Planetary roller screw

A technology of planetary rollers and rollers, which is applied to belts/chains/gears, mechanical equipment, transmission devices, etc., can solve the problems of restricting the promotion and application of planetary roller screws, complicated manufacturing processes, and difficult manufacturing, and achieves The effect of low processing cost, simple manufacturing process and reasonable structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments. But the following examples are not intended to limit the present invention, and all structures similar to the present invention and equivalent changes to it should be included in the protection scope of the present invention.

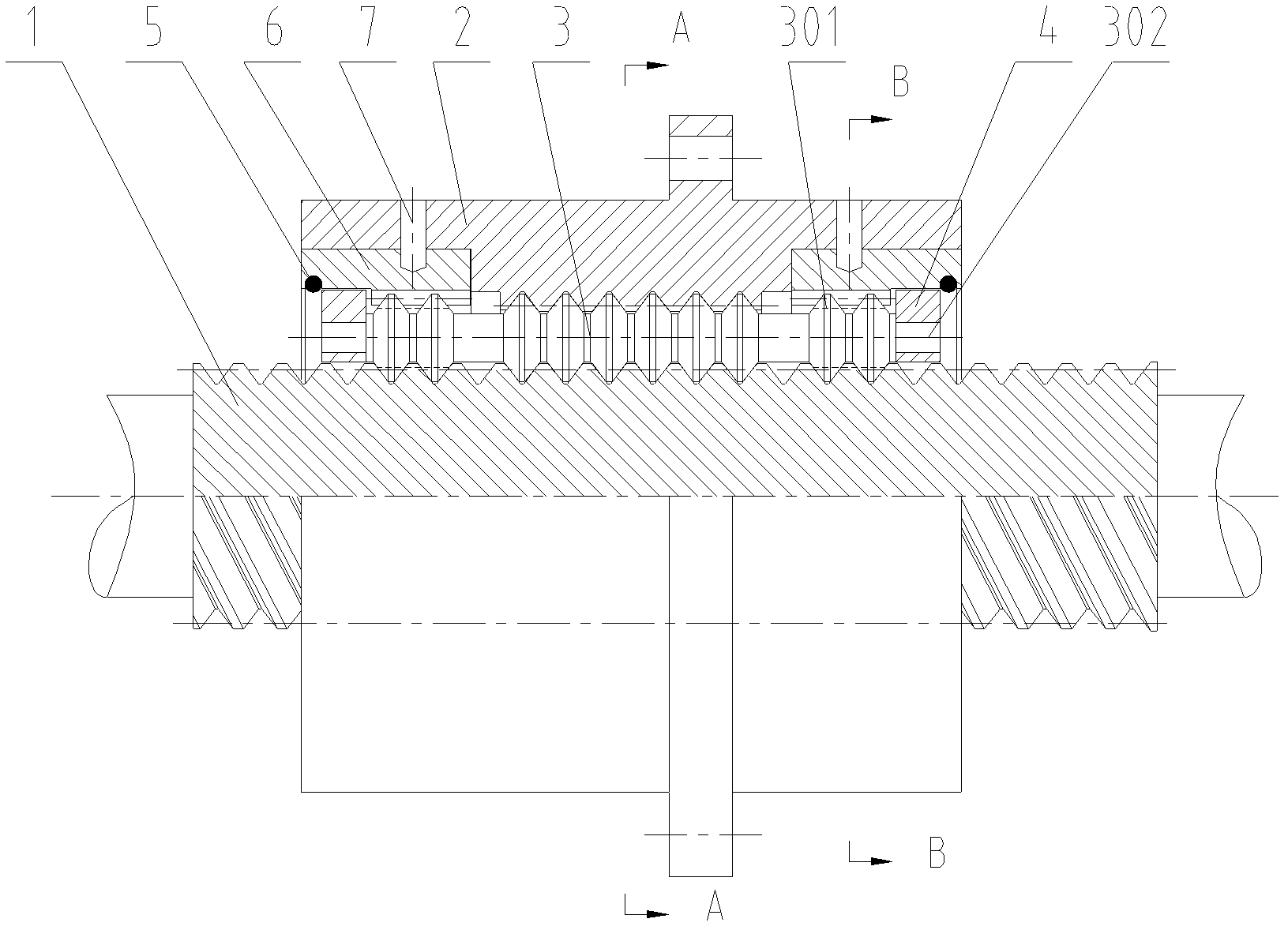

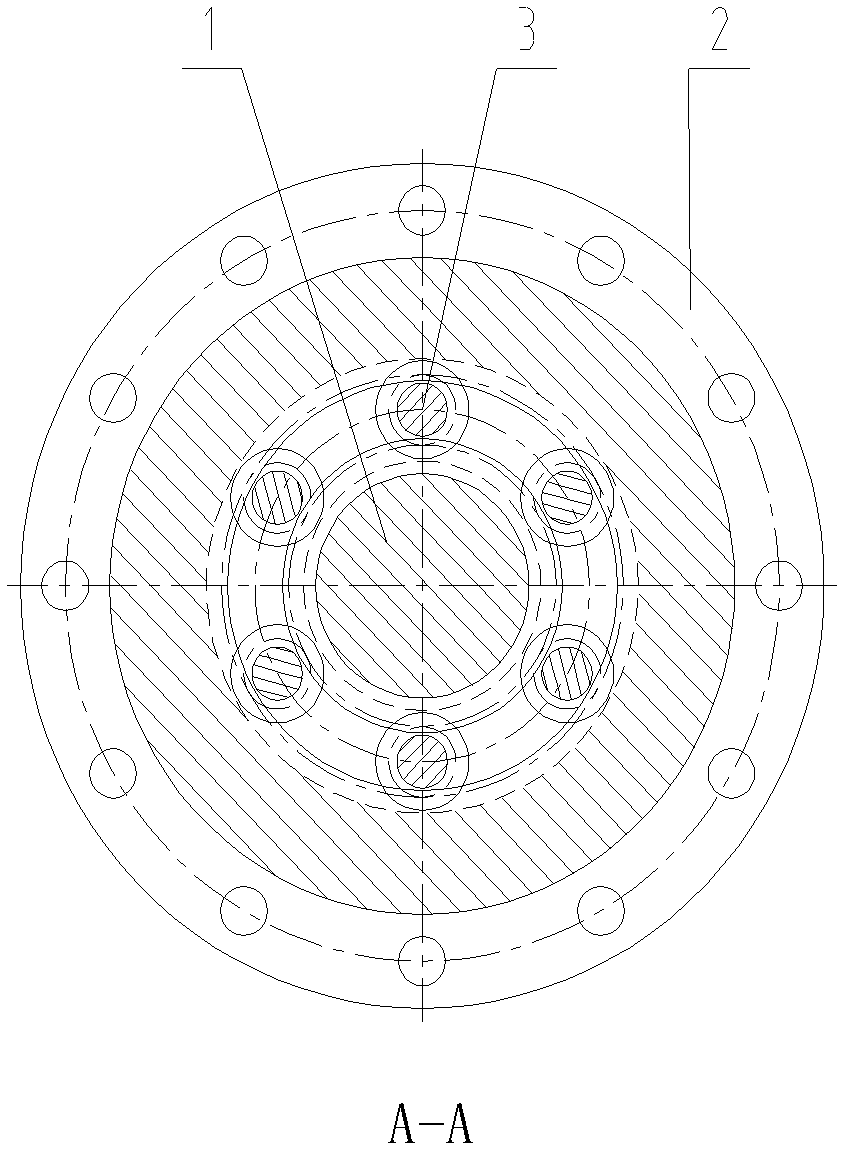

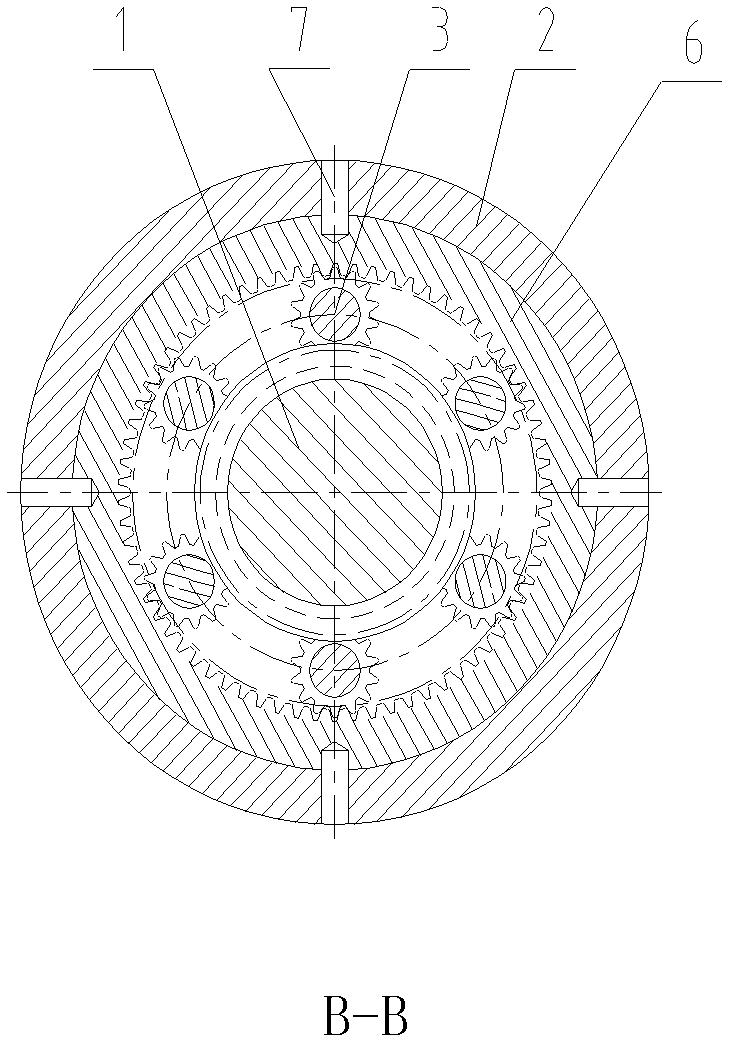

[0014] Please refer to figure 1 and figure 2 , The illustrated planetary roller screw includes a screw 1, a nut 2, a number of rollers 3, two roller cages 4, two elastic inner retaining rings 5 and two ring gears 6.

[0015] The thread of the screw rod 1 has a certain helix angle, and the profile of the thread is a triangular or arc thread. Said nut 2 is set outside the screw mandrel 1, and the middle part of the inner hole of the nut 2 is provided with a number of juxtaposed annular tooth sockets. It is the same as the pitch of the screw thread of the screw mandrel 1 .

[0016] The two inner ring gears 6 are respec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com