Coating device and coating method

A coating device and coating technology, which are applied to devices for coating liquid on surfaces, coatings, pre-treatment surfaces, etc., can solve problems such as inability to properly cure, insufficient, and difficulty in forming a coating film.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

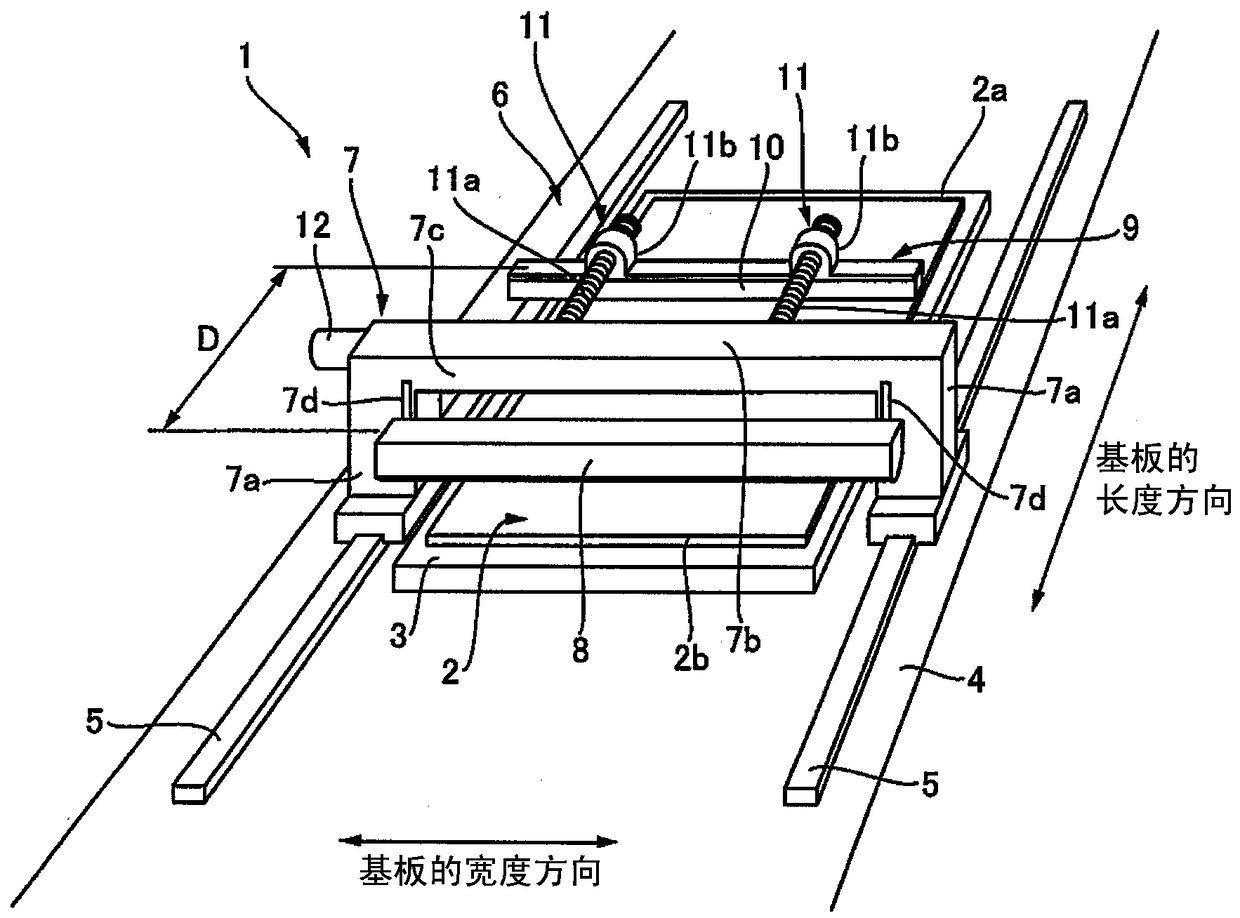

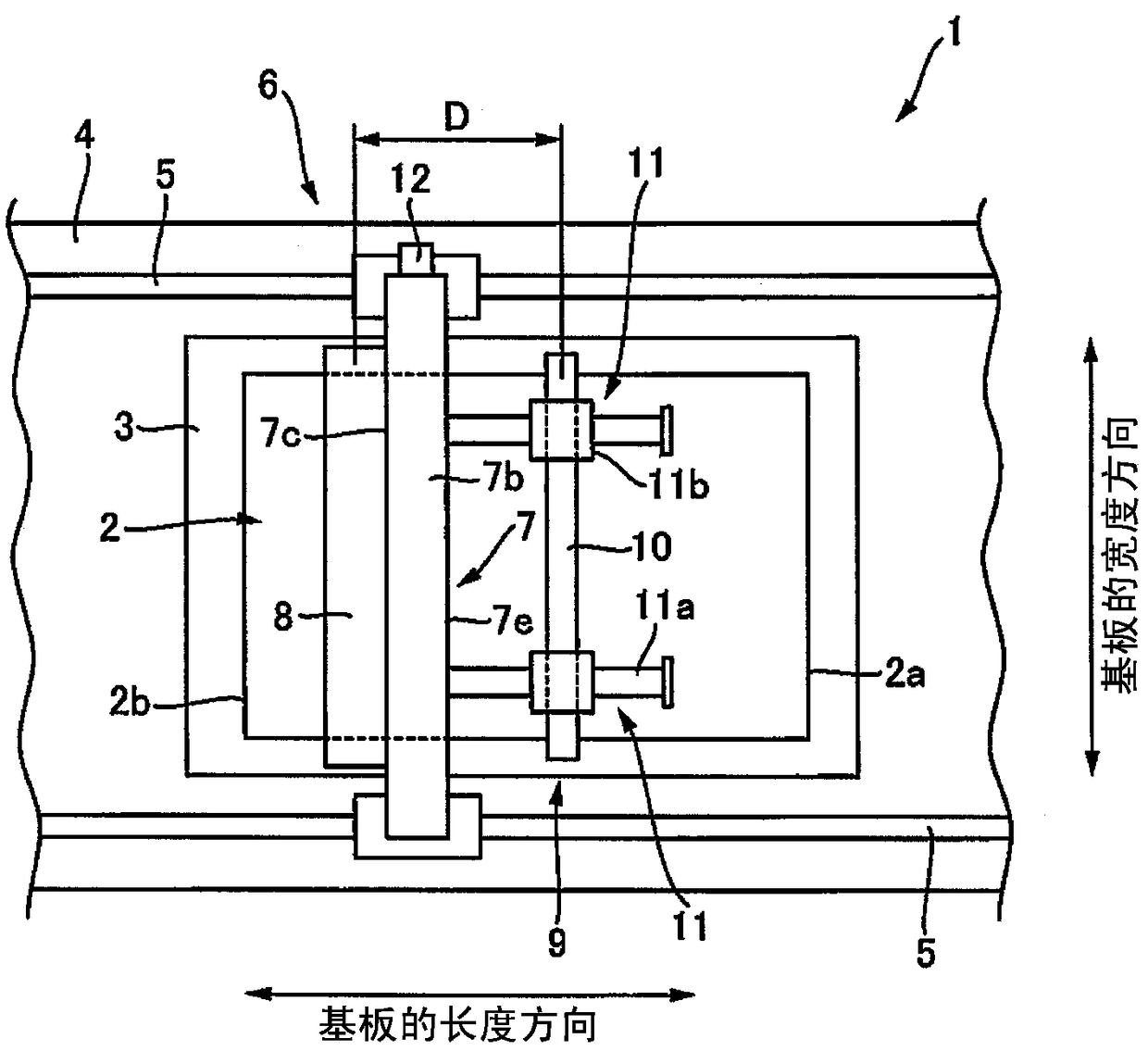

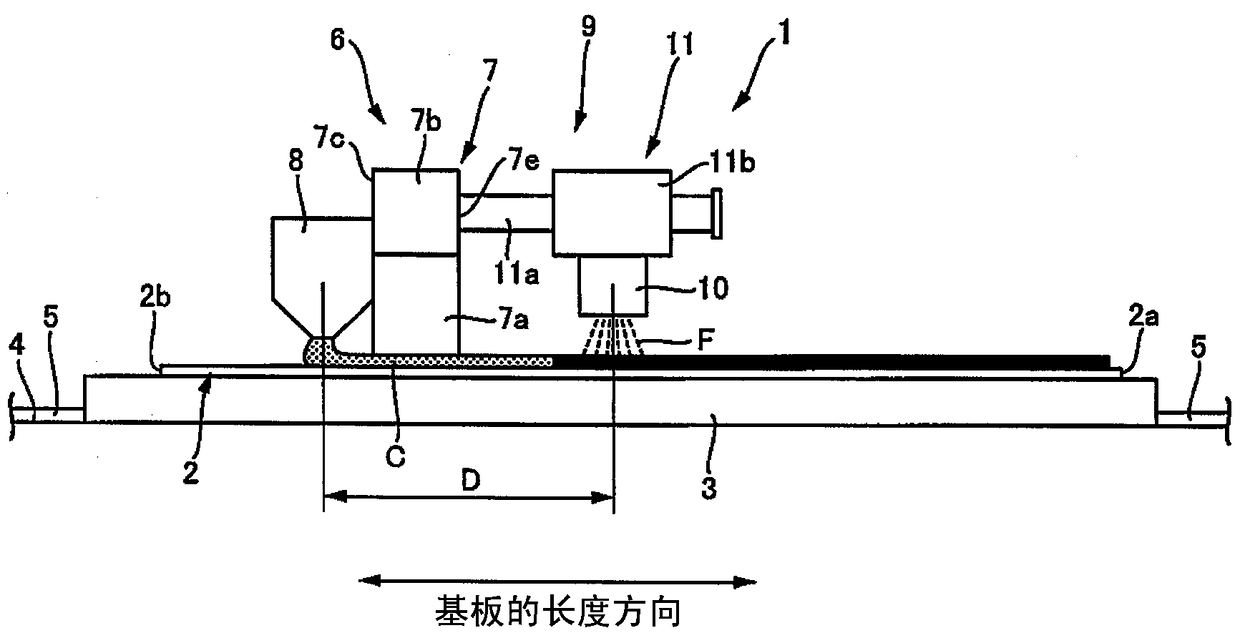

[0085] Hereinafter, preferred embodiments of the coating device and coating method of the present invention will be described in detail with reference to the drawings. figure 1 It is a perspective view showing the first embodiment of the coating device of the present invention, figure 2 yes figure 1 A top view of the coating device shown, image 3 is to pass figure 1 The illustrated coating device is a side view of a state where a coating film is formed on a substrate.

[0086] The coating device 1 of the first embodiment is as Figure 1 ~ Figure 3 As shown, it is mainly composed of a workbench (platform) 3, a pair of left and right traveling guide rails 5, and a coating film forming unit 6. The traveling rail 5 is provided along the longitudinal direction of the substrate 2 in a configuration that sandwiches the substrate 2 from both sides in the width direction on the base 4 outside the table 3, and the coating film forming unit 6 is arranged along the longitudinal d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com