Spring-return valve actuator using planetary gear train

A technology of valve actuators and planetary gears, which is applied in the field of spring return valve actuators, and can solve the problems of longer length of valve actuators, higher manufacturing costs, and increased number of parts and components

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] The present invention will be described in detail below with reference to schematic diagrams.

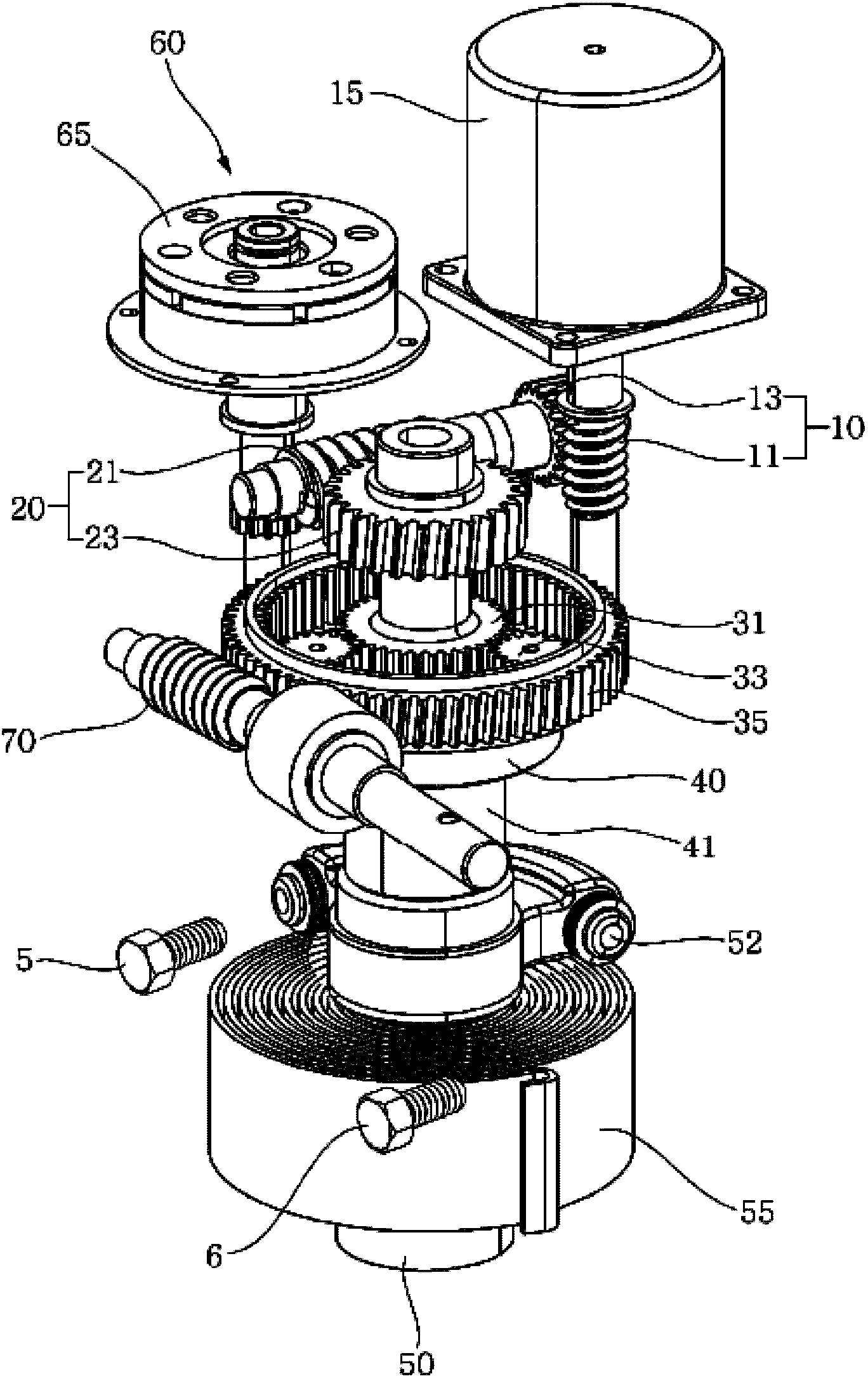

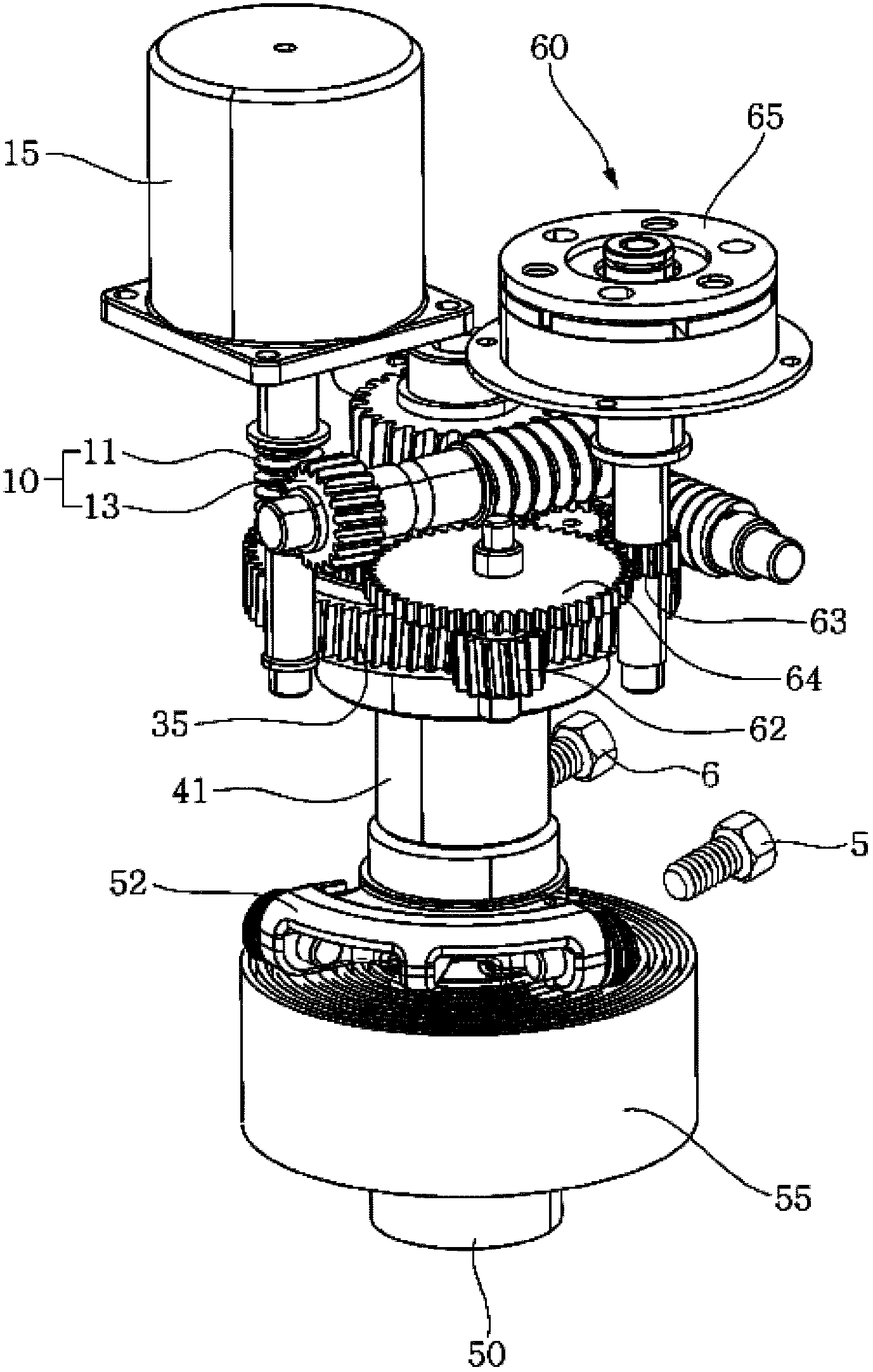

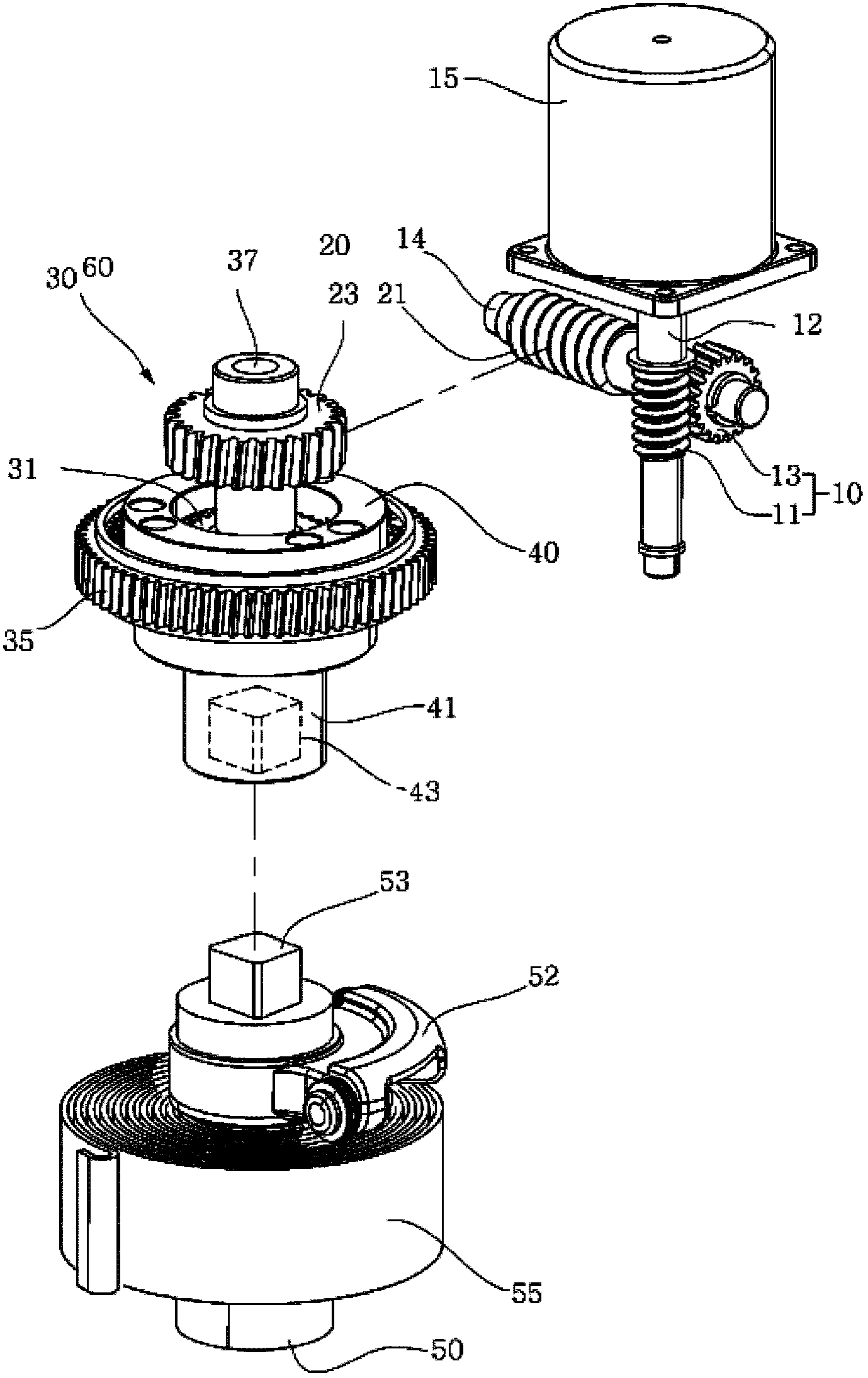

[0044] figure 1 It is a schematic front view of the main structure of the present invention; figure 2 yes figure 1 rear view of image 3 It is a schematic diagram of partial decomposition of the present invention; Figure 4 is a vertical sectional view of the assembled state of the present invention; Figure 5 It is a partial schematic diagram when the power of the handwheel is cut off; Figure 6 yes Figure 5 horizontal section of Figure 7 It is a partial schematic diagram under the power transmission state of the handwheel; Figure 8 yes Figure 7 horizontal sectional view.

[0045] The primary worm (11) connected to the rotary shaft (12) of the motor (15) and the corresponding primary worm gear (13) form the primary worm gear group (10);

[0046] The secondary worm (21) formed by the extension of the primary worm shaft (14) and the corresponding secondary worm ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com