Patents

Literature

689results about "Spring motor" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

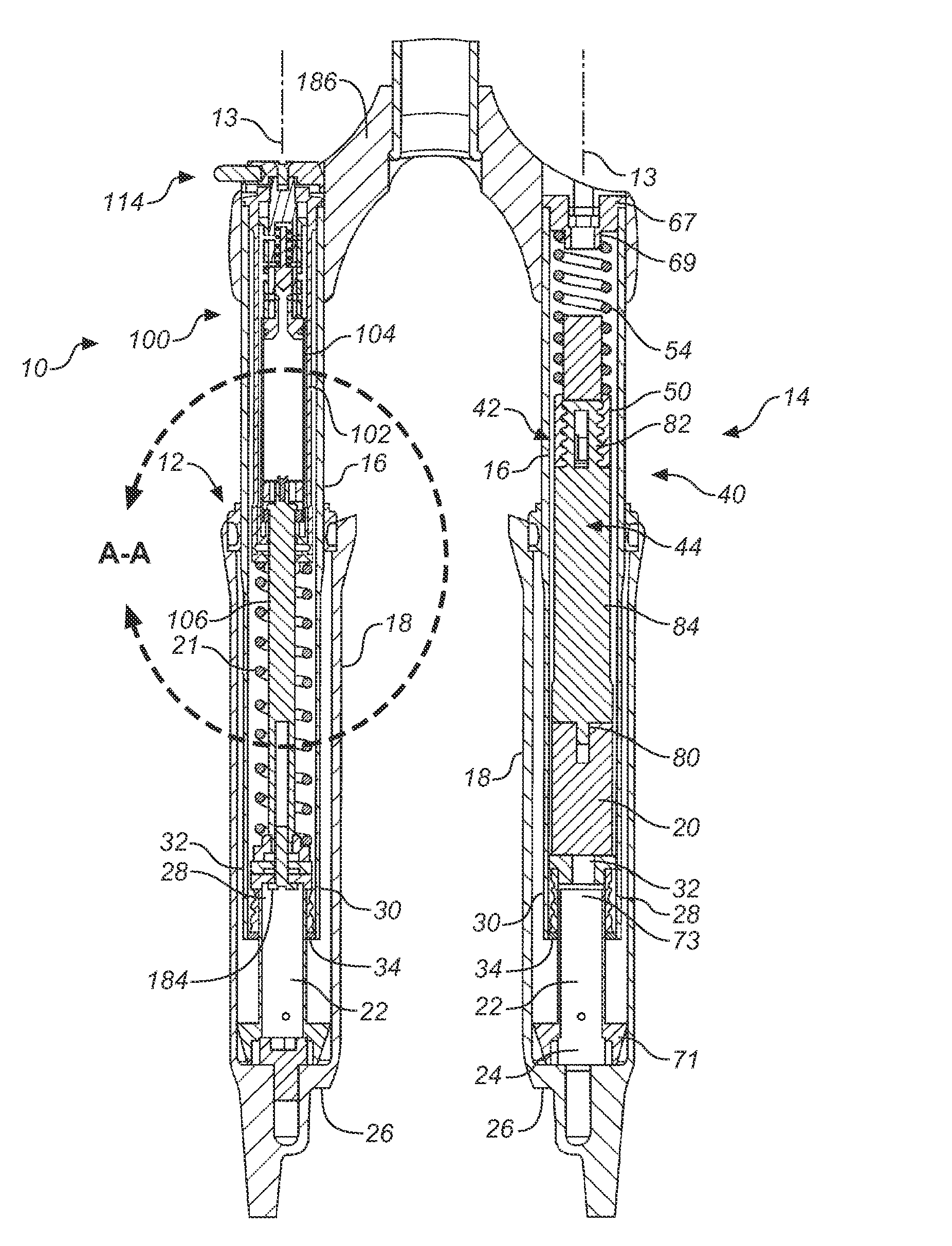

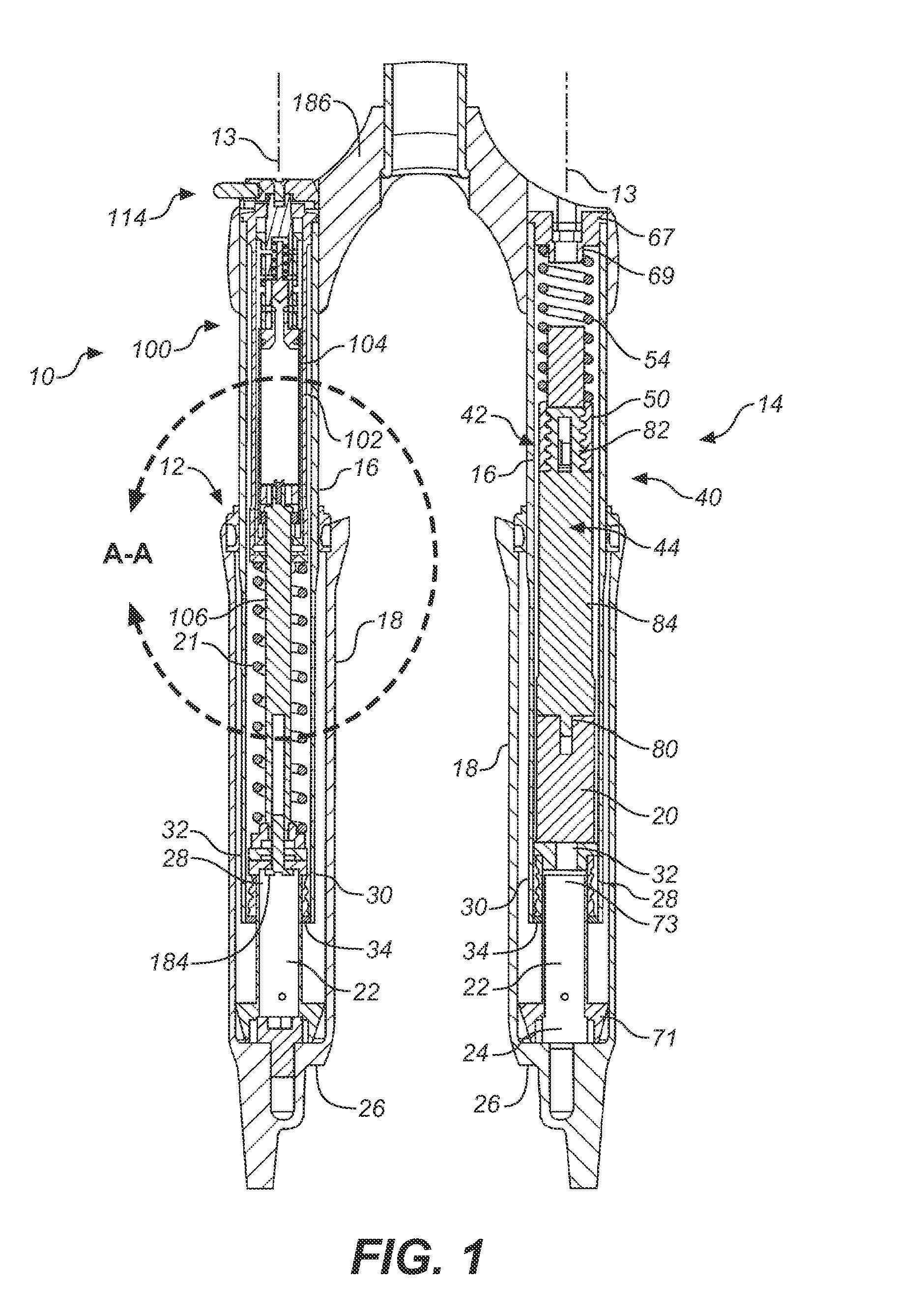

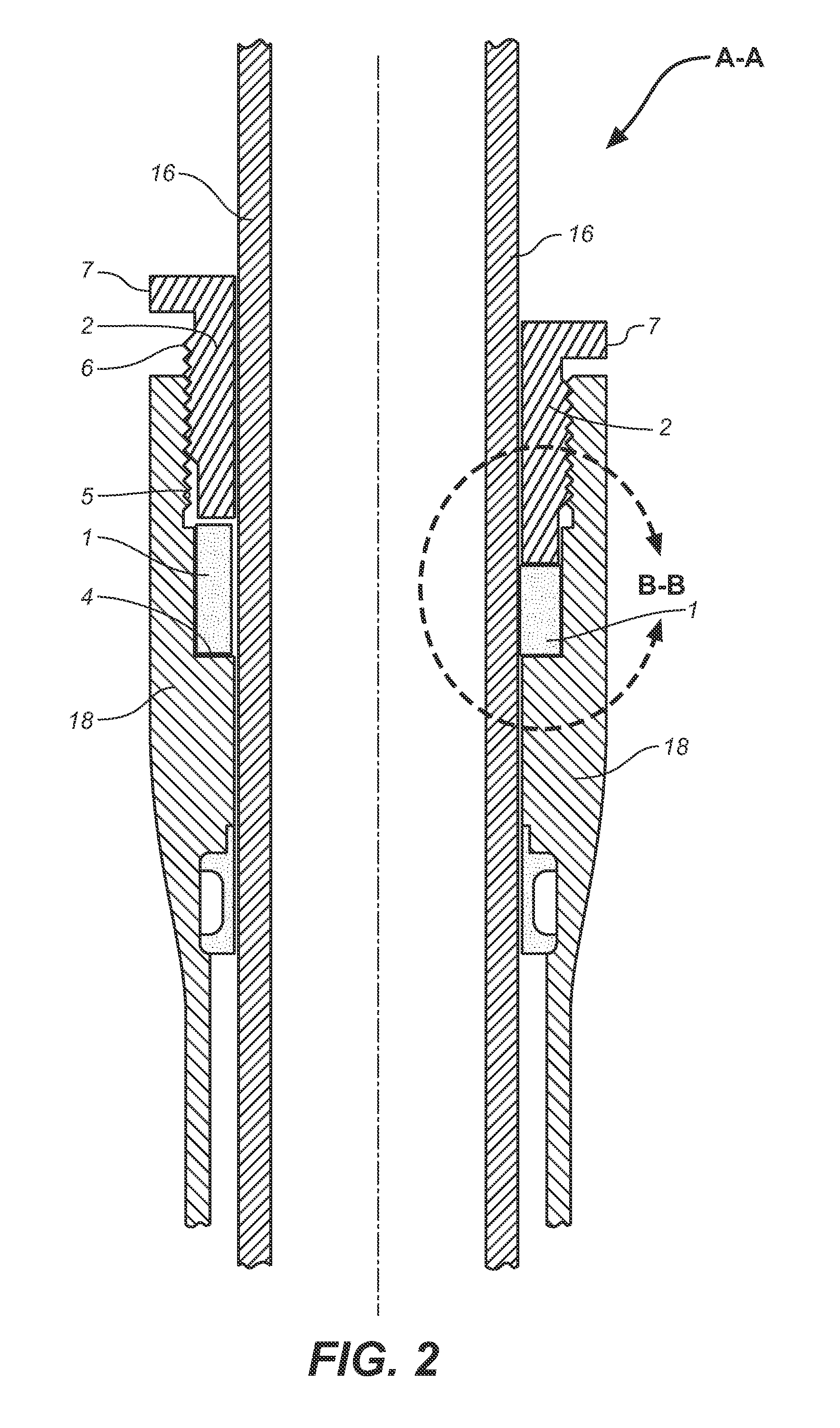

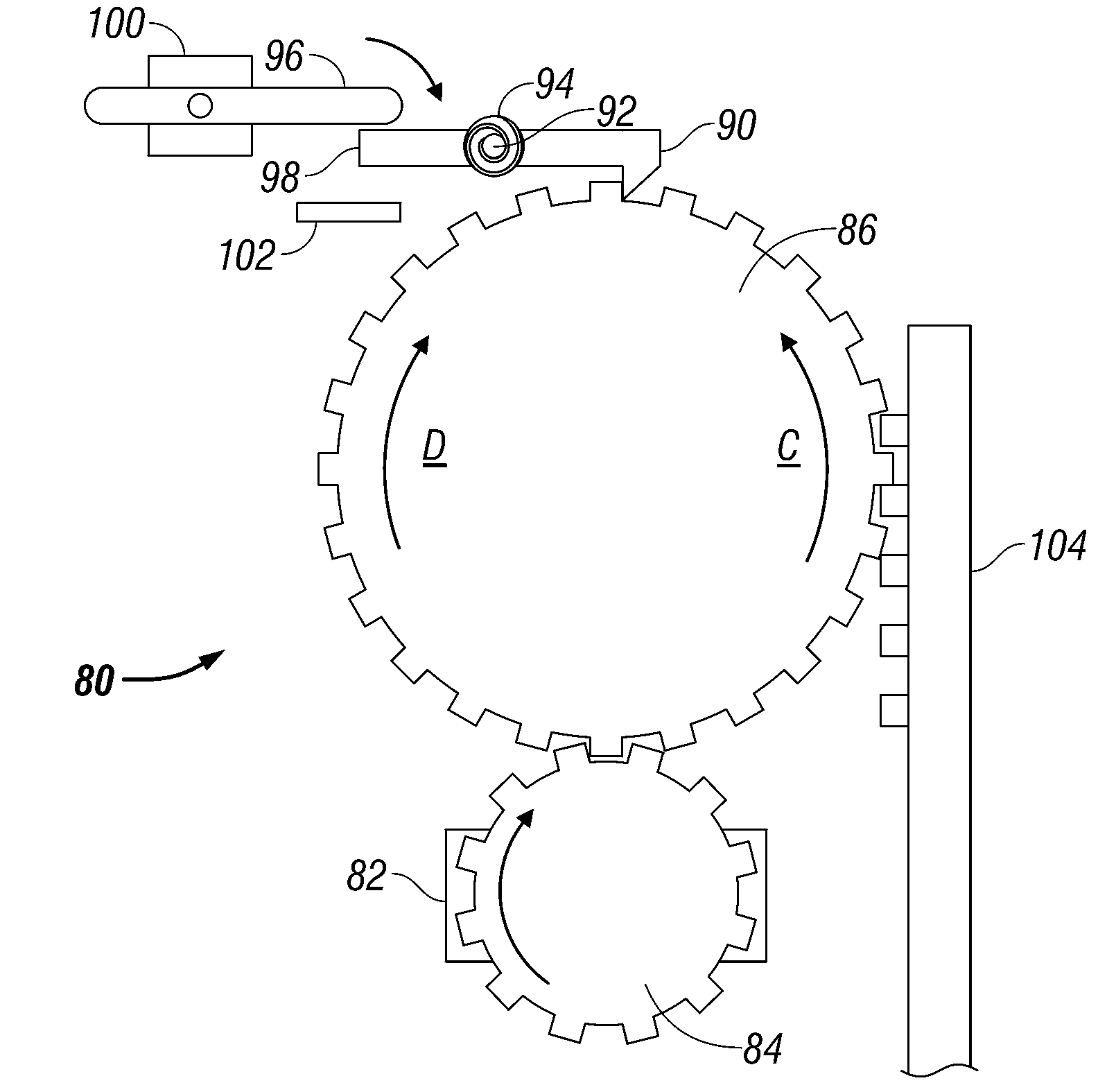

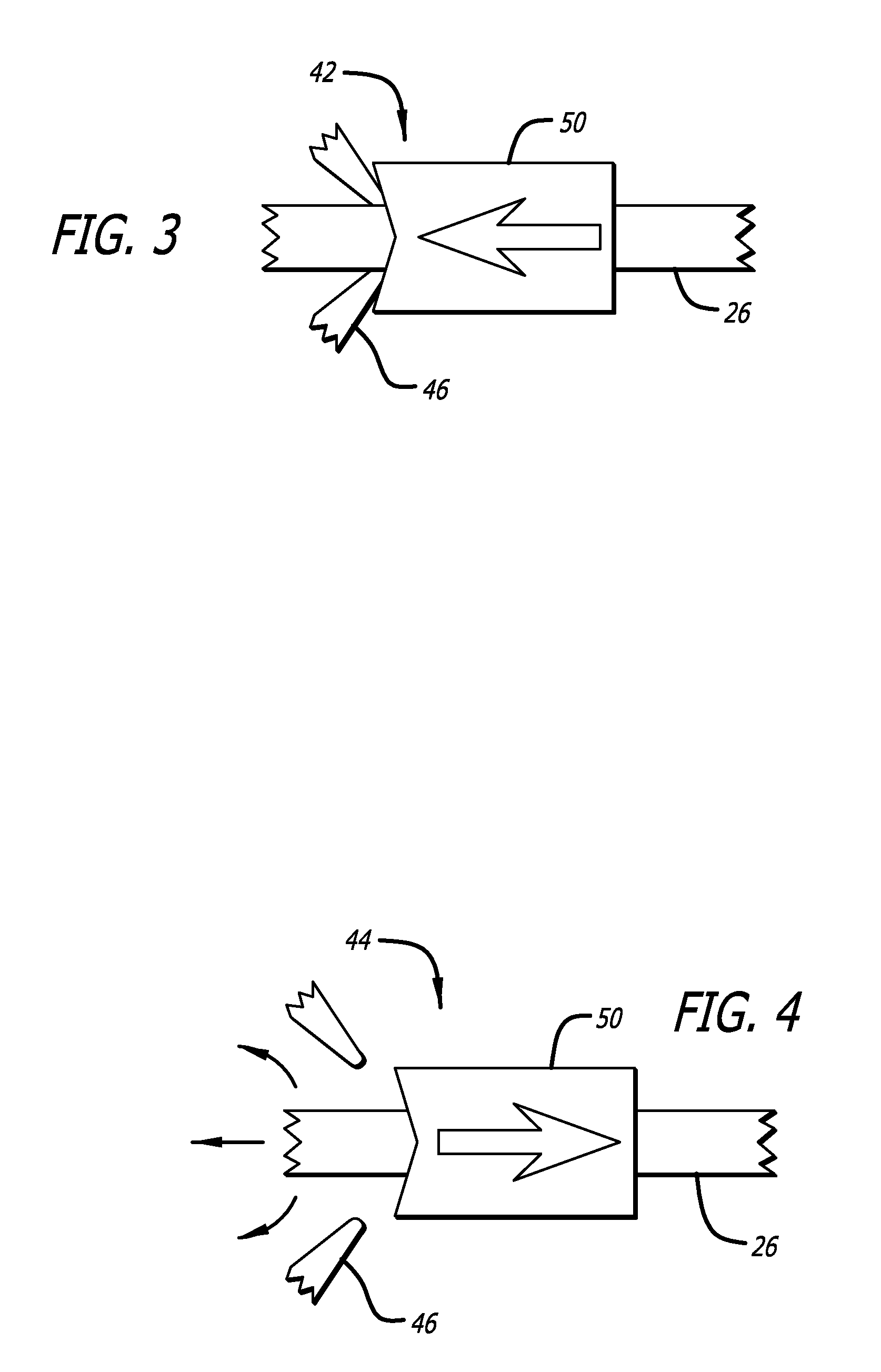

Methods and apparatus for suspension lock out and signal generation

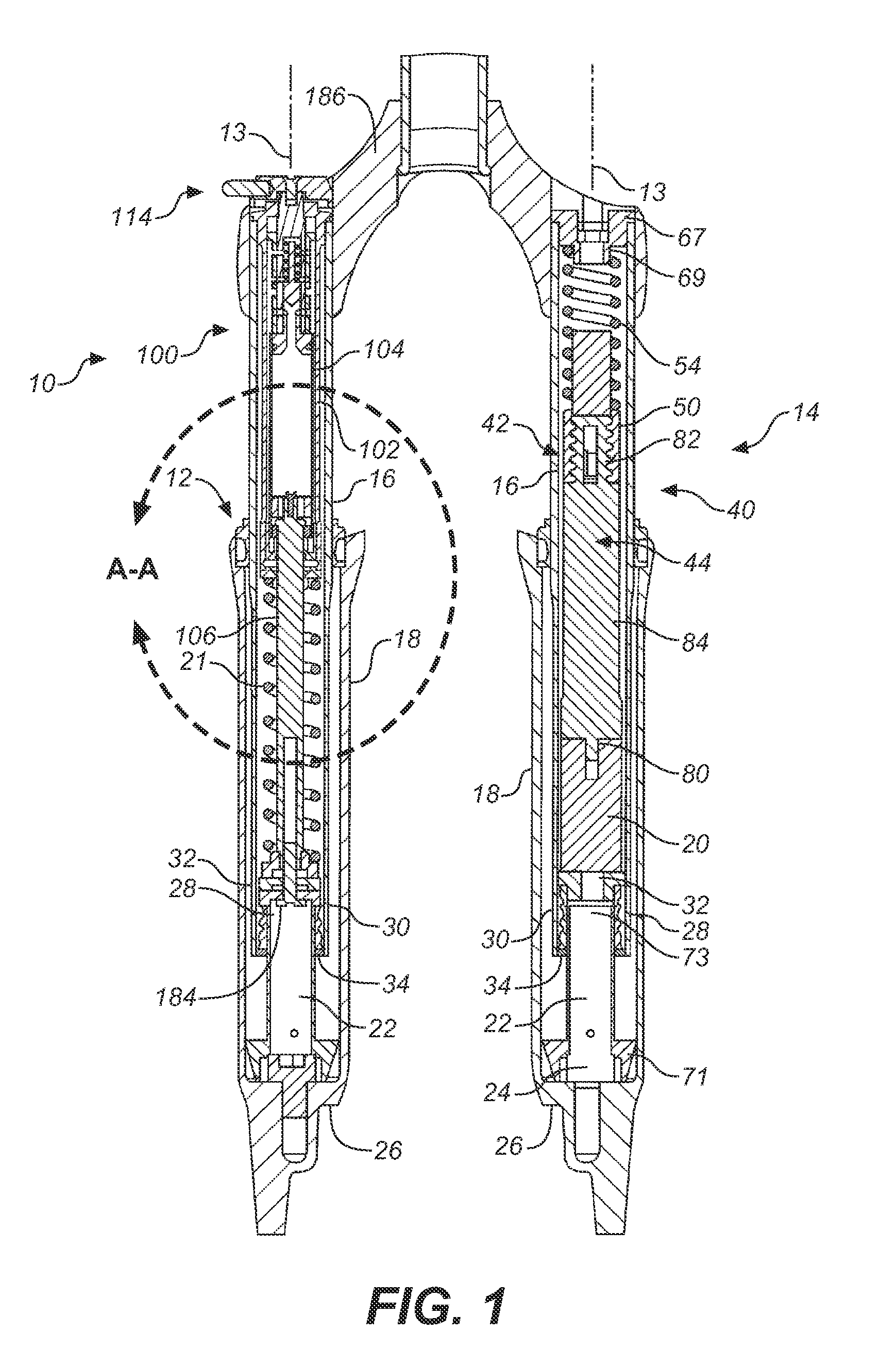

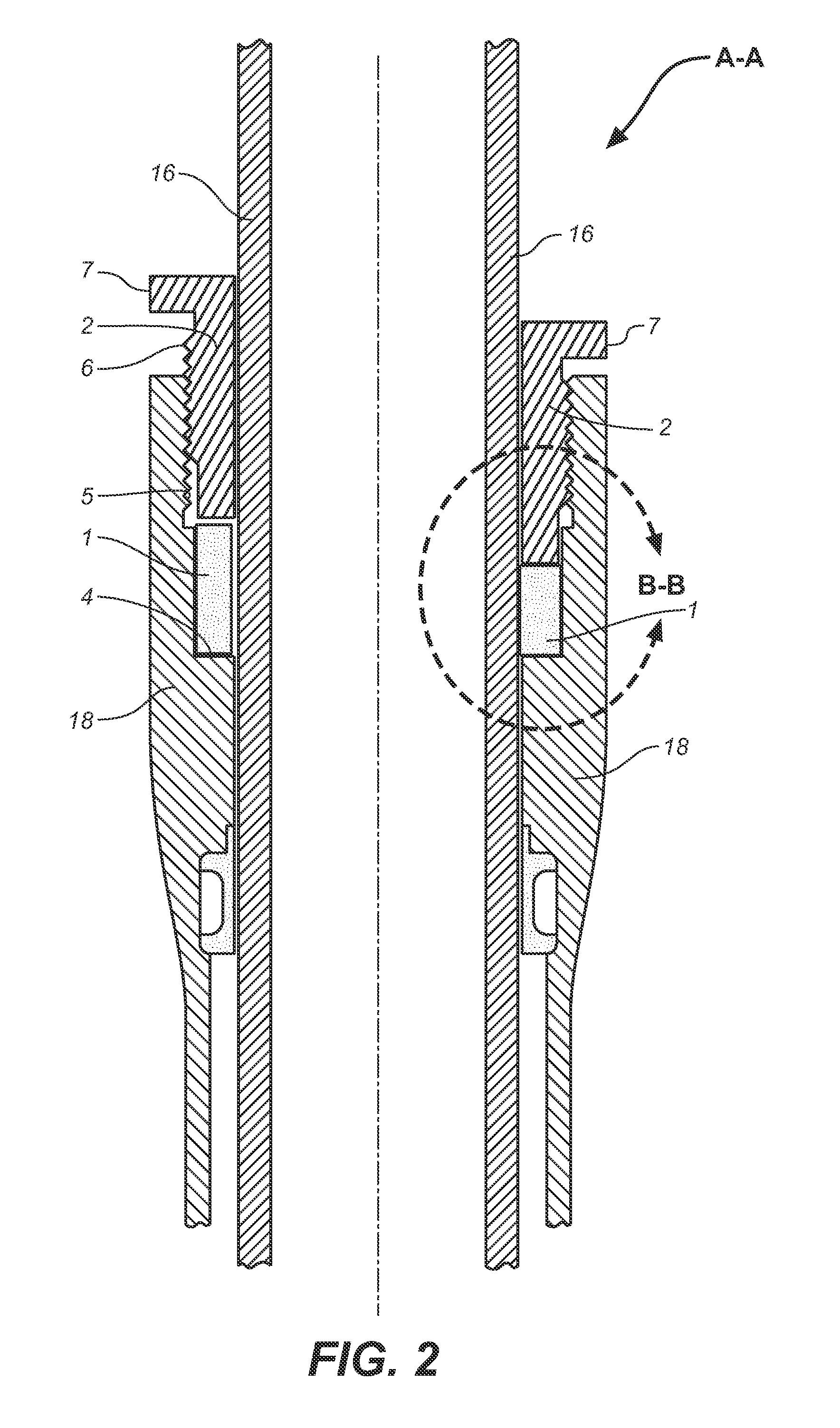

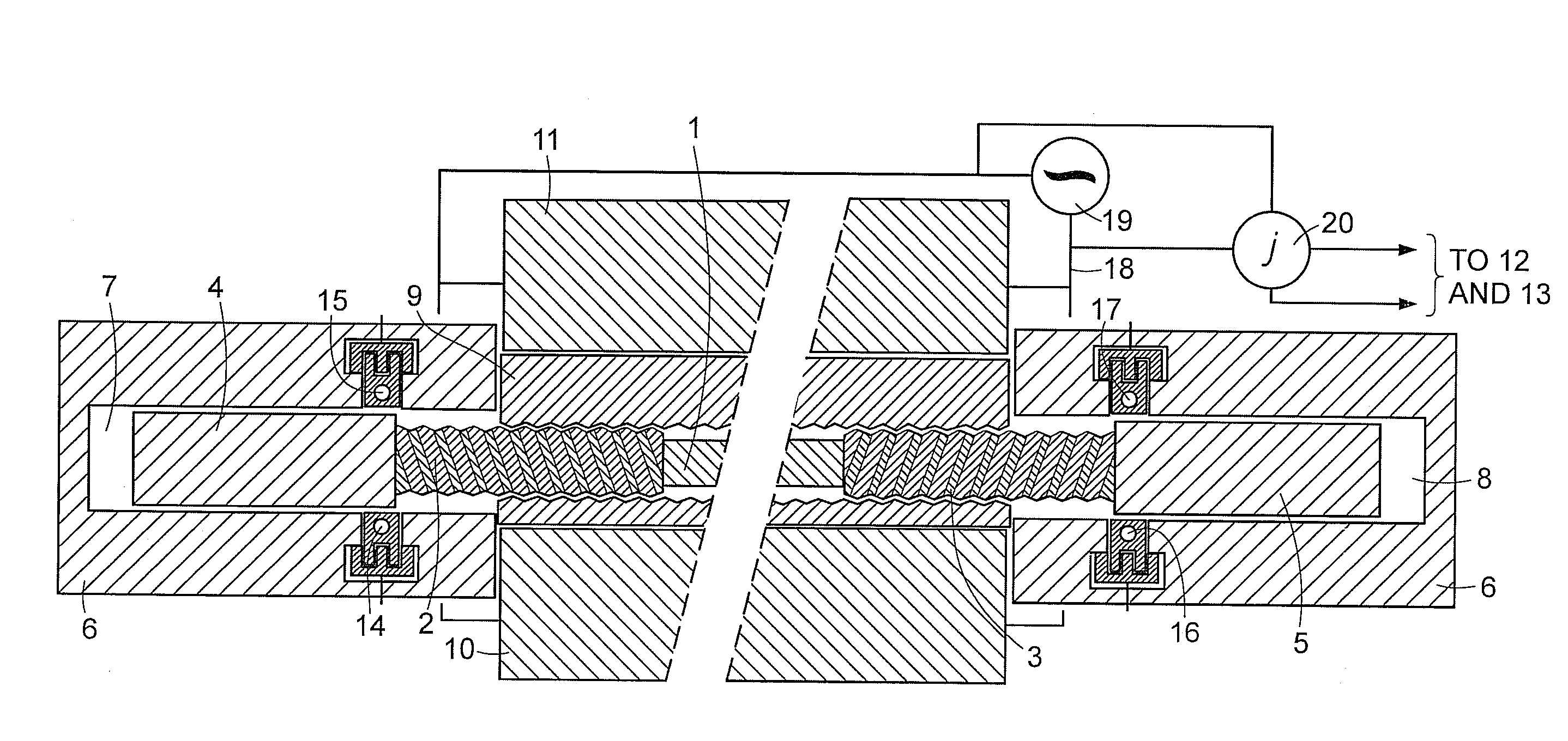

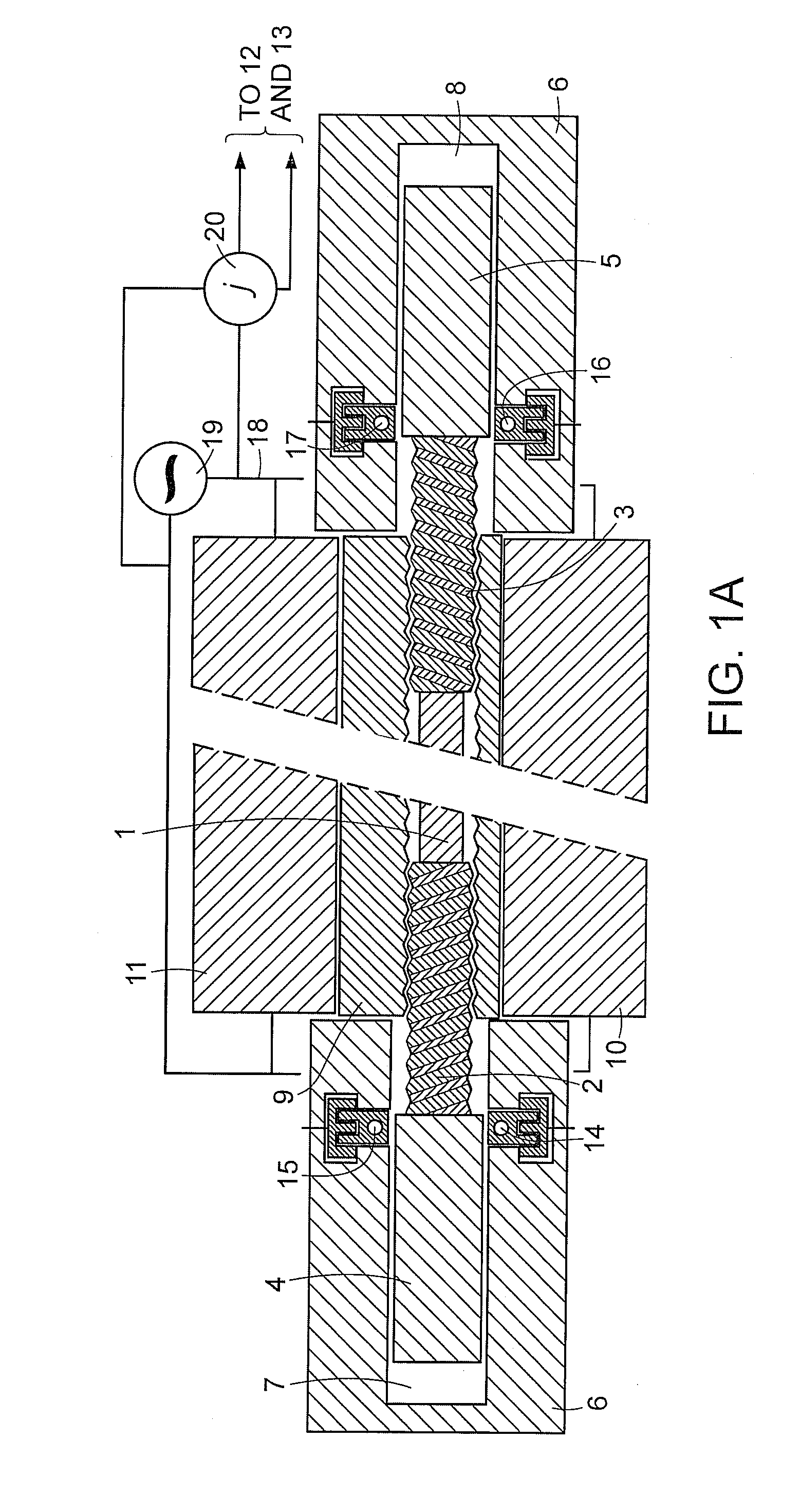

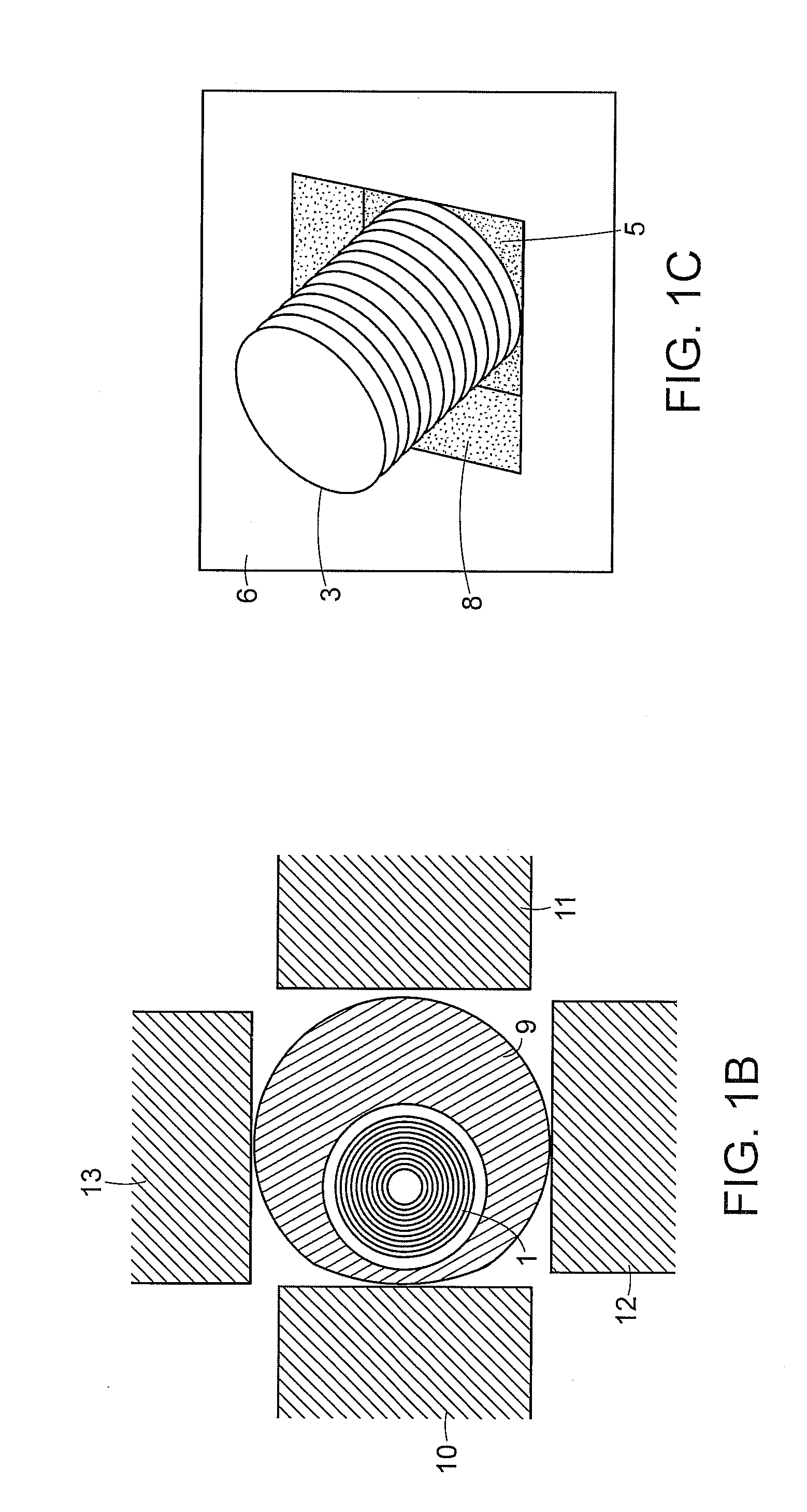

Methods and apparatus for regulating the function of a suspension system are disclosed herein. Suspension characteristics often contribute to the efficiency of a suspended system. Depending on the desired operating parameters of the suspended system, it may be desirable to alter the functional characteristics of the suspension from time to time in order to maintain or increase efficiency. The suspension hereof may be selectively locked into a substantially rigid configuration, and the damping fluid may be phase separated and / or cooled to increase damping rate during use (or offset rate degradation). The suspension hereof may generate power usable to achieve any or all of the foregoing or to be stored for use elsewhere in the suspended system or beyond.

Owner:FOX FACTORY

Methods and apparatus for suspension lock out and signal generation

Methods and apparatus for regulating the function of a suspension system are disclosed herein. Suspension characteristics often contribute to the efficiency of a suspended system. Depending on the desired operating parameters of the suspended system, it may be desirable to alter the functional characteristics of the suspension from time to time in order to maintain or increase efficiency. The suspension hereof may be selectively locked into a substantially rigid configuration, and the damping fluid may be phase separated and / or cooled to increase damping rate during use (or offset rate degradation). The suspension hereof may generate power usable to achieve any or all of the foregoing or to be stored for use elsewhere in the suspended system or beyond.

Owner:FOX FACTORY

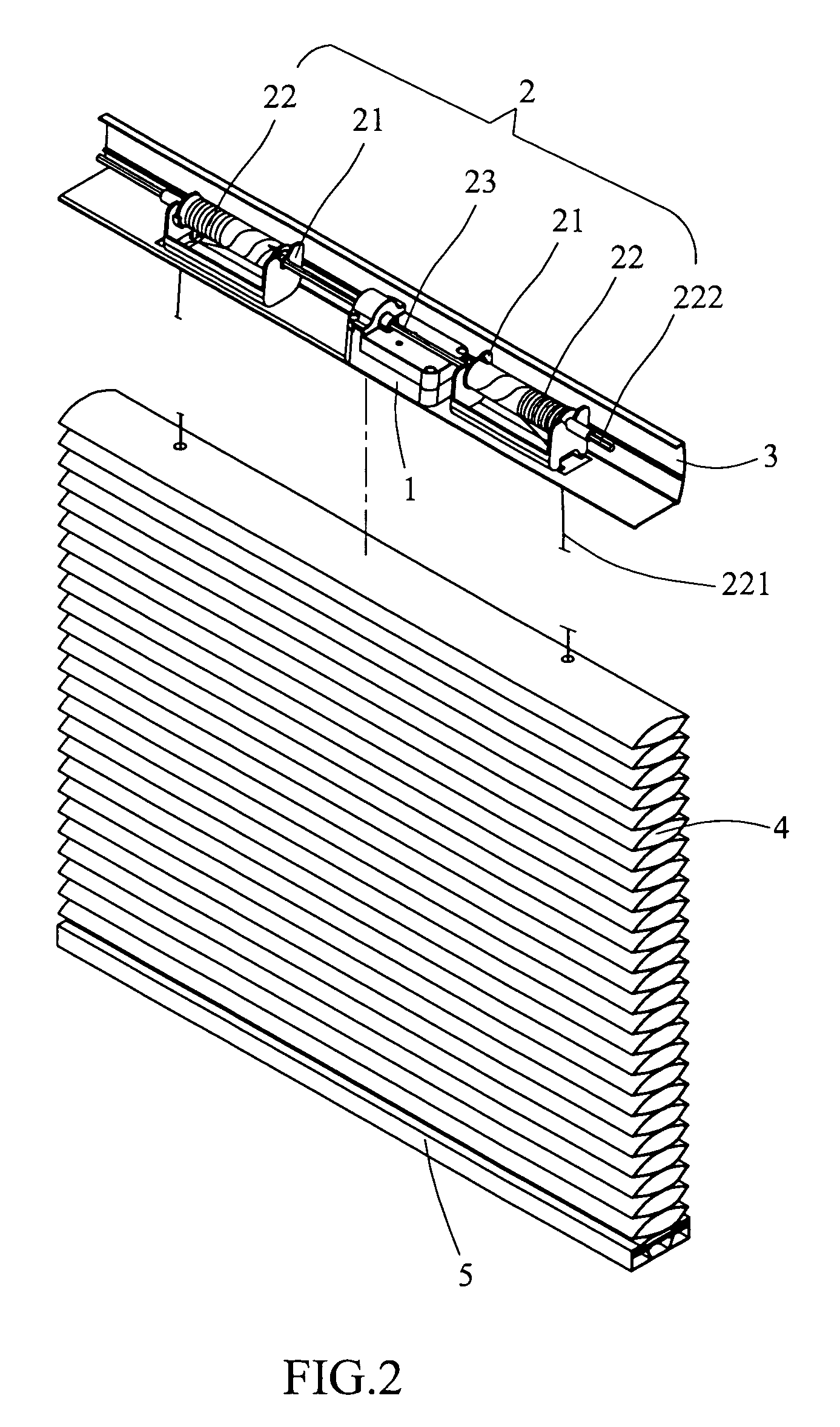

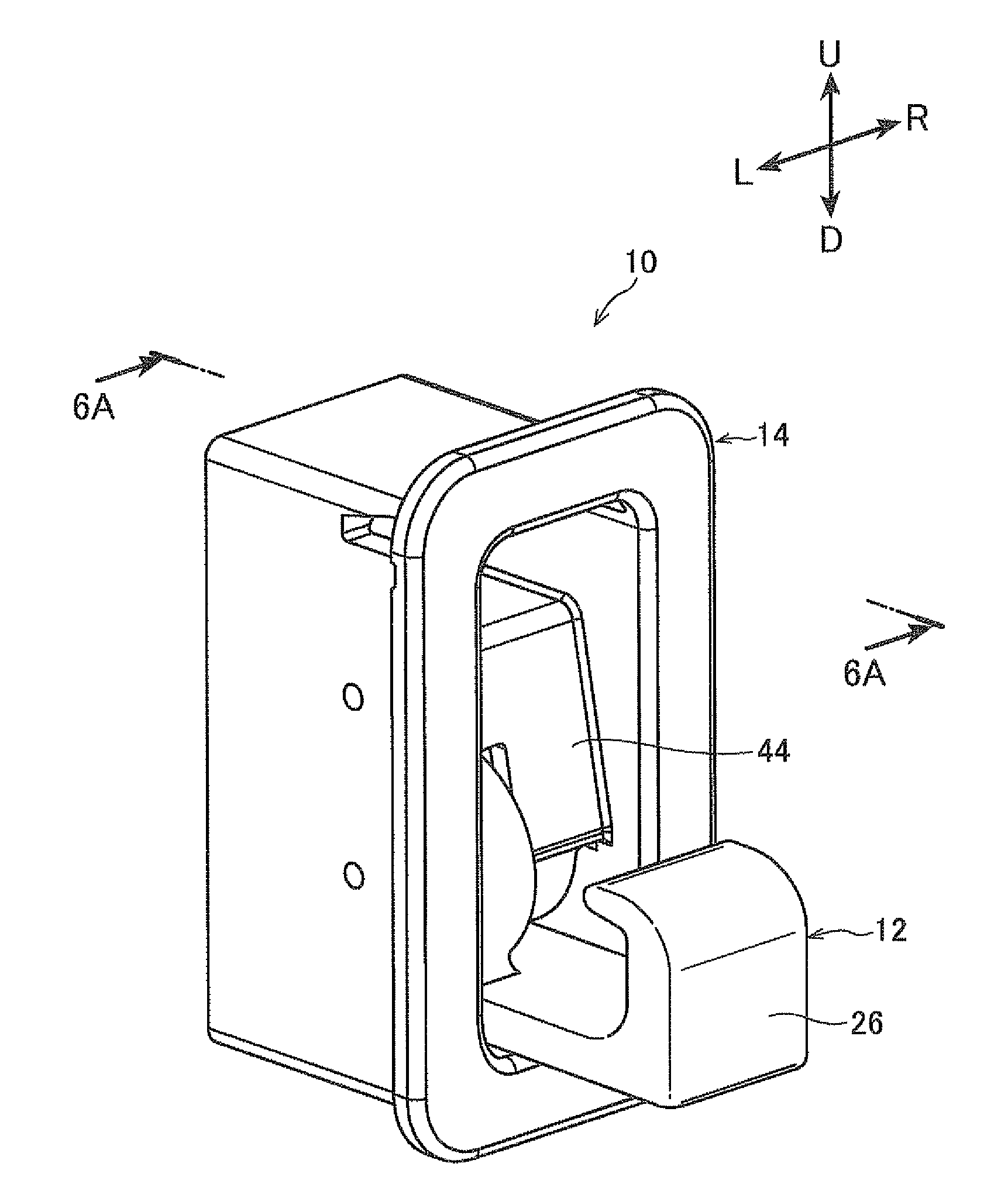

Passive entry side door latch release system

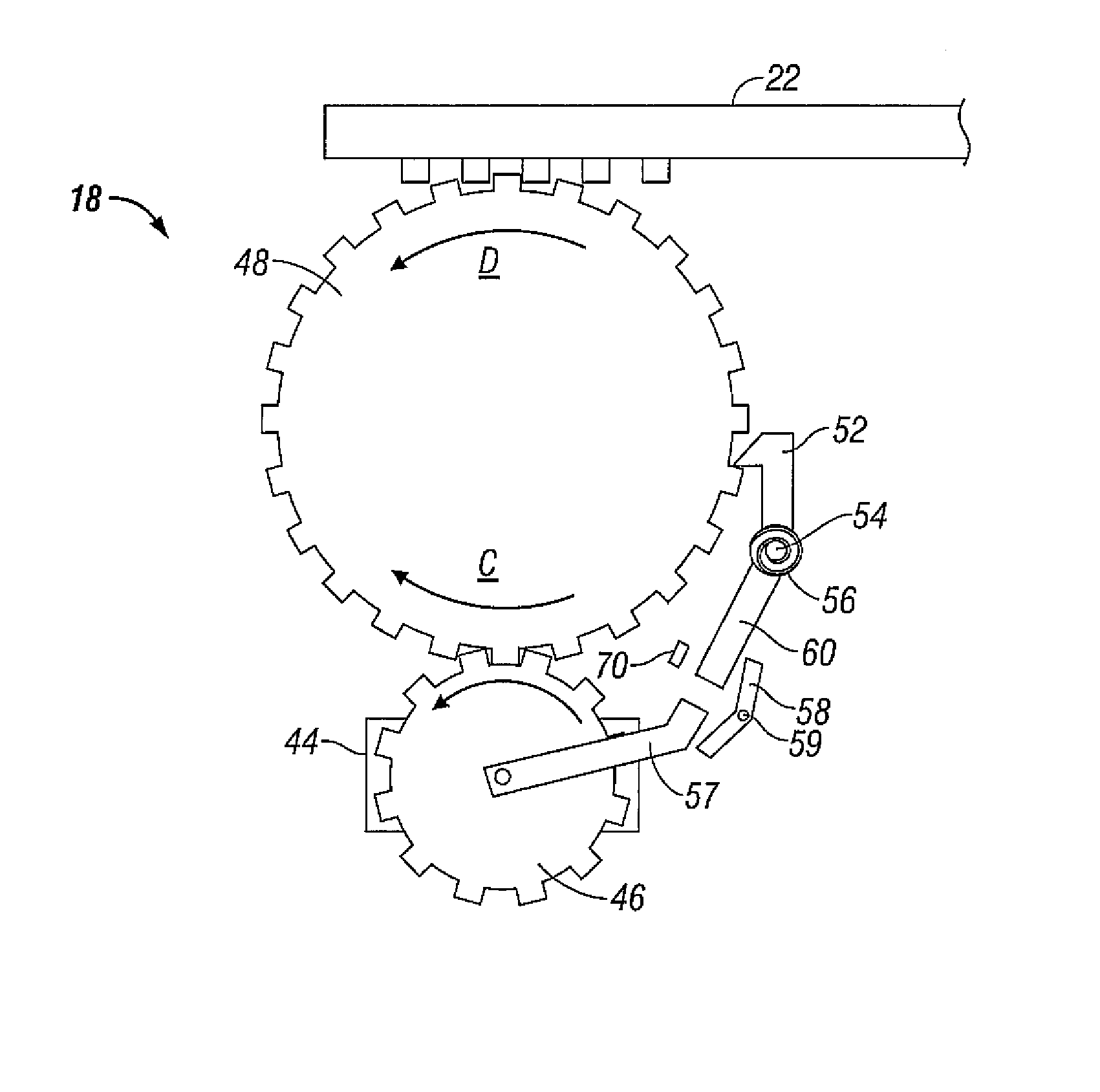

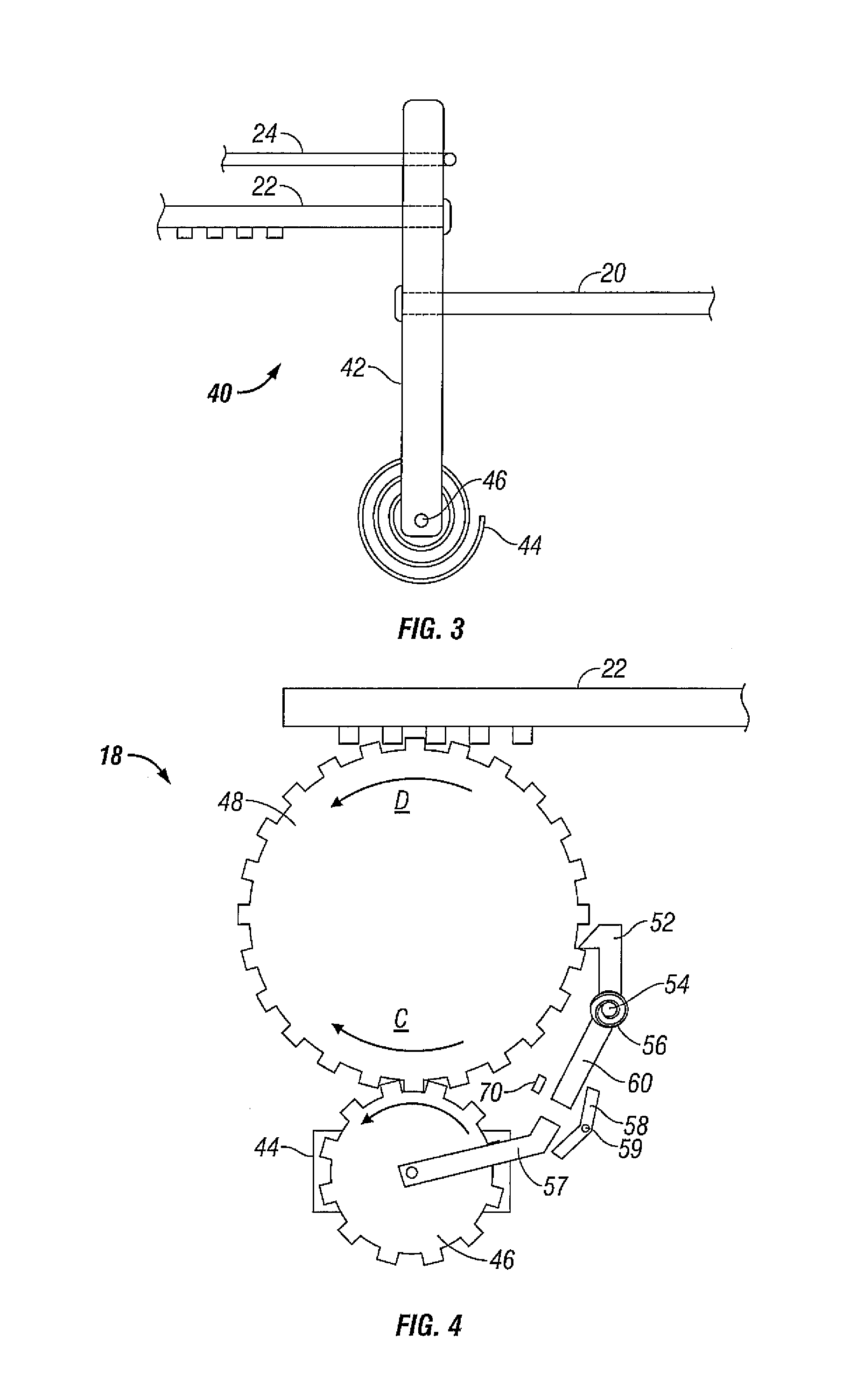

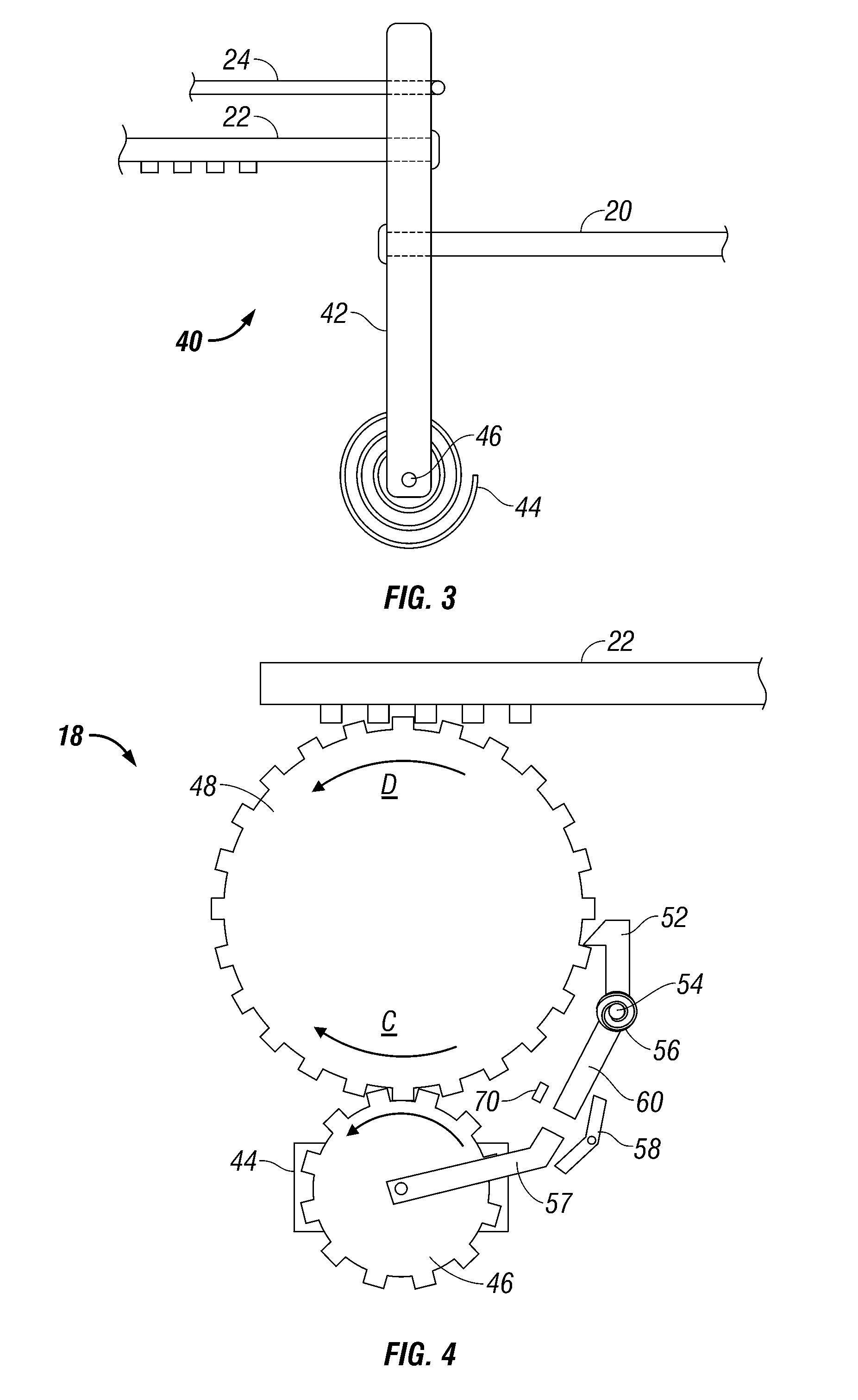

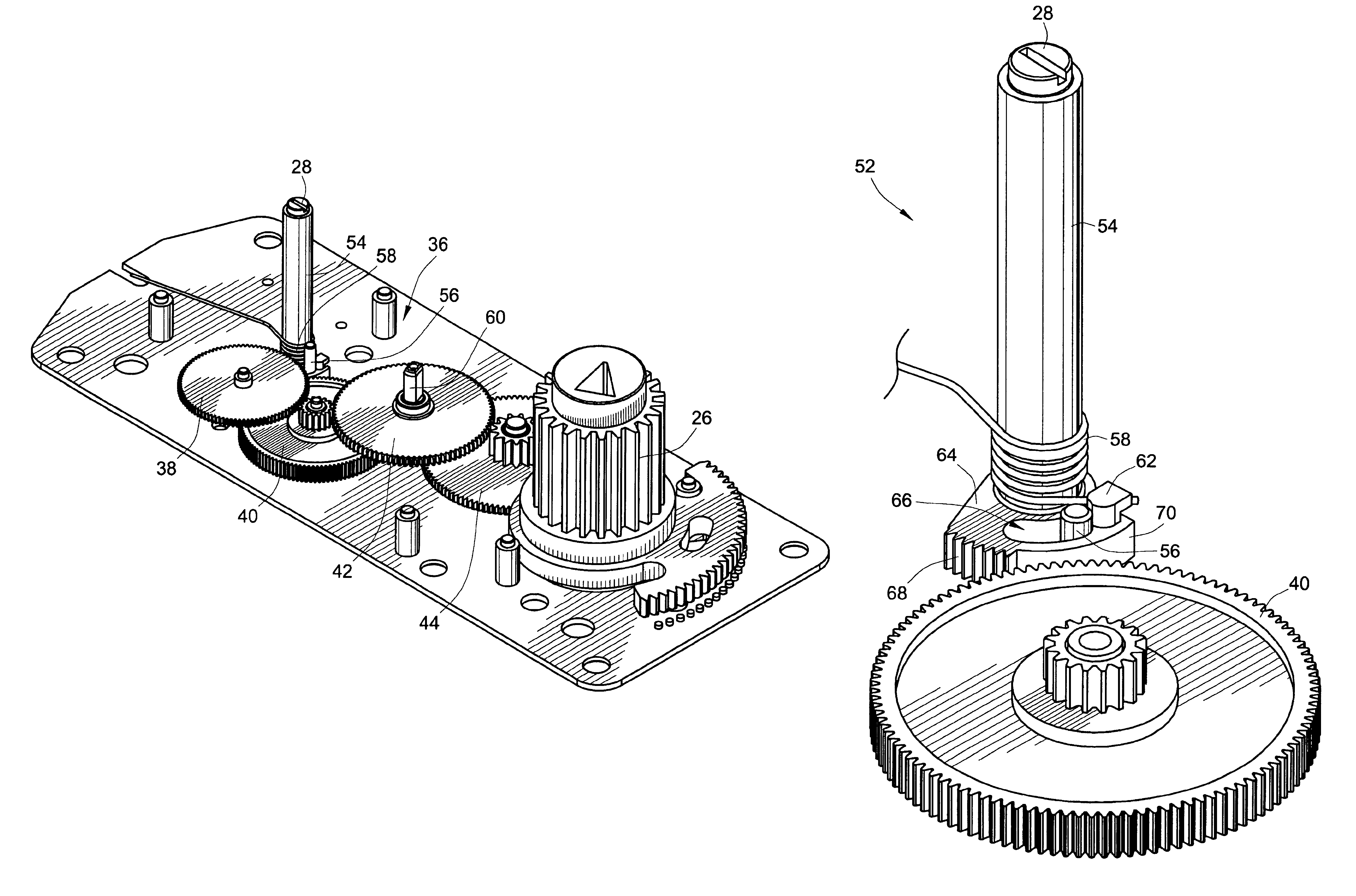

A vehicle passive entry side door latch release system engageable with a release cable connected a door latch includes a moveable linkage assembly engageable with the cable, and a motor including an output shaft engaged with a tensioning gear for driving a ratcheting gearwheel rotatably affixed to a coil spring, with the gearwheel including external teeth engageable with a rack affixed to the linkage to move the cable to unlatch the door latch. A pivotable ratcheting pawl may be engageable with the gearwheel to allow or prevent rotation of the gearwheel. Operation of the motor may drive the gear to drive the gearwheel in a rotary direction to energize the spring, and disengagement of the pawl from the gearwheel may allow stored energy in the spring to drive the gearwheel in an opposite rotary direction to thereby drive the rack to move the cable to unlatch the door latch.

Owner:FORD GLOBAL TECH LLC

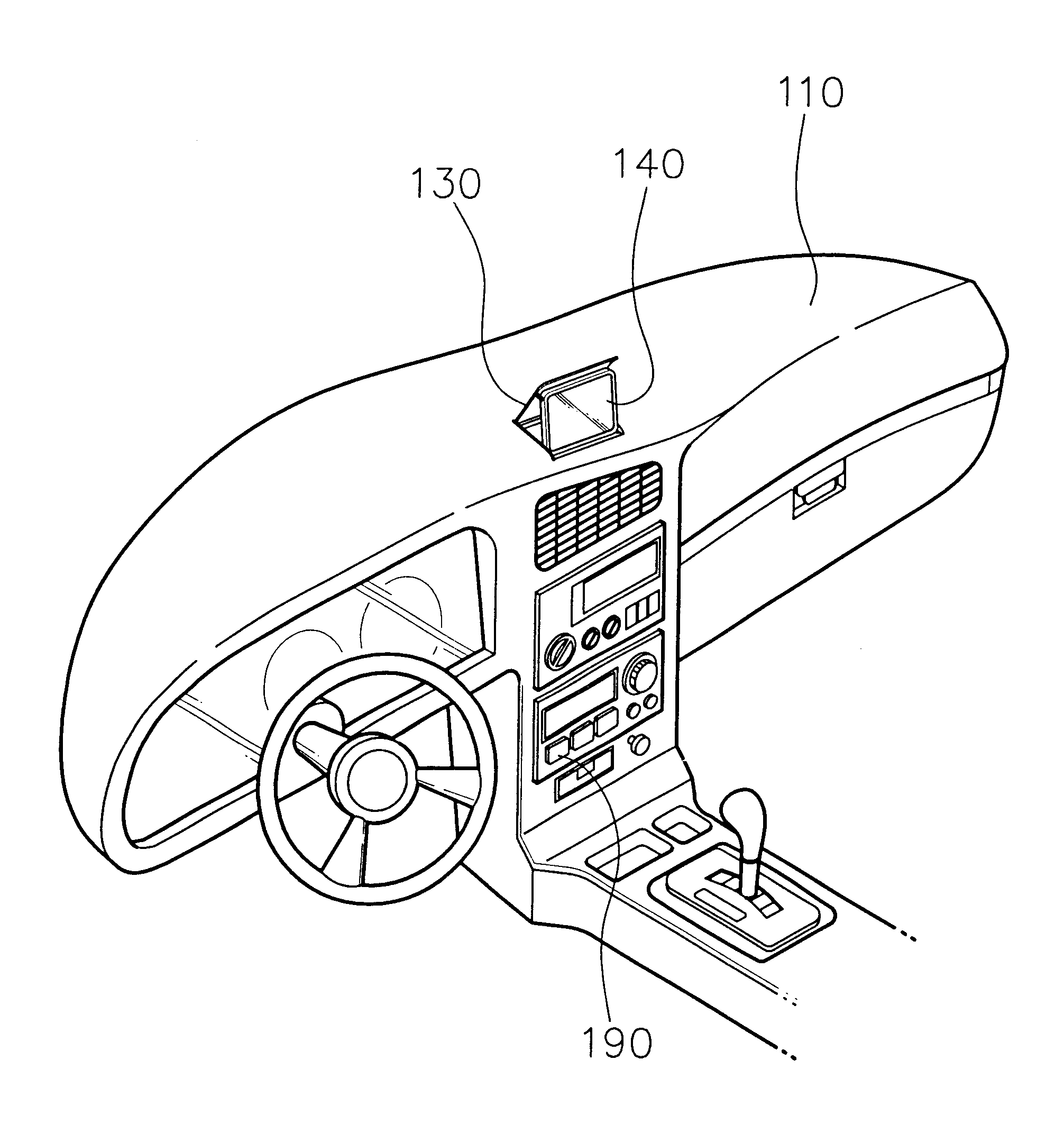

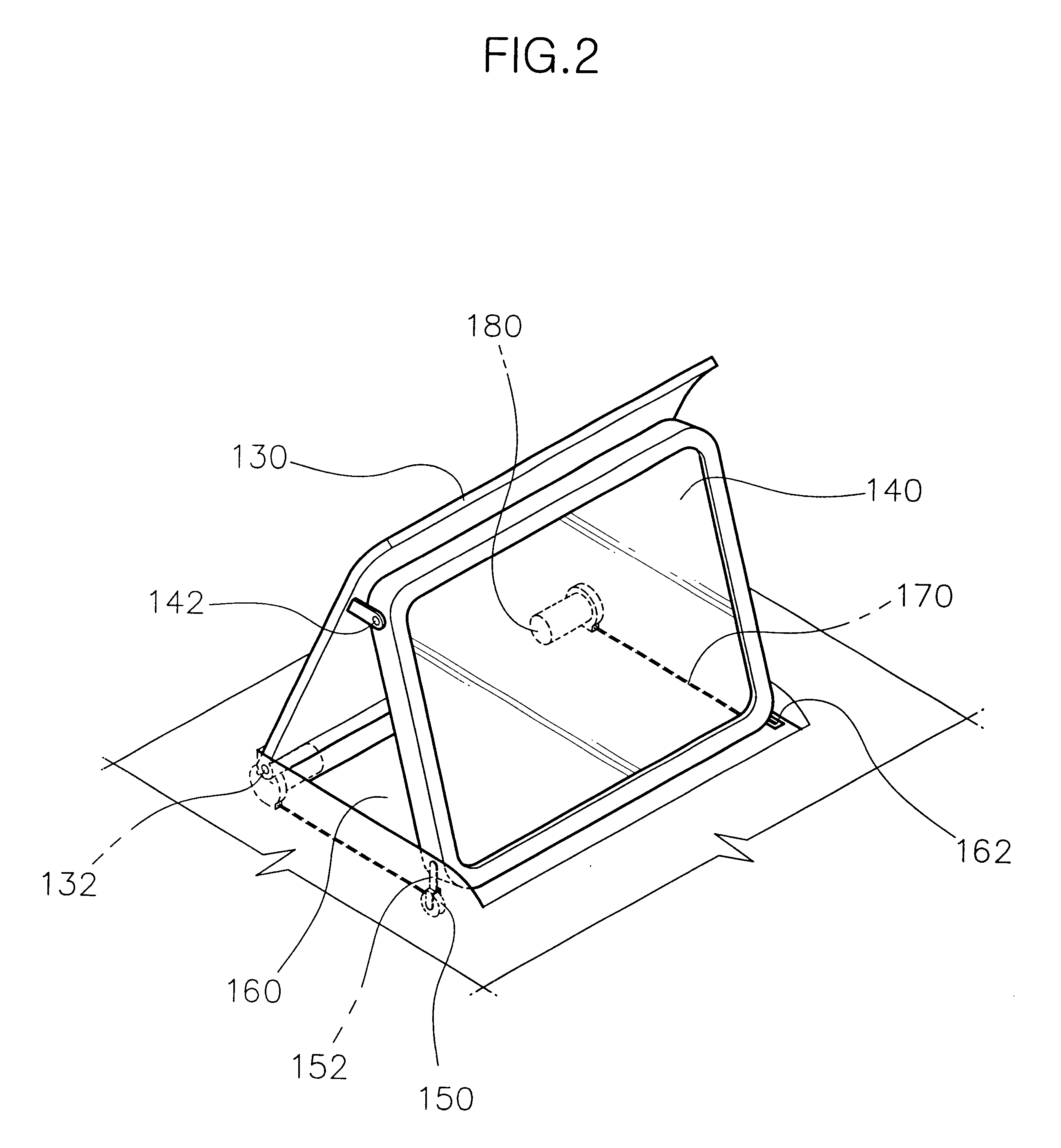

Monitor installed in dash panel of automobile and its usage

InactiveUS6354649B1Efficient use ofDriving safetyTelevision system detailsInstrument arrangements/adaptationsDashboardEngineering

A monitor installed in automobile's dash panel (110), includes: a reception member (120) inserted in the upper portion of the dash panel (110), the member having a predetermined space and opened top; a lid (130) hinged on one side of the reception member (120) so that is selectively opened or closed; lid opening means for controlling the opening or closing the lid (130); and a monitor (140) installed in the reception member (120) and hinged on the top inner surface of the lid (130) so that it becomes selectively erect when the lid (130) is opened.

Owner:LEE WON JONG

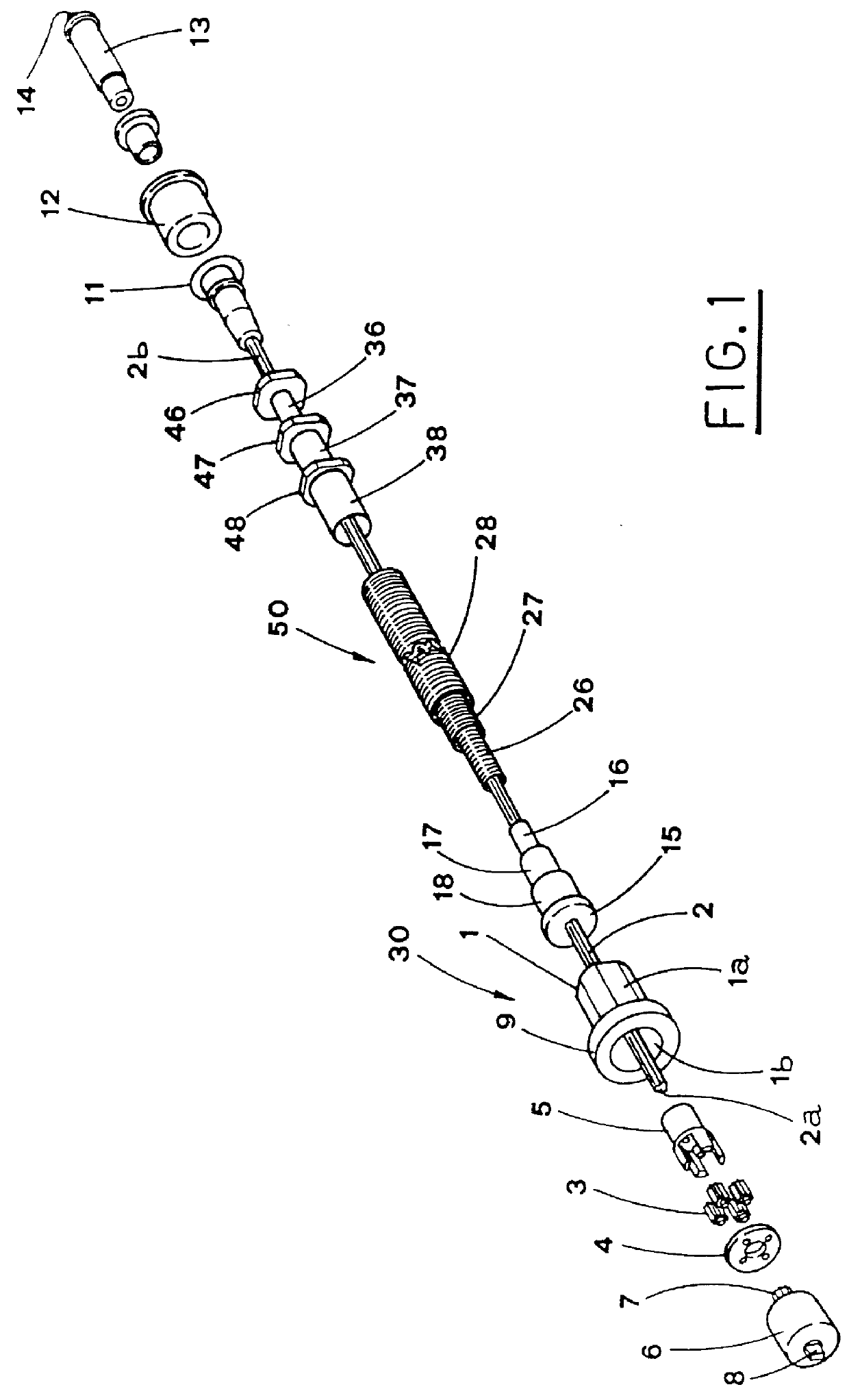

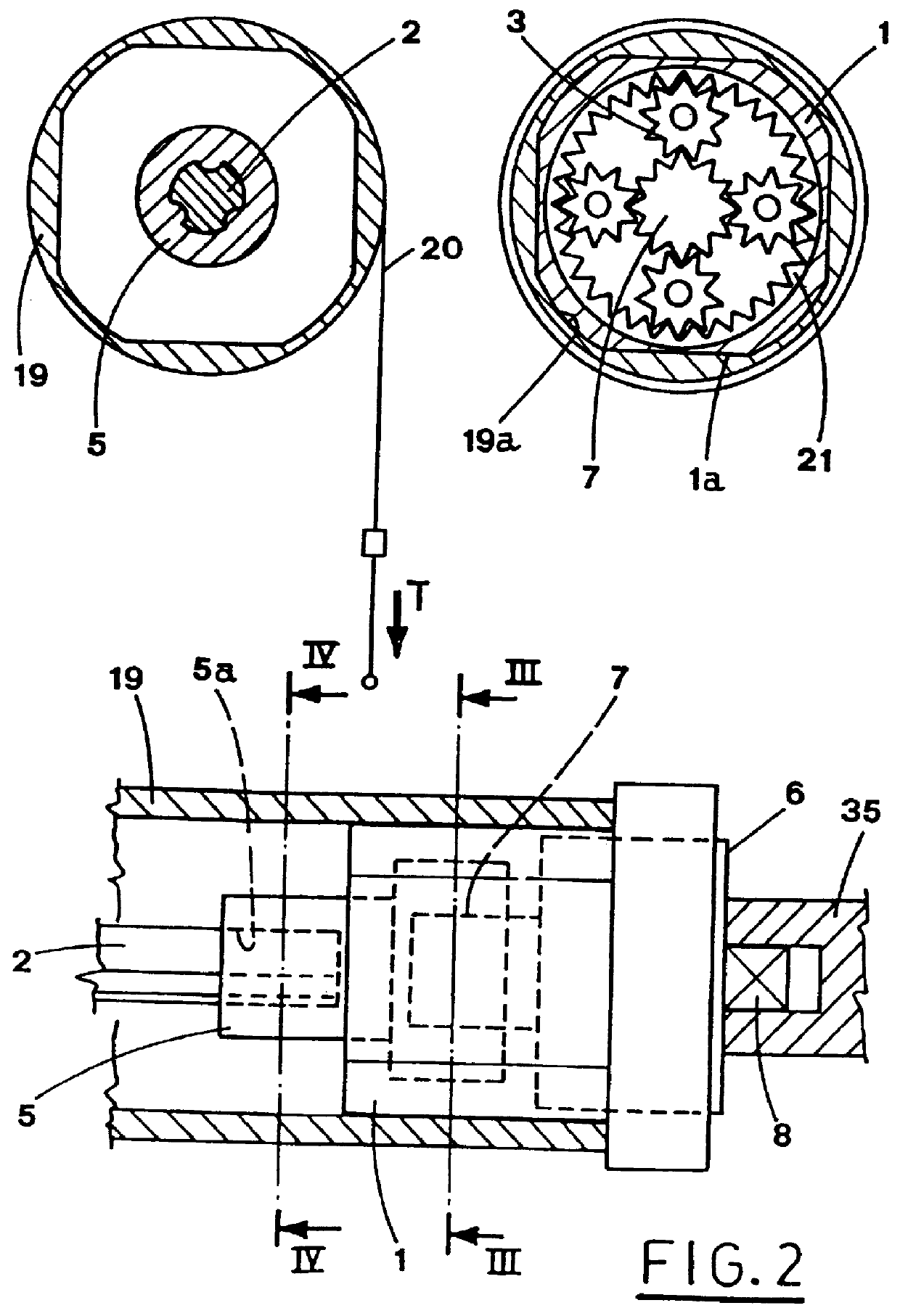

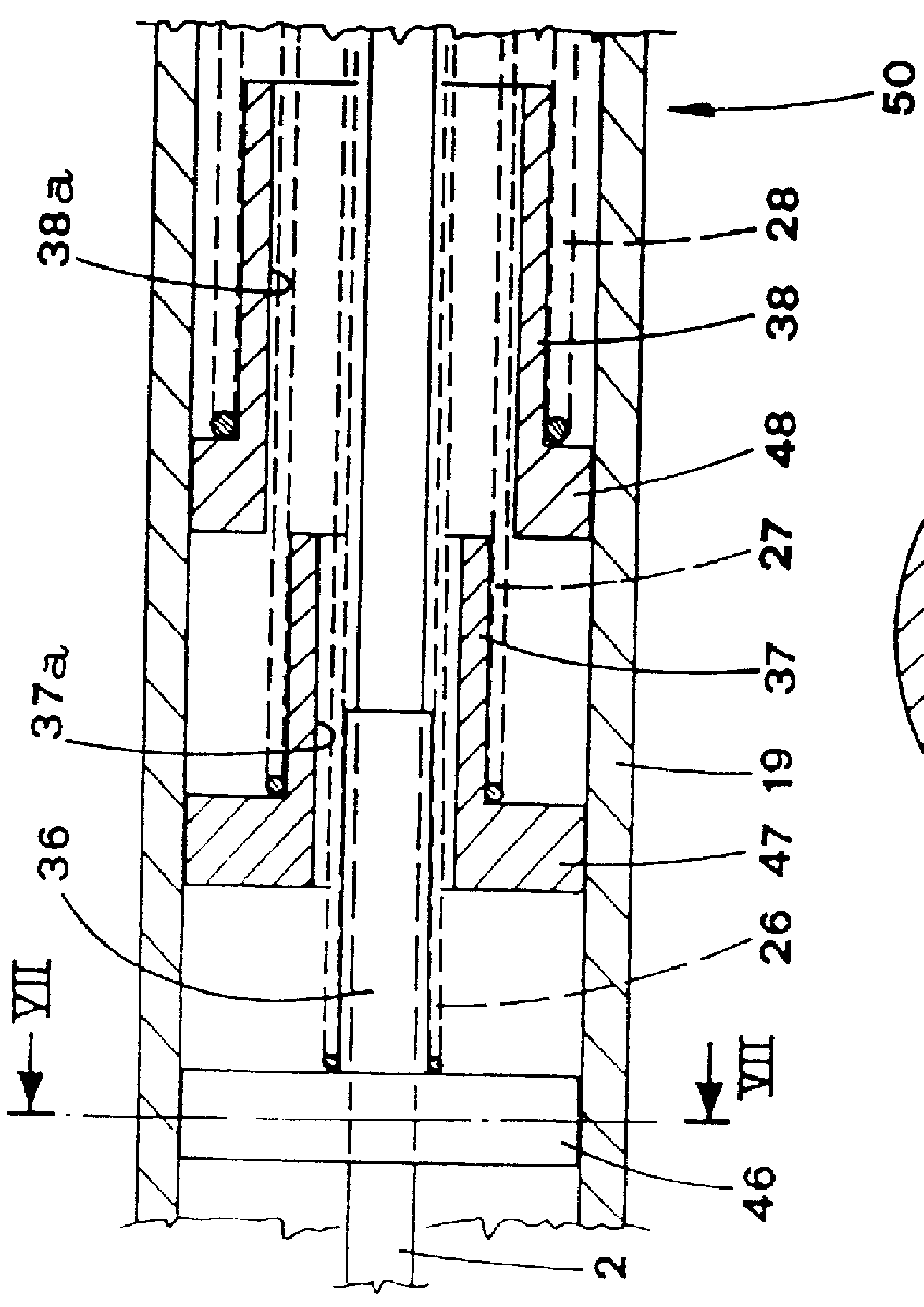

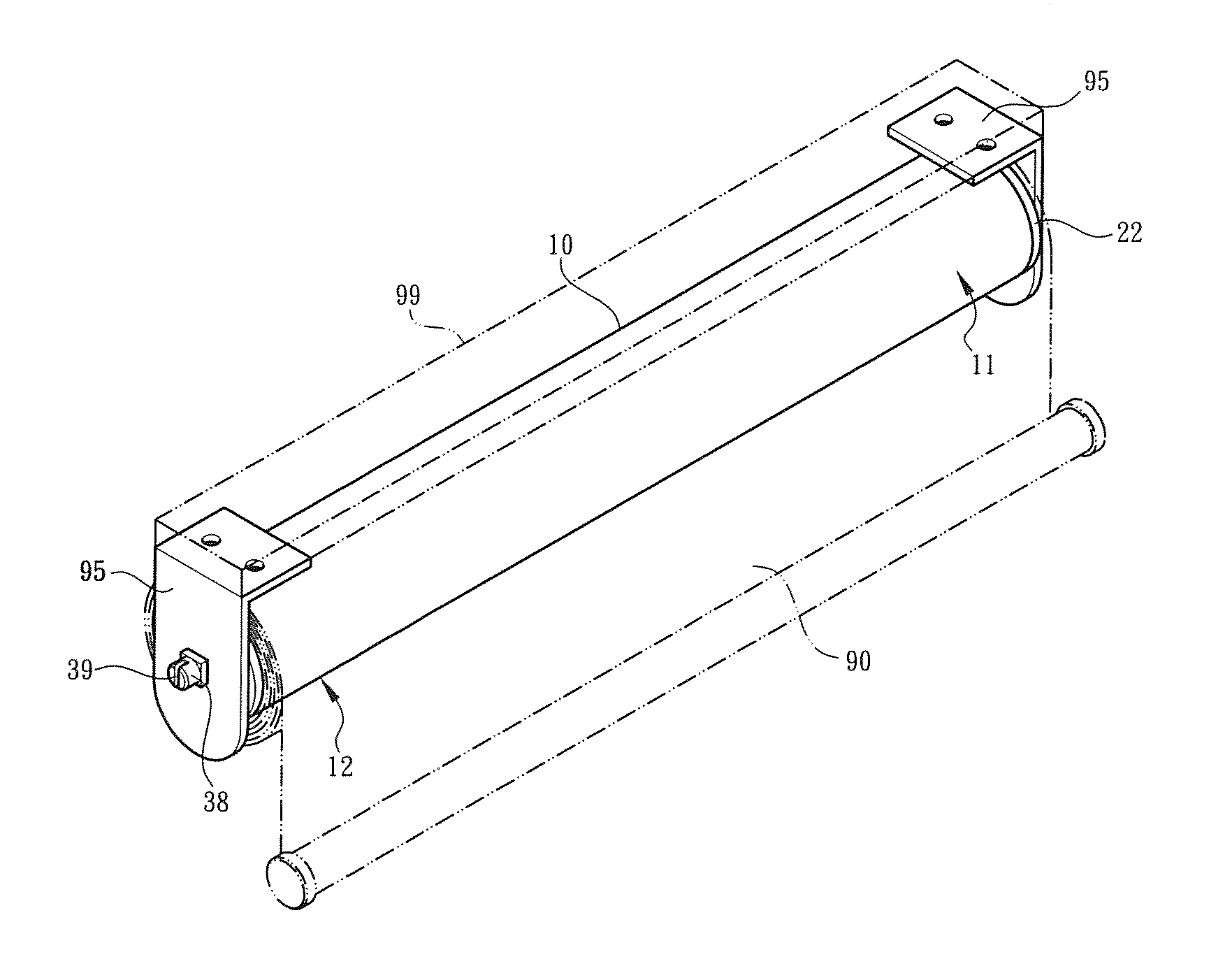

Spring device for rolling up a roller curtain

InactiveUS6123140ARapidly and easily introducedImprove curtain workingScreensSpring motorCouplingReducer

PCT No. PCT / IB97 / 00571 Sec. 371 Date Nov. 23, 1998 Sec. 102(e) Date Nov. 23, 1998 PCT Filed May 20, 1997 PCT Pub. No. WO97 / 44562 PCT Pub. Date Nov. 27, 1997Elastic means for rolling up a roller curtain include a plurality of springs (26,27,28) fastened rigidly to a common support (15) connected to a shaft (2) and with respective support and constraint elements (36,37,38) which are geometrically coupled to the roller (19). A device for connecting the springs to a stationary frame (35) of the curtain (20) reduces the number of springs torsional turns with respect to the number of turns of the roller (19) by interposition of a speed reducer between the shaft (2), to which the springs are fastened, the stationary frame (35) and the roller (19). The shaft (2) end is located closer to the most external support and constraint element (36) and its extremity has a disc (11) mounted thereto. The coupling device together with the springs (50), their supports (15,36,37,38), the shaft (2) and an external support cylindrical body (6) form a compact assembly, which is introduced into one head of the roller (19). The other head of the roller (19) features a cap (12), rotatably fastened to a cylindrical section of a support (13) which is locked to the stationary frame (35) by a tang (14). The geometrical coupling between the shaft (2) and the spring supports (15,36,37,38) allows for easy and quick relocation of the roll up device on each side of the window to which the roller curtain is to be mounted.

Owner:SILENT GLISS ITAL SRL

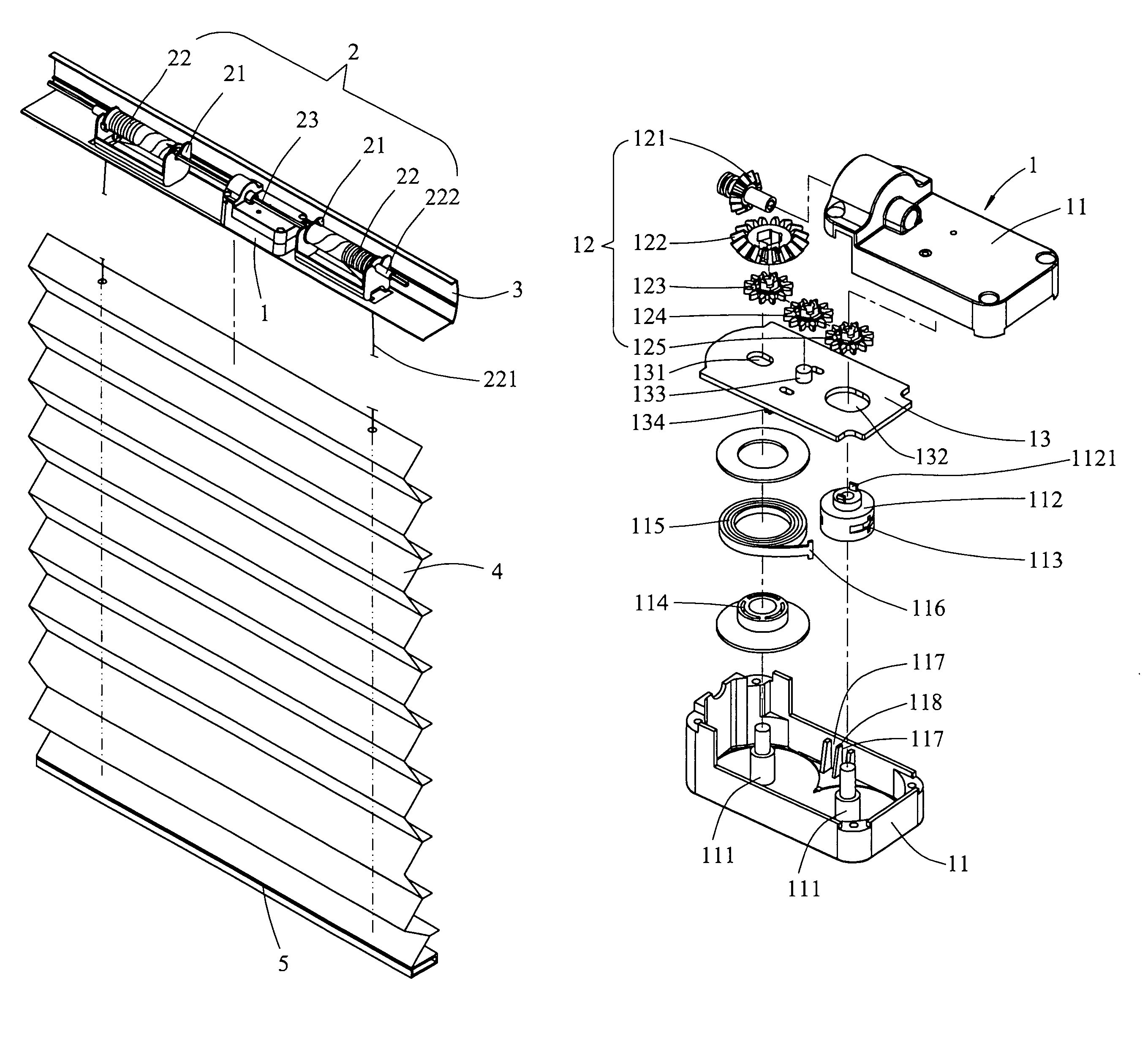

Control device for slat blinds

InactiveUS7866367B2Extensible doors/windowsSpring motorCoil springElectrical and Electronics engineering

Owner:CHING FENG BLINDS INC CO LTD

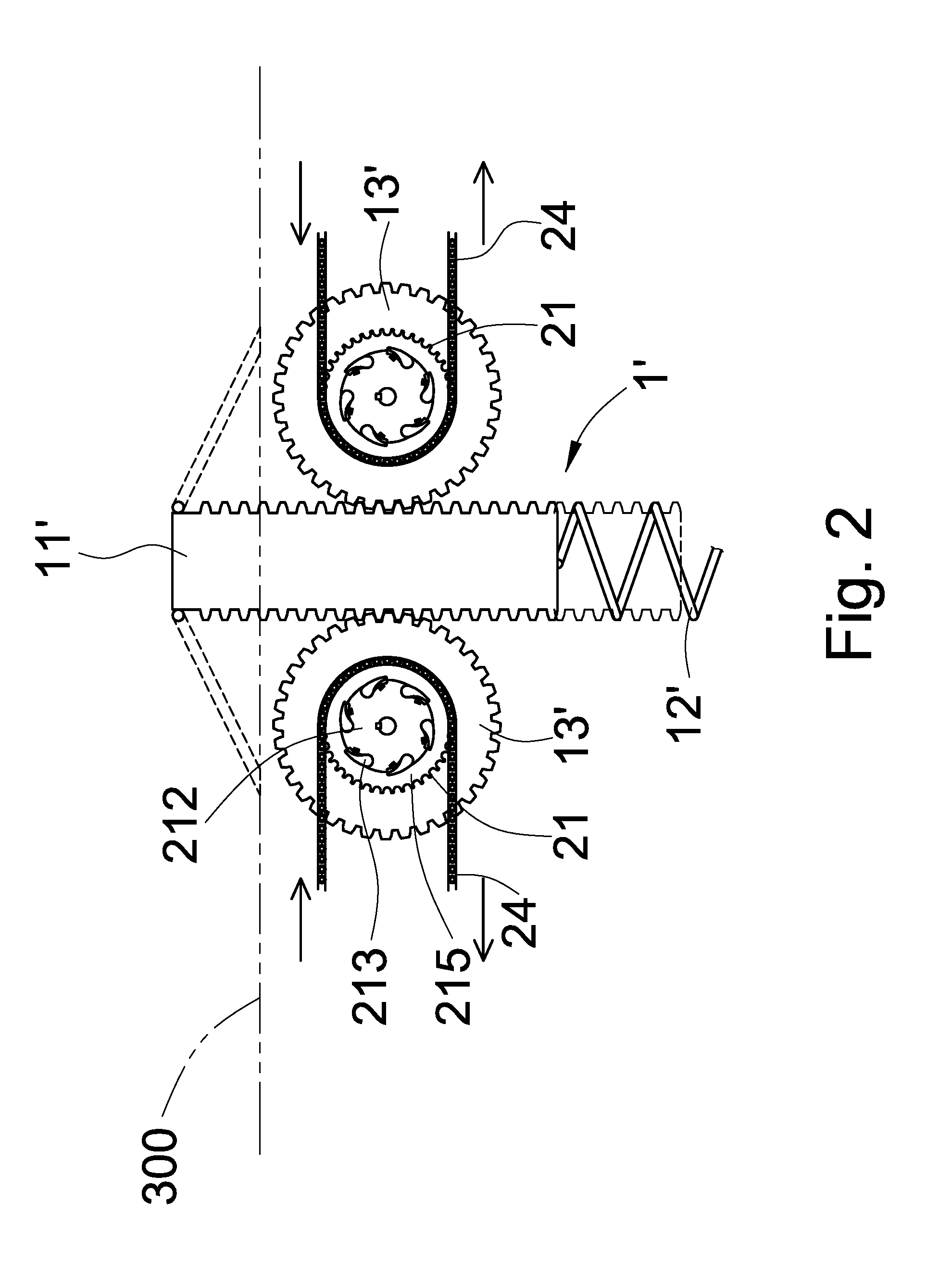

Passive entry side door latch release system

Owner:FORD GLOBAL TECH LLC

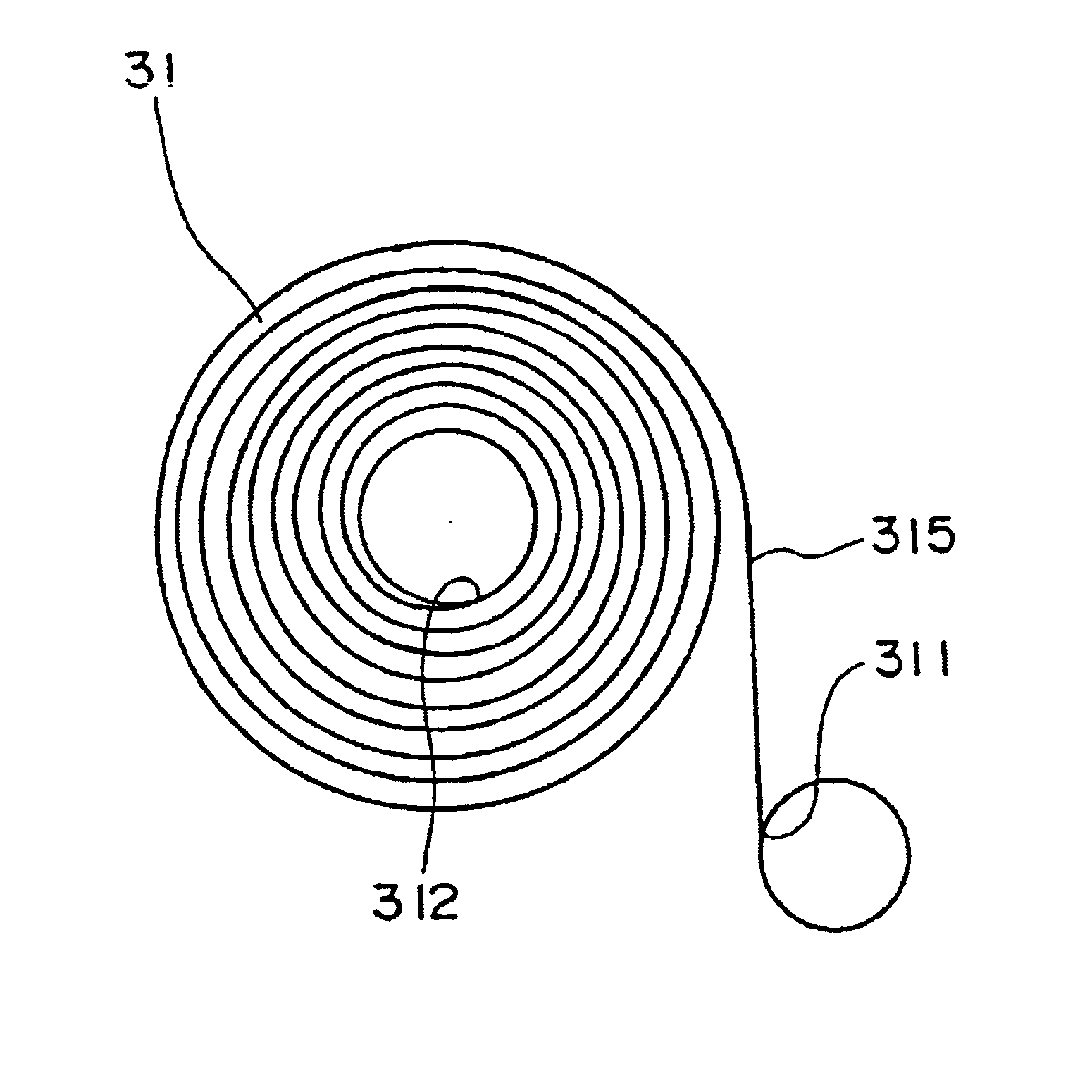

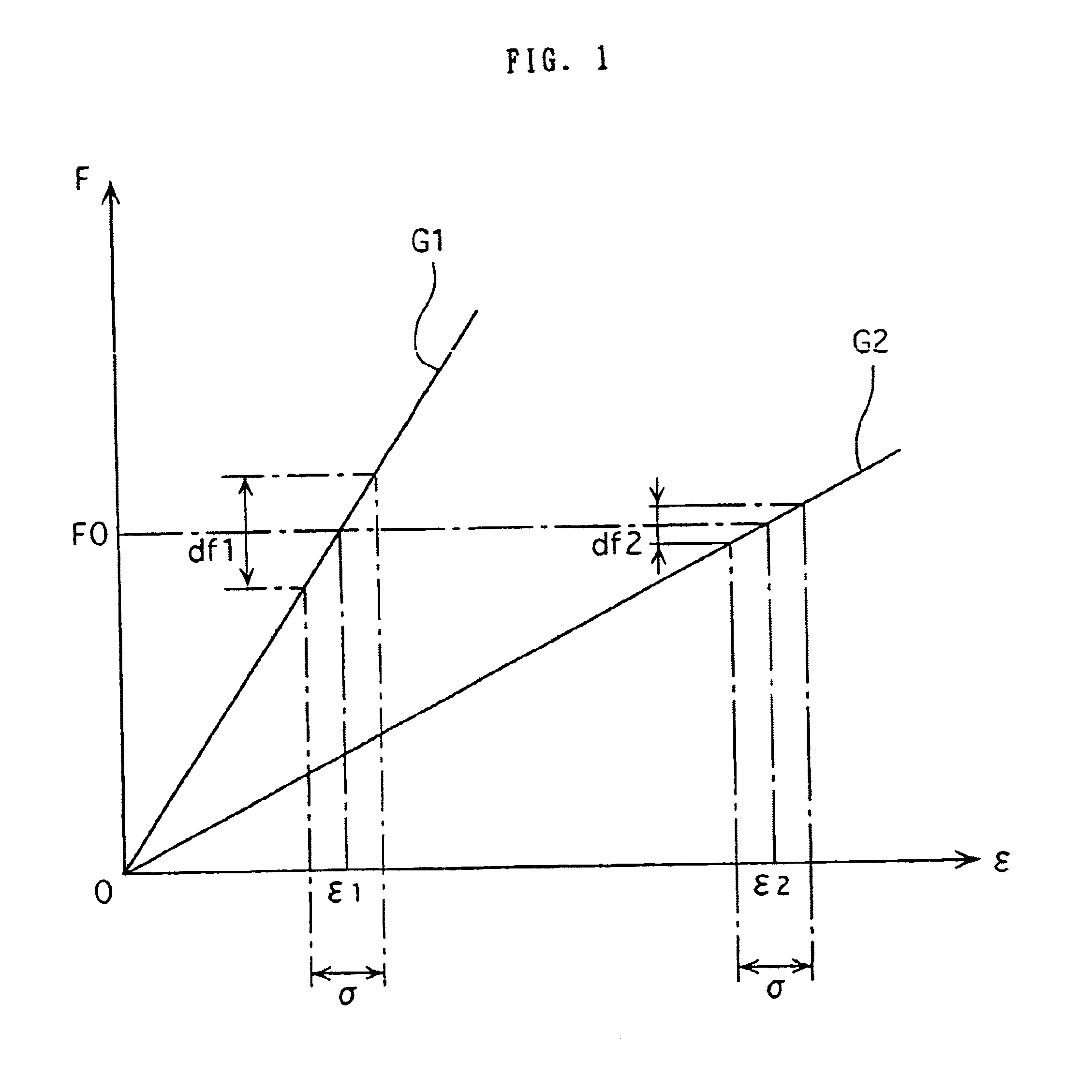

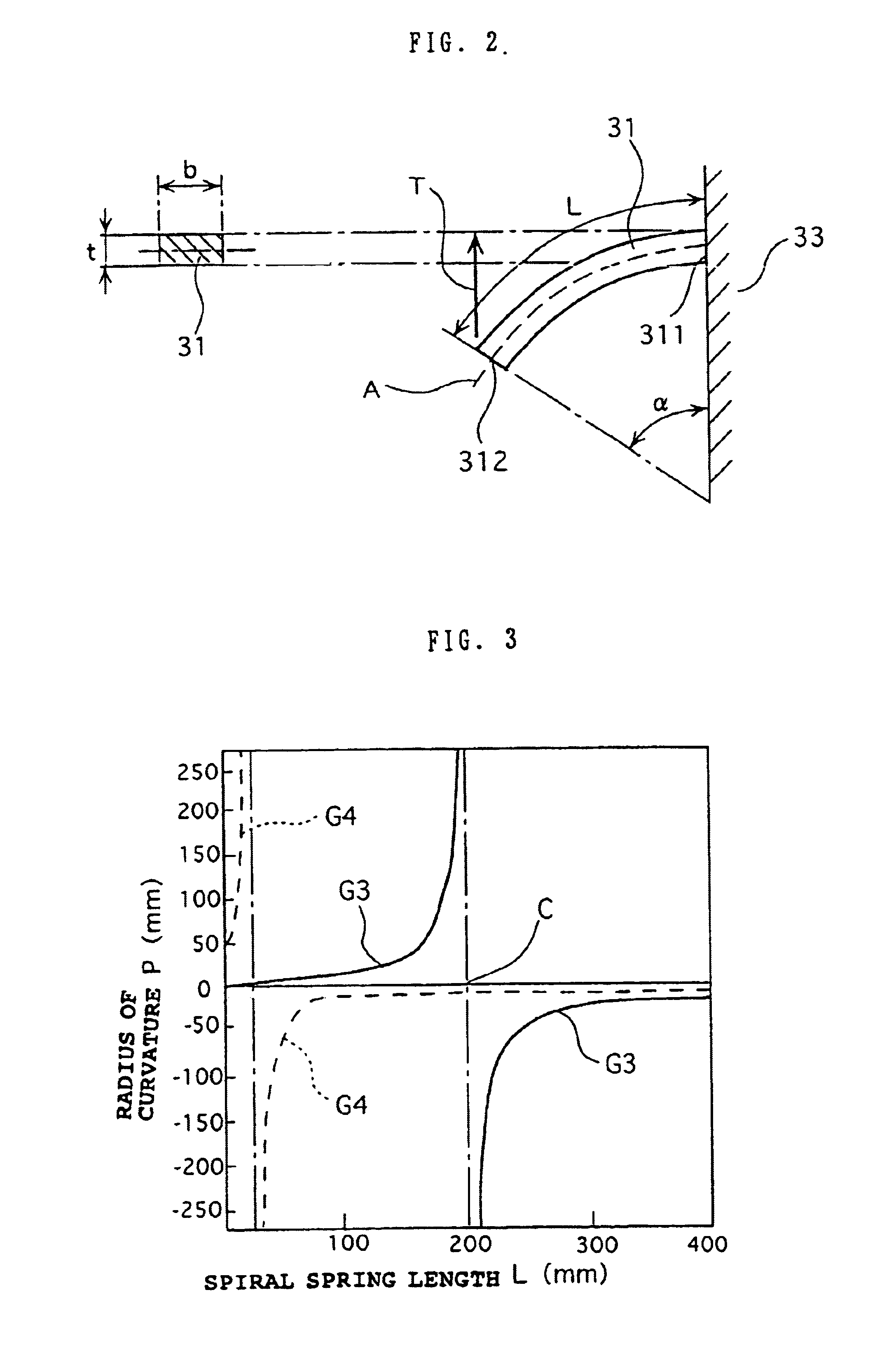

Spring, power spring, hair spring, driving mechanism utilizing them, and timepiece

InactiveUS6843594B1High stressHigh strengthSpring motorFrequency stabilisation mechanismShape changeMainspring

A mainspring used as a power source for a driving mechanism is made of an amorphous metal sheet, and has an S-shaped free-exploded shape. The curvature changing point where the curving direction of the free-exploded shape changes is formed on the inner end side of a middle point between the inner end on the winding side and the outer end serving as the other end of the inner end. Because of the high tensile stress and a low Young's modulus, the amorphous metal permits increase in mechanical energy stored in the mainspring.

Owner:SEIKO EPSON CORP

Transportation and power generating system of gravity and leaf springs

Owner:ESKANDR ASHRAF MAKRM DAWOUD

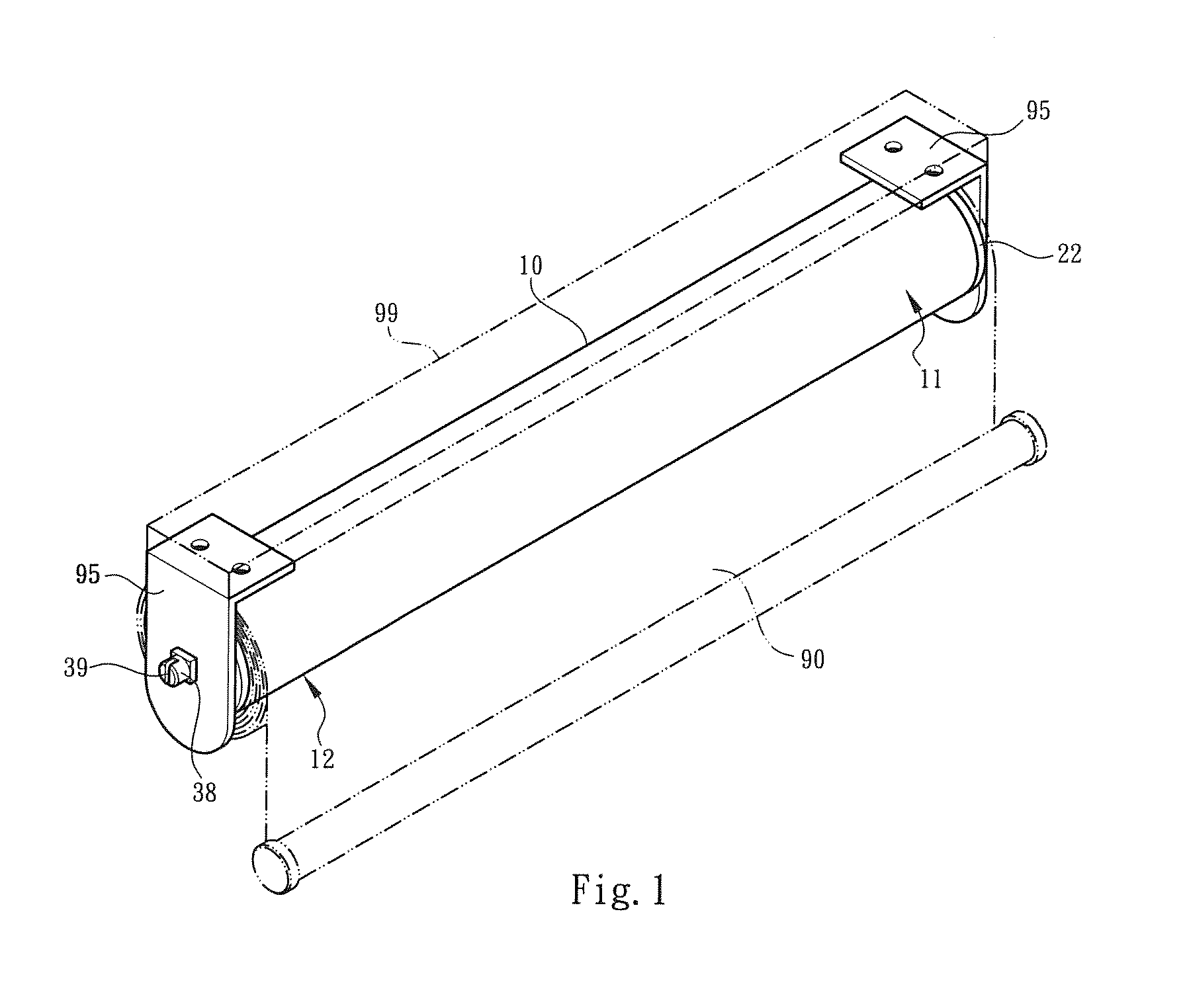

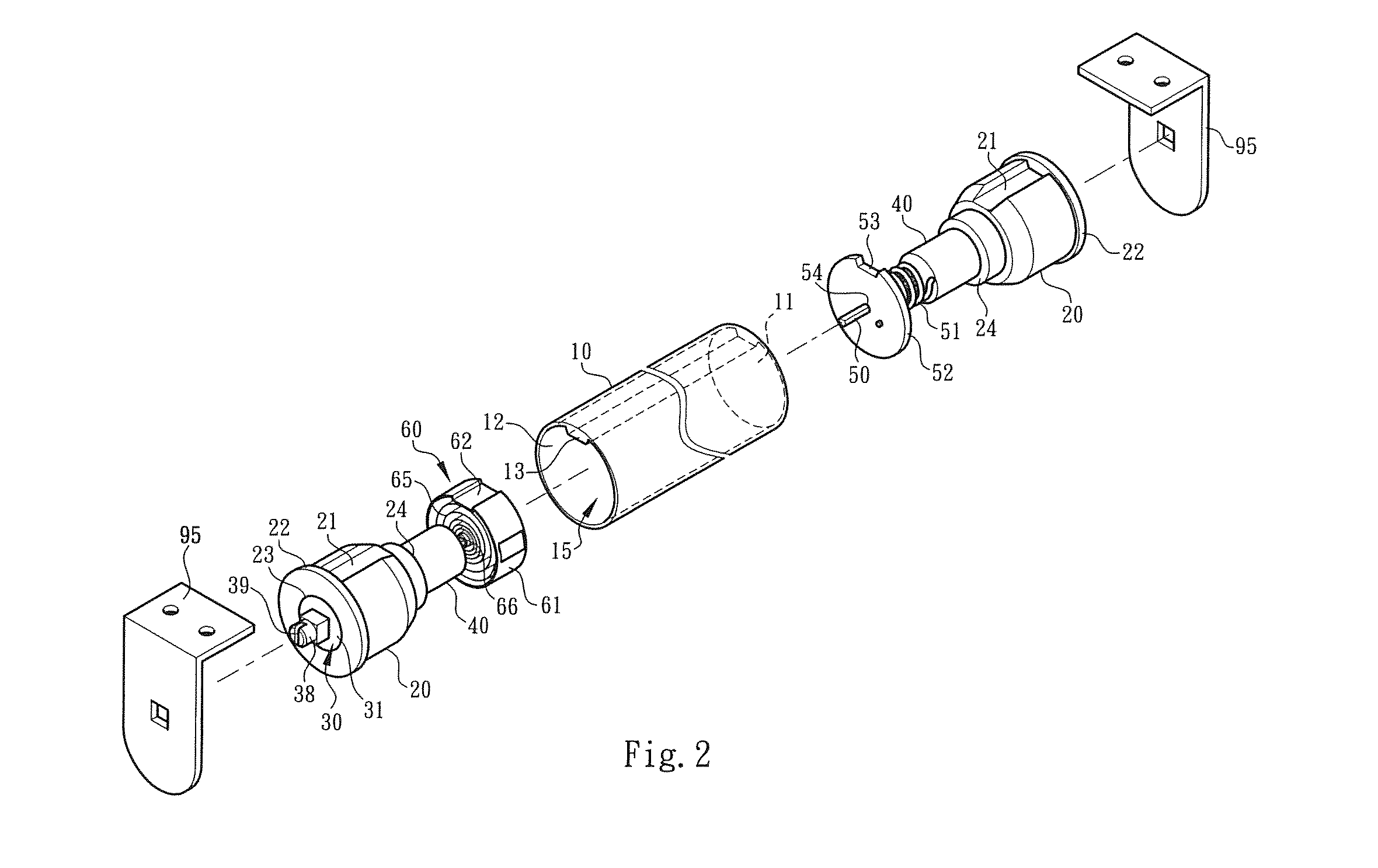

Spring-assisted cordless roller shade without clutch system

A spring-assisted cordless roller shade without clutch system includes a tubular body defining an internal space. A shade is wound on the tubular body. The internal space has a first section and a second section. In each of the first and second sections are mounted a connector, a central shaft assembled with the connector, a fixing member connected with the central shaft and a subsidiary shaft disposed on the fixing member. An elastic member is disposed between the connector and the central shaft to provide a frictional force. A rotational member and a torsion spring are mounted on the subsidiary shaft of the first section and rotatable along with the tubular body. A constant force belt spring module is assembled with the subsidiary shaft of the second section. When the operational force applied to the shade disappears, the shade is immediately located.

Owner:CHEN I MING +1

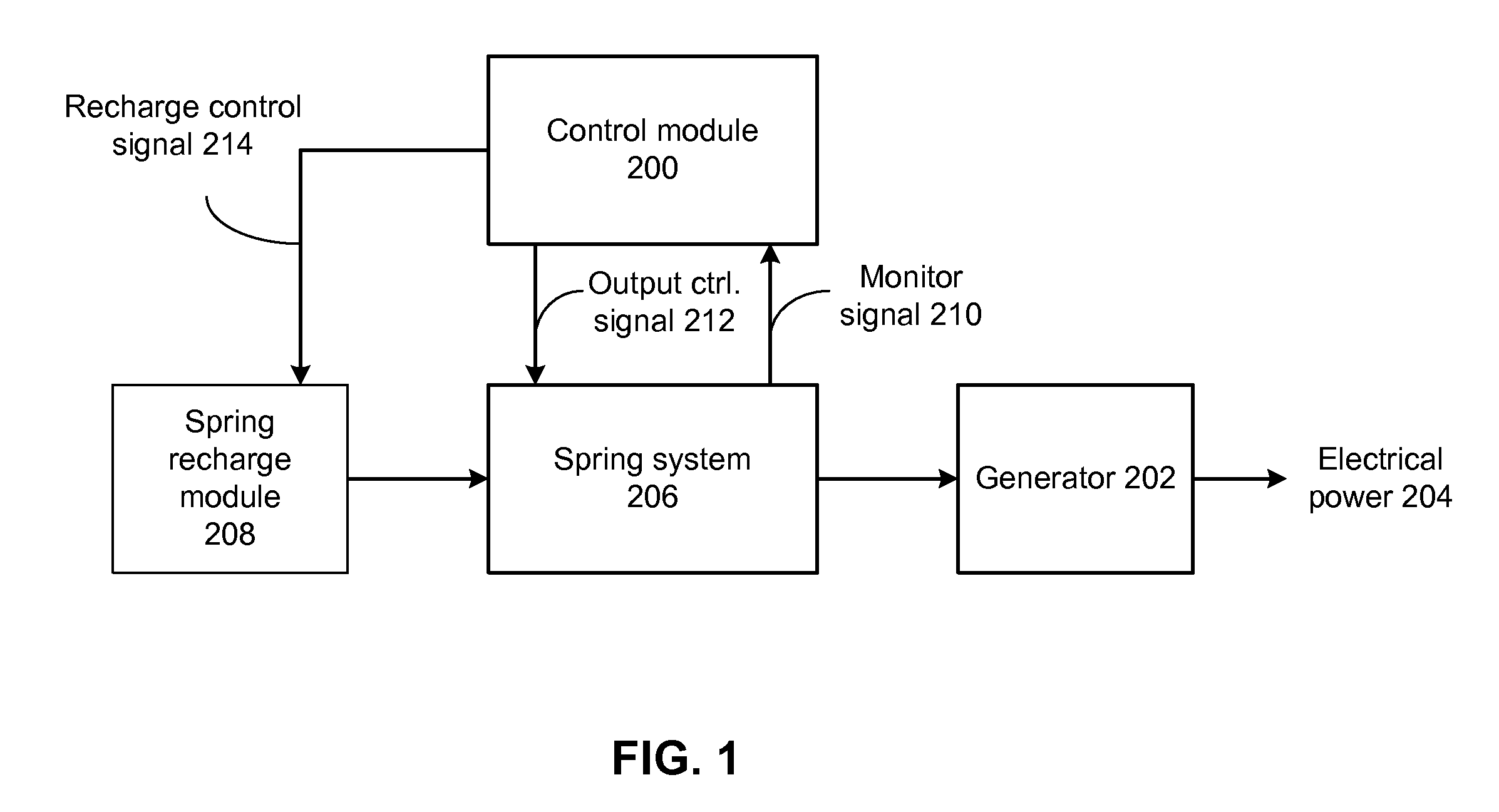

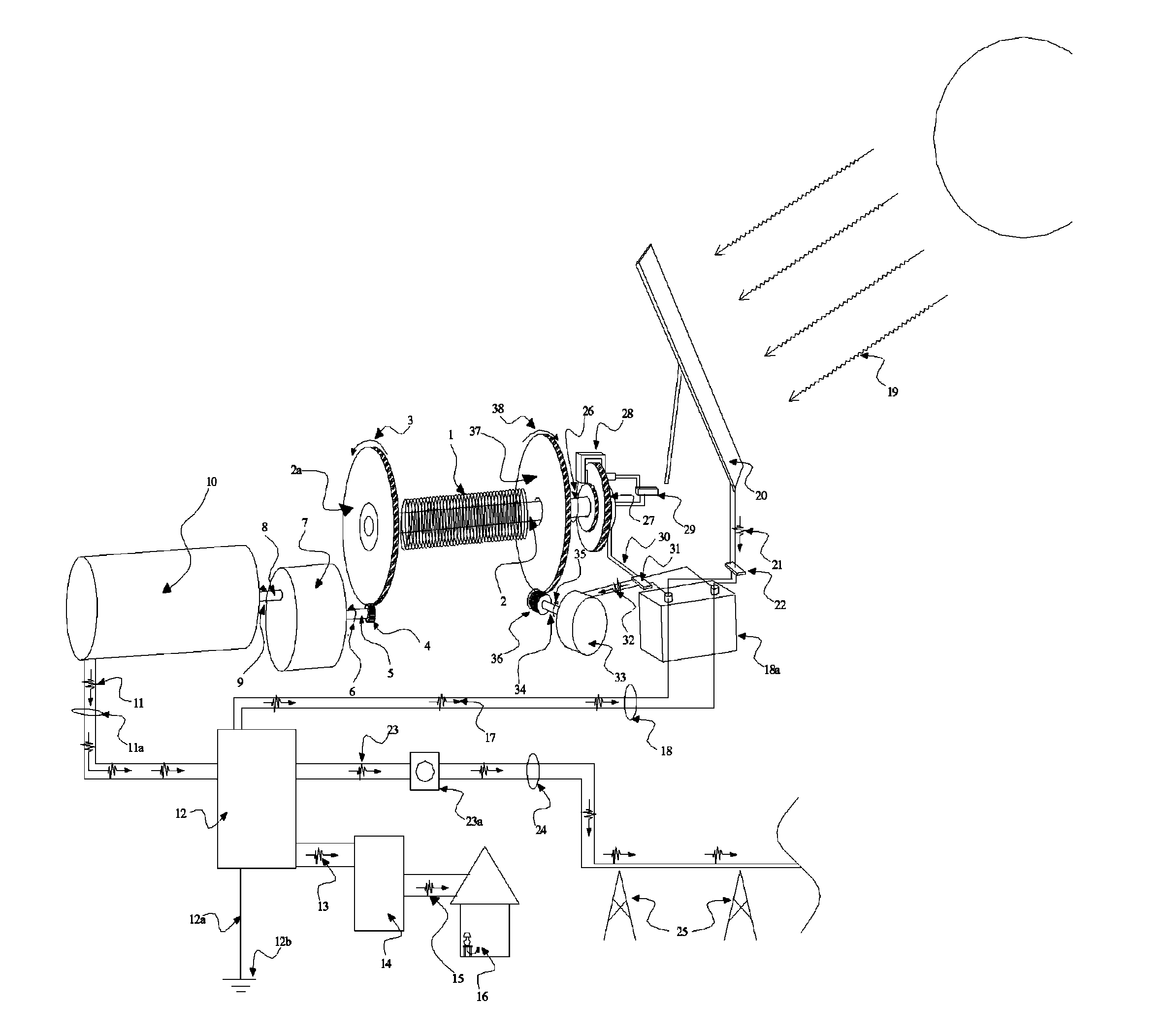

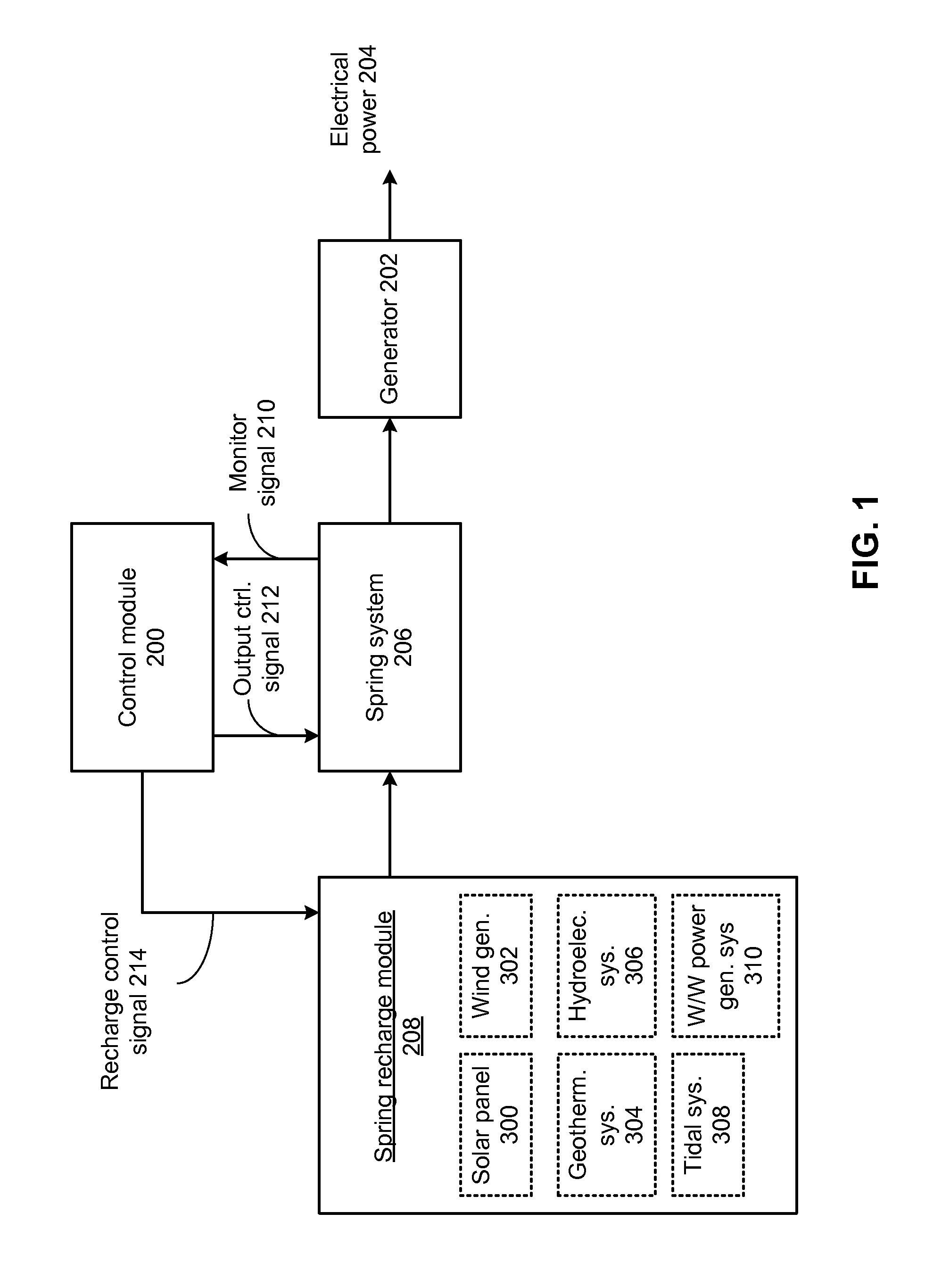

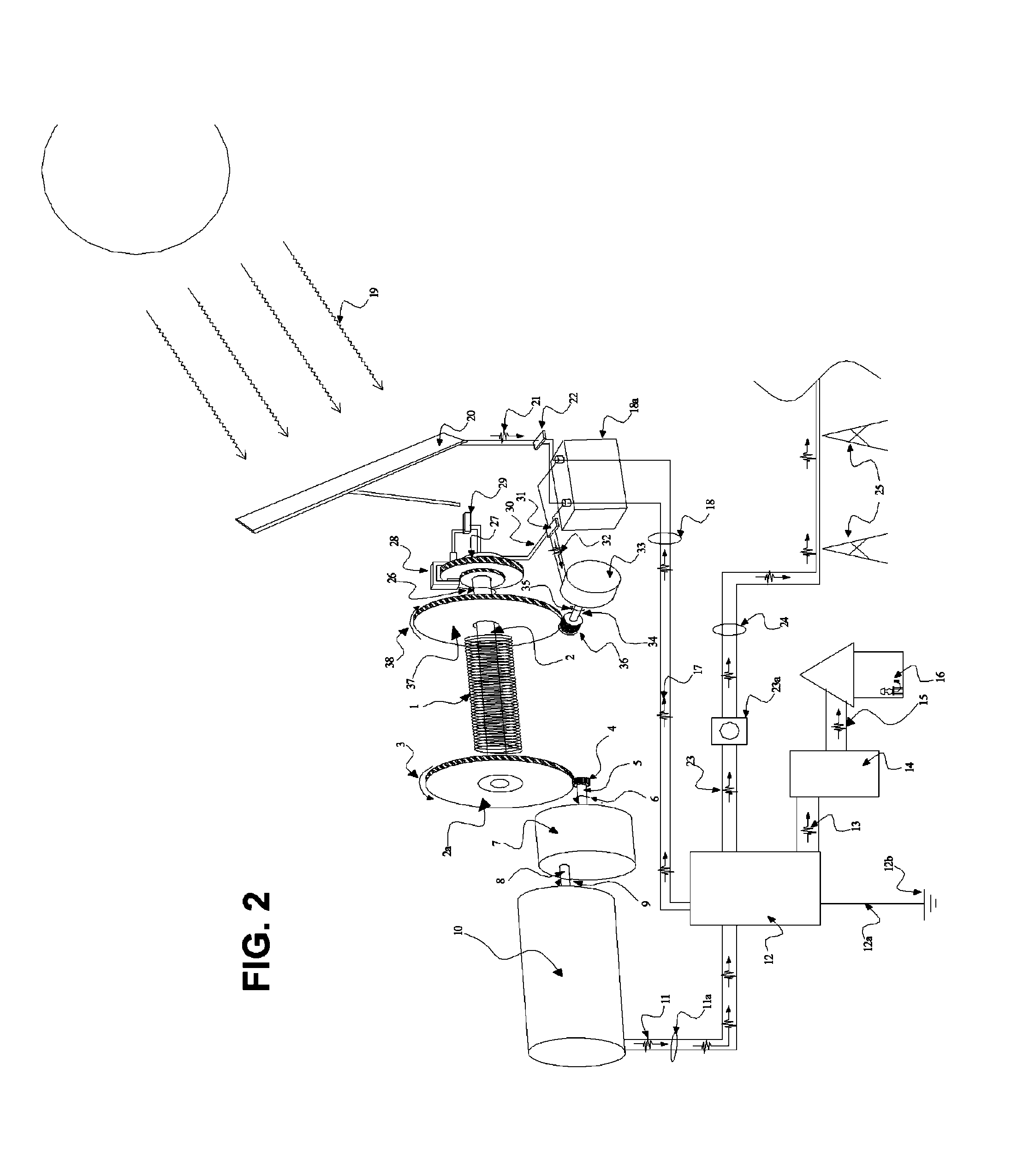

Self-sustaining electric power generating system

InactiveUS20090152867A1Batteries circuit arrangementsSecondary cells charging/dischargingStored energyState parameter

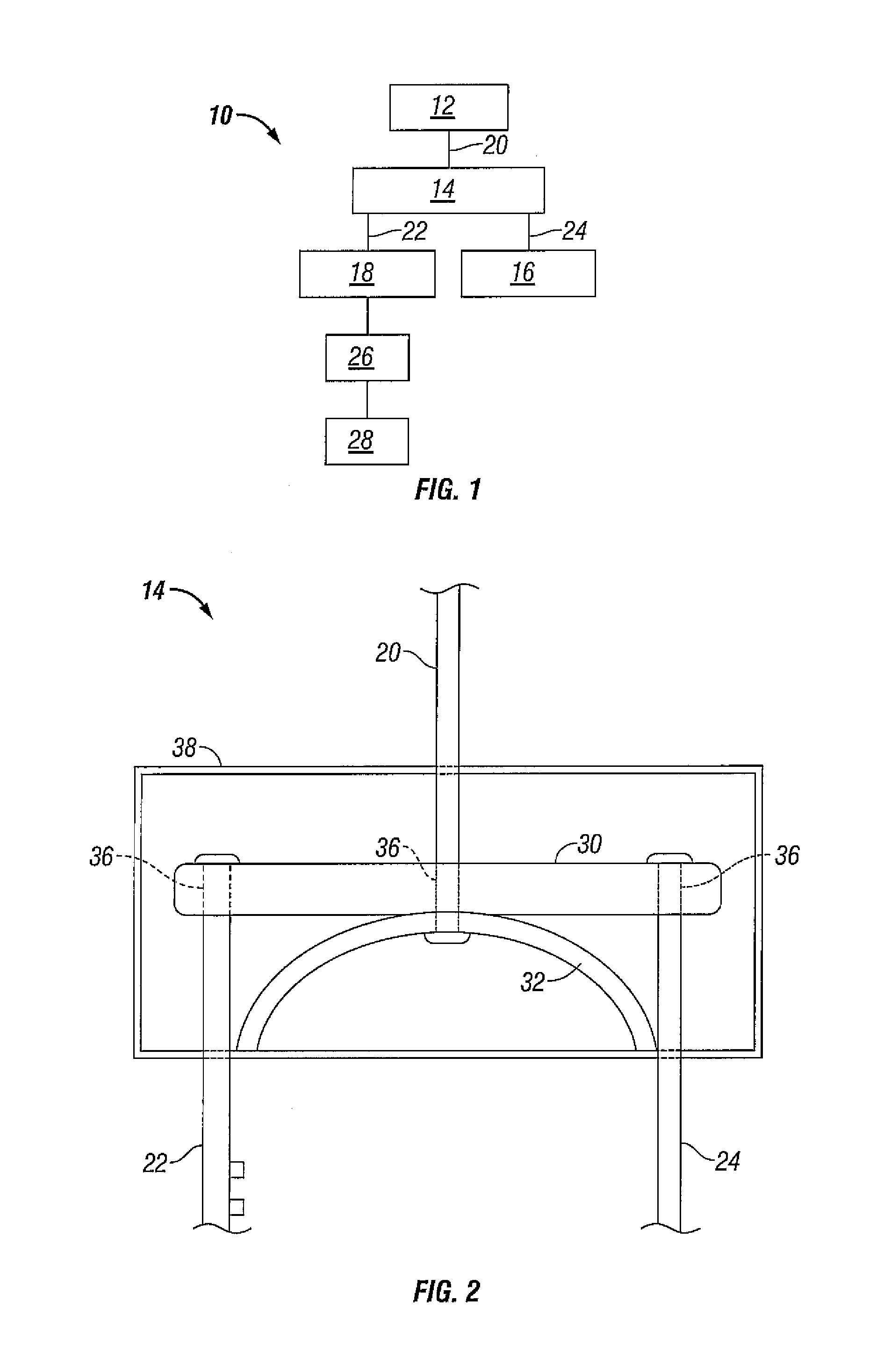

A self-sustaining electrical power generating system includes a spring system that stores stored energy, the spring system having an input for recharging the stored energy and an output for releasing the stored energy, wherein the spring system generates a monitor signal based on a status parameter of the spring system and wherein the spring system releases the stored energy in accordance with an output control signal. A generator converts the stored energy of the spring system into electric power. A spring recharge module recharges the stored energy of the spring system in response to a recharge control signal. A control module generates the recharge control signal and the output control signal, based on the monitor signal.

Owner:CRIPTONIC ENERGY SOLUTIONS

Rubber belt type energy accumulator

InactiveCN102661257ALow densityIncrease energy densitySpring motorMachines/enginesEngineeringArchimedean spiral

The invention discloses a rubber belt type energy accumulator and aims to provide a novel rubber belt type energy accumulator which is high in energy transformation ratio, high in energy density, light in weight and simple in structure. The rubber belt type energy accumulator comprises an end cover, a casing, a rubber belt, a rotary drum, multiple guiding rolling shafts, a power transmission shaft, a brake shaft and a brake device, wherein the rubber belt is supported by the multiple guiding rolling shafts to extend along an approximate Archimedes spiral. The rubber belt type energy accumulator can be used for storing and transforming kinetic energy; in the energy accumulation process, the kinetic energy inputted to the energy accumulator can be stored in the form of rubber belt elastic potential energy; and in the energy releasing process, the elastic potential energy stored in the rubber belt is transformed into kinetic energy which is outputted to the external environment. The rubber belt type energy accumulator is suitable for recycling braking energy of equipments such as vehicles and elevators.

Owner:SHANDONG UNIV OF TECH

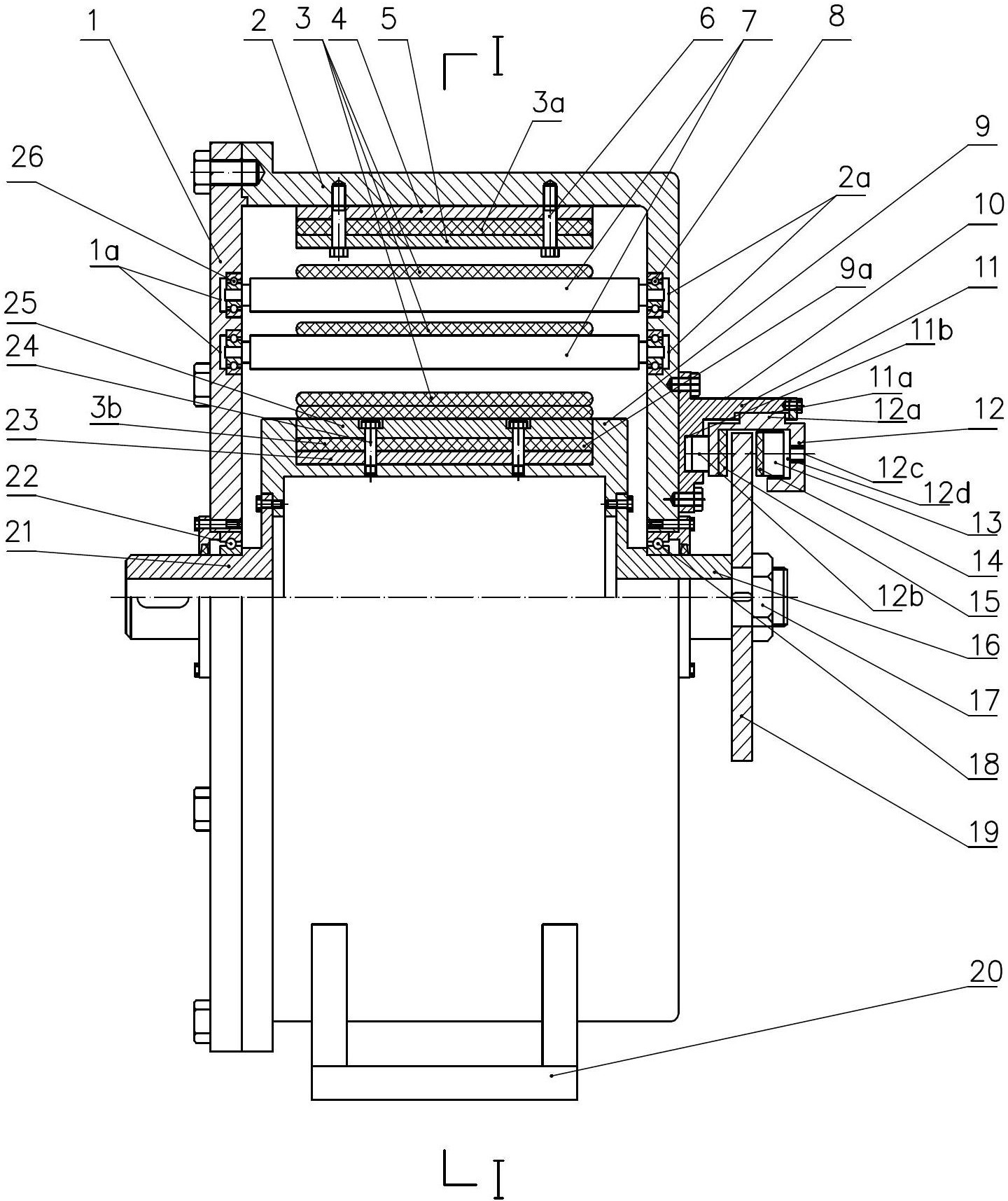

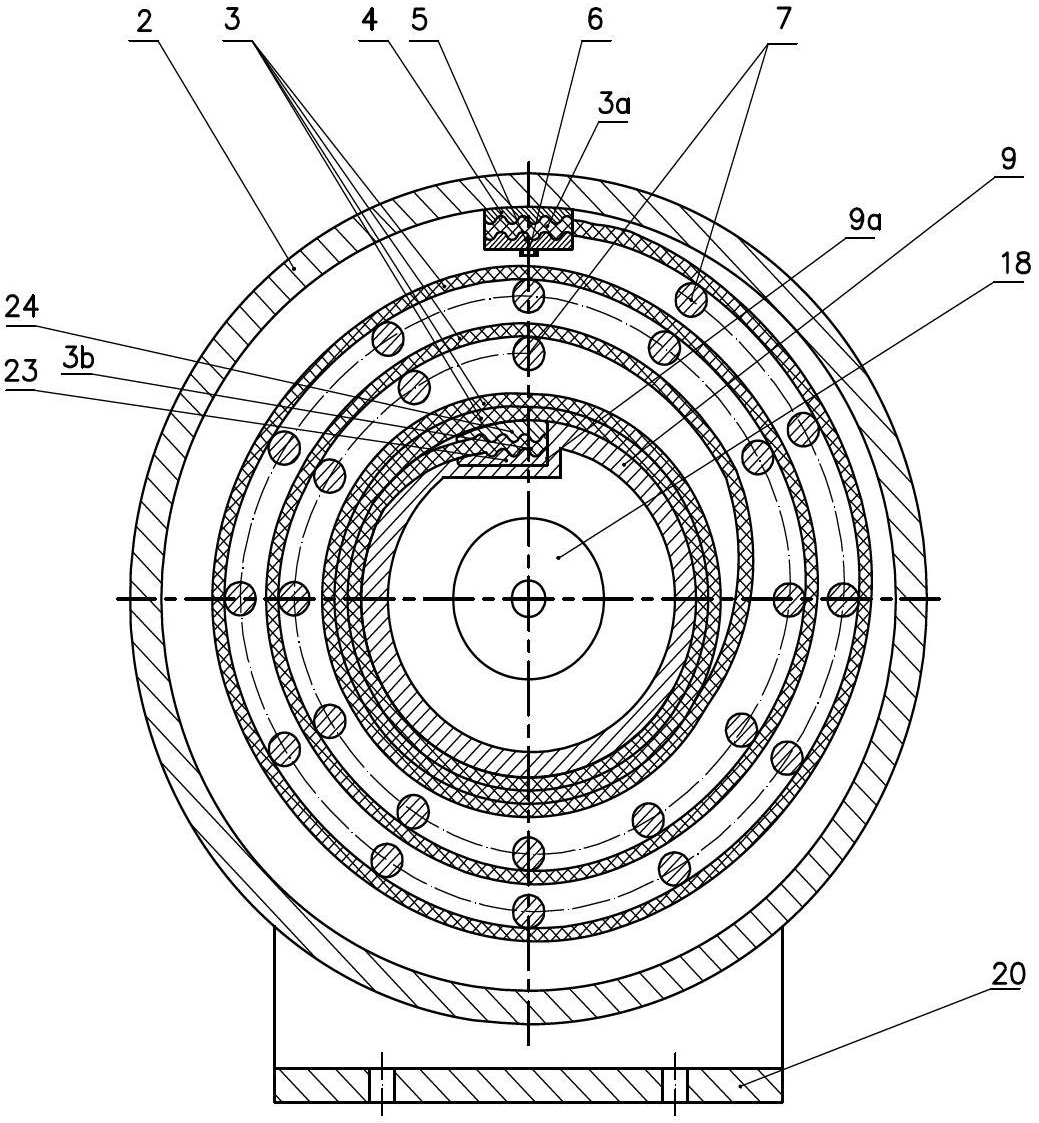

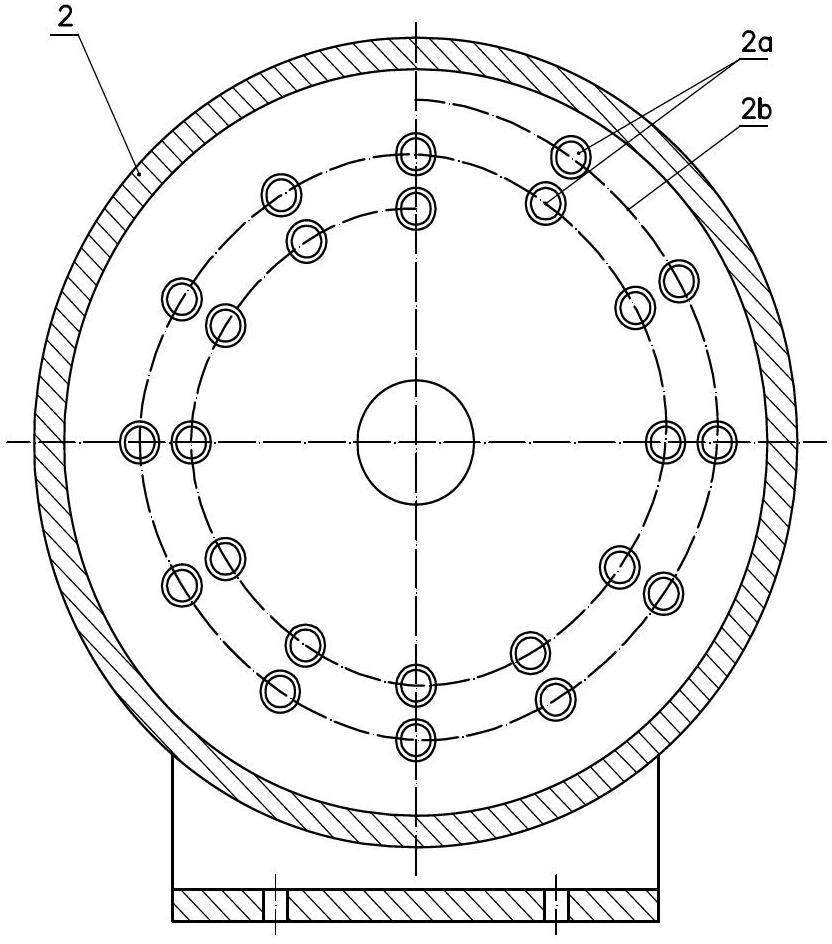

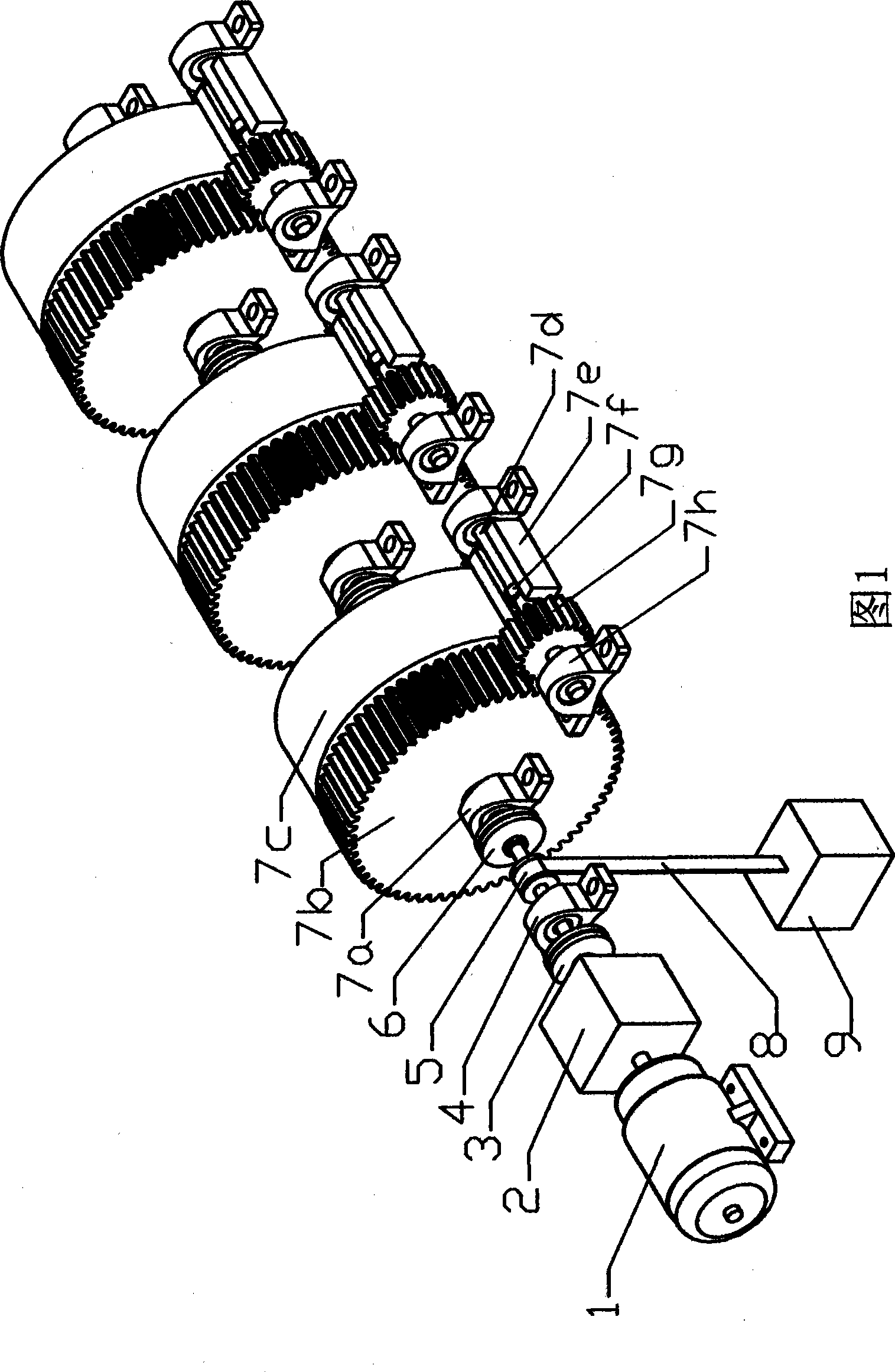

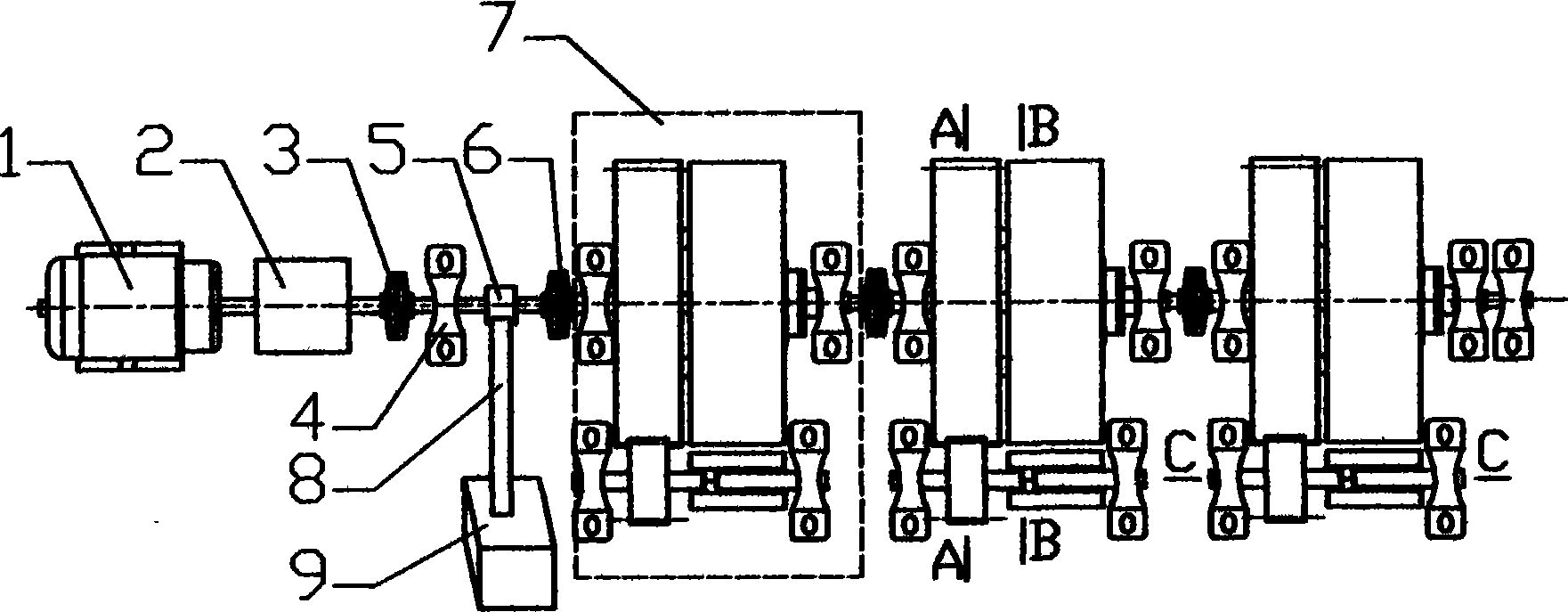

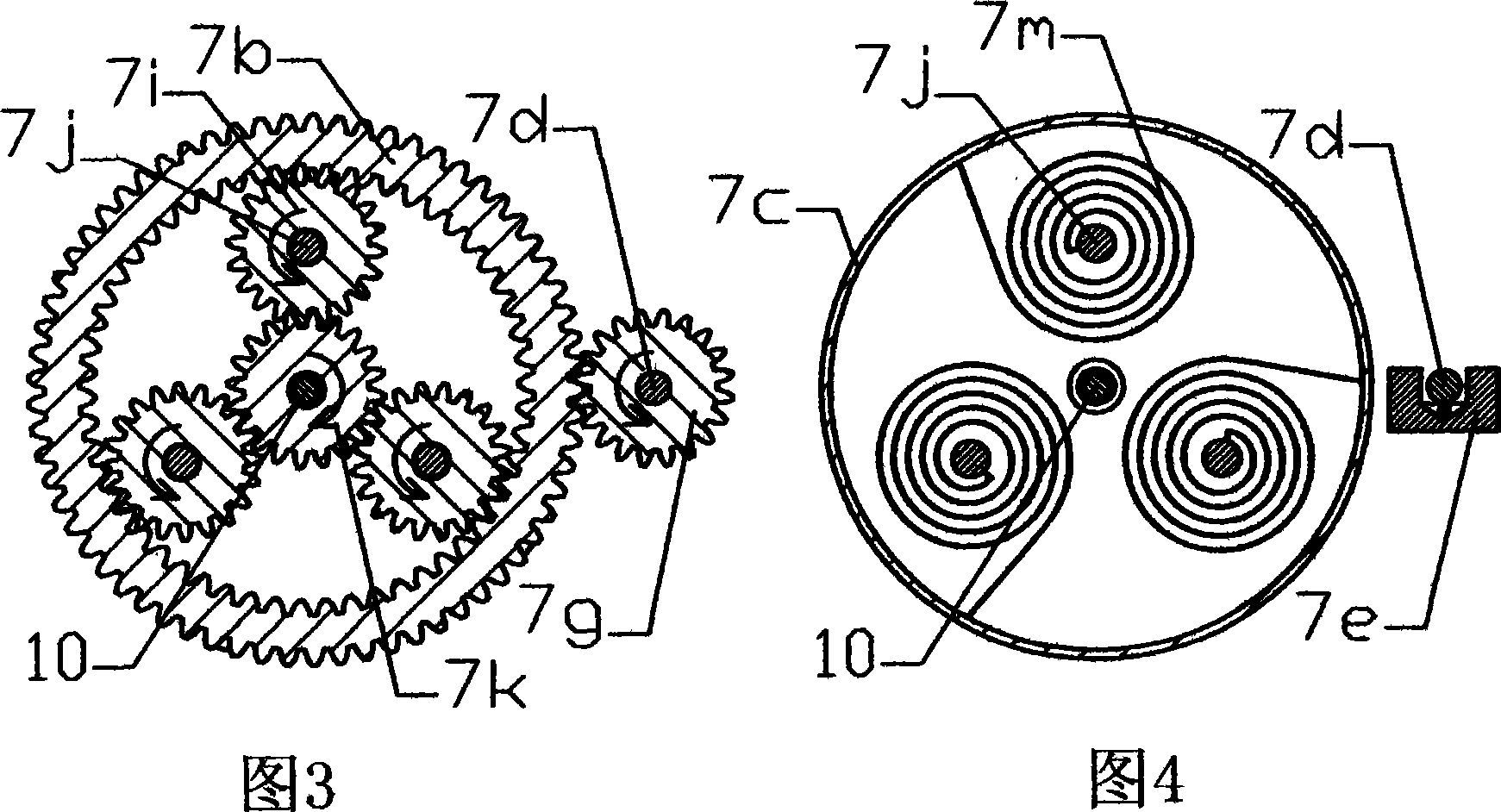

Motion mechanical energy storage and release device

The invention relates to a motion mechanical energy storage and release device, in particular to an energy-saving lifting device which realizes smooth release by energy stored in a flat spiral spring. The device comprises a frame, an electric motor, a gear box, a loading box driven by a drum wire cable, and a drive shaft which drives the drum to rotate and is divided into a left section and a right section by the drum, wherein, one section is connected with the gear box by a clutch, and the other section is in parallel connection with a plurality of energy storage devices internally provided with the flat spiral springs by a plurality of the clutches. The energy storage device comprises a driven shaft, the flat spiral spring and the like, the driven shaft is a hollow shaft, the drive shaft passes through the driven shaft, the input end of the driven shaft is connected with the drive shaft by the clutch, after the clutch is closed, the driven shaft and the drive shaft synchronously rotate, thereby the energy storage devices can store or release energy when the loading box falls or rises. The device stores energy particularly when materials are unloaded in a mine and releases energy when the materials are lifted by the flat spiral spring, and the device has the advantages of high energy storage efficiency, stable lifting operation, being safe and reliable, and energy conservation.

Owner:ZHEJIANG GONGSHANG UNIVERSITY

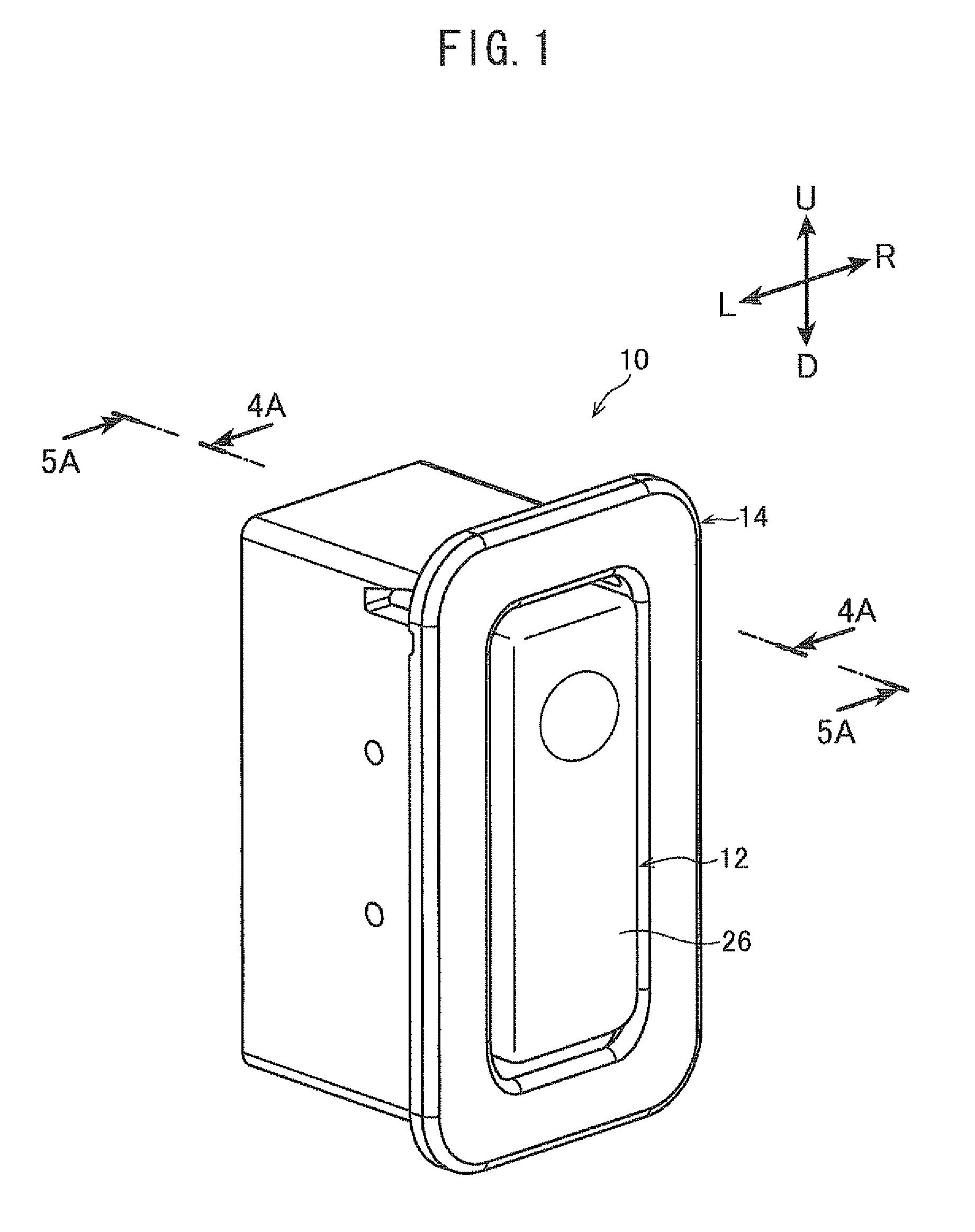

Operational mechanism for movable body

Owner:NIFCO INC

Lift assist mechanism

InactiveUS20110253714A1Improve ergonomicsMechanism is preventedSpring motorClosuresEngineeringMechanical engineering

Owner:BE INTPROP

Spring powered electric energy storage system

InactiveUS7834471B2Batteries circuit arrangementsSecondary cells charging/dischargingStored energyControl signal

Owner:CRIPTONIC ENERGY SOLUTIONS

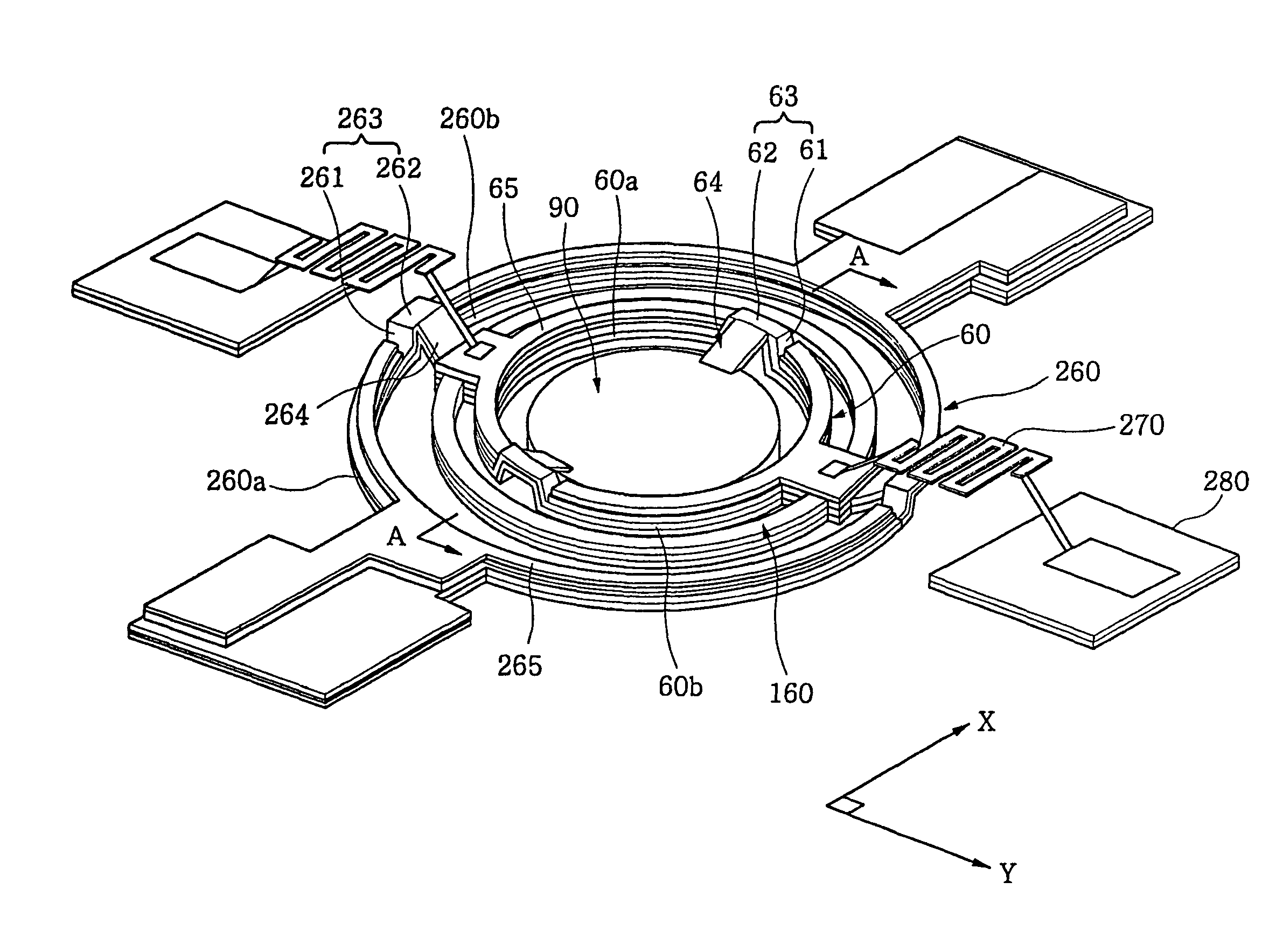

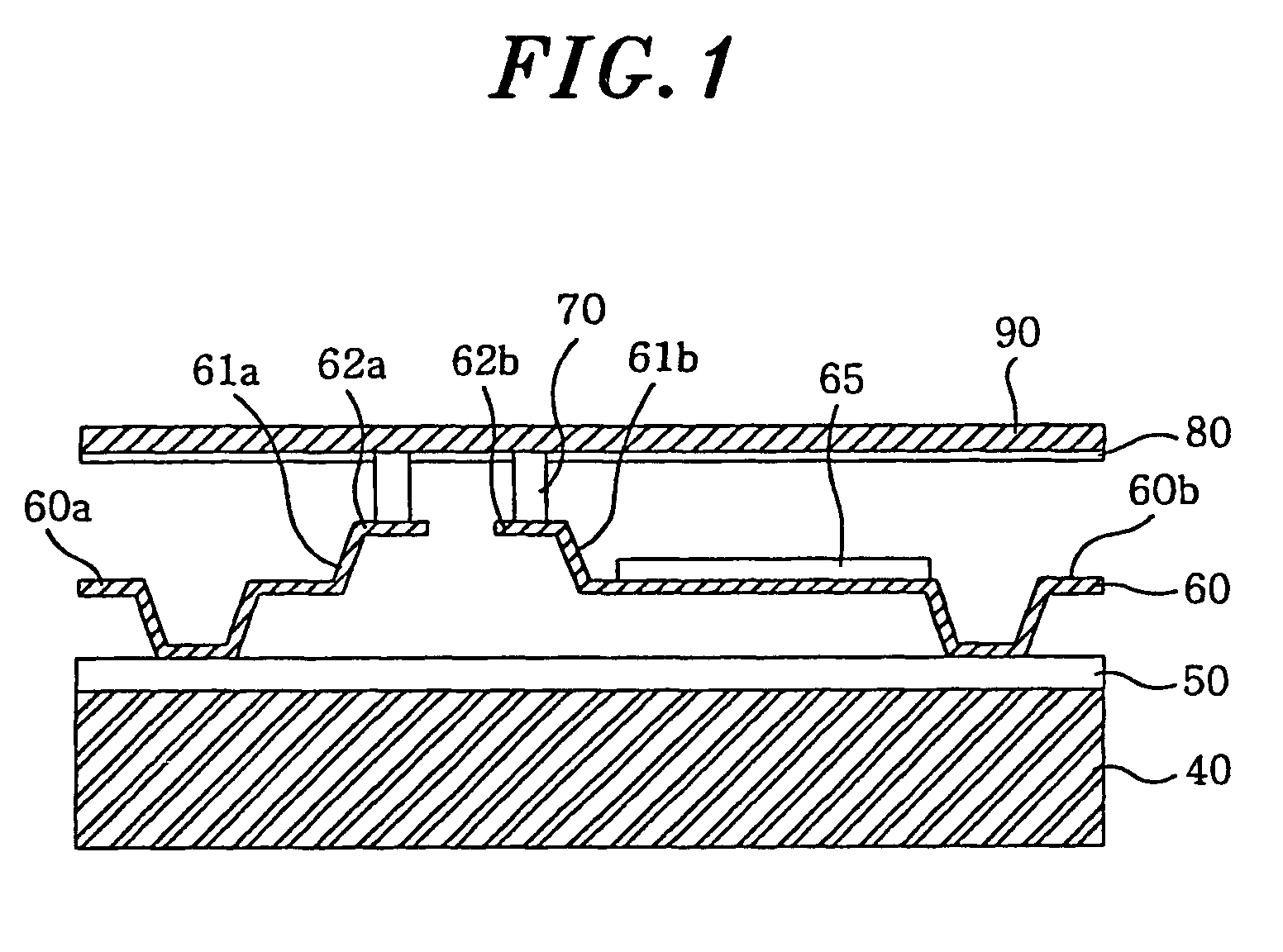

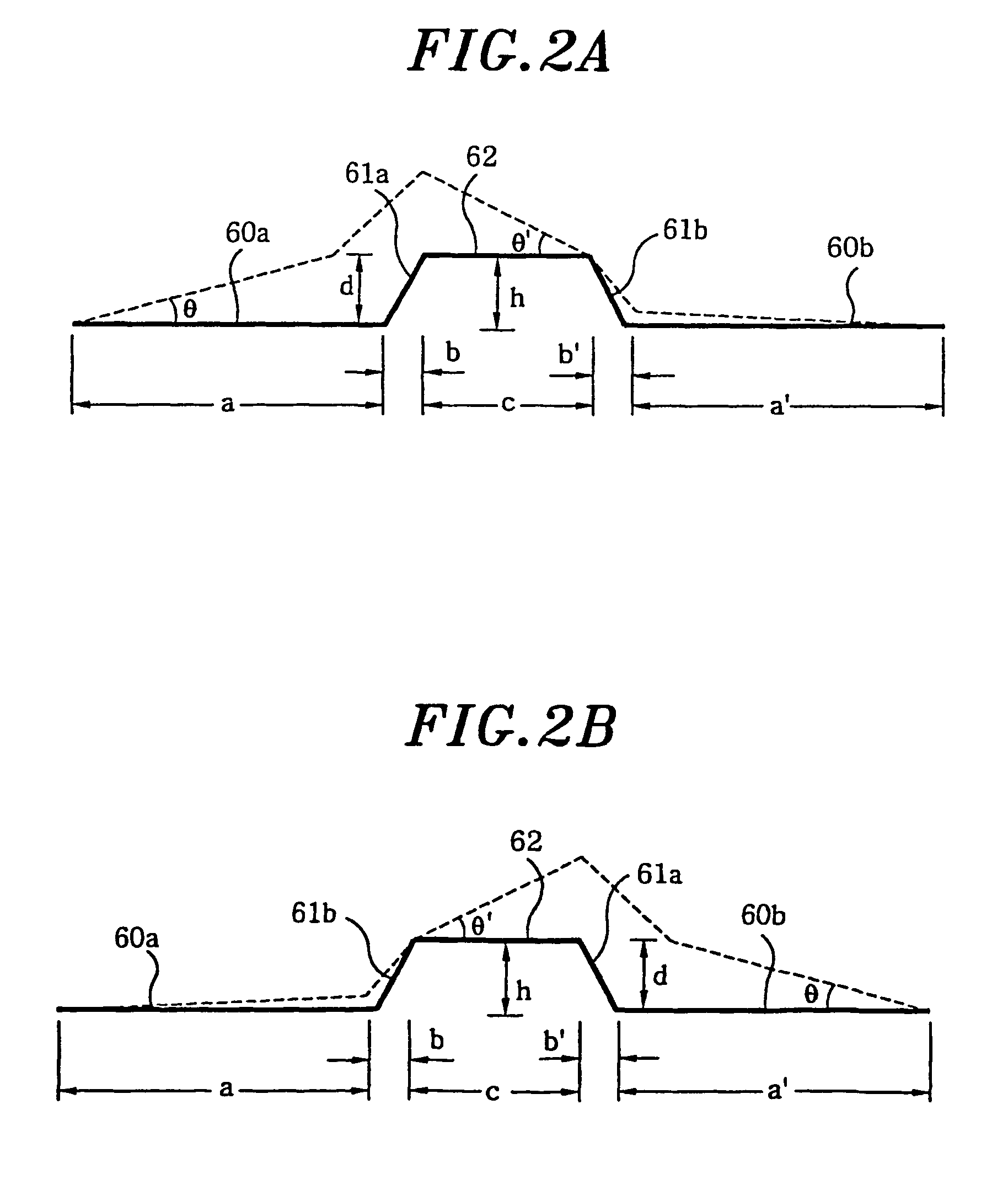

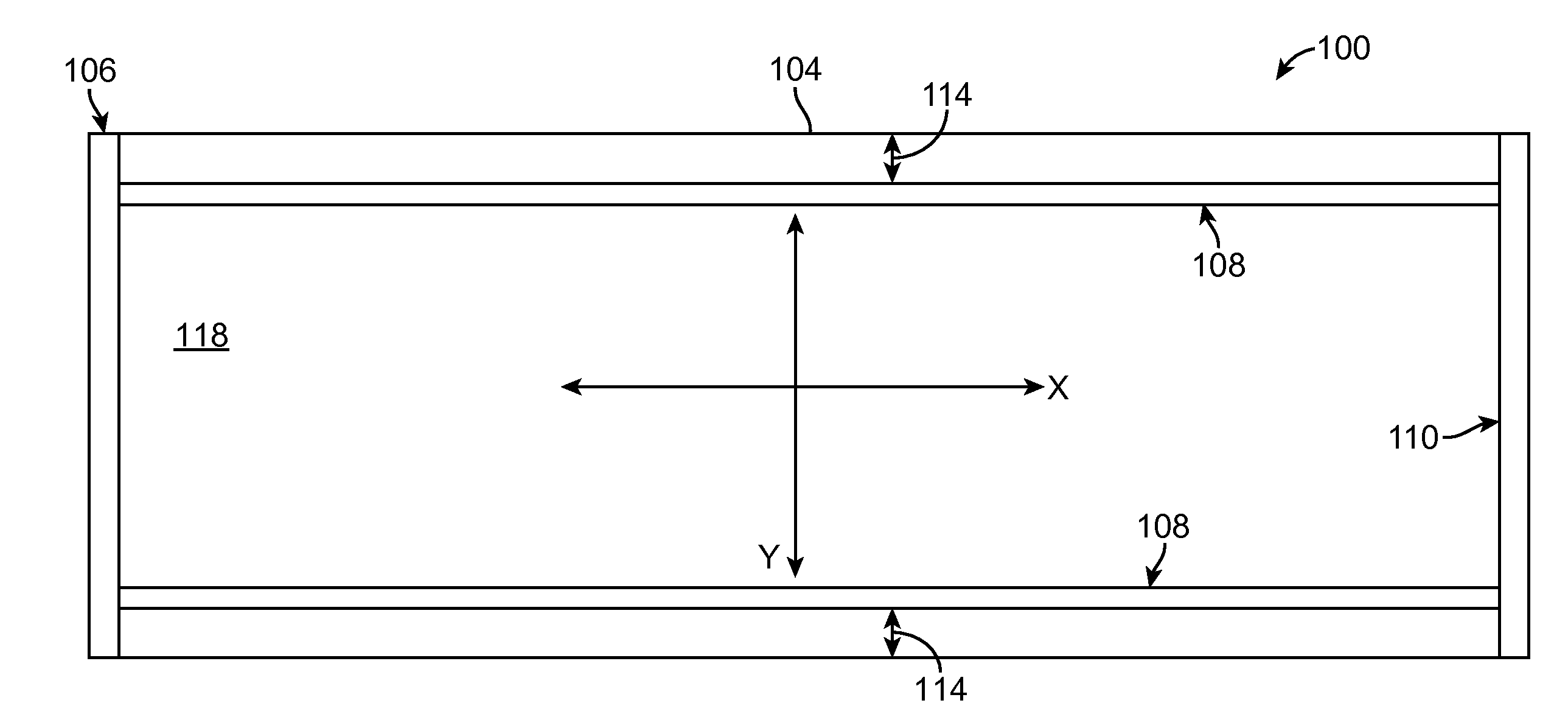

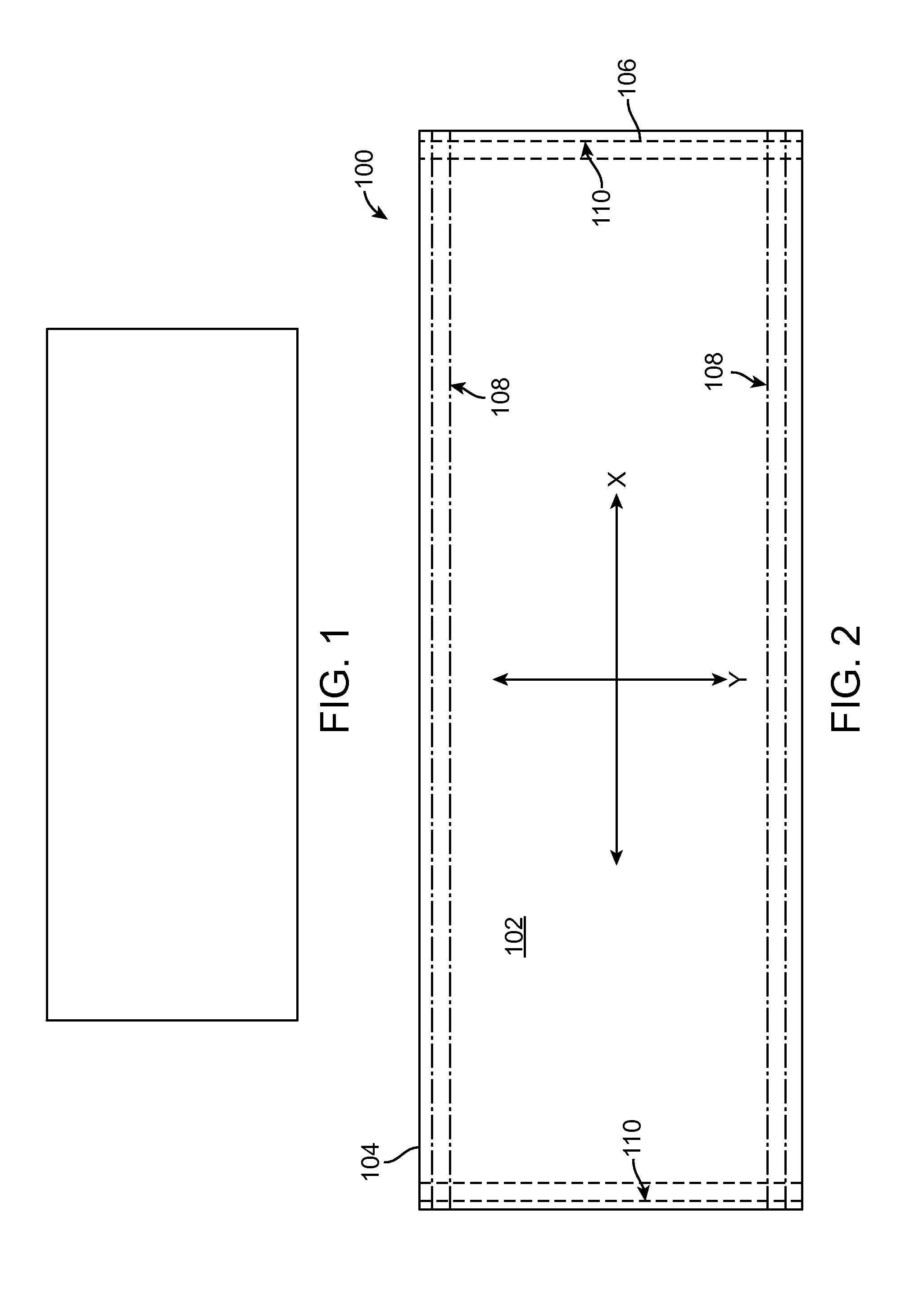

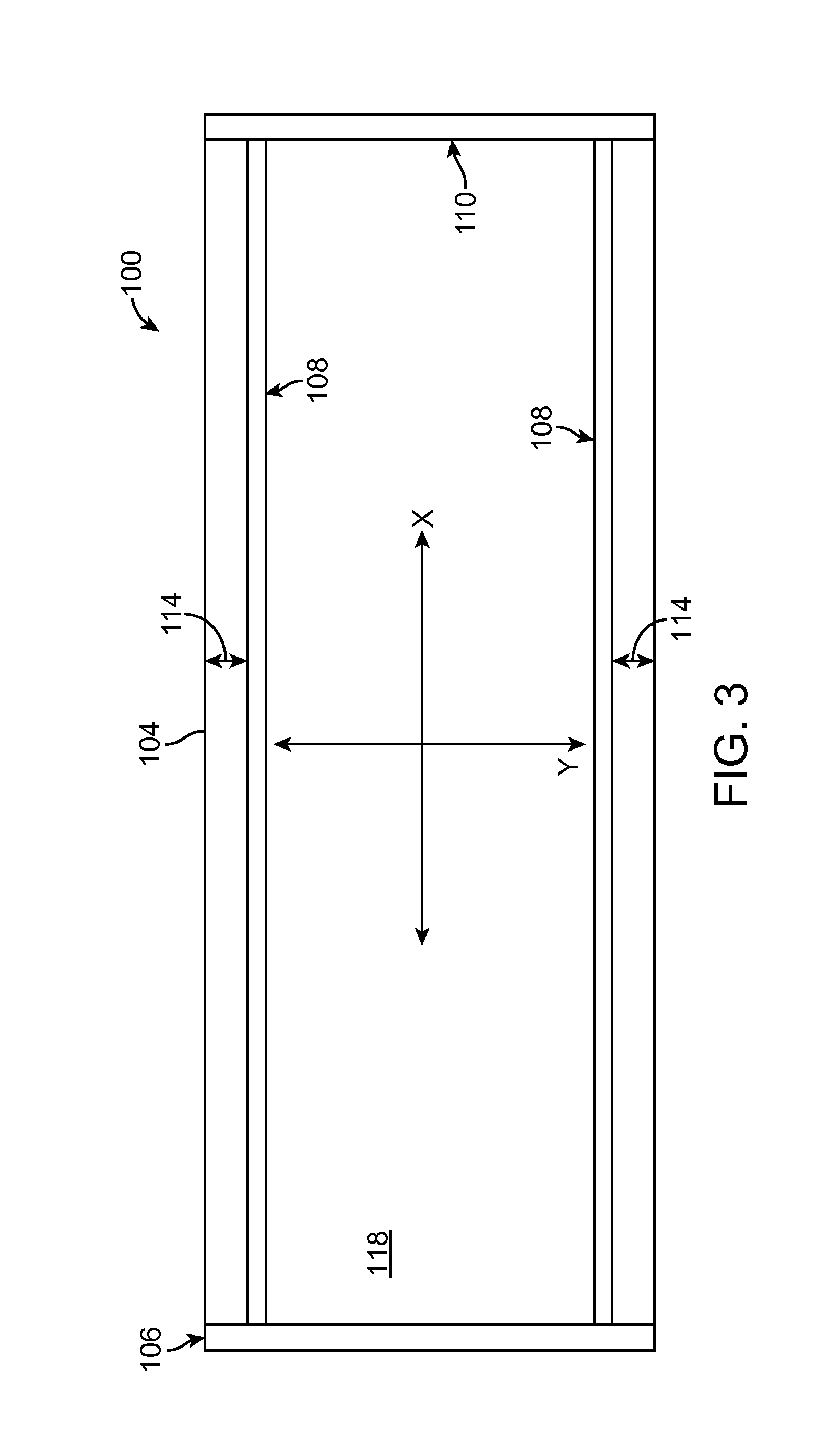

Micro piezoelectric actuator and method for fabricating same

InactiveUS6995499B2Displacement angle can be increasedIncrease displacementSpring motorPiezoelectric/electrostriction/magnetostriction machinesElastomerPiezoelectric actuators

There is provided a micro piezoelectric actuator, an optical switching device including the micro piezoelectric actuator and a method for fabricating the same. The optical switching device includes a mirror, a first actuator for adjusting the tilt angle of the mirror on the X axis, a second actuator for adjusting the tilt angles of the mirror and the first actuator on the Y axis and a driving substrate for applying a driving signal to the first and second actuators. Each of the actuators has membranes, a piezoelectric device formed on each of the membranes and a connecting part having two elastic bodies coupled to the membranes and a connecting member coupled between the two elastic bodies. In this way, the optical switching device can tilt the mirror on the X axis independently from the tilting thereof on the Y axis.

Owner:M2N

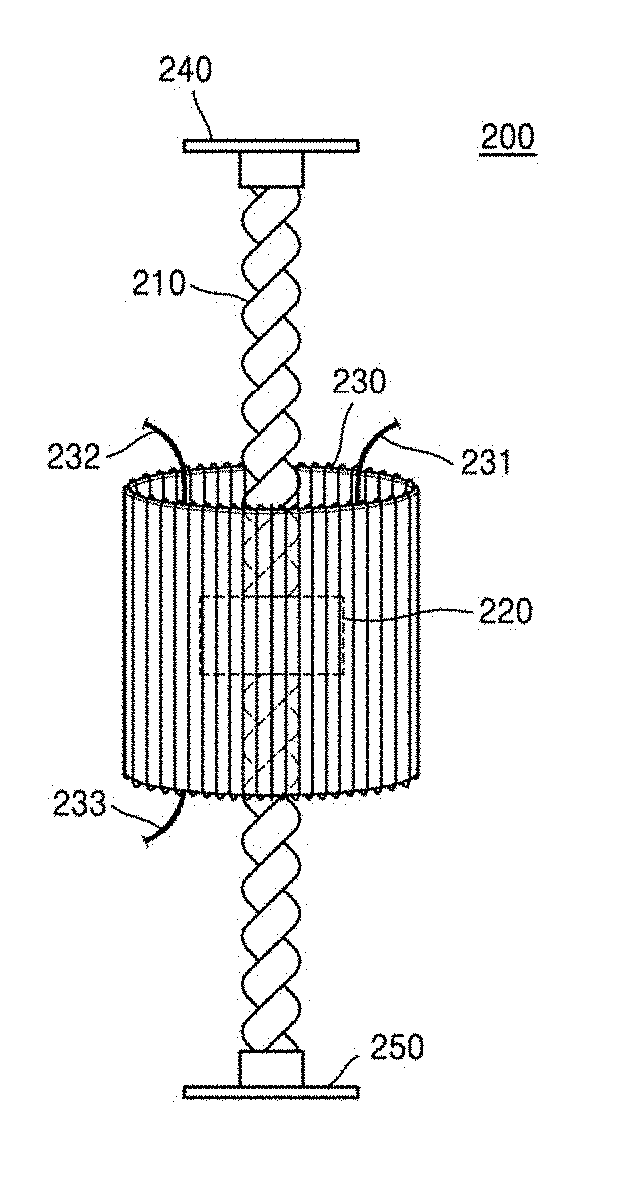

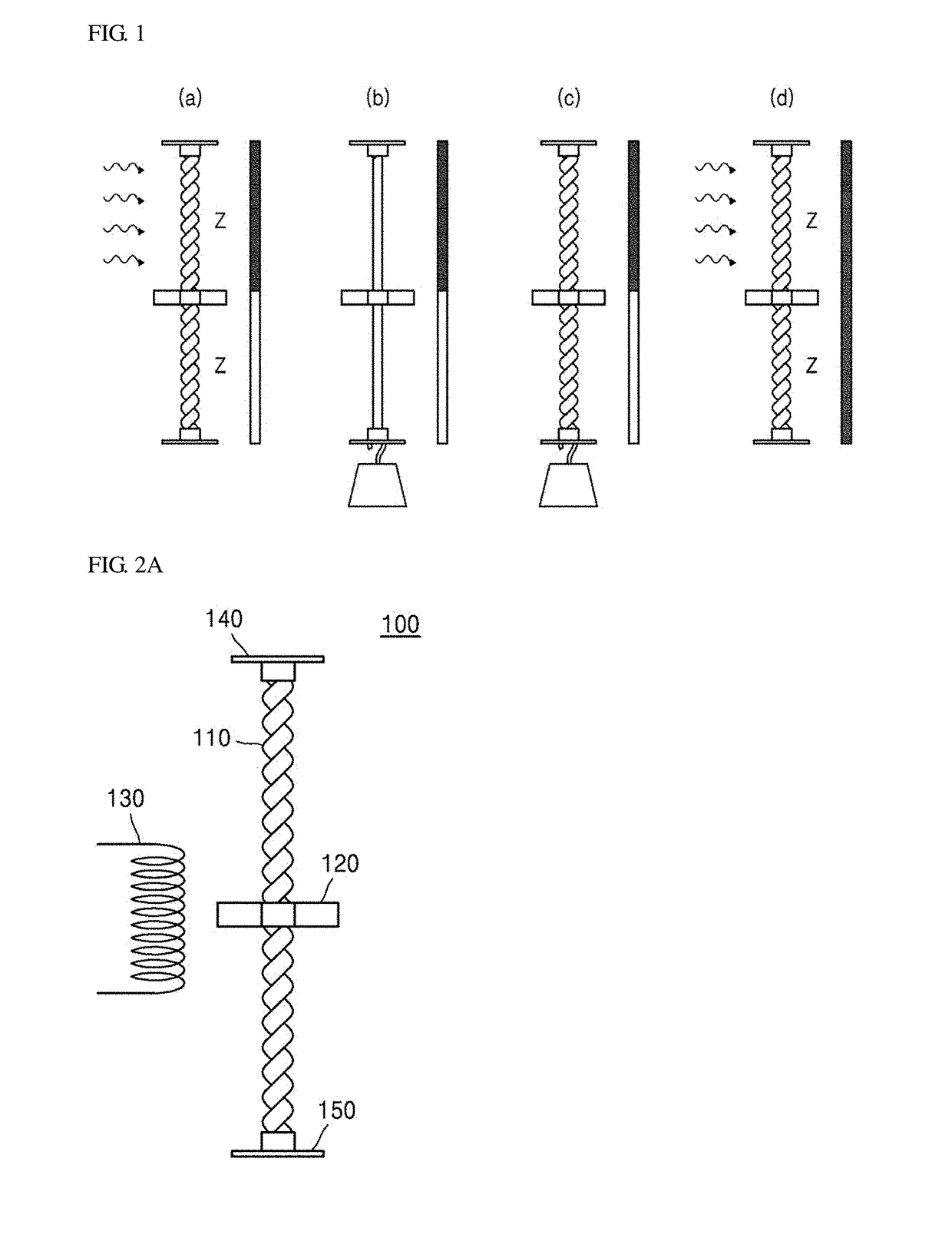

Rotation-type actuator actuated by temperature fluctuation or temperature gradient and energy harvesting device using same

InactiveUS20170314539A1Efficient thermal energyReversible and rapid and efficient actuationSpring motorMachines/enginesFiberMechanical energy

The present invention relates to a rotation-type actuator which includes a fiber having a twisted structure, which is manufactured by rotating the fiber in the opposite directions. Here, the fiber is divided into a top portion and a bottom portion with respect to the center thereof, at least one of the top and bottom portions of the fiber is fixed, and the top and bottom portions of the fiber each independently have a coiled shape as a chiral Z-type or chiral S-type structure. The rotation-type actuator has an excellent rotation speed, and also exhibits no significant decrease in rotation speed due to excellent durability and stability even when used for a long period of time. In addition, the rotation-type actuator uses a polymer fiber manufactured through electro spinning alone or using a polymer sheet obtained by aligning the polymer fiber in a single direction, and can efficiently convert heat energy, which is wasted in the air, into mechanical energy without providing a high temperature fluctuation since the rotation-type actuator has reversible, rapid and efficient actuation using persistent temperature gradient supplied from a temperature difference present in surrounding environments. Accordingly, energy harvesting devices, having improved efficiency and excellent service life characteristics in recovering heat energy as electrical energy using the rotation-type actuator, can be provided.

Owner:IUCF HYU (IND UNIV COOP FOUNDATION HANYANG UNIV)

Driving apparatus

InactiveUS20060219484A1Improve efficiencyLow costAuxillary drivesSpring motorOn boardAcceleration Unit

Owner:TOYODA GOSEI CO LTD

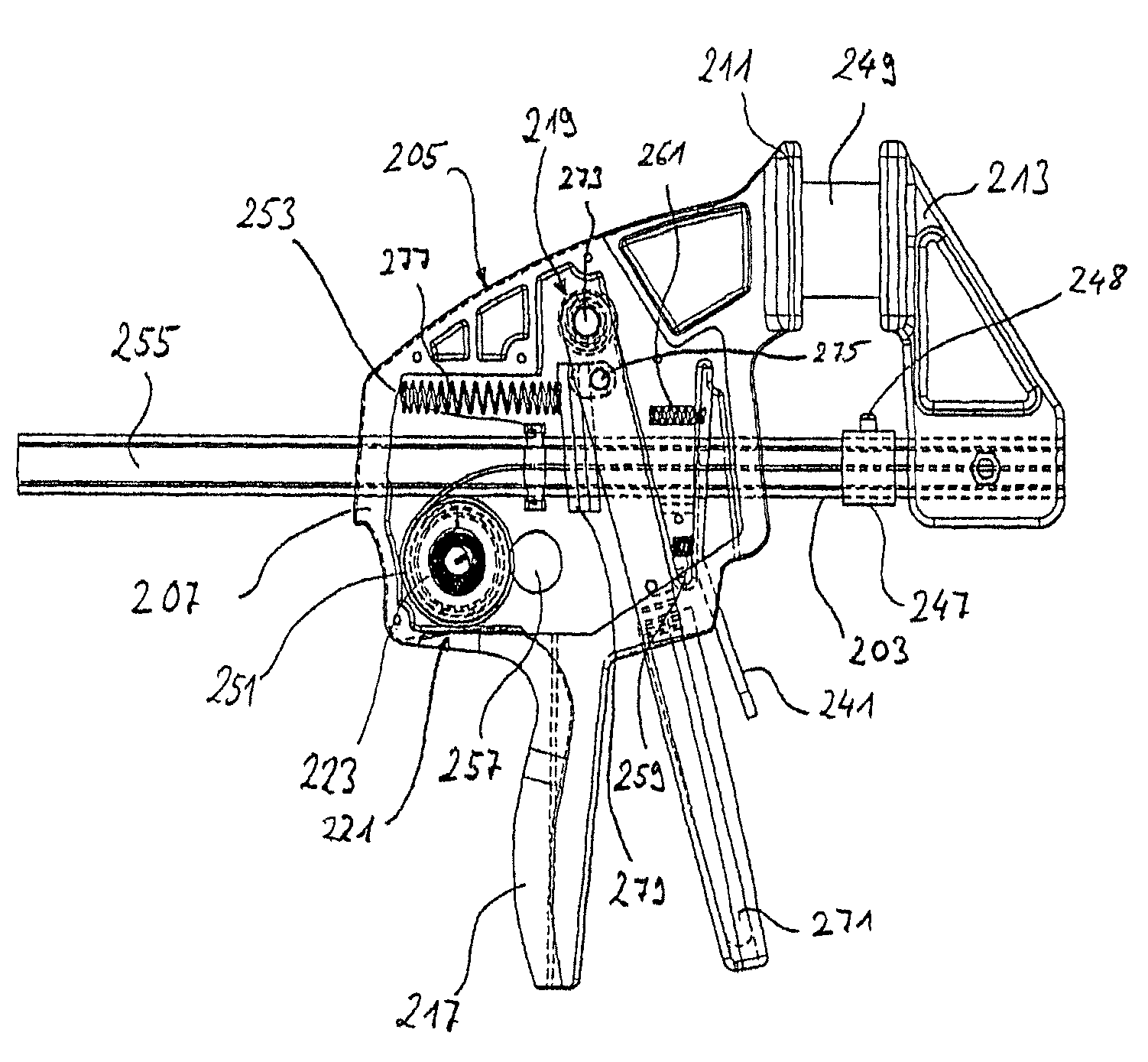

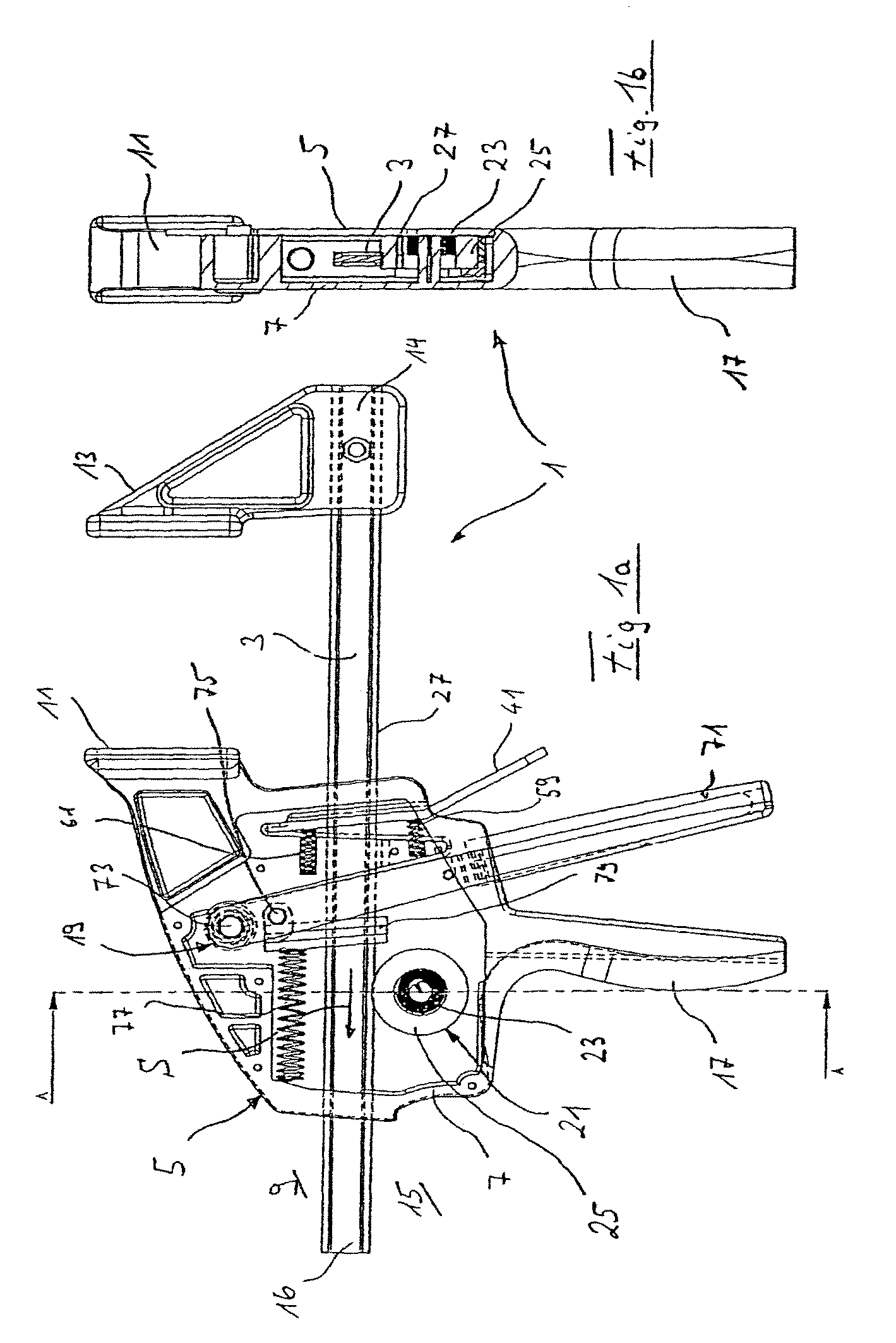

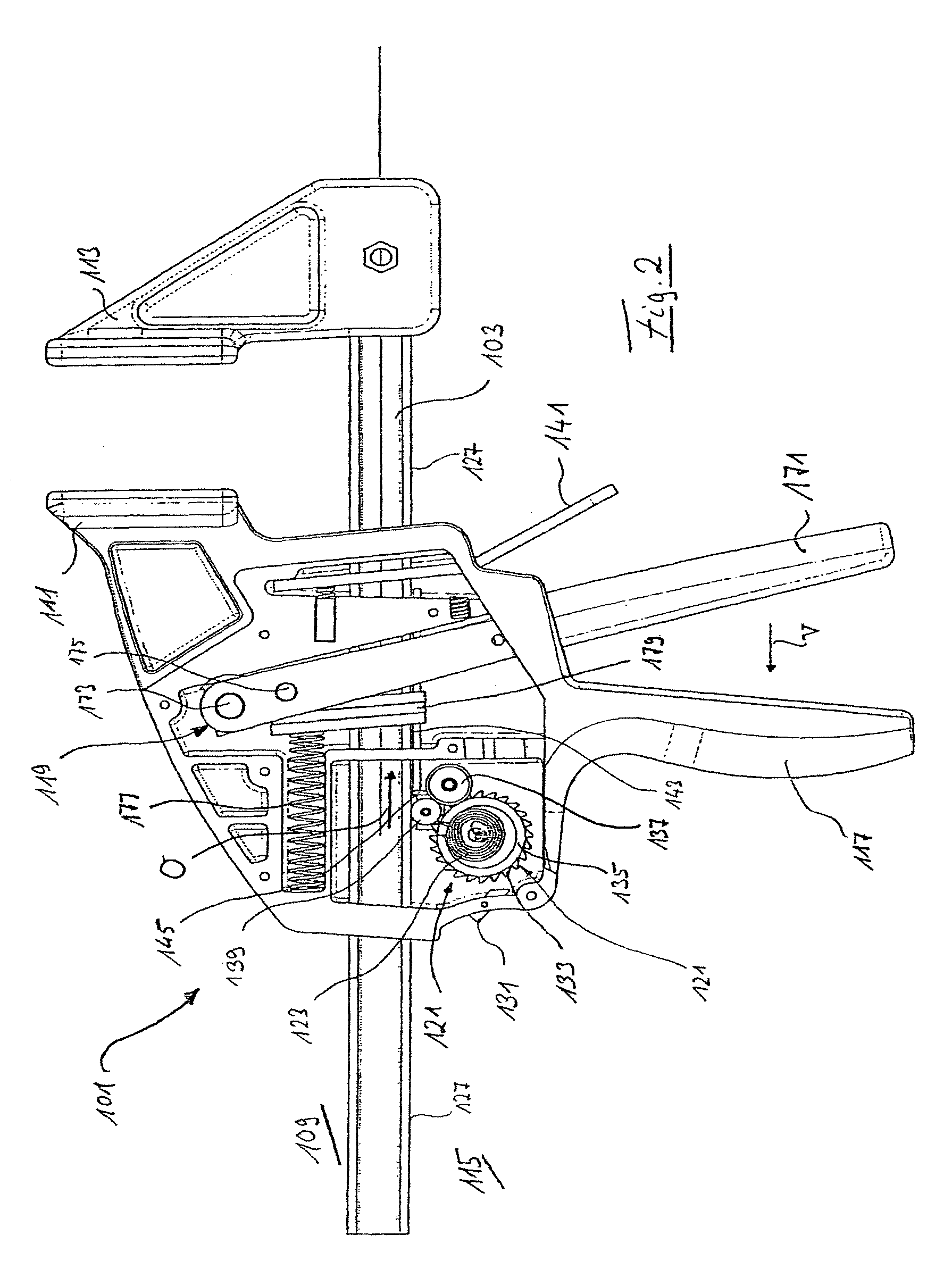

Clamping or spreading tool

ActiveUS7735813B2Easy to operateReduce weightSpring motorManual control with multiple controlled membersPush and pullEngineering

A clamping and / or spreading tool comprises a drive for displacement of a push or pull rod to which a movable jaw is fixed with respect to a support carrying a stationary jaw in longitudinal direction of the push and pull rod, the drive comprising a torsion spring and being adapted to enter torque transmitting engagement with the push or pull rod for displacement of the same.

Owner:IRWIN IND TOOL CO

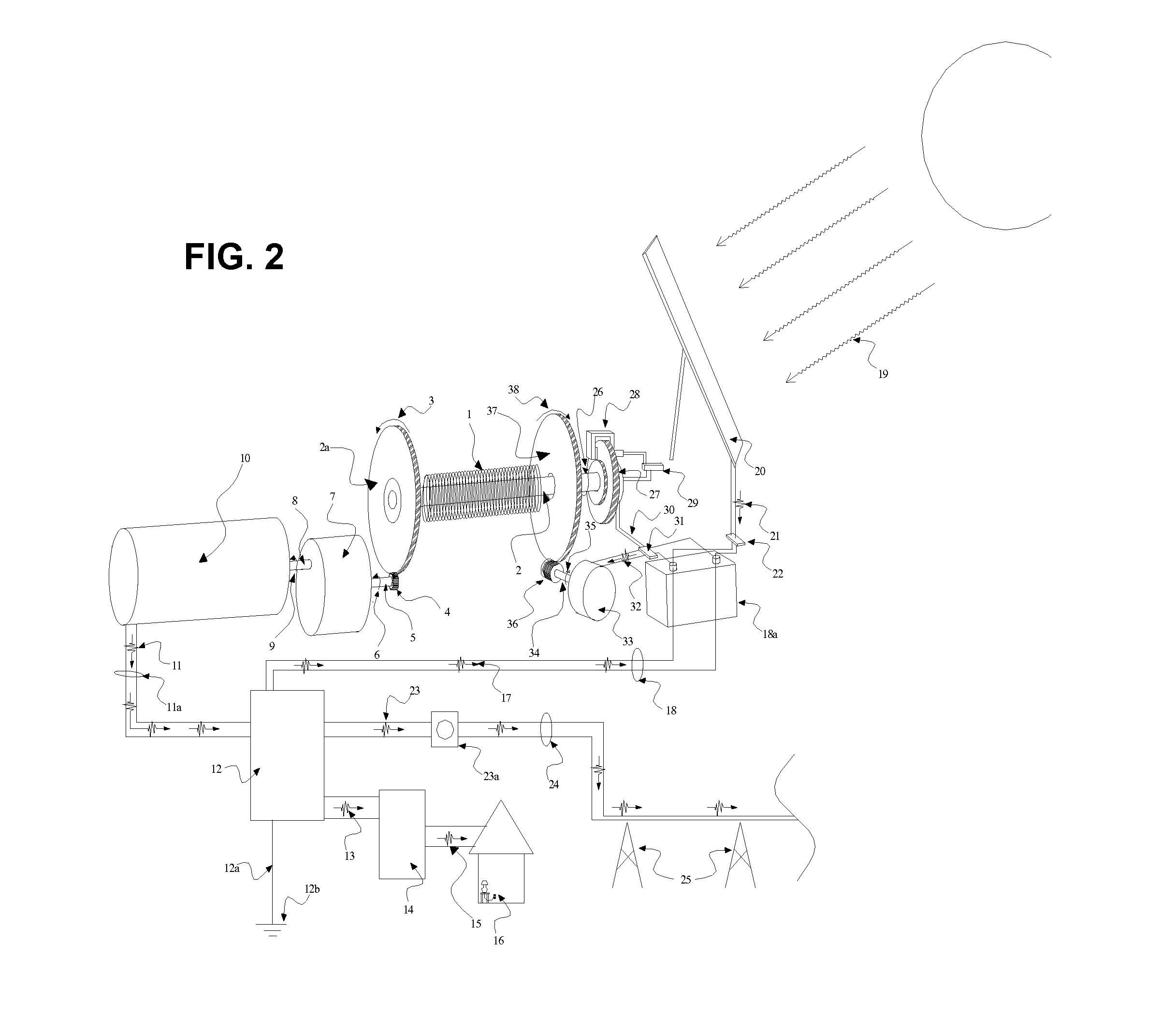

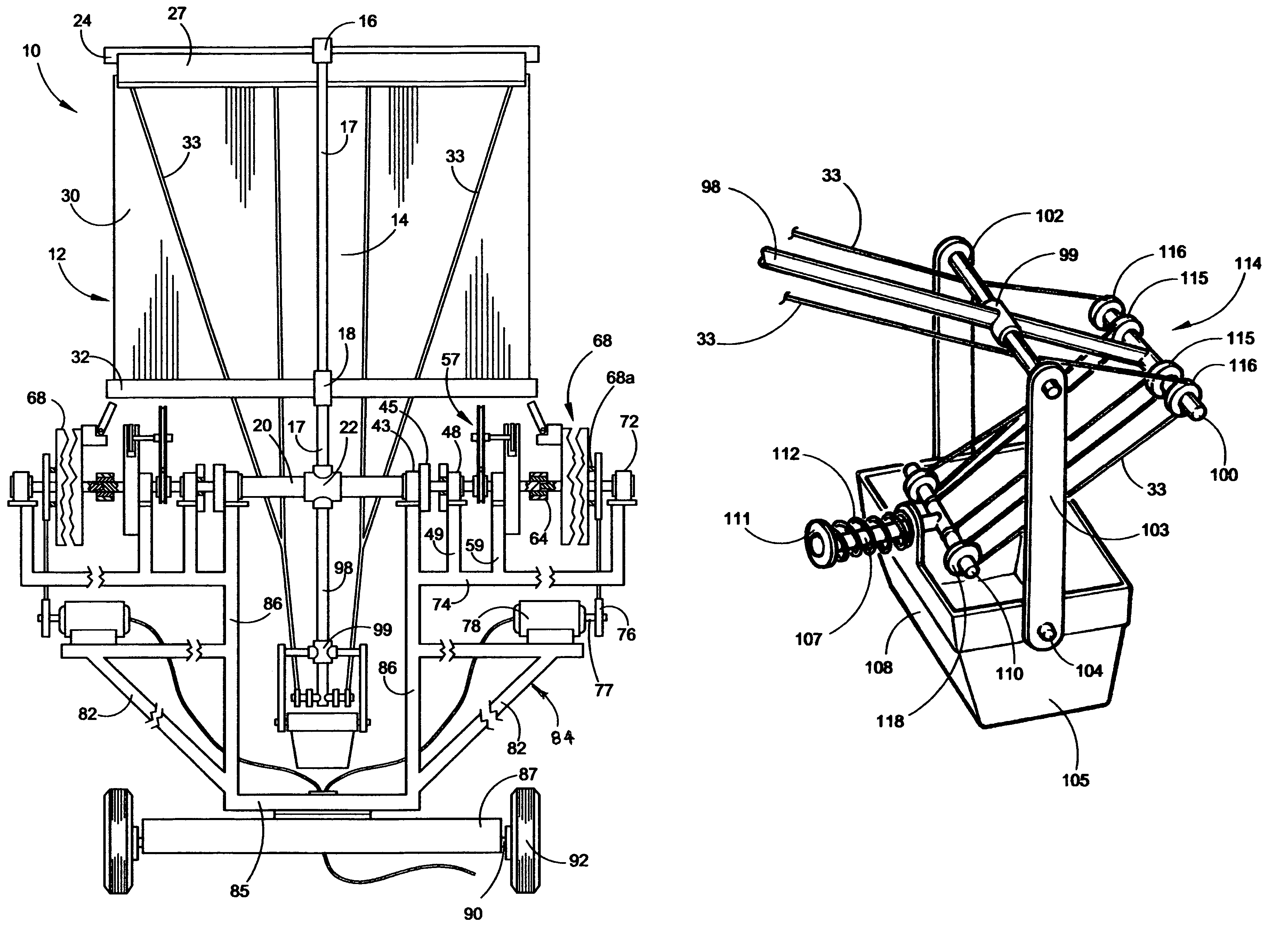

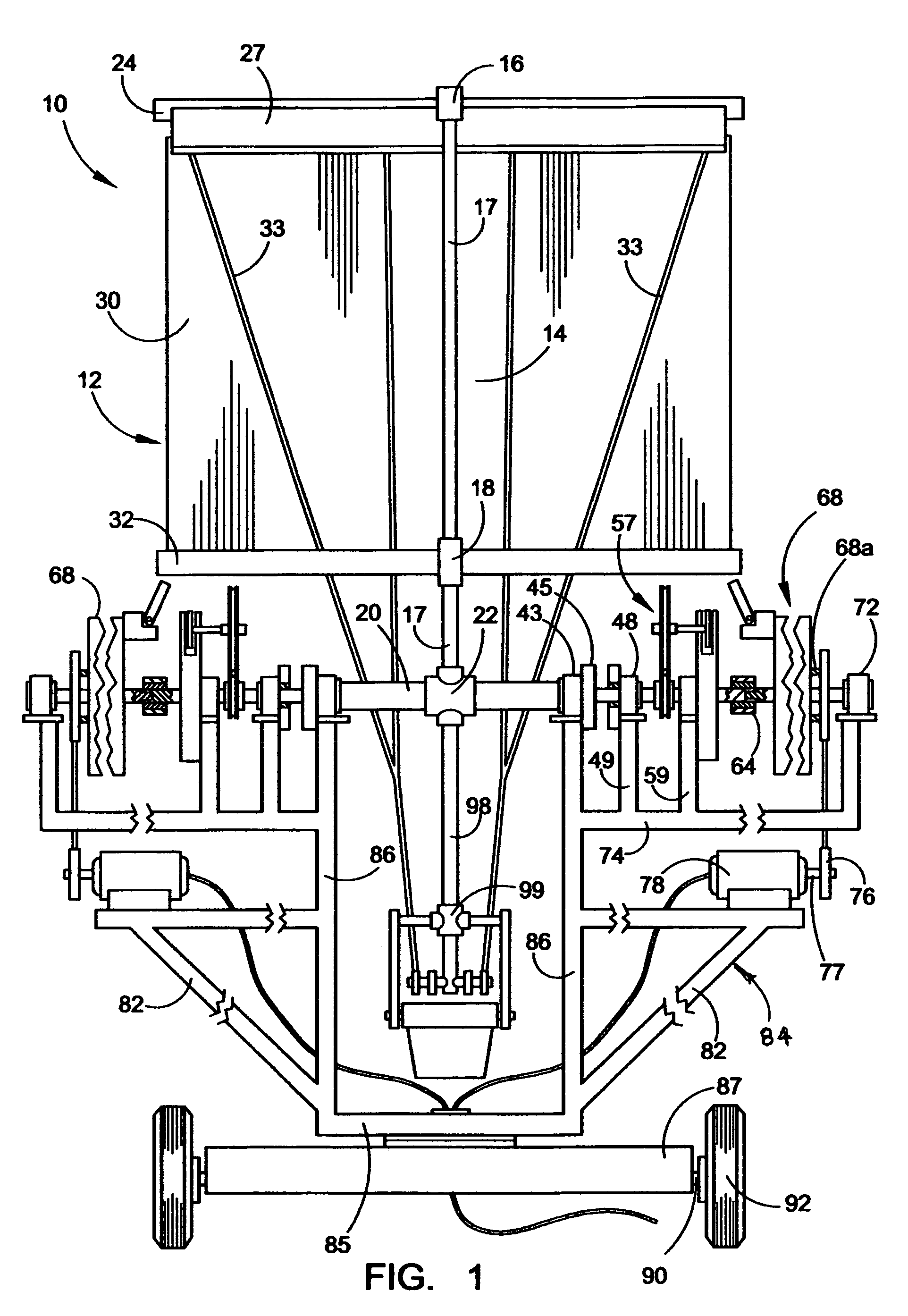

Wind powered pendulating land sail electricity generation system

Owner:MOORING JON

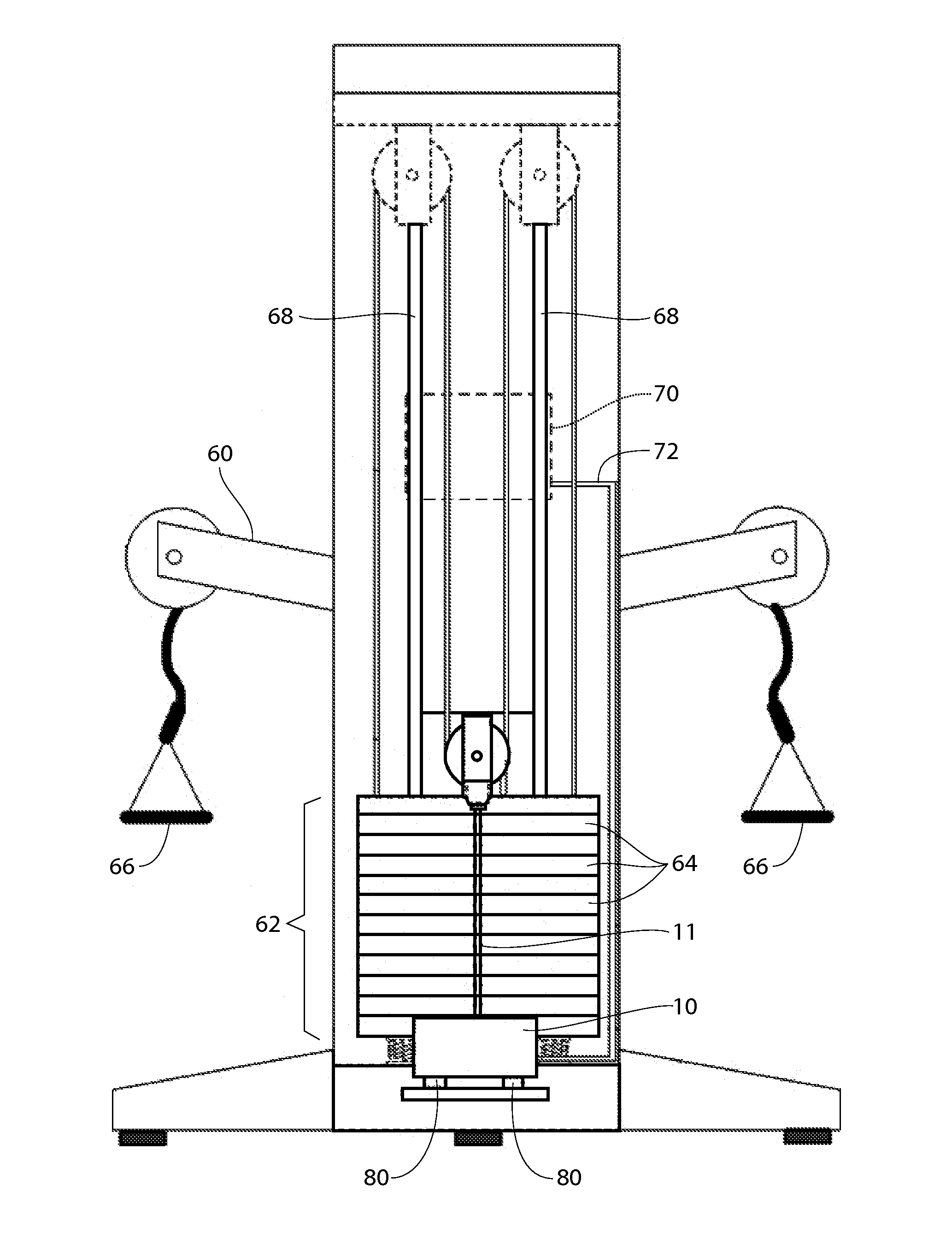

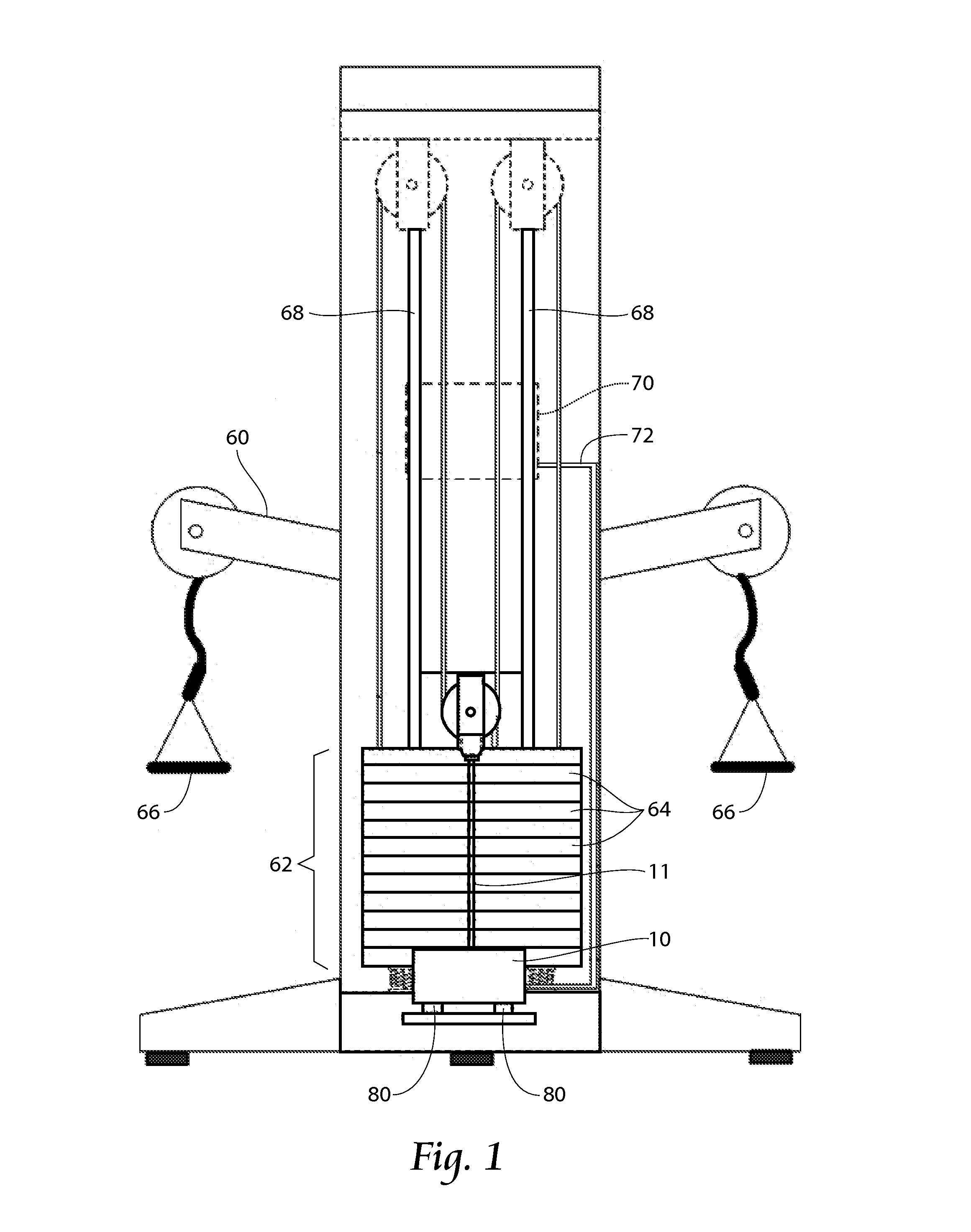

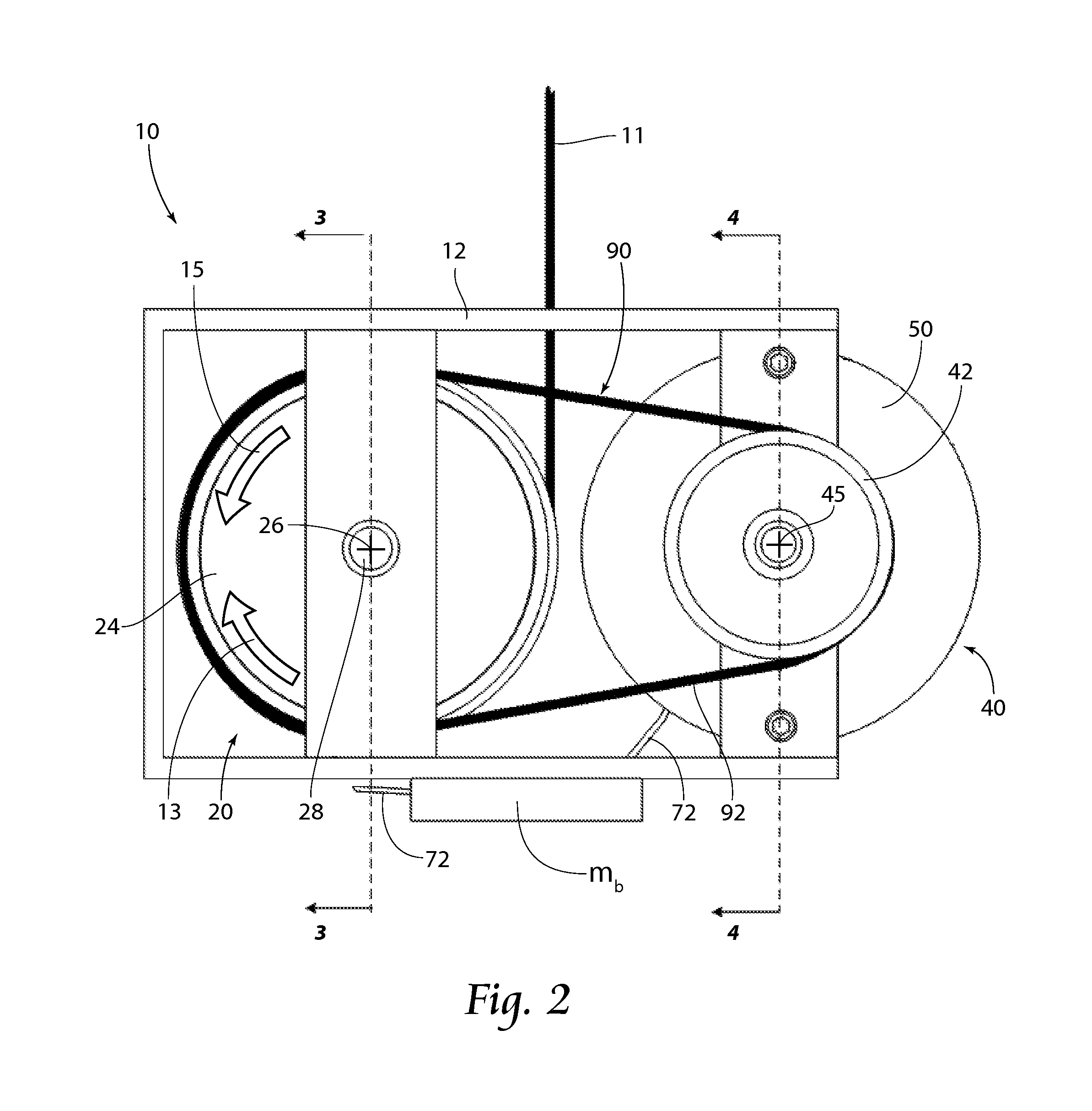

Systems and Methods Related to Coupling an Energy Harvester to Exercise Equipment

InactiveUS20150375028A1Quality improvementSpring motorBatteries circuit arrangementsEnergy harvesterSports equipment

A system and method for mechanically coupling an energy harvester to strength training type exercise equipment is disclosed. An energy harvester with unwanted vibration forces is mechanically isolated from exercise equipment by a system comprising a plurality of mechanically compliant vibration isolators and a ballast mass; a flexible cord, pre-loaded with a near constant force spring is used to transmit motion from the weight stack to the energy harvester; the flexible cord has a force limiting feature to pre-excessive force from being transmitted from the energy harvester to the weight stack during an exercise motion.

Owner:STRENGTH COMPANION

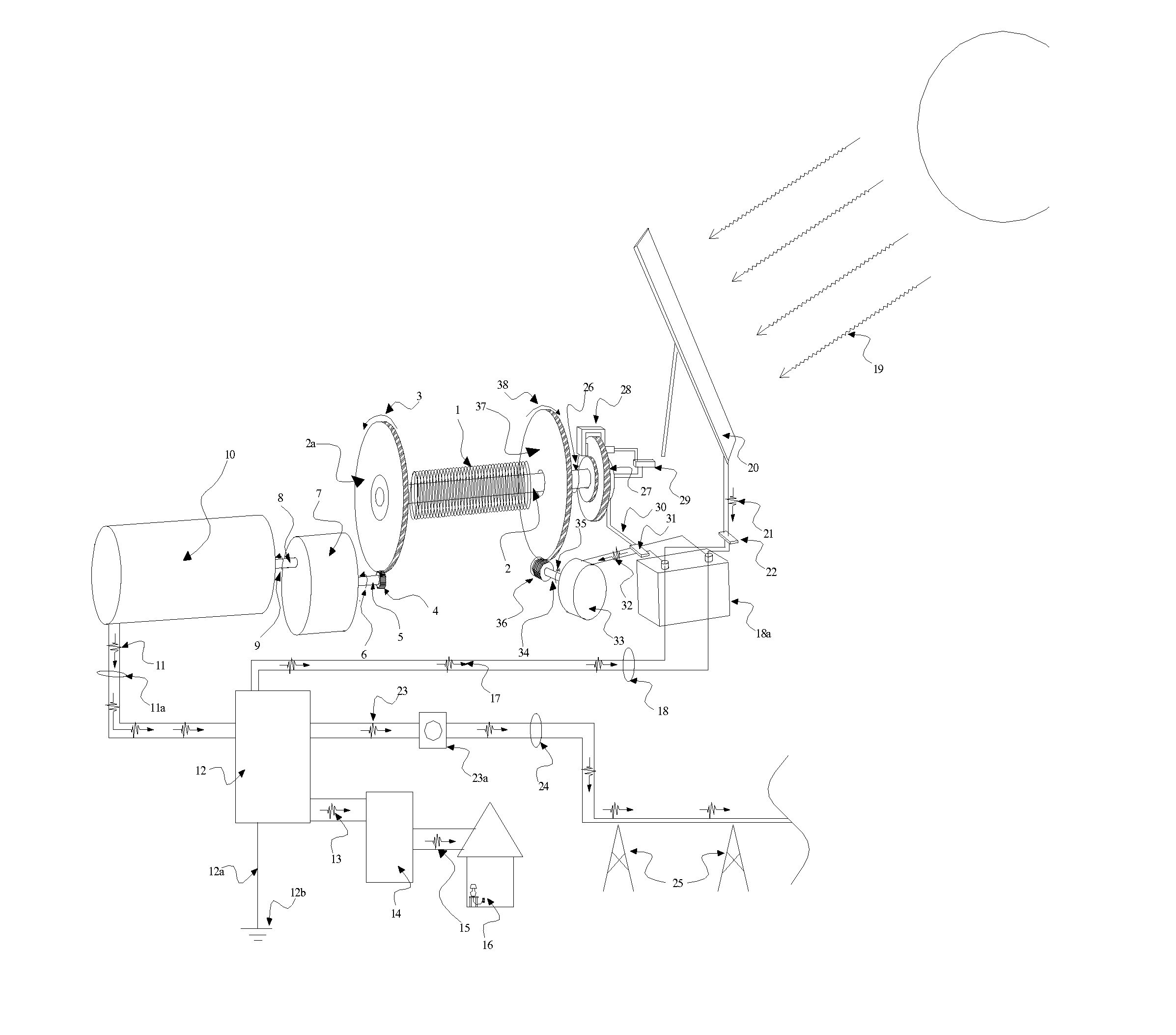

Electricity Generating Device by Applying Vehicle Weight

In an electricity generating device by applying vehicle weight, a rolling vehicle wheel is weighting down on a pressure receiver to actuate a driving mechanism having a restoring function. It is then able to provide a unidirectional rotating torque to drive a generating device to produce electrical power. The mechanical power transmission is performed by a transmission gear unit composed of a driving wheel and a follower wheel interconnected each other with a transmission means therebetween. When the vehicle weight is applied to the driving mechanism by pressing the vehicle wheel on the pressure receiver, the driving mechanism is forced to downwardly urge a ratchet wheel and a driving wheel to rotate that in turn causes the rotation of the follower wheel through the transmission means thereby driving the generating device to operate to produce electricity. The driving mechanism can recover its initial state with the aid of a balancing weight as soon as it has been liberate from the exerted pressure of the vehicle wheel. The device is to be installed flush with the road surface to work.

Owner:CHEN MING CHENG

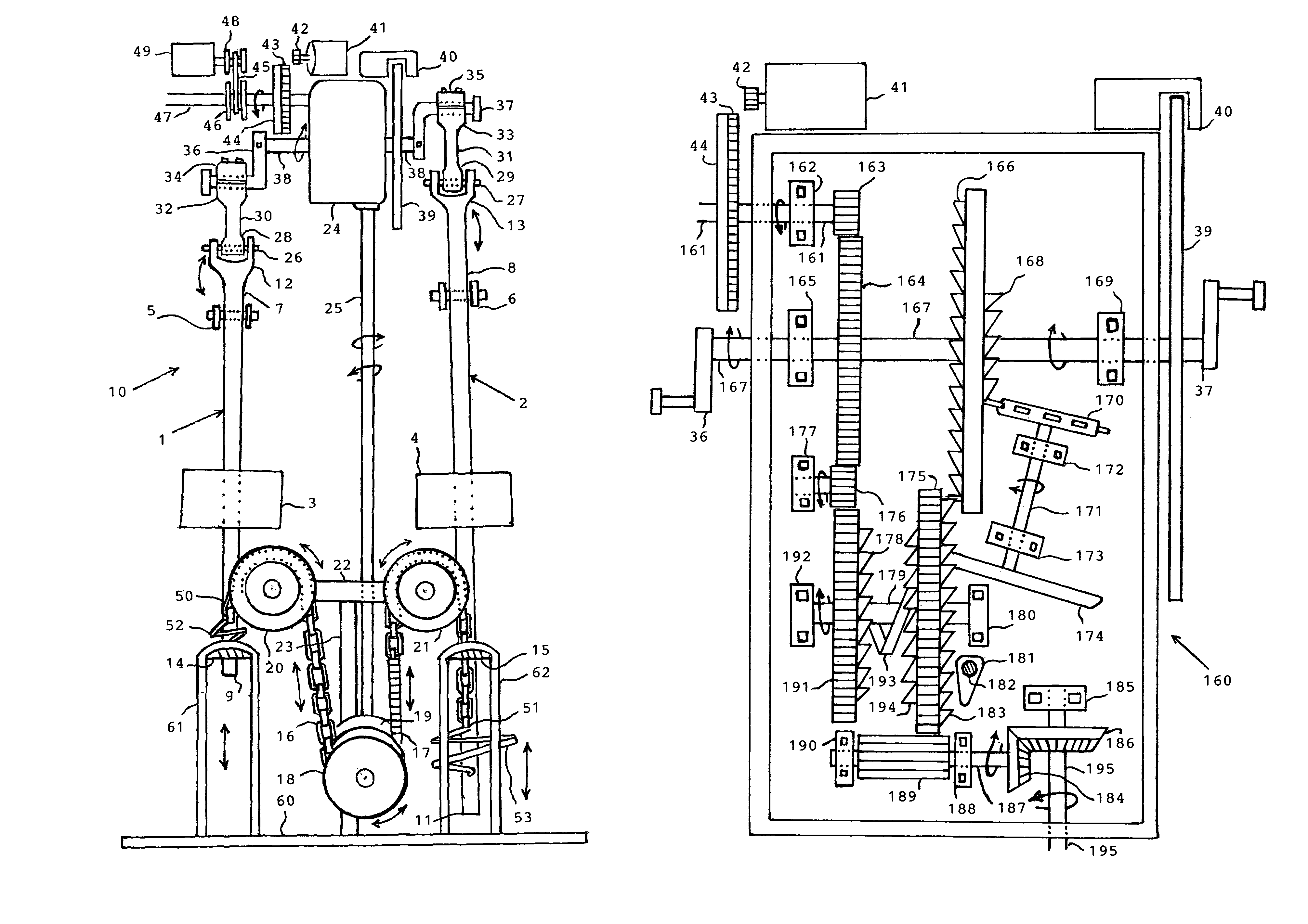

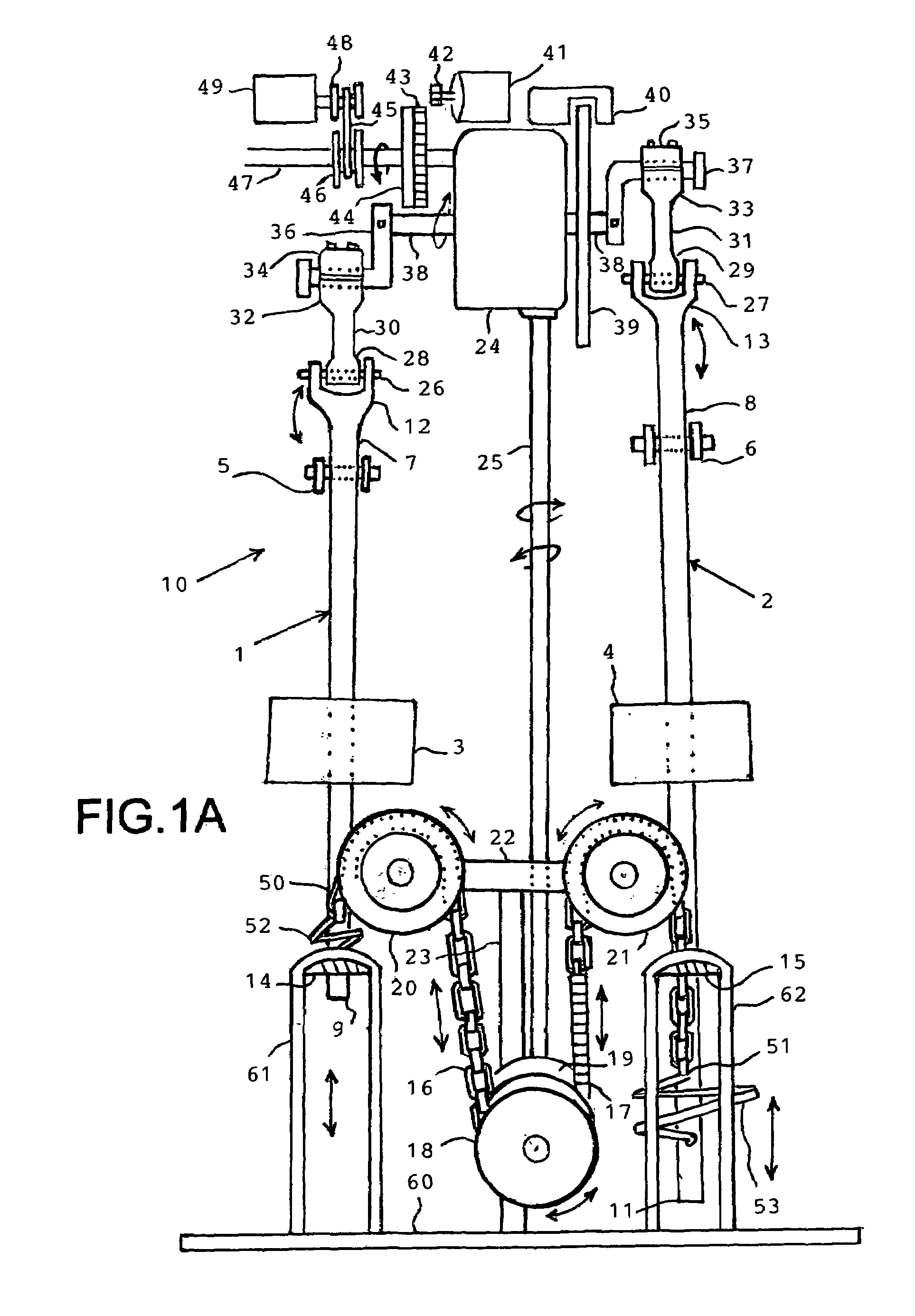

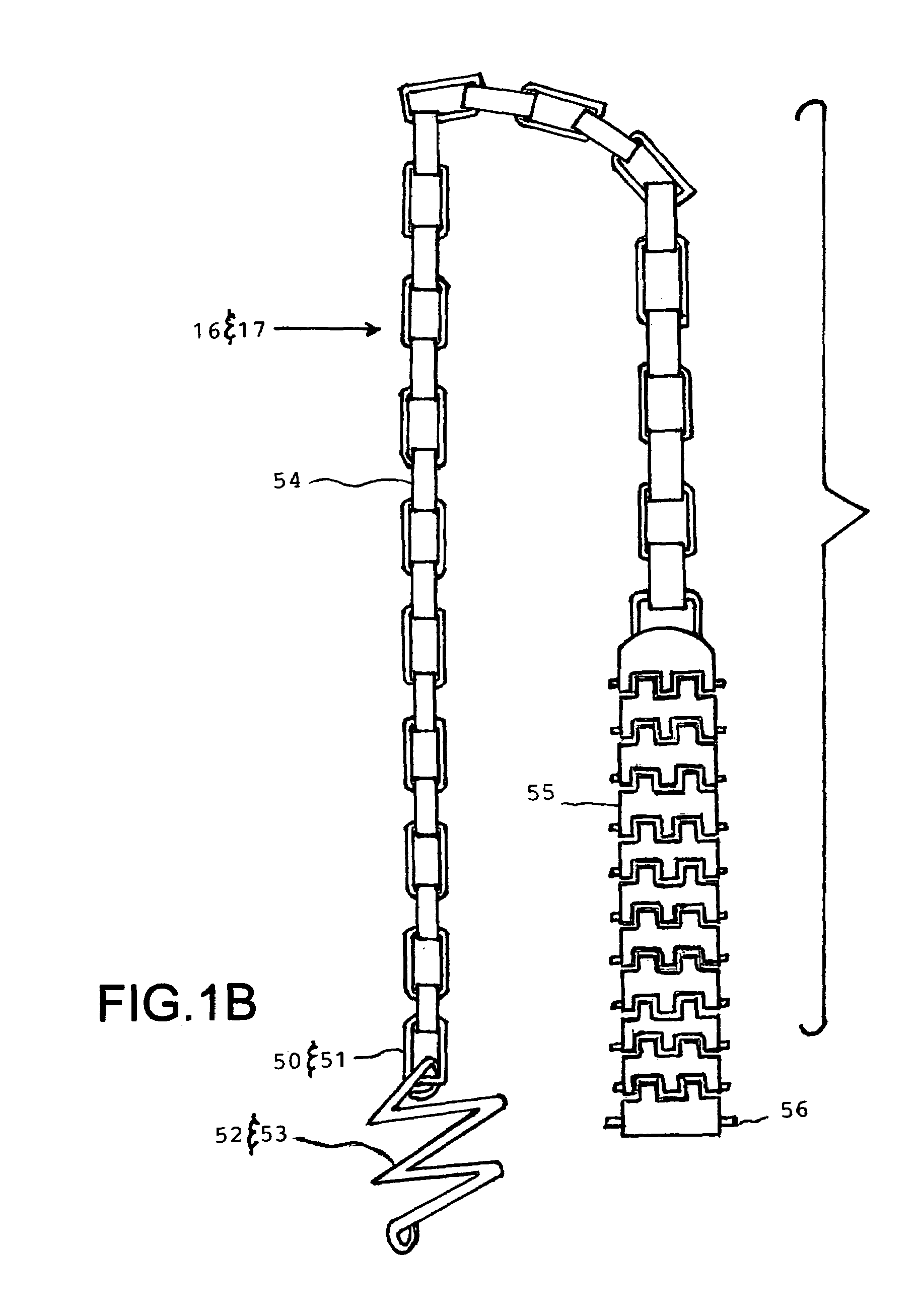

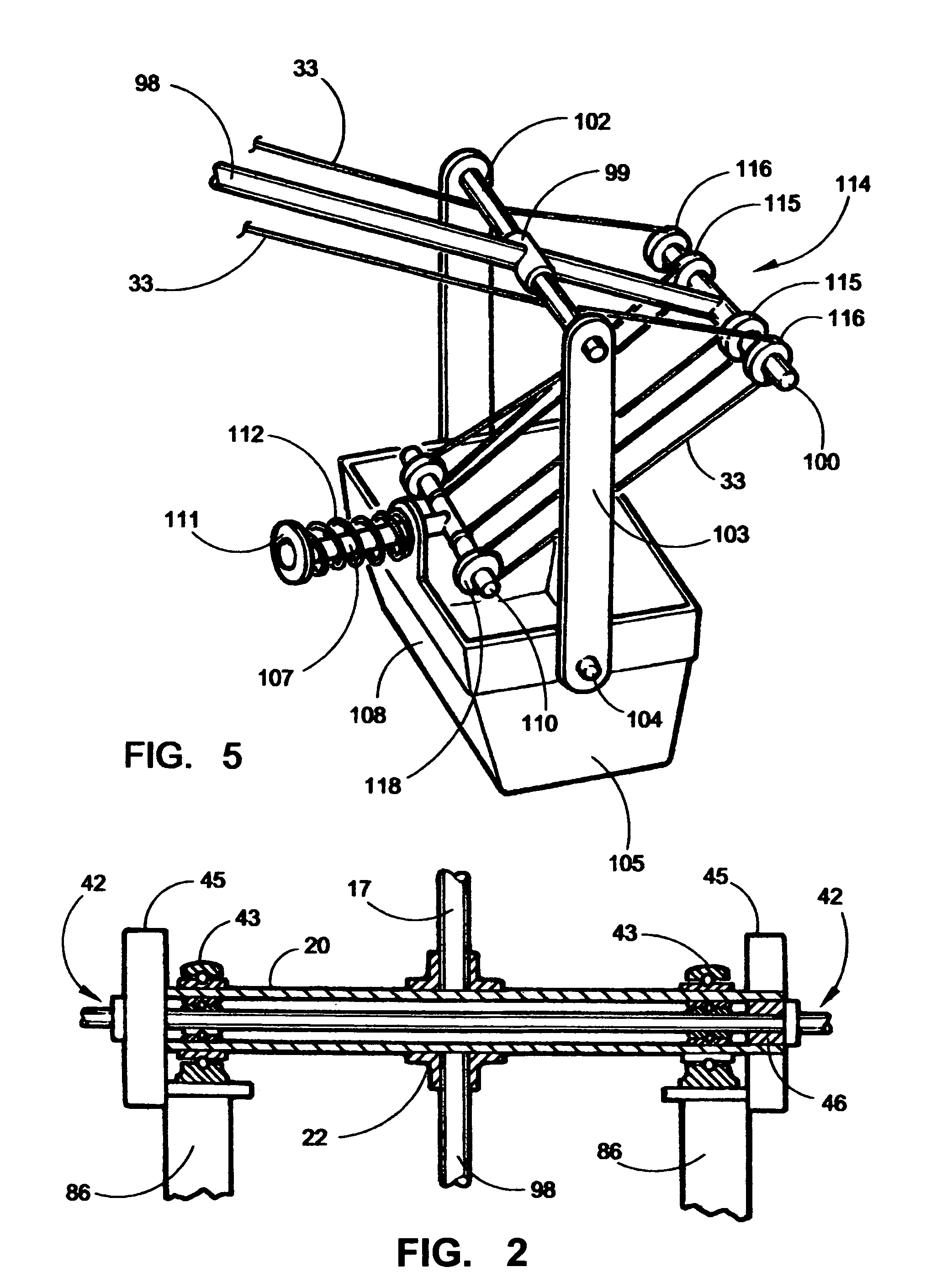

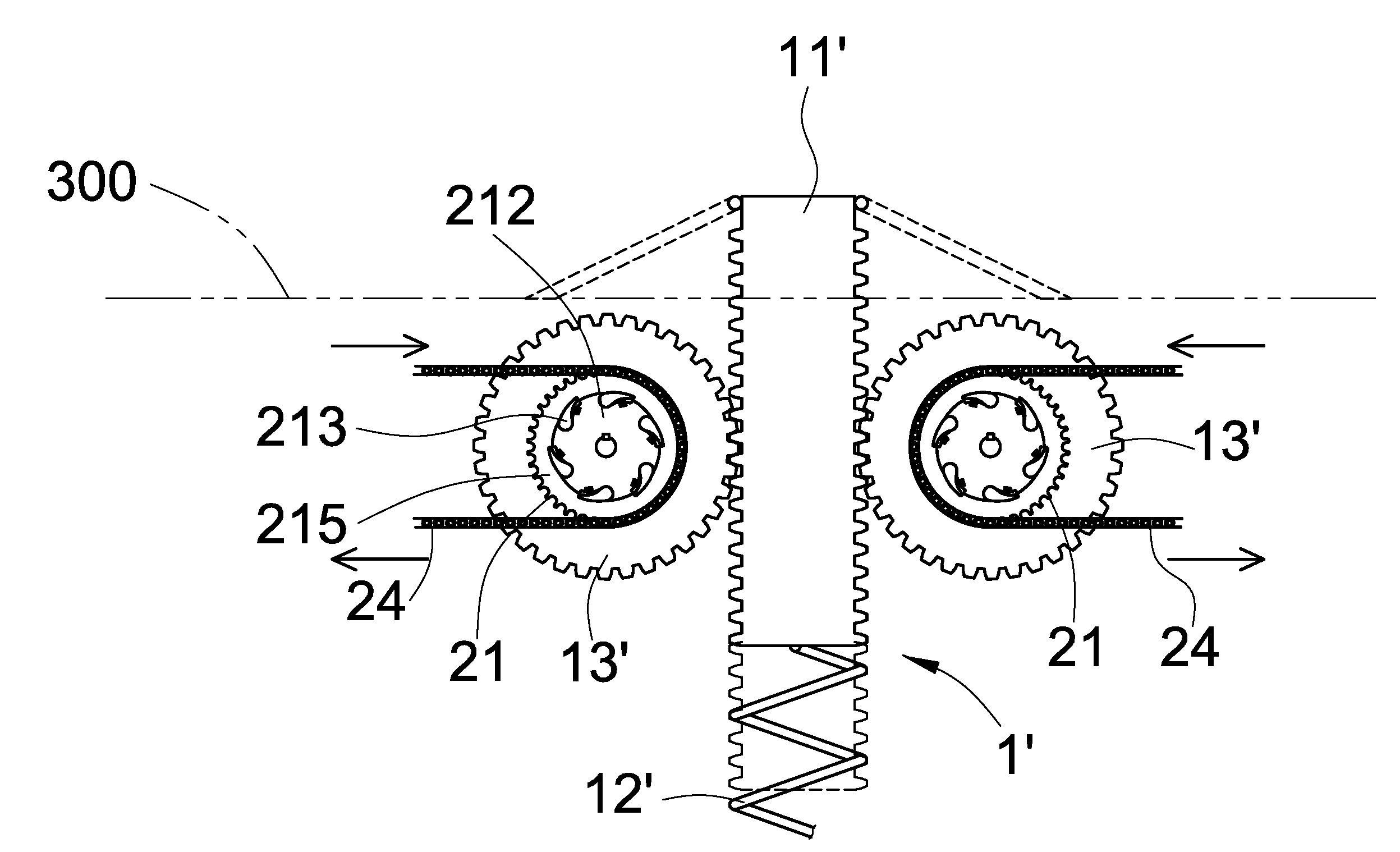

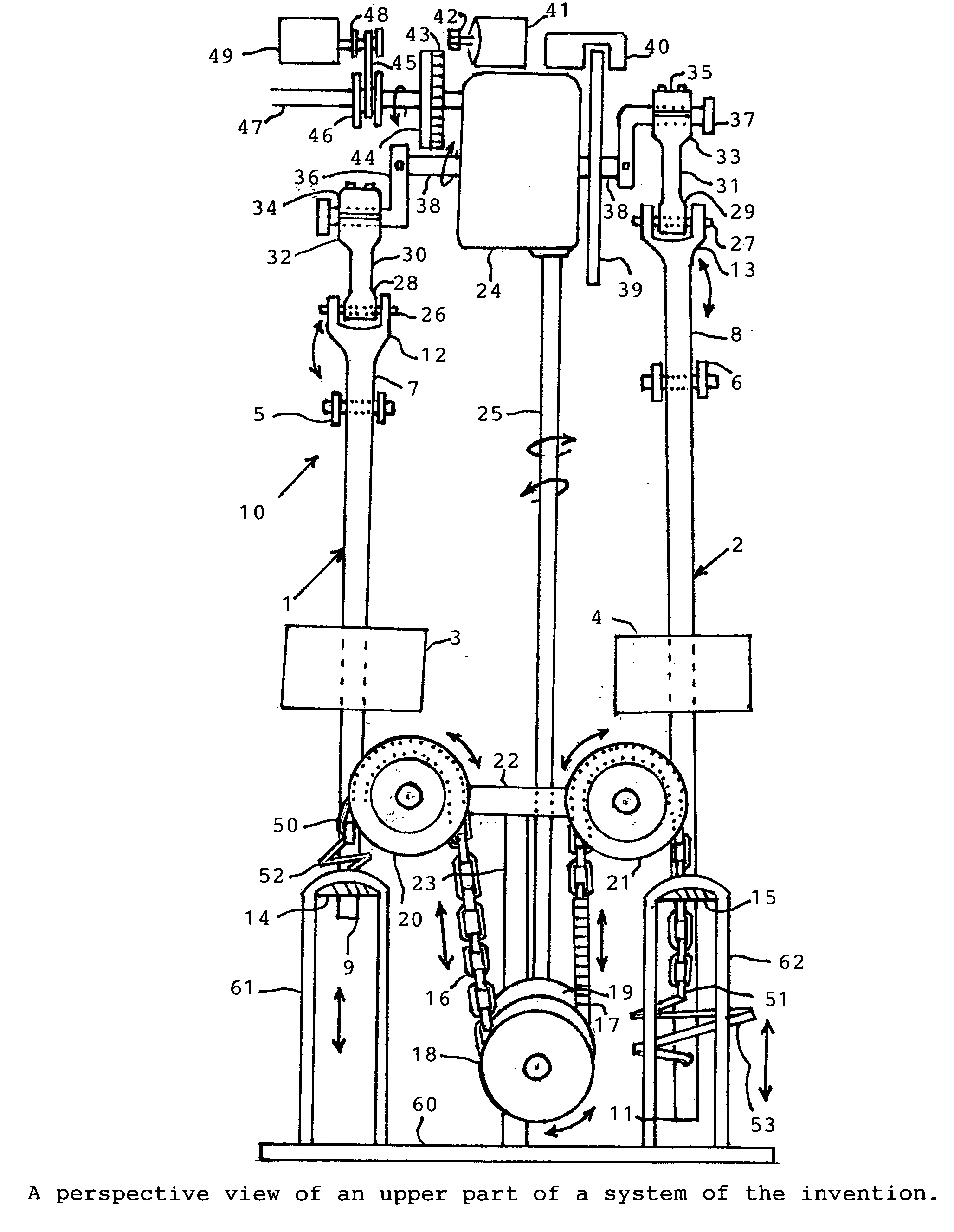

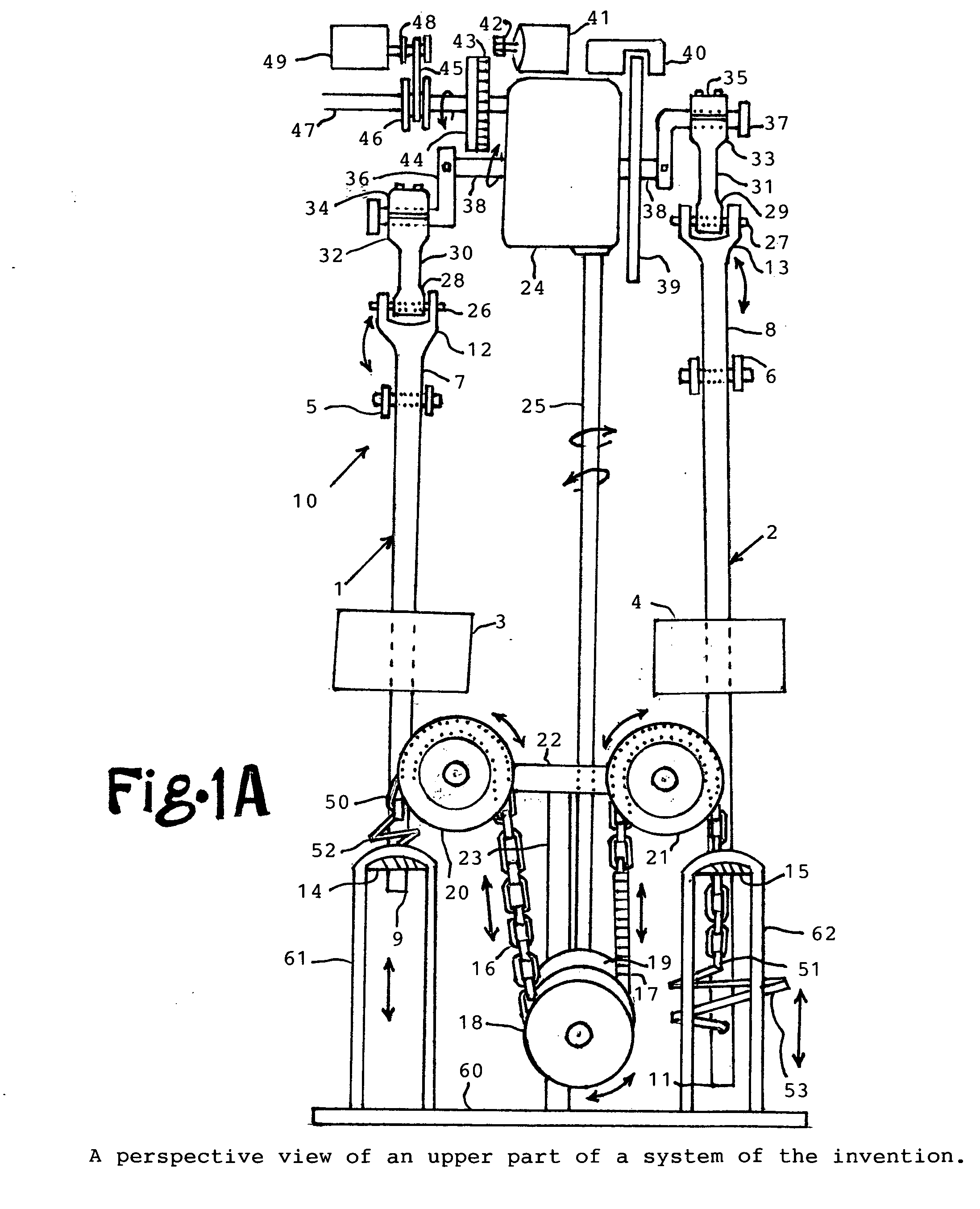

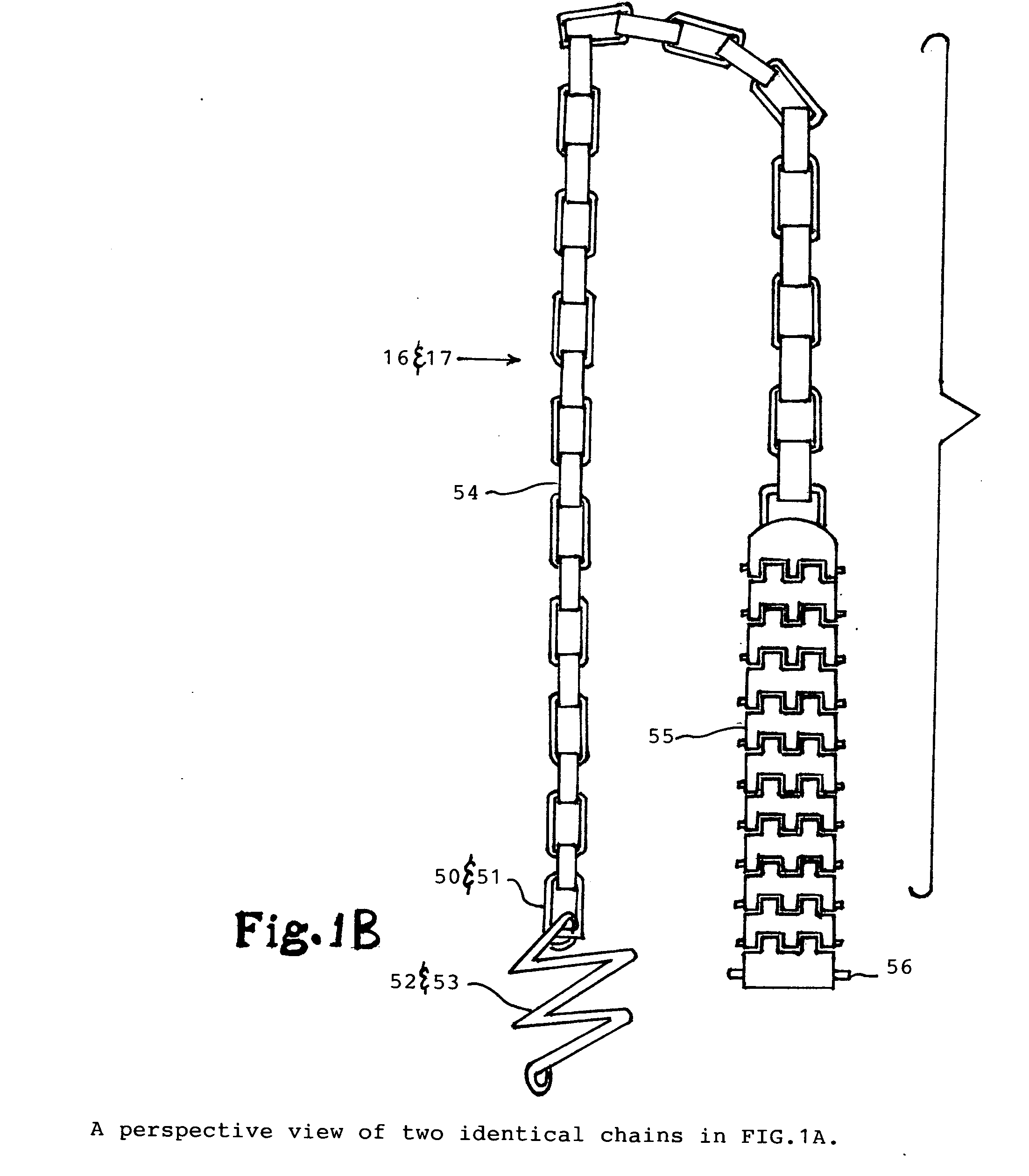

Transportation and power generating system of gravity and leaf springs

InactiveUS20060163876A1Simple and easy to useSimple and easy to and maintainSpring motorMachines/enginesEngineeringElectric generator

Two weights and or springs mounted on two pivoted beams. A short end of each beam is interconnected with a gearbox by a crank and trace. The gearbox is interconnected with two other ends of the beams by linkages. An electric starter with battery imparts kinetic energy to lift one weight and let the other weight descend. The gearbox regulates the oscillation of two beams. The operator turns the electric starter off after the system is started. An output shaft imparts rotary motion of the gearbox to drive a vehicle, an airplane, or an AC generator.

Owner:ESKANDR ASHRAF MAKRM DAWOUD

Devices for storing energy in the mechanical deformation of nanotube molecules and recovering the energy from mechanically deformed nanotube molecules

InactiveUS20080305386A1Recover mechanical energyRecover energySpring motorMaterial nanotechnologyStored energyEnergy recovery

An energy storage device includes at least one nanotube. An energy storage mechanism converts energy external to the device into the appropriate levels of strain on the at least one nanotube to produce stored energy, and an energy recovery mechanism converts the energy released by relaxing the at least one nanotube back to energy external to the device.

Owner:MASSACHUSETTS INST OF TECH

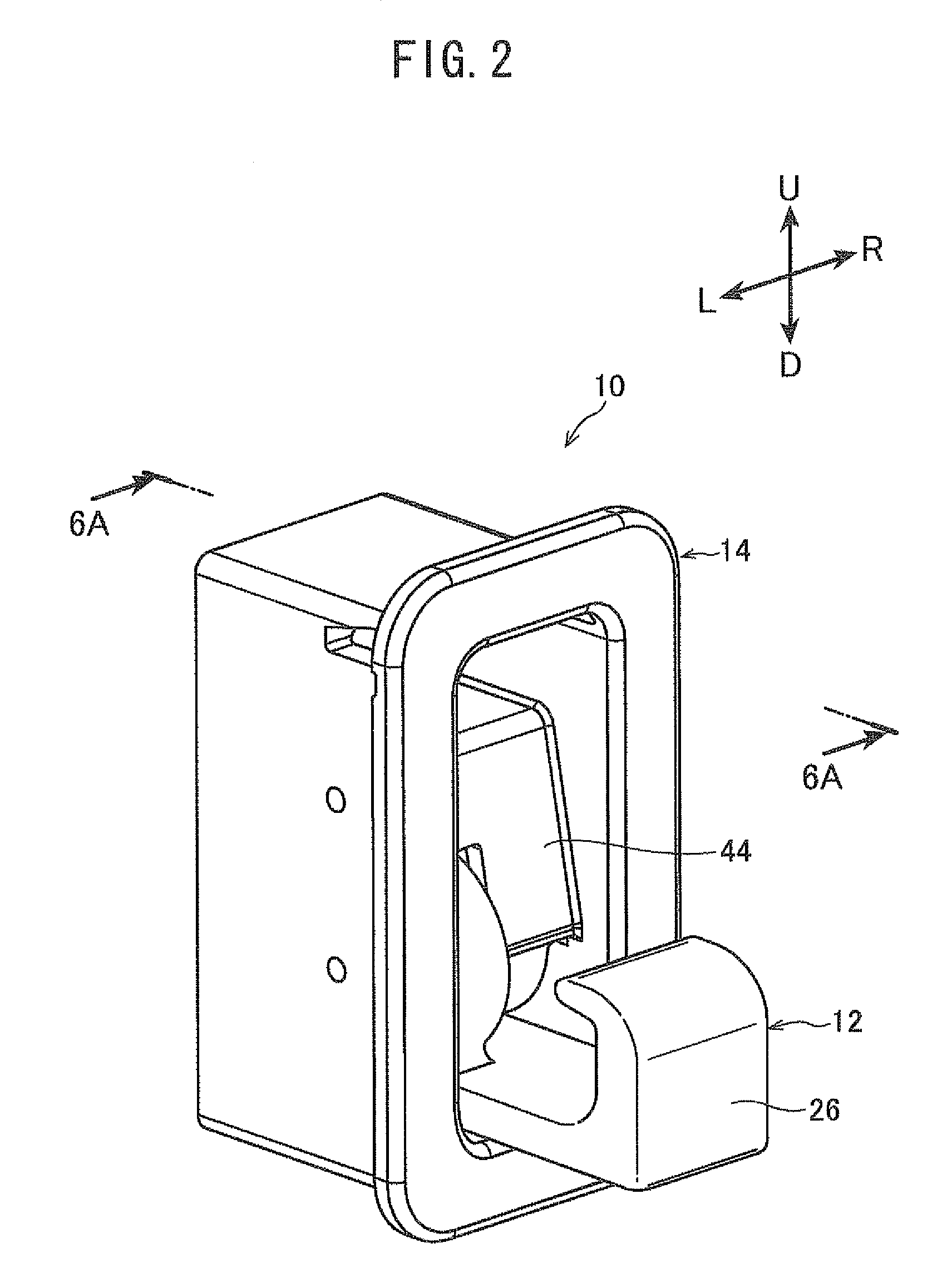

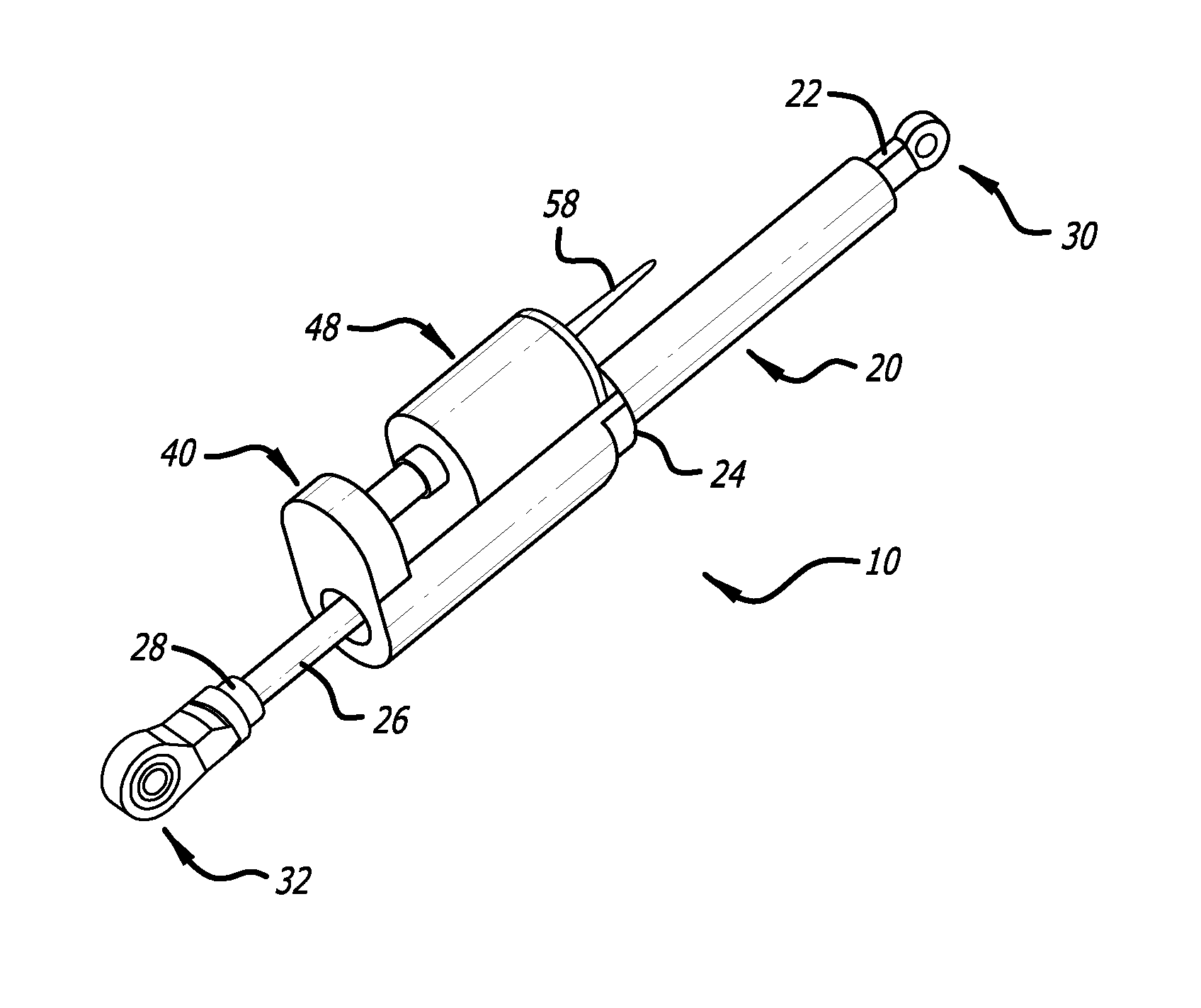

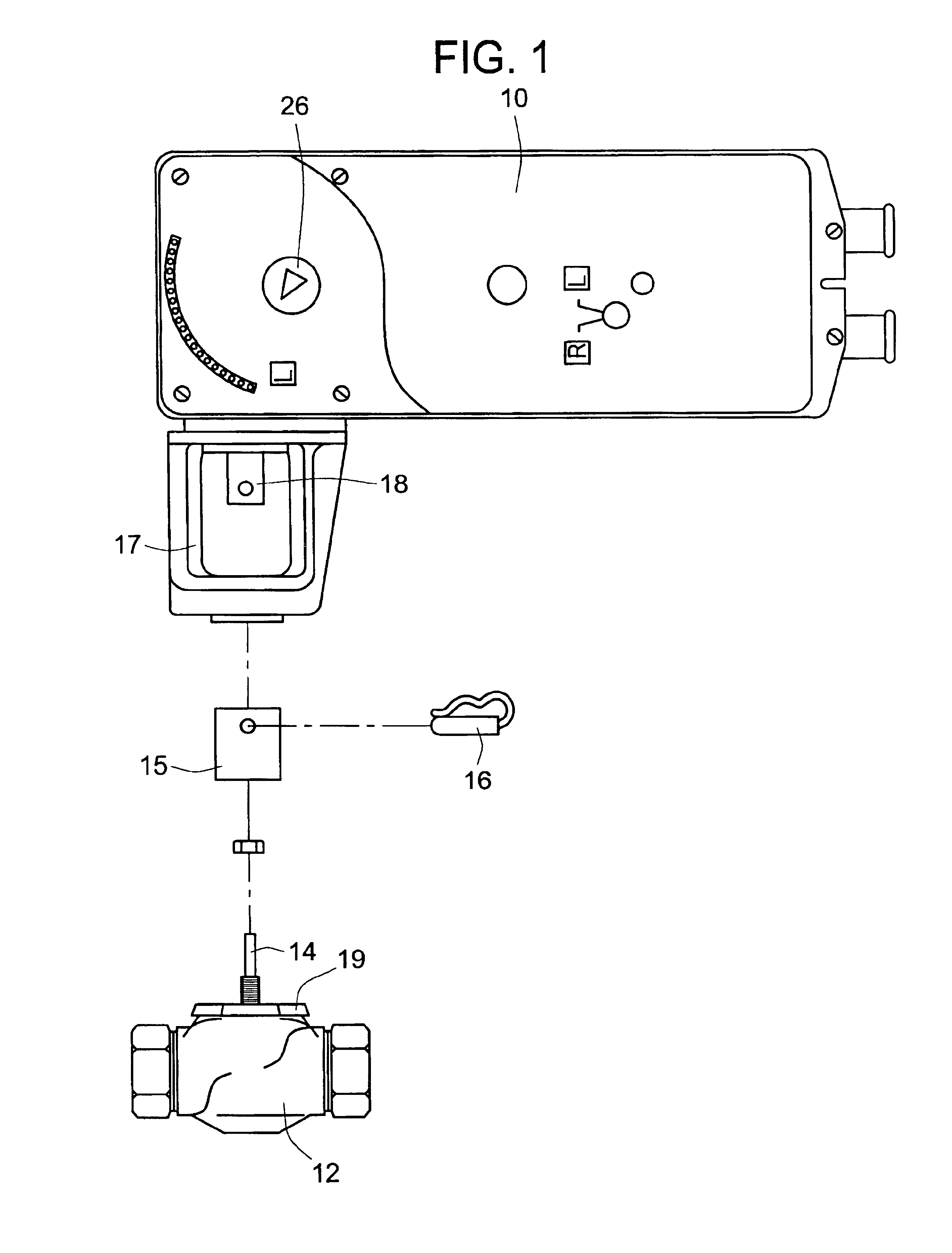

Linear actuator having manual override and locking mechanism

InactiveUS7066301B2Simple waySpring motorOperating means/releasing devices for valvesMotor driveLocking mechanism

A manual override mechanism is presented for a motor-driven linear actuator that allows the output rack and pinion of the actuator to be manually positioned. Once positioned, the output may be locked by a locking mechanism to prevent this output from translating to its quiescent position. When incorporated in a spring-return linear actuator, the manual override may be used to apply a preload on the spring before the driven device is connected. When the actuator is used to drive a valve or damper, the preload applies a positive closing force on the valve or damper in its zero position to ensure a tight closure of the valve or damper. The locking mechanism engages the gear train and opposes the closing force applied by the spring return of the actuator. To disengage the locking mechanism automatically, the motor applies a forward kick to the gear train. Manual disengagement is also provided.

Owner:TAC LLC

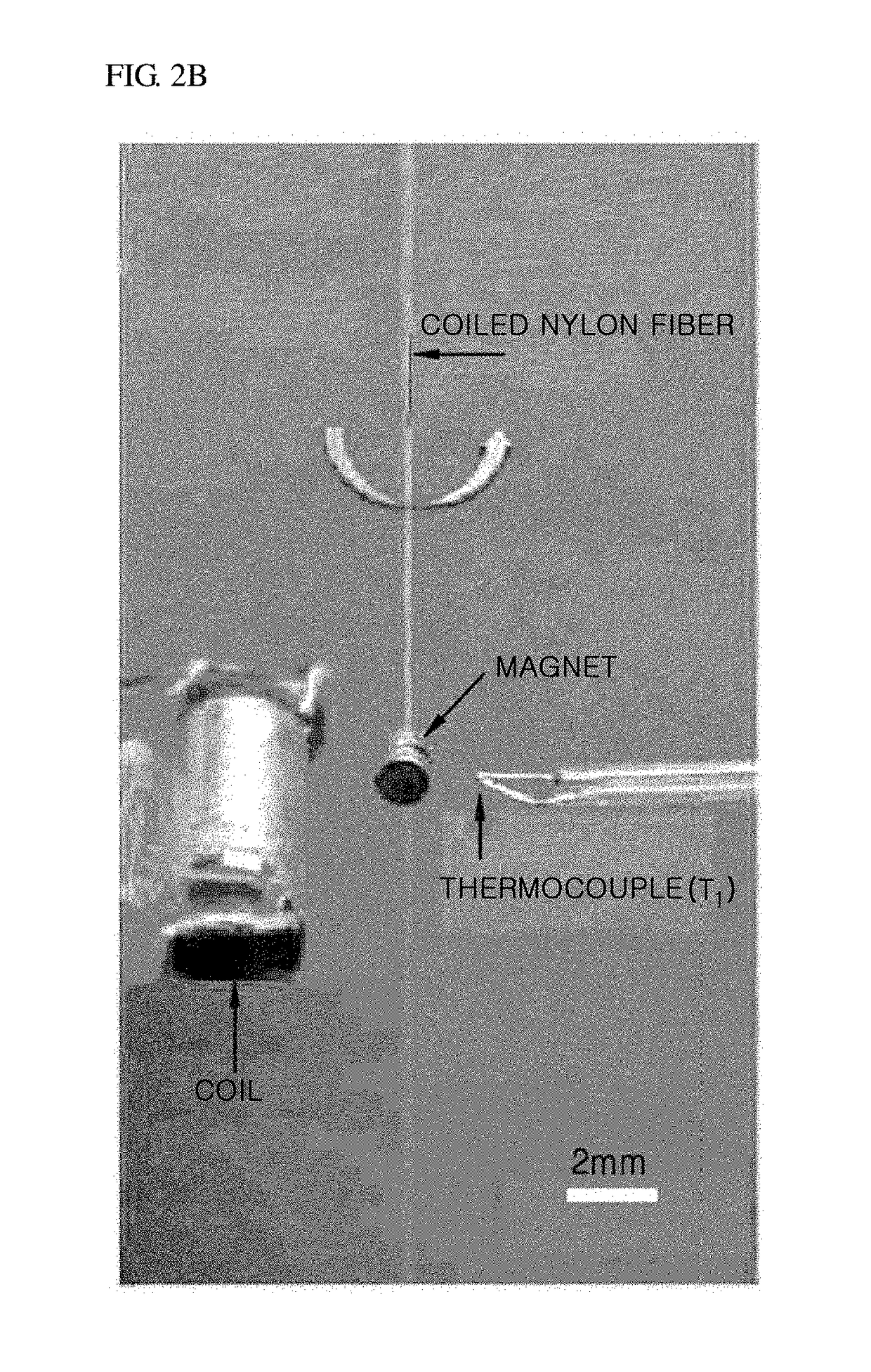

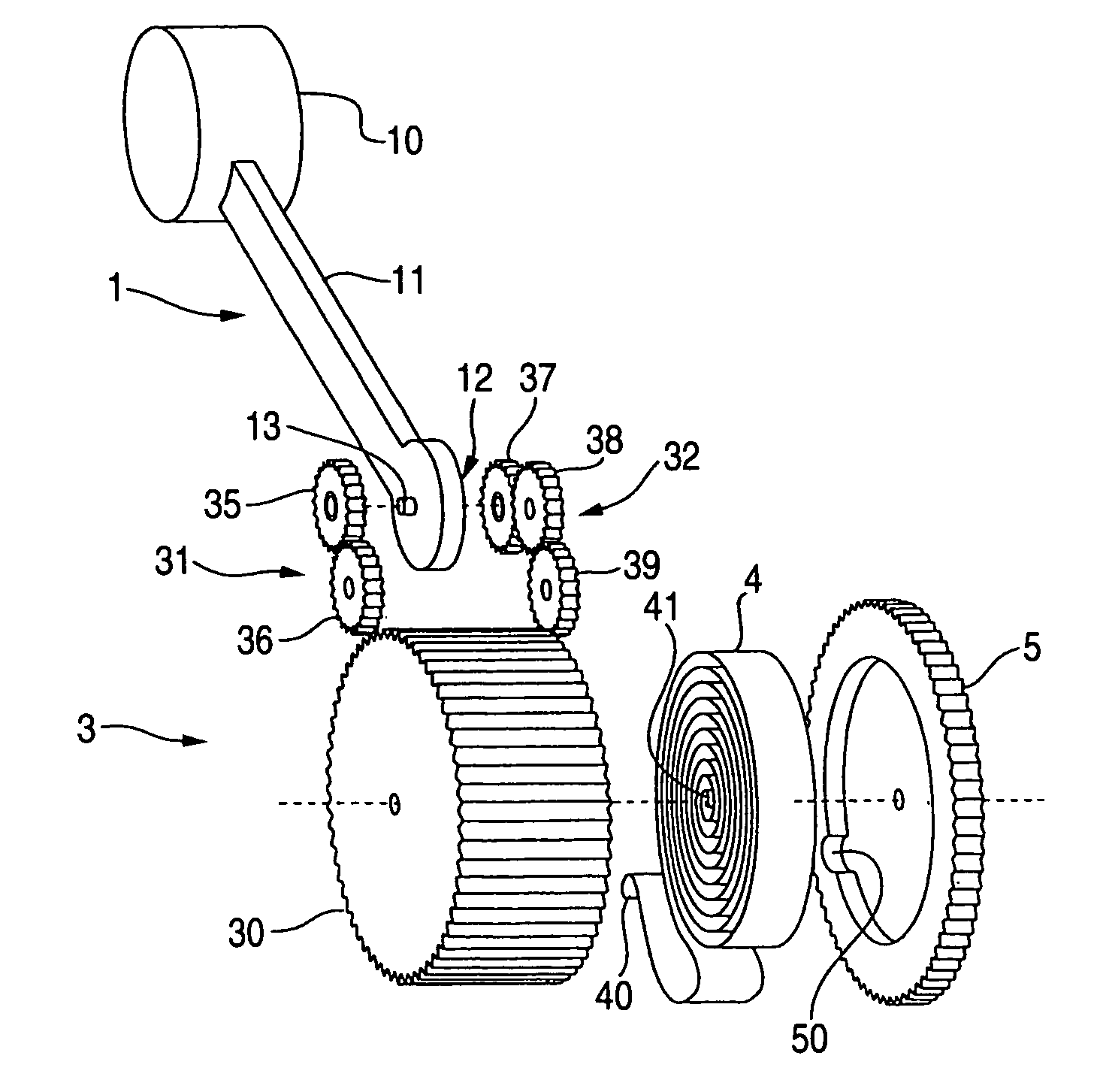

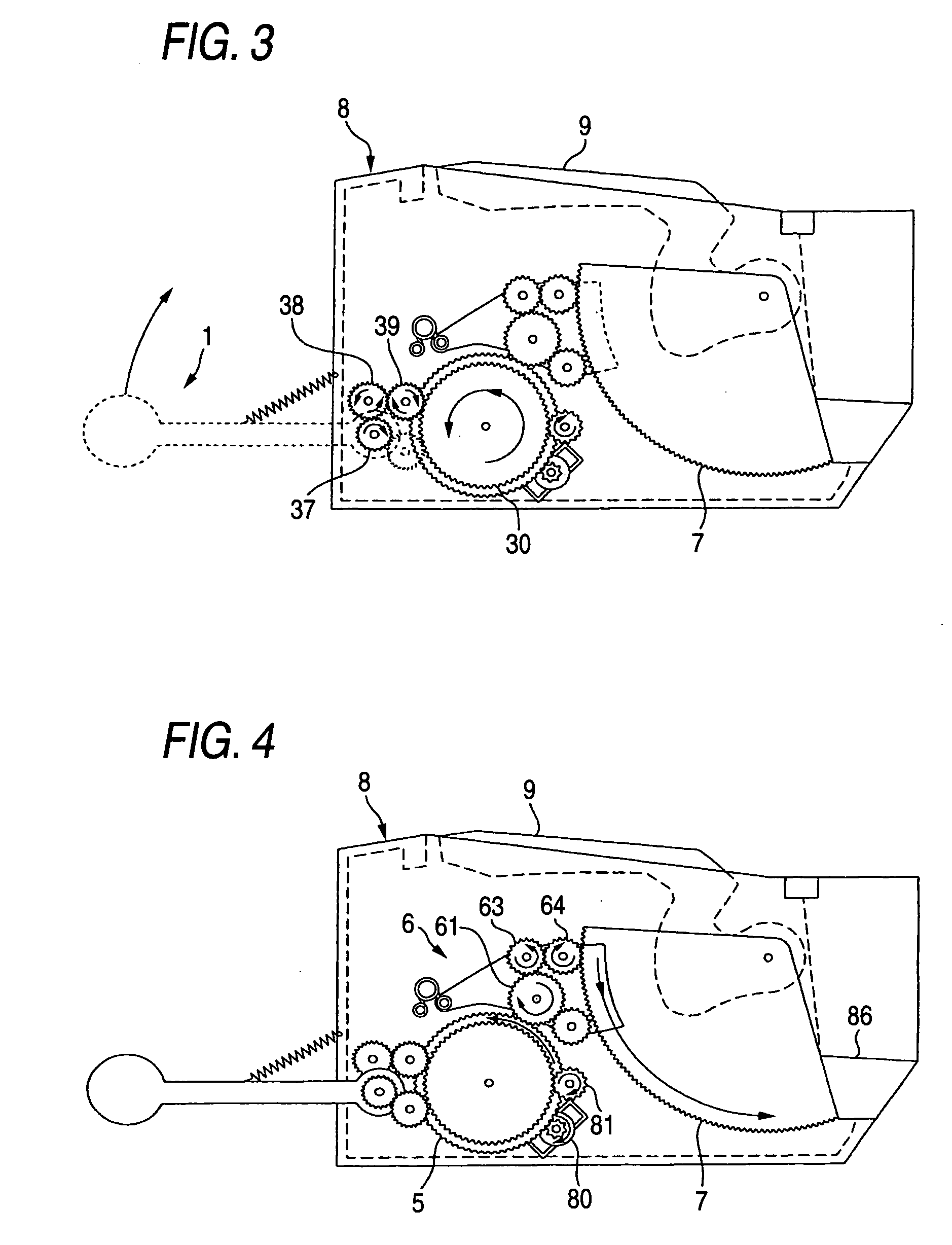

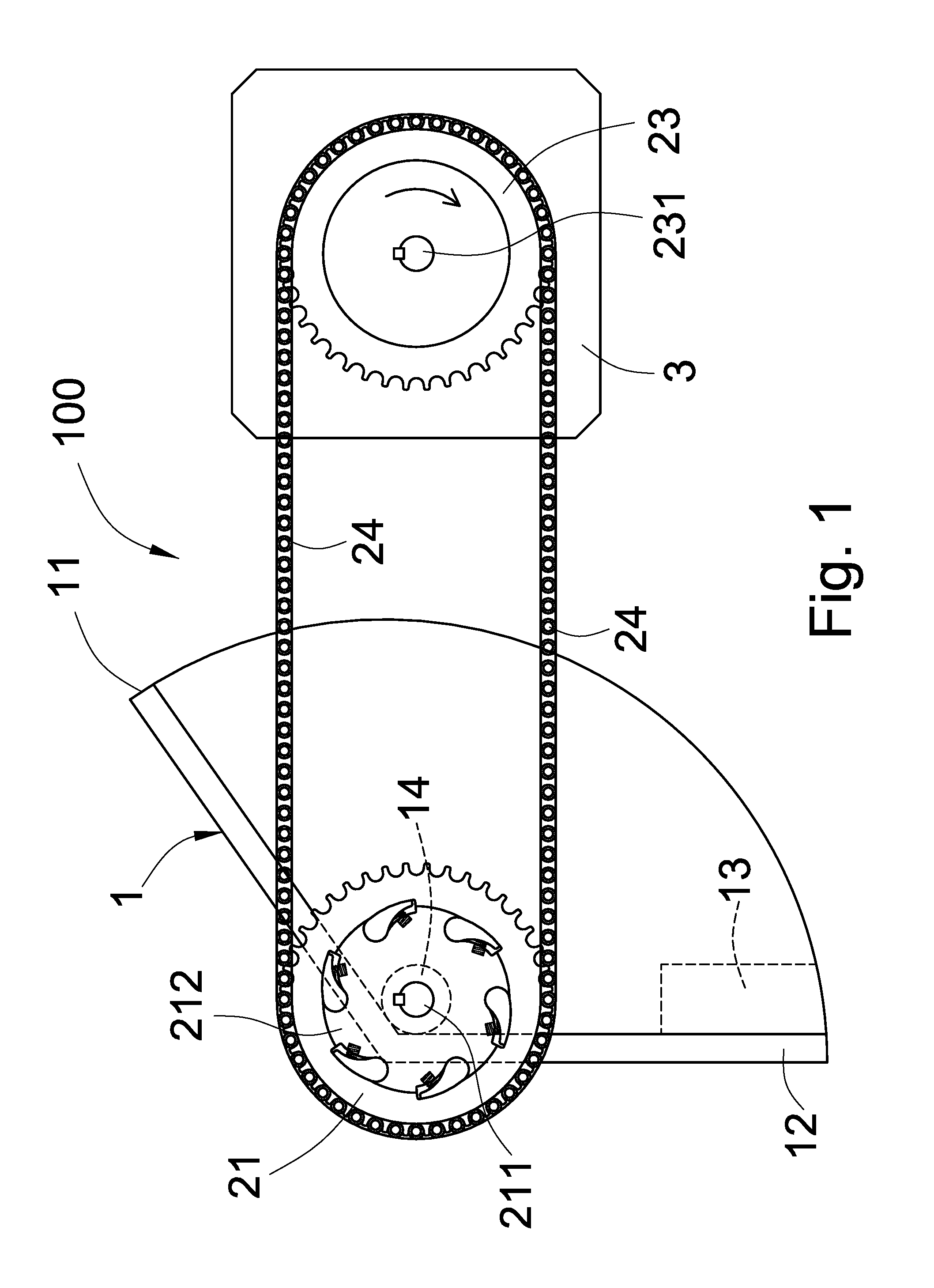

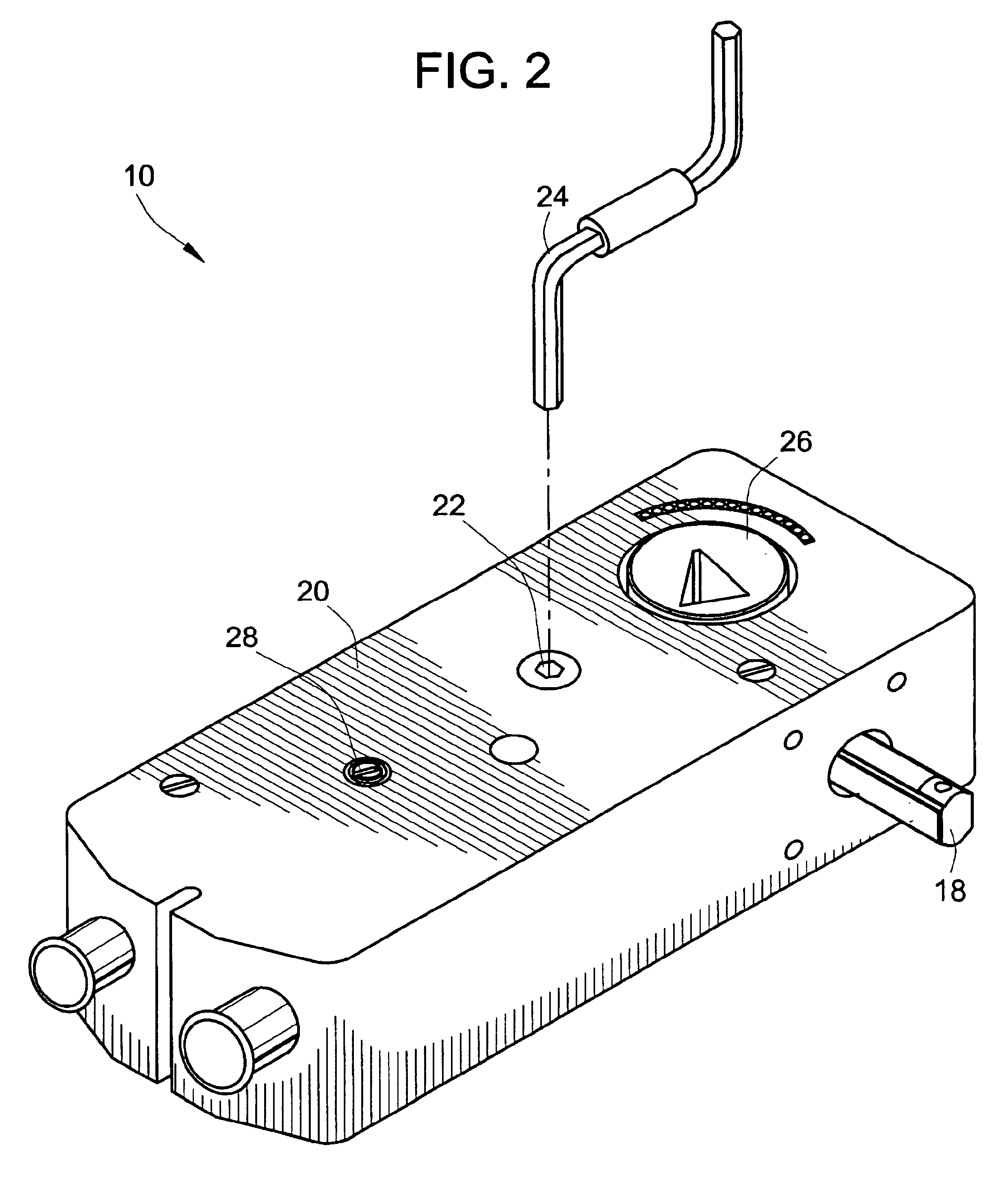

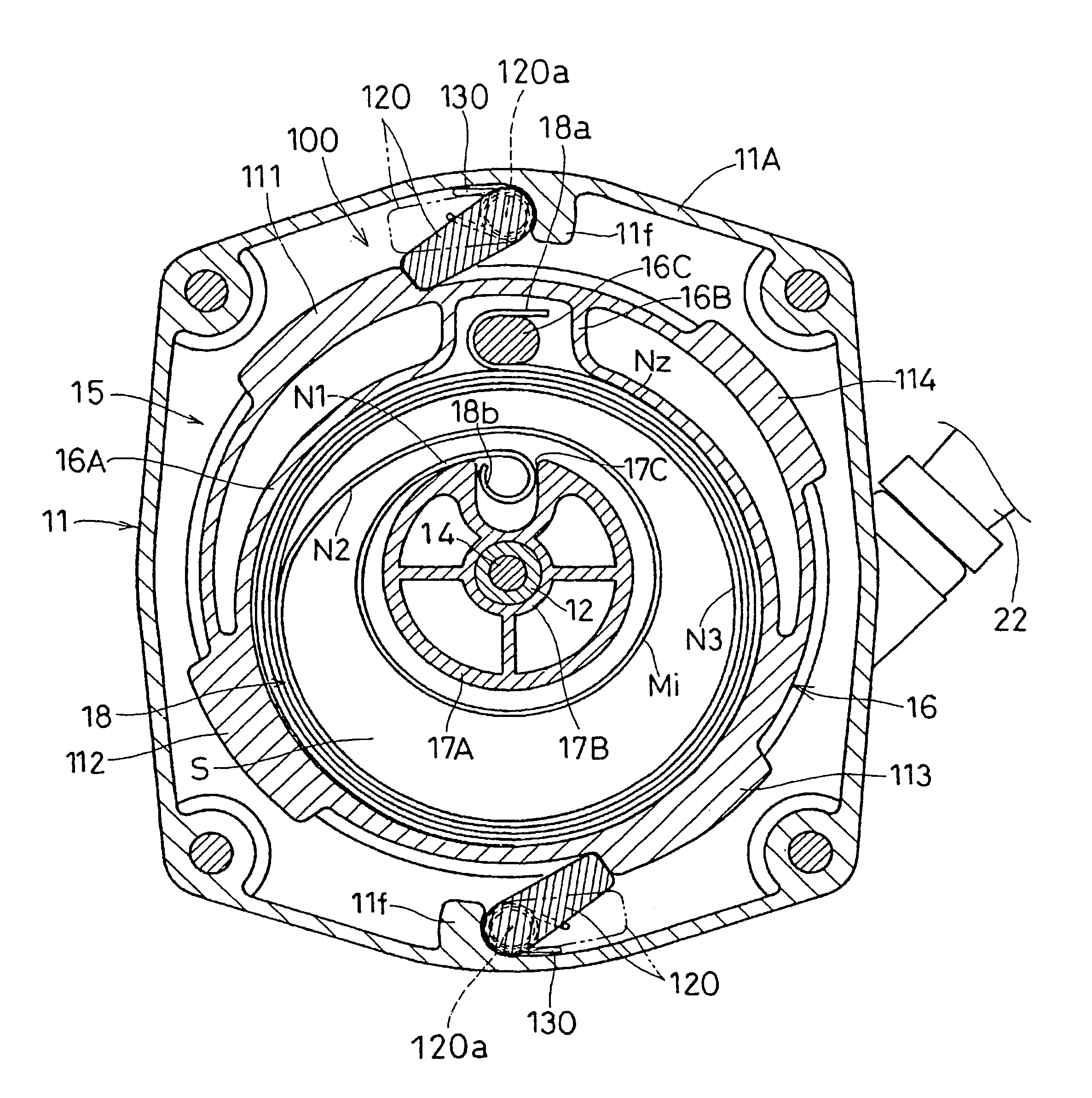

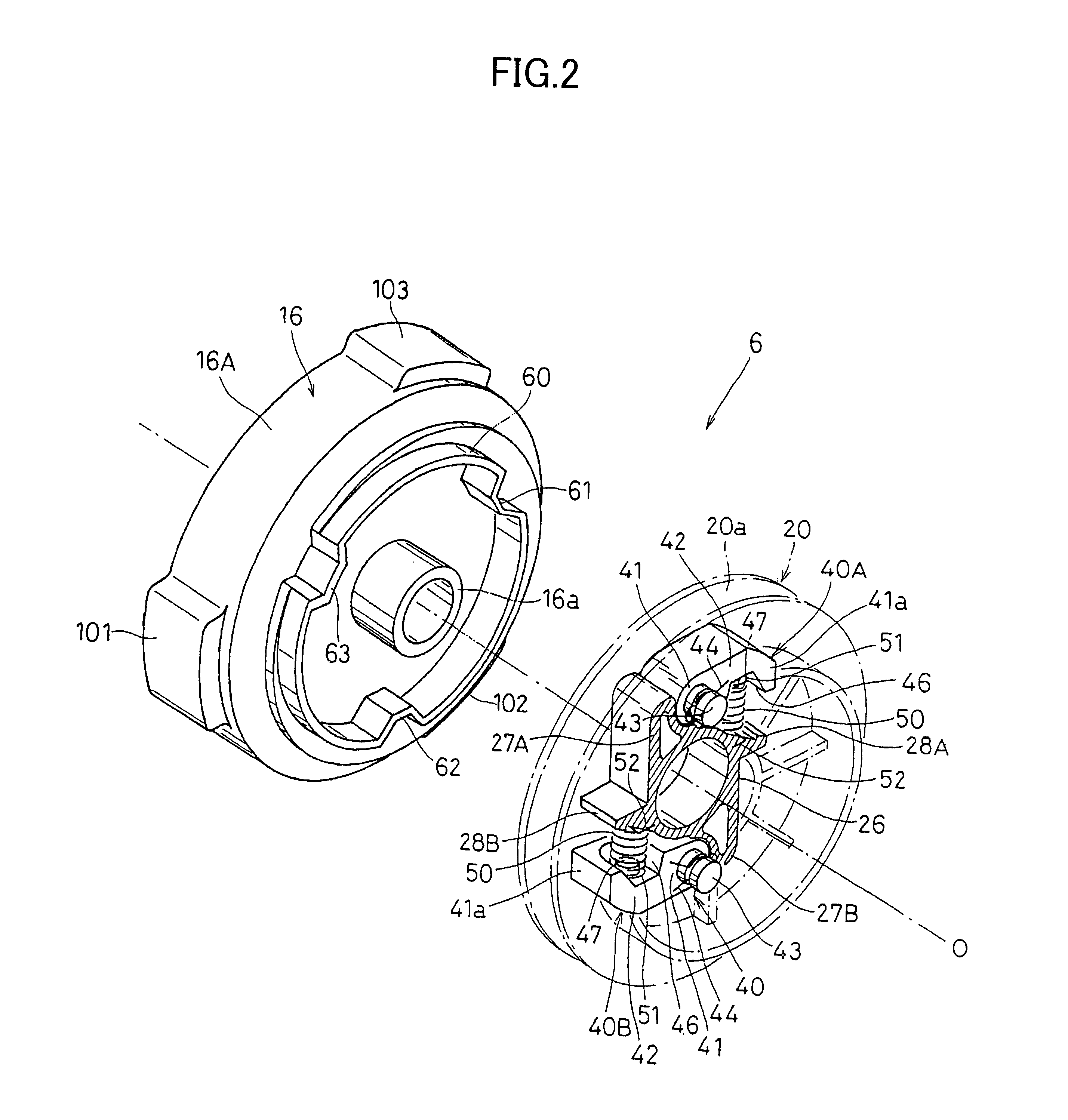

Starter

InactiveUS6679217B2Prevent rotationHigh mechanical strength and rigidity and precisionSpring motorPower operated startersCoil springEngineering

A recoil starter wherein unidirectional rotating means is enabled to sustain a larger magnitude of torque, obviating the employment of parts which are high in mechanical strength, in rigidity and in working precision, thus making it possible to reduce the weight and the manufacturing cost thereof. The recoil starter includes a driving member, a driven member, and buffering / power-accumulating means interposed between the driving member and the driven member. The buffering / power-accumulating means is enabled, during the driving process, to accumulate the power supplied through the driving process while alleviating impact to the driven member. The accumulated power is subsequently employed to drive the driven member. The recoil starter includes a spiral spring mechanism having a housing adjacent to the driving member, an actuating pulley adjacent to the driven member, a buffering / power-accumulating member interposed between the housing and the actuating pulley, and unidirectional rotating means for permitting rotation of the housing unidirectionally in a driving direction, where the unidirectional rotating means is disposed on the outer peripheral side of the spring housing.

Owner:STARTING IND CO LTD +1

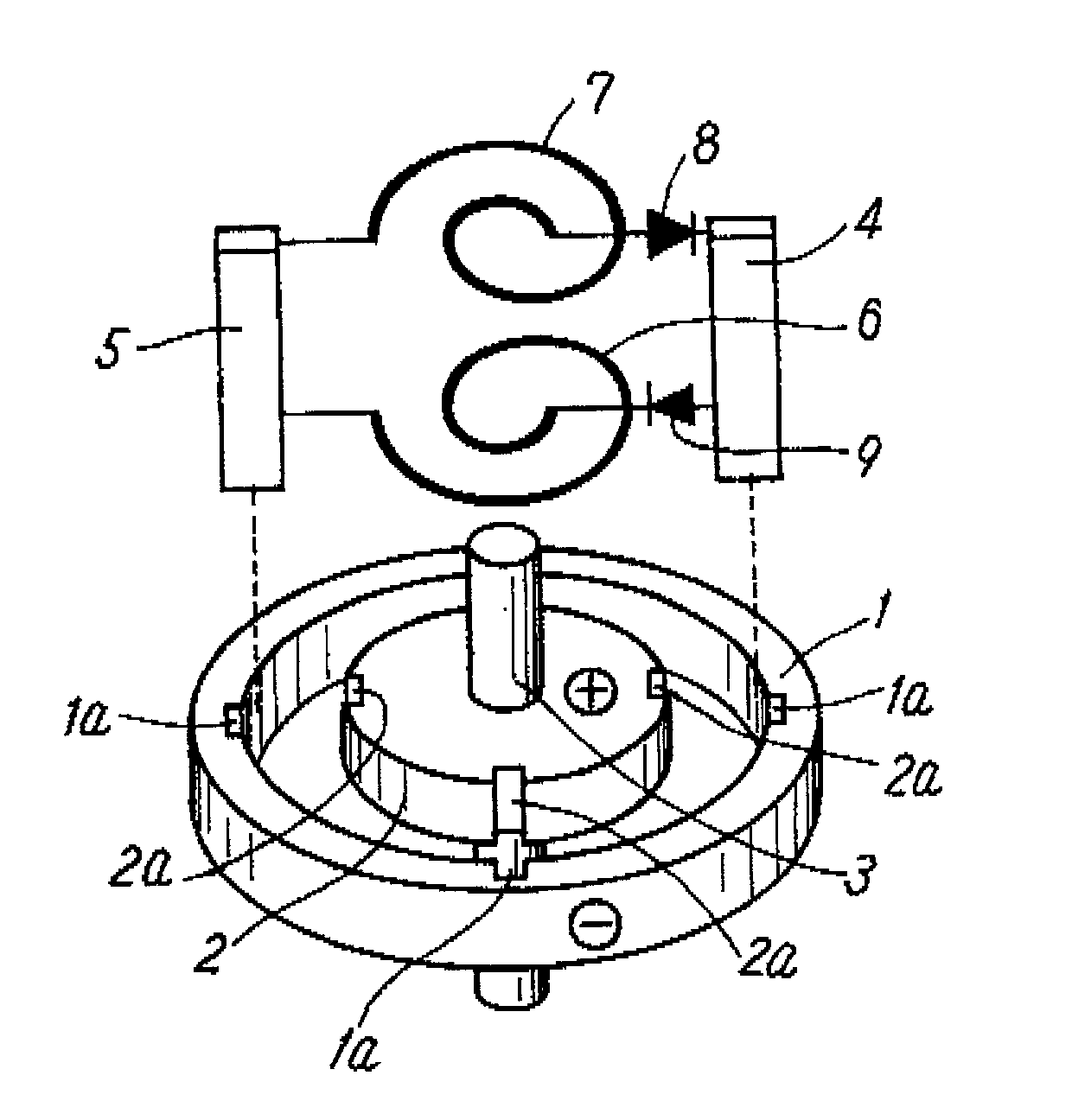

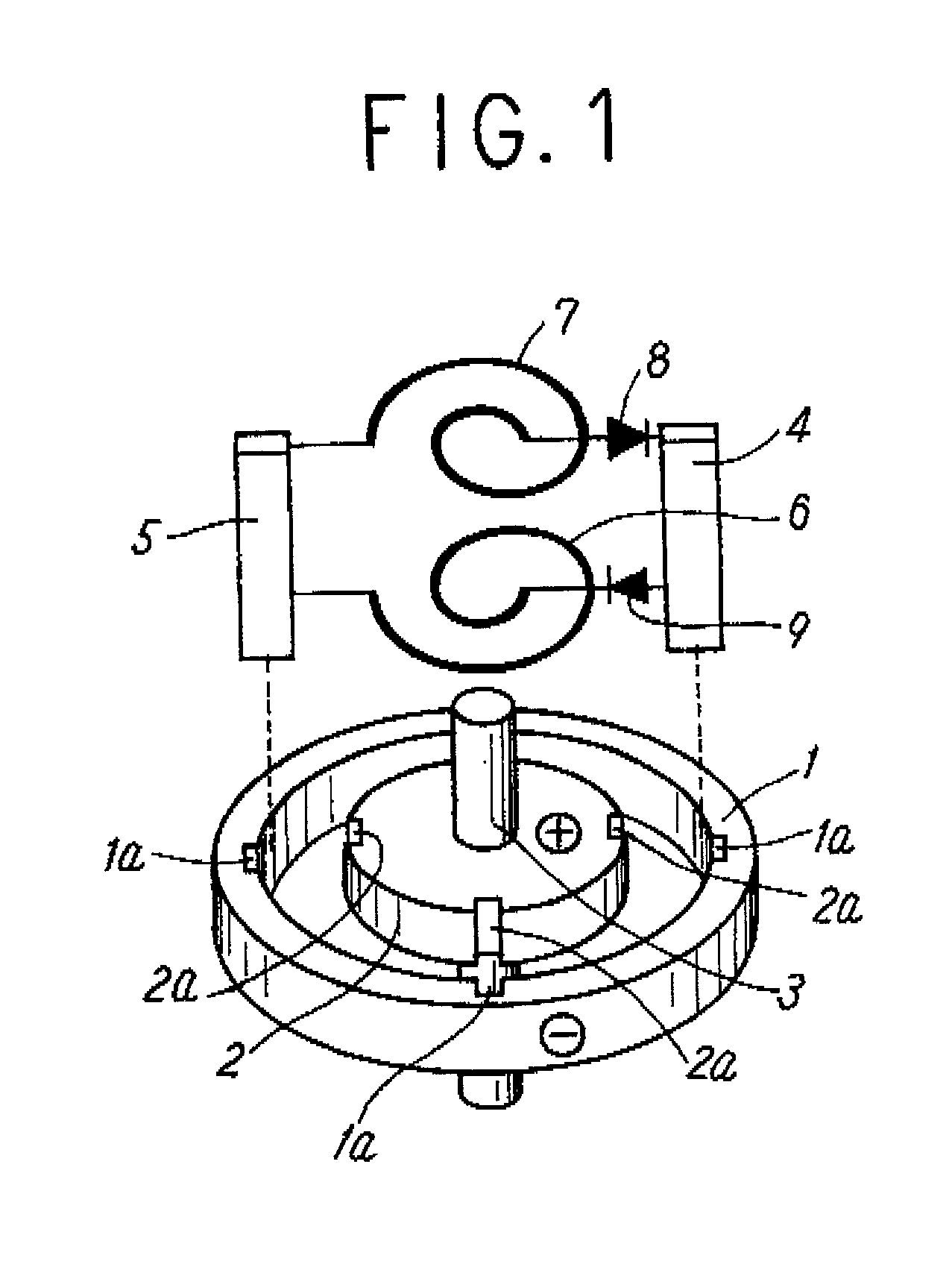

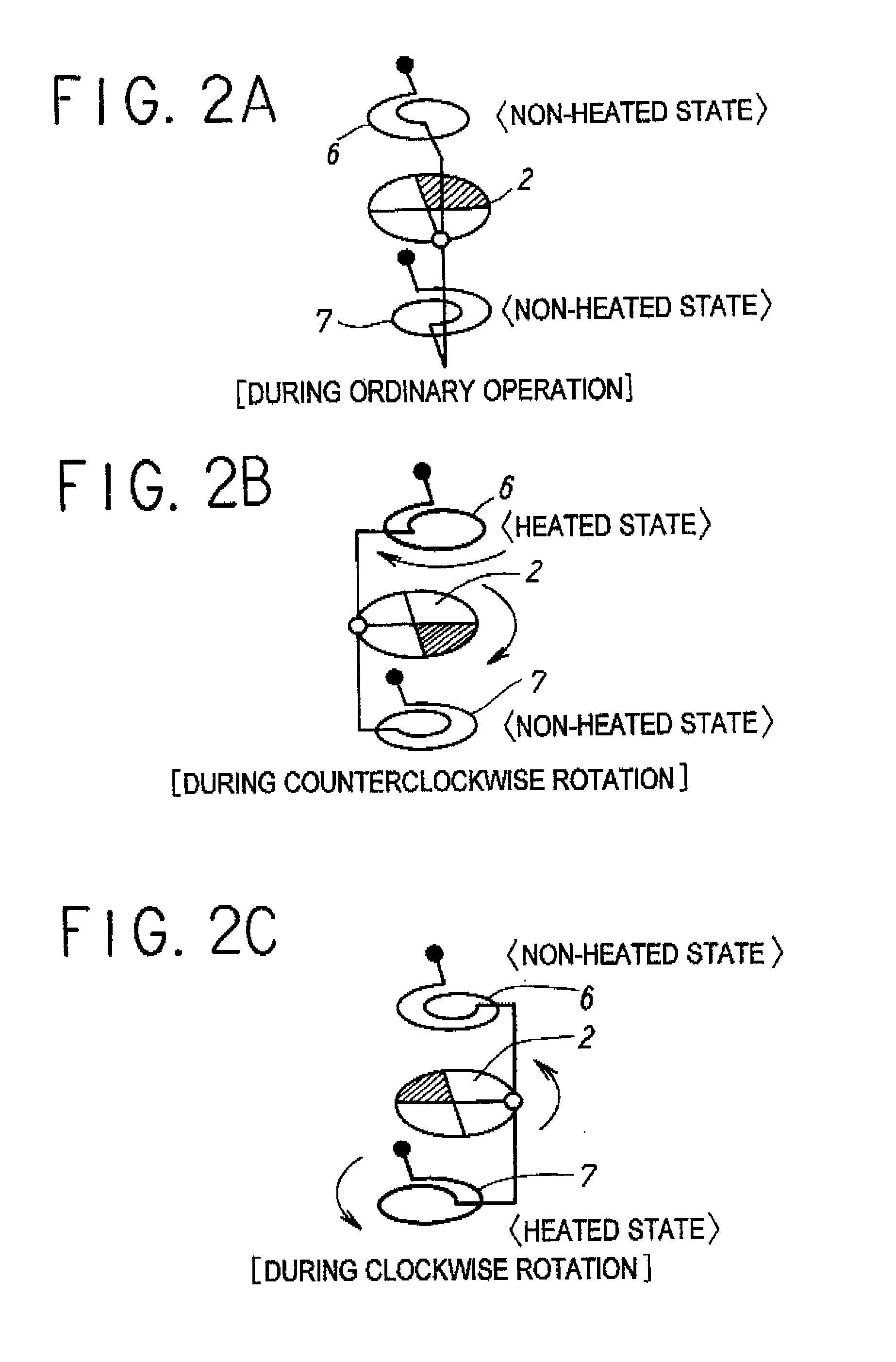

Continuous rotary actuator using shape memory alloy

To provide a continuous rotary actuator using a shape memory alloy, having a simple structure, being small and light-weighted, and having high torque, which can lock the rotation during non-energizing, an inner drum 2 rotating around the axis as a rotating shaft 3 is provided in an outer cylinder 1, wherein a first shape-memory-alloy torsion spring 6 and a second shape-memory-alloy torsion spring 7 wound in opposite directions and unwound to recoil due to electrical heating are fixed between the outer cylinder 1 and the inner drum 2, and wherein switching means 4 and 5 for alternately switching the electrical heating according to the rotation angle of the inner drum 2 are connected to the first and second shape-memory-alloy torsion springs 6 and 7.

Owner:NAT INST OF ADVANCED IND SCI & TECH

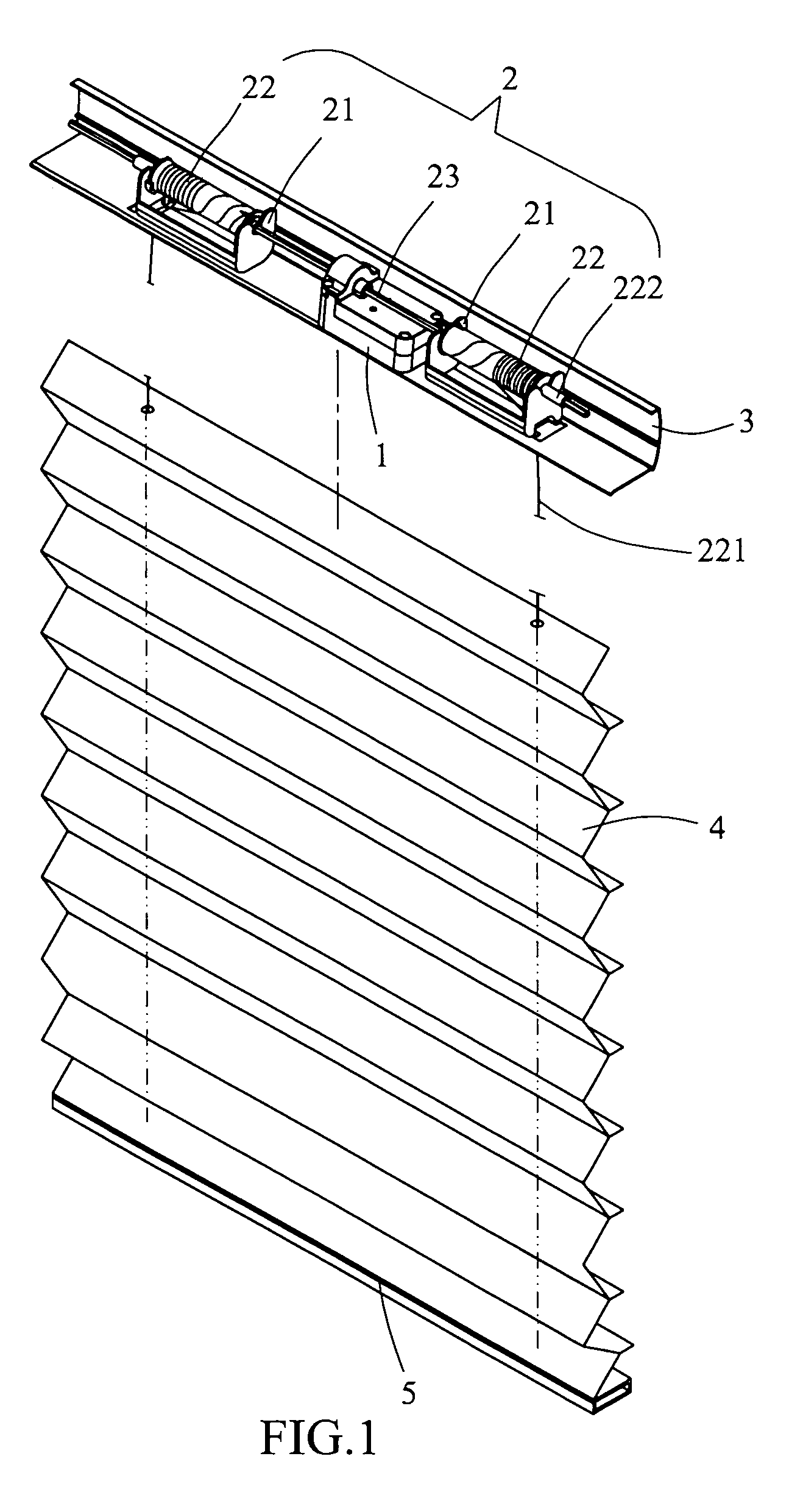

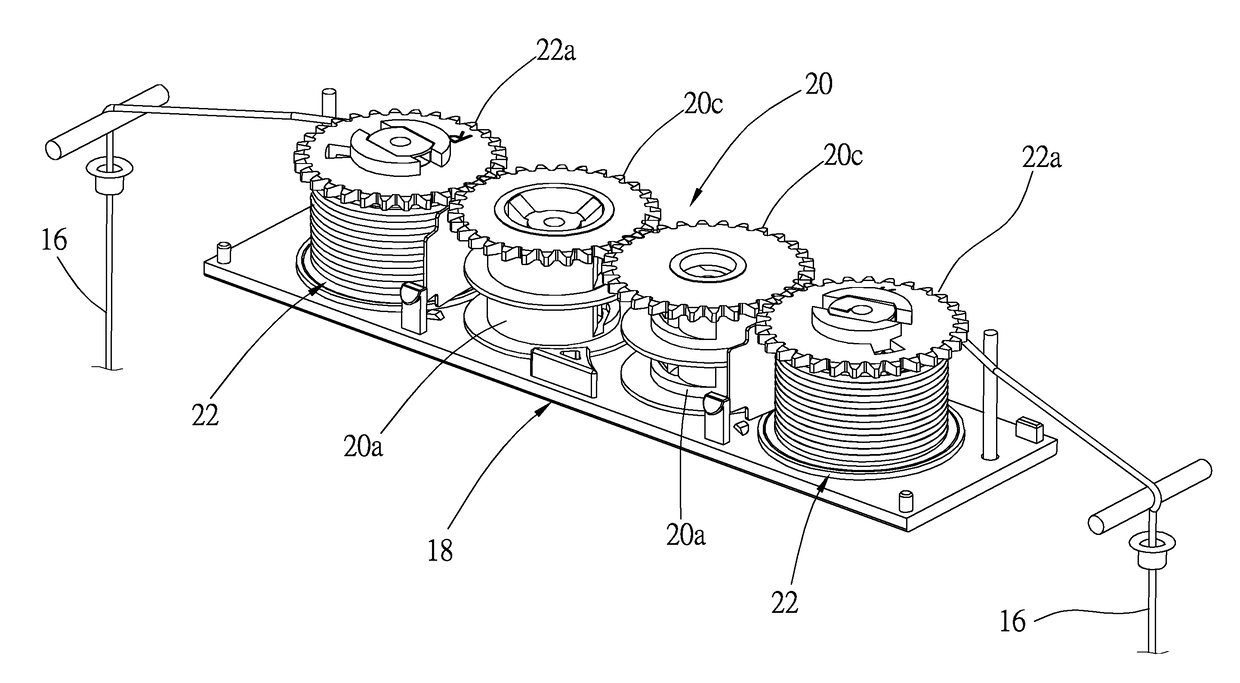

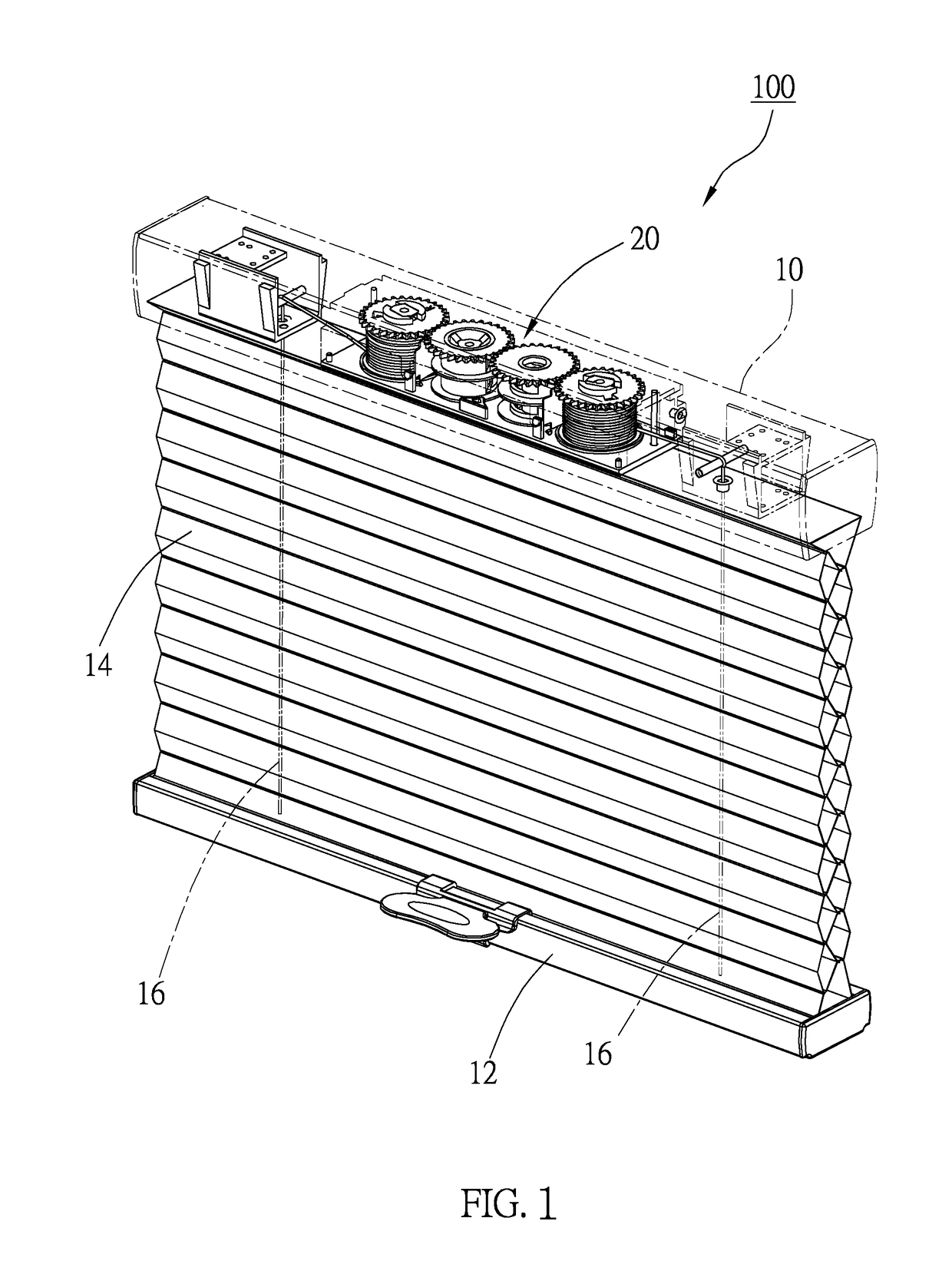

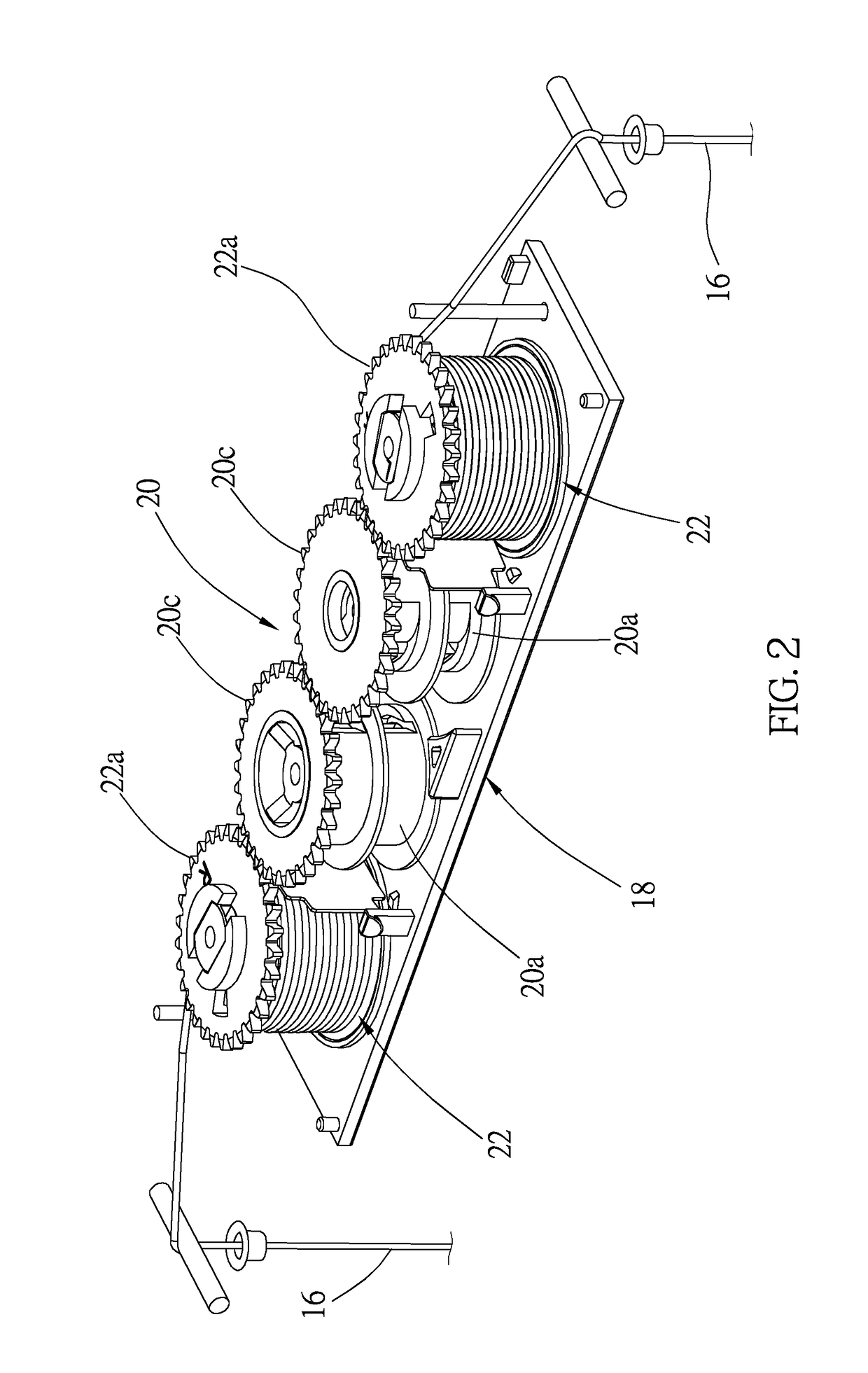

Spring box of cordless window covering and friction mechanism of the same

InactiveUS20170298688A1Increase frictionSpring motorDoor/window protective devicesPull forceEngineering

A spring box provided in one headrail of a window covering is disclosed, including a base, a post rotatably provided on the base to wind up a lifting cord, and a prestressing device which provides a pulling force to the post to rotate it in a predetermined direction. The spring box further includes a guiding member provided in the post to be rotated by the post, a movable member which moves along the guiding member in a non-rotating manner when the guiding member is rotated, and a friction member which is compressed and deformed to increase a friction between it and an inner wall of the post when the movable member is moved in a predetermined direction, providing a resistance effect to the rotation of the post, which makes one bottom rail of the window covering stay at a predetermined position.

Owner:NIEN MADE ENTERPRISE CO LTD

Device with roll mechanism

The present invention discloses a device that is comprised of a flexible material and a roll mechanism associated with the flexible material. A bistable resilient member maintains the flexible material flat due to a tension force within the body of the bistable resilient member in a first stable state, and maintains the flexible material to a rolled-up, bundled closed position after the tension force within the body of the bistable resilient member is fully released (the second stable state). Further, the bistable resilient member compels the flexible material to a self-roll-up motion (during a transition state) while a tension force within the body of the bistable resilient member is released.

Owner:ARHO INNOVATIONS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com