Patents

Literature

274results about How to "Avoid friction loss" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

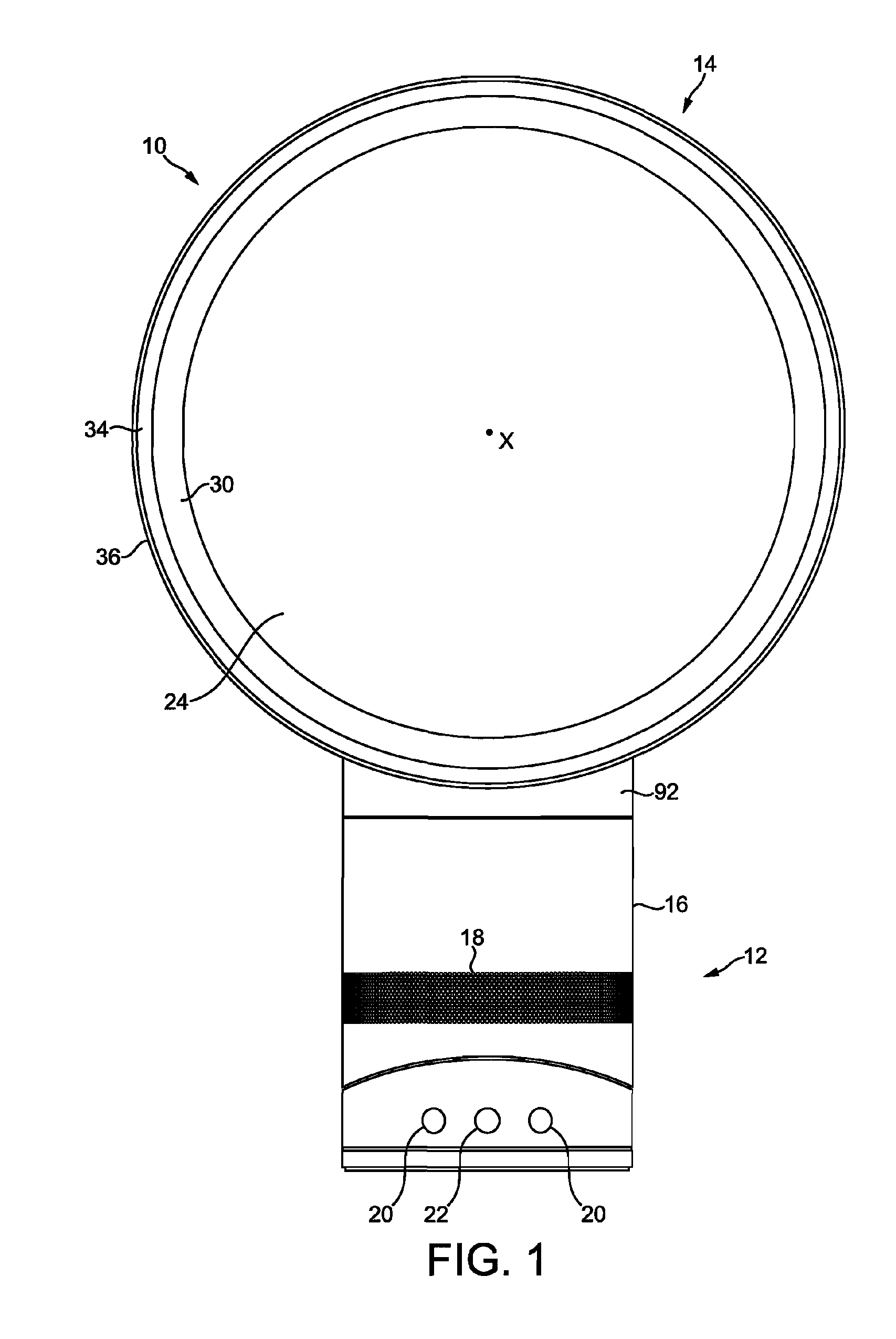

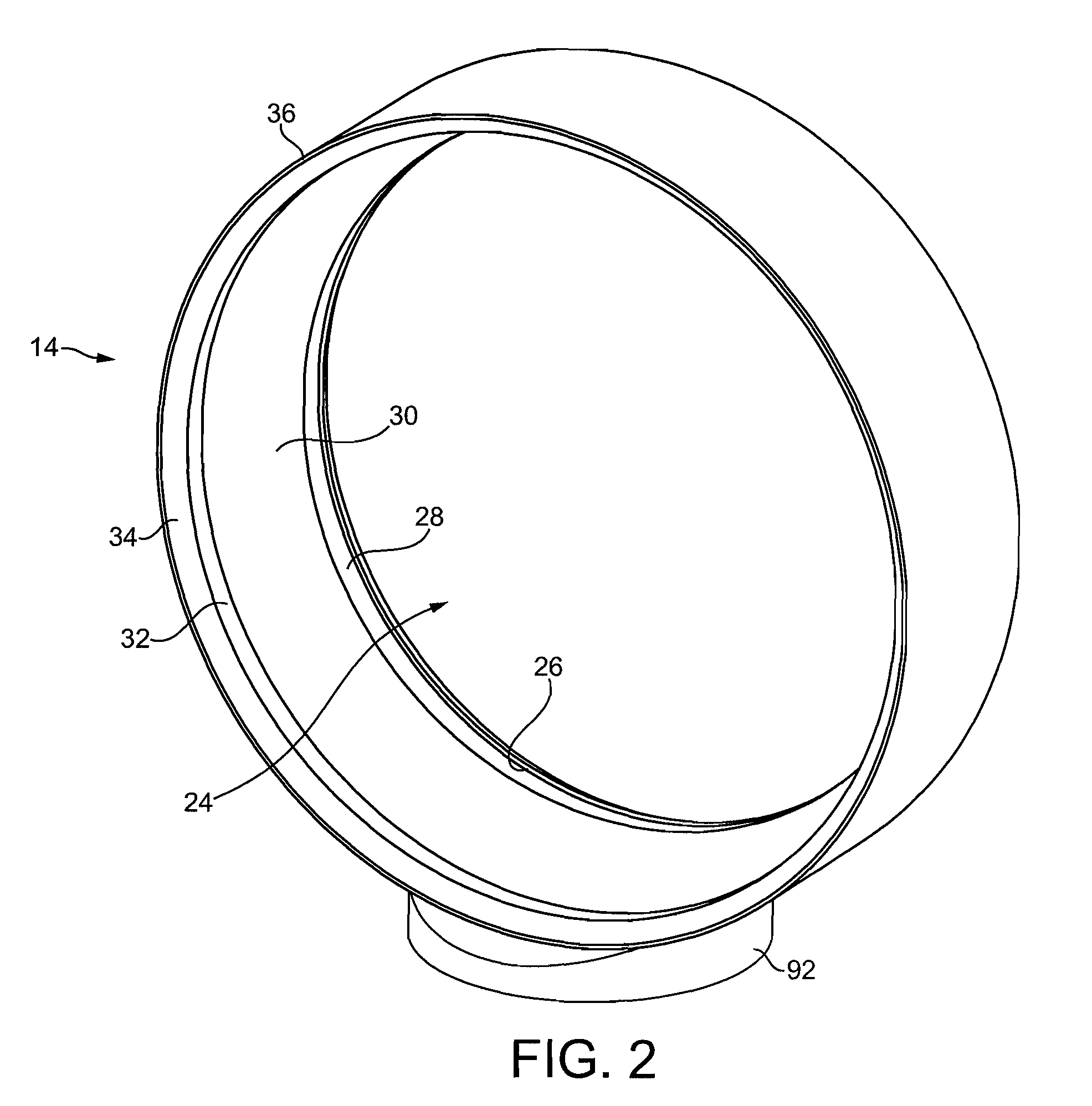

Fan assembly

InactiveUS20100226752A1Improve comfortReduce turbulenceCircumferential flow pumpsPump componentsImpellerEngineering

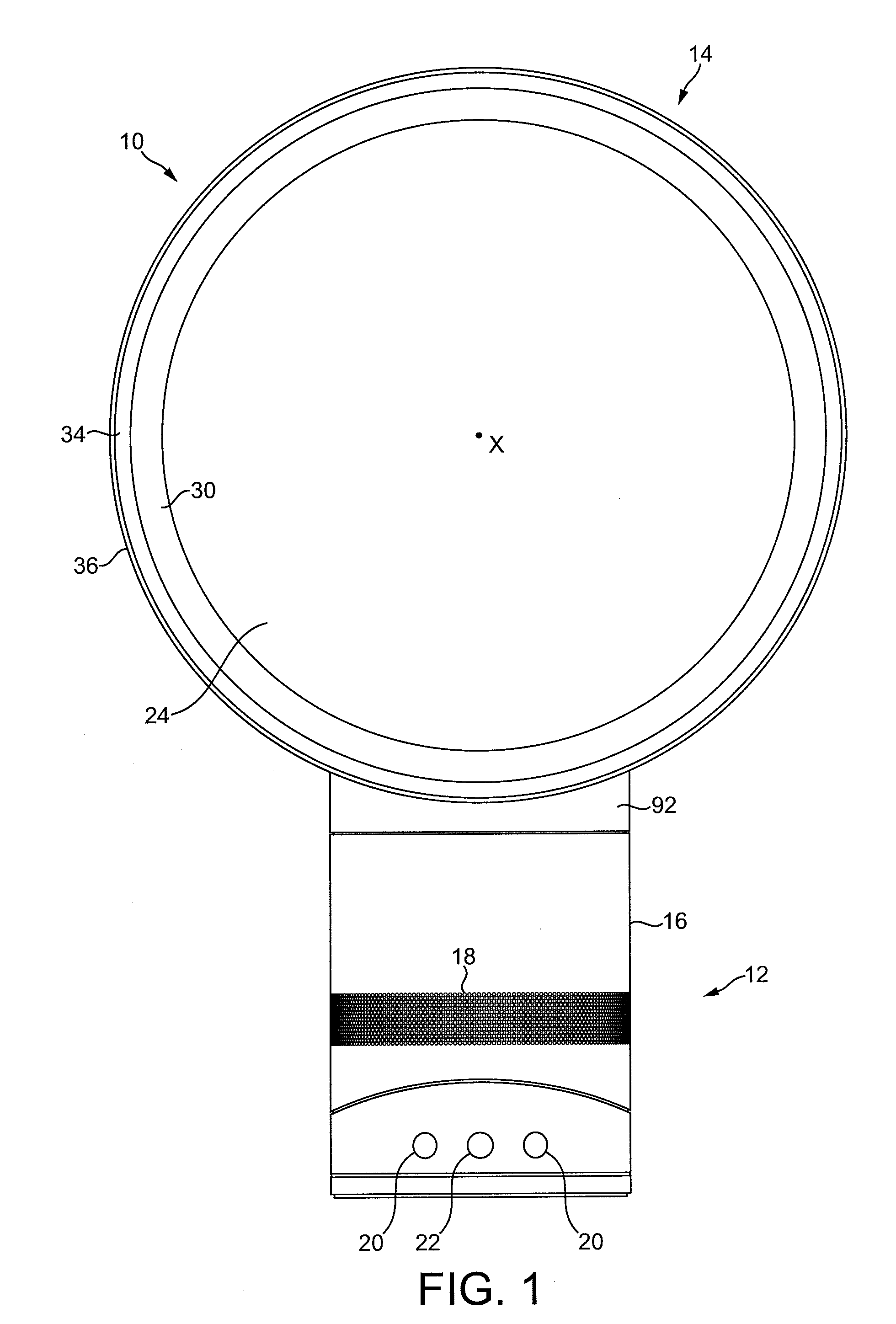

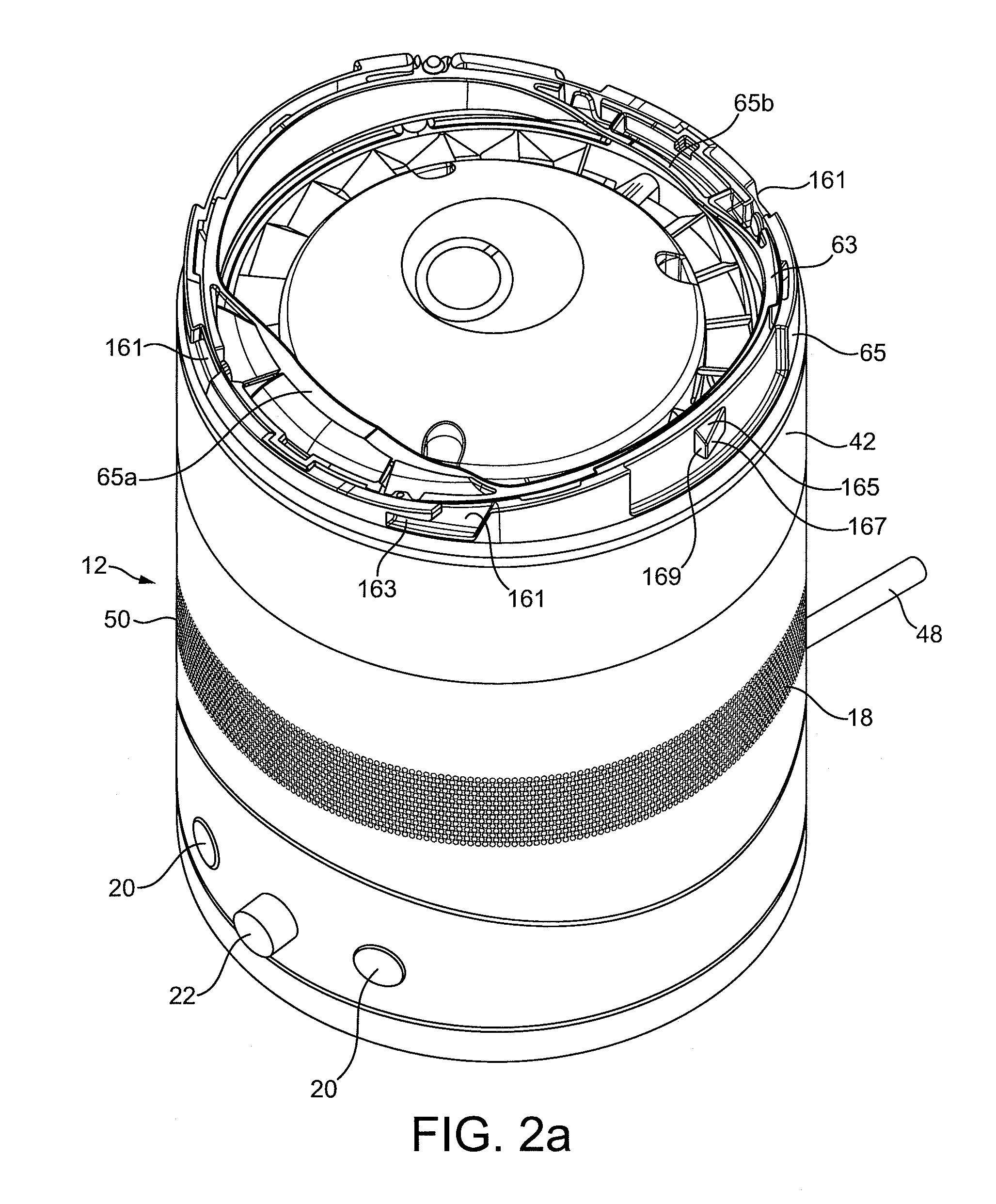

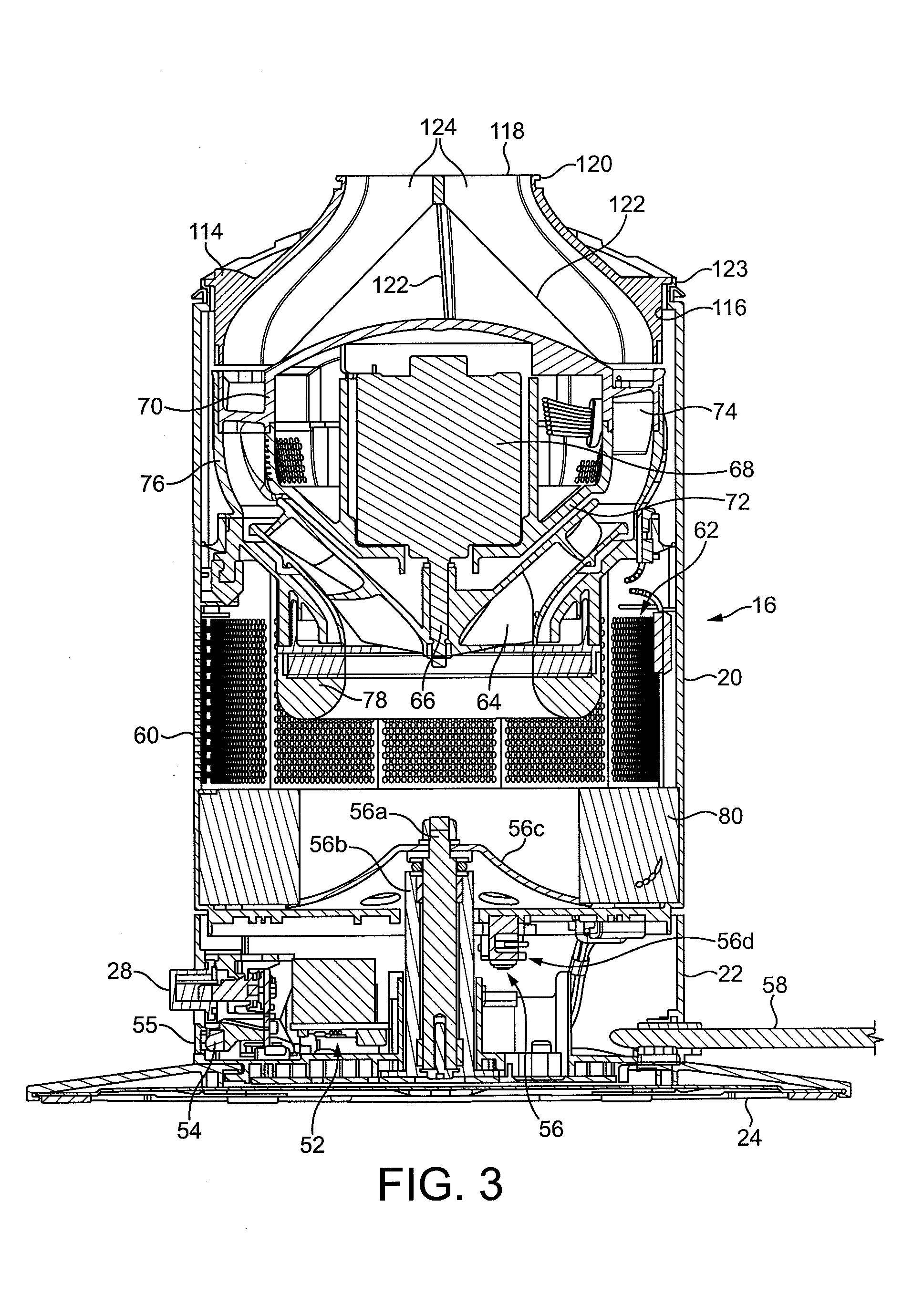

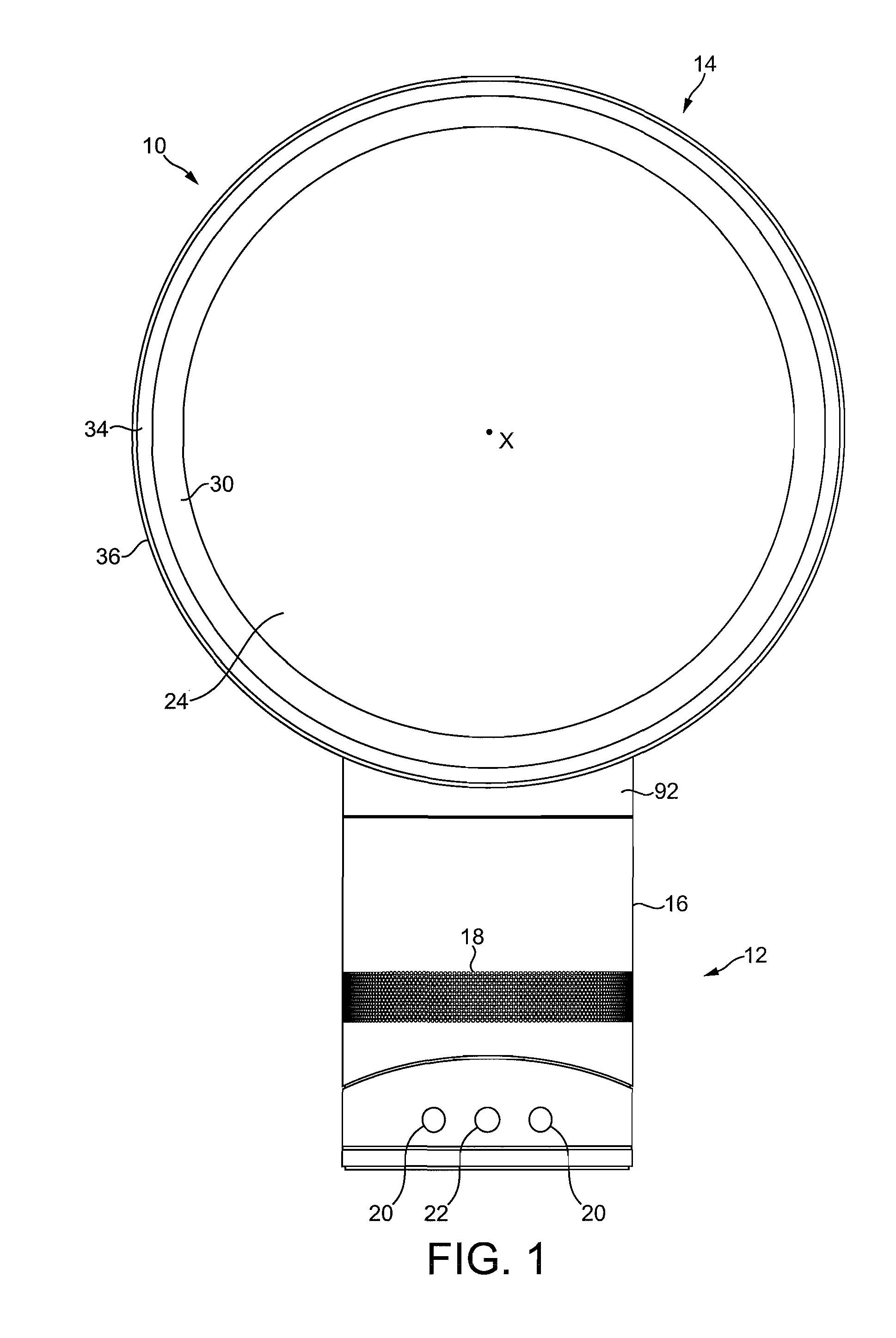

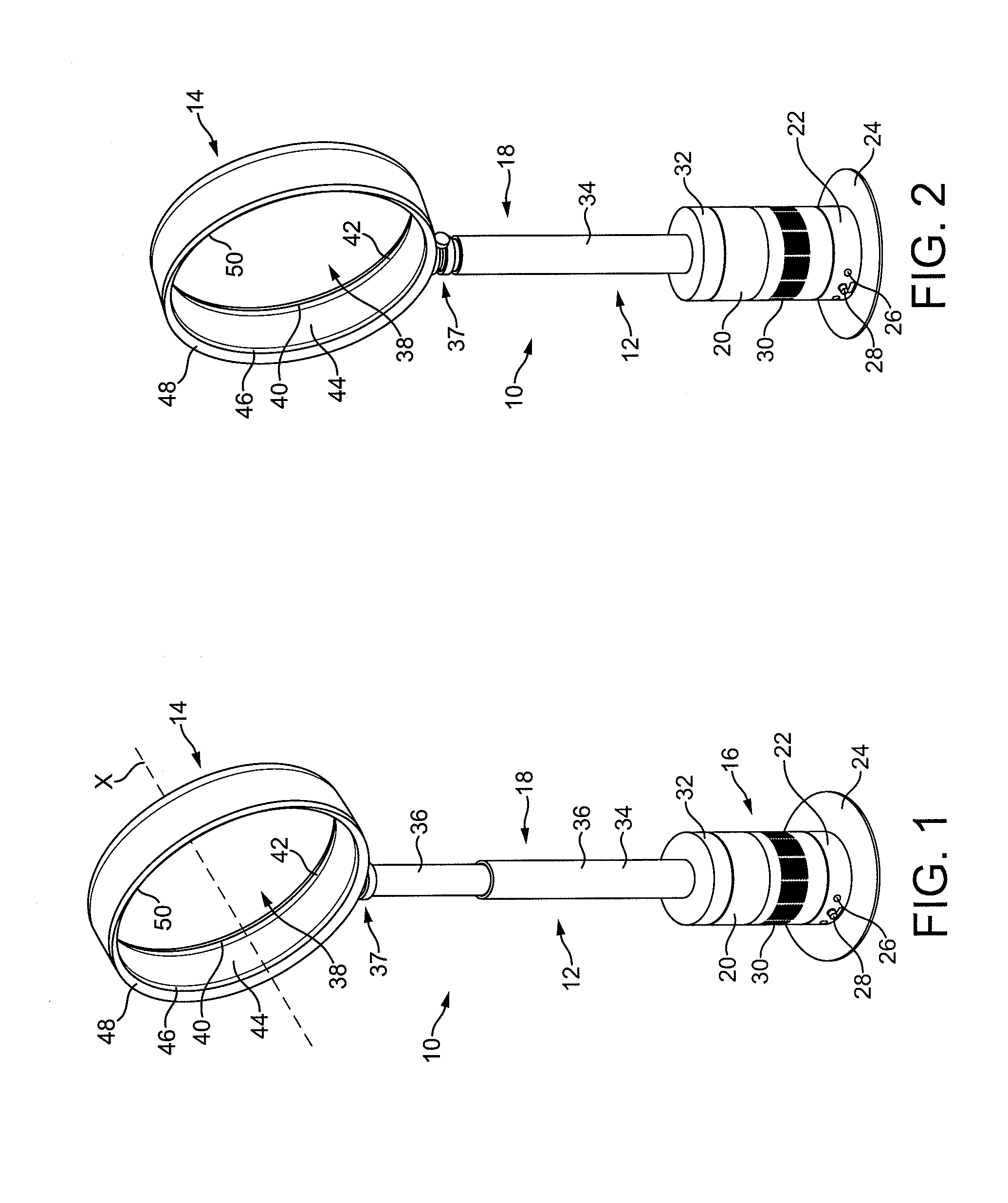

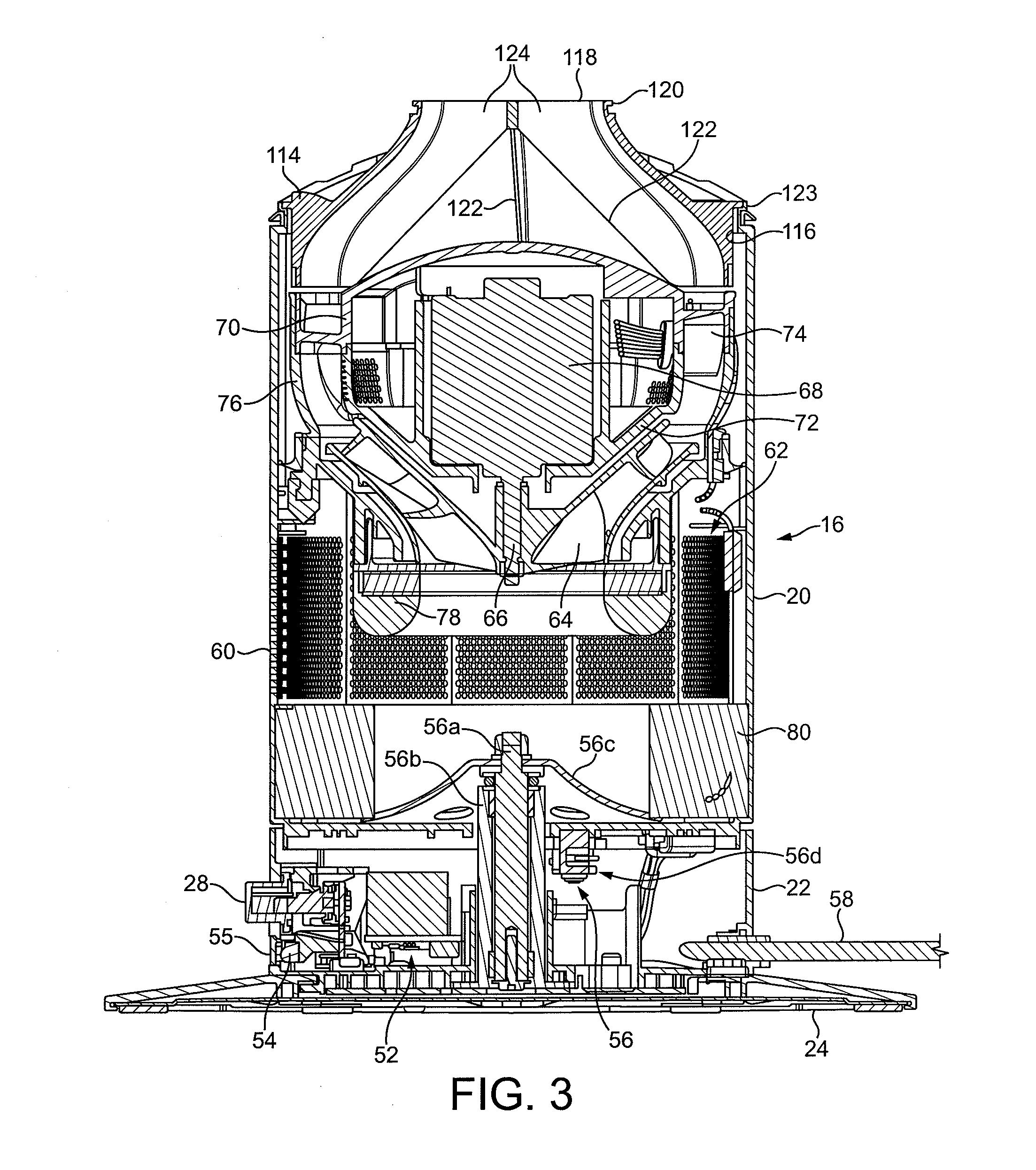

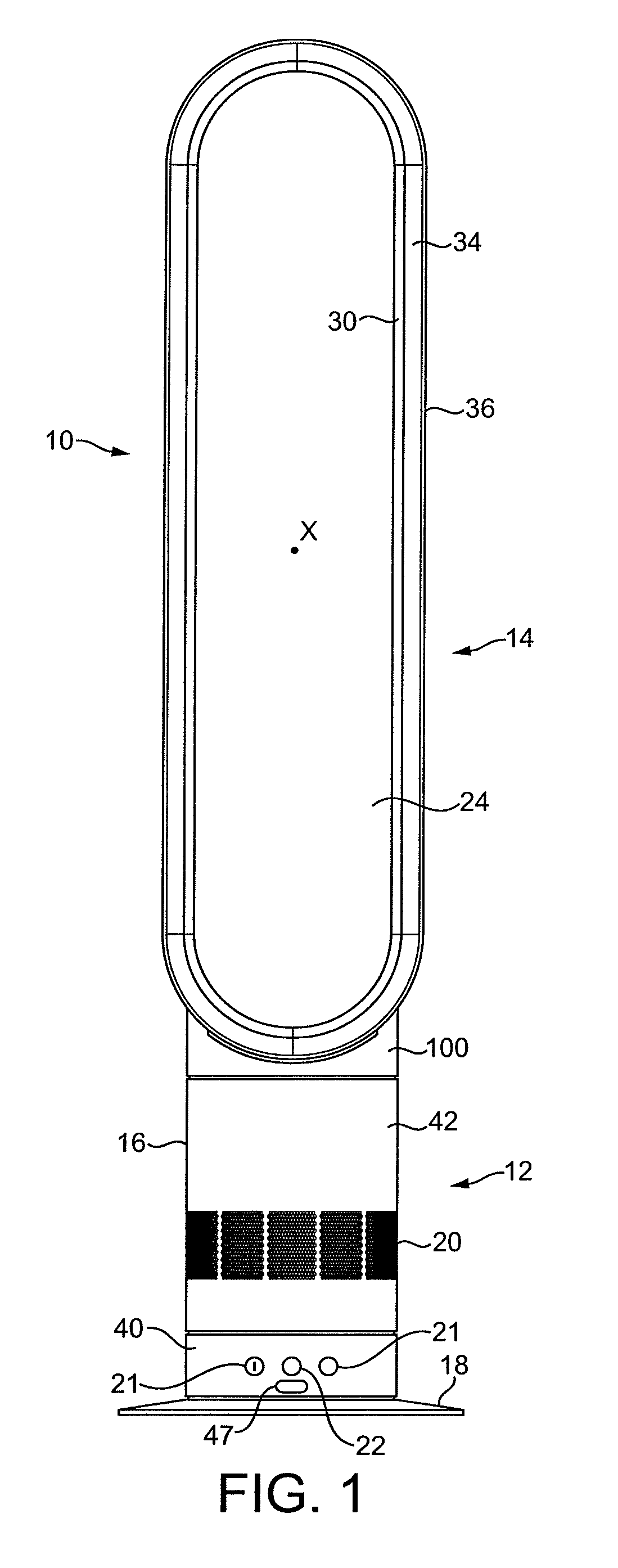

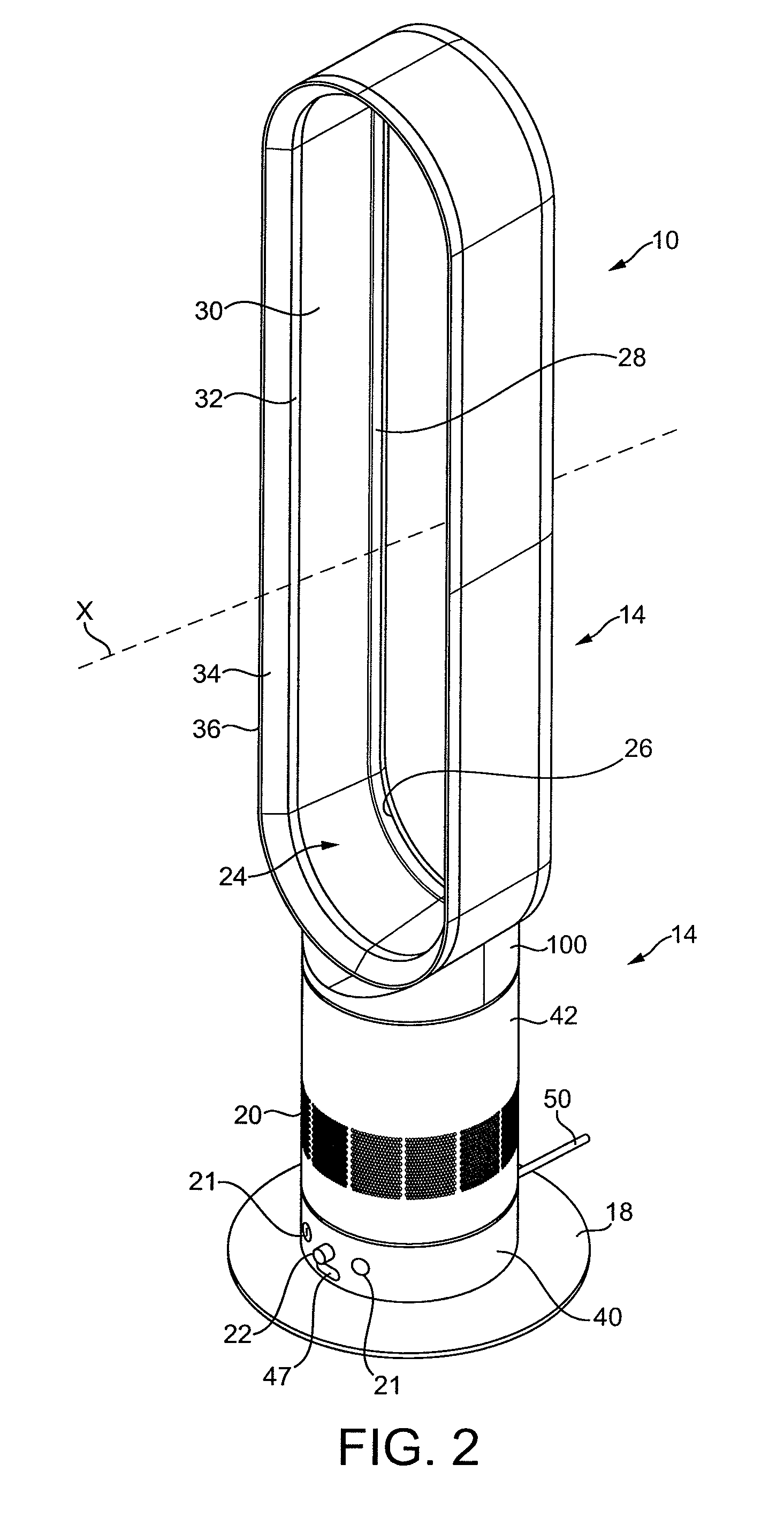

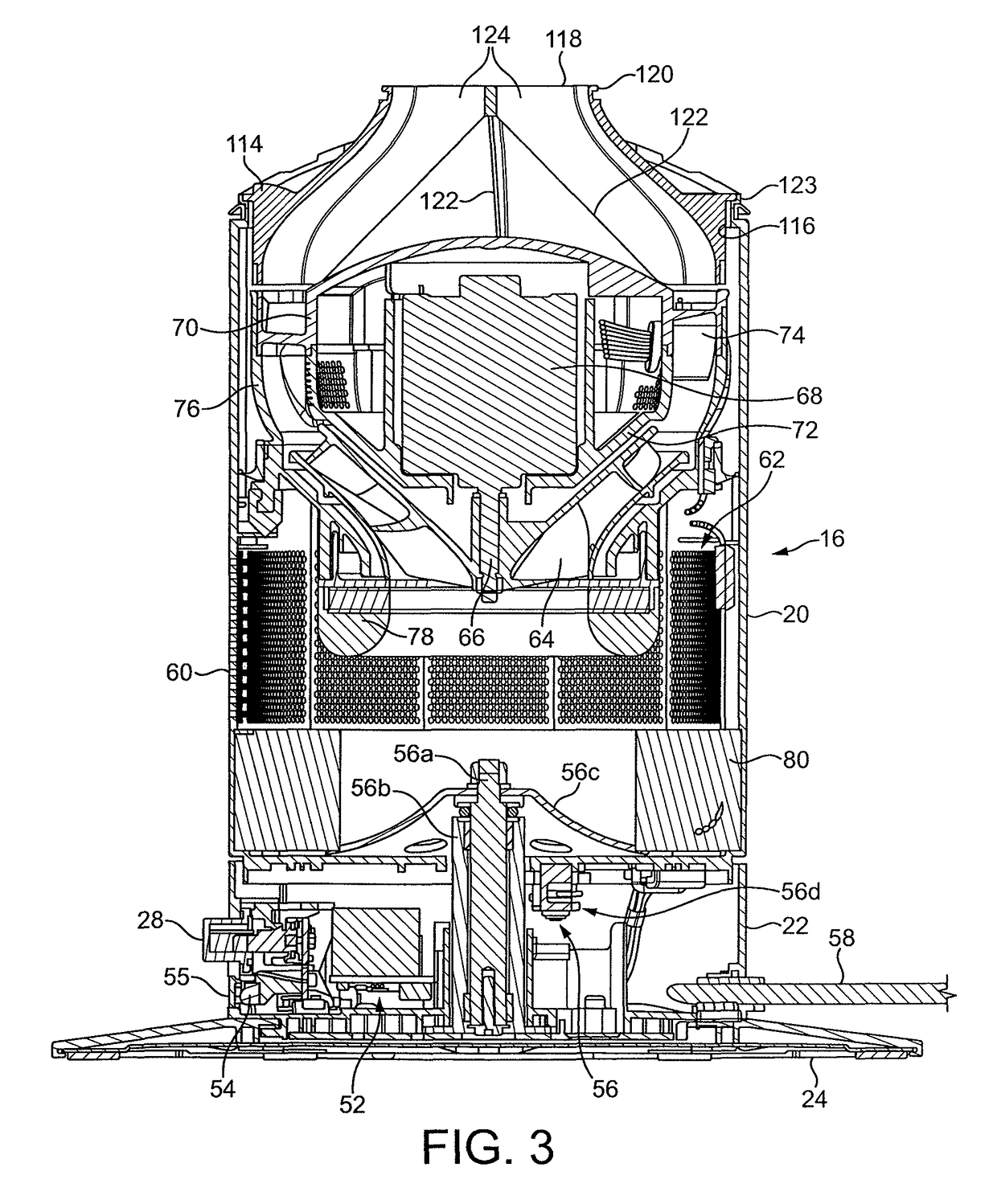

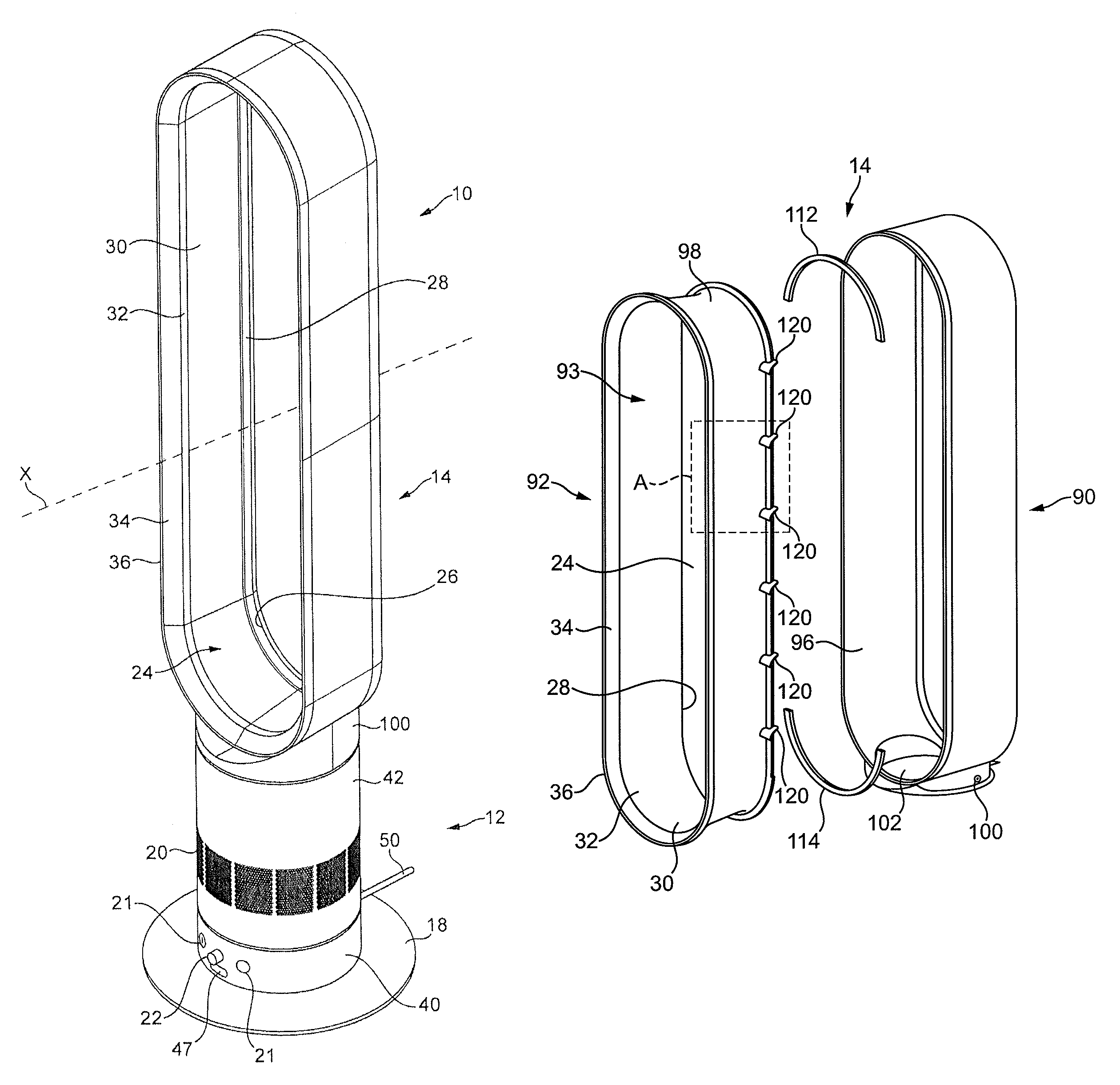

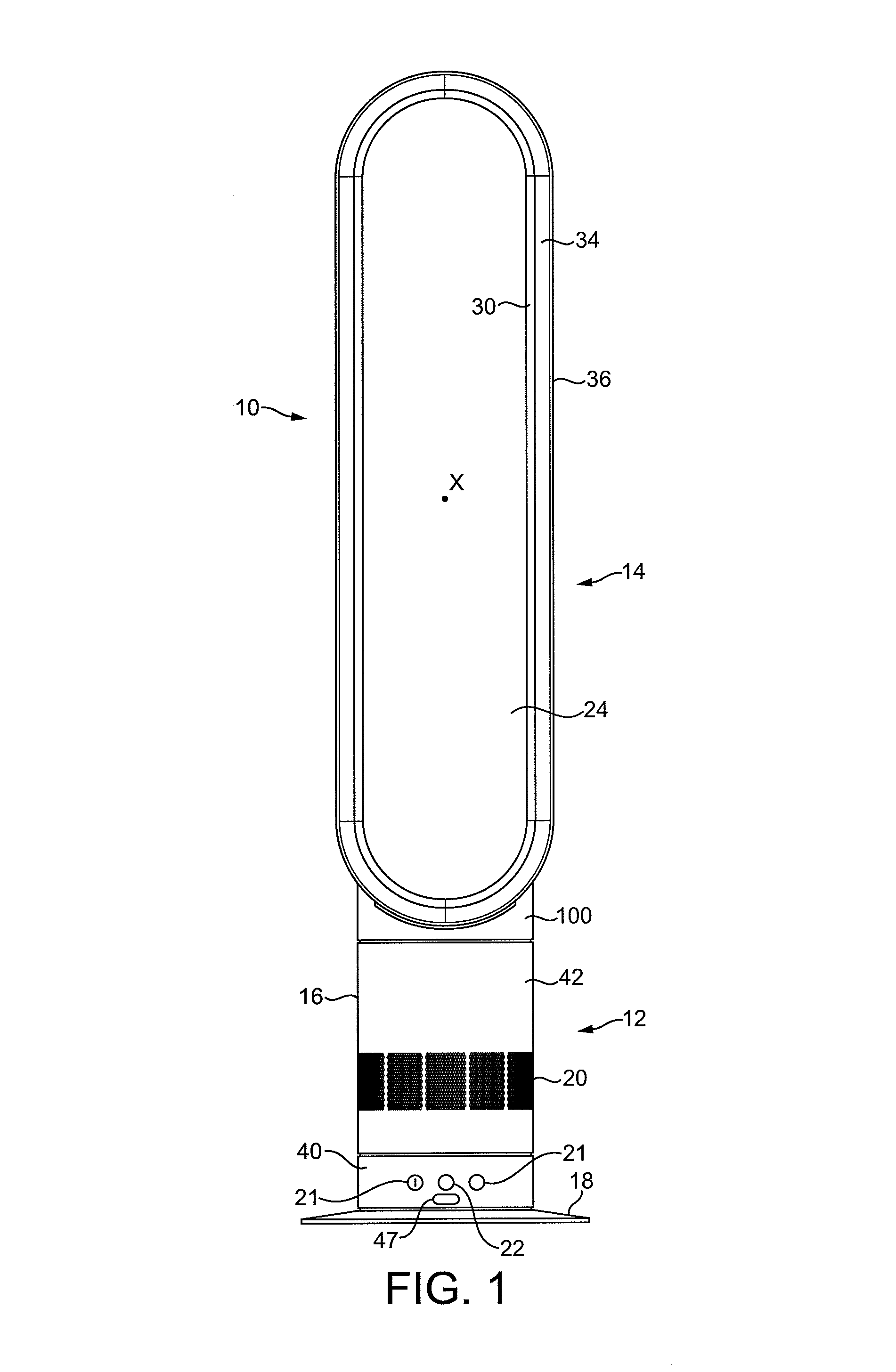

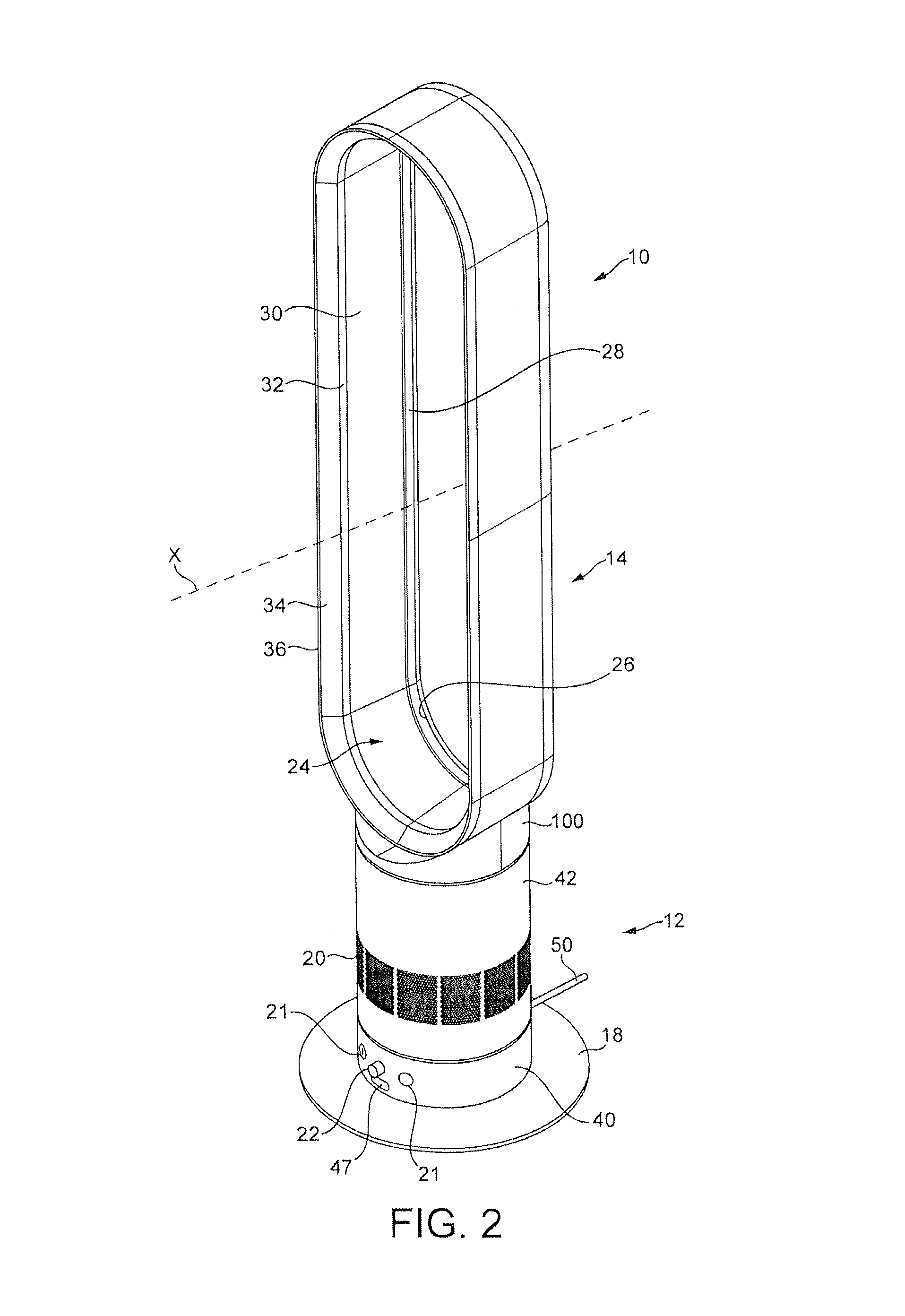

A fan assembly for creating an air current includes an air inlet, an air outlet, an impeller and a motor for rotating the impeller to create an air flow passing from the air inlet to the air outlet. The air outlet includes an interior passage for receiving the air flow and a mouth for emitting the air flow. The air outlet defines an opening through which air from outside the fan assembly is drawn by the air flow emitted from the mouth. The motor has a rotor which, in use, is capable of rotating at a speed of at least 5,000 rpm.

Owner:DYSON TECH LTD

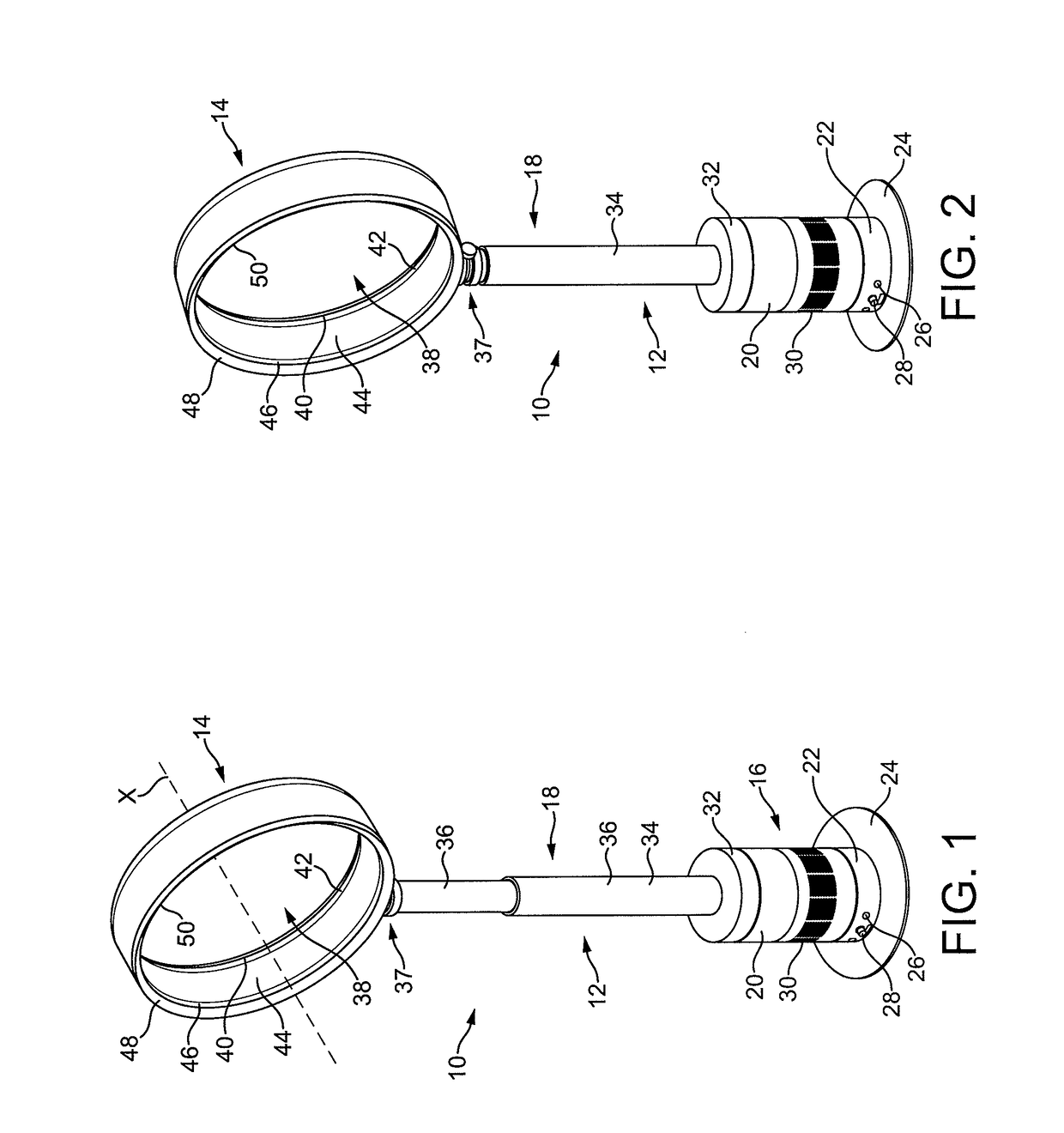

Fan assembly

ActiveUS20100226763A1Emission reductionWide operating speed rangePump componentsJet pumpsEngineeringAirflow

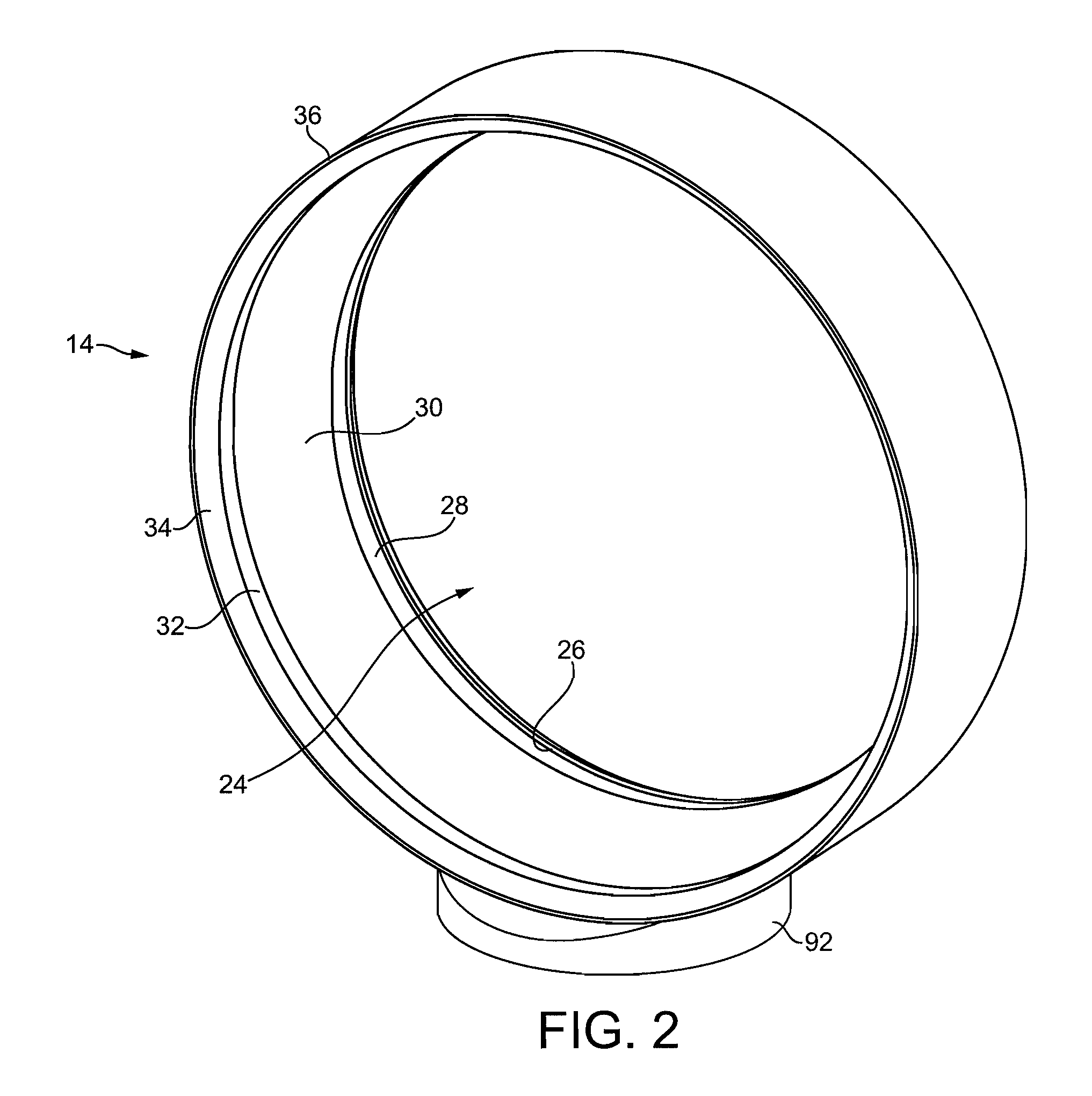

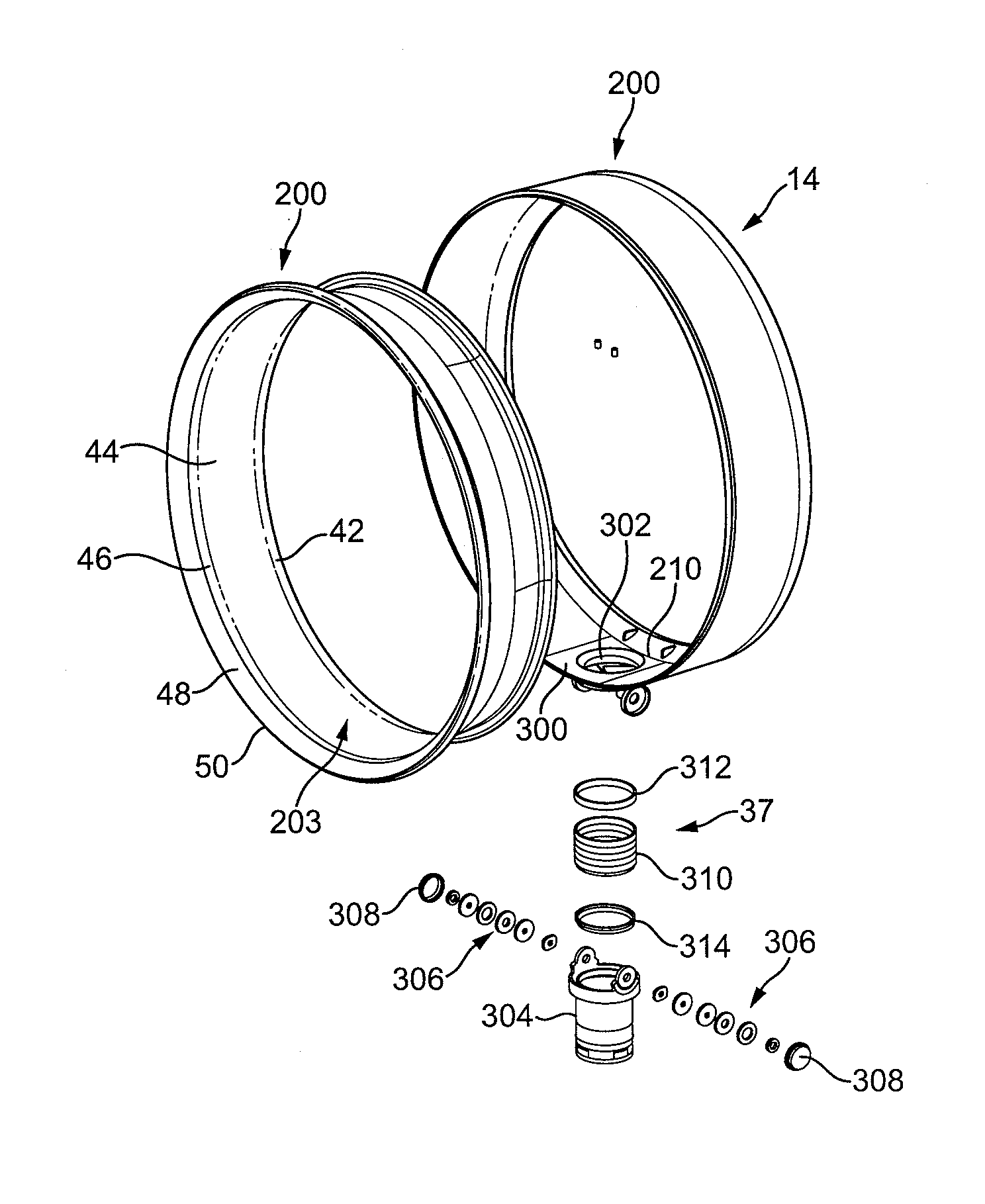

A bladeless fan assembly for creating an air current includes a nozzle mounted on a base. The nozzle comprises an interior passage and a mouth for receiving the air flow from the interior passage and through which the air flow is emitted from the fan assembly. The nozzle defines an opening through which air from outside the fan assembly is drawn by the air flow emitted from the mouth. The nozzle is detachable from the base, which is preferably sized to be accommodated within the opening of the nozzle for transportation.

Owner:DYSON TECH LTD

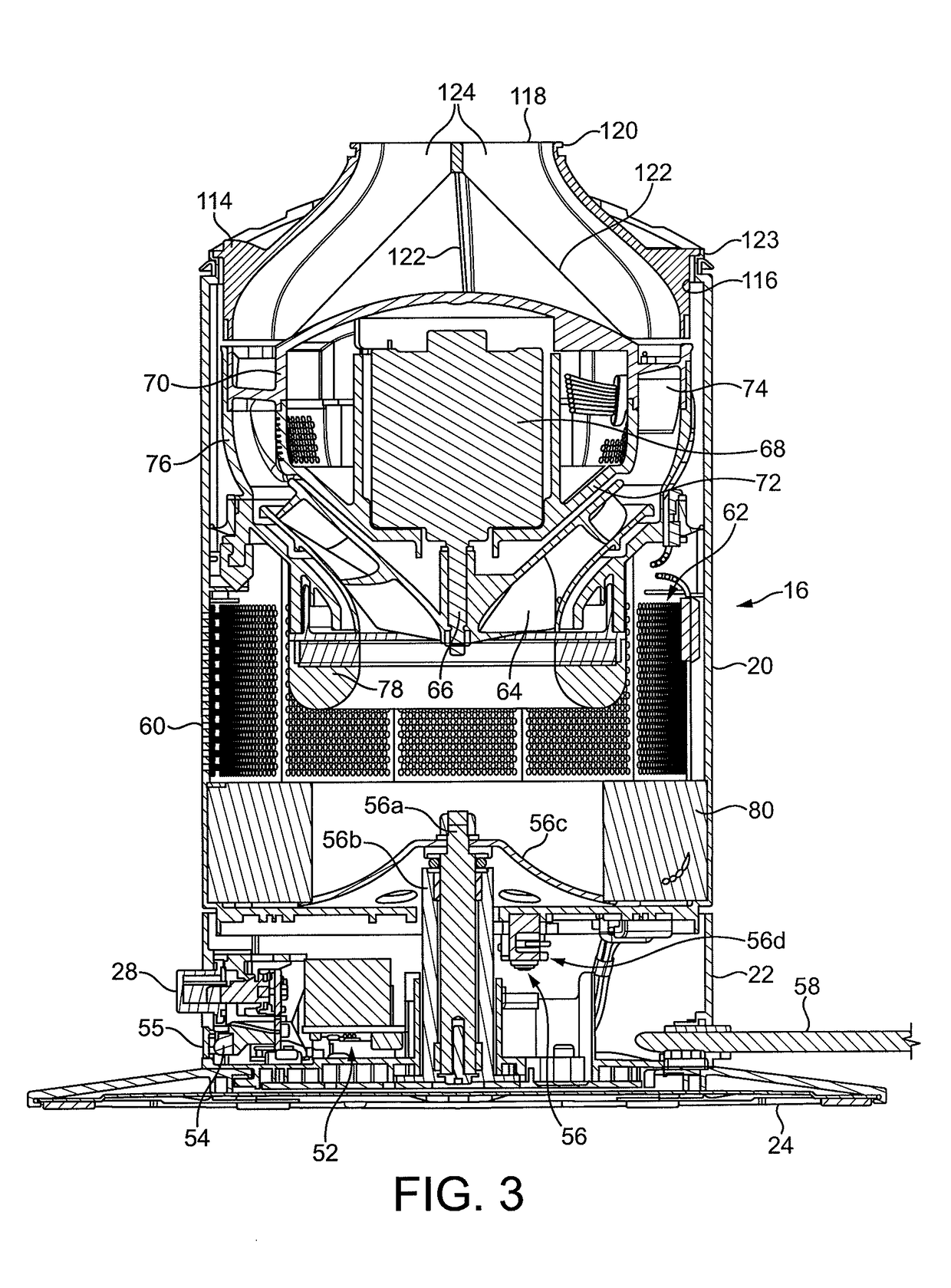

Fan assembly

InactiveUS20120033952A1Quick changeReduce in quantityDucting arrangementsPump componentsMotor driveEngineering

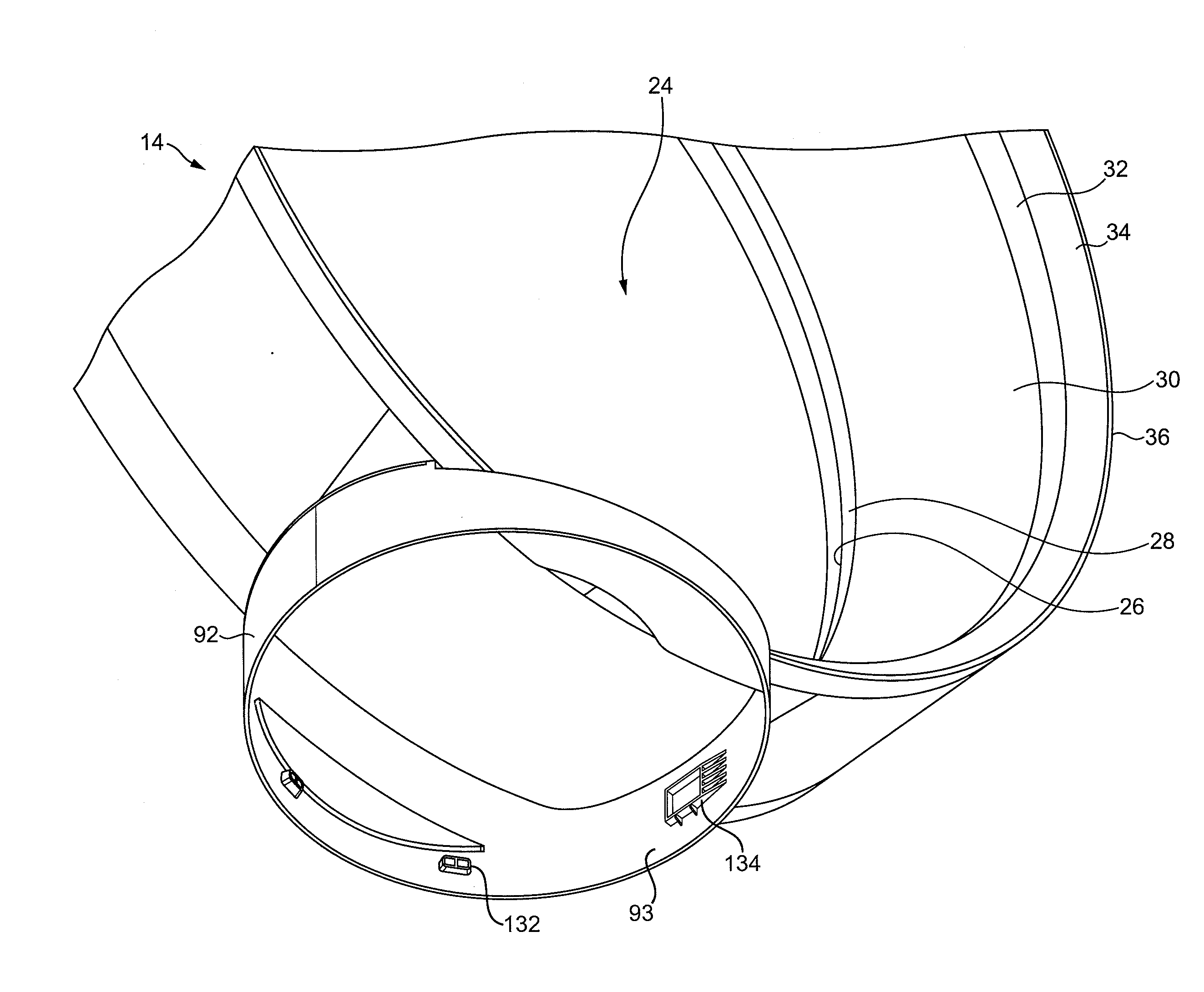

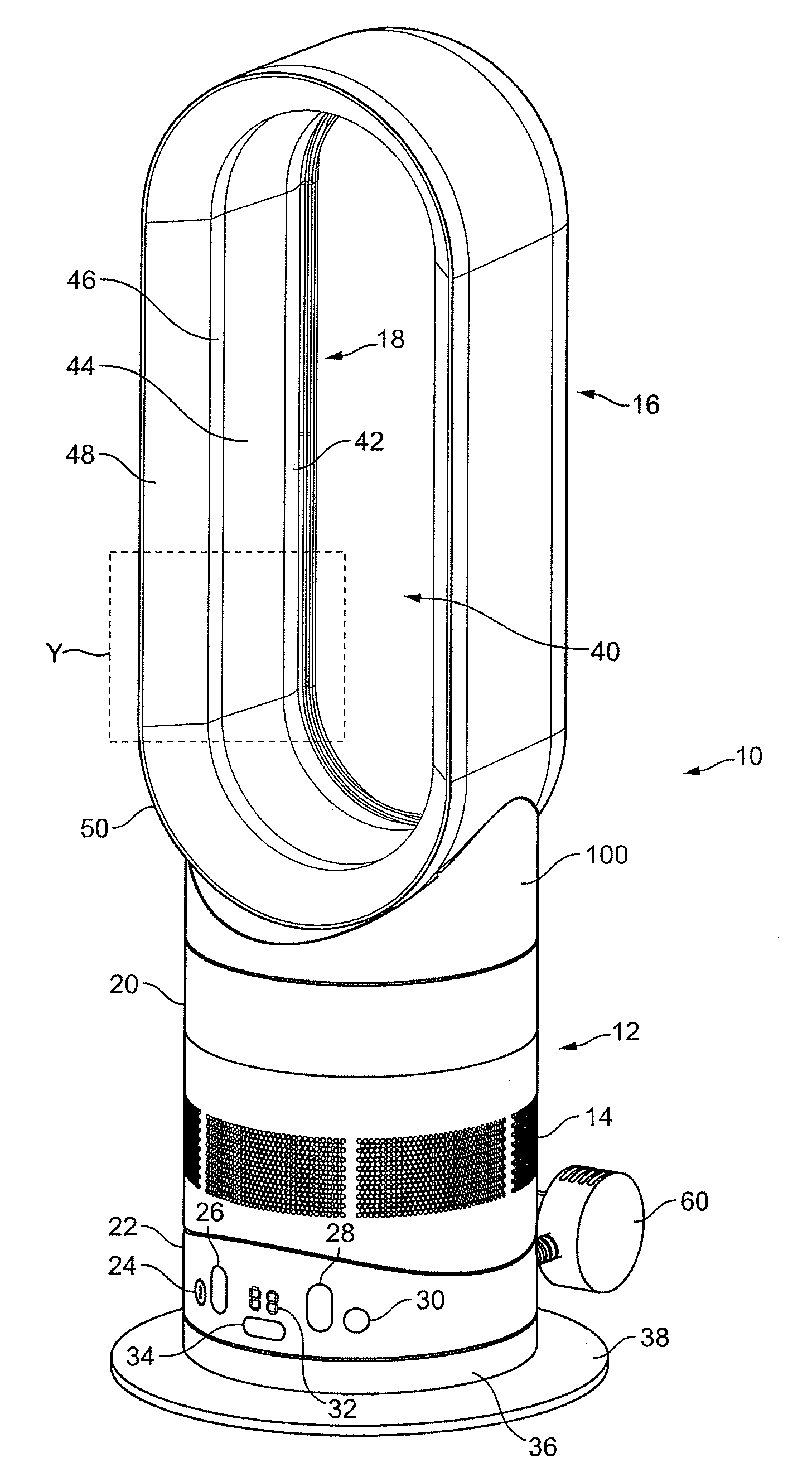

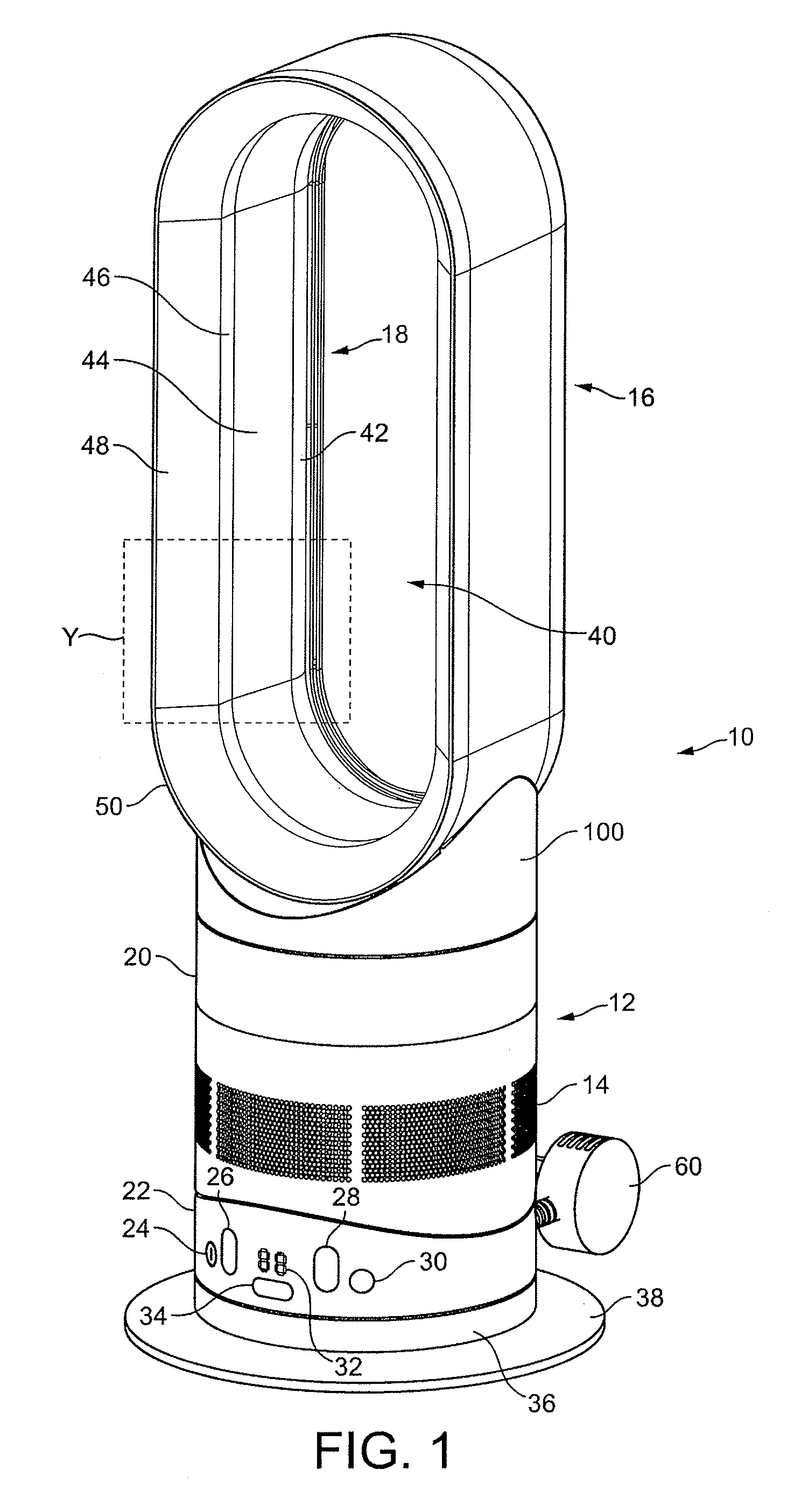

A fan assembly includes a motor-driven impeller for creating an air flow, a casing including an interior passage for receiving the air flow, and a plurality of air outlets for emitting the air flow from the casing. The casing defines and extends about an opening through which air from outside the casing is drawn by the air flow emitted from the air outlets. The fan assembly also includes at least one heater for heating at least a first portion of the air flow, and means for diverting at least a second portion of the air flow away from said at least one heater. The plurality of outlets includes at least one first air outlet for emitting the relatively hot first portion of the air flow and at least one second air outlet for emitting the relatively cold second portion of the air flow.

Owner:DYSON TECH LTD

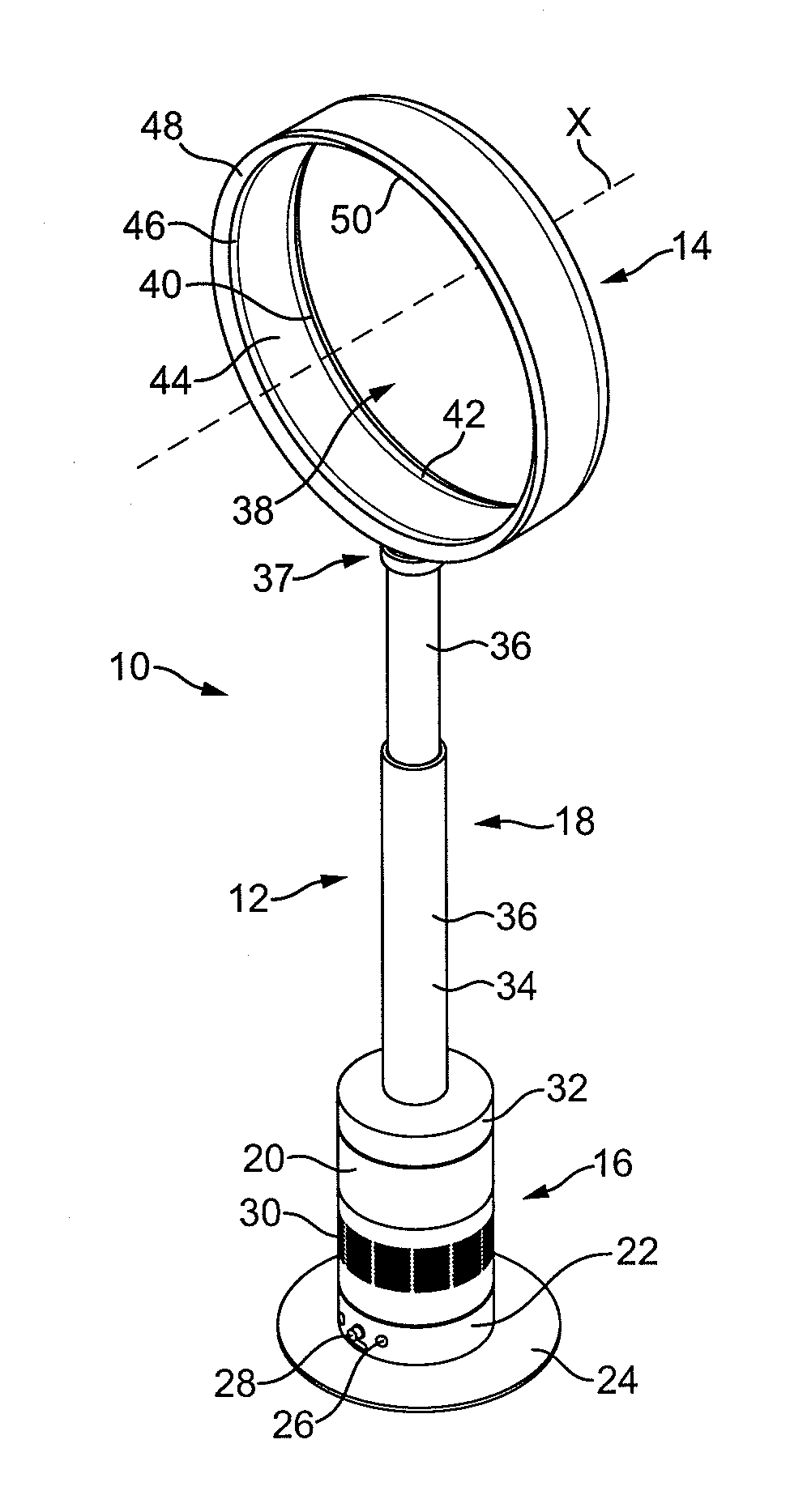

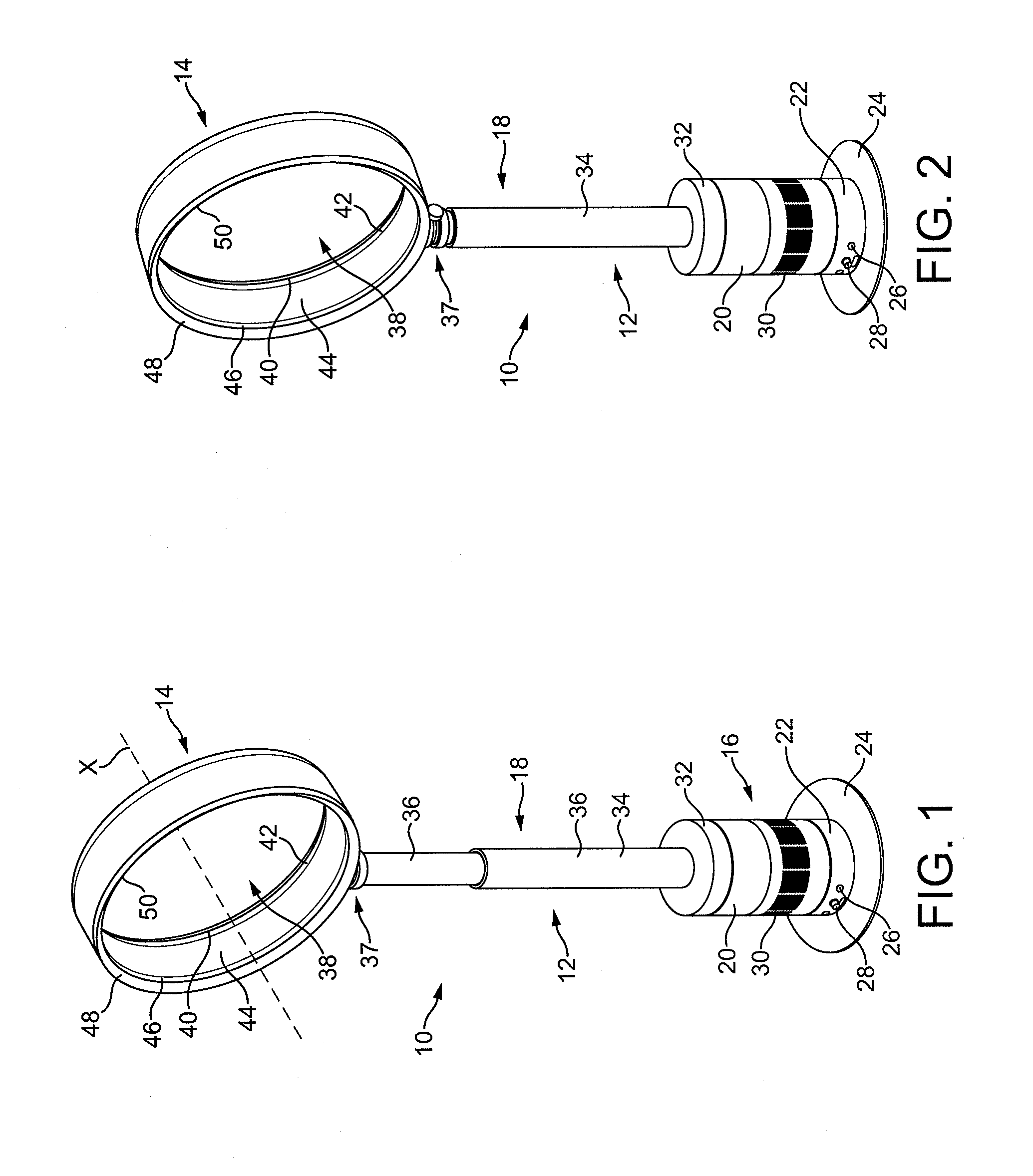

Fan assembly

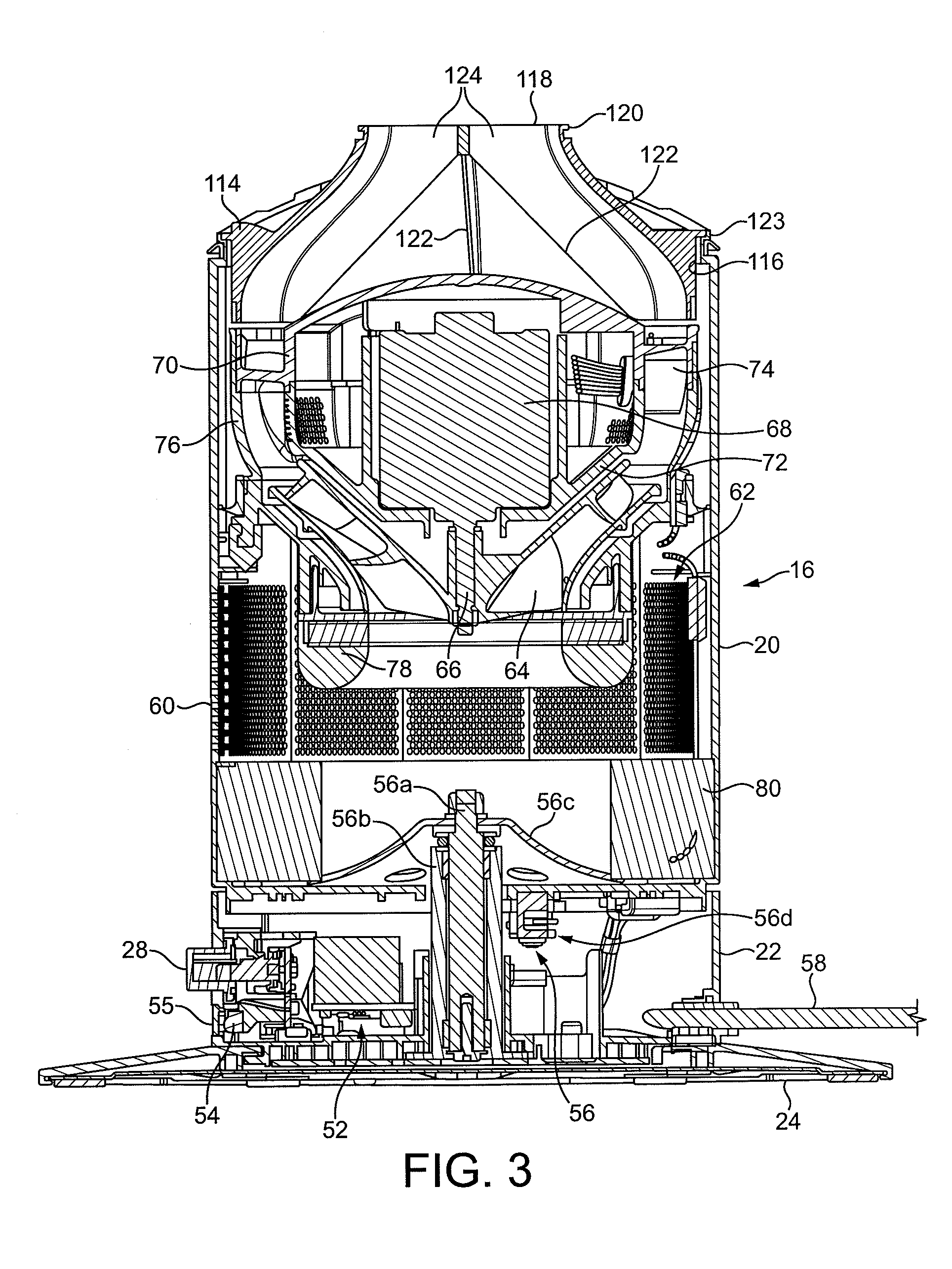

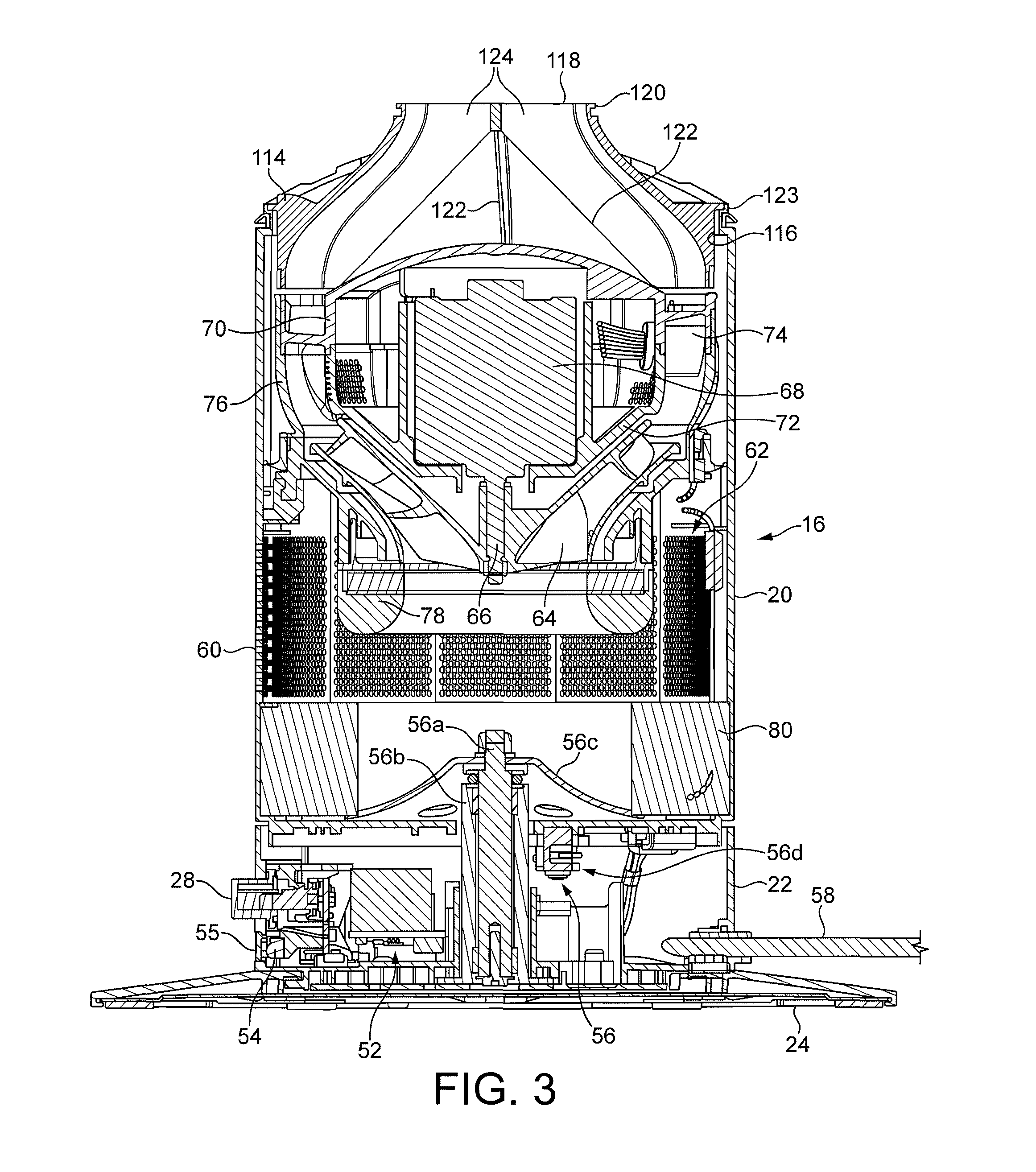

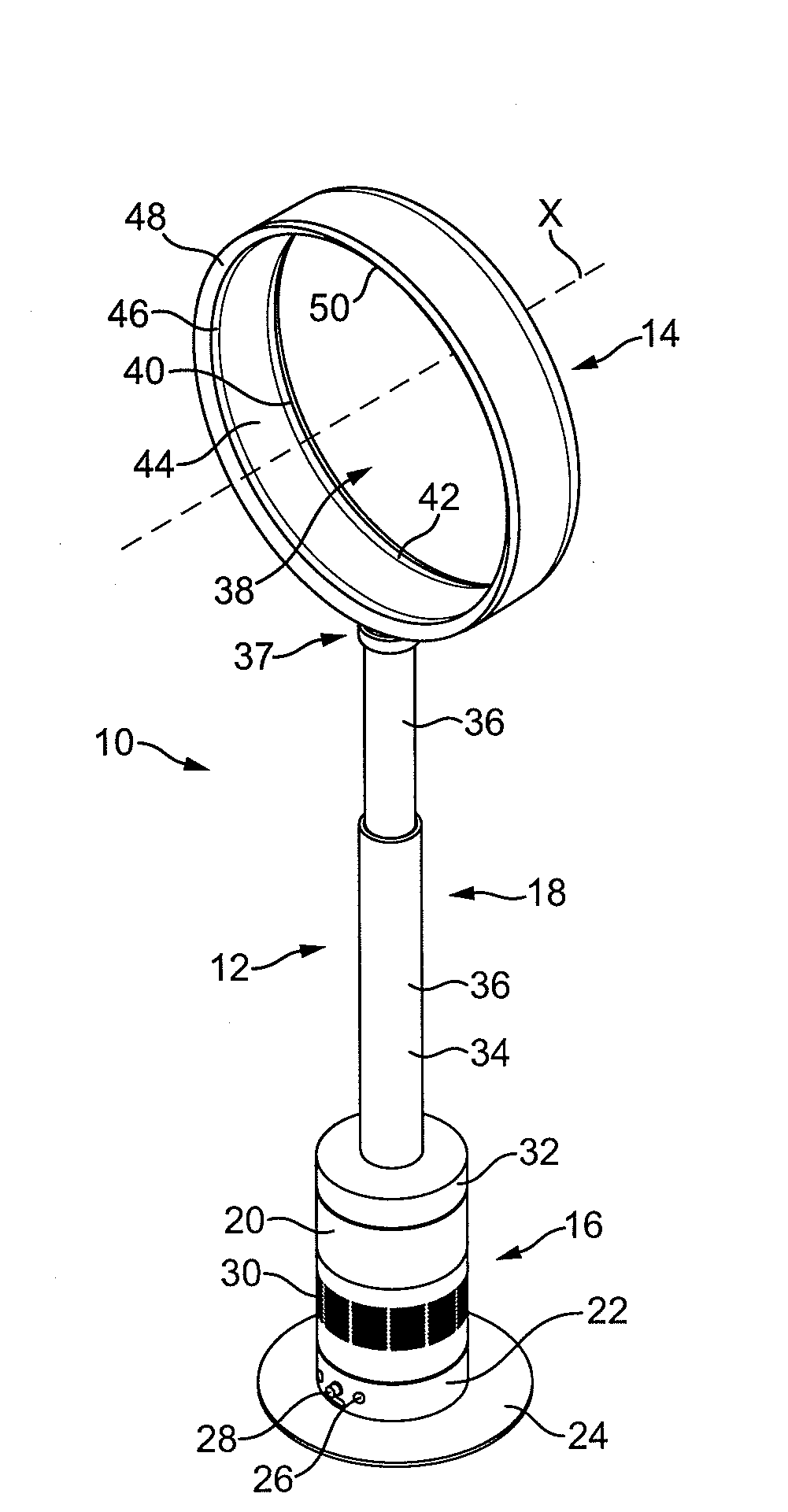

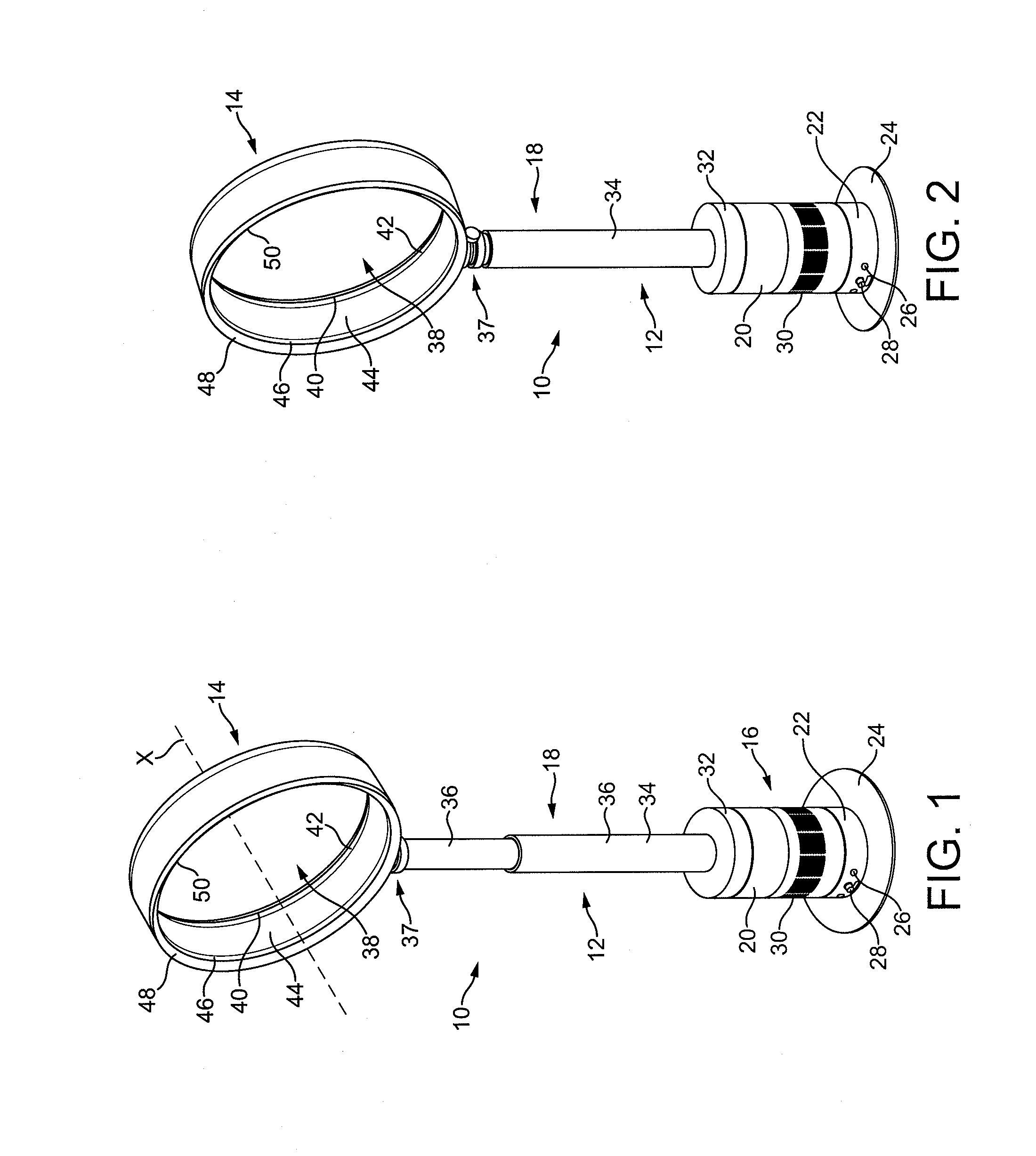

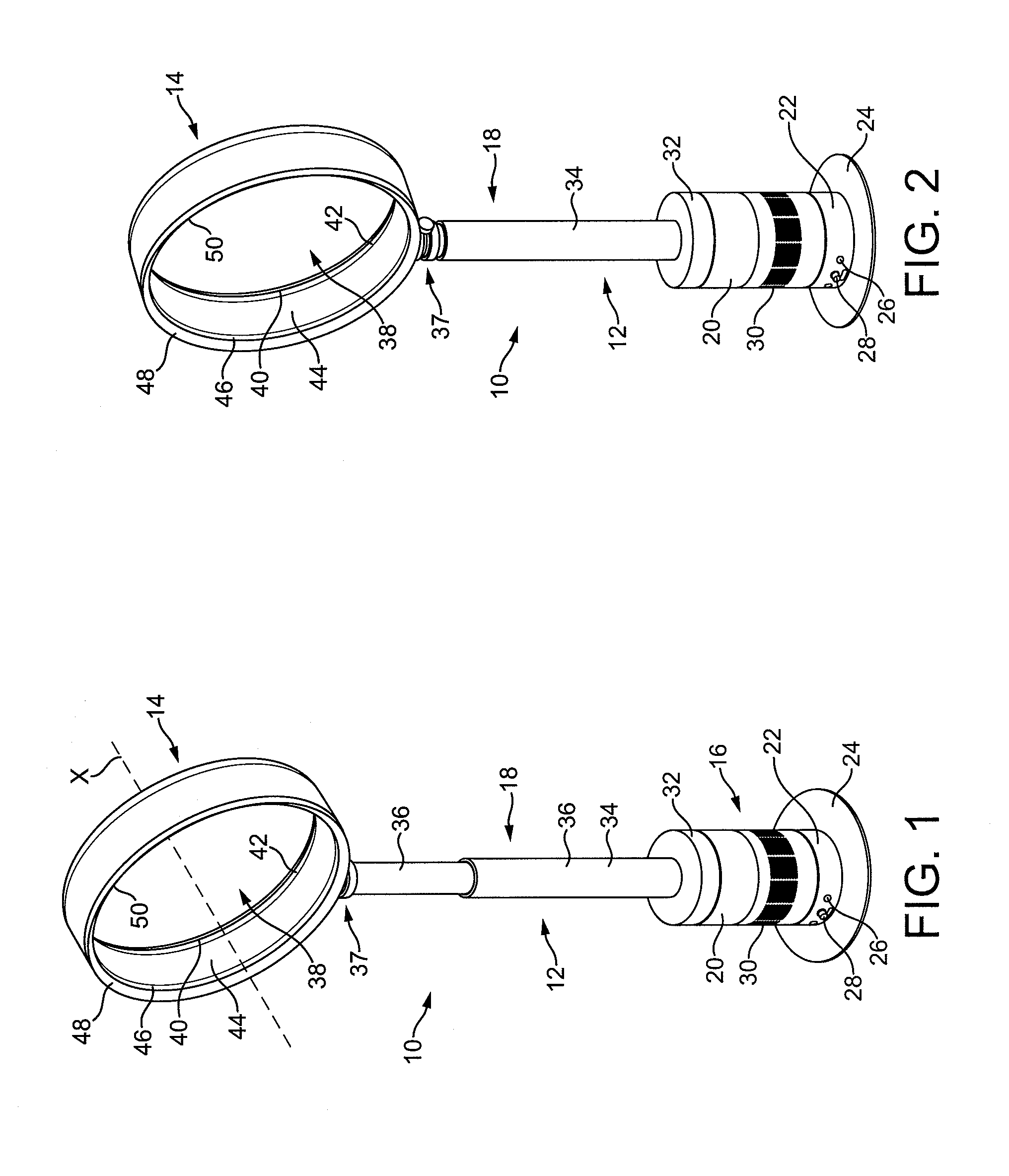

InactiveUS20100226753A1Lower center of gravityLess prone to falling overPump componentsJet pumpsEngineeringAirflow

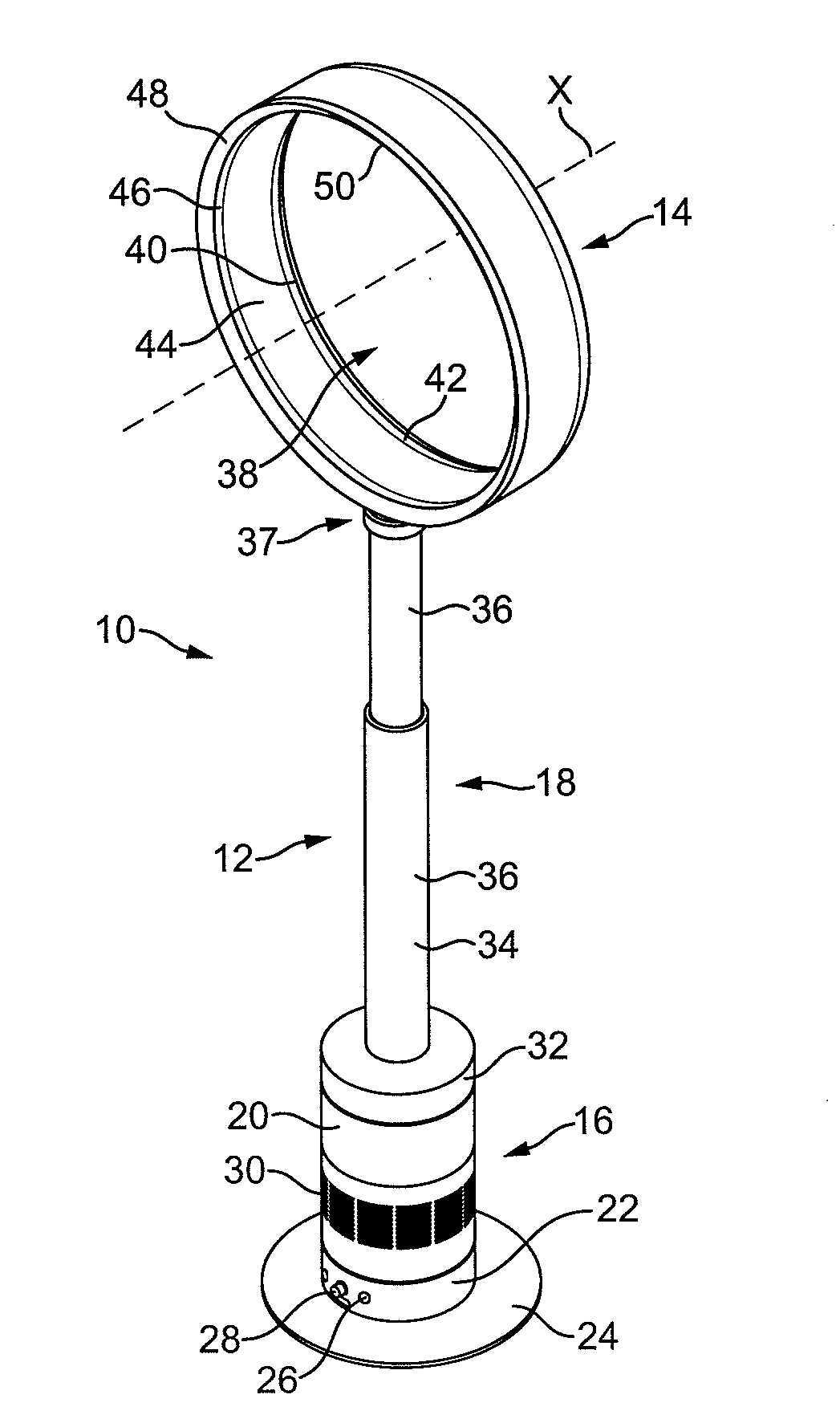

A fan assembly includes a device for creating an air flow and an air outlet for emitting the air flow. The air outlet is mounted on a stand for conveying the air flow to the air outlet. The fan assembly also includes a tilt mechanism for tilting the air outlet relative to at least part of the stand. The tilt mechanism comprises a flexible hose defining, at least in part, an air passage through the tilt mechanism.

Owner:DYSON TECH LTD

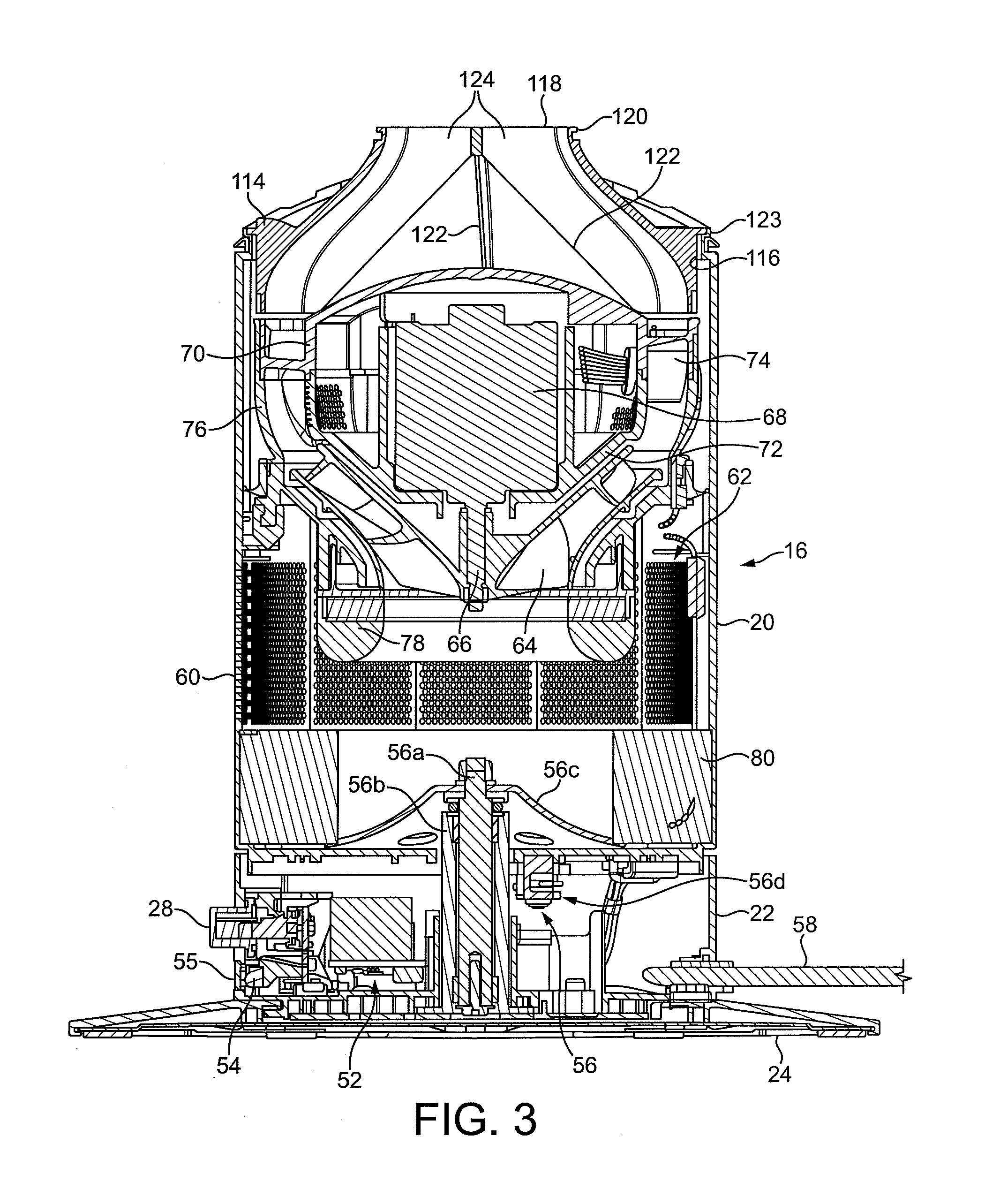

Fan assembly

A bladeless fan assembly includes a nozzle mounted on a base housing a motor and an impeller driven by the motor for creating an air flow. The nozzle includes an interior passage for receiving the air flow, a mouth for emitting the air flow, and a plurality of stationary guide vanes located within the interior passage and each for directing a portion of the air flow towards the mouth. The nozzle defines an opening through which air from outside the fan assembly is drawn by the air flow emitted from the mouth.

Owner:DYSON TECH LTD

Fan assembly

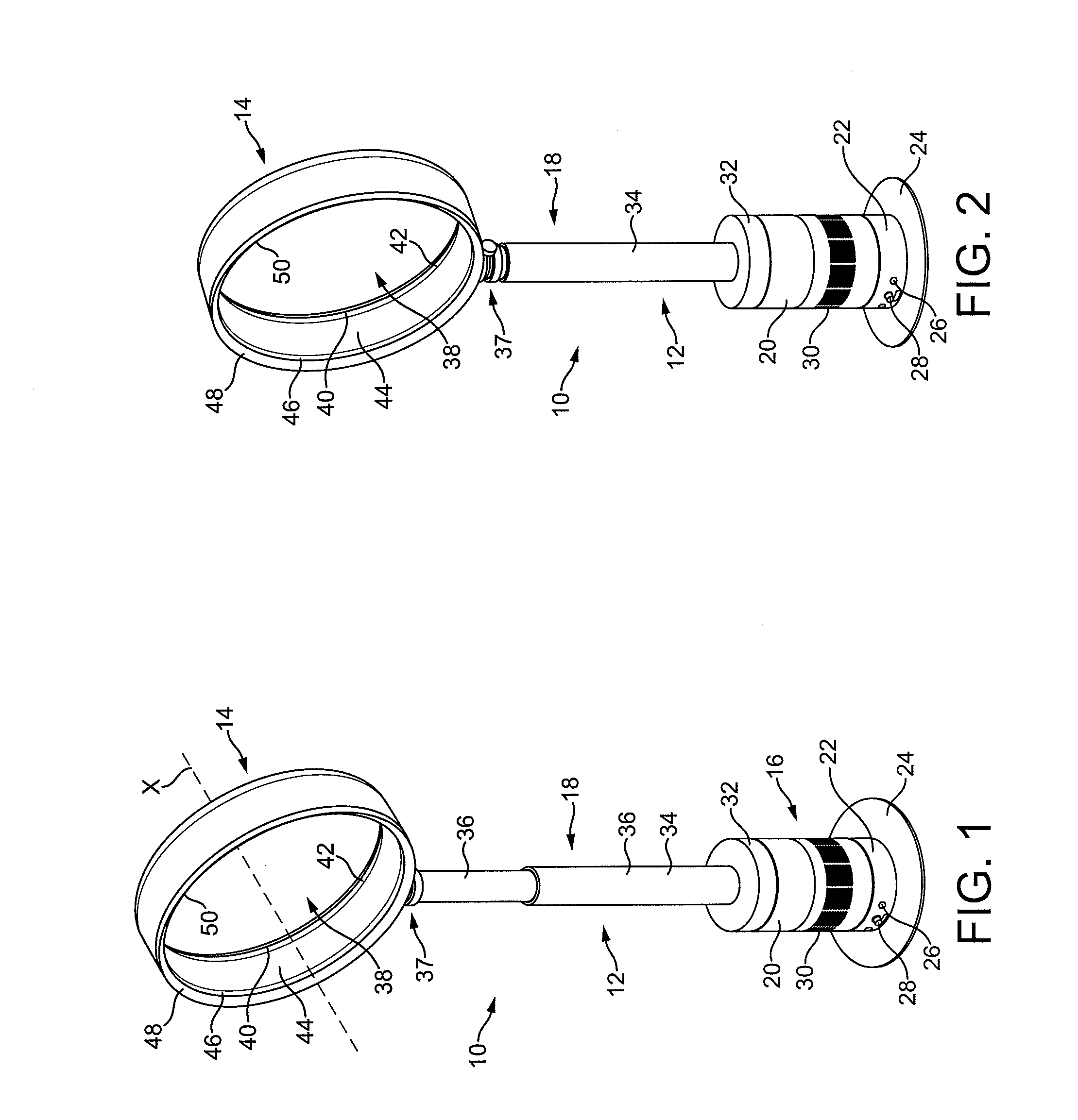

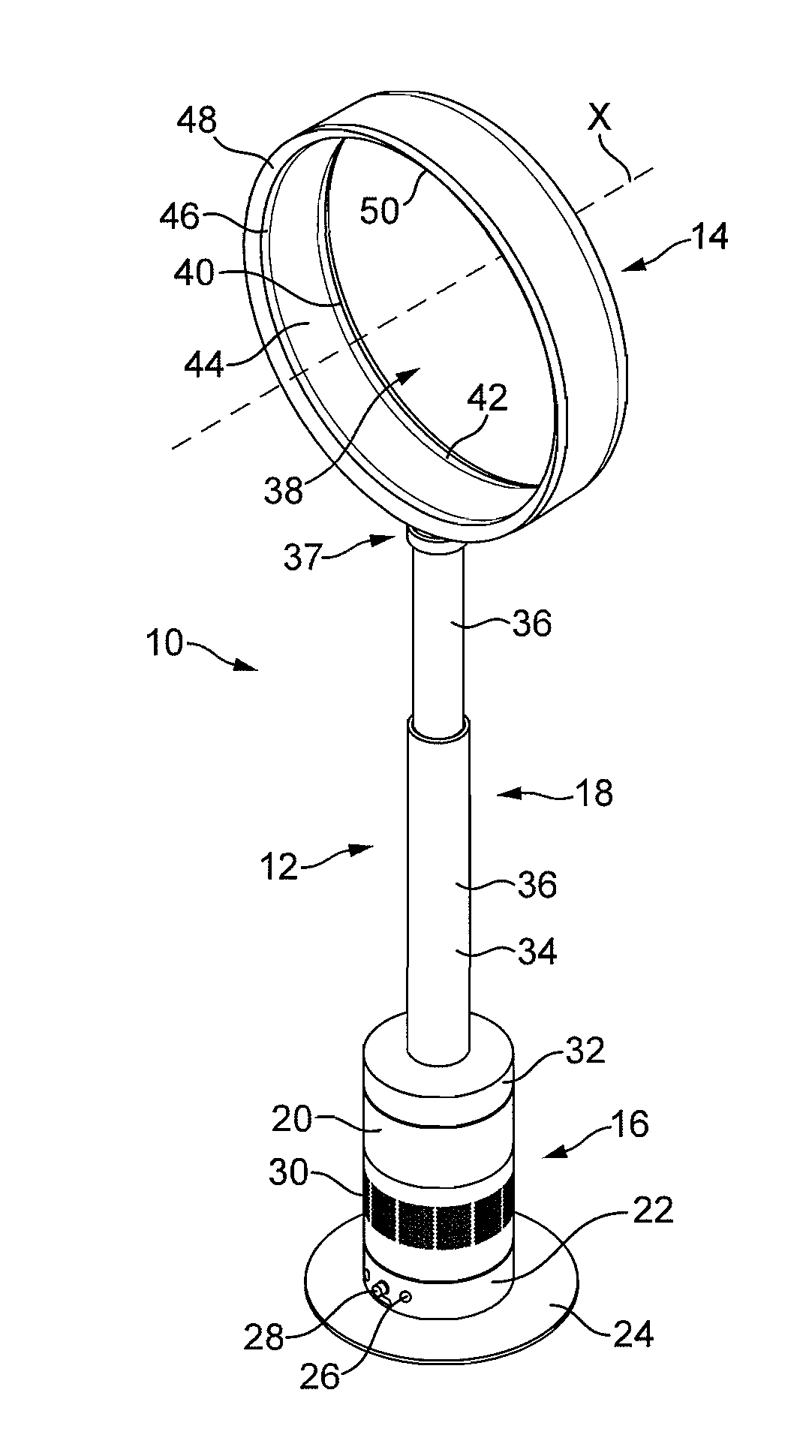

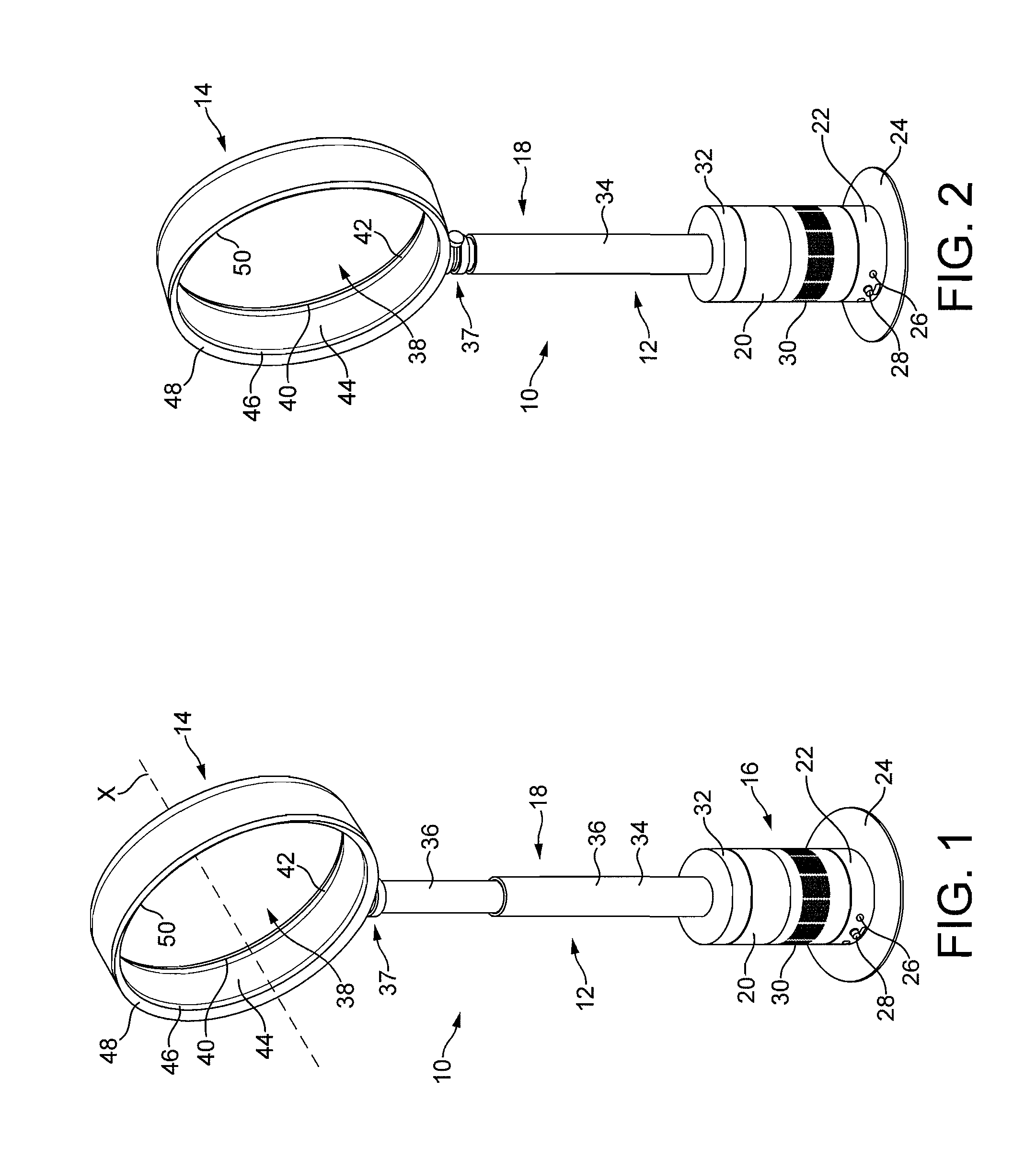

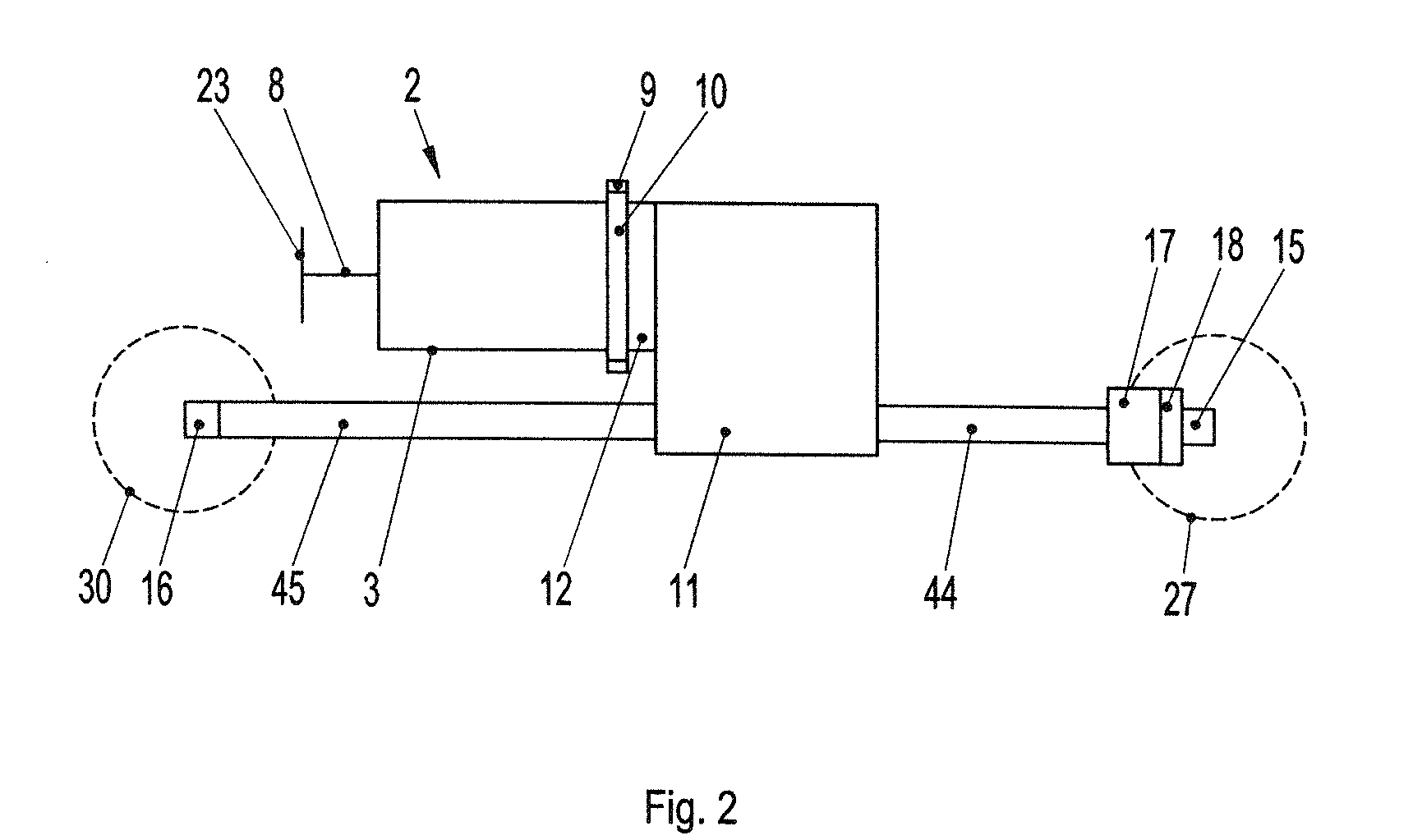

ActiveUS20100226750A1Optimize locationTravel efficientlyPropellersPump componentsEngineeringGravity center

A fan assembly for creating an air current includes an air outlet mounted on a stand. The stand includes a base and a body tiltable relative to the base. The fan assembly has a centre of gravity located so that when the base is located on a substantially horizontal support surface, the projection of the centre of gravity on the support surface is within the footprint of the base when the body is in a fully tilted position.

Owner:DYSON TECH LTD

Fan assembly

InactiveUS20100226749A1Losing little energy and velocityReduce complexityPump componentsLighting and heating apparatusEngineeringAirflow

A bladeless fan assembly includes a nozzle and a device for creating an air flow through the nozzle. The nozzle includes an interior passage, a mouth for receiving the air flow from the interior passage, and a surface located adjacent the mouth and over which the mouth is arranged to direct the air flow. The nozzle is mounted on a height adjustable pedestal.

Owner:DYSON TECH LTD

Fan

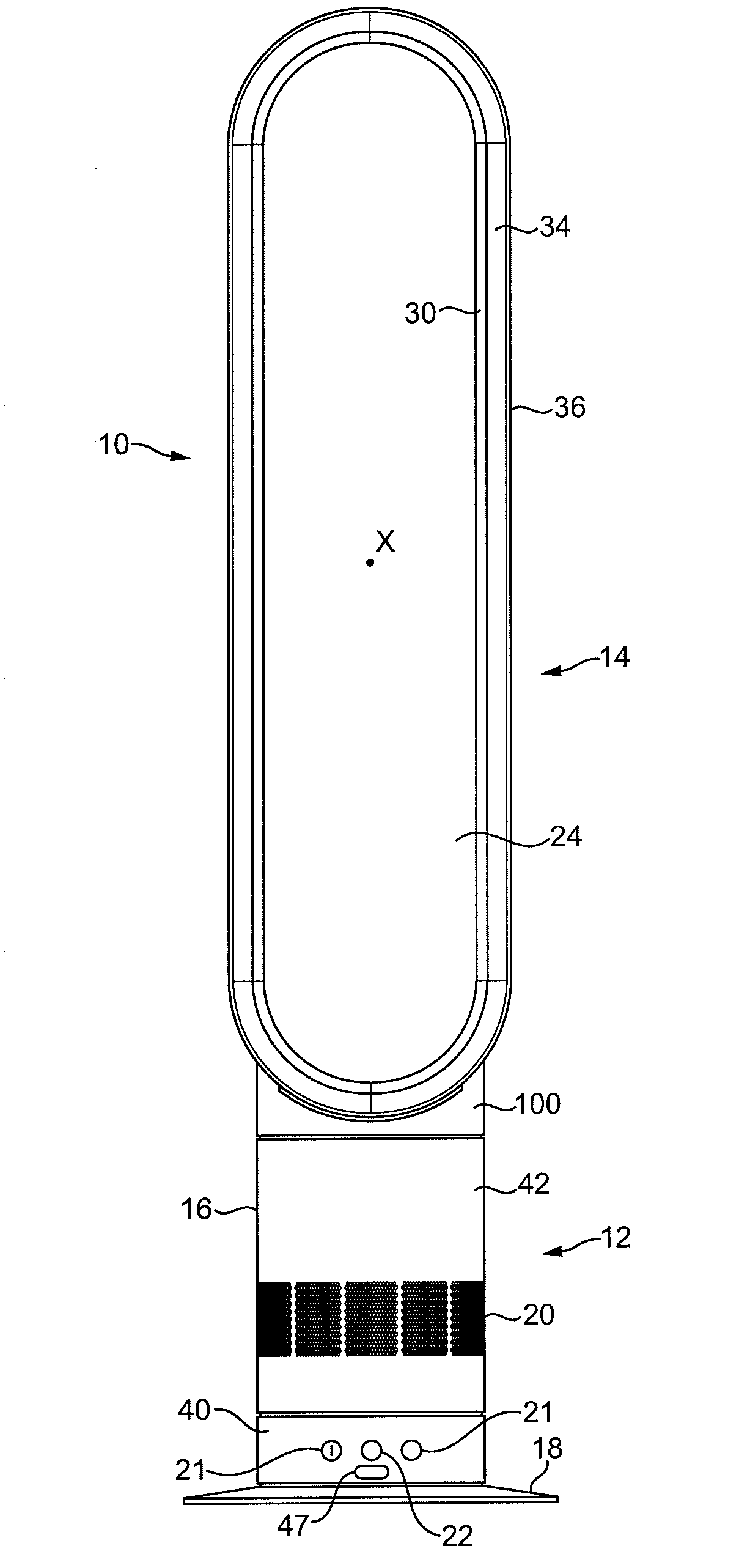

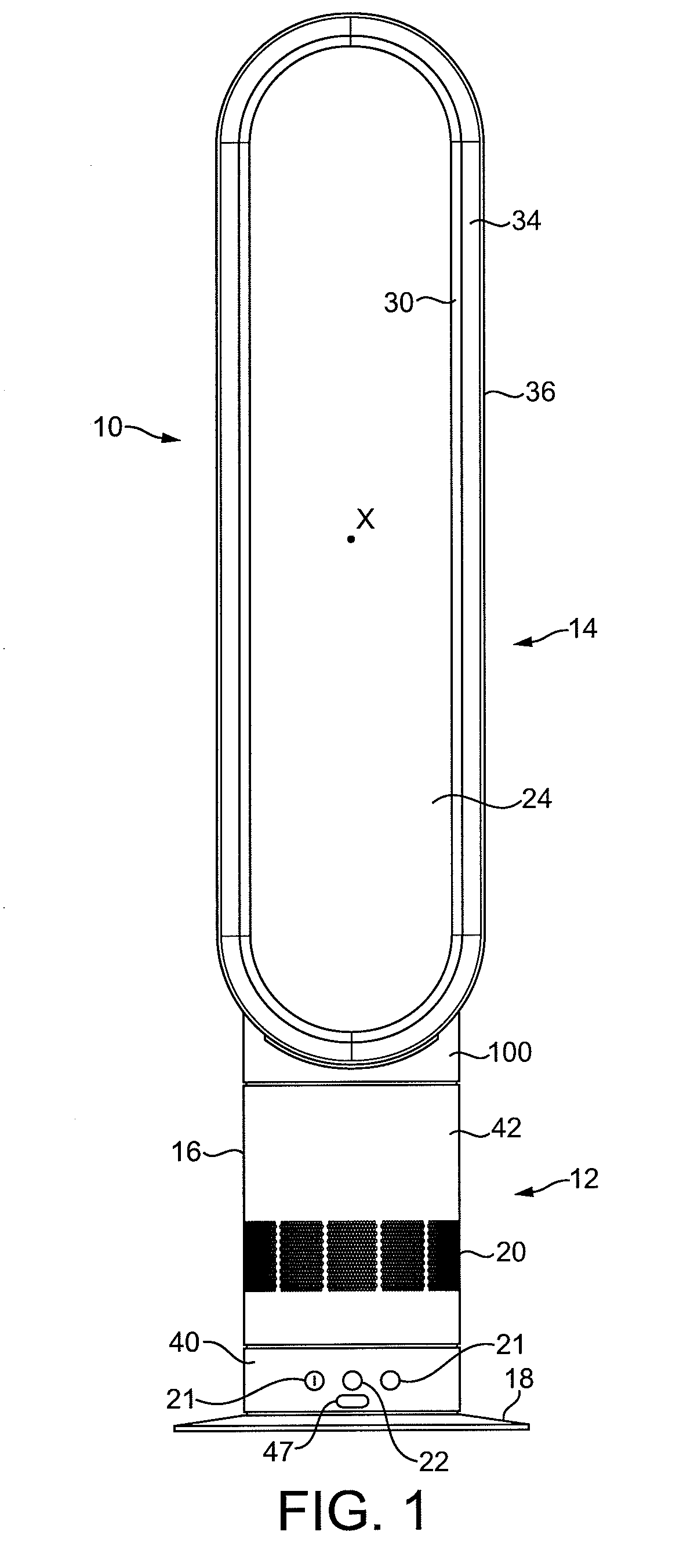

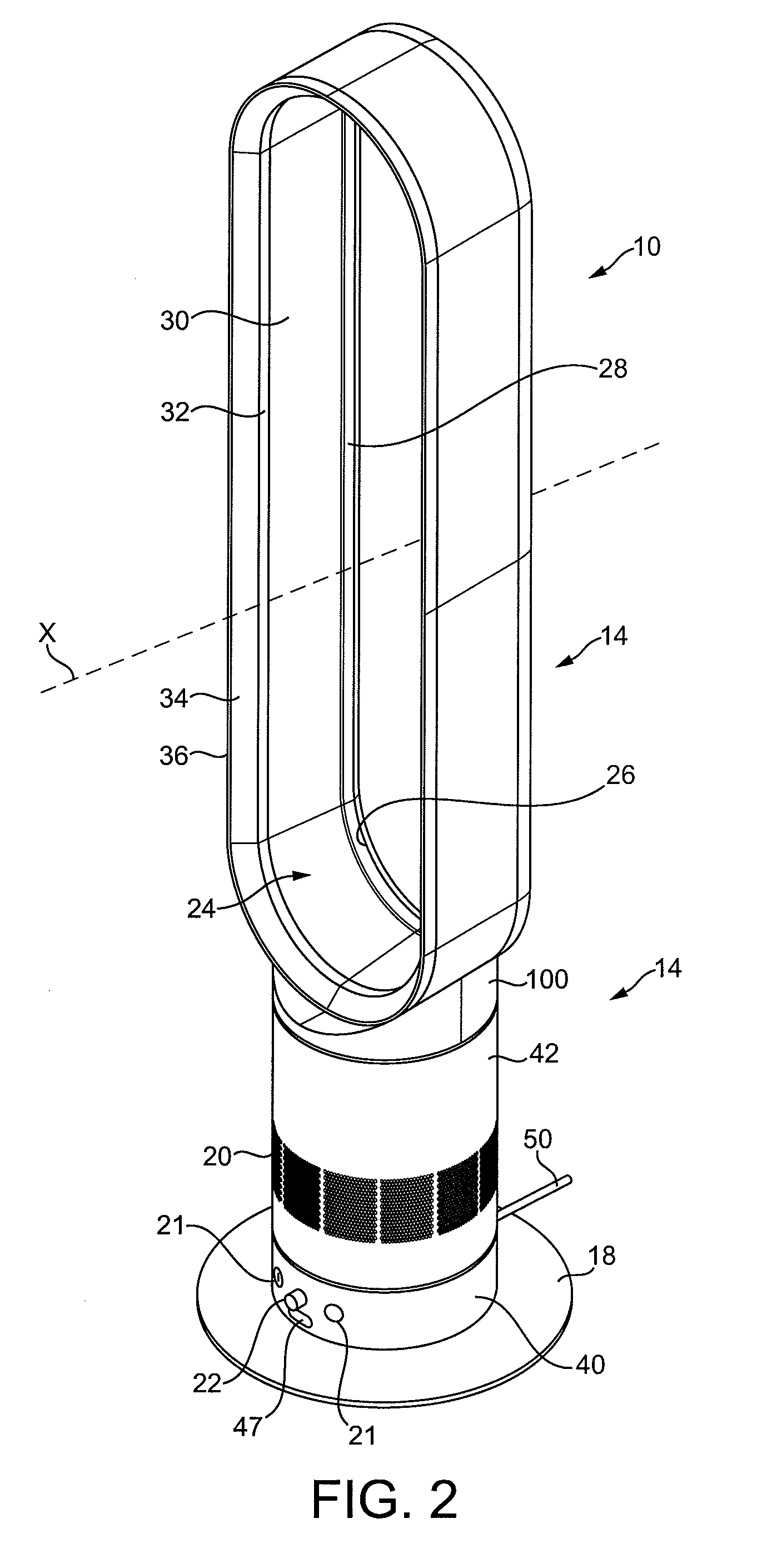

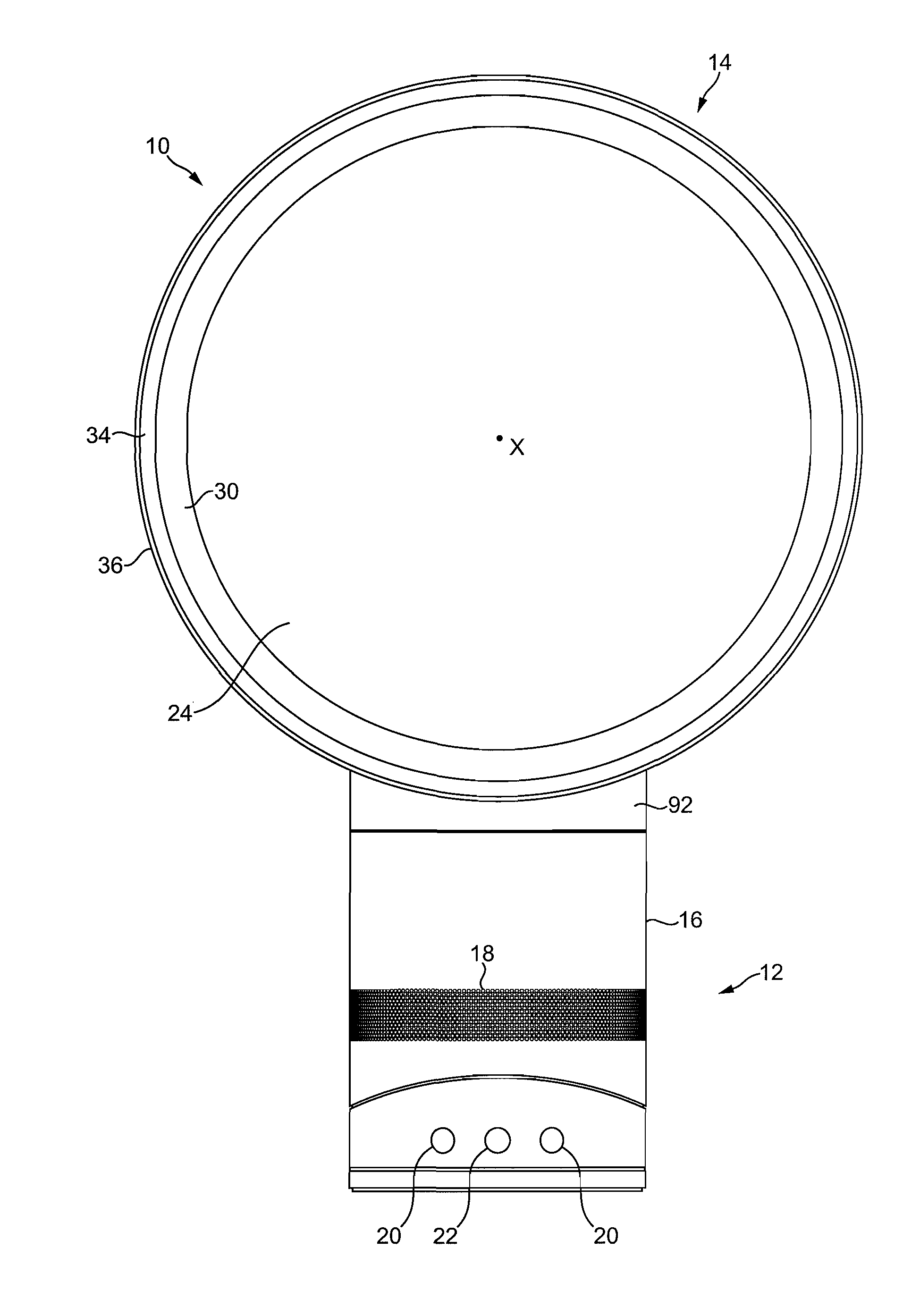

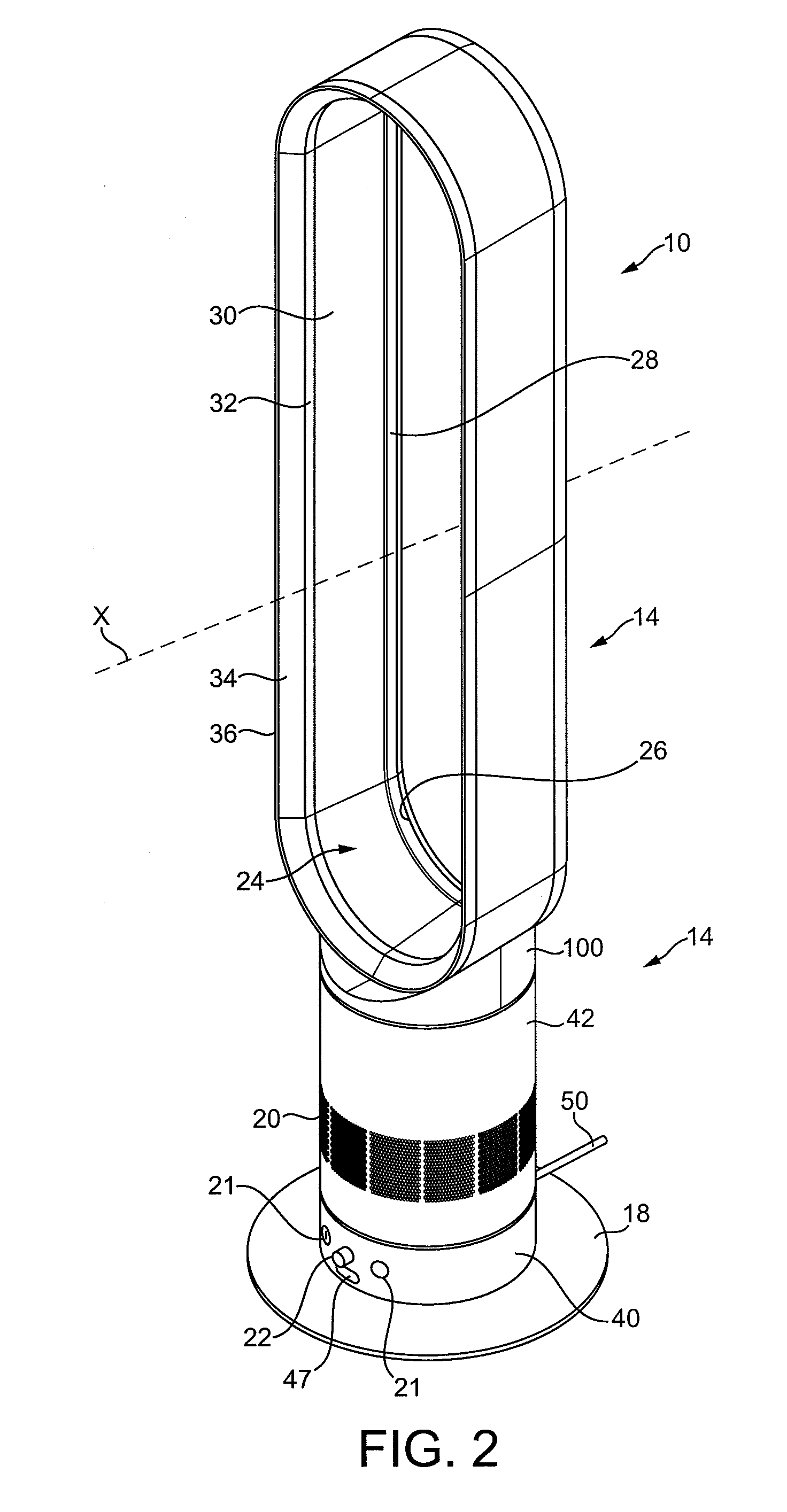

ActiveUS20110110805A1Emission reductionWide operating speed rangePositive displacement pump componentsJet pumpsImpellerRemote control

A fan assembly for creating an air current includes an air inlet, an air outlet, an impeller, a motor for rotating the impeller to create an air flow passing from the air inlet to the air outlet, the air outlet comprising an interior passage for receiving the air flow and a mouth for emitting the air flow, the air outlet defining an opening through which air from outside the fan assembly is drawn by the air flow emitted from the mouth, a control circuit for controlling the motor, a remote control for transmitting control signals to the control circuit, and at least one magnet for attaching the remote control to the air outlet.

Owner:DYSON TECH LTD

Fan assembly

InactiveUS20100226751A1Emission reductionWide operating speed rangePropellersPump componentsEngineeringAirflow

A fan assembly includes a device for creating an air flow and an air outlet for emitting the air flow, the air outlet being mounted on a pedestal including a base and a height adjustable stand. The base includes an oscillating mechanism for oscillating the stand and the air outlet.

Owner:DYSON TECH LTD

Fan assembly

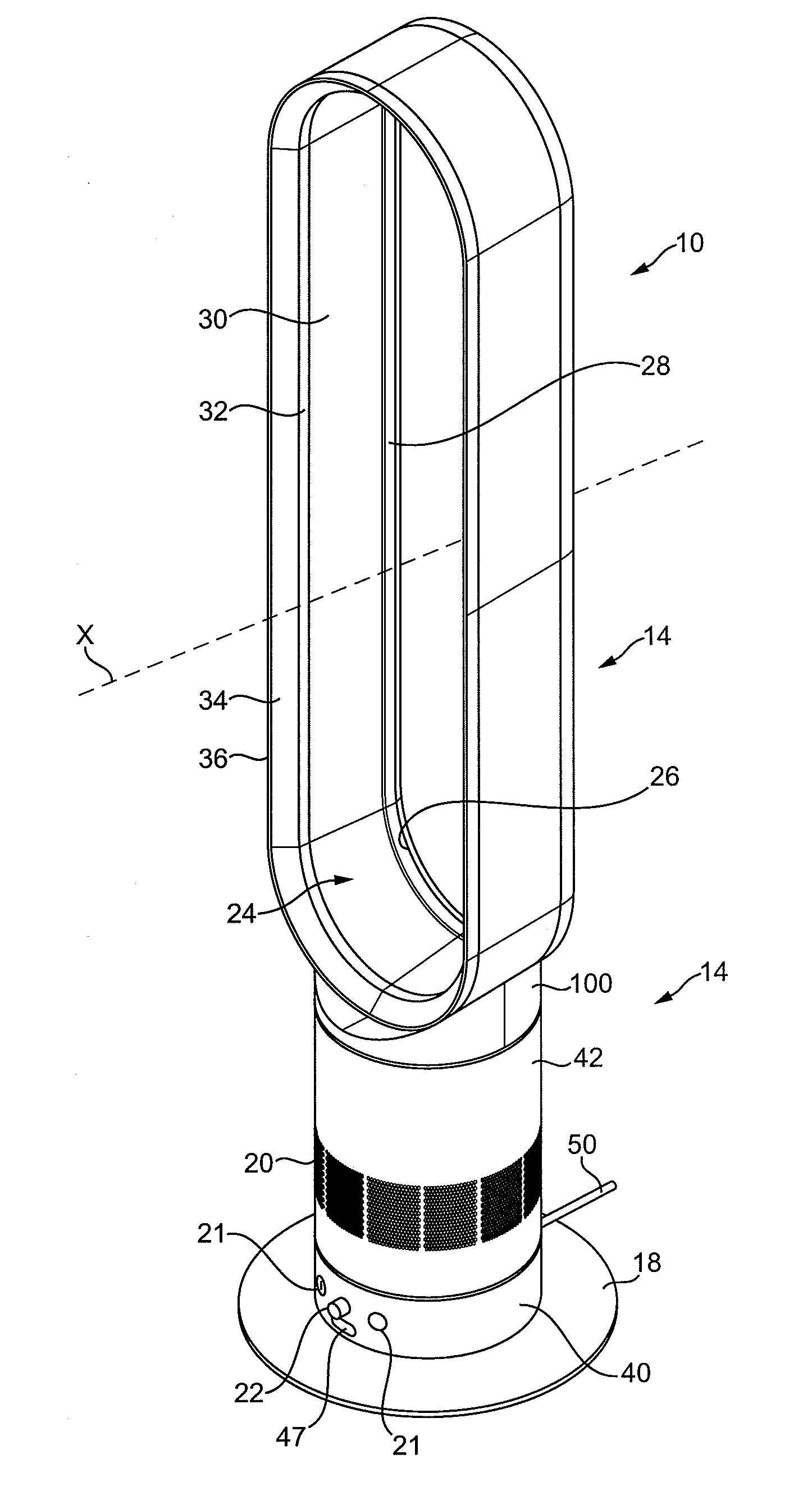

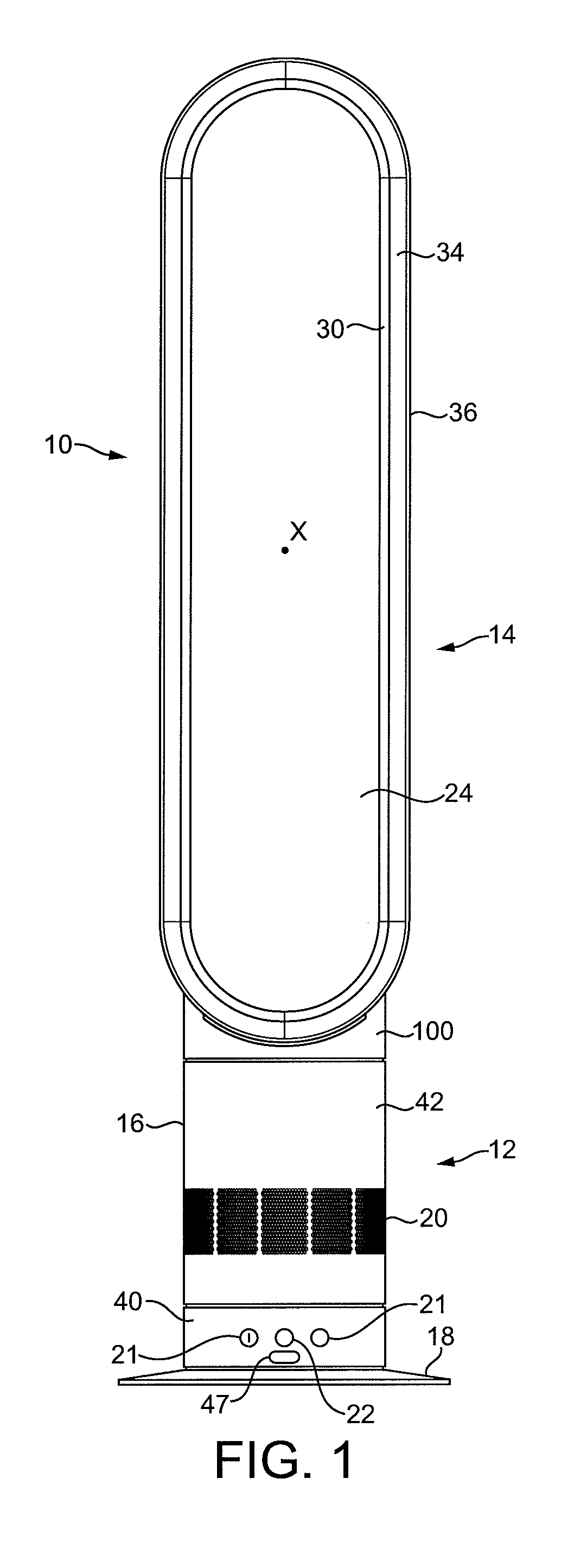

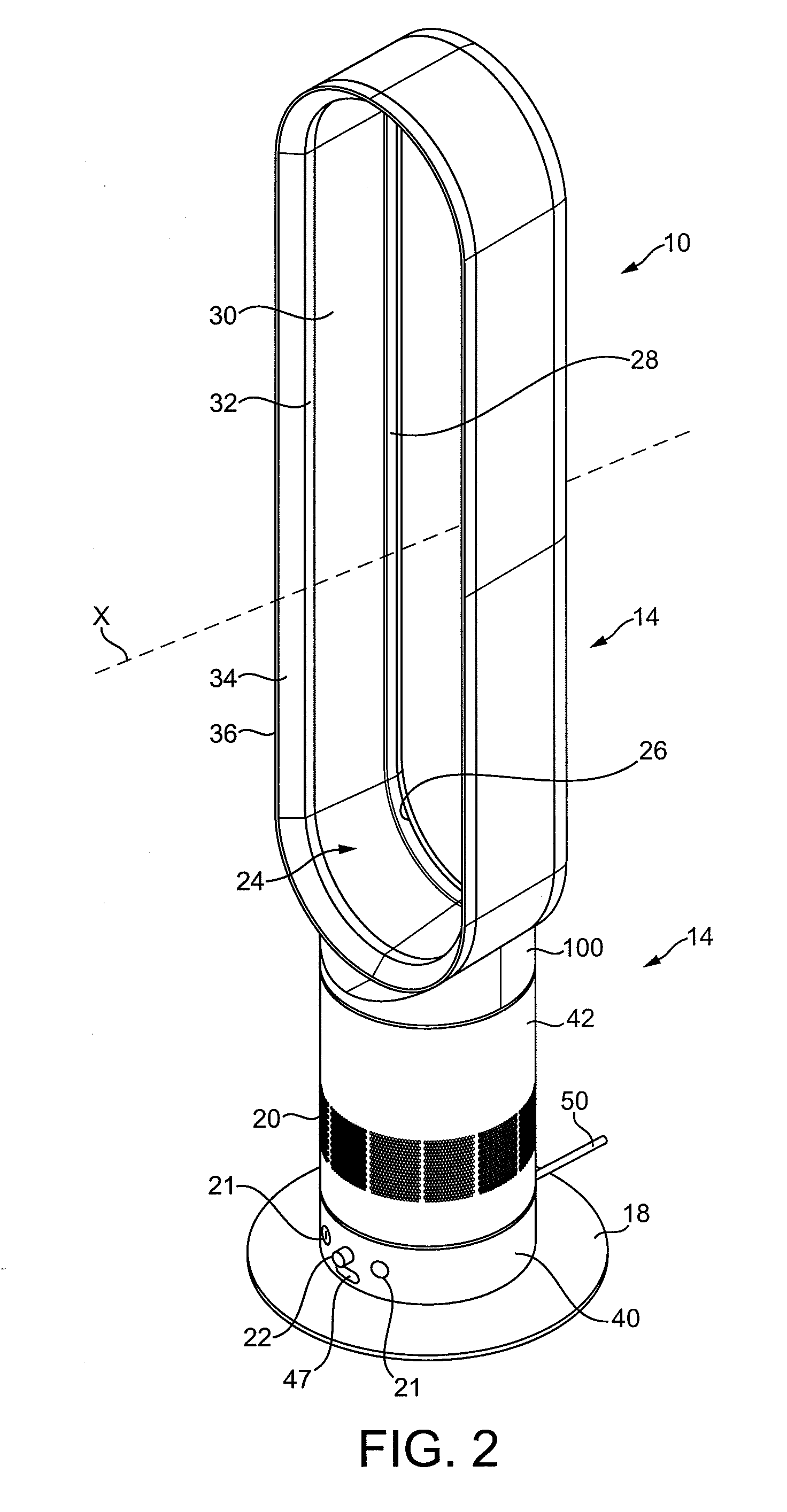

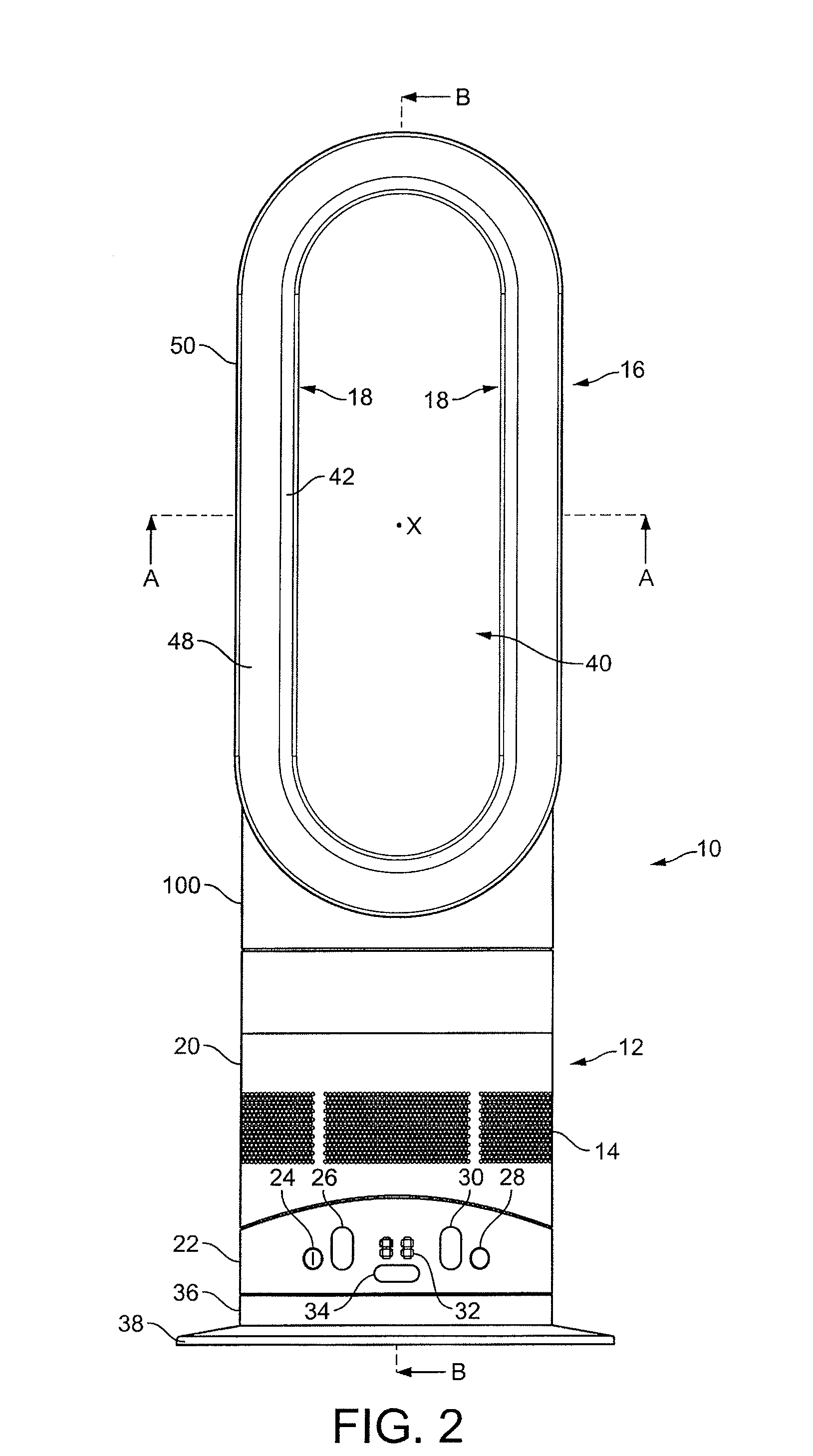

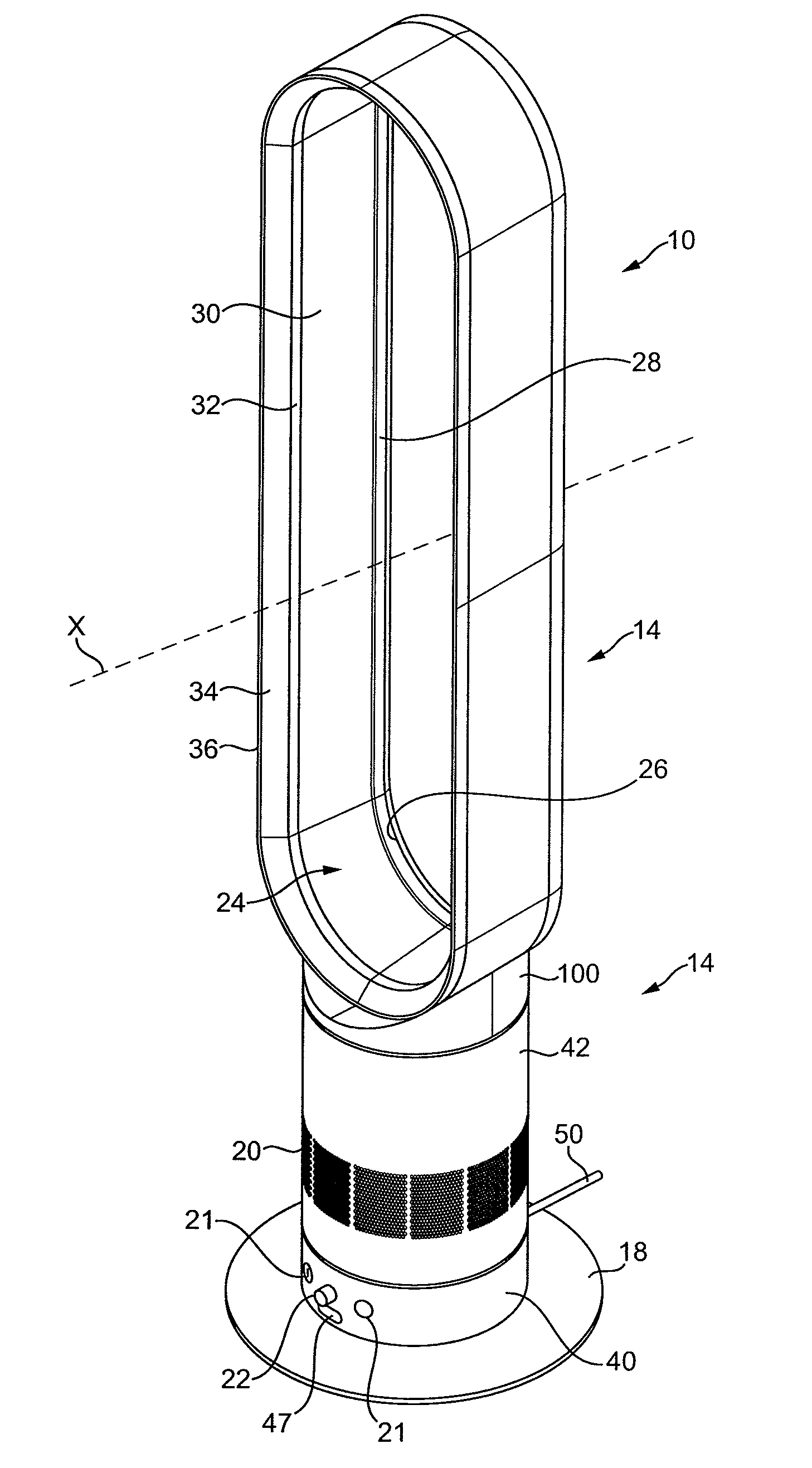

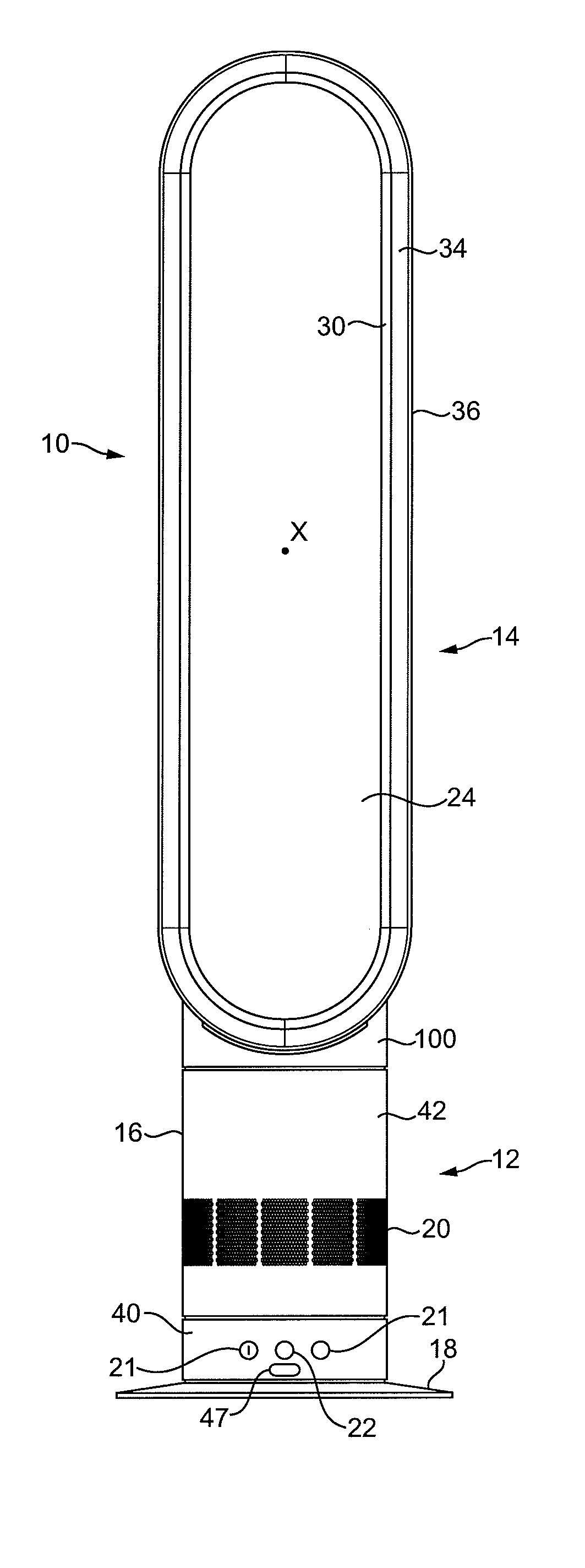

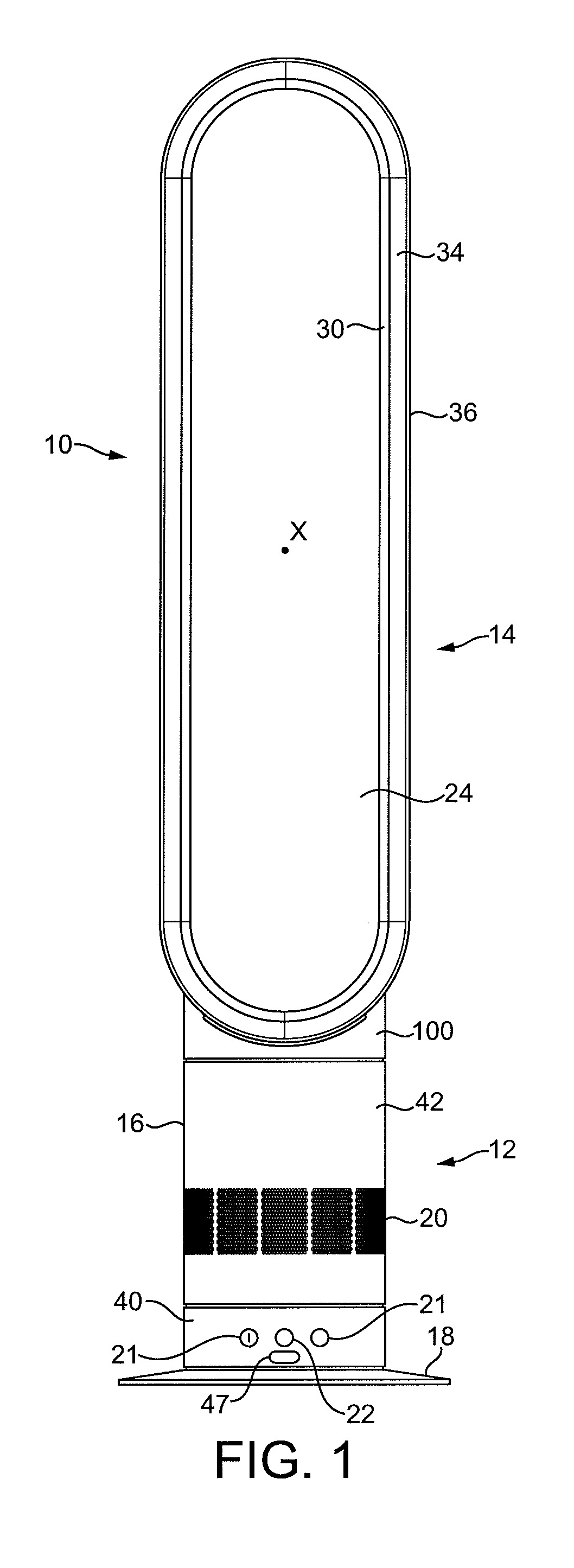

A fan assembly for creating an air current includes a base having an air inlet and an air outlet, the base housing an impeller and a motor for rotating the impeller to create an air flow passing from the air inlet to the air outlet. The fan assembly further includes a vertically oriented, elongate annular nozzle including an interior passage having an air inlet for receiving the air flow from the base and a mouth for emitting the air flow, the nozzle defining an opening through which air from outside the fan assembly is drawn by the air flow emitted from the mouth.

Owner:DYSON TECH LTD

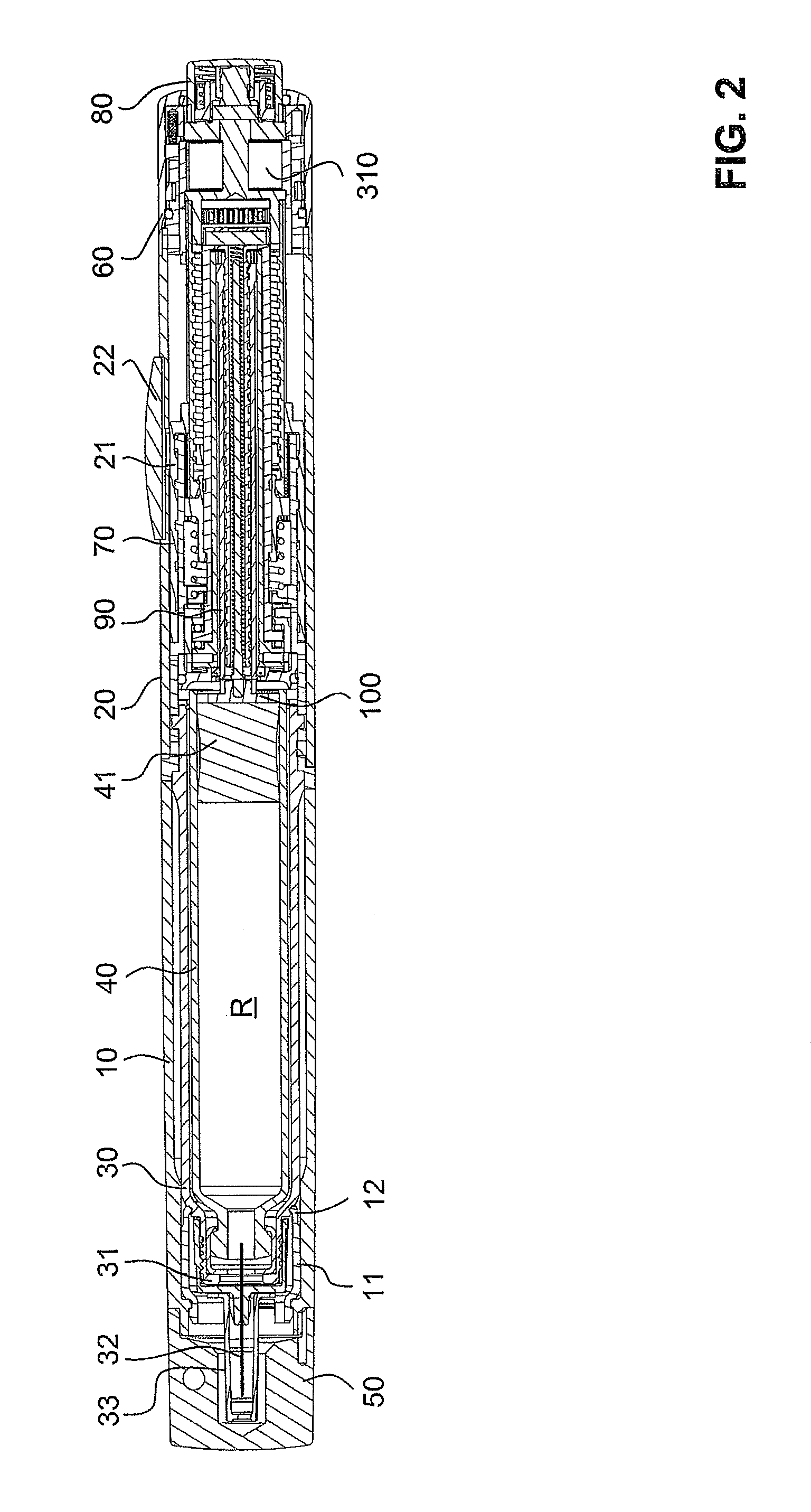

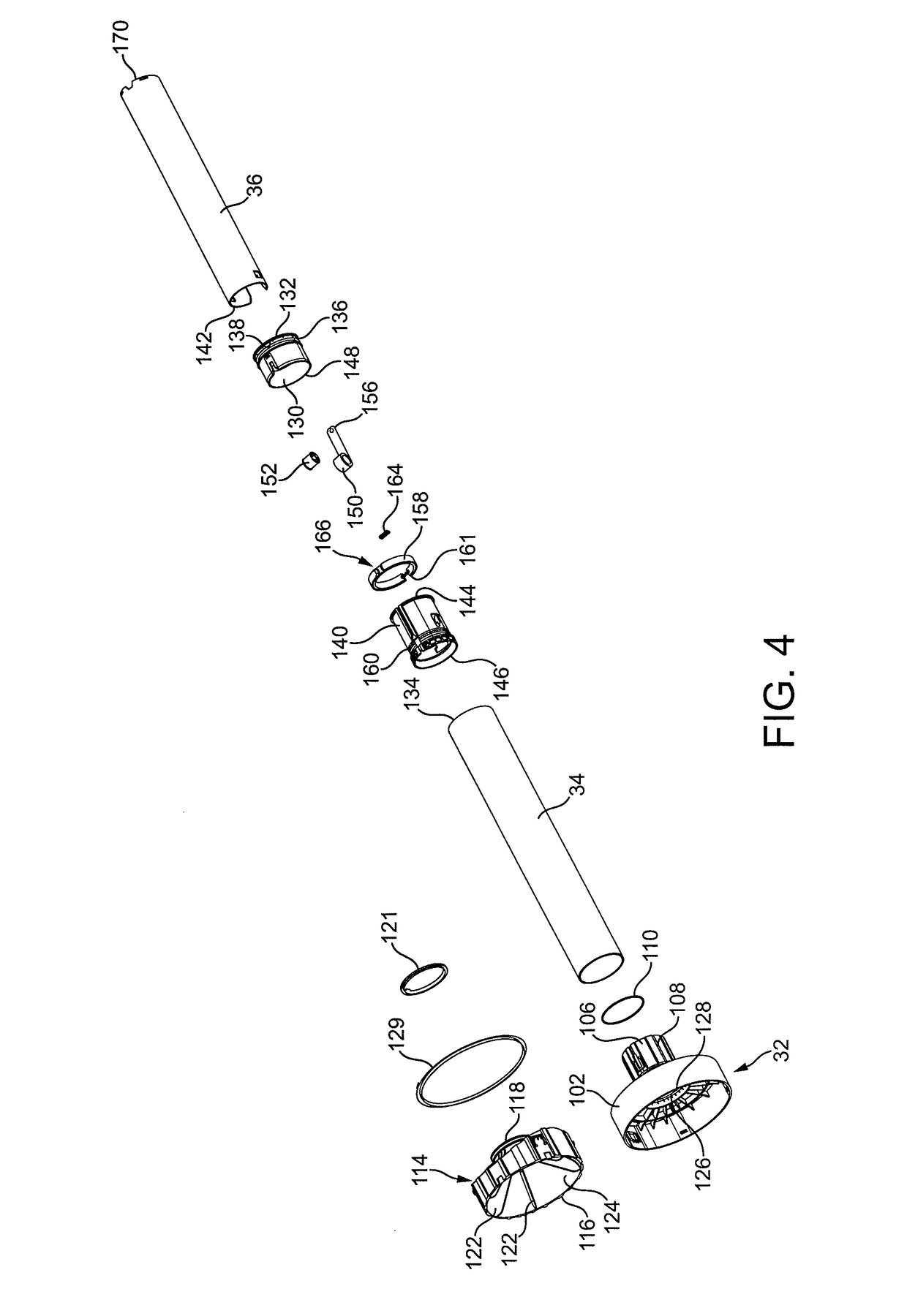

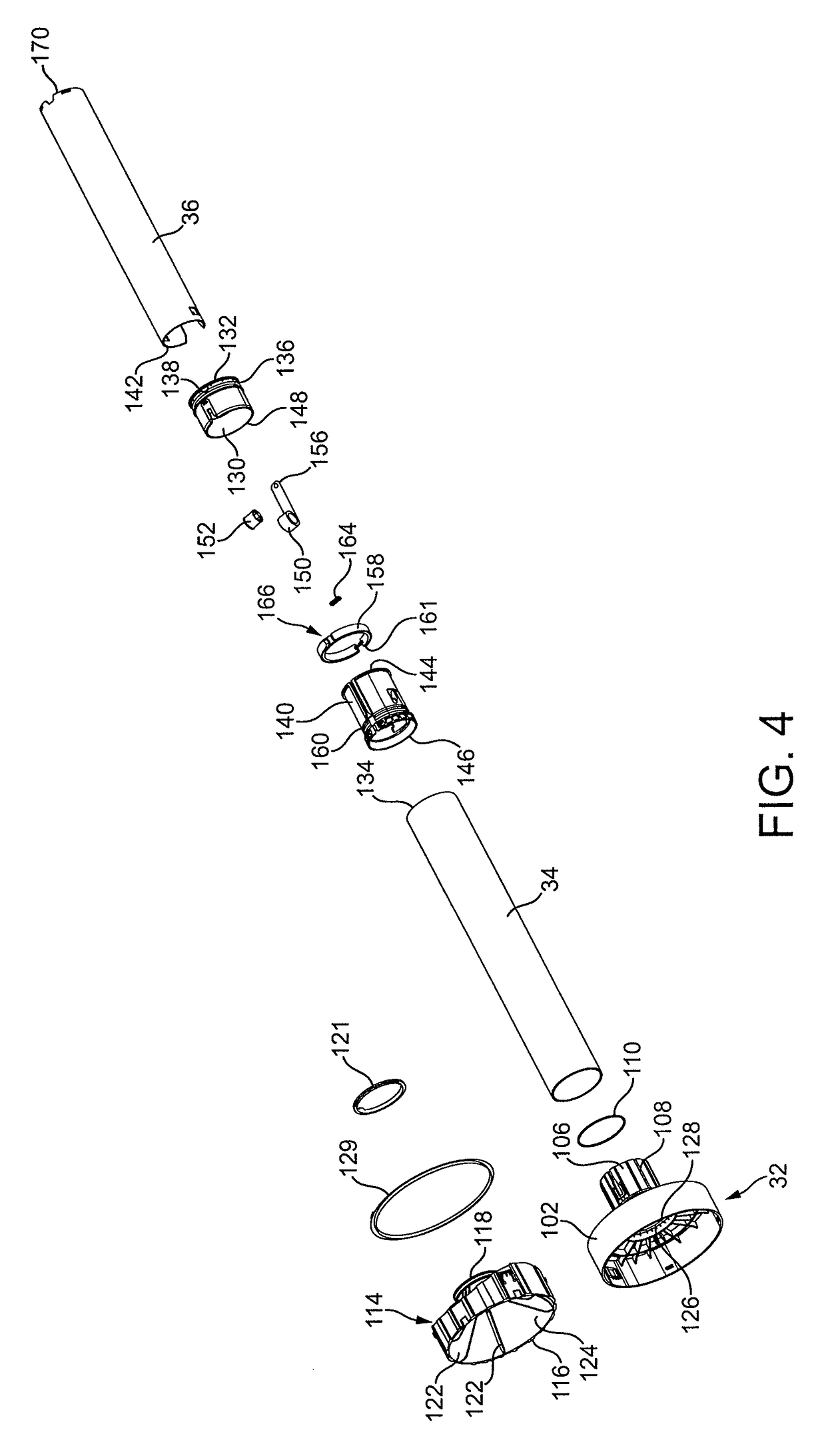

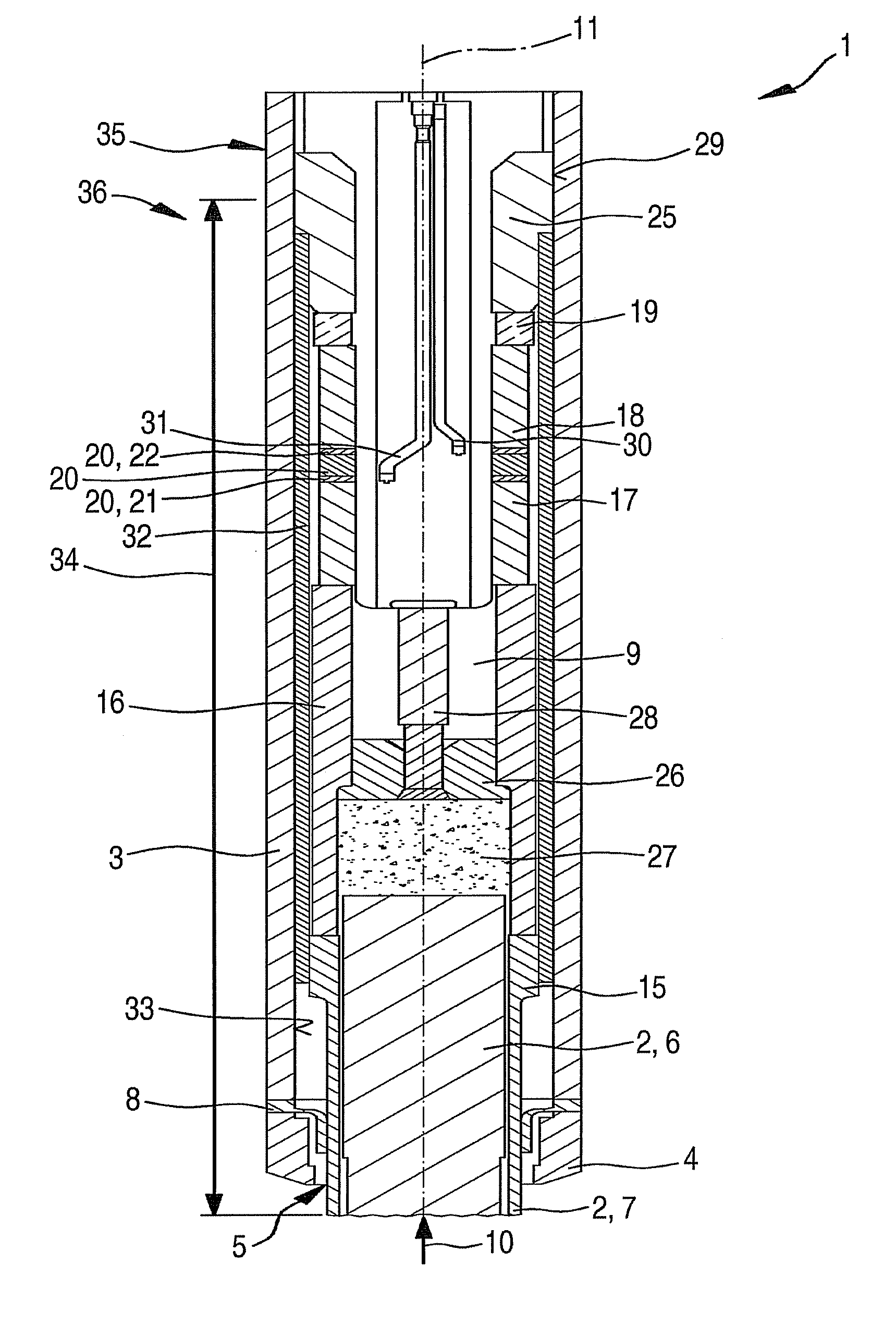

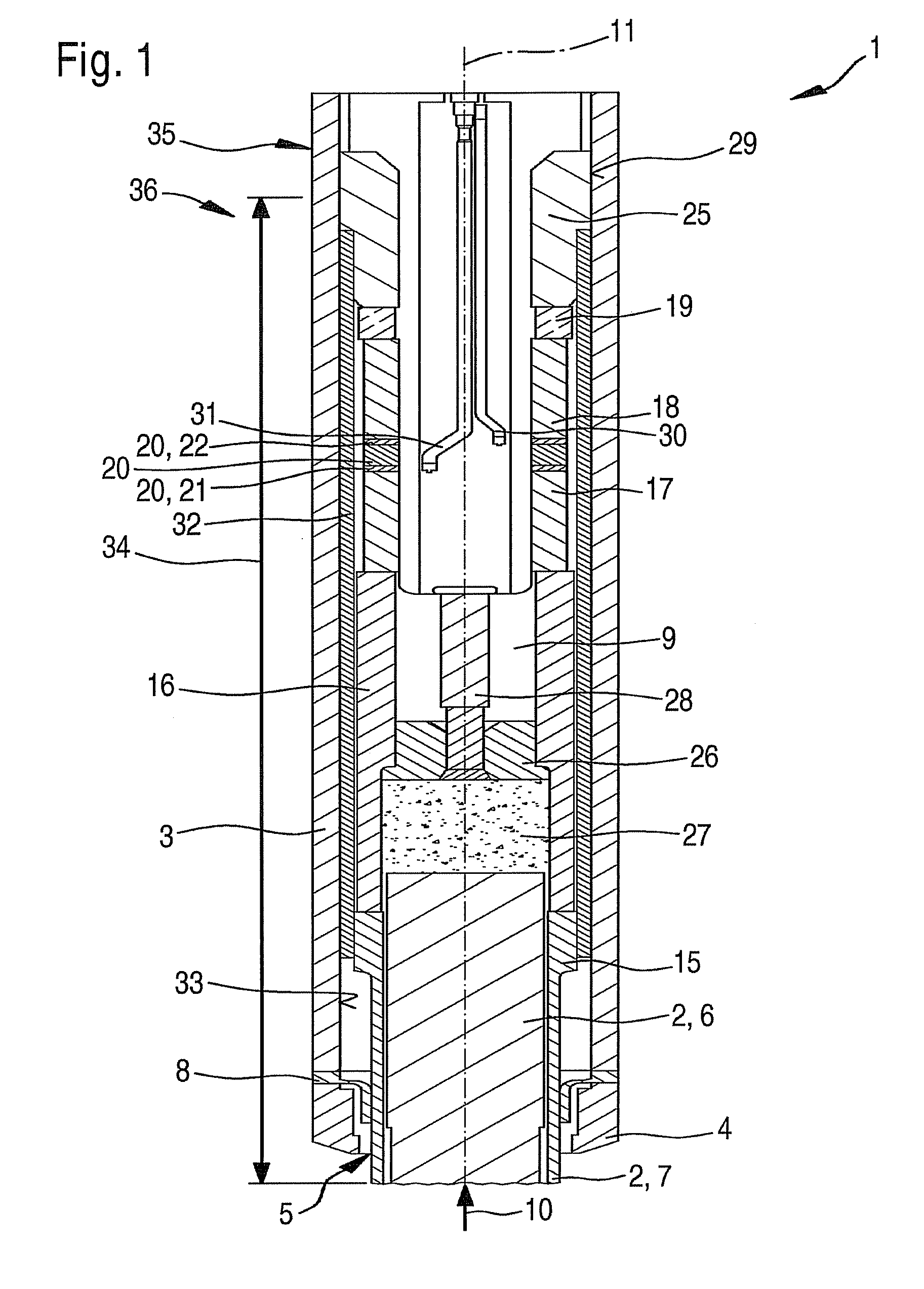

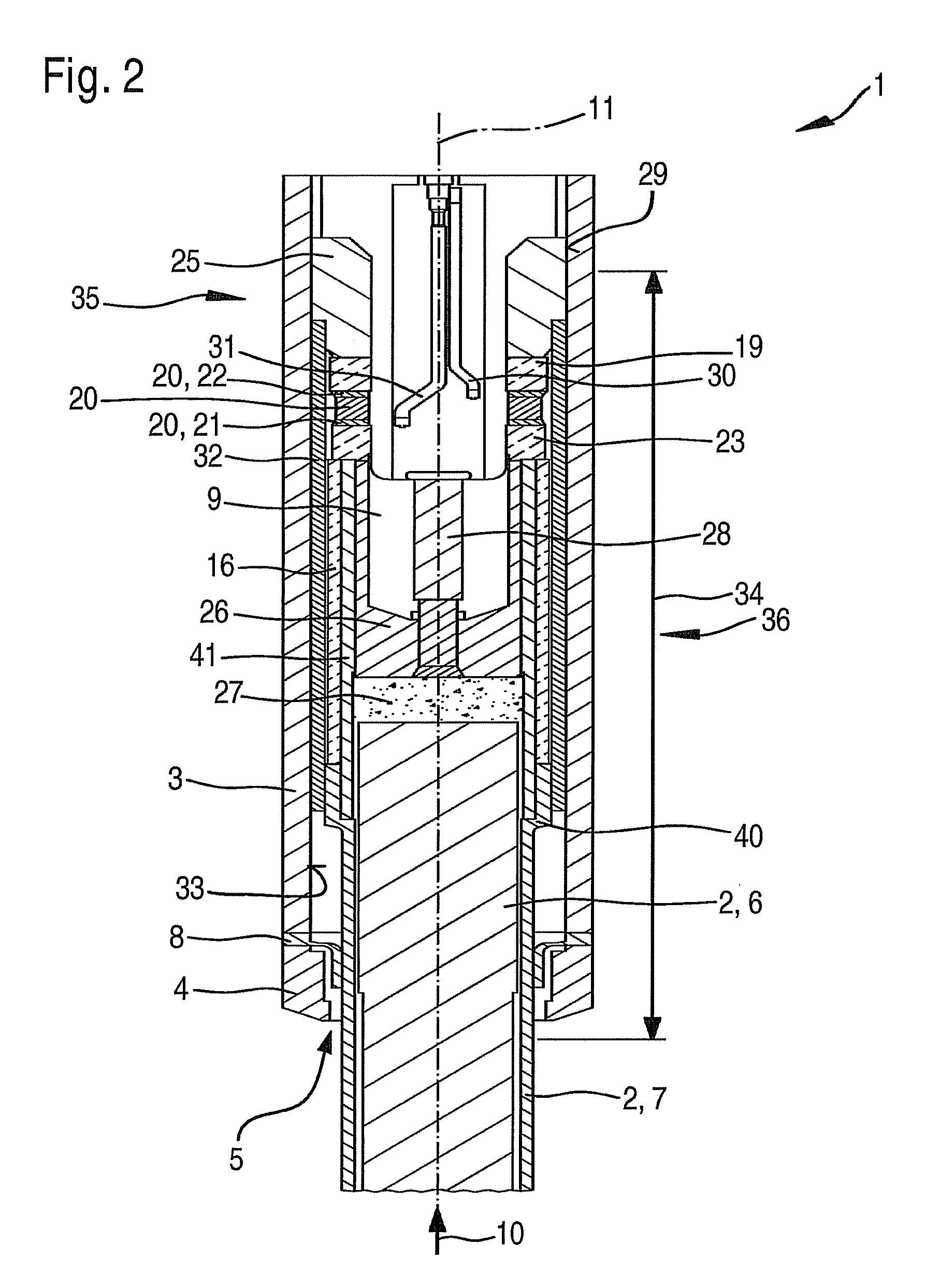

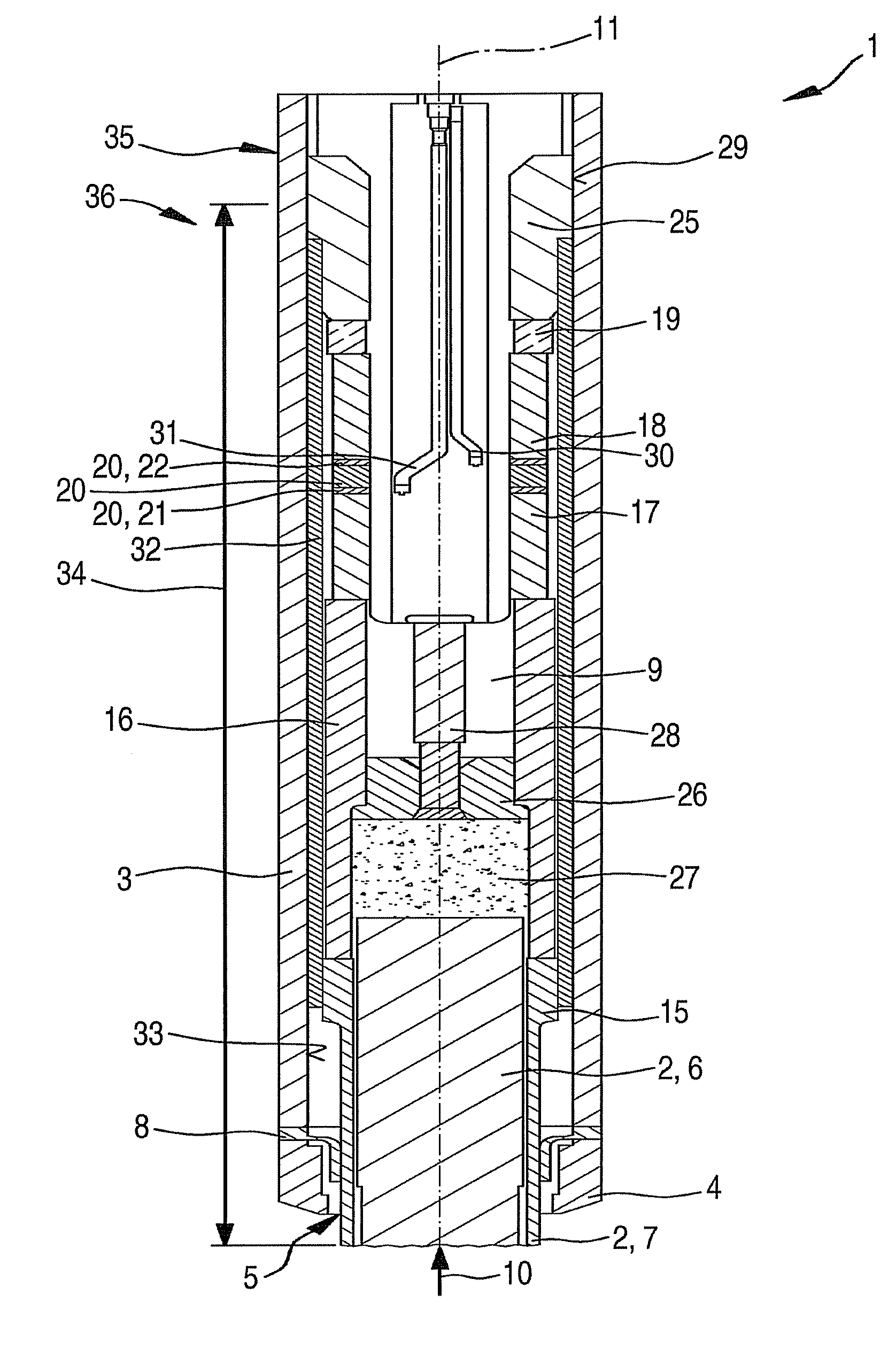

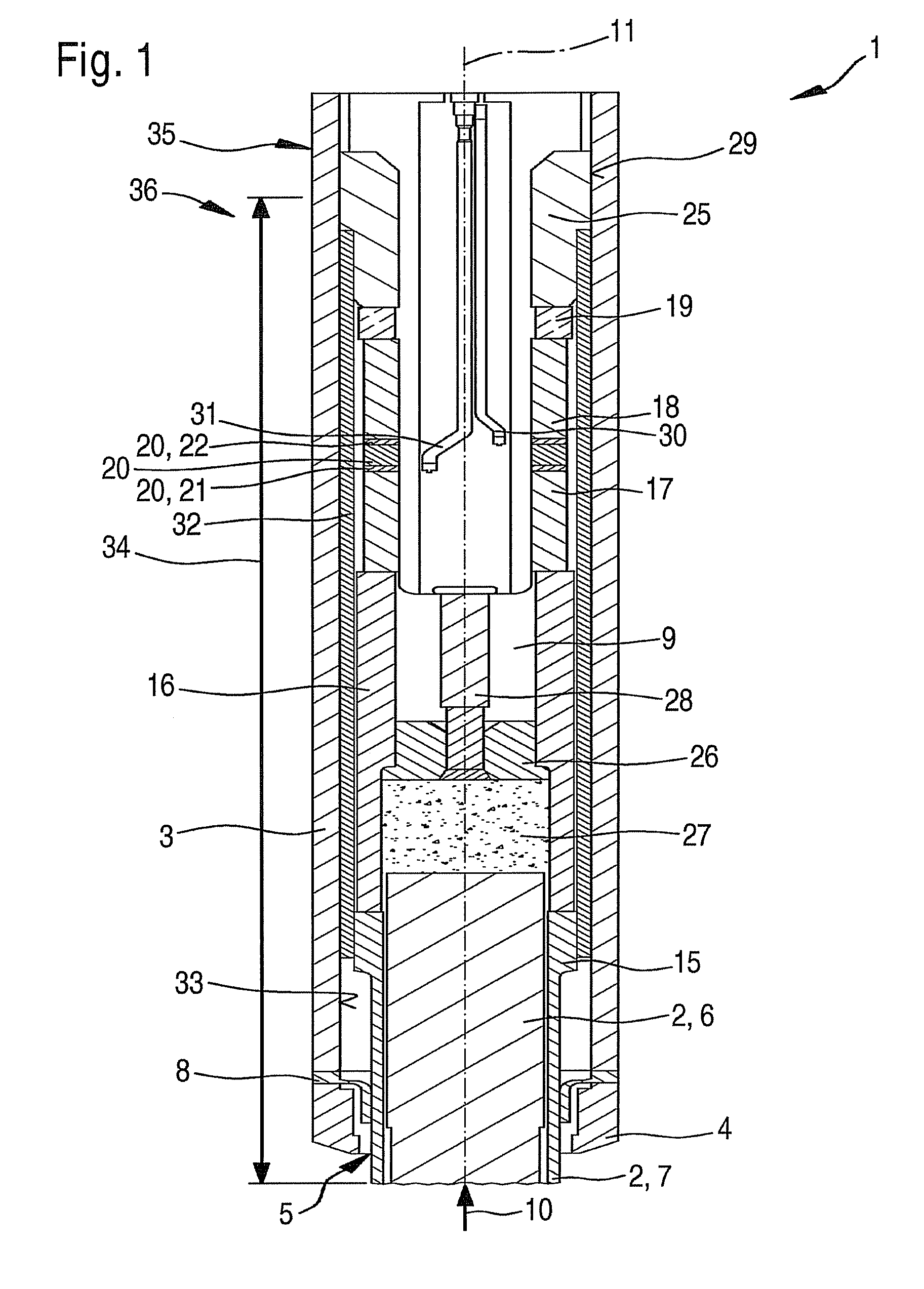

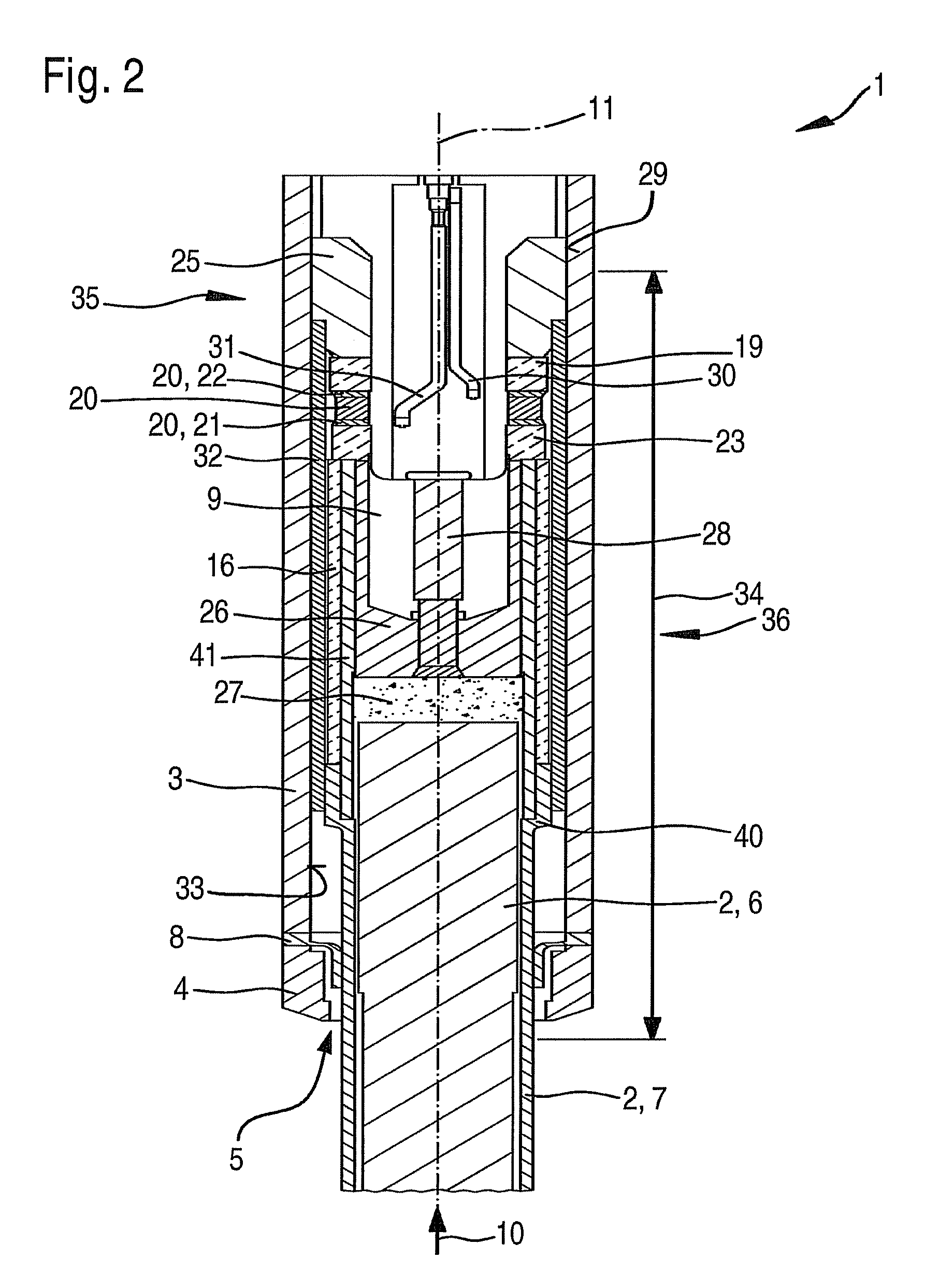

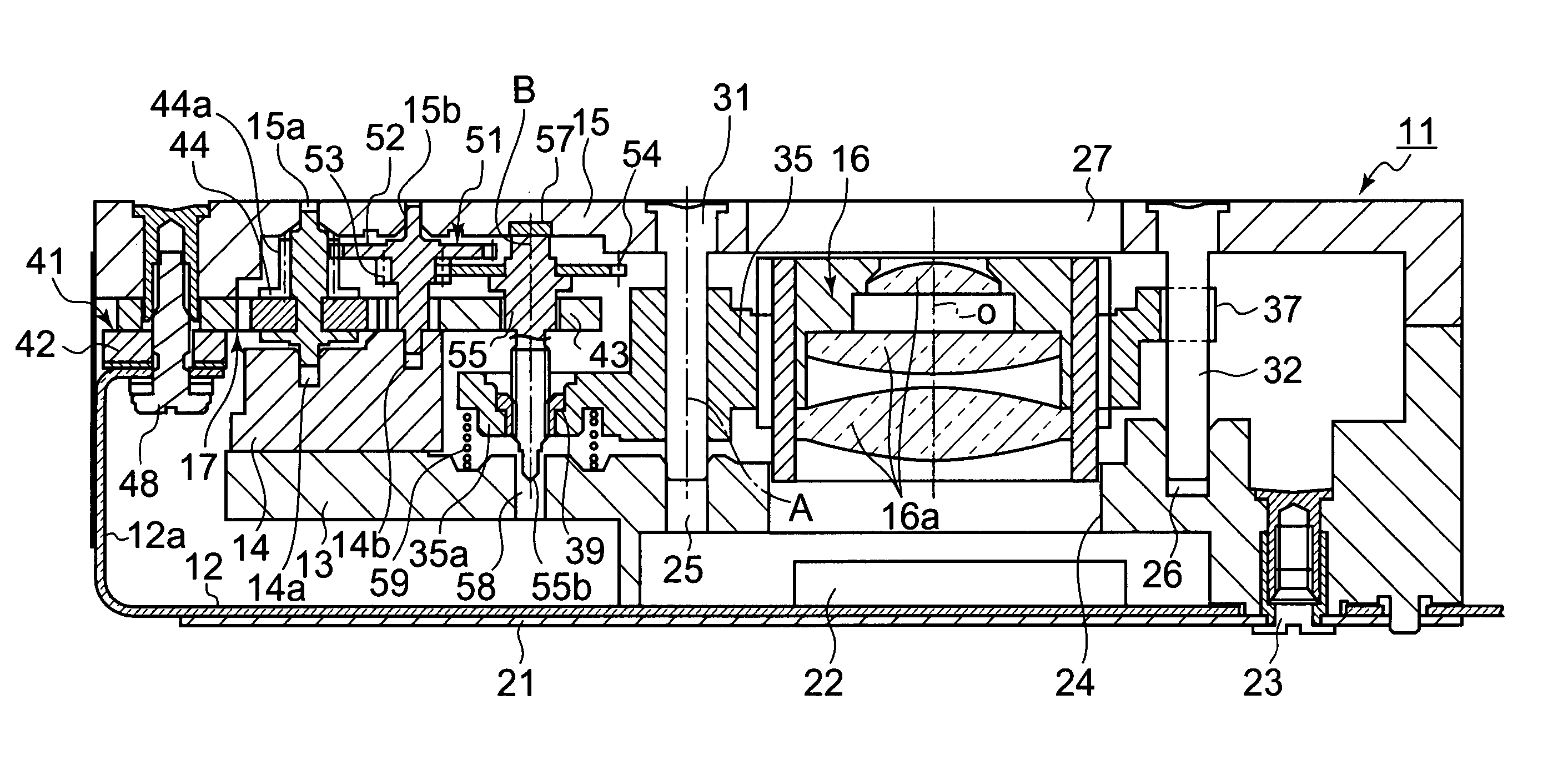

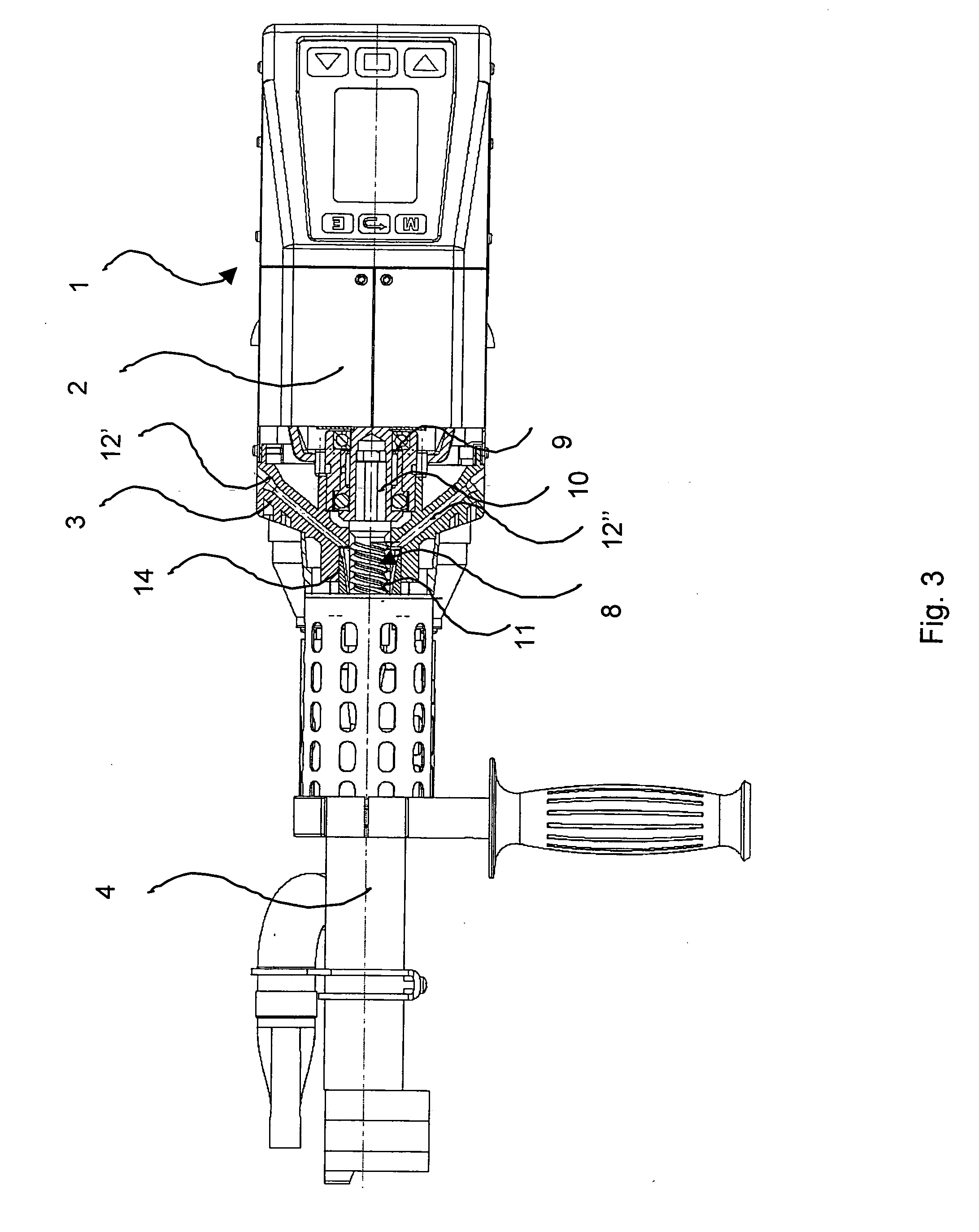

Injection device comprising several coupling mechanisms

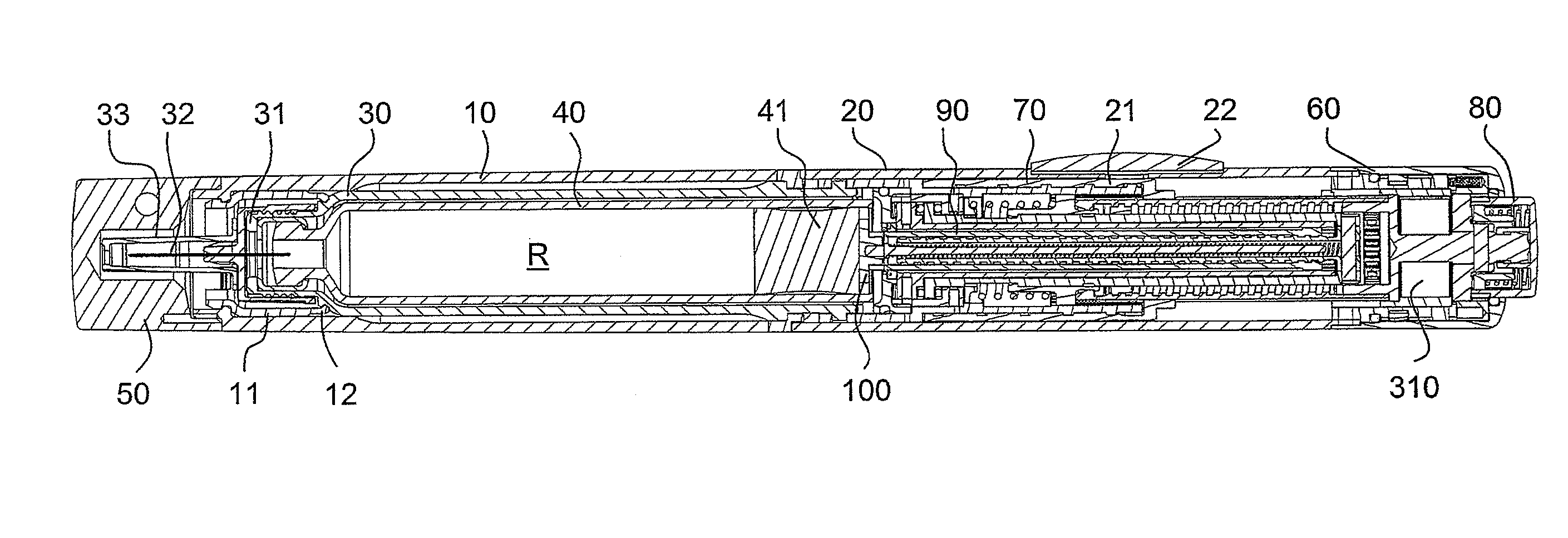

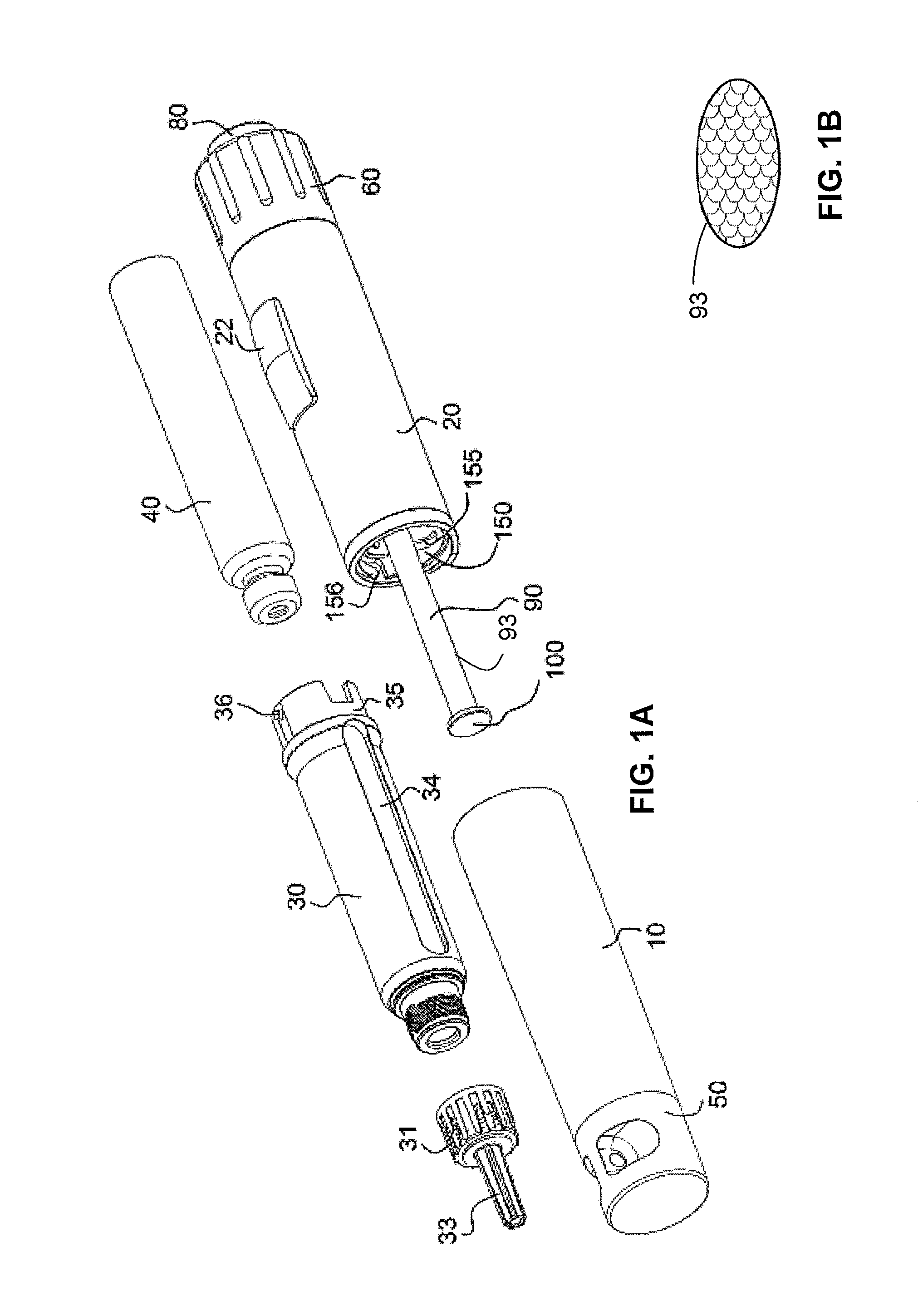

ActiveUS8491538B2Simplify the development processMinimize frictional lossAmpoule syringesAutomatic syringesCouplingEngineering

An injection device including a drive unit, a delivery unit, a dosing unit, a trigger for triggering an injection, a first coupling mechanism between the drive unit and the delivery unit, and a second coupling mechanism between the dosing unit and the drive unit, wherein the drive unit is tensioned by a rotation of the dosing unit and when the drive unit is tensioned the first coupling mechanism is disengaged and the second coupling mechanism is engaged, and wherein when an injection is triggered first the first coupling mechanism is engaged and then the second coupling mechanism is disengaged. In some embodiments, the device may include a third coupling mechanism which only releases the delivery unit after the engagement and disengagement which follow a triggering.

Owner:YPSOMED AG

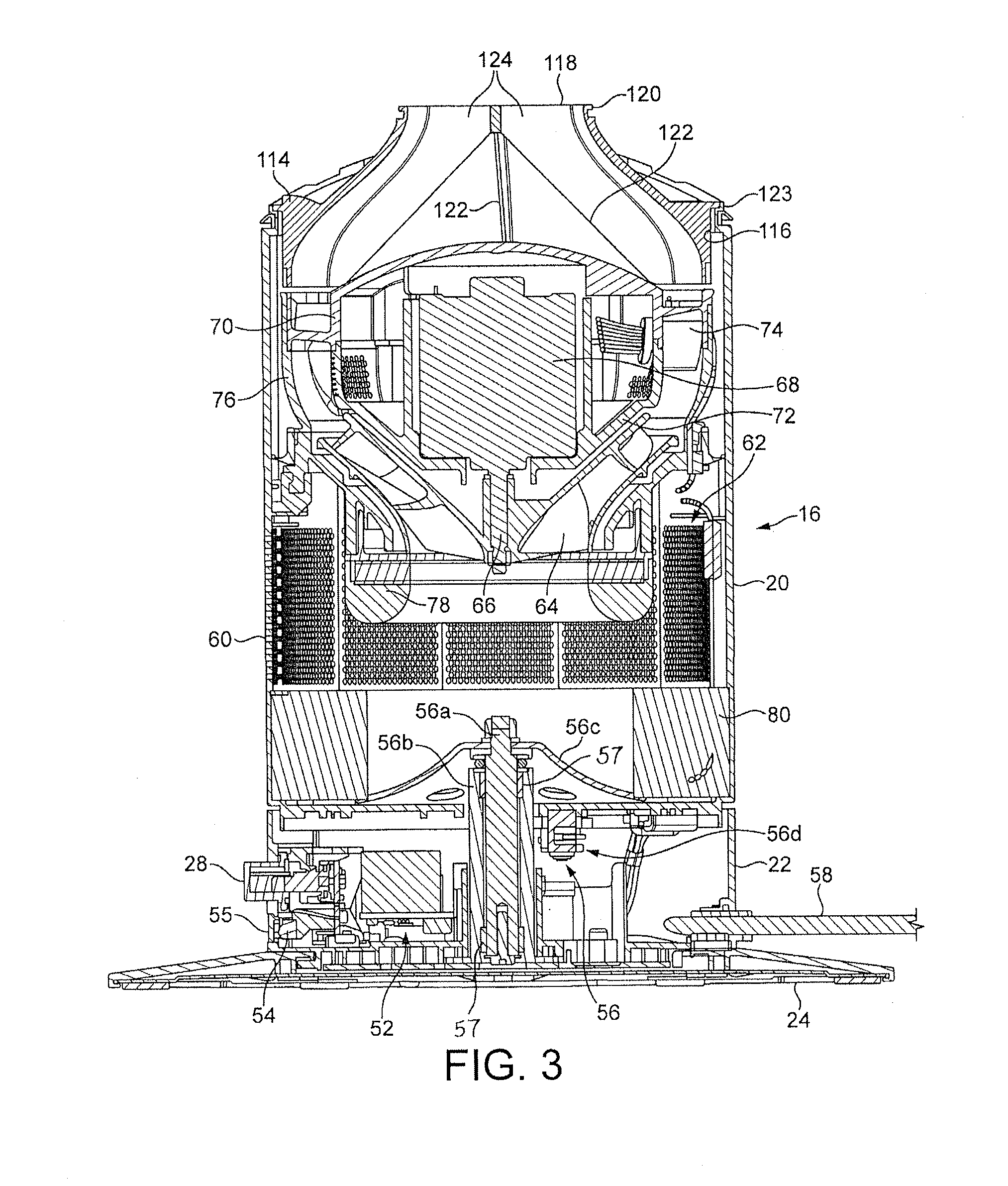

Fan assembly

InactiveUS8721286B2Centre of gravityLess prone to falling overPropellersPump componentsEngineeringAirflow

Owner:DYSON TECH LTD

Fan assembly

InactiveUS8403640B2Improve comfortReduce turbulenceCircumferential flow pumpsPump componentsImpellerEngineering

A fan assembly for creating an air current includes an air inlet, an air outlet, an impeller and a motor for rotating the impeller to create an air flow passing from the air inlet to the air outlet. The air outlet includes an interior passage for receiving the air flow and a mouth for emitting the air flow. The air outlet defines an opening through which air from outside the fan assembly is drawn by the air flow emitted from the mouth. The motor has a rotor which, in use, is capable of rotating at a speed of at least 5,000 rpm.

Owner:DYSON TECH LTD

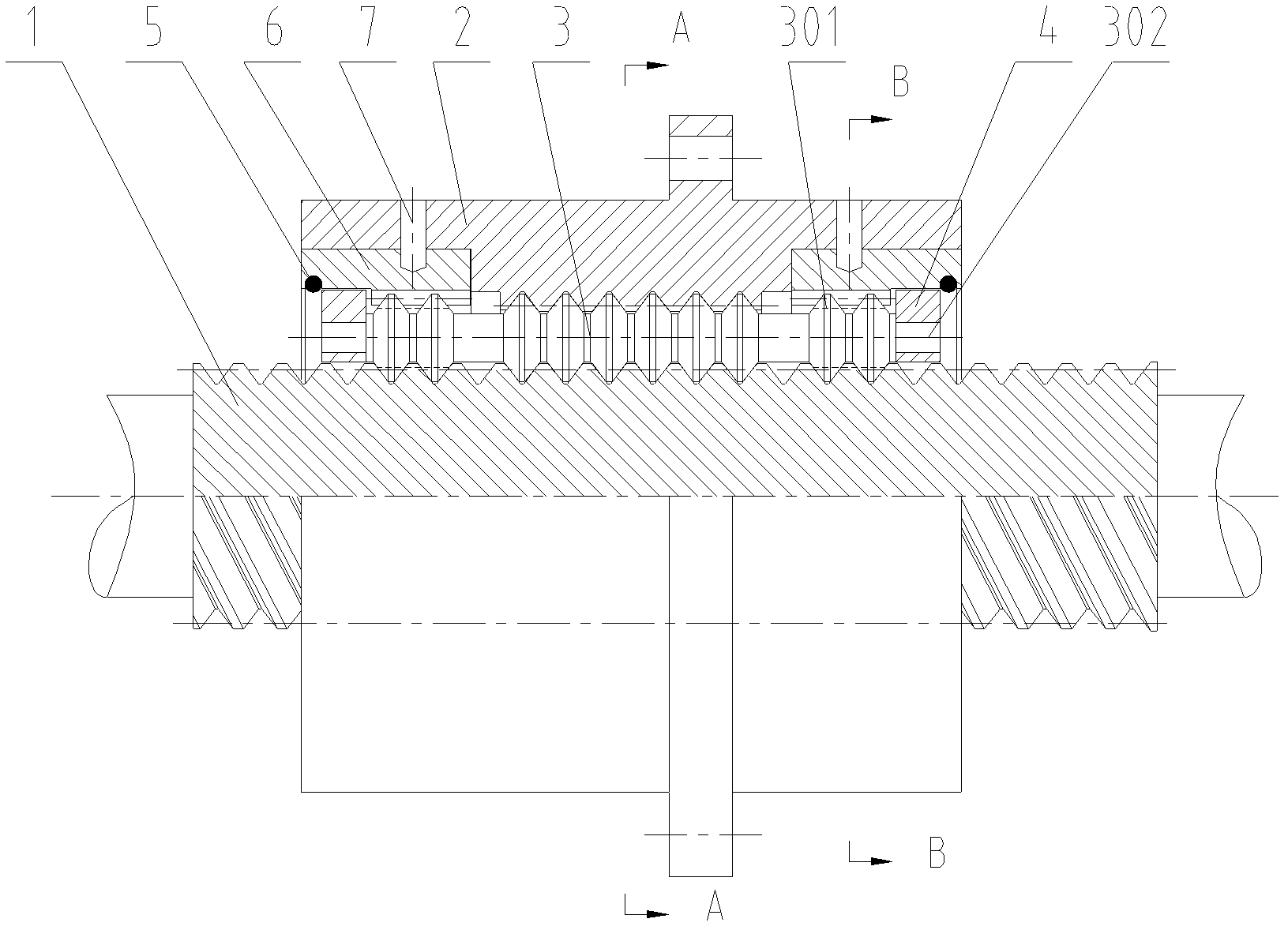

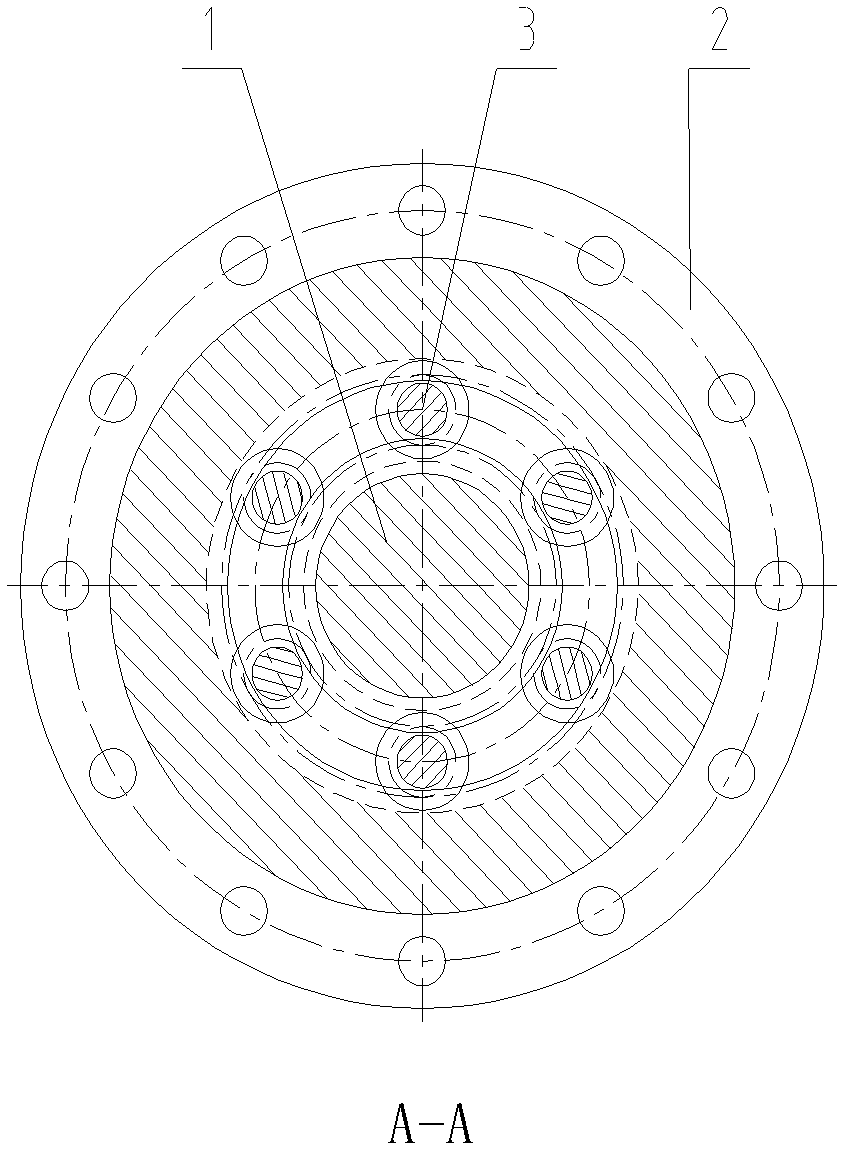

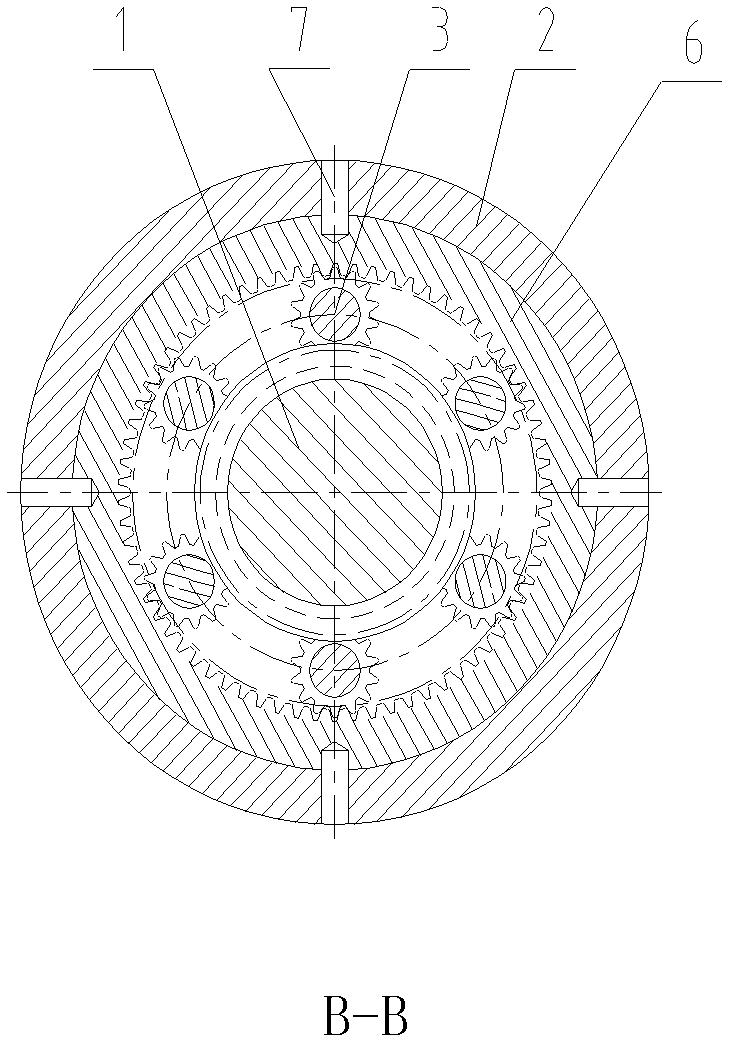

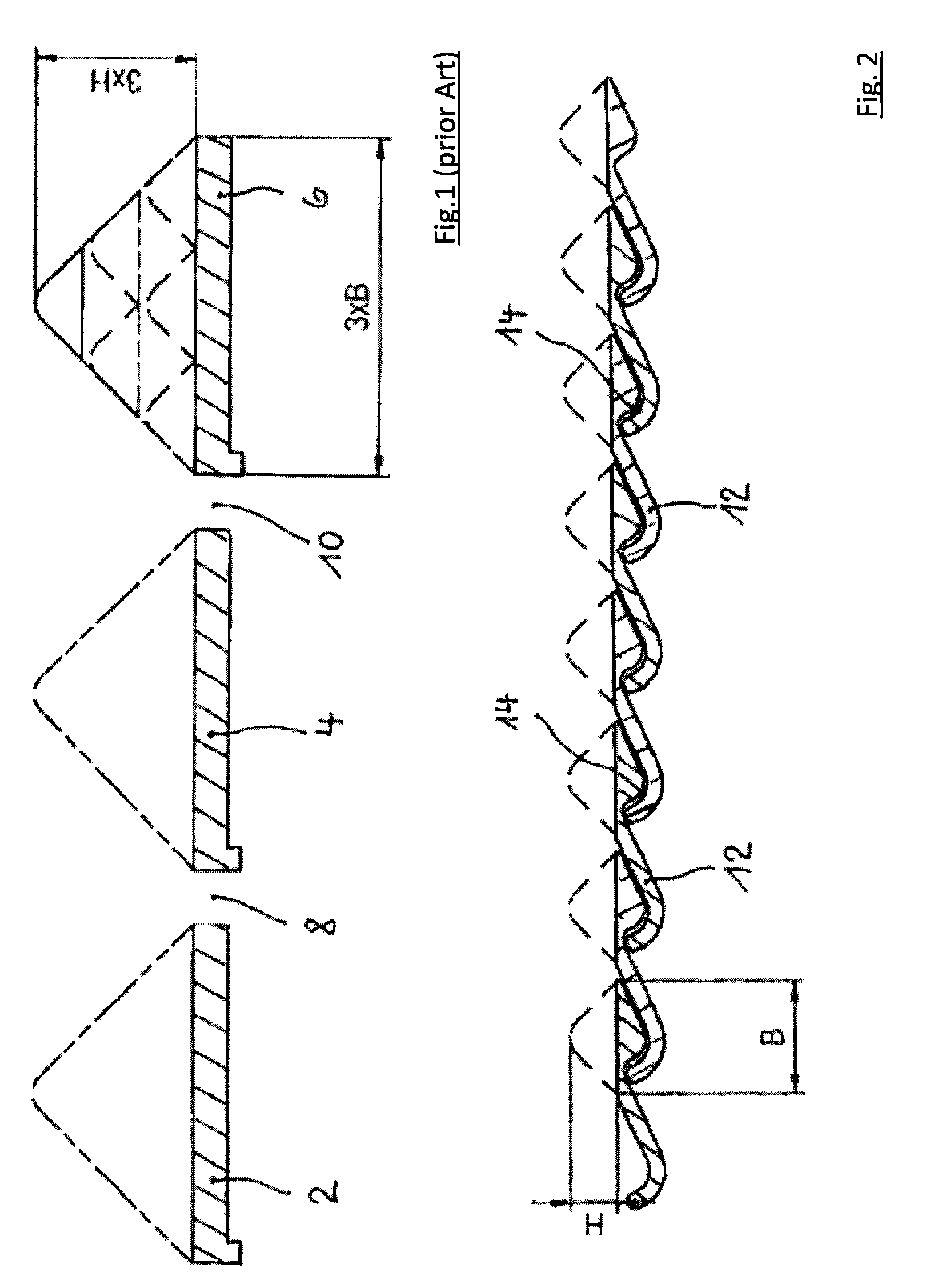

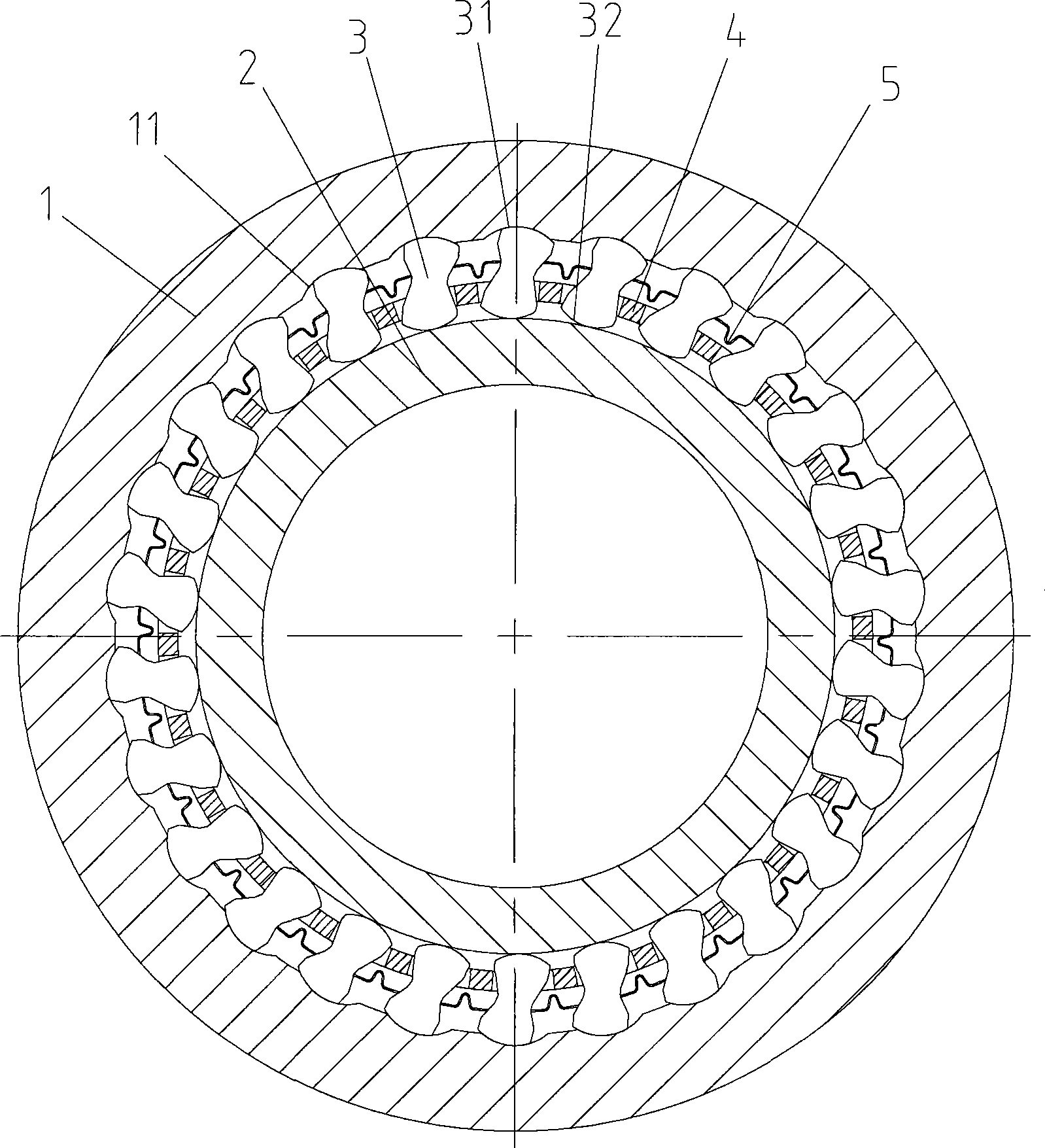

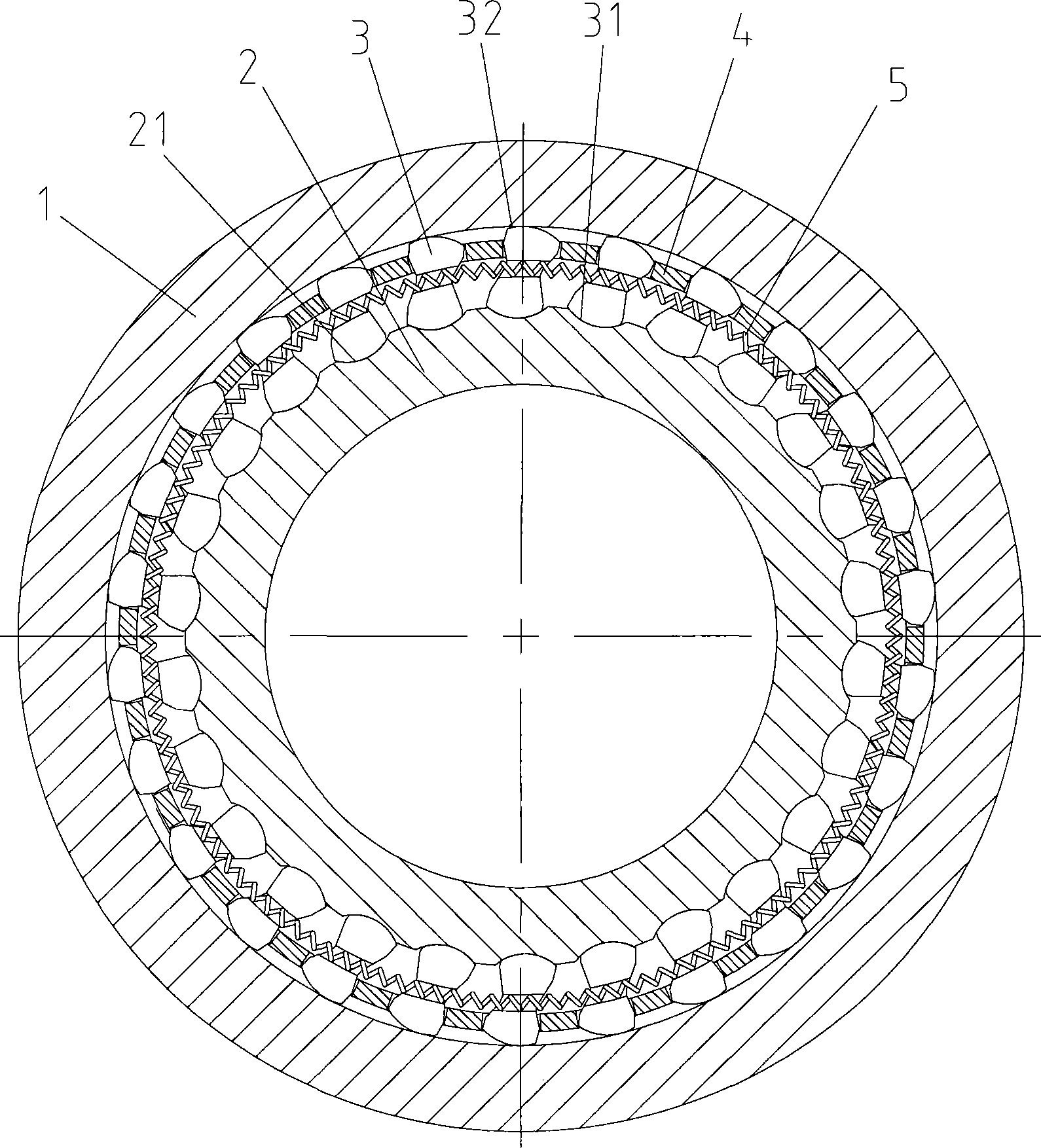

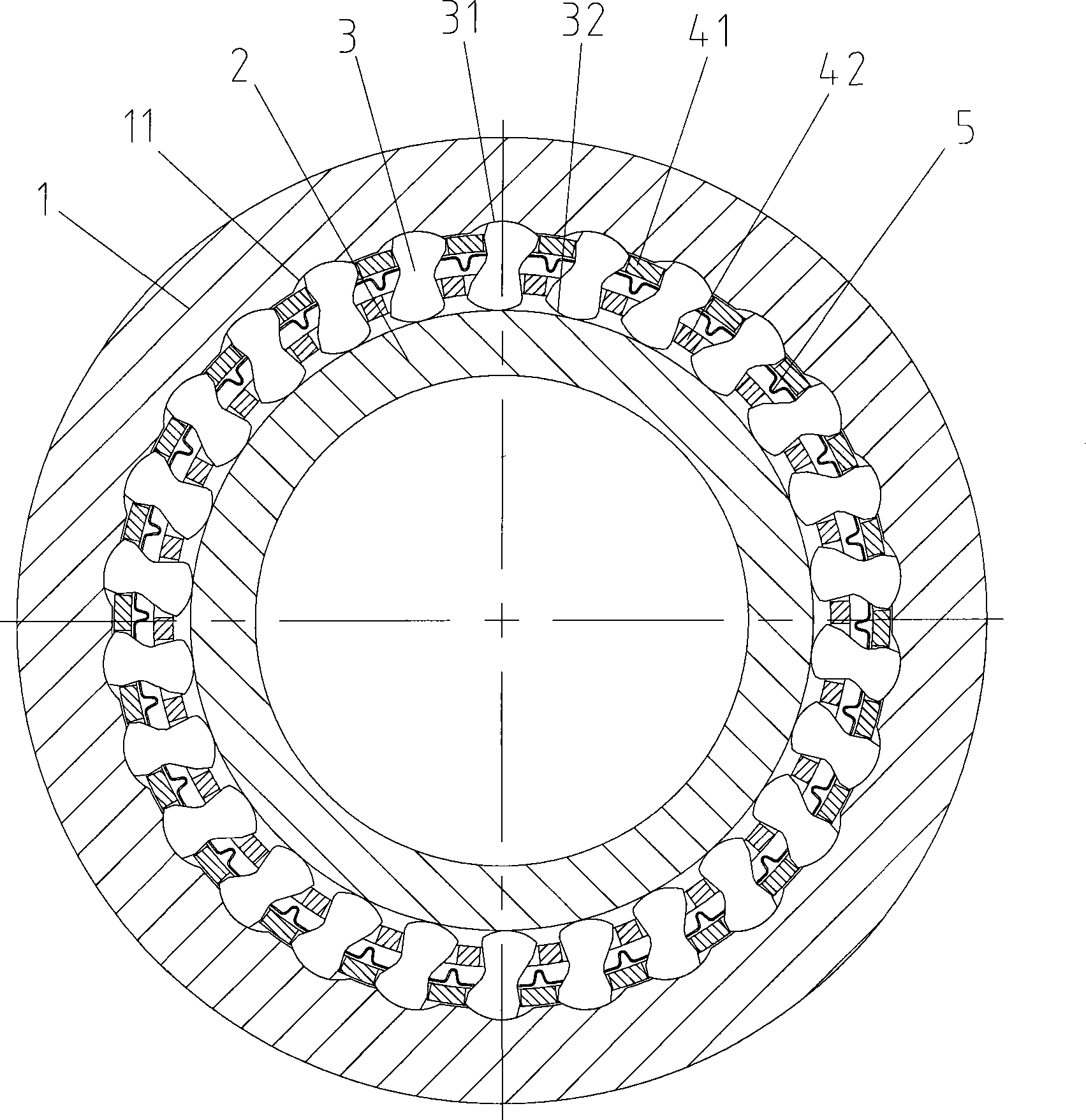

Planetary roller screw

InactiveCN102562986AImprove carrying capacityHigh movement precisionGearingNumerical controlOptical axis

The invention discloses a planetary roller screw which comprises a lead screw, a nut, two roller retainers, two elastic inner check rings, two inner gear rings and a plurality of rollers arranged between the lead screw and the nut; the two inner gear rings are respectively fixed at the two end parts of an inner hole of the nut, parallel annular tooth sockets are arranged at the middle part of the inner hole of the nut, the two roller retainers are respectively sleeved in the inner holes of the two inner gear rings and are respectively blocked and located by the two elastic inner check rings embedded in the inner gear rings, retaining holes, whose number is consistent with that of the rollers, are arranged on the roller retainers, parallel teeth embedded with the threads of the lead screw and the annular tooth sockets of the nut are arranged at the middle parts of the rollers, the two end parts of the rollers are plain spindle heads, and the plain spindle heads are respectively inserted in the retaining holes of the two roller retainers. The planetary roller screw has a reasonable structure, convenience for manufacture, high transmission efficiency, large bearing capacity, high movement precision and low manufacturing cost, so that the planetary roller screw can be extensively applied on such apparatuses as numerical control machine frames and harbor machinery, etc.

Owner:上海久能机电制造有限公司

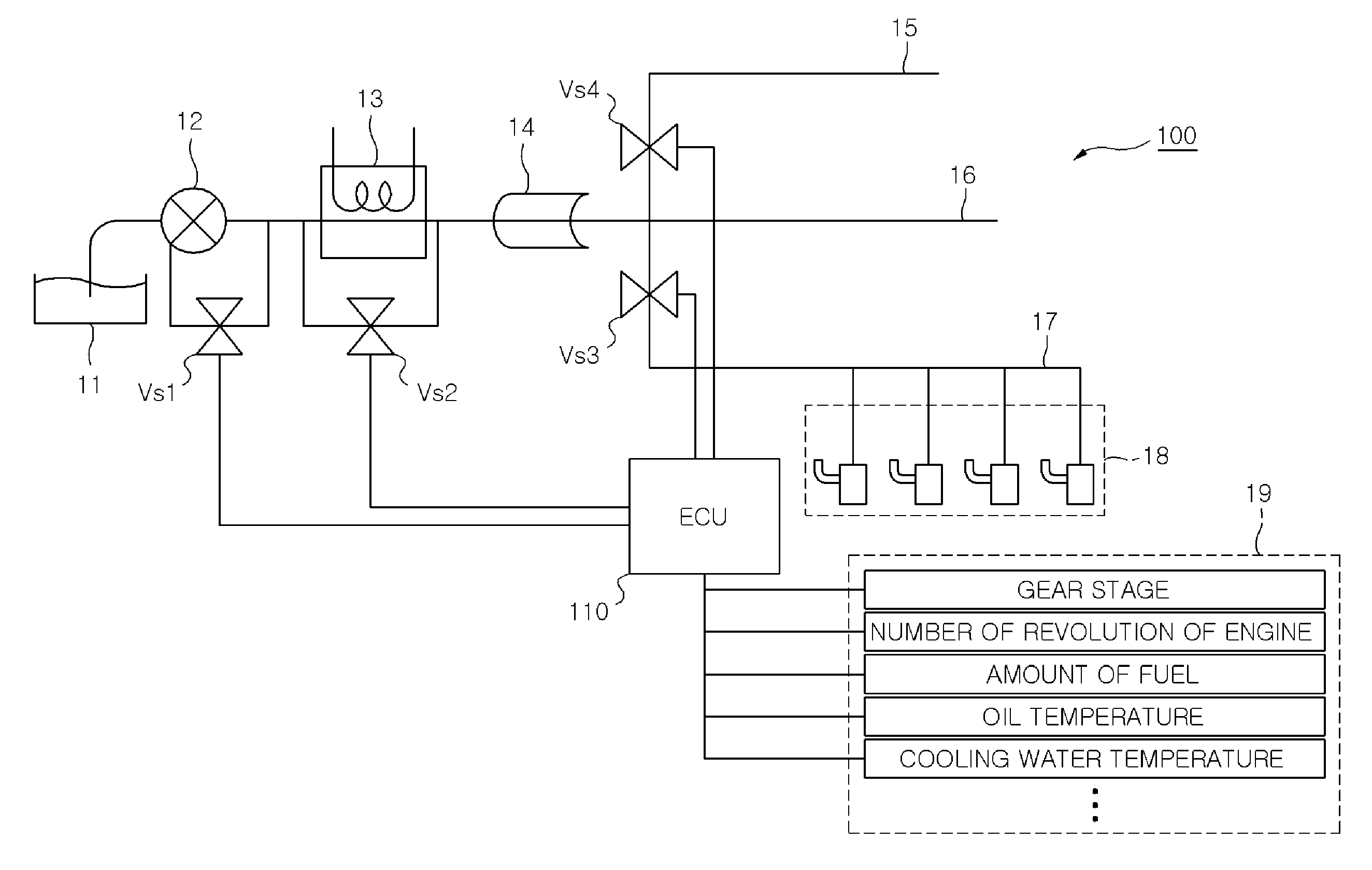

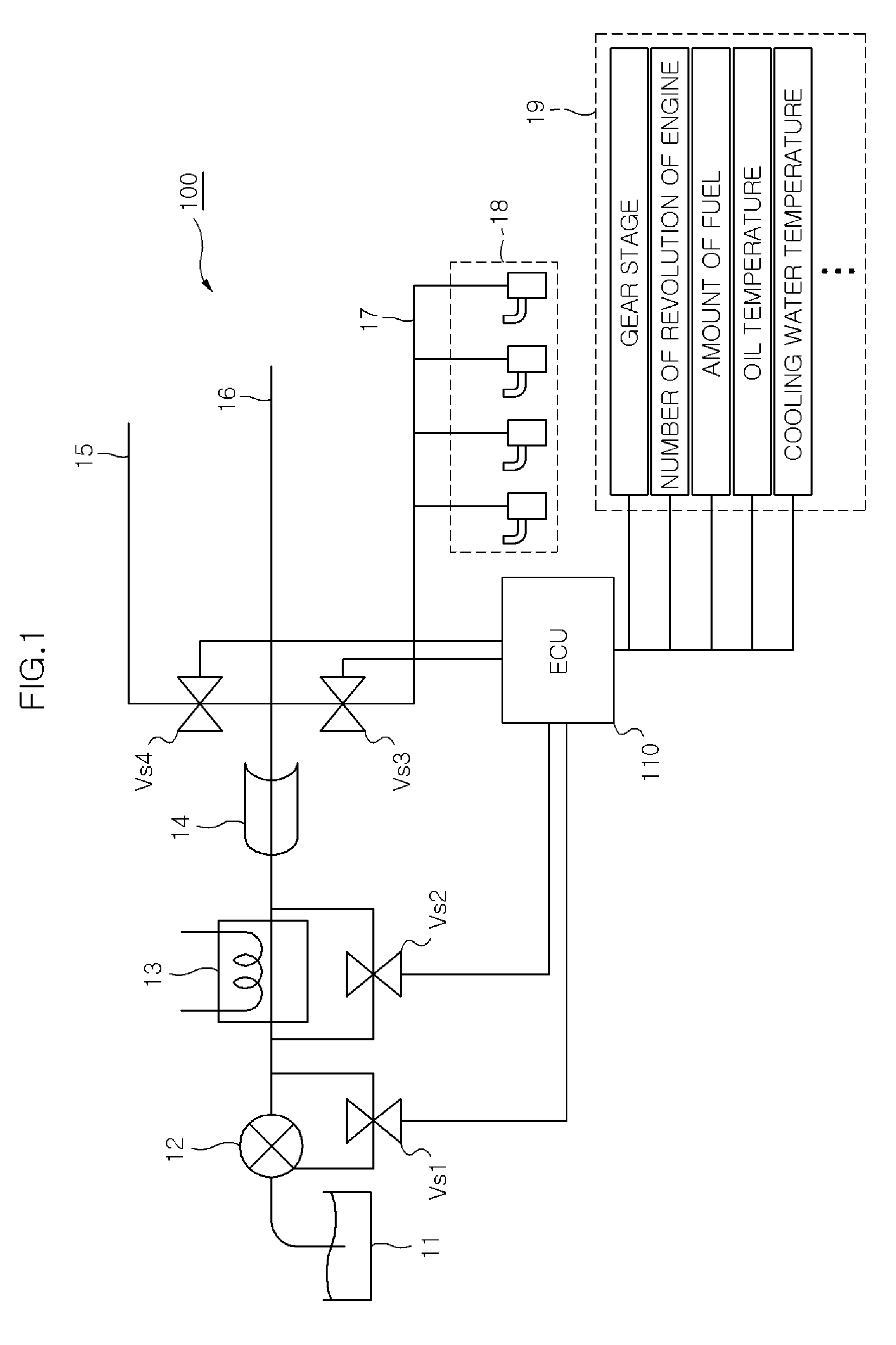

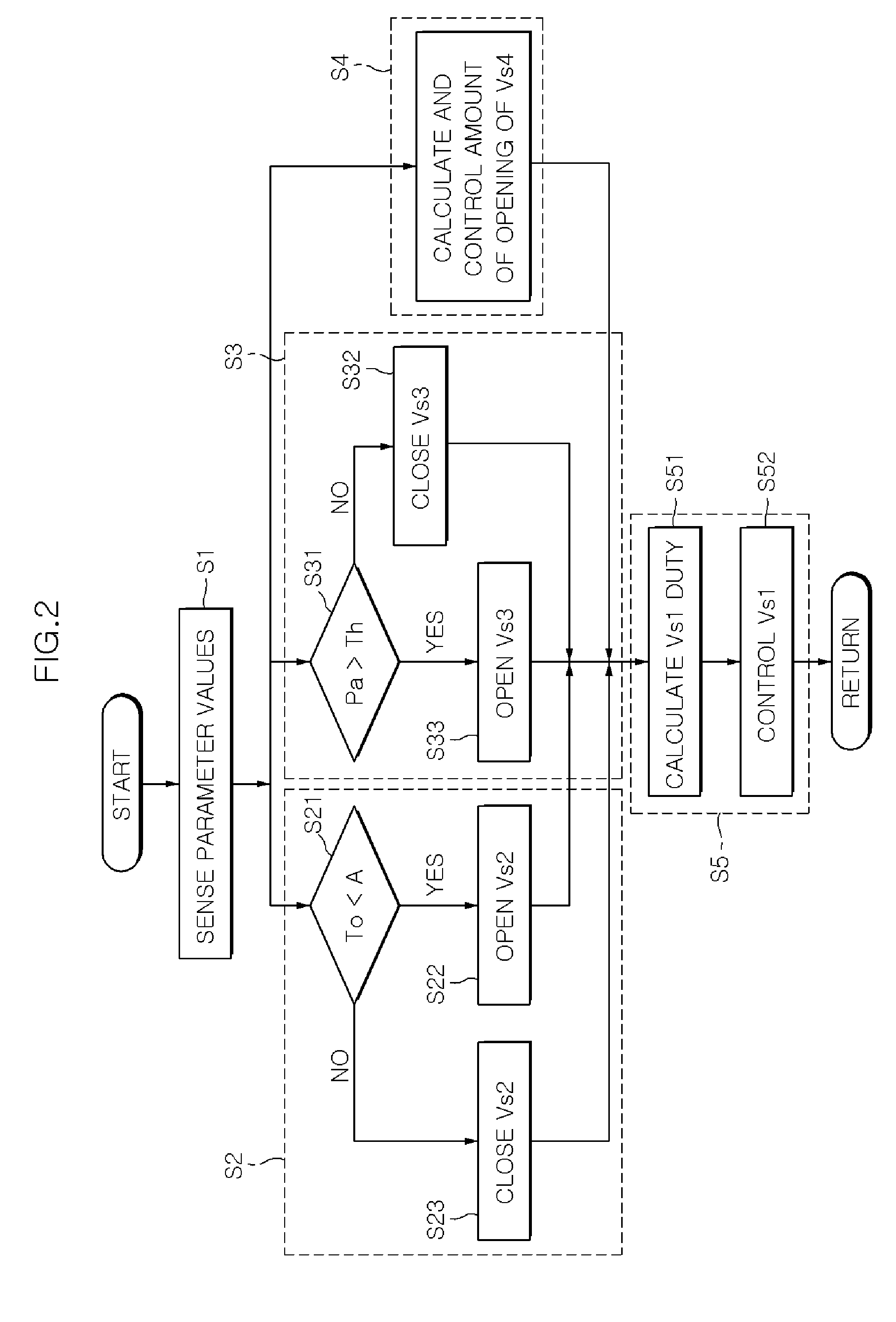

System for controlling hydraulic pressure and flow rate of oil in engine and control method thereof

InactiveUS20120048228A1Avoid friction lossLubrication of auxillariesLubricant conduit arrangementsElectronic controllerSolenoid valve

A system for controlling hydraulic pressure and flow rate of oil in an engine, may include a first solenoid valve disposed in a channel connecting an inlet and an outlet of an oil pump supplying oil from an oil pan to the engine, and an electronic controller controlling the first solenoid valve on the basis of number of revolution of the engine, load of the engine, and temperature of the oil.

Owner:HYUNDAI MOTOR CO LTD +1

Fan assembly

InactiveUS8469660B2Lower center of gravityLess prone to falling overPump componentsJet pumpsEngineeringAirflow

A fan assembly includes a device for creating an air flow and an air outlet for emitting the air flow. The air outlet is mounted on a stand for conveying the air flow to the air outlet. The fan assembly also includes a tilt mechanism for tilting the air outlet relative to at least part of the stand. The tilt mechanism comprises a flexible hose defining, at least in part, an air passage through the tilt mechanism.

Owner:DYSON TECH LTD

Fan assembly

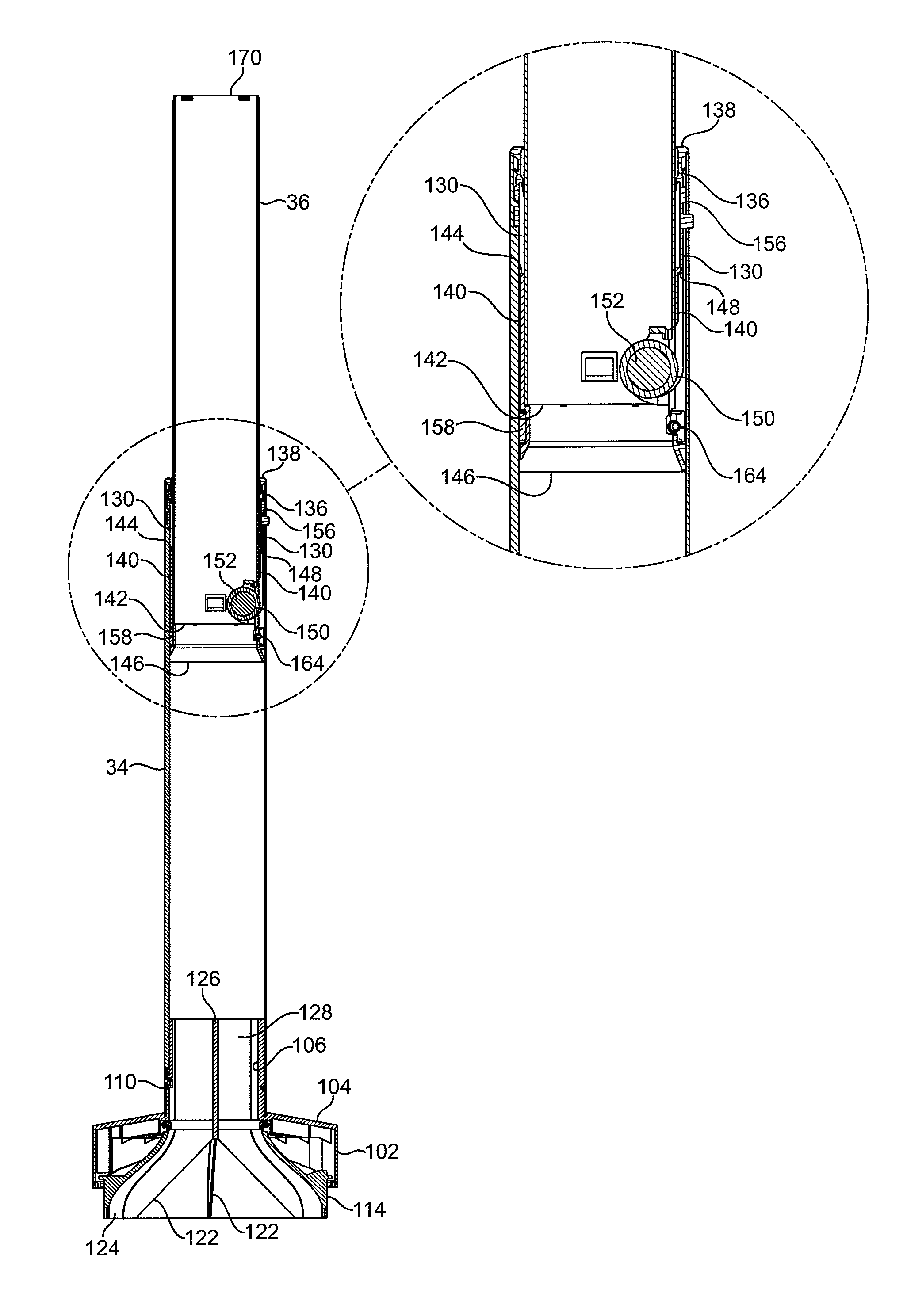

InactiveUS8408869B2Lower center of gravityLess prone to falling overPump componentsLighting and heating apparatusMainspringEngineering

A pedestal for a fan assembly includes a telescopic duct for conveying an air flow to an outlet of the fan assembly. The duct includes an outer tubular member having a first stop member, an inner tubular member located at least partially within and slidable relative to the outer tubular member, the inner tubular member having a second stop member for engaging the first stop member to inhibit withdrawal of the inner tubular member from the outer tubular member, and a mainspring rotatably mounted on the second stop member, the mainspring having a free end retained by the first stop member.

Owner:DYSON TECH LTD

Fan

InactiveUS8469658B2Lower center of gravityLess prone to falling overPump componentsLighting and heating apparatusImpellerEngineering

A floor standing pedestal fan for creating an air current includes a base housing an impeller and a motor for rotating the impeller to create an air flow, an air outlet, and a telescopic duct for conveying the air flow to the air outlet.

Owner:DYSON TECH LTD

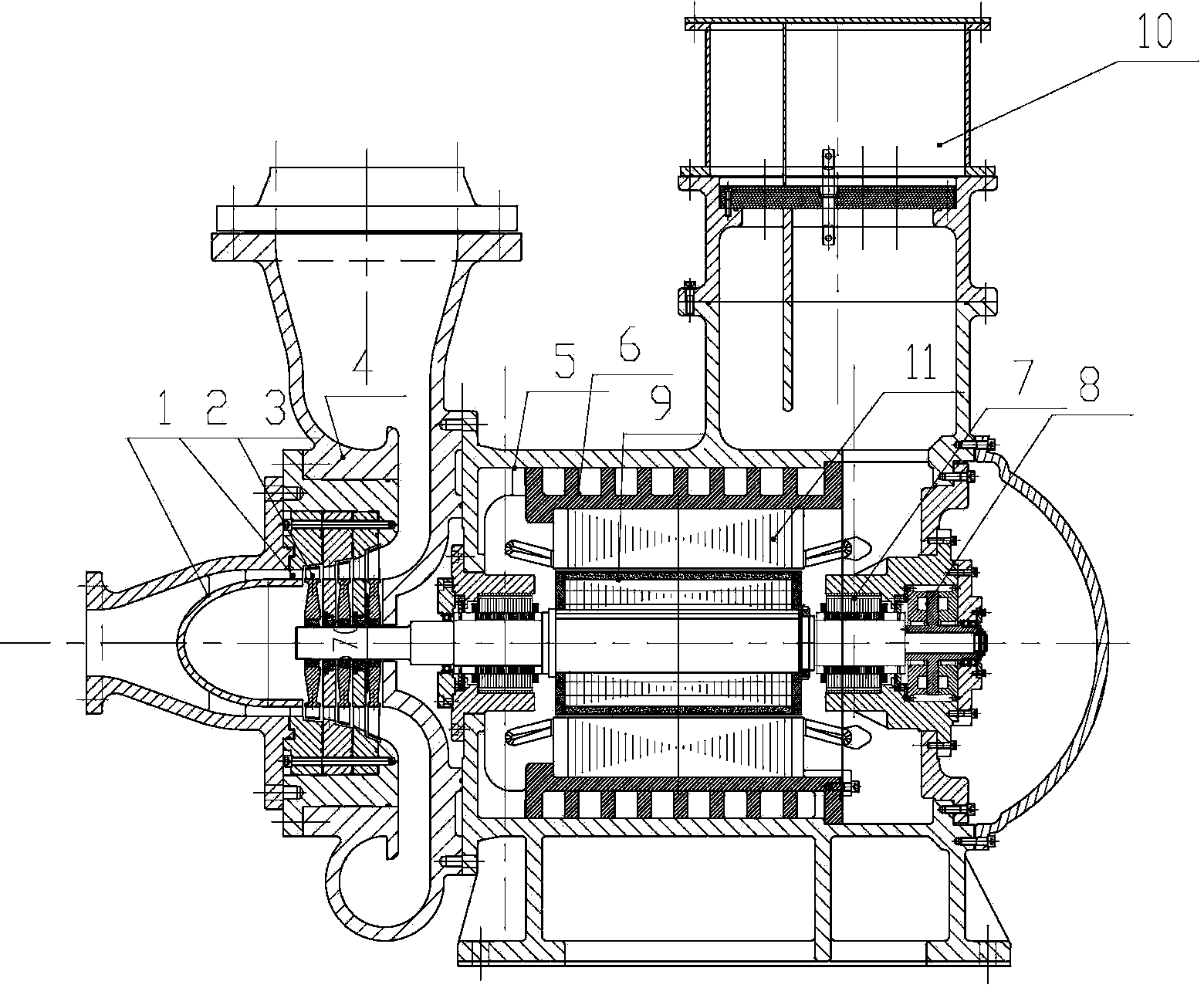

Integrated turbine set based on permanent magnetic and magnetic suspension technologies

ActiveCN103557036AAvoid friction lossImprove efficiencyMachines/enginesMechanical energy handlingGear wheelThrust bearing

The invention relates to an integrated turbine set based on permanent magnetic and magnetic suspension technologies. Turbomachinery is high in sealing performance, complex in gear system and large in energy loss. A turbine and a generator (or a motor) of a full-sealing structure are arranged on the same rotary shaft. One end of the rotary shaft is arranged in the turbine to conduct gas expansion (or compression). The other end of the rotary shaft is arranged in the generator (or the motor), a generator rotor is arranged, and a generator stator core and a winding are arranged on the outside of the generator rotor. A magnetic suspension supporting bearing and a magnetic suspension thrust bearing are sequentially arranged at the tail end of the shaft. All components of the generator are arranged in a generator casing. The generator (or the motor) and the turbine keep the same rotation speed and adopt the same casing, shaft-end sealing is not required, and a work medium of the whole turbine set can be absolutely free of leakage. A magnetic suspension bearing achieves non-contact supporting of the rotor, friction loss of the bearing is avoided, and the overall efficiency of the turbine set is improved.

Owner:浙江博旭新能源科技有限公司

Fan assembly

A bladeless fan assembly includes a nozzle mounted on a base housing a motor and an impeller driven by the motor for creating an air flow. The nozzle includes an interior passage for receiving the air flow, a mouth for emitting the air flow, and a plurality of stationary guide vanes located within the interior passage and each for directing a portion of the air flow towards the mouth. The nozzle defines an opening through which air from outside the fan assembly is drawn by the air flow emitted from the mouth.

Owner:DYSON TECH LTD

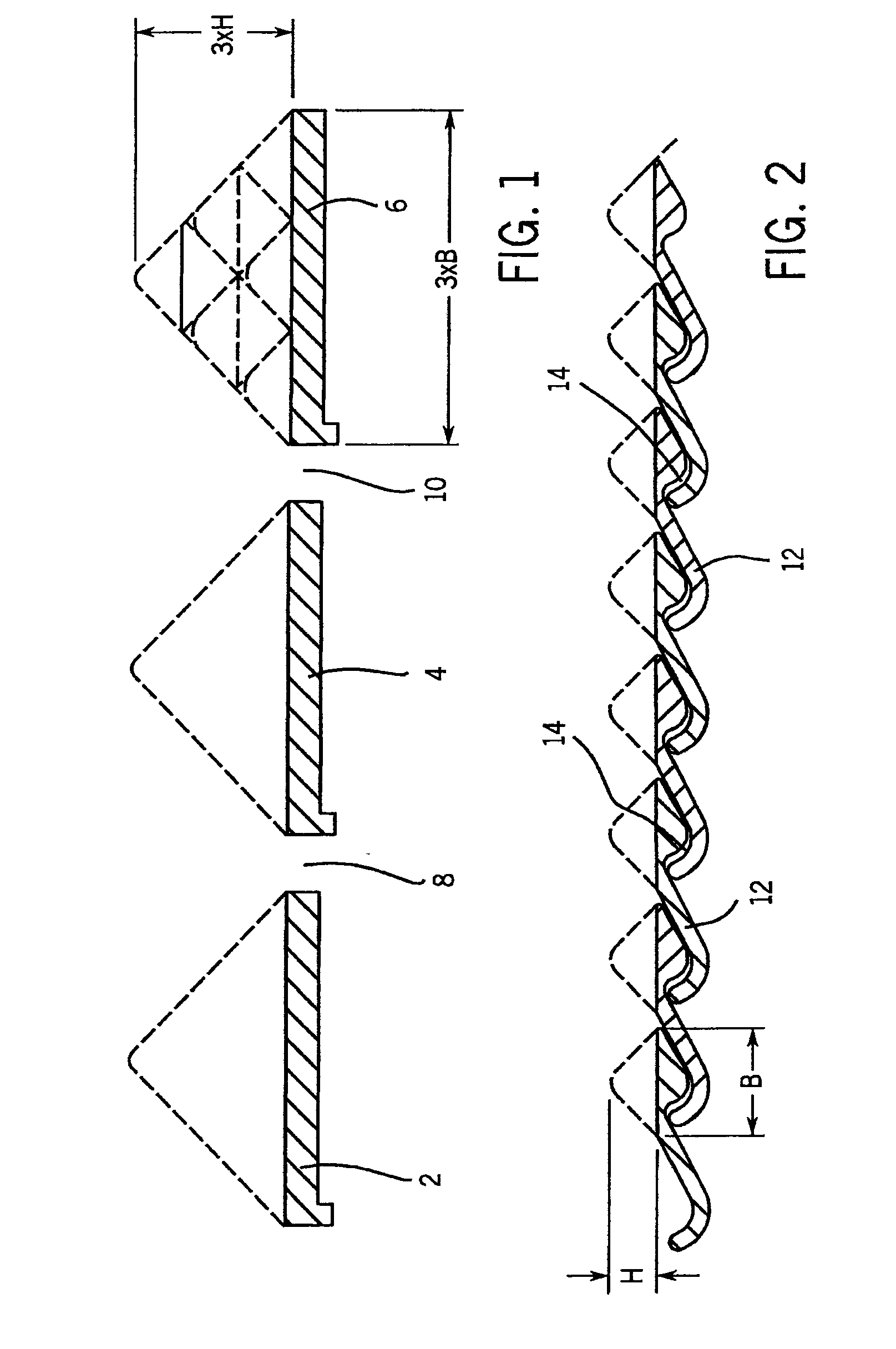

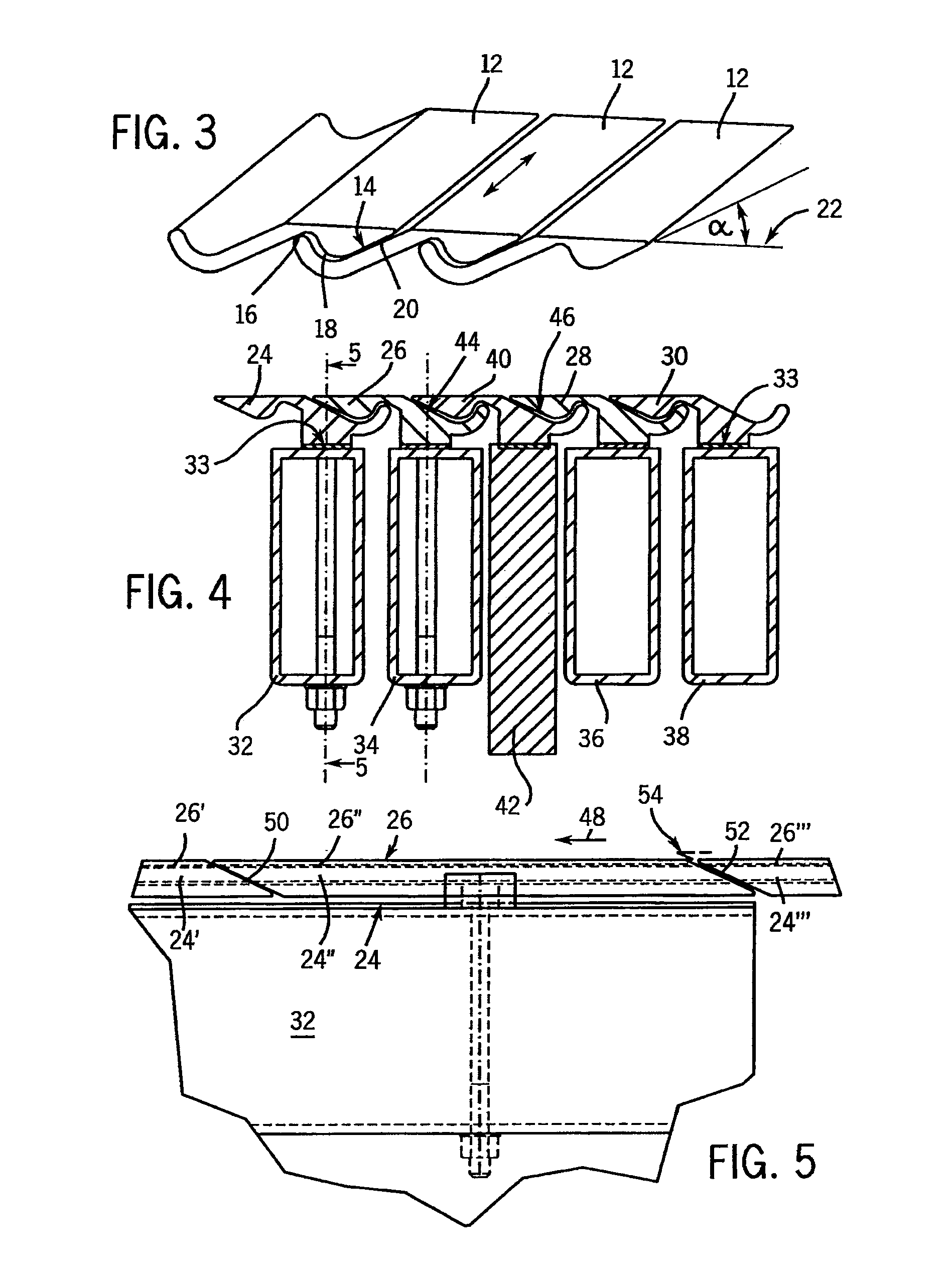

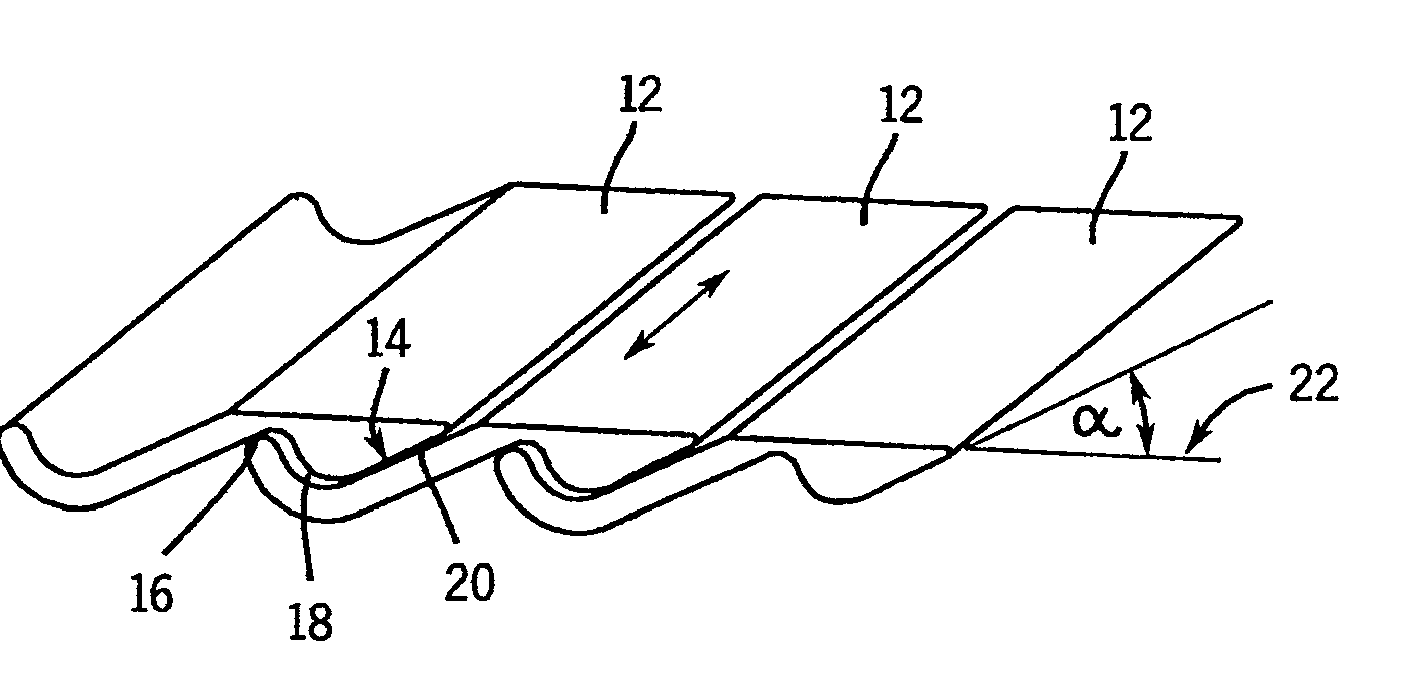

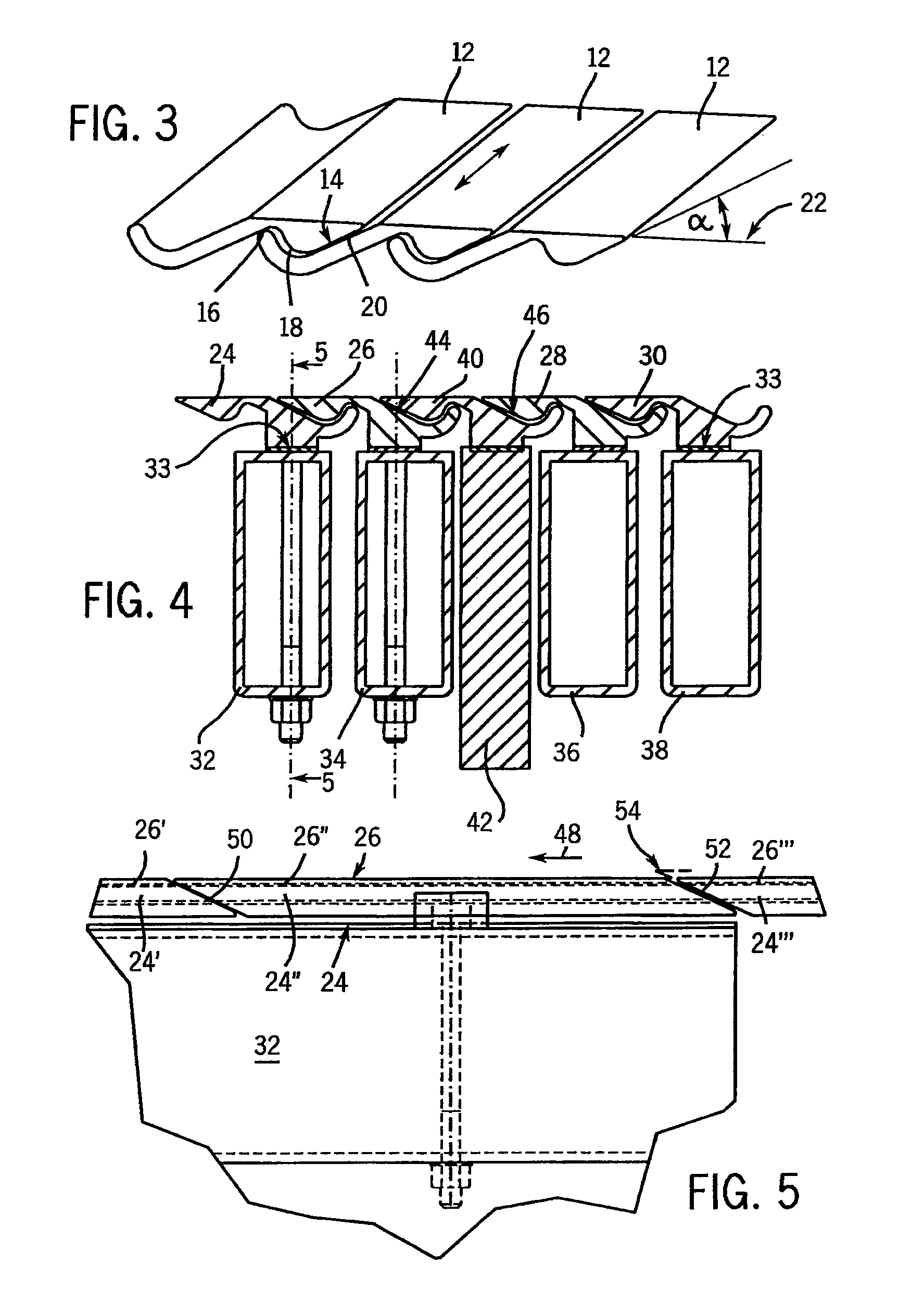

Method And Device For Cooling A Layer of Bulk Material On a Conveyor Grate

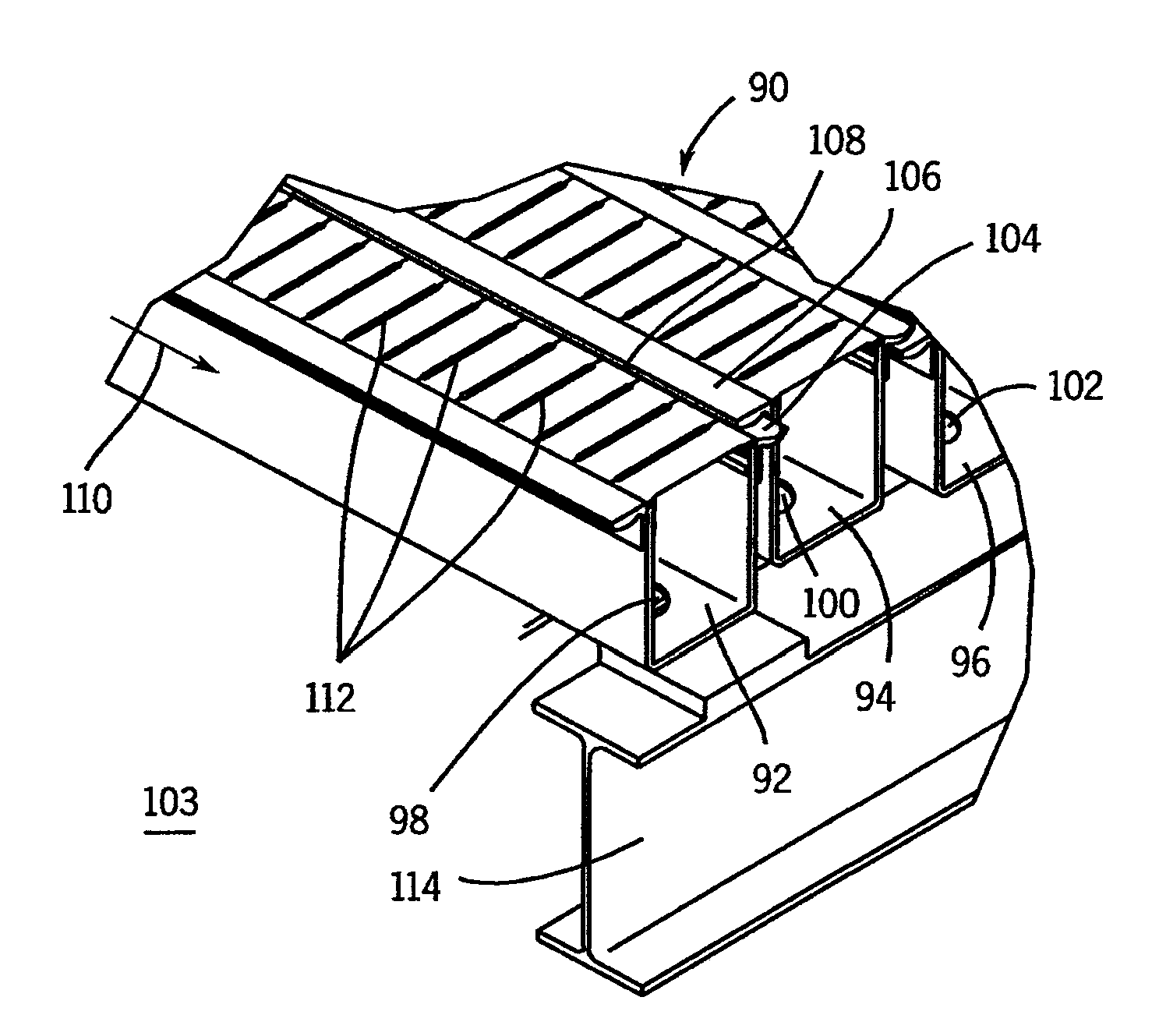

ActiveUS20080263888A1Simple designEasily manufacture and instalConveyorsDrying chambers/containersEdge regionEngineering

A conveyor grate for the transport and cooling of bulk material, for example cement clinker, comprises a grate floor having multiple planks (12), adjacently situated transverse to the direction of transport on associated support structures and operationally moved longitudinally relative to one another individually or in groups, with moving gaps (14) designed as blow openings situated therebetween, and a method for operating such a conveyor grate. The mutually facing side edges or side edge regions of two adjacent planks (12) form two complementary, mutually engaging profiles between which the moving gap (14) is formed. In the method according to the invention, at least a quantity of the cooling air is blown through the moving gaps (14) which is sufficient to blow the moving gaps (14) completely open.

Owner:VON WEDEL +1

Sheathed-element glow plug

InactiveUS20090165739A1Reliable measurementReduce gapIncandescent ignitionCombustion enginesEngineeringInternal combustion engine

A sheathed-element glow plug is used to be situated in a chamber in an internal combustion engine. The sheathed-element glow plug has a housing, a pin-shaped heating element, which extends partially from the housing and a pressure sensor which is situated in an inner chamber of the housing. A prestressing sleeve is provided, in this context, which applies a prestressing to the pressure sensor.

Owner:ROBERT BOSCH GMBH +1

Method and device for cooling a layer of bulk material on a conveyor grate

ActiveUS8132520B2Simple designEasy to manufactureConveyorsMuffle furnacesEngineeringMechanical engineering

A conveyor grate for the transport and cooling of bulk material, for example cement clinker, comprises a grate floor having multiple planks (12), adjacently situated transverse to the direction of transport on associated support structures and operationally moved longitudinally relative to one another individually or in groups, with moving gaps (14) designed as blow openings situated therebetween, and a method for operating such a conveyor grate. The mutually facing side edges or side edge regions of two adjacent planks (12) form two complementary, mutually engaging profiles between which the moving gap (14) is formed. In the method according to the invention, at least a quantity of the cooling air is blown through the moving gaps (14) which is sufficient to blow the moving gaps (14) completely open.

Owner:VON WEDEL +1

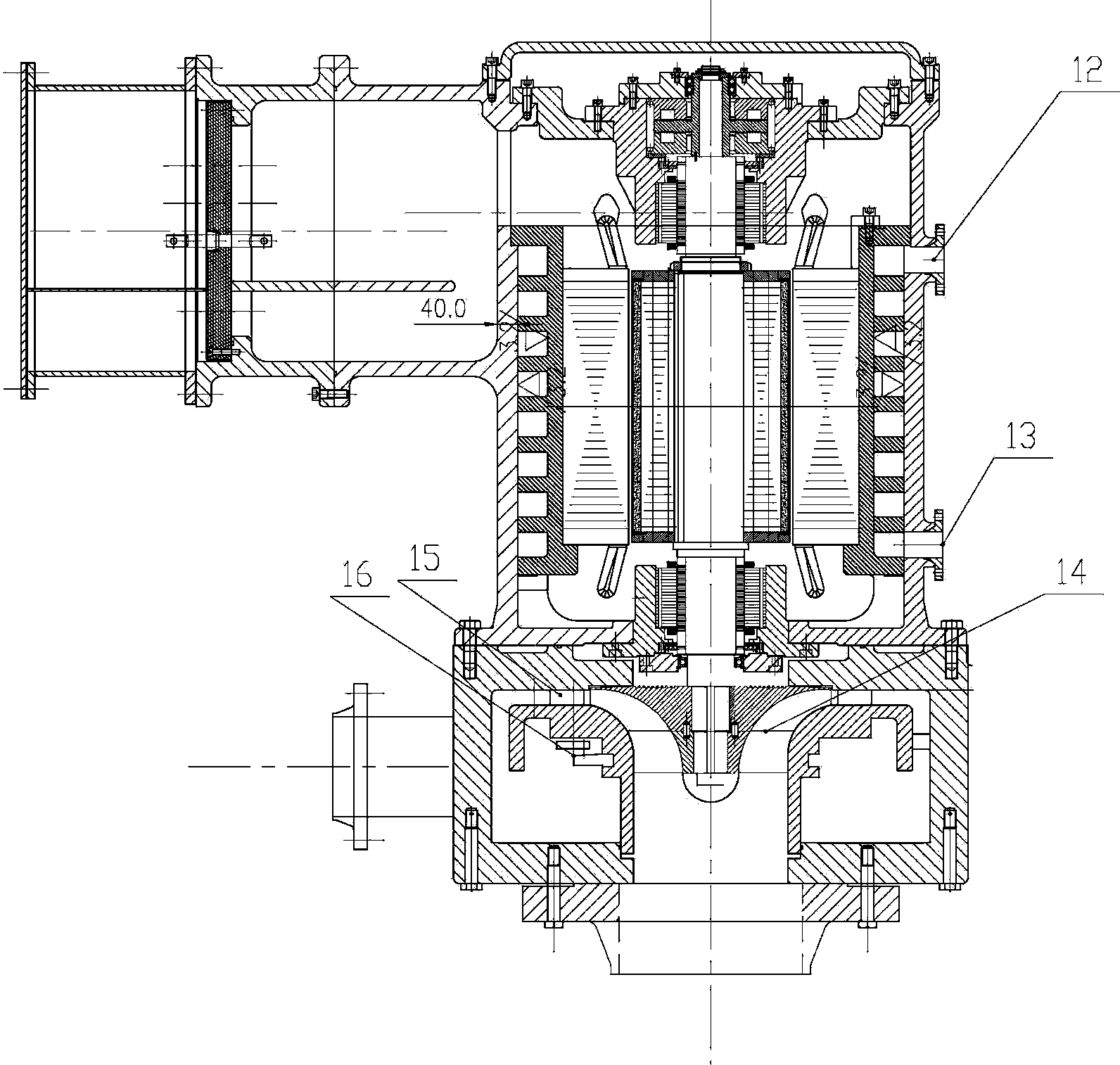

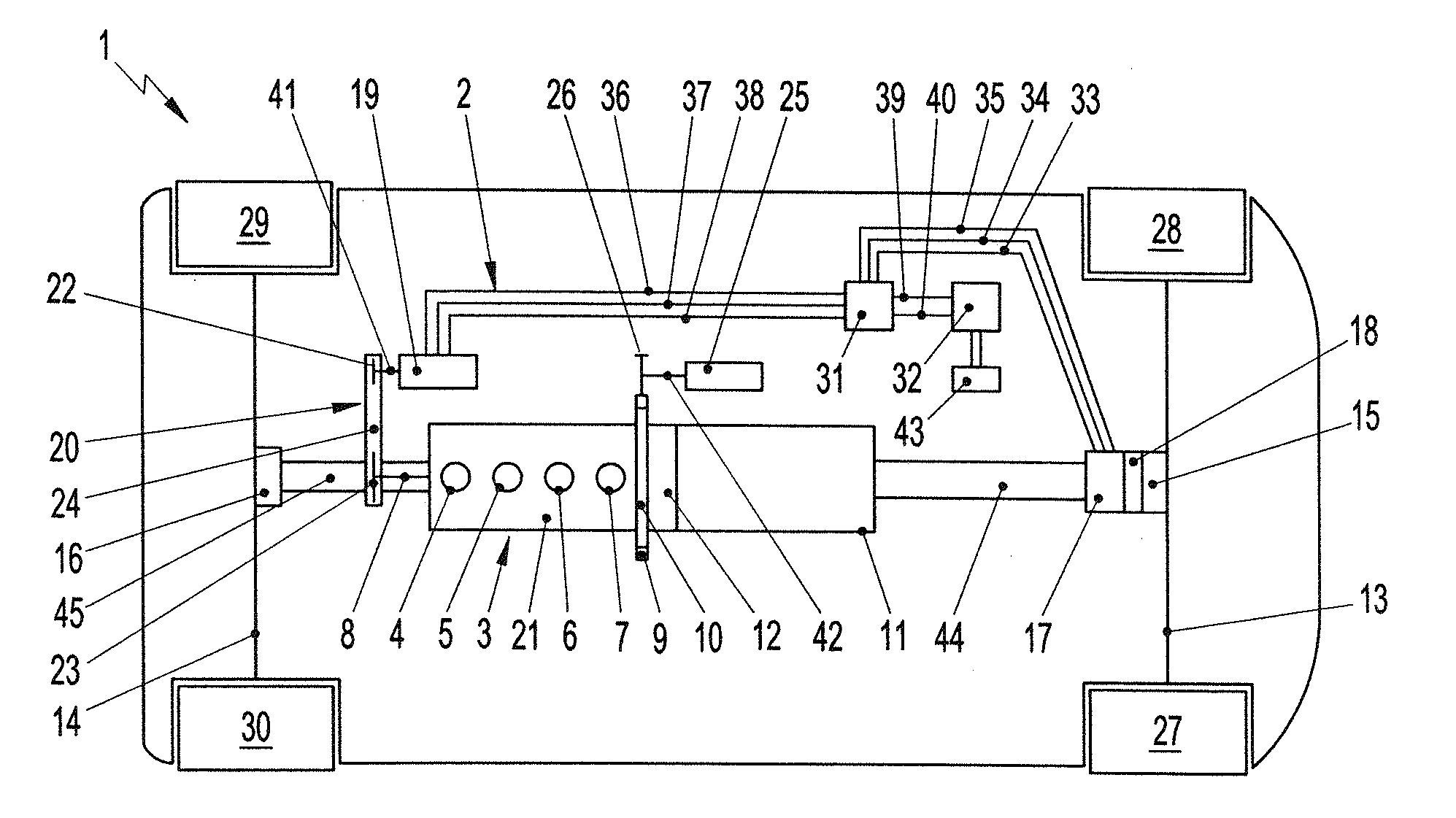

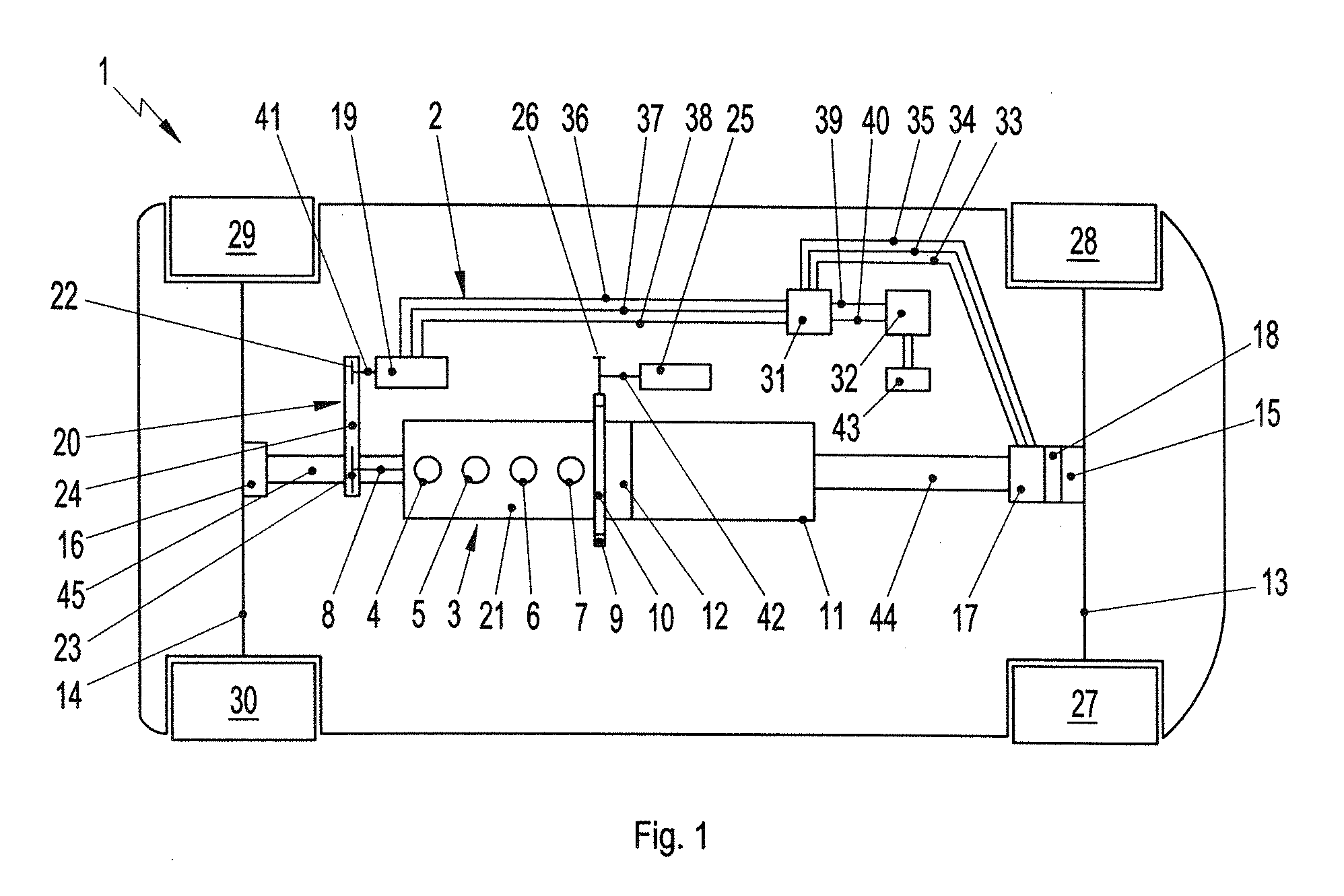

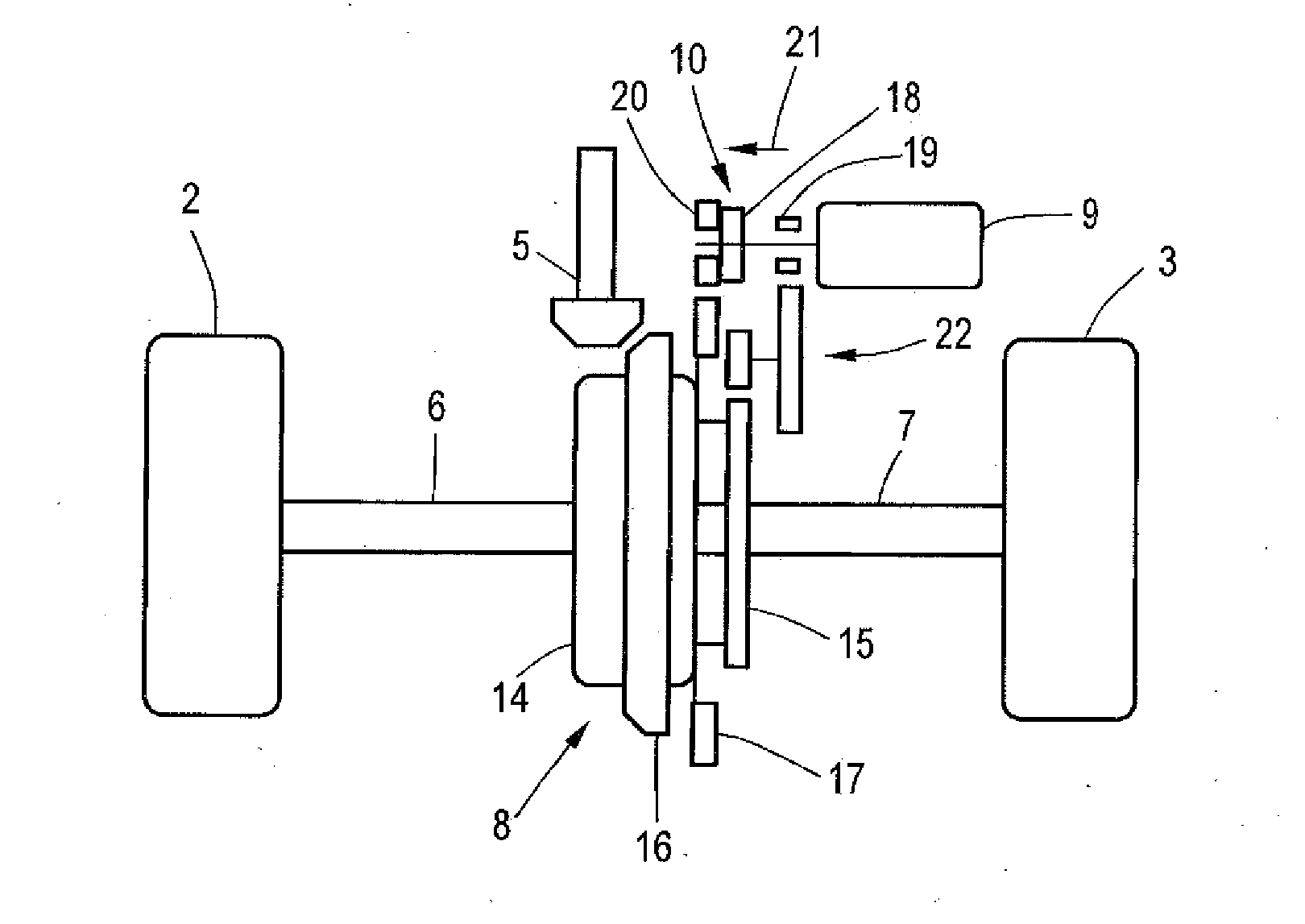

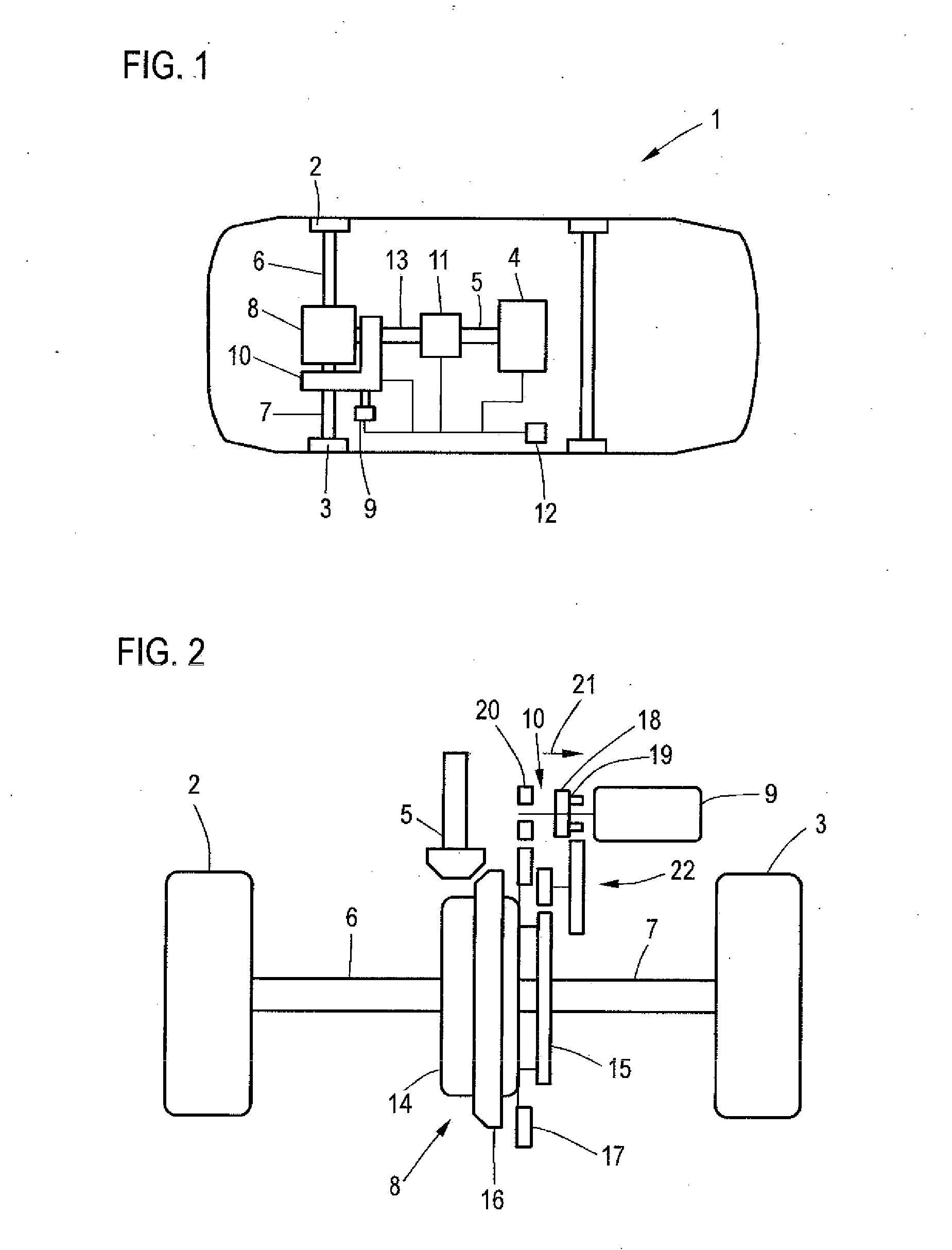

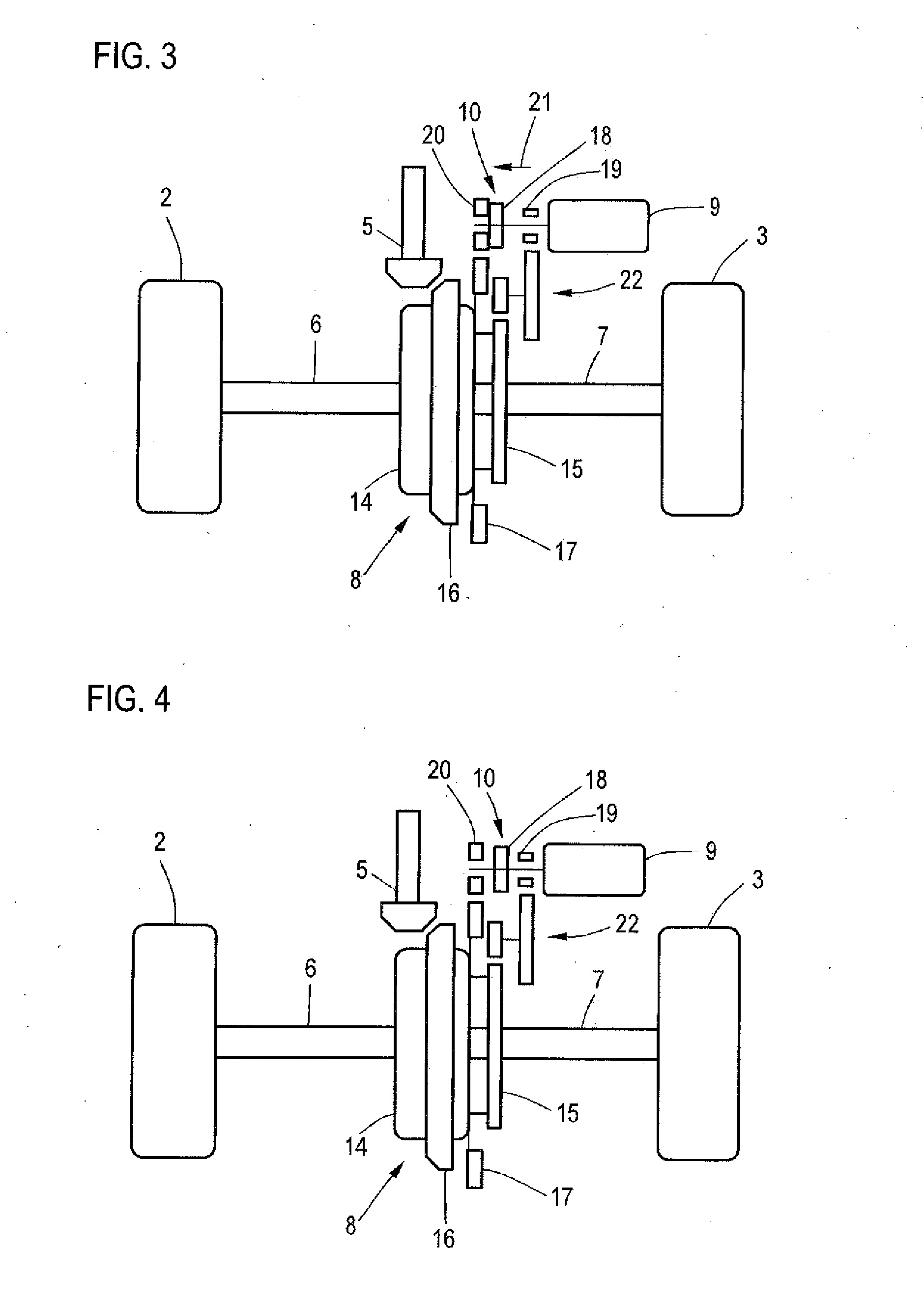

Drive system for a motor vehicle and motor vehicle having such a drive system

ActiveUS20120006152A1Reduced space requirementsAvoid friction lossGearingGas pressure propulsion mountingInternal combustion engineMotorized vehicle

A drive system (2) for a motor vehicle (1) has a transmission (11) for driving at least one drive axle (13, 14) of the motor vehicle (1). An internal combustion engine (3) optionally is connected operatively to the transmission (11) or decoupled therefrom. A first electric machine (17) optionally is connected operatively to the at least one drive axle (13, 14) or to an output shaft (39) of the transmission (11) or decoupled therefrom. A second electric machine (19) is connected operatively to the internal combustion engine (3).

Owner:DR ING H C F PORSCHE AG

Fan assembly

ActiveUS8052379B2Emission reductionAvoid friction lossPropellersPump componentsGravity centerEngineering

A fan assembly for creating an air current includes an air outlet mounted on a stand. The stand includes a base and a body tiltable relative to the base. The fan assembly has a center of gravity located so that when the base is located on a substantially horizontal support surface, the projection of the center of gravity on the support surface is within the footprint of the base when the body is in a fully tilted position.

Owner:DYSON TECH LTD

Sheathed-element glow plug

InactiveUS7712444B2Reliable measurementReduce gapIncandescent ignitionMachines/enginesEngineeringInternal combustion engine

Owner:ROBERT BOSCH GMBH +1

Drive method of hybrid power drive system

ActiveCN101373006AAvoid speed controlAvoid friction lossGas pressure propulsion mountingPlural diverse prime-mover propulsion mountingClutchHybrid drive

The invention provides a method for driving a hybrid drive system, wherein the drive system comprises a first drive source with an outputting shaft, a second drive source with an outputting shaft, a drive shaft connected to the outputting shaft of the second drive source, and a clutch connecting the outputting shaft of the first drive source and the outputting shaft of the second drive source, wherein, the clutch is a three-state outrunning clutch with an outrunning state, a jointing state and a two-way separating state. The method comprises the following steps: according to different operating conditions of the drive system, the three-state outrunning clutch is controlled to be in the outrunning state, the joint state and the two-way separating state respectively; and when the three-state outrunning clutch is in the two-way separating state, the two drive sources can run independently without interference or resistance, thereby increasing the utility rate of energy and facilitating control.

Owner:BYD CO LTD

Motor Vehicle

ActiveUS20150336453A1Implement protective functionCharge or dischargeHybrid vehiclesElectric propulsion mountingDrive motorEngineering

A motor vehicle, includes a drive motor for driving the motor vehicle, at least one additional motor and at least one differential for distributing a torque generated by the drive motor and transmitted by a drive shaft to a driven differential element of the differential to two output shafts. The motor vehicle includes a coupling device which can be controlled by a control device, and in a first coupling state directly or indirectly couples the additional motor with an output shaft, thereby rendering the distribution of the drive torque to the output shafts dependent on an additional torque exerted by the additional motor, and in a second coupling state directly or indirectly couples the additional motor with the driven differential element.

Owner:AUDI AG

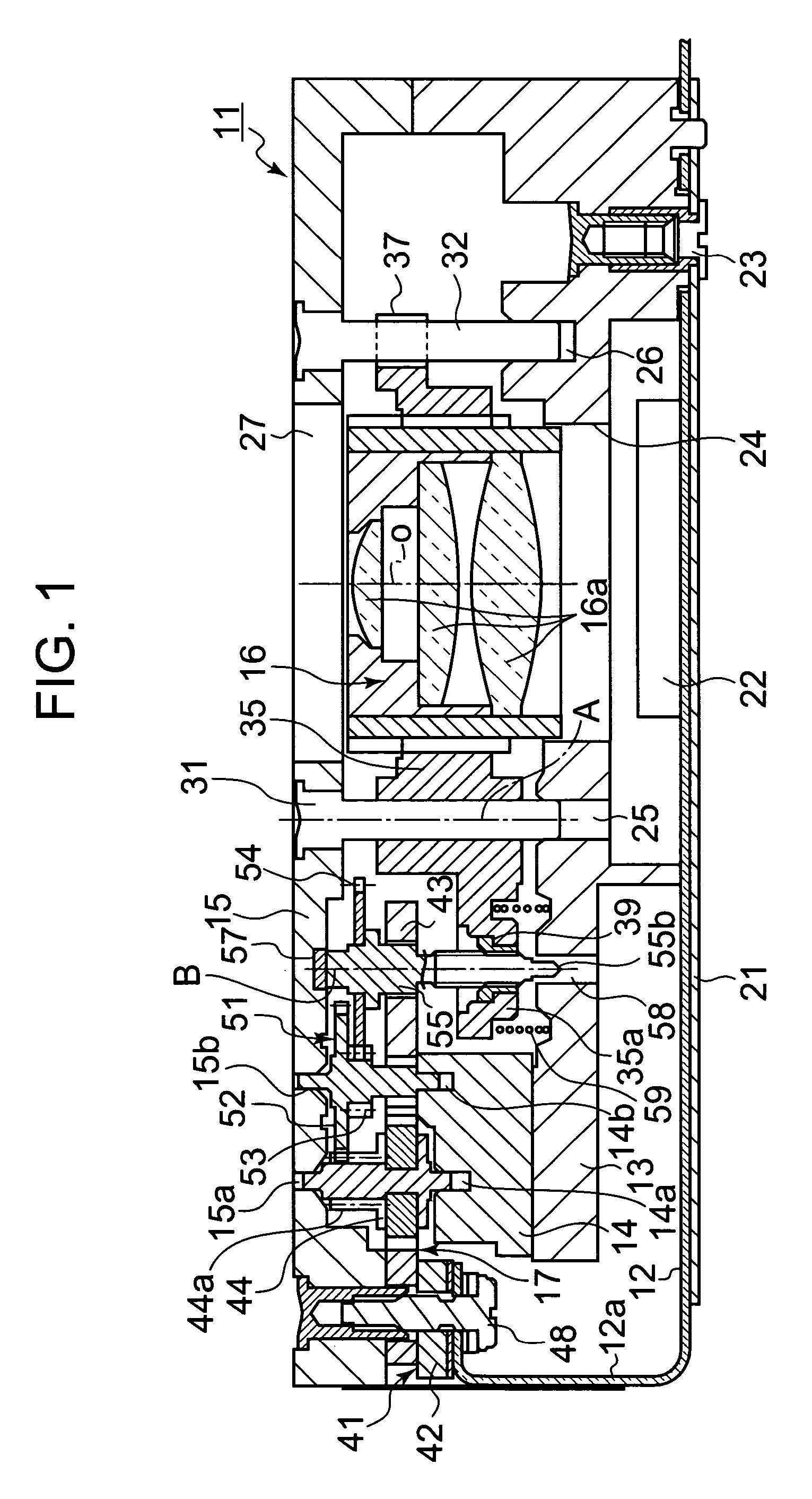

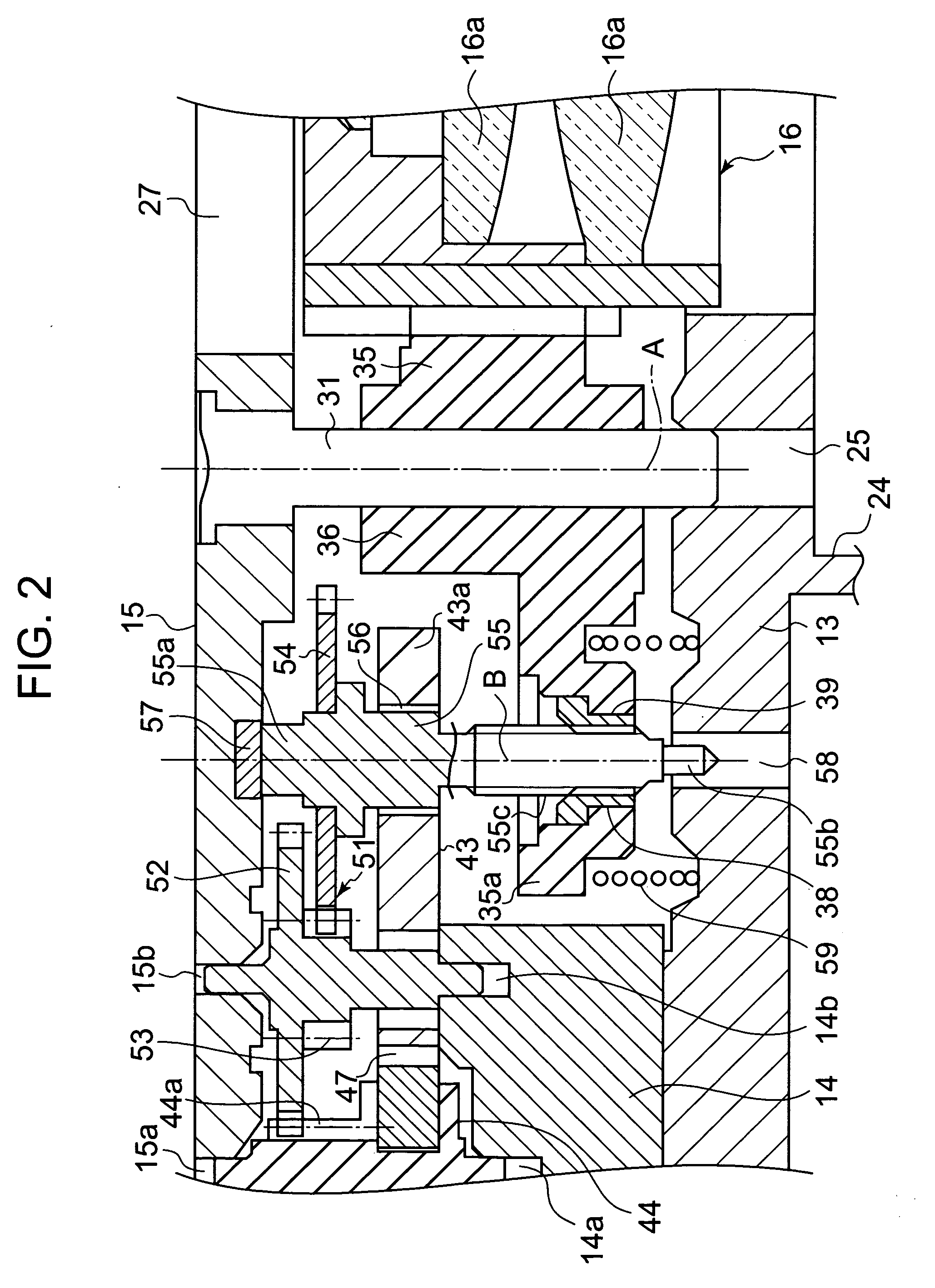

Optical module and camera module

InactiveUS20060016280A1Easy to assembleSmooth movementTelevision system detailsToothed gearingsOptical ModuleCoupling

An optical unit is disclosed which is capable of being easily assembled, enabling its optical element to smoothly move, and preventing friction loss from being generated around its nut member. A lens driving apparatus is provided for moving an optical element holder, which supports an optical element having an optical axis and is movable along a guide member, in an extension direction of the optical axis, using a nut integrally provided at the holder, and a lead screw threadedly coupled to the nut to rotate forward and backward by a driving unit. In the lens driving apparatus, the forward or backward rotation of the motor is transmitted to the lead screw via a reduction gear train. The lead screw is installed to be inclinedly movable with respect to the extension direction of the optical axis about threaded coupling portions of a threaded section of the lead screw and the nut.

Owner:SEIKO INSTR INC

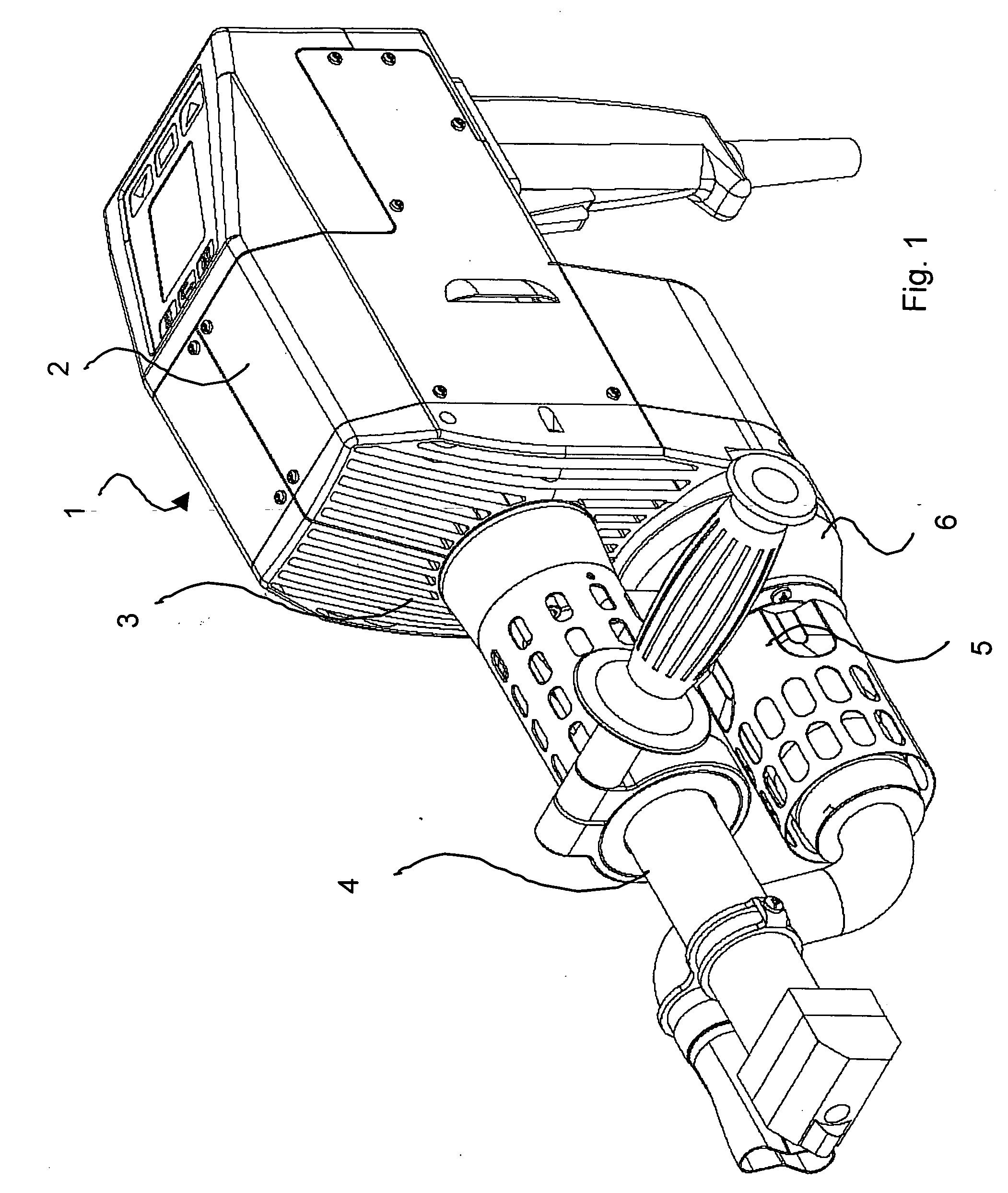

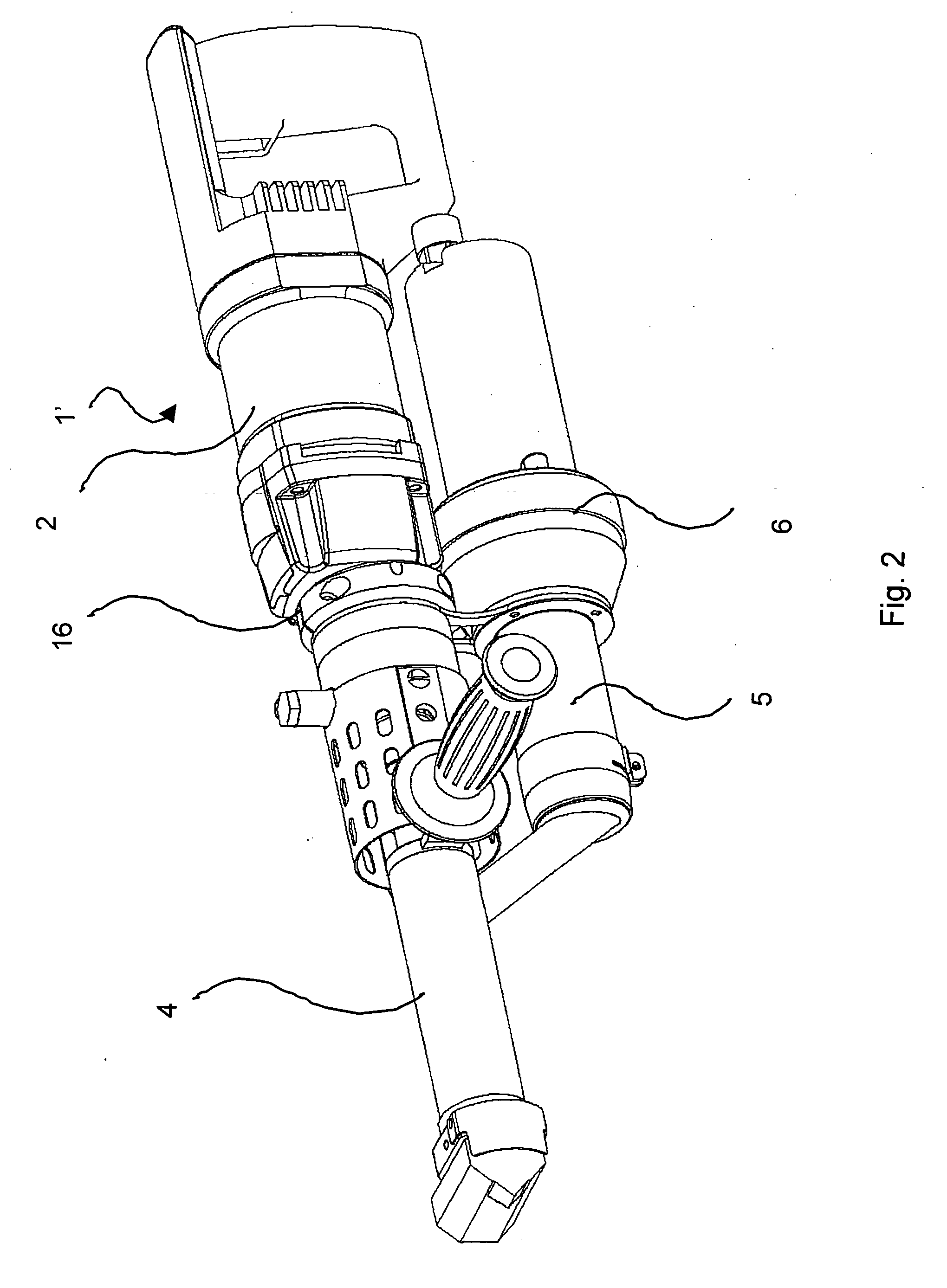

Handheld extruder welding device

ActiveUS20060054661A1Avoid distortionAvoid friction lossCooking-vessel materialsSynthetic materialsHand held

A handheld extruder welding device is provided for welding thermoplastic synthetic materials by means of an extrusion screw with a feed zone and a conveying / plasticizing zone. In the area of the feed zone, a feed channel with a ridge running in longitudinal direction is located in a sleeve. This ridge prevents the inserted plastic welding wire from twisting and looping inside and especially outside the handheld extruder welding device.

Owner:LEISTER TECHNOLOGIES

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com