Systems and Methods Related to Coupling an Energy Harvester to Exercise Equipment

a technology of energy harvester and exercise equipment, applied in the field of exercise equipment, can solve the problems of objectionable exercise feel for users, undetectable ripple forces and torques, and methods that have generally had substantial performance limitations, and achieve the effect of increasing the overall mass of the energy harvester

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032]Although the disclosure hereof is detailed and exact to enable those skilled in the art to practice the invention, the physical embodiments herein disclosed merely exemplify the invention which may be embodied in other specific structures. While the preferred embodiment has been described, the details may be changed without departing from the invention, which is defined by the claims.

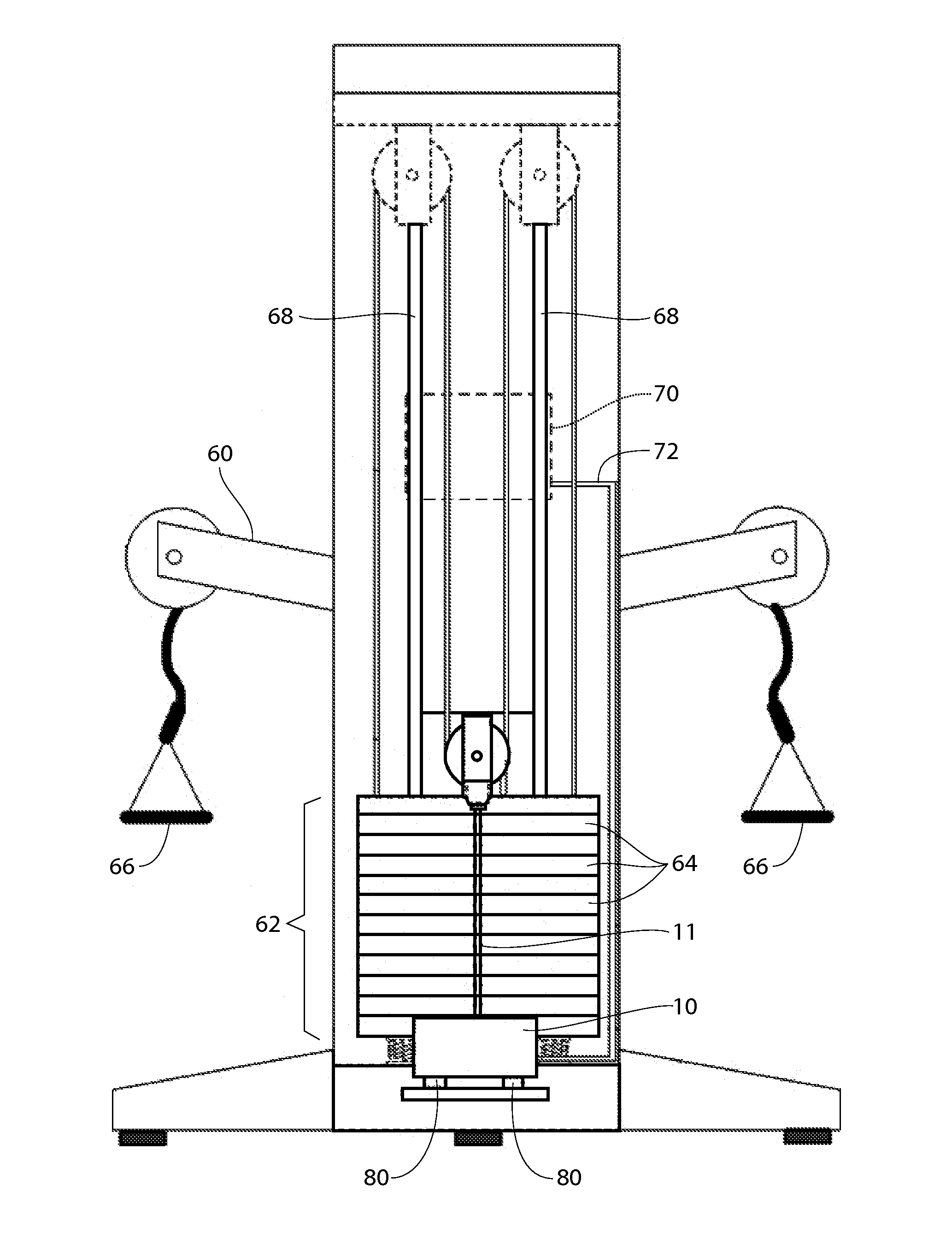

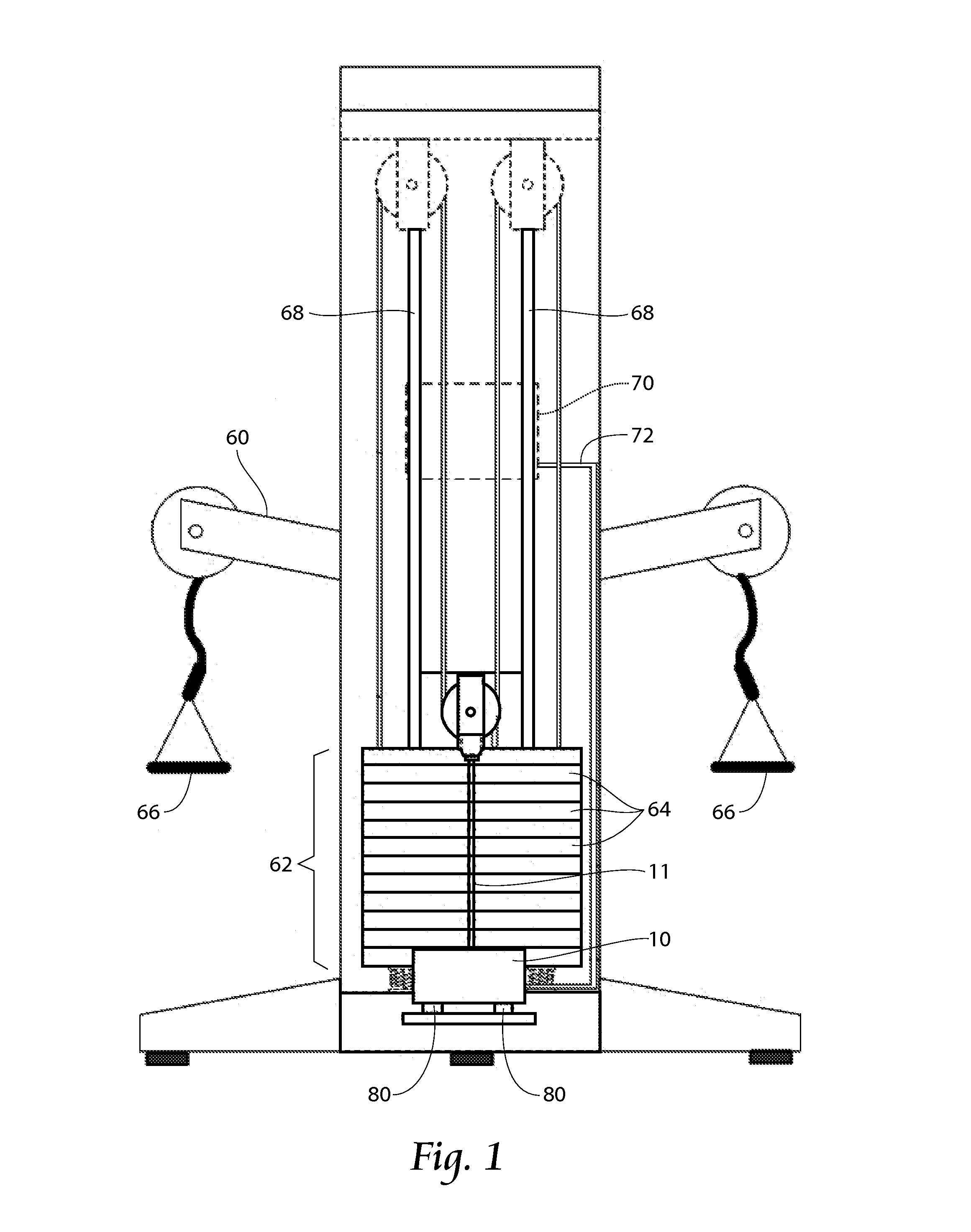

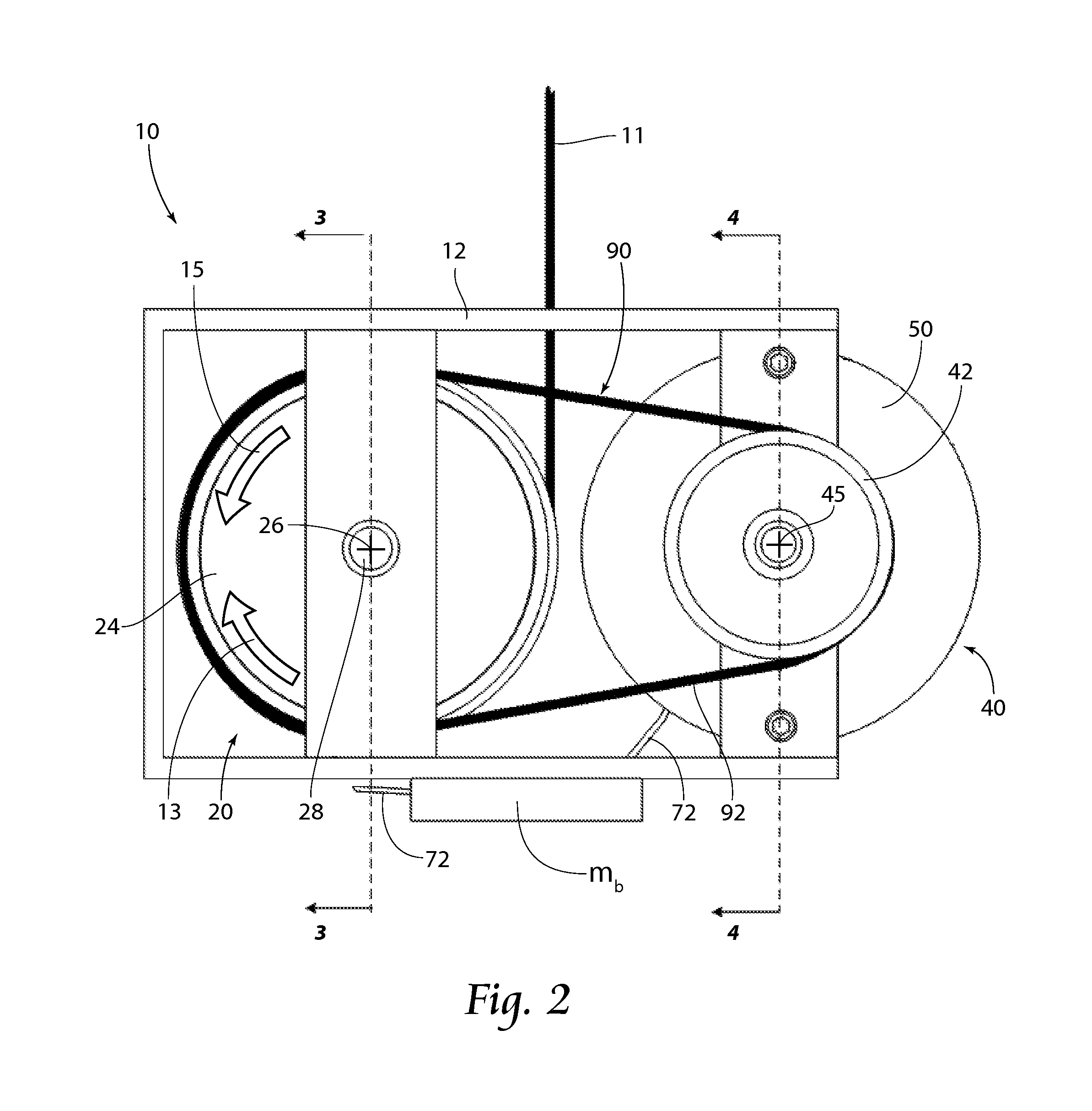

[0033]Referring now to the figures, FIG. 1 depicts an energy harvester 10 mechanically coupled to an exercise equipment machine 60 by a flexible cable, wherein the harvester 10 produces electrical power during an exercise motion performed by a user of the machine 60. The energy harvester 10 provides electrical power to an electronics unit 70 or other electrical storage element (e.g. capacitor or battery) or load (e.g., light(s), heating elements, battery chargers, etc.), which may be electrically connected to the harvester 10 by an electrical cord 72. As is generally known, strength training machi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com