No-drill rear sight scope mount base

a technology of scope and mount base, which is applied in the direction of scaffolding, machine supports, curtain suspension devices, etc., can solve the problems of the scope flexing on recoil, and achieve the effect of preventing minor upward recoil forces and any loss of accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

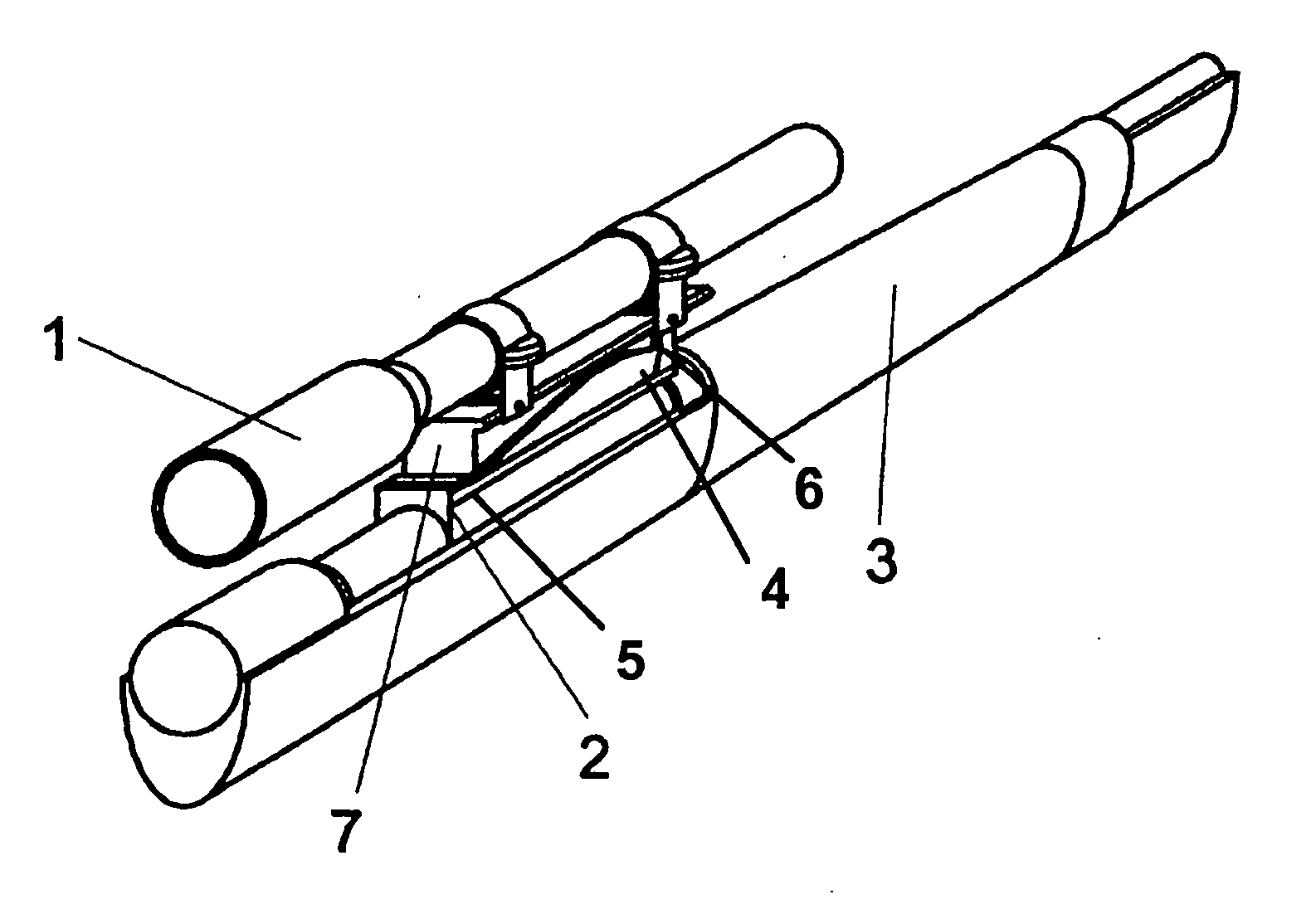

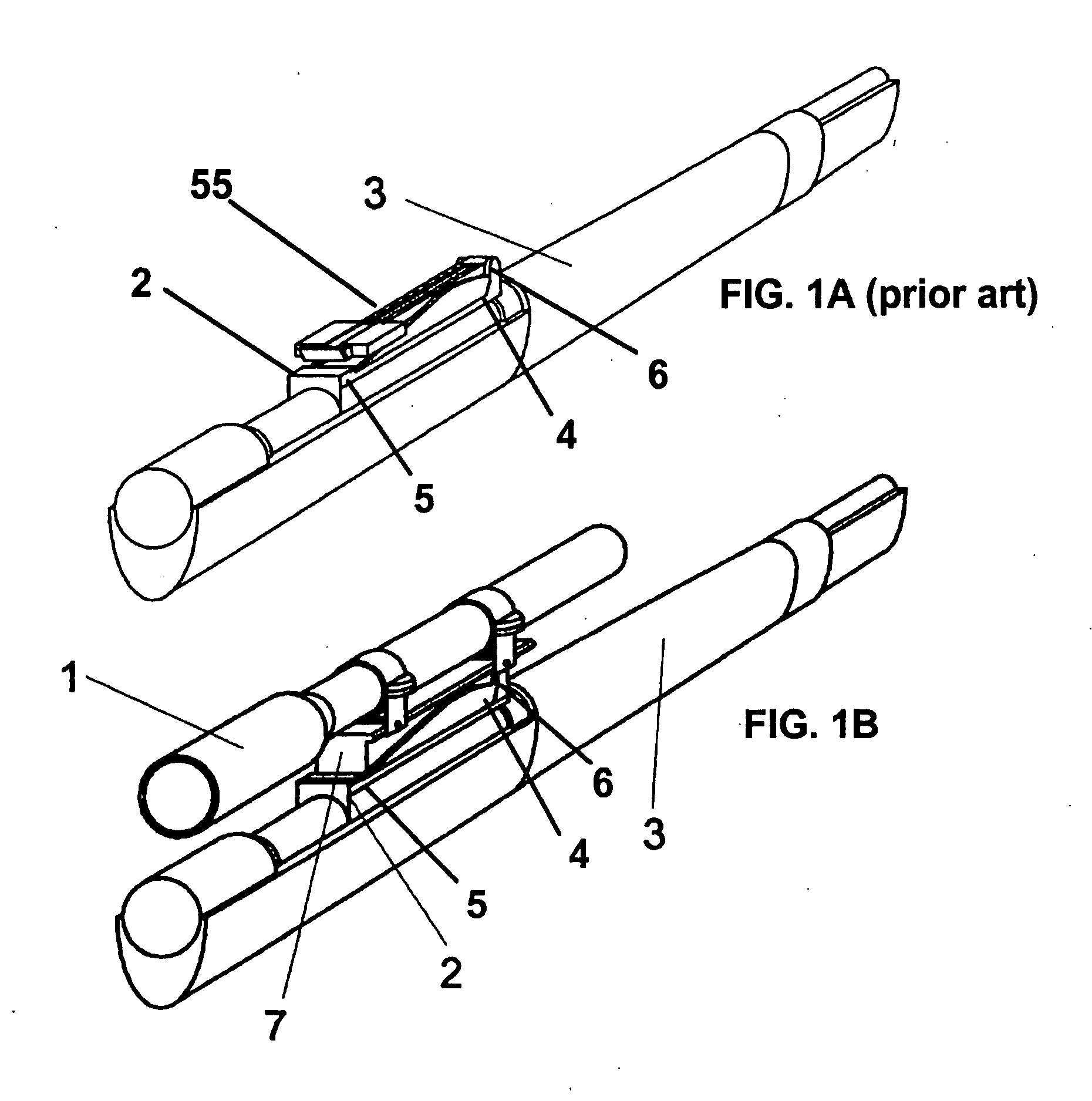

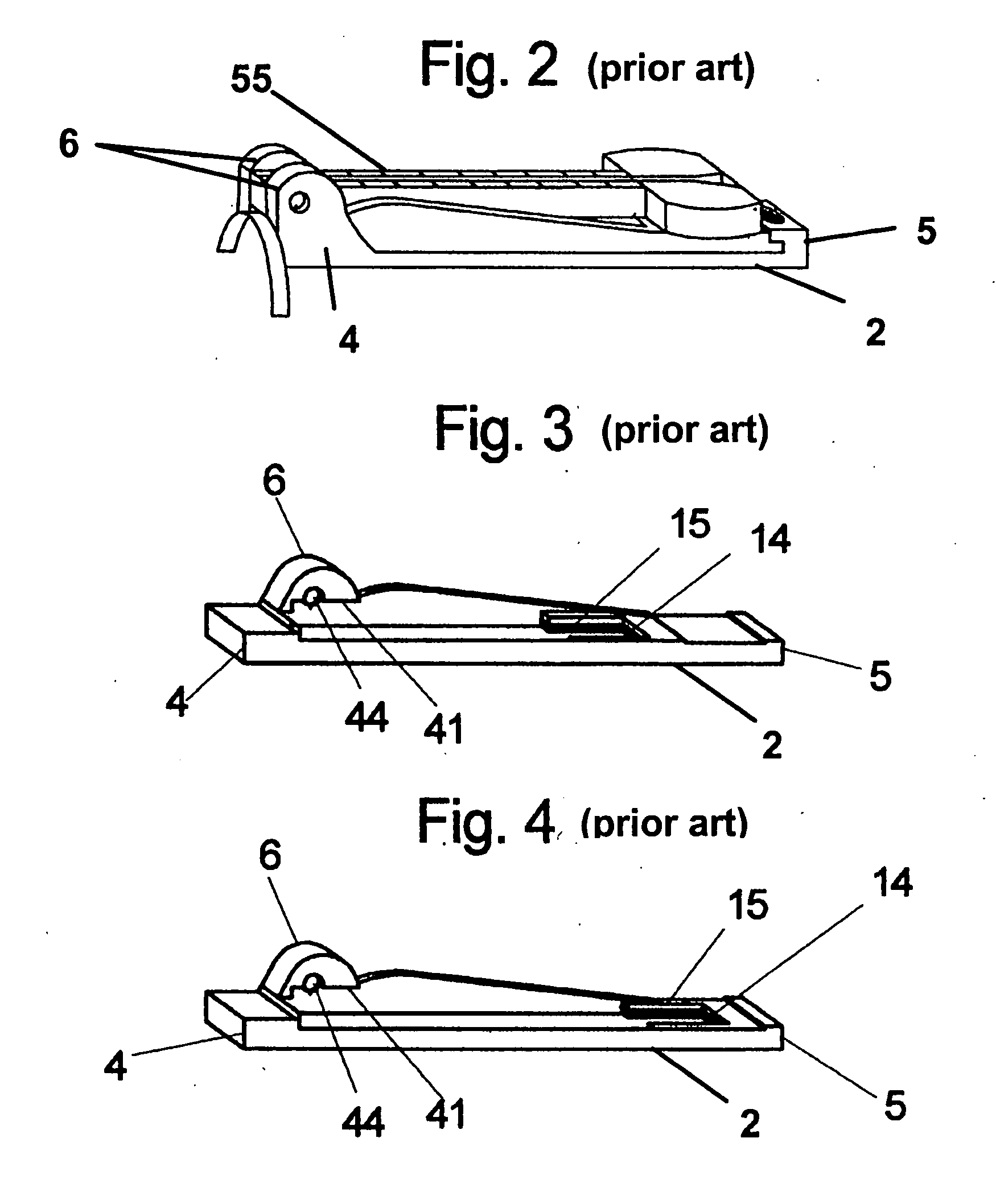

[0043]The success of my rear sight long eye relief scope mount is dependent on the preexistence of certain specific features in the host Mauser 98 (FIG. 1) long tangent rear sight base (FIG. 2);[0044]A—In the anterior portion (4), a pair of inwardly projecting, opposing, bosses (6) that project upwards on the sight base. There is also a boss through hole (44) in each of these said bosses (6). These through holes are positioned so that their upper circumference and horizontal diameter passes through the bosses' (6) lower side edge (42).[0045]B—In the posterior (5) of the sight base, a pair of opposing spring slots (15) is located longitudinally to the bore (36) in the sight base posterior.

[0046]The scope mount body (7) consists of top (10), bottom (11), side (12), front (8), and back (9). On the top of the body, you have the general configuration to accept the telescopic sight (54). The top back (10) also has three vertical screw holes. These three holes are central to the lateral bo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com