Patents

Literature

43results about How to "Avoid edge damage" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

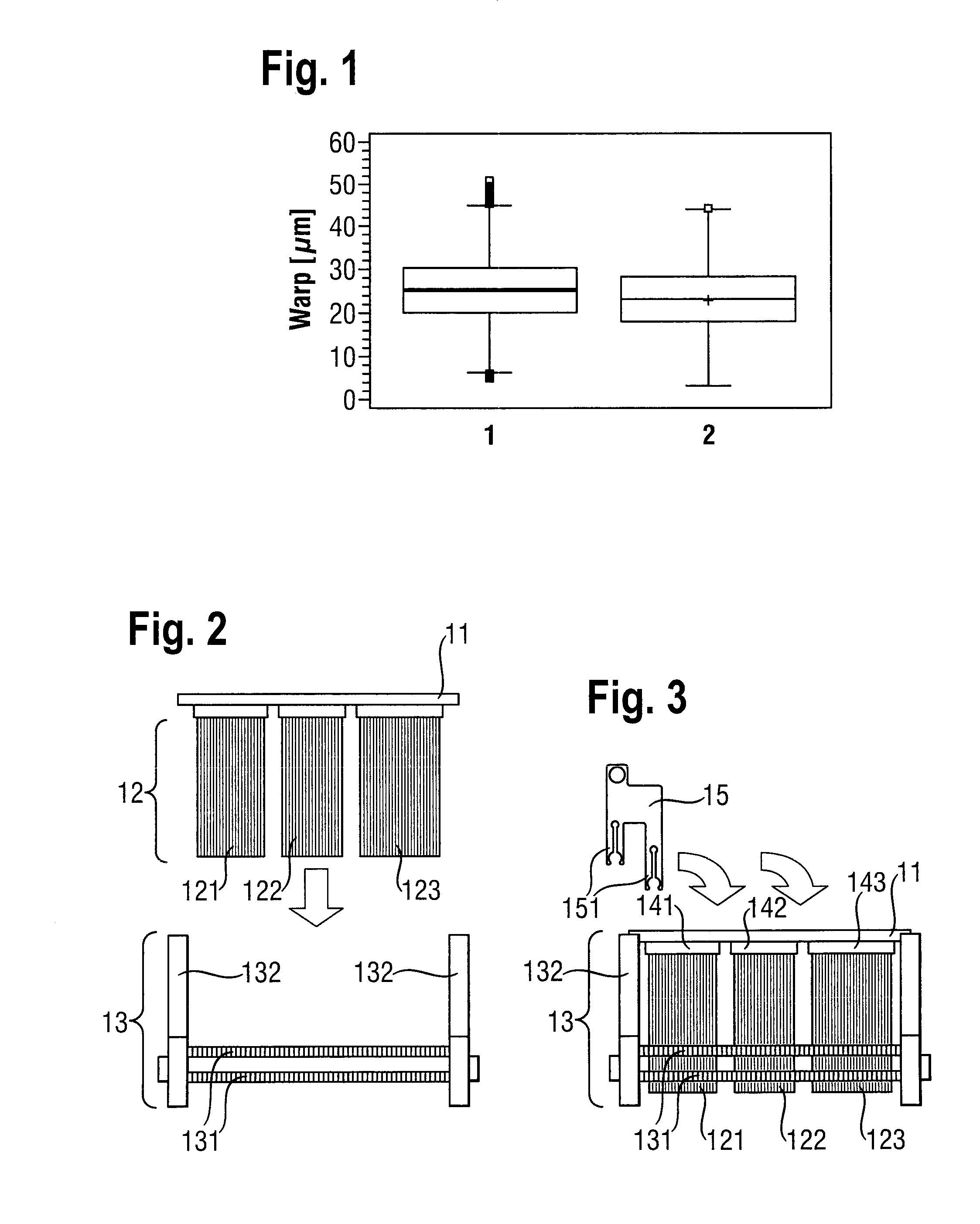

Magnetic tape

ActiveUS20190027181A1Improve surface smoothnessAvoid it happening againMagnetic materials for record carriersRecord information storageIn planeCoated surface

Provided is a magnetic tape in which an Ra measured regarding a surface of a magnetic layer is equal to or smaller than 1.8 nm, Int(110) / Int(114) of a hexagonal ferrite crystal structure obtained by an XRD analysis of the magnetic layer by using an In-Plane method is 0.5 to 4.0, a vertical squareness ratio of the magnetic tape is 0.65 to 1.00, full widths at half maximum of spacing distribution measured by optical interferometry regarding the surface of the back coating layer before and after performing a vacuum heating with respect to the magnetic tape are greater than 0 nm and equal to or smaller than 10.0 nm, and a difference between the spacings measured by optical interferometry regarding the surface of the back coating layer before and after performing the vacuum heating is greater than 0 nm and equal to or smaller than 8.0 nm.

Owner:FUJIFILM CORP

Magnetic tape having characterized backcoat layer and method of manufacturing the same

ActiveUS10475481B2Good electromagnetic propertiesReduce differential pressureBase layers for recording layersTape carriersMagnetic tapeMagnetic layer

The magnetic tape has a magnetic layer and a backcoat layer. The Ra on the magnetic layer side surface is less than or equal to 1.8 nm, the coefficient of friction measured on the base portion of the magnetic layer side surface is less than or equal to 0.35, and the Ra measured on the backcoat layer side surface is less than or equal to 5.0 nm. The backcoat layer contains a fatty acid ester. In addition, the FWHMbefore measured on the backcoat layer side surface before vacuum heating is greater than 0 nm but less than or equal to 10.0 nm, the FWHMafter after vacuum heating is greater than 0 nm but less than or equal to 10.0 nm, and the difference between the spacing measured on the backcoat layer side surface after and before vacuum heating is greater than 0 nm but less than or equal to 8.0 nm.

Owner:FUJIFILM CORP

Magnetic tape having characterized magnetic layer

ActiveUS10839850B2Avoid it happening againImprove surface smoothnessMagnetic materials for record carriersTape carriersCoated surfaceMagnetic tape

Provided is a magnetic tape in which an Ra measured regarding a surface of a magnetic layer is equal to or smaller than 1.8 nm, Int(110) / Int(114) of a hexagonal ferrite crystal structure obtained by an X-ray diffraction analysis of the magnetic layer by using an In-Plane method is 0.5 to 4.0, a vertical squareness ratio of the magnetic tape is 0.65 to 1.00, the back coating layer includes one or more kinds of component selected from the group consisting of fatty acid and fatty acid amide, and a C—H derived C concentration calculated from a C—H peak area ratio of C1s spectra obtained by X-ray photoelectron spectroscopic analysis performed on the surface of the back coating layer at a photoelectron take-off angle of 10 degrees is equal to or greater than 35 atom %.

Owner:FUJIFILM CORP

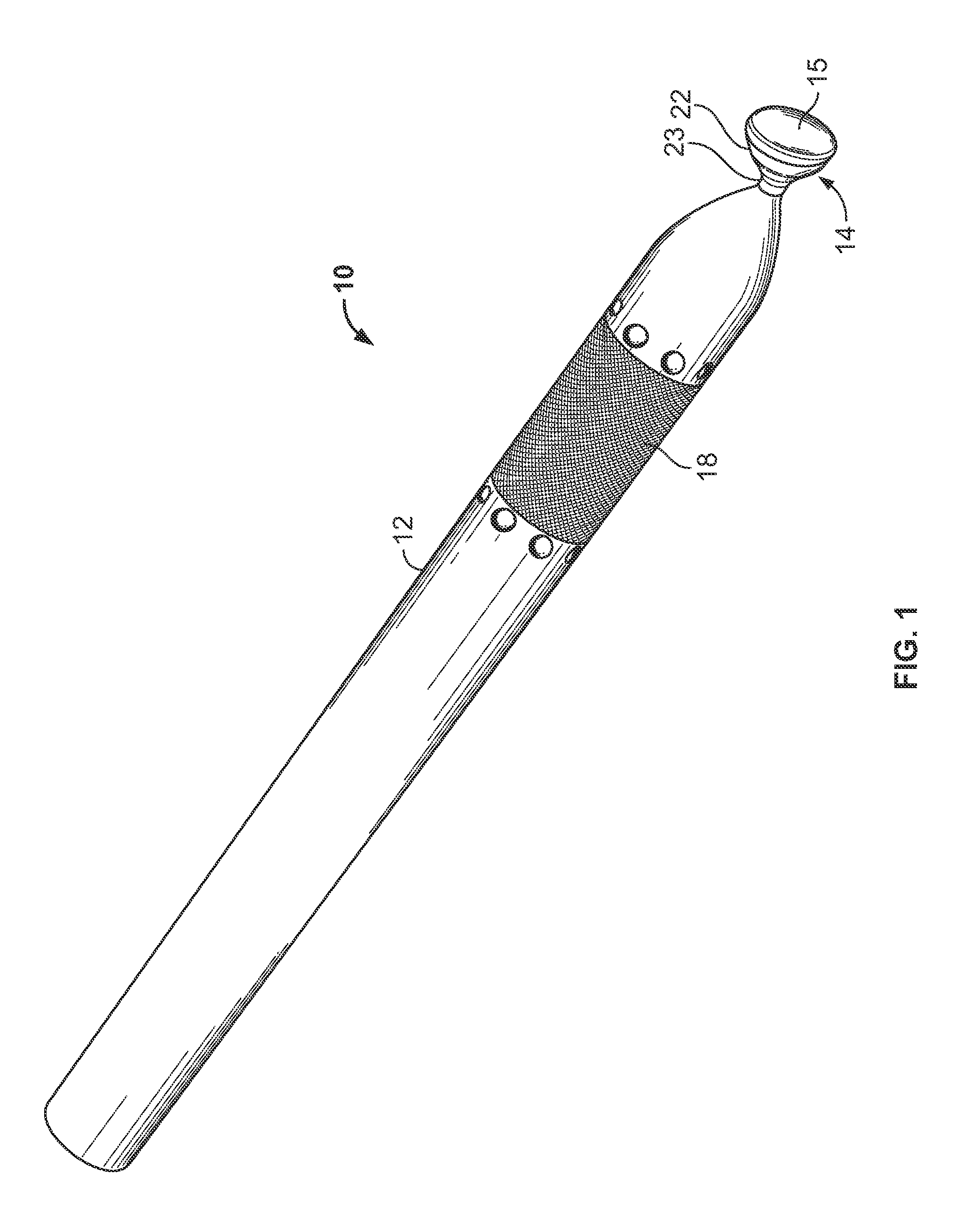

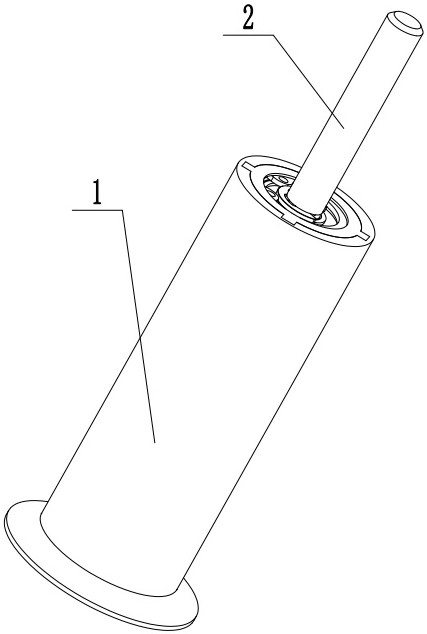

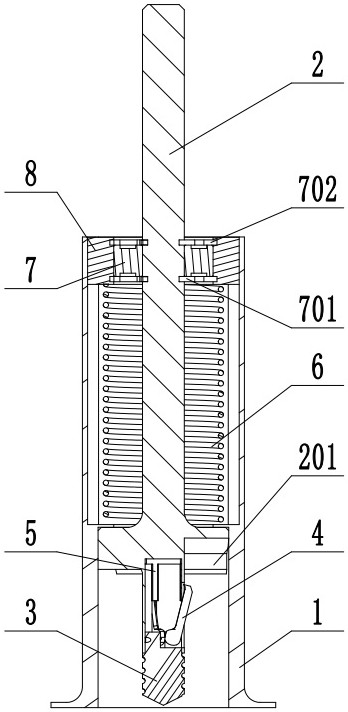

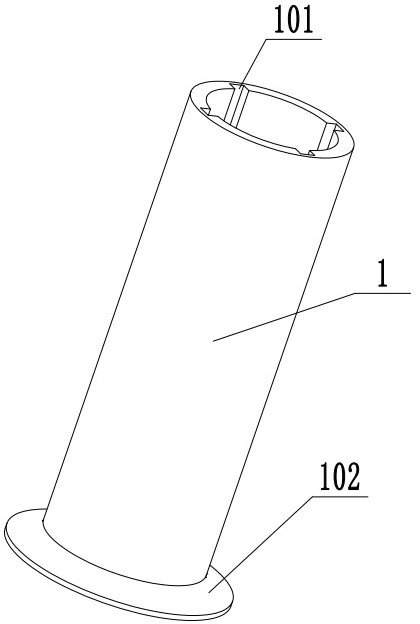

Stylus device for touch screen

InactiveUS20130141397A1Easy to viewAvoid edge damageInput/output processes for data processingCompressible materialEngineering

A stylus device for writing or drawing on a touch screen has an elongate barrel for gripping by a user and a stylus tip of rigid, non-compressible material secured to one end of the barrel and having an end face comprising a working surface configured for contact with the touch screen while writing or drawing. The stylus tip is oriented at a predetermined offset angle to the longitudinal axis of the barrel, such that the working surface is not perpendicular to the central longitudinal axis of the barrel. The working surface is applied to a touch screen to develop a contact patch between the working surface and screen sufficient to trigger an input on the screen.

Owner:DUNAGAN KELLY ALLAN

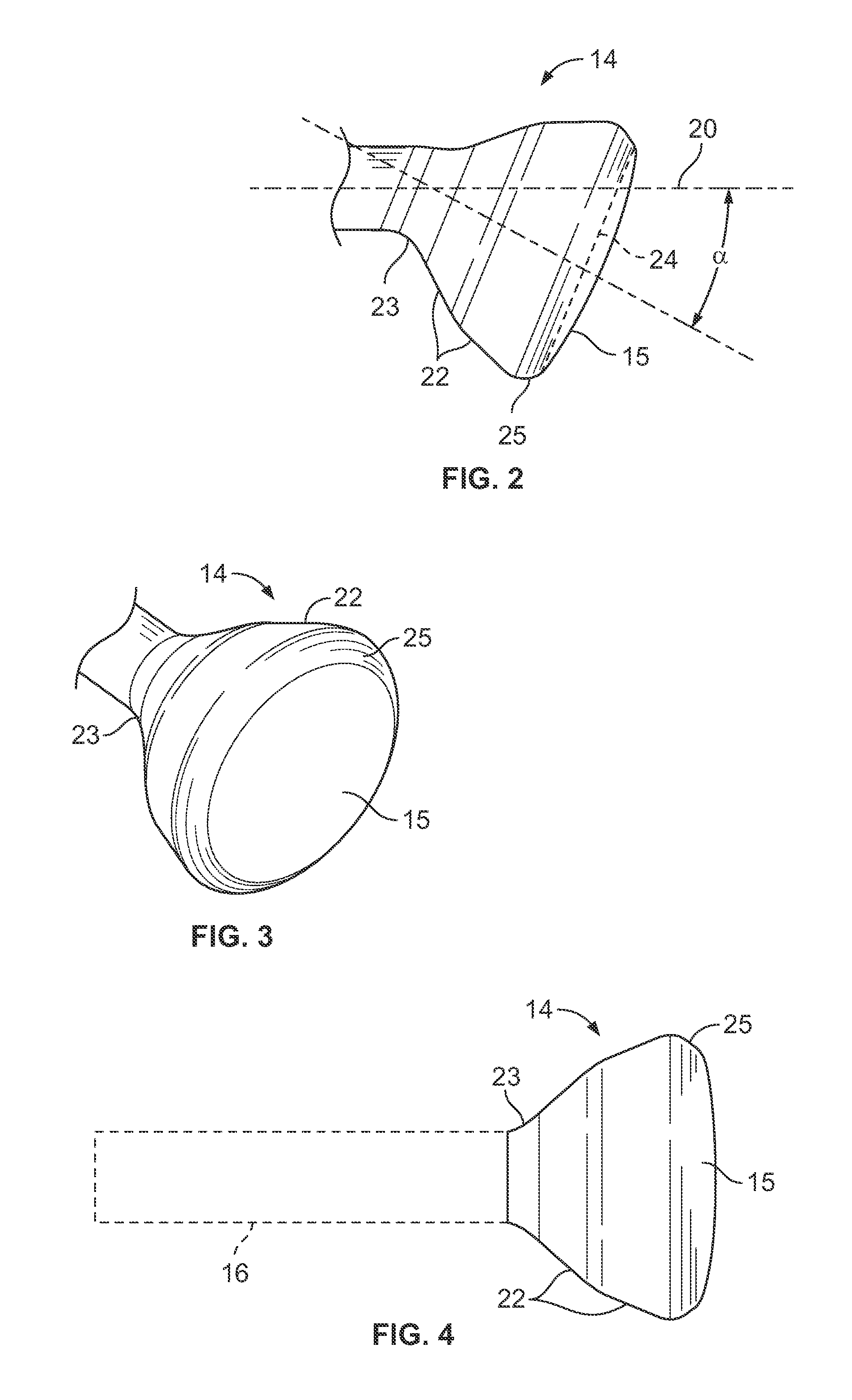

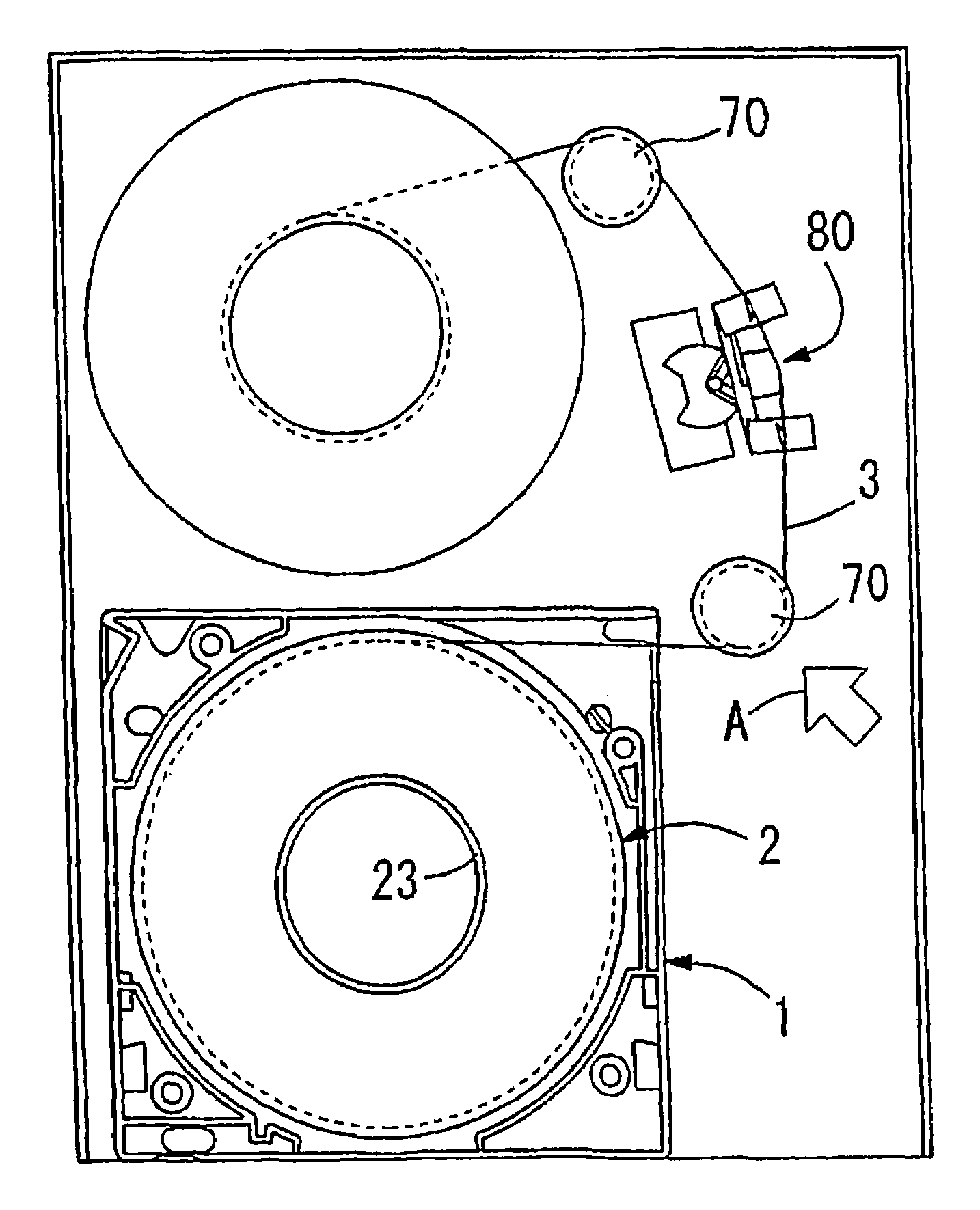

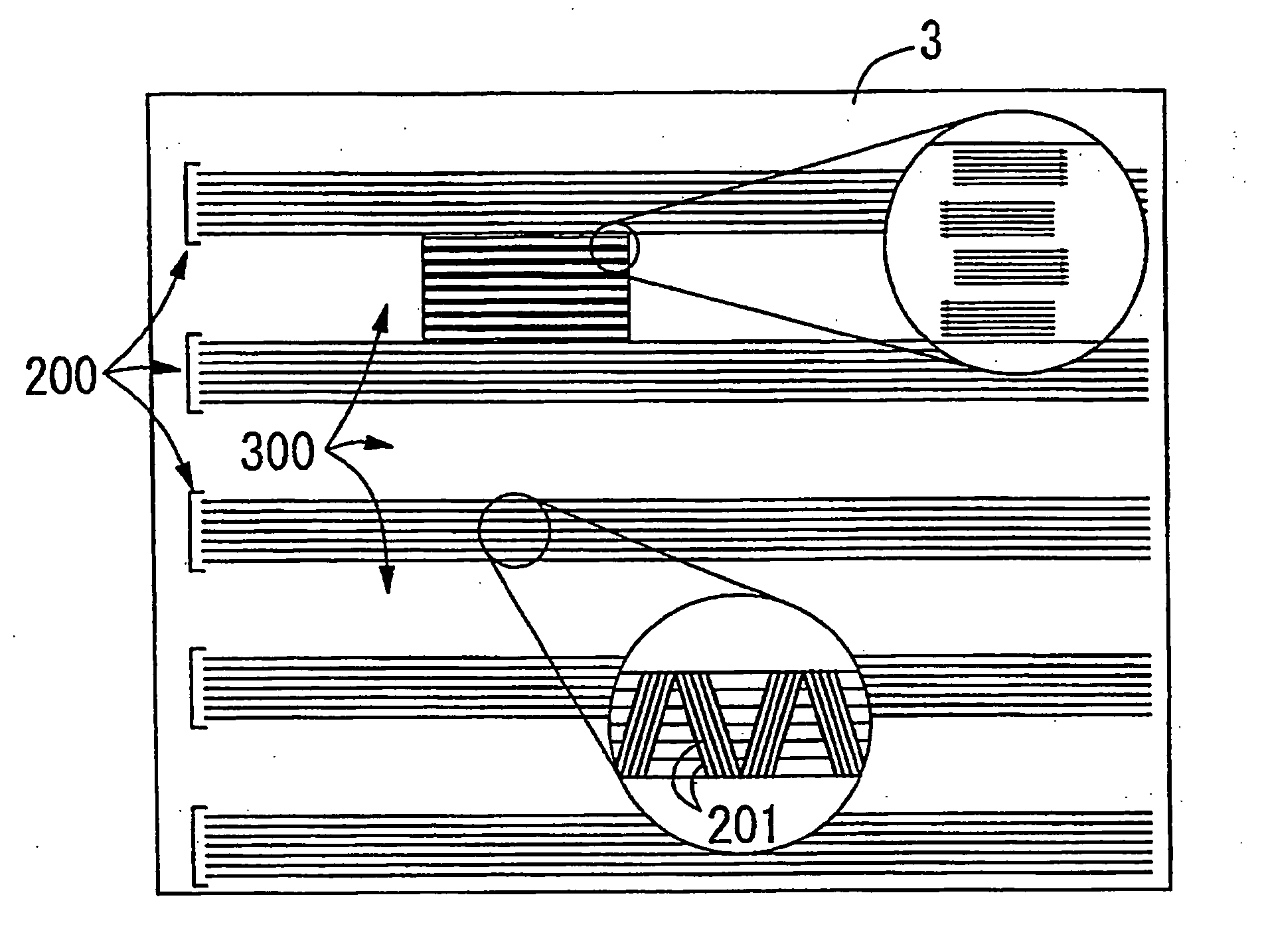

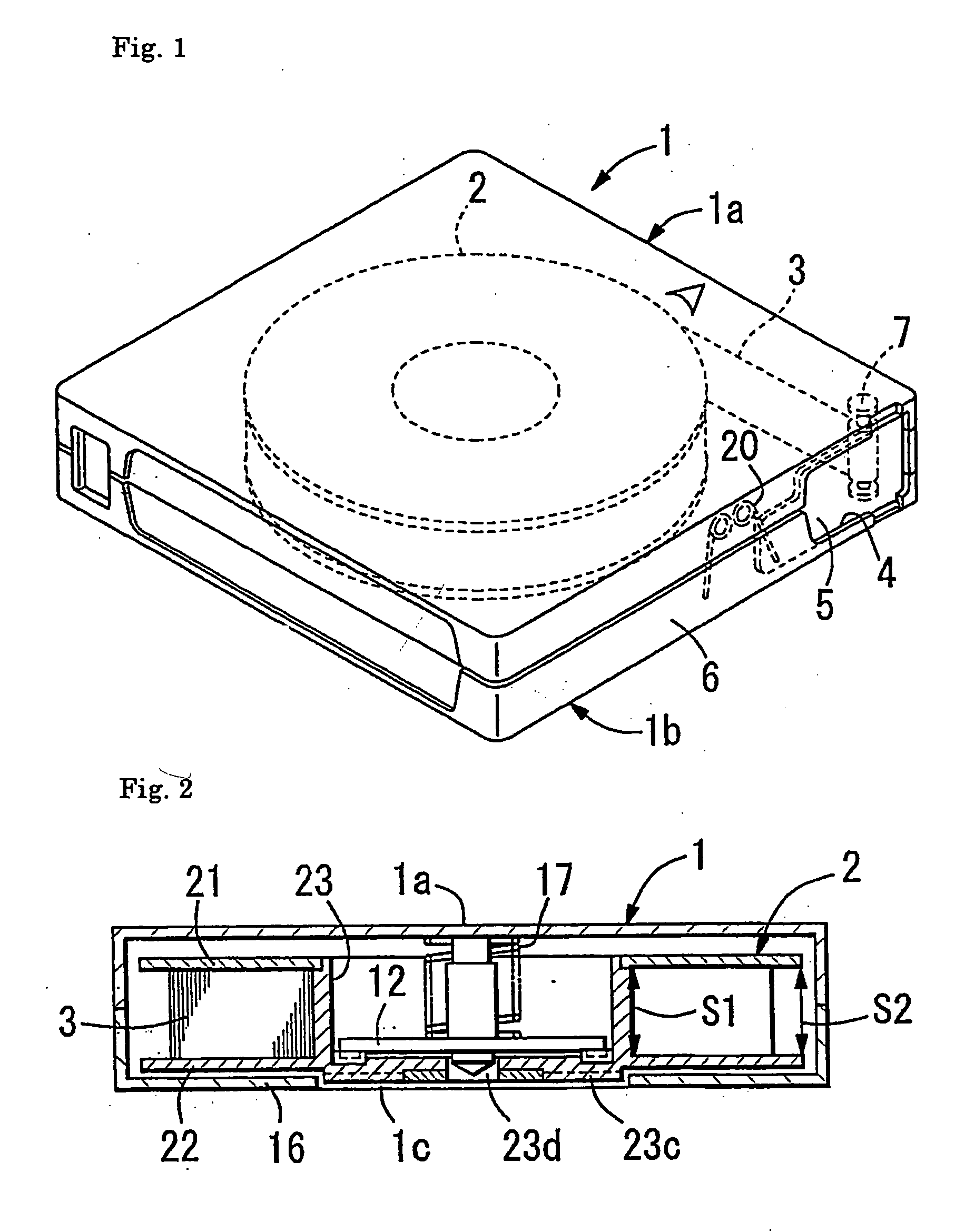

Magnetic tape and magnetic tape cartridge

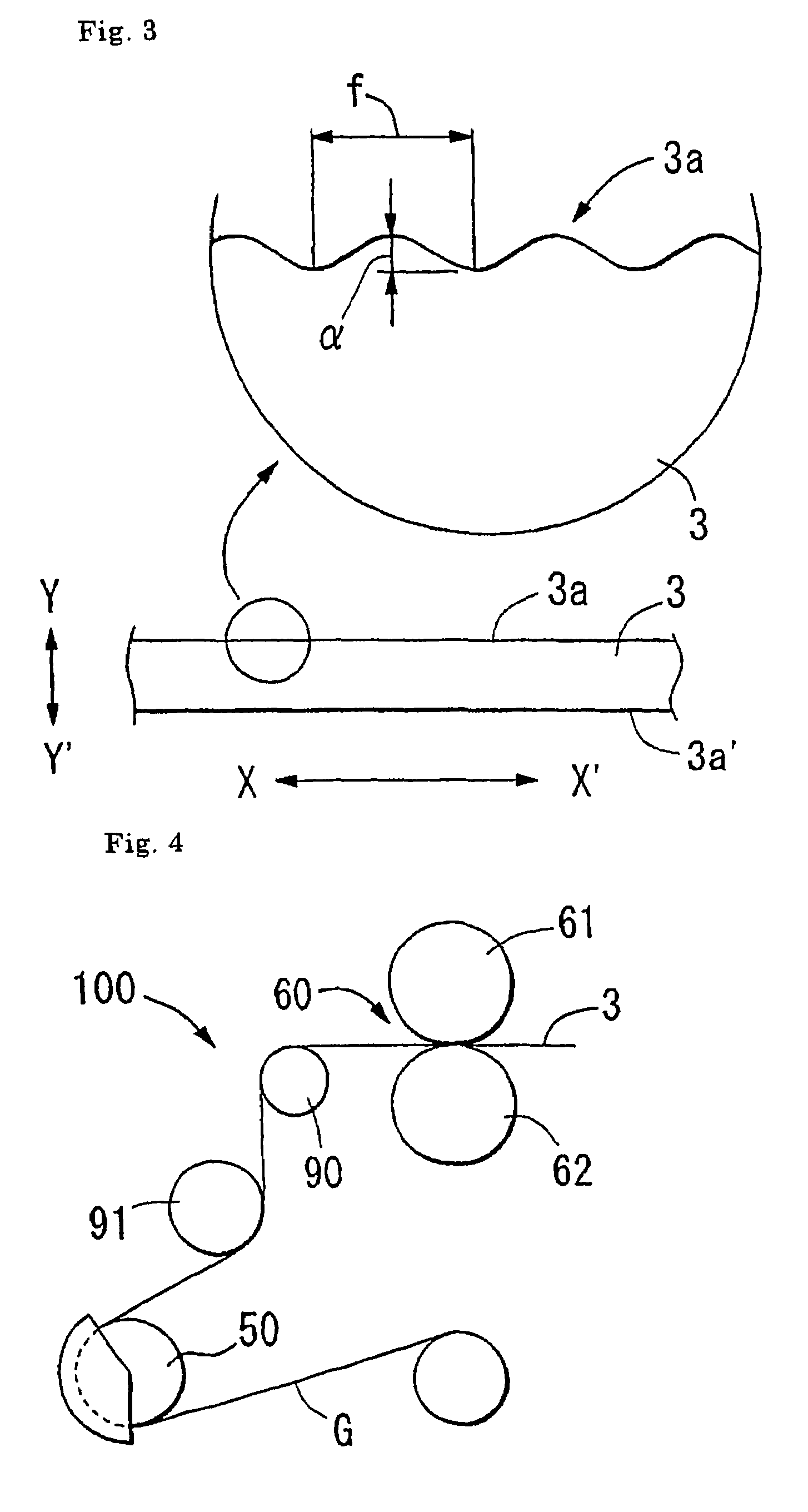

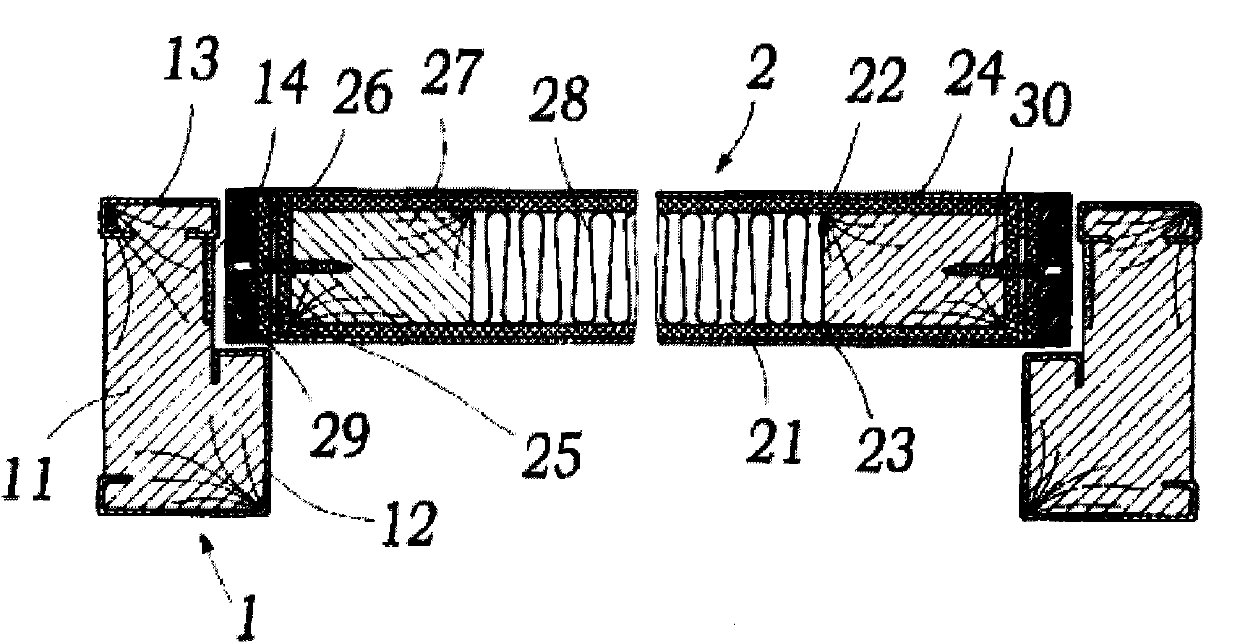

InactiveUS7092199B2Excellent off-track preventive performanceAvoid edge damageMagnetic materials for record carriersBase layers for recording layersMetre/secondMagnetic tape

A magnetic tape which is run at a speed of 4 m / sec. or higher and has recording tracks with a width of 21 μm or less, and which includes a non-magnetic support, at least one magnetic layer formed on one surface of the non-magnetic support, and a backcoat layer formed on the other surface of the non-magnetic support, wherein servo signals for controlling tracking are recorded on the magnetic layer or the backcoat layer, the value of (α / W) X (V / f) is 10 [s−1] or less, and / or the value of (α / W) is 0.1 or less, wherein V [mm / sec.] is the tape-running speed; α [μm] is an amount of a weave with a cycle of f [mm] on one edge of the tape or the other edge thereof, as the reference side, for the running of the tape; and W [μm] is a width of the recording track. The magnetic tape can decrease PES and off-track and thus is excellent in servo tracking performance.

Owner:MAXELL HLDG LTD

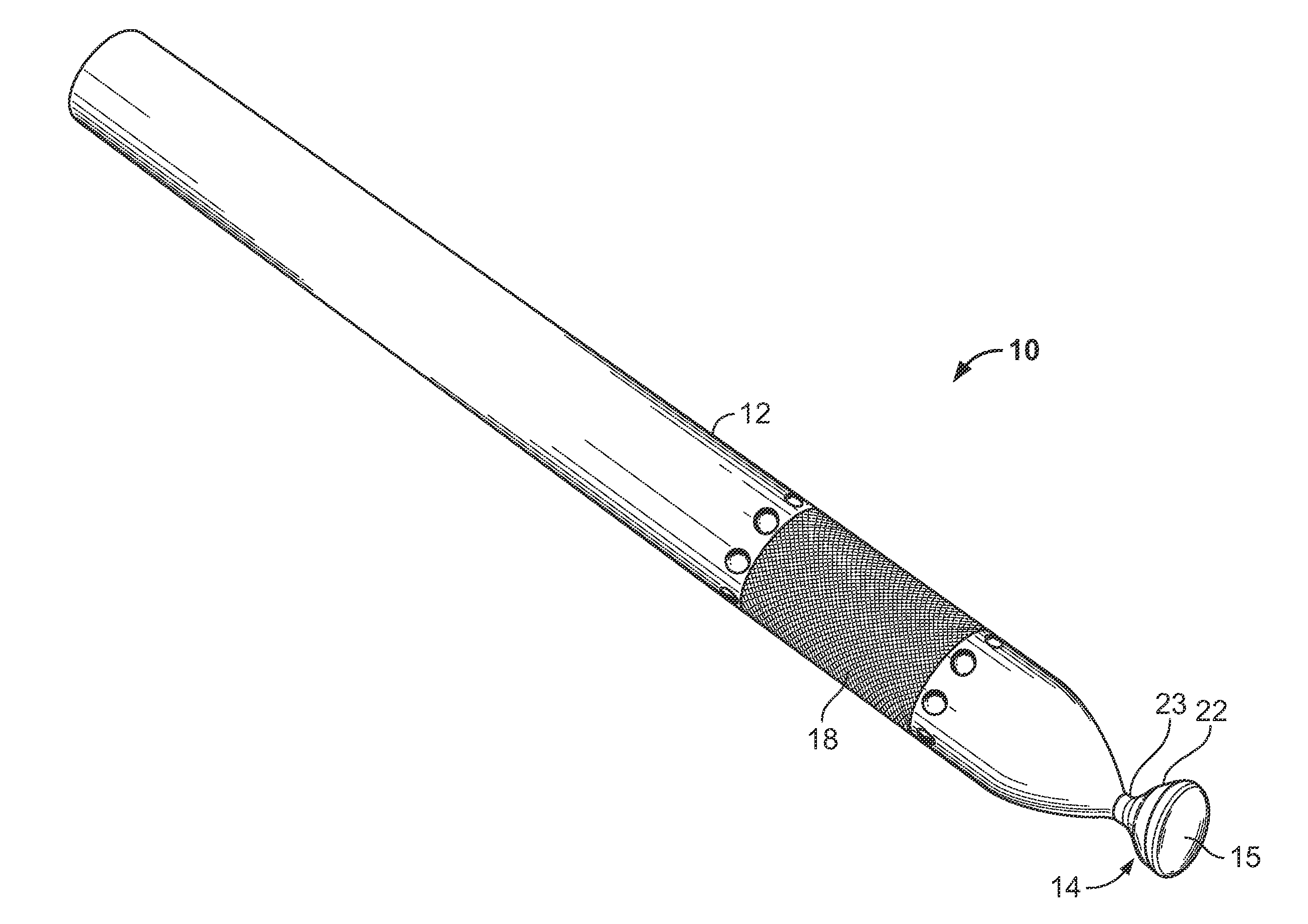

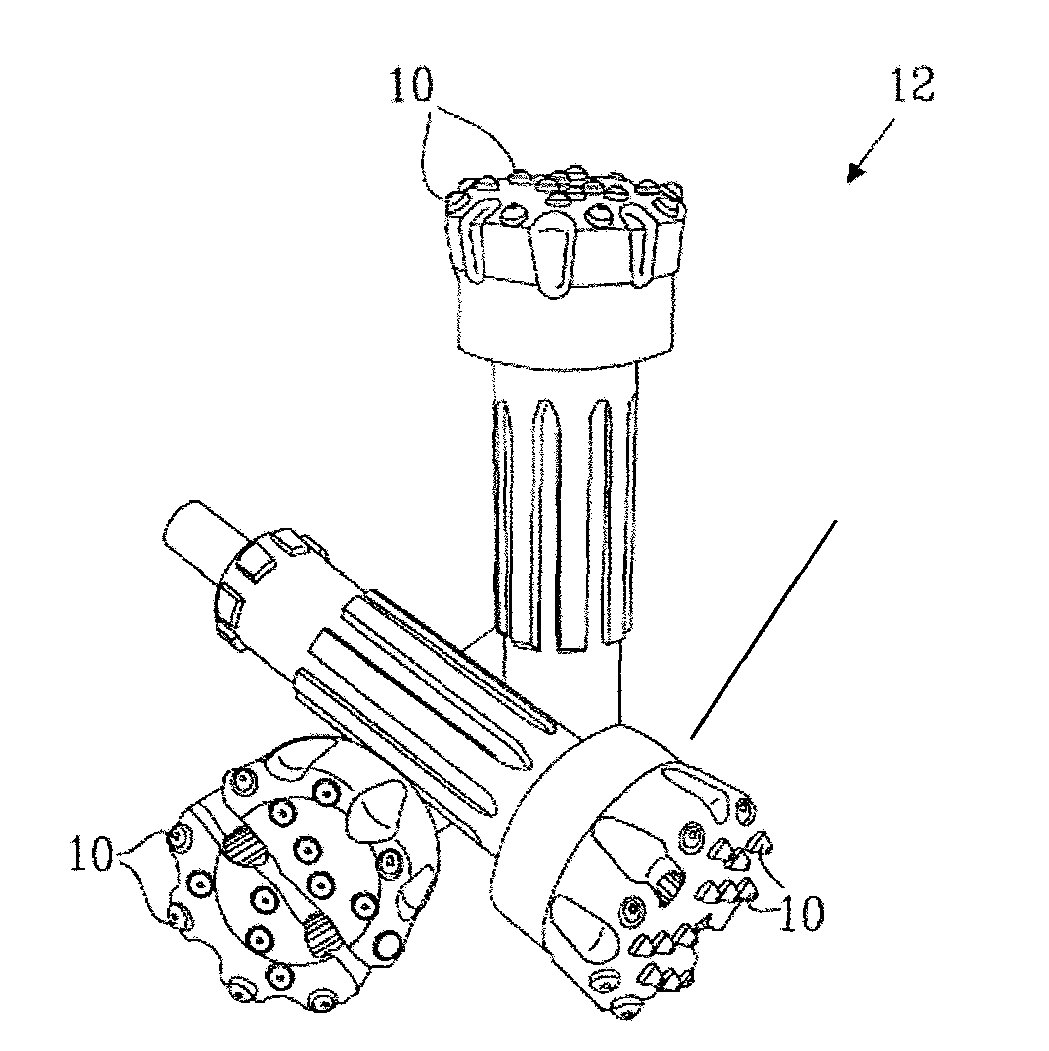

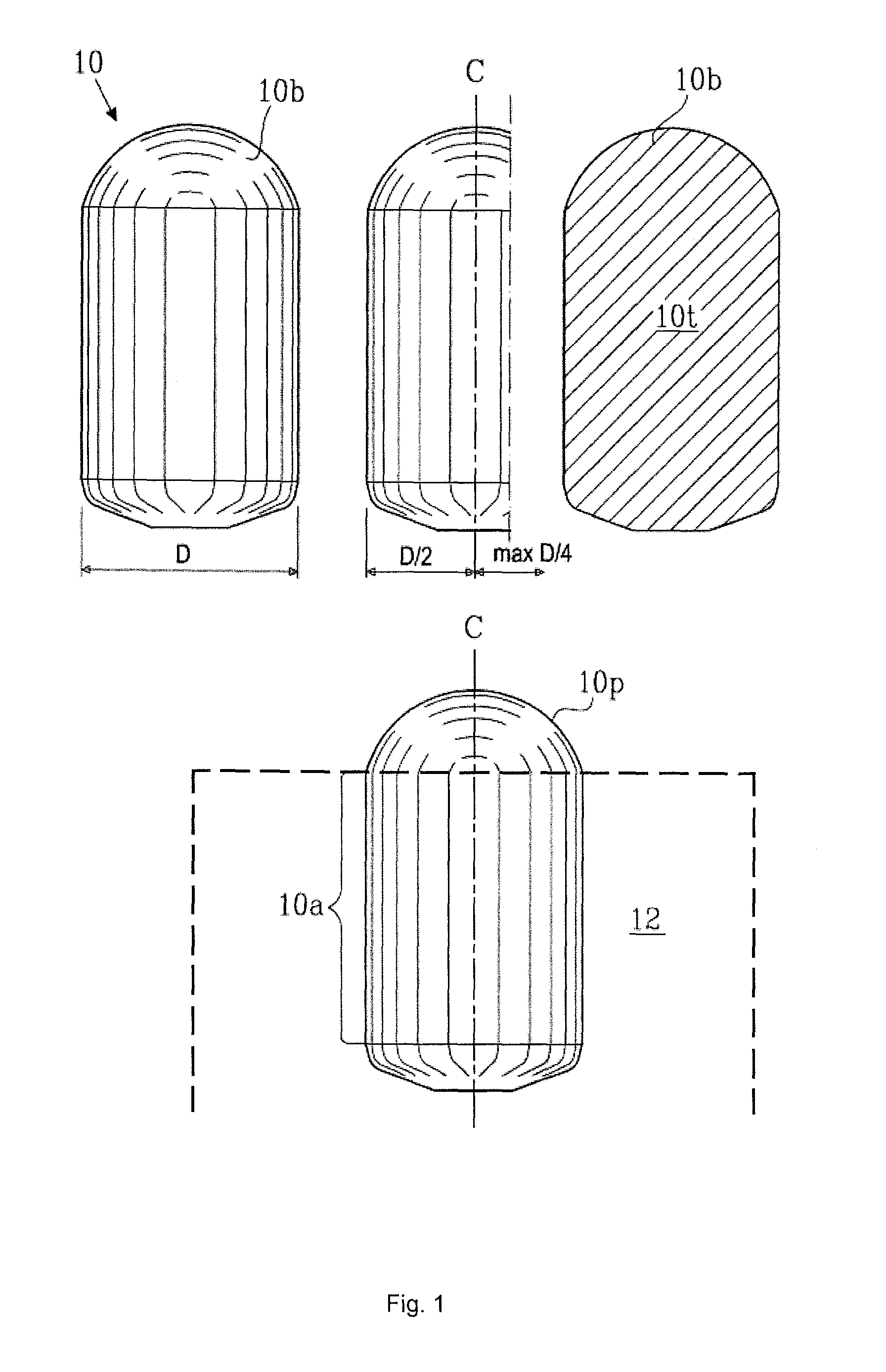

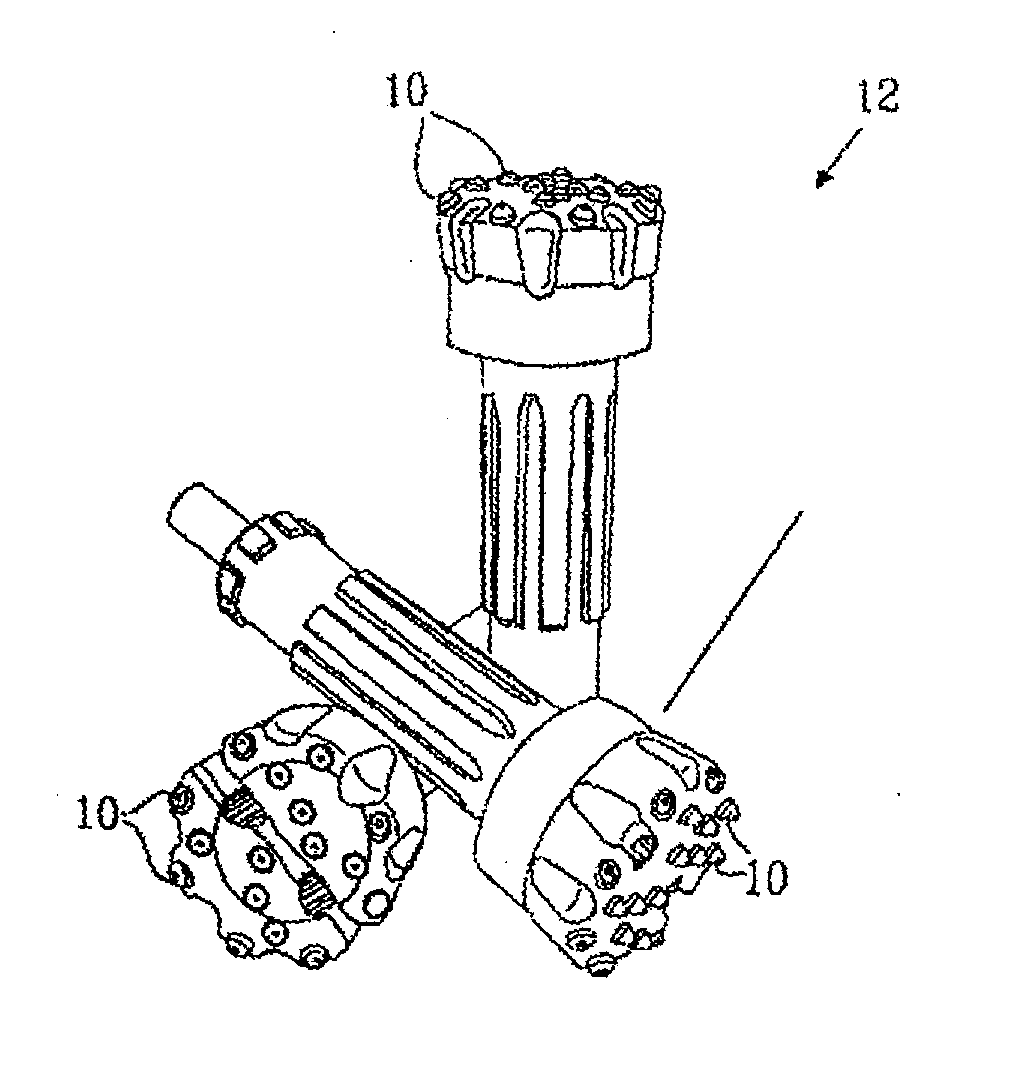

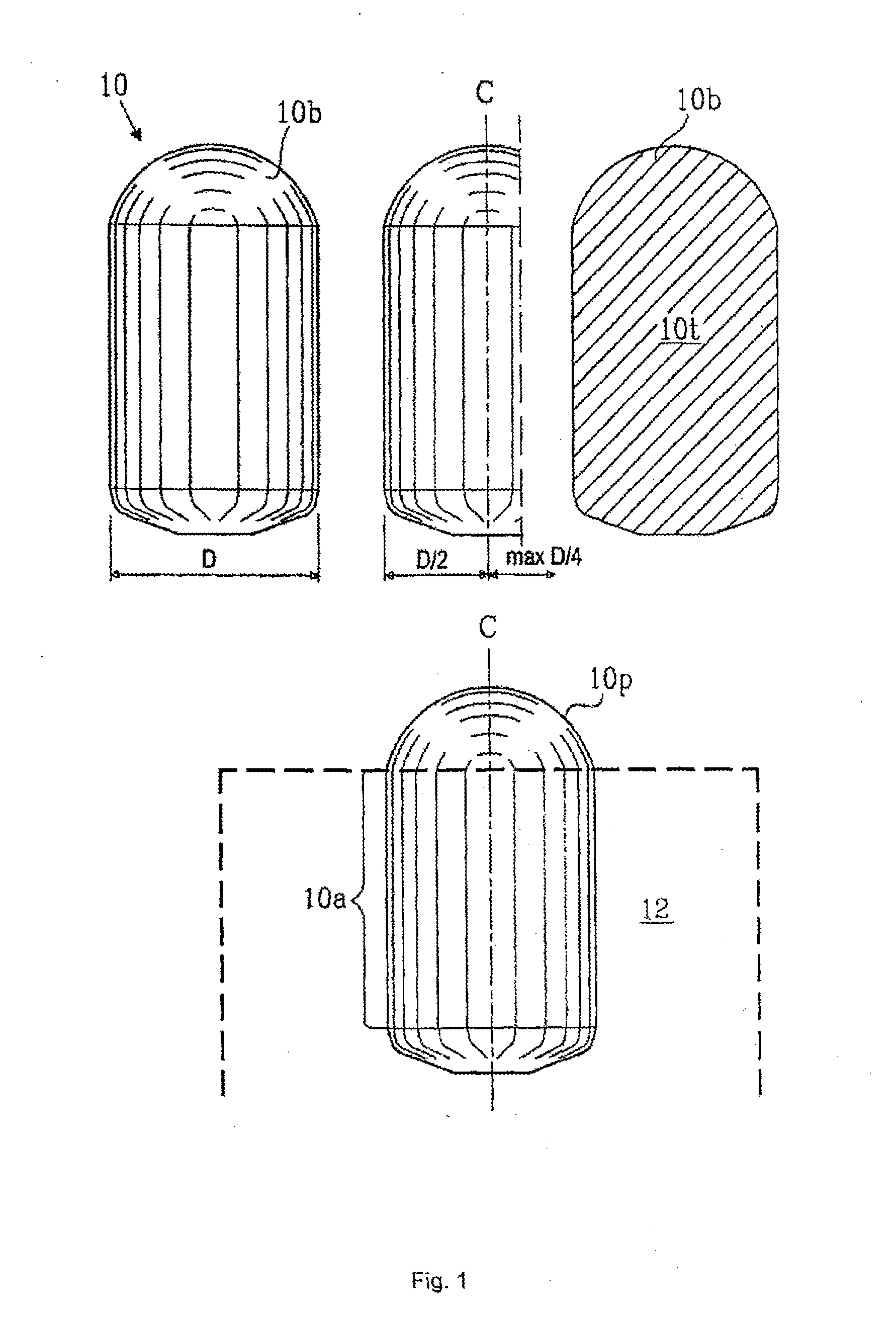

Drill bit for a rock drilling tool with increased toughness and method for increasing the toughness of such drill bits

ActiveUS20110000717A1Not to damageHigh energyPolishing machinesDrill bitsPaper documentDocument preparation

Drill bit (10) for a rock drilling tool (12), which drill bit (10) has a drilling surface (10b) that contacts rock during drilling. A longitudinal cross section (10t) of the drill bit (10) through the drilling surface (10b) exhibits the following relationships of Ltot(depth) / Ltot(5.0) and H(depth) / H(5.0) at the specied depths, where H(depth) / H(5.0) is measured according to a Vickers test and Ltot(depth) / Ltot(5.0) is measured according to the Palmqvist method, described in this document substantially along the drill bit's longitudinal axial centre line (C): (table (I)). If the drill bit (10) has en length (L) of 10 mm or greater, and a longitudinal cross section (10t) of the drill bit (10) through the drilling surface (10b) exhibits the following relationships of Ltot(depth) / Ltot(3.5) and H(depth) / H(3.5) at the specified depths, where H(depth) / H(3.5) is measured according to a Vickers test and Ltot(depth) / Ltot(3.5) is measured according to the Palmqvist method described in this document, substantially along the drill bit's longitudinal axial centre line (C): (table (II)). If the drill bit (10) has en length (L) less than 10 mm.

Owner:EPIROC DRILLING TOOLS AB

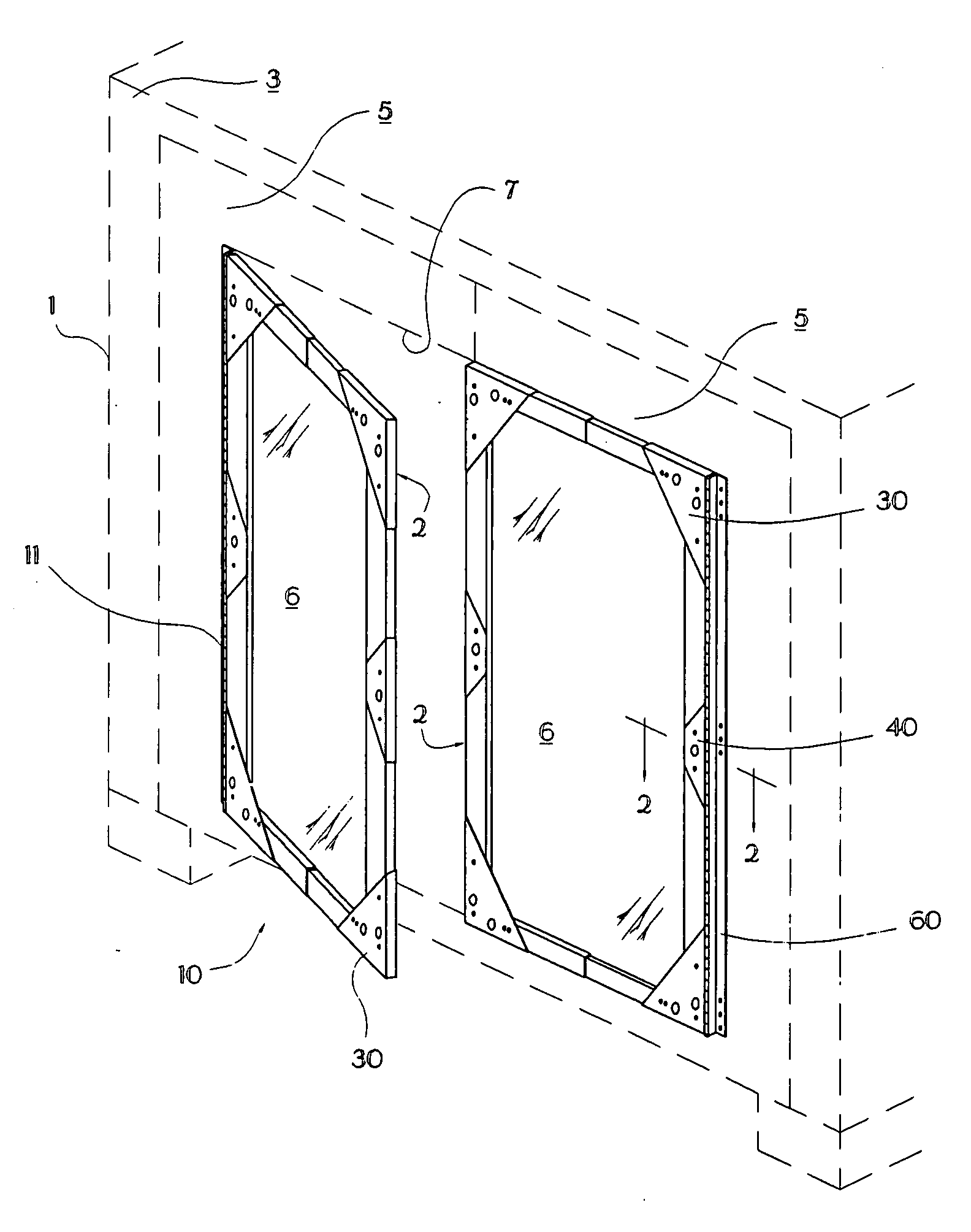

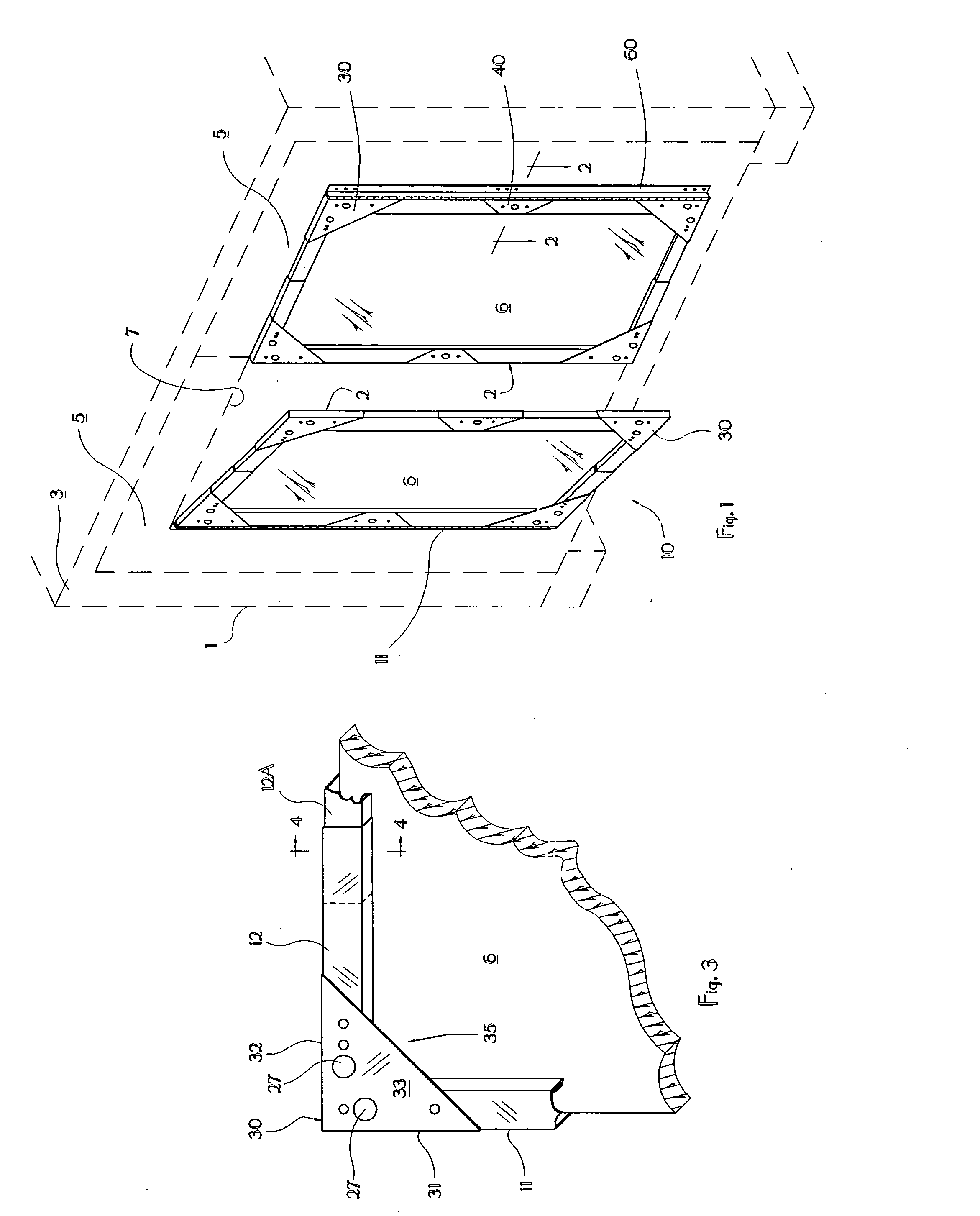

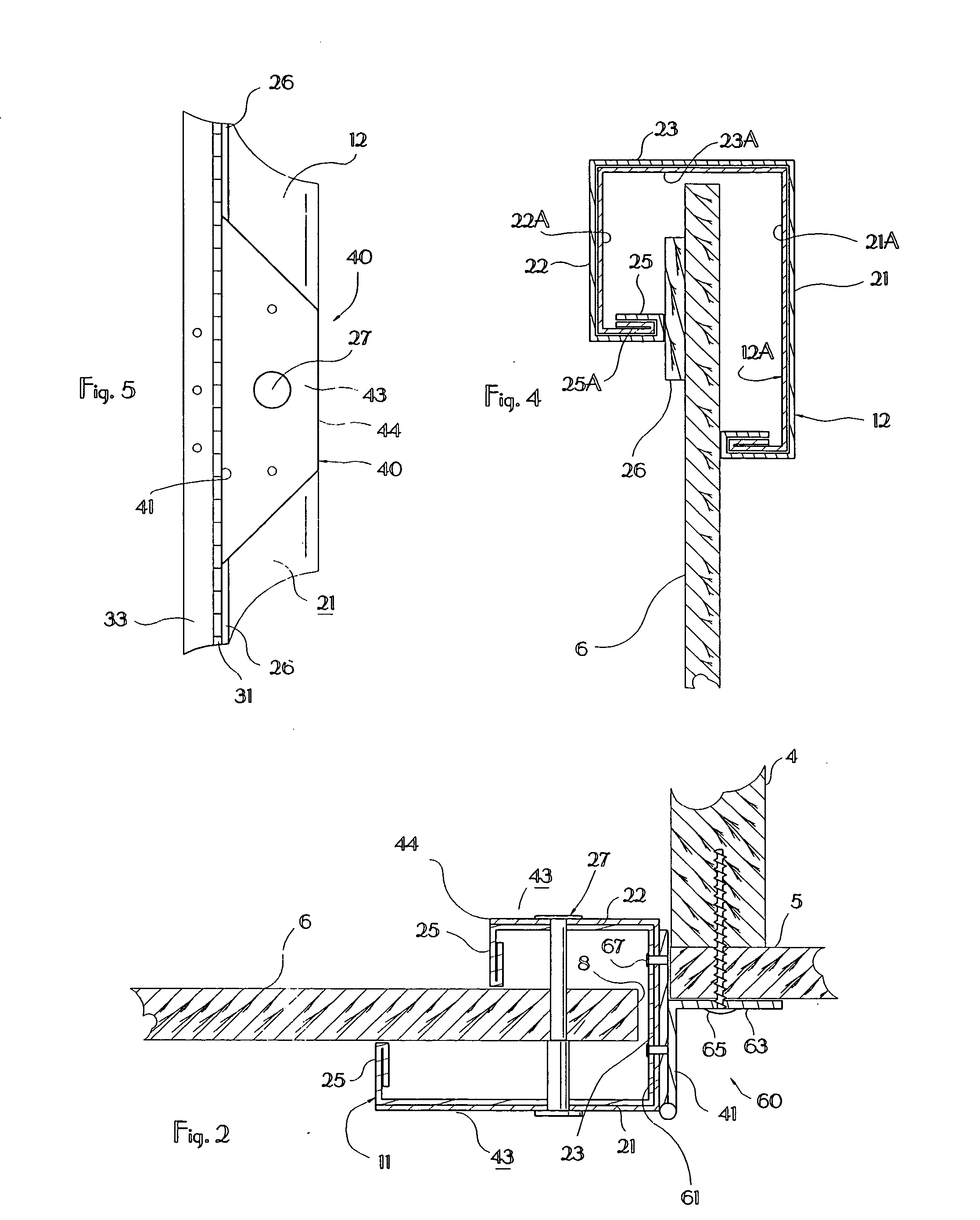

Door frame kit

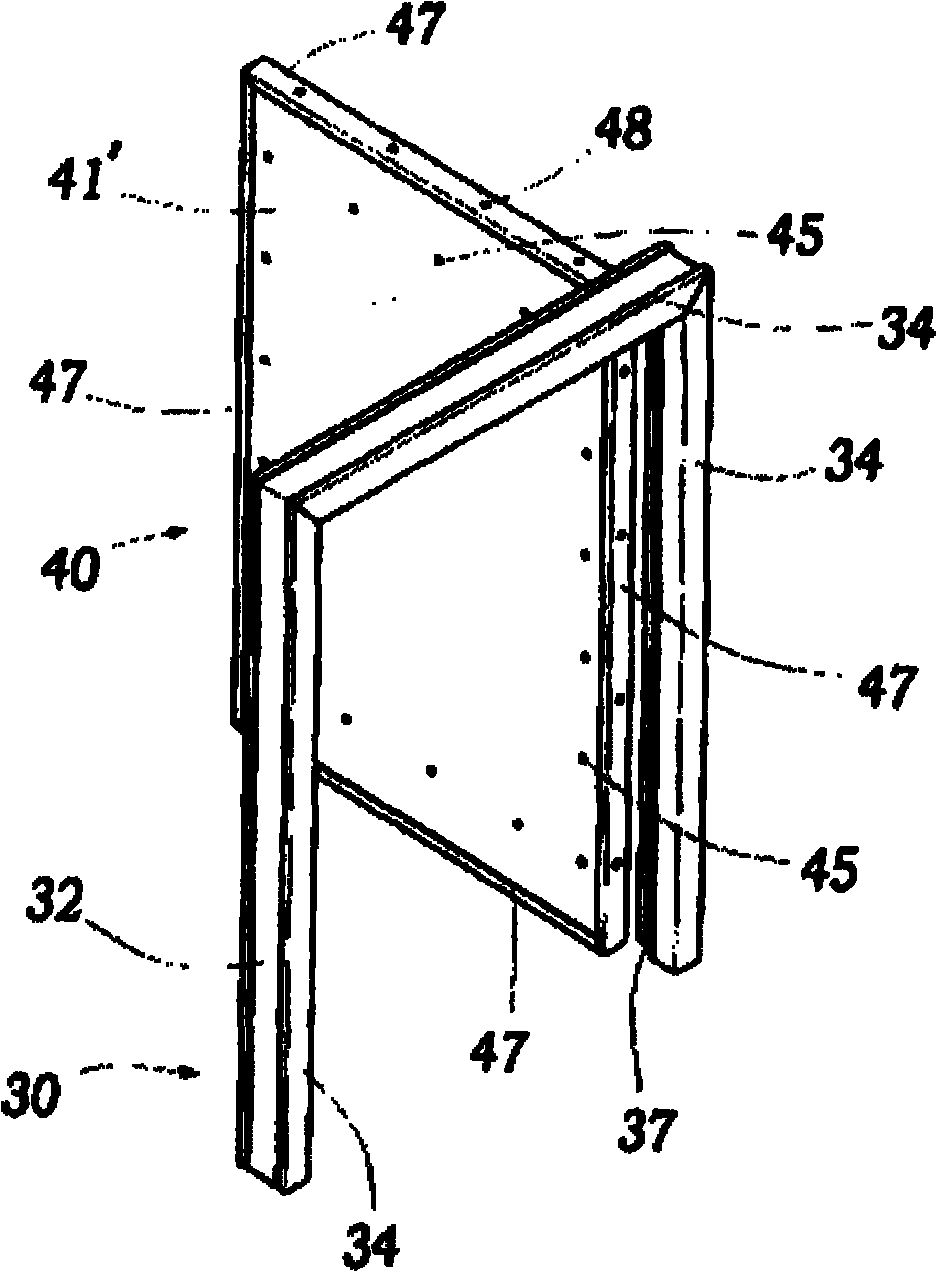

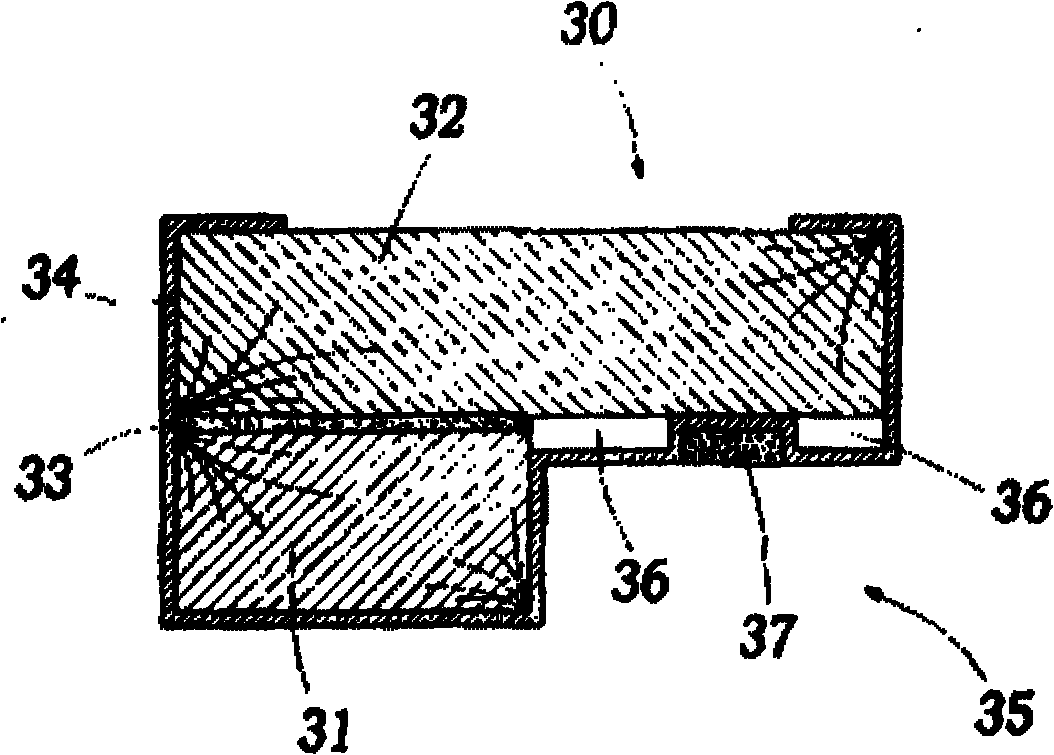

InactiveUS20040250475A1Avoid edge damageWarpage suppressionExtensible doors/windowsDoor/window applicationsVertical channelBiomedical engineering

Owner:SEAMAN BRIAN B

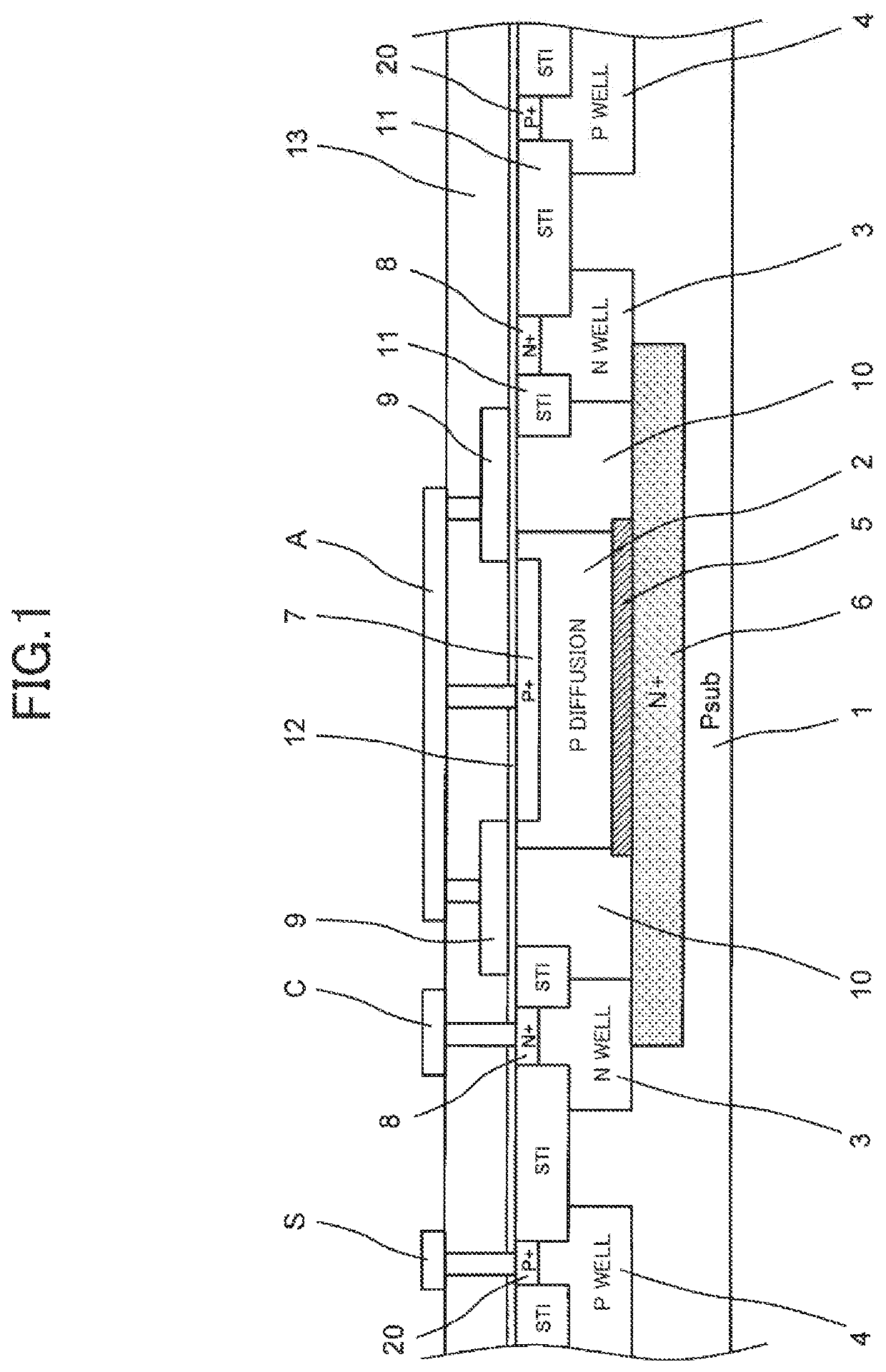

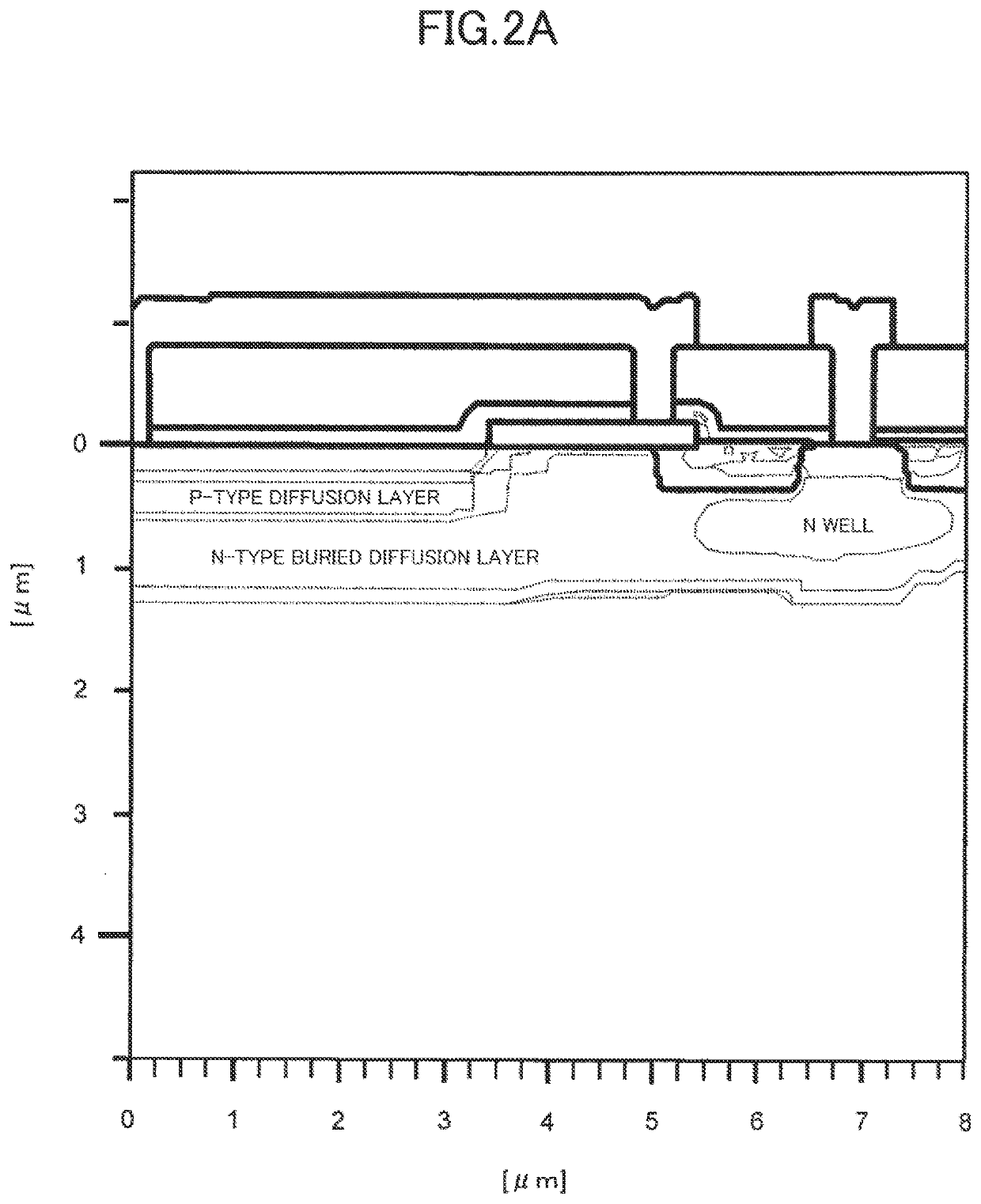

Avalanche photodiode

ActiveUS20200028019A1Uniform distribution of electric field strengthUniform operationDiodeElectrically conductiveSemiconductor

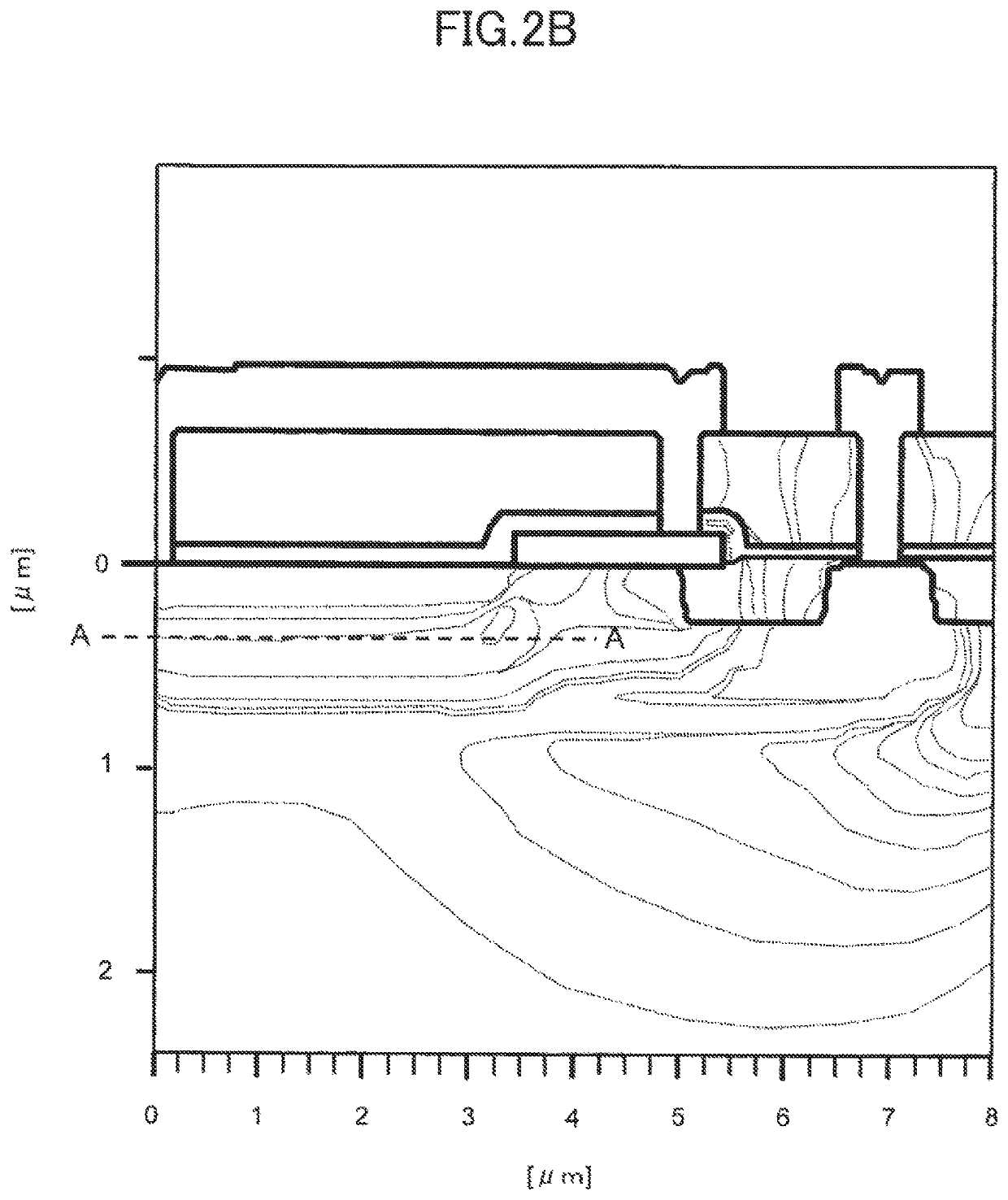

An avalanche photodiode includes a first-conductivity-type semiconductor layer formed within a first-conductivity-type semiconductor substrate; a first second-conductivity-type semiconductor layer formed so as to surround, in plan view for the substrate, with a gap width, the first-conductivity-type semiconductor layer; a second second-conductivity-type semiconductor layer formed deeper than the first-conductivity-type semiconductor layer and in contact with the bottom portion of the first-conductivity-type semiconductor layer; and a third second-conductivity-type semiconductor layer formed deeper than the second second-conductivity-type semiconductor layer and in contact with the bottom portion of the second second-conductivity-type semiconductor layer; anda fourth second-conductivity-type semiconductor layer formed between the first second-conductivity-type semiconductor layer and the third second-conductivity-type semiconductor layer so as to be in contact with at least a portion of a bottom portion of the first second-conductivity-type semiconductor layer; and a fifth second-conductivity-type semiconductor layer formed in an upper portion of the first second-conductivity-type semiconductor layer and having a higher impurity concentration than the first second-conductivity-type semiconductor layer.The first-conductivity-type semiconductor layer and the second second-conductivity-type semiconductor layer form an avalanche junction. The first and third second-conductivity-type semiconductor layers are electrically connected together via the fourth second-conductivity-type semiconductor layer such that the semiconductor substrate and the first-conductivity-type semiconductor layer are electrically isolated from each other.

Owner:SHARP KK

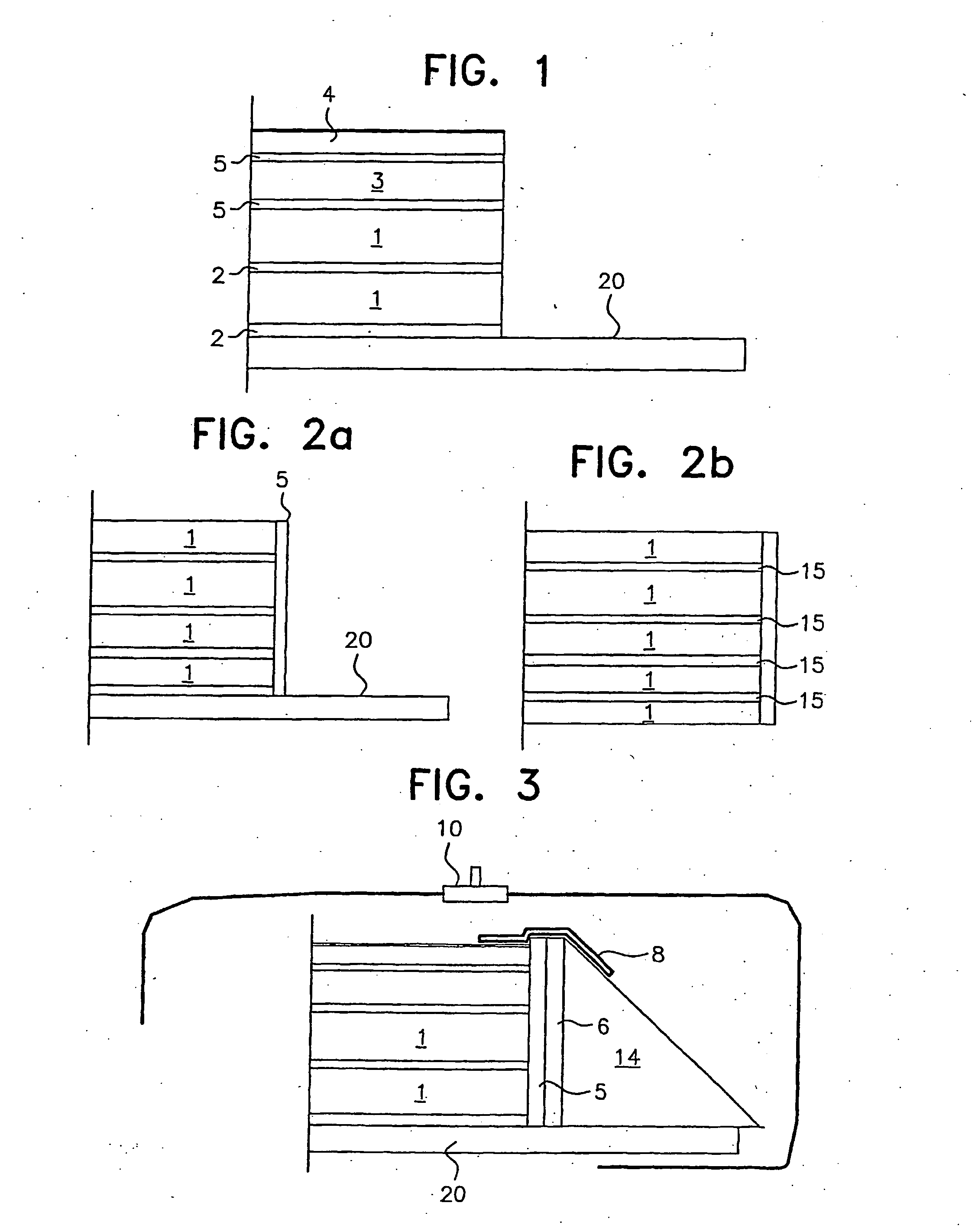

Pet as edge seal for multilaminated compositions

InactiveUS20060105121A1Improve protectionAvoid edge damageProtective equipmentSynthetic resin layered productsPolyethylene terephthalateEngineering

This invention provides an edge seal that employs Polyethylene Terephthalate (PET) adhered to the edge of a laminated glass by a layer adhesive material in order to improve the protection against environmental conditions. The edge seal claimed by this invention also acts as a scratch resistant material, helping to prevent edge marring during handling, transport and installation of the laminated glass product. This edge can be applied to architectural or transportation laminated glass constructions, either flat or curved, including bullet resistance glass.

Owner:AGP AMERICA

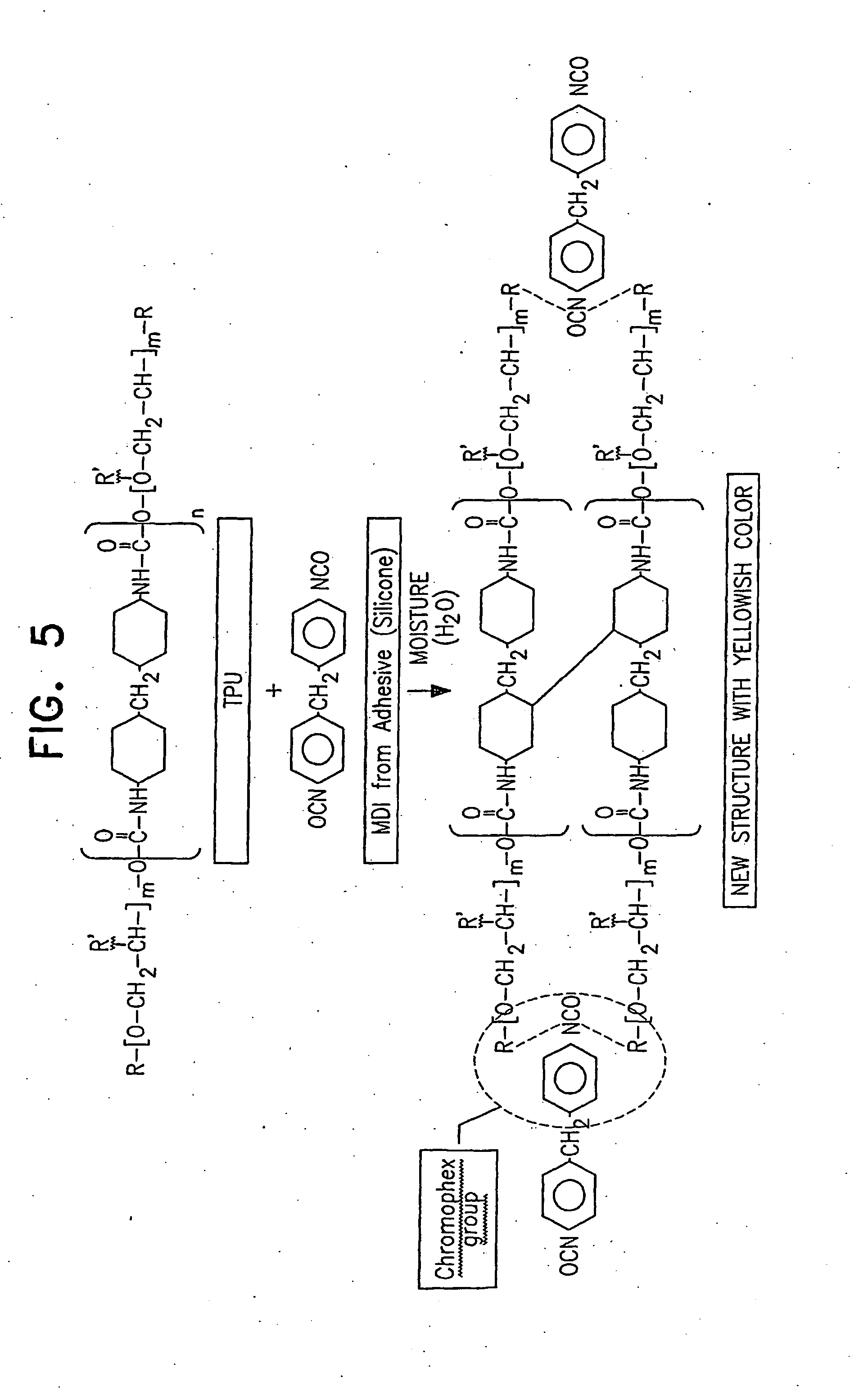

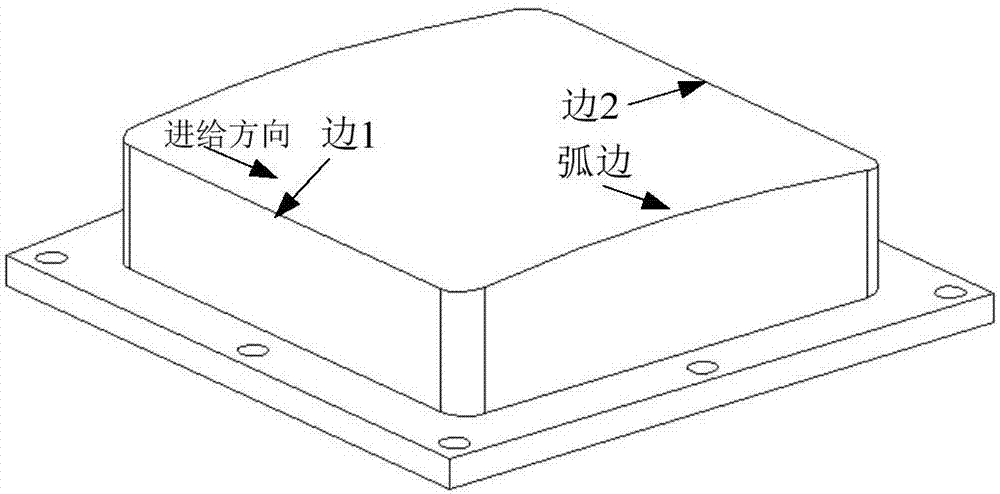

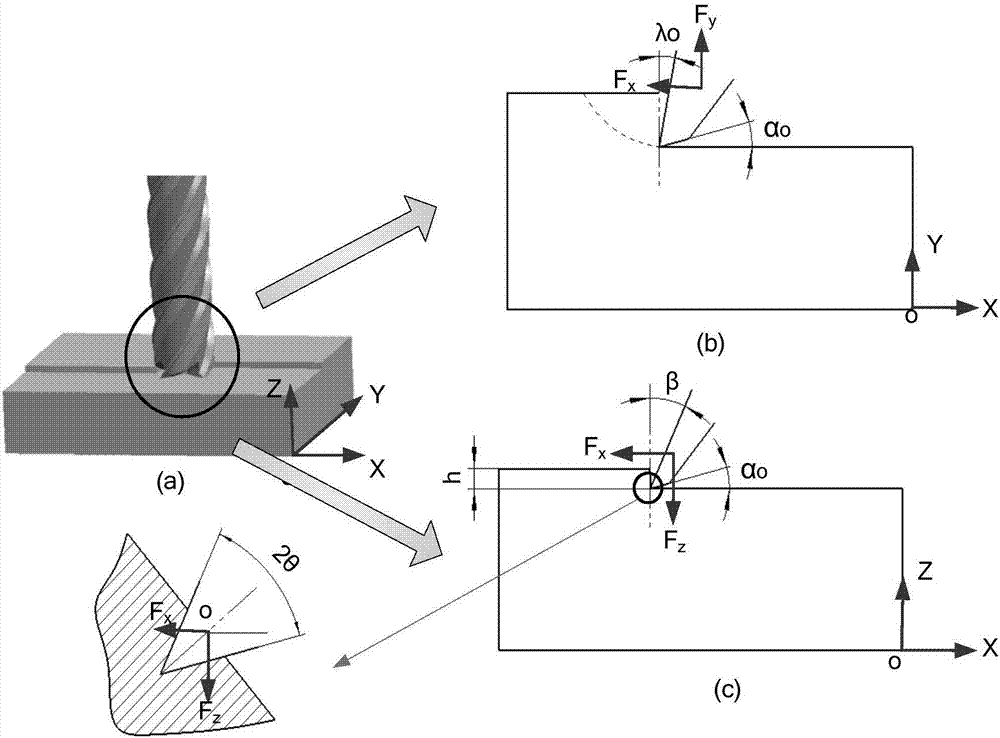

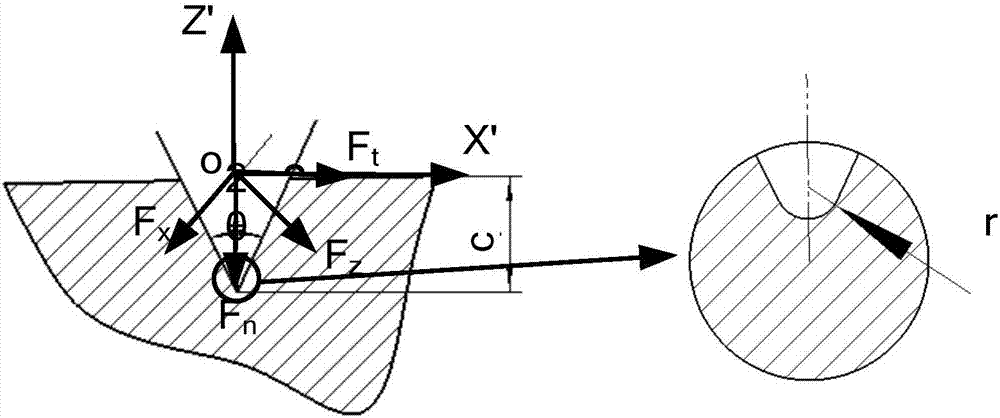

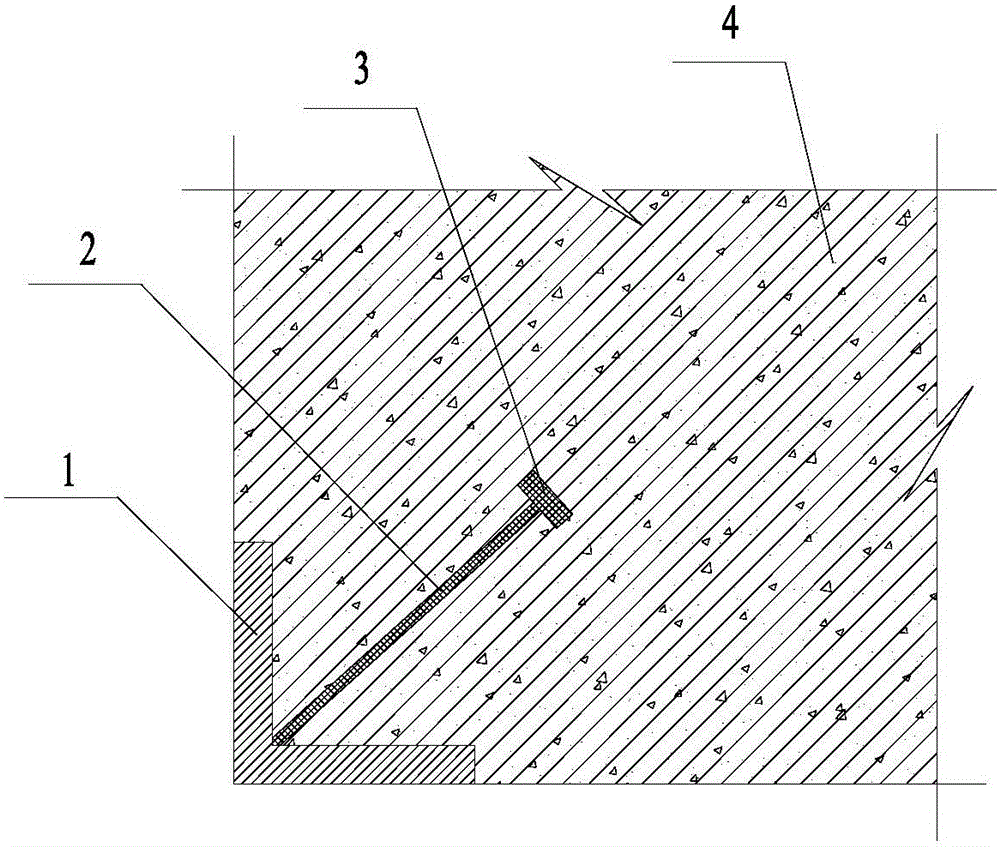

Milling machining method for wave-transmitting ceramic antenna window

ActiveCN107139343AMeet job requirementsImprove machined surface qualityStone-like material working toolsShear stressMachined surface

The invention discloses a milling machining method for a wave-transmitting ceramic antenna window and aims to solve the problems that existing wave-transmitting ceramic antenna windows are low in milling machining efficiency, high in rejection rate and poor in machining quality. The method is technically characterized by comprising the steps as follows: 1, the contact relationship between a cutting edge of a tool and the surface of a workpiece is obtained; the stress field intensity of the tip of the cutting edge of the tool is solved, the critical milling depth is obtained, and then machining process parameters of the workpiece are determined according to the critical milling depth; 2, the machining path of tool follows the principle that different tool path plans are adopted for different machining areas on the same plane, and the shearing stress on the machining edge points to the inside of a material; 3, the two-end feeding process is adopted for through holes, that is, the front surface and the back surface of the same through hole are machined sequentially, and the tool stop positions are kept inside the through holes. With the method, the machined surface of the wave-transmitting ceramic antenna window can be free of damage such as pits, microscopic cracks, edge damage, hole edge breakage and the like, and the working requirements of the wave-transmitting ceramic antenna window can be met.

Owner:HARBIN UNIV OF SCI & TECH +1

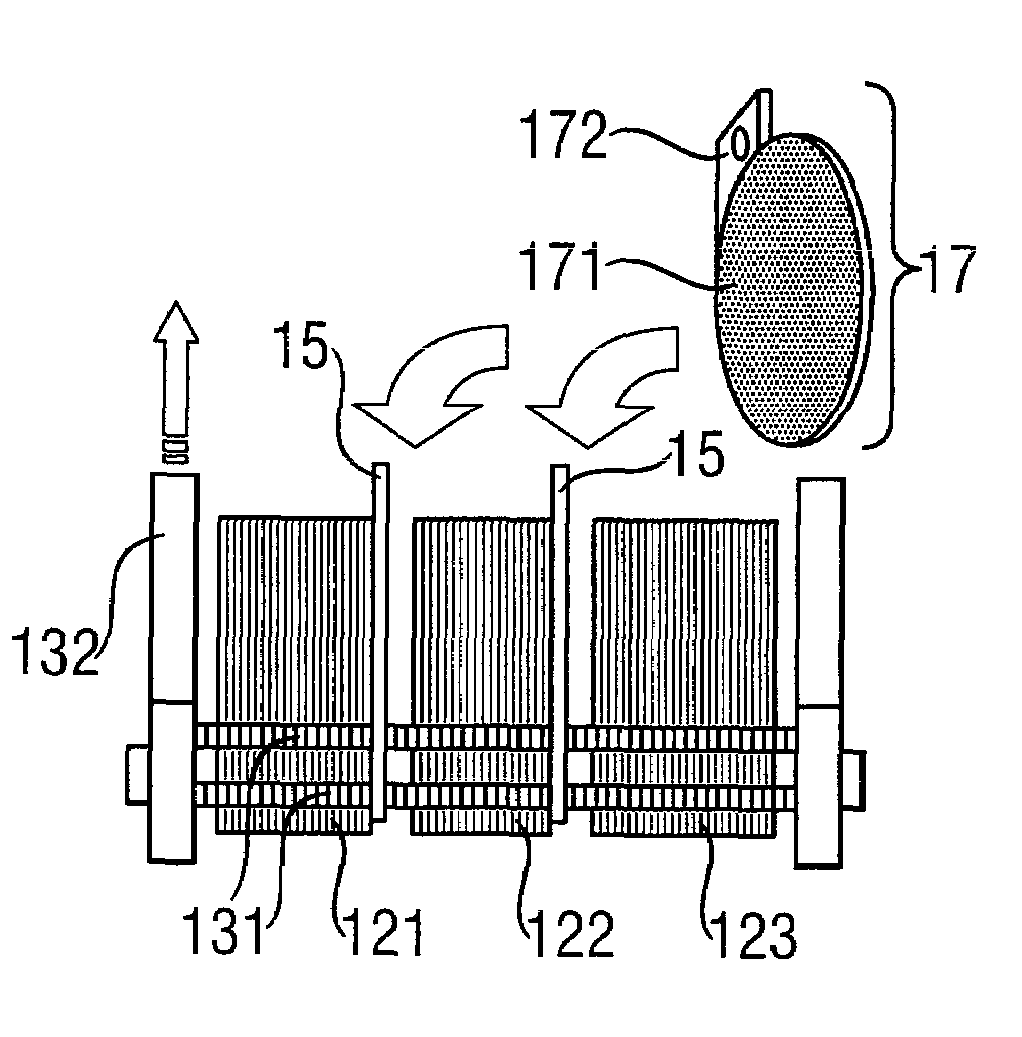

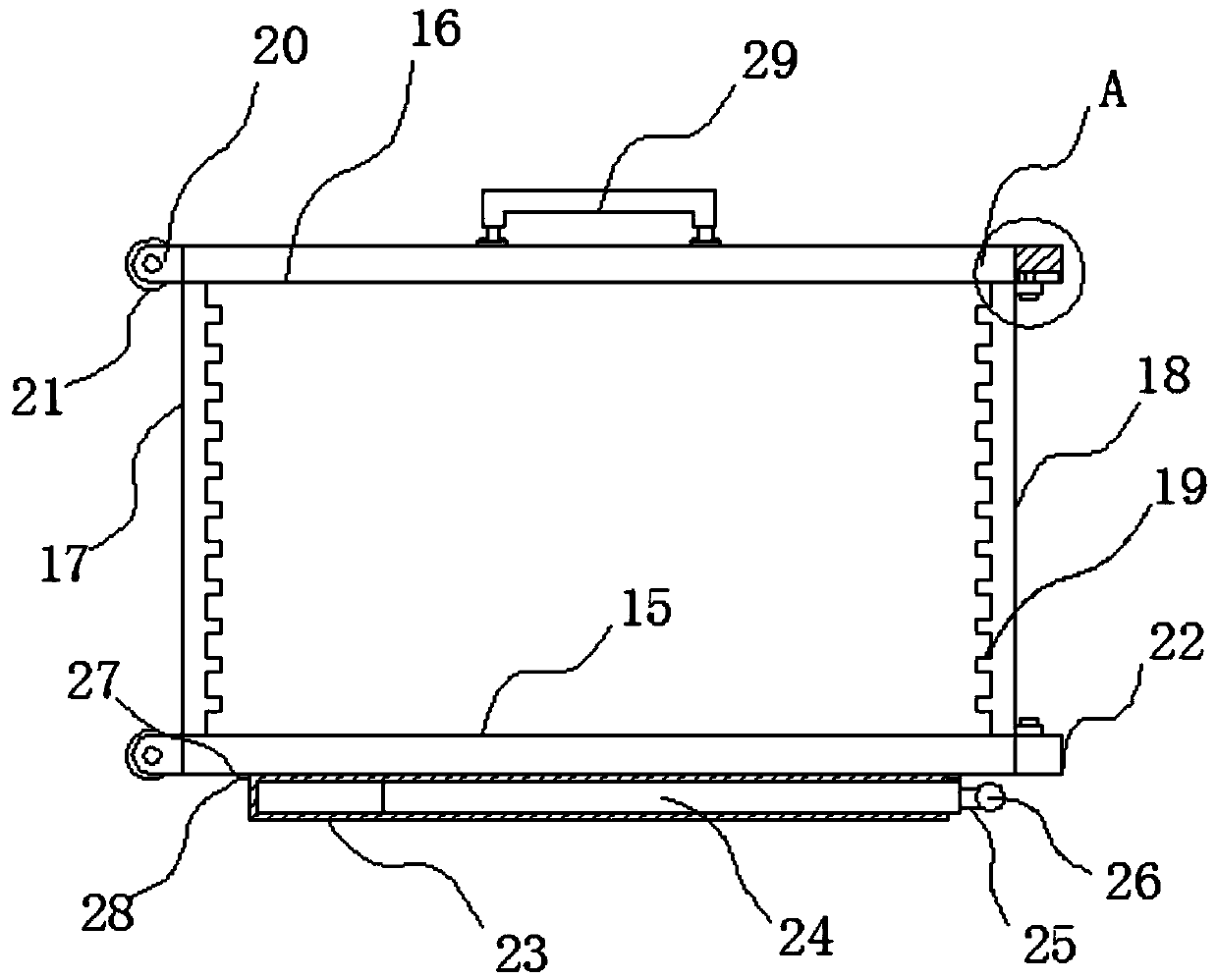

Shapable flexible display device

ActiveCN109887414AAchieve bendingRealize functionIdentification meansElectromagnetic interferenceEngineering

The invention discloses a shapable flexible display device, which comprises a flexible display panel and a plurality of electromagnetic units, wherein the plurality of electromagnetic units are arranged on the back surface of the flexible display panel; the plurality of electromagnetic units are adjacent to each other and are provided with a gap; each electromagnetic unit is electrically connectedwith the flexible display panel; and if the flexible display panel is electrified to at least two adjacent electromagnetic units, the electrified electromagnetic units generate electromagnetic force,so that the electrified electromagnetic units control the region of the corresponding flexible display panel to bend and keep bending in the gap through the electromagnetic force. According to the shapable flexible display device, the bending of any curved surface of the flexible display panel can be realized and the bending function can be kept according to requirements, and meanwhile, the edgedamage of the flexible display panel can be avoided.

Owner:YUNGU GUAN TECH CO LTD

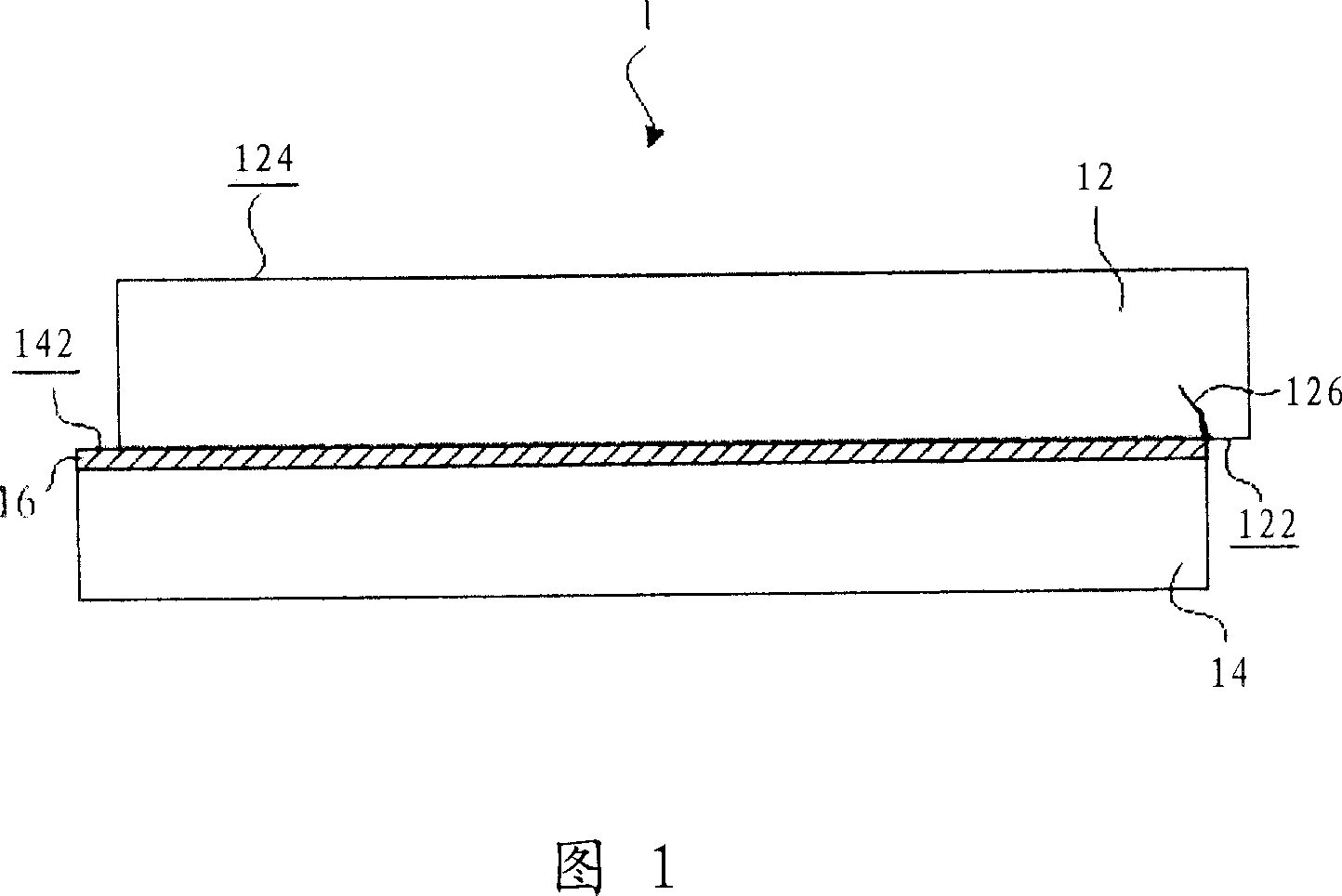

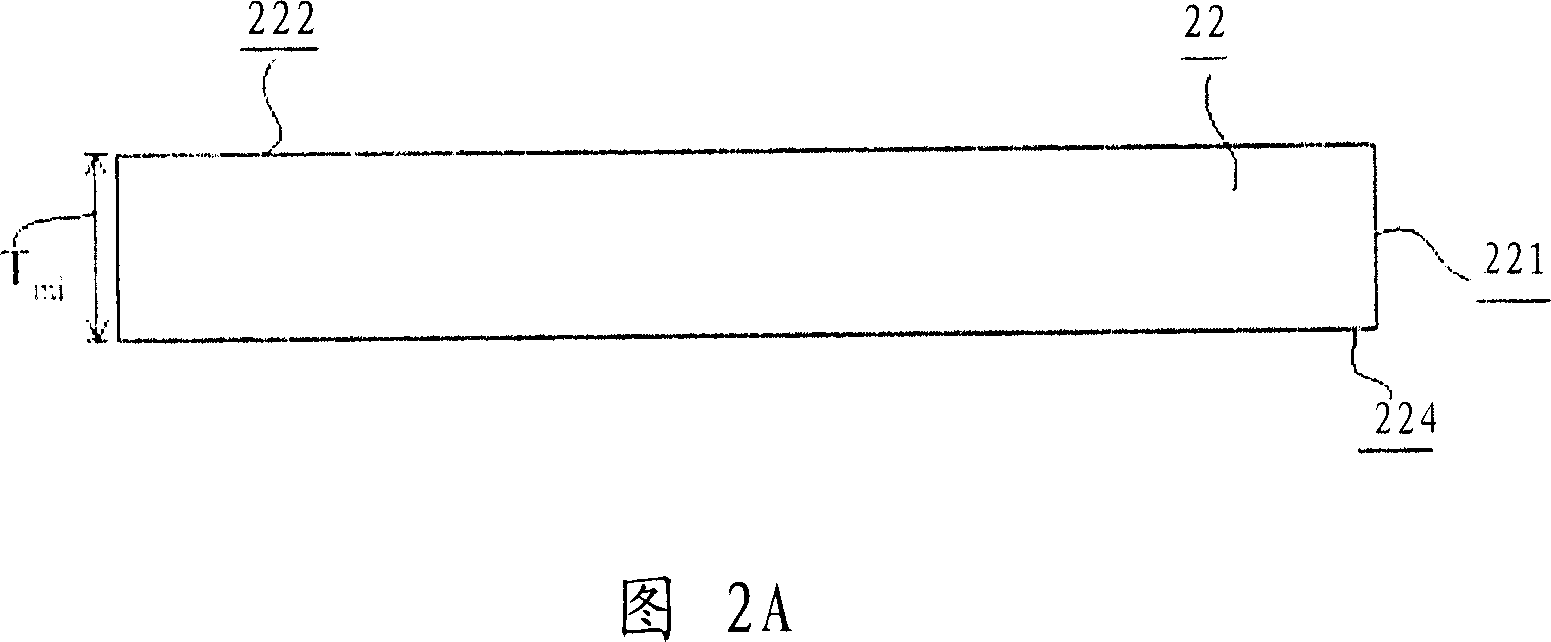

Technology for making composite crystal structure

InactiveCN1925128AImprove yieldAvoid edge damageSemiconductor/solid-state device manufacturingFracture mechanicsCrystal structure

Owner:SINO AMERICAN SILICON PROD

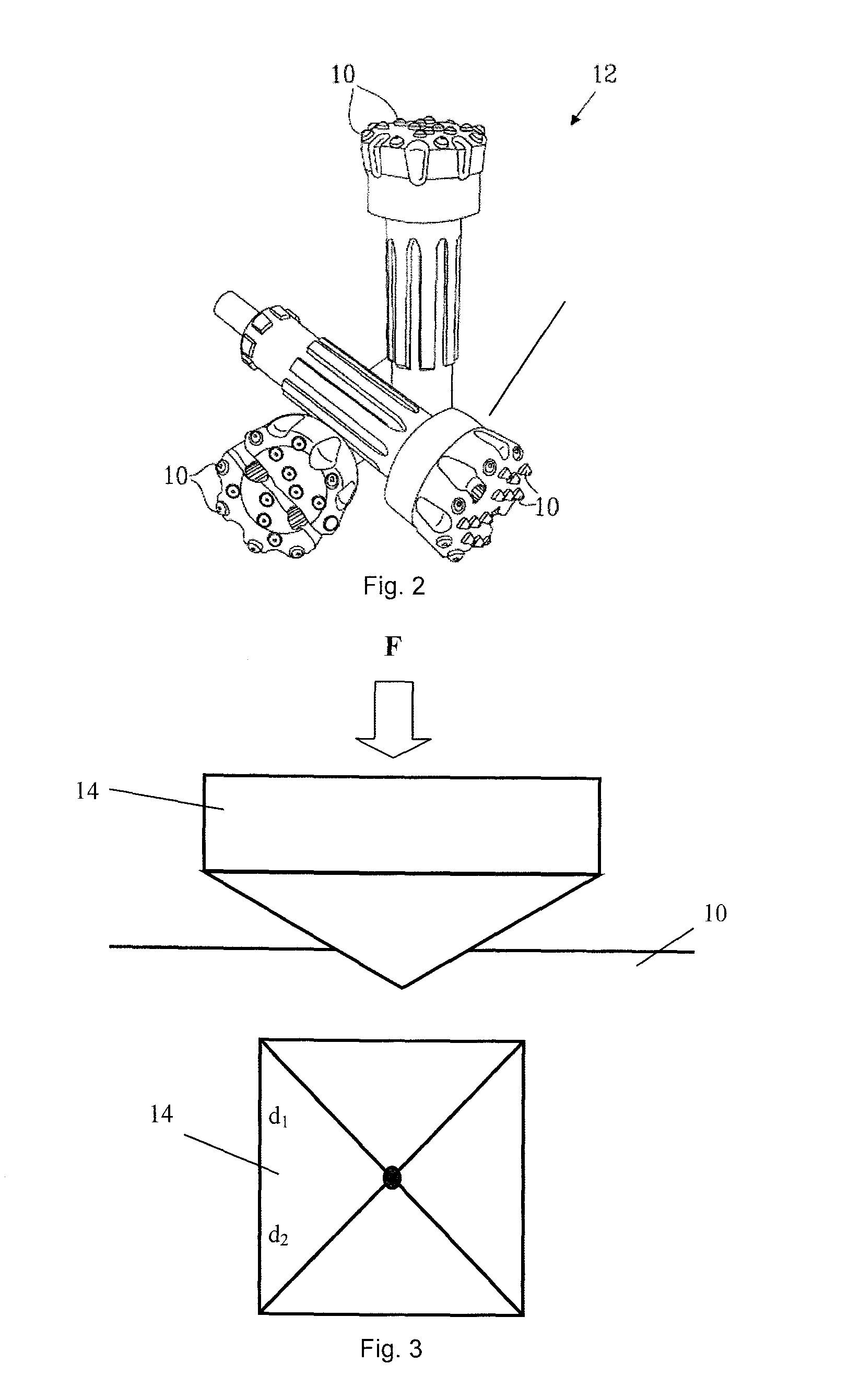

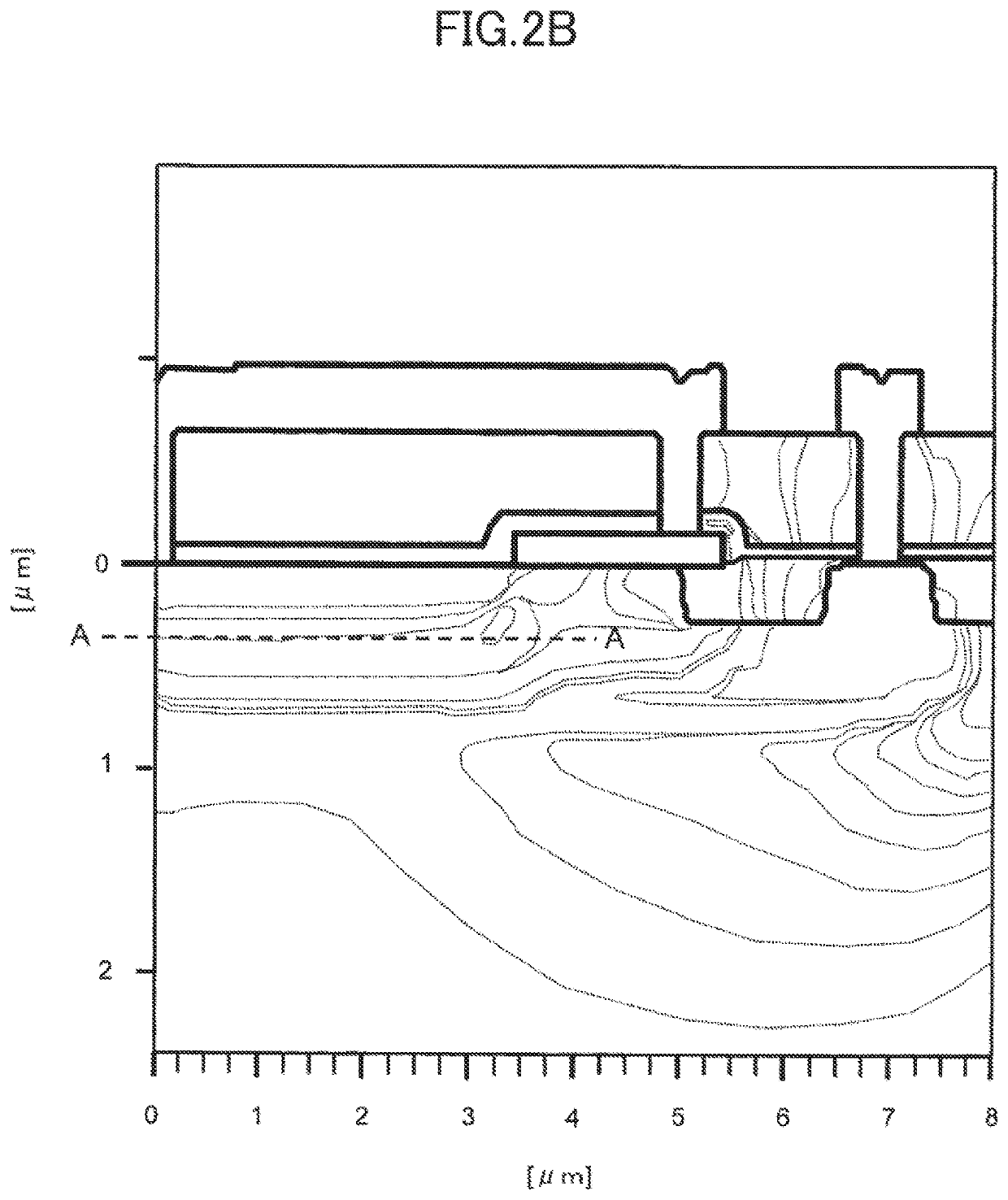

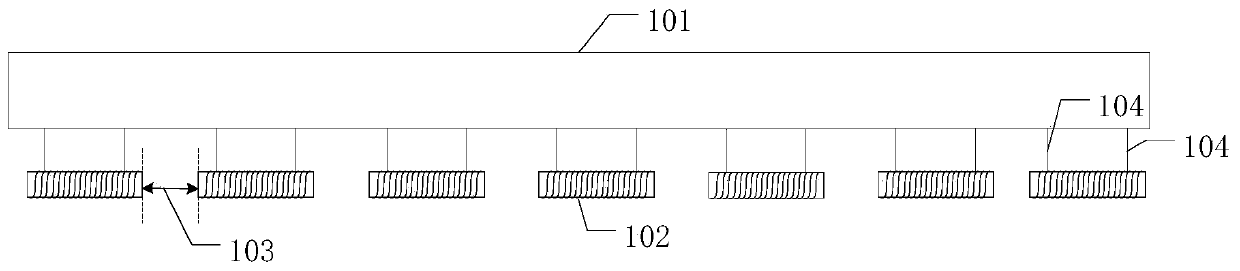

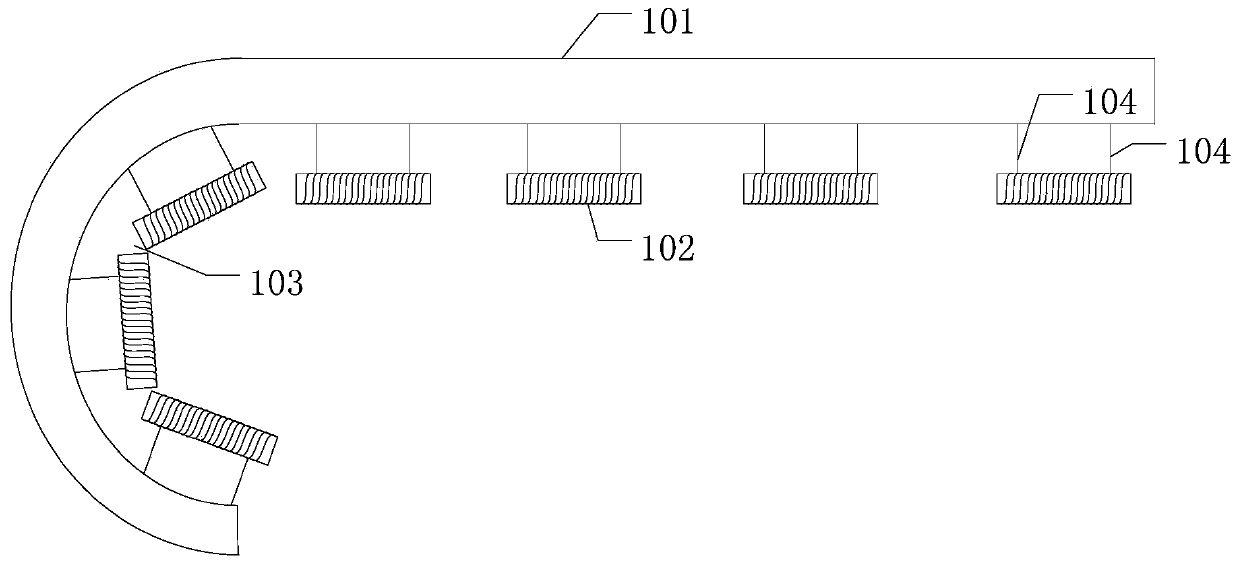

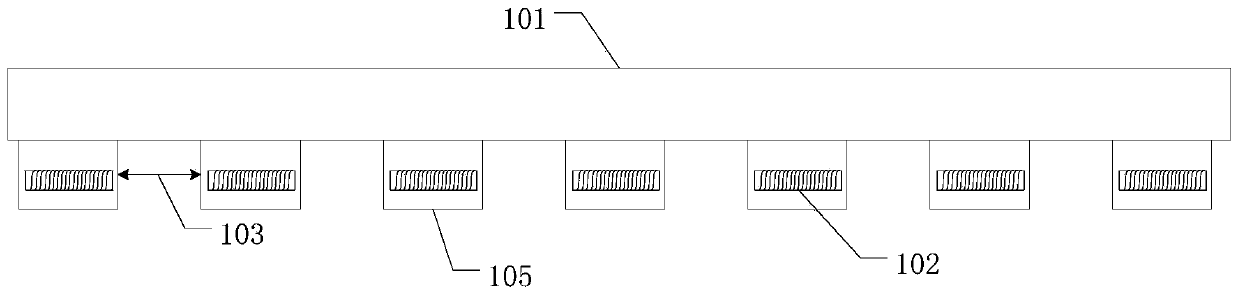

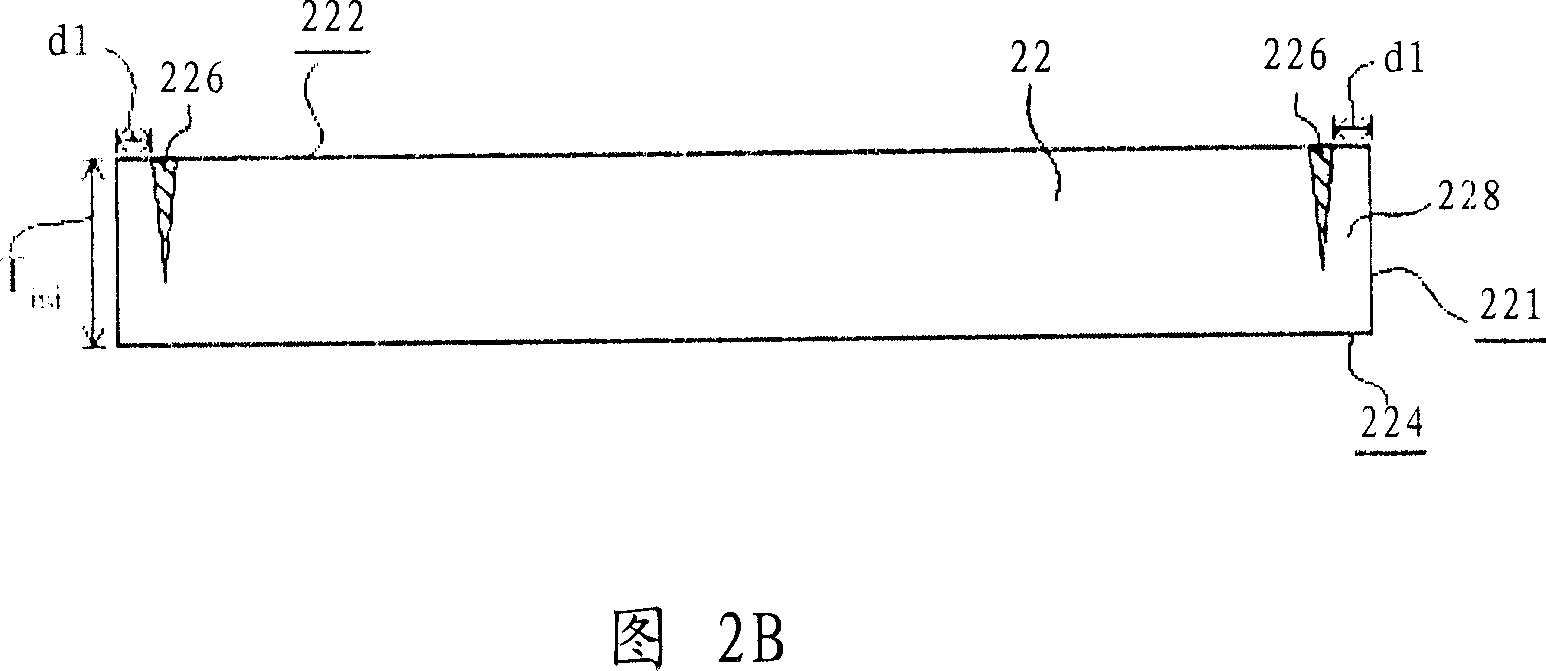

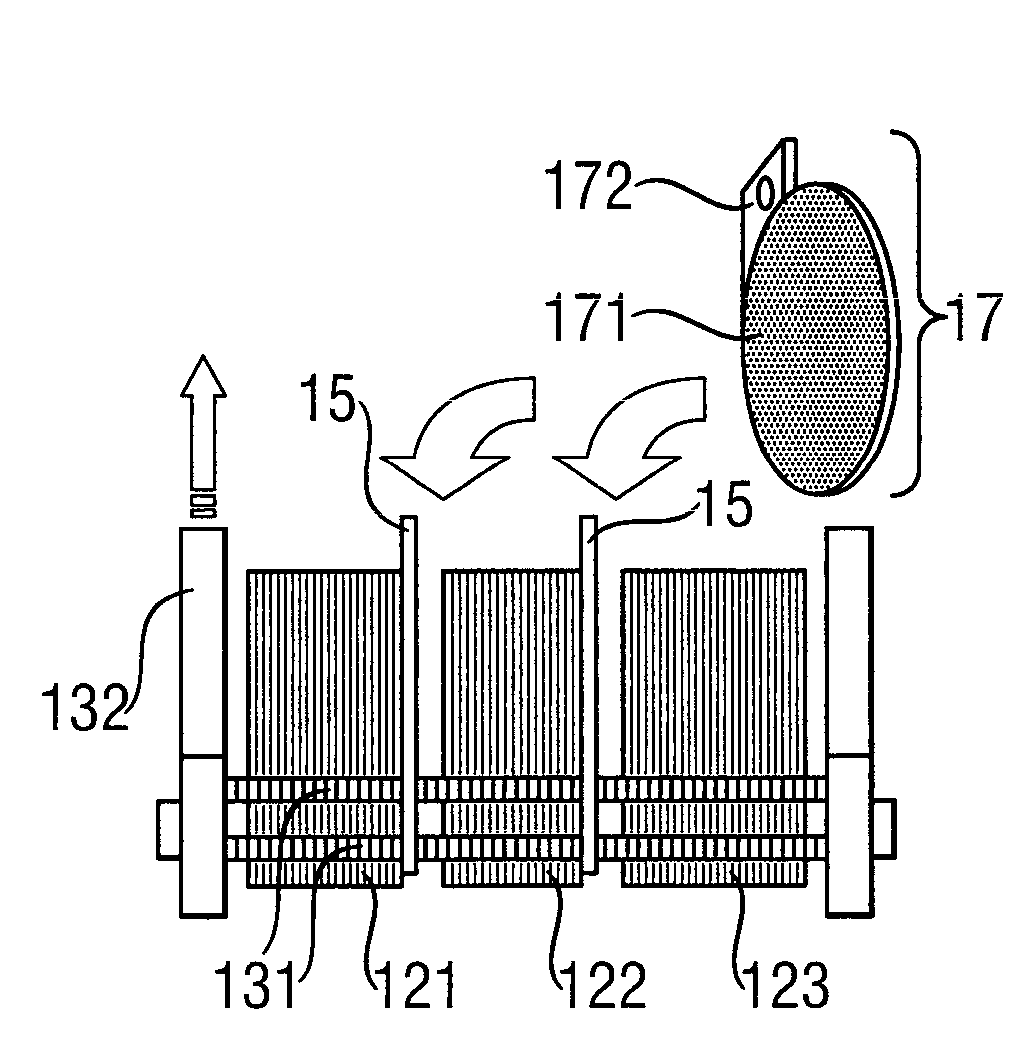

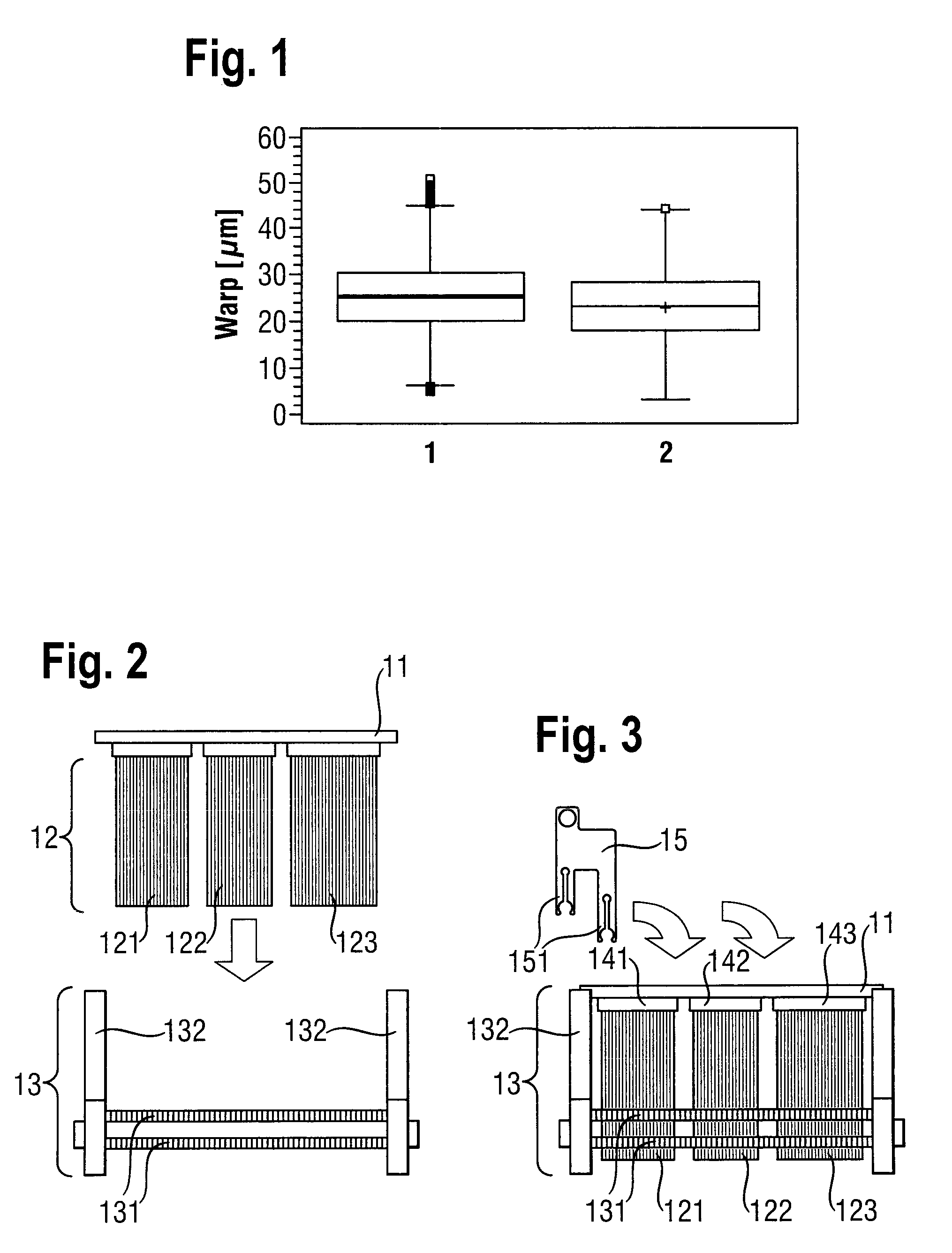

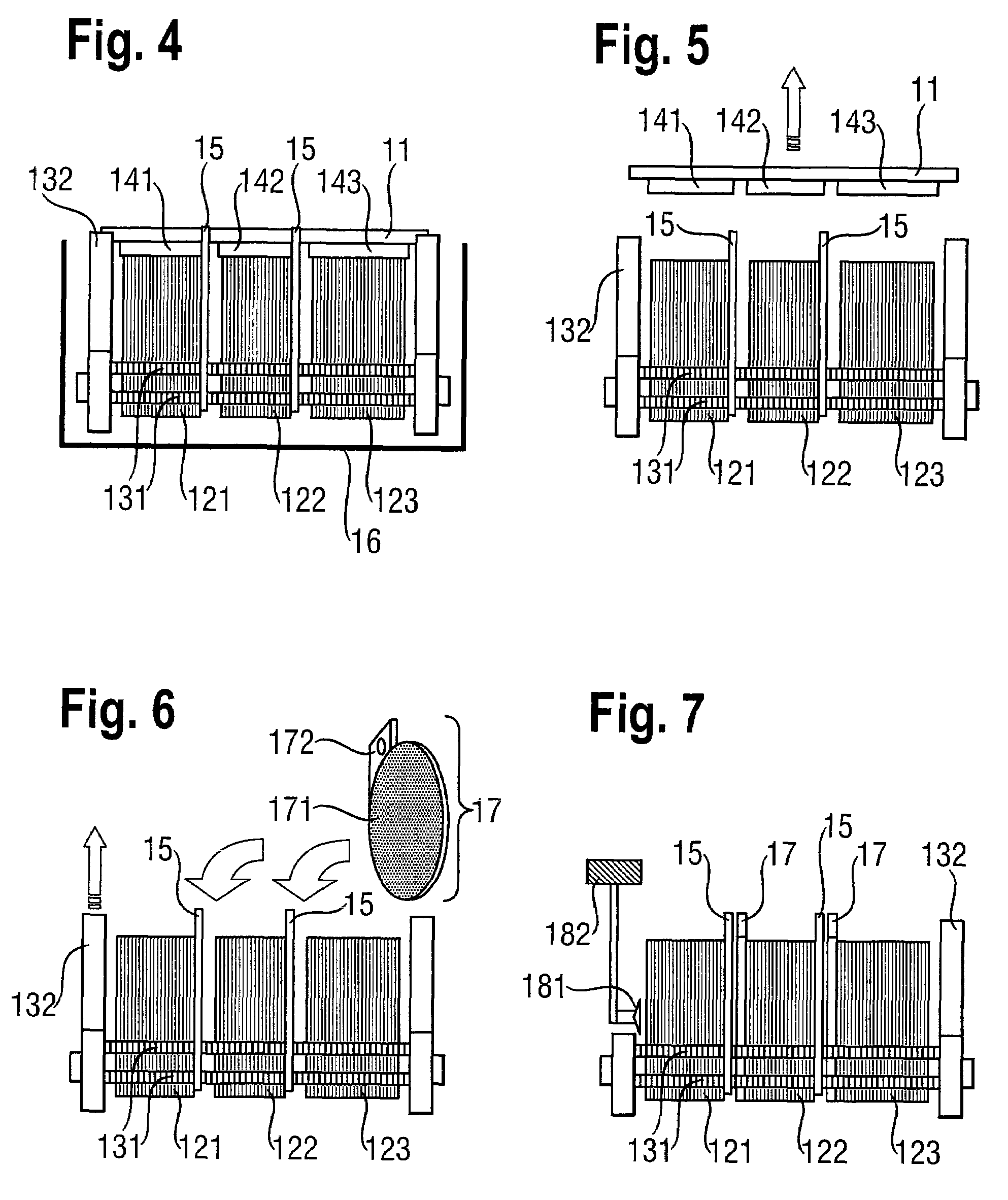

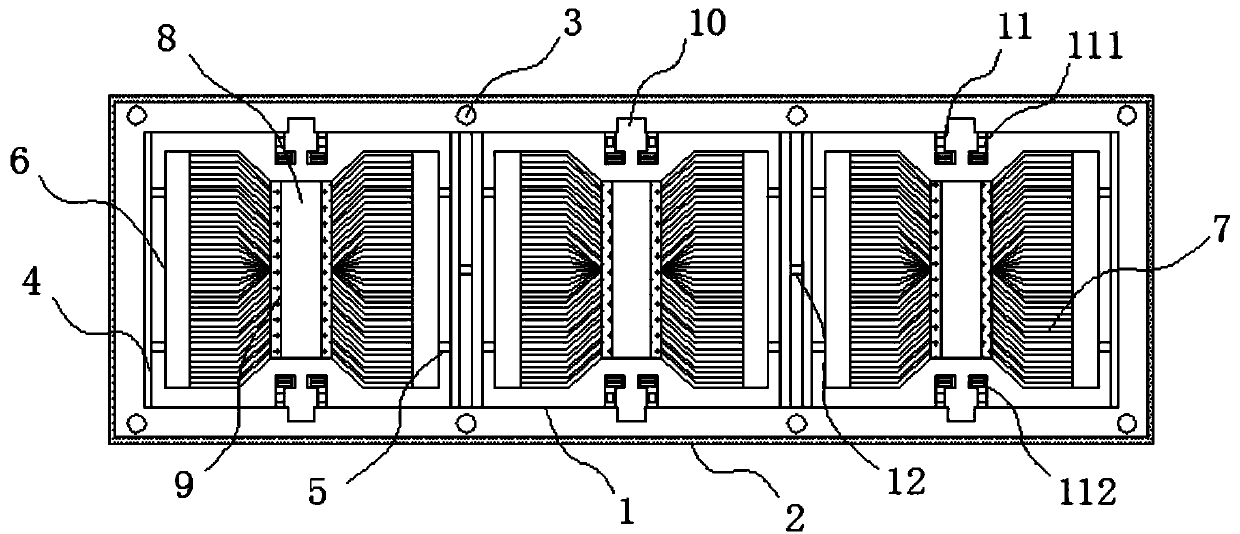

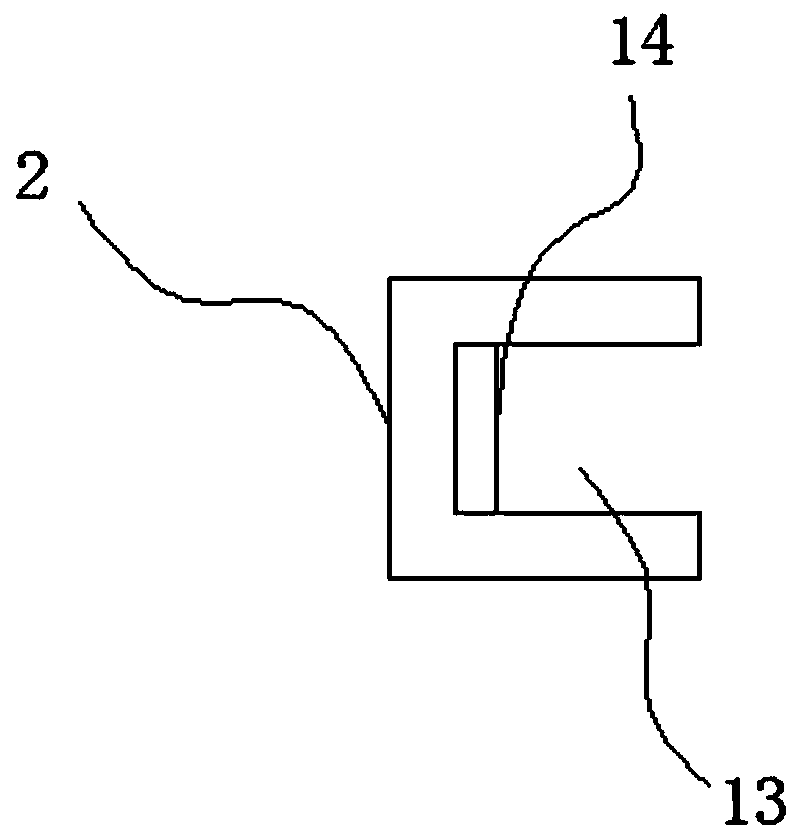

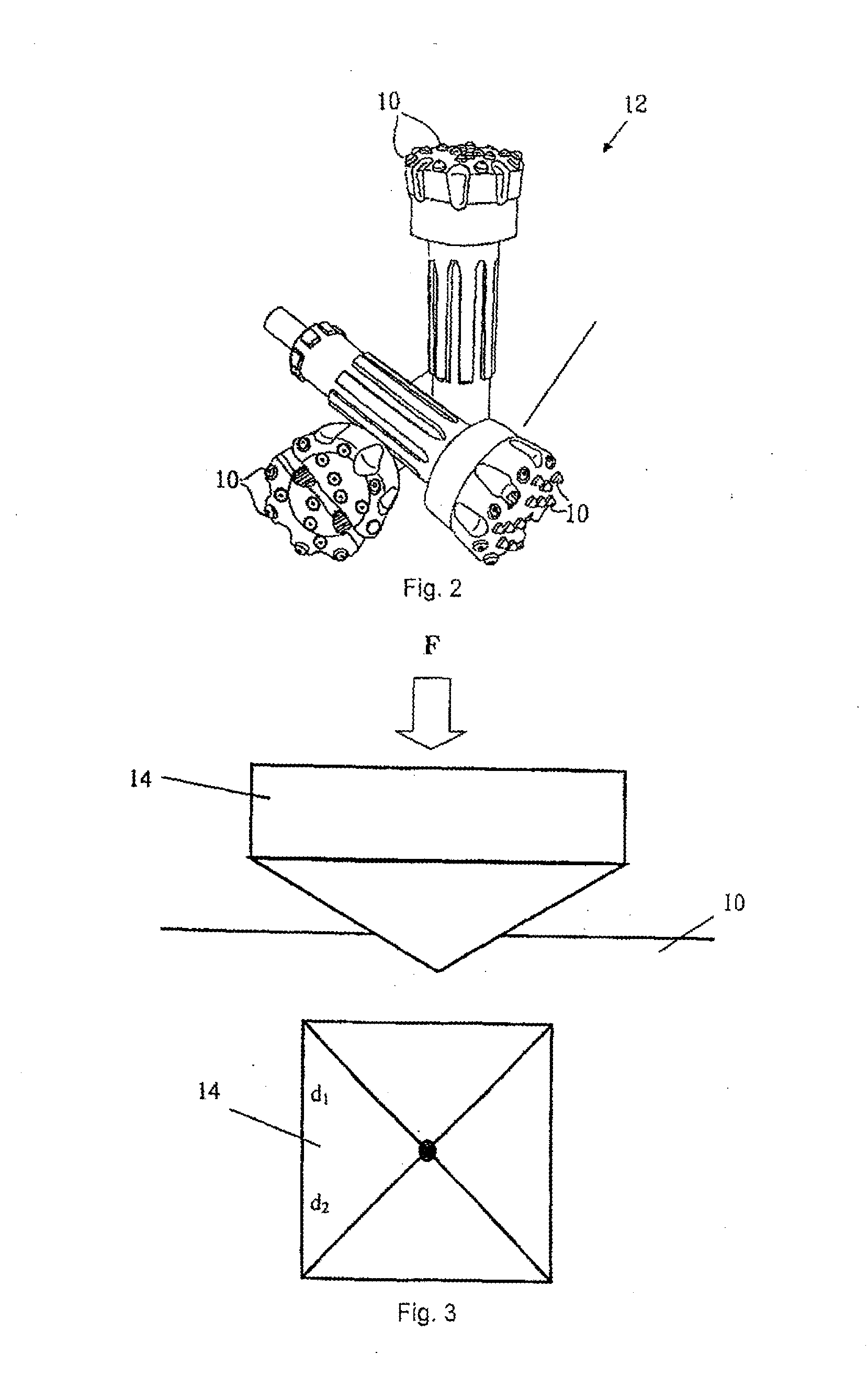

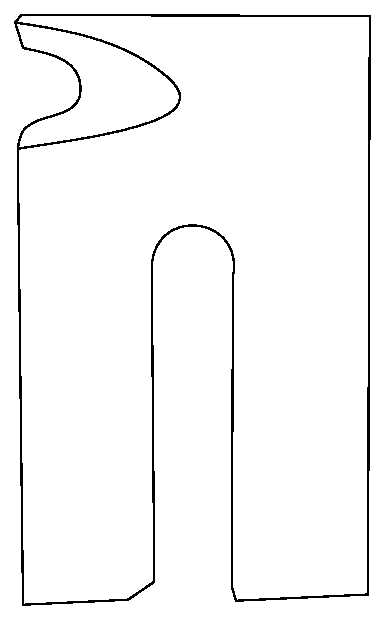

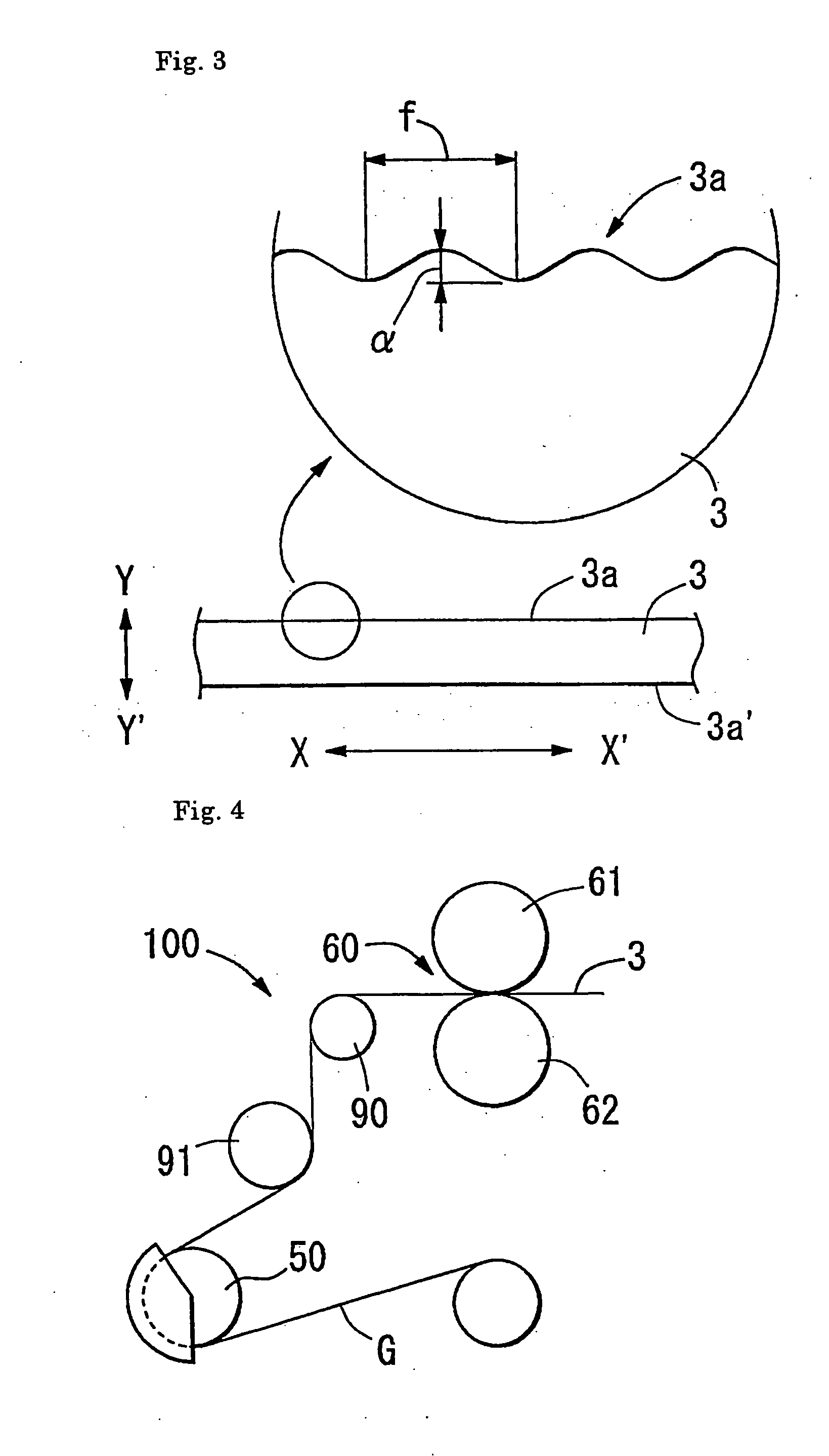

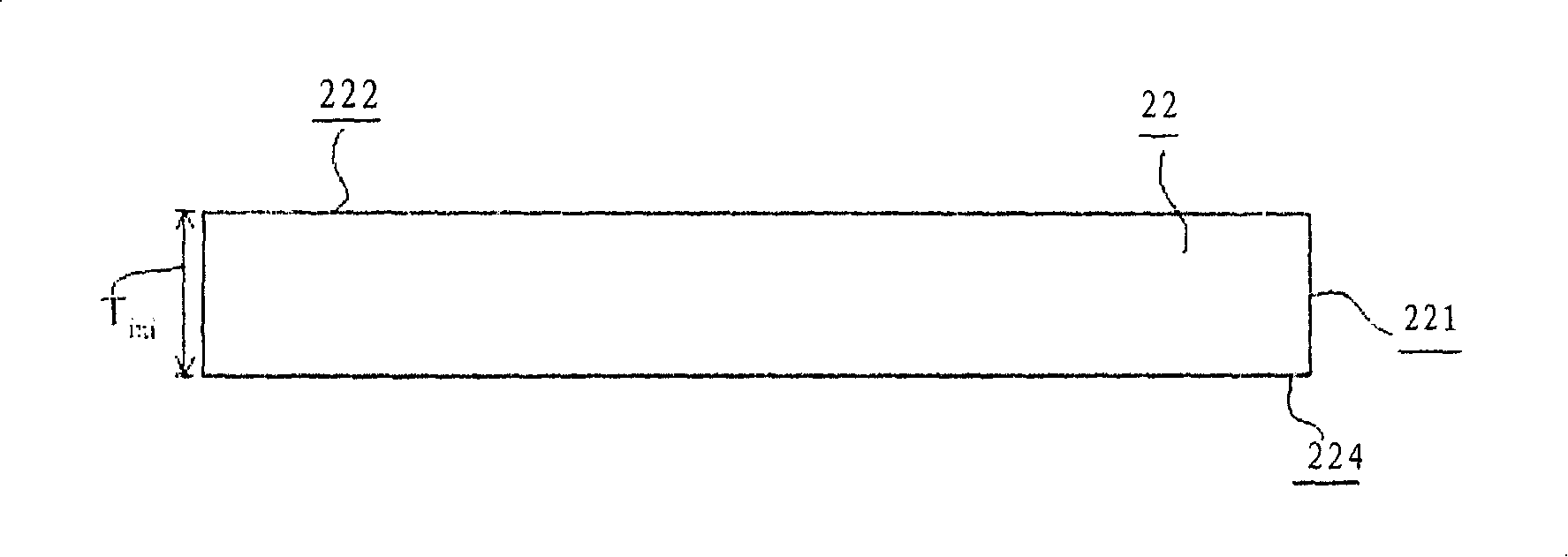

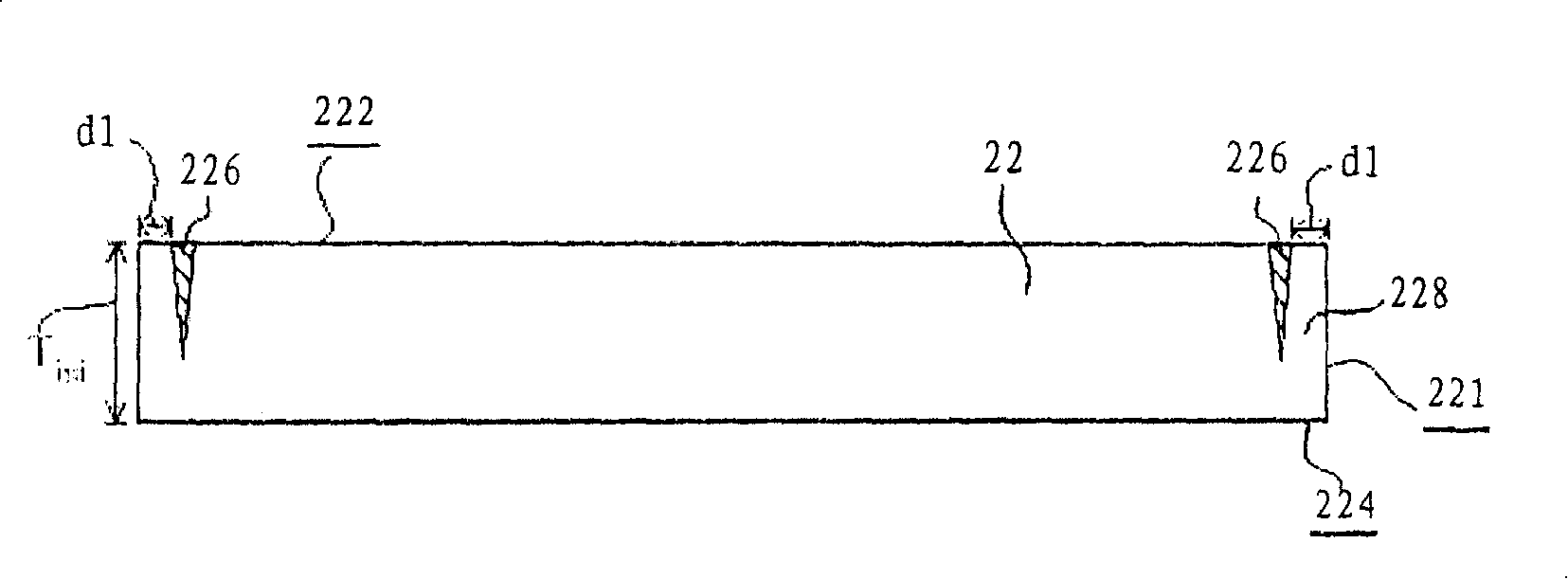

Method for simultaneously slicing at least two cylindrical workpieces into a multiplicity of wafers

ActiveUS20080099006A1Increase profitLarge lengthMetal sawing devicesSemiconductor/solid-state device manufacturingWafer stackingEngineering

Slicing multiple cylindrical workpieces into wafers by a multi wire saw with a gang length LG, is performed by:a) selecting a number n≧2 of workpieces from a stock of workpieces with different lengths, satisfying the inequalityLG≥(n-1)·Amin+∑i=1nL1(1)and making right-hand side of the inequality as large as possible, where Li with i=1 . . . n are for the lengths of the workpieces and Amin is a predefined minimum spacing,b) fixing the n workpieces successively in the longitudinal direction on a mounting plate while maintaining a spacing A≧Amin therebetween such that the relationshipLG≥(n-1)·A+∑i=1nLi(2)is satisfied,c) clamping mounting plates workpieces in a multi wire saw, andd) slicing the n workpieces perpendicularly to their longitudinal axis by means of the multi wire saw. Preferably, the wafer stacks are separated from one another by separating pieces after slicing, and at the same time are laterally supported.

Owner:SILTRONIC AG

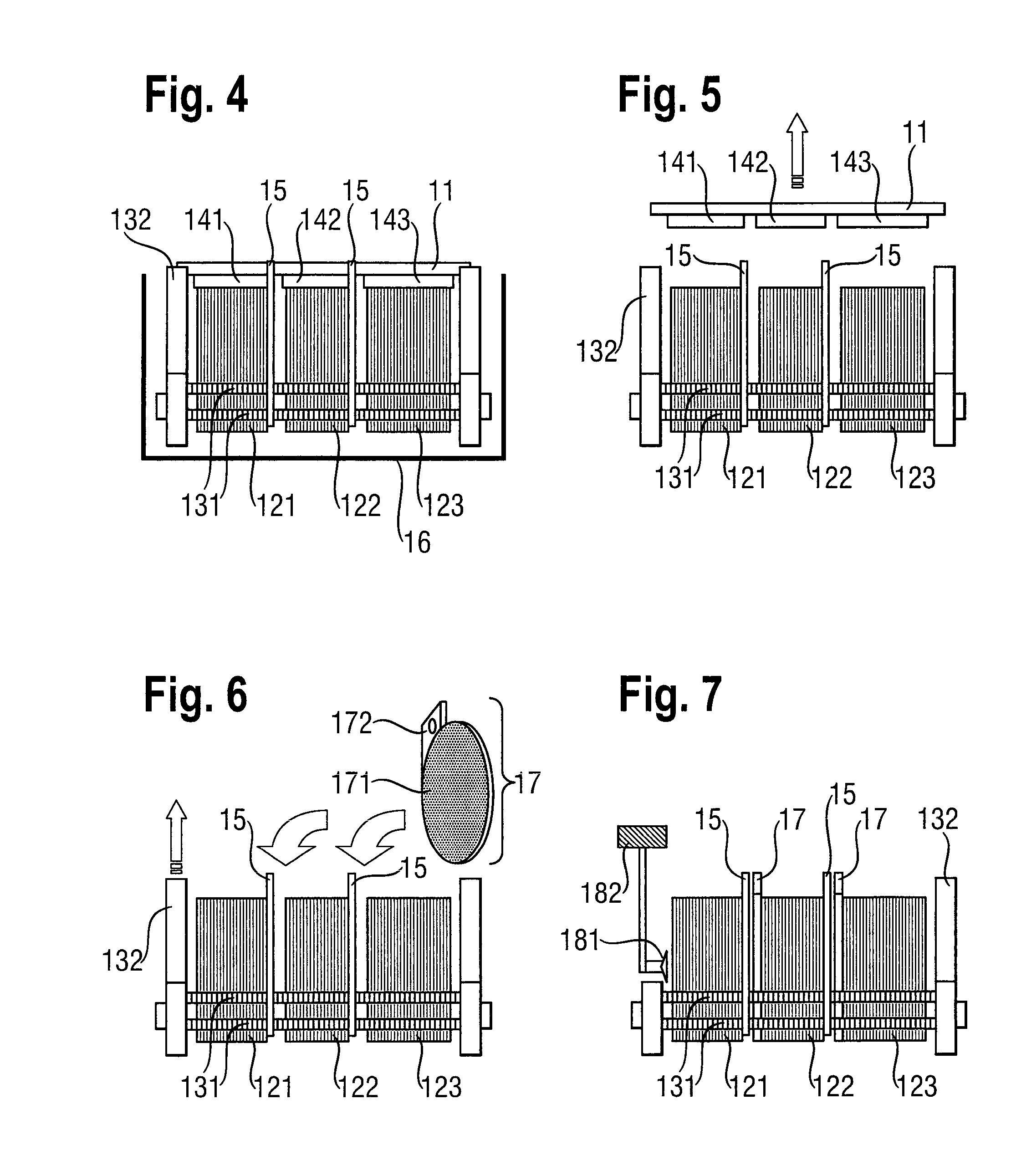

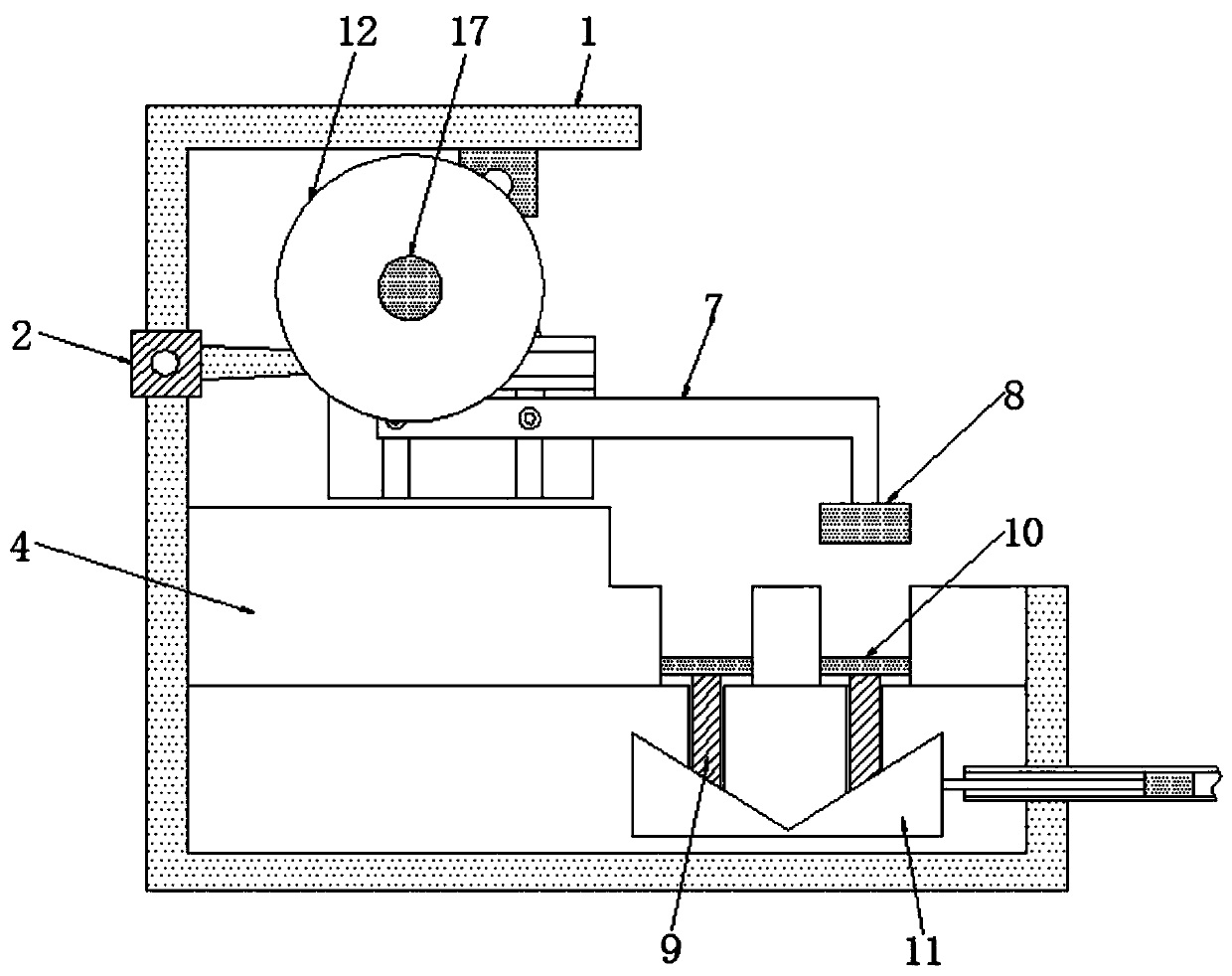

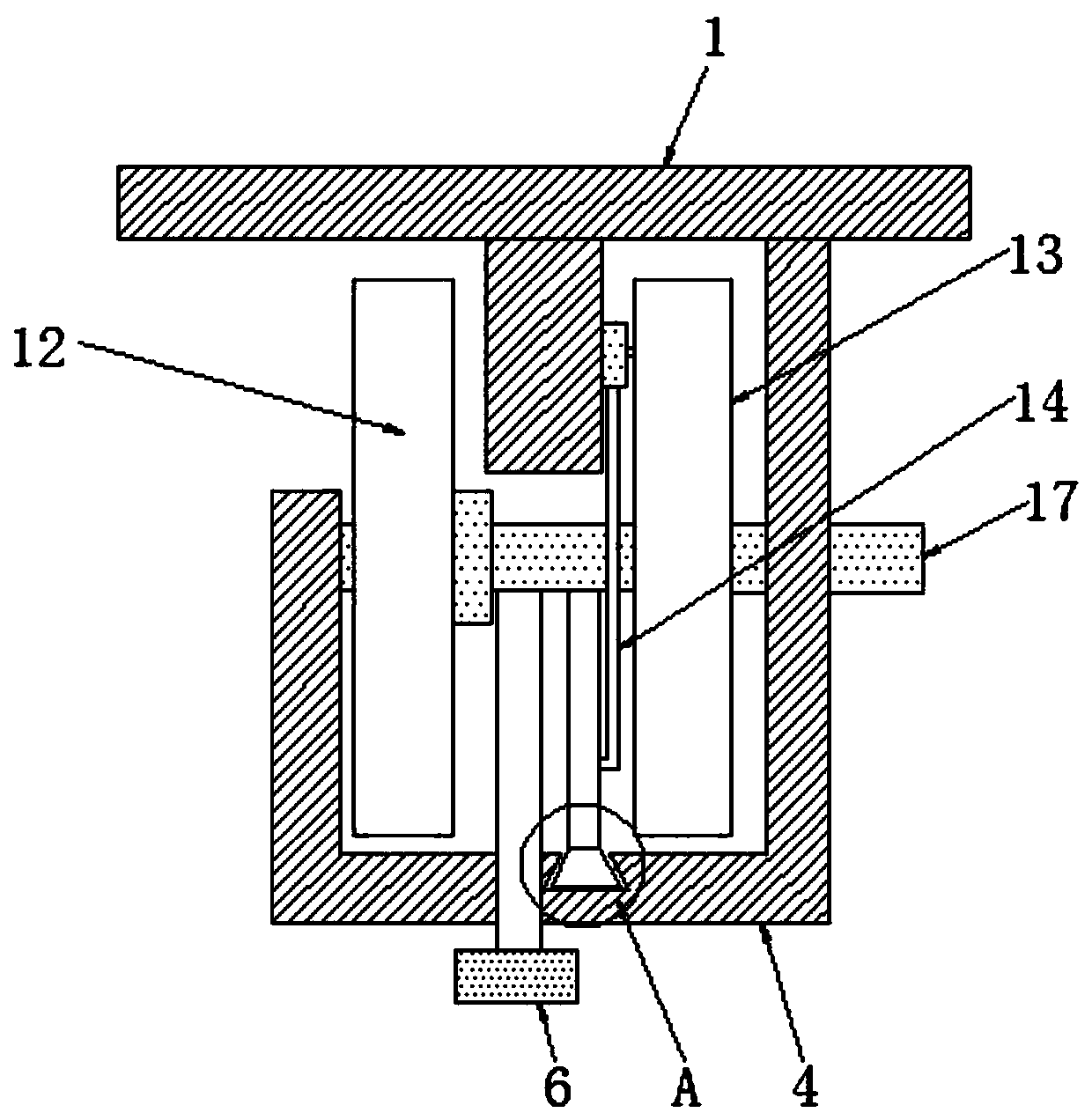

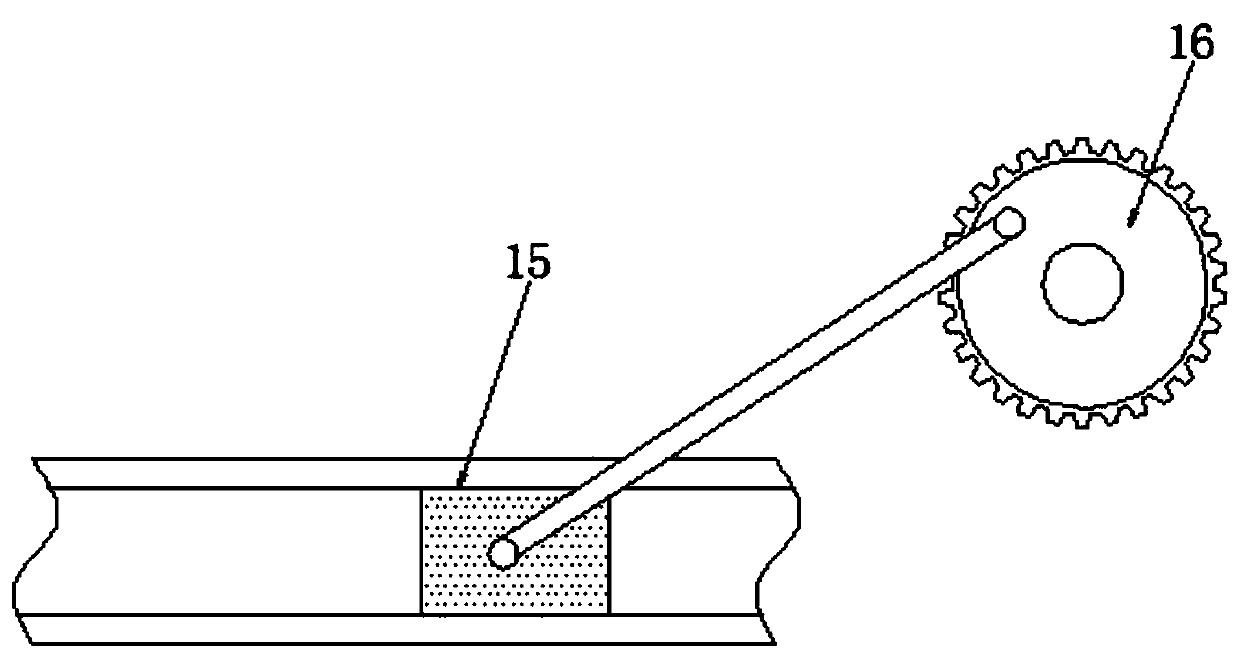

Tea cake making device capable of continuously working and preventing edges from being damaged

ActiveCN110447730AAvoid edge damageImprove work efficiencyPre-extraction tea treatmentReciprocating motionElectric machinery

The invention relates to the technical field of tea processing, and discloses a tea cake making device capable of continuously working and preventing edges from being damaged. The tea cake making device comprises an outer frame, the outer side of the outer frame is fixedly connected with a positioning block, a first rotating disk, a second rotating disk, a connecting rod, a limiting plate and a first sliding plate are matched for use, a pressing block reciprocates left and right and moves up and down, therefore, the device can continuously work, the working efficiency in the tea cake making process is improved, a recessed block reciprocates left and right, a motor does not need to be turned off after the tea cake is made, the tea cake can be clamped out without a clamping tool, a rotatingrod is movably connected to the interior of a gear, a belt is movably connected to the outer side of a second rotating rod, one side of the belt is movably connected with the rotating rod, and finallythe recessed block moves synchronously, so that the whole device is connected together, the operation can be completed by using only one motor, and the operation mode is more convenient and faster.

Owner:湖南辰投碣滩茶业开发有限公司

Composite fireproof door

InactiveCN102086750AKeep shapeAvoid edge damageFireproof doorsSealing arrangementsSolid woodAdhesive

The invention relates to a composite fireproof door. A composite fireproof door frame is formed by bonding two solid wood angle sections with unequal widths by using a heat insulating expansion adhesive; a protective steel plate is coated along the outer edge of each solid wood angle section; a predetermined distance exists between a part of the protective steel plate and each solid wood angle section so as to form an air heat insulating chamber; an expansion sealing strip is embedded into the protective steel plate relative to the edge of the composite fireproof door; the composite fireproof door is provided with two steel plates; the inner surfaces of the two steel plates are provided with a splint and a fireproof plate respectively; two side spaces between the two fireproof plates are provided with a wood structural material respectively; the steel plates, the splints and the fireproof plates are fixed on the wood structural materials through screws; spaces between the two wood structural materials and the two fireproof plates are filled with heat insulating materials; and the periphery of the composite fireproof door is coated with a C-shaped sheathing steel sheet and is fixed on the wood structural materials by screws. By the structure, fire prevention, heat insulating and smoke and fire intrusion prevention effects are achieved under the condition of fire.

Owner:邓学开

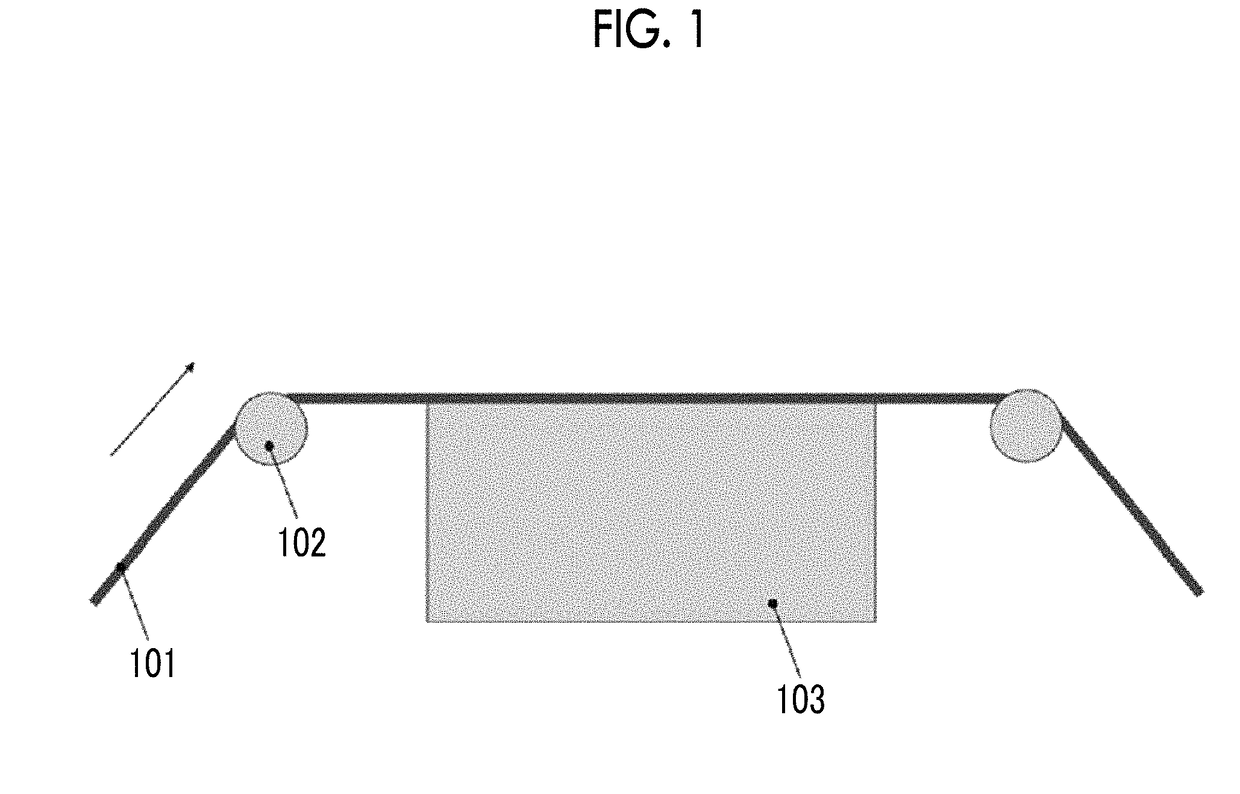

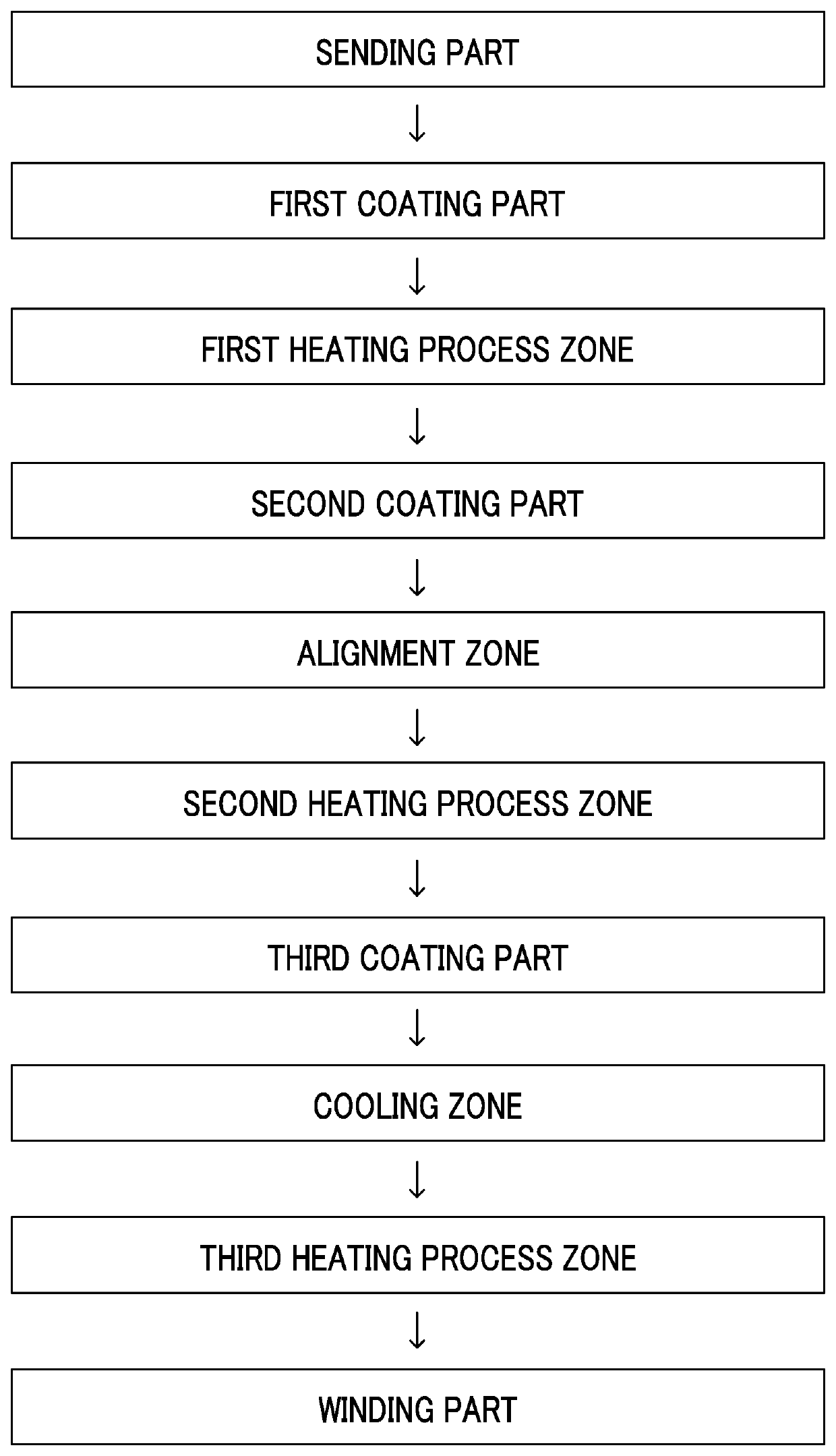

Non-oriented silicon steel and production method thereof

The invention discloses a non-oriented silicon steel and a production method thereof. Molten steel is smelted by adopting a vacuum induction furnace. Molten steel is directly cast into a cast belt with the thickness between 1mm and 3mm through a pair of crystallization rollers rotating in opposite directions. The casting temperature of the molten steel is between 1500 DEG C and 1700 DEG C. The cast belt is subjected to one pass or multiple passes hot rolling and rolled into hot-rolled strip steel with thickness being 0.7mm and 2.5 mm. The hot rolling temperature is between 800 DEG C and 1150 DEG C, and the hot-rolled strip steel is coiled into a roll at the temperature between 500 DEG C and 800 DEG C. Normalizing annealing is conducted on the hot-rolled steel roll after the hot-rolled steel roll is subjected to a levelling or tension levelling working procedure with the elongation rate being 1.0% and 5.0%, and the normalizing annealing temperature is between 700 DEG C and 1000 DEG C. After the steel roll after normalizing annealing is subjected to cold rolling and the final annealing and coating working procedures, low-iron loss and high magnetic induction non-oriented silicon steel products are acquired. The non-oriented silicon steel products manufactured with the production method has high-proportion magnetic induction-favorable <100> and <110> structures, and the product magnetic induction is above 1.80 T.

Owner:SHAGANG GROUP +2

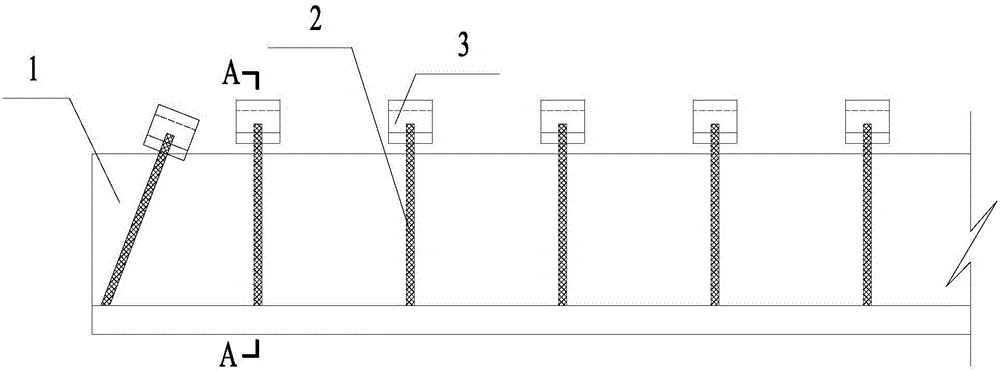

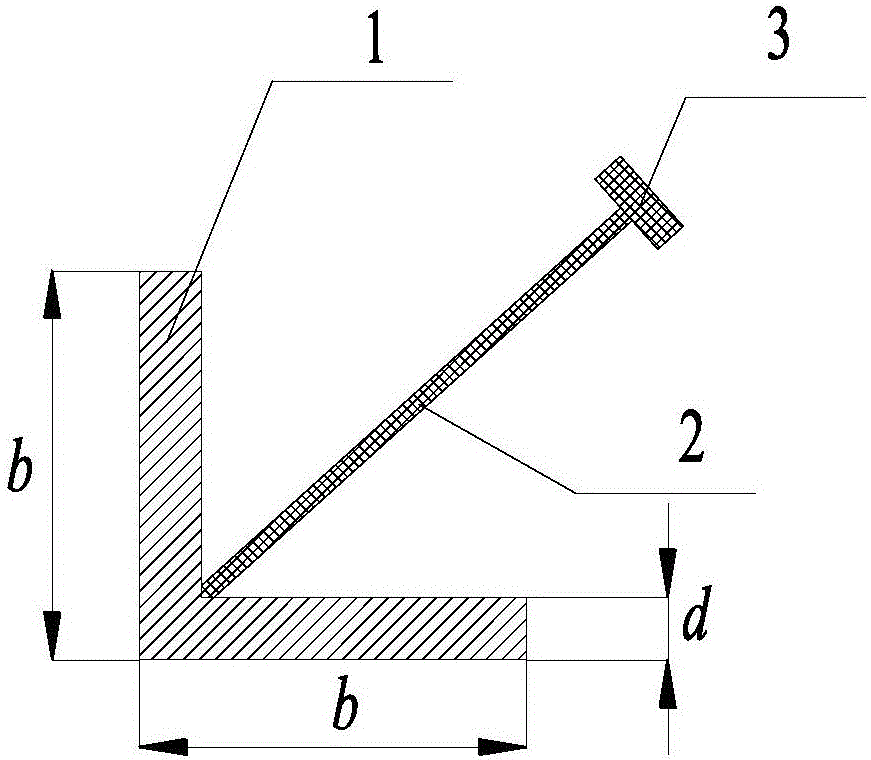

Corner reinforcing member of shield tunnel duct piece and application method thereof

ActiveCN105114100AAvoid edge damageLow costUnderground chambersTunnel liningReinforced concreteDie casting

The invention provides a corner reinforcing member of a shield tunnel duct piece and an application method thereof, and belongs to the field of shield tunnel technology. The corner reinforcing member comprises an angle steel matching a corner of a shield tunnel duct piece, an anchoring rod and an anchor head. One end of the anchoring rod is connected with the angle steel, and the other end is connected with the anchor head. The application method comprises the following steps of mounting a corner reinforcing member in a duct piece preformed die before performing a duct piece; respectively fixing the anchoring rod and the anchor head of the corner reinforcing member to steel bars of the duct piece; and injecting forming material in the duct piece preformed die to form the duct piece. The corner reinforcing member is particularly suitable for reinforcement of a corner of a shield tunnel reinforced concrete duct piece, the corner reinforcing member is formed before die casting a duct piece and arranged in the duct piece when steel bars are mounted during a duct piece die casting process, corner damage caused by overlarge local stress in a corner of the shield tunnel reinforced concrete duct piece can be prevented, and the corner reinforcing member is scientific, reasonable and low in cost.

Owner:TONGJI UNIV

Method for simultaneously slicing at least two cylindrical workpieces into a multiplicity of wafers

ActiveUS7766724B2Increase profitGuaranteed maximum utilizationSemiconductor/solid-state device manufacturingGrinding feed controlWafer stackingEngineering

Slicing multiple cylindrical workpieces into wafers by a multi wire saw with a gang length LG, is performed by:a) selecting a number n≧2 of workpieces from a stock of workpieces with different lengths, satisfying the inequalityLG≥(n-1)·Amin+∑i=1nL1(1)and making right-hand side of the inequality as large as possible, where Li with i=1 . . . n are for the lengths of the workpieces and Amin is a predefined minimum spacing,b) fixing the n workpieces successively in the longitudinal direction on a mounting plate while maintaining a spacing A≧Amin therebetween such that the relationshipLG≥(n-1)·A+∑i=1nLi(2)is satisfied,c) clamping mounting plates workpieces in a multi wire saw, andd) slicing the n workpieces perpendicularly to their longitudinal axis by means of the multi wire saw. Preferably, the wafer stacks are separated from one another by separating pieces after slicing, and at the same time are laterally supported.

Owner:SILTRONIC AG

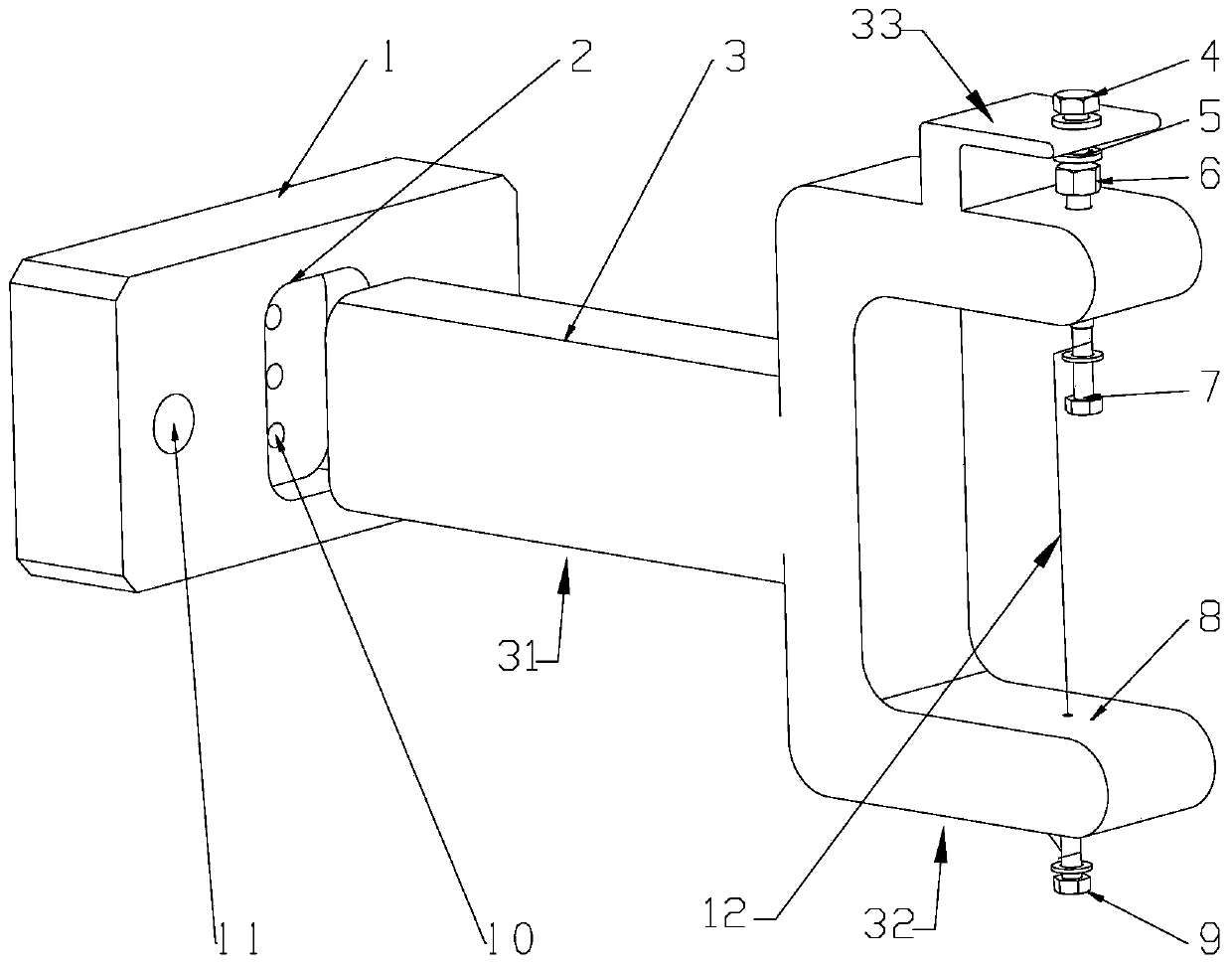

Lead frame and supporting and positioning device for lead frame stacking

ActiveCN111199943AAvoid edge damageAvoid damageSemiconductor/solid-state device detailsSolid-state devicesStructural engineeringLead frame

The invention discloses a lead frame and a supporting and positioning device for lead frame stacking. The lead frame comprises a frame body and islands, wherein supporting blocks are inserted into theouter side of the frame body; the supporting blocks are copper-aluminum alloy heat conduction blocks; each supporting block is provided with an inserting groove at the inserting position of the framebody; a fixed block and a movable block are arranged on the two sides between a bottom plate and a top plate; block grooves matched with the supporting blocks are formed in the opposite sides of thefixed block and the movable block up and down at equal intervals; a lower supporting block and an upper supporting block are fixedly arranged on the two sides of the bottom plate and the two sides ofthe top plate respectively; universal wheels are installed on the lower supporting block and the upper supporting block on the side of the fixed block; a sleeve with an opening in one side is fixedlyarranged at the bottom of the bottom plate; and a pull rod is installed in the sleeve in a sliding mode. According to the invention, a protective structure can be provided for the edge of the frame body, the heat dissipation effect of the whole frame structure is improved, internal elements cannot be extruded and damaged, a draw-bar box structure can be formed after stacking, and the moving and carrying are convenient.

Owner:TAIZHOU YOURUN ELECTRONICS

Drill Bit For A Rock Drilling Tool With Increased Toughness And Method For Increasing The Toughness Of Such Drill Bits

ActiveUS20130183887A1Reduce manufacturing costFewer drill bit rupturesEdge grinding machinesDrill bitsToughnessDrill bit

Drill bit (10) for a rock drilling tool (12), and a method of increasing the toughness of the drill bit, which drill bit (10) has a drilling surface (10b) that contacts rock during drilling. A longitudinal cross section (10t) of the drill bit (10) through the drilling surface (10b) exhibits certain relationships of Ltot(depth) / Ltot(5.0) and H(depth) / H(5.0) at the specified depths, along the drill bit's longitudinal axial center line (C) if the drill bit has a length (L) of 10 mm or greater, and Ltot(depth) / Ltot(3.5) and H(depth) / H(3.5) at the specified depths, if the drill bit has a length (L) of 10 mm or less.

Owner:EPIROC DRILLING TOOLS AB

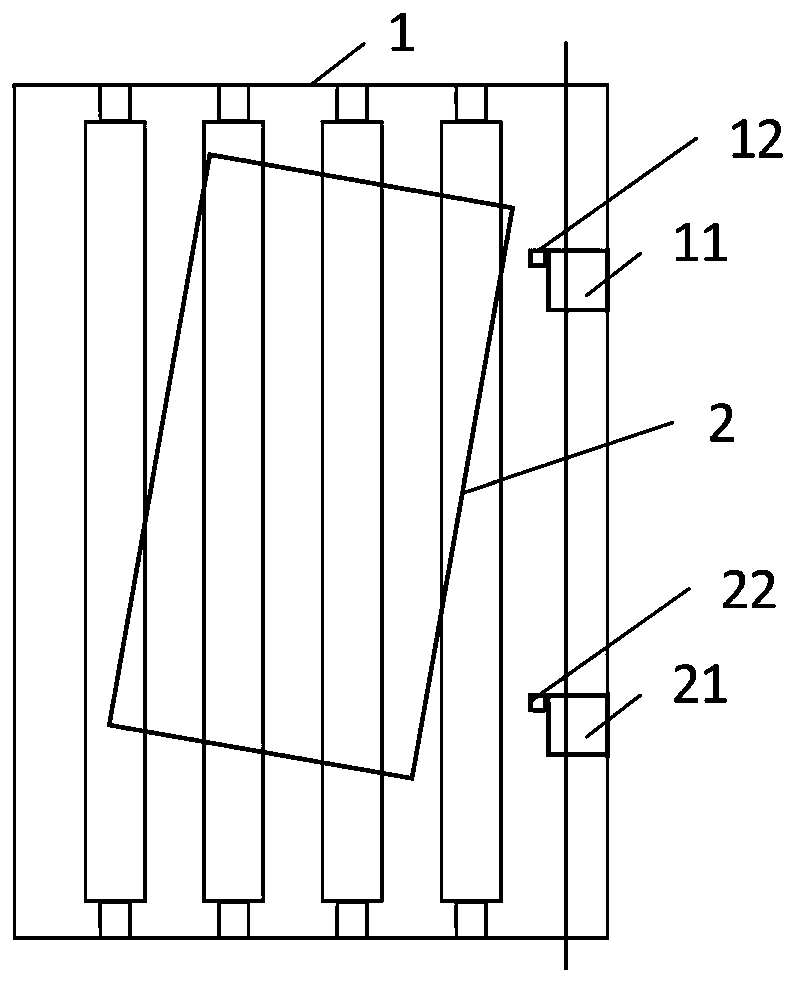

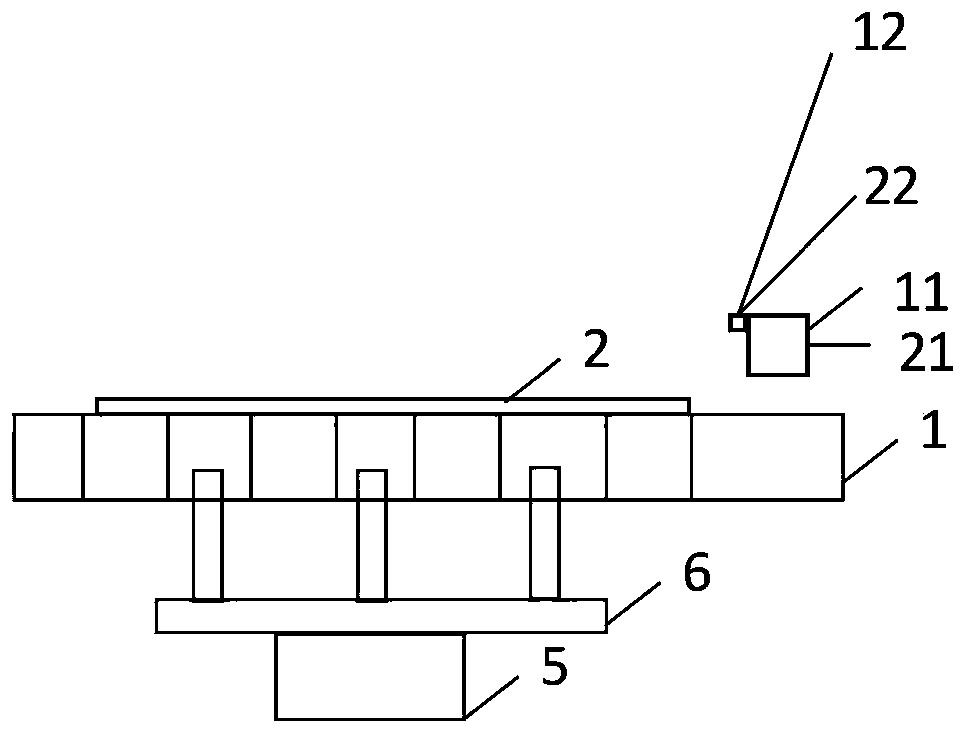

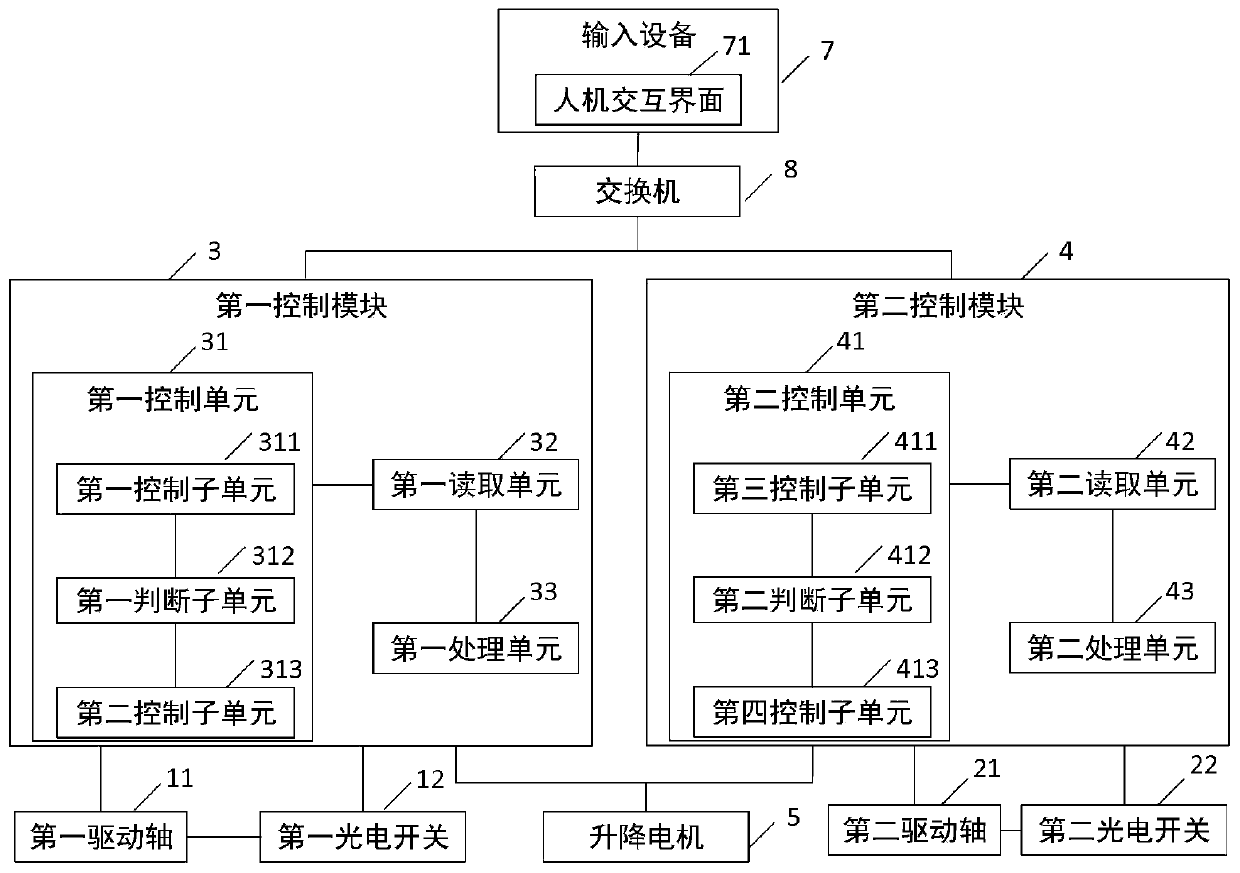

Alignment control system and method for glass deviation

InactiveCN110092198AEliminate deviationAvoid scratchesConveyorsControl devices for conveyorsControl systemGlass production

The invention provides an alignment control system and method for glass deviation, and relates to the technical field of glass production. The system comprises a first driving shaft and a second driving shaft arranged above a conveying roller way and perpendicular to a conveying direction, a first photoelectric switch and a second photoelectric switch for detecting first edge points and second edge points of glass, a first control module for controlling the first driving shaft to move to the first edge points and calculating first displacement distances needed to correct the glass by the firstdriving shaft, a second control module for controlling the second driving shaft to move to the second edge points and calculating second displacement distances needed to correct the glass by the second driving shaft, and a lifting motor for hoisting the glass to correct the glass by the first driving shaft and the second driving shaft. The glass is corrected in a stop state, and the peripheral edges cannot be collided, so that the lower surface scratch and the edge scratch of the glass are effectively prevented when the deviation of the glass is effectively eliminated.

Owner:CHINA TRIUMPH INT ENG

Linear edge cutter used for solar photovoltaic modules

The invention discloses a linear edge cutter used for solar photovoltaic modules. The linear edge cutter comprises a cutter body. A diamond wire used for edge cutting is stretched and drawn on the cutter body. According to the edge cutter, linear cutting is completed through one diamond wire to conduct edge cutting, and the linear edge cutter is convenient to install, easy to adjust and low in cost.

Owner:JA XINGTAI SOLAR CO LTD

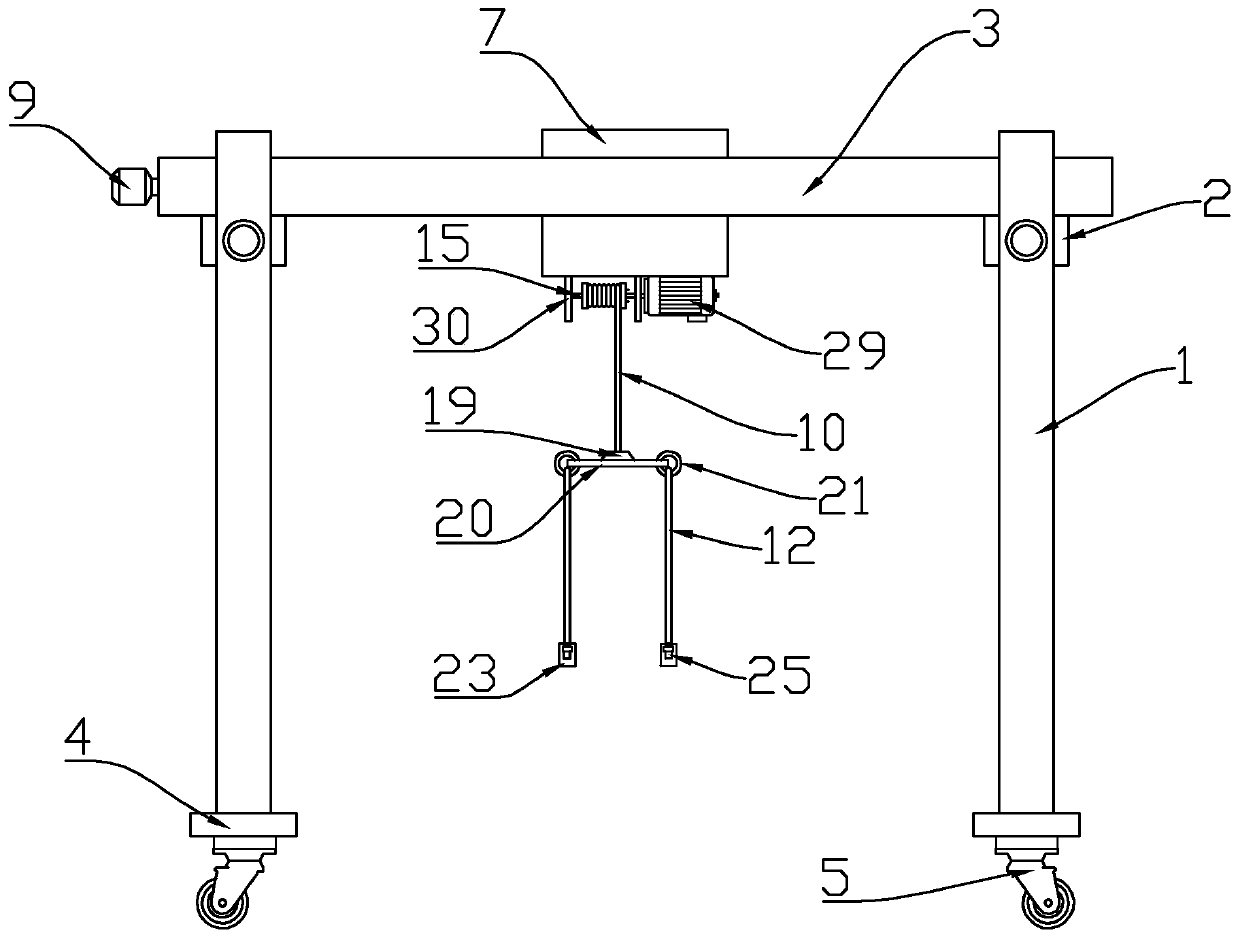

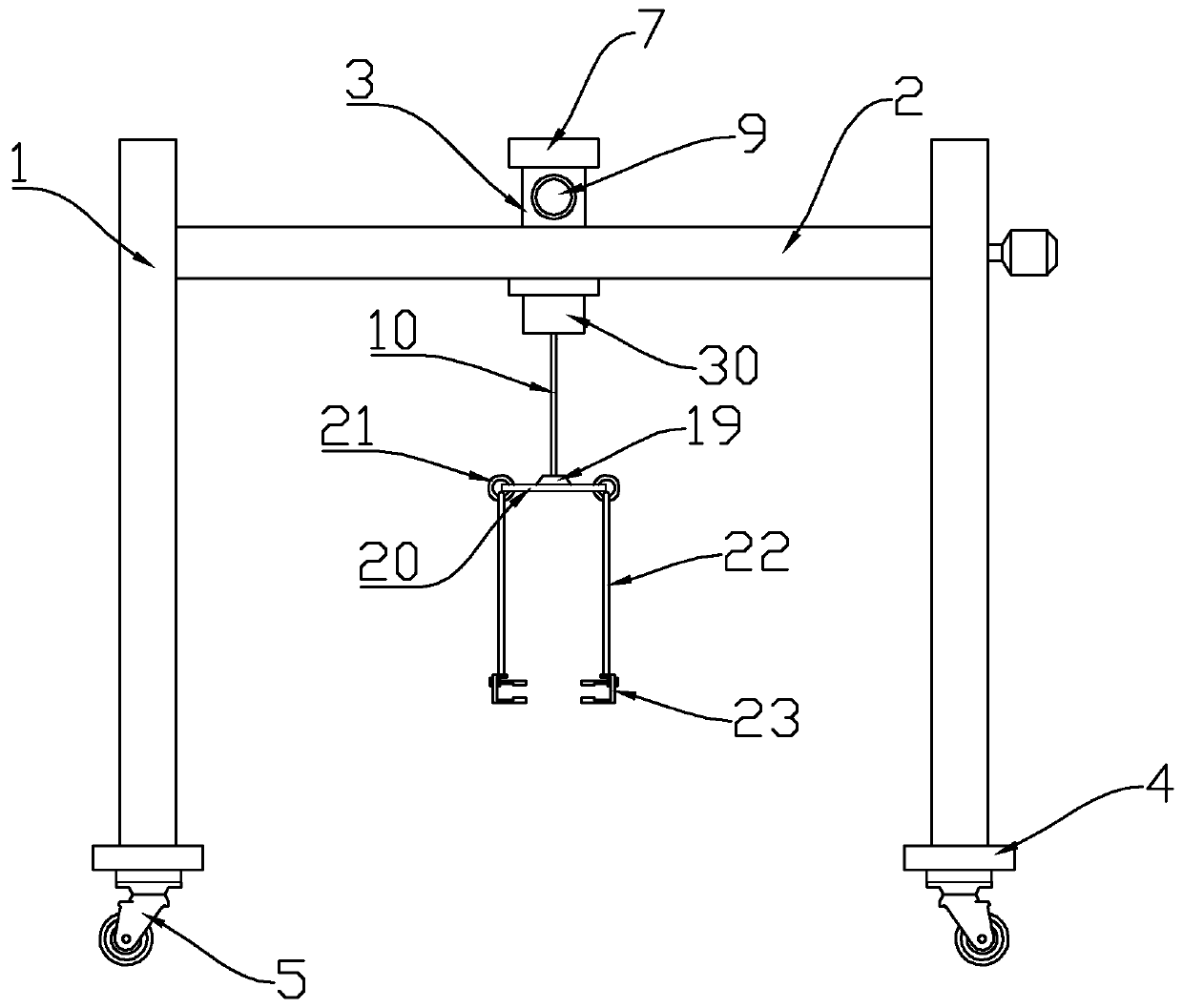

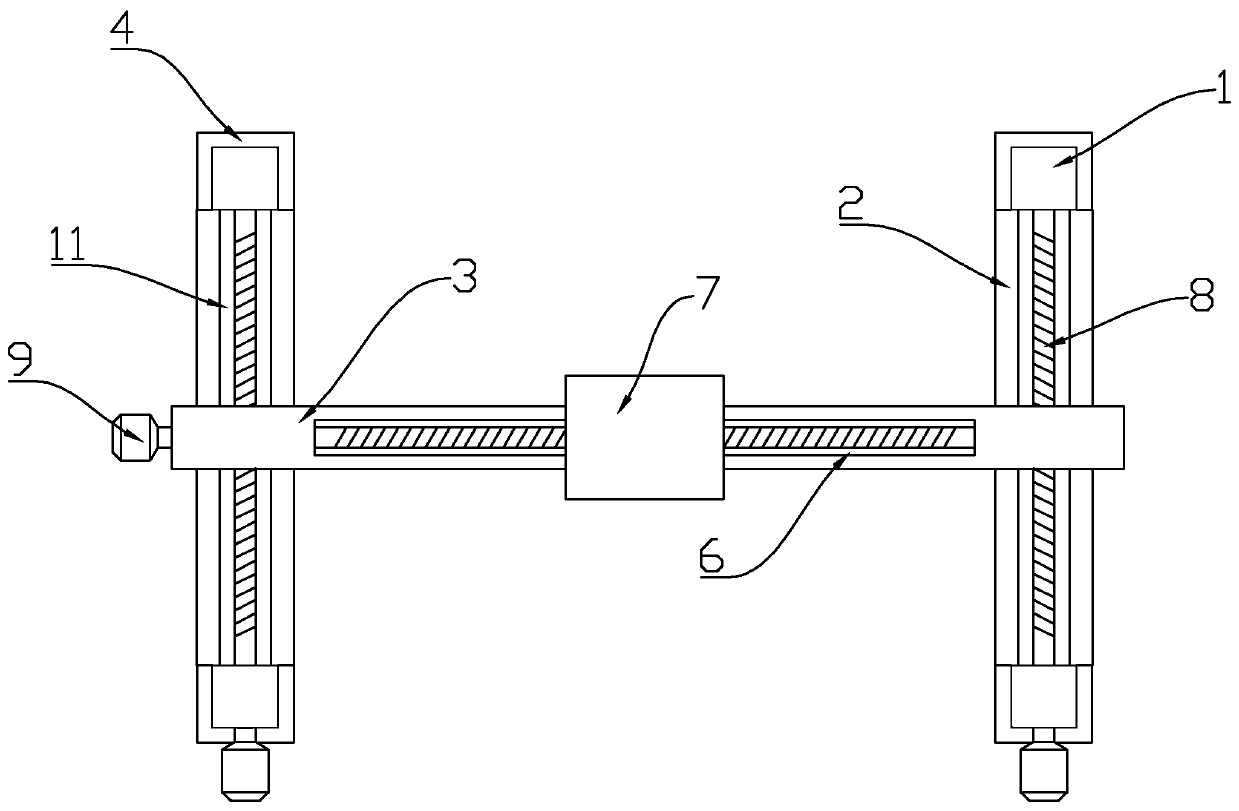

Intelligent efficient hoisting device for carrying metal composite plate

InactiveCN111017708AAvoid leaningWon't fallTravelling cranesTrolleysClassical mechanicsStructural engineering

The invention relates to the technical field of carrying hoisting, in particular to an intelligent efficient hoisting device for carrying a metal composite plate. The intelligent efficient hoisting device comprises vertical rods and cross rods, wherein each cross rod is fixedly welded between the top ends of two corresponding vertical rods. By arranging a transverse movement mechanism and a vertical movement mechanism, a horizontal movement slider can move to any position of a plane defined by the four vertical rods, the acting force concentration point can be located over the center positionof the metal composite plate, and the metal composite plate is prevented from inclining. By arranging a lifting mechanism, the metal composite plate can be lifted, under the action of universal wheels, by pushing the whole hoisting device, the metal composite plate can be moved, fixing pieces can firmly clamp the metal composite plate and prevent the metal composite plate from falling, the metal composite plate is within the space defined by the four vertical rods and can be protected at the moment, and the situation that the metal composite plate collides with a container and causes edge damage is avoided. The intelligent efficient hoisting device has remarkable beneficial effects and is suitable for popularization.

Owner:OKUMTEC TECH WENZHOU CO LTD

Magnetic tape and magnetic tape cartridge

InactiveUS20060227460A1Excellent off-track preventive performanceAvoid edge damageMagnetic materials for record carriersBase layers for recording layersMagnetic tapeEngineering

A magnetic tape which is run at a speed of 4 m / sec. or higher and has recording tracks with a width of 21 μm or less, and which includes a non-magnetic support, at least one magnetic layer formed on one surface of the non-magnetic support, and a backcoat layer formed on the other surface of the non-magnetic support, wherein servo signals for controlling tracking are recorded on the magnetic layer or the backcoat layer, the value of (α / W)×(V / f) is 10 [s−1] or less, and / or the value of (α / W) is 0.1 or less, wherein V [mm / sec.] is a tape-running speed is; α [μm] is an amount of a weave with a cycle of f [mm] on one edge of the tape or the other edge thereof as the reference side for the running of the tape; and W [μm] is a width of the recording track. The magnetic tape can decrease PES and off-track and thus is excellent in servo tracking performance.

Owner:MAXELL HLDG LTD

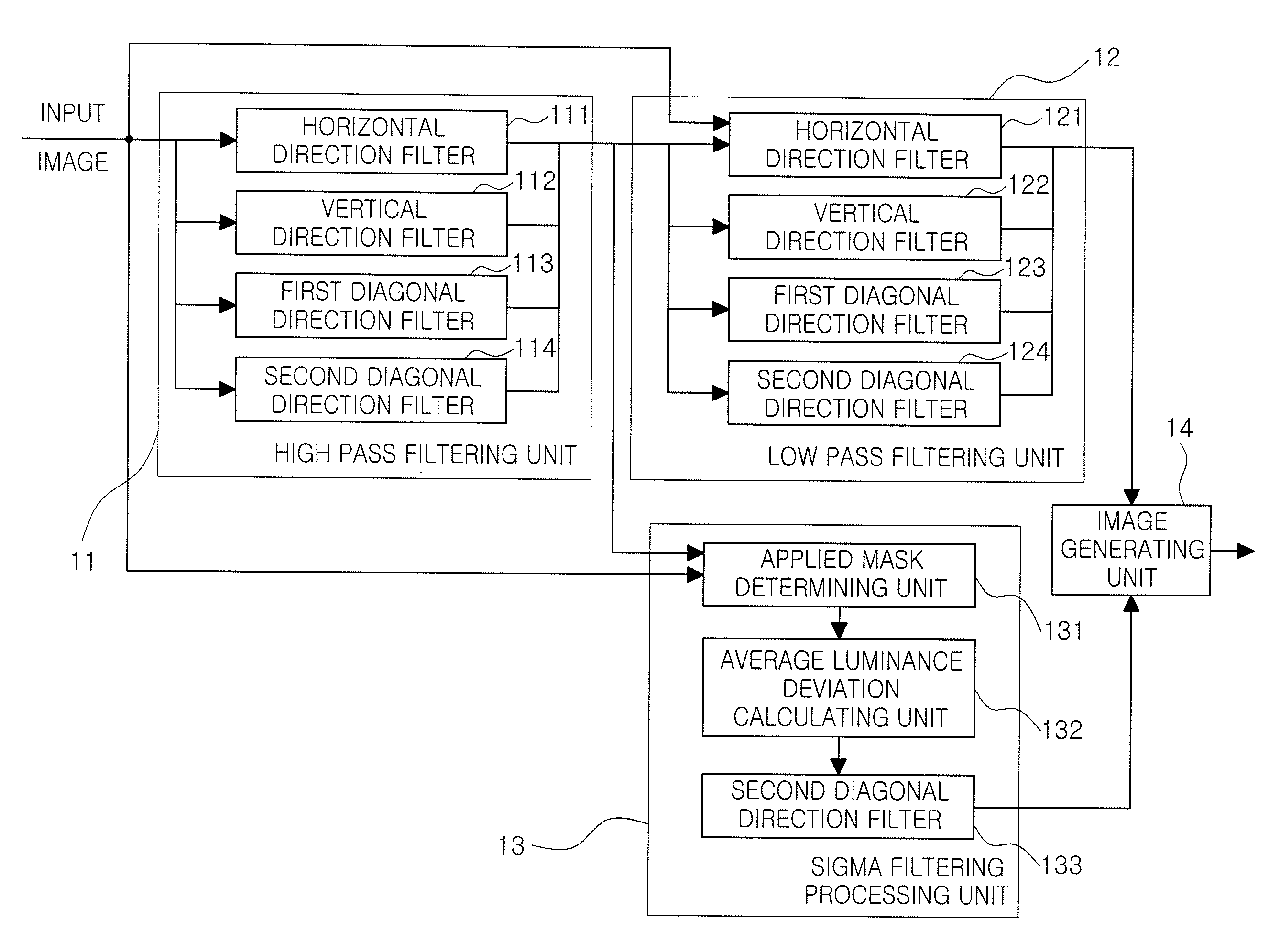

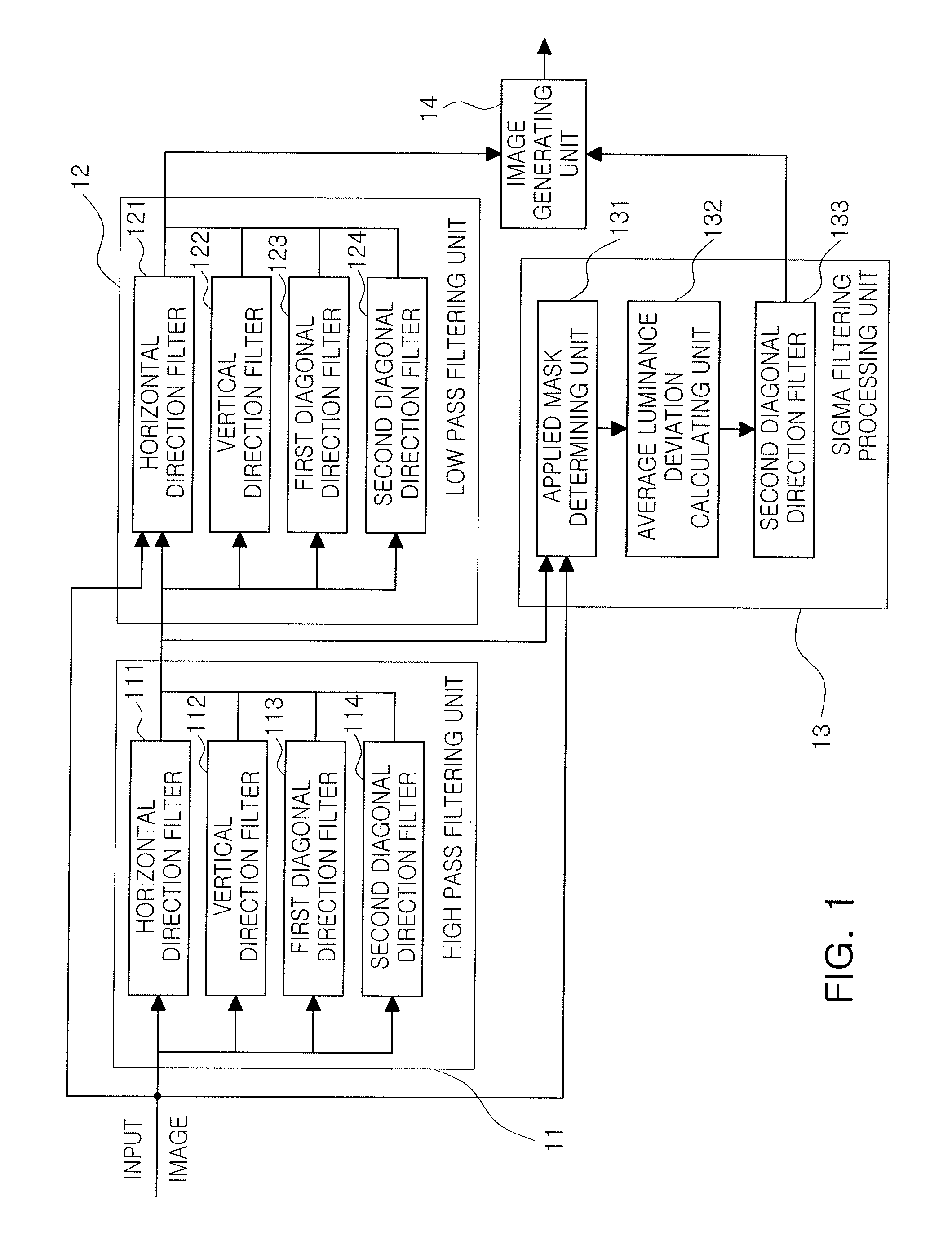

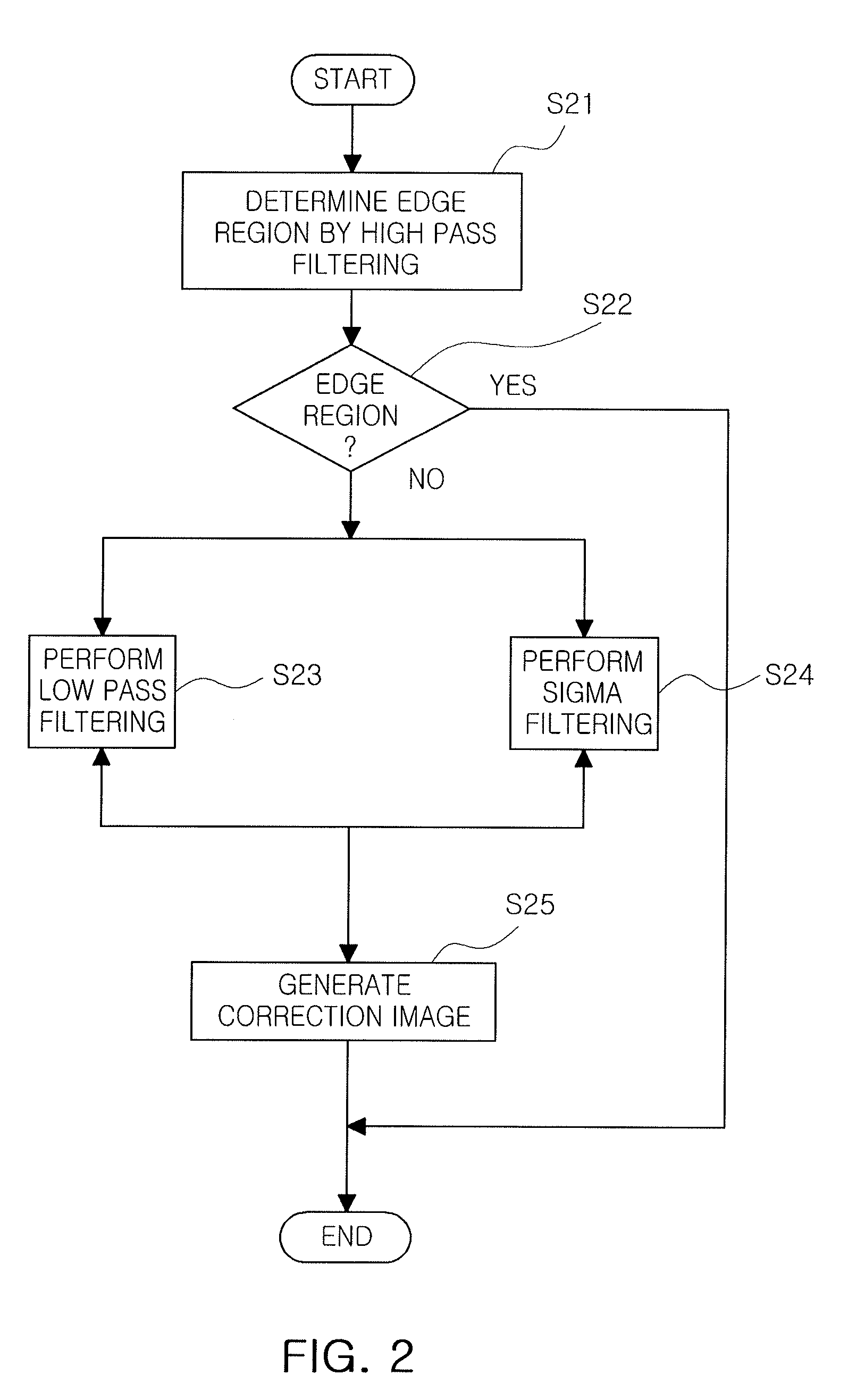

Method and apparatus for reducing noise of digital image

ActiveUS20120170863A1Reduce noiseAvoid edge damageImage enhancementImage analysisComputer visionDigital image

There are provided a method and an apparatus for reducing noise in a digital image capable of reducing noise while preventing damage to an edge of a digital image. The apparatus includes: a high pass filtering unit determining an edge region of an input image; a low pass filtering unit performing low pass filtering on a region of the input image determined not to be the edge region by the high pass filtering unit; and a sigma filtering unit performing sigma filtering on the region of the input image determined not to be the edge region by the high pass filtering unit.

Owner:SAMSUNG ELECTRO MECHANICS CO LTD

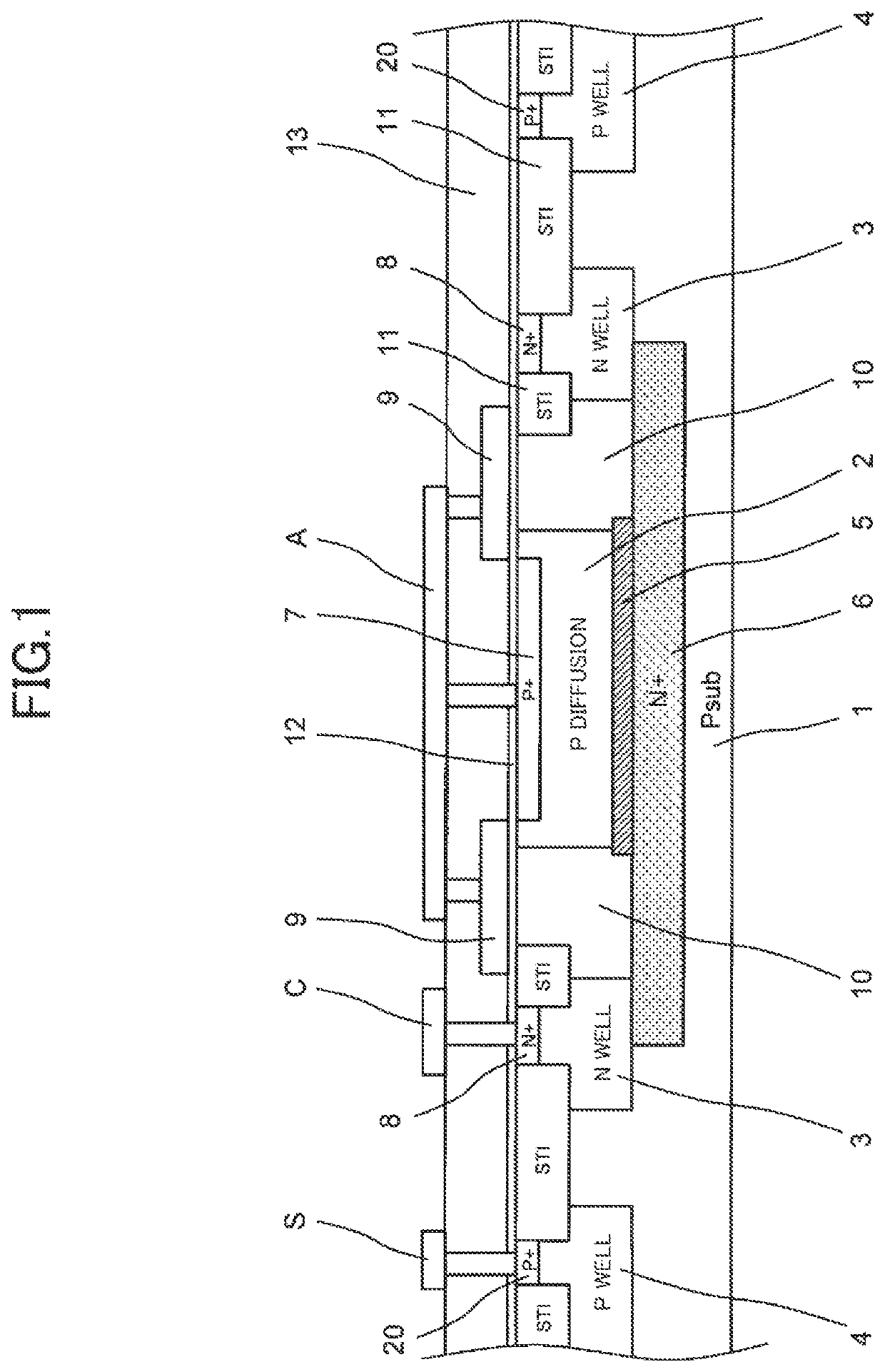

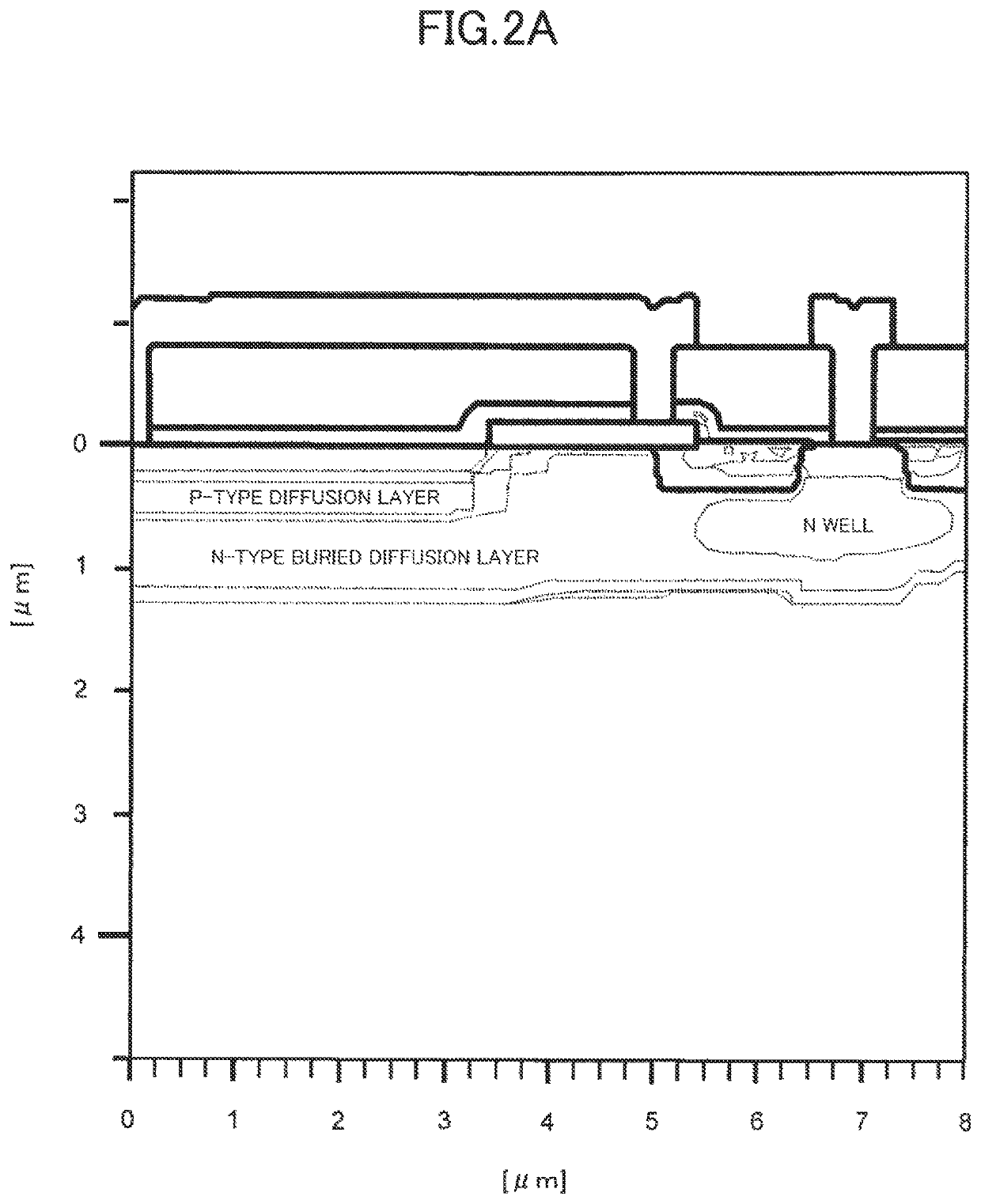

Avalanche photodiode

ActiveUS10847668B2Avoid edge damageUniform distribution of electric field strengthDiodeSemiconductorMaterials science

An avalanche photodiode includes a first-conductivity-type semiconductor layer; a first second-conductivity-type semiconductor layer; a second second-conductivity-type semiconductor layer; a third second-conductivity-type semiconductor layer; a fourth second-conductivity-type semiconductor layer; a fifth second-conductivity-type semiconductor layer.The first-conductivity-type semiconductor layer and the second second-conductivity-type semiconductor layer form an avalanche junction. The first and third second-conductivity-type semiconductor layers are electrically connected together via the fourth second-conductivity-type semiconductor layer such that the semiconductor substrate and the first-conductivity-type semiconductor layer are electrically isolated from each other.

Owner:SHARP KK

Temperature-controllable drinks holder

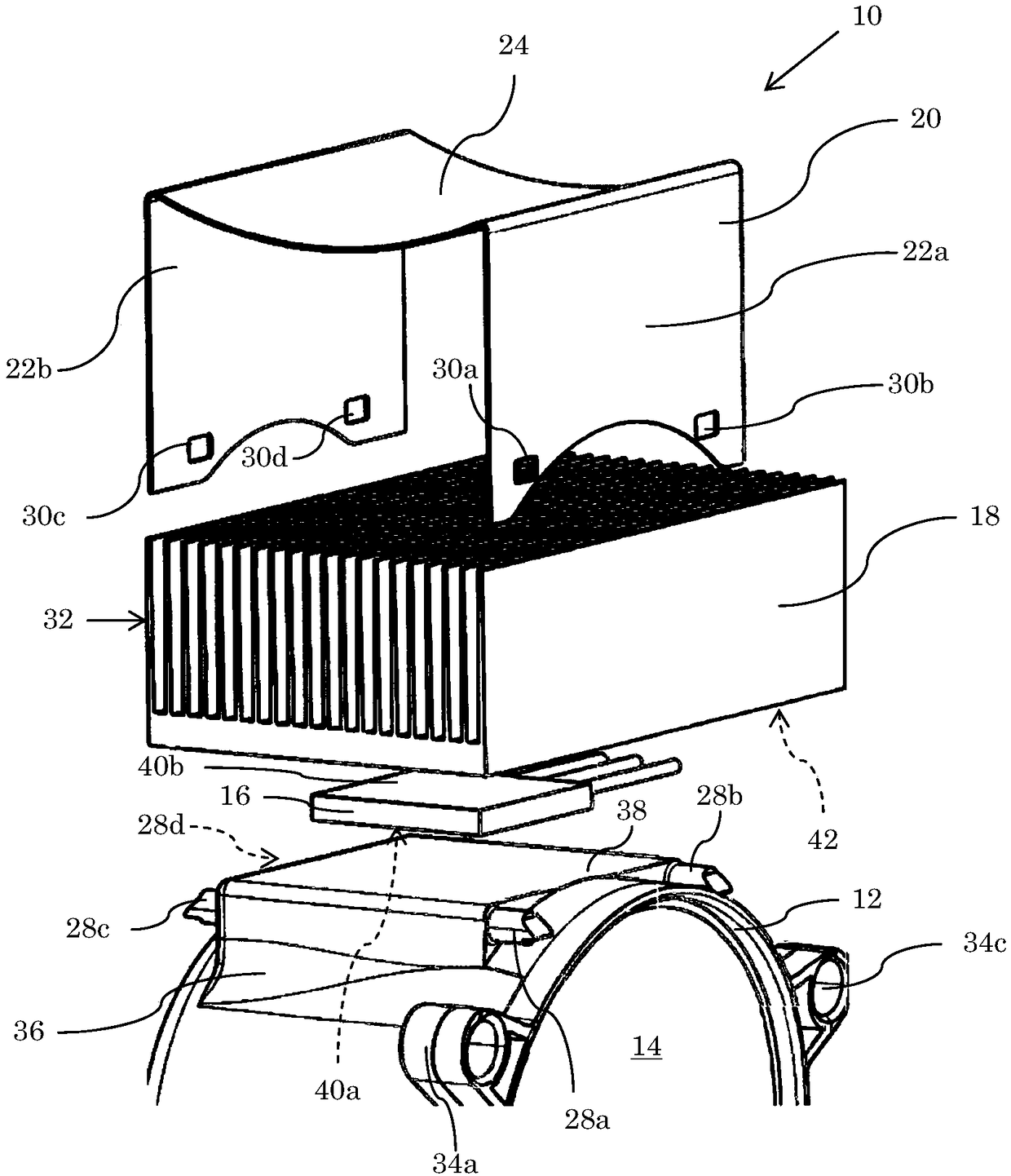

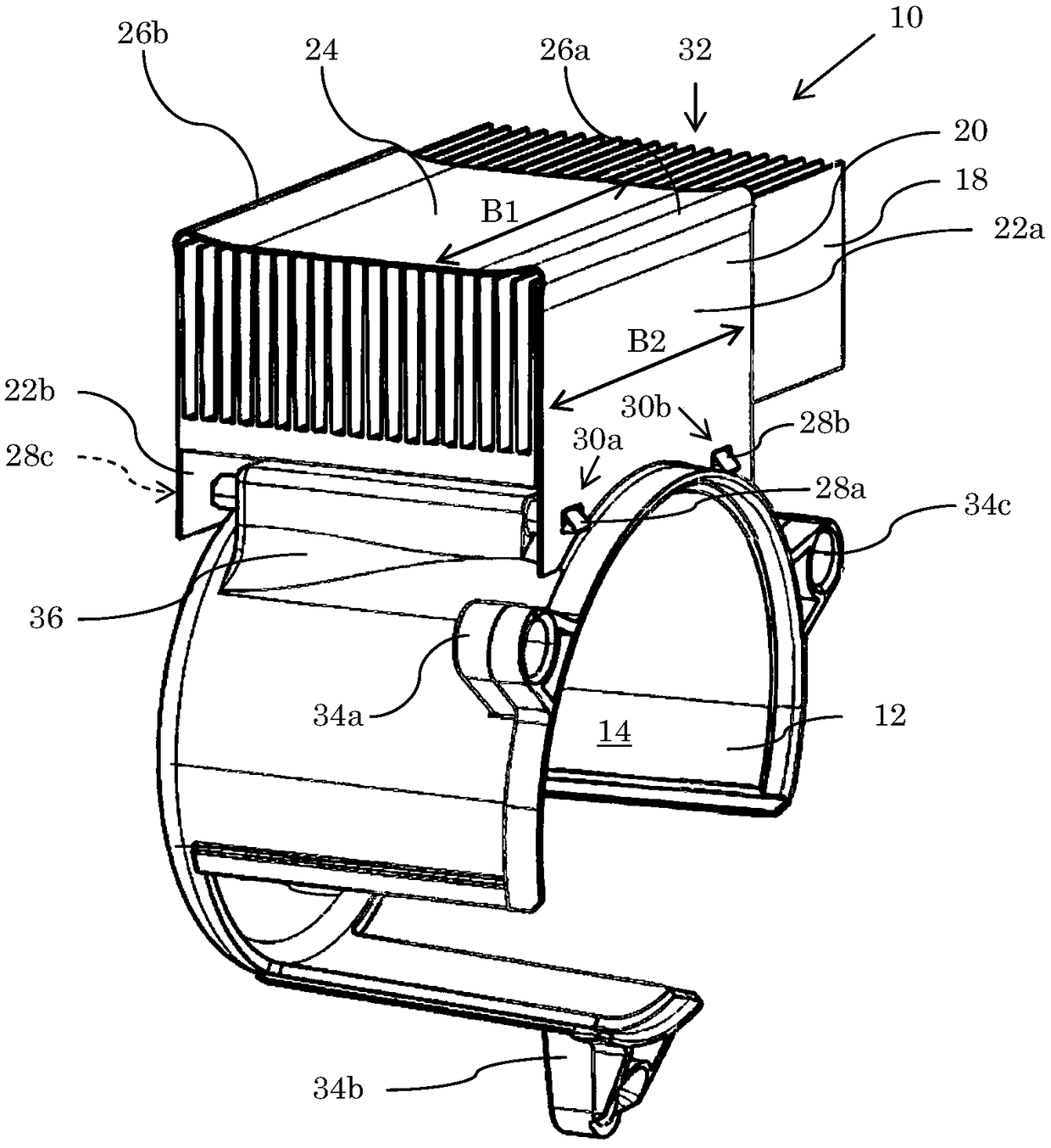

InactiveCN109070785AAvoid damageAvoid unexpected temperature effectsVehicle arrangementsMachines using electric/magnetic effectsDashboardTemperature control

The invention relates to a temperature-controllable drinks holder (10), with a receiving device (12) which is configured for receiving a drinking vessel (54), and provides a temperature-control chamber (14) for the drinking vessel (54); a Peltier element (16) which is coupled in a heat-transmitting manner to the temperature-control chamber (14); a heat transport body (18) which is coupled in a heat-transmitting manner to the Peltier element (16); and a fastening device (20) which is configured to fasten the Peltier element (16) and the heat transport body (18) to the receiving device (12), wherein the fastening device (20) is configured to fasten the Peltier element (16) and the heat transport body (18) releasably to the receiving device (12). The invention furthermore relates to a dashboard (50) for a vehicle (100), and to a vehicle (100) with such a temperature-controllable drinks holder (10).

Owner:GENTHERM INC

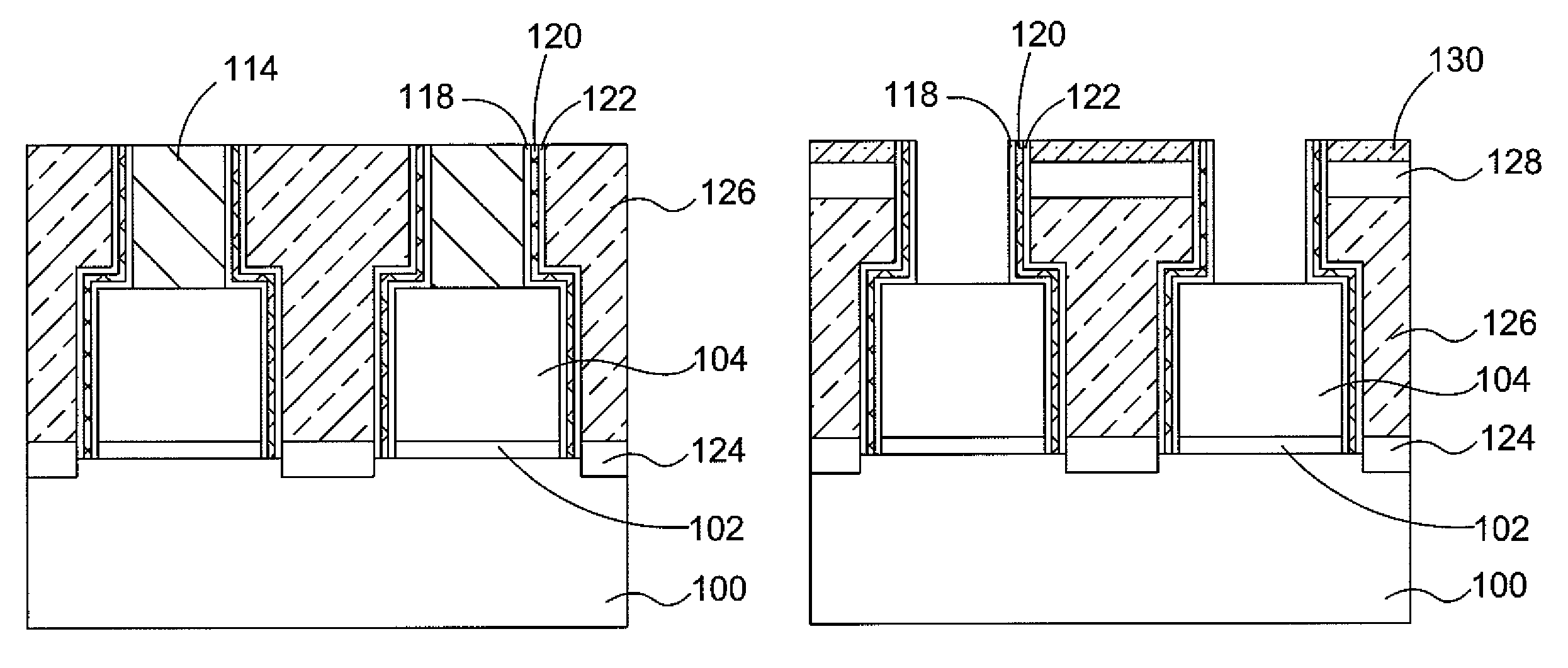

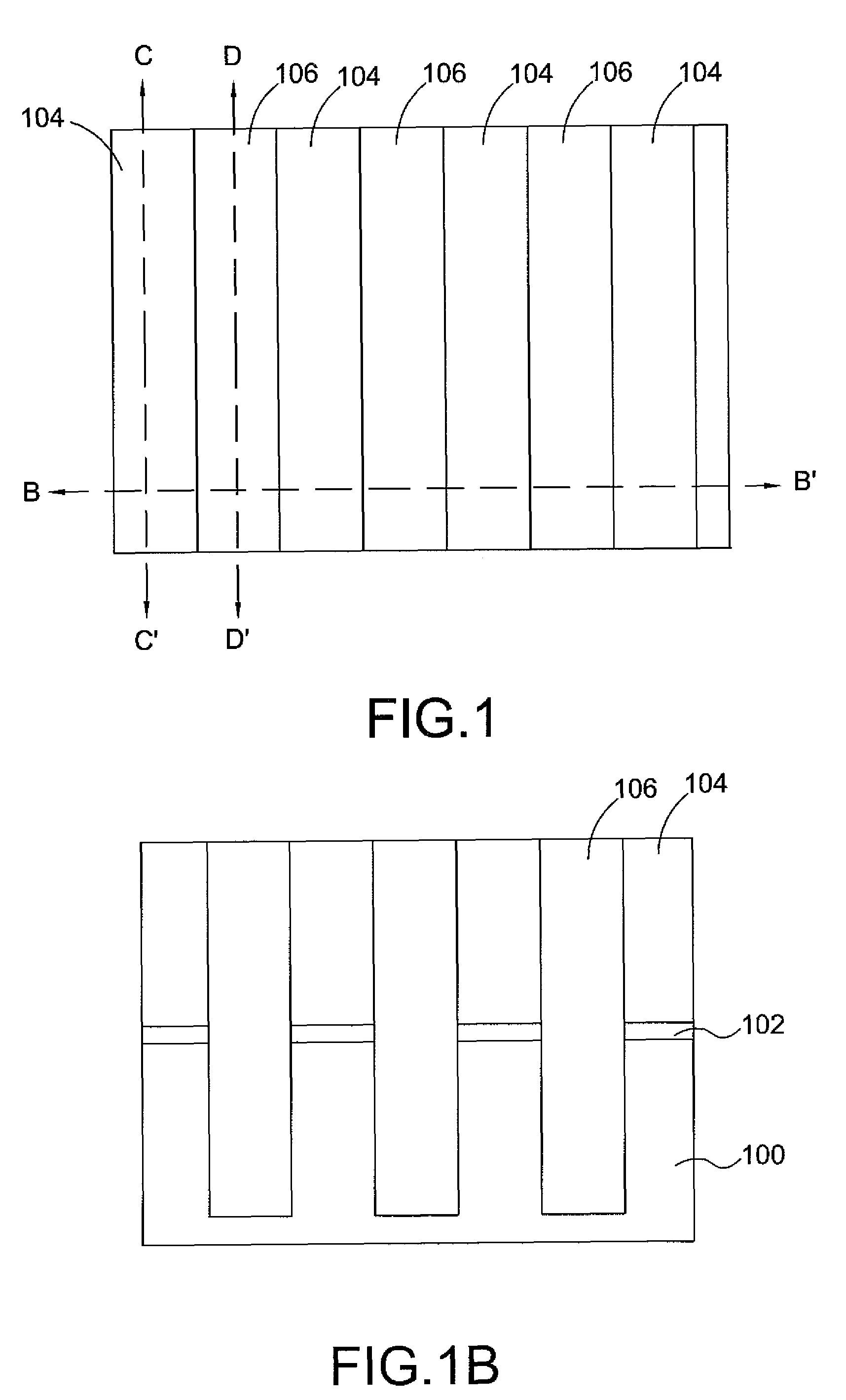

Method for forming a semiconductor device

ActiveUS7855124B2Avoid edge damageEasy to controlSolid-state devicesSemiconductor/solid-state device manufacturingDielectric layerSemiconductor

A method for forming a semiconductor device, includes the steps of providing a substrate; forming a patterned stack on the substrate including a first dielectric layer on the substrate, a first conductive layer on the first dielectric layer and a mask layer on the first conductive layer, wherein a width of the mask layer is smaller than a width of the first conductive layer; forming a second dielectric layer on the sidewall of the patterned stack; forming a third dielectric layer on the substrate; forming a second conductive layer over the substrate; and removing the mask layer and a portion of the first conductive layer covered by the mask layer to form an opening so as to partially expose the first conductive layer.

Owner:NAN YA TECH

Technology for making composite crystal structure

InactiveCN100399540CImprove yieldAvoid edge damageSemiconductor/solid-state device manufacturingFracture mechanicsCrystal structure

Owner:SINO AMERICAN SILICON PROD

Explosion-proof edge wood two-way linear hole opener

Owner:沧州德安防爆特种工具制造有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com