Patents

Literature

241results about How to "Realize multiple use" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

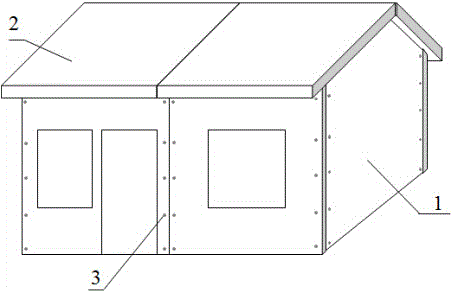

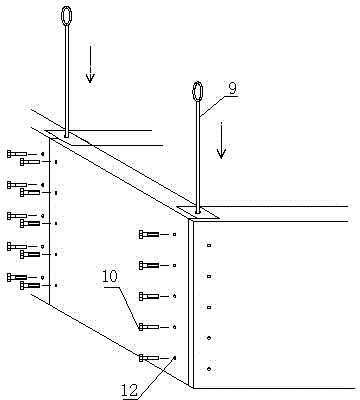

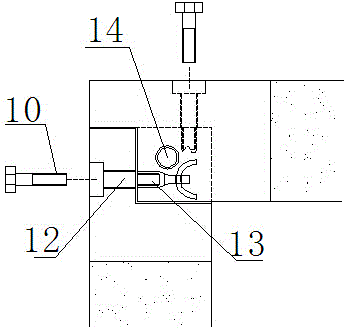

Reinforced concrete frame gridding slab prefabricated energy-saving house

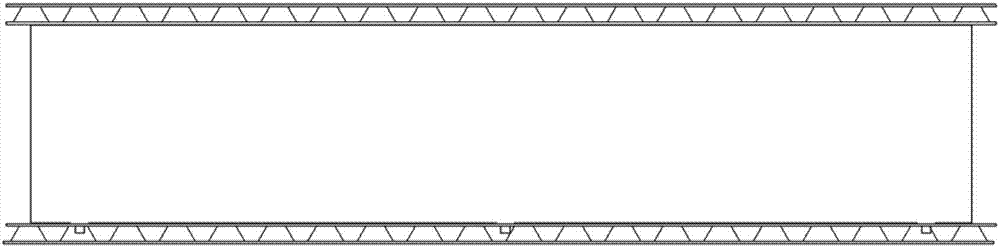

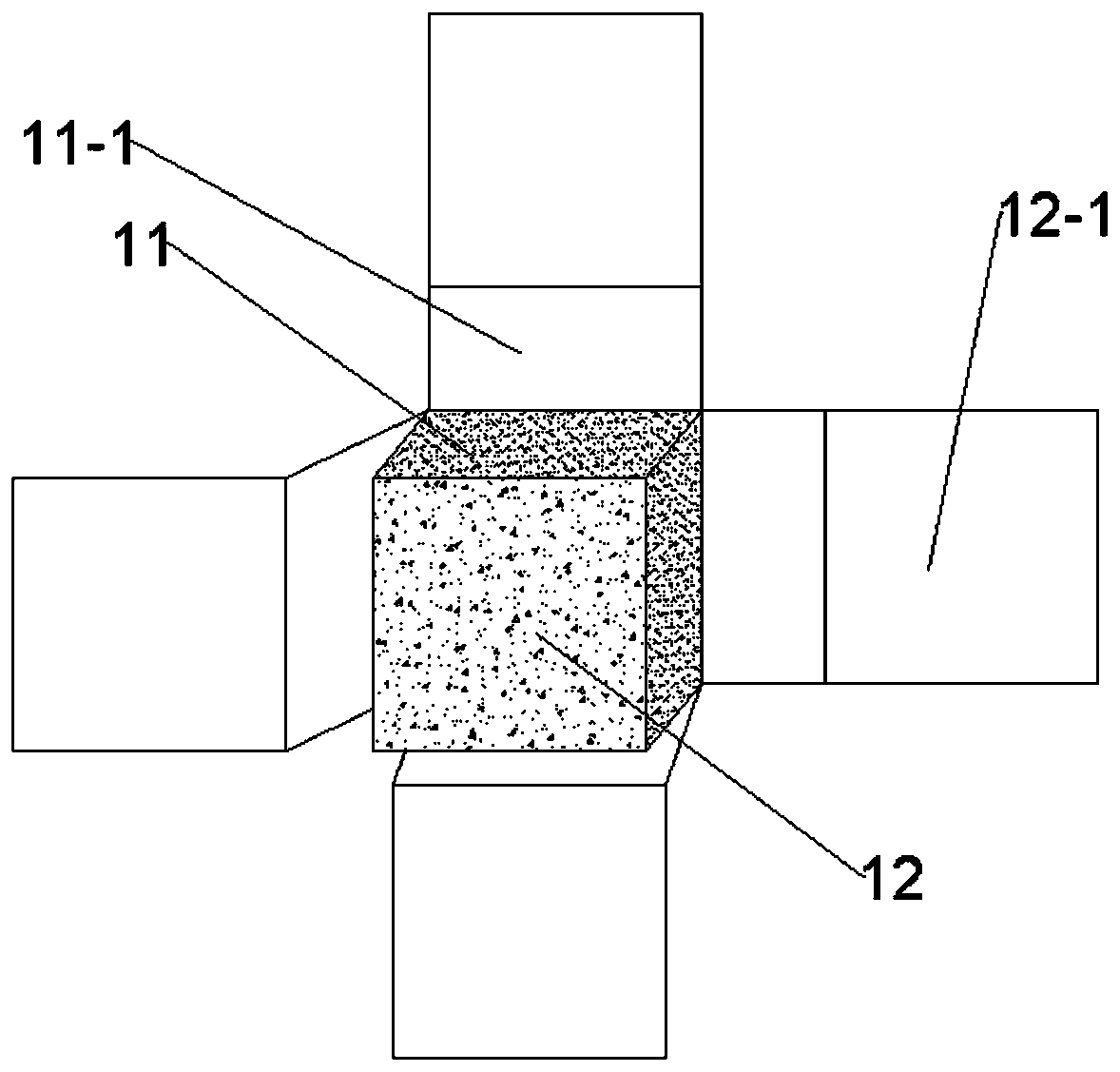

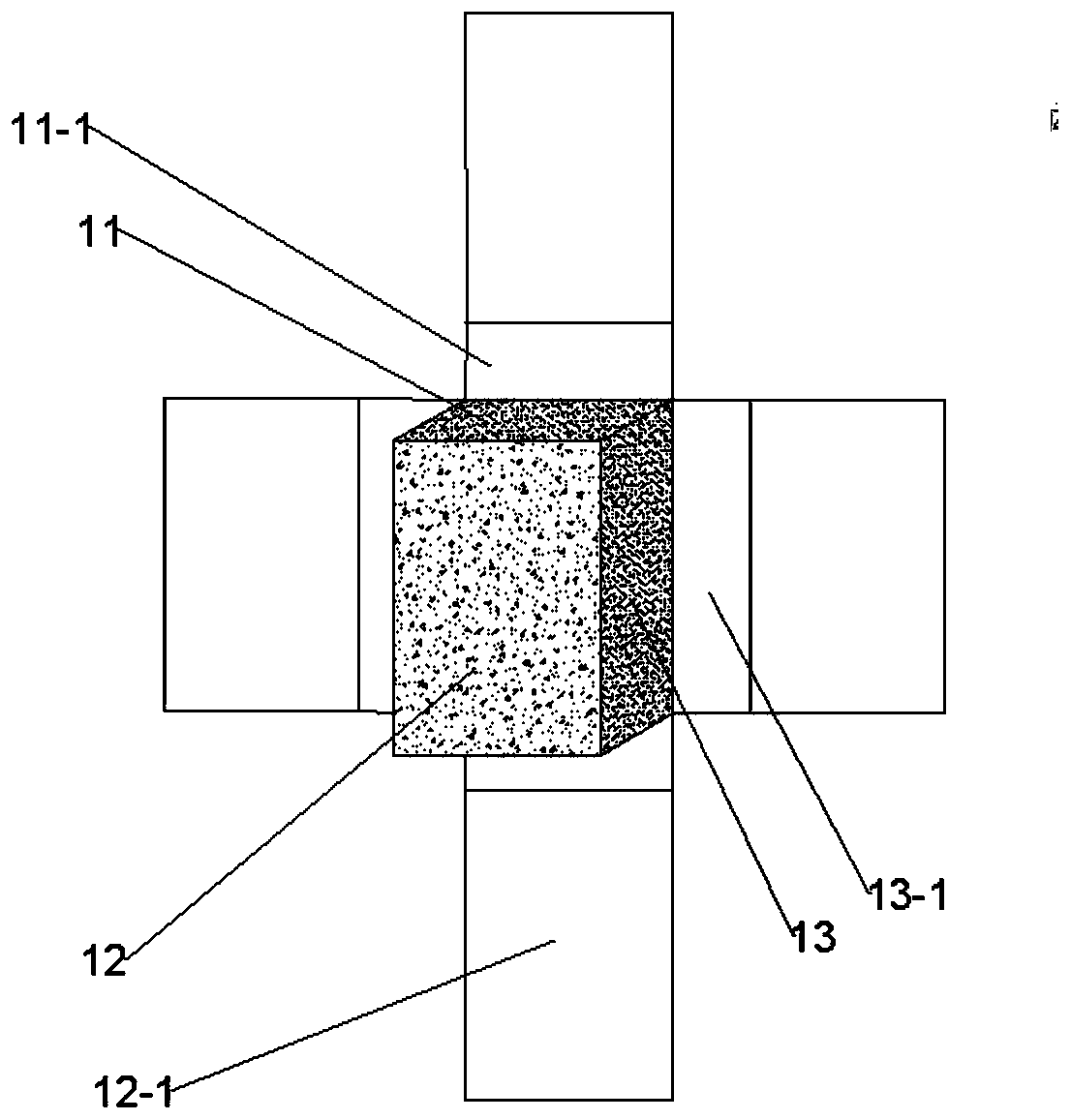

The invention relates to a reinforced concrete frame gridding slab prefabricated energy-saving house. The reinforced concrete frame gridding slab prefabricated energy-saving house is assembled by prefabricated frame gridding concrete wallboards, floor slabs, roof boards, prefabricated frame gridding concrete foundation section and accessories, wherein the prefabricated slabs are formed in a mutually mechanical occlusion and connection manner; the prefabricated slabs are fixed by means of fixing bolts, pin ribs or post-tensioned prestressed reinforcements; a frame gridding type concrete slab frame is a #-shaped reinforced concrete load-bearing frame consisting of longitudinal and horizontal ribs; each of four sides of the slab frame is provided with mechanical connection connectors, and preformed holes or is provided with pre-embedded connecting pieces; two surfaces or one surface of each slab of the slab frame are / is covered with a heat insulating material, a decorative finish layer or a concrete protecting layer. The reinforced concrete frame gridding slab prefabricated energy-saving house realizes light weight, full assembly as well as disassembly and shift availability of a house with a prefabricated concrete structure.

Owner:徐曼

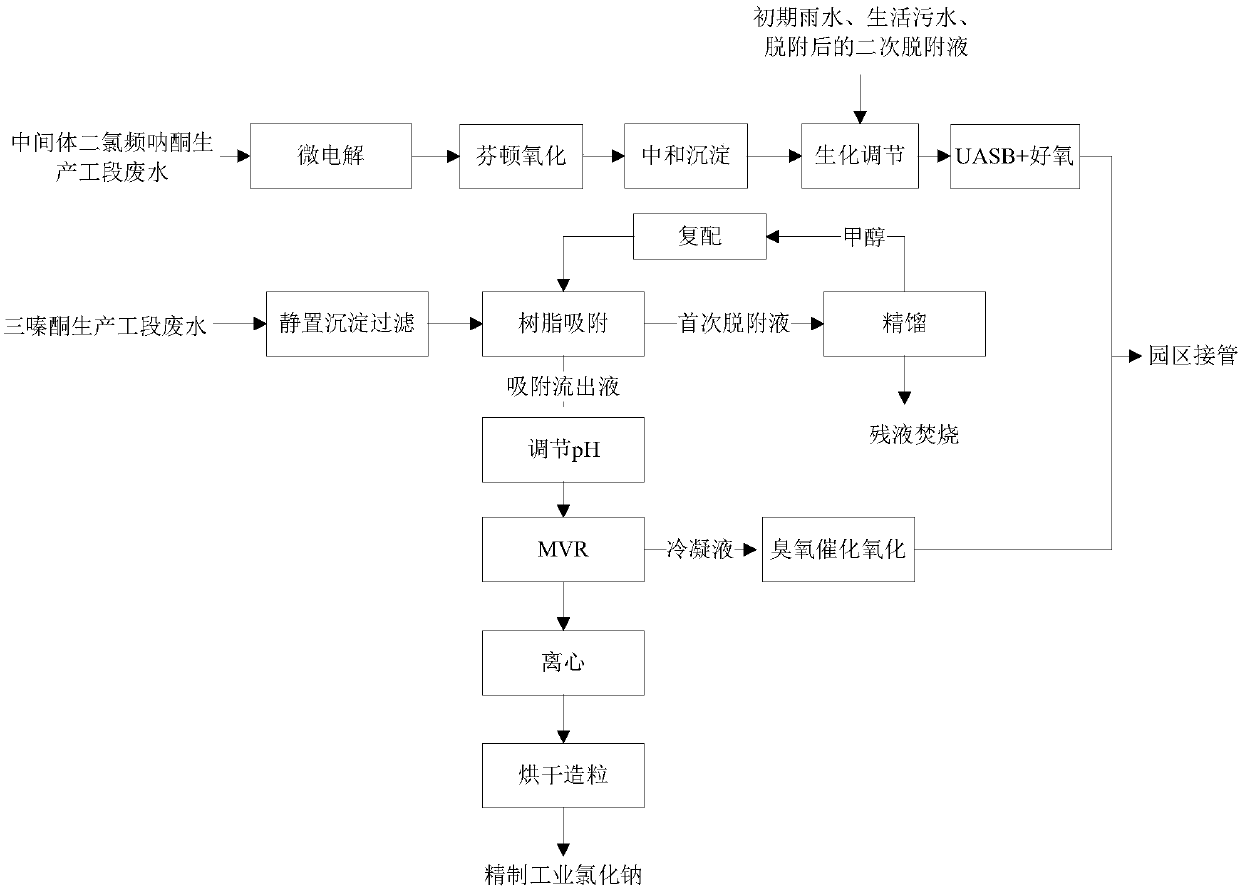

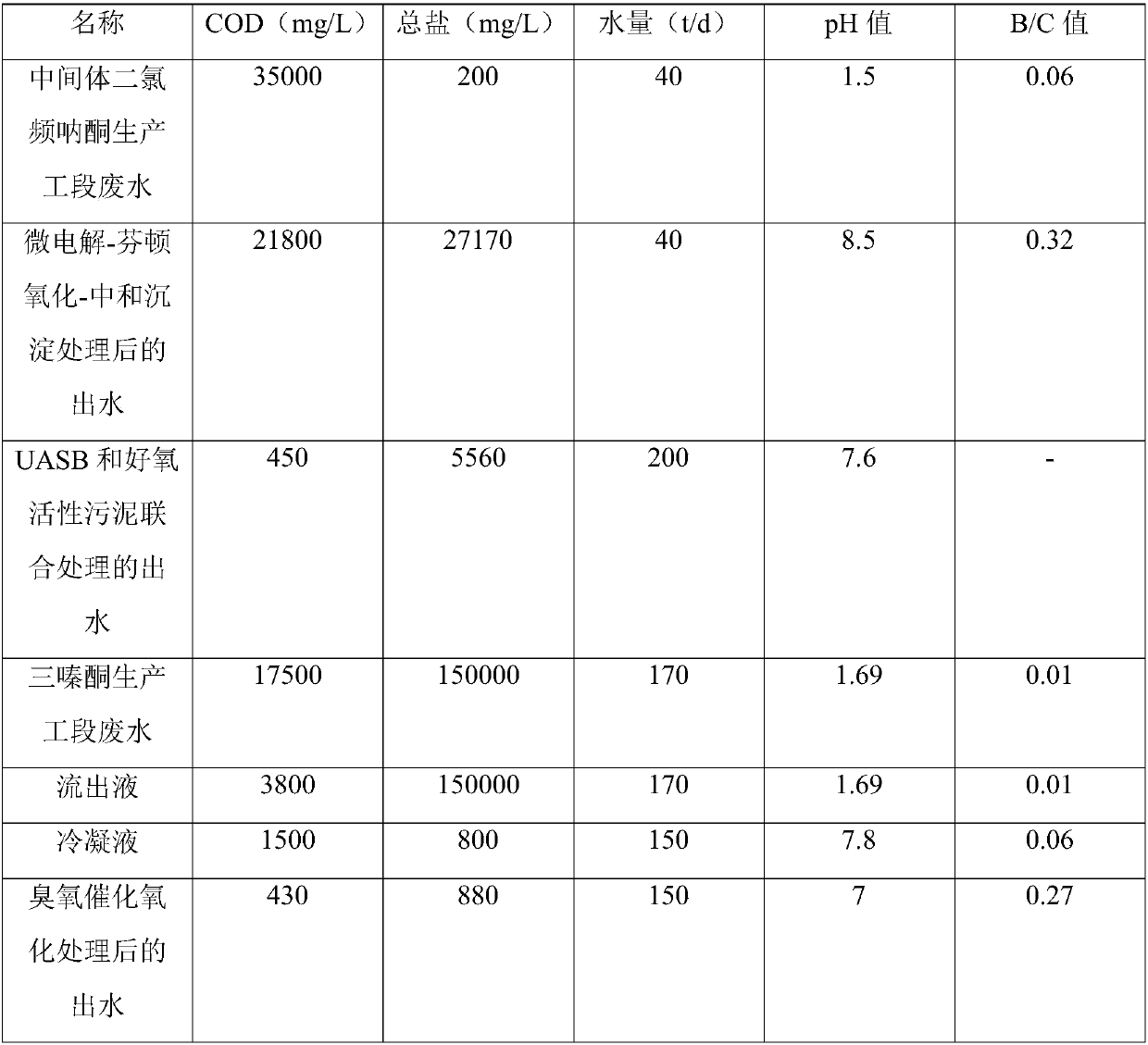

Triazone pesticide wastewater up-to-standard emission synergistic salt recycling treatment method

ActiveCN107935308ARealize recycling of resourcesEasy to handleWater contaminantsTreatment with aerobic and anaerobic processesChemistryPesticide

The invention discloses a triazone pesticide wastewater up-to-standard emission synergistic salt recycling treatment method and belongs to the technical field of pesticide wastewater treatment. The method comprises the following steps: separately collecting and treating wastewater of a triazone pesticide preparation process, performing combined treatment of microelectrolysis-Fenton oxidation-neutralization and sedimentation treatment and UASB (Upflow Anaerobic Sludge Blanket) and aerobiotic activity sludge on wastewater of an intermittent dichloropinacolin production section, performing resinadsorption treatment on wastewater of a triazone production section, recycling sodium chloride, finally combining effluents of the two modes, and accessing to a garden tube network for garden management. By adopting the triazone pesticide wastewater up-to-standard emission synergistic salt recycling treatment method disclosed by the invention, efficient and stable treatment on high-salt, high-COD(Chemical Oxygen Demand) and biorefractory wastewater is achieved, and the purpose of up-to-standard emission of triazone pesticide wastewater is achieved; the method is simple and convenient to operate and has the advantages of high efficiency, low consumption, high stability, convenience of maintenance, and the like, and sodium chloride in the wastewater can be recycled and reused.

Owner:江苏南大华兴环保科技股份公司

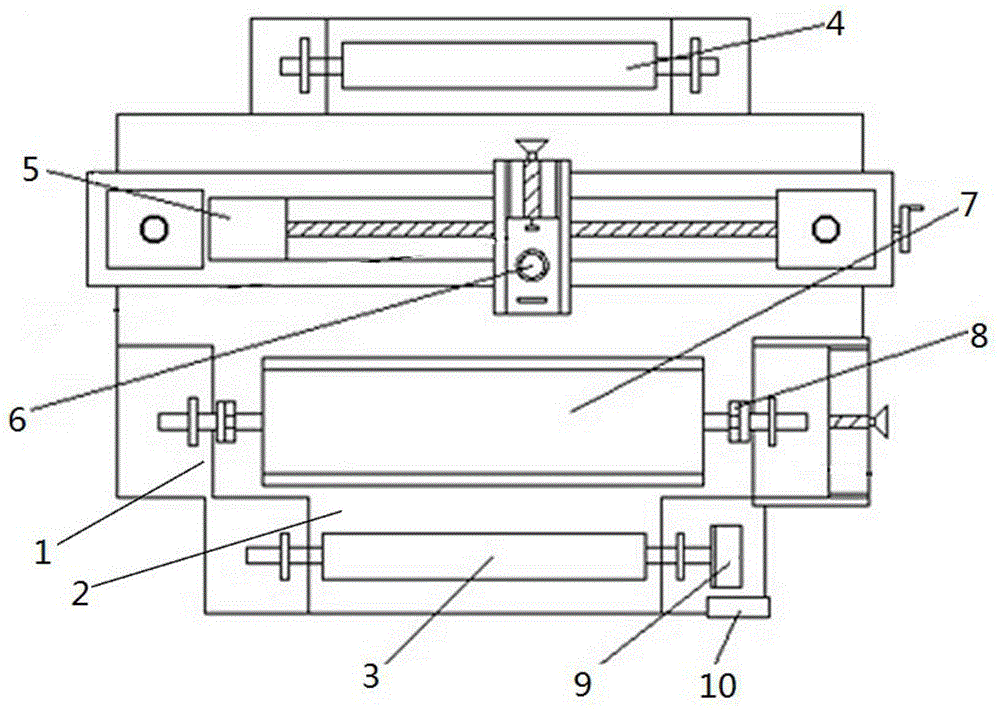

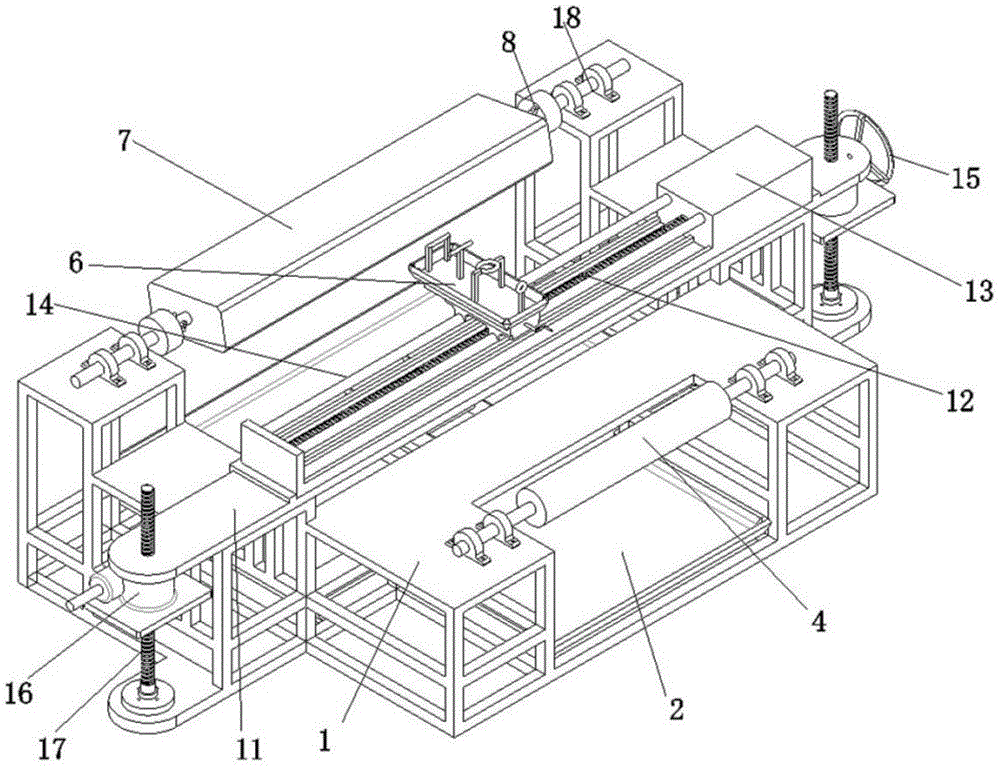

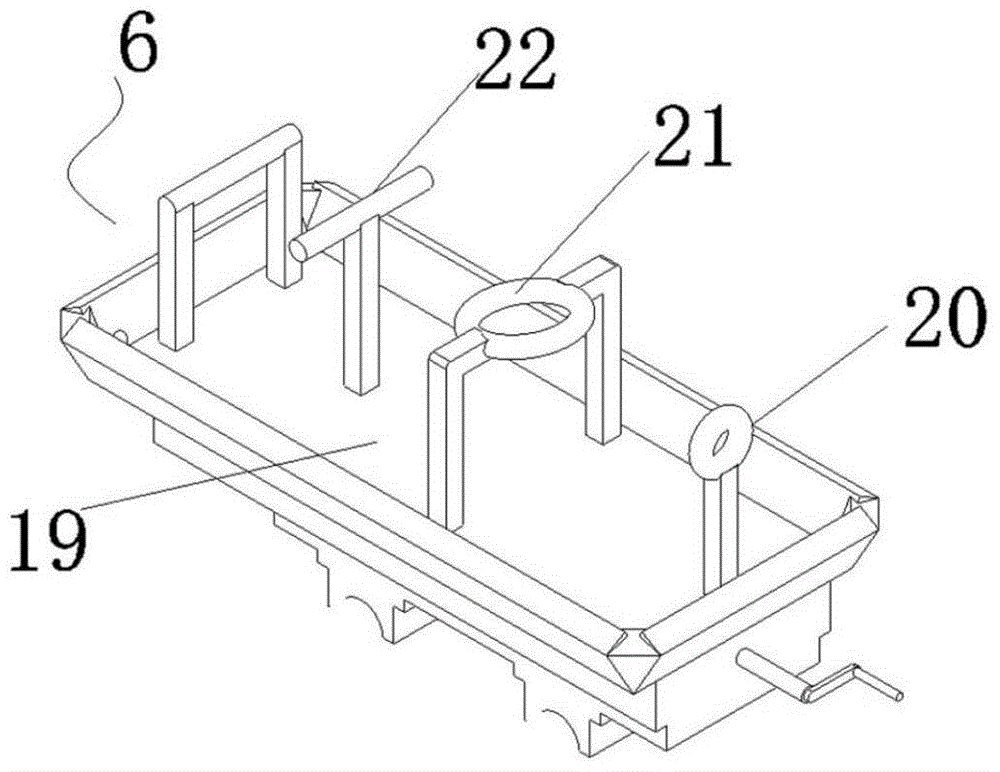

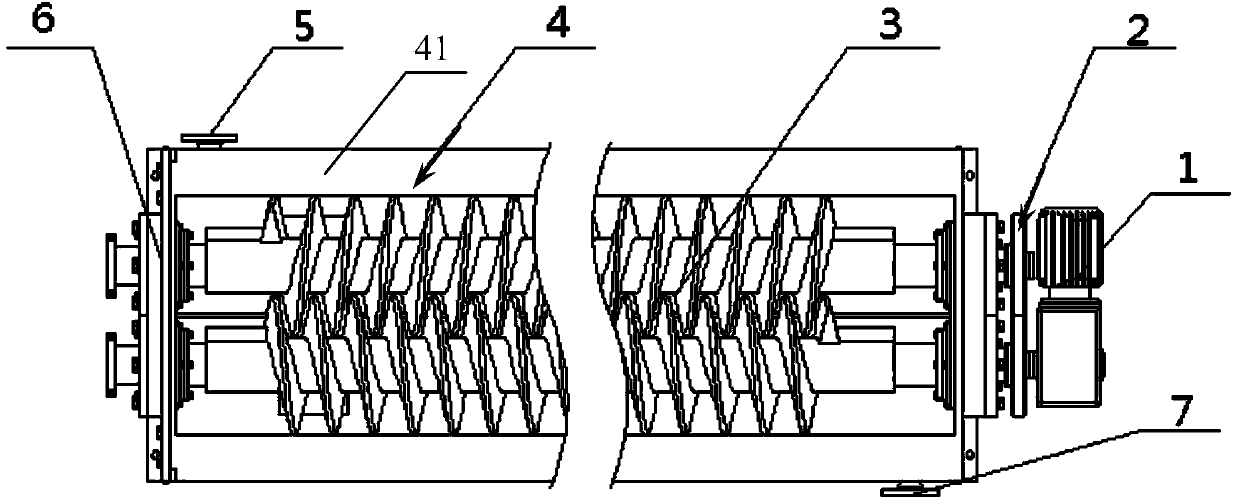

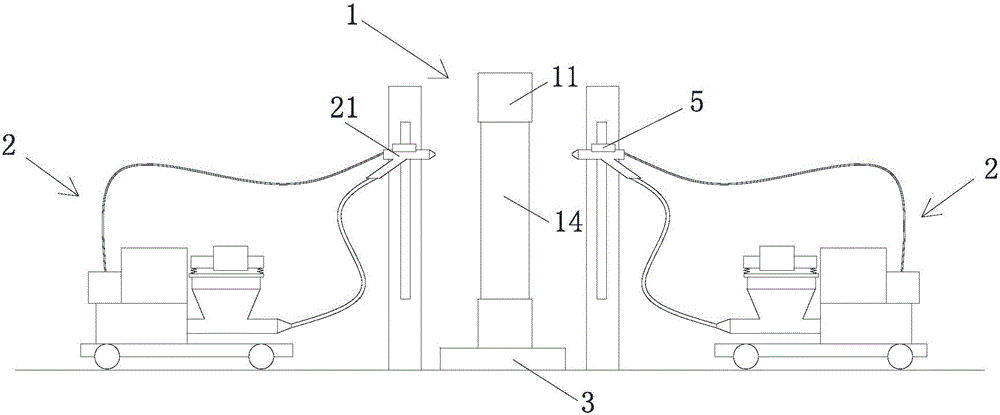

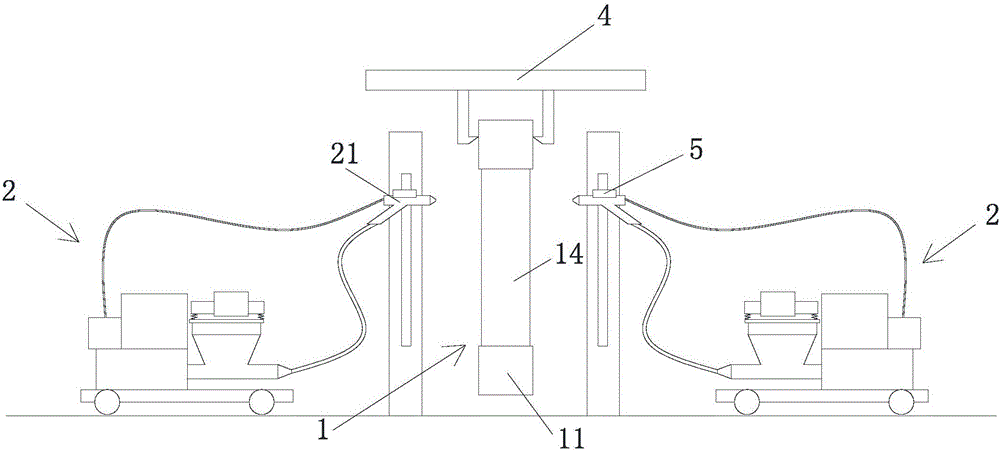

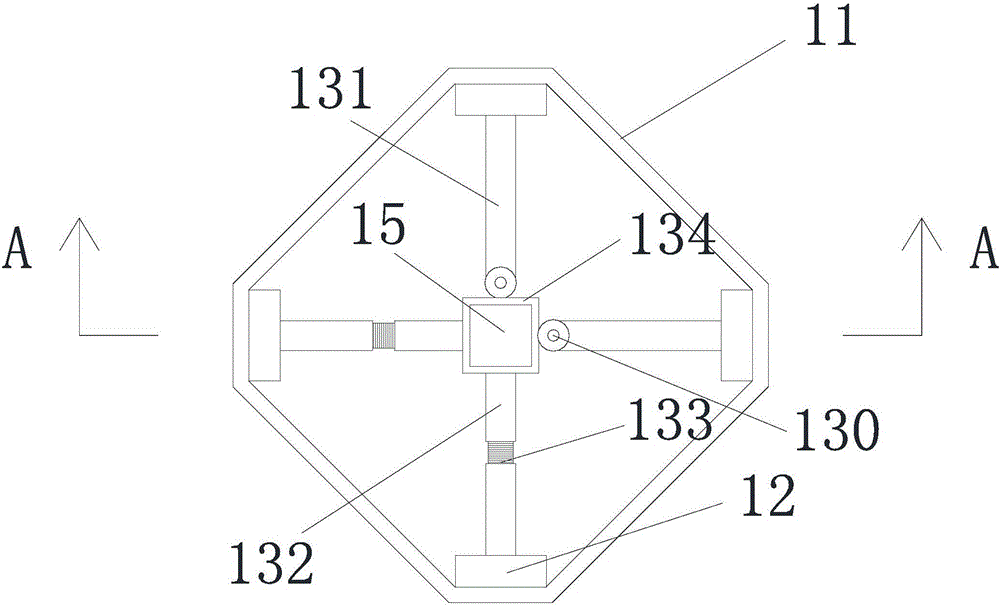

Numerical control winding apparatus and method for square glass fiber reinforced plastic air pipe

The invention discloses a numerical control winding apparatus for a square glass fiber reinforced plastic air pipe. The numerical control winding apparatus comprises a rack, a pay-off roller, a guide device, a yarn arranging device, a square mandrel winding device and a numerical control system. The pay-off roller, the guide device, the yarn arranging device, the square mandrel winding device and the numerical control system are arranged on the rack and sequentially connected through glass fiber yarn. The yarn arranging device comprises a base arranged on the rack. A servo motor, a lead screw and a guide rail which are connected with the servo motor, and a yarn nozzle installed on the guide rail and connected with the lead screw. The numerical control system is connected with the servo motor. The invention further discloses a numerical control winding method for the square glass fiber reinforced plastic air pipe. By the adoption of the numerical control winding apparatus for the square glass fiber reinforced plastic air pipe, the yarn arranging device and the square mandrel winding device are synchronously controlled through the numerical control system to move, the winding angle of the square glass fiber reinforced plastic air pipe is controlled, the glass fiber yarn is provided through the yarn arranging device, the tension of the fiber yarn can be adjusted at any time to control the quality of a product, numerical control is achieved, and the machining quality and efficiency of the square glass fiber reinforced plastic air pipe are improved.

Owner:CHONGQING UNIV

Ferric oxide, graphene oxide and N-F codoped visible light response electrode as well as preparation method and application thereof

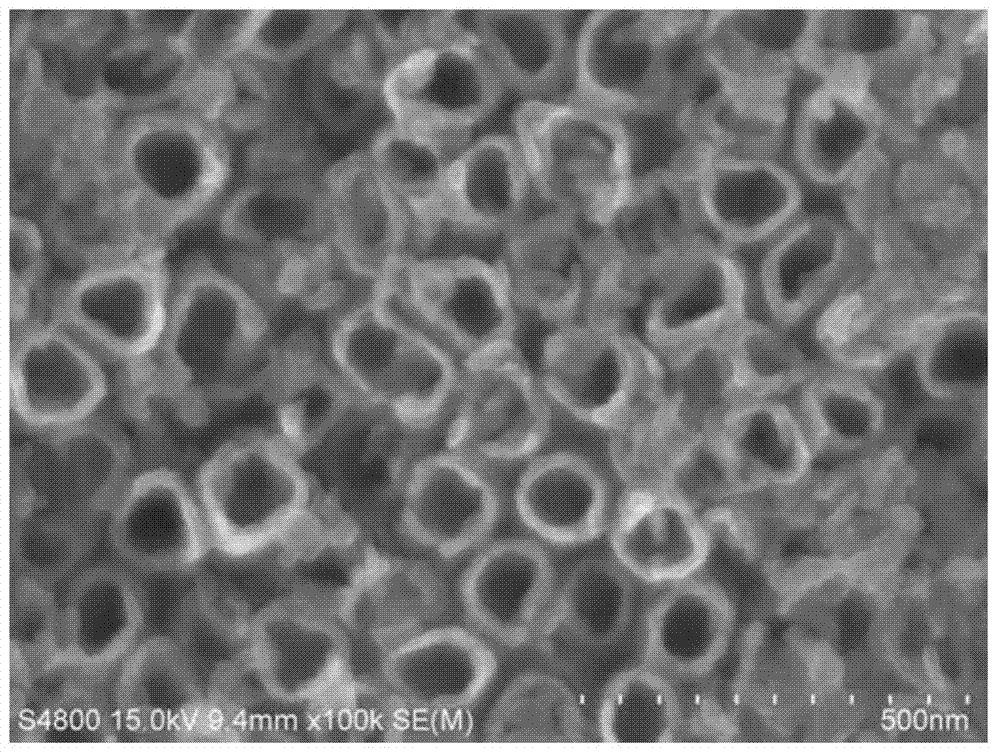

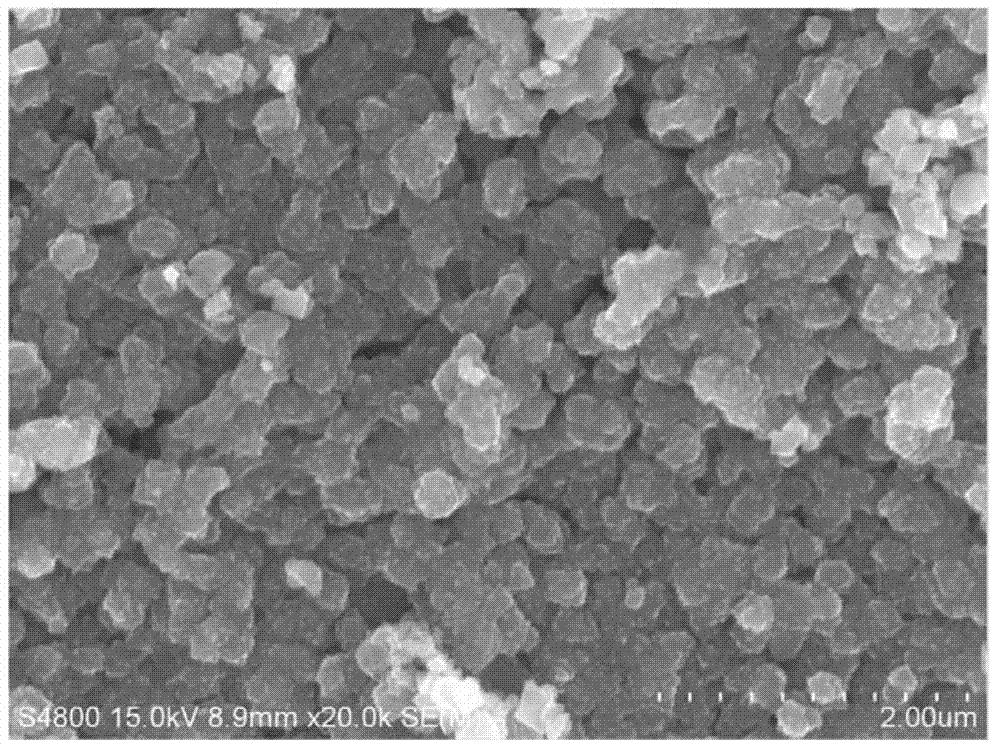

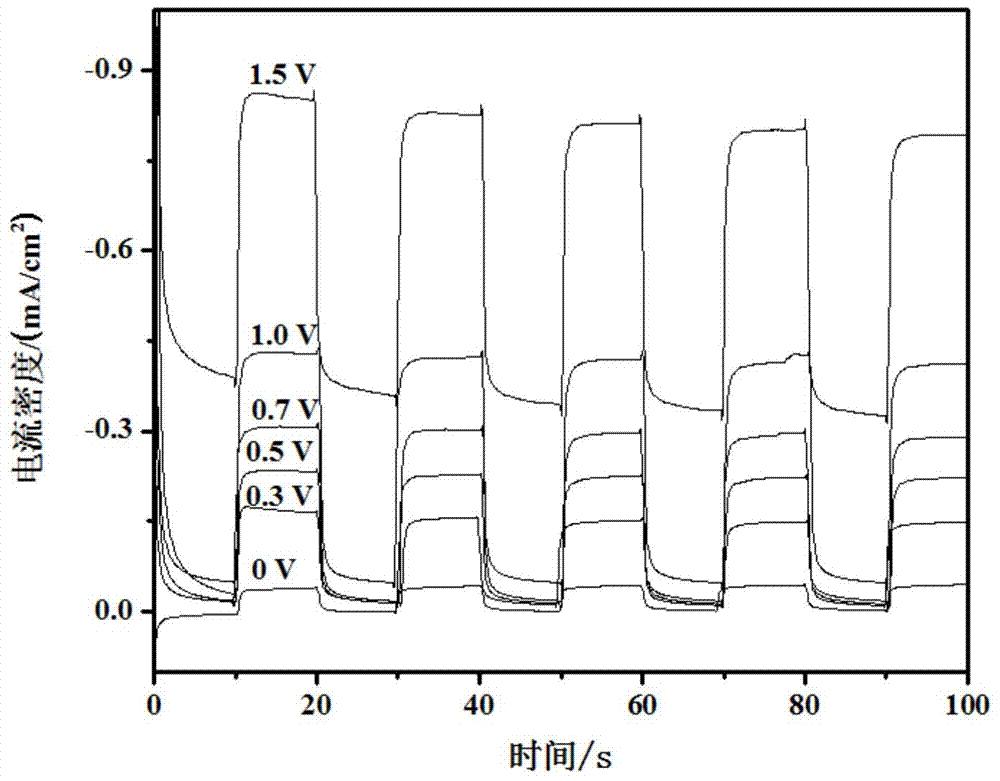

InactiveCN104724788ALow costEasy to prepareWater/sewage treatment by irradiationWater contaminantsAir atmosphereLight response

The invention discloses a ferric oxide, grapheme oxide and N-F codoped visible light response electrode as well as a preparation and application thereof. The method comprises the following steps: (1) mixing a TiO2-NTs electrode with NH4F under an air atmosphere, and calcining the mixture to obtain an N, F-TiO2 electrode; (2) immersing the N, F-TiO2 electrode in Fe(NO3)3, using a graphite electrode as an anode, using a platinum sheet as a cathode, using Na2SO4 as an electrolyte, and dissolving graphene to get a grapheme electrolyte; (3) drying the immersed electrode serving as a cathode, using the graphite electrode as a anode, and electrically depositing the electrodes in grapheme electrolyte; and (4) using the electrode which is processed in the step (3) as an anode, using graphite as a cathode, and using KOH as an electrolyte to perform electric deposition, cleaning and drying the electrically deposited electrode. In the electrode provided by the invention, after ferric oxide and grapheme oxide are codoped, the photo electron and cavity separation effect is good, the photo-electric current is high, the effect for treating chromium-containing wastewater through photo-electro cooperation is good, no secondary pollution exists, and the treated wastewater is reusable.

Owner:ZHEJIANG GONGSHANG UNIVERSITY

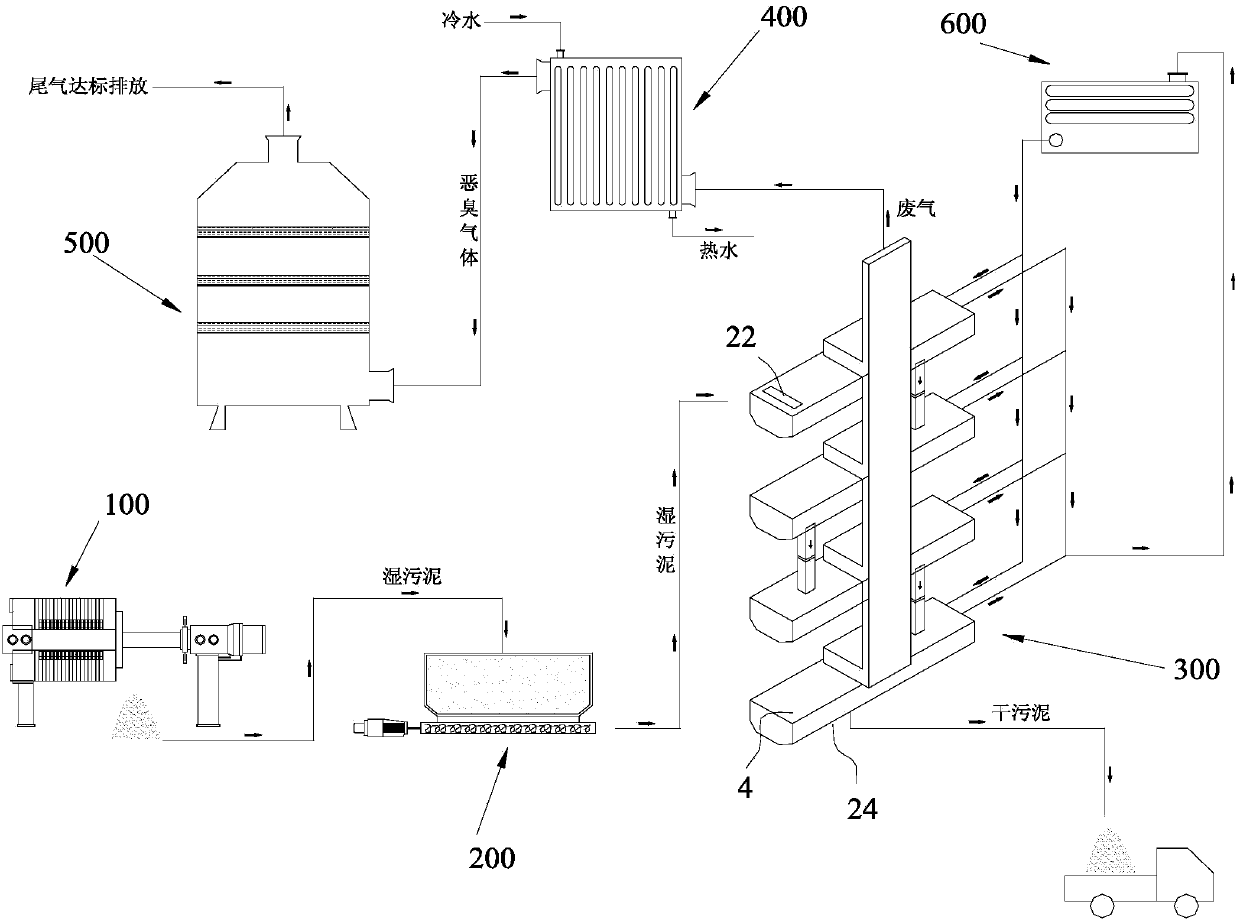

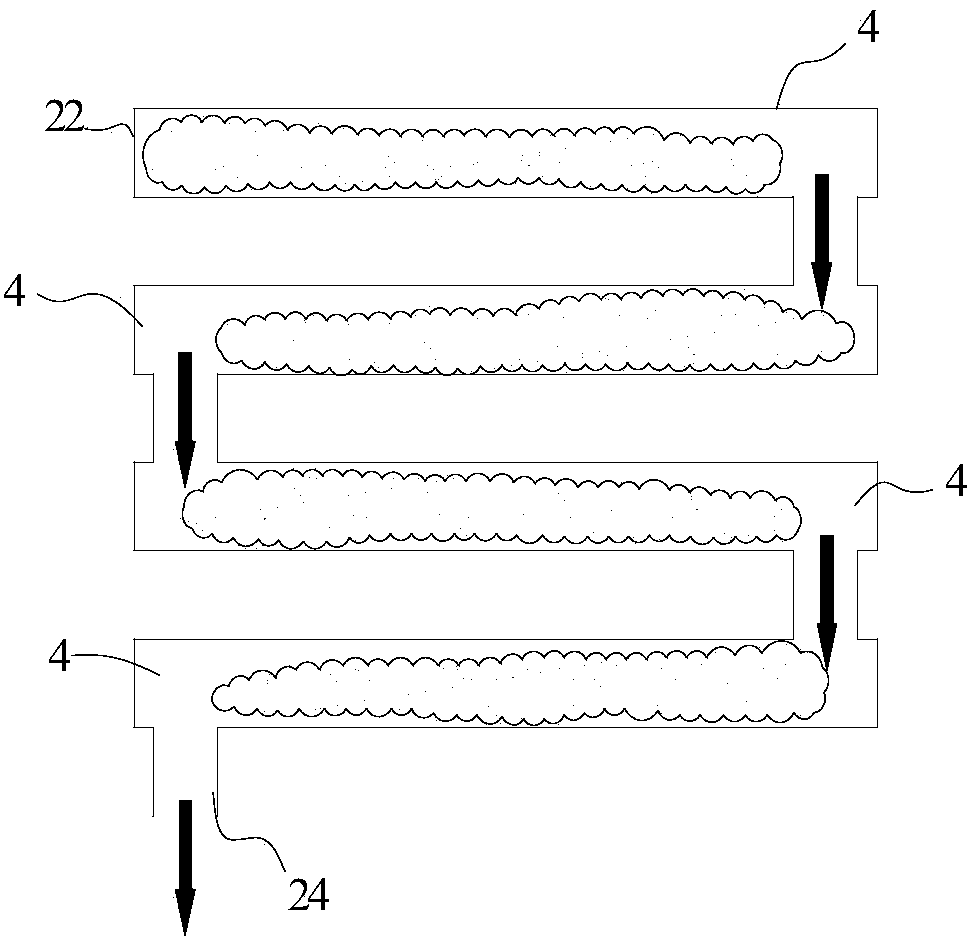

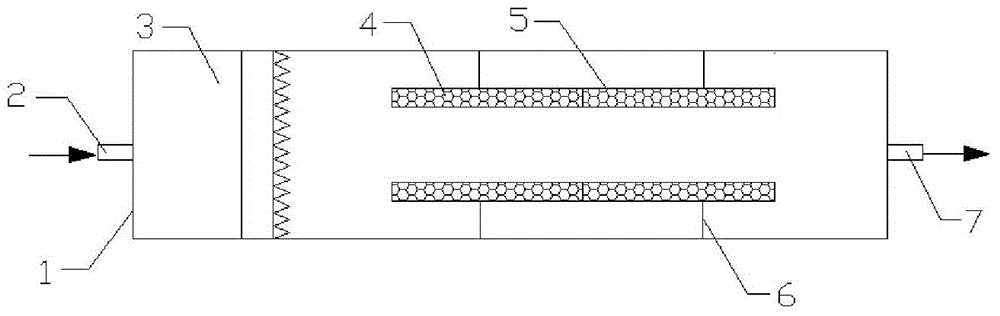

Sludge drying system

ActiveCN103992018AAchieve recyclingAvoid wastingSludge treatment by de-watering/drying/thickeningSludge treatment by thermal conditioningSteam condensationSludge

The invention discloses a sludge drying system, which comprises a filter press, a sludge storage hopper, a sludge dryer, a steam condenser, a deodorization tower and a hot oil furnace, wherein the sludge dryer comprises at least two layers of drying cabinets which are laminated from top to bottom, and drying devices respectively positioned in the drying cabinets, each drying cabinet is provided with a feeding end, a discharging end and an exhaust end, each drying device is provided with an oil inlet for leading hot oil to the drying device, and an oil outlet for outputting the hot oil; the drying cabinets are connected through the feeding ends and the discharging ends, and are connected in series and communicated by taking connecting points as serial points; and the exhaust ends are connected in series and then are connected with a gas inlet of the steam condenser, a gas outlet of the steam condenser is connected with a gas inlet of the deodorization tower, each oil inlet is gathered and connected to an oil outlet end of the hot oil furnace, each oil outlet is gathered and connected to an oil inlet end of the hot oil furnace. The sludge drying system can recycle hot oil, and can also recycle exhausted hot waste gas, and promotes heat utilization rate and sludge drying efficiency.

Owner:GUANGZHOU HISEN ENVIRONMENTAL PROTECTION CO LTD

Oxygen analysis probe solid electrolyte under high-temperature and low-oxygen condition and preparation method

The invention discloses an oxygen analysis probe solid electrolyte under a high-temperature and low-oxygen condition and a preparation method, belonging to the technical field of preparation of an oxygen analysis probe. The oxygen analysis probe solid electrolyte under the high-temperature and low-oxygen condition is a quinary system solid electrolyte (ZrO2)(1-x-y-z-w) (Yb2O3)x(Al2O3)y(MgO)z(CaO)w, wherein x is greater than or equal to 0.04 but less than or equal to 0.055, y is greater than or equal to 0.003 but less than or equal to 0.01, z is greater than or equal to 0.01 but less than or equal to 0.02 and w is greater than or equal to 0.008 but less than or equal to 0.015. According to the preparation method disclosed by the invention, the phase composition proportion in a material is controllably adjusted by converting the compounding proportion of a raw material and adjusting a corresponding thermal treatment system, the sintering energy consumption and cost are greatly lowered in the preparation process, and the obtained solid electrolyte can achieve transient evolution from a room temperature tissue to a high temperature tissue and can be repeatedly used under the condition that the structure of the solid electrolyte is not damaged.

Owner:胡永刚

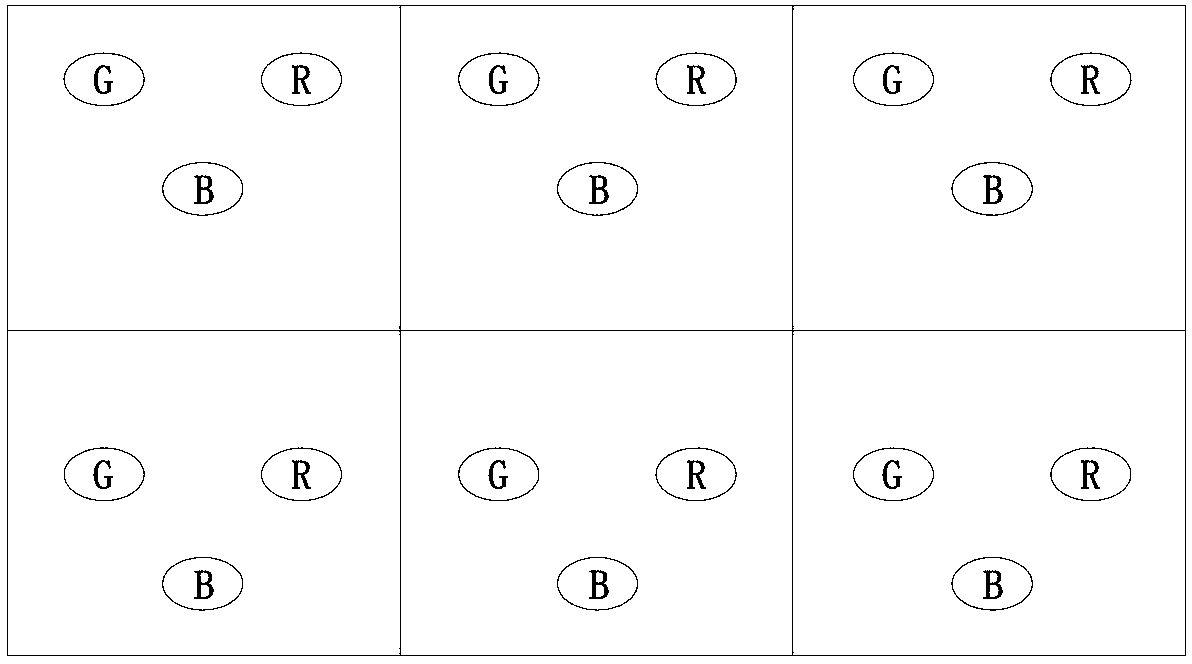

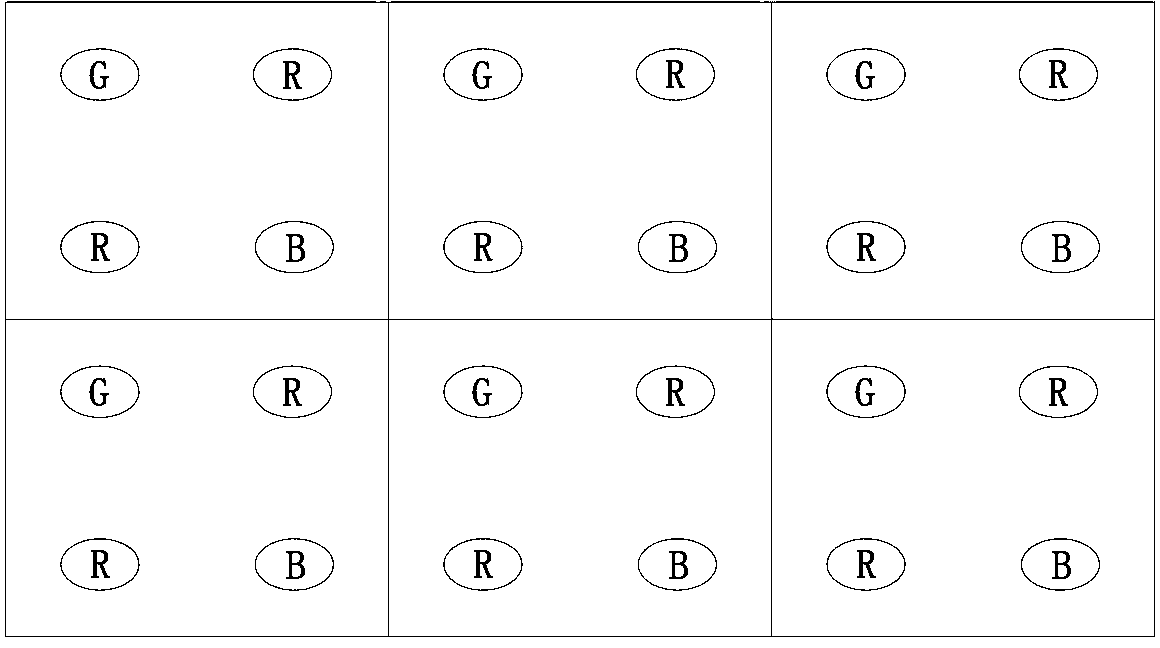

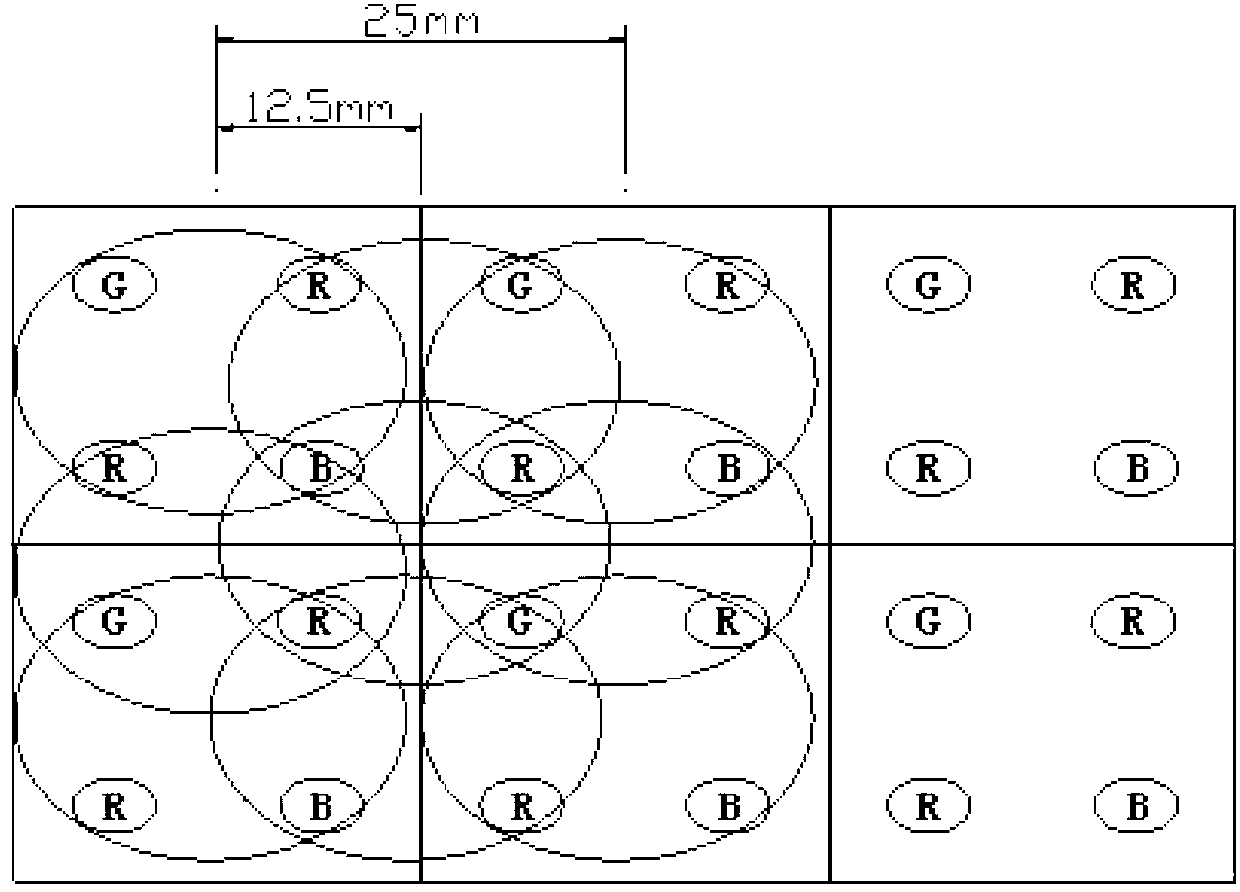

Pixel share display method, device and system for light-emitting diode (LED) display screen

ActiveCN103000092AReduce in quantityImprove overall utilizationStatic indicating devicesIdentification meansPixel densityLED display

The invention discloses a pixel share display method, device and system for a light-emitting diode (LED) display screen. The pixel share display method comprises receiving input images; multipexing LED lamps on the LED display screen, obtaining display pixels with the pixel density equal to N times of the arrangement density of the LED lamps, and enabling N to be a natural number and no smaller than 12; and enabling pixel points of the input images to be output to the display pixels of the LED display screen so as to display the input images. The problem that the utilization rate of the LED lamps is low in the prior art is solved, and the effects of improving utilization efficiency of the LED lamps and reducing the number of the used LED lamps are achieved.

Owner:北京虚拟动点科技有限公司

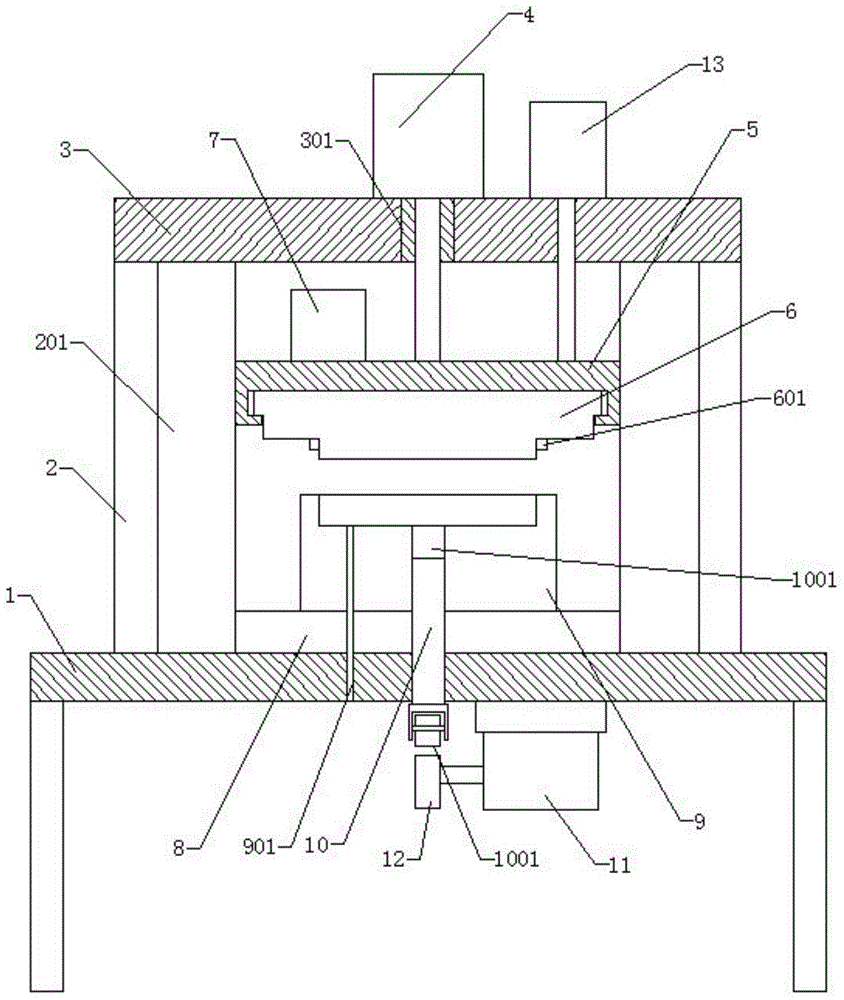

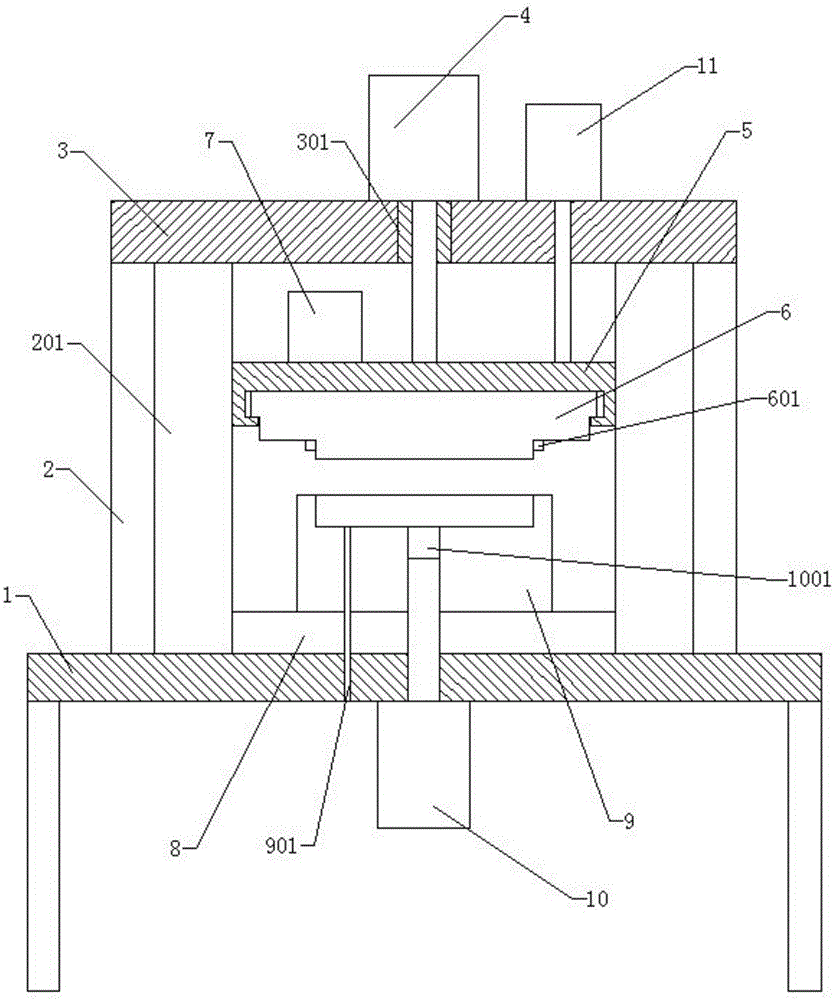

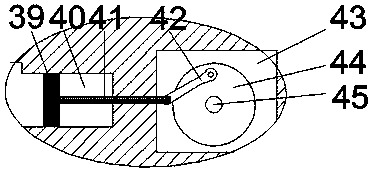

Casting device capable of being continuously used

The invention discloses a casting device capable of being continuously used. The casting device comprises a working table and further comprises a supporting frame, a top plate, a hydraulic cylinder, an upper mold hanging plate, an upper mold, a high-pressure casting box, a lower mold installation plate, a lower mold, an ejector rod, a motor, a cam disk and a high-pressure spraying device. Compared with the prior art, the upper mold and the lower mold are pushed by the hydraulic cylinder to be assembled, melted metal liquid is injected into cavities of the upper mold and the lower mold through the high-pressure casting box, after the metal liquid is solidified, and the upper mold is pulled by the hydraulic cylinder to move upwards; meanwhile, the high-pressure spraying device sprays high-pressure gas, releasing agents are mixed into the gas, the cam disk is driven by the motor to rotate, when the highest point of the cam disk reaches the top end, the ejector rod is pushed to upwards move, a casting is released from the lower mold, the casting can be smoothly related accordingly, a traditional sand mold is replaced, one mold can be repeatedly used, and the casting cost is reduced.

Owner:东至县文元瓷砖加工厂

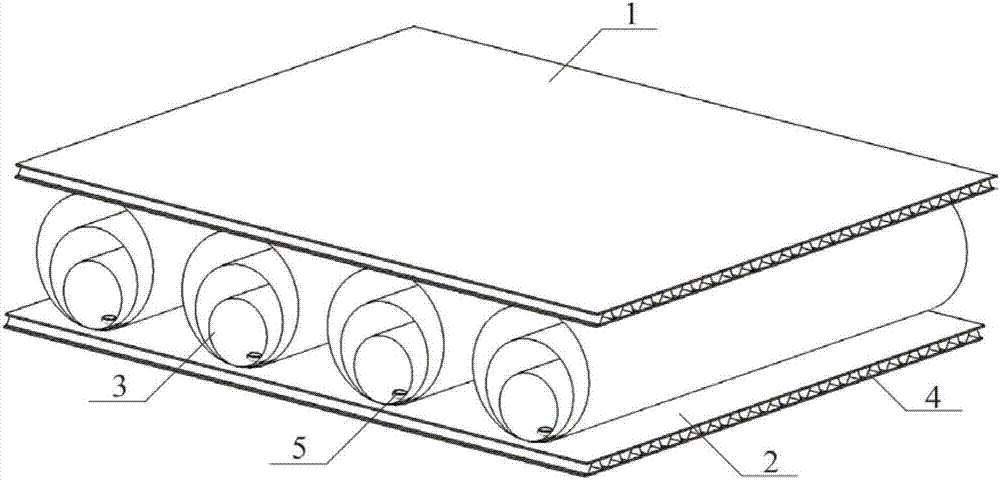

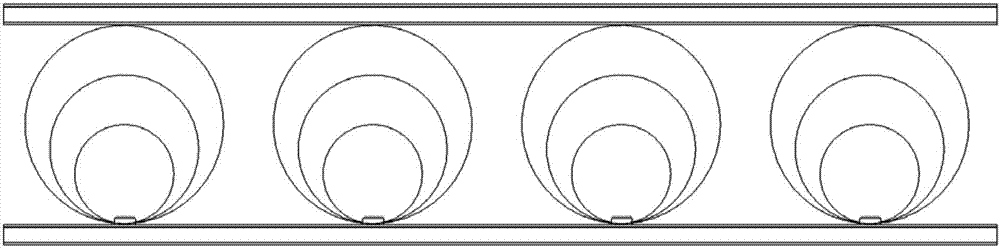

Engaged round pipe shock-resistance multistage energy absorbing device

InactiveCN106892314AImprove protectionIncrease the volume specific energy absorptionElevatorsDevice formEnergy absorption

The invention discloses an engaged round pipe shock-resistance multistage energy absorbing device. The device comprises an upper-layer panel, a middle engaged round pipe combined sandwich layer and a lower-layer panel. The middle engaged round pipe combined sandwich layer is an embedded composite structure formed by longitudinally placing multiple round pipes with different diameters in parallel. The upper-layer panel and the lower-layer panel are trapezoidal corrugated sandwich plates, wherein trapezoidal corrugated layers are placed in the transverse directions of structures to improve the transverse energy absorbing characteristics of the structures. A layered multistage buffer energy absorbing device formed through the embedded round pipe section design can reduce initial peak value loads borne by the structures through the design of round pipes with different sizes, improves the volume ratio energy absorption of the structures, saves the space to the greatest extent, and meanwhile, can select corresponding energy absorbing environments according to impact loads with different magnitudes.

Owner:BEIHANG UNIV

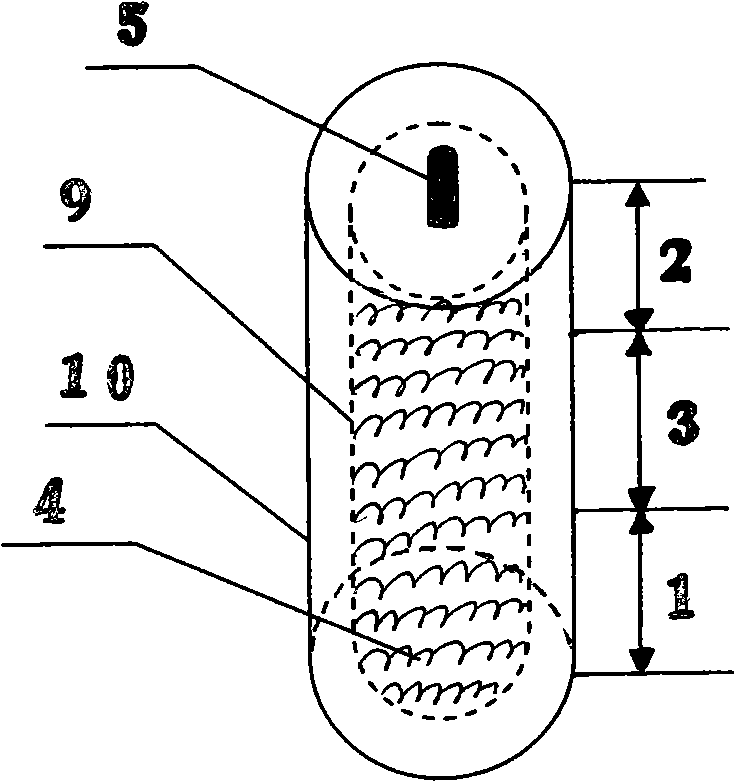

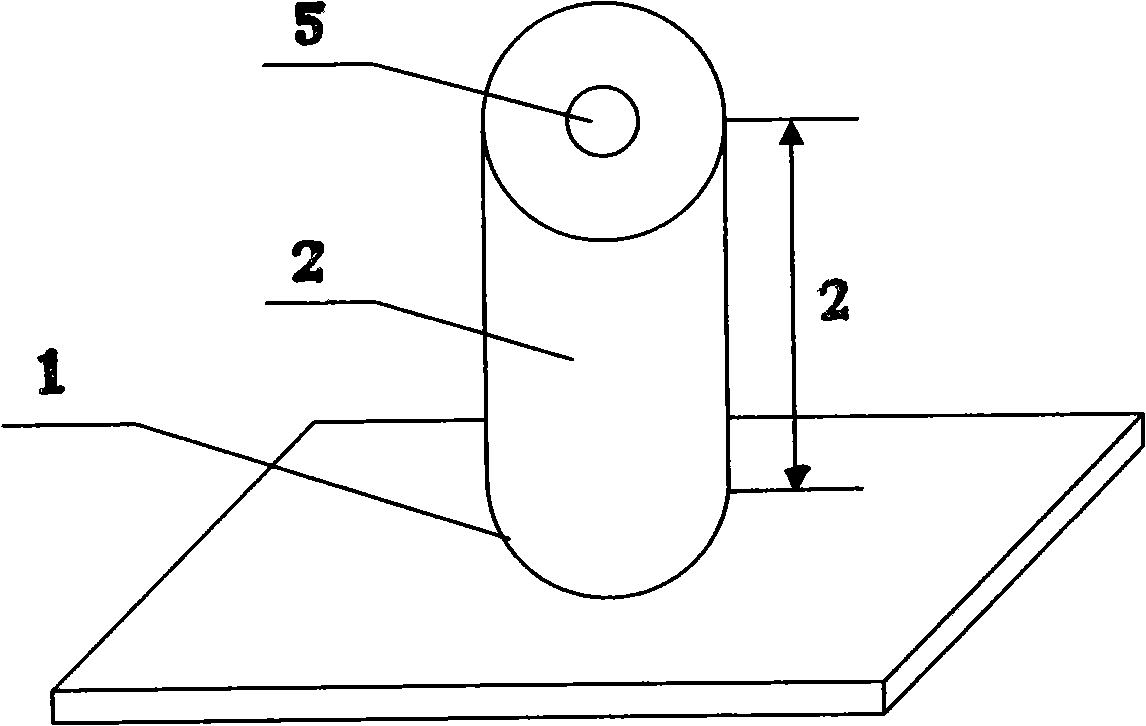

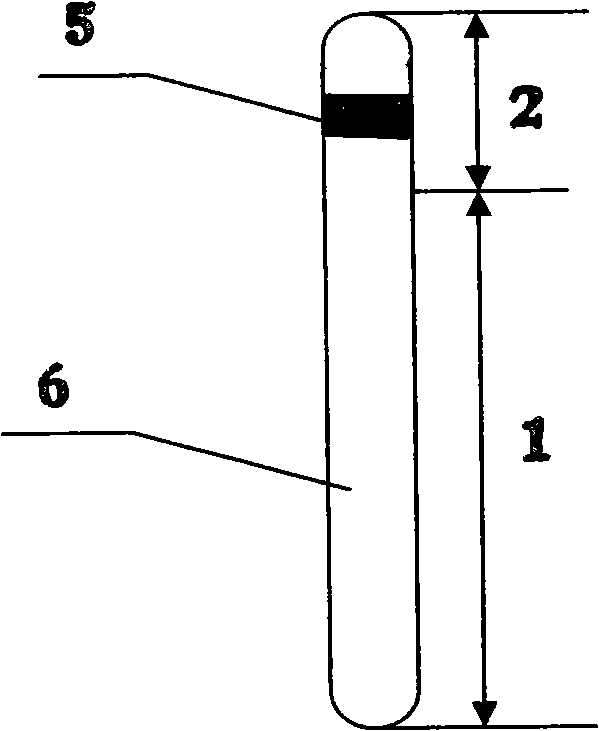

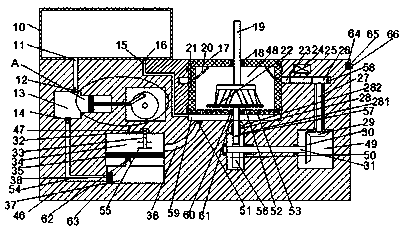

Spraying type pipeline manufacturing equipment

InactiveCN105881701AFast formingImprove molding qualityMouldsCoatingsEngineeringMechanical engineering

The invention relates to spraying type pipeline manufacturing equipment. The spraying type pipeline manufacturing equipment comprises a mold core assembly and a spraying assembly, wherein the mold core assembly is vertically arranged, and the peripheral size of the mold core assembly is variable; and the spraying assembly is used for spraying materials on continuous circumferential surface of the mold core assembly so as to form a pipe-shaped structure. The invention aims to provide the spraying type pipeline manufacturing equipment. The spraying type pipeline manufacturing equipment has the advantages that the peripheral size of the mold core assembly is variable, the vertical side surface, formed by a coating layer, of a pipe-shaped mold plate is subjected to material spraying through the spraying assembly, forming of a pipe body can be rapidly completed, and the forming quality is high; and moreover, after the pipe body is solidified, the mold core assembly can be taken out by being contracted, and repeated utilization is achieved.

Owner:福建首聪世豪实业有限公司

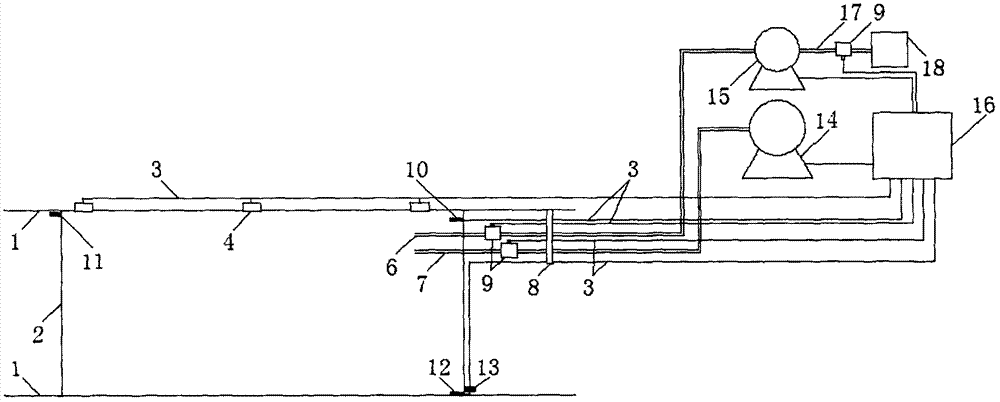

Anti-impaction air bag type sealing method capable of achieving remote automatic control for coal mine tunnel in disastrous environment

InactiveCN107269311AReduce oxygen concentrationRealize multiple usePump controlPositive-displacement liquid enginesAutomatic controlHigh intensity

The invention discloses an anti-impaction air bag type sealing method capable of achieving remote automatic control for a coal mine tunnel in a disastrous environment. A device used by the method comprises an air bag, fixers and a PLC which can be controlled remotely. The air bag adopts a polyimide film composite high-strength glass fiber waving cloth as a sealing material, and the length, the width and the height of the cloth are 10m, 3m, and 2.5m correspondingly; the fixers are connected with the upper end of the air big through fixing bands, and connected with electric wires, and the air bag is connected with an air pump through an air inlet pipe, and connected with a water pump through a water inlet pipe; the air pump is connected with a nitrogen source through an air suction pipe, and electromagnetic valves are mounted on the air inlet pipe, the water inlet pipe and the air suction pipe correspondingly; and a gas pressure sensor is mounted on one side of the air bag, a safety valve is mounted on the other side of the air bag, and a water level sensor and a water drainage valve are mounted at the lower end of the air bag. The anti-impaction air bag type sealing method can achieve remote automatic control in the overall process of achieving rapid sealing of the coal mine tunnel, workers do not need to conduct operating on site, and the anti-impaction air bag type sealing method has the advantages of being short in sealing forming time, high in efficiency, low in air leakage ratio and the like.

Owner:XIAN UNIV OF SCI & TECH

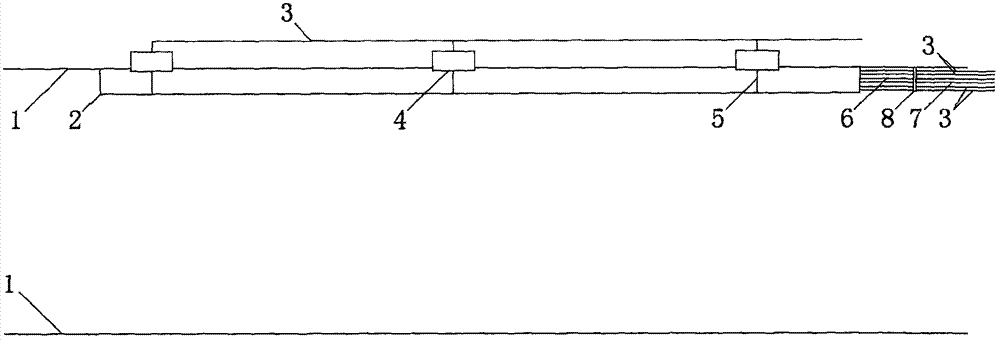

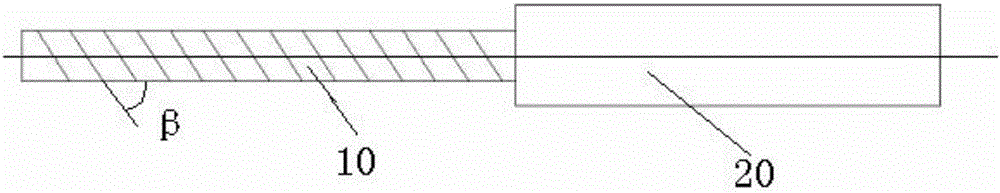

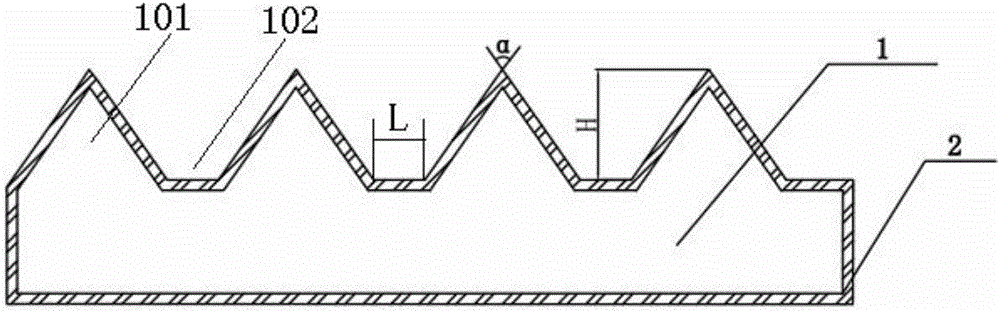

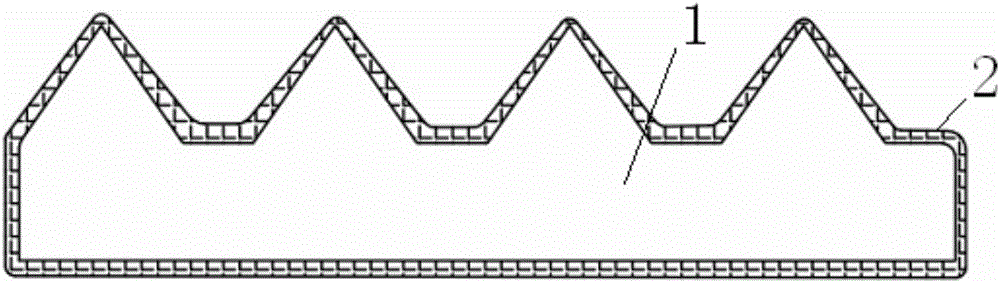

Segmented slightly light-concentrating welding belt and preparation thereof

InactiveCN106449836ARealize multiple useIncrease output powerFinal product manufacturePhotovoltaic energy generationOhmic contactEngineering

The invention discloses a segmented slightly light-concentrated welding belt and preparation thereof. The segmented slightly light-concentrating welding belt includes a welding belt body. The body is provided with a tooth-profile section and a flat section which are sequentially connected and alternatively disposed along the length of the body. The upper surface of the tooth-profile section is provided with a plurality of convex teeth. The tooth-profile section and its adjacent flat section are respectively welded on two adjacent cells, wherein the tooth-profile section is welded on the illuminated faces of one cell while the flat section is welded on the dark face of the other cell. The invention has the advantages of concentrated light, high output power of modules, good ohmic contact and outstanding welding quality as the flat section is welded on the back of the cell and thereby forming a flat contact patch between the flat section and a back electrode.

Owner:TRINA SOLAR CO LTD

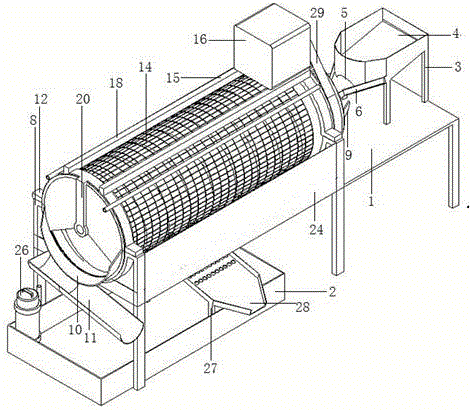

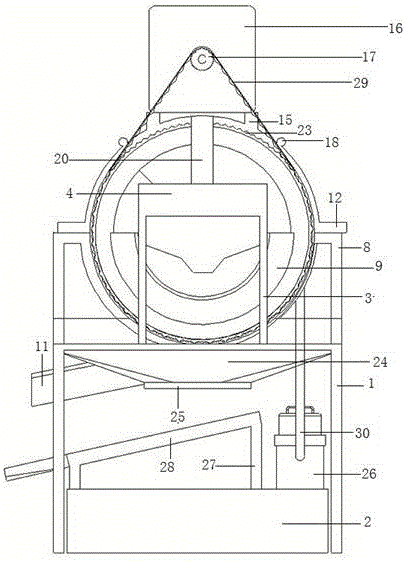

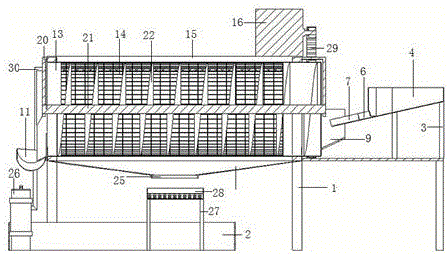

Eggshell peeling machine

The invention relates to the technical field of eggshell peeling equipment, in particular to an eggshell peeling machine. The design that a large number of eggs can be stored in a feed box is utilized, the inner part of the feed box is a bevel, and an arc-shaped egg outlet is formed in the front end of the arc-shaped egg outlet, so that the egg outlet speed can be retarded; only two eggs pass through an egg outlet passage in the front end of an egg collecting tank once, so that a great number of eggs are prevented from entering a net box at the same time; the net box is mounted in a net box bracket and a collar clamp through a copper sleeve, so that the net box can rotate; a driving synchronous pulley at a motor shaft end drives a driven synchronous pulley to rotate through a synchronous belt, so that automatic rotation of the net box is realized; eggshells are beat to be broken under the rotation of the net box, and are separated from egg bodies due to the rotation of the net box; spiral plates are welded to a spiral shaft on a spiral shaft support plate, so that eggs can be pushed towards the egg outlet from an egg inlet; an egg outlet tank is welded to the egg outlet, and the eggs from the net box can slide out of the egg outlet tank; and water spray pipes are connected with a water pump through a water pipe, so that water can be sprayed into the net box through water spray holes for rinsing the eggshells, and residues are avoided.

Owner:龙彦旭

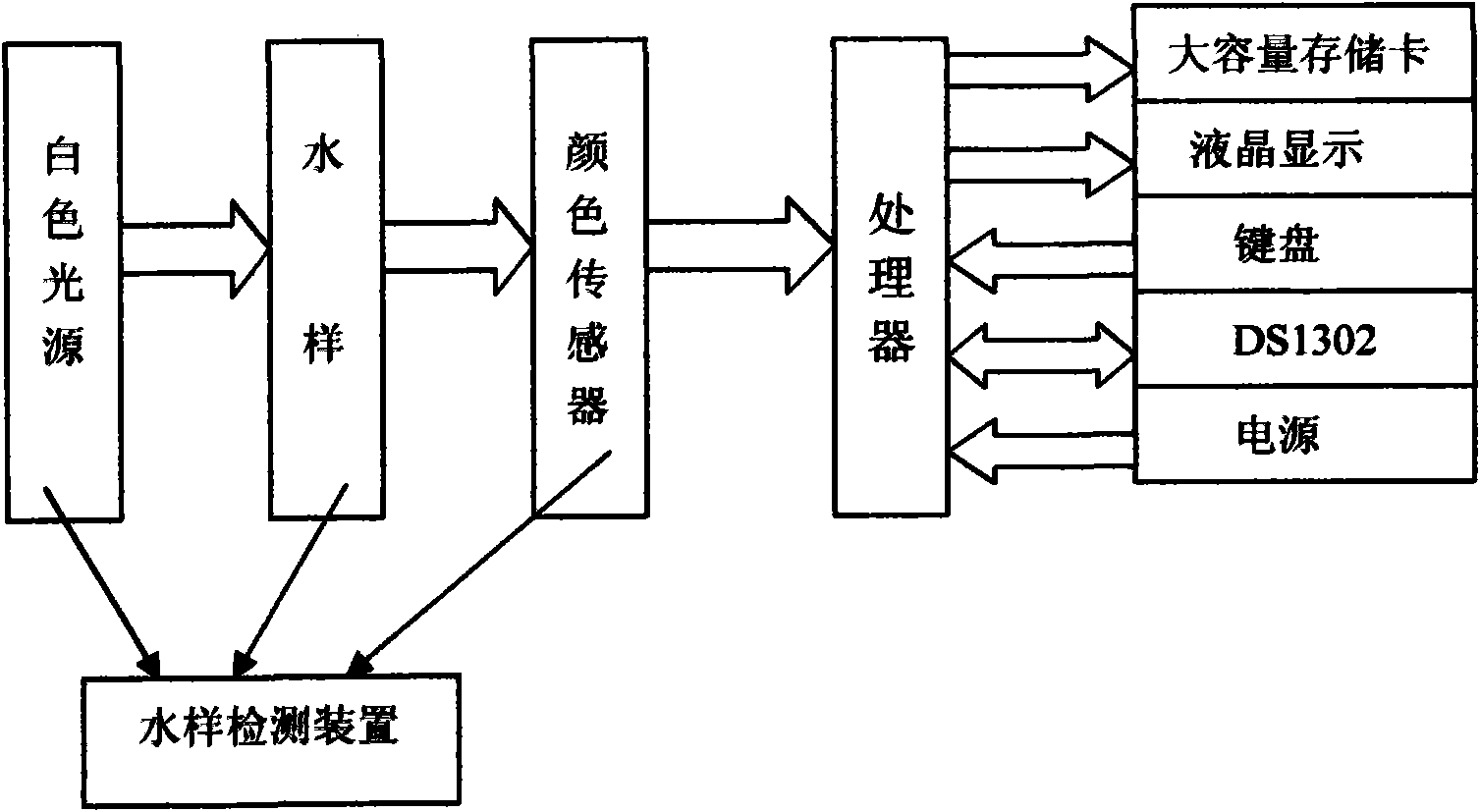

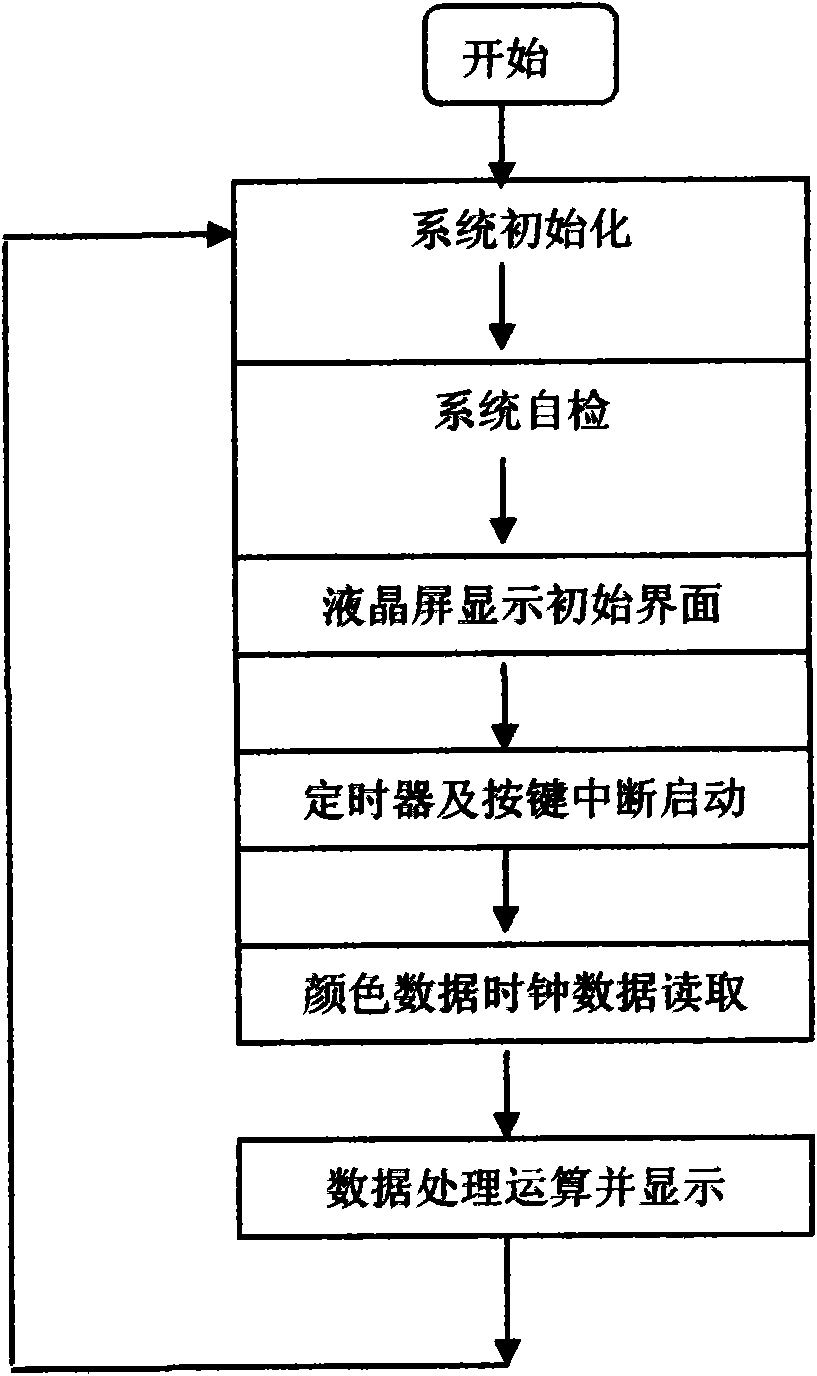

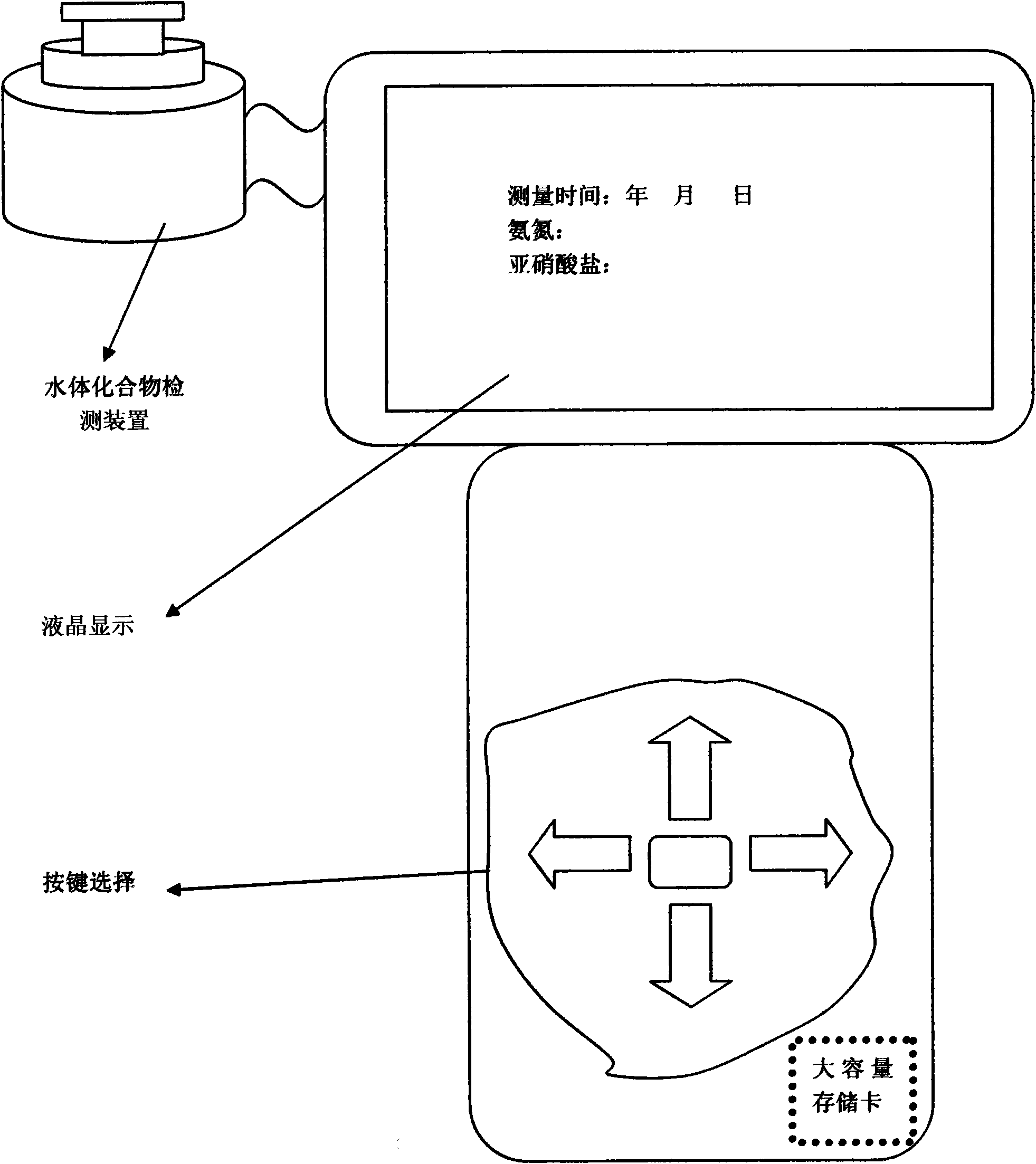

Multispectral water quality analyzer

InactiveCN102435555AImplement storageHigh measurement accuracyColor/spectral properties measurementsData acquisitionHand held

The invention relates to a multispectral water quality analyzer. The analyzer is characterized in that: the analyzer comprises a water quality detection part, a water quality analysis part and a power supply module; the water quality detection part comprises a camera obscura, and a light source generation device, a container for containing a liquid to be detected and a color sensor which are positioned in the camera obscura, and white light emitted by the light source generation device irradiates the liquid to be detected and reflects the color of the liquid to the color sensor; and the water quality analysis part comprises a central processor module, and a liquid crystal display module, a clock module, a hand-held button module and a storage module which are connected with the central processor module, the central processor module which is connected with the color sensor receives the chroma value obtained through the detection of the color sensor, compares the chroma value with data in an experiment database and displays the result on a liquid crystal screen. The light source generation device projects the color of the liquid to the color sensor through irradiating the liquid by the white light, and the water quality analysis part converts the data into water quality parameters through the datum acquisition and the datum processing and determines the compound content in a reagent by detecting the chroma value obtained through the reflection, so the analyzer of the invention has the advantages of small occupied space of equipment, less apparatus, good determination interference resistance, low cost, and high metering precision.

Owner:QINGDAO AGRI UNIV

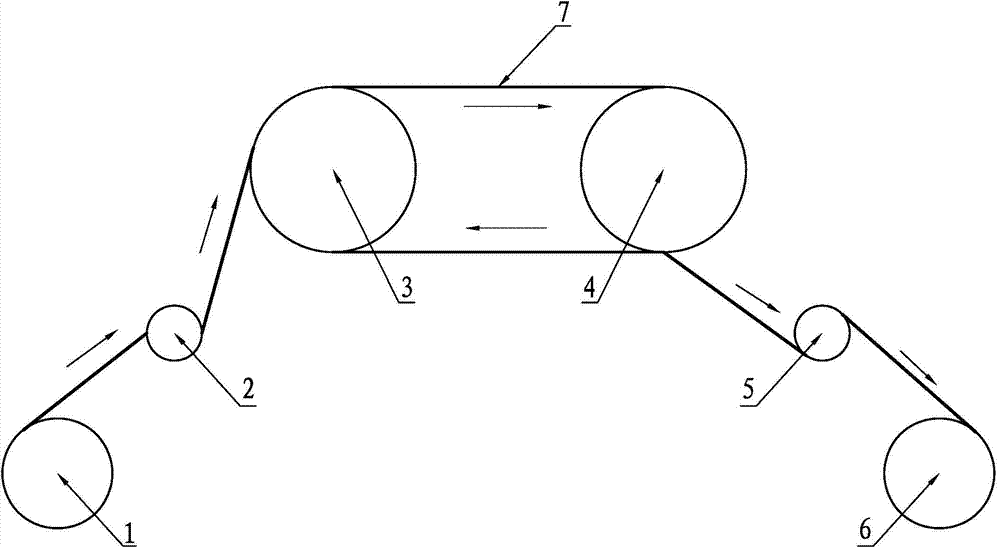

Polycrystalline silicon chip cutting method capable of saving steel wire

InactiveCN103692563AGuarantee quality and efficiencyGuaranteed processing efficiencyFine working devicesControl systemIngot

The invention discloses a polycrystalline silicon chip cutting method capable of saving a steel wire. A cutting steel wire is coiled in from a wire inlet guide wheel and coiled out from a wire outlet guide wheel through a front pulley after being released from a wire releasing wheel and is coiled on a wire retracting wheel through a rear pulley, an electric appliance control system comprises the wire releasing wheel, the wire inlet guide wheel, the wire outlet guide wheel and the wire retracting wheel, a steel wire transmission mechanism drives the cutting steel wire to do high-speed forward and reverse interval alternating linear motion so as to cut a polycrystalline silicon ingot, and the rotating directions of the wire releasing wheel, the wire inlet guide wheel, the wire outlet guide wheel and the wire retracting wheel can be alternately controlled by the electric appliance control system during a cutting process. The steel wire transmission mechanism is driven to rotate in 0.55-0.65 unit time according to an anticlockwise direction by the electric appliance control system after the steel wire transmission mechanism rotates in a unit time according to a clockwise direction, the rotation can be recurrently carried out in such a way, not only can the using amount of the cutting steel wire be reduced, but also the cutting action of silicon carbide cutting particles in mortar can be fully utilized, thus the using amount of the mortar is saved, and the processing cost of a polycrystalline silicon chip is reduced.

Owner:JIANGSU ZHAOJING PHOTOELECTRIC TECH DEV

Greenhouse gas discharging-reducing and commercialized utilization method

InactiveCN101285661AAchieve emission reductionRealize comprehensive utilizationIndirect heat exchangersEnvironmental indexGreenhouse

The invention provides a method for reducing the emission of greenhouse gas and utilizing the greenhouse gas commercially. The greenhouse gas is taken as a working medium and is sealed inside a cavity body to realize the reduction of emission of the greenhouse gas. The emission reduction index is directly sold commercially, thereby realizing the first kind of commercial application; a heat transfer element is sold commercially, thereby realizing the second kind of commercial application; the heat transfer element is applied to the energy-saving / novel energy, particularly to the emission reduction, the emission reduction index realizes the third kind of commercial application. The method not only is an environmental index by investment but also realizes the effective commercial application of the greenhouse gas, and plays an important role in the process of slowing down or removing the global greenhouse effect.

Owner:李建民

Continuous casting device

The invention discloses a continuous casting device. The continuous casting device comprises a worktable which comprises a supporting frame, a top plate, a hydraulic cylinder, an upper mould hanging plate, an upper mould, a high-pressure pouring box, a lower mould installation plate, a lower mould, an ejection hydraulic cylinder and a high-pressure sprayer. Compared with the prior art, the upper mould and the lower mould are pushed through the hydraulic cylinder to be closed, molten metal is poured into a cavity of the upper mould and the lower mould through the high-pressure pouring box, the hydraulic cylinder pulls the upper mould to move upwards after the molten metal is condensed, the high-pressure sprayer sprays high-pressure gas at the same time, the gas is doped with release agents, and the ejection hydraulic cylinder upwards ejects a casting piece out. In this way, the casting piece leaves the mould successfully, a traditional sand mould is replaced, the set of moulds can be used many times, and the casting cost is reduced.

Owner:池州市华兴天骑精密机械铸造有限公司

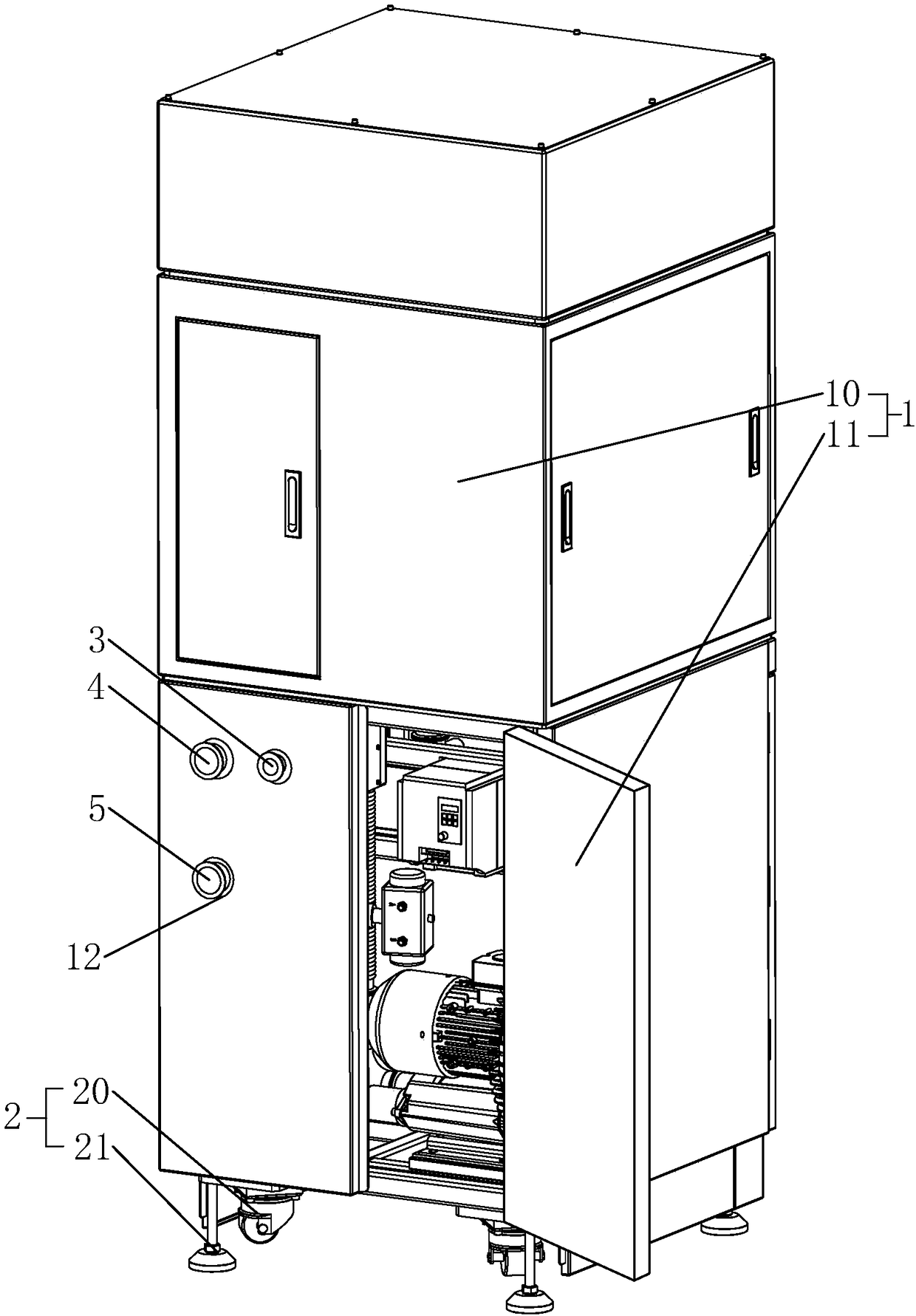

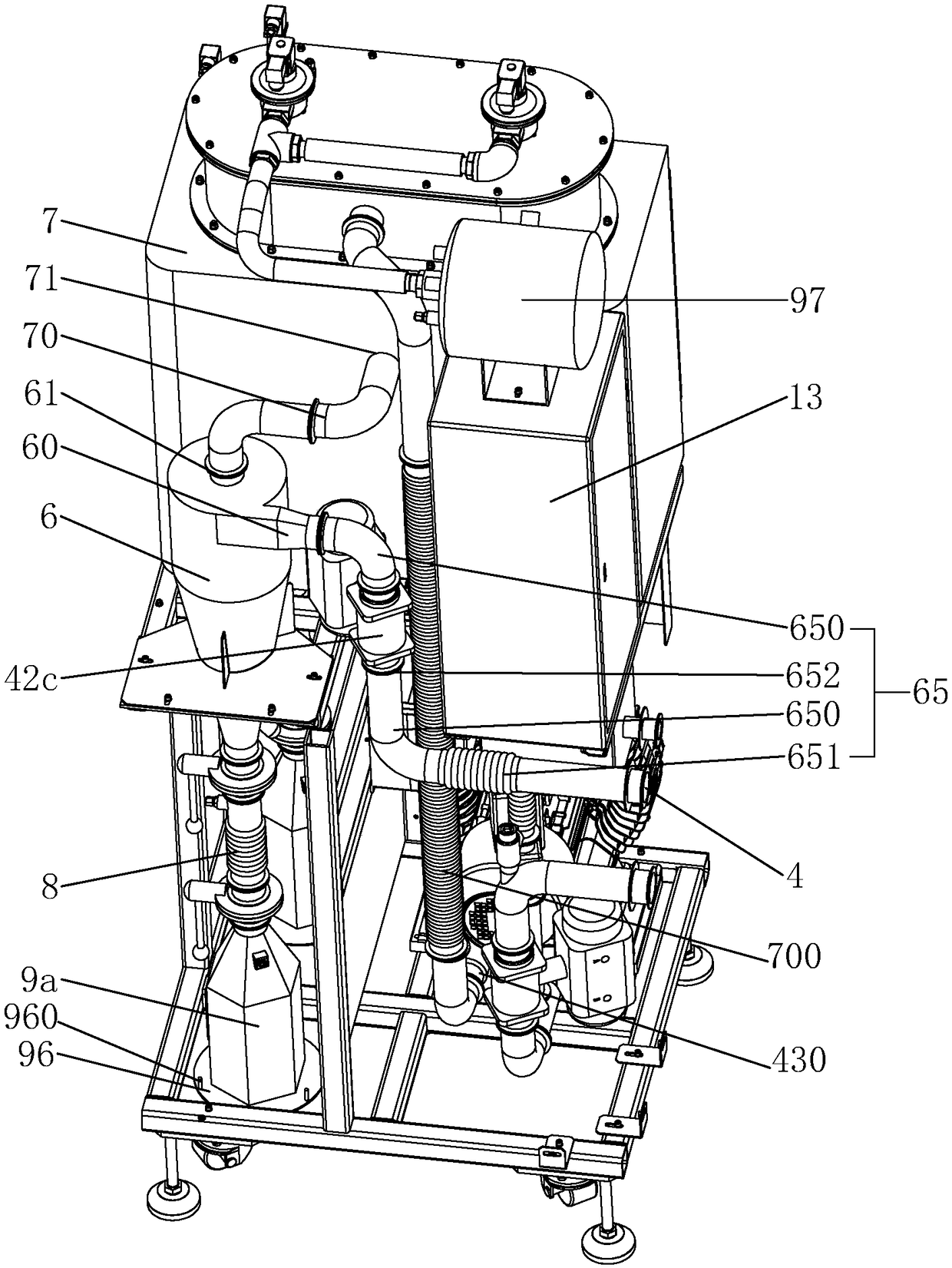

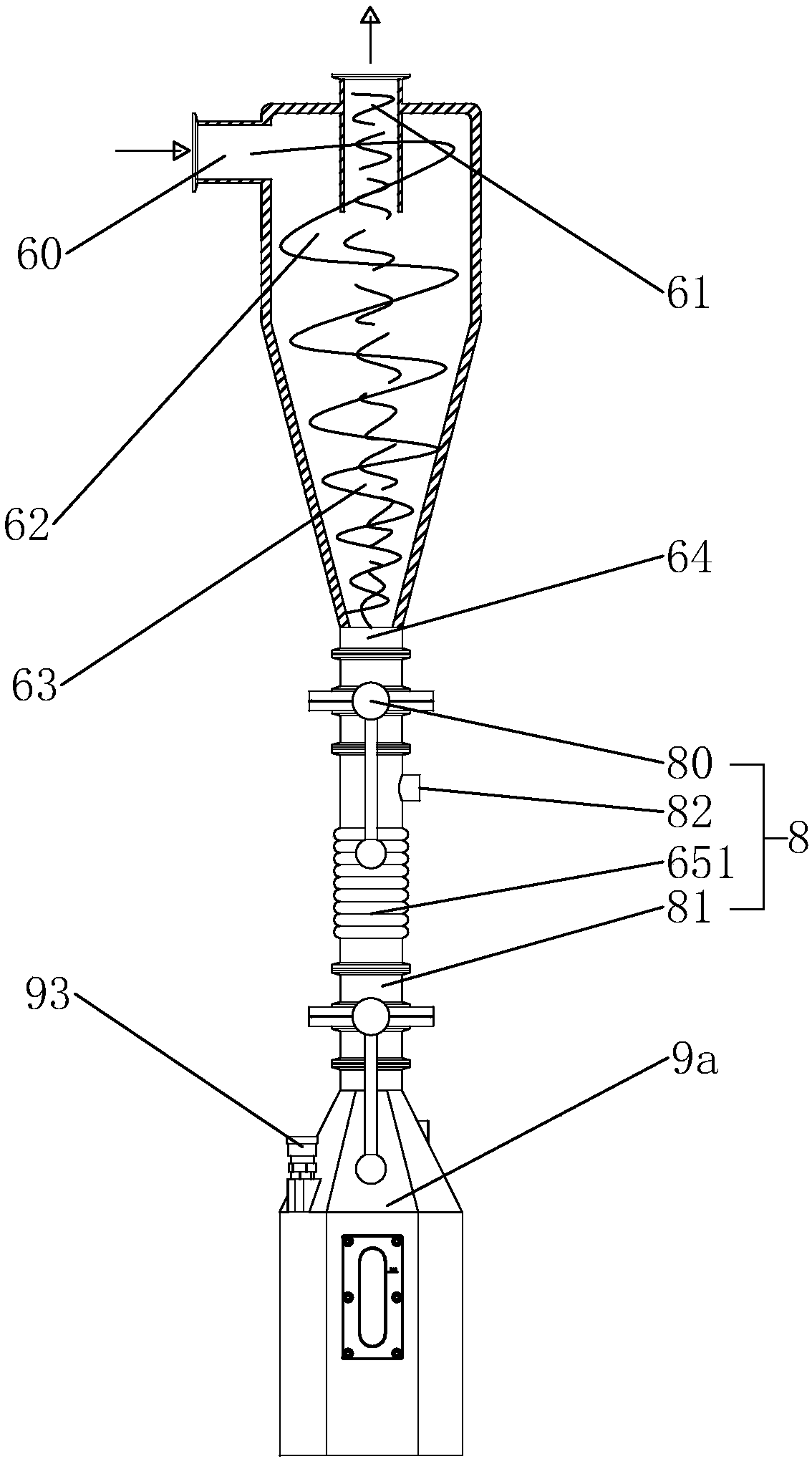

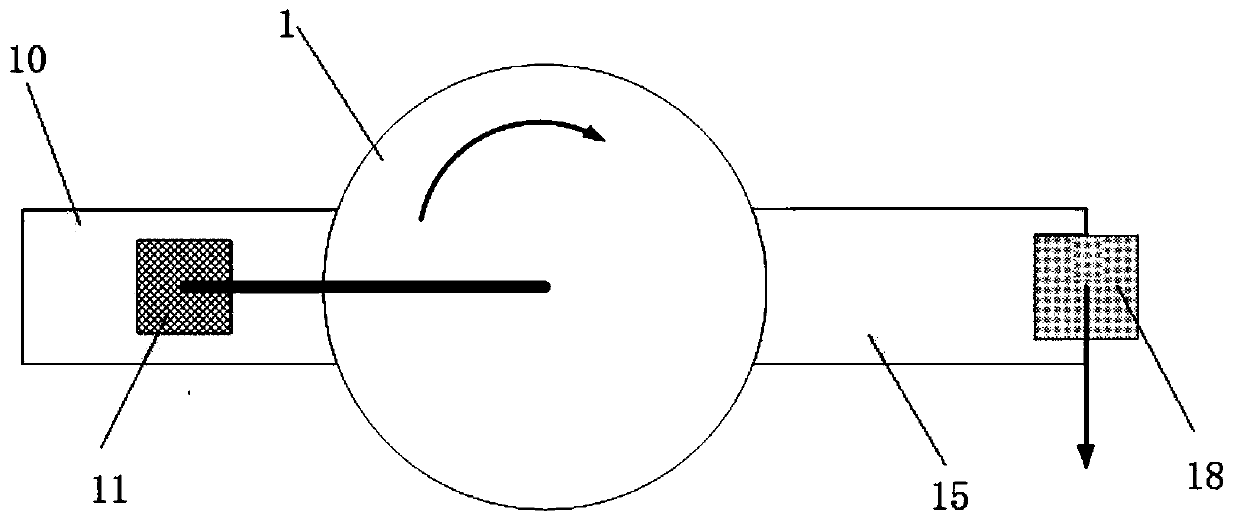

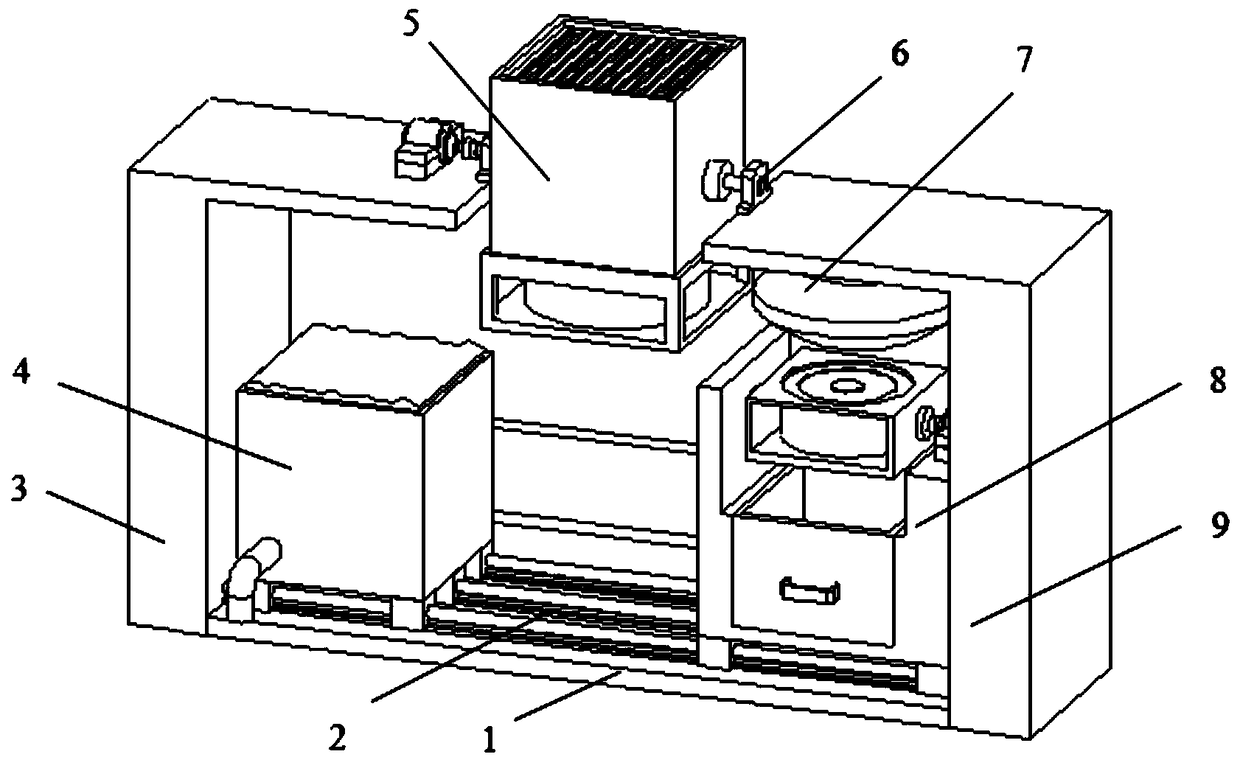

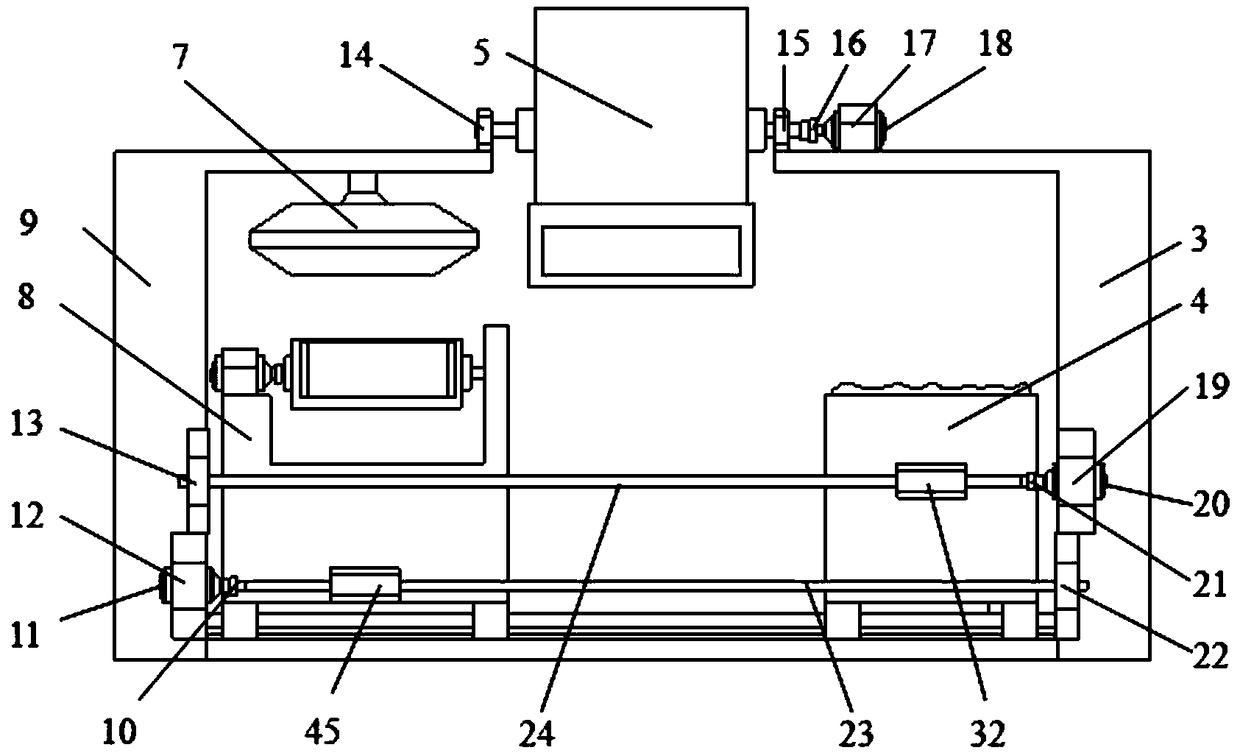

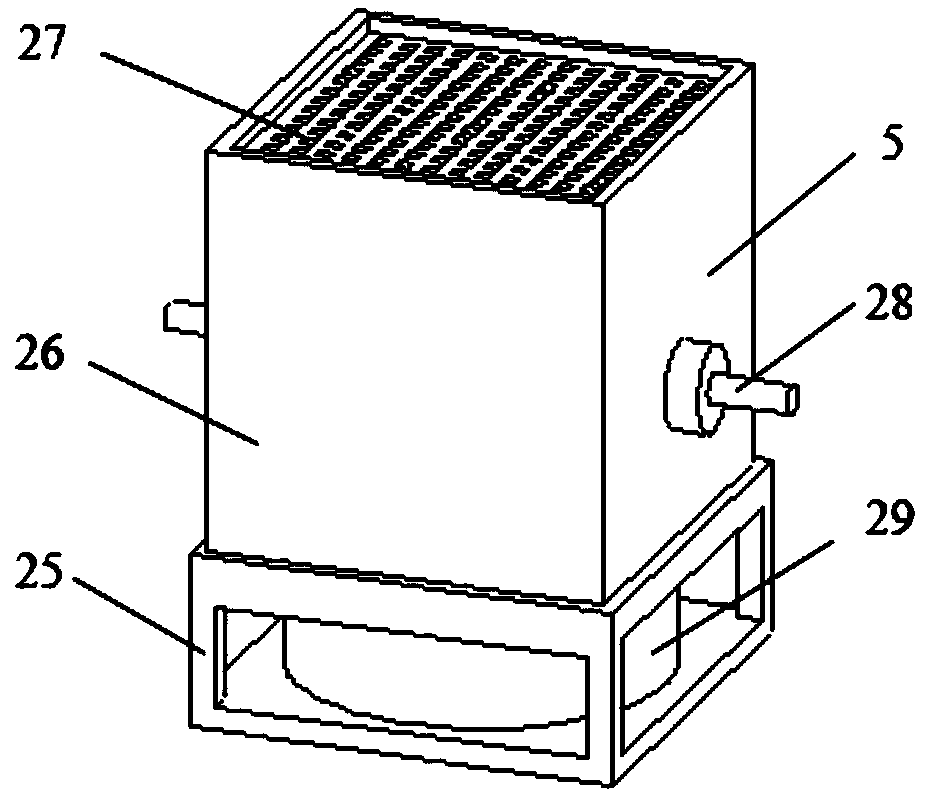

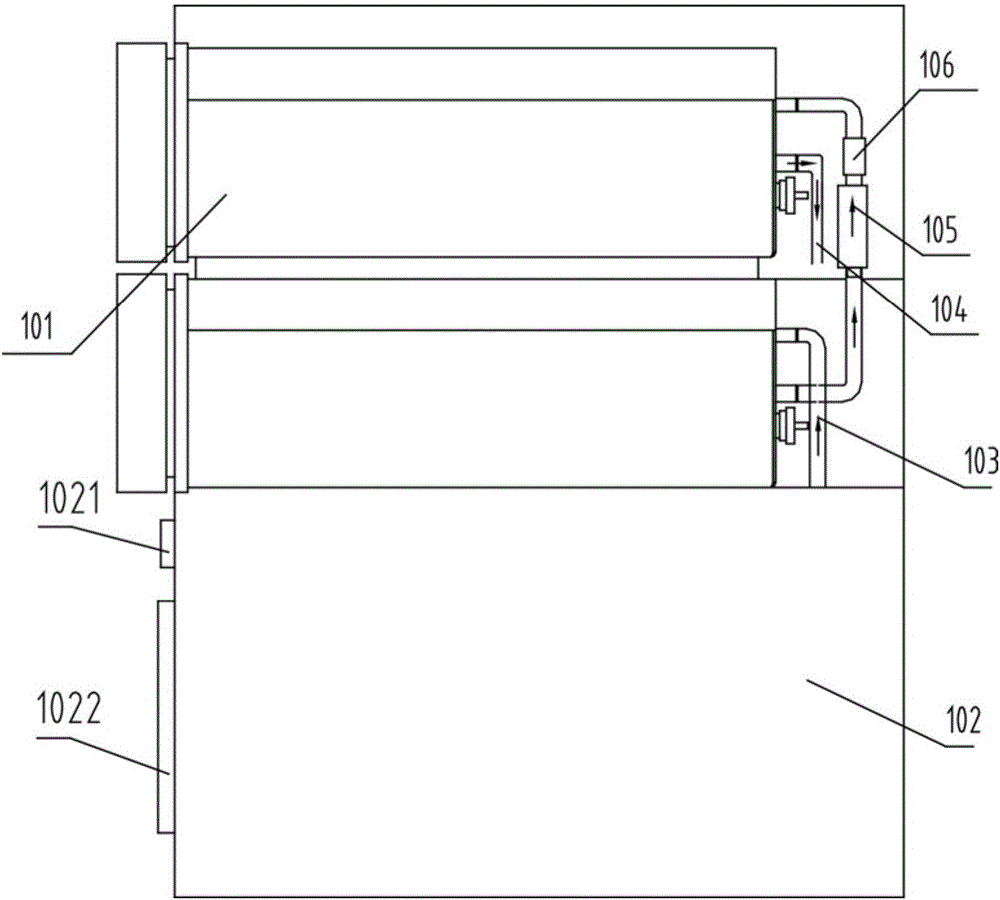

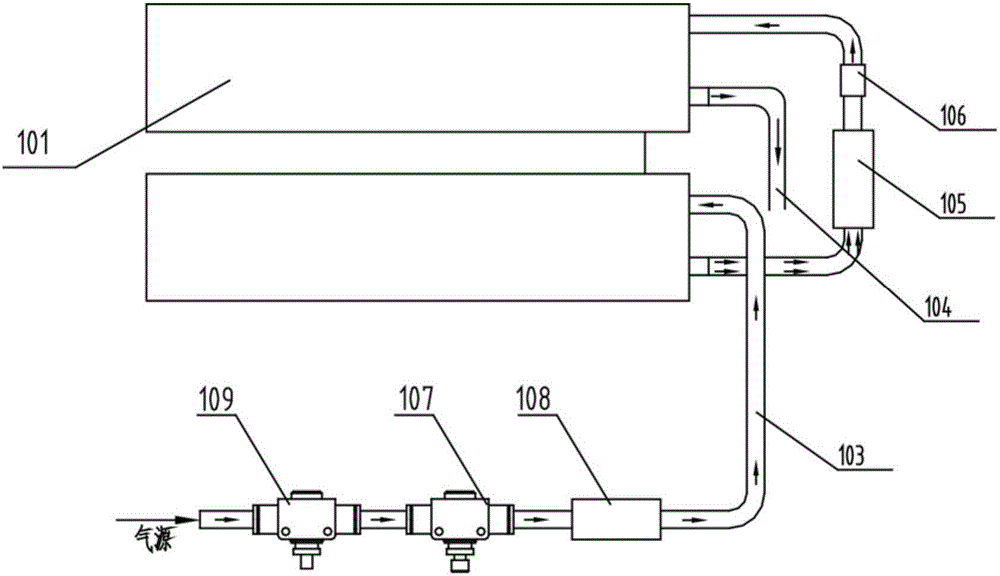

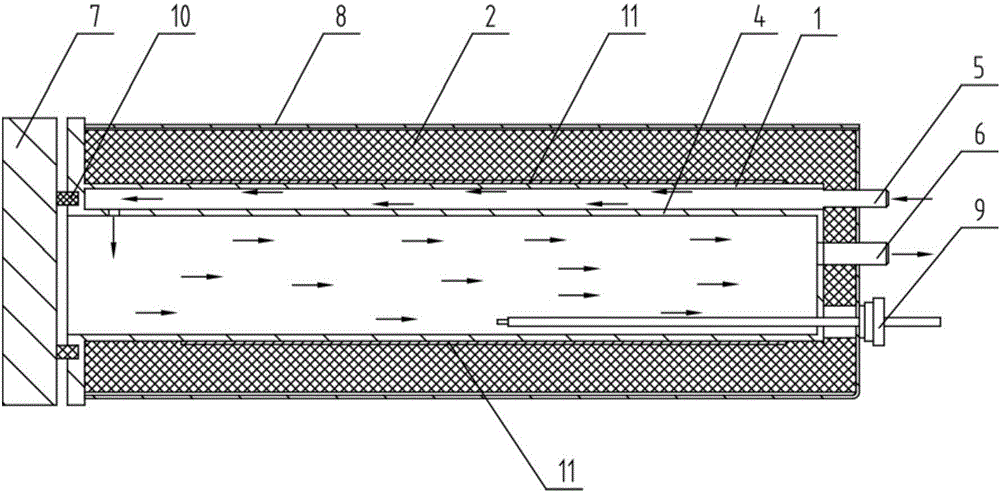

Active back-blowing cleaning equipment for selective laser melting manufacturing

ActiveCN108115131ARealize multiple useNo adsorptionAdditive manufacturing apparatusIncreasing energy efficiencyTuyereSmoke

The invention discloses active back-blowing cleaning equipment for a selective laser melting manufacturing. The active back-blowing cleaning equipment comprises a cabinet body and a filtrating devicearranged in the cabinet body, wherein the filtrating device is connected between an air intake and an air return port of a forming chamber of a SLM equipment; the filtrating device comprises at leastone filter element; a back-blowing device which is used for blowing air from inside to outside is arranged in the filter element; an air inlet of the back-blowing device communicates with an air tankfor supplying inert gas to the air inlet of the back-blowing device; an air outlet communicates with the outside through a bleeding port arranged on the cabinet body; a valve set for selecting gas toenter the air return port or discharging the gas to air through the bleeding port is arranged between the bleeding port and the air return port; and the back-blowing device can be used for reversely blowing smoke dust particulate matter on the filter element so as to remove the particles blocked on the filter element, and replacement of the filter element during one-time printing process of the SLM equipment is avoided.

Owner:BEIJING E PLUS 3D TECH CO LTD

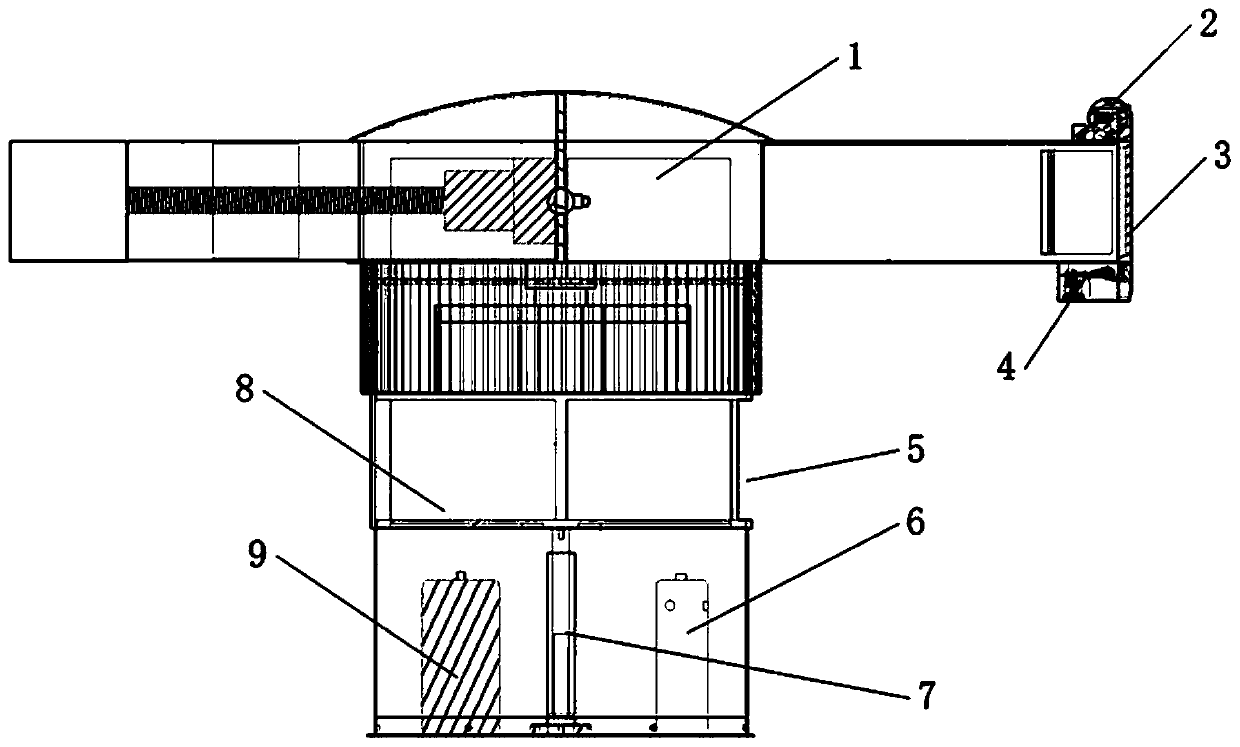

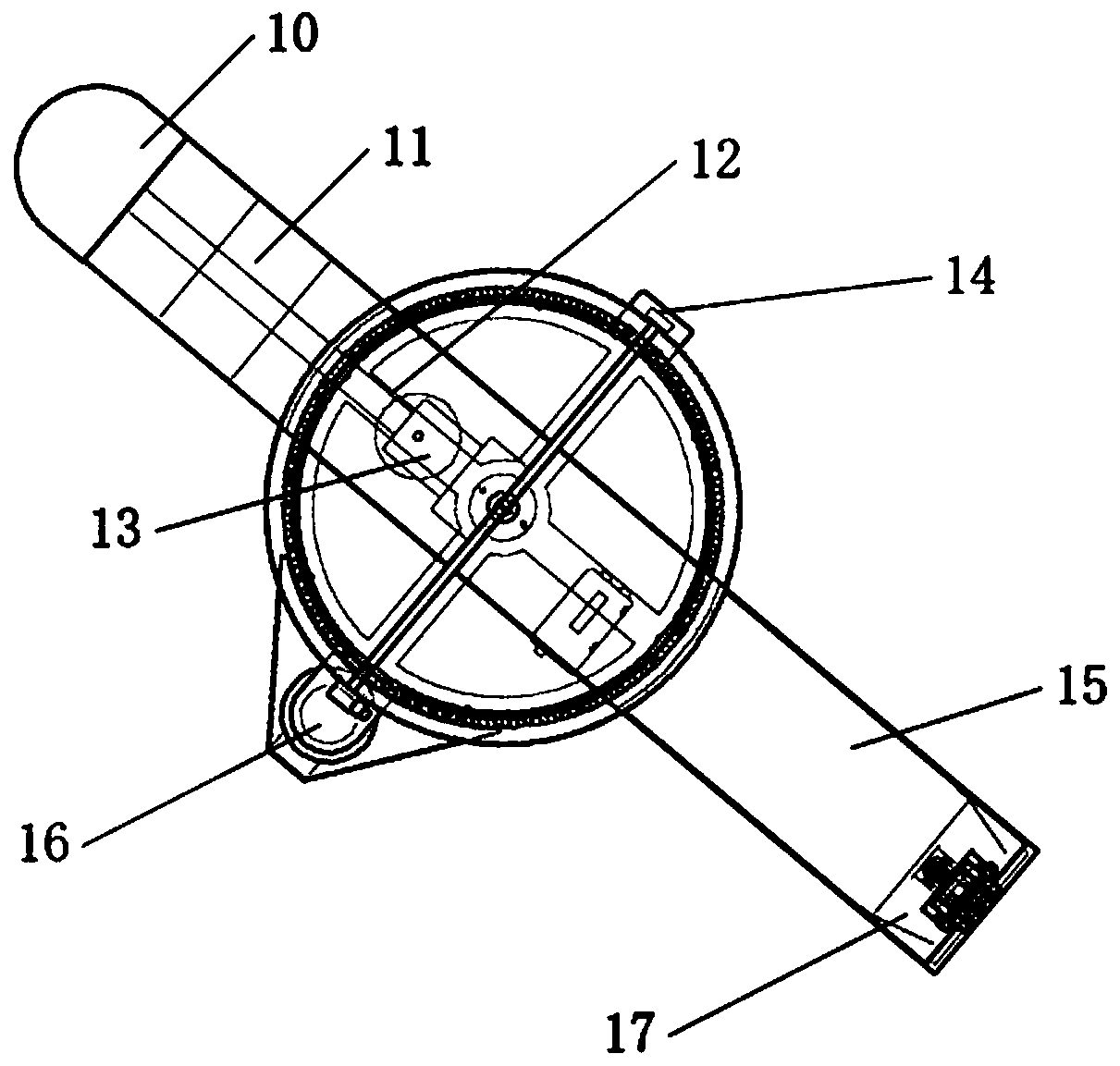

Space rotary release device and rotary release method

ActiveCN110254754ARealize multiple useRealize multiple deliveryCosmonautic component separationControl releaseEngineering

The invention relates to a space rotary release device and a rotary release method, and belongs to the field of space release devices. The problems that in the prior art, a space release device cannot be used repeatedly, the release direction and the release speed cannot be adjusted, and the release has great recoil force and disturbance to a platform are solved. According to the space rotary release device, a balancing weight is installed on a counterweight cantilever to balance the rotational inertia of a target release object on the cantilever, so that stable release of the object is kept; the release speed and the release direction of the target object are adjusted by controlling the rotation speed of a release cantilever and the uncovering time of a front cover; an air cylinder is arranged to drive a tray to move up and down to complete the multi-time filling of the target object to the release cantilever, and multiple times of the release can be completed. According to the space rotary releasing device, the release speed and direction of the target object can be adjusted, and meanwhile, the balancing weight can ensure the balance during rotation release, the recoil force is small, and the disturbance is small.

Owner:BEIJING MECHANICAL EQUIP INST

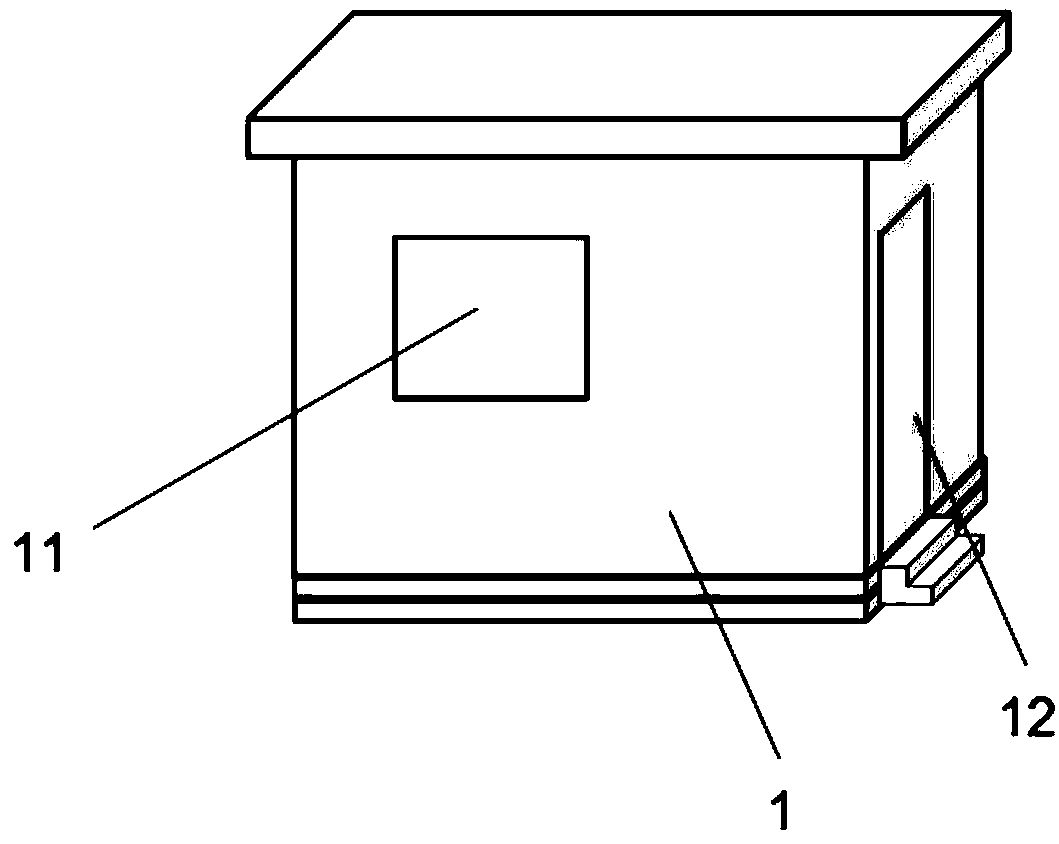

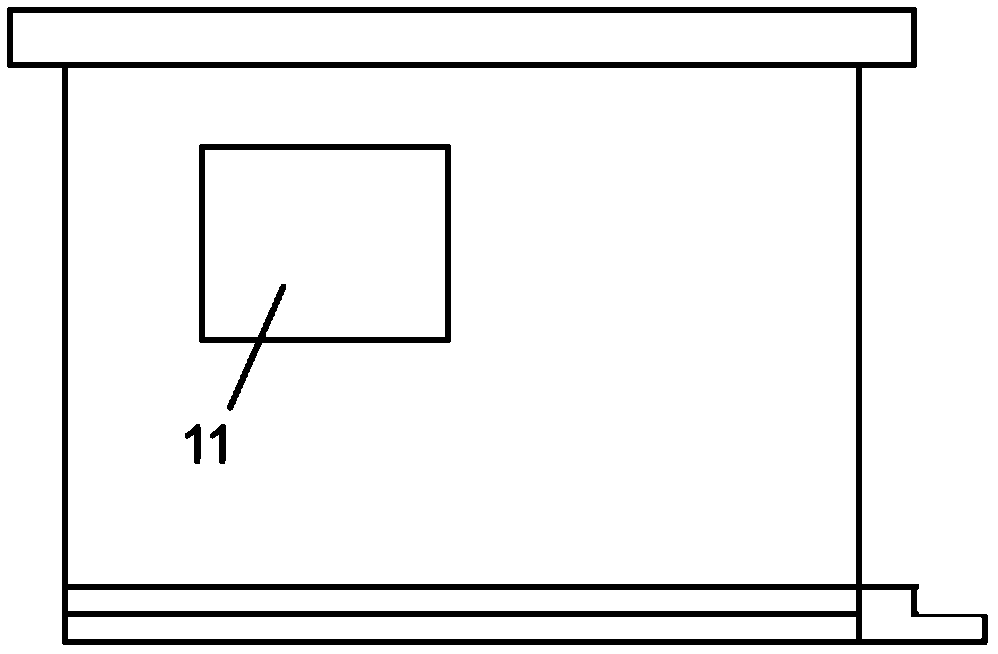

System and method for measuring energy saving rate of building insulation material

InactiveCN109521049AImprove accuracyHigh simulationMaterial heat developmentElectricityBuilding insulation materials

The invention provides a system and method for measuring an energy saving rate of a building insulation material. The measuring system comprises at least two identical detection rooms and further comprises at least one air conditioner and a wireless data transmission device, wherein each detection room comprises floor, enclosure walls and a roof; each air conditioner is provided with an independent power supply; the independent power supply is connected with an electricity meter; and the wireless data transmission device is used for transmitting data of the electricity meter. The measuring method comprises the following steps: respectively mounting to-be-measured sample plates and comparative sample plates in different detection rooms; respectively recording the power consumption data acquired by the electricity meters of the detection rooms provided with the to-be-measured sample plates and comparative sample plates as Qsample and Qcompare; and calculating the saving rate n of the power consumption according to a formula n=(Qsample-Qcompare) / Qcompare*100%. The evaluation method has the advantages that a detected value of the heat-insulating property is closer to an actual value after application of a building envelope, and reliable reference data is provide for application and popularization of the building insulation material, particularly an insulating mould coating.

Owner:CHINA TEST & CERTIFICATION INT GRP CO LTD

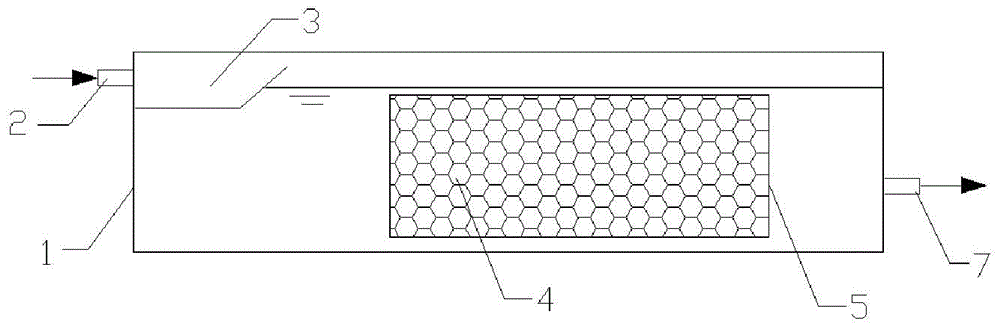

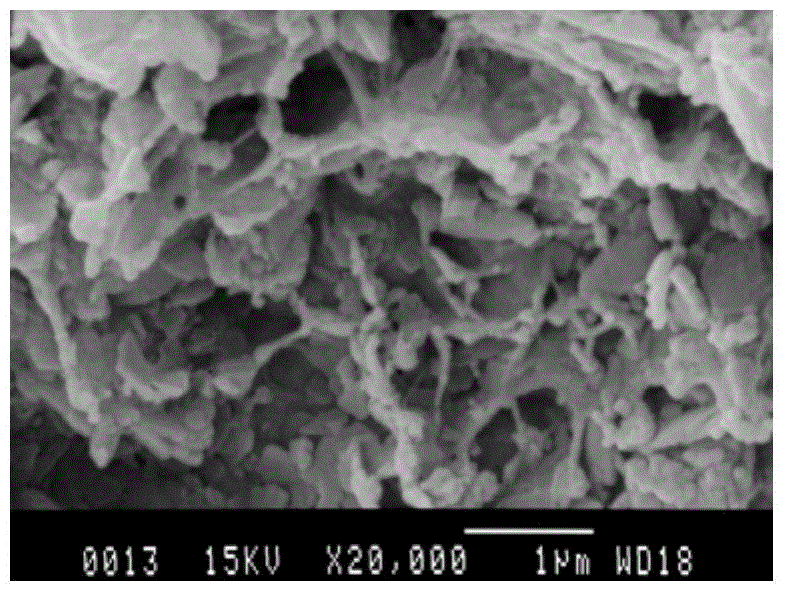

Method for preparing and purifying coal slag-zeolite composite purified ball and experimental device

InactiveCN104549171AAchieve purificationImprove mechanical propertiesOther chemical processesCombustible gas purificationSlagAdhesive

The invention relates to a method for preparing and purifying a coal slag-zeolite composite purified ball and an experimental device. The method comprises the following steps: uniformly mixing pretreated coal slags and zeolites by a mass ratio of 2 to 1; putting into a ball maker; adding a PVA organic adhesive to prepare a coal slag-zeolite composite purified ball; drying and then soaking in fresh water; taking out, drying again, and directly putting in water for use; after use, heating to perform regeneration and reutilization. The coal slag-zeolite composite purified ball can be used repeatedly, has the advantage of preventing secondary pollution of environment and can be used as a filler medium for water purification. The ammonia nitrogen removal rate and COD removal rate on polluted water are respectively as high as 57.2% and 51.2%. The coal slag-zeolite composite purified ball prepared by the method disclosed by the invention is good in mechanical properties, high in impact load resistance, rich in pores so as to provide a relatively large attachment place for microorganisms, wide in raw material source, simple to prepare, economical, practical and low in operating cost.

Owner:OCEAN UNIV OF CHINA

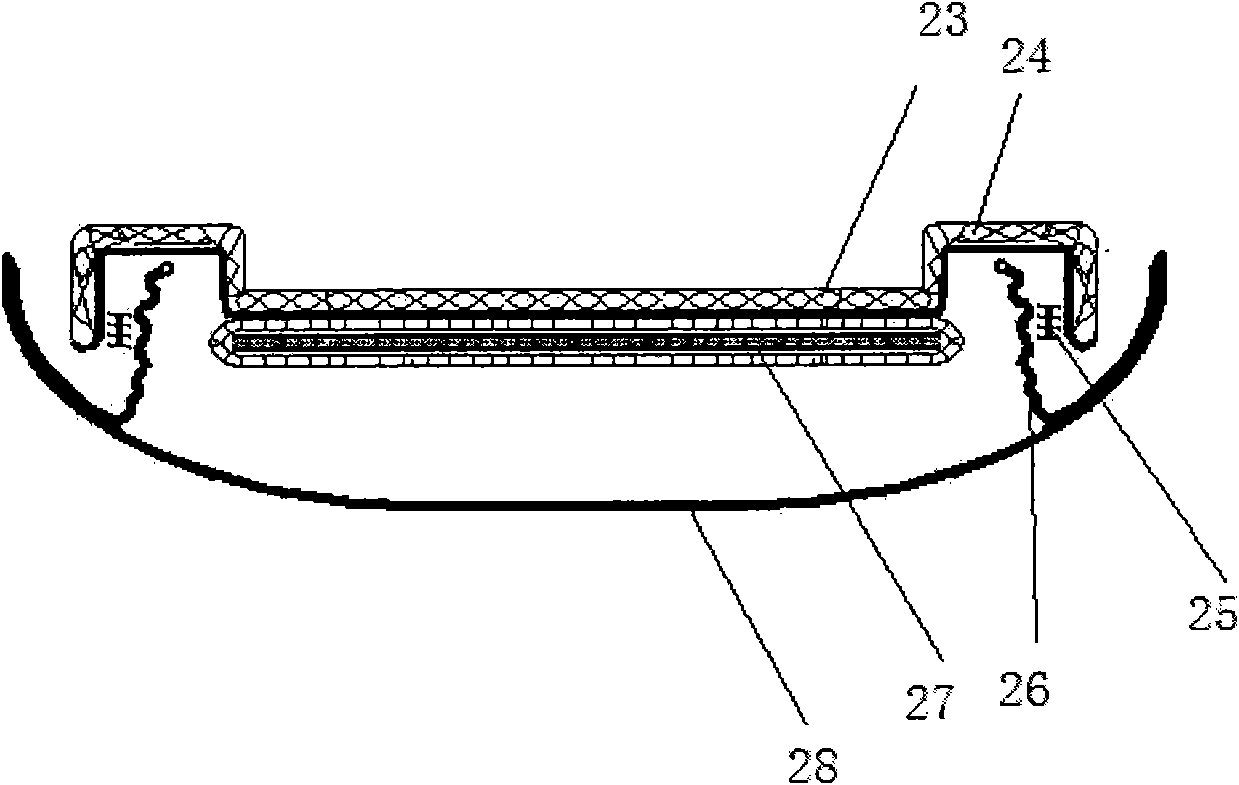

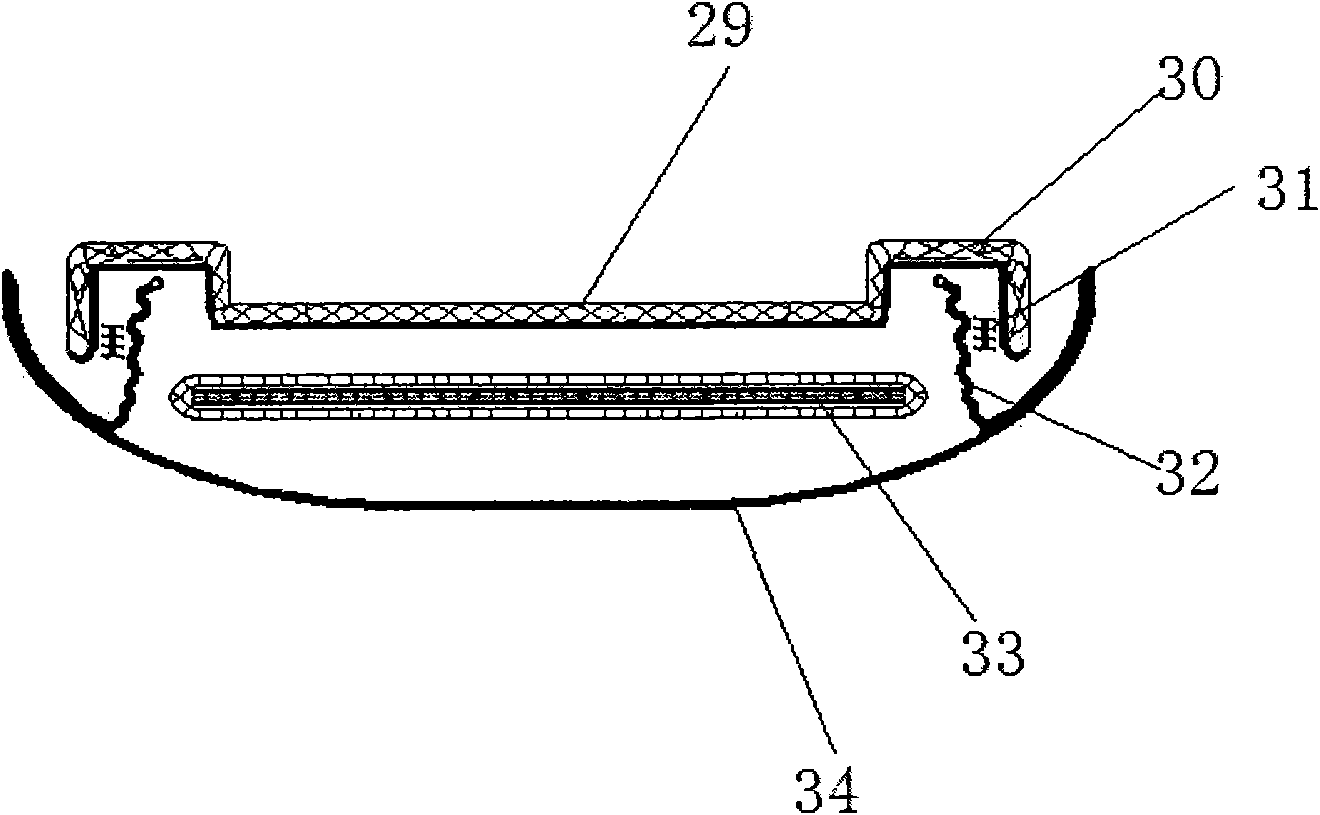

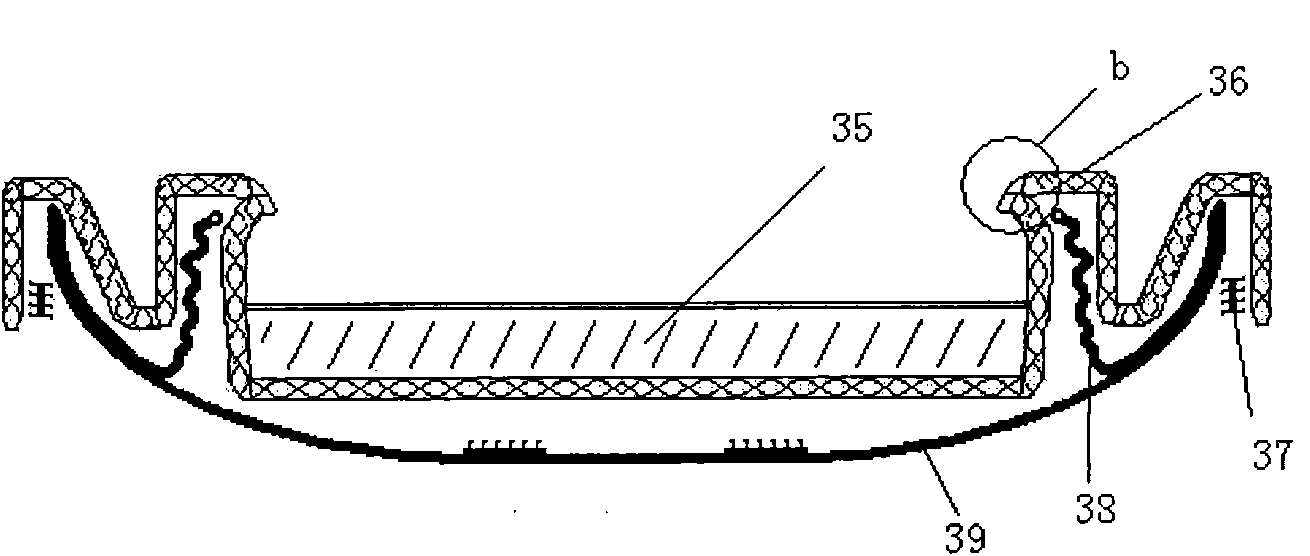

Hygienic product

InactiveCN101843543AOvercome the disadvantage of only one-time useRealize multiple useSanitary towelsBandagesEngineeringMechanical engineering

The invention discloses a hygienic product. The hygienic product comprises a spacer layer, an absorbing layer and a bottom substrate layer, wherein the spacer layer is contacted with a human body; the absorbing layer is positioned in the middle; the bottom substrate layer is positioned below the absorbing layer and is far away from the spacer layer; the spacer layer is connected with the absorbing layer to form an absorbing body; the bottom substrate layer is detachably connected with the absorbing body; the absorbing layer consists of at least two sub-absorbing layers and at least one flow guide layer; the flow guide layer is arranged between adjacent two sub-absorbing layers; the sub-absorbing layers and the flow guide layer are superposed in turn from top to bottom; the flow guide layer is a flow guide net surface provided with deflector holes which are convex holes projecting outwards from the upper surface and the lower surface of the flow guide layer; bottom holes of the deflector holes are positioned on the flow guide net surface; and top holes of the deflector holes are far away from the flow guide net surface. The layers of the hygienic product can be split for using and can be used repeatedly, so the product has the characteristics of environmental protection, economy and excellent air permeability and prevents reverse leakage of liquid; and liquid absorbing situation can be directly observed from bottom, so a vivid prompt of the need of replacing the hygienic product is given to a user.

Owner:王卓群

Preparation method of composite ceramic

The invention provides a preparation method of a composite ceramic. The preparation method of the composite ceramic comprises the following steps that fiber cloth is bonded on the surface of a bulletproof back plate; a plurality of packaged ceramic small blocks are bonded on the surface of the fiber cloth; the fiber cloth is bonded on the surface of the plurality of packaged ceramic small blocks to form a ceramic plate; and the ceramic plate is cured to obtain the composite ceramic. The composite ceramic prepared by the method provided by the invention forms a new integral ceramic plate, and has the shock wave isolation effect, so that the anti-multiple attack ability is remarkably enhanced; the ceramic small blocks are bonded to one another, so that the overall bending strength is remarkably improved, the structural integrity and the bulletproof performance of the ceramic small blocks are not reduced under a long-term static load or dynamic load; and after impact, the damaged ceramicsmall blocks can be removed and replaced with the new ceramic small blocks in order to be used for multiple times and improve the use efficiency of the ceramic plate, and even in an emergency situation, the ceramic plate can be repaired. The invention further provides a composite ceramic.

Owner:BEIJING TONGYIZHONG NEW MATERIAL TECH CORP

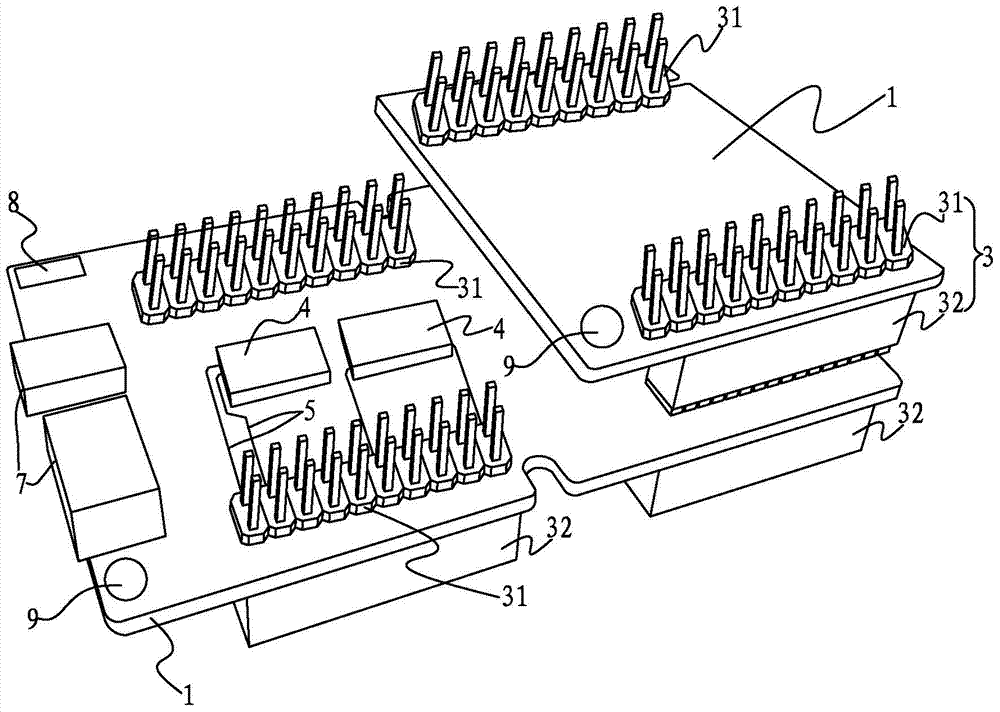

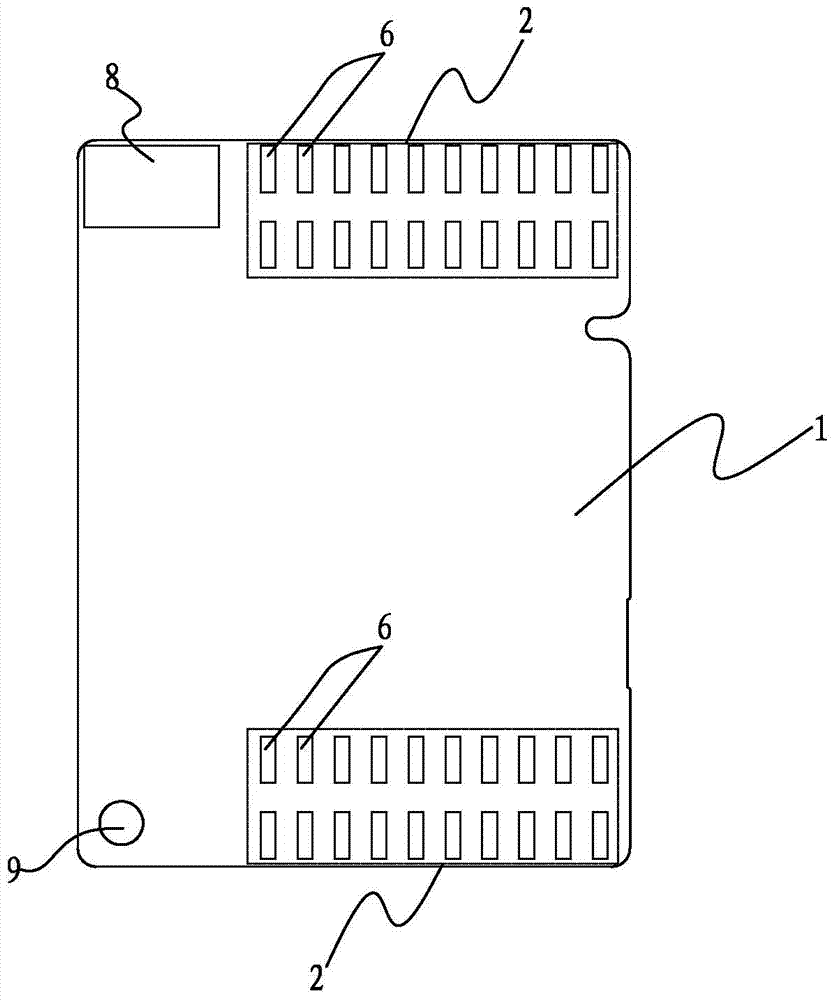

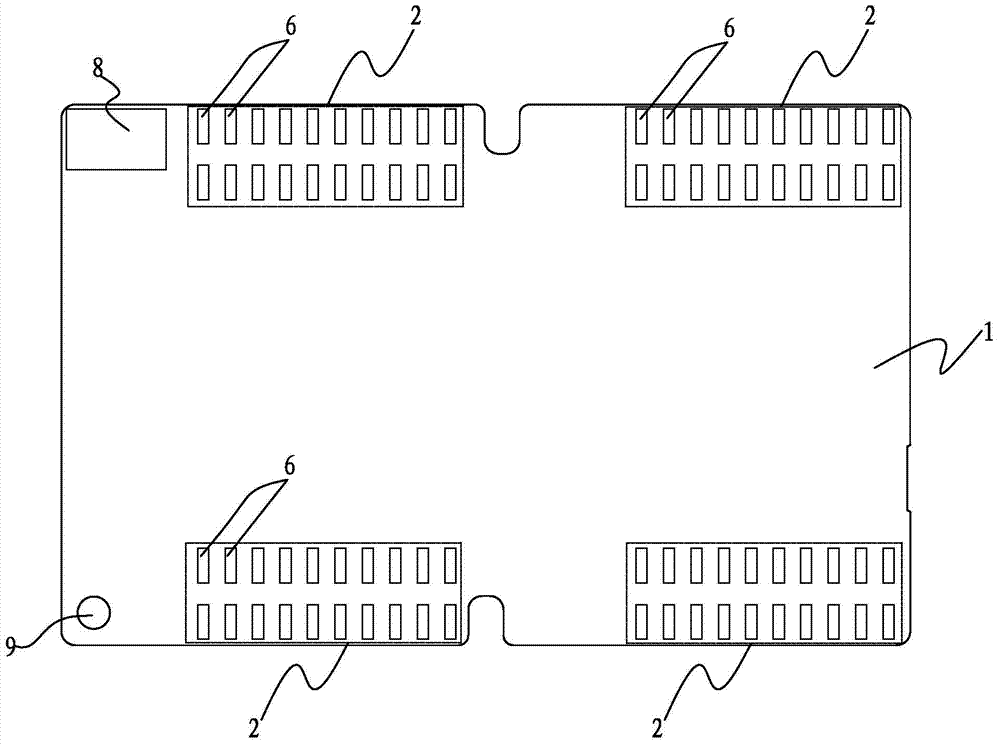

General modular circuit board structure

InactiveCN104125708ARealize multiple useEasy to shareElectrical connection printed elementsPrinted circuit non-printed electric components associationElectricityComputer module

The invention discloses a general modular circuit board structure. The general modular circuit board structure comprises at least two circuit boards which are connected with each other; a plurality of interfaces which are used for carrying an electric connector are distributed on every circuit board; the interfaces are connected with an electronic element which is arranged on the corresponding circuit board through a conductive pattern; function signal sets can be transmitted through the interfaces and via the electric connector which is carried on the interfaces due to the circuit boards which are connected with each other; the interfaces which are corresponding to the same function signal set and are arranged on the different circuit boards comprise the consistent interface pin definition. According to the general modular circuit board structure, the repeated use of the circuit boards which are corresponding to function modules respectively can be implemented and accordingly resources are saved and the development cycle is shortened; the interfaces which are used for transmitting the same function signal set and arranged on the circuit boards comprise the general unified interface pin definition and accordingly the sharing of the circuit boards is facilitated and the consumption cost of users is reduced; the circuit boards which are connected with each other comprise a stacking structure in the vertical direction and accordingly the space is saved and the connection is reliable.

Owner:大连酒游科技有限公司

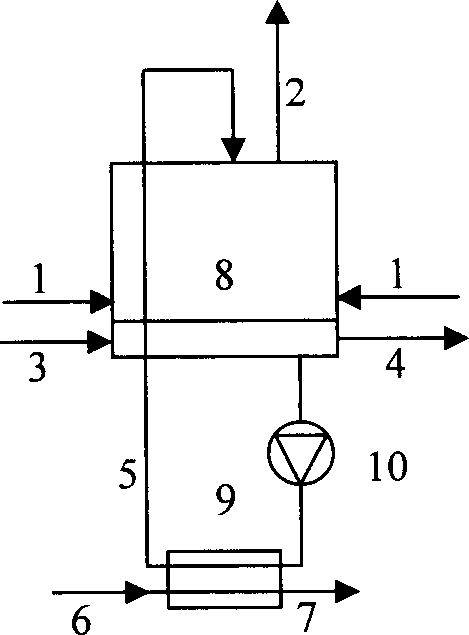

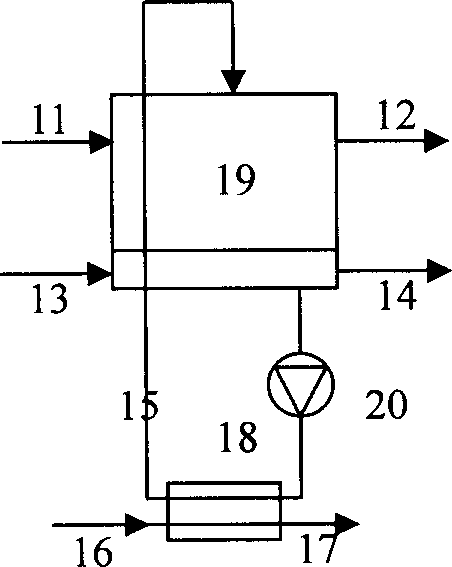

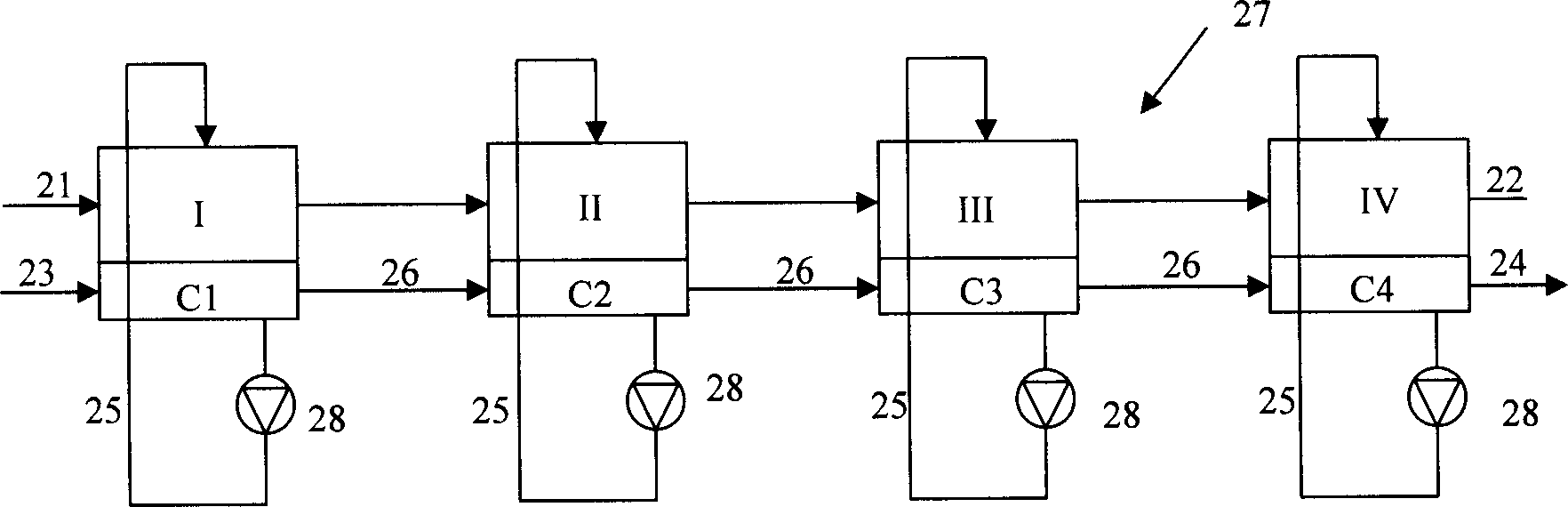

Method for concentrating solution

InactiveCN1415908ARealize multiple useIncrease motivationLighting and heating apparatusAir conditioning systemsStrong solutionsEnrichment methods

A solution concentration method characterizes in classifying the solution into 2-6 stages according to the differential concentration range of strong solution and weak solution in which the condensed range of each stage solution is only a part of entire solution concentration range, that is partial concentration and a complete concentration range is formed by combining the multistage, so as to realize multistage concentration. Energy can be used many times under different conditions during the 2-6 stages concentration, namely, not need energies from outside.

Owner:格瑞智慧人居环境科技(江苏)有限公司

Magnetic grinding material screening, filtering and recovery device and method

PendingCN109366343AHigh degree of automationAchieve separationEdge grinding machinesSievingAqueous solutionEngineering

The invention relates to a magnetic grinding material screening, filtering and recovery device and method. The magnetic grinding material screening, filtering and recovery device comprises a base, a screening device, a filtering device, a grinding material recovery device and sliding rails. The multiple sliding rails which are parallel to each other are fixed to the base, and the filtering deviceand the grinding material recovery device are connected with the base in a sliding mode through the sliding rails. The screening device is arranged above the filtering device and the grinding materialrecovery device. The method comprises the steps that magnetic grinding materials, workpieces, a grinding fluid mixture and water are poured into the screening device, and magnetic grinding particlesprecipitate at the bottom of a screening barrel; the magnetic grinding materials are attracted at the bottom of the barrel wall of the screening barrel by a small electromagnet; grinding chips and anaqueous solution inside the screening barrel are poured into a filtering barrel, and the grinding chips are filtered out by a sponge; the magnetic grinding materials are attracted by a large electromagnet; and after drying treatment is accomplished, the large electromagnet is deenergized, and the magnetic grinding materials are recovered. The magnetic grinding material screening, filtering and recovery device and method have the advantages that separation of the grinding materials and the workpieces can be rapidly achieved, recovery of the magnetic grinding materials can be efficiently accomplished, and the degree of automation is high.

Owner:UNIV OF SCI & TECH LIAONING

Gas-saving type protective gas drying box

ActiveCN106052322AReduce usageLow costDrying gas arrangementsDrying solid materialsElectric energyProcess engineering

The invention relates to the technical field of a coal sample detecting device, in particular to a gas-saving type protective gas drying box. The gas-saving type protective gas drying box comprises a plurality of drying cavities, a main air inlet pipe, a main exhaust pipe and a control unit. Gas channels of the plurality of drying cavities are arranged in series. The main air inlet pipe is used for pumping protective gas into the plurality of drying cavities and the protective gas after use is discharged through the main exhaust pipe. A heating component is arranged in each drying cavity. The control unit is used for controlling the heating speed of each heating component and the on-off of the main air inlet pipe. According to the gas-saving type protective gas drying box provided by the invention, the repeated usage of the protective gas can be realized, the usage amount of the protective gas can be greatly saved, the cost can be saved and the labour intensity of the operating personnel can be reduced. The protective gas carries a part of heat when getting into one drying cavity from another drying cavity, so that a preheating effect can be played and the warming time of the drying cavity where the protective gas enters is shortened. Accordingly, the electric energy consumption can be reduced and the cost can be further saved.

Owner:长沙开元仪器有限公司

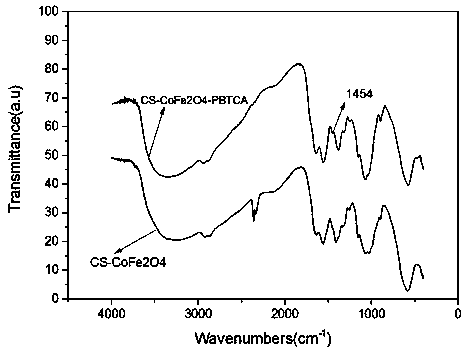

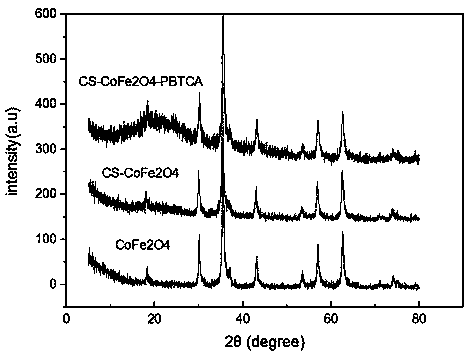

Preparation method and application of amidation modified magnetic chitosan microspheres

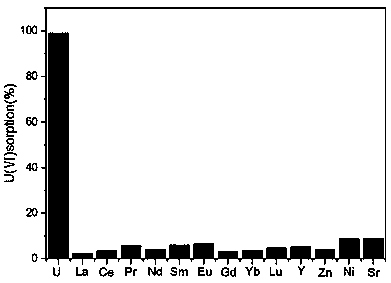

InactiveCN110368912AImprove mechanical propertiesLarge adsorption capacityOther chemical processesAlkali metal oxides/hydroxidesCross-linkNanoparticle

The invention discloses a preparation method and application of amidation modified magnetic chitosan microspheres. The preparation method of the amidation modified magnetic chitosan microspheres specifically comprises the following steps: CoFe2O4 nano-particles are synthesized by adopting a hydrothermal method; magnetic chitosan microspheres are formed under a cross-linking effect of glutaraldehyde through a reversed-phase emulsion polymerization method; and 2-phosphonobutane-1,2,4-tricarboxylic acid (PBTCA) is grafted onto the magnetic chitosan microspheres through an amide reaction, so thatthe amidation modified magnetic chitosan microspheres are obtained. The amidation modified magnetic chitosan microspheres prepared by the preparation method disclosed by the invention have good mechanical properties and sufficient adsorption sites, so that adsorption capacity to U(VI) in wastewater is large, and removal capability is good. The amidation modified magnetic chitosan microspheres adsorbing U(VI) can be quickly separated and analyzed from an adsorbed substrate (wastewater) by a magnetic field, and a new way is provided for U(VI) removal in wastewater.

Owner:CHONGQING TECH & BUSINESS UNIV

Control device applied to continuous blood glucose monitoring sensor

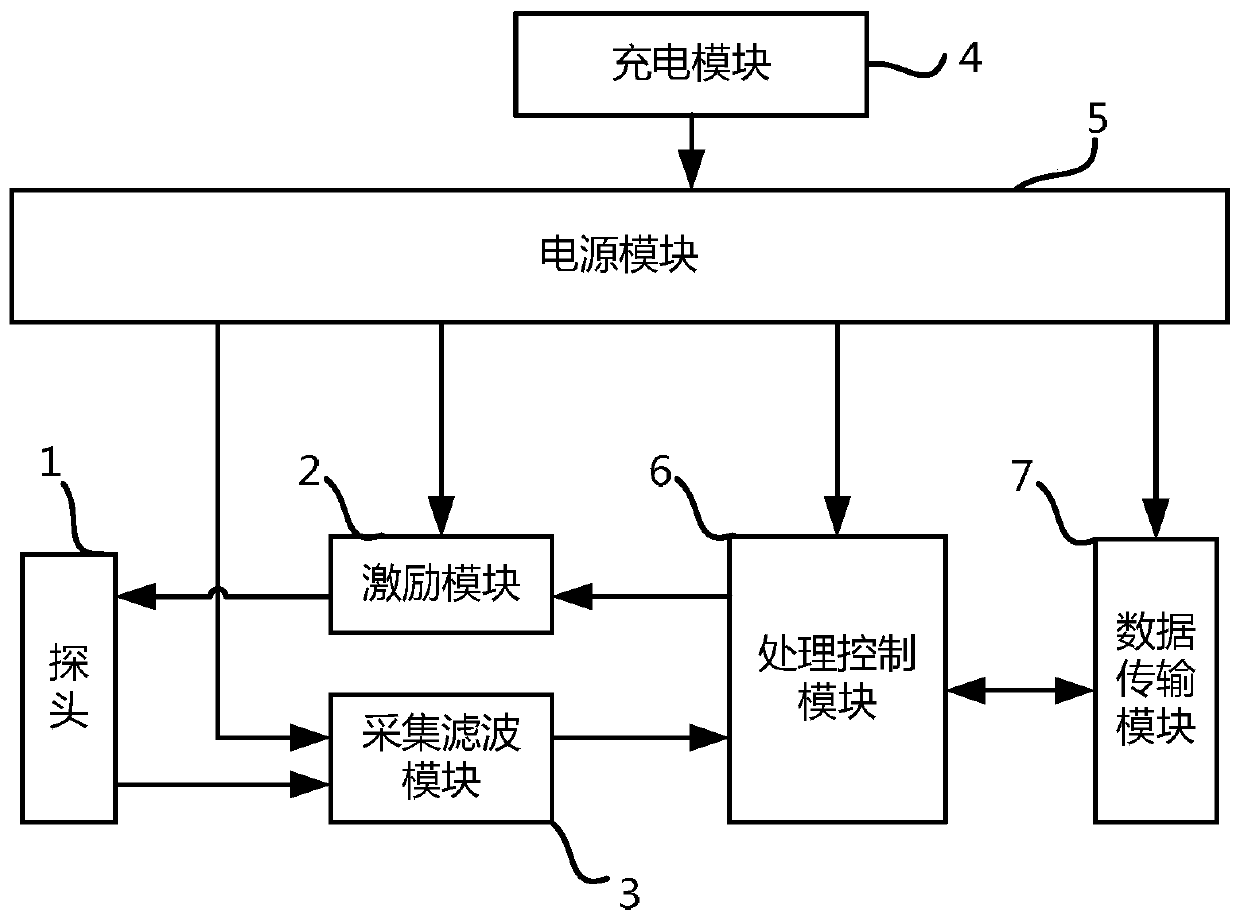

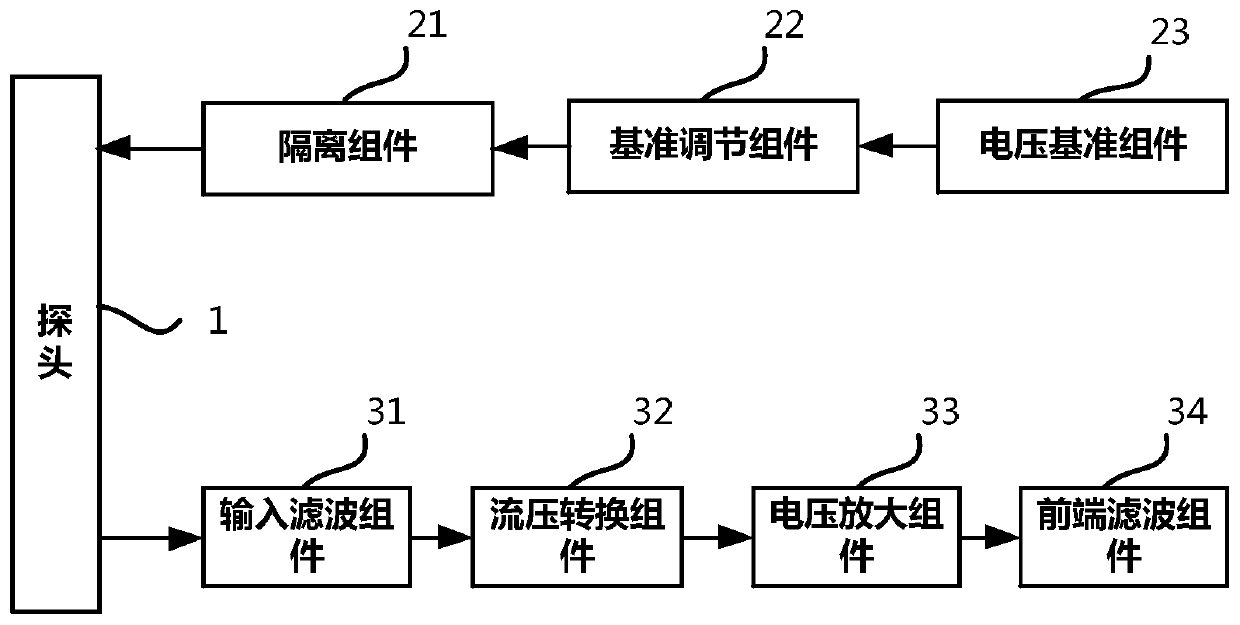

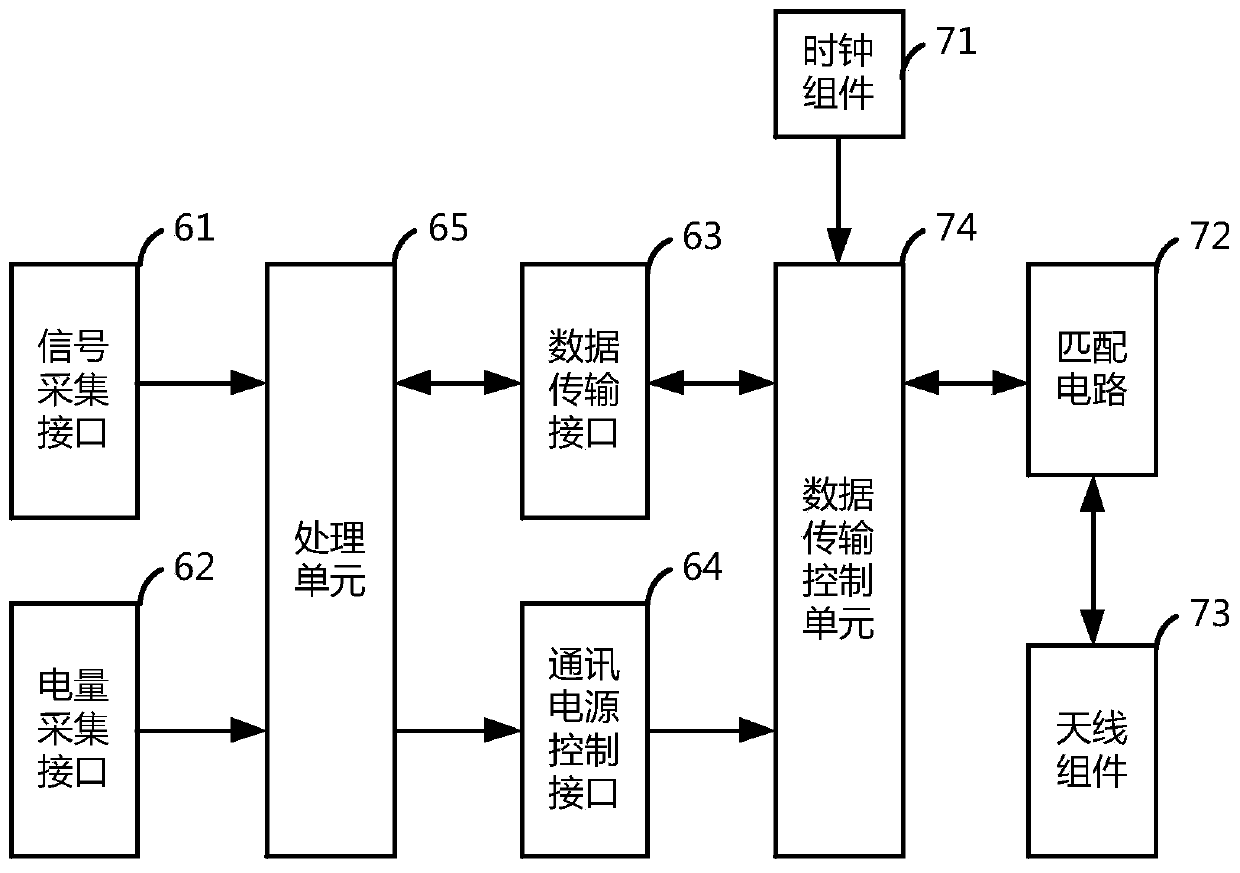

InactiveCN111381540AAccurate acquisitionRealize multiple useProgramme controlComputer controlGlucose sensorsMedical equipment

The invention relates to the technical field of medical equipment, in particular to a control device applied to a continuous blood glucose monitoring sensor. The invention provides the control deviceapplied to a continuous blood glucose monitoring sensor, comprising: a probe configured to receive a current signal from a blood glucose sensor and apply voltage excitation to the blood glucose sensor; an excitation module which is configured to apply voltage excitation to the probe; an acquisition filtering module which is configured to filter, amplify and send a signal from the probe to the processing control module; a processing control module which is configured to control the data transmission module to send the processed current signal to a user display interface; a data transmission module which is configured to send a current signal to a user display interface according to an instruction of the processing control module; a power supply module which is configured to supply power tothe excitation module, the acquisition filtering module, the processing control module and the data transmission module; and a charging module which is configured to repeatedly charge the power supplymodule.

Owner:SHAANXI QINMING MEDICAL CO LTD

Portable mop cleaning device

InactiveCN108742397AReduce wasteSimple structureCarpet cleanersFloor cleanersWater storageWater resources

The invention discloses a portable mop cleaning device which comprises a box. A first water storage box is arranged on the upper side of the box, a discharging pipeline communicated with a water pumpworking cavity is arranged on the lower side of the first water storage box, a first one-way valve is arranged in the discharging pipeline, a second one-way valve is arranged on the inner bottom wallof the water pump working cavity, a water inlet pipeline is arranged in the lower side of the second one-way valve, a piston working cavity is formed in the right inner wall of the water pump workingcavity, and a piston is arranged in the piston working cavity. According to the device, a mop can be multi-directionally cleaned in the cleaning processing process, so that cleaning efficiency and cleaning quality are greatly improved, sewage is repeatedly filtered, a sewage treatment agent is added, stirring of the a stirring arm is run, so that sewage treatment quality is higher in sewage treatment process, the sewage is recycled after being pumped by a water pump, fresh water resources are greatly saved, and waste of water resources is reduced.

Owner:诸暨市务实软件技术有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com