Patents

Literature

63 results about "Strong solutions" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

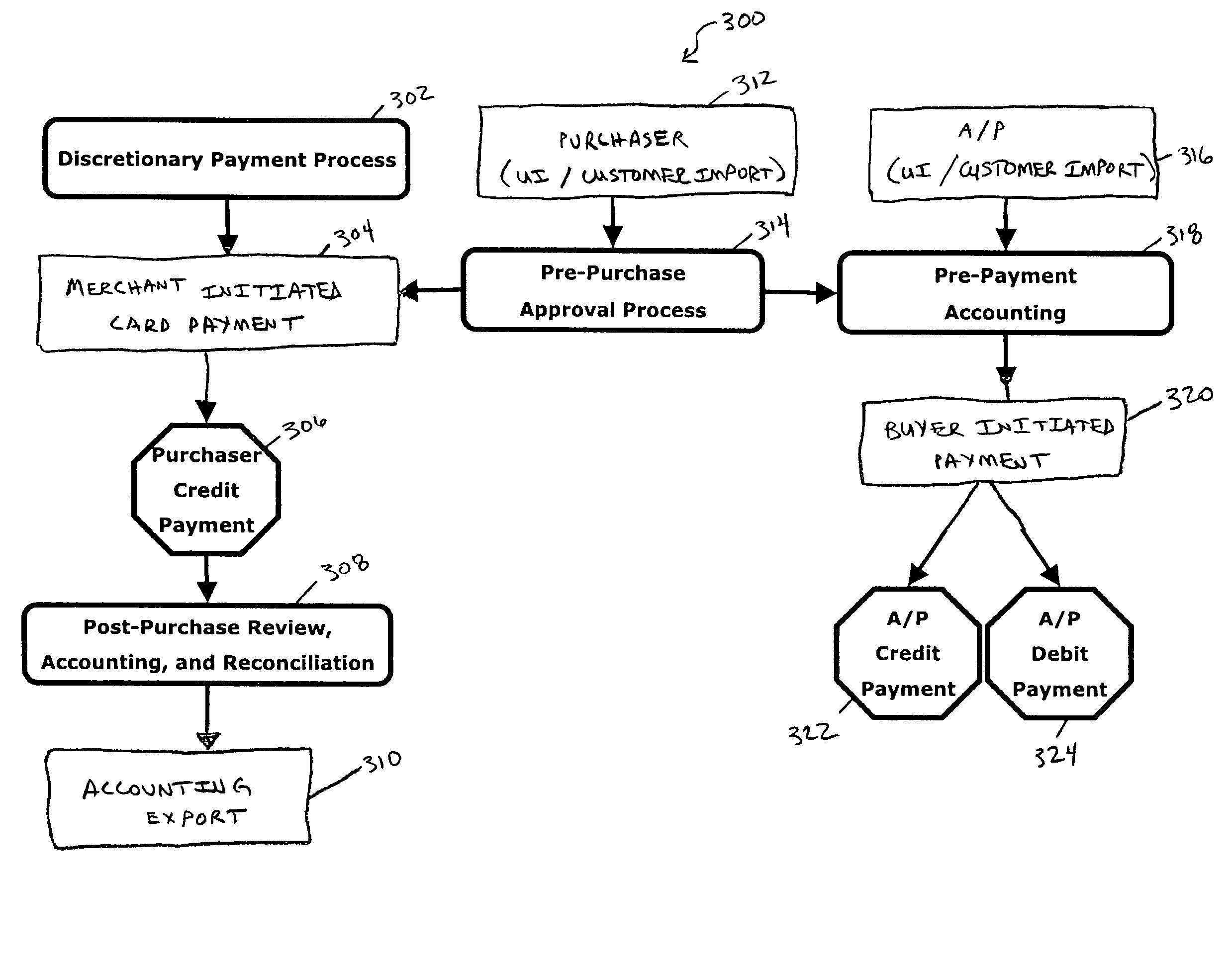

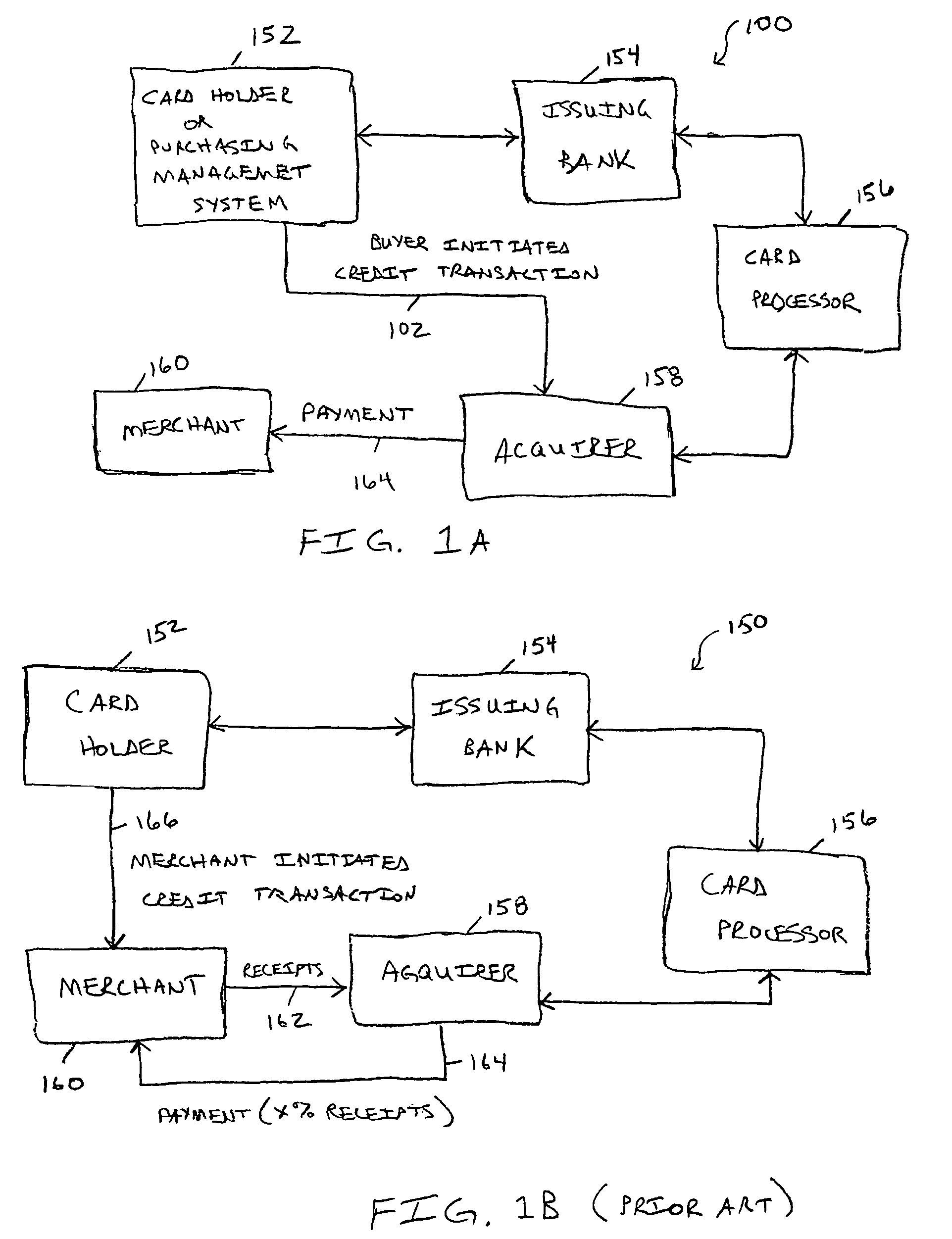

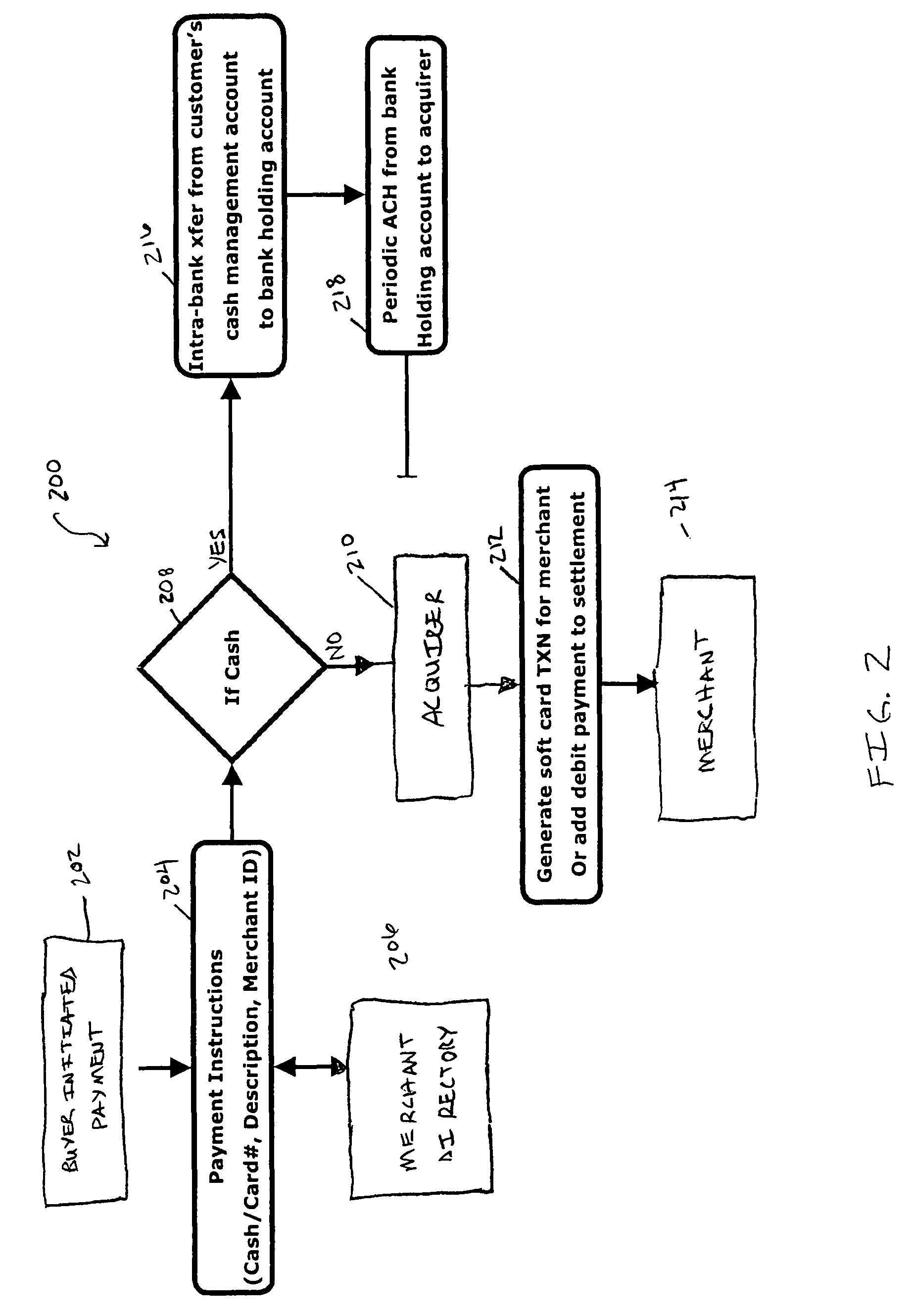

Method and system for pushing credit payments as buyer initiated transactions

ActiveUS7895119B2Advantageous and efficient and powerful solutionFinanceAnonymous user systemsCredit cardStrong solutions

A method and system are disclosed for pushing credit payments as buyer initiated transactions. The buyer communicates payment instructions to initiate payment of accounts payable items so that the existing credit card infrastructure can be used to make payments to merchants without a credit card transaction being initiated by the merchants. In this way, a buyer can push credit payments into the system without having to communicate with the merchant, and these transactions can be processed as credit transactions with respect to standard settlement procedures, for example, as used by credit card receipt acquirers. This ability to push credit payments provides an advantageous, efficient and powerful solution to handling accounts payable operations, particularly in a corporate environment. And a purchasing management system can be used to manage and control these activities and to allow selection, or automatic selection based upon merchant profiles, of whether to make payments as pushed credit payments or cash / debit transactions.

Owner:BANK OF AMERICA CORP

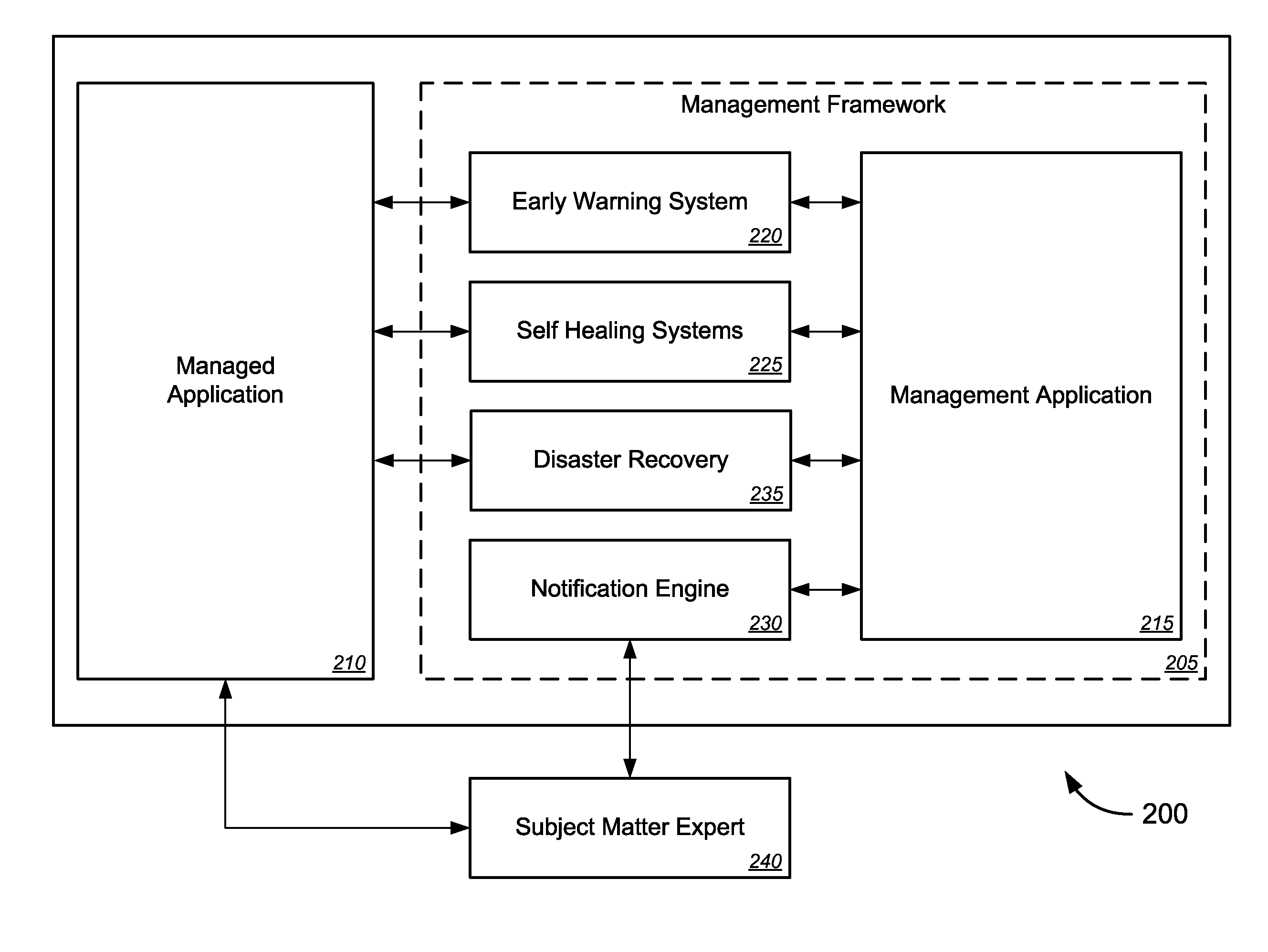

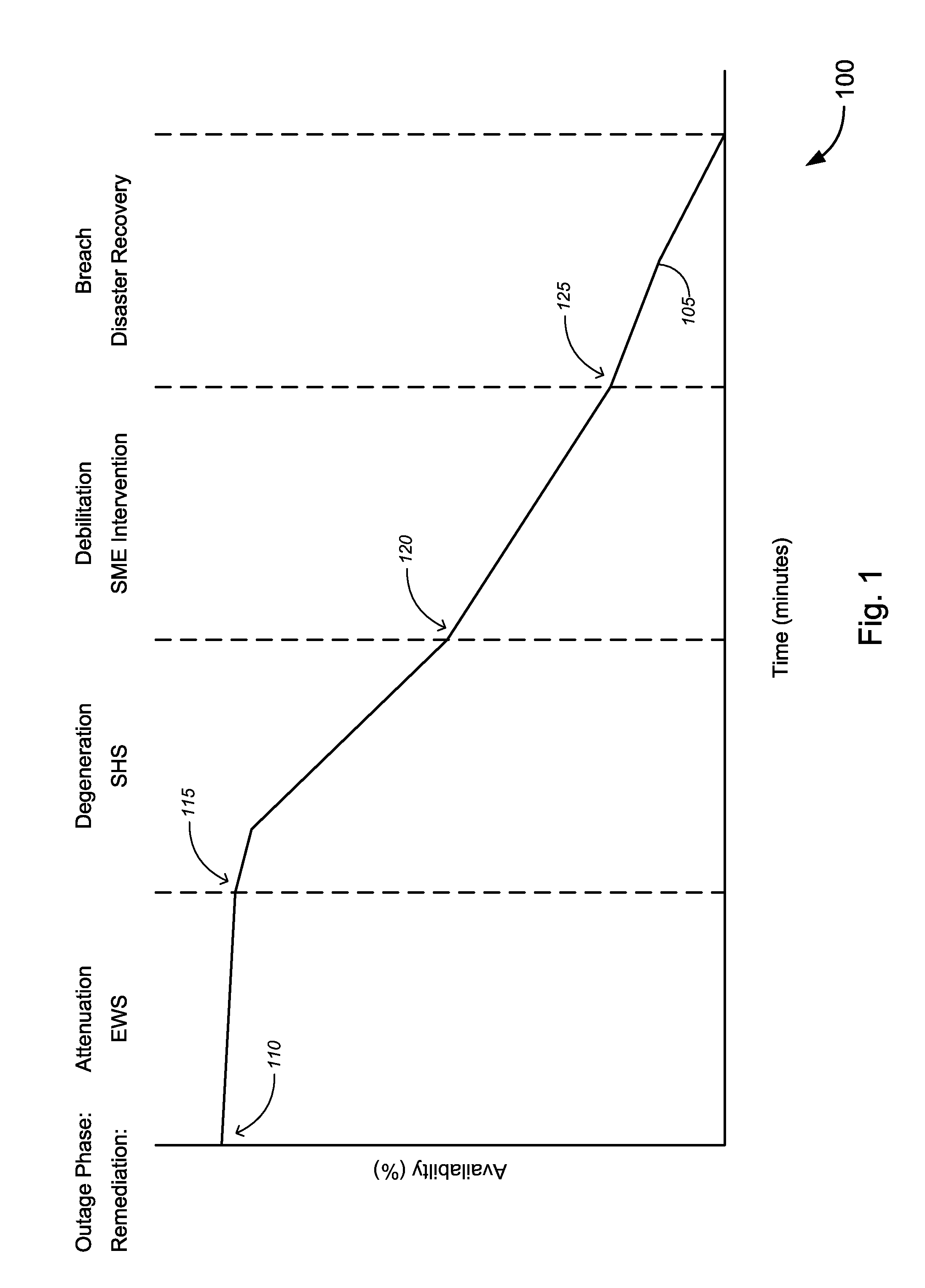

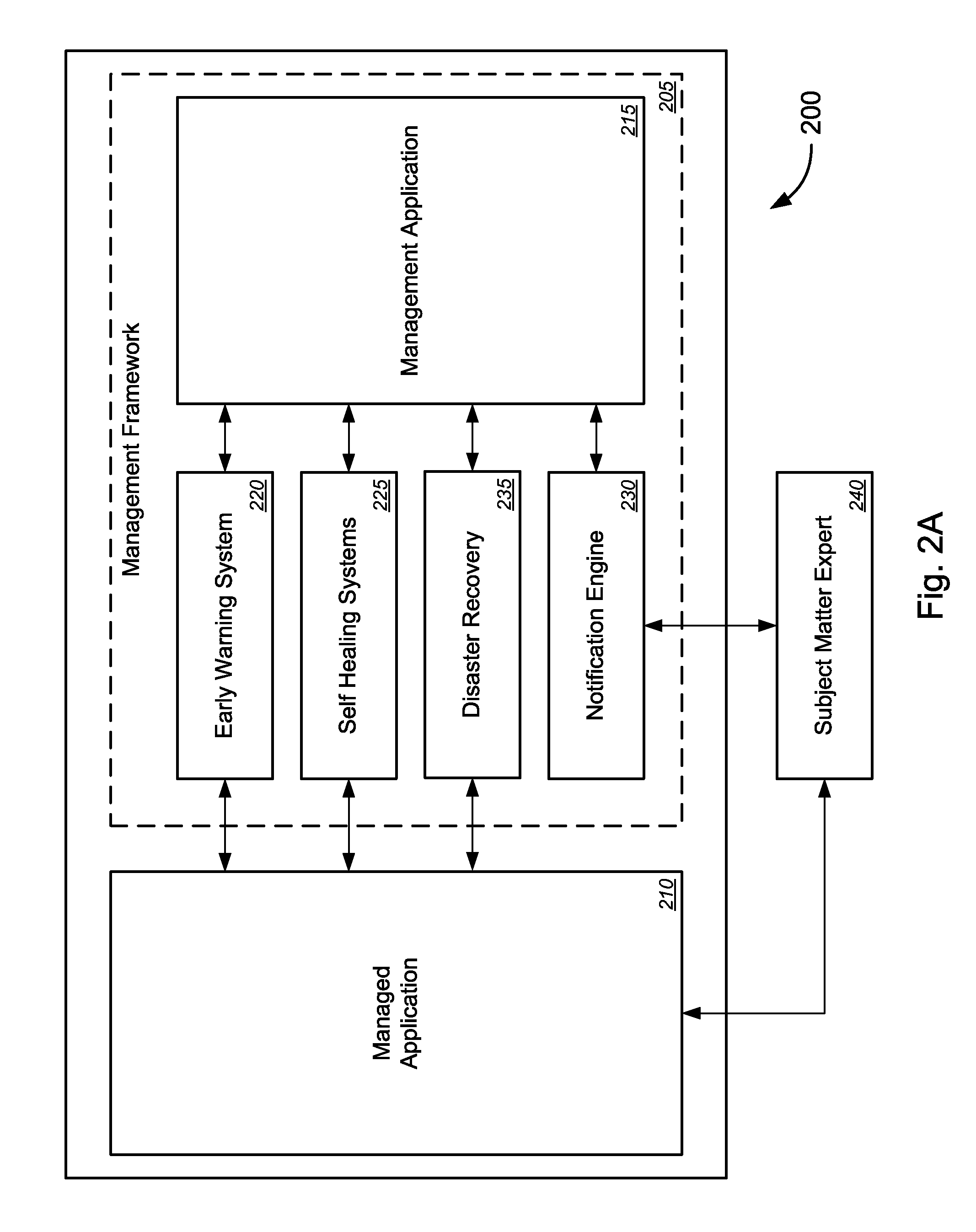

Autonomous Service Management

ActiveUS20140310564A1Robust solutionPreventing potential downtimeHardware monitoringNon-redundant fault processingApplication lifecycle managementStrong solutions

Novel tools and techniques that offer more robust solutions for application service management. Some such solutions provide a service management framework for managing a software application. In some cases, the framework can include multiple tools to detect and / or remedy application problems at a variety of different levels. In another aspect, some solutions can define multiple application lifecycle phases, ranging from minor impairment to catastrophic failure. For each of such phases, the service management framework can define one or more diagnostic criteria and / or one or more corrective actions that can be taken to remedy a suboptimal condition of the application.

Owner:CENTURYLINK INTPROP

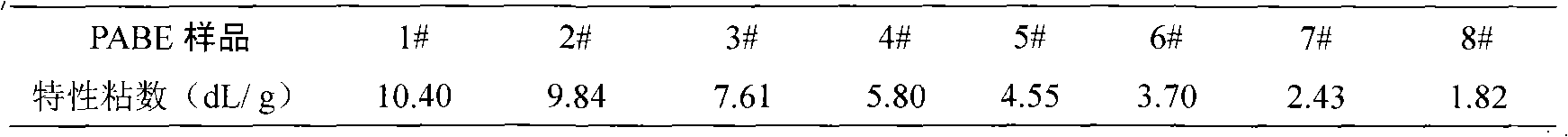

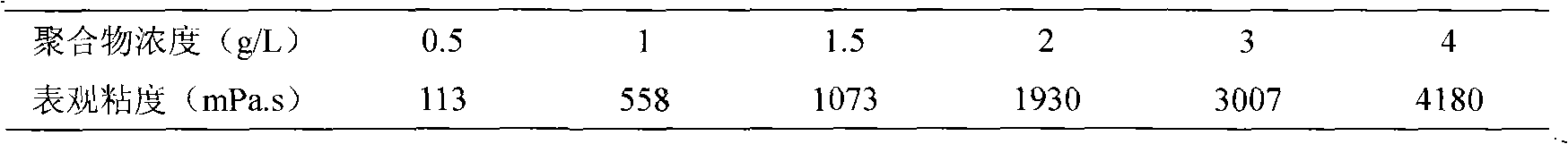

Comb-typed amphiphilic water-soluble co-polymer, method for preparing same and use

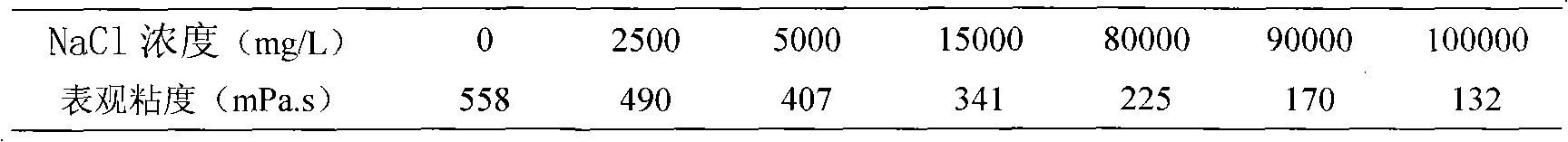

The invention discloses a comb-type amphipathicity water-solubility multipolymer and a method for making the same as well as an application. The method is characterized in that: 20 portions of acrylamide, 0.1 to 10 portions of negative ion monomer, 0.5 to 15 portions of at least one of the surface activity macromolecular monomer 4-vinyl benzyl alkylphenol polyoxyethylene ether or / and allyl alkylphenol polyoxyethylene ether and 30 to 600 portions of deionized water are added into a three-necked reaction bulb, the pH value of the solution is adjusted to between 4 and 9, N2 is introduced into the solution for 30 minutes, 0.002 to 0.3 portion of evocating agent sulphate is added at the temperature of between 30 and 70 DEG C to react 12 to 36 hours in order to prepare PABE which is diluted by water to obtain the PABE strong solution; the comb-type amphipathicity water-solubility multipolymer which can viscosify, has salt resistance and the low surface tension as well as the molecular association ability and can be used for the fuel scavenge. The multipolymer is prepared into a water solution with a mass concentration between 0.3 and 3g / L and a surface active agent concentration between 0.01 and 2mmol / L, the water solution is added into a blending container with a stirring device and is stirred evenly at room temperature so that the polymer oil-displacing agent which can viscosify and shear-resistant and has excellent anti-aging performance in a hyperhaline state and at the temperature of 70 DEG C. The PABE has the double function of a tackifier and a macromolecule surfactant. Infinitesimal low molecular surface active reagent is added into the PABE solution, thereby evidently increasing the apparent viscosity of the solution, reducing the surface tension and the oil-water boundary tension of the solution and contributing to improving the recovery ratio.

Owner:CHENGDU UNIVERSITY OF TECHNOLOGY

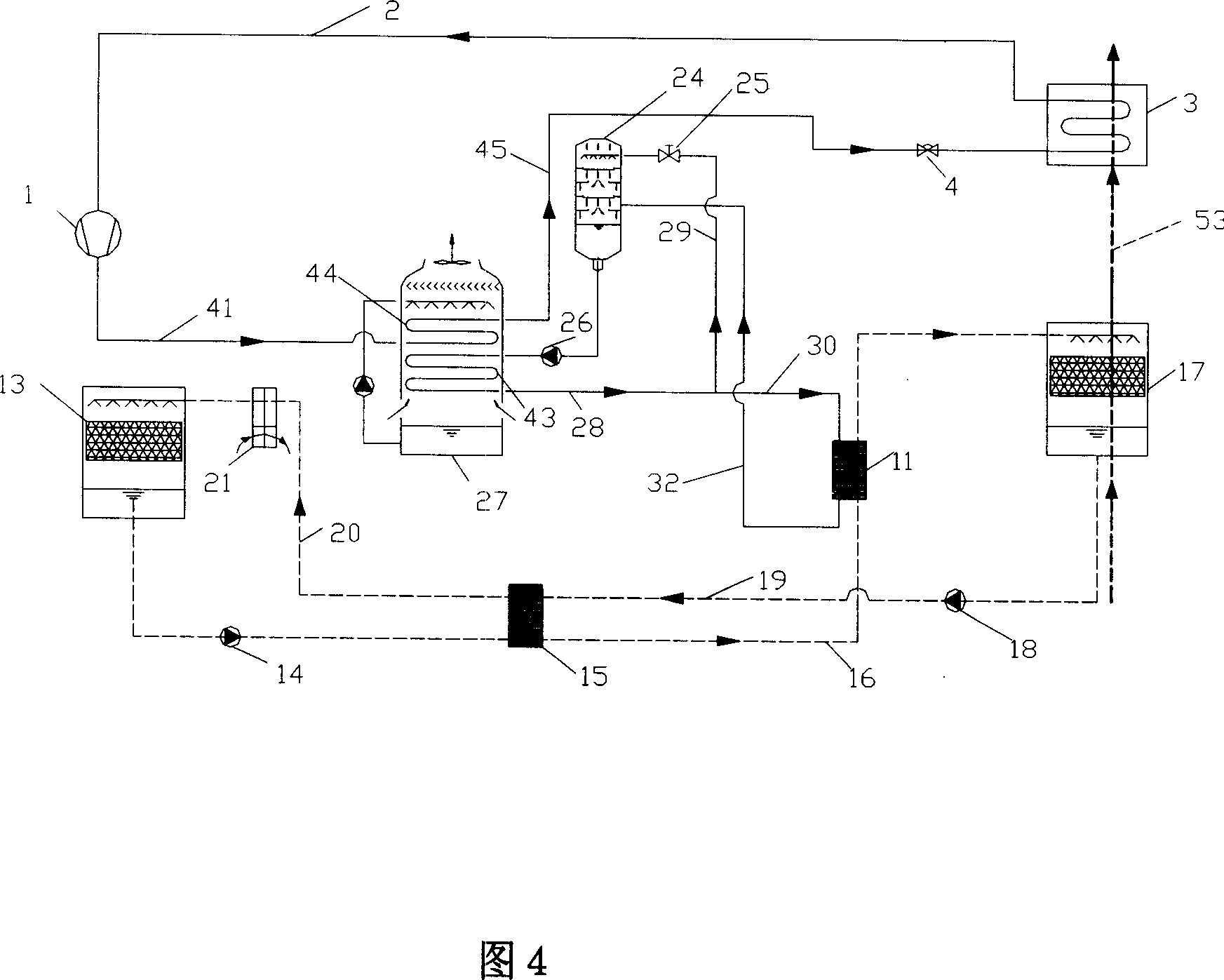

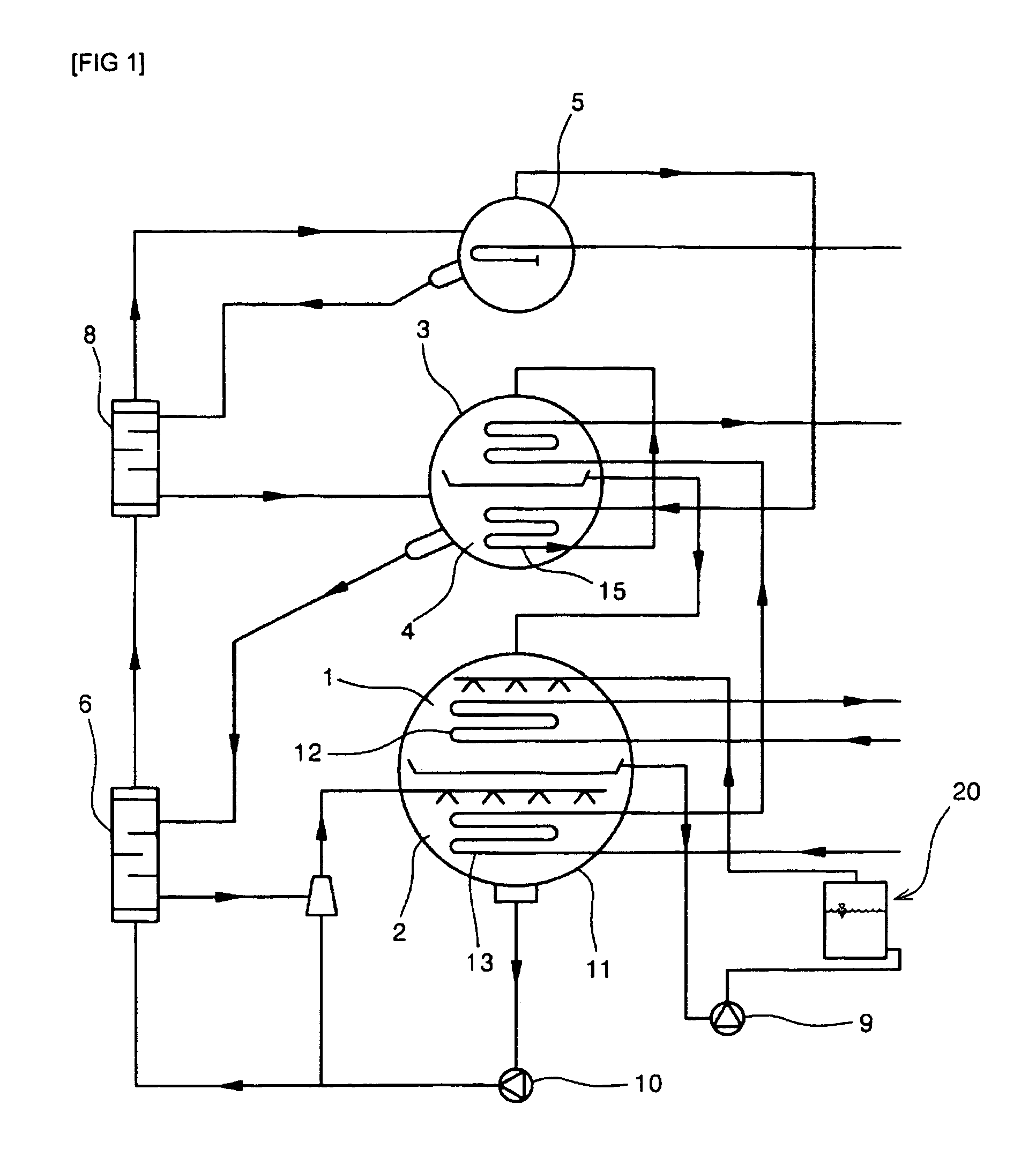

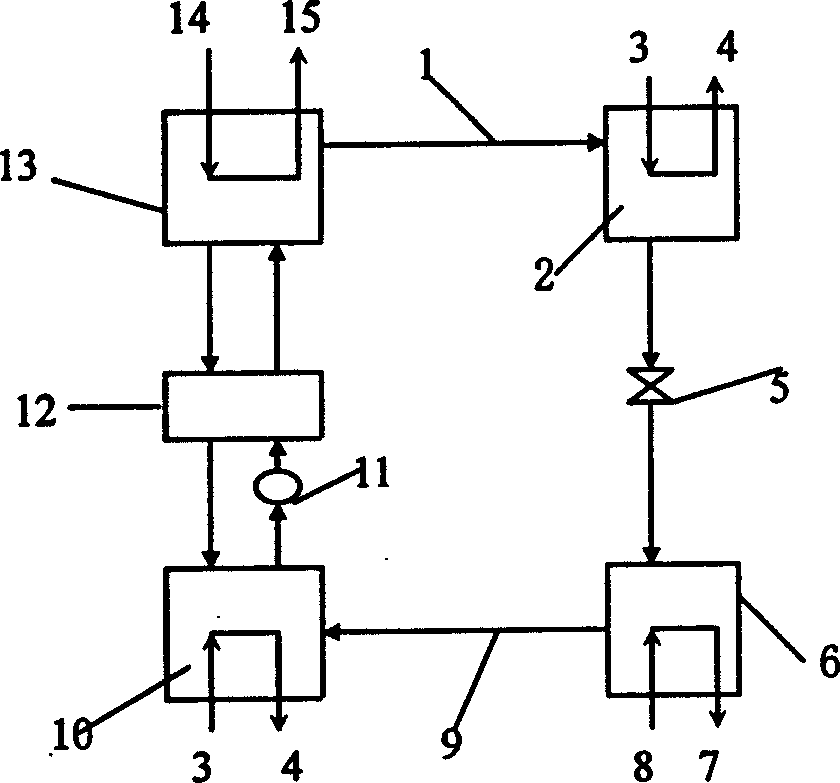

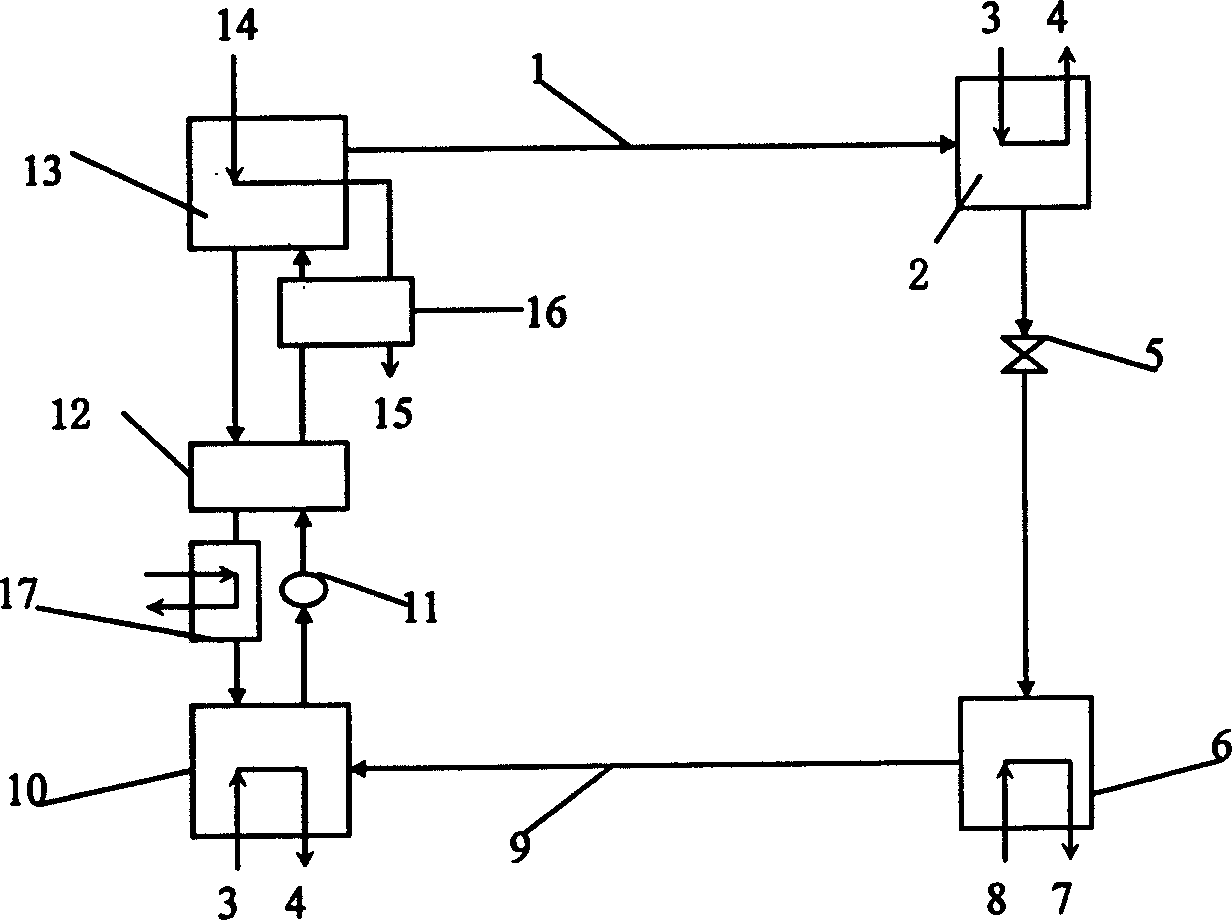

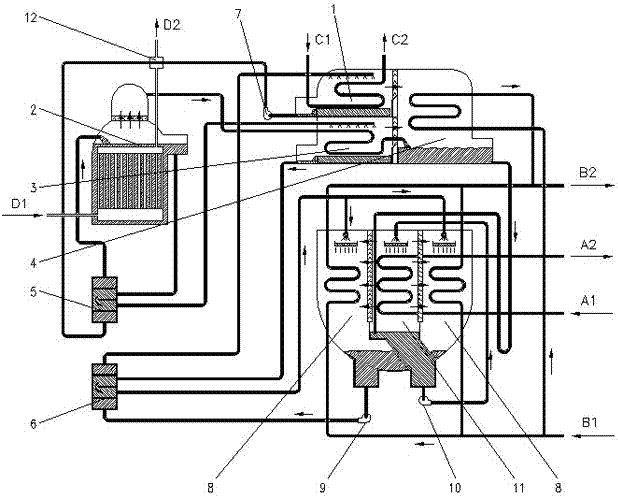

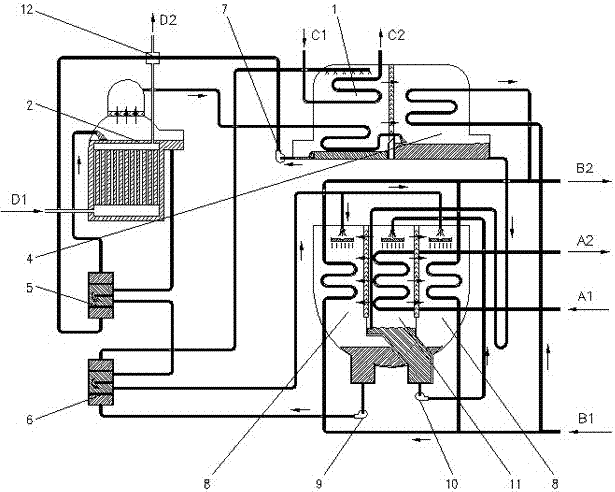

High-efficiency low-temperature absorptive refrigerating machine

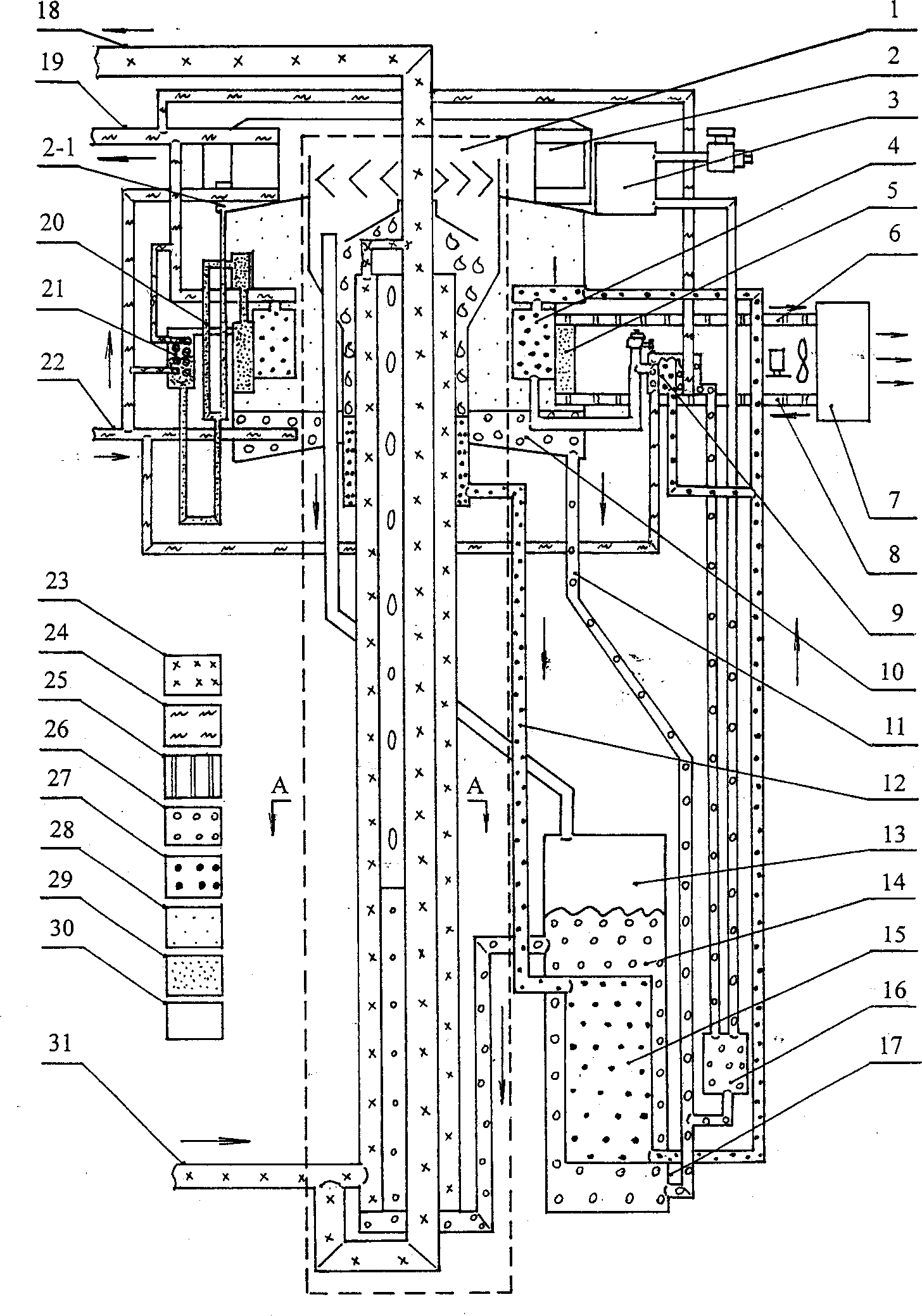

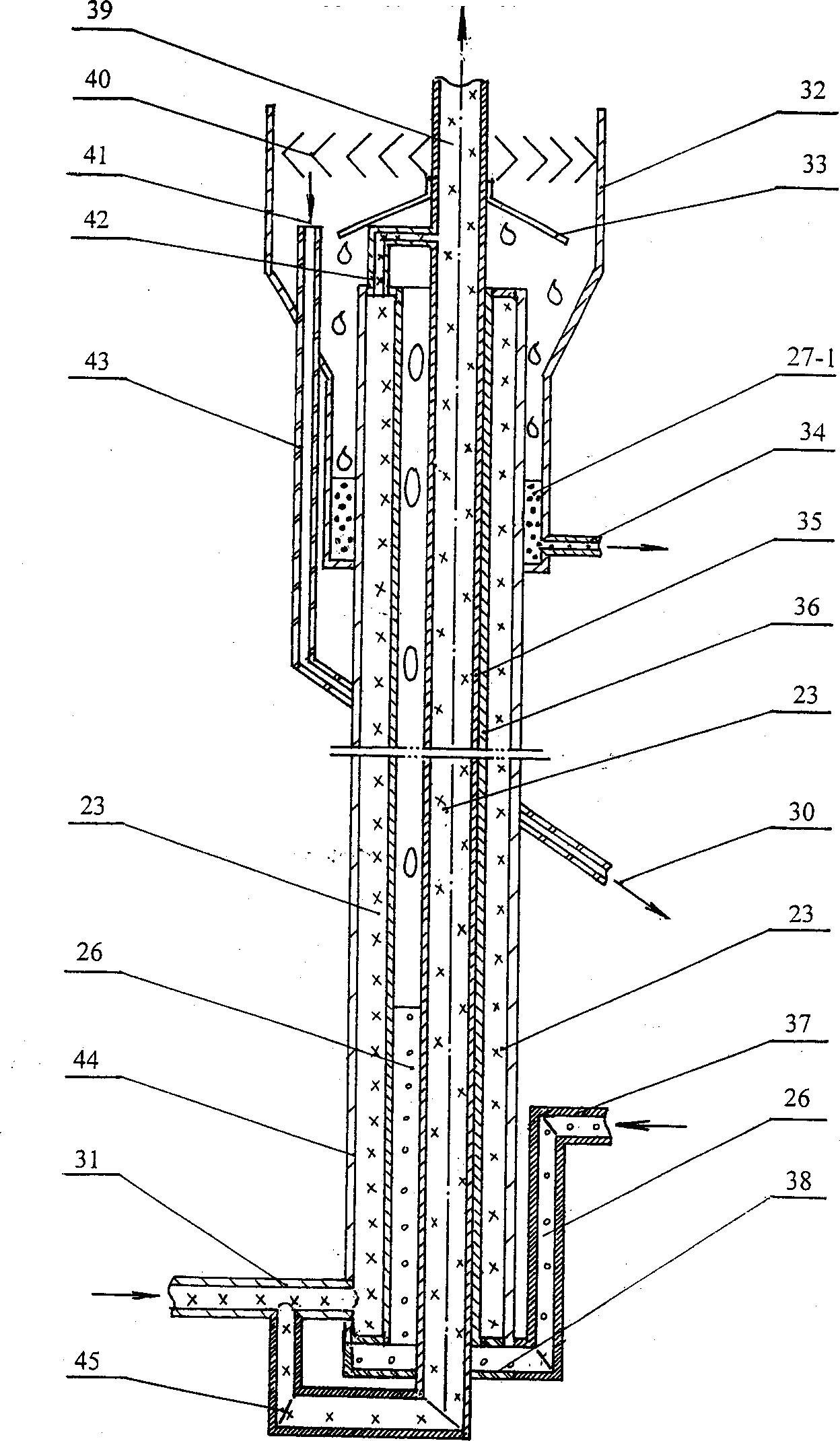

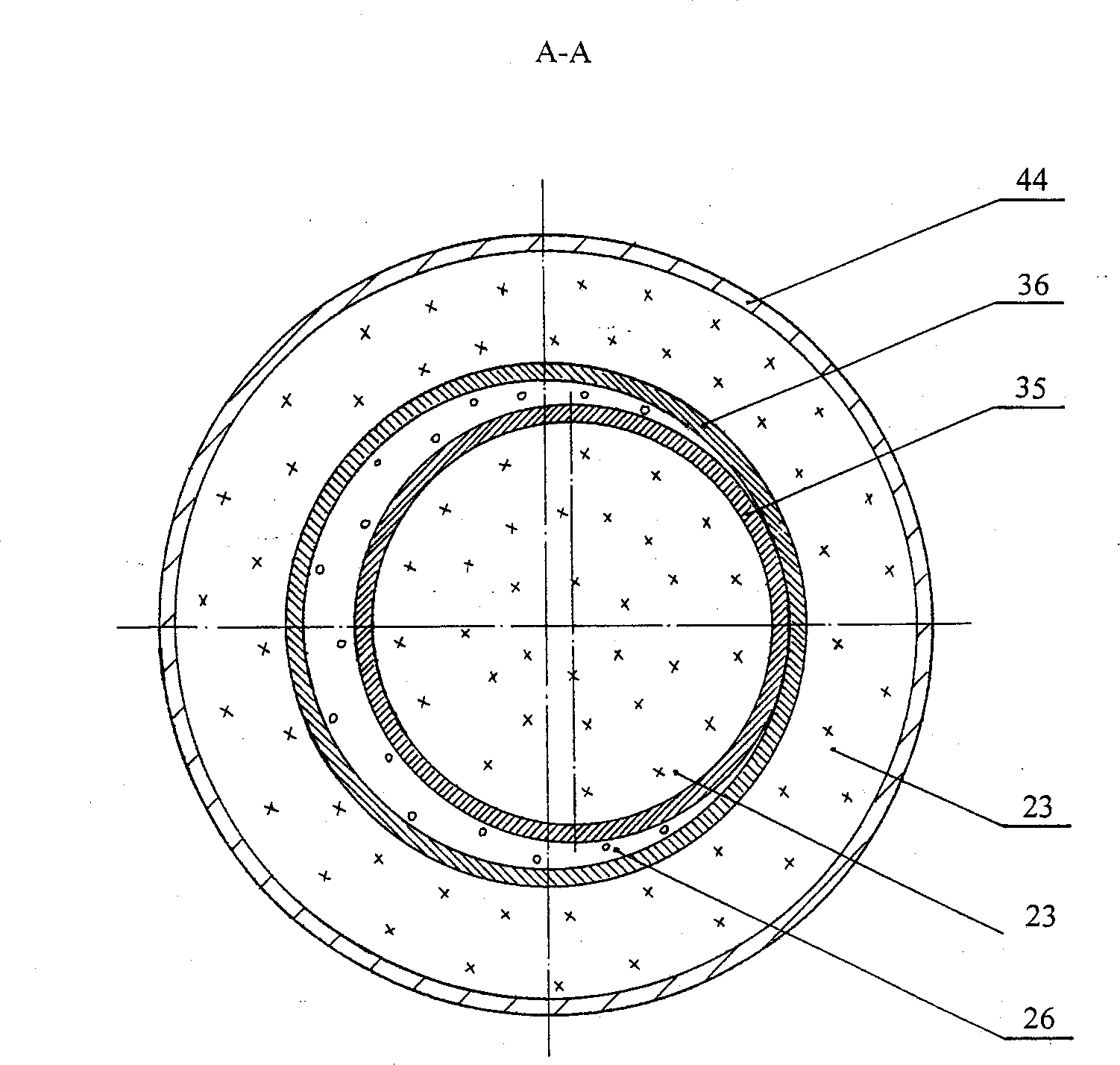

InactiveCN101196351AGuarantee job stabilityGuarantee working reliabilityClimate change adaptationFood preservationRefrigeration temperatureLiquid storage tank

The invention discloses a high efficient low temperature absorption refrigerating machine, which is a signal grade ammonia absorption refrigeration machine with low refrigeration temperature by utilizing strong solution to recover rectify heat, absorption heat and calorific potential. A medium and low temperature generator is arranged between a high temperature generator and a dephlegmator, which is able to recover the generating heat by utilizing a first solution heat exchanger and a second solution heat exchanger; a medium temperature absorber is positioned between a solution throttle valve and the low temperature generator, which recovers the rectify heat by utilizing the heat exchanger in the dephlegmator and recovers the absorption heat by utilizing the heat exchanger arranged in the medium temperature absorber as well as stores the potential by utilizing an ammonia liquid storage tank and a solution storage tank. By applying simple and reliable calorific potential system, the invention is able to effectively utilize the regenerative energy and the valley electricity and to achieve the refrigeration temperature as 30 DEG C. under zero, and has the advantages of high efficiency, saving energy and steady performance, etc.; therefore, the invention is particularly suitable for occasions needing low refrigeration temperature for freezing or chilling food.

Owner:HENAN UNIV OF SCI & TECH

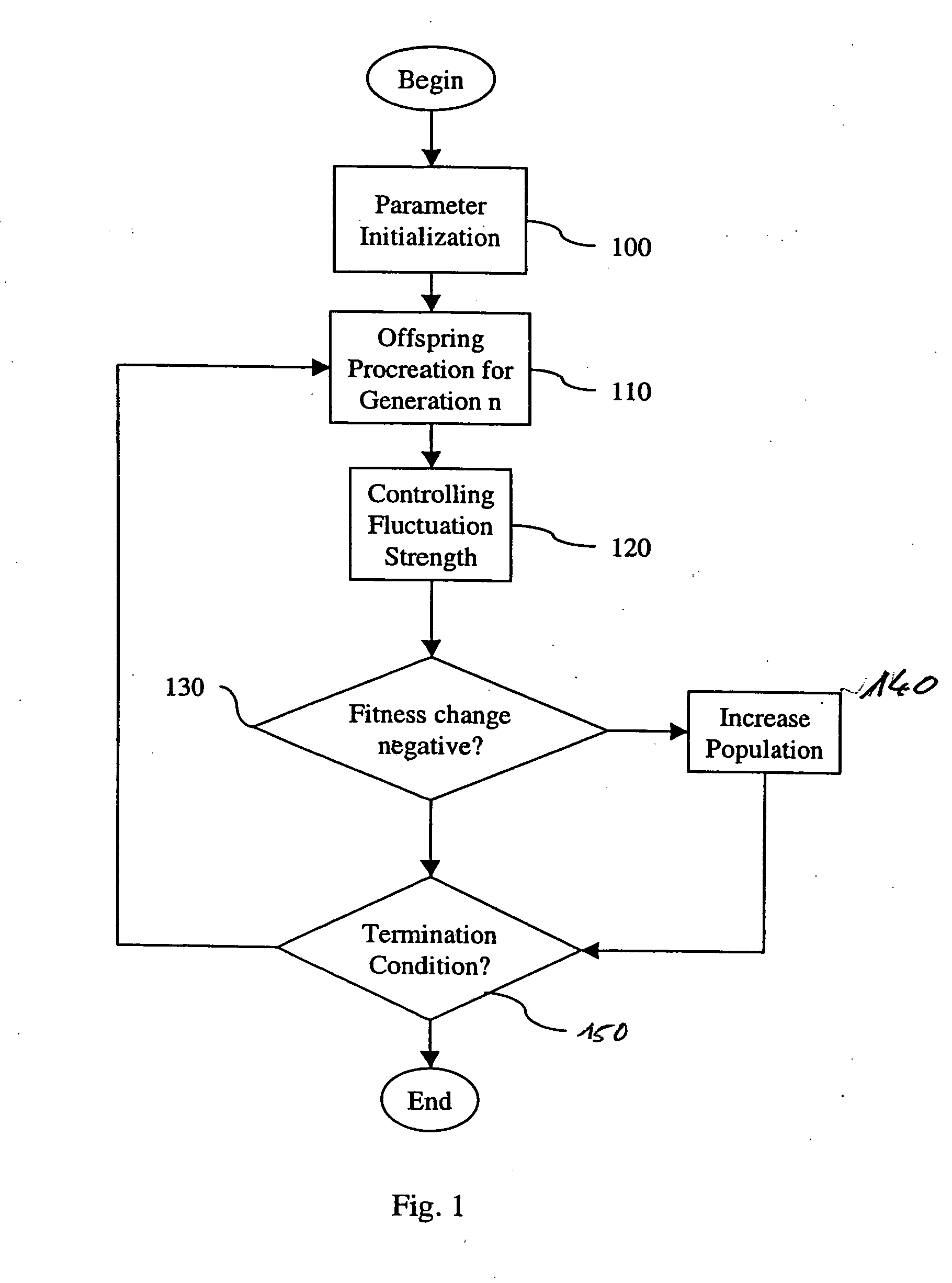

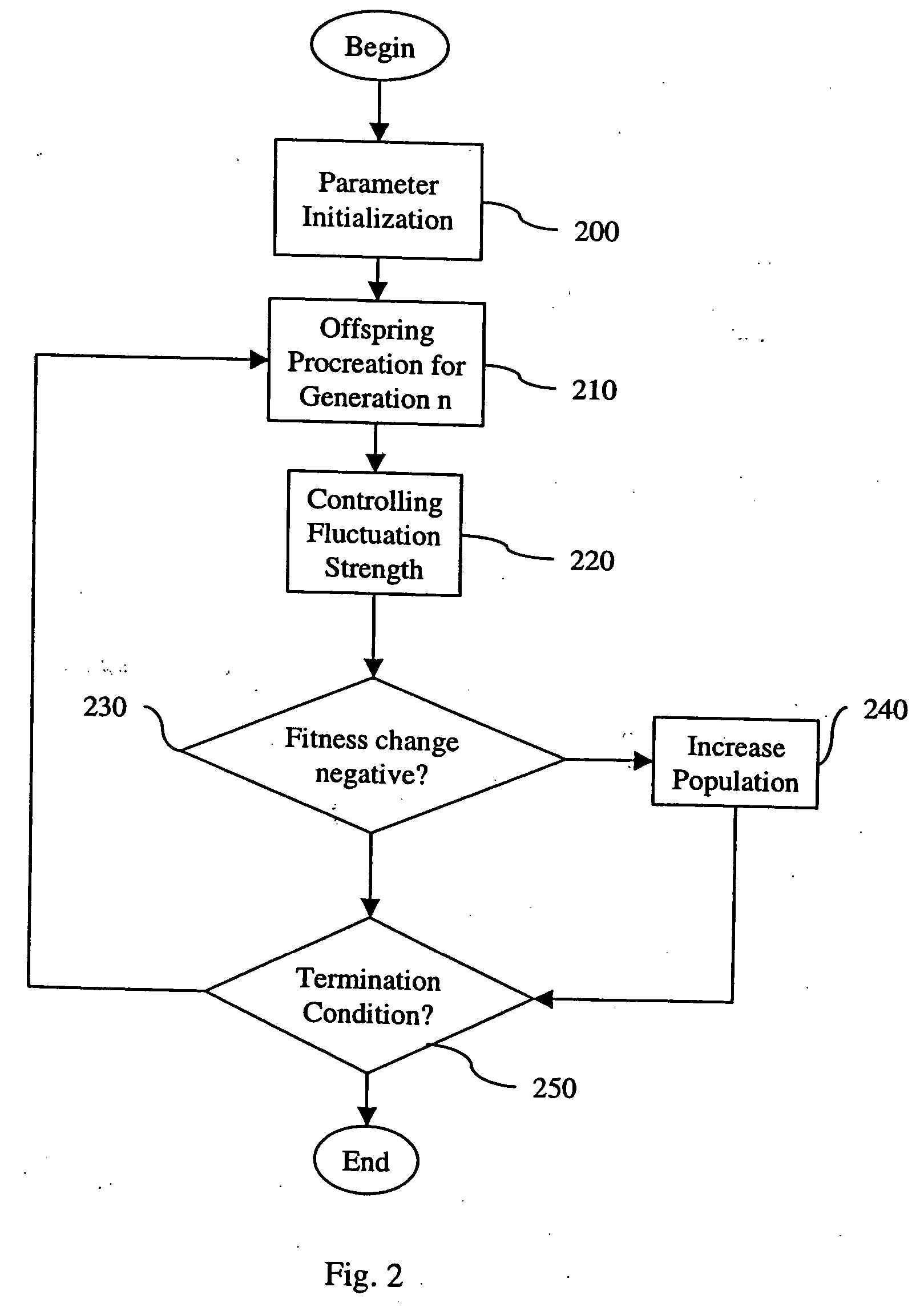

Evolutionary search for robust solutions

InactiveUS7783583B2Reduce distanceReduce in quantityDigital computer detailsForecastingStrong solutionsAlgorithm

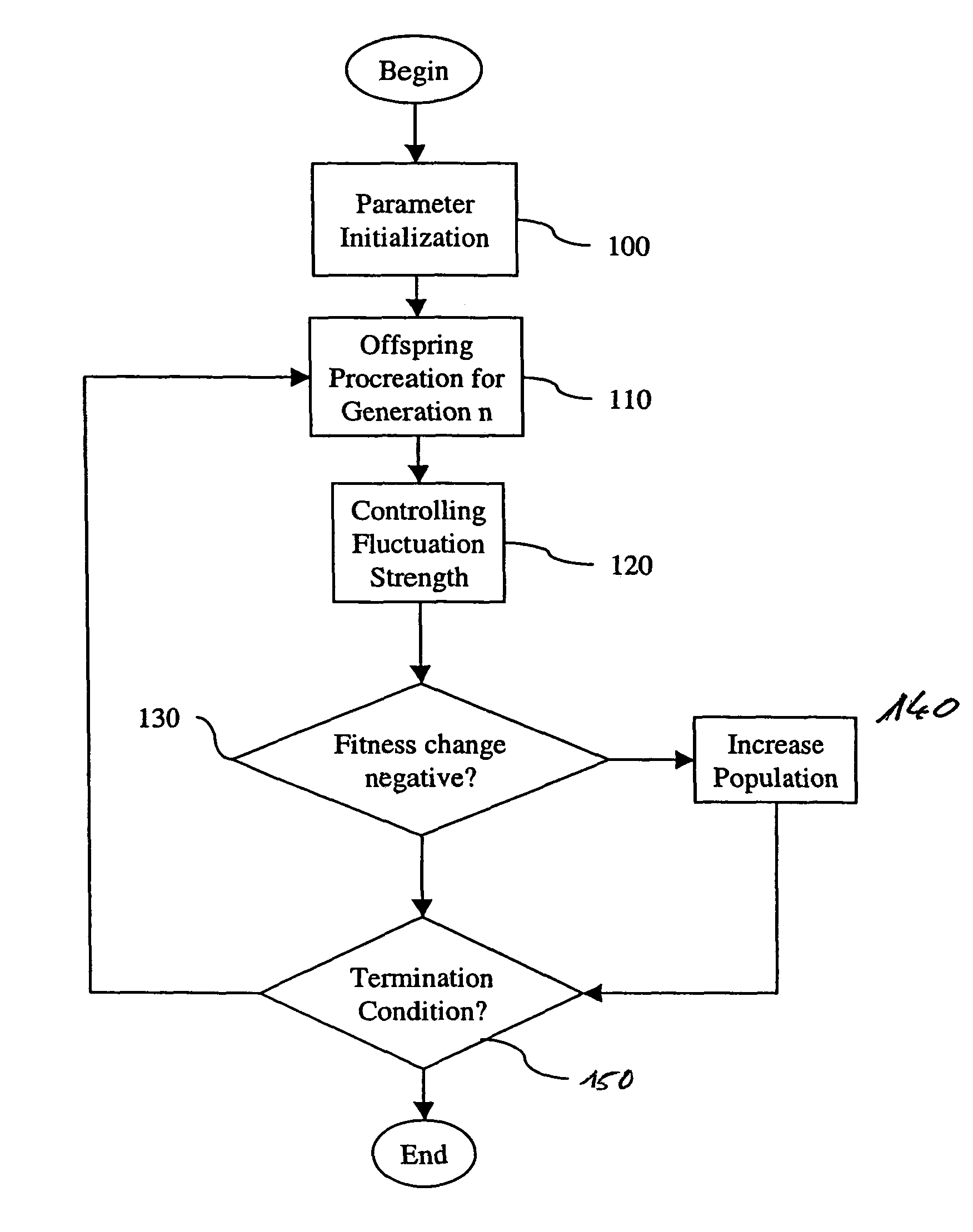

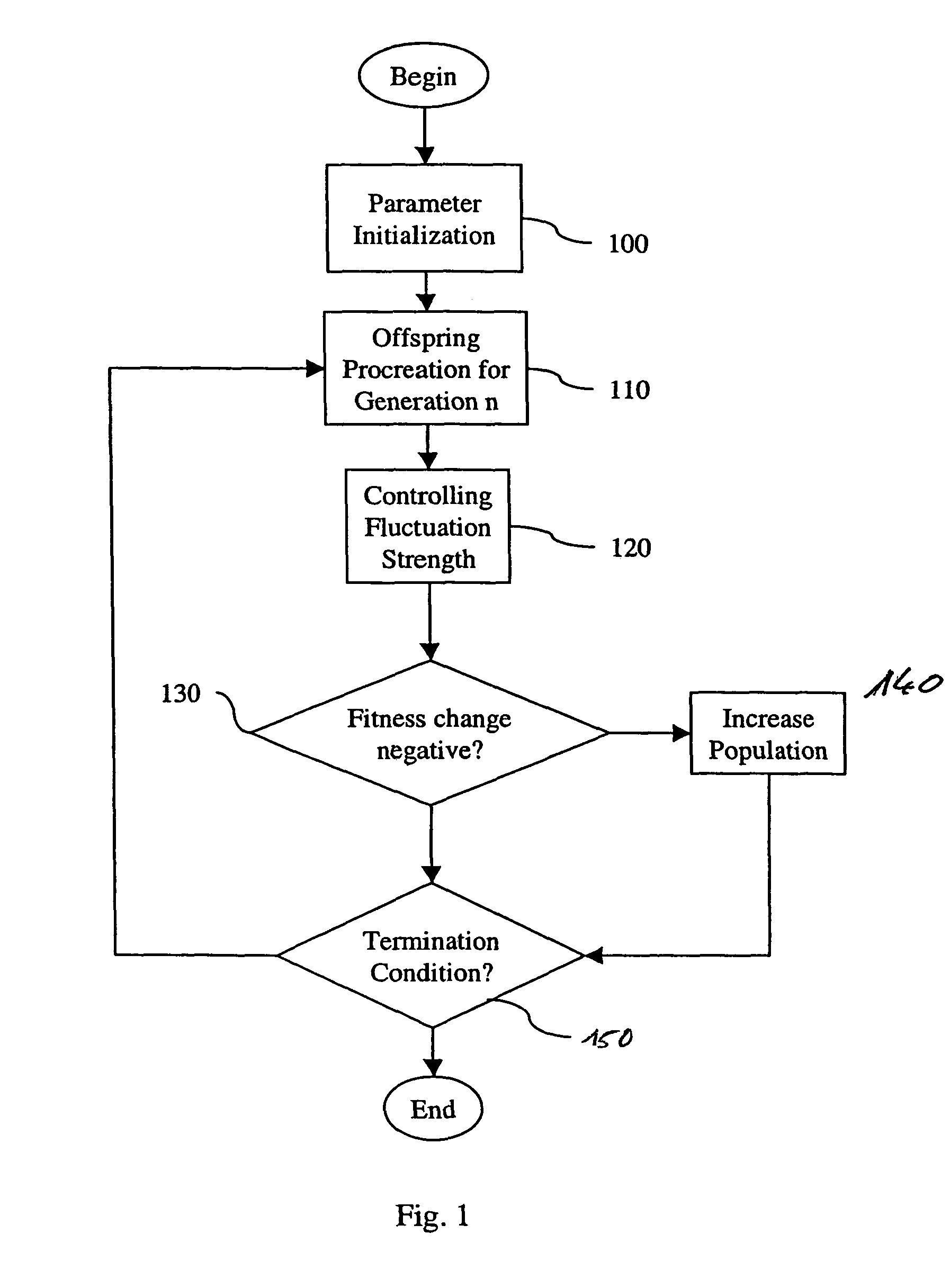

One embodiment of the present invention is a method for optimizing a parameter set comprising object parameters, the method comprising the steps of: (a) creating an initial population of a plurality of individual parameter sets, the parameter sets comprising object parameters describing a model, structure, shape, design or process to be optimized and setting the initial population as a current parent population; (b) for each individual parameter set in a parent population mutating the parameters and optionally recombining the parameters to create an offspring population of individual parameter sets, wherein the strength of an individual object parameter mutation is enlarged by a noise contribution to enhance the robustness of the optimization; (c) evaluating a quality of each individual in the offspring population; (d) selecting individuals of the offspring population to be the next parent generation; and (e) repeating steps (b) through (d) until a termination criterion is reached.

Owner:HONDA RES INST EUROPE

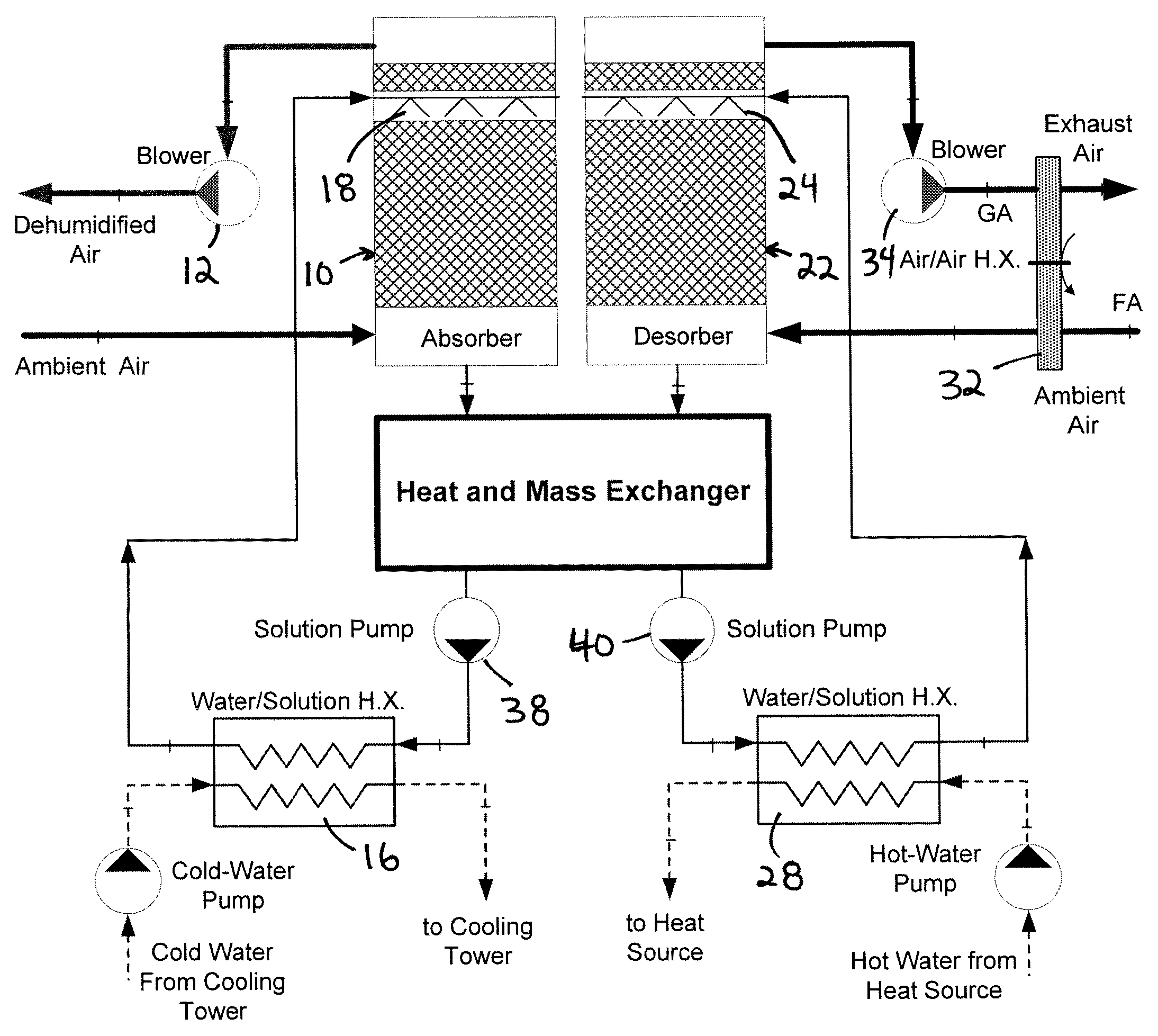

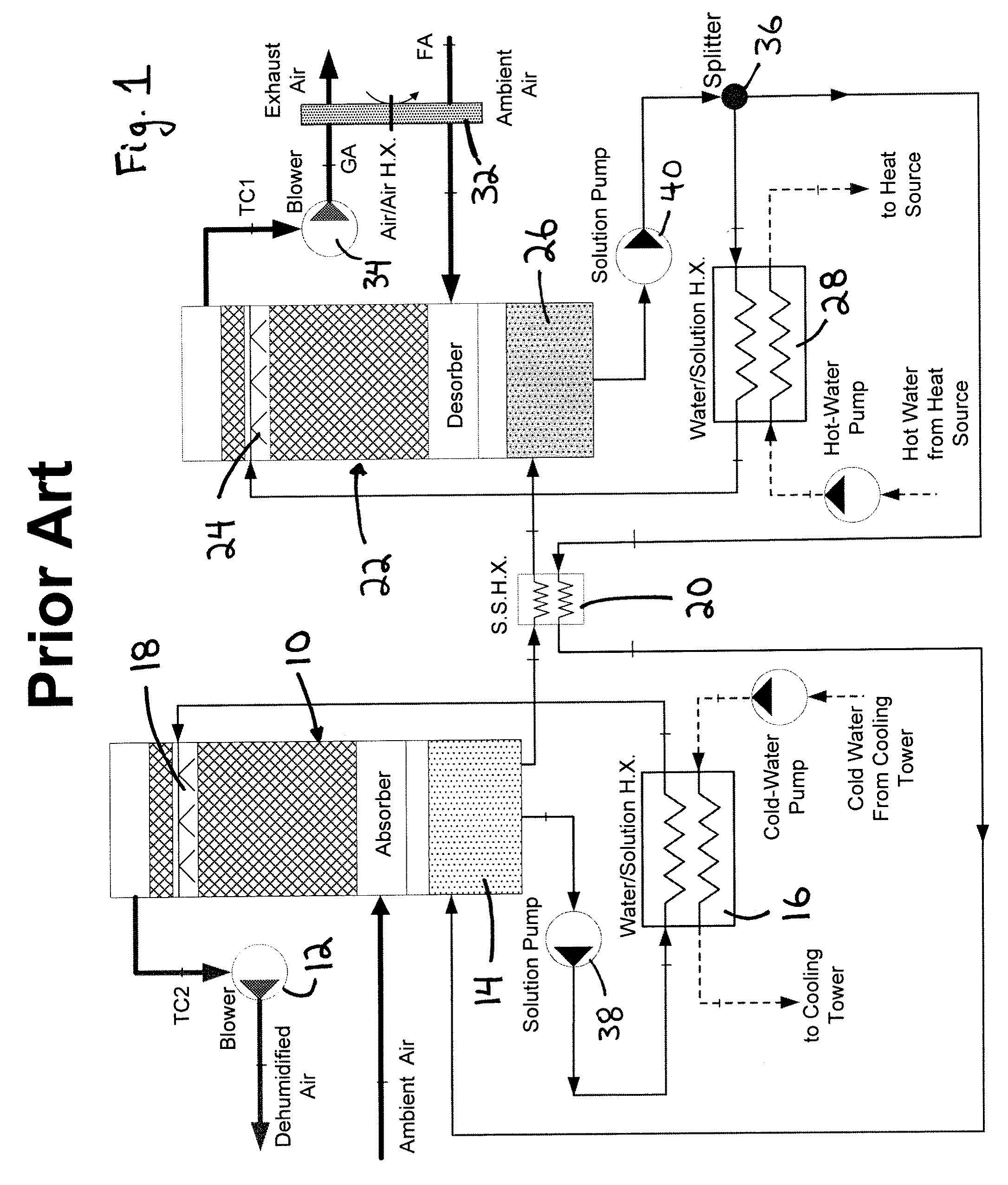

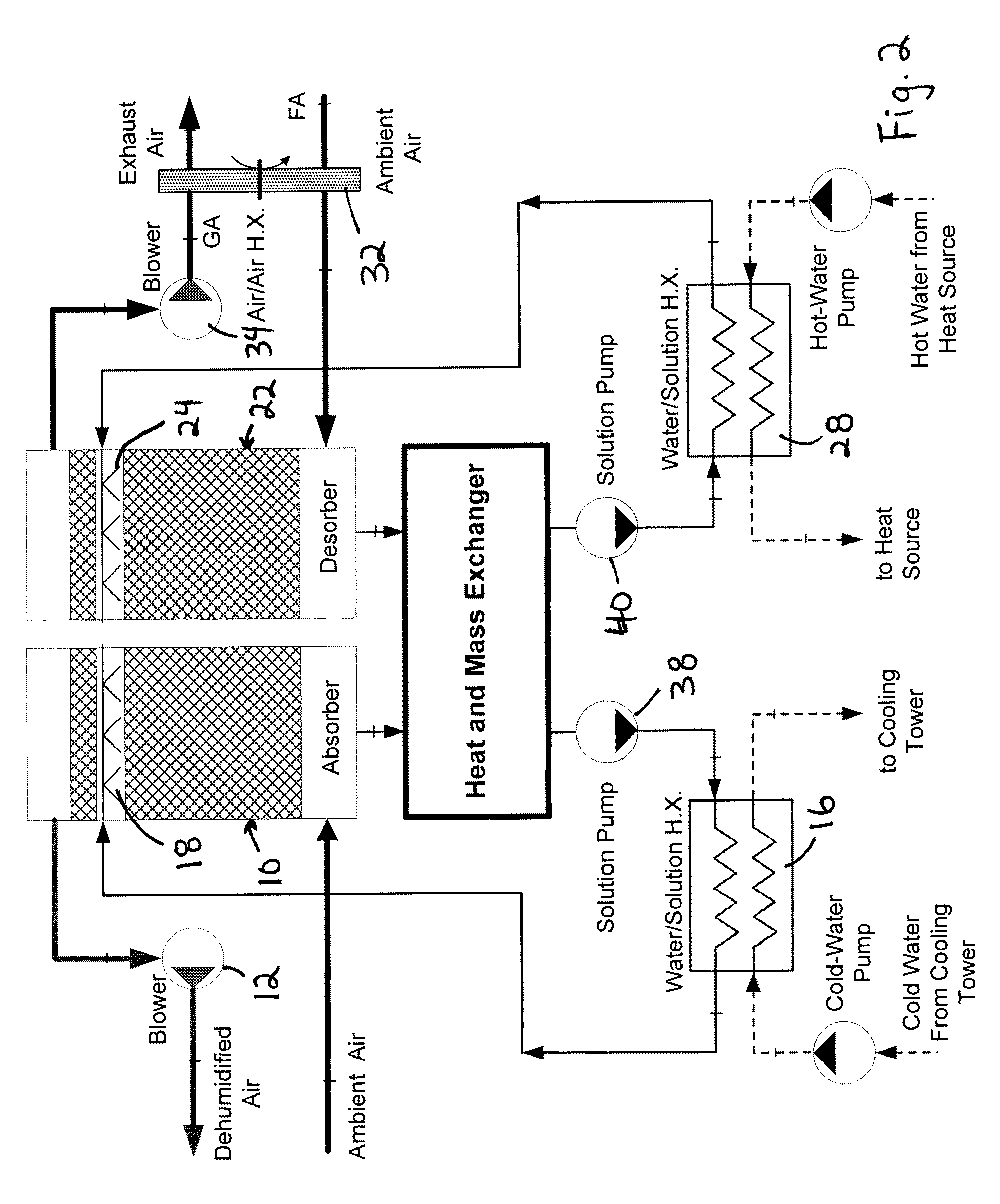

Liquid desiccant dehumidification system and heat/mass exchanger therefor

ActiveUS8887523B2Easy to moveSteam/vapor condensersStationary conduit assembliesStrong solutionsEngineering

A heat and mass exchanger for a liquid desiccant air conditioning / dehumidification system. The exchanger comprises an absorber solution section operably connected to the system's absorber / dehumidification section and a desorber solution section operably connected to the system's desorber / regeneration section. A partition separating those sections includes at least two interconnecting ports positioned to facilitate flow of relatively weak solution from the absorber solution section into the desorber solution section; and the flow of relatively strong solution from the desorber solution section into the absorber solution section—as well as allowing heat transfer therebetween.

Owner:TECHNION RES & DEV FOUND LTD

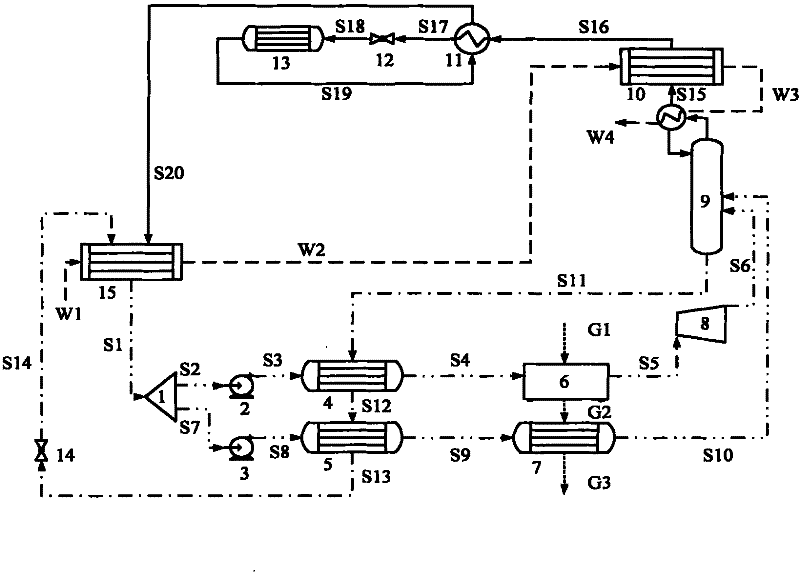

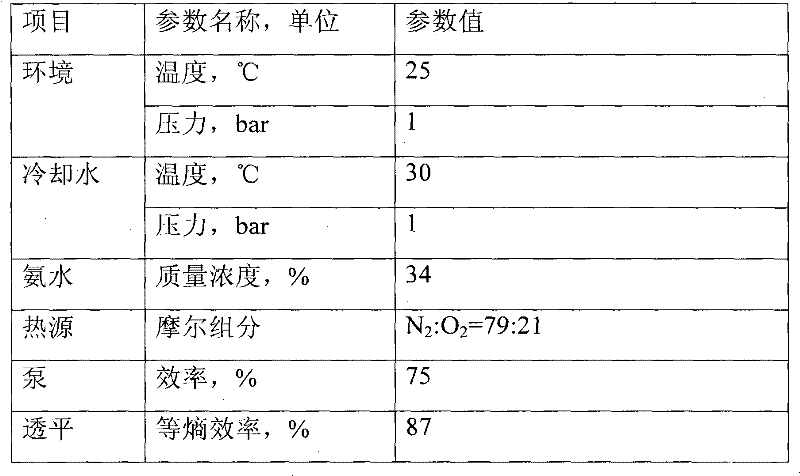

Mixed working medium thermal circulating system and method for power and refrigeration cogeneration

ActiveCN102242985AAchieve the goal of energy saving and emission reductionReduce irreversible lossClimate change adaptationEnergy efficient heating/coolingEvaporationCogeneration

The invention discloses a mixed working medium thermal circulating system and method for power and refrigeration cogeneration. In the system, an ammonia and water mixture is utilized as a working medium, and the middle / low temperature heat is utilized as a heat source. The method comprises the following steps: heating the ammonia water working medium to obtain superheated steam; introducing the superheated steam into a turbine to do work; introducing the exhaust steam of the turbine into a rectification tower to supply heat for the rectification process; introducing the ammonia generated by the rectification tower into an evaporator after condensing, undercooling and throttling; throttling a dilute solution subjected to waste heat recovery, introducing the throttled dilute solution into aabsorber, mixing with the ammonia from the evaporator and condensing; and introducing a heat source into a steam generator firstly, and then introducing the heat source into a waste heat solution heat exchanger. The steam generator adopts the ammonia water strong solution as the working medium, the variable temperature evaporation feature of the ammonia water strong solution is well matched with the temperature of the heat source, thus the irreversible loss of the heat exchange process in the steam generator is reduced; simultaneously the exhaust steam of the turbine directly enters into the rectification tower to supply the rectifying heat without condensation, thus the irreversible loss caused by the variable temperature condensation of the ammonia water working medium is avoided; and the mixed type heat transfer is adopted, thus the irreversible loss of the heat exchange process is reduced.

Owner:江苏中国科学院能源动力研究中心 +1

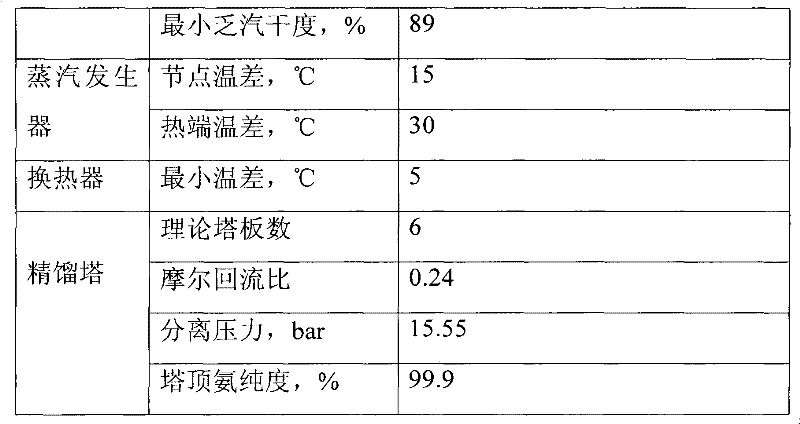

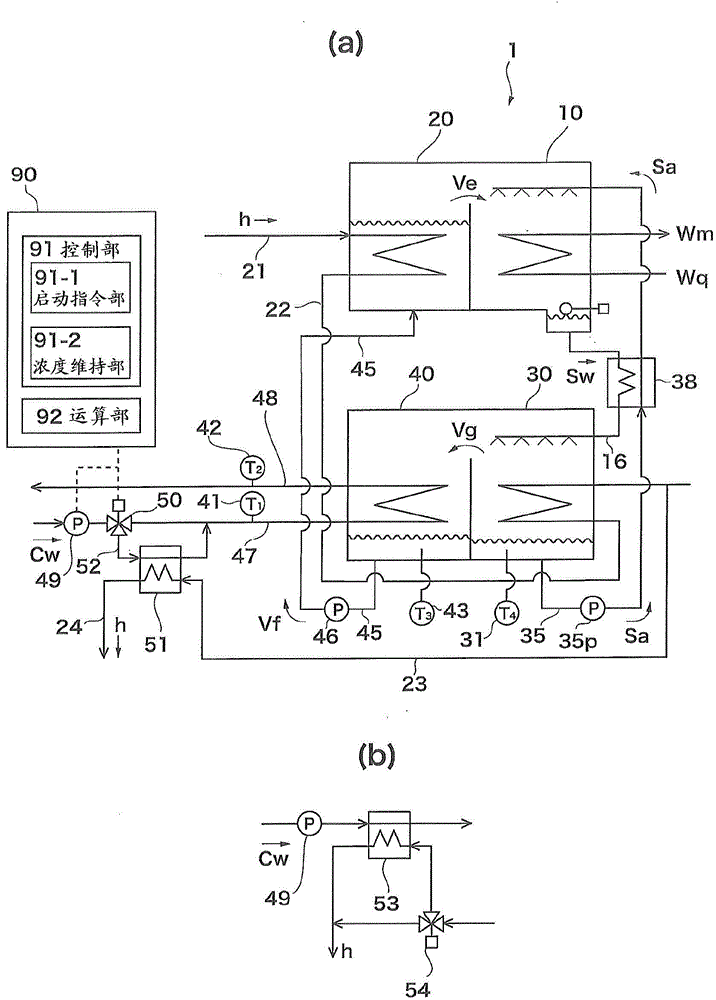

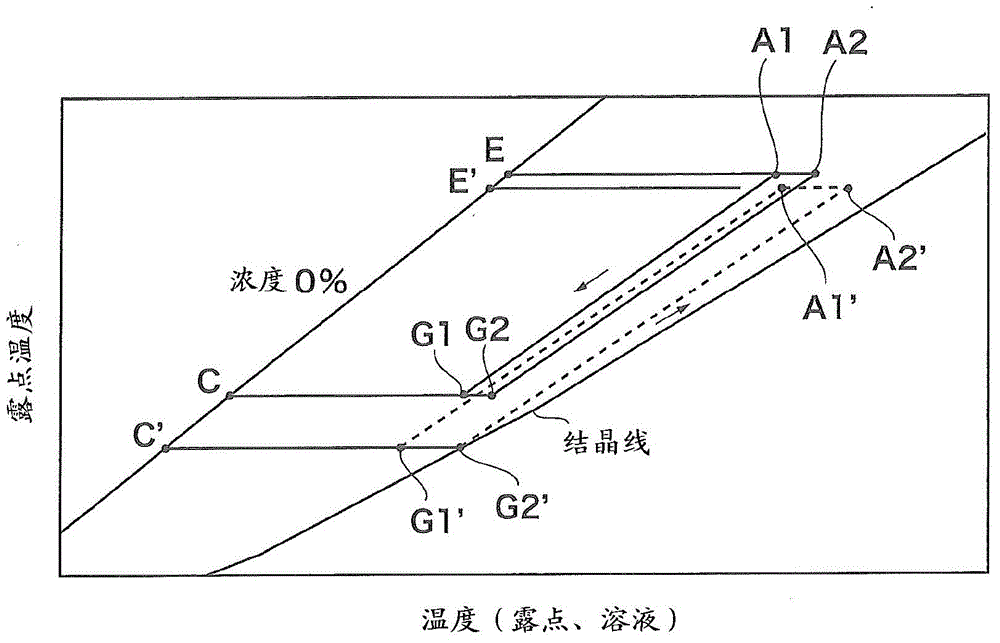

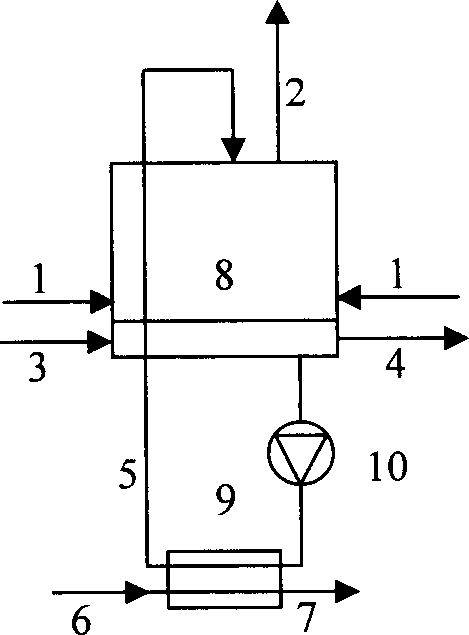

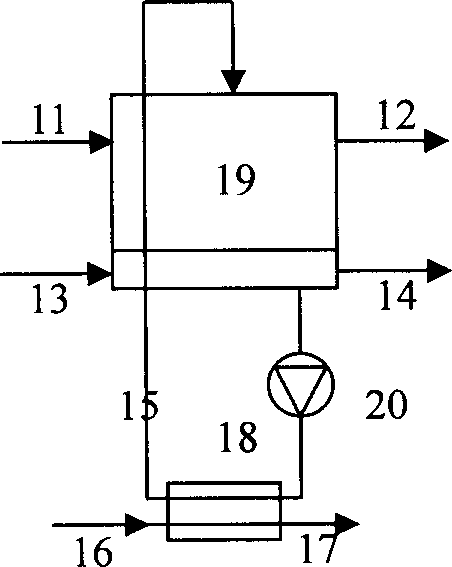

Reverse-flow solution desiccant fresh air handling unit driven by heat pump

InactiveCN103104957AReduce irreversible lossImprove efficiencyEnergy recovery in ventilation and heatingLighting and heating apparatusStrong solutionsProcess engineering

The invention relates to a reverse-flow solution desiccant fresh air handling unit driven by a heat pump. The fresh air handling unit comprises a first gas-liquid contact exchange module, and a second gas-liquid contact exchange module, wherein a solution outlet of the first gas-liquid contact exchange module is communicated with a spray device of the second gas-liquid contact exchange module through a first pipeline; a solution outlet of the second gas-liquid contact exchange module is communicated with a spray device of the first gas-liquid contact exchange module through a second pipeline; a heat pump circulation pipeline is successively connected with a first end of a compressor, a condenser, an expansion valve, an evaporator and a second ends of the compressor to form circulation; and the first pipeline performs heat exchange through the condenser, and the second pipeline performs heat exchange through the evaporator. According to the reverse-flow solution desiccant fresh air handling unit, the evaporator is used for cooling a strong solution output from an outlet of a regeneration module, and the condenser is used for heating a dilute solution output from an outlet of a dehumidification module, thus effectively using energy of heat recovery between the dehumidification module and the regeneration module, and optimizing the system efficiency.

Owner:BEIJING SINOREFINE AIR CONDITIONING TECH +1

Carboxymethyl chitosan/ polyvinyl alcohol porous composite material and preparation method thereof

InactiveCN102286184AGood biocompatibilityImprove liquid absorption capacityAbsorbent padsBandagesWound dressingBiocompatibility Testing

The invention relates to a carboxymethyl chitosan / polyvinyl alcohol porous composite material, which comprises the following raw materials in percentage by weight: 4 to 22 percent of carboxymethyl chitosan, 10 to 30 percent of polyvinyl alcohol, 3 to 5 percent of acetic acid, 5 to 10 percent of inorganic acid, 5 to 10 percent of cross-linking agent, 1 to 5 percent of foaming agent, 0.5 to 2 percent of antibacterial agent, 1 to 5 percent of softening agent and the like. A preparation method for the composite material comprises the following steps of: stirring the polyvinyl alcohol till full dissolution, pouring the dissolved polyvinyl alcohol into the dissolved carboxymethyl chitosan, adding the inorganic acid, the cross-linking agent, the foaming agent, the softening agent and the antibacterial agent, heating the solution to the temperature of between 90 and 100 DEG C, pouring the solution into a die, continuously reacting the solution for 6 to 9 hours at the temperature of between 60 and 100 DEG C, cooling the product, and repeatedly washing the product by using distilled water. The prepared material has the characteristics of good biocompatibility, excellent antibacterial effect, strong solution absorption, biodegradability, good attachment to the skin and the like, is quick in hemostasis, antibacterial and anti-inflammatory, has the function of promoting wound healing, and is suitable for making various wound dressings.

Owner:威海世创医疗科技有限公司

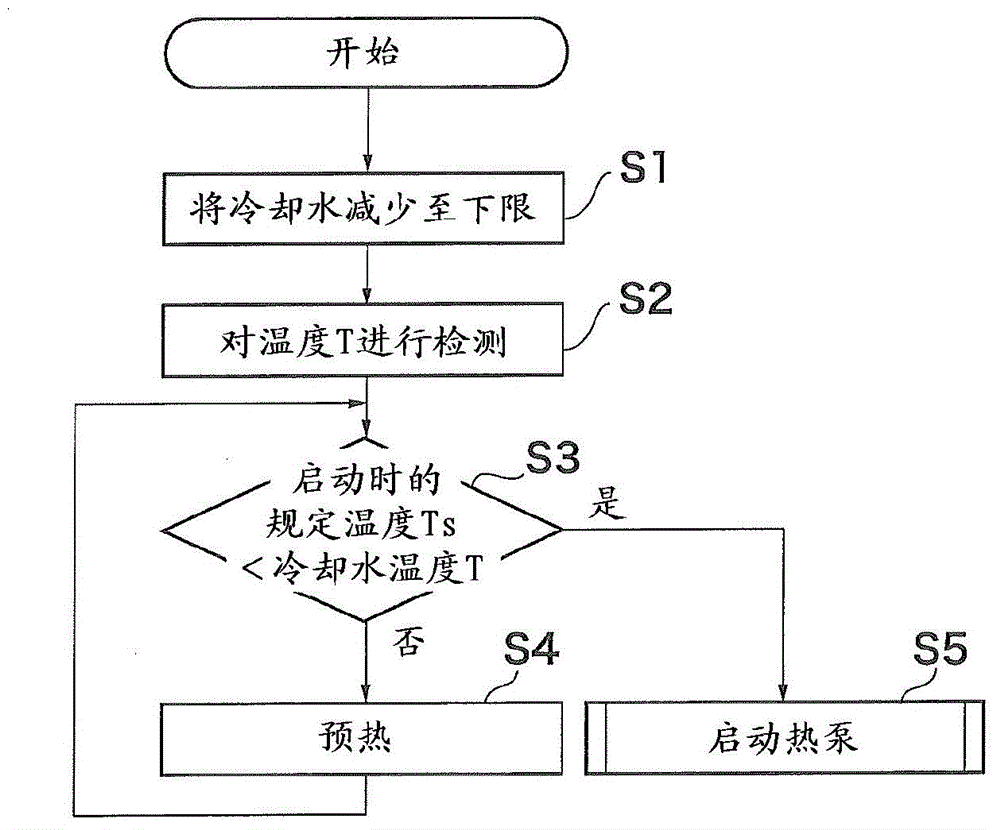

Absorption heat pump

ActiveCN104949378AClimate change adaptationEnergy efficient heating/coolingStrong solutionsAbsorption heat pump

The invention provides an absorption heat pump which can operate even though when supplied cooling water is relatively low in temperature. The absorption heat pump comprises an absorber, a regenerator, a condenser, a cooling water warmer, and a controller. The absorber makes a solution absorb steam of a refrigerating fluid to become a dilute solution, and a heated medium is heated by using absorption heat which is generated when the solution becomes the dilute solution. The regenerator heats the dilute solution by using a heat source medium, and refrigerating fluid steam is generated from the dilute solution, so that the solution becomes a strong solution whose concentration is higher than that of the dilute solution. The condenser uses the refrigerating fluid steam which is generated in the regenerator by cooling water to capture heat to perform condensation on the refrigerating fluid steam. The cooling water warmer gives heat to the cooling water which is supplied to the condenser, the heat not being the heat captured by the refrigerating fluid steam, so that the cooling water is heated. The controller regulates temperature rise amount in the cooling water warmer, and maintains concentration of the strong solution not to exceed a specified concentration.

Owner:EBARA REFRIGERATION EQUIP & SYST CO LTD

Circulation production process for glyphosate

ActiveCN101402652AHigh removal rateReduce pollutionGroup 5/15 element organic compoundsPhosphatePhosphorus trichloride

The invention discloses a technology for the circular production of glyphosate, which pertains to the technical field of pesticide. An alkyl ester process is adopted to produce the glyphosate; chlorine and yellow phosphorus are used for producing phosphorus trichloride; the phosphorus trichloride and methanol react to produce dimethyl phosphate which is taken as a raw material to prepare the glyphostate and glyphostate mother solution; triethylamine separated from the glyphostate mother solution is reused and after the triethylamine is separated, alkali mother solution is then obtained; after sodium is removed by a membrane process, the alkali mother solution is divided into strong solution and weak solution, with the strong solution being used for preparing a glyhosate ammonium aqua and the weak solution being electrolyzed to obtain sodium hydroxide solution, chlorine and hydrogen, wherein, sodium hydroxide is used for recovering the triethylamine, the sodium hydroxide solution is used for neutralizing thin methanol, the chlorine is used for synthesizing phosphorus trichloride and the hydrogen is used for other purposes. The technology for the circular production of glyphosate has good effect in triethylamine recovery, high recovery rate, low cost and high removal rate of sodium chloride in the alkali mother solution, forms large-scale circular production of the glyphosate, and is characterized by reduction in logistics cost, high comprehensive utilization, less environmental pollution, compliance with the development concept by industrial recycling economy and remarkable comprehensive benefits.

Owner:JIANGXI JINLONG CHEM

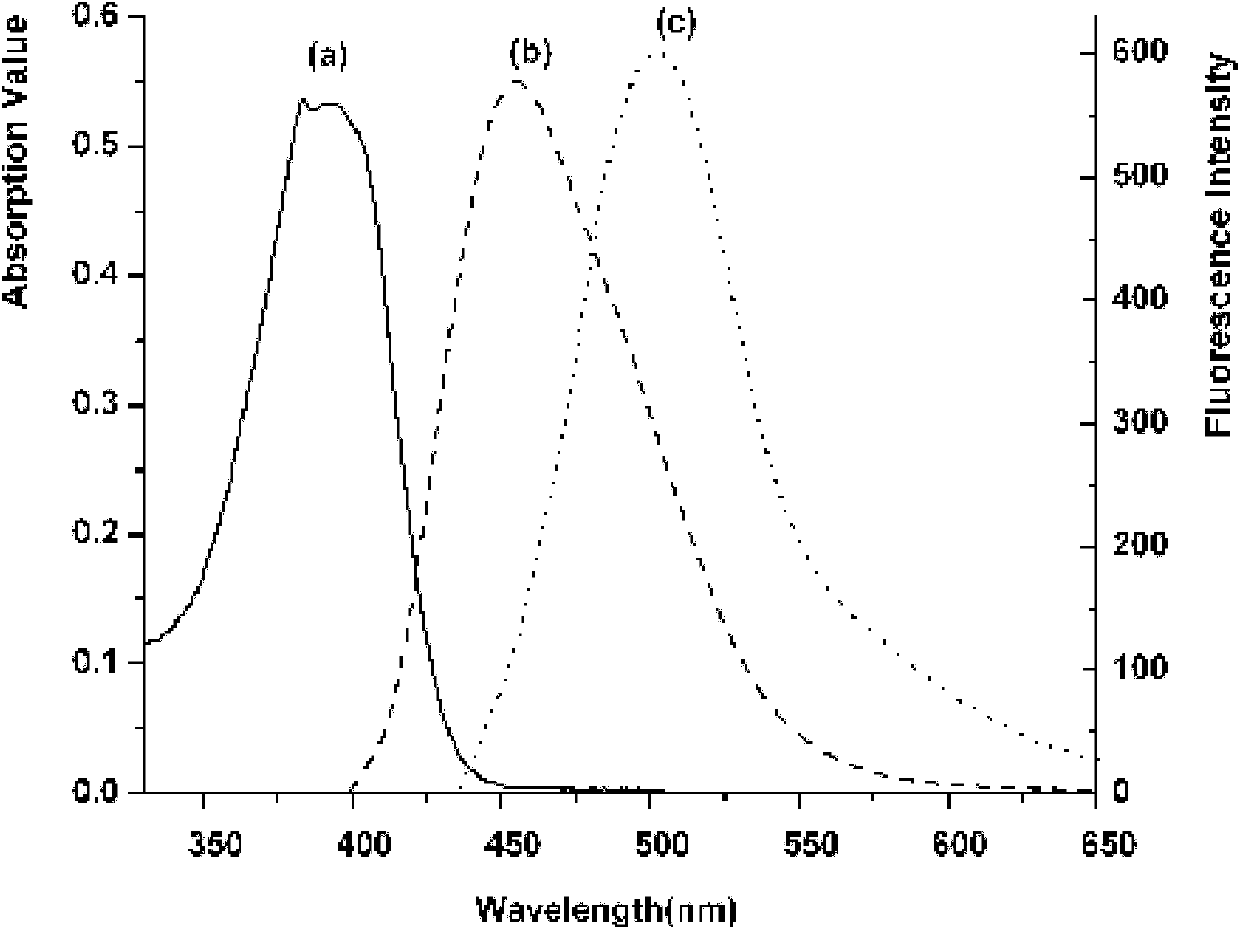

Organic boron difluoride complex and preparation method thereof

InactiveCN102040617AHigh molar absorptivityChemically stableGroup 3/13 element organic compoundsLuminescent compositionsQuantum yieldOrganic base

The invention discloses an organic boron difluoride complex which is a compound the structural formula I of which is shown in the specification, wherein R1 and R2 are OCH3, H or Cl independently respectively; R3 and R4 are H, NO2, Br, CH3 or OCH3 independently respectively; the complex has stable chemical properties, strong thermal stability, high fluorescence quantum yield and large molar absorption coefficient; furthermore, the complex not only has strong solution fluorescence, but also has significant solid fluorescence. The invention further discloses a preparation method of the organic boron difluoride complex, and the organic boron difluoride complex is prepared by carrying out room temperature or reflux reaction on a ligand and boron trifluoride diethyl etherate in an anhydrous organic solvent in the presence of organic base; and the method has the advantages of mild reaction conditions, short reaction time, high product yield and fastness and simpleness in separation and purification.

Owner:ZHEJIANG SCI-TECH UNIV

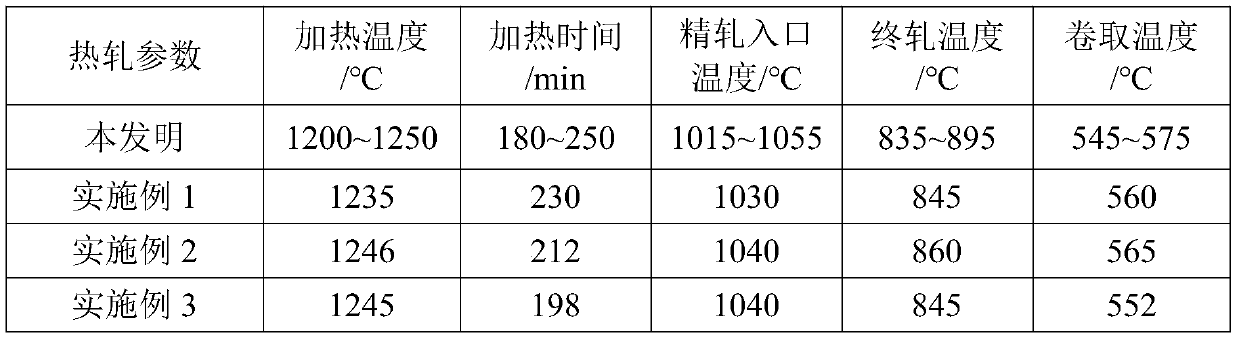

280 Mpa grade cold-rolled strip for automobile structure and manufacturing method thereof

InactiveCN111304540AMeet the processing requirementsLow carbon equivalentSteelmakingStrong solutions

The invention relates to a 280 Mpa grade cold-rolled strip for an automobile structure. The 280 Mpa grade cold-rolled strip is composed of the following components in percent by weight: 0.09-0.13% ofC, less than or equal to 0.05% of Si, 0.8-1.0% of Mn, 0.02-0.03% of P, less than or equal to 0.015% of S, 0.025-0.05% of Als and the balance Fe and inevitable impurities. A manufacturing method of the280 Mpa grade cold-rolled strip for the automobile structure comprises a steelmaking step, a hot rolling step, an acid continuous rolling step and a continuous annealing step. Any microalloy elementsare not added into the cold-rolled strip and C and Mn elements are reduced to the greatest extent to reduce the carbon equivalent so as to guarantee the welding quality. By adding a small amount of strong solution strengthening element P, mechanical property indexes: the yield strength is greater than or equal to 280 Mpa, the tensile strength is greater than or equal to 440 MPa and the ductilityis greater than or equal to 30%, are achieved finally by means of process control such as steelmaking, hot rolling, acid continuous rolling and continuous annealing, so that the processing and using demand of an automobile structural part is met.

Owner:SD STEEL RIZHAO CO LTD

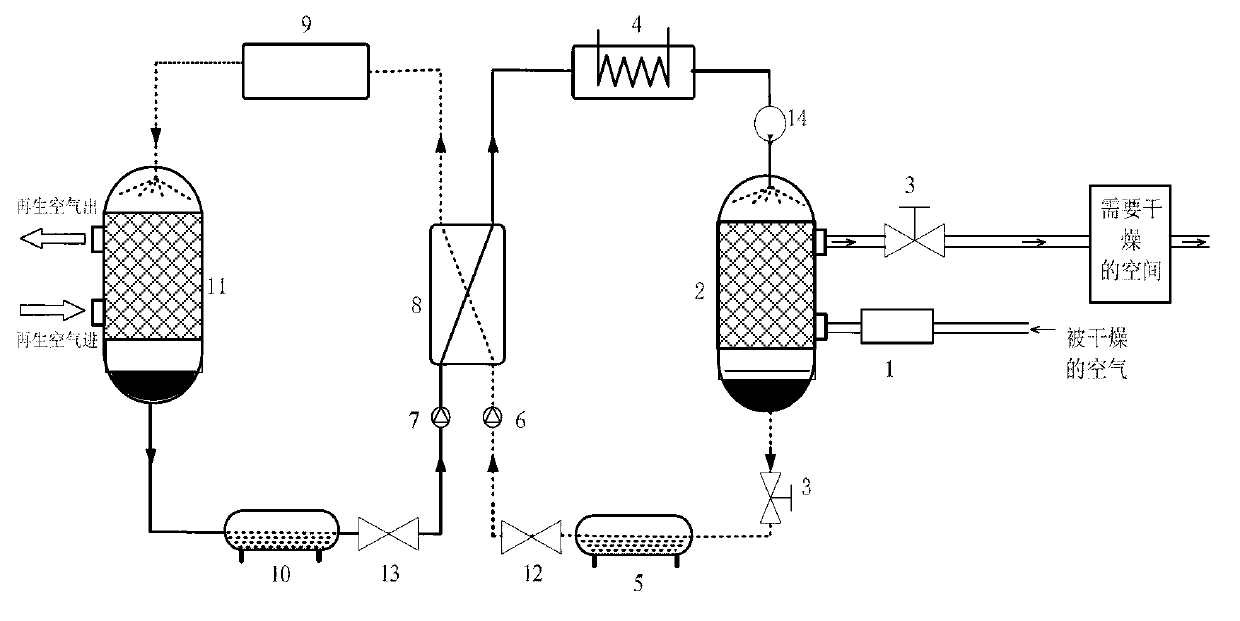

Pressurizing solution deep dehumidifying device and pressurizing solution deep dehumidifying method

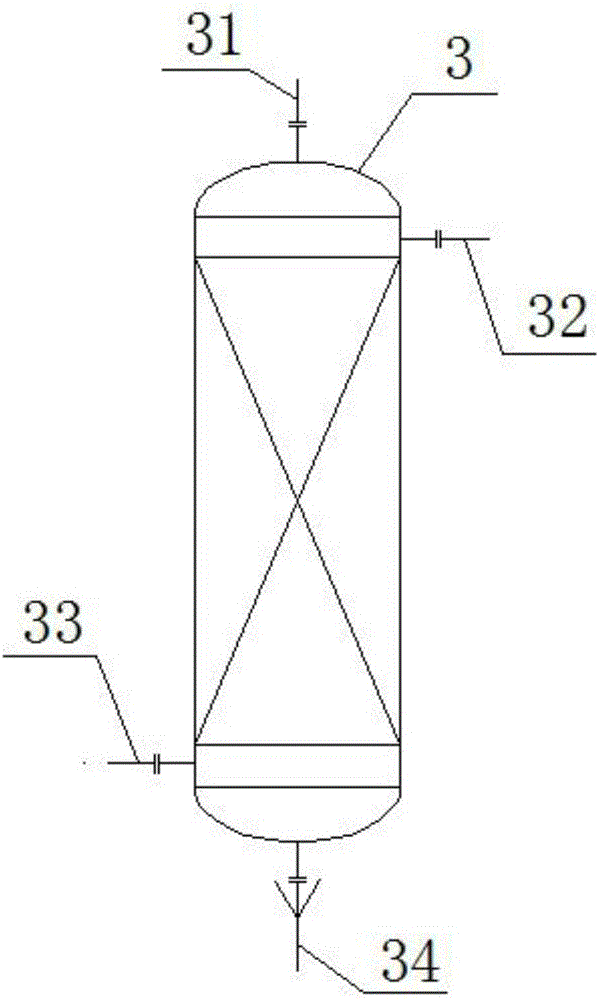

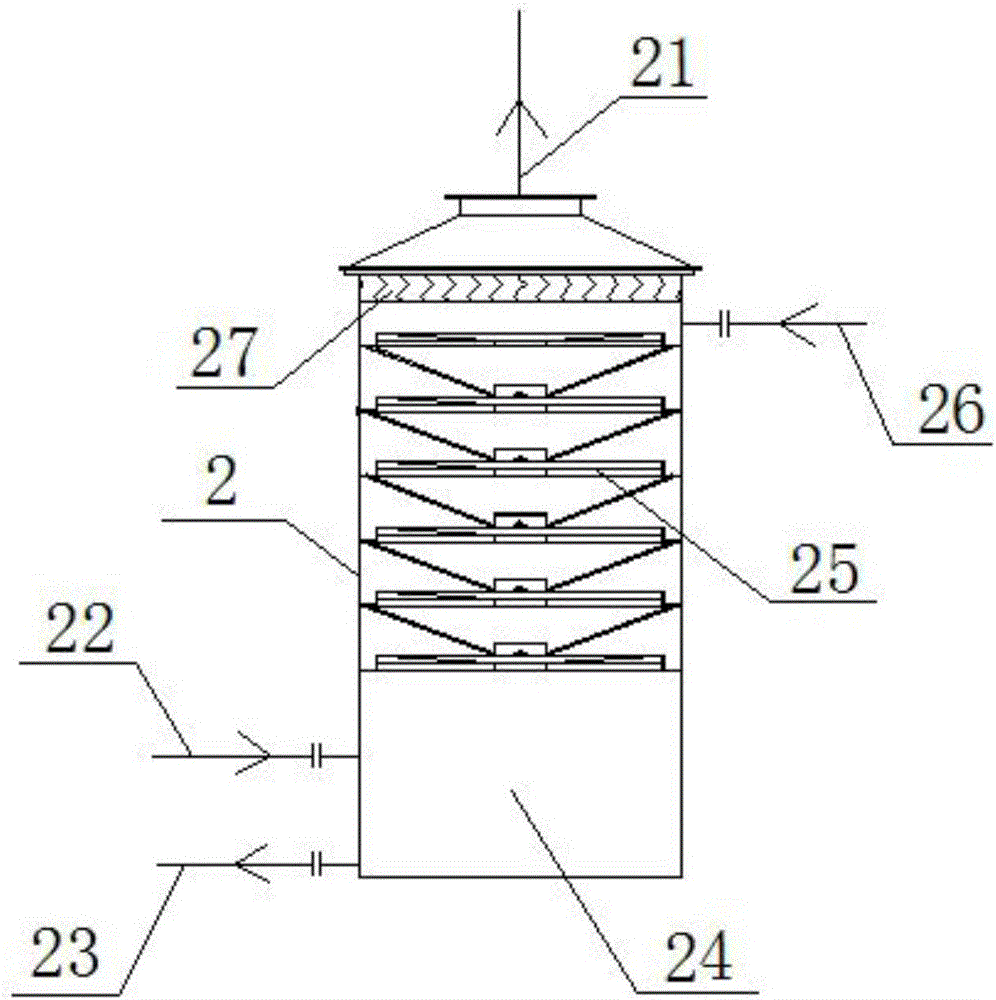

InactiveCN102989269AMeet the requirements of deep dehumidificationDispersed particle separationStrong solutionsWater vapor

The invention discloses a pressurizing solution deep dehumidifying device and a pressurizing solution deep dehumidifying method. In the pressurizing solution deep dehumidifying device, air and a strong solution are pressurized to a certain high-pressure state and then conveyed into a dehumidifier so as to be dehumidified, the dehumidified air and a weak solution are throttled to a normal-pressure state by a throttle valve, thus providing dry air with very low humidity, so as to dry spaces or objects which need to be dried. A throttled weak solution flowing out from the dehumidifier is conveyed into a normal-pressure regenerator through a solution pump for regeneration, and then is recycled while achieving a certain concentration. Because the pressurized air has higher water vapor partial pressure than the air under normal pressure, thus increasing the difference of the water vapor partial pressure between the air and a solution surface, and further enhancing the dehumidifying process; after contacting with a dehumidifying solution, the air can also reach the water vapor partial pressure approximate to the solution surface, after dehumidified high-pressure air is throttled to normal-pressure air, the lower water vapor partial pressure is got, and therefore deep dehumidified and dried air with lower moisture content can be obtained.

Owner:东南大学常州研究院

Technology for brewing loquat wine

InactiveCN1597908AMany medicinal ingredientsIncrease health functionAlcoholic beverage preparationYeastFruit wine

The invention discloses a new wine making technique and its application to make fruit wines, like loquat wine, and its main steps as follows: 1. loquat wine making technique: (1) fermenting, extracting, and guaranteeing quality: crushing loquat kernels into powder, adding in yeast to ferment for 3 months, and simultaneously adding in a proper amount of white spirit until the white spirit just immerges the powder, filter-pressing the leavening dry and obtaining strong solution No.1 and filter residue No.1; (2) soaking, extracting, filtering and pressing-dry: adding in a proper amount of white spirit, soaking the filter residue No.1 for 10 days and continuing fermentation, making extraction on the soaked substance many times to obtain strong solutions No.1-No.5; (3) blending loquat wine: blending the strong solutions No.1-No.5 with white spirit by existing wine blending technique into the loquat wine, and then fermenting loguat juice by yeast for 1 month, where the follow-up processing method is completely consistent with the wine making technique of loquat kernels.

Owner:倪正权

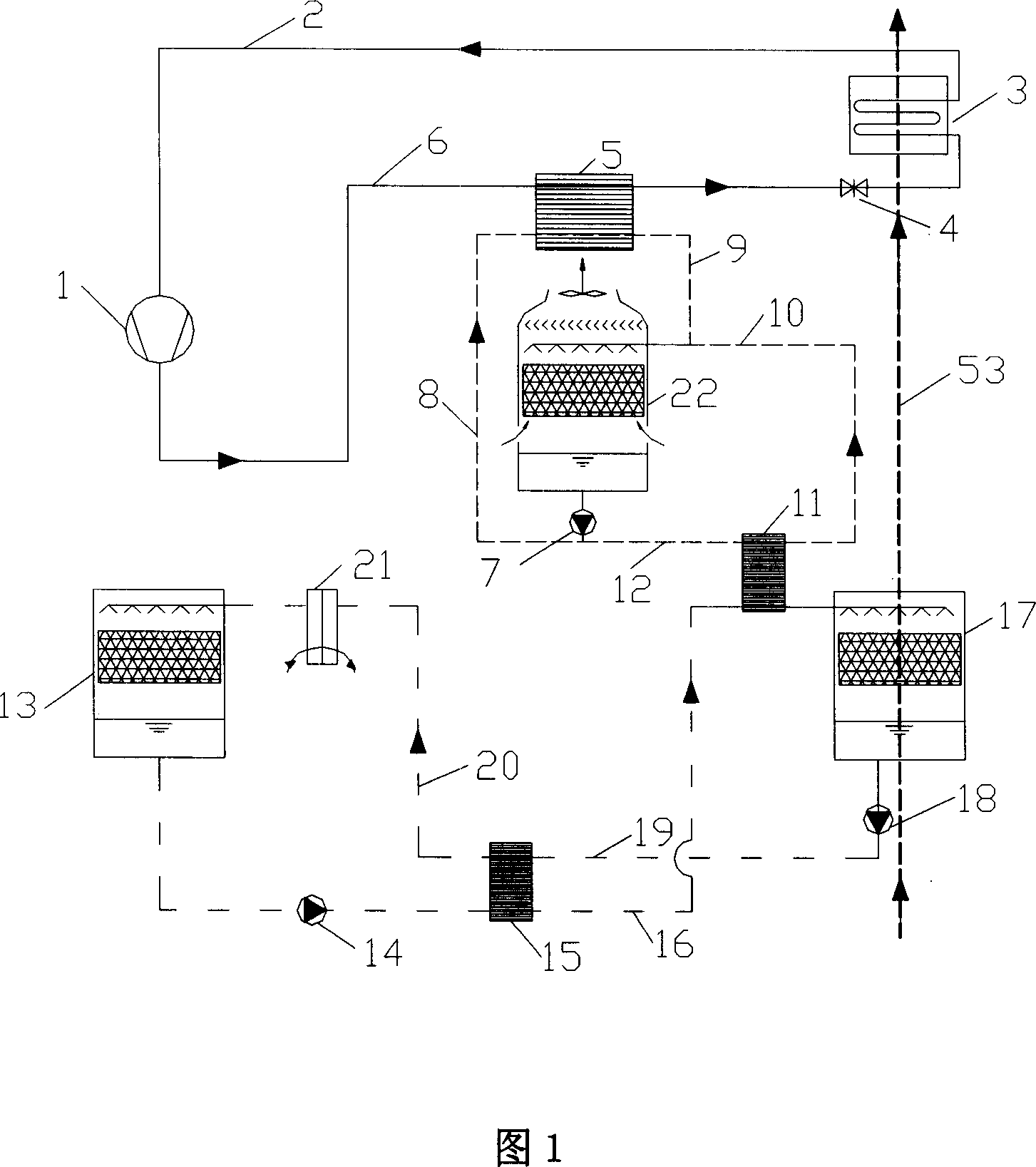

Refrigerating unit of air condition by dehumidifying, evaporative cooling solution

InactiveCN101004277AReduce intermediate heat exchange linksCompact structureLighting and heating apparatusAir conditioning systemsStrong solutionsEvaporation

The present invention discloses a solution dehumidification evaporation cooling air-conditioning refrigeration equipment. It includes compressor, evaporator, throttling mechanism, solution cooling device, regenerator, strong solution pump, dehumidifier dilute solution pump and heater. It is characterized by that a direct contact type heat exchanger and an evaporation type heat exchanger are added in said equipment.

Owner:XI'AN UNIVERSITY OF ARCHITECTURE AND TECHNOLOGY

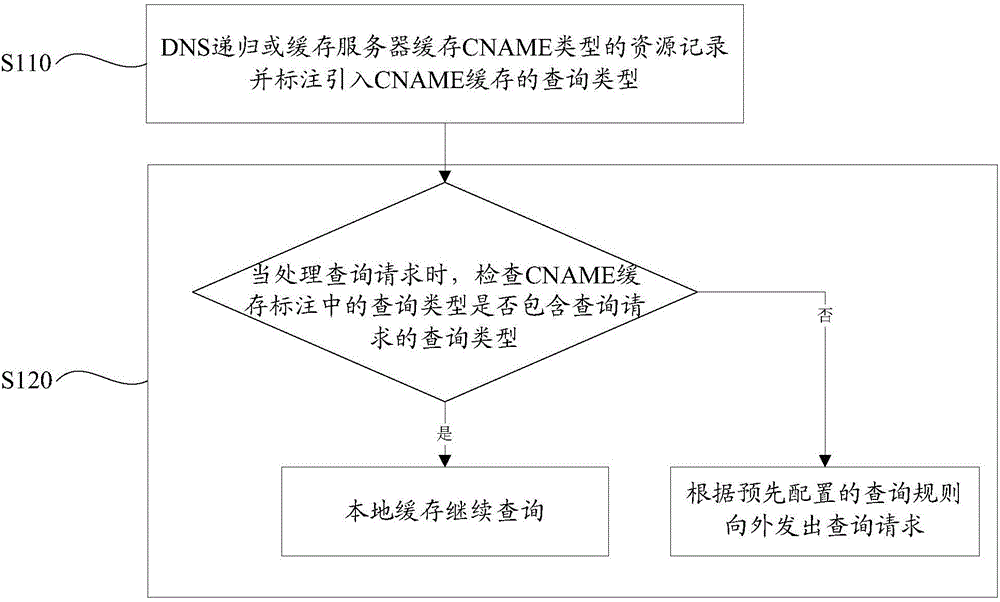

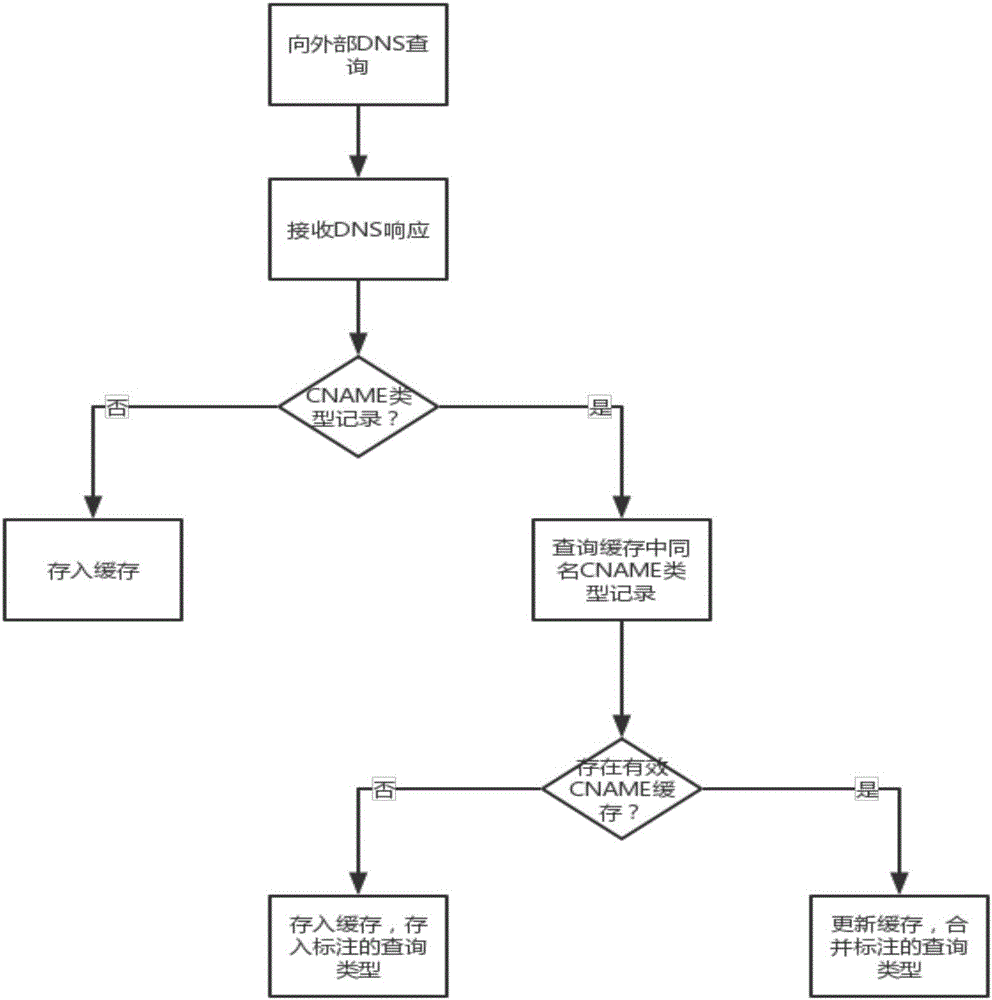

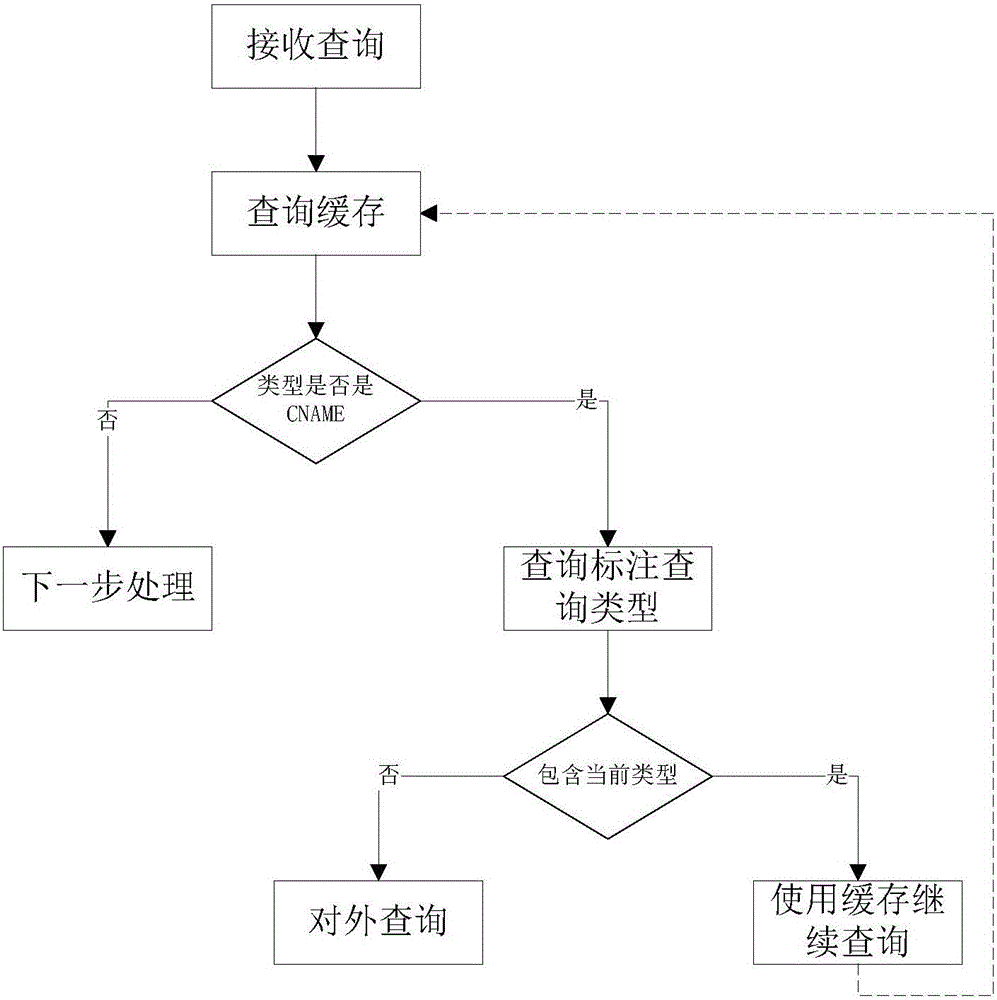

Method and system of preventing DNS strong solution result from being polluted

ActiveCN106817436ASolve the needs of mirroring and otherSolve problems that interfere with strong solution resultsWebsite content managementTransmissionDomain nameStrong solutions

The invention discloses a method and a system of preventing a DNS strong solution result from being polluted, and belongs to the DNS resolution and management technology field. The method comprises steps that a DNS recursion or cache server is used to mark a query type used for introducing a cache in a CNAME type resource record, and when the CNAME cache occurs during subsequent processing of a query request; whether the query type in the CNAME cache mark comprises the current query type is checked at first; when the query type in the CNAME cache mark comprises the current query type, the cache is used for the next step of query; and when the query type in the CNAME cache mark does not comprise the current query type, the CNAME cache is ignored, and the query request is transmitted outwards according to a configured query rule. The technical scheme provided by the invention is used to solve a problem that because of network mirror image and other requirements, the strong solution result is interfered by the CNAME type cache record having the same domain name in the cache during the strong solution of the specific type query result of the domain names by broadcast and TV, operators, or other access providers.

Owner:INTERNET DOMAIN NAME SYST BEIJING ENG RES CENT

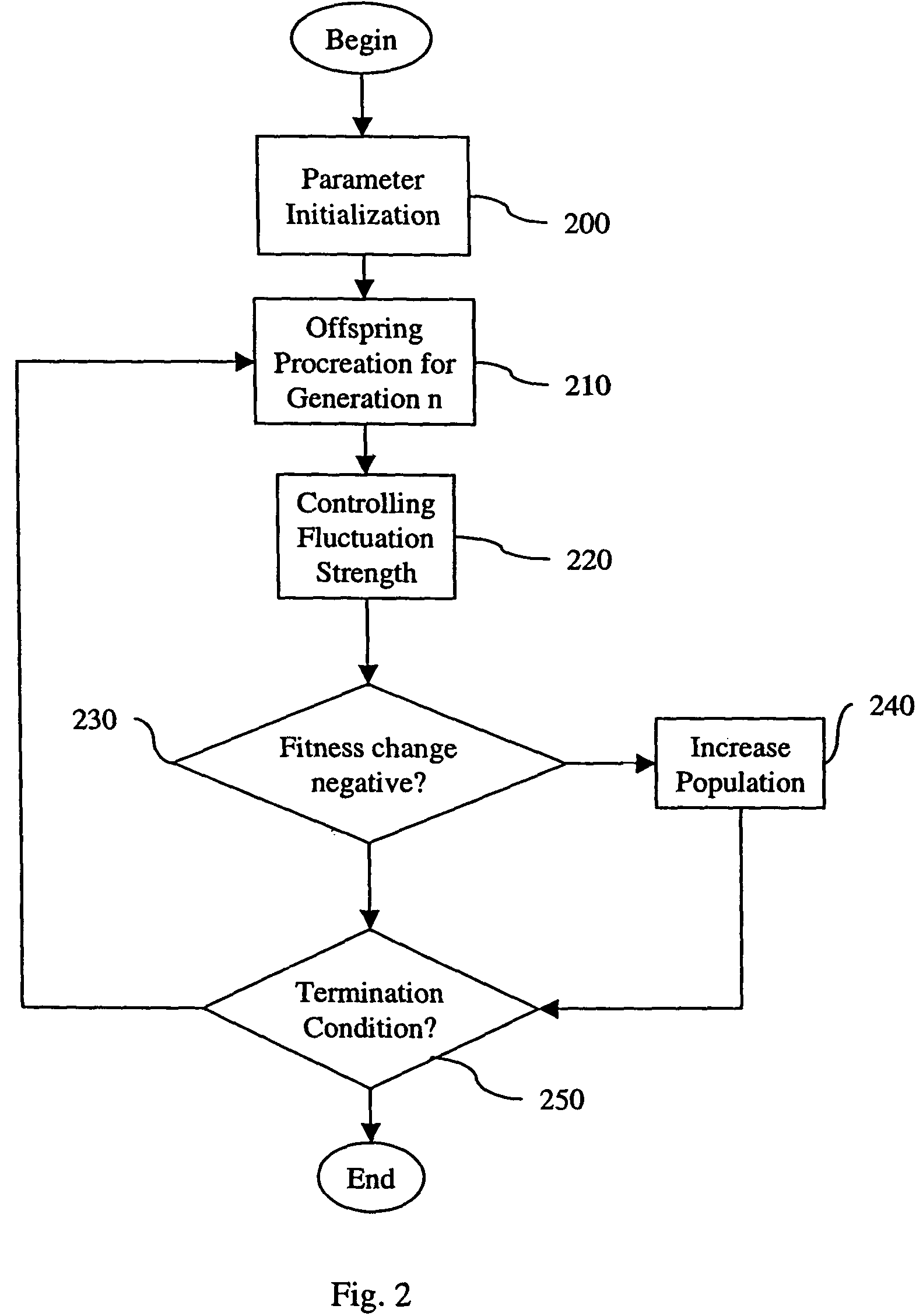

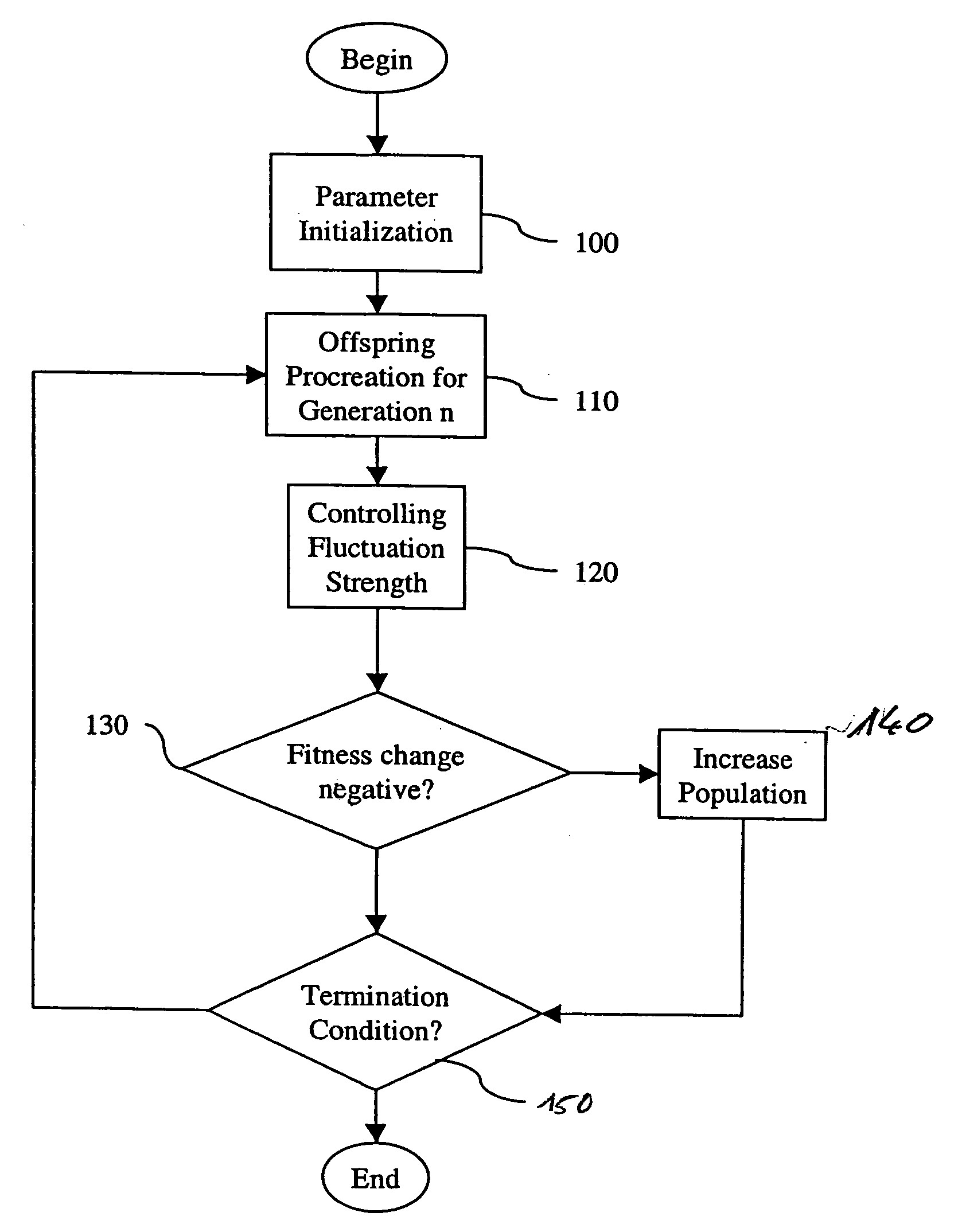

Evolutionary search for robust solutions

InactiveUS20070094167A1Reduce distanceReduce residual distanceDigital computer detailsForecastingStrong solutionsAlgorithm

One embodiment of the present invention is a method for optimizing a parameter set comprising object parameters, the method comprising the steps of: (a) creating an initial population of a plurality of individual parameter sets, the parameter sets comprising object parameters describing a model, structure, shape, design or process to be optimized and setting the initial population as a current parent population; (b) for each individual parameter set in a parent population mutating the parameters and optionally recombining the parameters to create an offspring population of individual parameter sets, wherein the strength of an individual object parameter mutation is enlarged by a noise contribution to enhance the robustness of the optimization; (c) evaluating a quality of each individual in the offspring population; (d) selecting individuals of the offspring population to be the next parent generation; and (e) repeating steps (b) through (d) until a termination criterion is reached.

Owner:HONDA RES INST EUROPE

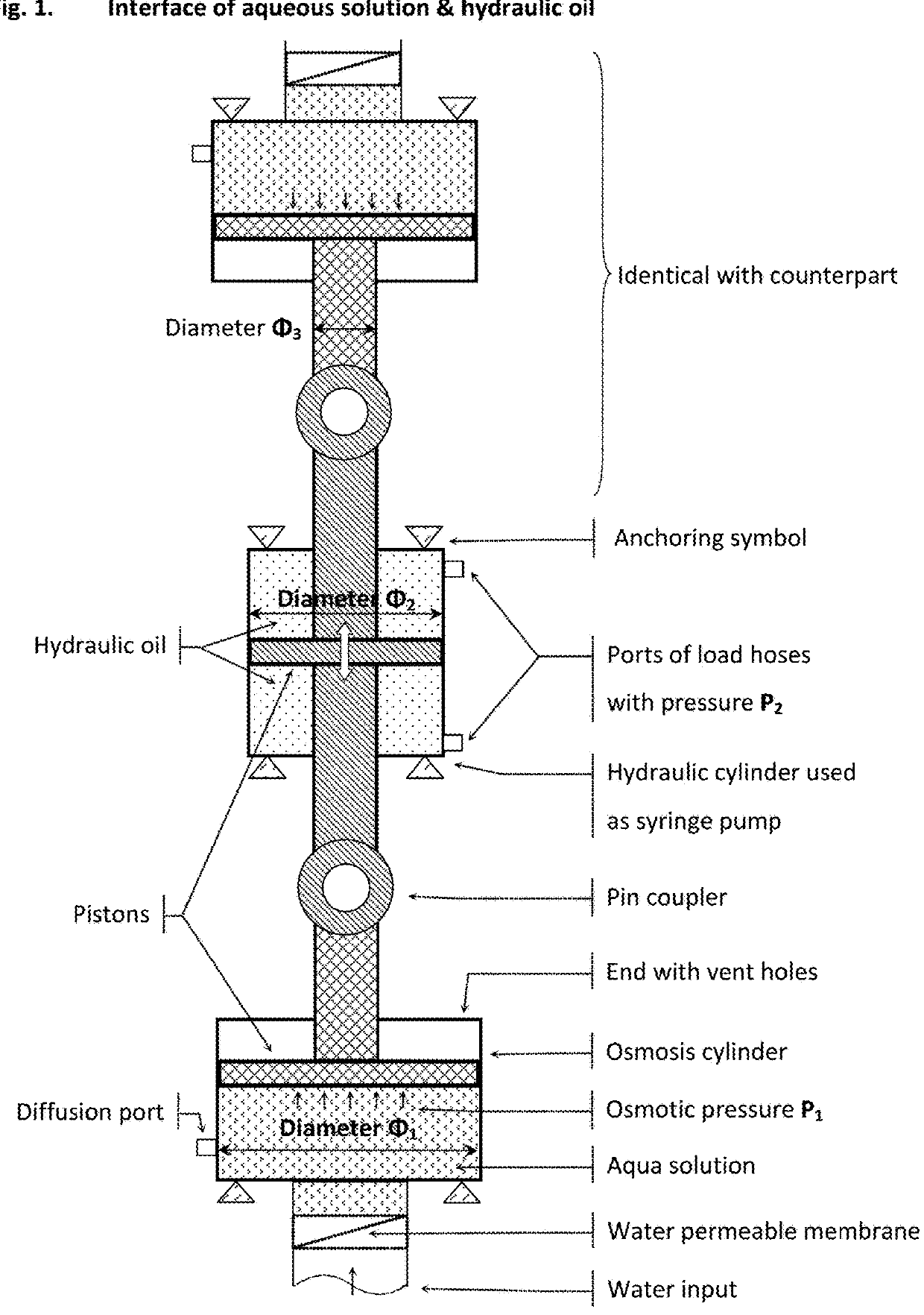

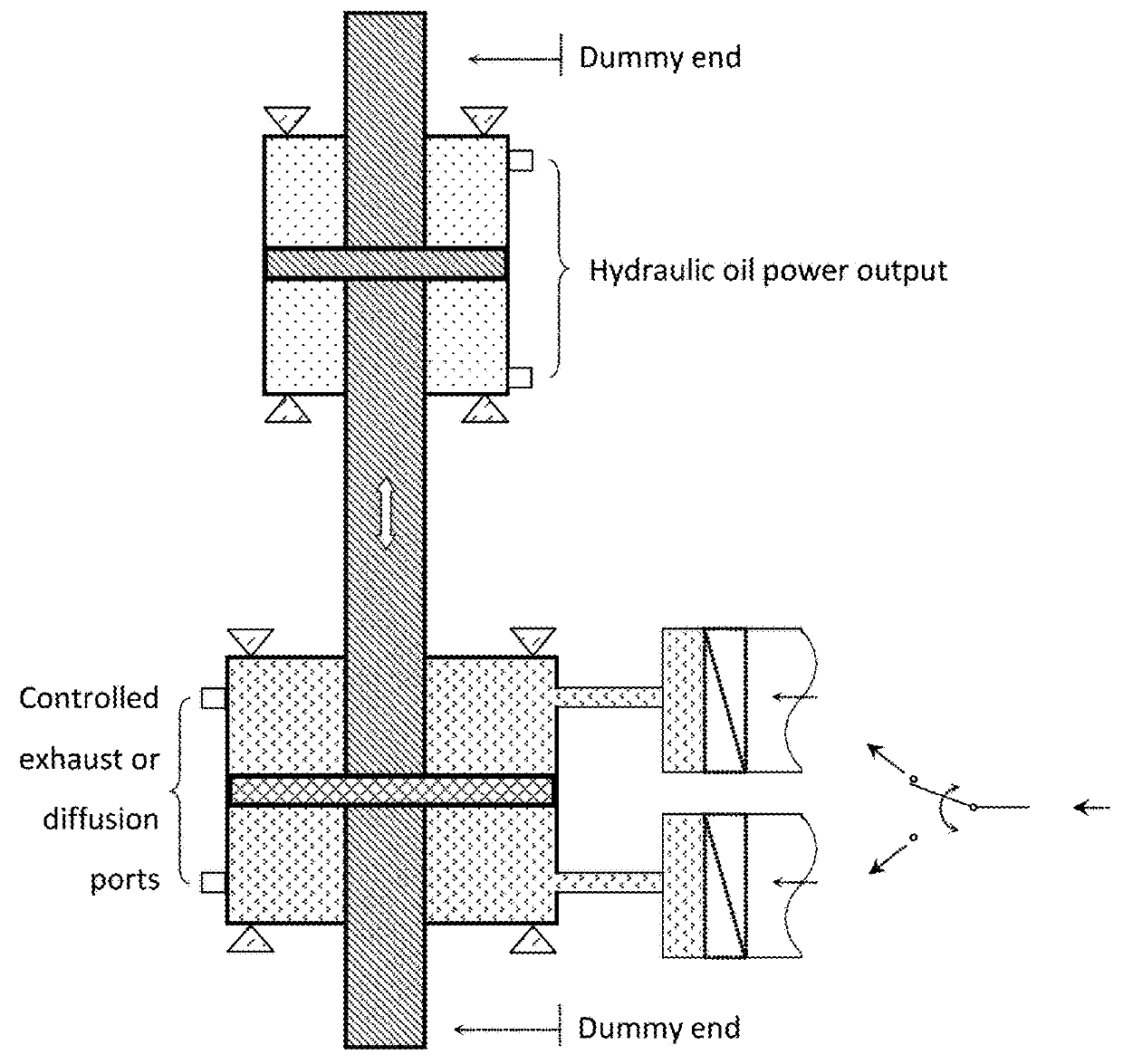

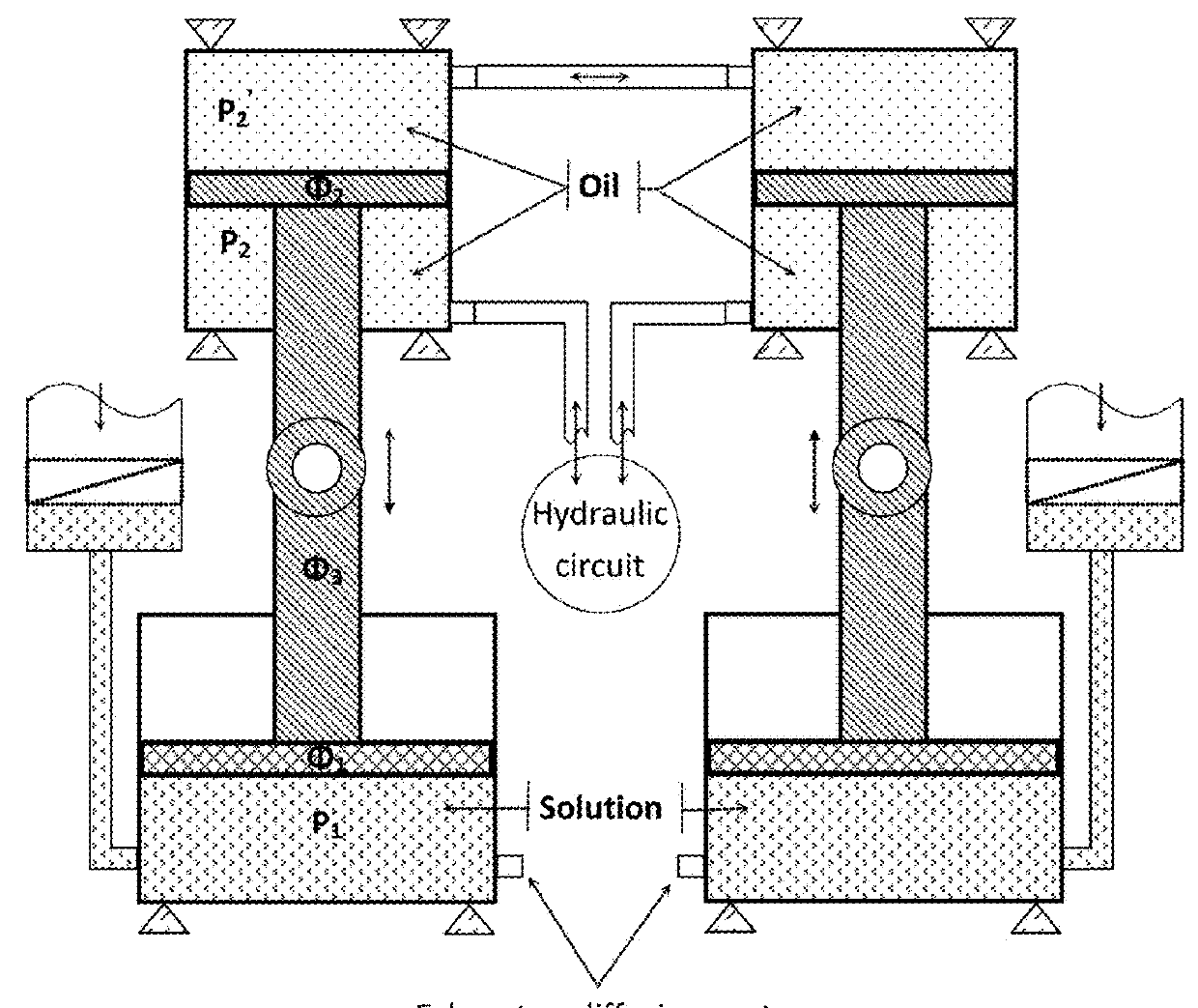

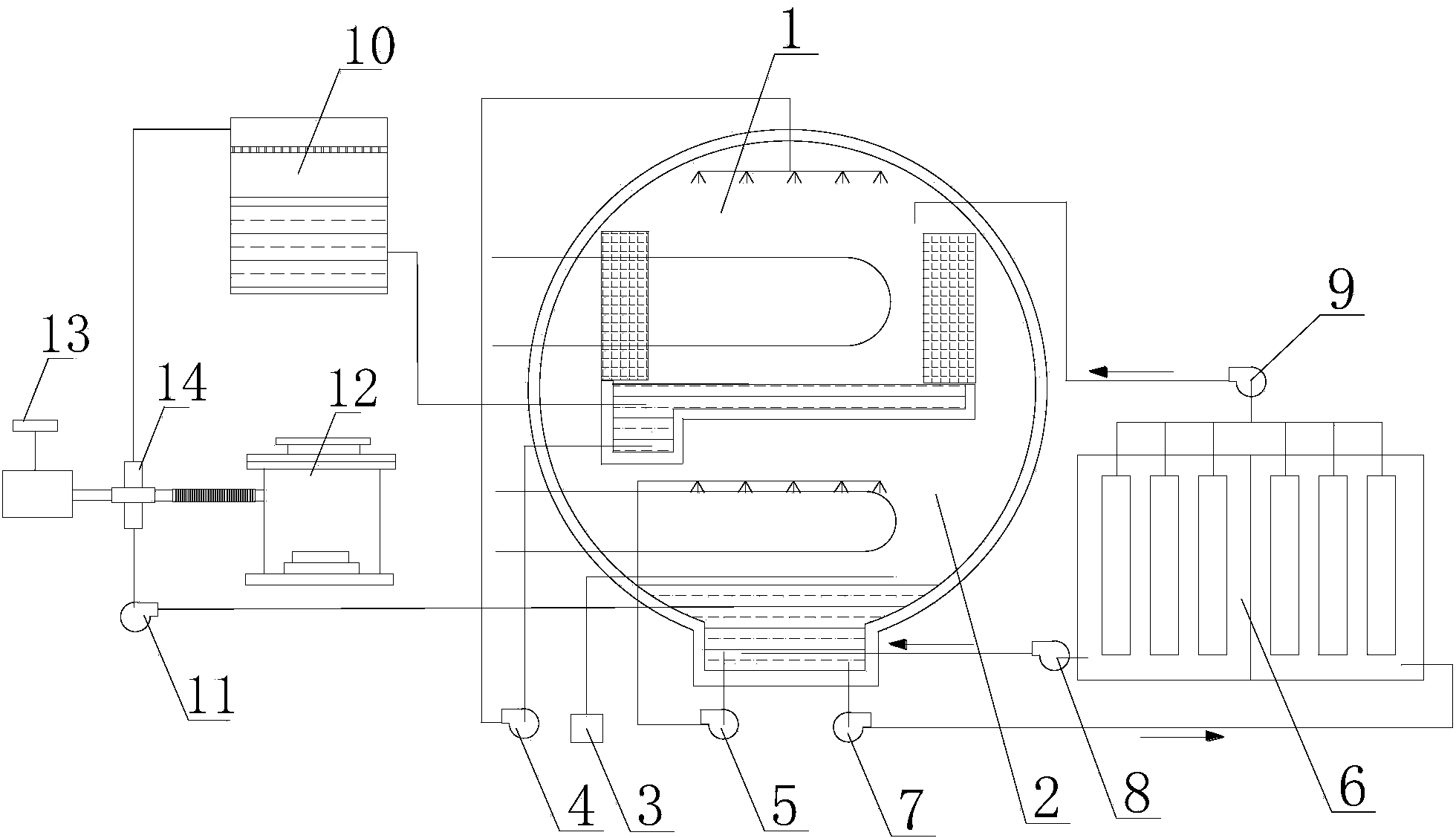

Osmosis energy storage & restoration system and indirect solar powerplant

InactiveUS20180180034A1Lighter and cheapThin frameGeneral water supply conservationSeawater treatmentEnergy absorptionFresh water organism

Natural water evaporation is a buffered process with huge energy absorption from solar & its derivative wind energy. When large surface shallow pool filled with aqueous solution is exposed under sky, the most portion of natural energy will be spent for pulling water out of water molecules cluster, yet there is still some energy for splitting water from solutes, then the concentration increases, in turn, despite the main former energy is sacrificed, but the stronger solution can redeem most the latter energy during a process of Pressure Retarded Osmosis (PRO), via membranes separating solution & available water in situ, then the redeemed energy serves as utilizable power output, with the assistance of key units or components: the osmotic to hydraulic pressure transformer, the hydraulic oil current rectification fluidic circuit & a hydraulic motor. With minor adaptation, same mechanism can also be embodied as: mobile osmosis engine, osmosis vehicle battery, yard synergy-osmosis power system, Grid electricity and miscellaneous renewable energy to osmosis energy storage, even desert to oasis remediation with seawater intake solar-via-osmosis powerplant & parasitic freshwater factory.

Owner:WEI YANMING

Lithium bromide flashing absorption type refrigerating machine

InactiveCN103512264AReduce consumptionReduce pollutionClimate change adaptationEnergy efficient heating/coolingDaily operationStrong solutions

The invention discloses a lithium bromide flashing absorption type refrigerating machine which comprises an evaporator (1), an absorber (2), a compressor (3), an evaporator pump (4) and an absorber reflux pump (5). A membrane separation filter (6) is arranged outside the absorber (2), the membrane separation filter is provided with a liquid inlet, a liquid outlet and a water outlet, and the liquid inlet, the liquid outlet and the water outlet are connected with a dilute solution outlet of the absorber (2), a strong solution inlet of the absorber (2) and a water inlet of the evaporator (1) respectively. The lithium bromide flashing absorption type refrigerating machine further comprises a flash evaporator (10), a liquid inlet pipe of the flash evaporator (10) stretches into the position below the liquid level of the evaporator (1), and a gas outlet pipe of the flash evaporator (10) is connected to the position below the liquid level of the absorber (2) through a four-way part (14). One of the two remaining ports of the four-way part (14) is communicated with an interface active agent generator (12), and the other port is communicated with a negative pressure pump (13). According to the lithium bromide flashing absorption type refrigerating machine, daily operation cost is reduced, the cooling water amount is reduced, and electric energy consumed by the pump is lowered.

Owner:昆山市周市溴化锂溶液厂

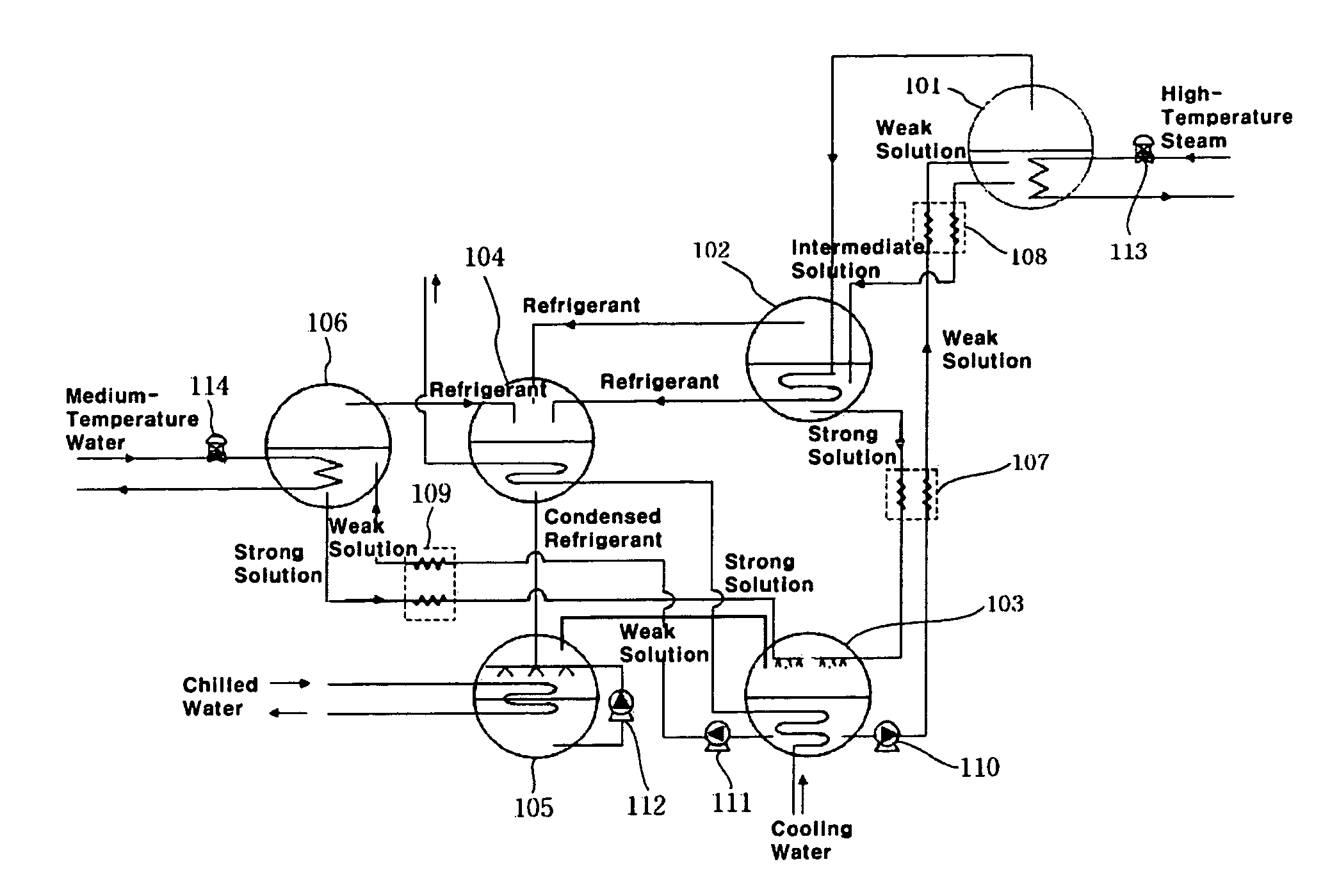

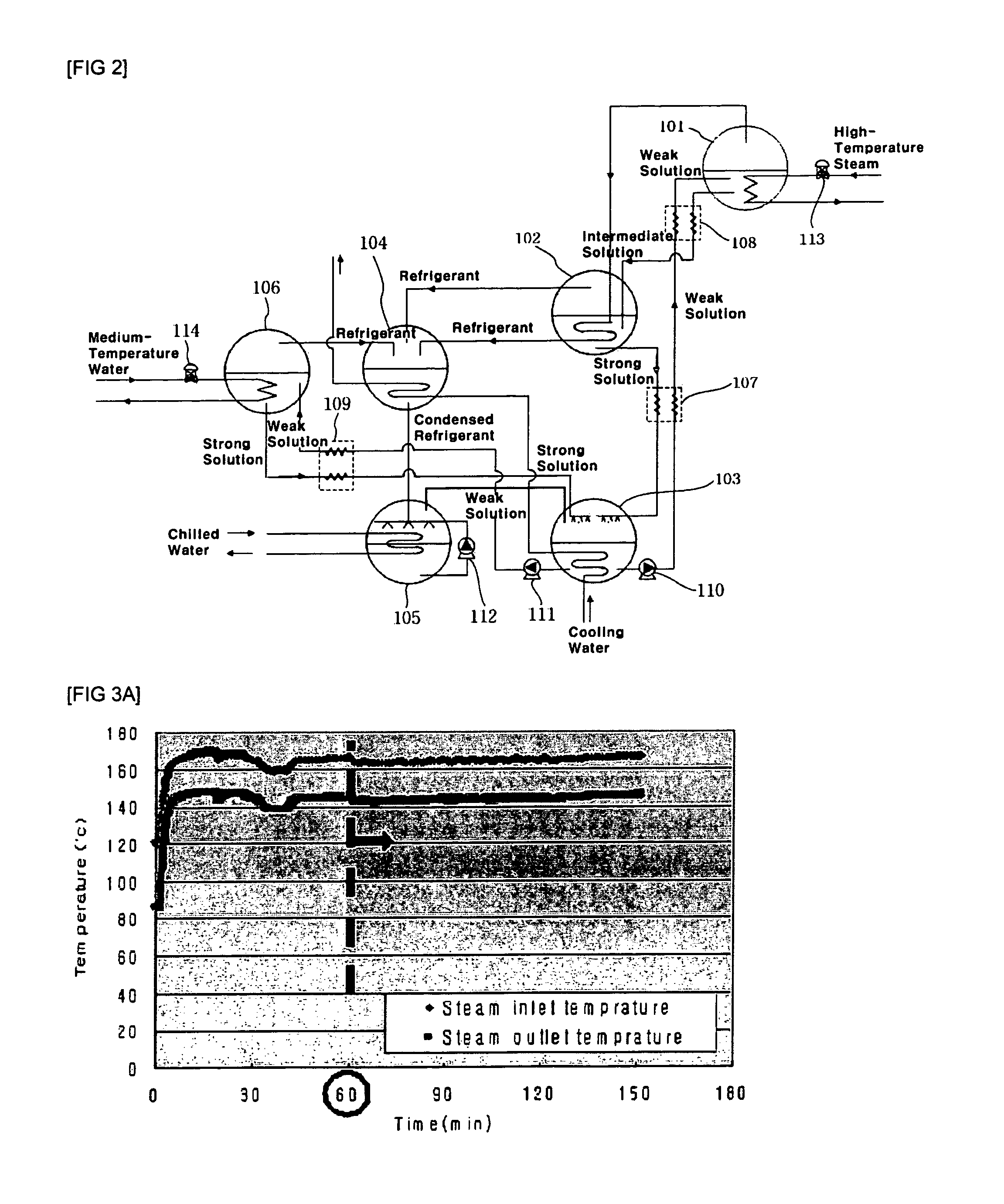

Hybrid absorption chiller

ActiveUS7624588B2Increase productionWaste heat can be utilizedCircuit monitoring/indicationDomestic cooling apparatusStrong solutionsEngineering

The present invention relates to hybrid absorption chiller, which uses high-temperature steam and medium-temperature water generated in industrial processes as a heat source, the hybrid absorption chiller including a high temperature generator that uses the high-temperature steam as a heat source so that the heat exchange with refrigerant is carried out; a low temperature generator that uses the heat of condensation of the refrigerant steam, generated in the high temperature generator, as a heat source so that the heat exchange with refrigerant is once again carried out; a generator for medium temperature water that uses the medium-temperature water as a heat source so that the heat exchange with refrigerant is carried out; a hybrid condenser that simultaneously condenses the refrigerants which are respectively heat-exchanged in the high temperature generator, the low temperature generator, and the generator for medium temperature water; an evaporator that uses latent heat of vaporization of the refrigerant condensed in the hybrid condenser so as to obtain chilled water; an absorber that receives a strong solution from the low temperature generator and the generator for medium temperature water and absorbs the refrigerant steam evaporated by obtaining latent heat of vaporization in the evaporator so as to produce a weak solution; and solution pumps that are installed in both sides of the absorber so as to supply the weak solution produced in the absorber to the high temperature generator and the generator for medium temperature water, respectively.

Owner:POSTECH ACAD IND FOUND +1

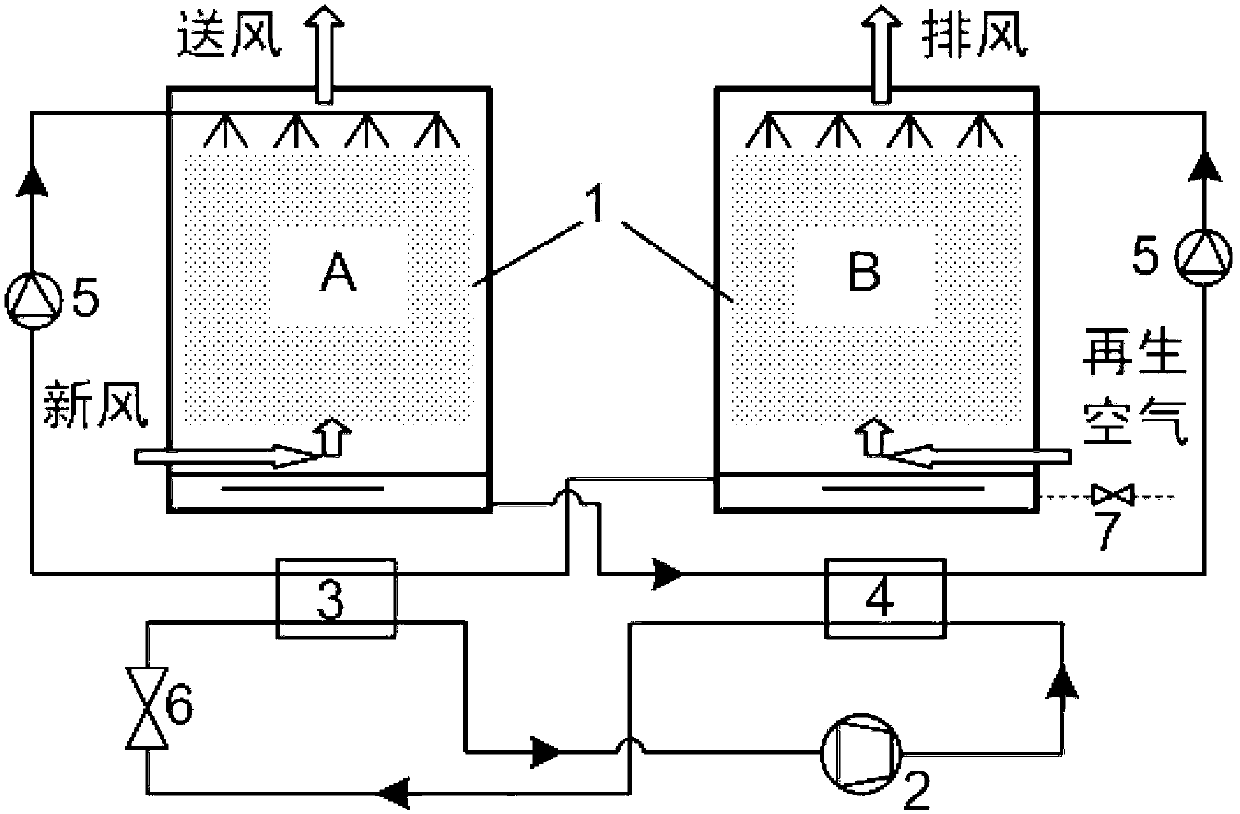

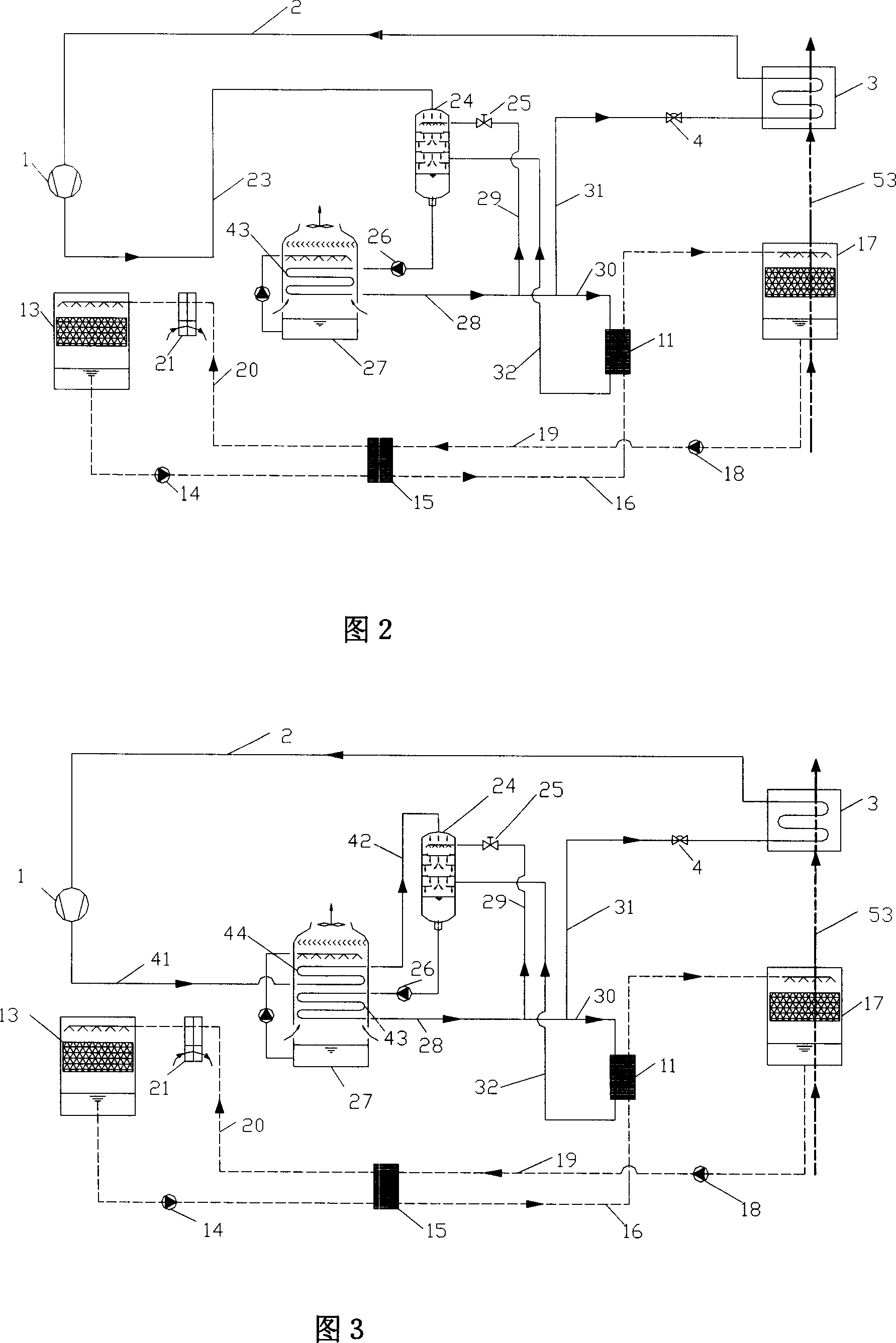

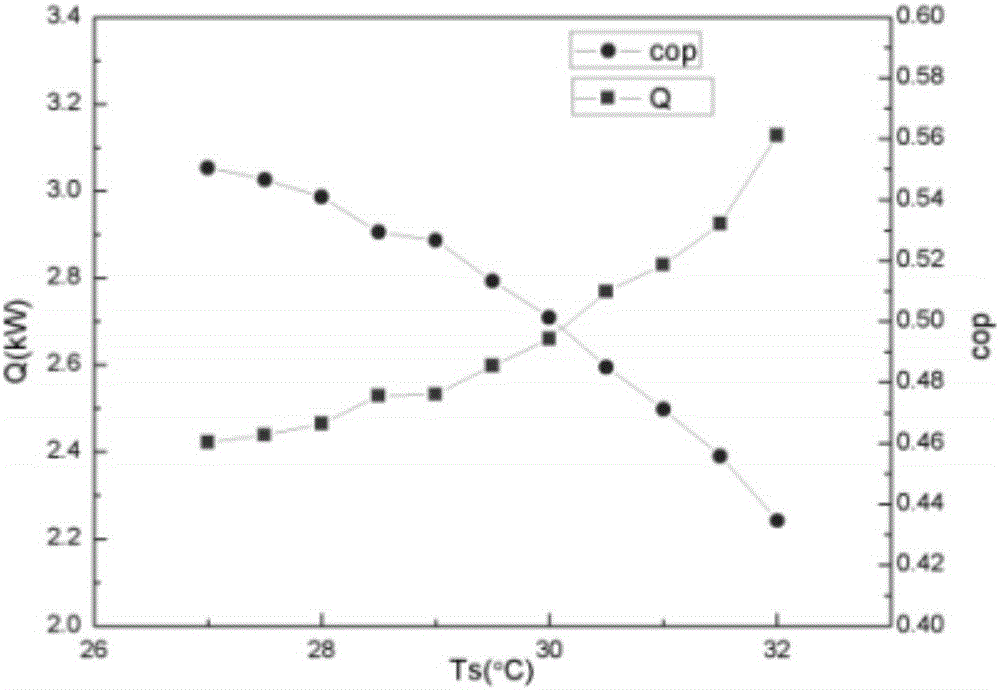

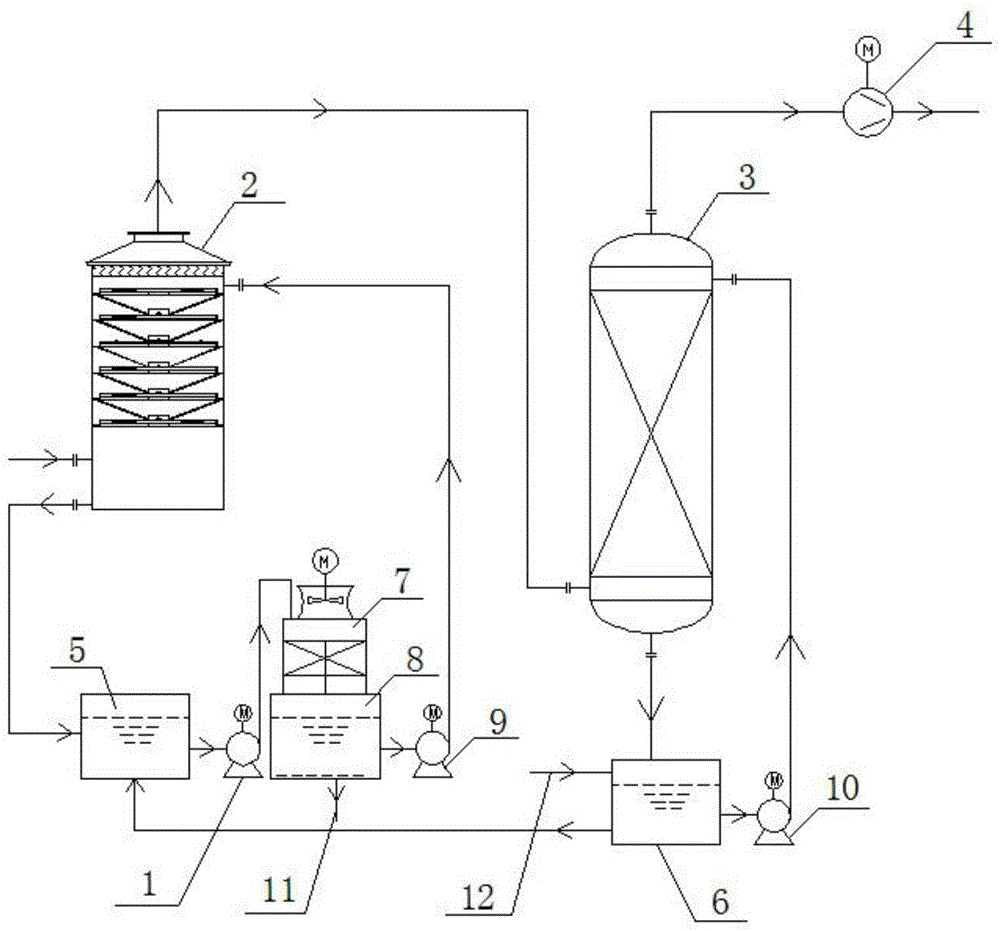

Air treatment system combining trans-critical circulation and solution dehumidification system

ActiveCN106288097AAchieve coolingImprove performanceLighting and heating apparatusAir conditioning systemsTranscritical cycleStrong solutions

The invention discloses an air treatment system combining trans-critical circulation and a solution dehumidification system. The air treatment system is characterized in that the system comprises a trans-critical compression subsystem and a solution dehumidification subsystem, heat discharged by a high-pressure side of the trans-critical compression subsystem serves as a heat source of the solution dehumidification subsystem, the solution dehumidification subsystem comprises a strong solution dehumidification unit and a dilute solution regenerating unit, and a dehumidification process is a heat insulation dehumidification process. The invention further discloses an air treatment system combining trans-critical circulation and a solution dehumidification system, and a dehumidification process is a constant-temperature dehumidification process. Reasonable energy coupling of the trans-critical circulation and the solution dehumidification system is achieved, dehumidification and temperature falling of the air can be simultaneously achieved, overall performance of the dehumidification system is improved, the heat discharged by the high-pressure side of the compression subsystem basically meets regenerated heat requirements when trans-critical compression refrigeration circulation refrigerating temperature ranges from 7 DEG C to 12 DEG C and can completely meet the regenerated heat requirements when the cooling temperature of a dehumidifying agent drops, compression work can be decreased by 10% or more, and the system is simple in structure and excellent in overall economy and environmental protection.

Owner:ZHEJIANG UNIV

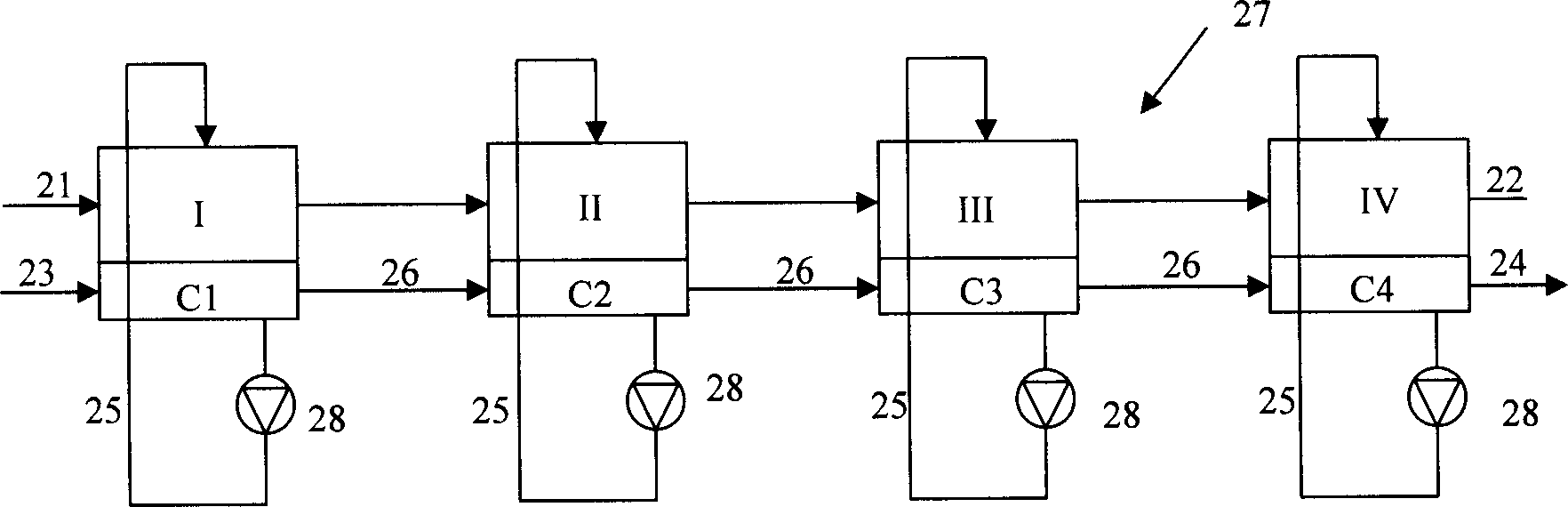

Method for concentrating solution

InactiveCN1415908ARealize multiple useIncrease motivationLighting and heating apparatusAir conditioning systemsStrong solutionsEnrichment methods

A solution concentration method characterizes in classifying the solution into 2-6 stages according to the differential concentration range of strong solution and weak solution in which the condensed range of each stage solution is only a part of entire solution concentration range, that is partial concentration and a complete concentration range is formed by combining the multistage, so as to realize multistage concentration. Energy can be used many times under different conditions during the 2-6 stages concentration, namely, not need energies from outside.

Owner:格瑞智慧人居环境科技(江苏)有限公司

Reusable device for release of caught fishing accessories

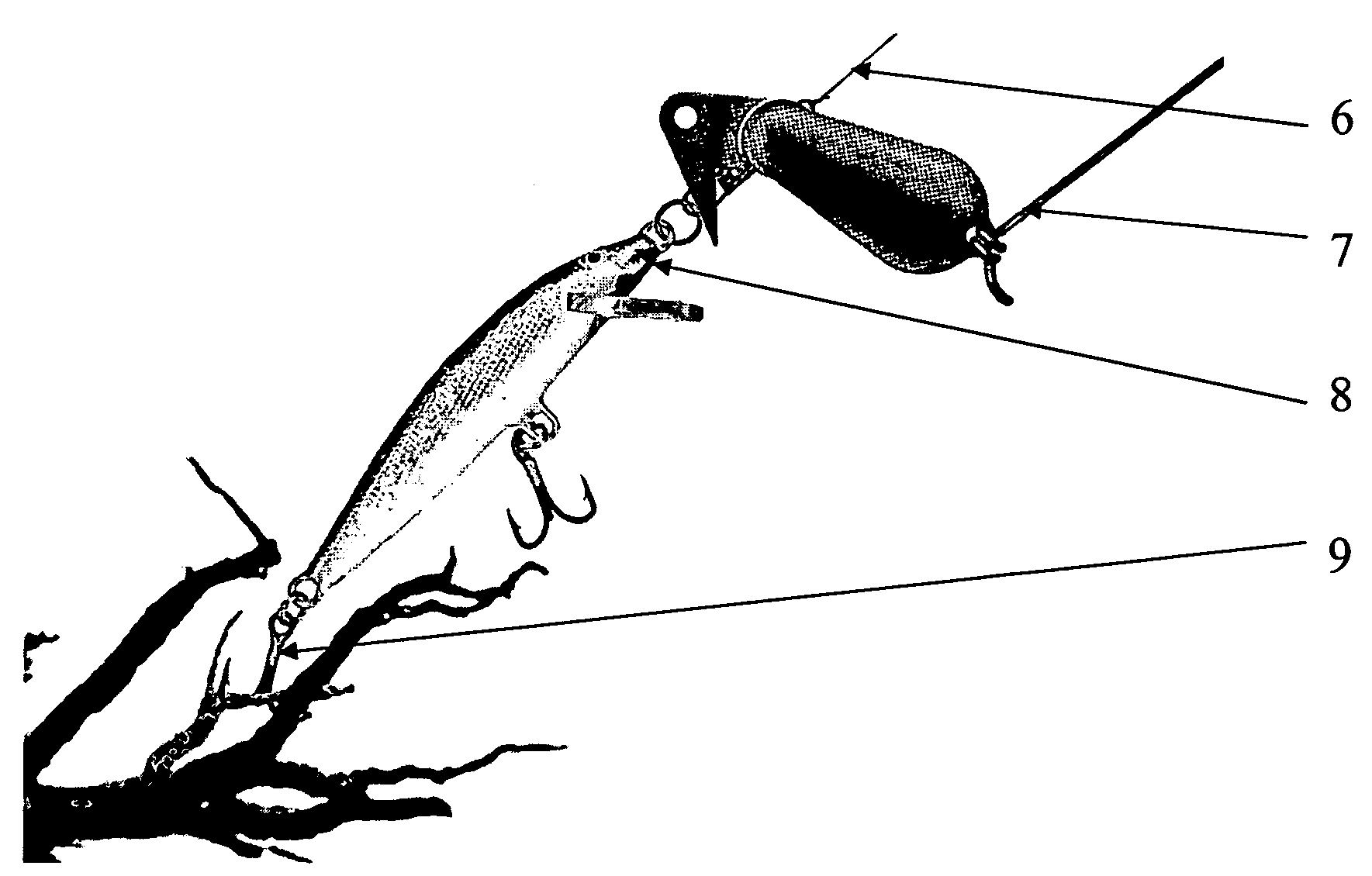

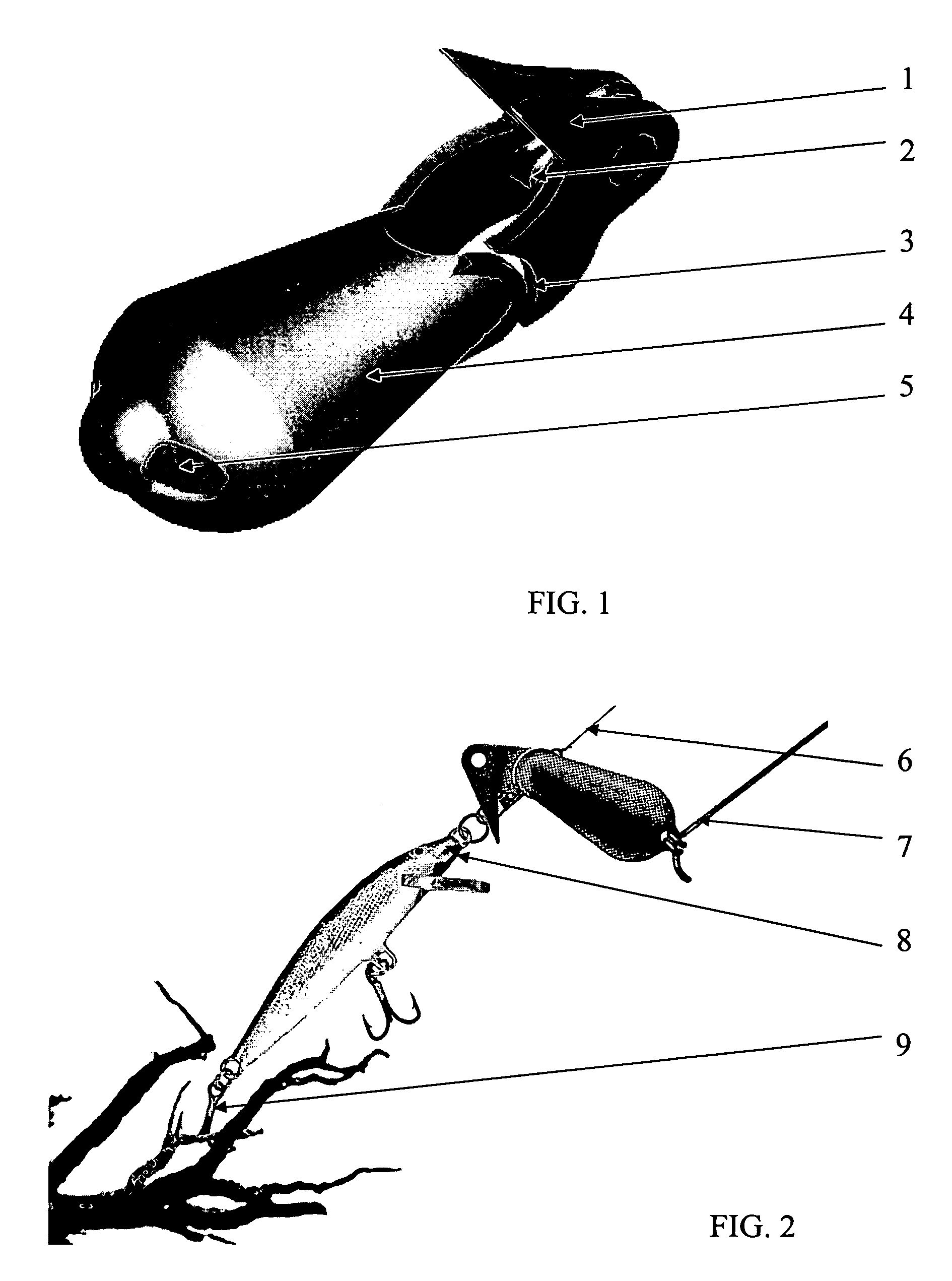

A small reusable lure retriever device formed as one piece metal casting and comprising features to enable the device to slide down onto the fishing line 6 using the gravity force, pull the tied string 7 into the water, rotate and grip the lure 8 mounting fixture while providing robust solution to rescue the caught fishing lures, tackles and bait rigs or different type and size.

Owner:GROIS INVENTORS CORP

Double-temp-raising produced overcooling absorption and single effect, afterheat absorbing refrgerating system

InactiveCN1563857AReduce the temperatureModerately reduced areaEnergy efficient heating/coolingClimate change adaptationStrong solutionsDistribution system

Heat exchanger of working medium of solution heat source and heat exchanger of solution cold water added to system based on single action absorption type cooling distribution system makes dilute solution passing through solution heat exchanger and before entering into generator be preheated in new added heat exchanger of working medium of solution heat source by heat source working medium discharged from generator. Dual temperature rise is realized in circulation. Before entering into absorber, the strong solution is pre-cooled in new added heat exchanger of solution cold water. The two added heat exchanger constitute new circulating flow, parameters of the circulating state are changed. Module functions are enhanced. Available temp of heat source is even lower. Difference in temp of heat source working medium between in and out absorption type refrigerate machine is increased so that machine is compact.

Owner:UNIV OF SHANGHAI FOR SCI & TECH

Cresent passage solution elevating vapor generator for absorption refrigerator with half-moon like pass

InactiveCN1336507ABig liftSimple structureEnergy efficient heating/coolingSorption machinesStrong solutionsLower grade

The invention relates to channel with crescent cross-section to life solution and steam generator used in absorption refrigeration. The pipe composed of inner tube and outer tube is placed in cartridge heater. Dilute solution comes into slit shaped channel from button part of the pipe and strong solution is discharged out of the cavity for collecting high-pressure water vapor on the upper part. In the invented generator low-grade heat source can be utilized as well as solar energy to life solution from low spot to high place automatically, realizing self-circulation. The absorption refrigeration having the invented assembly exhibits notable merits of high effect, energy saving, safety, noiselessness, pollution free.

Owner:XI AN JIAOTONG UNIV

Low-temperature desulfuration and denitration system

ActiveCN106000048ASolve processing problemsLow investment costUsing liquid separation agentAir quality improvementLiquid wasteAtmospheric air

The invention discloses a low-temperature desulfuration and denitration system which comprises a rotational flow tower and a first waste gas outlet formed in the top of the rotational flow tower, the first waste gas outlet is connected with an orifice plate corrugated packing absorption tower, the bottom of the rotational flow tower is provided with a water tank, the water tank is provided with a first waste liquid outlet, the first waste liquid is connected with a hot water pond, the hot water pond is connected with a cooling water tower, the bottom of the cooling water tower is provided with a cooling water pond, the orifice plate corrugated packing absorption tower is connected with an alkali liquor pond, the alkali liquor pond is connected with an alkali liquor circulating pump and the hot water pond simultaneously, the alkali liquor circulating pump is connected with the orifice plate corrugated packing absorption tower, exhaust afterheat is fully utilized to process a used strong solution, the problem of absorption solution processing is solved, emission of a plenty of afterheat to the atmosphere is avoided, energy is saved, and the environment is protected; nitric oxides and sulfide are jointly processed, system equipment is reduced, and investment cost is lowered greatly; sulfite formed after the sulfide is absorbed is fully utilized for reducing the nitric oxides, consumption of absorbent is reduced, and cost is saved.

Owner:GUANGDONG CODE OF ENVIRONMENTAL PROTECTION ENG CO LTD

Method for removing pigment and ichangin of inulin produced through full-film technology

The invention discloses a method for removing pigment and ichangin of inulin produced through a full-film technology. The method includes the following steps that first, a cichorium intybus water extracting solution is intercepted by an ultrafiltration membrane, macromolecules of non-inulin components are removed, and accordingly a clear solution is obtained; second, the ultrafiltration membrane clear solution is pretreated by a nanofiltration membrane, the content of salt in the solution is lowered, and the strong solution is qualified under the conditions that the electric conductivity is lower than 1000 S and the acidity PH value is 6.5-7; third, the feed solution pretreated by the nanofiltration membrane is subjected to decoloration and debitterizing treatment through macroporous resin, and the purposes that the solution is colorless and free of bitterness and the electric conductivity is lower than 200 S are achieved; fourth, the feed solution subjected to decoloration and debitterizing treatment through the macroporous resin is dehydrated and desalted through the nanofiltration membrane. According to the method, membrane method separation and macroporous resin absorption are reasonably combined, and the optimum decoloration and debitterizing effects are achieved on the inulin produced by cichorium intybus; compared with products in the same industry, the bitterness is the same, the color scale is lowest, pollution is minimum, and the solid inulin yield is highest and reaches 10%.

Owner:JUNZHU DALIAN BIOLOGICAL IND CO LTD

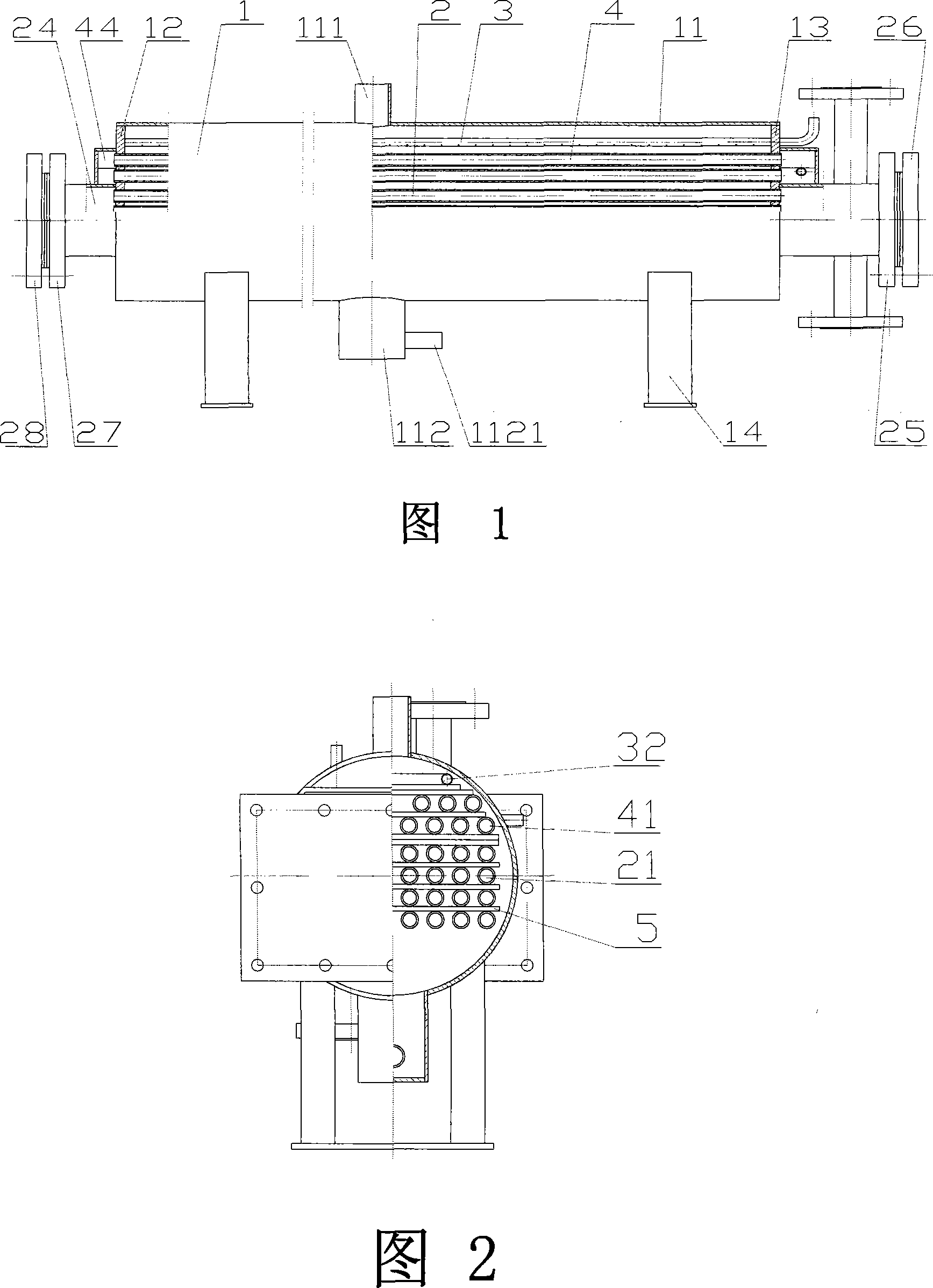

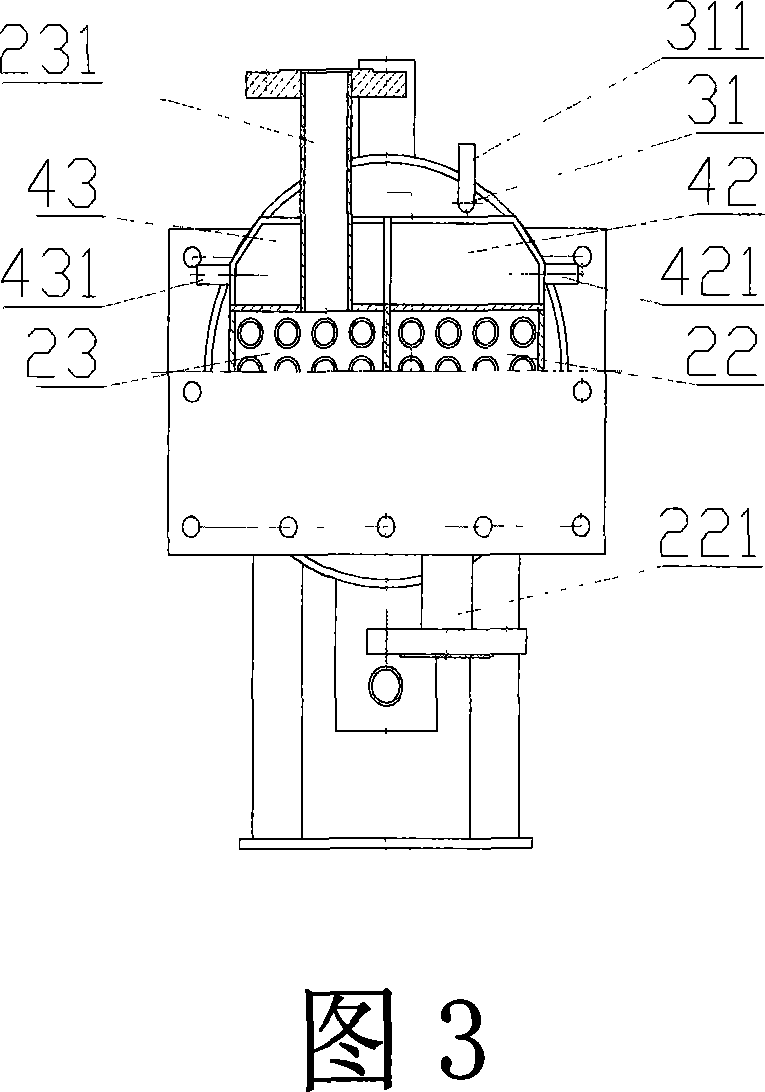

Ammonia absorber with solution cooling down absorption segment and silk screen corrugated filler layer

InactiveCN101118106AImprove cycle efficiencyEasy to clean regularlyEnergy efficient heating/coolingClimate change adaptationStrong solutionsFilling materials

The present invention discloses an ammonia absorber with a solution refrigeration absorption section and a silk screen corrugated filling material layer, and relates to an absorber of an ammonia absorption type refrigerator. The present invention comprises a casing, a cooling water cooling absorption section component, and a dilute solution spaying distribution pipe component; a left pipe plate and a right pipe plate are respectively arranged at the left end and the right end of a tube body on the casing; the absorber also comprises a strong solution cooling absorption section component, the two ends of each heat transfer pipe of an upper heat transfer pipe bundle are respectively inserted and welded in the pipe orifices of the left pipe plate and the right pipe plate, an upper pipe bundle inlet cavity and an upper pipe bundle outlet cavity are respectively arranged on the two sides of the right pipe plate, an upper pipe bundle returning cavity is arranged on the left pipe plate, a strong solution inlet pipe is arranged on the upper pipe bundle inlet cavity, a strong solution outlet pipe is arranged on the upper pipe bundle outlet cavity; the silk screen corrugated filling material layer is arranged between each layer of pipes of the spaying distribution pipe, the upper heat transfer pipe bundle and the lower heat transfer pipe bundle. The present invention aims to improve the circulation efficiency of the system and the heat transfer medium efficiency of the absorber, and to improve the effectiveness of the liquid film distribution on the outer surface of a parallel pipe bundle.

Owner:SOUTHEAST UNIV

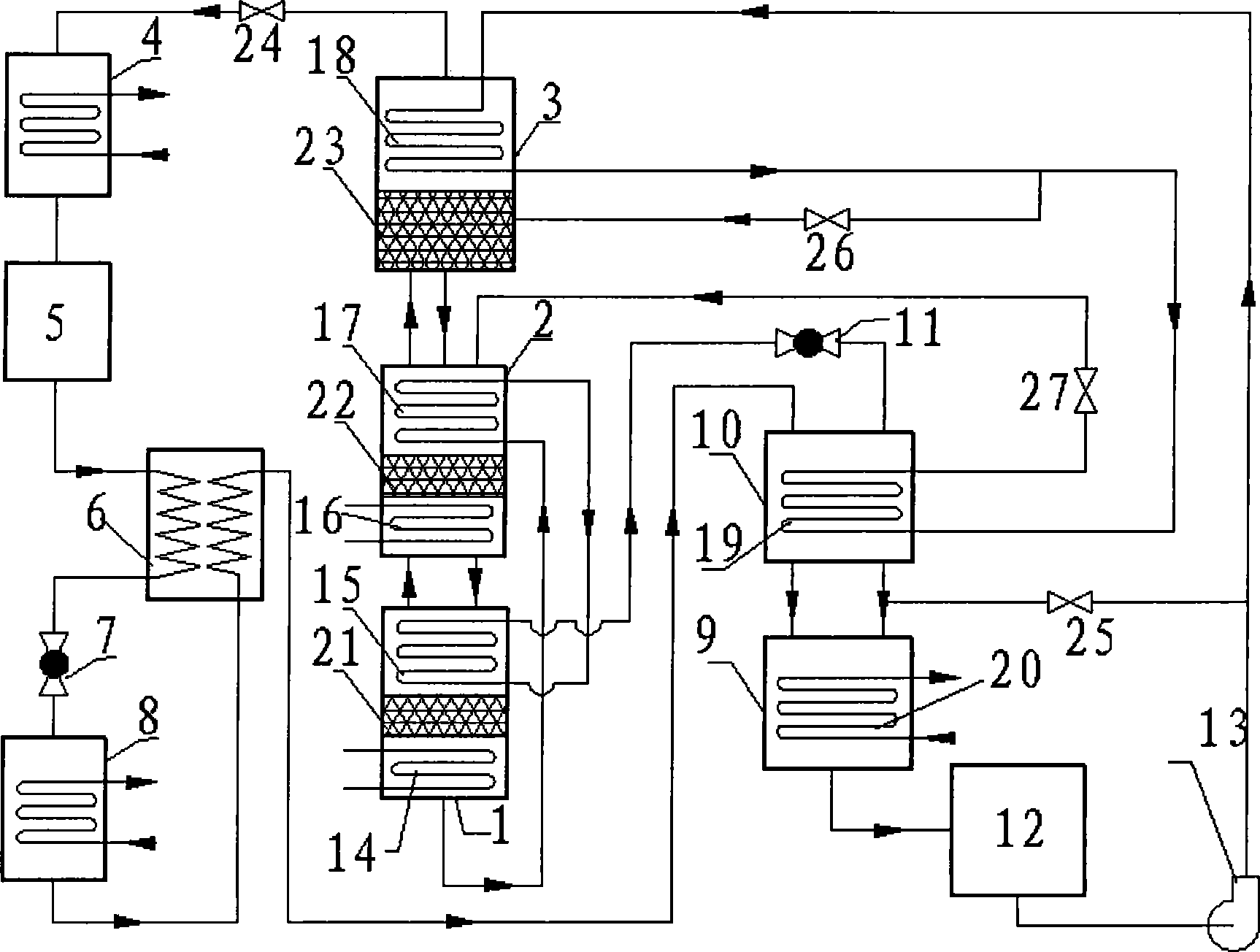

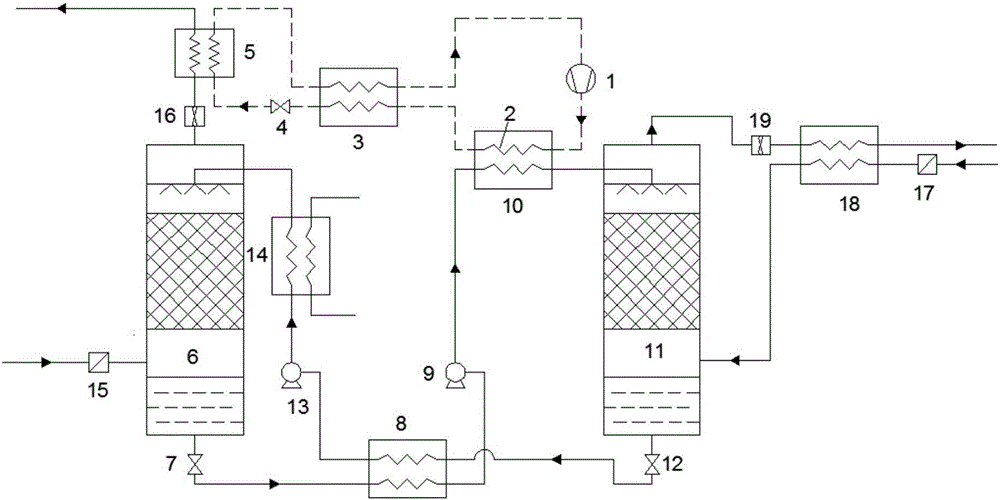

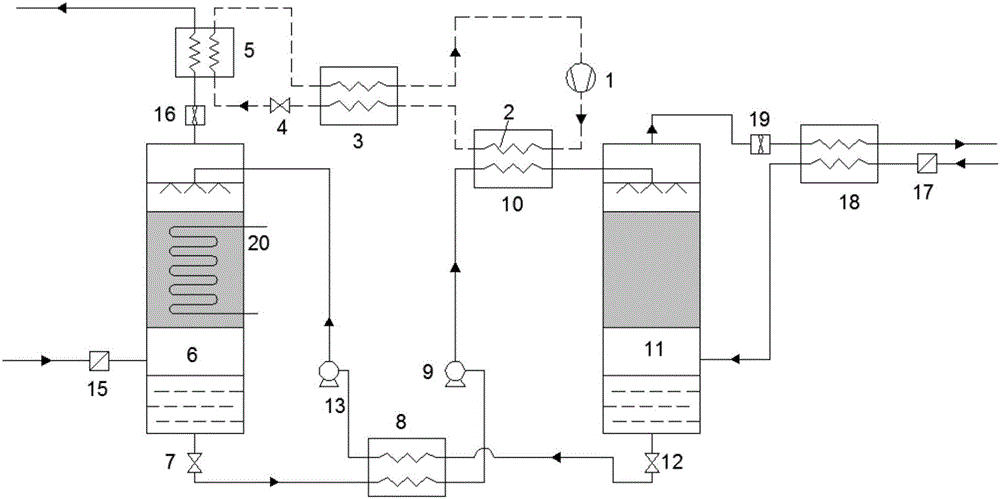

Flue gas and hot water single-double-effect combined type lithium bromide absorption water chilling unit

InactiveCN107504710AReduce accessSmall sizeMechanical apparatusBoilers/analysersStrong solutionsFlue gas

The invention relates to a flue gas and hot water single-double-effect combined type lithium bromide absorption water chilling unit, and belongs to the technical field of air conditioning equipment. The flue gas and hot water single-double-effect combined type lithium bromide absorption water chilling unit comprises a hot water side generator (1), a flue gas side high pressure generator (2), a flue gas side low pressure generator (3), a condenser (4), a high temperature heat exchanger (5), a low temperature heat exchanger (6), a second solution pump (7), an absorber (8), a first solution pump (9), a coolant pump (10), an evaporator (11) and a flue gas solution heat exchanger (12). The hot water side generator (1) and the flue gas side low pressure generator (3) are arranged in a cavity, and a heat transfer pipe bundle is arranged up and down. The second solution pump (7) is arranged at a strong solution outlet of the flue gas side low pressure generator (3). The water chilling unit can fully utilize the hot water with the temperature being decreased to conduct refrigeration.

Owner:SHUANGLIANG ECO ENERGY SYST CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com