Double-row track feed type system for specific feeding of vertical LED lead frame

A technology of track feeding and lead frame, which is applied in the direction of electrical components, circuits, semiconductor devices, etc., can solve the problems of slowing down the production speed, numerous working steps, and low output, and achieve the effect of eliminating the feeding time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

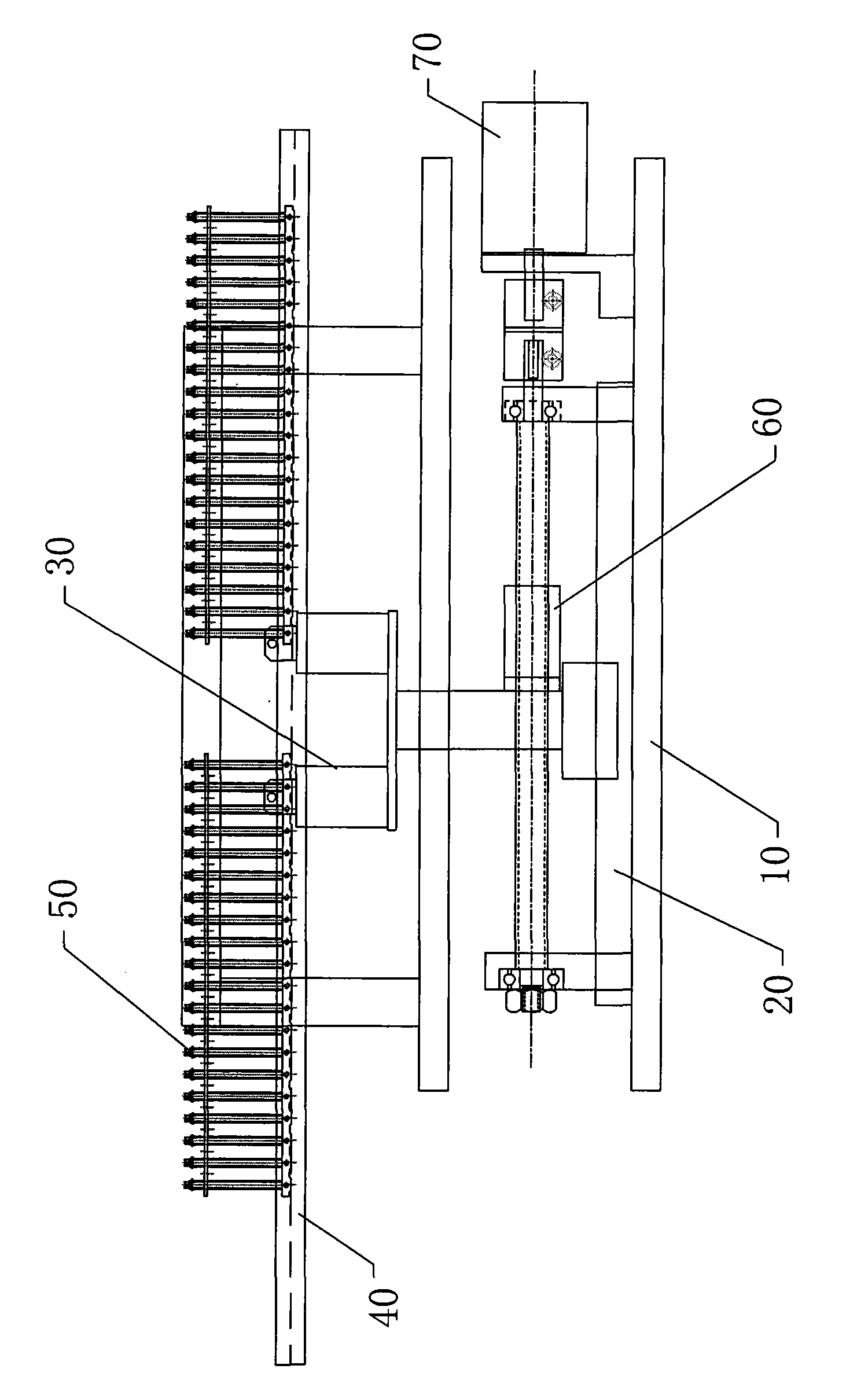

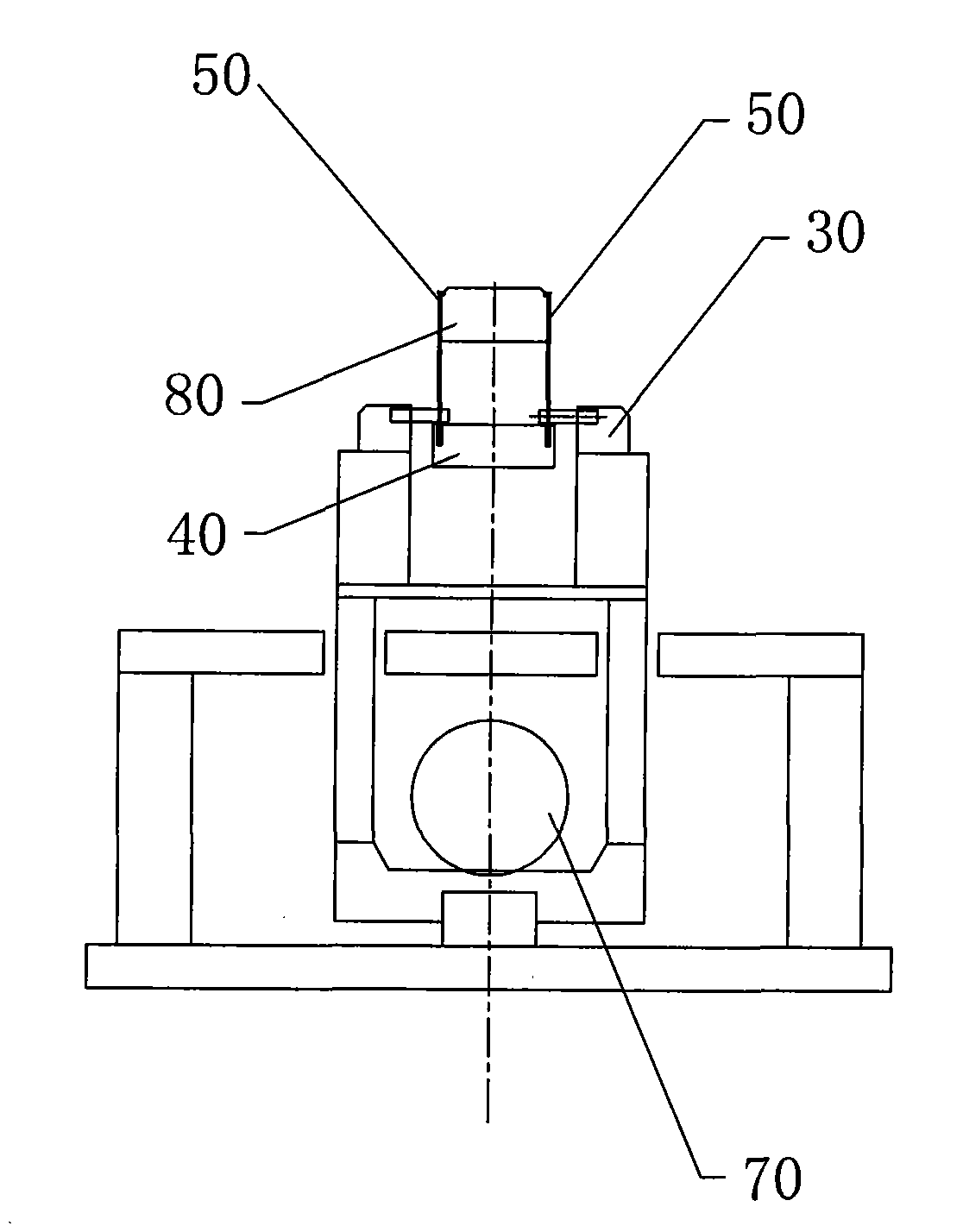

[0024] refer to figure 1 with figure 2 , the present invention is implemented like this:

[0025] A double-row track feeding type specific feeding system for vertical LED lead frames, including a chassis 10, a slider device 20 is arranged on the upper side of the chassis 10, and a bracket claw 30 is arranged on the slider device 20. The bracket claw 30 can be Sliding on the slider device 20, two rows of transport rails 40 are provided on the upper side of the bracket claw 30, the transport rails 40 are used to transport the LED bracket 50 from the input position to the output position, and the bracket claws 30 are used to transfer the LED bracket 50 products from the input To the output position, a motor 70 device is also provided on the chassis 10, and a ball screw 60 is connected on the output shaft of the motor 70. The ball screw 60 is used to move the position of the bracket claw 30, and the motor 70 is used to provide the ball screw 60. of rotational power. Two rows o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com