Reduction gear of vertical type circular sawing machine

A technology of circular sawing machine and deceleration device, which is applied in the direction of sawing machine device, transmission device, gear transmission device, etc., which can solve the problem of high output speed of vertical circular saw, improve the degree of mechanization and automation, small impact load, and total transmission greater effect than

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

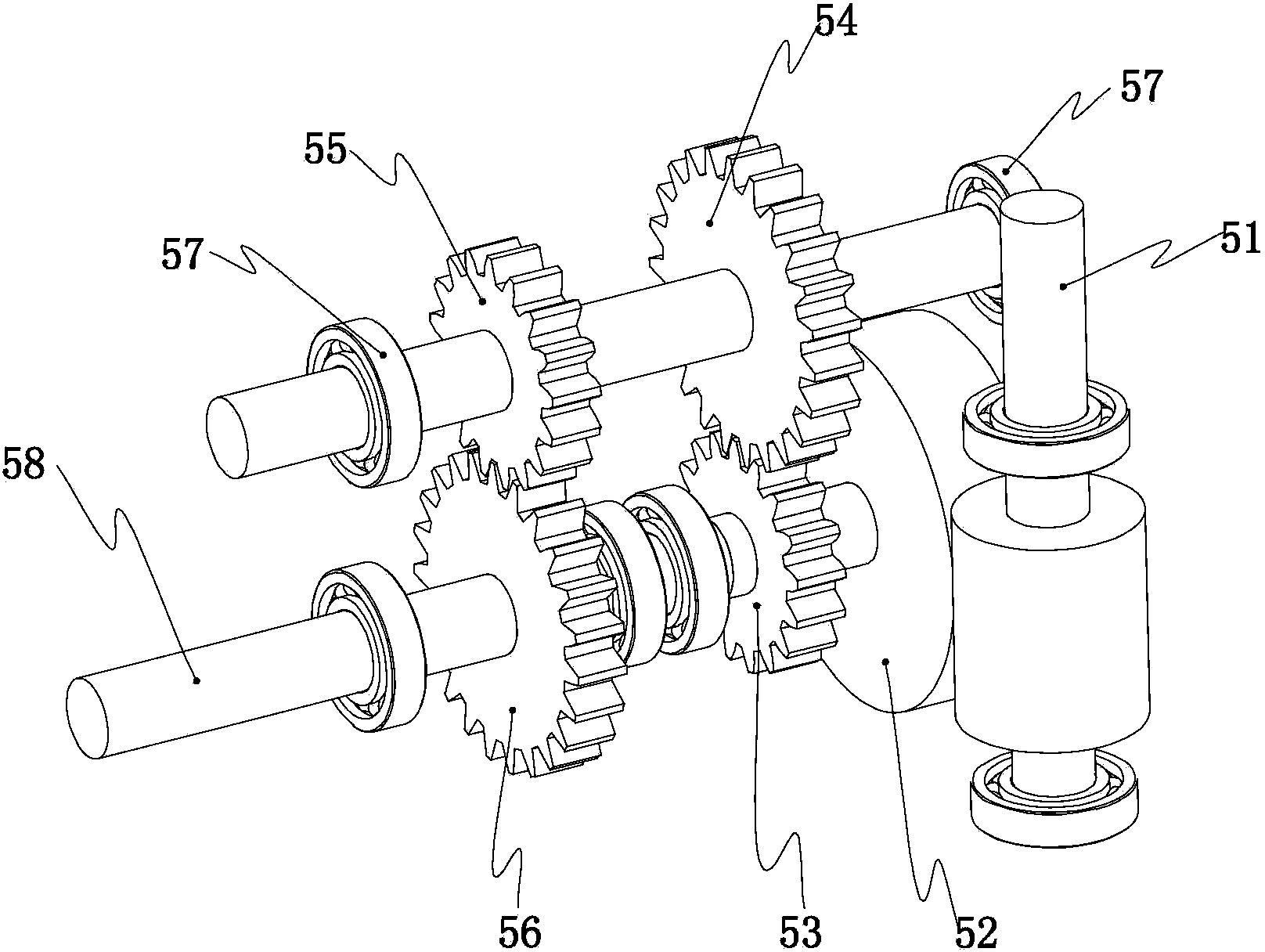

[0016] Such as Figure 1 to Figure 3 As shown, the present invention includes a worm 51 , a worm wheel 52 , a first gear 53 , a second gear 54 , a third gear 55 , a fourth gear 56 and a bearing 57 . The present invention will be described in detail below in conjunction with the accompanying drawings.

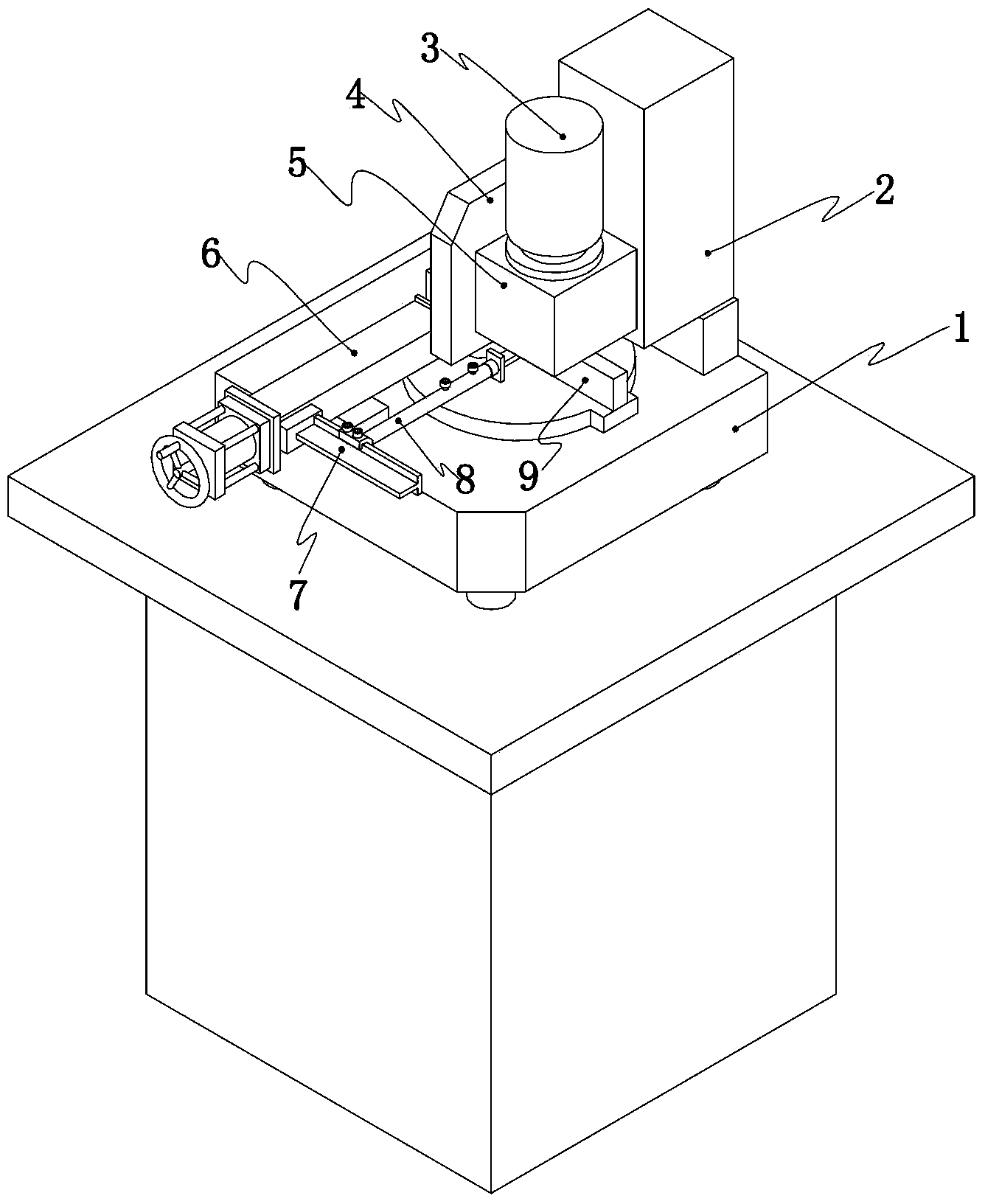

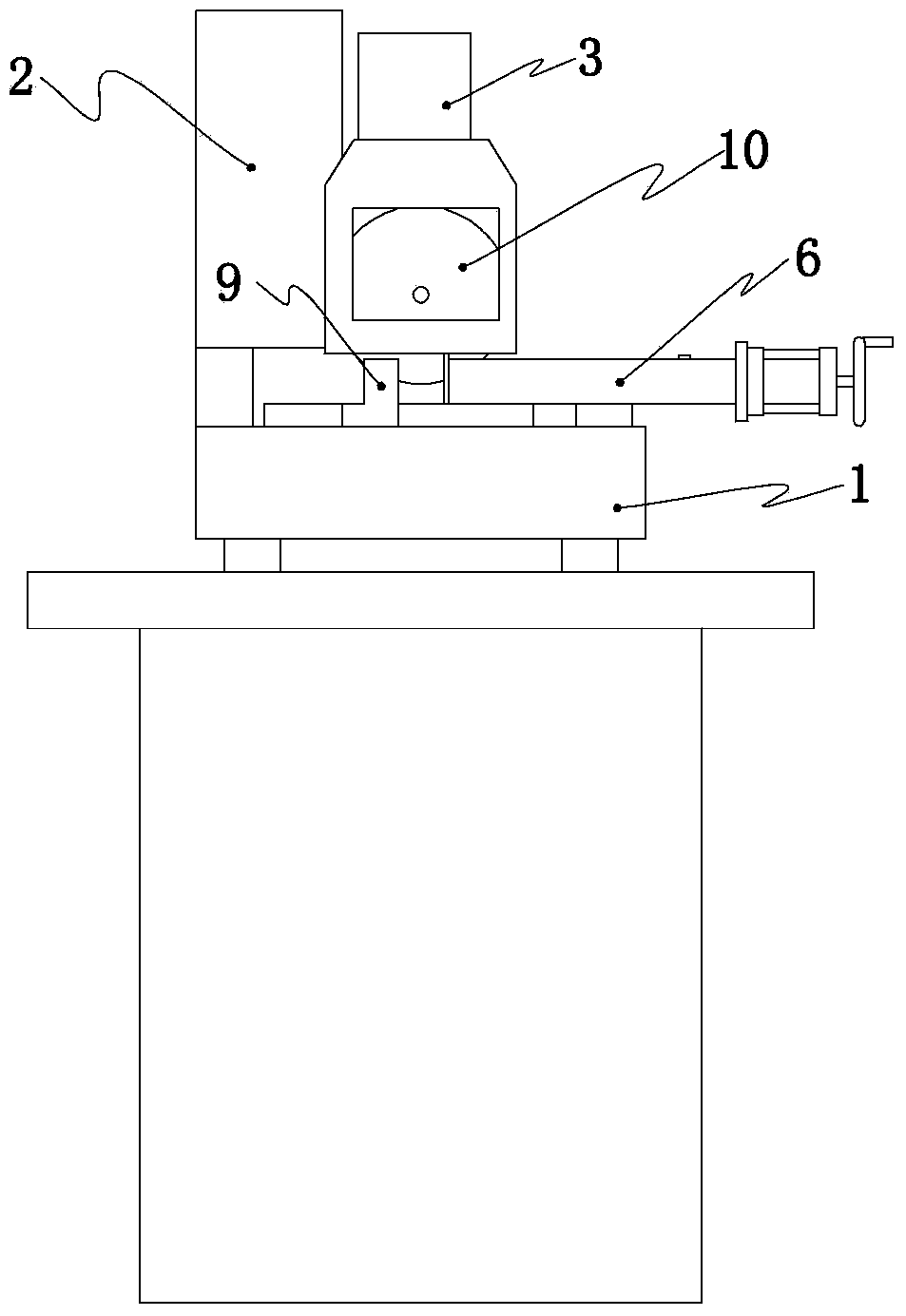

[0017] Such as figure 1 , figure 2 As shown, a fixed block 9 is provided at the middle position on the upper surface of the workbench 1, and the fixed block 9 is a rectangular metal block arranged along the direction of material entry and exit. A hydraulic device 2 is provided on the back side of the workbench 1. The hydraulic device 2 is provided with a hydraulic cylinder and a column. Under the action of the hydraulic cylinder, the motor 3 and the deceleration device 5 arranged on the front side of the hydraulic device 2 can be driven to move up and down along the column. . The deceleration device 5 is fixed on the hydraulic device 2 through the deceleration box casing, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com