Patents

Literature

144 results about "Multi-wire saw" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A multi-wire saw is a cutting machine designed to slice hard materials. This device is especially important in the solar cell industry. Over 80% of the world's solar cell production requires the cutting of silicon ingots into wafers. As a result, multi-wire sawing is an important process in the photovoltaic and microelectronics industries.

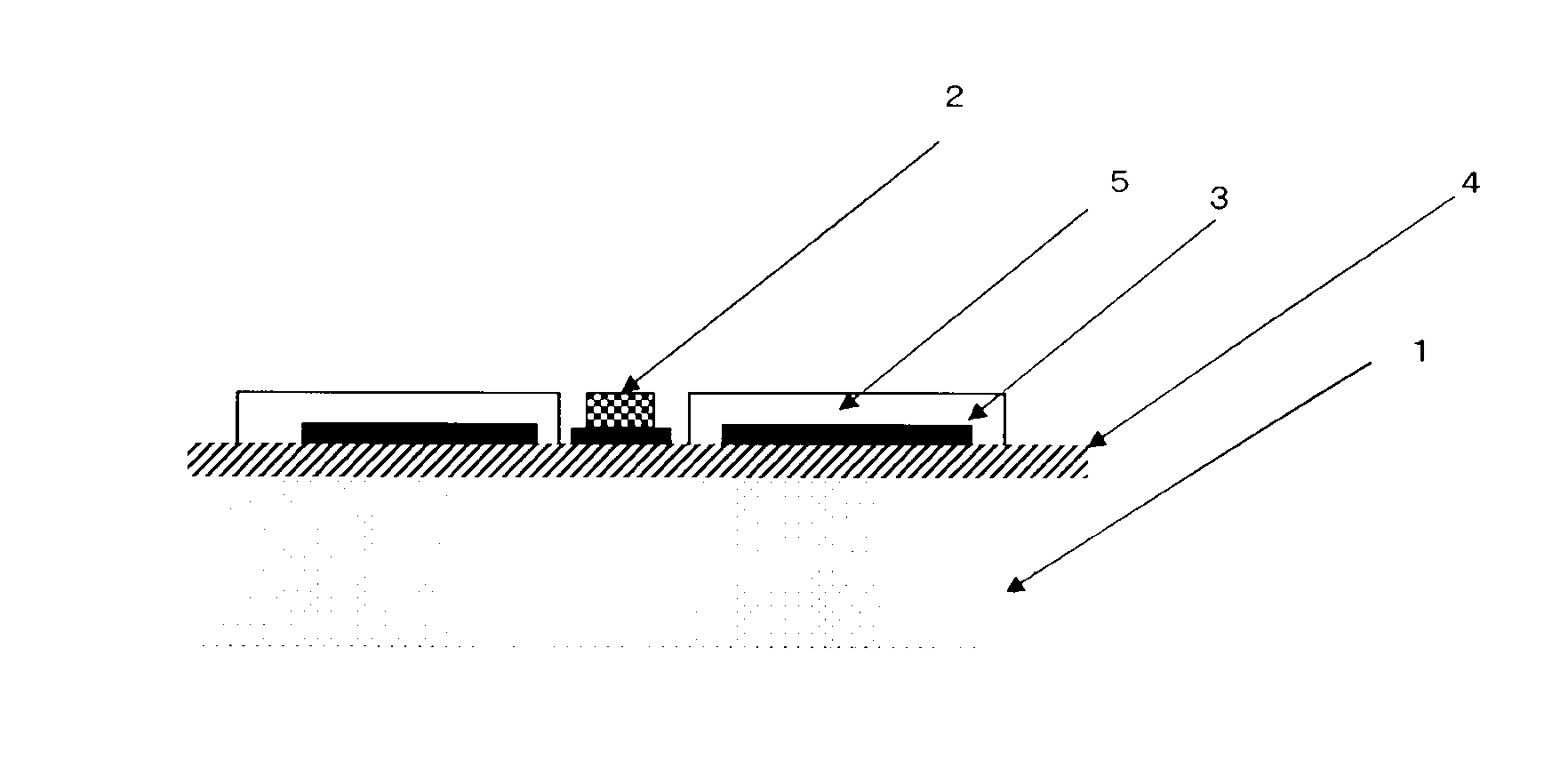

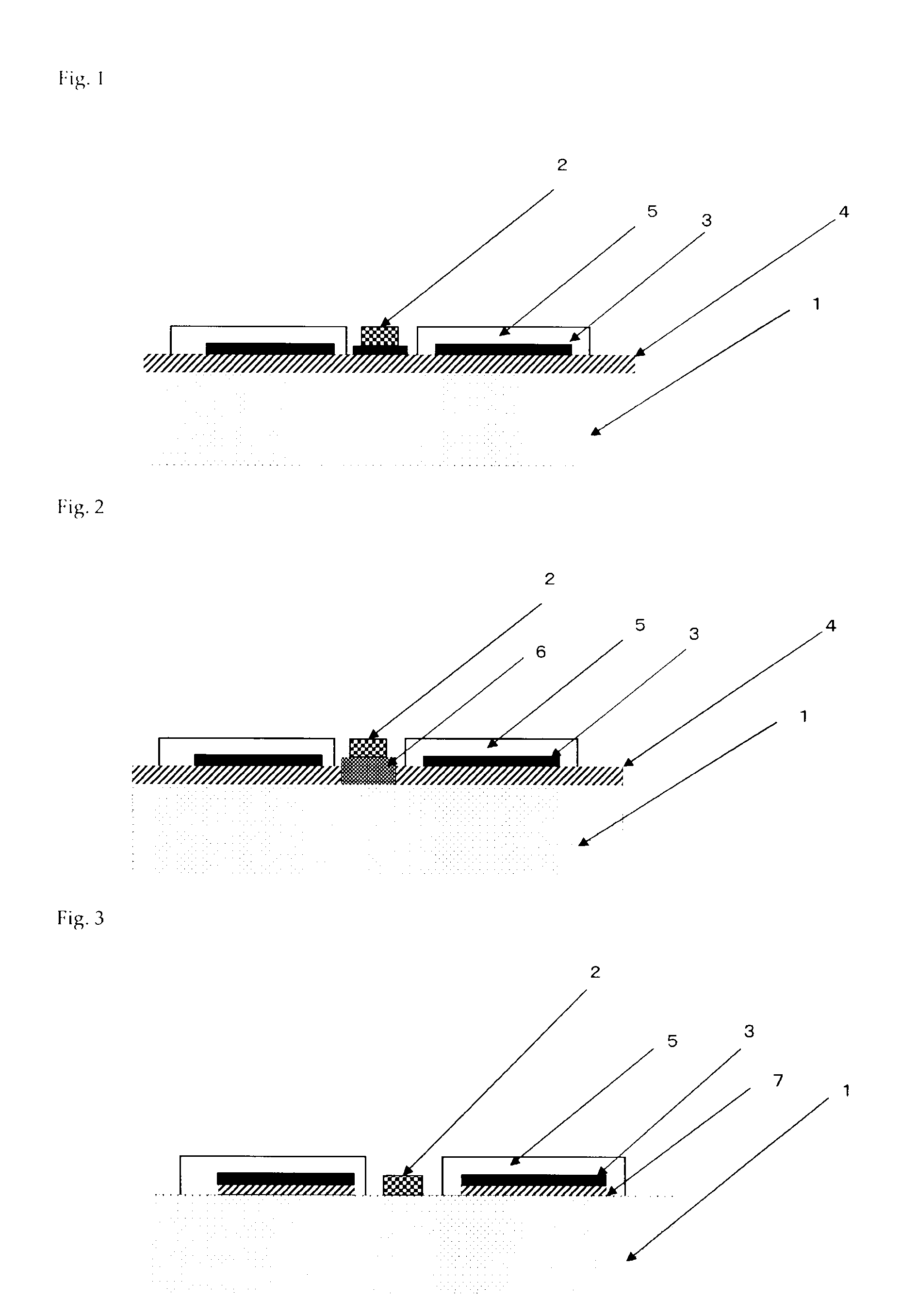

Substrate comprising aluminum/graphite composite, heat dissipation part comprising same, and LED luminescent member

ActiveUS20110316038A1Efficient productionReduce material lossSemiconductor/solid-state device detailsSolid-state devicesFlexural strengthThermal expansion

A process for producing a substrate, which comprises processing an aluminum / graphite composite into plates having a thickness of 0.5-3 mm using a multi-wire saw under the following conditions (1) to (4): (1) the wires have abrasive grains bonded thereto which are one or more substances selected from diamond, C—BN, silicon carbide, and alumina and have an average particle diameter of 10-100 μm; (2) the wires have a diameter of 0.1-0.3 mm; (3) the wires are run at a rate of 100-700 m / min; and (4) the composite is cut at a rate of 0.1-2 mm / min. The aluminum / graphite composite has a surface roughness (Ra) of 0.1-3 μm, a thermal conductivity at 25° C. of 150-300 W / mK, a ratio of the maximum to the minimum value of thermal conductivity in three perpendicular directions of 1-1.3, a coefficient of thermal expansion at 25-150° C. of 4×106 to 7.5×10−6 / K, a ratio of the maximum to the minimum value of coefficient of thermal expansion in three perpendicular directions of 1-1.3, and a three-point bending strength of 50-150 MPa.

Owner:DENKA CO LTD

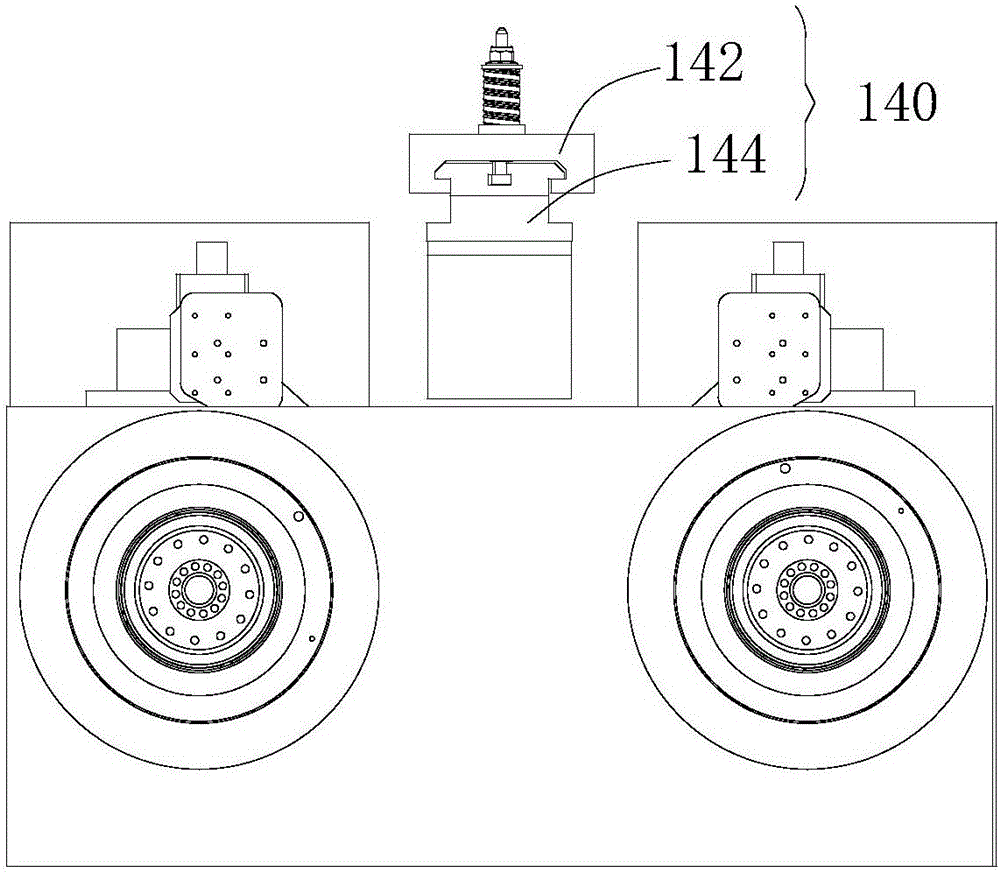

Multi-wire sawing machine for silicon wafers

InactiveCN106426585AShorten the fulcrum distanceReduce the amplitudeGrinding machine componentsWorking accessoriesEngineeringPatch cable

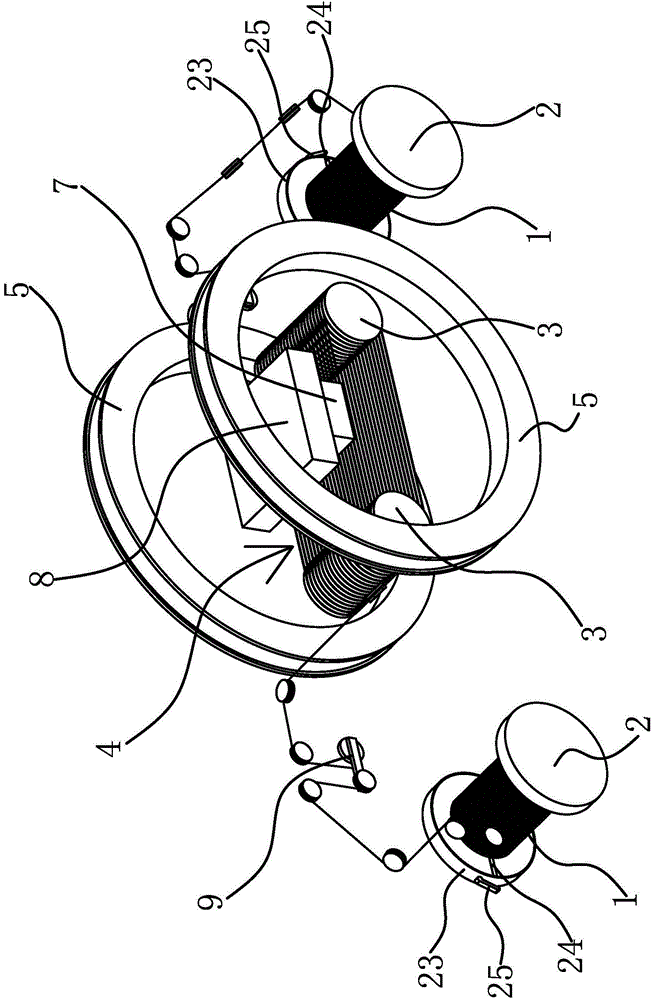

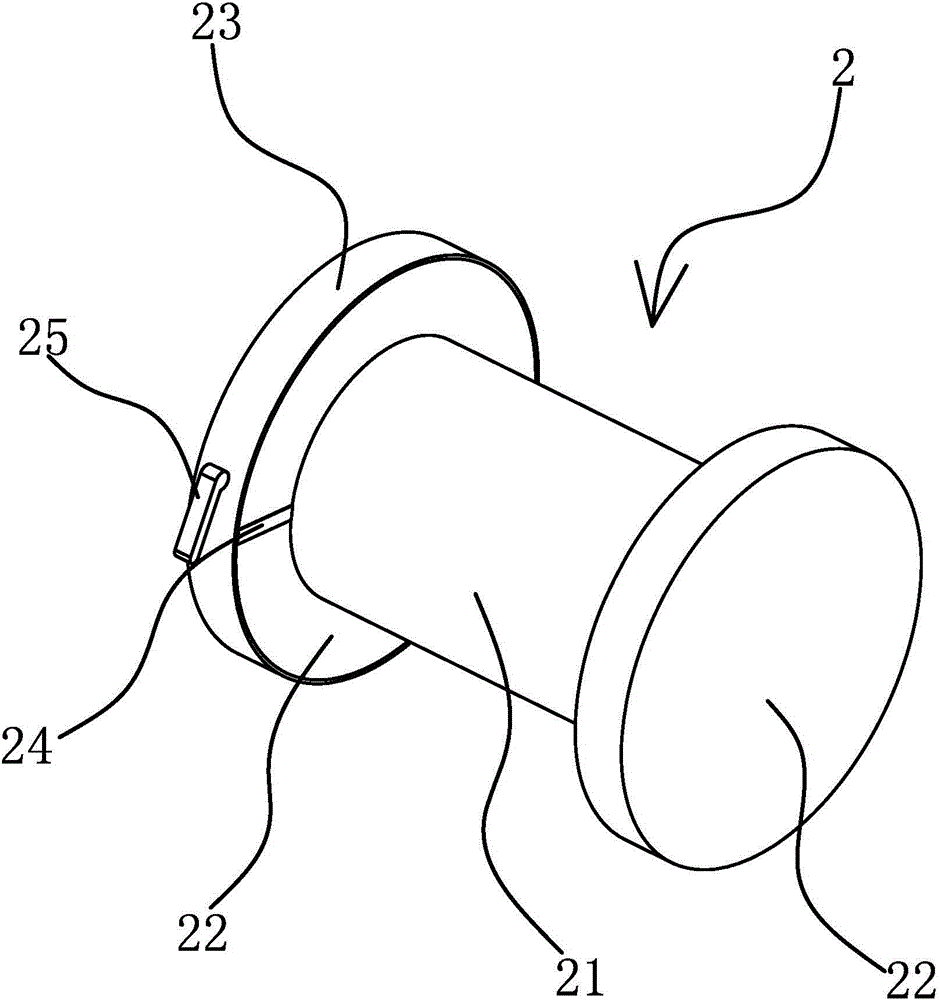

The invention relates to a multi-wire sawing machine for silicon wafers. The multi-wire sawing machine comprises a rack, a guide wheel assembly fixed to the rack, a crystal supporting assembly, a wire net and a vibration damper, wherein the guide wheel assembly comprises a plurality of sets of guide wheels which are arranged in pairs; the crystal supporting assembly is located on the outer side of the part between at least one pair of guiding wheels; the net wire surrounds the multiple sets of guiding wheels which are arranged in pairs; the vibration damper is located between the guiding wheels and comprises a roller structure and a supporting structure used for supporting the roller structure, the roller structure is connected with the wire net in an abutted manner, and the supporting structure is fixedly connected with the rack; and the crystal supporting assembly and the vibration damper are installed on the two sides of the wire net. According to the multi-wire sawing machine for the silicon wafers, on one hand, the fulcrum distance of the wire net is shortened, the amplitude of the wire net is reduced, and therefore the probability that the wire net jumps out of a guide wheel groove is reduced, and the wire breaking problem caused by wire jumping is solved; and on the other hand, the wire arch of the wire net is correspondingly reduced, the sawing efficiency of the wire net can be improved, and therefore the production efficiency is improved, the probability of edge breaking caused when the silicon wafers go out of a cutter edge is reduced, and the yield of products is improved.

Owner:GCL POLY ENERGY HLDG

Method of cutting high-hardness material with multi-wire saw

InactiveUS20150202700A1Keep for a long timeWork lessMetal sawing toolsFine working devicesWire rodReciprocating motion

In a method of cutting a high-hardness material with a multi-wire saw, an ingot of the high-hardness material is sliced into a plurality of wafers by cutting the ingot at multiple points simultaneously with the multi-wire saw. The method comprises repeating a run cycle of reciprocating motion of a wire of the multi-wire saw so that the relationships (1) c1≧20, given C1=b / a and (2) 0.35≦c2≦1.55, given c2=d / a are satisfied, where a is a maximum total contact length defined as a sum of the lengths of the ingot as projected onto multiple cut points when projecting the ingot onto the wire in a direction in which the ingot is going to be cut, b is a continuous travel distance of the wire, and d is a length of the wire newly fed in each said run cycle.

Owner:HITACHI METALS LTD

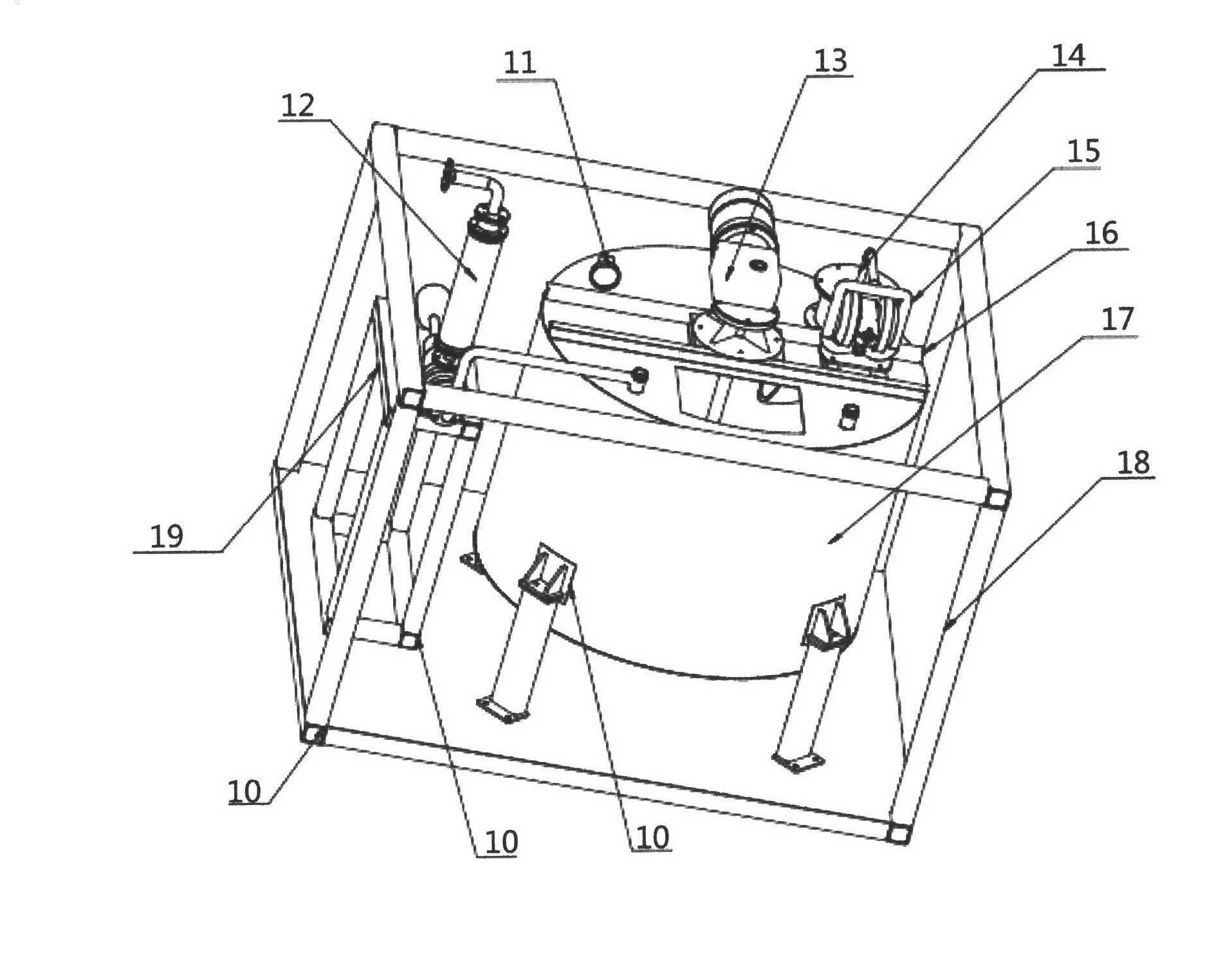

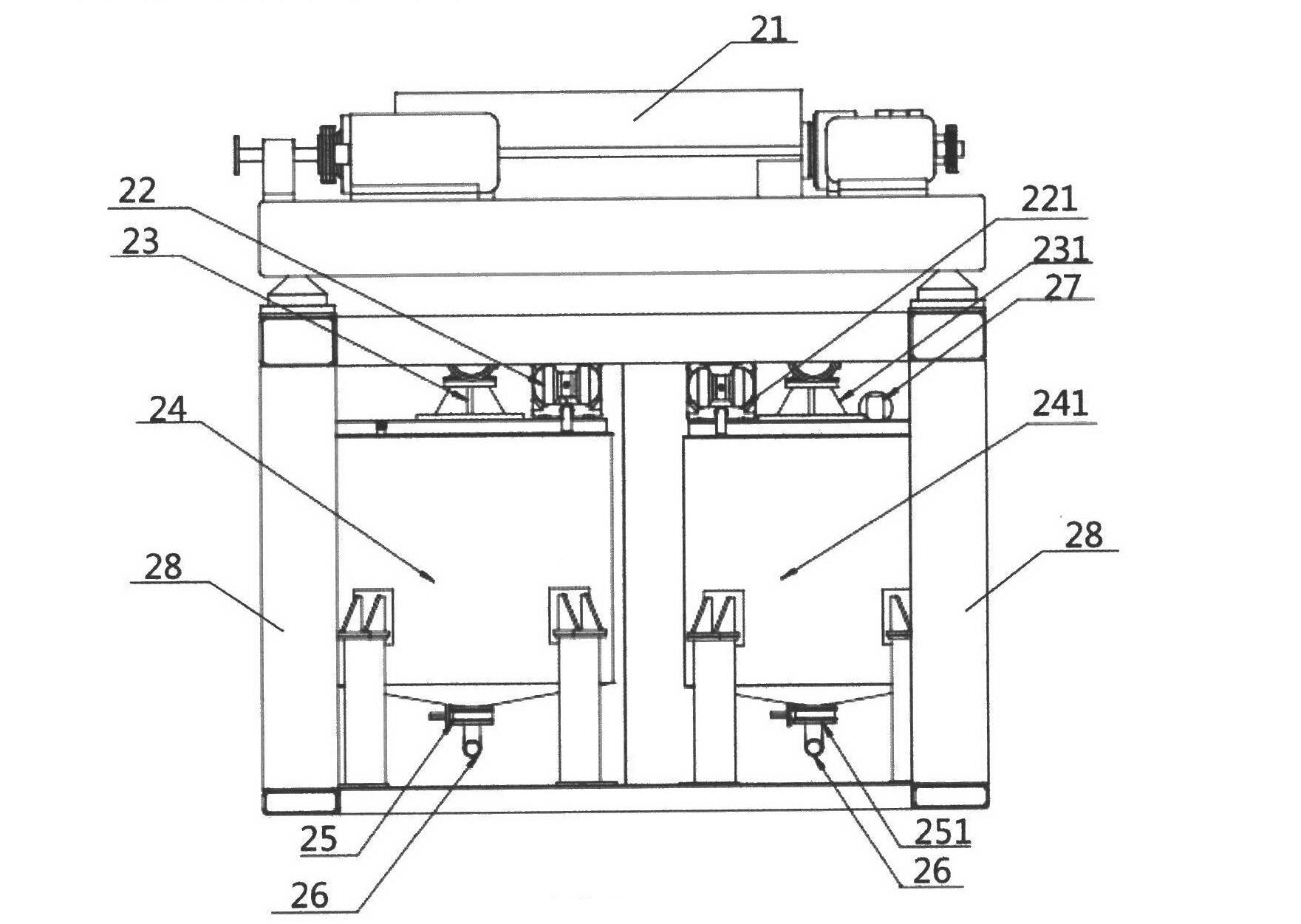

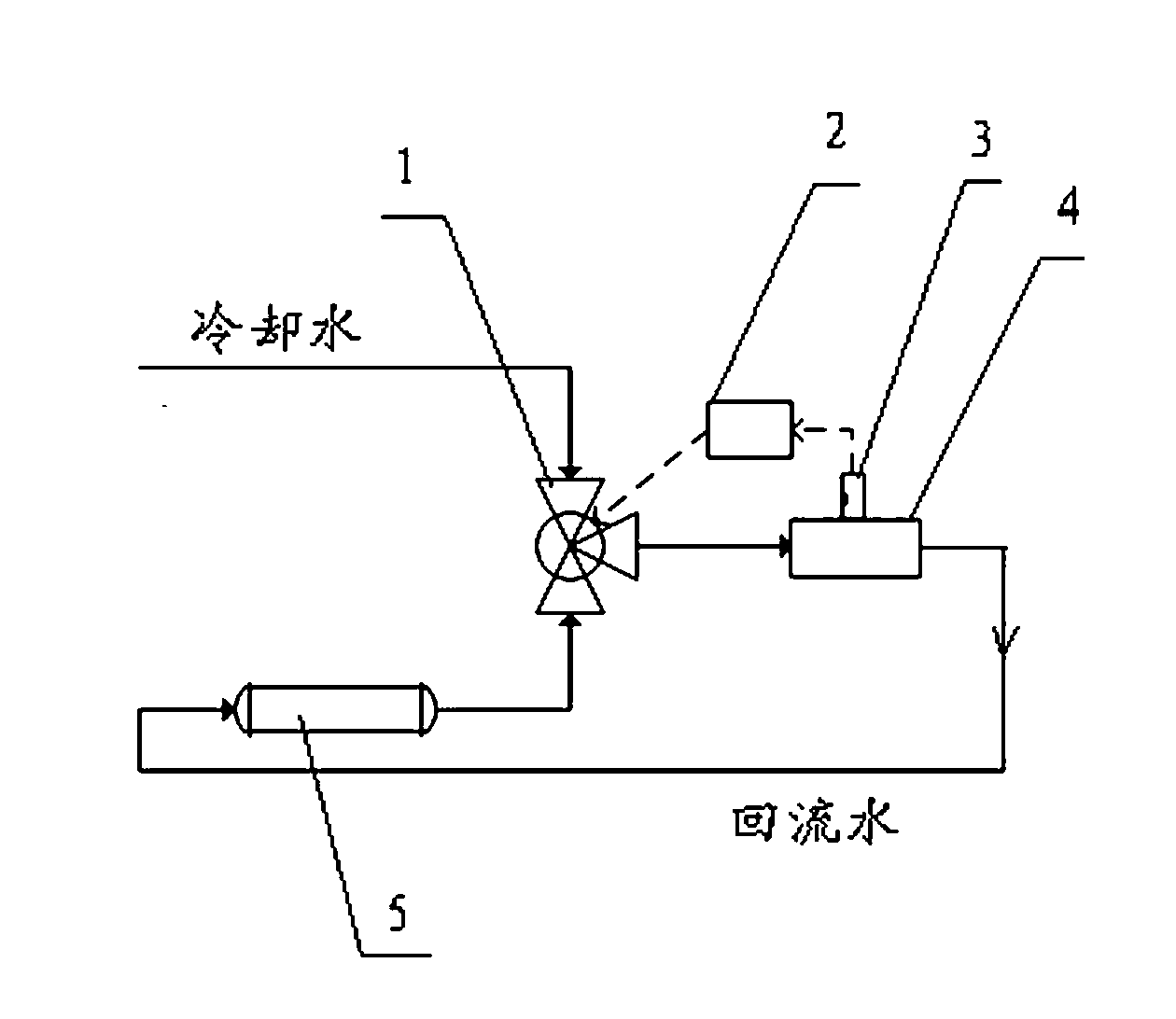

Cutting fluid circulating device for multi-wire sawing machine

ActiveCN105269698AImprove water qualityWon't happenWorking accessoriesFine working devicesWater useWater storage

The invention relates to a cutting fluid circulating device for a multi-wire sawing machine, and solves the defects of no structure reasonability of a cutting fluid circulating system, generation of a lot of foams in cutting by cutting fluid and influence on the quality of silicon chips in the prior art. In the cutting fluid circulating device for the multi-wire sawing machine, an overflow port is formed in a water tank, and is communicated with a filter by an overflow pipe; the filter is communicated with a water storage barrel by a water return pipe; the overflow pipe is serially connected with a first settling barrel; a water return pipe is serially connected with a second settling barrel; cutting fluid overflowing by the overflow port is settled by the first settling barrel, and is filtered by the filter; the cutting fluid filtered by the filter is settled by the second settling barrel, and finally enters the water storage barrel for recycling; and the cutting fluid is settled, filtered and settled to obtain excellent water quality, so that the cutting fluid cannot generate a lot of foams in circulation, and the water use level of the cutting fluid circulating system is reduced.

Owner:郎溪品旭科技发展有限公司

Processing method of samarium cobalt magnetic steel

ActiveCN105047394ASolve crackingSolve the phenomenon of falling cornersInductances/transformers/magnets manufactureMagnetic materialsSamarium cobaltGlass sheet

The invention relates to a processing method of samarium cobalt magnetic steel. The processing method comprises the steps as follows: (1) using an inside diameter slicer to process sintering samarium cobalt work-blank with qualified magnetic performance into a square strip, or using wire electrical discharge machining to form a column, or using trepan boring machining to form a circular long strip; (2) polishing the excircle of the column; (3) sticking the square strip, the column or the circular long strip on a glass plate; (4) fixing the glass plate stuck with the square strip, the column or the circular long strip on the working table of a multi-wire sawing machine; (5) using the multi-wire sawing machine to cut the square strip, the column or the circular long strip into thickness which is less than 2mm, wherein the machining line uses theta 0.12 to 0.25 mm steel wire while using the multi-wire sawing machine to cut; (6) taking out the product after the cutting is finished and using a alkali liquor to heat and boil for 10 to 60 min, and fishing the product out from the alkali liquor, cleaning and drying. The samarium cobalt magnetic steel slice processed by the invention could avoid crack and edge failure, and the product percent of pass is more than 90%.

Owner:HUNAN AEROSPACE MAGNET & MAGNETO

Ultrasonic free grinding material multi-wire saw cutting method and special purpose device

InactiveCN103101120AHigh precisionSawing effect is goodFine working devicesStone-like material working toolsWire cuttingContact mode

The invention relates to an ultrasonic free grinding material multi-wire saw cutting method and a special purpose device. When an existing grinding material multi-wire saw cutting method is adopted to cut crisp and hard materials, generally cutting efficiency is low and cutting precision is not high. By the adoption of the novel ultrasonic free grinding material multi-wire saw cutting method and the special purpose device, ultrasonic energy is skillfully used for cutting and sawing in auxiliary mode so as to enable ultrasonic waves to be transmitted in a direct contact mode and generate action at the front edge of cutting, the technical limitation that prior ultrasonic saw cutting only can be used for mono-wire saw cutting of solidified grinding materials and consumption of friction is large is overcome, the method and the device is suitable for multi-wire saw cutting of various materials of the crisp and hard materials, cutting speed can be largely increased, roughness if a saw cutting face is lowered, cutting loss is lowered, saw cutting precision is raised, and the rate of finished products is improved.

Owner:赵钧永

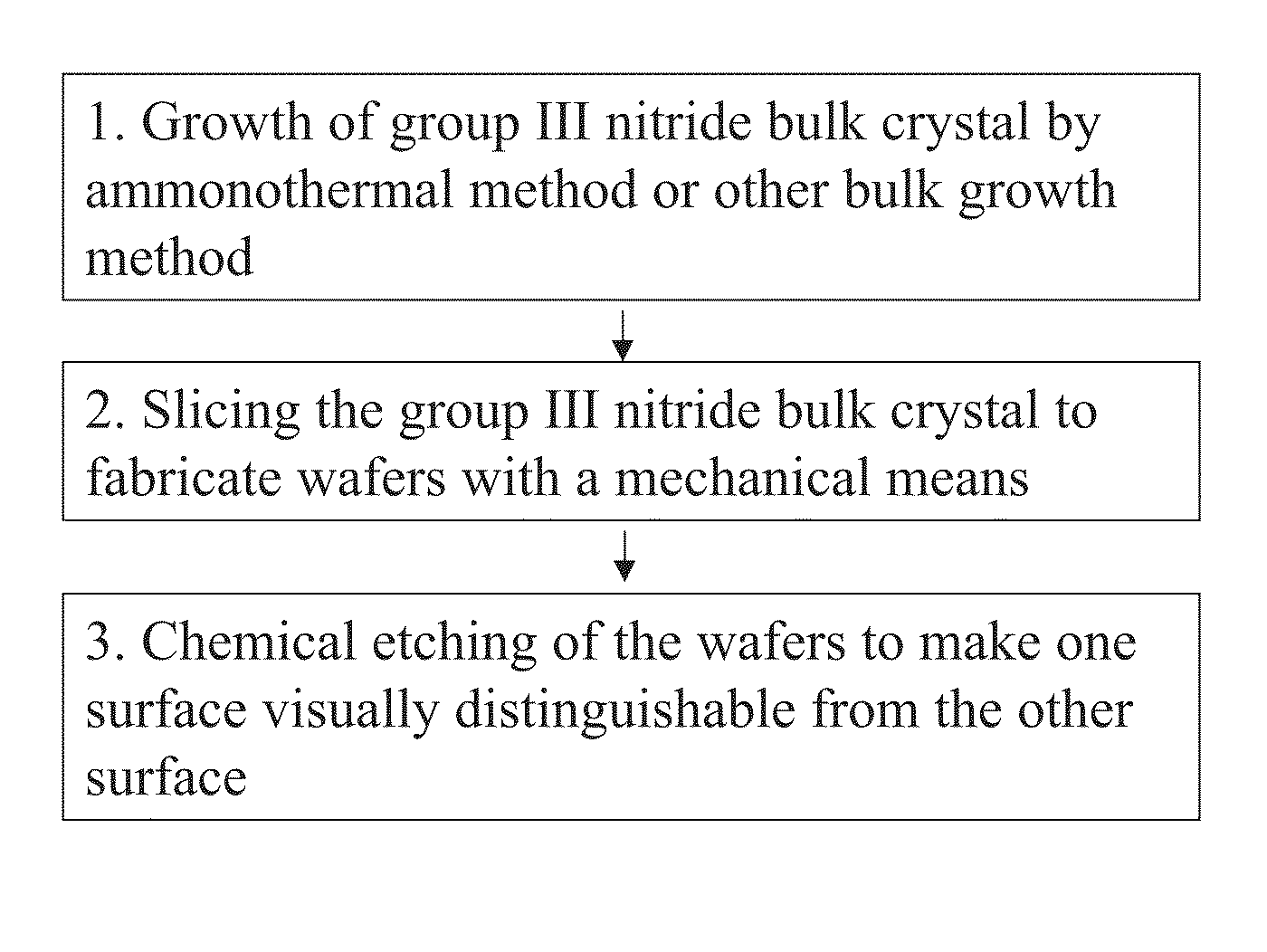

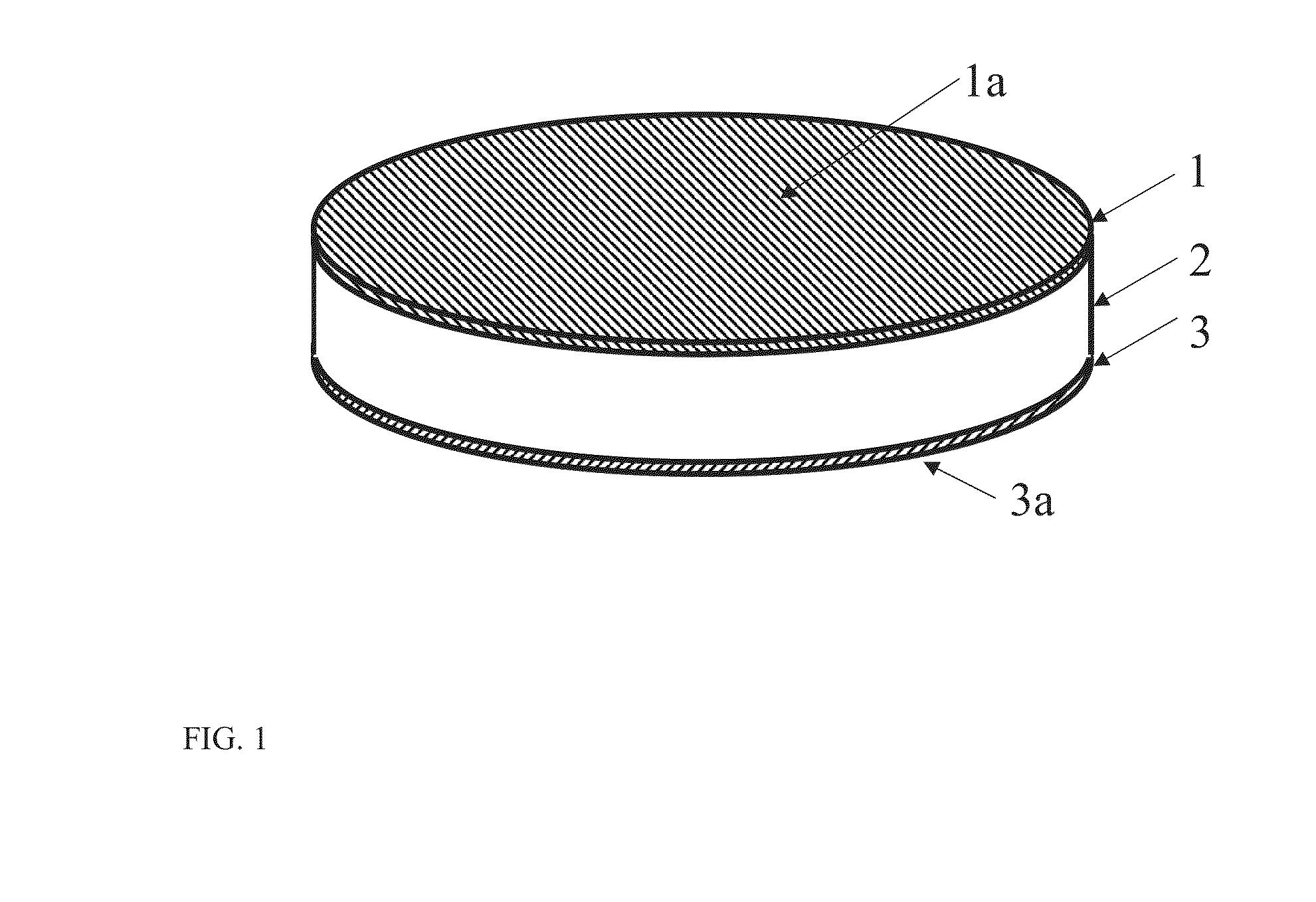

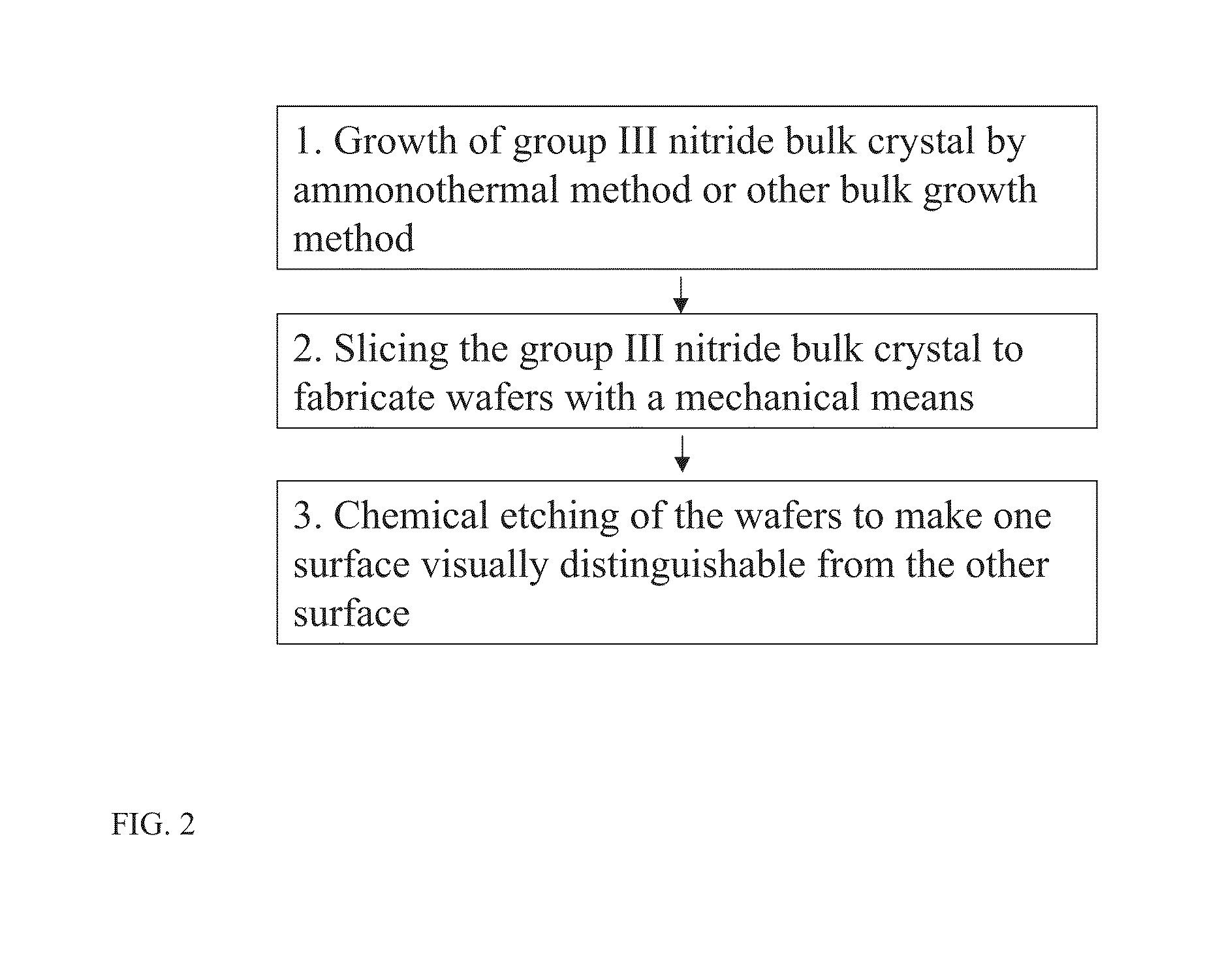

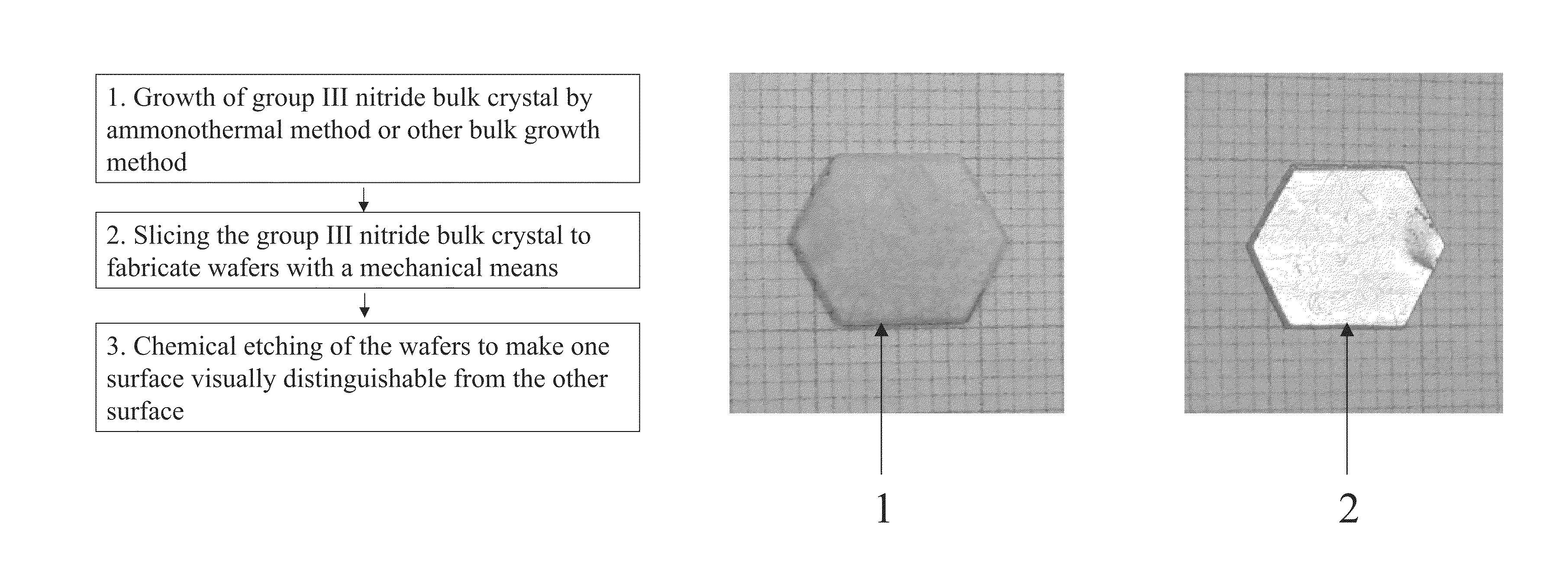

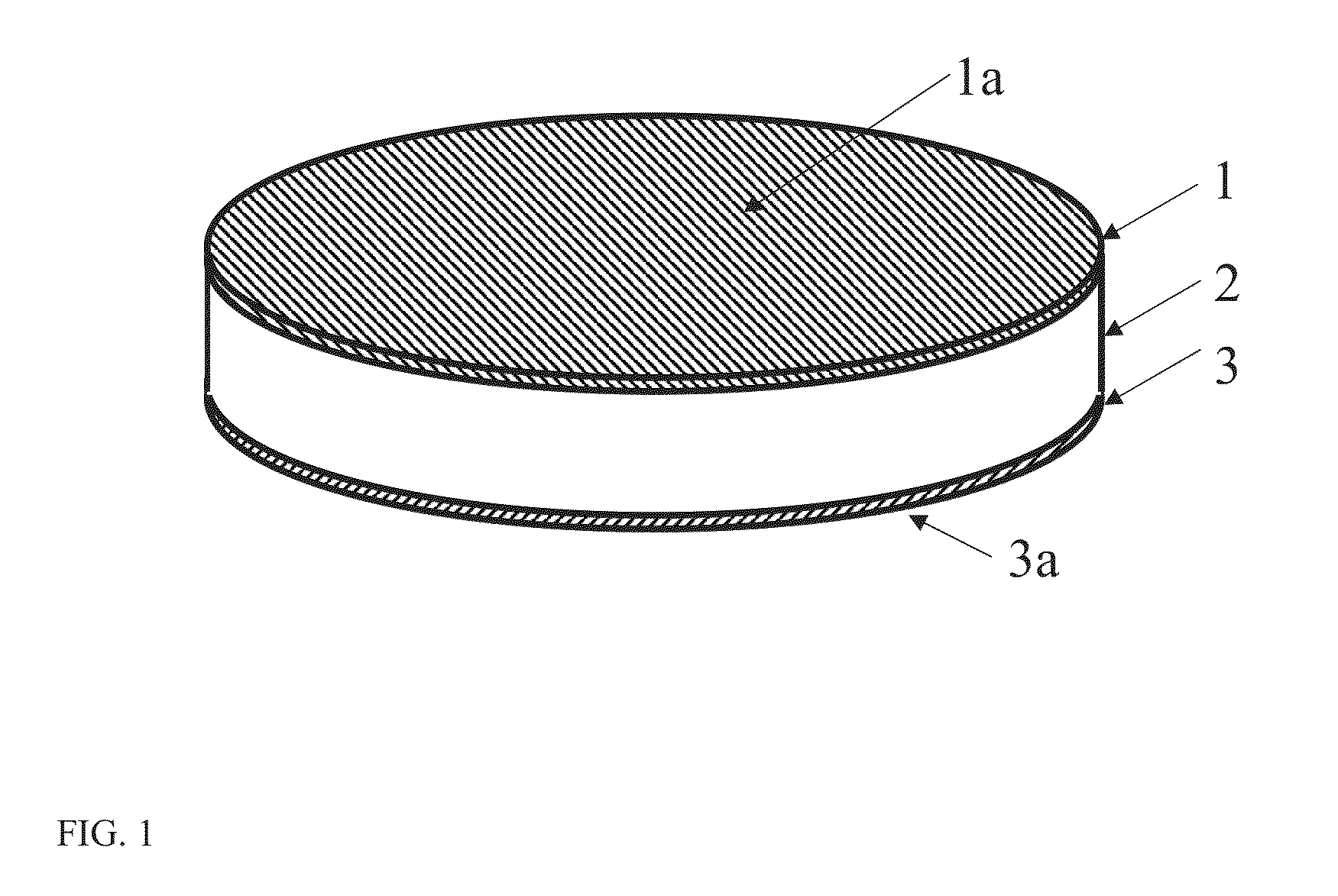

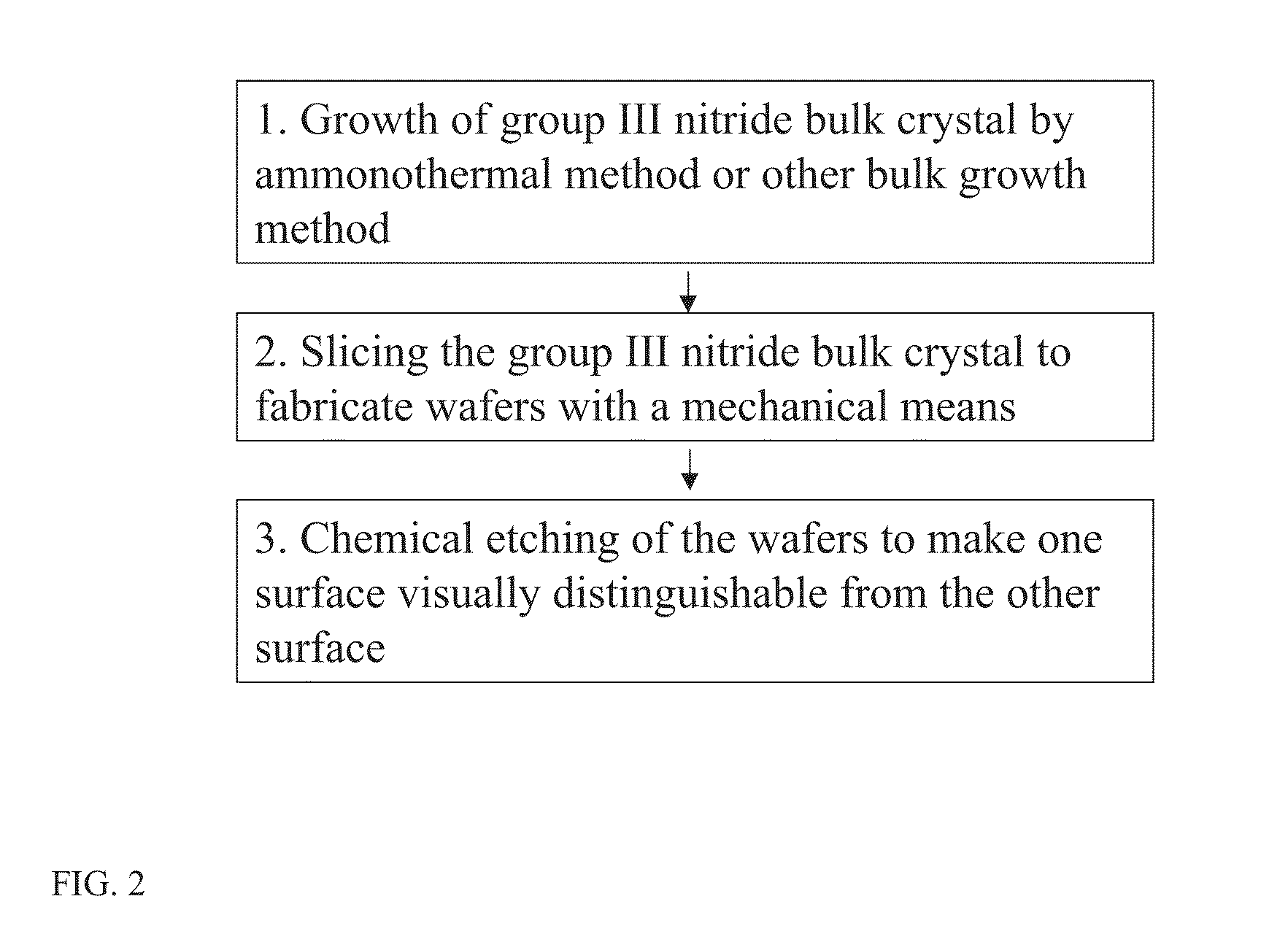

Group iii nitride wafer and its production method

ActiveUS20140065796A1Polycrystalline material growthFrom normal temperature solutionsBulk crystalWafering

The present invention discloses a group III nitride wafer such as GaN, AlN, InN and their alloys having one surface visually distinguishable from the other surface. After slicing of the wafer from a bulk crystal of group III nitride with a mechanical method such as multiple wire saw, the wafer is chemically etched so that one surface of the wafer is visually distinguishable from the other surface. The present invention also discloses a method of producing such wafers.

Owner:SEOUL SEMICONDUCTOR

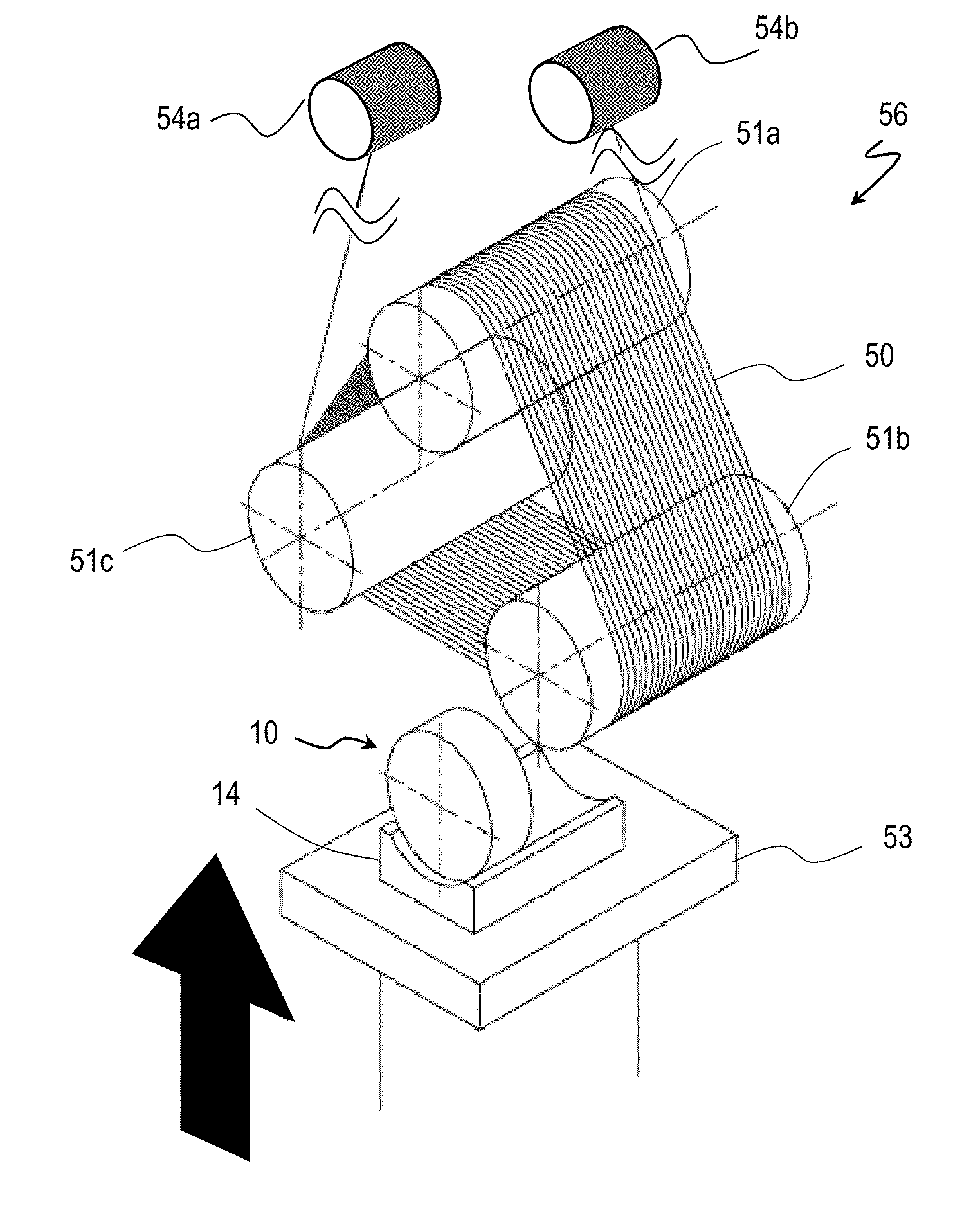

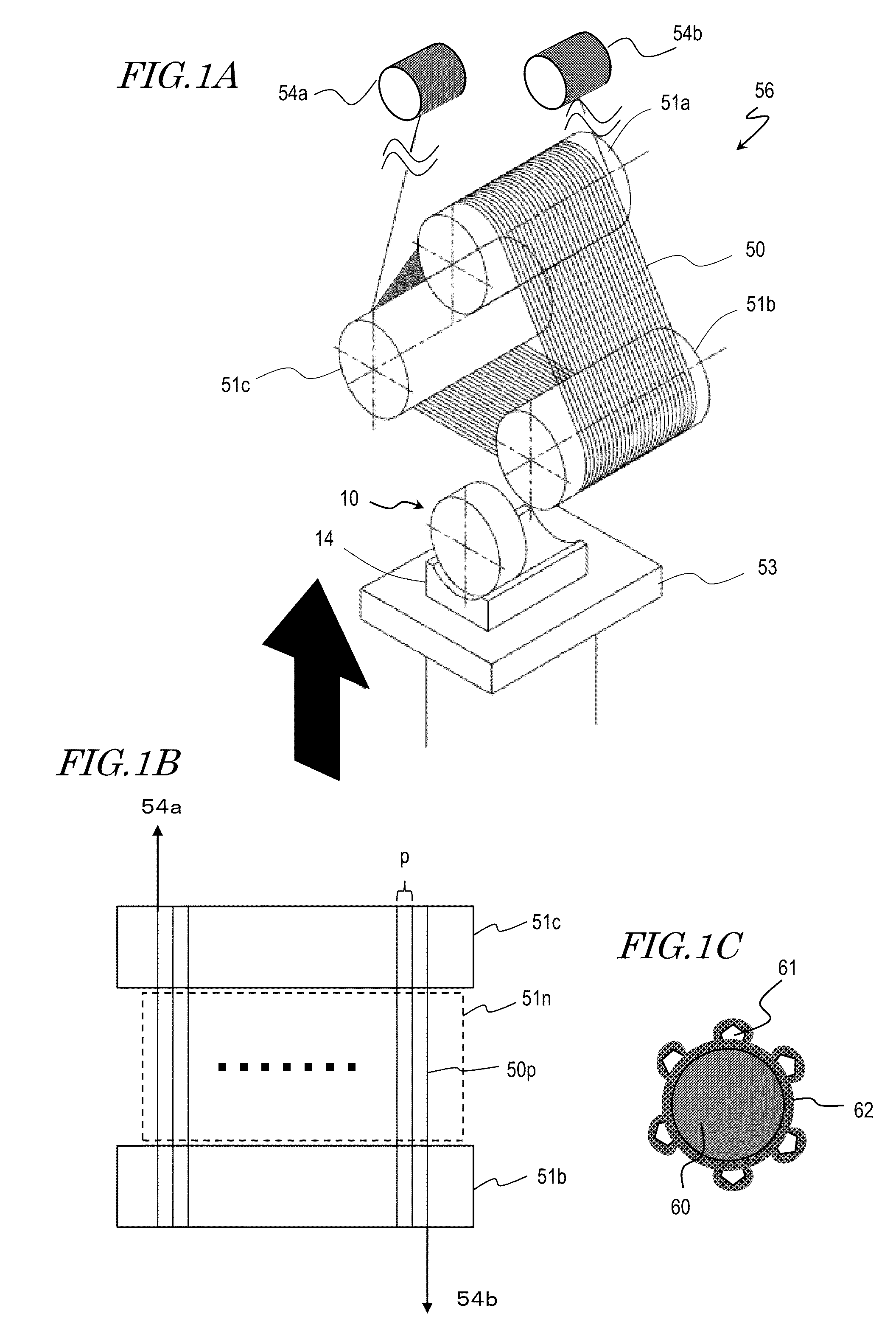

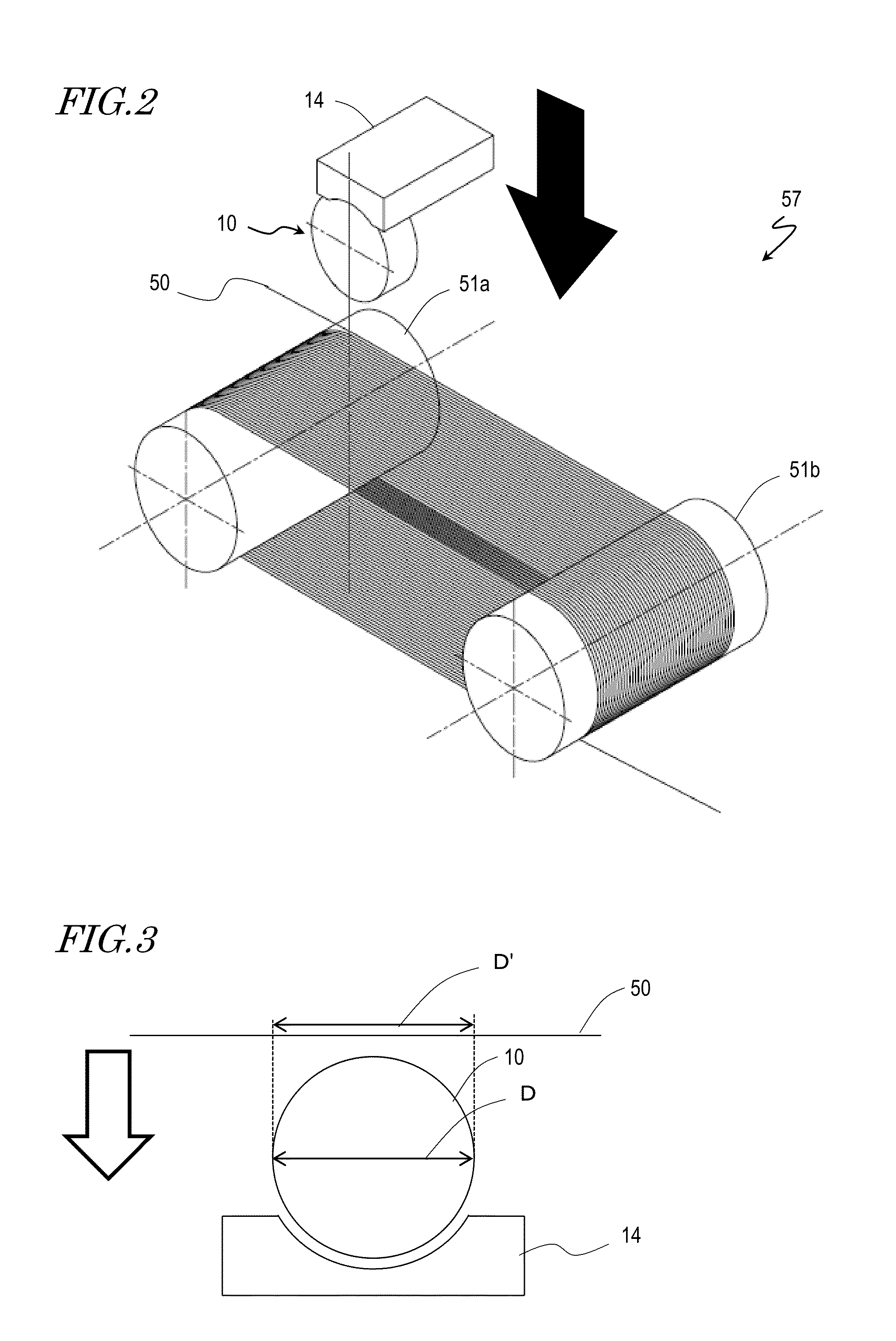

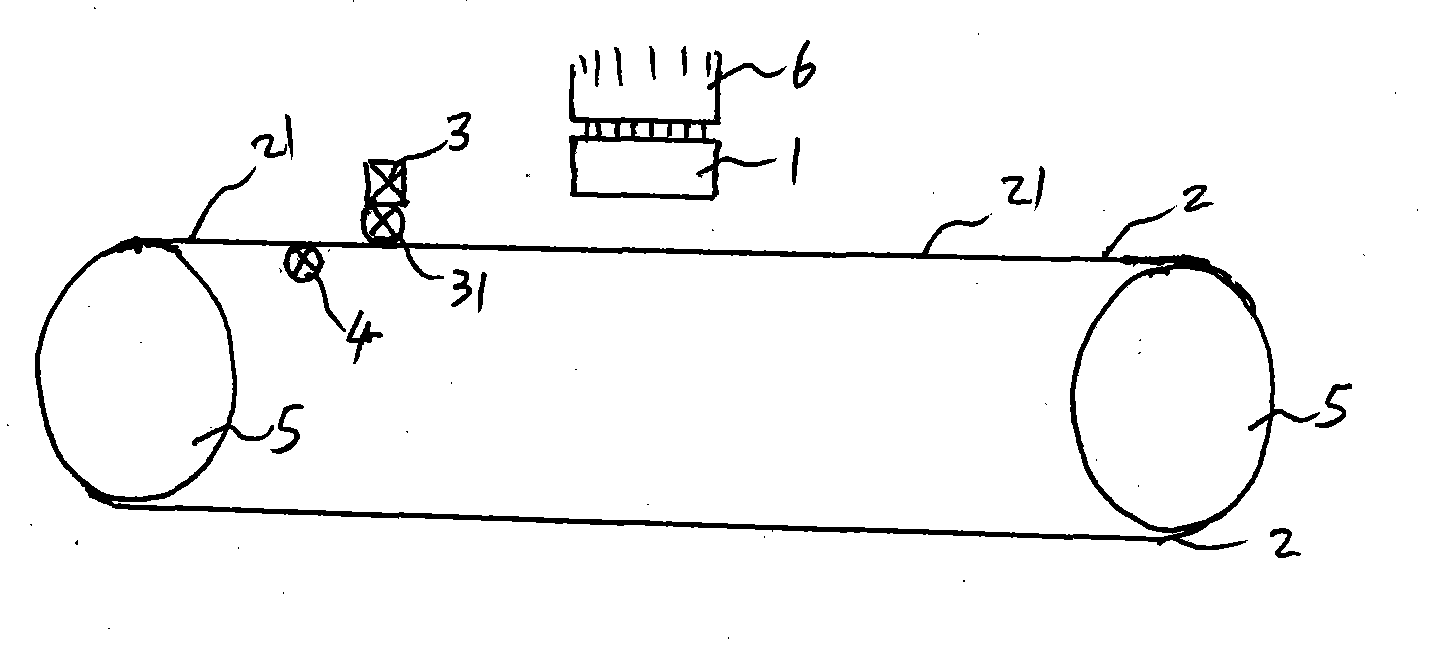

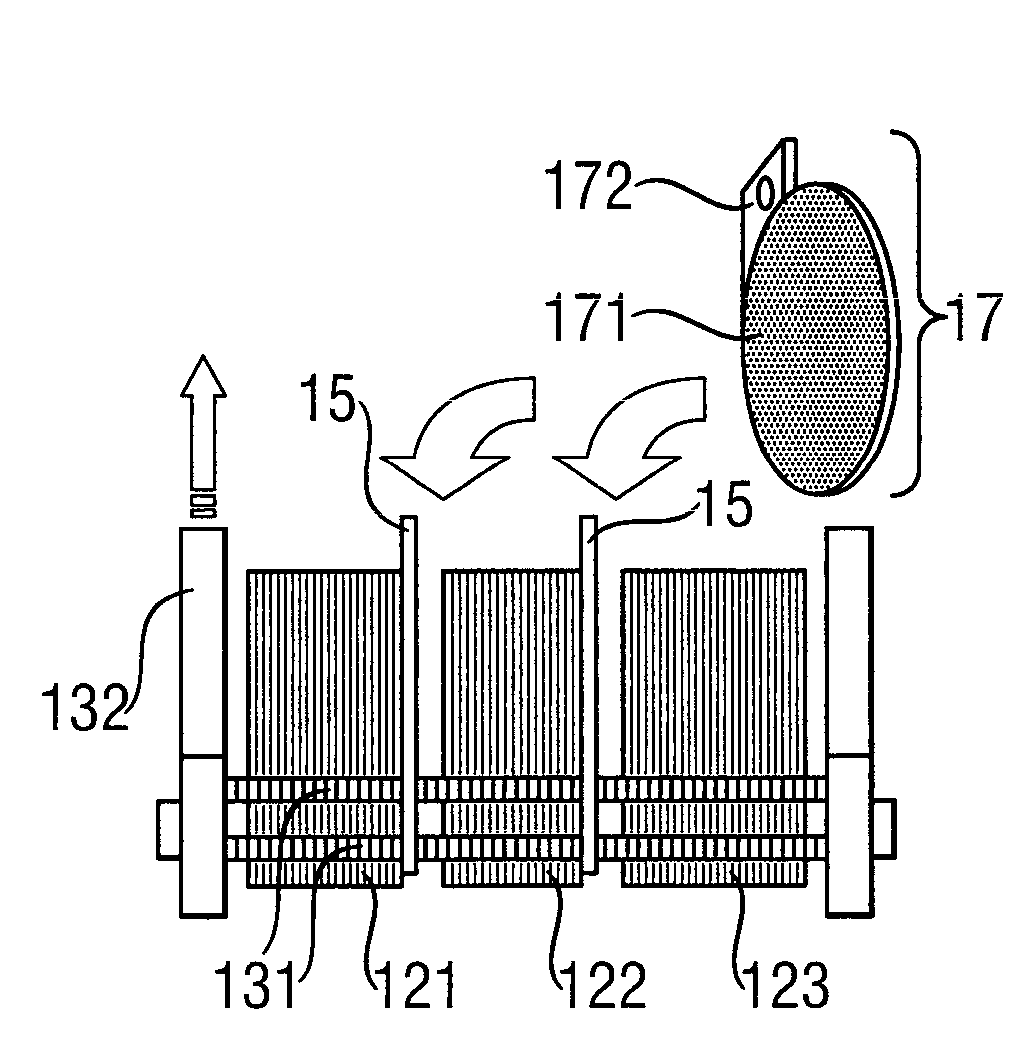

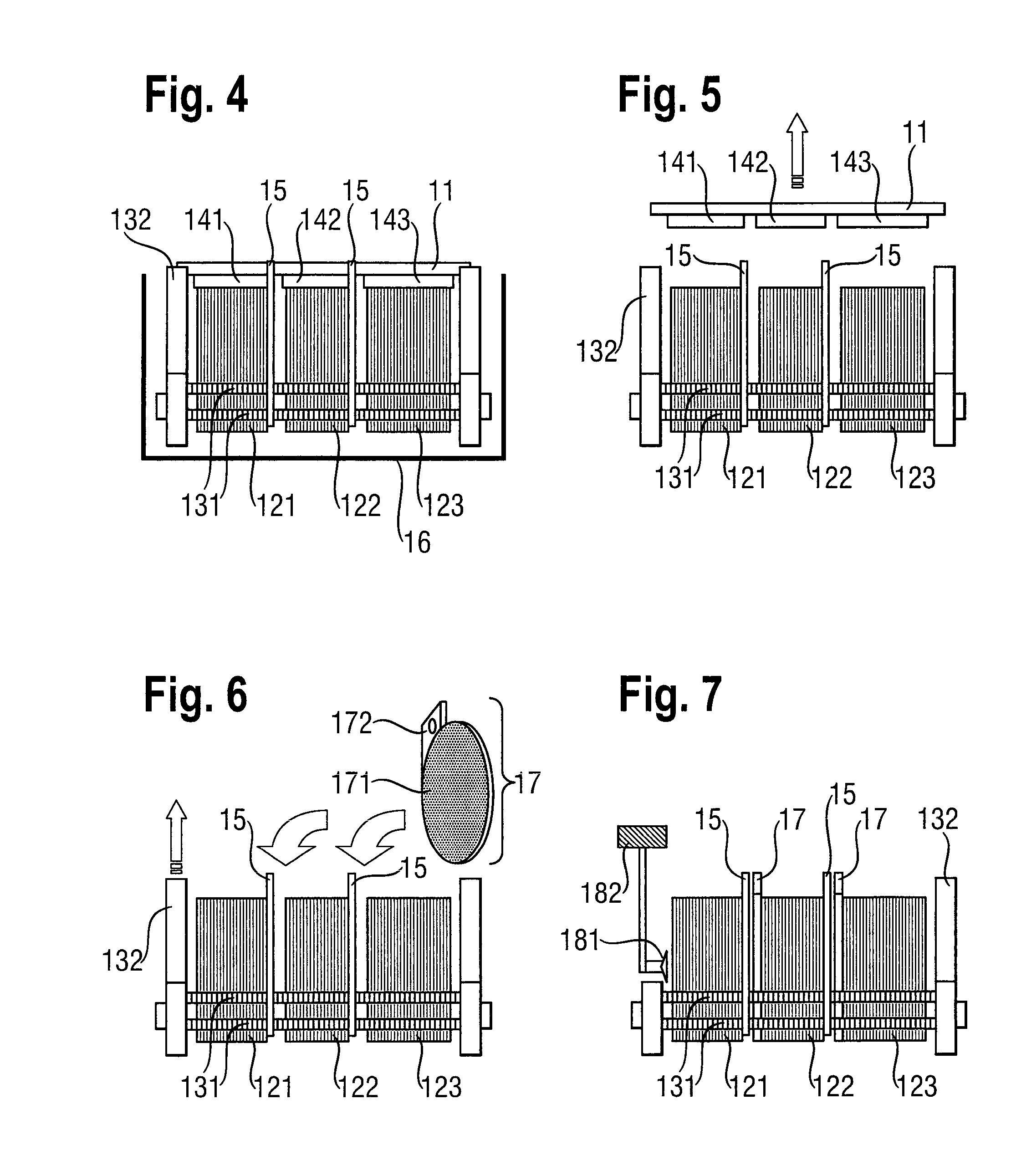

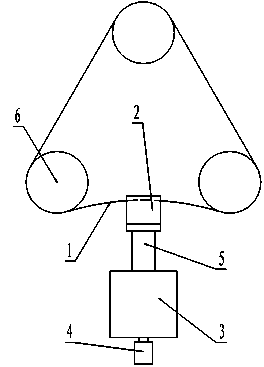

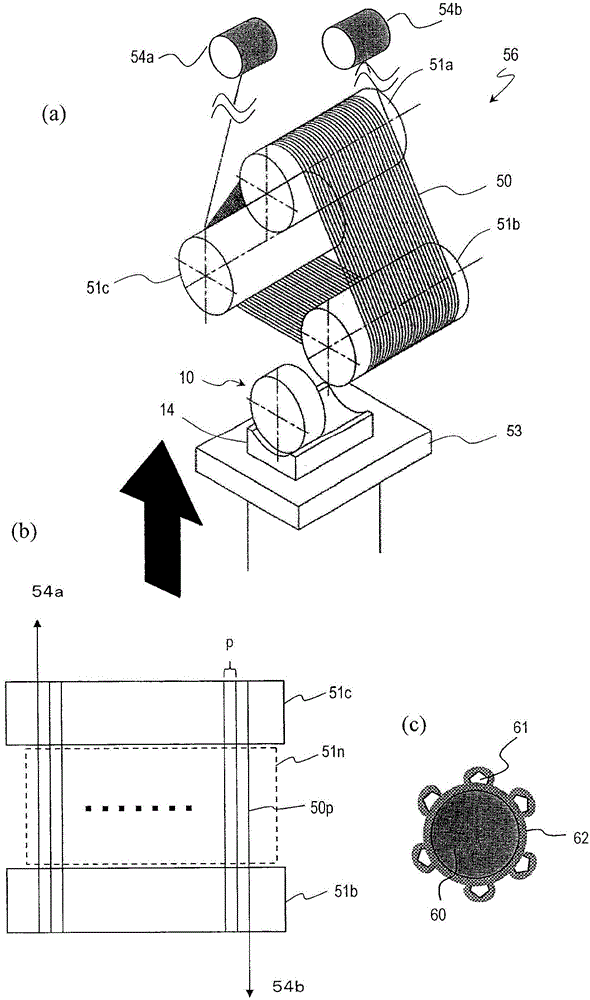

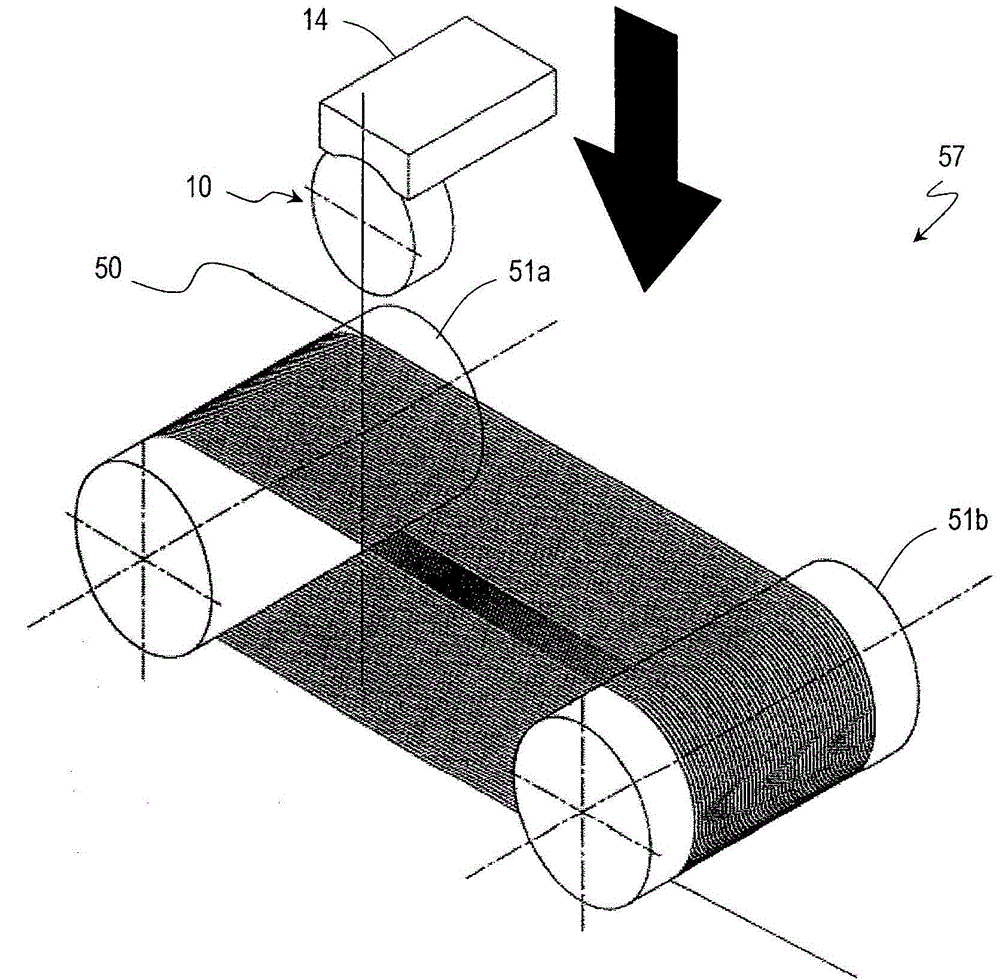

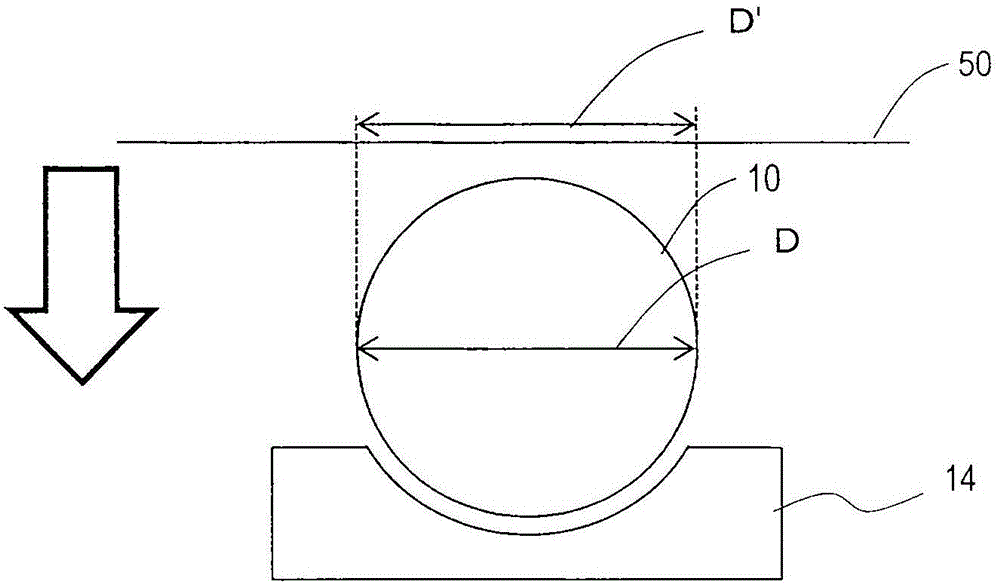

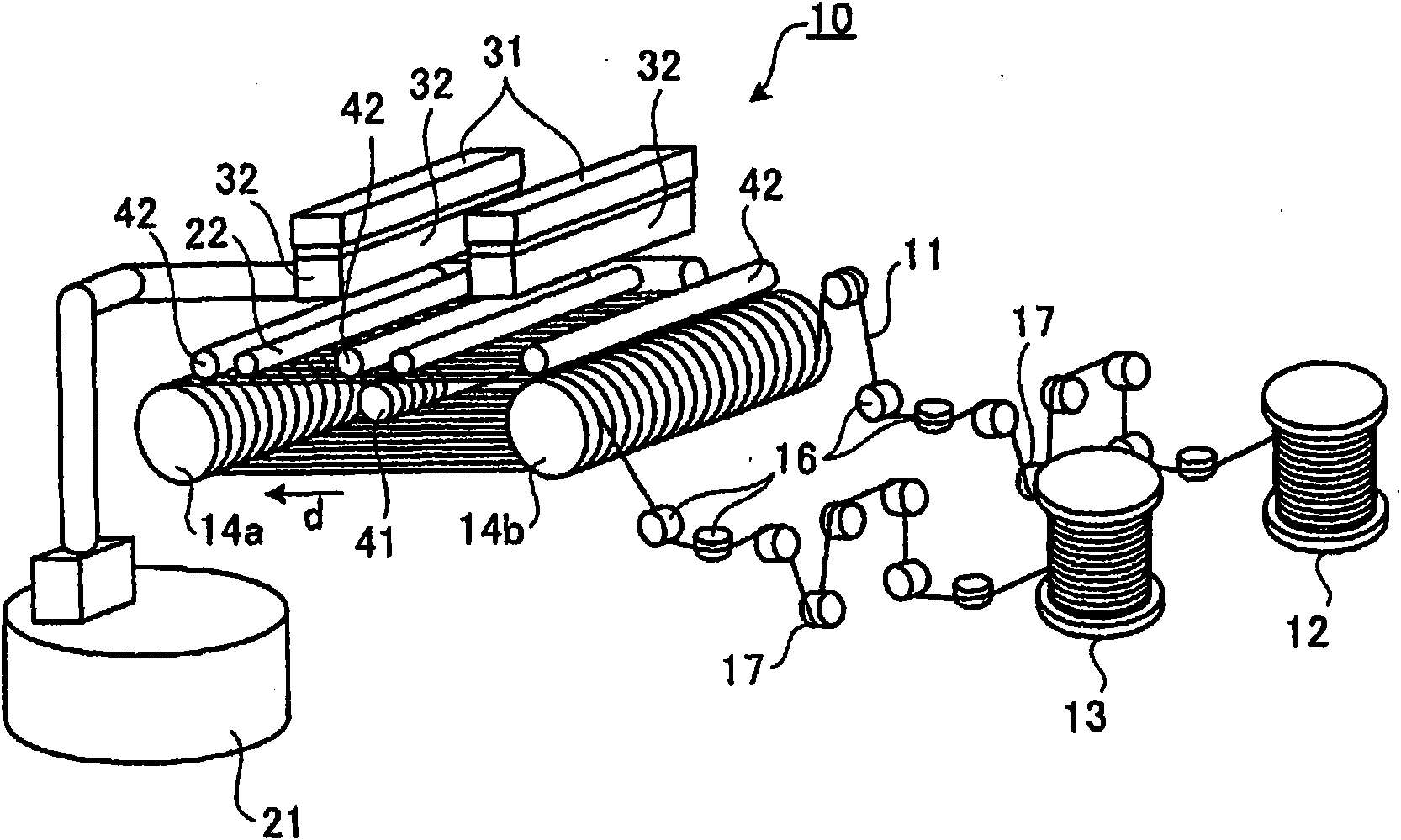

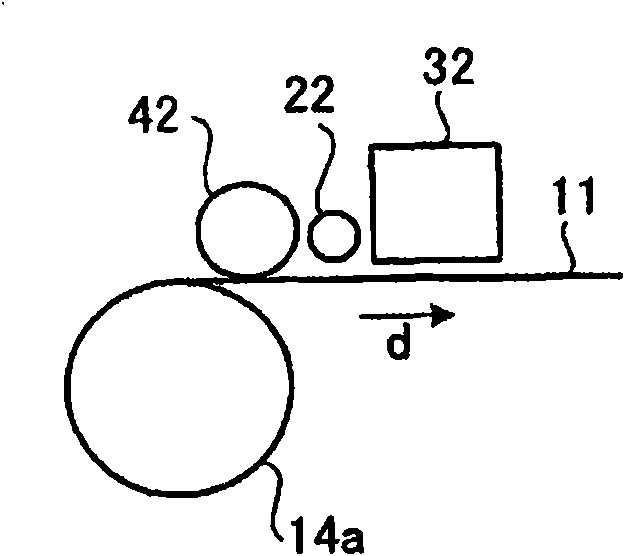

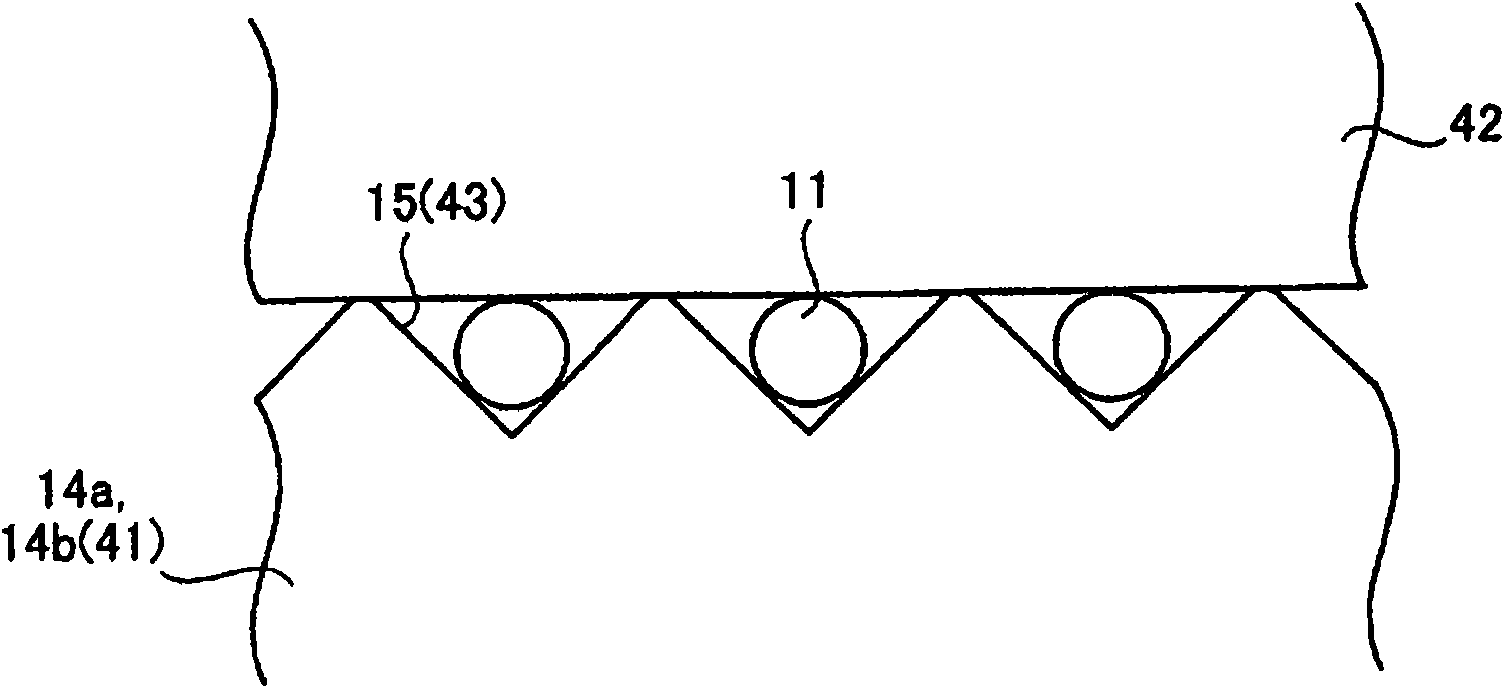

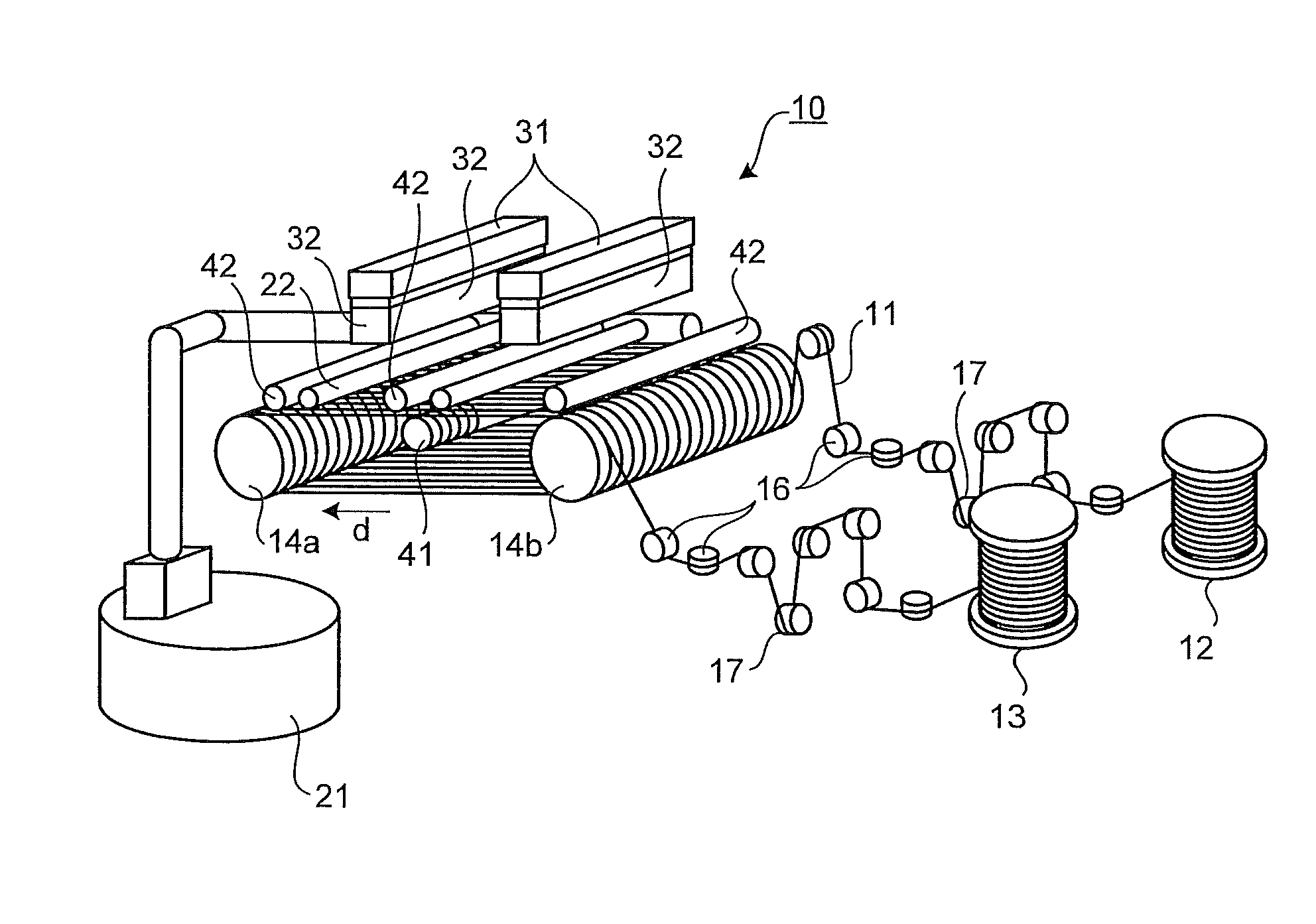

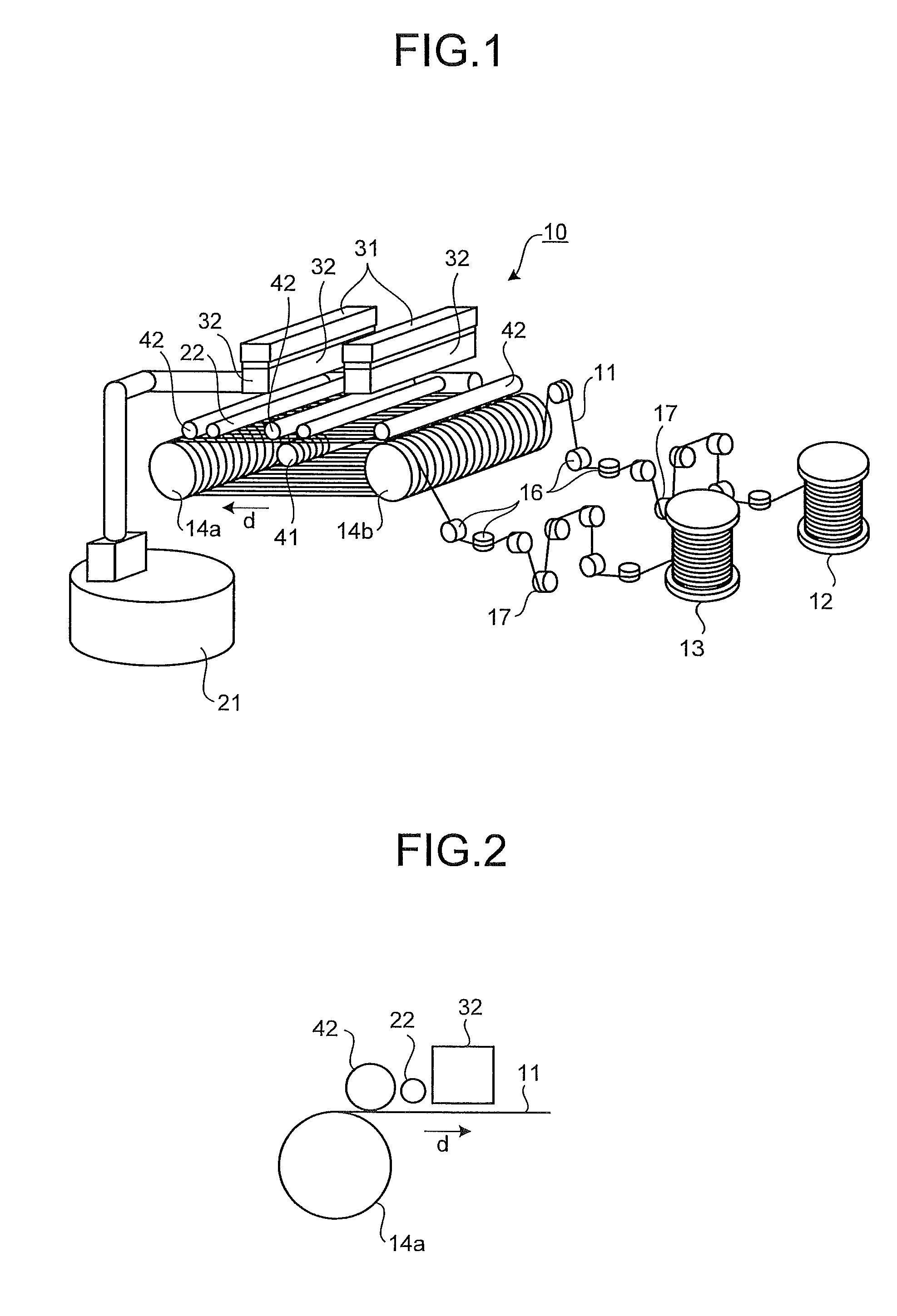

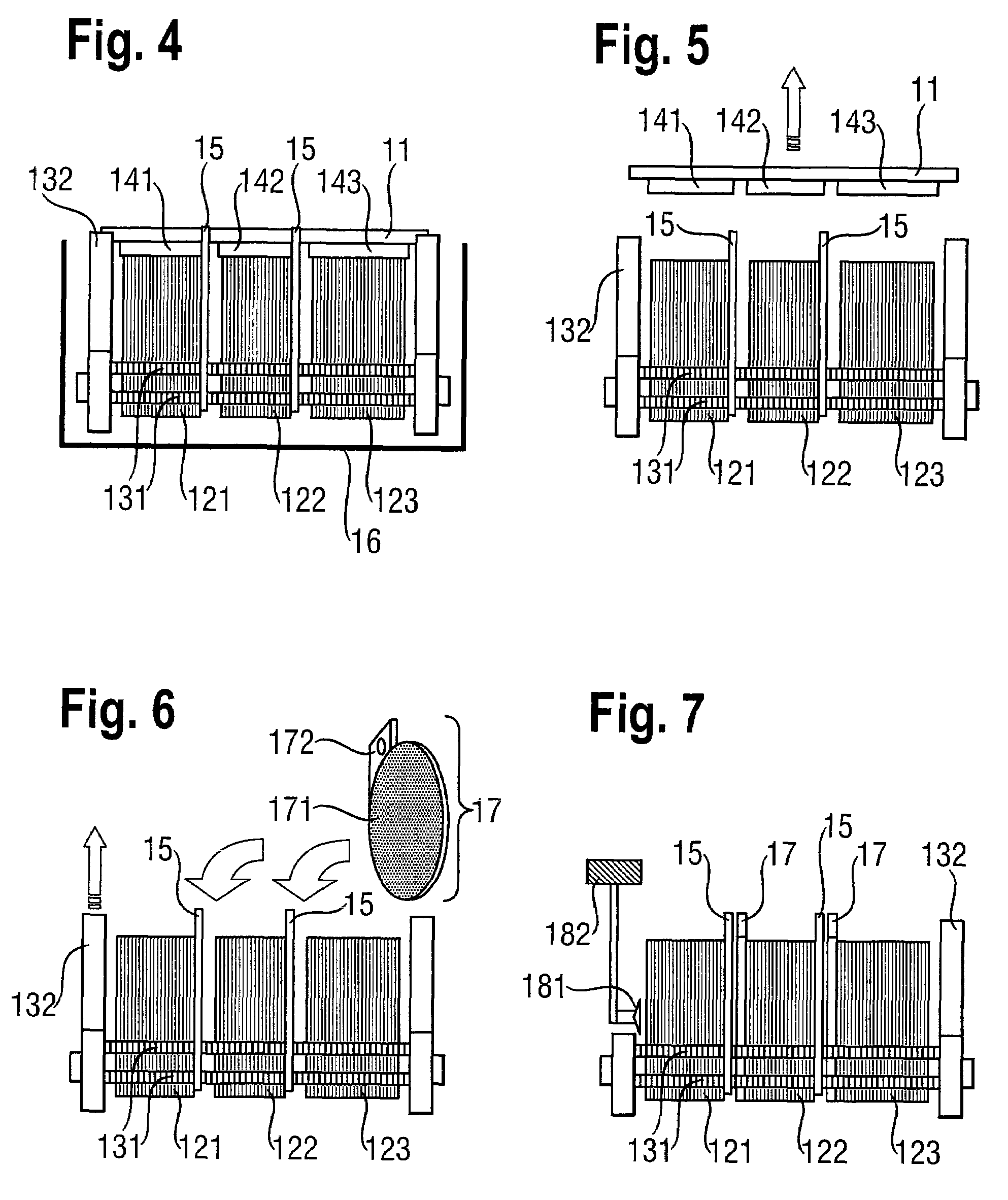

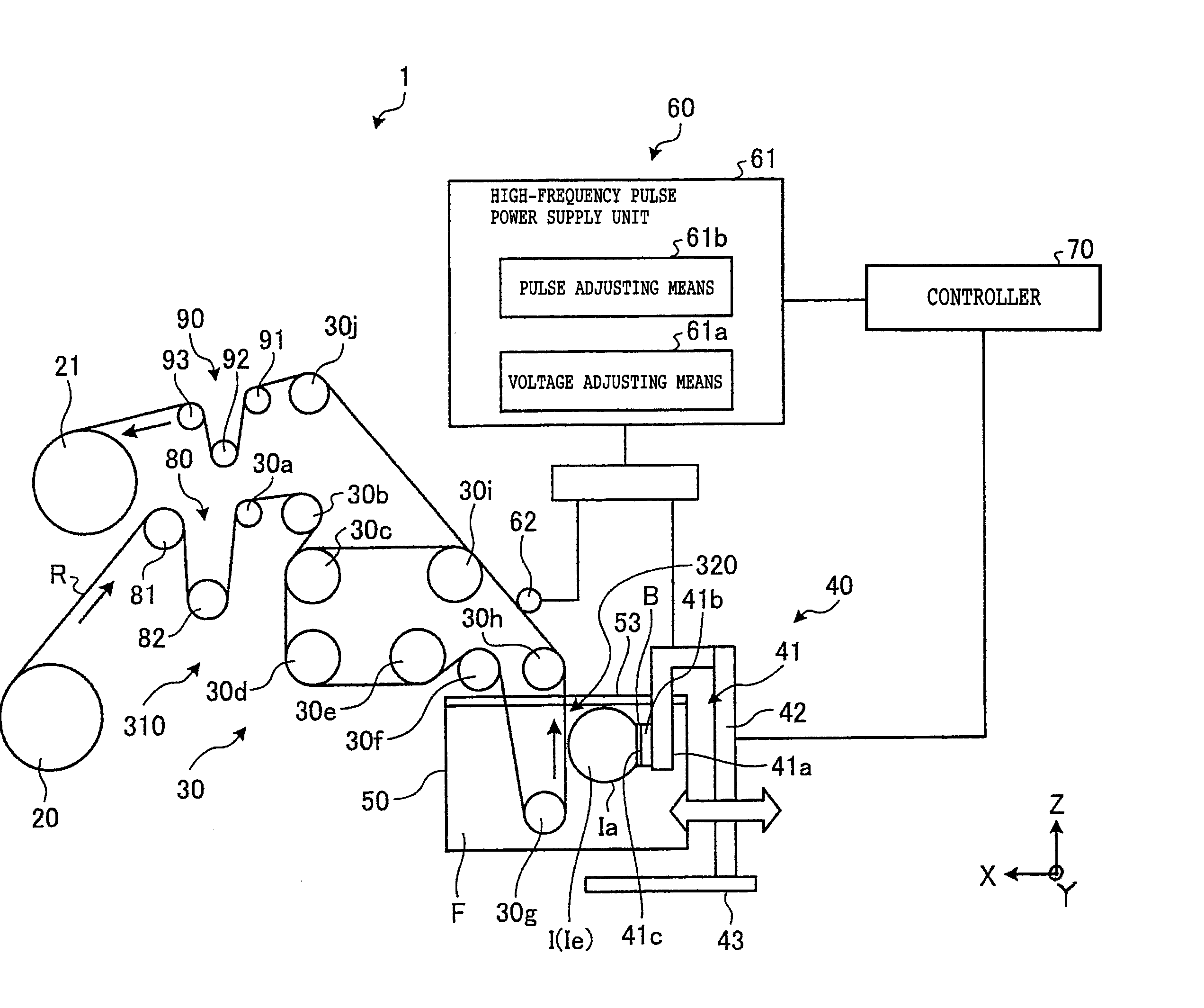

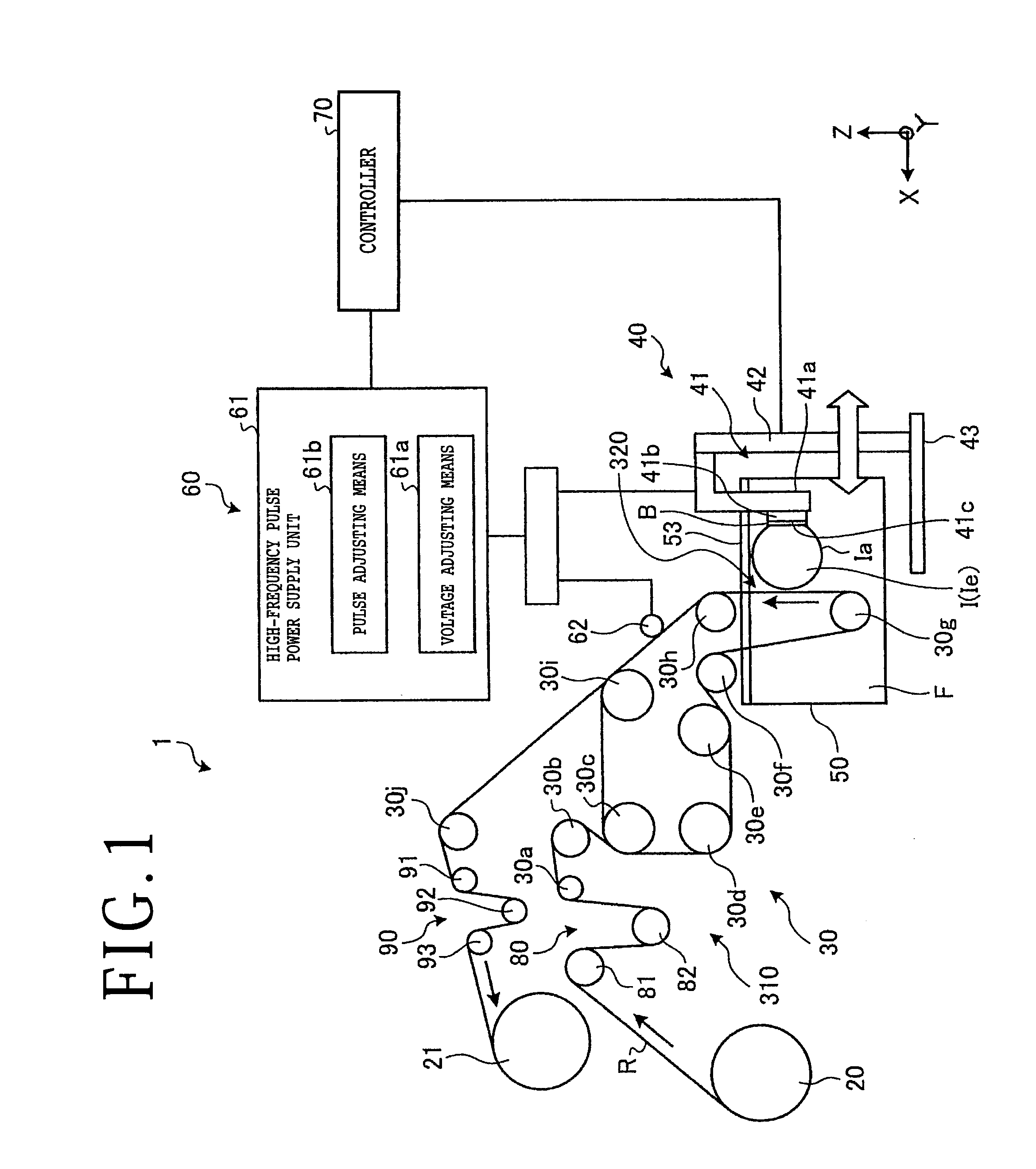

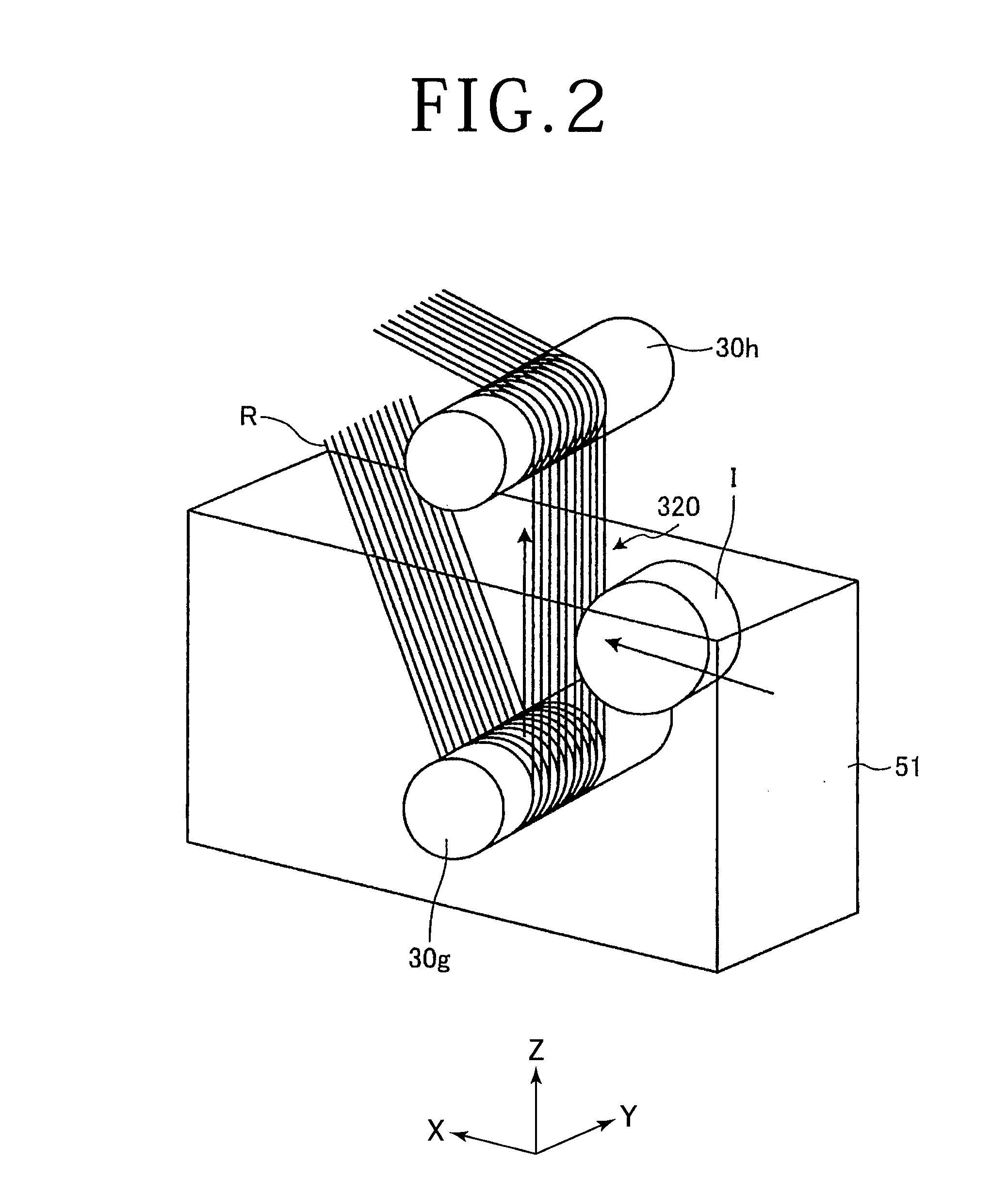

Multi-wire saw and method for cutting ingot

InactiveUS20100163009A1Increase productionReduce thickness variationMetal sawing devicesBelt grinding machinesIngotEngineering

To provide a multi-wire saw that, at the start of cutting of an ingot, prevents a wire from being displaced in grooves of guide rollers due to the wire being lifted. A wire is wound around a plurality of wire guide rollers to be positioned in a feeding direction of an ingot, and in this state, a wire-lifting restraining member that is a body of rotation and restrains the wire from being lifted by being brought into contact with the wire is disposed near the wire guide rollers.

Owner:MITSUBISHI ELECTRIC CORP

Group III nitride wafer and its production method

Owner:SEOUL SEMICONDUCTOR

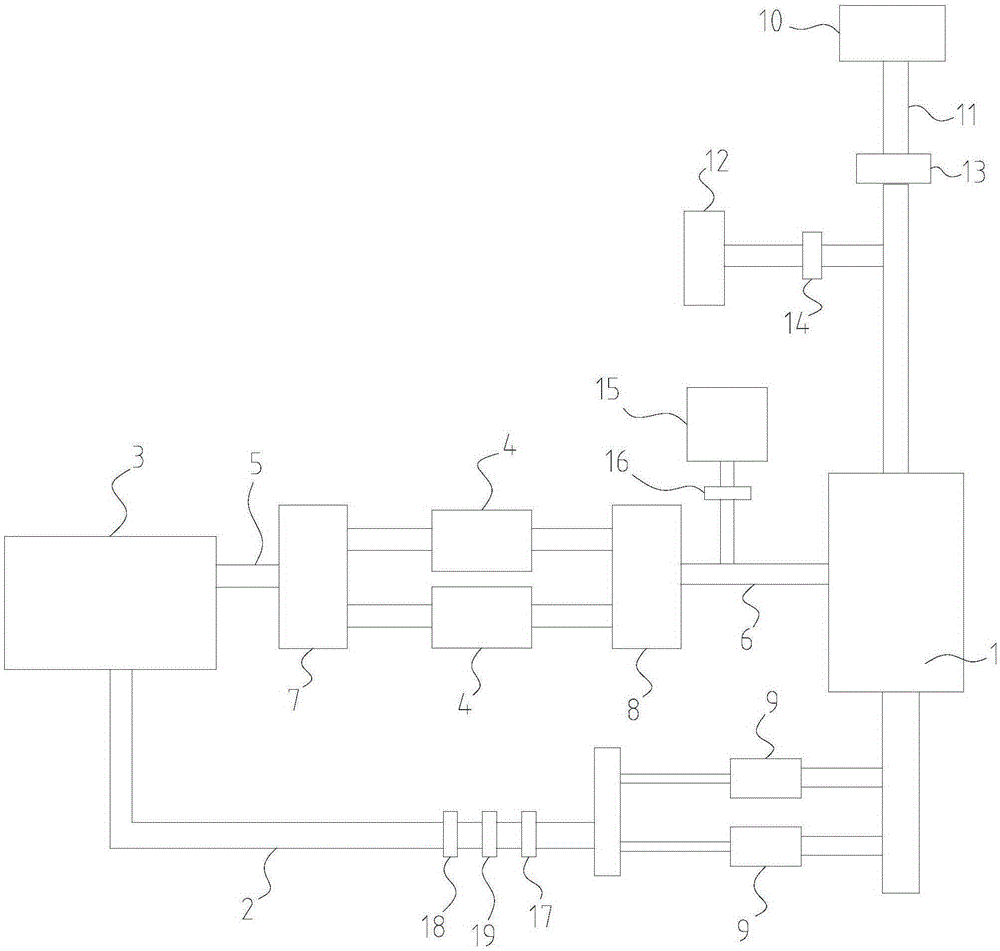

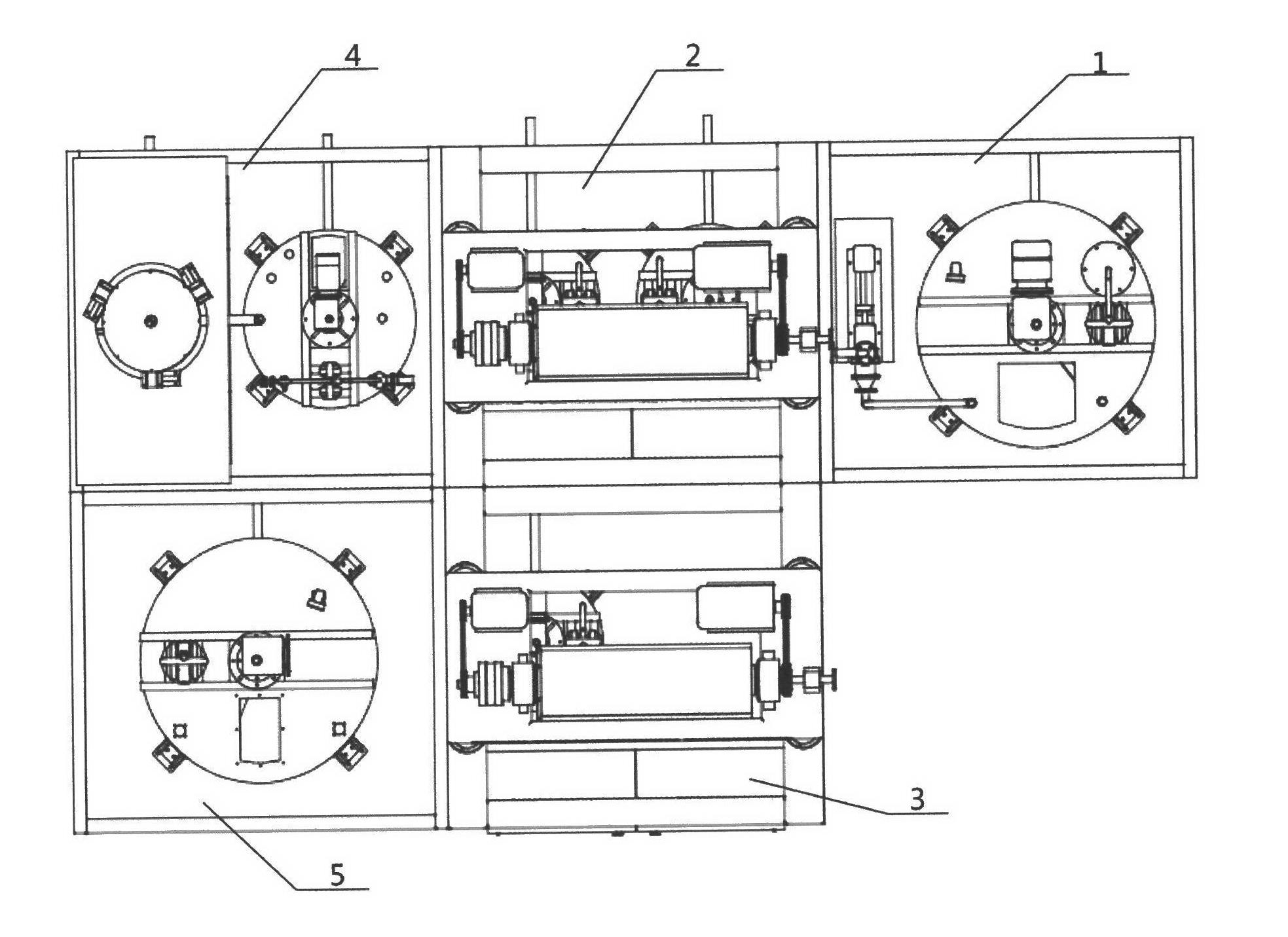

Modular combined on-line recycling treatment system for drained slurry generated by cutting silicon crystal using multi-wire-saw

ActiveCN102528956AImprove construction efficiencyReasonable structureCentrifugal force sediment separationWorking accessoriesAviationProduct system

The invention discloses a modular combined on-line recycling treatment system for drained slurry generated by cutting silicon crystal using a multi-wire-saw, and belongs to the technical field of recycling of the drained slurry generated by cutting silicon crystal. The modular combined on-line recycling treatment system mainly comprises a collection system, a primary separation system, a secondary separation system, a mixing system, a finished product system and a profile steel frame, wherein outlet pipes of slurry conveying pipes of the collection system, the primary separation system, the secondary separation system, the mixing system, and the finished product system adopt PVC (polyvinyl chloride) soft interfaces and fast interfaces, and a control signal line and a flat power wire adopt concealed aviation plugs and security control panels; the whole system equipment is controlled by a man-machine dialogue interface, and is fully and automatically controlled; and when the system is used, the system can be assembled freely according to the size of a user site, the system can be combined at random according to different sizes, so the construction efficiency is greatly improved, the structure is reasonable, the sealing performance is good, and the efficiency is high.

Owner:江苏晔宗环保科技有限公司

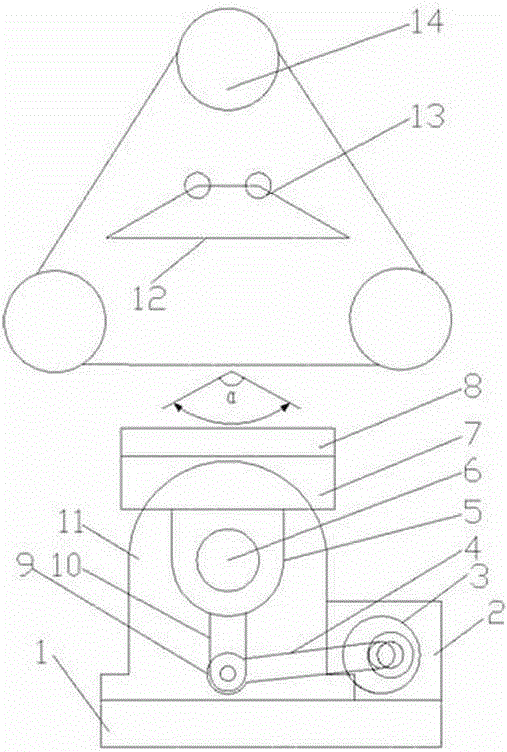

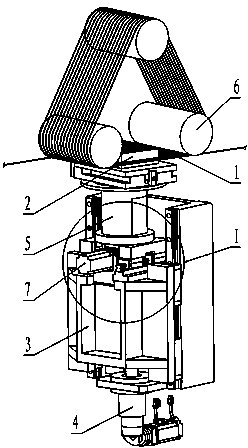

Multi-wire saw for cutting high-hardness materials

InactiveCN103600427ALarge swingSimple exerciseWorking accessoriesFine working devicesWire cuttingHardness

The invention discloses a multi-wire saw for cutting high-hardness materials. The multi-wire saw comprises a workbench capable of oscillating under driving of an oscillating component. A stock plate is placed on the workbench. A multi-wire cutting mechanism is arranged above the workbench and comprises three sheaves in triangular arrangement and wound with cutting wires. The oscillating component comprises a lifter and further comprises a rocker arm; the lifter is provided with provided with a pair of bearing blocks and two ends of a center shaft are mounted in the bearing blocks rotationally; the part, between the two bearing blocks, of the center shaft, is fixedly sleeved with a bearing bush, and the top end of the bearing bush is fixed with the bottom of the workbench; an oscillating rod is fixedly mounted at the bottom of the bearing bush and particularly mounted on an oscillating shaft, two ends of the oscillating shaft are rotationally mounted on a rocker arm support, and the rocker arm support is fixedly mounted on the lifter; one end of the rocker arm is connected to the oscillating shaft while the other end of the rocker arm is mounted on an eccentric shaft, and the eccentric shaft is driven by a motor which is fixedly mounted on the lifter.

Owner:SUZHOU QIMENG CRYSTAL MATERIAL PROD

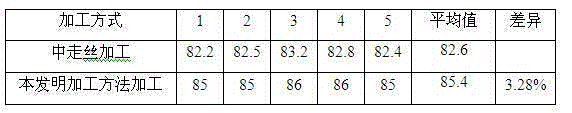

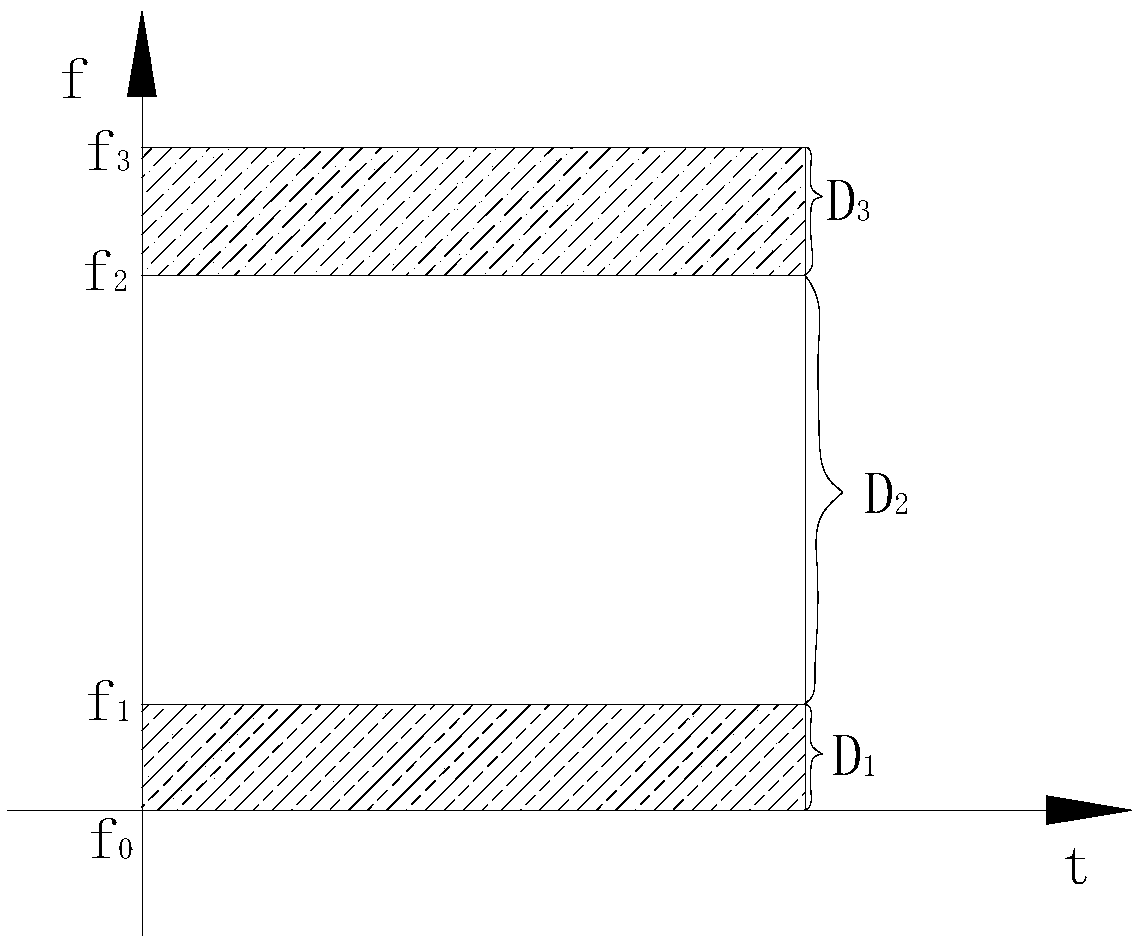

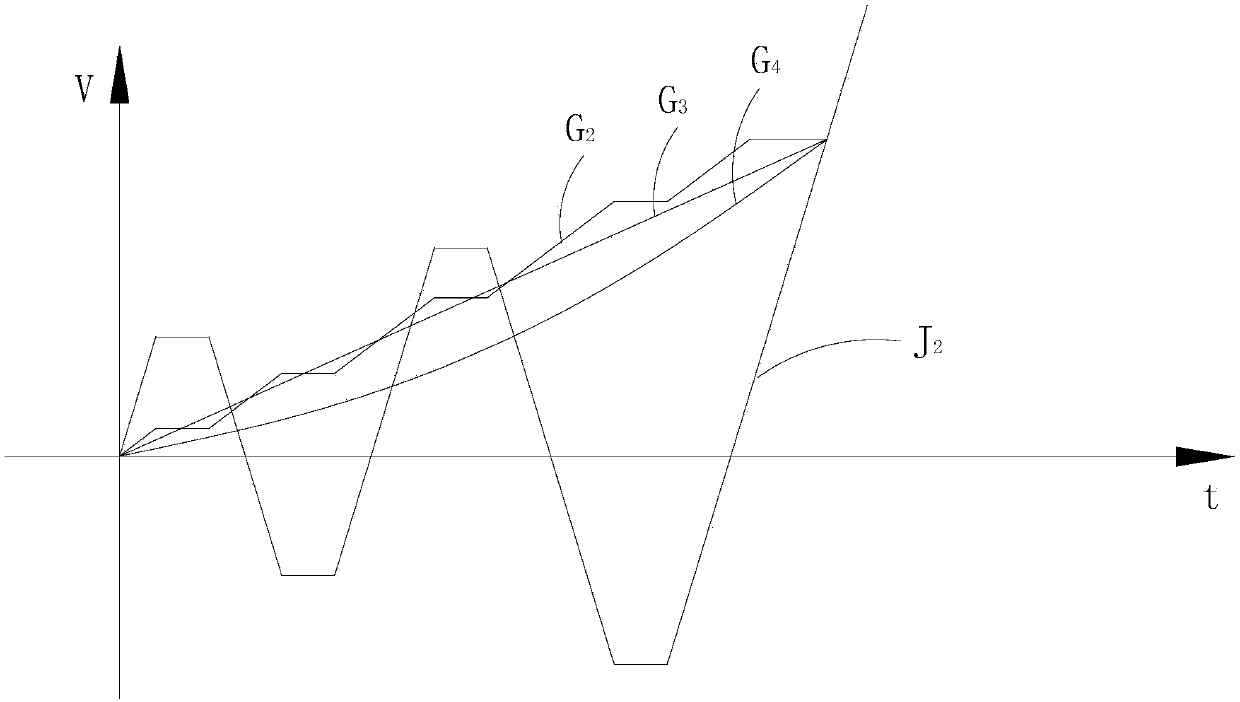

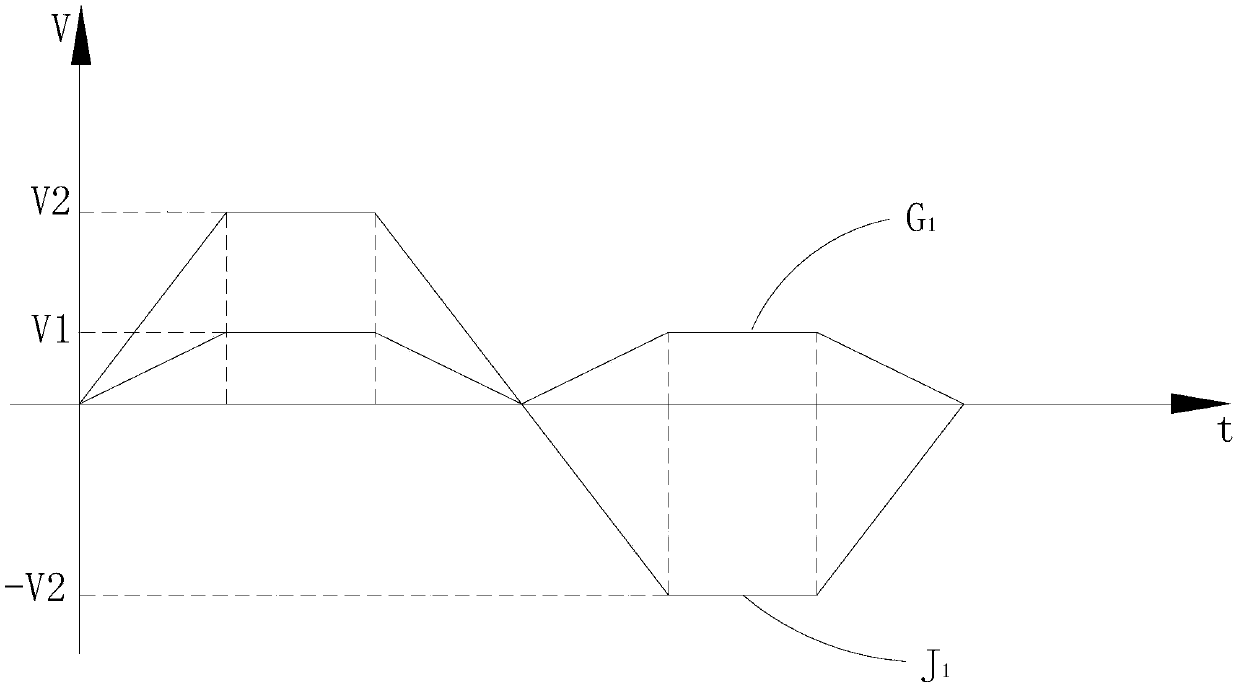

Diamond wire cutting method

The invention relates to a diamond wire cutting method. The method includes a cutter feeding stage, a vibrating cutting stage and a cutter discharging stage, and a multi-wire sawing machine is used for cutting silicon bars, silicon blocks and the like. In the vibrating cutting stage, the workpiece feeding speed and the diamond wire speed are both periodically changed, the workpiece feeding speed is changed along with changing of the diamond wire speed, when a diamond wire moves at a constant speed, a workpiece also moves at a constant speed, when the diamond wire moves in a deceleration mode,the workpiece also moves in a deceleration mode, and when the diamond wire moves in an accelerating mode, the workpiece also moves in an accelerating mode, so that difference value fluctuation betweenthe workpiece feeding speed and the diamond wire speed is reduced, and wire arching of the diamond wire is reduced so as to reduce wire consumption and a wire breaking risk of the diamond wire; meanwhile, cutting capacity of the diamond wire is guaranteed, obvious cutting marks on the surfaces of silicon wafers are reduced, and silicon wafers with the better quality are obtained.

Owner:GCL POLY ENERGY HLDG

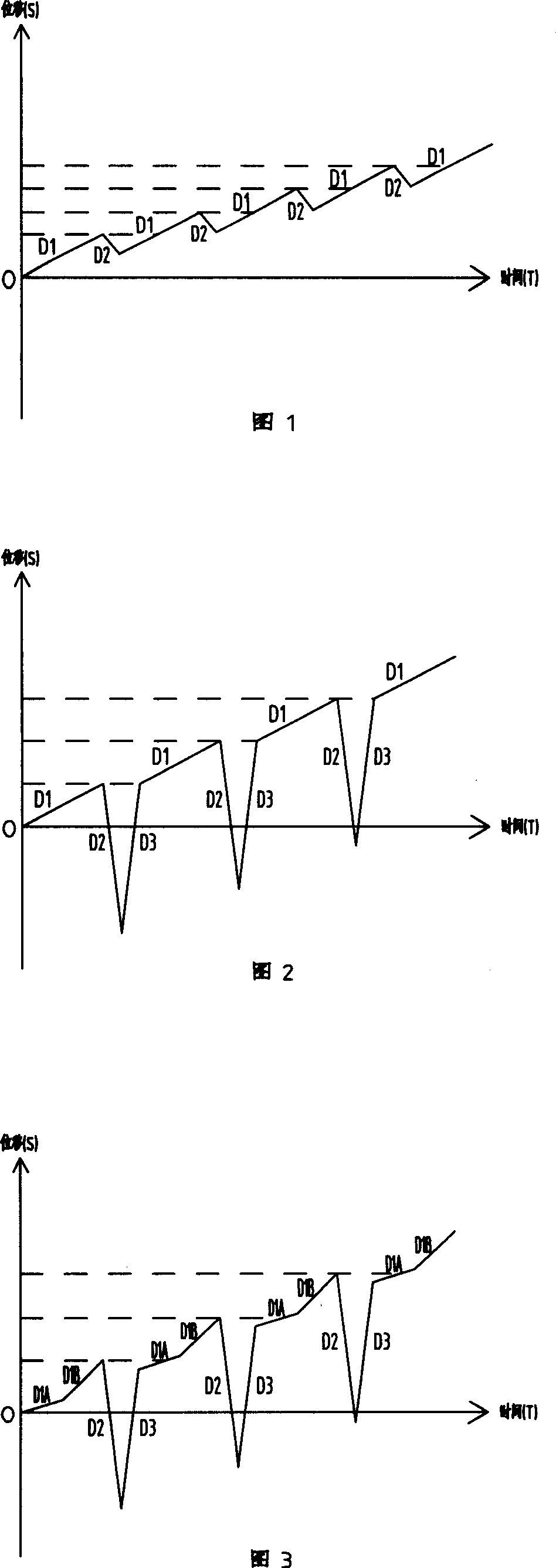

Feeding controlling means for multi-wire saw working bench

InactiveCN101015943AMeet expectationsEasy to implementFine working devicesFret sawsControl mannerWorkbench

The invention discloses a feeding control method for feeding abrasive sand into the multi-line cutter workbench at the lower part of the contact face between steel wire and work-piece. The invention is characterized in that the workbench feeding is changed from continuous feeding into intermittent reciprocal feeding. The invention has simple control, and 20-50% improved cutting efficiency when cuts diamond (HRC65-85) and carbon silicon (HRC75-95), to reduce cost.

Owner:HUNAN YUJING MACHINE

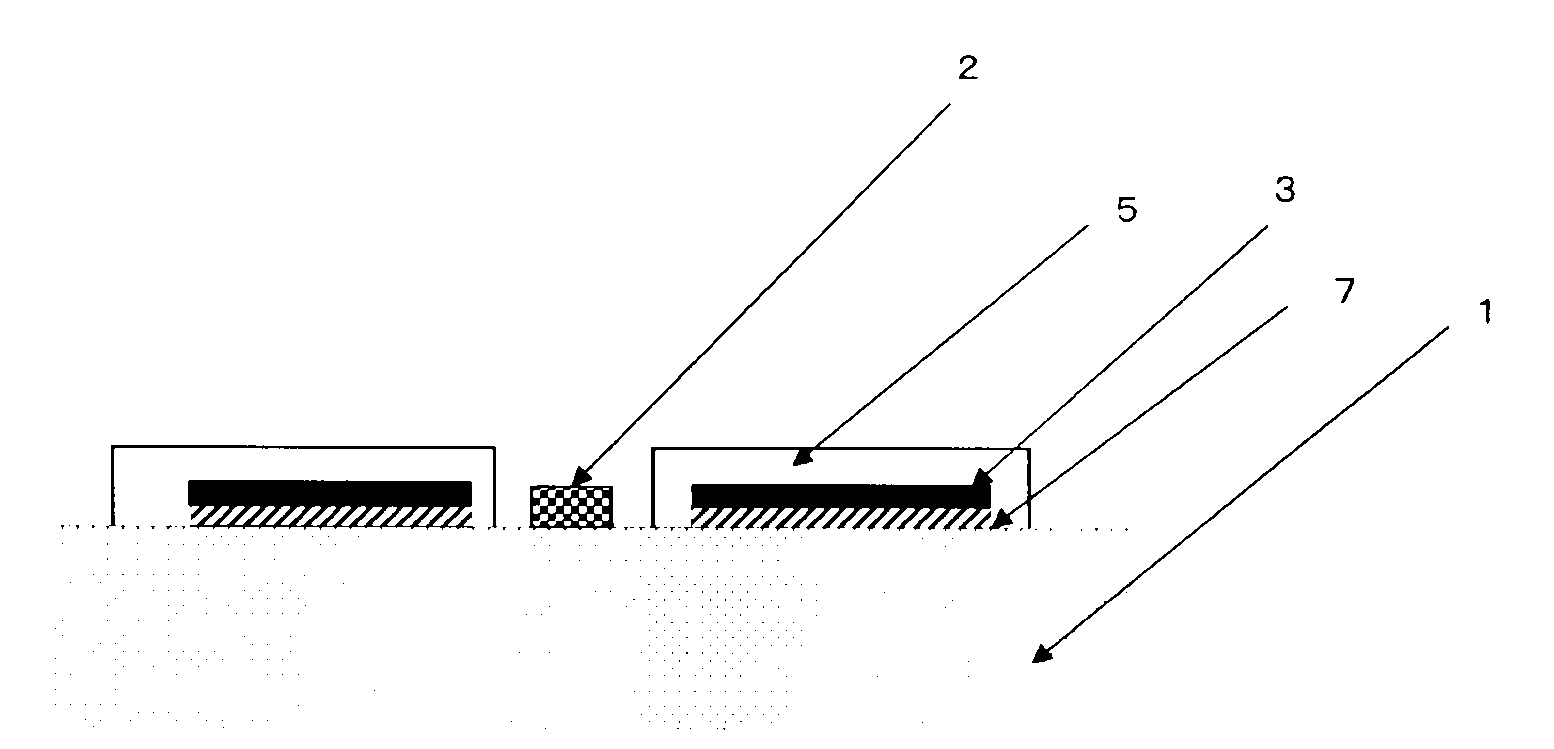

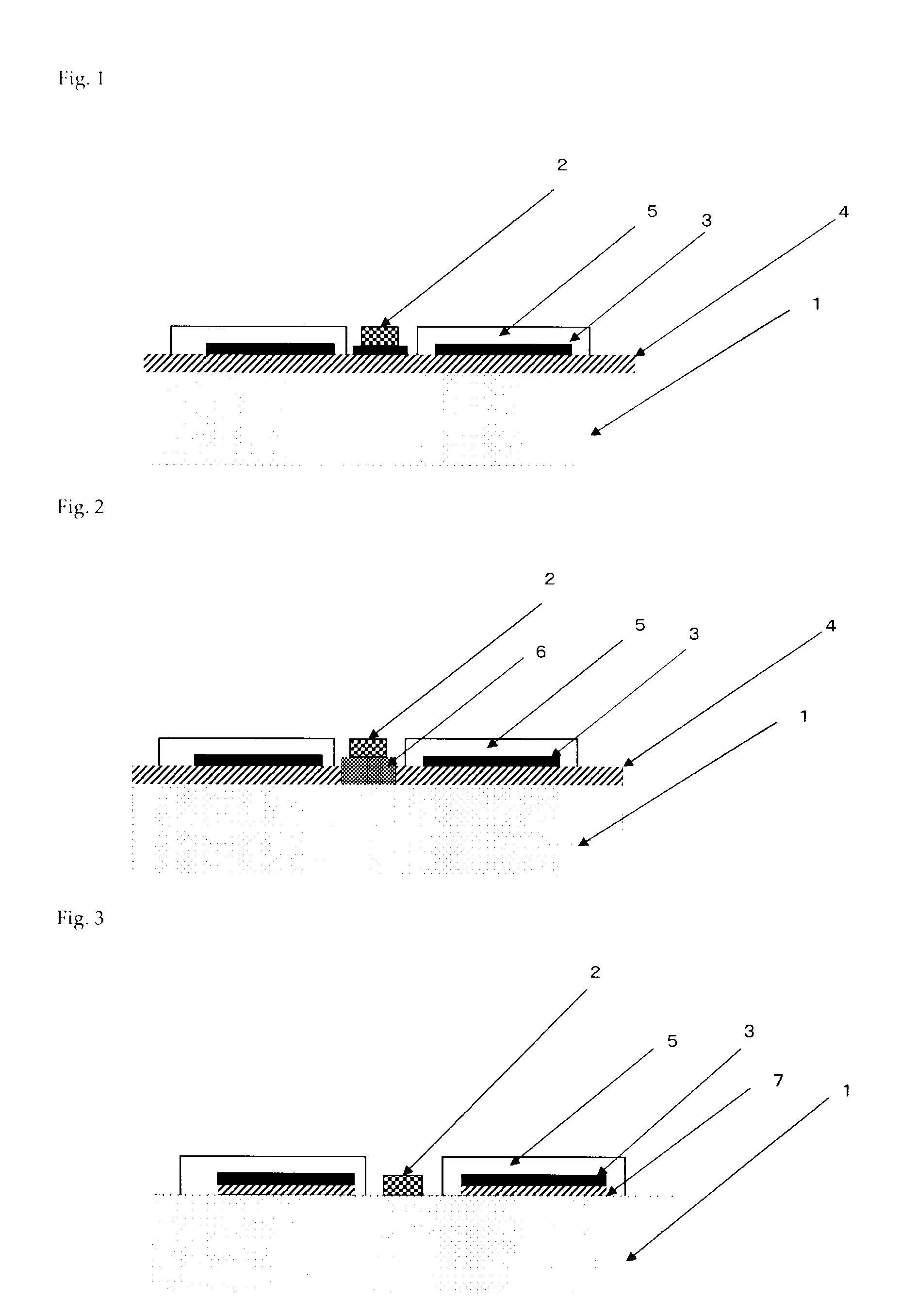

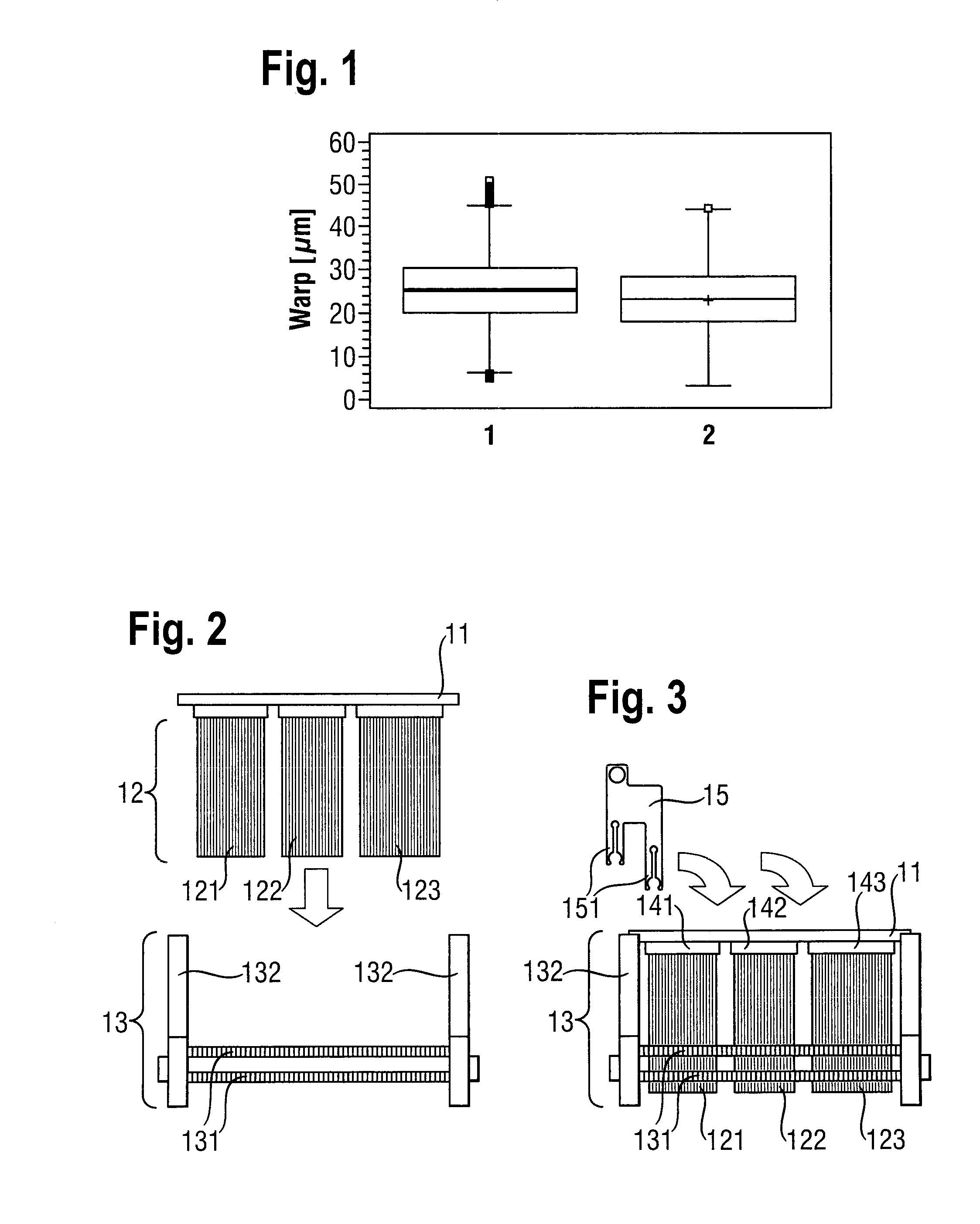

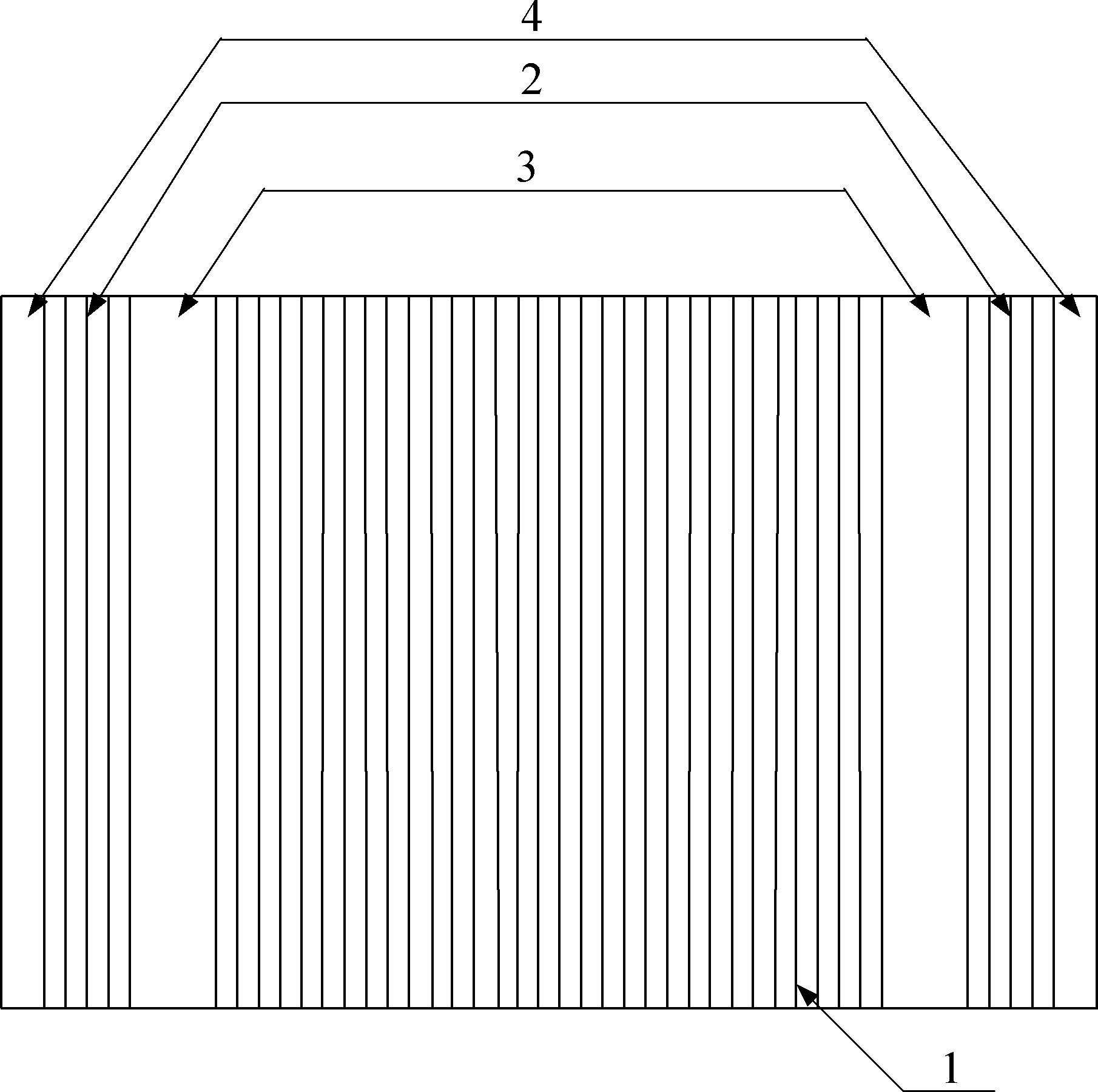

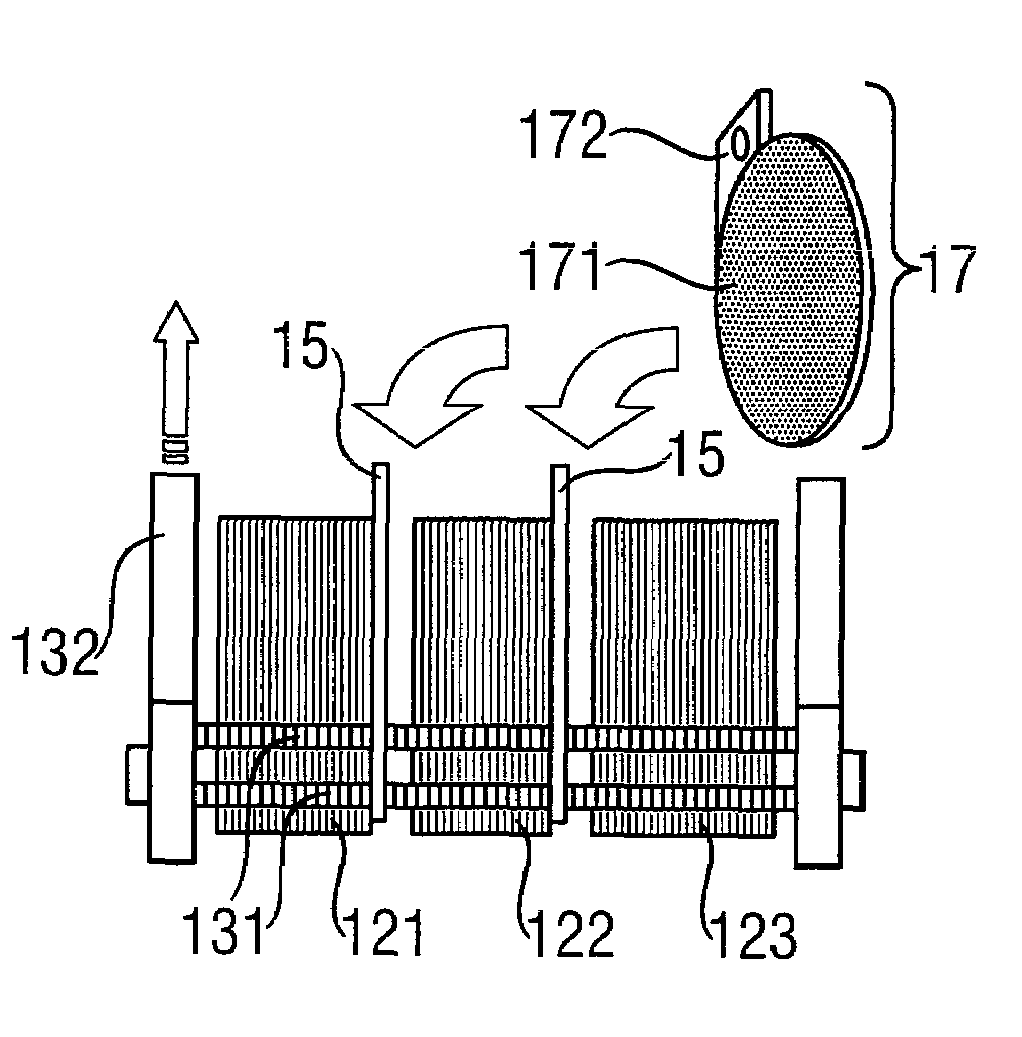

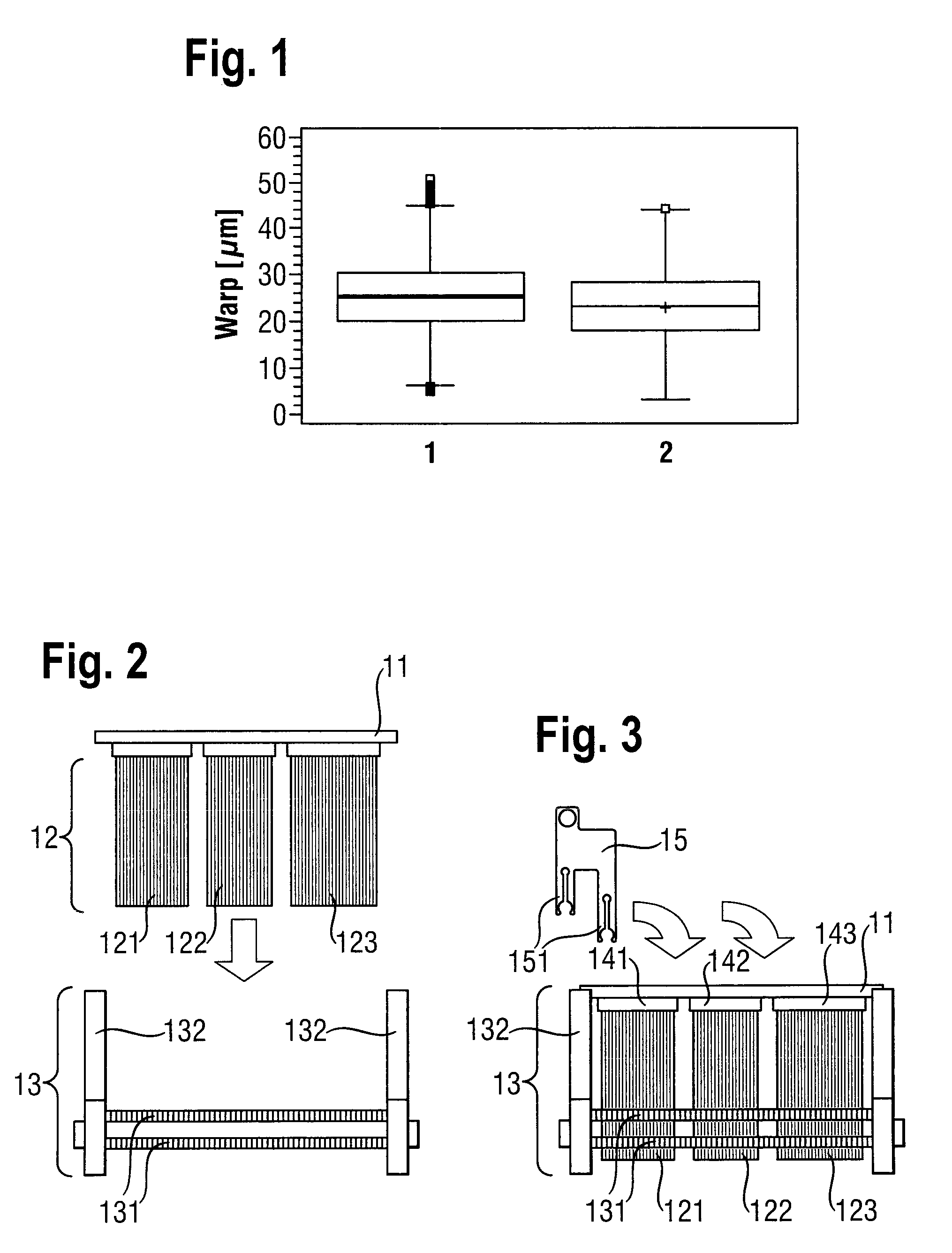

Method for simultaneously slicing at least two cylindrical workpieces into a multiplicity of wafers

ActiveUS20080099006A1Increase profitLarge lengthMetal sawing devicesSemiconductor/solid-state device manufacturingWafer stackingEngineering

Slicing multiple cylindrical workpieces into wafers by a multi wire saw with a gang length LG, is performed by:a) selecting a number n≧2 of workpieces from a stock of workpieces with different lengths, satisfying the inequalityLG≥(n-1)·Amin+∑i=1nL1(1)and making right-hand side of the inequality as large as possible, where Li with i=1 . . . n are for the lengths of the workpieces and Amin is a predefined minimum spacing,b) fixing the n workpieces successively in the longitudinal direction on a mounting plate while maintaining a spacing A≧Amin therebetween such that the relationshipLG≥(n-1)·A+∑i=1nLi(2)is satisfied,c) clamping mounting plates workpieces in a multi wire saw, andd) slicing the n workpieces perpendicularly to their longitudinal axis by means of the multi wire saw. Preferably, the wafer stacks are separated from one another by separating pieces after slicing, and at the same time are laterally supported.

Owner:SILTRONIC AG

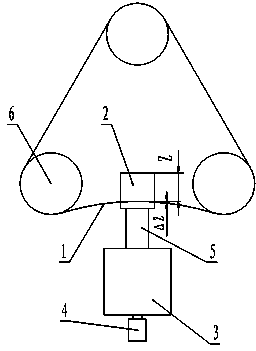

Multi-wire sawing machine capable of eliminating arc influence of sawing wires

ActiveCN103909585AReduce processing costsReduced total cutting timeFine working devicesEngineeringPulley

The invention provides a multi-wire sawing machine capable of eliminating arc influence of sawing wires. The multi-wire sawing machine is provided with a grooved pulley assembly, sawing wires, a lifter, a lifting driving mechanism and a worktable; the sawing wires are wound around the pulley assembly to form a sawing wire net, the lower end of the lifter is assembled with the lifting driving mechanism, the worktable is arranged above the lifter, and a workpiece to be sawn is clamped on the worktable. The multi-wire sawing machine is characterized by further comprising a horizontal feed mechanism consistent with the moving direction of the sawing wires; the horizontal feed mechanism is arranged between the lifter and the worktable. The multi-wire sawing machine has the advantages that the position of the workpiece is changed in due time by use of the horizontal feed mechanism, so that the influence of the arc of the sawing wires on the completeness of the cut surface of the workpiece is eliminated, and therefore, the total sawing time of the workpiece is shortened, the production efficiency is improved, and the processing cost of slicing a brittle material is reduced.

Owner:唐山晶玉科技股份有限公司

Application method of multi wire saw in Nd-Fe-B cutting

InactiveCN101200101AReduce manufacturing costStone-like material working toolsWire tensionWire cutting

The invention relates to an application method of a multi wire cutting machine in cutting nd-fe-b, whose steps comprise the starting of a wire saw; testing the set parameters of wire tension force, time waiting for cutting, time of delaying cutting, time of slurry refluxing and time of cleaning every steps; operating all shafts and wheels to original options; setting the parameters of cutting value, cutting speed, wire retreating speed and unloading position; opening a slurry valve and starting a slurry supplying system; installing a baffle and a slurry baffle curtain and closing a cabinet door; pressing a start cutting button and beginning cutting. The invention can guarantee that the wire saw can cut thin nd-fe-b sheet, the production cost is reduced, and the considerable economic benefit can be produced.

Owner:NINGBO KONIT IND +1

NdFeB permanent magnetic material processing method and device

InactiveCN104015268AReduce the amount of processingReduce machining accuracyFine working devicesAdhesiveEngineering

The invention discloses a NdFeB permanent magnetic material processing method which includes the step of material binding and the step of cutting. In the step of material binding, a material plate is attached to a smooth and flat cushion plate in an adhesive mode through an adhesive, bar-shaped materials to be processed are attached together through the adhesive, the attached bar-shaped materials to be processed are positioned and attached to the material plate for processing, and the adhesive can not permeate the cushion plate; in the step of cutting, a cutting zero point is determined, cutting parameters are set, arc cutting, wire retracting and unloading are sequentially finished after cutting through a multi-wire sawing machine, and the cutting parameters are set in the mode that unwinding tension is 10-40 N, winding tension is 10-40 N, cutting speed is 10-500 mm / s, reciprocating time is 10-60 S, arc suppression time is 500-2000 S, and new wire feeding speed is 20-40 m / min.

Owner:SINO MAGNETICS TECH

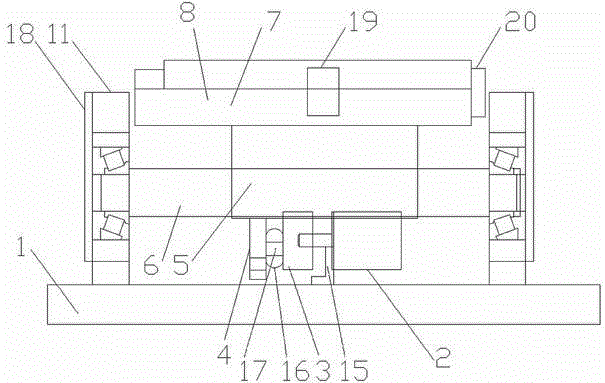

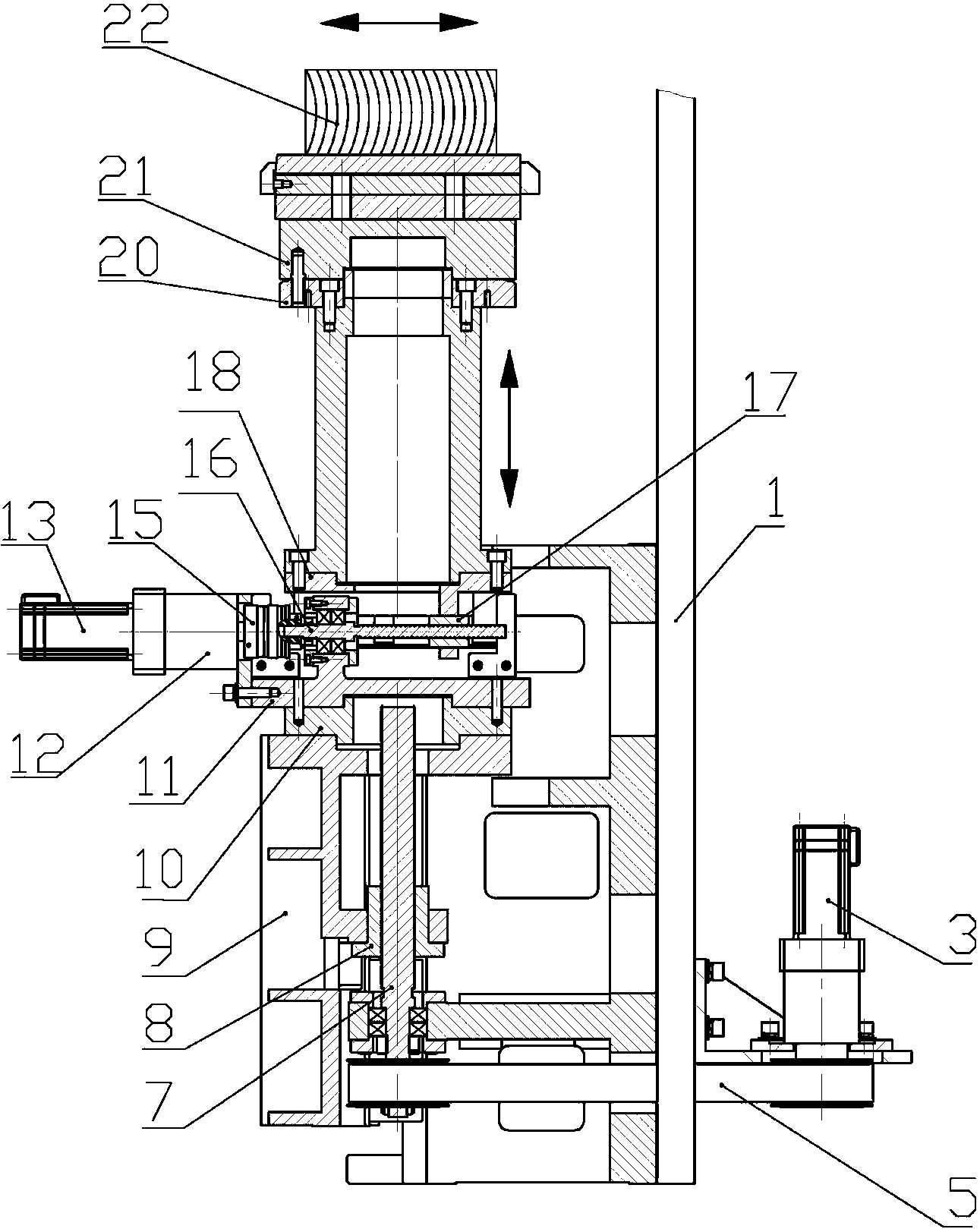

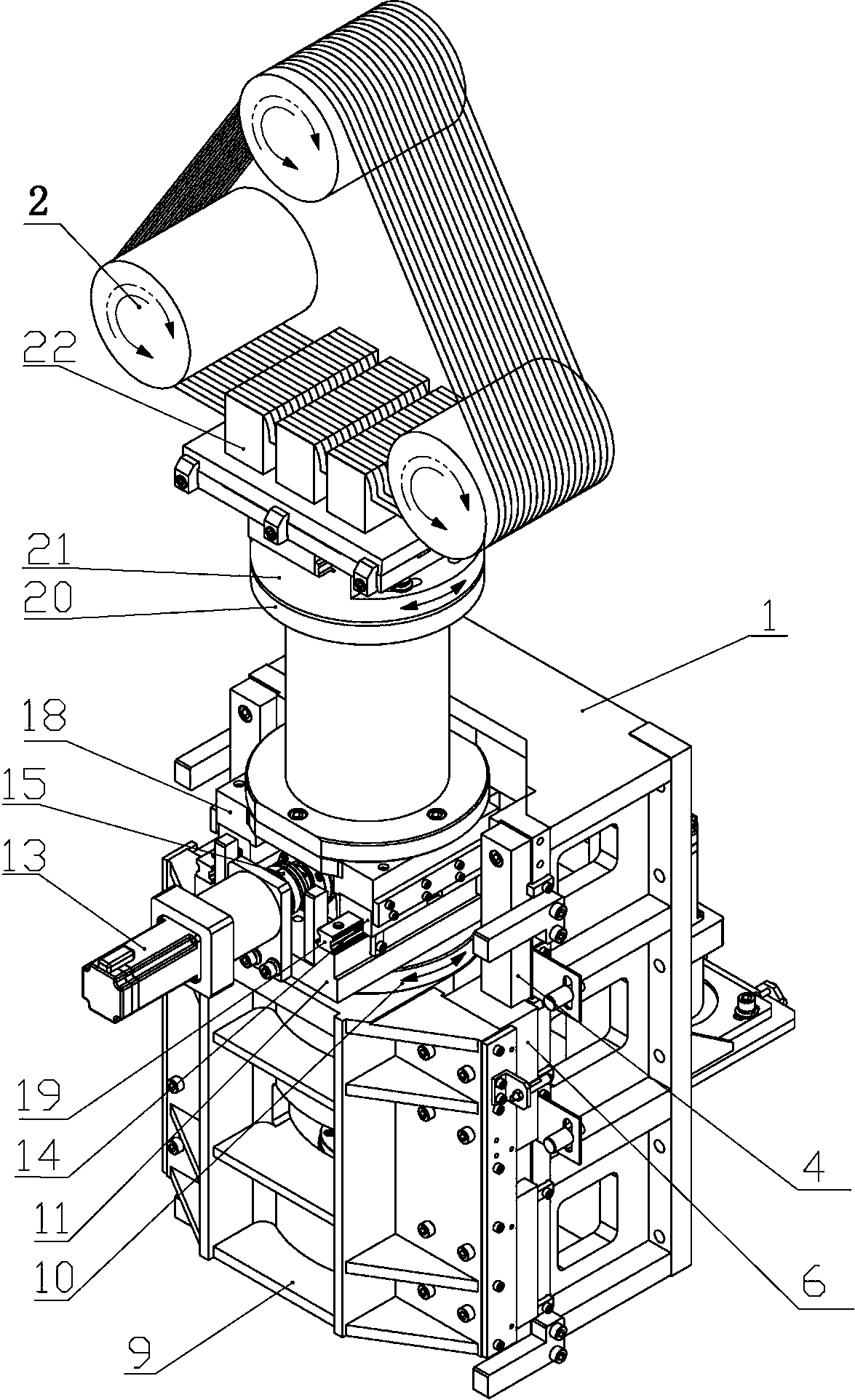

Worktable of multi-wire sawing machine

ActiveCN102837372ASimple structureImprove work efficiencyWorking accessoriesFine working devicesMechanical engineeringMulti-wire saw

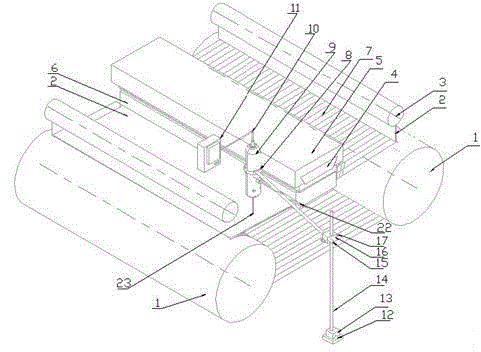

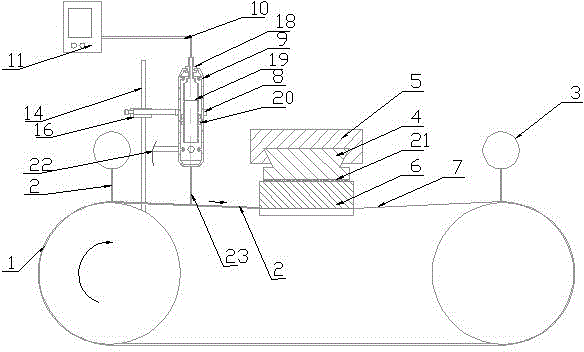

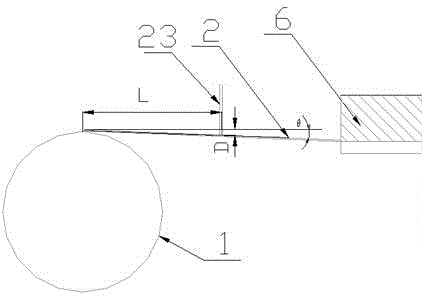

The invention discloses a worktable of a multi-wire sawing machine for processing a hard and brittle material curved surface. The curved surface is formed by the motion of a straight edge line, the worktable comprises a stander (1), a vertical sliding seat (9) driven by a vertical driving mechanism is arranged on the stander (1), the worktable of the multi-wire sawing machine is characterized in that a horizontal fixed seat (11) is arranged on the vertical sliding seat (9), a horizontal sliding seat (18) driven by a horizontal driving mechanism is arranged on the horizontal fixed seat (11), and the worktable (21) is arranged on the horizontal sliding seat (18); and a control device realizes the synthetic feeding of the worktable (21) in the vertical and the horizontal directions through the controls of the vertical driving mechanism and the horizontal driving mechanism. The worktable disclosed by the invention can simultaneously realize the feeding in two directions so as to finish the multi-wire sawing of the hard and brittle material curved surface, thereby greatly improving the work efficiency.

Owner:HUNAN YUJING MACHINE

Method of cutting high-hardness material with multi-wire saw

ActiveCN104786376AReduce workloadImprove sharpnessMetal sawing toolsFine working devicesReciprocating motionIngot

In a method of cutting a high-hardness material with a multi-wire saw, an ingot of the high-hardness material is sliced into a plurality of wafers by cutting the ingot at multiple points simultaneously with the multi-wire saw. The method comprises repeating a run cycle of reciprocating motion of a wire of the multi-wire saw so that the relationships (1) c1≧20, given C1=b / a and (2) 0.35≰c2≰1.55, given c2=d / a are satisfied, where a is a maximum total contact length defined as a sum of the lengths of the ingot as projected onto multiple cut points when projecting the ingot onto the wire in a direction in which the ingot is going to be cut, b is a continuous travel distance of the wire, and d is a length of the wire newly fed in each said run cycle.

Owner:HITACHI METALS LTD

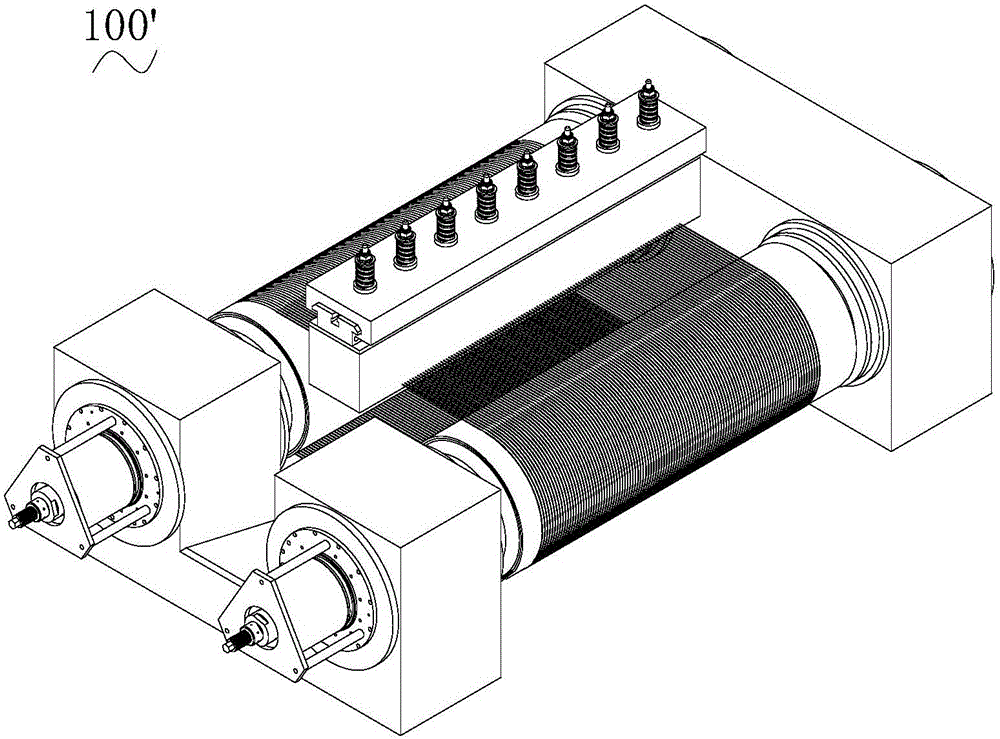

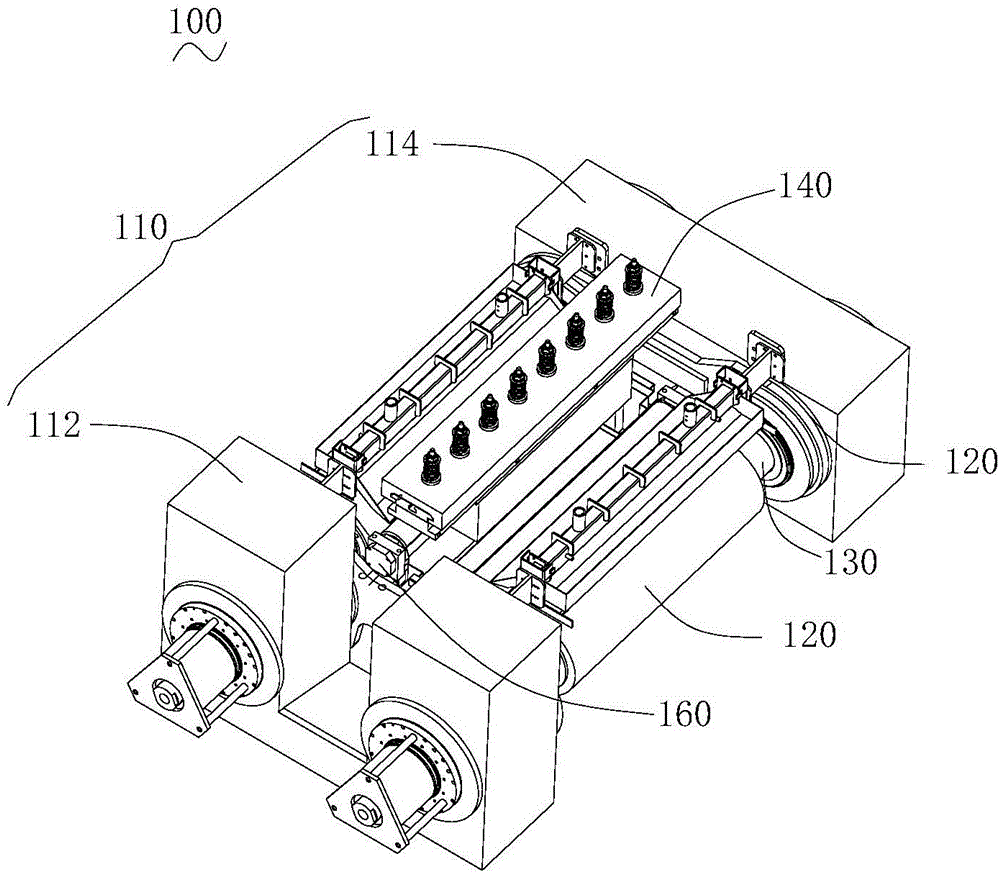

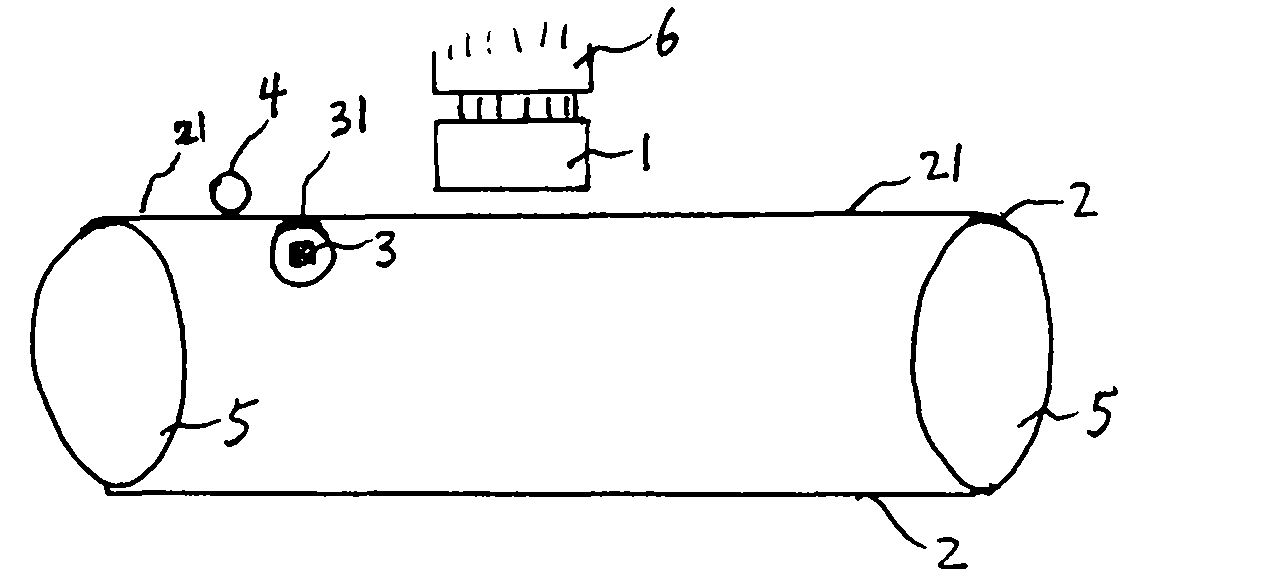

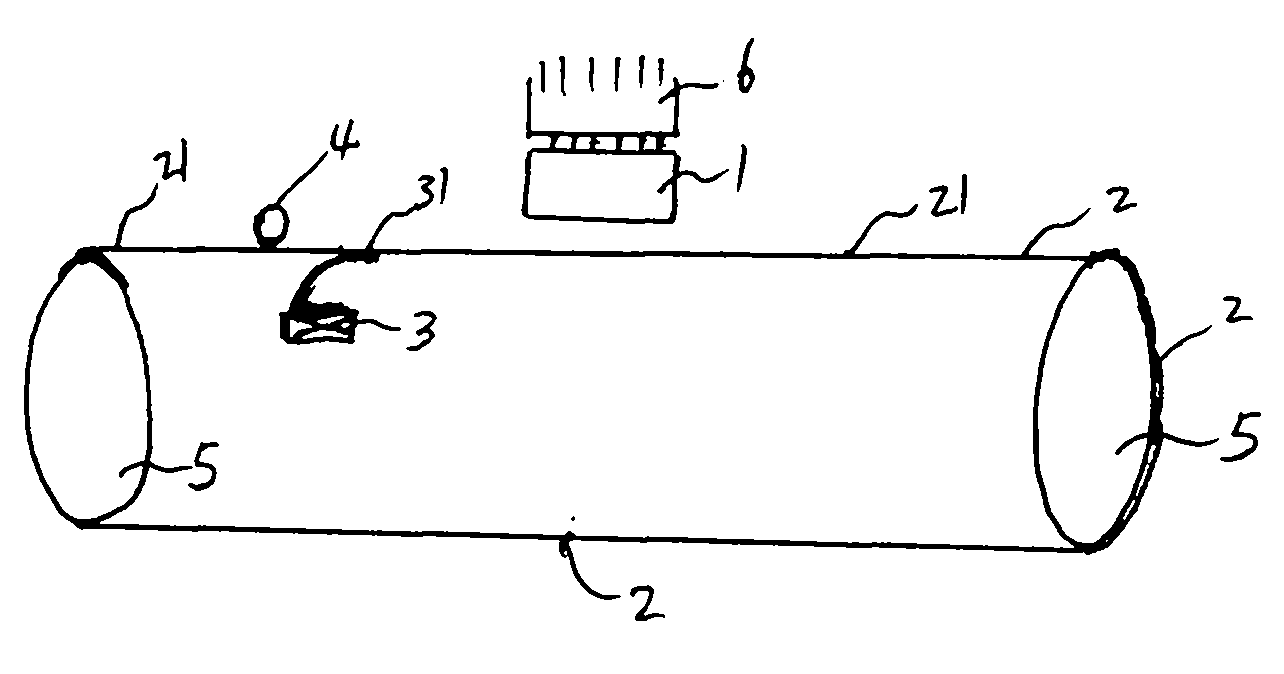

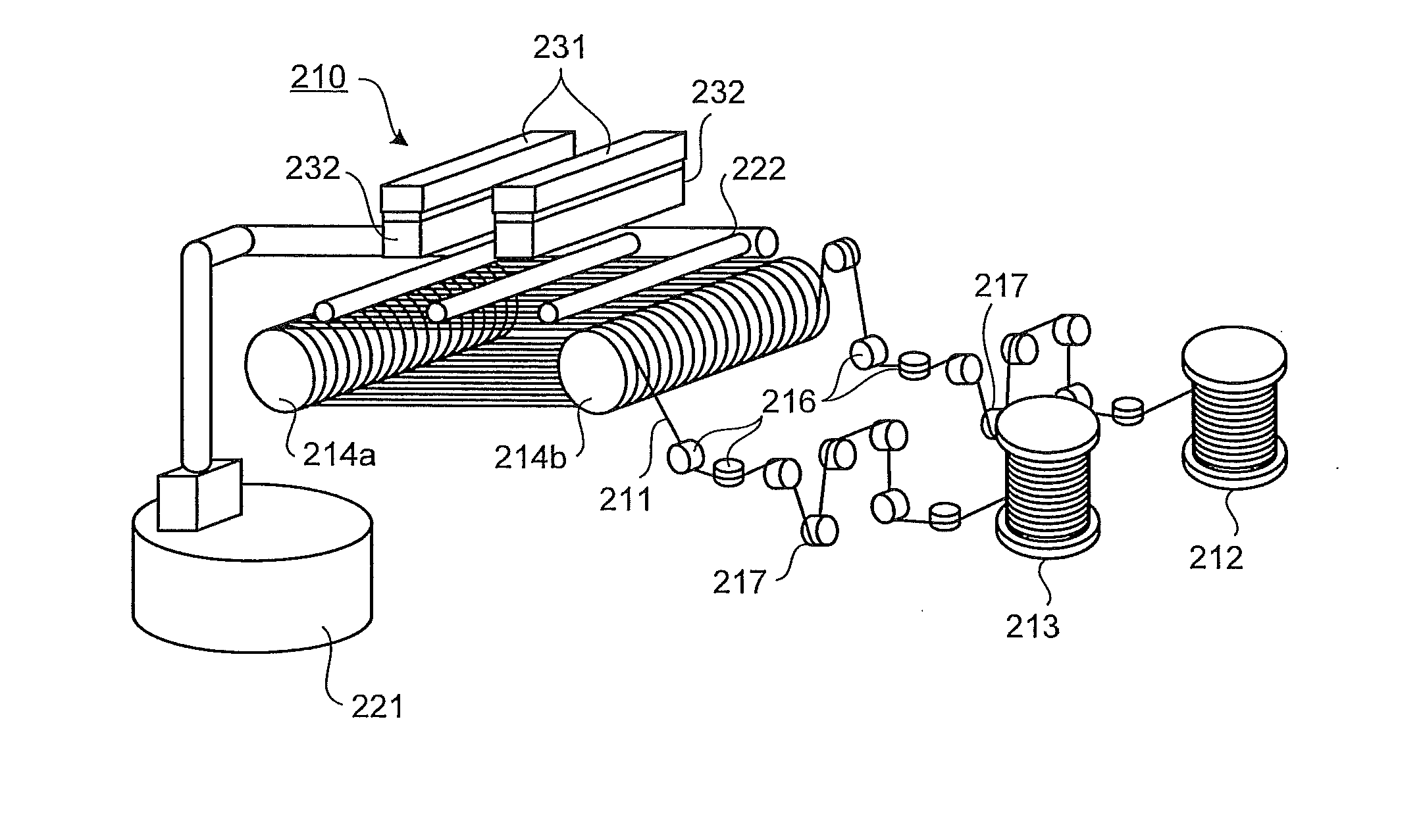

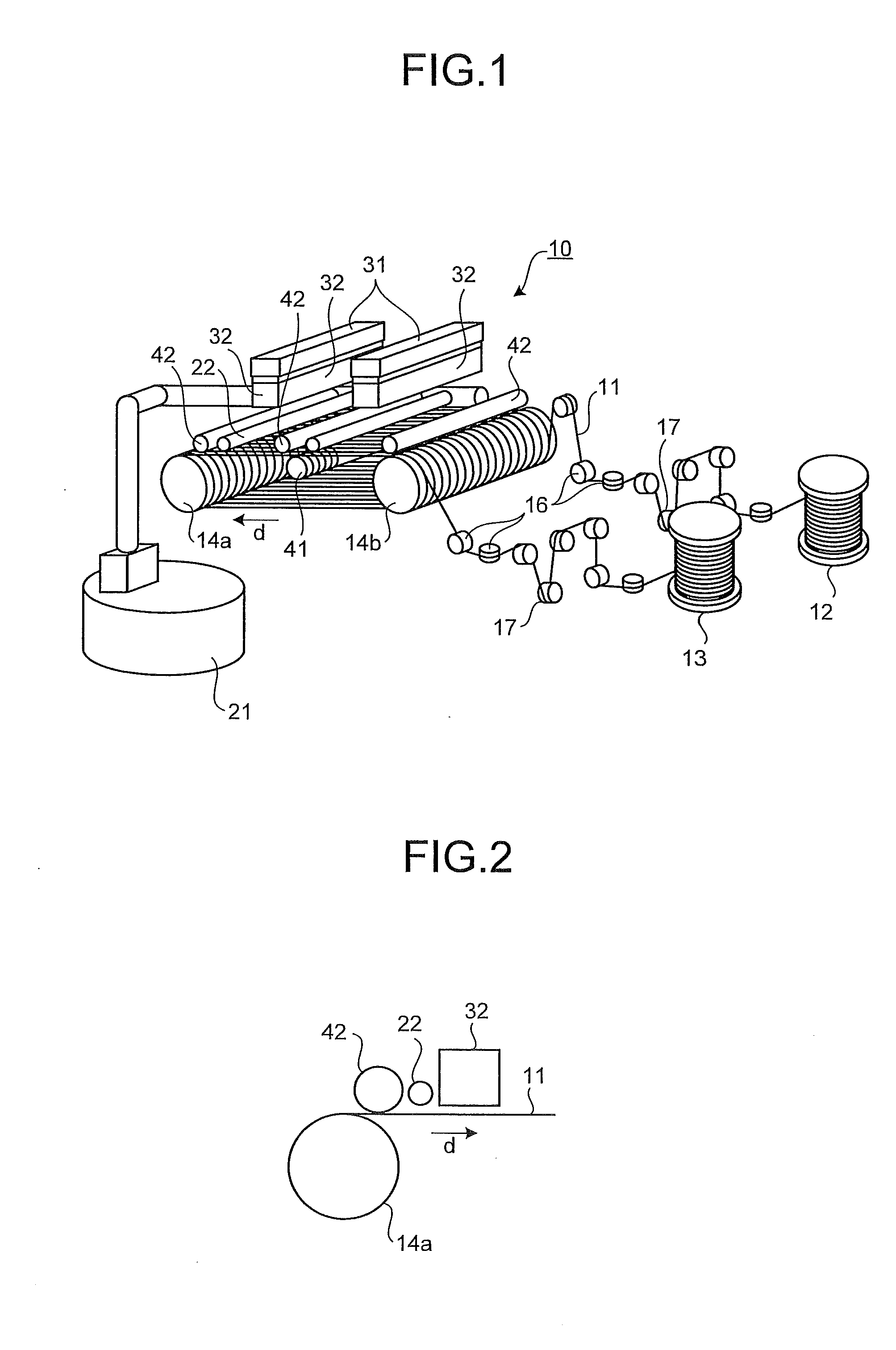

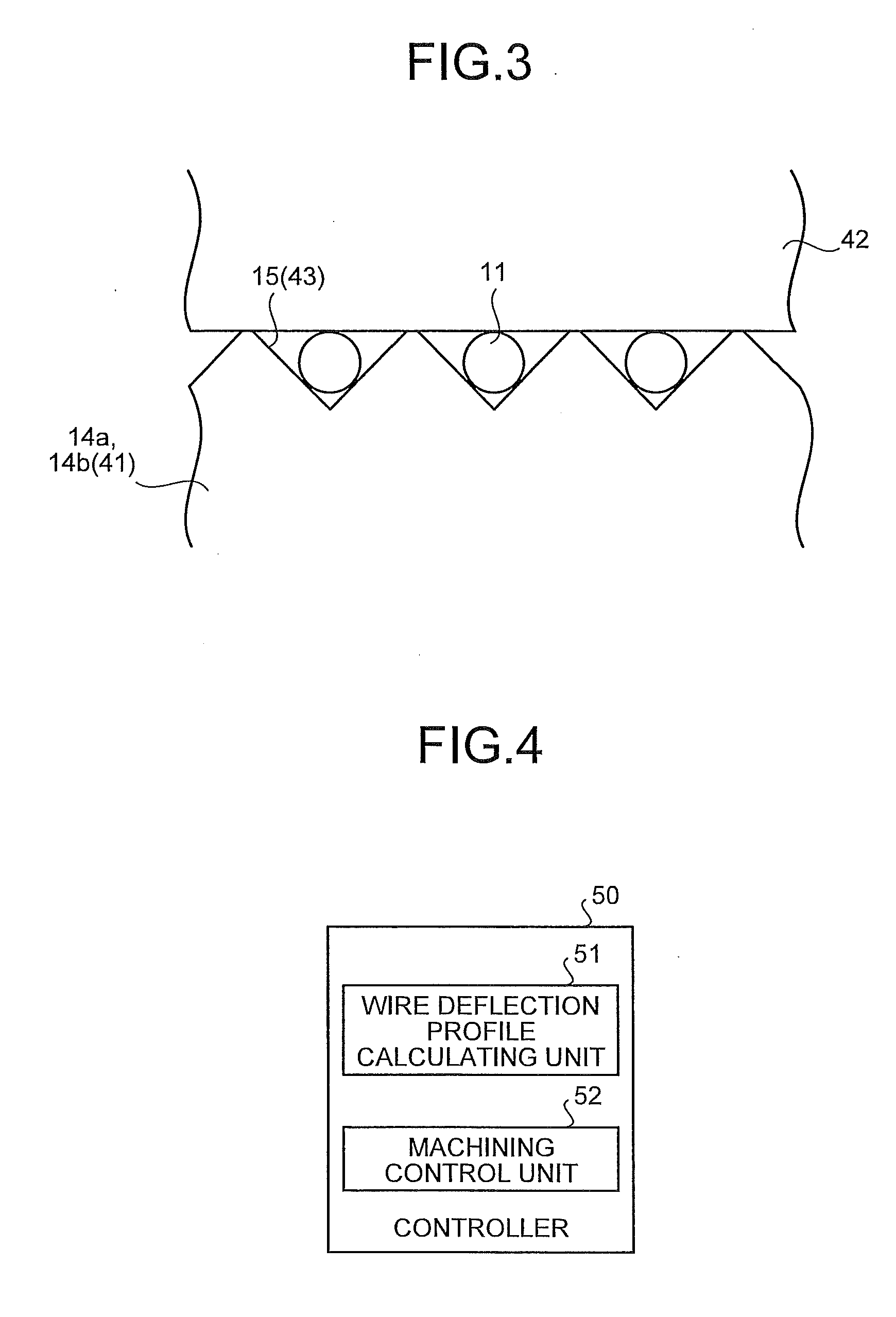

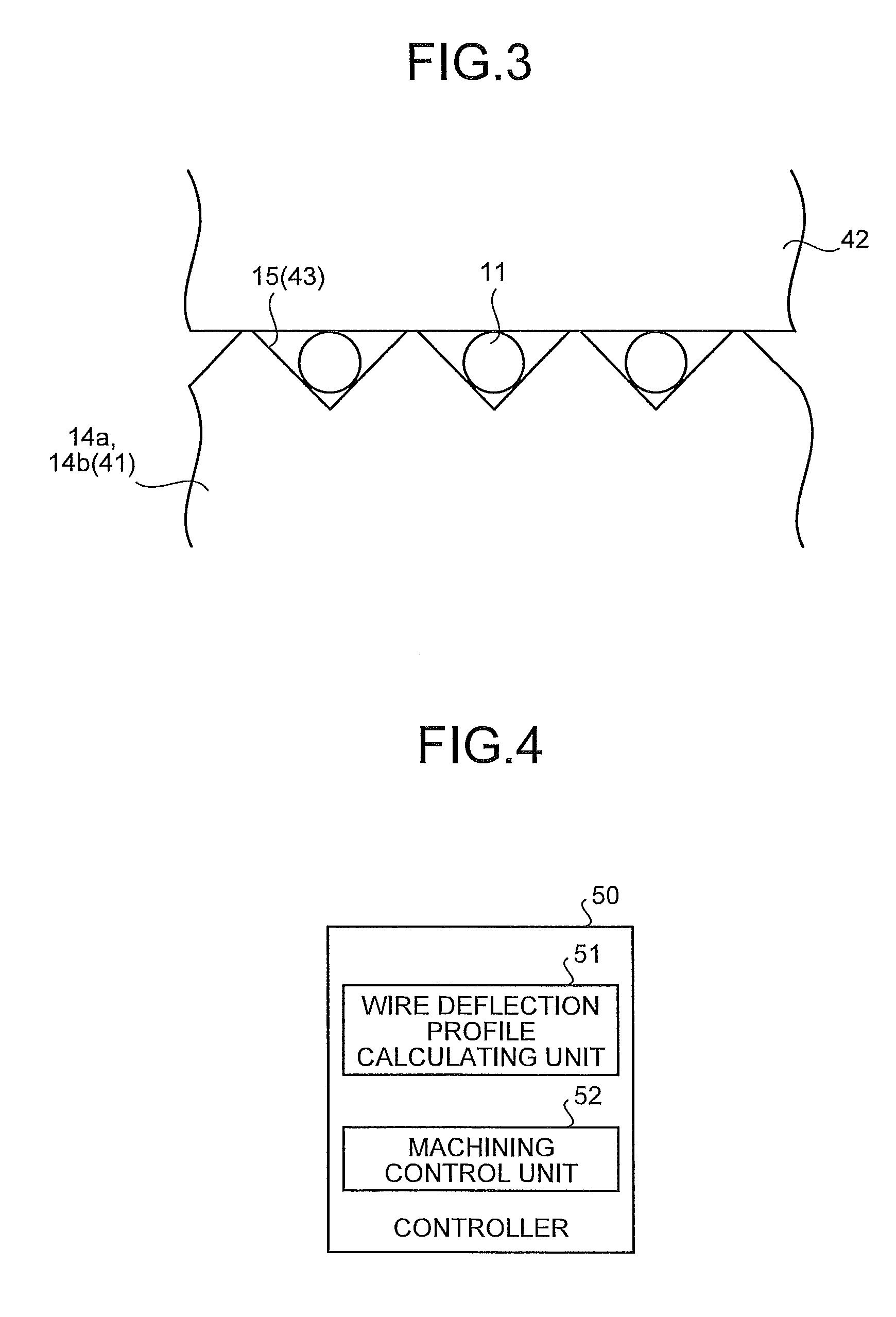

Multi-wire saw and method of cutting ingot

InactiveCN101687306AAvoid displacementPrevent disengagementMetal sawing devicesSemiconductor/solid-state device manufacturingIngotMulti-wire saw

Provided is a multi-wire saw that can prevent wires from being displaced in guide roller grooves due to the lifting of the wires when the cutting of an ingot is started. Wires (11) are wound around wire guide rollers (14a, 14b, 41), and positioned in the feeding direction of an ingot (32). In such a state, restraining members (42) comprising rotary bodies which are brought into contact with the wires (11), thereby restraining the lifting of the wires are disposed near the wire guide rollers (14a, 14b, 41).

Owner:MITSUBISHI ELECTRIC CORP

Multi-wire sawing wire net system

InactiveCN103182747AAdjustable widthEliminates the step of re-weaving the wire meshWorking accessoriesFine working devicesEngineeringMechanical engineering

The invention discloses a multi-wire sawing wire net system. The multi-wire sawing wire net system comprises an unwinding reel, a winding reel, a main roller and cutting wires wound on the main roller, the cutting wires are formed into a wire net on the main roller, the wire net is divided into a cutting wire net surface and a non-cutting wire net surface, the cutting wires of one side of the cutting wire net surface are wound into a cutting area and at least one adjusting area in the groove of the main roller, the cutting wires on the adjusting area can be used for adjusting the width of the cutting area, so that reweaving is avoided each time when silicon blocks or silicon rods are replaced, consequently , the production time is saved, and the production efficiency is increased.

Owner:ZHEJIANG YUHUI SOLAR ENERGY SOURCE

Online monitoring device and method for wire bow of wire mesh of multi-wire sawing machine

InactiveCN106313353ARealize online monitoringRealize monitoringWorking accessoriesFine working devicesMiddle lineDistance sensors

The invention discloses an online monitoring device and method for a wire bow of a wire mesh of a multi-wire sawing machine. The wire bow is an important factor influencing the quality of slices of the multi-wire sawing machine, but cutting areas are severe in environment and lack effective means for conducting online monitoring on the wire bow. The monitoring device and method involve a distance sensor, a shell, a protection gas inlet pipe, a support and a wire bow display module, the distance by which the mortar plane on the wire mesh deviates from the balance position during processing can be monitored online, and therefore the angle of the wire bow of the wire mesh is calculated. By means of the online monitoring device and method, online monitoring of the wire bow in the sawing process is achieved, and important application value for improving the slice quality and evaporating adjustment process parameters is achieved.

Owner:TIANJIN UNIV OF TECH & EDUCATION TEACHER DEV CENT OF CHINA VOCATIONAL TRAINING & GUIDANCE +1

Multi-wire saw and method for cutting ingot

InactiveUS8256407B2Increase productionReduce thickness variationMetal sawing devicesBelt grinding machinesIngotEngineering

To provide a multi-wire saw that, at the start of cutting of an ingot, prevents a wire from being displaced in grooves of guide rollers due to the wire being lifted. A wire is wound around a plurality of wire guide rollers to be positioned in a feeding direction of an ingot, and in this state, a wire-lifting restraining member that is a body of rotation and restrains the wire from being lifted by being brought into contact with the wire is disposed near the wire guide rollers.

Owner:MITSUBISHI ELECTRIC CORP

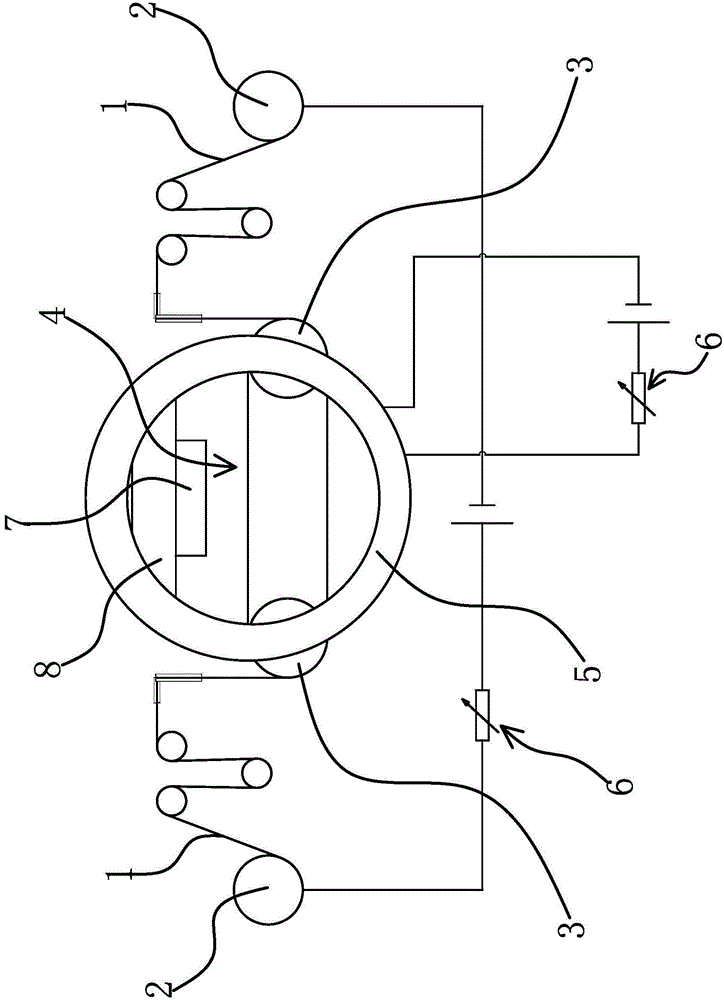

Magnetic-field-aided multi-wire-saw cutting machine

InactiveCN104057543AAvoid disconnectionHigh cutting forceMagnetsFine working devicesElectricityPower flow

The invention provides a magnetic-field-aided multi-wire-saw cutting machine, and belongs to the technical field of wire saw cutting. The problem that an existing multi-wire-saw cutting machine is low in cutting efficiency is solved. The magnetic-field-aided multi-wire-saw cutting machine comprises a wire saw, two wire storage wheels and a plurality of guide wheels, wherein two ends of the wire saw are respectively wound on the wire storage wheels; when the wire storage wheels rotate, one end of the wire is taken up, and the other end of the wire saw is paid off; the wire saw is laid on the guide wheels to form a cutting part which consists of multiple parallel wire saws and is used for cutting a to-be-processed workpiece; the two ends of the wire saw are respectively and electrically connected with a power supply device; currents on the cutting part have the same direction; two sides of the cutting part are provided with a magnetic field generating device which can generate a magnetic field to enable the direction of ampere force applied to the parallel wire saws to be opposite to the feeding direction of the to-be-processed workpiece. According to the magnetic-field-aided multi-wire-saw cutting machine, when the wire saw is powered on, the magnetic field generating device generates the magnetic field; the powered-on parallel wire saws on the cutting part is subjected to the ampere force, so that cutting force for cutting the to-be-processed workpiece of the parallel wire saws is enhanced.

Owner:王金生 +1

Method for simultaneously slicing at least two cylindrical workpieces into a multiplicity of wafers

ActiveUS7766724B2Increase profitGuaranteed maximum utilizationSemiconductor/solid-state device manufacturingGrinding feed controlWafer stackingEngineering

Slicing multiple cylindrical workpieces into wafers by a multi wire saw with a gang length LG, is performed by:a) selecting a number n≧2 of workpieces from a stock of workpieces with different lengths, satisfying the inequalityLG≥(n-1)·Amin+∑i=1nL1(1)and making right-hand side of the inequality as large as possible, where Li with i=1 . . . n are for the lengths of the workpieces and Amin is a predefined minimum spacing,b) fixing the n workpieces successively in the longitudinal direction on a mounting plate while maintaining a spacing A≧Amin therebetween such that the relationshipLG≥(n-1)·A+∑i=1nLi(2)is satisfied,c) clamping mounting plates workpieces in a multi wire saw, andd) slicing the n workpieces perpendicularly to their longitudinal axis by means of the multi wire saw. Preferably, the wafer stacks are separated from one another by separating pieces after slicing, and at the same time are laterally supported.

Owner:SILTRONIC AG

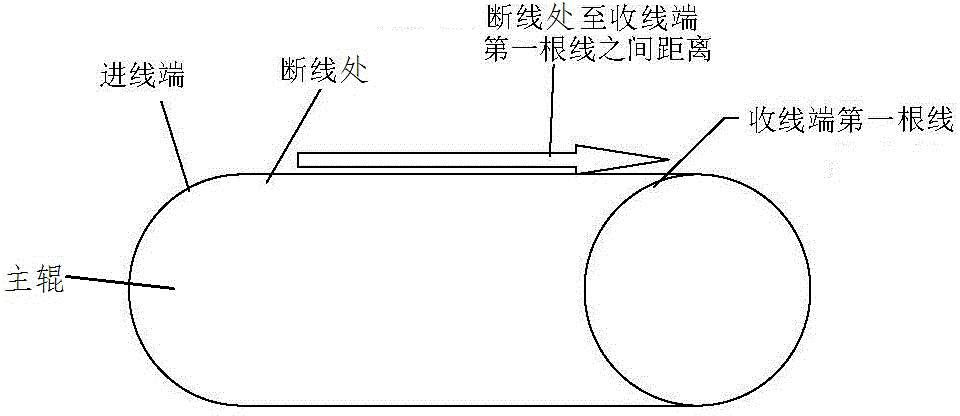

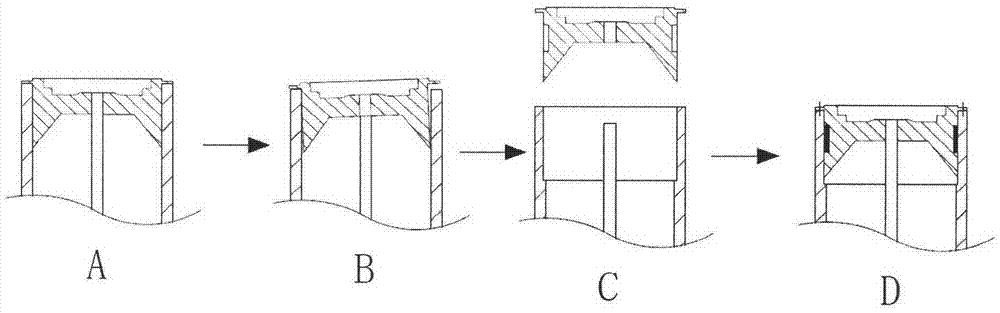

Handling method adopted after cutting wire breakage of multi-wire sawing machine

The invention discloses a handling method adopted after cutting wire breakage of a multi-wire sawing machine. For improving the repair success rate of damaged silicon crystal bars on the multi-wire sawing machine, the handling method adopted after the cutting wire breakage of the multi-wire sawing machine comprises the following steps of 1 shearing incompact cutting wires at the wire breakage position and enabling a distance between two wire ends of each cutting wire to be 10cm larger than each slot distance of main roller wire slots; 2 polishing two wire ends and enabling the diameter of the wire ends of each polished cutting wire to be 1 / 3-1 / 2 of the diameter of each non-broken cutting wire, wherein the polishing length of each wire end is at least 5cm; 3 overlapping and welding the polished cutting wire ends; 4 winding the incompact sections of the cutting wires on a main roller and starting the main roller to enable the cutting wire to be in a tensioning state; 5 turning the main roller to drive the cutting wire sections at the breakage welding position to the indirect cutting stress position. Silicon crystal bars are not required to be taken from a workpiece clamp, an original cutting point is easy to find and reset, errors are decreased during cutter resetting, and the repair success rate of the damaged silicon crystal bars can be improved.

Owner:HUNAN RED SUN PHOTOELECTRICITY SCI & TECH

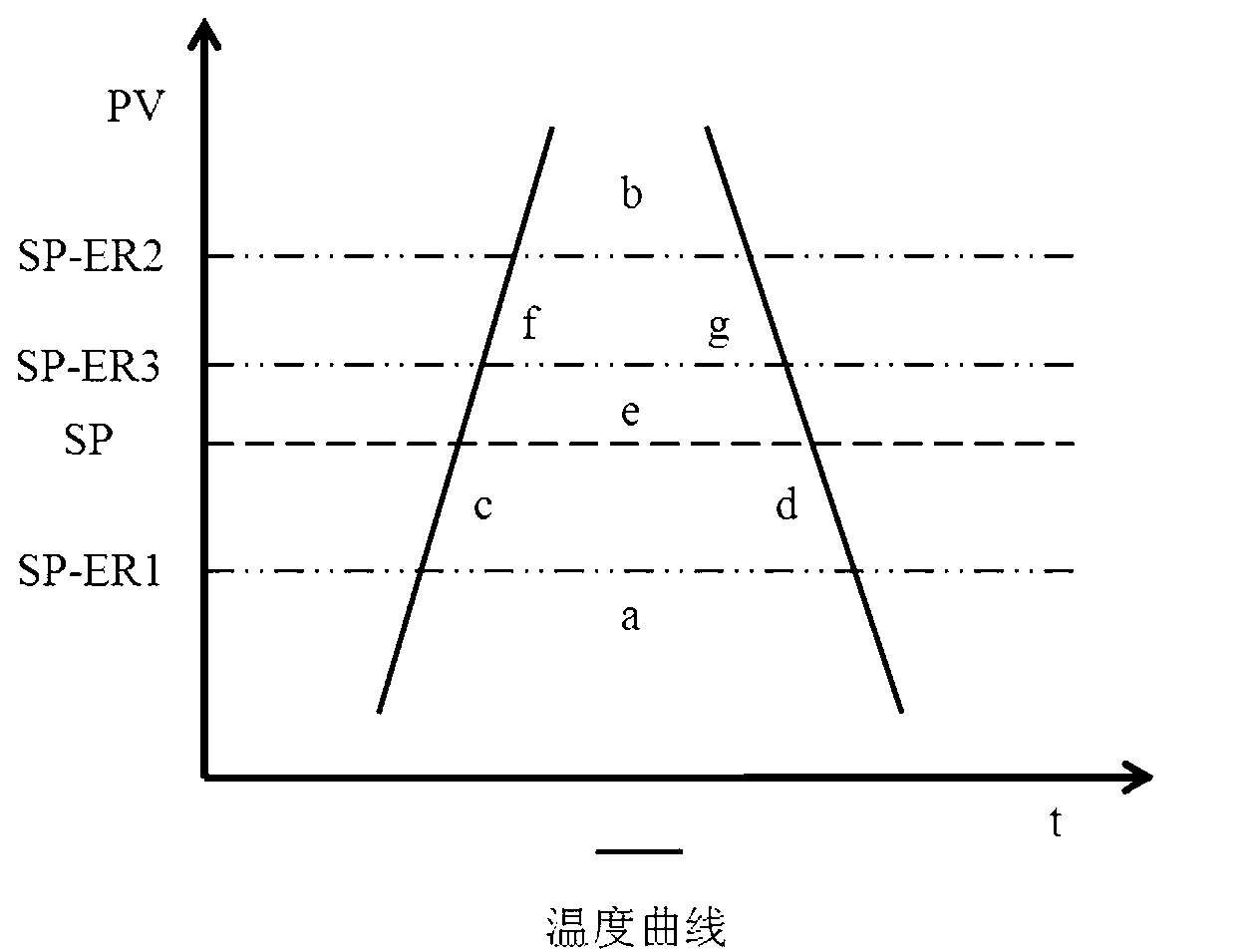

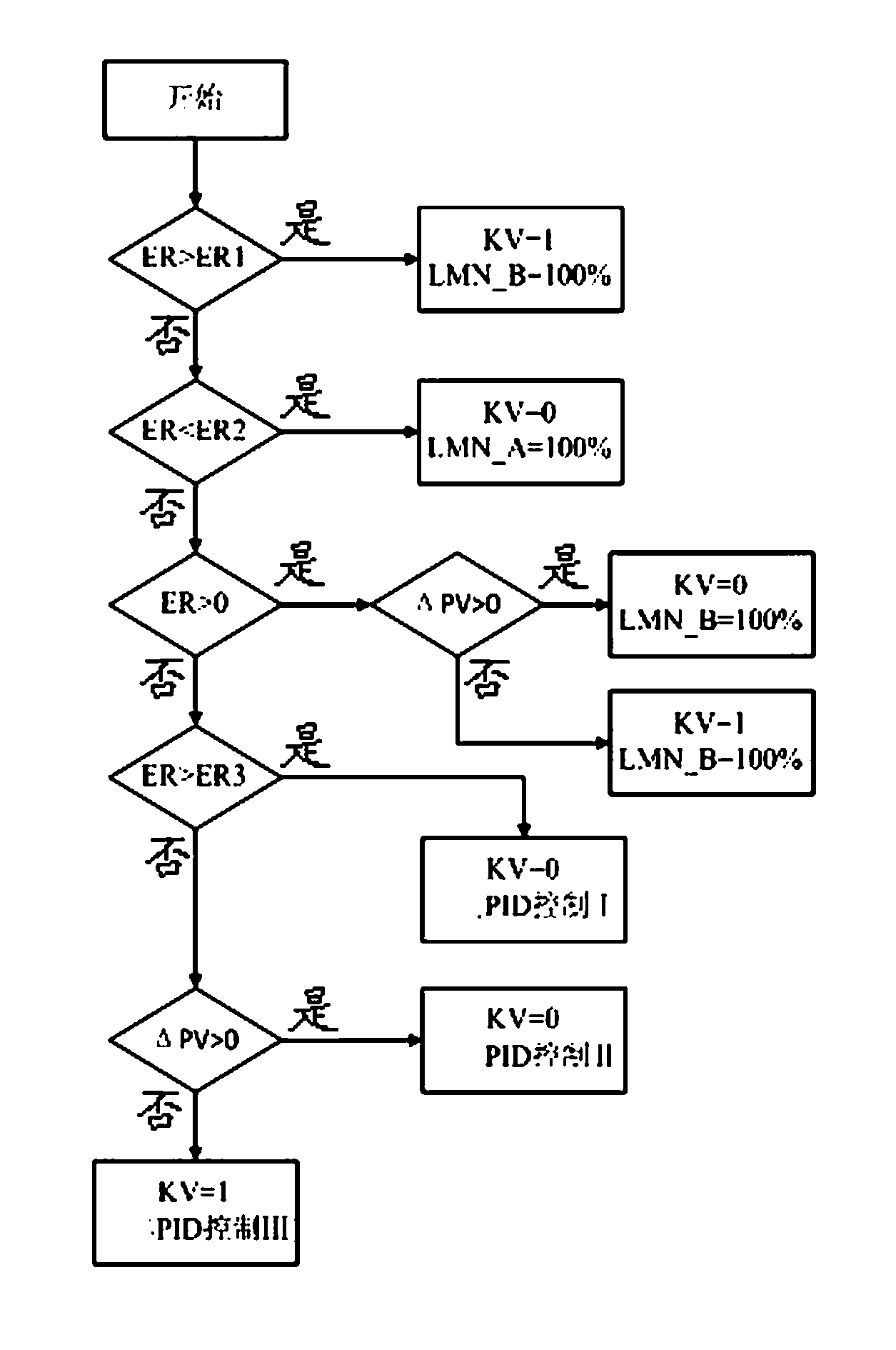

Intelligent PID control system for roller temperature of multi-wire saw, and control method thereof

InactiveCN103294081AStable temperatureImprove product qualityAuxillary controllers with auxillary heating devicesTemperature controlControl system

The invention belongs to the technical field of temperature control systems and discloses an intelligent PID control system for roller temperature of a multi-wire saw, and a control method thereof. The intelligent PID control system for the roller temperature of the multi-wire saw is characterized in that real-time temperature of rollers is collected in real time through a temperature sensor and a PLC (programmable logic controller) with an internal PID closed-loop control module, different temperature changes are distinguished according to preset control programs, operating modes of an online heating device and the PID closed-loop control module are switched, analog signals are output to control the online heating device, the rollers and the opening of a three-way adjusting valve which is connected with cooling water and which feeds water to the rollers, temperature and flow of incoming water are changed for the rollers, and the roller temperature is kept stable. The system and the method combing intelligent control and traditional PID control have the advantages that the limits of the traditional PID control in actual production are overcome and efficiency in controlling roller temperature of the multi-wire saw is improved.

Owner:THE 45TH RES INST OF CETC

Substrate comprising aluminum/graphite composite, heat dissipation part comprising same, and LED luminescent member

ActiveUS8883564B2Efficient productionReduce material lossSemiconductor/solid-state device detailsSolid-state devicesFlexural strengthThermal expansion

A process for producing a substrate, which comprises processing an aluminum / graphite composite into plates having a thickness of 0.5-3 mm using a multi-wire saw under the following conditions (1) to (4): (1) the wires have abrasive grains bonded thereto which are one or more substances selected from diamond, C—BN, silicon carbide, and alumina and have an average particle diameter of 10-100 μm; (2) the wires have a diameter of 0.1-0.3 mm; (3) the wires are run at a rate of 100-700 m / min; and (4) the composite is cut at a rate of 0.1-2 mm / min. The aluminum / graphite composite has a surface roughness (Ra) of 0.1-3 μm, a thermal conductivity at 25° C. of 150-300 W / mK, a ratio of the maximum to the minimum value of thermal conductivity in three perpendicular directions of 1-1.3, a coefficient of thermal expansion at 25-150° C. of 4×106 to 7.5×10−6 / K, a ratio of the maximum to the minimum value of coefficient of thermal expansion in three perpendicular directions of 1-1.3, and a three-point bending strength of 50-150 MPa.

Owner:DENKA CO LTD

Multi-wire saw

InactiveUS20160368069A1Reduce adjustmentReduce adverse effectsMetal sawing devicesSemiconductor/solid-state device manufacturingEngineeringWire wrap

Disclosed herein is a multi-wire saw including a wire, a set of guide rollers, an adjusting unit for adjusting tension of the wire wrapped around the guide rollers, a fixing base for fixing a workpiece to be cut by the wire wrapped around the guide rollers, and a moving mechanism for moving the workpiece fixed to the fixing base toward the wire. The adjusting unit includes an adjust roller around which the wire is wrapped, a rotational speed control section for controlling the rotational speed of the adjust roller, and a supply roller around which the wire is wrapped to be supplied to the adjust roller. The supply roller is provided with a wire shifting mechanism for suitably changing the axial position of the wire in the axial direction of the supply roller to thereby prevent the axial position of the wire wrapped around the adjust roller from being fixed.

Owner:DISCO CORP

Repair method of MB multi-wire sawing machine guide wheel

The invention discloses a repair method of an MB multi-wire sawing machine guide wheel. The repair method of the MB multi-wire sawing machine guide wheel comprises the steps of inner diameter expanding, end cover selection and machining, sizing, cold fitting, curing, fastening, fine machining, dynamic balancing correction and the like. The first key point of the repair technology is that an outer barrel body of the abraded guide wheel is subjected to the inner diameter expanding, so that the inner side wall of the outer barrel body of the abraded guide wheel with expanded inner diameter can be in interference fit with the outer side wall of an end cover; the middle of the outer side wall of the end cover is provided with a groove for accommodating glue, so that the corresponding positions of the end cover groove and the outer barrel body of the guide wheel. By adopting a mechanical connecting-bonding match method, the outer barrel body and the end cover can be firmly connected, and loosening during working is avoided. The second key point is that the concentricity of a bearing bush hole of the end cover and the central axis of the outer barrel body of the guide wheel is smaller than or equal to 0.01mm through correction and fine machining, the end face circle run-out of the end cover is smaller than or equal to 0.05mm, vibration produced during high-speed guide wheel rotation and net shake are inhibited, smooth surface of a cut silicon wafer is ensured, and cutting accuracy is improved.

Owner:SUZHOU RUNDE NEW MATERIAL

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com