Patents

Literature

222 results about "Mainspring" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A mainspring is a spiral torsion spring of metal ribbon—commonly spring steel—used as a power source in mechanical watches, some clocks, and other clockwork mechanisms. Winding the timepiece, by turning a knob or key, stores energy in the mainspring by twisting the spiral tighter. The force of the mainspring then turns the clock's wheels as it unwinds, until the next winding is needed. The adjectives wind-up and spring-powered refer to mechanisms powered by mainsprings, which also include kitchen timers, music boxes, wind-up toys and clockwork radios.

Multi-charge gas-cylinder pistol

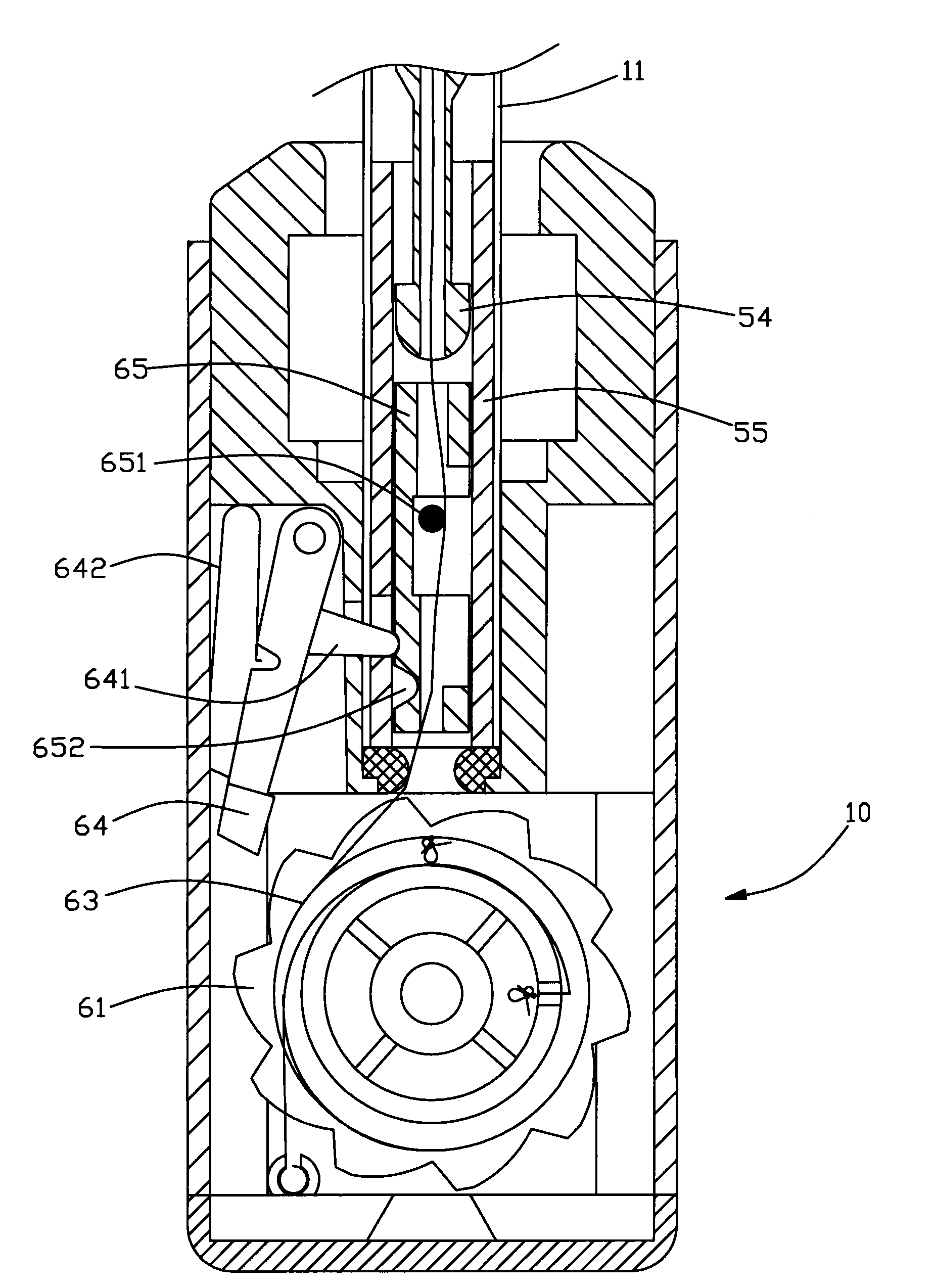

InactiveUS6494194B2Improve reliabilityHigh performance featuresFiring/trigger mechanismsAmmunition loadingGas cylinderMainspring

Owner:ZAKRYTOE AKTSIONERNOE OBSHCHESTVO GRP ANICS

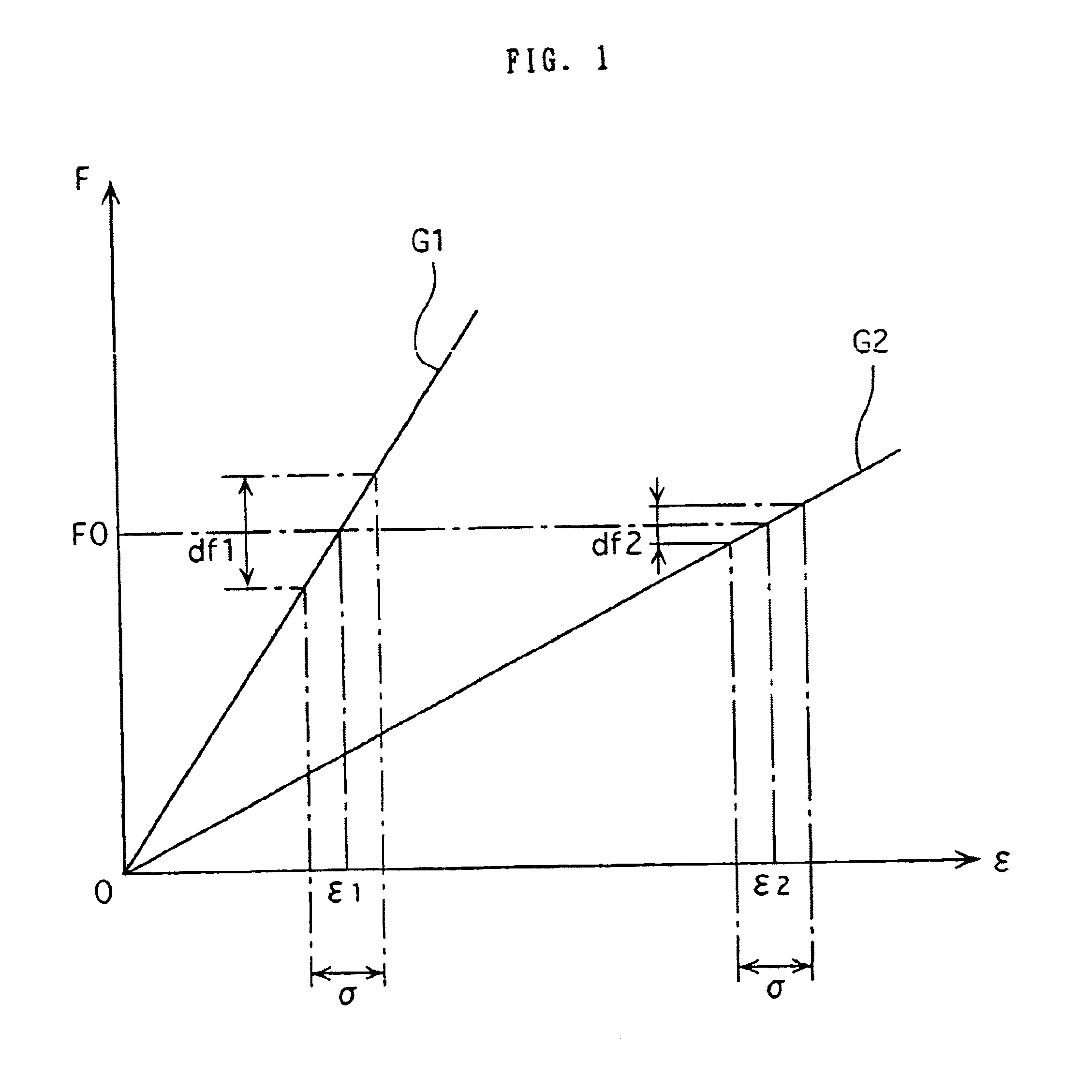

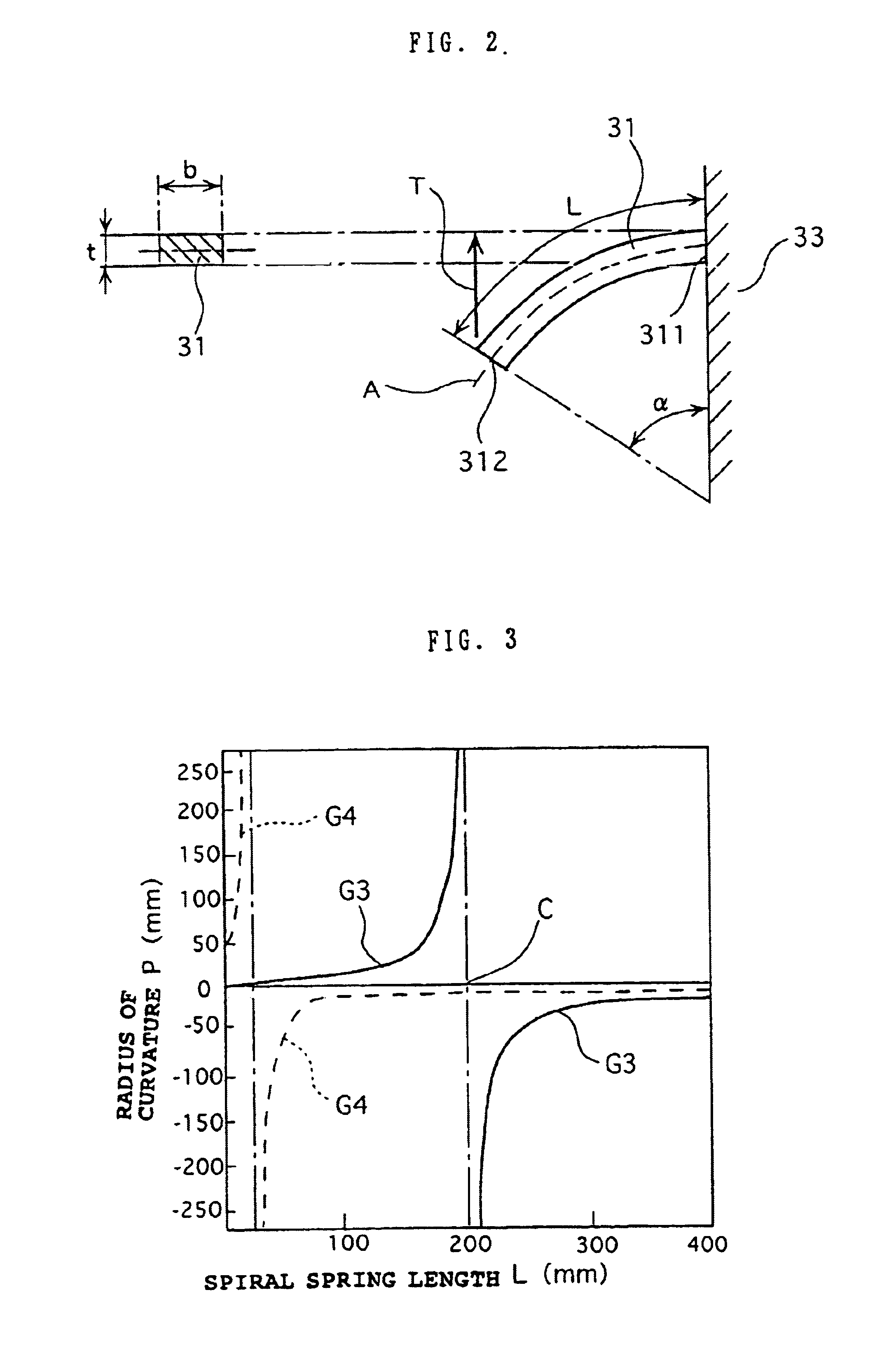

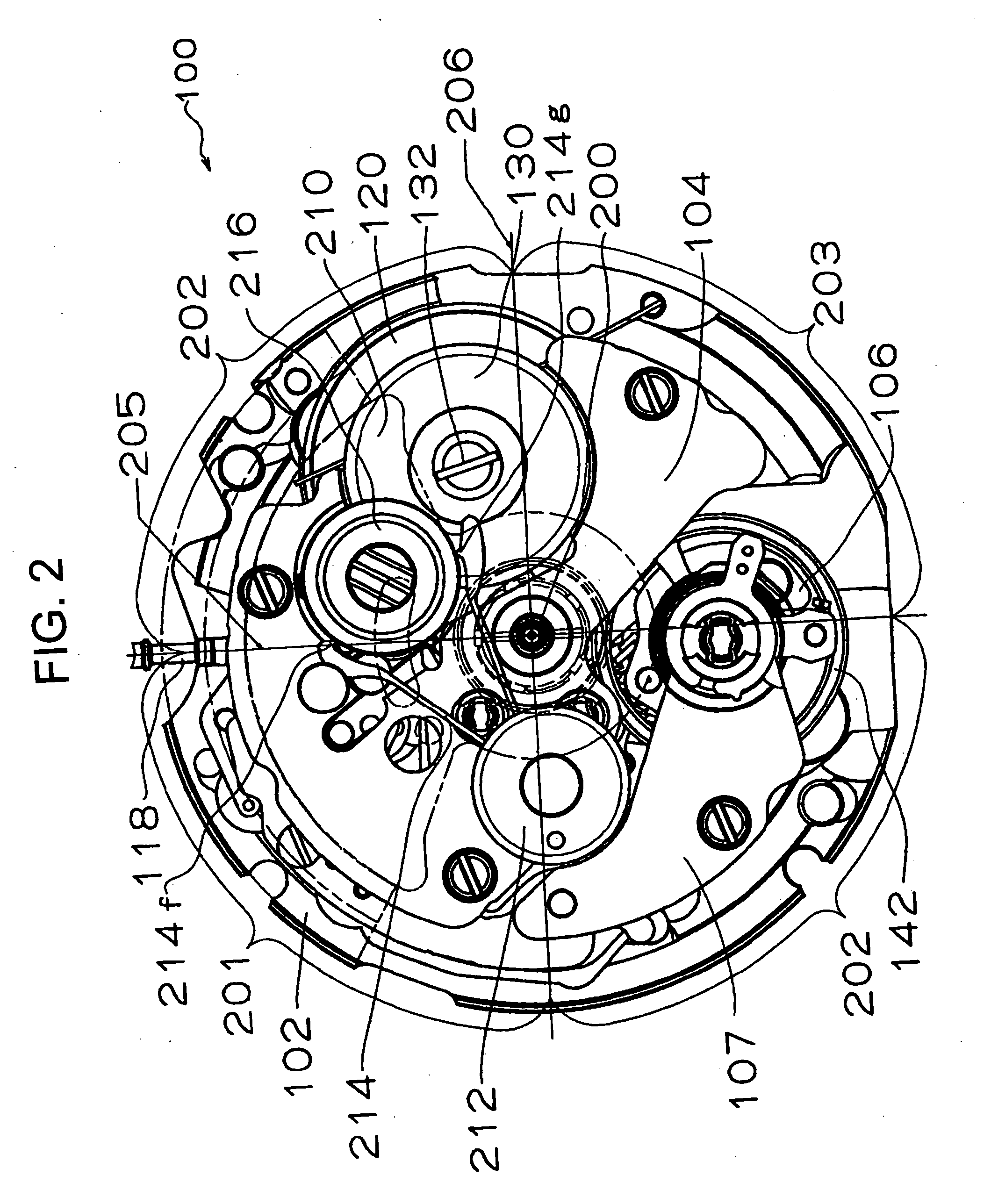

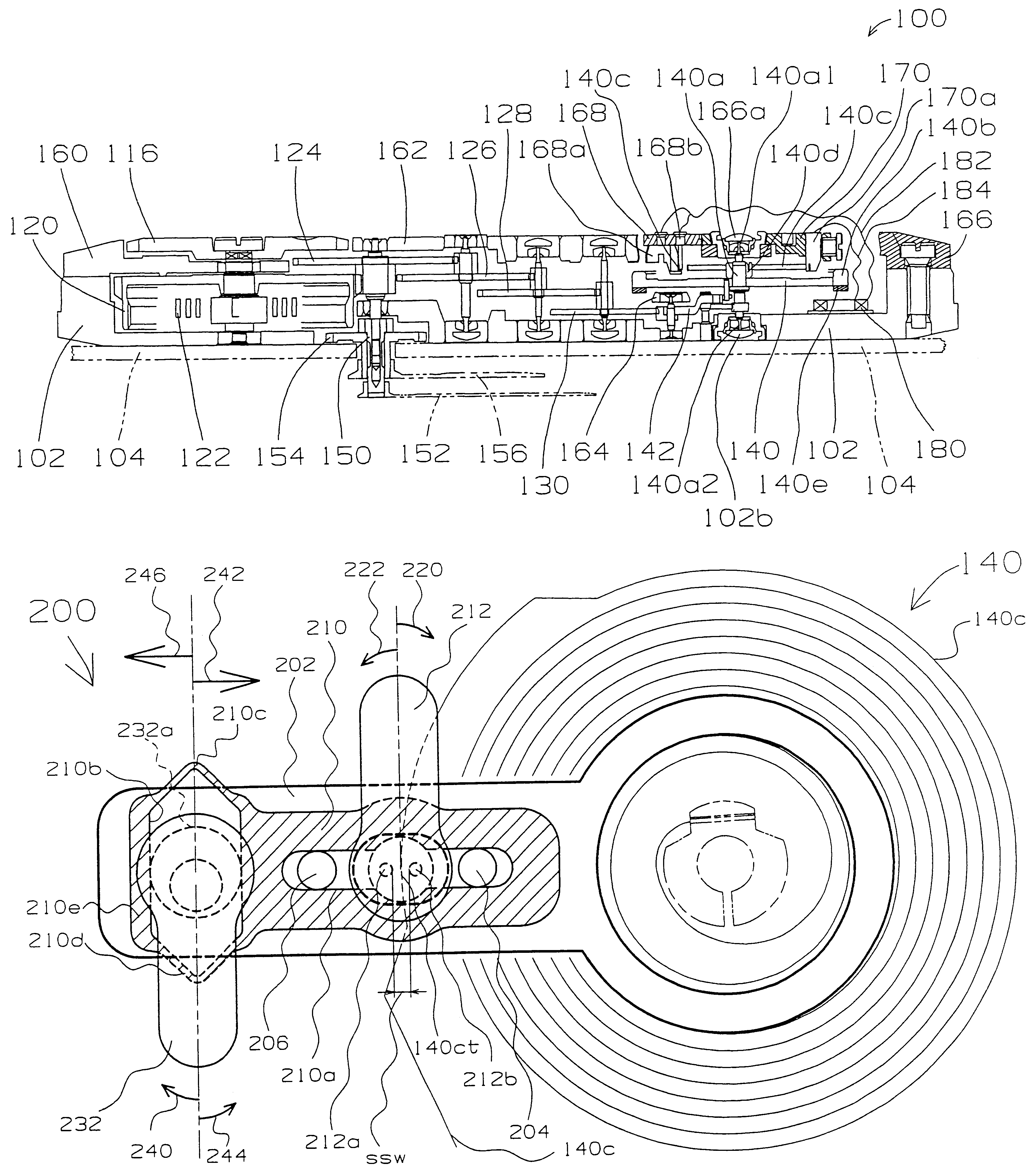

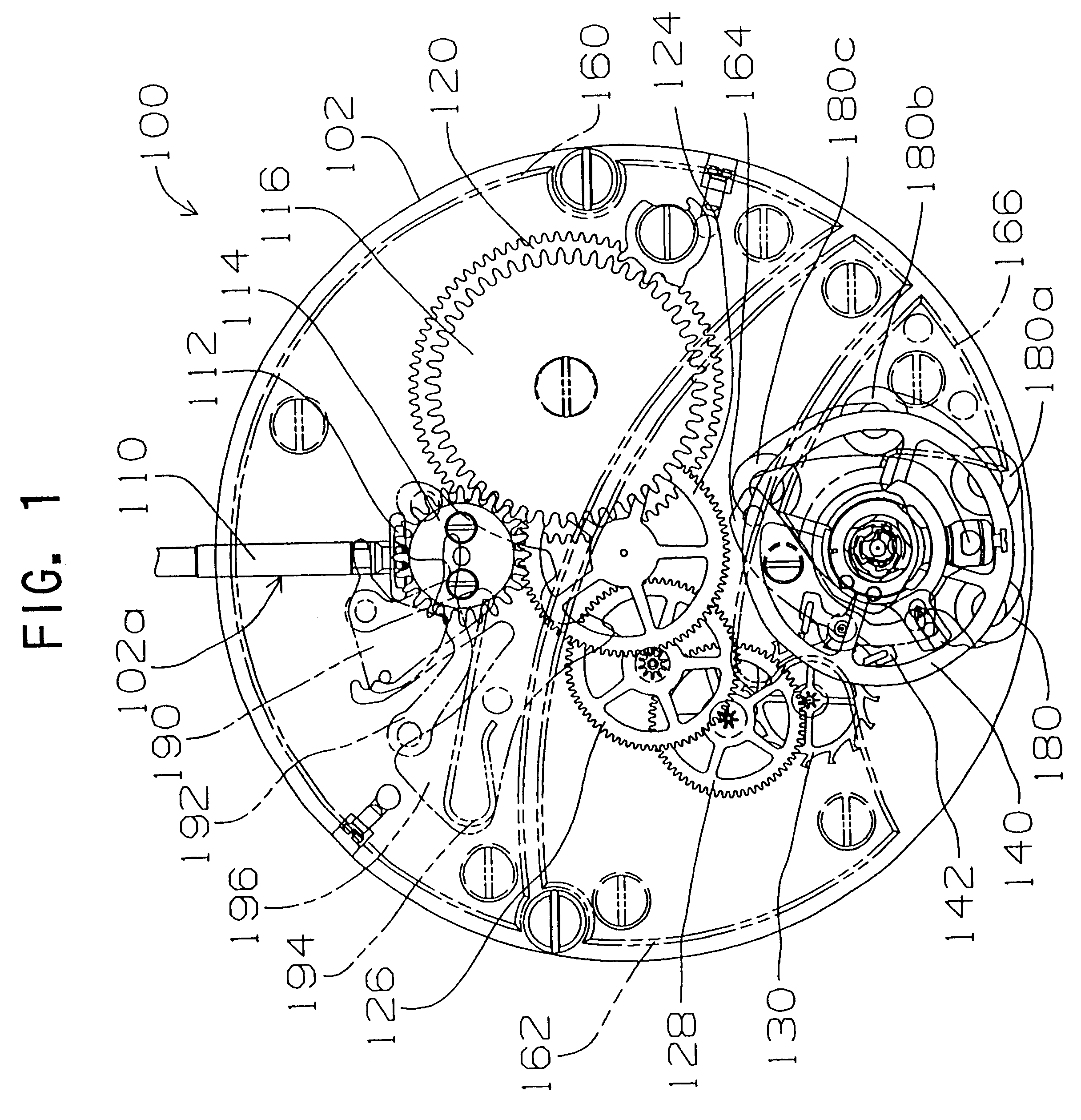

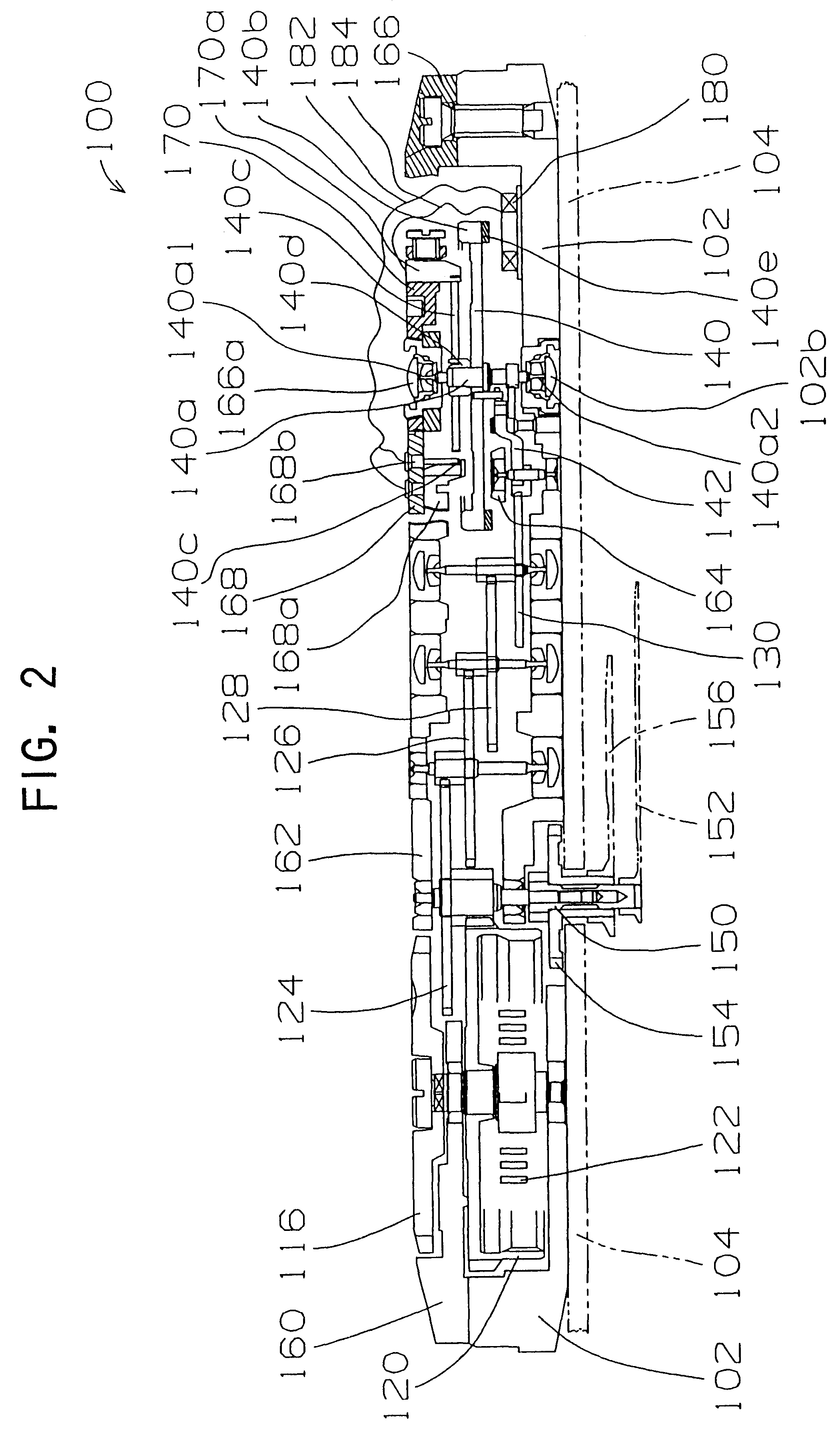

Spring, power spring, hair spring, driving mechanism utilizing them, and timepiece

InactiveUS6843594B1High stressHigh strengthSpring motorFrequency stabilisation mechanismShape changeMainspring

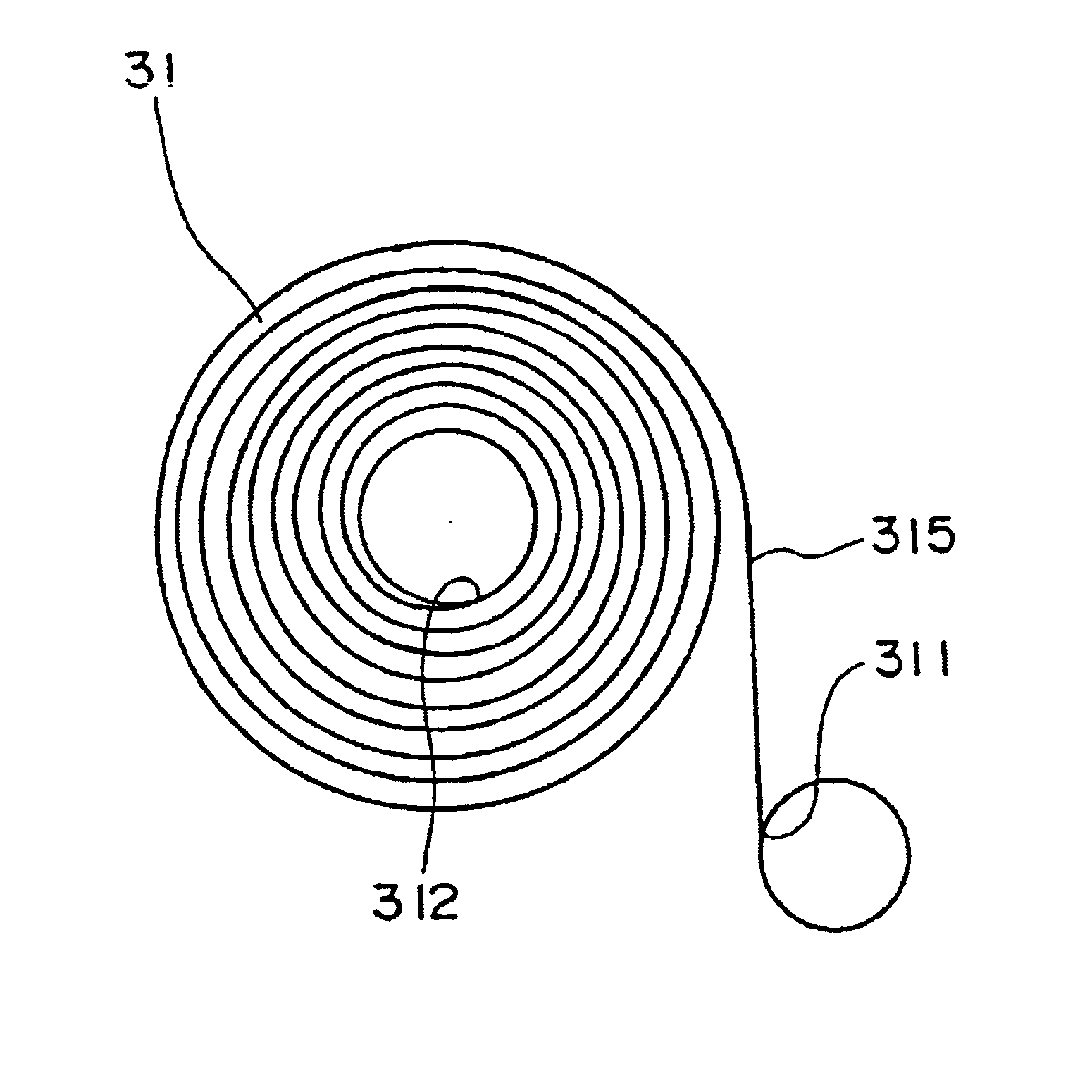

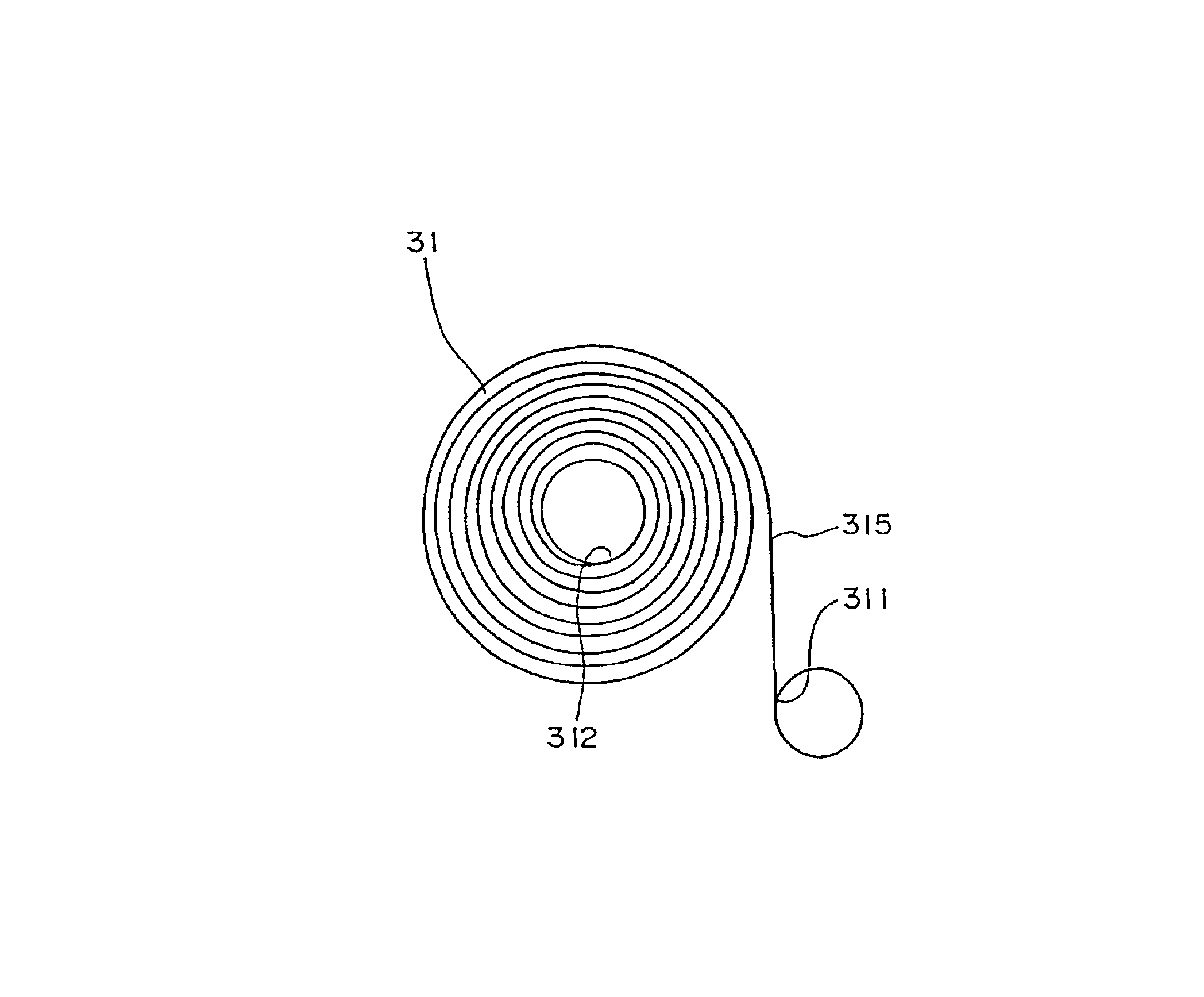

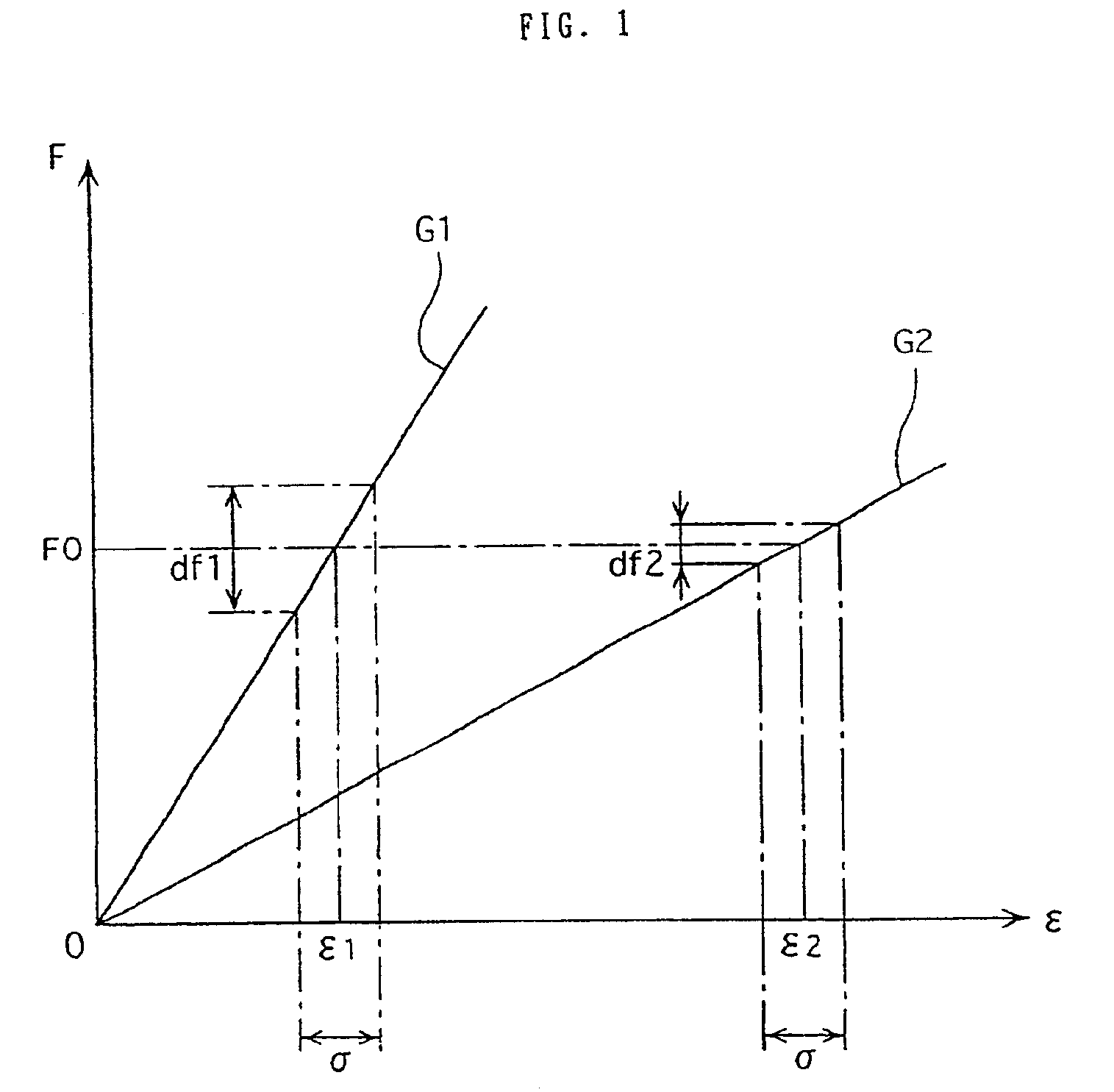

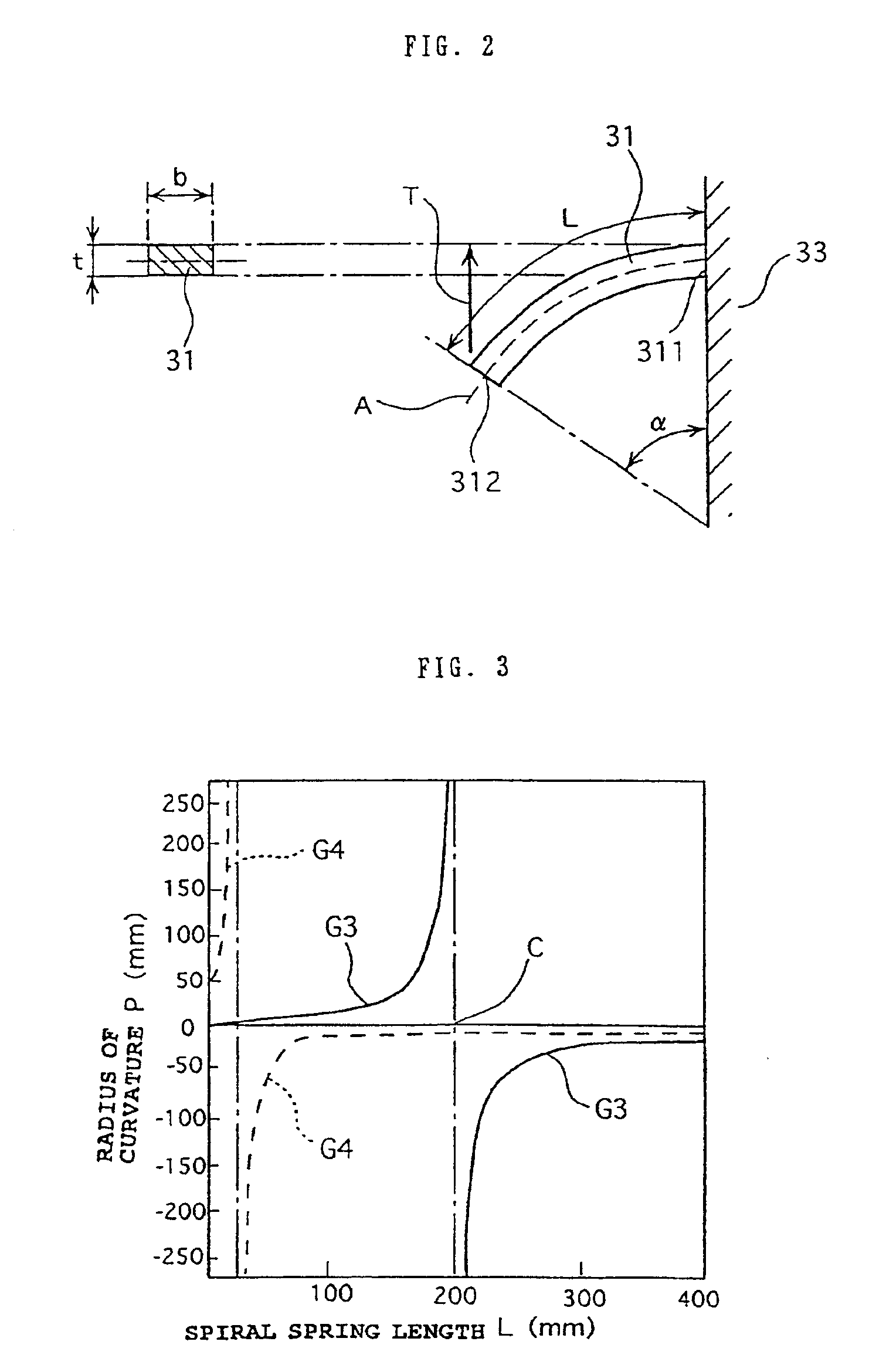

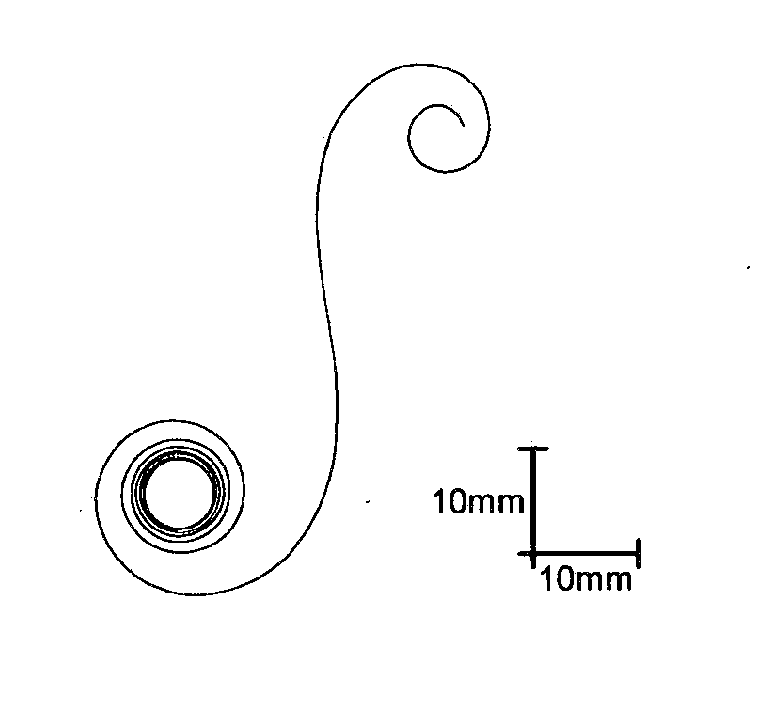

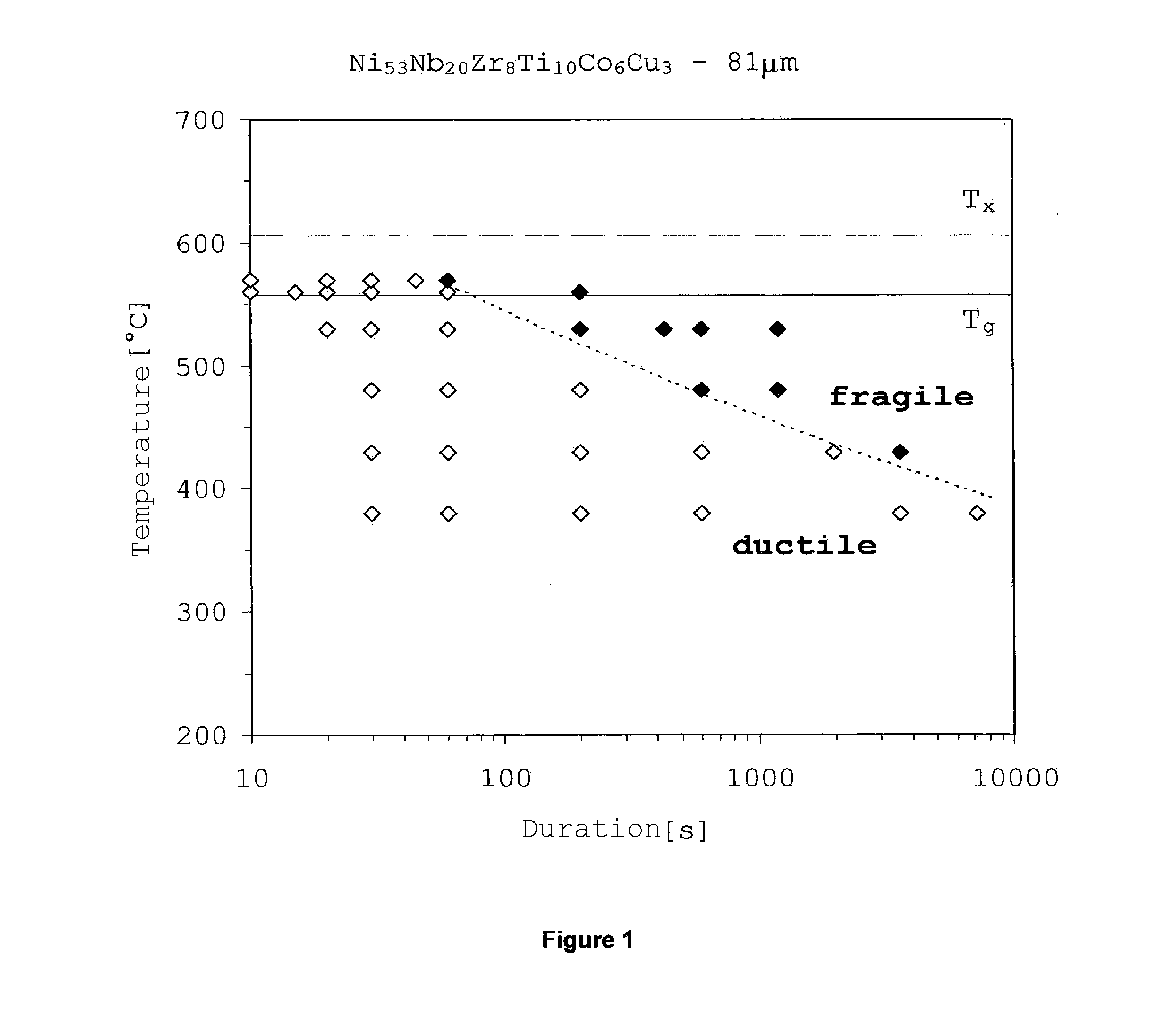

A mainspring used as a power source for a driving mechanism is made of an amorphous metal sheet, and has an S-shaped free-exploded shape. The curvature changing point where the curving direction of the free-exploded shape changes is formed on the inner end side of a middle point between the inner end on the winding side and the outer end serving as the other end of the inner end. Because of the high tensile stress and a low Young's modulus, the amorphous metal permits increase in mechanical energy stored in the mainspring.

Owner:SEIKO EPSON CORP

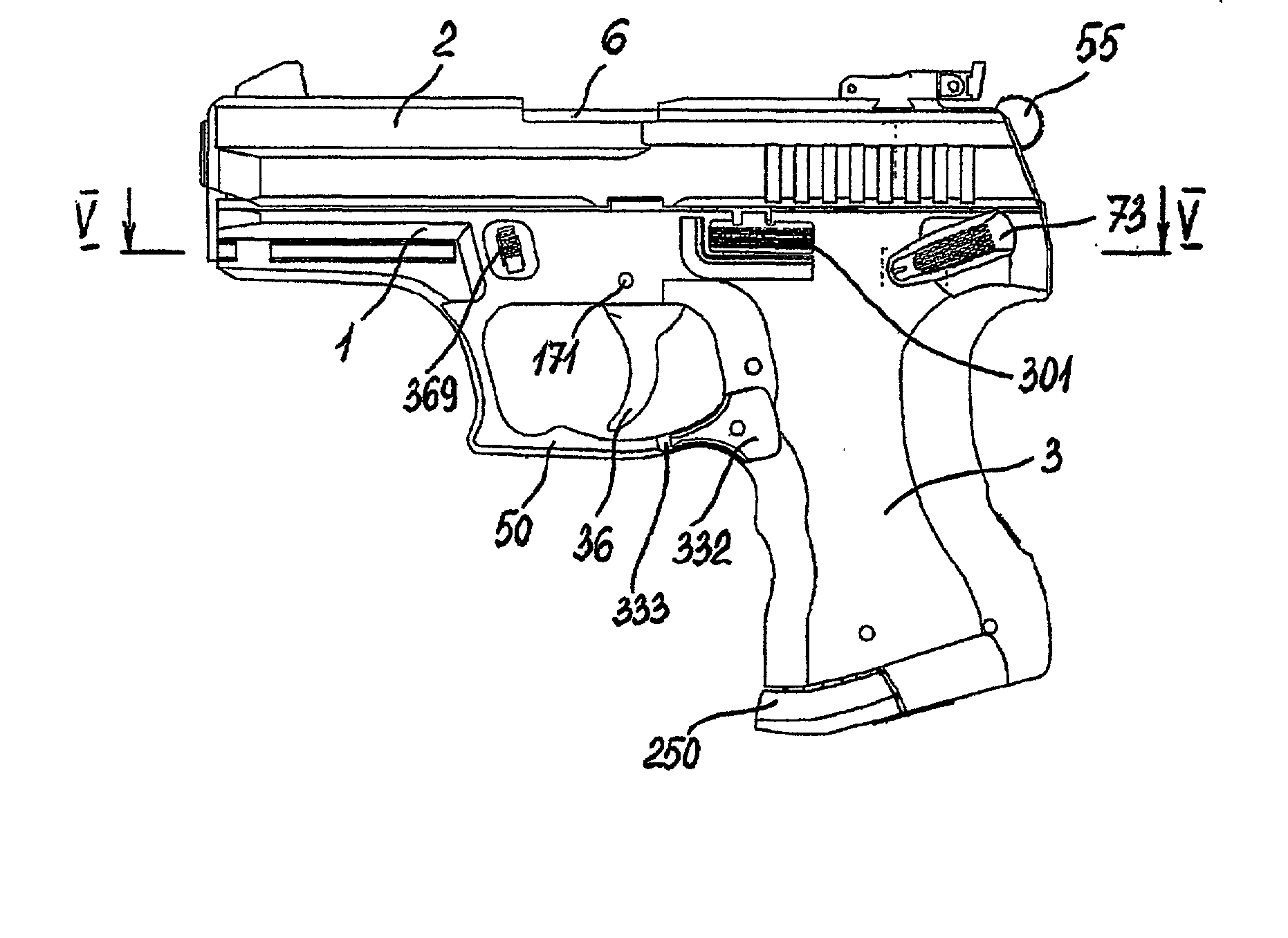

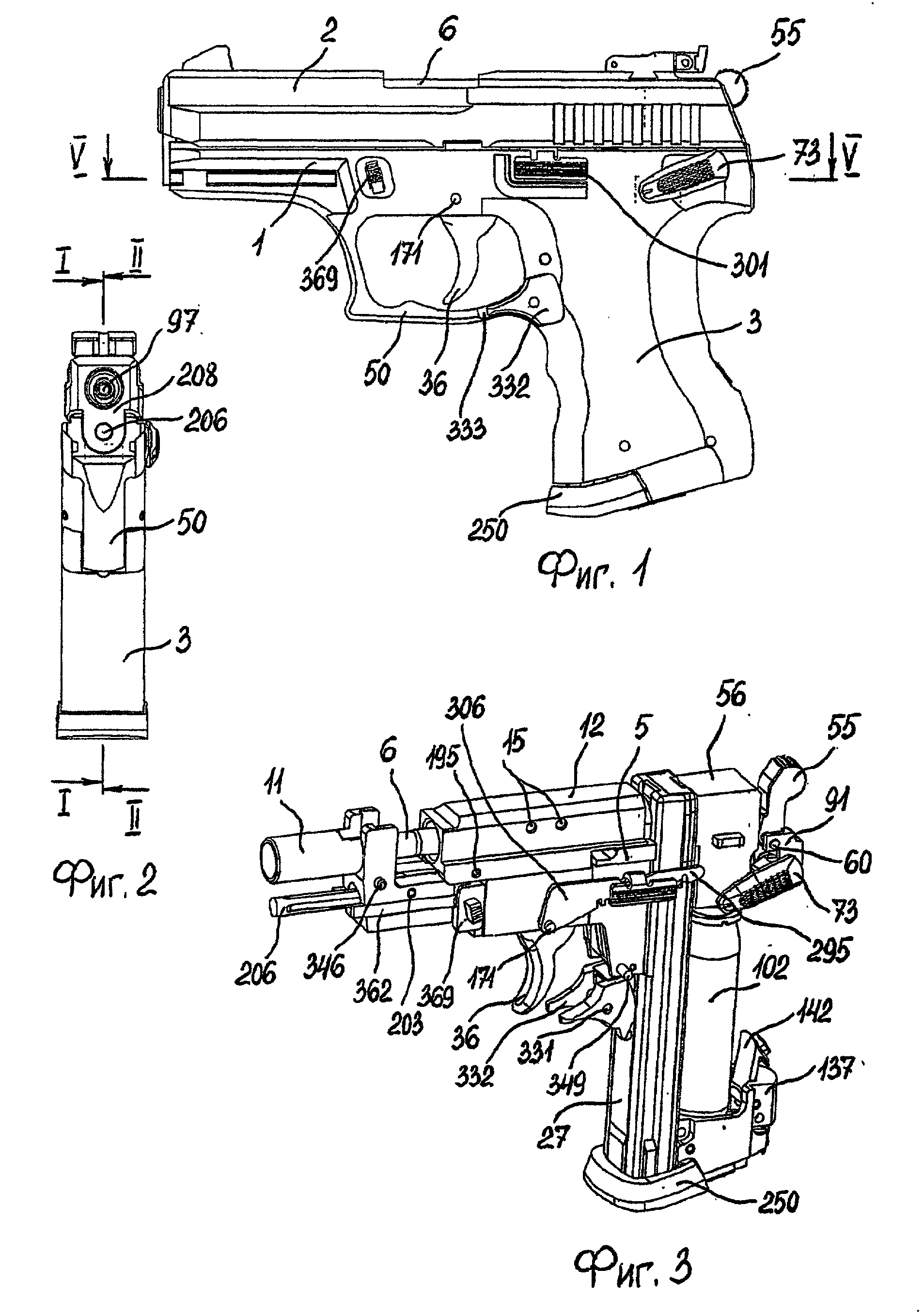

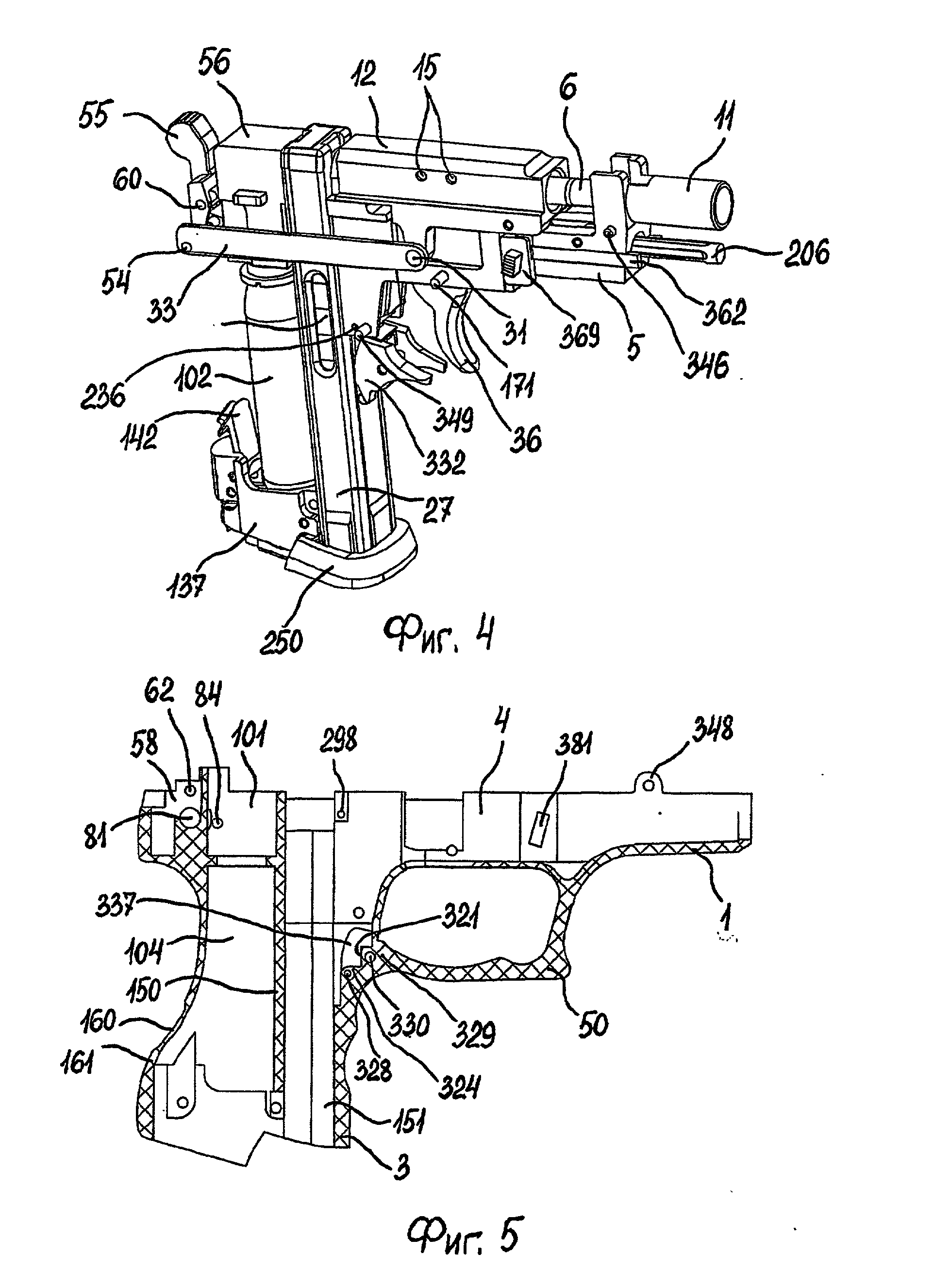

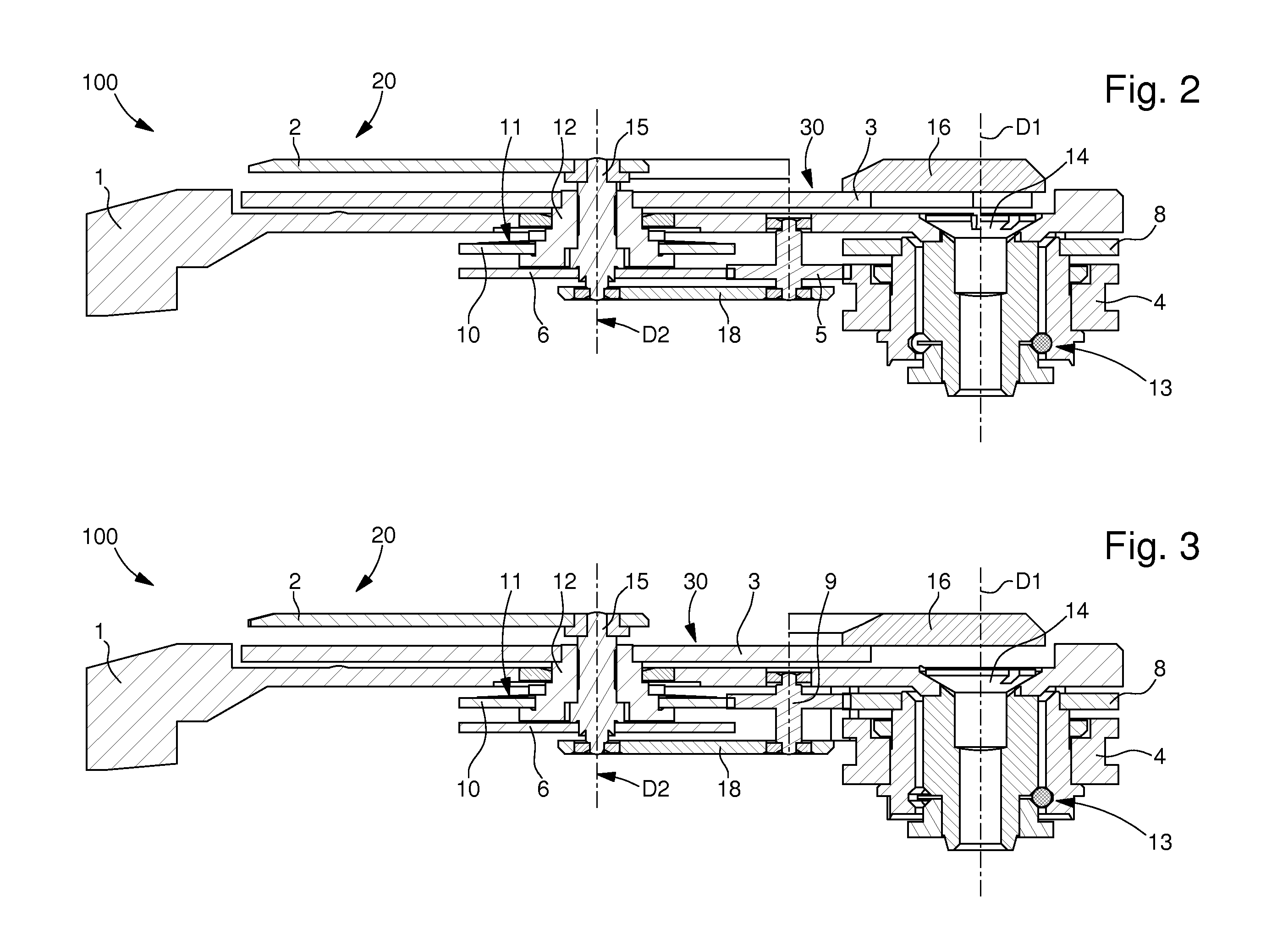

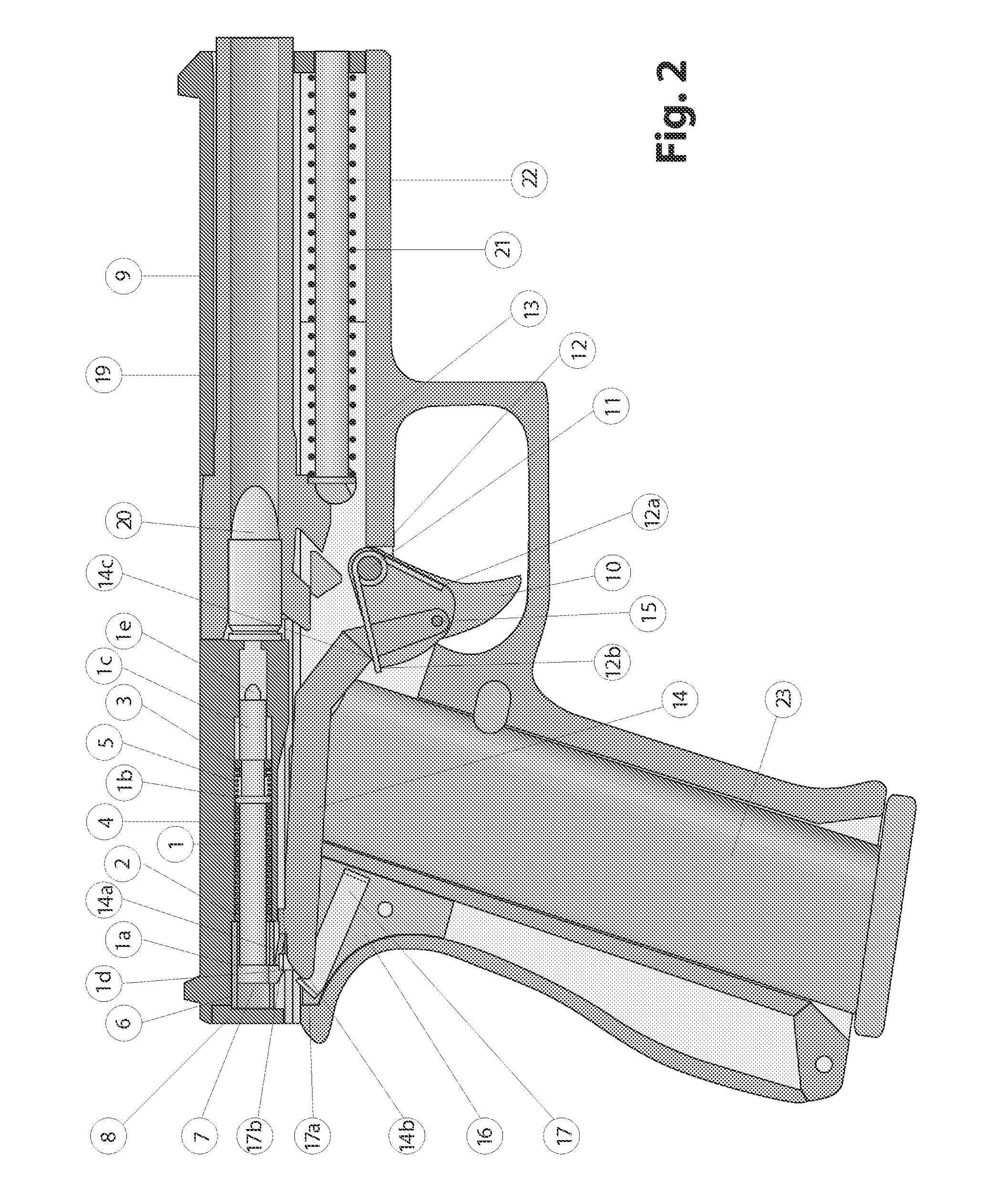

Repeating gas-cylinder pistol

InactiveUS20020139362A1Improve reliabilityImprove and broaden functional potentialityFiring/trigger mechanismsAmmunition loadingGas cylinderMainspring

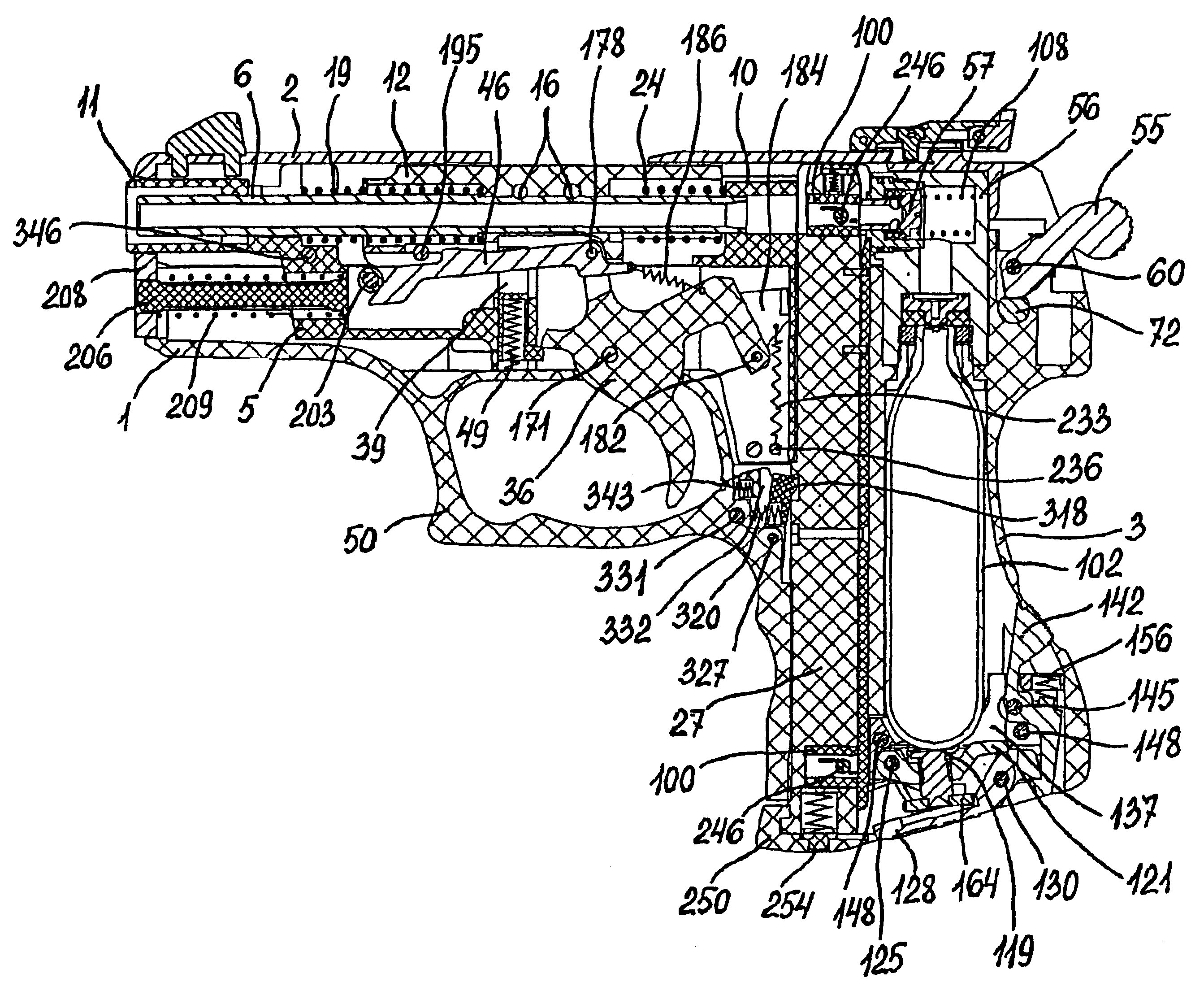

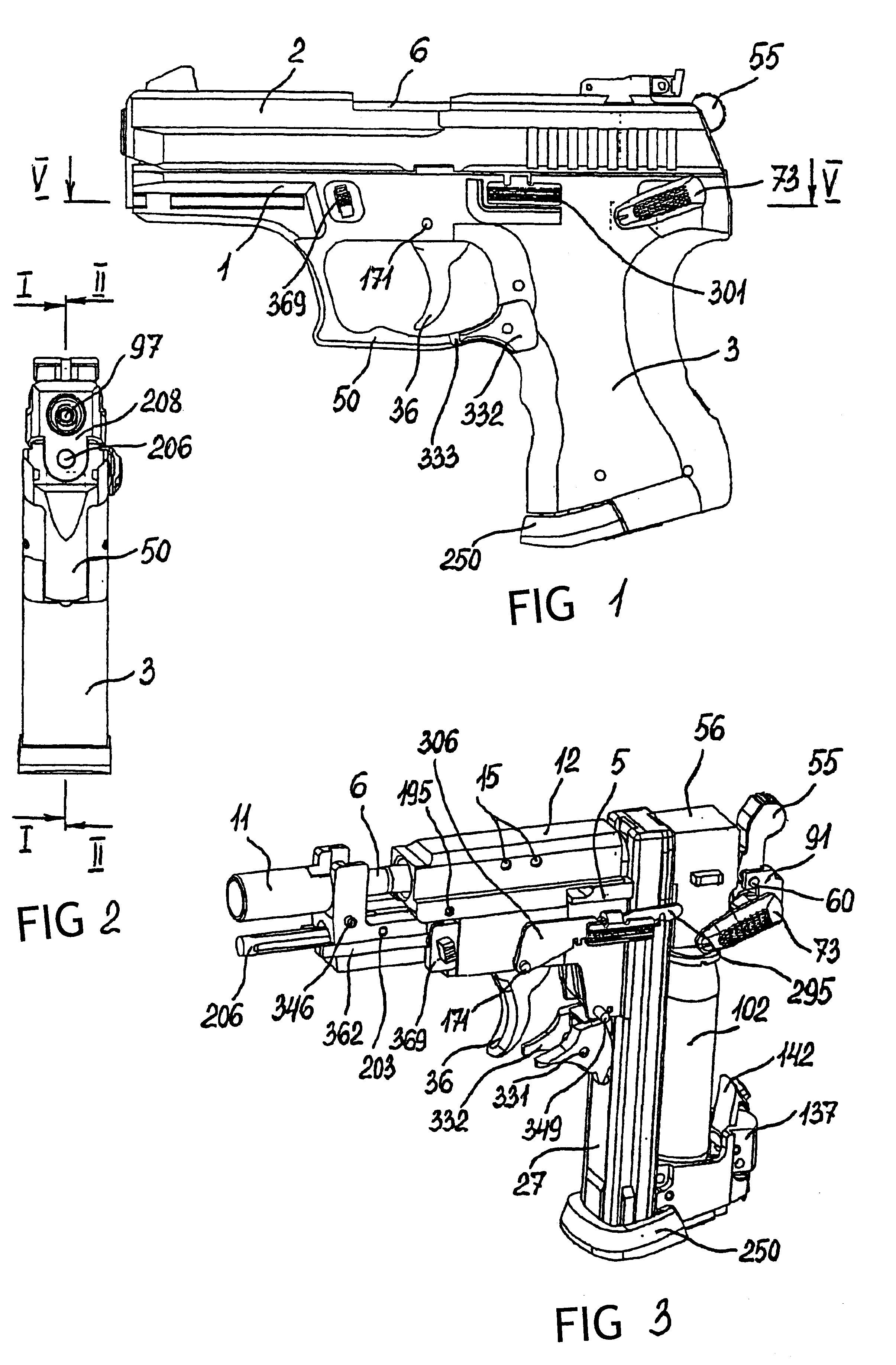

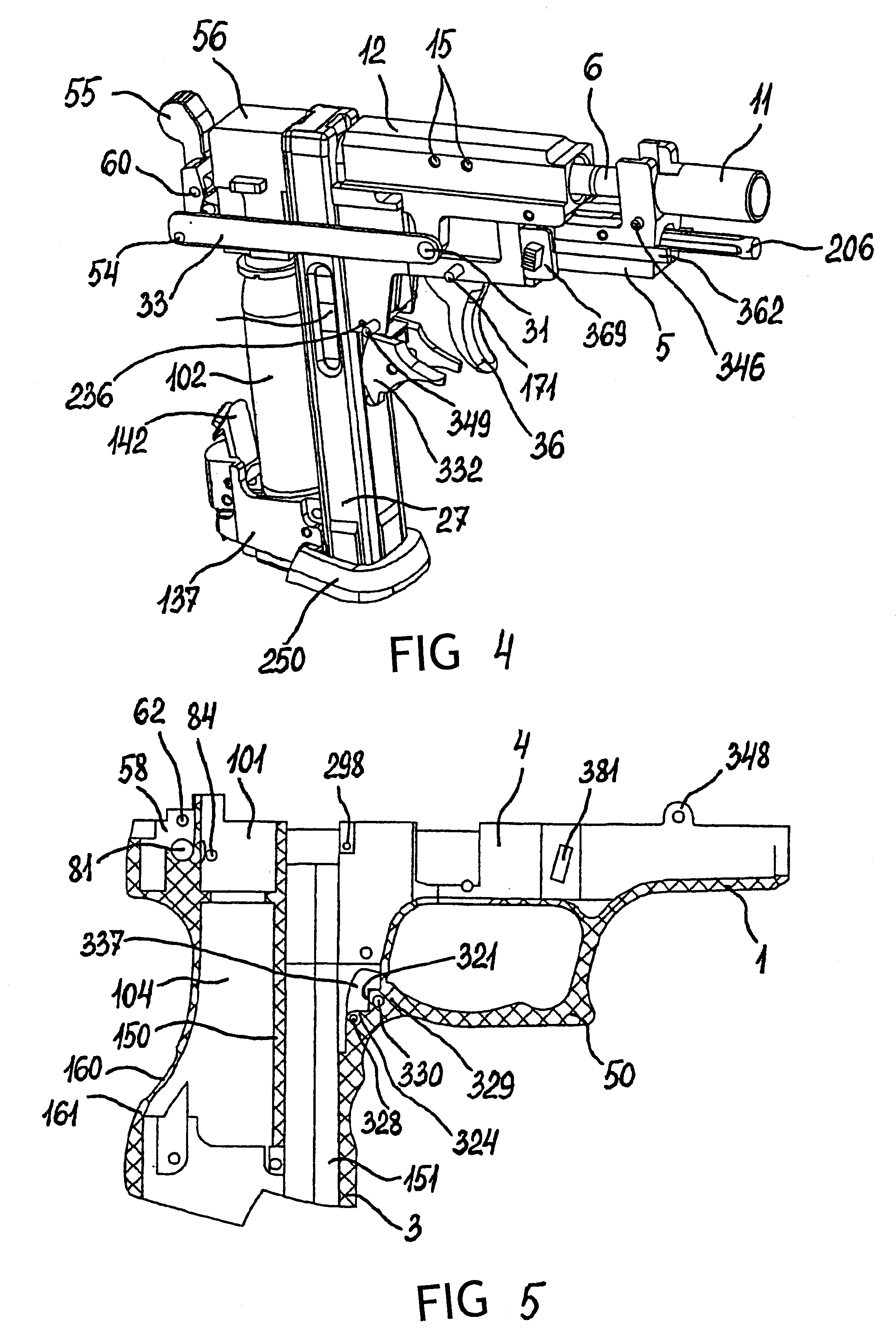

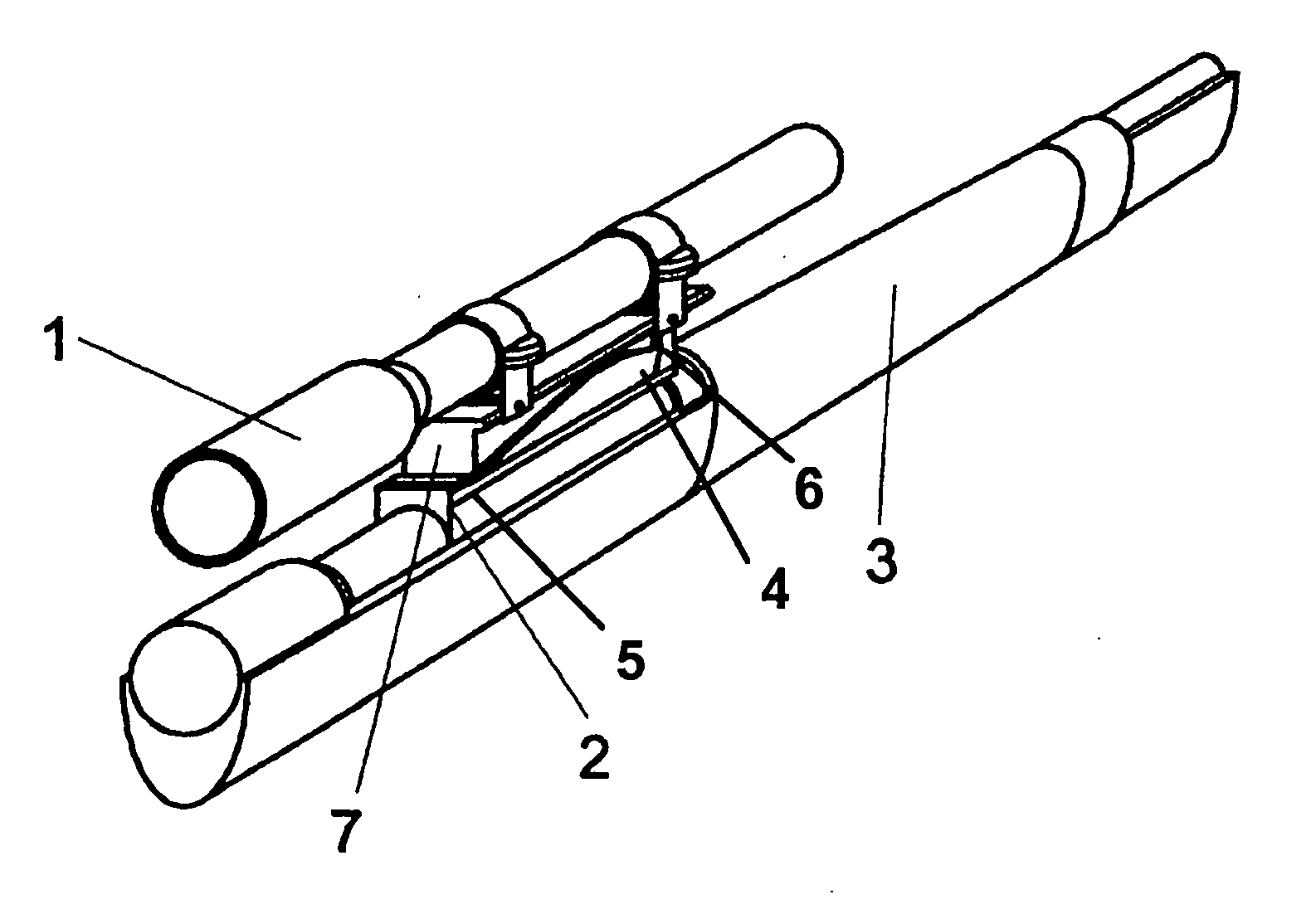

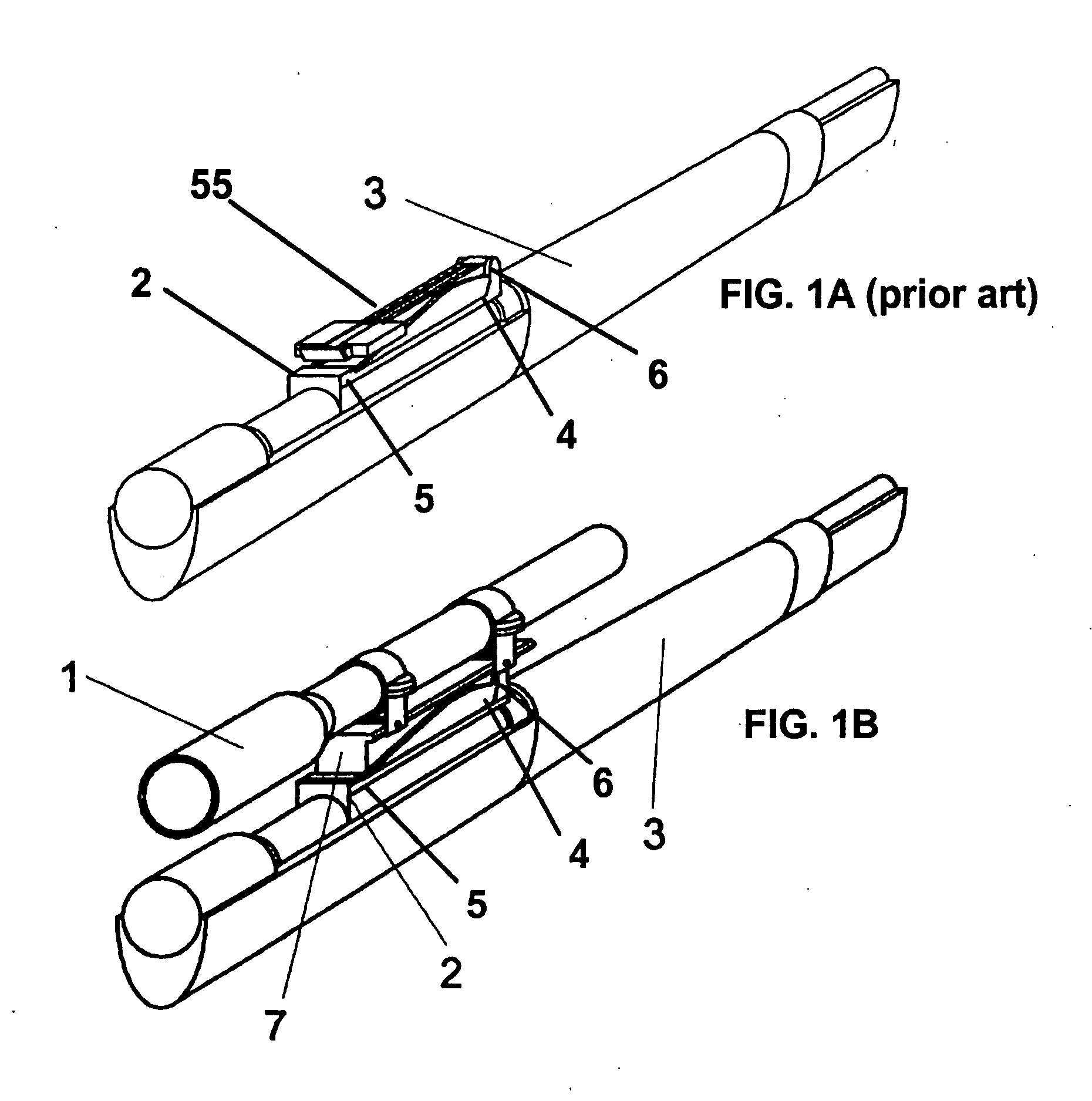

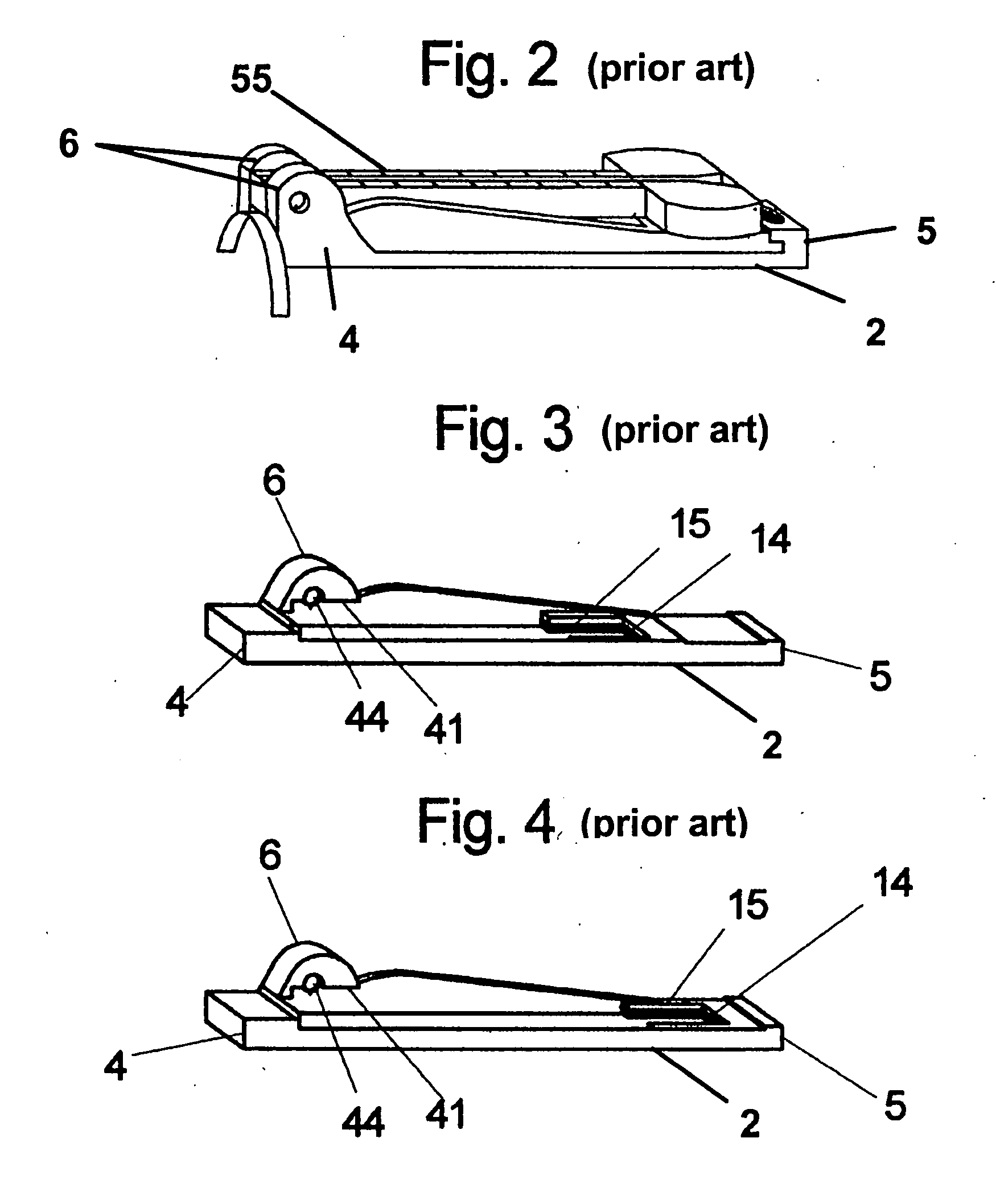

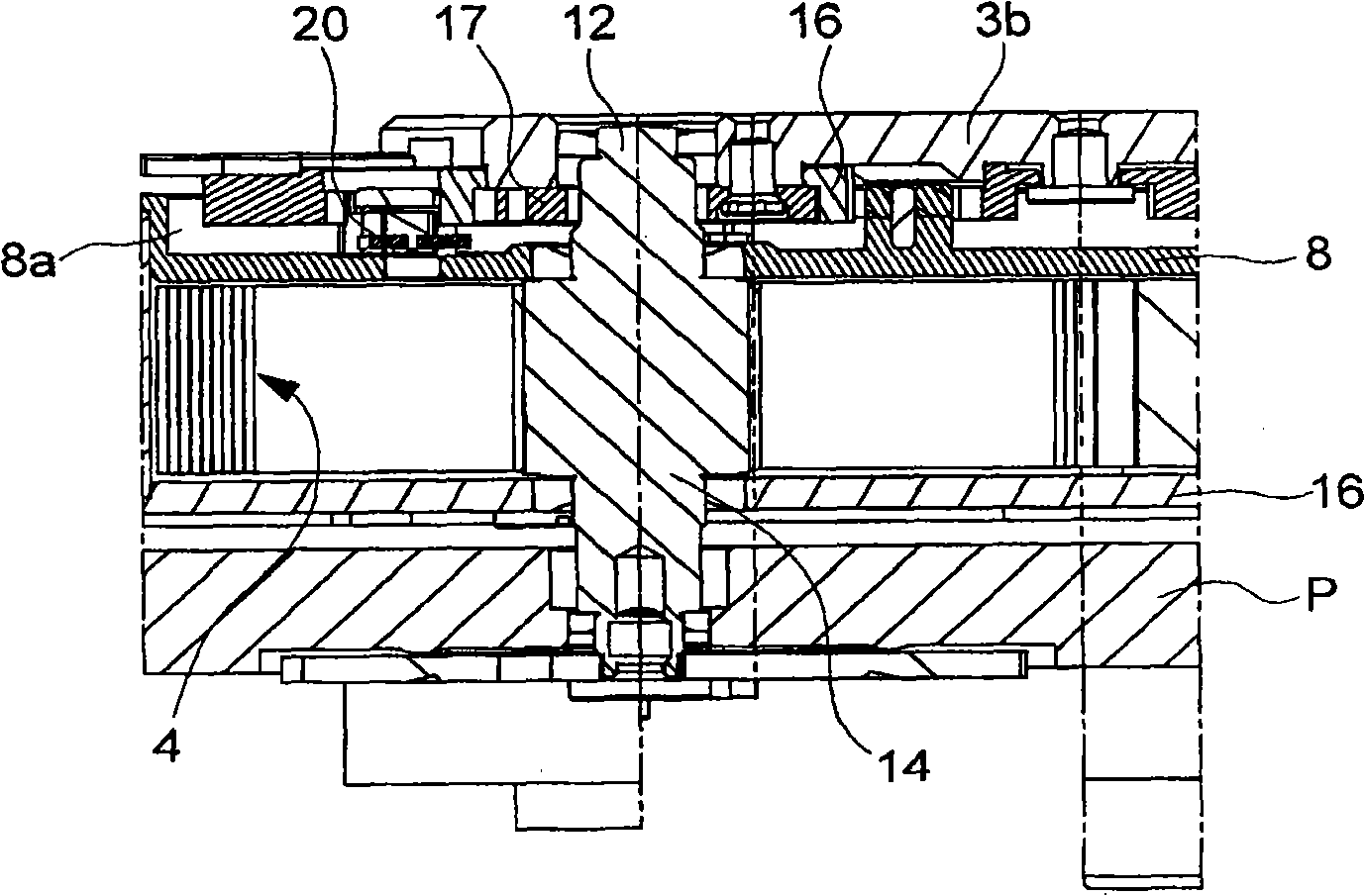

The present invention relates to compressed gas-operated firearms and more particularly to repeating gas cylinder pistols with conveyer feed of bullets for shooting. The pistol comprises a hollow pistol frame (1) made integral with a grip (3) and a trigger bow (50), a movable barrel (6) with a bullet bore (97), a load (12) and a mainspring (19) disposed on the barrel (6), a valve (57) installed in a gas chamber (110) inside a body (56), a gas cylinder (102) installed inside a rear hollow interior (104) of the grip (3), a magazine (27) installed in a front hollow interior (151) of the grip (3), separated from a rear hollow interior (104) by a partition (150), a striker-and-trigger mechanism installed inside the pistol frame (1) and on the trigger bow (50) and interacting with the movable barrel (6) and the magazine (27) for supplying bullets (246) and portions of gas from the gas cylinder (102) to the bullet bore (97) of the barrel (6), a mechanism for installing the gas cylinder (102), disposed below the gas cylinder (102) in the grip (3). In a hollow interior (4) of the pistol grip (1) a support (5) is installed, which serves as a base for the movable barrel (6) that moves along the support (5) under the action of the striker-and-trigger mechanism. The magazine is equipped with containers (100), each container (100) accommodating one bullet (246), and is installed so that an upper part of the magazine (27), extending above the pistol frame (1), is disposed between the barrel (6) and the valve (57), and the bullet opening (98) provided in a front wall (99) of the magazine (27), through which the bullet (246) under the effect of a portion of gas gets into the bullet bore (97) of the barrel (6), is disposed coaxially with the bullet bore (97), with the valve (57) and the container (100) which assumes such position before each shot. A breech block (2)is installed above the pistol frame (1).

Owner:ZAKRYTOE AKTSIONERNOE OBSHCHESTVO GRP ANICS

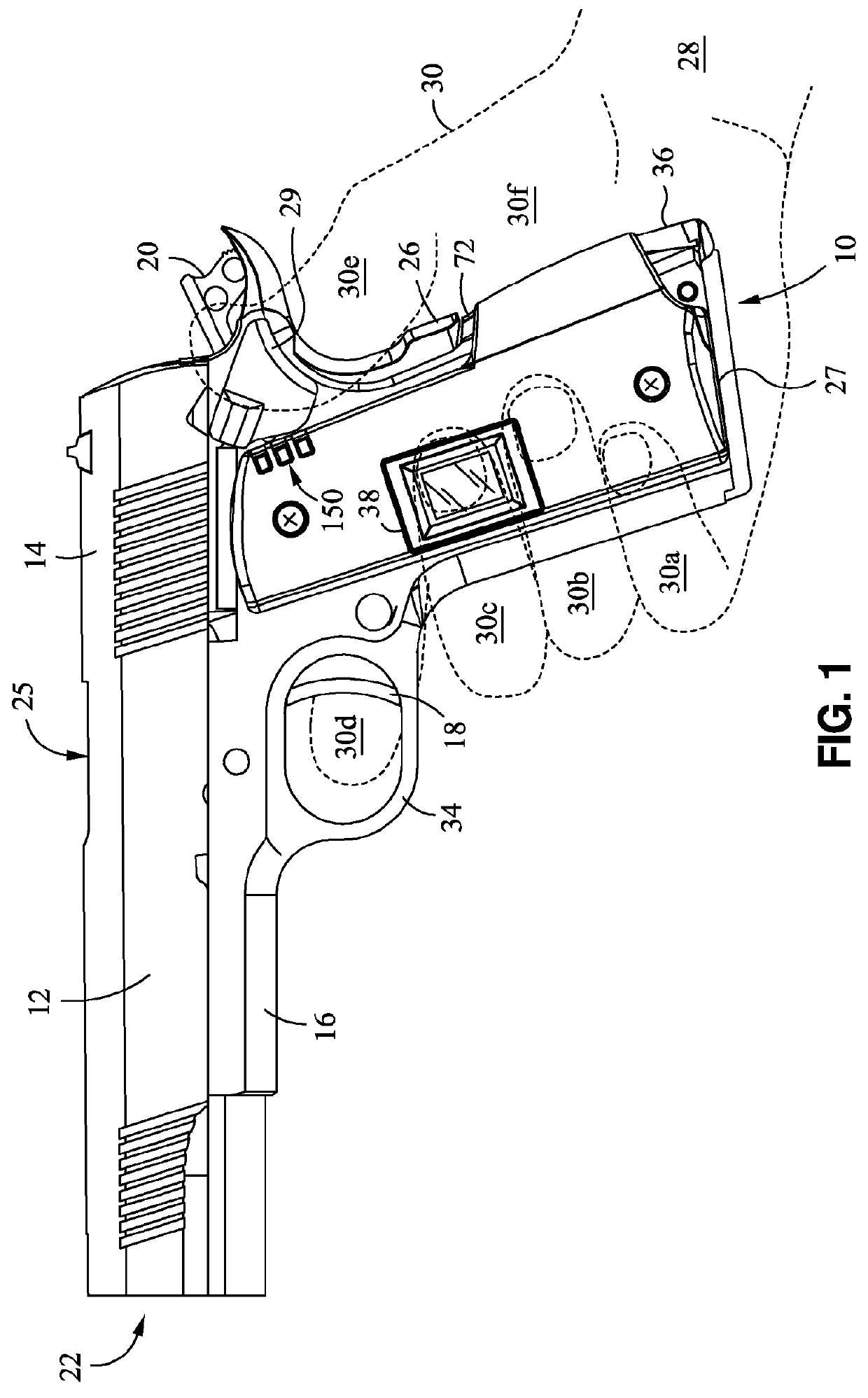

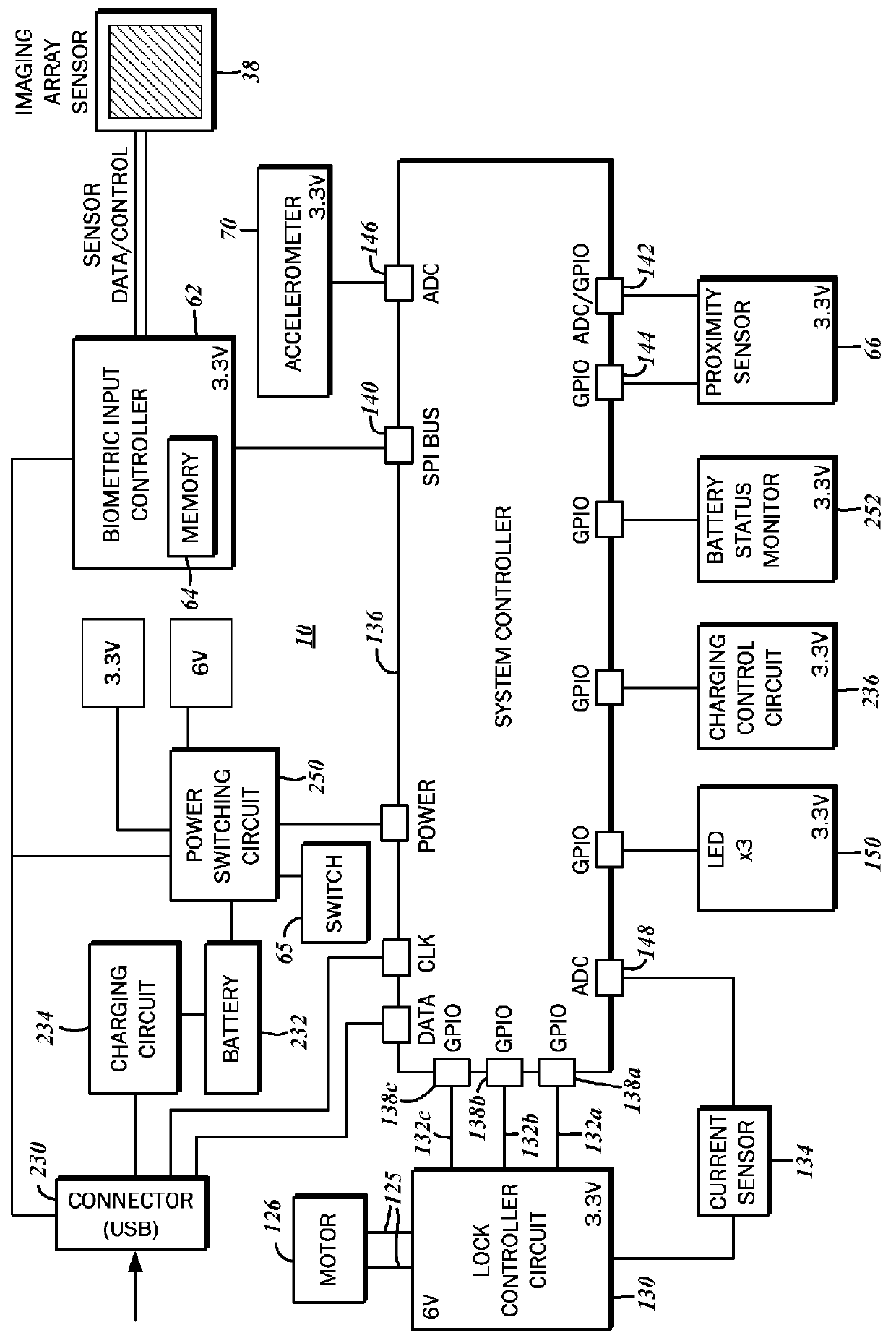

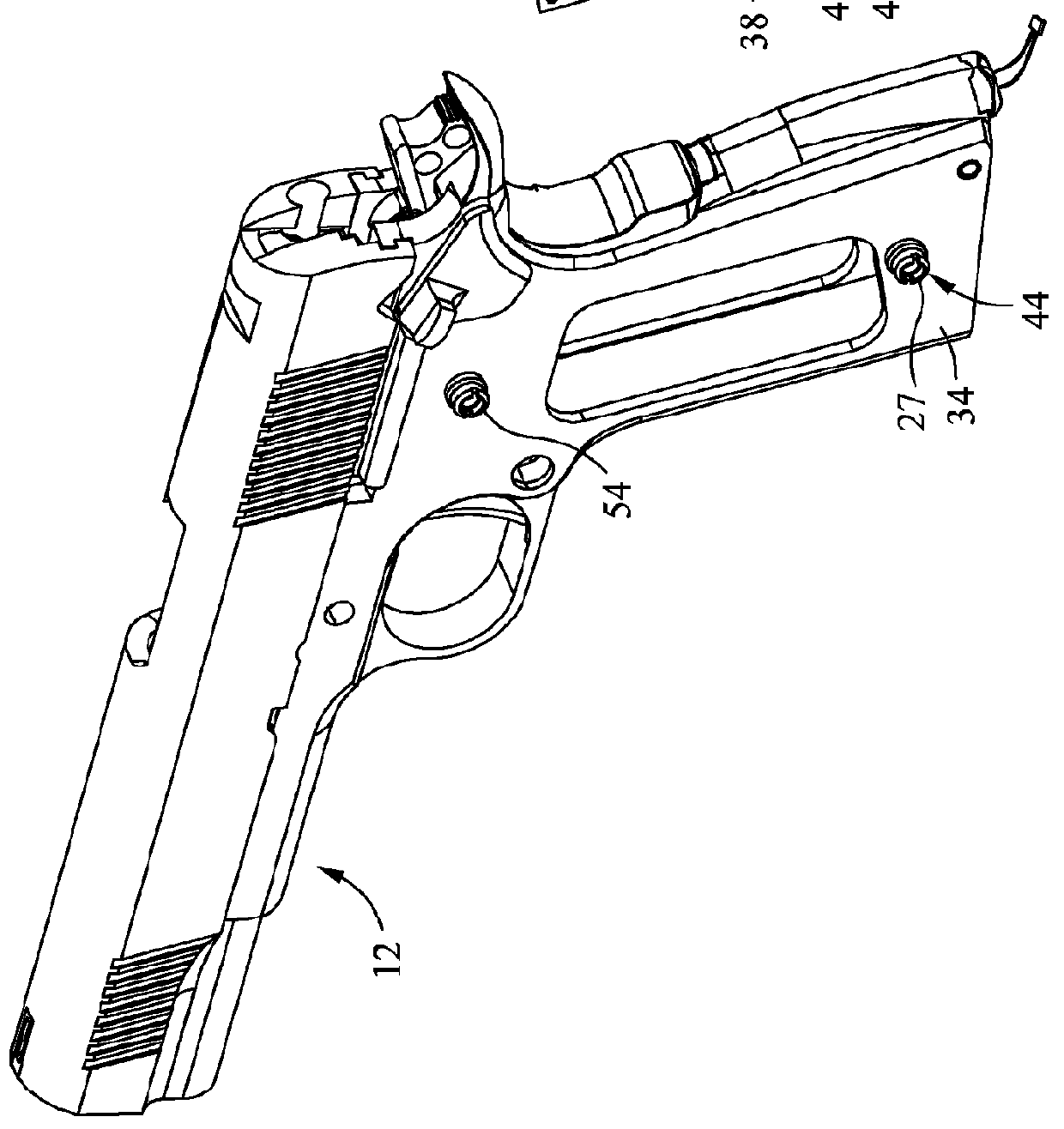

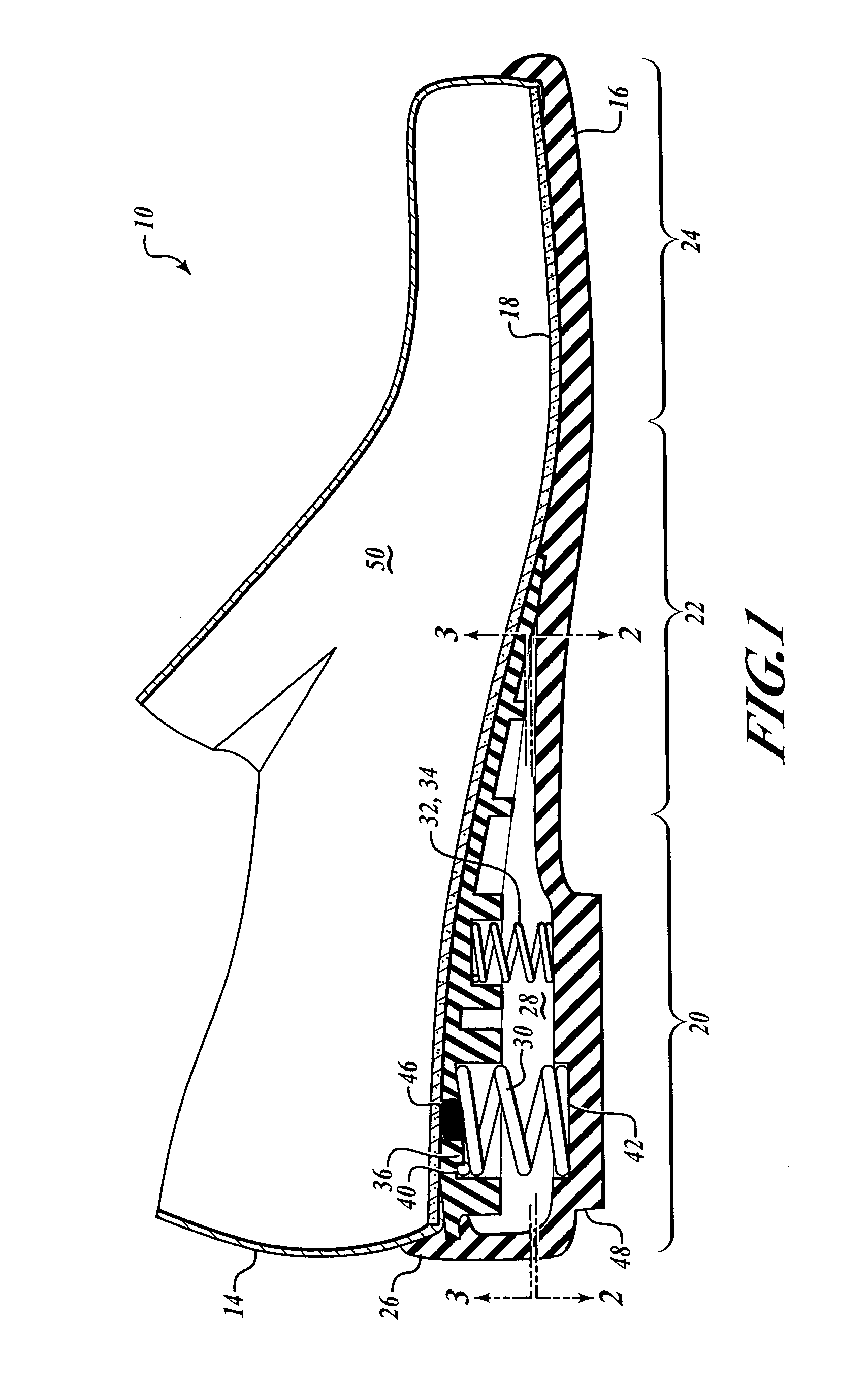

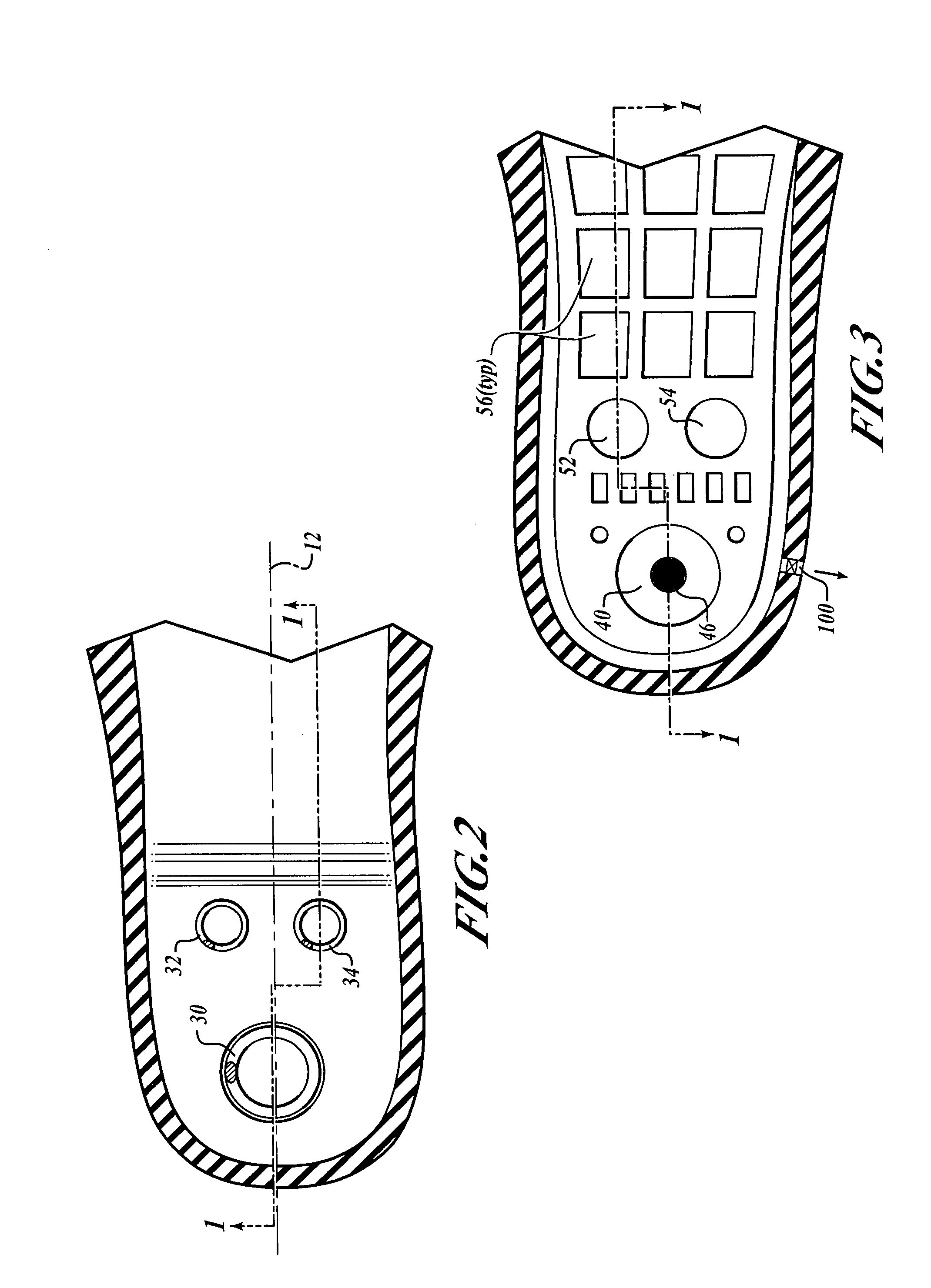

Firearm safety lock

A lock for a firearm with a grip safety, and a sear engageable to a biased hammer in a cocked position and releasable by a trigger is disclosed. The lock has a housing defining a first bore within which a mainspring that biases the hammer is received, as well as a second bore. There is a locking pin retractable into and extendible out of the second bore of the housing. When the locking pin is in an extended position, the grip safety is restricted to an engaged state, blocking movement of the trigger. An actuator disposed in the housing and cooperatively linked to the locking pin provides the motive force for retracting and extending the locking pin.

Owner:INTELLIGUN

Fan assembly

InactiveUS8408869B2Lower center of gravityLess prone to falling overPump componentsLighting and heating apparatusMainspringEngineering

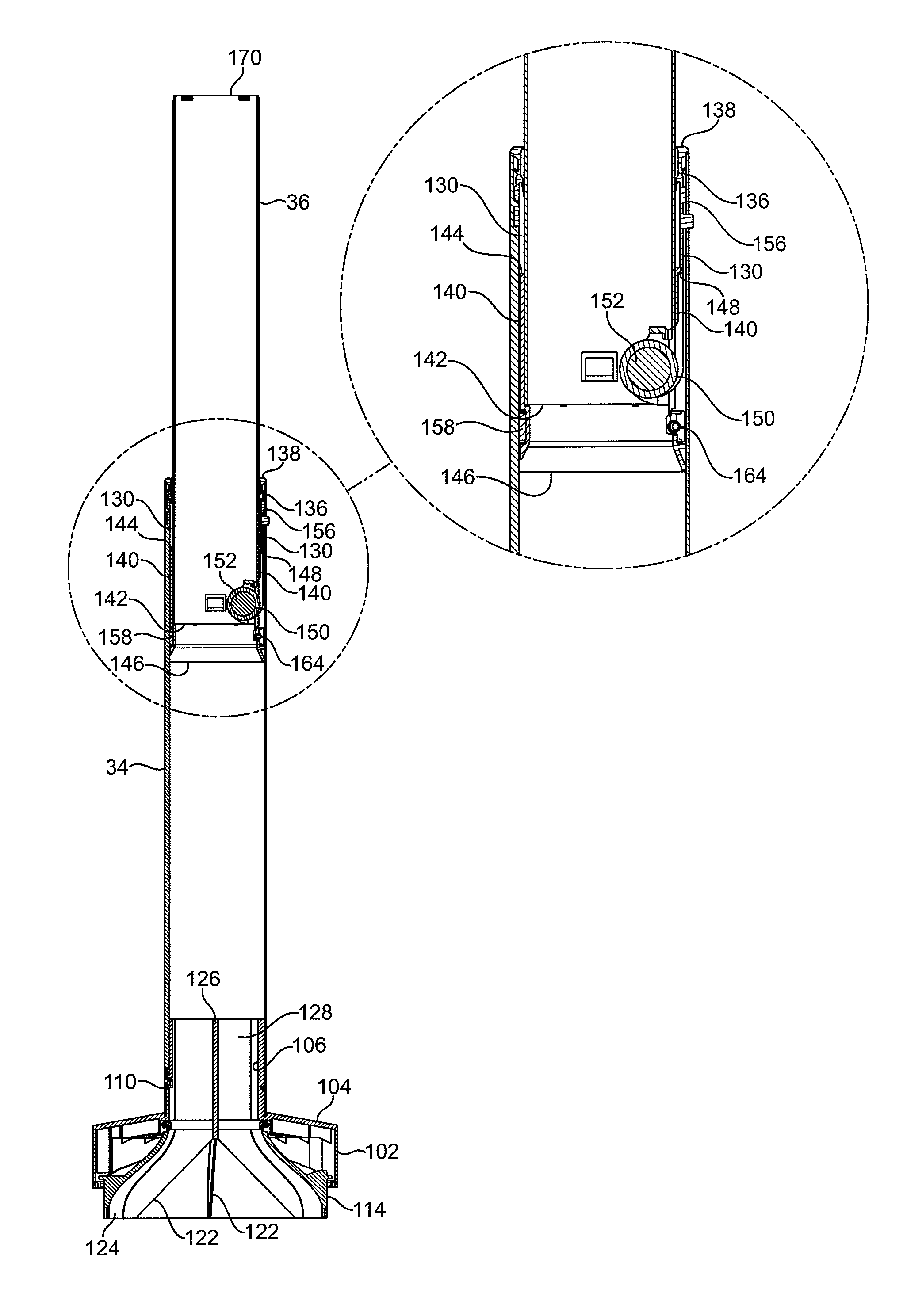

A pedestal for a fan assembly includes a telescopic duct for conveying an air flow to an outlet of the fan assembly. The duct includes an outer tubular member having a first stop member, an inner tubular member located at least partially within and slidable relative to the outer tubular member, the inner tubular member having a second stop member for engaging the first stop member to inhibit withdrawal of the inner tubular member from the outer tubular member, and a mainspring rotatably mounted on the second stop member, the mainspring having a free end retained by the first stop member.

Owner:DYSON TECH LTD

Ventilated and resilient shoe apparatus and system

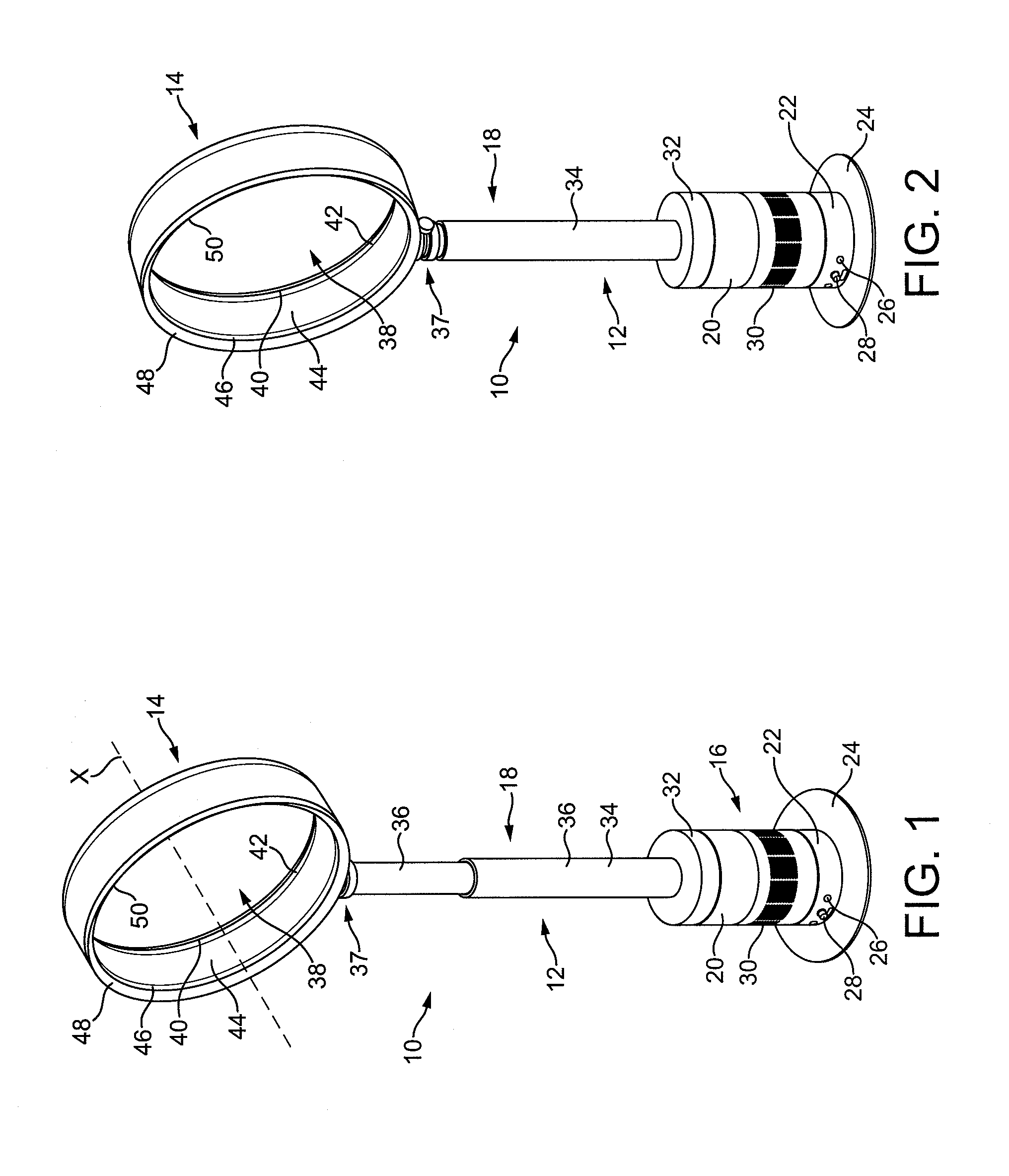

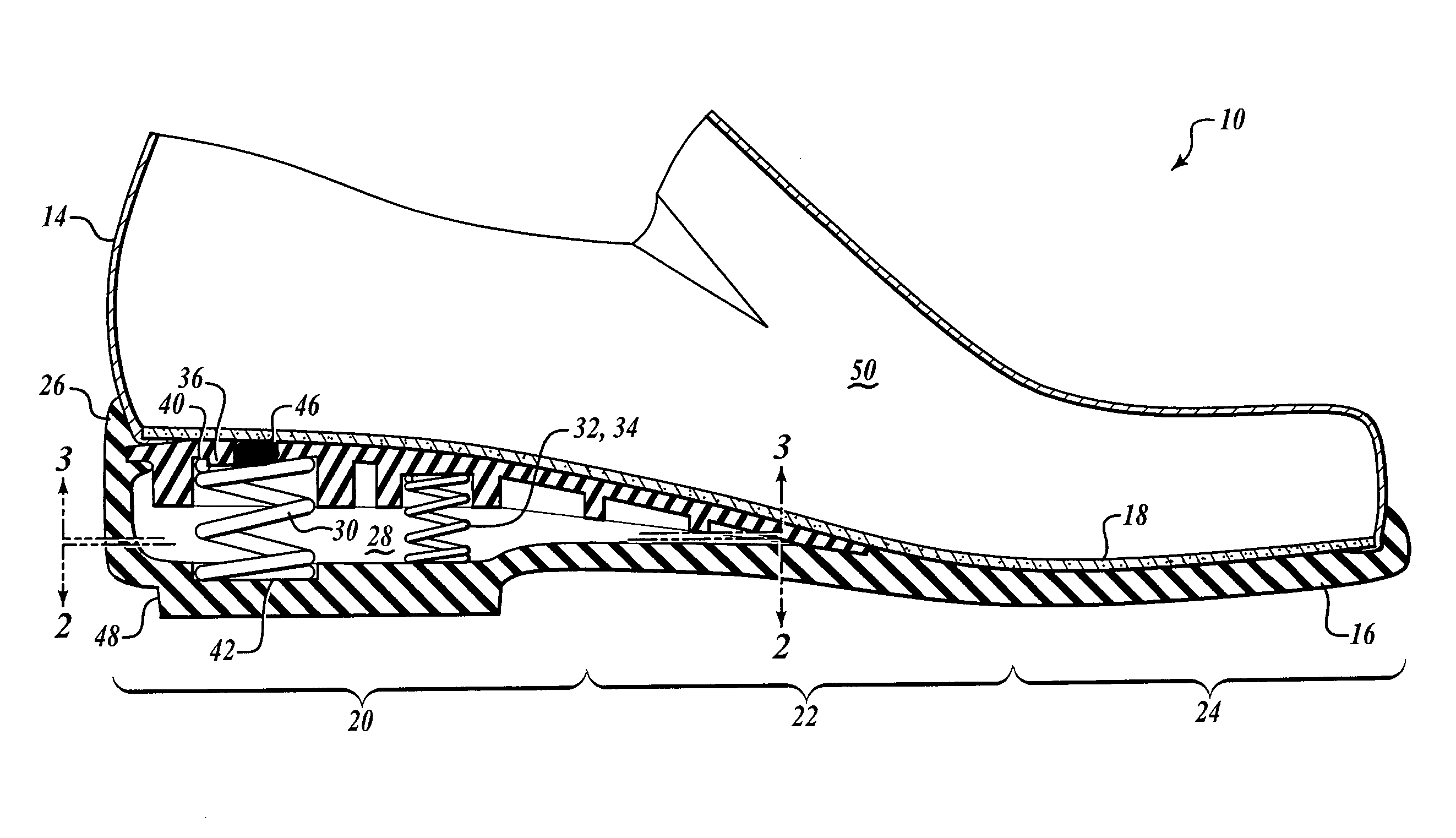

An improved shoe includes an apparatus and system for ventilating inside the shoe and a resilient shoe. External air desirably enters the shoe around the wearer's foot and flows through holes in the sole into aeration chambers. The air circulates to the heel by a suction valve and is controllably directed out to the exterior of the shoe through a one-air air exhaust valve, ventilating the wearer's foot while an individual is walking. The heel is made from a resilient material and has a cavity extending under the entire instep portion of the shoe's upper. Compression springs are placed in the cavity, including a mainspring located at approximately the heelstrike point and two auxiliary springs for stability located forward of the mainspring toward the shoe's toe. The action of the springs is distributed throughout the sole by a resilient layer of softer rubber adjacent the sole to provide for a resilient walking experience.

Owner:ELNEKAVEH ALEXANDER

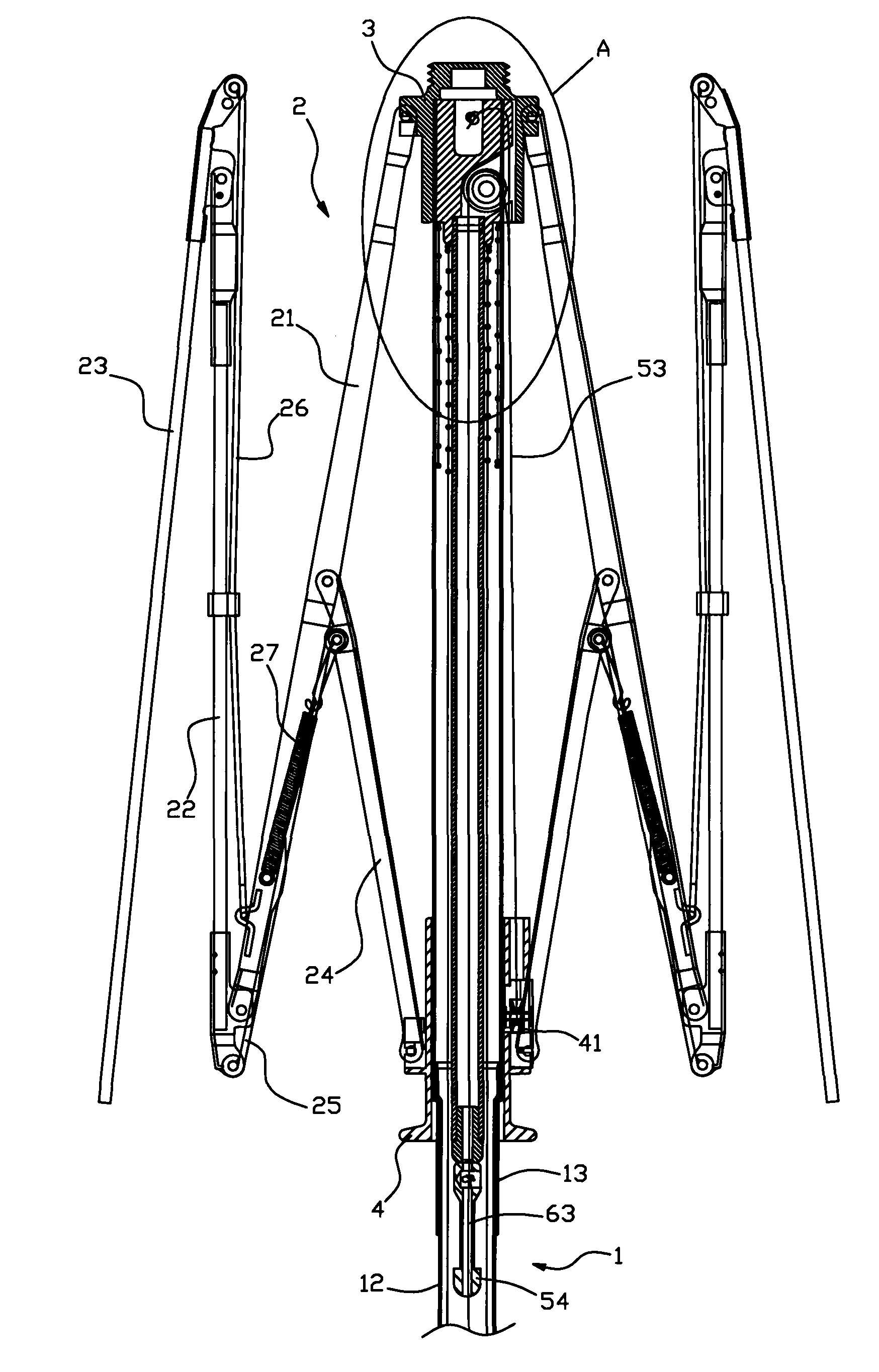

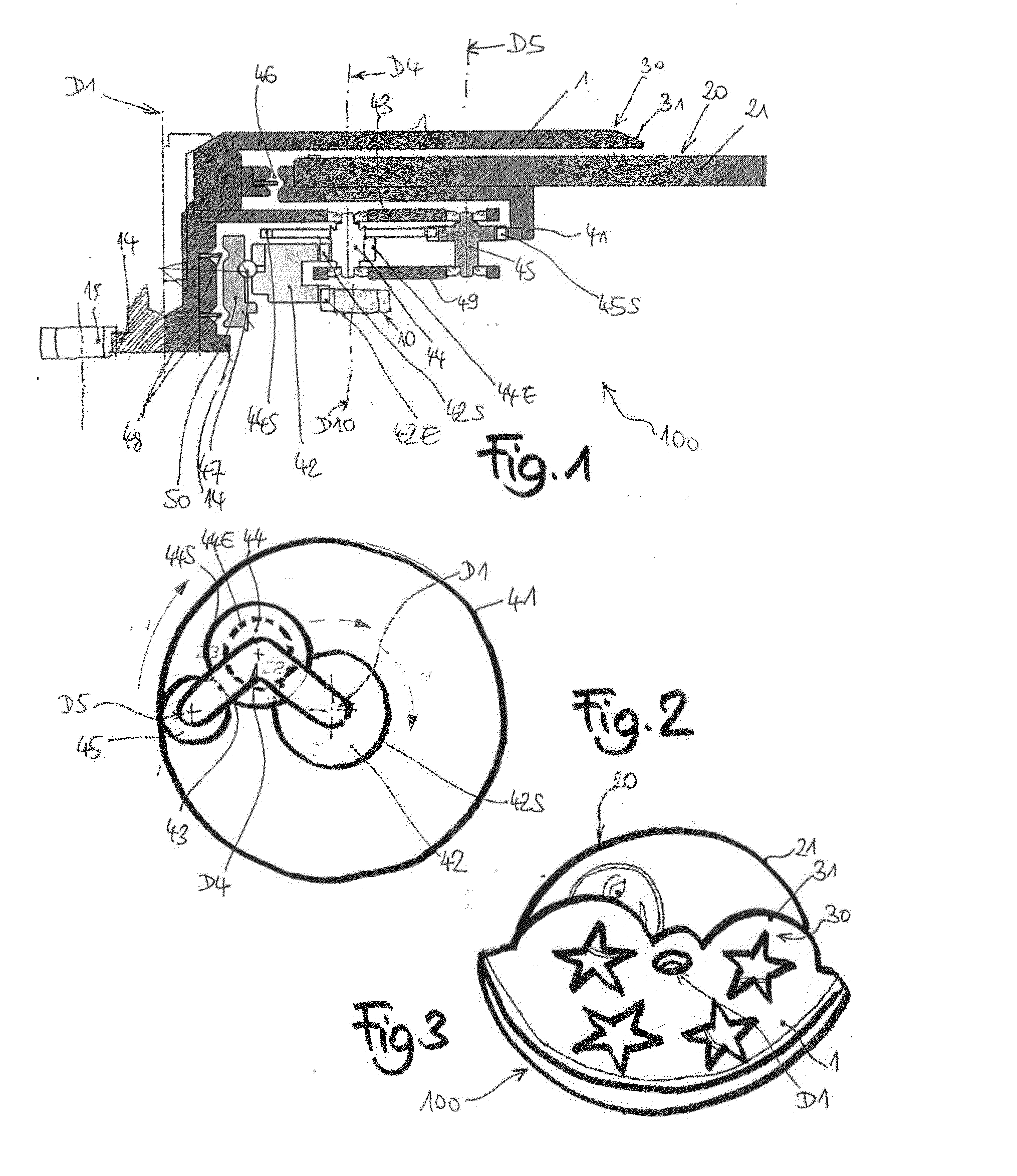

Safely foldable automatically expanding/collecting umbrella

The invention discloses a safely foldable automatically expanding / collecting umbrella, which comprises a telescopic umbrella middle rod, an expandable umbrella rib device and a ratchet and pawl device, wherein the ratchet and pawl device is arranged in the umbrella head. The spindle of a ratchet is provided with a rope; the ratchet is connected with a clockwork spring; the clockwork spring is tightened when the ratchet rotates counterclockwise, and the ratchet rotates clockwise when the clockwork spring is loosened; and a ratchet spring which is used for driving a pawl to match with the ratchet is arranged in the umbrella head. When the middle rod is pressed in an umbrella closing process, under the braking action of the pawl, the ratchet only can rotate clockwise; and under the action ofthe clockwork spring, the ratchet rotates clockwise to collect the rope, wherein if the middle rod is incautiously released in the clockwise rotation of the ratchet, the rope is tightened but the ratchet cannot rotate counterclockwise, so the rope can fix the middle rod to prevent the middle rod from being sprung off. Therefore, the safely foldable automatic expanding / collecting umbrella has the effect of safety protection.

Owner:XIAMEN FU TAI UMBRELLA INDS

Spring, mainspring, hairspring, and driving mechanism and timepiece based thereon

InactiveUS6863435B2High stressHigh strengthFrequency stabilisation mechanismDynamo-electric converter controlShape changeMainspring

A mainspring used as a power source for a driving mechanism is made of an amorphous metal sheet, and has an S-shaped free-exploded shape. The curvature changing point, where the curving direction of the free-exploded shape changes is formed on the inner end side of a middle point between the inner end on the winding side and the outer end serving as the other end of the inner end. Because of the high tensile stress and a low Young's modulus, the amorphous metal permits increase in mechanical energy stored in the mainspring.

Owner:SEIKO EPSON CORP

No-drill rear sight scope mount base

A scope mount base design which readily accepts onto a preexisting rear sight base without any alteration of the sight base except for the easy removal of the original sight leaf and mainspring. This scope mount invention achieves solid lockup by the use of the appropriate sized threaded support fixtures and scope mount configuration to successfully engage these rear sight slots that originally contained the sight leaf and mainspring, and thus achieve strong lockup of the scope mount to the sight base.

Owner:SPINELLI MICHAEL ANGELO

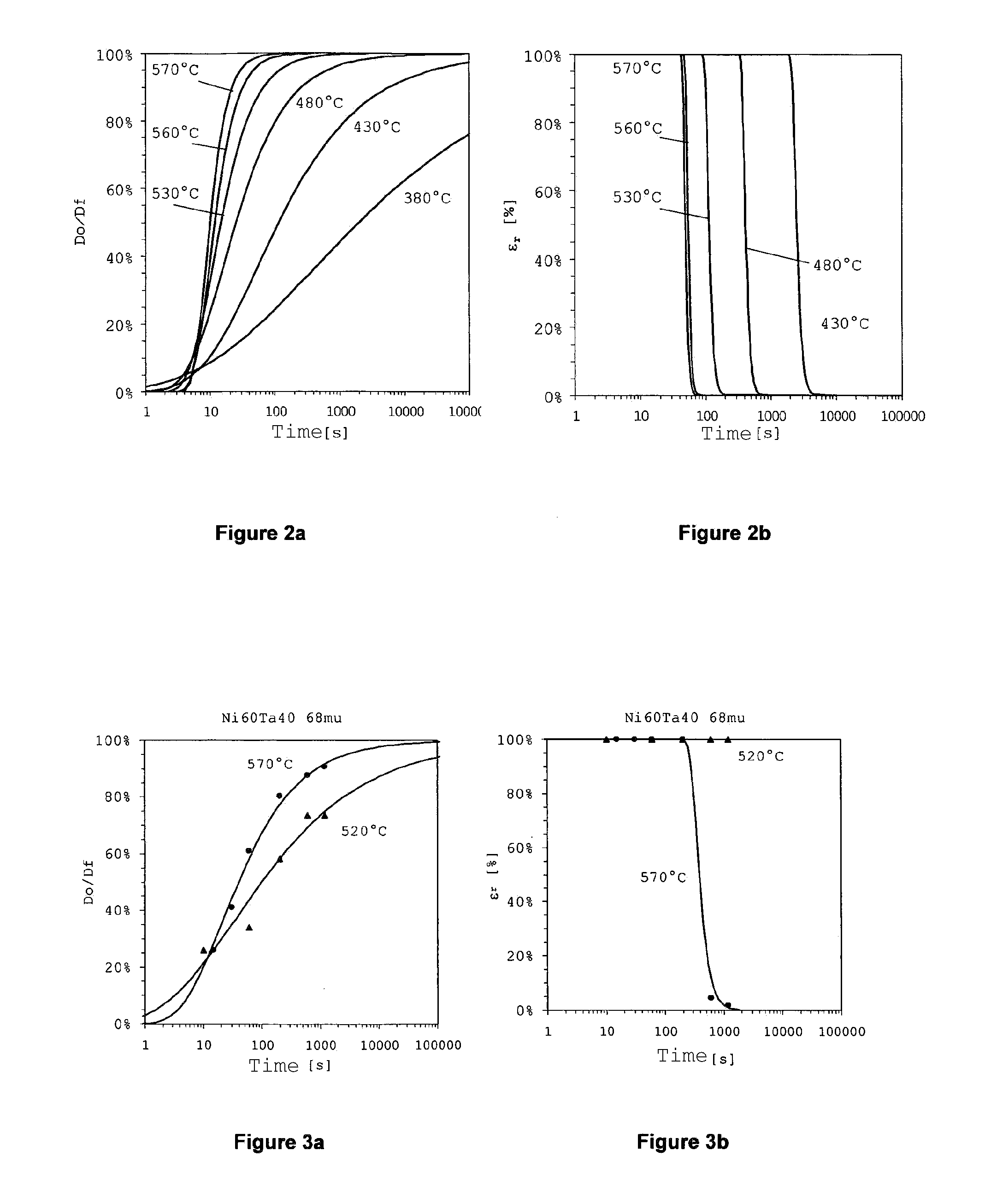

Method for making a spring for a timepiece

The invention relates to a method for making a spring for a timepiece that comprises at least one monobloc ribbon of metal glass including at least one curvature. The method is characterized in that said method comprises the step of shaping by means of plastic-deformation said monobloc ribbon in order to obtain at least a portion of said curvature.

Owner:ROLEX SA

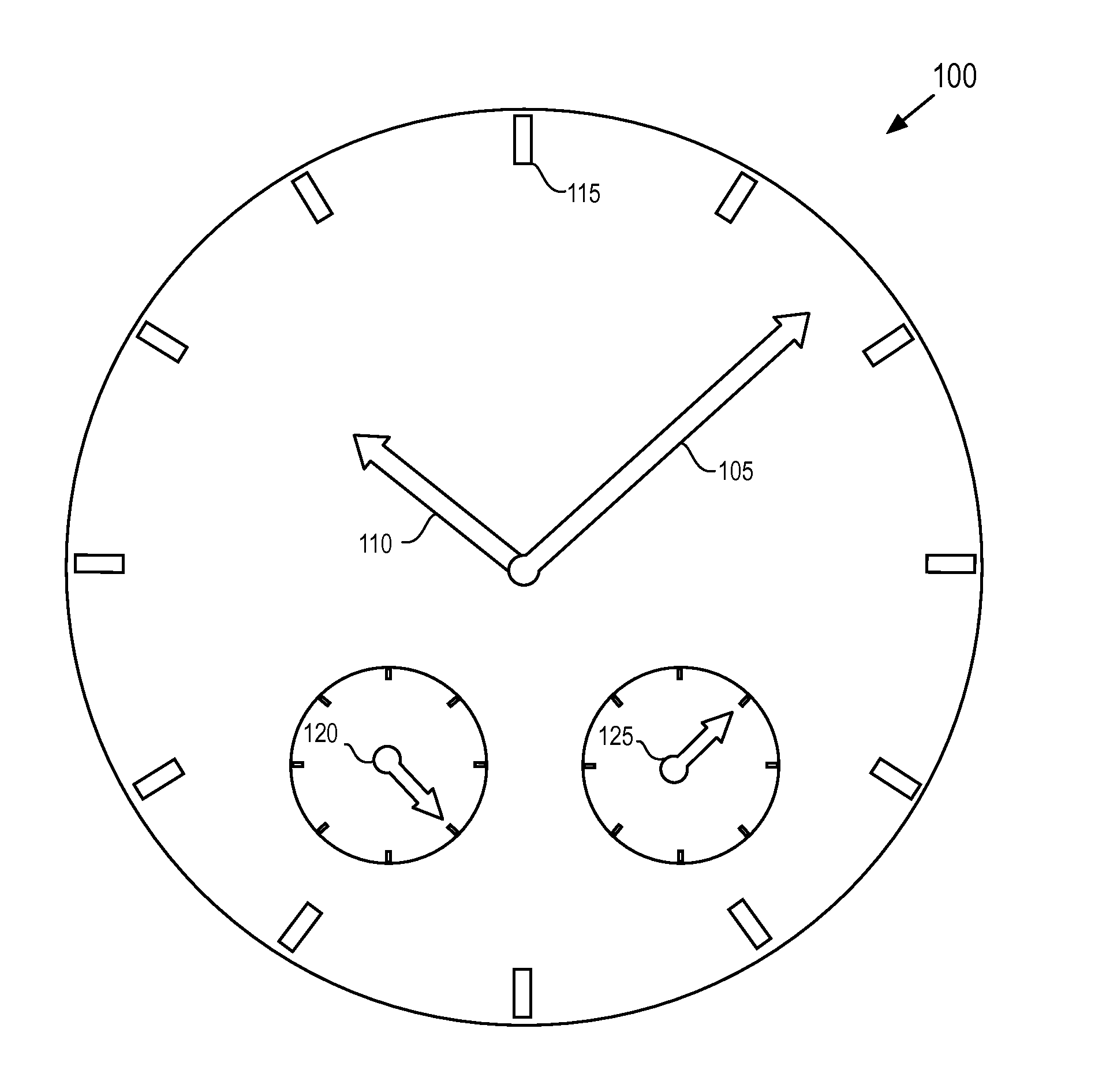

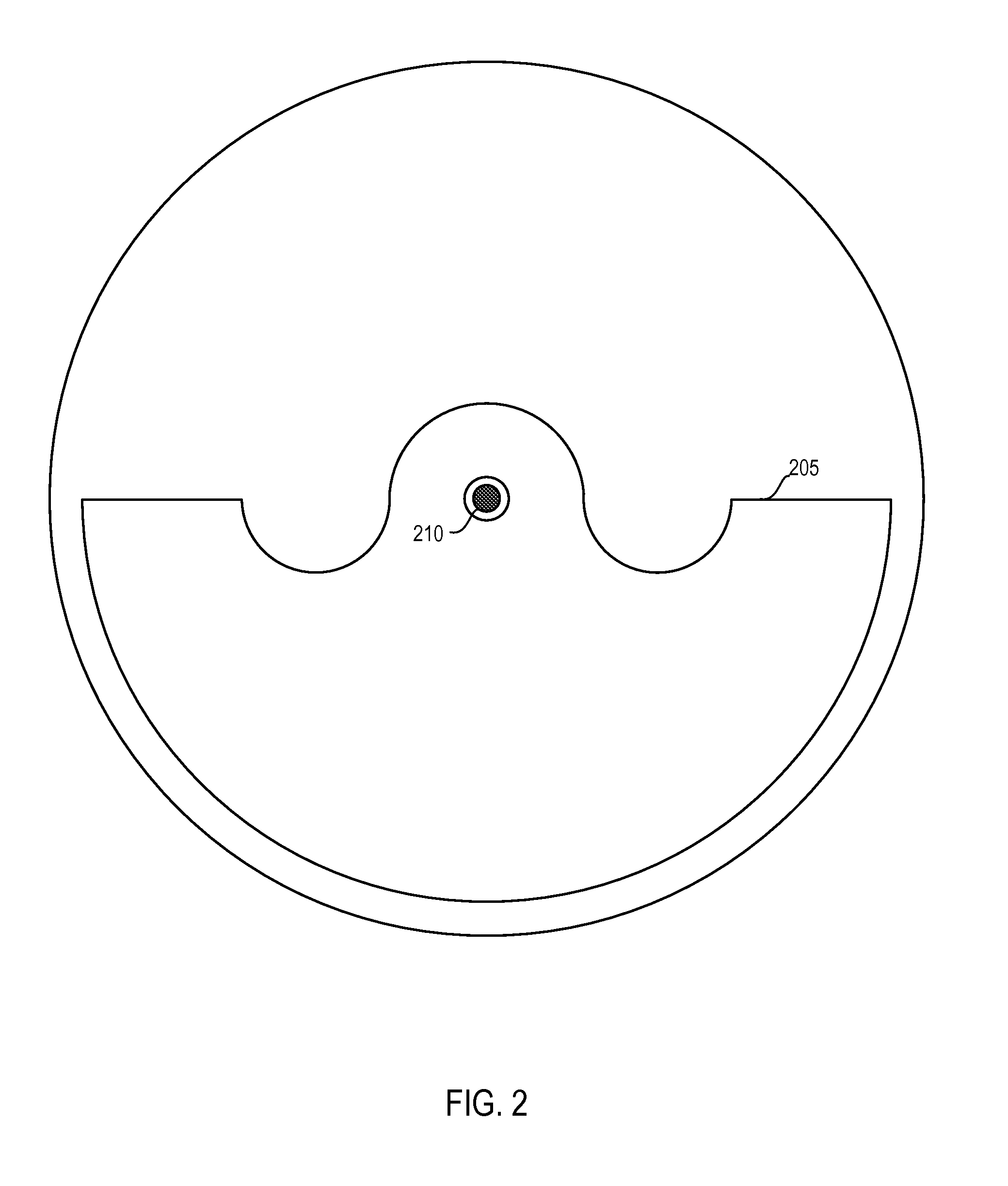

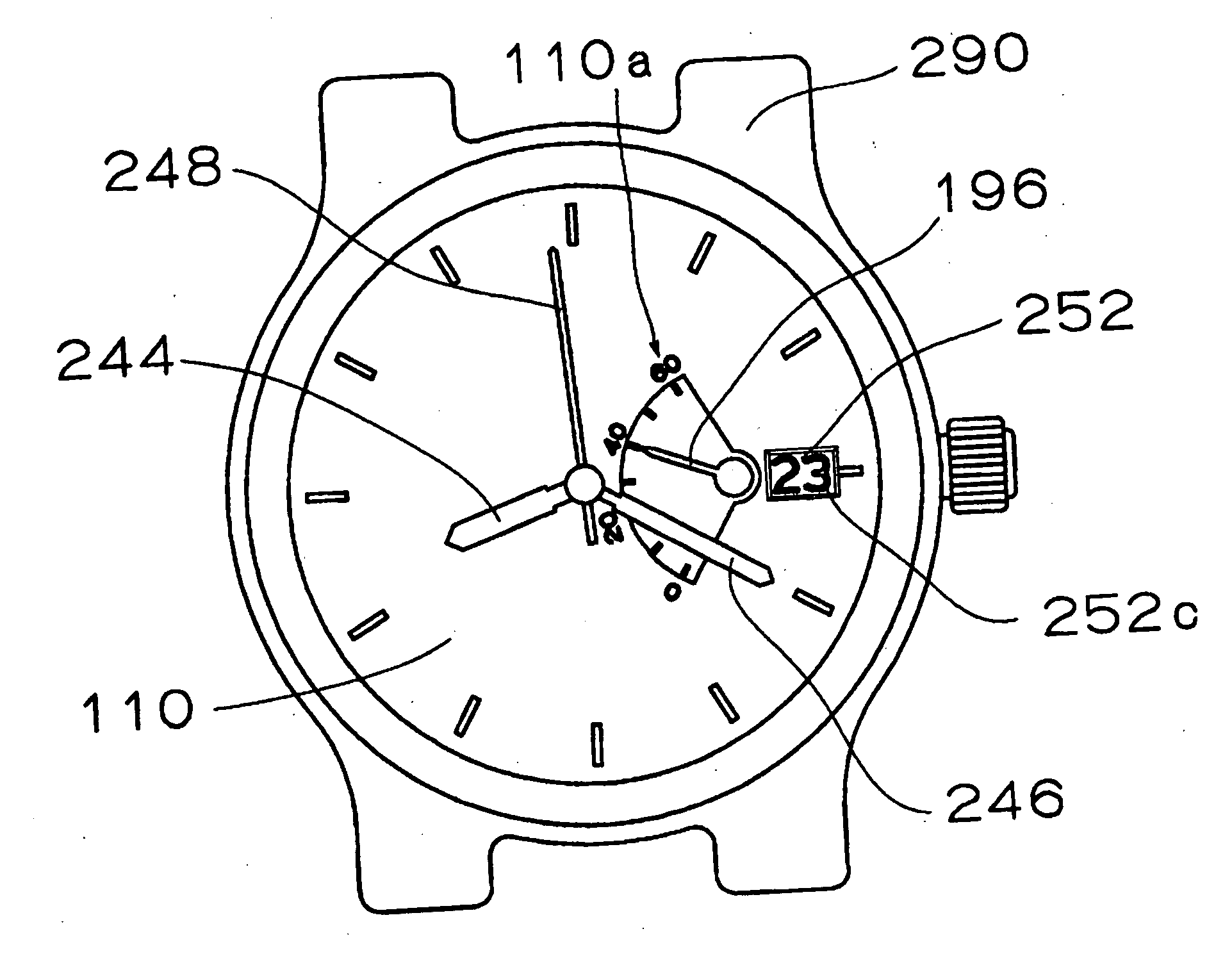

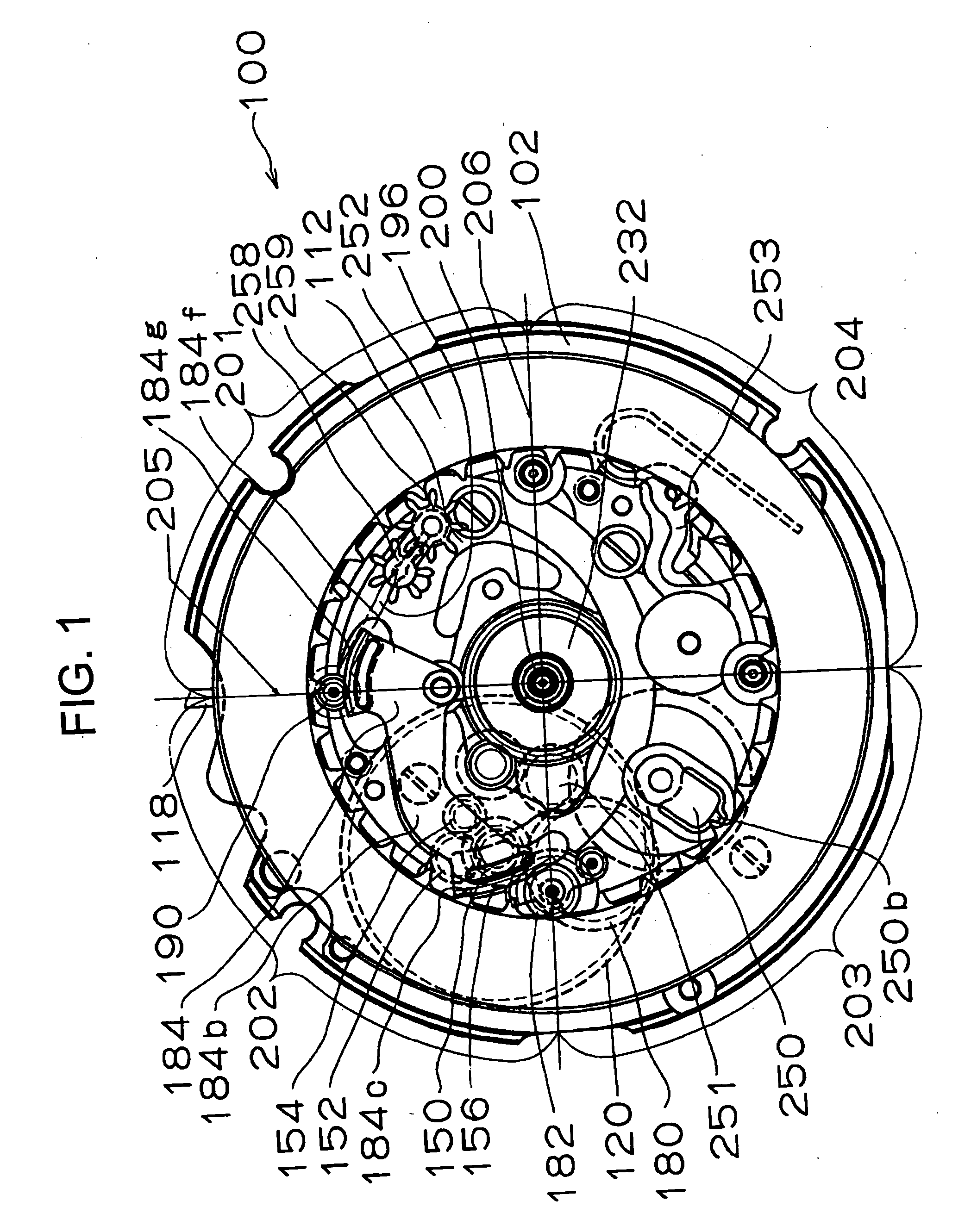

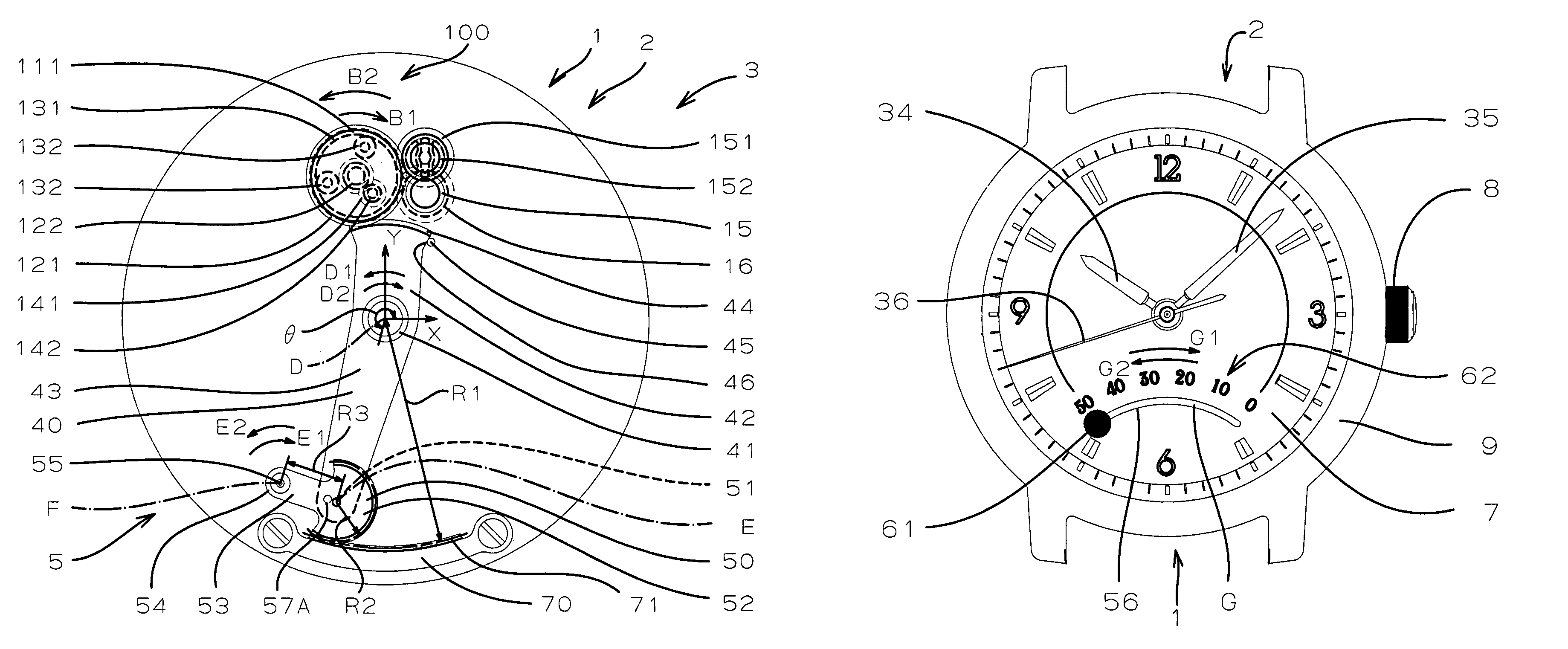

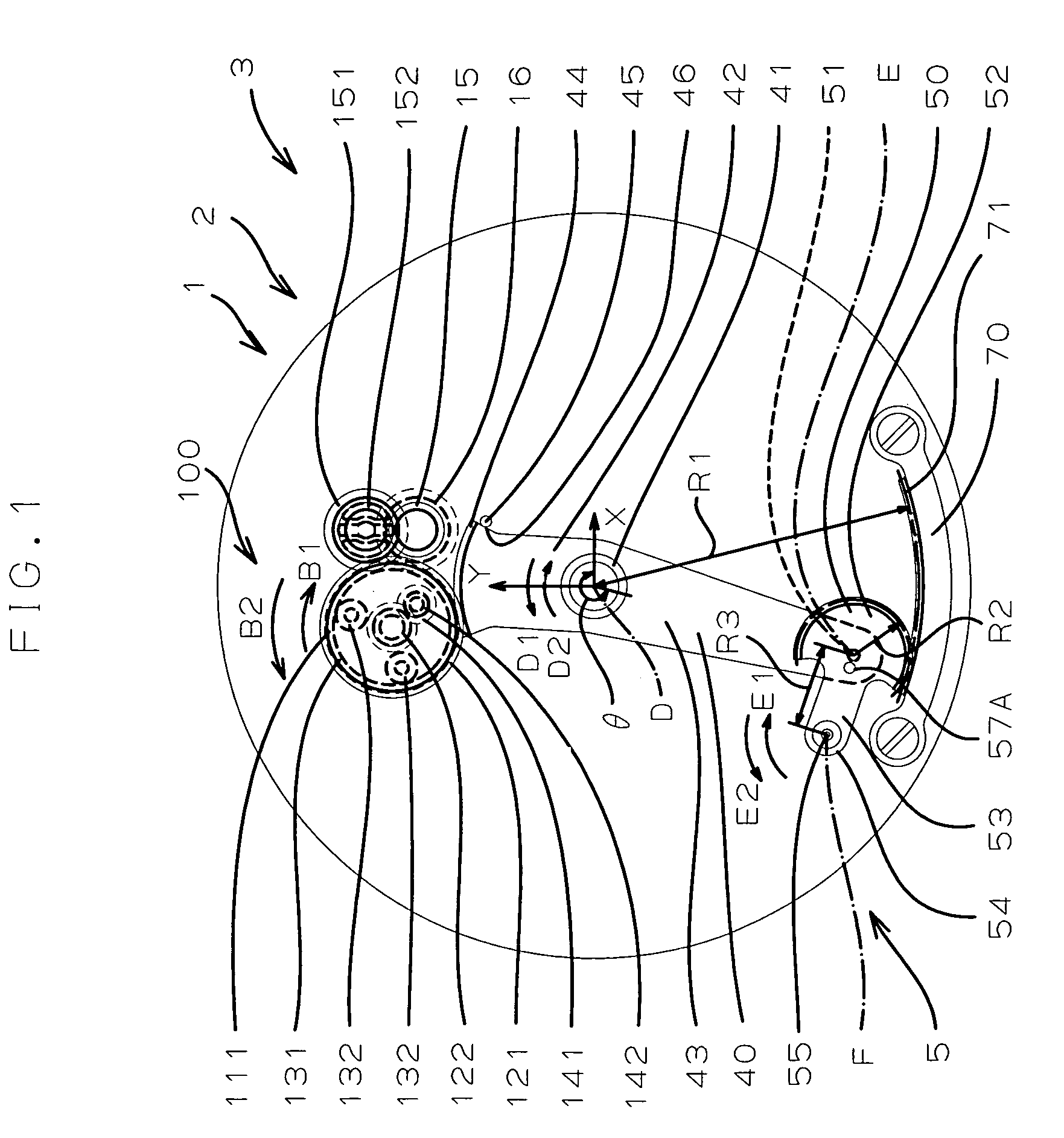

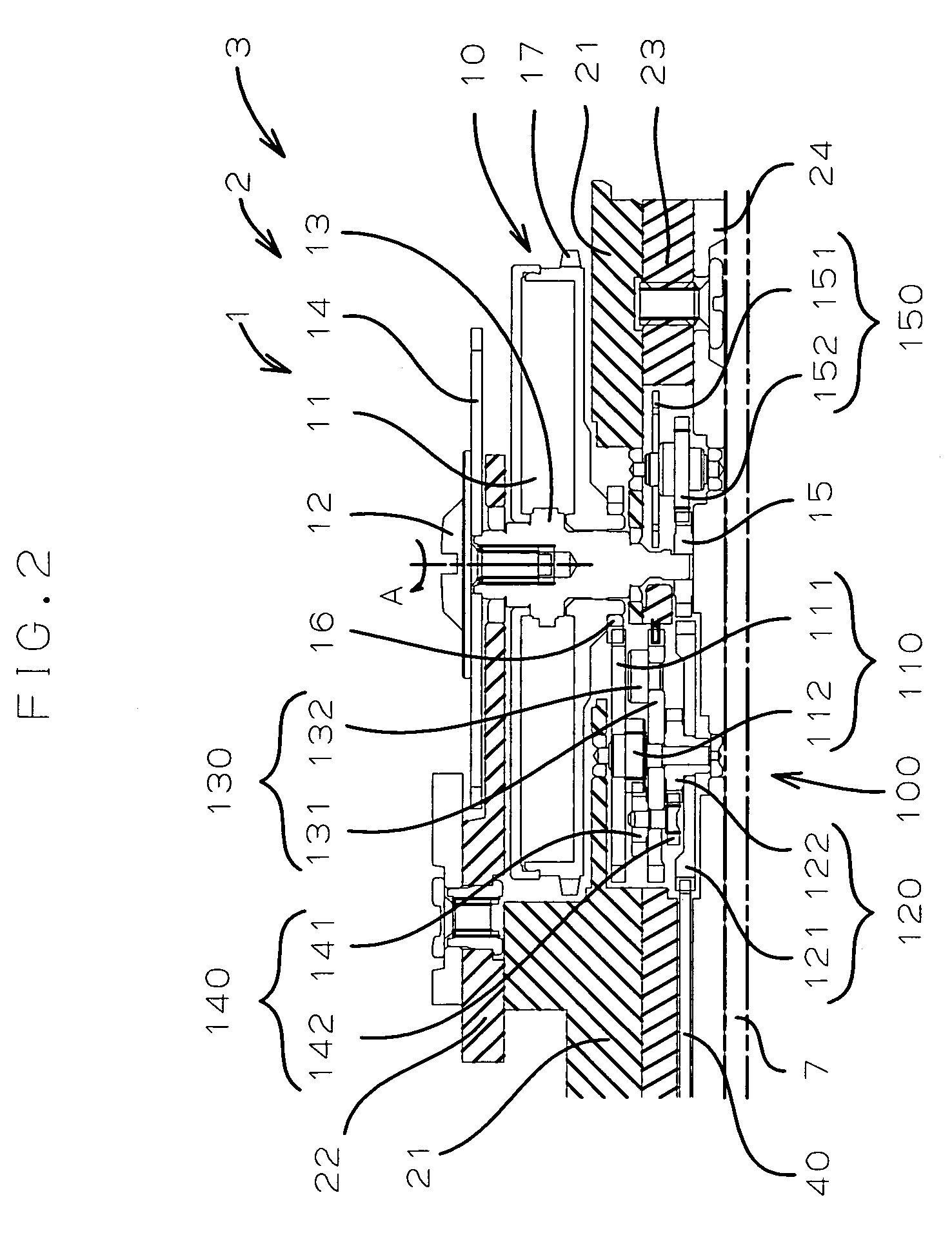

Self-winding mechanical watch with activity tracking

An exemplary mechanical watch has a face including an indicator of current time and one or more indicators of physical activity of a wearer of the mechanical watch. The watch further includes a mainspring to store energy and transfer the energy to a balance wheel and gear train to measure the passage of time, a rotor to rotate about a pivot point in response to movements of a wrist of the wearer of the mechanical watch, a rotor gear coupled to the rotor, and an activity-tracking wheel coupled to one of the one or more indicators of physical activity. Movement of the rotor causes the rotor gear to translate the movement of the rotor into winding of the mainspring and into an indication of physical activity of a wearer of the mechanical watch by causing or controlling rotation of the activity-tracking wheel.

Owner:DP TECH

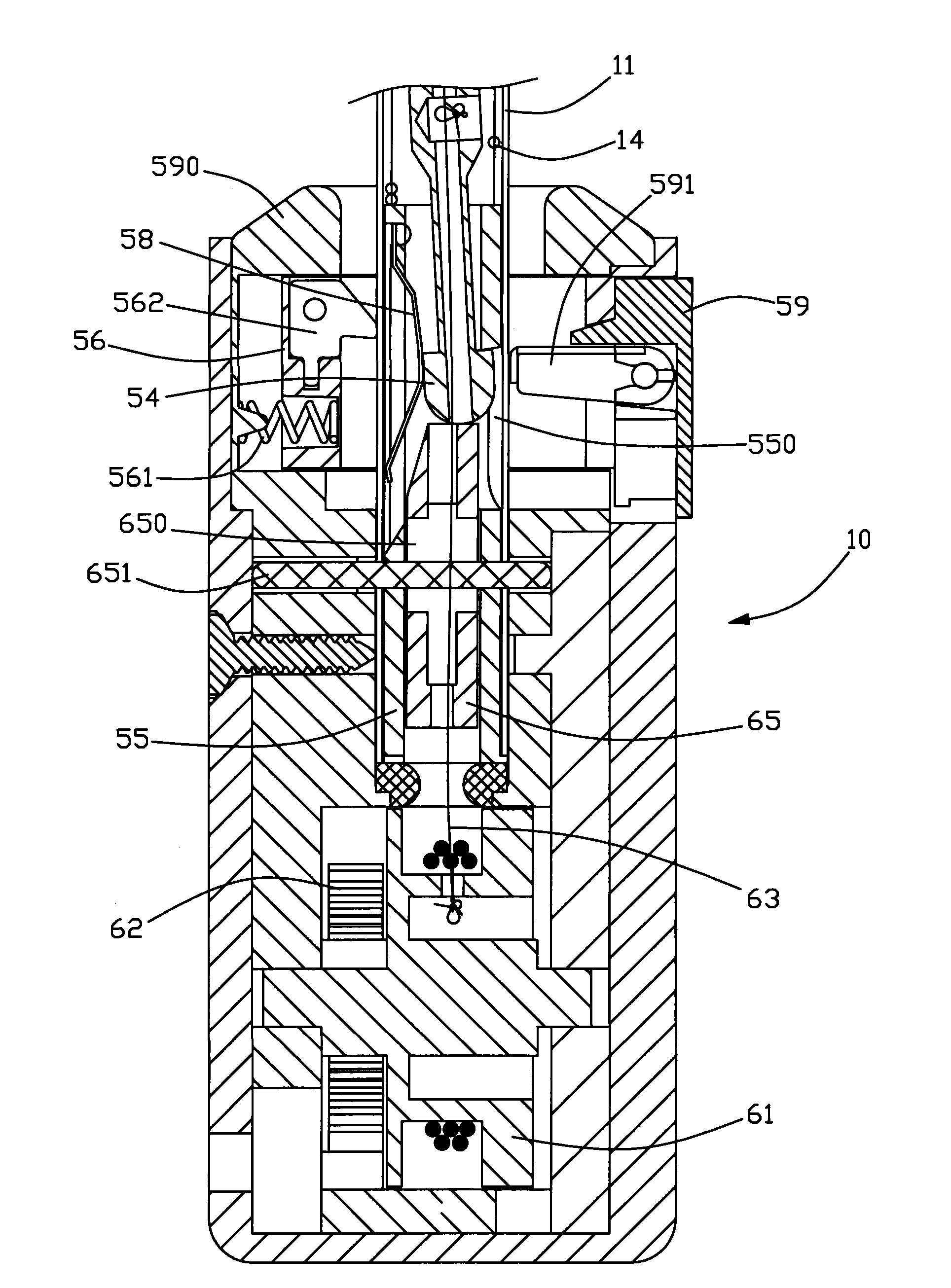

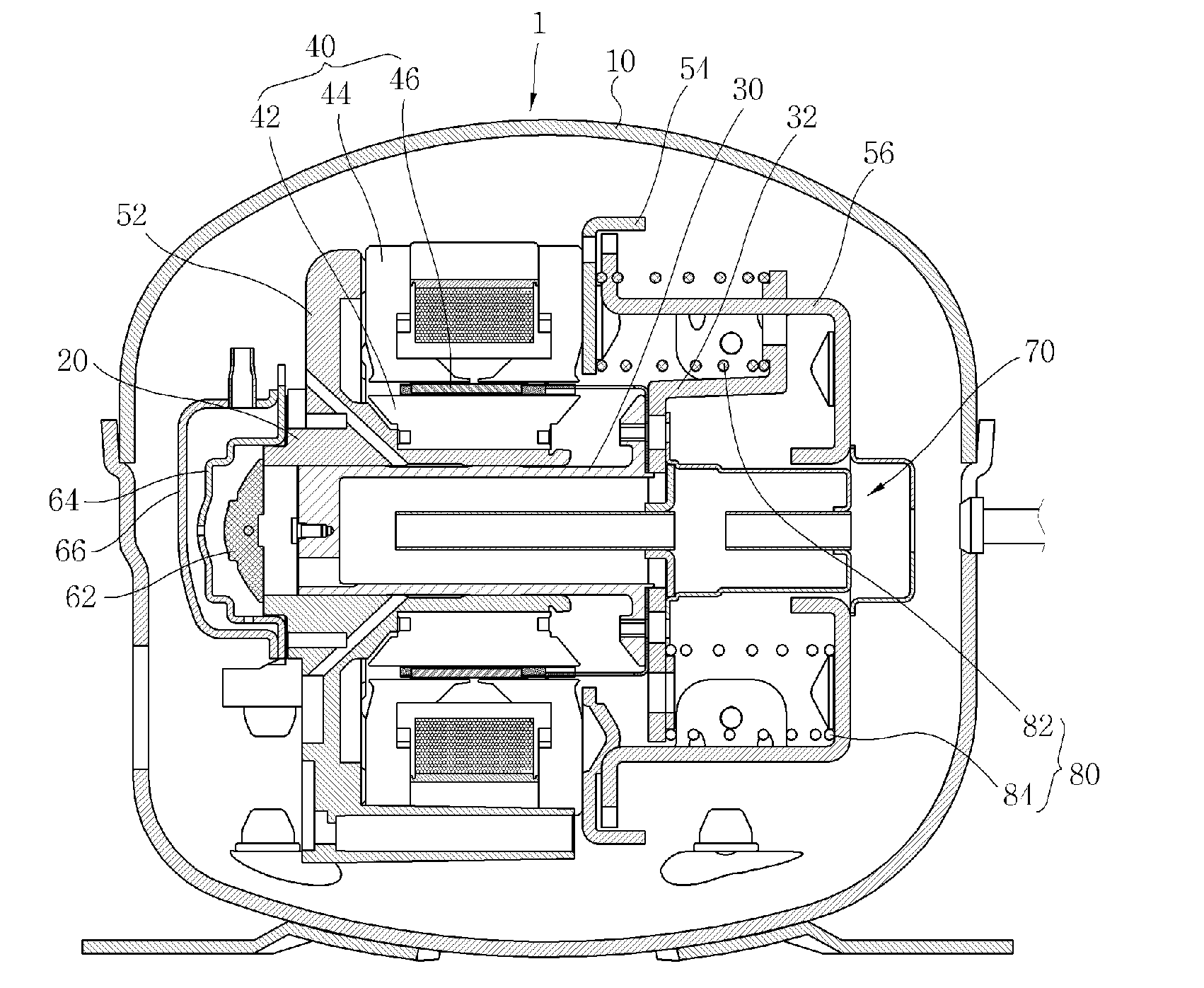

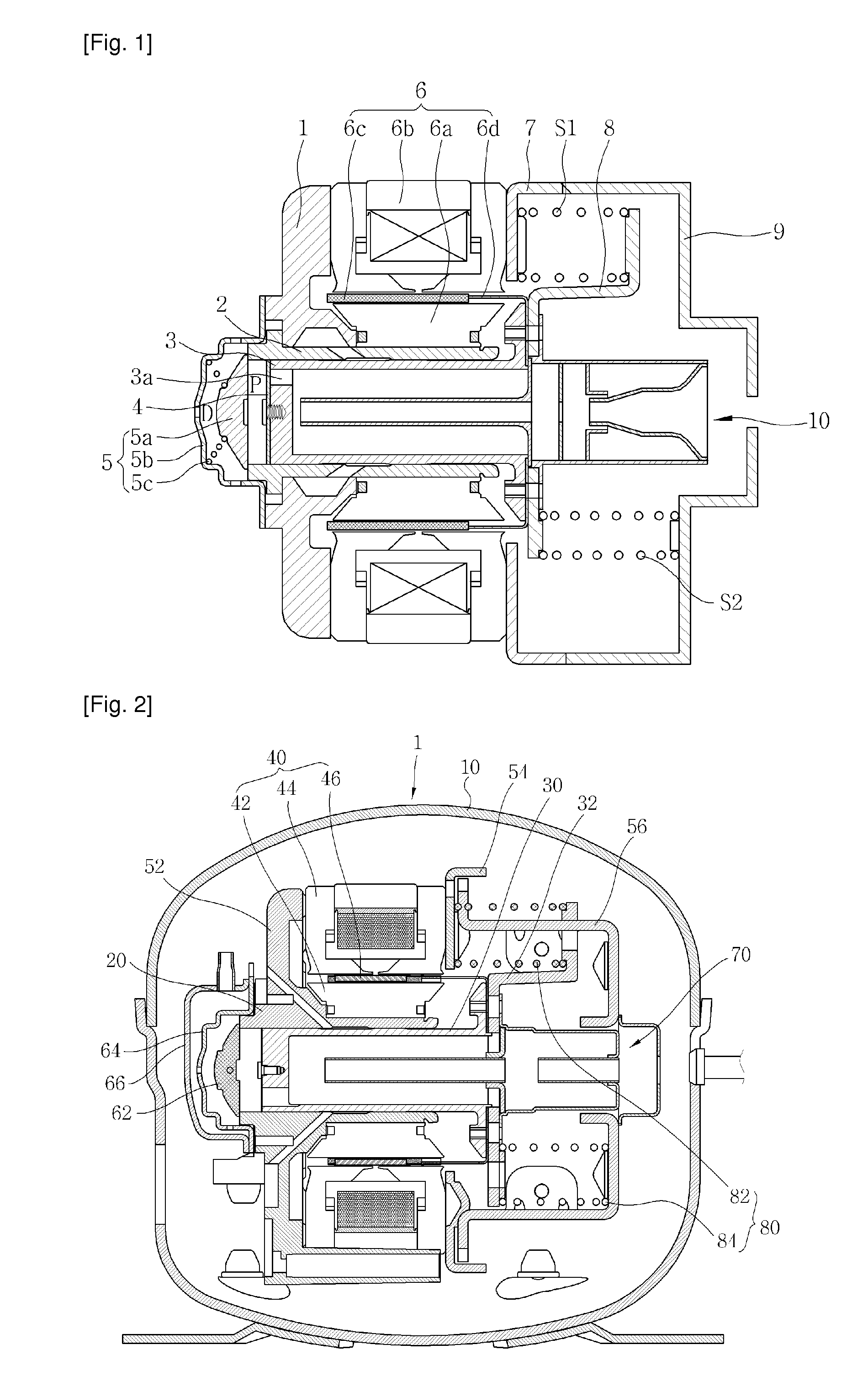

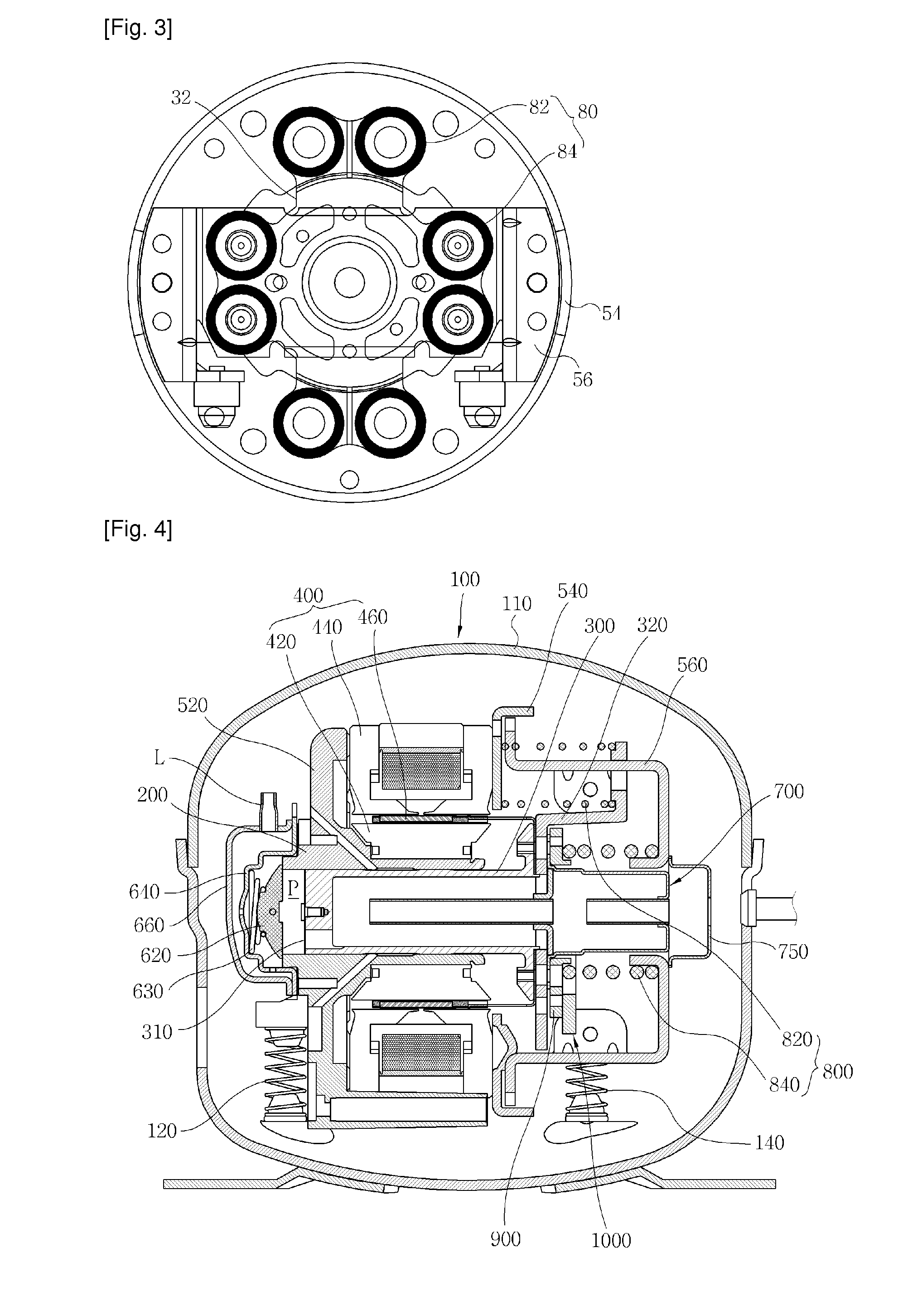

Linear compressor

ActiveUS20100266429A1Reduce part costSimplified installation procedurePositive displacement pump componentsPiston pumpsReciprocating motionResonance

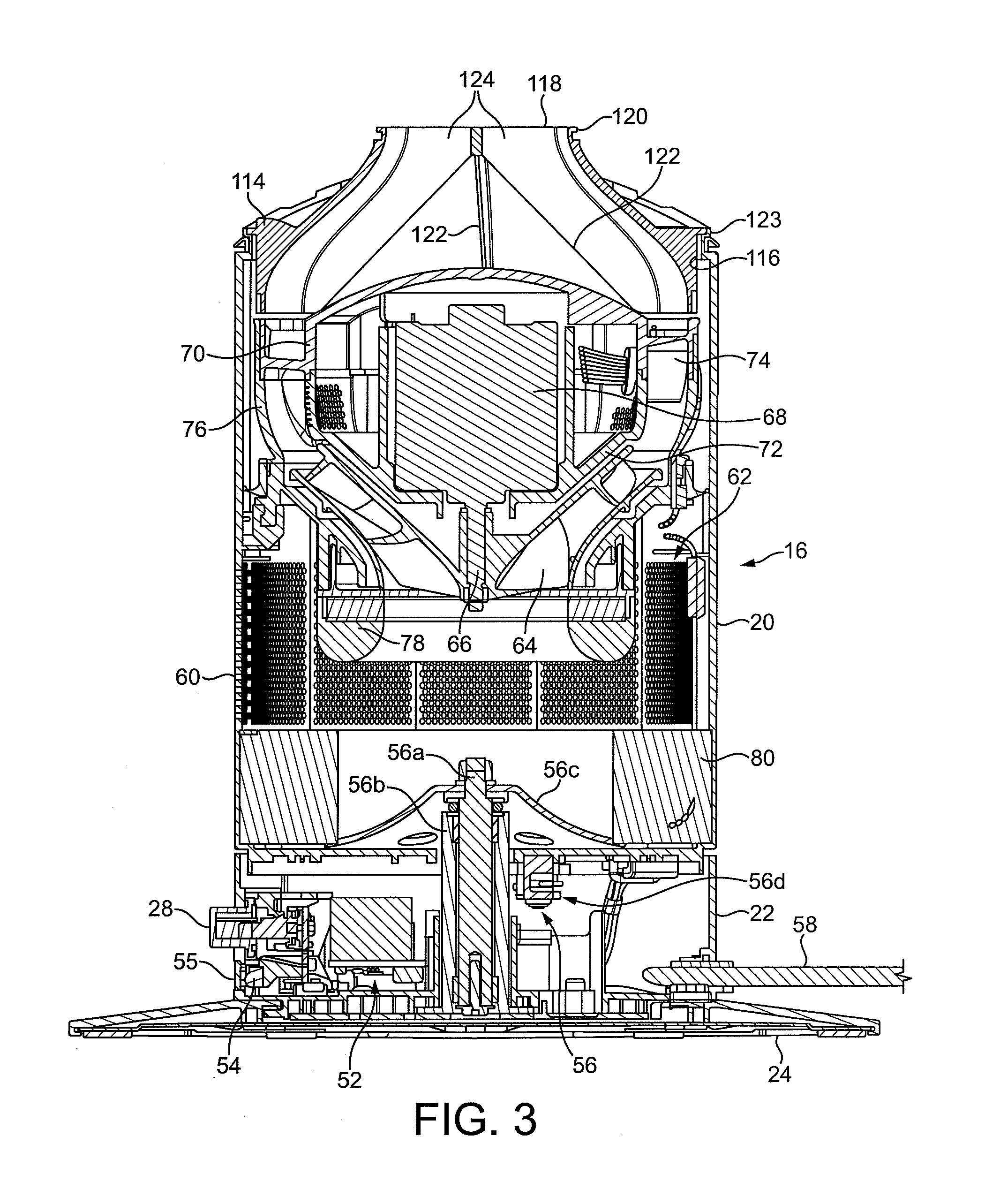

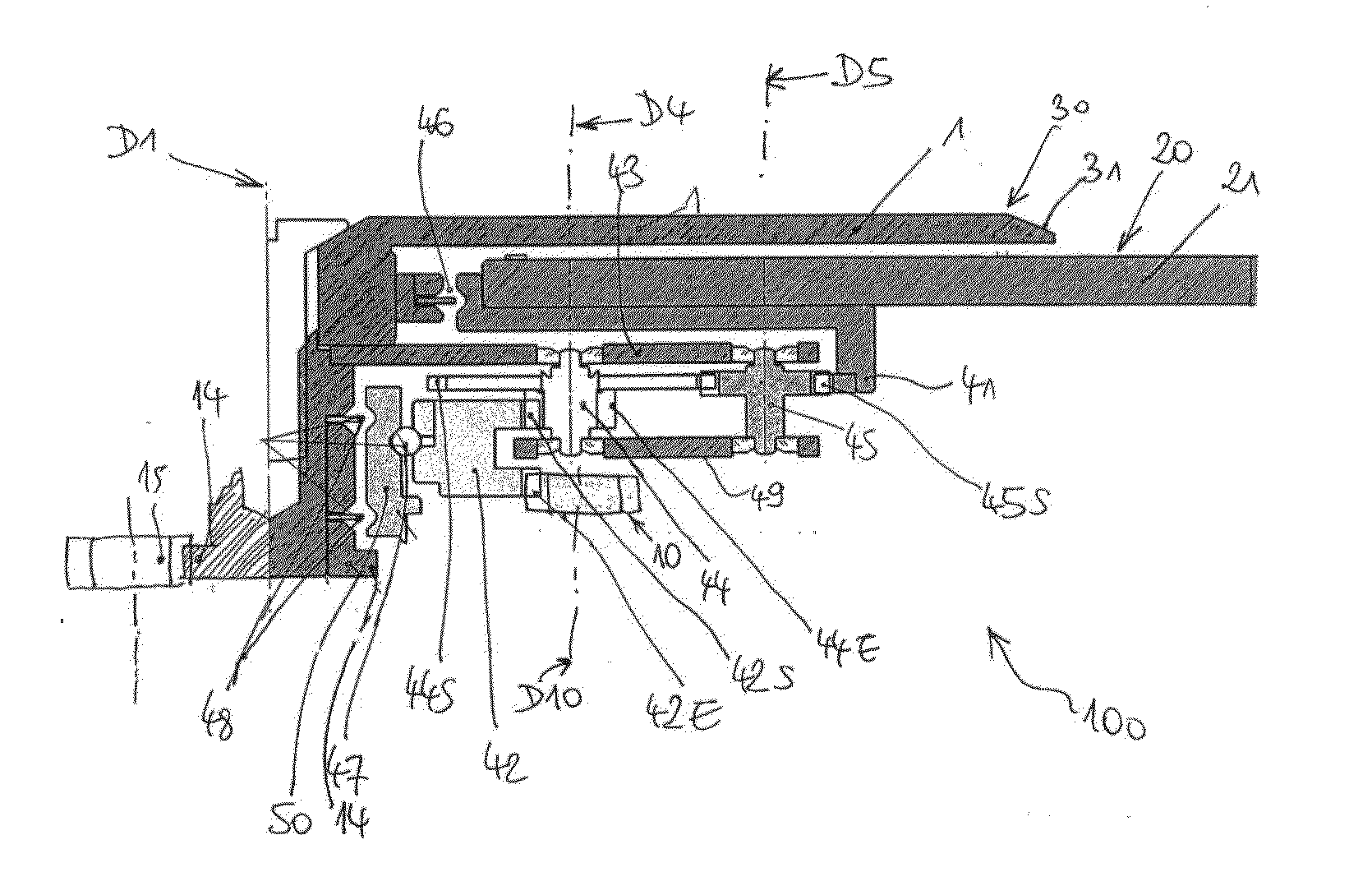

The present invention relates to a linear compressor (100); and more particularly, to a linear compressor (100) provided with three mainsprings (820,840) having a resonance frequency synchronized with an operating frequency, where the resonance frequency can be adjusted without varying initial positions of mainsprings (820,840) although an additional mass member (1000) may be added. The linear compressor (100) comprises: a fixed member, which includes a cylinder (200) for providing a refrigerant compression space; a movable member, which includes a piston (300) for compressing refrigerant inside the cylinder (200), a center portion that coincides with the center of the piston (300), and a support extended in a radial direction the piston (300), and which makes a linear reciprocating motion about the fixed member; a plurality of front mainsprings (820), each of which has one end being supported on a front side of the support of the supporter (320) and the other end being supported on the fixed member, and which are located symmetrically about the center of the piston (300); a single rear mainspring (840) which has one end being supported on a rear side of the supporter (320) and the other end being supported on the fixed member; and a plurality of mass members (1000) coupled to a rear side of the supporter (320), having a predetermined distance from the outer diameter of the rear mainspring (840).

Owner:LG ELECTRONICS INC

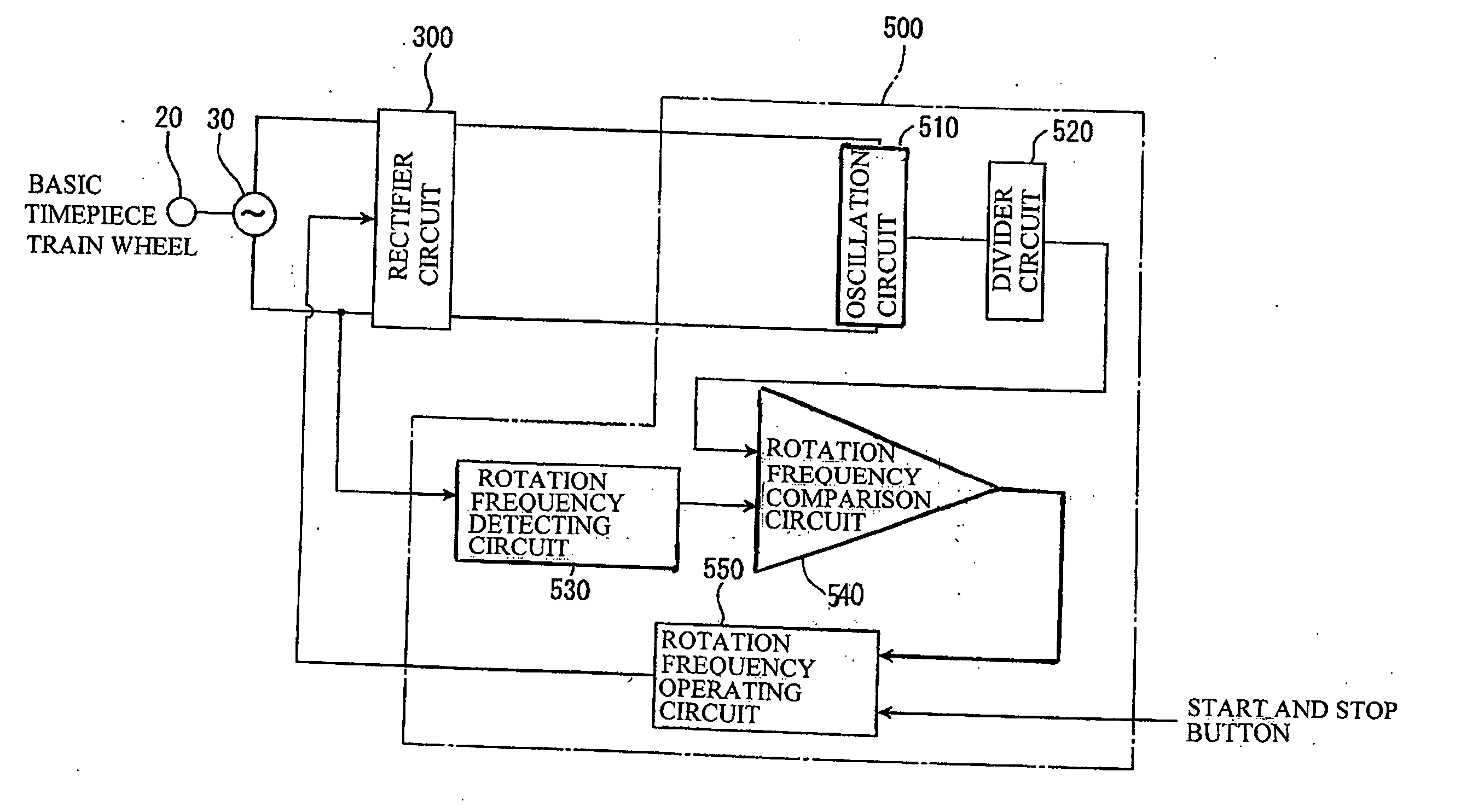

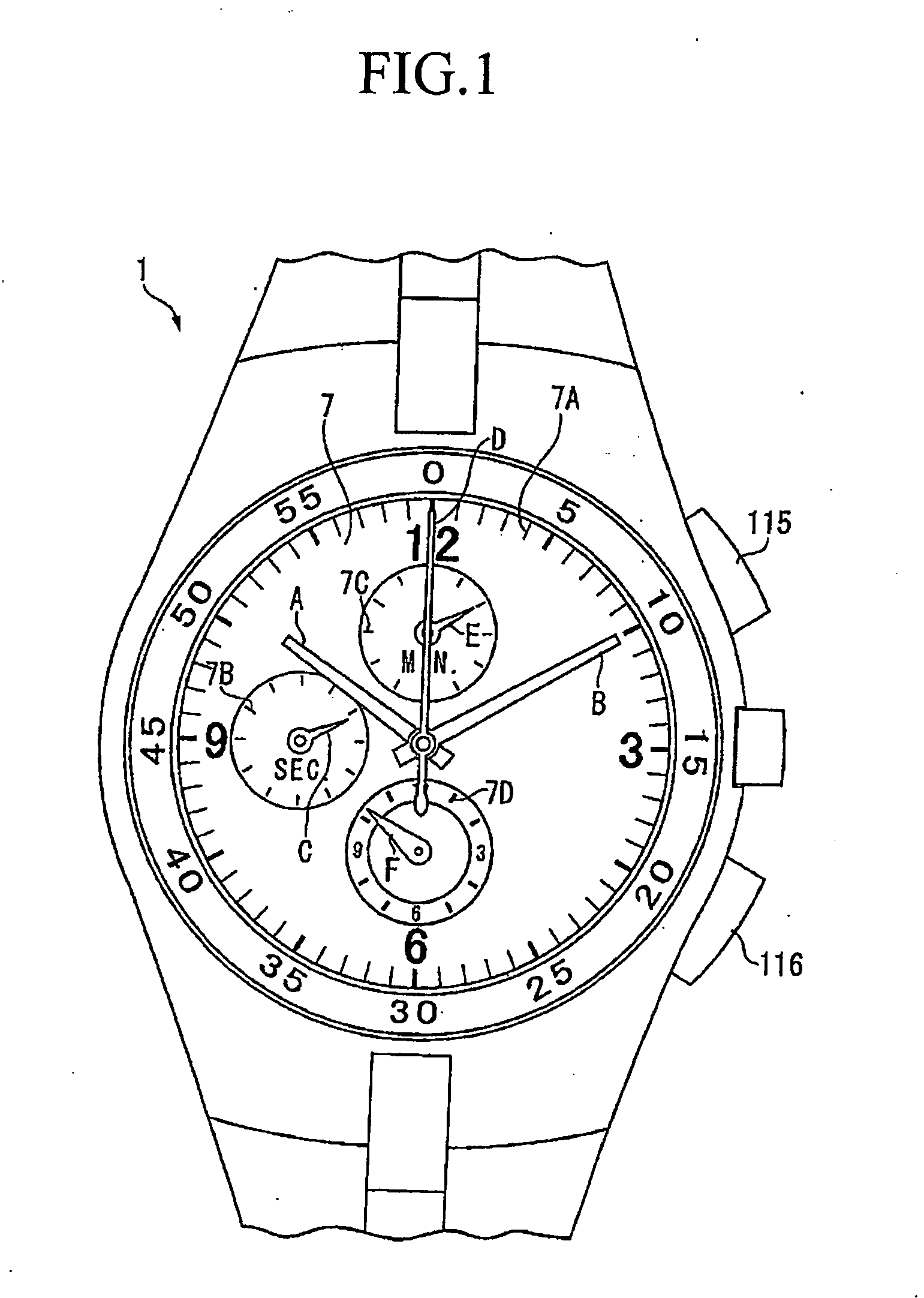

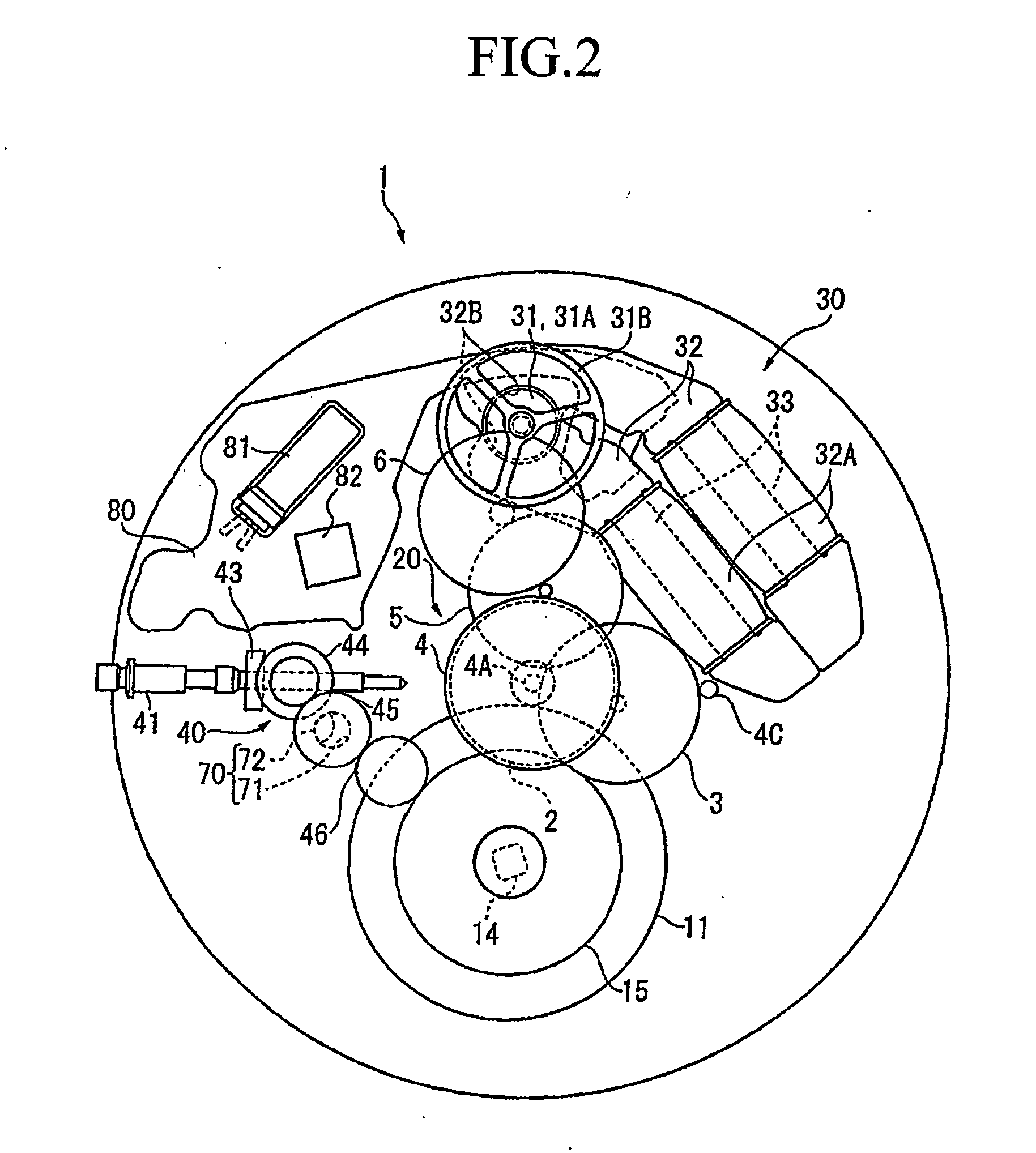

Stopwatch and watch

InactiveUS20050041535A1Mechanical unknown time interval measurementElectromechanical unknown time interval measurementMainspringEngineering

A timepiece having basic timepiece pointers, chronograph information pointers, a mechanical energy storage section, a train wheel, a power generator, and a control section. The basic timepiece pointers are rotated to indicate the standard time. The chronograph information pointers are rotated to indicate chronograph information. The mechanical energy storage section includes a mainspring. The train wheel is disposed between the mechanical energy storage section and the pointers, and transmits energy from the mechanical energy storage section to the pointers. The power generator has a rotating rotor connected to the train wheel, and generates electric power upon receiving the energy from the mechanical energy storage section. The control section is energized by the electric power produced by the power generator, and controls the rotation cycle of the rotor.

Owner:SEIKO EPSON CORP

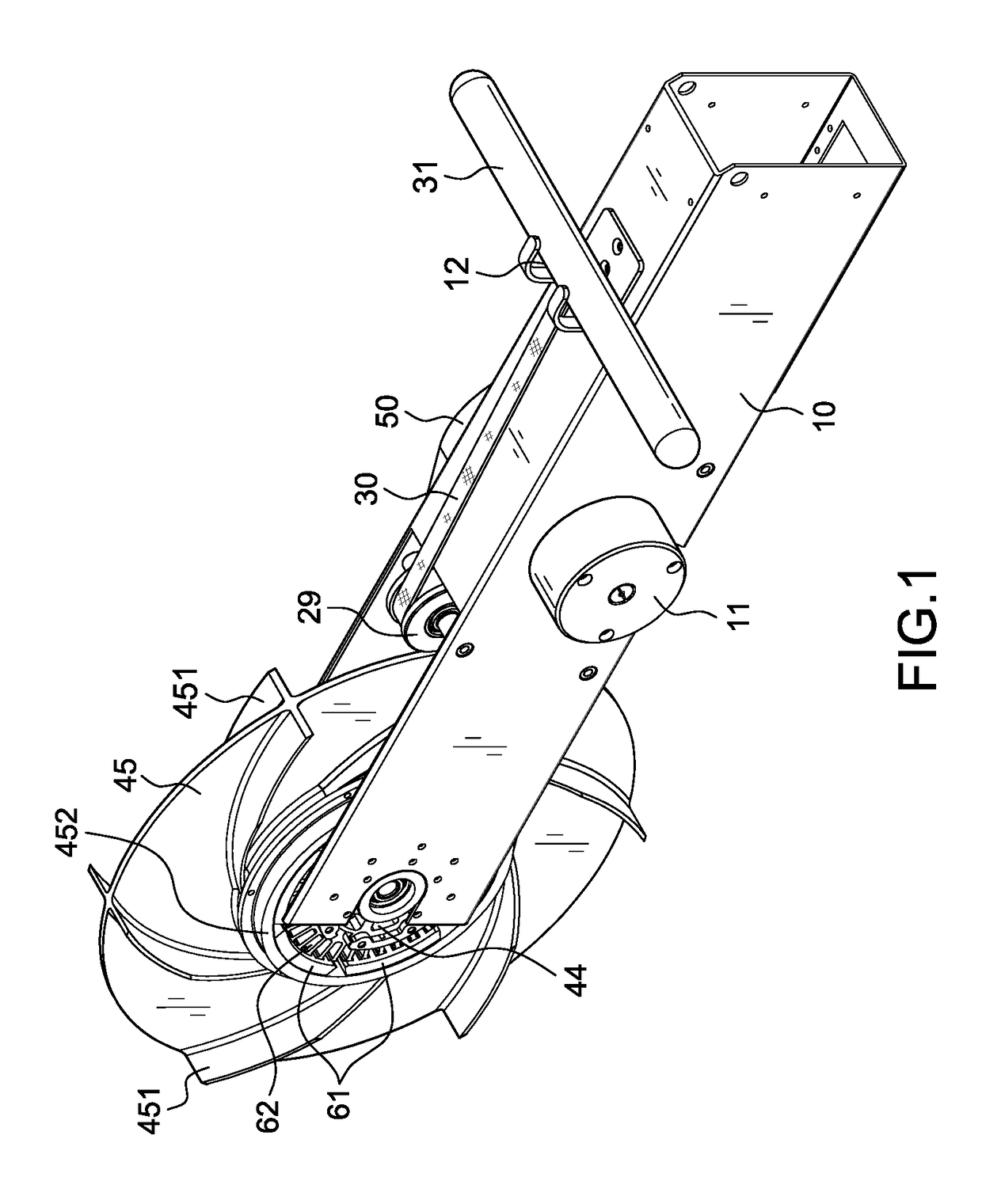

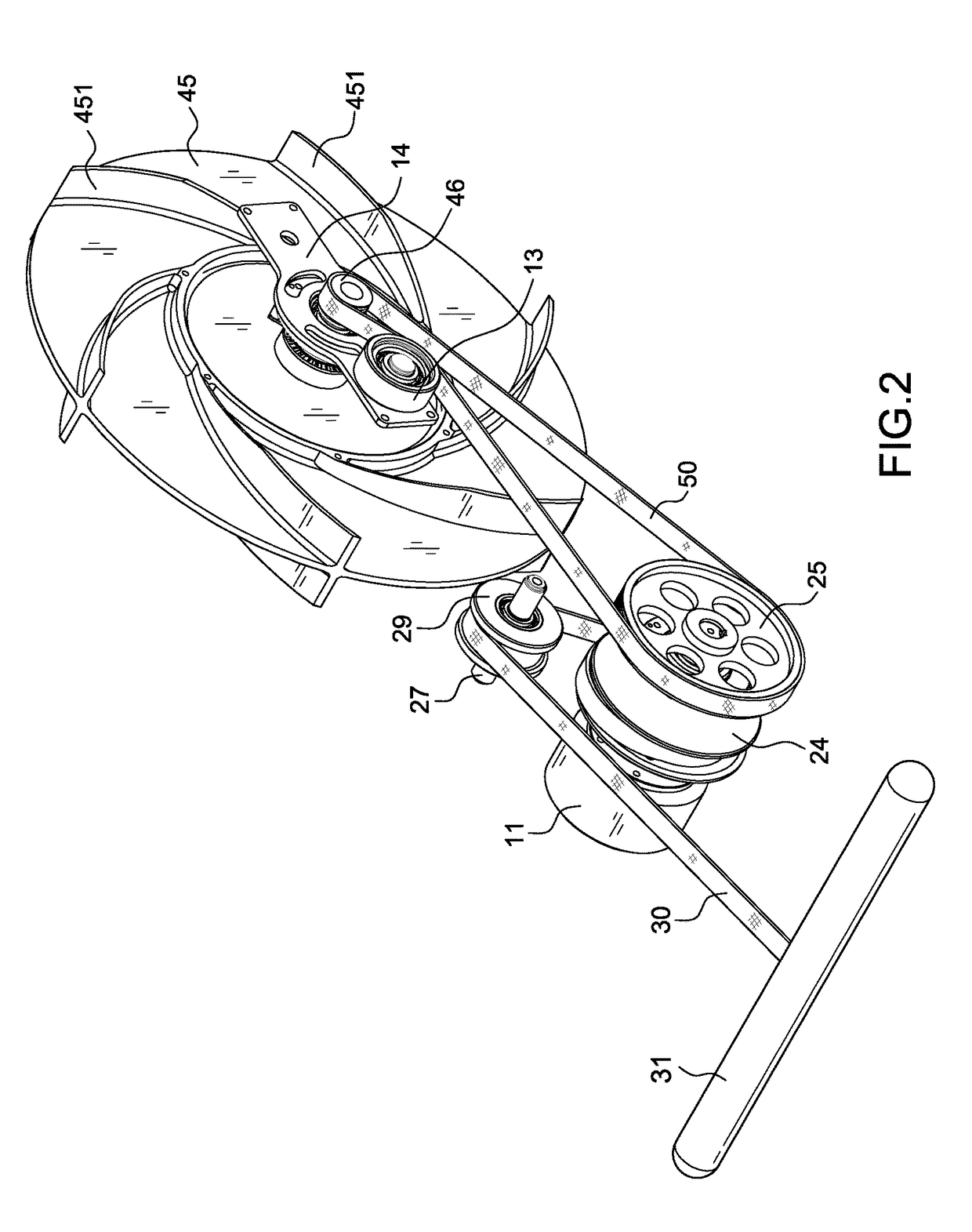

Pull exercise training device

A pull exercise training device has a frame body, a reel including a shaft, a rolling wheel, a driver pulley wheel and at least one mainspring, a band connected to the rolling wheel with an end, a load force device including a first axle through a flywheel and a driven pulley wheel, a one way clutch disposed between the first axle and the flywheel, a belt winding around the driver pulley wheel and the driven pulley wheel, a generator set, and a control circuit having a controller electrically connected to a resistor, an armature, and an interface for operation.

Owner:CHI HUA FITNESS

Spring brake

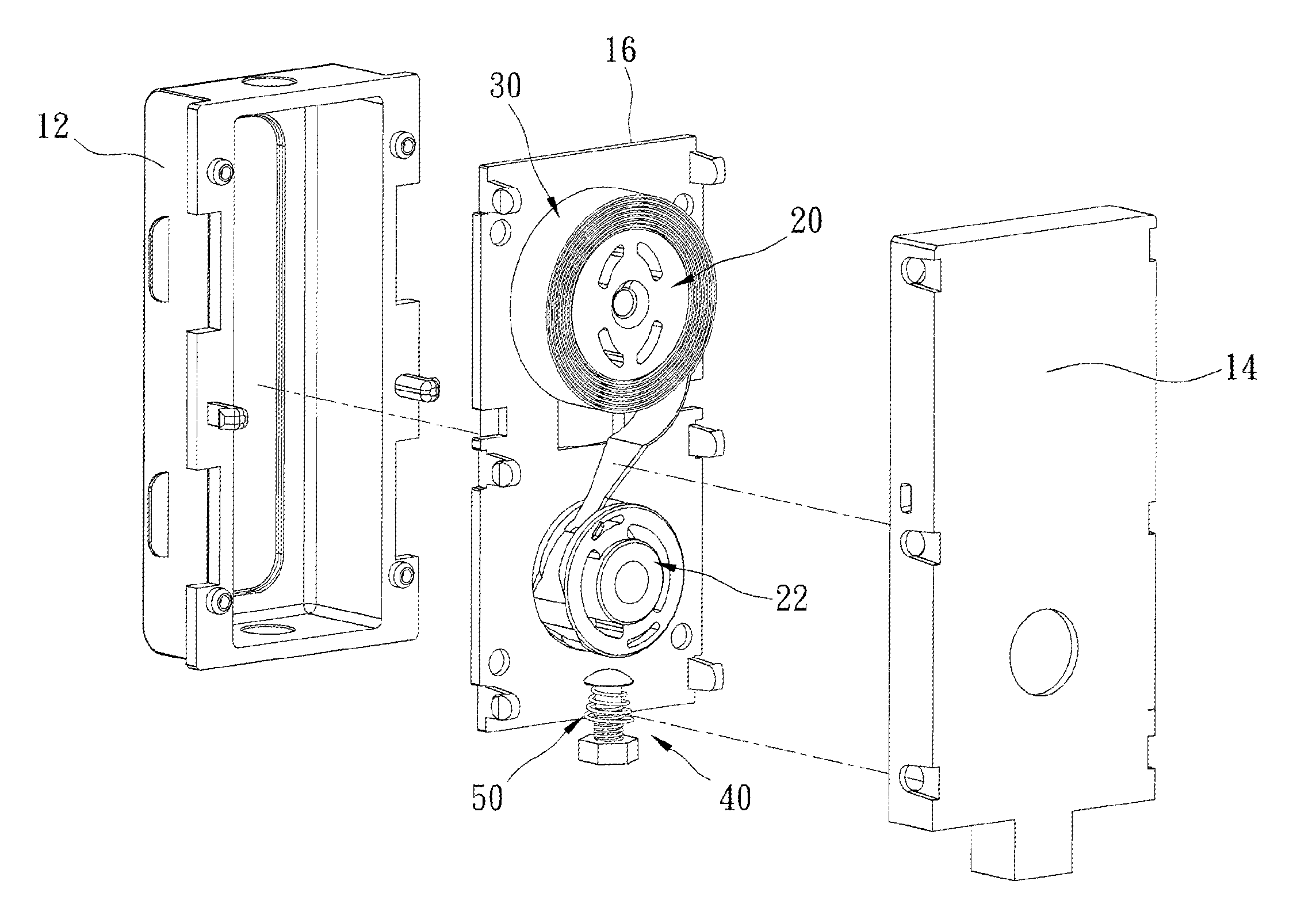

InactiveUS20130087415A1Stable spring forceStable forceSpring motorDoor/window protective devicesMainspringEngineering

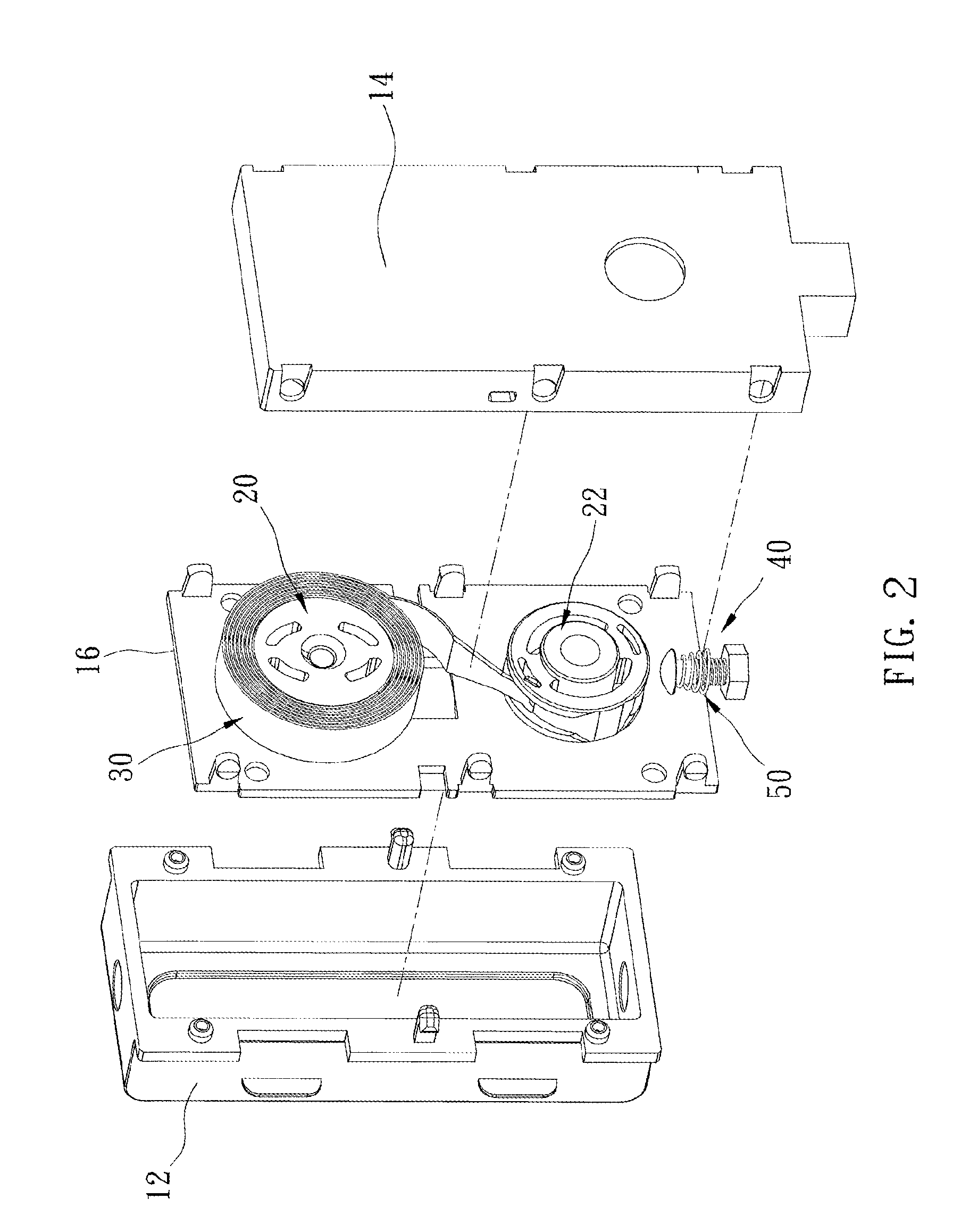

A spring brake includes a base, on which a first reel and a second reel are pivoted. A mainspring has opposite ends connected to the first reel and the second reel. A stop device has a pressing portion to press the mainspring when the mainspring is wound on the second reel. Therefore, the pressing portion of the stop device will touch the mainspring when the mainspring is wound on the second reel and give the mainspring a resistance to offset the recovery force of the mainspring.

Owner:NIEN MADE ENTERPRISE CO LTD

Mechanical timepiece

A storage device comprises a first seconds wheel, engaging with a mainspring, and a second seconds wheel, a setting wheel for connecting these two seconds wheels, a yoke on which said setting wheel is pivotably mounted, the pivot axis of this yoke and that of the second seconds wheel being coaxial, a stop wheel kinematically linked with said first seconds wheel, a finger fixedly connected to said yoke, a storage spring for exerting upon said yoke a force tending to separate said finger from said stop wheel, whereas the force exerted upon said setting wheel by said mainspring serves to press said finger against said stop wheel, so that the latter is wound to the point where a tooth of said stop wheel abuts against said finger.

Owner:MONTRES JOURNE

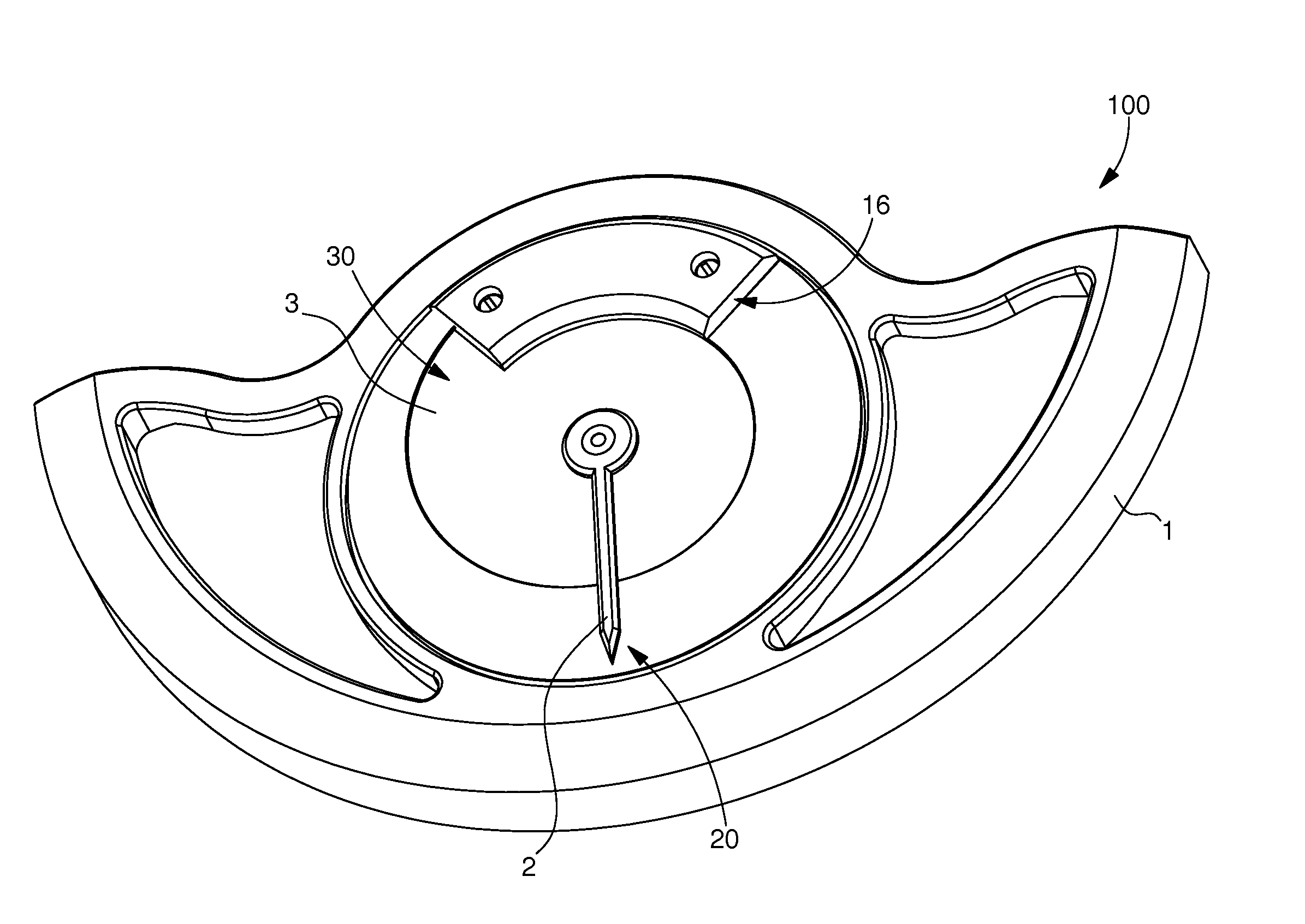

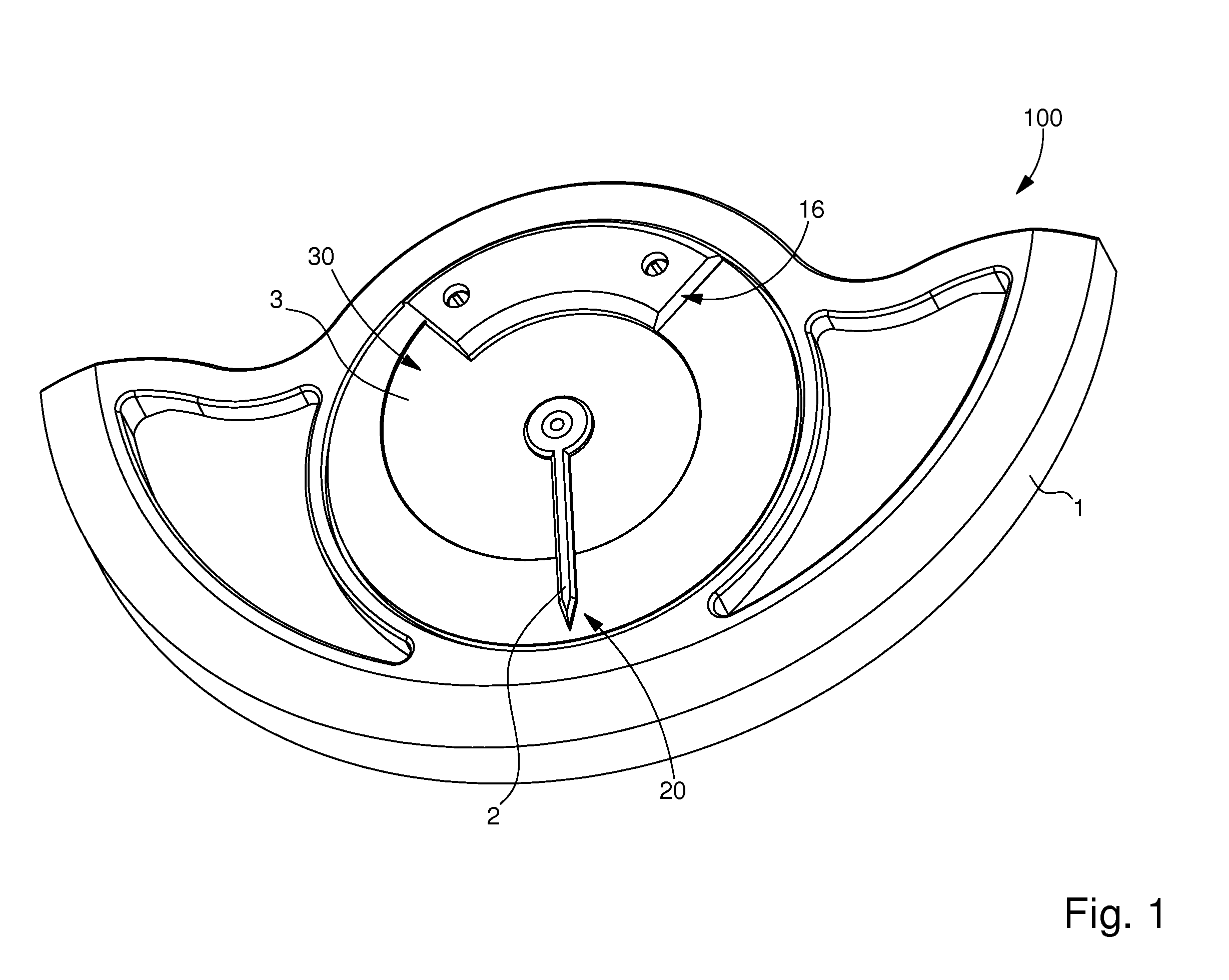

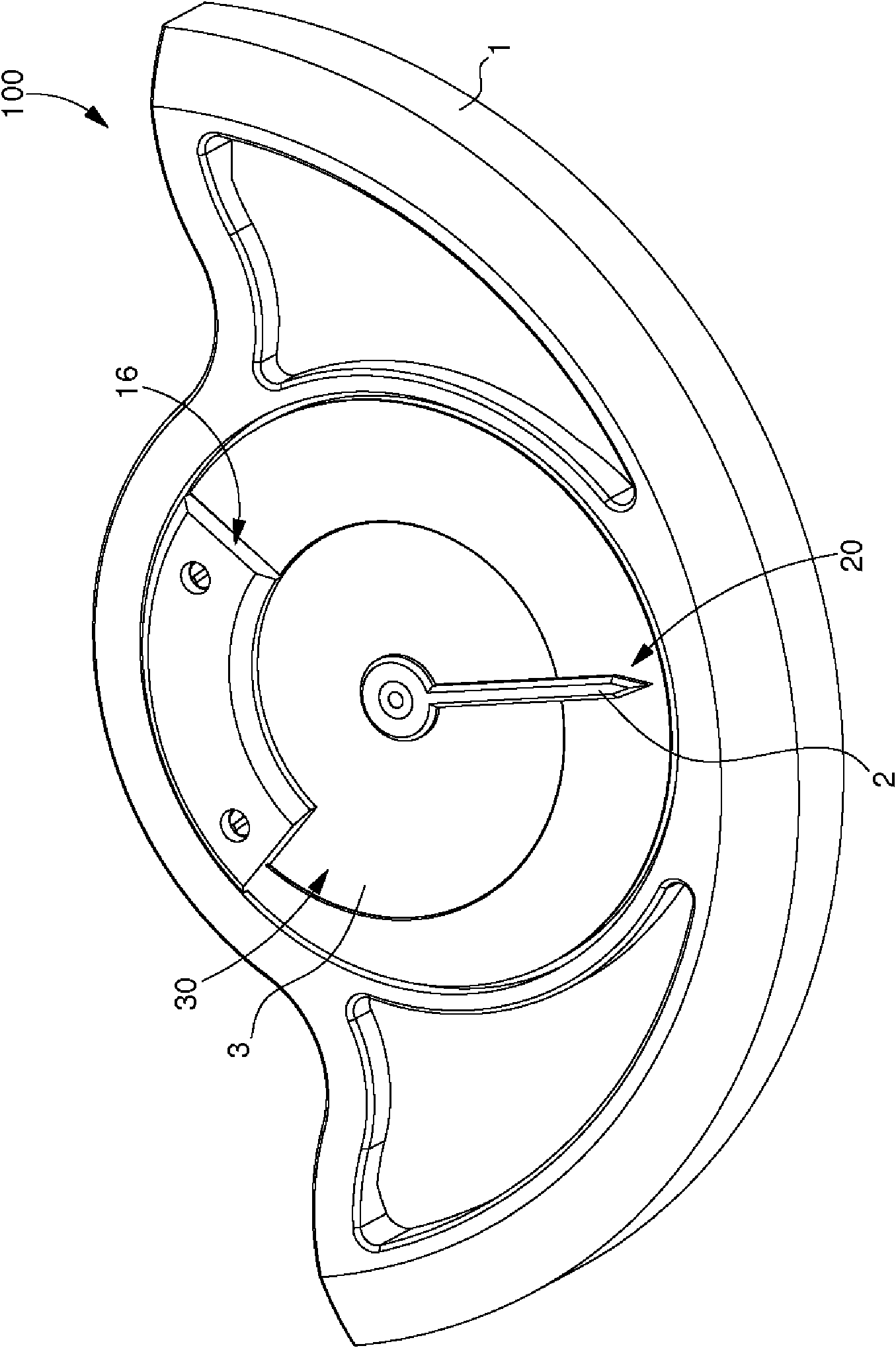

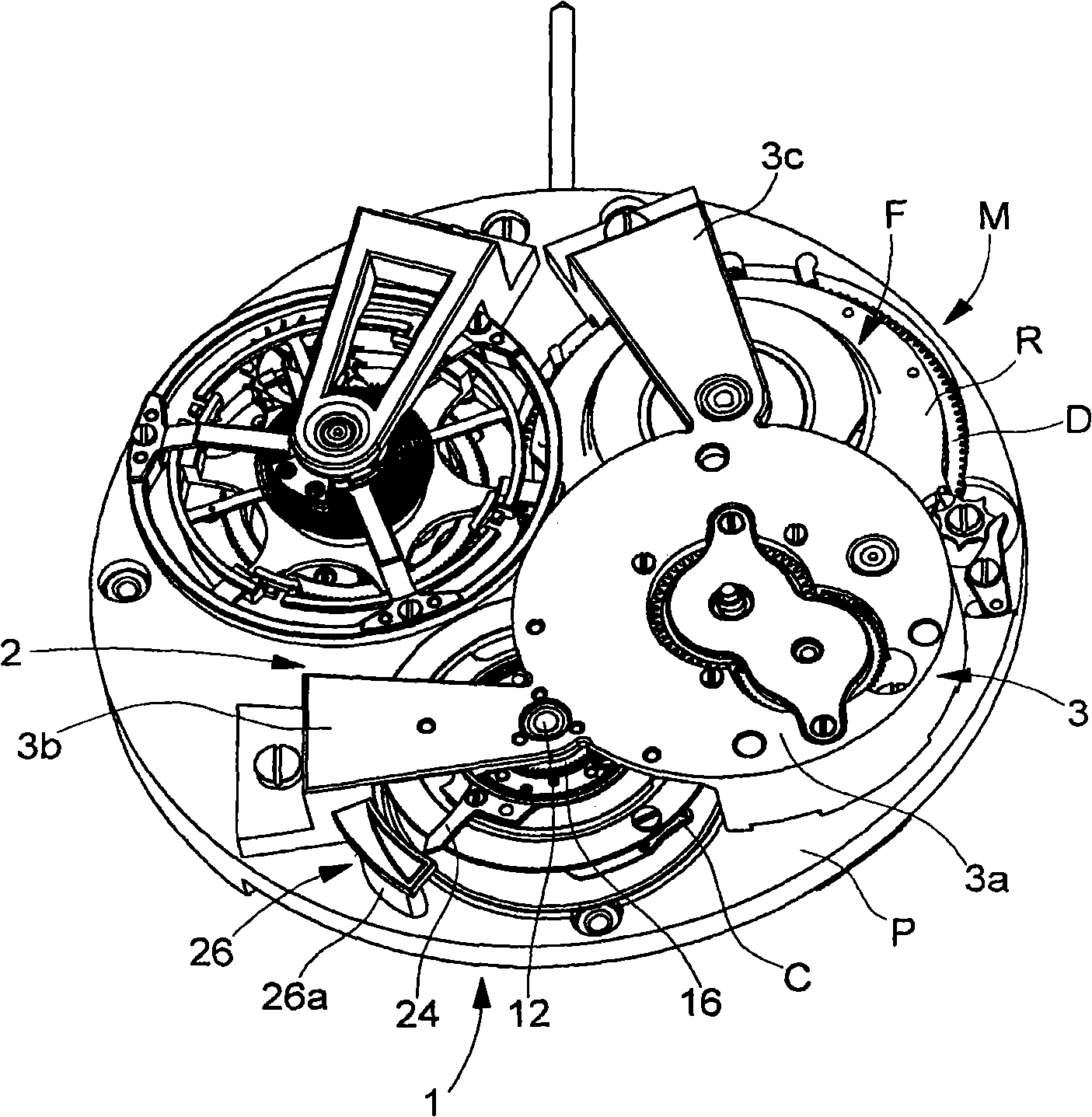

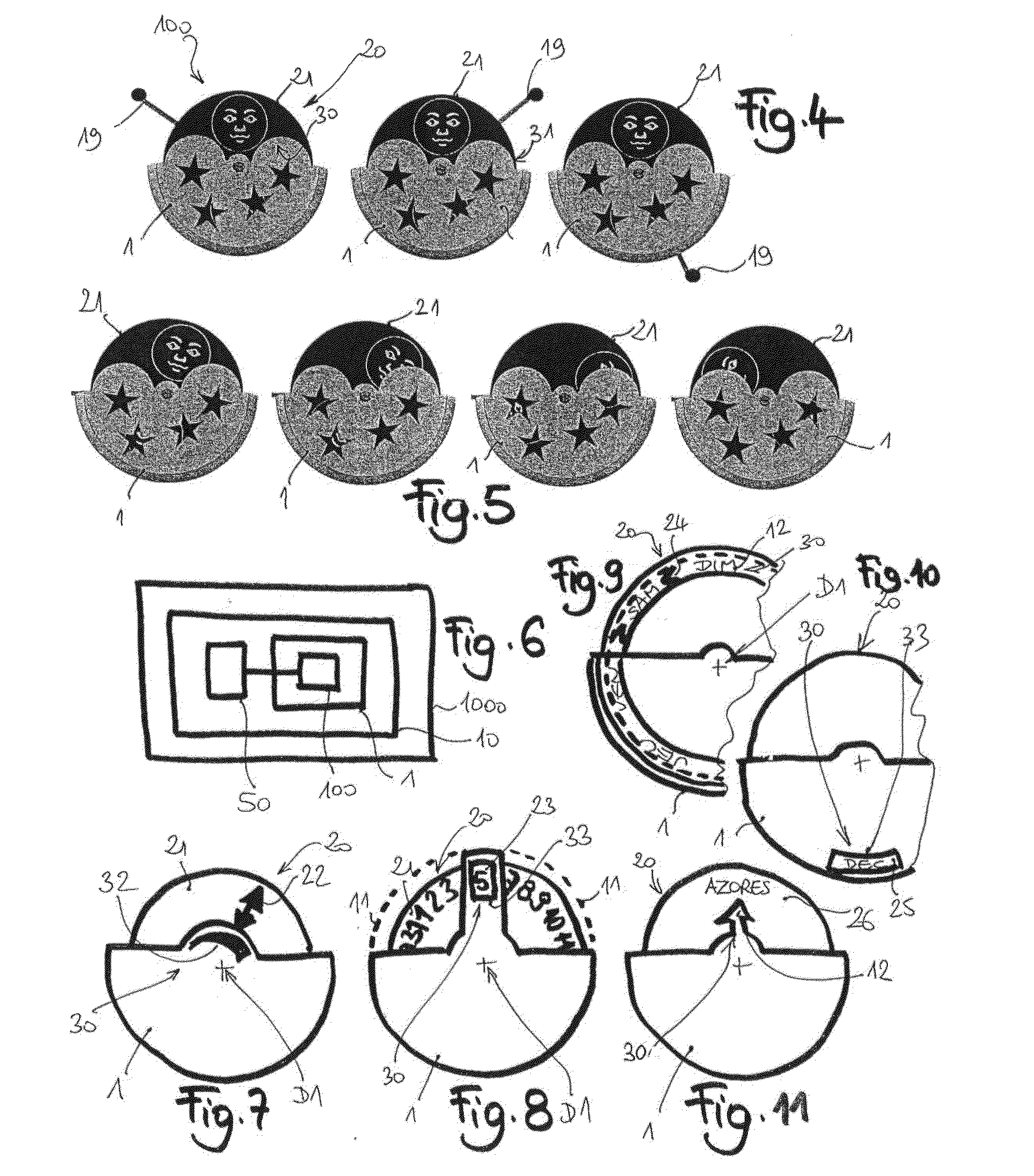

Oscillating weight for an automatic winding watch, including a power reserve indicator device integrated in said oscillating weight

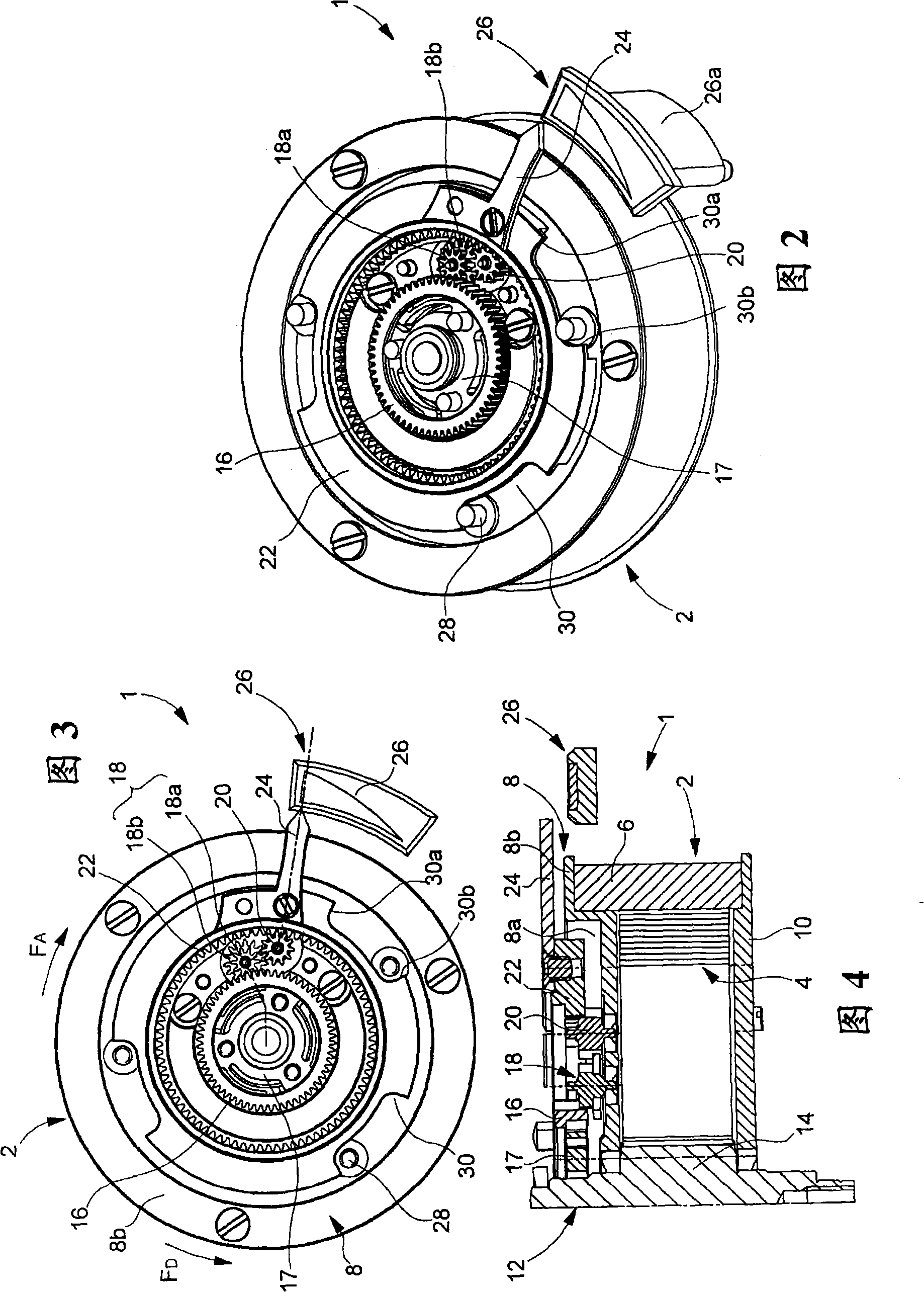

The invention concerns an oscillating weight (1) for an automatic winding watch, including a power reserve indicator device (100) integrated in said oscillating weight (1) and including means (20) for displaying the power reserve by comparison to complementary display means (30), said display means (20) and complementary display means (30) being integrated in said oscillating weight (1).Said display means (20) and complementary display means (30) are movably mounted to rotate synchronously, at a given moment, relative to said oscillating weight (1).The invention also concerns an automatic winding watch including an oscillating weight (1) of this type, whose movements are transmitted to a mainspring of said watch.

Owner:BLANCPAIN SA

Timepiece having mainspring winding state display apparatus including deformed segment gear

InactiveUS20050162982A1Reduce stepsReduce the impactTime indicationEscapementsMainspringCentre of rotation

To provide a timepiece having a mainspring winding state display apparatus constituted to be able to arrange a rotational center of a winding mark hand at an arbitrary pertinent position in a movement of a timepiece. A movement is provided with a barrel complete, and a speed reducing mechanism cooperatively moved with a barrel gear for reducing a speed of rotation of the barrel gear, that is, a planetary unit. A segment gear is provided to be rotatable based on an output of the planetary unit. A winding mark indicator is rotated based on operation of the segment gear. A mainspring winding state display member displays a state of winding a mainspring based on rotation of the winding mark indicator.

Owner:SEIKO INSTR INC

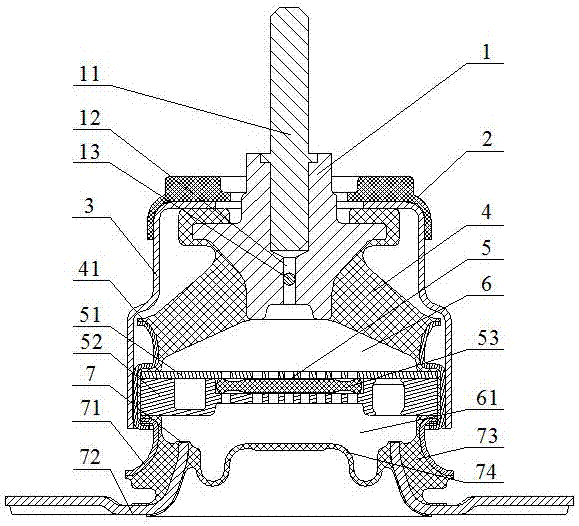

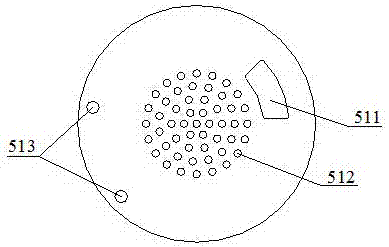

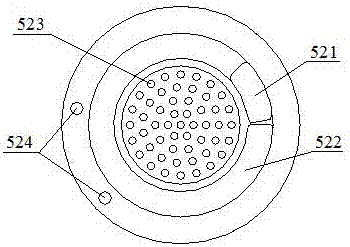

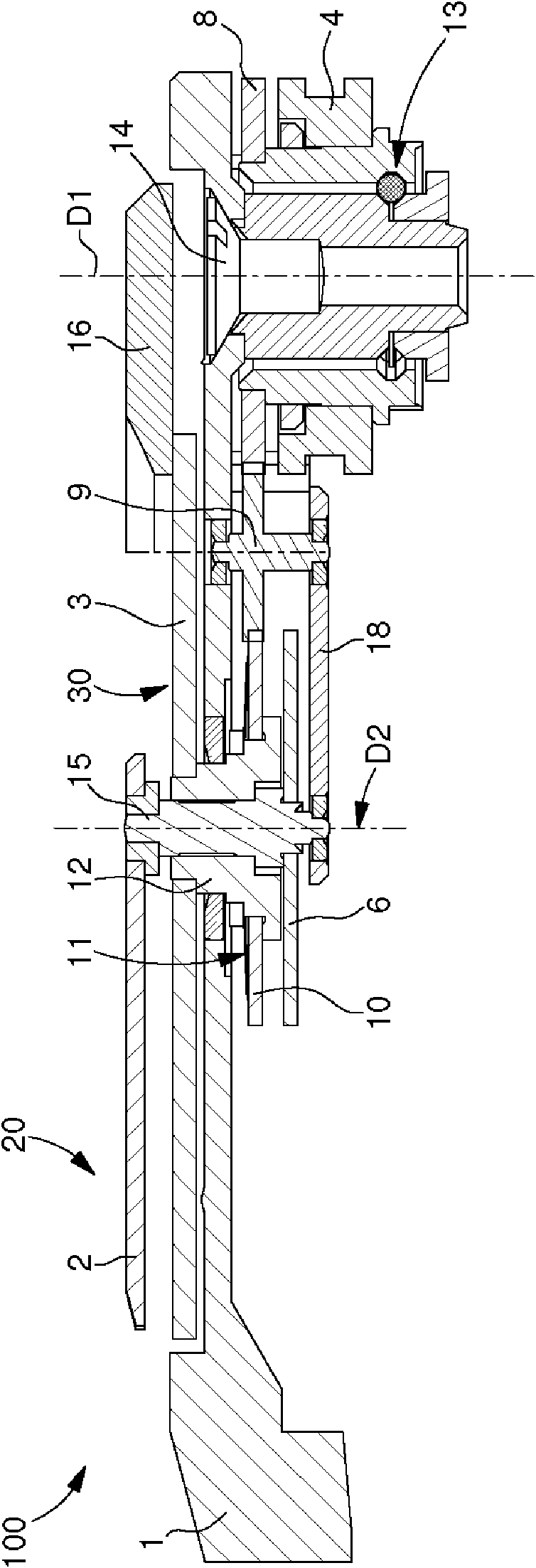

Two-level vibration isolation hydraulic mount

PendingCN107366710AReduce vibrational energySimple structureSpringsShock absorbersVehicle frameMainspring

The invention discloses a two-level vibration isolation hydraulic mount comprising an inner core, a limiting cover, an anti-collision cover, a runner assembly and a connecting bolt. A rubber mainspring is arranged on the lower portion of the inner core. The outer side wall of the lower portion of the rubber mainspring is provided with a mainspring outer framework. The lower portion of the limiting cover is installed on the outer side wall of the mainspring outer framework in an interference pressing mode. The top of the limiting cover is installed at the top of the rubber mainspring in a pressing mode. The anti-collision cover covers the top of the limiting cover. A vibration isolation seat is arranged at the bottom of the rubber mainspring. A sealed liquid cavity is formed between the vibration isolation seat and the rubber mainspring and is divided into an upper liquid cavity body and a lower liquid cavity body through the runner assembly. The lower portion of the connecting bolt is arranged in a threaded hole in the upper portion of the inner core. The threaded hole communicates with the upper liquid cavity body through a liquid filling hole. The liquid filling hole forms interference sealing through a steel ball. According to the two-level vibration isolation hydraulic mount, the first level of vibration isolation is conducted on excitation vibration through the rubber mainspring and the runner assembly, the second level of vibration isolation is conducted through a vibration isolation spring on the vibration isolation seat after attenuation, and thus vibration energy transmitted onto a vehicle frame is lowered to the minimum.

Owner:QIDONG YONGXING RUBBER PROD

Mechanical timepiece with timed annular balance rotating angle control mechanism

InactiveUS6431746B1Avoid excessive changesEffective controlEscapementsFrequency stabilisation mechanismMainspringEngineering

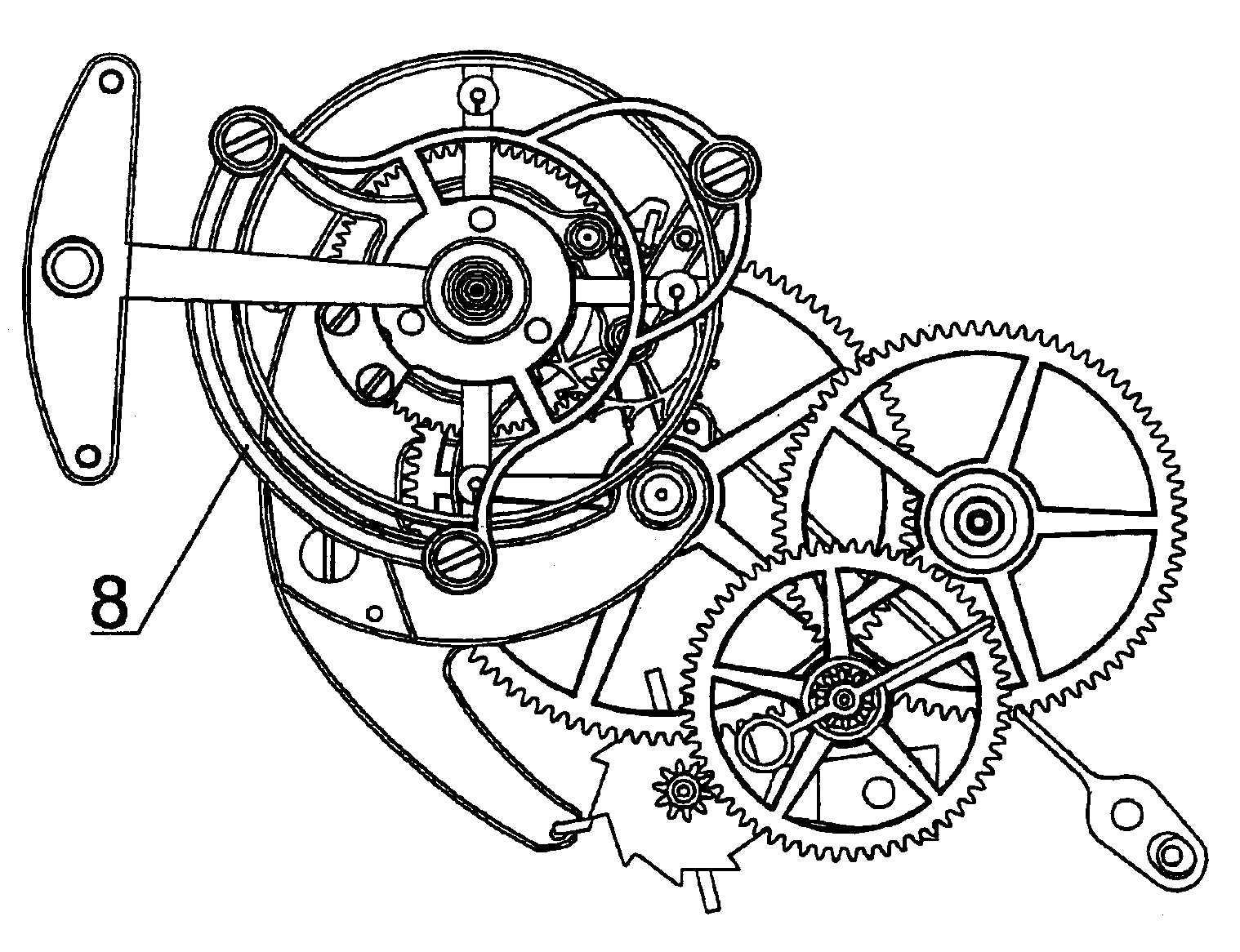

A mechanical timepiece has a power source comprised of a mainspring for undergoing rewinding movement to generate a rotational force. A front train wheel undergoes rotation in accordance with a rotational force generated during rewinding movement of the mainspring. An escapement / speed-control device controls rotation of the front train wheel. The escapement / speed-control device has a balance with a hairspring for undergoing alternately repeating rotational movement in left and right directions. An escape wheel and pinion undergoes rotation in accordance with rotation of the front train wheel. A pallet fork controls rotation of the escape wheel and pinion in accordance with rotational movement of the balance. A switch mechanism outputs an ON signal when a rotation angle of the balance reaches a predetermined threshold angle or greater, outputs an OFF signal when the rotation angle of the balance does not exceed the predetermined threshold angle. A rotation angle control mechanism supresses rotation of the balance when the switch mechanism outputs an ON signal.

Owner:SEIKO INSTR INC

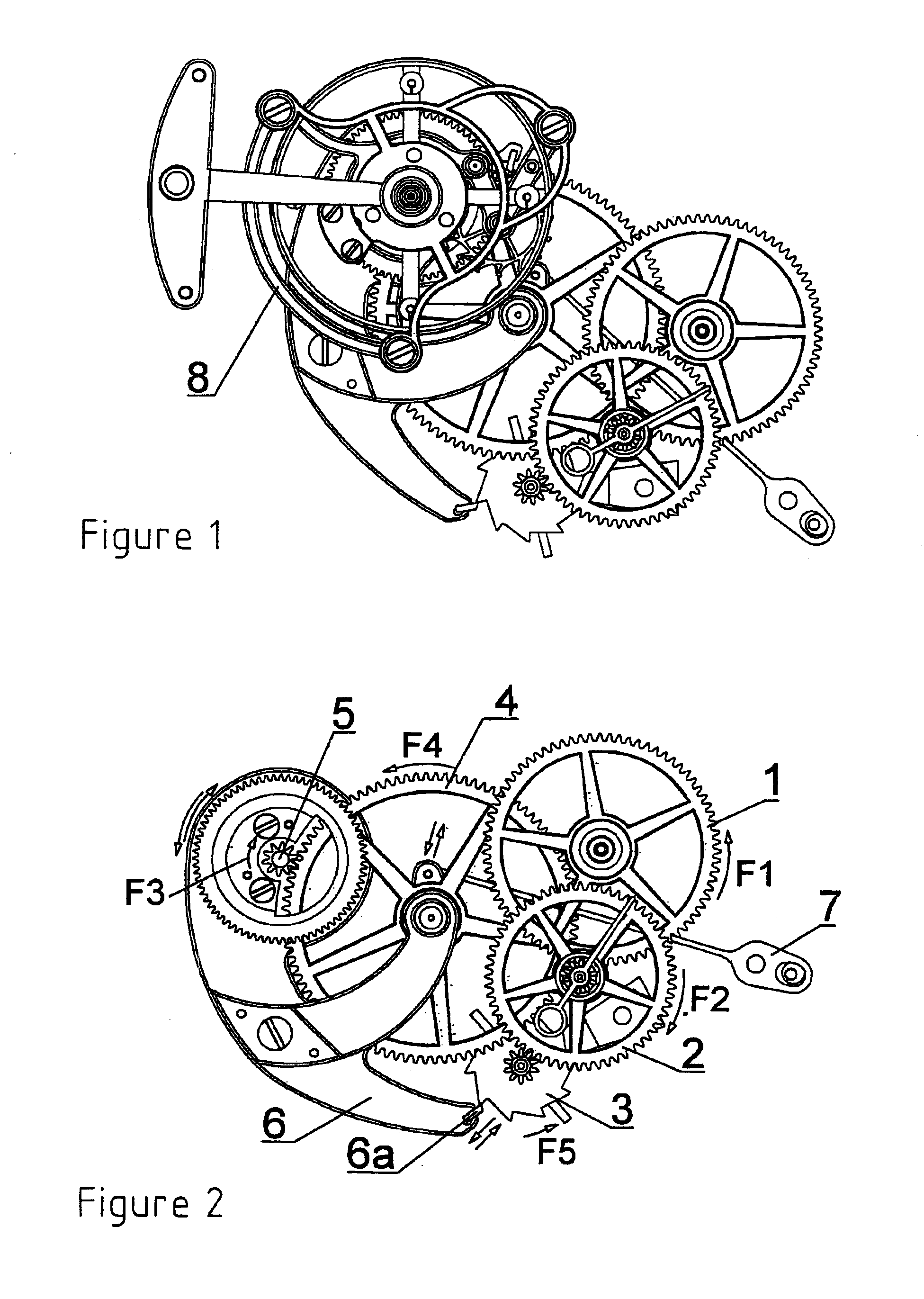

Power reserve indicator built into the oscillating weight of a movement with automatic winding

The invention concerns an oscillating weight (1) for an automatic winding watch, including a power reserve indicator device (100) integrated in said oscillating weight (1) and including means (20) for displaying the power reserve by comparison to complementary display means (30), said display means (20) and complementary display means (30) being integrated in said oscillating weight (1). Said display means (20) and complementary display means (30) are movably mounted to rotate synchronously, at a given moment, relative to said oscillating weight (1). The invention also concerns an automatic winding watch including an oscillating weight (1) of this type, whose movements are transmitted to a mainspring of said watch.

Owner:BLANCPAIN SA

Variable-runner semi-active hydraulic suspension

The invention discloses a variable-runner semi-active hydraulic suspension, which comprises a hydraulic suspension body and an electronic control device, wherein the hydraulic suspension body comprises a rubber mainspring, a runner assembly, a packing cup, a bottom cover, a bolt and a liquid inlet pipeline, and the rubber mainspring, the runner assembly, the packing cup and the bottom cover are sequentially assembled into a whole from top to bottom; the bolt is in pressing rivet connection with the bottom cover, and the rubber mainspring comprises an inner core, an inner skeleton, an outer skeleton and a rubber body which are vulcanized into a whole; the runner assembly comprises a runner body, an upper runner plate, a lower runner plate, a decoupling film and a variable flow valve, and the side wall of the runner body is provided with two openings; the variable flow valve is provided with two openings and is in fit assembly with the runner body, and the electronic control device is in driving connection with the variable flow valve and can drive the variable flow valve and the runner body to relatively rotate. The variable-runner semi-active hydraulic suspension provided by the invention has a good damping effect when an engine is in an idling condition and a cruising condition.

Owner:ASIMCO NVH TECH CO LTD ANHUI

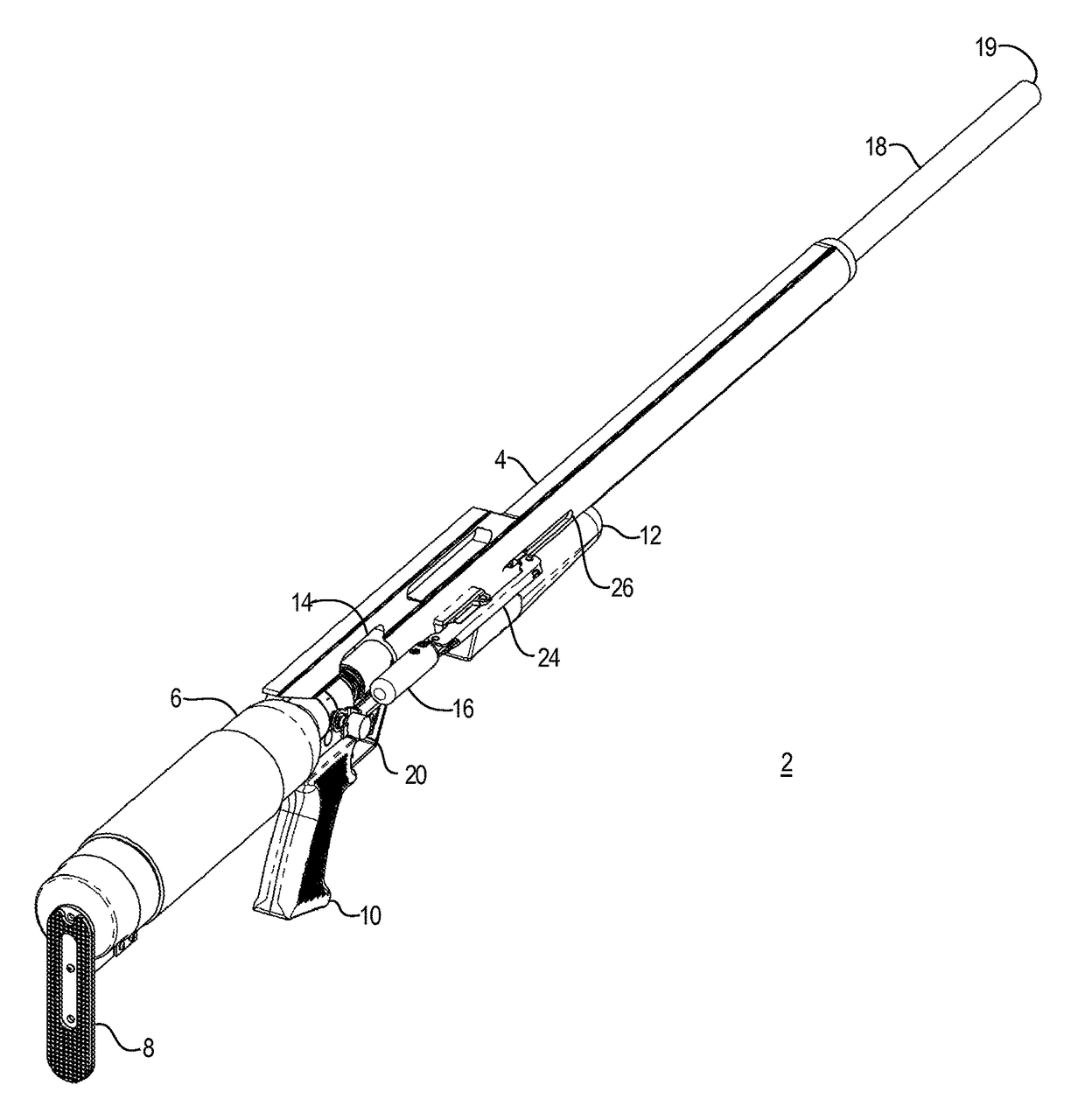

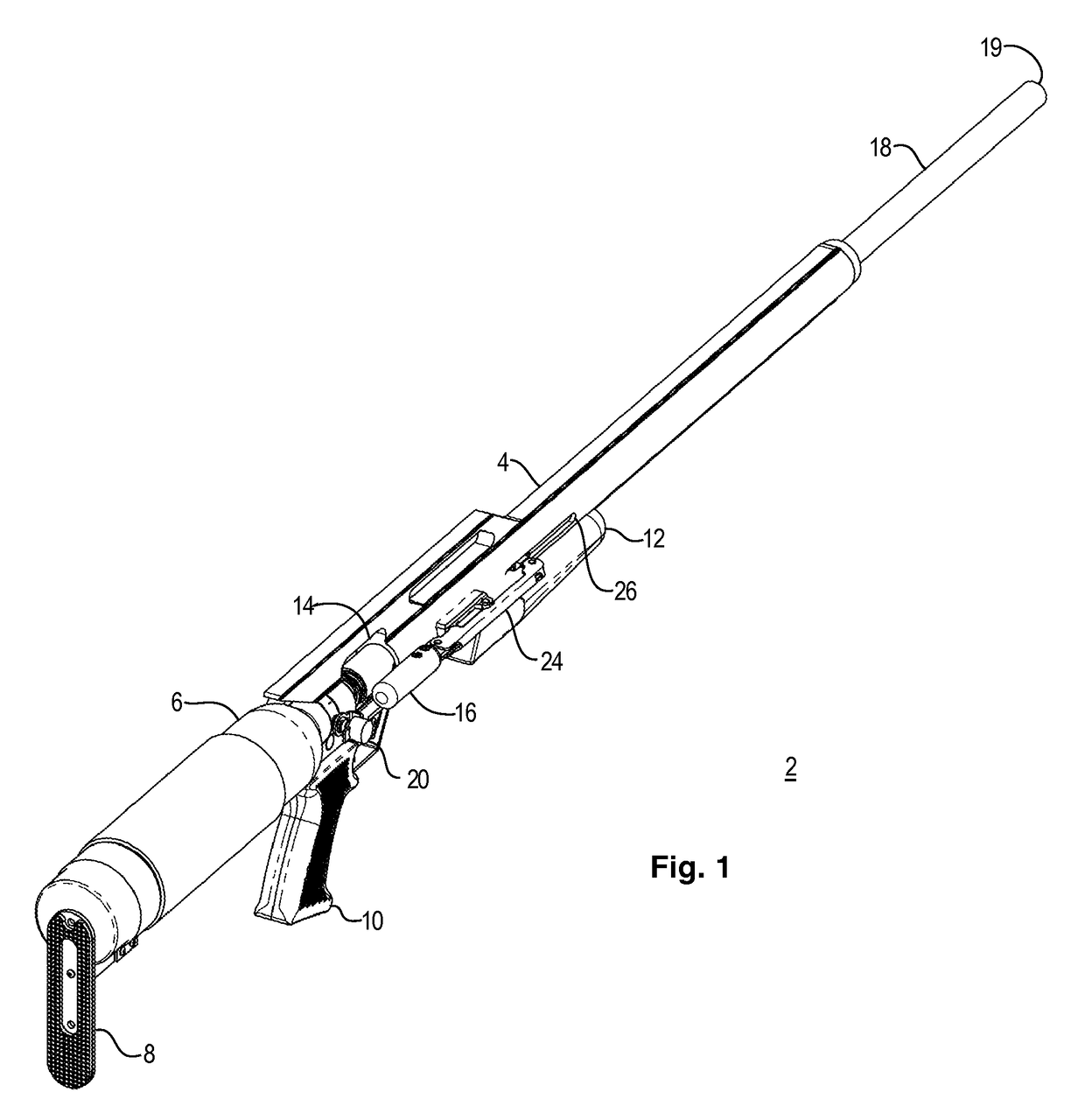

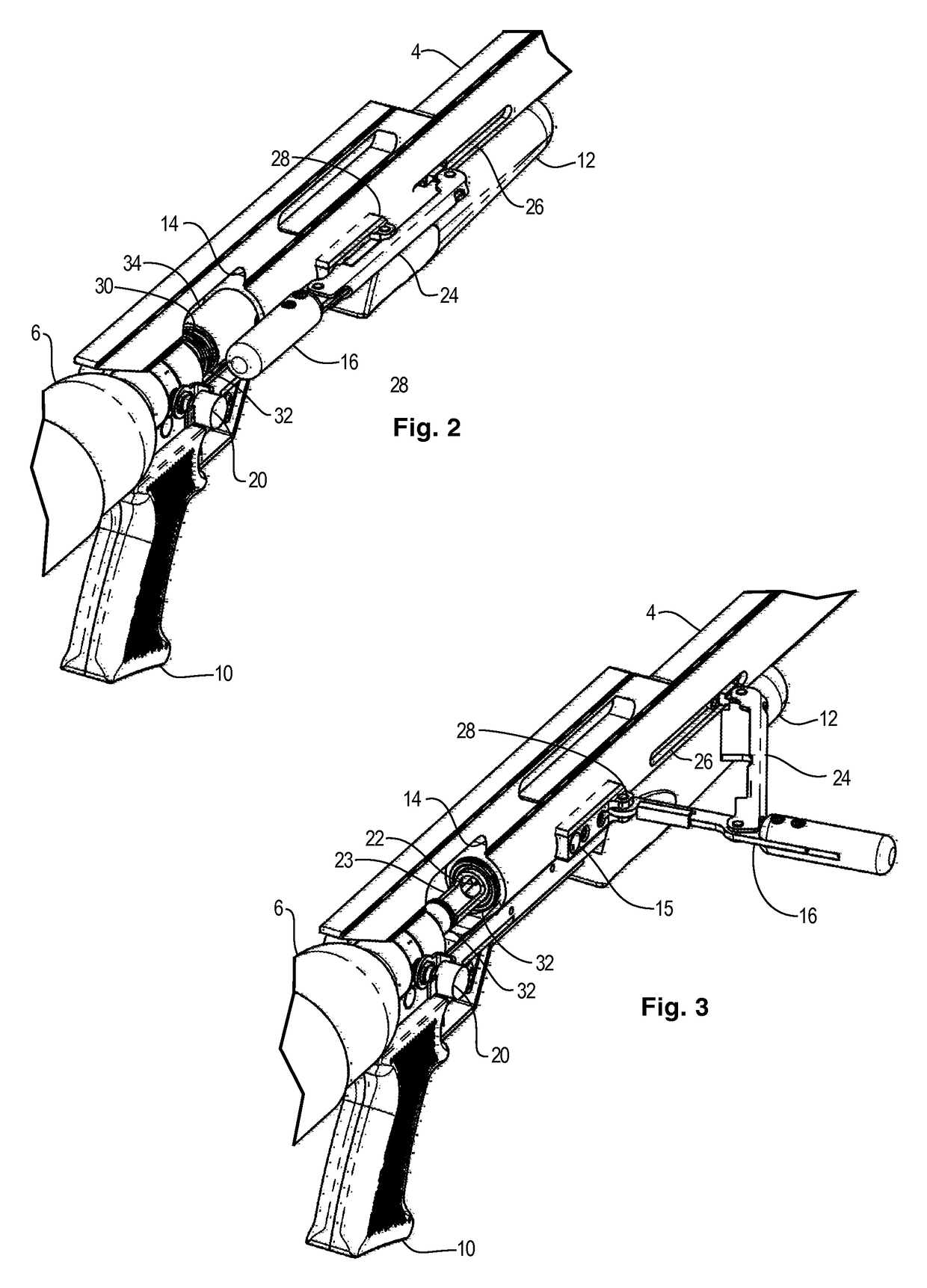

Compressed gas gun with improved operating mechanism

A compressed gas gun with a cocking mechanism that provides a mechanical advantage in compressing a mainspring, while providing a two stage loading and cocking action that accesses and seals a breech through utilization of an intermediate cocking member.

Owner:MCCASLIN JOHN A

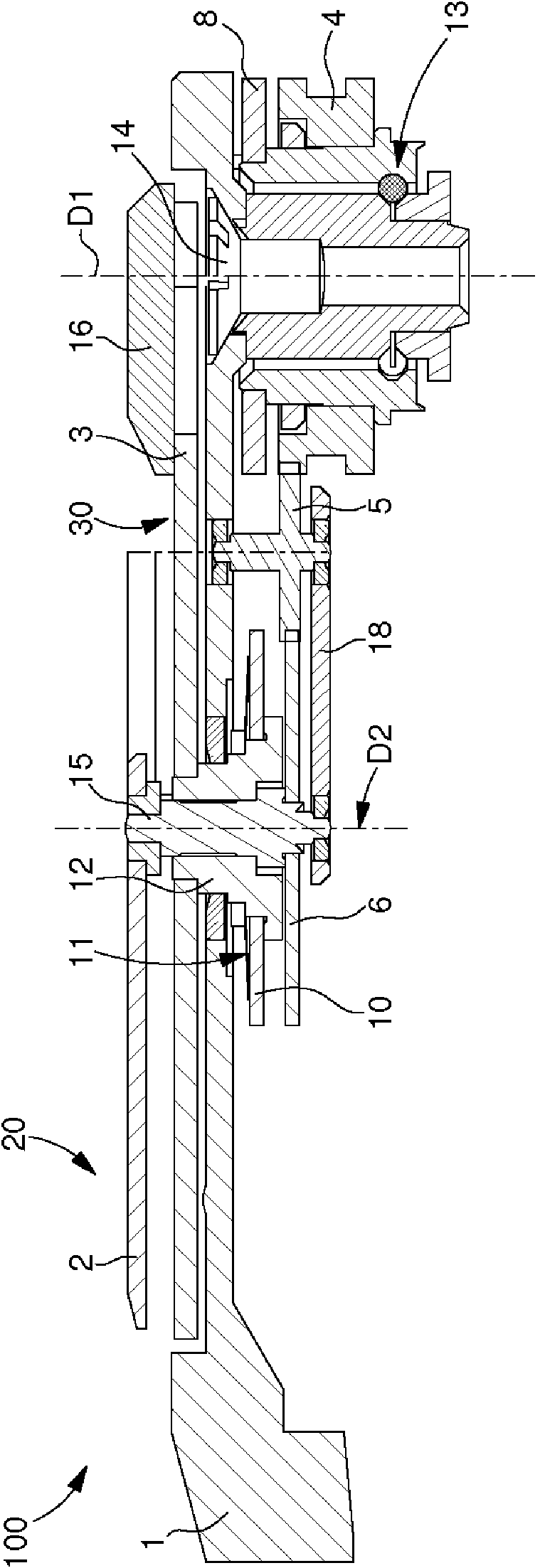

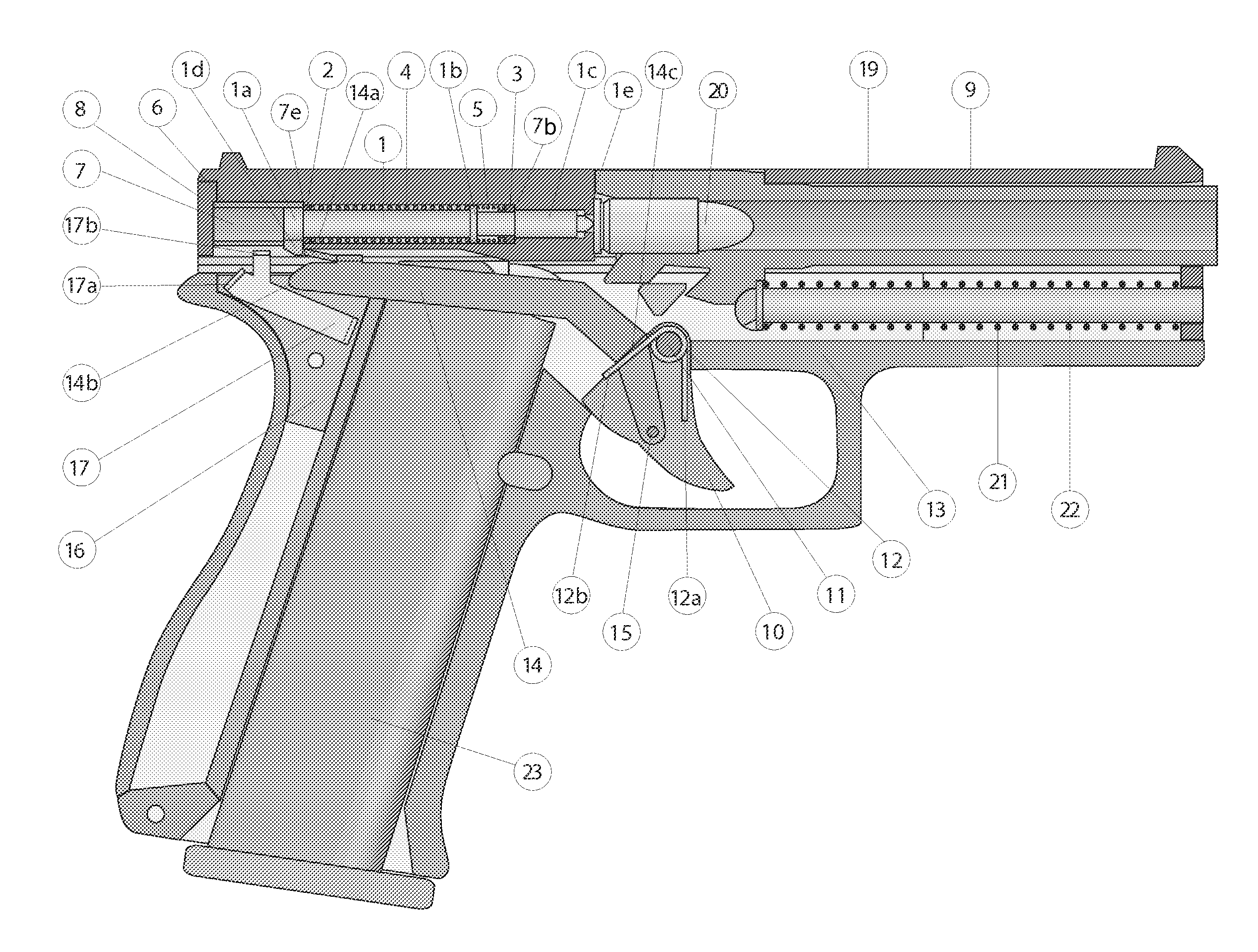

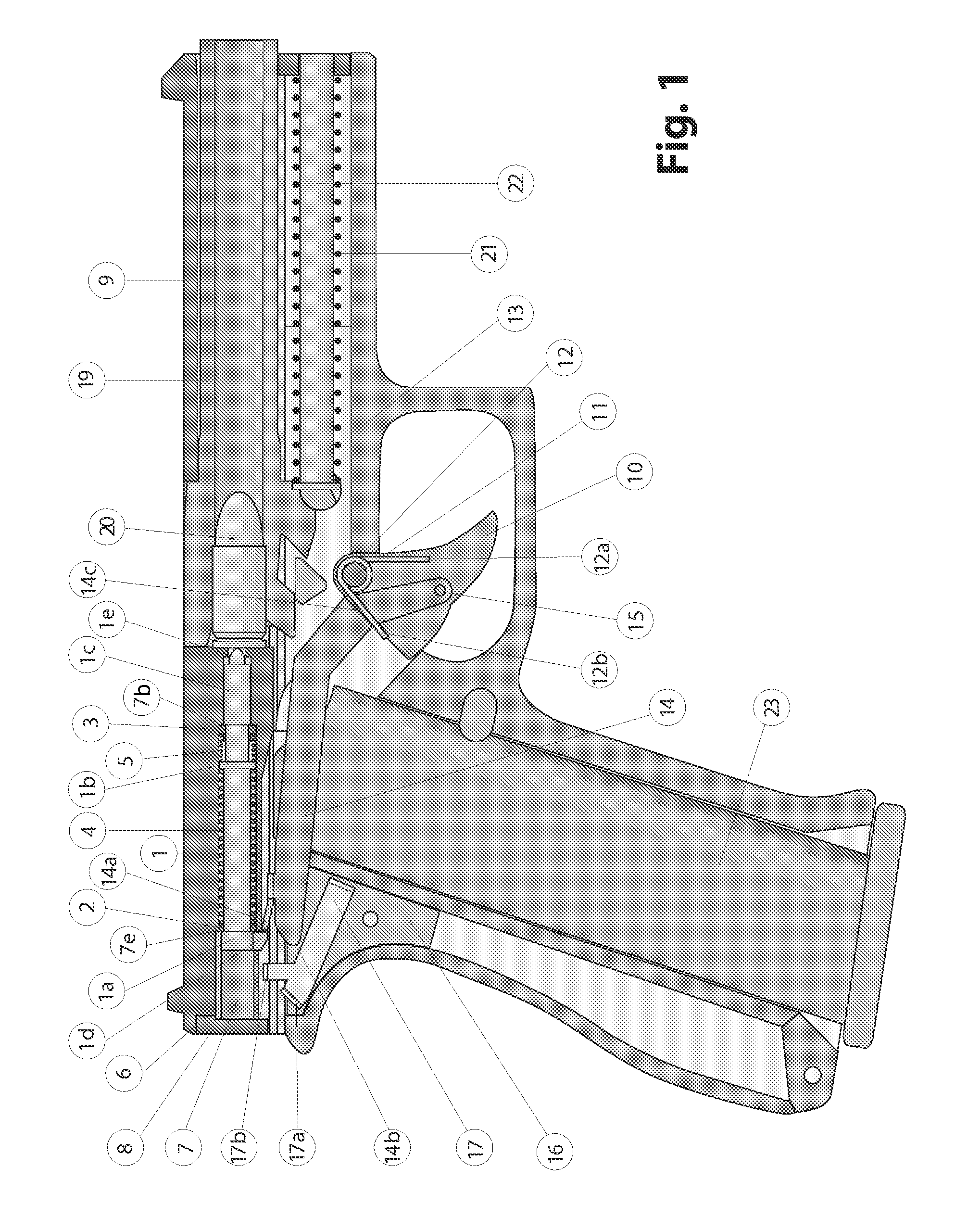

Double action short reset trigger system

ActiveUS8176836B2Safe to carryEasy to useFiring/trigger mechanismsBreech mechanismsMainspringShort circuit

The mechanism is simple, with longer service life, and allows for a safe carrying for prolonged periods and quick subsequent shots of the firearms. The striker (1) has a middle enlargement (1b) that is closer to the front enlargement (1c). The rear face of the middle enlargement (1b) serves as a forward rest for the mainspring (4). The forward face is a rear rest for the safety spring (5) with its front part resting on the rear face of the axially floating ring (3) with an internal diameter smaller than the external diameter of the front (1c) and middle (1b) enlargements. The external diameter is greater than the internal diameter of the front enlargement (1c). Between the rear part of the mainspring (4) and the bushing (6) there is a second axially floating ring (2) with an internal diameter smaller than the external diameter of the rear (1a) and middle (1b) enlargements. The spring (12) that returns the trigger (10) is pushing the trigger (10) forward and the trigger bar (14) up.

Owner:PEEV VLADIMIR GEORGIEV

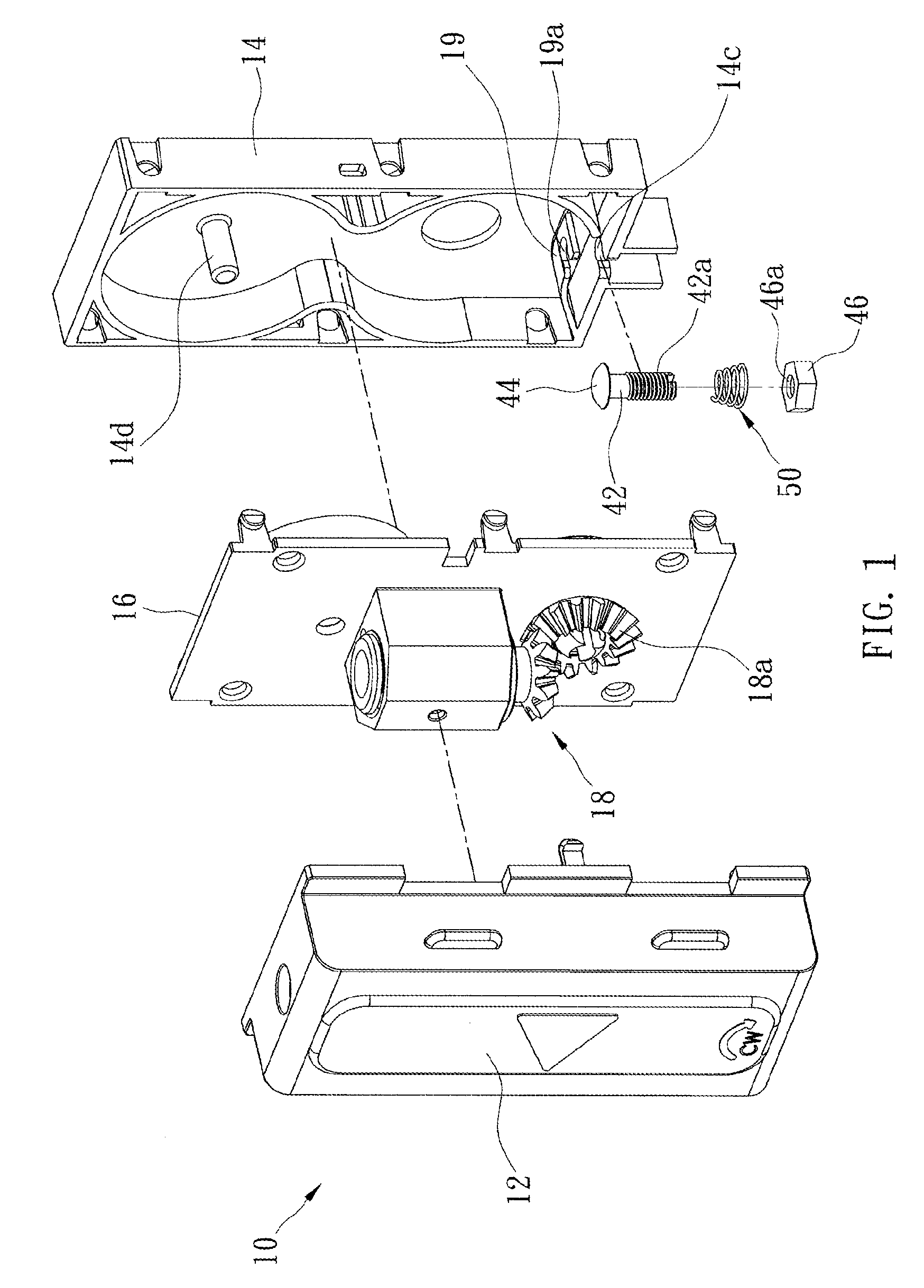

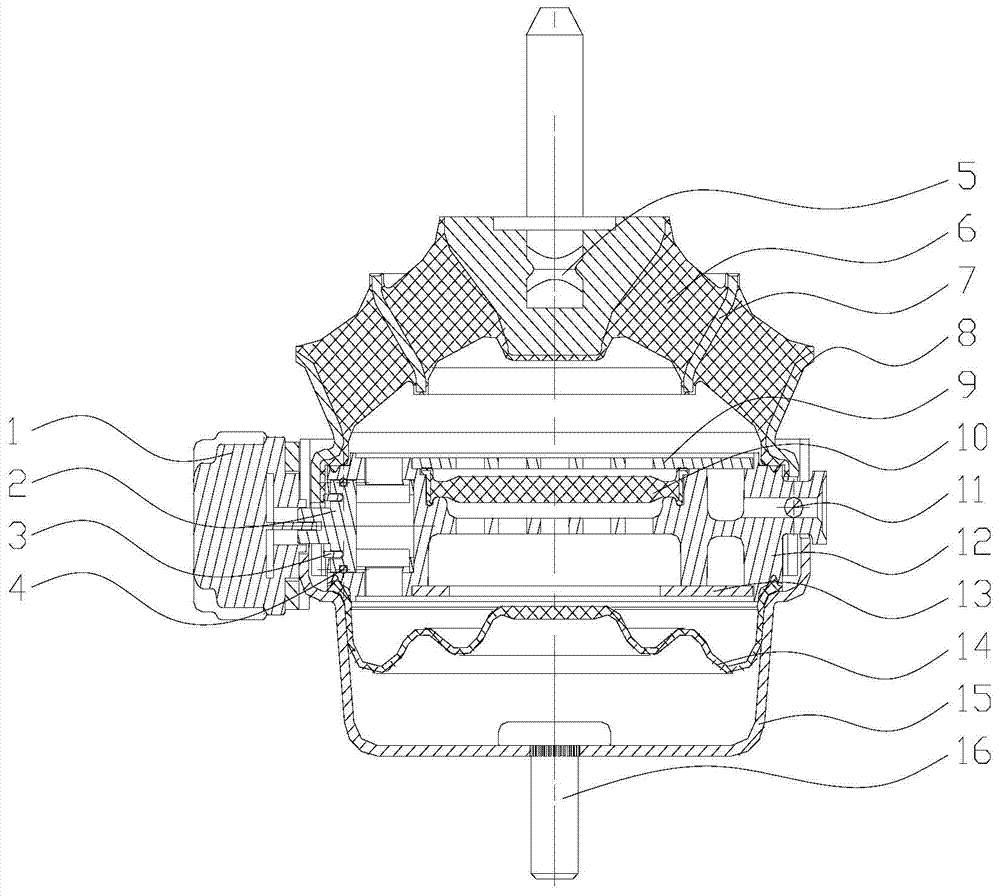

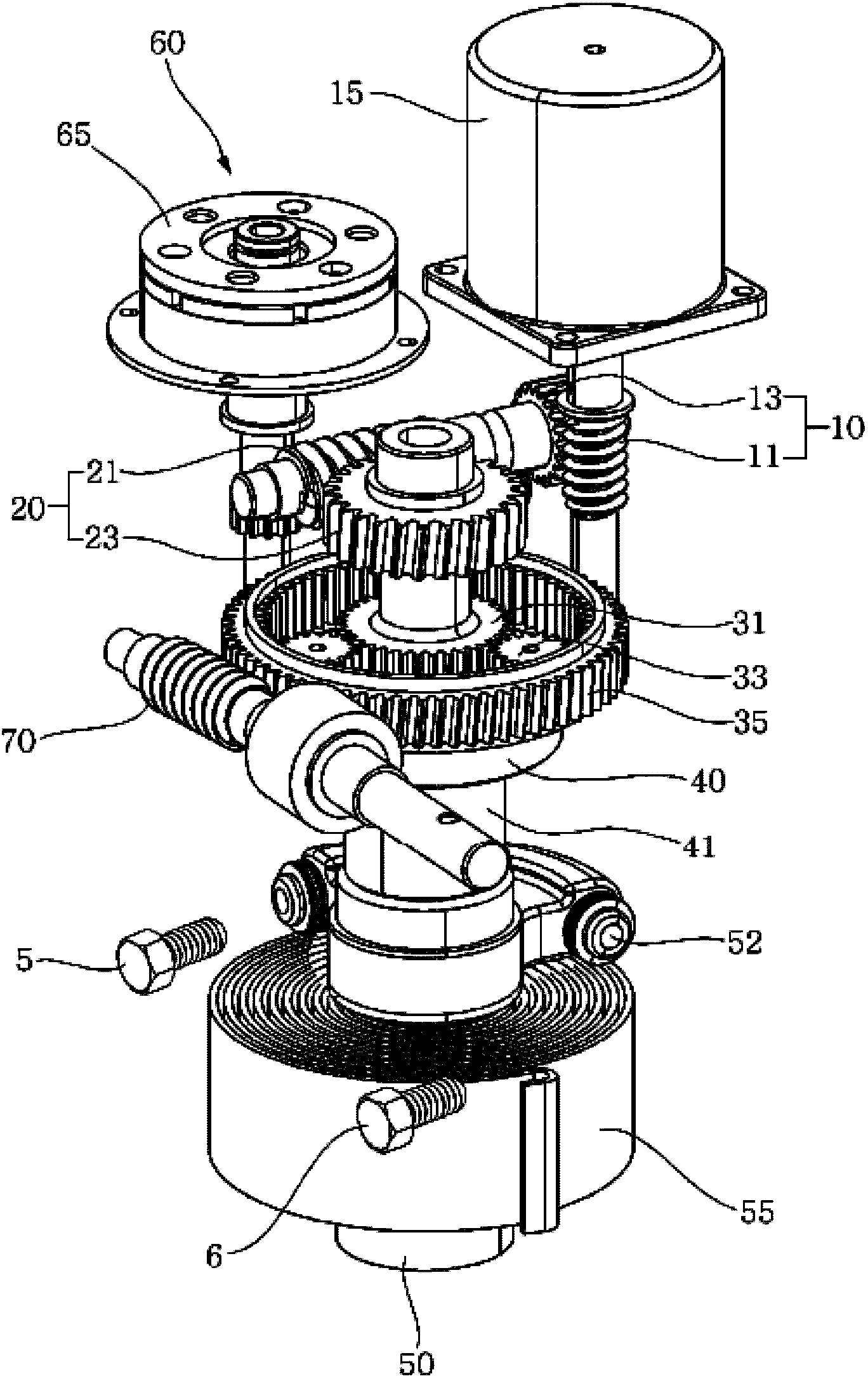

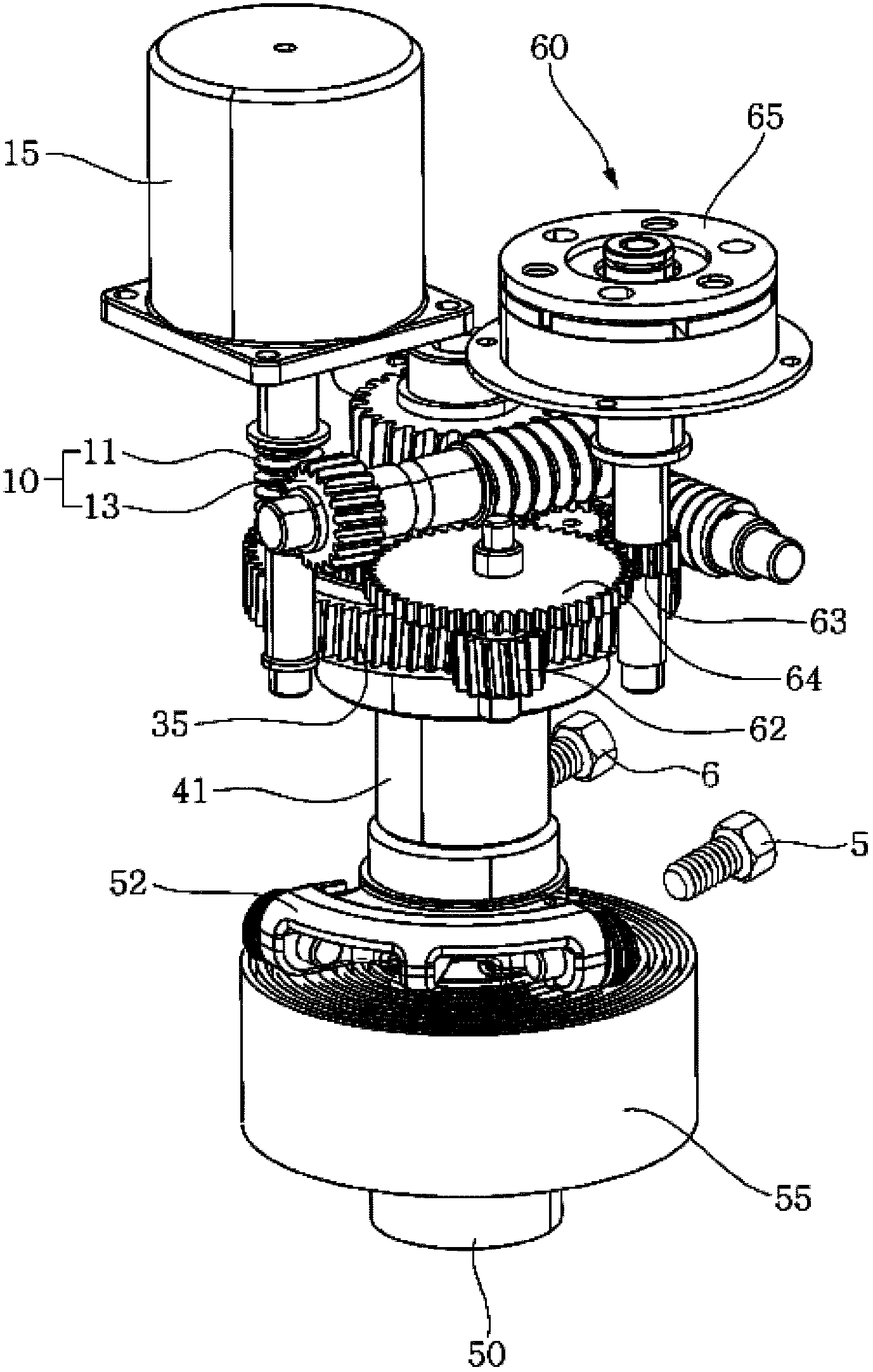

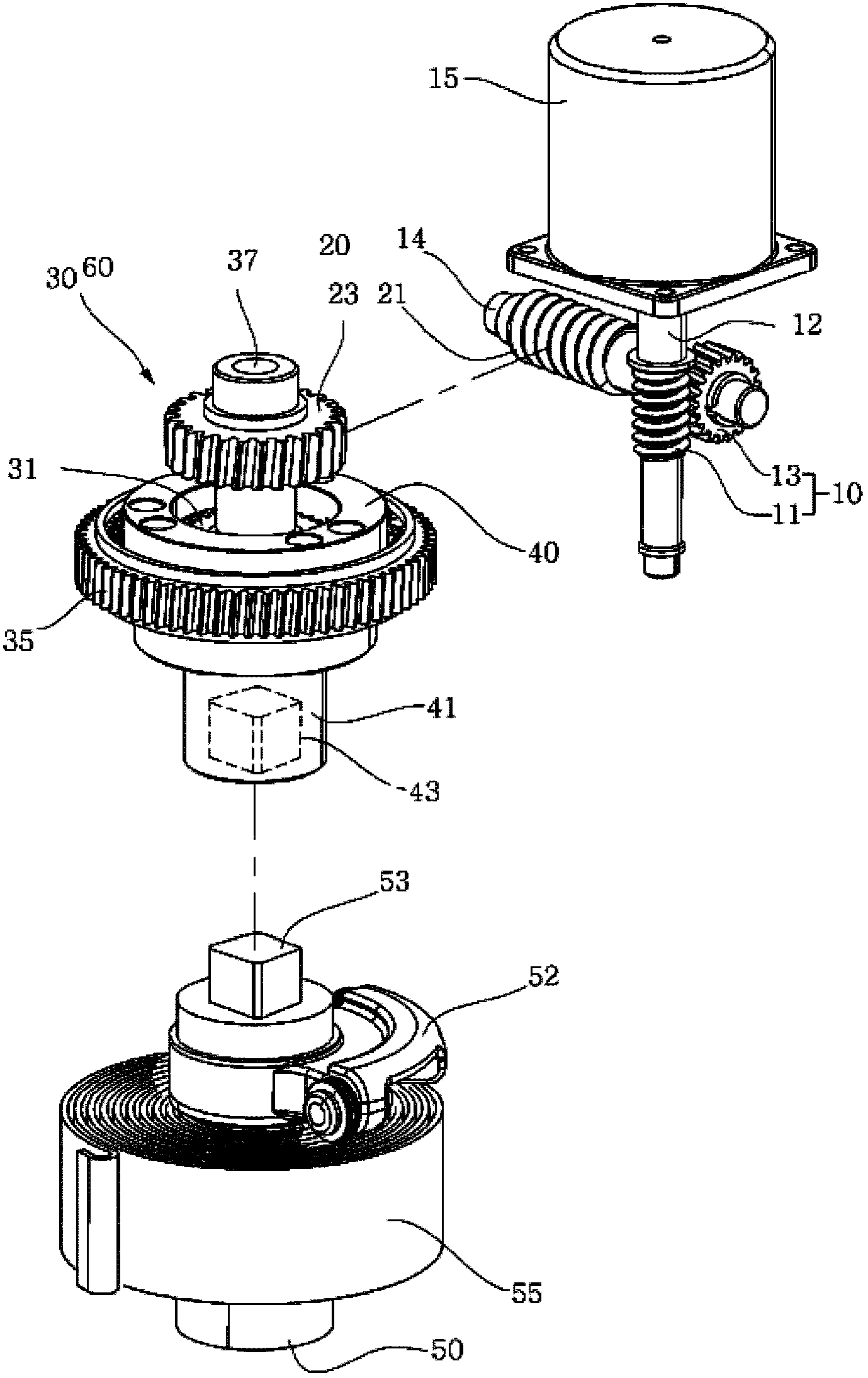

Spring-return valve actuator using planetary gear train

ActiveCN103511717AEasy to set upEasy to observeOperating means/releasing devices for valvesValve actuatorMainspring

The invention provides a spring-return valve actuator using a planetary gear train. The spring-return valve actuator comprises a revolving shaft of a motor, a primary worm wheel and worm set, a secondary worm wheel and worm set, a sun wheel, the planetary gear train, a planetary gear train support, a power spring shaft, a brake unit, a shiftable worm and a hand wheel mechanism. The primary worm wheel and worm set is connected with the revolving shaft and composed of a primary worm and a primary worm wheel. The secondary worm wheel and worm set is composed of a secondary worm and a secondary worm wheel, wherein the secondary worm is coaxial with a primary worm wheel shaft, and the secondary worm wheel corresponds to the secondary worm. The sun wheel is coaxial with the secondary worm wheel, and the planetary gear train is composed of the sun wheel, a planetary gear and a gear ring. The planetary gear train support is in linkage with the planetary gear train and provided with an output shaft on the lower portion. The power spring shaft is connected with the output shaft and provided with a limiting device and a power spring. The brake unit comprises a spragging gear and has a brake function, wherein the spragging gear is meshed with external teeth of the gear ring. The shiftable worm can be in linkage with a revolving eccentric wheel and be meshed with and separated from the external teeth of the gear ring. The hand wheel mechanism is connected to the other end of the shiftable worm through a pin and can provide revolving power.

Owner:(株)银河

Thermocompensated spring and method for manufacturing the same

ActiveUS8641023B2Avoid manufacturing stepsReduce scrap rateVibration dampersFrequency stabilisation mechanismMetallic materialsMainspring

The invention relates to a method of manufacturing a spring for a timepiece, including the following steps: (a) forming a body using first and second metallic materials secured to each other; (b) decreasing the section of the body; and winding the body to form the spring. The invention also relates to the spring obtained via the method. The invention concerns the field of regulating members for timepieces.

Owner:NIVAROX FAR

Timepiece comprising a device indicating the power reserve

ActiveCN101281386ASmall space requirementGearworksHorological winding mechanismsGear wheelMainspring

The present invention concerns a timepiece including a movement fitted with a power reserve indicator device, said timepiece including a barrel closed by a cover, a mainspring housed in said barrel and respectively connected to a barrel arbour and means for winding said mainspring, said indicator device including a differential gear kinematically connected by a first input to the barrel arbour, by a second input to the barrel and by an output to a power reserve indicator member and wherein the differential gear frame is arranged coaxially to the barrel arbour, characterized in that the second differential gear input is secured to the barrel cover, in that the differential gear output is formed by an inner toothed crown, in that the inner toothed crown is kinematically connected to the first input by at least first and second planetary wheel sets meshed with each other and in that the at least two planetary wheel sets are carried by the cover.

Owner:MONTRES BREGUET

Display on the oscillating weight of a self-winding movement

ActiveUS20130336096A1Easy to implementHighly robustVisual indicationFrequency stabilisation mechanismMainspringEngineering

Device (100) for displaying a magnitude on an oscillating weight (1) for a self-winding timepiece movement (10) comprising a means (20) of displaying said magnitude by comparison to a complementary display means (30).Said display means (20) pivots coaxially to said oscillating weight (1), and is subject to a general pivoting motion resulting from the combination of a first pivoting motion synchronous with that of said oscillating weight (1), and a second pivoting motion resulting from said display means (20) being pivoted by said movement (10) relative to said complementary display means (30) integral with said oscillating weight (1).Oscillating weight (1) including such a device (100).Self-winding watch including an oscillating weight (1) comprising such a device (100), and whose motions are transmitted to a mainspring of said watch.

Owner:BLANCPAIN SA

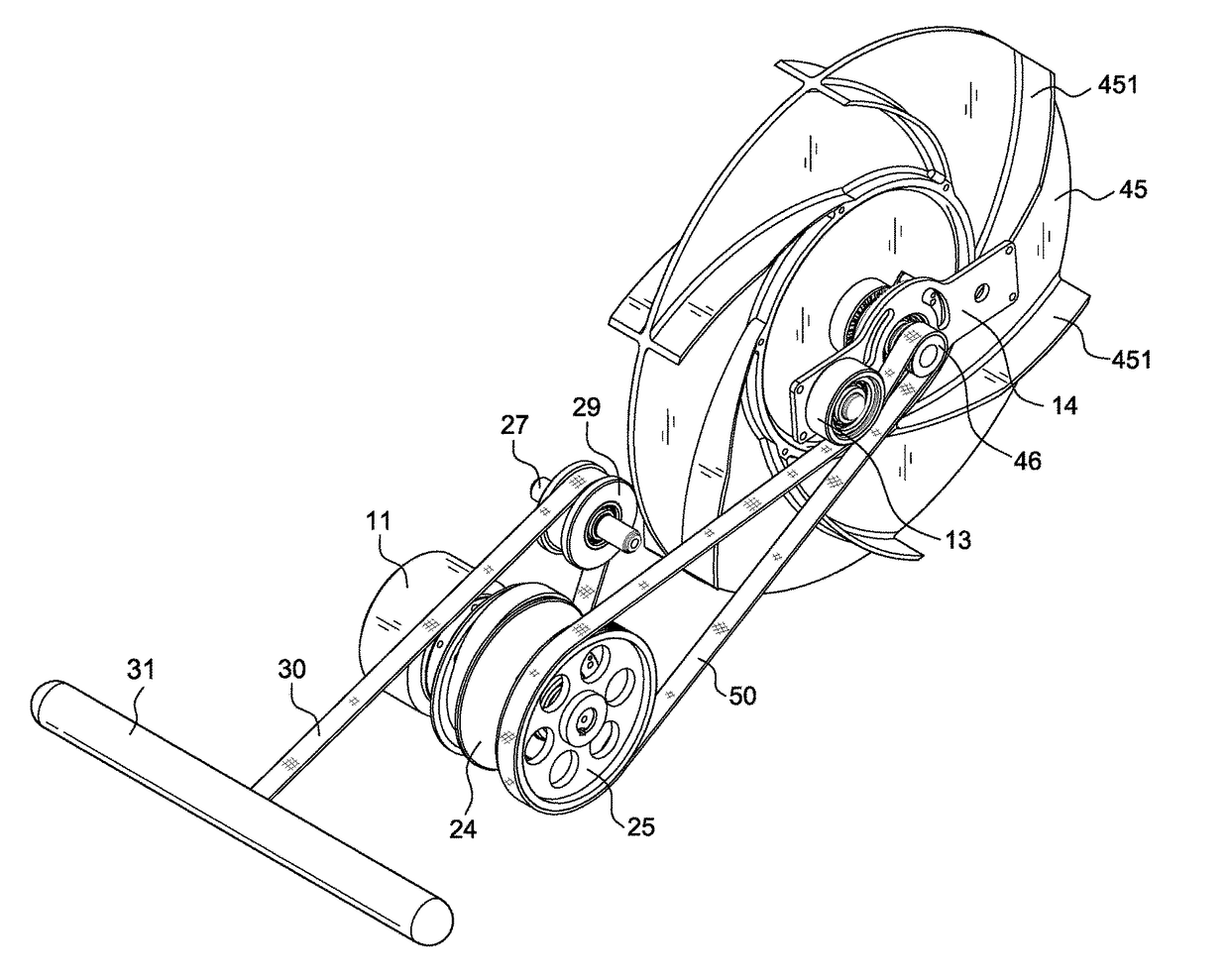

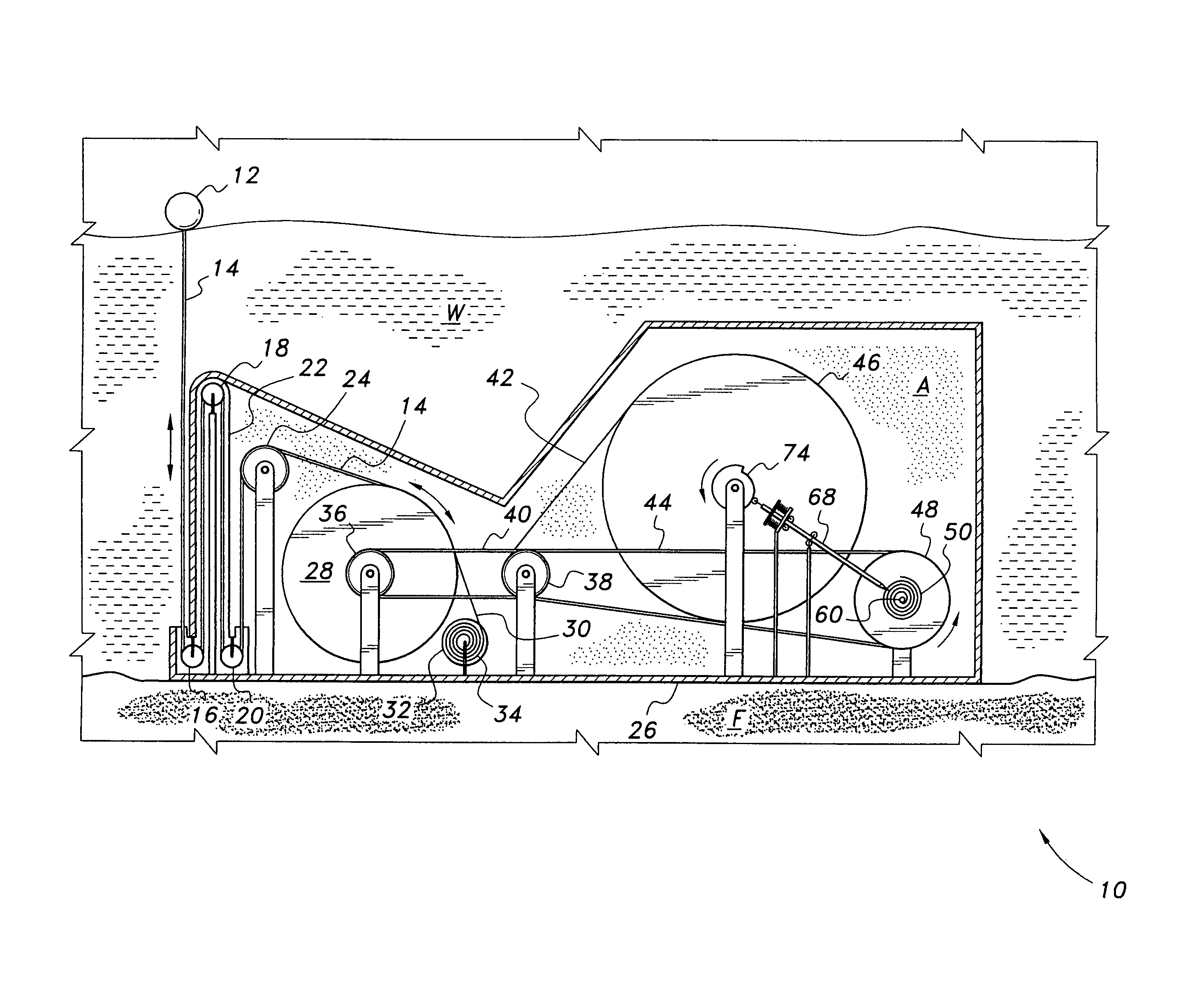

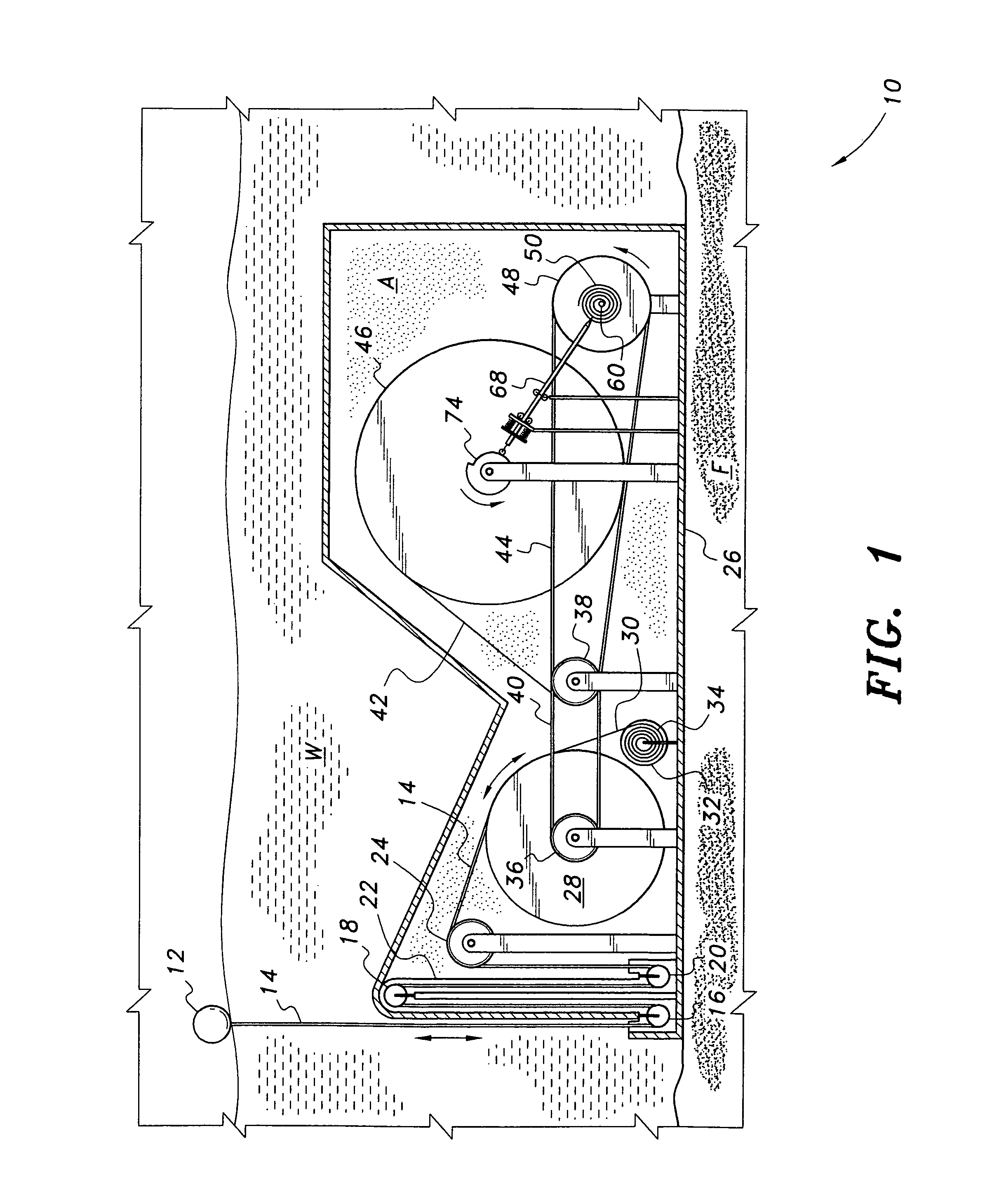

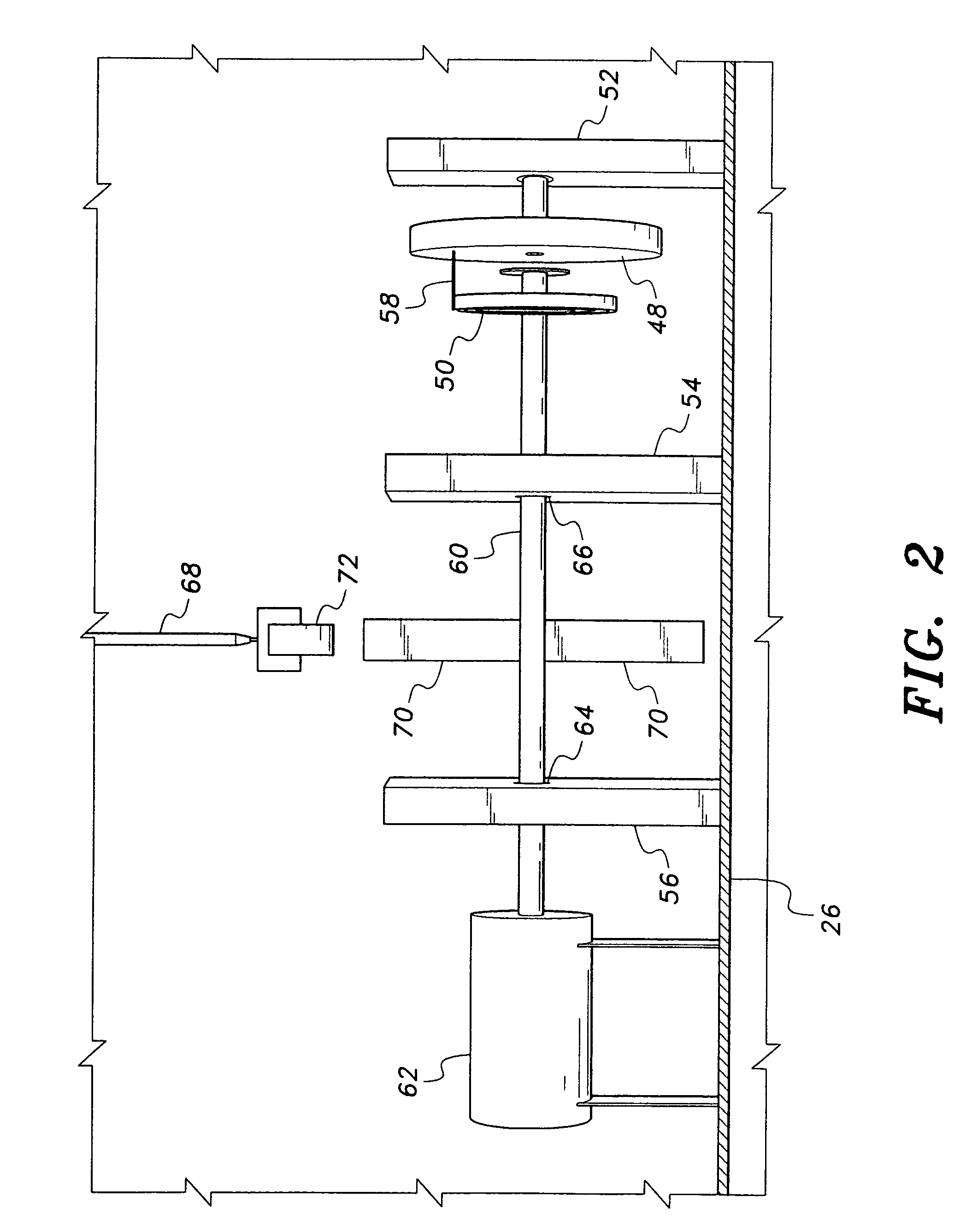

Wave-based power generation system

The wave-based power generation system has a buoy or float retained by a cable that enters an underwater power generating station. The cable enters the station housing through an inverted U-tube having upturned inlet and outlet ports, which prevent water from entering the housing. The buoy cable passes over an inlet pulley assembly disposed within the U-tube and has its free end secured to a take-up reel or sheave. A driver pulley is mounted on a shaft coaxial with the take-up reel shaft, and is constrained to unidirectional rotation. Rotation of the driver pulley is coupled to a mainspring pulley and a timing pulley through an idler pulley. A mainspring is compressed by rotation of the mainspring pulley until a cam wheel coaxial with the timing wheel releases a brake, causing the mainspring to expand and rotate a generator shaft to produce electricity.

Owner:KING FAHD UNIVERSITY OF PETROLEUM AND MINERALS

Residual wound quantity display mechanism of timepiece and timepiece with residual wound quantity display mechanism

To provide a residual wound quantity display mechanism of a timepiece, in which it is possible to change a way of a display without changing a basic structure, and a timepiece with the mechanism concerned. A residual wound quantity display mechanism of a mechanical timepiece has an output gearwheel rotating in compliance with a change in a residual wound quantity of a mainspring; a drive lever possessing monolithically a fan-shaped gearwheel part meshing with the output gearwheel, and an arm part extending from a rotation center of the fan-shaped gearwheel part in a direction different from a fan-shaped portion of the fan-shaped gearwheel part; a display member possessing a drive gearwheel part rotatably supported to a tip part of the arm part of the drive lever, and a display arbor formed monolithically in the drive gearwheel part in a site separated from a rotation center of the drive gearwheel part; and a fixation gearwheel possessing a fixation tooth part with which a tooth part of the drive gearwheel part of the display member meshes. Typically the fixation gearwheel adopts a form of the internally-toothed gearwheel.

Owner:SEIKO INSTR INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com