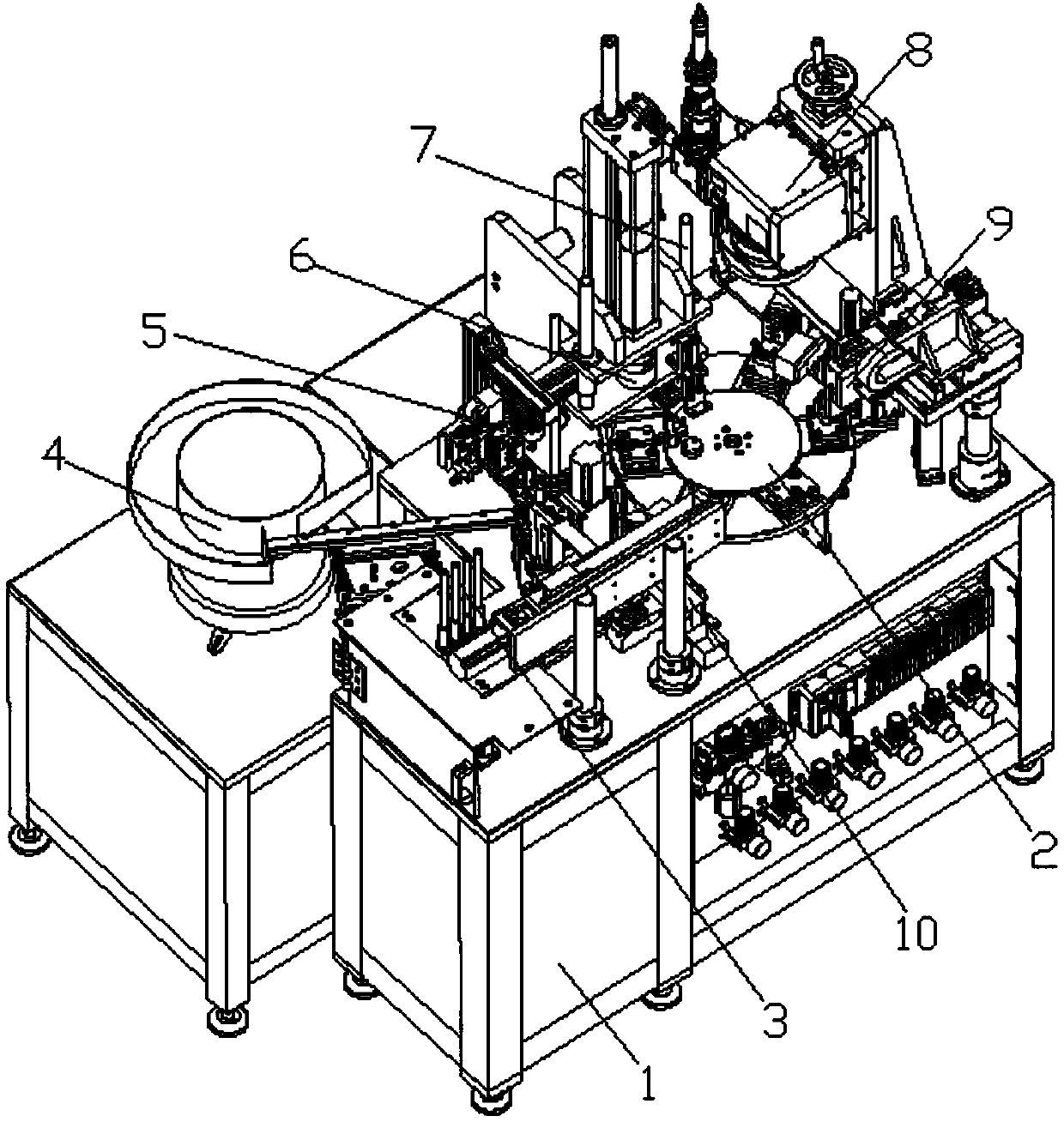

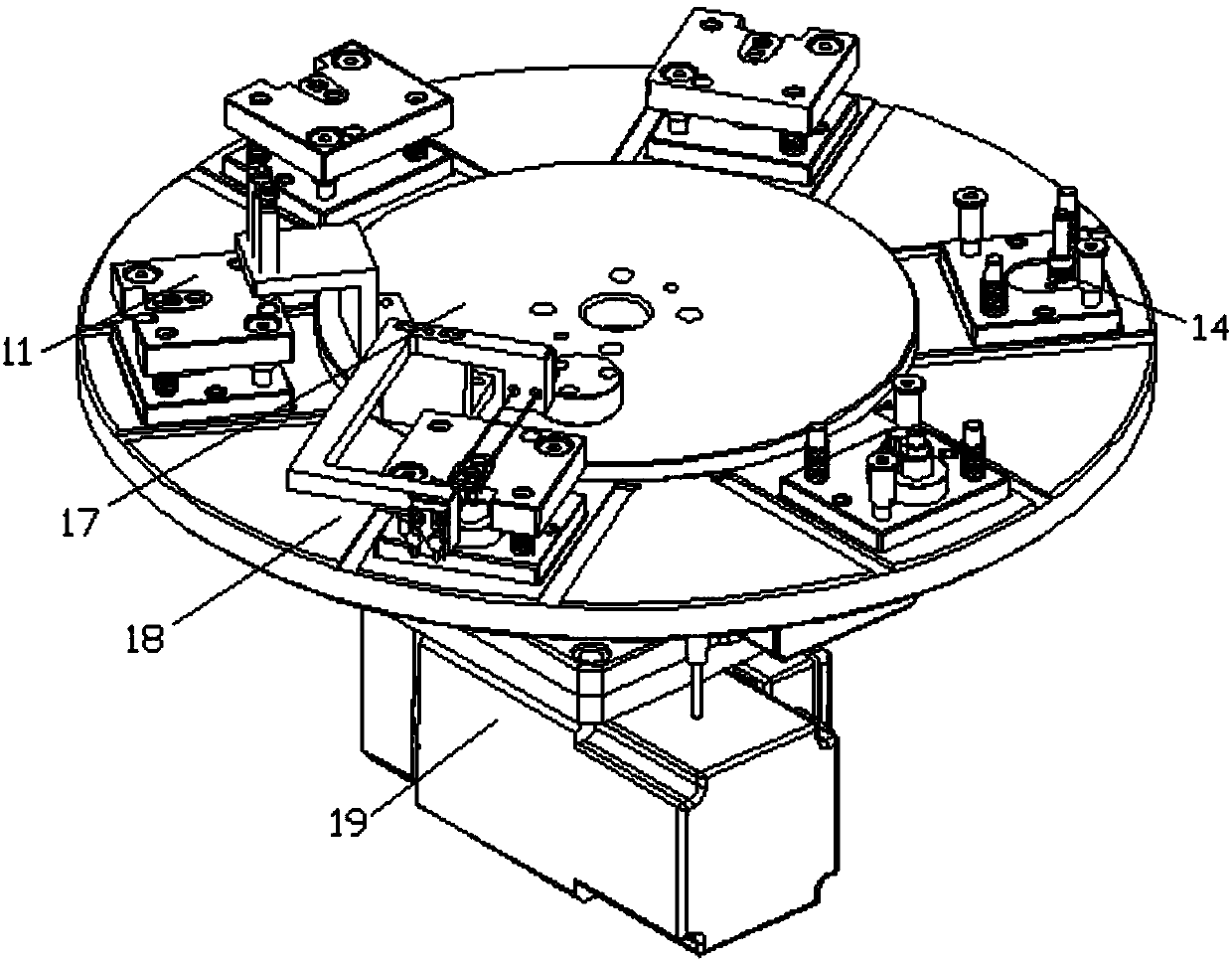

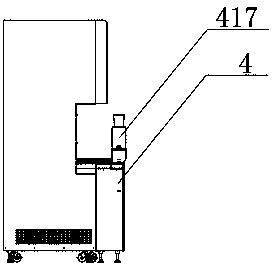

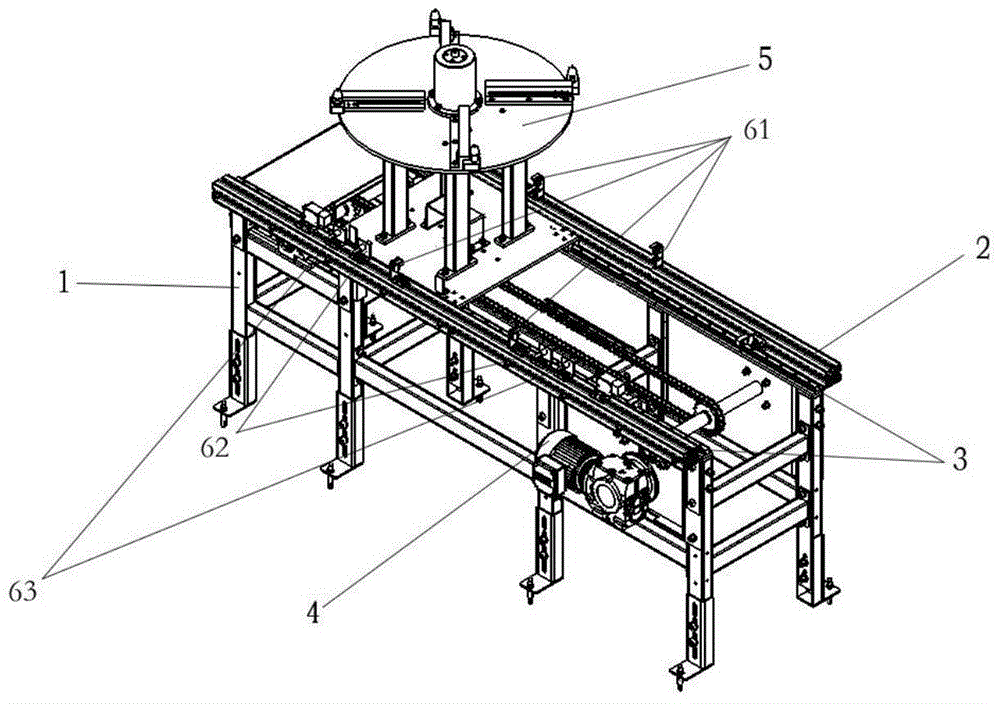

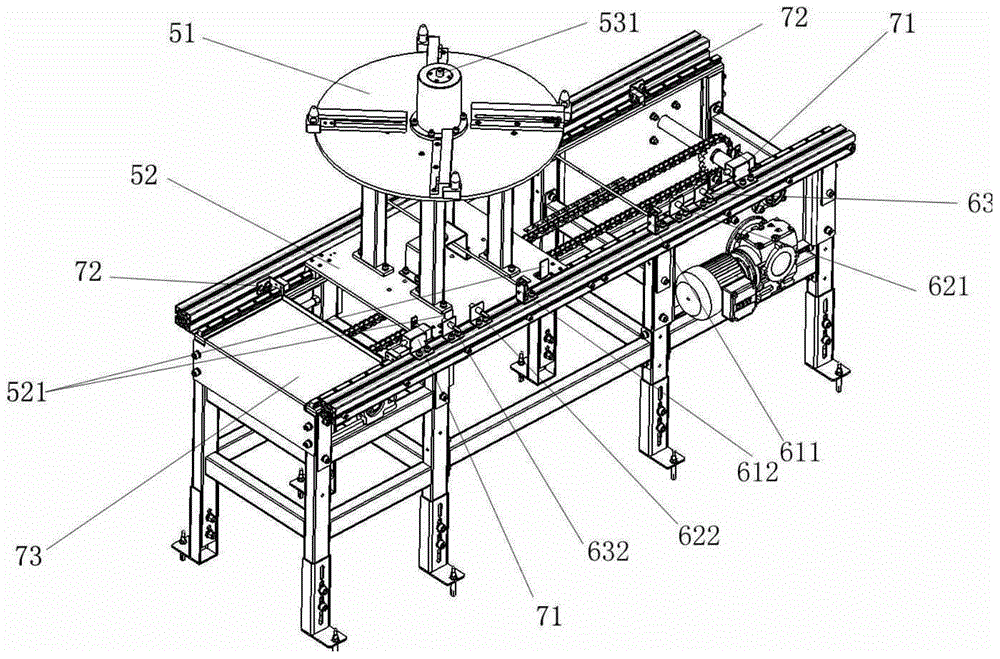

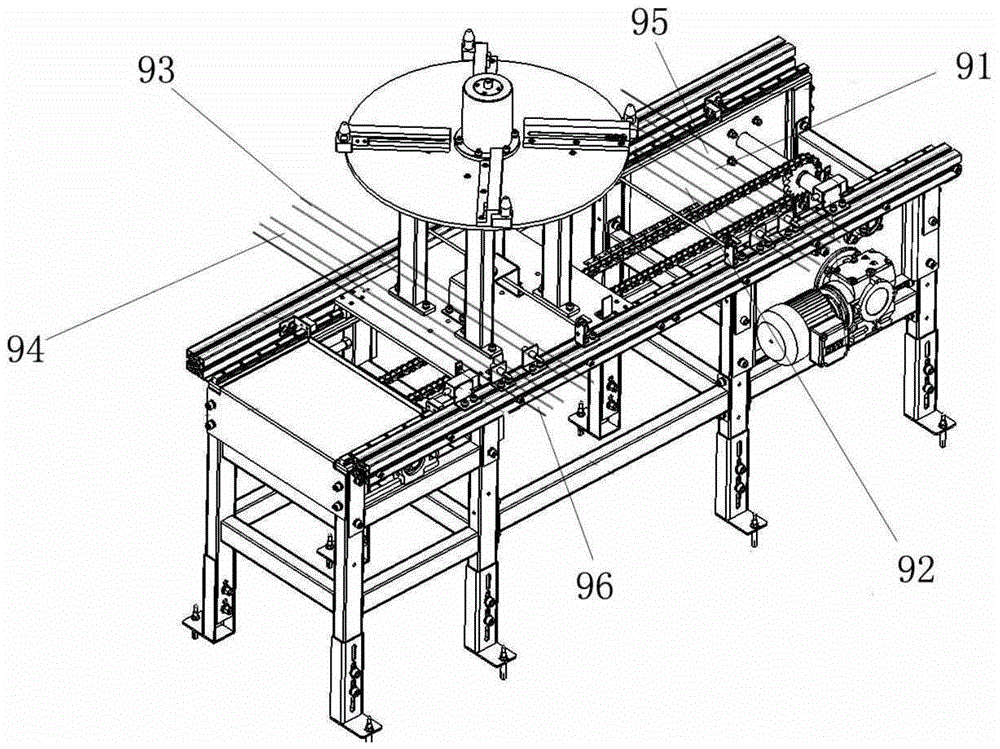

Full-automatic camshaft assembling machine

InactiveCN107717435ATimely detectionHigh positioning accuracyAssembly machinesLaser beam welding apparatusDistribution controlButt joint

The invention relates to a full-automatic camshaft assembling machine. The full-automatic camshaft assembling machine comprises a rack and a power distribution control cabinet arranged in the rack; arotating disk device is arranged on the middle portion above the rack; and a shaft feeding device, a cam vibrating feeding disk, a cam feeding device, a press-fitting device, a floating shaft pressingdevice, a laser welding device, a flaw detecting device and a discharging device in butt joint with carrier assemblies are sequentially arranged above the rack in the rotating direction of a rotatingdisk. According to the full-automatic camshaft assembling machine, by means of the shaft feeding device, a shaft is placed in the carrier assembly on the rotating disk device, and the carrier assembly rotates clockwise along the rotating disk and sequentially rotates onto the cam feeding device to perform cam feeding, onto the press-fitting device so as to press a cam into a matching groove of the shaft, onto the floating shaft pressing device to push down the shaft to be clamped with the matching groove, onto the laser welding device to perform laser welding on the matched portion of the shaft and the cam, onto the flaw detecting device to detect bruised damage and scratches, and onto the discharging device to perform discharging; and the assembling process of the cam and the shaft is completed, the positioning precision is high, and defective products are detected in time.

Owner:DONGGUAN RONGGONG AUTOMATION TECH CO LTD

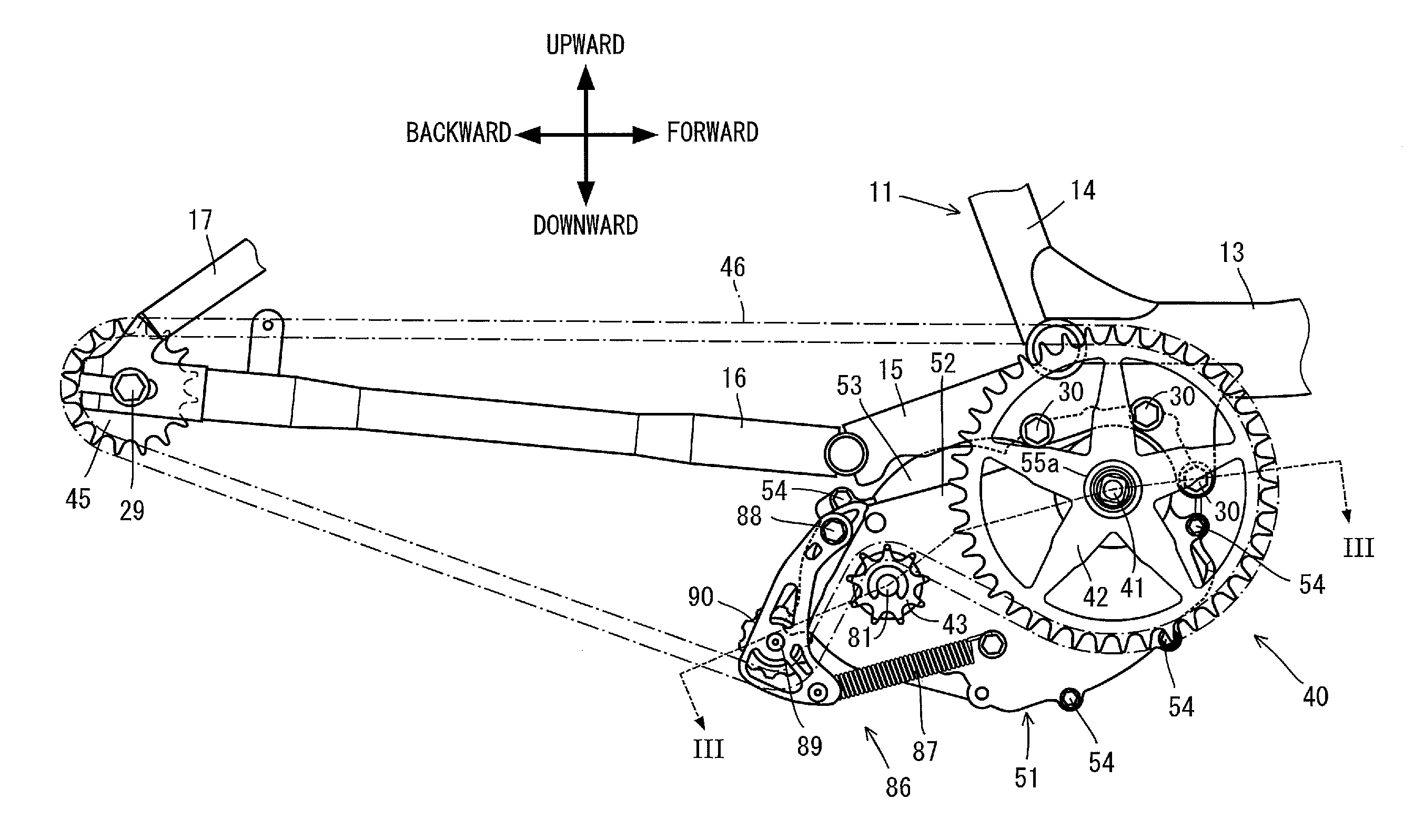

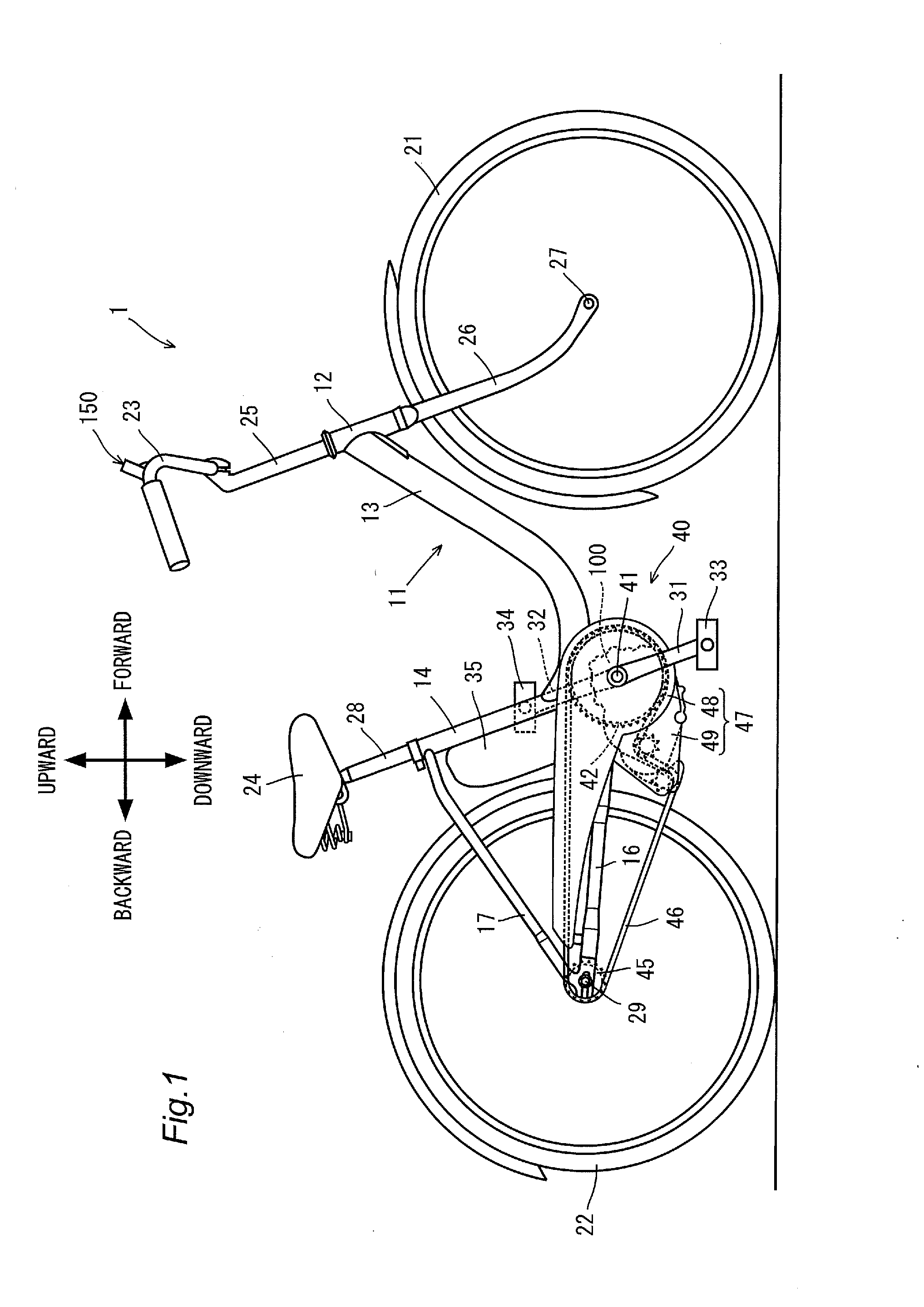

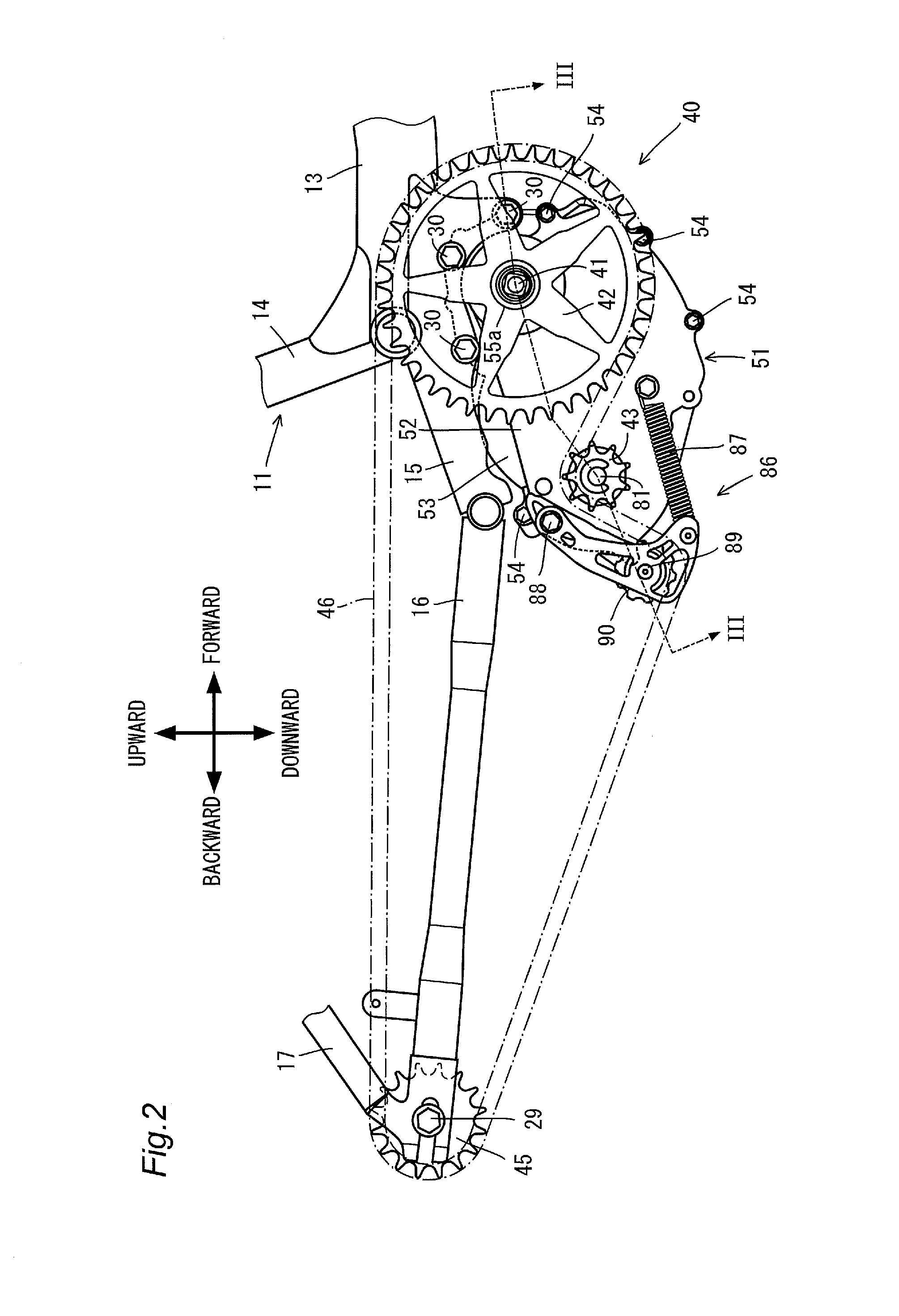

Driving unit and battery-assisted bicycle

A driving unit and a battery-assisted bicycle include a stopping assist control without making a rider feel uncomfortable. The driving unit includes a crankshaft to which pedals are to be connected, a torque detector that detects a torque generated at the crankshaft, and an assist control stopping unit that stops an assist control based on an amplitude of a torque detected by the torque detector while the crankshaft rotates in a prescribed rotation angle range.

Owner:YAMAHA MOTOR CO LTD

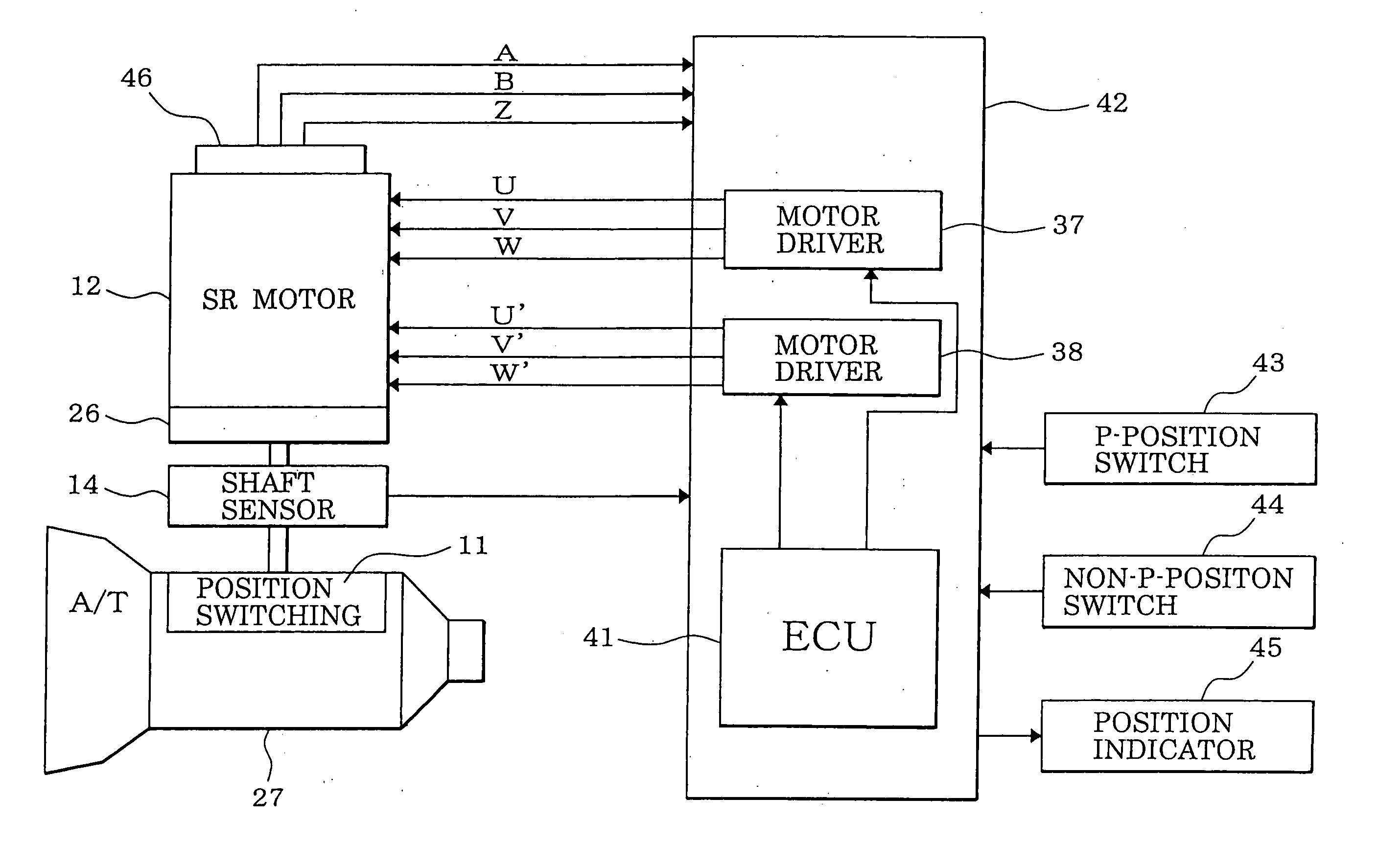

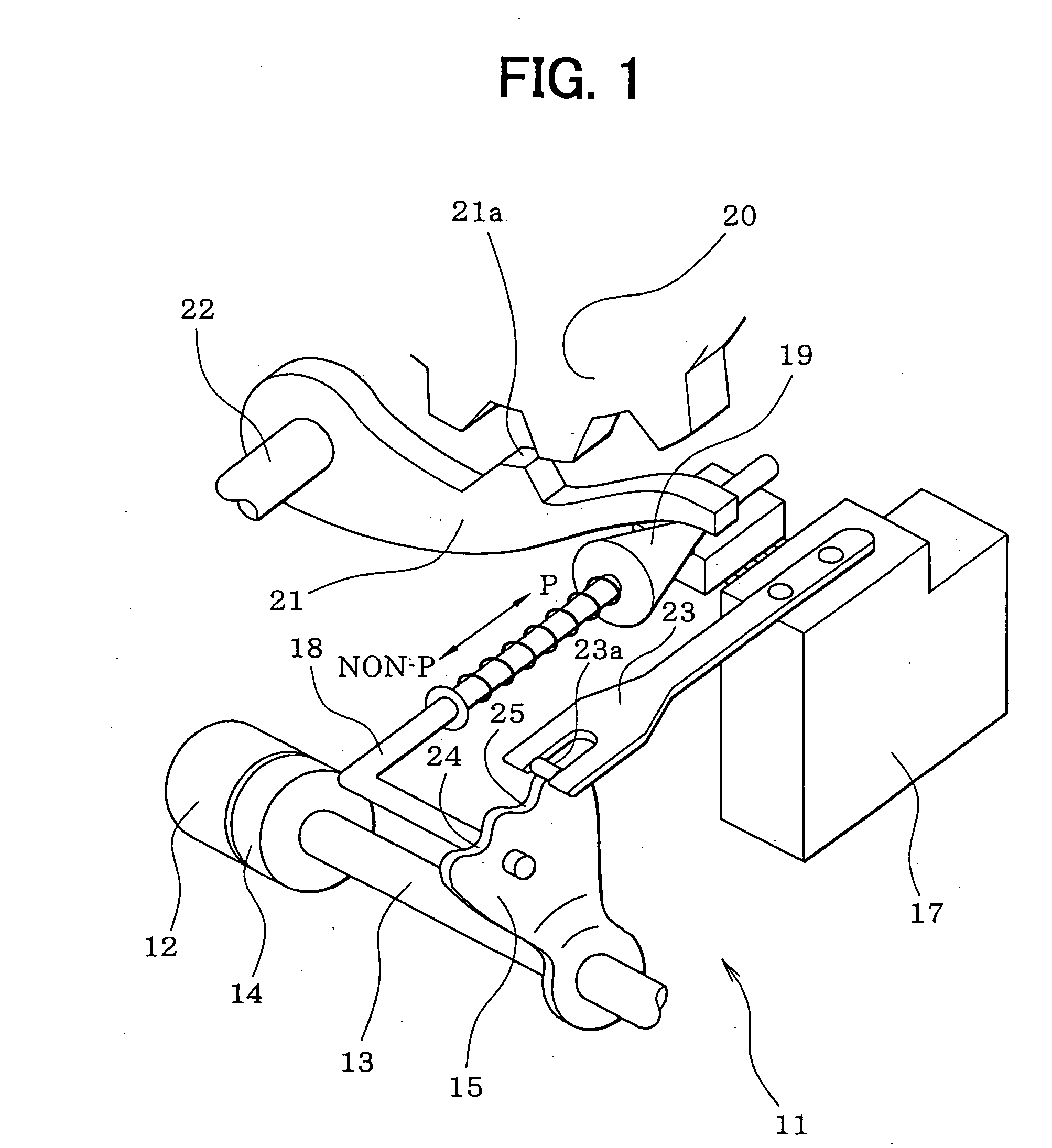

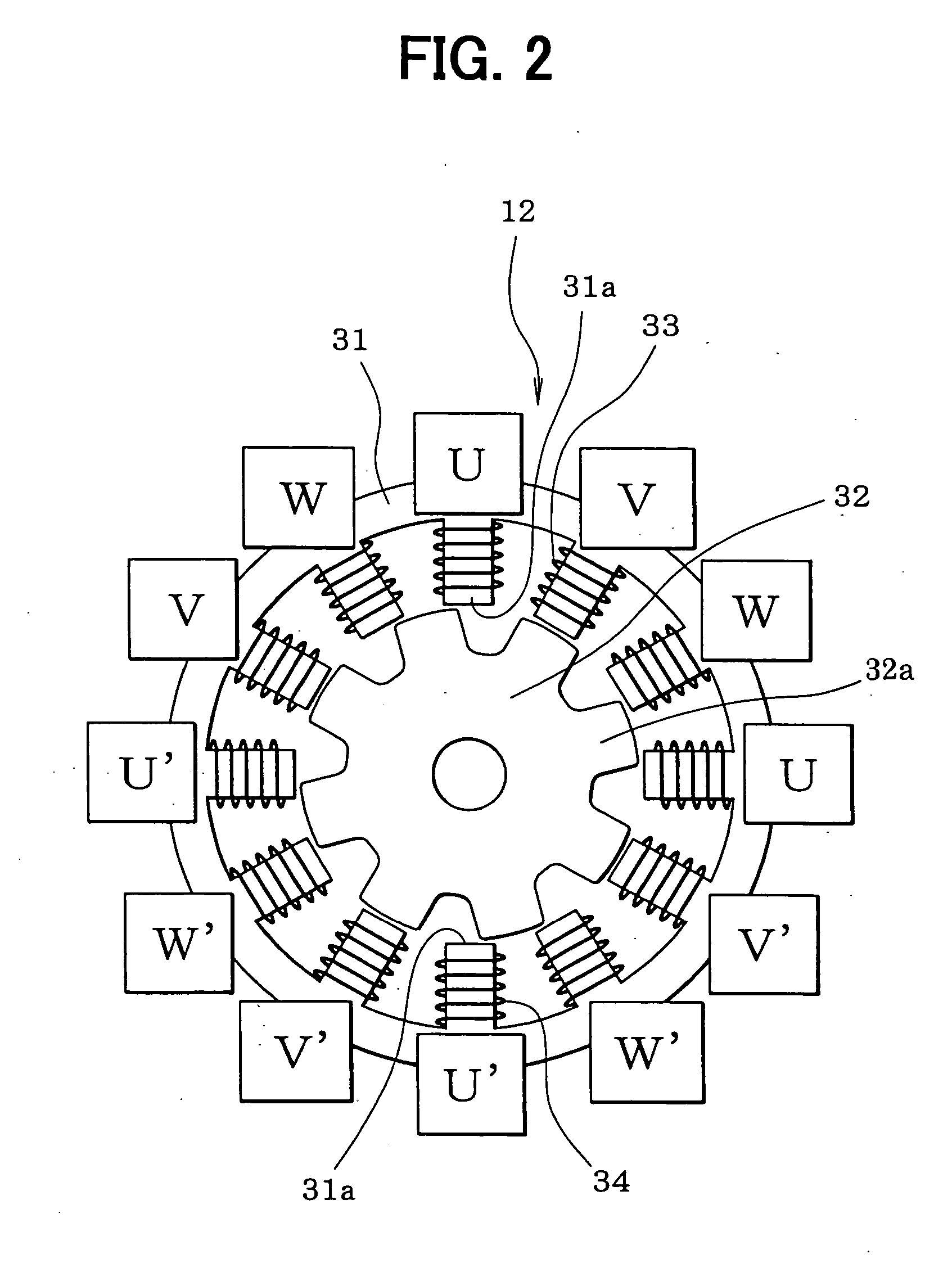

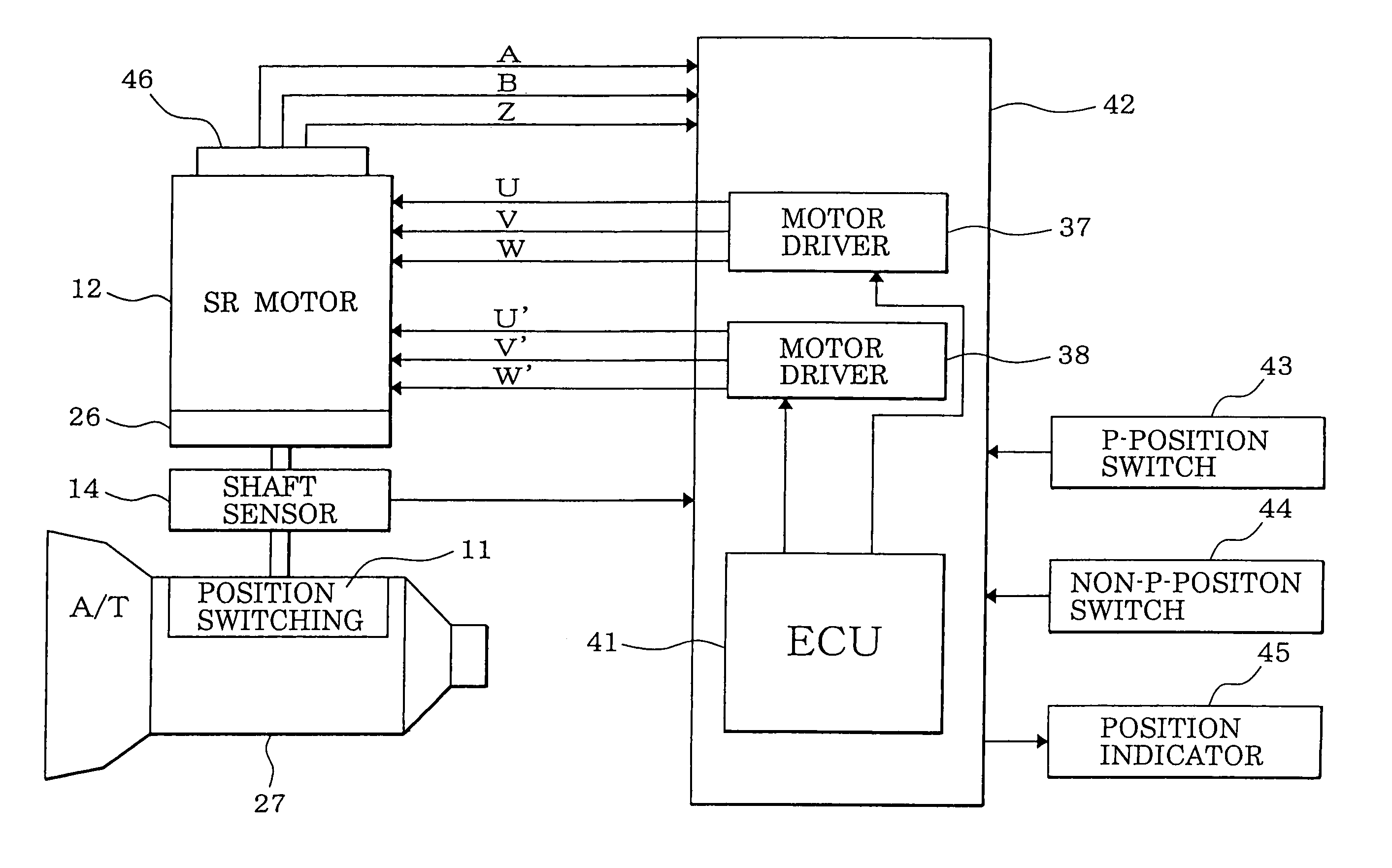

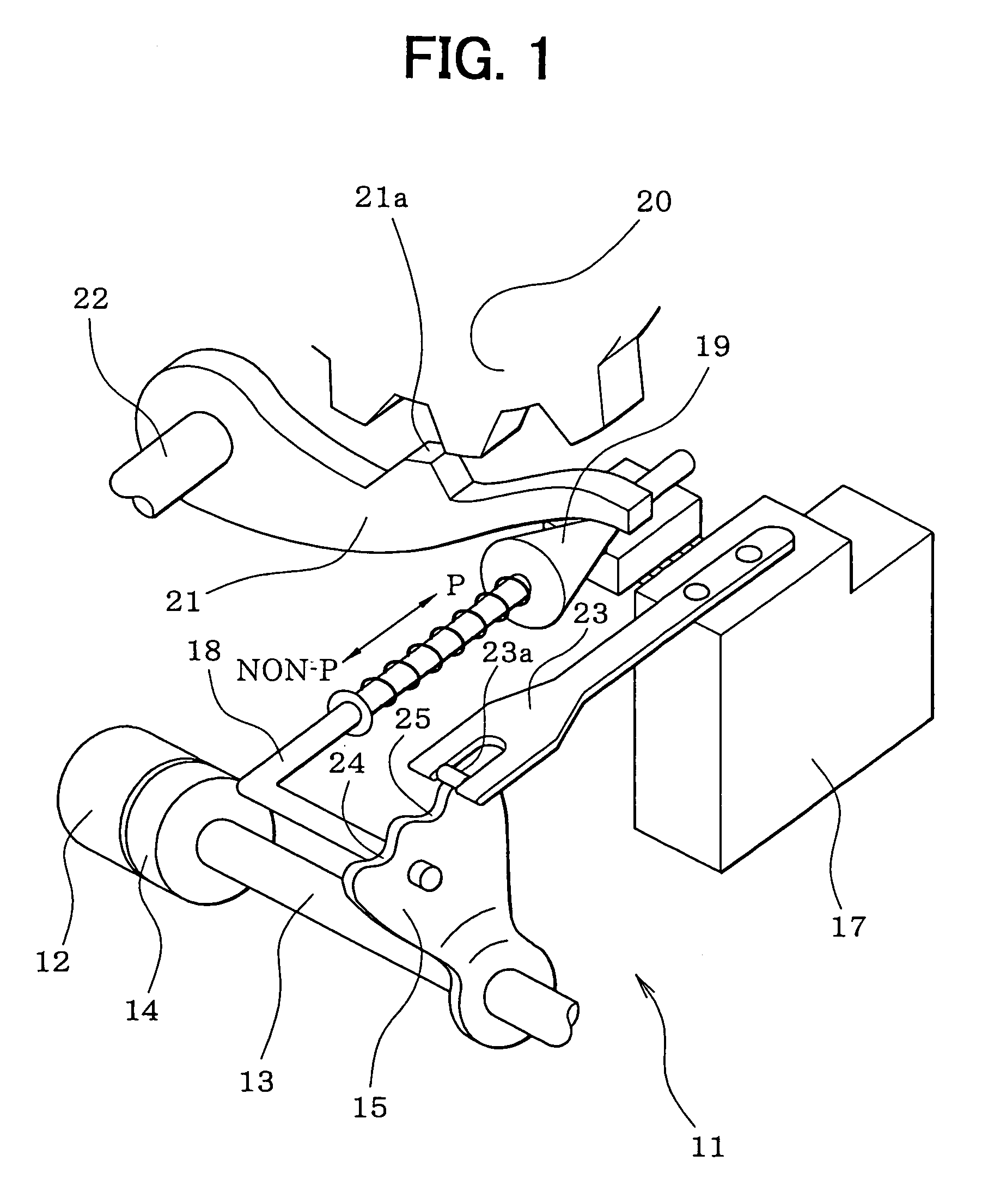

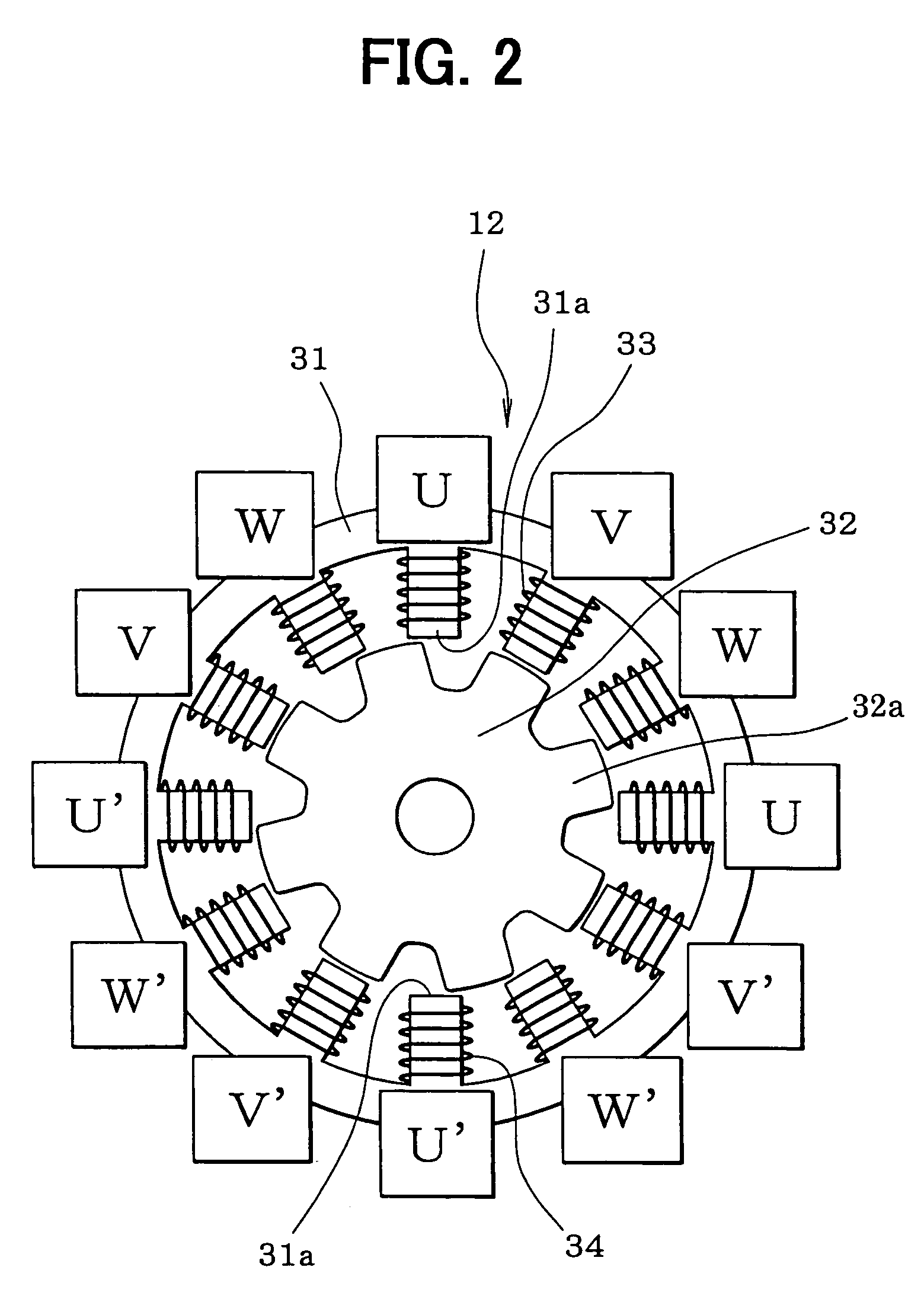

Motor control apparatus having current supply phase correction

ActiveUS20060006827A1Increase rotation speedStop preciseSynchronous motors startersAC motor controlPhase correctionMotor drive

In a motor-driven shift position switching device, when the difference between a target position and the rotation position of a rotor has become smaller than a prescribed value in a motor feedback control, a transition is made to a deceleration control. A phase lead correction amount for correcting the phase lead of the current supply phase with respect to the rotor rotation phase is set in accordance with the rotor rotation speed. Thus, proper braking force suitable for the rotor rotation speed is exerted on the rotor and the rotor can be decelerated smoothly as it approaches the target position. Further, in the period when the current supply to the motor is kept off, the shift position switching determination ranges are set wider than in the period when the current supply to the motor is on.

Owner:TOYOTA MOTORS KABISHIKI KAISHA 50

System for Dynamically Controlling the Torque Output of a Pneumatic Tool

ActiveUS20090055028A1Reduce probabilityStop preciseDerricks/mastsTemperatue controlPneumatic toolHeating effect

Pneumatic tightening tools can be used for high speed assembly of critical bolts to precise loads by dynamically controlling the output power of the pneumatic tool during a tightening cycle using an electronically controlled air pressure regulator to reduce the tightening rate, or the load increase per impact for impact or impulse tools, to enable the tool to be stopped precisely at a specified stopping load or torque. For prevailing torque fasteners, the output power of the pneumatic tool is dynamically controlled to minimize the speed of rotation during rundown, to minimize the heating effects associated with such torque fasteners, and to then increase the power from the tool, as required, to provide the torque to reach the specified stopping load or torque. The maximum air pressure supplied to the pneumatic tool can be limited, depending on the expected torque required to tighten the fastener to the specified load or torque.

Owner:INNOVATION PLUS

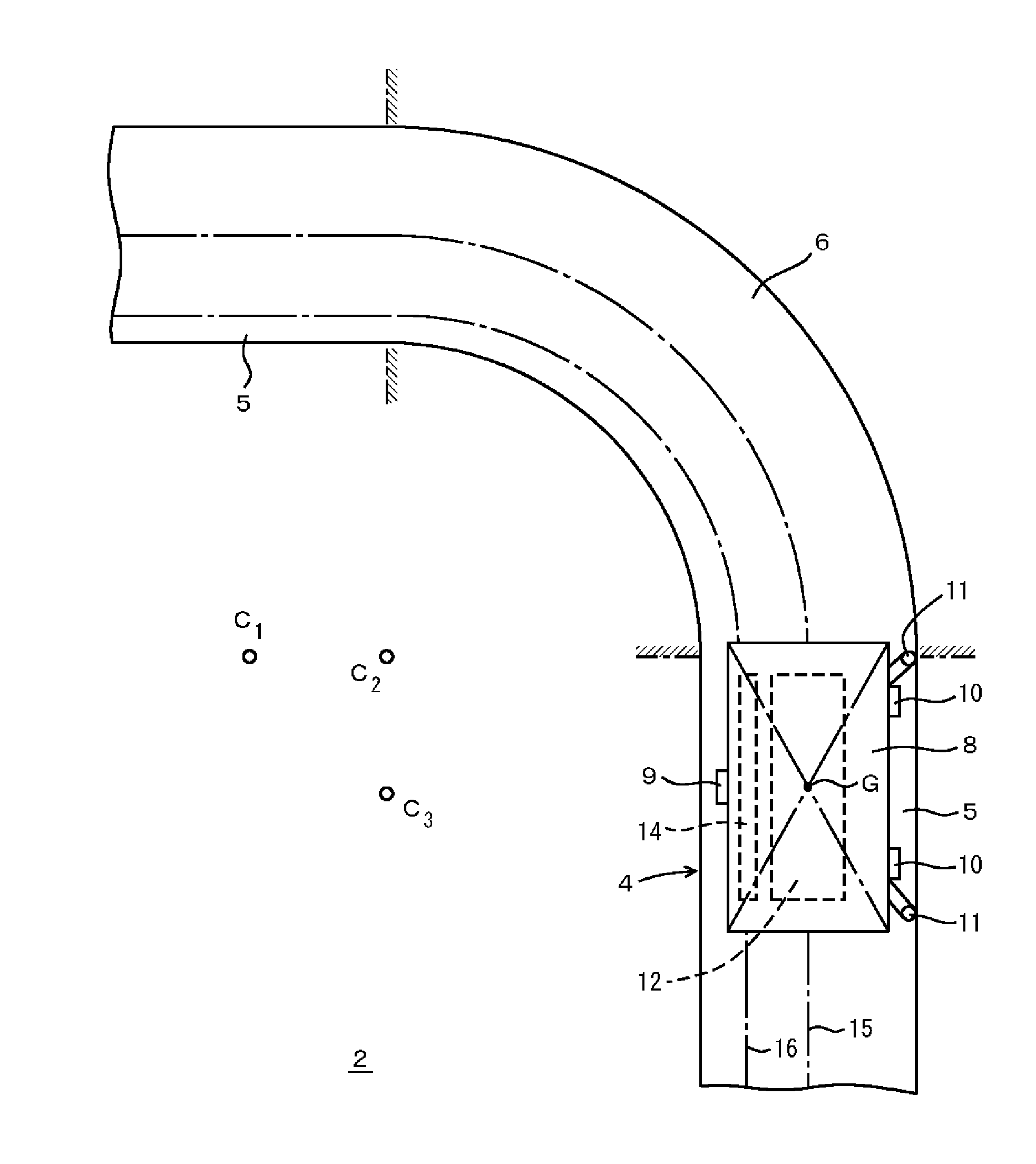

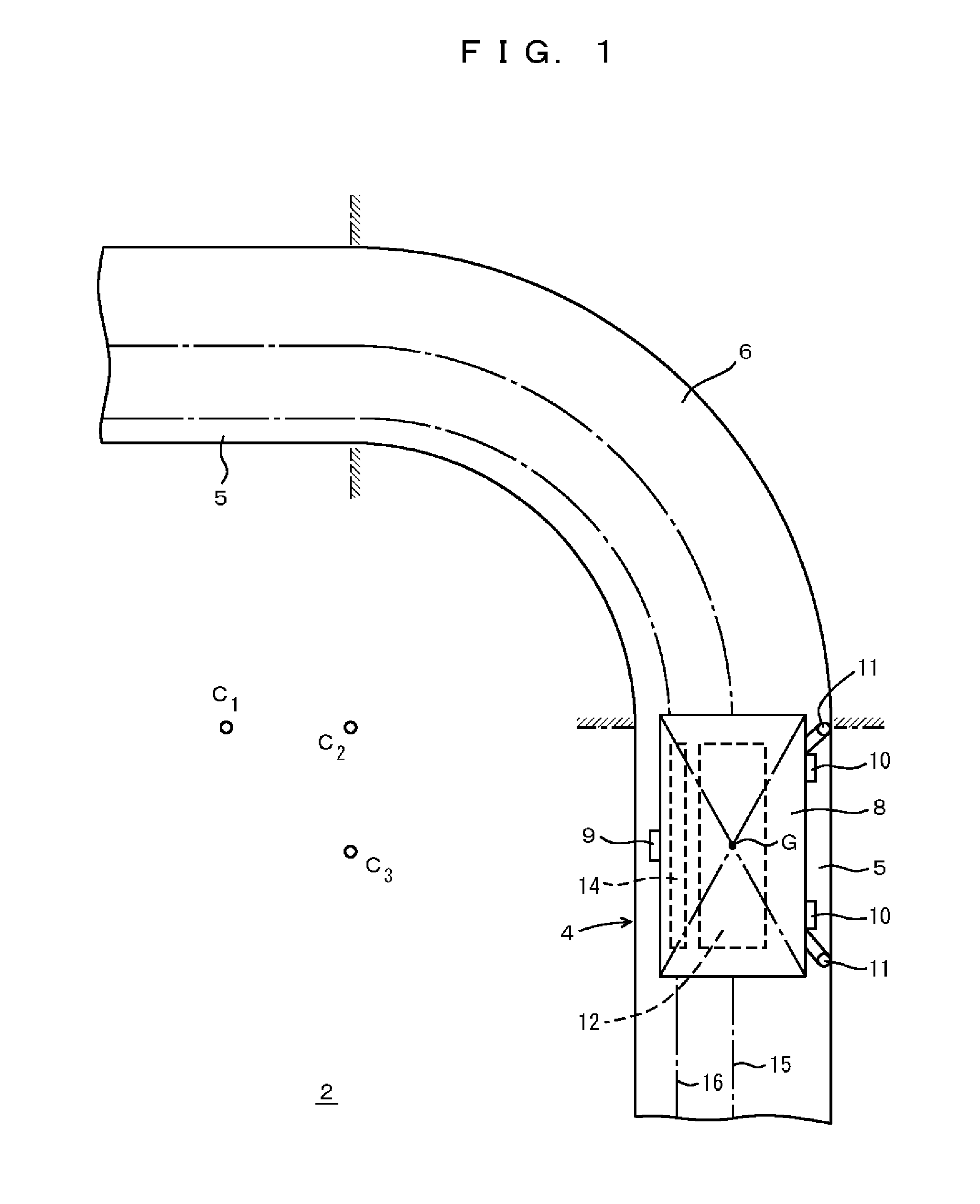

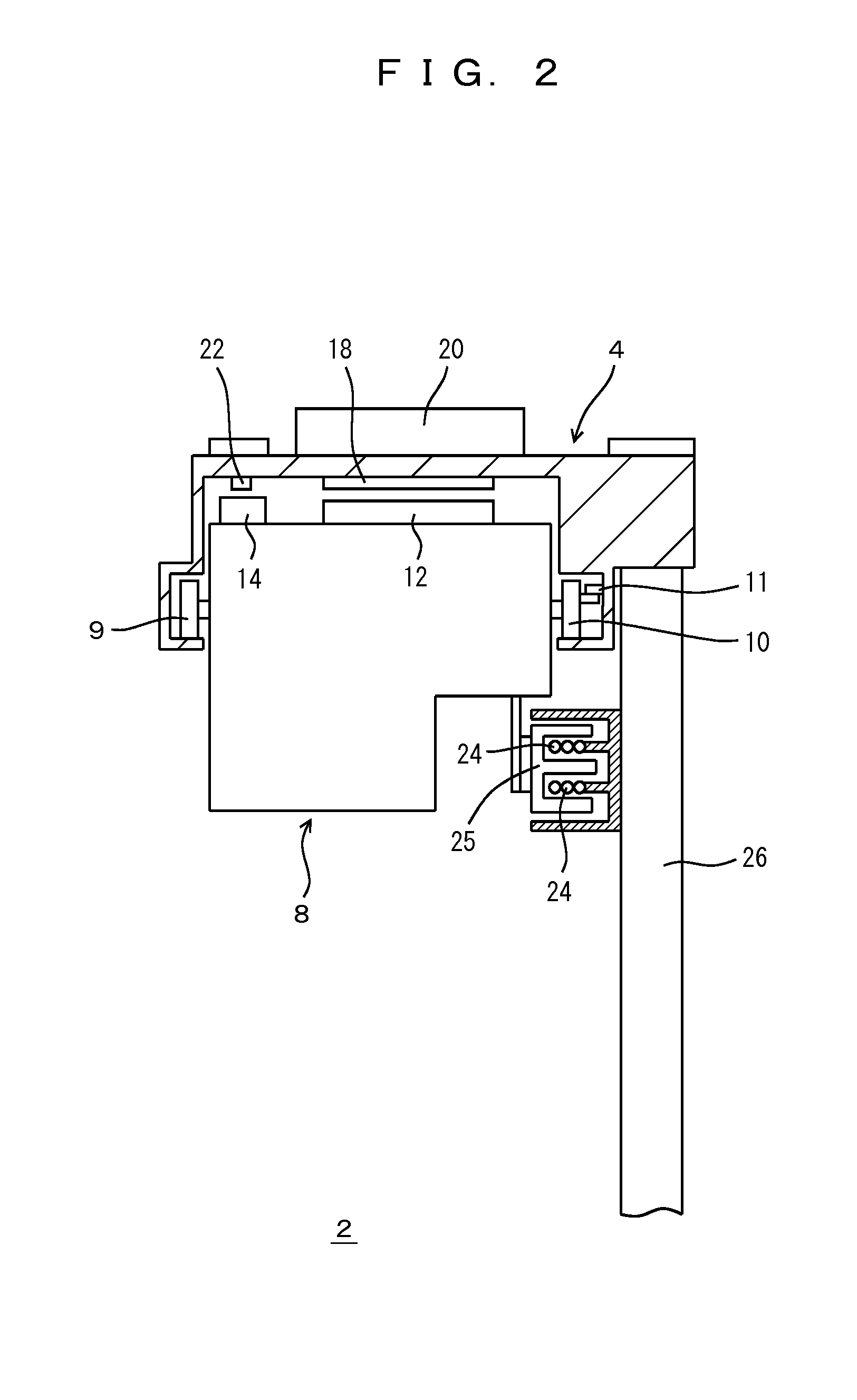

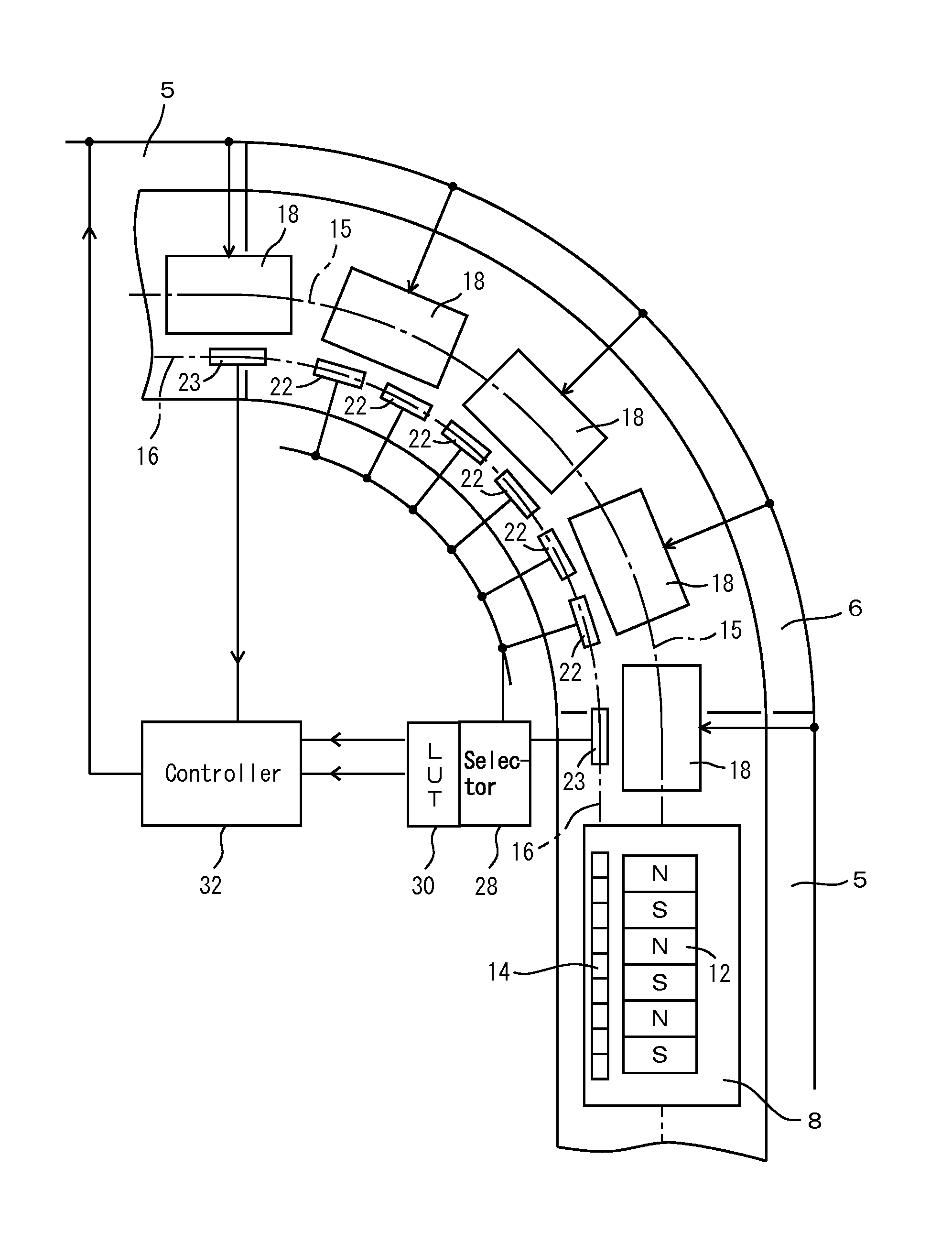

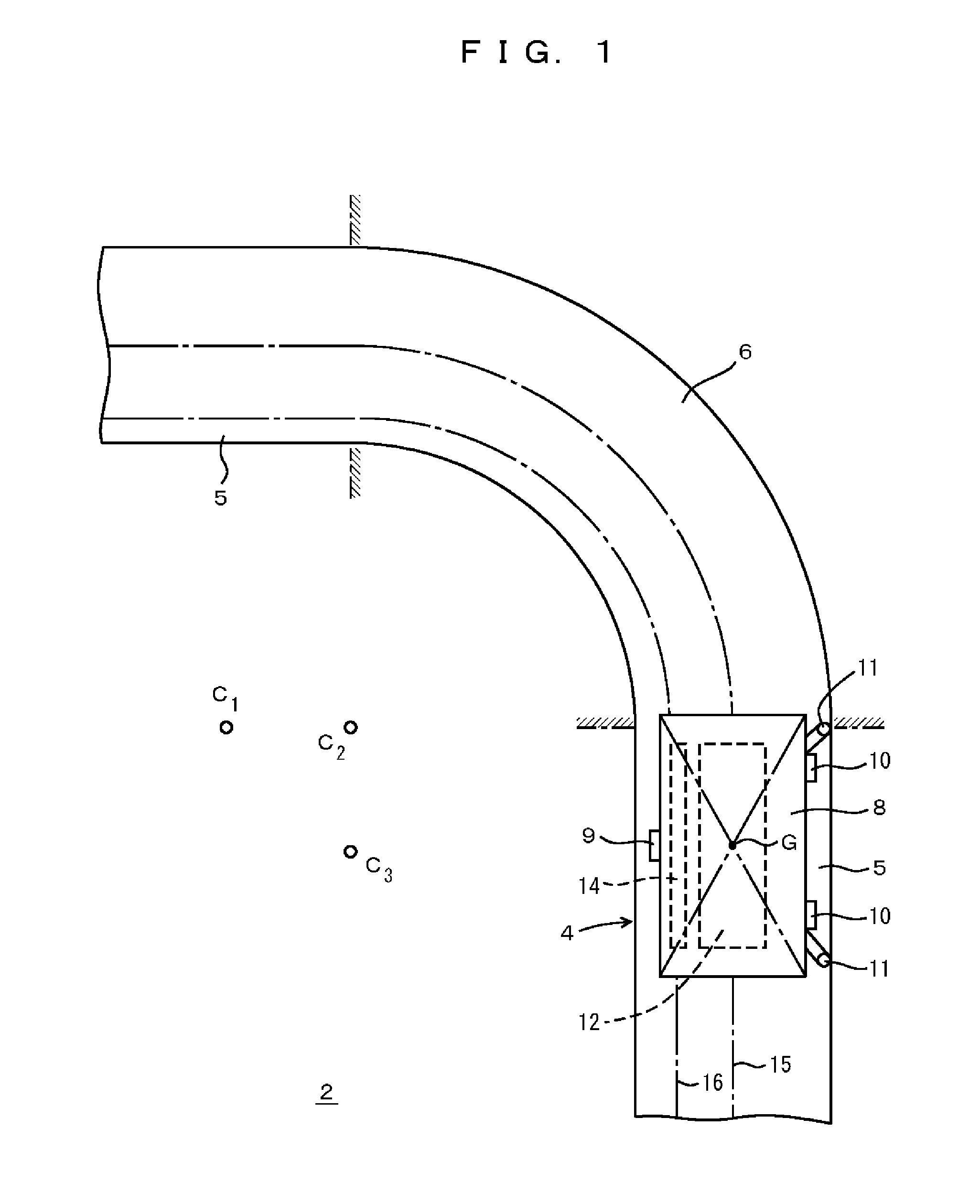

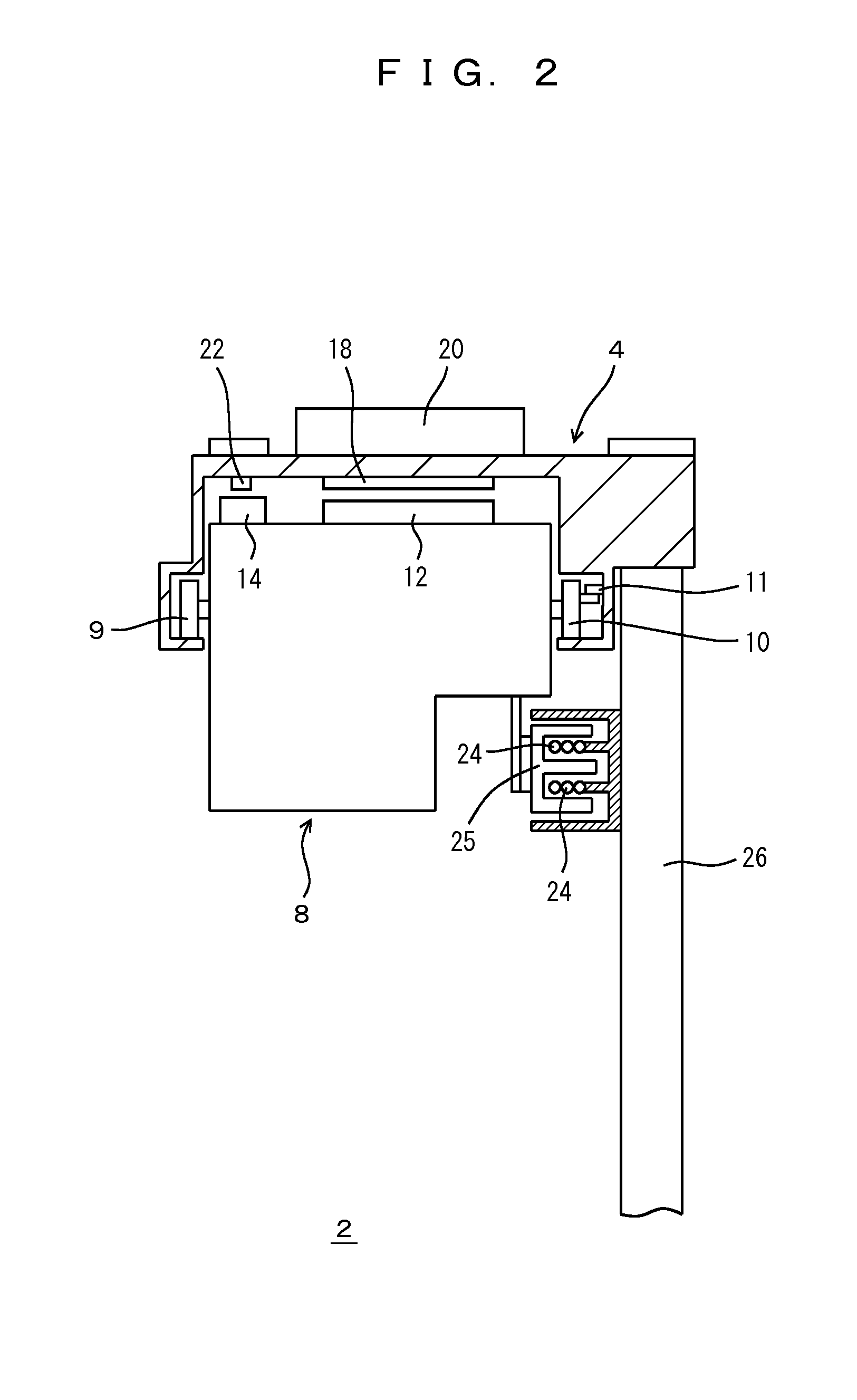

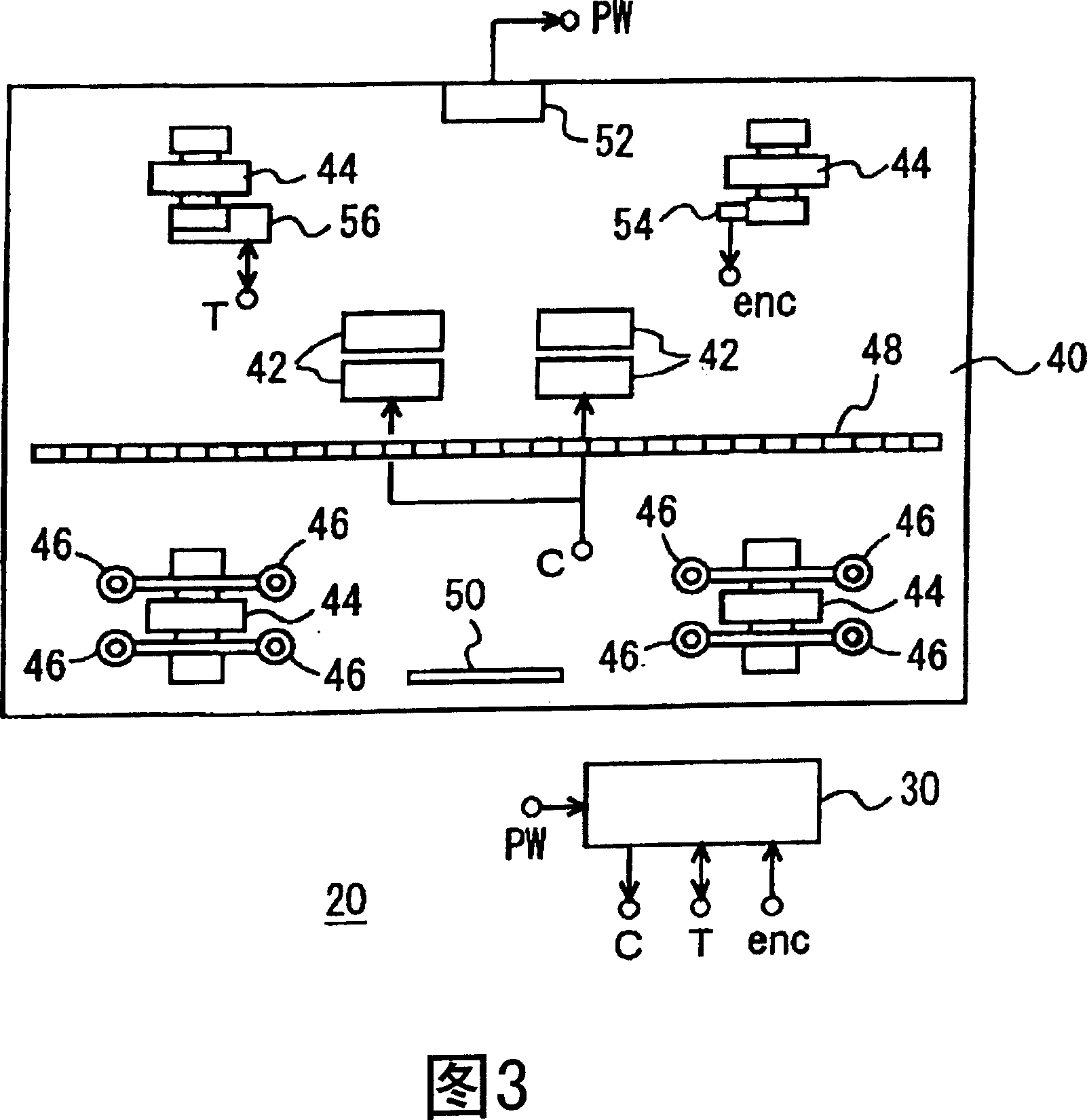

Moving body system and method for controlling travel of moving body

ActiveUS20140142792A1Improve accuracyPrecise positioningDigital data processing detailsNon-mechanical conveyorsSimulationPosition shift

A detector detects positions of a moving body in a travel direction at a position shifted from a center of control of travel of the moving body in a direction different than the travel direction of the moving body. Positions of the center of control in the travel direction relative to the output of the detector is stored in a storage unit for at least a curved section of a travel route of the moving body, and the travel of the moving body is controlled by a controller, based on the positions of the center of control read out from the storage unit.

Owner:MURATA MASCH LTD

Automatic milky tea maker

An automatic milky tea maker comprises a low-temperature preservation chamber, an icemaker case and a normal-temperature chamber. A guide rail box is arranged in front of the low-temperature preservation chamber, the icemaker case and the normal-temperature chamber. A sauce output device, a large fruit grain output device, a cover output device and a juice pump are arranged in the upper portion ofthe low-temperature preservation chamber. A full-automatic icemaker is arranged in the icemaker case, a cup discharger, a fructose output device, a powder output device and a stirring device are arranged in the upper portion of the normal-temperature chamber, the middle of the normal-temperature chamber is internally provided with a tea water and purified water outlet, the lower portion of the normal-temperature chamber is provided with a water barrel placement area, and a milky tea conveying platform is arranged in the guide rail box. The automatic milky tea has advantages that cup discharging, water agent feeding, powder feeding, sauce feeding, stirring, milk cover feeding and final outputting are all realized mechanically, so that unmanned milky tea making is realized; by design of different feeding types and feeding sequences, a refrigerator is designed for materials requiring refrigeration, an ice making component is provided aiming at different demands of cold and hot drinks, and accordingly different customer demands can be met.

Owner:杭州黑石机器人有限公司

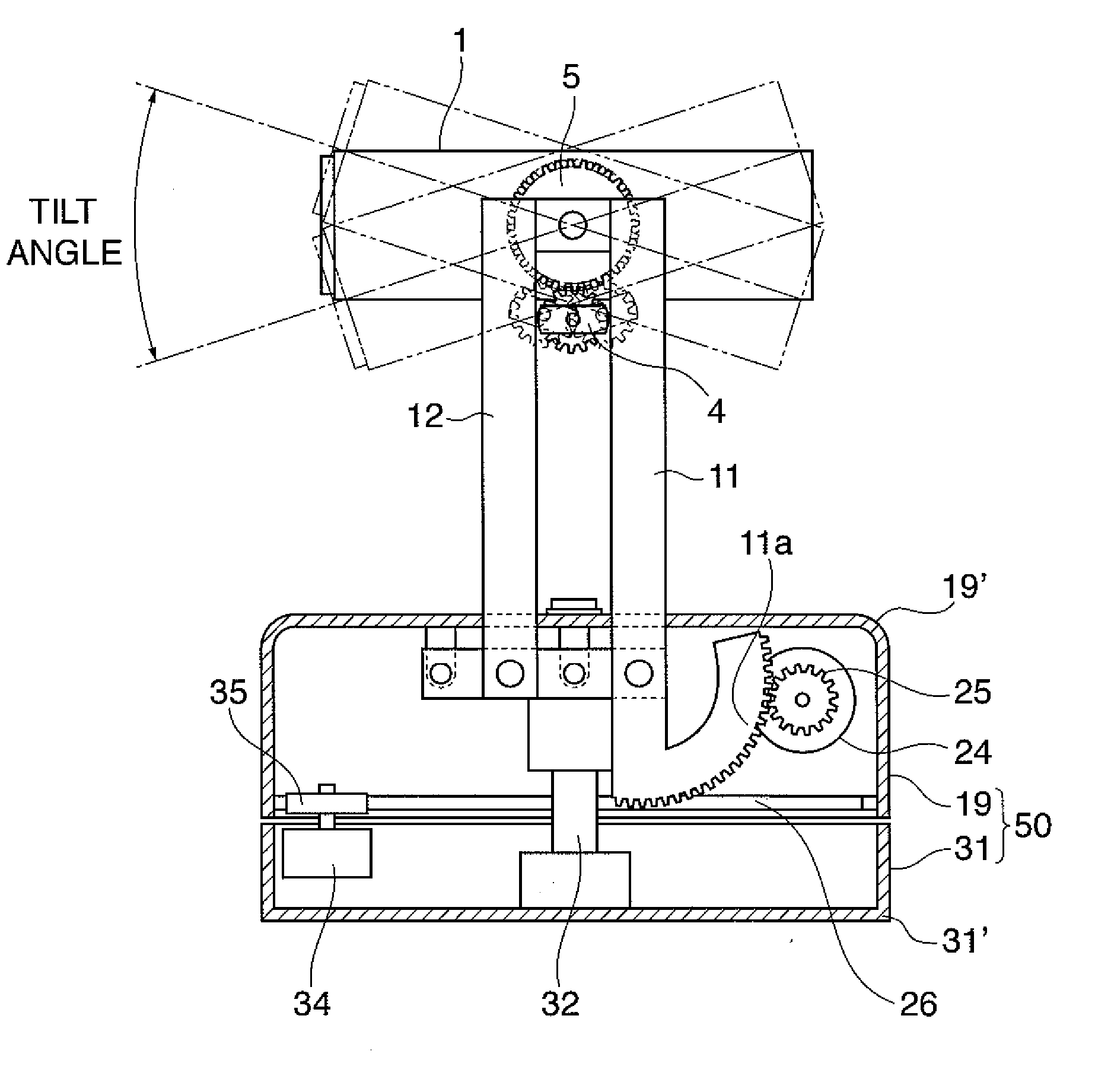

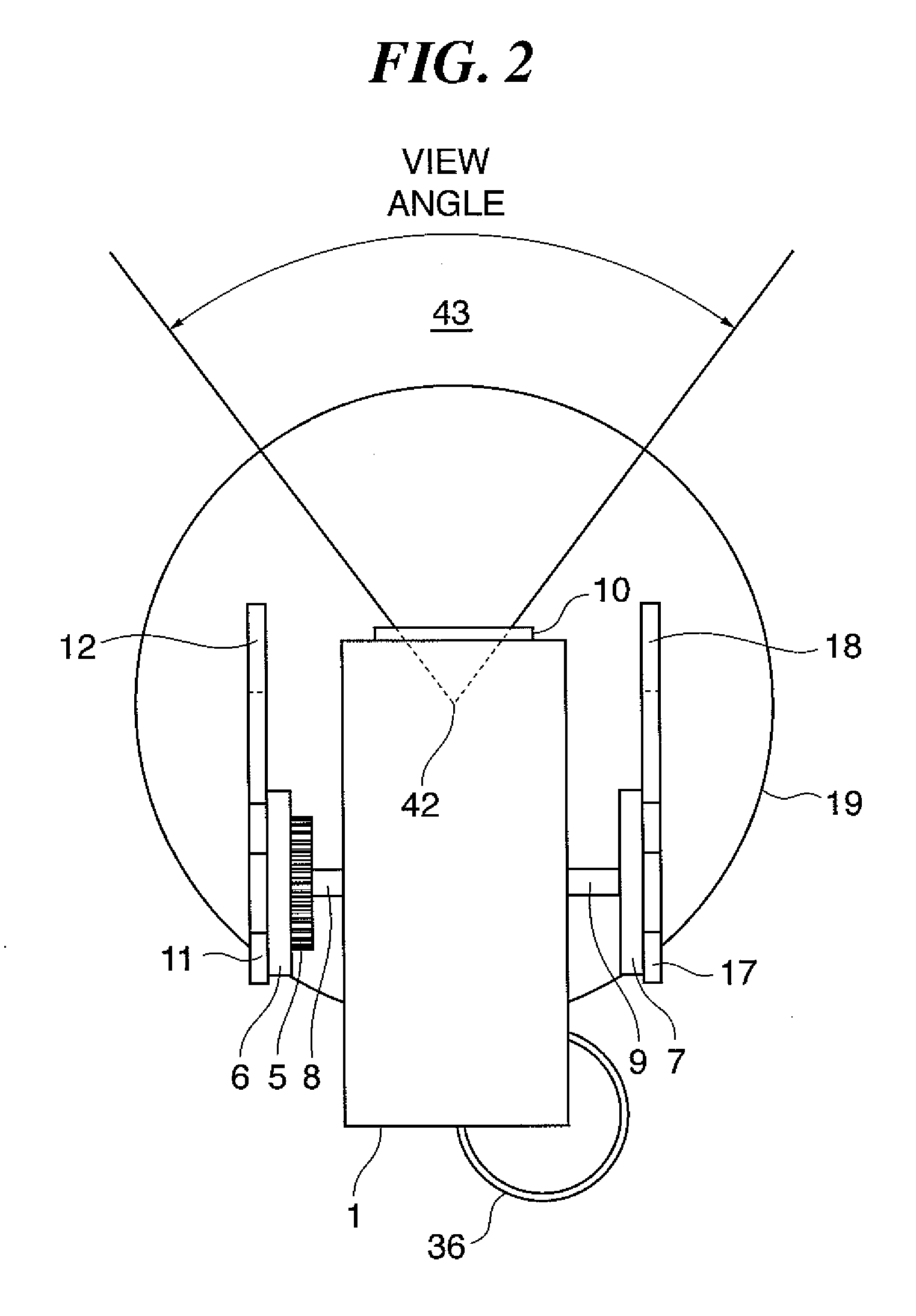

Panhead

InactiveUS20070019106A1Optimization mechanismForce is smallTelevision system detailsColor television detailsOptical axisEngineering

A panhead which is capable of appropriately operating an image pickup device by a simple mechanism thereof. A fixed unit is set on a base of a camera-attached panhead. A pan rotation unit is supported on the pan fixed unit, for rotation within a plane parallel with the upper surface of the pan fixed unit. Two parallel-link mechanisms connect between a camera unit and the pan rotation unit and move the camera unit to a predetermined position in which a direction of an optical axis of the image pickup device is able to be maintained, depending on the use mode of the camera unit.

Owner:CANON KK

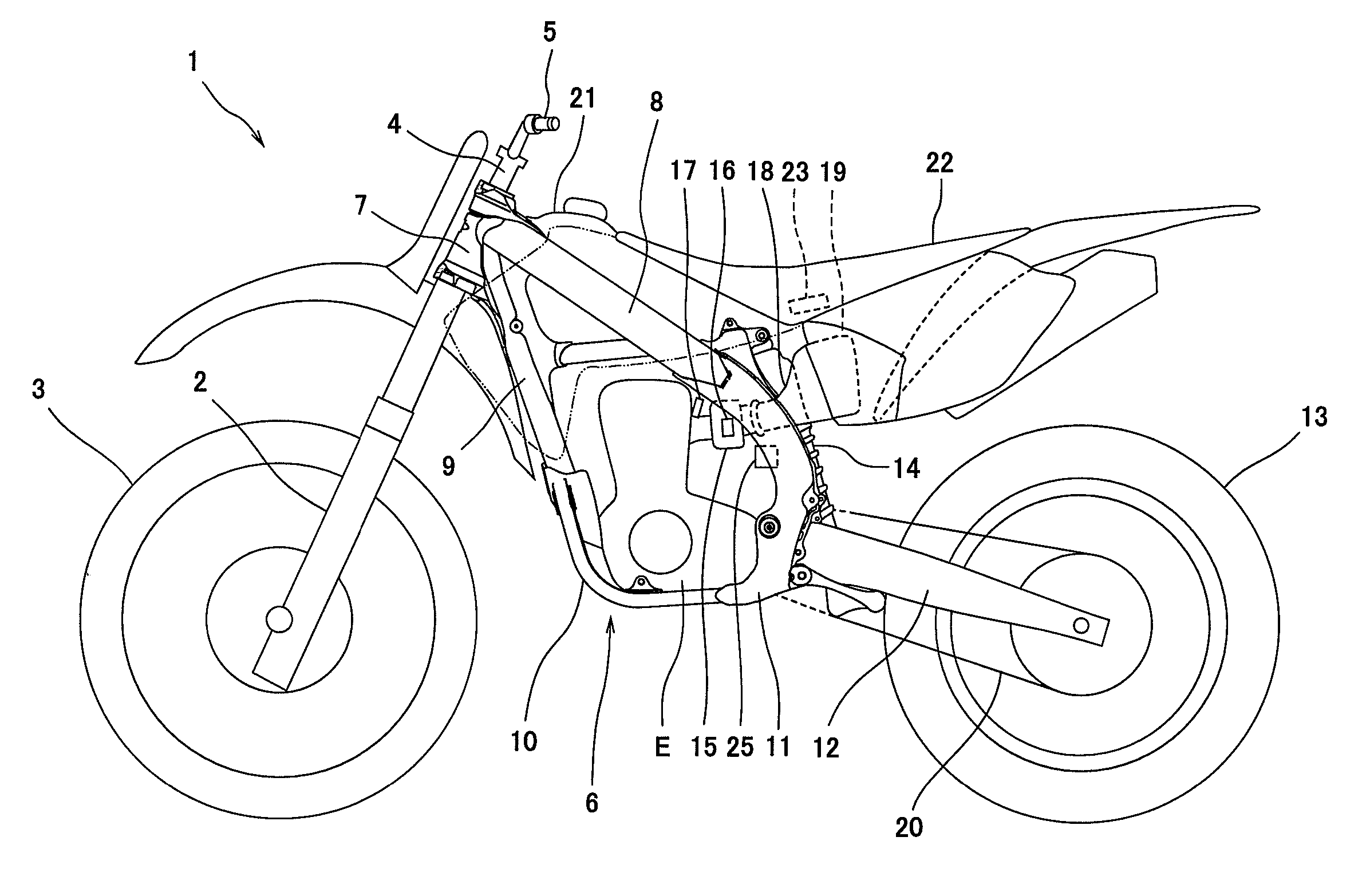

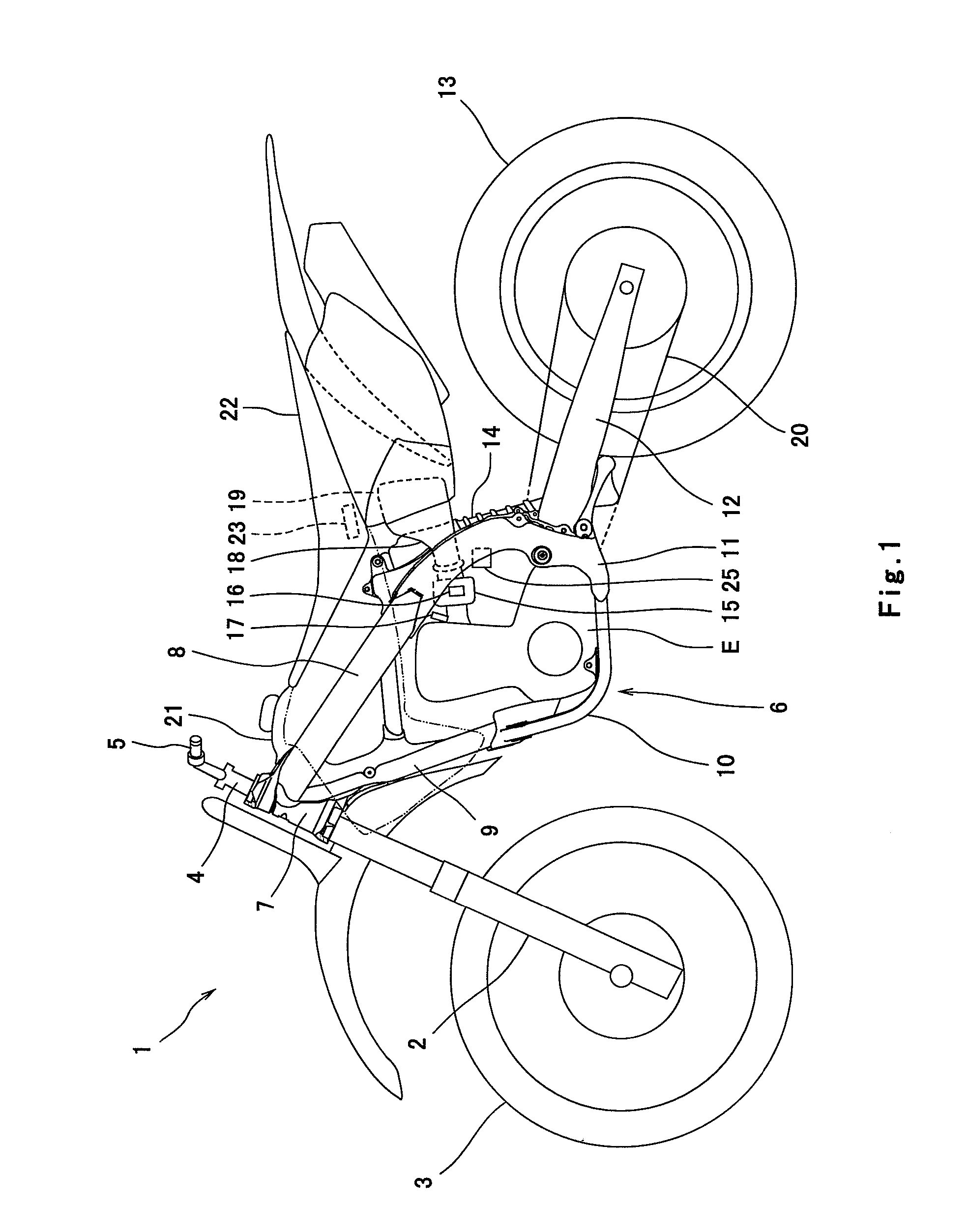

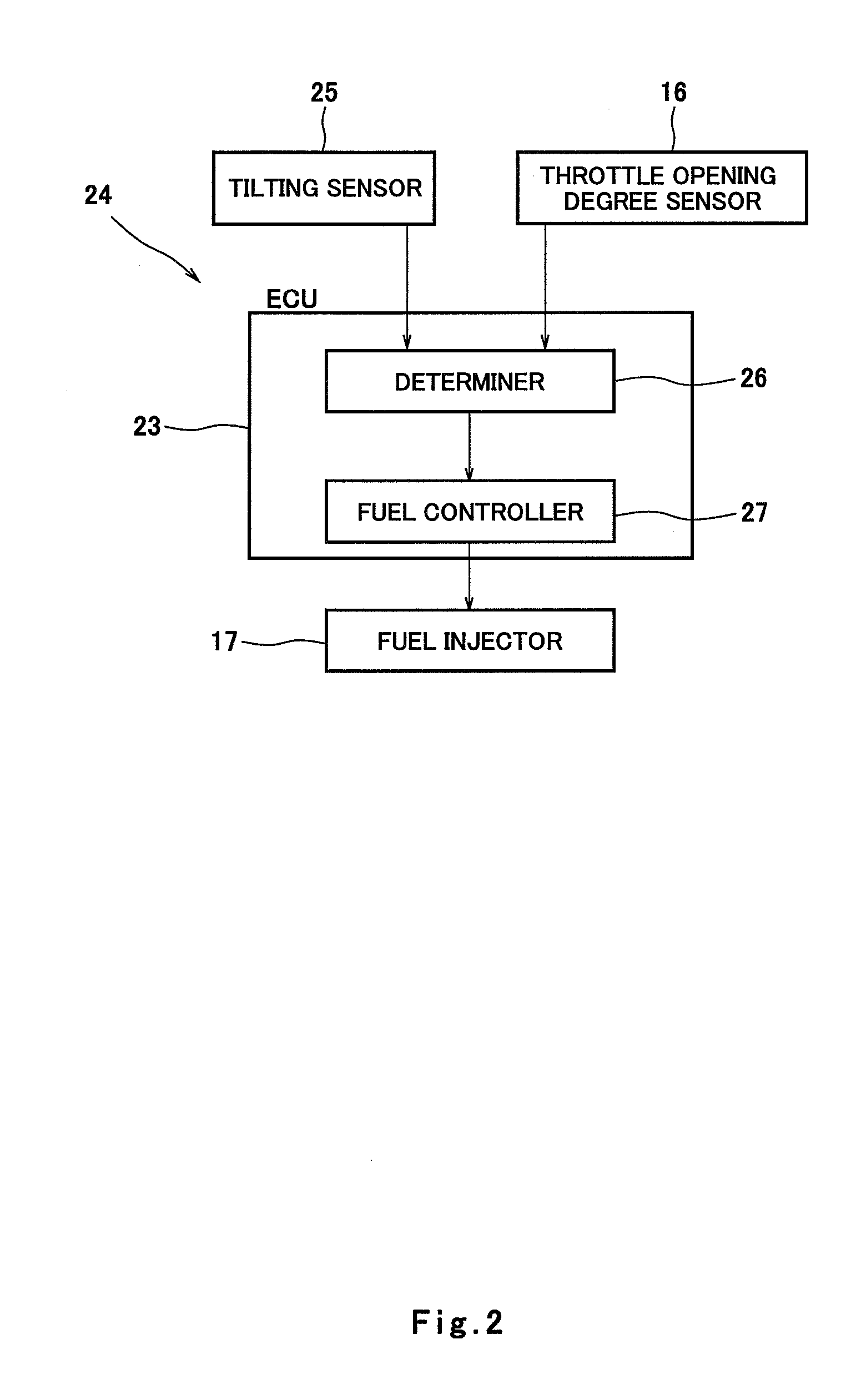

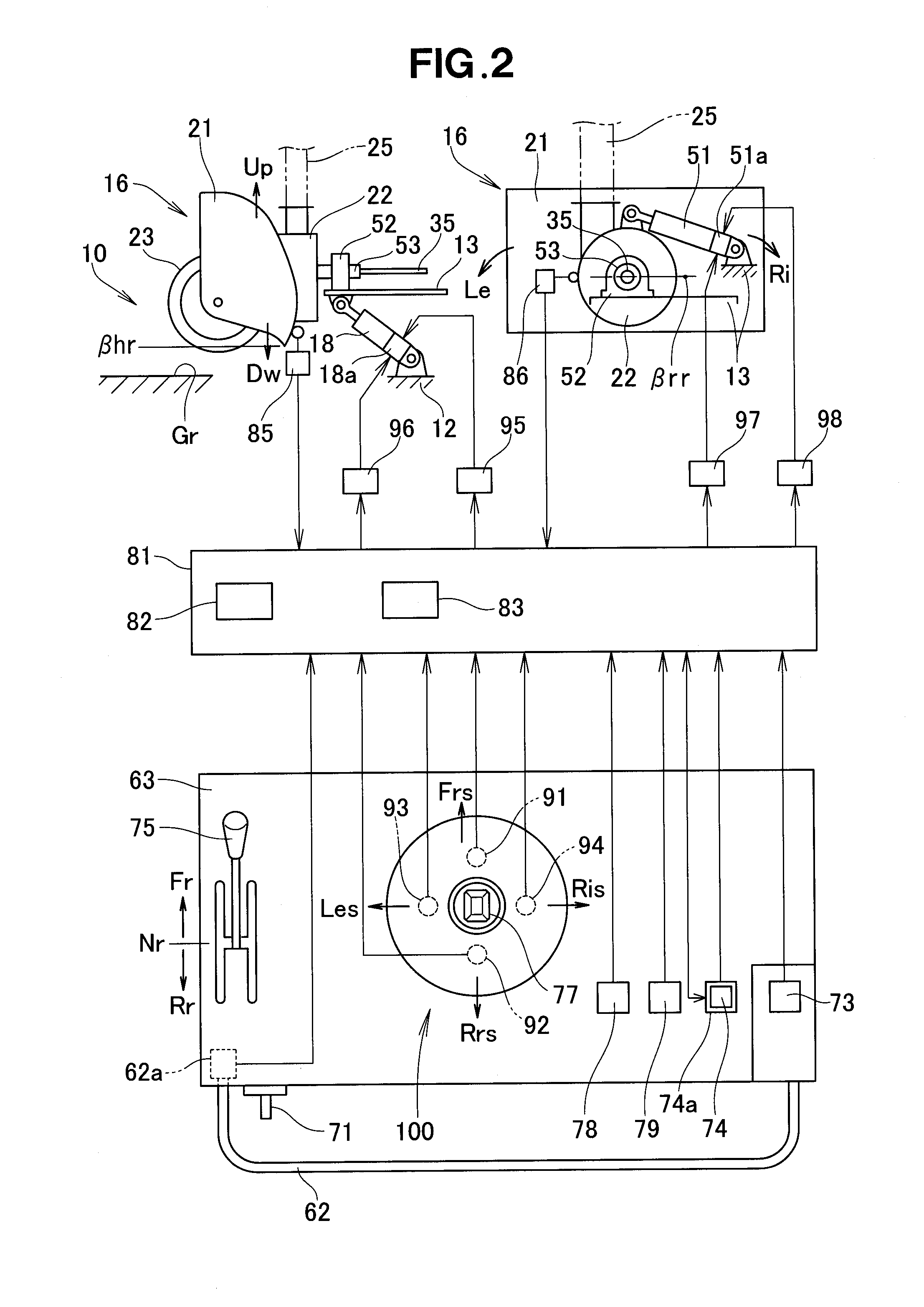

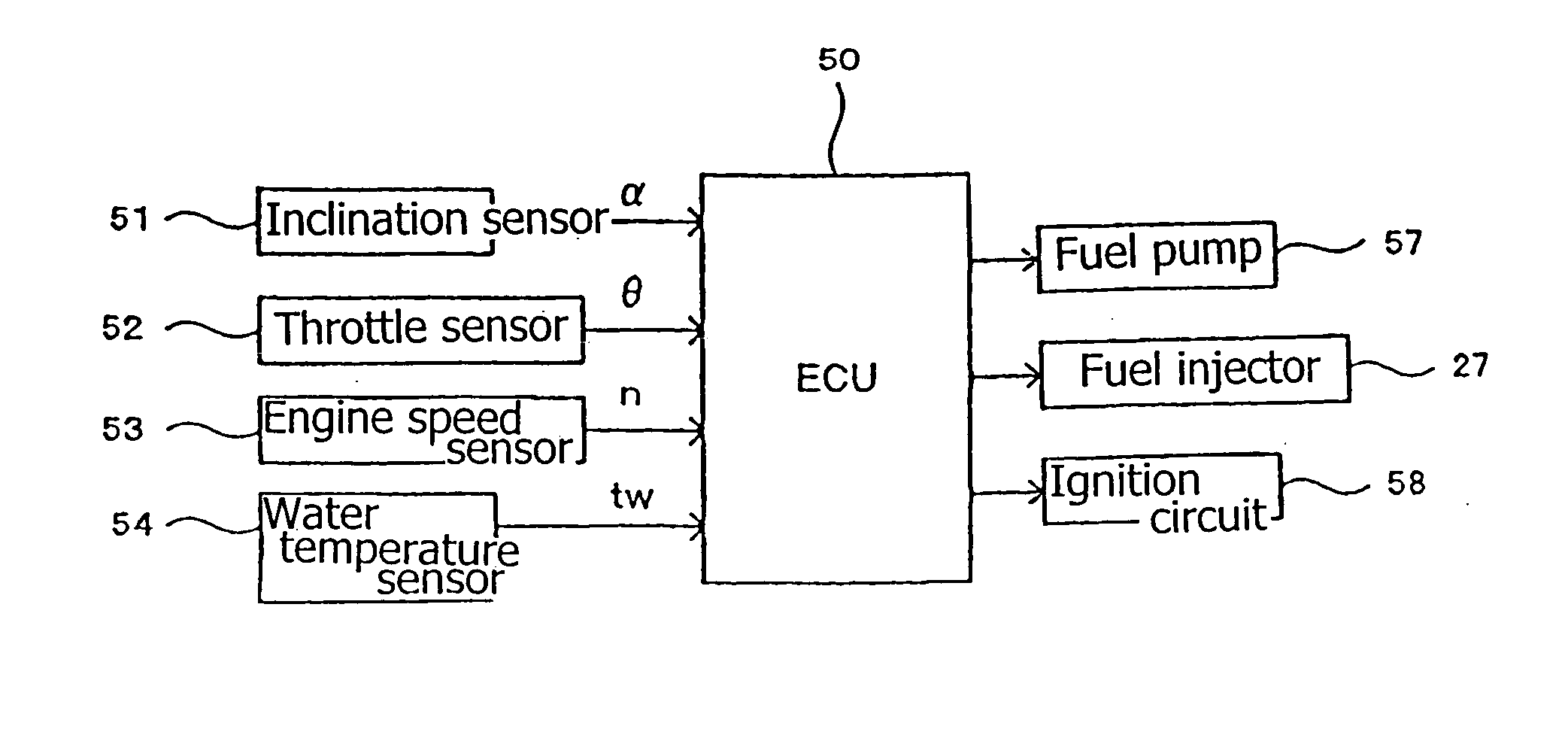

Vehicle and method of determining whether or not to stop engine mounted in vehicle

ActiveUS20090012676A1Stop preciseDigital data processing detailsAnimal undercarriagesIn vehicleEngine mount

A vehicle including an engine, a tilting sensor configured to detect that a vehicle body of the vehicle has been tilted a predetermined angle or larger, a driving state sensor configured to detect a driving state of the vehicle using a component other than the tilting sensor, and a determiner configured to determine whether or not to stop the engine, based on a signal received from the tilting sensor, and a signal received from the driving state sensor.

Owner:KAWASAKI MOTORS LTD

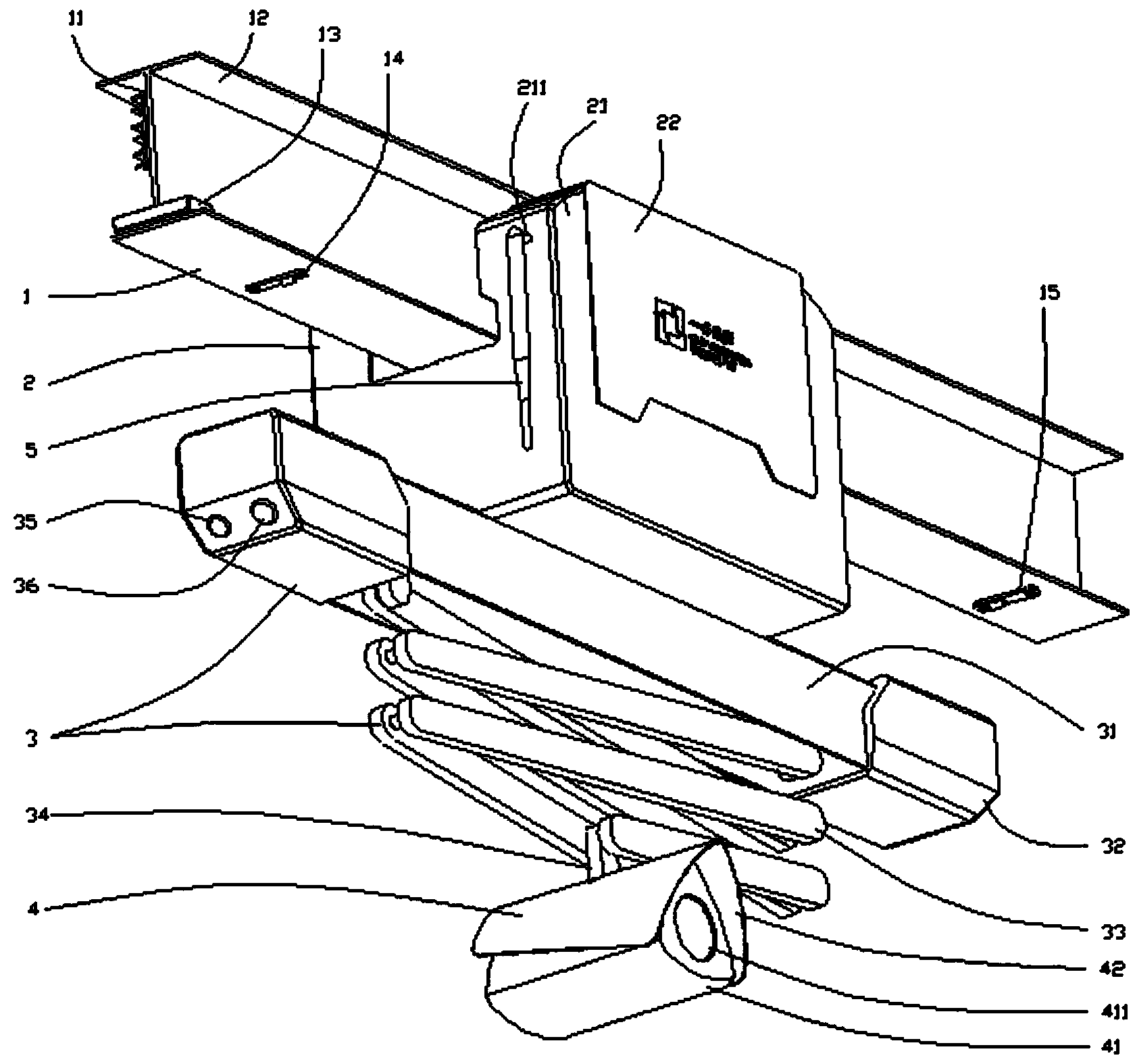

Suspending automatic-patrol robot

ActiveCN103913243AImprove visibilityAccurate trackingTransmission systemsPyrometry using electric radation detectorsWireless transmissionMonitoring system

The invention discloses a suspending automatic-patrol robot, and aims to provide a suspending automatic-patrol robot which can replace workers and save labor. The suspending automatic-patrol robot comprises a rail mechanism and a rail machine system and is characterized in that the rail machine system is matched with the rail mechanism, the lower side of the rail machine system is connected with a mechanical arm mechanism, the lower side of the mechanical arm mechanism is connected with a temperature picture monitoring system, and the rail machine system is connected with a wireless transmission system. The suspending automatic-patrol robot is mainly used for power security monitoring and control.

Owner:ZHUHAI YADO MONITORING TECH CO LTD

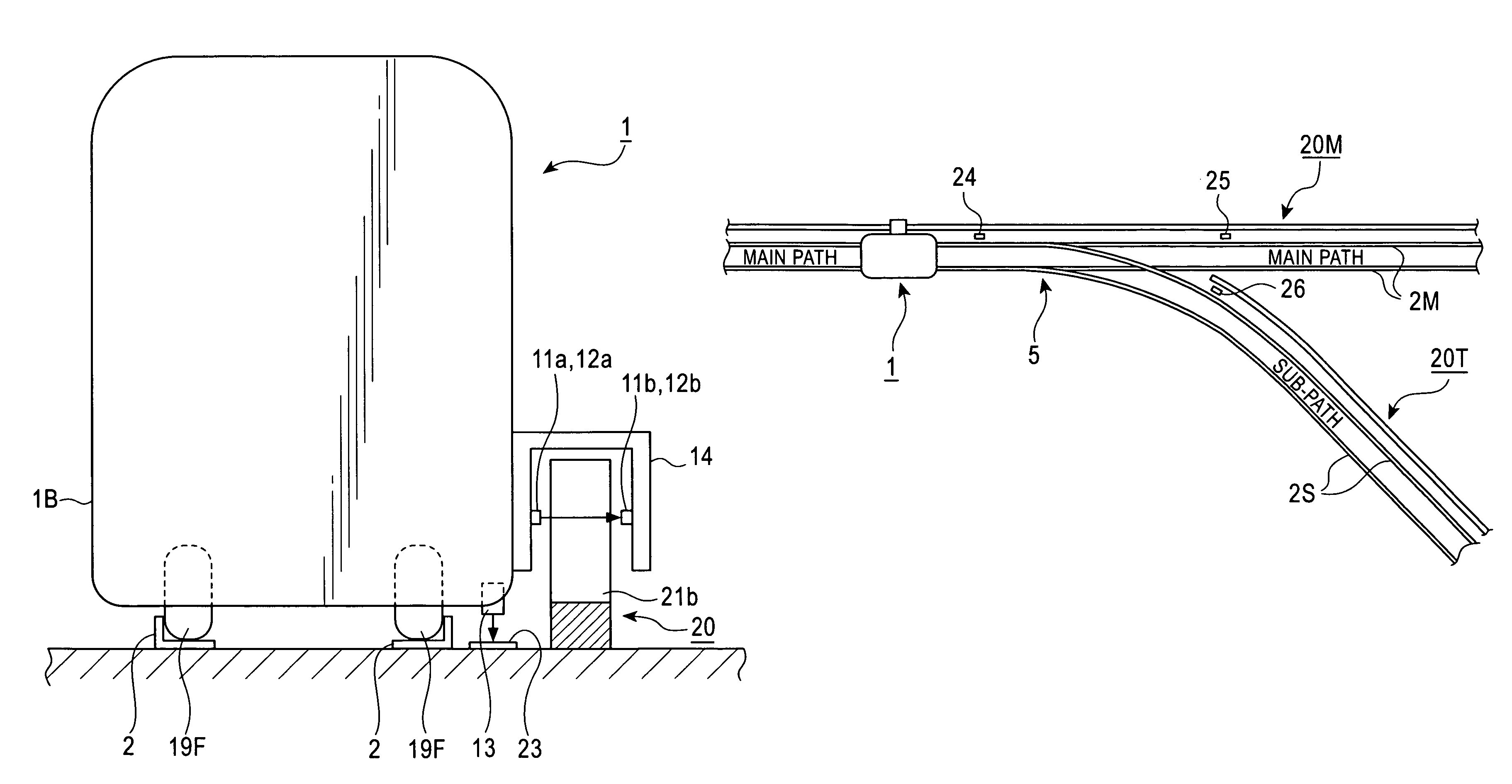

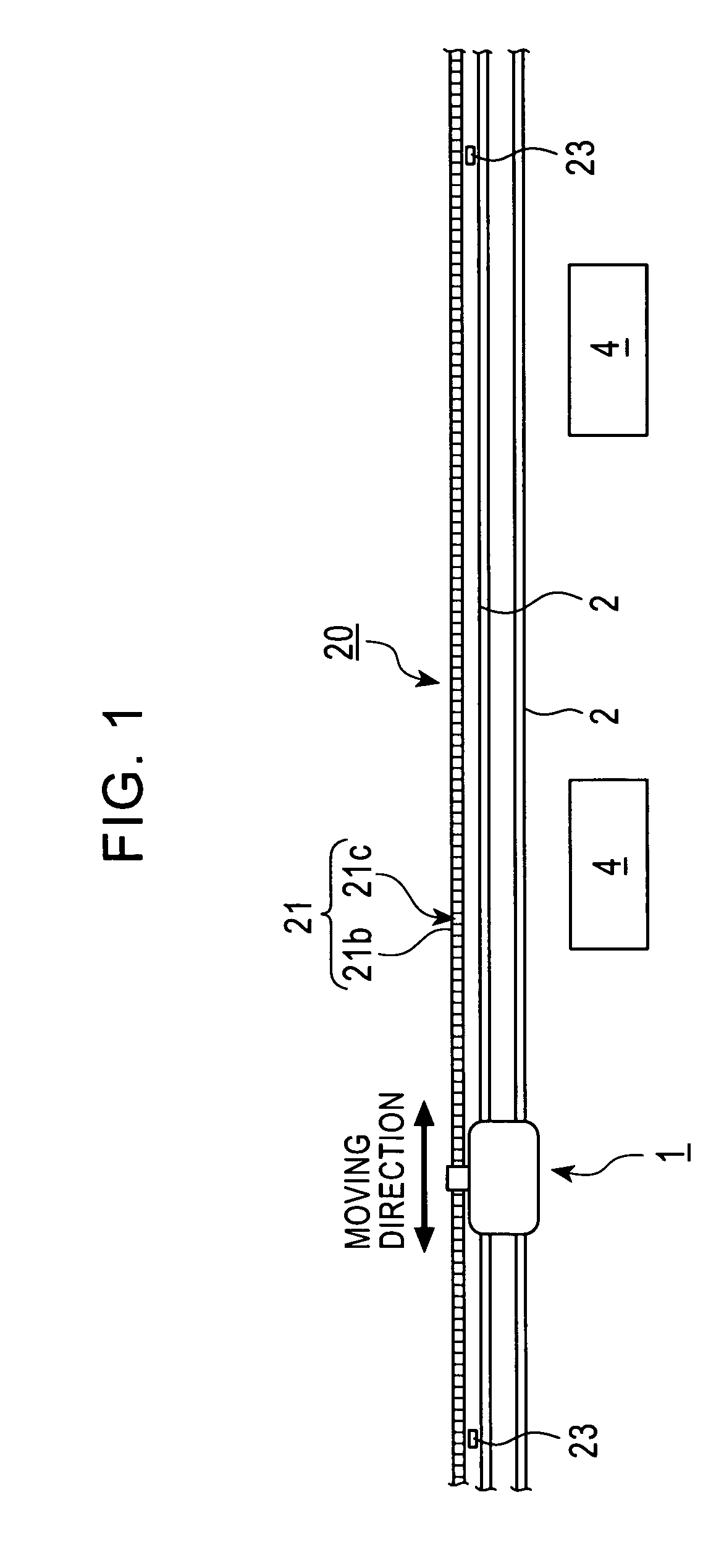

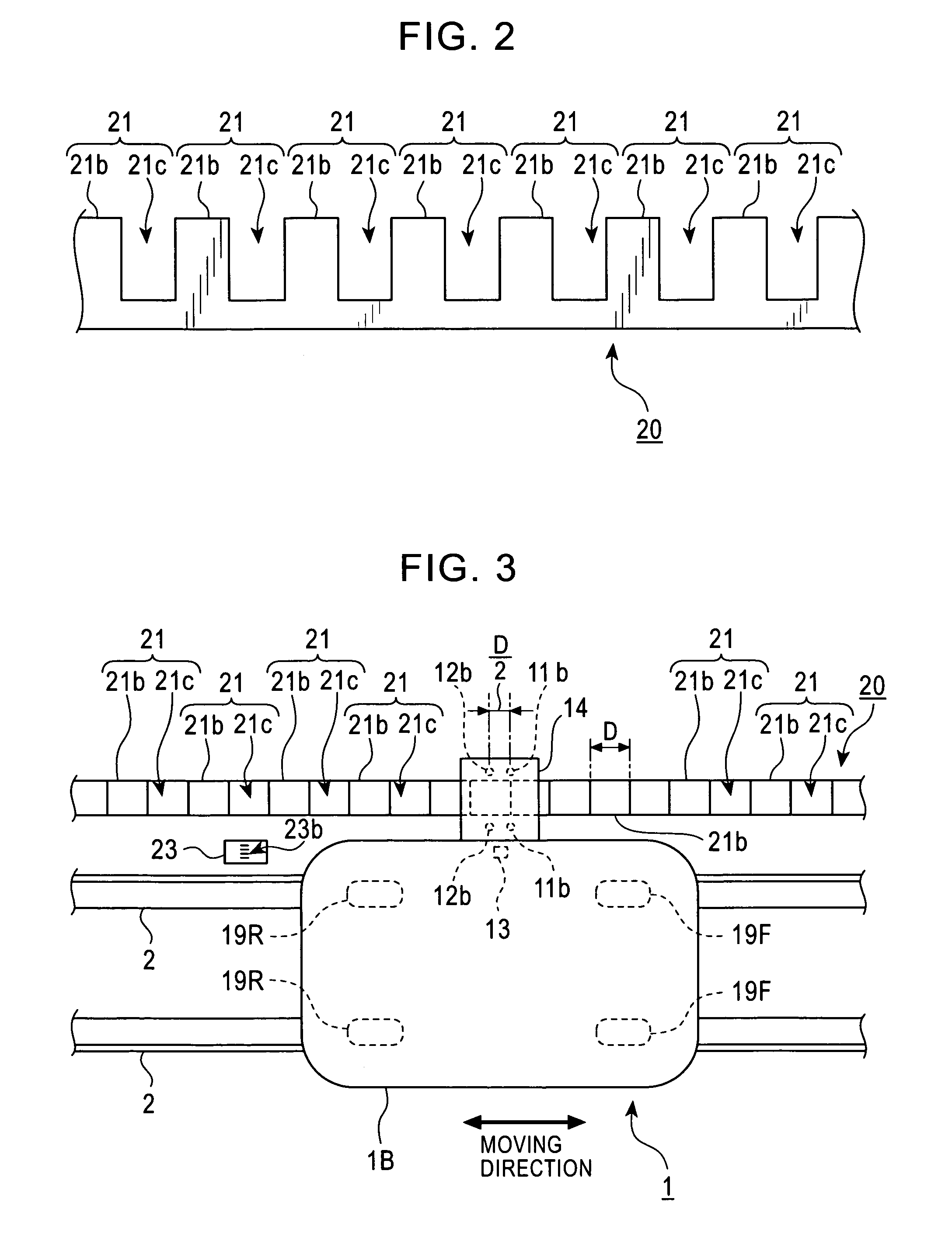

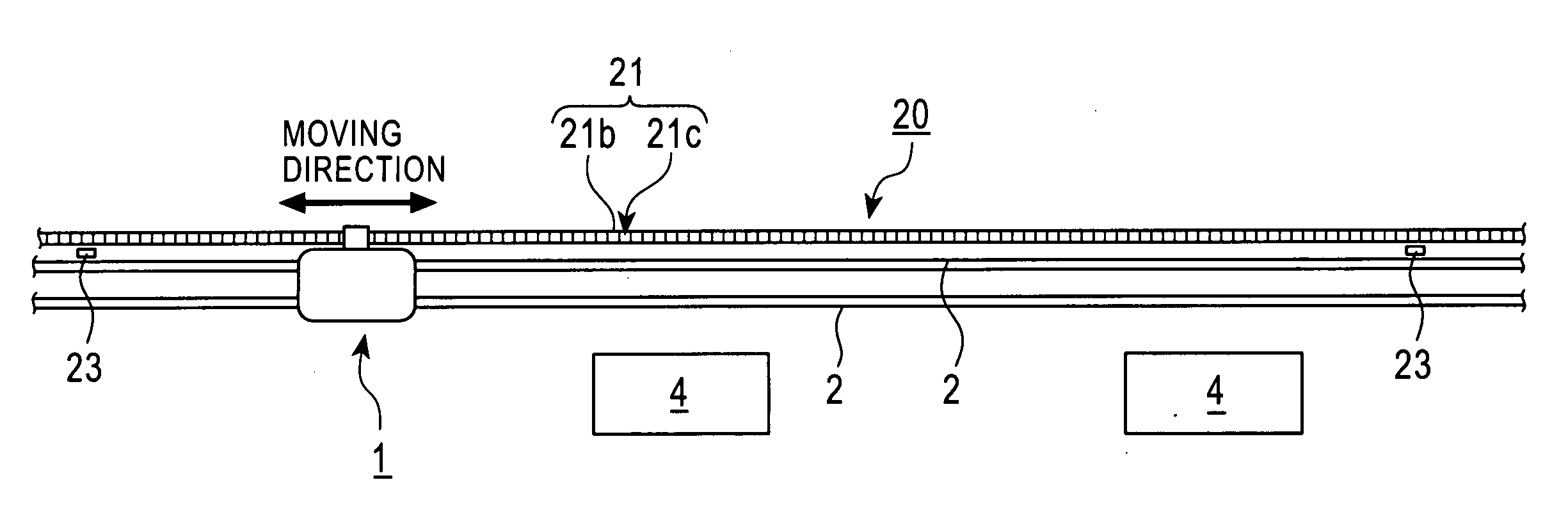

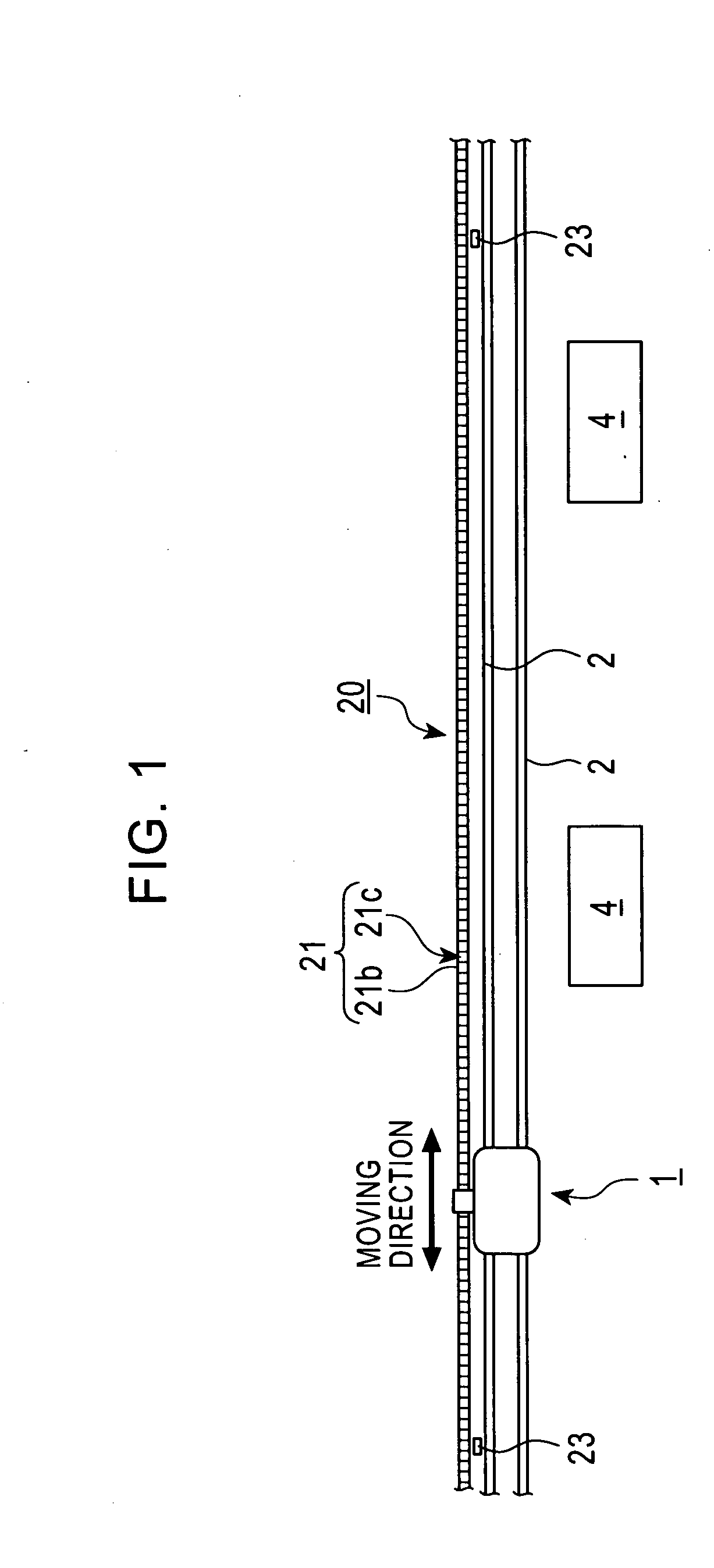

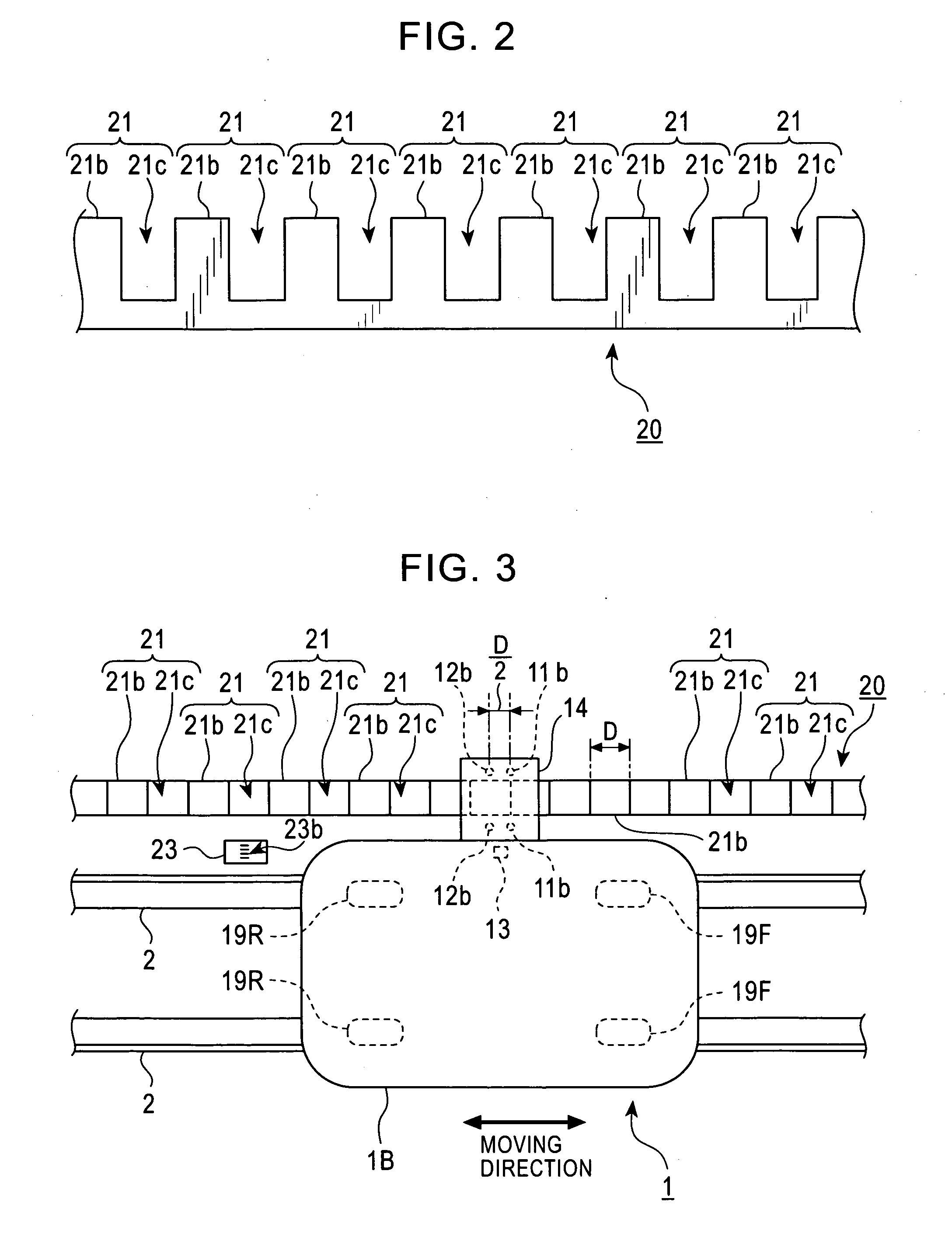

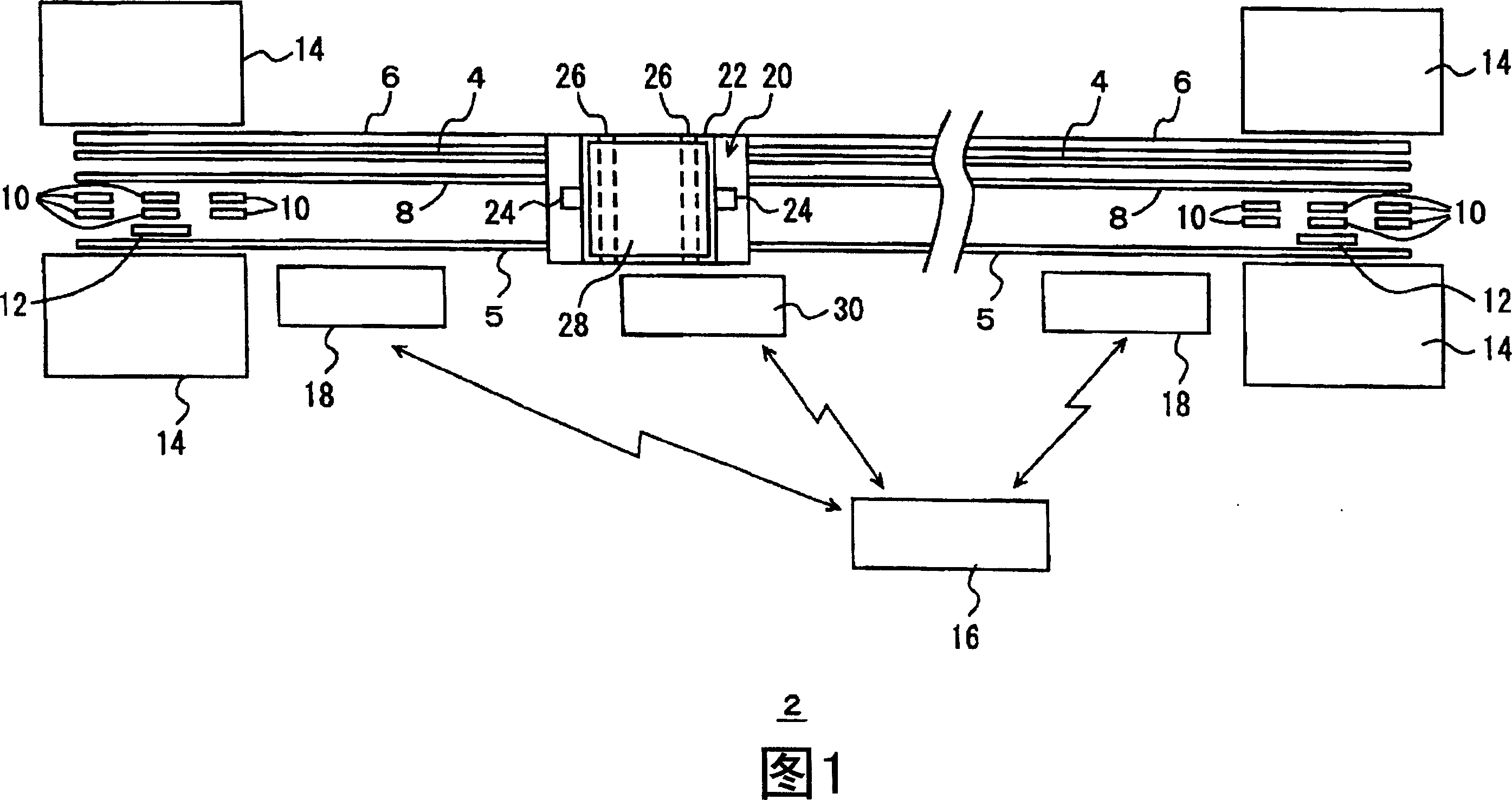

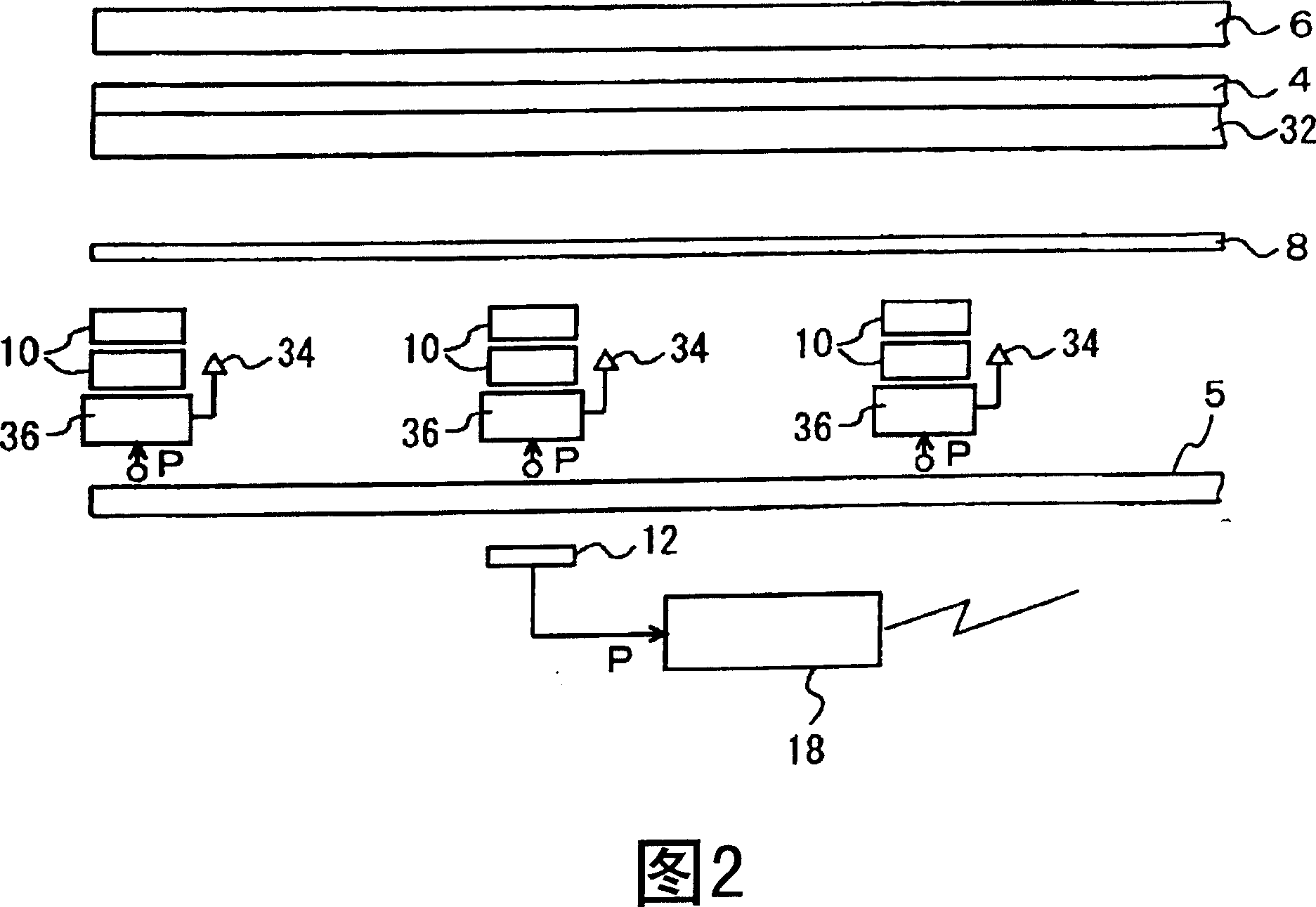

Moving body system

InactiveUS7426424B2Stop preciseMore reliableDigital data processing detailsTemperatue controlEngineeringStacker

It is an object of the present invention to provide a moving body system which can determine the moving position of a vehicle, stacker crane, or other moving body wherever on a moving path having a branching portion or a joining portion the moving body is, the system being able to precisely stop the moving body at any position and enabling the moving body to move fast to a stop position. A moving body system includes a vehicle 1 moving along running rails 2, 2 constituting a moving path having a joining portion and a detected member 20 laid along the running rails 2, 2. The detected member 20 includes a large number of mark members 21, 21, . . . in a direction in which the vehicle 1 moves. The vehicle 1 includes a first detecting sensor 11 and a second detecting sensor 12 which detect the mark members of the detected member 20.

Owner:MURATA MASCH LTD

Automatic transfer device and transfer method

The invention relates to an automatic transfer device. Existence sensors are set for sensing whether workpieces are arranged on a motion component or not so as to control operation time of a power component, speed reduction sensors are set for enabling the motion component to reduce speed before the stop position and reduce inertia of the motion component during stopping so as to improve operation stability of the transfer device and letting the motion component to stay in the accurate stopping position, and stop sensors are set for controlling the stopping time of the power component so as to enable the motion component to stop in the stop position. The existence sensors, the speed reduction sensors and the stop sensors realize automatic control motion process of circulating of workpieces from the feed position to the discharge position and to the feed position again. Furthermore, the invention provides an automatic transfer method of the automatic transfer device.

Owner:苏州久工自动化科技有限公司

Moving body system

InactiveUS20050203699A1Stop preciseMore reliableDigital data processing detailsTemperatue controlEngineeringStacker

It is an object of the present invention to provide a moving body system which can determine the moving position of a vehicle, stacker crane, or other moving body wherever on a moving path having a branching portion or a joining portion the moving body is, the system being able to precisely stop the moving body at any position and enabling the moving body to move fast to a stop position. A moving body system includes a vehicle 1 moving along running rails 2, 2 constituting a moving path having a joining portion and a detected member 20 laid along the running rails 2, 2. The detected member 20 includes a large number of mark members 21, 21, . . . in a direction in which the vehicle 1 moves. The vehicle 1 includes a first detecting sensor 11 and a second detecting sensor 12 which detect the mark members of the detected member 20.

Owner:MURATA MASCH LTD

Motor control apparatus having current supply phase correction

InactiveUS7005814B2Increase rotation speedStop preciseSynchronous motors startersAC motor controlPhase correctionMotor drive

In a motor-driven shift position switching device, when the difference between a target position and the rotation position of a rotor has become smaller than a prescribed value in a motor feedback control, a transition is made to a deceleration control. A phase lead correction amount for correcting the phase lead of the current supply phase with respect to the rotor rotation phase is set in accordance with the rotor rotation speed. Thus, proper braking force suitable for the rotor rotation speed is exerted on the rotor and the rotor can be decelerated smoothly as it approaches the target position. Further, in the period when the current supply to the motor is kept off, the shift position switching determination ranges are set wider than in the period when the current supply to the motor is on.

Owner:TOYOTA MOTORS KABISHIKI KAISHA 50

Moving body system and method for controlling travel of moving body

ActiveUS9292018B2Improve accuracyAccurate conversionNon-mechanical conveyorsRailway signalling and safetySimulationPosition shift

A detector detects positions of a moving body in a travel direction at a position shifted from a center of control of travel of the moving body in a direction different than the travel direction of the moving body. Positions of the center of control in the travel direction relative to the output of the detector is stored in a storage unit for at least a curved section of a travel route of the moving body, and the travel of the moving body is controlled by a controller, based on the positions of the center of control read out from the storage unit.

Owner:MURATA MASCH LTD

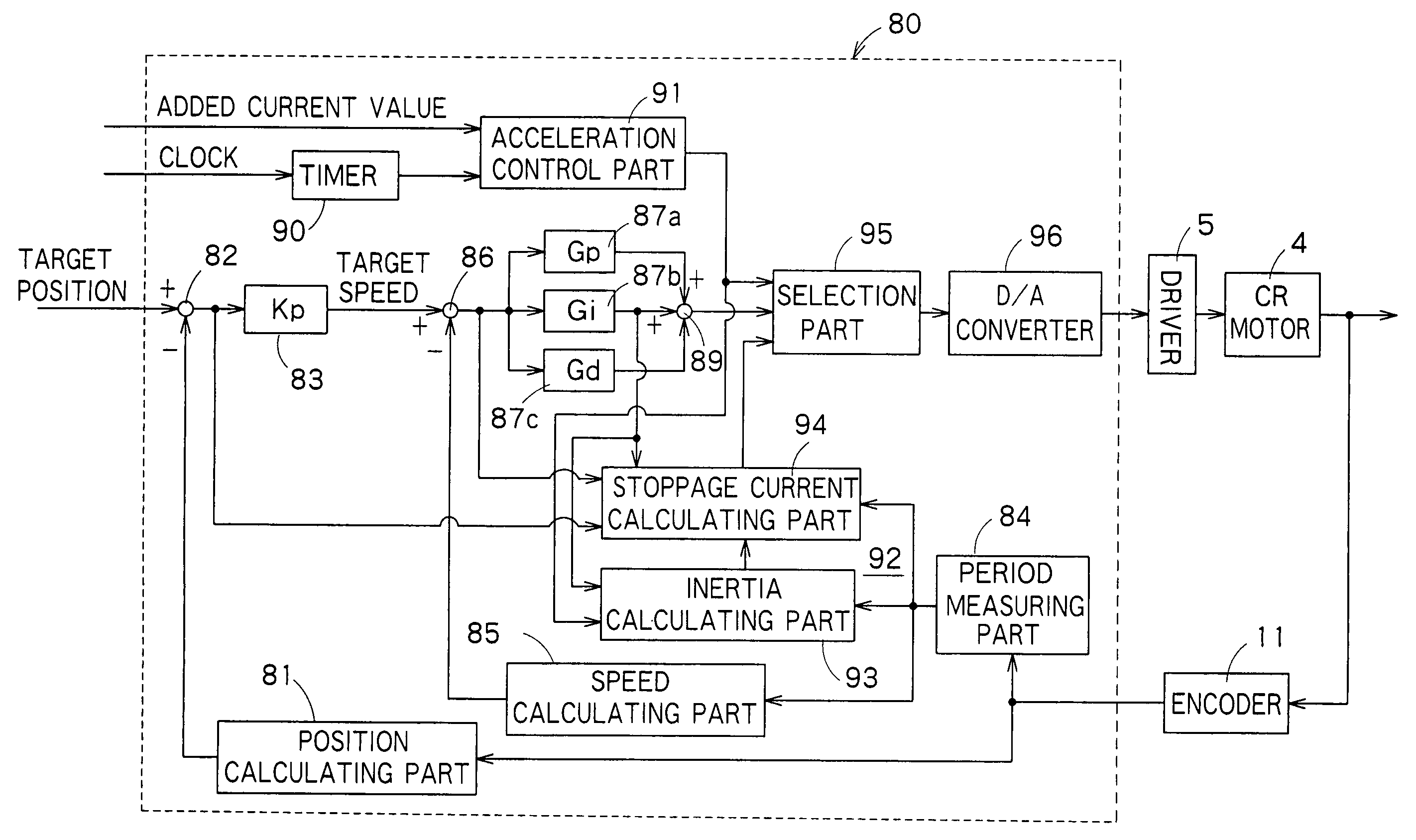

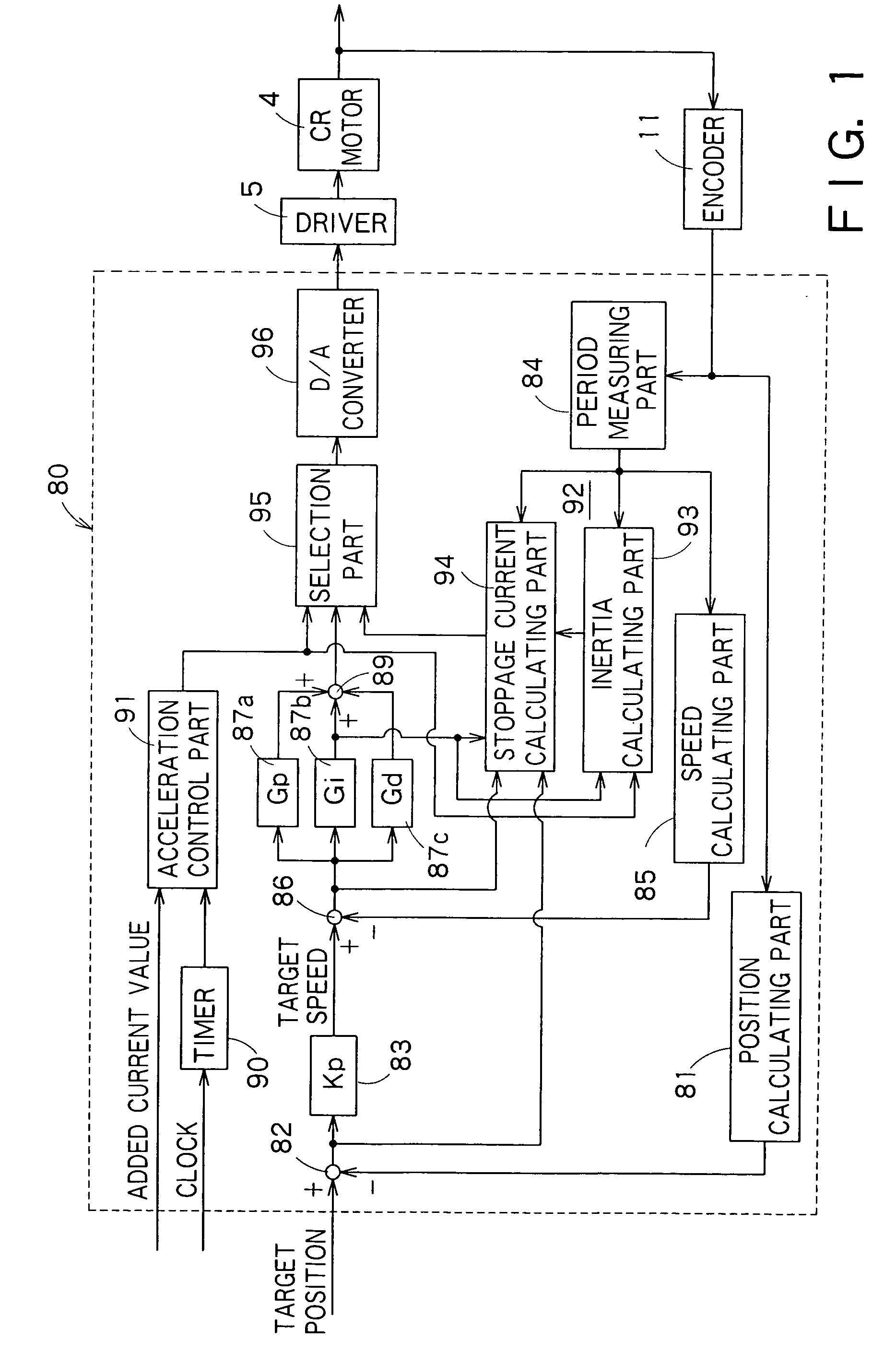

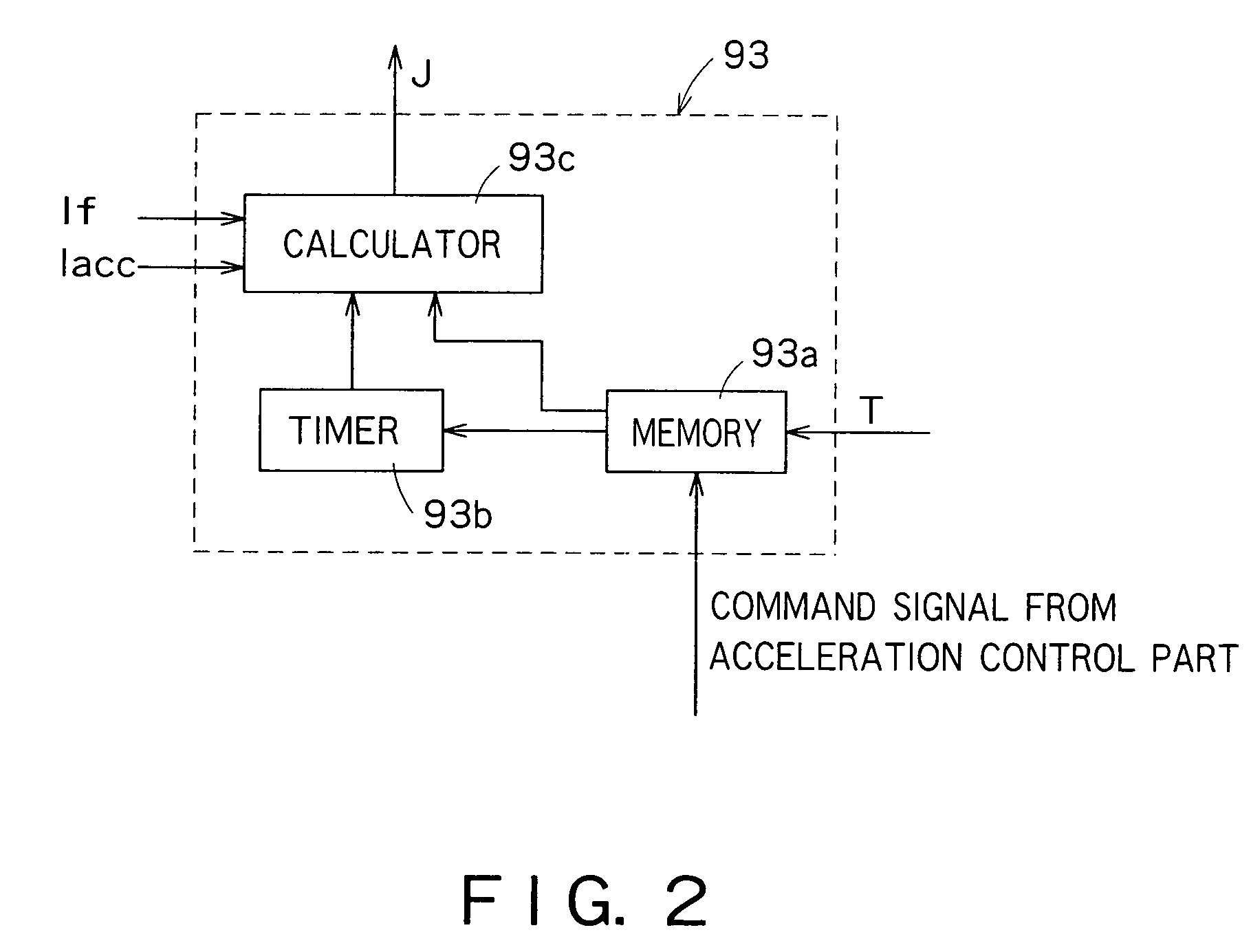

Control unit and method for controlling motor for use in printer, and storage medium storing control program

InactiveUS20050146555A1Stop preciseSpacing mechanismsField or armature current controlControl theoryAngular acceleration

There is provided a control unit capable of rapid and precise stoppage of an object to be driven by a motor for use in a printer. The control unit has a speed control part to control the object by acceleration control, constant speed control, deceleration control, and stoppage control by controlling a current to be applied to the motor, and also an inertia calculating part to calculate inertia of the object based on angular acceleration of the motor under the acceleration control of the object, and current values to be applied to the motor under the acceleration control and the constant speed control of the object. The speed control part uses the calculated inertia for controlling the current to be applied to the motor.

Owner:SEIKO EPSON CORP

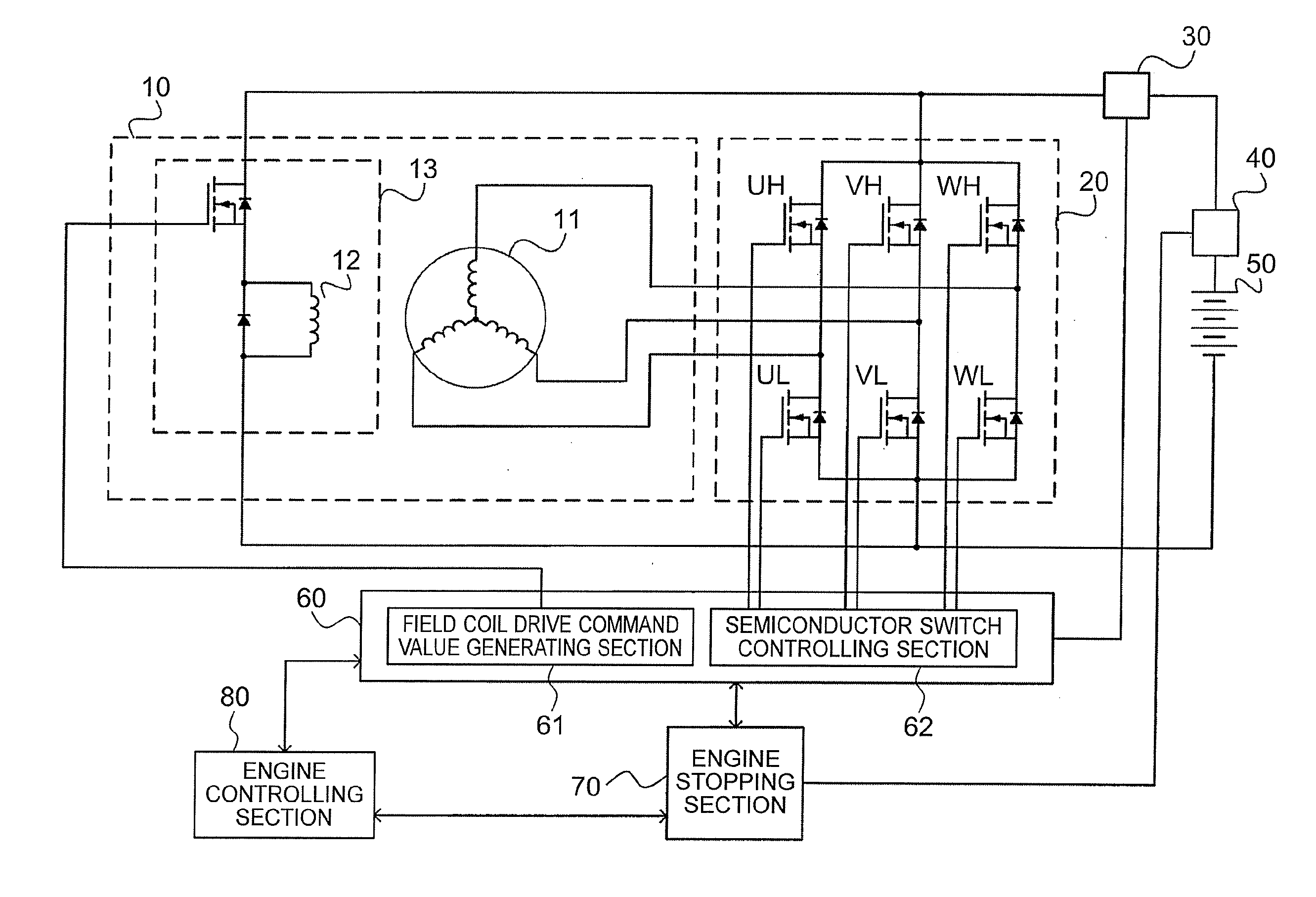

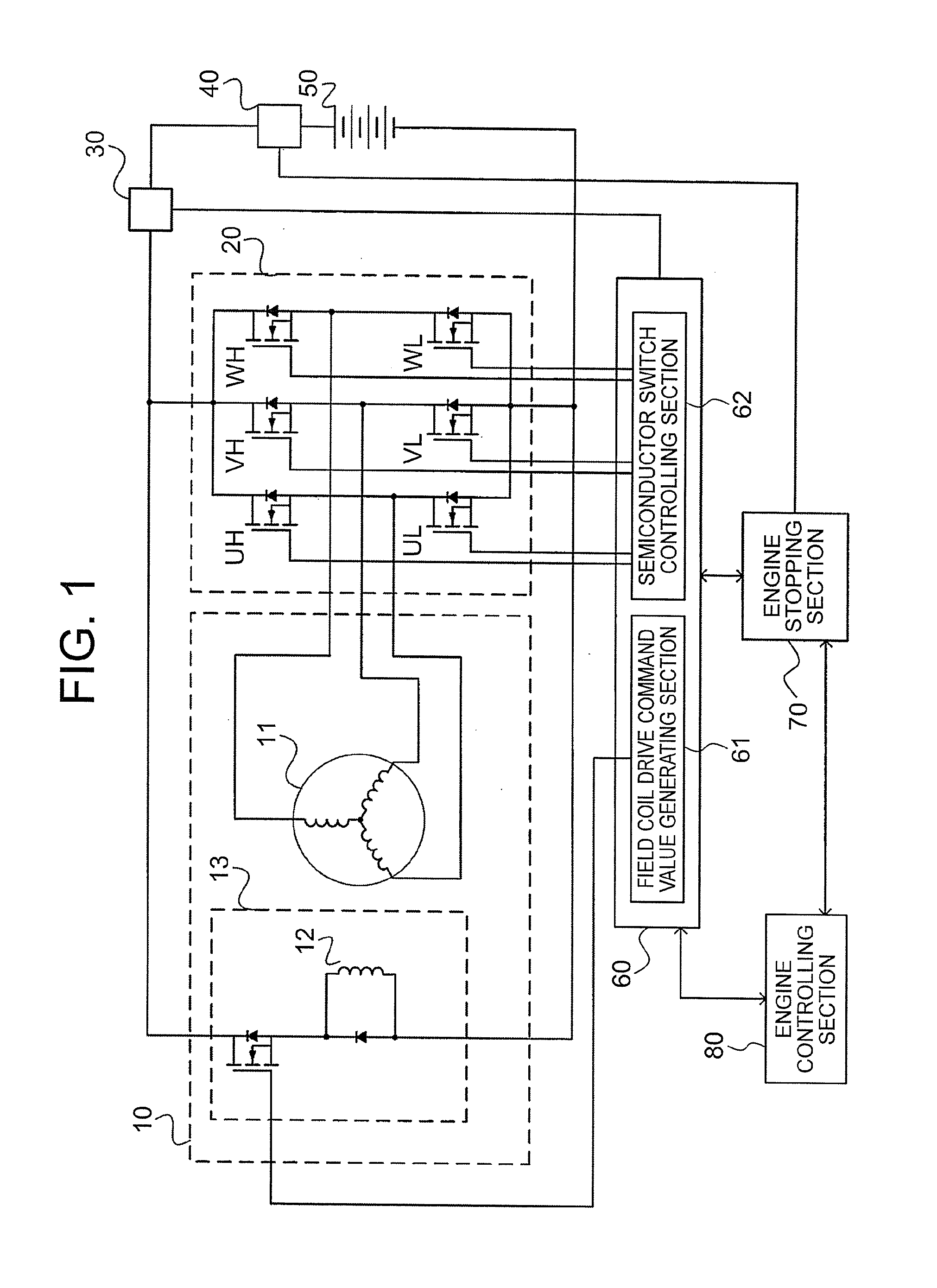

Engine stop control apparatus and engine stop control method

ActiveUS20150377162A1Solve the large power consumptionImprove energy efficiencyAnalogue computers for vehiclesElectrical controlBrake torqueControl theory

An engine stopping section first selects, when an engine stop condition is satisfied, a power-generation braking mode in which a power-generation braking torque is applied to the engine by a power generation operation of the generator, to thereby apply the power-generation braking torque to the engine, and then selects a short-circuit braking mode in which a short-circuit braking torque is applied to the engine by short-circuiting each energization phase of an armature coil with a semiconductor switch and by causing a field current to flow through a field coil, to thereby apply the short-circuit braking torque to the engine.

Owner:MITSUBISHI ELECTRIC CORP

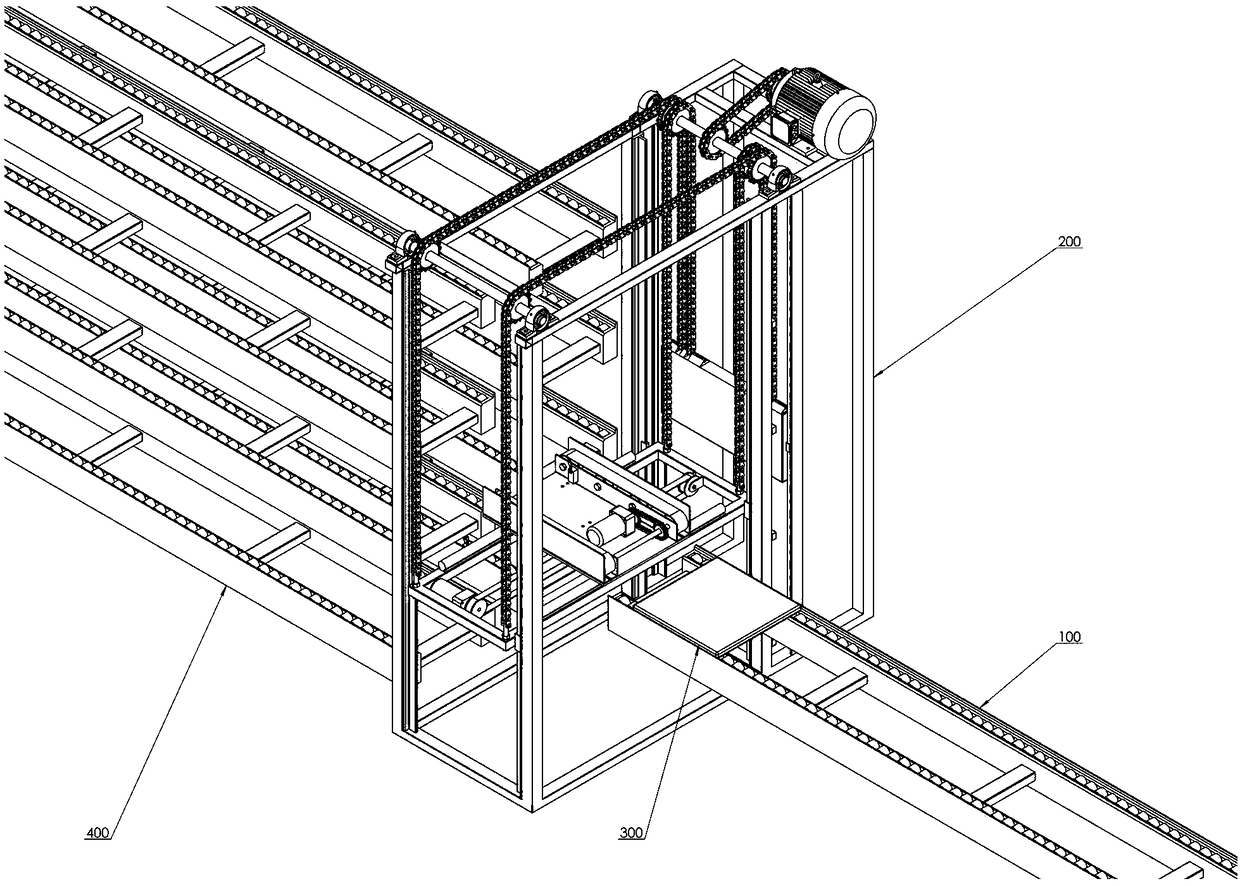

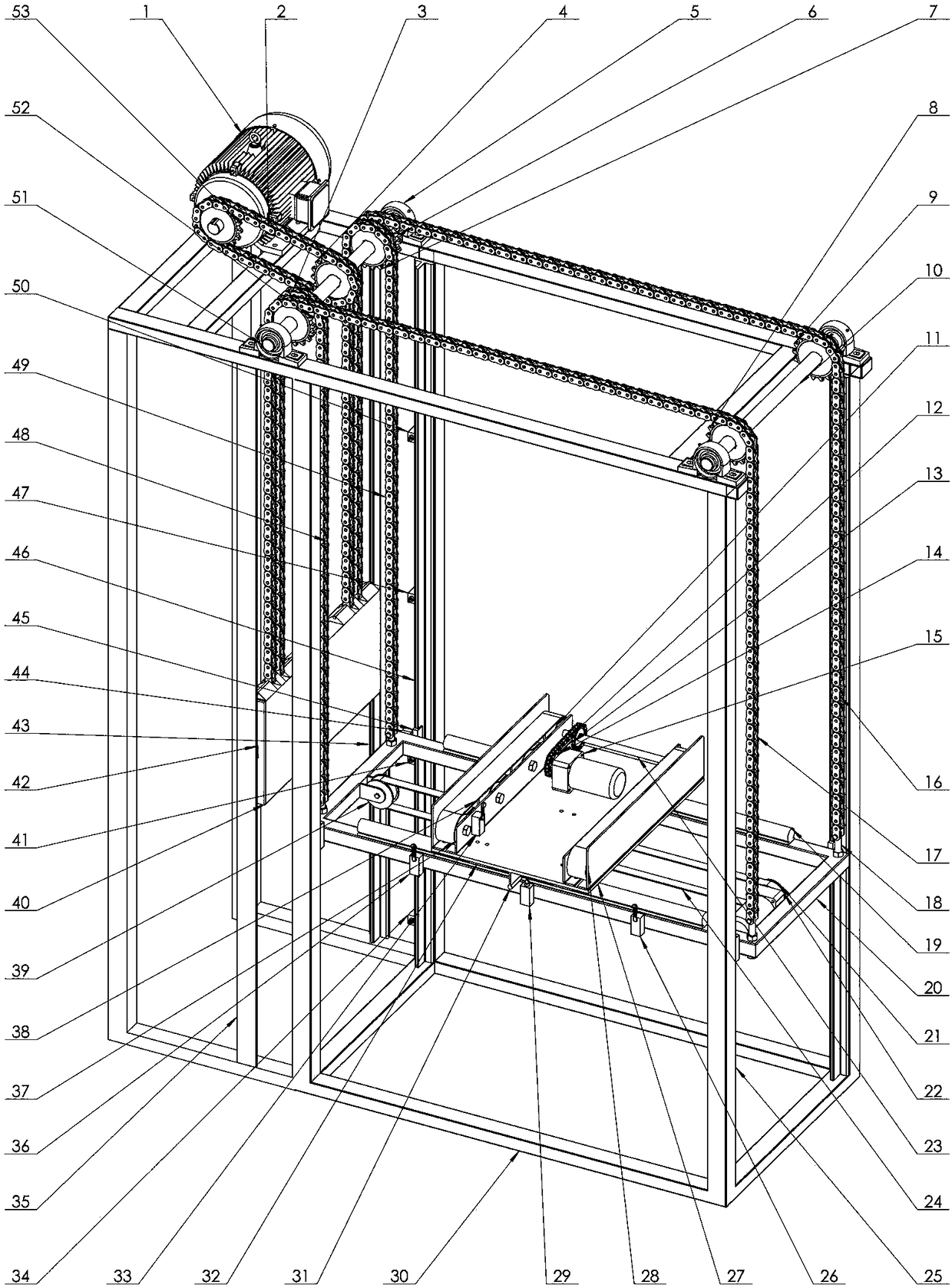

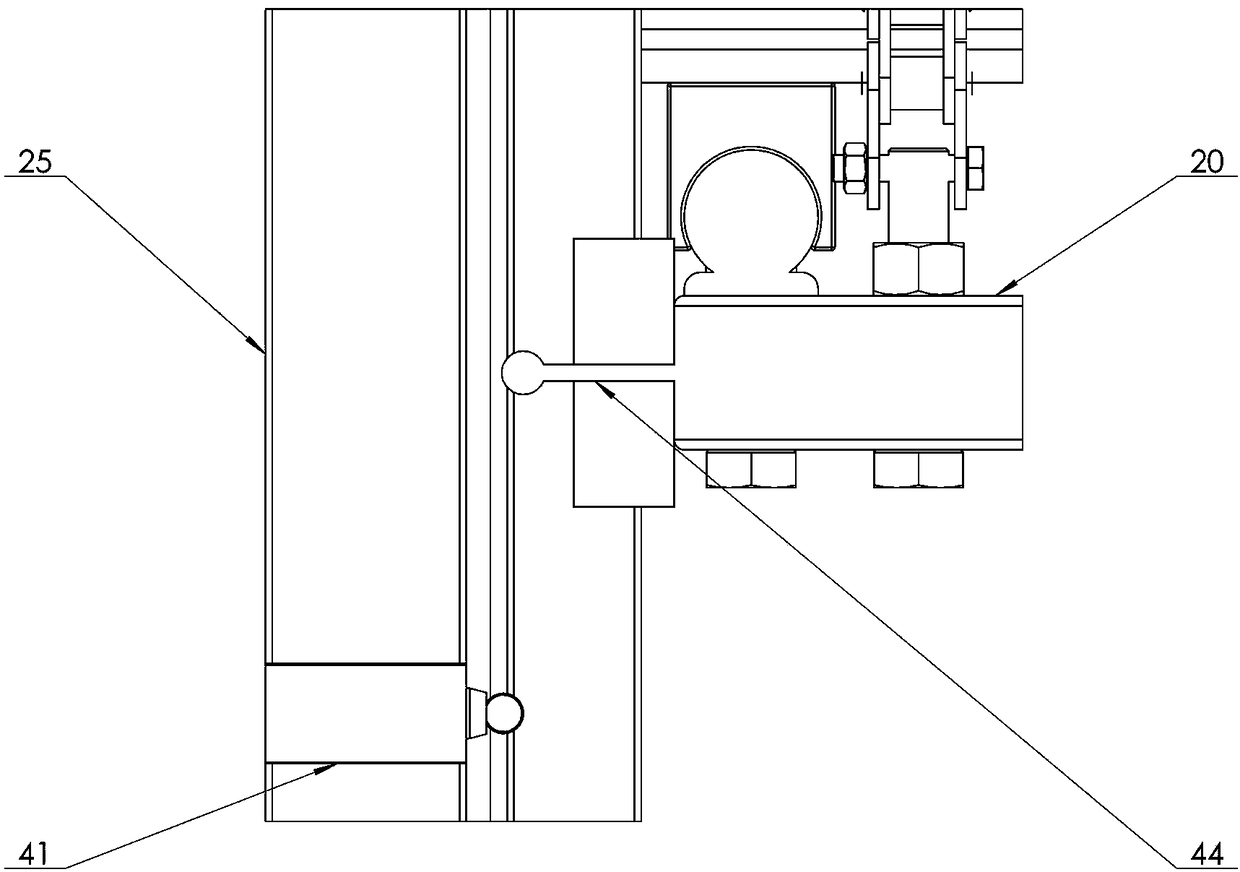

Rising and falling horizontal transferring machine

ActiveCN108516307AReduce loadSimple control circuitControl devices for conveyorsMechanical conveyorsMotor driveEngineering

The invention belongs to the technical field of transferring machines and discloses a rising and falling horizontal transferring machine which comprises a transferring machine support, a rising and falling moving assembly and a horizontal moving and plate conveying assembly. A layer limit switch is arranged on the transferring machine support. The rising and falling moving assembly drives a risingand falling moving framework through a three-phase asynchronous band-type brake motor. The rising and falling moving framework is dragged through a chain. The horizontal moving and plate conveying assembly comprises a horizontal moving device and a plate conveying device. The horizontal moving device is provided with a horizontal limit switch, and a horizontal moving direct-current speed reducingmotor drives a horizontal moving bottom plate. The plate conveying device is provided with a plate in-place switch, and a plate conveying direct-current speed reducing motor drives a pattern conveying belt to drive a tool plate. The rising and falling horizontal transferring machine is simple in structure and reliable in performance, and the problem of connection between single triple speed chains of an inlet and an outlet of an aging house and multi-layer triple speed chain in the aging house can be solved.

Owner:WUHAN UNIV OF TECH

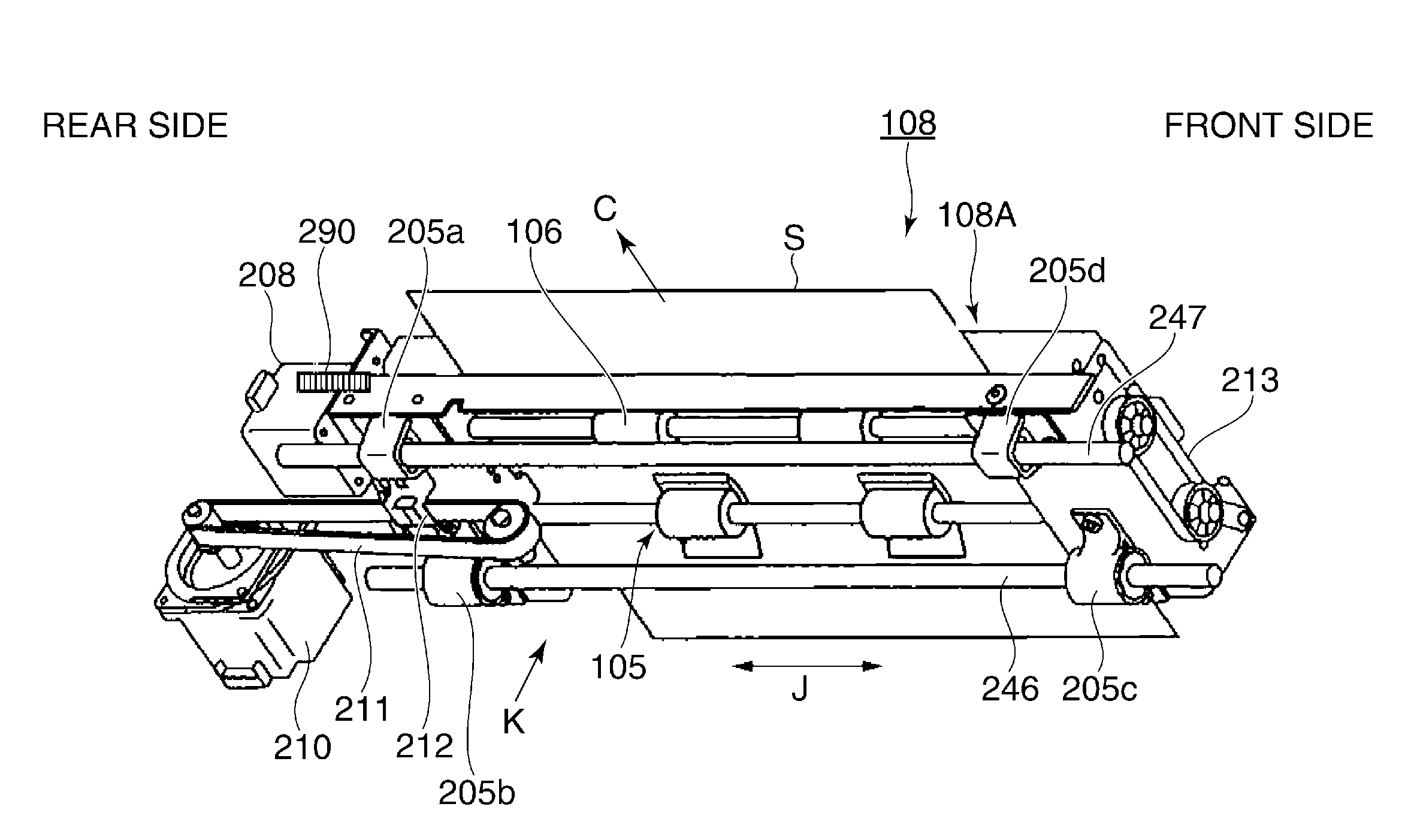

Rail table system

InactiveCN1931628AGuaranteed travel speedStop preciseElectric propulsionElectricitySynchronous motor

This invention provided a track mounted jumbo systerm. In this system, a primary coil (10) of a linear synchronous motor is arranged at the fixing side in the vicinity of a station, and a magnet row (48) of the linear synchronous motor is arranged at a stacker crane (20). A primary coil (42) of a linear induction motor is arranged at the stacker crane (20), and a secondary conductor (8) is continuously arranged between the stations at the fixing side. The power of the linear induction motor is obtained from a non-contact electricity receiving part (52) by supporting the weight of the stacker crane (20) by a traveling wheel (44), and by supporting swiveling forces acting from the linear induction motor and the linear synchronous motor by a guide roller (46). The primary coil (10) is operated in the vicinity of the station by detecting a magnet position in the magnet row (48), and stopped by detecting an absolute position of the stacker crane (20) with respect to the station by an ABS linear sensor (12).

Owner:MURATA MASCH LTD

Sheet processing apparatus that corrects lateral deviation of a sheet

InactiveUS20130300055A1Stop preciseRegistering devicesElectrographic process apparatusEngineeringDelayed time

A sheet processing apparatus which enables a sheet to be stopped at a target position with precision even when the sheet is stopped by moving a heavy unit such as a shift unit. A drive unit moves a moving unit so as to move a sheet, which is being conveyed, in a direction perpendicular to a conveying direction of the sheet. An output unit detects movement of the moving unit and output a signal in synchronization with movement of the moving unit. A control unit issues a stop instruction to the drive unit based on a delay time from when a start instruction to the drive unit is issued until when the signal in synchronization with the movement of the drive unit is output, and a target moving amount required for the moving unit to move to a target position.

Owner:CANON KK

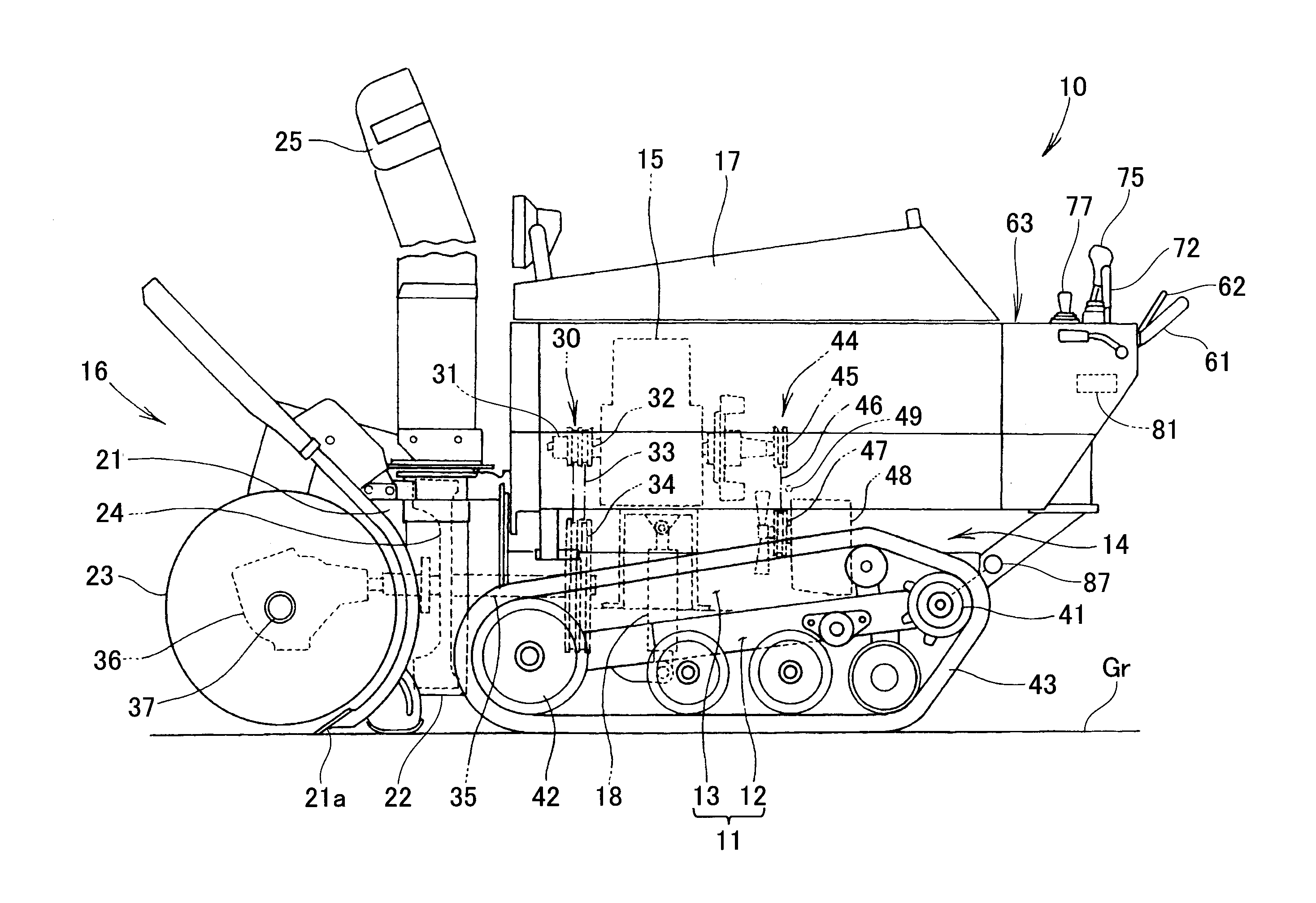

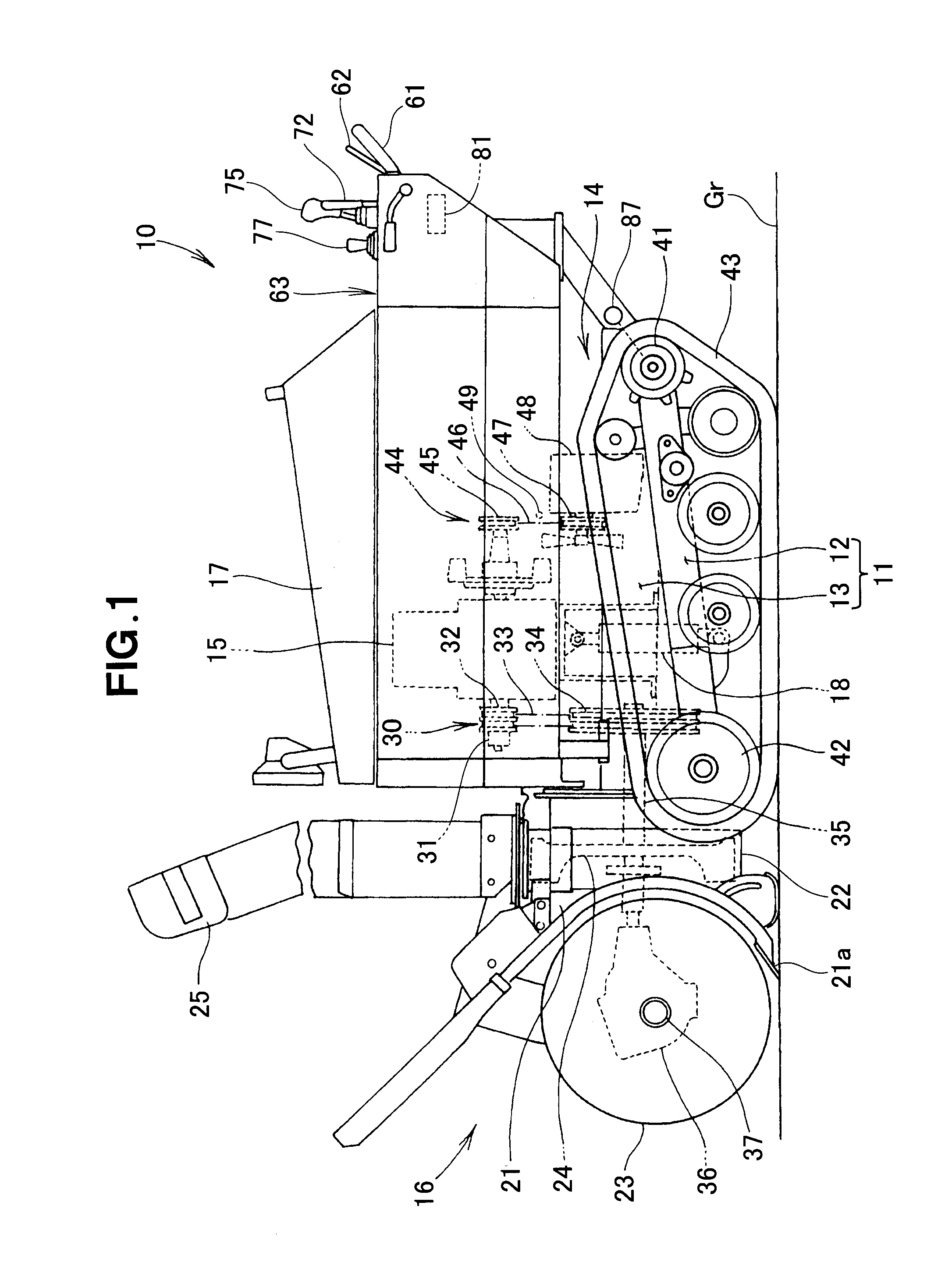

Snow plow

A snow plow includes a control unit for raising an auger housing to a predetermined upper limit angle when travel device is reversing, and an acceleration sensor for detecting acceleration produced in the auger housing. The control unit determines an angle of inclination of the auger housing on the basis of the acceleration. When the travel device starts moving forward after having temporarily moved in reverse, the control unit sets an intermediate lowering target angle of inclination, which is in the lowering path of the auger housing from the upper limit angle to a pre-reversing angle of inclination, in accordance with the forward acceleration; lowers the auger housing at a given lowering speed from the upper limit angle to the intermediate lowering target angle of inclination; and lowers the auger housing at a gradually decreasing lowering speed from the intermediate lowering target angle of inclination to the pre-reversing angle of inclination.

Owner:HONDA MOTOR CO LTD

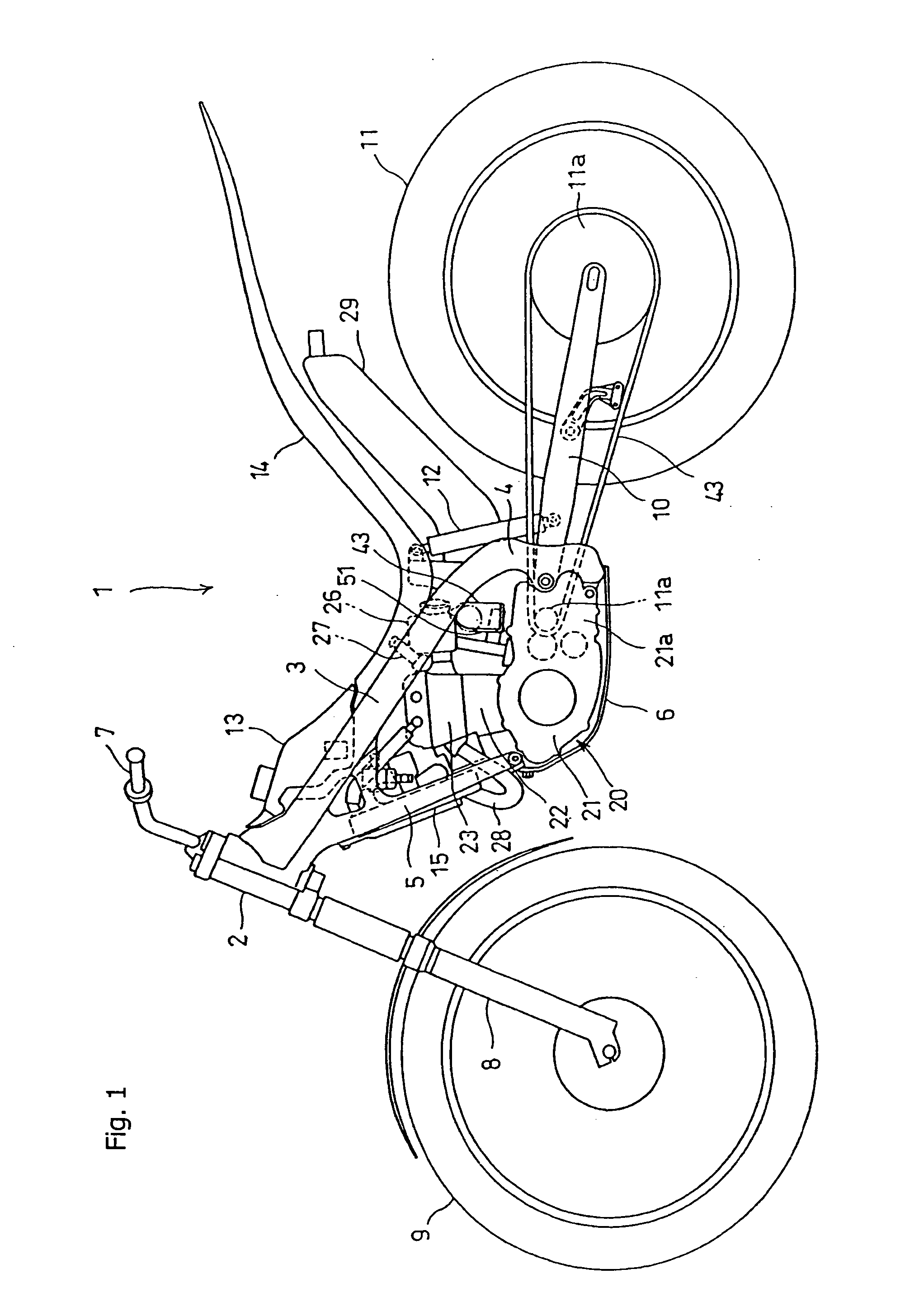

Vehicle-mounted control system and method for an internal combustion engine

ActiveUS20060020385A1Stop preciseAnalogue computers for vehiclesElectrical controlCombustionControl system

A vehicle-mounted internal combustion engine controller is provided that can properly stop an internal combustion engine in accordance with an operational state no matter whether a vehicle body is inclined. The vehicle-mounted internal combustion engine controller comprises an inclination sensor for detecting vehicle body inclination; a mechanism for determining the operational state of a combustion engine; and a controller for stopping the operation of the combustion engine in accordance with a vehicle body inclination and an operational state. The cutoff mechanism stops the operation of the vehicle-mounted internal combustion engine when it is judged that a vehicle body inclination angle a detected by the inclination sensor is greater than a predetermined angle A for a greater or equal period of time as a threshold stop time T1, T2 setting, which varies with the operational state determined by the operational state sensor.

Owner:HONDA MOTOR CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com