Magnetic grinding material screening, filtering and recovery device and method

A recovery device and technology for magnetic abrasives, applied in the fields of magnetic separation, chemical instruments and methods, and sieves, etc., can solve the problems of waste of resources, failure to recycle and reuse the aqueous solution of magnetic abrasives, and failure to dry the abrasives in time. The effect of a high degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be described in detail below in conjunction with the accompanying drawings, but it should be pointed out that the implementation of the present invention is not limited to the following embodiments.

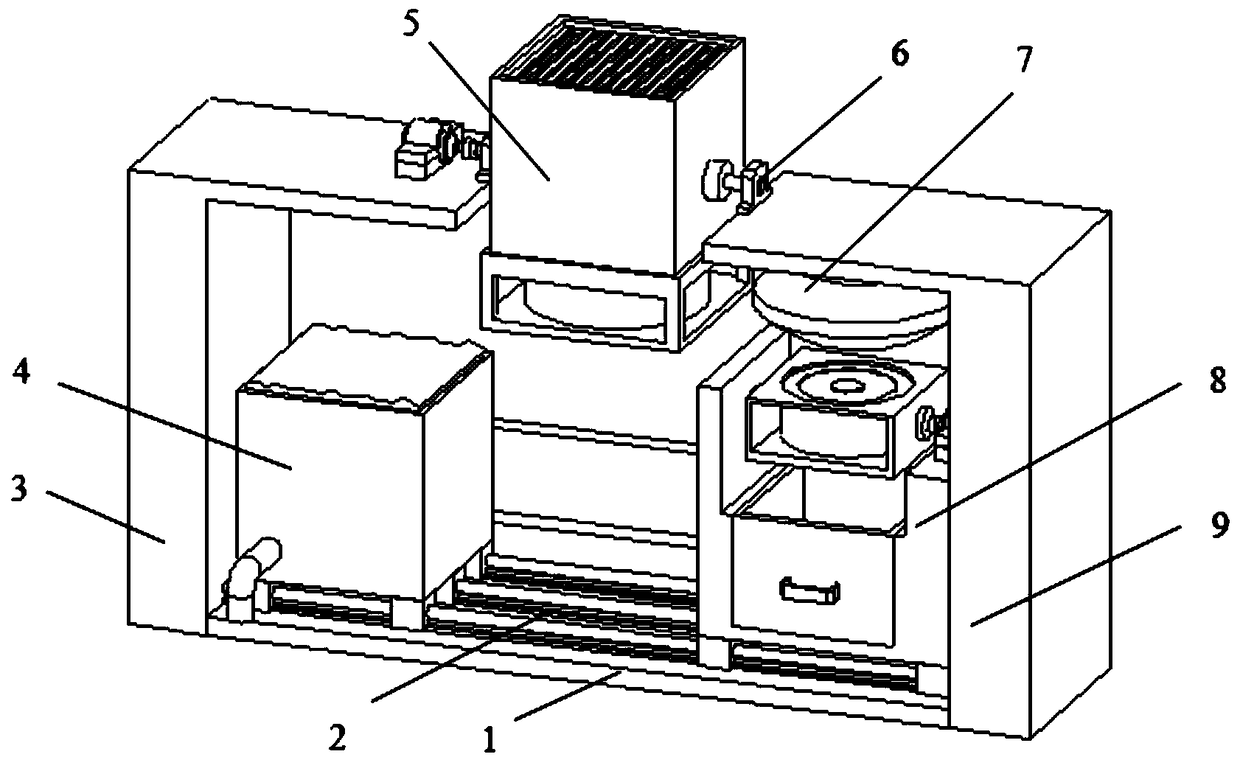

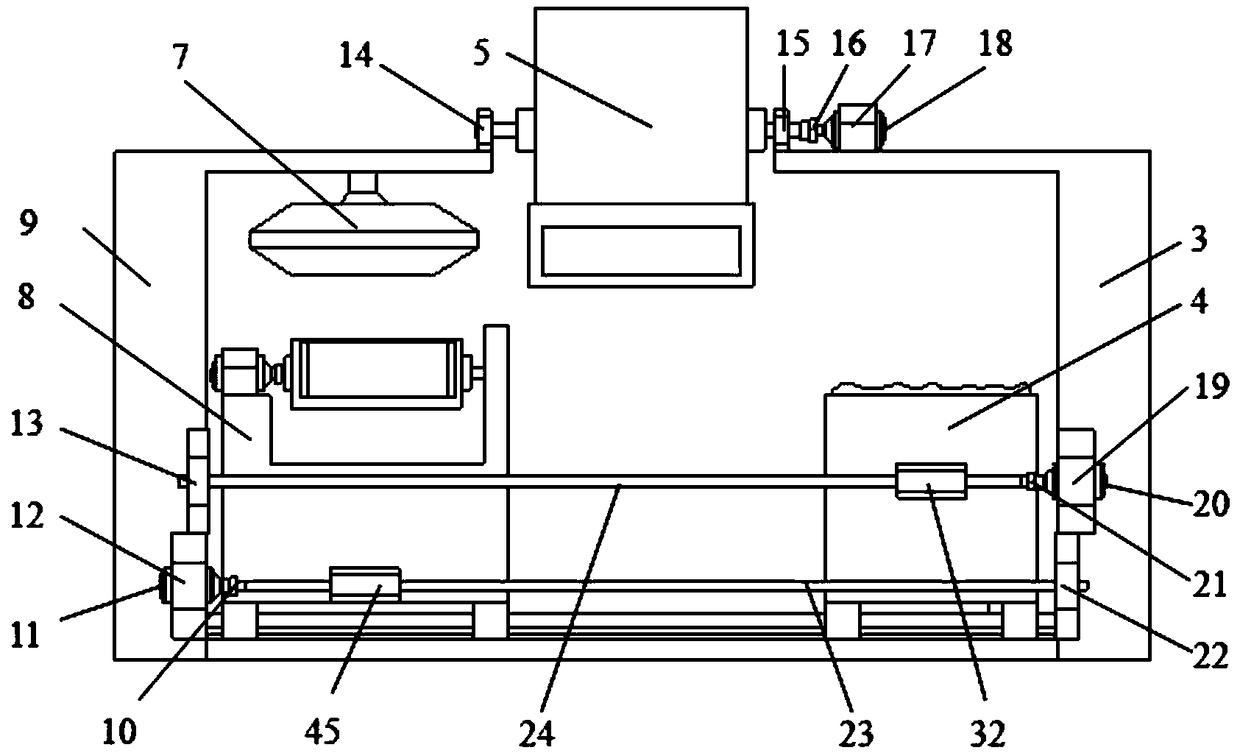

[0029] See figure 1 , figure 2 , a magnetic abrasive screening, filtering, recycling device, including a base 1, a screening device 5, a filtering device 4, an abrasive recycling device 8, a slide rail 2, and a plurality of slide rails 2 parallel to each other are fixed on the base 1, and the filtering The device 4 and the abrasive recycling device 8 are slidingly connected to the base 1 through the slide rail 2; the screening device 5 is arranged above the filtering device 4 and the abrasive recycling device 8; the filtering device 4 and the abrasive recycling device 8 can be moved to the screening device 5 respectively Directly below.

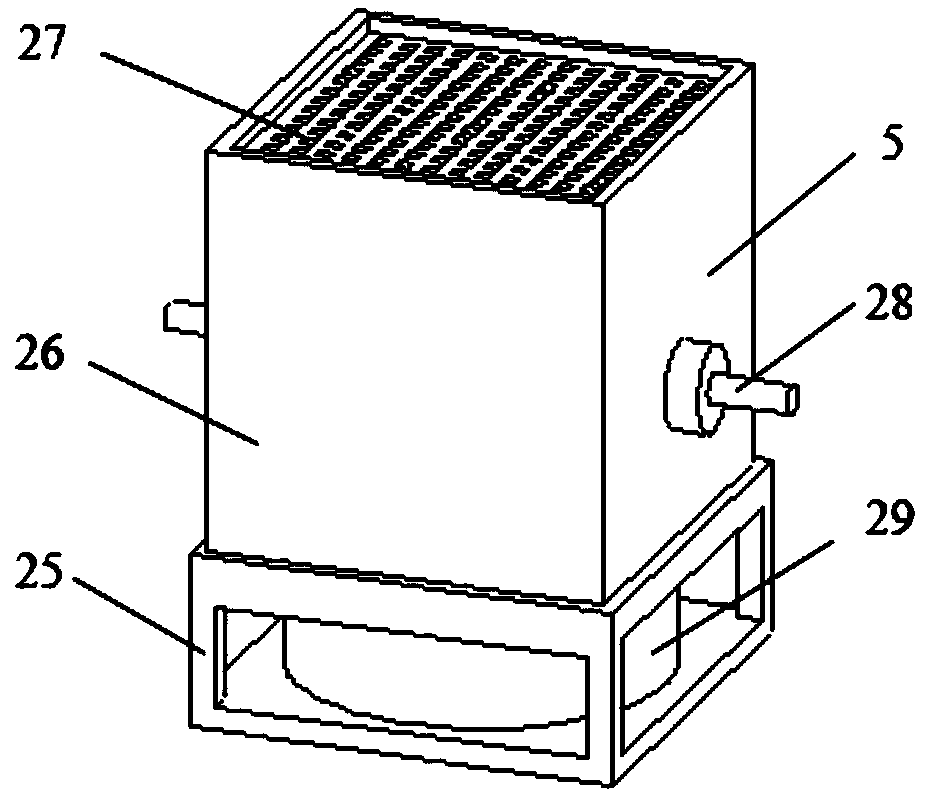

[0030] See Figure 1-Figure 3 , the screening device 5 comprises a screening support frame, a support bea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com