Patents

Literature

141results about How to "Reduced Compression Power Consumption" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

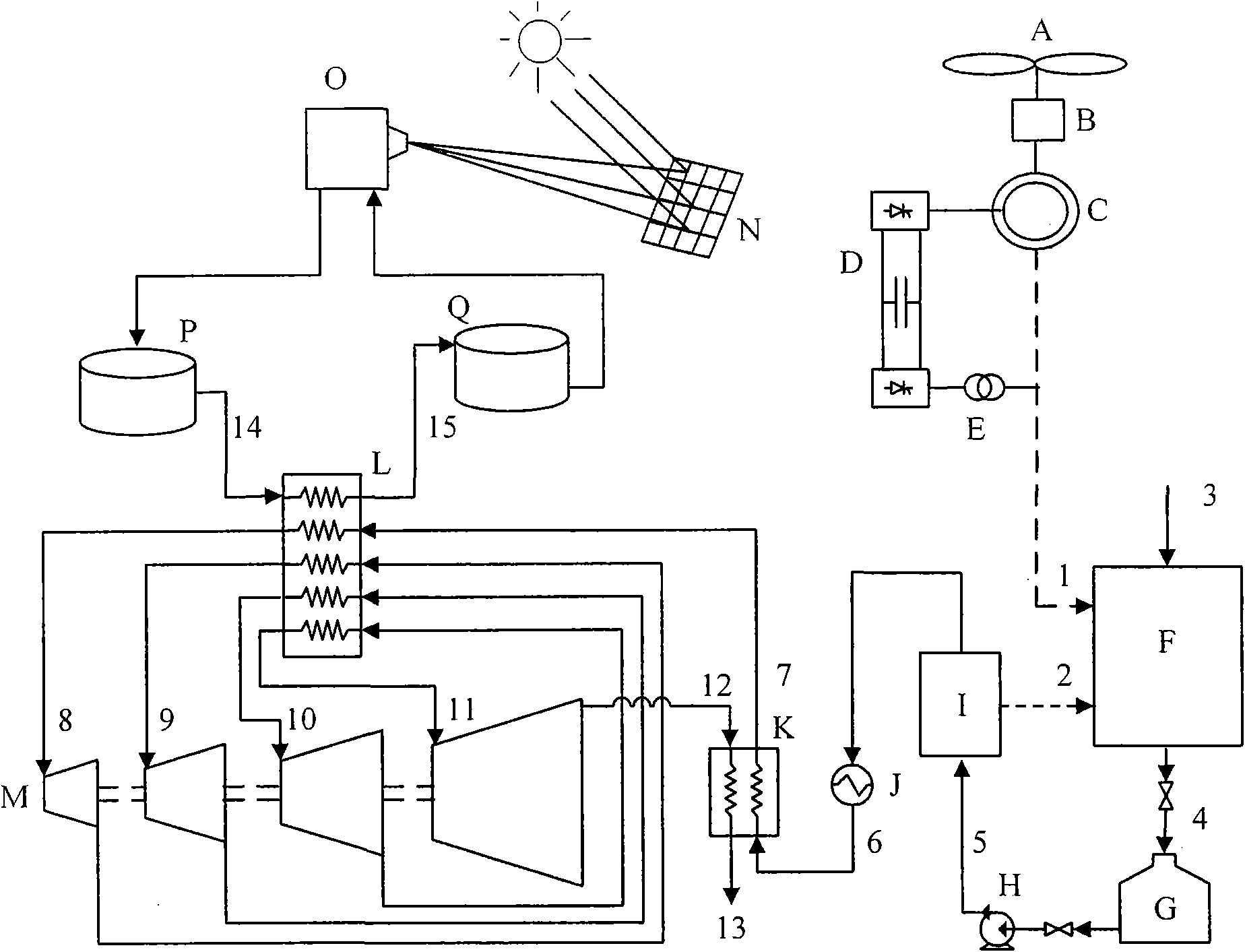

Wind and solar hybrid energy storage and power generation integration system and process

ActiveCN102062052ATo achieve complementary useImprove working abilitySolidificationLiquefactionThermal energyCollector device

The invention discloses a wind and solar hybrid energy storage and power generation integration system and process. The system comprises a wind power generation subsystem, a solar energy storage subsystem, a liquefied air subsystem and a power subsystem. The process comprises the following steps: solar energy is gathered by a thermal collector to obtain heat energy, the heat energy is stored in heat storge medium; wind energy is converted to electric energy, the wind power is used to liquefy air and stored in the liquefied air; and when electricity is required, the liquefied air is pressurized to recycle cold energy for the air liquefying process, then the air is heated by the high temperature heat storge medium which stores solar energy to obtain high temperature and high pressure air, and finally the air is sent to a multistage reheating turbine to expand and do work. The system of the invention recycles the cold energy of the liquefied air to reduce the wasted work for air liquefying; a pump is used to increase the pressure of the working medium, thus reducing the wasted work for compressing the working medium; the turbine utilizes recycled heat for exhaustm, thus effectively utilizing heat energy; solar energy is utilized to heat the working medium at the inlet of the turbine, thus increasing the expansion efficiency of the turbine; and wind energy and solar energy can be utilized for complementation, energy storage and power generation can be integrated and the system of the invention has wide application prospect.

Owner:葛洲坝中科储能技术有限公司

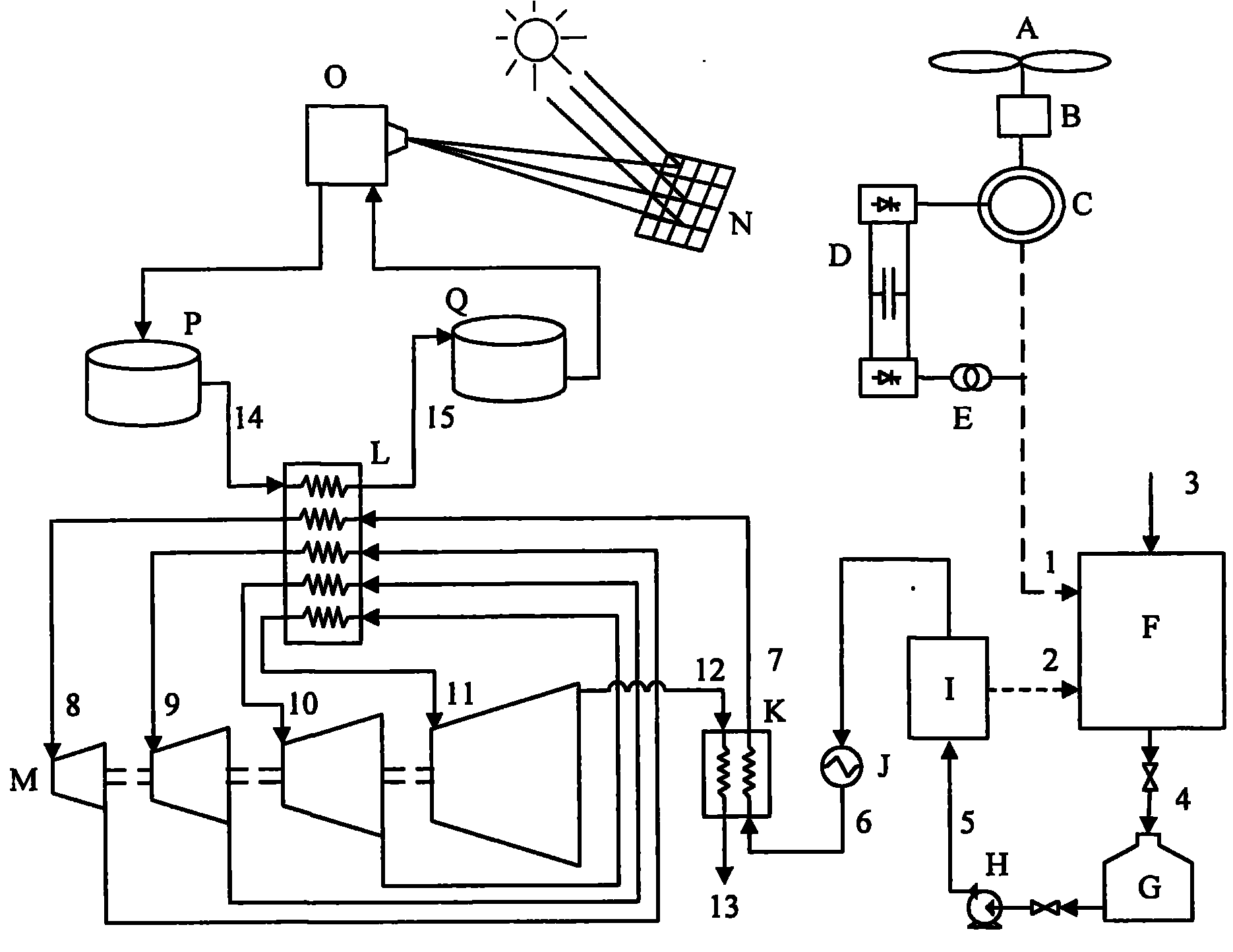

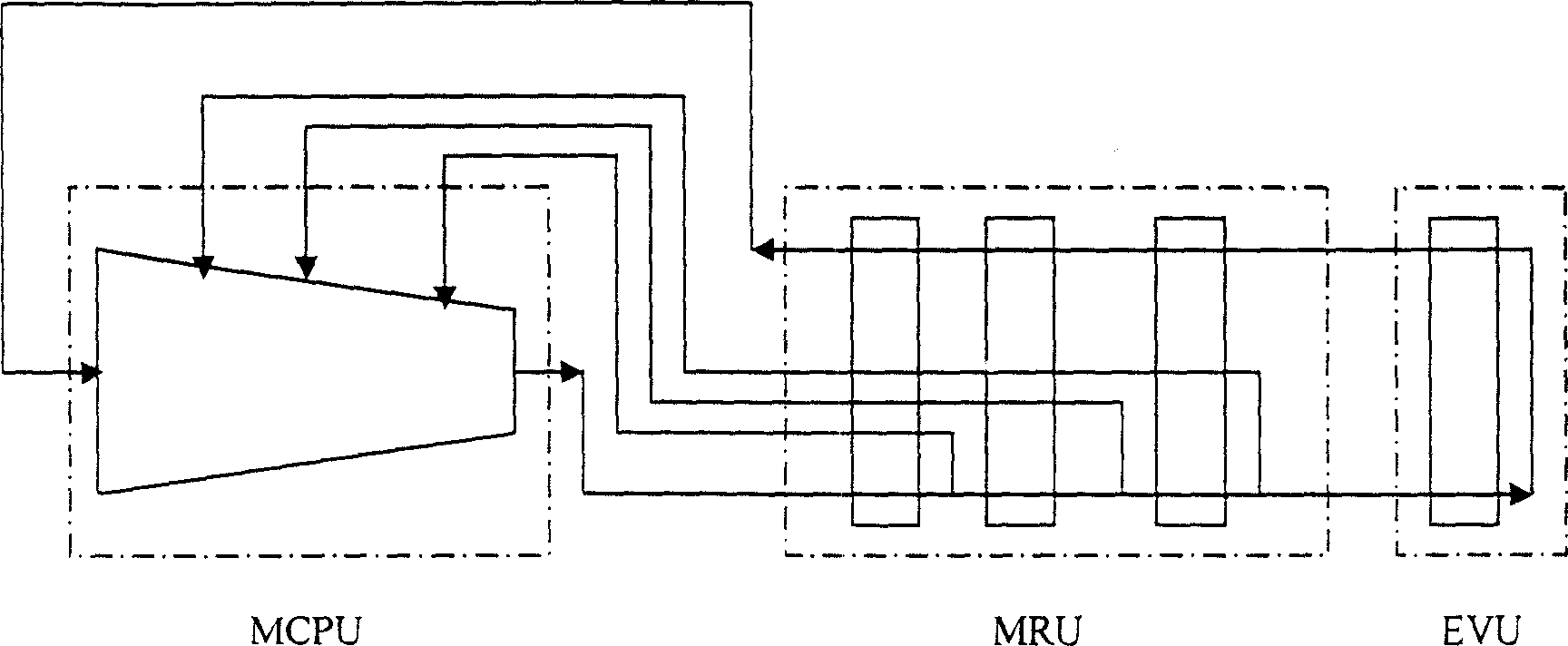

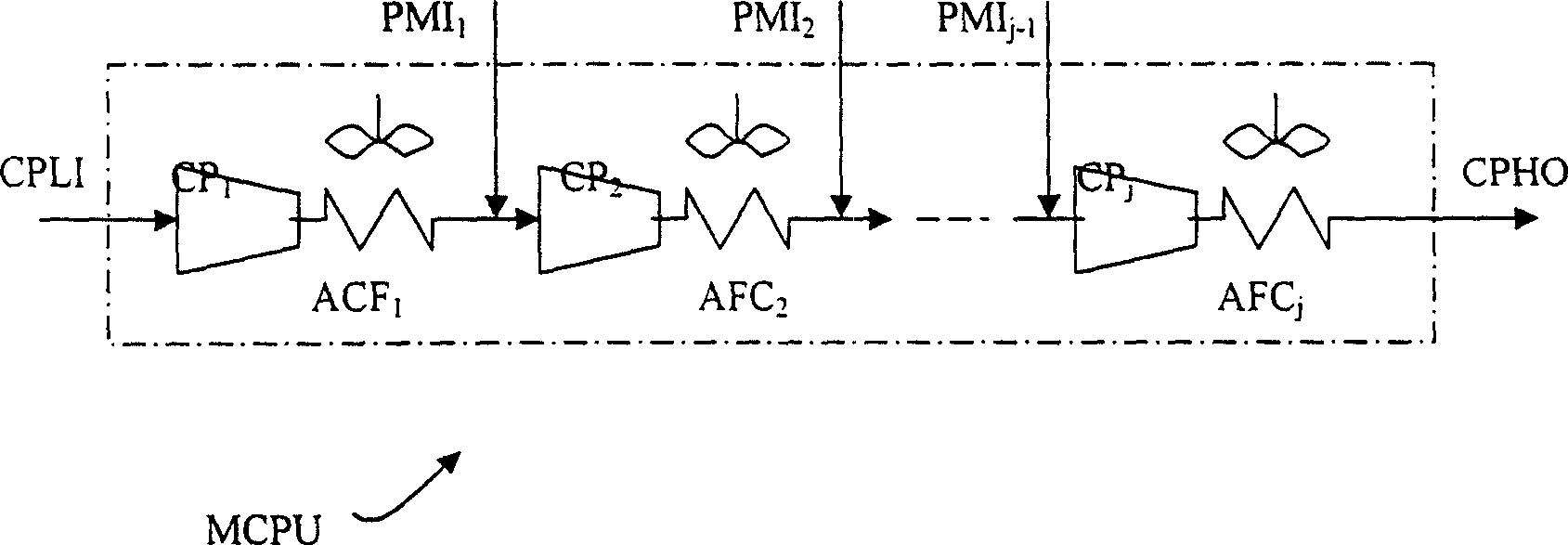

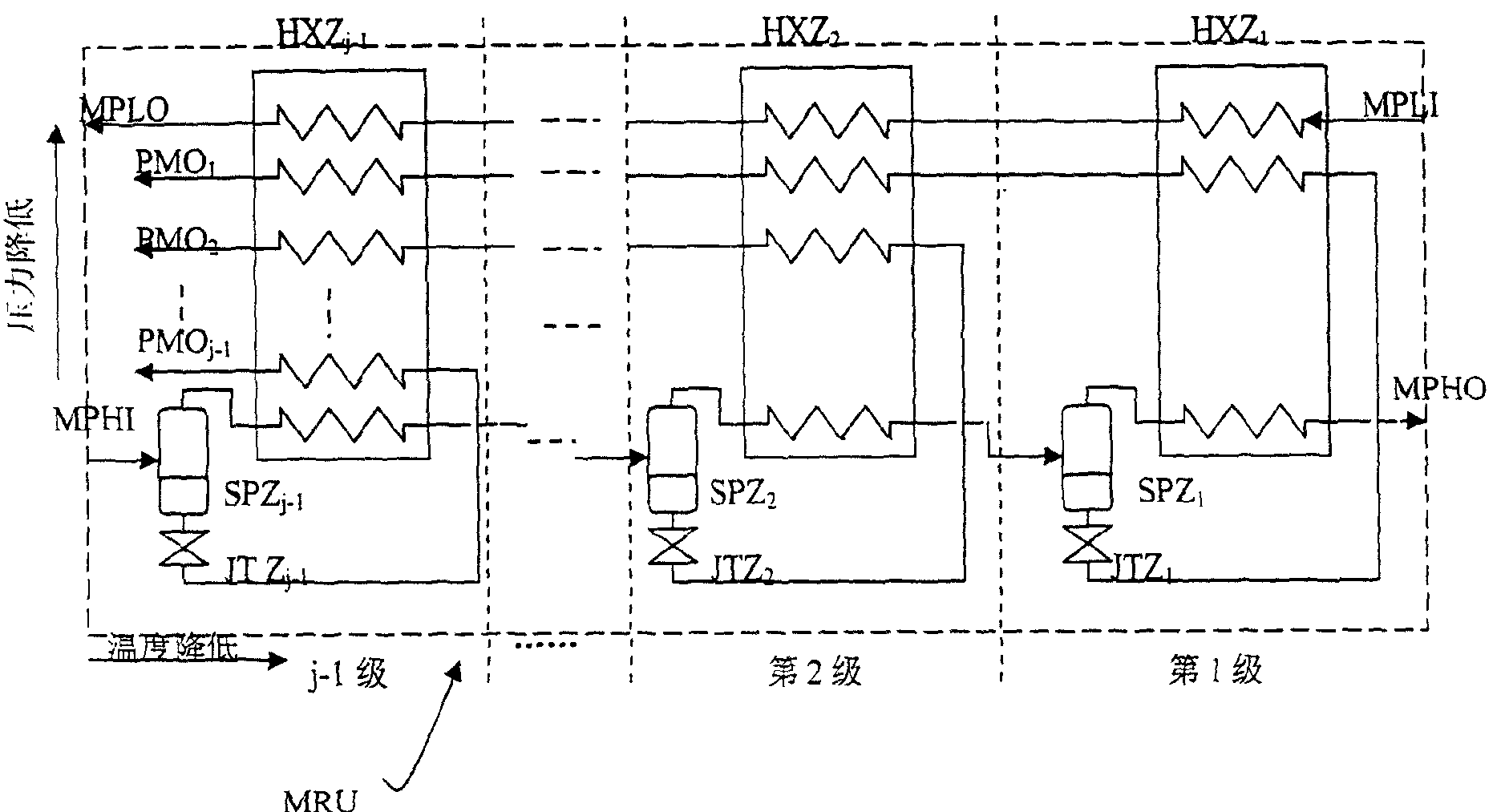

Multiple pressure grade mixed working medium cryogenic throttling refrigeration system

ActiveCN1683844AHigh thermal efficiencyGood throttling effectSolidificationLiquefactionProduct gasEngineering

The multiple pressure stage mixed work medium cryogenic throttling refrigeration system consists of several stages of compressor set unit MCPU, back heating pre-cooling unit MRU and evaporator unit EVU. The connection mode includes connecting the high pressure outlet of MCPU to the high pressure inlet of MRU, connecting the low pressure inlet of MCPU to the low pressure outlet one MRU, connecting the high pressure outlet operate MRU to the inlet of EVU, and connecting the outlet of EVU to the low pressure inlet of MRU. The present invention adopts high efficiency multiple-element mixed work medium. The refrigeration system has lowered irreversible loss of compression and back heating process thermodynamically, reduced loss in the practical flow and heat exchange process, and thus high thermodynamic efficiency, and is especially suitable for large and middle scale low temperature refrigerating and gas liquefying fields.

Owner:TECHNICAL INST OF PHYSICS & CHEMISTRY - CHINESE ACAD OF SCI

Piston reciprocating internal-combustion engine working substance flow system and its device

InactiveCN101289956AHigh thermal efficiencyEasy to achieve coolingNon-fuel substance addition to fuelInternal combustion piston enginesAir compressionControl set

The invention discloses a working substance flowing system of a piston reciprocating internal combustion engine and regulation and control setting thereof. An upper end of a frame moving up and down along the rotation of a power shaft is connected with an engine cylinder piston [7]; the lower end of the frame is made into a pressure cylinder piston [5]; an air inlet pipe[14], an air inlet check valve[2] and an air compression check valve[3] are arranged on a bottom cover plate of the pressure cylinder; air sucked from the air inlet pipe[14] by the pressure cylinder is sprayed by water mist for intercooling in compression; compressed air is stored in an air storage channel, tangentially supplied to an air inlet[10] of an engine cylinder sleeve; a rod head of the air compression check valve[3] is connected with the compressed air regulating and controlling device. An exhaust port [12] of the engine cylinder is arranged in the rear side of the cylinder top; a pressurized air bypass channel tightly pressed on the lower side of a flashboard-type exhaust valve [21] and an air suction check valve [22] of the upper side of a vent-pipe inlet cool an exhaust system and exhaust air and have the effects of both decontamination and preventing an exhaust gas turbine from surging. The supercharging mechanism has compact structure, indirect transmission, stable pressurization and cooling function; the working substance flowing system is provided with the regulating and controlling device with optimized performance and is convenient to the actualization of a small and medium sized engine.

Owner:肖光宇

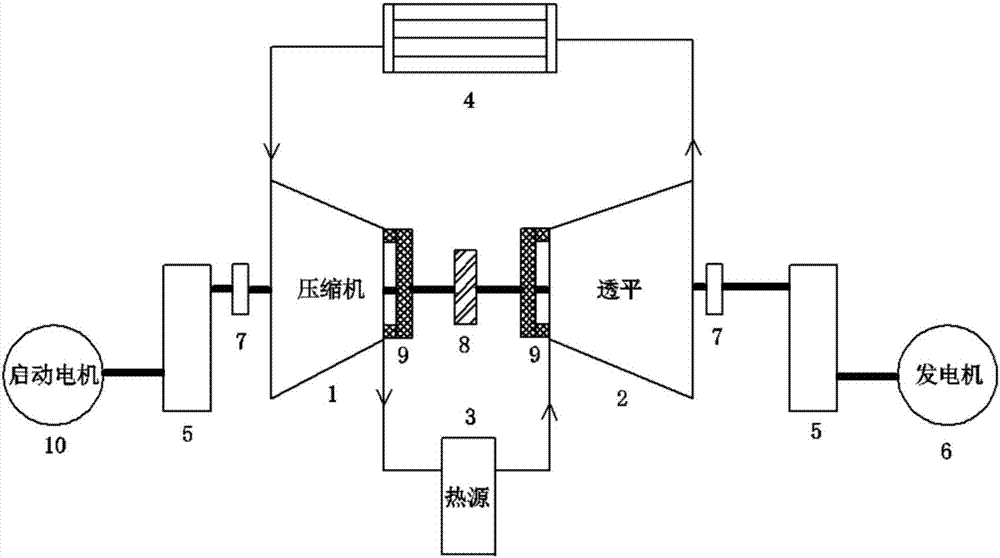

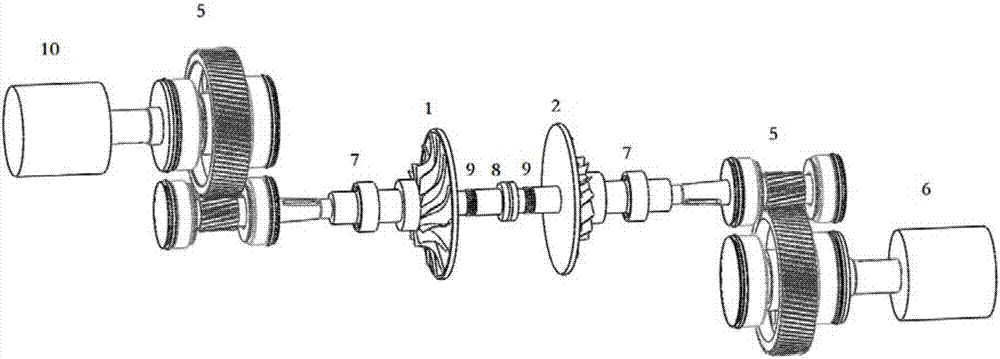

Supercritical carbon dioxide centrifugal compressor and radial-inward-flow turbine coaxial structure

InactiveCN107461227AViscosity of working mediumSmall working fluid viscositySteam engine plantsMotor driveElectric machine

The invention discloses a supercritical carbon dioxide centrifugal compressor and radial-inward-flow turbine coaxial structure. A supercritical carbon dioxide working medium sequentially flows through a centrifugal compressor to improve pressure and a heat source to improve temperature, and finally after output work in a radial-inward-flow turbine, the supercritical carbon dioxide working medium enters a cooler to be cooled and circulates to enter the centrifugal compressor again. A start motor drives the coaxial structure to start working through one gearbox, the coaxial structure is formed by the radial-inward-flow turbine and the centrifugal compressor through a rotor shaft, the centrifugal compressor is driven by one part of output work of the radial-inward-flow turbine, and the other part of output work of the radial-inward-flow turbine is output into a generator through the other gearbox. Radial bearings are arranged at the shaft ends of the two sides of the coaxial structure, a thrust bearing is arranged in the middle of the coaxial structure, and the type adapting to the corresponding rotary shaft rotating speed can be selected. Furthermore, the form of supercritical carbon dioxide dry gas seals is adopted in sealing parts. The supercritical carbon dioxide centrifugal compressor and radial-inward-flow turbine coaxial structure has the prominent beneficial effects of being simple and compact in structure, high in pneumatic efficiency, low in manufacturing cost and the like and has wide market prospects.

Owner:XI AN JIAOTONG UNIV

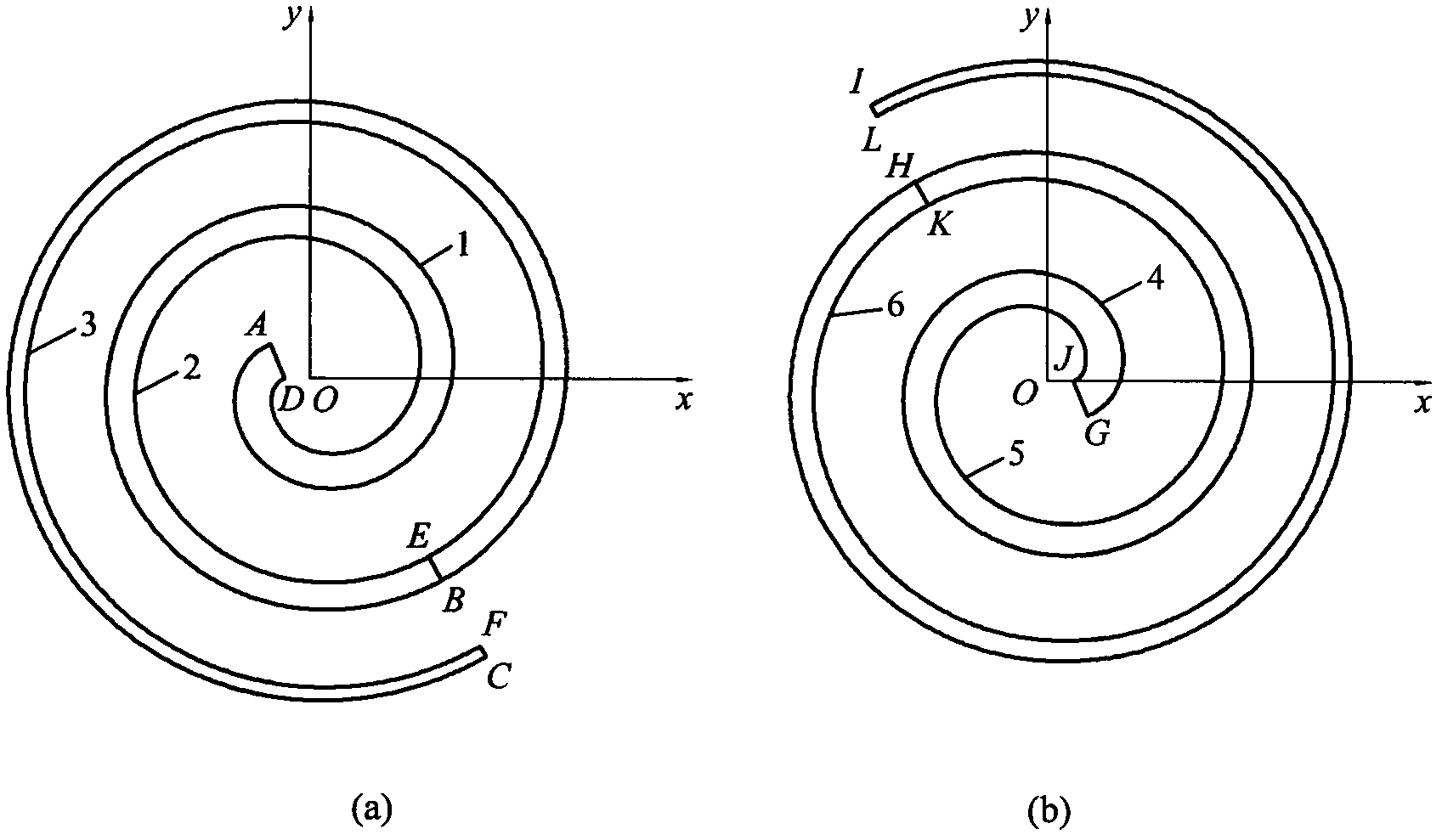

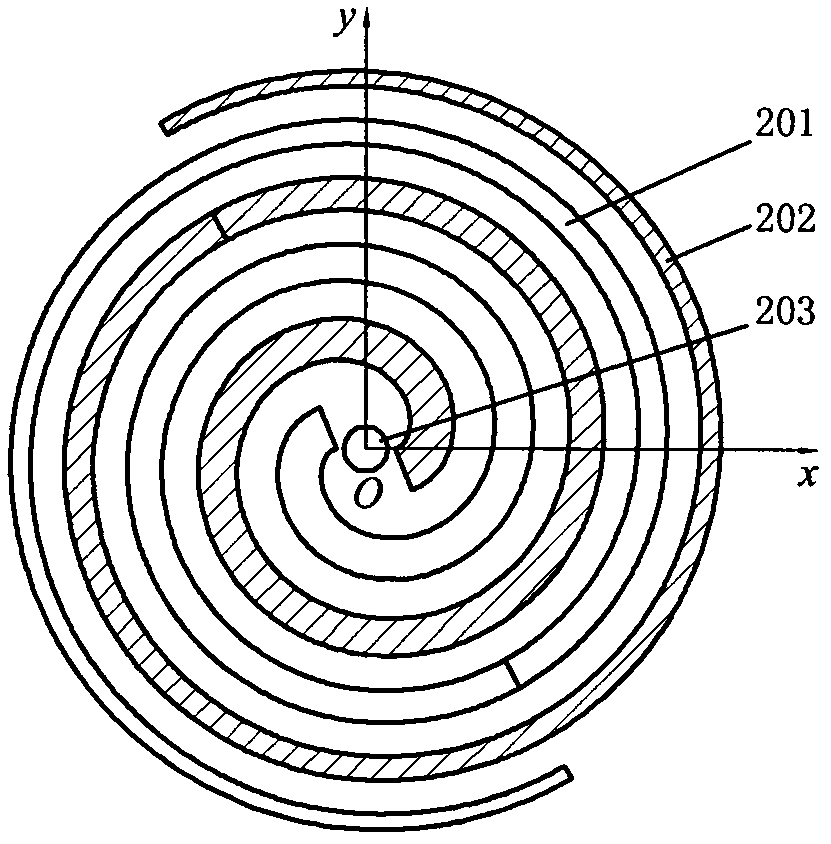

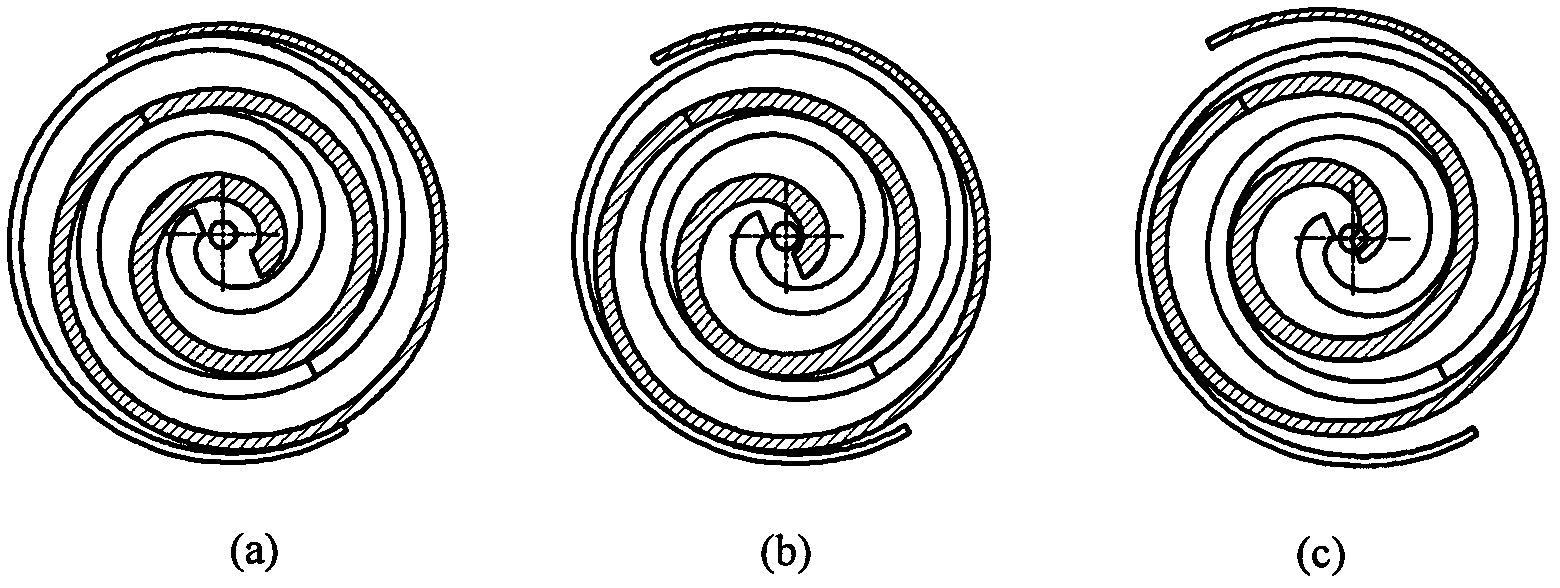

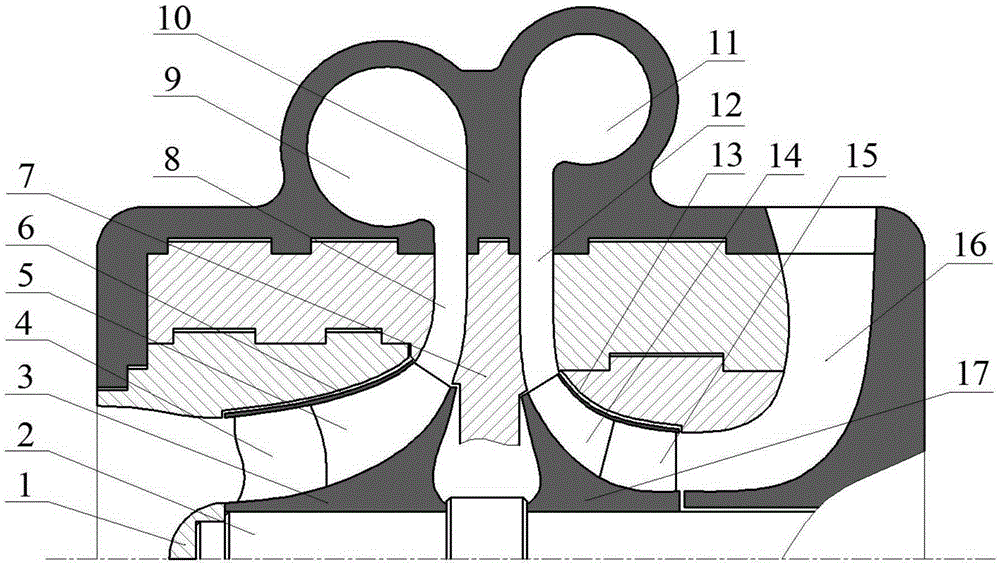

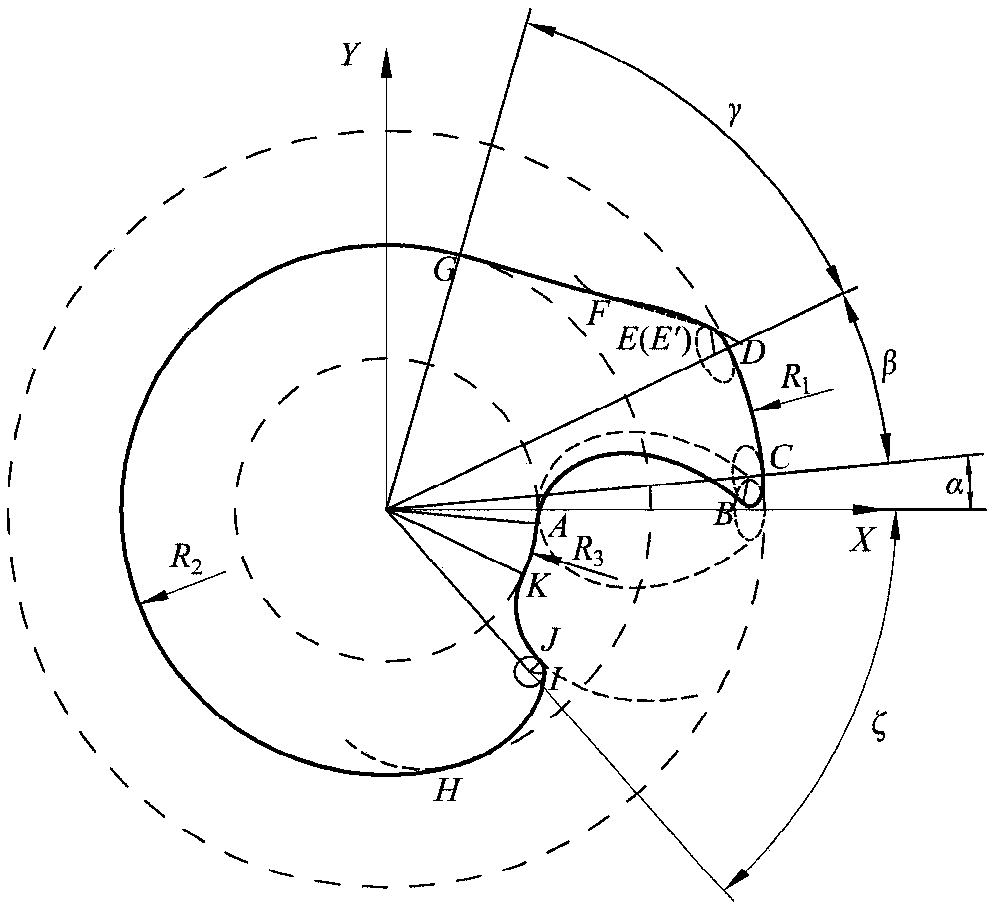

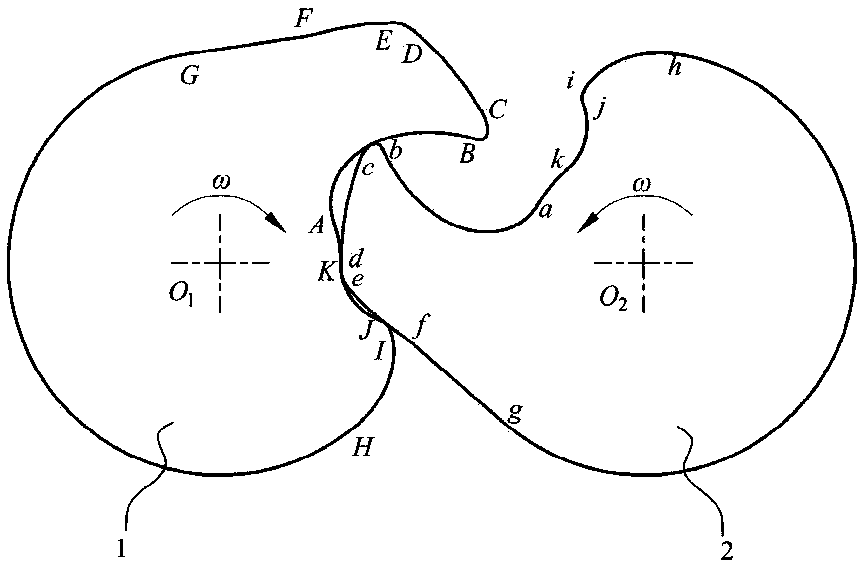

Scroll wrap profile of liquid-injected scroll compressor

InactiveCN103047135AStrong enoughExtended service lifeRotary piston pumpsRotary piston liquid enginesInvoluteEngineering

The invention relates to a scroll wrap profile of a liquid-injected scroll compressor. Outer profiles of a static scroll wrap and a dynamic scroll wrap are composed of a section of a variable diameter base circle involute, and the inner profiles of the static scroll wrap and the dynamic scroll wrap are composed by smoothly connecting a variable diameter base circle involute at a center part and normal equidistant curves of the variable diameter base circle involute of the outer ring. The scroll wrap refers to a scroll wrap with compression chamber variational meshing clearance and the wall thickness of the scroll wrap changing gradually. The meshing part close to a central air outlet of the compression chamber is provided with the meshing clearance which forms a pressure unloading channel to the air outlet with small clearance internal leakage, so that the problems of surge pressure in the compression chamber or liquid impacting which are produced by incompressible liquid with relatively large spraying volume. The meshing point of a suction cavity formed by the scroll wrap has no meshing clearance, so that the suction cavity is completely isolated from the compression chamber; at the same time, the wall thickness of the scroll wrap changes thinner gradually from the center to the outer ring, so that the central part of the scroll wrap has enough strength; and the wall thickness at the outer ring of the scroll wrap is relatively thin, so that area utilization rate of a scroll plate is effectively increased.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

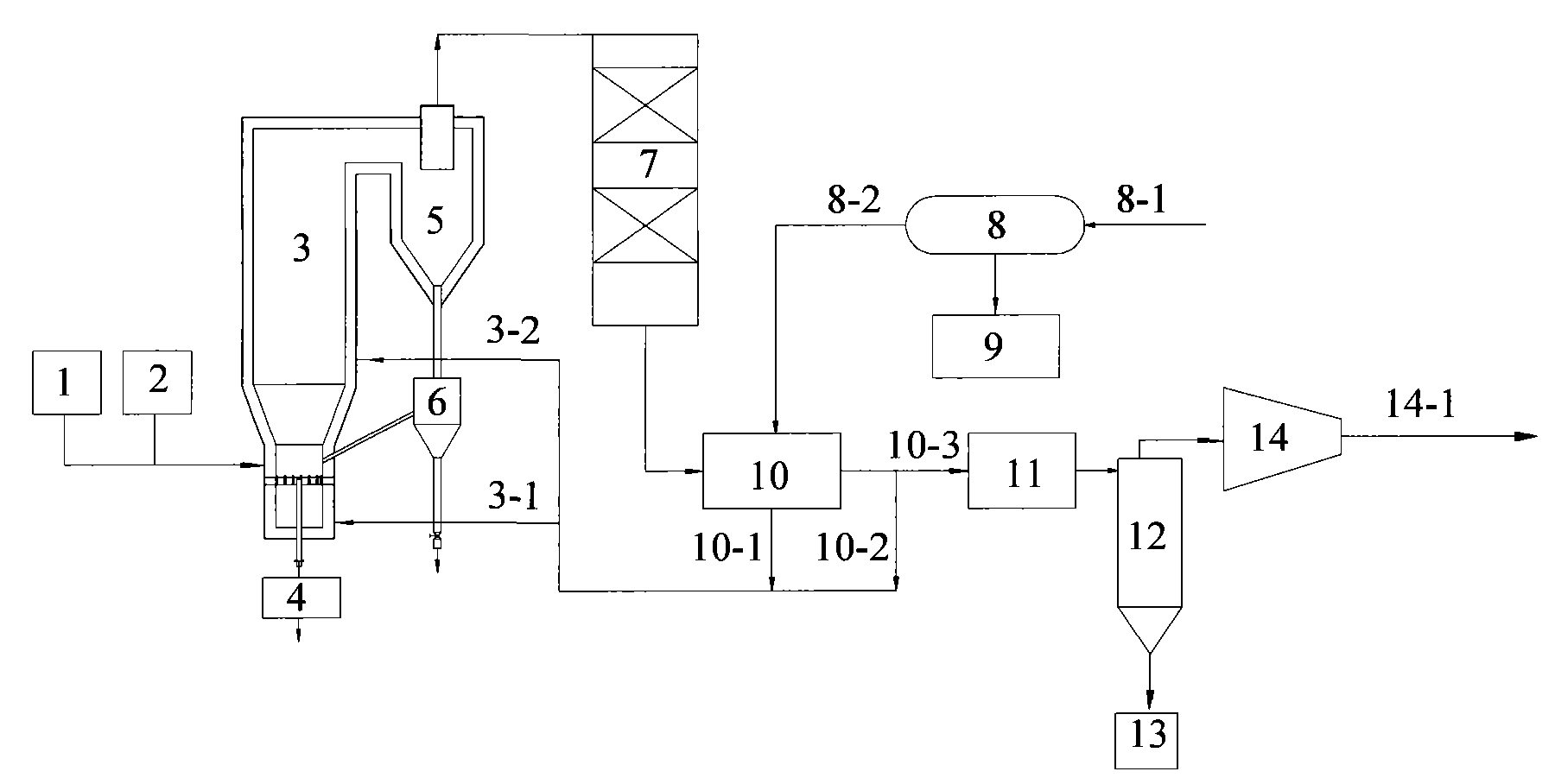

Method for reducing emission of carbon dioxide by circulating fluidized bed temperature flue gas circulation oxygen combustion

InactiveCN101634449ARealize rational utilizationHigh thermal efficiencyFluidized bed combustionDispersed particle separationResource utilizationWater vapor

The invention relates to a method for reducing emission of CO2 by circulating fluidized bed temperature flue gas circulation oxygen combustion, which is a method for realizing CO2 emission reduction applied in a circulating fluidized bed boiler based on the technology of temperature flue gas circulating oxygen combustion. The method comprises the following steps: feeding fuel and desulfurater into the circulating fluidized bed boiler, taking the gas mixture of O2 and circulating flue gas as combustion agent, passing through the heating surface at the tail by the flue gas generated by combustion, heating O2 (concentration is 96.5%-98.5%) from an air separation unit, generating temperature flue gas at the temperature of 140-150 DEG C, taking the gas mixture composed of 30%-70% of the temperature flue gas and O2 as oxidant to delivery to a furnace for combustion, carrying out dedusting by a deduster, multi-level condensation and dehydration and compression on the residual flue gas (volume concentration of CO2 is larger than 95%), and realizing resource utilization or storing in a sealing manner. The circulating glue gas is rich in vapor, entrainment unburned carbon and active desulfurater; the method enhances radiant heat exchange in the furnace, solves the problem of insufficient amount of convection heat transfer, improves combustion efficiency and desulfuration efficiency of the furnace, and can realize near-zero emission of gas pollutant; besides, the method can also lower comprehensive power consumption of space division and CO2 compression, and improve generating efficiency.

Owner:SOUTHEAST UNIV

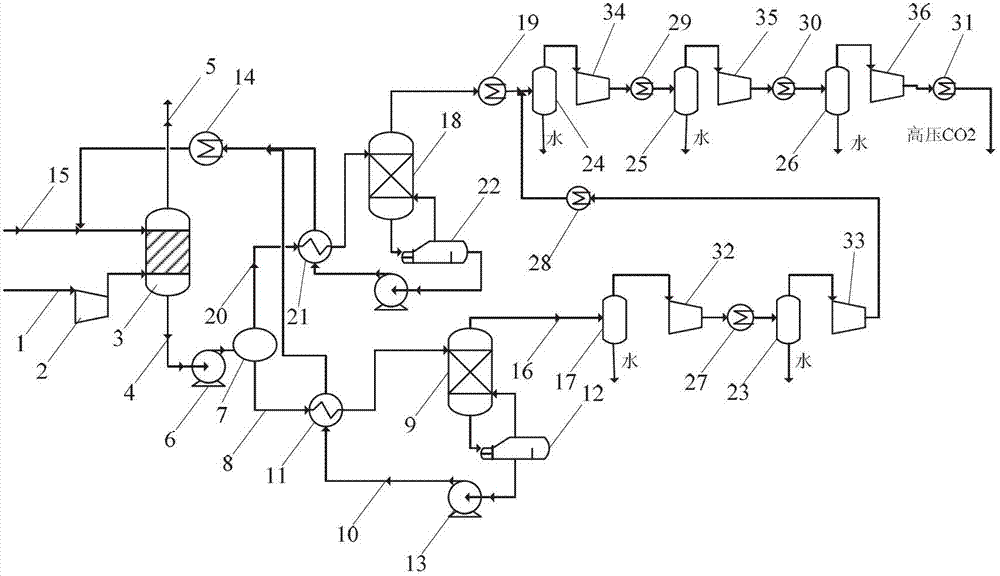

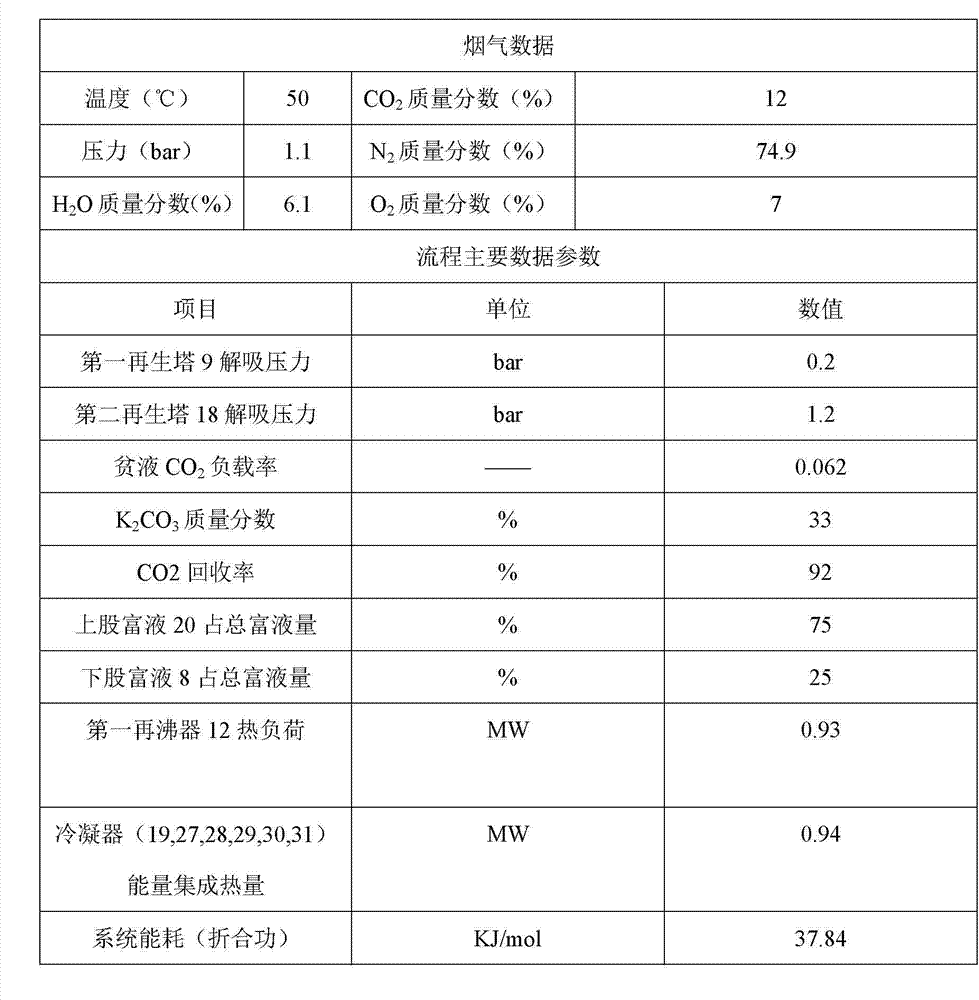

Method and system for reducing consumption in capturing process of CO2 through chemical absorption

ActiveCN102895860AReduce heat loadLow regeneration energy consumptionDispersed particle separationBy chemical separationWater vaporDesorption

The invention relates to a method and a system for reducing consumption in a capturing process of CO2 through chemical absorption, belongs to the fields of energy utilization, energy conservation and environmental protection. Based on the common CO2 capturing process, the method comprises the following steps that: an absorbent in an absorption tower is used for absorbing CO2 in flue gas and forming a pregnant solution, the obtained pregnant solution is divided into two branches, the two branches of pregnant solution is subjected to CO2 separation in two regeneration towers with different pressures, and waste heat generated during a high-pressure desorption process of the pregnant solution is taken as a heat source of a low-pressure desorption process; CO2 air flows mixed with water vapor after treatment by the regeneration towers are treated by multiple stages of gas-liquid separators, condensers and compressors, so that high-pressure liquid-station CO2 is obtained. With the adoption of the method and the system provided by the invention, the heat consumption during the whole desorption process is reduced, so that the efficient desorption of the pregnant solution flows is realized; under the premise that the capturing rate is 92%, the regenerated energy consumption of an optimal system obtained after improvement of the process is 37.84KJ (reduced work) / mol, and is reduced by 19.77% compared with the energy consumption of 47.16KJ (reduced work) / mol before improvement, and therefore, a new method is provided for reducing the energy consumption for capturing the CO2 with the low energy consumption in thermal power plants.

Owner:NORTH CHINA ELECTRIC POWER UNIV (BAODING)

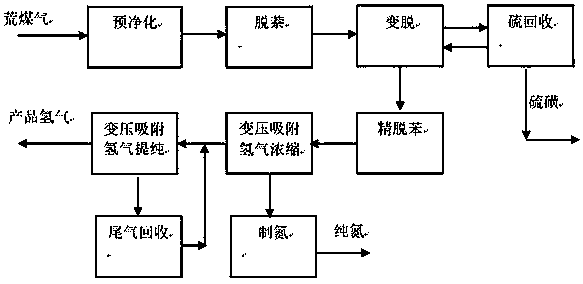

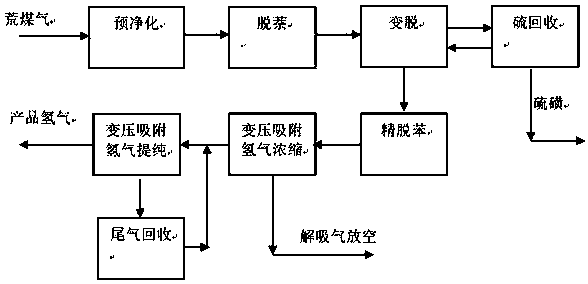

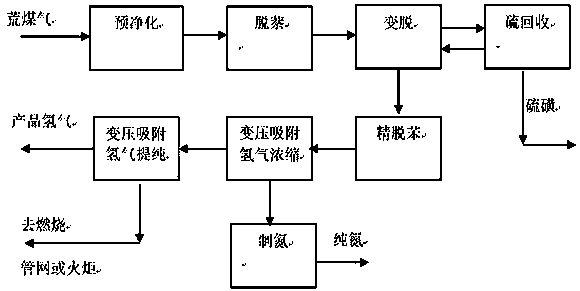

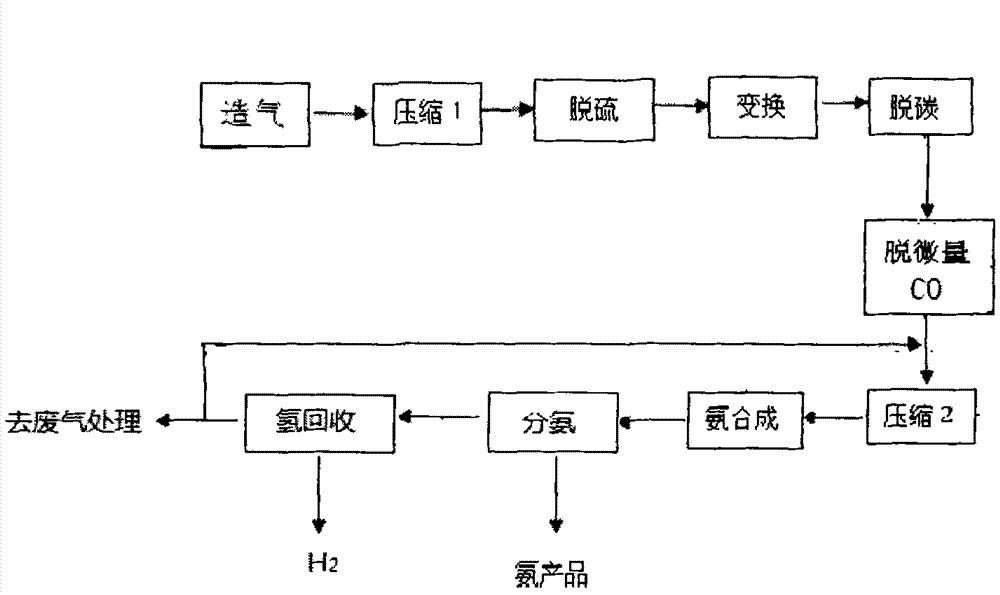

Low-energy-consumption high-yield method for preparing hydrogen from raw gas

InactiveCN107758615AReduce consumptionEmission reductionNitrogen purification/separationHydrogen separation using solid contactSulfurNitrogen

The invention discloses a low-energy-consumption high-yield method for preparing hydrogen from raw gas. The method comprises the following procedures: pre-cleaning; naphthalene removal; transformationand desulfurization; sulfur recovery; refined debenzolization; pressure swing adsorption for hydrogen production; recovery of tail gas; nitrogen production; etc. After pretreatment and naphthalene removal, raw gas is allowed to enter the procedure of transformation and desulfurization so as to obtain more hydrogen and increase the yield of hydrogen, and then desulfurization is carried out in a desulfurization tower; then pure hydrogen is prepared through the procedure of refined debenzolization and the procedure of pressure swing adsorption for hydrogen production; through the procedures of tail gas recovery and nitrogen production, effective hydrogen in desorbed gas is recovered, and hydrogen yield is further increased; and pure nitrogen with a purity of 99% or more is further prepared through a nitrogen production unit. The method provided by the invention substantially reduces the energy consumption of an apparatus for hydrogen production from raw gas, increases hydrogen yield, recovers almost all the effective hydrogen component in the desorbed gas, realizes recovery and graded utilization of each component in the raw gas while guaranteeing low energy consumption and high yield, and by-produces sulfur, pure nitrogen and the other products while preparing pure hydrogen.

Owner:SICHUAN TECHAIRS

Auxiliary heat dissipation device applied to refrigerator compressor

ActiveCN105443355ANo noiseImprove performancePositive displacement pump componentsPump parameterEngineeringRefrigerated temperature

Owner:SOUTH CHINA UNIV OF TECH

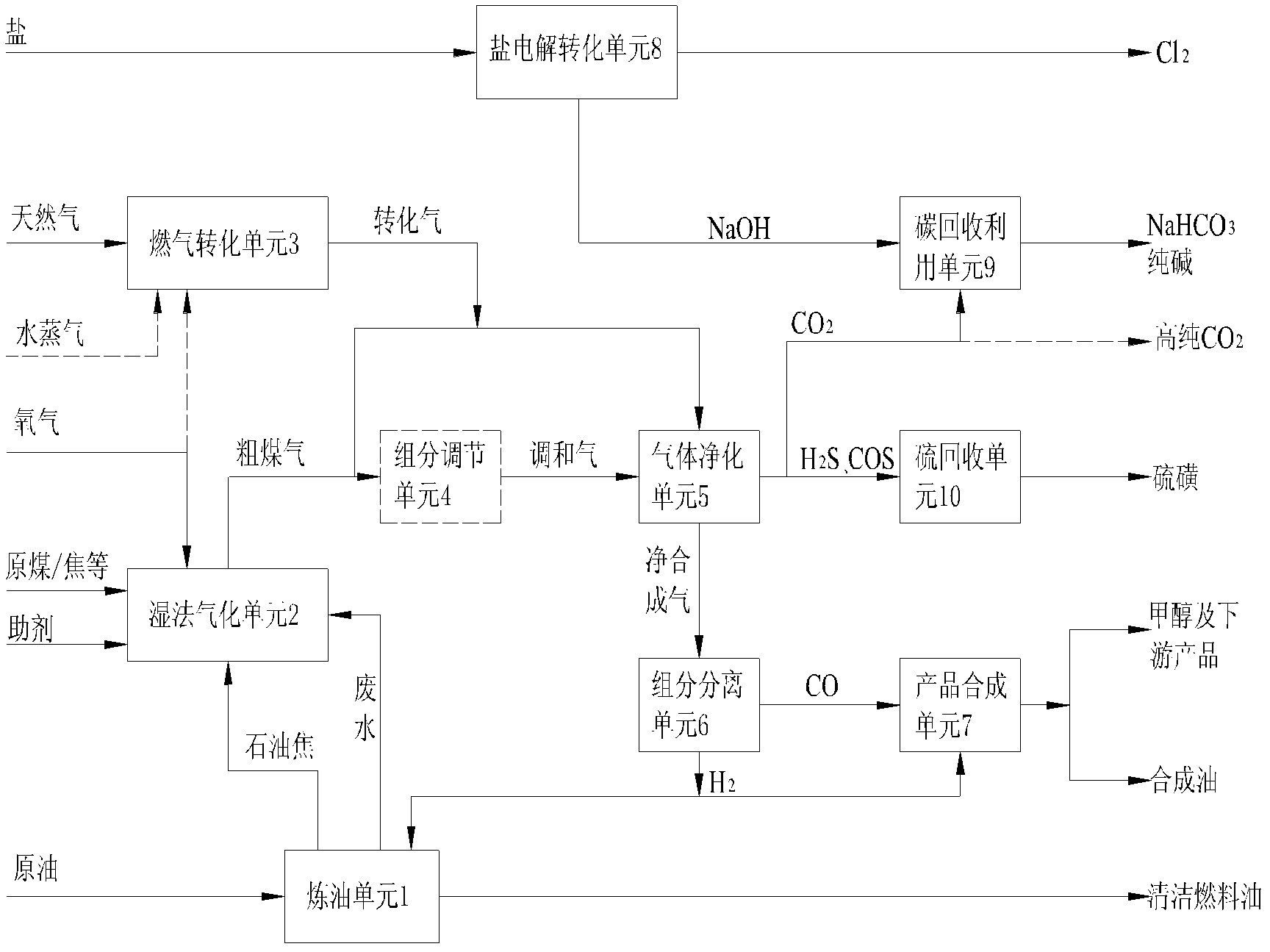

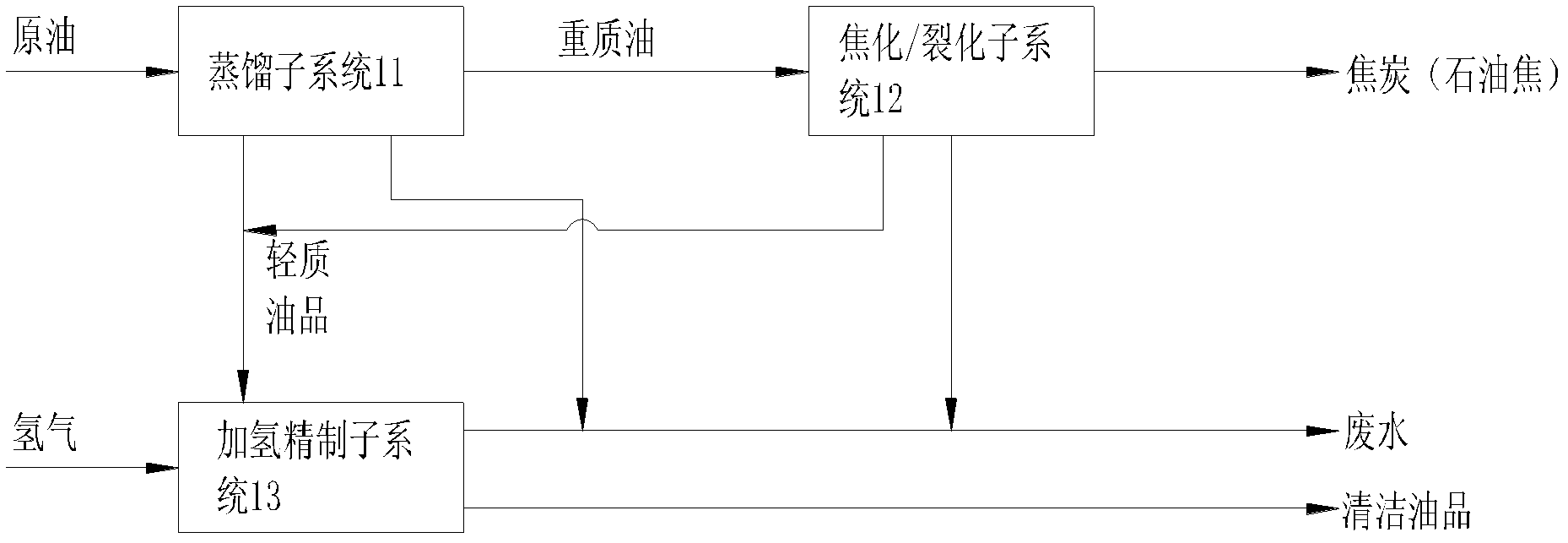

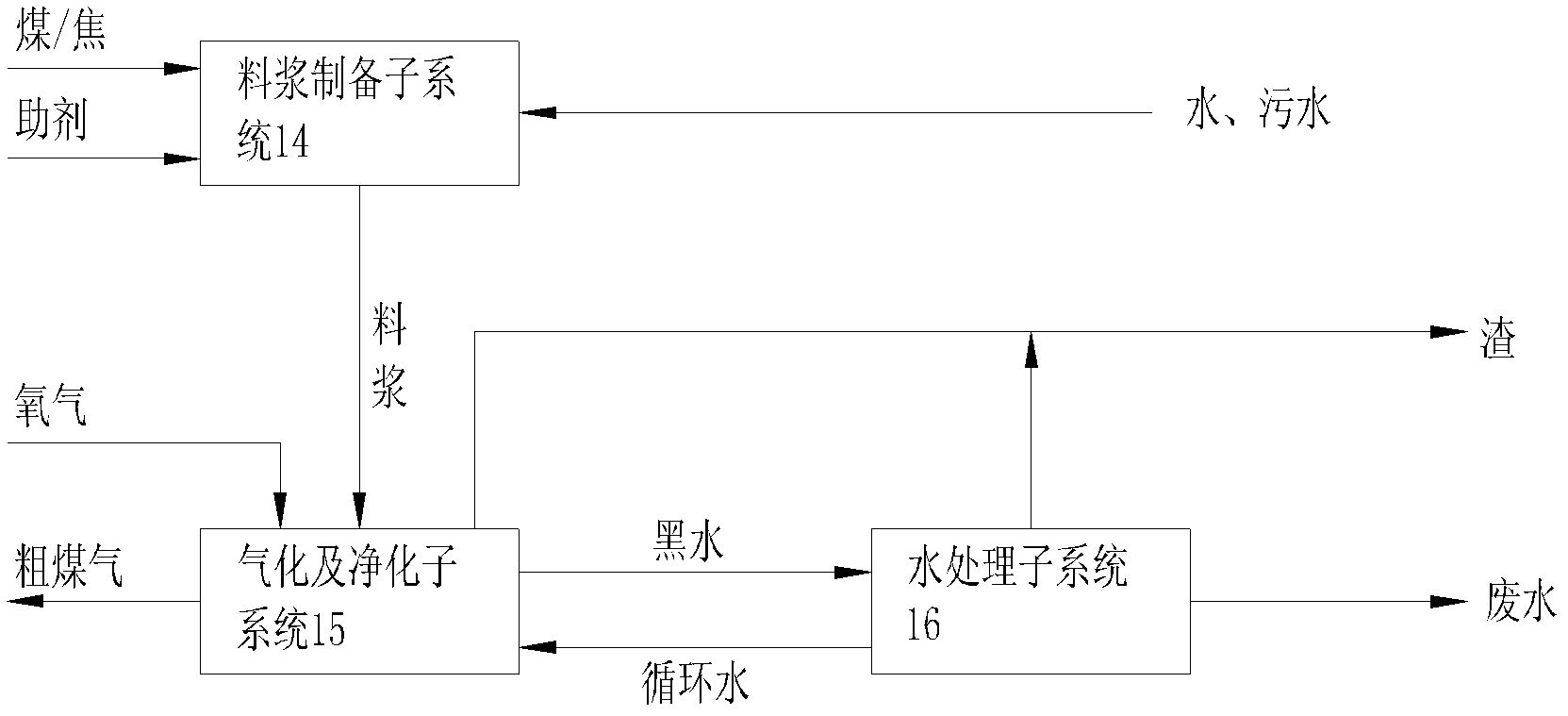

Method for co-producing various chemical products by taking coal, petroleum, natural gas and salt as raw materials

ActiveCN102660330ASolve the problem of clean utilizationQuality improvementHydrogenOrganic compound preparationOil processingElectrolysis

The invention relates to a method for co-producing various chemical products by taking coal, petroleum, natural gas and salt as raw materials. The method includes the steps of petroleum processing, slurry gasification, natural gas conversion, chemical product synthesis and salt electrolysis conversion. By reasonably using the coal, the petroleum, the natural gas and the salt resources, the energyand chemical overall goals of saving non-renewable resources and relieving environmental pollution can be achieved, and construction basis, solution and technical support are provided for Chinese large and super-huge energy industry base construction.

Owner:SHAANXI YANCHANG PETROLEUM GRP +1

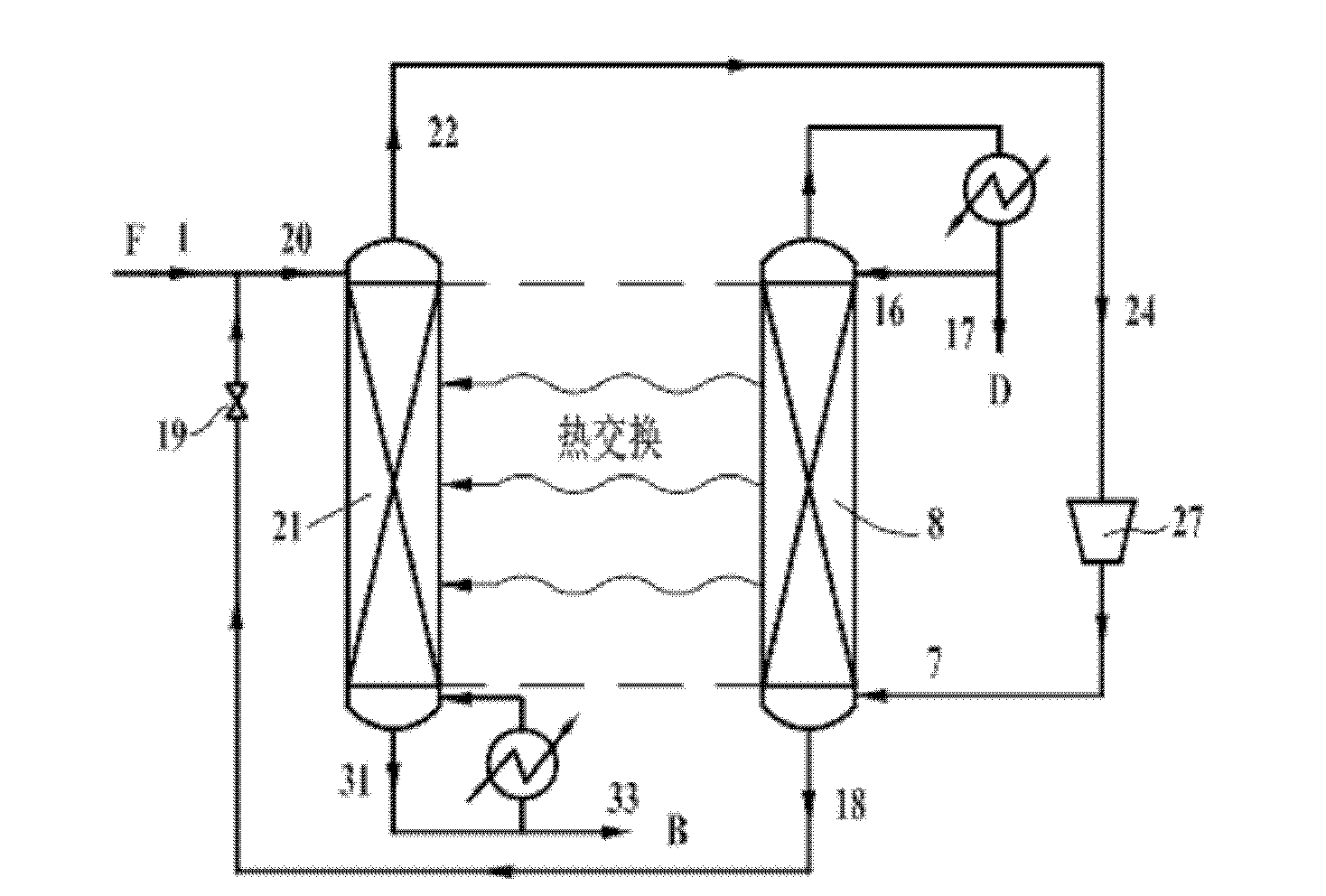

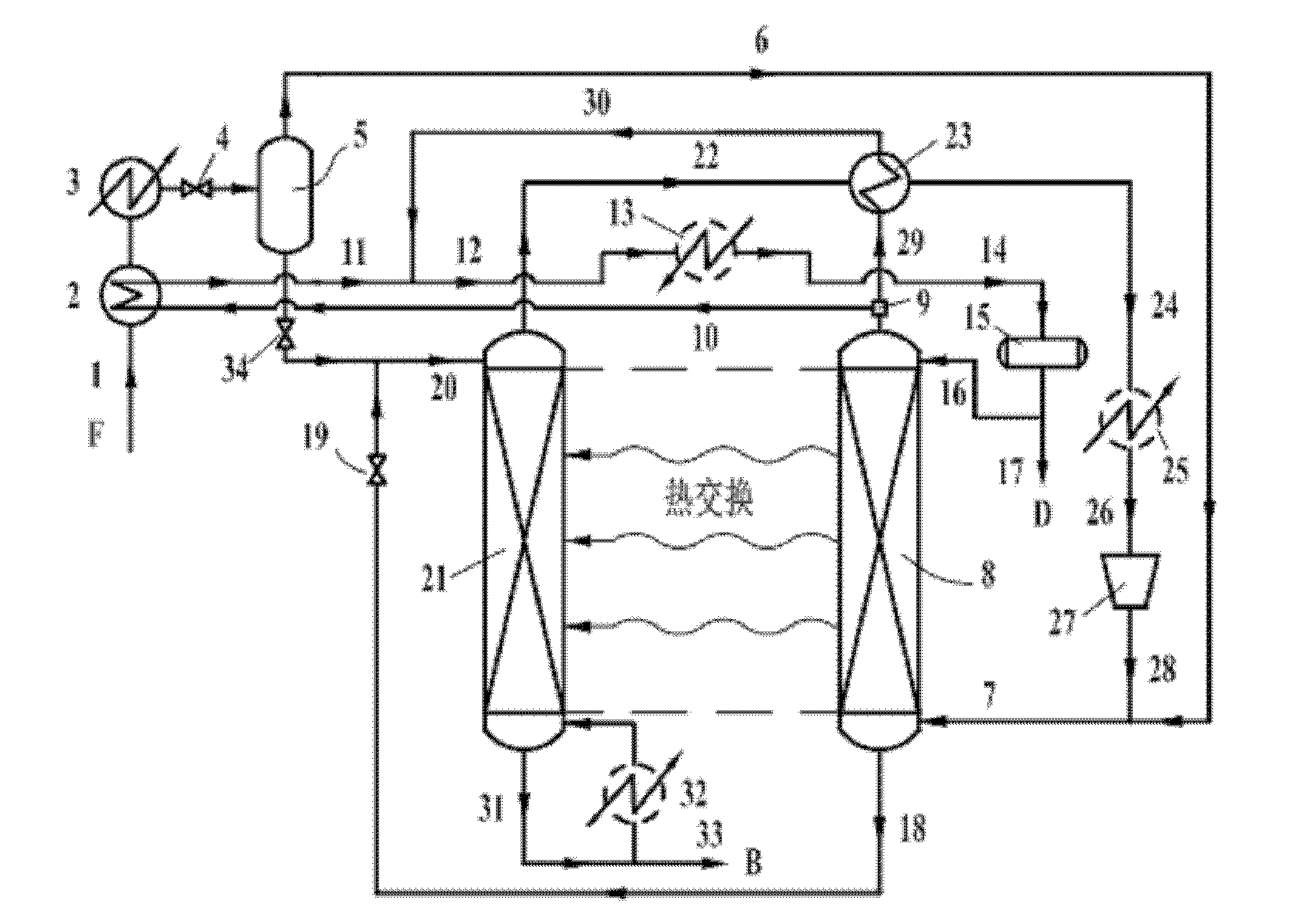

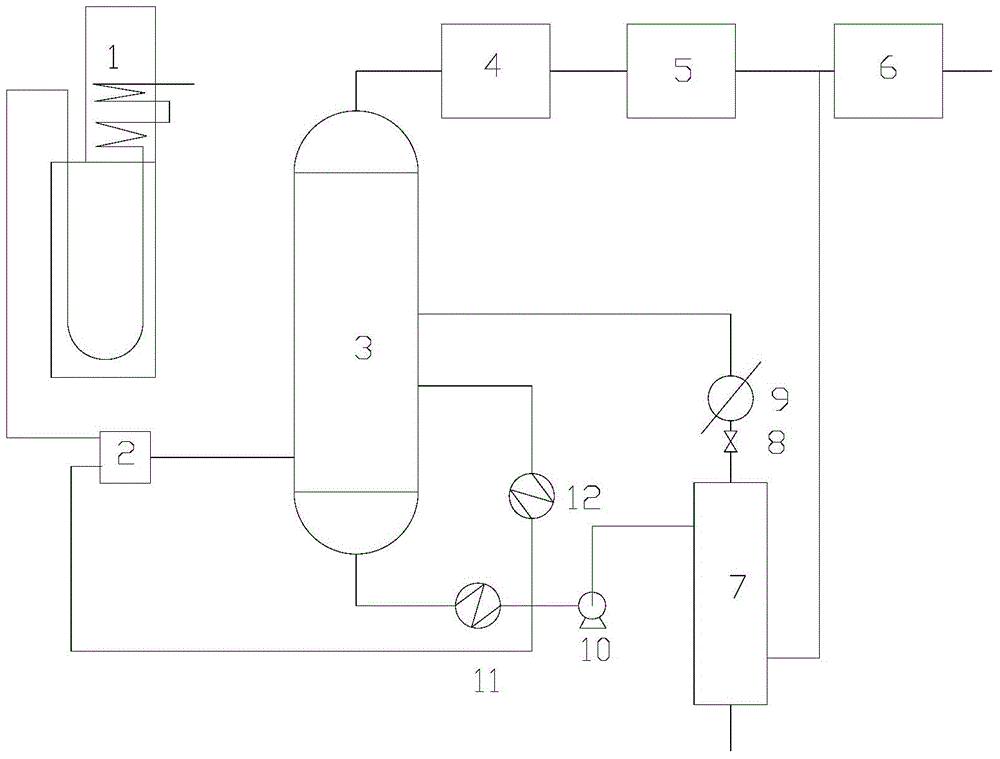

Flash evaporation feed type internal heat integration energy-saving rectifying device and method

InactiveCN101874934AReduce gas volumeReduced Compression Power ConsumptionDistillation regulation/controlFractional distillationVapor–liquid separatorReboiler

The invention relates to a flash evaporation feed type internal heat integration energy-saving rectifying device and a method, and the device comprises a system heat recovery heat exchanger, a feed preheater, a gas-liquid separator, a rectifying section, an auxiliary condenser, a stripping section, a compressor, an auxiliary reboiler and the like. The device is mainly characterized in that the gas-liquid separator is arranged on a feed pipeline; raw material liquid passes through the system heat recovery heat exchanger for heating and the feed preheater for further pre-heating and then enters into the gas-liquid separator; gas separated by the gas-liquid separator directly enters into tower bottom at the rectifying section, and liquid passes through a pressure reducing valve for reducing pressure and then enters into the top part of the stripping section; in addition, one part of saturated steam at tower top at the rectifying section is used for pre-heating fed materials, and the other part of the saturated steam is used for heating a gas overheater at the tower top at the stripping section. Compared with an ordinary internal heat integration rectifying tower, the adoption of the method and the device can greatly reduce the total energy consumption during the rectifying process, save operation cost and further achieve the purposes of energy conservation and synergy.

Owner:TIANJIN UNIV

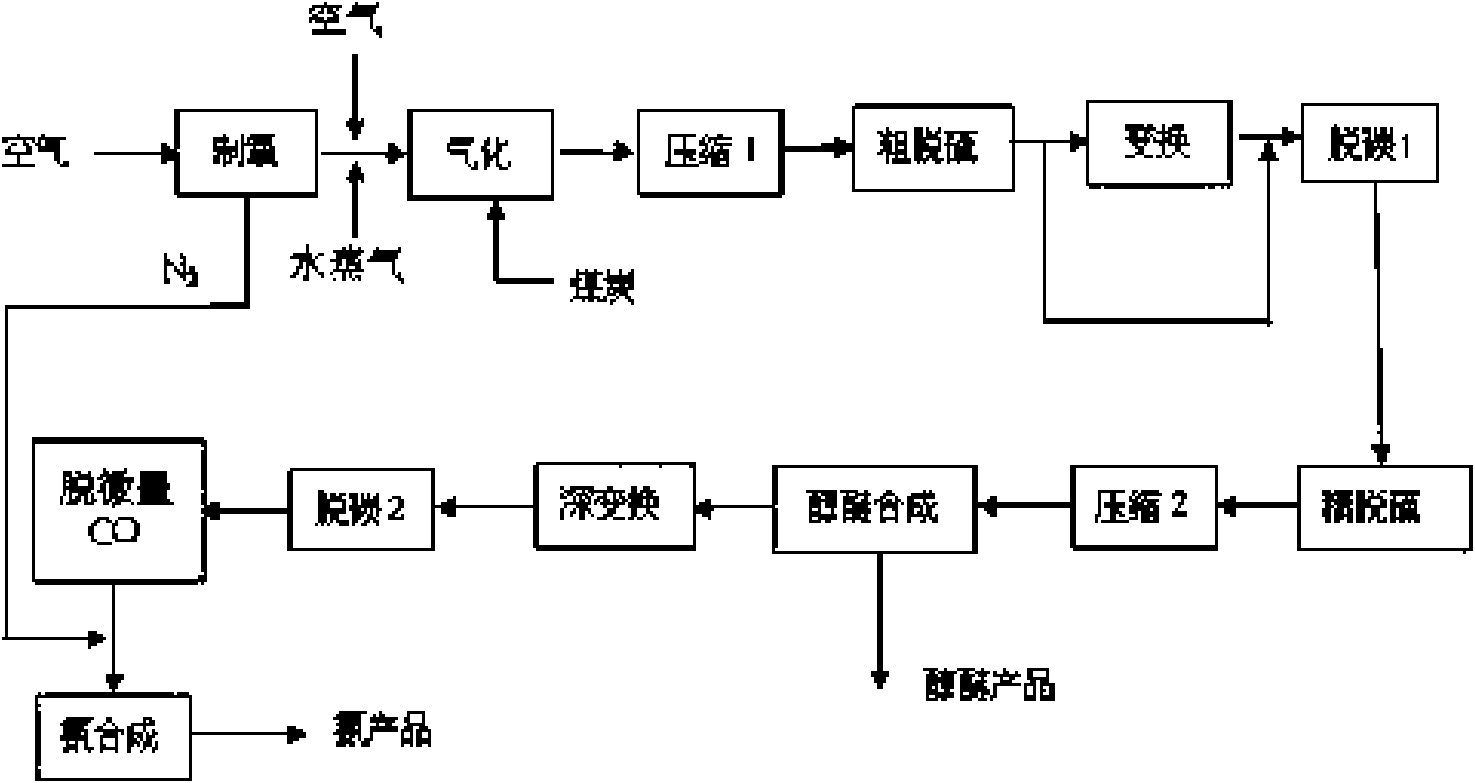

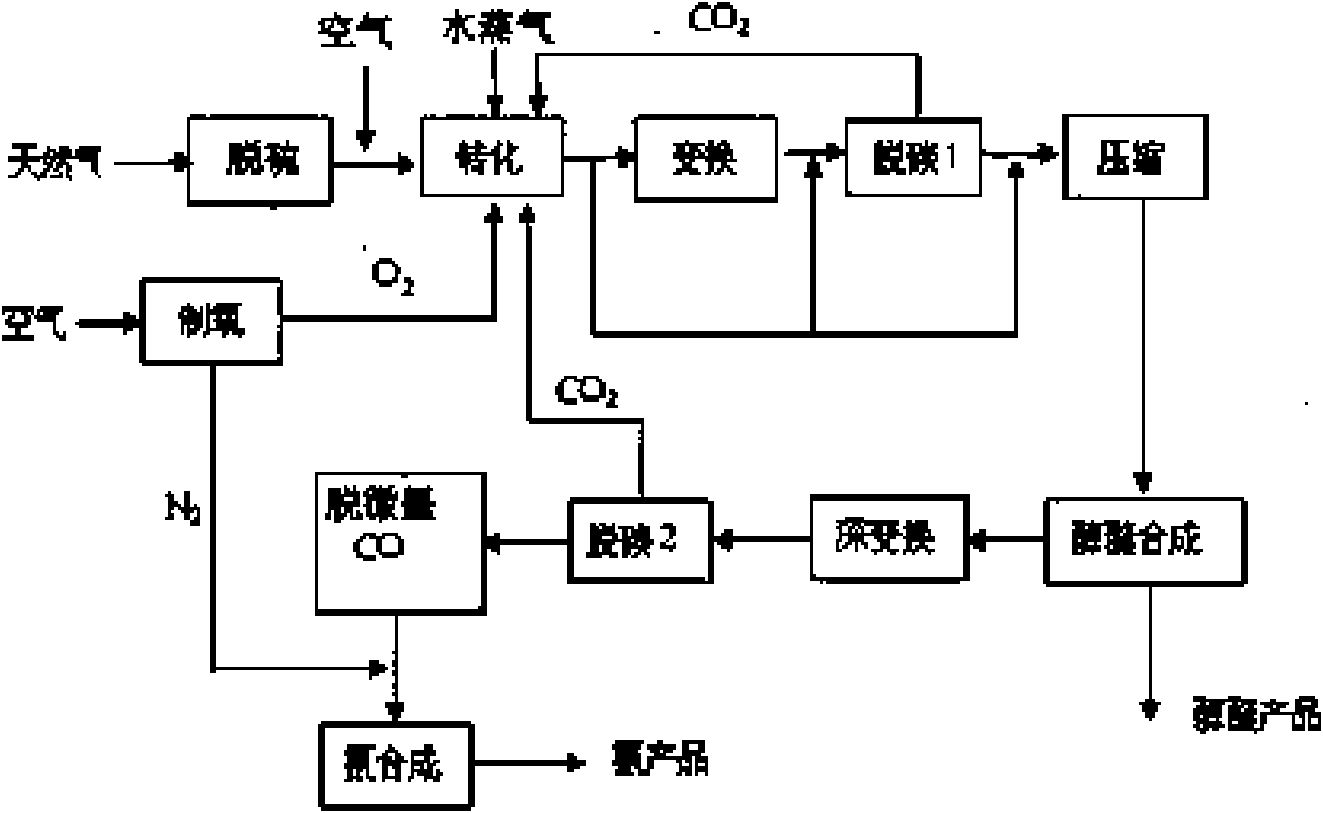

Process for producing alcohol-ether hydrazine under medium/low-pressure

InactiveCN101602649AAvoid disadvantages such as increased energy consumptionReduced Compression Power ConsumptionPreparation by oxo-reaction and reductionOxygen compounds by oxo-reactionProduction lineState of art

The invention provides a process for producing alcohol-ether hydrazine under medium / low-pressure, which solves the disadvantages of an alcohol-combining process in the prior art. A competitive replacement choice of the process is to serially connect alcohol-ether synthesis and ammonia synthesis into one production line, wherein alcohol-ether synthesis is performed first, and then ammonia synthesis is performed, but alcohol-ether synthesis and ammonia synthesis are relatively independent of the separation of respective products thereof; different proportion and the yield proportion of two products are flexible to regulate; ammonia synthesis does not need the process of additionally adding synthesis gas for compression; and the total pressure is 4 to 15 MPa. The process has the advantages of effectively reducing the power consumption of compression, realizing the flexible proportion regulation of alcohol or ether products, improving the efficiency of the whole technological process, reducing production cost to the utmost extent and laying a foundation for technical progress of the coal chemical industry and large-scale comprehensive development.

Owner:FUZHOU UNIV +1

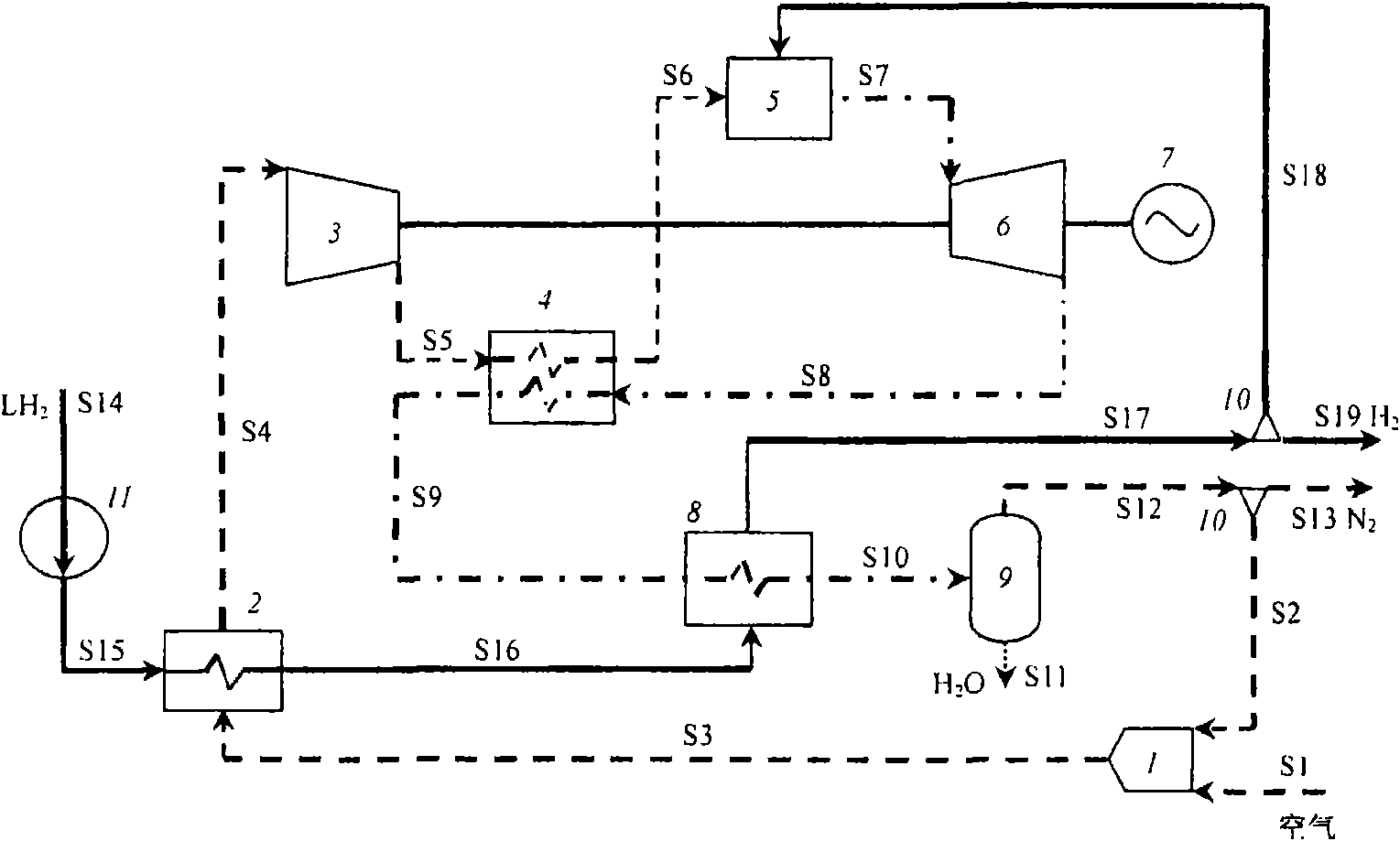

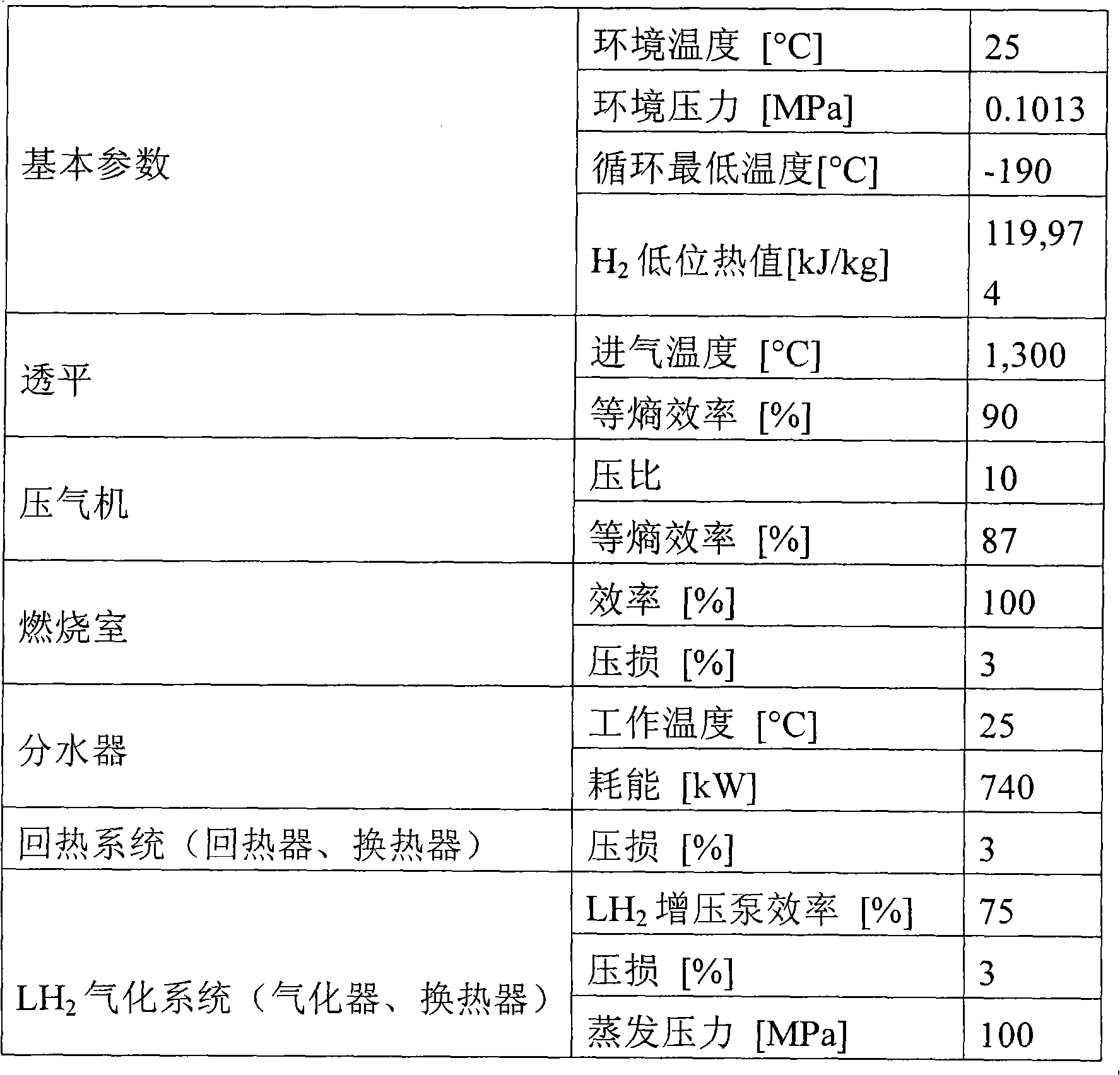

Method and device for zero emission of carbon dioxide by utilizing liquid hydrogen condensation

ActiveCN101566104AAchieve efficiencyEnvironmental protection is goodTurbine/propulsion engine coolingGas turbine plantsLiquid hydrogenNitrogen gas

The invention relates to the technical field of energy sources, in particular to a Brayton system and a flow for zero emission of carbon dioxide (CO2) by utilizing liquid hydrogen (LH2) condensation. The system is formed by coupling a semi-closed and regenerated Brayton cycle and a liquid hydrogen (LH2) gasification unit, the liquid hydrogen gasification unit is taken as a low-temperature cold source of the semi-closed and regenerated Brayton cycle so as to ensure that the condensation process of the semi-closed and regenerated Brayton cycle obtains low temperature far lower than ambient temperature, the Brayton cycle adopts a nitrogen working medium and hydrogen fuel, and no CO2 is produced during the combustion; therefore, the zero emission of various environment-harmful pollutions comprising the CO2 is realized under the condition of no need of additional energy consumption. At the same time, relative to the prior Brayton cycle with the nitrogen working medium which takes the environment as a cold source, the thermodynamic property of the Brayton system is greatly improved, so the Brayton system has good economical efficiency and broad engineering application prospect.

Owner:江苏中国科学院能源动力研究中心 +1

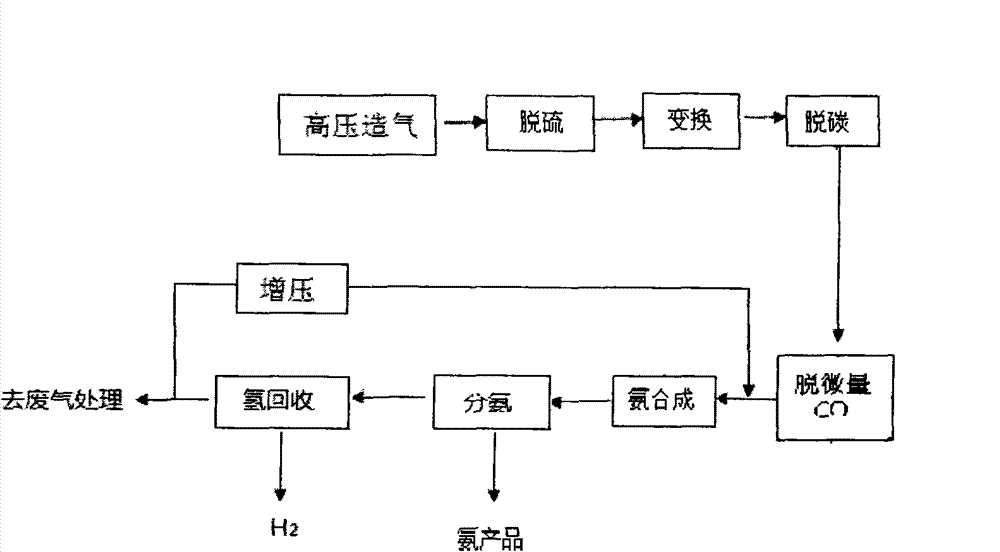

Method for synthesizing low pressure ammonia

InactiveCN102815721AReduce hydrogen contentSimple installationAmmonia preparation/separationChemistryPower consumption

The invention discloses a method for synthesizing low pressure ammonia and belongs to the technical field of a synthesis ammonia process. The method is characterized in that a synthetic system adopts a method of a pure ruthenium based catalytic agent or a method combining an iron catalytic agent and a ruthenium catalytic agent, ammonia synthesis total pressure is 5-10MPa, ratio of hydrogen and nitrogen of feed gas is 0.5-1.46, and ammonia synthesis temperature is 300-425 DEG C, airspeed of the feed gas is 3000-15000h-1. Compared with a traditional process, after ammonia in gas at an outlet of a synthetic tower is separated, hydrogen content is greatly reduced, recirculation is not needed, and the gas can be directly sent to a hydrogen extraction device, so that a recycle compressor is not arranged. As for a field adopting a high pressure gas making process with synthetic pressure of 5-7MPa, an ammonia synthesis production line can remove the recycle compressor and a circulator, devices are simplified, power consumption is substantially reduced, and big economic benefits can be obtained accordingly.

Owner:福州开发区科盛催化材料有限公司

Intercooling type multistage axial flow air compressor and working method thereof

PendingCN106989066AReduced Compression Power ConsumptionReduce the temperaturePump componentsAxial flow pumpsCold airEngineering

The invention discloses an intercooling type multistage axial flow air compressor and a working method thereof. The lower ends of movable vanes are connected with a hub. The upper ends of static vanes are connected with a casing. The lower ends of the static vanes are movably connected with the hub. Multiple cold air inlet ring cavities and multiple cold air exhaust ring cavities are formed in the casing. Multiple first inner cooling runners and multiple second inner cooling runners are arranged in the casing. A third inner cooling runner is arranged in each static vane. Each static vane corresponds to one cold air inlet ring cavity, one cold air exhaust ring cavity, one first inner cooling runner and one second inner cooling runner. A cooling medium outlet of each cold air inlet ring cavity communicates with a cooling medium inlet of the corresponding cold air exhaust ring cavity through the corresponding first inner cooling runner, the third inner cooling runner in the corresponding static vane and the corresponding second inner cooling runner in sequence. According to the multistage axial flow air compressor and the working method thereof, power consumption of the air compressor can be reduced, and pressure losses of working media can be effectively avoided.

Owner:HUANENG POWER INTERNATIONAL +1

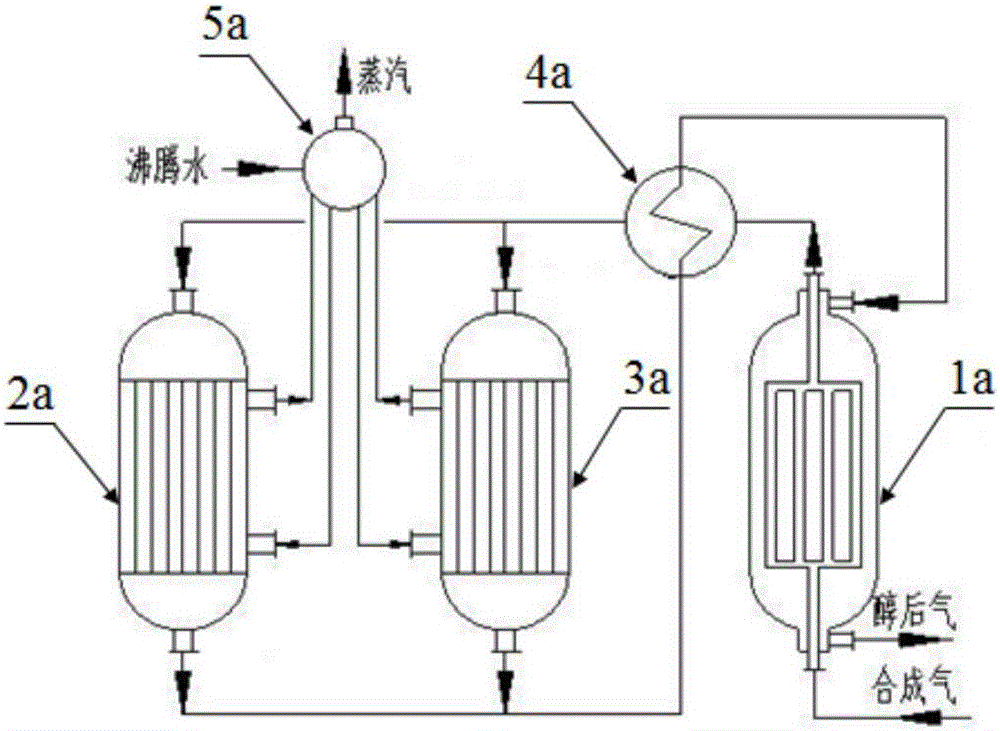

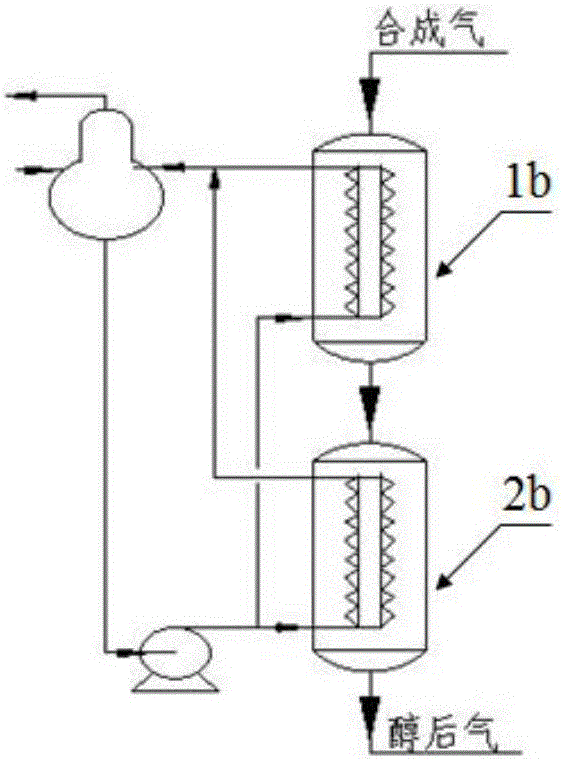

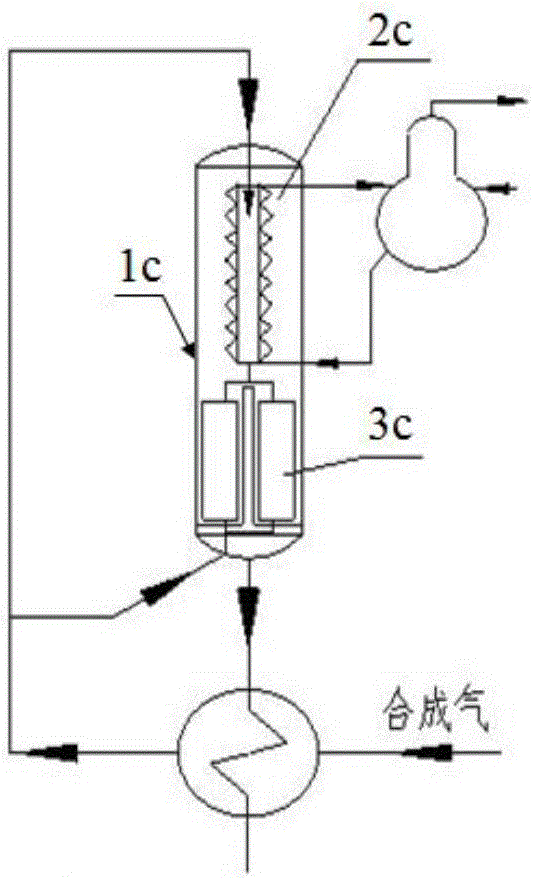

Energy-saving inter-section high low temperature gradient alcohol-division two-stage alcohol generation method and energy-saving inter-section high low temperature gradient alcohol-division two-stage alcohol generation device

ActiveCN105753646AReduce CO concentrationGuaranteed conversion rateOrganic compound preparationHydroxy compound preparationSyngasAlcohol

The invention discloses an inter-section high low temperature gradient alcohol-division two-stage alcohol generation method which comprises the following steps: respectively reheating fresh synthesis gas and recycle gas, mixing the fresh synthesis gas with the recycle gas, introducing the mixed gas into a first reactor, and enabling part of carbon oxides to react to obtain methyl alcohol; cooling a mixture containing synthesis gas and methyl alcohol steam output from the first reactor, guiding the mixture to flow to a first methyl alcohol separator, separating out methyl alcohol, pressurizing the separated gas, preheating, then introducing into a second reactor, and enabling part of carbon oxides to react to obtain methyl alcohol; cooling a mixture containing synthesis gas and methyl alcohol steam output from the second reactor, guiding the mixture to flow to a second methyl alcohol separator, separating out methyl alcohol, preheating the separated gas which separately serves as the recycle gas and fresh synthesis gas, mixing the recycle gas and the fresh synthesis gas, and feeding the mixture into the first reactor so as to perform next round of circulating preparation of methyl alcohol. The invention further discloses an inter-section high low temperature gradient alcohol-division two-stage alcohol generation device. The method is relatively high in single-pass alcohol net value and relatively small in circulation ratio, achieves a ton-alcohol steam yield as high as 1.2-1.3 ton, and is high in energy heat recovery amount.

Owner:NANJING GOODCHINA CHEM TECH

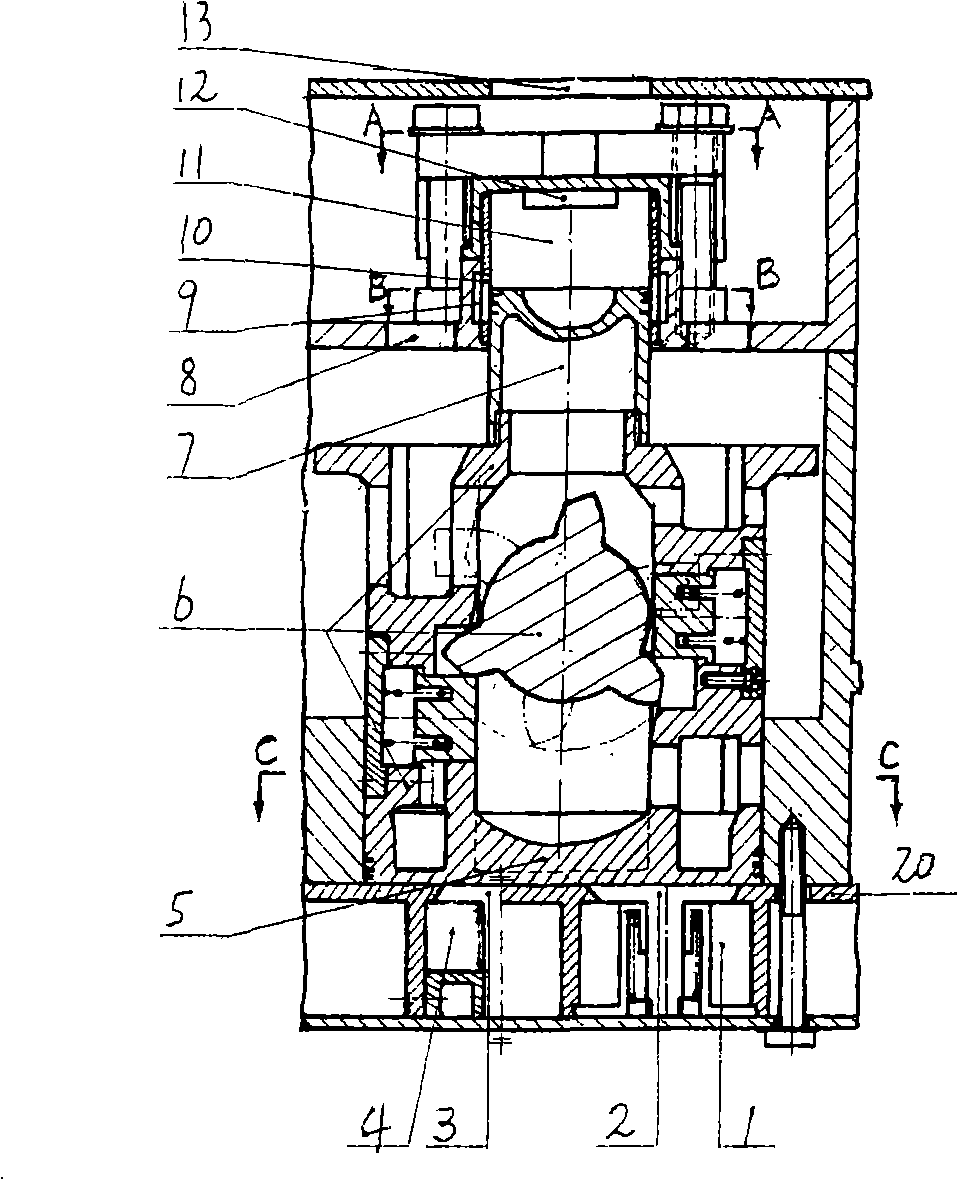

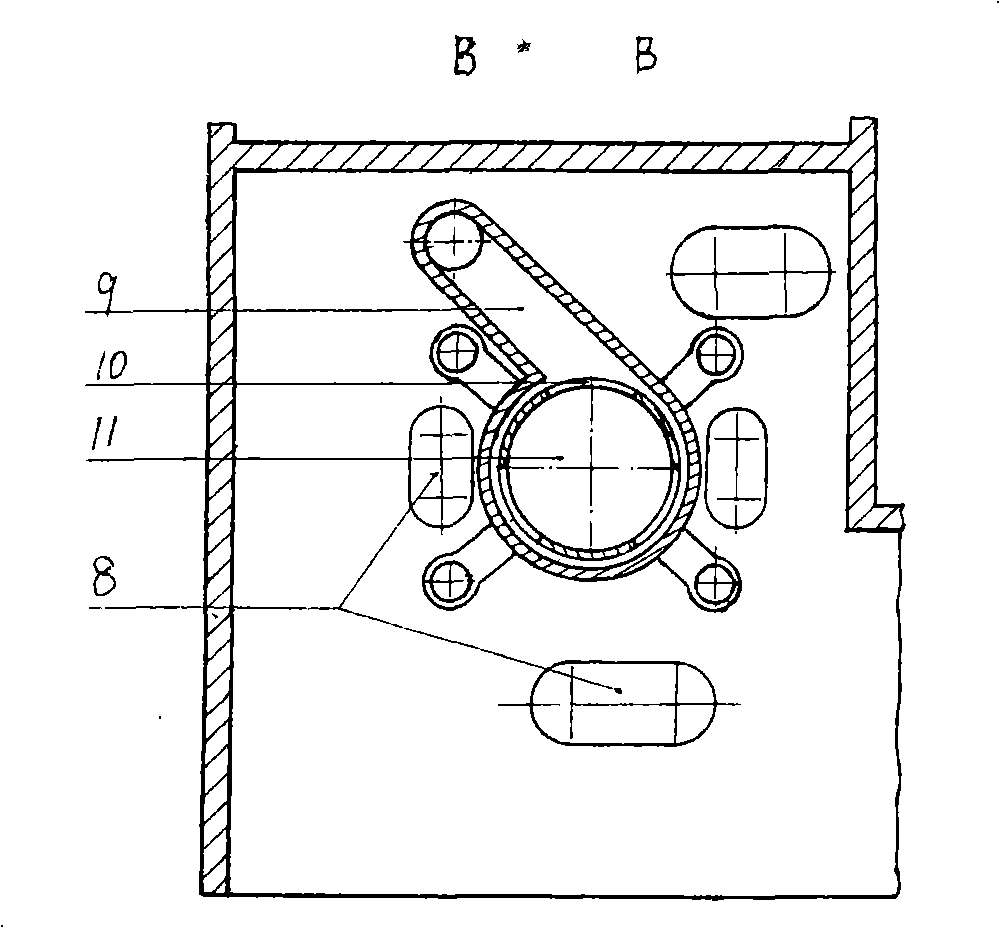

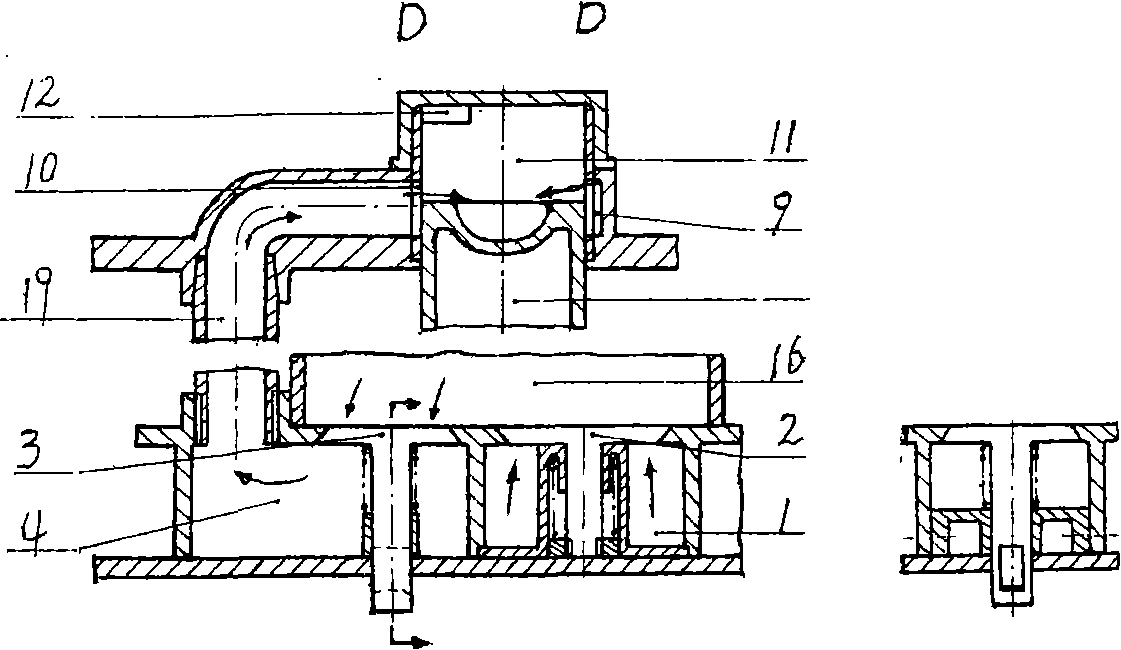

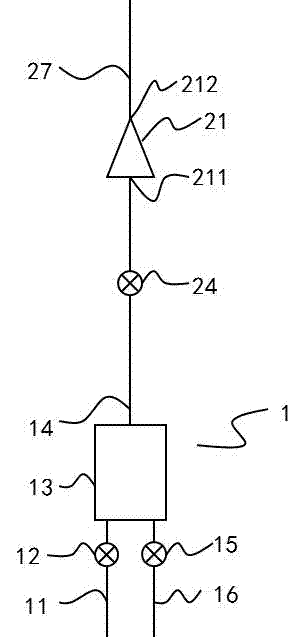

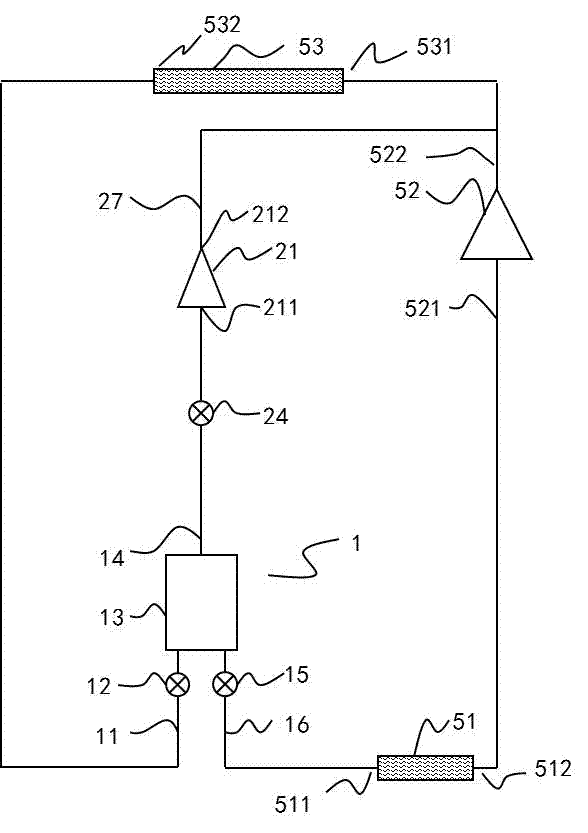

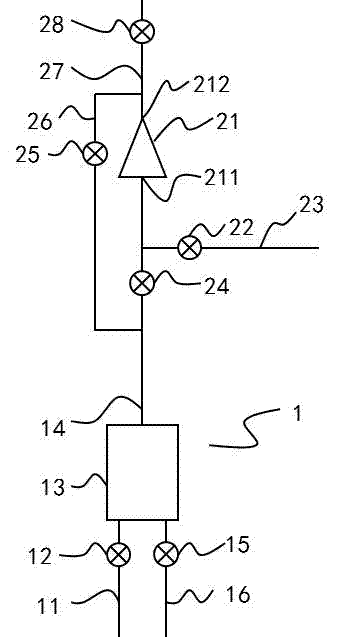

Pulse tube expansion machine

ActiveCN103206802AReduced suction pressureReduced Compression Power ConsumptionCompressorCompression machinesEngineeringMechanical engineering

The invention relates to a pulse tube expansion machine and a heat pump or a refrigerating machine comprising the pulse tube expansion machine. The pulse tube expansion machine comprises a pulse tube (13) and a compressor (21), an inflow pipeline (11) and an outflow pipeline (16) are arranged on the pulse tube (13), a low-pressure end (211) of the compressor (21) is connected with the pulse tube (13), and a high-pressure end (212) of the compressor (21) is connected into a high-pressure pipeline (522) of an external circulation system. Steam evaporated from high-pressure liquid in the pulse tube (13) is conveyed to the external high-pressure pipeline after extracted and compressed by the compressor (21), and the pressure in the pulse tube continuously reduces along with continuous extraction of the steam, so that the liquid expansion process is realized. In the process, the steam cannot be expanded to have low pressure, is directly compressed to have high pressure and is outputted for other purposes, so that the steam expansion process is avoided, energy use efficiency is improved, and the pulse tube expansion machine can be used for the heat pump or the refrigerating machine and the like to replace a throttling valve.

Owner:朱绍伟

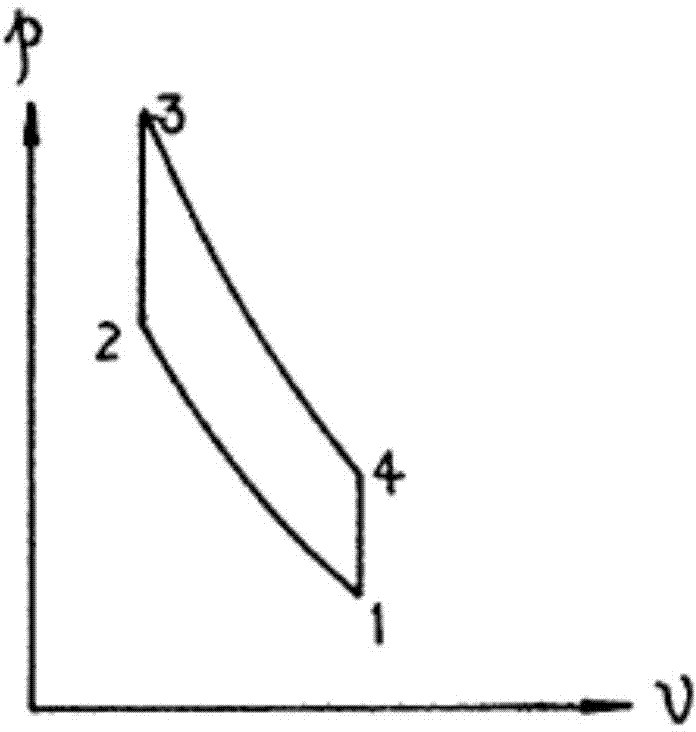

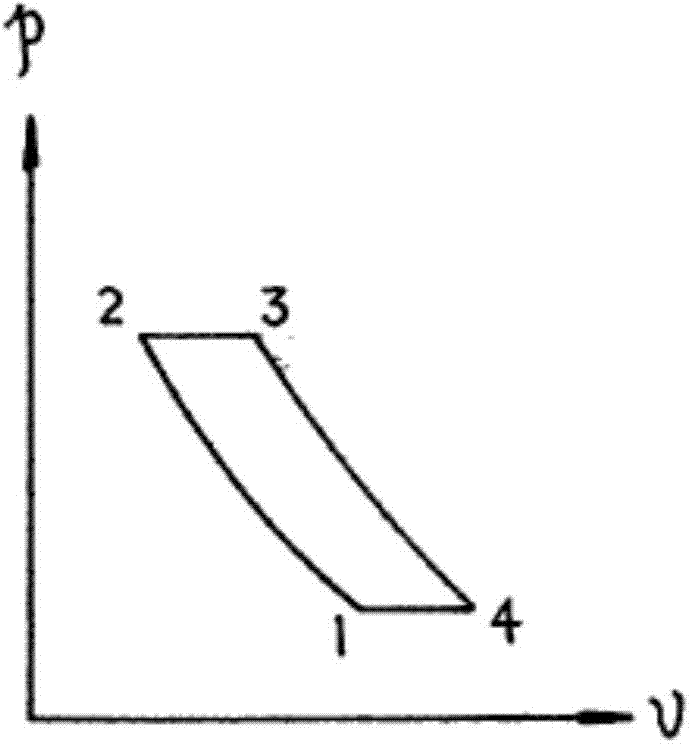

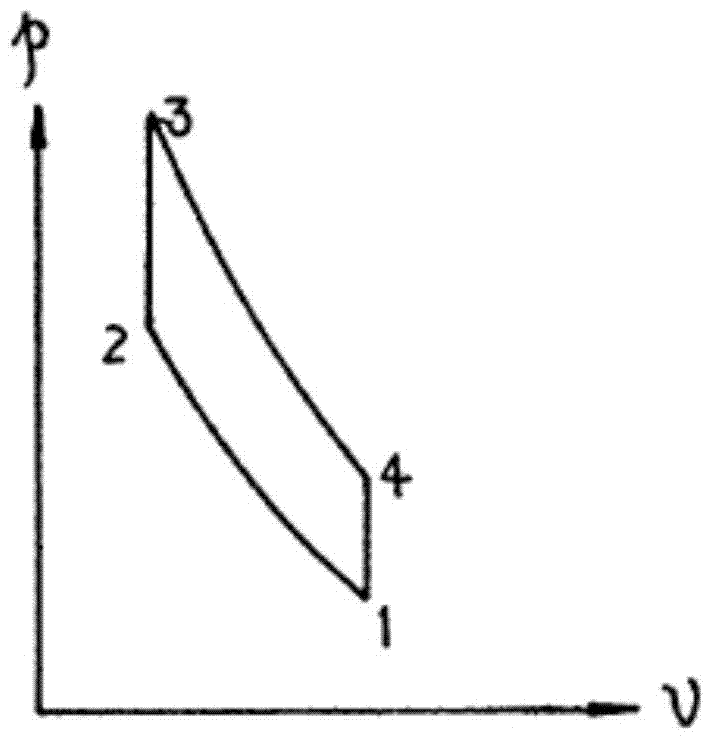

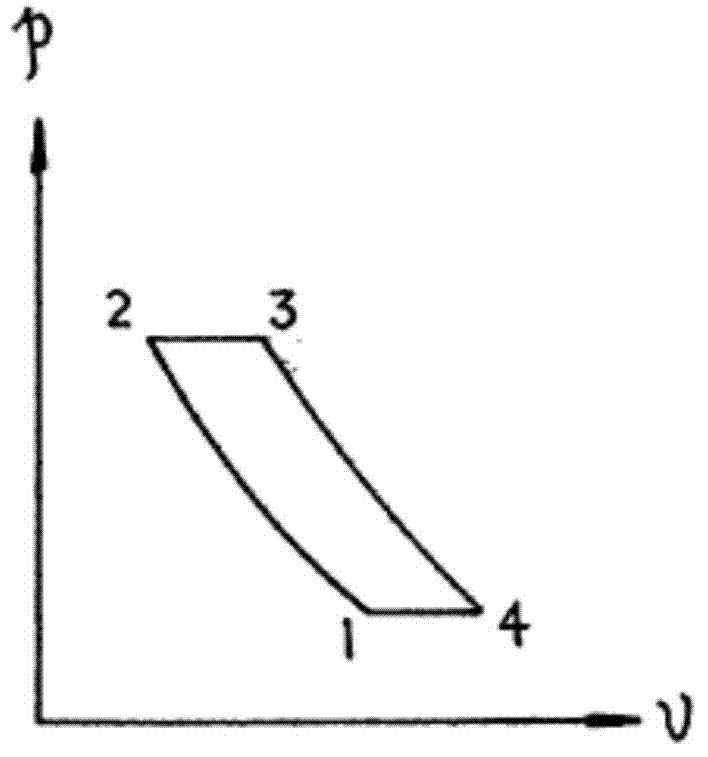

Semi-closed type timing constant-volume thermodynamic circulation method and system of prime motor

ActiveCN103883399AReduced Compression Power ConsumptionReduce fresh working fluid temperatureInternal combustion piston enginesGas turbine plantsThermal dilatationPrime mover

The invention provides a semi-closed type timing constant-volume thermodynamic circulation method and a semi-closed type timing constant-volume thermodynamic circulation system of a prime motor. The thermodynamic circulation method comprises six processes, namely multi-compression-stage intercooling, countercurrent heat exchanging, timing constant-volume burning, adiabatic expansion, aftercooling, and carbon dioxide and water removal. Heat-power conversion is achieved in the thermodynamic circulation. In the process of multi-compression-stage intercooling, compression power consumption is lowered; in the process of countercurrent heat exchanging, the enthalpy of an expanded working medium is recovered to participate in thermodynamic circulation; the process of timing constant-volume burning effectively inhibits the generation of harmful pollutants such as HC, CO, PM and NOx; in the process of adiabatic expansion, complete expansion for working is achieved; in the process of aftercooling, the working medium is further cooled to the environment temperature and the expansion ratio in the process of adiabatic expansion is enhanced; in the process of carbon dioxide and water removal, the carbon dioxide and the water generated in the process of timing constant-volume burning are removed; the remaining work mediums participate in the next thermodynamic circulation. By the method and the system, the direction is defined for designing a high-efficiency low-pollutant-emission and high-performance prime motor in the future.

Owner:GREEN ENERGY HIGH TECH GRP +5

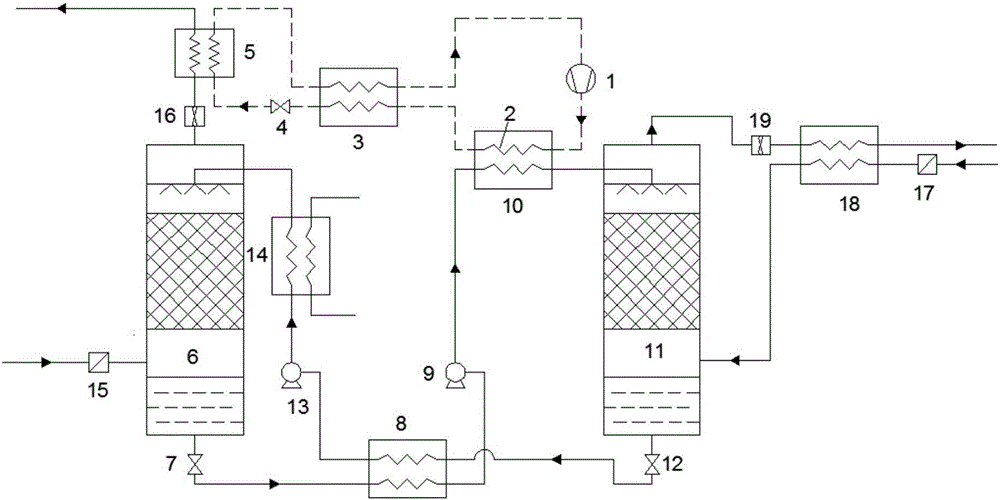

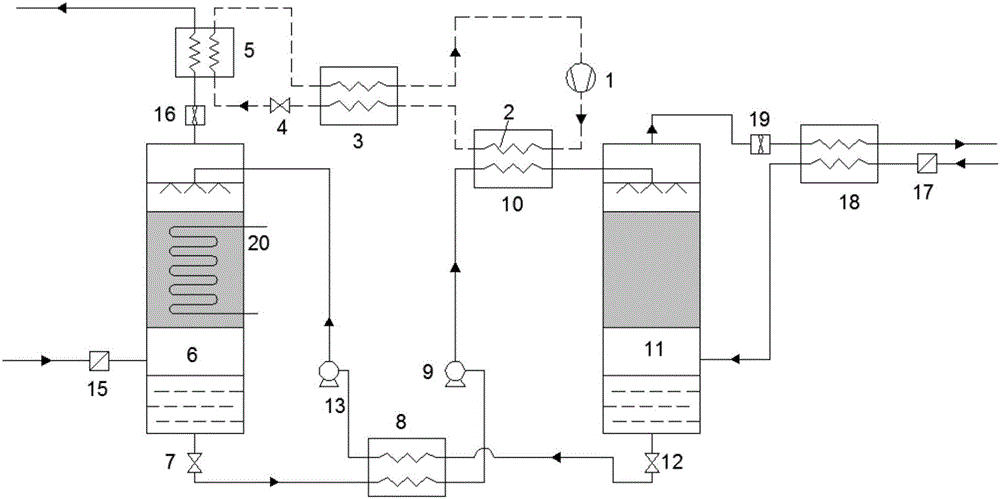

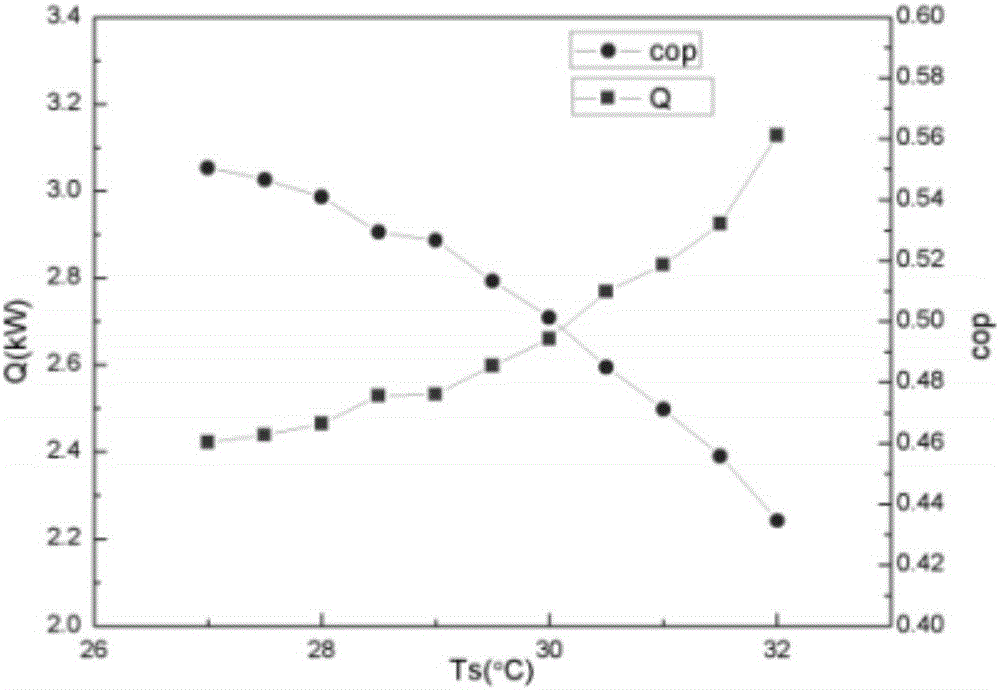

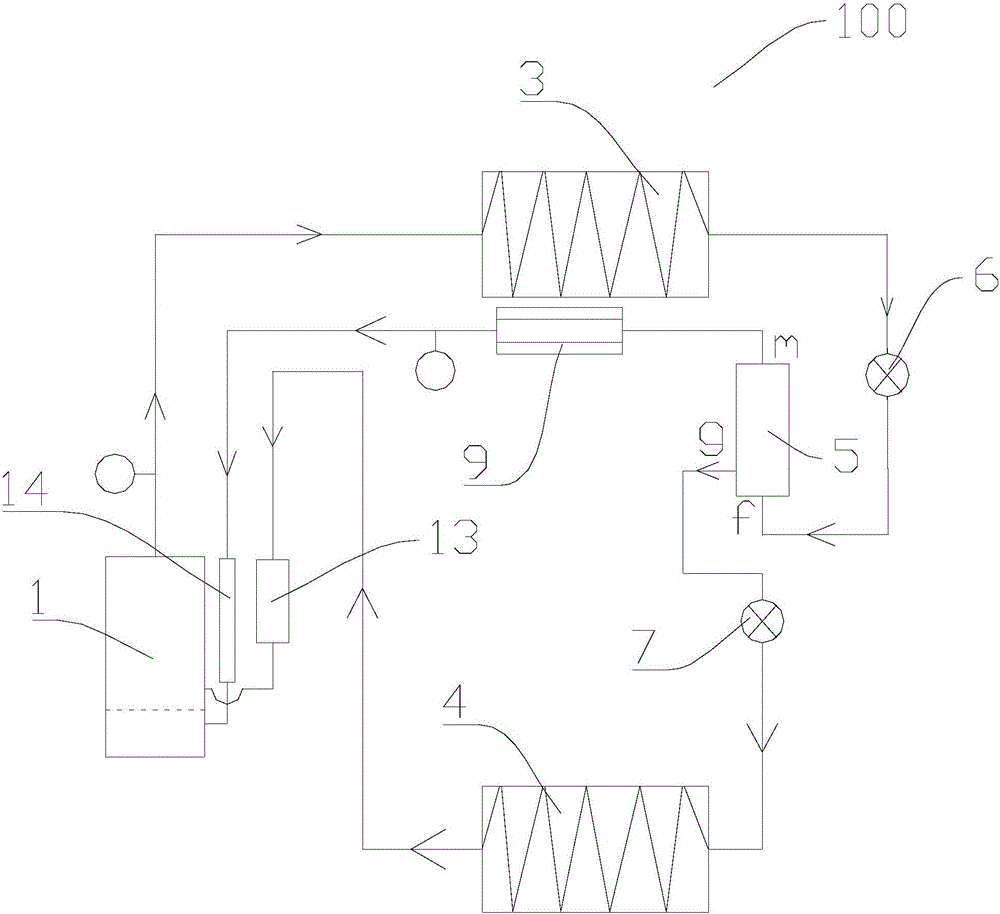

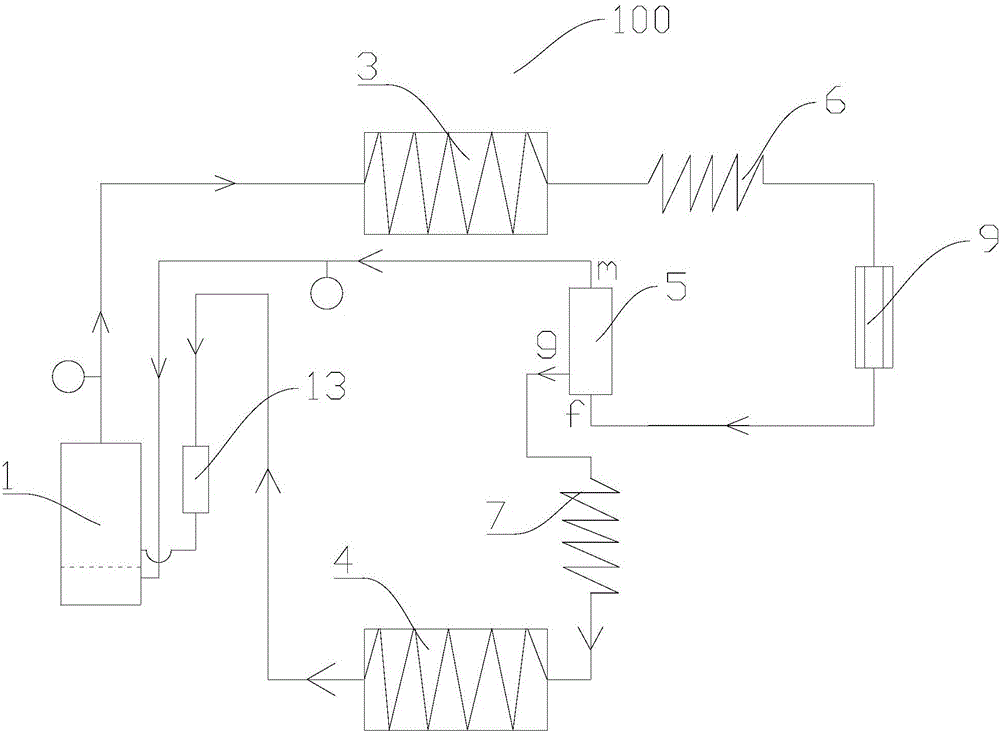

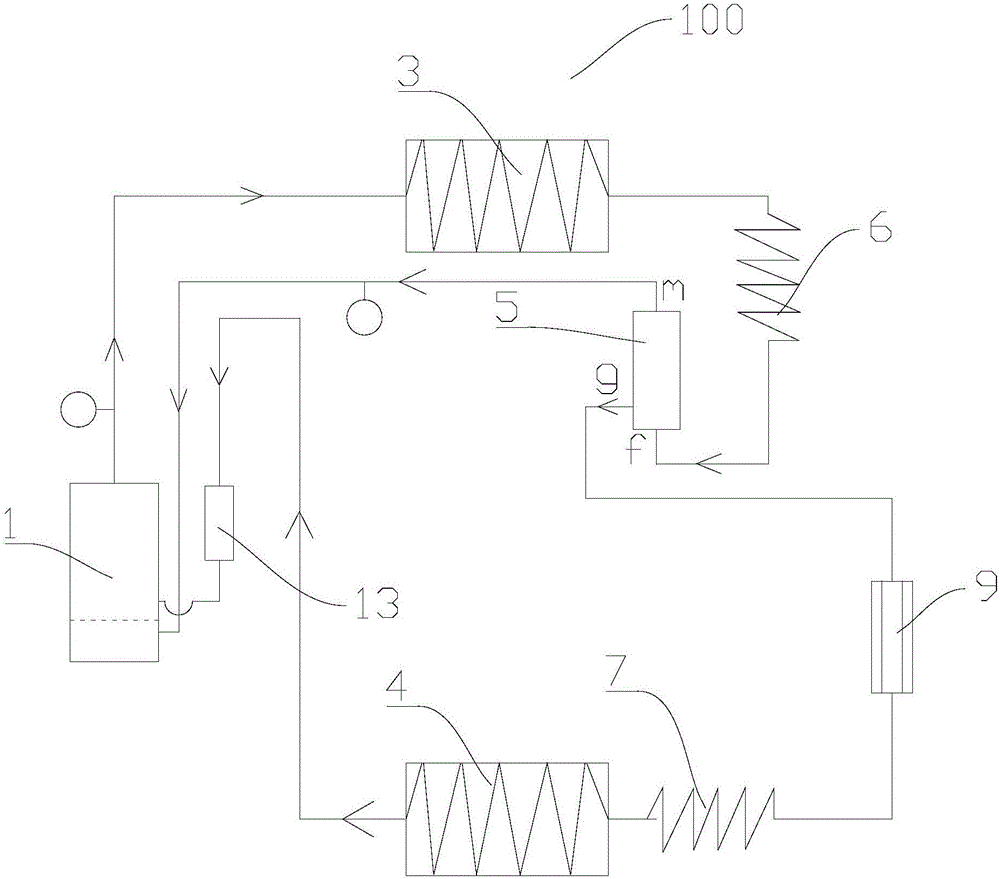

Air treatment system combining trans-critical circulation and solution dehumidification system

ActiveCN106288097AAchieve coolingImprove performanceLighting and heating apparatusAir conditioning systemsTranscritical cycleStrong solutions

The invention discloses an air treatment system combining trans-critical circulation and a solution dehumidification system. The air treatment system is characterized in that the system comprises a trans-critical compression subsystem and a solution dehumidification subsystem, heat discharged by a high-pressure side of the trans-critical compression subsystem serves as a heat source of the solution dehumidification subsystem, the solution dehumidification subsystem comprises a strong solution dehumidification unit and a dilute solution regenerating unit, and a dehumidification process is a heat insulation dehumidification process. The invention further discloses an air treatment system combining trans-critical circulation and a solution dehumidification system, and a dehumidification process is a constant-temperature dehumidification process. Reasonable energy coupling of the trans-critical circulation and the solution dehumidification system is achieved, dehumidification and temperature falling of the air can be simultaneously achieved, overall performance of the dehumidification system is improved, the heat discharged by the high-pressure side of the compression subsystem basically meets regenerated heat requirements when trans-critical compression refrigeration circulation refrigerating temperature ranges from 7 DEG C to 12 DEG C and can completely meet the regenerated heat requirements when the cooling temperature of a dehumidifying agent drops, compression work can be decreased by 10% or more, and the system is simple in structure and excellent in overall economy and environmental protection.

Owner:ZHEJIANG UNIV

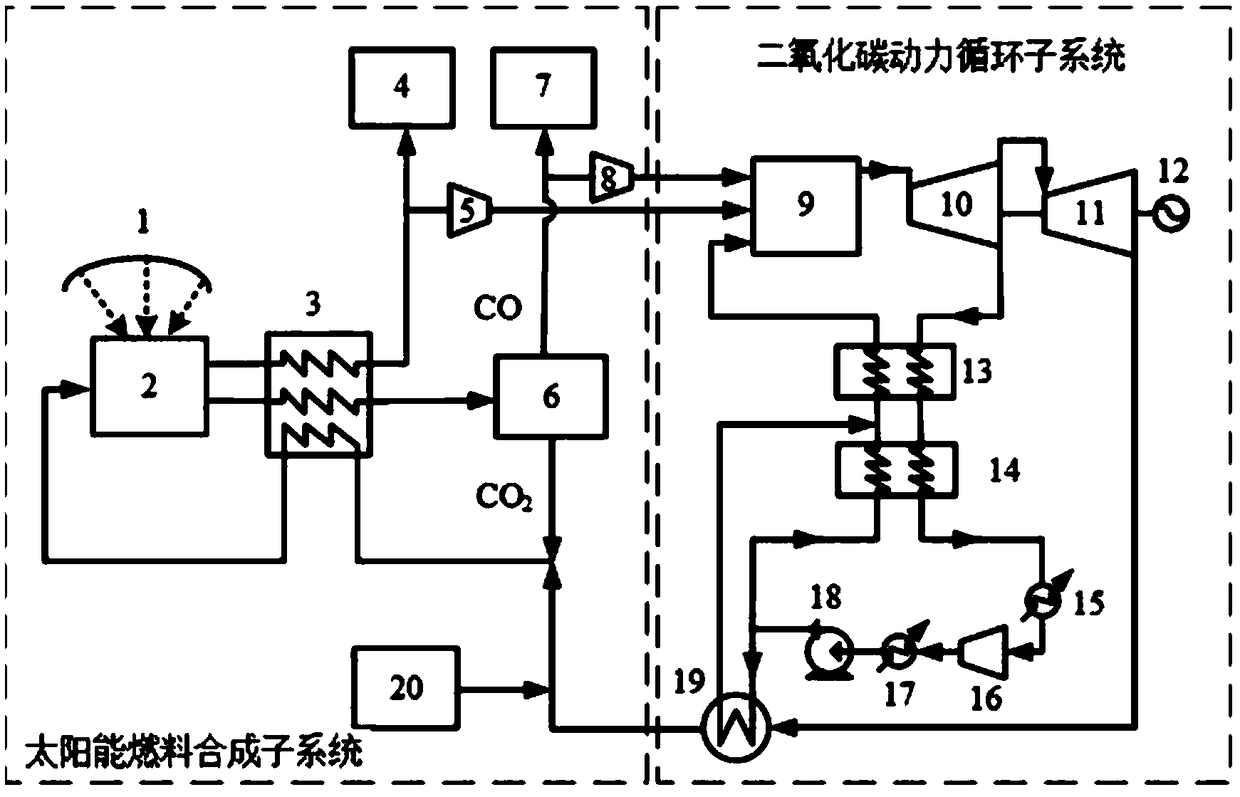

Zero-release electricity generation system and method using solar energy to drive thermal decomposition of carbon dioxide

PendingCN109458258ASatisfy material balanceOvercome the effects of volatility and intermittencyEnergy inputGas turbine plantsCarbon dioxideCombustion chamber

The invention discloses a zero-release electricity generation system and method using solar energy to drive thermal decomposition of carbon dioxide in the field of solar thermal electricity generation. The zero-release electricity generation system mainly comprises a solar high-temperature thermal chemical reactor, a heat regenerator, a gas storage chamber, a combustion chamber, a turbine, a compressor, a pump and the like. In the system, collective high-temperature solar energy provides heat for thermal chemical decomposition of carbon dioxide, produced carbon monoxide and oxygen are pressurized and fed into the combustion chamber to be combusted for direct heating, and carbon dioxide is driven for power cycle generation. Surplus carbon monoxide and oxygen produced by thermochemistry arestored in the gas storage chamber to adapt to the change of solar radiation intensity. The system utilizes solar energy high-temperature thermal chemical reaction for stable energy storage, and efficient clean electricity generation is conducted through the carbon dioxide power cycle. The two are coupled, so that influence of solar energy fluctuation on electricity generation units is avoided, andefficient and stable output of solar thermal electricity generation is realized.

Owner:NORTH CHINA ELECTRIC POWER UNIV (BAODING)

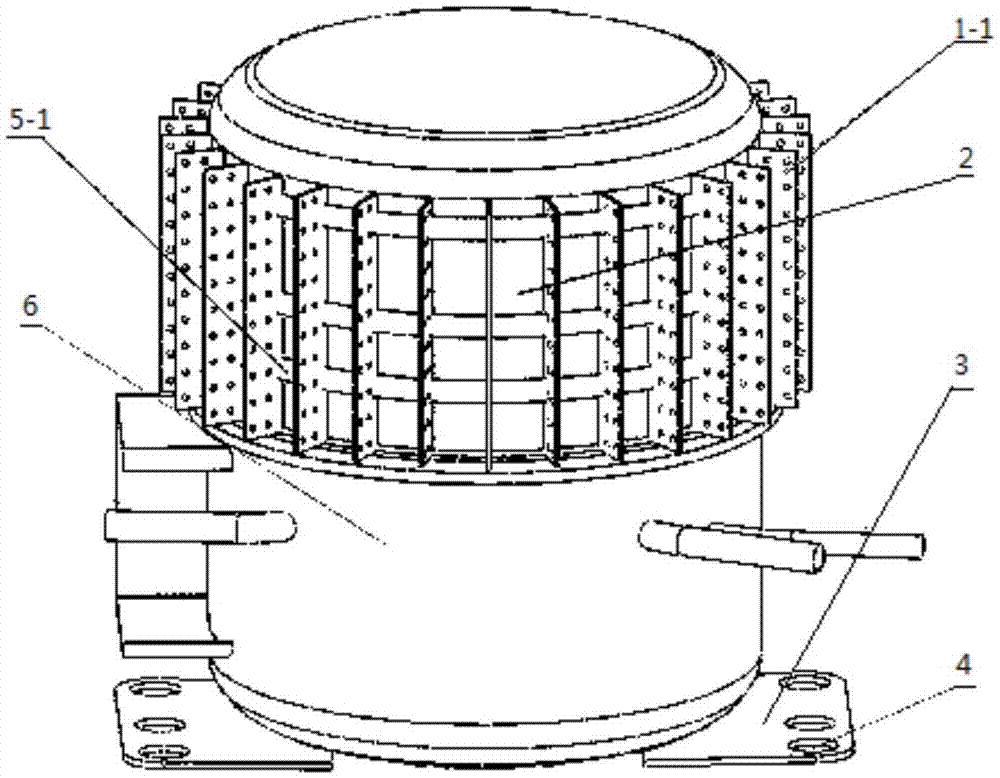

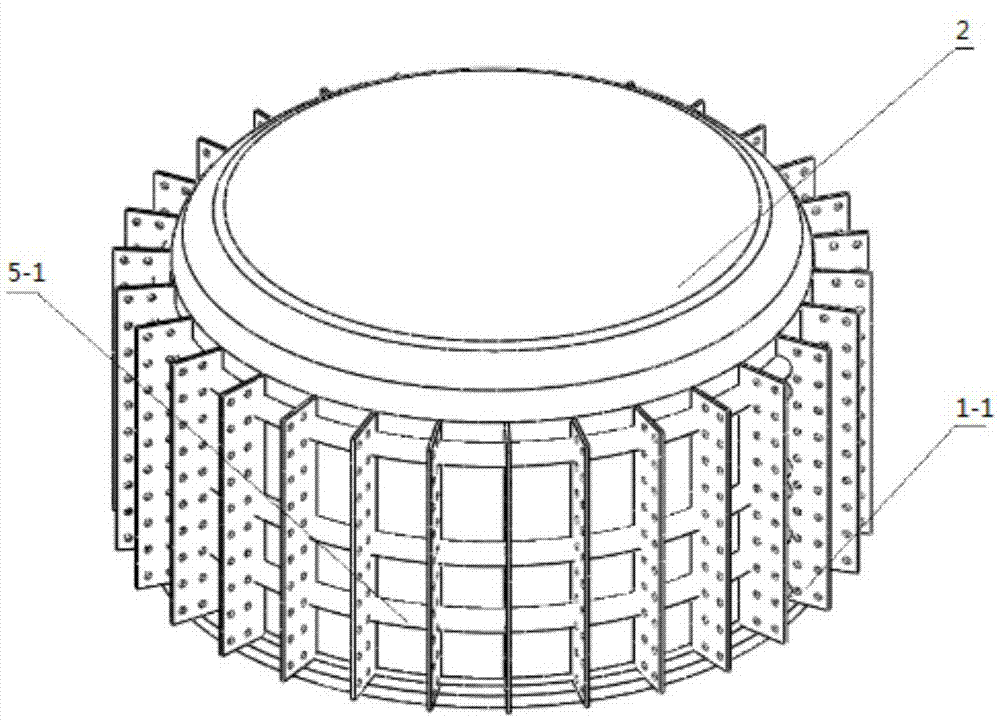

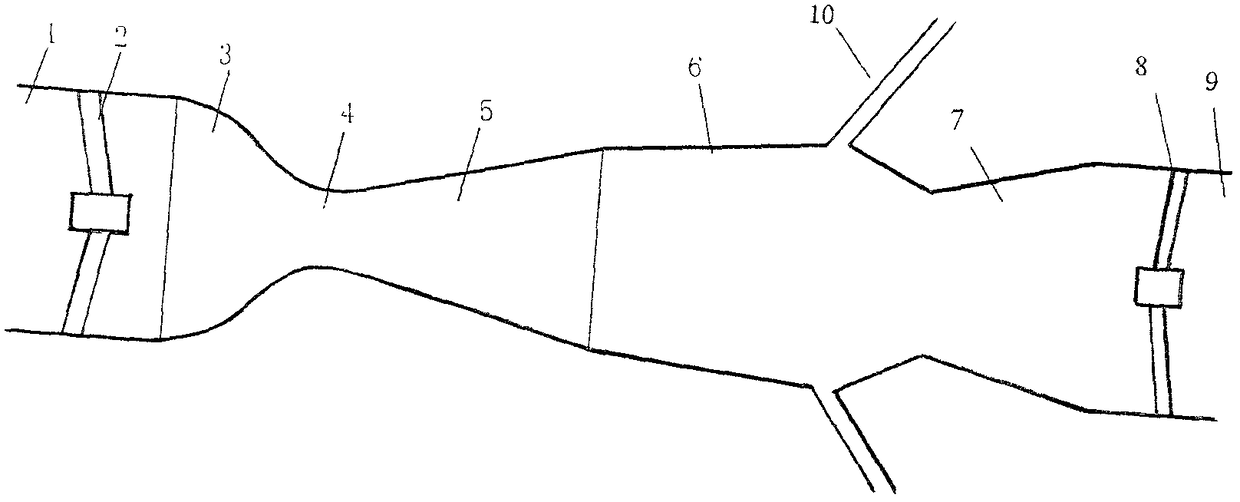

Non-concentric variable cross section GWF device

ActiveCN108514805AControl reasonable distributionEasy to separateGas treatmentDispersed particle separationMomentumEngineering

The invention discloses a non-concentric variable cross section GWF device, which is mainly successively integrated by a device entry end, a device jet pipe, a device diffusion section connected withthe device jet pipe and a device exit end. The device jet pipe is successively integrated by a constricted section, a throat part, an expansion section and a working section. different from existing concentric circle cross section GWF devices, the invention has the following beneficial effects: the concentric circle cross section design of an original device jet pipe section is abandoned and the structural design of a non-concentric variable cross section is created, additional centrifugal force is generated at each area of each cross section of the jet pipe channel, centrifugal action of thecentrifugal force on liquid drops is increased, a vortex stagnation zone with low spinning momentum is eliminated, and separation and recycling efficiency of natural gas is far higher than separationand recycling efficiency of a J-T valve and a turbo expander. In comparison with a concentric circle cross section GWF device, the non-concentric variable cross section GWF device also obviously showsoutstanding advantages.

Owner:闫家义 +1

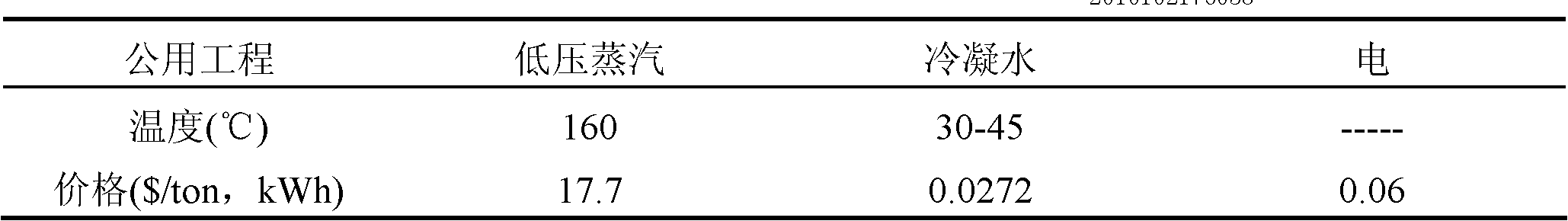

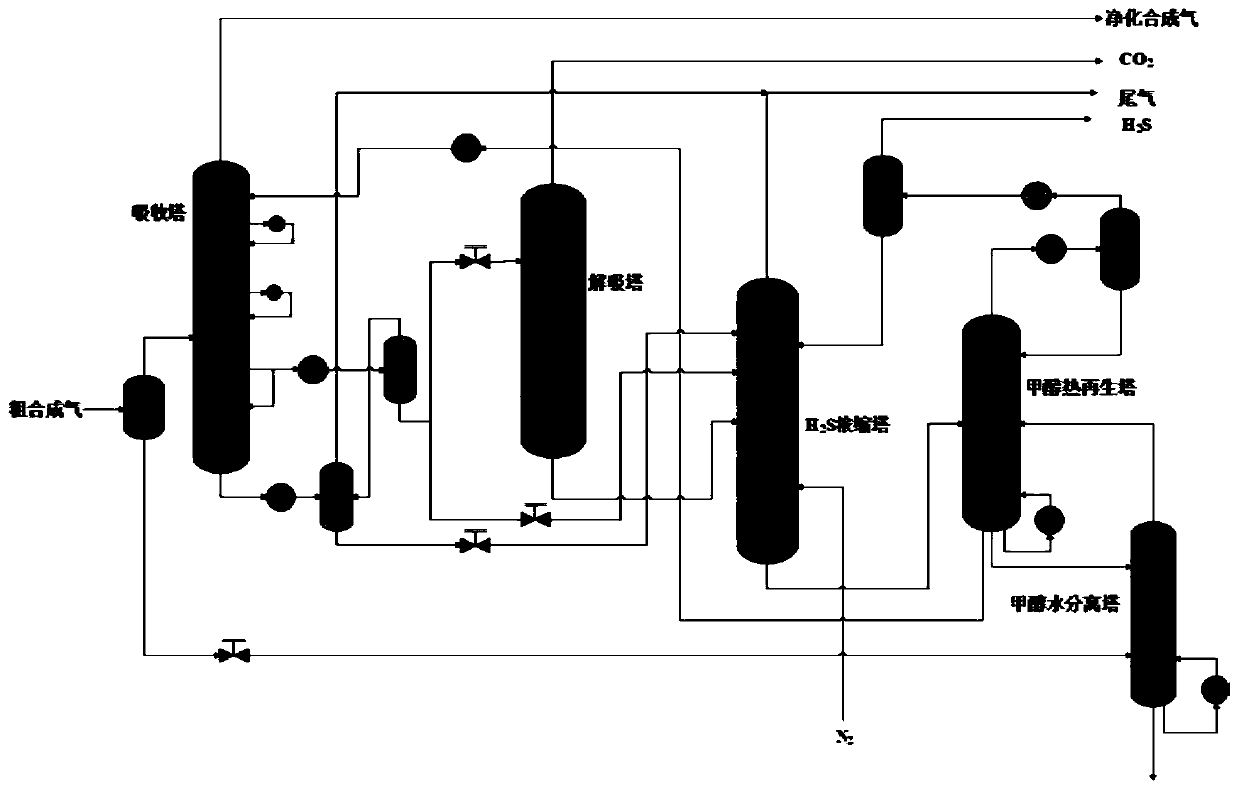

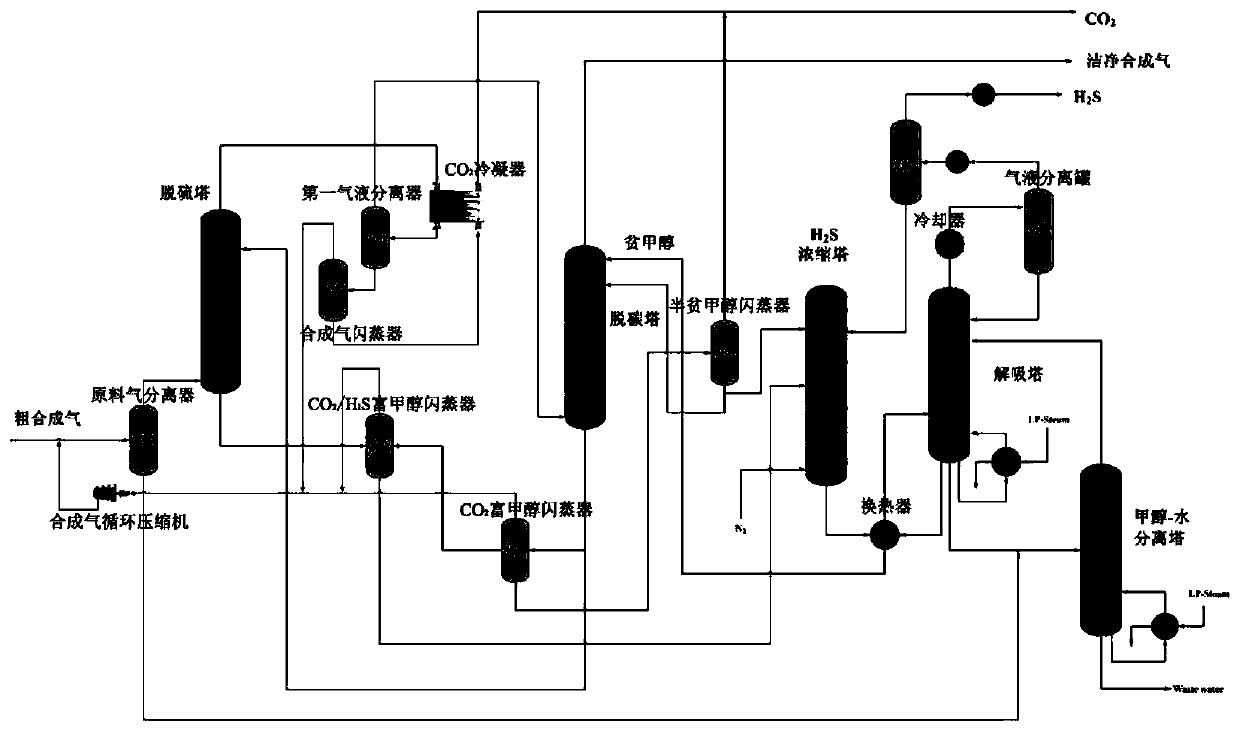

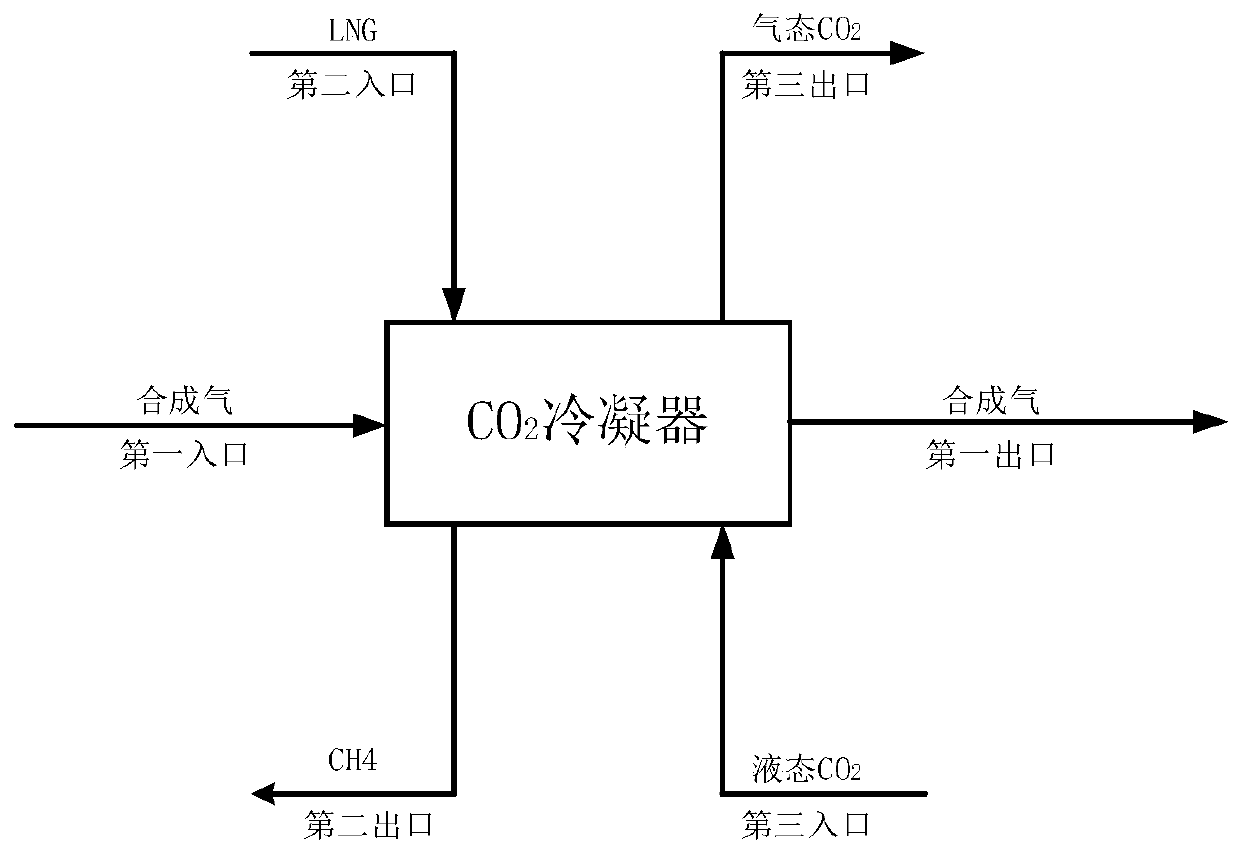

Low-temperature methanol washing process method and device with low energy consumption and high carbon capture rate

The invention belongs to the technical field of coal chemical industry, and particularly relates to a low-temperature methanol washing process method and device with low energy consumption and high carbon capture rate. The device comprises a feed gas separator, a desulfurization tower, a CO2 condenser, a synthesis gas flash evaporator, a CO2 / H2S methanol-rich flash evaporator, a decarburization tower, a CO2 methanol-rich flash evaporator, a semi-lean methanol flash evaporator, an H2S concentration tower, a desorption tower and a methanol-water separation tower which are connected in sequence.According to the process, the cooling capacity of LNG and the carbon dioxide liquefaction process of low-temperature methanol washing are coupled, the purity of captured carbon dioxide can be improved, methanol consumption in the original low-temperature methanol washing process can be reduced, and the cooling capacity and compression power consumption in the low-temperature methanol washing process are further reduced. According to the process, higher resource utilization rate can be realized, carbon emission is reduced, the consumption of lean methanol is reduced by 15%-45%, the total energyconsumption is reduced by 10%-50%, and the carbon capture rate is increased by 20%-50%. Meanwhile, the cost of an adjusting process in a factory is reduced through small equipment modification, and the method and the device can be widely applied to optimization of a traditional process.

Owner:SOUTH CHINA UNIV OF TECH

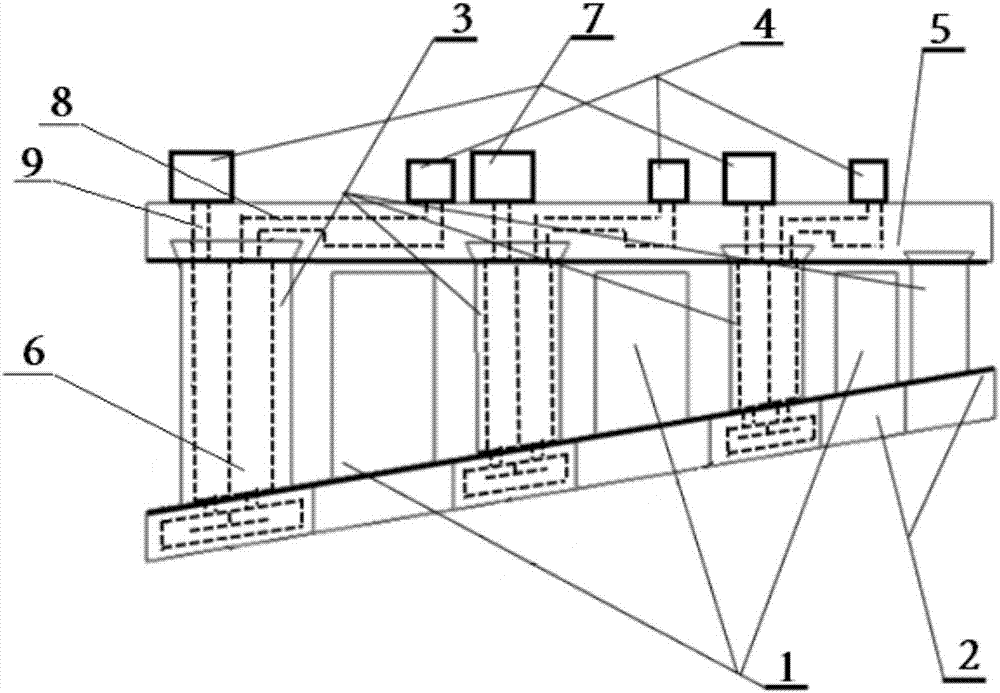

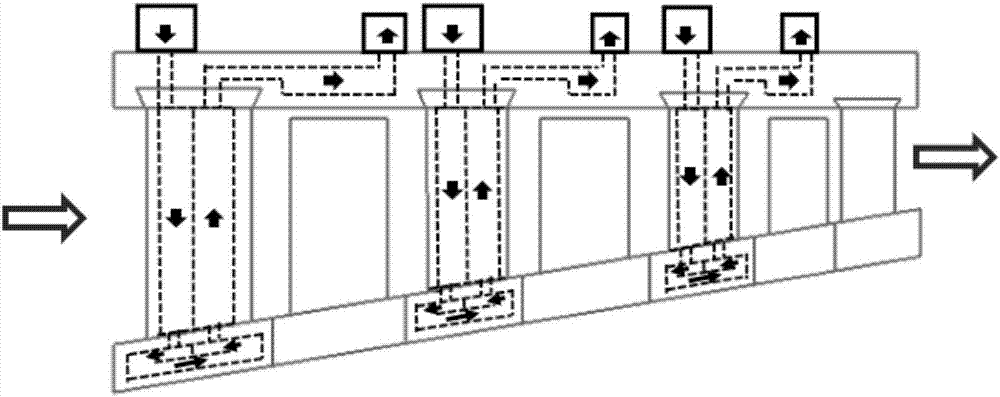

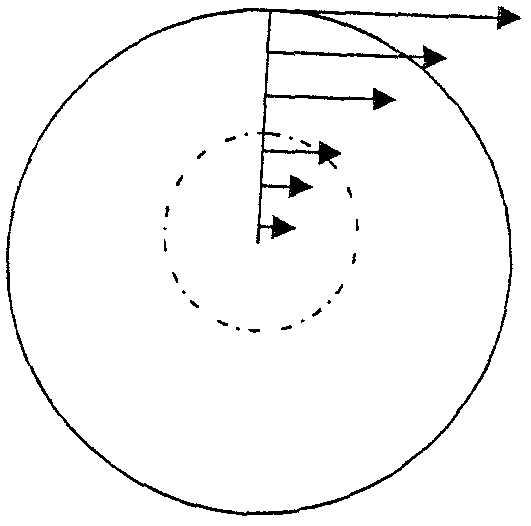

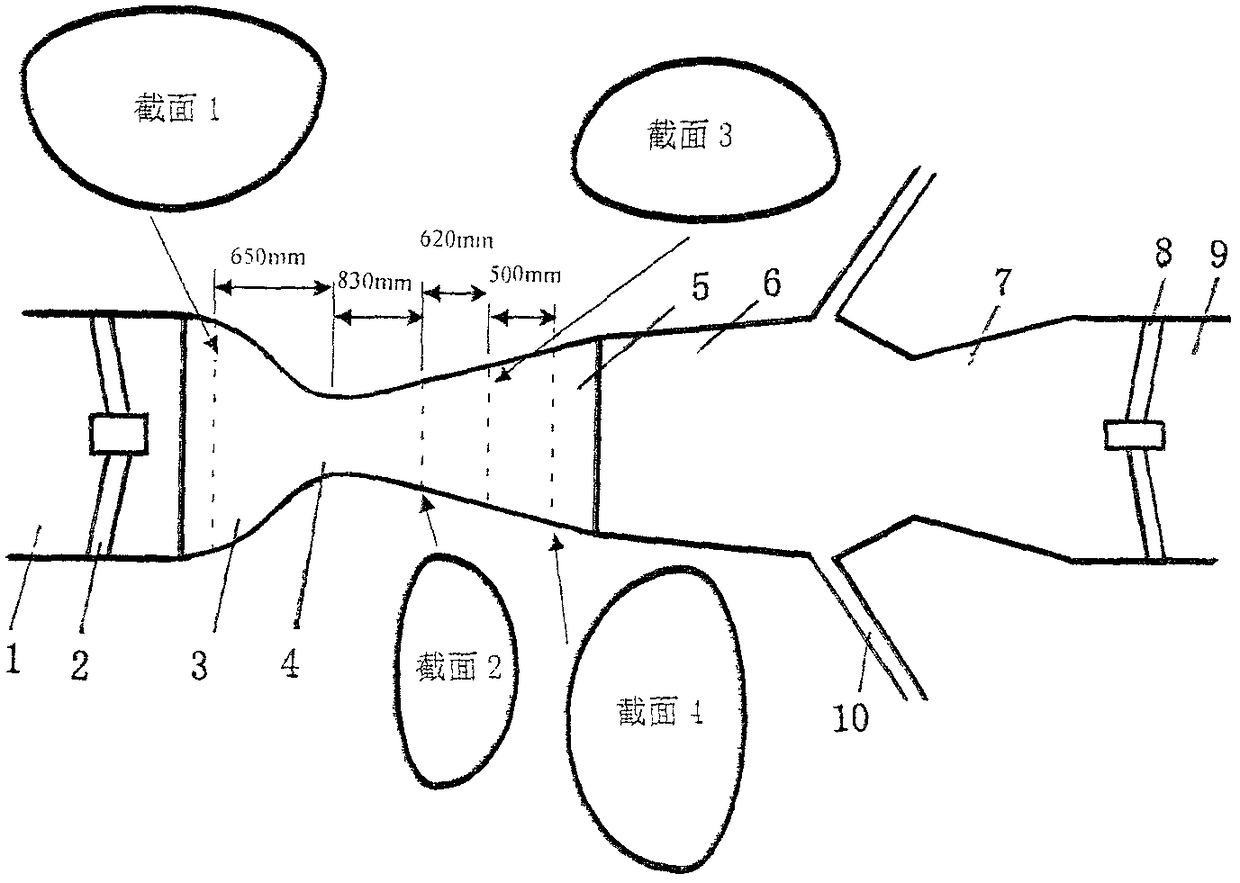

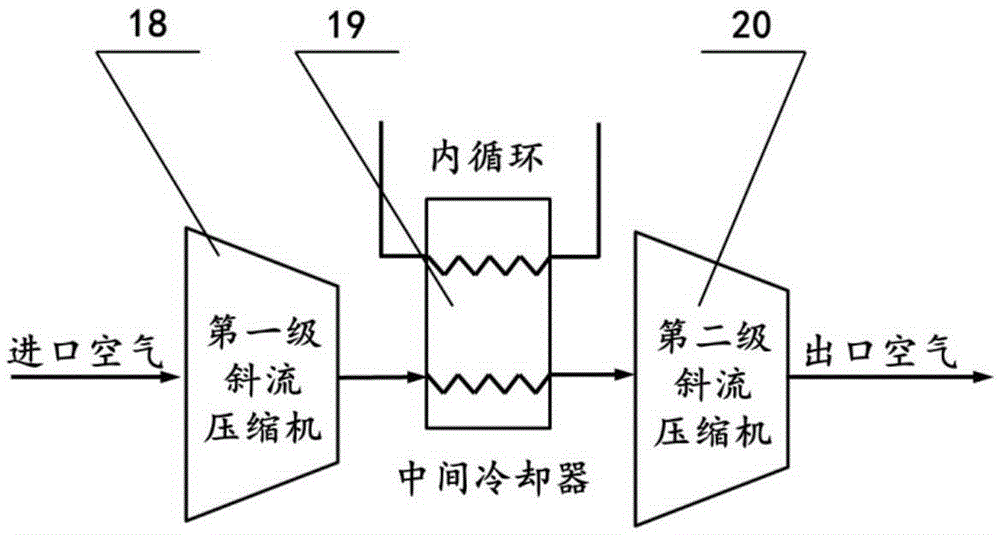

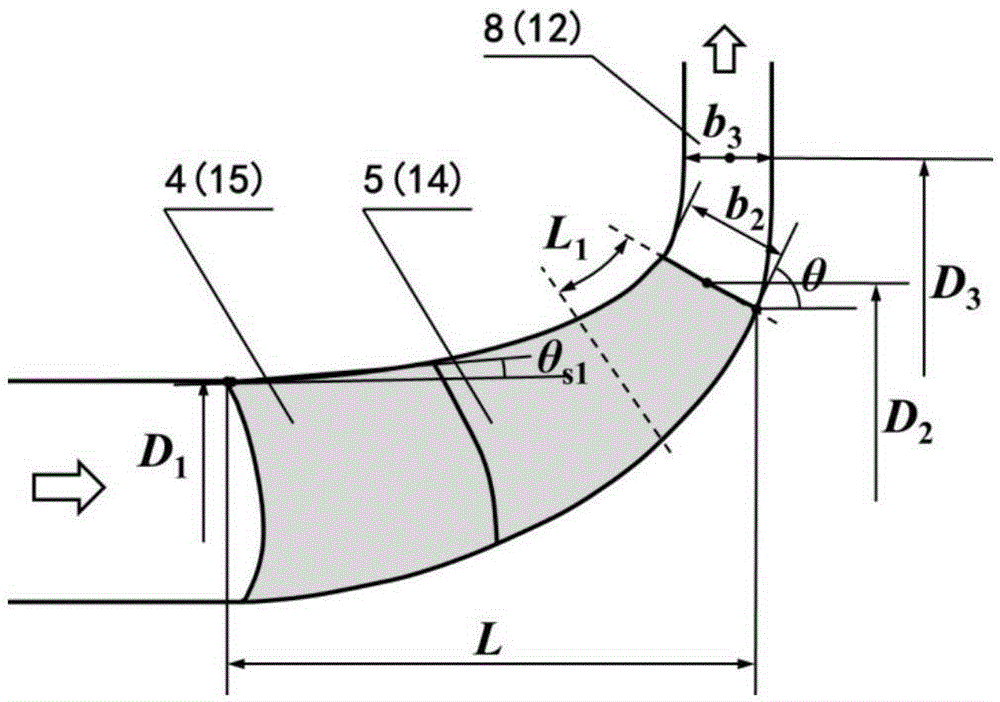

Two-stage mass-flow oblique flow compressor with stage intercooling

ActiveCN105275853AMeet needsOvercome first-level design difficultiesPump componentsPump installationsOff designEngineering

The invention discloses a two-stage mass-flow oblique flow compressor with stage intercooling. The two-stage mass-flow oblique flow compressor comprises two stages of oblique flow compressor bodies, and an interstage cooler is connected between the stages. The two-stage mass-flow oblique flow compressor is characterized in that an oblique flow impeller with obvious axial characteristic at the front end and the blade top large curvature characteristic at the back end is matched with an inlet gradually-decreased type curve vaneless diffuser to improve the performance of the first stage of impeller, and the requirement of the mass-flow compressor is met; and meanwhile, in the second stage, the oblique flow impeller and the oblique flow vaneless diffuser are adopted for improving the off-design performance of the impeller. The two-stage mass-flow oblique flow compressor has the beneficial effects of being large in flow, saving in power dissipation, high in efficiency, simple and compact in structure and the like; the problems that when a multi-stage centrifugal compressor structure is adopted in an existing extra-large and oversized order air separation set, the design difficulty is too large, and the performance is bad are solved, the problems that when a multi-stage axial flow and centrifugal compressor is adopted, the structure is complex, and the reliability is poor are solved, the performance of the second-stage compressor body can be improved, and the two-stage mass-flow oblique flow compressor is particularly suitable for the air separation set with the order ranging from 110000 Nm<3> / h to 150000 Nm<3> / h.

Owner:XI AN JIAOTONG UNIV

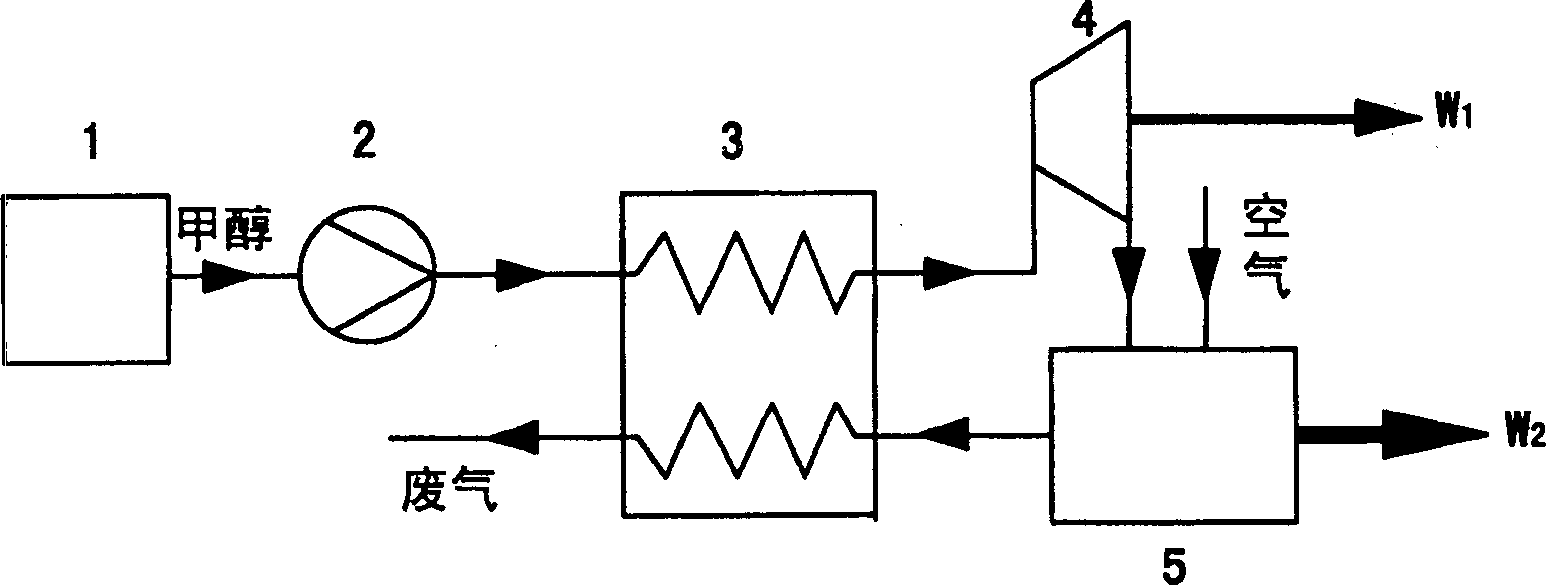

Methanol dynamic device and work done method by methanol pyrolysis

InactiveCN1779218AEmission reductionReduced Compression Power ConsumptionInternal combustion piston enginesGaseous engine fuelsLiquid fuelTurbine

A methanol power engine comprises methanol tank, pump, heat exchanger / cracking unit, turbine and engine. The heat exchanger / cracking unit is linked to the pump, turbine and the engine. The turbine is linked to the engine. The exhaust from the engine is used to heat methanol for cracking. After compressed, methanol flows into the heat exchanger / cracking unit and cracks with the heat from the engine exhaust. The cracked gas moves the turbine then the engine. The exhaust gas is exhaled after the heat exchanger. Compared with liquid fuel, less CO and hydrocarbons are exhausted. NOx content could also be decreased by ultra amount of air.

Owner:INST OF ENGINEERING THERMOPHYSICS - CHINESE ACAD OF SCI

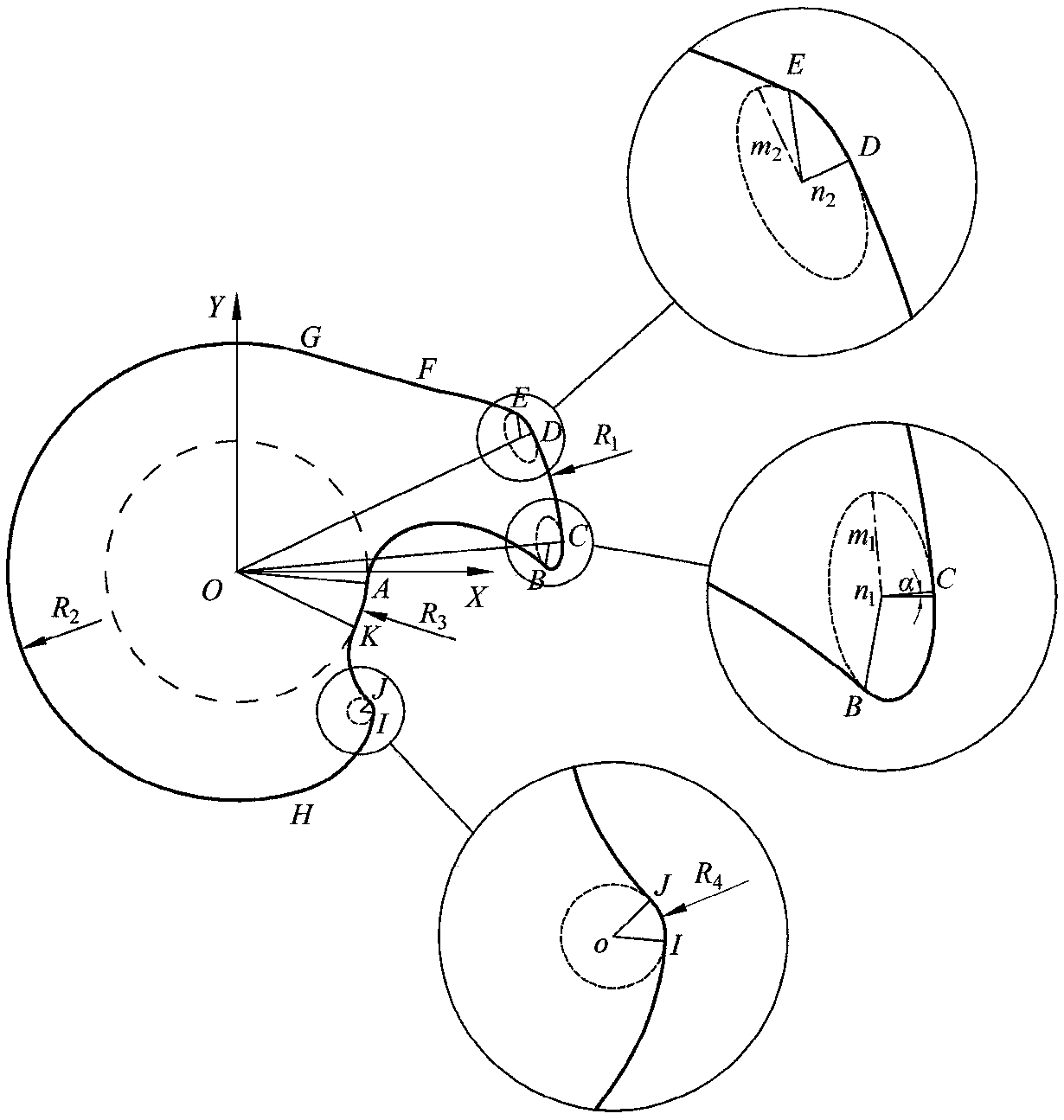

Straight jaw rotor of claw type vacuum pump and profile design method of straight jaw rotor

ActiveCN108757464AIncreased engagement rangeEngagement wire lengthGeometric CADRotary piston pumpsEllipseCycloid

The invention discloses a straight claw rotor of a claw type vacuum pump and a profile design method of the straight claw rotor. The straight claw rotor is composed of eleven segments of curves comprising four segments of arcs, two segments of elliptical arcs, two segments of elliptical arc envelope lines, one segment of equidistant curve of a cycloid, one segment of line segment and one segment of envelope line. The rotor uses the elliptical arcs and the envelope lines of the elliptical arcs to construct the profile at the top of a claw and the tip of the claw, and uses the arcs and the equidistant curve of the cycloid to construct the profile at the bottom of the claw, adjacent curves are all connected smoothly, no non-smooth connection point exists, and the mechanical properties, the meshing performance and the sealing performance of the straight jaw rotor are improved. Two rotors meshing with each other are identical and the correct meshing of the profile can be achieved. The rotorhas a smaller clearance volume and improves the compression ratio of the claw vacuum pump. The top of the claw is more flat, the meshing range is large, a mesh line is long, and abrasion is further reduced. The rotor enriches profile types of claw type rotors and promotes the development of claw type vacuum pumps.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

Air conditioner only having refrigeration function and control method thereof

ActiveCN105783313AImprove energy efficiencyImprove abilitiesMechanical apparatusCompression machines with non-reversible cycleVapor–liquid separatorEngineering

The invention discloses an air conditioner only having a refrigeration function and a control method thereof. The air conditioner only having the refrigeration function comprises a double-cylinder compressor, an outdoor heat exchanger, an indoor heat exchanger, an air-liquid separator and a refrigerant heat sink; an air suction port of a first air cylinder is communicated with a first liquid storage device; the exhaust volume ratio of a second air cylinder to the first air cylinder ranges from 1% to 10%; the air-liquid separator comprises an air outlet, a first interface and a second interface; the air outlet is connected to the second air cylinder; a first throttling element with an adjustable opening is connected between the first interface and the outdoor heat exchanger in series; and a second throttling element with an adjustable opening is connected between the second interface and the indoor heat exchanger in series; and the refrigerant heat sink is connected between the air outlet and the air suction port of the second air cylinder in series. The energy efficiency of the air conditioner only having the refrigeration function is effectively improved.

Owner:GD MIDEA AIR-CONDITIONING EQUIP CO LTD +1

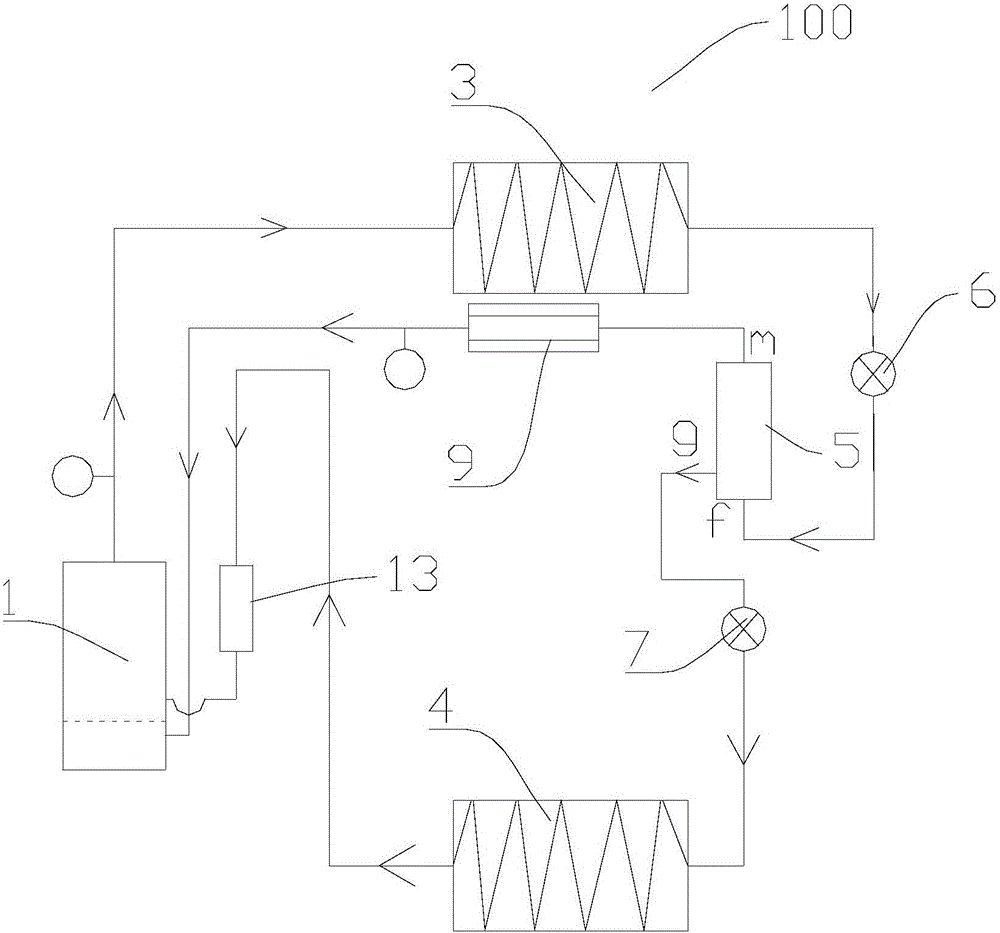

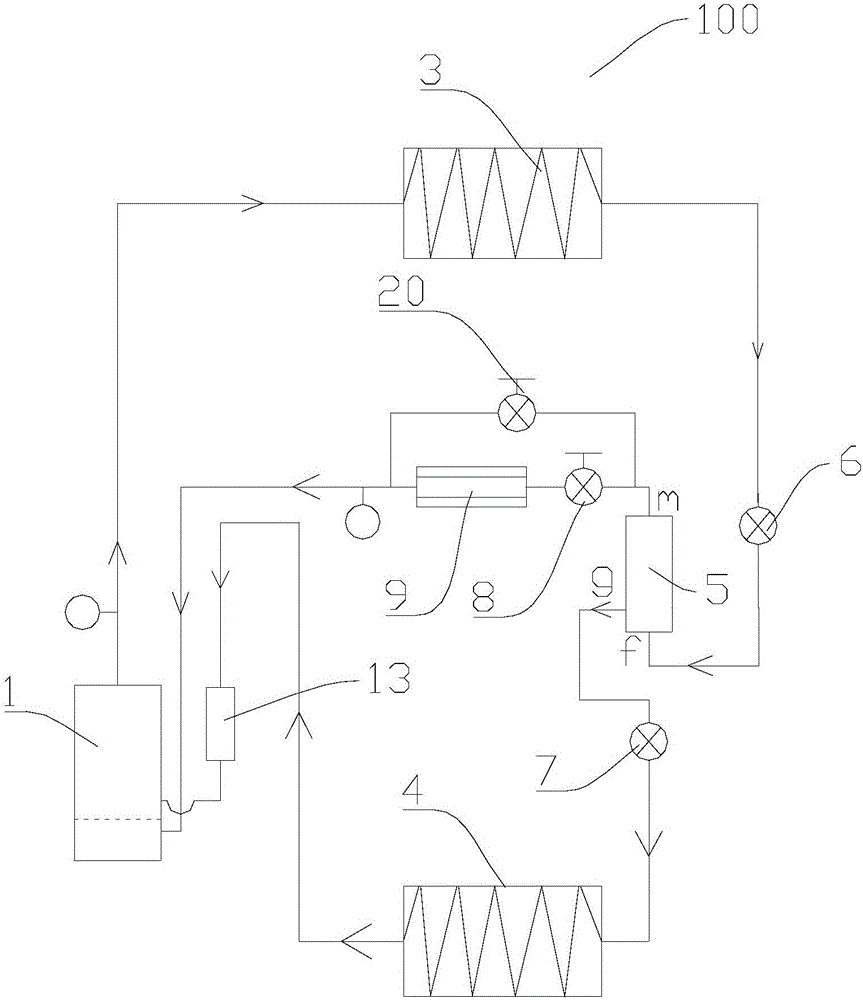

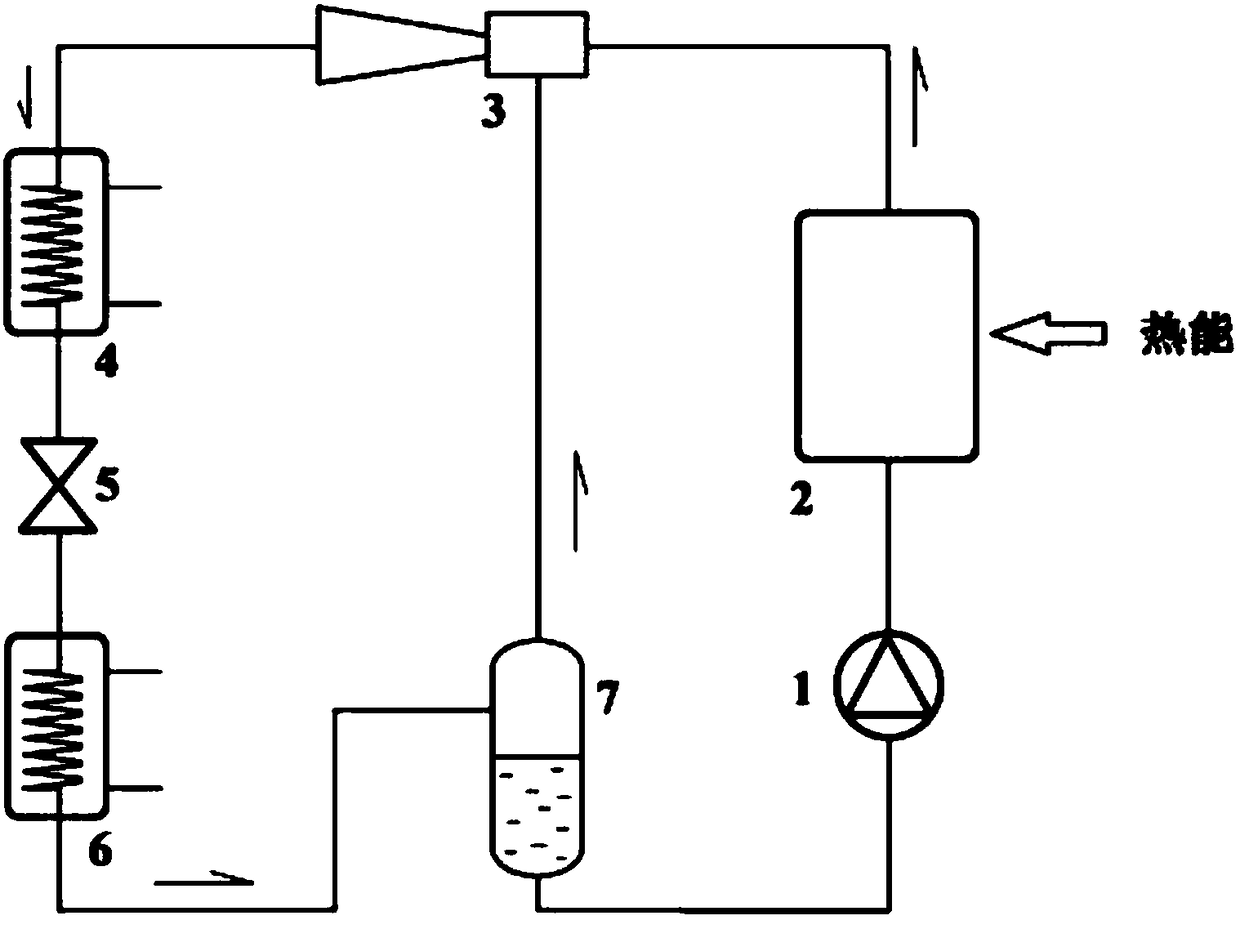

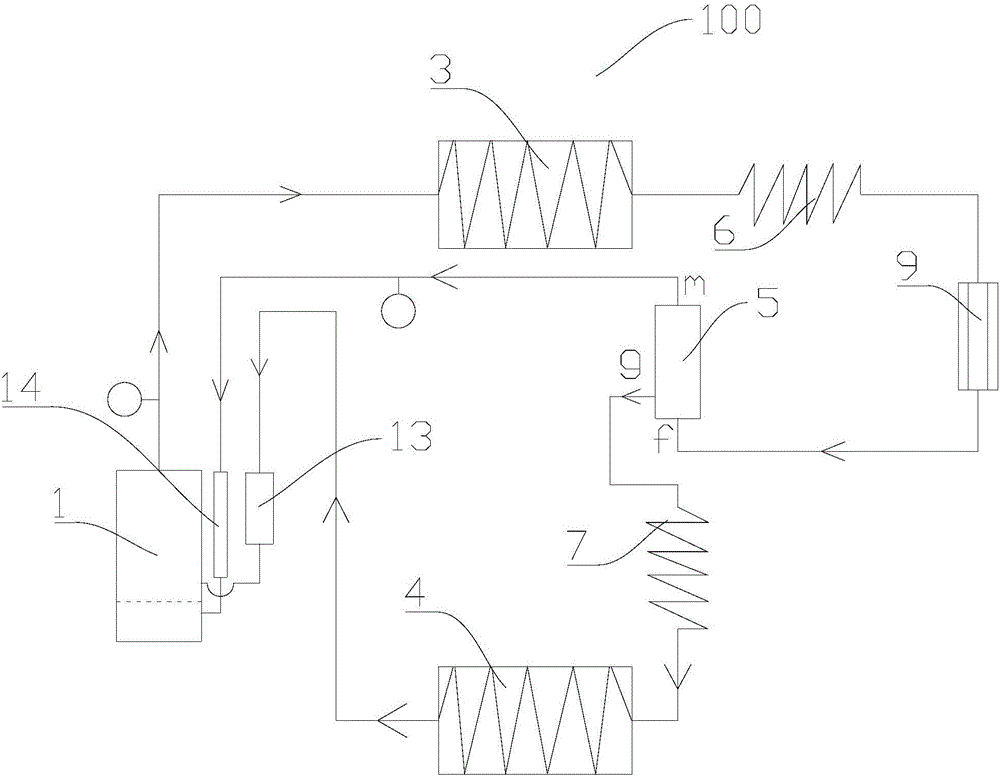

Transcritical reverse circulation system and method

ActiveCN108397929AGuaranteed uptimeReduced Compression Power ConsumptionCompression machinesVapor–liquid separatorGas phase

The invention provides a transcritical reverse circulation system and method which take heat energy as the driving force, realize transcritical reverse circulation of a working medium and provide coldsource or heat source for the outside world. The transcritical reverse circulation system comprises a heater, an ejector, a cooler, a throttle valve, an evaporator, a gas-liquid separator and a working medium pump which communicate in sequence through pipelines, a saturated gas phase outlet of the gas-liquid separator communicates with a gas ejecting inlet of the ejector to form the reverse circulation system, a saturated liquid phase outlet of the gas-liquid separator communicates with the inlet of the working medium pump, and the outlet of the working medium pump communicates with the heater and the high-pressure inlet of the ejector in sequence to form a positive circulation system.

Owner:INST OF MECHANICS - CHINESE ACAD OF SCI

Method for reducing ethene device energy consumption

ActiveCN105566029AImprove recycling efficiencyReduce energy consumptionHydrocarbon purification/separationHydrocarbonsSolvent basedProcess engineering

The invention discloses a method for reducing ethene device energy consumption. The method comprises cooling pyrolysis gas from an outlet of a pyrolysis furnace through a quench cooler, feeding the cooled pyrolysis gas into an oil washing tower, carrying out substance separation, discharging quenching oil from the bottom of the oil washing tower, feeding a part of the quenching oil into the quench cooler, returning a part of the quenching oil back to the oil washing tower, feeding a part of the quenching oil into an extraction tower, carrying out solvent-based extraction, returning the material at the top of the extraction tower back to the oil washing tower and discharging an asphalt phase at the bottom of the extraction tower, wherein the solvent used in the extraction tower is pyrolysis gas from an outlet of an ethene device compressor.

Owner:CHINA PETROLEUM & CHEM CORP +1

Single-refrigeration type air conditioner and control method thereof

InactiveCN105758036AImprove energy efficiencyImprove abilitiesCompressorMechanical apparatusVapor–liquid separatorProcess engineering

The invention discloses a single-refrigeration type air conditioner and a control method thereof.The air conditioner comprises a double-cylinder compressor, an outdoor heat exchanger, an indoor heat exchanger, a gas-liquid separator and a cold medium cooler.The gas suction opening of a first cylinder is communicated with a first liquid storage device.The exhaust volume ratio of a second cylinder to the exhaust volume ratio of the first cylinder ranges from 1% to 10%.The gas-liquid separator comprises a gas outlet, a first connector and a second connector.The gas outlet is connected with the second cylinder.A first throttling element for fixing the opening degree is connected between the first connector and the outdoor heat exchanger in series.A second throttling element for fixing the opening degree is connected between the second connector and the indoor heat exchanger in series.The cold medium cooler is connected between the first throttling element and the first connector in series, or the cold medium cooler is connected between the second throttling element and the second connector in series.The efficiency of the single-refrigeration type air conditioner is effectively improved.

Owner:GD MIDEA AIR-CONDITIONING EQUIP CO LTD +1

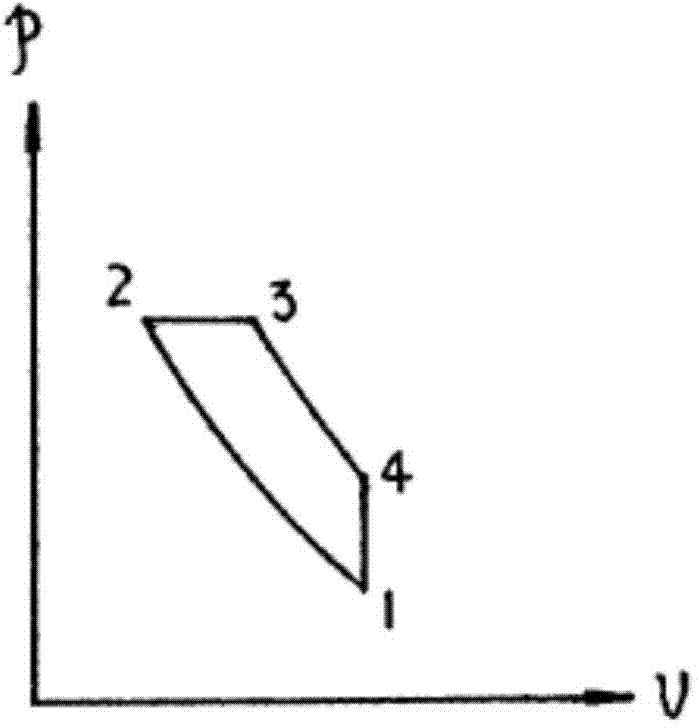

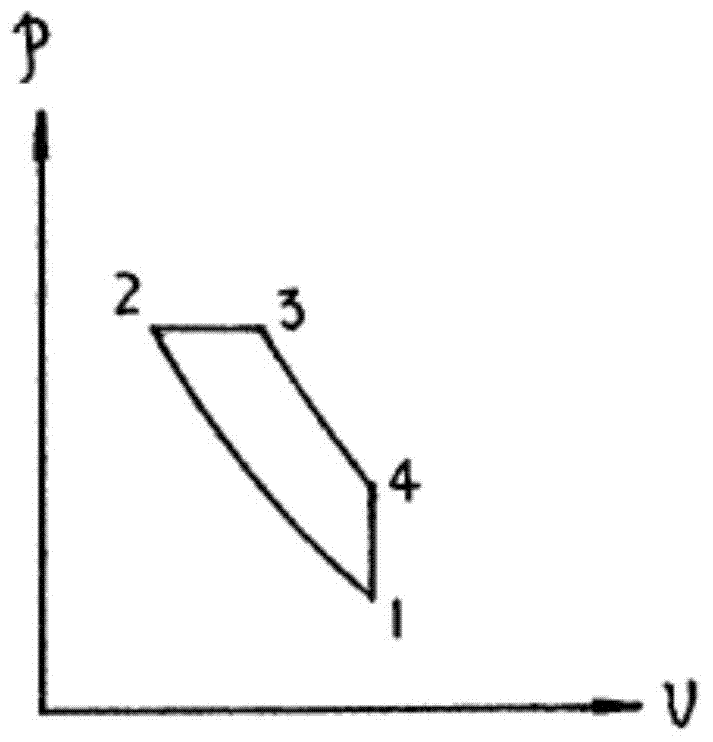

Half-closed constant-pressure internal combustion thermodynamic cycle method and half-closed constant-pressure internal combustion thermodynamic cycle system for prime mover

ActiveCN103939214ARaise the initial temperatureIncrease heat power conversion rateGas turbine plantsJet propulsion plantsCyclic processThermal energy

The invention provides a half-closing constant pressure internal combustion thermodynamic cycle method and a half-closed constant-pressure internal combustion thermodynamic cycle system for a prime mover. A cycle process comprises a multi-level compression stage intercooling process, a countercurrent flow process, a constant-pressure combustion process, an adiabatic expansion process, a post-cooling process and a carbon dioxide and water removal process, wherein the compression power consumption in the multi-level compression stage intercooling process is reduced; exhaust energy in the countercurrent flow process is recovered, and the cycle thermal energy use ratio is improved; the constant-pressure combustion process adopts independent oxygen supply, the compression power consumption is reduced, meanwhile, a working medium does not contain nitrogen, NOx is not generated, an inert gas is adopted as the working medium, and the process is clean and efficient; carbon dioxide and water generated by the combustion process are partially or completely removed according to the type of a first working medium, the fresh working medium quantity demand is small, and the half-closed constant-pressure internal combustion thermodynamic cycle method is applied in environments such as underwater and oxygen deficit.

Owner:GREEN ENERGY HIGH TECH GRP +5

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com