Milling machining method for wave-transmitting ceramic antenna window

A ceramic antenna and milling processing technology, which is applied in the direction of stone processing tools, stone processing equipment, manufacturing tools, etc., can solve the problems of poor processing quality, edge damage, high scrap rate, etc., and achieve the effect of improving the quality of the processed surface

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

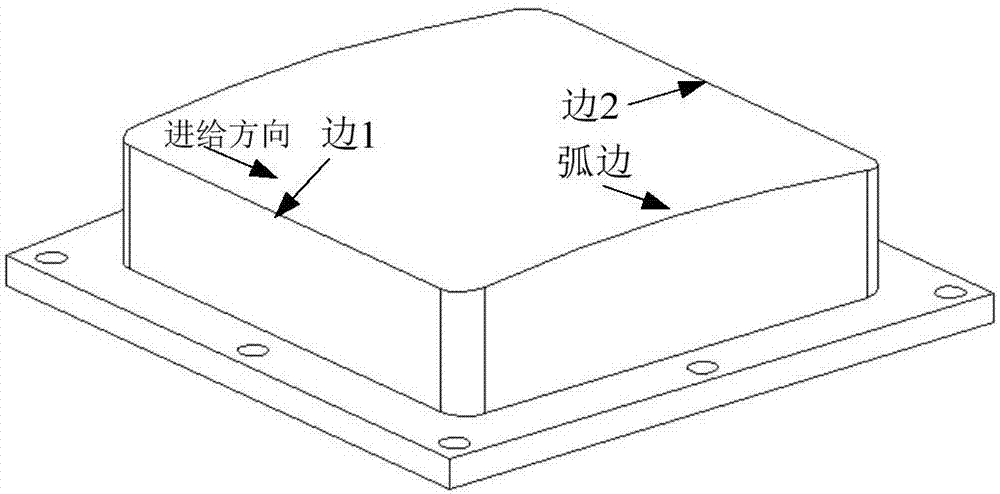

[0021] Since the wave-transparent ceramic antenna window is often made of wave-transparent Si3N4 ceramic material, its typical structural parameters are: refer to figure 1 , the outside is a stepped structure, the size of the upper step is 106mm×106mm, and the surface is curved; the size of the lower step is 134mm×1334mm, the interior is a cavity, and there are 8 Φ6mm through holes on the lower step, so the following Taking the structural parameters and the wave-transmitting Si3N4 ceramic material as an example, the specific implementation of the present invention will be described in detail.

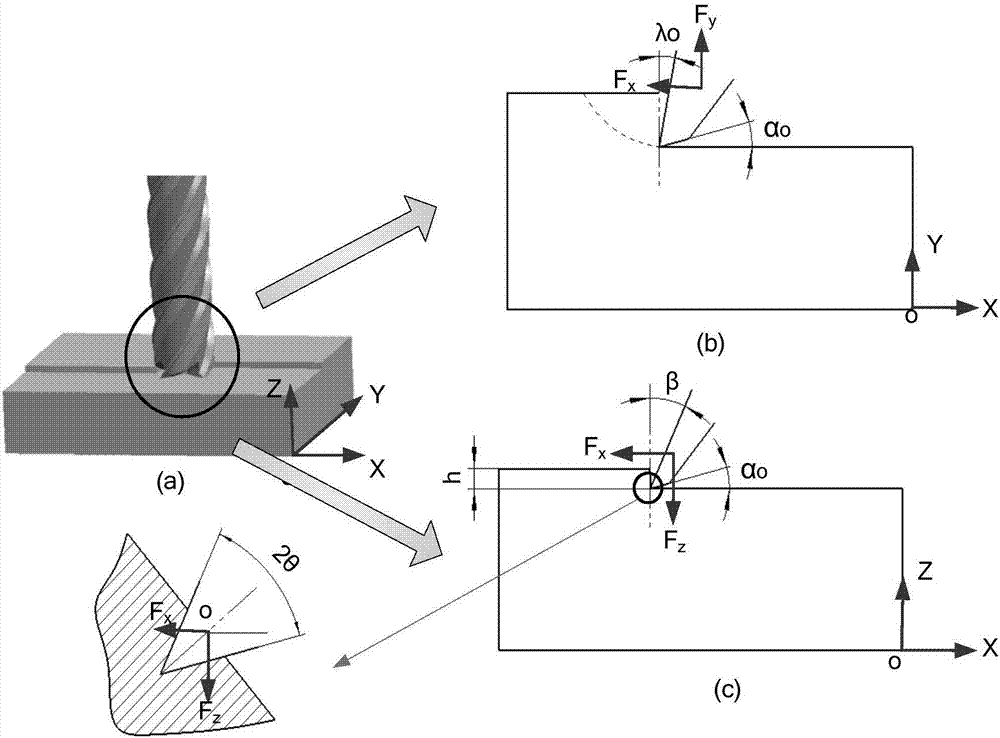

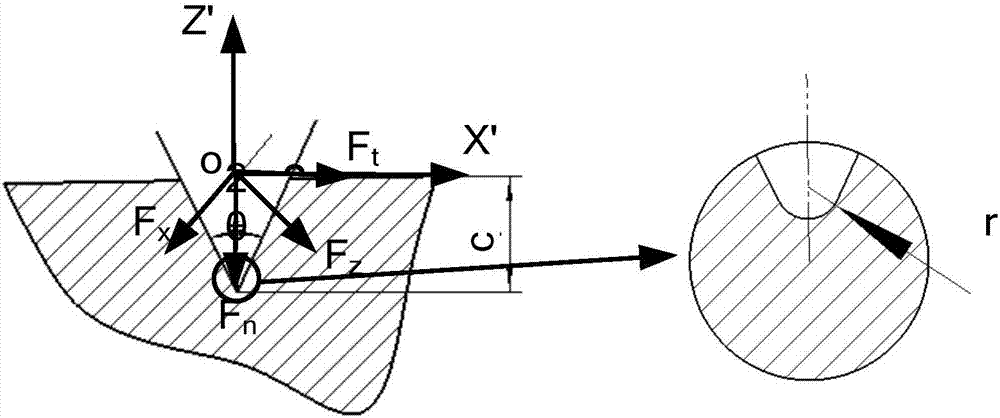

[0022] 1. Calculating the critical milling depth: the schematic diagram of the planar milling process of the wave-transparent ceramic antenna window is as follows figure 2 As shown in (a), the contact relationship between the cutting edge of the tool and the workpiece is as follows figure 2 As shown in (b) and (c), through coordinate transformation, after transforming XOZ coordinates...

PUM

| Property | Measurement | Unit |

|---|---|---|

| elastic modulus | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com