Rubber belt type energy accumulator

A technology of rubber belts and accumulators, which is applied in the direction of machines/engines, elastic motors, mechanical equipment, etc., can solve the problems of high technical difficulty and high cost, and achieve the effects of high energy density, light weight, and high energy conversion efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

[0019] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

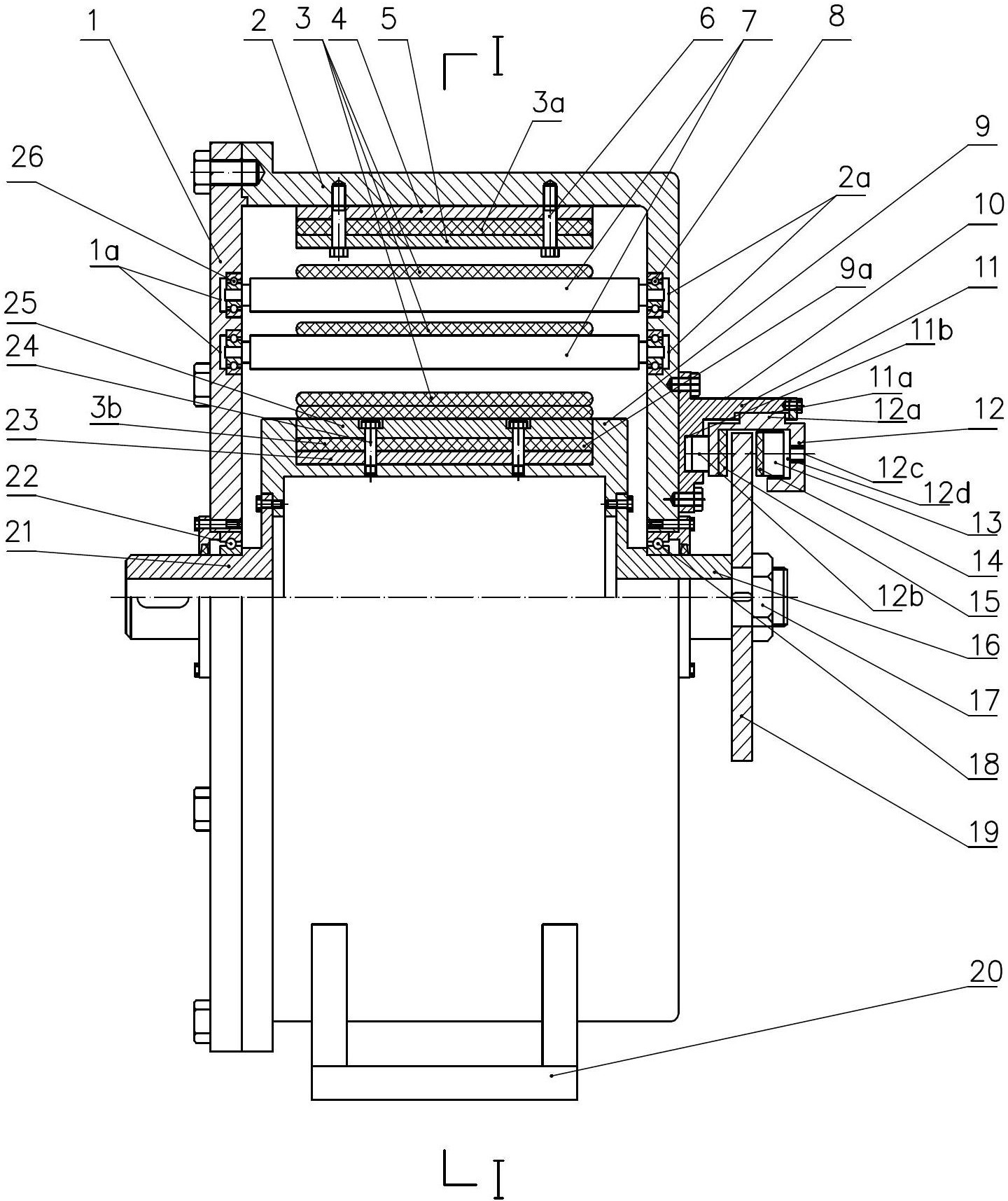

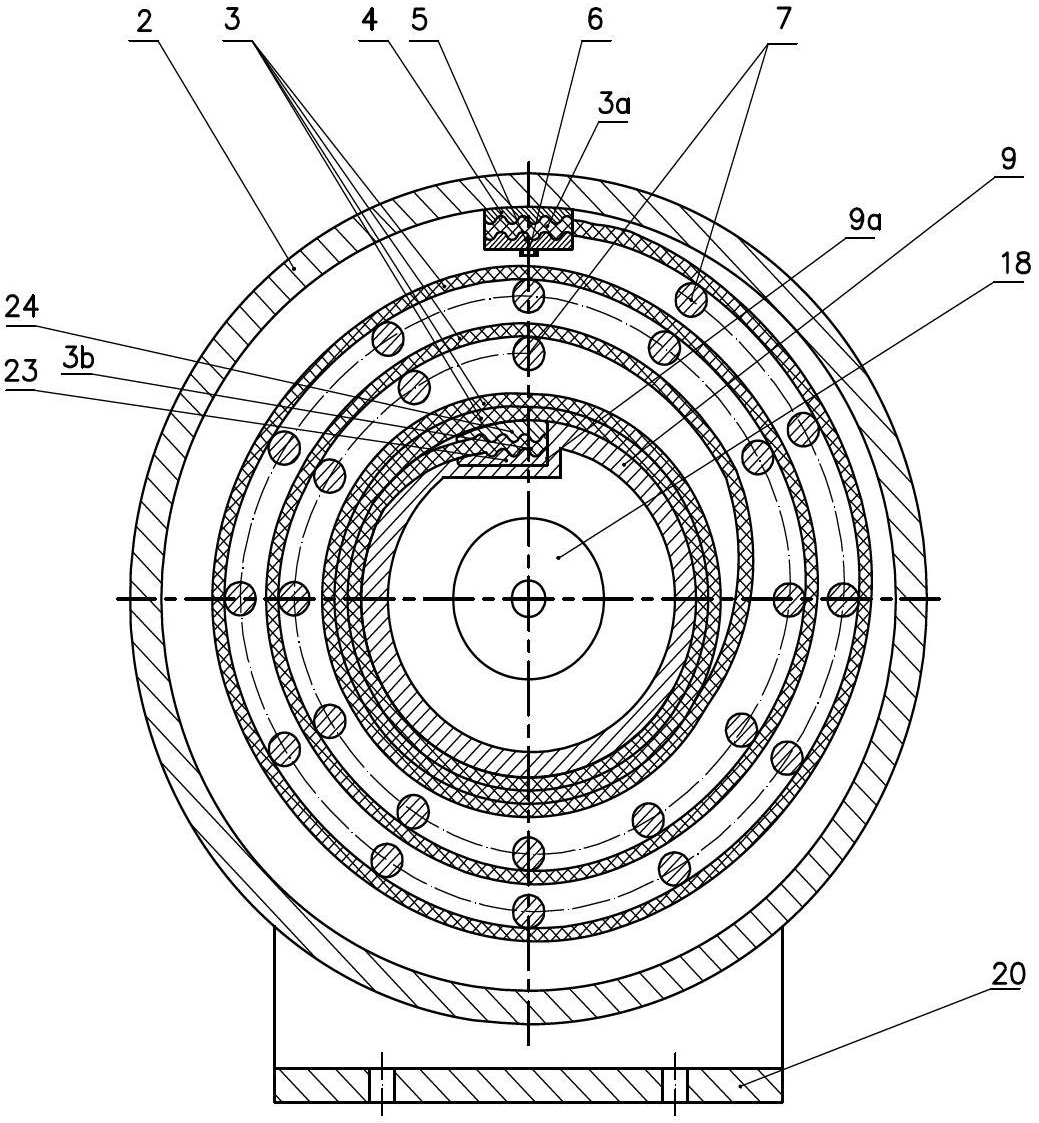

[0020] Such as figure 1 and figure 2 As shown, the rubber belt accumulator according to Embodiment 1 of the present invention includes: an end cover 1, a housing 2, a rubber belt 3, a roller 9, a plurality of guide rollers 7, a power transmission shaft 21, a brake shaft 16 and a brake shaft. Moving device 10, wherein rubber band 3 adopts single rubber band.

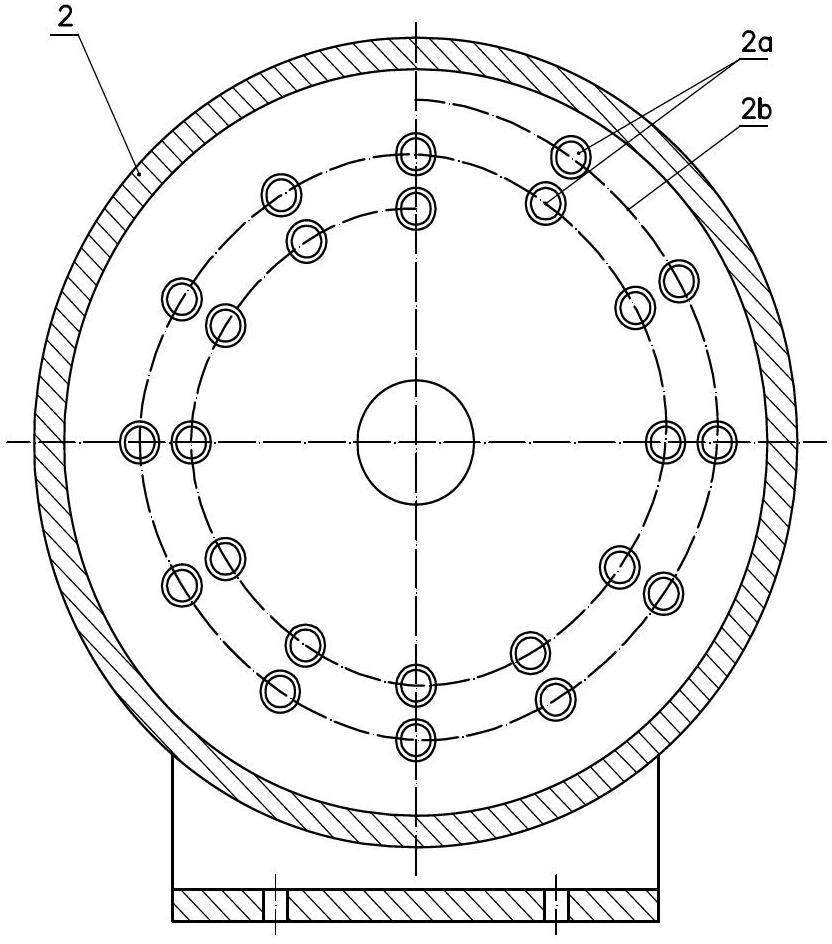

[0021] The end cover 1 and the shell 2 are split structures. The end cover 1 and the shell 2 are fixedly connected by bolts. The end cover and the shell form a cavity inside. In order to ensure the accuracy of the installation position of the end cover 1 and the housing 2, the right side of the housing 2 is fixedly connected to the brake device 10, and the housing 2 has a mounting base 20, which is used to fix the rubber belt type accumulator during use. The left end of the drum 9 is connecte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com