Segmented slightly light-concentrating welding belt and preparation thereof

A preparation process and welding ribbon technology, which is applied in the field of segmented micro-concentrating welding ribbon and its preparation, can solve the problems of limited mass production and the inability to reuse light, so as to increase reliability, reduce the risk of hidden cracks and fragments, The unique effect of the structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] In order to make the content of the present invention more clearly understood, the present invention will be further described in detail below based on specific embodiments and in conjunction with the accompanying drawings.

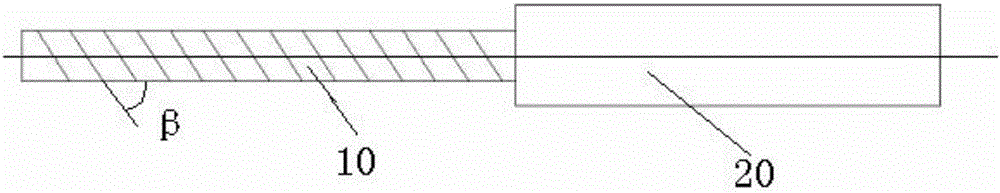

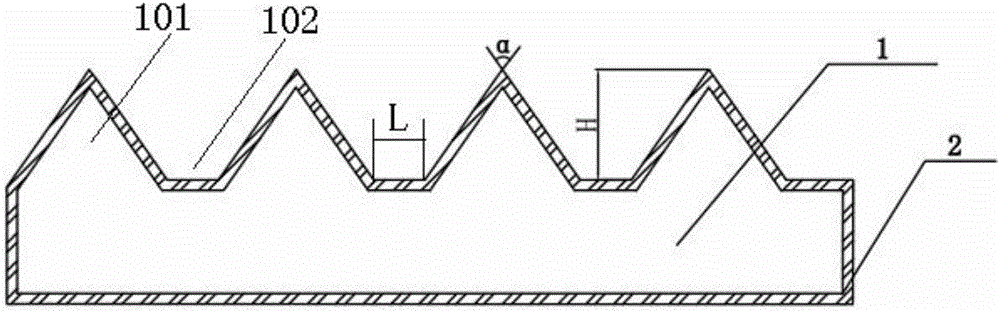

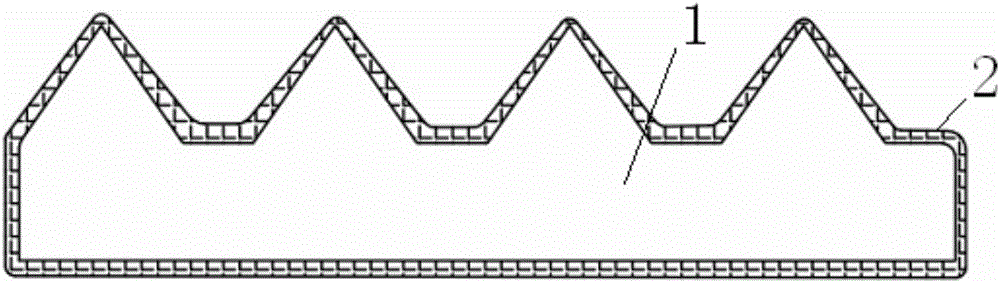

[0036] Such as figure 1 , 2 As shown, a segmented micro-concentrating welding ribbon includes a body, and the body has toothed sections 10 and flat sections 20 that are sequentially connected and alternately arranged along its length direction, and the upper section of the toothed section 10 A plurality of protruding teeth 101 are arranged on the surface, and adjacent toothed sections 10 and flat sections 20 are respectively welded on two adjacent battery pieces, and in two adjacent battery pieces, the toothed section 10 is welded To the light-receiving surface of one of the battery sheets, the flat section 20 is welded to the backlight surface of the other battery sheet; wherein, the lengths of the toothed section 10 and the flat section 20 can b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com