Patents

Literature

381 results about "Feeding types" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

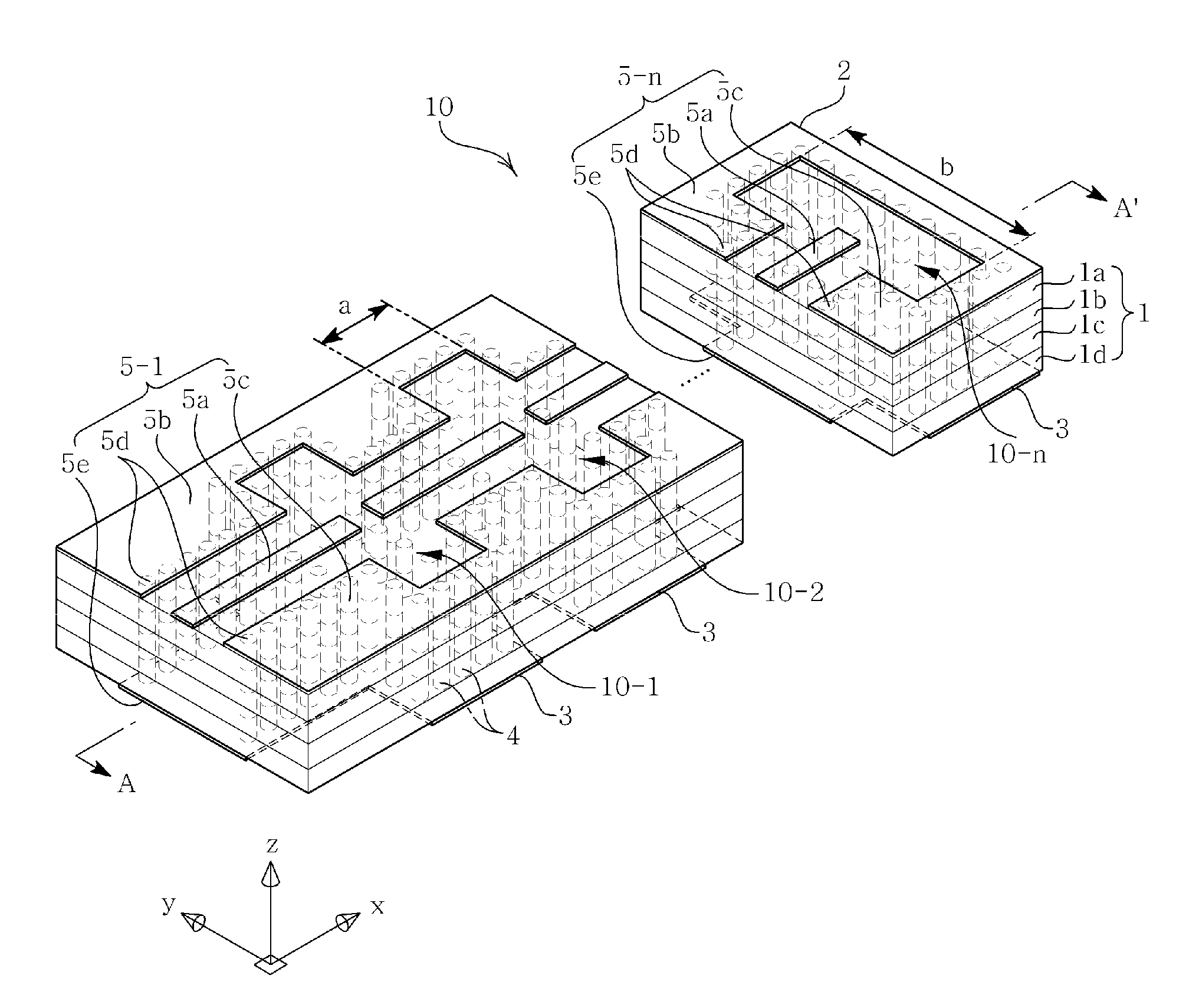

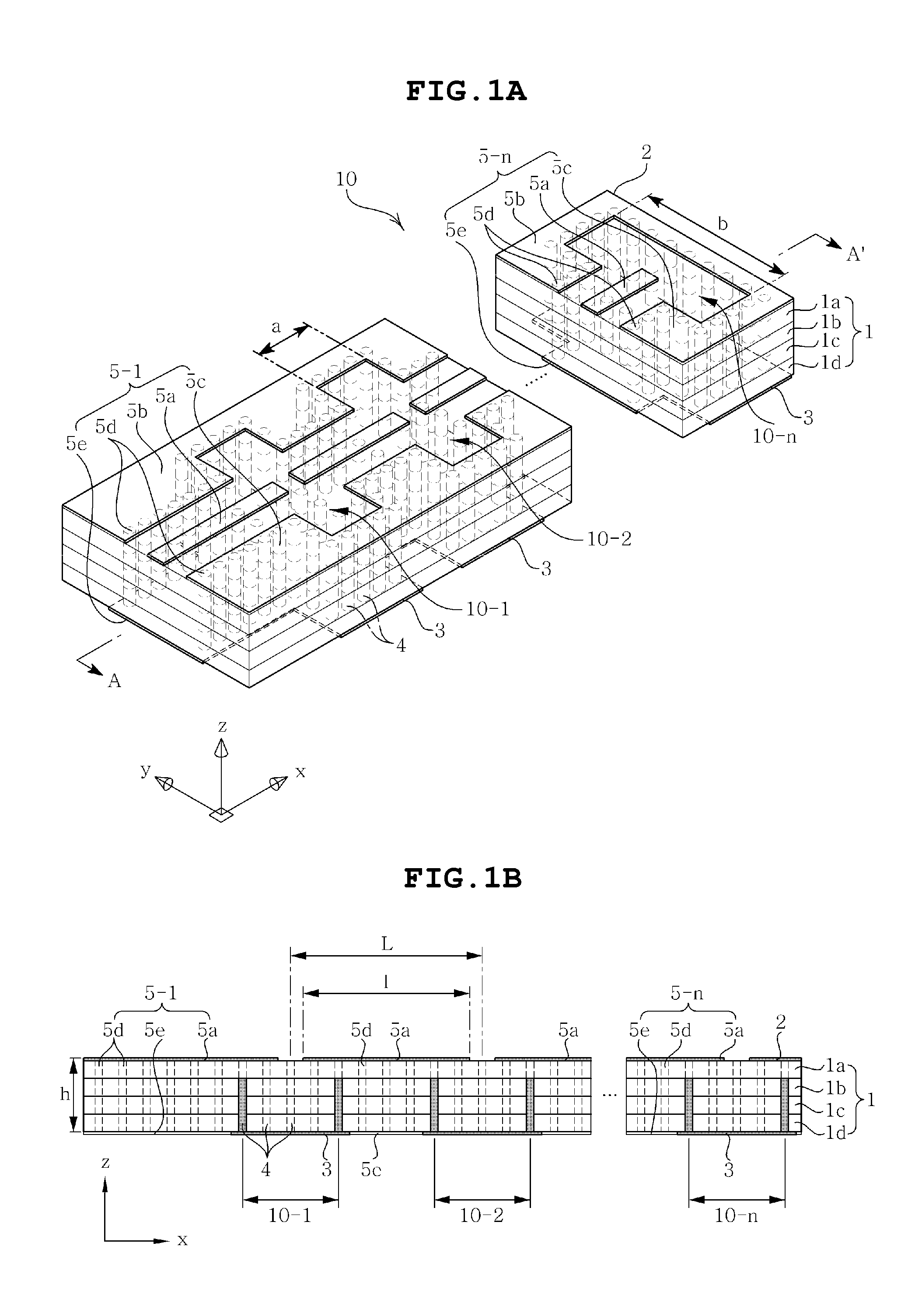

Dielectric resonator array antenna

InactiveUS20140043189A1Improve featuresIndividually energised antenna arraysElectrically short antennasTime delaysDielectric resonator antenna

Disclosed herein is a dielectric resonator array antenna including one or more series-feed type array elements installed to be arranged in parallel in a multilayer substrate, wherein first high frequency signals having the same or different phases or time delays are adjusted to be applied to the respective series-feed type array elements and respective radiated 1D array beams are individually used or combined to adjust beamforming of 2D array beams. Also, since the series-feed type array element is configured by connecting a plurality of dielectric resonator antennas in series, it can be easily and simply fed in series through coupling generated by the intervals between the feeding lines of the pertinent feeding unit of the plurality of dielectric resonator antennas connected in series. In addition, the broadband characteristics can be obtained by using the plurality of dielectric resonator antennas, whereby the overall antenna performance can be enhanced.

Owner:SAMSUNG ELECTRO MECHANICS CO LTD +1

Shredder

Owner:ROYAL SOVEREIGN QINGDAO

Online nondestructive detection system and method of quality of manufacturing members of metal additional materials

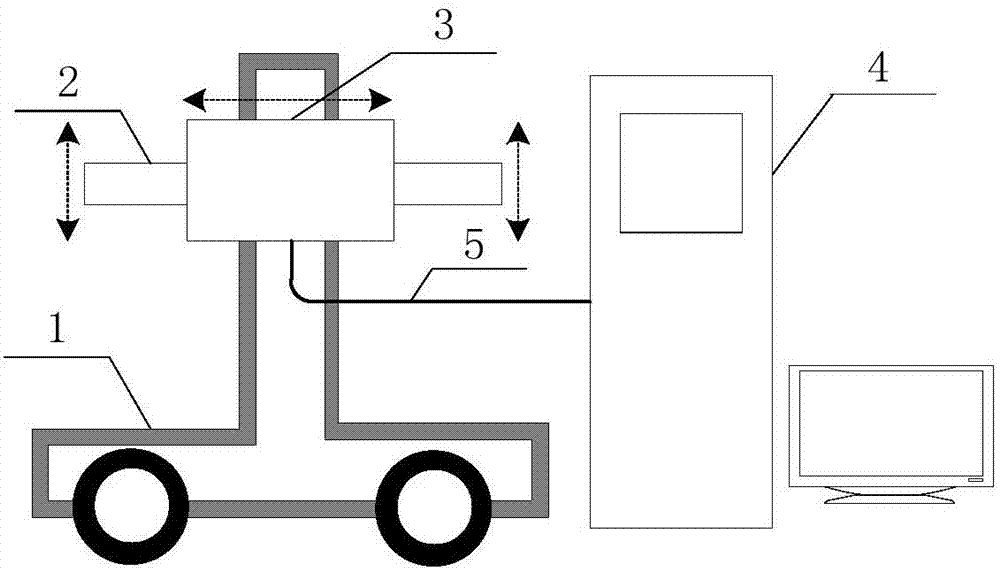

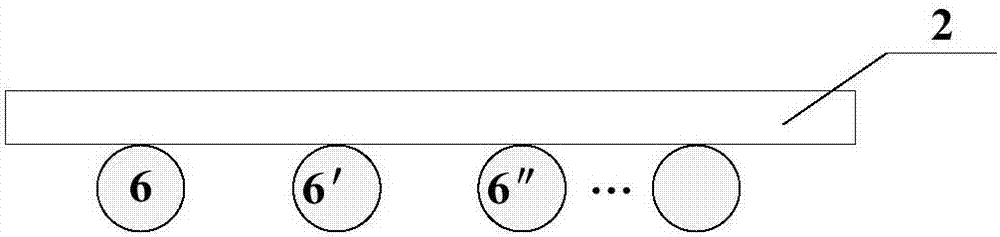

ActiveCN107402044ARealize online non-destructive testingReduce in quantityMeasurement devicesMarine engineeringControl system

The invention discloses an online nondestructive detection system and method of quality of manufacturing members of metal additional materials and belongs to the field of online nondestructive detection. The system comprises a moving detection vehicle, a guidance rail, an online signal detection module and a control system. A column is arranged on the vehicle body of the moving detection vehicle. The guidance rail is movably connected to the column. The online signal detection module is movably connected to the guidance rail. Multiple probes are integrated into the online signal detection module and comprise probes used for detecting compositions, defects, deformation, stress, size precision and surface coarseness. During detection, the probes can be embedded into a 3D printing head of a feeding type additional material manufacturing device or be fixed on the moving detection vehicle. The probes are in signal connection with the control system. The invention also provides a method for carrying out online nondestructive detection of the system. According to the invention, the system and the method are widely applicable, highly expandable and capable of achieving onsite or remote online detection of manufacturing processes of feeding type metal additional materials.

Owner:HUAZHONG UNIV OF SCI & TECH

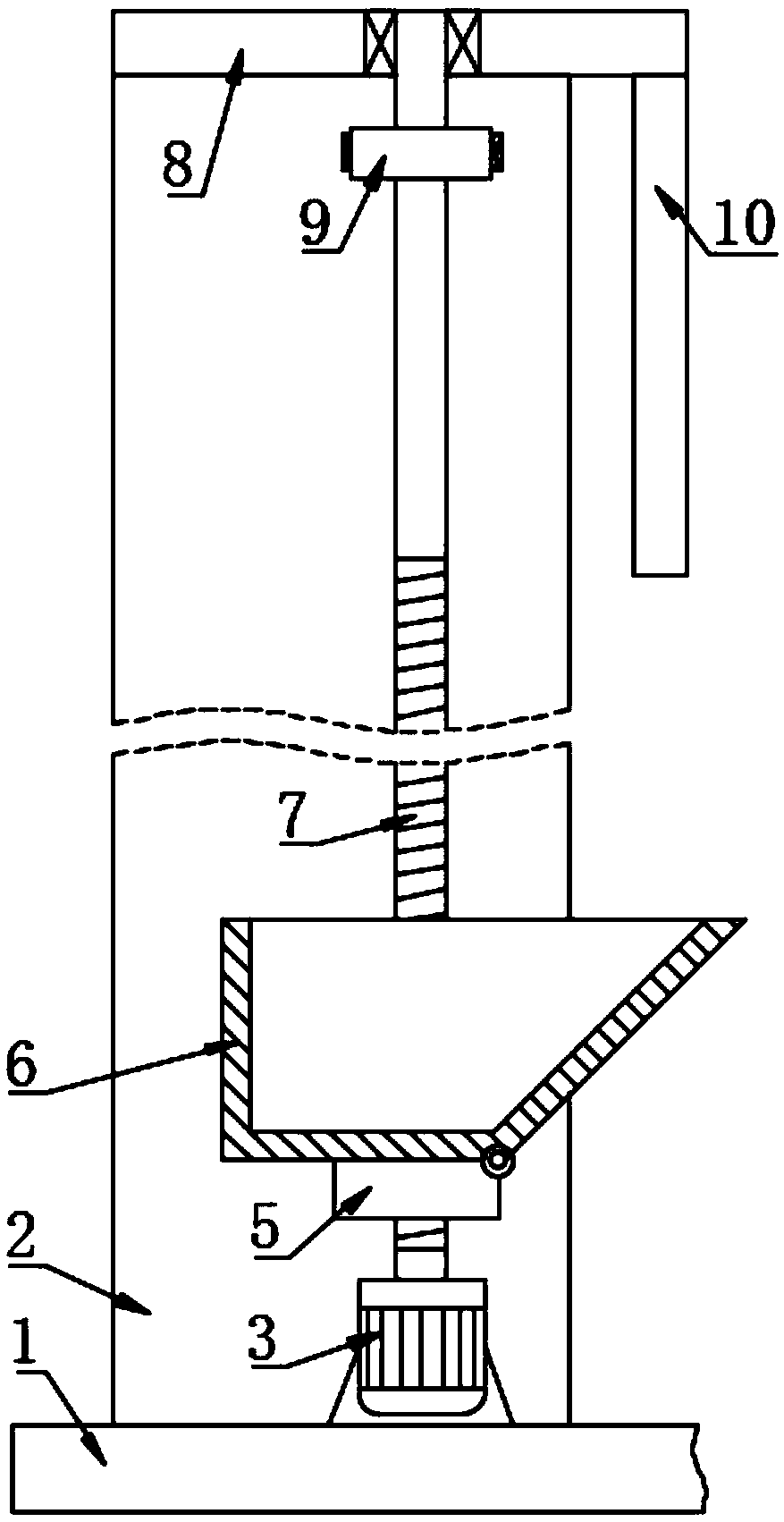

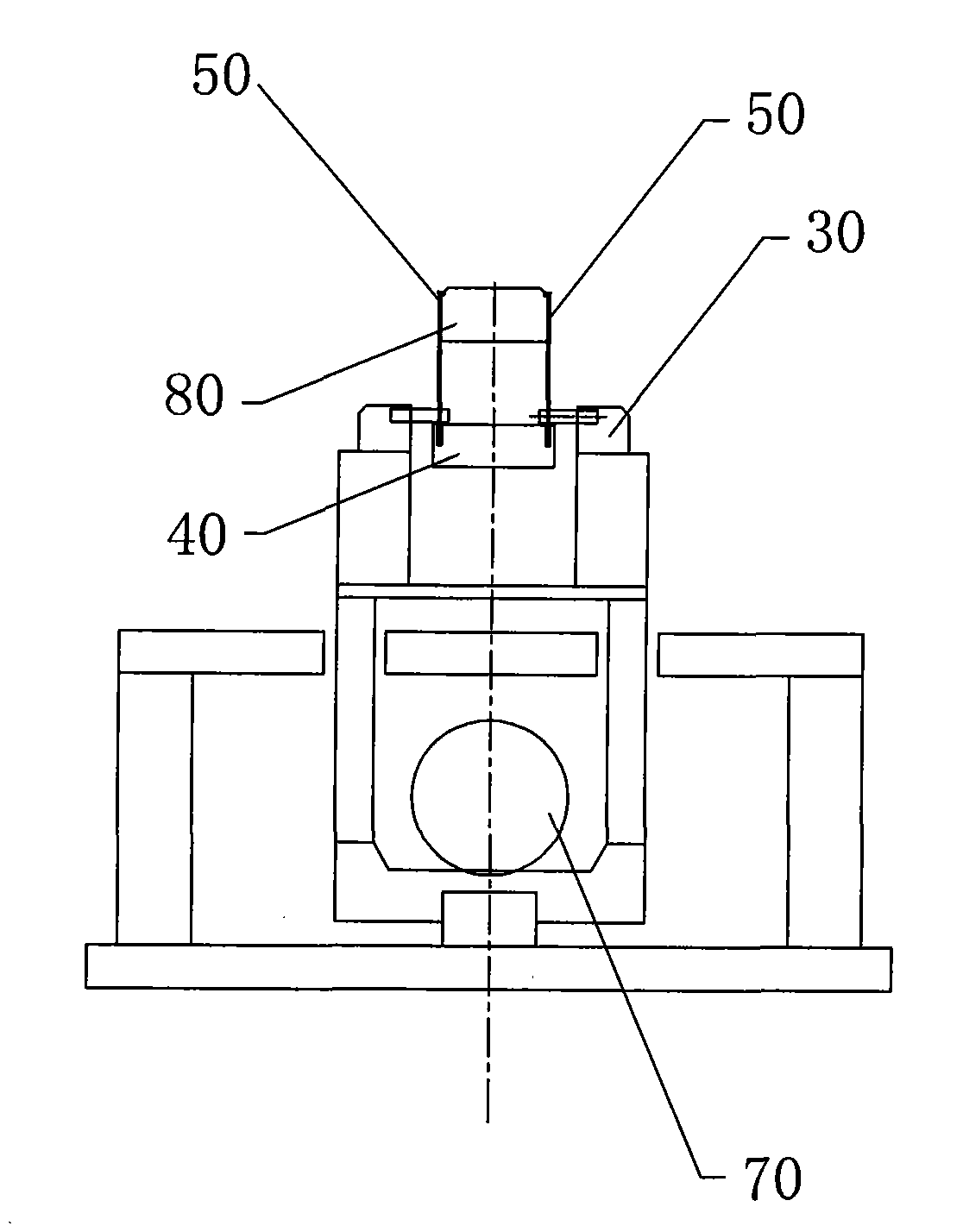

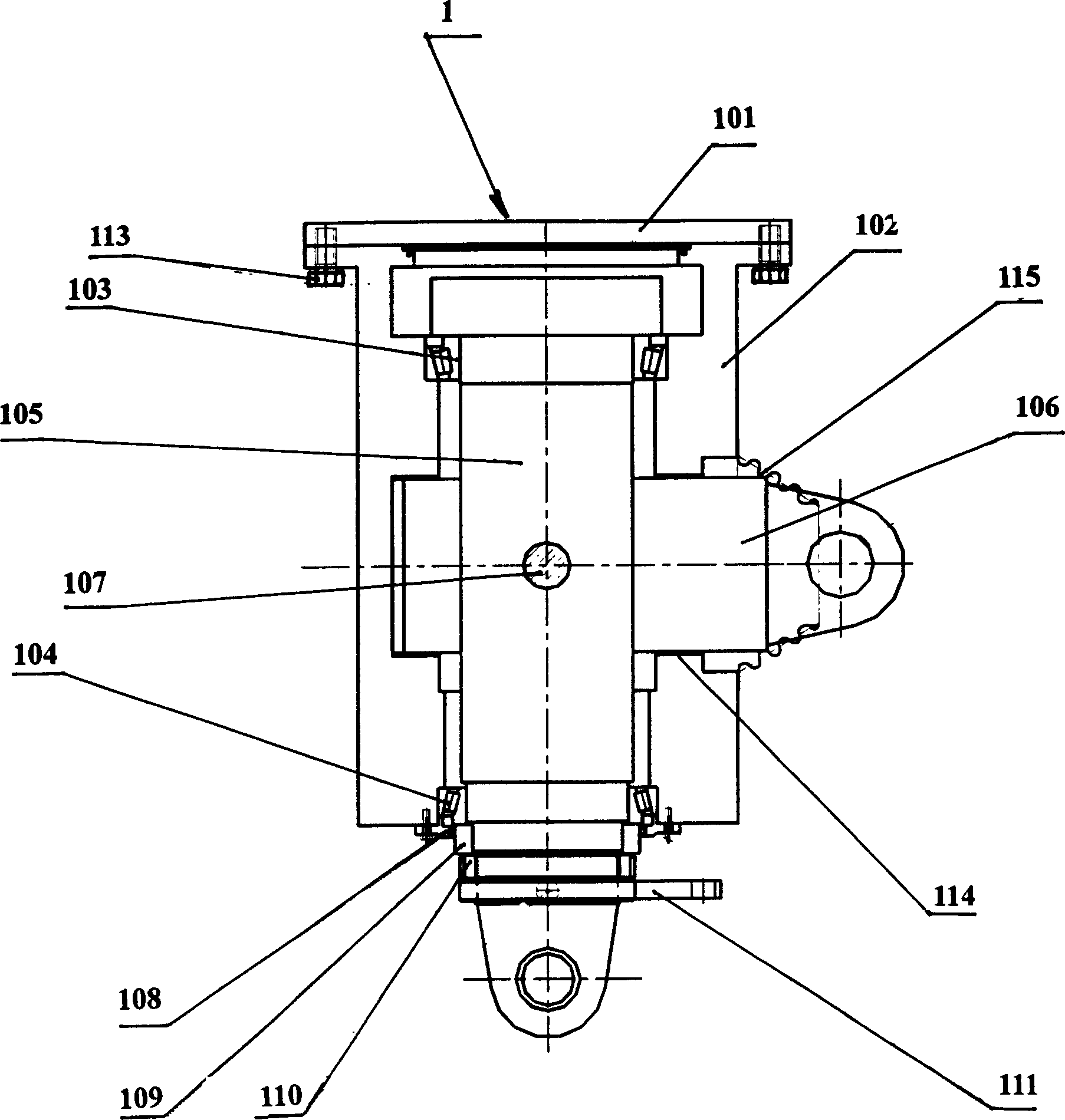

Variable structure adaptive feed type rope saw

InactiveCN102229009ALarge diameter rangeGuaranteed tensionMetal sawing devicesHydraulic cylinderControl system

The invention mainly aims to provide a variable structure adaptive feed type rope saw for cutting composite pipes with different diameters amphibiously. The rope saw consists of a clamping mechanism, a cutting mechanism, a feeding mechanism and a tensioning mechanism; the clamping mechanism comprises a V-shaped plate, the V-shaped plate is formed by folding two mutually independent half plates, each half plate is connected with respective sliding block, and the sliding block and a guide rail I form a sliding pair; the two half plates fixed on respective sliding blocks can move relatively in the radial direction along the guide rail I; the half plates are connected with a hydraulic cylinder respectively, and the hydraulic cylinder is connected with a control system; and the lower ends of the half plates are connected with clamping claws through fixing pins, and the rear ends of the clamping claws are connected with the hydraulic cylinder. The rope saw is suitable for the pipes with diameters of phi 300 to phi 1,500 millimeters, so the diameter range of the cut pipes is greatly expanded; and meanwhile, different cutting speeds can be automatically adjusted according to different cutting states to adapt the rope saw, and the cutting efficiency is improved.

Owner:HARBIN ENG UNIV

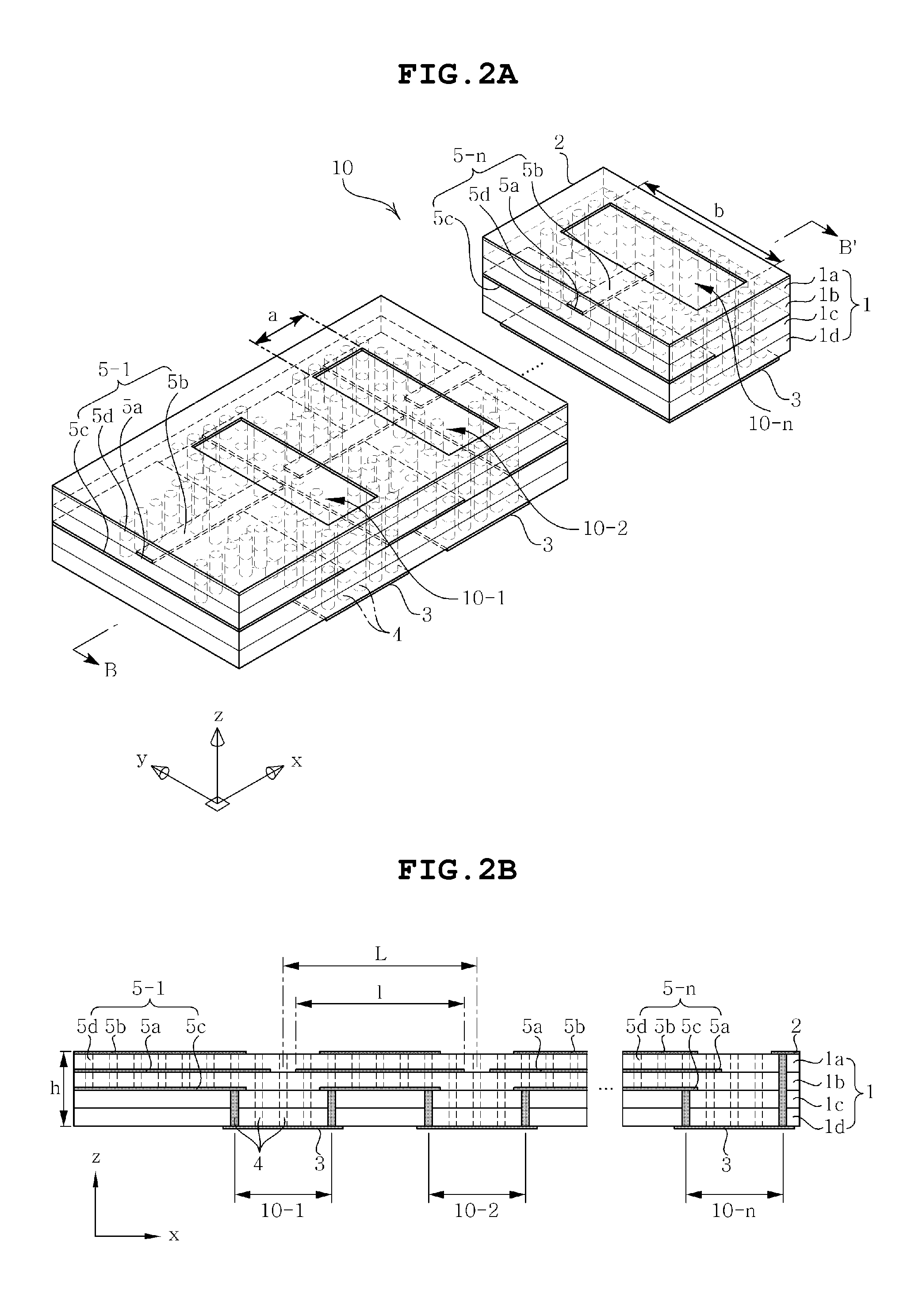

Shredder

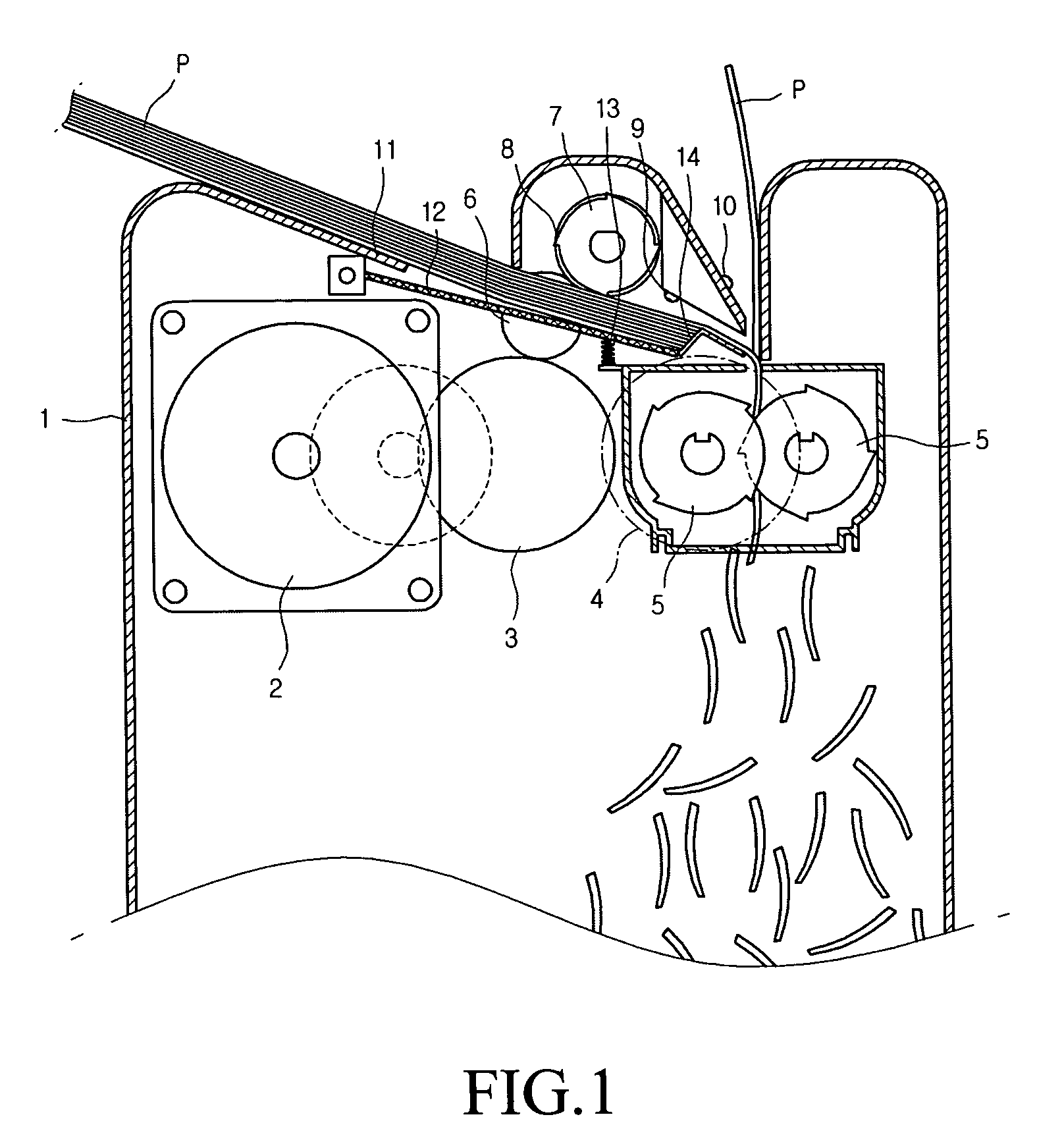

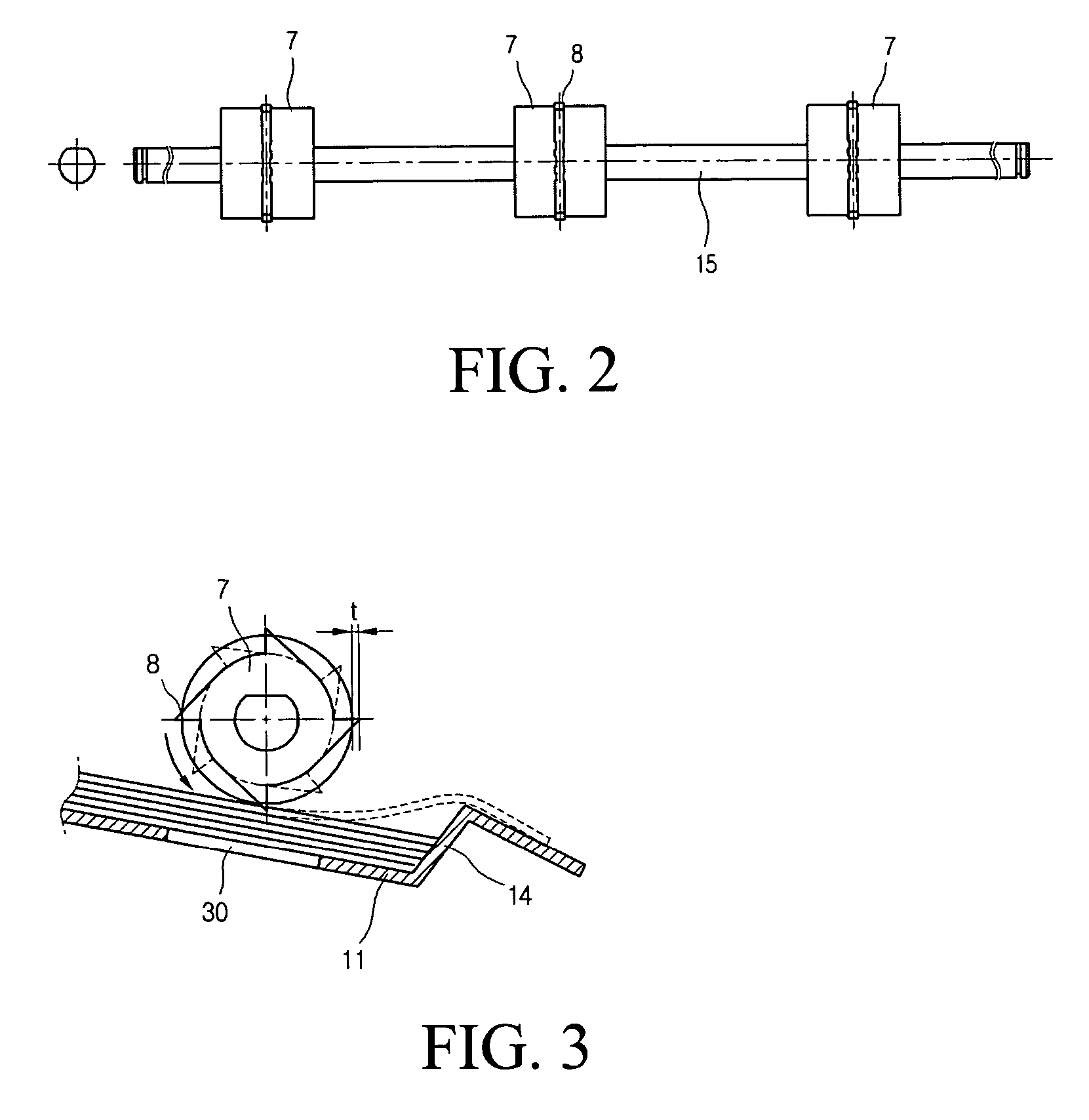

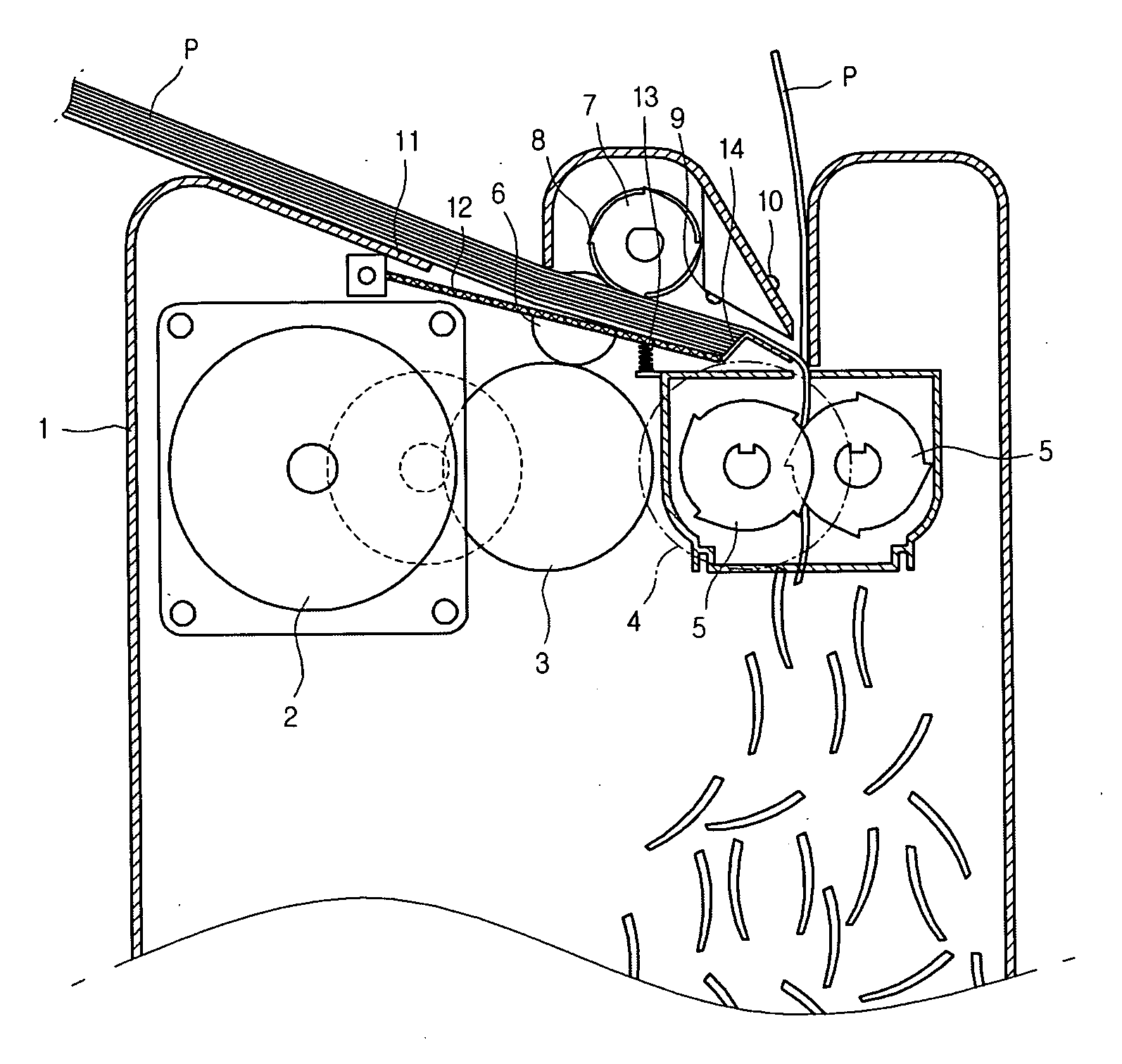

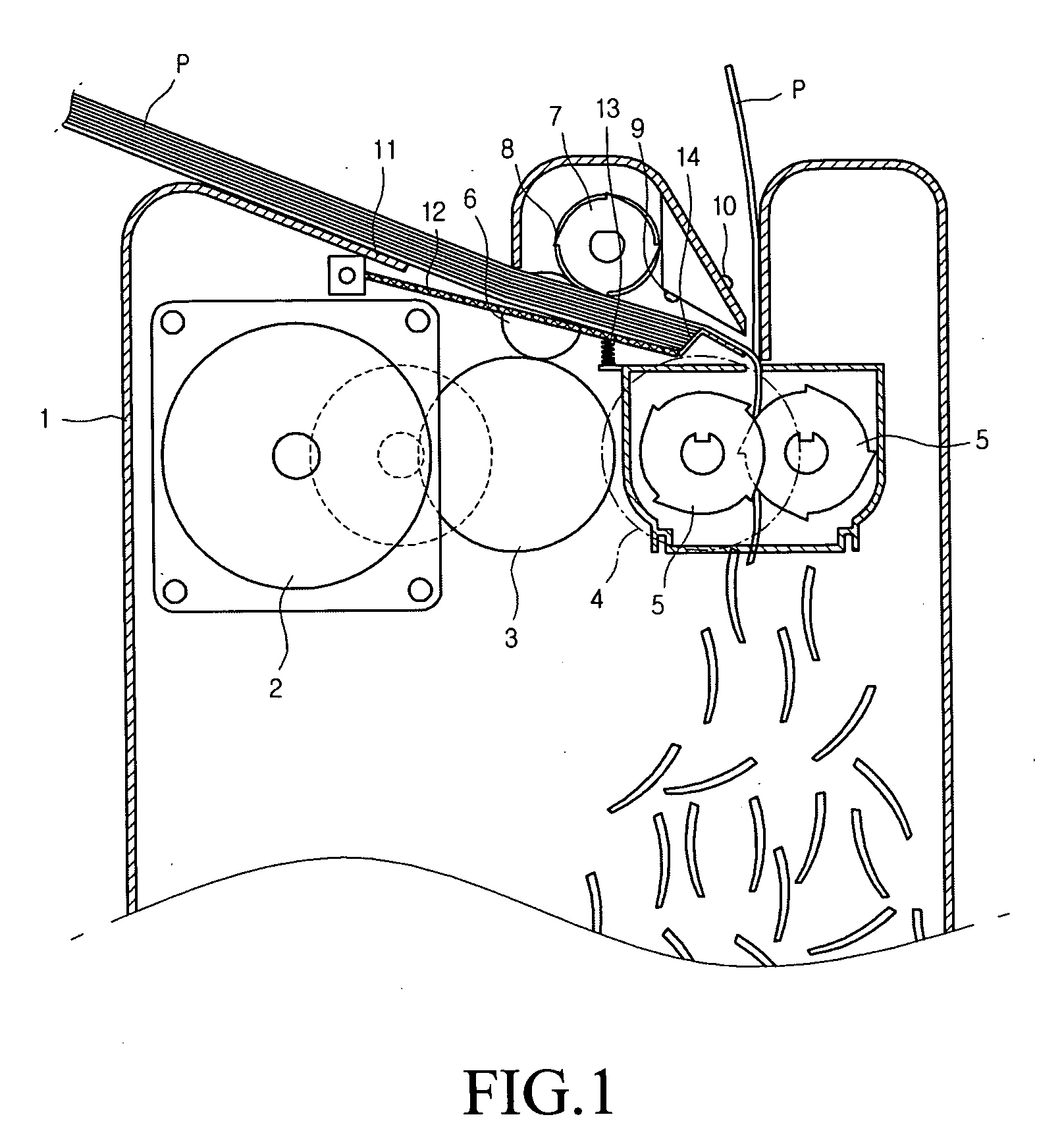

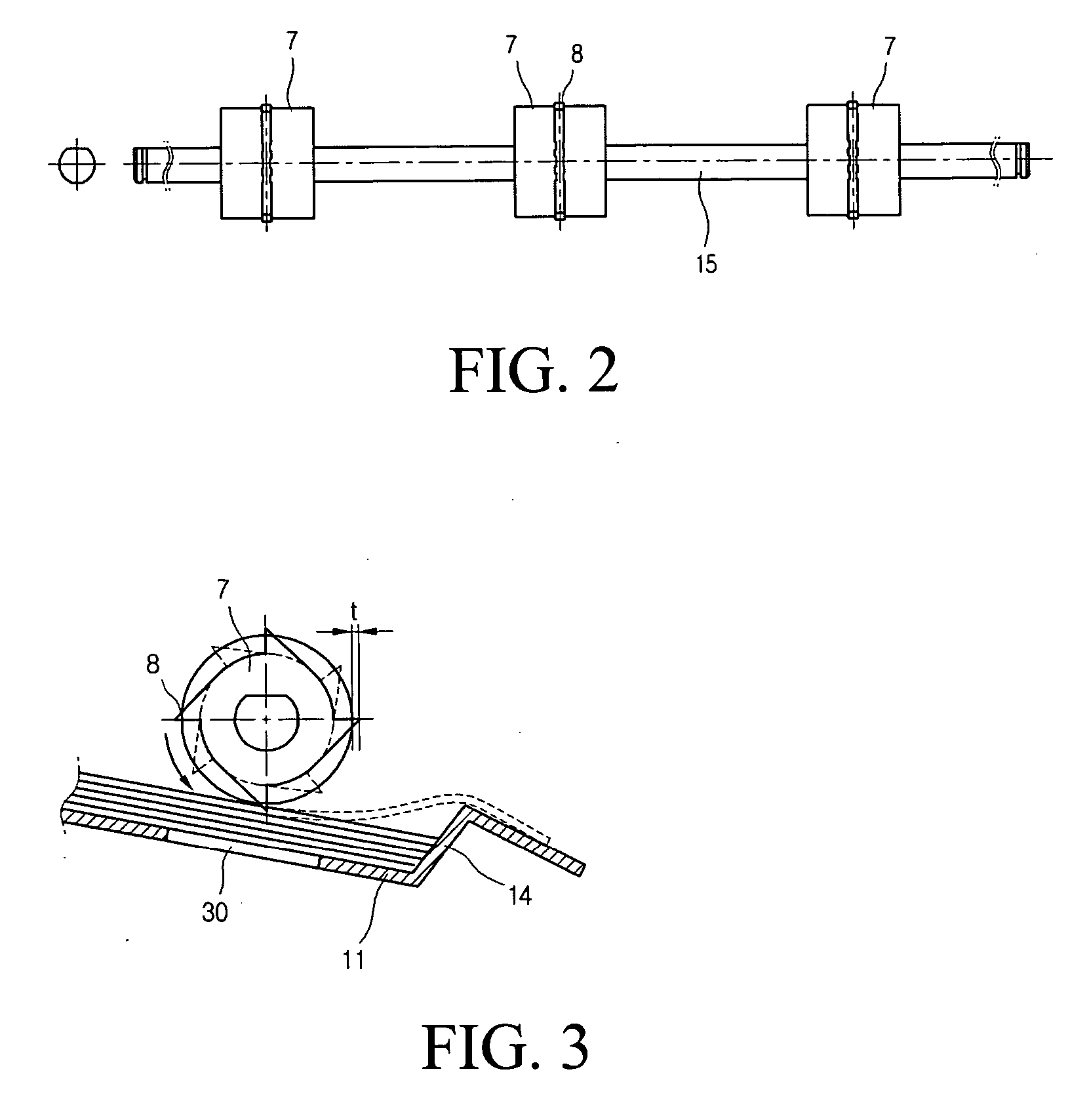

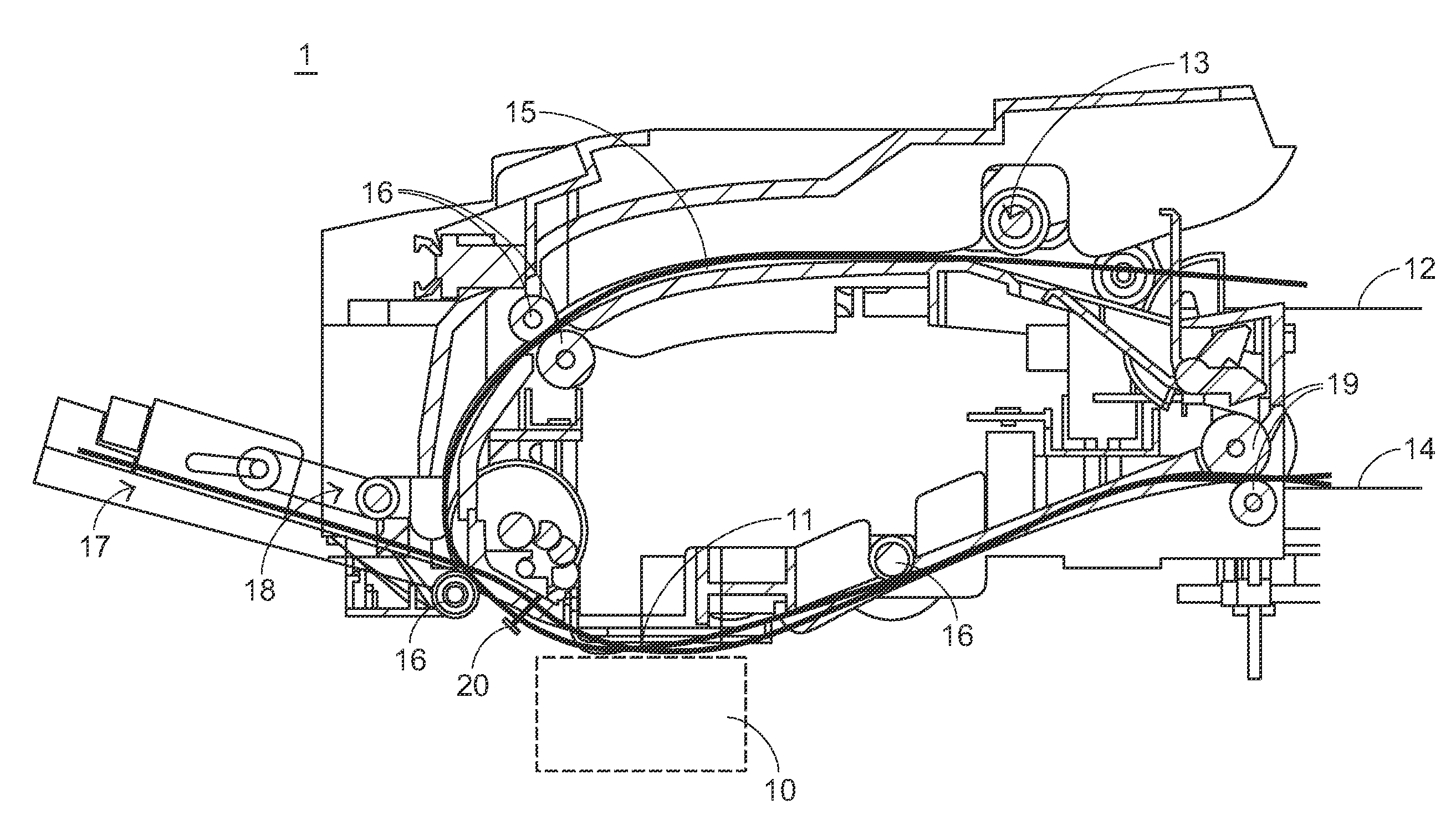

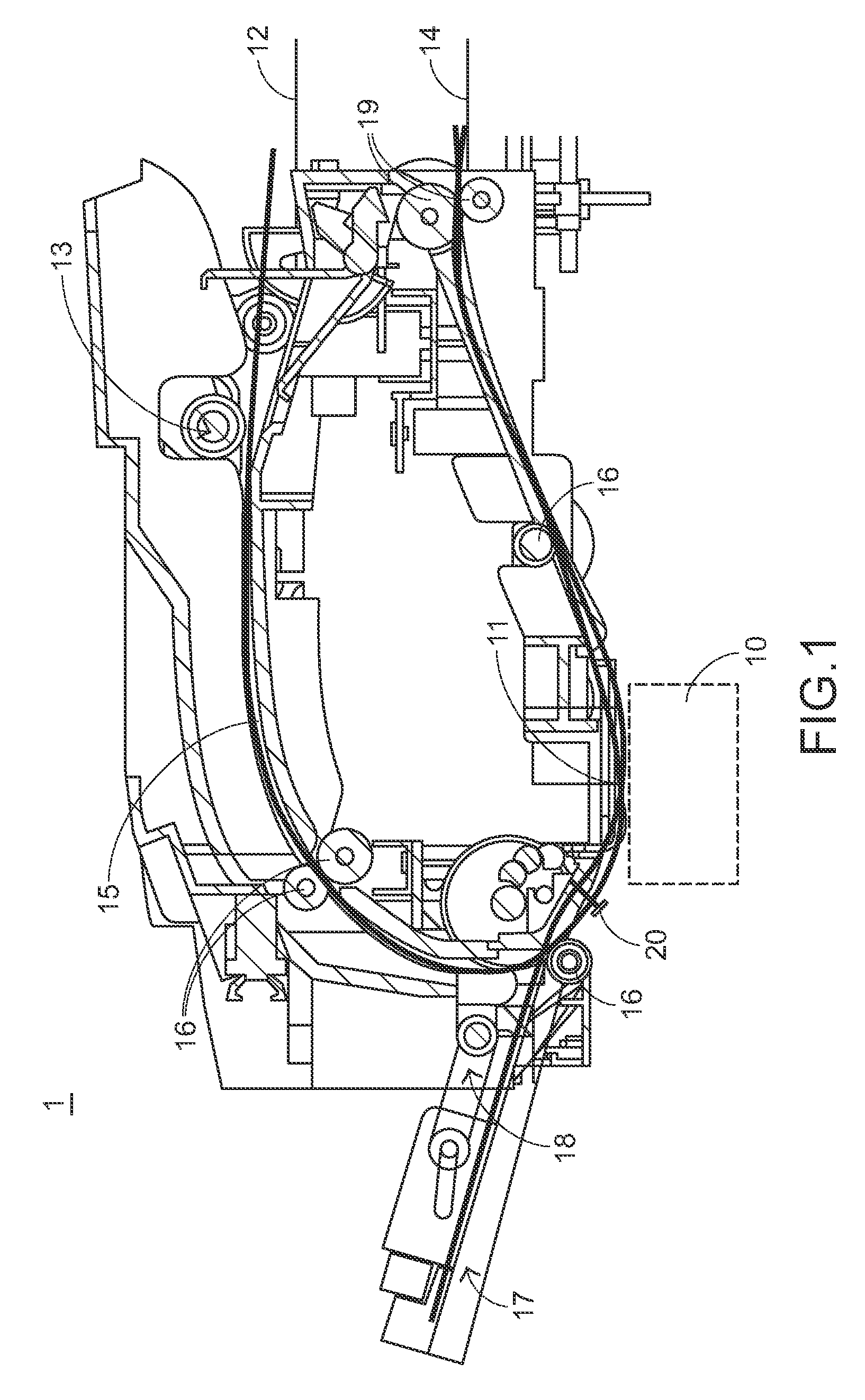

InactiveUS20060179987A1Shorten operation timeReduce overloadCocoaGrain treatmentsElectric machineryEngineering

A shredder is provided for allowing a user to select a desired feed type from a manual paper feeding type and an automatic paper feeding type. An embodiment of the shredder includes a driving motor; a connection part transmitting a dynamic force of the driving motor; a cutter shredding paper sheets inputted by a dynamic force transmitted from the connection part; a manual paper feeding part manually supplying paper sheets to the cutter; and an automatic paper feeding part automatically supplying paper sheets to the cutter by the dynamic force provided from the connection part.

Owner:ROYAL SOVEREIGN QINGDAO

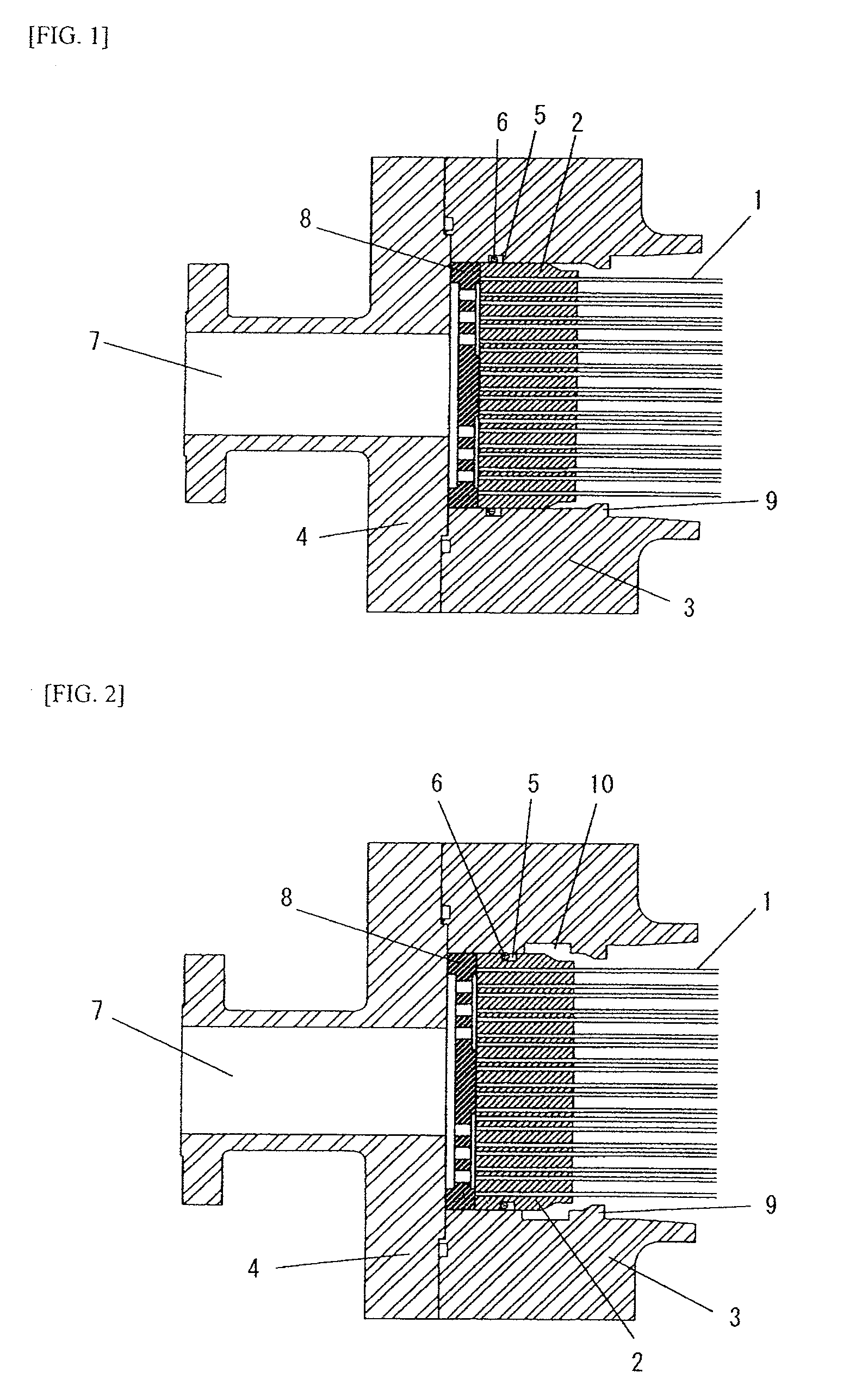

Shell feed type gas separation membrane module

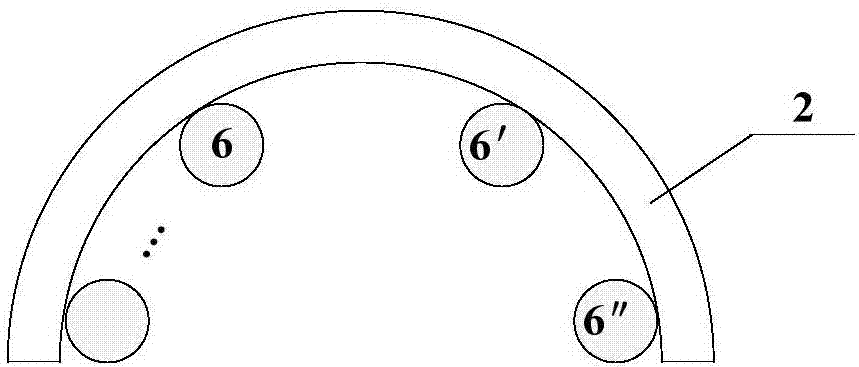

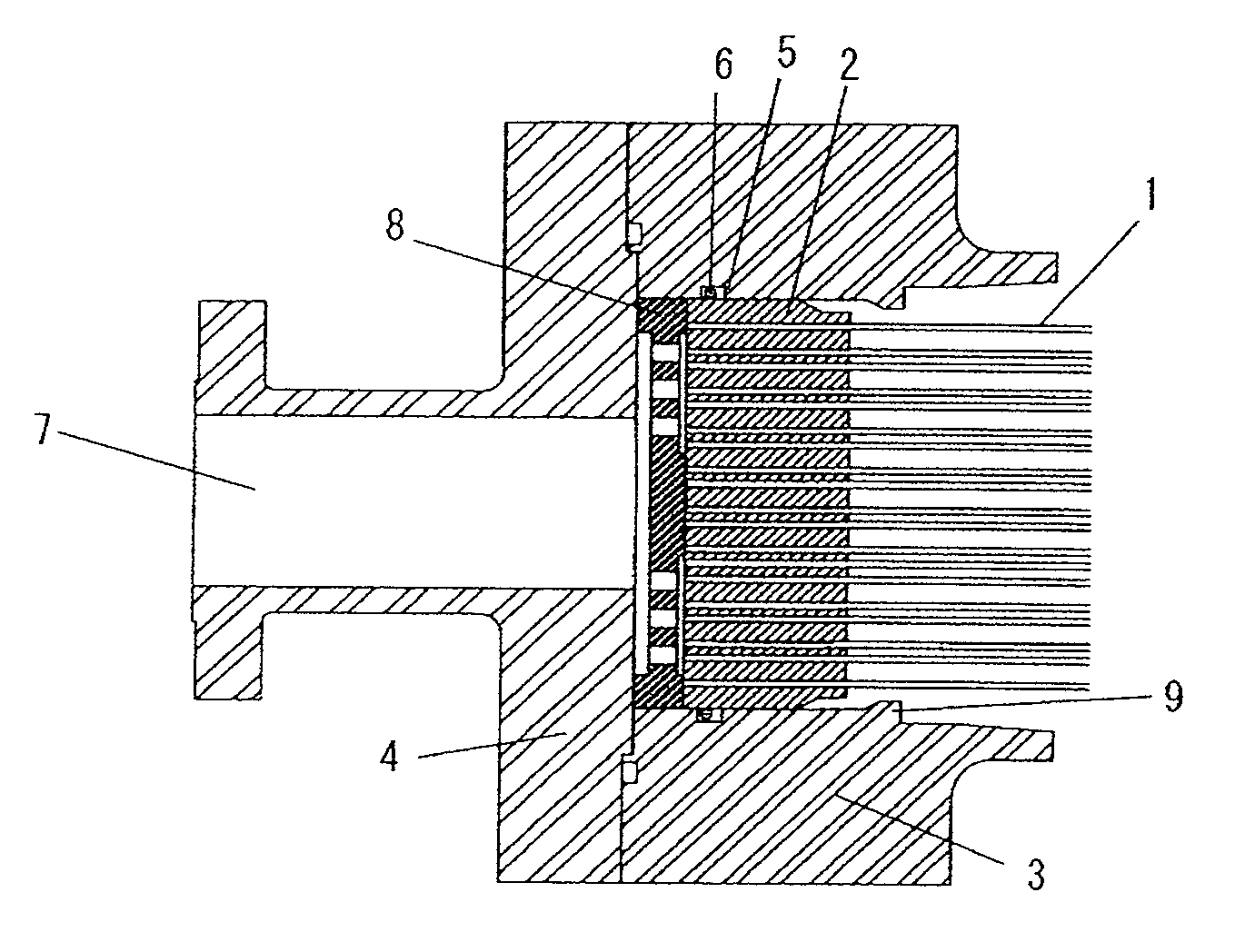

InactiveUS20100326278A1Reduce riskSimple structureMembranesSemi-permeable membranesHollow fibreFiber bundle

A gas separation membrane module has a vessel housing a hollow fiber element including a hollow fiber bundle consisting of a number of hollow fiber membranes (1) and a tube sheet (2) holding one end of the hollow fiber bundle. The interior of the vessel is partitioned by the tube sheet (2) into two spaces consisting of a raw gas chamber and a permeate gas chamber. A high-pressure mixed gas is fed into the raw gas chamber where gas separation is carried out. The gas separation membrane module has a configuration where during operation, the tube sheet (2) is supported by means of a perforated plate (8) in the vessel by a pressure from the mixed gas fed to maintain airtightness between the two spaces and when the tube sheet (2) receives a pressure in the reverse direction to that applied during the operation of the gas separation membrane module, the tube sheet (2) is forced to move within the vessel by the pressure in the reverse direction, thereby losing airtightness between the two spaces.

Owner:UBE IND LTD

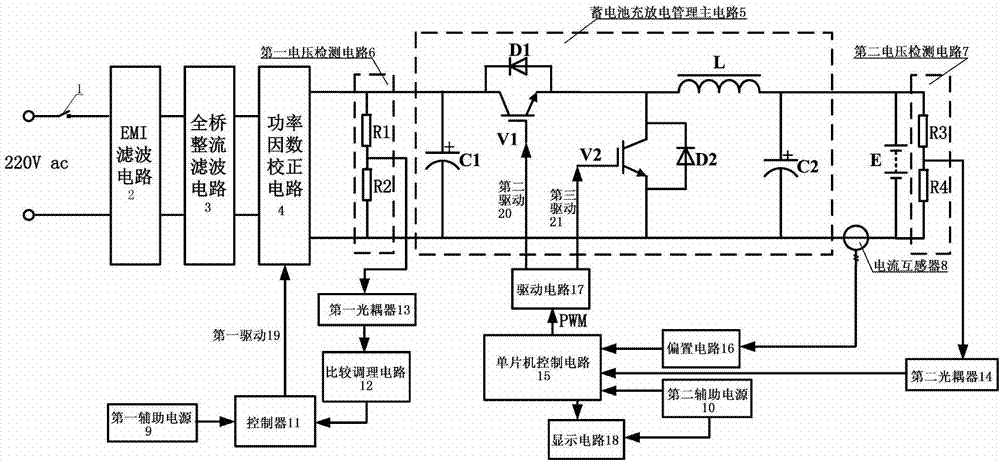

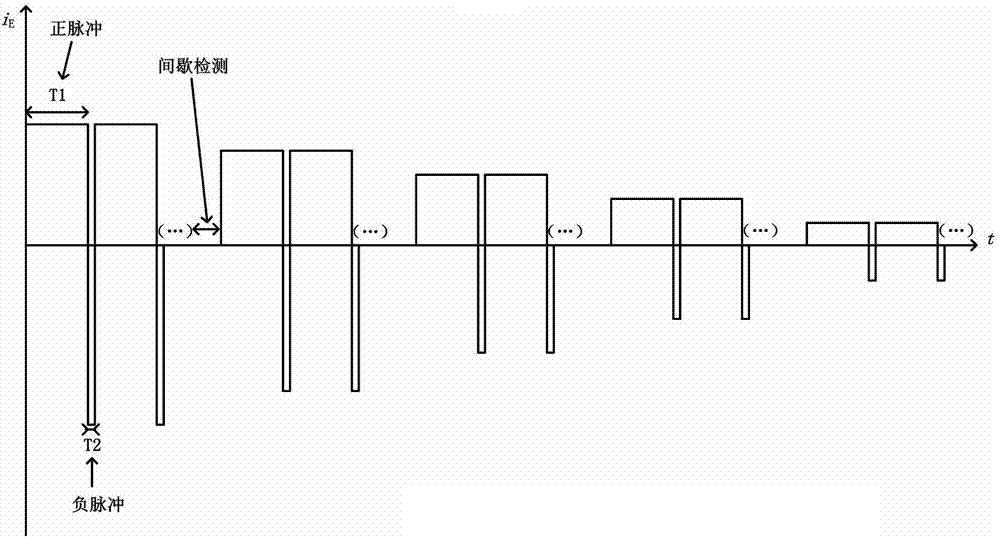

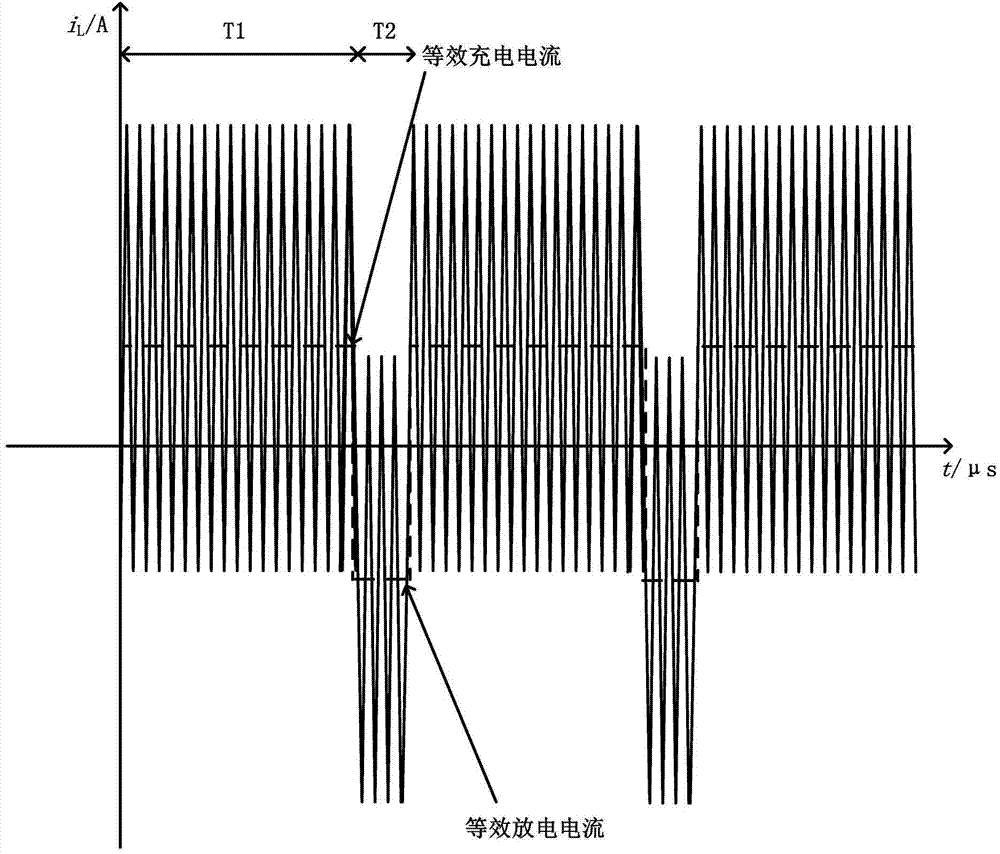

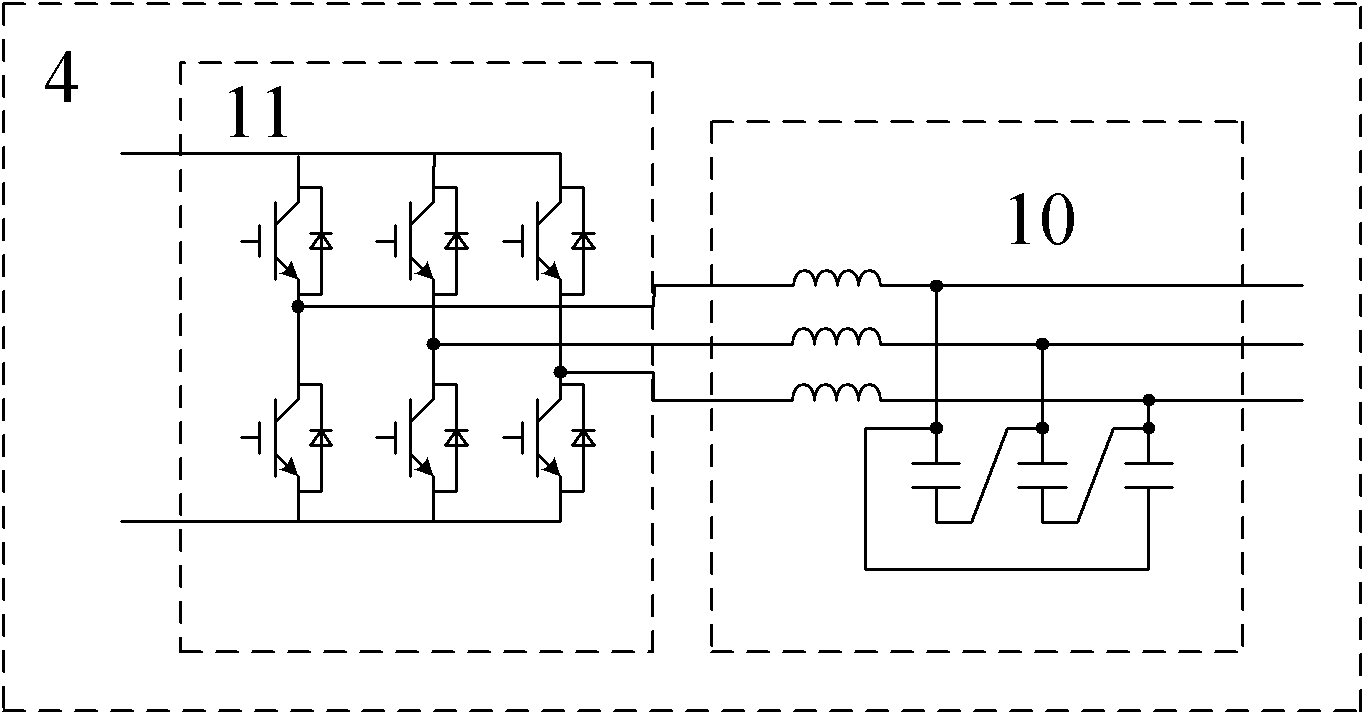

Energy feed type variable-constant-current and positive-negative-pulse fast charging device and method

ActiveCN104753146AReduce shockExtended service lifeBatteries circuit arrangementsSecondary cells charging/dischargingFull bridgeFast charging

The invention belongs to the technical field of electricity, relates to charging equipment and method, in particular to an energy feed type variable-constant-current and positive-negative-pulse fast charging device and method. The fast charging device is characterized in that alternating currents sequentially pass an air switch, an EMI filter circuit, a full-bridge rectifying and filter circuit and power factor correction circuit, the power factor correction circuit is respectively connected with a controller and a first voltage detecting circuit, the controller is respectively connected with a comparison and conditioning circuit and a first auxiliary power supply, a storage battery charging and discharging management main circuit is respectively connected with the first voltage detecting circuit and a second voltage detecting circuit, a current transformer is respectively connected with an output filter capacitor, the storage battery and a bias circuit, a second optical coupler is respectively connected with the second voltage detecting circuit and a single-chip microcomputer control circuit, the single-chip microcomputer control circuit is respectively connected with a second auxiliary power supply, a display circuit, a drive circuit and the bias circuit, and the display circuit is connected with the second auxiliary power supply. The energy feed type variable-constant-current and positive-negative-pulse fast charging device is simple in structure, convenient to operate, short in charging time and high in electric energy utilization rate.

Owner:青岛艾迪森科技股份有限公司

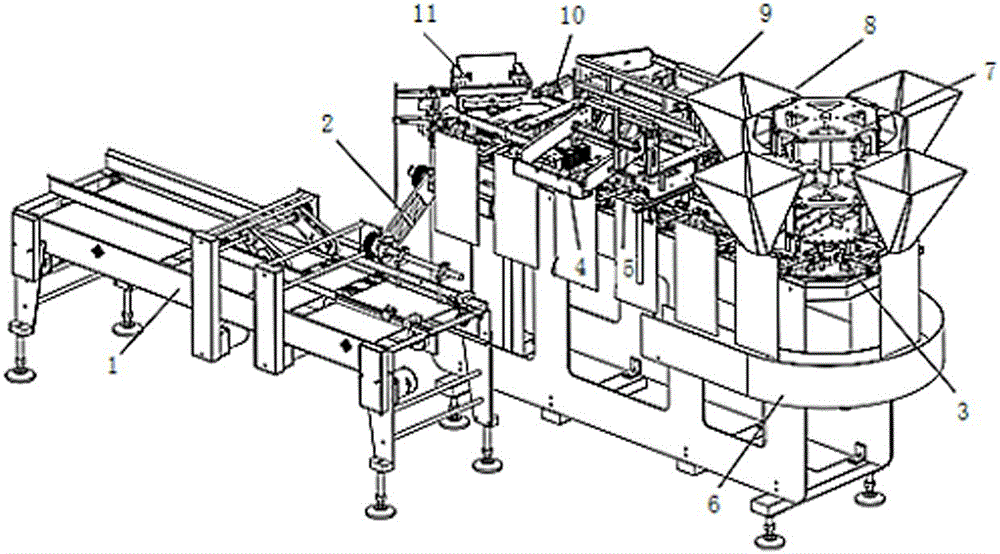

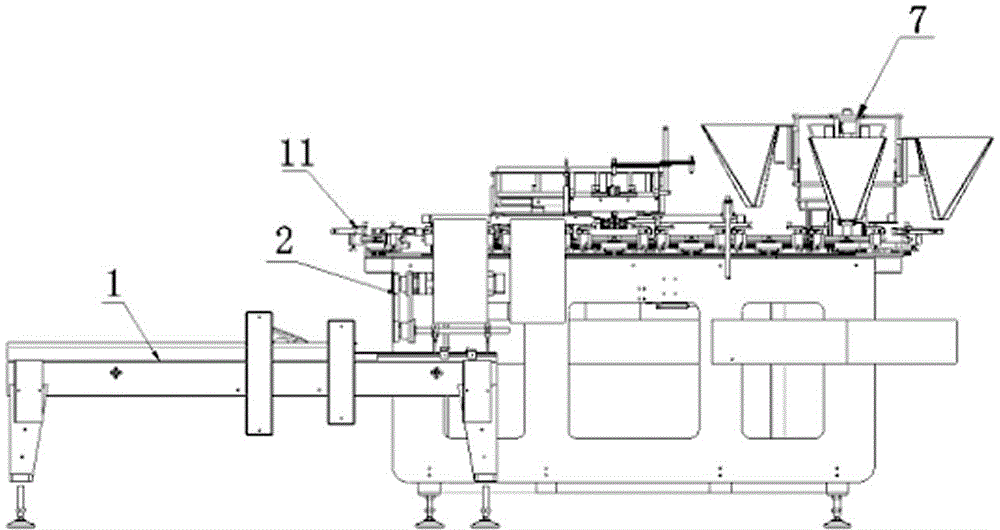

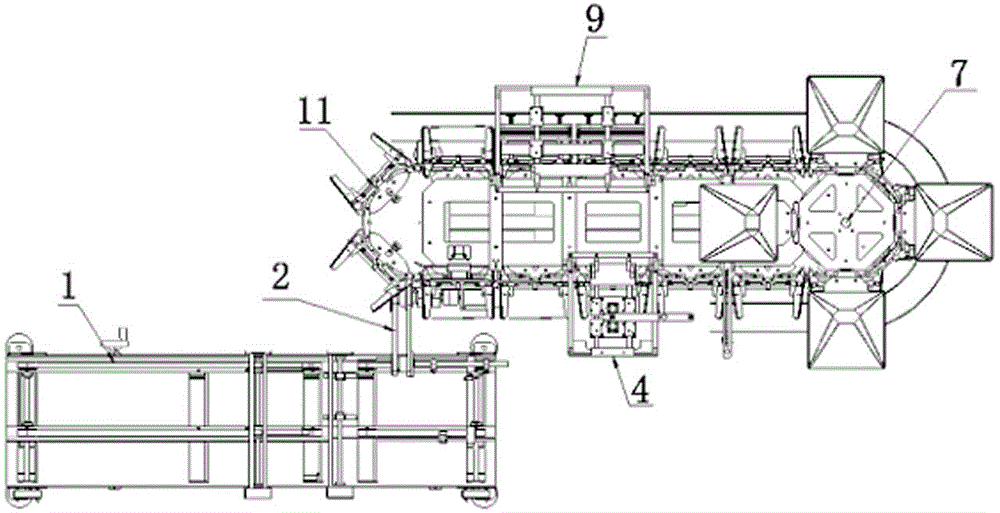

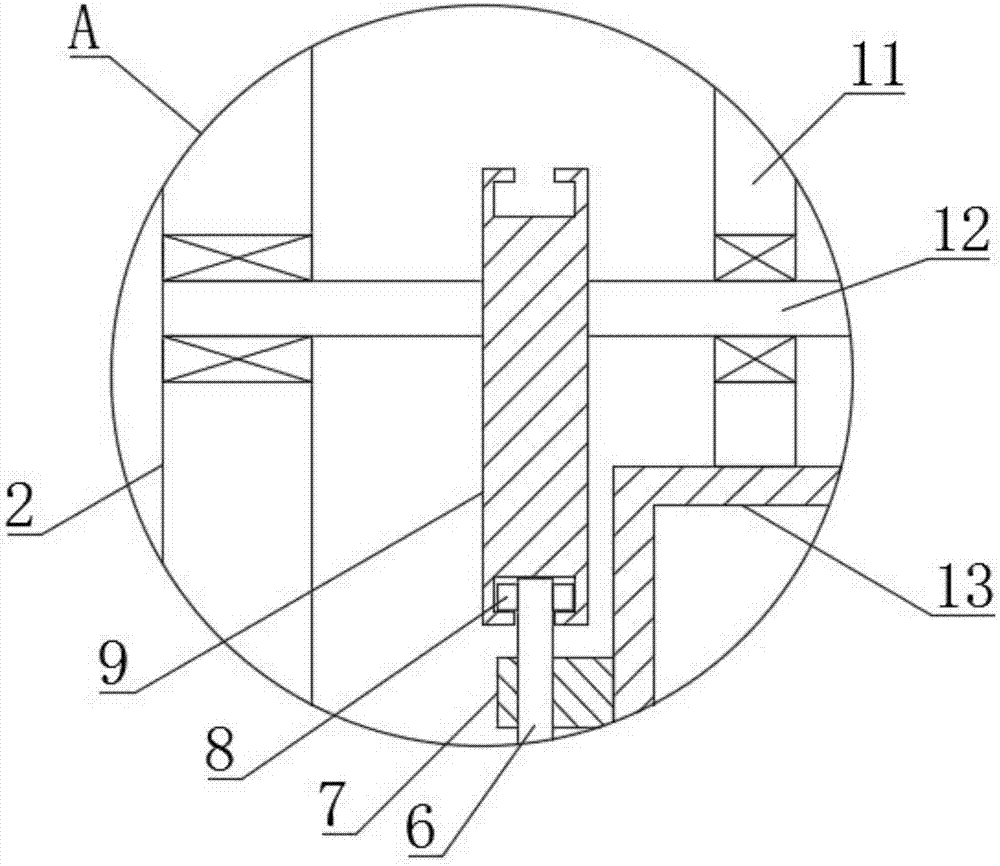

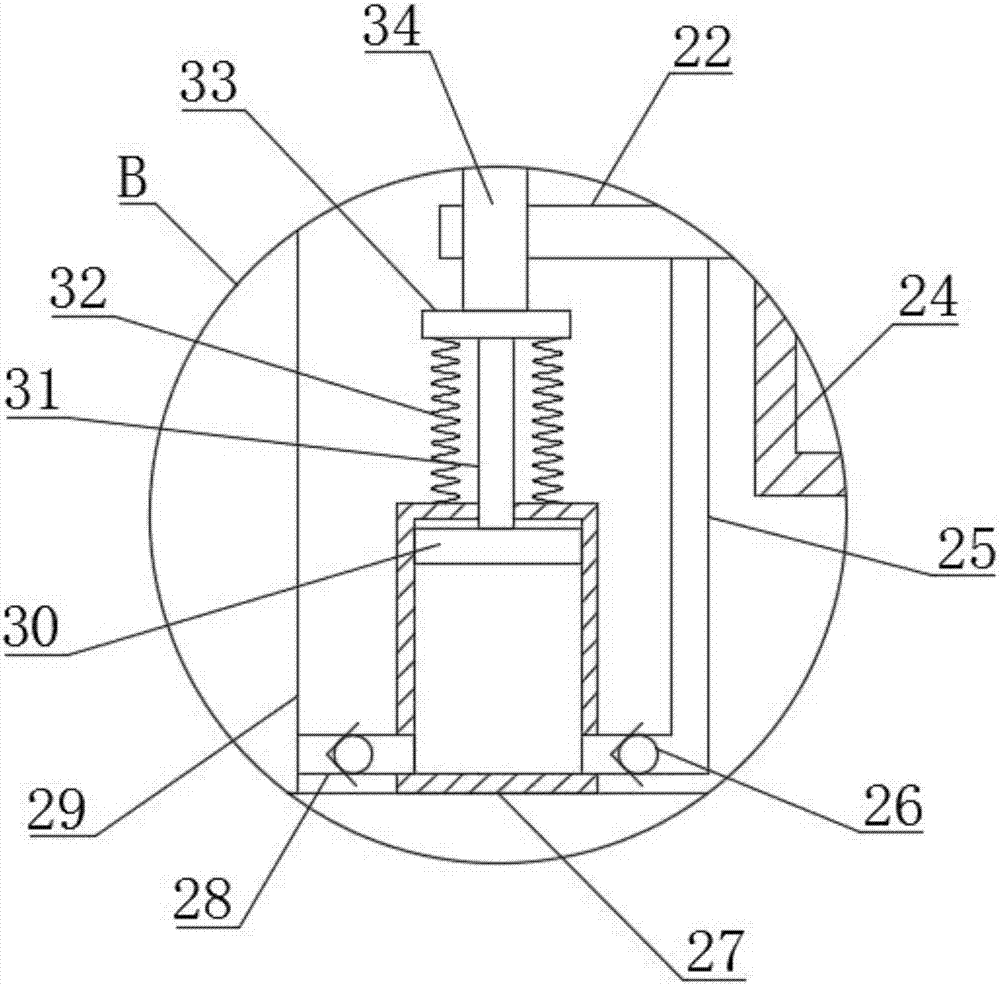

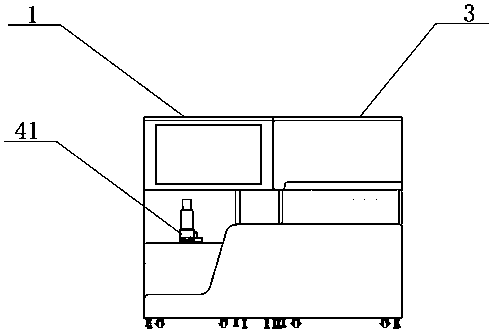

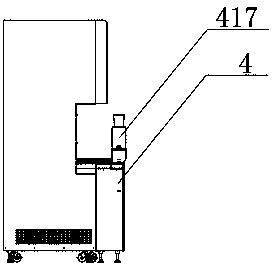

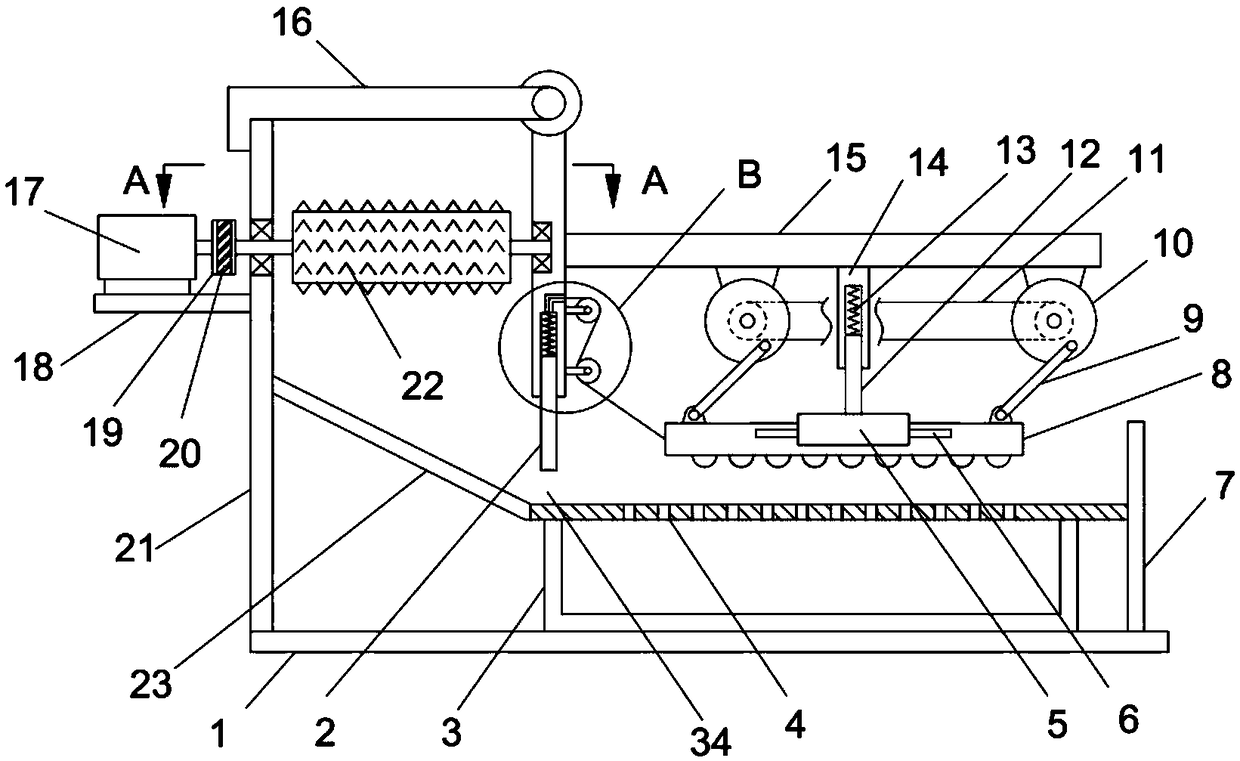

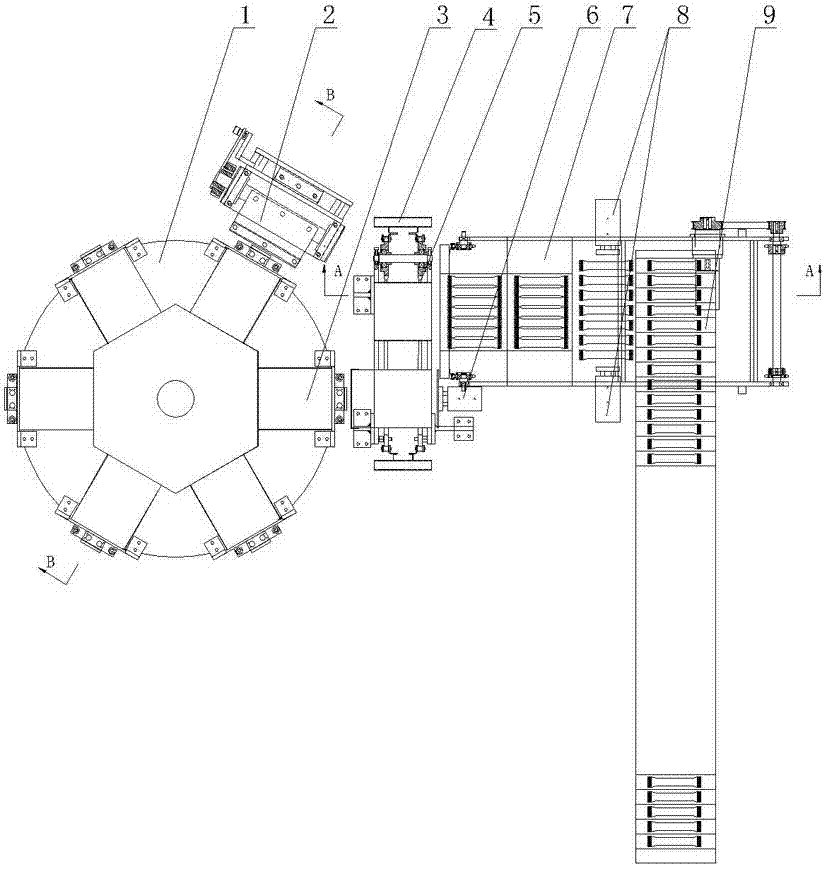

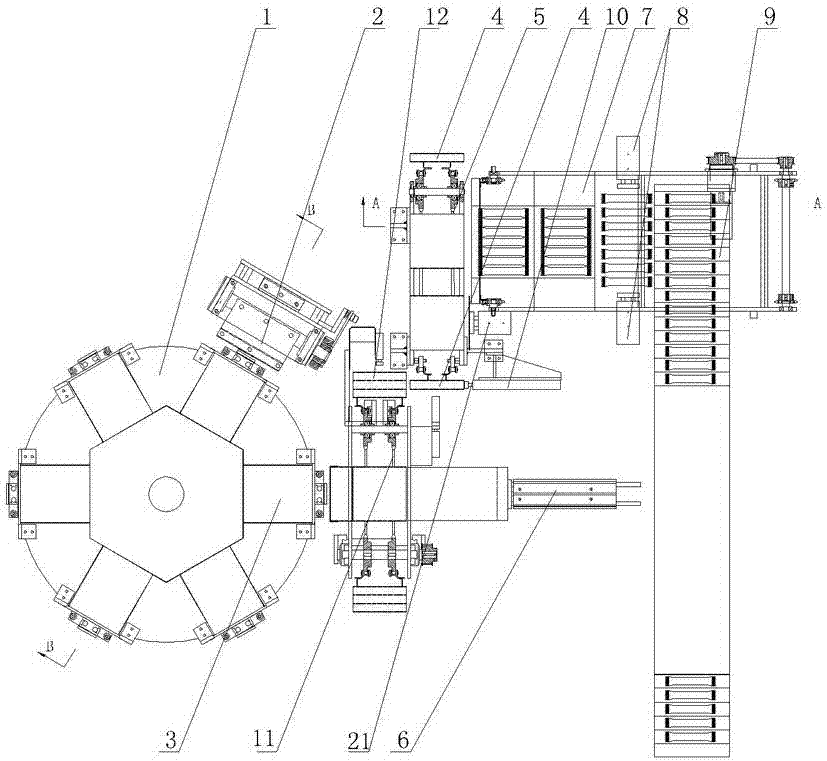

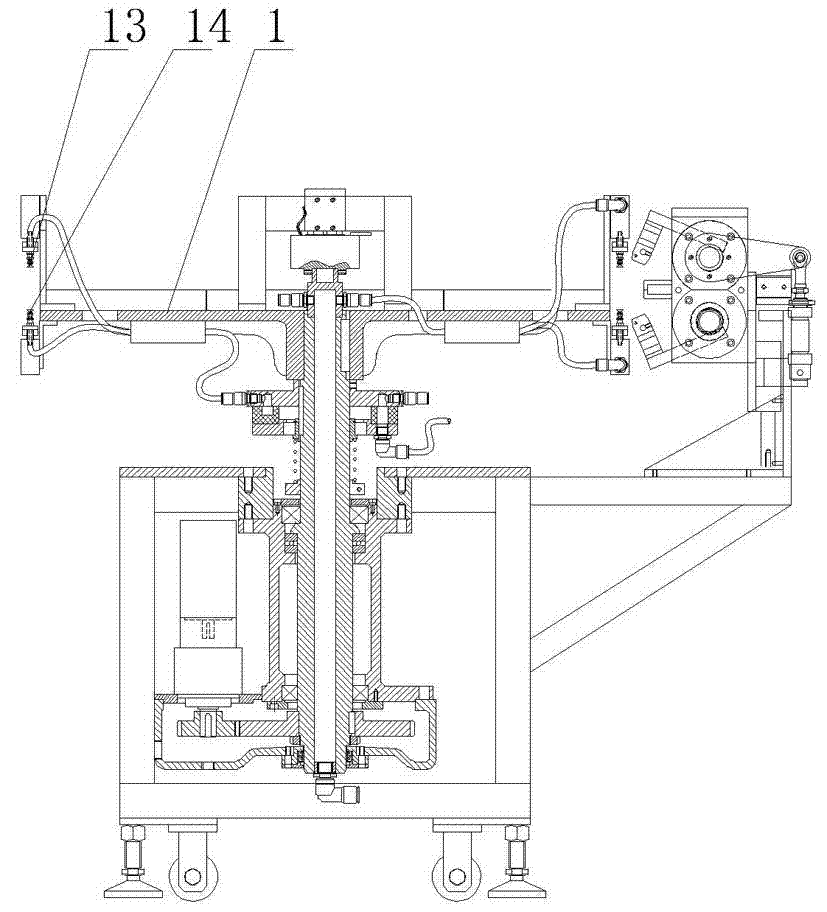

Full-automatic prefabricated bag feed type packing machine

InactiveCN104627394ALarge package sizeLarge packing capacityWrapper twisting/gatheringPackaging automatic controlOutput deviceMechanical engineering

The invention discloses a full-automatic prefabricated bag feed type packing machine which comprises a bag conveying and releasing device, a bag taking device, a rotary driving device, a bag opening device, an air blowing device, an auxiliary conveying belt, a discharge device, a finished product detecting device, an upper sealing device and a finished product output device. The bag taking device is located above the right end of the bag conveying and releasing device. The bag taking device is fixedly installed below the left end of the rotary driving device. The rotary driving device drives and is connected with a plurality of clamping devices which are evenly distributed on the rotary driving device. The bag opening device and the upper sealing device are located on the two sides of the middle section of the rotary driving device. The air blowing device is fixedly installed at the upper end of the right side of the bag opening device. The discharge device and the finished product detecting device are located at the right end of the rotary driving device. The finished product detecting device is located on the left side of the discharge device. The auxiliary conveying belt is located at the right end of the rotary driving device and located below the discharge device. The finished product output device is located at the left end of the rotary driving device. The full-automatic prefabricated bag feed type packing machine is larger in packing size and higher in packing capacity.

Owner:SHANGHAI GOFLYING PACKING MACHINERY MFGCO LTD

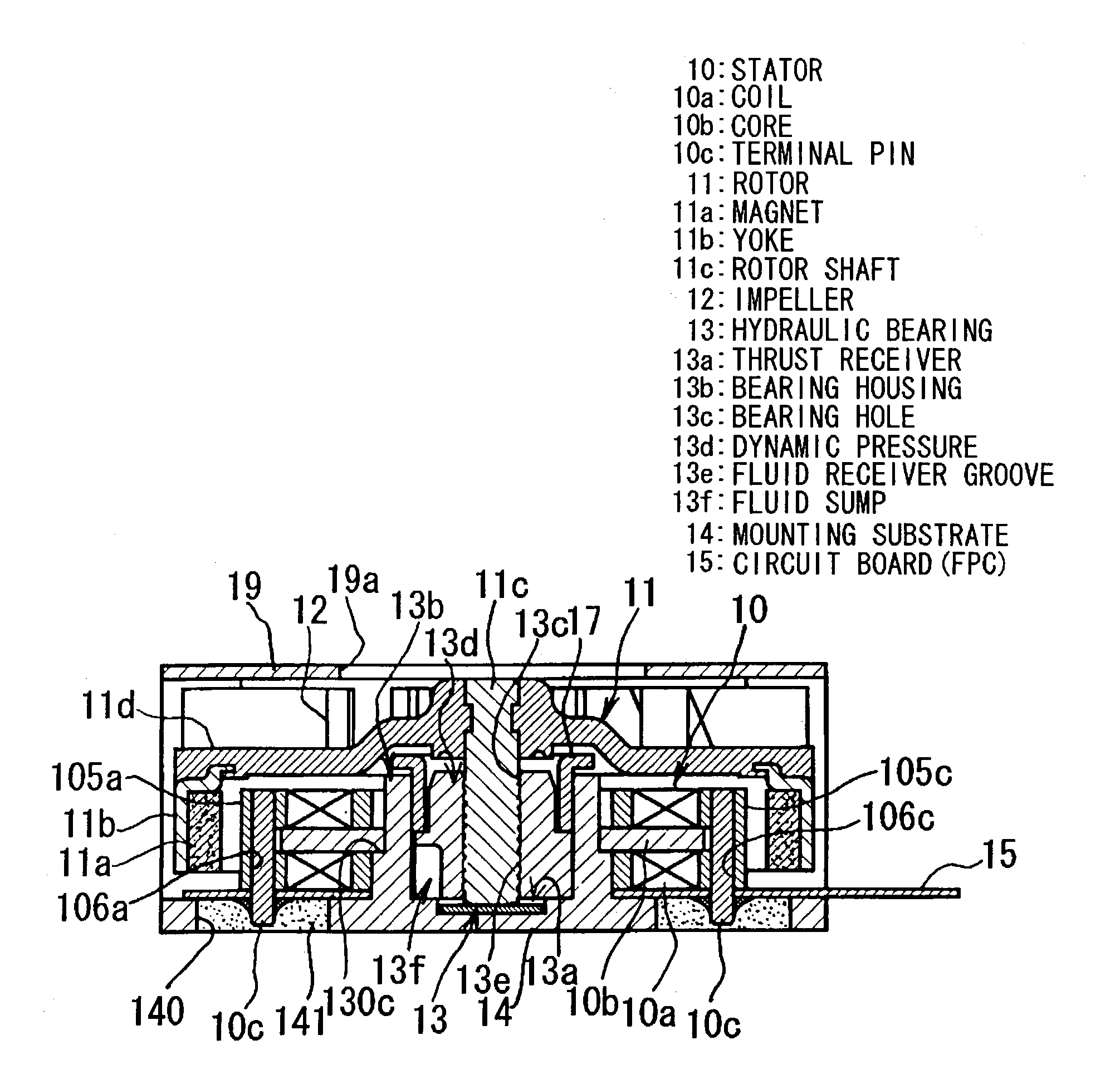

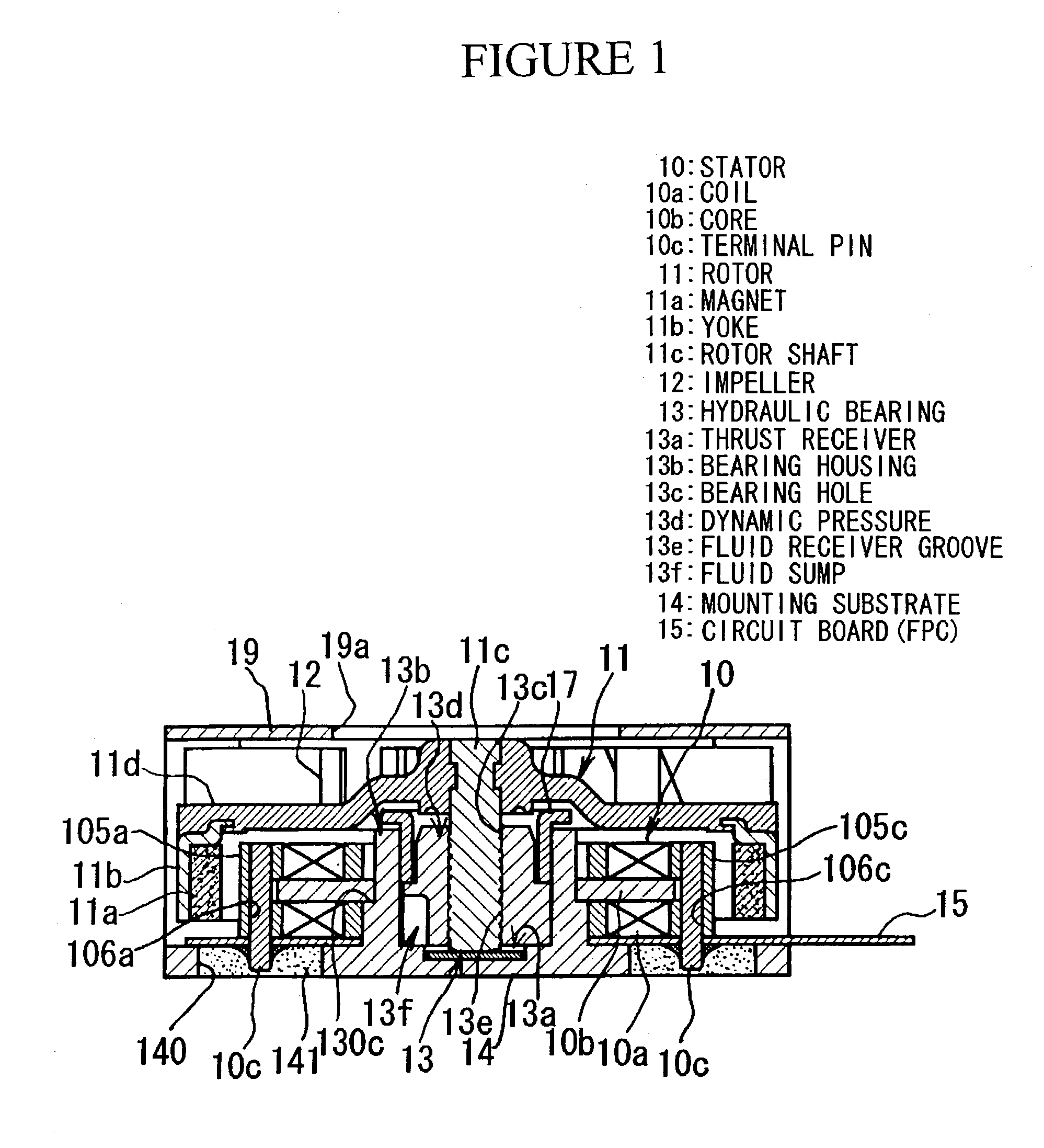

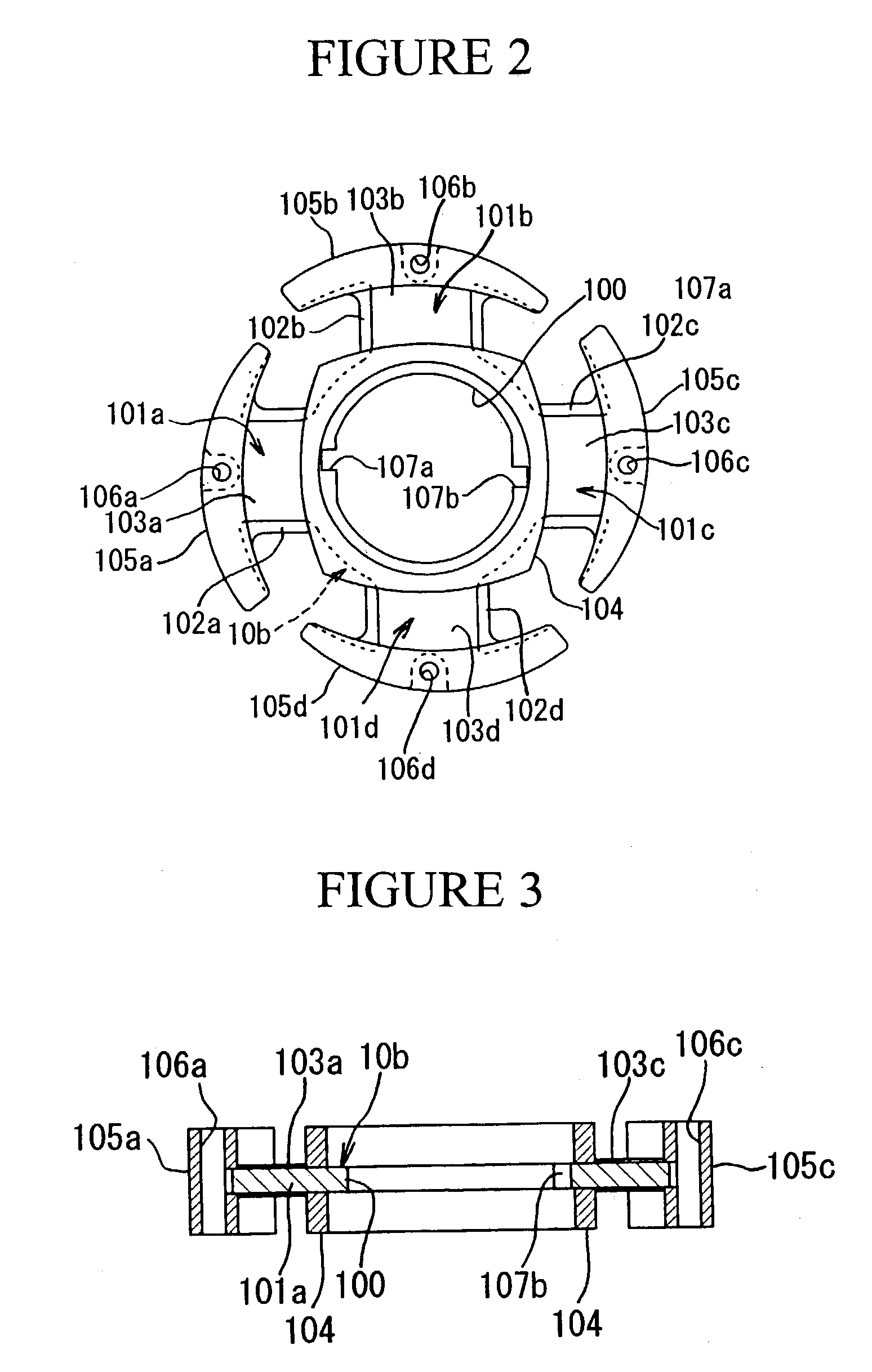

Fluid dynamic pressure bearing for small flat motor, small flat motor, fan motor, and forced air feed type air cell

This invention has a stator 10 having a coil 10a wound on a core 10b, a rotor 11 having a yoke 11b that holds a magnet 11a facing the core 10a, in which an impeller 12 is attached to the rotor 10 that is supported by a hydraulic bearing 13 having a fluid sump 13f that communicates with the thrust receiver 13a of a bearing housing 13b and a fluid receiver groove 13c, and that is formed around the outer periphery of a hydraulic sleeve 13d fitted within the inner cylinder of the bearing housing 13b.

Owner:NAMIKI PRECISION JEWEL CO LTD

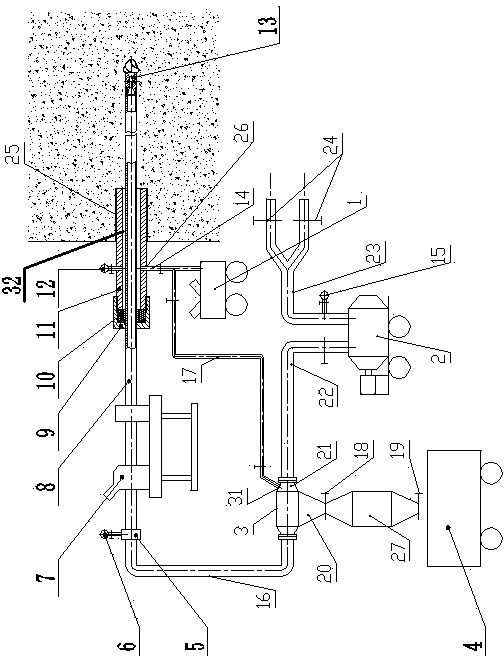

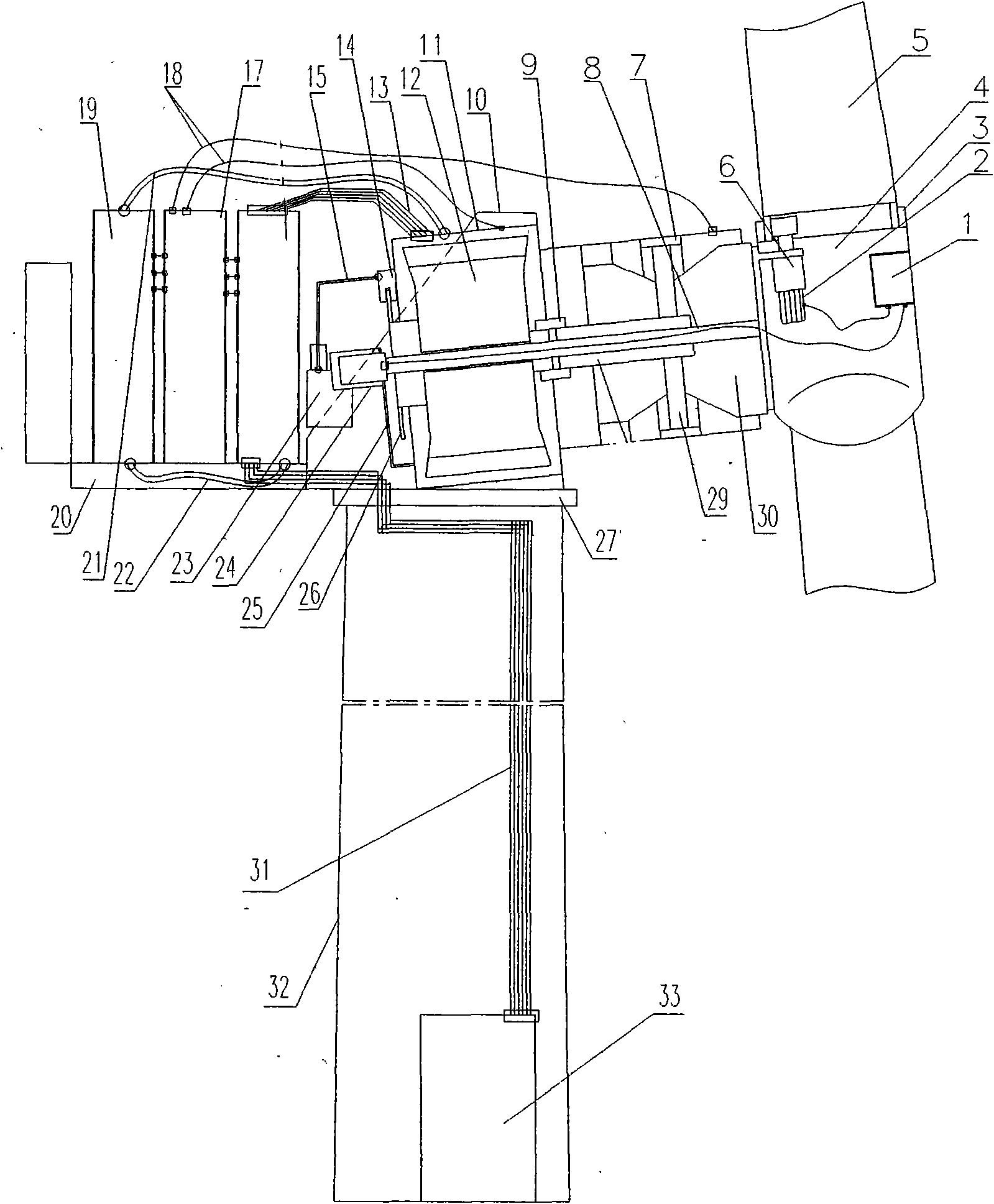

Fully-sealed wind power slagging gas-drainage deep well drilling system and method

The invention discloses a fully-sealed wind power slagging gas-drainage deep well drilling system and method. The fully-sealed wind power slagging gas-drainage deep well drilling system comprises a drilling rod with inner holes, an inverted-spinning smashing dust-collection drill is arranged at the front end of the drilling rod, and the rear portion of the drilling rod is connected to a drilling machine. An orifice-sealed pipe, sealing fillers and a sealed pressing cover are arranged on the drilling rod. An air inlet portion with annular section is formed between the orifice-sealed pipe and the outer wall of the drilling rod, and the air inlet portion is connected with a movable type air compressor through a first connecting pipe. The rear end of the drilling rod is connected with a second connecting pipe through a pneumatic rotary connector, the second connecting pipe is connected with a drainage conveying pipeline slagging device, and the slagging port of the slagging device is connected with a slagging cylinder. The air outlet of the slagging cylinder is connected with a gas drainage pump through a third connecting pipe, and the gas drainage pump is connected with a gas drainage pipe. According to the fully-sealed wind power slagging gas-drainage deep well drilling system and method, pressing feeding type wind force in the outer annular space of the drilling rod and the drainage type wind force of the inner holes of the drilling rod can be utilized to discharge the coal scraps smoothly to carry out solid-gas separation, fully-sealed type wind power scrap discharge is achieved, the fact that hole-drilling operation is conducted continuously and safely is ensured, and working efficiency is improved.

Owner:HENAN POLYTECHNIC UNIV

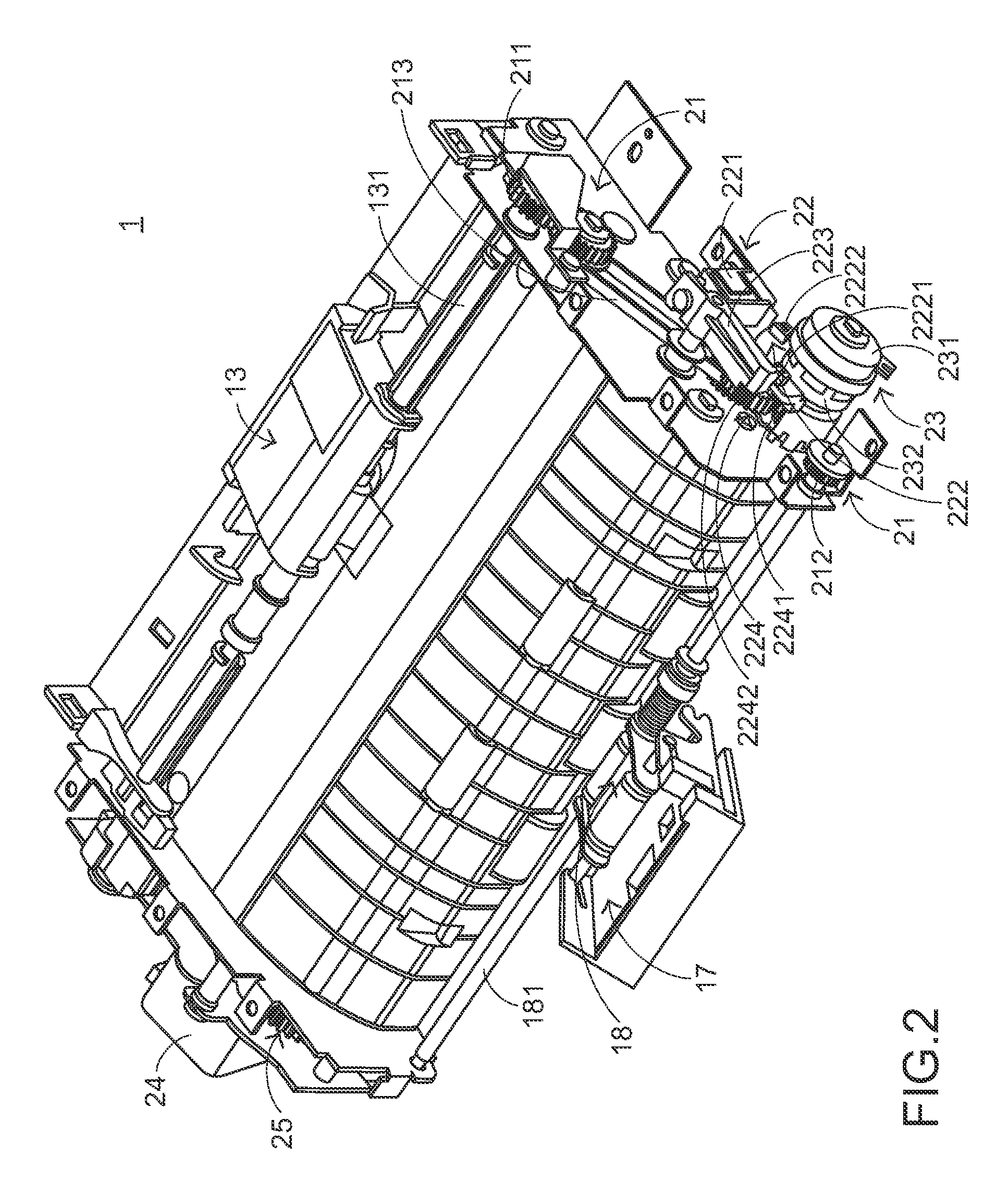

Sheet-feeding type scanning apparatus and automatic sheet feeding method

A sheet-feeding type scanning apparatus and an automatic sheet feeding method are provided. The sheet-feeding type scanning apparatus includes a scanning module, a first sheet input tray, a first sheet pick-up roller assembly, a sheet ejecting tray, a sheet transfer channel, a plurality of transfer roller assemblies, a sheet ejecting roller assembly, a sheet-feeding sensor and a clutch module. Once a first sheet article of multiple sheet articles placed on the first sheet input tray are fed into the internal portion of the sheet-feeding type scanning apparatus to trigger the sheet-feeding sensor, the clutch module is disabled. At this moment, a second sheet article placed on the first sheet input tray fails to be fed by the first sheet pick-up roller assembly. Therefore, the double feeding problem is solved.

Owner:PRIMAX ELECTRONICS LTD

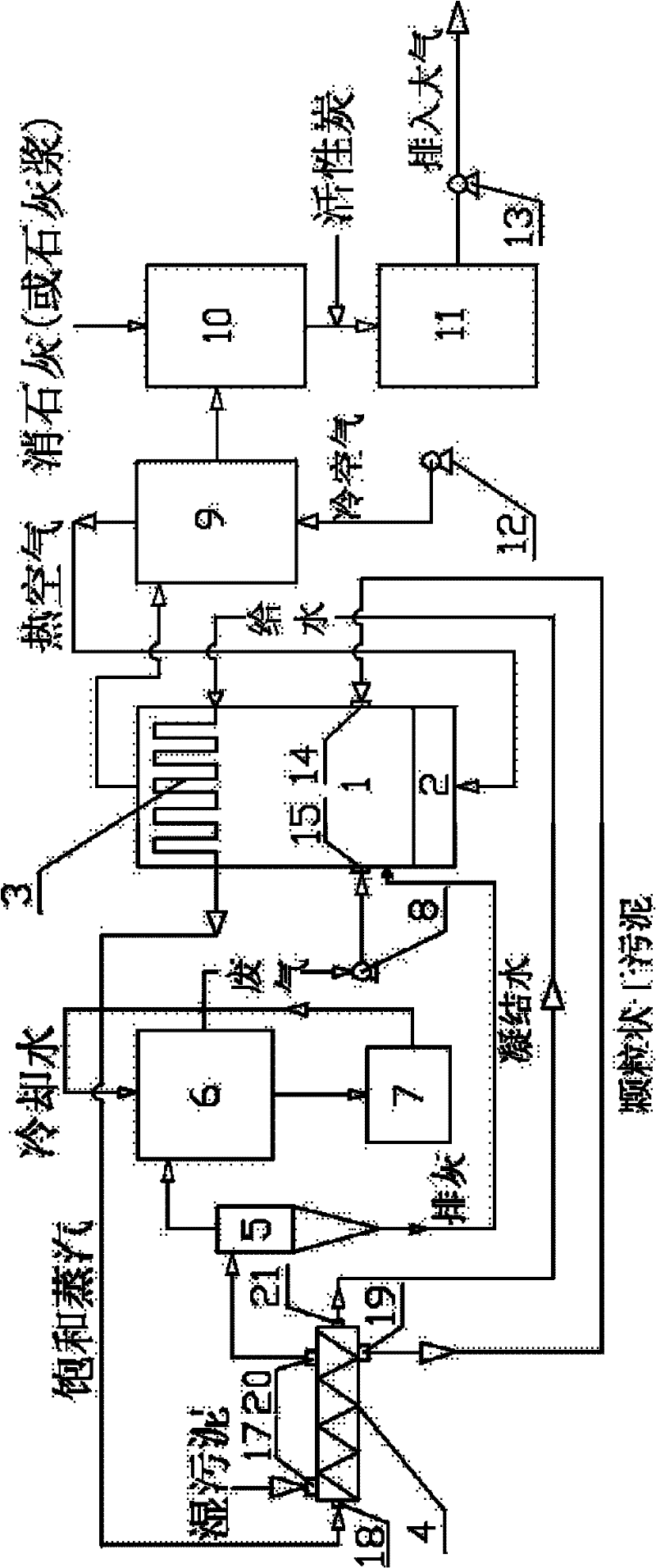

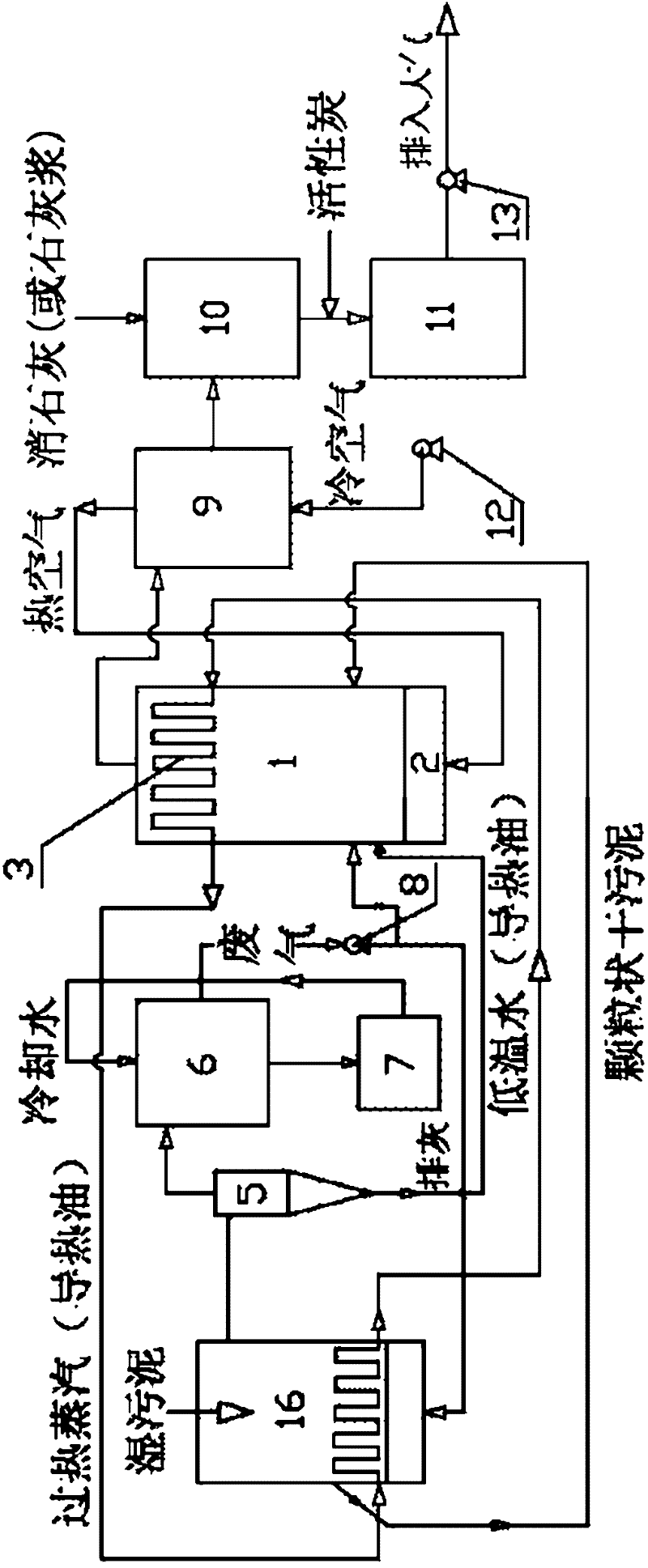

Energy self-feed type fluidized bed sludge incineration and tail gas pollution control system

ActiveCN102252331AAchieve self-sufficiencyAchieve balanceSludge treatment by de-watering/drying/thickeningIndirect carbon-dioxide mitigationAir preheaterWater vapor

The invention relates to an energy self-feed type fluidized bed sludge incineration and tail gas pollution control system. The system comprises a fluidized bed incinerator, a waste heat boiler, a sludge dryer, a separator, a spray dehydrating tower, a sewage treatment pool, an air preheater, an acid air absorption tower, a bag-type dust collector, an air blower and an induced draft fan. Wet sludge is dried in the dryer (a heat source is steam produced through combustion of dried sludge), and the dried sludge (granular) is conveyed into a fluidized bed and combusted; as the calorific value of the dried sludge is high, the normal combustion can be kept, and the heat produced through combustion is used for drying the wet sludge, so that an energy conversion process is finished. Waste air which contains water vapor and comes from the dryer is sprayed and dehydrated by a spray condensation tower and then is conveyed into a fluidized bed and is combusted. The self feed of sludge incineration energy can be realized, the waste water and waste air produced at each treatment section can be subjected to deodorization and innocent treatment, and the system has the advantages of high energy utilization rate, good treatment effect, and the like, and a small amount of pollutant is discharged.

Owner:BRIGHT THERMAL EQUIP CO LTD

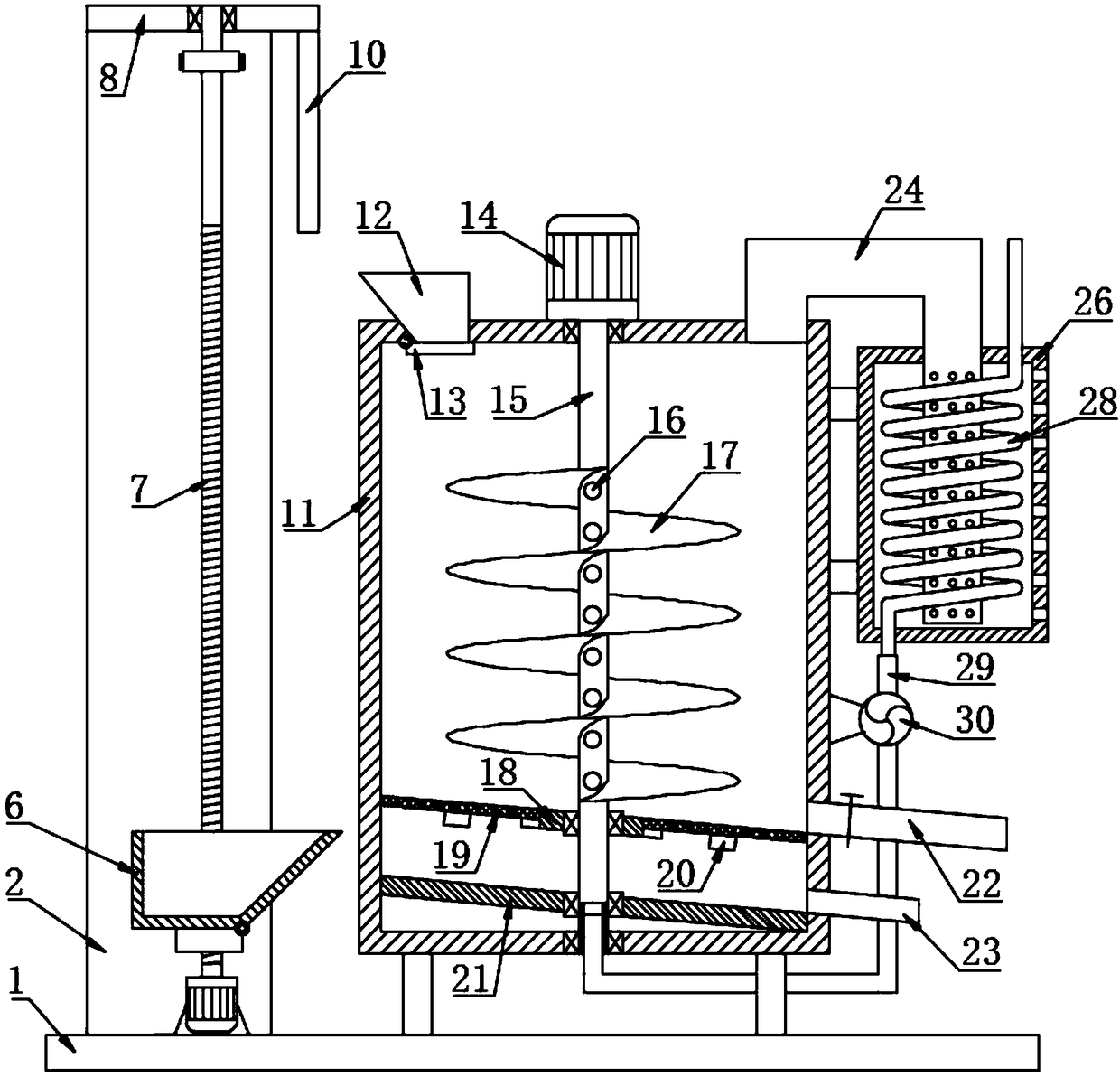

Self-feeding type energy-saving grain drying device

InactiveCN108800832AEvenly heatedImprove drying effectFood processingDrying gas arrangementsSpiral bladePulp and paper industry

The invention discloses a self-feeding type energy-saving grain drying device comprising a base. A drying barrel is fixed to the top of the base through a support, a rotating tube is arranged in the center in the drying barrel, and the upper end and the lower end of the rotating tube are rotationally connected with the top wall and the bottom wall of the drying barrel correspondingly. A second speed reducing motor is fixedly arranged at the center of the top of the drying barrel, a motor shaft at the bottom end of the second speed reducing motor is fixedly connected with the top end of the rotating tube, and spiral blades are fixedly mounted at the tube section, located above a screen plate, of the rotating tube. A plurality of one-way air outlet holes are uniformly formed in the tube section, between the spiral blades, of the rotating tube. A hot air blower is fixedly arranged at the right part of the side wall of the drying barrel, the air inlet end and the air outlet end of the hotair blower are connected with hot air tubes correspondingly, and the air outlet end of each hot air tube is connected into the rotating tube. The hot air blower is used for introducing hot air into the rotating tube, the hot air is discharged from the one-way air outlet holes to dry grains, and the heat is uniformly distributed; and the spiral blades are driven by the rotating tube to rotate to drive the grains to roll, so that the grains are heated more uniformly when dried, and the drying effect is good.

Owner:FUJIAN FUXIN AGRI TECH DEV CO LTD

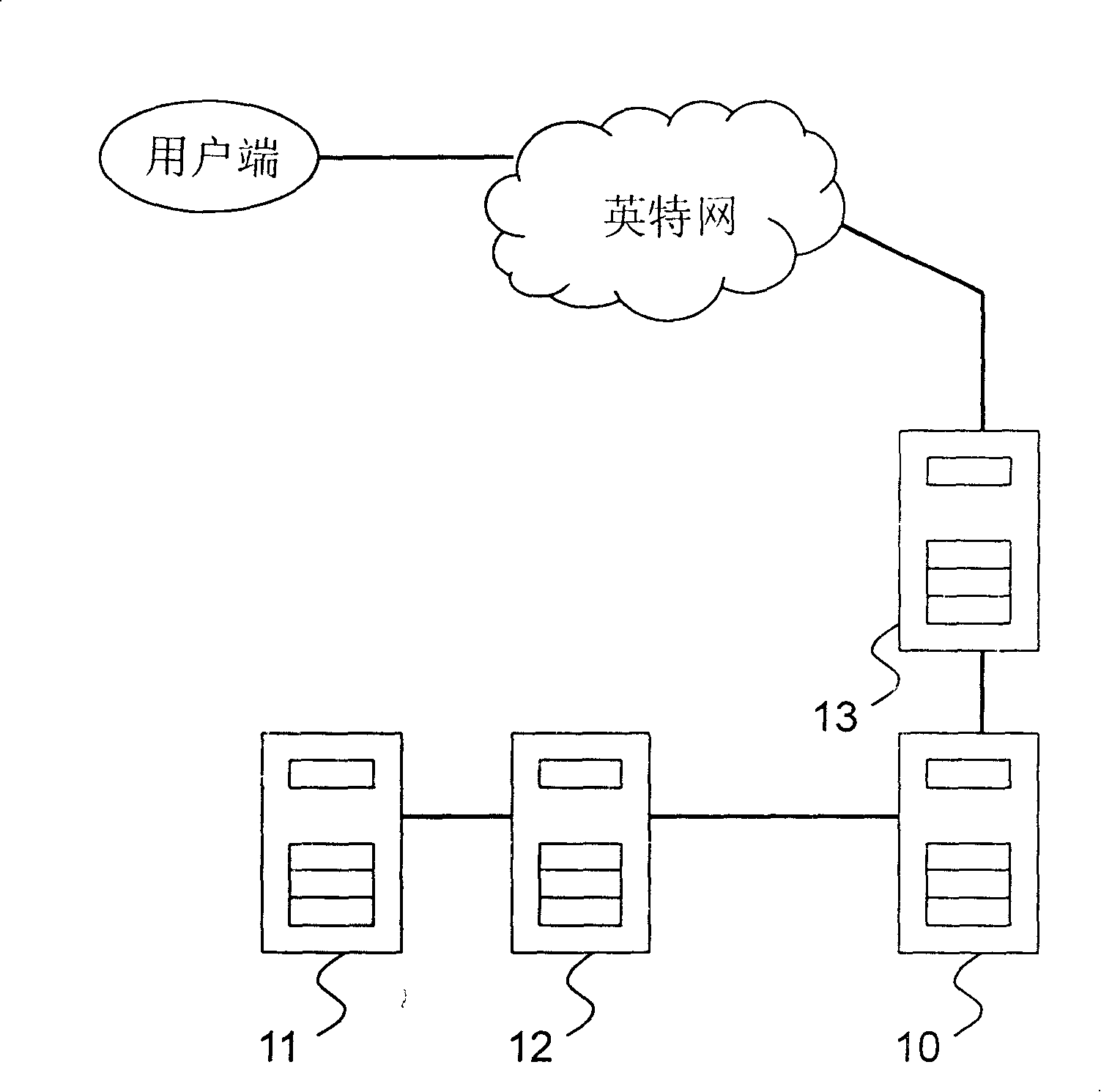

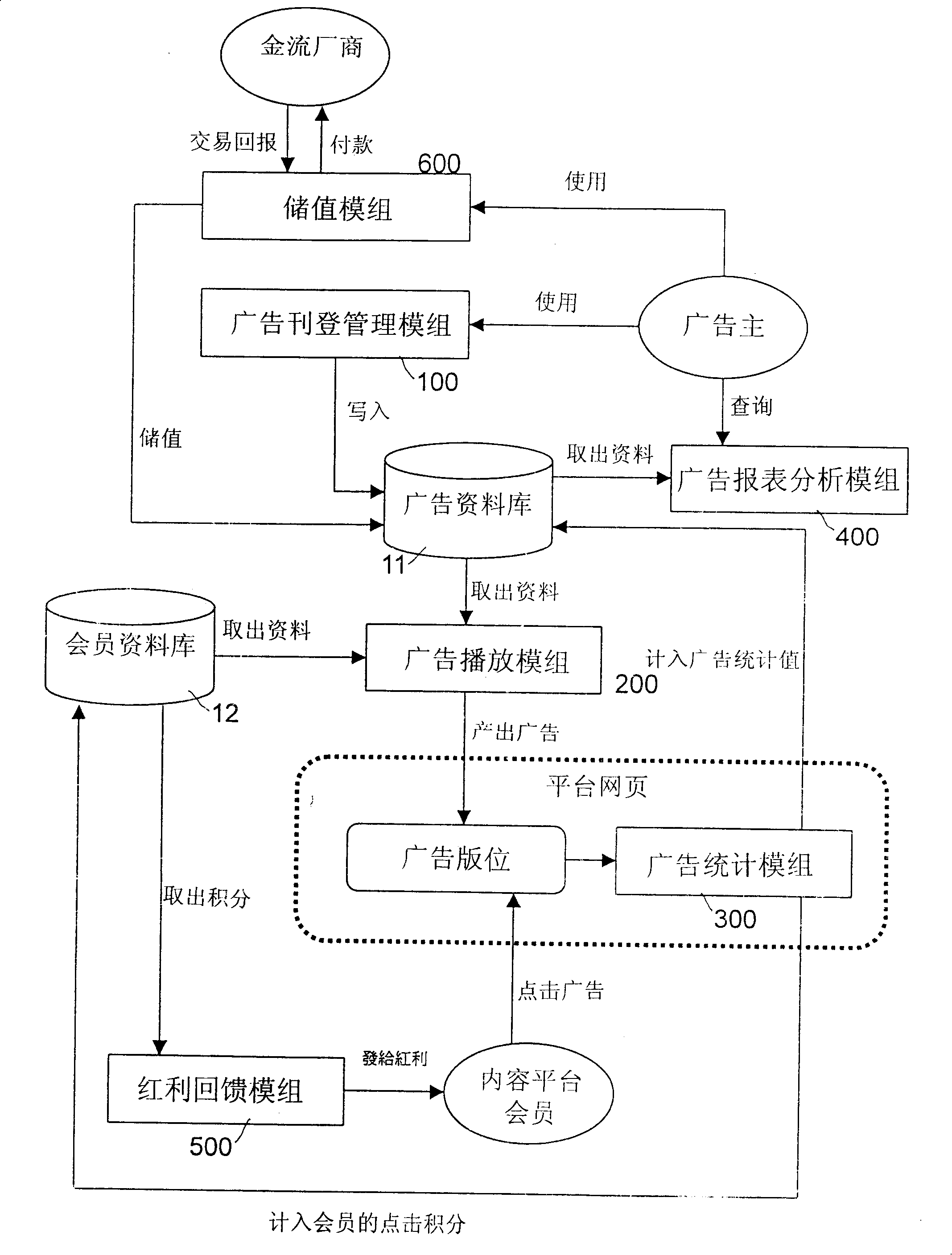

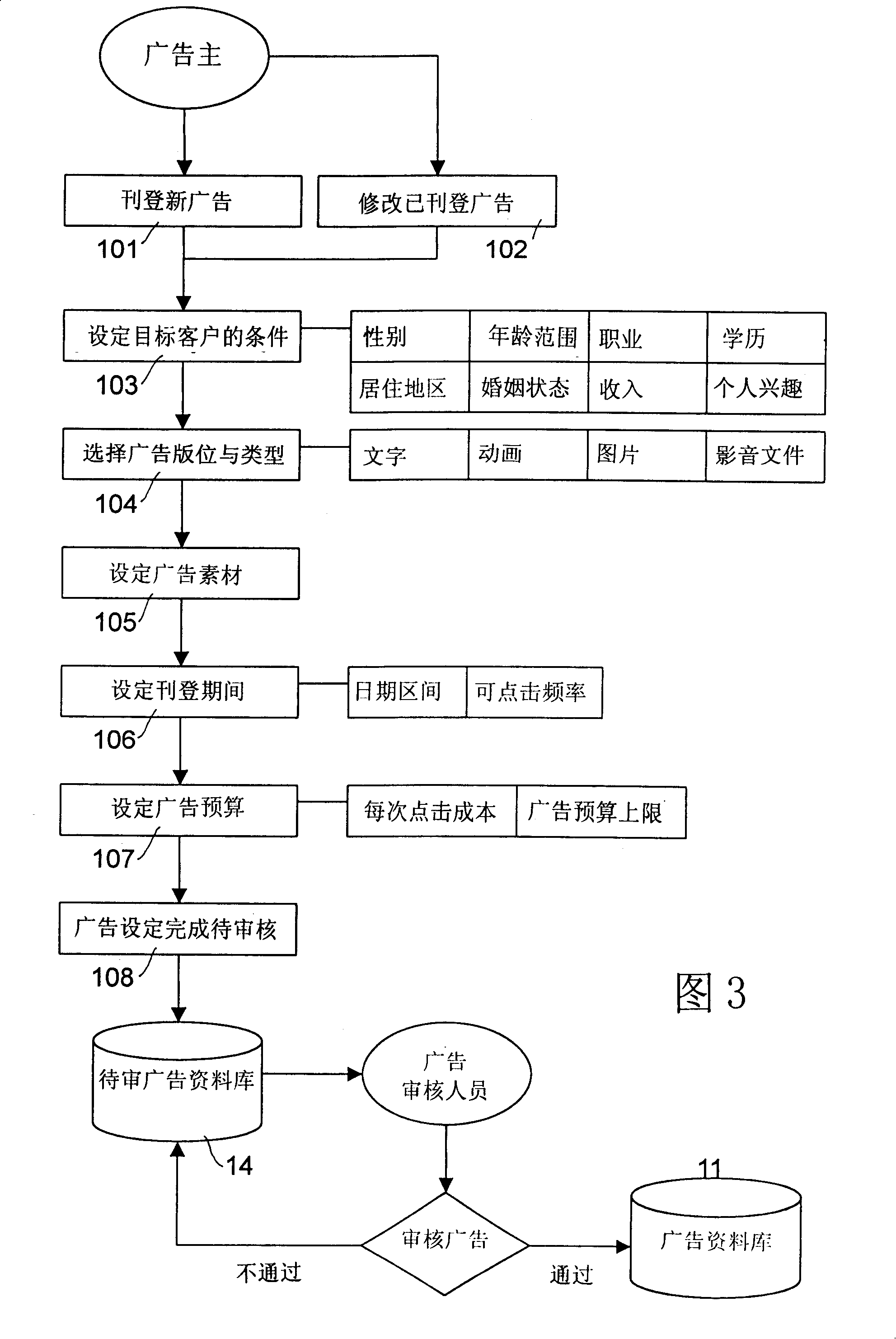

System for management of mutually feeding type website advertisement

InactiveCN101226618AEnsure advertising effectivenessIncrease advertising revenueCommerceCredit cardManagement system

A mutual-fed website advertisement management system comprises an advertisement data base, a member data base, a value storing module, an advertisement publishing module, an advertisement playing module and a bonus back-feeding module, wherein the advertiser can publish advertisement via the advertisement publishing module, remits deposit in the value storing module as the advertising fee, the content of the advertisement is stored in the advertisement data base and can assign member who has specific conditions to play, when the website member plays the advertisement, the bonus back-feeding module sends bonus to the member who plays the advertisement as the feedback, simultaneously, the value storing module deducts the deposit or automatically deducts money by using credit card as the advertisement cost, basing on the method, member has bonus feedback when plays advertisement, which increases the willing of the member to play advertisement, also the advertiser can promote sales and increase playing rate aiming at specific consumer groups. Further, the invention enables the advertiser to design, monitor and control the exposure of the single advertisement to every member or the times of clicking advertisement, thereby reaching mutual benefit.

Owner:SUNFUN INFO

Self-feeding type quantitative matching concrete mixer

InactiveCN107263729AQuality improvementEasy to operateMixing operation control apparatusIngredients proportioning apparatusArchitectural engineeringFeed type

The invention discloses a self-feeding type quantitative proportioning concrete mixer. The boards are respectively fixed with sand boxes, cement boxes and stone boxes, and the sand box, cement box and the bottom of the left side wall of the stone box are all provided with discharge ports; the left support plate and the right support plate are rotatably connected with a first shaft, and the second Three first cams are installed on a rotating shaft, the bottom of the first cam is connected with the first connecting rod through the pin shaft, the bottom of the first connecting rod is connected with a baffle, and the three baffles are respectively matched with the discharge port; Fixed installation with a stirring box. The invention makes the baffle plate move up and down through the rotation of the first cam to control the automatic unloading of sand, gravel and cement; the discharge ports of different sizes are set to automatically proportion the materials, which greatly improves the working efficiency.

Owner:康泽波

Formulation and method of manufacturing an almond leaf fodder

An improved animal feed or fodder formulation for grazing animal is provided. The animal feed is formulated such that a significant portion of the nutrient is derived from almond leaves or almond leaf by-products. The animal feed formulation may be used on any grazing type of livestock including, cattle, sheep, goats, horses, or pigs. The formulation may also be used in a number of different feed types.

Owner:CHOU CHIN PAO

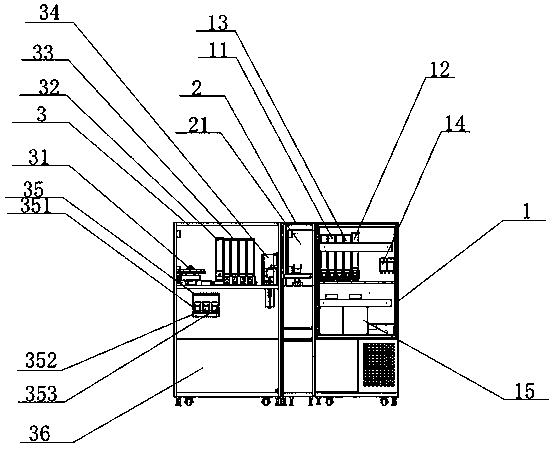

Automatic milky tea maker

An automatic milky tea maker comprises a low-temperature preservation chamber, an icemaker case and a normal-temperature chamber. A guide rail box is arranged in front of the low-temperature preservation chamber, the icemaker case and the normal-temperature chamber. A sauce output device, a large fruit grain output device, a cover output device and a juice pump are arranged in the upper portion ofthe low-temperature preservation chamber. A full-automatic icemaker is arranged in the icemaker case, a cup discharger, a fructose output device, a powder output device and a stirring device are arranged in the upper portion of the normal-temperature chamber, the middle of the normal-temperature chamber is internally provided with a tea water and purified water outlet, the lower portion of the normal-temperature chamber is provided with a water barrel placement area, and a milky tea conveying platform is arranged in the guide rail box. The automatic milky tea has advantages that cup discharging, water agent feeding, powder feeding, sauce feeding, stirring, milk cover feeding and final outputting are all realized mechanically, so that unmanned milky tea making is realized; by design of different feeding types and feeding sequences, a refrigerator is designed for materials requiring refrigeration, an ice making component is provided aiming at different demands of cold and hot drinks, and accordingly different customer demands can be met.

Owner:杭州黑石机器人有限公司

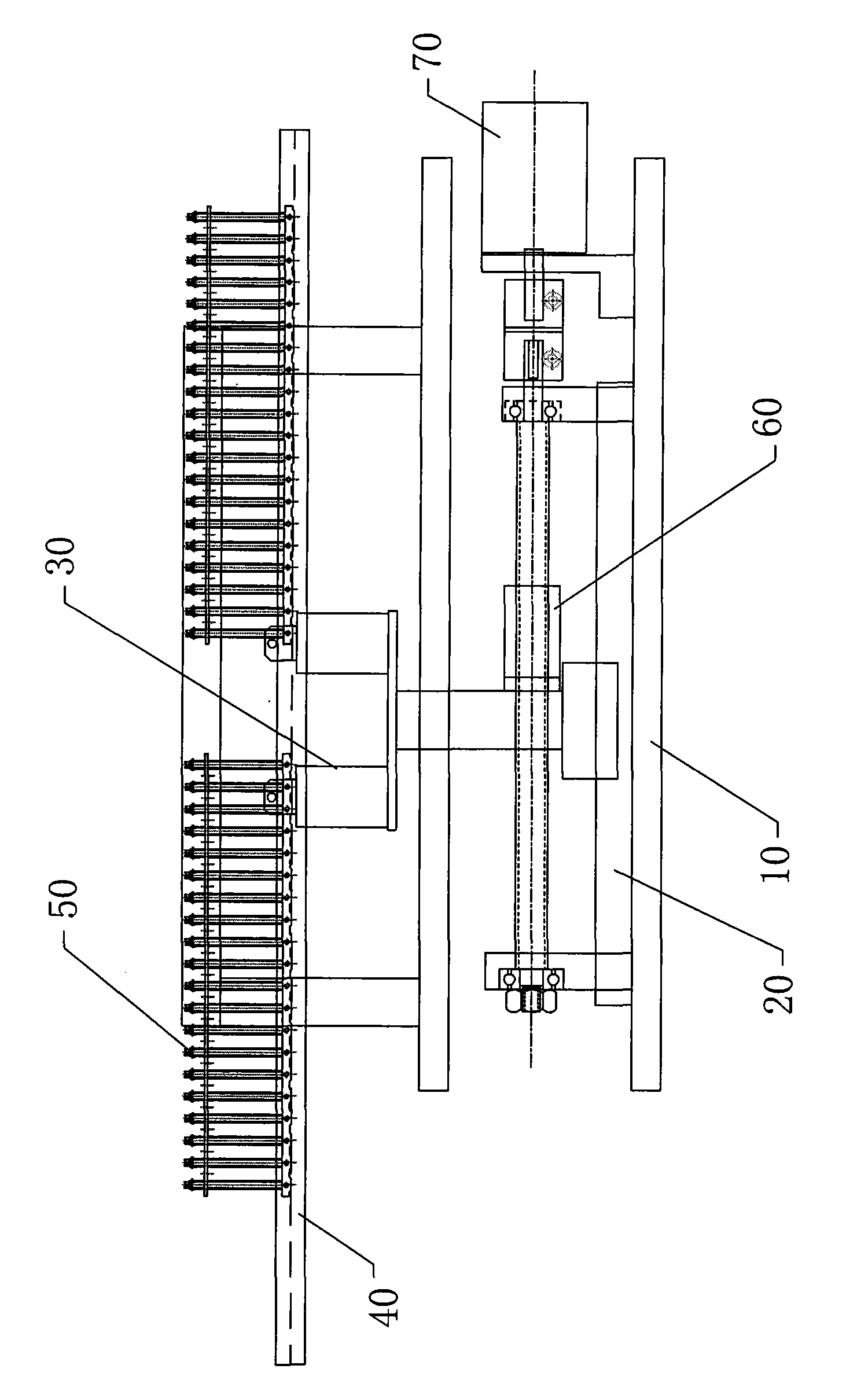

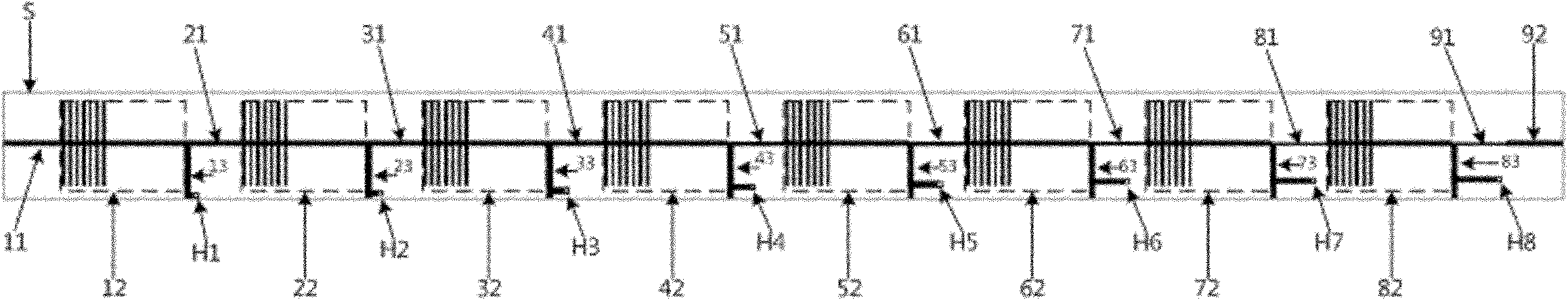

Double-row track feed type system for specific feeding of vertical LED lead frame

The invention relates to a feeding system, in particular to a double-row track feed type system for specific feeding of a vertical LED lead frame, which is applied to a wire bonder. The system comprises a base frame, wherein a sliding block device is arranged at the upper side of the base frame, a support claw is arranged on the sliding block device and can slide on the sliding block device, two rows of delivery tracks are arranged at the upper side of the support claw and used for delivering an LED support to the output position from the input position, the support claw is used for transferring the LED support product to the output position from the input position, a motor device is also arranged on the base frame, a ball screw is connected on a motor output shaft and used for moving theposition of the support claw, and the motor is used for providing the rotating powder for the ball screw. The invention has the beneficial effects that the system utilizes the two rows of the tracks for feeding so that the feeding and the discharging of the materials can be respectively performed; the double-row track feeding system can perform back-forth feeding and is used for supplying materials in parallel for an operating platform; and the system aims at eliminating the feeding time, keeping the normal running of production and improving the production efficiency.

Owner:英展有限公司

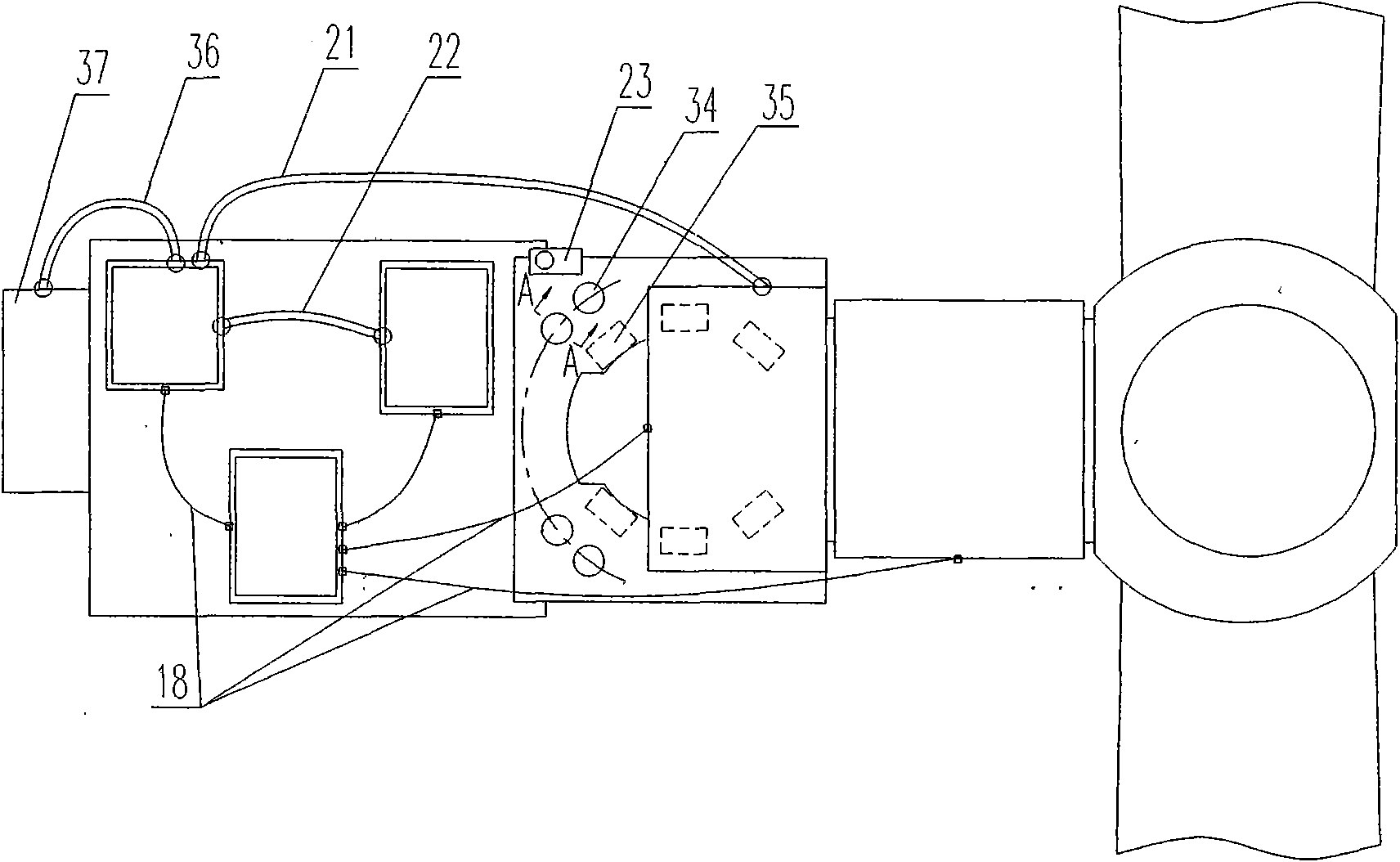

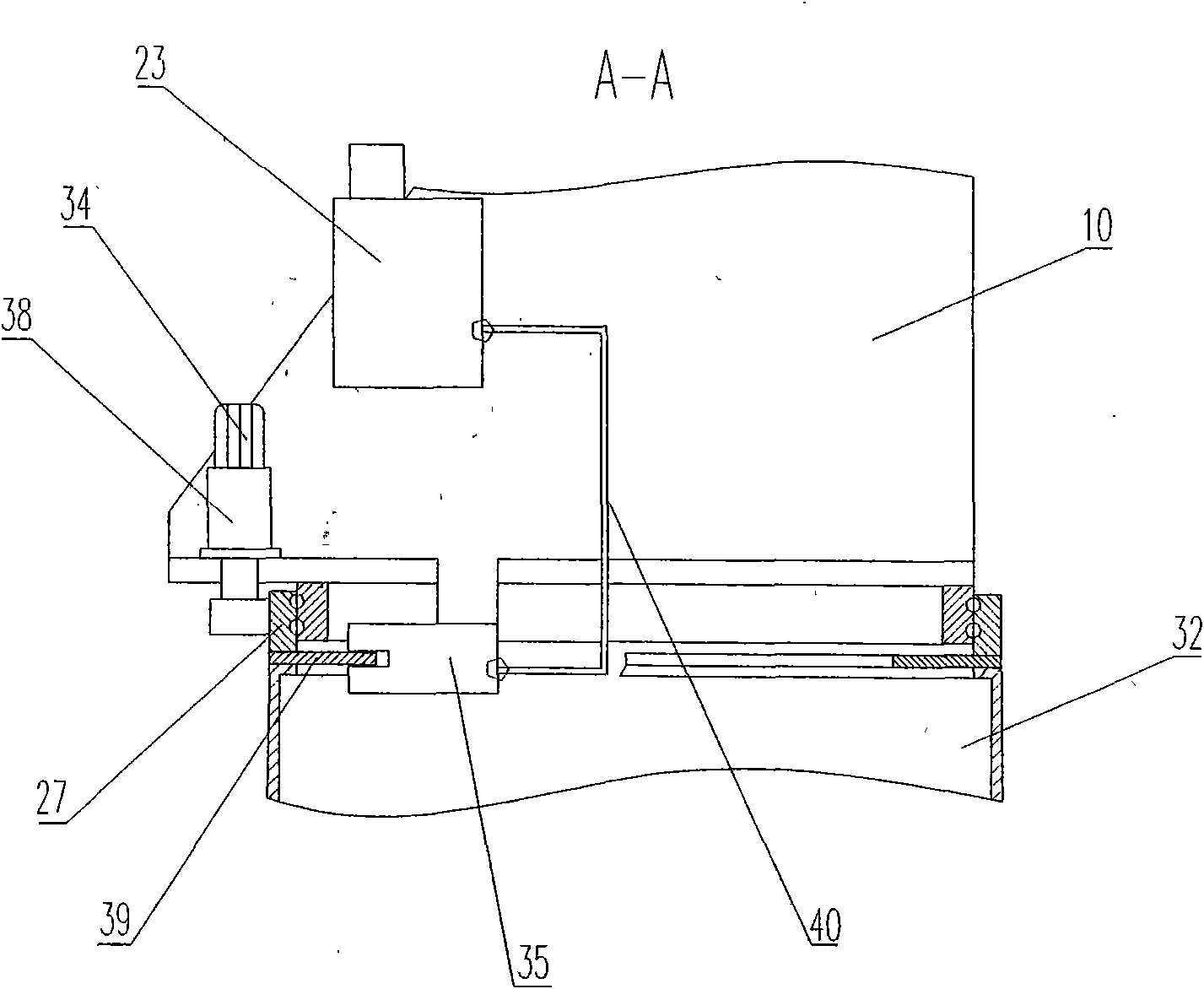

Grid-connected hybrid-driven variable-pitch variable-speed constant-frequency wind turbine generator set

InactiveCN101660499AReduce maintenance costsImprove reliabilityWind motor controlMachines/enginesConstant frequencyLow speed

The invention provides a grid-connected hybrid-driven variable-pitch variable-speed constant-frequency wind turbine generator set which is developed against two popular types of direct-driven type anddouble-feed type in China presently. The grid-connected hybrid-driven variable-pitch variable-speed constant-frequency wind turbine generator set consists of an impeller system, a transmission system, a support system, a yaw system, a hydraulic system, a temperature control system and an electrical system, wherein the impeller system is directly connected with a flange of a planet carrier of a speed increasing box of the transmission system, and comprises three blades, a wheel hub and a variable-pitch control unit, a casing of a stator of a generator of the transmission system and a casing ofan inner gear ring of the speed increasing box are respectively fixed on a rotary support of a support system by the way of a front flange and a back flange, and the generator is a synchronous permanent magnet generator. The grid-connected hybrid-driven variable-pitch variable-speed constant-frequency wind turbine generator set adopts a primary planetary gearbox and the low-speed permanent magnetsynchronous generator, thereby having the advantages of small volume, simple structure, fewer maintenance items of the set, low maintenance cost, no need of special hoisting equipment, sufficient space for meeting the requirements of maintenance and ergonomics, and optimal maintainability of all the parts.

Owner:HARBIN HAFEI IND

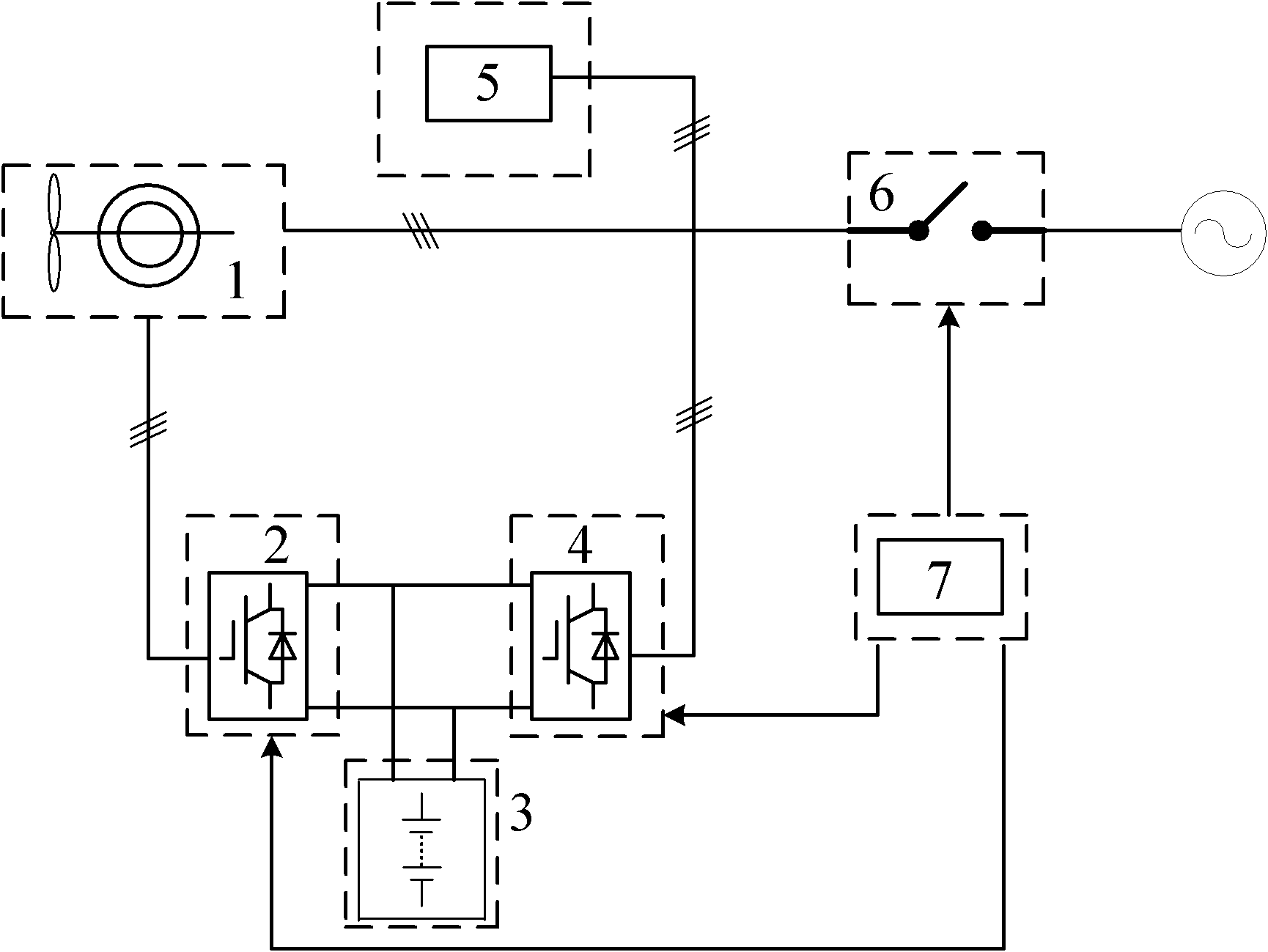

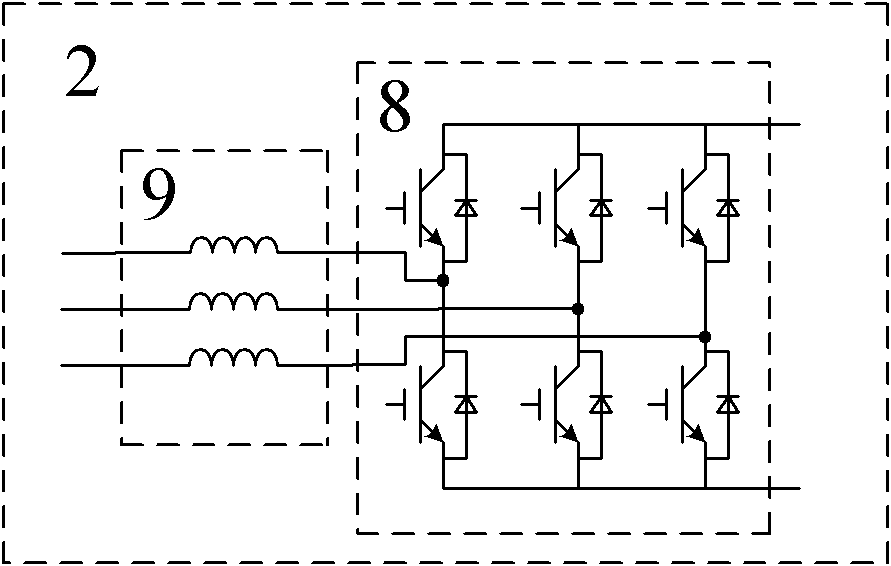

Double-feed wind power generating system with energy storage function

InactiveCN101917013AControllable slip power exchangeImprove power qualitySingle network parallel feeding arrangementsAc network load balancingPower qualityElectric power system

The invention relates to a double-feed wind power generating system with energy storage function, comprising a double-feed type wind power generator, an alternating-current excitation power supply, a monitoring device, a grid-connection contactor and an energy storing device, wherein one end of the grid-connection contactor, a stator winding of the double-feed type wind power generator, and the alternating-current end of a stator side converter are together connected with a load, and the other end of the grid-connection contactor is connected with a power grid; the alternating-current end of the alternating-current excitation power supply is connected with the energy storing device; and the monitoring device controls the communication state of the grid-connection contactor to realize the conversion of an independent running mode or a grid-connection running mode of the system and controls the working states of a rotor side converter and the stator side converter according to the current running mode. When carrying out grid-connection running, the double-feed wind power generating system can actively participate in the running and the control of an electric system to provide active power and reactive power compensation and improve the quality of electric energy; when carrying out independent loaded running, the double-feed wind power generating system can achieve the dynamic balance of the active power and the reactive power at a generation side and an electric load side to ensure the safe, economic, efficient and high-quality running of wind power equipment and the load.

Owner:HUAZHONG UNIV OF SCI & TECH

Frequency-scanning antenna array based on CRLH-TL

InactiveCN102117972ASimple structureHigh bandwidthIndividually energised antenna arraysElectricityImpedance transformer

The invention provides a frequency-scanning antenna array based on a CRLH-TL (composite right / left -handed transmission line) and belongs to the field of microwave technology. The antenna array comprises a feed network and unit antennas, wherein the feed network comprises CRLH-TLs and a matching network, and both the CRLH-TLs and the matching network are made of copper-clad media plates; a coupled line, lambada / 4 impedance transformers and single stubs are molded on a metal layer on the upper surface of each media plate and connected with a grounding plate on the lower surface of each media plate through metallized through holes. Every unit antenna is a micro-strip feed type quasi-yagi antenna made of a copper-clad media plate, and comprises a half-wave dipole antenna and two directors. The frequency-scanning antenna array realizes the CRLH-TL structure through the coupled line and can greatly reduce the leaky wave radiation in a feed network and increase the scanning range of the antenna array. Since non-uniform feeding to the unit antennas is realized through the matching network, the antenna array is endowed with the characteristics of high gain and low sidelobe.

Owner:XI AN JIAOTONG UNIV

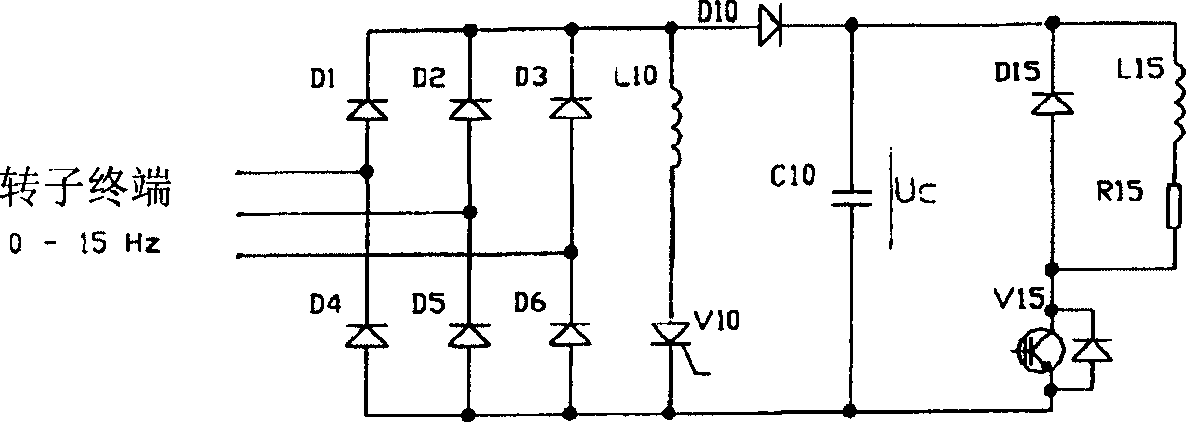

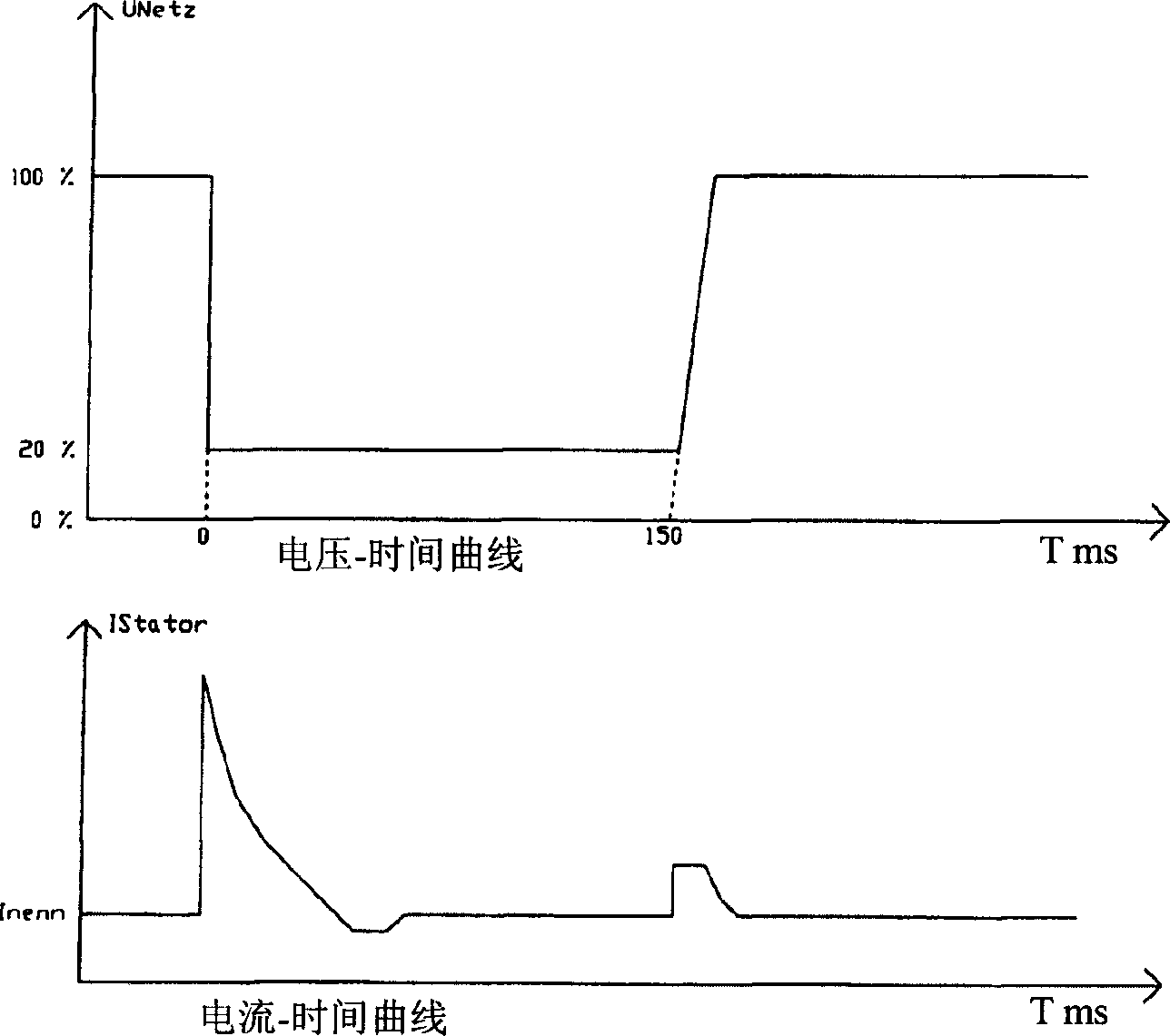

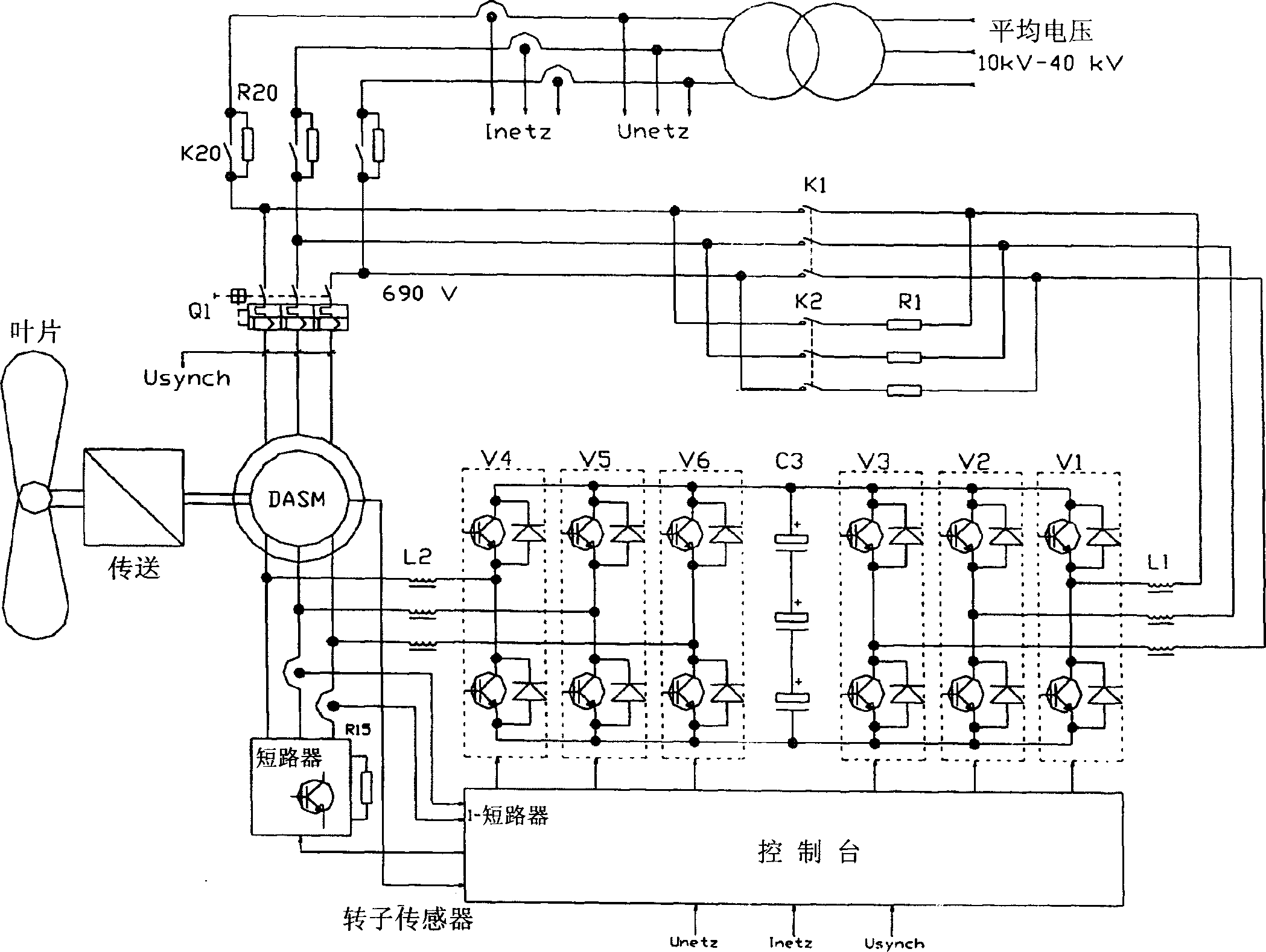

Circuit to be used in a wind power plant

InactiveCN1625831AEfficient modificationReliable controlGenerator control circuitsDC motor speed/torque controlPower stationEngineering

The invention relates to a circuit with variable rotational speed, especially for wind power plants, comprising a doubly-fed asynchronous generator (DASM), a crowbar, an additional resistor (R15) and a converter. In order to meet the needs of the network provider so that a dedicated permanent connection to the network is guaranteed so that the wind power plant can be started and stabilized during and after a medium voltage short circuit in the network, additional resistors can be switched on and off quickly The regulation is carried out with the aid of the system in such a way that the converter can be temporarily at least partially disconnected in the event of a short circuit in the network. The rotor current is temporarily taken up by the additional resistor and disconnected after the rotor short-circuit current disappears, so that the converter can then be connected again and be able to supply the desired effective short-circuit current to the network.

Owner:VESTAS WIND SYST AS

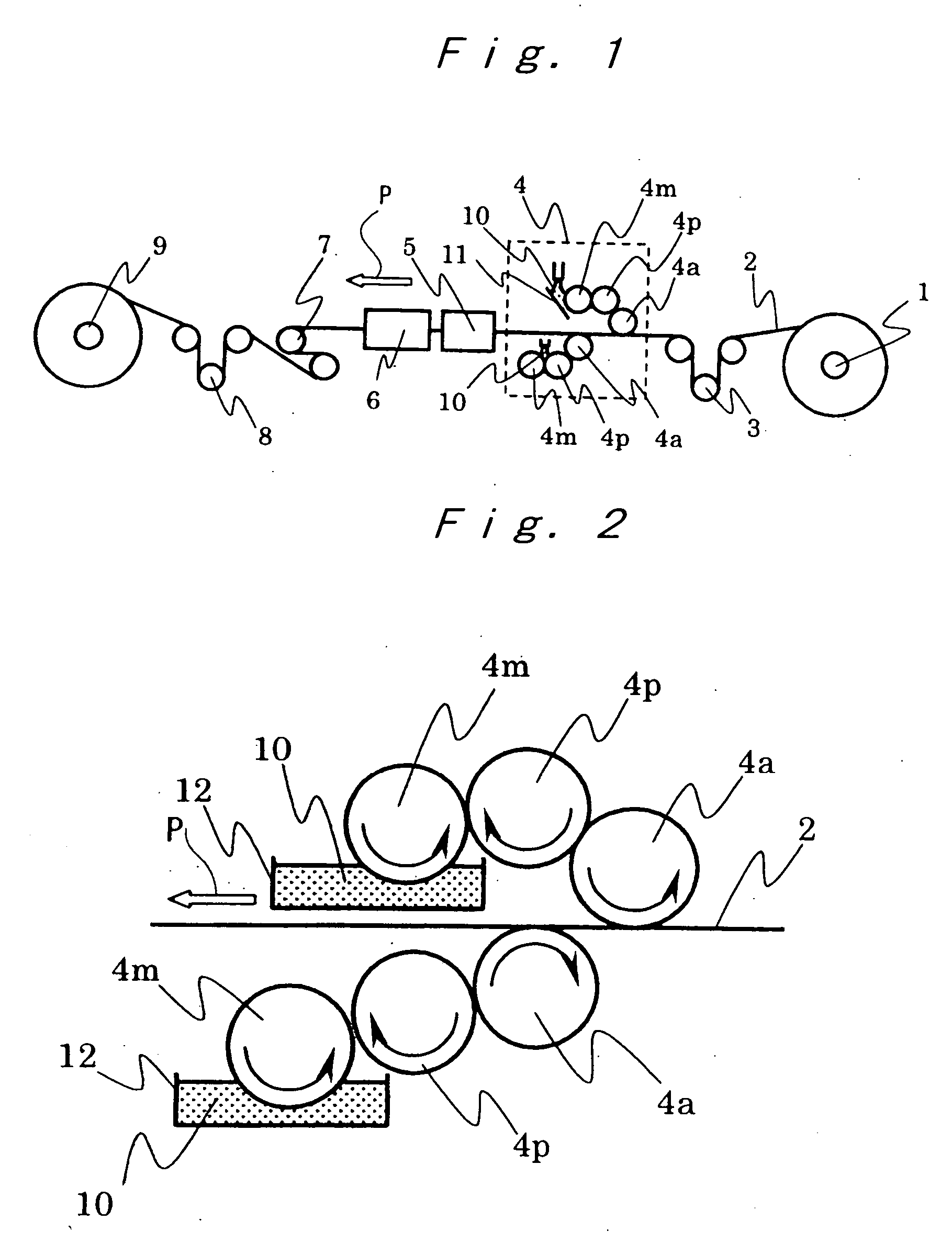

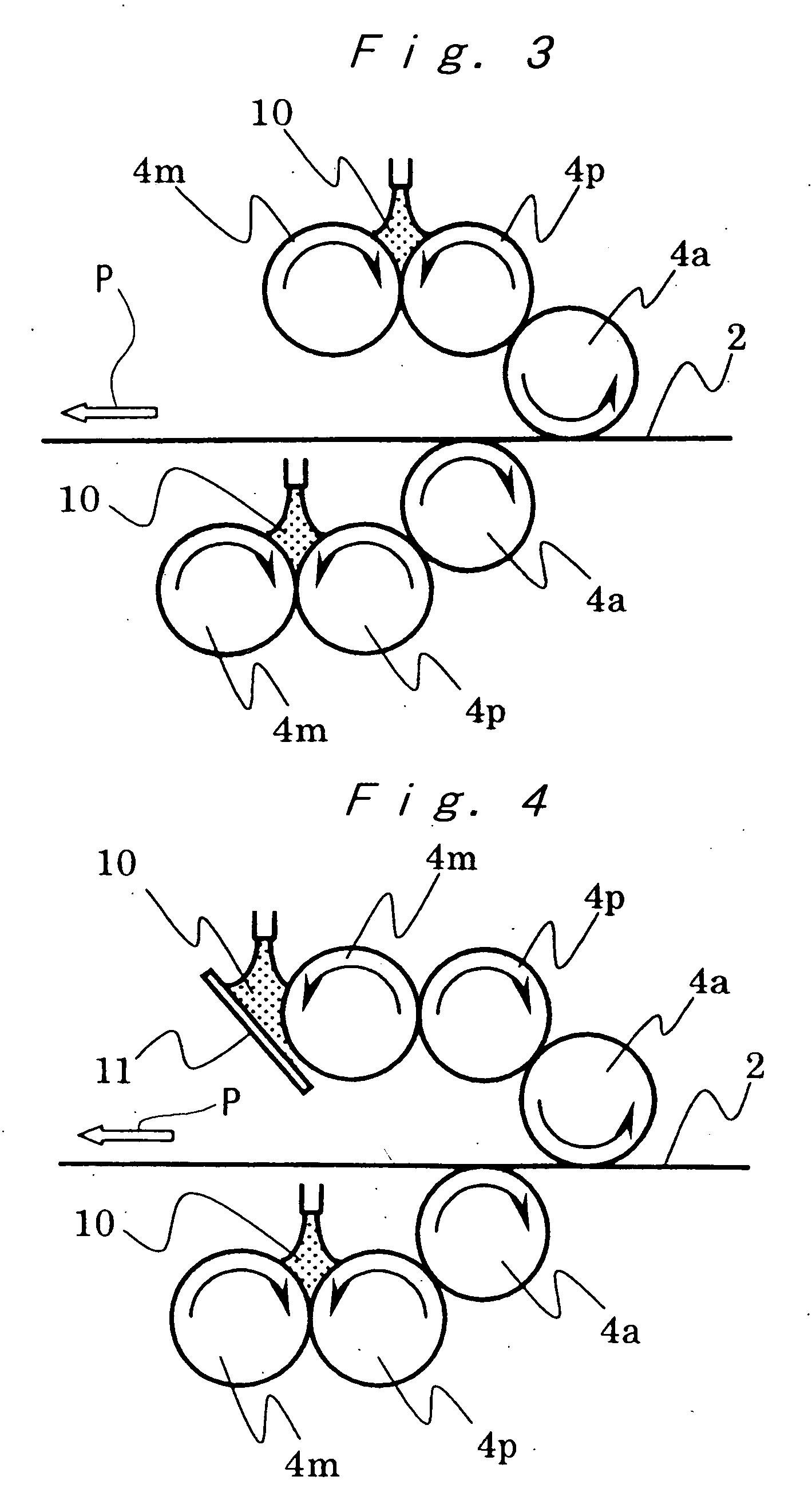

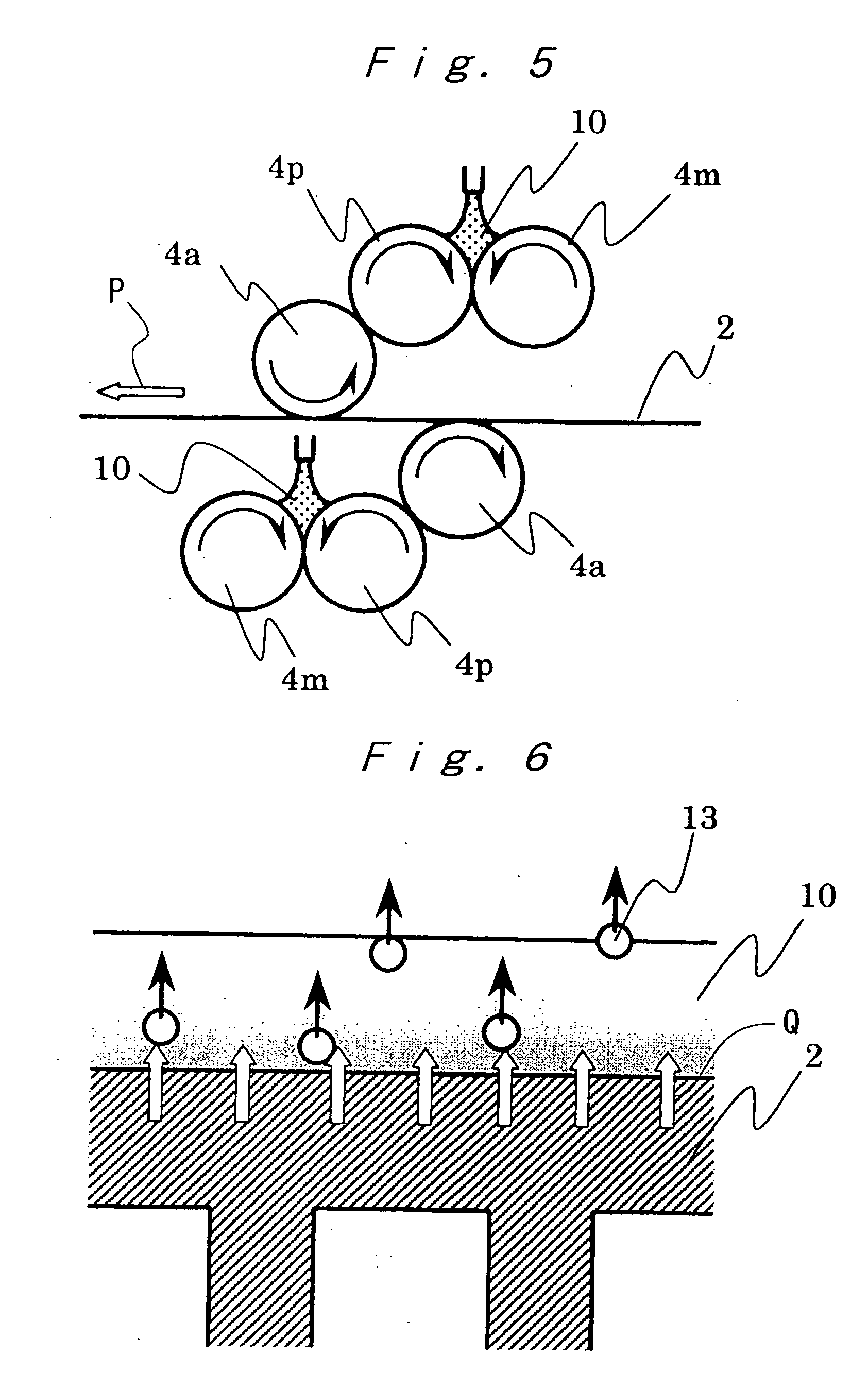

Coating apparatus for an aluminum alloy heat exchanger member, method of producing a heat exchanger member, and aluminum alloy heat exchanger member

InactiveUS20060243778A1Impart corrosion resistanceCooking-vessel materialsHot-dipping/immersion processesPowder mixtureTransfer system

An coating apparatus, wherein the apparatus applies a coating, onto a surface of an aluminum alloy member for a heat exchanger to be assembled by brazing, with a top-feed-type roll transfer system having at least three rolls, the coating being obtained by mixing into an organic binder a metal powder, a flux powder, a powder mixture thereof, or a compound containing a metal component and a flux component, wherein rotation directions of transfer rolls of the apparatus arranged above a surface to be coated of an aluminum alloy extruded member that moves in a horizontal direction, satisfy a relationship in which a rotation direction of a coated-metal roll for coating, which rotates in a direction opposite to a moving direction of the extruded member, and a rotation direction of a metal roll for adjusting an adhesion amount of the coating by contacting with the above roll, are opposite to each other; and a method of producing an aluminum alloy heat exchanger member using the apparatus; and an aluminum alloy heat exchanger member.

Owner:FURUKAWA SKY ALUMINUM CORP

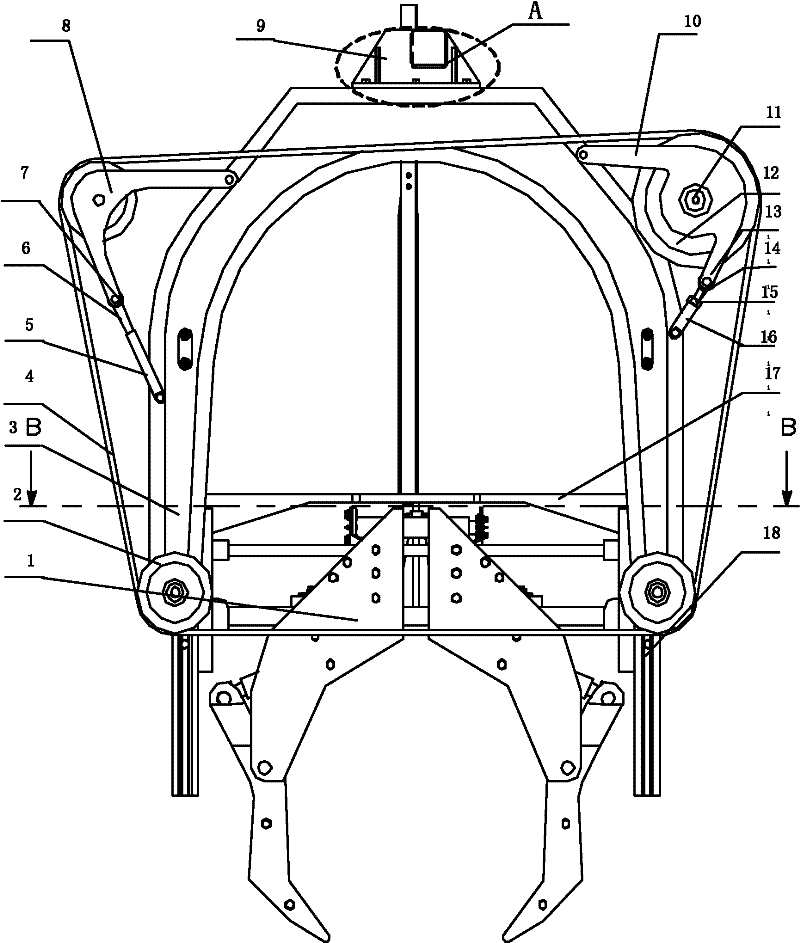

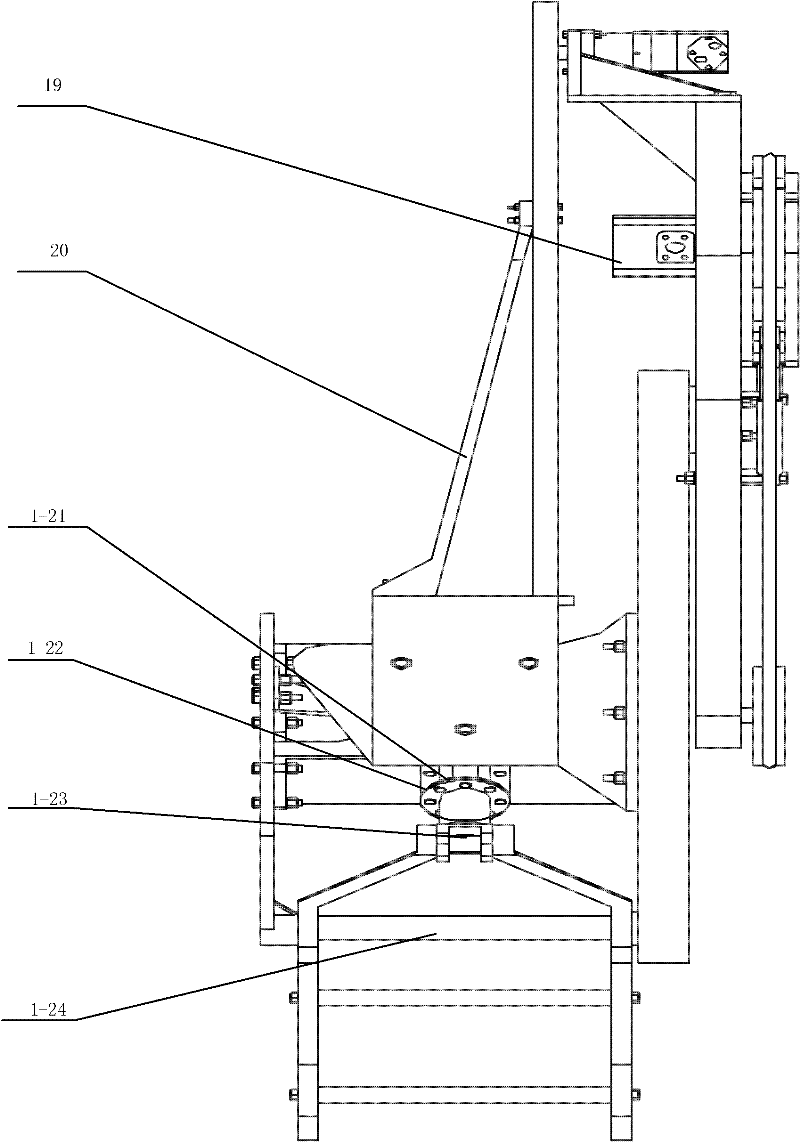

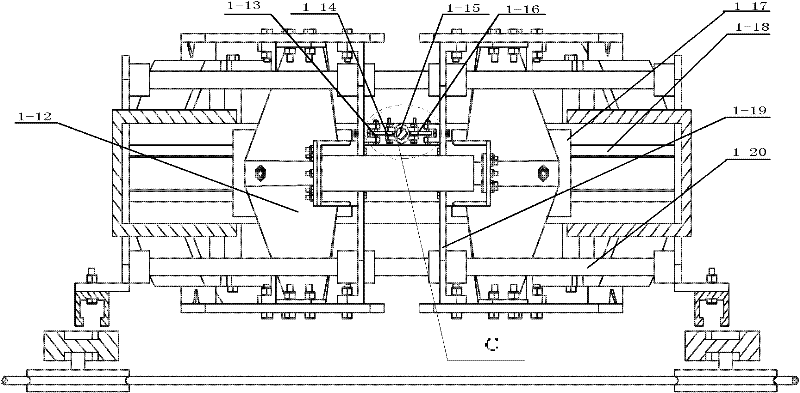

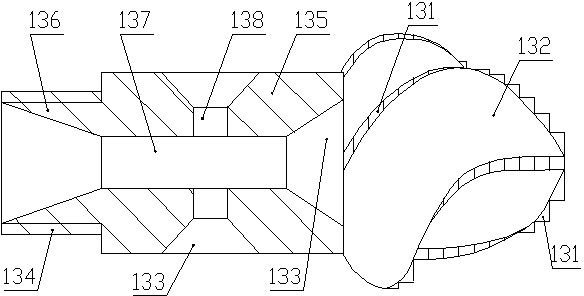

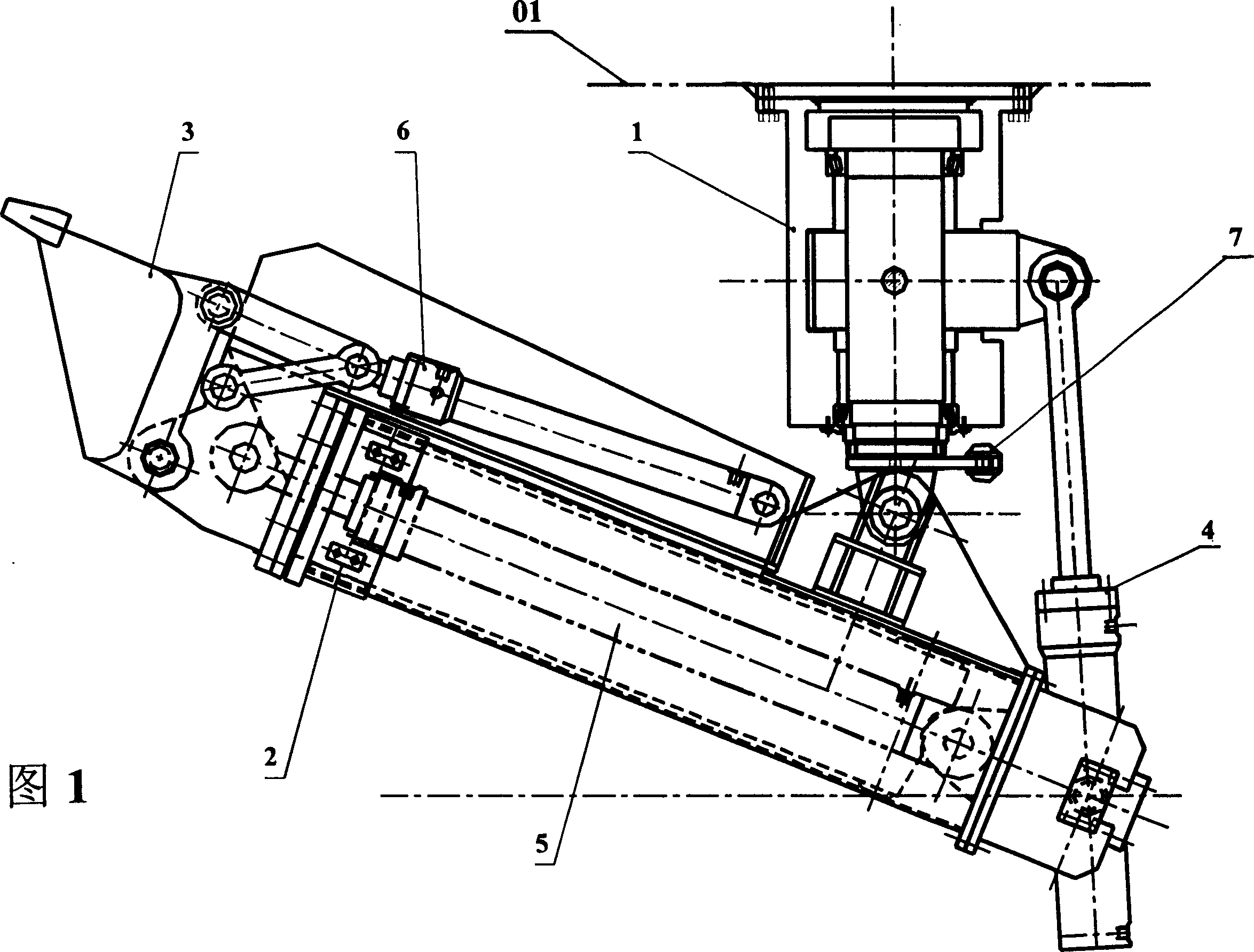

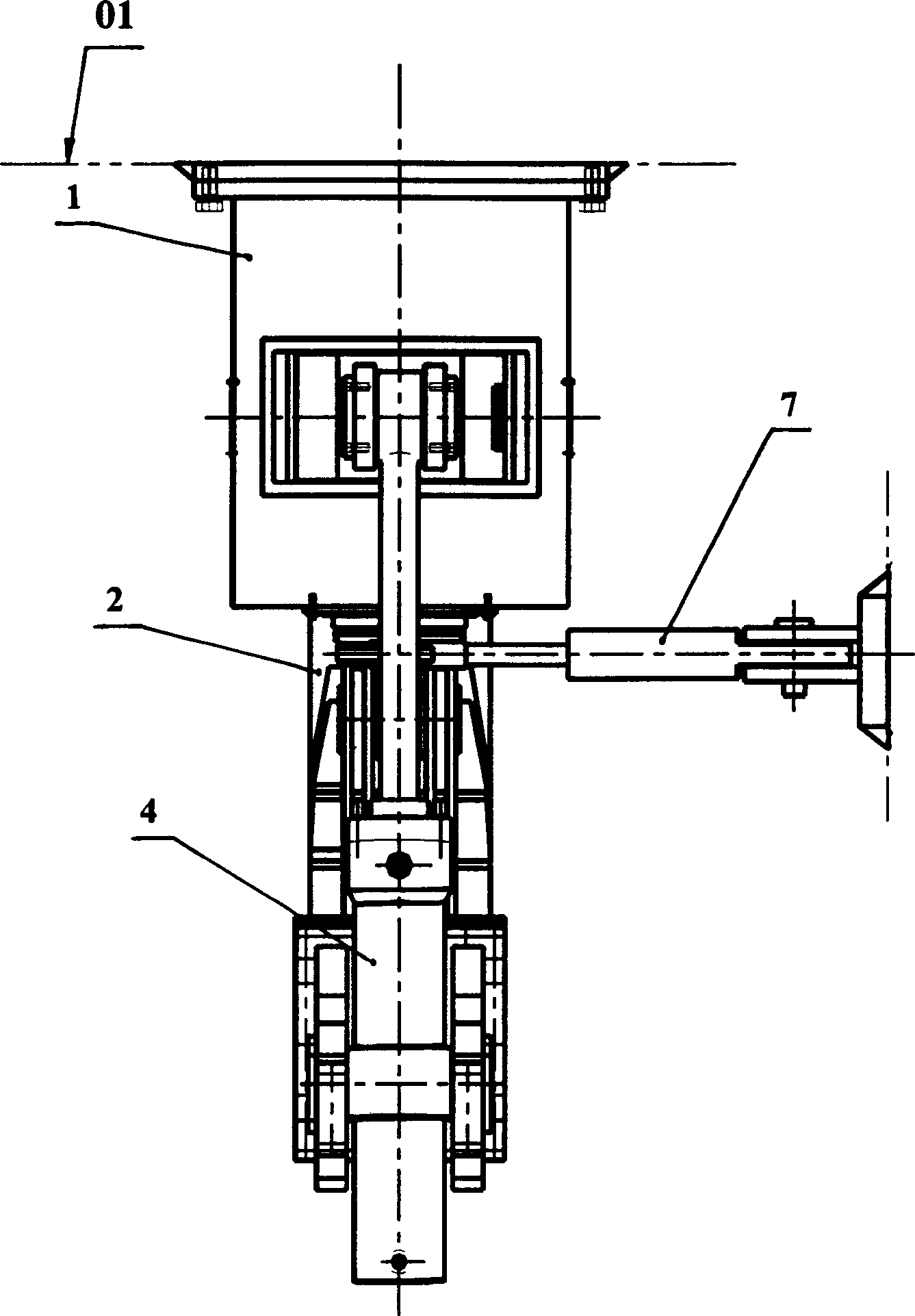

Telescope feed type manipulator in backhoe digging, and application in tunnel shield machine and pipe pushing jack

InactiveCN1687538ASmall footprintImprove structural strengthMechanical machines/dredgersTunnelsEngineeringSoil texture

The present invention discloses a kind of sleeve counter shoveling and excavating manipulator and its application in shield machine and push bench. The present invention on structure mainly replaces the connecting rod organ in traditional excavator with gearing hydraulic pressure. It's comprised of support of rotation, extension sleeve, bucket device, moveable arm cylinder, shakeable pole cylinder, bucket cylinder and turning cylinder. The movement of its excavating device is also mainly drove by the extension of cylinder, therefore the said sleeve counter shoveling and excavating manipulator is provided with the advantages as occupying small space, high structure intensity and rigidity, and strong excavating force. Besides the renewable percussive drill makes the present invention have staving function, which can adopt more soil textures of excavation. The present invention provides more suitable excavating mechanism for shield and push excavator in tunnel construction, so it makes the excavator be able to adapt various soil layer, reduce workers' work intensity, and improve the constructing efficiency.

Owner:SHANGHAI TUNNEL ENGINEERING CO. LTD.

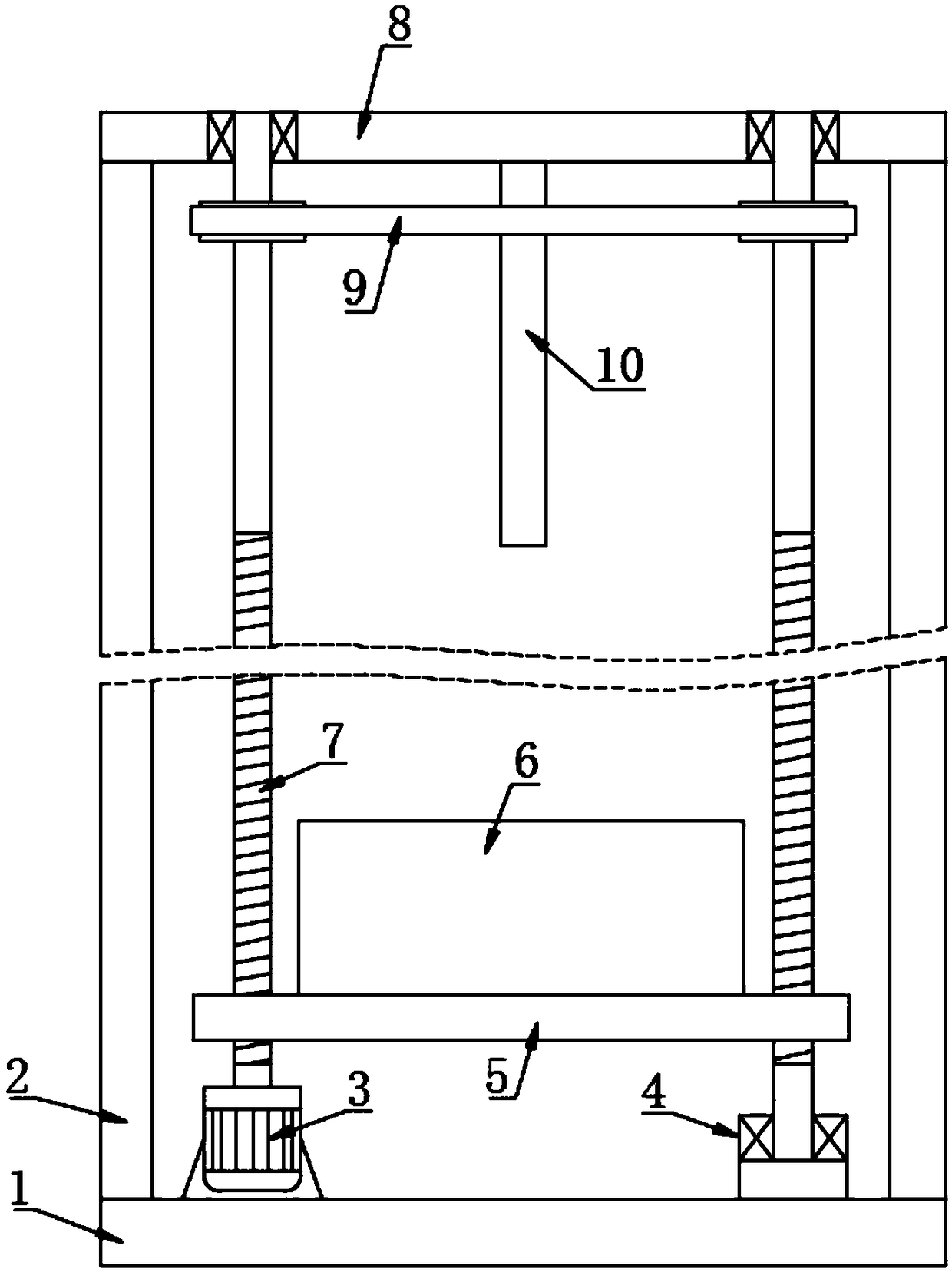

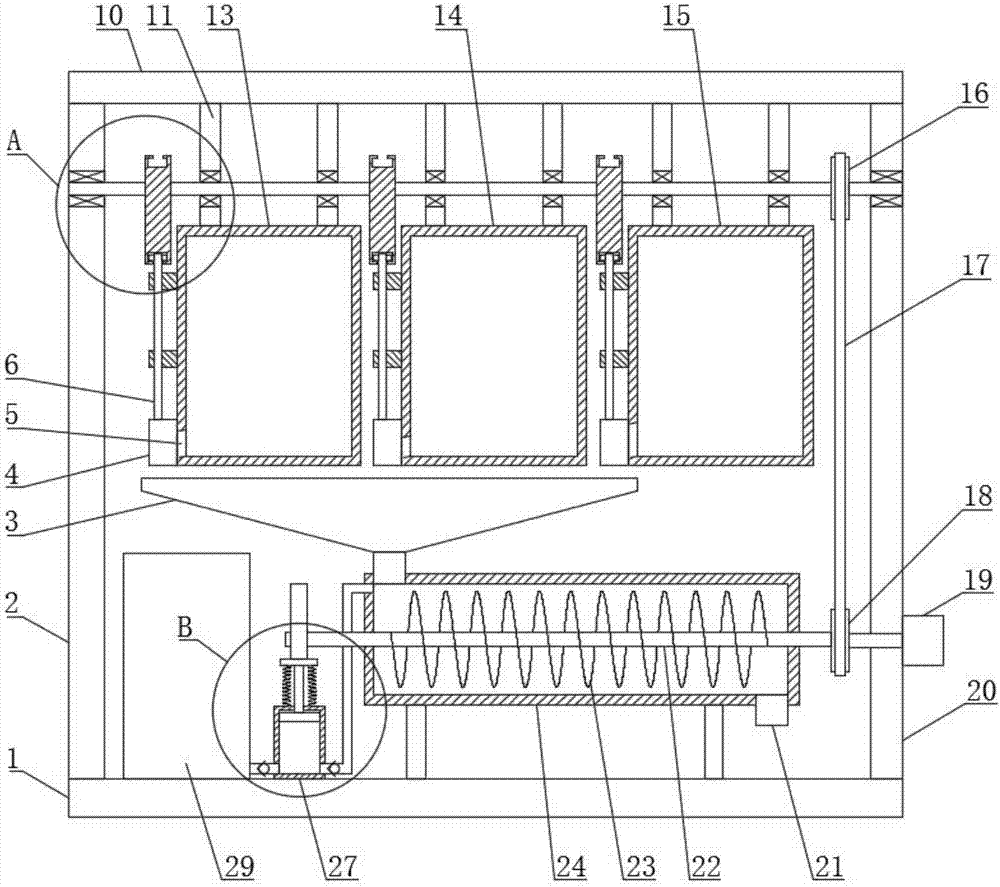

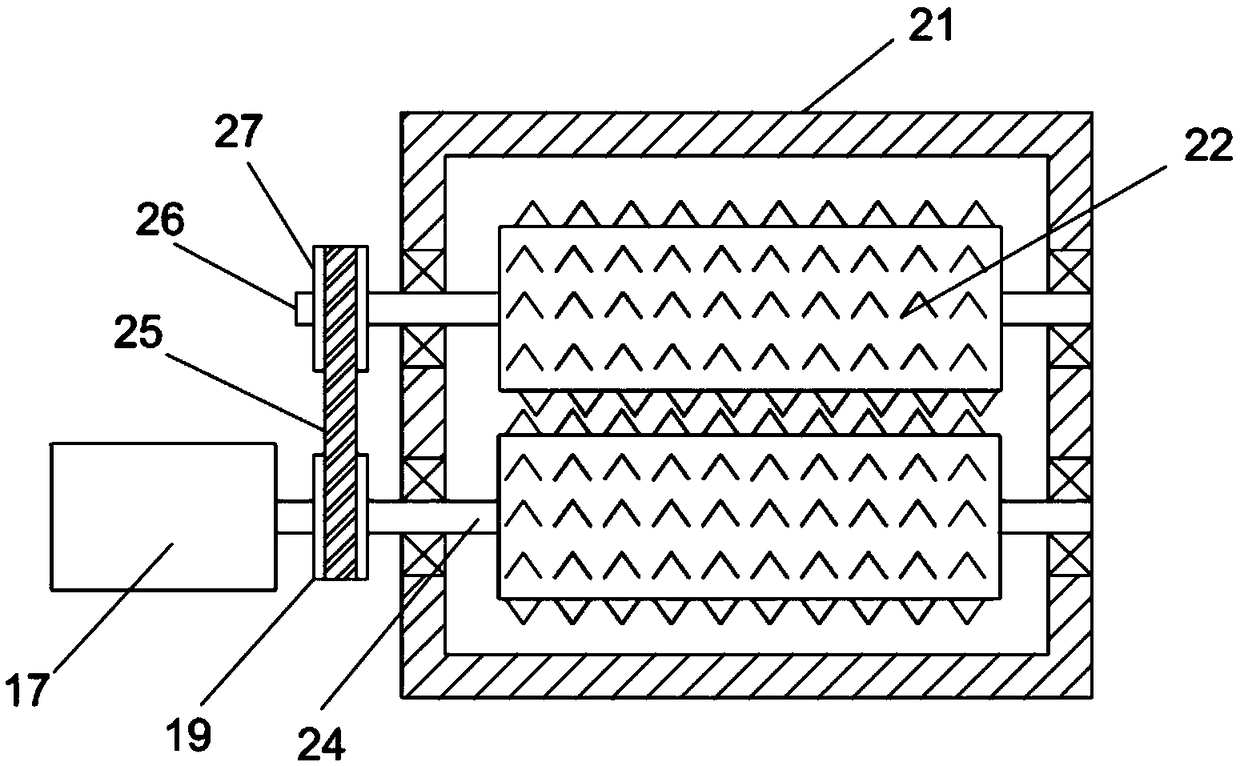

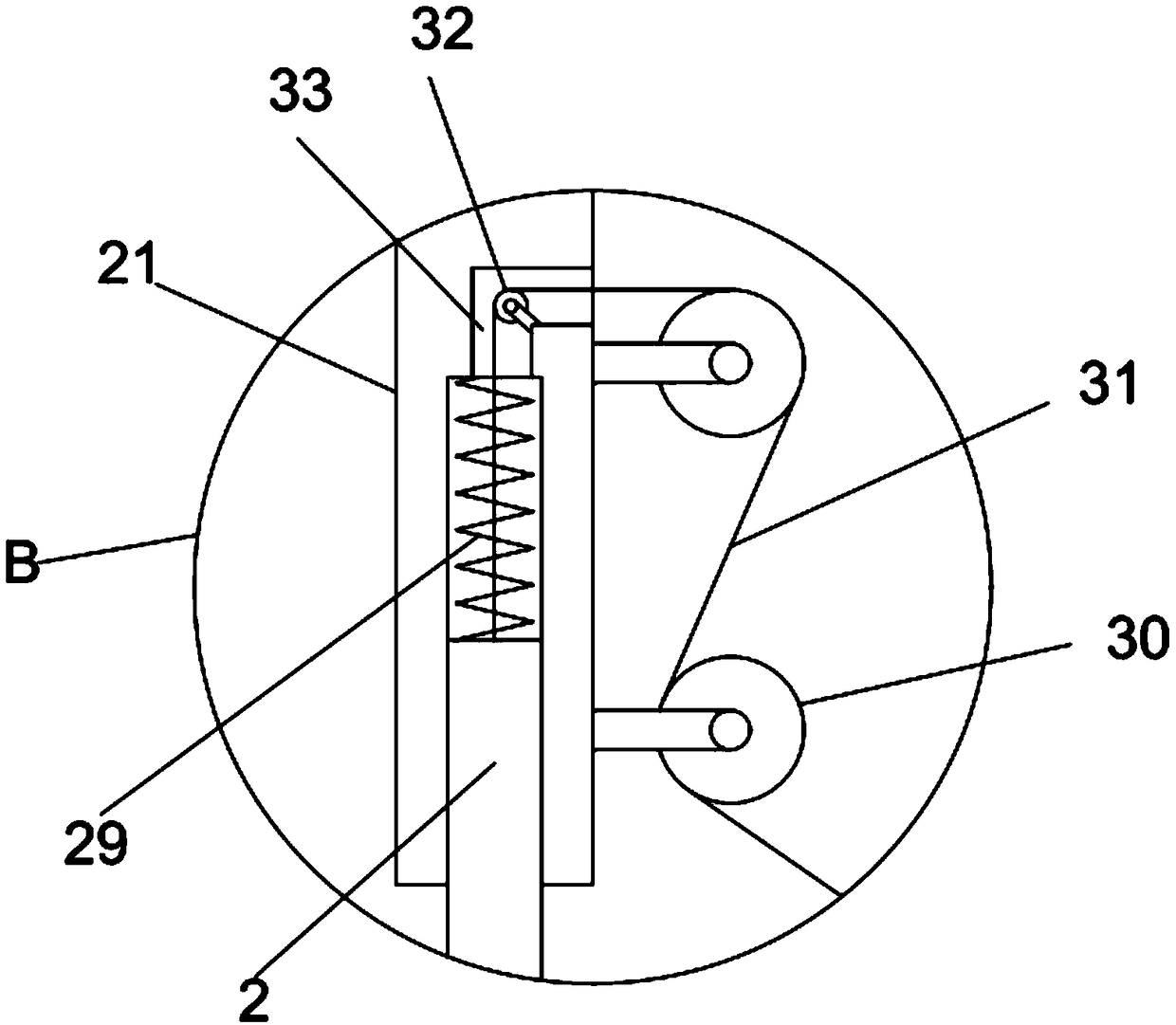

Intermittent feeding type coal briquette coarse crushing device for coal mine mining

InactiveCN108714473ARealize extrusion crushingFully brokenGrain treatmentsCoal briquetteReciprocating motion

The invention discloses an intermittent feeding type coal briquette coarse crushing device for coal mine mining. The intermittent feeding type coal briquette coarse crushing device comprises a bearingplate. A crushing box is fixedly installed on the bearing plate vertically. A rotating cover plate is arranged on the top of the crushing box in a rotating manner. A drive motor is fixedly installedon the outer wall of the left side of the crushing box through a support. The left end of a pulling rope penetrates the interior of a resetting spring and is fixed to the upper end of a sliding baffle. A guide sliding groove is horizontally formed in the side wall of a crushing pressing plate. A clamping block embedded in the guide sliding groove in a sliding manner is fixedly installed on the inner side wall of the sliding support. According to the intermittent feeding type coal briquette coarse crushing device, by means of rotating of a crushing roller, the extruding and crushing effect on coal briquettes is achieved, by means of vertical reciprocating motion of the sliding baffle, the coal briquettes on a material guide oblique plate enter a screening plate intermittently, the coal briquettes falling on the screening plate are extruded and rubbed repeatedly through the crushing pressing disc, excessive centralizing of the coal briquettes is avoided, the rubbing and crushing effectsof the crushing pressing disc are improved greatly, the coal briquettes are crushed more fully, the screening plate has a screening function, and it is ensured that the coal briquettes on the screening plate are refined fully.

Owner:SHANDONG INST OF BUSINESS & TECH

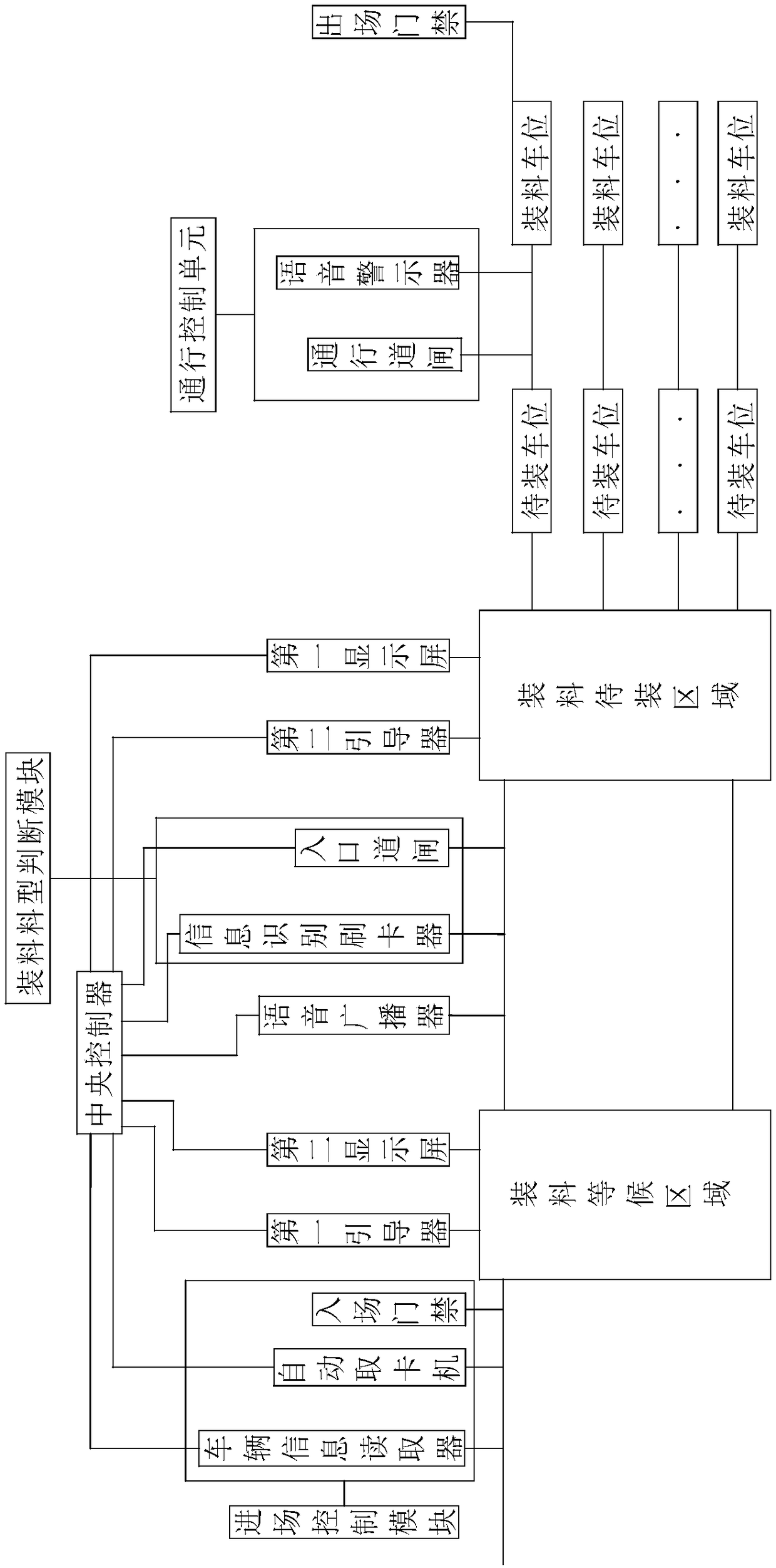

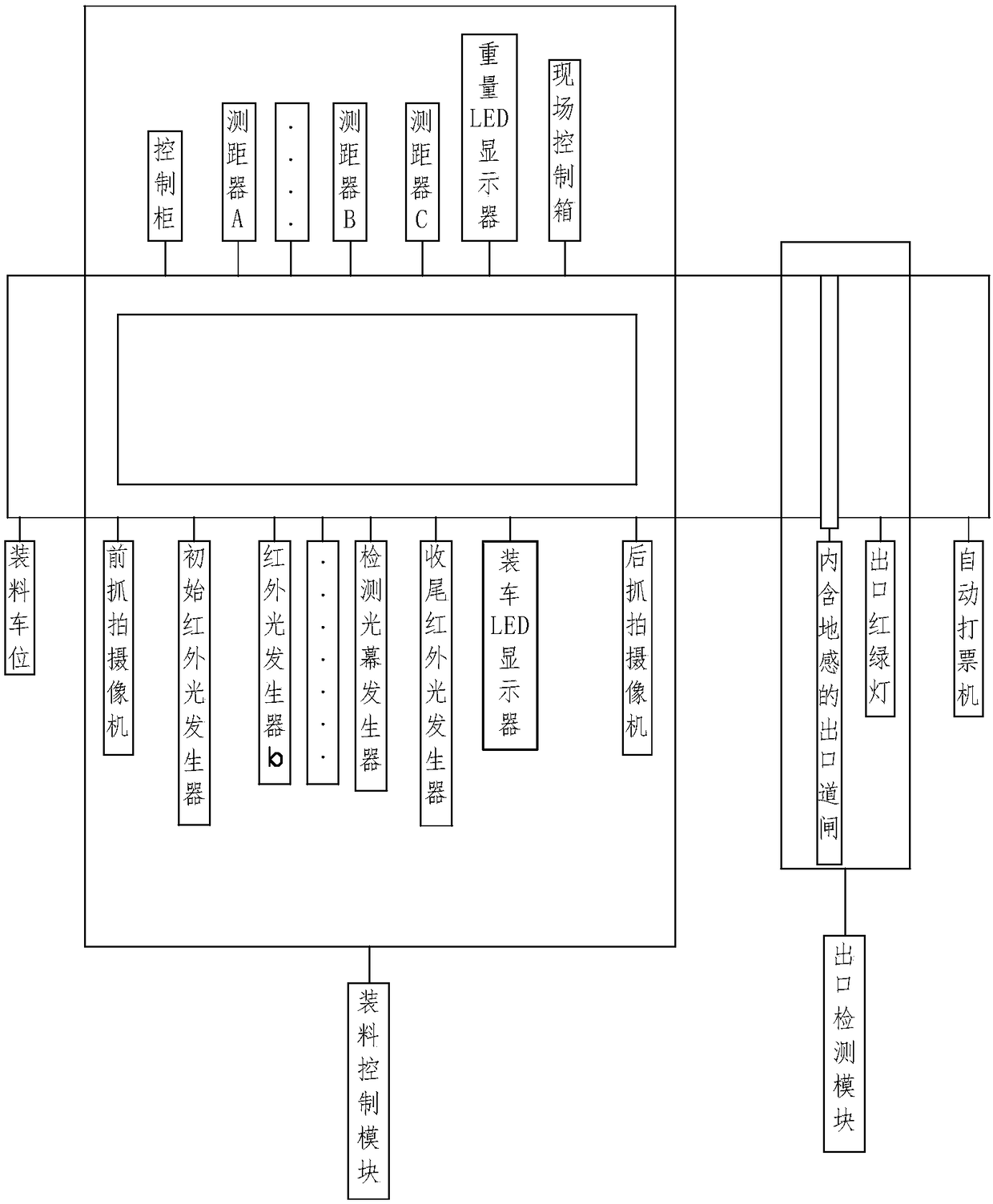

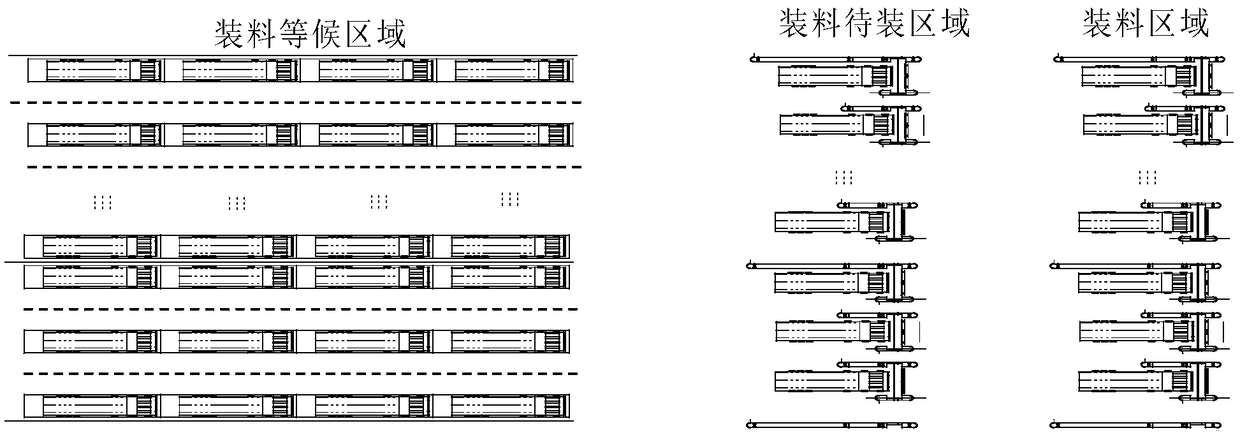

Automatic truck loading management system

PendingCN108922006AImprove intelligent controlImprove loading speedChecking apparatusIndividual entry/exit registersTruckManagement system

The invention discloses an automatic truck loading management system which comprises an entering queuing unit. The entering queuing unit comprises a loading waiting area and a feed to-be-loaded area.The loading waiting area comprises a plurality of different feed type waiting areas, and each feed type waiting area comprises a plurality of queuing truck spaces. First guiding devices are arranged in all the feed type waiting areas correspondingly, and all the first guiding devices are electrically connected with a central controller. The feed to-be-loaded area comprises a plurality of to-be-loaded truck spaces of different feed types, and feed-type judgment modules arranged at inlets of all the to-be-loaded truck spaces. Second guiding devices are arranged on all the to-be-loaded truck spaces correspondingly, and all the second guiding devices are electrically connected with the central controller. The automatic truck loading management system further comprises loading truck spaces formed behind all the to-be-loaded truck spaces correspondingly. Truck loading control units are arranged on all the loading truck spaces correspondingly. Compared with the prior art, feed trucks can be queued orderly, the loading speed is increased, starting and stopping of the trucks are accurately controlled, and the working efficiency is improved.

Owner:重庆欢腾科技有限公司

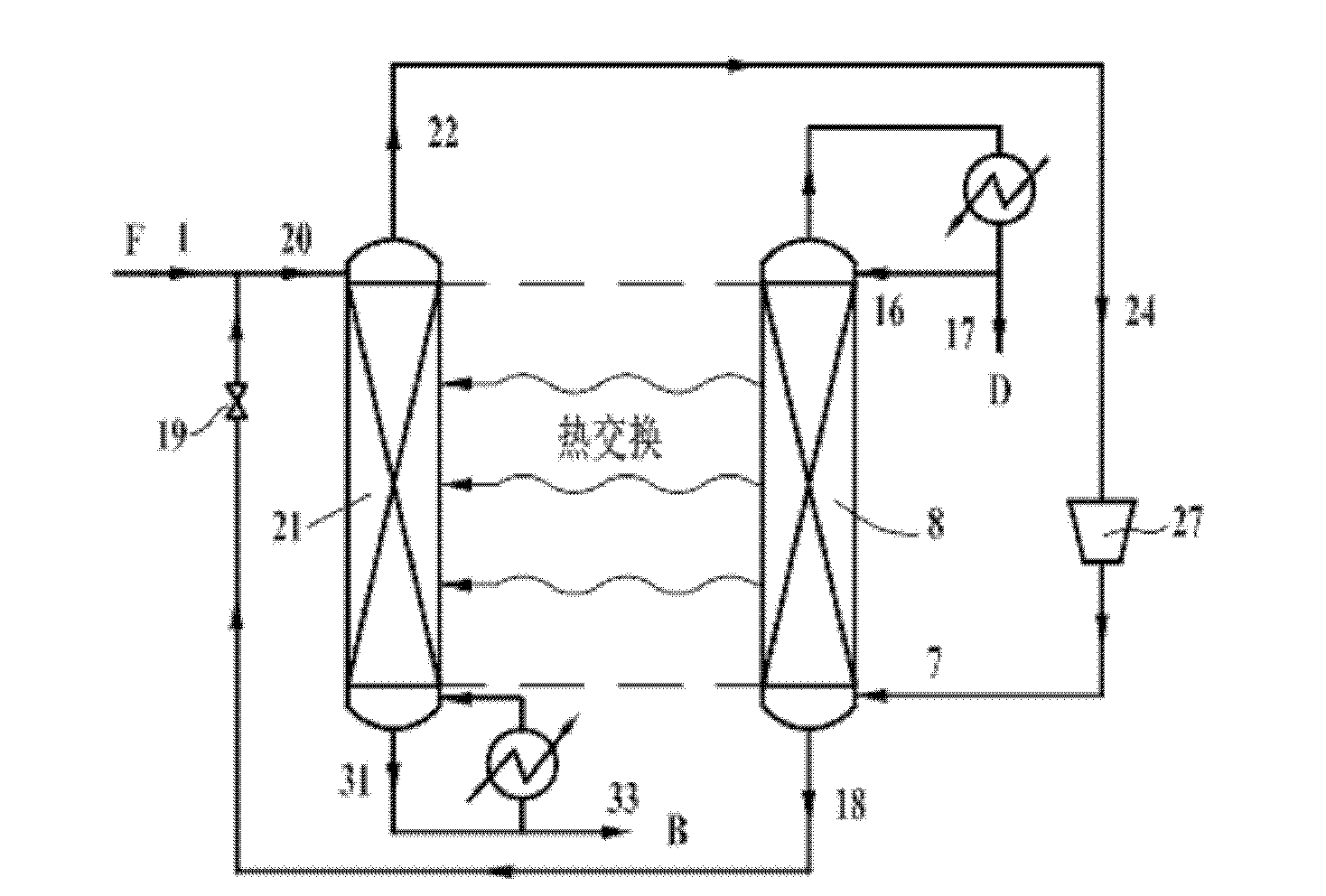

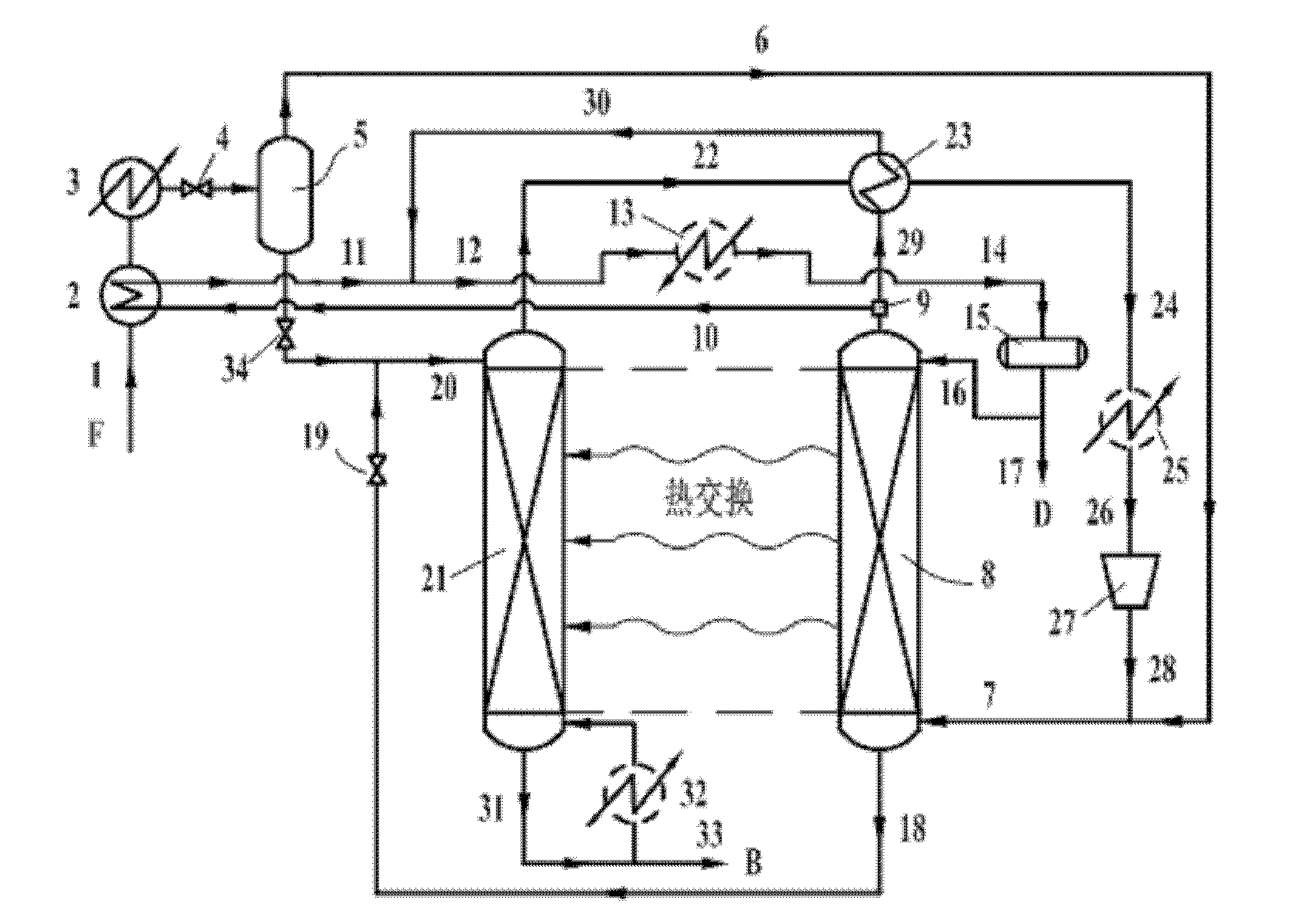

Flash evaporation feed type internal heat integration energy-saving rectifying device and method

InactiveCN101874934AReduce gas volumeReduced Compression Power ConsumptionDistillation regulation/controlFractional distillationVapor–liquid separatorReboiler

The invention relates to a flash evaporation feed type internal heat integration energy-saving rectifying device and a method, and the device comprises a system heat recovery heat exchanger, a feed preheater, a gas-liquid separator, a rectifying section, an auxiliary condenser, a stripping section, a compressor, an auxiliary reboiler and the like. The device is mainly characterized in that the gas-liquid separator is arranged on a feed pipeline; raw material liquid passes through the system heat recovery heat exchanger for heating and the feed preheater for further pre-heating and then enters into the gas-liquid separator; gas separated by the gas-liquid separator directly enters into tower bottom at the rectifying section, and liquid passes through a pressure reducing valve for reducing pressure and then enters into the top part of the stripping section; in addition, one part of saturated steam at tower top at the rectifying section is used for pre-heating fed materials, and the other part of the saturated steam is used for heating a gas overheater at the tower top at the stripping section. Compared with an ordinary internal heat integration rectifying tower, the adoption of the method and the device can greatly reduce the total energy consumption during the rectifying process, save operation cost and further achieve the purposes of energy conservation and synergy.

Owner:TIANJIN UNIV

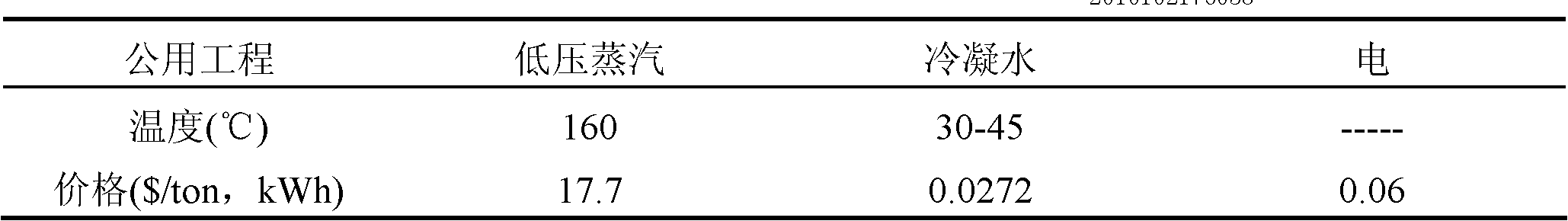

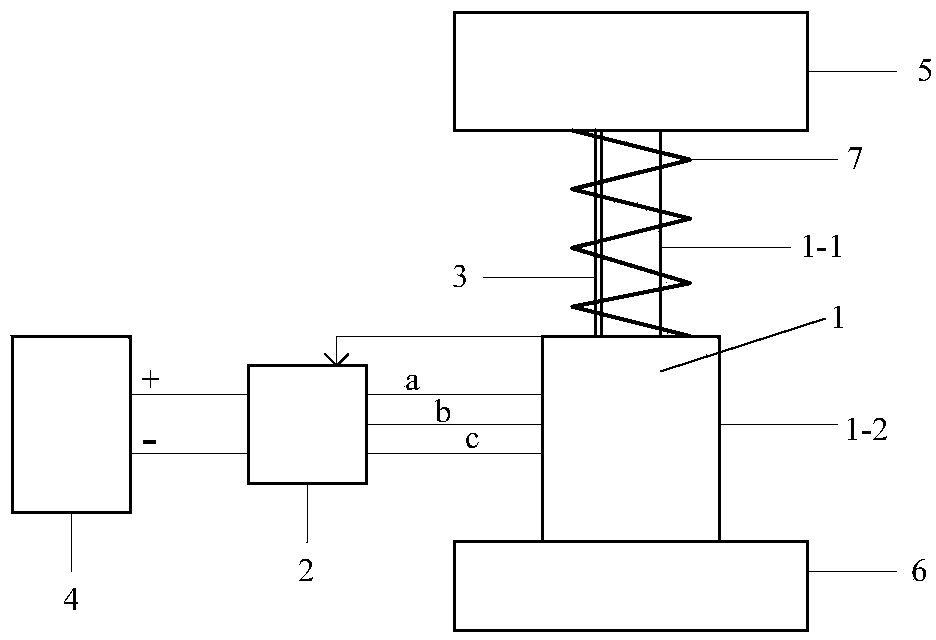

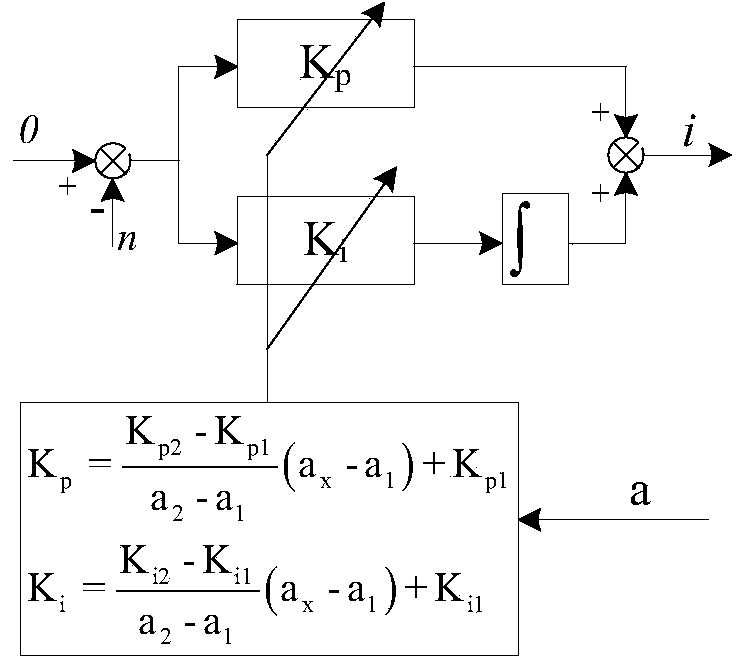

Feed-type electromagnetic damping vibration attenuation control method for vehicle suspension

InactiveCN103770594AWith feed functionImprove reliabilityResilient suspensionsDevice formClosed loop

The invention discloses a feed-type electromagnetic damping vibration attenuation control method for a vehicle suspension. The method is applicable to an electromagnetic damping vibration attenuation device formed by a cylindrical fault-tolerant permanent-magnet linear motor, a motor controller, a speed sensor and a storage battery. Since the motor controller figures out the speed and the acceleration of the cylindrical fault-tolerant permanent-magnet linear motor according to the signal of the speed sensor, calculates the proportionality coefficient Kp and the integral coefficient Ki of a variable parameter PI based on the absolute value of the acceleration in real time and controls the cylindrical fault-tolerant permanent-magnet linear motor to run by adopting a speed closed-loop vector control strategy, the electromagnetic vibration attenuation function is realized, the vibration energy is recovered, the electromagnetic damping coefficient can be adjusted in real time according to the actual situation, the vibration attenuation performance of the suspension and the smoothness of a 'man-vehicle' system are improved and the energy is saved.

Owner:JIANGSU UNIV

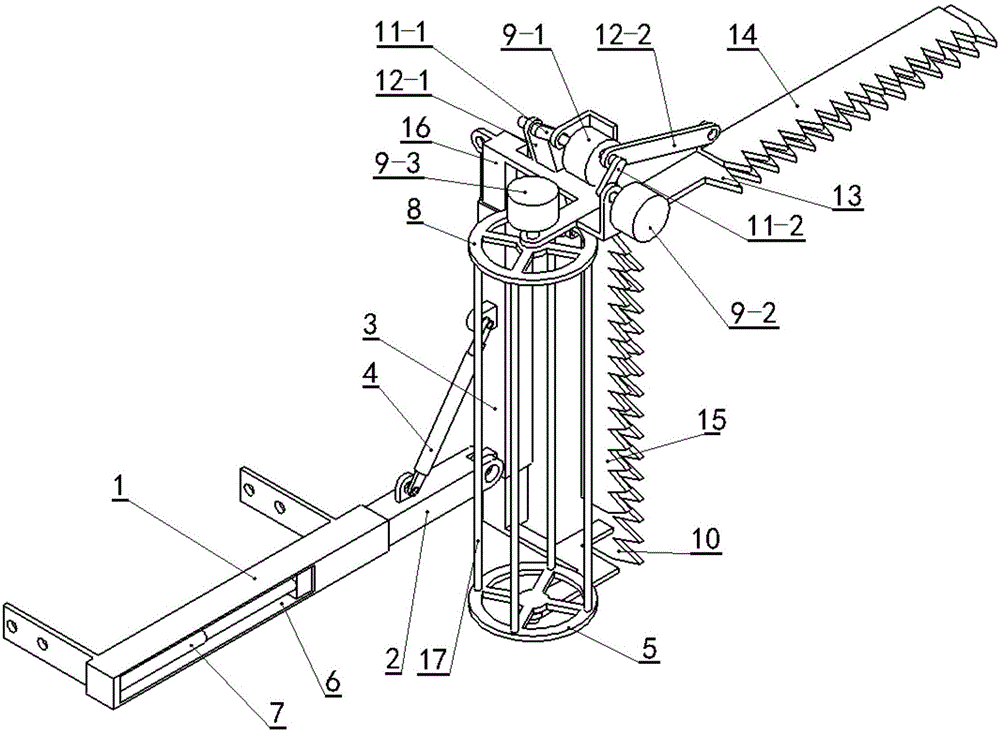

Feed type high-effect grape branch shearing machine

ActiveCN105052575AImprove resection rateImprove clippingCuttersMotor driven pruning sawsAgricultural engineeringKnife blades

The invention discloses a feed type high-effect grape branch shearing machine. The feed type high-effect grape branch shearing machine comprises a bearing support, a first telescopic device, a transversely-moving supporting arm, a second telescopic device, a swing frame, a vertical movable support, a third telescopic device, a torque output device, a feeder, a first crank, a first connecting rod, a vertical fixed blade and a vertical movable blade. The feed type high-effect grape branch shearing machine is more reasonable in structure and higher in shearing effect, and the grape branch shearing rate is greatly increased.

Owner:URUMQI YOUNIKE BIOLOGICAL SCI & TECH CO LTD

Horizontally feeding type packing machine

The invention discloses a horizontally feeding type packing machine. The machine is provided with a rotary disc, and an opening device, a heat-sealing device and a feeding station are arranged on the rotary disc. The machine is characterized in that a feeding device is arranged on a corresponding side of the feeding station and comprises a feeding belt and a feeding chain, wherein the feeding belt is perpendicular to the feeding chain, an accommodating box is arranged on the feeding chain driven by a motor and is in a horizontal state and aligns to the feeding station when corresponding to the feeding station, and a pushing cylinder is arranged right in front of the feeding station. According to the structure of the machine, materials can be pushed horizontally to the feeding station of the machine in a horizontal pushing mode, the defect of scattering caused by falling of the materials in the prior art is overcome, and the feeding speed and the working efficiency are high.

Owner:WENZHOU RUIDA MACHINERY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com