Patents

Literature

221results about How to "High cutting force" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

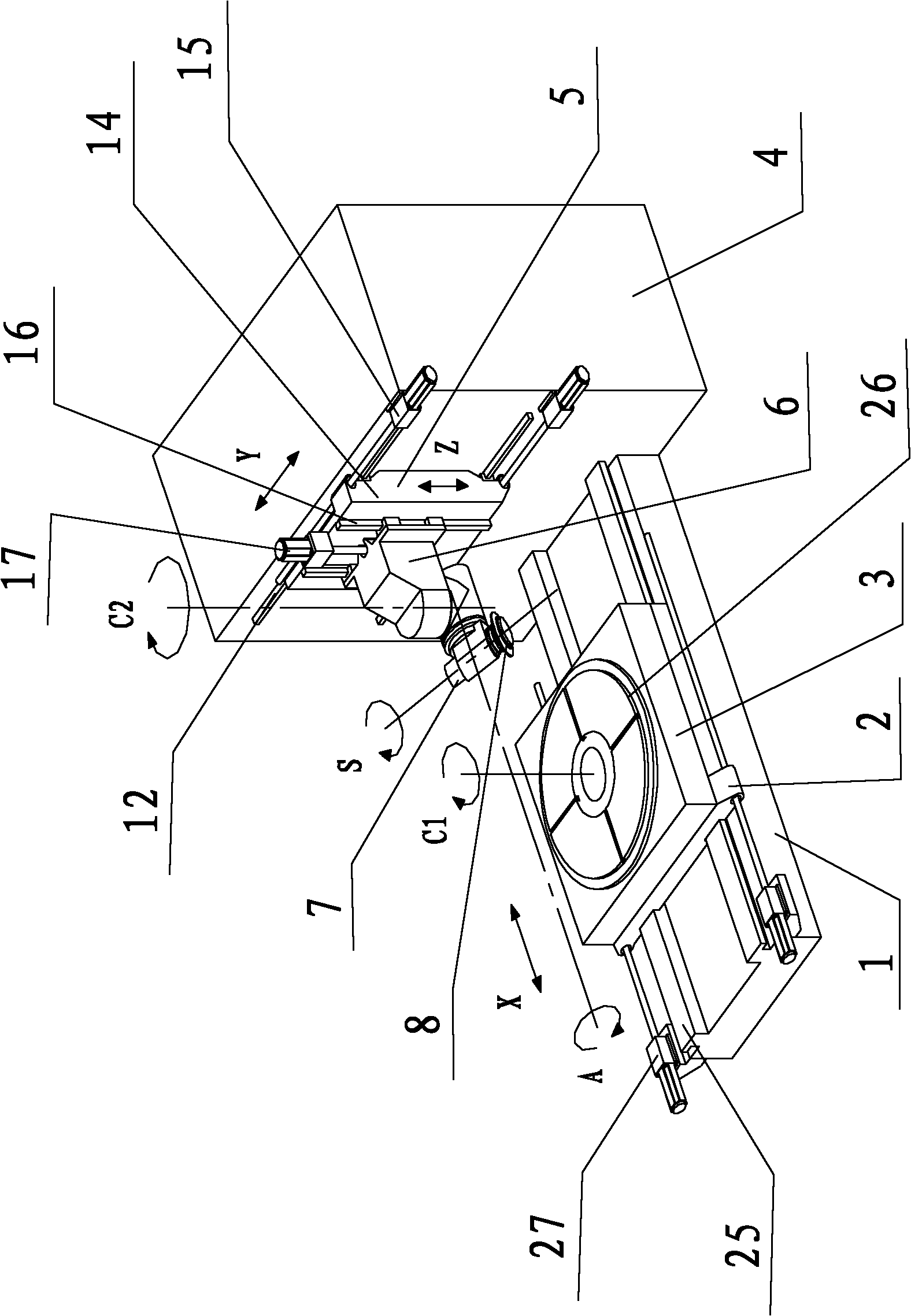

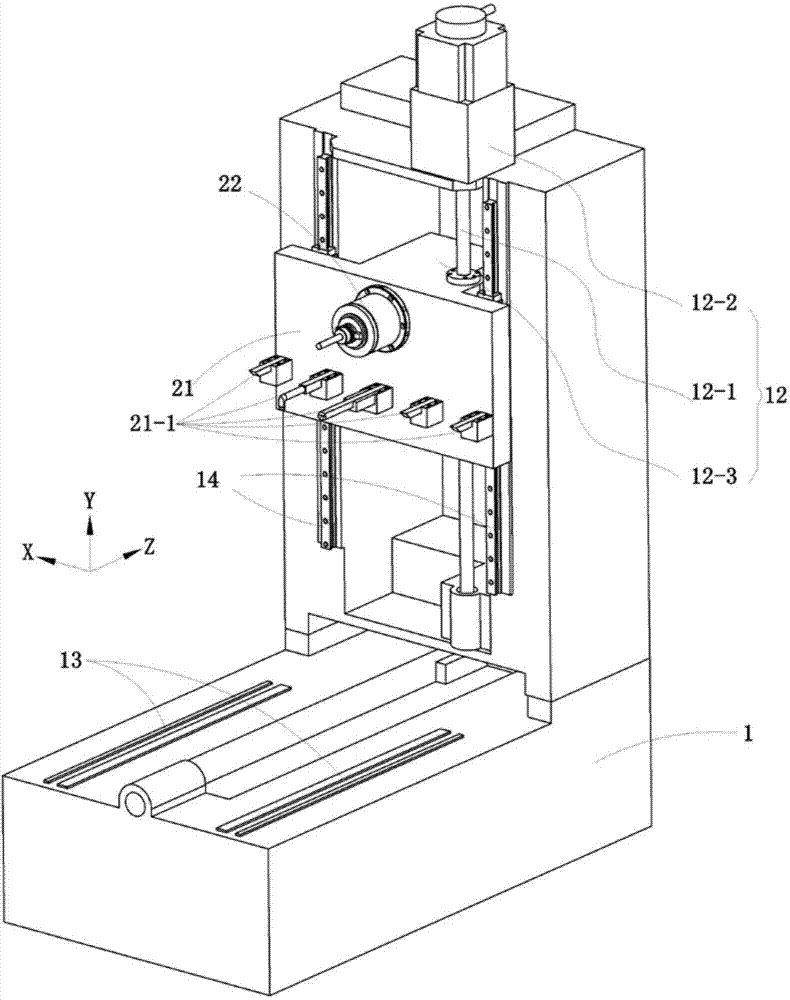

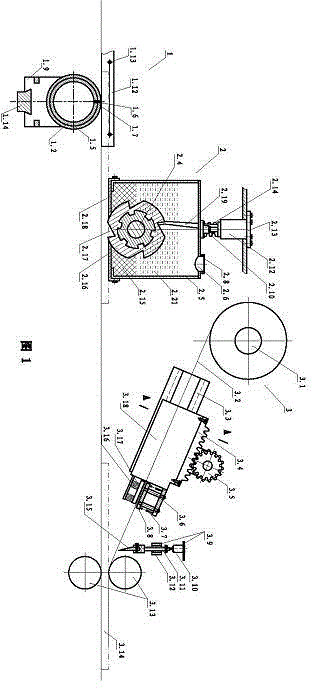

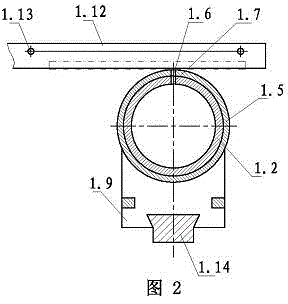

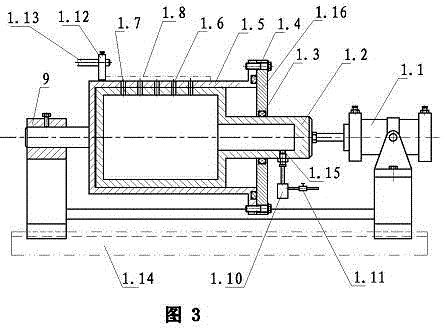

Large-scale numerical control gear machining machine tool

ActiveCN102151909AImprove machining accuracyImprove processing efficiencyLarge fixed membersDriving apparatusLinear motionImpeller

The invention provides a large-scale numerical control gear machining machine tool which has six numerical control coordinate axes, namely X, Y, Z, A, C1 and C2 and adopts a two plus four layout manner. A workpiece has two freedom motion, namely linear motion along the X axis and rotational motion around the C1 axis; and a tool has four freedom motion, namely linear motion along the X axis and the Z axis and rotational motion around the A axis and the C2 axis. The large-scale numerical control gear machining machine tool adopts a six-axis (X, Y, Z, A, CI and C2 axis) five-linkage (X, Y, Z, A and C2 axis linkage) structure; the five numerical control coordinate axes, namely the X, Y, Z, A and C2 axes carry out interpolation motion; and the indexing movement of the workpiece is controlled by the C1 axis to process all tooth surfaces. The rotational axis of the workpiece, namely the C1 axis only finishes the indexing movement and does not participate in the interpolation motion formed bythe tooth surfaces so as to improve the processing precision and the processing efficiency of a large-scale gear. The large-scale numerical control gear machining machine tool can be constructed intoa gear miller or a gear grinder, thereby realizing the curved surface machining of a cylindrical gear, a bevel gear, an impeller and others with the indexing features.

Owner:秦川机床工具集团股份公司

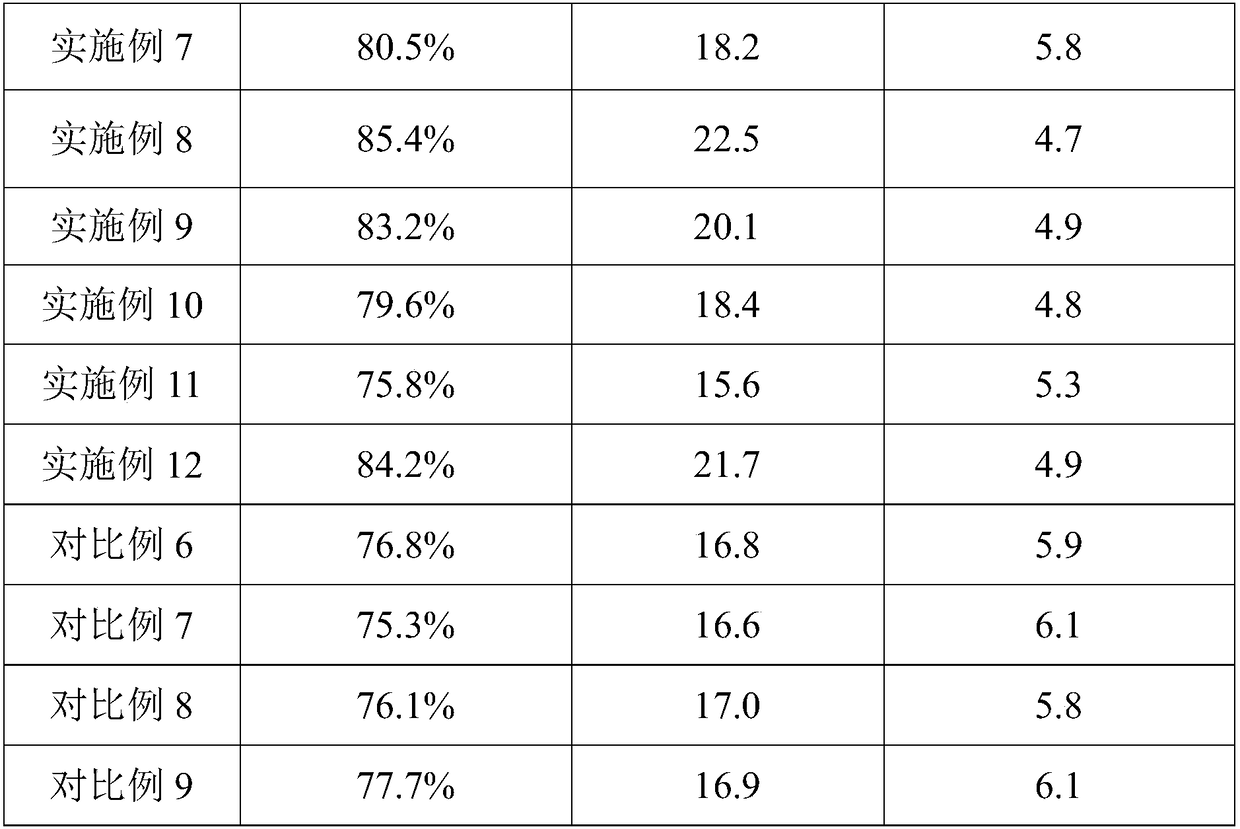

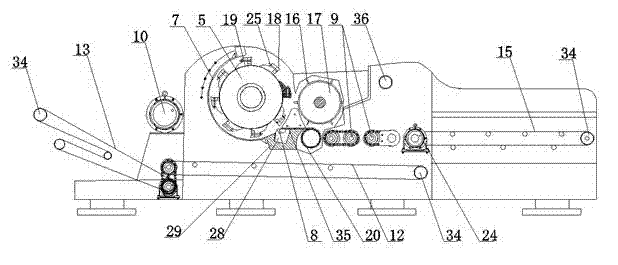

Automatic plastic tube cutting machine

The invention discloses an automatic plastic tube cutting machine, comprising a power transmission device, a feeding device, a blanking device, a safe protection device, a control device and a counter. The power transmission device transmits power to the feeding device, a plastic tube enters the blanking device through a guide tube under the driving of two pairs of rollers with opposite rotary directions, a relay controls a cylinder to drive a cutter to cut and a time adjustable delay timer adjusts the motion speed of the cutter, thus the control for blanking length is implemented. An inclination angle, which is 5 to 6 degrees, is formed by the lower plane of the cutter with respect to a horizontal direction; the width of a cutter guide concave slot of a cutter positioning block can be adjusted according to the cutter; the spacing between every pair of the rollers is adjustable; the counter can record the times of tube blanking automatically; and the safe protection device puts motion components under protection. By adopting such a structure, the automatic plastic tube cutting machine not only can cut the plastic tubes of different specifications, but also prominently reduces the labor intensity of operating staff and accordingly, remarkably enhances the working efficiency.

Owner:SHANDONG HUASHENG PESTICIDE APPL MACHINERY CO LTD

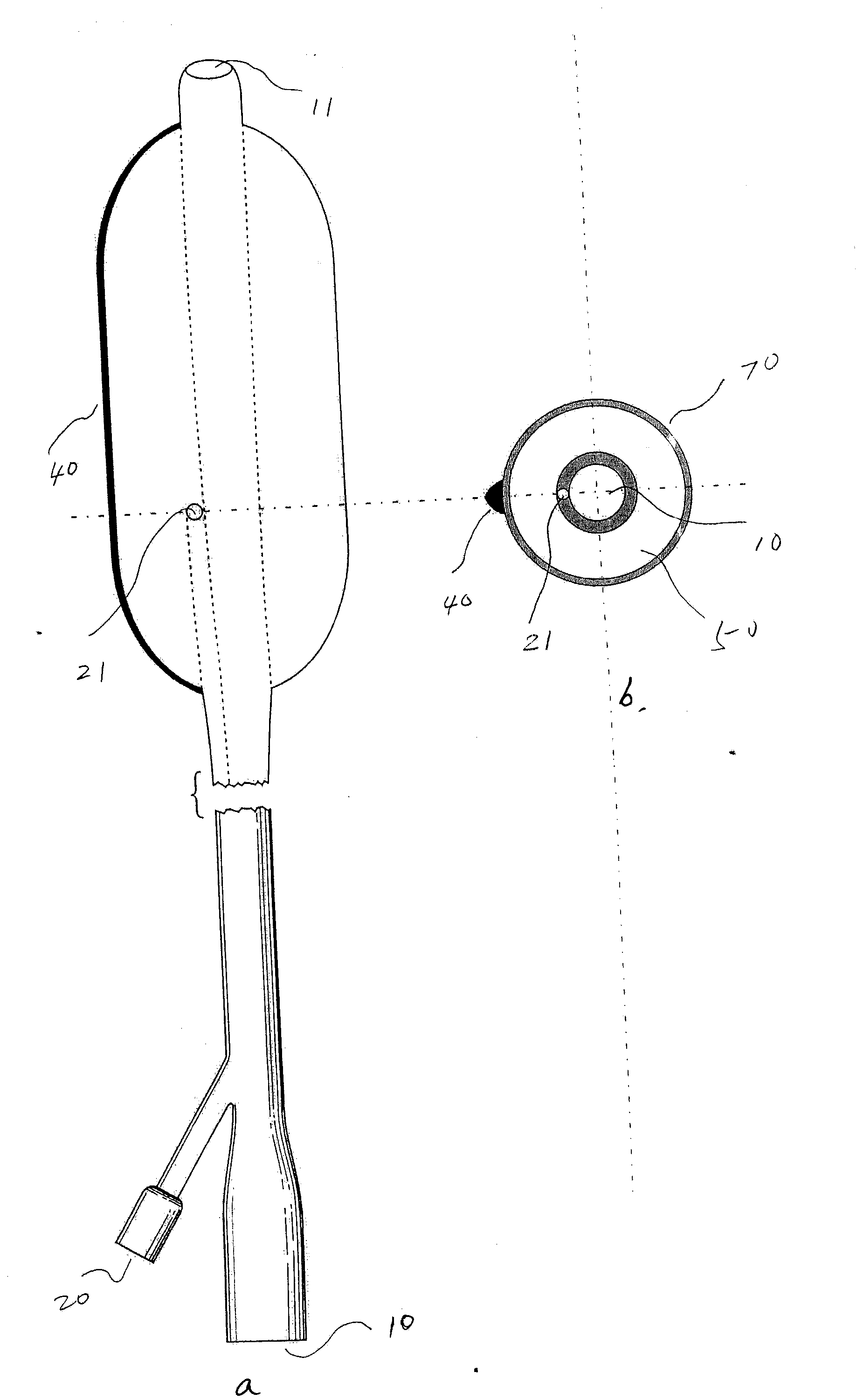

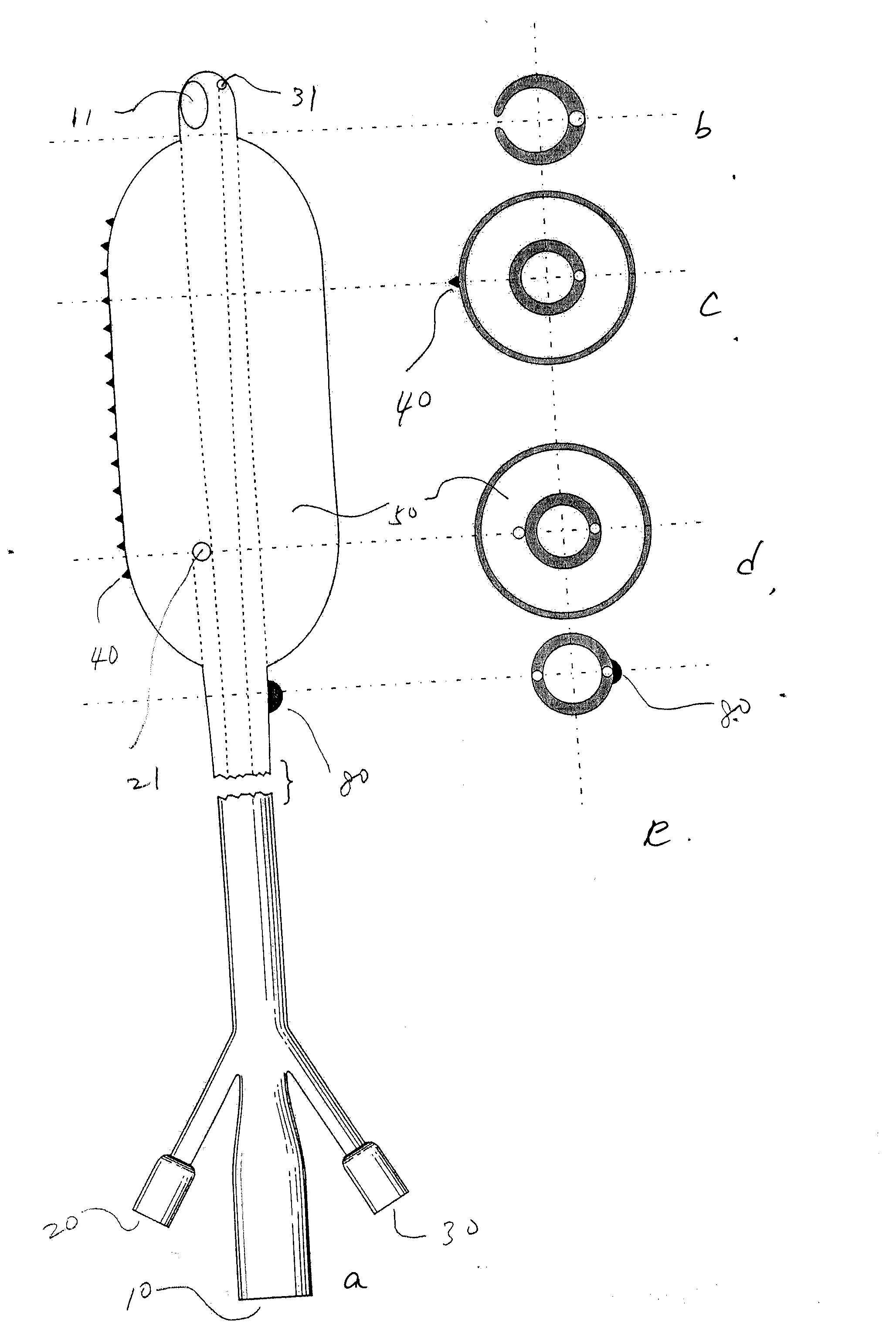

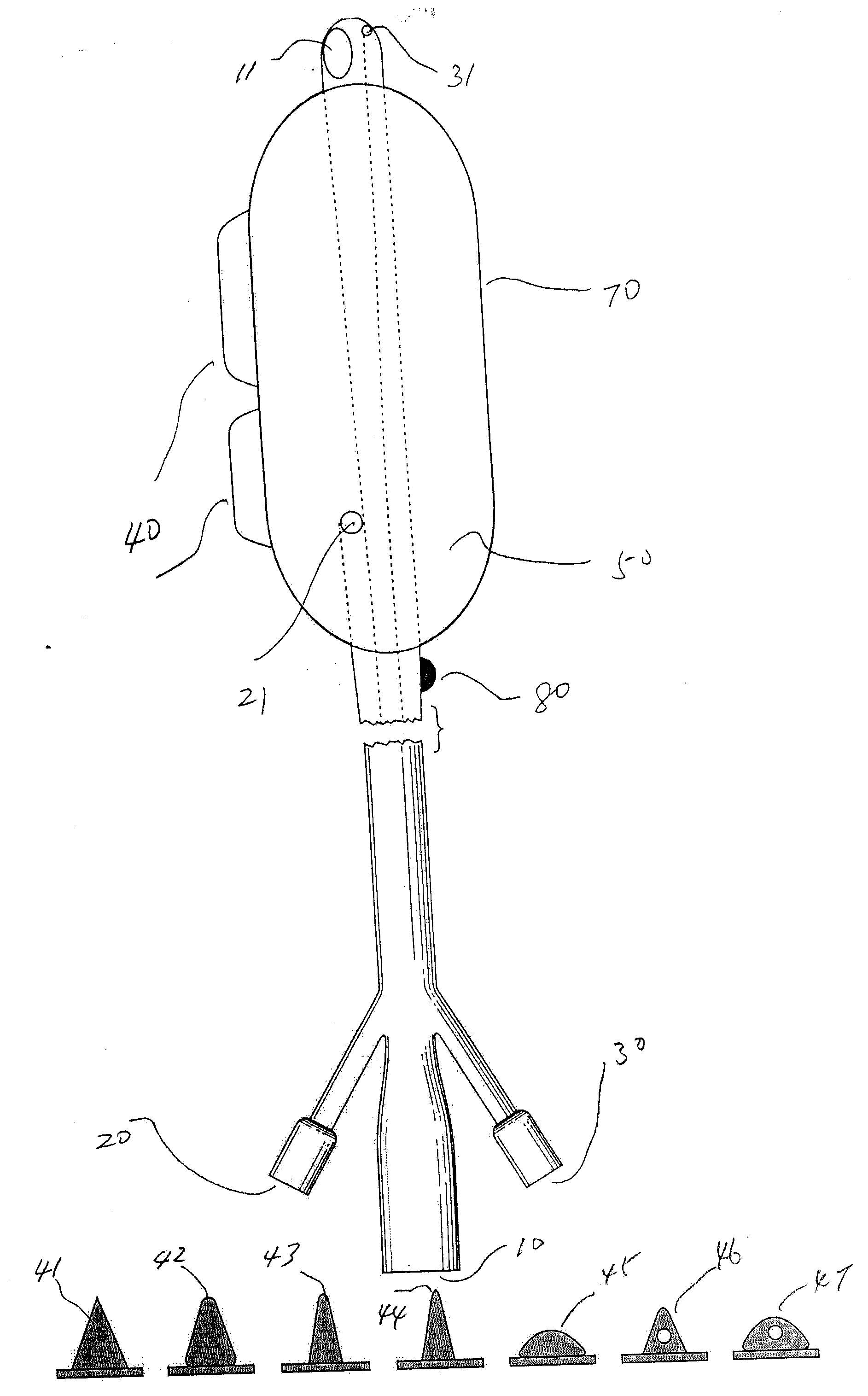

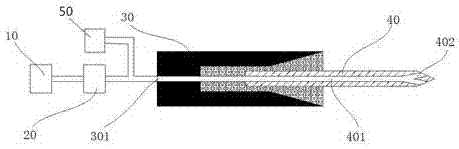

Targeted dilatation forming balloon catheter

InactiveCN103656843AGuaranteed placementPrecise targeted expansionBalloon catheterEnemata/irrigatorsLong axisShort urethra

The invention relates to the minimally invasive therapy technology and a minimally invasive therapy instrument, in particular to a method and instrument for forming a targeted balloon of a living body catheter cavity, namely a minimally invasive surgery method and instrument for carrying out targeted rear urethra balloon dilatation forming on the rear narrowed urethra of the male, wherein the rear narrowed urethra might be caused by the BPH, a tumor, an inflammation and the like. The targeted dilatation balloon dilatation catheter is provided with at least one targeted dilatation balloon, wherein one cavity is used for draining or conveying body liquid or gases and another cavity is used for filling a targeted catheter cavity dilatation balloon. At least a row of protrusions for targeted dilatation forming or a protrusion for targeted dilatation forming is arranged on the surface of the targeted dilatation balloon in the direction of the long axis. The protrusions or the protrusion for targeted dilatation forming aligns with a zone or a part, needing targeted dilatation forming, of the catheter cavity and expands in a certain manner, at a certain speed and under the certain pressure to form the balloon. Thus, the targeted dilatation forming protrusion or protrusions form selective partial high intensity of pressure and high shearing force on the targeted forming zone of the catheter cavity and targeted dilatation forming of the catheter cavity is achieved.

Owner:HANGZHOU LANGYOU MEDICAL SCI & TECH

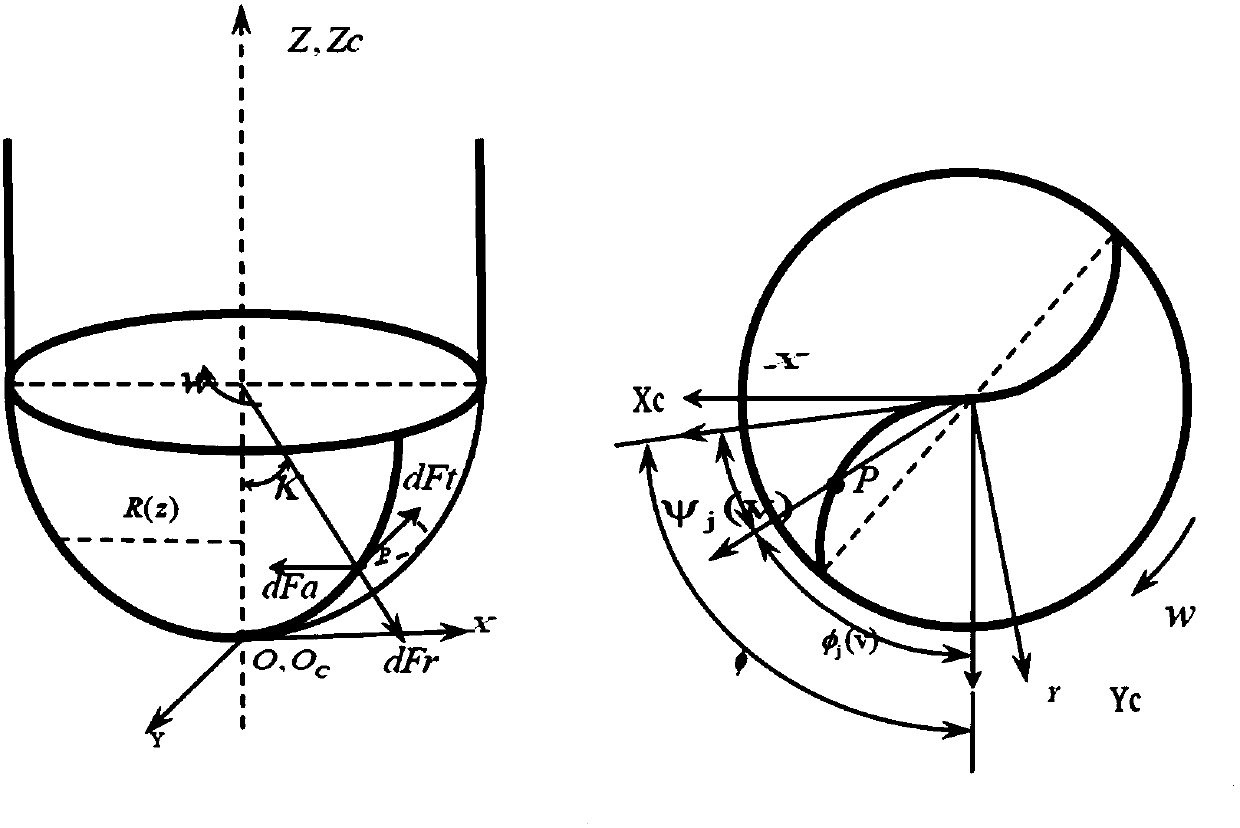

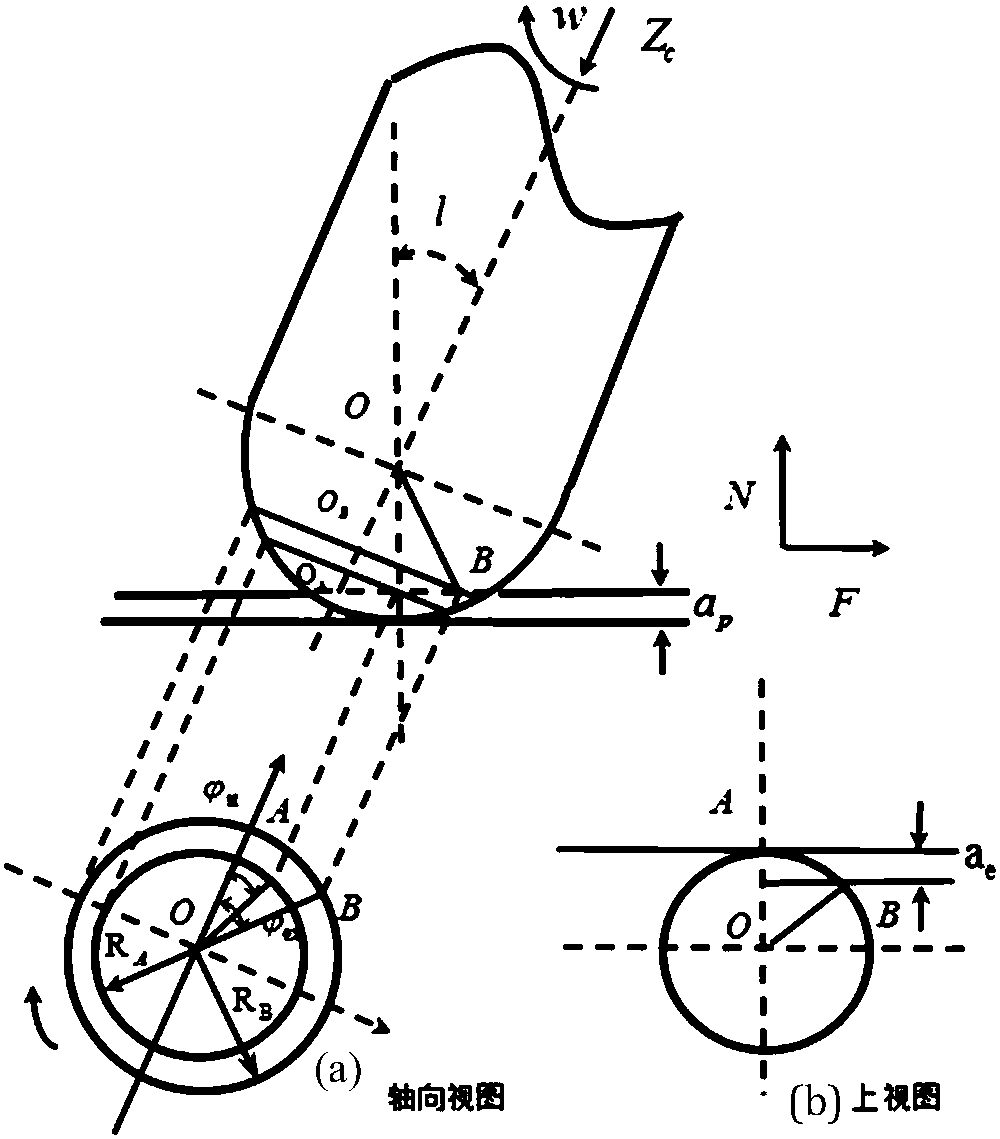

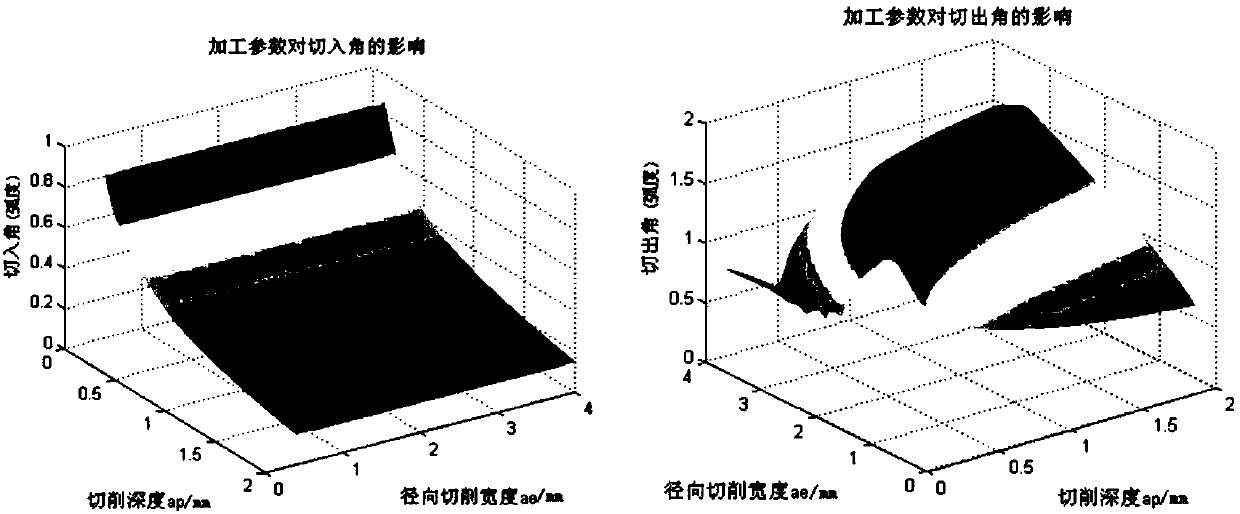

Method for predicting multi-axis titanium alloy milling force of ball-end milling cutters

InactiveCN107944176ALittle effect of helix angleHigh cutting forceGeometric CADDesign optimisation/simulationPredictive methodsMilling cutter

The invention discloses a method for predicting multi-axis titanium alloy milling force of ball-end milling cutters. The method includes building multi-axis milling force models with consideration oninfluence of inclined angles of cutters on cut-in angles and cut-out angles on the basis of mechanics models of the three-axis ball-end milling cutters; carrying out cutting experiments; identifying milling force coefficients by means of linear regression according to measured cutting force at different feed speeds; carrying out simulation analysis on influence of machining parameters and geometric parameters of the cutters on the cutting force. The method has the advantage that certain theoretical bases can be provided for optimizing multi-axis milling machining technological methods.

Owner:SHANGHAI COMPOSITES SCI & TECH CO LTD

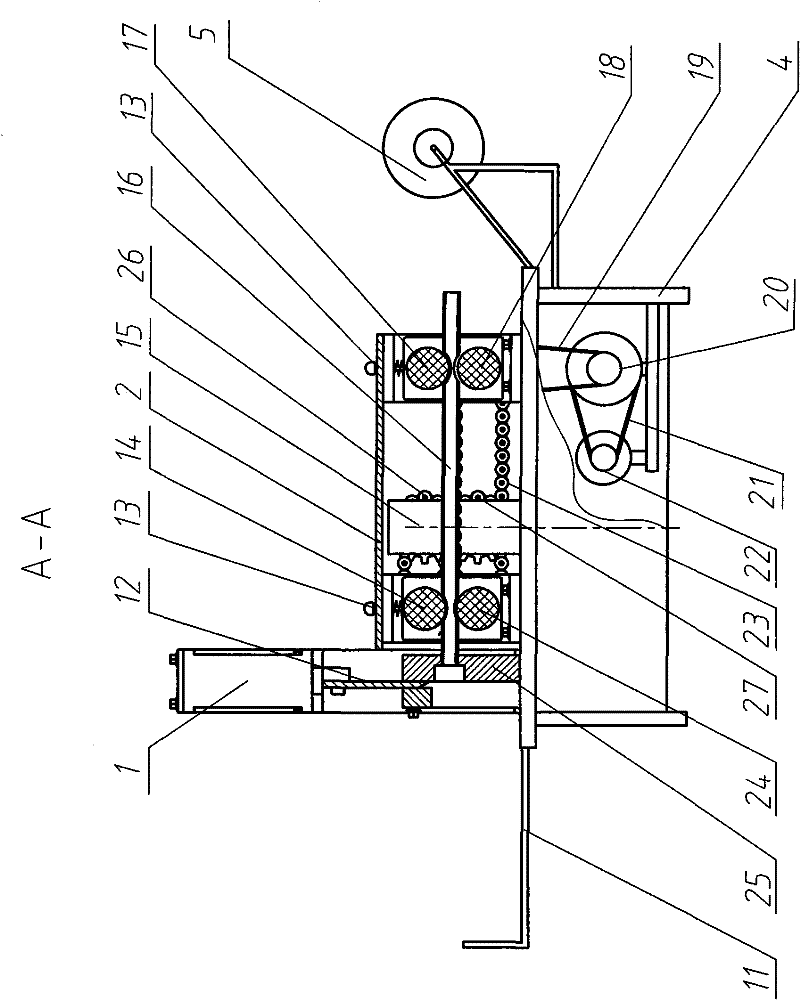

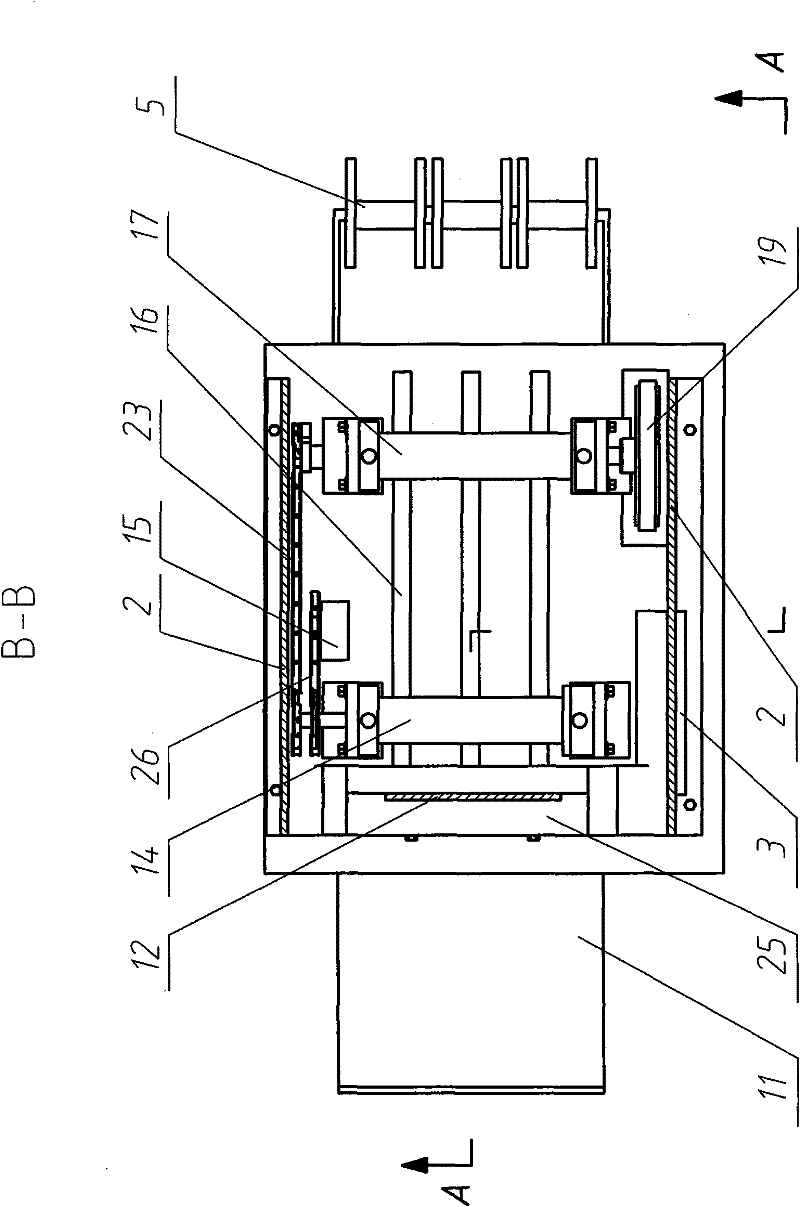

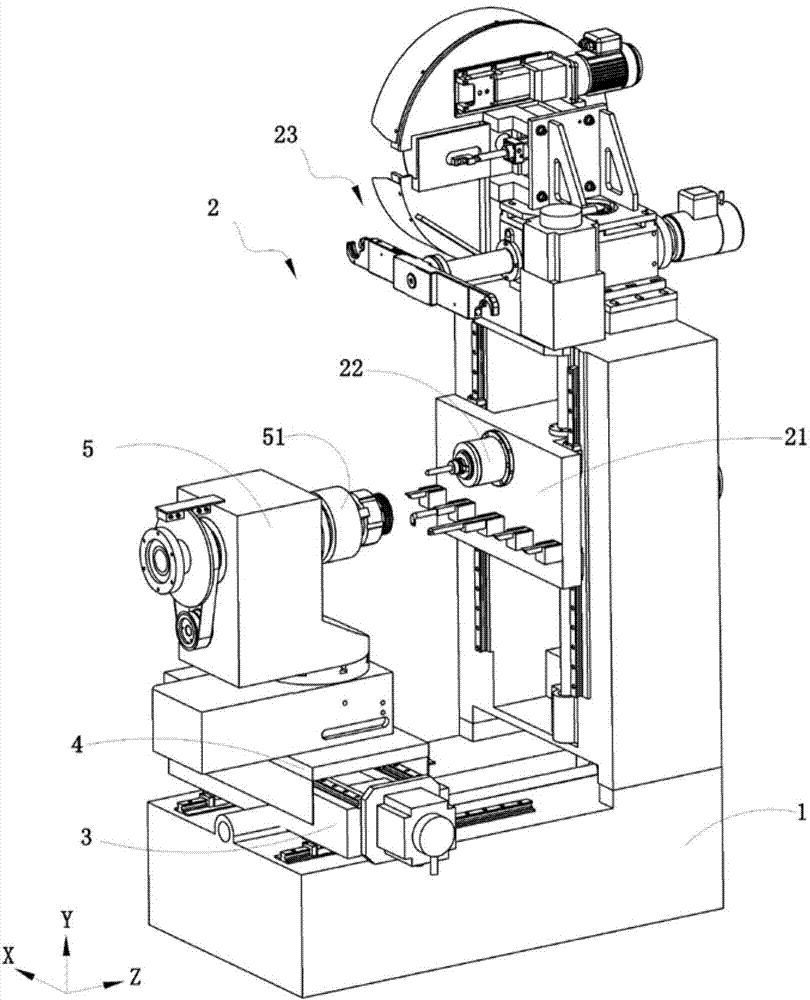

Turning, milling and drilling comprehensive numerical control equipment

ActiveCN103921120AReduce typesReduce in quantityFeeding apparatusOther manufacturing equipments/toolsEngineeringMechanical engineering

The invention relates to turning, milling and drilling comprehensive numerical control equipment which comprises a base, a machining cutter device, a workbench base, a workbench and a rotary spindle seat. The base is provided with a Z-axis drive device and a Y-axis drive device. The machining cutter device comprises a cutter holder which is mounted on the Y-axis drive device and can move along a Y axis. The workbench base is mounted on the Z-axis drive device and located on one side of the machining cutter device. An X-axis drive device is further disposed on the workbench base. The workbench is mounted on the X-axis drive device and can move along an X axis. A rotary shaft in the Y-axis direction is disposed on the workbench. The rotary spindle seat is mounted on the rotary shaft and can rotate at different angles. The rotary spindle seat is provided with a clamp spindle and a spindle transmission device for driving the clamp spindle to rotate. A clamp for clamping workpieces is disposed on the clamp spindle. The turning, milling and drilling comprehensive numerical control equipment has the advantages that during complex workpiece production, a workpiece can be clamped on the clamp at one step to complete various working procedures, and working efficiency and product quality are increased greatly.

Owner:中山建德工业有限公司

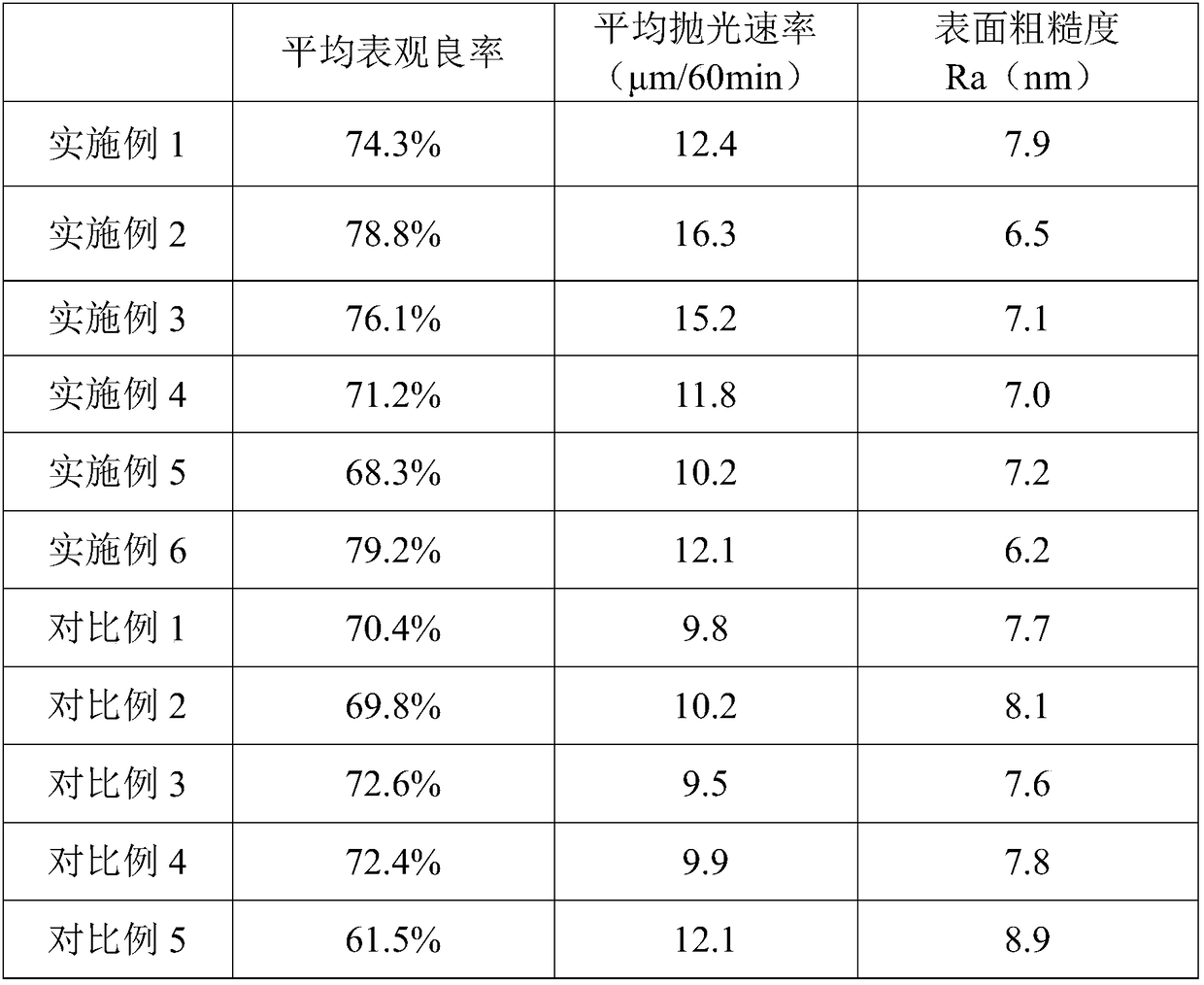

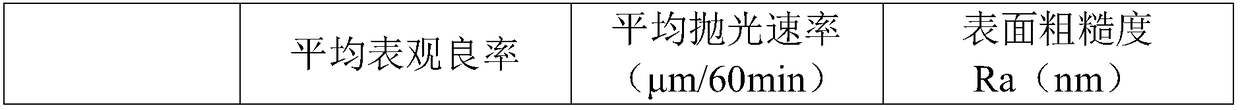

Polishing powder, polishing liquid for glass and preparation method thereof, glass and electronic product

InactiveCN108864948AHigh fluorine contentLow costTelephone set constructionsPolishing compositions with abrasivesMohs scale of mineral hardnessHardness

The invention discloses polishing powder, a polishing liquid for glass, and a preparation method thereof, glass and electronic products, relates to the technical field of glass polishing. The polishing powder is prepared from 50 to 60% of cerium oxide, 20 to 30% of lanthanum oxide and 10 to 20% of fluorine; D50 of the polishing powder is 1.0 to 1.6 mu m, D90 of the polishing powder is 2.4 to 2.6 mu m, the Moh's hardness is 7 to 8. The polishing liquid is prepared from 50 to 60% of the polishing powder, 0.5 to 1% of a suspension agent, 1 to 10% of a dispersing agent, 1 to 5% of a flatting agent, 1 to 5% of a grinding aid and the balance of water. By controlling the content, particle size distribution and hardness of the polishing powder, high cutting rate can be guaranteed and scratch can be reduced. In addition, through adding the suspension agent, the dispersing agent, the flatting agent and the grinding aid, the suspension, dispersion, leveling and uniformity properties of the polishing powder and the grinding efficiency are improved are improved, the polishing liquid has the advantages of excellent suspension and dispersion properties, high polishing rate and good surface quality.

Owner:LENS TECH CHANGSHA

Crusher

InactiveCN102806126AHigh cutting forceSmooth crushing processGrain treatmentsAgricultural engineeringStructural engineering

The invention discloses a crusher. The crusher comprises a charging device, a discharging device, a feeding device and a crushing device; the feeding device consists of feeding rollers and a material poking roller; the crushing device consists of a rotor, a fixed cutter and a filter screen; the circumference of the rotor is provided with fly-cutter seats; the included angles between the adjacent fly-cutter seats are equal on the circumference; fly-cutters are fastened on the fly-cutter seats through bolts; gaps are reserved between blades of the fly cutters and the fixed cutter; the fixed cuter is fastened on a fixed cutter beam by a bolt through a pressing plate; the fixed cutter beam is connected with the feeding rollers through a feeding transition plate; and the feeding rollers are parallel to each other, and the rotation directions of the feeding rollers are consistent with each other; and the material poking roller is fixed on a material fixing roller cover in which a hinge is taken as a rotation center. The crusher is high in crushing efficiency, low in energy consumption, and good in effect of crushing wood, core wood, cotton straw and other biomass, is suitable for crushing municipal solid waste and industrial refuse simultaneously and runs stably.

Owner:CHANGSHA UNIVERSITY OF SCIENCE AND TECHNOLOGY

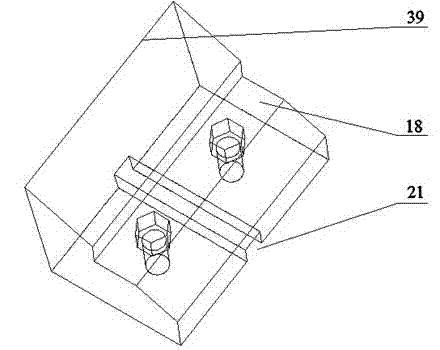

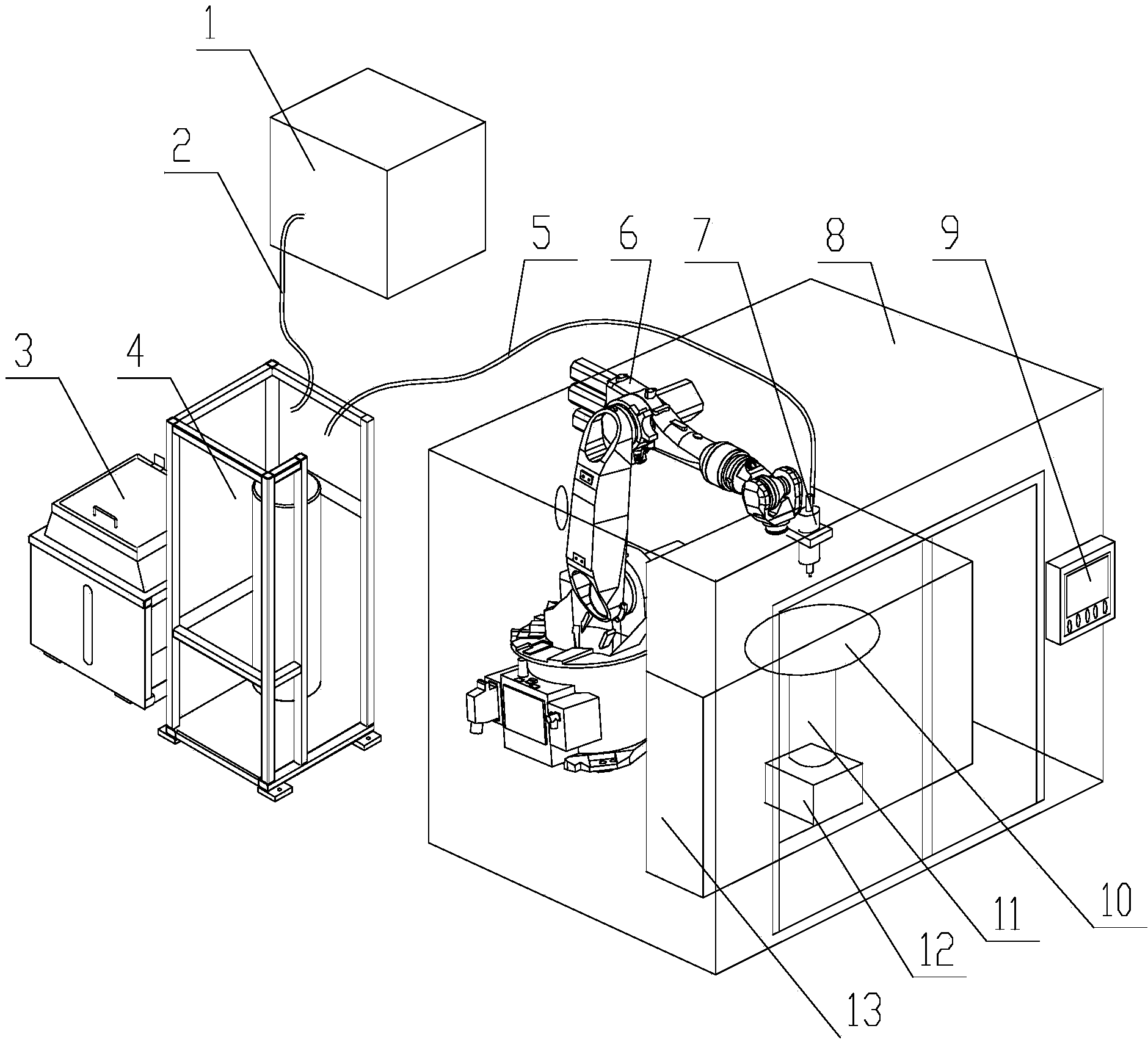

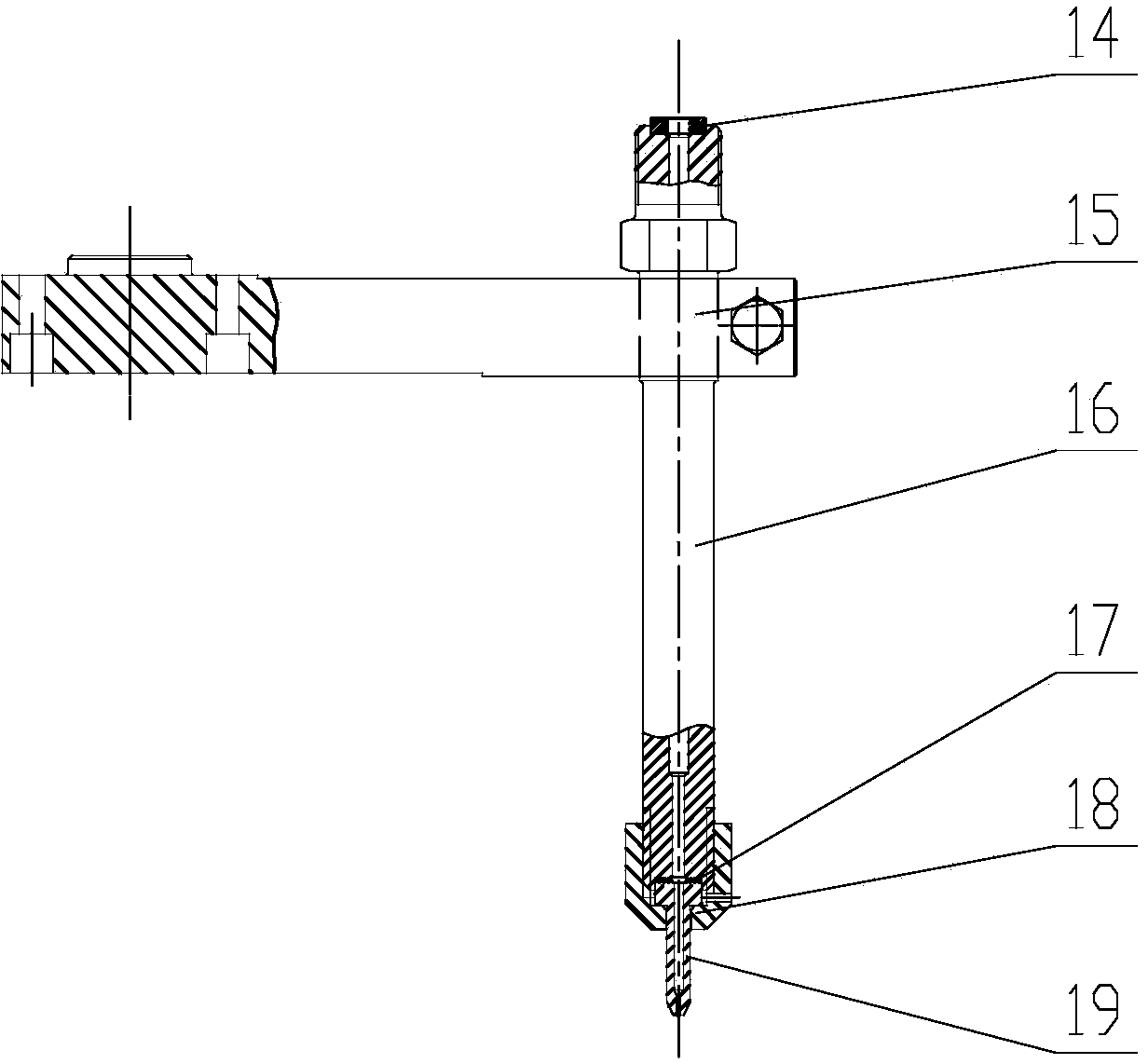

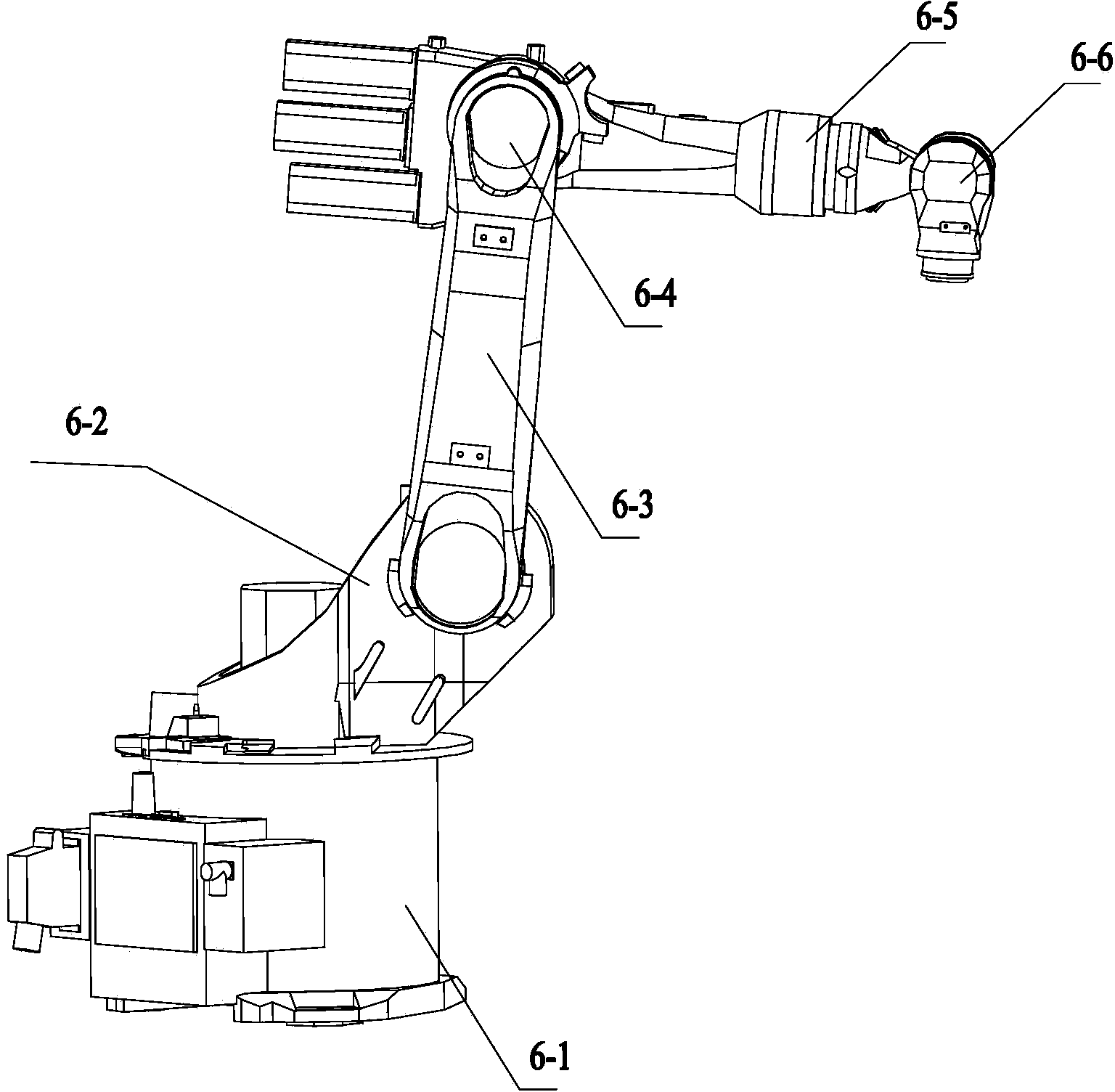

Suspension abrasive water jet cutting equipment

InactiveCN104175230AIncrease flexibilityLong conveying distanceAbrasive machine appurtenancesAbrasive blasting machinesEngineeringHigh pressure water

The invention relates to suspension abrasive water jet 3D cutting equipment adopting a seven-shaft intelligent robot, in particular to suspension abrasive water jet cutting equipment which comprises a high-pressure pump station used for providing cutting power, an abrasive filling device and a suspension abrasive generating device used for producing abrasive, wherein a discharge hole of the abrasive filling device is connected with a feed hole of a high-pressure container arranged in the suspension abrasive generating device through a feed pipe, a water inlet of the abrasive filling device is connected with a water outlet of the high-pressure container arranged in the suspension abrasive generating device through a water inlet pipe; high-pressure water generated by the high-pressure pump station is connected with a tee joint arranged in the suspension abrasive generating device through a high-pressure pipe. The product provided by the invention adopts a pre-mixing suspension abrasive cutting technology, the cutting pressure is low, and the efficiency is high; the equipment adopts a high-pressure hose as a suspension abrasive conveying pipeline, the conveying distance is long, and the equipment ensures that a nozzle device can realize high-precision motion of any track and any angle in space under the drive of a robot actuator.

Owner:西安远诚机电科技有限公司

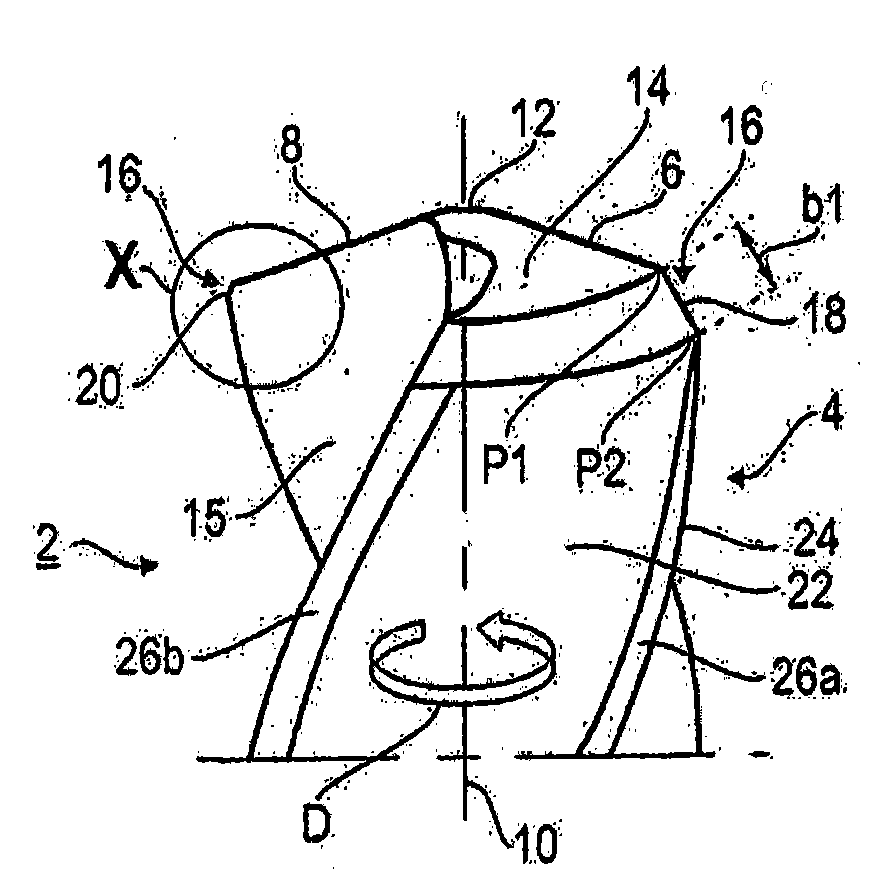

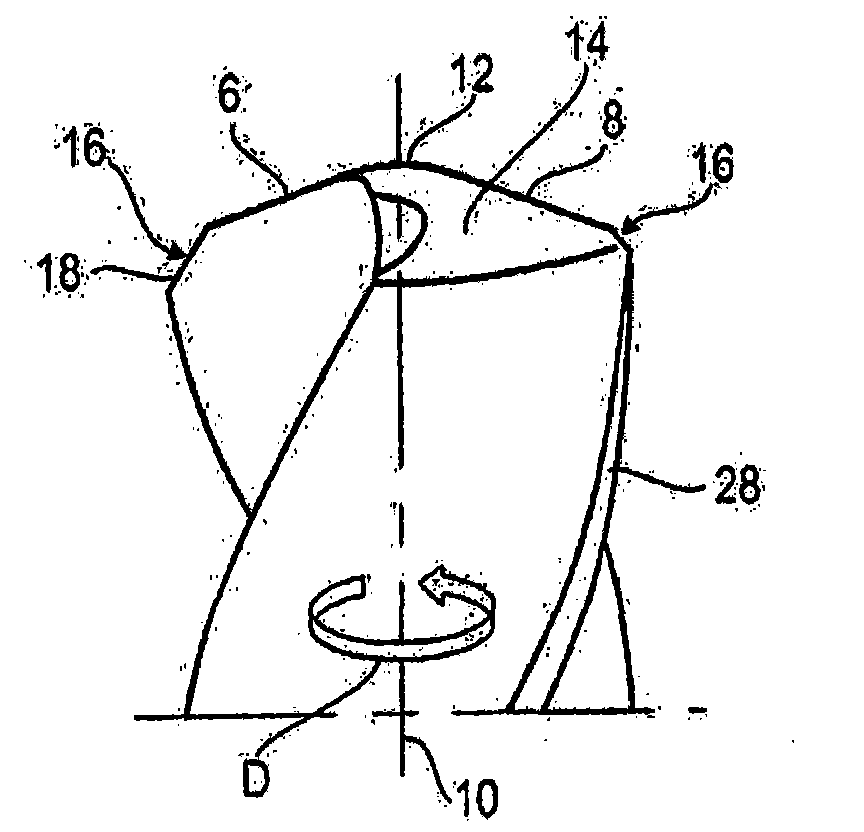

Rotary tool, in particular drill

In order to provide a rotary tool, in particular a drill (2), with a long service life together with high-quality drill holes, particularly in the case of through bores, the invention provides a cutting head (4) which extends along a rotational axis (10) and has a plurality of main cutting edges (6, 8) which extend radially outwards and each end at a cutting corner (16) having a corner bevel, wherein the corner bevels are of differing designs, specifically in the form of a roughing bevel (18) and in the form of a finishing bevel (20).

Owner:KENNAMETAL INC

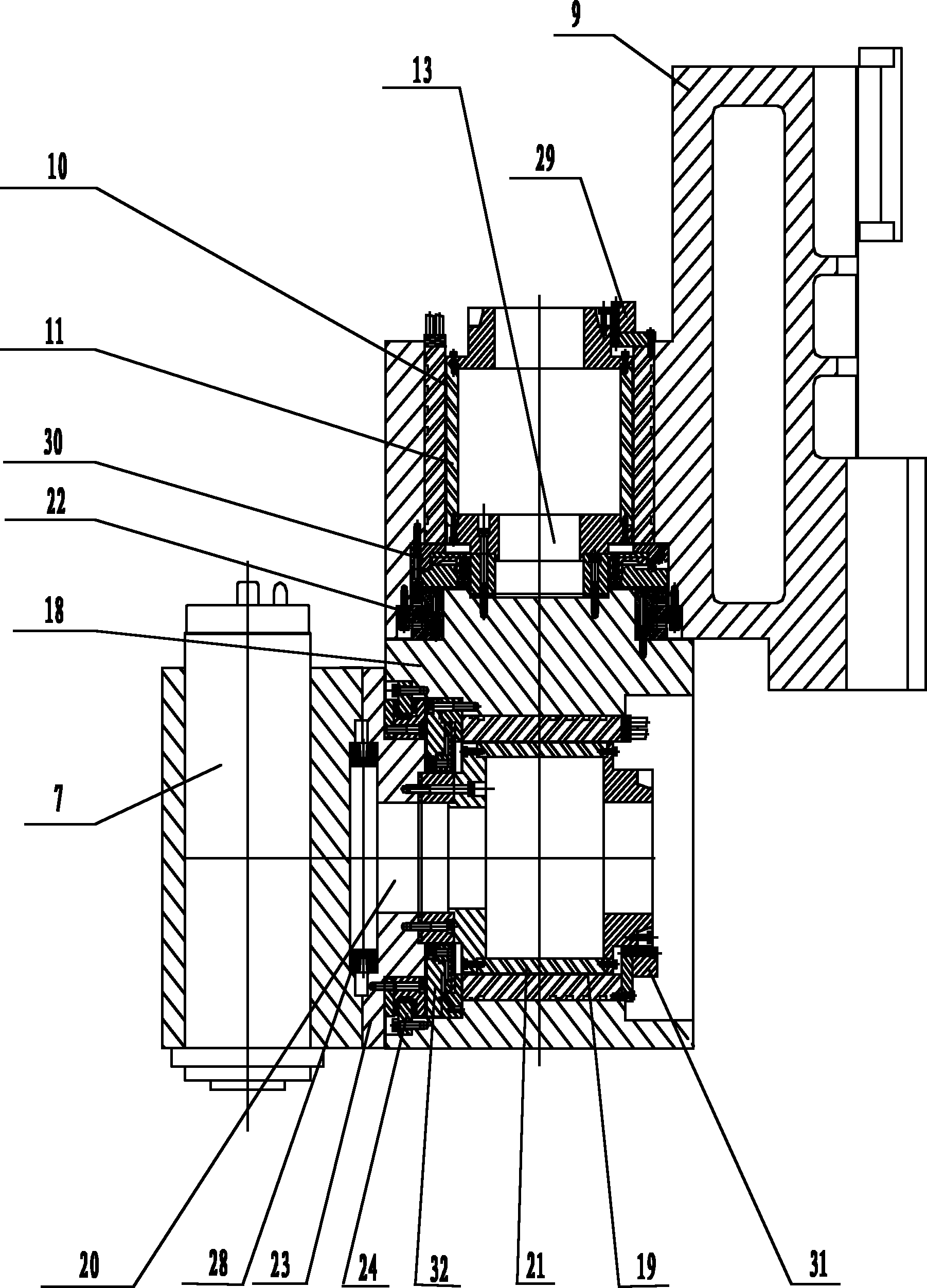

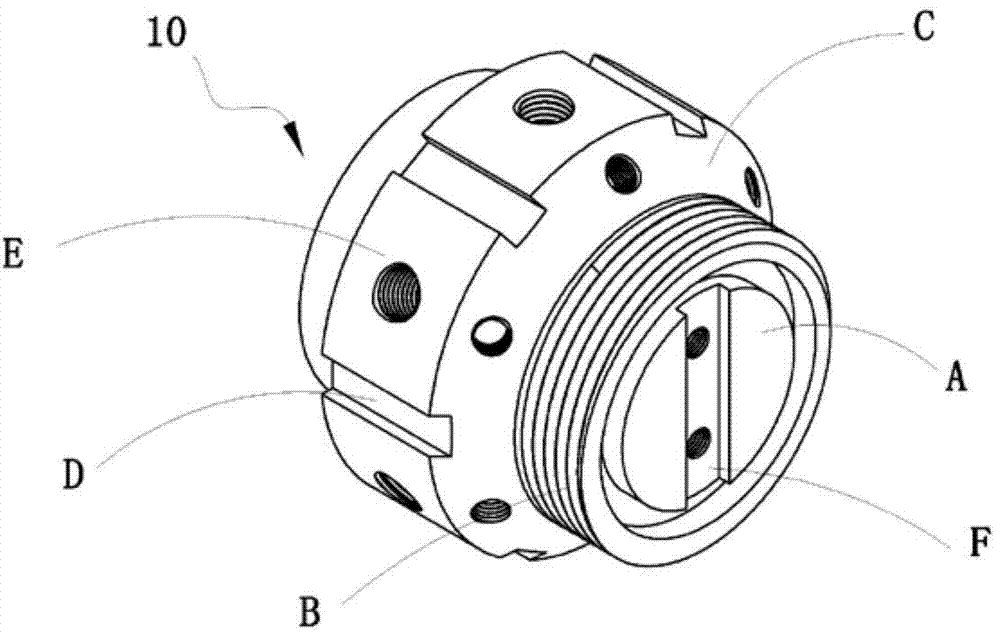

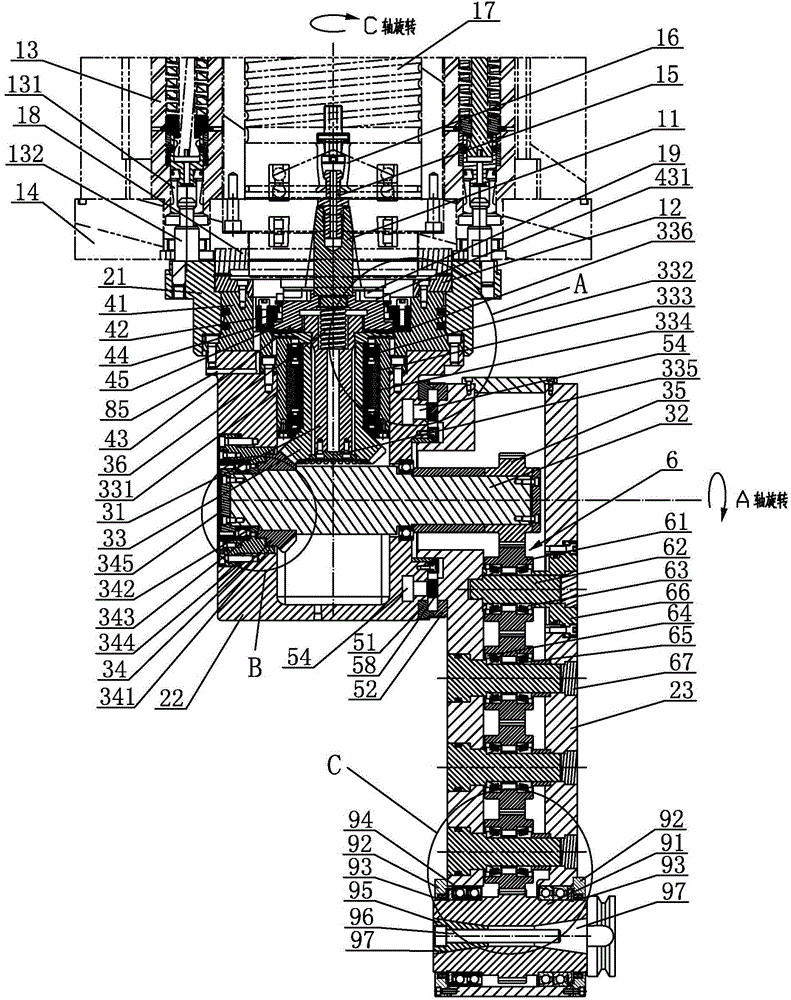

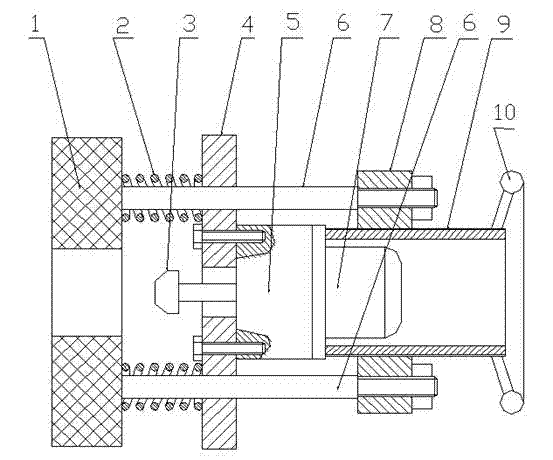

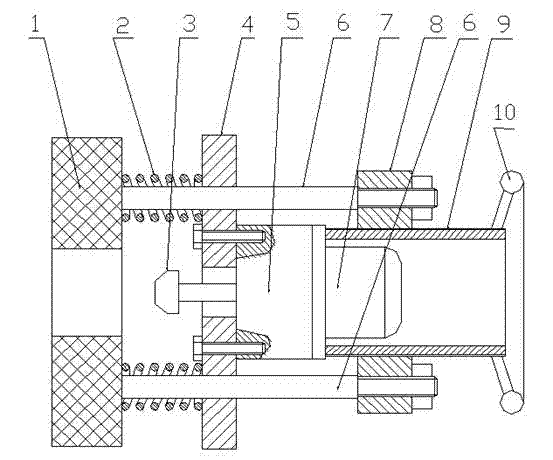

Universal side milling head for milling square rams

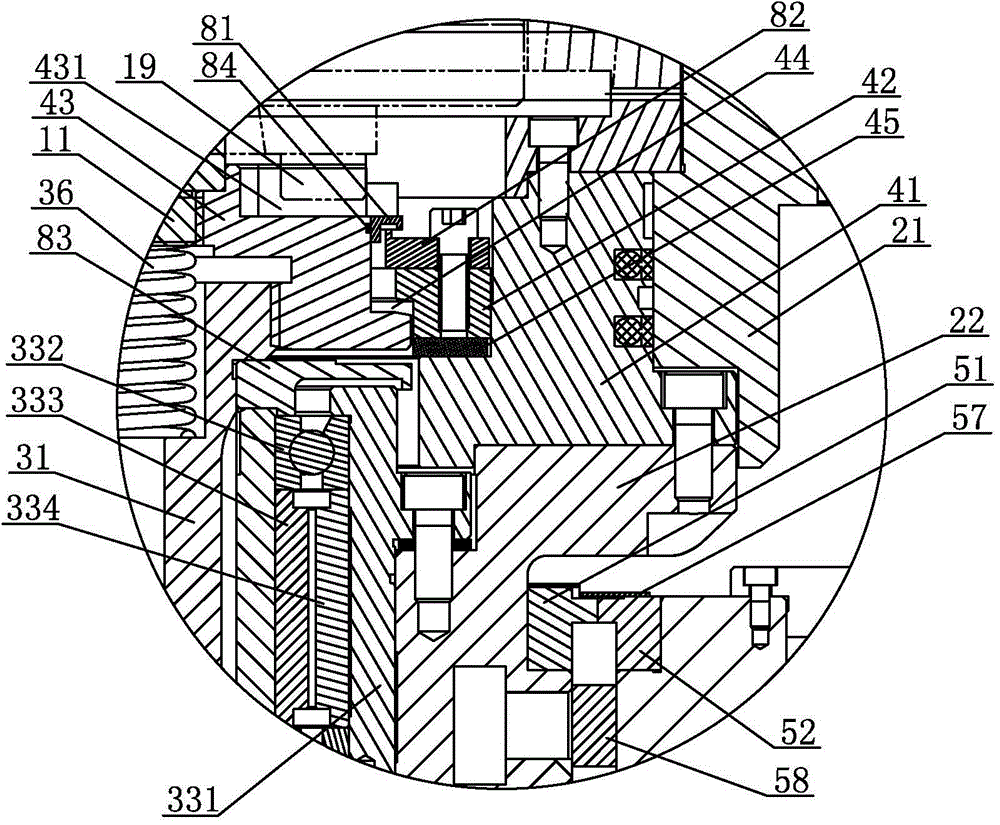

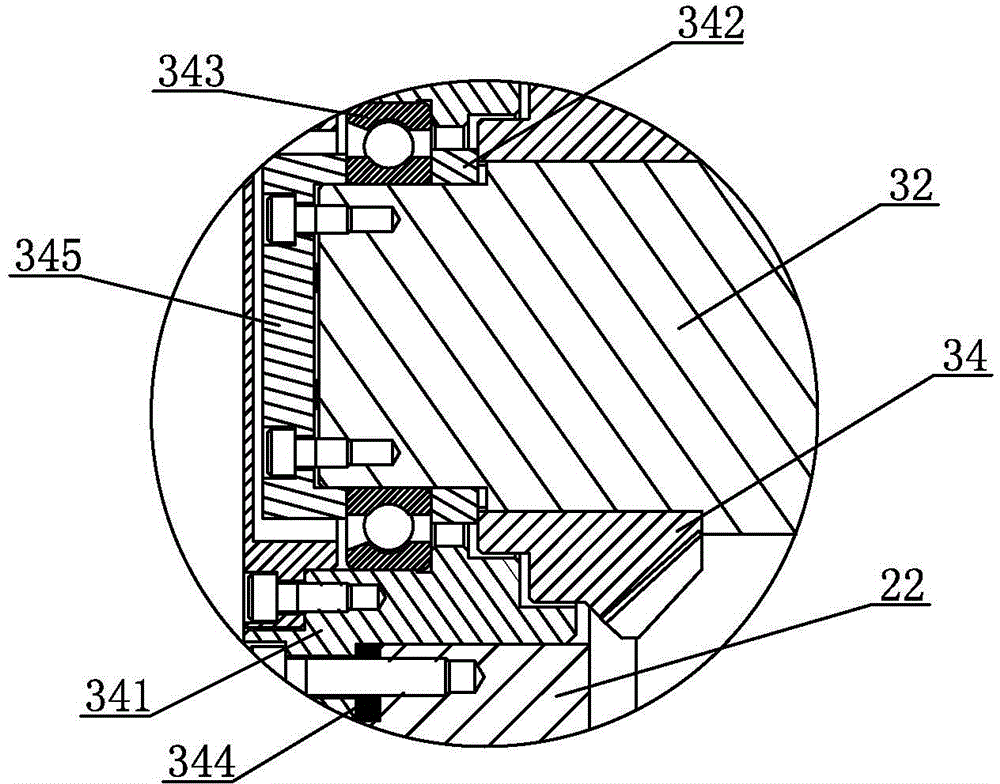

ActiveCN104551811AWith C-axis automatic indexing functionSolve non-transferable defectsLarge fixed membersMilling equipment detailsGear wheelEngineering

The invention discloses a universal side milling head for milling square rams. The universal side milling head comprises a C-axis auto-rotating mechanism. The C-axis auto-rotating mechanism comprises a pull ring disposed within an upper box, a rotating inner gear and a rotating outer gear; the pull ring is connected to an inner hole of the upper box in a centered manner; the pull ring is connected with the rotating inner gear through a screw; the upper end of the pull ring is connected with a lower chain wheel through a screw; the lower end of the pull ring is connected with the lower box through a screw; the rotating outer gear is connected with a machine tool spindle; the upper end of the rotating outer gear is connected with the lower end of a taper shank in a threaded manner; the lower end of the rotating outer gear is connected with the input end of the transmission mechanism; the rotating inner gear sleeves the rotating outer gear; a longitudinal gap is provided between a tooth portion of the rotating inner gear and a tooth portion of the rotating outer gear. The universal side milling head has the function of C-axial automatic rotating, is high in automation level and fills the blank of the machining field of complex parts, especially those requiring multi-angle machining through access into a deep cavity.

Owner:NINGBO HAITIAN PRECISION MASCH CO LTD

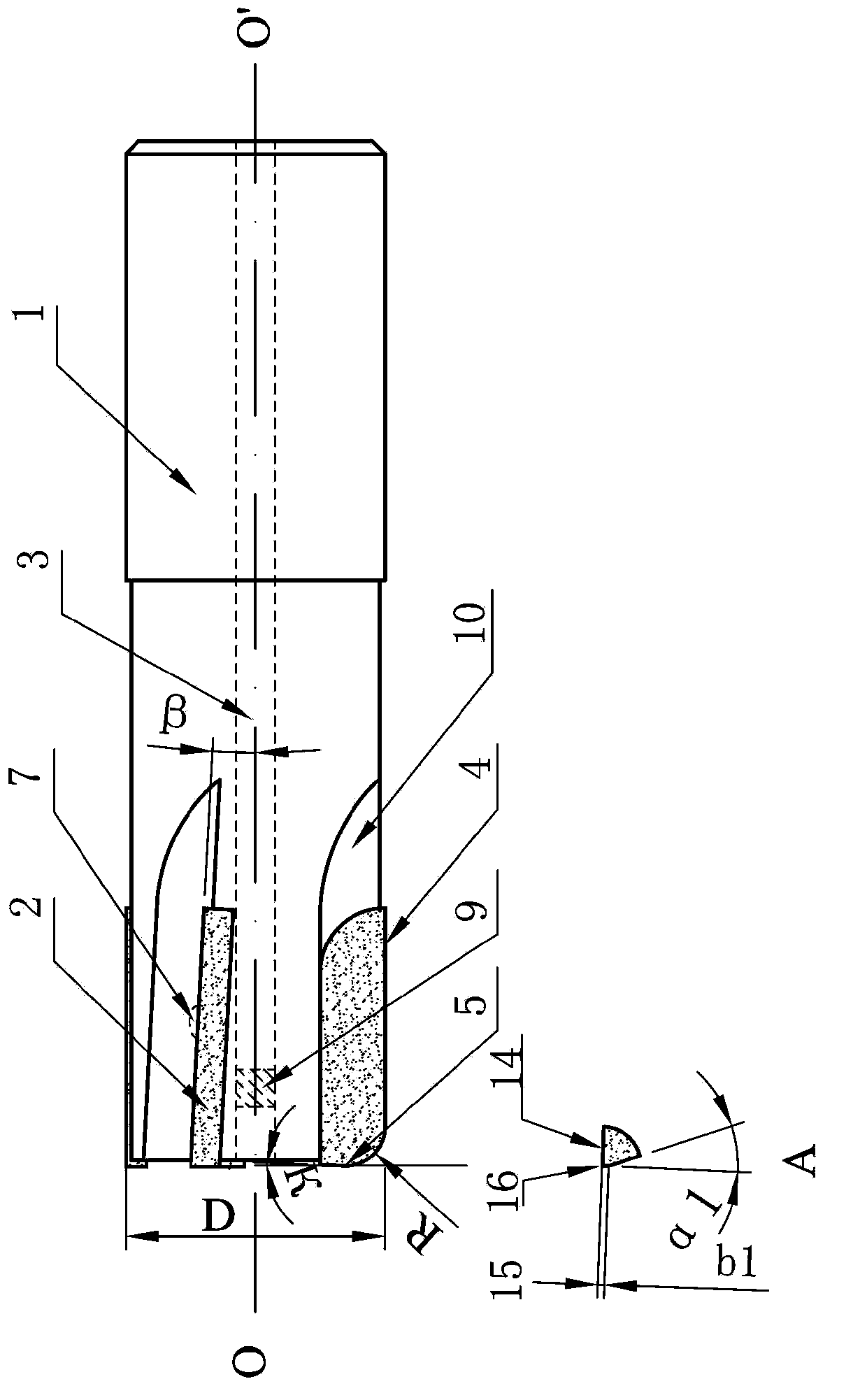

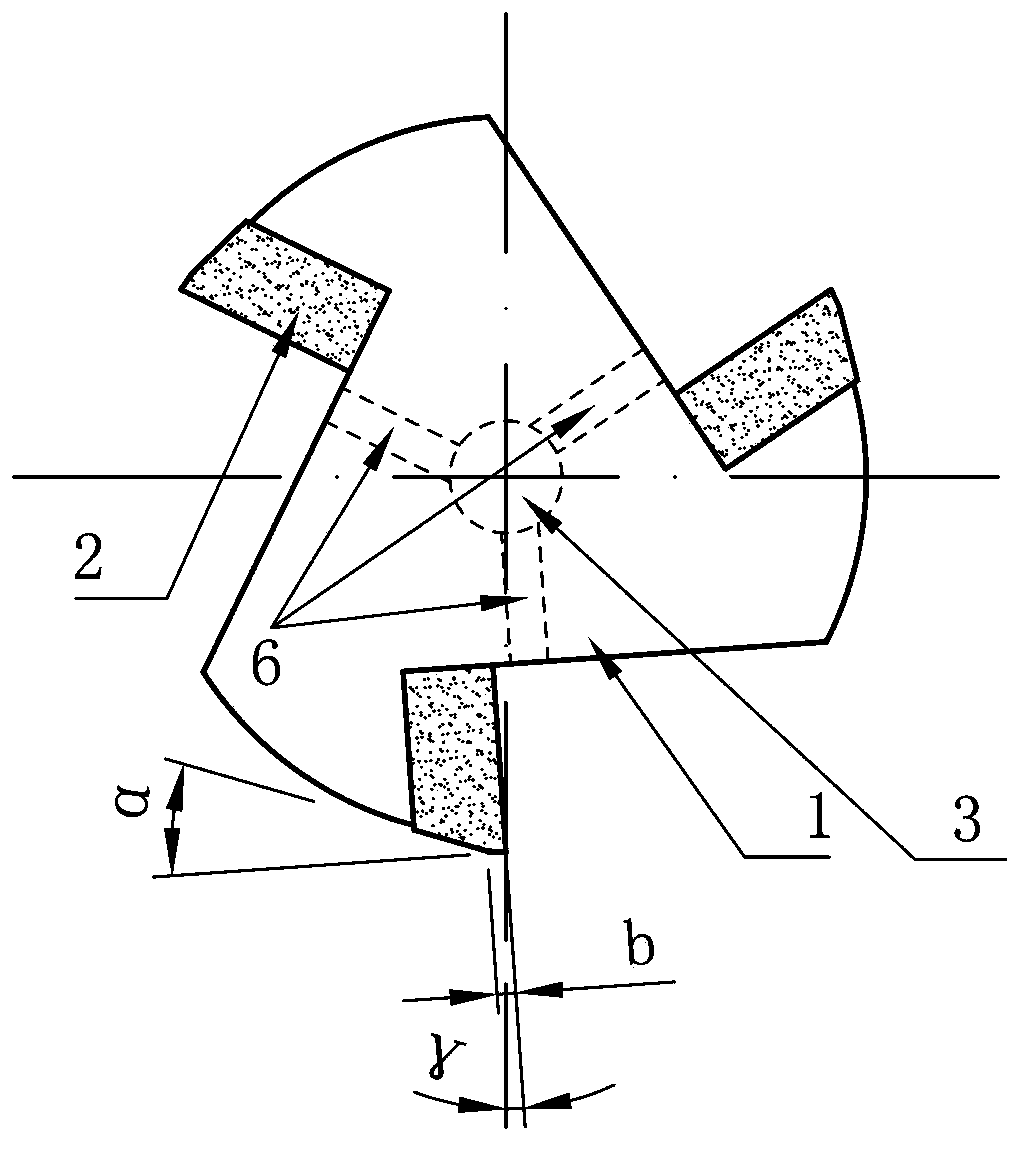

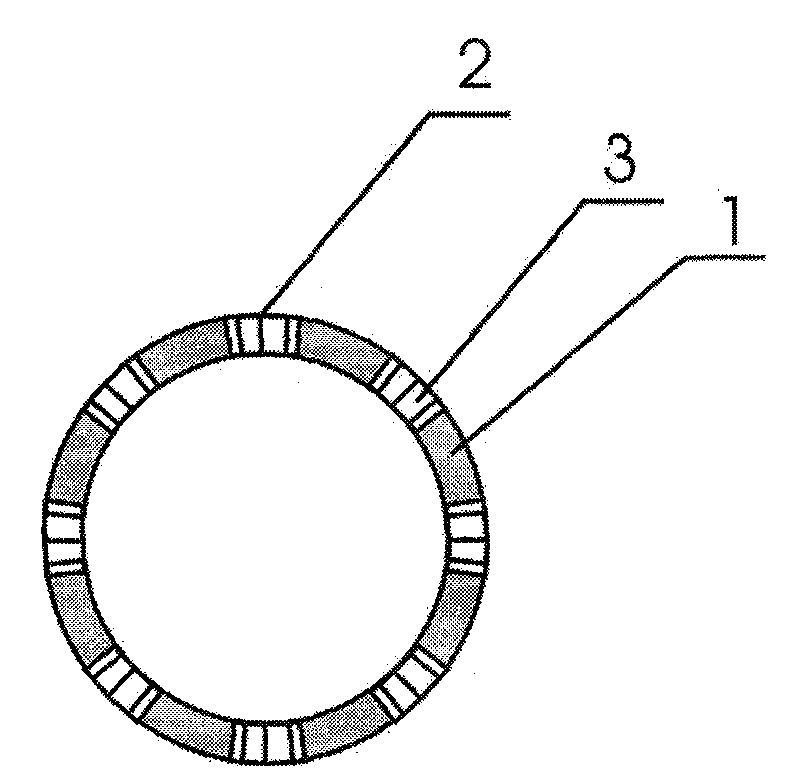

Polycrystalline diamond milling cutter

ActiveCN103658795AEasy millingSolve the sticky knife problemMilling cuttersMilling cutterPolycrystalline diamond

The invention provides a milling cutter which is used for processing a forming surface and can rotate around a central axis. The milling cutter comprises a rigid cutter body (1), polycrystalline diamond blades (2) respectively fixed on tooth bases as well as a cooling structure, wherein the cutter body is provided with at least two tooth bases (10) which are parallelly arranged at an interval; the polycrystalline diamond blades (2) can axially extend and can exceed the tail end of the rigid cutter body (1) so as to form end teeth (4), and the outmost radial sides of the polycrystalline diamond blades can limit circumference teeth (3); the cooling structure comprises a main cooling channel (3) formed in the cutter body and cooling holes (6,8) which are communicated with the main cooling channel (3) and can supply a cooling fluid to the blades (2).

Owner:JUNTEC ULTRA HARD TOOLS CO LTD

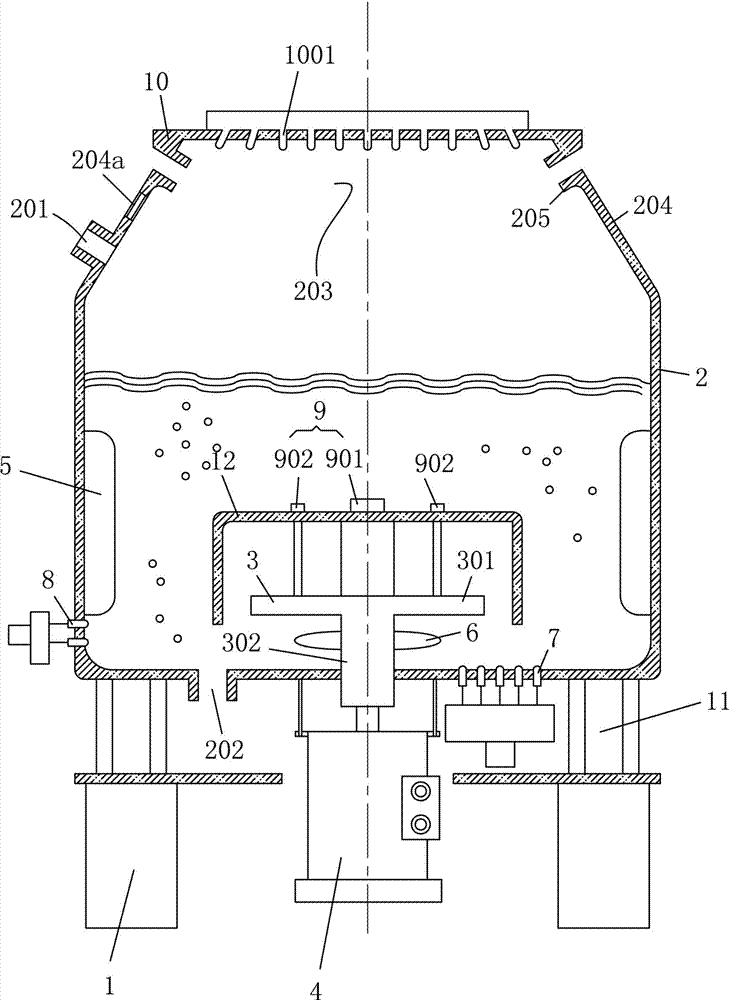

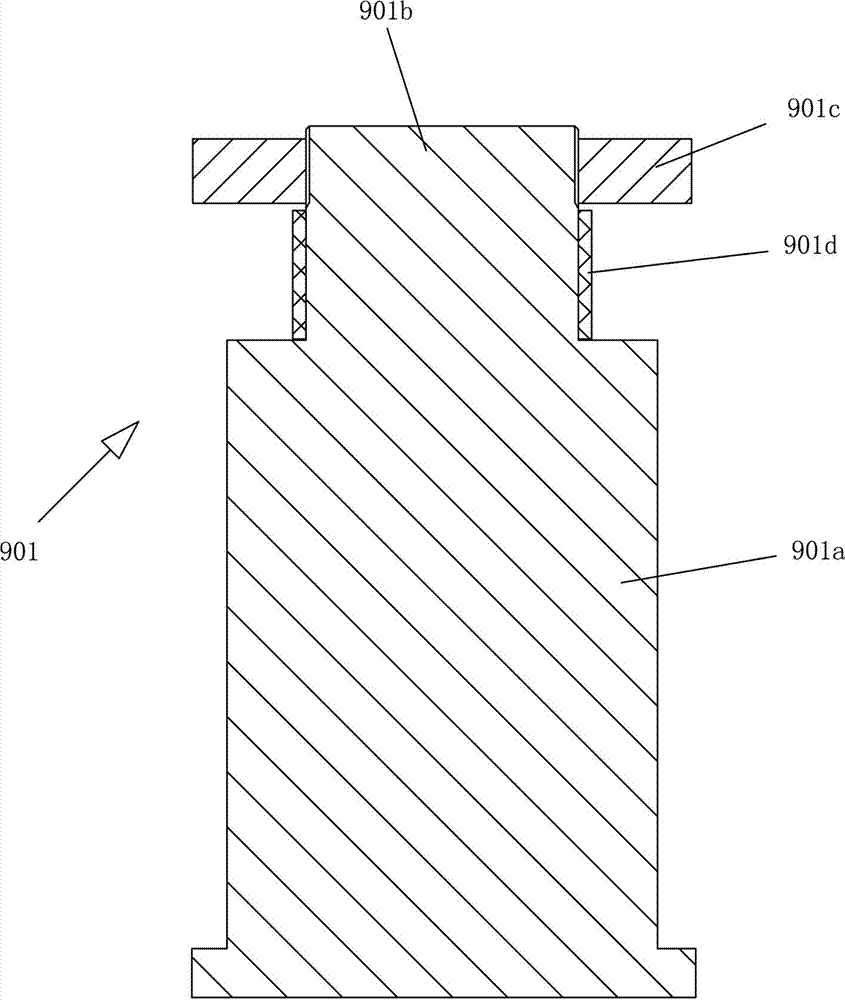

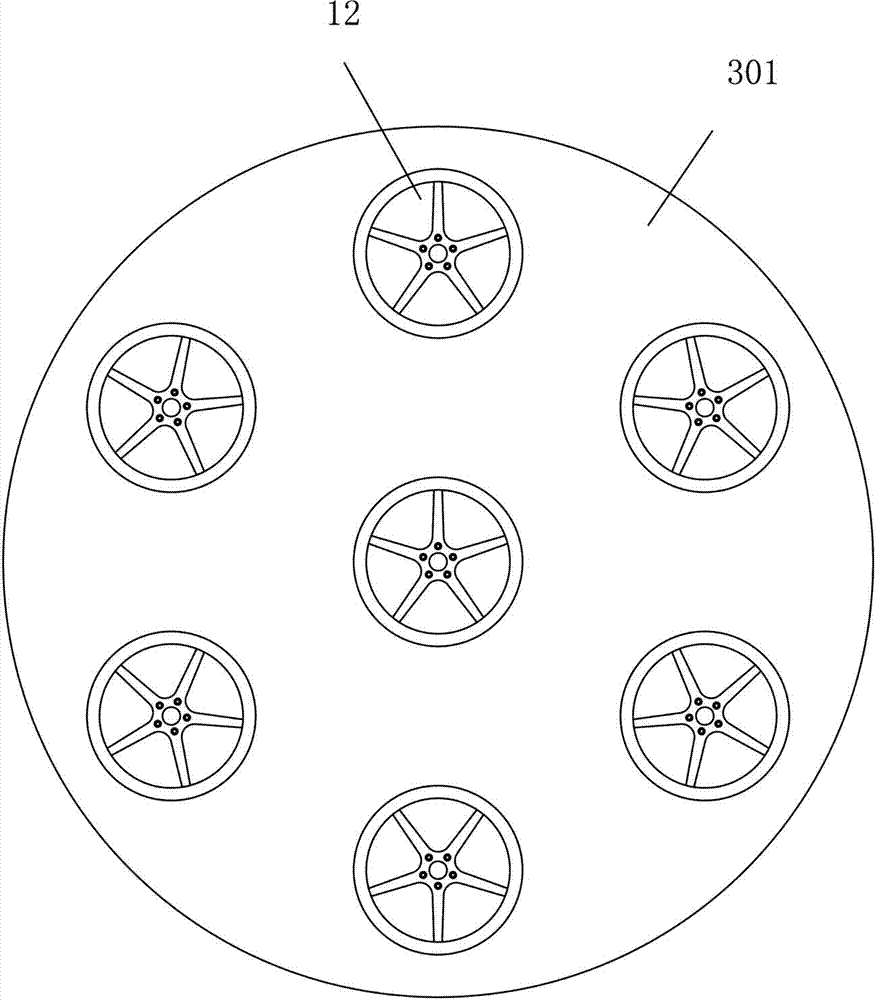

Hub polishing and lapping machine

The invention discloses a hub polishing and lapping machine which comprises a base, a material lapping barrel installed on the base, a fixing device and a rotating motor. The material lapping barrel is provided with a loading port, an unloading port and an opening, a flying wheel disc is installed at the bottom of the material lapping barrel, the fixing device is arranged on an upper surface of the flying wheel disc and used for fixing hubs on the flying wheel disc, and the rotating motor drives the flying wheel disc to rotate. The hub polishing and lapping machine is rapid in polishing speed and good in polishing effects.

Owner:ZHEJIANG GINHENRY NEW TECH DEV

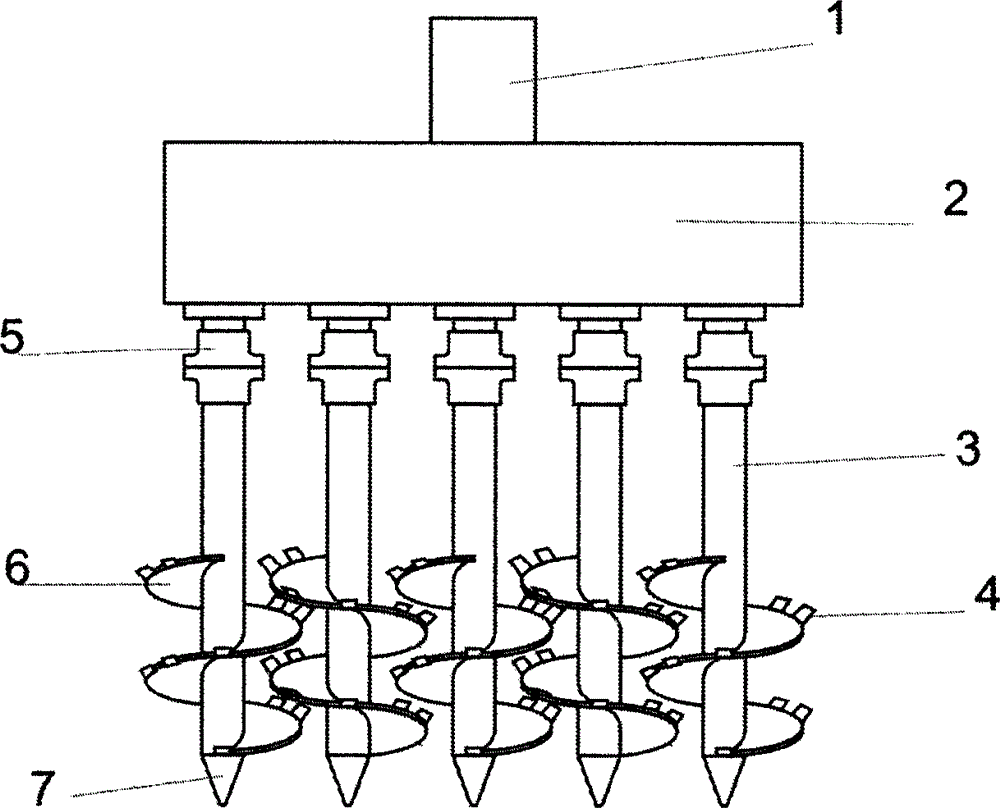

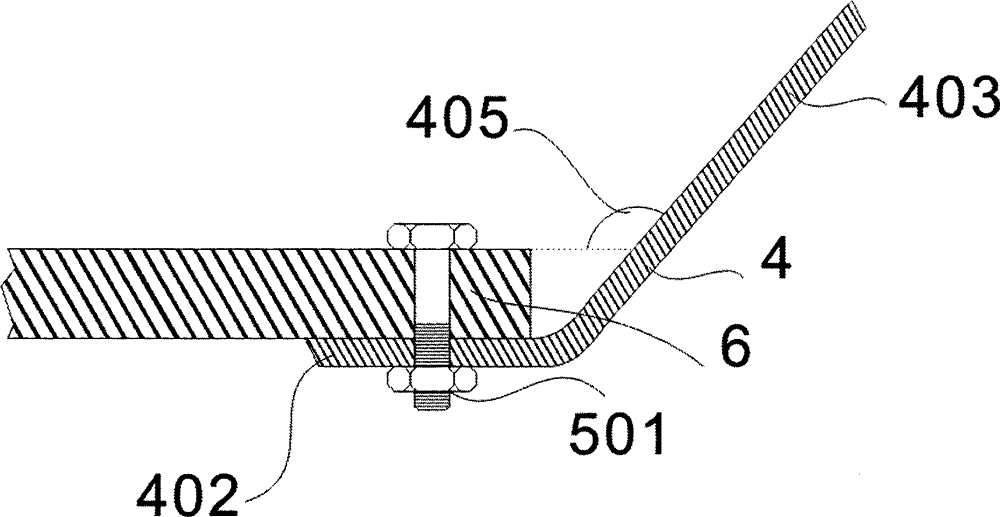

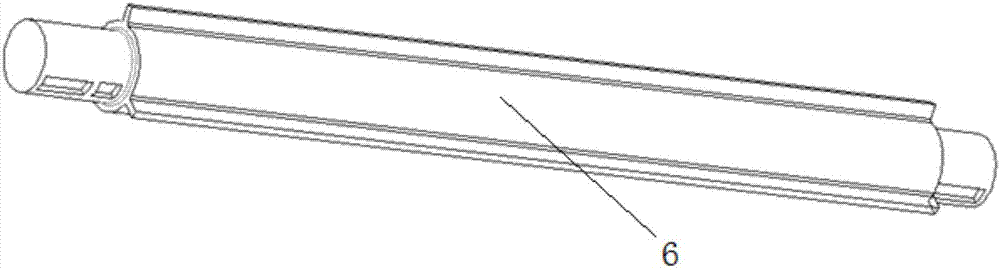

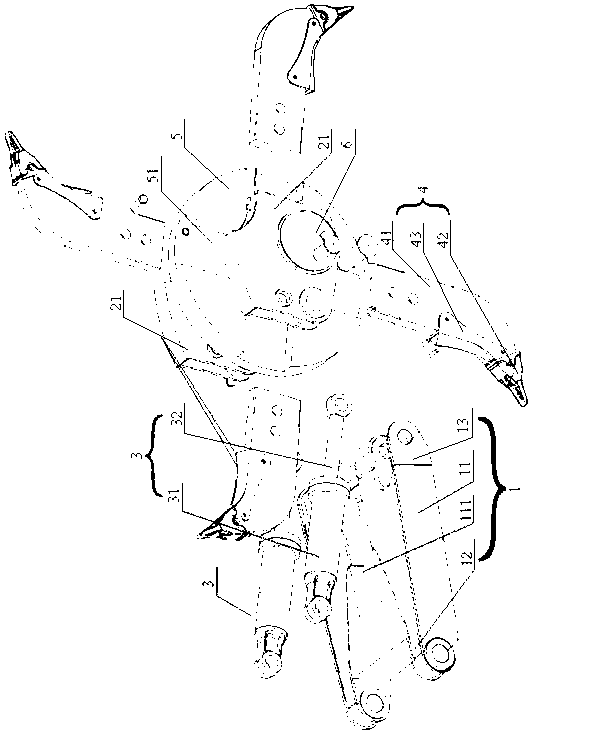

Deep ploughing, deep scarification and ridge smashing device

InactiveCN104521344AReduce travel resistanceReduce cutting forceTilling equipmentsSocial benefitsScarification

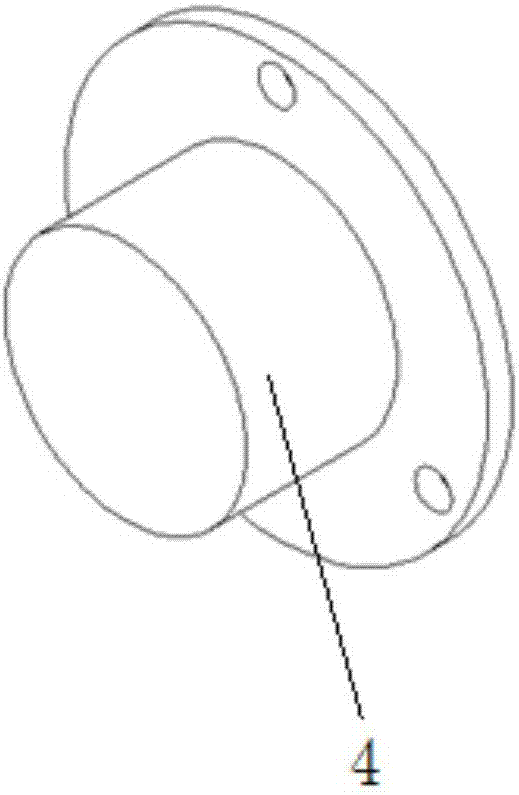

The invention discloses a deep ploughing, deep scarification and ridge smashing device. The device comprises a motor 1, a transmission case 2 and at least two ridge smashing drill bits. Each ridge smashing drill bit comprises a screw shaft 3, ridge smashing cutters 4, a connecting flange 5 arranged on the top of the screw shaft, a screw blade 6 and a drill tip 7. Each screw blade 6 is mounted on the corresponding screw shaft 3, and the ridge smashing cutters 4 are arranged on the outer edge of each screw blade. The deep ploughing, deep scarification and ridge smashing device is characterized in that the distance from ridge smashing cutter heads of the ridge smashing mechanism to the screw shafts is larger than half the distance between the external diameter parts of every two adjacent screw shafts and smaller than the distance between the external diameter parts of every two adjacent screw shafts. The deep ploughing, deep scarification and ridge smashing device solves the problems that a ridge smashing machine in the prior art is not thorough in cutting of large soil blocks and bad in ridge smashing effect, tillage efficiency is improved, and the application and popularization economic benefits and social benefits are very obvious.

Owner:GUANGXI WUFENG MACHINERY CO LTD

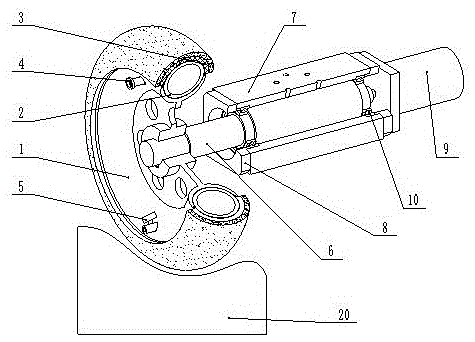

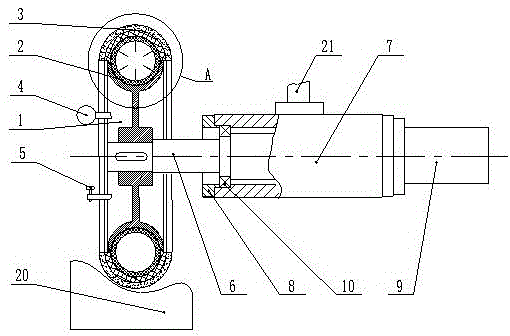

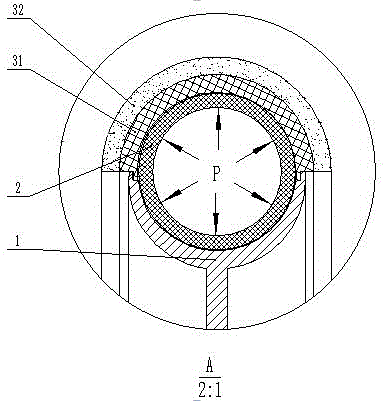

Flexibly movable drilling machine with large drilling and cutting force

InactiveCN102513576AEasy to moveReduce labor intensityPortable drilling machinesHydraulic cylinderEngineering

The invention provides a flexibly movable drilling machine with large drilling and cutting force. The flexibly movable drilling machine is characterized in that a fixing guide column is mounted on the back face of an annular electromagnetic chuck; a movable sliding board is mounted on the upper surface of the guide column; working mechanisms, such as a reducing box, a motor and the like, are mounted and fixed on the upper surface of the sliding board; and the sliding board is driven to move forward and backward by a hydraulic cylinder consisting of an annular piston cylinder arranged at the end part of the guide column and an annular piston. The flexibly movable drilling machine disclosed by the invention is simple in structure and flexible and convenient to use. Meanwhile, the flexibly movable drilling machine disclosed by the invention has the advantages that the labor intensity is reduced and the drilling and cutting force is greater. The flexibly movable drilling machine can be used in places for outside maintenance and other movable operations.

Owner:JIANGSU MASTER COMP SYST INTEGRATION

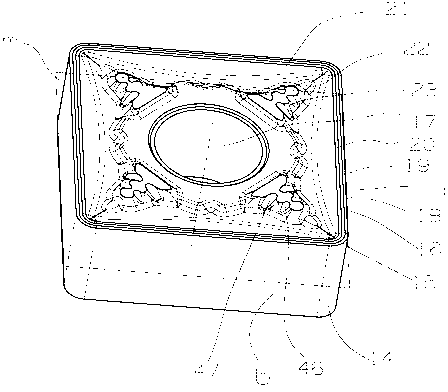

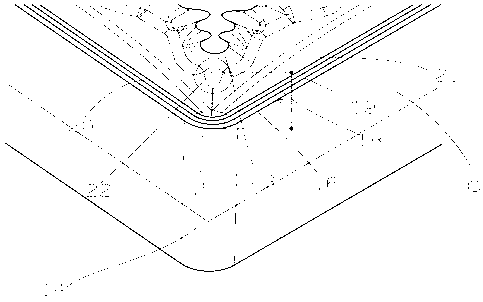

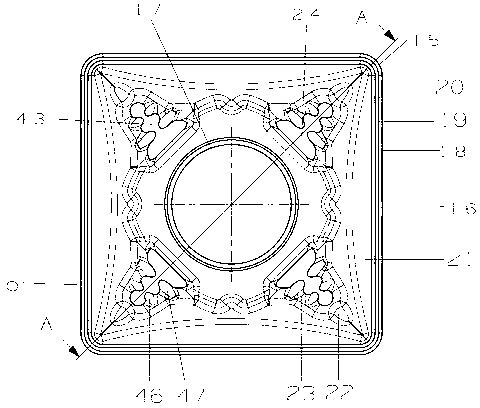

Indexable cutting insert for rough machining

ActiveCN103009333AImprove impact resistanceGuaranteed impact resistanceMetal-working hand toolsEdge strengthEngineering

The invention discloses an indexable cutting insert for rough machining. An insert body is a polygonal body, the geometrical center is provided with a mounting through hole, a chip breaker body is arranged around the mounting through hole, and cutting units are respectively distributed at the included angle between each two neighboring sides. The indexable cutting insert is characterized in that each cutting unit consists of a main cutting edge and an auxiliary cutting edge; each of the main cutting edge and the auxiliary cutting edge is provided with a chamfer plane and an arris plane, and a first front insert face and a second front insert face are connected with the chip breaker body through concave bottoms; at each cutting unit, the chip breaker body is provided with a boss, the surface of the boss gradually rises to form a first chip breaker and a second chip breaker, a first concave is formed between the ridge of the first chip breaker and the ridge of the second chip breaker, a second concave is formed between the second chip breaker and the chip breaker body, and both the first concaves and the second concaves are smoothly connected with the concave bottoms. Under the premise of guaranteeing the edge strength of the insert, the cutting resistance is decreased, the indexable cutting insert has high chip-breaking ability, and the overall cutting performance is good.

Owner:OKE PRECISION CUTTING TOOLS CO LTD

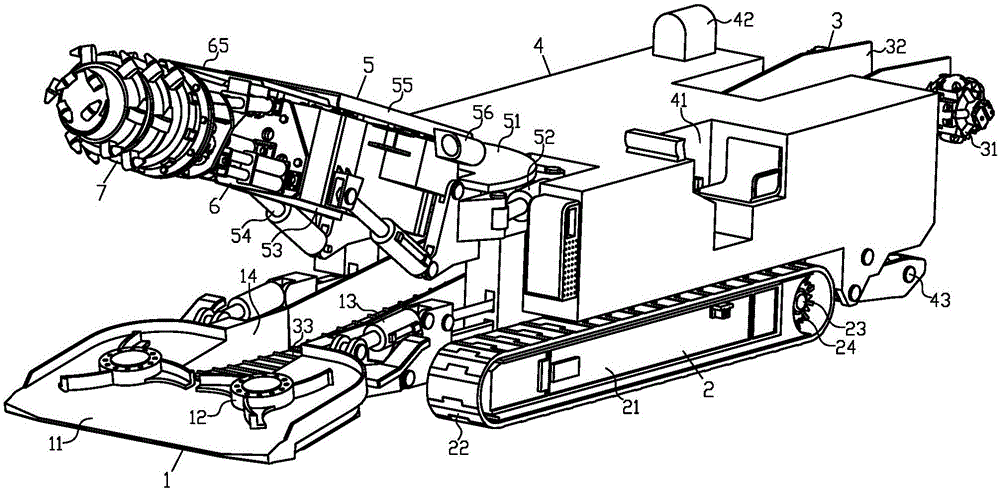

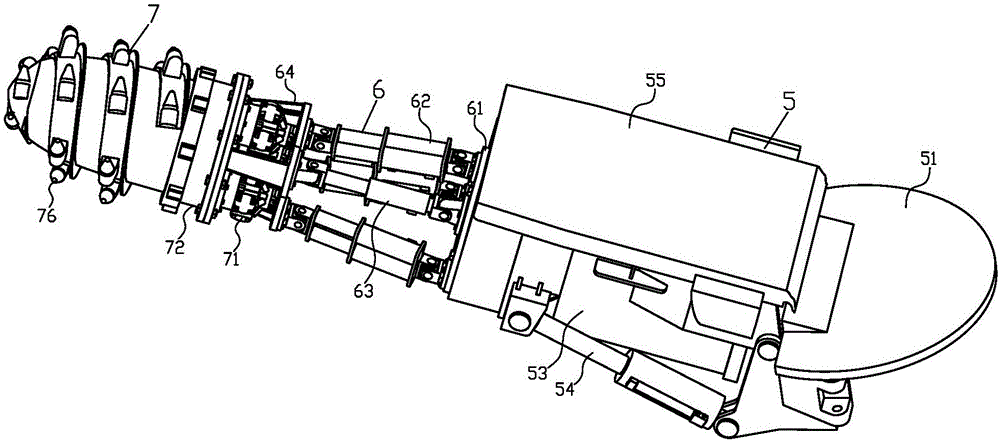

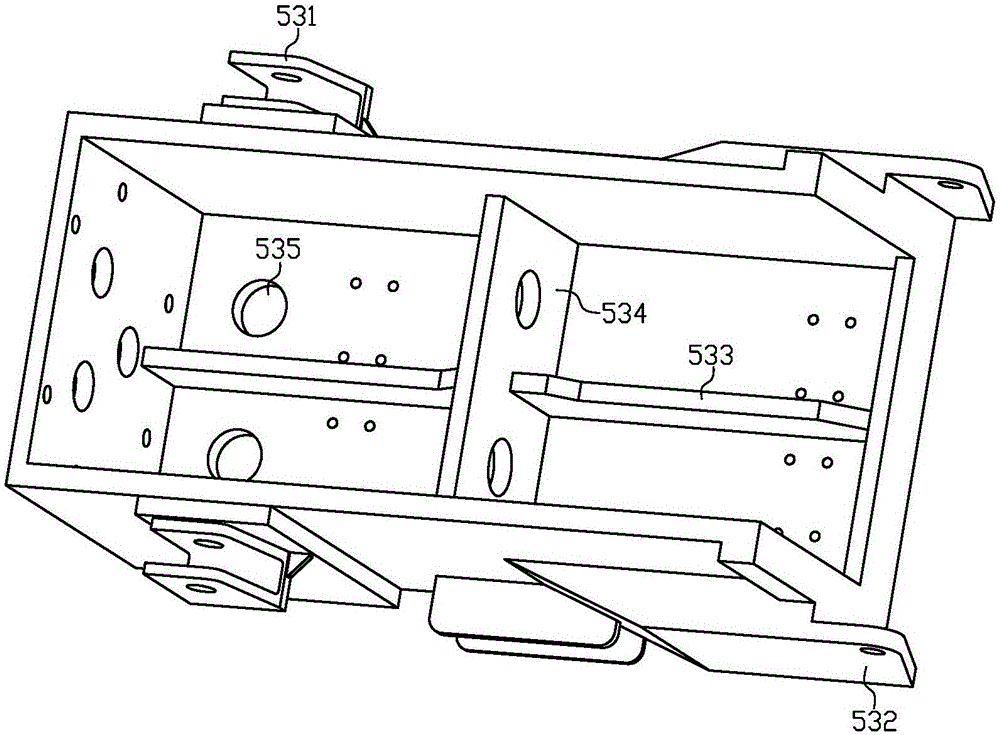

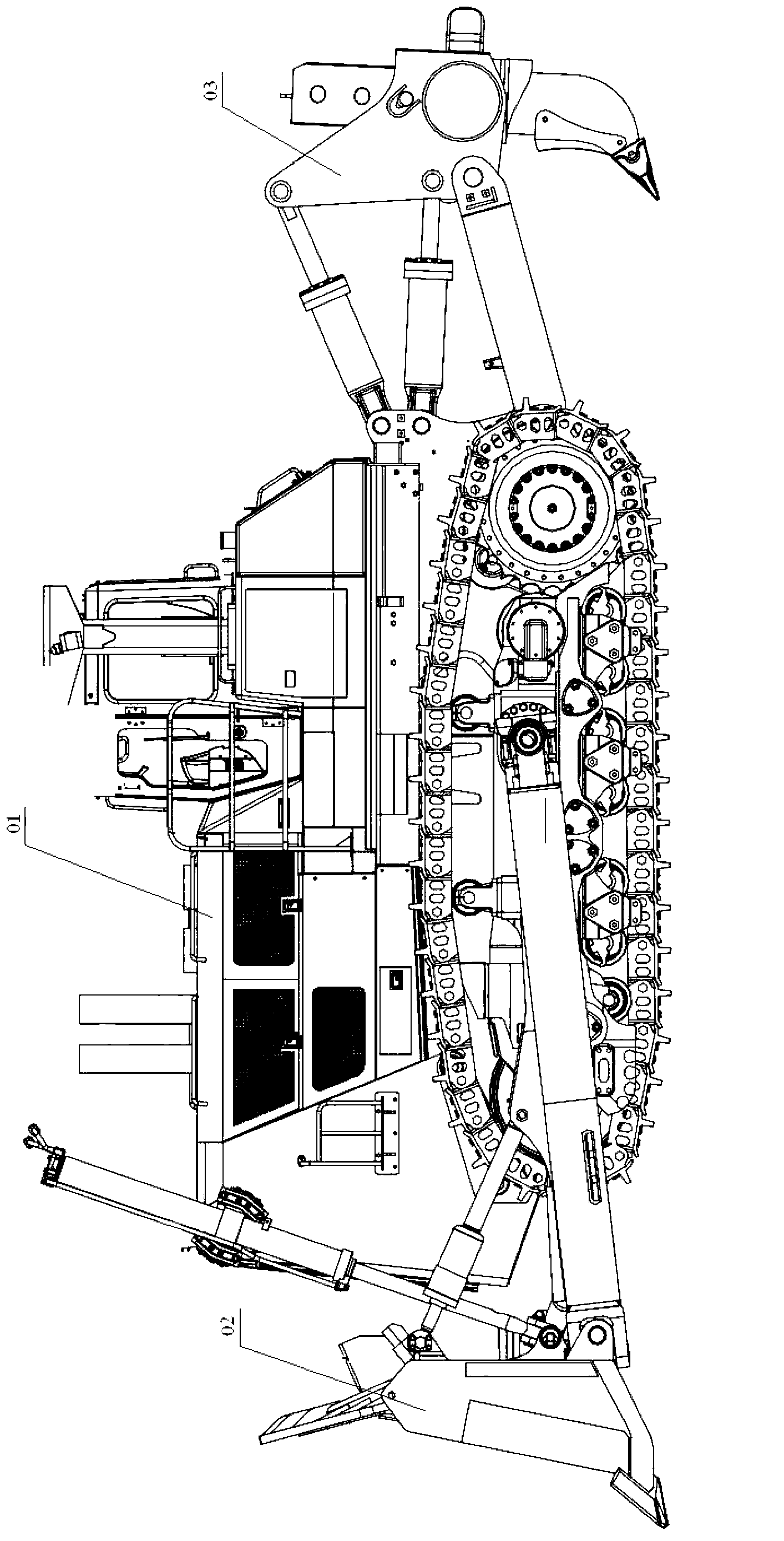

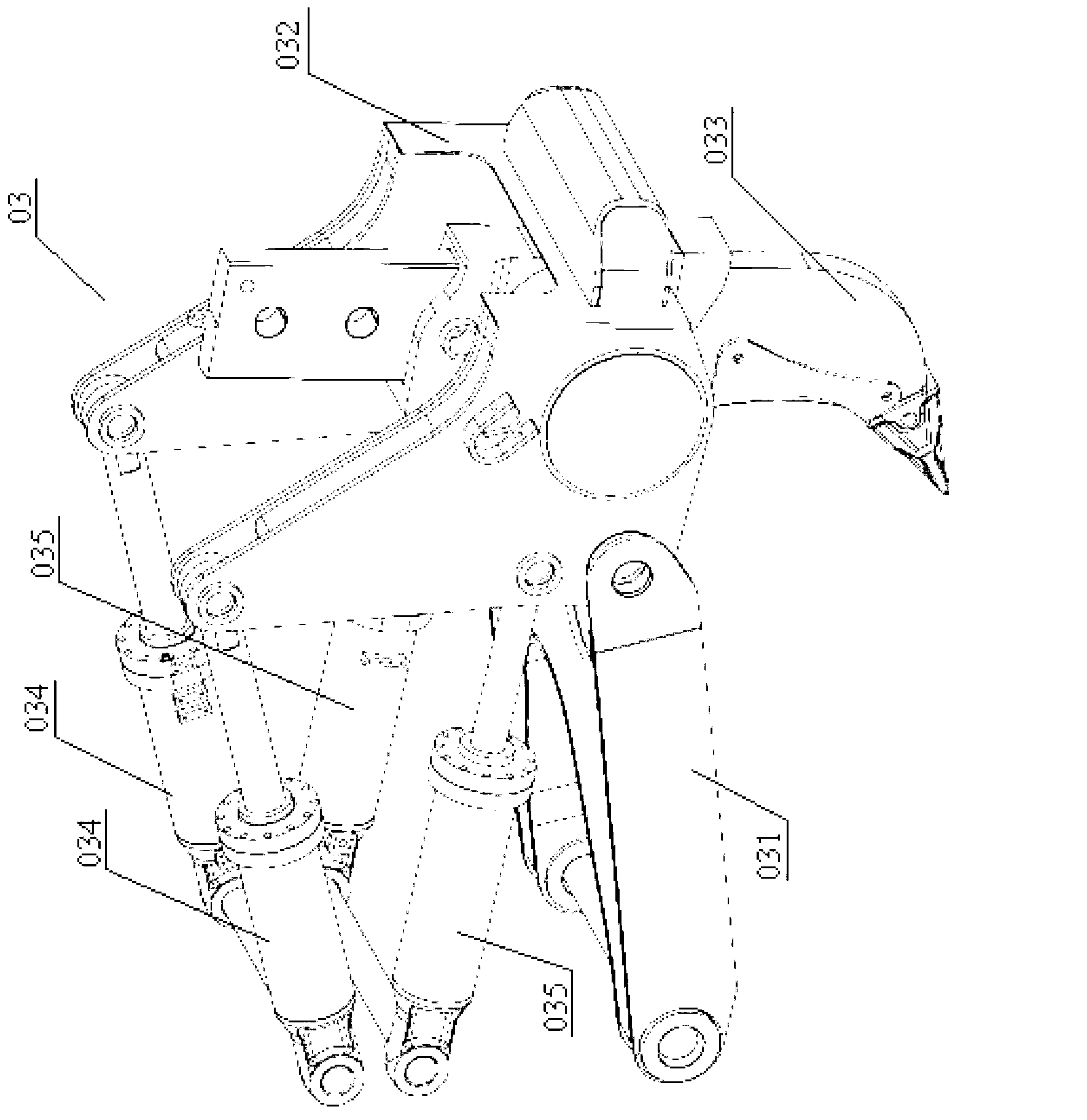

Six-freedom-degree series-parallel full-hydraulic tunneling machine

The invention discloses a six-freedom-degree series-parallel full-hydraulic tunneling machine. The six-freedom-degree series-parallel full-hydraulic tunneling machine comprises a loading part, walking parts, a scraper conveyor, a machine body, a two-freedom-degree rotation base, a parallel-connection working arm and a cutting head. The loading part is located at the front end of the machine body. The machine body is arranged on the walking parts. The cutting head is connected with the machine body through the parallel-connection working arm and the two-freedom-degree rotation base in sequence. The walking parts are driven by walking motors arranged on caterpillar band frames. Two conveying motors arranged on the tail portion of the scraper conveyor drive a scraper chain so that materials can be conveyed through the scraper conveyor. The cutting head is driven by three cutting motors at the same time. The cutting head has four independent movement freedom degrees including one space independent movement freedom degree and three space independent rotation freedom degrees. Two redundancy rotation freedom degrees exist in the horizontal direction. The six-freedom-degree series-parallel full-hydraulic tunneling machine has the advantages that the operation space is large and posture adjustment is convenient. The six-freedom-degree series-parallel full-hydraulic tunneling machine further has the advantages of being compact in structure, good in control decoupling property, convenient to adjust and maintain, and the like.

Owner:ANHUI UNIV OF SCI & TECH

Spherical diamond stacking abradant and preparation method thereof

ActiveCN107722935AImprove grinding effectGood self-sharpeningOther chemical processesPolyvinyl alcoholCutting force

The invention discloses a spherical diamond stacking abradant and a preparation method thereof. The spherical diamond stacking abradant is prepared from, by weight, 10-50% of diamond micro powder, 45-89% of pure water and 1-5% of bonding agent, wherein the grain diameter of the diamond micro powder is 1-100 micron, and the bonding agent is composed of starch, cellulose and polyvinyl alcohol. The spherical diamond stacking abradant has the advantages of having large cutting force, excellent self-sharpening performance, continuous grinding force and a better grinding effect, and can effectivelyprevent products from being scratched.

Owner:绍兴自远磨具有限公司

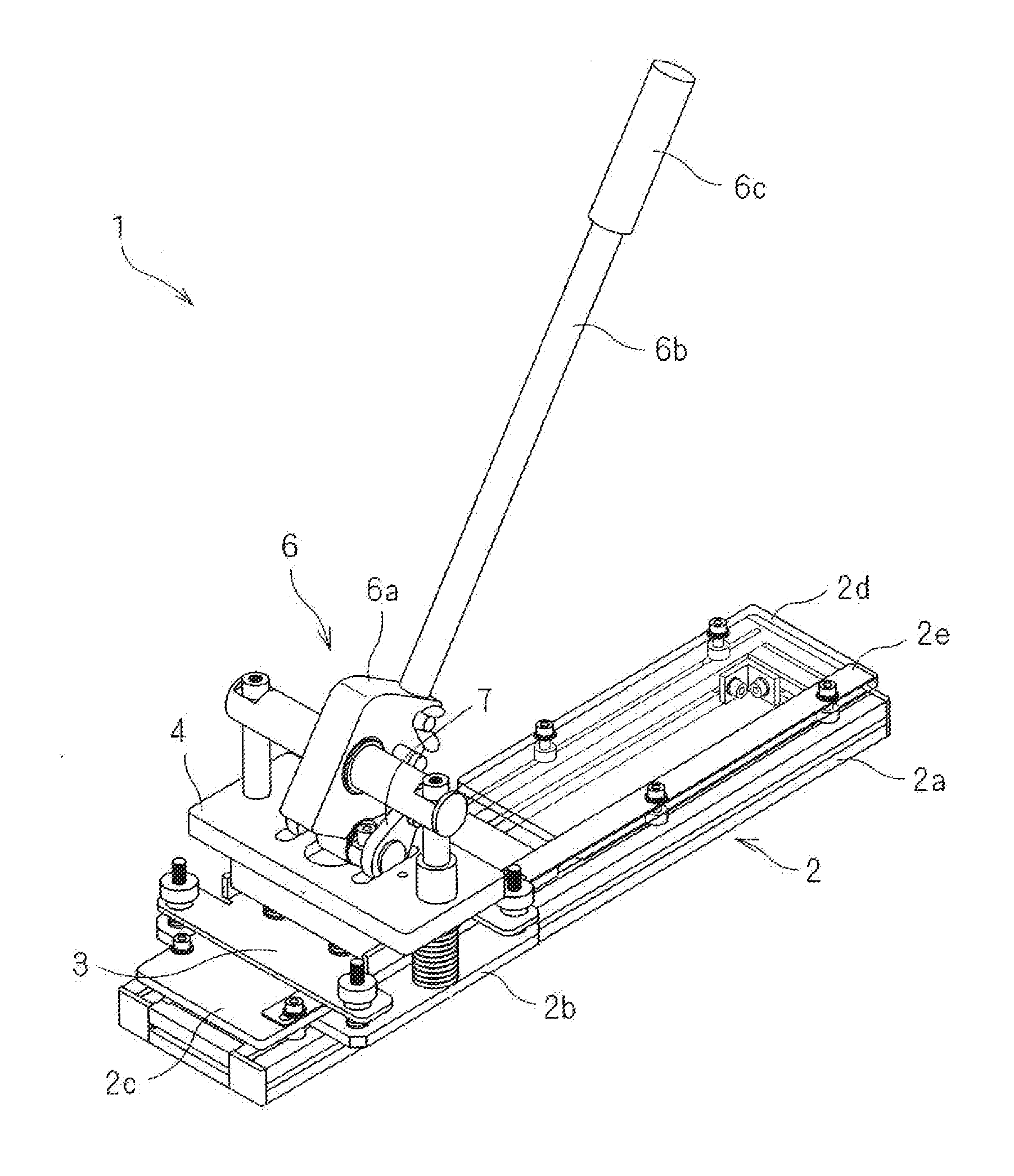

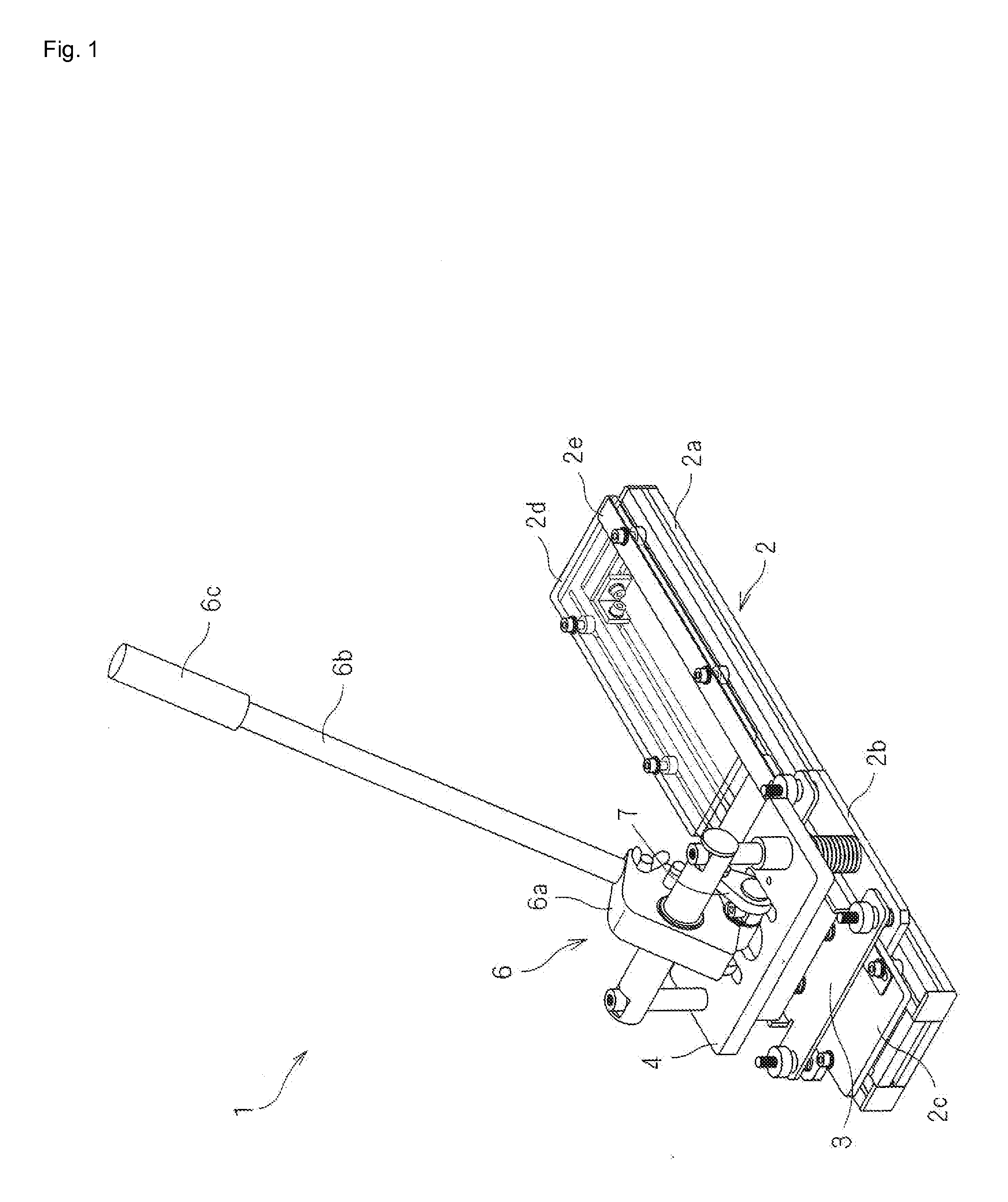

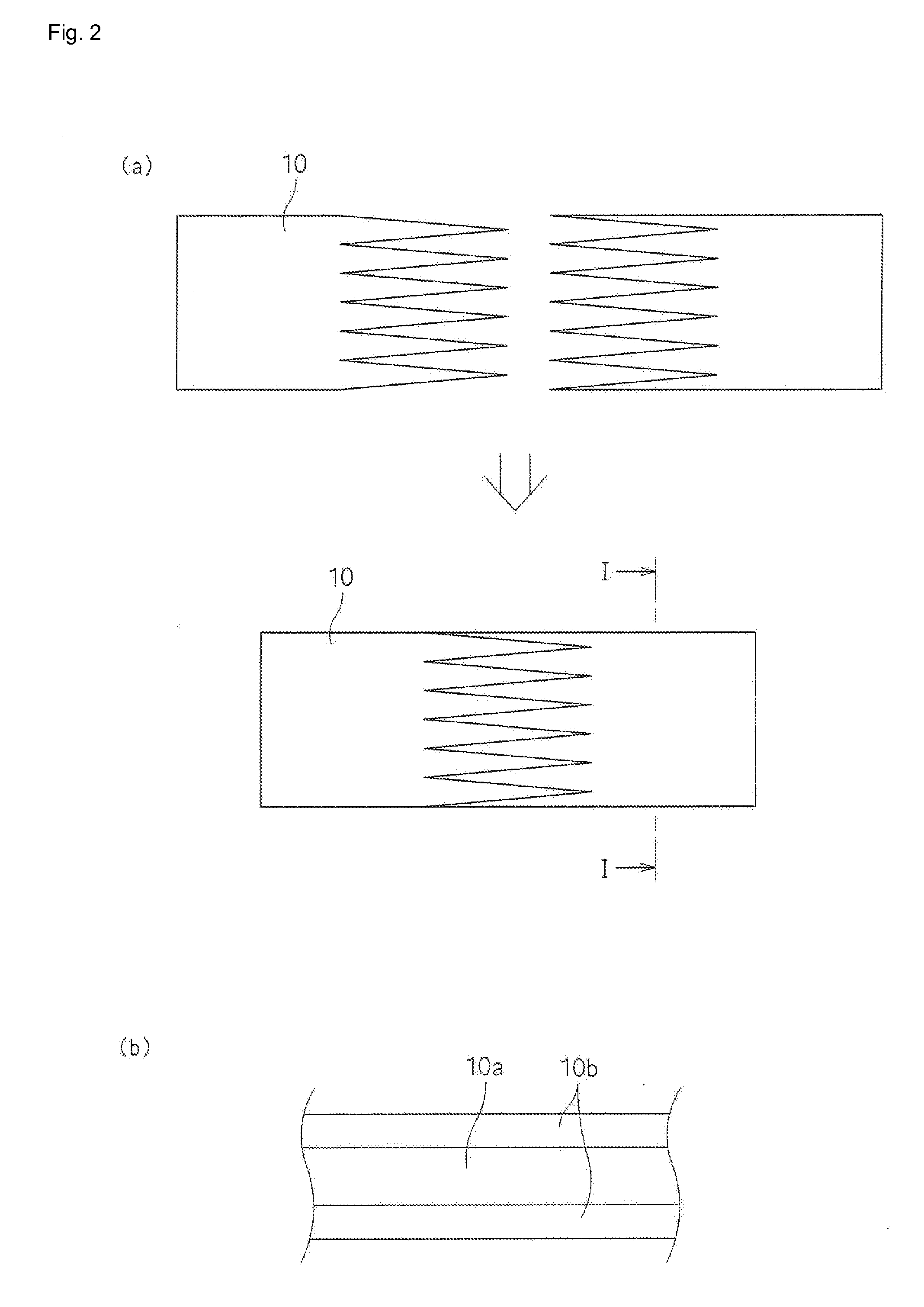

Sheet cutter and belt processing tool

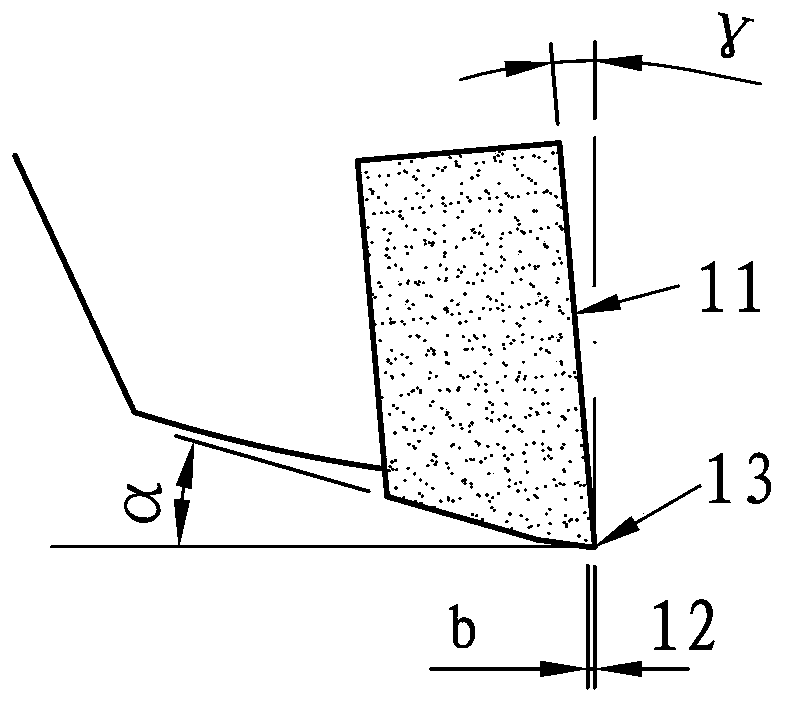

InactiveUS20110314982A1High cutting forceImprove operating forceMetal working apparatusEngineeringLeather belt

A sheet cutter applied to a belt processing tool or the like is provided. The belt processing tool includes a mounting table 2 for mounting a belt thereon; a die holding plate 4 being ascendable and descendable with respect to the mounting table, and having a lower surface to which a Thomson die is fixed; a stripper plate 3 being installed ascendably and descendably above the mounting table, and pressing the upper surface of the belt during descent, and having a slit through which the blade of the Thomson die passes; an operation member including a planar cam and a lever for rotating the planar cam, the planar cam being fixed to the mounting table and pivotally supported on a rotary shaft, and moving up and down by rotation, and having a surface for pressing downward the die holding plate; a means for energizing upward the stripper plate; and a locking member for restricting the raised end of the stripper plate.

Owner:NITTA CORP

Novel disc type flexible grinding wheel machining tool

InactiveCN105598833AHigh Adaptive Profiling CapabilityImprove material removal rateGrinding headsDrive motorEngineering

The invention discloses a novel disc type flexible grinding wheel machining tool which comprises a grinding wheel disc hub, a pressure maintaining wheel, a flexible rubber base grinding wheel, a pressure monitor, a pressure adjusting valve, a rotating shaft, a connecting base, a bearing end cover, a driving motor and a bearing. The novel disc type flexible grinding wheel machining tool is characterized in that the grinding disc hub is mounted at the output end of the rotating shaft through flat keys; the pressure maintaining wheel is mounted on the grinding wheel disc hub; the flexible rubber base grinding wheel is fixedly mounted on the grinding wheel disc hub through an S-shaped barb; the rotating shaft is mounted inside the connecting base through the bearing and the bearing end cover; the driving motor is connected with the rotating shaft to drive the rotating shaft to rotate; the pressure adjusting valve and the pressure monitor are mounted on the pressure maintaining wheel. The novel disc type flexible grinding wheel machining tool has the advantages of good curved surface profiling property, high air tightness, pressure controllability, high machining efficiency and the like.

Owner:厉志安

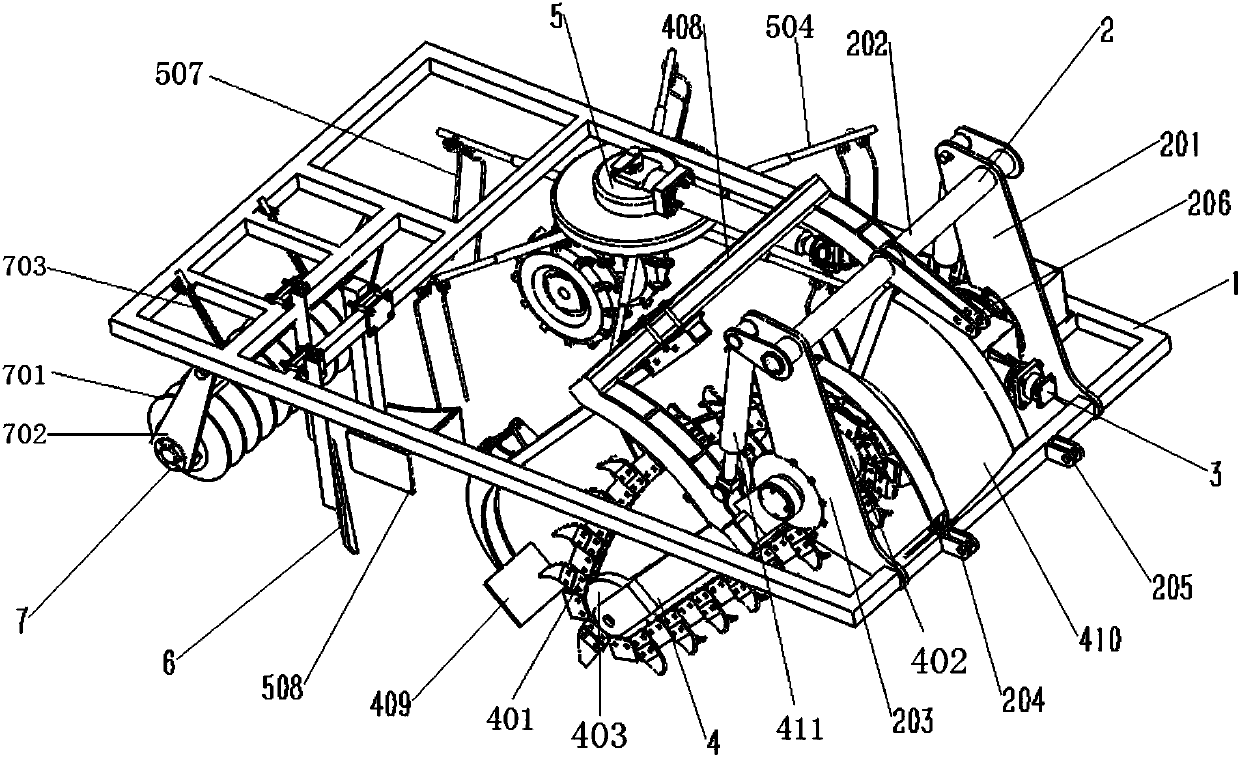

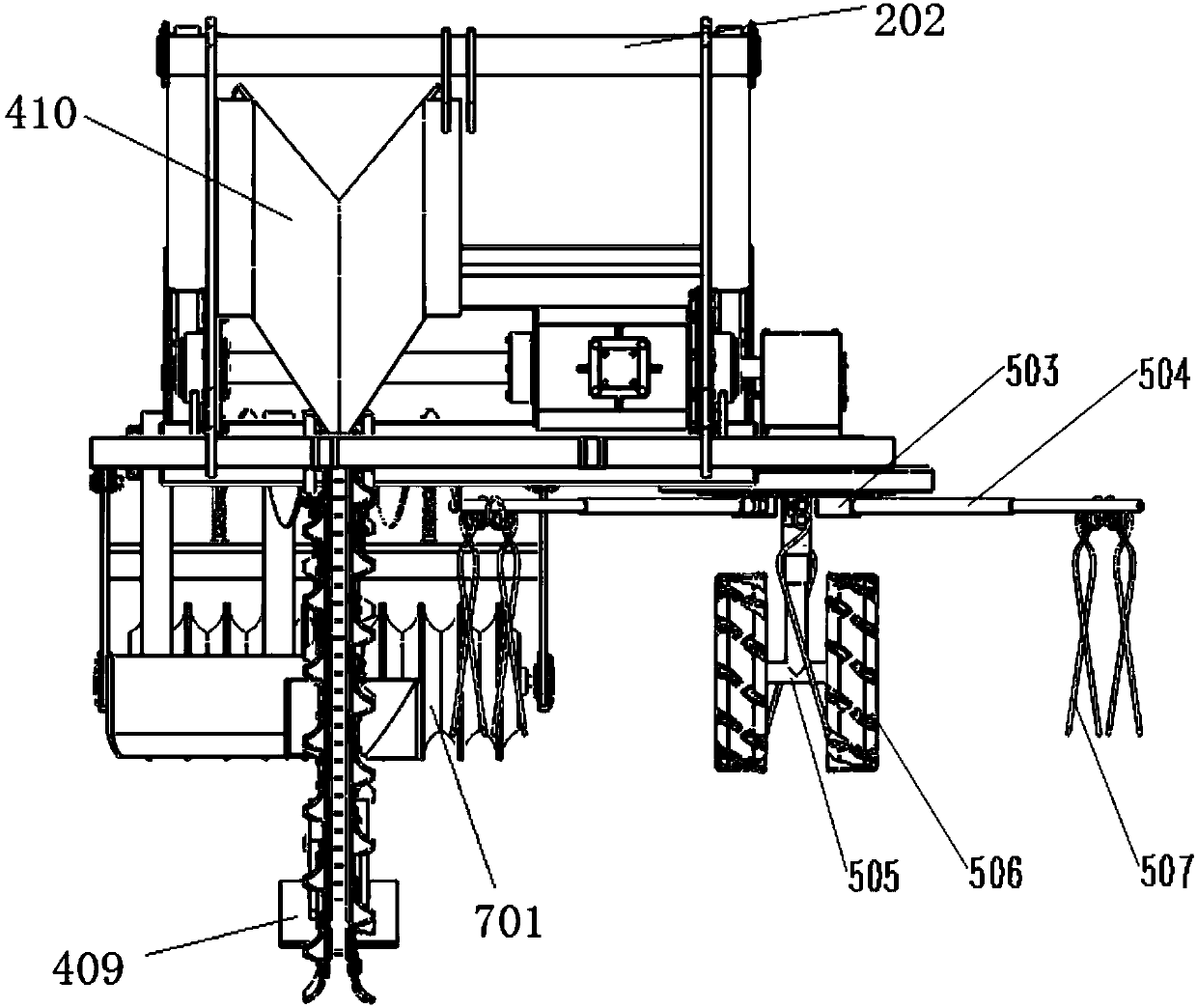

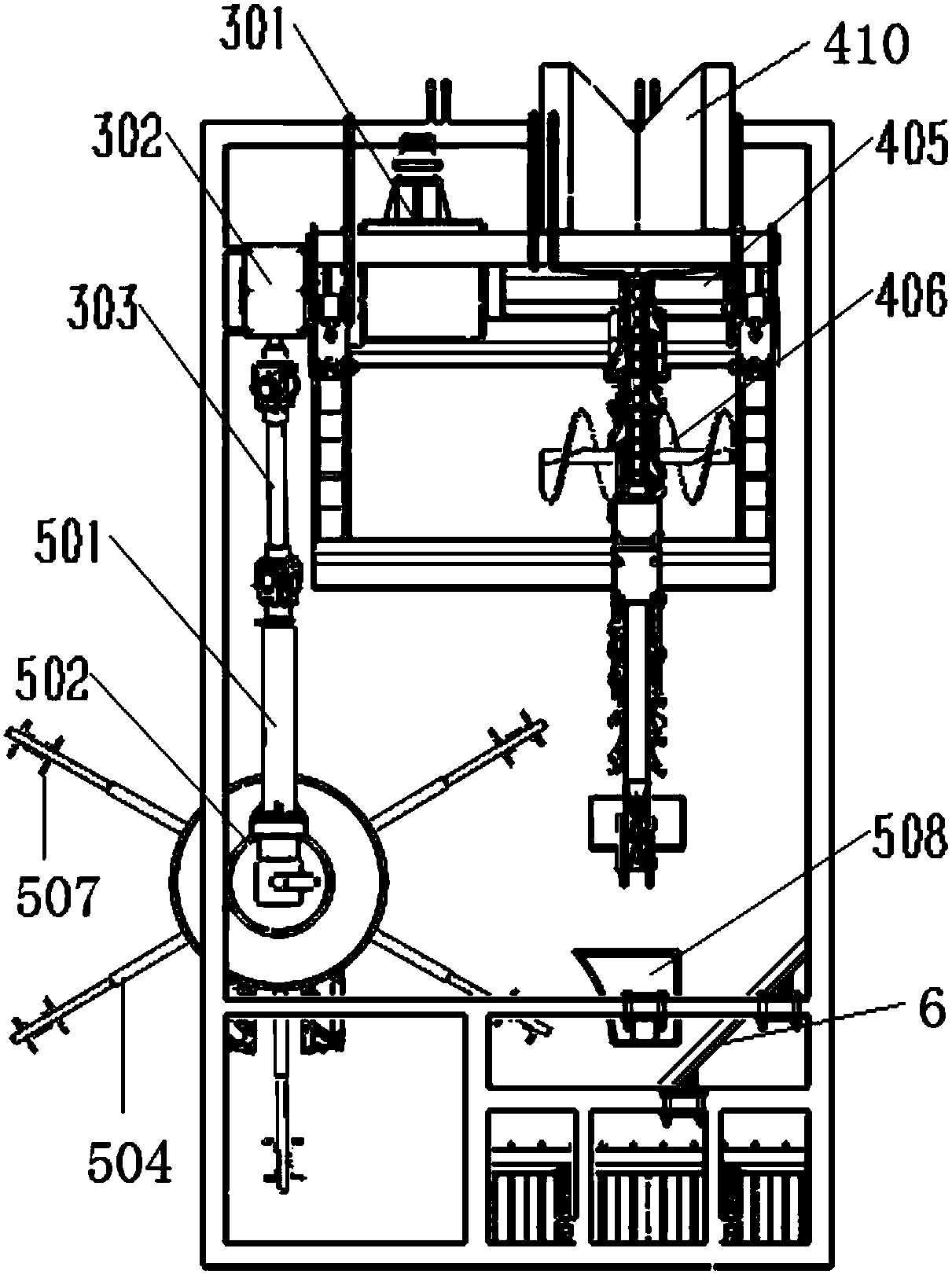

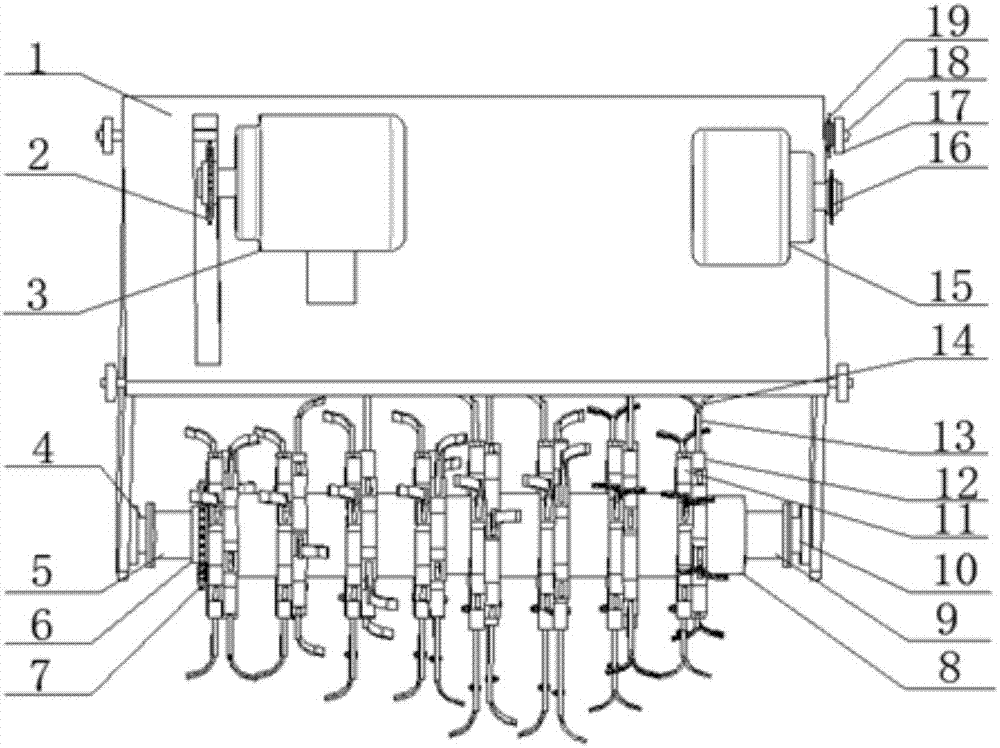

Centralized straw trench-burying and returning integrated machine

PendingCN107710926AHigh cutting forceGood effectSpadesPloughsAgricultural scienceAgricultural engineering

The invention discloses a centralized straw trench-burying and returning integrated machine which is characterized by comprising a rack, a transmission system, and a suspension device, a ditching device, a raking device, an earthing device and a pressing device which are fixed on the rack in sequence from the front to the rear, wherein the input end of the transmission system is connected with anoutput shaft of a tractor, and the output end of the transmission system is connected with the ditching device and the raking device; the suspension device is used for fixing the rack onto the tractor; a ditching direction of the ditching device is a traveling direction of the tractor; the raking device is used for raking straws into a ditch opened by the ditching device; the earthing device is used for filling soil opened by the ditching device into the ditch; and the pressing device is used for pressing the filled soil in the ditch. The integrated machine disclosed by the invention does notneed single power and is simple in architecture, great in operating width and high in efficiency. The functional integration degree is high, the operations of ditching, raking, earthing and pressing of straw trench-burying and returning are completed in a field piece at one time after harvesting, and industrialized promotion is conveniently realized.

Owner:NANJING AGRICULTURAL UNIVERSITY

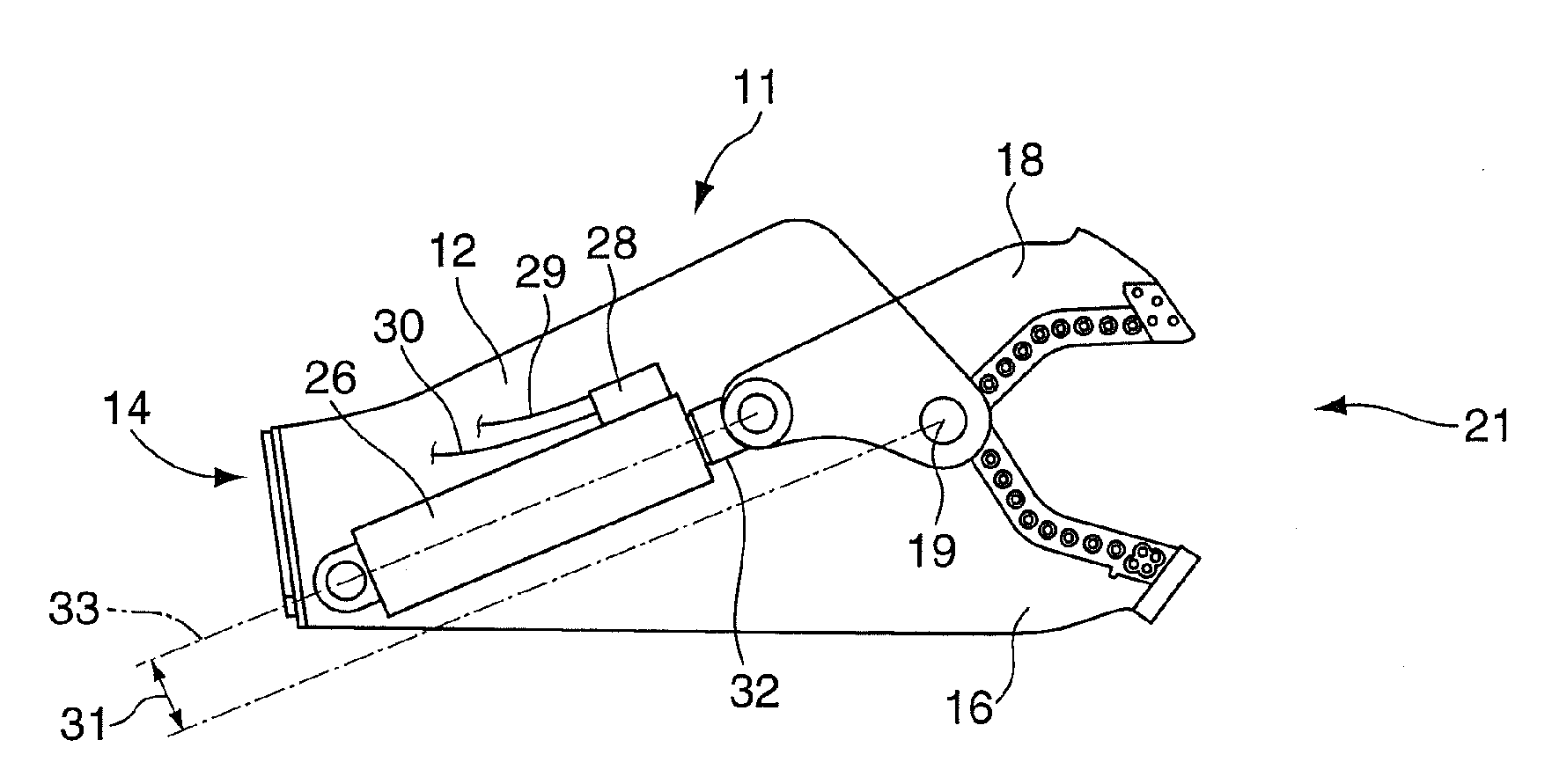

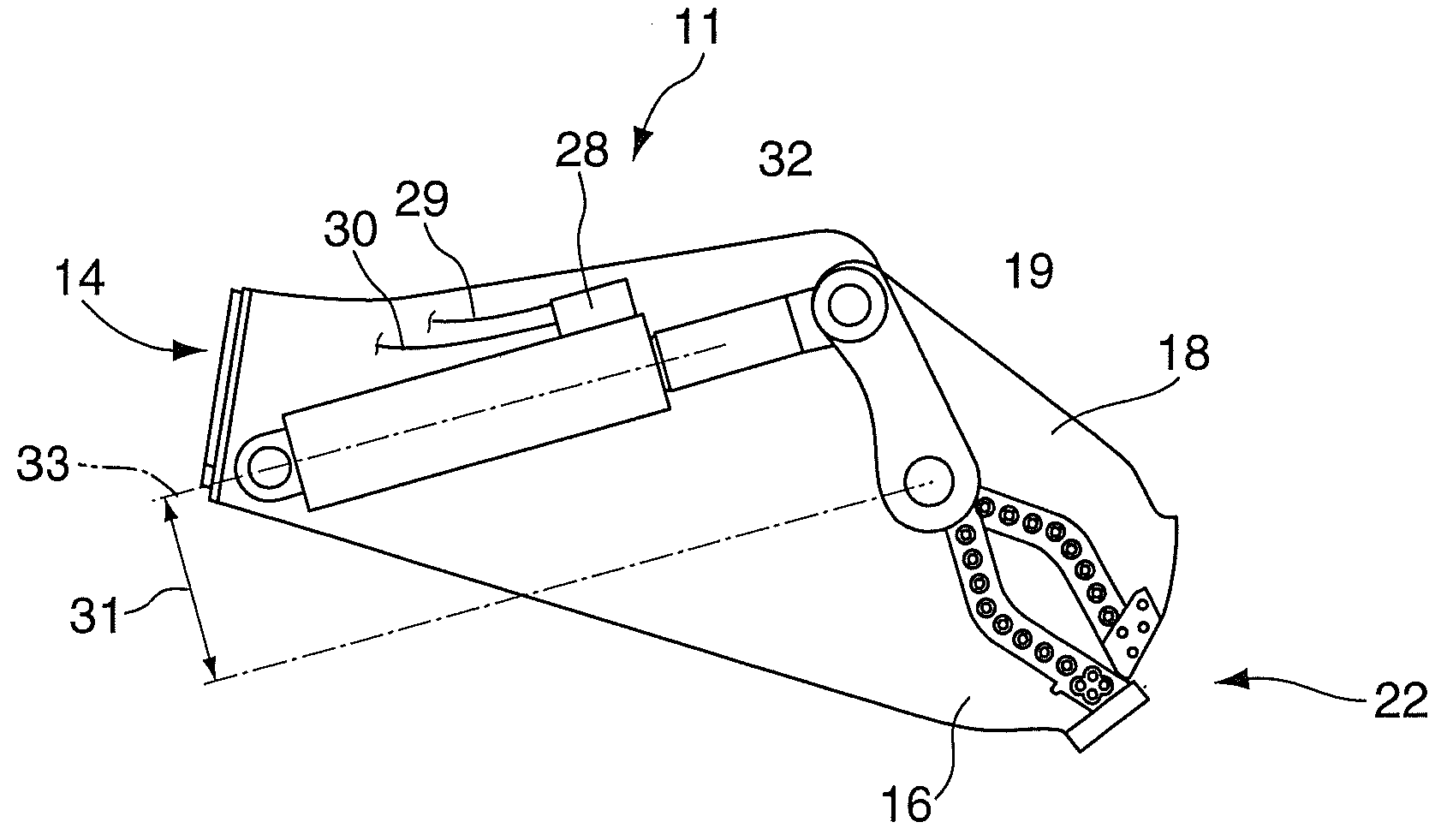

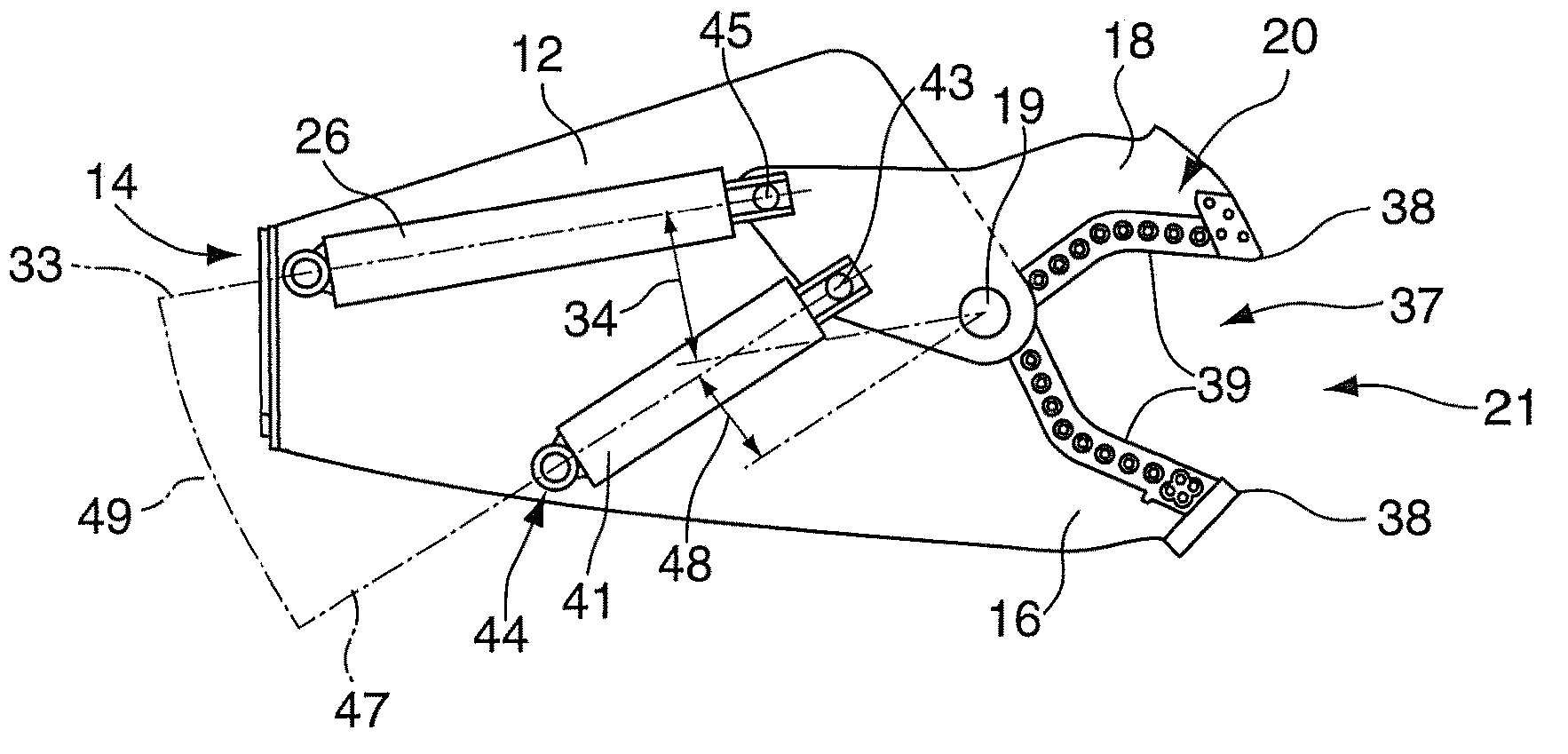

Method of activating a mountable hydraulic appliance and such mountable hydraulic appliance

ActiveCN102091823AAvoid damageKeep the pivoting motionBuilding repairsSoil-shifting machines/dredgersHydraulic cylinderStructural engineering

The invention relates to a method of activating a mountable hydraulic appliance, and to such mountable hydraulic appliance for the shearing or crushing of structures, in particular for demolition, communication or recycling, said appliance having an upper jaw and a lower jaw at least one of which is pivotally hinged on a bearing axis arranged on the housing, the hinged jaw being activated by a first hydraulic cylinder and by at least one further hydraulic cylinder acting thereon so as to be moved from an open position to a cutting position and / or a closed position and vice versa, the hydraulic cylinders which act upon the hinged jaw being either pressurised simultaneously, or the initiation of a closing movement of the at least one hinged jaw from an open position being such that initially only one hydraulic cylinder is pressurised and, as the required compression force increases during the closing movement, the at least one further hydraulic cylinder is equally pressurised.

Owner:DEMOLITION & RECYCLING EQUIP

Overturning and throwing machine for producing organic fertilizer and nutritional matrix

ActiveCN107162666AAdaptableAdjustable lengthBio-organic fraction processingOrganic fertiliser preparationAgricultural engineeringOrganic fertilizer

The invention relates to an overturning and throwing machine for producing an organic fertilizer and a nutritional matrix. The overturning and throwing machine comprises a frame, a walking mechanism arranged behind the frame and an overturning and throwing mechanism arranged at the lower part of the frame, the walking mechanism is driven by a transmission motor, the overturning and throwing mechanism is driven by an overturning and throwing motor, the overturning and throwing mechanism comprises an overturning and throwing shaft, a plurality of overturning and throwing cutter discs arranged on the overturning and throwing shaft, and overturning and throwing shaft sleeves, the overturning and throwing cutter discs and the overturning and throwing shaft sleeves are alternately distributed, every overturning and throwing cutter disc is provided with a cutter shaft, and a cutter head is arranged at the upper end of every cutter shaft. Compared with overturning and throwing machines in the prior art, the overturning and throwing machine has the following advantages: the diameter of the overturning and throwing cutter discs is adjustable, so the overturning and throwing at different depths are realized according to different material depths; the length of the cutter shafts is adjustable, and can be combined with the diameter of the cutter discs to generate different overturning and throwing depths; the length of the shaft sleeves is adjustable, so the width of an overturning and throwing gap can be adjusted according to the kind of the material, and different shaft sleeve lengths can be set according to the kind and the water content of a fermentation material during the installation of the overturning and throwing shaft; and the type of the cutter heads is adjustable, so different cutter head types can be set according to the characteristics of different fermentation materials.

Owner:TONGJI UNIV

Anchor drilling machine provided with protection function and used for oil drilling

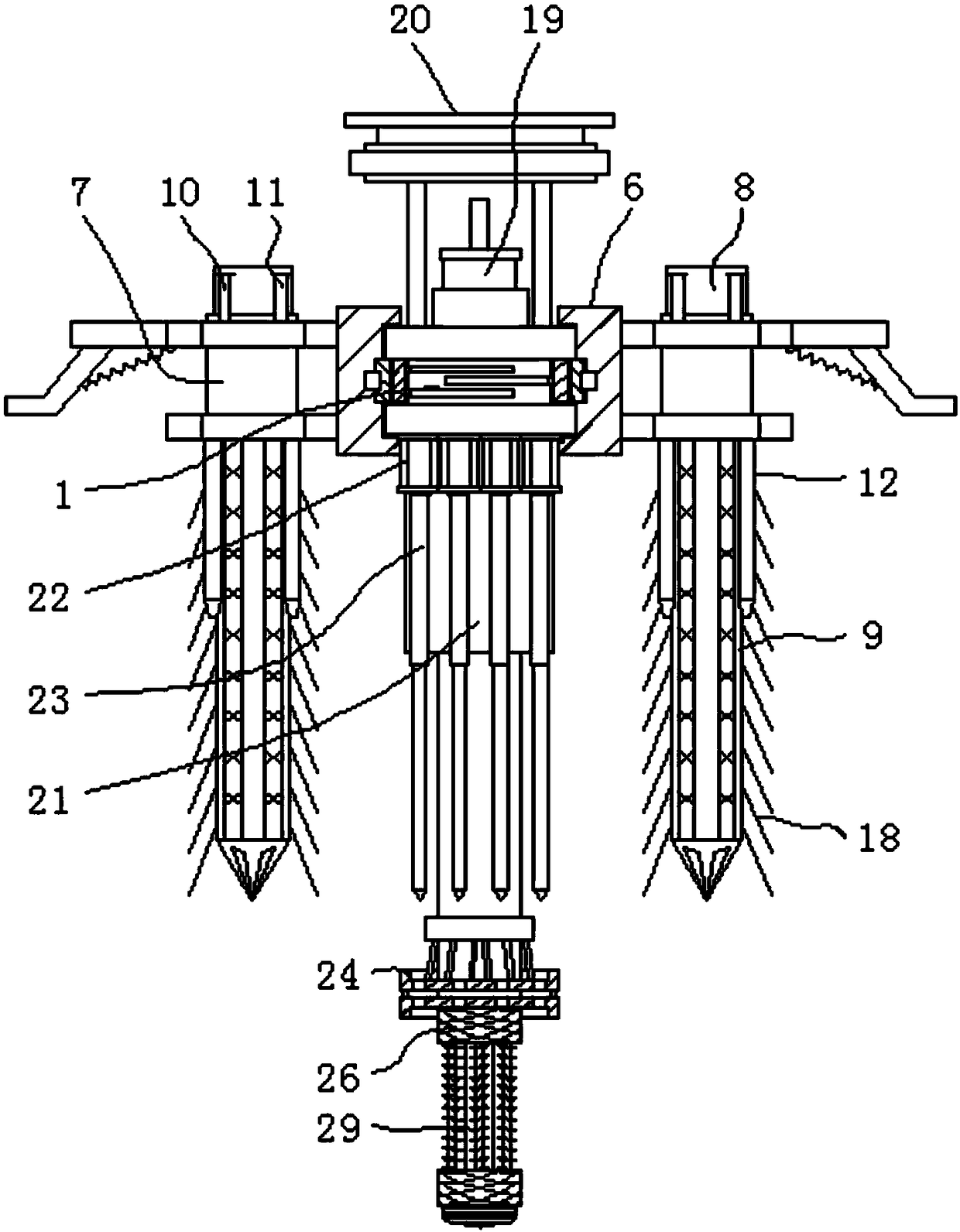

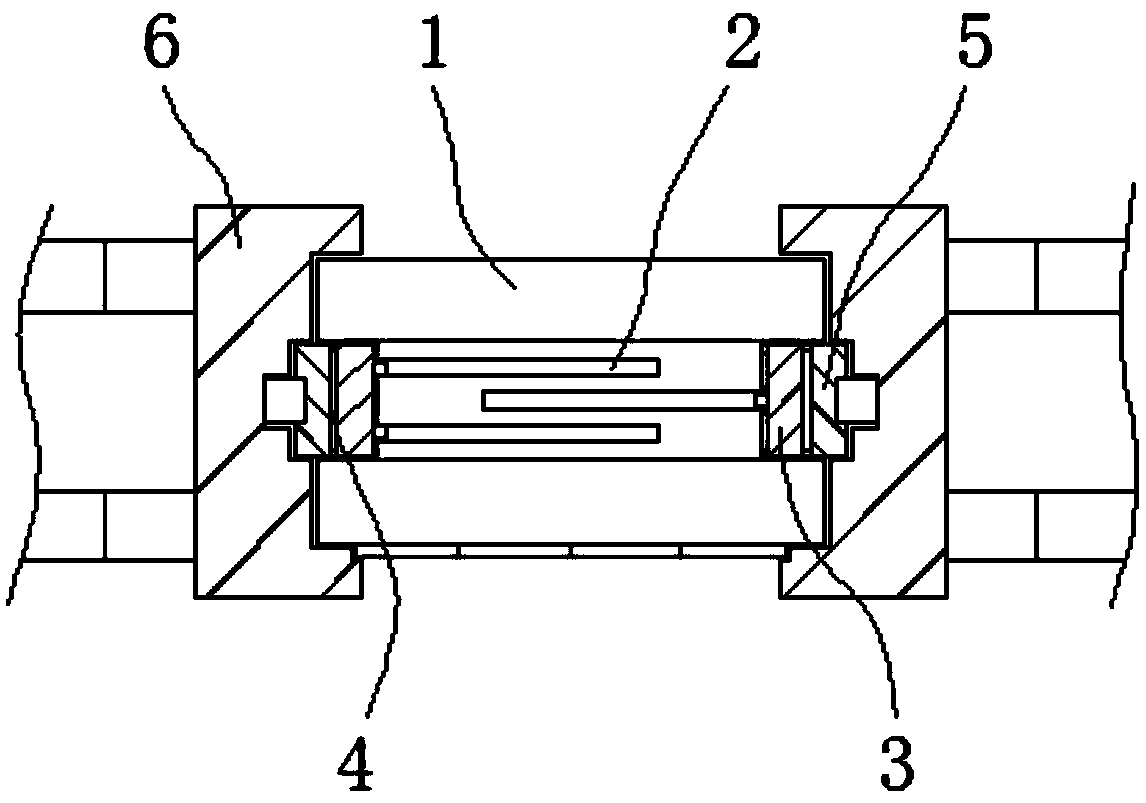

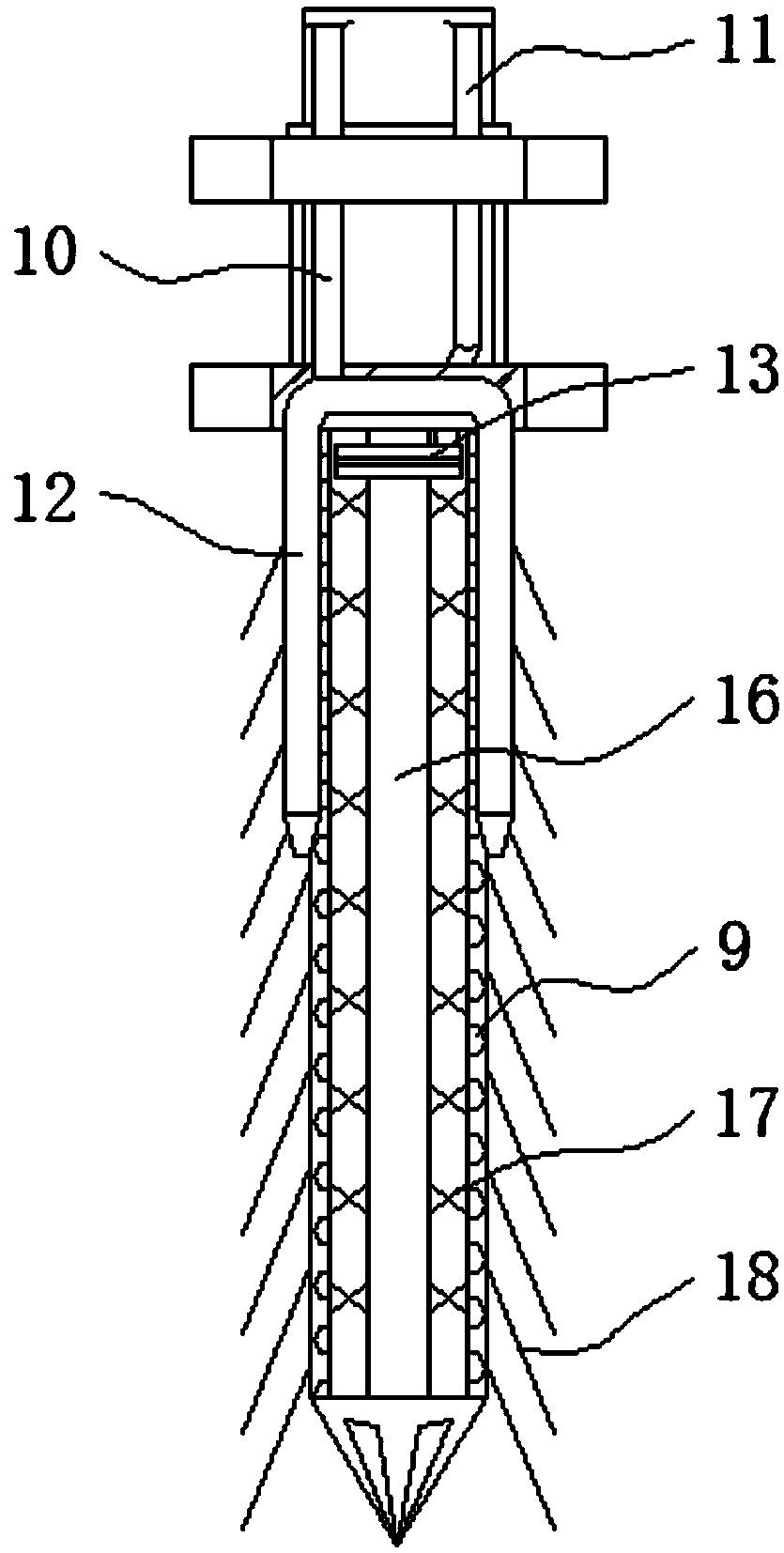

InactiveCN109322684AImprove rotational flexibilityGuaranteed rotational flexibilityEarth drilling toolsConstructionsHydraulic cylinderOil drilling

The invention discloses an anchor drilling machine provided with a protection function and used for oil drilling. The anchor drilling machine provided with the protection function and used for oil drilling comprises an installation top seat, auxiliary drilling rods and a main drilling rod. A sliding groove is formed in the surface of the installation top seat, an inner sliding ring is arranged onthe outer side of the middle of the installation top seat, a control motor seat is arranged at the upper end of the auxiliary drilling rod, the auxiliary drilling rods are separately positioned on theleft and right sides of a collar plate, a hydraulic cylinder is arranged above the outer side of the main drilling rod, and the main drilling rod is positioned below the collar plate. According to the anchor drilling machine provided with the protection function and used for oil drilling, the sizes of the collar plate and an outer sliding ring are matched with each other, the outer sliding ring is arranged on the outer side of the mounting top seat in a clamped mode and is attached to a cushion layer on the outer wall of the inner sliding ring, and the size of the inner sliding ring is matched with the size of the sliding groove on the installation top seat, namely, the inner sliding ring has rotating capability on the installation top seat, the outer sliding ring has rotating capabilityon the cushion layer, and the collar plate has rotating capability on the outer sliding ring, so that the collar plate has very high rotating flexibility in a layer-by-layer nesting mode.

Owner:魏武康

Bulldozer and earth-loosening device thereof

ActiveCN103161187AHigh cutting forceImprove workabilitySoil-shifting machines/dredgersAngular momentumEngineering

The invention provides an earth-loosening device. The earth-loosening device comprises a connecting frame, a lifting oil cylinder and an earth-loosening tool, wherein one end of the connecting frame is used for connecting with a bulldozer body of a bulldozer in a hinged mode, and the other end of the connecting frame is provided with a tool mounting base, one of a cylinder barrel of the lifting oil cylinder and a piston rod of the lifting oil cylinder is hinged to a bulldozer body, and the other one of the cylinder barrel of the lifting oil cylinder and the piston rod of the lifting oil cylinder is hinged to the connecting frame or the tool mounting base, the earth-loosening tool is arranged on the tool mounting base, and the earth-loosening tool is rotationally arranged relative to the tool mounting base under the drive of a power source. Compared with the prior art, the earth-loosening tool is rotationally arranged relative to the tool mounting base under the drive of the power source, angular momentum produced in a rotating process is converted into cutting force of the earth-loosening tool to treat and process the ground, and with cutting force formed by tractive force of the bulldozer, the cutting force in an earth-loosening device operation process is significantly increased, the operation capacity of the earth-loosening device is improved, application range of the earth-loosening device is expanded, and work efficiency is improved. The invention further provides the bulldozer which is provided with the earth-loosening device on the basis of the earth-loosening device.

Owner:SHANTUI CONSTR MASCH CO LTD

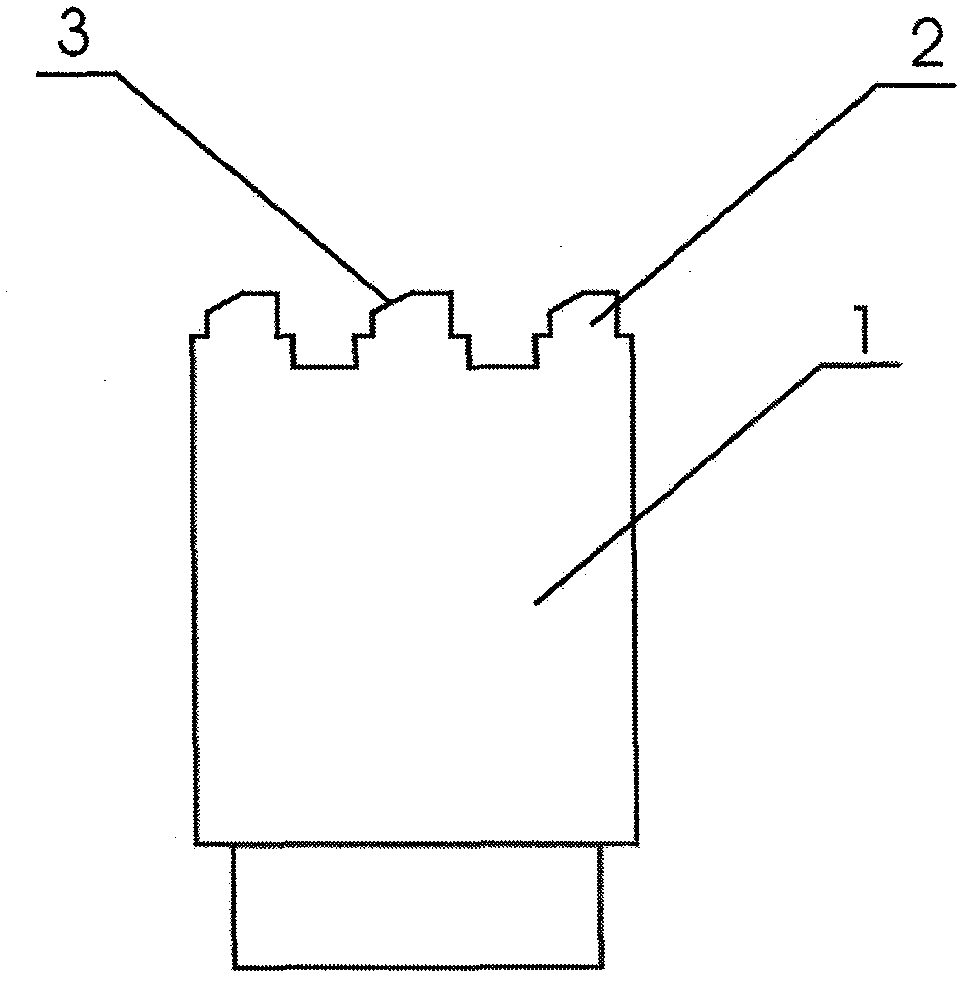

Diamond bit with large saw-teeth

The invention aims to provide a diamond bit with large saw-teeth, which is good in cutting force and durability, high in effectiveness for a given period of time, pipe-sticking avoidance, and good adaptive capacity for weak abrasive formation. The diamond bit comprises a body and drill teeth, wherein the drill teeth adopt a polygonal shape or a convex saw-toothed shape, and are annularly arranged at the top end of the body; and an inclined plane is formed at the top end of each drill tooth.

Owner:GUILIN DIAMOND IND TECHN

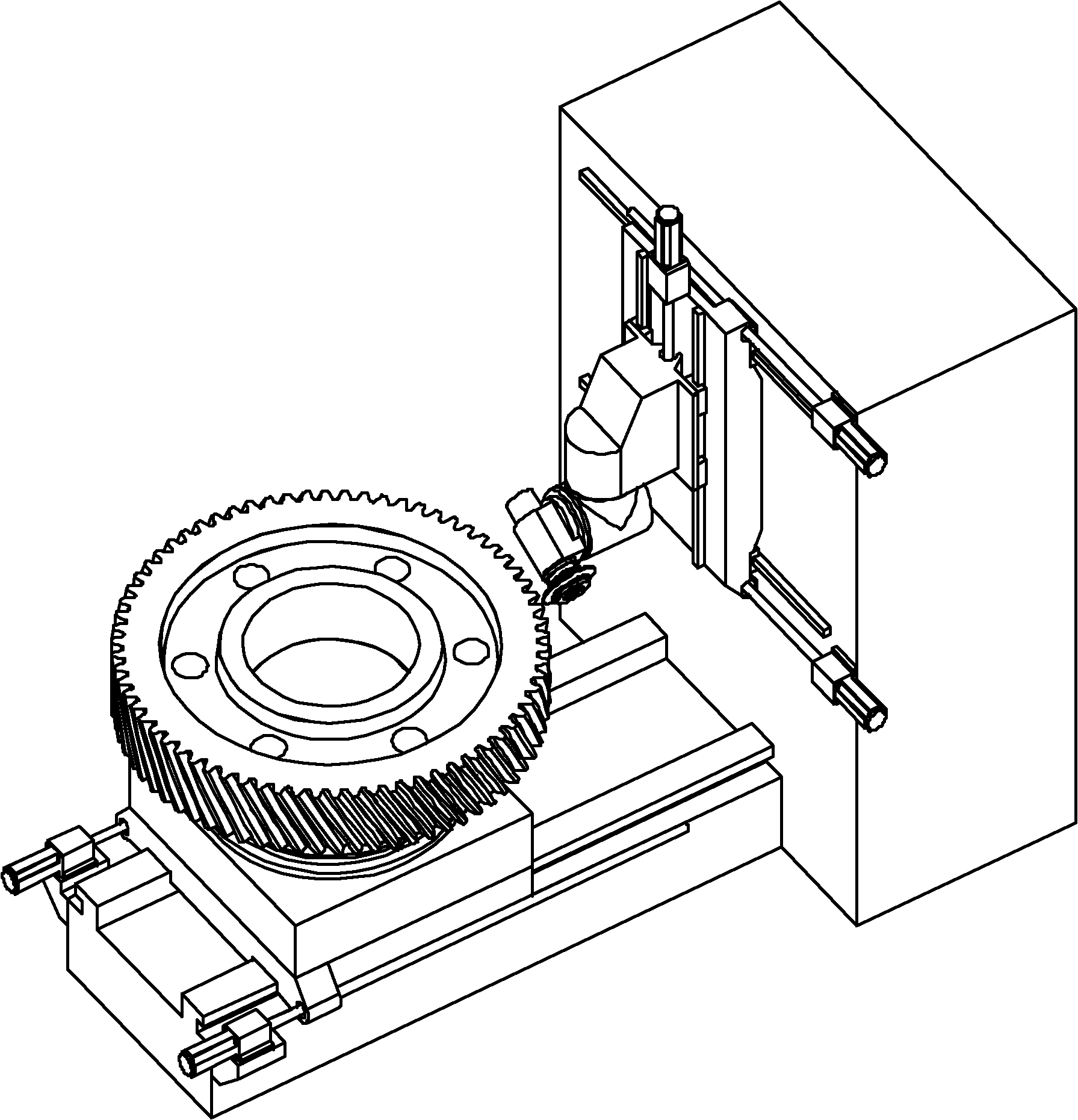

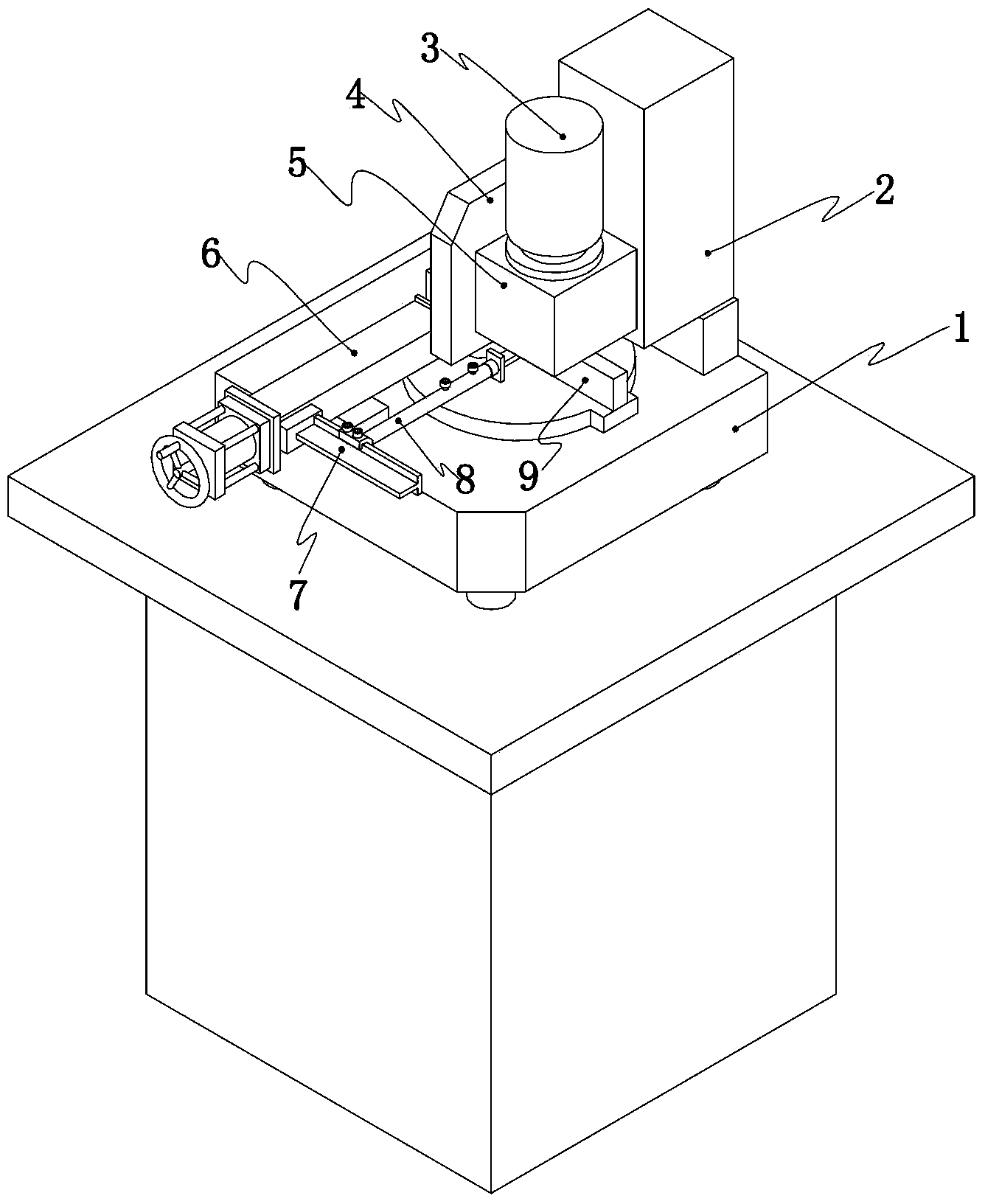

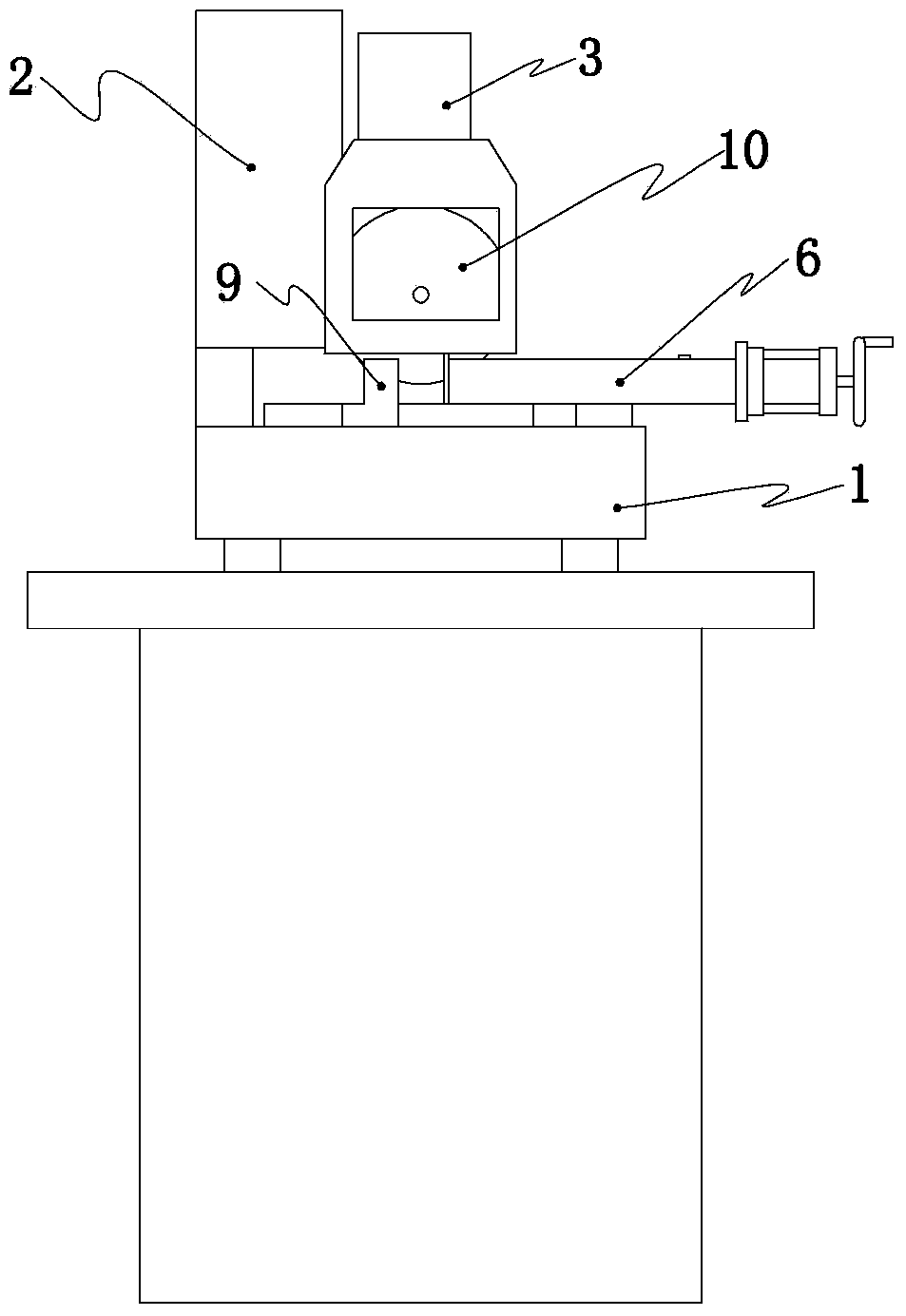

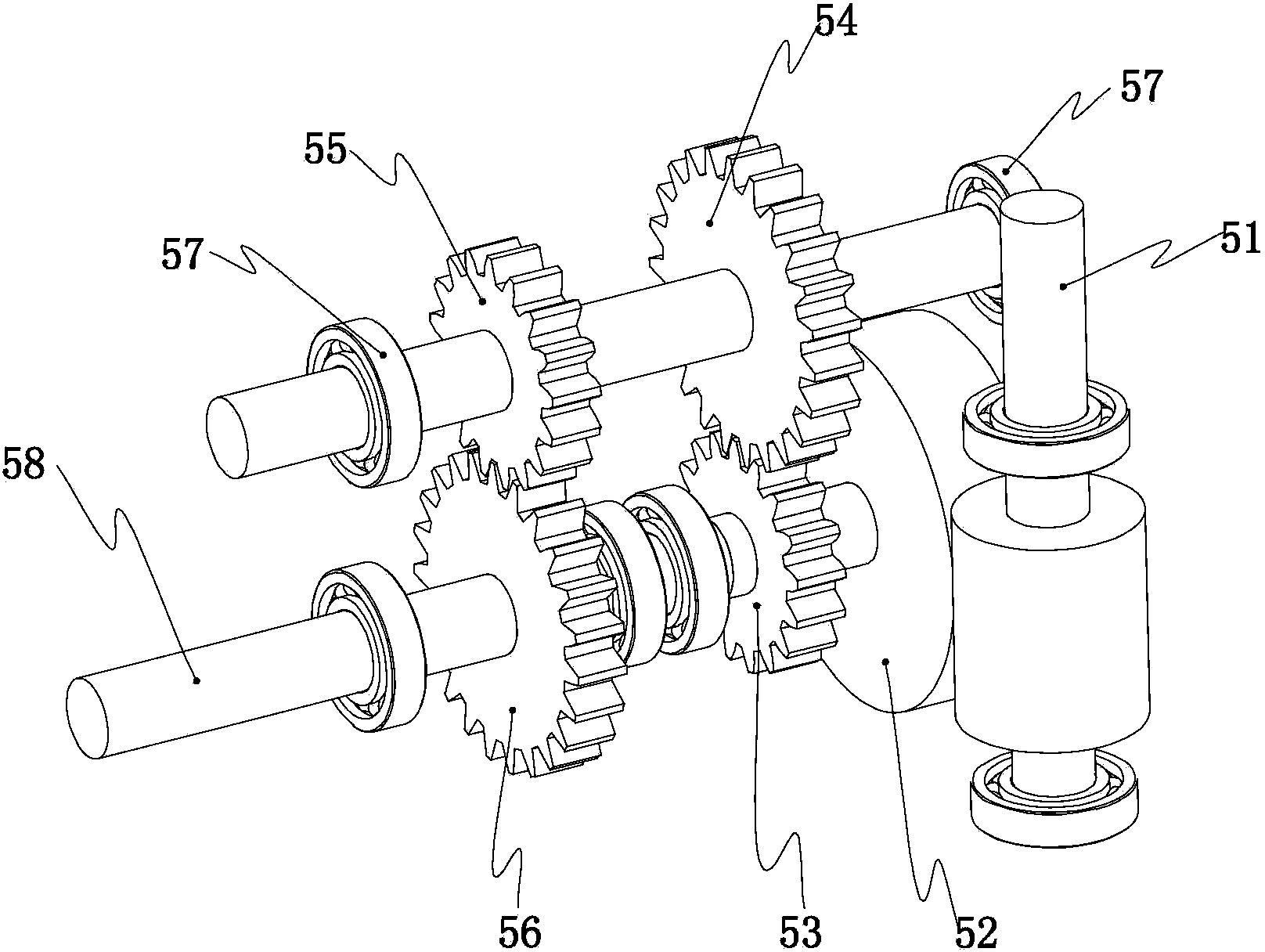

Reduction gear of vertical type circular sawing machine

InactiveCN103527716ALarge transmission ratioSmooth transmissionMetal sawing devicesToothed gearingsCircular discThree level

The invention provides a reduction gear of a vertical type circular sawing machine and relates to the technical field of vertical type circular sawing machines. The reduction gear of the vertical type circular sawing machine is mainly used for solving the problem that the output rotation speed of an exiting vertical type circular sawing machine is high. The reduction gear of the vertical type circular sawing machine comprises a worm wheel and worm pair and two gear pairs. A vertically placed worm is connected with the upper wall and the lower wall of a reduction gearbox through a bearing. A worm wheel matched with the worm is connected with the side wall of the reduction gearbox through a bearing. The worm wheel and the worm form a first-level reduction mechanism. A first gear is coaxially connected with the worm wheel. A second gear meshed with the first gear in a matched mode is connected with the left side wall and the right side wall of the reduction gearbox through a bearing. The first gear and the second gear form a second-level reduction mechanism. A third gear is coaxially connected with the second gear. A fourth gear meshed with the third gear in a matched mode is connected to the side walls of the reduction gearbox through a bearing. The third gear and the fourth gear form a third-level reduction mechanism. The reduction gear is provided with the three levels of reduction mechanisms, so that the rotation speed of a circular saw is appropriate, and the sawing efficiency is improved.

Owner:JINAN RONGDA MACHINERY MFG

Box pasting and folding machine with automatic paper correcting and window pasting functions

ActiveCN105172209AAvoid normal shipping impactWill not be affected by normal deliveryContainer making machineryRolling paperGlue line

The invention discloses a box pasting and folding machine with automatic paper correcting and window pasting functions. The box pasting and folding machine comprises a machine frame, a paper rolling shaft, a glue barrel and a paper cutter. The glue barrel can slide up and down in the vertical direction of the machine frame, detachable glue distributing wheels are arranged in the glue barrel, and pawls abut against the outer contour faces of the glue distributing wheels. A shell type moving bar is arranged on the part, located in front of the glue barrel, of the machine frame, and at least a row of outer air suction holes communicated with a shell cavity is formed in the outer wall of the moving bar in the axial direction. An air suction barrel is arranged in the moving bar shell cavity in sealed and sliding modes, and an extraction hole communicated with an inner cavity of the air suction barrel is formed in the shaft body of an extending section and communicated with an air extractor. A row of inner air suction holes is formed in the wall of the air suction barrel. A sliding frame is arranged on a sliding rail in a sliding mode. A sliding table is connected to a fixed guide rail in a sliding mode, a movable holding plate and a fixed holding plate are arranged on the sliding table in parallel, and a pair of paper conveying press rollers is correspondingly arranged behind the paper cutter. According to the box pasting and folding machine, ground paper can be quickly corrected, the glue distributing amount is sufficient, glue lines are uniform, and the box pasting quality is good.

Owner:YANCHENG HONGJING MACHINERY SCI & TECH CO LTD +1

Preparation method of high-cutting and high-brightness alumina polishing powder

ActiveCN106698489ASimple processSimple methodAluminium compoundsOther chemical processesGranularityCutting force

The invention discloses a preparation method of high-cutting and high-brightness alumina polishing powder. The method comprises the steps of raw material acid treatment, hydrothermal reaction, calcination and crushing. The preparation method is simple and effective, and is carried out by using present devices; the method allows the increase of the cutting force of alumina to have no influences on the polishing brightness; and the method has good granularity controllability and high applicability; and the alumina polishing powder prepared through the method increases the stainless steel polishing rate by 40% or above and increases the brightness by 30%.

Owner:HANGZHOU ZHIHUAJIE TECH

Iron casting drilling device and drilling method thereof under inner cooling and low temperature trace lubricating condition

PendingCN107570766AGood cooling effectImprove cooling uniformityTransportation and packagingMaintainance and safety accessoriesCast ironProduct gas

The invention provides an iron casting drilling method under an inner cooling and low temperature trace lubricating condition. An iron casting drilling device comprises an oil mist generating component, a machine tool spindle and a cutter; the oil mist generating component comprises a gas supplying part and an atomizing device; the atomizing device comprises a gas inlet and a gas outlet, and the gas supplying part is connected to the atomizing device by a pipeline by the gas inlet; the low temperature compressed gas supplying part refers to a gas cooling device or direct charging of low temperature gas; the machine tool spindle is provided with a spindle inner cooling hole along an axial direction, and the spindle inner cooling hole is communicated with the gas outlet; the cutter is fixedly connected to the machine tool spindle and is provided with a cutter inner cooling hole along the axial direction; the cutter inner cooling hole is communicated with the spindle inner cooling hole, acutting edge of the cutter is provided with a plurality of cutter inner cooling outlets, and the cutter inner cooling outlets are communicated with the cutter inner cooling hole. The iron casting drilling device adopts an inner cooling manner for processing, and is good in lubricating effect, good in cooling effect and fast in chip removal.

Owner:GUANGDONG UNIV OF TECH

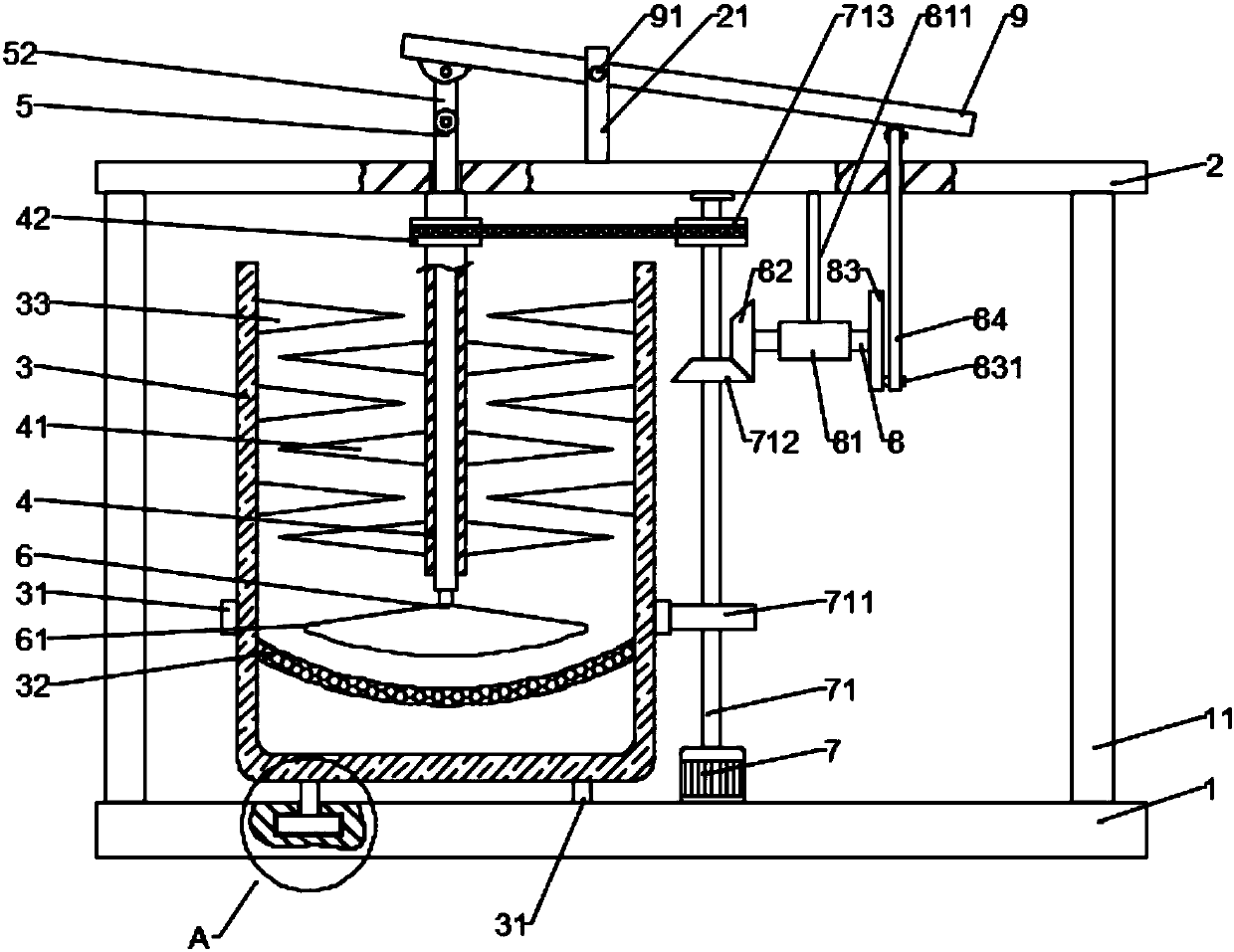

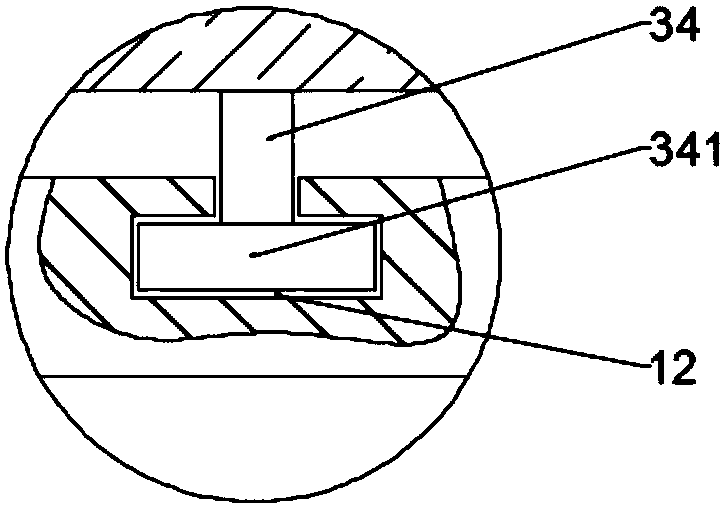

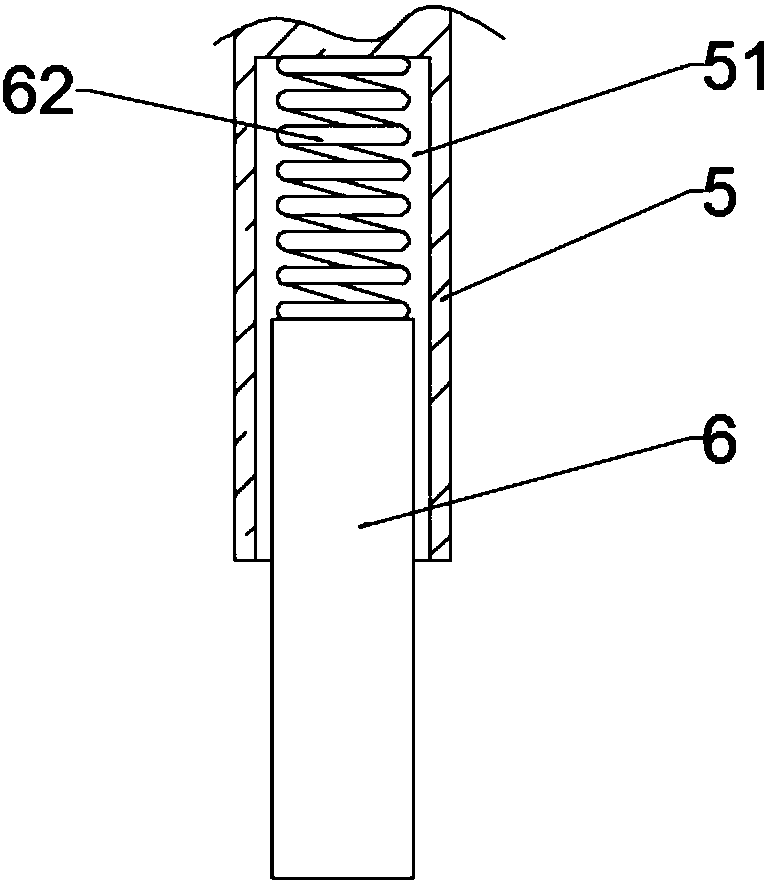

Efficient juicer for improving juice yield

The invention discloses a high-efficiency juice extractor with improved juice yield, comprising a base, a juice extraction barrel, a hollow shaft, a movable rod and a pressing plate. In the juice extractor of the present invention, the fruit is processed by crushing and then extruding, which effectively improves the juice yield of the fruit, and can fully extract the juice in the pomace by repeatedly squeezing the pomace, thereby avoiding waste. ; Through the reverse rotation of the first blade and the second blade, the cutting force is increased and the crushing efficiency is improved; through the elastic connection between the sliding rod and the movable rod, the pressure plate can be closely fitted with the filter plate, thereby ensuring the extrusion The lever mechanism formed by the pressure plate and the vertical frame achieves the effect of saving labor and effectively reduces the energy consumption; through the setting of the pressure plate driving component, the crushing and extrusion are carried out at the same time, which ensures the continuity of the work, and also makes it easier to Start and stop operations.

Owner:南京辰略信息科技发展有限责任公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com