Technology for making composite crystal structure

A technology of composite crystal and sheet structure, which is applied in semiconductor/solid-state device manufacturing, electrical components, circuits, etc., and can solve problems such as increasing process complexity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

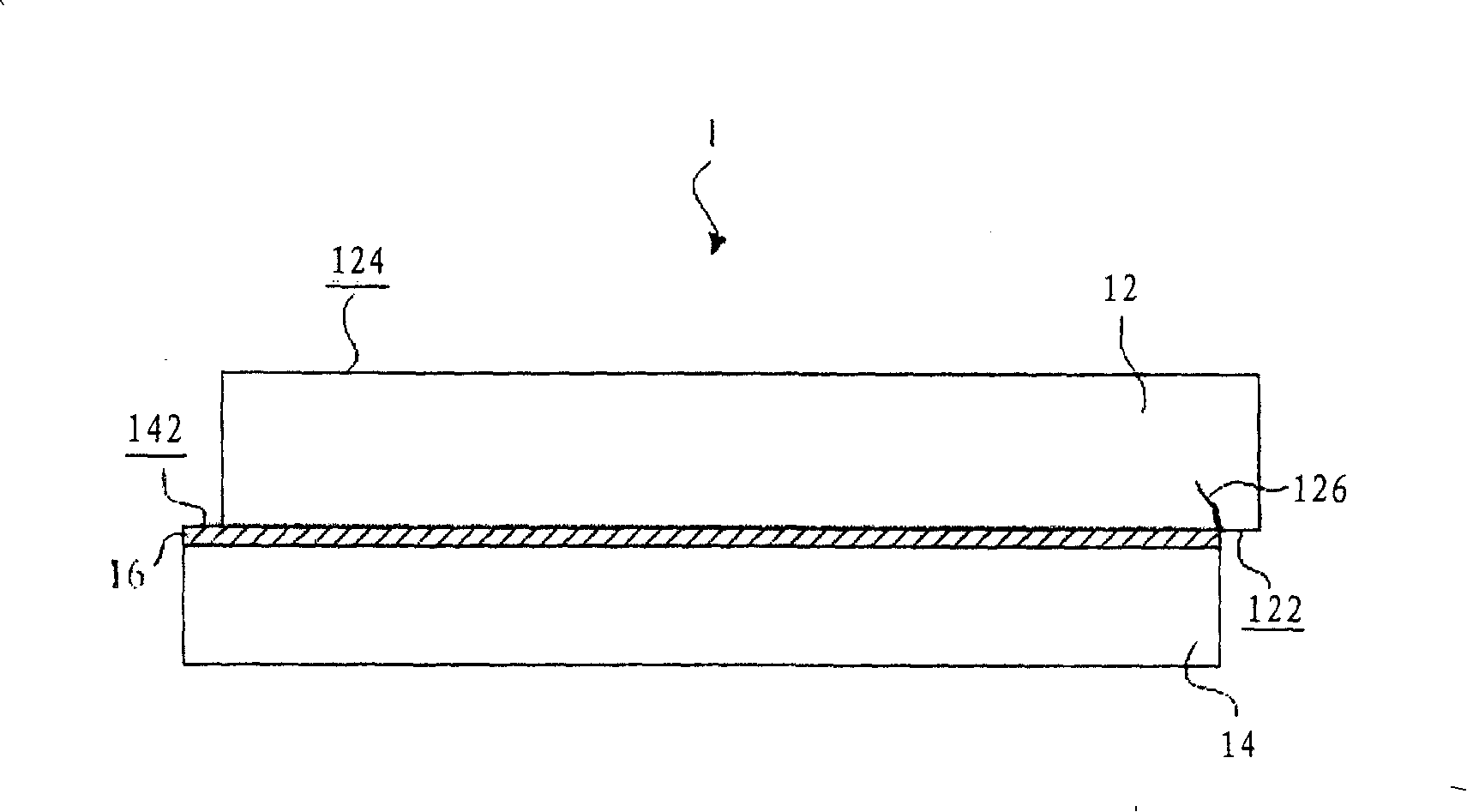

[0027] The present invention provides a method for manufacturing a composite wafer structure, in particular, fracture is actively controlled during the composite wafer fabrication process, thereby avoiding edge damage of the composite wafer structure. Several preferred specific embodiments according to the present invention are disclosed as follows.

[0028] Please refer to Figure 2A to Figure 2H as shown, Figure 2A to Figure 2H is a sectional view for describing the manufacturing method according to the first preferred embodiment of the present invention.

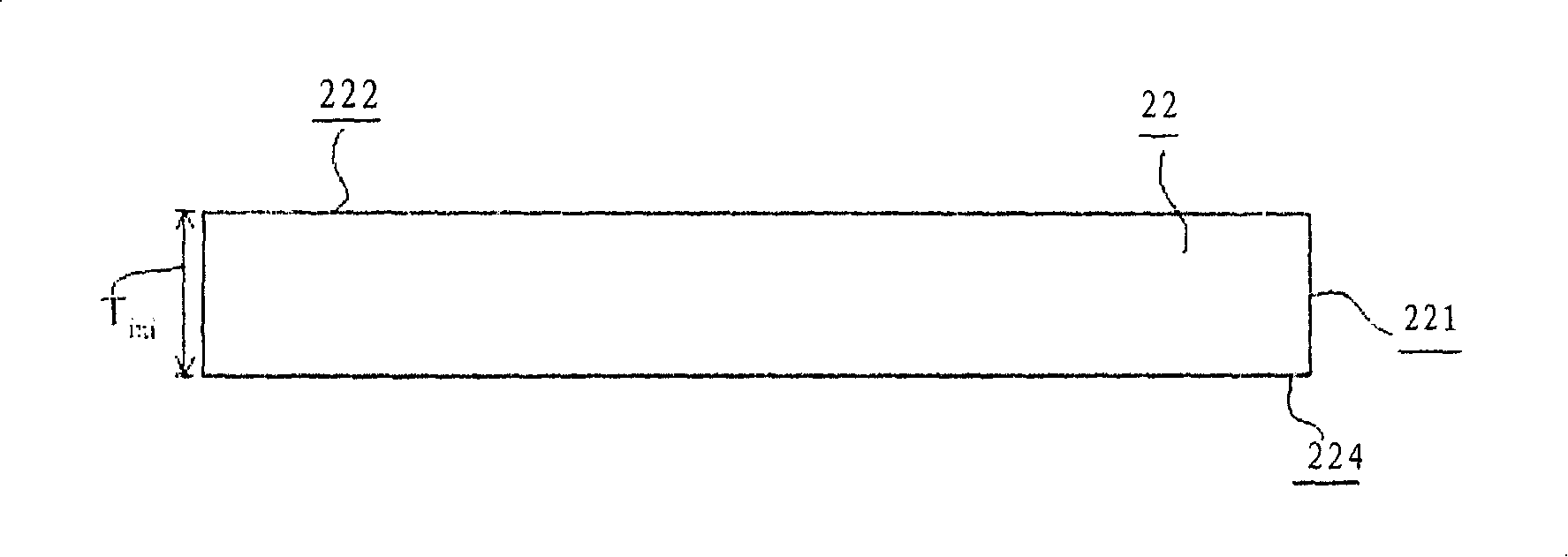

[0029] First, if Figure 2A As shown, a device wafer 22 is prepared. The device wafer 22 has a first circumference (Circumference) 221 , a bonding surface 222 and a bottom surface 224 .

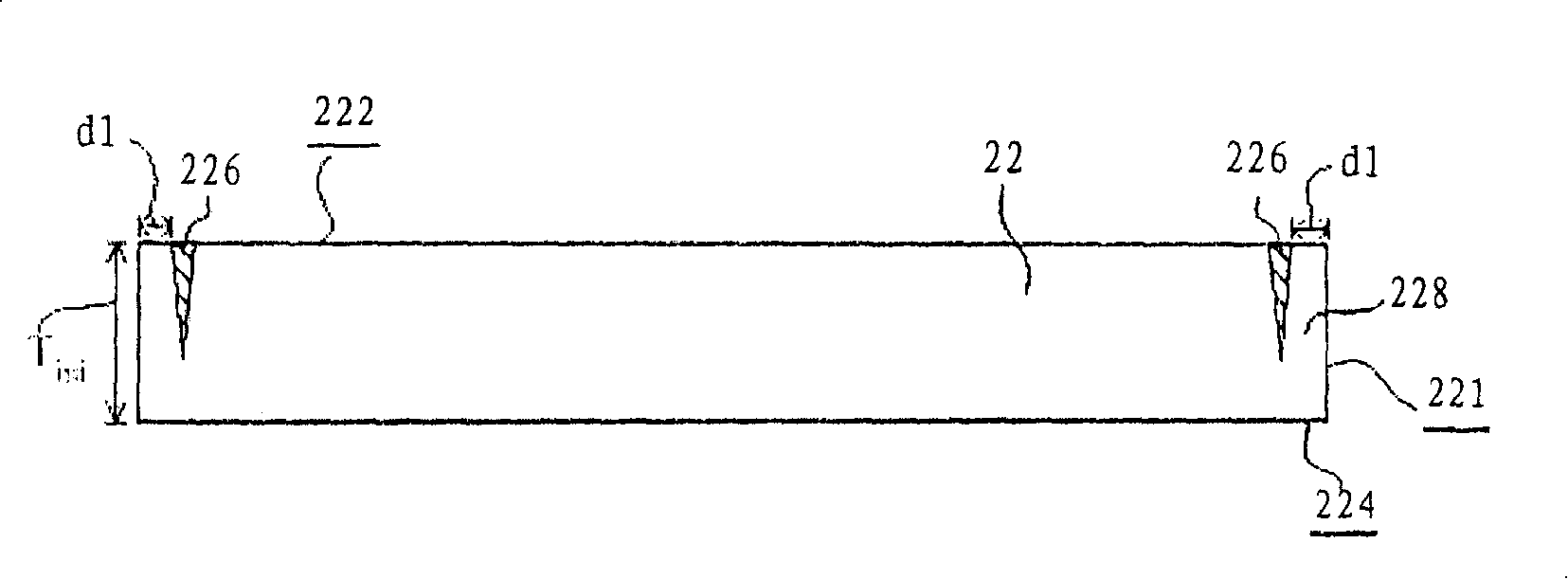

[0030] Next, on the bonding surface 222 of the device wafer 22, a groove (Groove) 226 is formed along the first circumference 221 of the device wafer 22, such as Figure 2B shown. It should be noted that there is a margin (Margin)...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com