Rail table system

A trolley system and trolley technology, applied in the system field, can solve problems such as cost increase and inability to solve stop accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

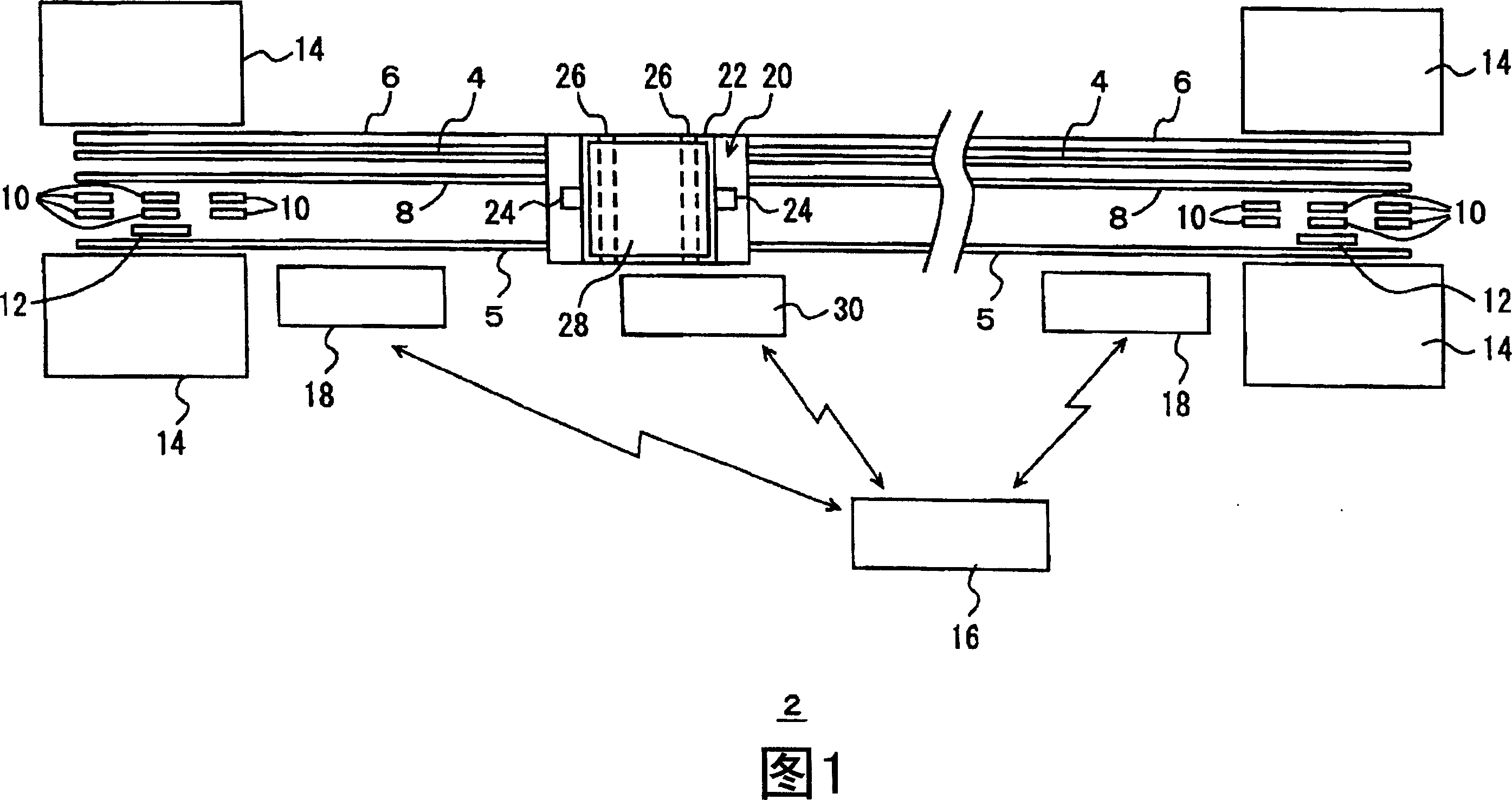

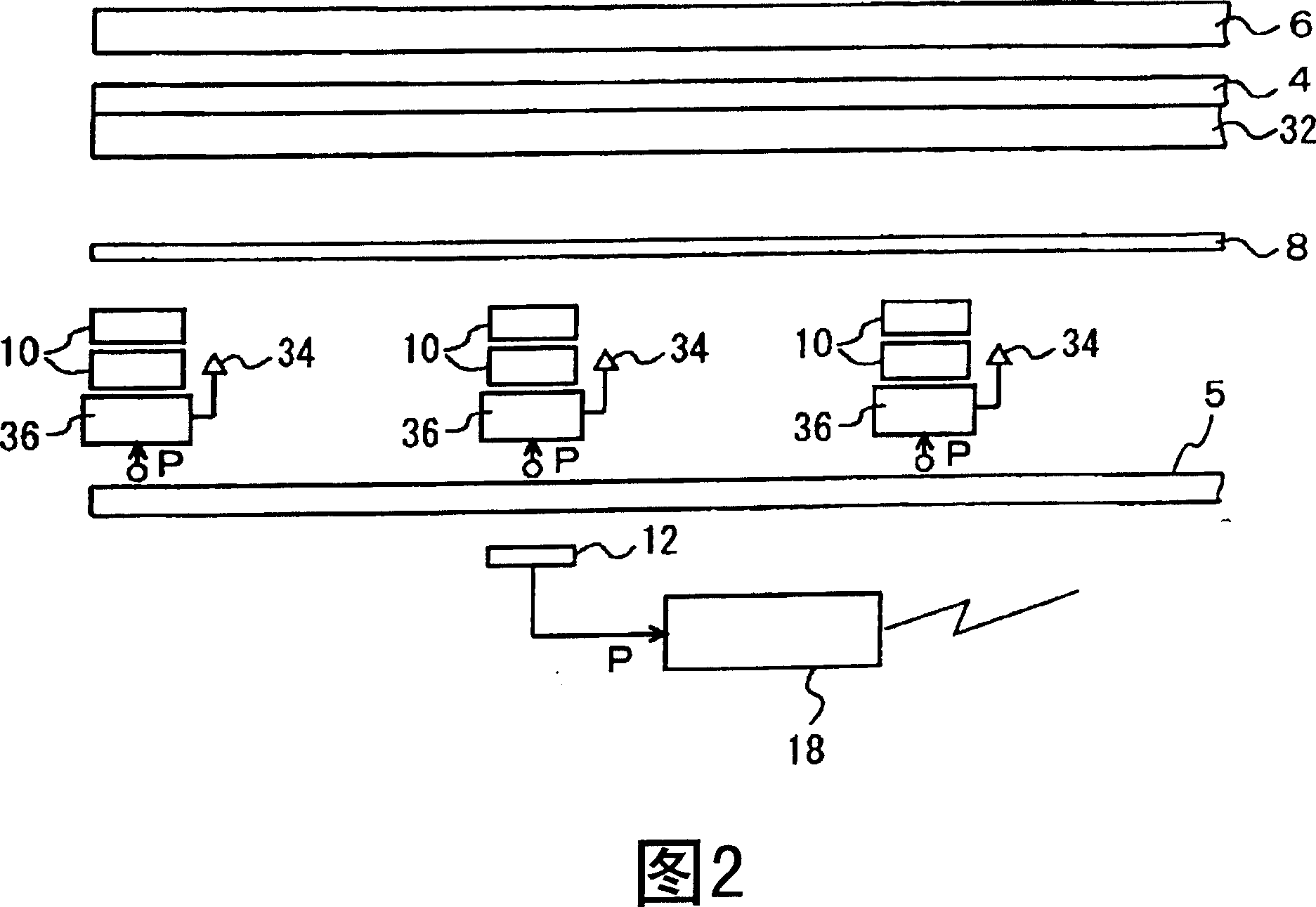

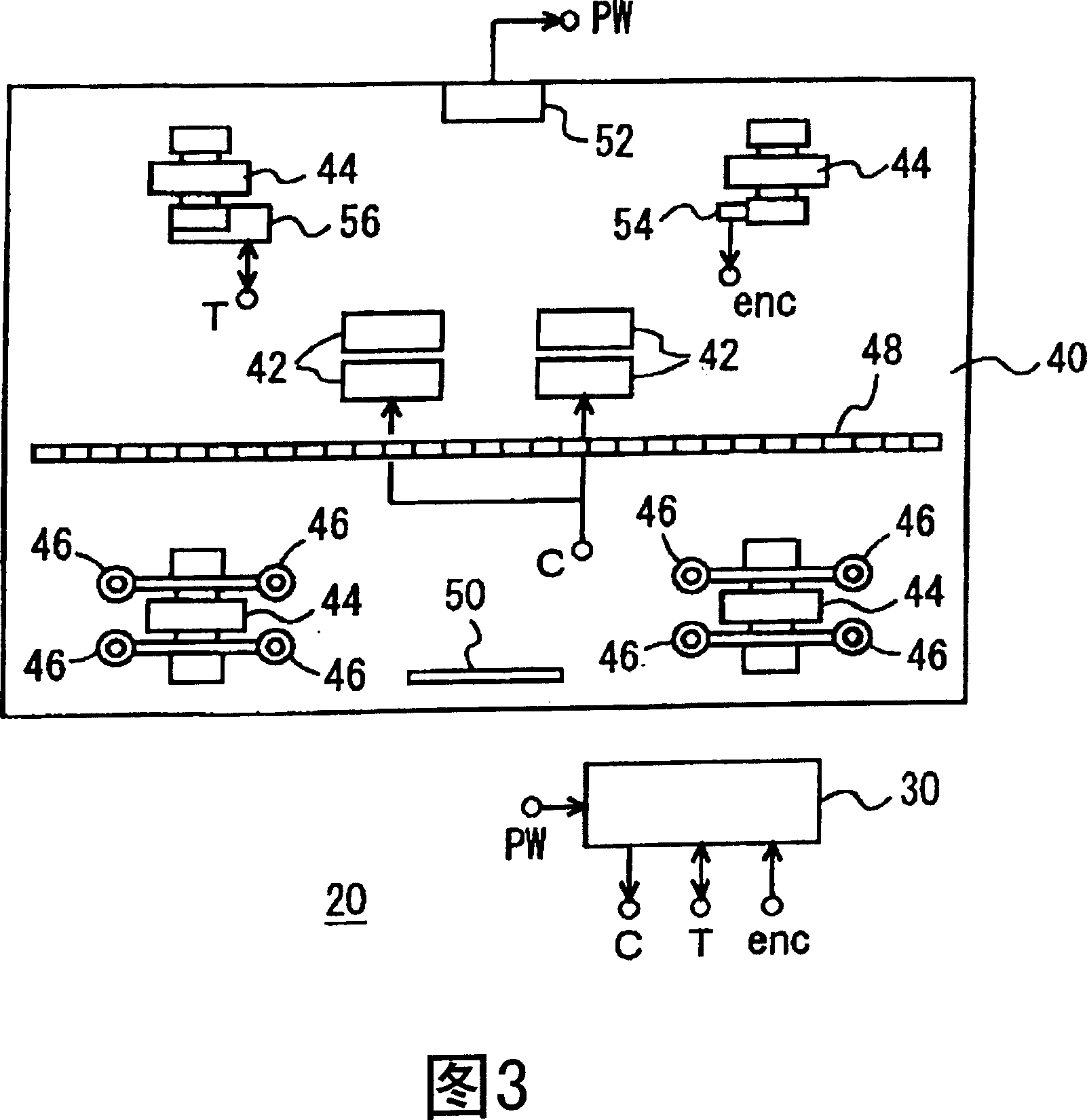

[0024] 1 to 8 show the embodiment and its modifications. In the figure, 2 is a trolley system, which can be regarded as a system for transporting boxes containing multiple liquid crystal substrates in a clean room. 4 and 5 are running rails, 6 is a power supply rail for non-contact power supply, 8 is a secondary conductor of a linear induction motor (LIM), and 10 is a primary coil of a linear synchronous motor (LSM). 12 is an ABS linear sensor, which detects the absolute position of the stacking crane 20 relative to the stop position of the docking station 14 , and 16 is a control unit, which controls the entire rail trolley system 2 . Also, 18 is a docking station control unit, which controls the primary coil 10 and the like of the linear synchronous motor using signals from the ABS linear sensor 12 and the like.

[0025] 20 is a stacking crane, 22 is a lifting platform, which moves up and down along the mast 24, and uses a transfer mechanism 26 such as a sliding fork to tra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com