Patents

Literature

169 results about "Contact patch" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Contact patch is the portion of a vehicle's tire that is in actual contact with the road surface. It is commonly used in the discussion of pneumatic (i.e. pressurized) tires, where the term is used strictly to describe the portion of the tire’s tread that touches the road surface. The term “footprint” is used almost synonymously. Solid wheels also exhibit a contact patch which is generally smaller than the pneumatic “footprint”.

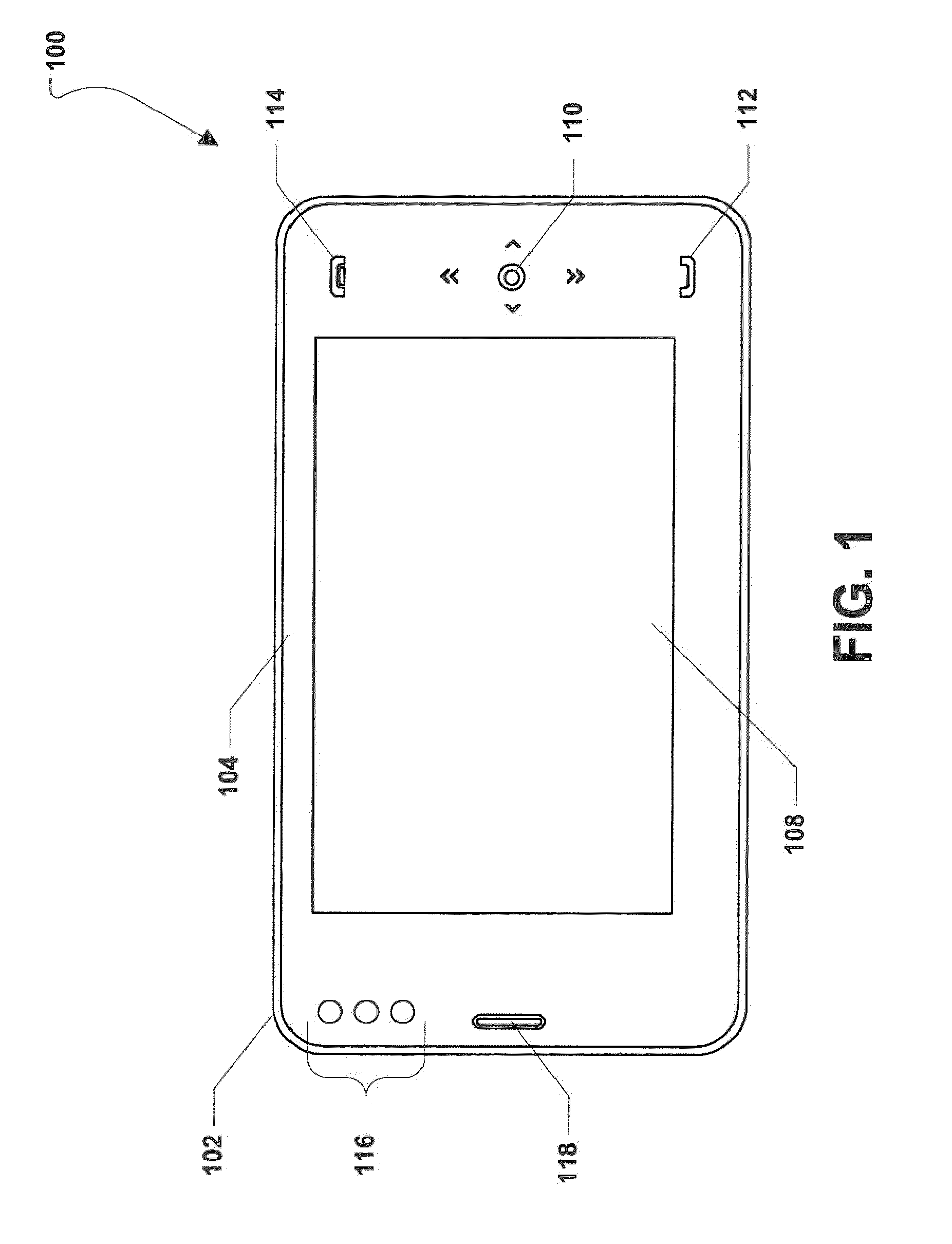

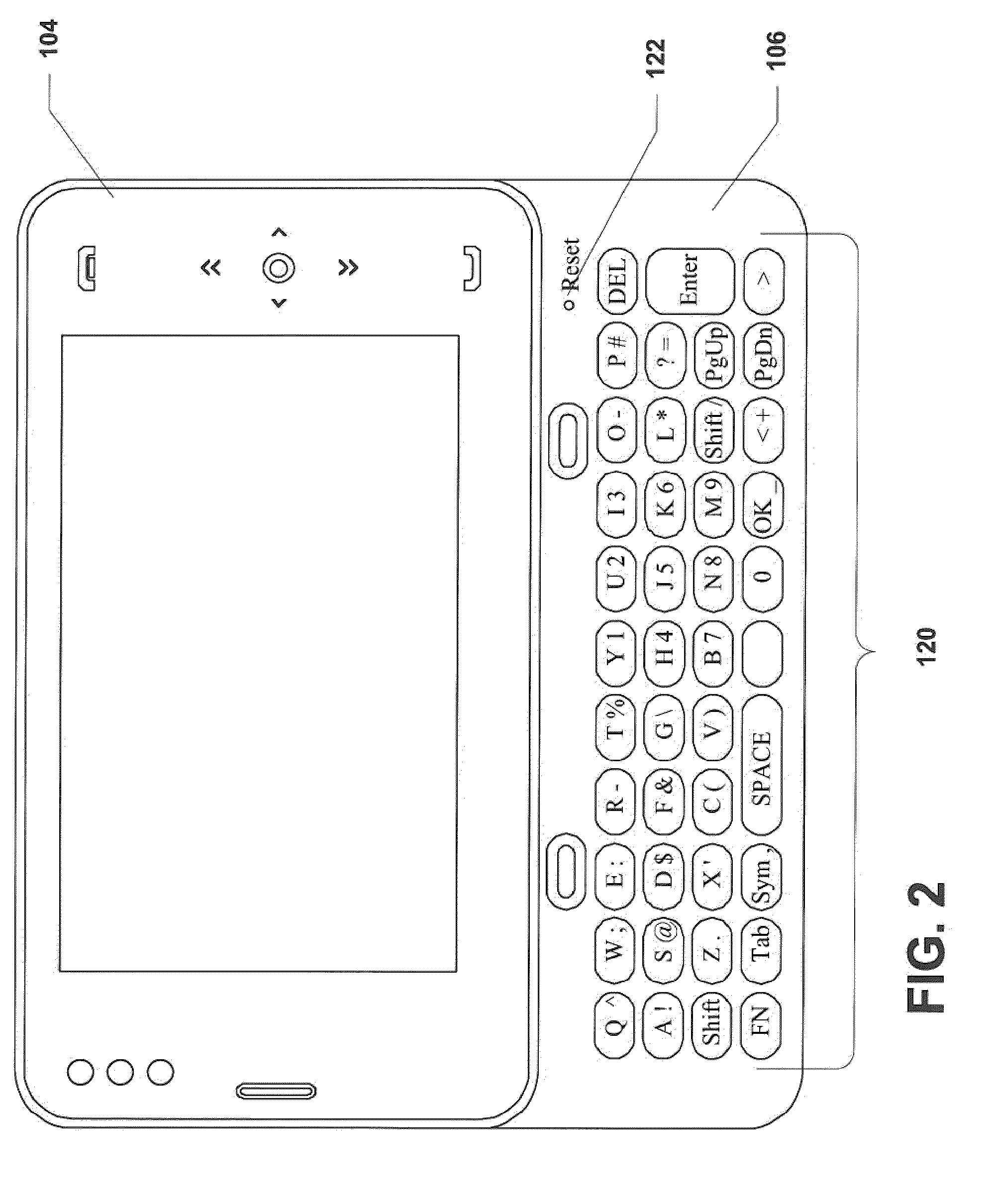

Keyboard for a portable computing device

InactiveUS20100277414A1Input/output for user-computer interactionCathode-ray tube indicatorsComputer scienceContact patch

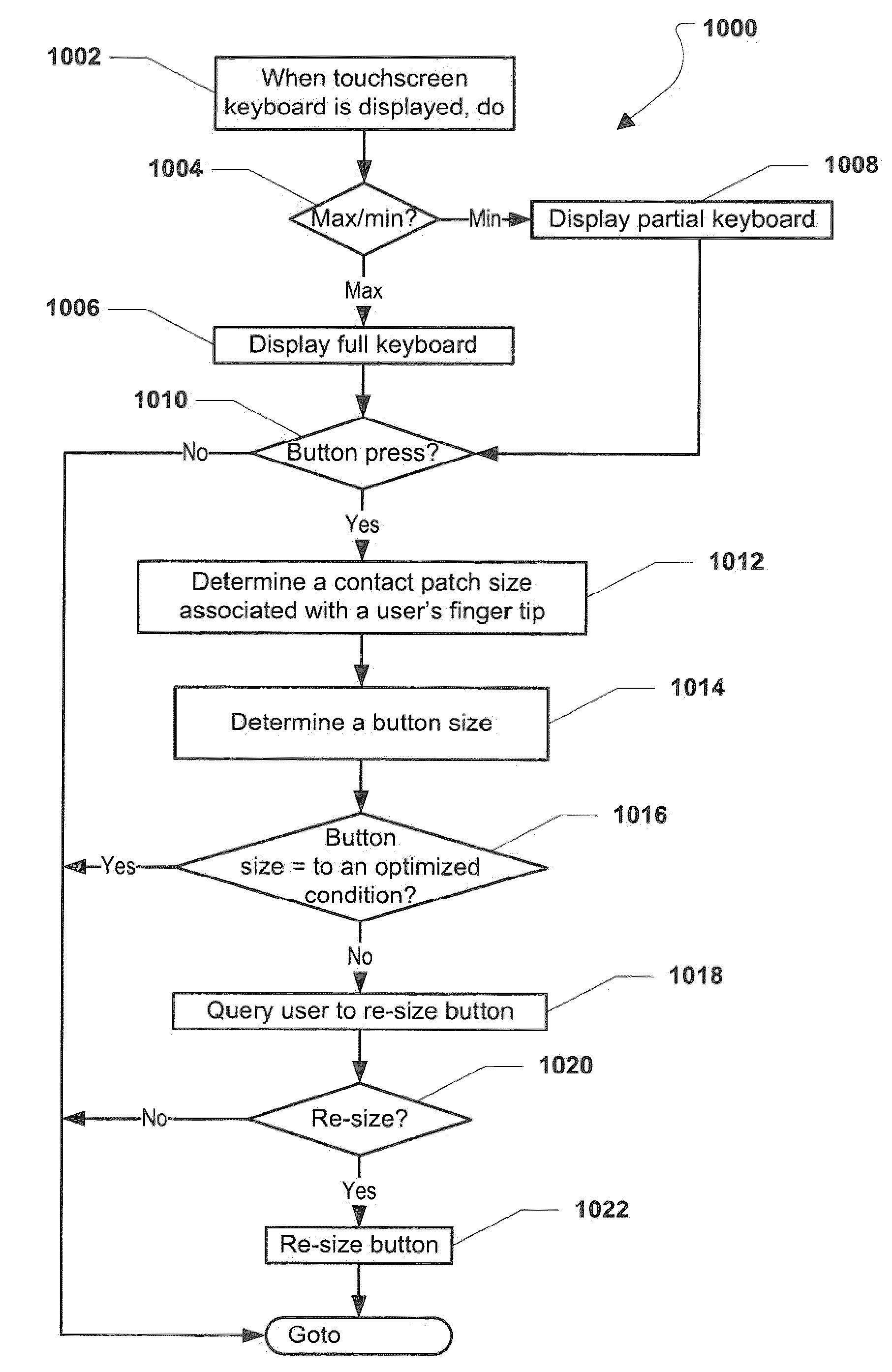

A method for managing a virtual keyboard is disclosed and may include detecting whether a button is pressed and determining a contact patch size associated with a user digit pressing the button. The method may also include determining a button size associated with the button, determining whether the button size satisfies an optimized condition, querying a user to re-size the button when the button size does not satisfy the optimized condition, and automatically re-sizing the button so the button size satisfies the optimized condition. Further, the method may include querying a user to re-size all buttons and automatically re-sizing all buttons based on an optimized button size.

Owner:QUALCOMM INC

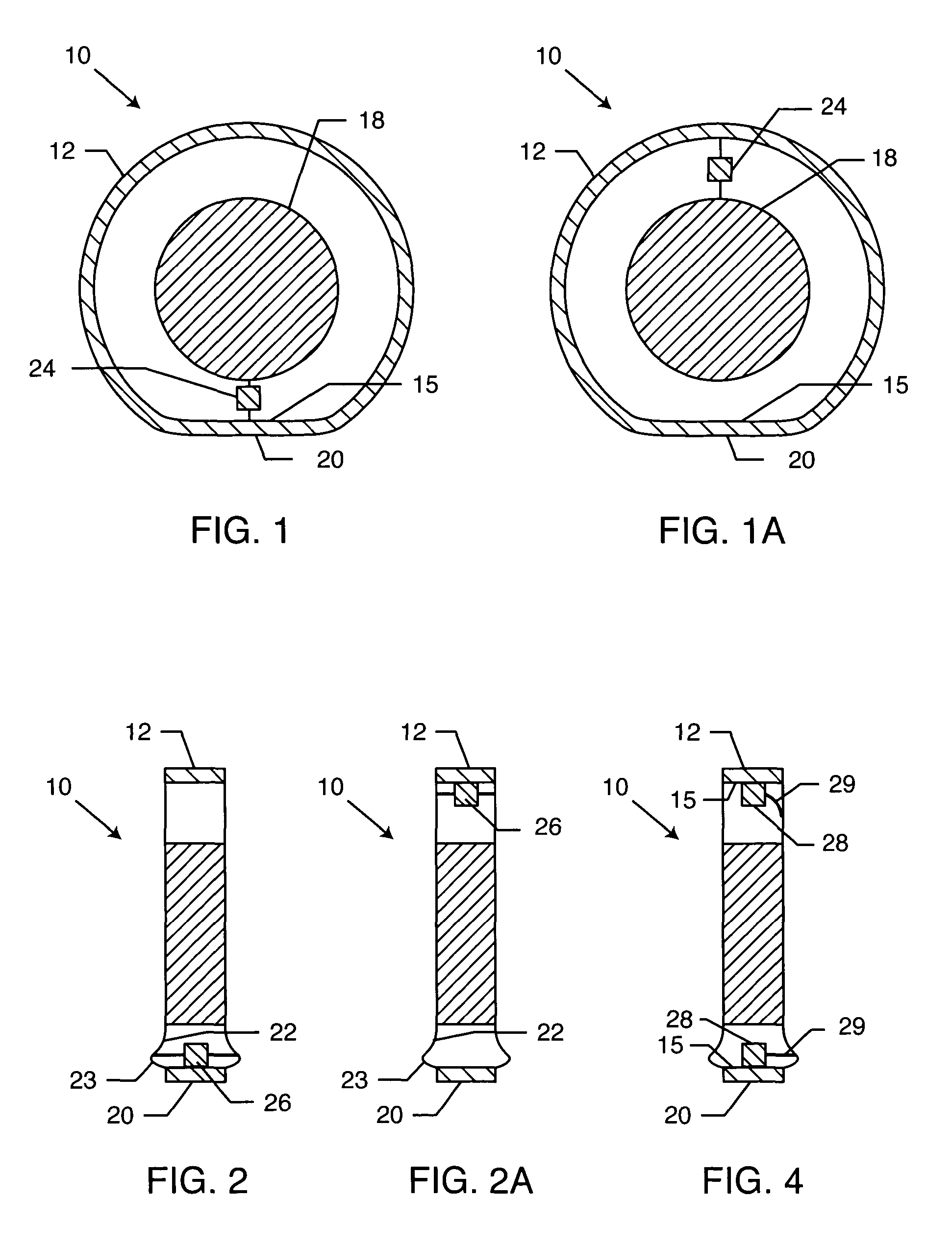

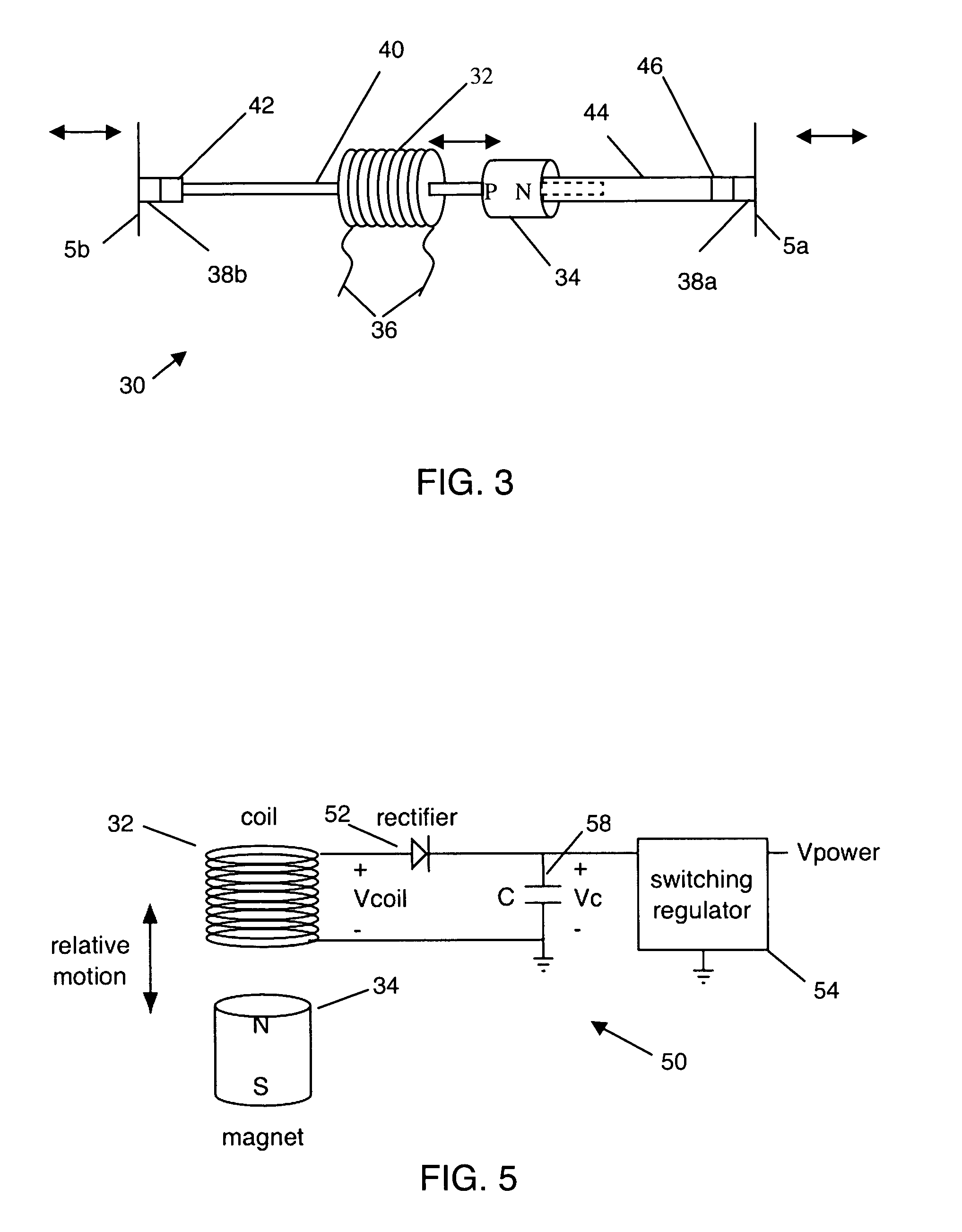

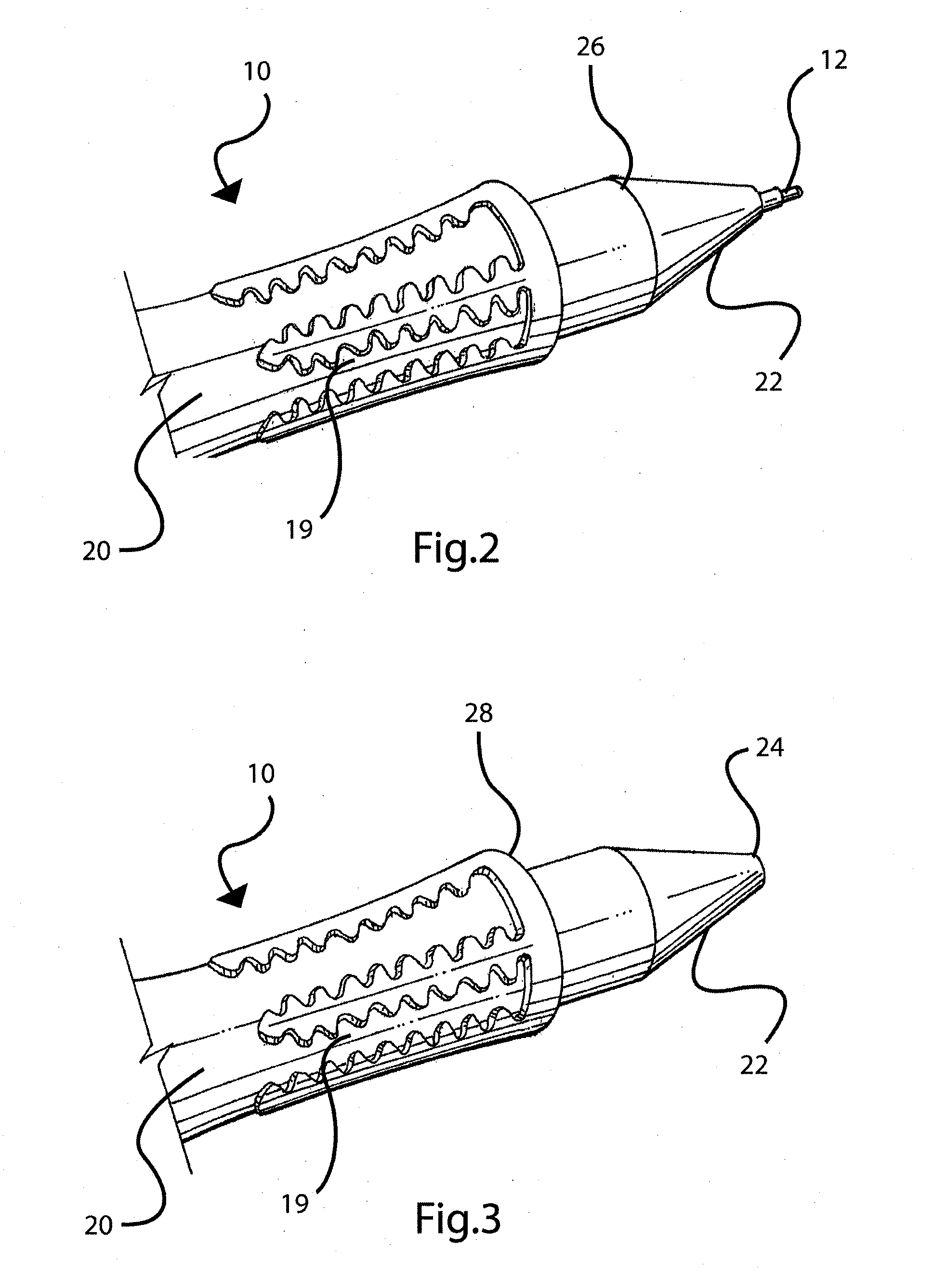

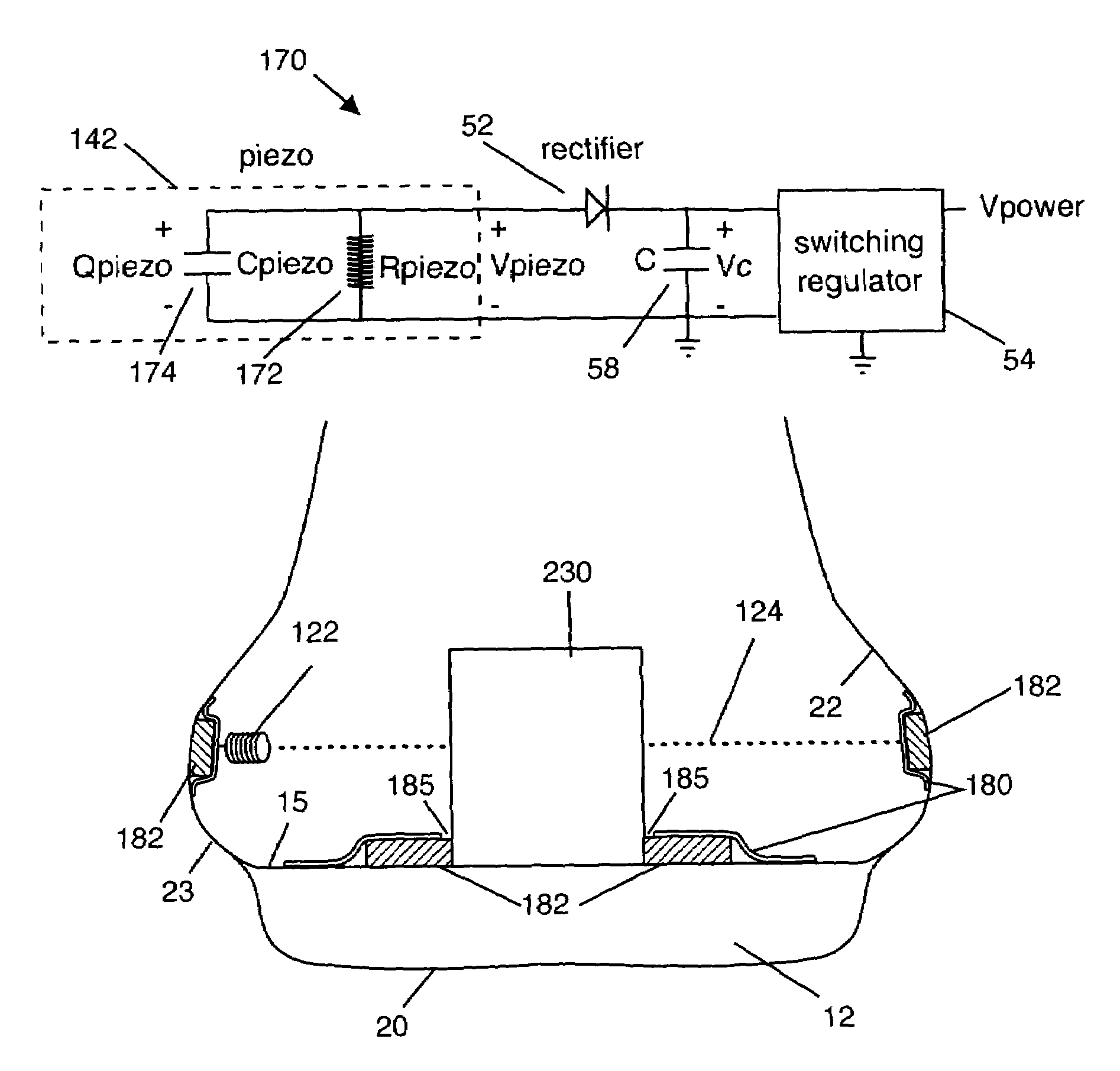

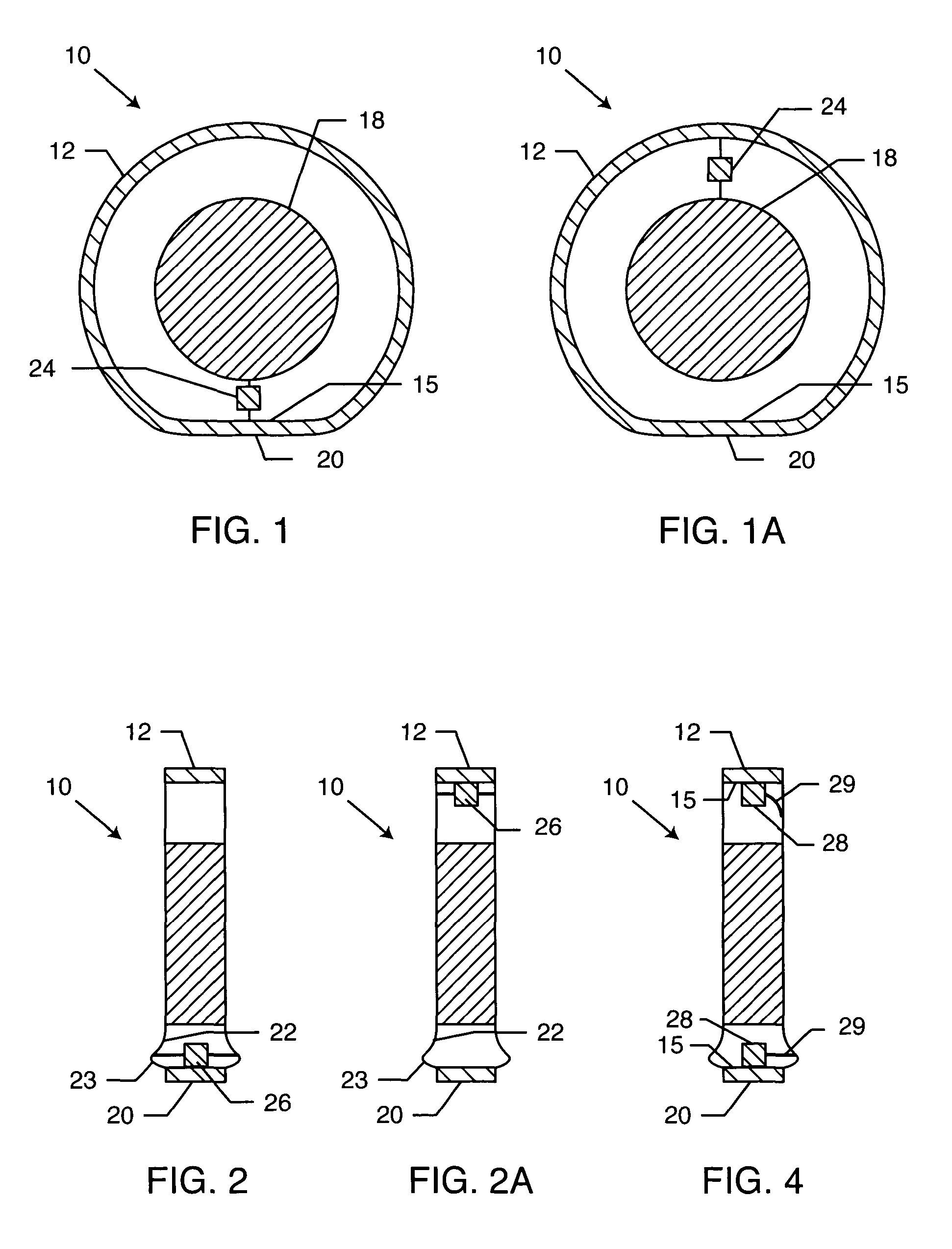

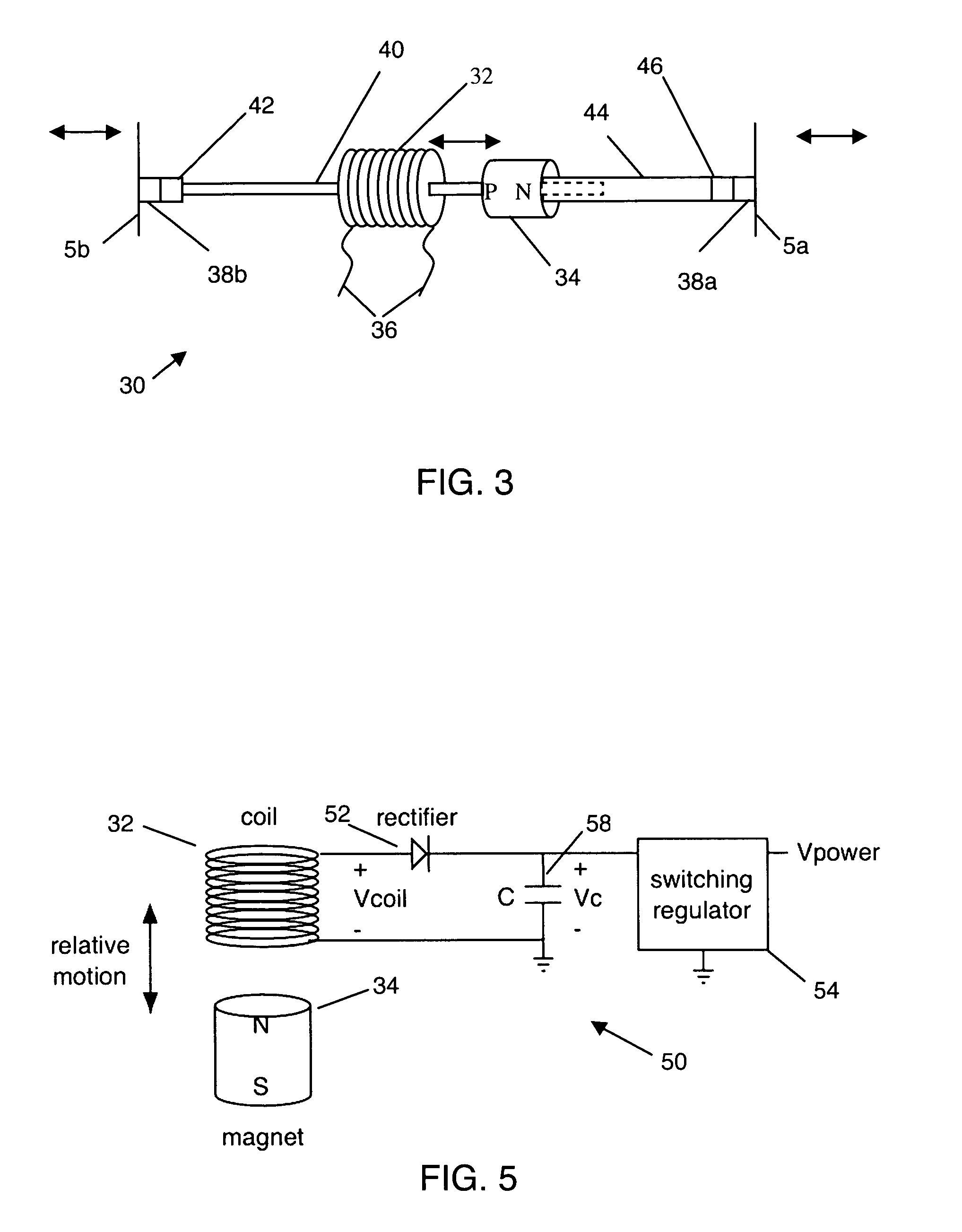

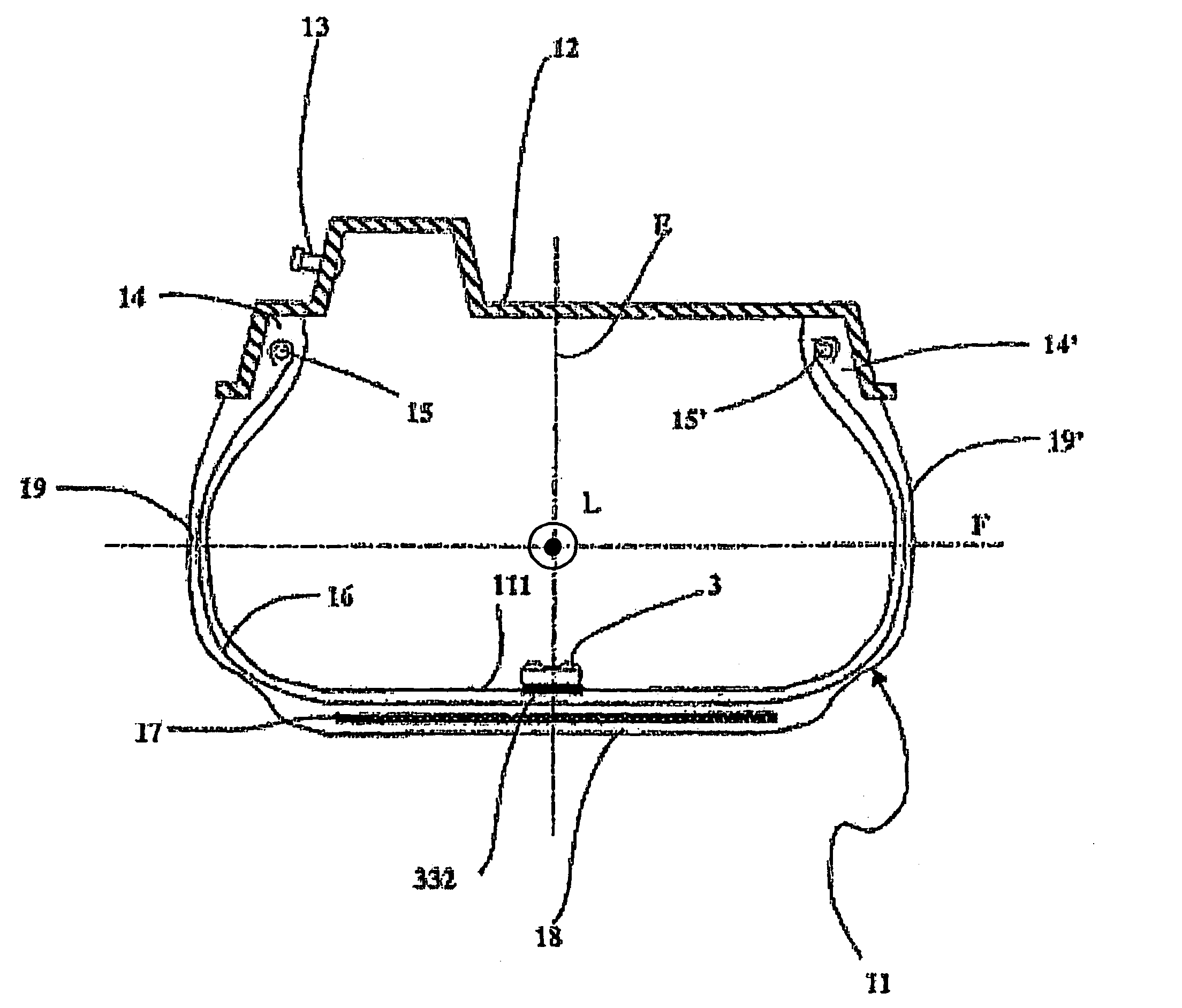

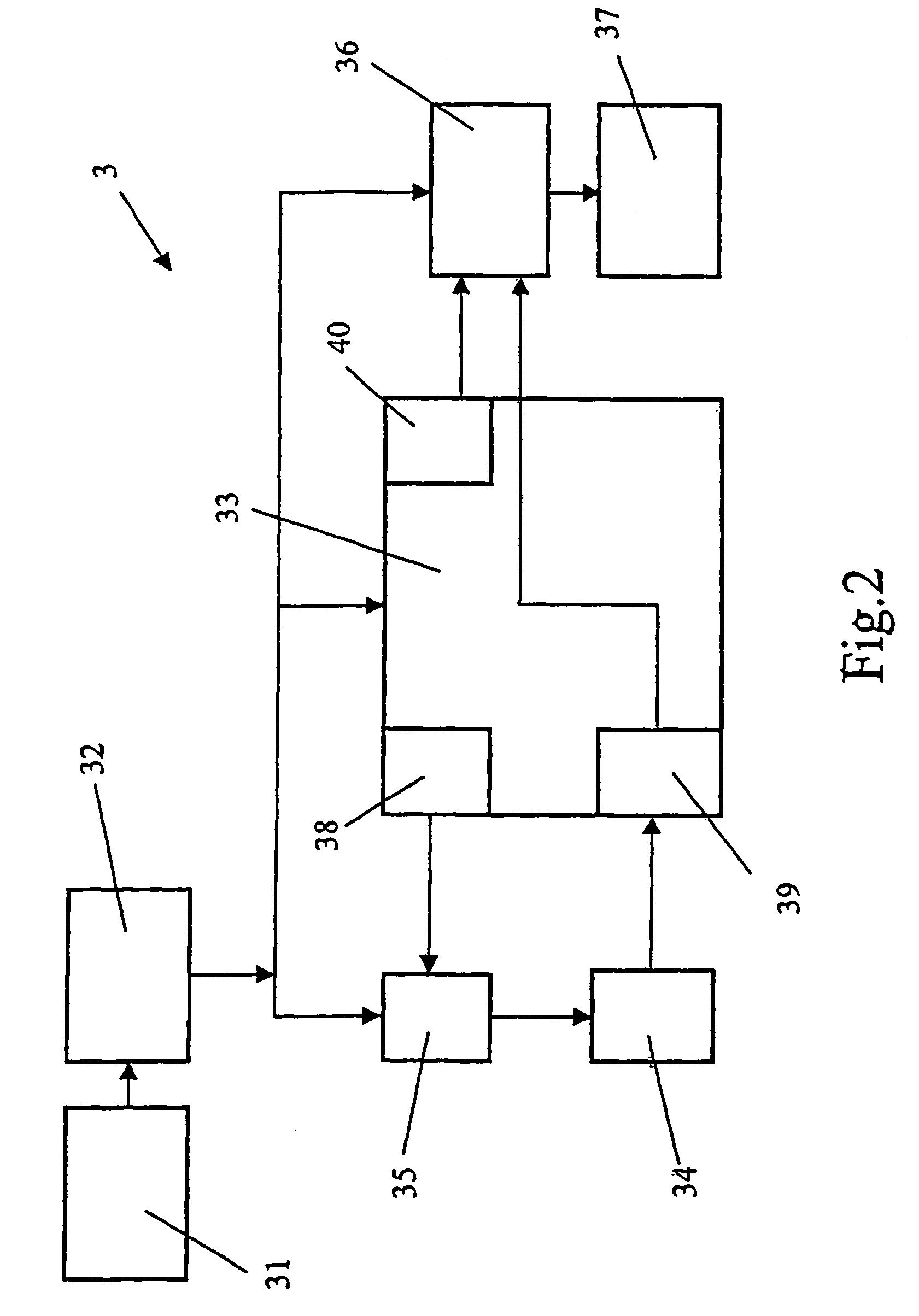

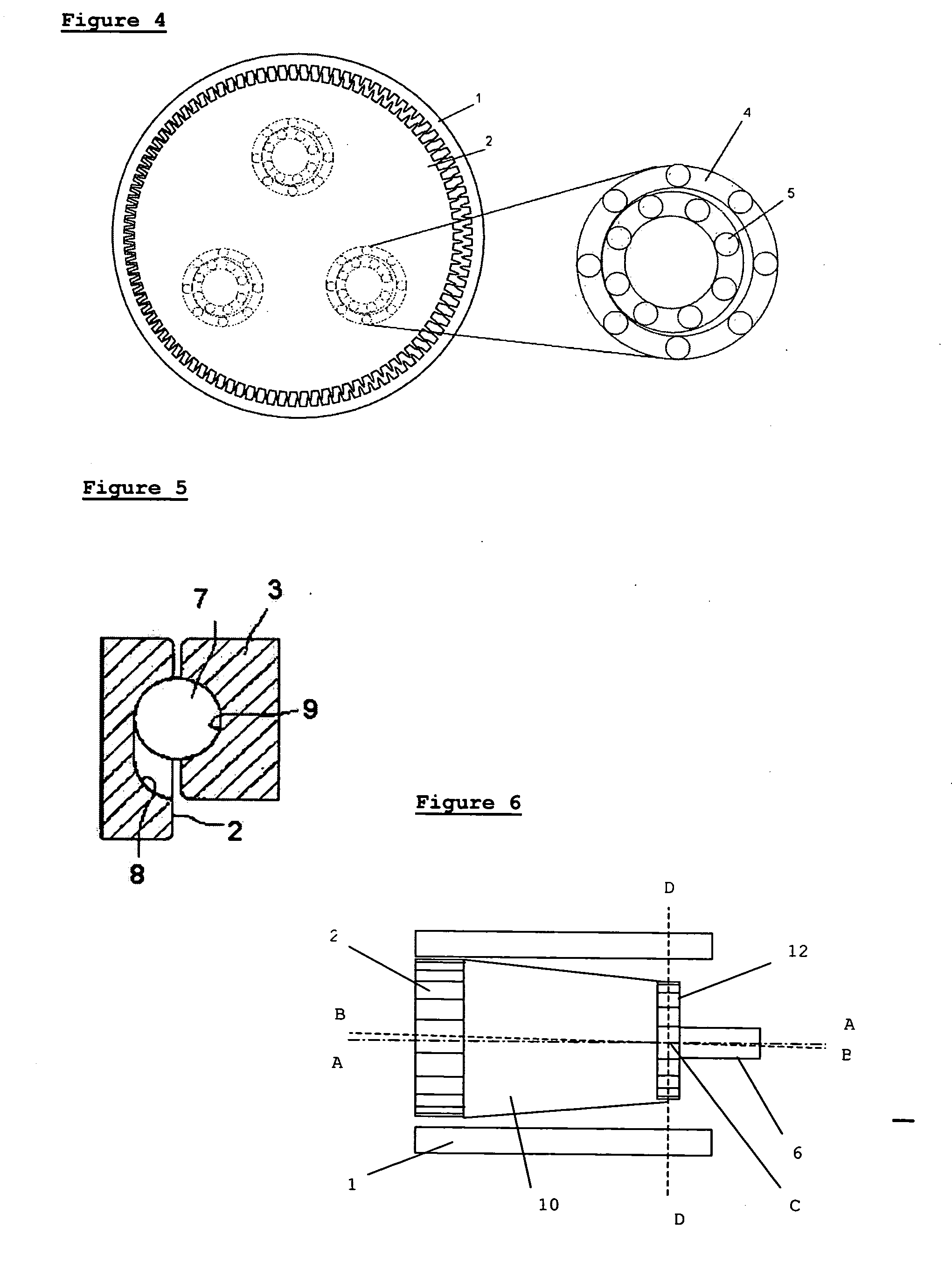

Apparatus and method for energy generation within a tire

InactiveUS20040100100A1No damageNot to damageFlexible wall reciprocating enginesTyre measurementsCapacitanceRotary pump

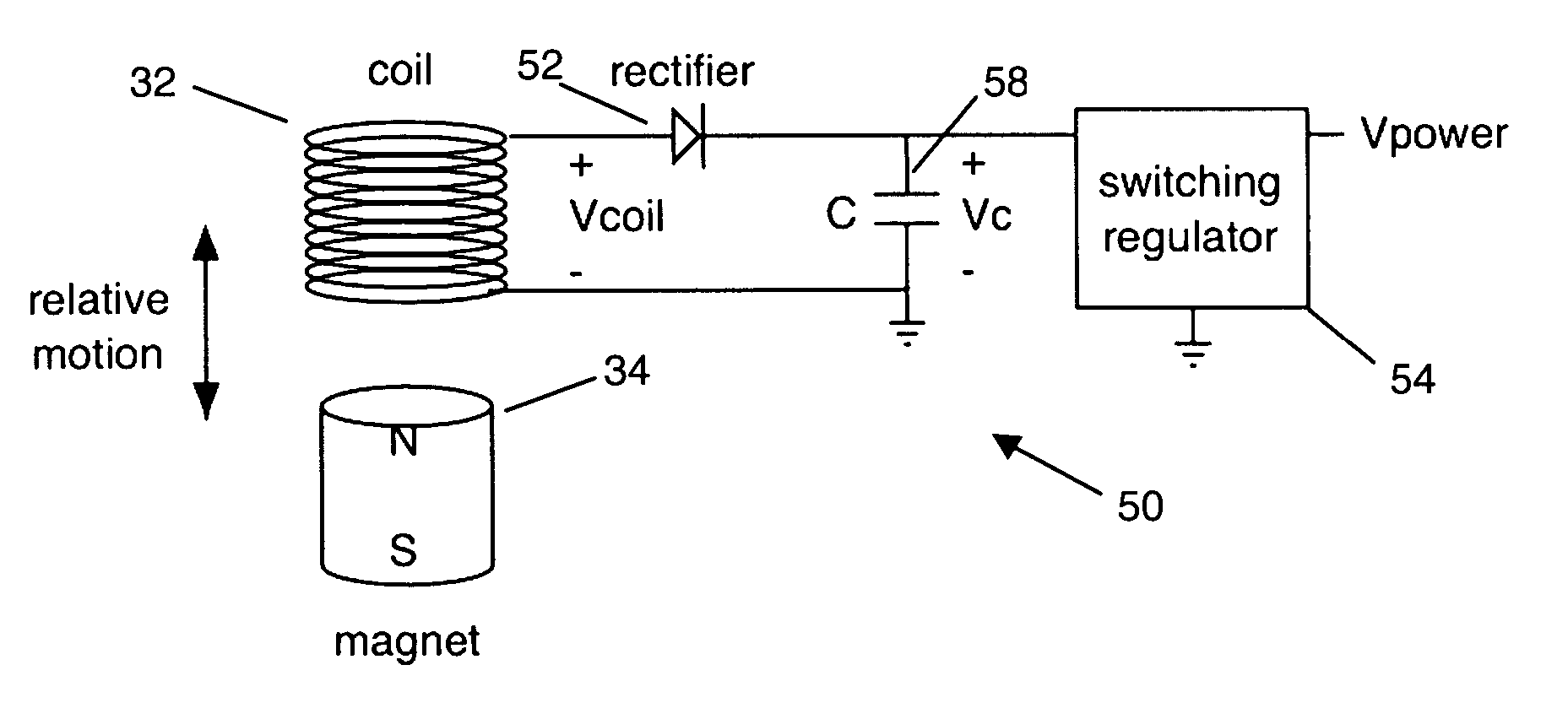

Energy for in-tire use is generated from the load induced reciprocating deflection of the tire inner walls above the tire-to-road contact patch adjacent to the shoulder of the tire. This energy is used to power in-tire monitoring electronics. For pulsatile energy generation with capacitive capture, the capacitor is optimally selected in real-time as a function of pulse width to maximize energy capture, or as a function of the pulse-captured energy. The resulting energy pulses are also used to measure the time duration of the contact patch from which the contact patch length is determined thus providing real-time tire geometry and, with tire pressure, real time tire load and, with temperature, tire air molar content. The loads on all tires provide real time vehicle mass and mass distribution. For electrical energy generation, magnet-coil, piezo-electric, and other power conversions are applicable. For non-electric energy generation, fluid bellows, rotary pump, and other power conversions are applicable. Further, run flat tires are designed with a cutout to accommodate and protect electronic devices mounted on an inner surface when running flat.

Owner:WILSON KITCHENER CLARK

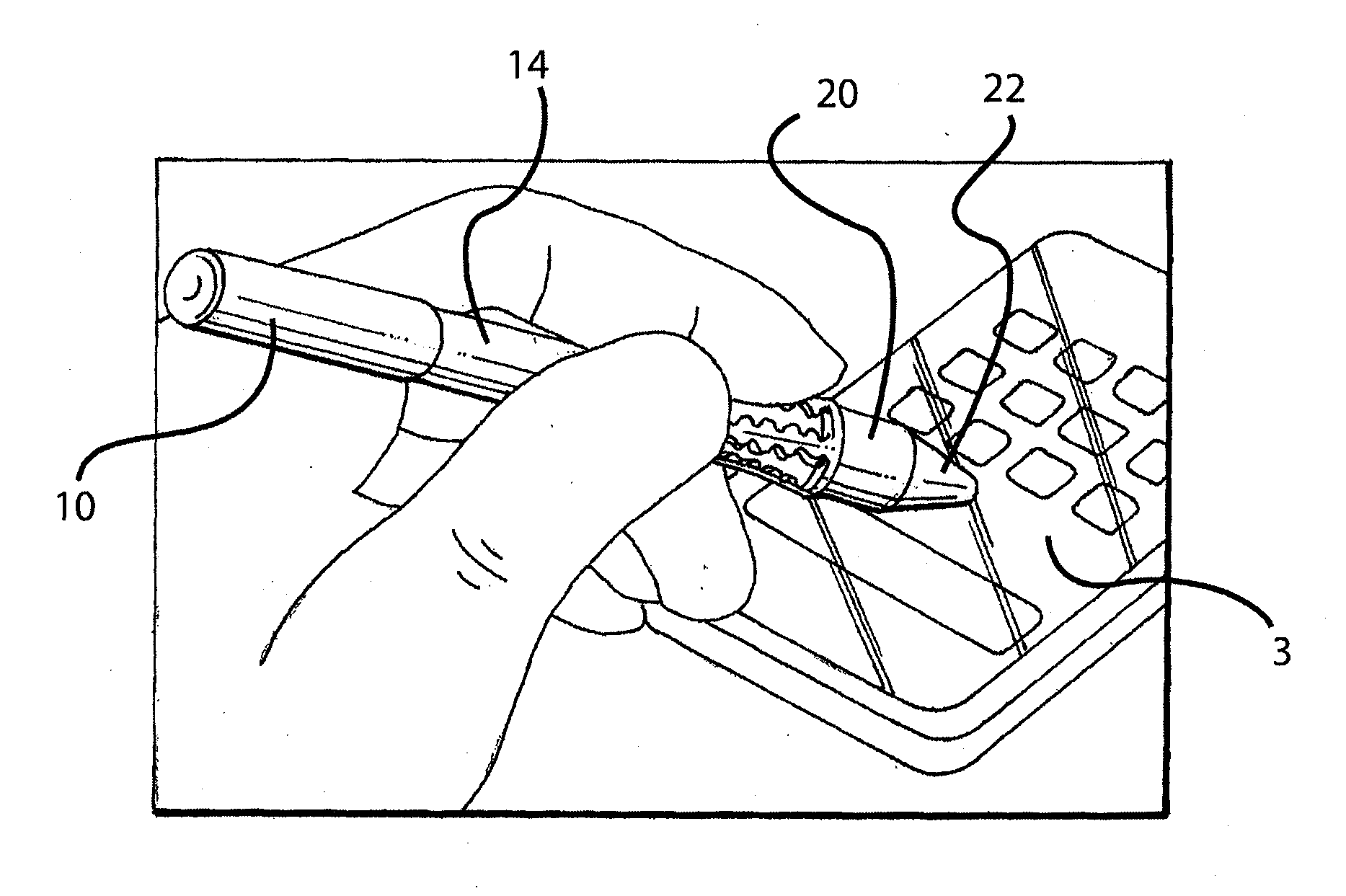

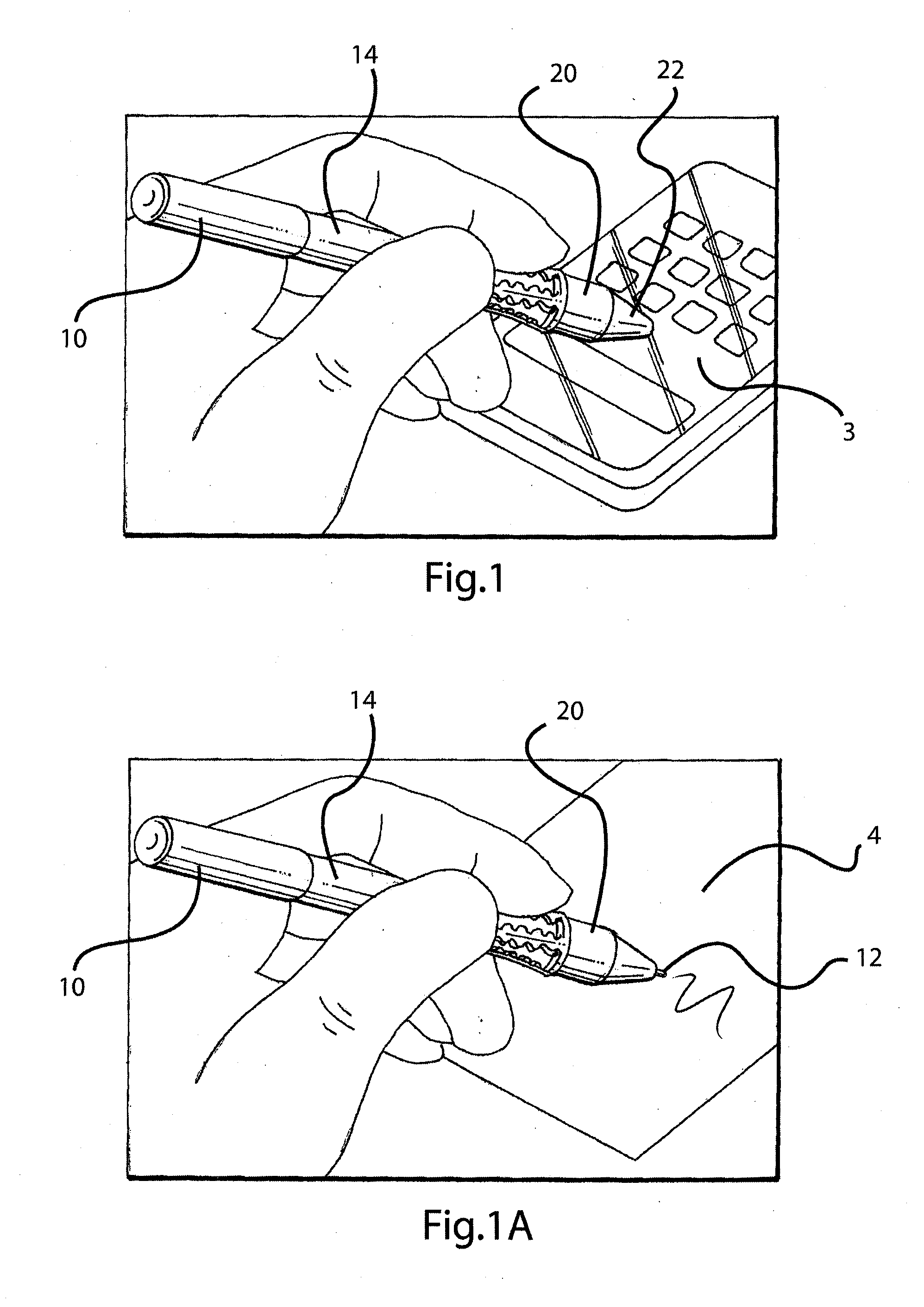

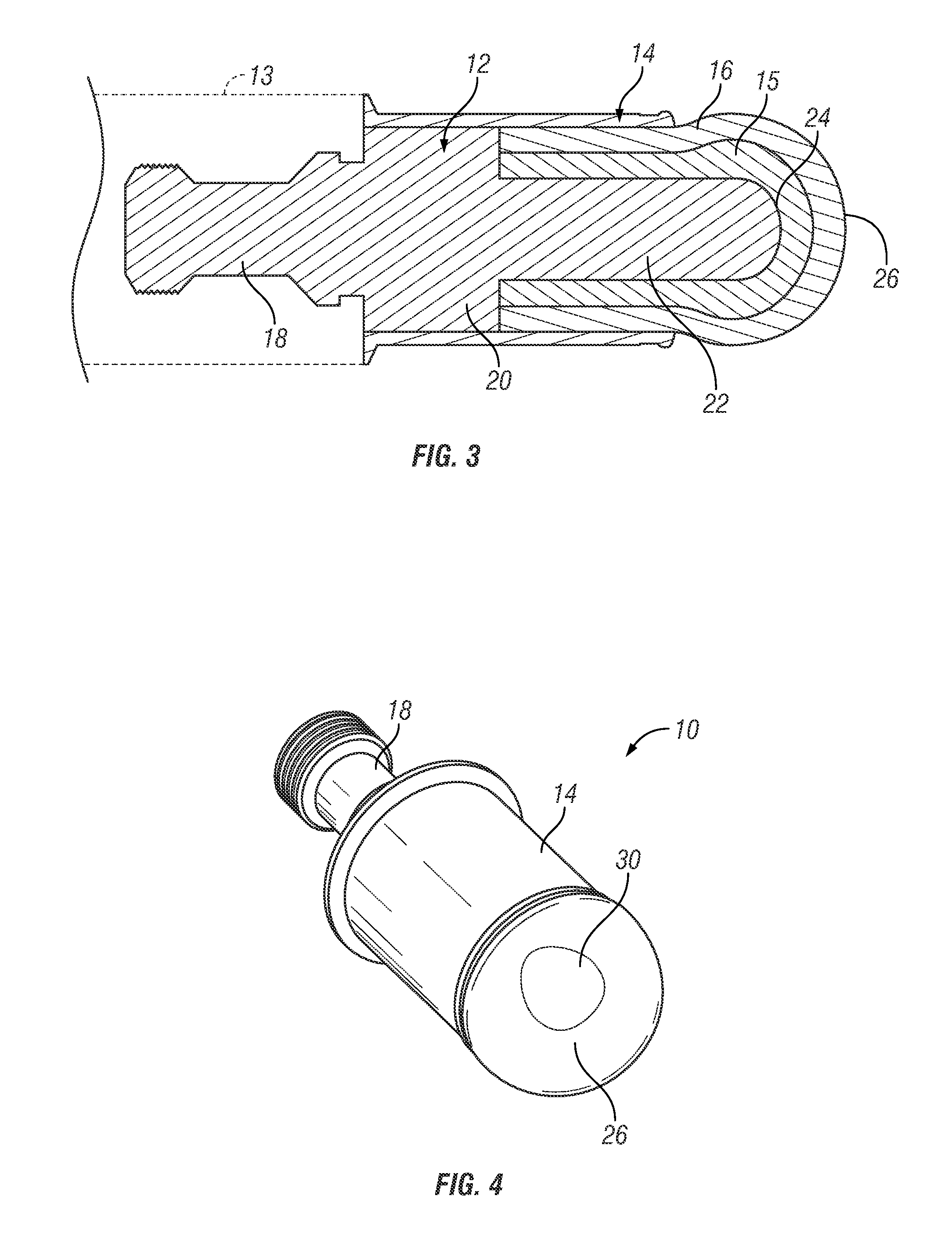

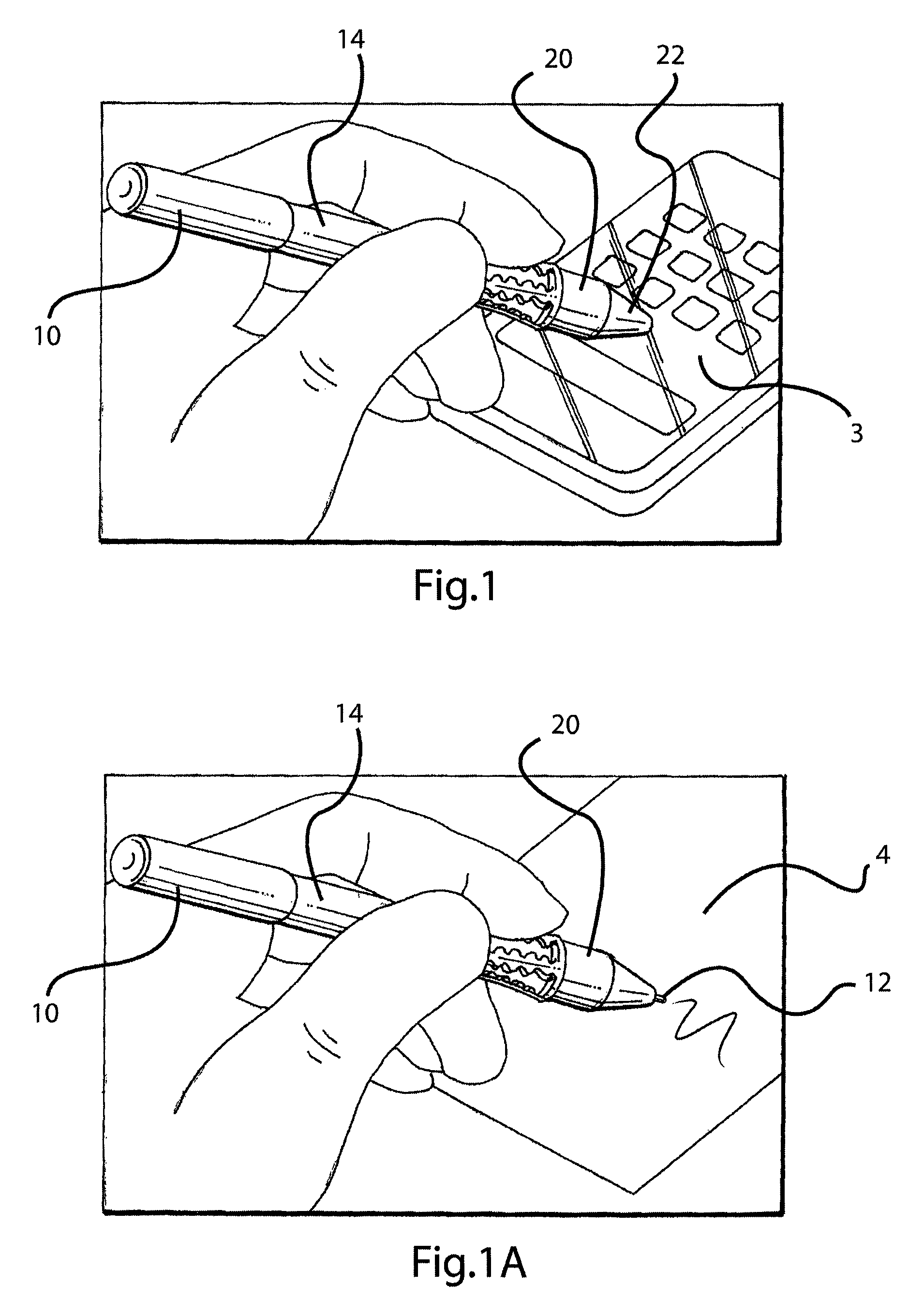

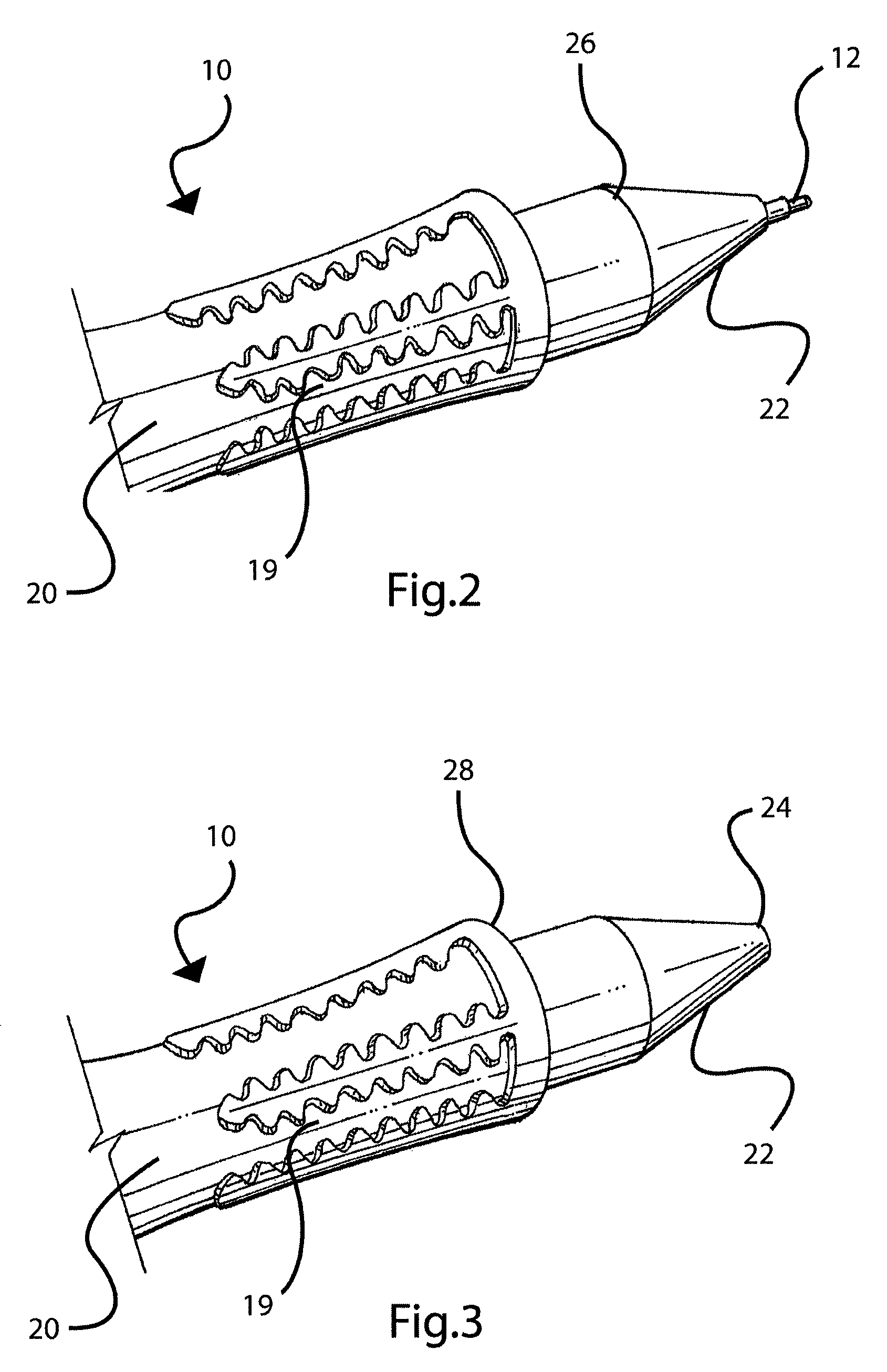

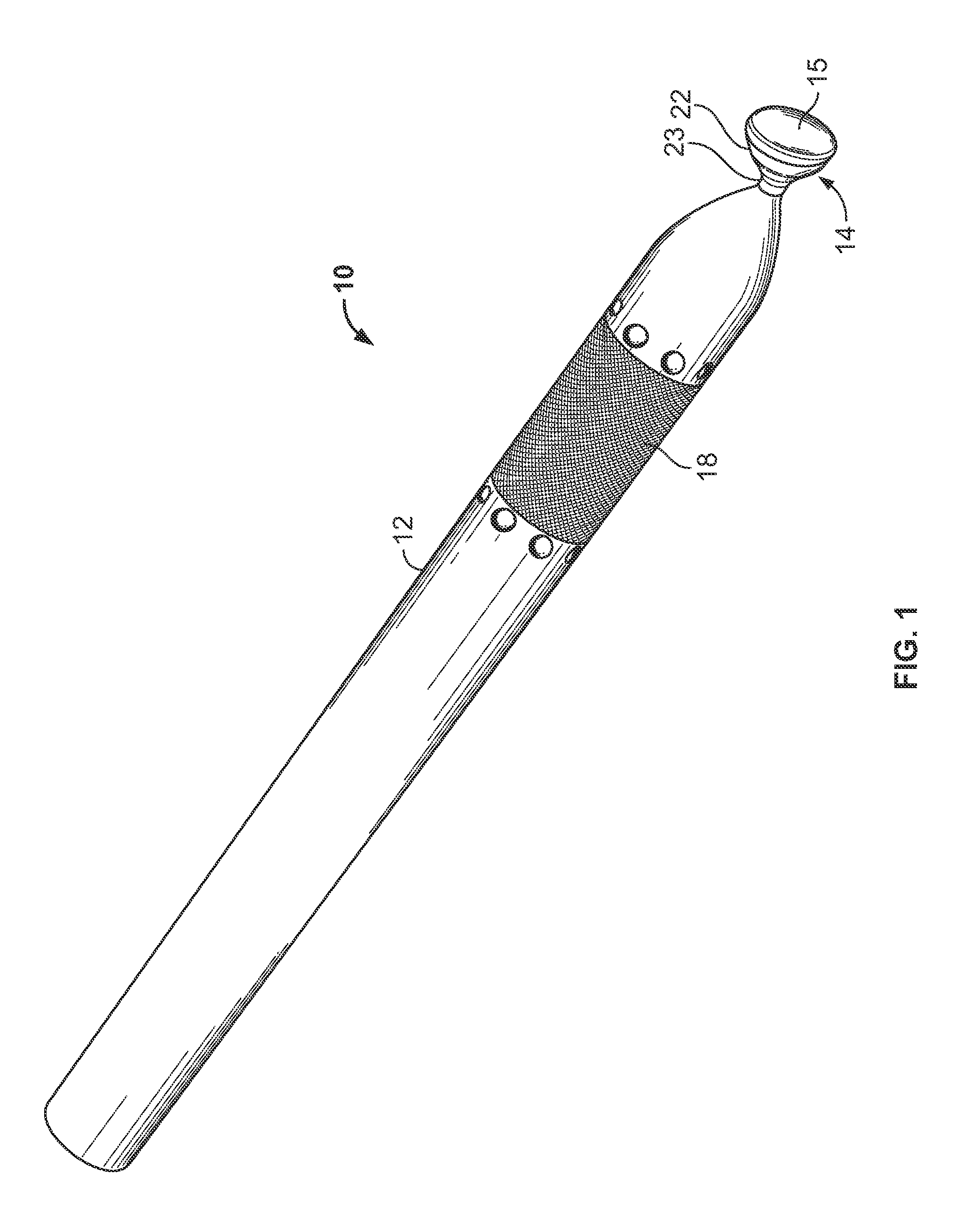

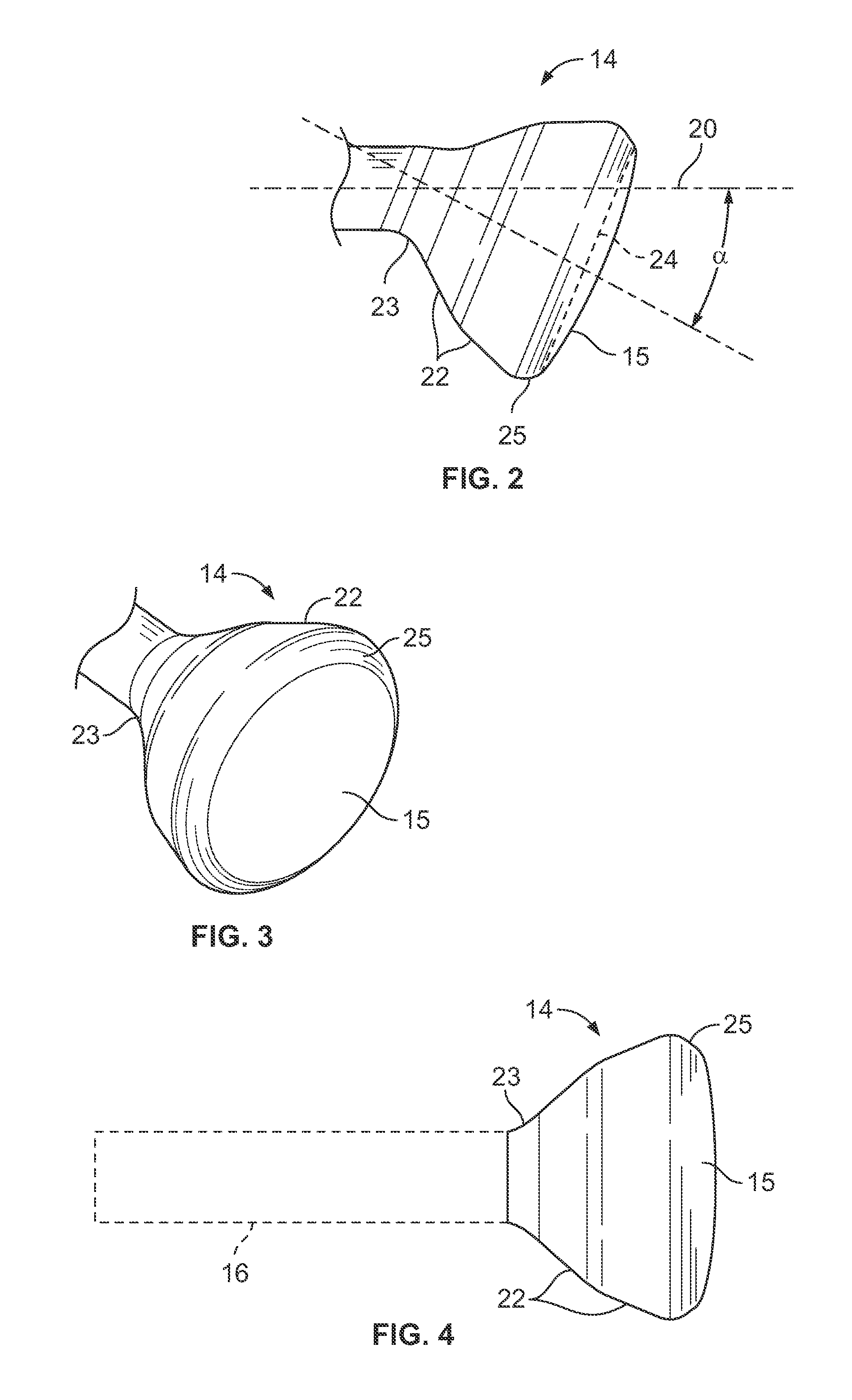

Electrically conductive touch pen

ActiveUS20130038579A1Easy to useEffective insulationWriting connectorsBall-point pensEngineeringTouchscreen

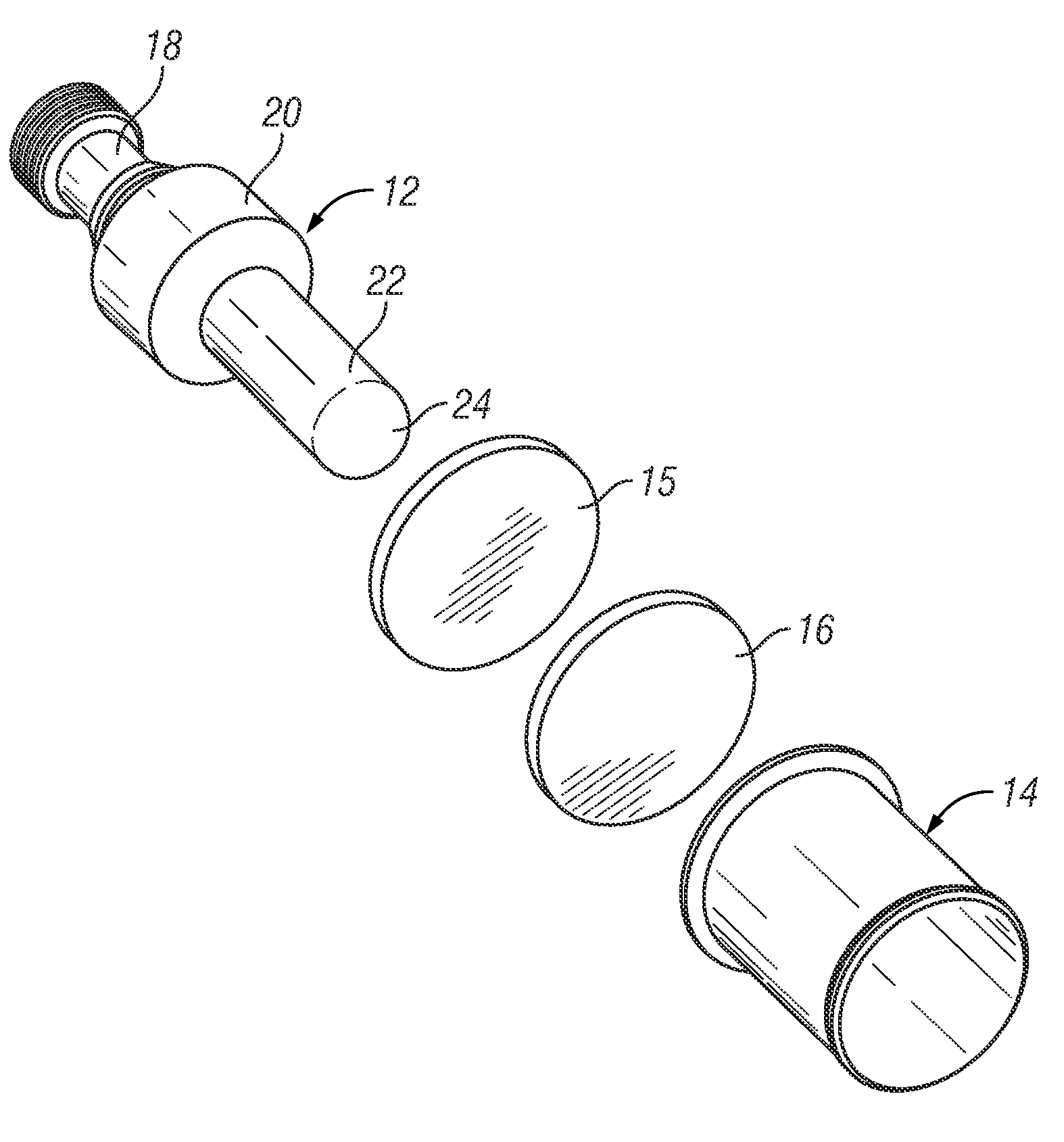

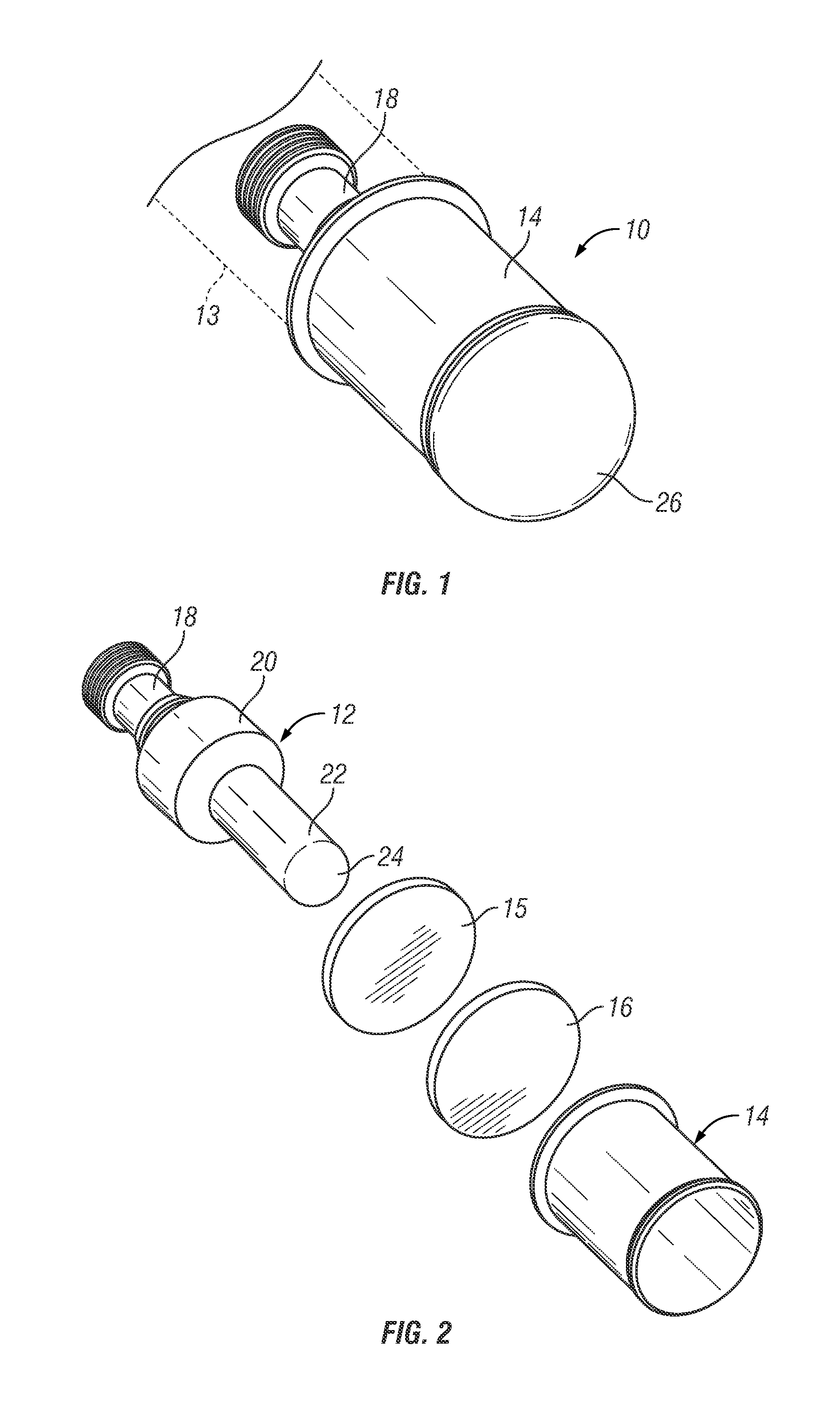

A combination writing pen and stylus is disclosed. The device has an internal ink cartridge deployable through a hole in the stylus tip. The stylus tip extends from a sleeve that is formed of a conductive elastomeric material. The sleeve extends up a rigid shaft of the device such that it contacts a sufficient ground. The stylus tip may be coated with a protective material that adjusts the coefficient of friction and prevents carbon deposits on the touch screen. A sufficient contact patch is achieved to simulate a human finger so as to overcome false positives from common touch screen logic. This is done by altering tip geometries around an air cavity within the sleeve.

Owner:PIXEL PEN LLC

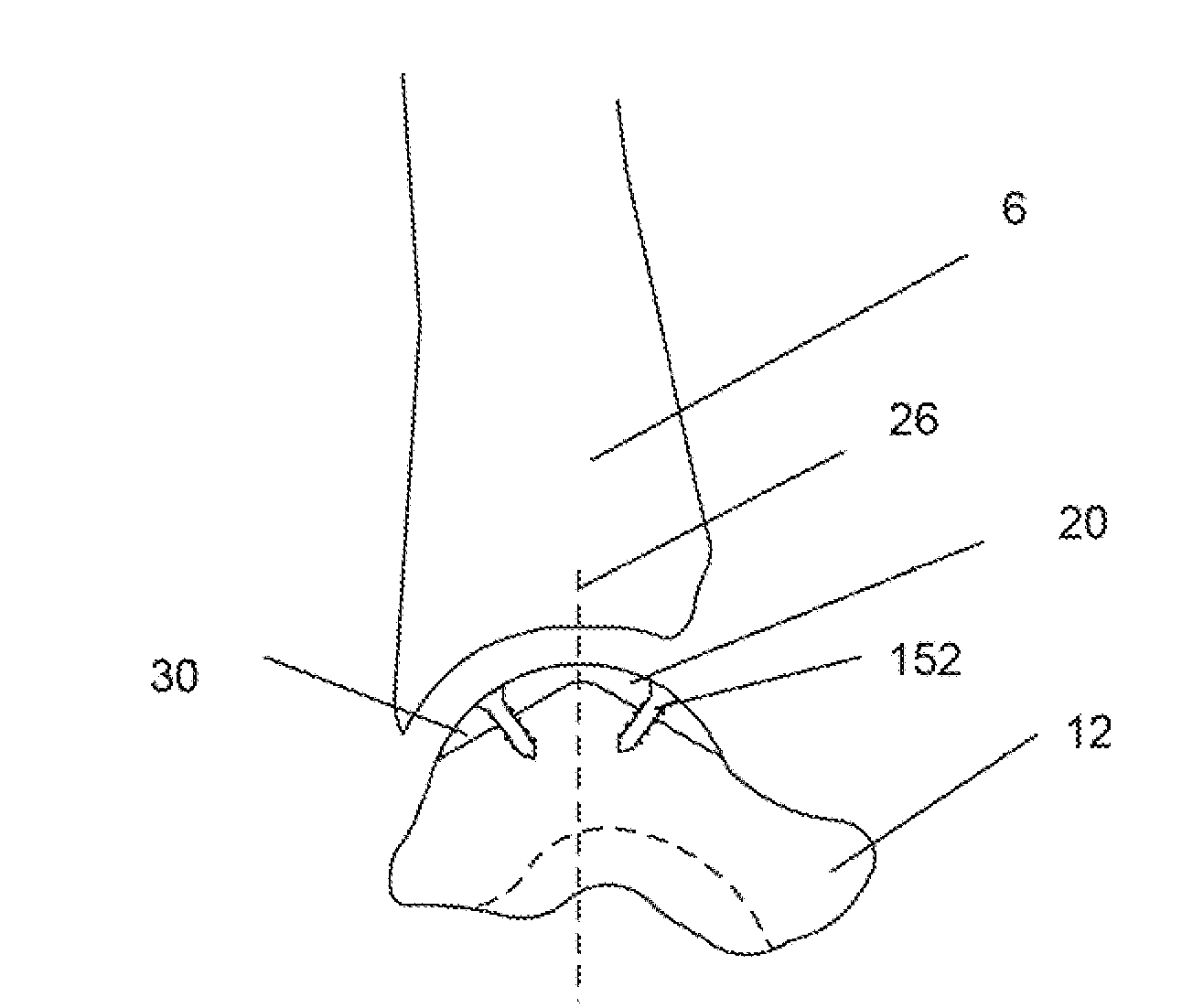

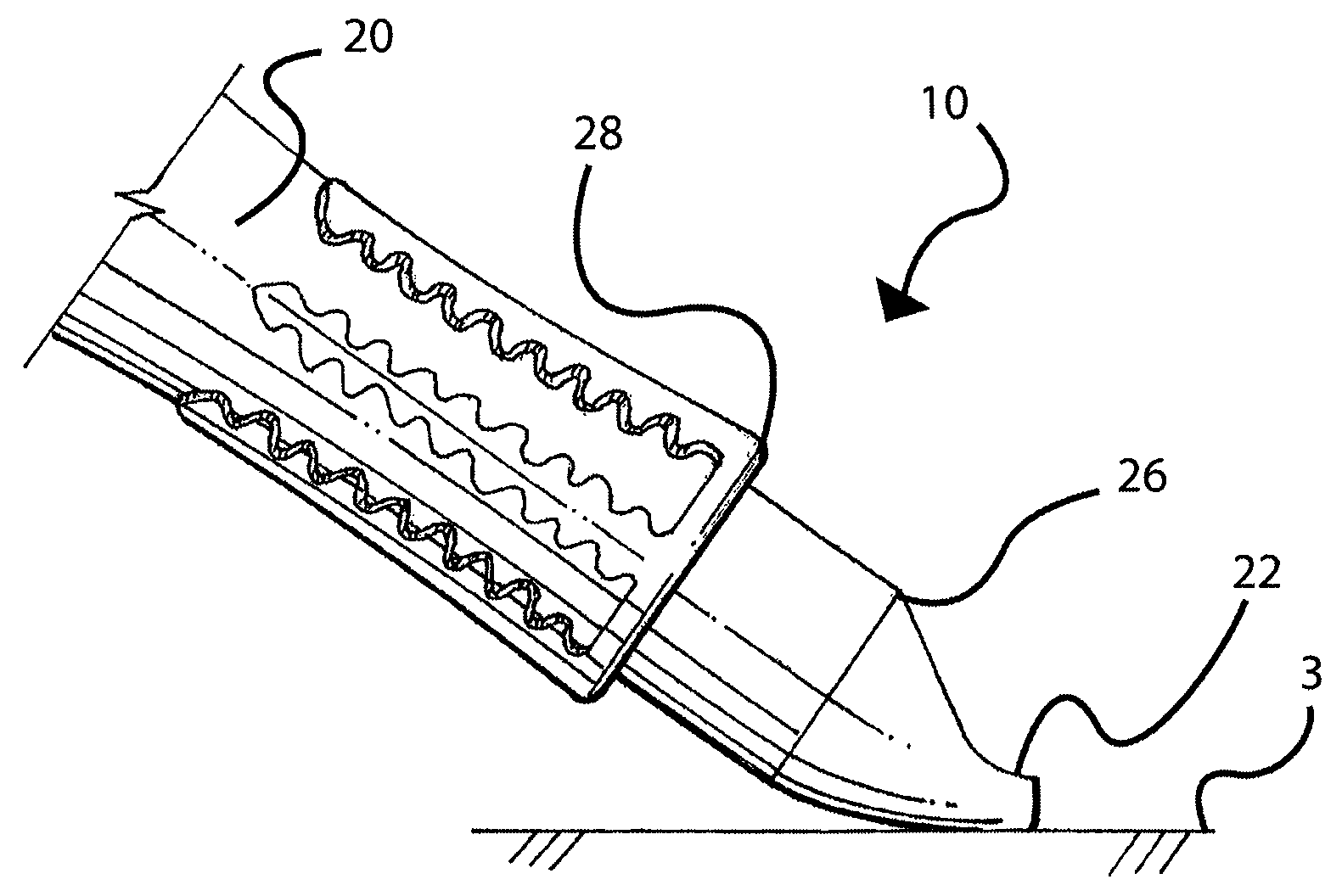

Bone prosthesis

A partial bone prosthesis and methods of using the same are disclosed herein. The partial bone prosthesis can be configured for use, for example, on the superior side of the talus or an end of a long bone, such as the tibia. The partial bone prosthesis can anchor to the perimeter of the contact patch between the bone and the prosthesis. For example, the prosthesis can be attached to the talus without drilling holes through the talus, preserving structural integrity and blood flow within the talus.

Owner:TALUS MEDICAL

Apparatus and method for energy generation within a tire

InactiveUS7285868B2Sufficient powerEliminate needFlexible wall reciprocating enginesTyre measurementsCapacitanceRotary pump

Energy for in-tire use is generated from the load induced reciprocating deflection of the tire inner walls above the tire-to-road contact patch adjacent to the shoulder of the tire. This energy is used to power in-tire monitoring electronics. For pulsatile energy generation with capacitive capture, the capacitor is optimally selected in real-time as a function of pulse width to maximize energy capture, or as a function of the pulse-captured energy. The resulting energy pulses are also used to measure the time duration of the contact patch from which the contact patch length is determined thus providing real-time tire geometry and, with tire pressure, real time tire load and, with temperature, tire air molar content. The loads on all tires provide real time vehicle mass and mass distribution. For electrical energy generation, magnet-coil, piezo-electric, and other power conversions are applicable. For non-electric energy generation, fluid bellows, rotary pump, and other power conversions are applicable. Further, run flat tires are designed with a cutout to accommodate and protect electronic devices mounted on an inner surface when running flat.

Owner:WILSON KITCHENER CLARK

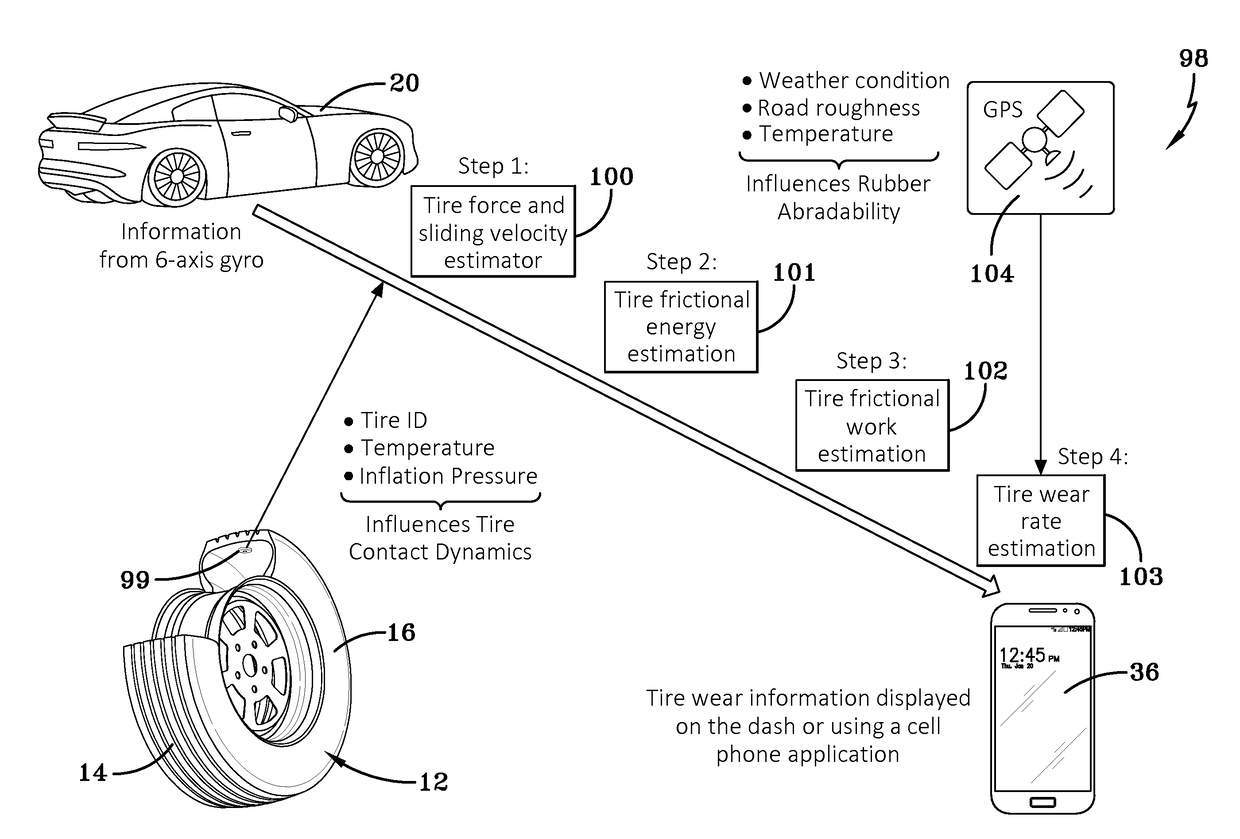

Indirect tire wear state prediction system and method

ActiveUS20170113494A1Great tractionError minimizationSatellite radio beaconingTyre measurementsState predictionPrediction system

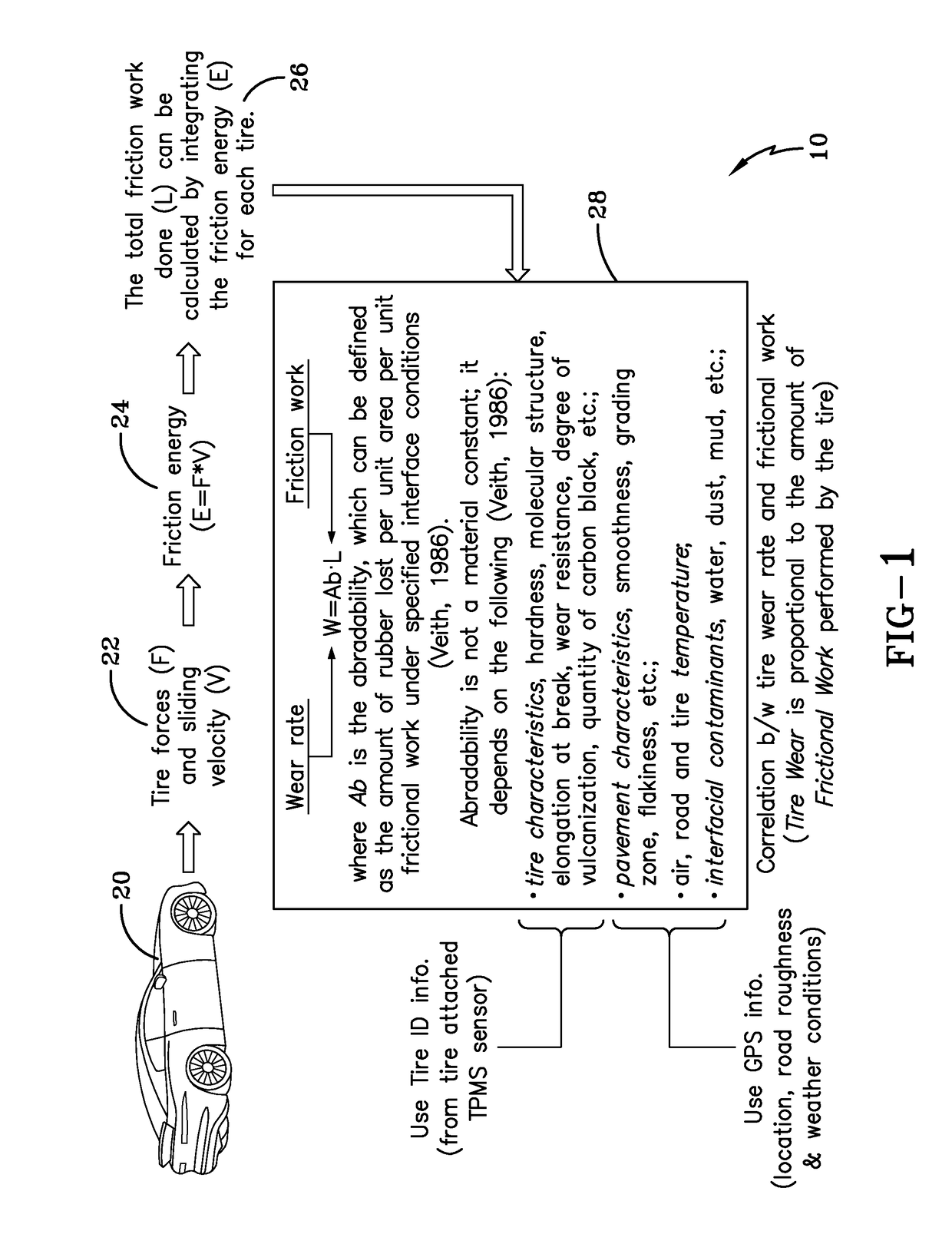

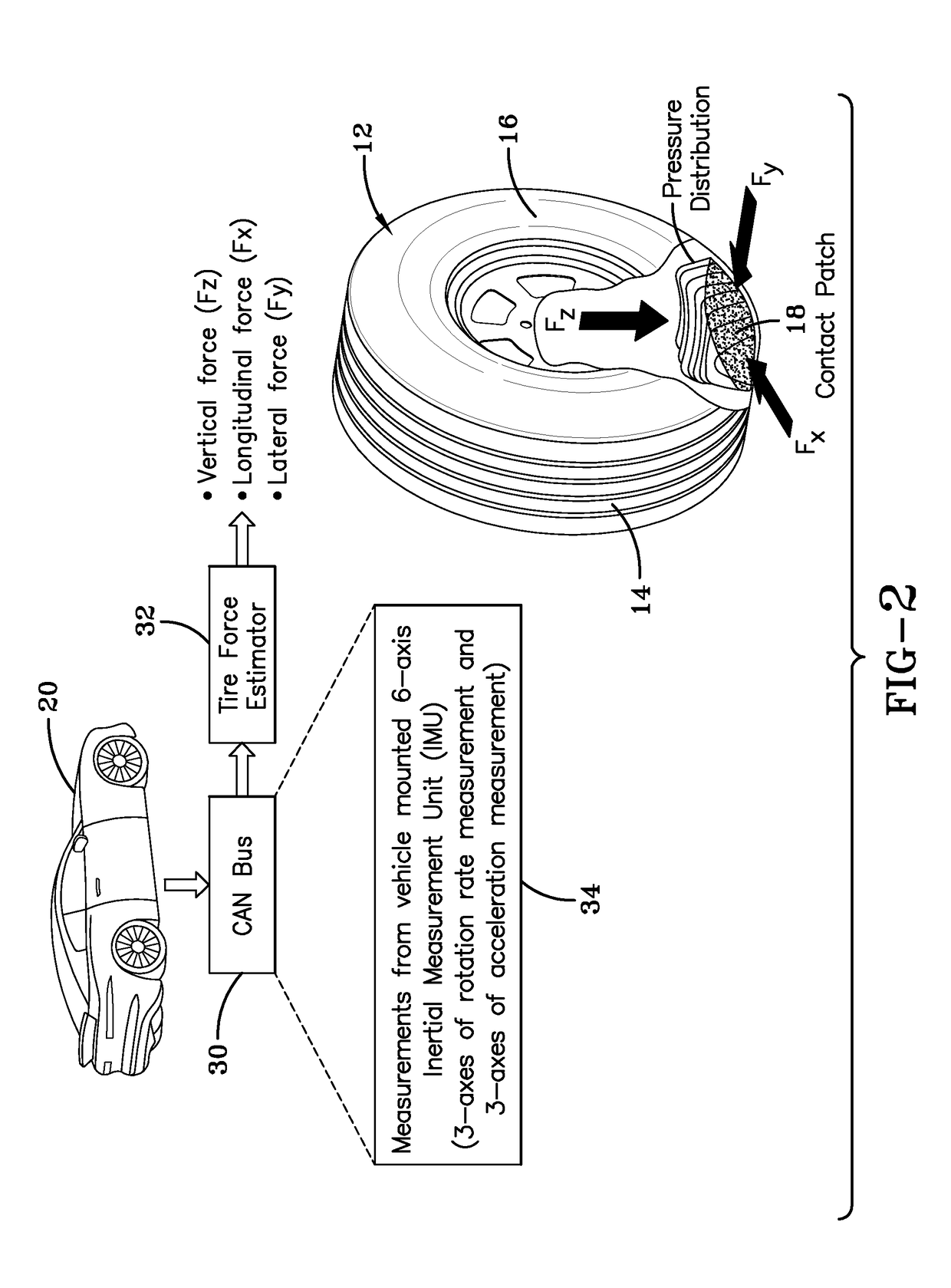

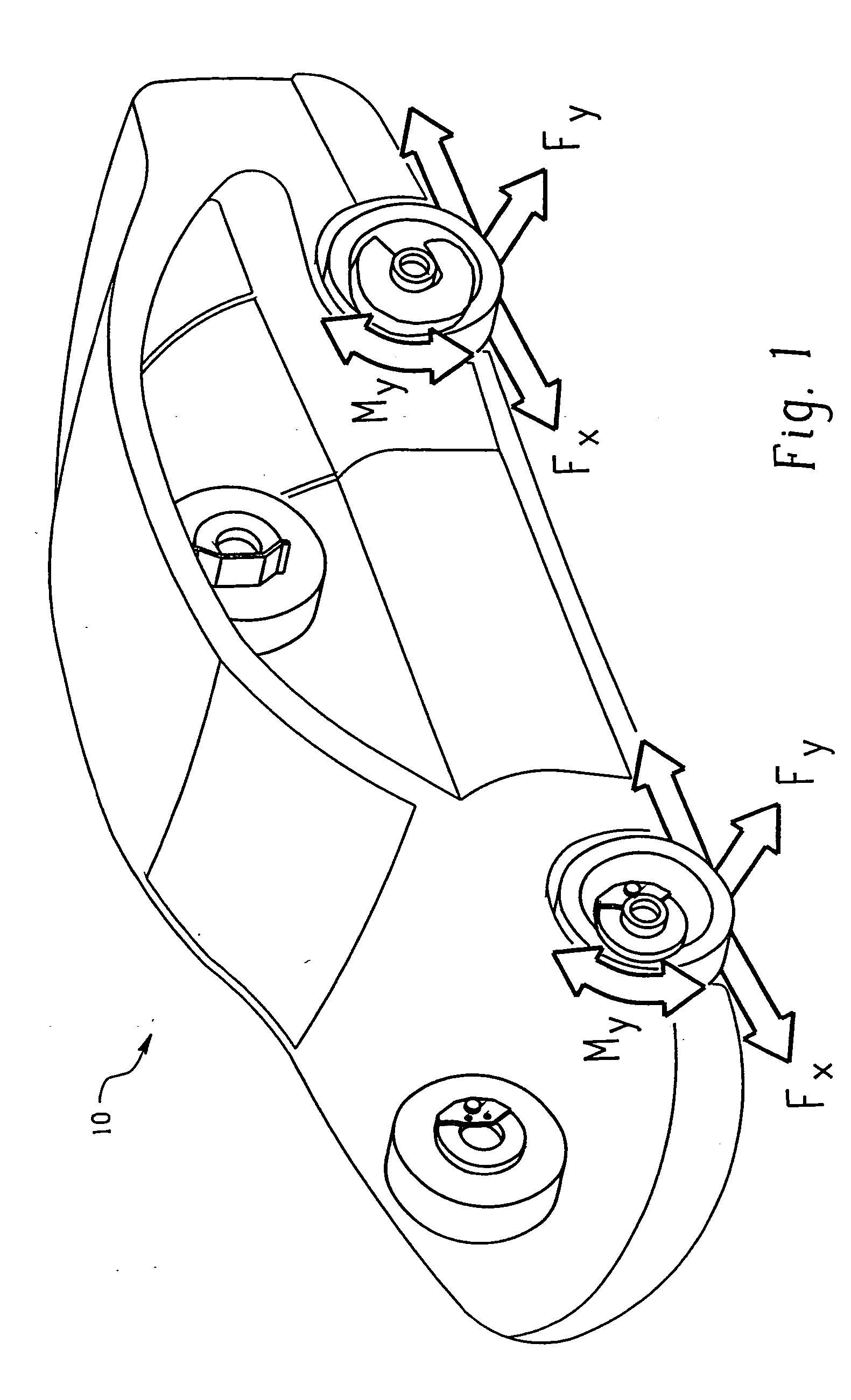

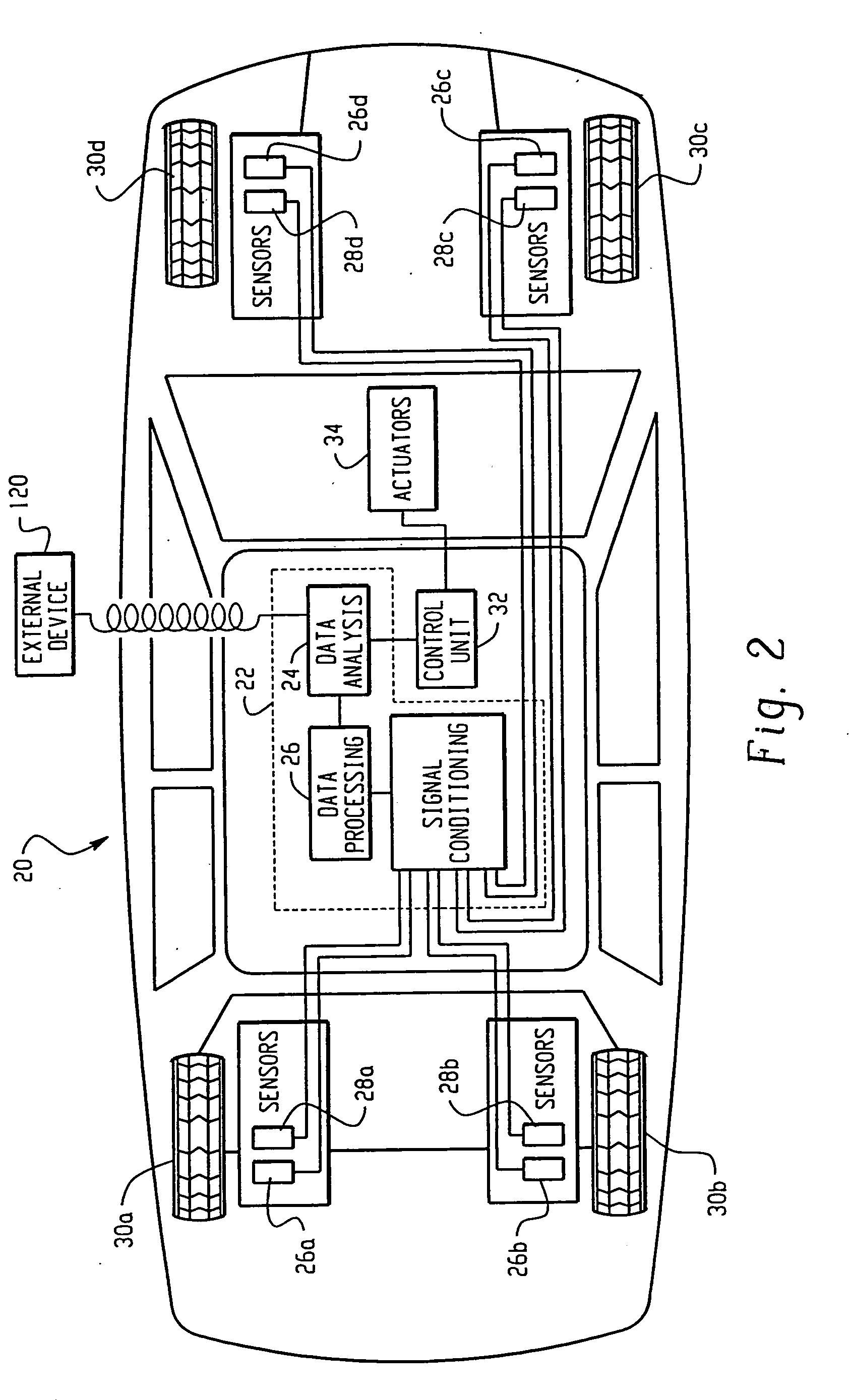

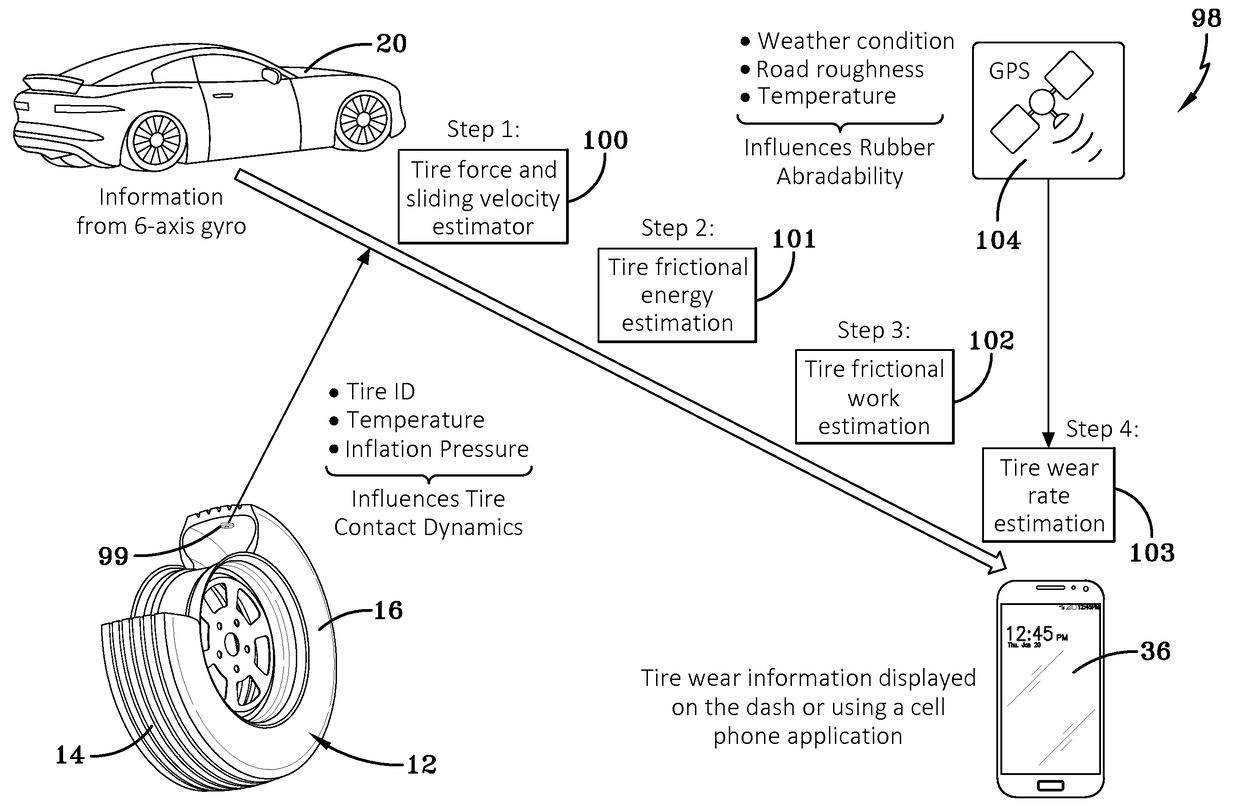

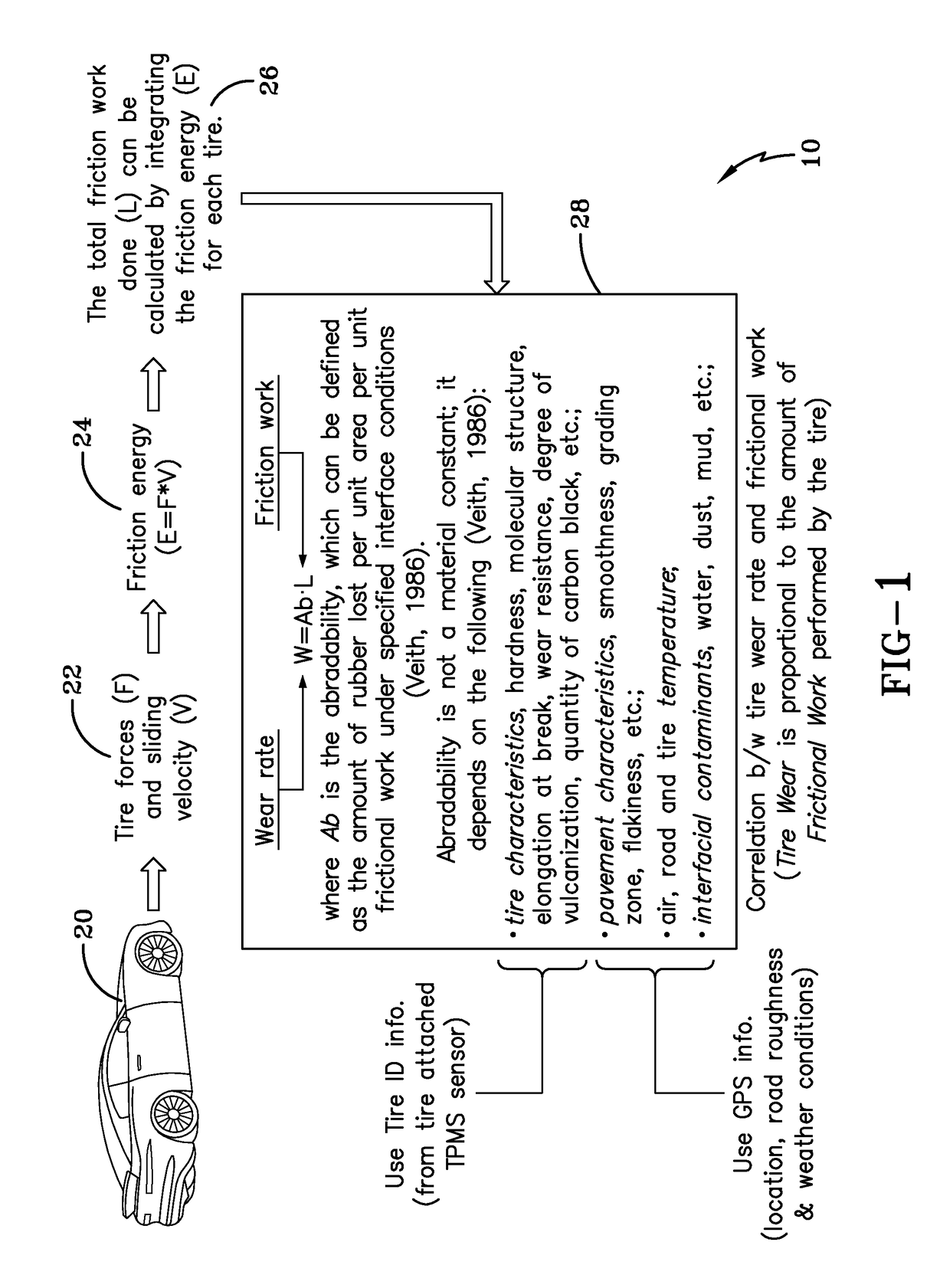

A tire wear state estimation system estimates forces and sliding velocity generated in a tire contact patch, determines frictional energy from the tire force and sliding velocity, and generates an estimate of tire wear state based upon the frictional work done by the tire. A tire wear estimate, pursuant to the system and methodology, is made by determining the amount of frictional work performed by the tire through the integrated use of tire-mounted, GPS sourced, and vehicle-mounted sensor information.

Owner:THE GOODYEAR TIRE & RUBBER CO

Stylus tip device for touch screen

InactiveUS20120146957A1Accurate writing and drawingWrite accuratelyInput/output processes for data processingCompressible materialConductive materials

A writing or drawing tip device for attachment to a touch screen stylus or handle has a rigid body of conductive material with a forward end mandrel having a rounded or elliptical tip, at least one layer of compressible material extending over the tip to produce a deformable rounded tip, and a retaining device which secures the compressible layer to the body at a location to the rear of the rounded tip. The deformable tip is applied to a touch screen to develop a contact patch between the compressible material layer and screen sufficient to trigger an input on the screen, with the amount of force applied to the tip determining the size of the contact patch.

Owner:DUNAGAN KELLY ALLAN

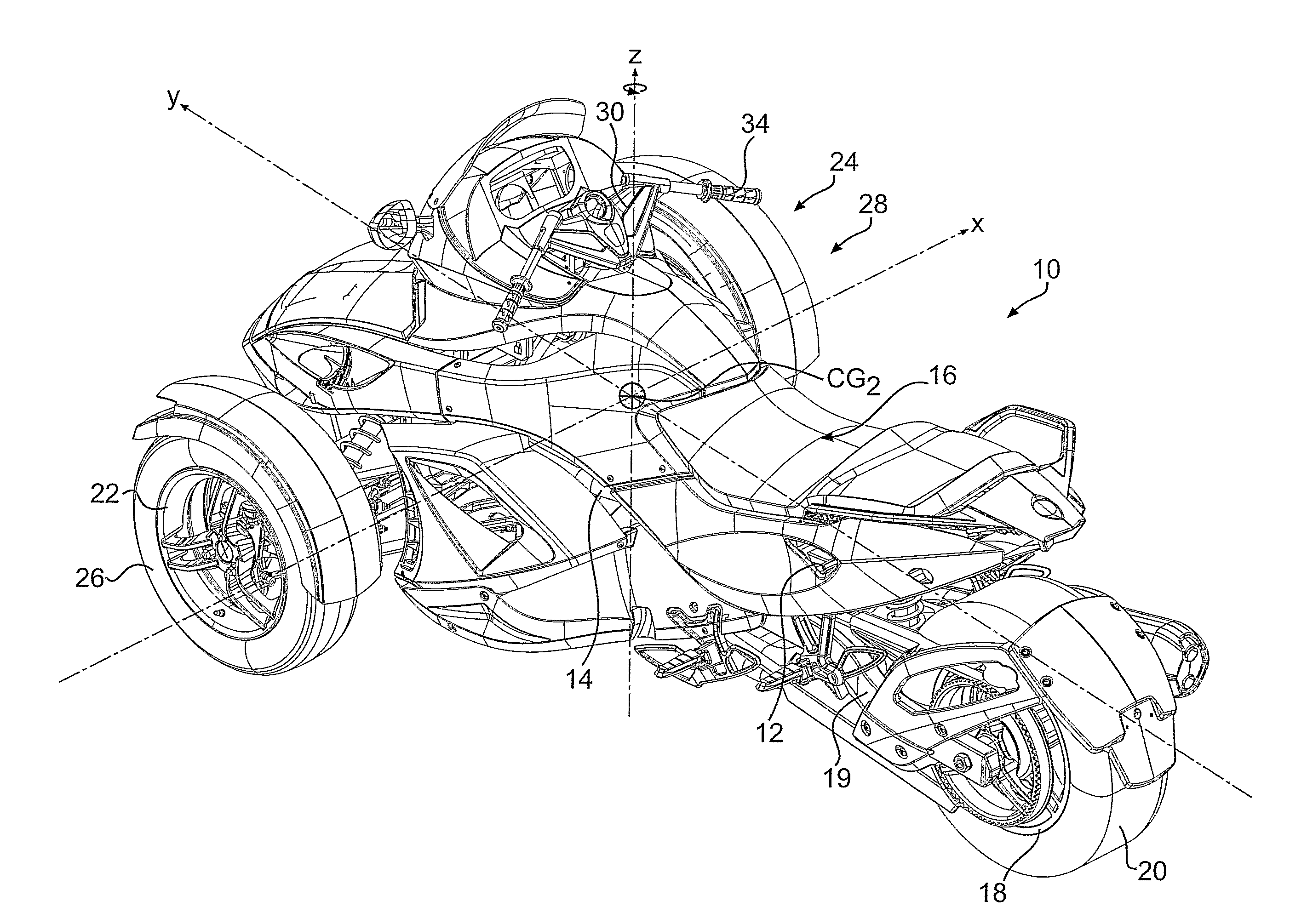

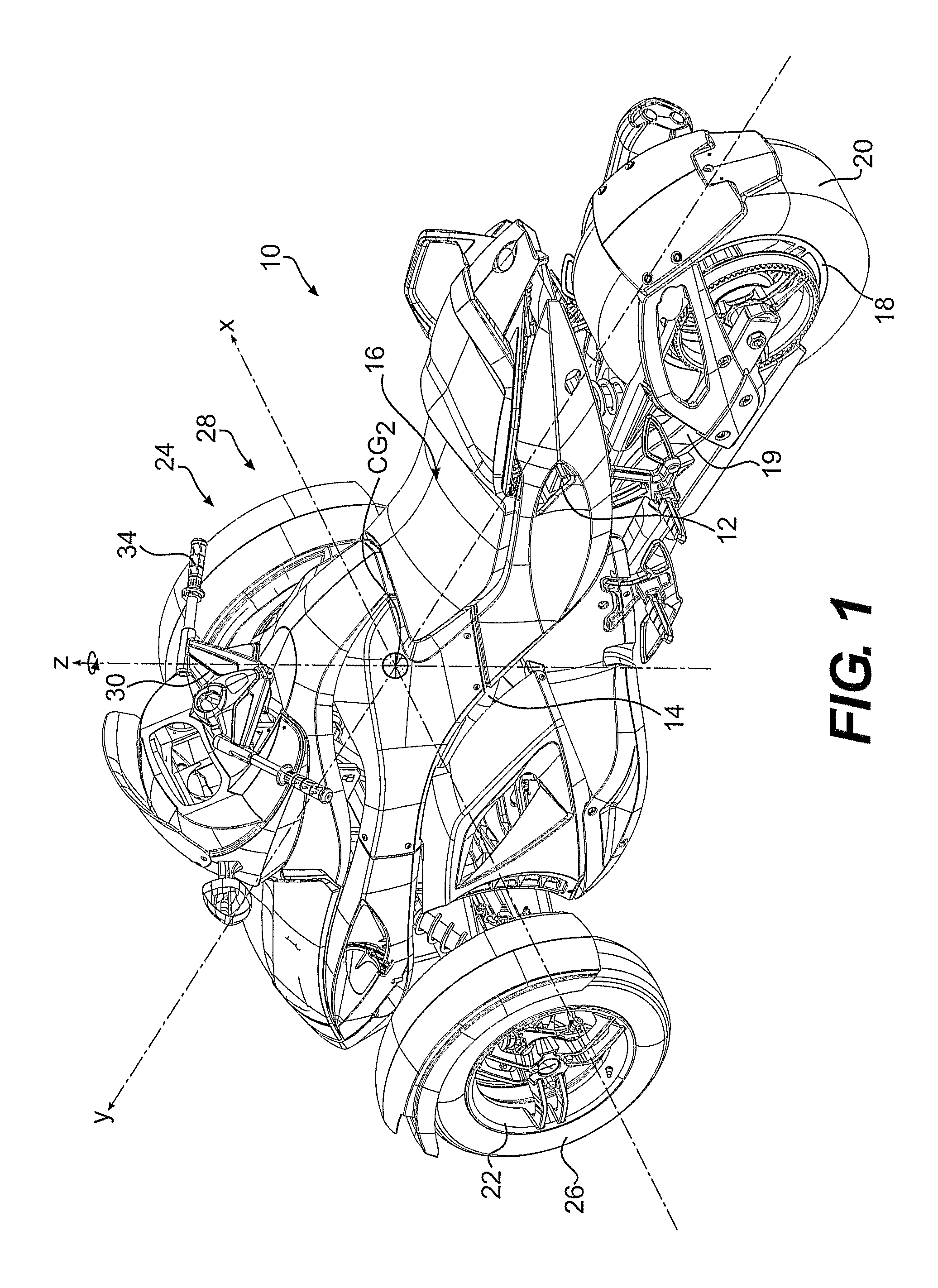

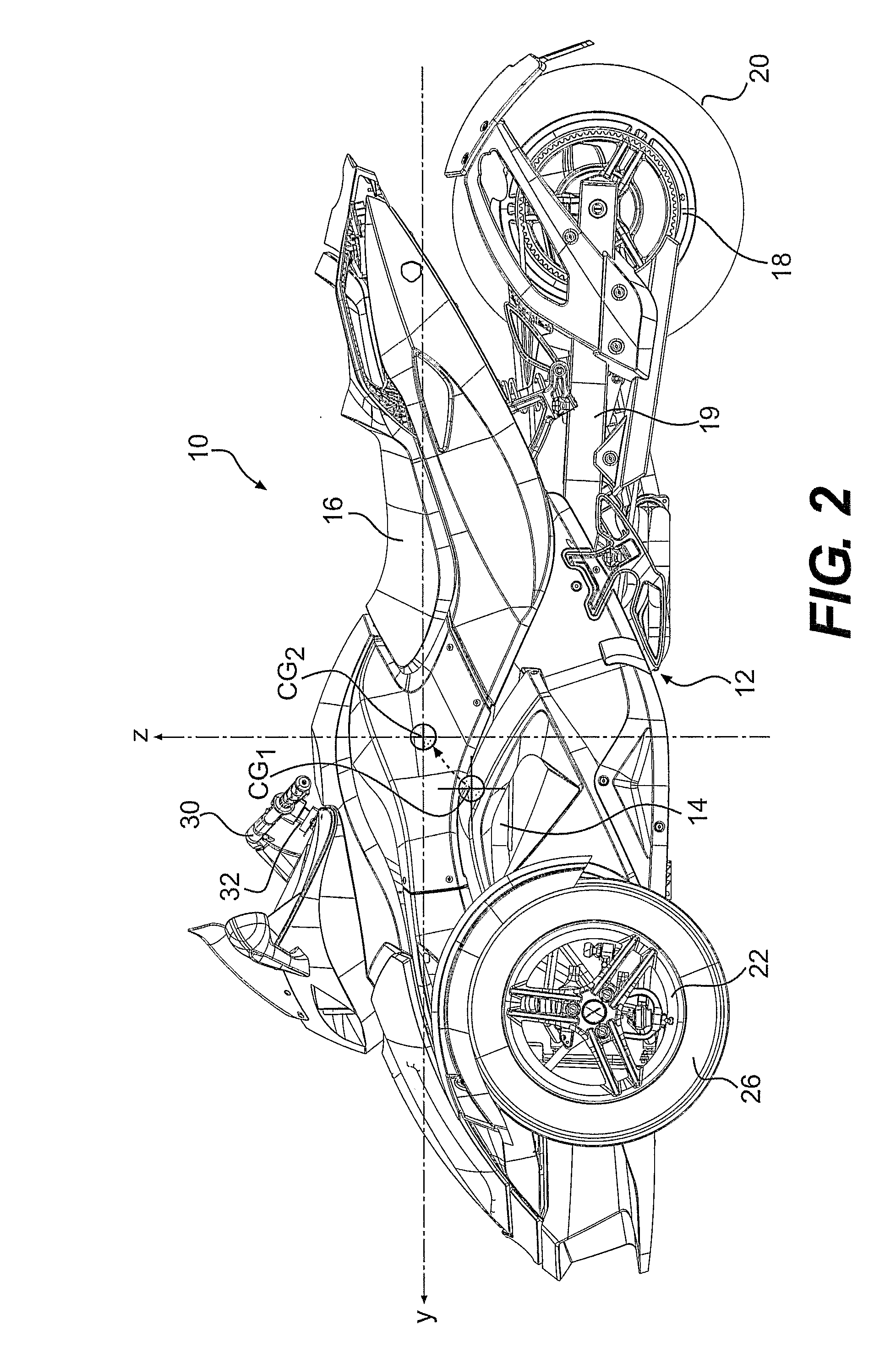

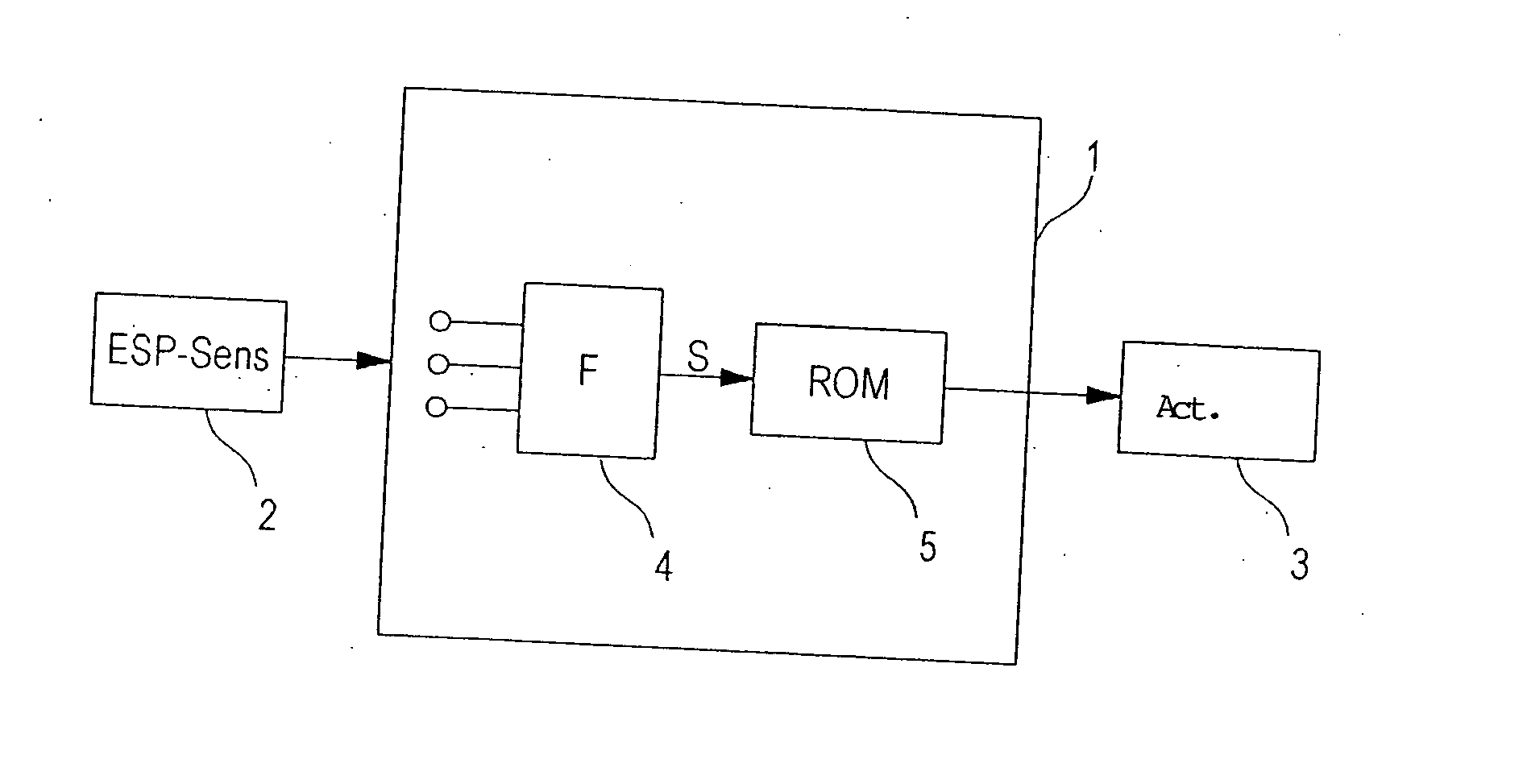

Three-wheel vehicle electronic stability system

InactiveUS20090152940A1Avoid oversteerLimited front wheel liftCyclesApplication and release valvesRolloverSingle Center

The present invention provides a three-wheel vehicle (10) having an electronic vehicle stability system and a method for stabilizing a three-wheel vehicle. The three-wheel vehicle (10) features a left (22) and right front wheel (24) laterally spaced apart and a single centered rear wheel (18) each having a tire contact patch which together define a triangular pattern of contact tire patches defining left and right rollover axis. The electronic vehicle stability system is adapted to calculate a dynamic status of the vehicle (10) based on inputs received from sensors and to output signals to the braking system to generate a specific moment about one of the left and right rollover axis when the calculated dynamic status of the vehicle exceeds a predetermine threshold indicative of a precursory condition of rollover. The present invention also provides a three-wheel vehicle having a yaw sensor positioned within a radius of 25 cm about the vertical axis (Z) to improve the accuracy of the yaw measurements provided to the electronic vehicle stability system.

Owner:BOMBARDIER RECREATIONAL PROD INC

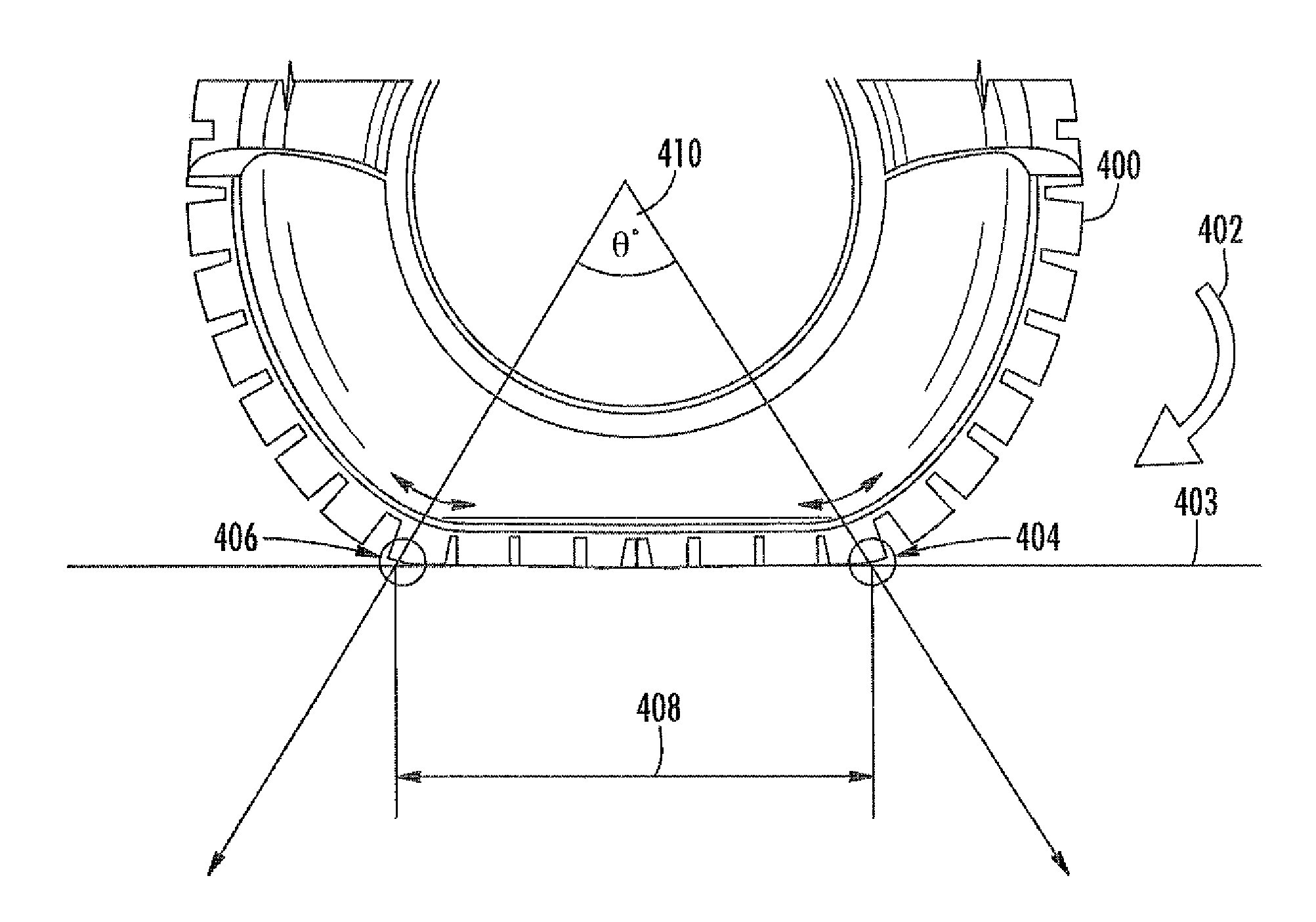

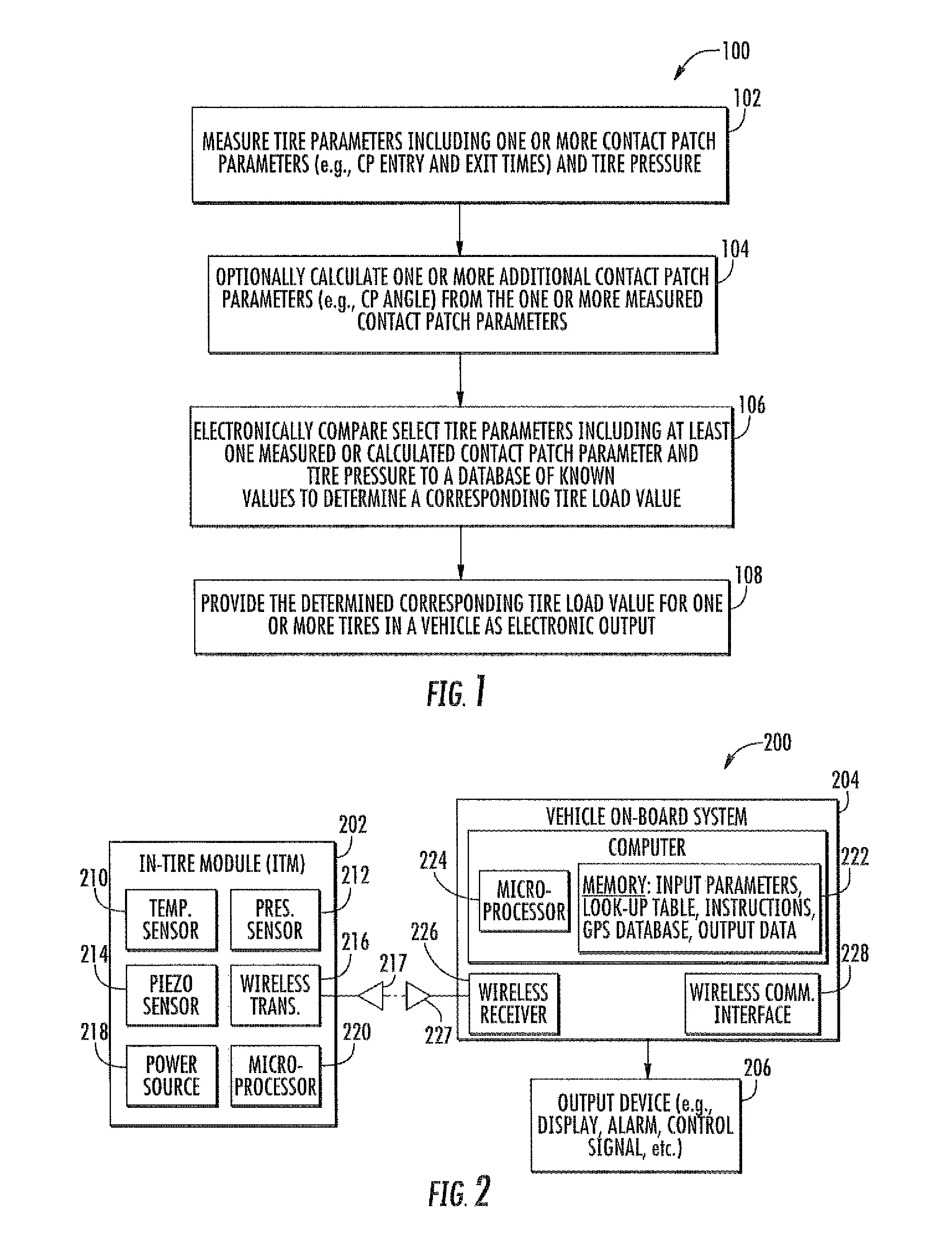

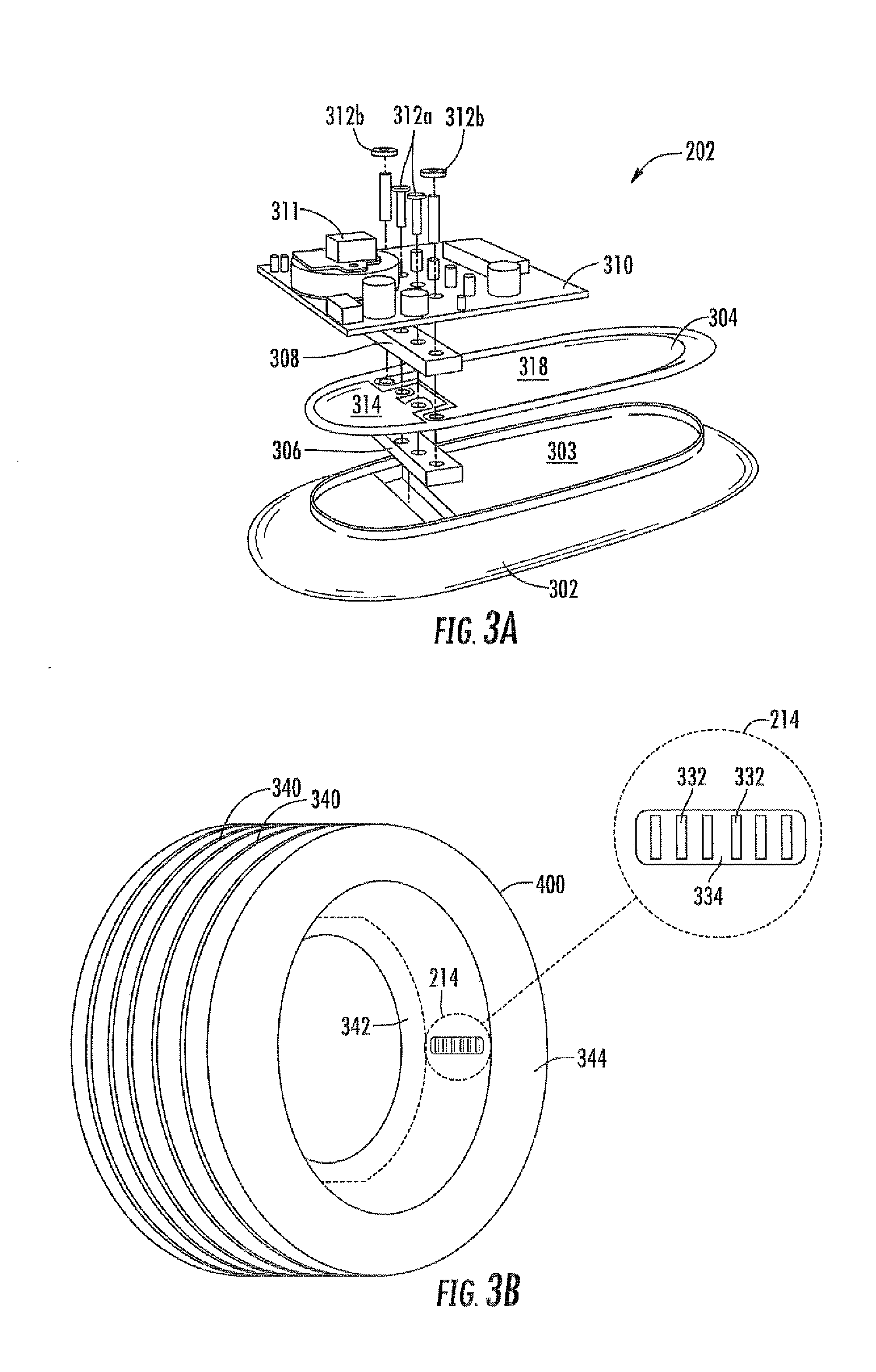

Piezoelectric based system and method for determining tire load

Systems and methods of determining tire load from measured tire parameters include using a piezoelectric based sensor to obtain one or more contact patch parameters (e.g., contact patch entry time, contact patch exit time total contact patch time and contact patch angle) and one or more additional sensors to obtain tire pressure. Selected contact patch parameter measurements and pressure values are then compared with known combinations of contact patch parameter values and pressure values stored in a look-up table. A corresponding determined tire load value is then provided as electronic output.

Owner:MICHELIN & CO CIE GEN DES ESTAB MICHELIN

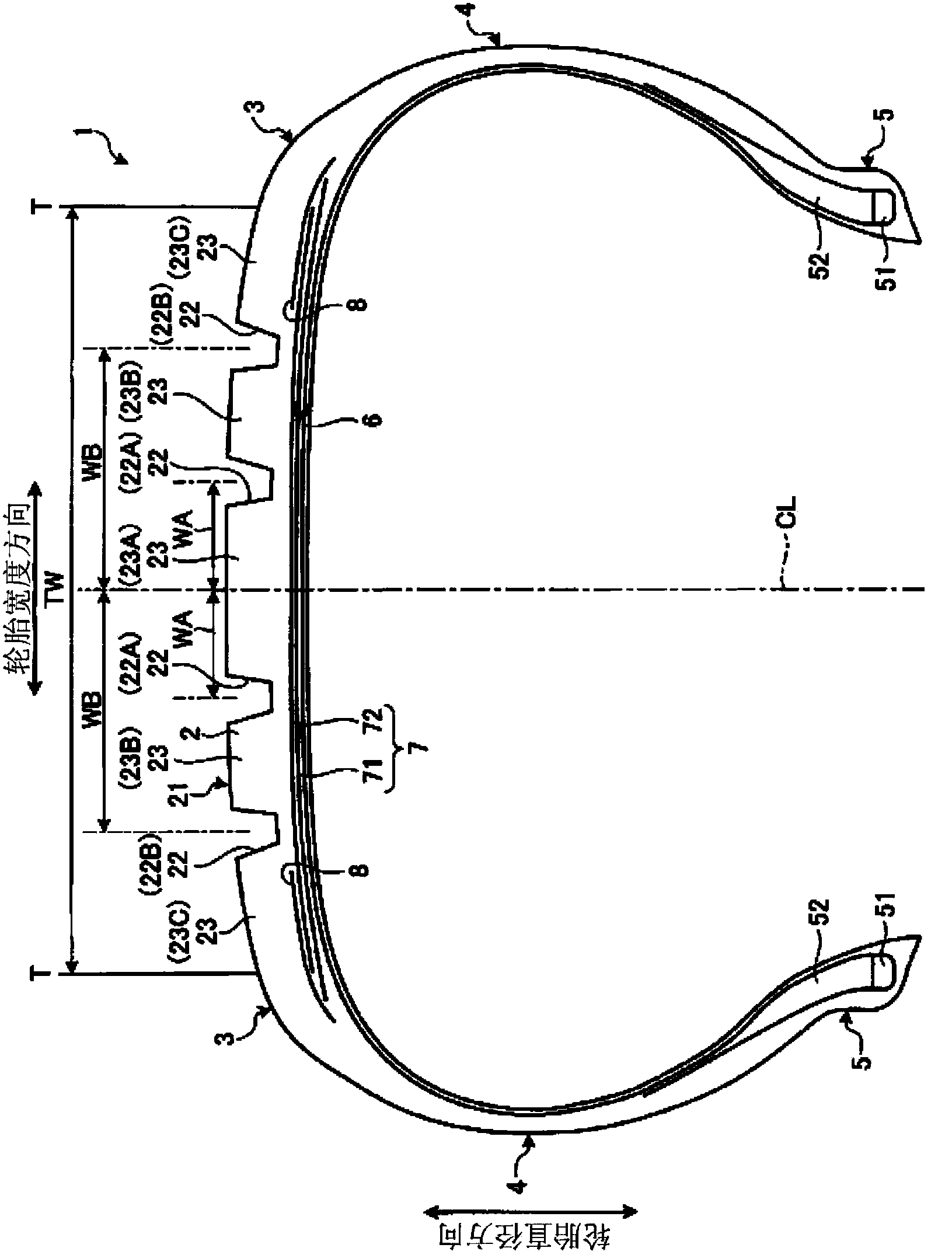

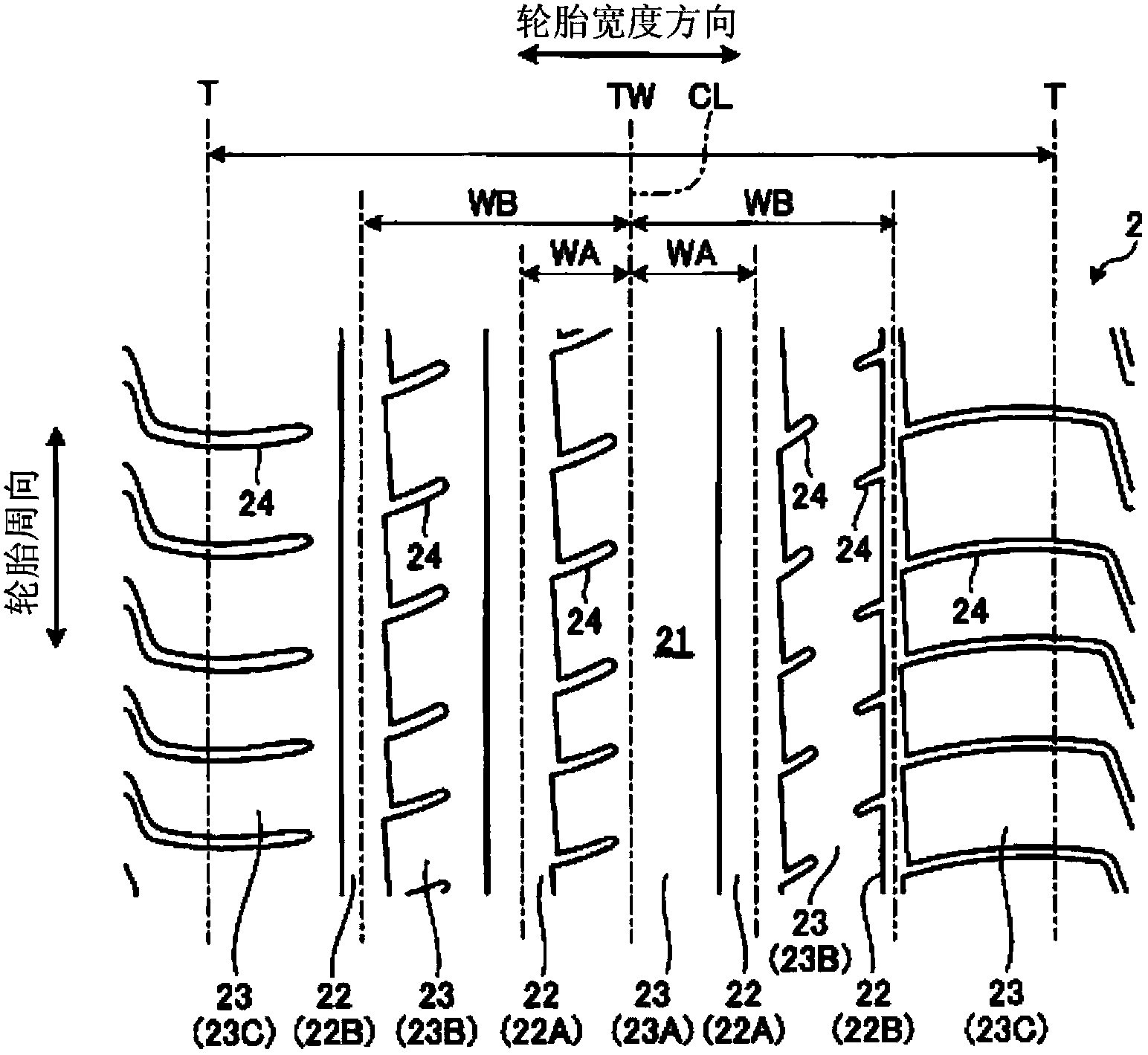

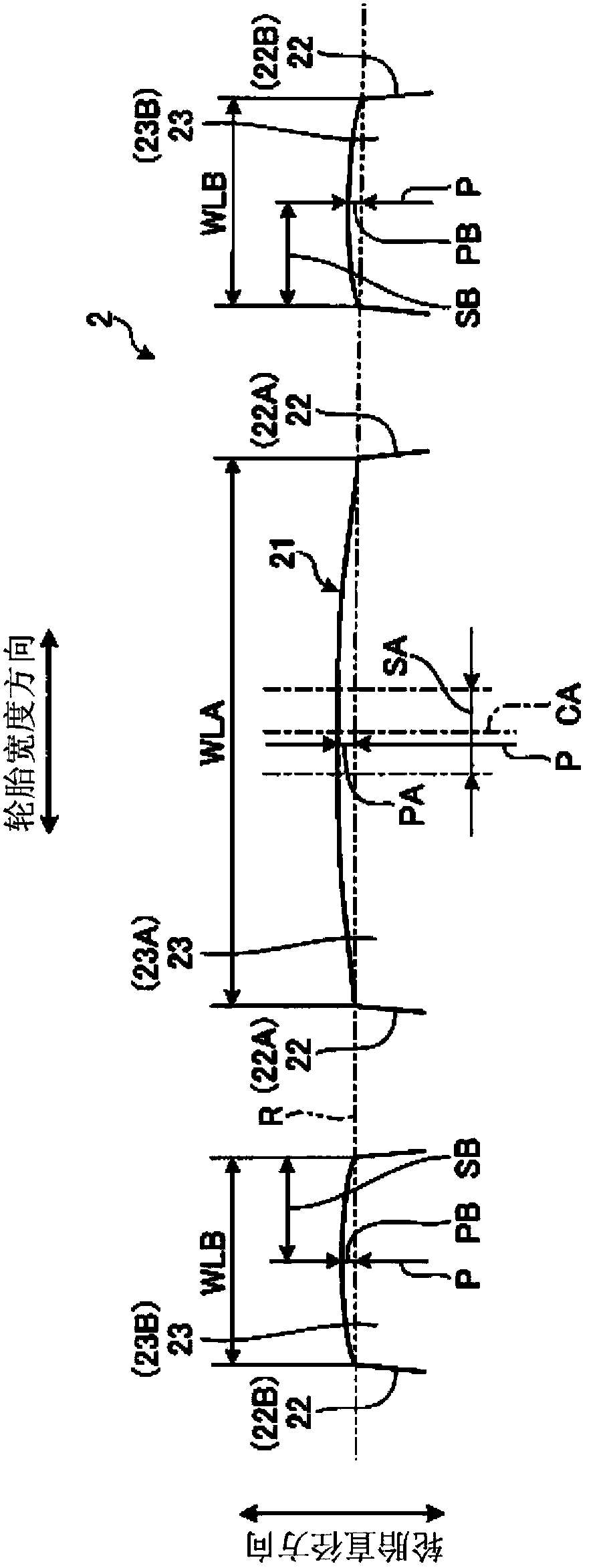

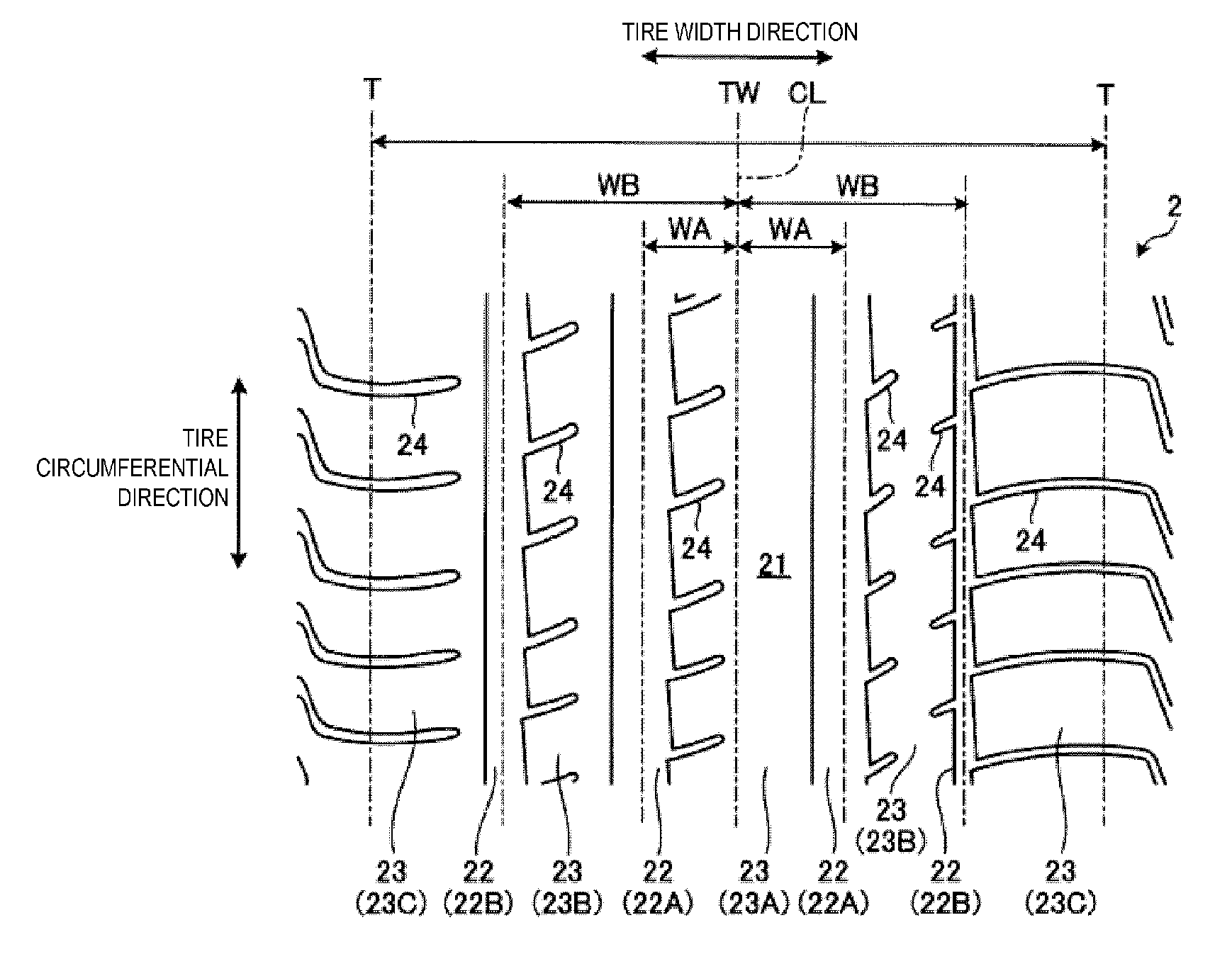

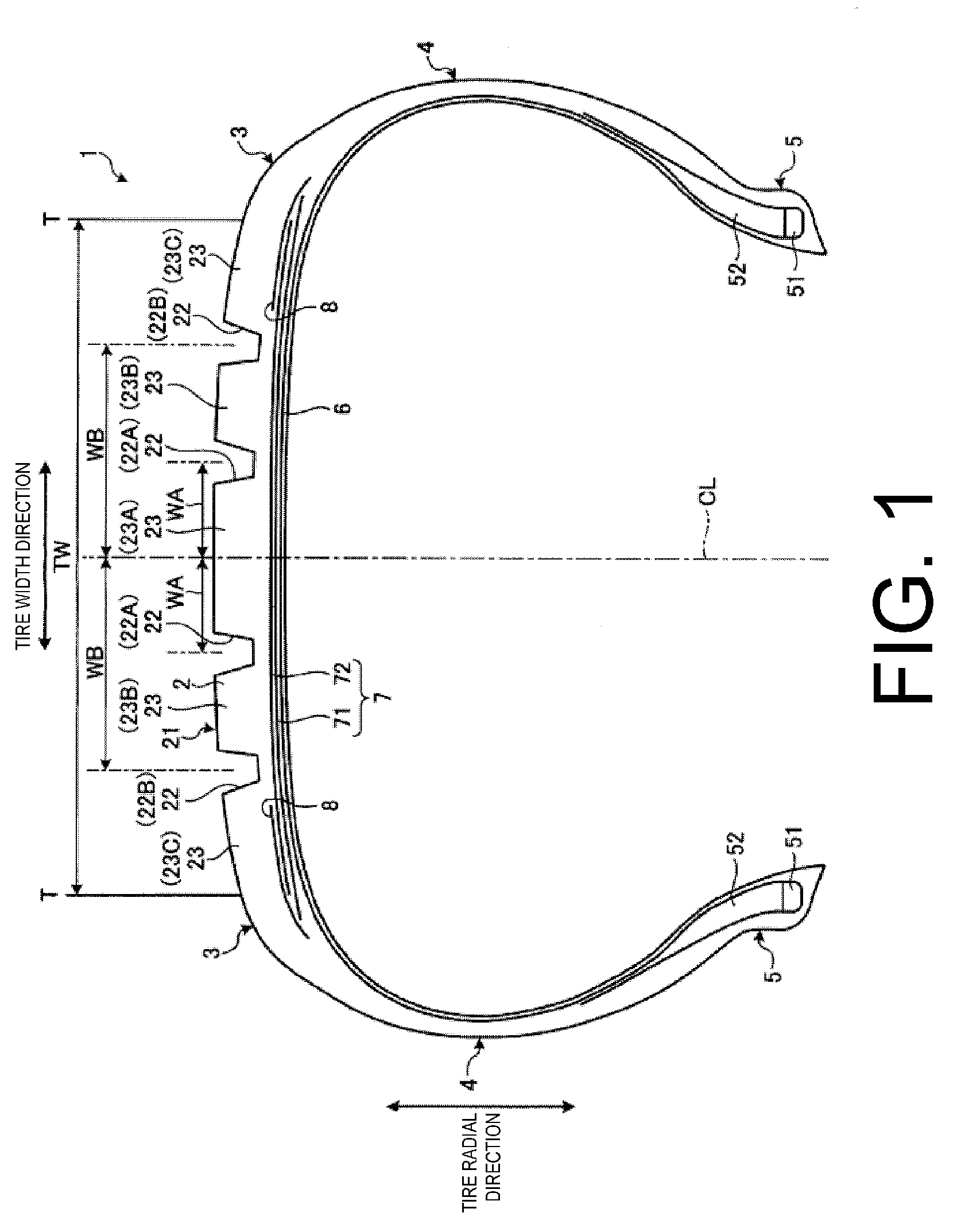

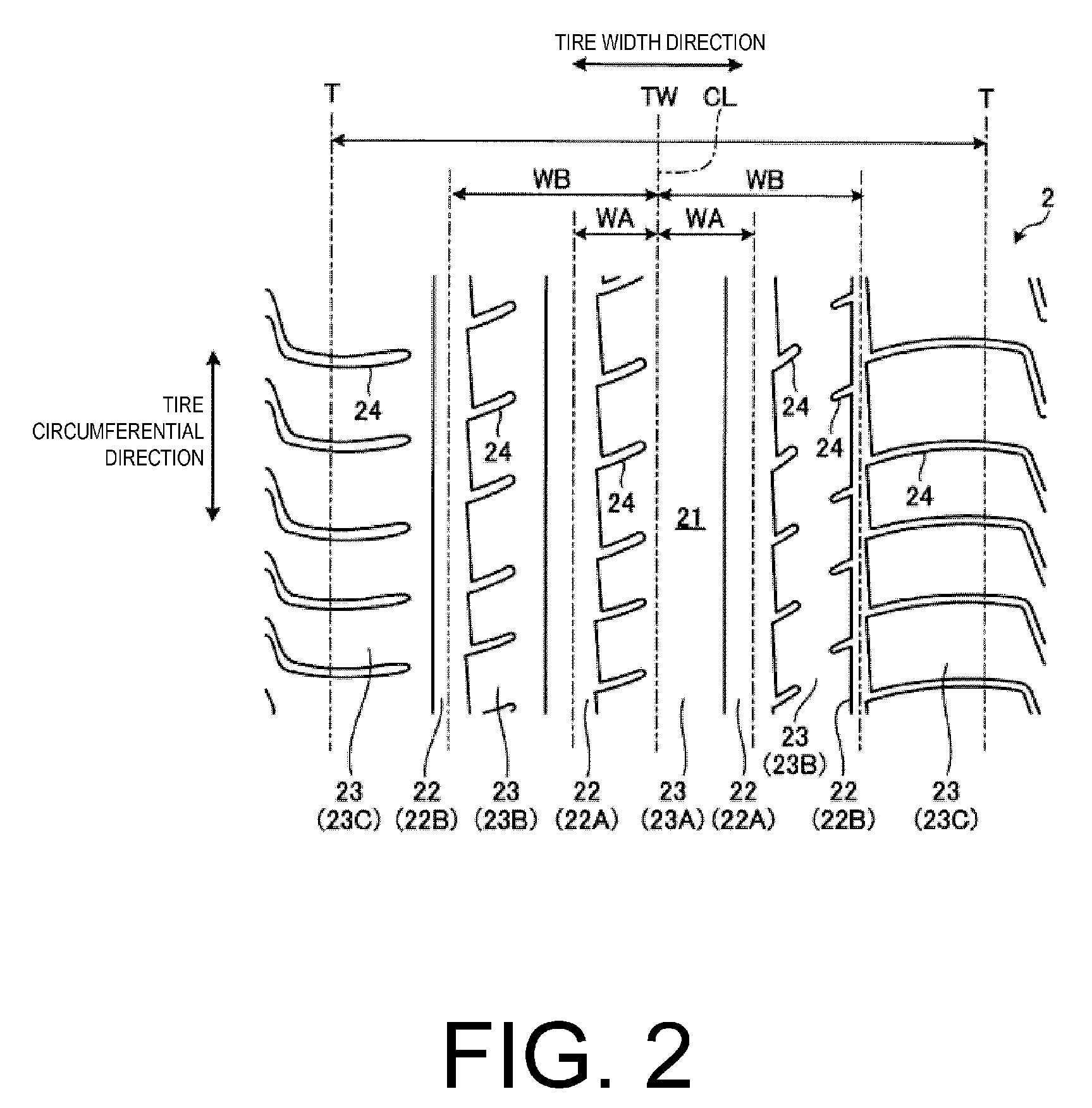

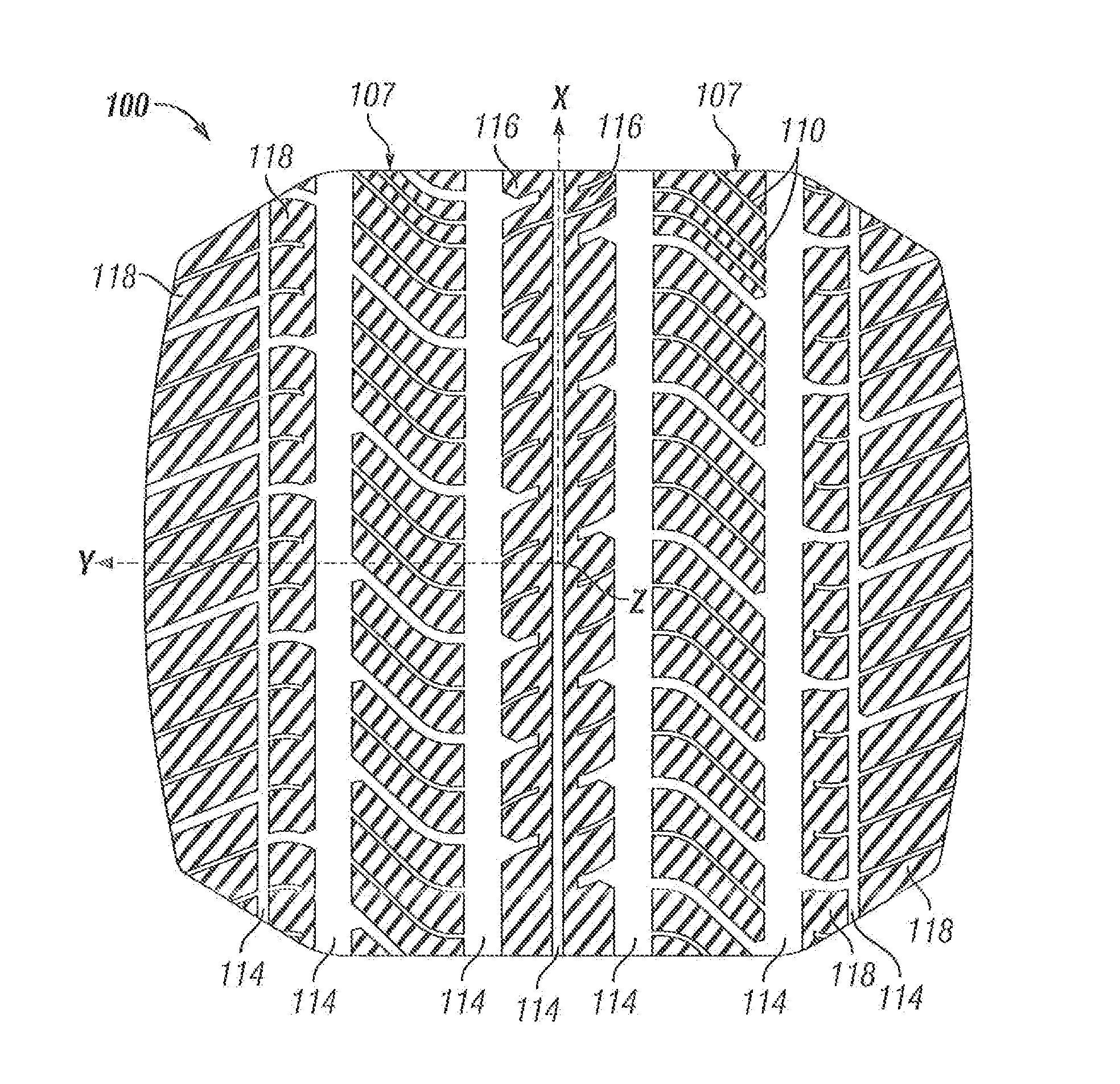

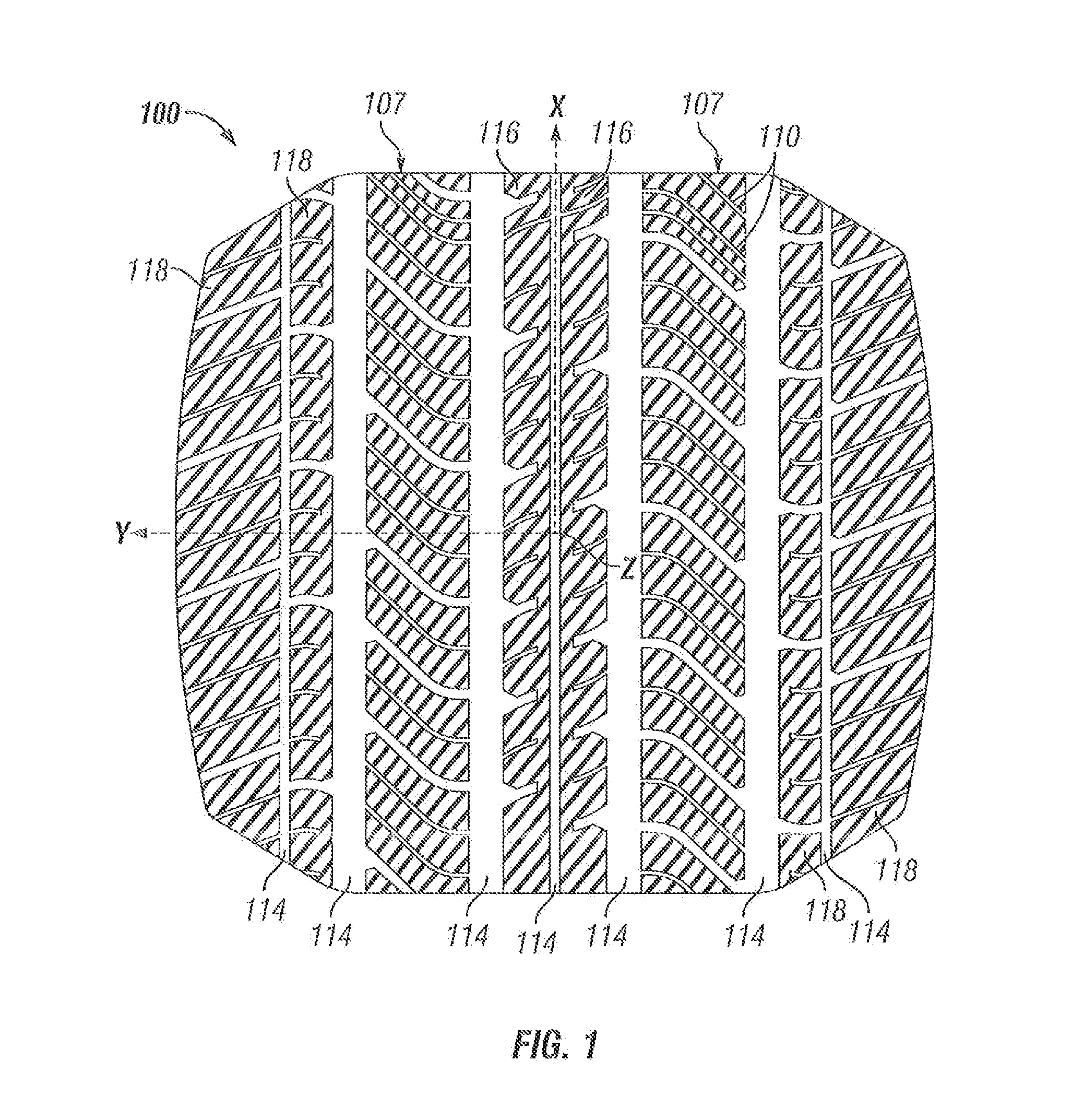

Pneumatic tire

ActiveCN103640437AGood grounding effectImprove driving stabilityTyre tread bands/patternsEngineeringContact patch

The contact patch of the center land portion partitioned by the center side main grooves (22A)protrudes outward in the tire radial direction from the overall standard profile line R of the tread portion. The maximum protruding amount PA is not less than 1.0% and not more than 2.5% of the tire width direction dimension of the center land portion. The contact patch of the intermediate land portion partitioned by the center side main groove and the shoulder side main groove protrudes outward in the tire radial direction from the standard profile line. The maximum protruding amount is not less than 0.7% and not more than 2.0% of the tire width direction dimension of the intermediate land portion. The maximum protruding amount of the center land portion is greater than the maximum protruding amount of the intermediate land portion.

Owner:THE YOKOHAMA RUBBER CO LTD

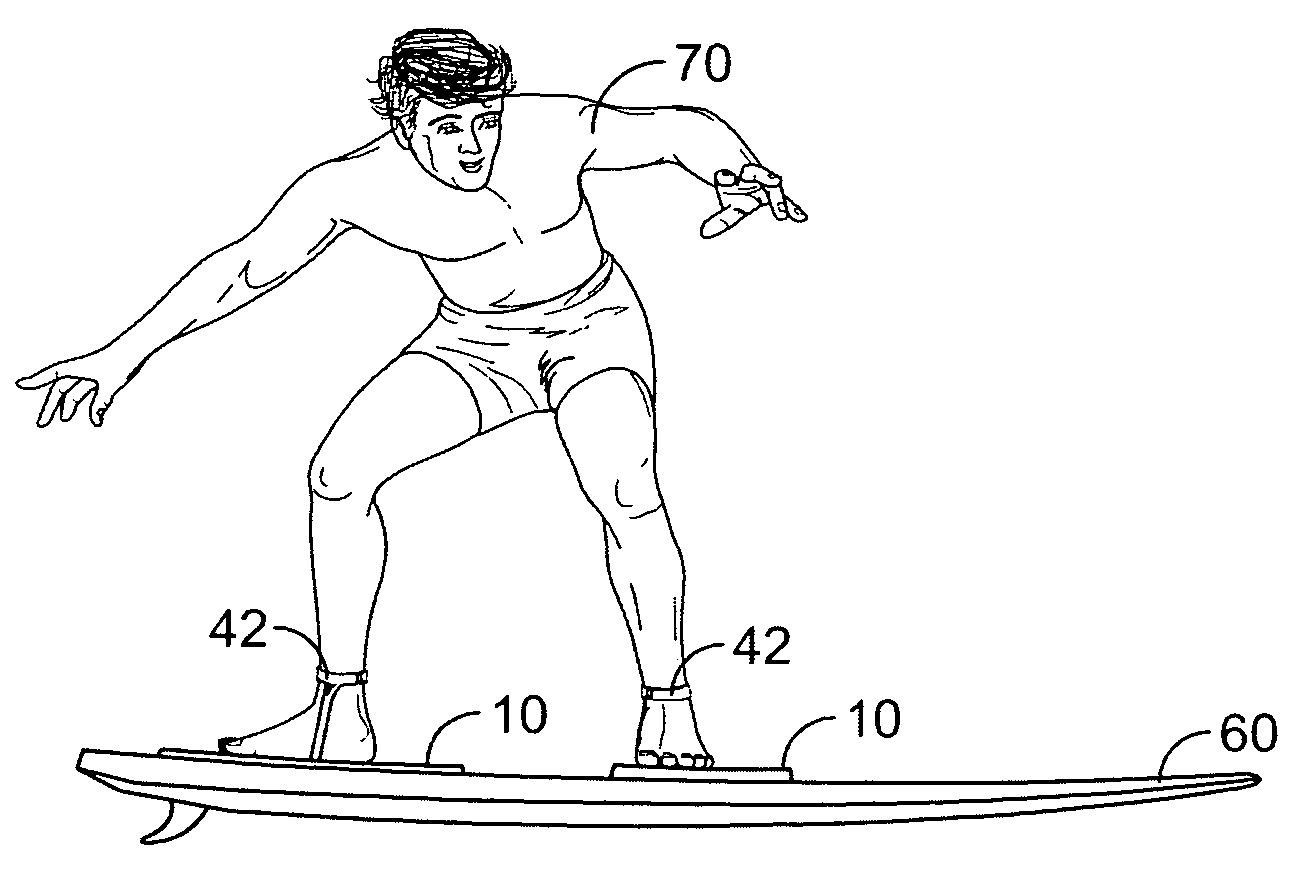

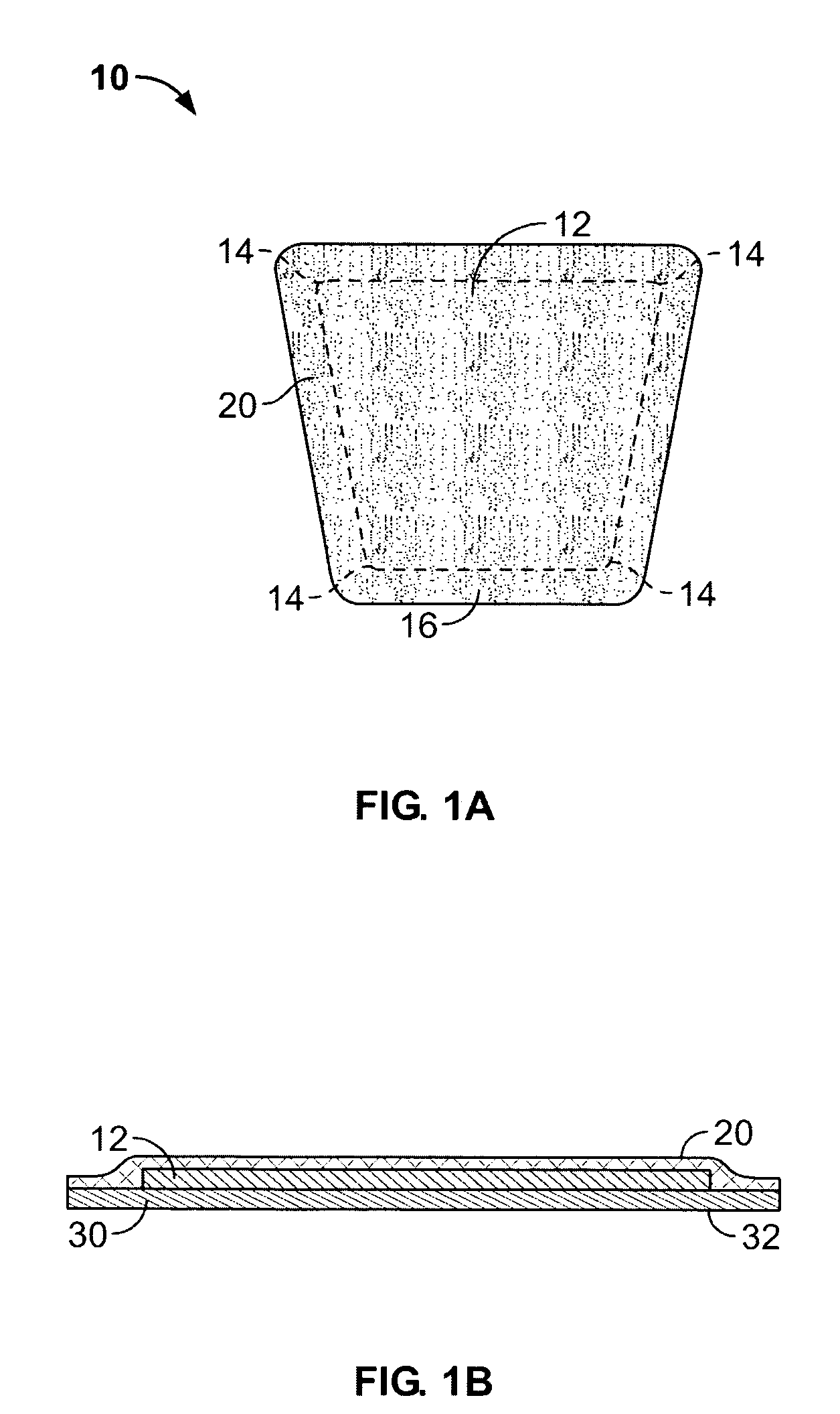

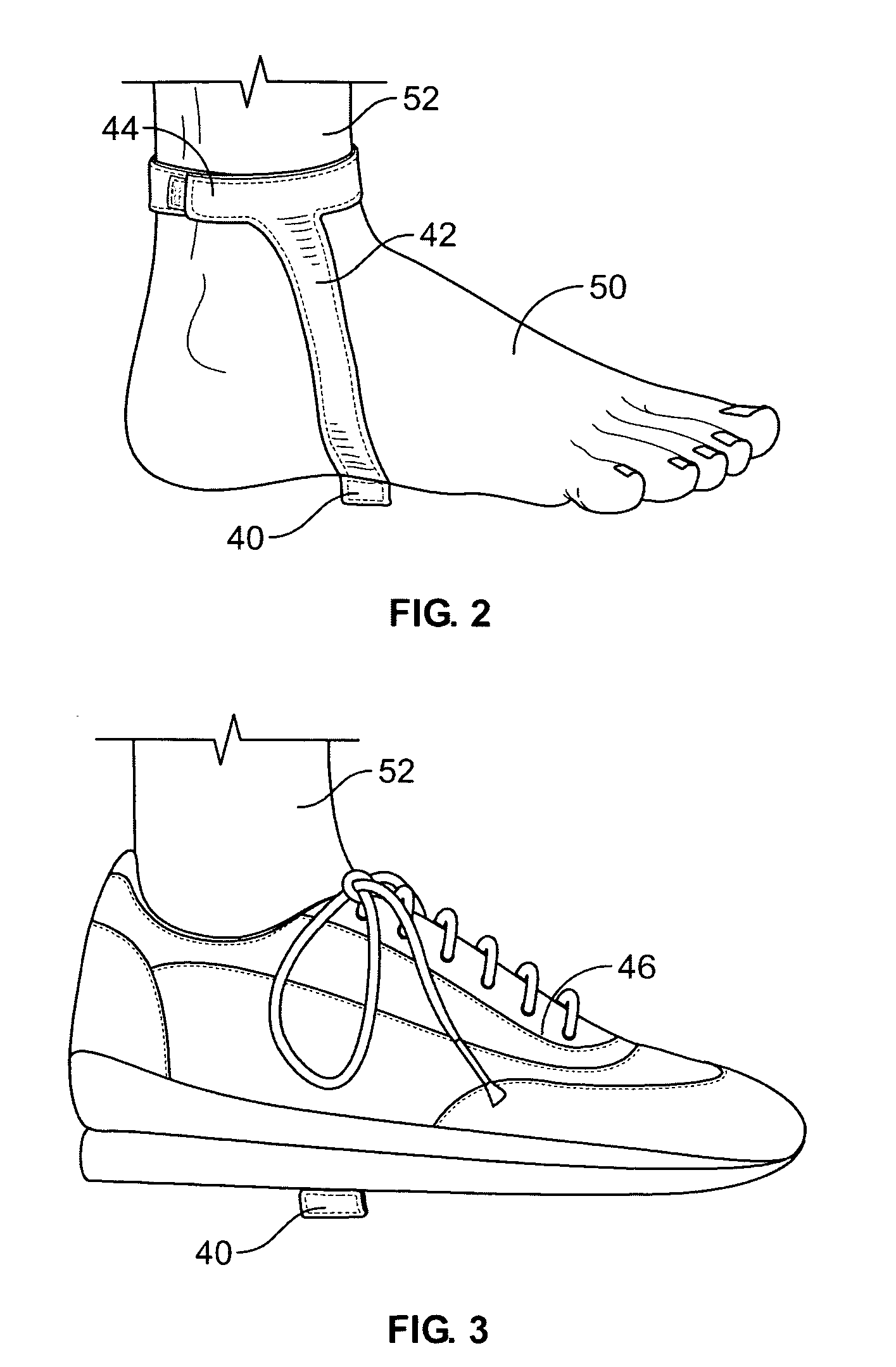

Sport board contact system

A contact system for a sport board allows a rider to maintain contact between her feet and the sport board while performing aerial maneuvers. The boarder wears magnetic footwear such as a bootie (for surfing), sheath (for surfing), or shoe (for skateboarding) with an affixed magnet. The board has a contact patch that includes a plate of ferrous metal or another magnet oriented such that it attracts the magnetic footwear. The contact patch is positioned such that it will be stood on by the boarder. During normal boarding and aerial maneuvers, magnetic attractive forces between the footwear and the contact patch will maintain contact between the boarder's feet and the board. However, when the boarder falls, the magnetic attractive forces do not bind the boarder's feet to the board.

Owner:NORRIS BRADLEY KENNETH

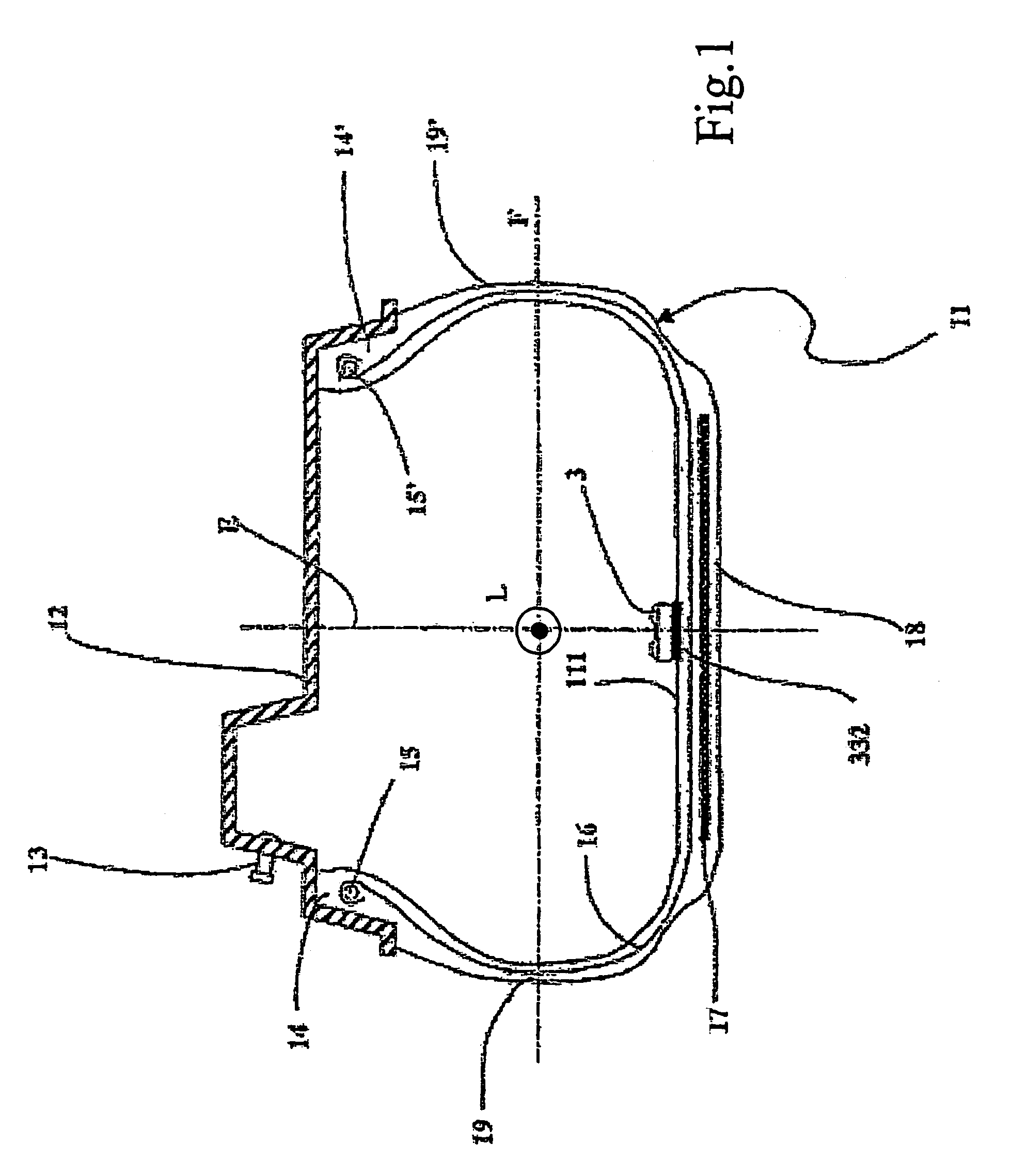

Method and system for generating electrical energy within a vehicle tyre

ActiveUS7415874B2Sufficient powerA large amountPiezoelectric/electrostriction/magnetostriction machinesTyre measurementsElectricityLow speed

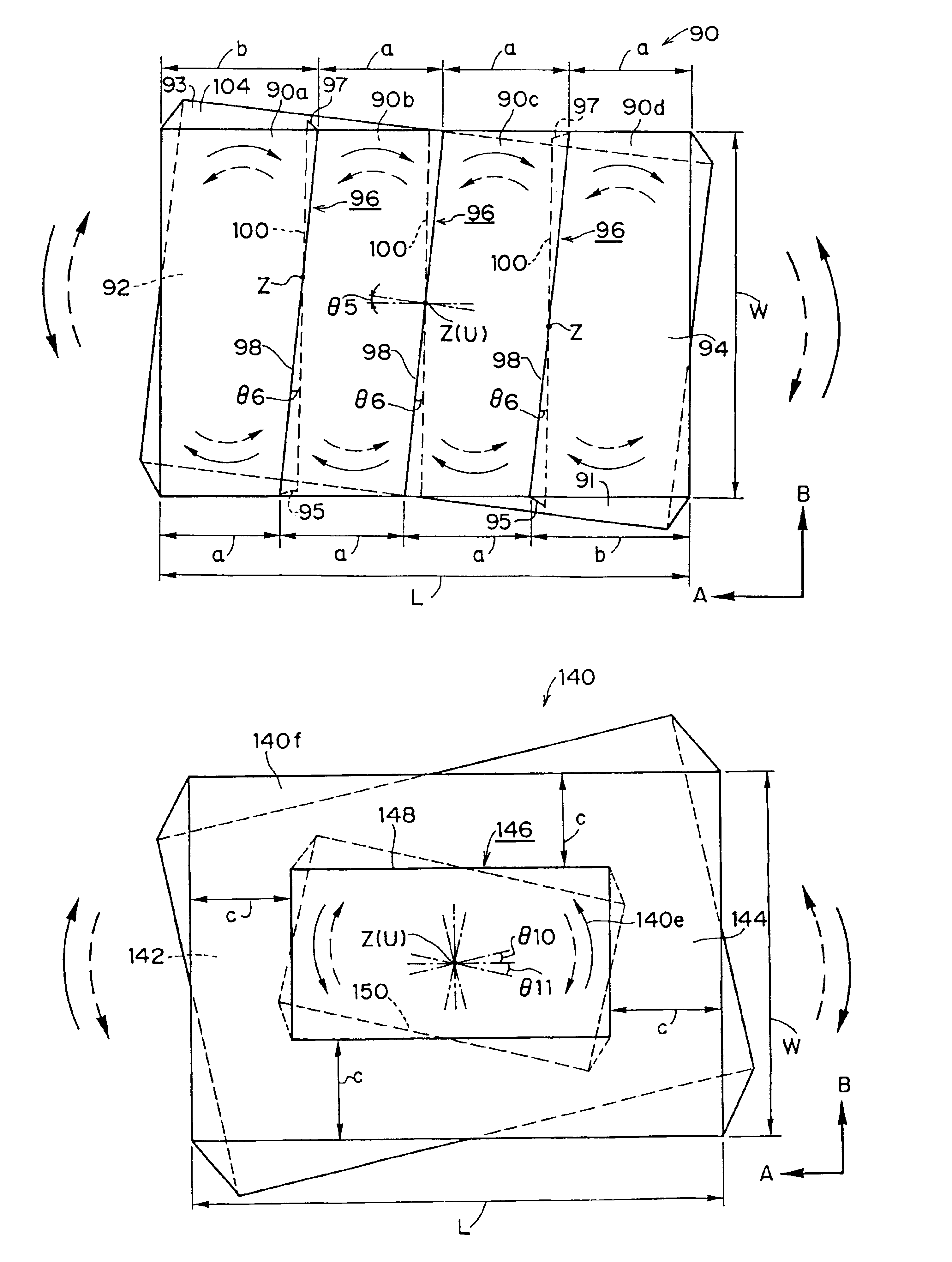

A tire has a piezoelectric flexing element associated with an energy storage device (e.g., a capacitor). The piezoelectric flexure element is mounted in cantilever fashion in a housing so as to be positioned substantially along a plane orthogonal to a radial direction of the tire and, so that a first end of the piezoelement is restrained by the housing. A loading mass is coupled to the second end of the piezoelectric flexure element. A small gap is formed between the inner walls of the housing and the outer surface of the loading mass in order to allow limited flexure of the piezo-electric element. The housing including the piezoelectric is mounted in a tire portion in correspondence of a tread area of the tire, preferably on the inner surface of the tire. The piezoelectric element flexes under the action of the radial acceleration when the tire rotates. The loading mass and the gap are chosen to obtain a) small entity oscillations of the flexure element substantially during a complete revolution of the tire when the tire rotates at low speed; b) large entity oscillations of the flexure element substantially only during the passage of the tire portion including the piezoelectric element in the contact patch. Sufficient electrical power for powering an electronic device included within the tire is obtained, together with a long durability of the piezoelectric element.

Owner:PIRELLI TYRE SPA

Pneumatic Tire

ActiveUS20130240101A1Improve steering stabilityImprove propertiesTyre tread bands/patternsNon-skid devicesEngineeringContact patch

The contact patch of the center land portion partitioned by the center side main grooves protrudes outward in the tire radial direction from the overall standard profile line of the tread portion. The maximum protruding amount is not less than 1.0% and not more than 2.5% of the tire width direction dimension of the center land portion. The contact patch of the intermediate land portion partitioned by the center side main groove and the shoulder side main groove protrudes outward in the tire radial direction from the standard profile line. The maximum protruding amount is not less than 0.7% and not more than 2.0% of the tire width direction dimension of the intermediate land portion. The maximum protruding amount of the center land portion is greater than the maximum protruding amount of the intermediate land portion.

Owner:YOKOHAMA RUBBER CO LTD

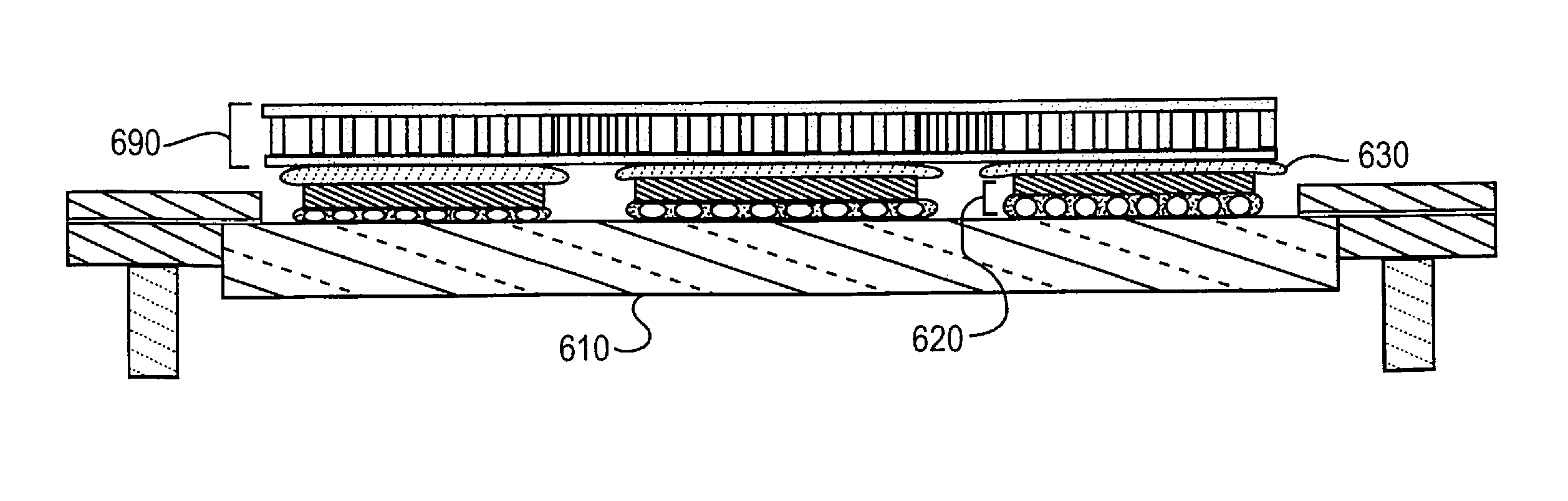

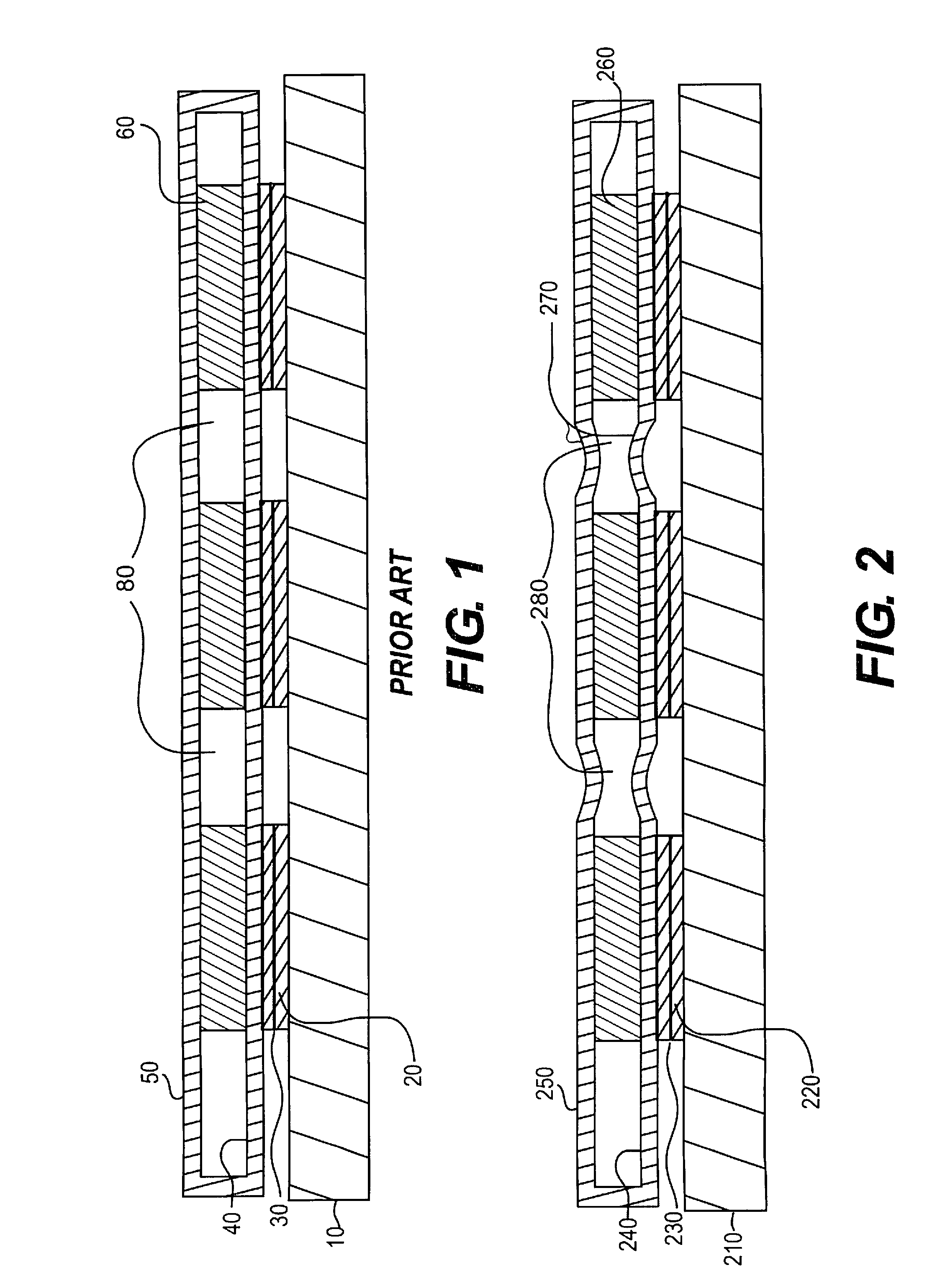

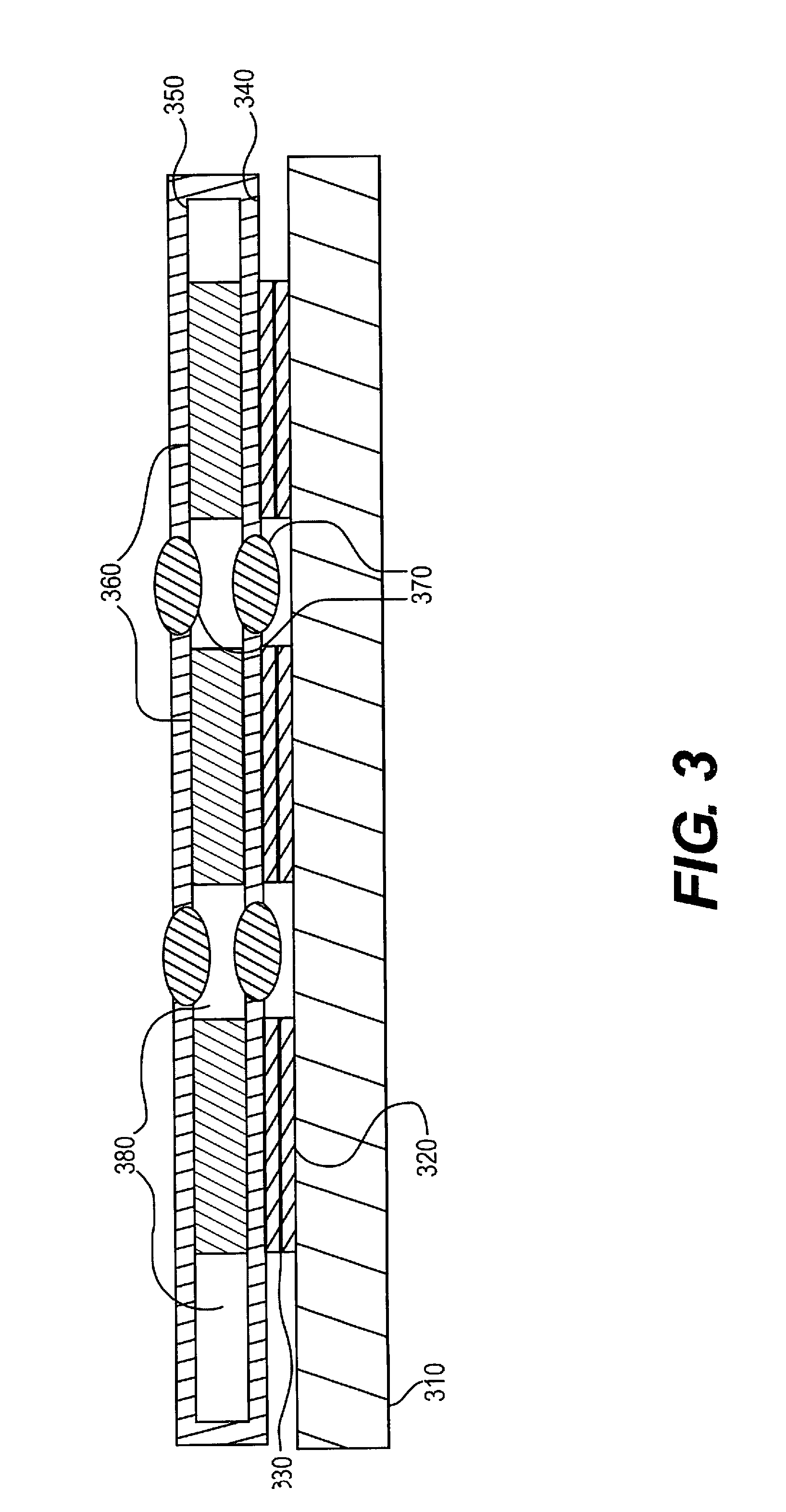

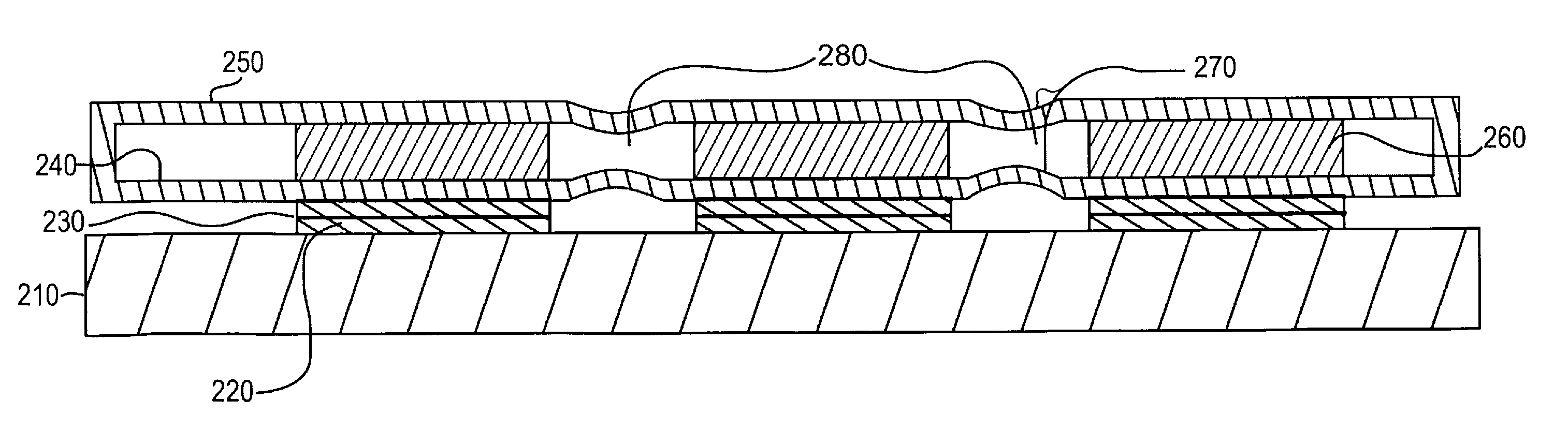

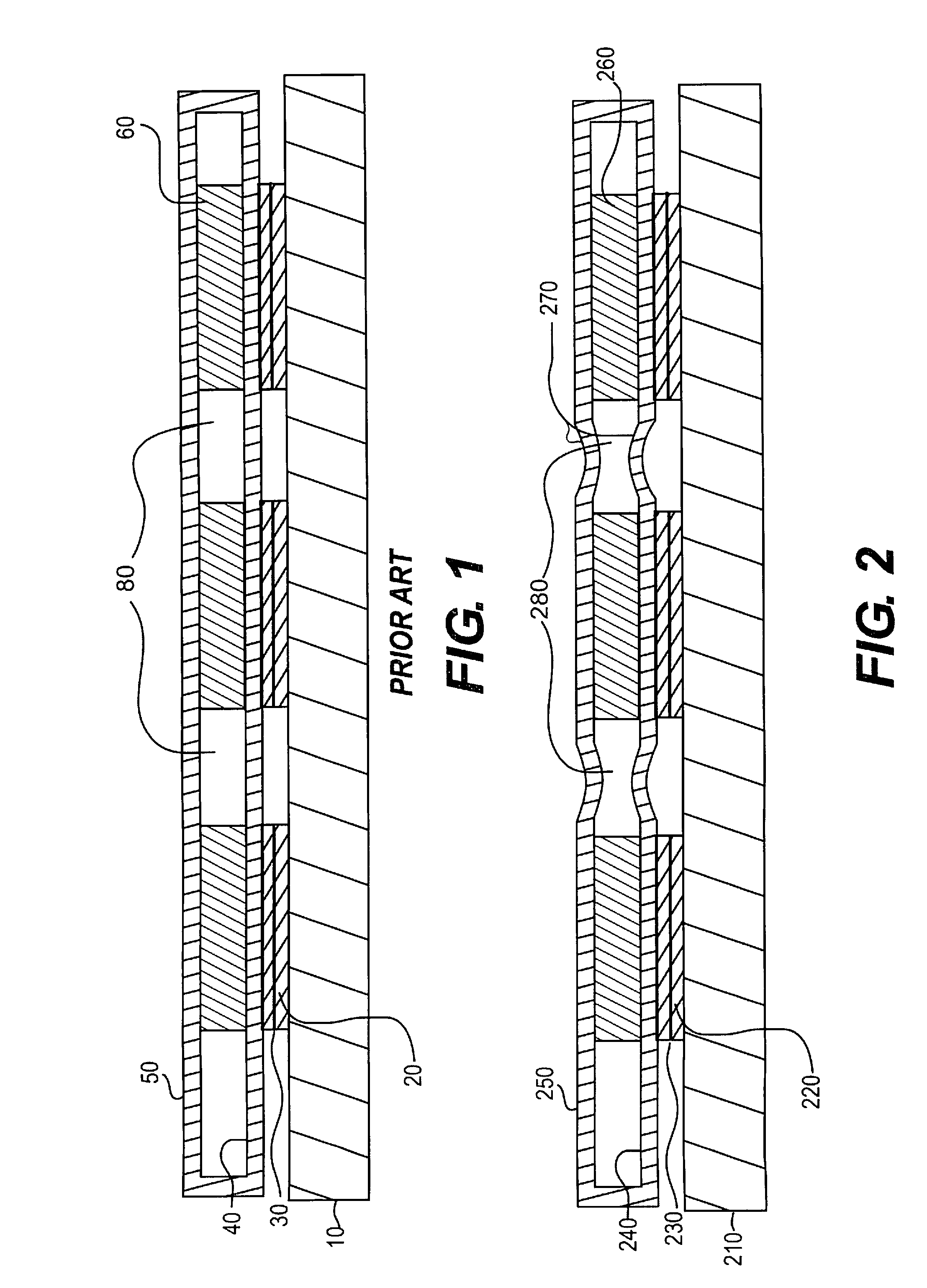

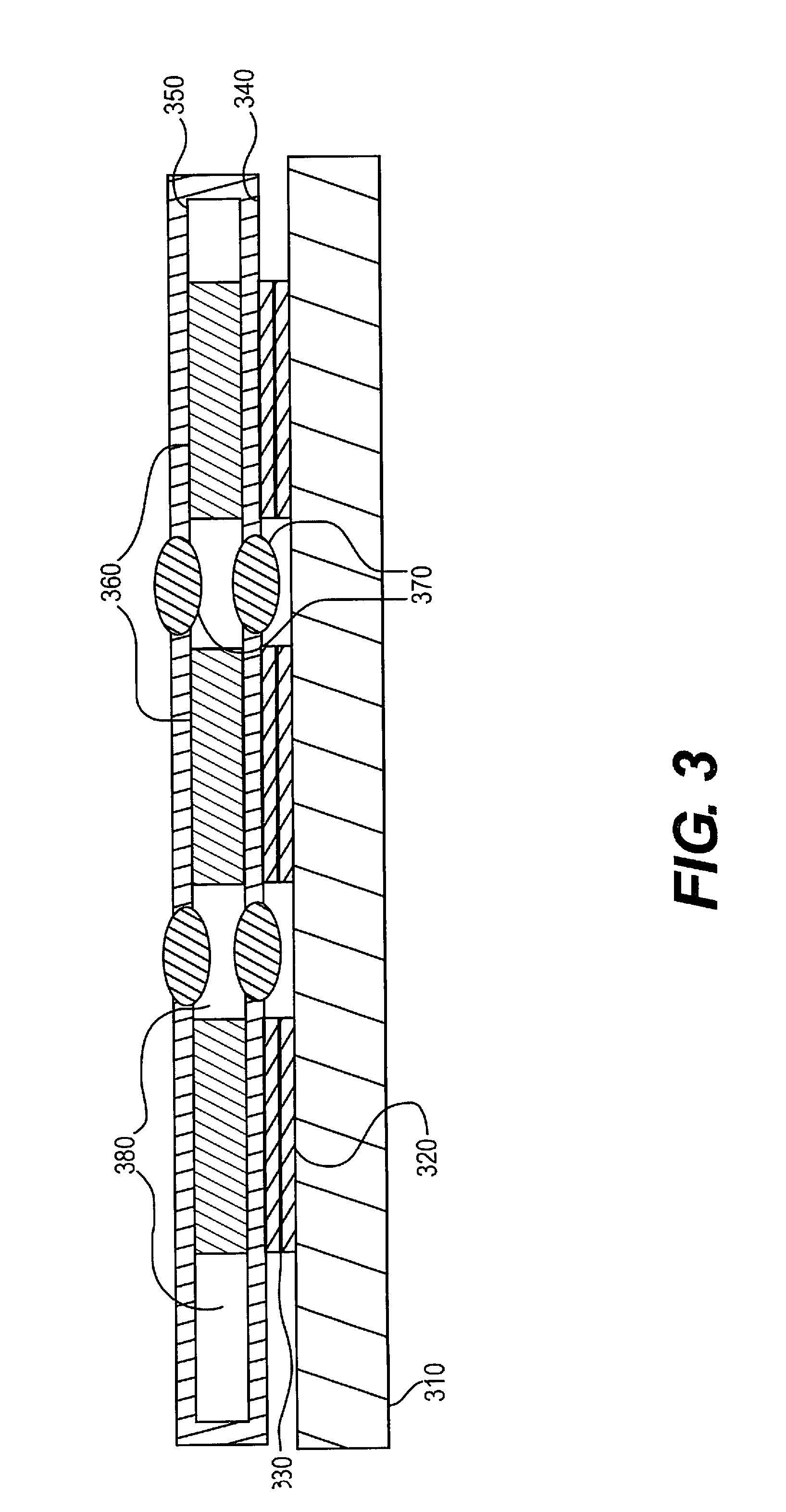

Flexible Heat Sink With Lateral Compliance

InactiveUS20130214406A1Semiconductor/solid-state device detailsSolid-state devicesShear stressComputer module

A multi-chip module (MCM) structure comprises more than one semiconductor chip lying in a horizontal plane, the MCM having individual chip contact patches on the chips and a flexible heat sink having lateral compliance and extending in a plane in the MCM and secured in a heat exchange relation to the chips through the contact patches. The MCM has a mismatch between the coefficient of thermal expansion of the heat sink and the MCM and also has chip tilt and chip height mismatches. The flexible heat sink with lateral compliance minimizes or eliminates shear stress and shear strain developed in the horizontal direction at the interface between the heat sink and the chip contact patches by allowing for horizontal expansion and contraction of the heat sink relative to the MCM without moving the individual chip contact patches in a horizontal direction.

Owner:I N T E R N A T I O N A L BUSINESS MACHINES

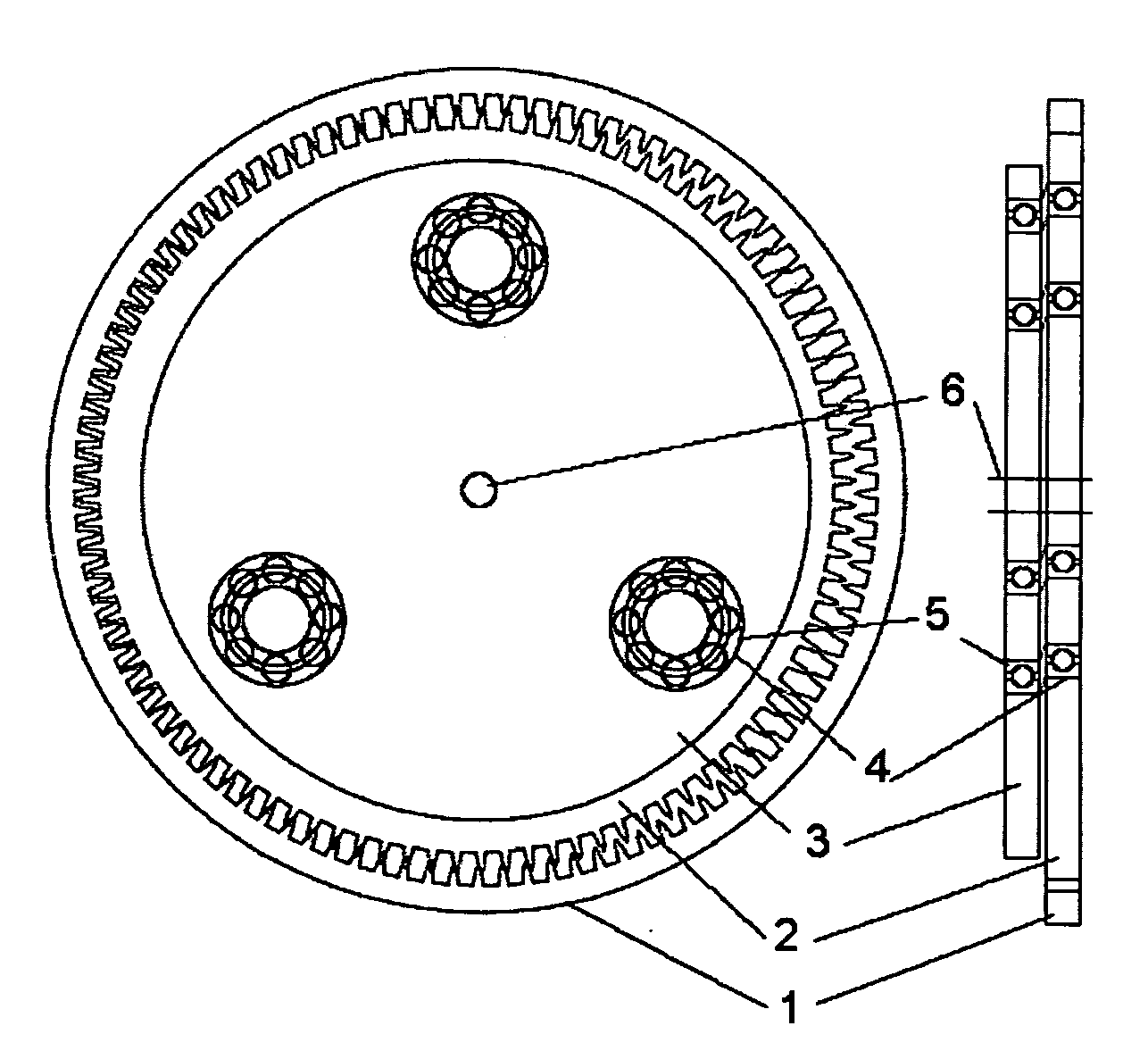

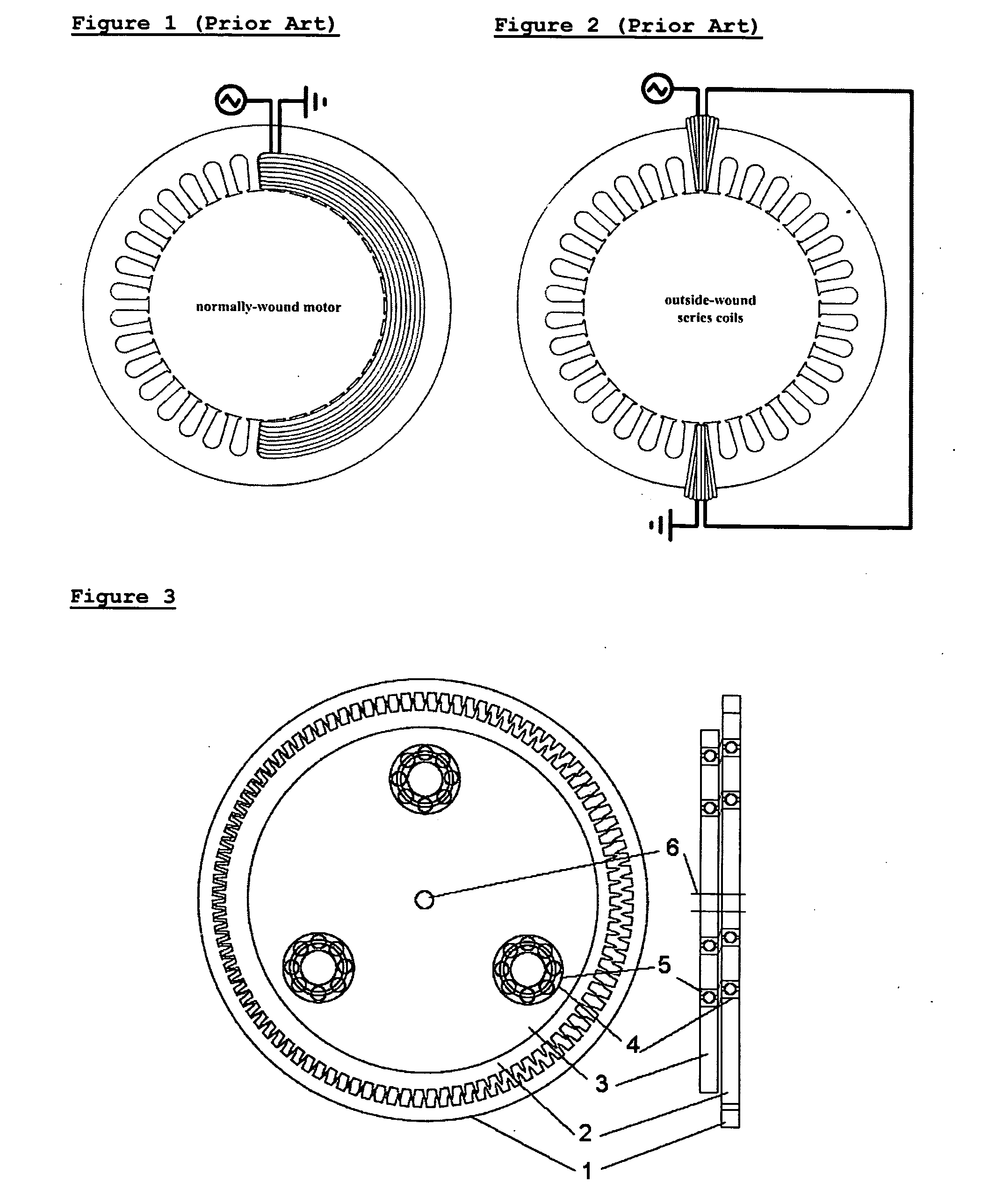

Motor using magnetic normal force

InactiveUS20090009011A1Propulsion systemsSupports/enclosures/casingsMagnetic tension forceConductive materials

Owner:BOREALIS TECH LTD

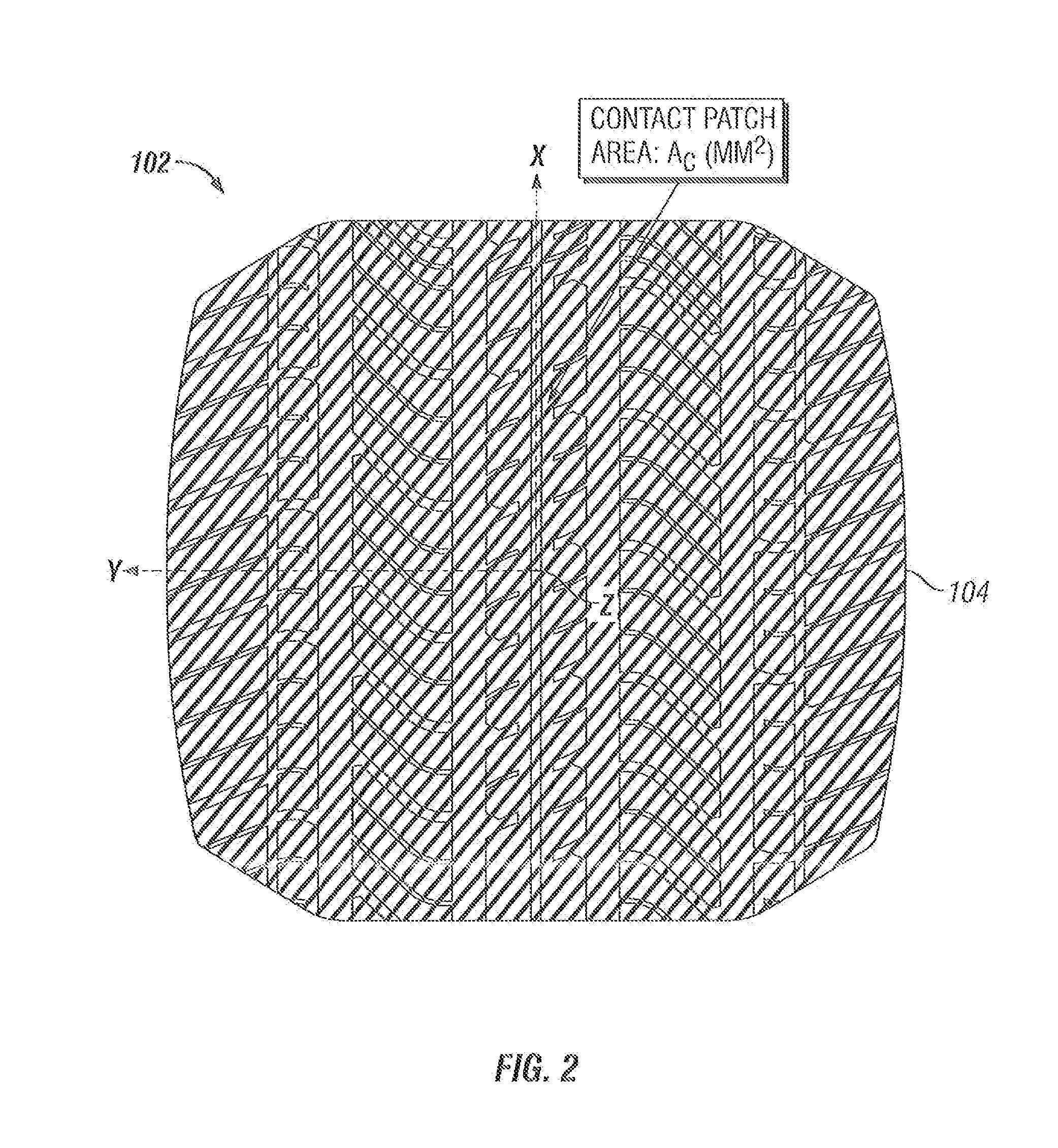

Tire with tread having improved snow and dry traction

This invention relates generally to tires having treads that have a configuration and / or properties for providing suitable snow and dry traction, and, more specifically, to a tire that has a tread that has a maximum value for sipe density in the contact patch, a minimum value for lateral groove density in the contact patch, and a minimum value for the longitudinal contact surface ratio. In certain embodiments, the pitch length of pitches or repeating units of tread geometry along the circumferential direction of the tire is within a certain range and the tread depth is below a specified value. Tires with treads having a configuration that falls within these design parameters exhibit a desirably good level of snow and dry traction.

Owner:MICHELIN & CO CIE GEN DES ESTAB MICHELIN

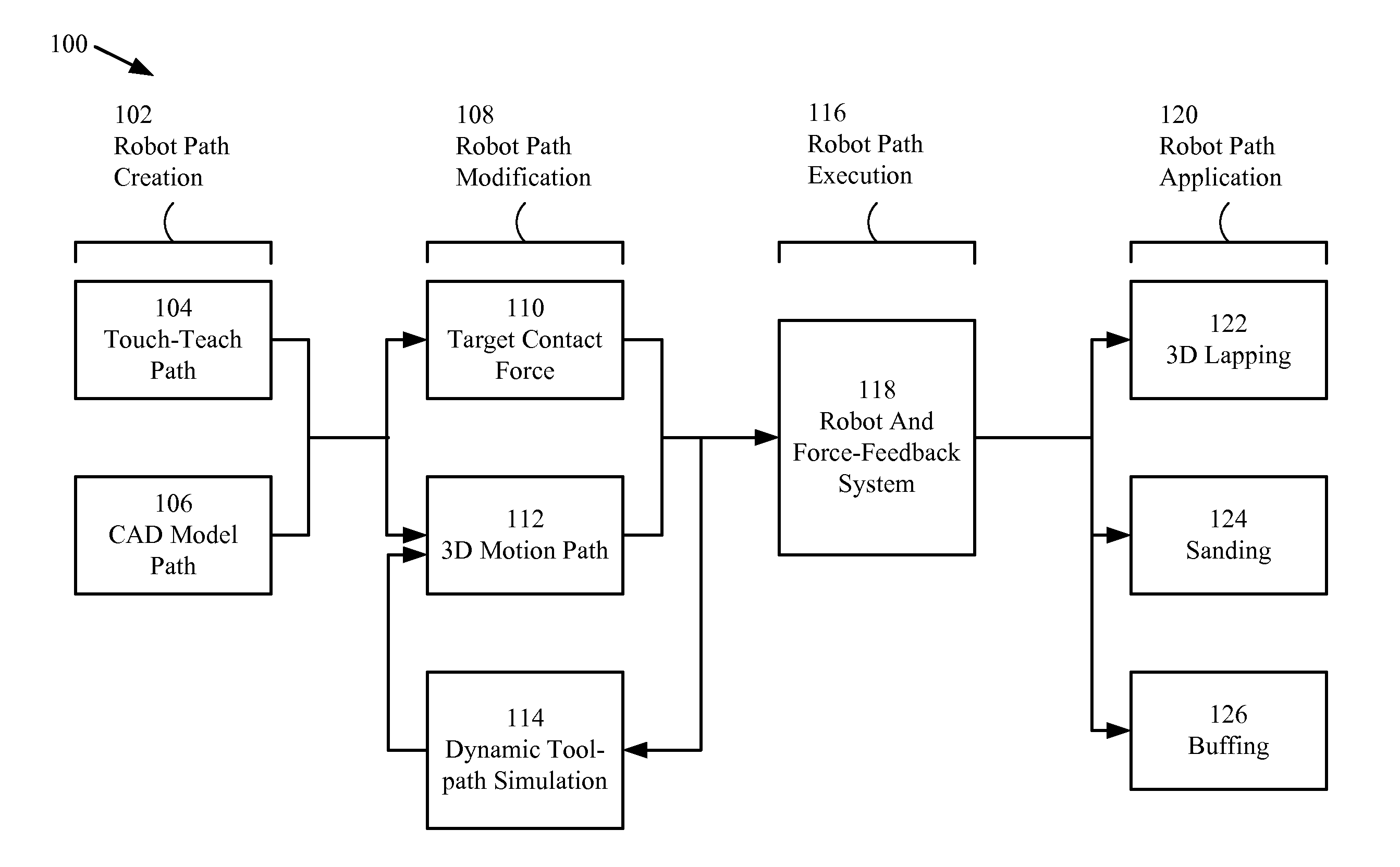

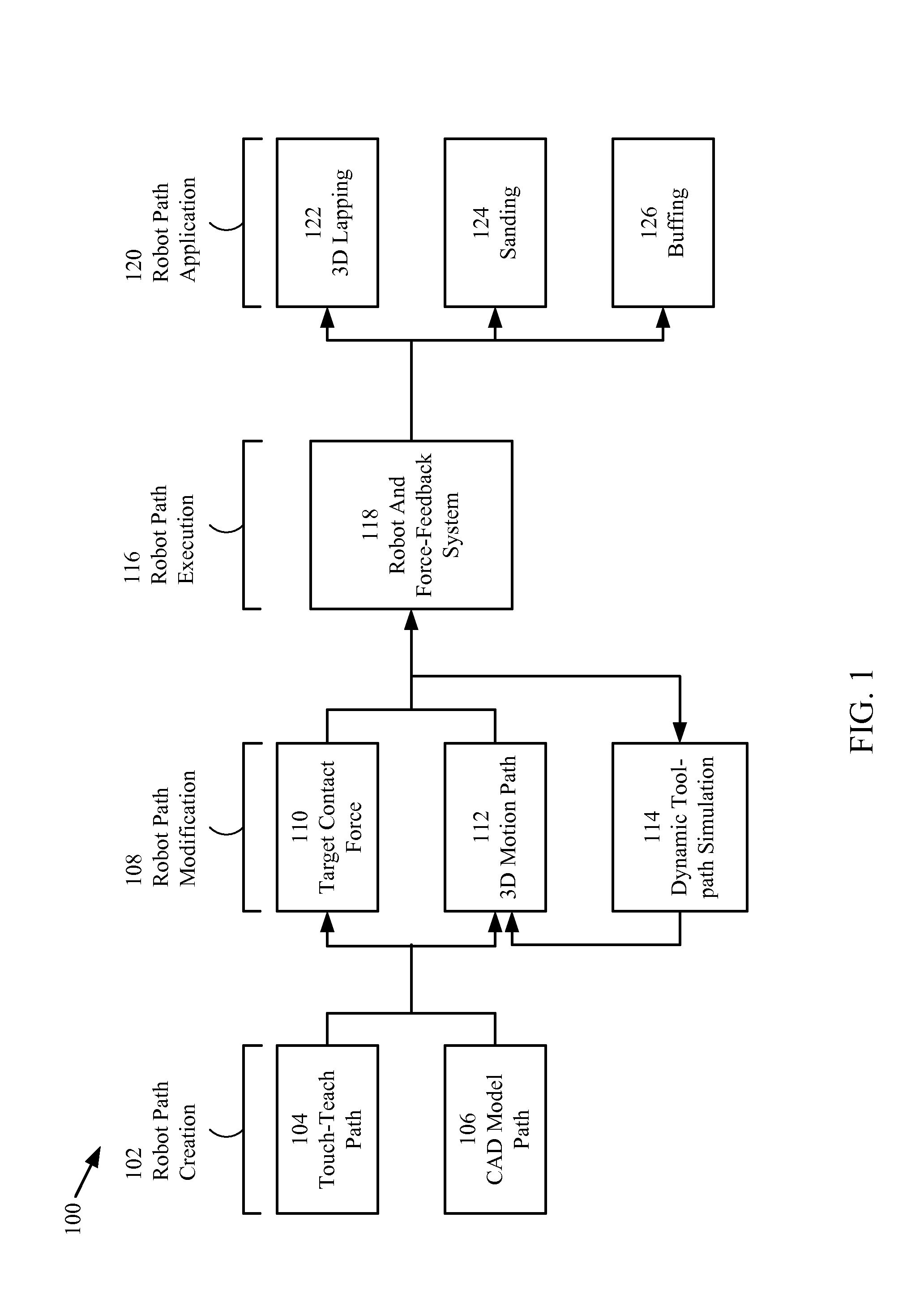

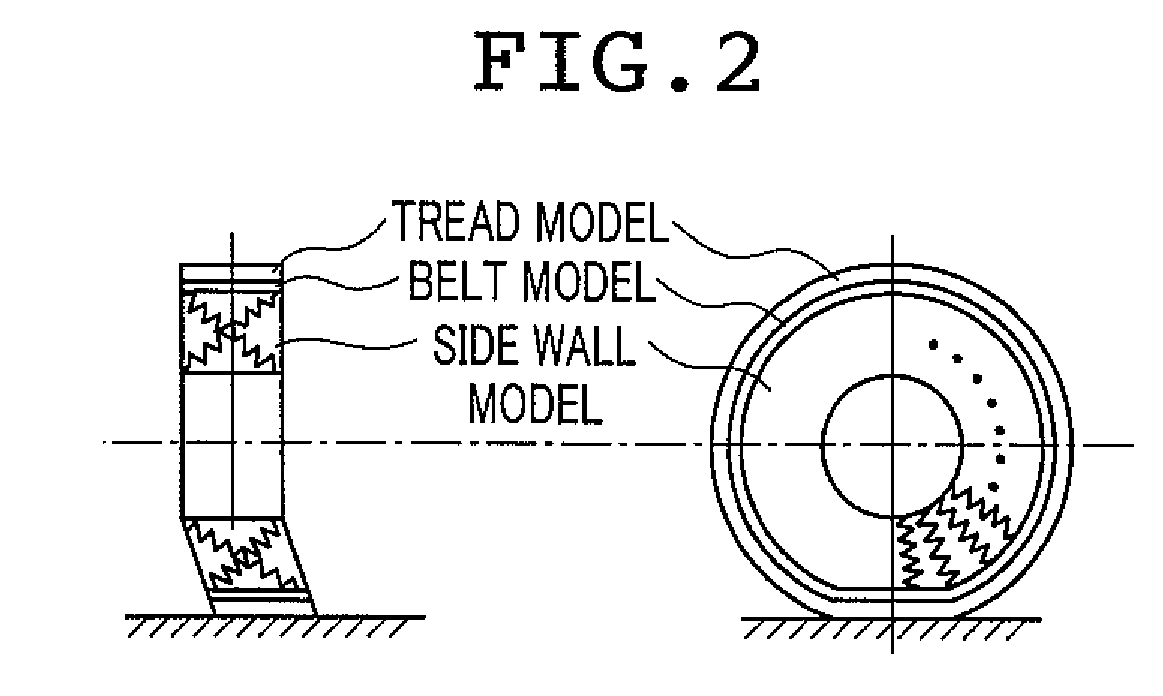

Contact patch simulation

InactiveUS20140088746A1Programme-controlled manipulatorTotal factory controlContact patchSurface finishing

A method and an apparatus for smart automation of robotic surface finishing of a three-dimensional surface of a workpiece is described. A finite element analysis simulation is conducted providing data for generation of a three-dimensional path along the surface of the workpiece. The finite element can include properties of the workpiece, finishing tool, and the robot configured to maneuver the finishing tool. The surface of the workpiece is finished using one or more surface finishing tools along the three-dimensional path. The surface of the workpiece includes at least a flat region and a curved region.

Owner:APPLE INC

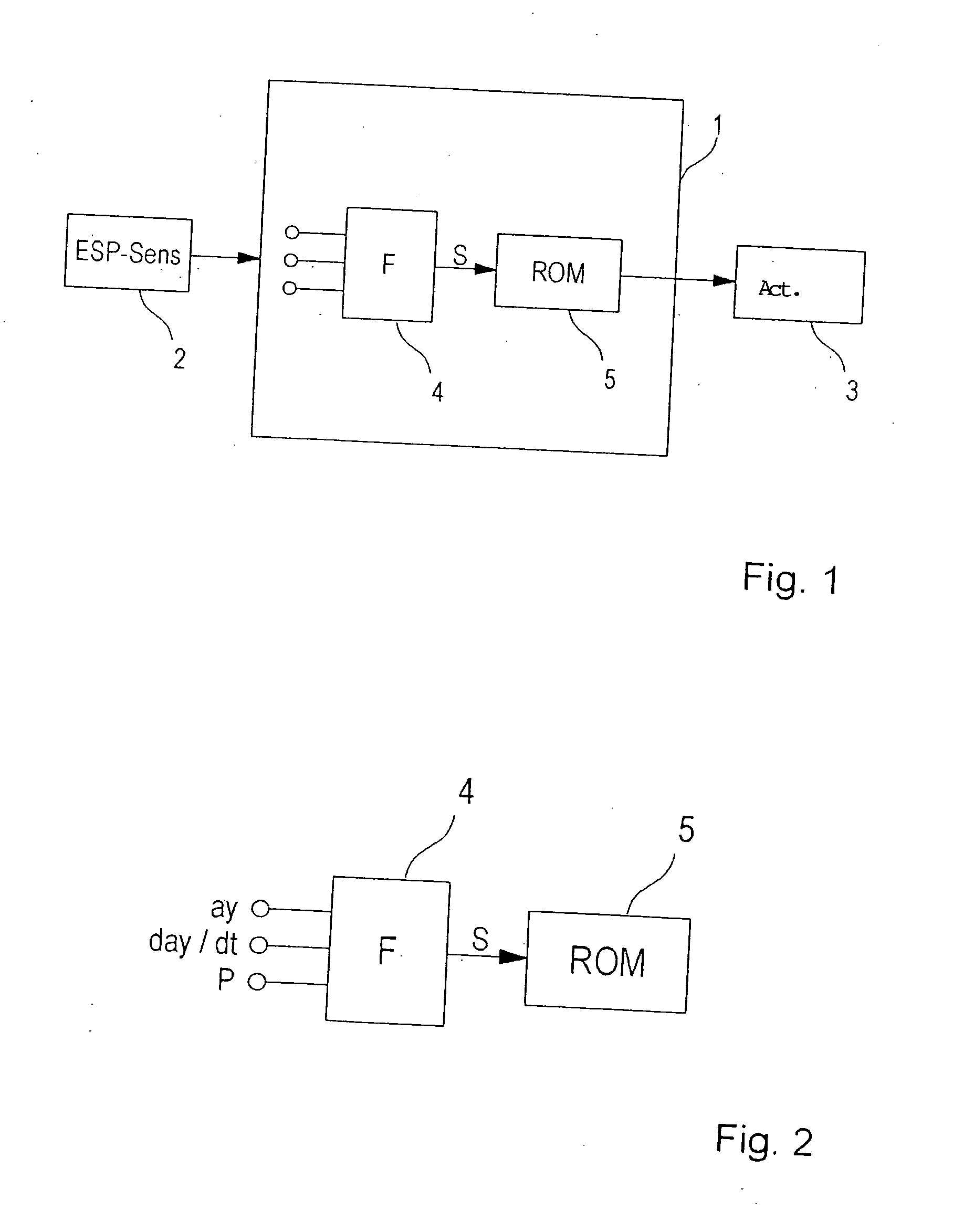

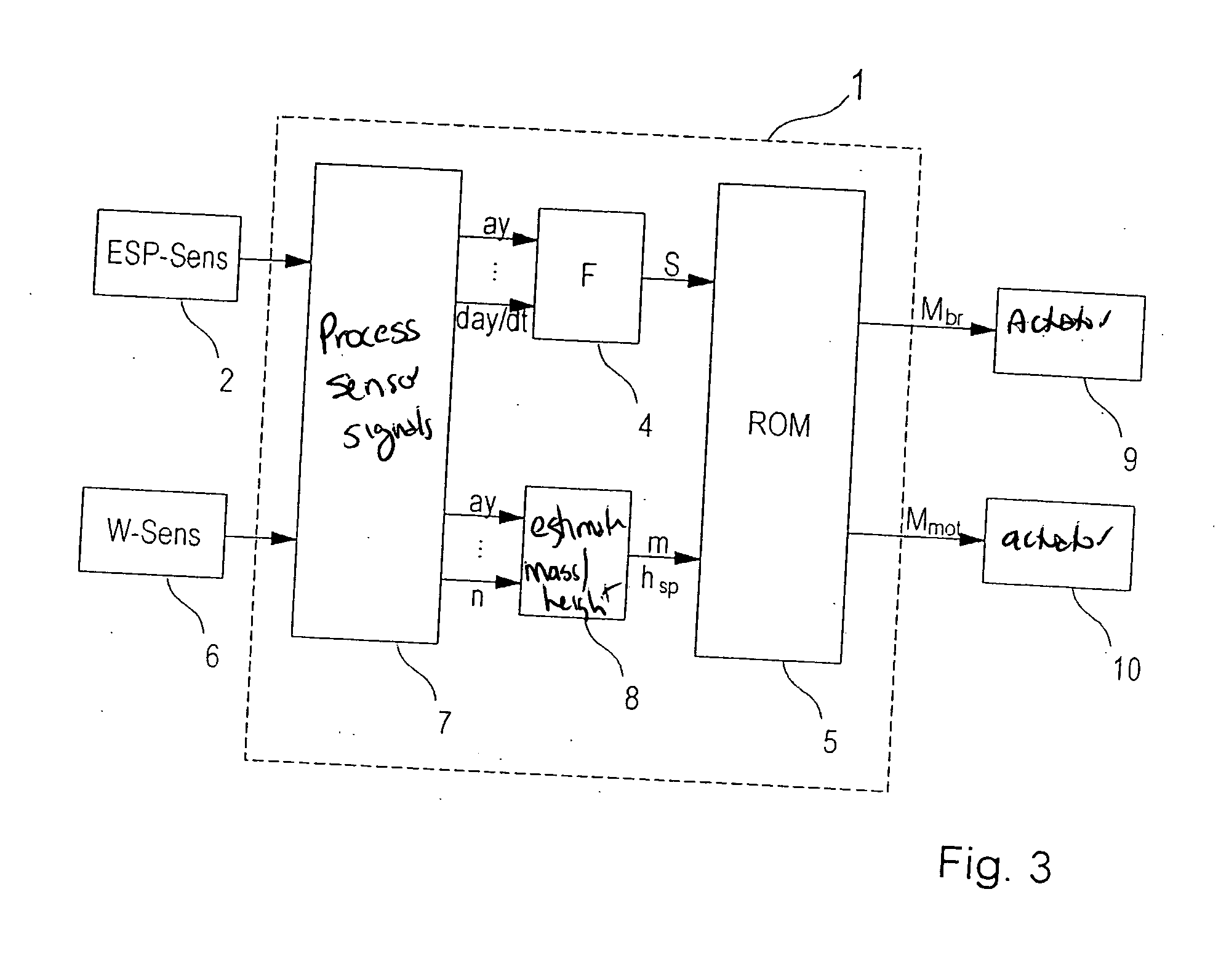

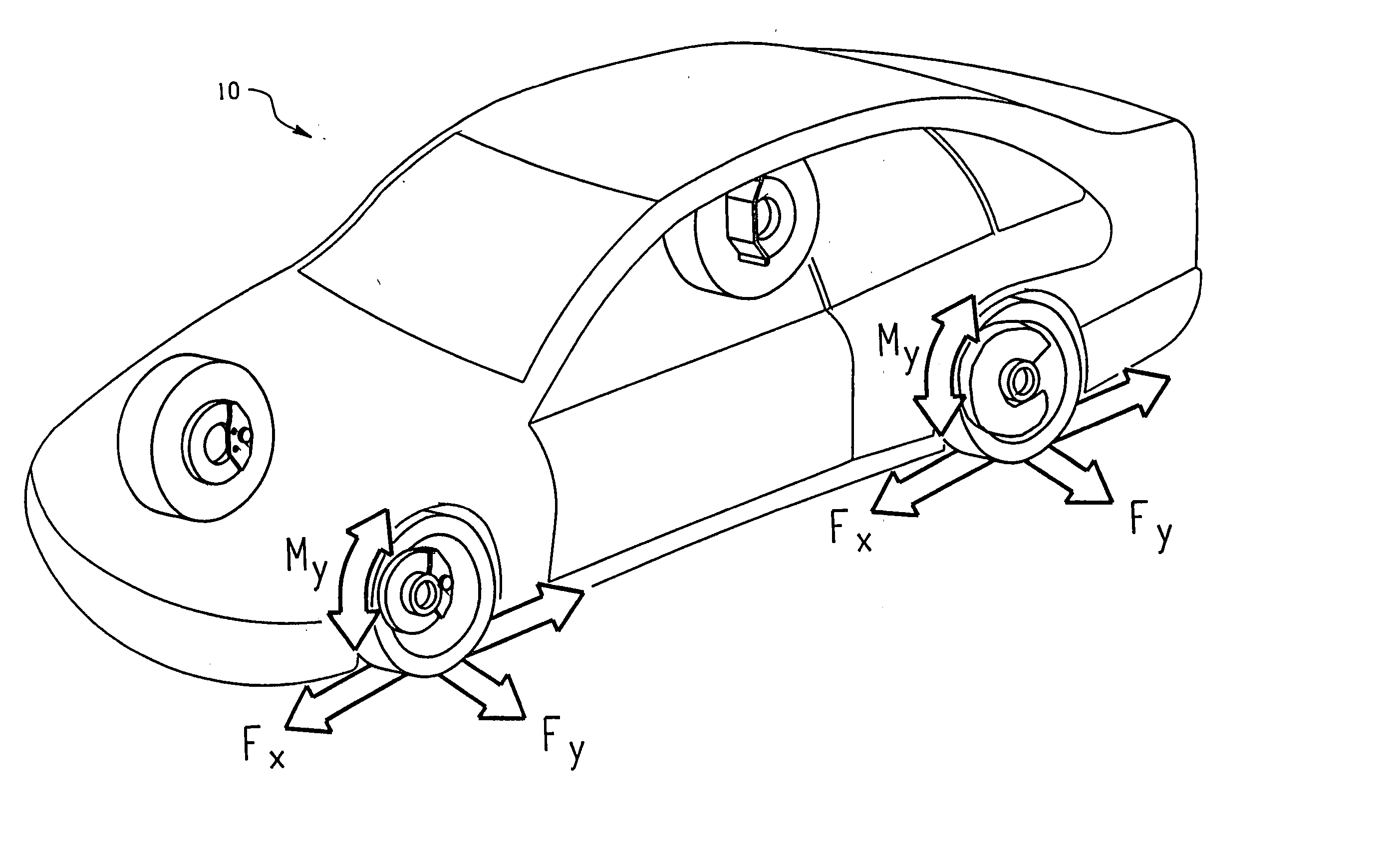

Vehicle dynamics control system adapted to the load condition of a vehicle

InactiveUS20070078581A1Tendency increaseImprove availabilityVehicle body stabilisationAnalogue computers for trafficContact patchVehicle dynamics

A method for rollover stabilization of a vehicle in critical driving situations, in which a rollover stabilization algorithm intervenes in the driving operation in a critical situation, using an actuator in order to stabilize the vehicle. Different loading states of the vehicle may be taken into consideration in that the vehicle mass as well as the characteristic speed and the ratio of the contact patch forces of the wheels are ascertained, and the rollover stabilization algorithm is executed as a function of the vehicle mass and the estimated vehicle center of gravity.

Owner:ROBERT BOSCH GMBH

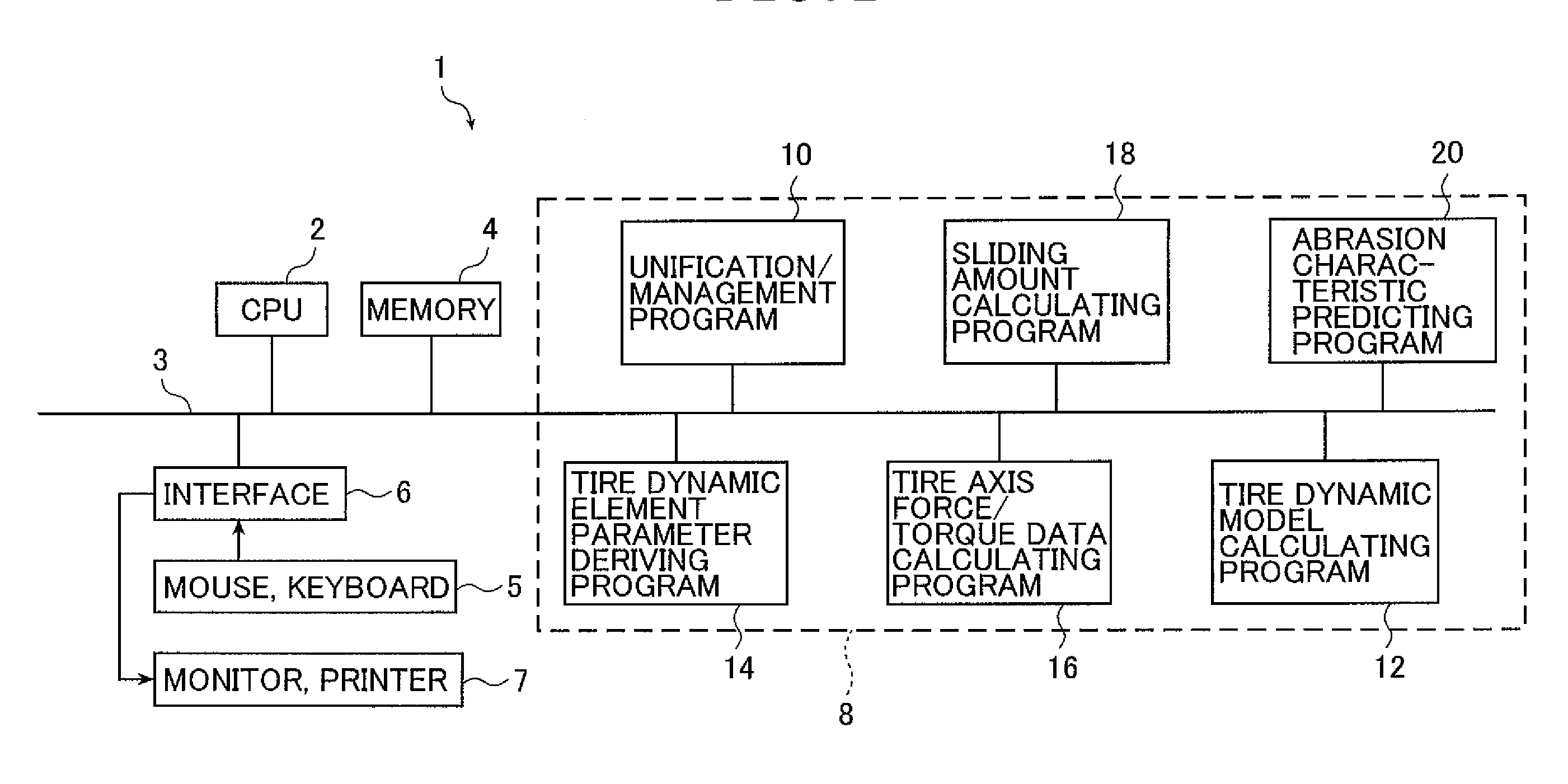

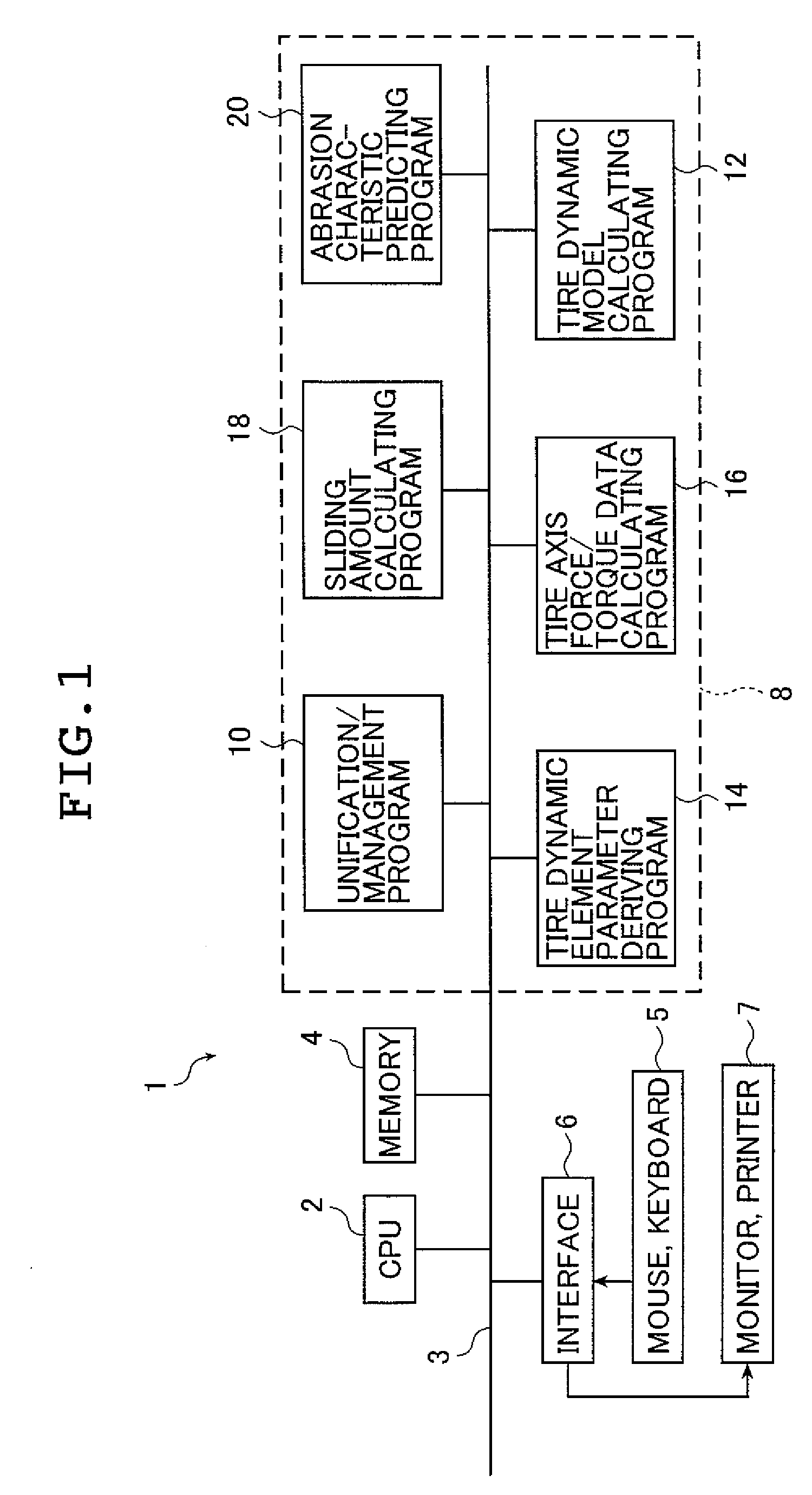

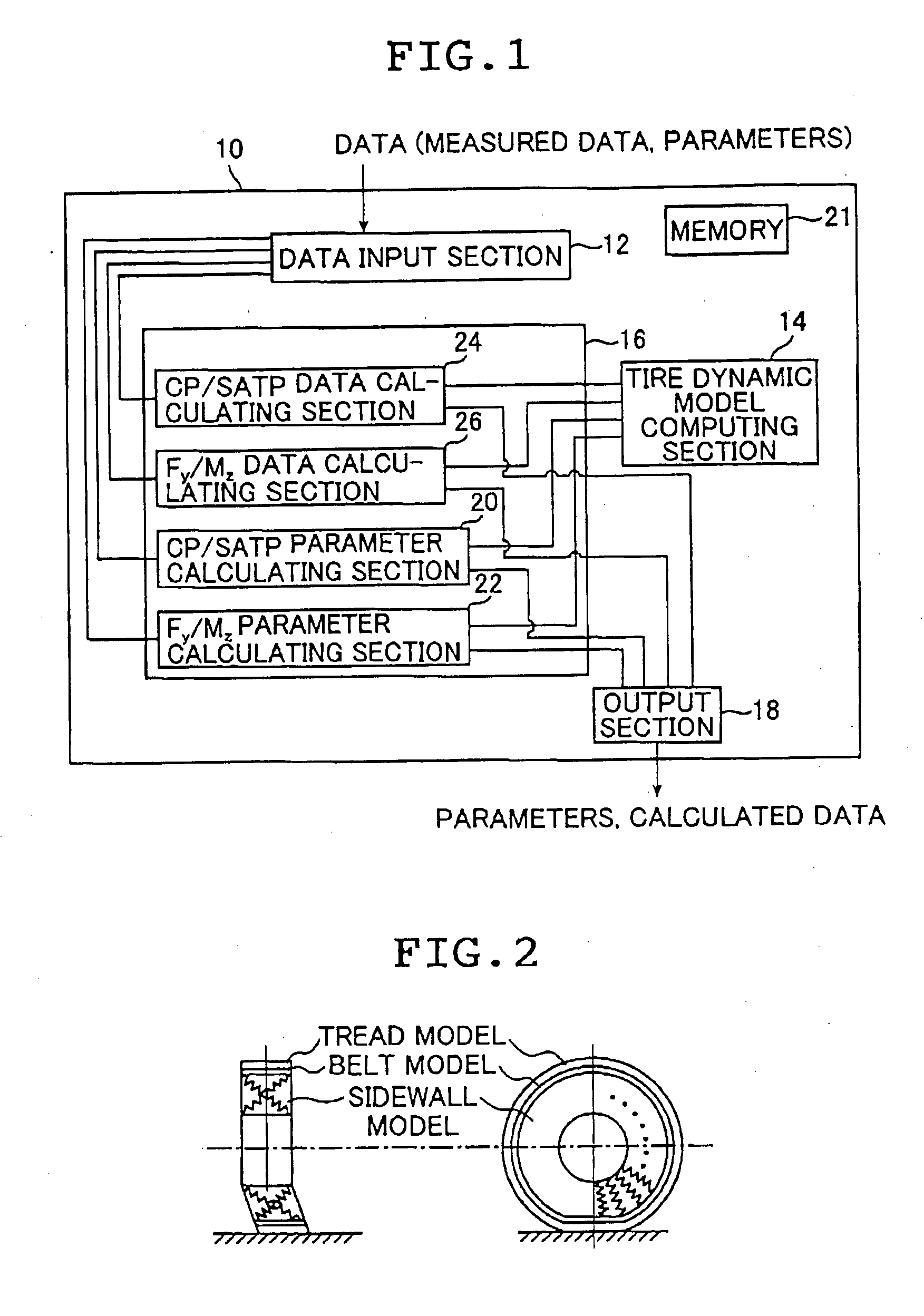

Tire Abrasion Predicting Method, Tire Designing Method, Tire Manufactring Method Tire Abrasion Predicting Sytem, and Program

ActiveUS20080228411A1Improve accuracyPlug gaugesAutomatic initiationsPredictive methodsDynamic models

In a prediction of abrasion characteristic of a tire, a characteristic curve of a tire axis force generated on a tire rotation axis at the slip ratio applied to the tire and changed depending upon the slip ratio is acquired. From the characteristic curve, values of tire dynamic element parameters determining the characteristic curve are derived based on a tire dynamic model constituted by the tire dynamic element parameters. Furthermore, a tire sliding amount based on a sliding region, the sliding region and an adhesive region formed on the contact patch of the tire at the applied slip ratio are calculated by applying the values of the tire dynamic element parameters to the model. Lastly, an abrasion characteristic of a tread part of the tire at the applied slip ratio is predicted by using the tire sliding amount with abrasion characteristic data of a tread rubber of the tread part. According to the prediction results, a tire is designed and produced.

Owner:YOKOHAMA RUBBER CO LTD

Flexible heat sink with lateral compliance

InactiveUS8736048B2Semiconductor/solid-state device detailsSolid-state devicesShear stressComputer module

A multi-chip module (MCM) structure comprises more than one semiconductor chip lying in a horizontal plane, the MCM having individual chip contact patches on the chips and a flexible heat sink having lateral compliance and extending in a plane in the MCM and secured in a heat exchange relation to the chips through the contact patches. The MCM has a mismatch between the coefficient of thermal expansion of the heat sink and the MCM and also has chip tilt and chip height mismatches. The flexible heat sink with lateral compliance minimizes or eliminates shear stress and shear strain developed in the horizontal direction at the interface between the heat sink and the chip contact patches by allowing for horizontal expansion and contraction of the heat sink relative to the MCM without moving the individual chip contact patches in a horizontal direction.

Owner:I N T E R N A T I O N A L BUSINESS MACHINES

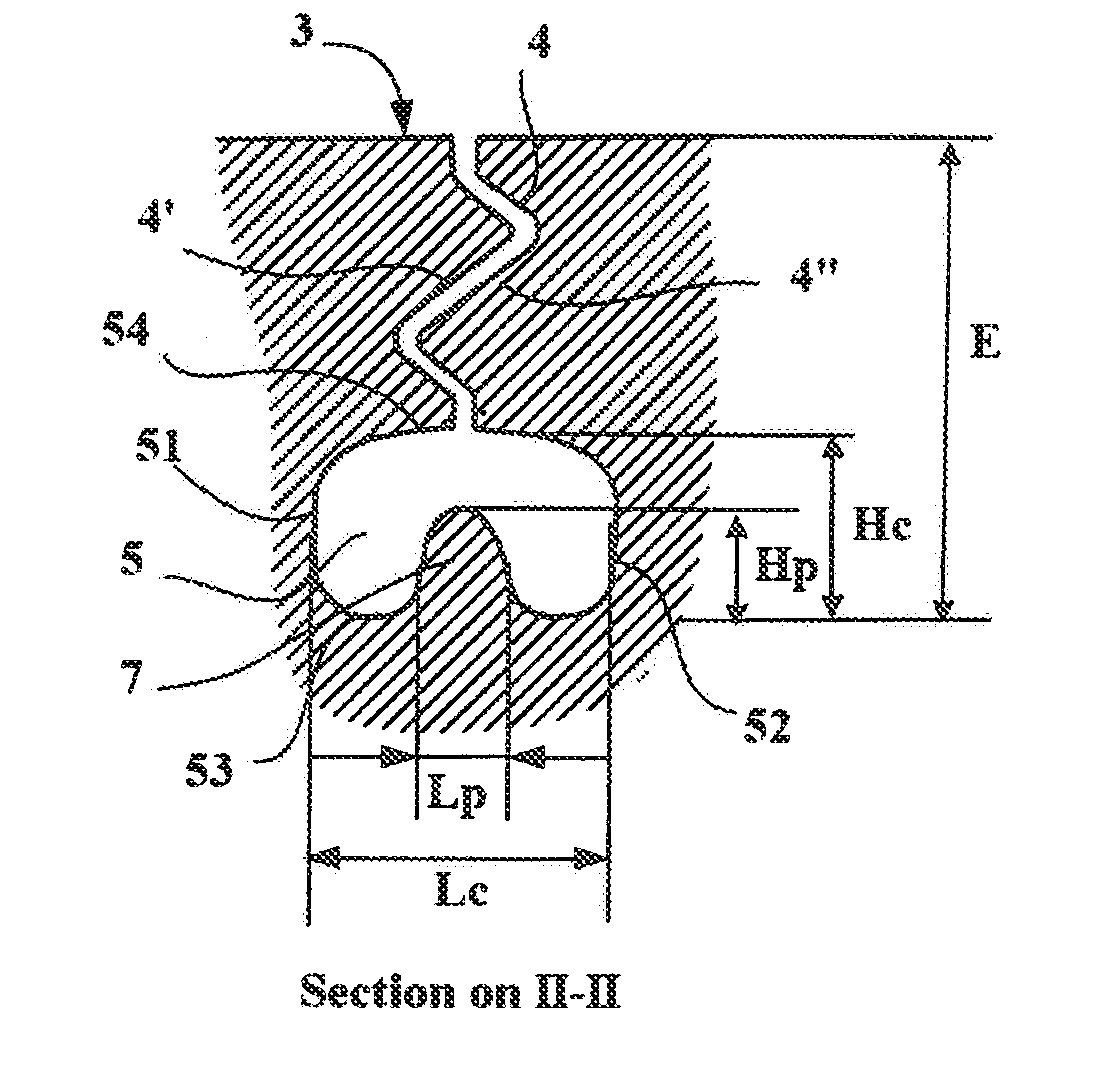

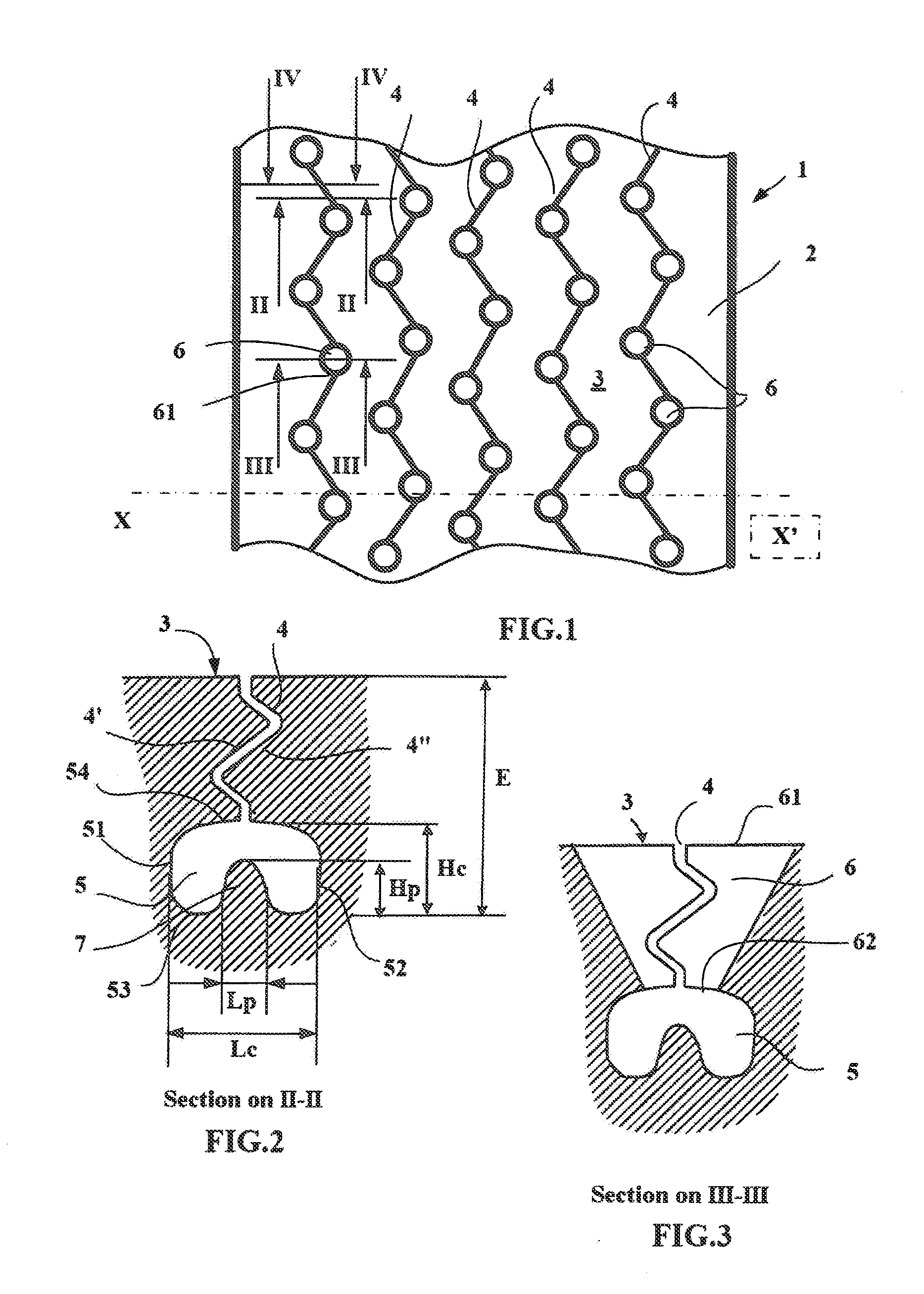

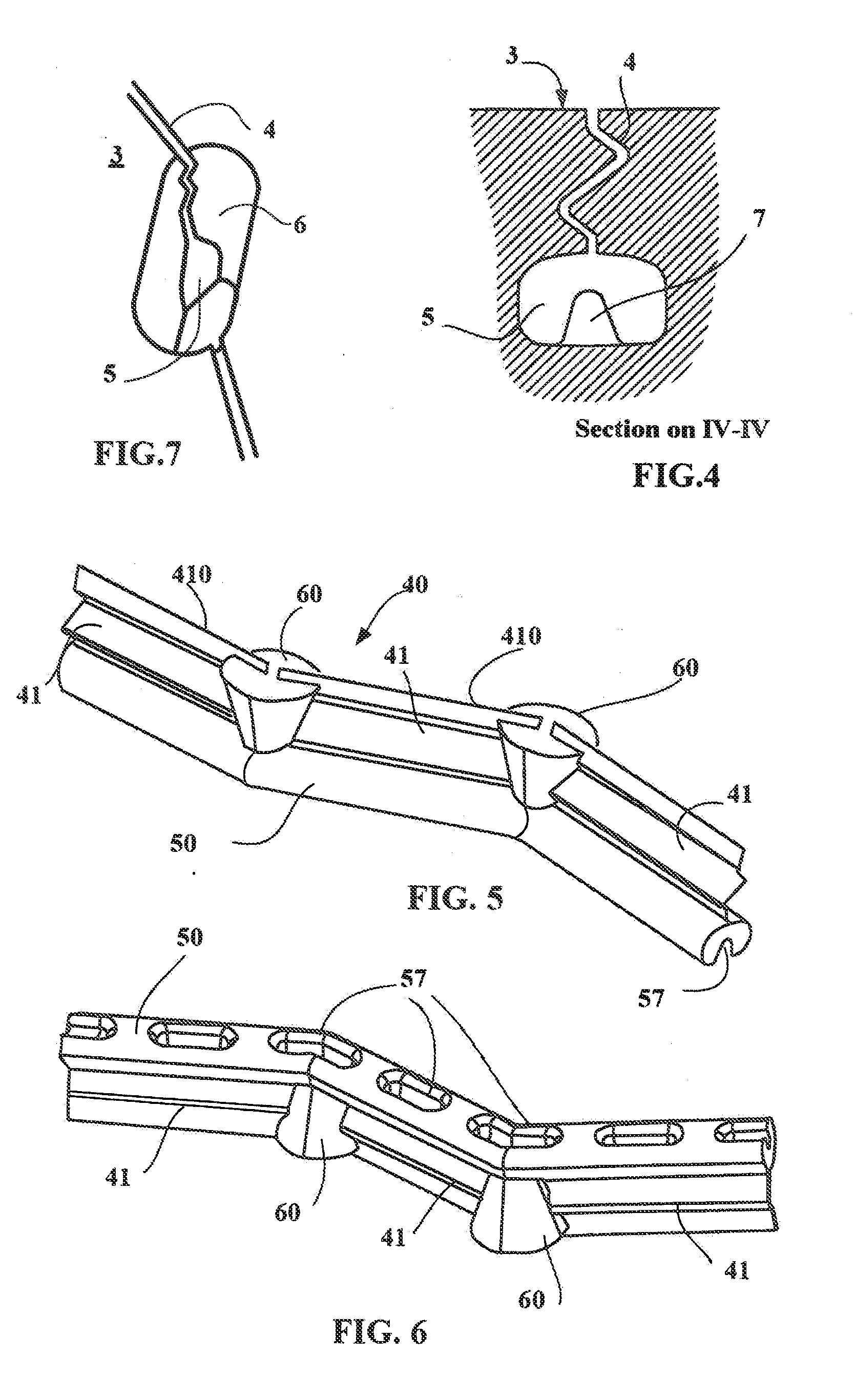

Tire tread for a trailer-type heavy vehicle and molding component

A tread and a tire for a heavy vehicle, and a molding element therefor, this tread comprising a plurality of sipes of circumferential overall orientation and of width (Li), each of these sipes extending into the depth of the tread over a depth (P) that is less than the mean thickness (E) of the tread, each sipe being extended radially inwards by a channel having lateral walls that, when the tread has become partially worn, delimit a new groove, these lateral walls connecting to a bottom , each sipe connecting together a plurality of drainage wells, each formed in the thickness of the tread opening via a first opening onto the tread surface the maximum dimension of which is at least equal to twice the width of the sipe and via a second opening into a channel; for each sipe of circumferential overall orientation, there is at least one drainage well in the contact patch and, in the continuation of each drainage well, a protrusion on the bottom of the channel.

Owner:MICHELIN & CO CIE GEN DES ESTAB MICHELIN +1

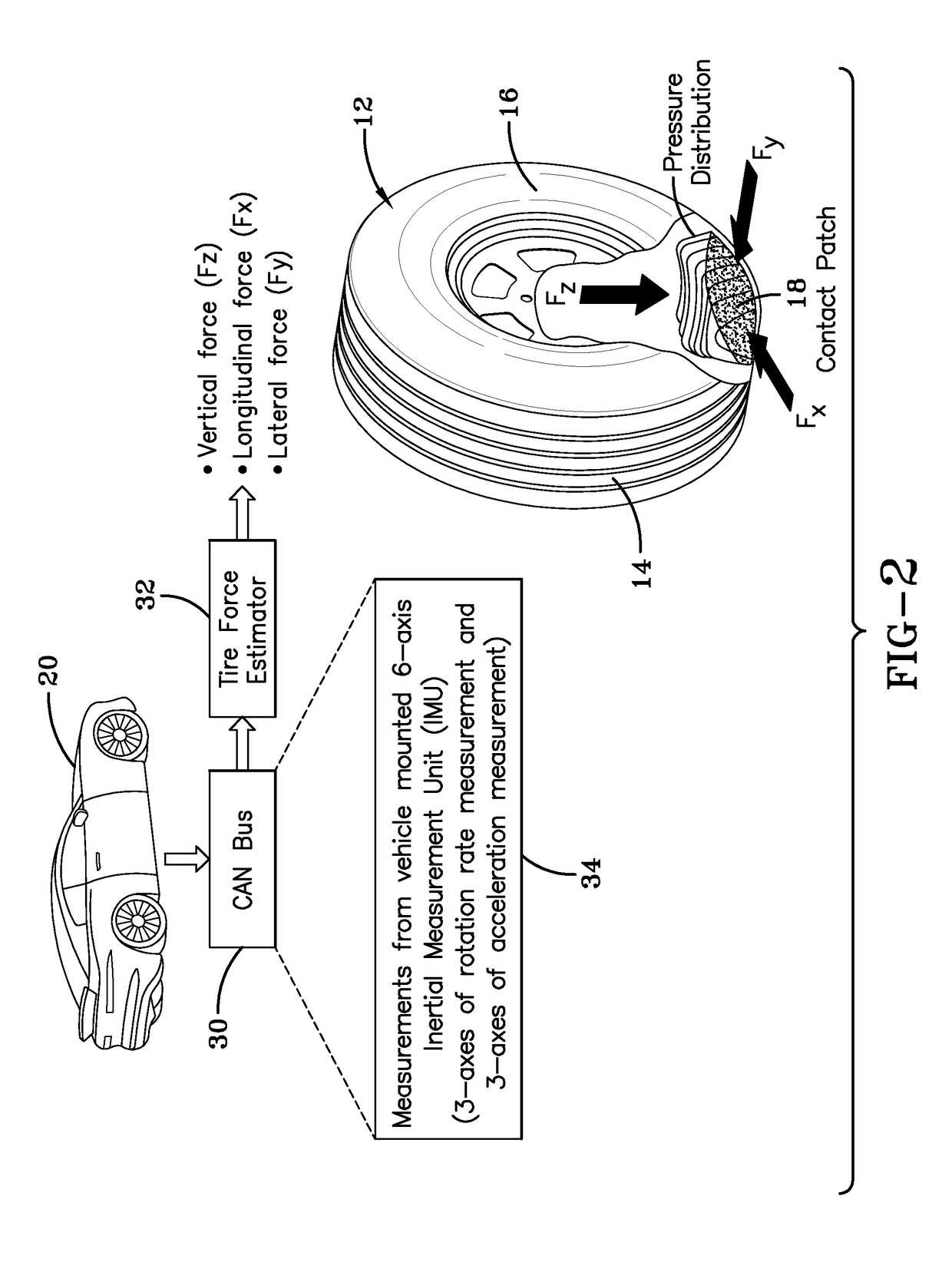

System and method for predicting tire forces using tire deformation sensors

InactiveUS20050005692A1Eliminate needRoads maintainenceElectric/fluid circuitEngineeringVertical force

A system and method for predicting the forces generated in the fire contact patch from measurements of tire deformations, including separating the lateral force, the vertical force, and the circumferential torque using measurements of tire deformations. A system and method for using a trained neural network or bilinear equations to determine any combination or permutation of one or more of any of the following from tire sidewall deformation sensors, e.g., magnetic tire sidewall torsion measuring (SWT) sensors: the lateral force acting on the tire, the circumferential torque acting on the tire, the longitudinal force acting on the tire, the vertical force acting on the tire, and forces and / or torques having any one or more of the foregoing as components thereof.

Owner:GIUSTINO JAMES M

Indirect tire wear state prediction system and method

ActiveUS9873293B2Error minimizationSatellite radio beaconingTyre measurementsState predictionFrictional energy

A tire wear state estimation system estimates forces and sliding velocity generated in a tire contact patch, determines frictional energy from the tire force and sliding velocity, and generates an estimate of tire wear state based upon the frictional work done by the tire. A tire wear estimate, pursuant to the system and methodology, is made by determining the amount of frictional work performed by the tire through the integrated use of tire-mounted, GPS sourced, and vehicle-mounted sensor information.

Owner:THE GOODYEAR TIRE & RUBBER CO

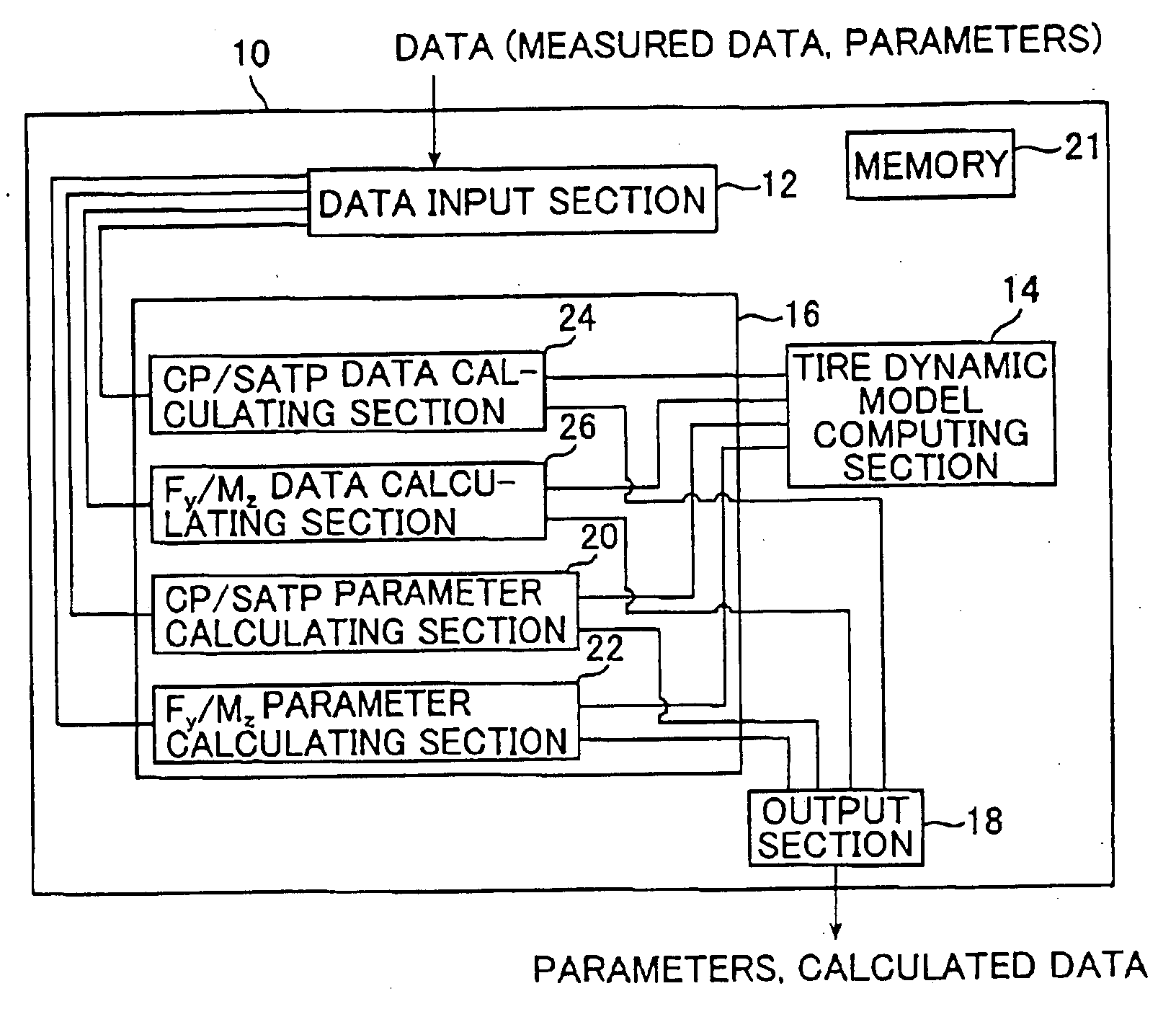

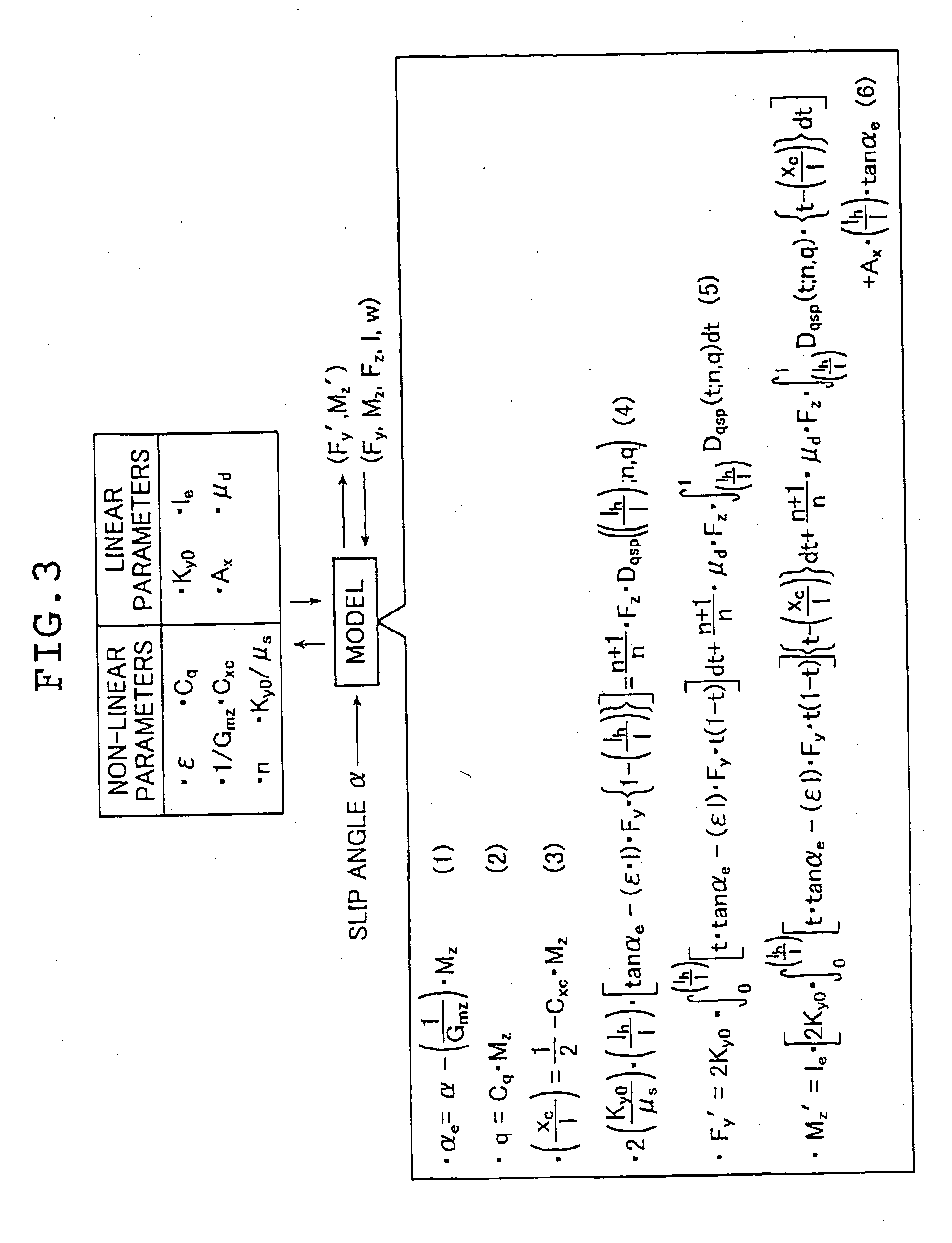

Tire parameter deriving method, tire cornering characteristic calculating method, tire designing method, vehicle dynamics analyzing method, and program

A method for tire parameter derivation, tire cornering characteristic calculation and tire design is used with a tire dynamic model constituted by using a plurality of tire dynamic element parameters including stiffness and friction coefficient and parameter defining a distribution of contact pressure of the tire. The parameters and tire cornering characteristic are derived by using the combined sum of squared residuals being obtained by weighted addition of a first sum of squared residuals of lateral force and a second sum of squared residuals of self-aligning torque. The tire dynamic model is a model for calculating a lateral force and for calculating a self-aligning torque separately as a lateral force-based torque component generated by the lateral force applied on a contact patch of the tire and a longitudinal force-based torque component generated by a longitudinal force applied on the contact patch of the tire.

Owner:THE YOKOHAMA RUBBER CO LTD

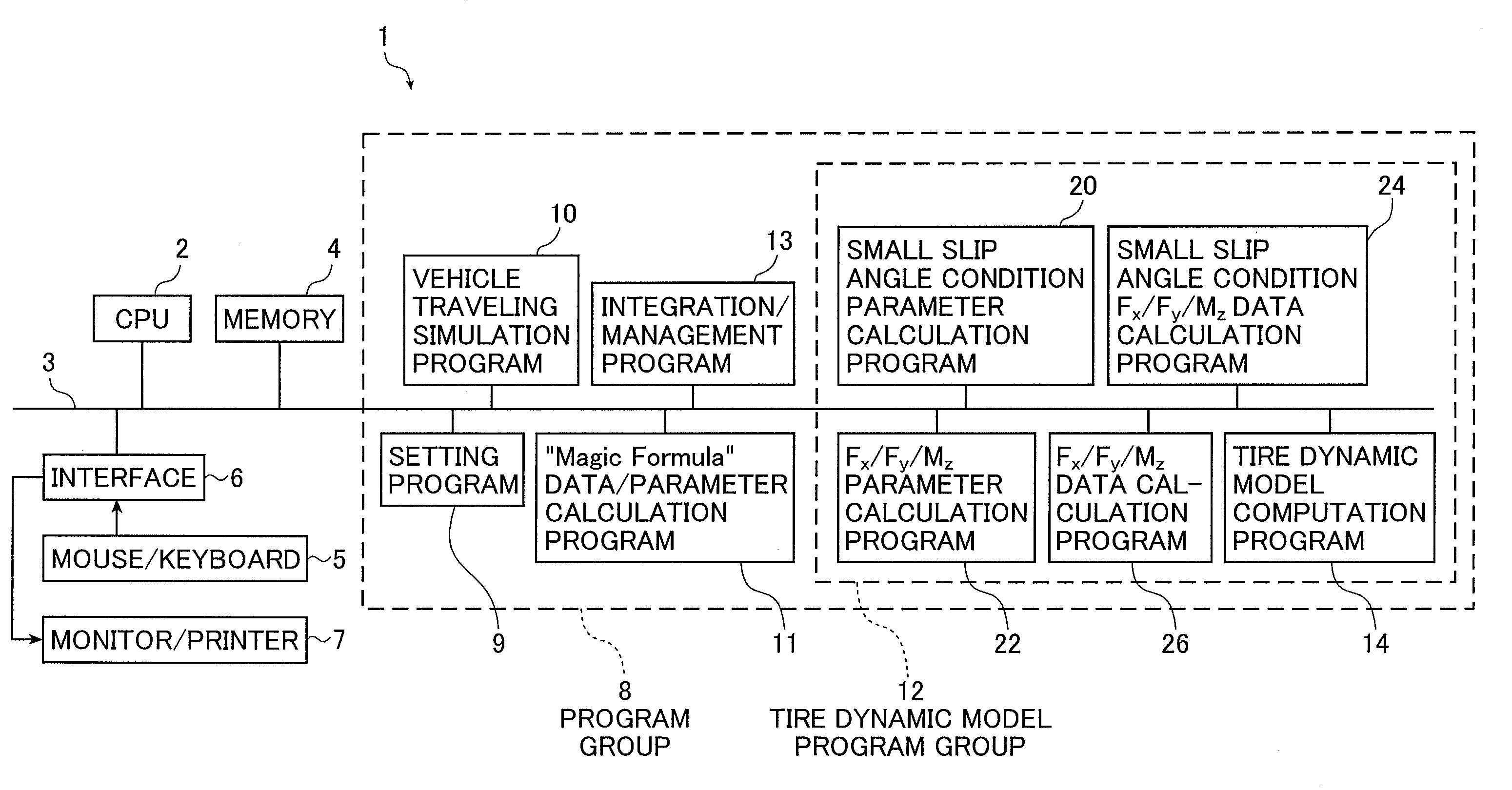

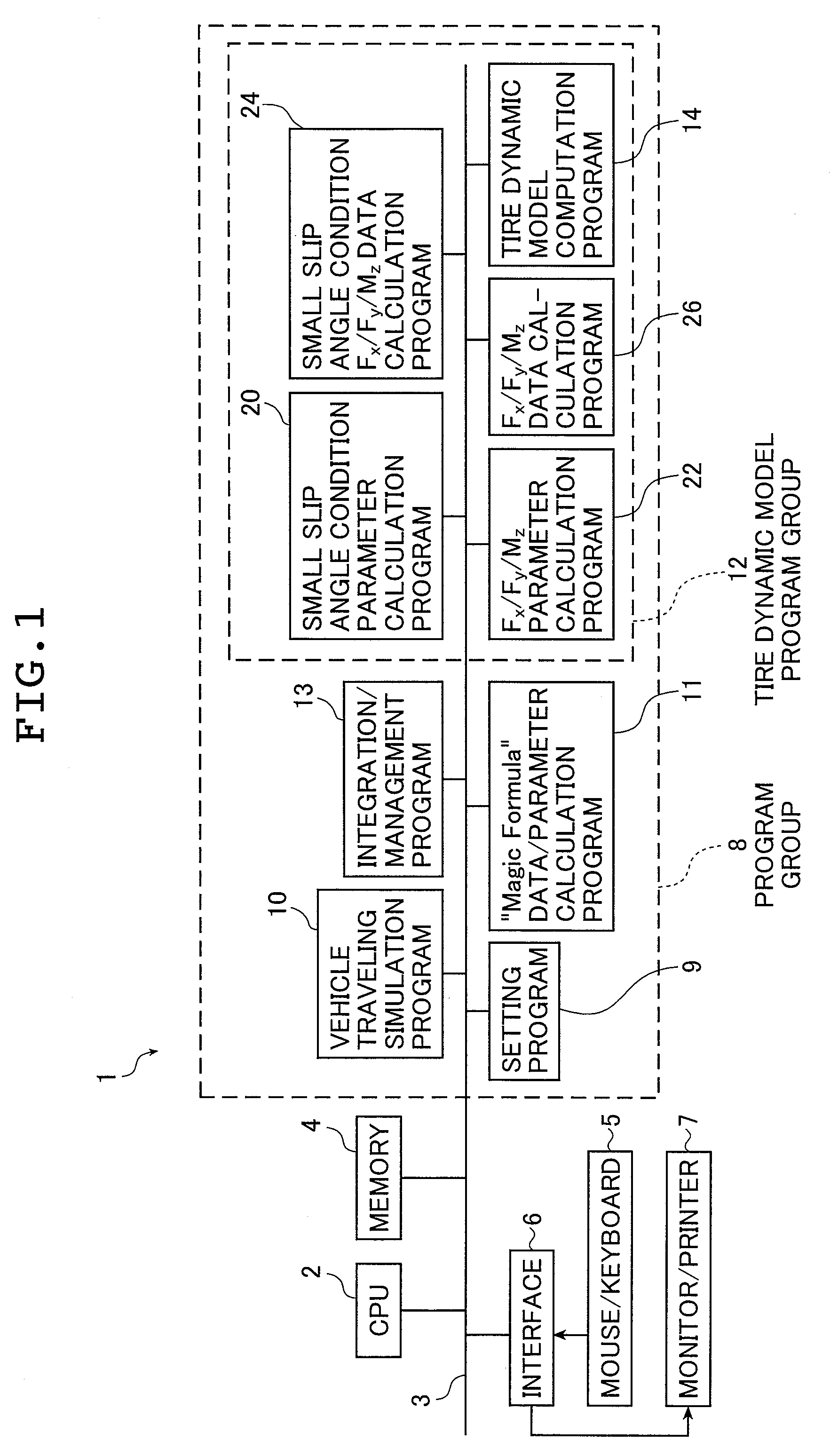

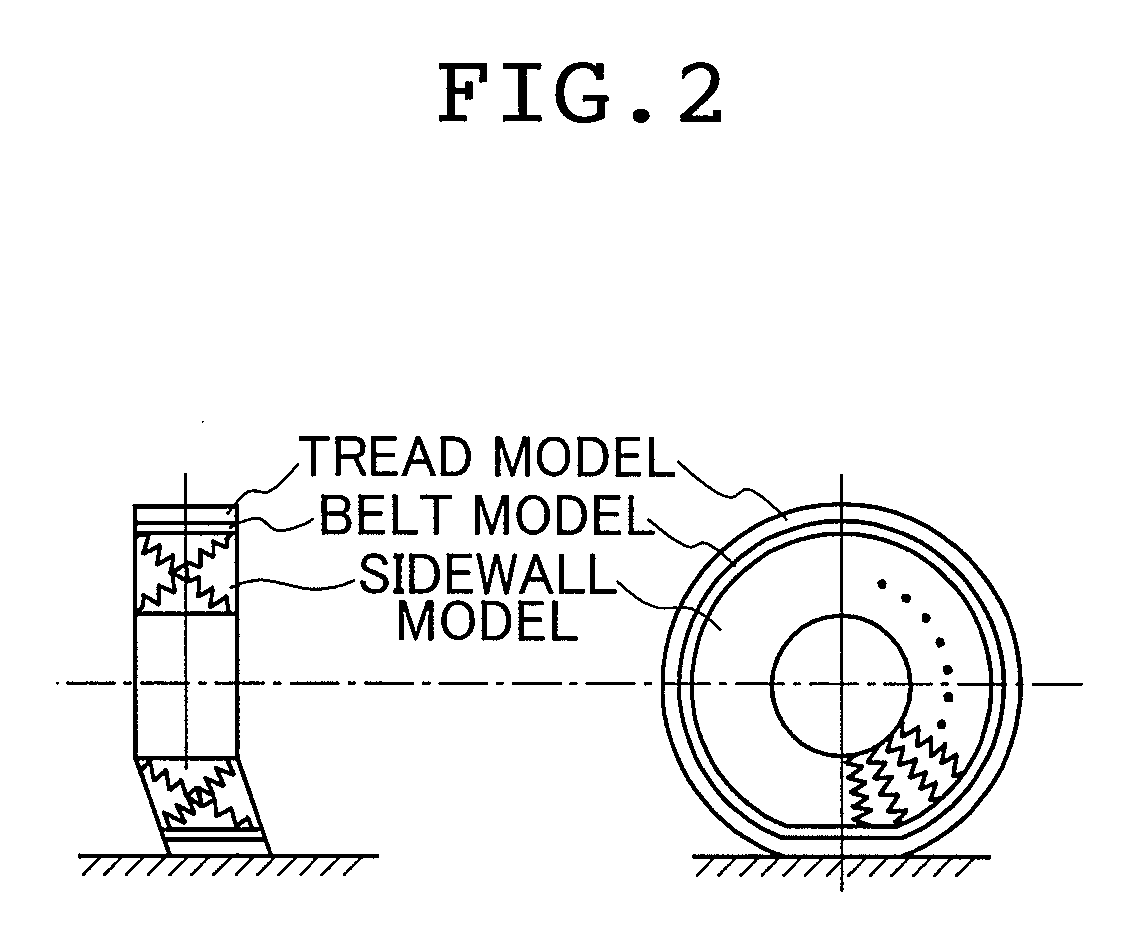

Tire characteristic calculation method, tire dynamic element parameter value derivation method, vehicle traveling simulation method, and tire designing method and vehicle designing method in which consideration is given to tire friction ellipse

InactiveUS20080059134A1Efficient executionEfficiently determinedTyre partsComputation using non-denominational number representationEllipseDynamic models

Values of multiple tire dynamic element parameters are set for a tire dynamic model constructed using the tire dynamic element parameters for calculating a tire axial force and a self-aligning torque under a given slip ratio. Next, the values of the tire axial force and the self-aligning torque are calculated using the tire dynamic model and output. The tire dynamic model allows a center position of a contact patch thereof against a road surface to move in accordance with a longitudinal force that occurs as the tire axial force when a slip ratio in a braking / driving direction is given so that a position of the contact patch moves in a longitudinal direction due to the longitudinal force. When designing a vehicle or when designing a tire, the tire dynamic model is used.

Owner:THE YOKOHAMA RUBBER CO LTD

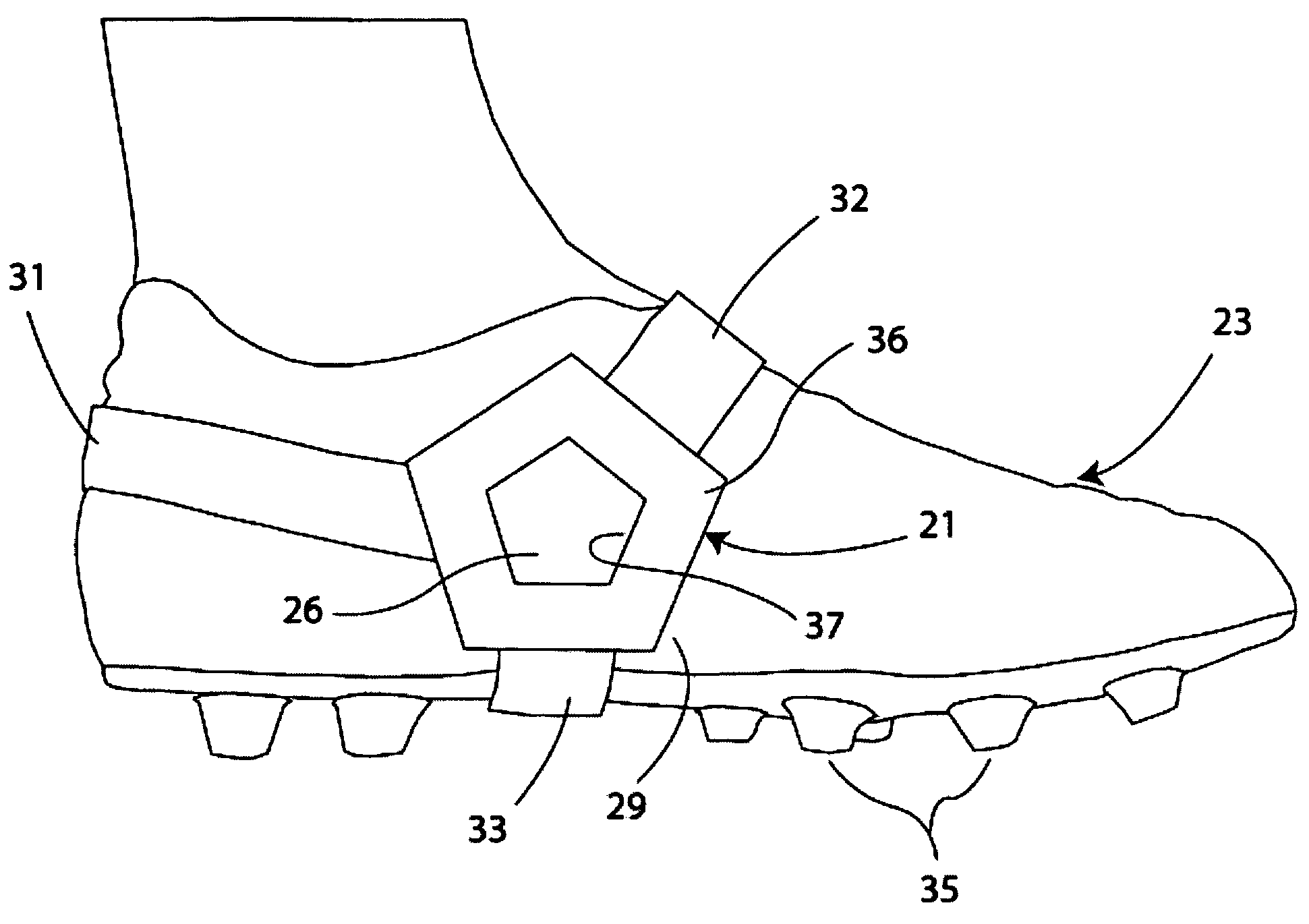

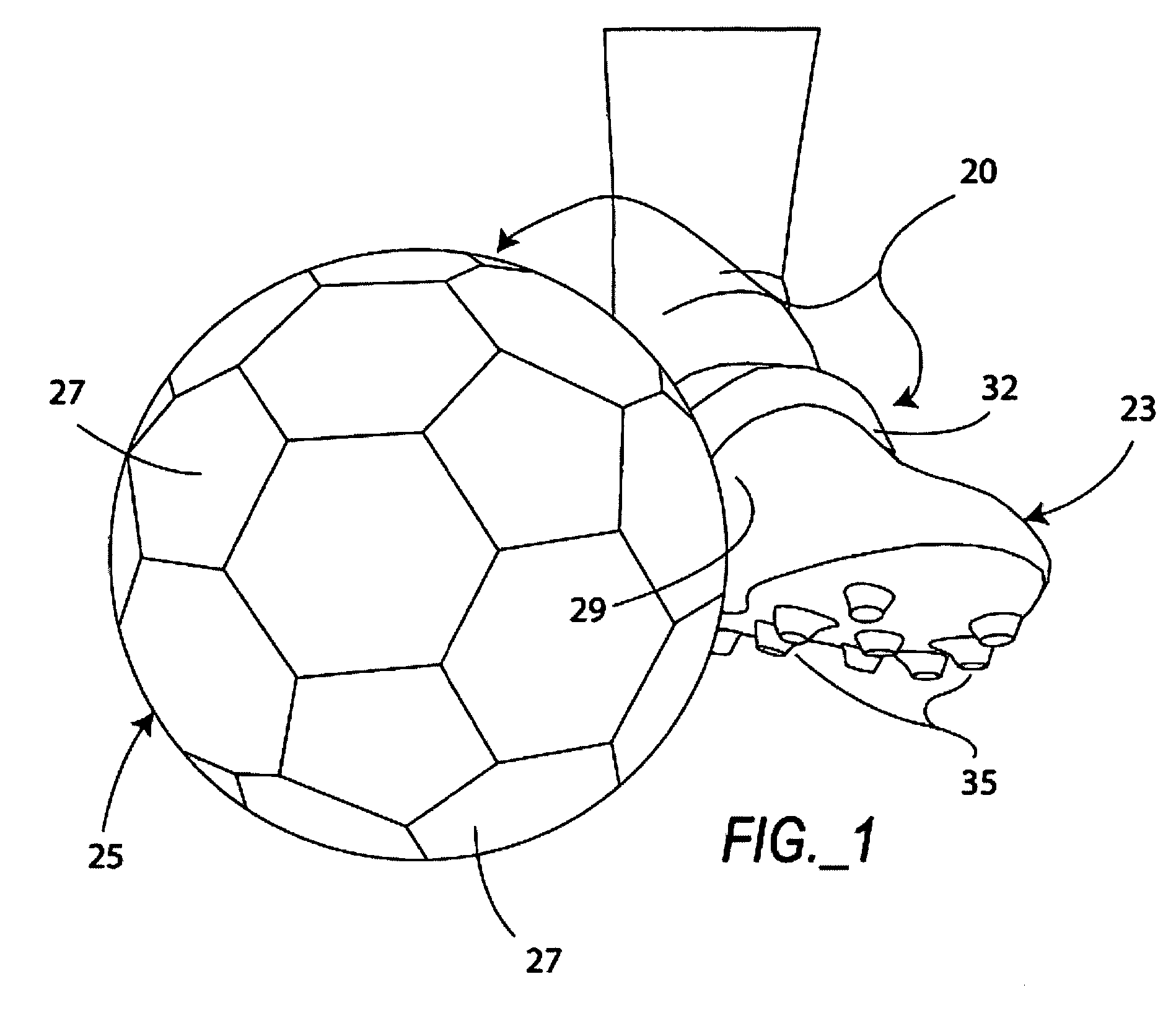

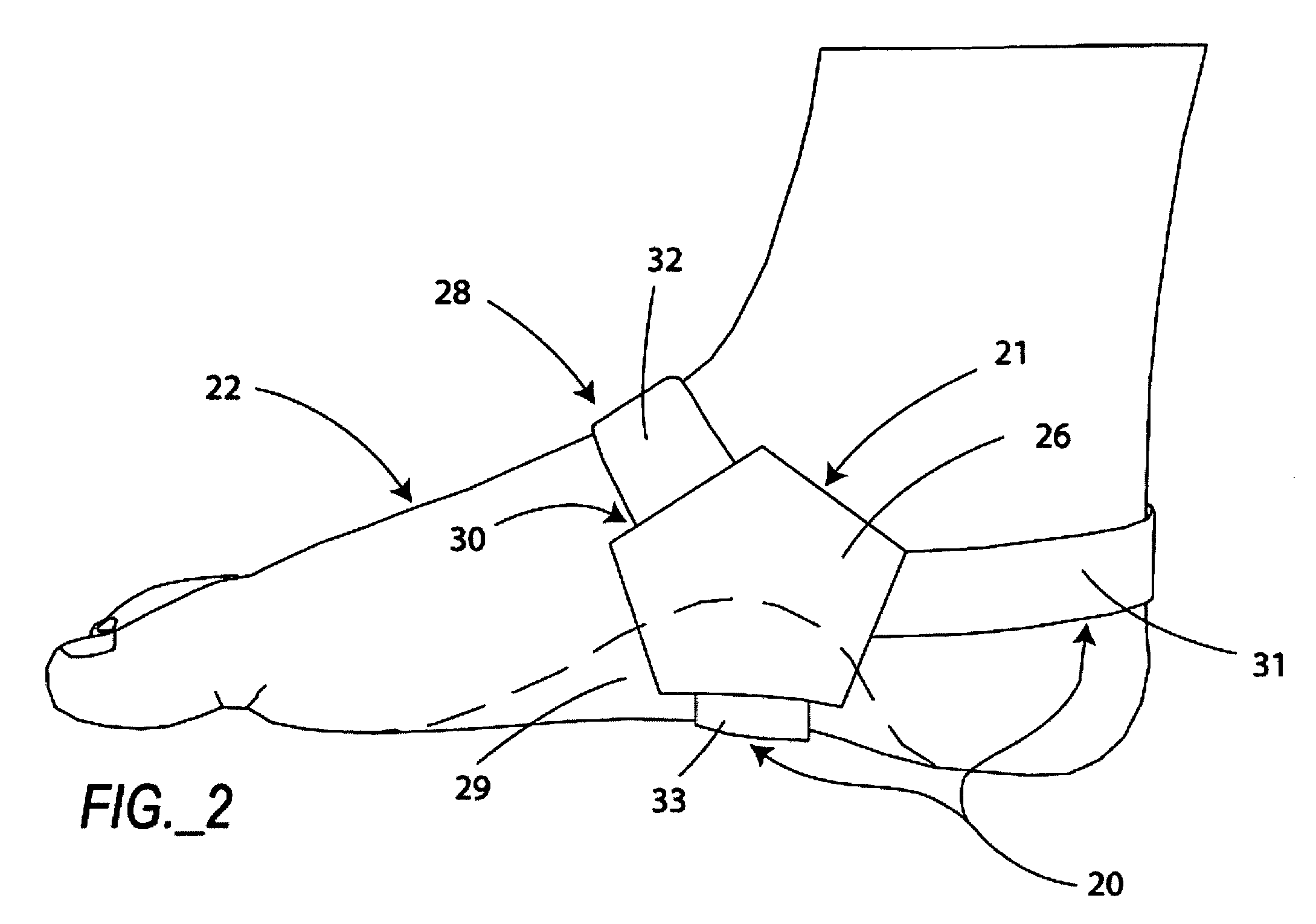

Soccer training apparatus and method

Owner:KOS ALEXANDER I +1

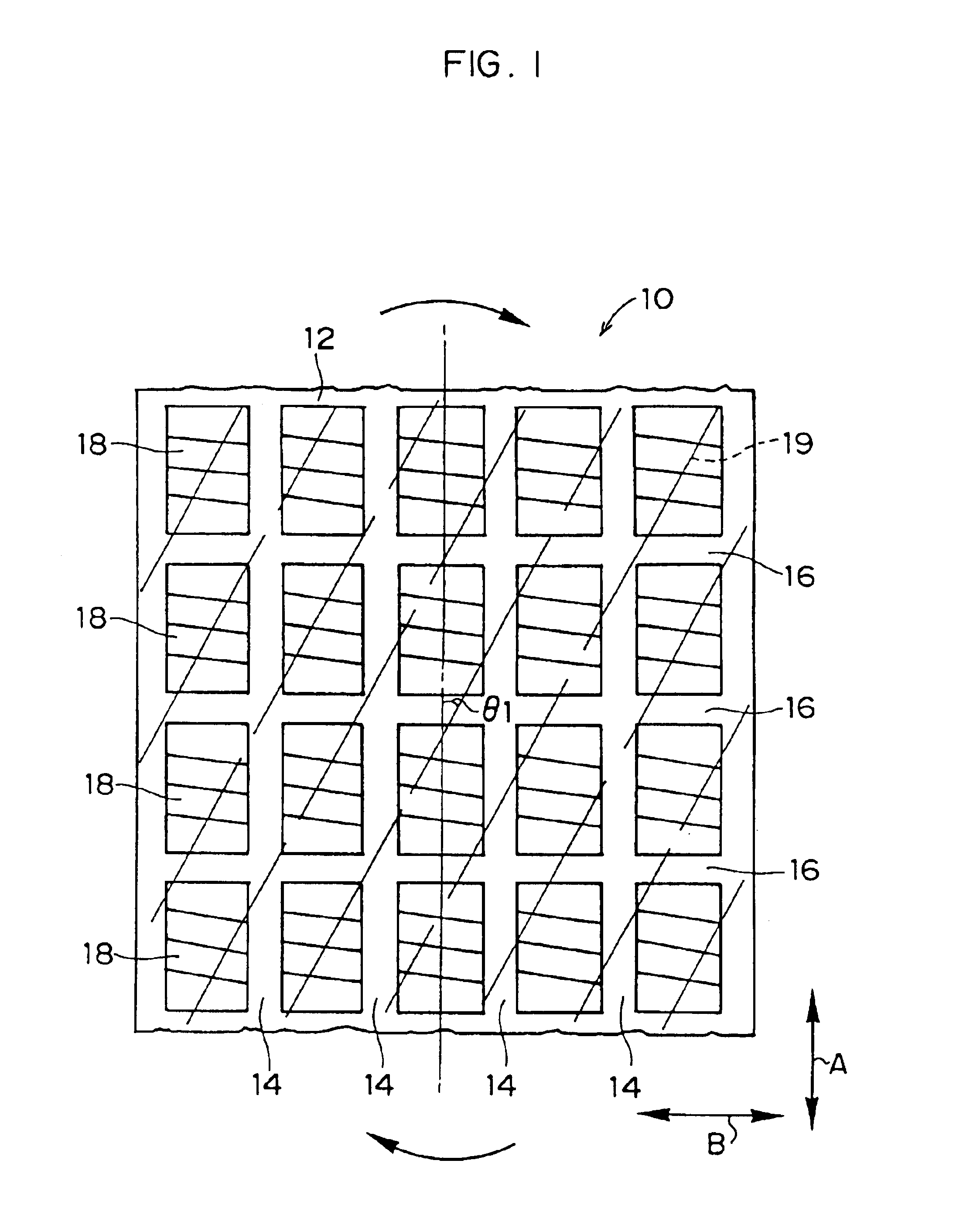

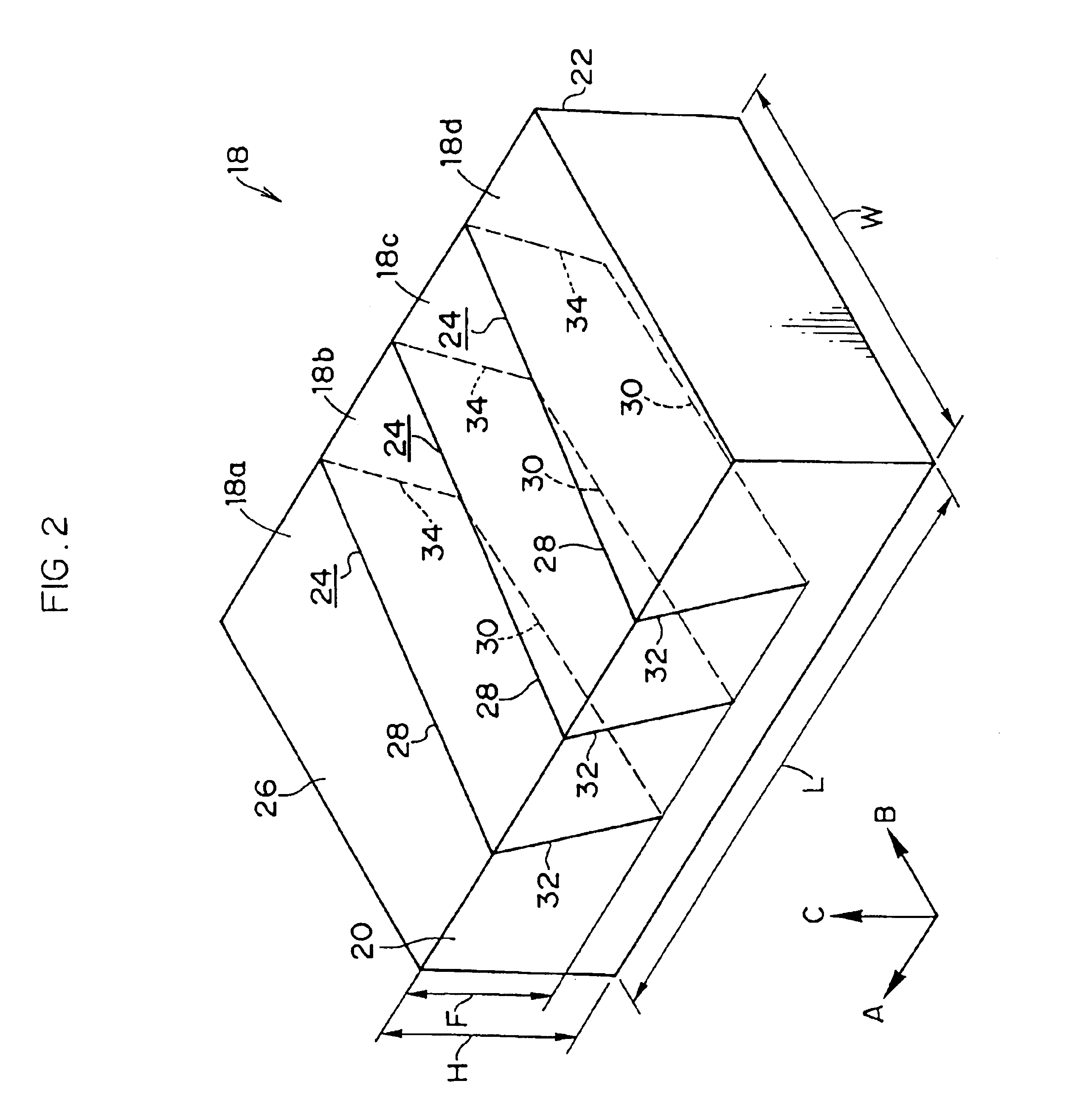

Pneumatic tire including twisted sipe

A pneumatic tire.In a block 18 formed on a tread surface, a sipe 24 which is twisted at a predetermined angle from a surface portion 28 toward a bottom portion 30 is provided. Due to ground contact pressure exerted on a contact patch area 26, small blocks 18a to 18d rotate, so that adjacent small blocks abut each other with a strong force. As a result, leaning of the small blocks 18a to 18d is suppressed, and a contact patch area area on the contact patch area 26 increases, so that performance on ice and snow improves. Moreover, due to rotation of the small blocks 18a to 18d, a torque (SAT) for restoring the small block to an original shape is generated, so that SAT generated by steel cords can be suppressed.

Owner:BRIDGESTONE CORP

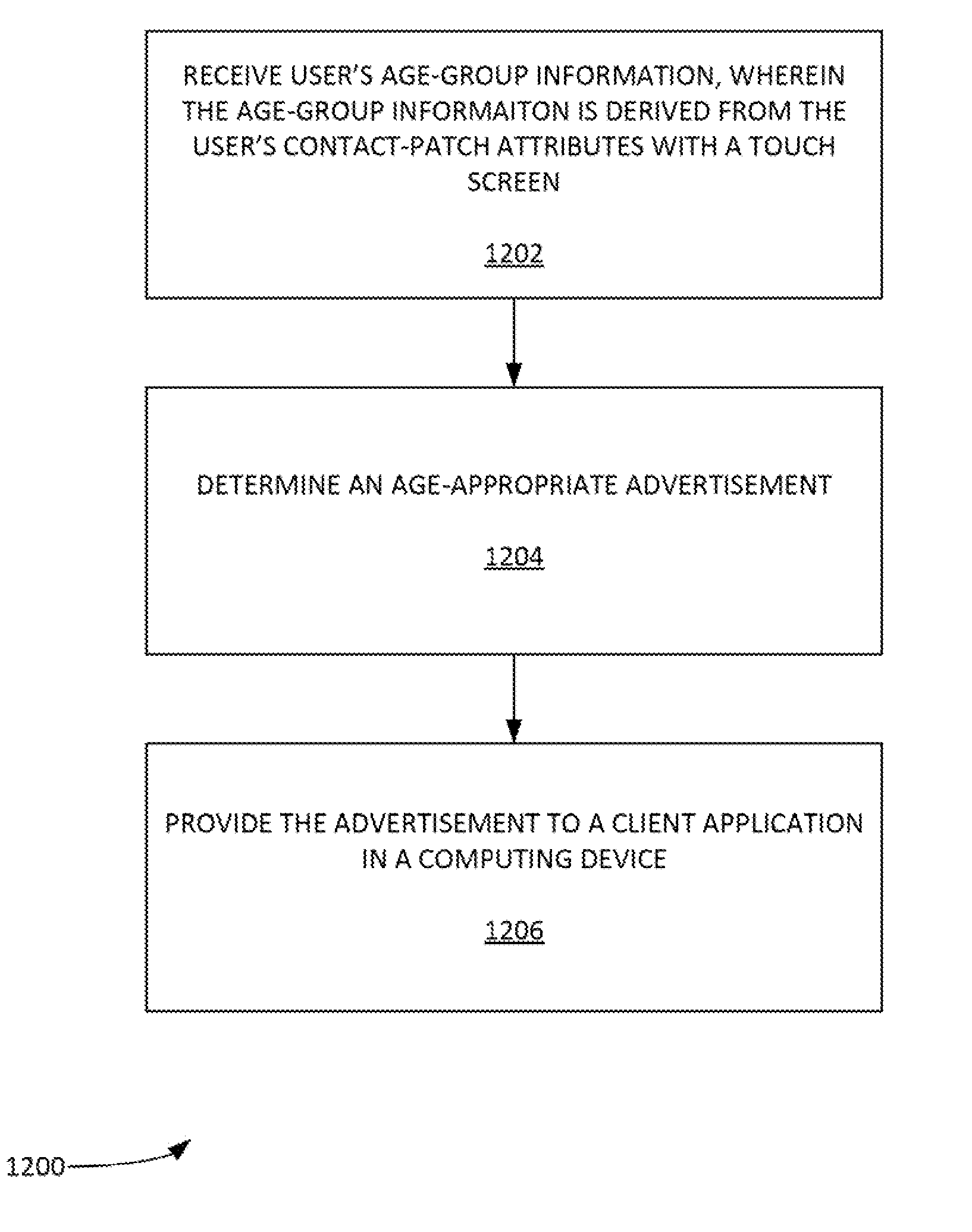

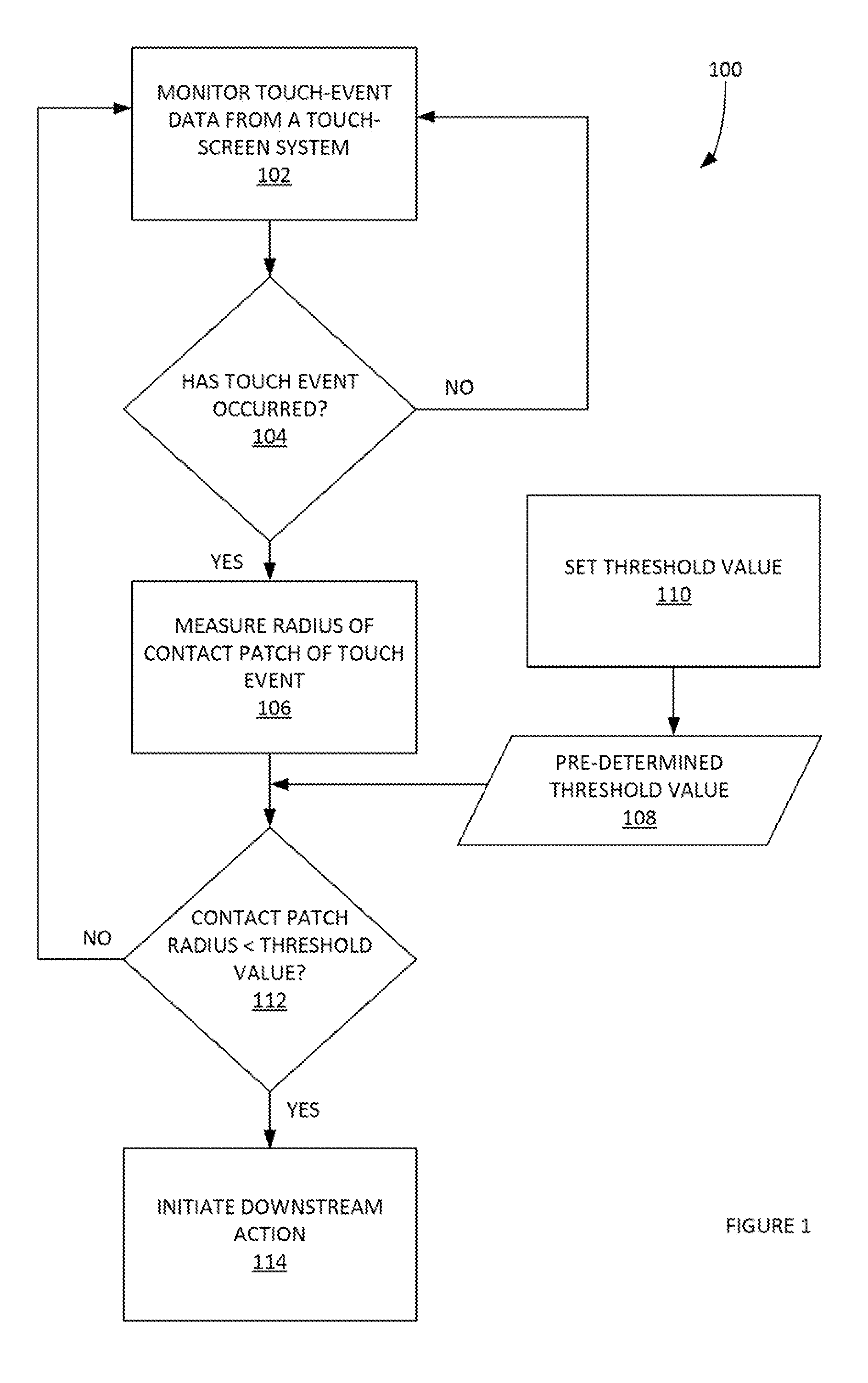

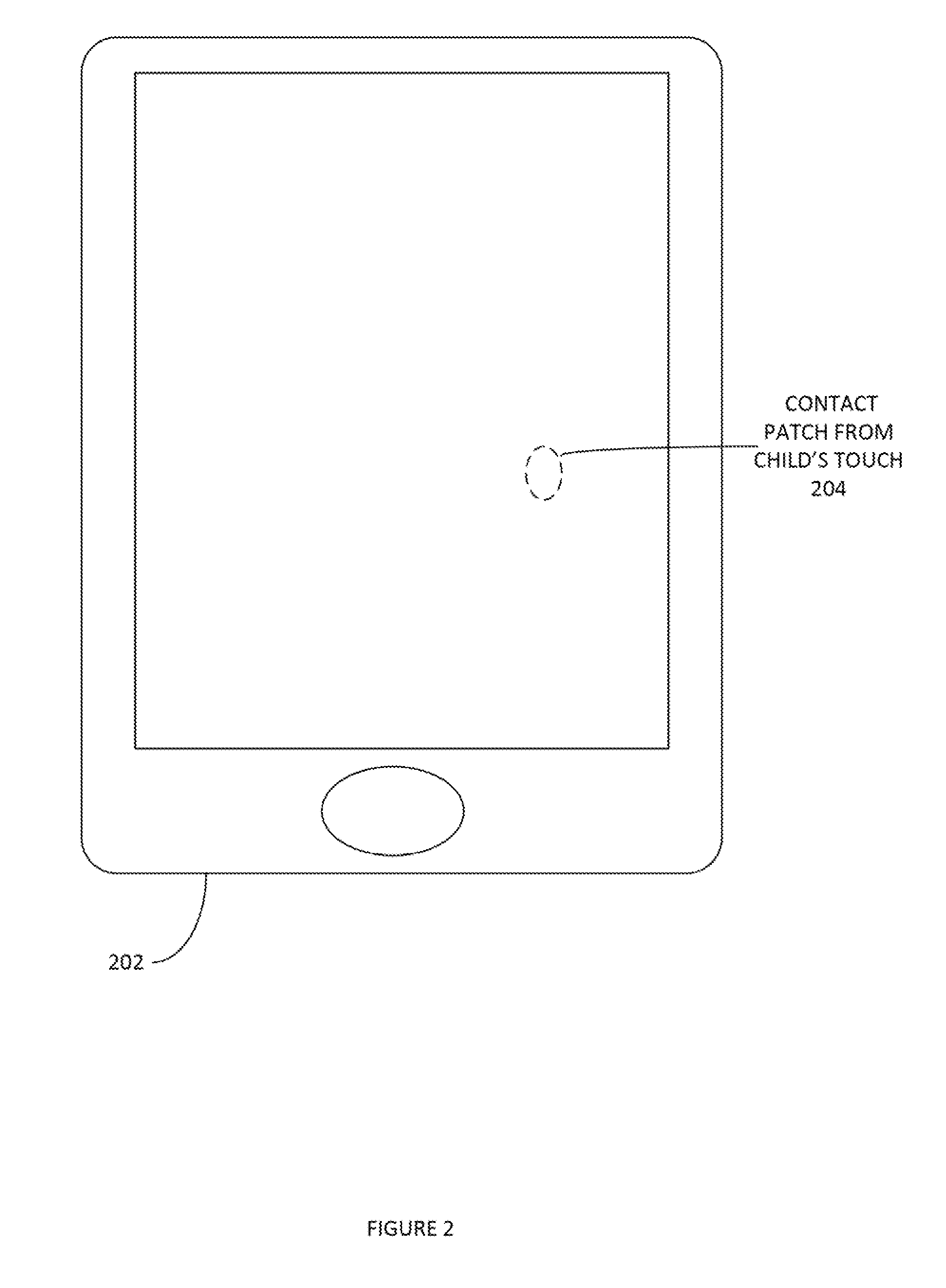

Setting computing device functionality based on touch-event properties

In one example, a computer-implemented method can include the step of receiving a finger-contact patch attribute from a user of a touch screen system. A user's age group can be determined according to a finger-contact patch attribute. The user's age group can be provided to a server. A pixel width of the finger-contact patch of less than thirty pixels can be measured. A historical mean finger-contact patch area of a historical user of the touch screen system can be calculated. The finger-contact patch attribute from the user can be determined to be substantially less than the historical mean finger-contact patch area of the historical user. An advertisement to display on a computing device of the touch-screen system can be received. An appropriate age group appropriate of the advertisement can be determined. The advertisement can be filtered when a current user is in the child-age group and the appropriate age group appropriate of the advertisement is an adult age group.

Owner:KARMARKAR AMIT V +2

Electrically conductive touch pen

ActiveUS8847930B2Easy to useEffective insulationWriting connectorsBall-point pensEngineeringCarbon deposit

A combination writing pen and stylus is disclosed. The device has an internal ink cartridge deployable through a hole in the stylus tip. The stylus tip extends from a sleeve that is formed of a conductive elastomeric material. The sleeve extends up a rigid shaft of the device such that it contacts a sufficient ground. The stylus tip may be coated with a protective material that adjusts the coefficient of friction and prevents carbon deposits on the touch screen. A sufficient contact patch is achieved to simulate a human finger so as to overcome false positives from common touch screen logic. This is done by altering tip geometries around an air cavity within the sleeve.

Owner:PIXEL PEN LLC

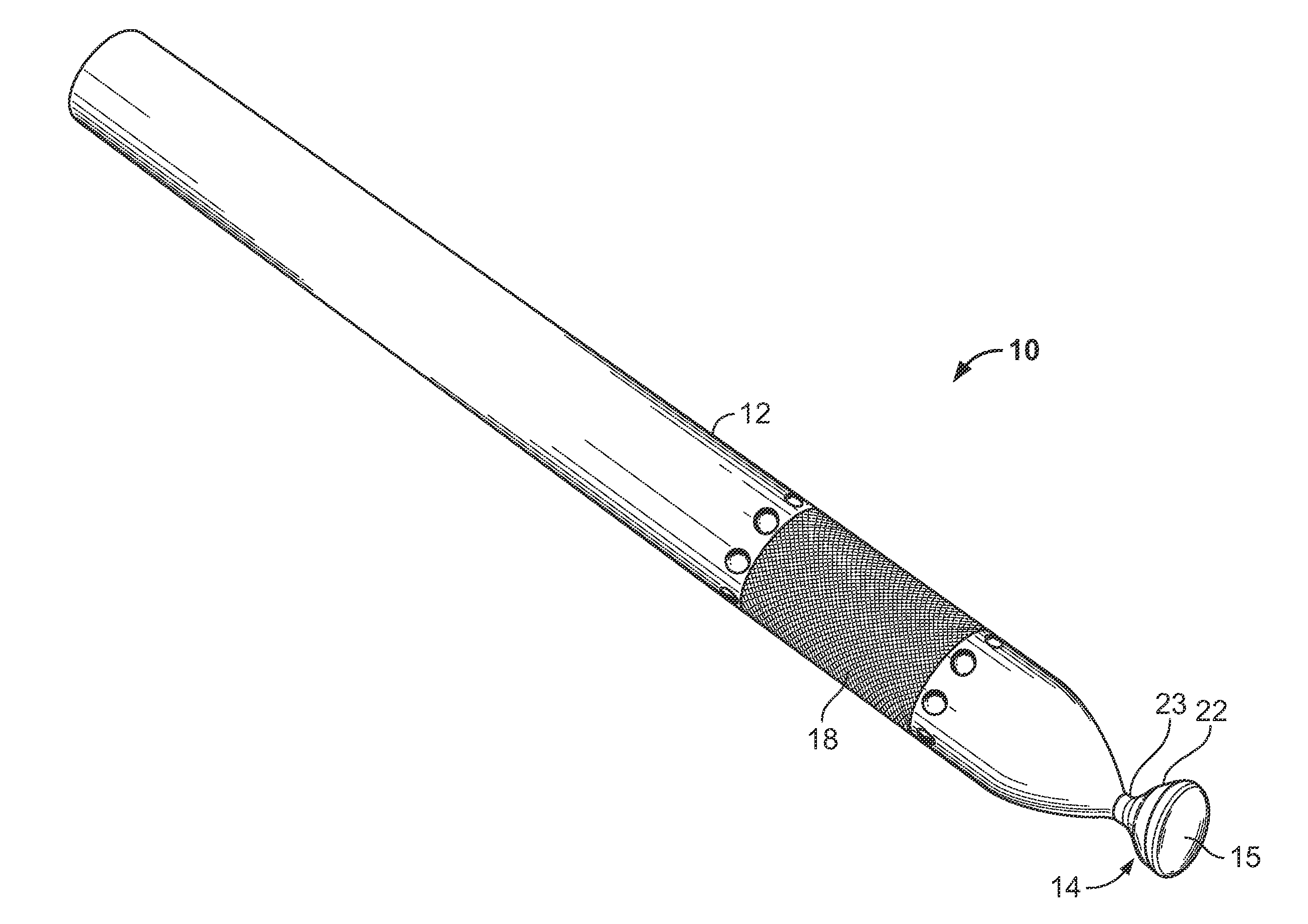

Stylus device for touch screen

InactiveUS20130141397A1Easy to viewAvoid edge damageInput/output processes for data processingCompressible materialEngineering

A stylus device for writing or drawing on a touch screen has an elongate barrel for gripping by a user and a stylus tip of rigid, non-compressible material secured to one end of the barrel and having an end face comprising a working surface configured for contact with the touch screen while writing or drawing. The stylus tip is oriented at a predetermined offset angle to the longitudinal axis of the barrel, such that the working surface is not perpendicular to the central longitudinal axis of the barrel. The working surface is applied to a touch screen to develop a contact patch between the working surface and screen sufficient to trigger an input on the screen.

Owner:DUNAGAN KELLY ALLAN

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com