Patents

Literature

38 results about "Partial decomposition" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

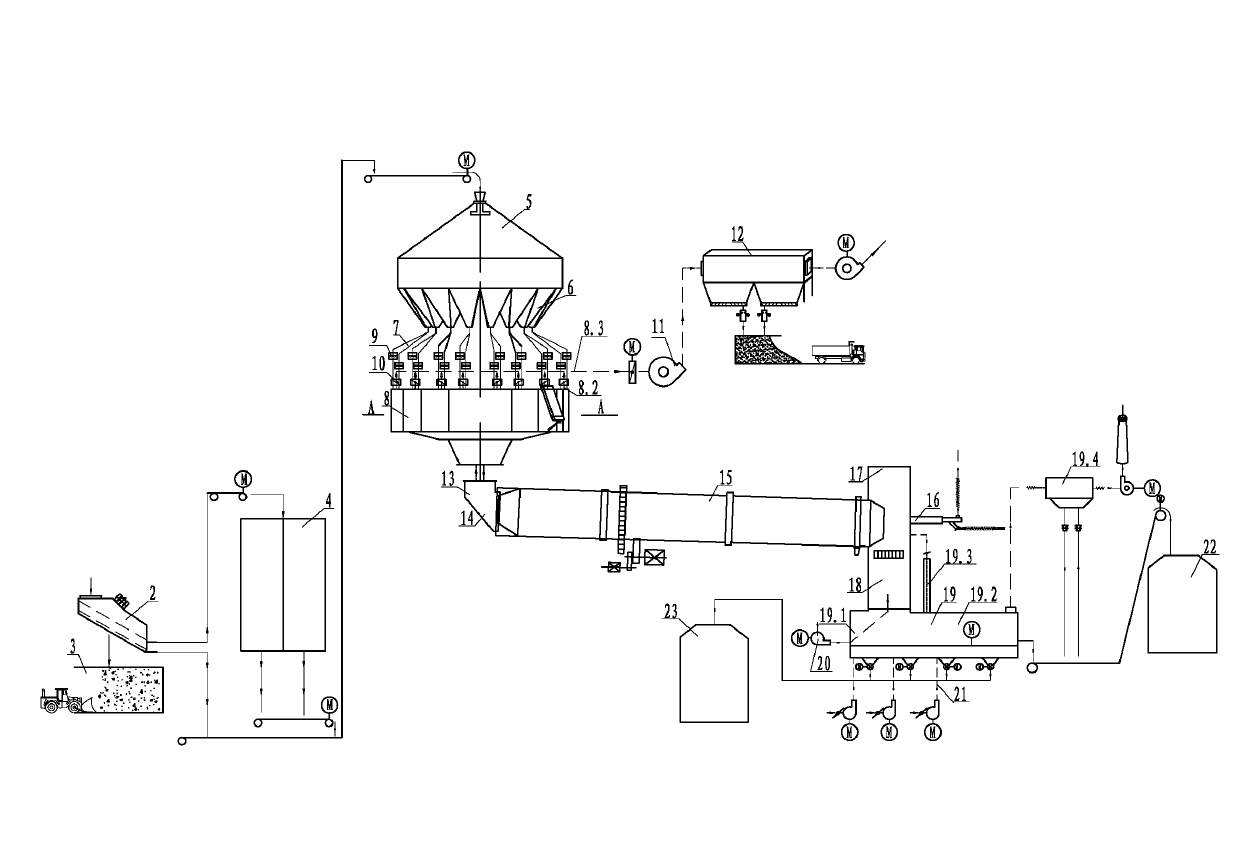

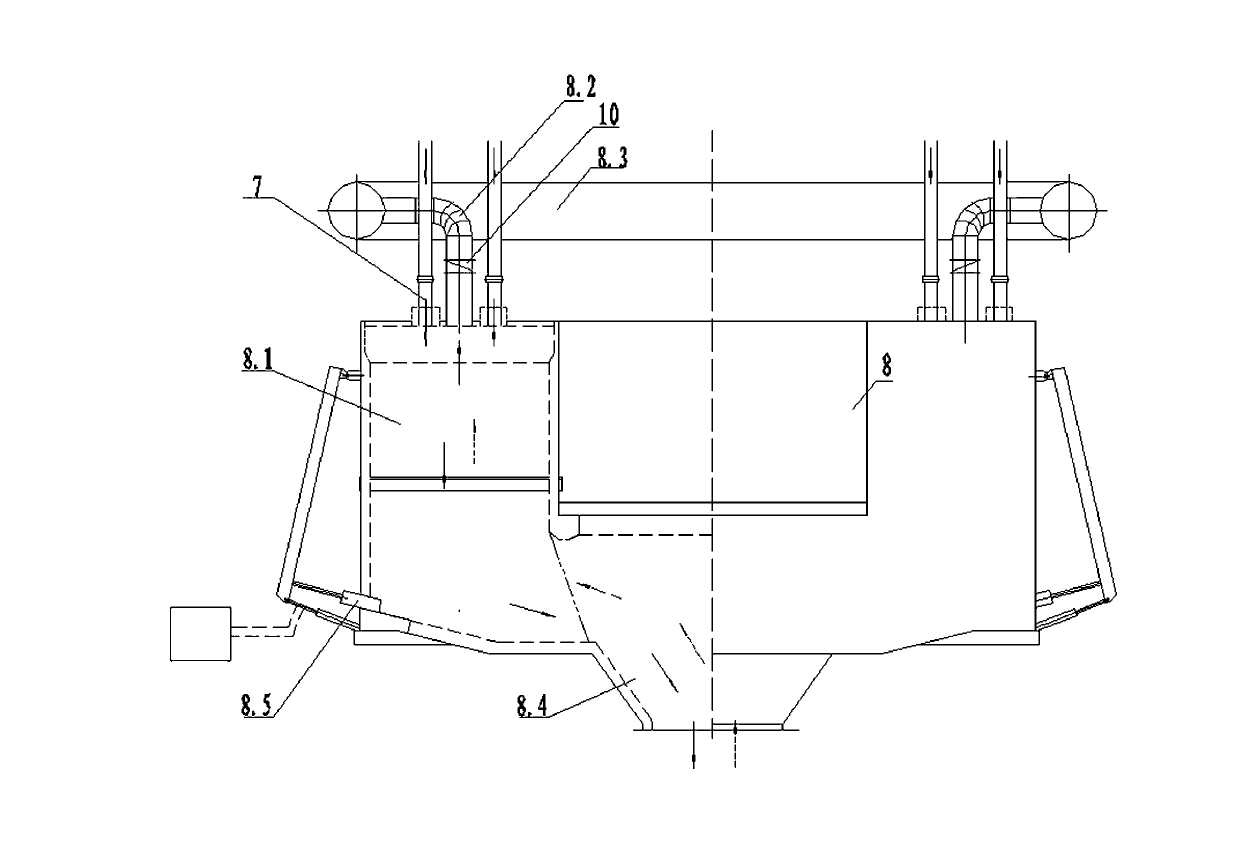

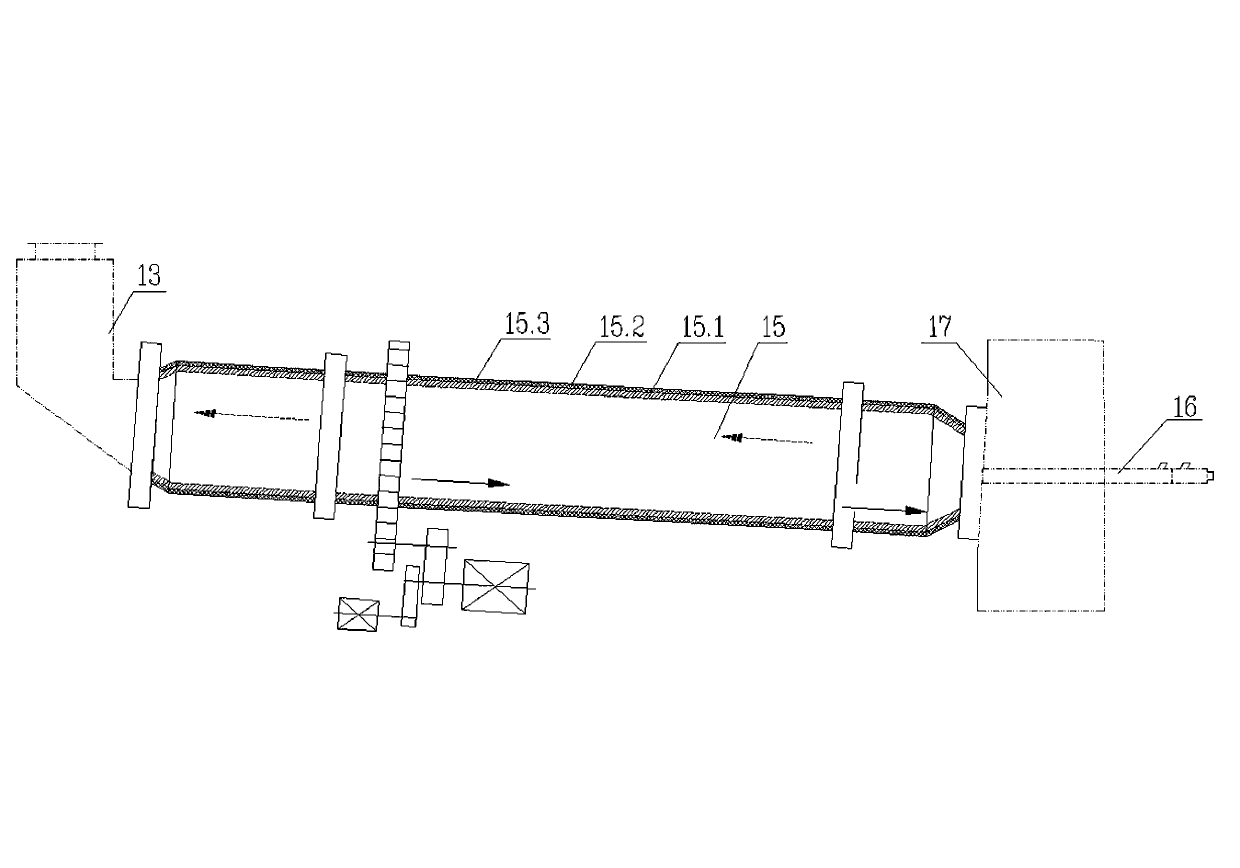

Energy-conservation and emission-reduction type active lime calcination method and apparatus

ActiveCN103304157AGranularity Requirements RelaxedImprove resource utilizationLime productionExhaust gas emissionsExhaust fumes

The invention provides a burning method for preparing an energy-conservation and emission-reduction type active lime. The method comprises the following steps: subjecting the raw material (1) limestone to size grading; respectively and evenly distributing the limestone of different grades into each preheating chamber (8.1) of a novel vertical preheater (8), preheating and partially decomposing the limestone with high temperature exhaust gas and introducing the limestone into a rotary kiln (15); calcining and decomposing the limestone under the action of a temperature field to allow CO2 to be produced and the limestone to become lime; and allowing the lime to enter into a shaft well device (18) for annealing and heat exchange, then introducing the lime into a cooling machine (19) for cooling and carrying out screening to separate blocky lime from powdery lime, thereby obtaining finished products, i.e., blocky lime and powdery lime. The invention further provides an apparatus composed of a size grading device (2), a distributor (5), a distribution warehouse (6), the novel vertical preheater (8), the rotary kiln (15), a kiln hood (17), a combustor (16), the shaft well device (18) and the cooling machine (19) for the method. The method and the apparatus provided by the invention has the characteristics of an expandable range of the size of the raw material limestone, low heat consumption, high production efficiency, a high activity degree of the products, low discharge of SO2 and exhaust gas, low cost, simple and convenient operation and capacity of meeting needs of larger-scale industrial production.

Owner:泰安中意重型工业设备有限公司

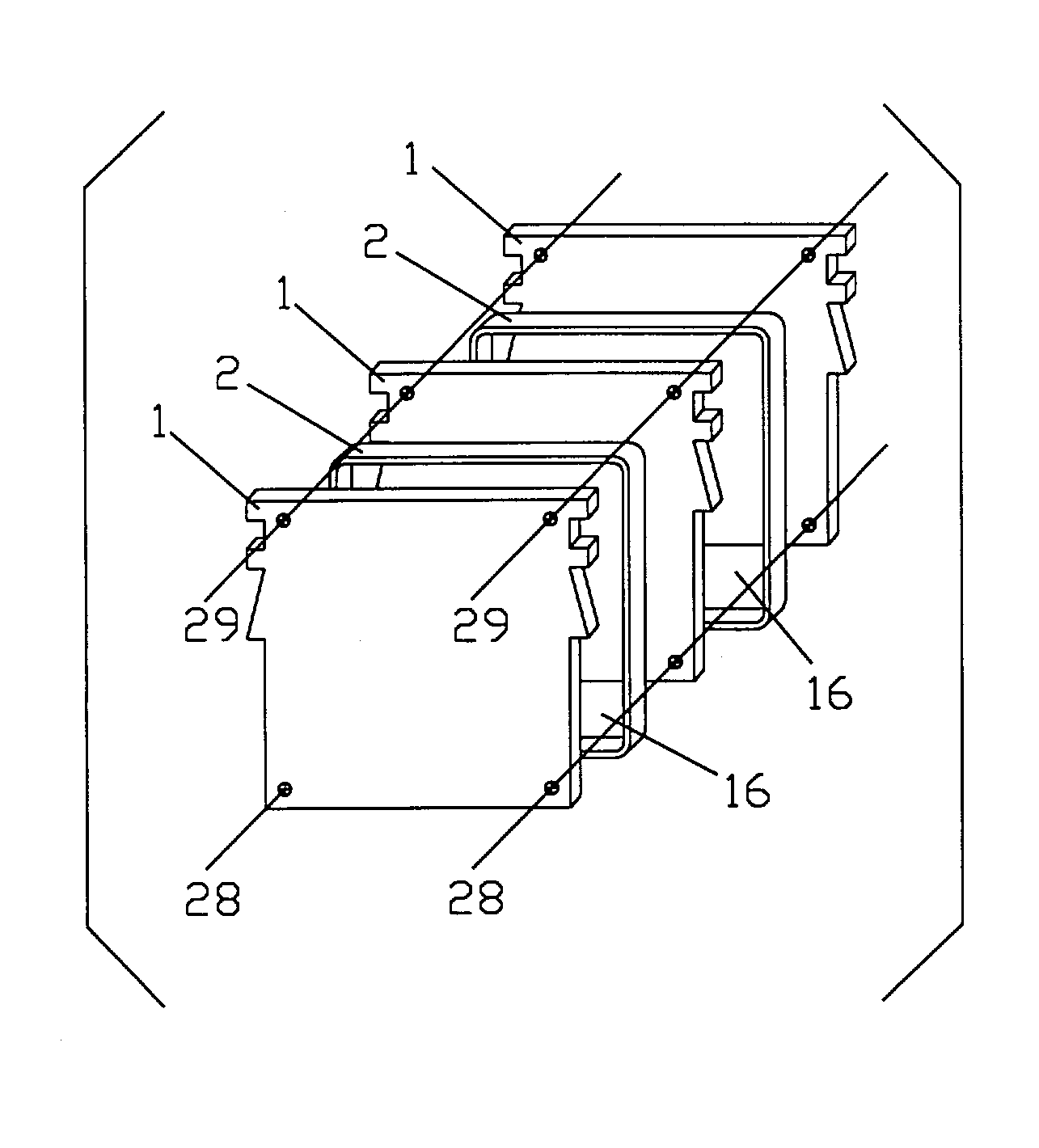

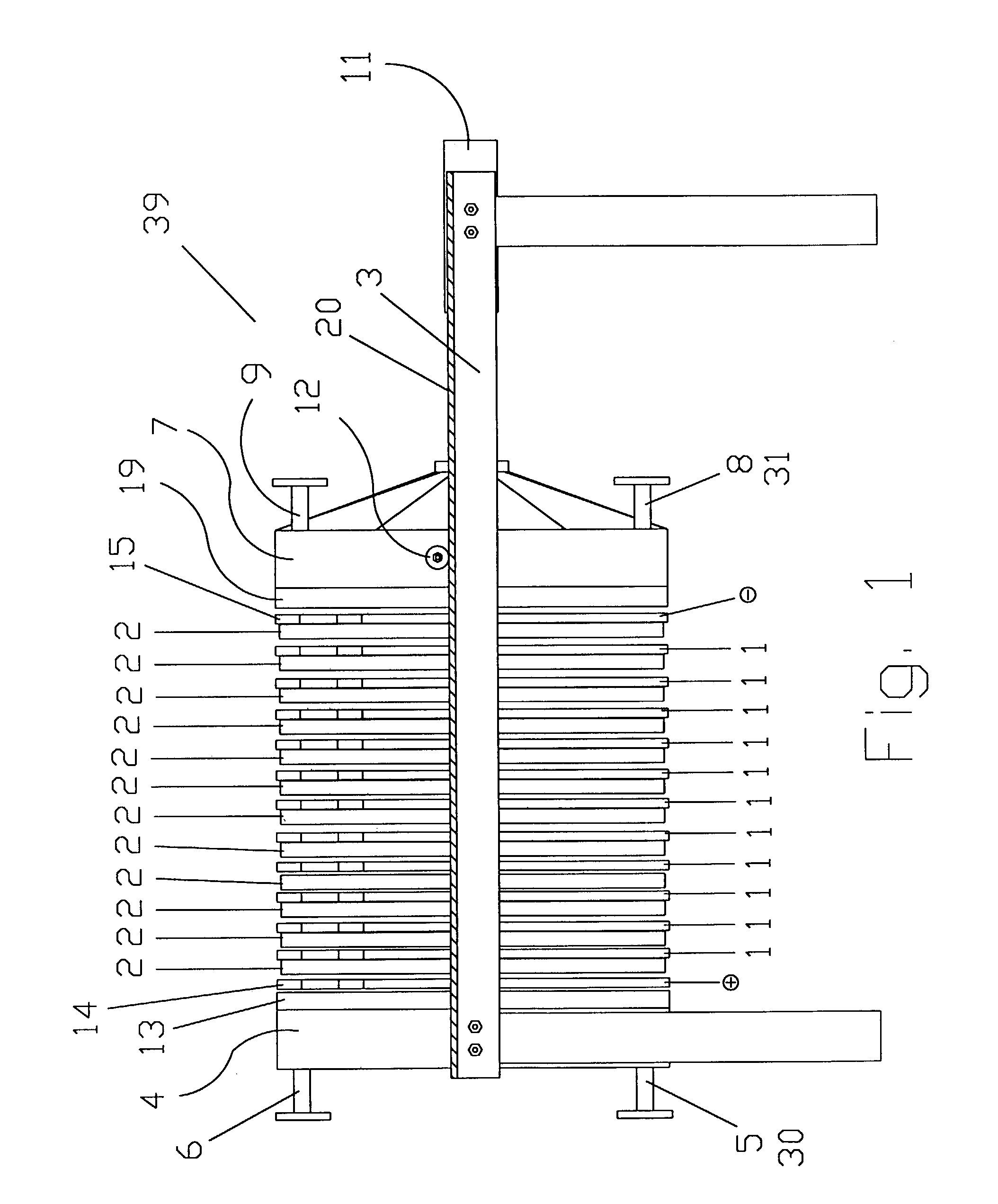

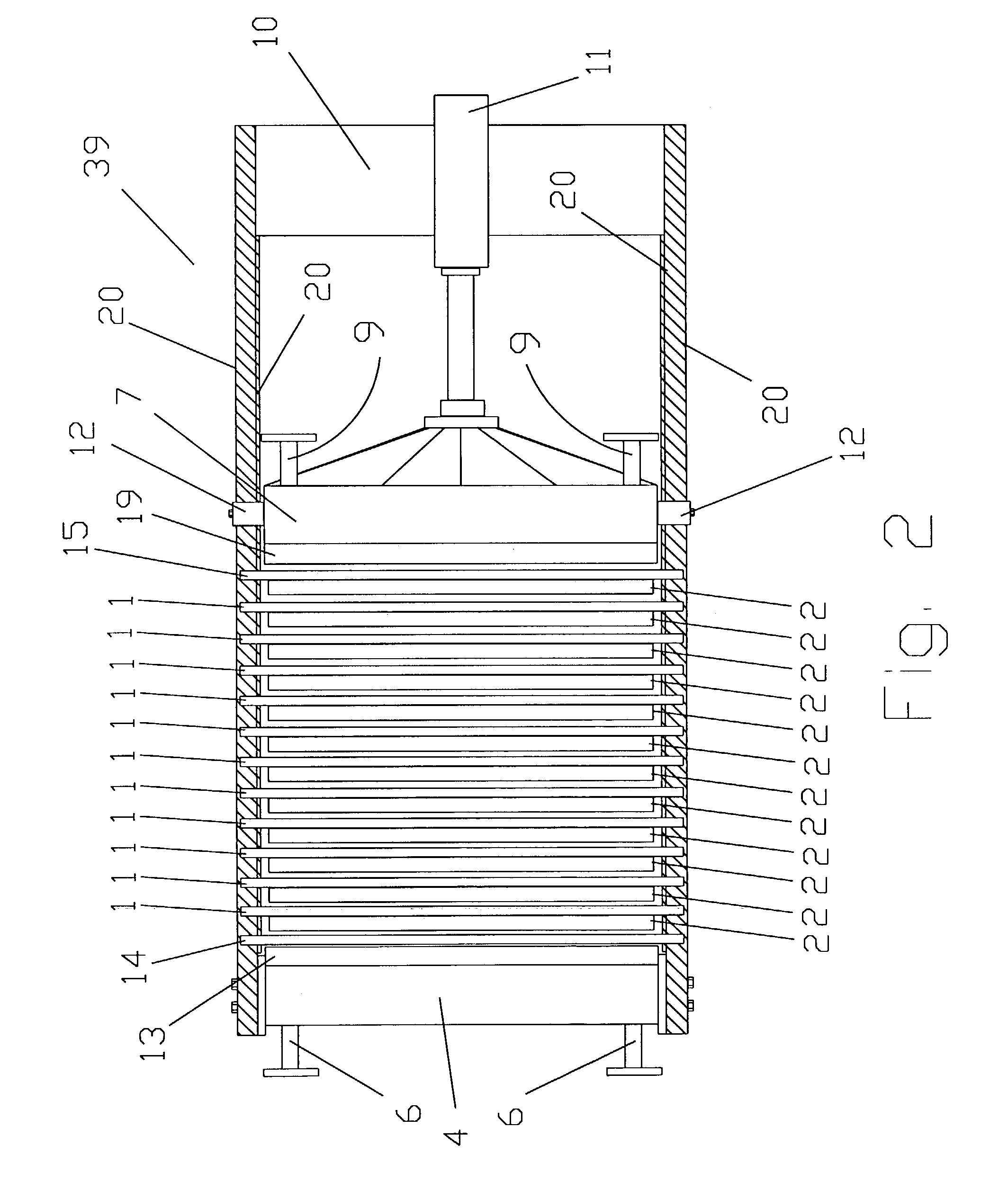

Industrial wastewater treatment and metals recovery apparatus

InactiveUS7309408B2Easy to manufactureElectrostatic separatorsLiquid separation by electricityElectrochemical responseElectrolysis

An apparatus for industrial wastewater treatment and the electrolytic recovery of metals from solutions is disclosed. It comprises two or more plates with electricity conducting surfaces arranged in parallel and separated by insulating gaskets, two heads and a hydraulic ram or other mechanical means to press the group of plates between the heads. Plates and gaskets pressed together form chambers where metal recovery and other electrochemical reactions take place. Holes bored on the plates or on the gaskets separating them allow the solutions to flow in and out of the chambers. The solutions in the chambers close the electrical circuit between the conducting surfaces of the plates and allow an electrical current to flow from one plate to the other closing also a circuit between the terminals of an electrical current source. The apparatus can be easily manufactured by retrofitting a conventional filter press to perform electrochemical reactions assisting in the separation and partial decomposition of anions and cations and the recovery of metals by electrolysis. The gaskets between plates may form channel-like chambers of intricate flow path creating a high turbulence that permits oxidation and reduction reactions as well as electrolytic metal recovery to effected at a wide range of current densities.

Owner:BENAVIDES ALFONSO GERARDO

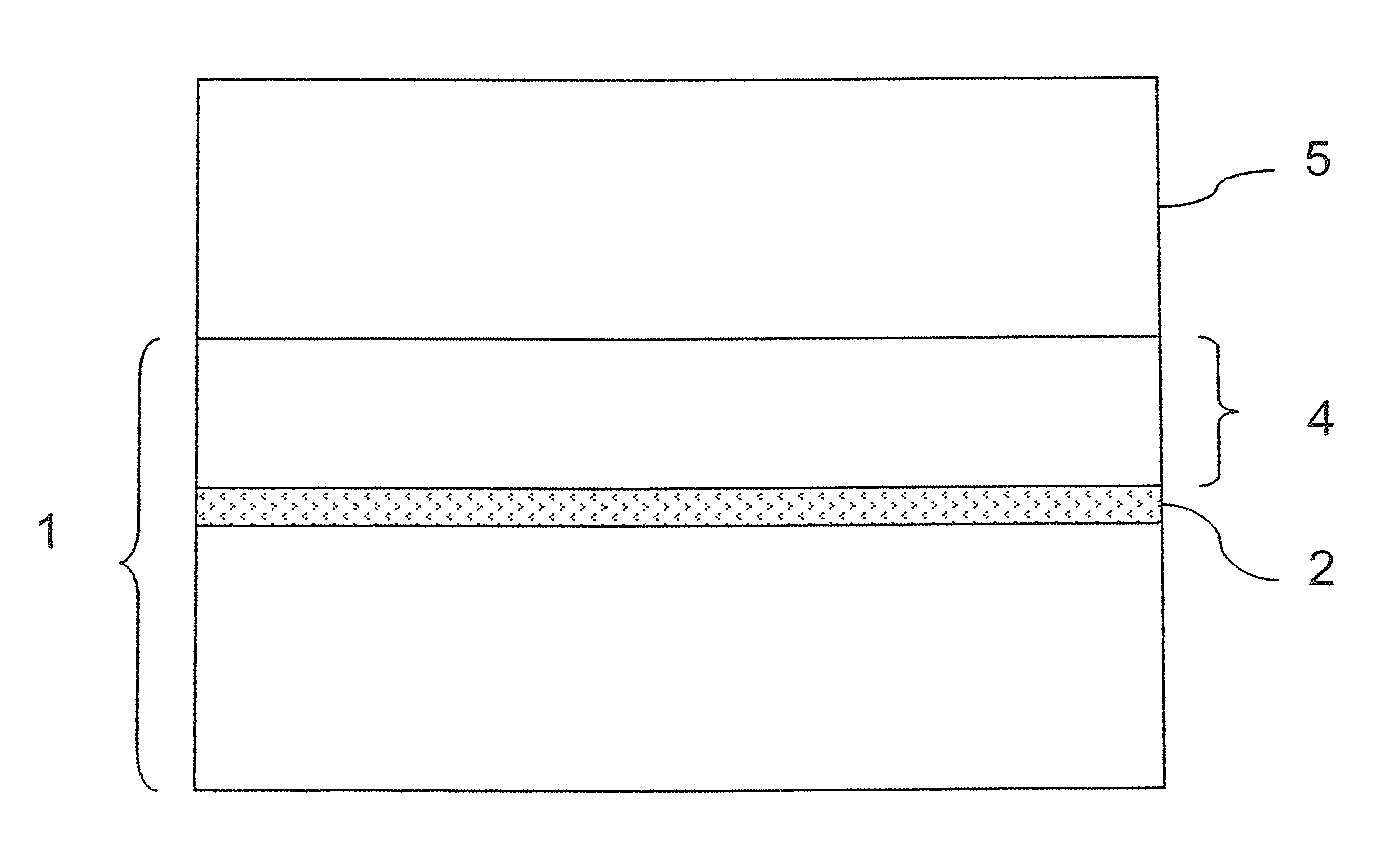

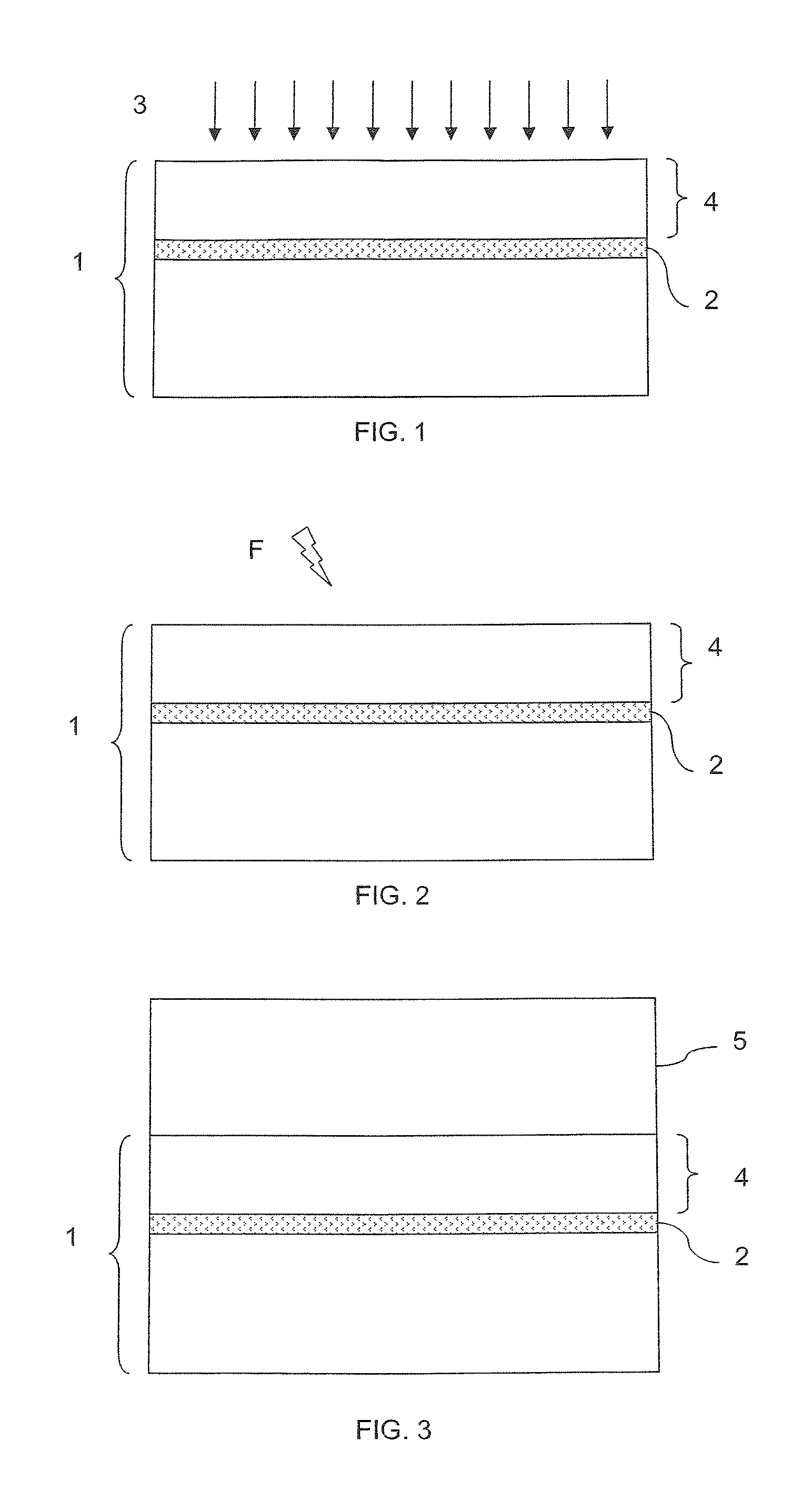

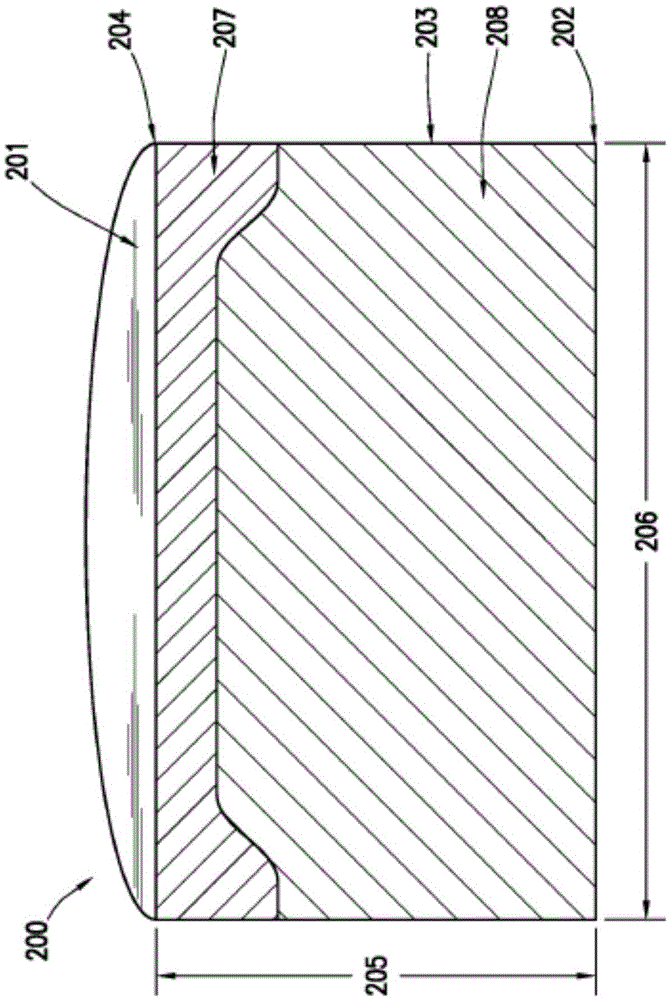

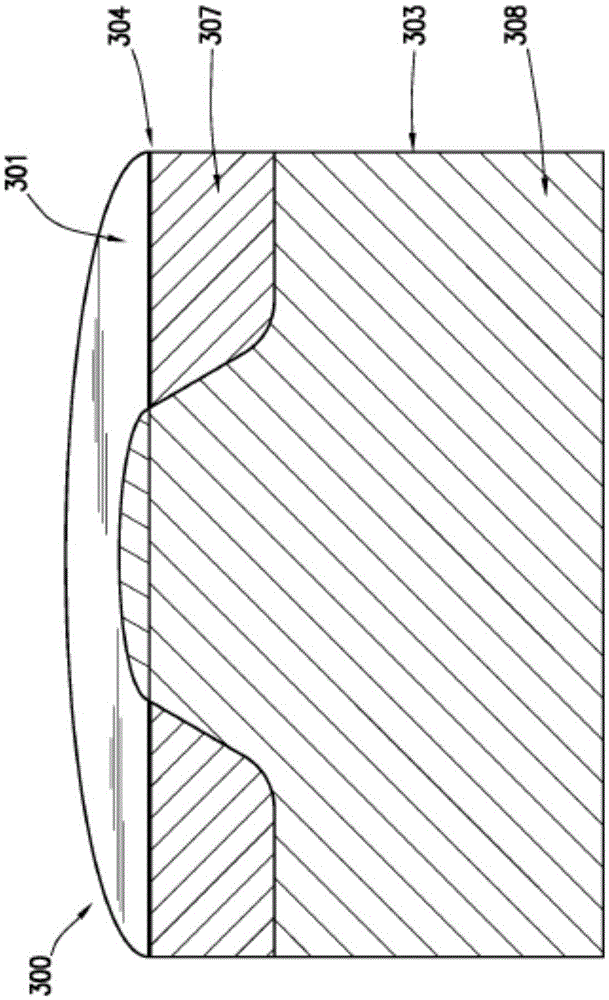

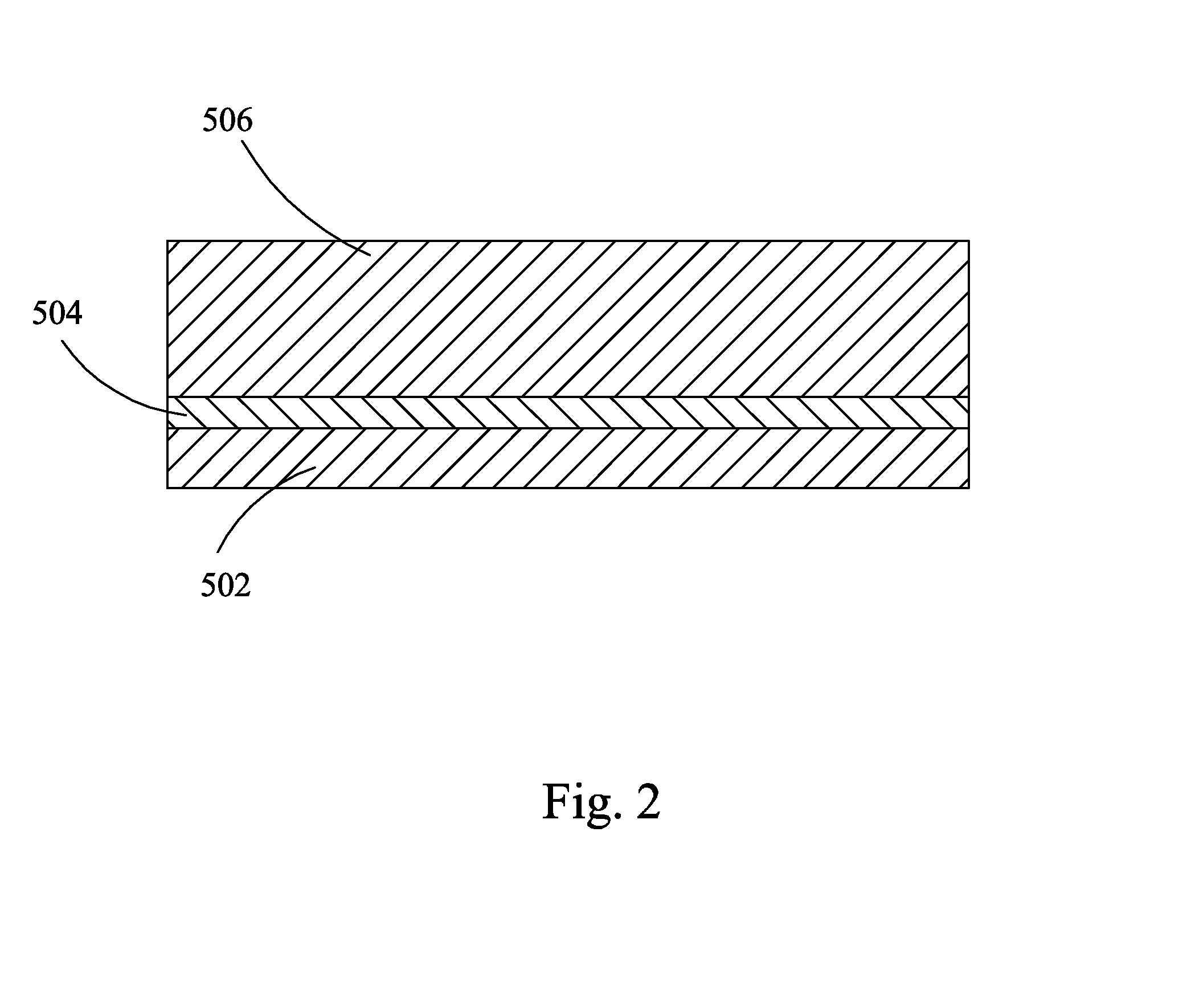

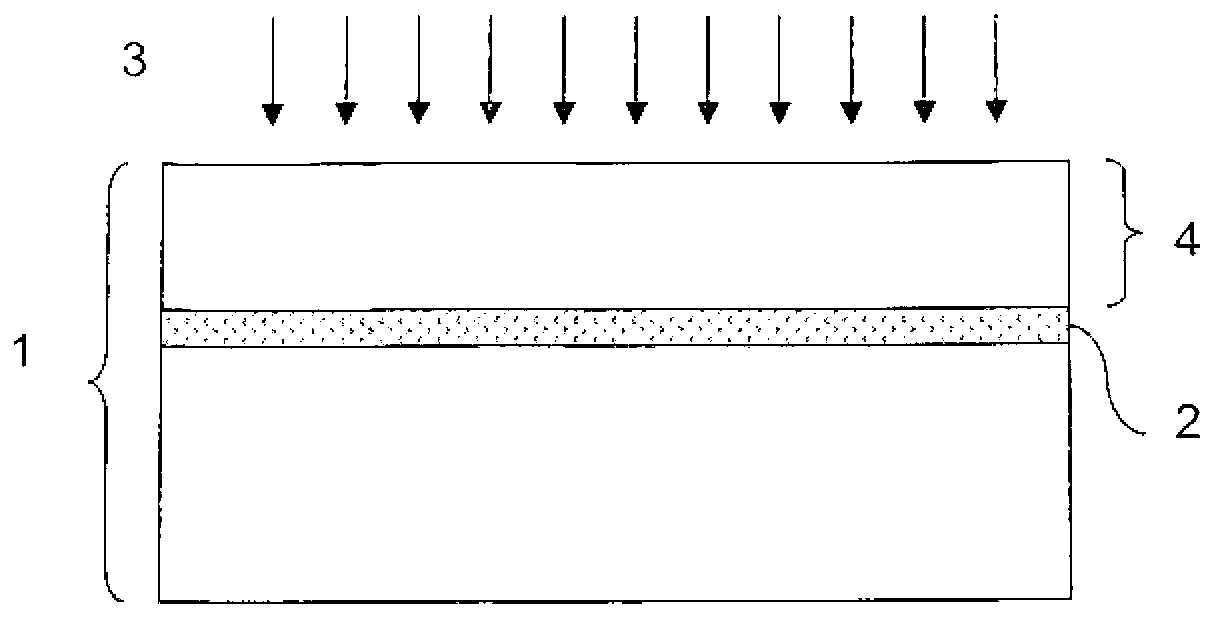

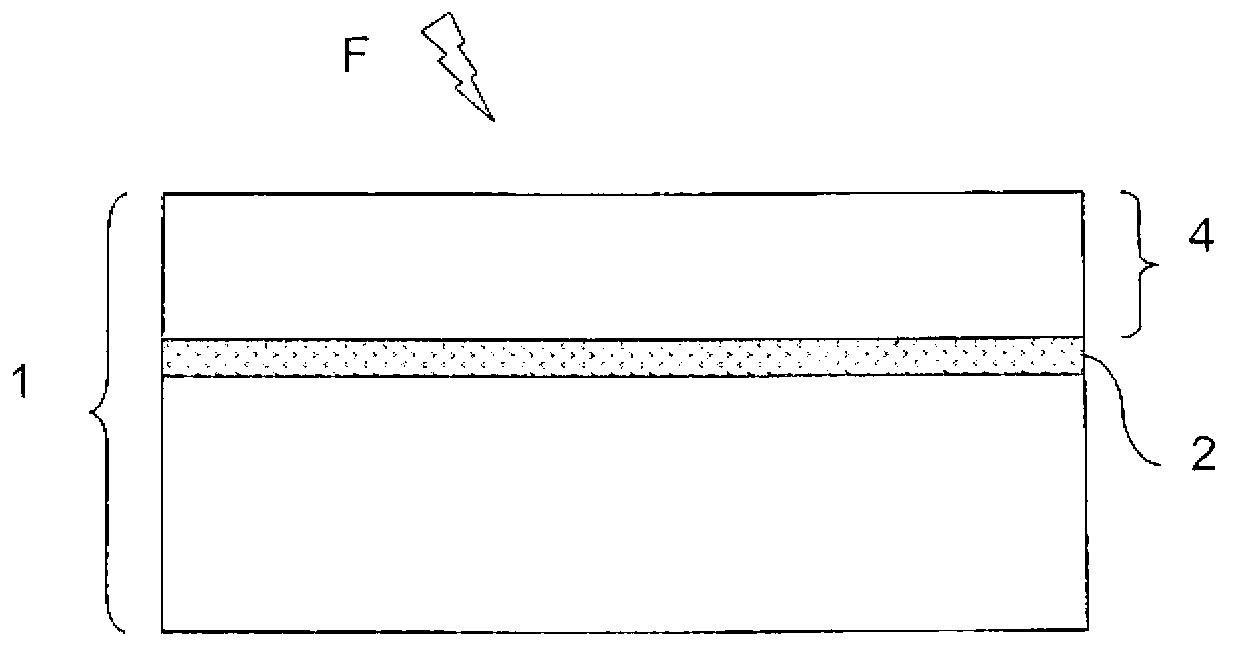

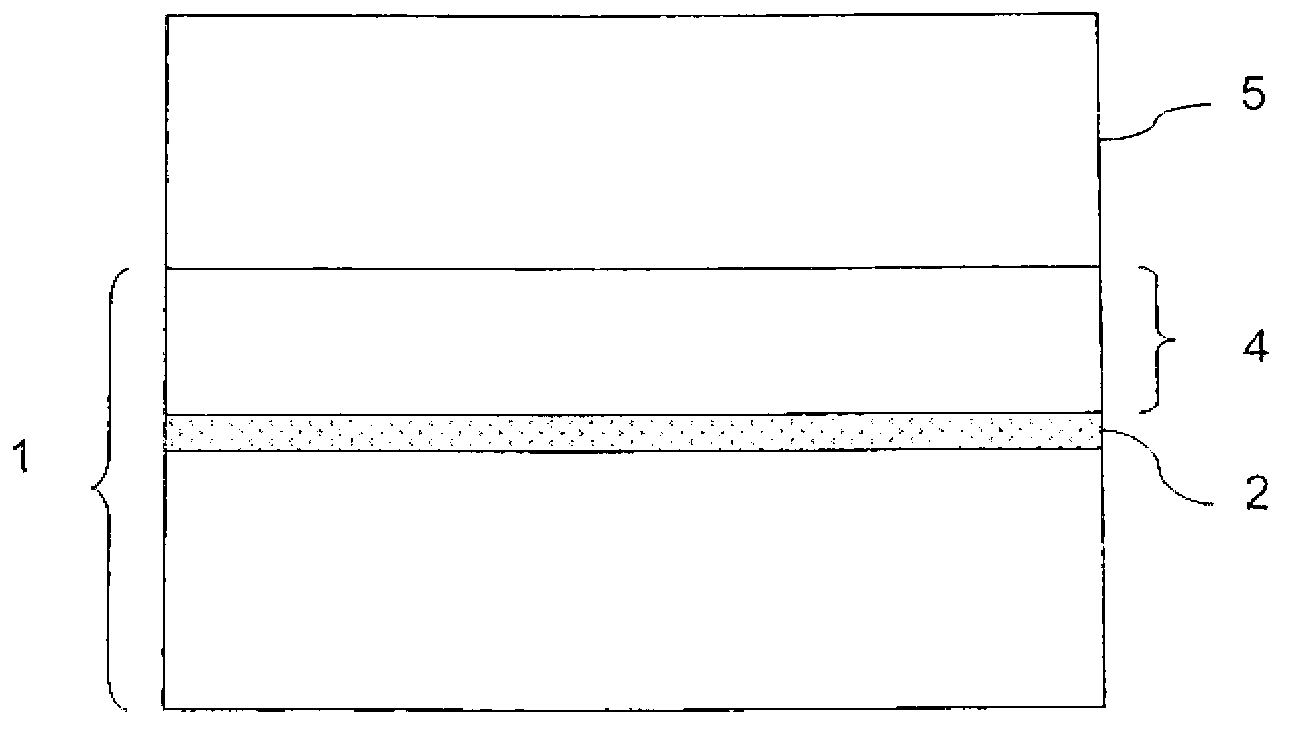

Method for preparing a substrate by implantation and irradiation

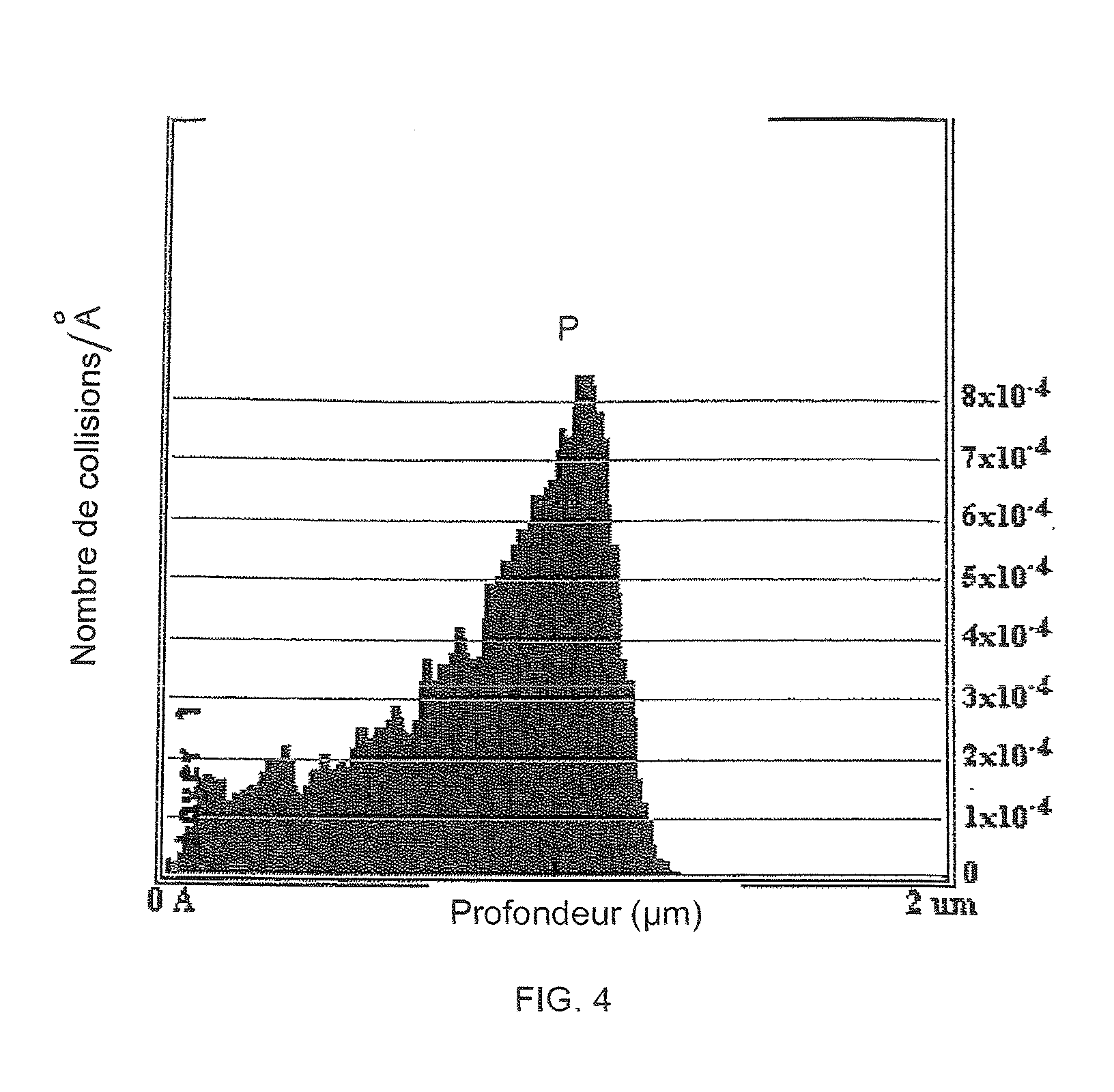

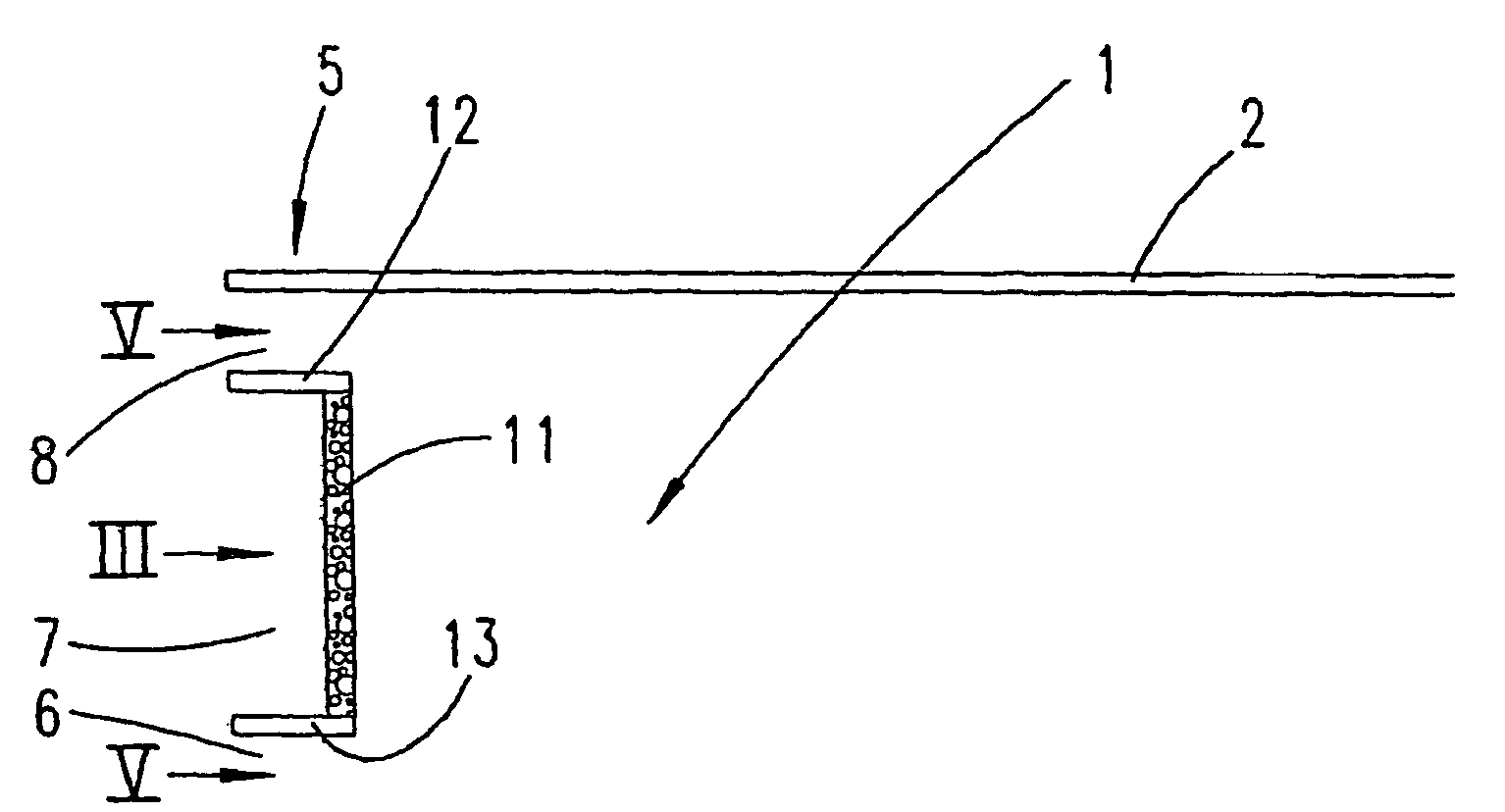

ActiveUS20130072009A1Reduce lightSemiconductor/solid-state device manufacturingLight fluxProcess region

A method for preparing a substrate for detaching a layer by irradiation of the substrate with a light flux for heating a buried region of the substrate and bringing about decomposition of the material of that region to detach said detachment layer. The method includes fabricating an intermediate substrate including a first buried layer, and a second covering layer that covers all or part of the first layer, with the covering layer being substantially transparent to the light flux and with the buried layer formed by implantation of particles into the substrate, followed by absorbing the flux, and selectively and adiabatically irradiating a treated region of the buried layer until at least partial decomposition of the material constituting it ensues.

Owner:SOITEC SA

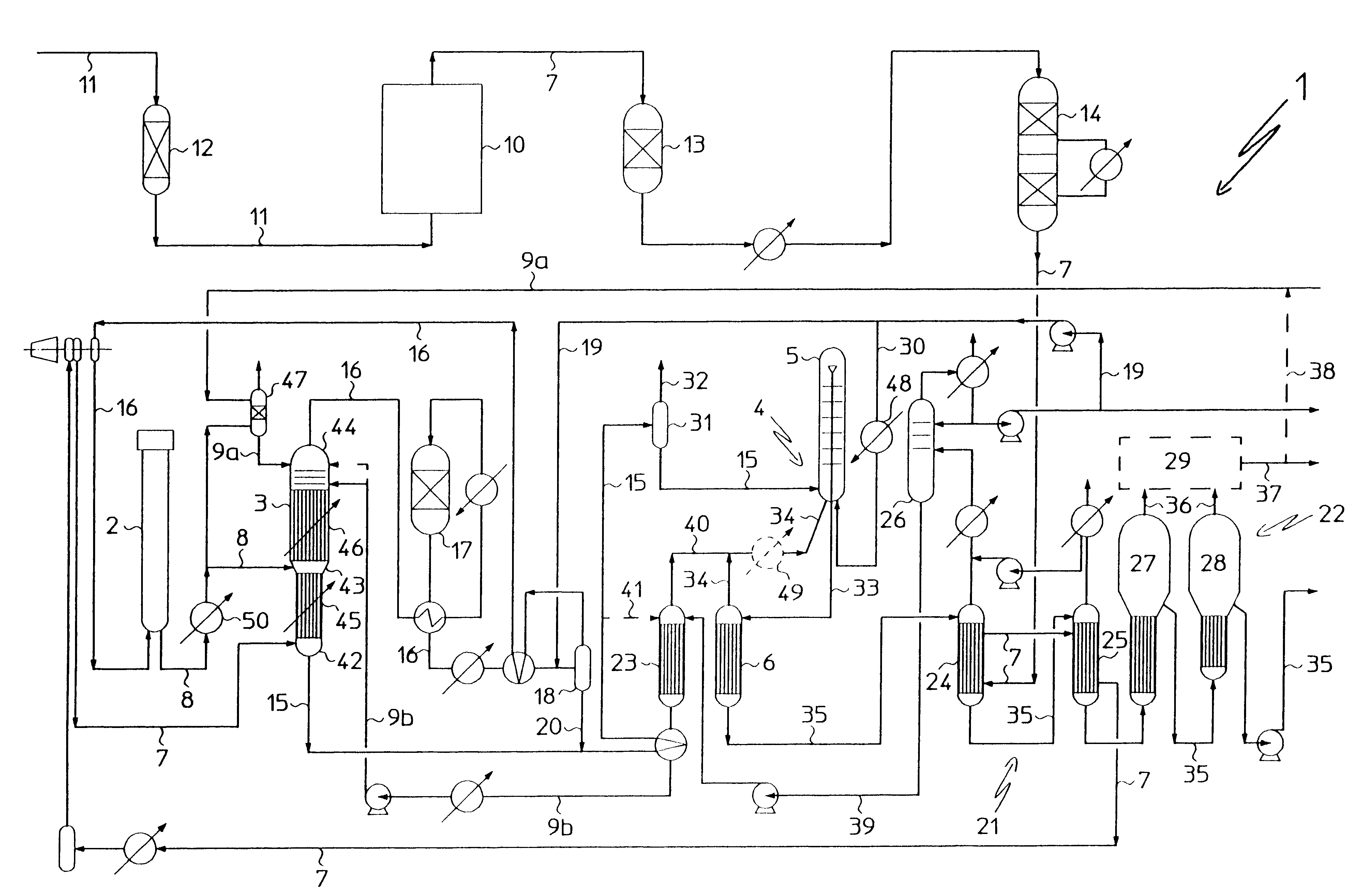

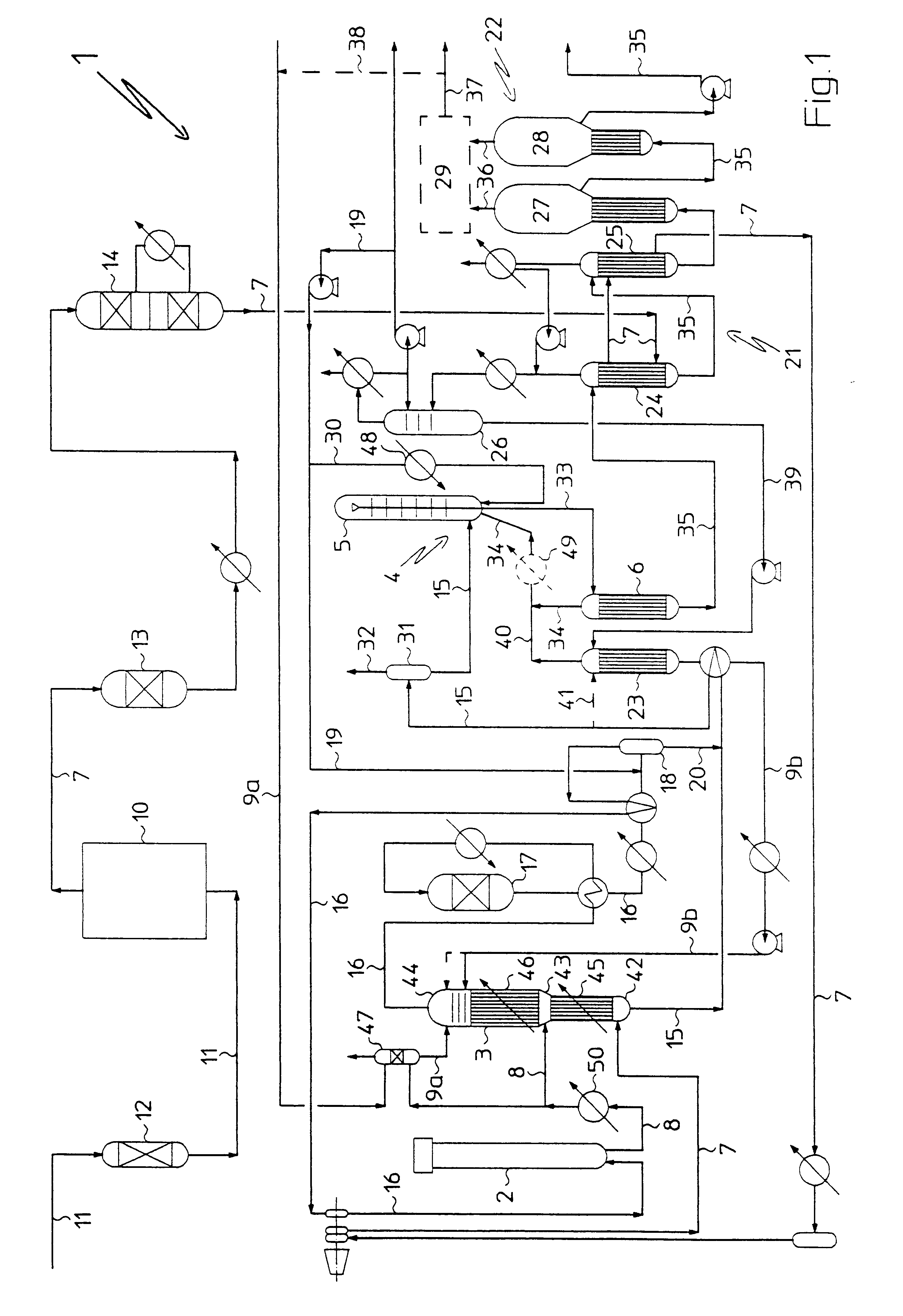

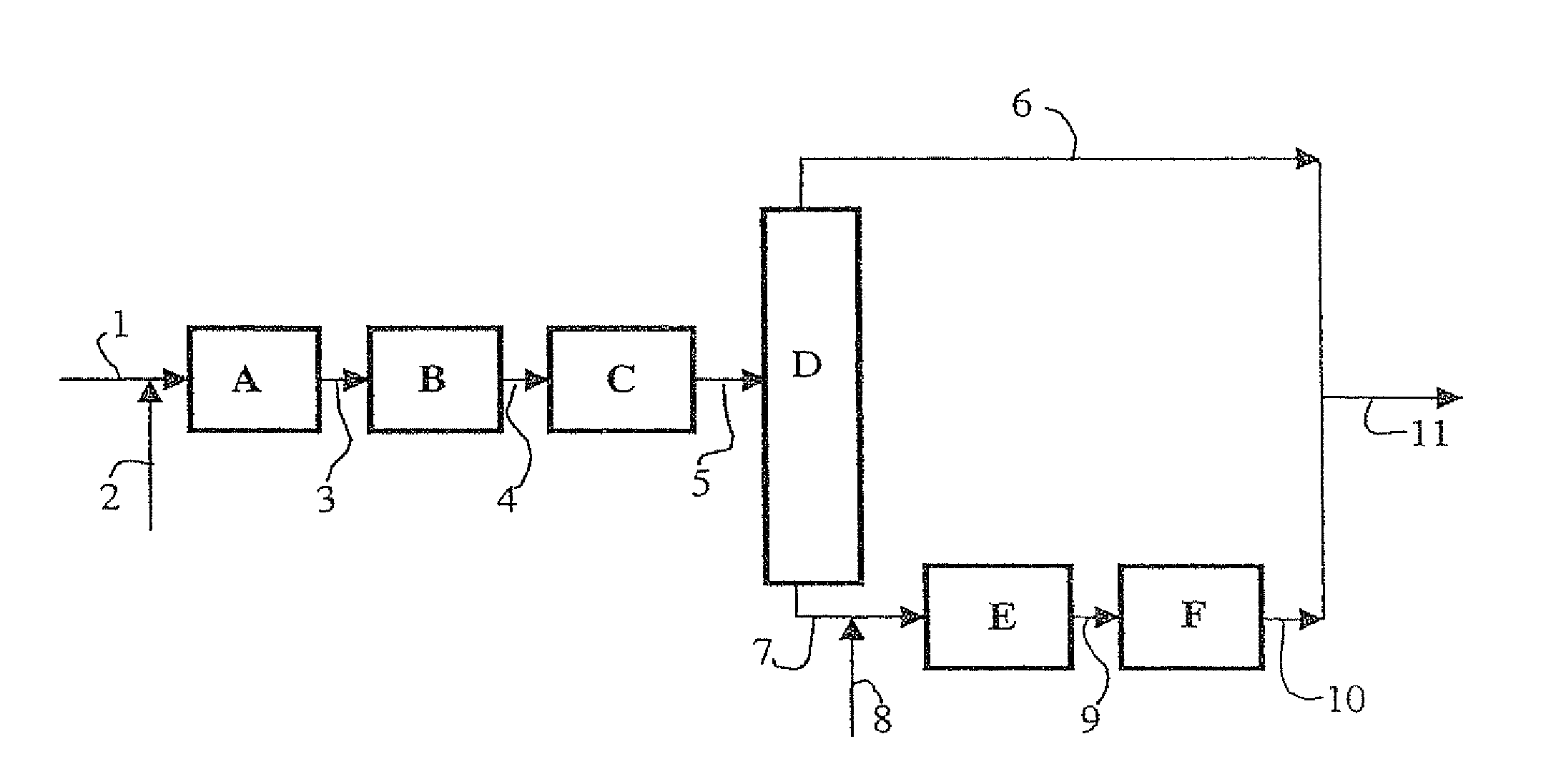

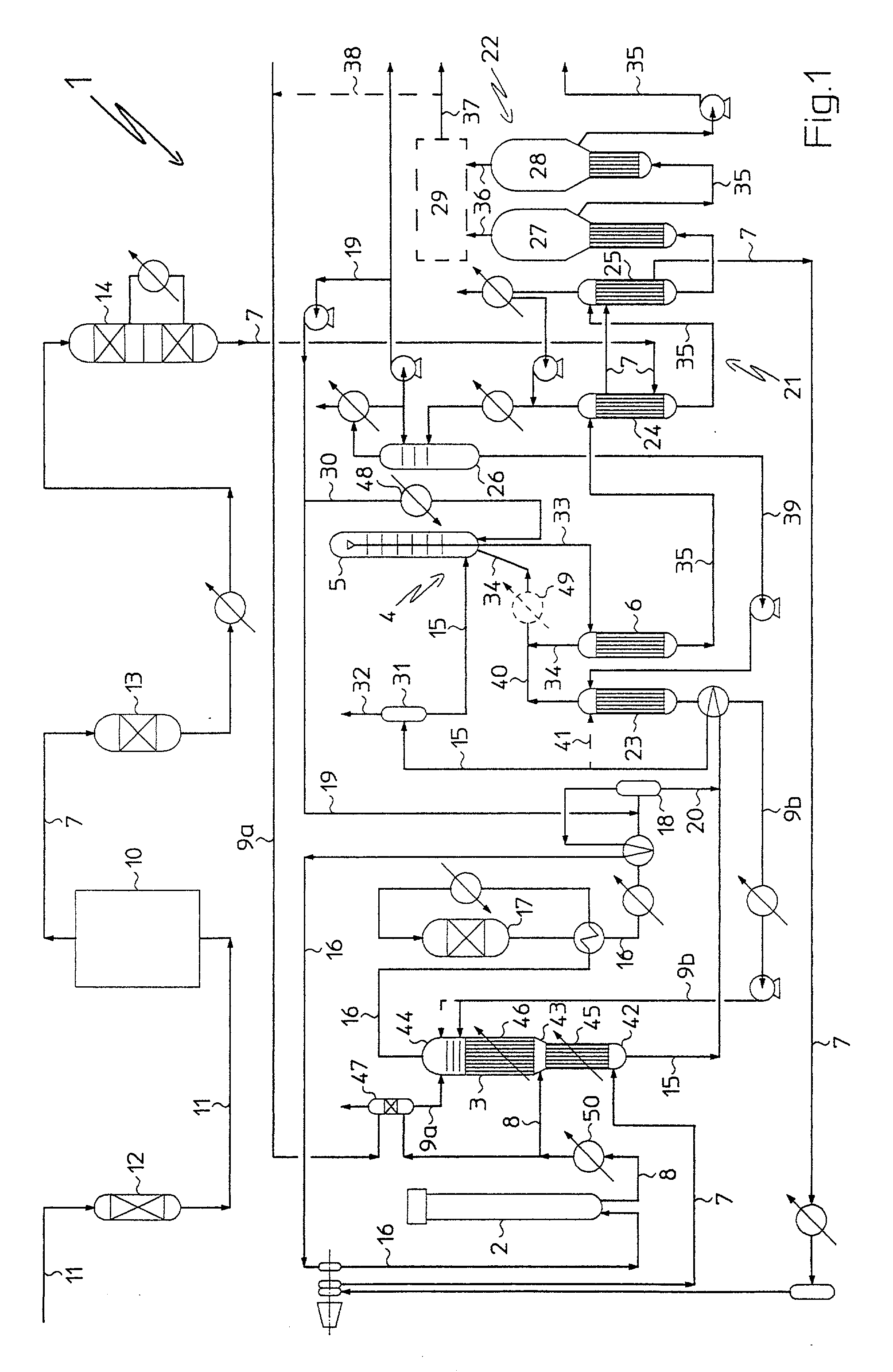

Process for combined production of ammonia and urea

InactiveUS6231827B1High yieldReduce consumptionUrea derivatives preparationOrganic compound preparationSteam reformingCarbamate

A process for the combined production of ammonia and urea of the type comprising an ammonia synthesis reactor (2), a urea synthesis reactor (5) and a urea recovery section (21) stands out for the fact of submitting at least a part of a flow comprising carbamate in aqueous solution coming from the urea recovery section (21) to a partial decomposition treatment, to obtain a flow comprising ammonia and carbon dioxide in vapor phase and a flow comprising diluted carbamate in aqueous solution, which is fed together with a gas flow comprising hydrogen, nitrogen and carbon dioxide, preferably obtained by hydrocarbons steam reforming, and a flow comprising ammonia coming from the ammonia synthesis reactor (2) to a carbamate synthesis section (3), where ammonia and carbon dioxide are caused to react, to obtain a flow comprising carbamate in aqueous solution and a gas flow comprising hydrogen and nitrogen. The flow comprising carbamate in aqueous solution is then sent to the urea synthesis reactor (5), while the gas flow comprising hydrogen and nitrogen is sent to the ammonia synthesis reactor (2).

Owner:UREA CASALE SA

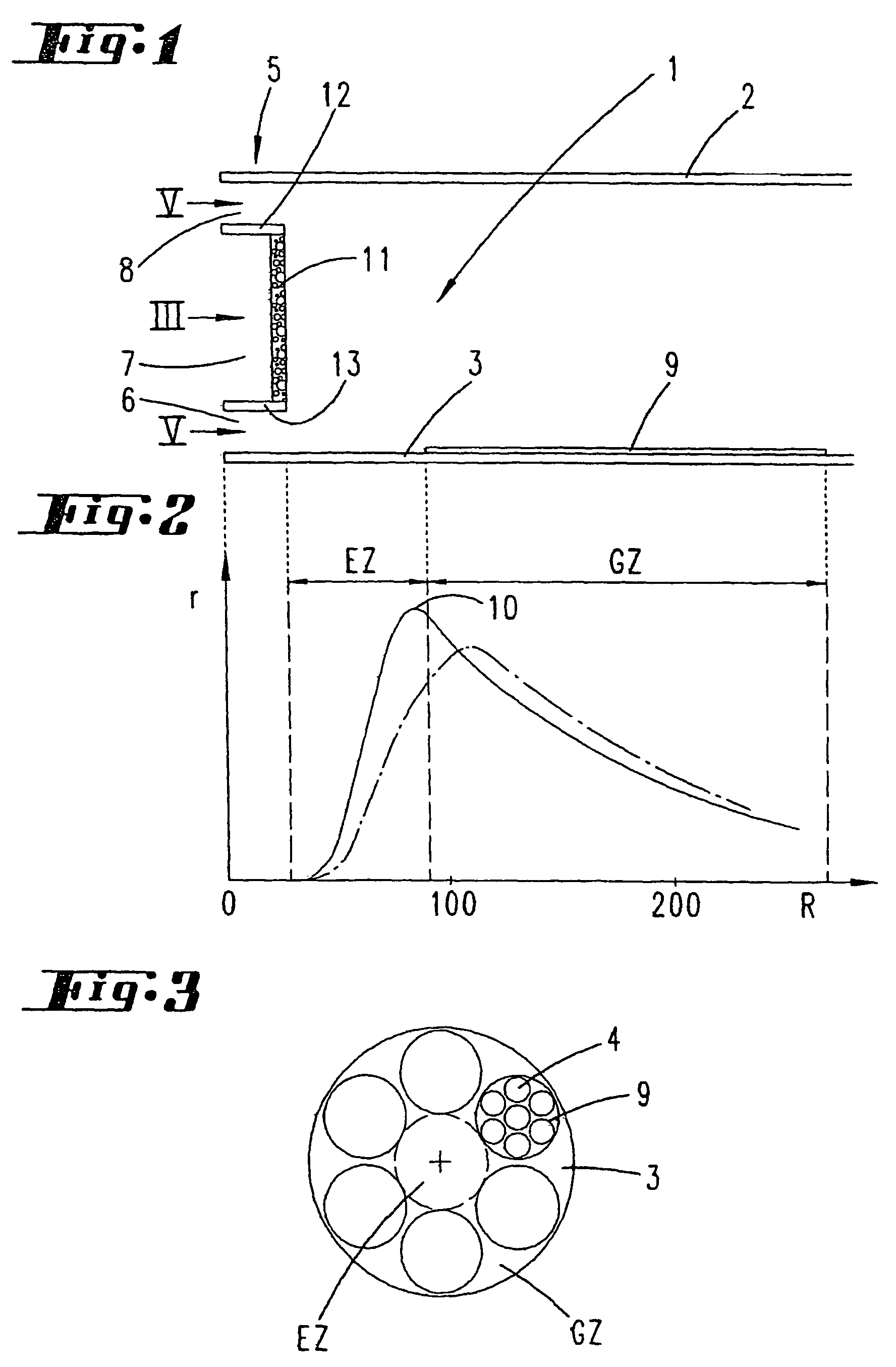

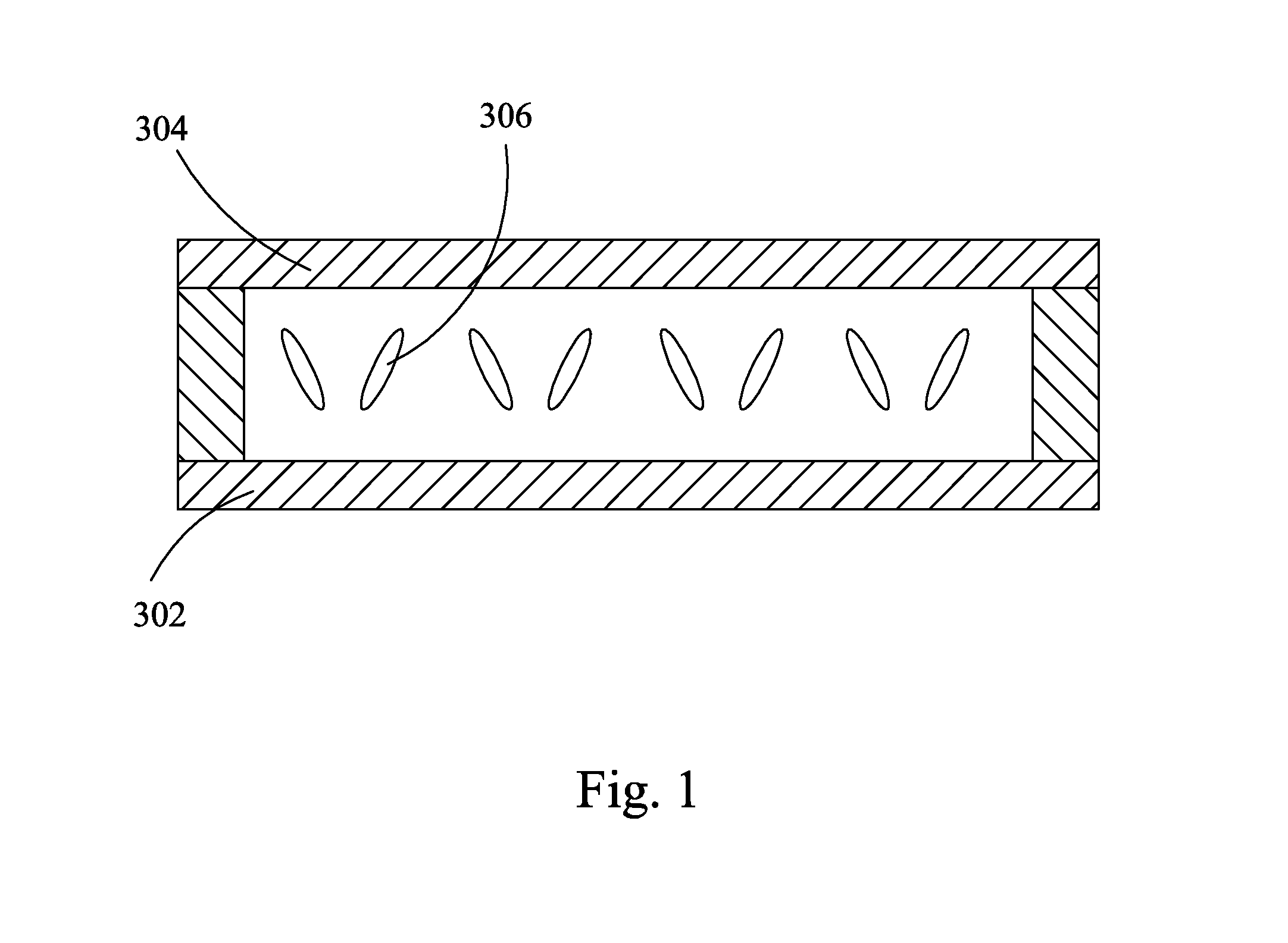

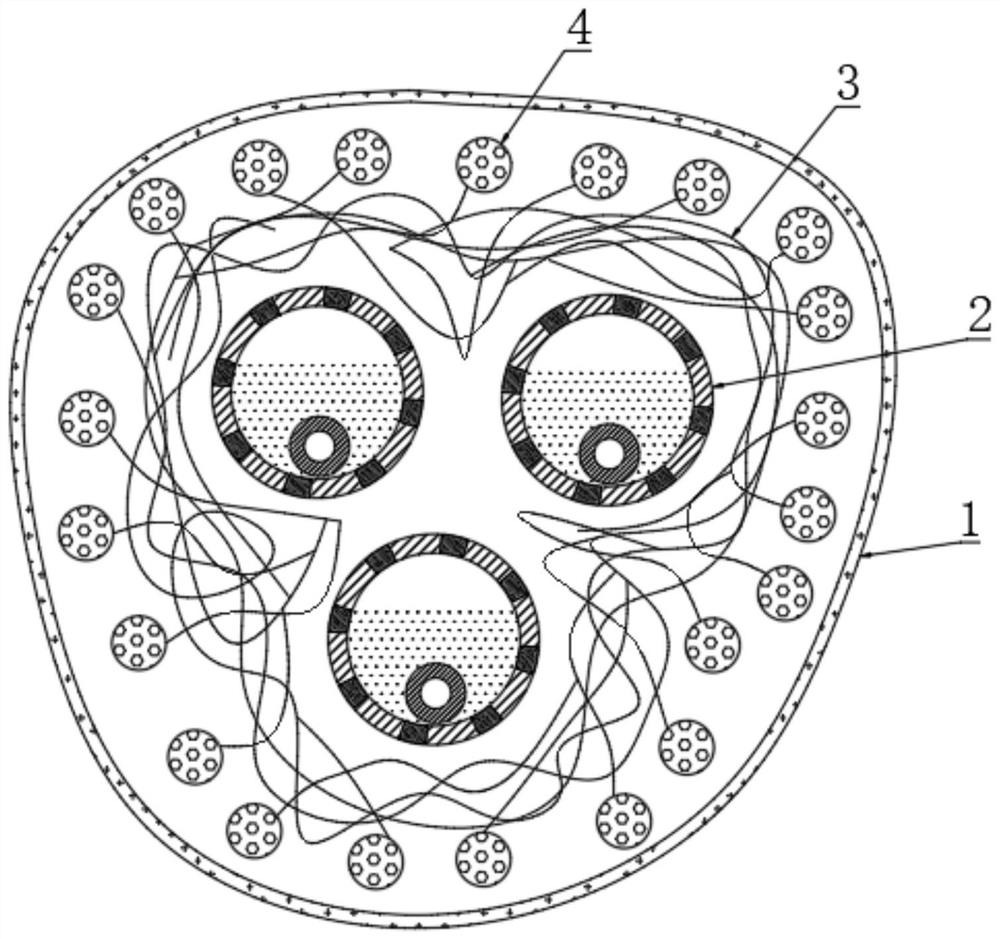

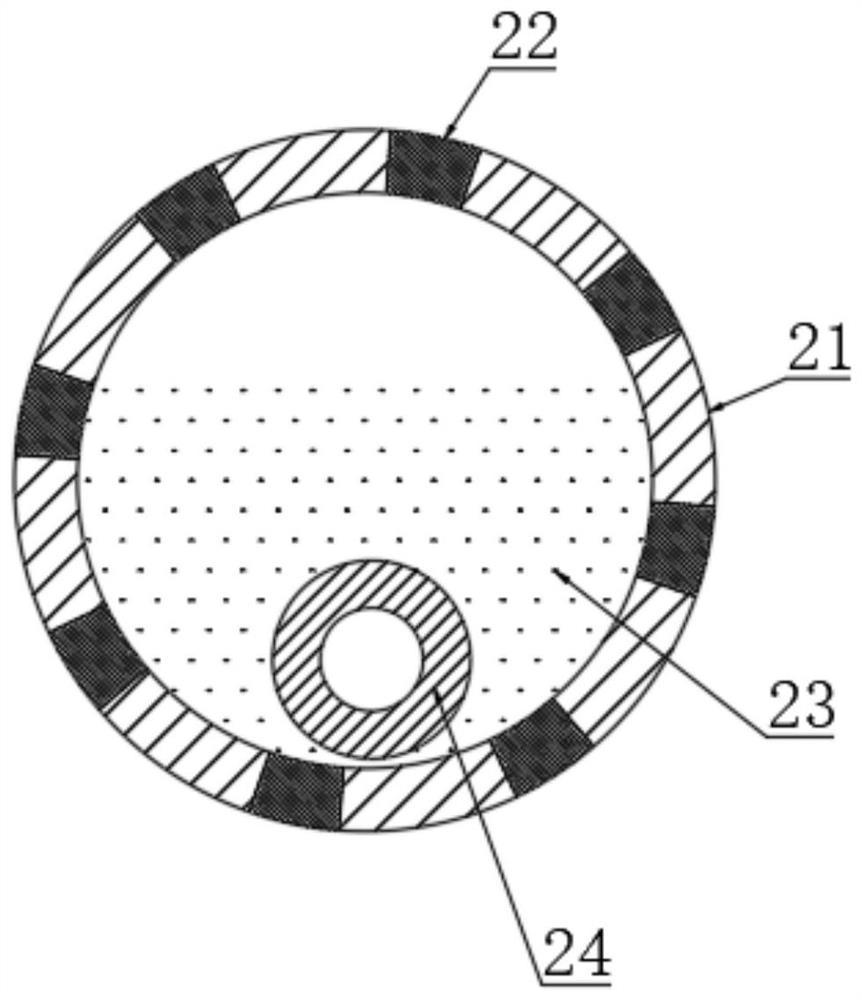

Inlet system for an MOCVD reactor

ActiveUS7625448B2Polycrystalline material growthFrom chemically reactive gasesDecompositionProduct gas

The invention relates to a device for depositing especially crystalline layers on at least one especially crystalline substrate in a process chamber comprising a top and a vertically opposing heated bottom for receiving the substrates. A gas-admittance body forming vertically superimposed gas-admittance regions is used to separately introduce at least one first and one second gaseous starting material, said starting materials flowing through the process chamber with a carrier gas in the horizontal direction. The gas flow homogenises in an admittance region directly adjacent to the gas-admittance body, and the starting materials are at least partially decomposed, forming decomposition products which are deposited on the substrates in a growth region adjacent to the admittance region, under continuous depletion of the gas flow. An additional gas-admittance region of the gas-admittance body is essential for one of the two starting materials, in order to reduce the horizontal extension of the admittance region.

Owner:AIXTRON AG

Partially decomposed catalyst and hydrocarbon oxidation processes using the same

The present invention is related to a hydrocarbon oxidation process. The process comprises bringing one or more hydrocarbons into contact with a source of oxygen in the presence of a radical initiator and a catalyst. The catalyst comprises an organic metal complex located on a catalyst support, and is obtained by partial decomposition of the organic metal complex. For example, the process can be used to produce dimethyl carbonate from dimethoxy methane. The invention is also related to a partially decomposed catalyst that comprises a silica support and an organic metal complex, wherein at least 5% of the organic compound remains in the catalyst. The organic metal complex comprises an organic compound and a metal-based compound wherein the metal is selected from copper, nickel, and combinations thereof. The invention is also related to a process for manufacturing of a catalyst comprising mixing L-arginine, a Cu-based compound, water, and optionally another metal-based compound to form a solution; impregnating the solution onto a silica support to form a catalyst precursor; and partially decomposing the L-arginine to form the catalyst so that at least 5% of L-arginine remains in the catalyst.

Owner:EXXON RES & ENG CO

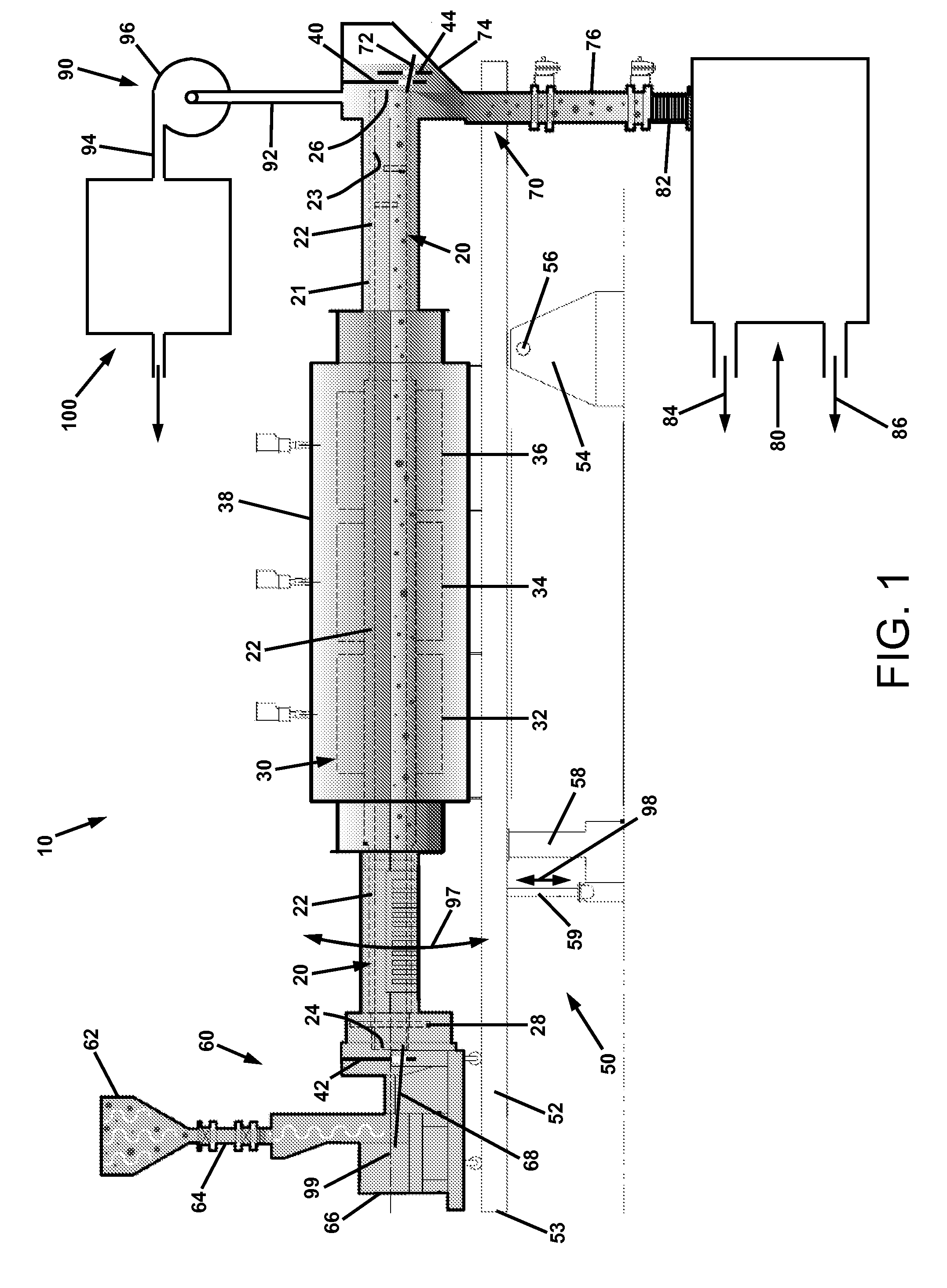

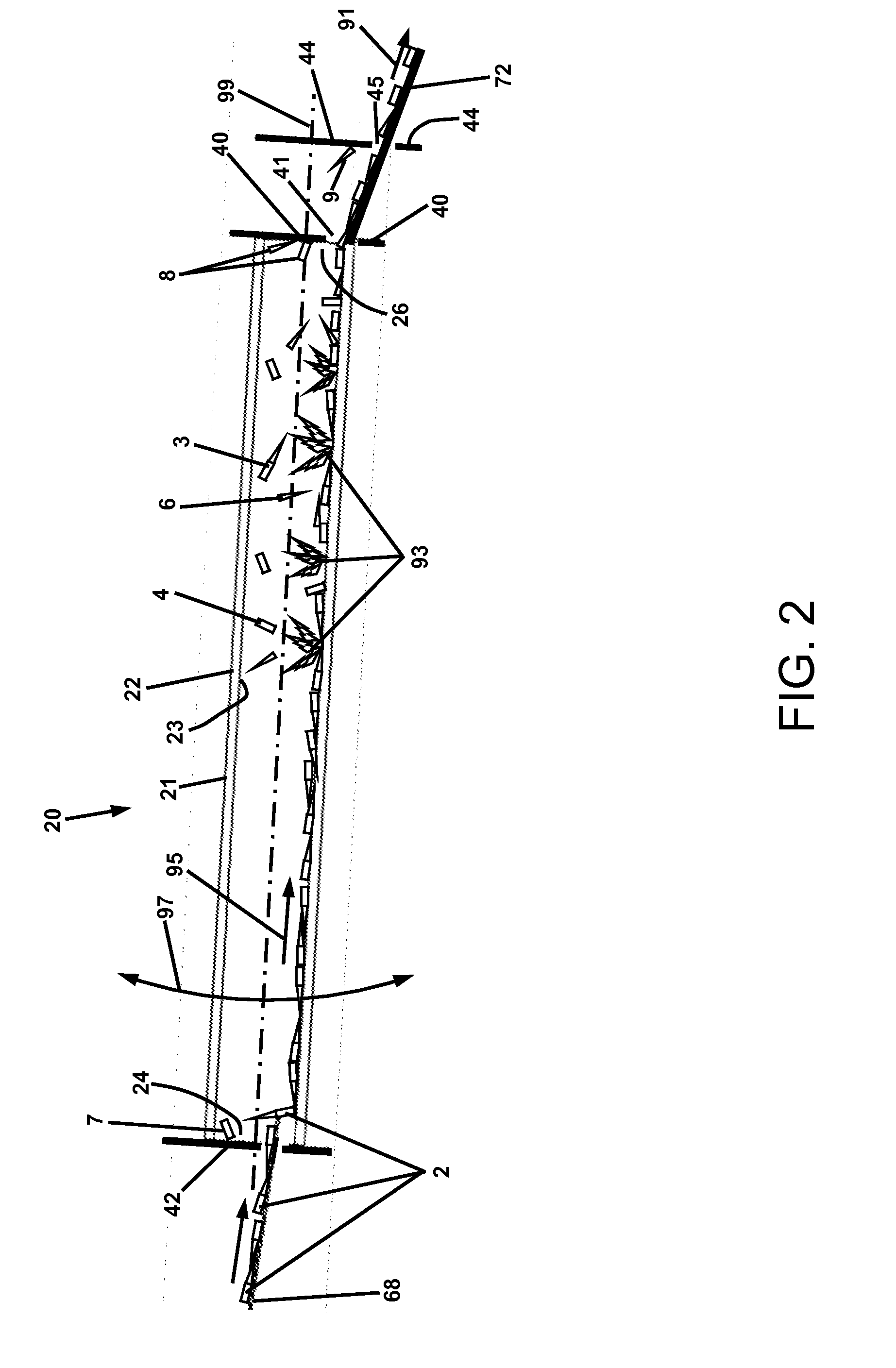

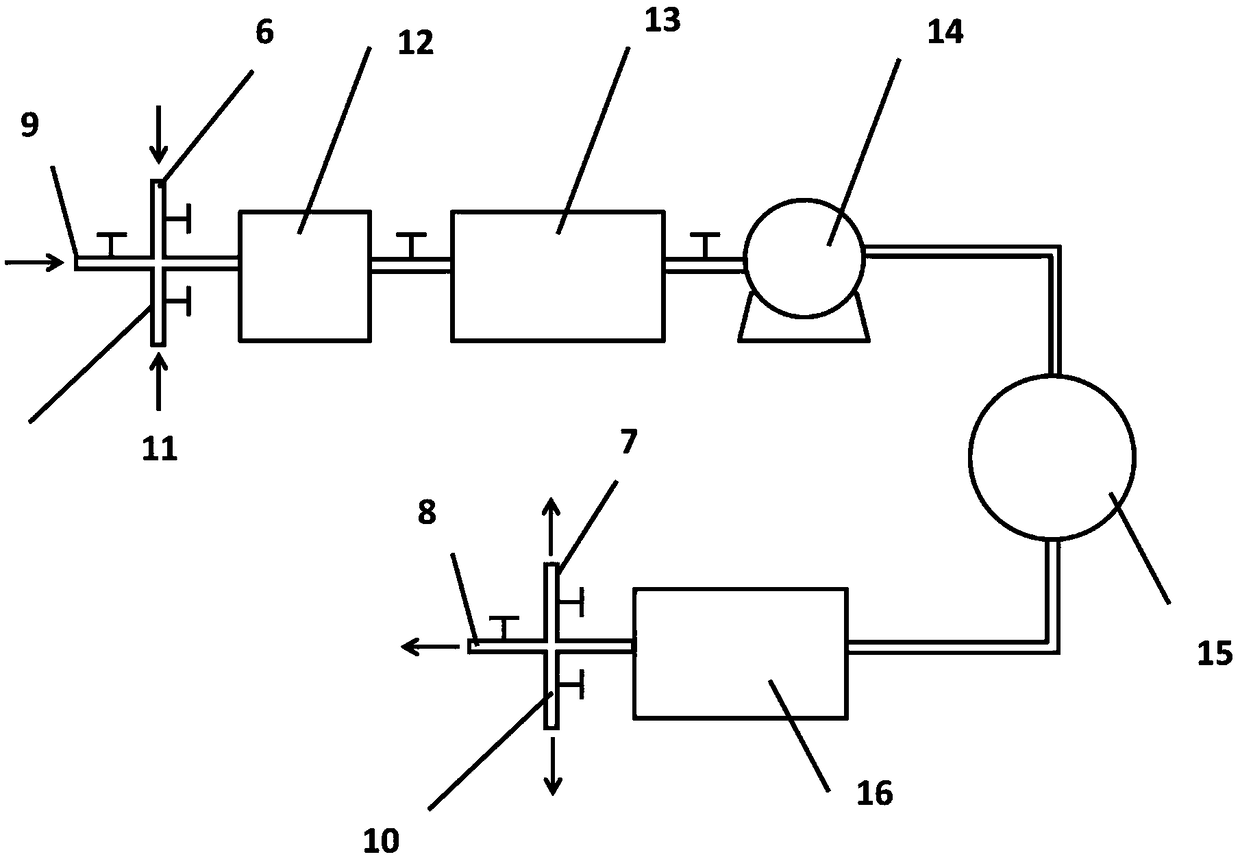

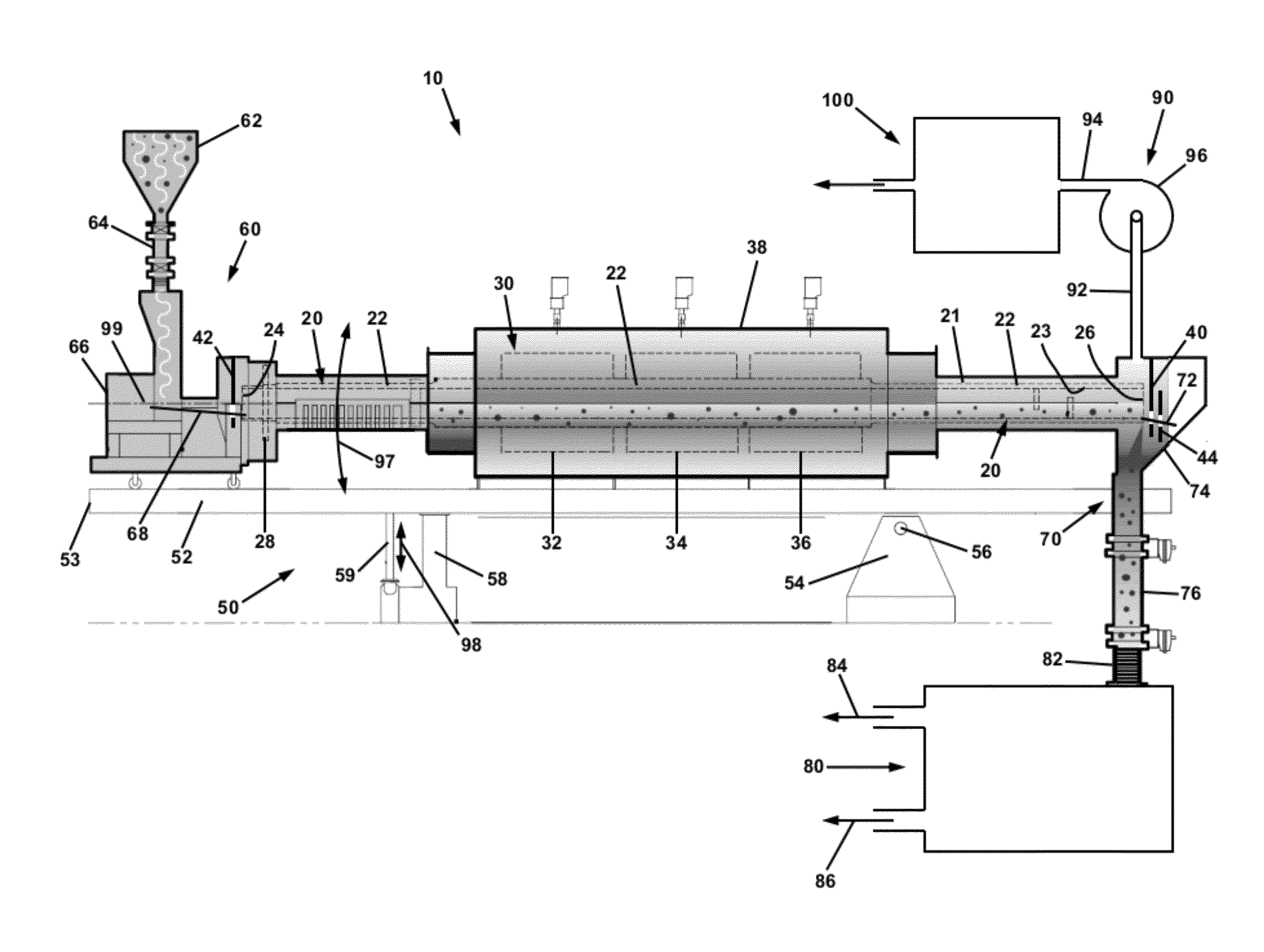

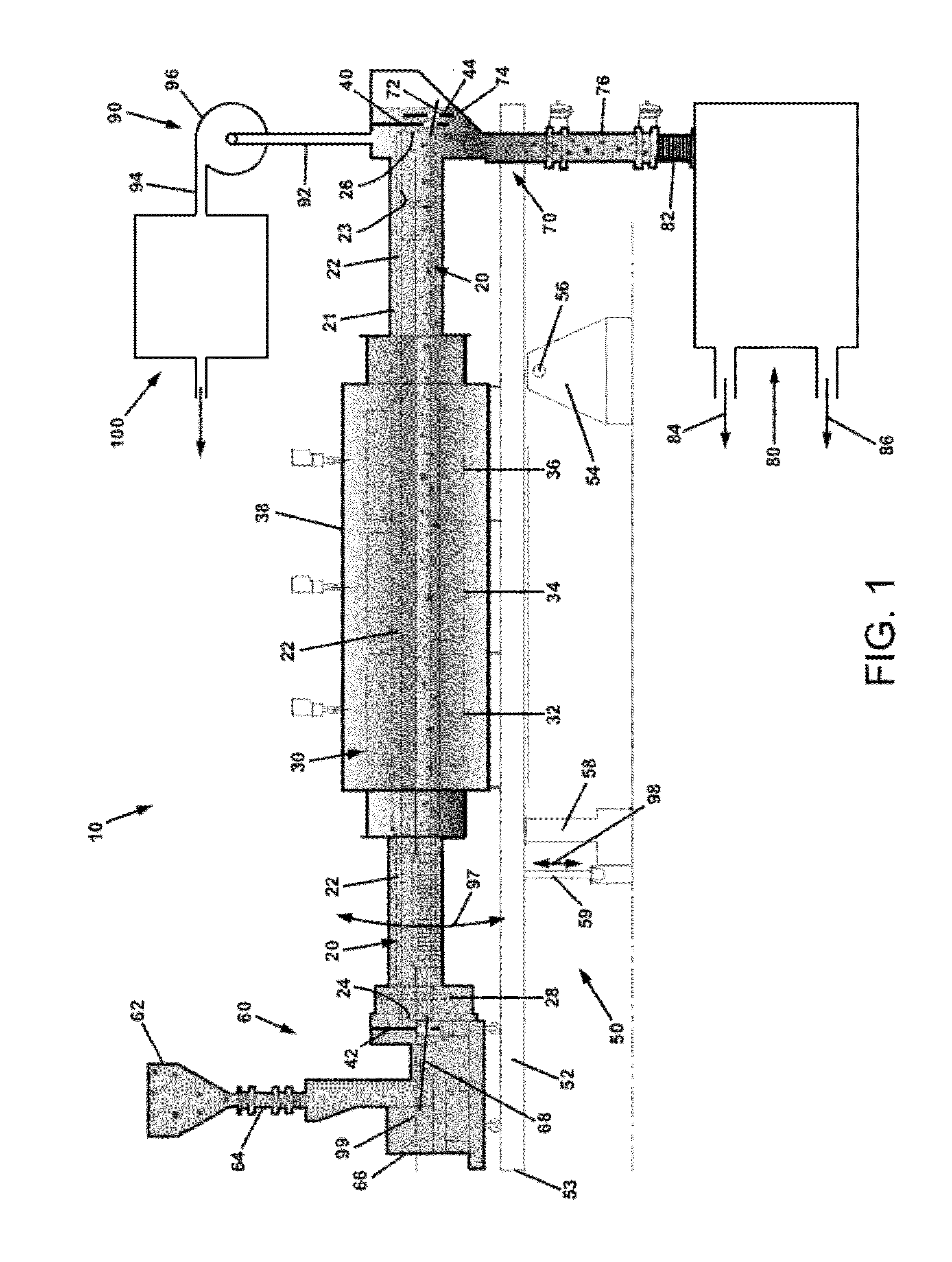

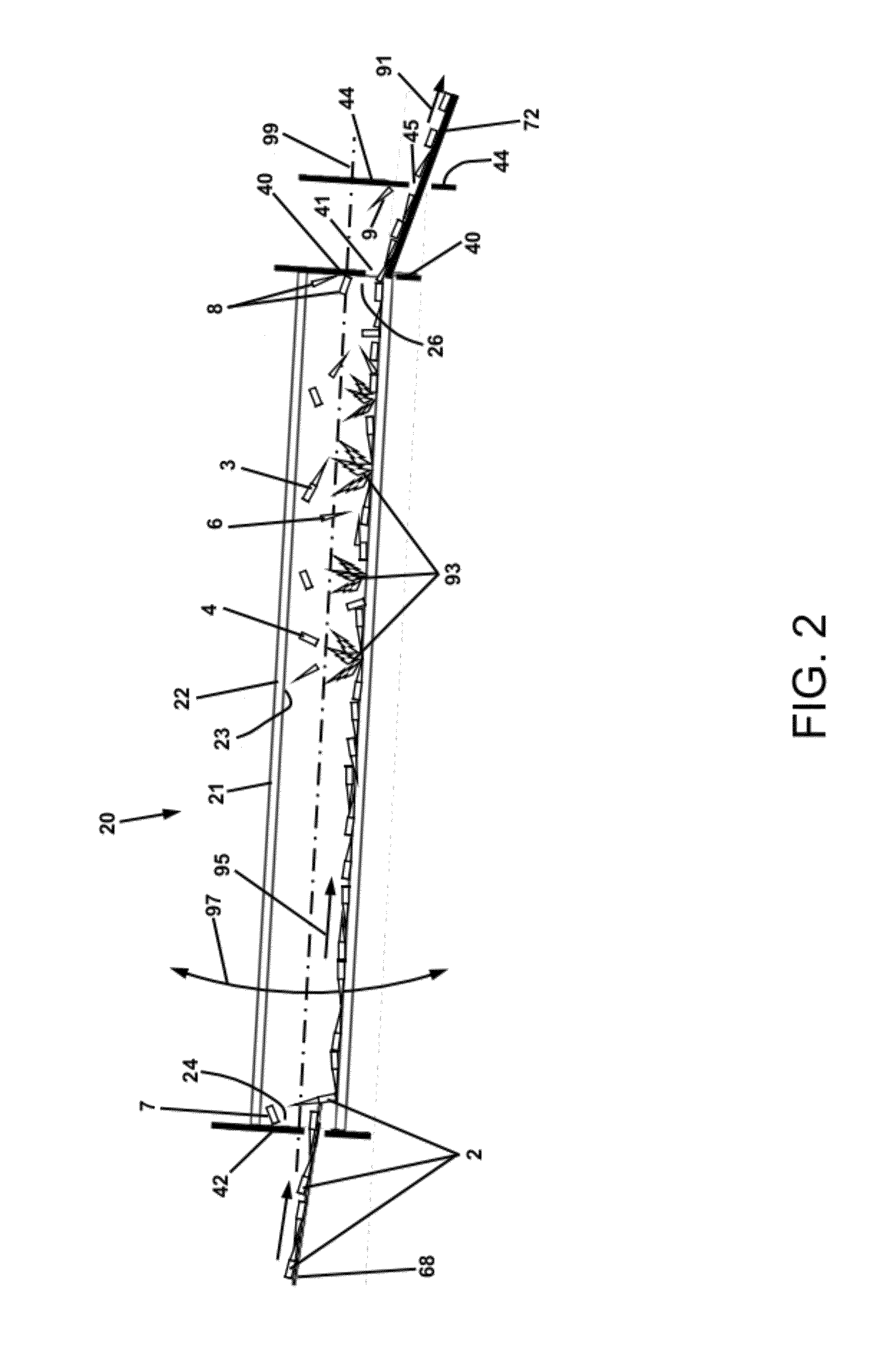

Method and apparatus to demilitarize munition energetics

ActiveUS20120259149A1Maximized recovery/recycling or responsible disposalAmmunitionBlastingThermodynamicsCombustion

A method of demilitarizing an energetic is disclosed. The method comprises indirectly heating the energetic in a chamber to a temperature below a combustion temperature of the energetic to at least partially decompose the energetic and substantially preclude combustion of the energetic such that the indirect heating produces a decomposition gas, and separating at least a portion of the decomposition gas from the chamber. The method may further comprise monitoring the decomposition gas and / or passing the separated decomposition gas through an air abatement system. The method may further comprise adjusting at least one of the following: the indirect heating of the energetic, the separating of the decomposition gas, the air abatement system, and a residence time of the energetic in the chamber. The energetic may be a bulk energetic.

Owner:U S DEMIL

Process for the production of a desulfurized gasoline from a gasoline fraction that contains conversion gasoline

InactiveUS8652321B2Reduce sulfur contentHydrocarbon by hydrogenationHydrocarbon purification/separationAlkyl transferFractionation

Owner:INST FR DU PETROLE

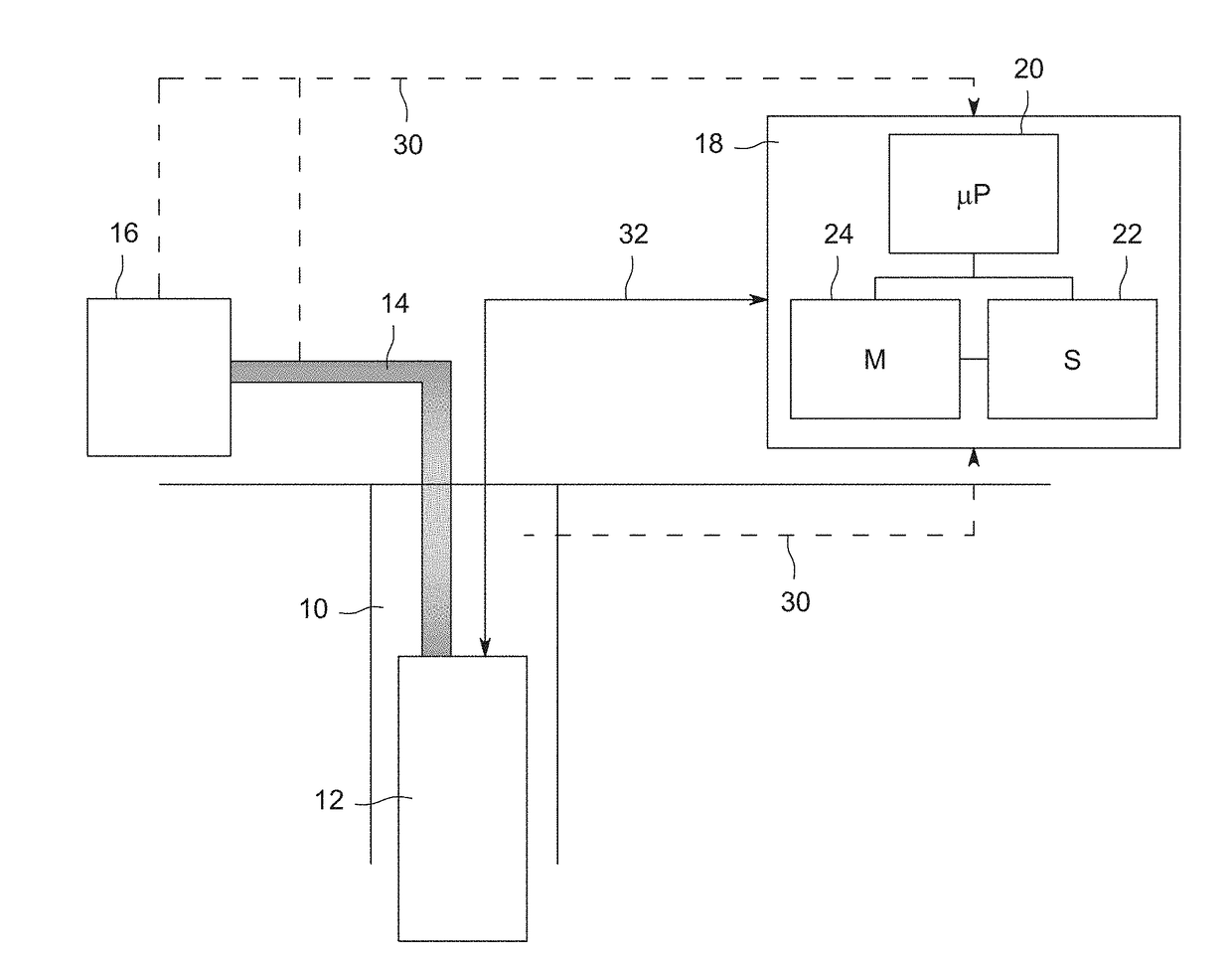

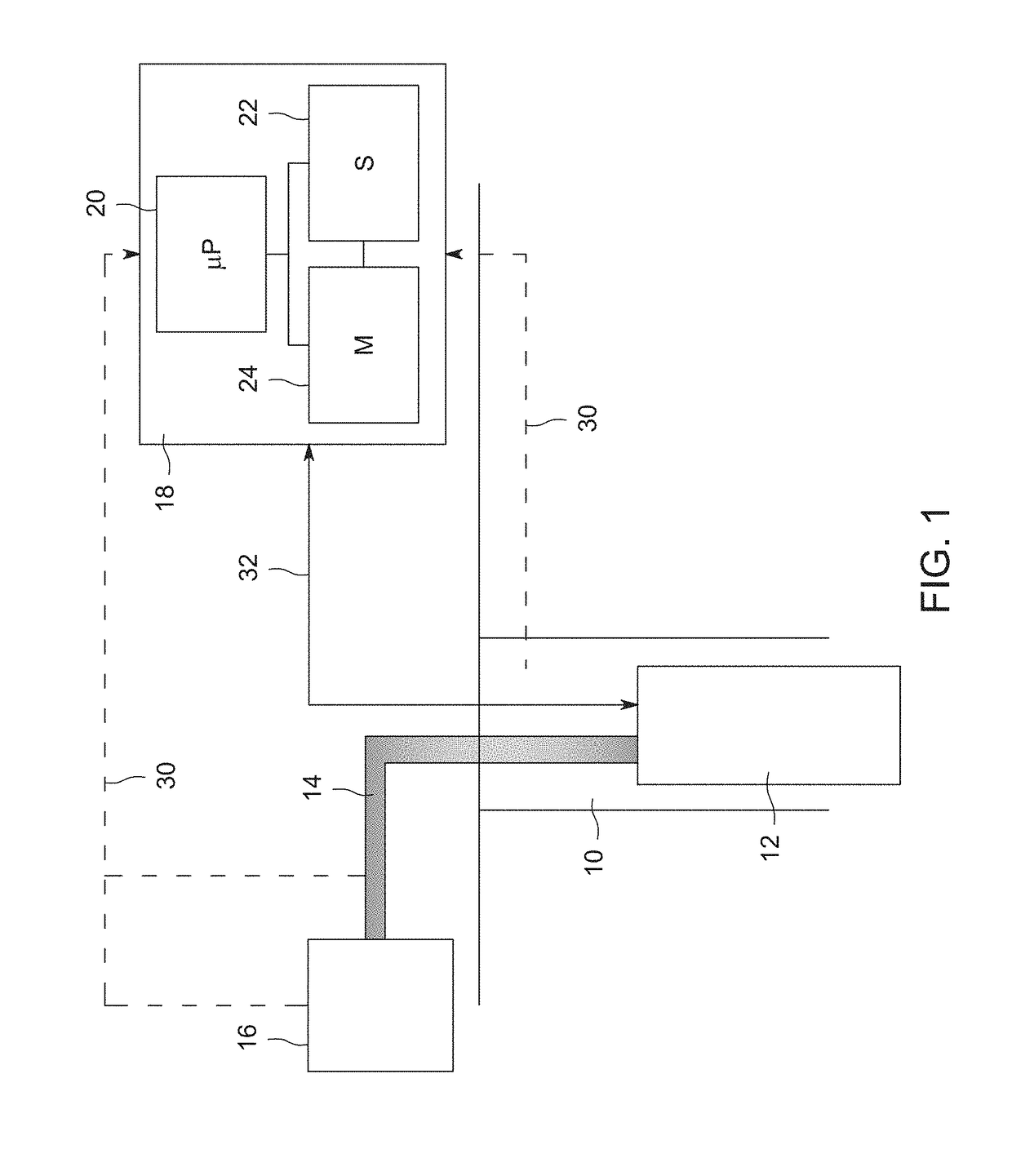

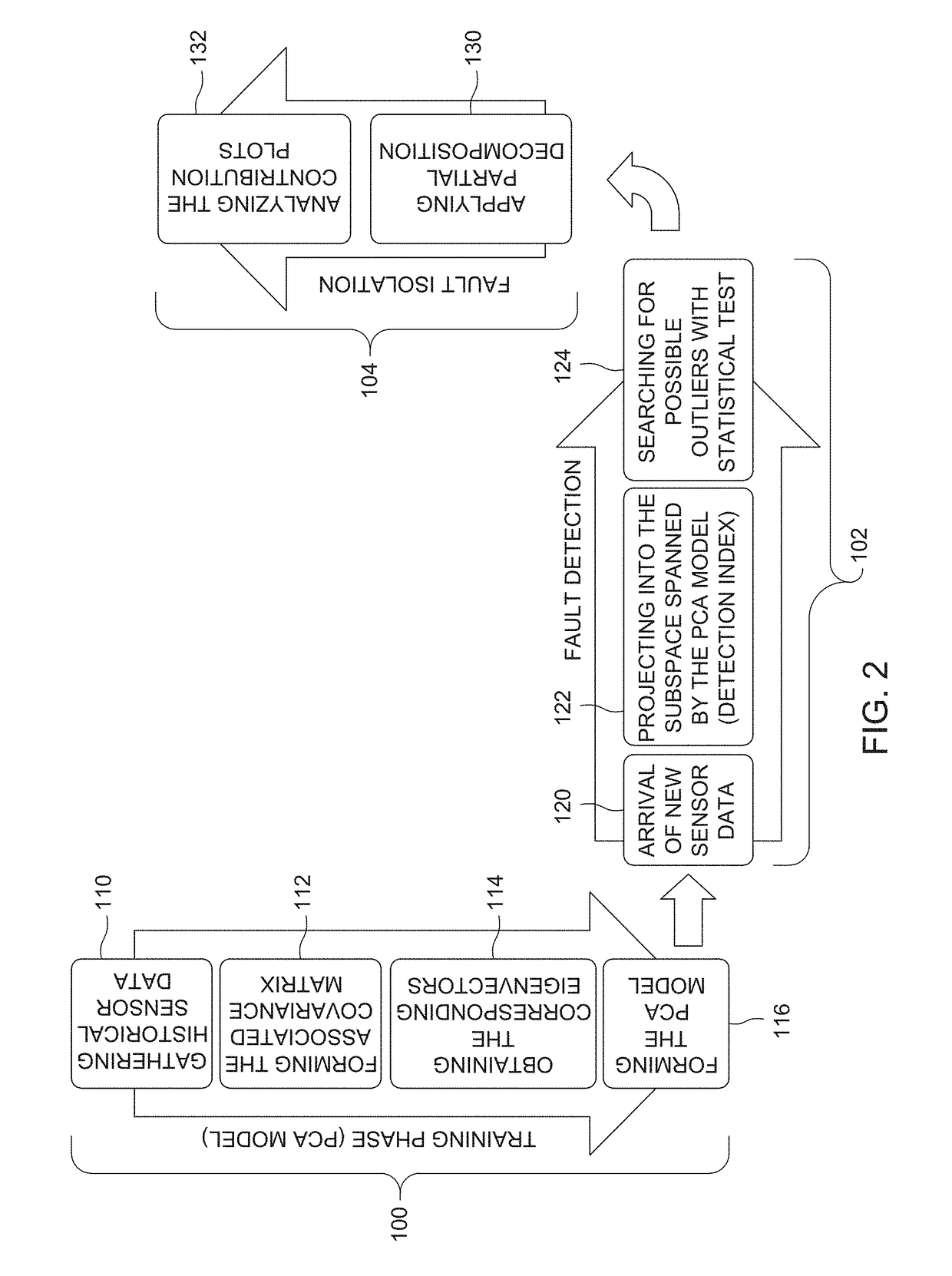

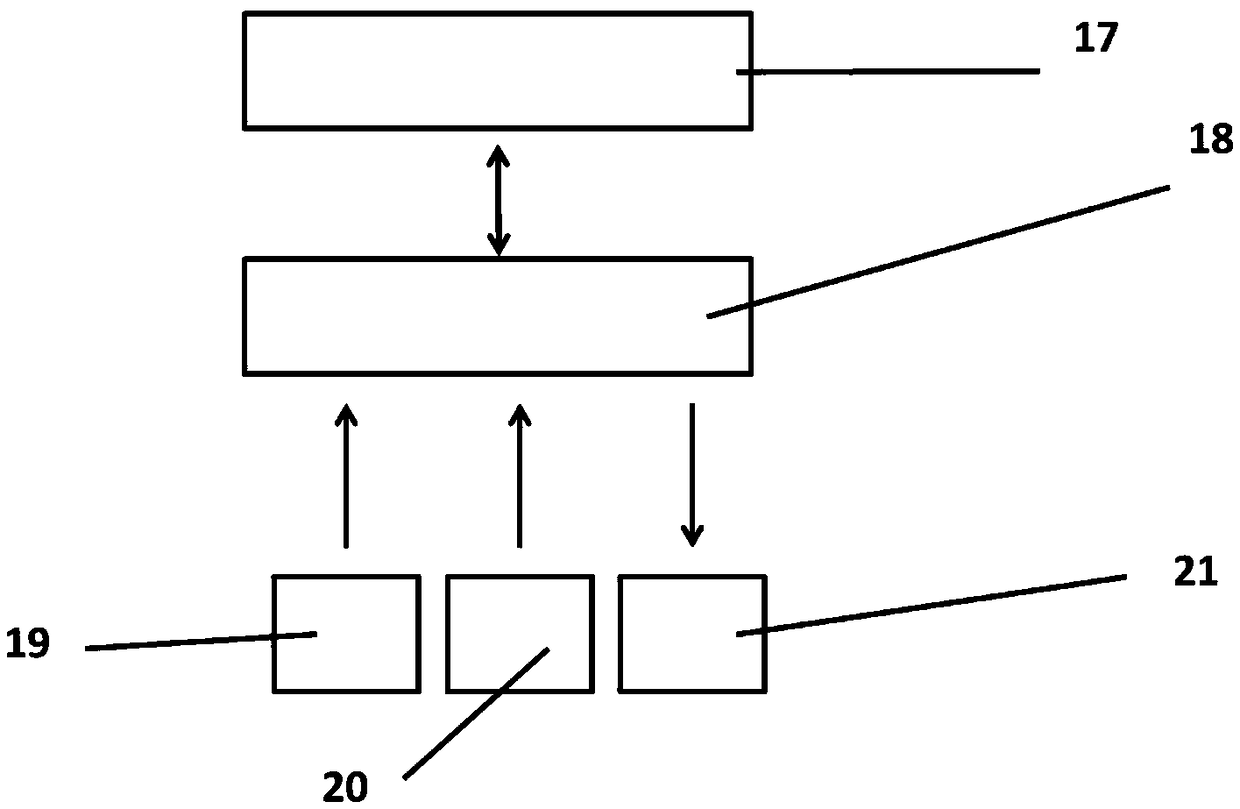

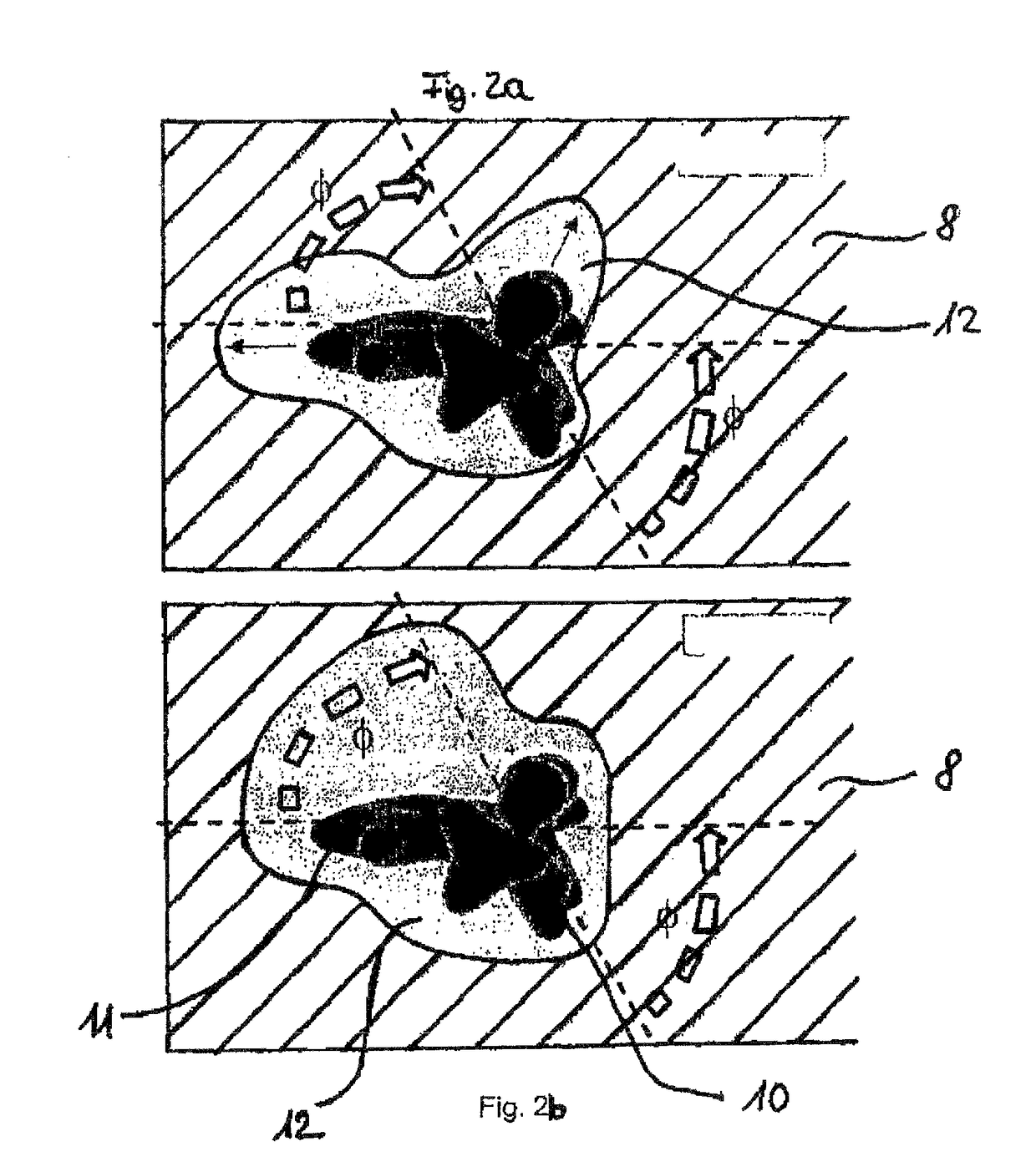

Method for detection and isolation of faulty sensors

PendingUS20180087954A1Volume/mass flow by thermal effectsTesting/monitoring control systemsPrincipal component analysisMultivariate statistical

Technical effects of the invention include use of a data-driven multivariate statistical method for the detection and isolation of sensor faults applied in a virtual flow metering context. In one implementation, the data-driven multivariate statistical method employs principal components analysis, weighted squared prediction error, and partial decomposition contribution plots.

Owner:GE OIL & GAS UK LTD

Process for combined production of ammonia and urea

InactiveUS20010002245A1High yieldReduce consumptionUrea derivatives preparationPhysical/chemical process catalystsSteam reformingCarbamate

A process for the combined production of ammonia and urea of the type comprising an ammonia synthesis reactor (2), a urea synthesis reactor (5) and a urea recovery section (21) stands out for the fact of submitting at least a part of a flow comprising carbamate in aqueous solution coming from the urea recovery section (21) to a partial decomposition treatment, to obtain a flow comprising ammonia and carbon dioxide in vapor phase and a flow comprising diluted carbamate in aqueous solution, which is fed together with a gas flow comprising hydrogen, nitrogen and carbon dioxide, preferably obtained by hydrocarbons steam reforming, and a flow comprising ammonia coming from the ammonia synthesis reactor (2) to a carbamate synthesis section (3), where ammonia and carbon dioxide are caused to react, to obtain a flow comprising carbamate in aqueous solution and a gas flow comprising hydrogen and nitrogen. The flow comprising carbamate in aqueous solution is then sent to the urea synthesis reactor (5), while the gas flow comprising hydrogen and nitrogen is sent to the ammonia synthesis reactor (2).

Owner:UREA CASALE SA

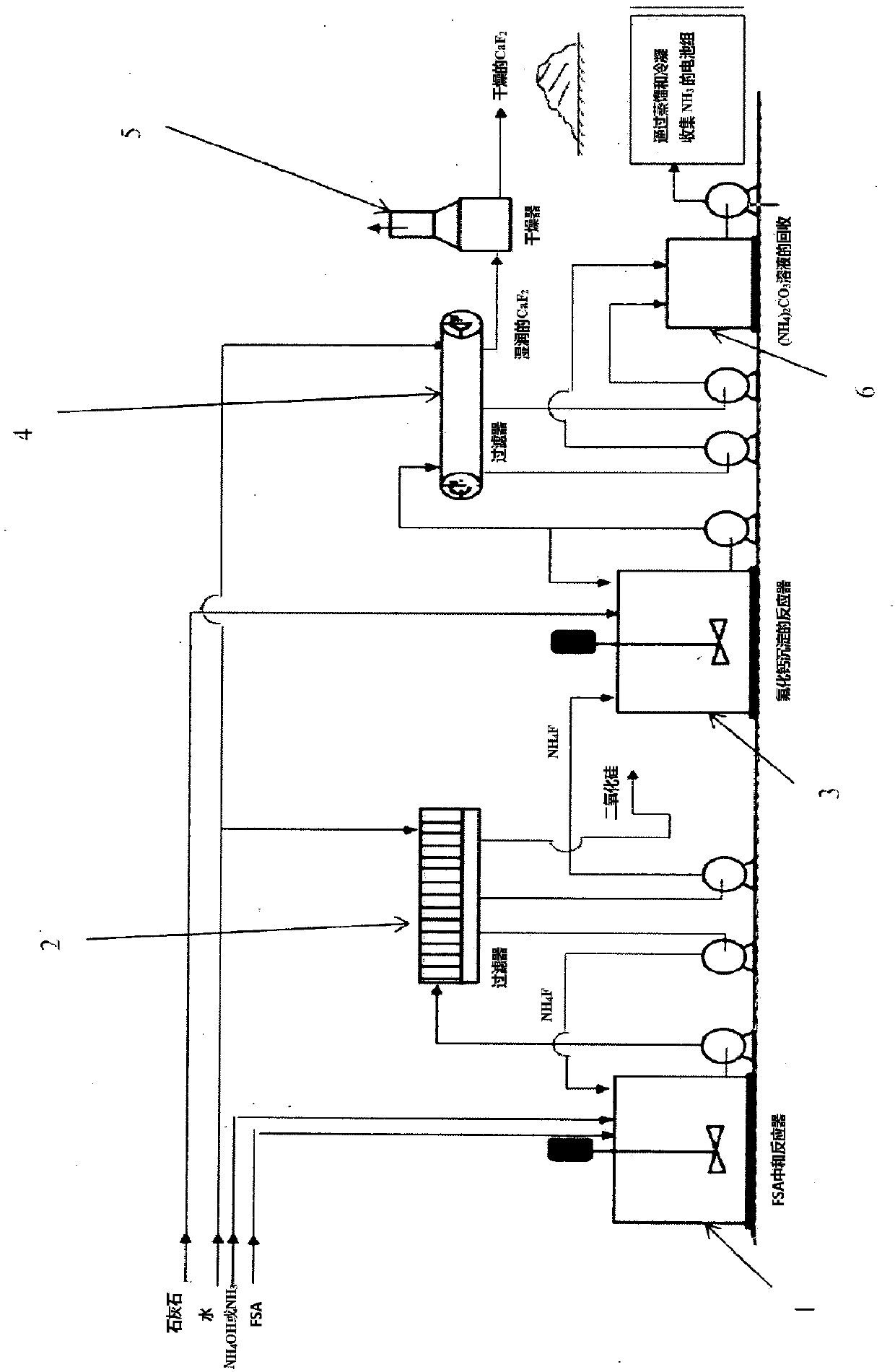

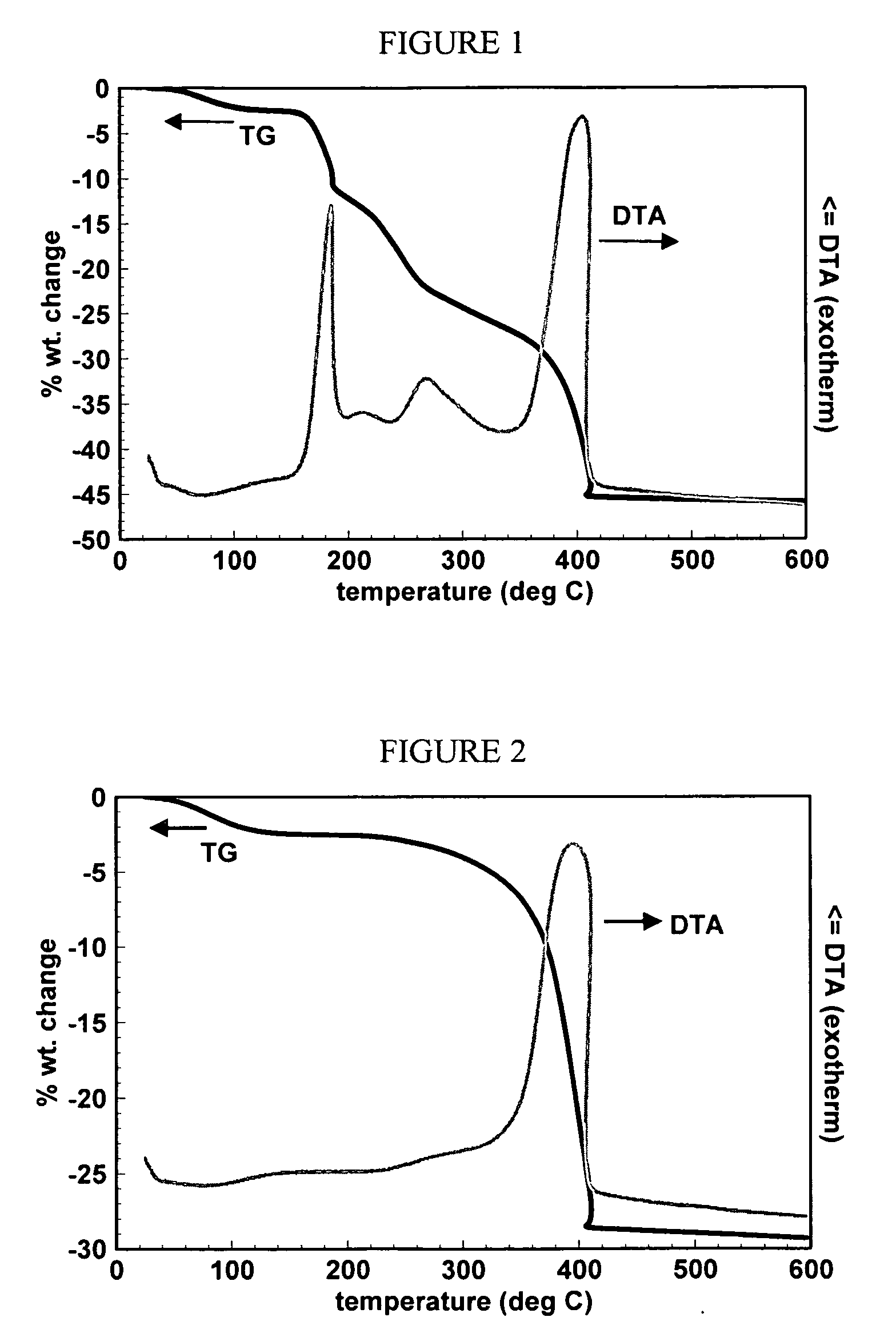

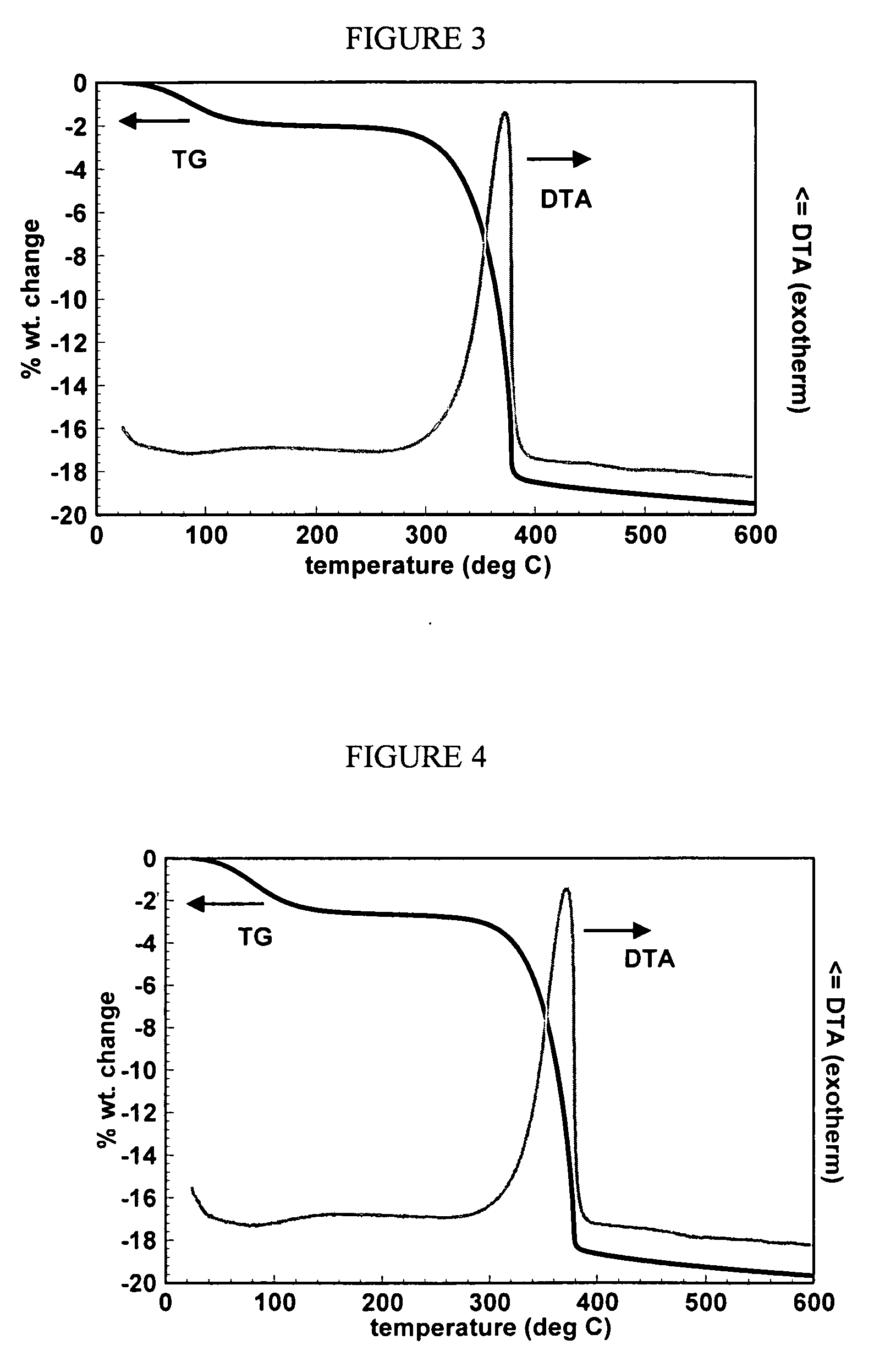

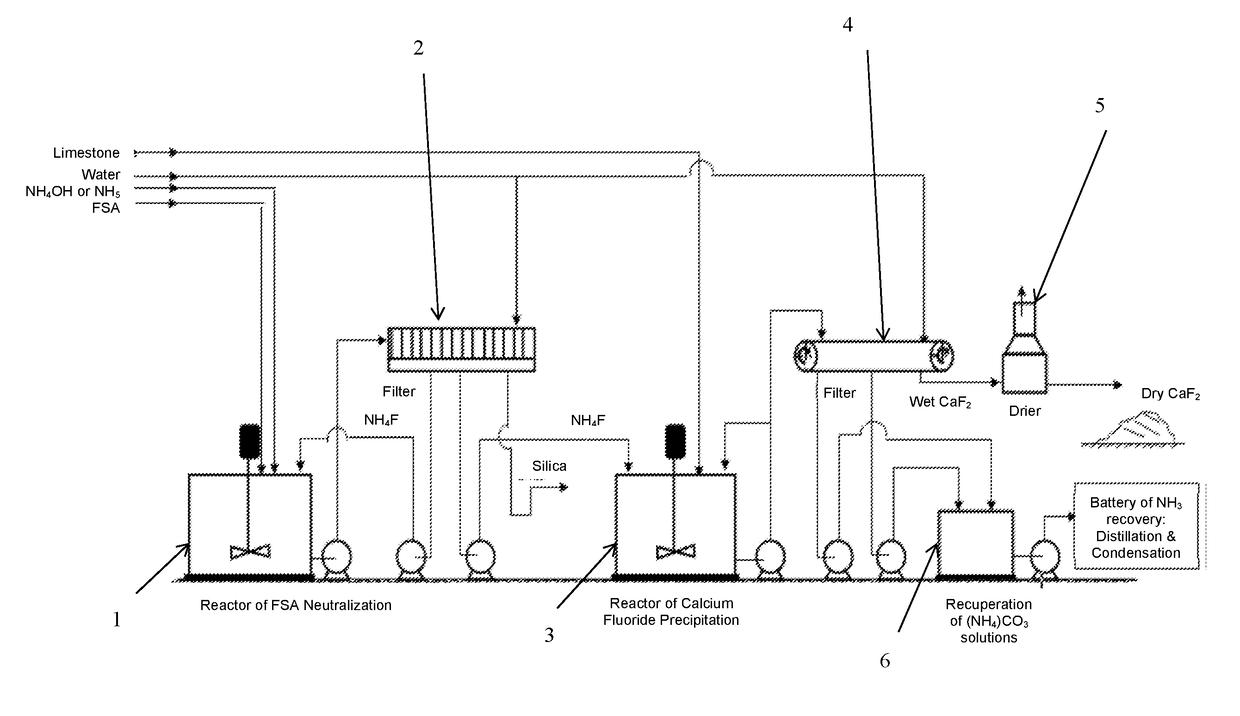

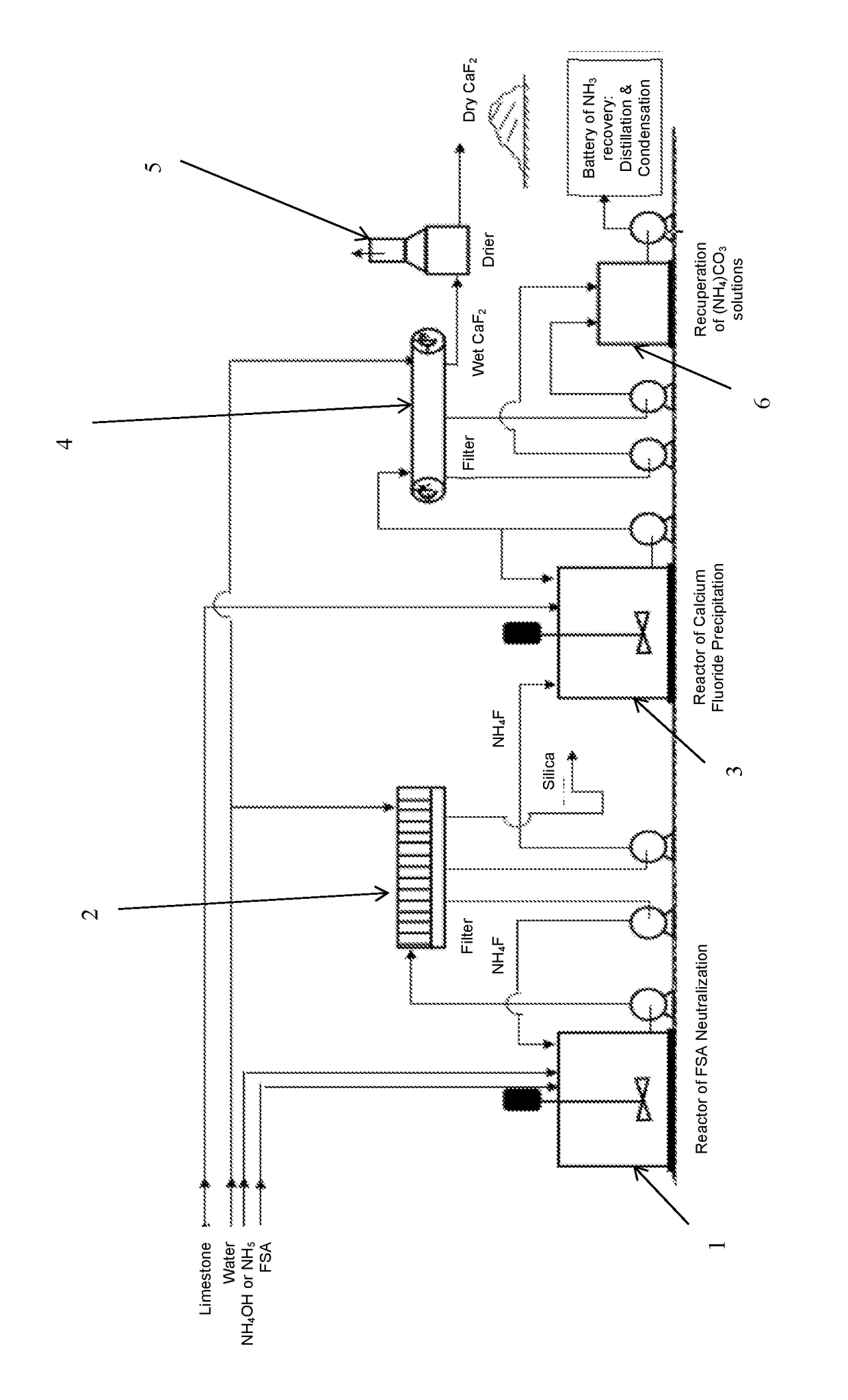

Process for preparing calcium fluoride from fluosilicic acid

The invention relates to a process for preparing synthetic calcium fluoride (CaF2) (min 90 wt% CaF2) from fluosilicic acid. Said process includes the following steps: (a) reacting fluosilicic acid (H2SiFe) with ammonium hydroxide or ammonia in a first reactor (1) so as to obtain a first thick suspension, filtering said first suspension so as to obtain a filtrate containing an ammonium fluoride solution, (b) precipitating the ammonium fluoride solution, obtained in the form of a filtrate in step (a), with calcium carbonate in dry form or in the form of a suspension having a concentration of between 10 and 80 wt%, in a second reactor (3) so as to produce a second suspension containing the calcium fluoride and the ammonium carbonate, filtering said second suspension so as to obtain a filter cake containing calcium fluoride, and a filtrate containing an ammonia carbonate solution, washing and drying said filter cake so as to obtain calcium fluoride and a washing filter cake containing an ammonium hydroxide solution, wherein a portion of the second suspension, of from 10 to 70 wt%, is recycled to the second reactor (3) so as to enhance the crystallization of the calcium fluoride, changein most of the ammonia from the second reactor in step (b) due to partial decomposition of the ammonium carbonate under reactor conditions, then washing and sending said ammonia back into the first reactor, and collecting and treating, by means of distillation and condensation, the ammonium carbonate solutions obtained as filtrate and washing filter cake in step (b), so as to recover the liquid ammonia which is recycled to the first reactor (1).

Owner:OCP

Partially decomposed catalyst and hydrocarbon oxidation processes using the same

ActiveUS20060293544A1Oxygen-containing compound preparationOrganic compound preparationArginineOxygen

Owner:EXXON RES & ENG CO

Kaolin processing

The embodiment of kaolin quality improvement includes a chemical, heating method for processing kaolin to high brightness levels and lower viscosities. This permits addition of natural titania for greater opacity in commercial paper coating. Mechanism of brightness improvement includes removal of iron oxides and iron sequestered by natural organic acids. Viscosity is improved by removal of organic and at least partial decomposition of expandable clay, such as montmorillonite.Kaolin crude is dispersed preferably with Calgon at minimum level. Classification to desired particle size is followed by adding 0.2 percent sodium sulfate decahydrate. After raising pH to 8.5 with dilute sodium hydroxide the slip is heated to 65 to 70 degrees centigrade for 5 to 60 minutes. Cooled to at least 40 degrees centigrade, the slip is bleached with sodium hydrosulfite. Time of bleach is 20 minutes at pH 3 to 3.5. Efficient filtration and rinsing is critical, a 2:1 ratio of water to dry clay rinse preferable.

Owner:BUNDY WAYNE M

Process For Preparing Calcium Fluoride From Fluosilicic Acid

PendingUS20180155207A1Competitive costSilicaCalcium/strontium/barium fluoridesDistillationHexafluorosilicic acid

The invention relates to a process for preparing synthetic calcium fluoride (CaF2) (min 90% CaF2 by weight) from fluosilicic acid, comprising the following steps:(a) reacting fluosilicic acid (H2SiF6) with ammonium hydroxide or ammonia in a first reactor so as to obtain a first slurry; filtering said first slurry so as to obtain a filtrate containing a solution of ammonium fluoride;(b) precipitating the solution of ammonium fluoride obtained as a filtrate in step (a) with calcium carbonate as a dry form or as a suspension at a concentration ranging from 10 to 80% by weight in a second reactor so as to produce a second slurry containing calcium fluoride and ammonium carbonate; filtering said second slurry so as to obtain a filter cake containing calcium fluoride and a filtrate containing a solution of ammonium carbonate; washing and drying said filter cake so as to obtain calcium fluoride and a filter cake washing containing a solution of ammonium carbonate; wherein a portion of the second slurry ranging from 10 to 70% is recycled to the second reactor (3) so as to enhance calcium fluoride crystallization;(c) evolving the major part of ammonia from the second reactor (3) in step (b) because of the partial decomposition of ammonium carbonate under reactor conditions and then scrubbing and returning said ammonia to the first reactor, and gathering and treating by distillation and condensation both ammonium carbonate solutions obtained as the filtrate and the filter cake washing in step (b) to recover liquid ammonia which is recycled to the first reactor (1).

Owner:OCP

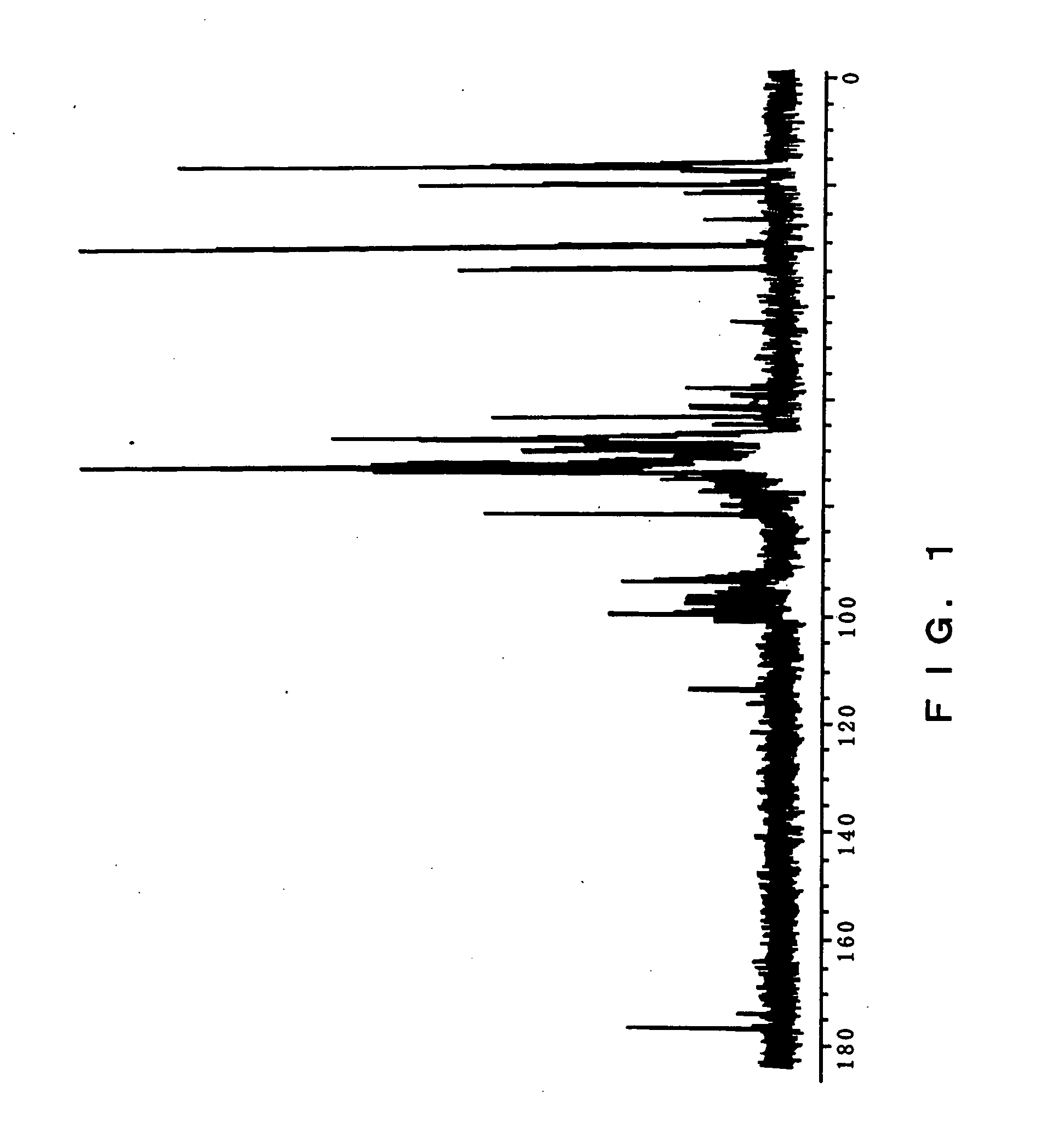

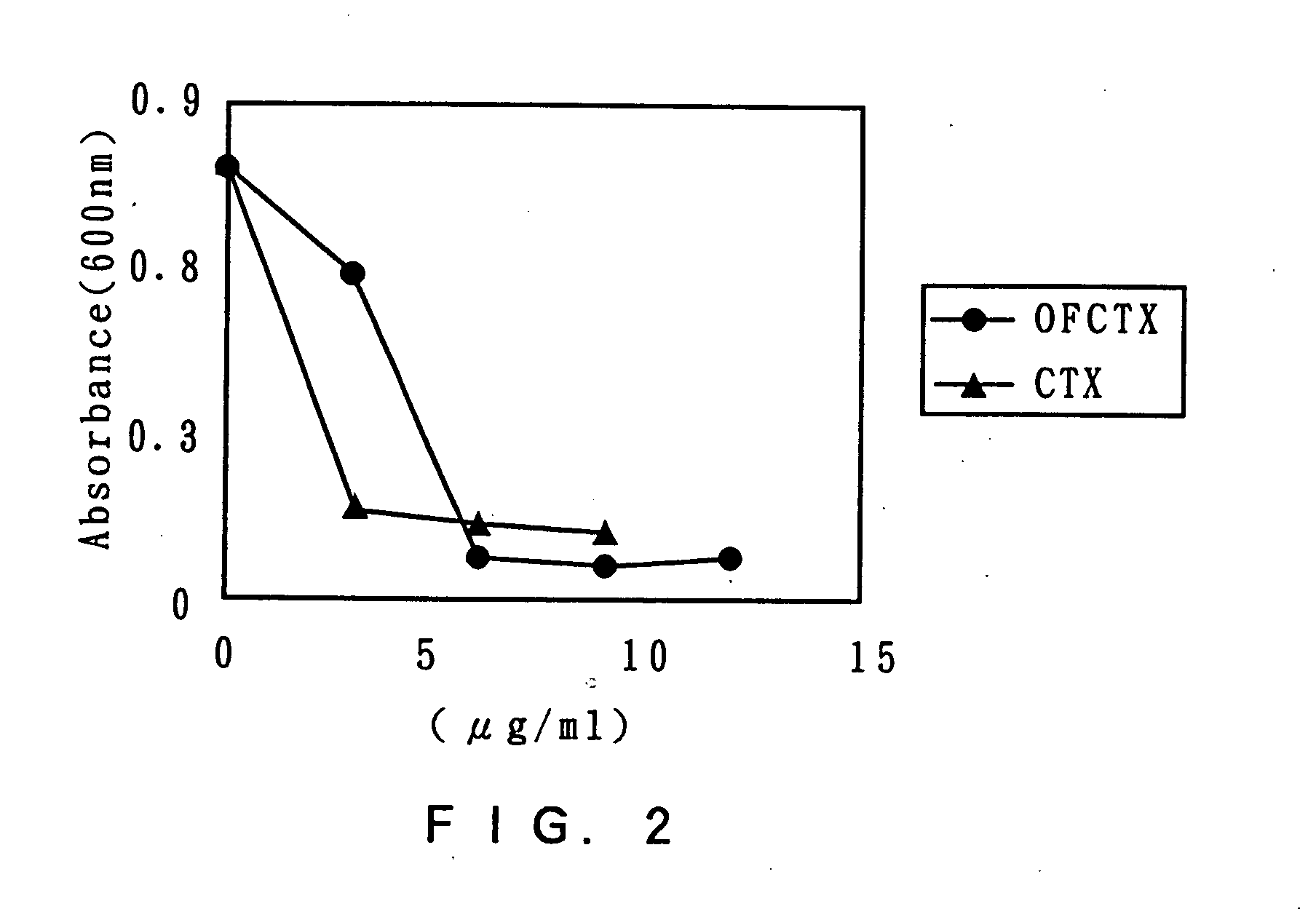

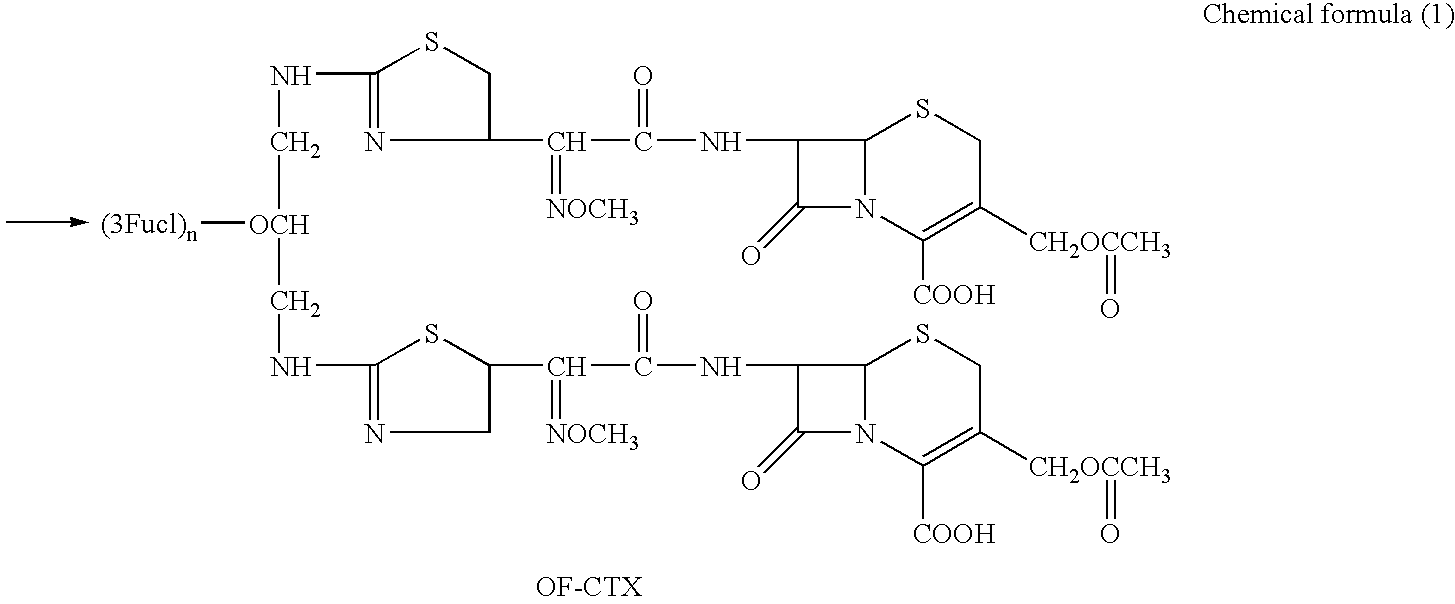

Antibacterial agents and process for producing the same

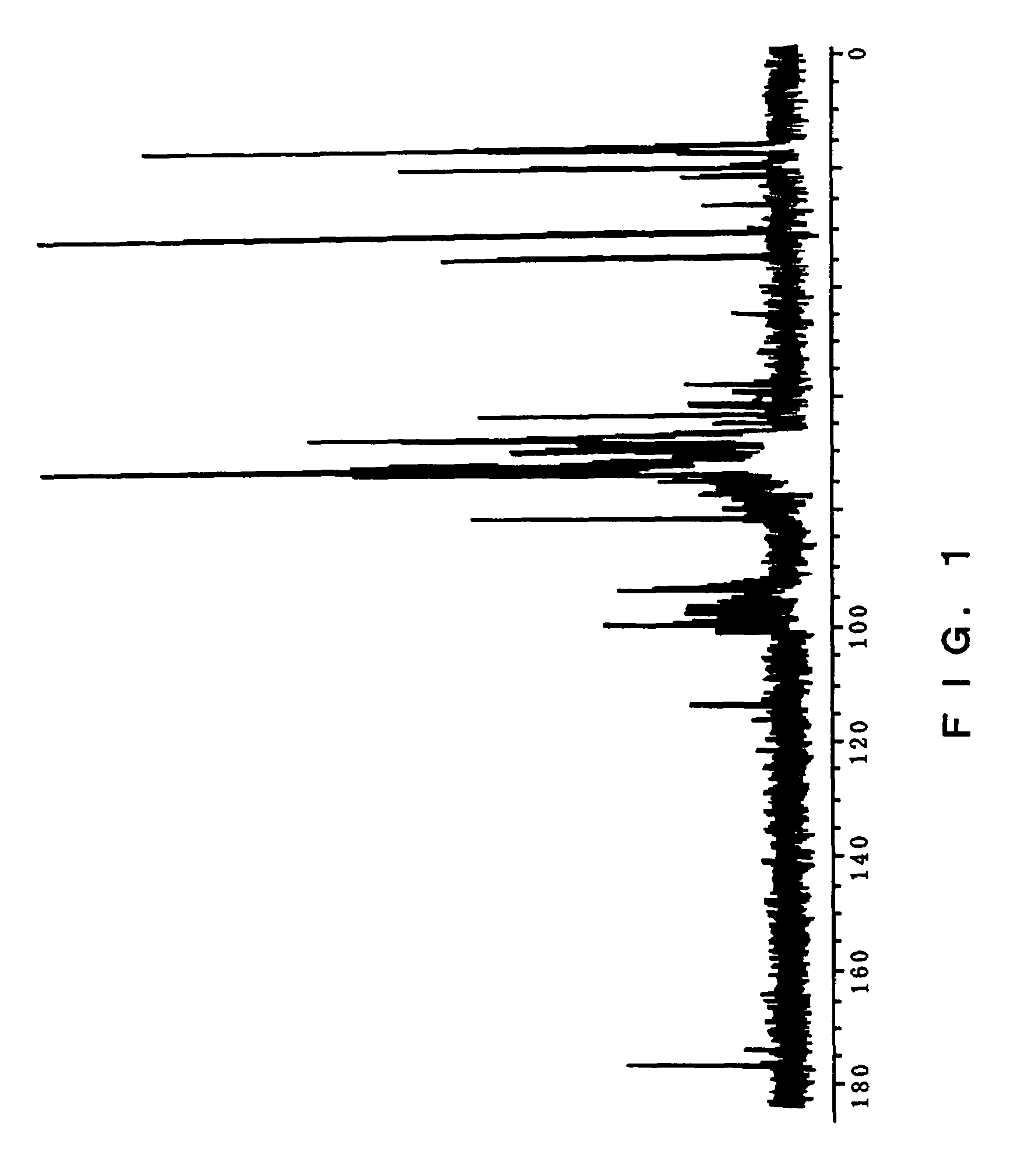

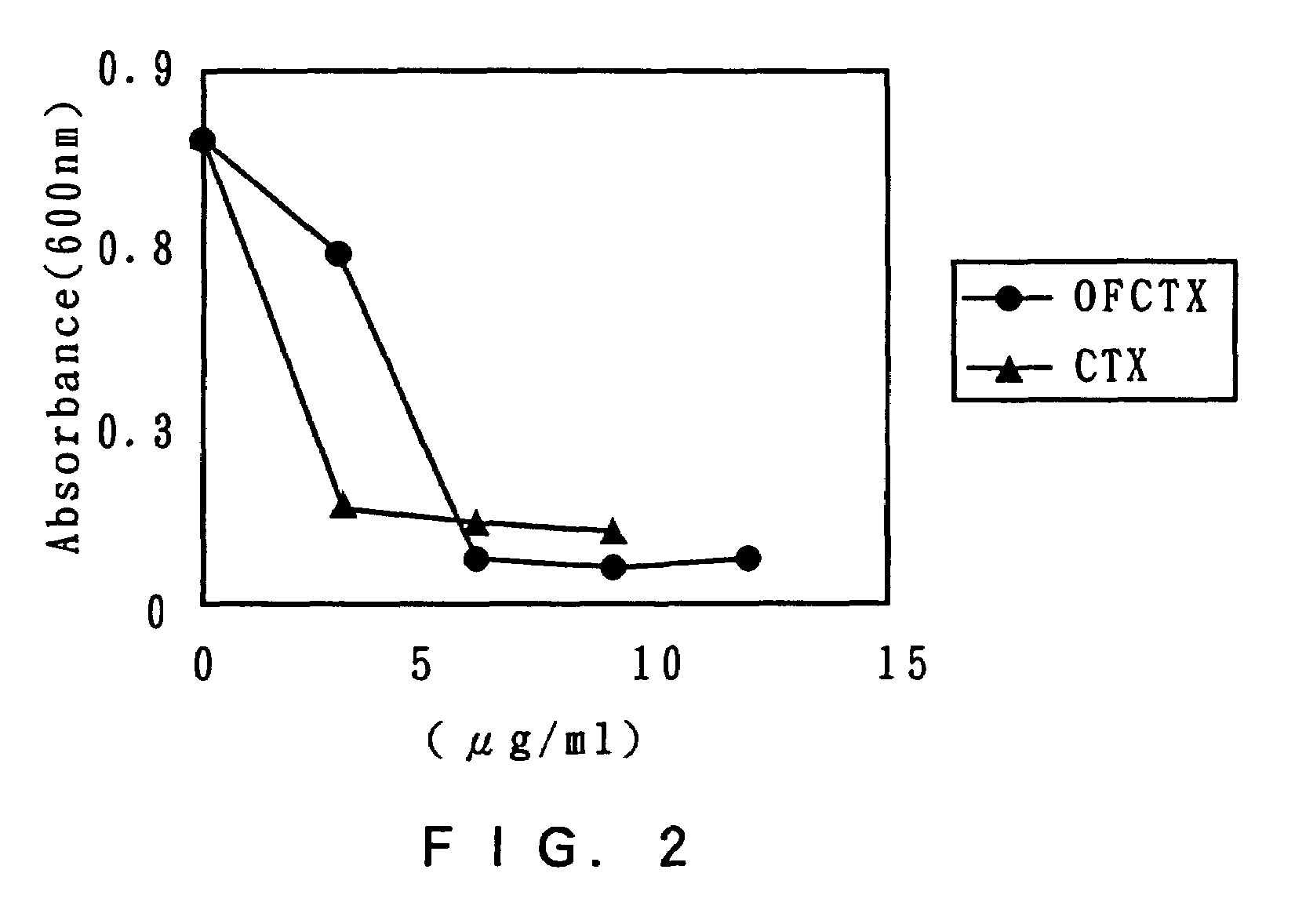

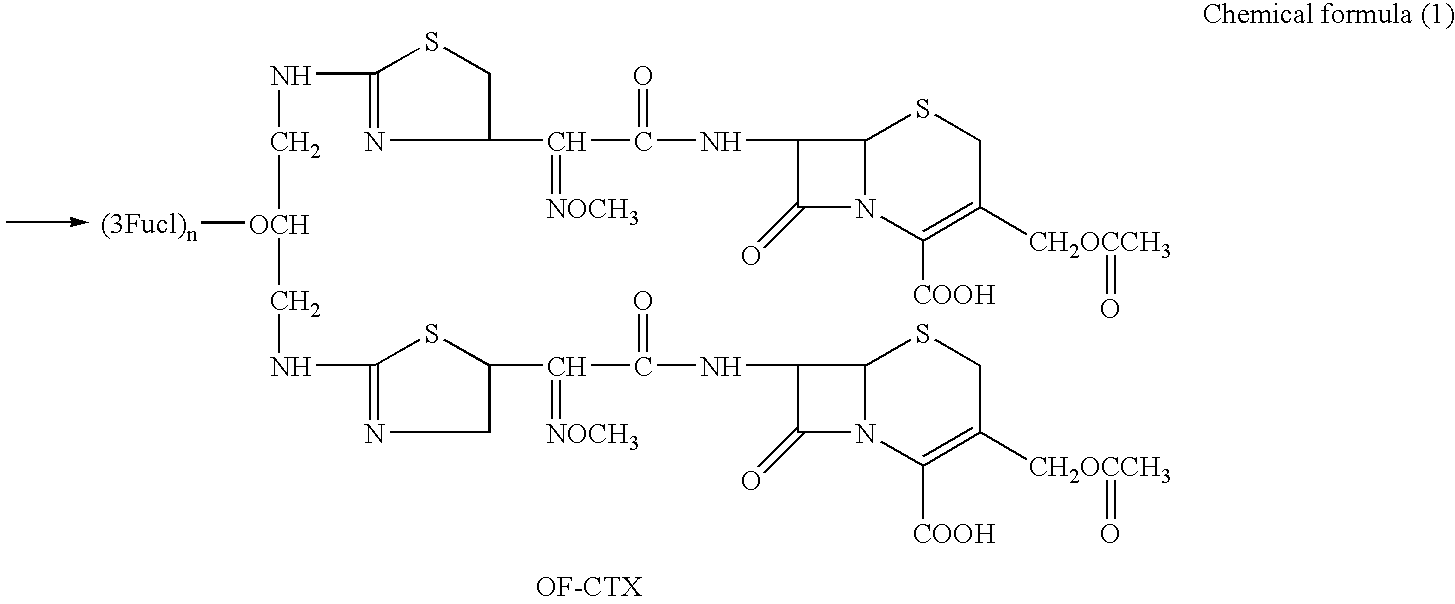

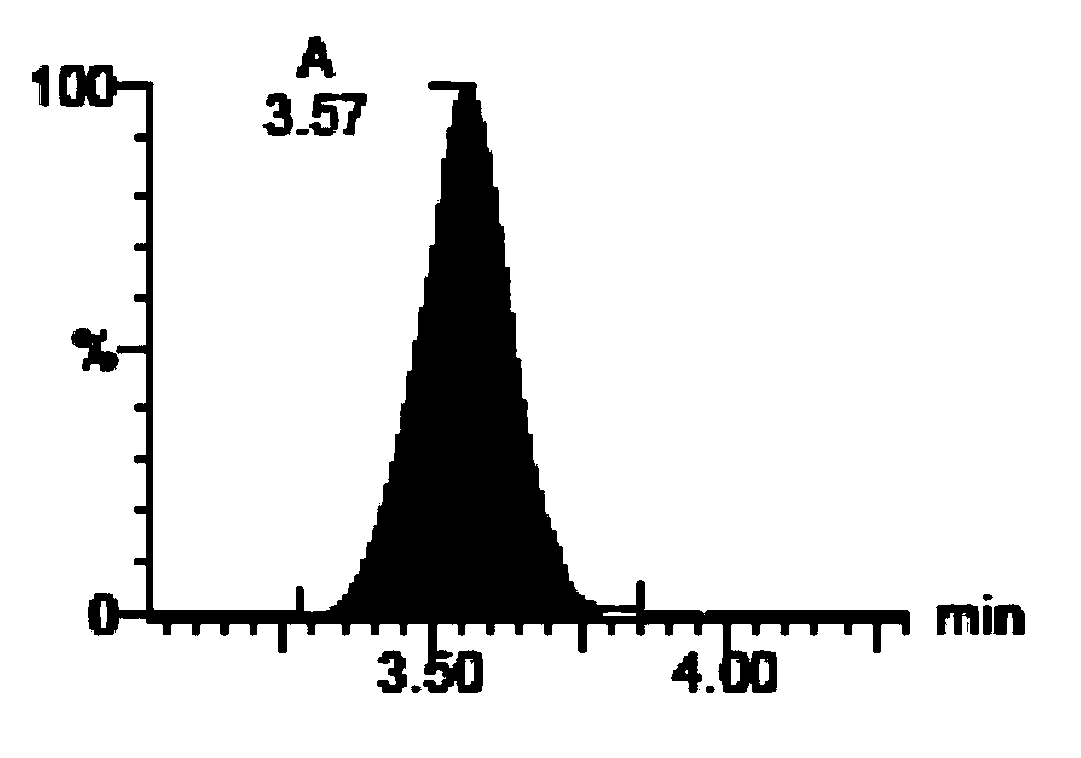

InactiveUS7498317B2Improve antibacterial propertiesAntibacterial agentsBiocideChemical structureSulfated polysaccharides

An antibacterial agent showing a high affinity for Helicobactor pyroli and having an antibacterial effect specific to H. Pyroli. The agent has a chemical structure wherein an antibacterial substance is bonded to a sulfated polysaccharide or an oligosaccharide prepared by partial decomposition of the sulfated polysaccharide. Preferable embodiments are those having the chemical structure represented by Y—OCH(AH2NHR)n or Y—BH2NHR, wherein Y represents a sulfated polysaccharide or an oligosaccharide prepared by partial decomposition of the sulfated polysaccharide; A a carbon derived from aldehyde group occurring through the reduction of the reduced end sugar of Y and subsequent oxidation of the resulting product with an oxidant; B a carbon derived from the aldehyde group at the reduced end sugar of Y; R an antibacterial substance with a primary amino group or with an amino group introduced therein or represents an antibacterial substance derivative prepared by bonding an antibacterial substance through a spacer to the carbon A or the carbon B; and n=1 or 2.

Owner:YAKULT HONSHA KK

Soyasapogenol composition

InactiveCN103635184APromote absorptionImprove bioavailabilityCosmetic preparationsNervous disorderD-GlucopyranoseSoyasapogenol B

Provided is a soy saponin composition having high bodily absorption characteristics. The soyasapogenol composition contains soyasapogenol B and 3-O-D-glucuronopyranosyl soyasapogenol B. The weight ratio (B / A) of the 3-O-D-glucuronopyranosyl soyasapogenol B to the soyasapogenol B is in the range of 0.001-10. The composition can be produced by means of partial decomposition of a sugar chain residue of a soy saponin B group glycoside by means of acid.

Owner:J OIL MILLS INC

Cement clinker and preparation method

The invention discloses cement clinker. The raw materials are prepared by the following materials by weight ratio: 37-77 percent of waste crushed stone concrete, 10-20 percent of iron ore, 10-20 percent of chromium salt slag, 1-10 percent of clay, 5-15 percent of coal and 1-4 percent of sulfuric-acid residue. The method for preparing the cement clinker comprises the following steps: 1, crushing and pre-homogenization; 2, raw material homogenization; 3, preheating and decomposition: a preheater is used for completing preheating and partial decomposition of the raw materials; 4, cement clinker sintering: after completing preheating and predecomposition in a cyclone preheater, the raw materials enter a rotary kiln for sintering of the clinker in the next procedure; and 5, cement grinding, so as to obtain the cement clinker. According to the invention, the use amount of high-quality limestone can be reduced, Cao and Mgo contained in chromium salt slag do not need thermal decomposition, and each ton of clinker can save raw materials by 10-20 percent; and due to fluxing and mineralization action of microelements, the viscosity of a liquid phase is reduced, and the mechanical strength of the cement clinker is greatly enhanced.

Owner:田翔鹰

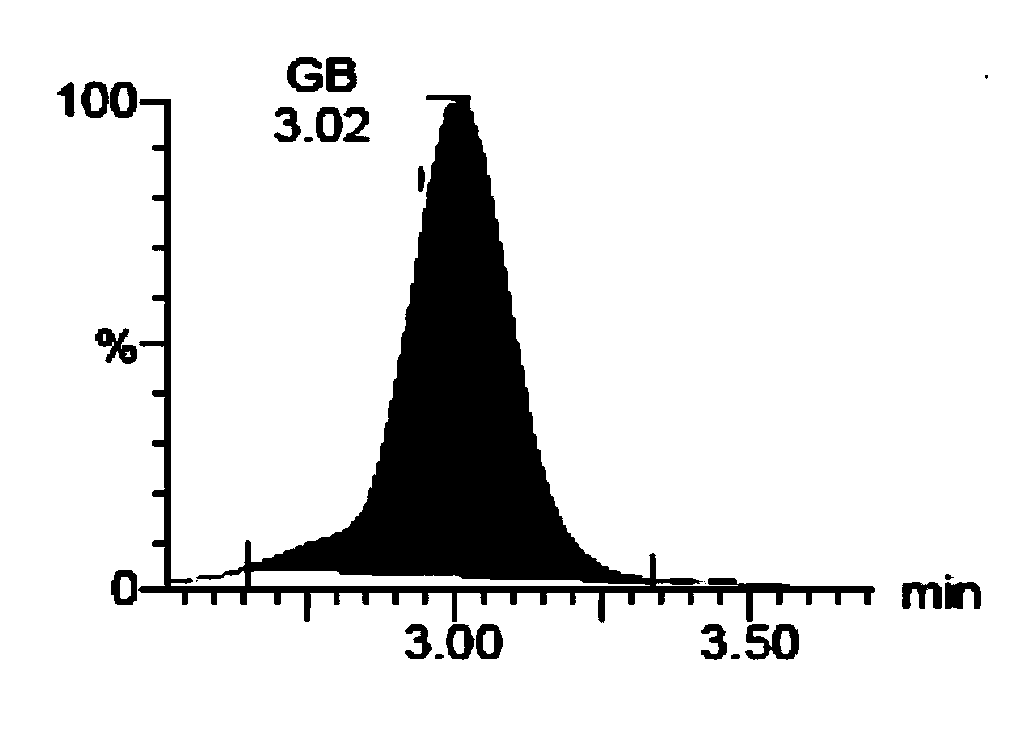

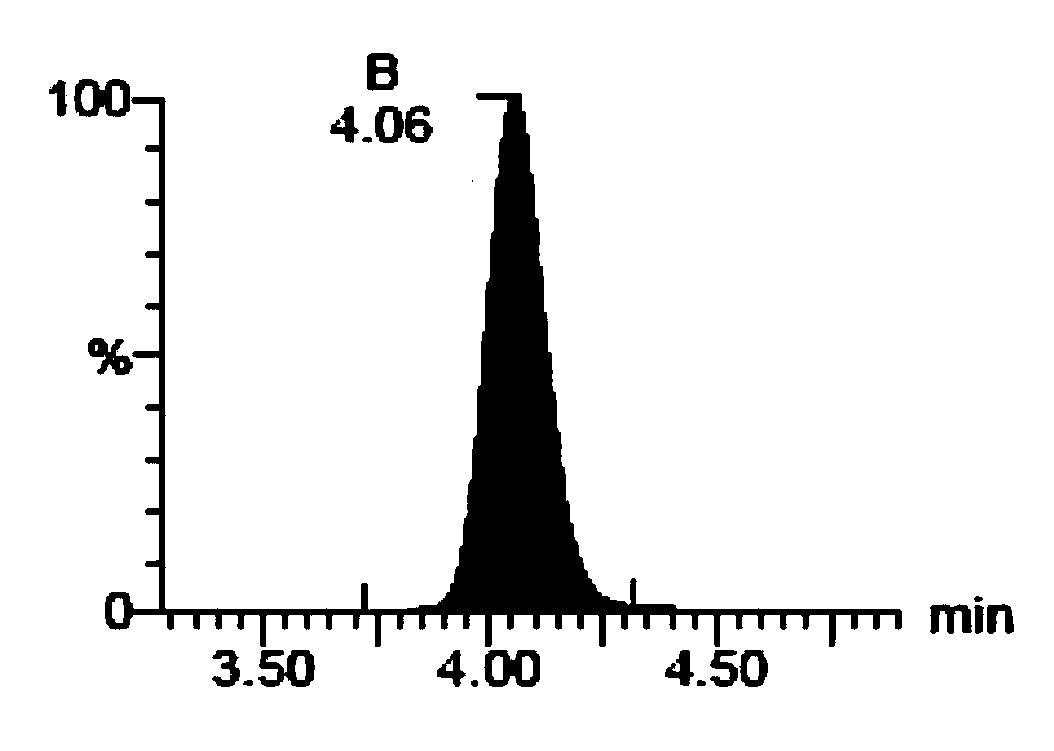

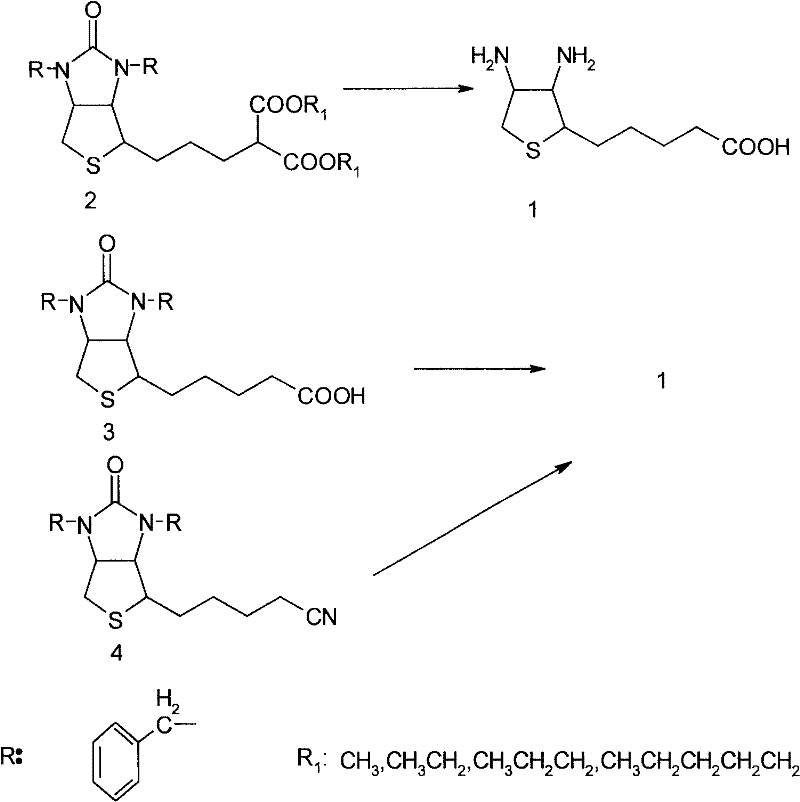

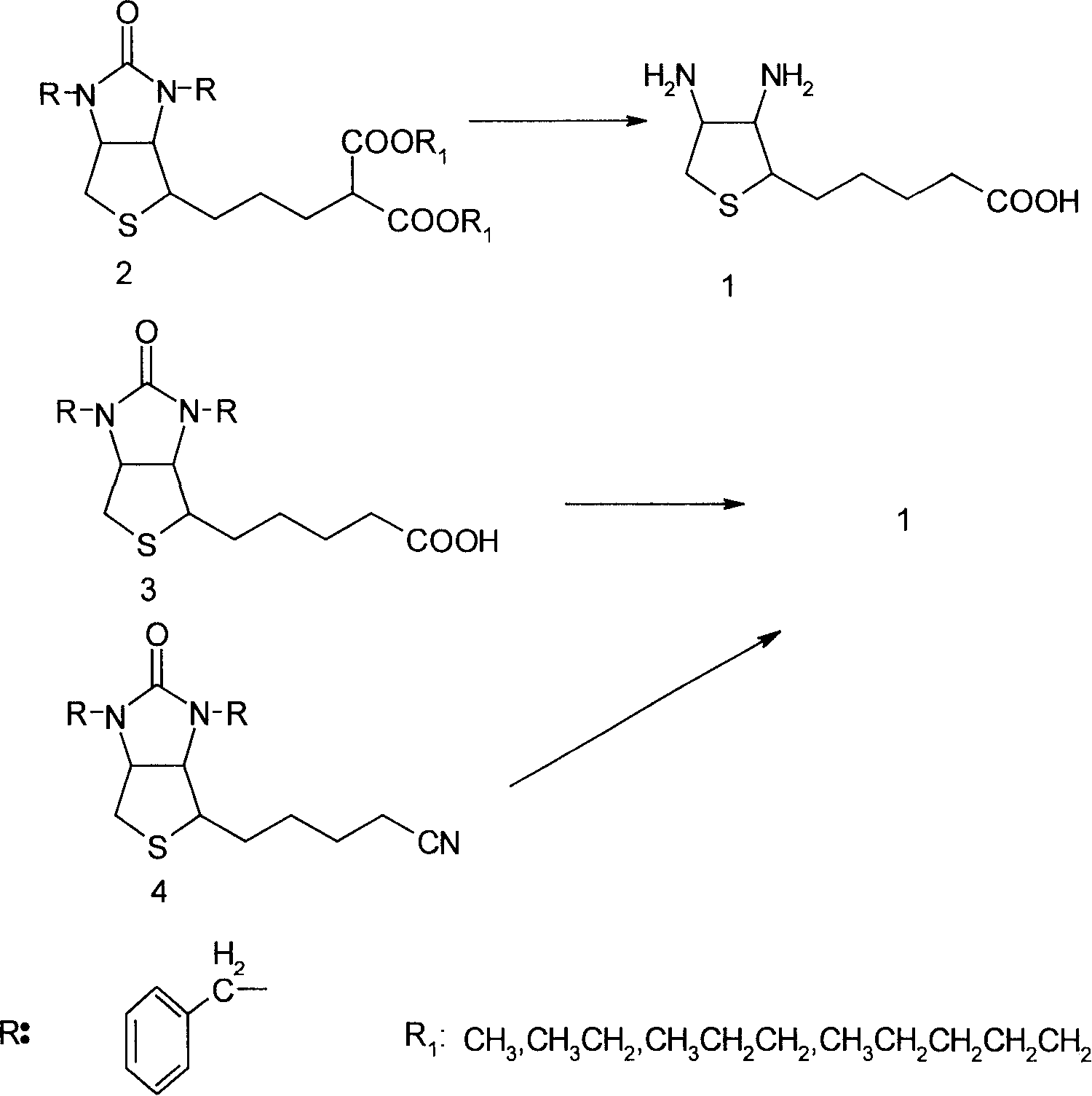

Method for synthesizing (2S,3S,4S)-5-(3,4-diamino-tetrahydrothiophene-2-base) valeric acid

ActiveCN101195611BEasy to controlAvoid decompositionOrganic chemistrySynthesis methodsLithium hydroxide

The invention discloses a synthesis method of (2S, 3S, 4S)-5-(3, 4-diamino-thiophane-2-group) valeric acid, while prior method has long reaction and partial decomposition of product in reaction caused by concentrated halogen acid, to affect the quality of d-biotin. The invention processes reflux reaction on diethyl malonate condensate, cyano compound or bis-benzyl biotin in halogen acid, adds glacial acetic acid later, refluxes until no single-benzyl biotin and d-biotin exist in product, concentrates to remove unreacted halogen acid and glacial acetic acid, adds absolute ethyl alcohol, freezes to 0-5DEG C, adds lithium hydrate to neutralize and precipitate white solid crystals, filters, poaches filter cake via absolute ethyl alcohol, and dries to obtain target product. The invention has short reaction and controllable reaction end, which leads glacial acetic acid in later reaction to effectively avoid diamino acid being decomposed in concentrated halogen acid, to improve product yieldand content.

Owner:ZHEJIANG MEDICINE CO LTD XINCHANG PHAMACEUTICAL FACTORY

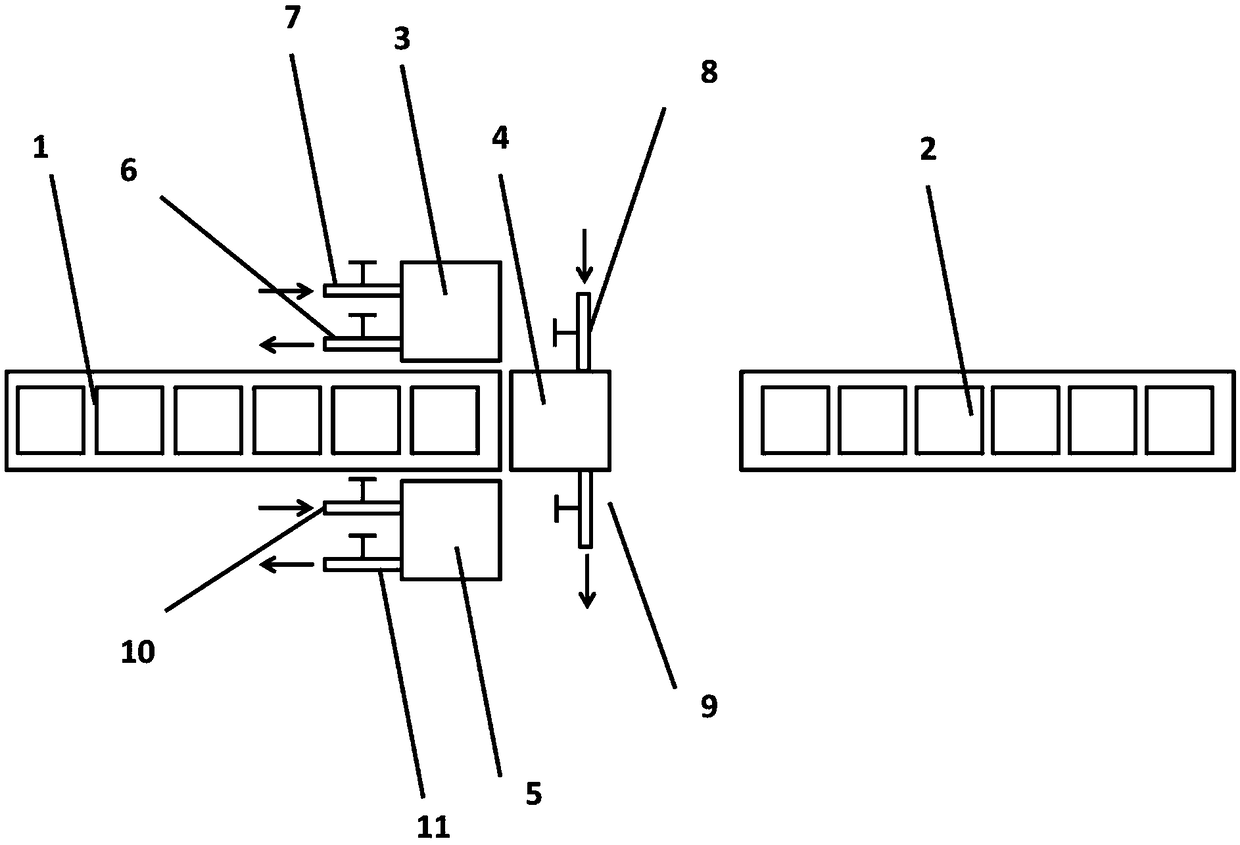

Cooling controllable heat treatment production equipment

PendingCN109234519AAddress stressSolve the problem of deformation or even crackingFurnace typesHeat treatment process controlHigh pressureQuenching

The invention relates to cooling controllable heat treatment production equipment, which comprises a solid melting furnace (1) and a quenching chamber, and also comprises a CO2 circulation supply system and an intelligent control system, wherein the quenching chamber is a high-pressure container and is connected with the CO2 circulation supply system to form circulation through a high-pressure pipeline; the intelligent control system is respectively separately connected with a valve of the high-pressure pipeline, a thermocouple of the quenching chamber and the a pressure sensor, and is used for controlling the cooling speed of a workpiece in the quenching chamber. Compared with the prior art, the equipment has the advantages that through the connection of the intelligent control system, the CO2 circulation supply system and the quenching chamber, the flow rate of CO2 high pressure gas or supercritical fluid gas is controlled; some problems of the existing cooling stage after the aluminum alloy solid melting treatment, including such as the problems of partial decomposition of solid solutions due to insufficient air cooling speed, the problems of deformation scattering differences due to air cooling air flow direction, flow rate and workpiece placement position changes, and the problems of deformation or even cracking due to stress generated by of complicated structurestructurecomplication elements caused by stress due to too high water cooling speed can be solved.

Owner:SHANGHAI YIBAI IND FURNACES CO LTD

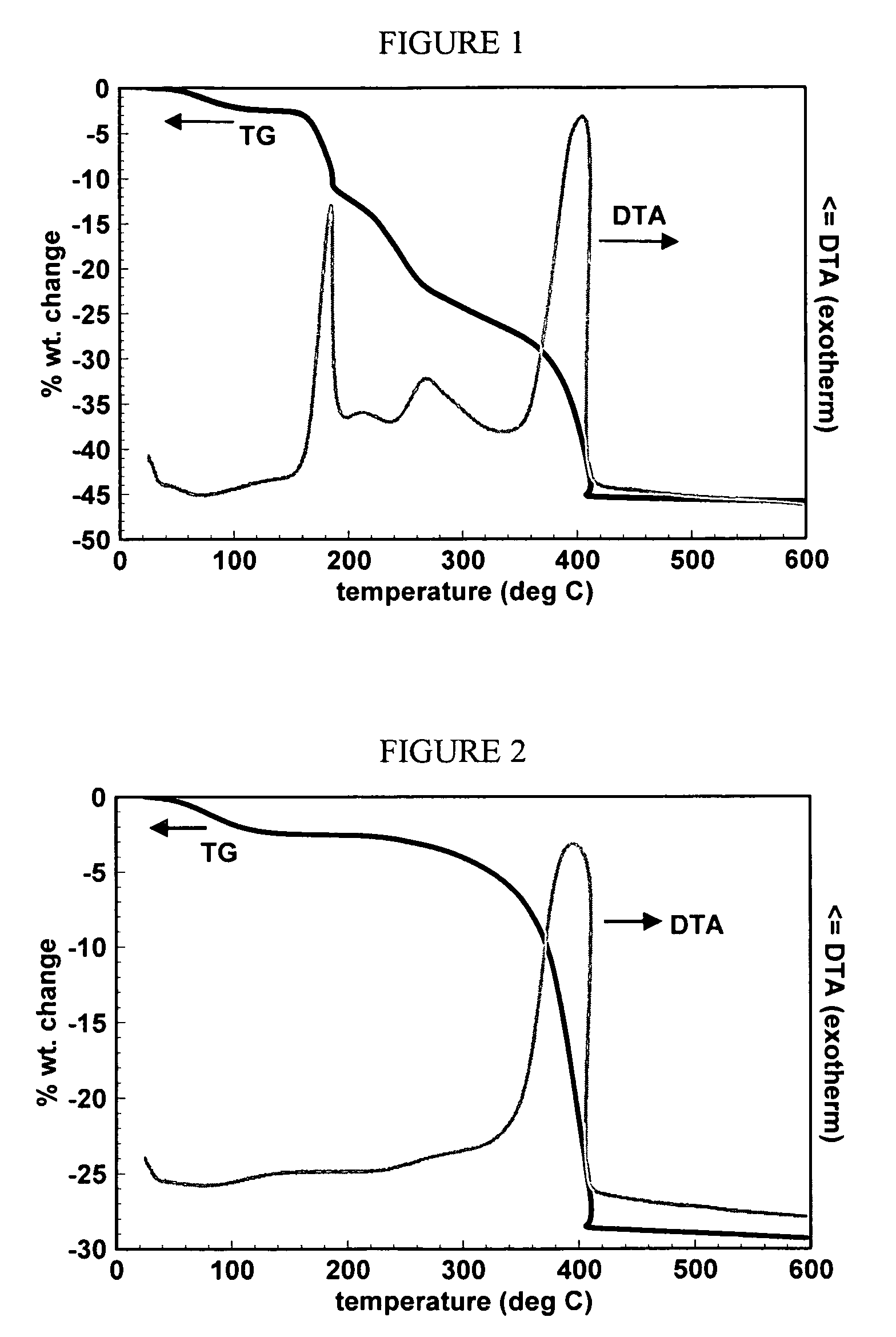

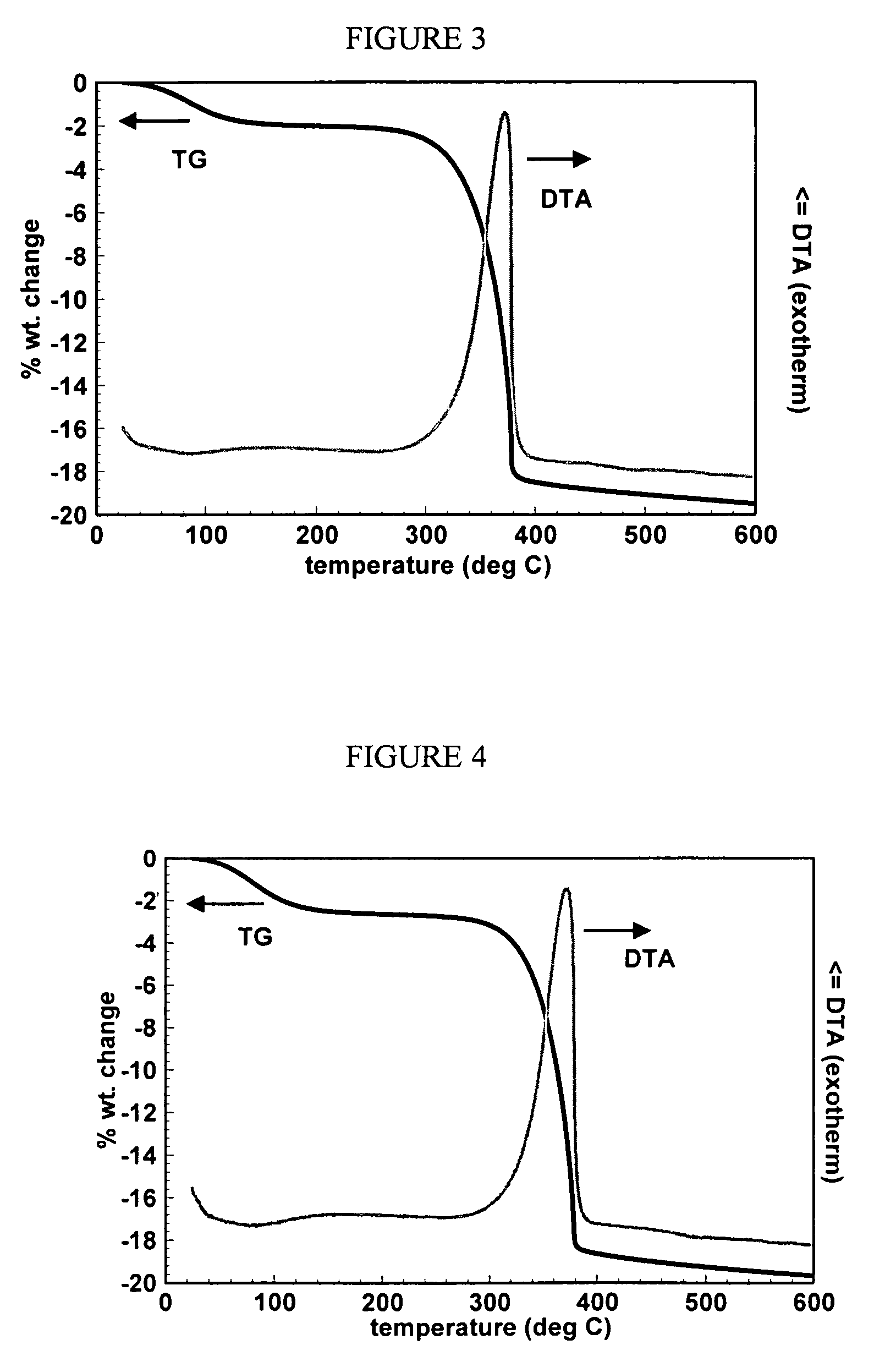

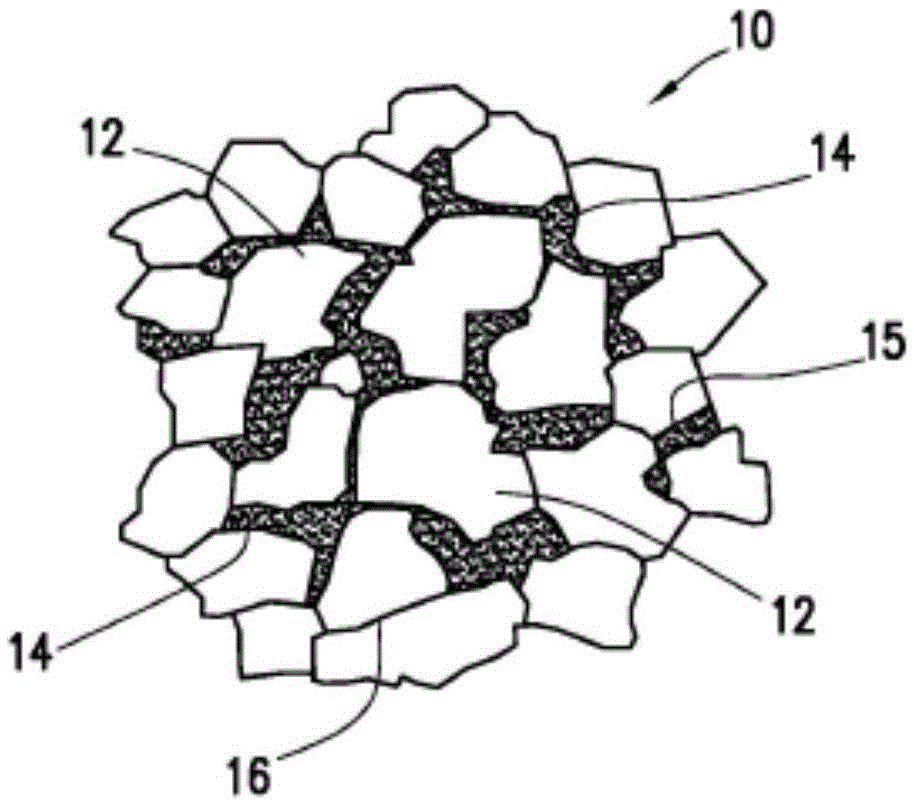

Thermally stable polycrystalline diamond and methods of making the same

A method of making a cutting element includes subjecting a mixture of diamond particles and a carbonate material to high-pressure high- temperature sintering conditions to form a sintered carbonate-polycrystalline diamond body having a diamond matrix of diamond grains bonded together and carbonates residing in the interstitial regions between the diamond grains, the carbonate material having a non-uniform distribution throughout the diamond matrix. The carbonate-polycrystalline diamond body is subjected to a controlled temperature, a controlled pressure condition or a combination thereof, to effect an at least partial decomposition of the carbonate material.

Owner:SMITH INT INC

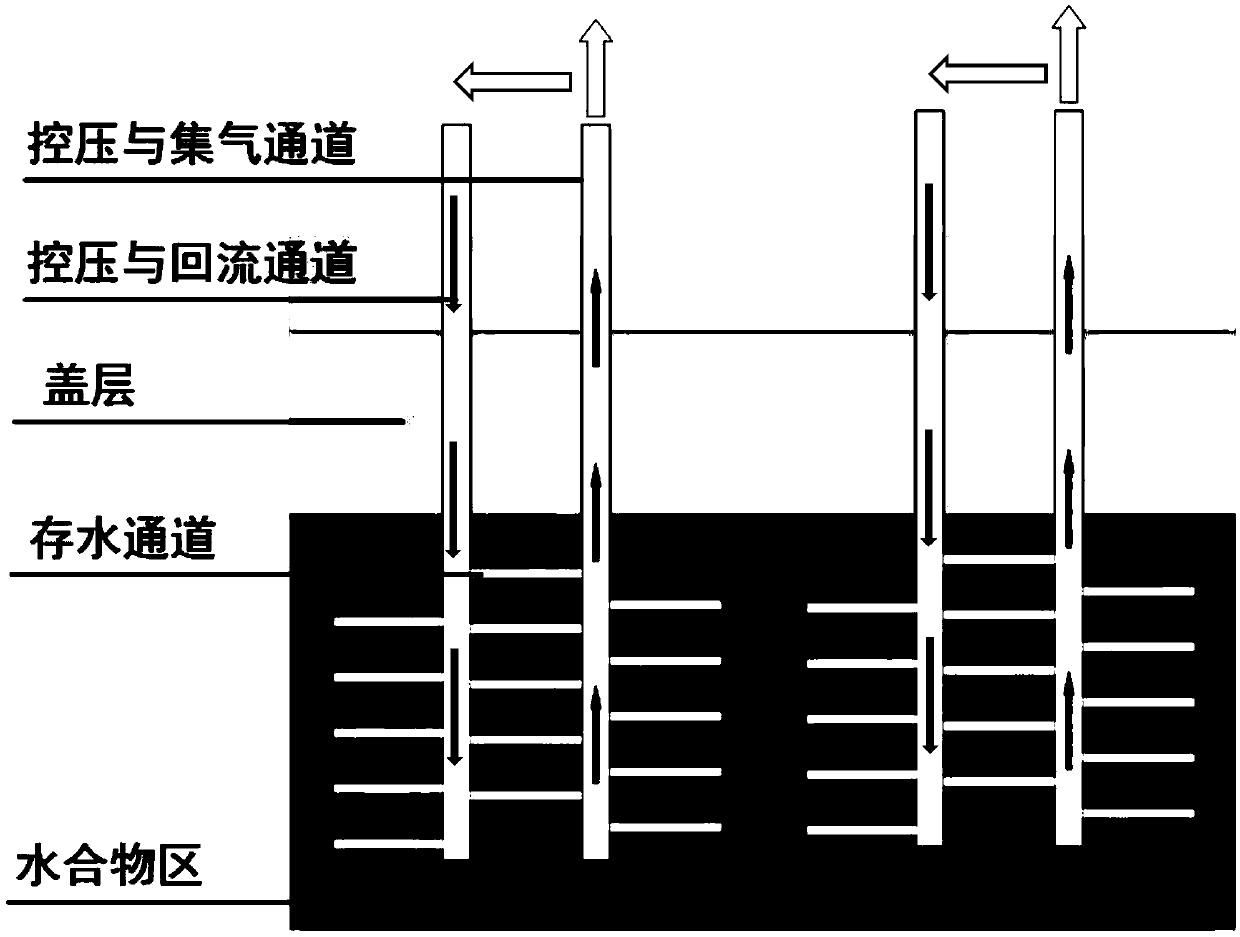

Marine natural gas hydrate exploitation method combined to pressure-reduced water flow erosion method

InactiveCN107829711AControl stable decomposition speedSolve problems in the mining processConstructionsFluid removalEnvironment waterWater flow

The invention belongs to the technical field of marine natural gas hydrate exploitation and seawater desalination, and relates to a marine natural gas hydrate exploitation method combined to a pressure-reduced water flow erosion method. Based on influences of water flowing to stable existing of hydrate, a marine natural gas hydrate exploitation method combined to the pressure-reduced water flow erosion method is provided by decomposition of the hydrate due to chemical potential difference between a hydrate phase and an environment water phase in a water flowing process and influences of the water flowing speed to hydrate decomposition speed and through a pressure-reduced exploitation method. By the method, preliminary partial decomposition of the hydrate of a reservoir is implemented by pressure-reduced exploitation at first, the permeability of a peripheral region of the reservoir is improved, decomposition gas controls pressure difference of the reservoir to implement continuous water flowing in a hydrate exploitation process, and step-by-step stable and efficient decomposition of the hydrate is realized by control over the water flowing speed. The method is easy to implement, and large-scale commercial exploitation of the hydrate is realized favorably.

Owner:DALIAN UNIV OF TECH

Method for synthesizing (2S,3S,4S)-5-(3,4-diamino-tetrahydrothiophene-2-base) valeric acid

ActiveCN101195611AEasy to controlAvoid decompositionOrganic chemistryLithium hydroxideSynthesis methods

The invention discloses a synthesis method of (2S, 3S, 4S)-5-(3, 4-diamino-thiophane-2-group) valeric acid, while prior method has long reaction and partial decomposition of product in reaction caused by concentrated halogen acid, to affect the quality of d-biotin. The invention processes reflux reaction on diethyl malonate condensate, cyano compound or bis-benzyl biotin in halogen acid, adds glacial acetic acid later, refluxes until no single-benzyl biotin and d-biotin exist in product, concentrates to remove unreacted halogen acid and glacial acetic acid, adds absolute ethyl alcohol, freezes to 0-5DEG C, adds lithium hydrate to neutralize and precipitate white solid crystals, filters, poaches filter cake via absolute ethyl alcohol, and dries to obtain target product. The invention has short reaction and controllable reaction end, which leads glacial acetic acid in later reaction to effectively avoid diamino acid being decomposed in concentrated halogen acid, to improve product yield and content.

Owner:ZHEJIANG MEDICINE CO LTD XINCHANG PHAMACEUTICAL FACTORY

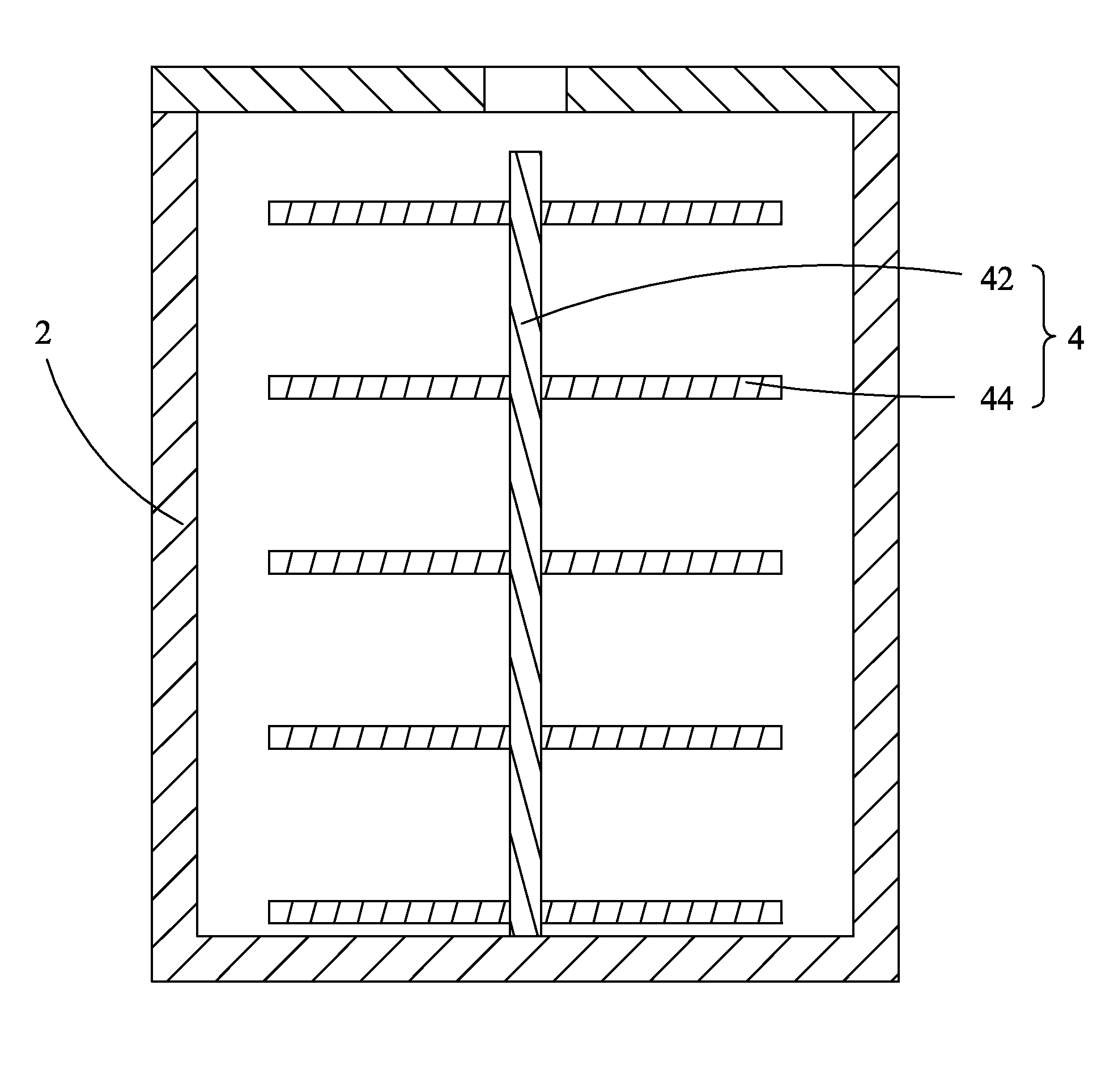

Heat conduction device included crucible

The present invention provides a heat conduction device included crucible, which includes: a crucible body and a heat conduction device arranged in the crucible body. The heat conduction device has a tree-like configuration, which includes a heat-dissipative trunk and multiple levels of heat dissipative branches mounted to the heat-dissipative trunk. Each level of the heat dissipative branches includes a plurality of branch units and the branch units are arranged to project out from an outer surface of the heat-dissipative trunk. The heat conduction device included crucible of the present invention uses the tree-like heat conduction device arranged in the crucible body to transfer heat in every direction within the crucible body so that during a vapor deposition operation, an organic material received in the crucible body can be heated uniformly thereby avoiding the phenomenon of partial decomposition of the organic material occurring in the prior art technique due to non-uniform heating of the organic material and thus effectively improving the vapor deposition efficiency and vapor deposition performance.

Owner:TCL CHINA STAR OPTOELECTRONICS TECH CO LTD

Antibacterial agents and process for producing the same

InactiveUS20050130934A1Improve antibacterial propertiesEliminate side effectsAntibacterial agentsBiocideChemical structureSulfated polysaccharides

An antibacterial agent showing a high affinity for Helicobactor pyroli and having an antibacterial effect specific to H. Pyroli. The agent has a chemical structure wherein an antibacterial substance is bonded to a sulfated polysaccharide or an oligosaccharide prepared by partial decomposition of the sulfated polysaccharide. Preferable embodiments are those having the chemical structure represented by Y—OCH(AH2NHR)n or Y—BH2NHR, wherein Y represents a sulfated polysaccharide or an oligosaccharide prepared by partial decomposition of the sulfated polysaccharide; A a carbon derived from aldehyde group occurring through the reduction of the reduced end sugar of Y and subsequent oxidation of the resulting product with an oxidant; B a carbon derived from the aldehyde group at the reduced end sugar of Y; R an antibacterial substance with a primary amino group or with an amino group introduced therein or represents an antibacterial substance derivative prepared by bonding an antibacterial substance through a spacer to the carbon A or the carbon B; and n=1 or 2.

Owner:YAKULT HONSHA KK

Method for calcination treatment of cement raw material

The invention relates to the technical field of finish machining of cement production, and in particular relates to a method for calcination treatment of a cement raw material. The method comprises the following steps: 1, preheating the raw material, namely filling a preheater with the raw material to finish preheating and partial decomposition of the raw material by virtue of the preheater; 2, calcining a clinker, namely filling a rotary kiln with the preheated raw material for calcination; 3, cooling the clinker; and 4, grinding the clinker, namely grinding the cement clinker (together with a gelling agent, a performance adjusting material and the like) to an appropriate particle size (represented by fineness, specific area and the like) to form a certain grain composition, increase the hydration area of the clinker, accelerate hydration, and meet requirements of coagulation and solidification of a cement paste. The method is novel in design, reasonably makes use of advantages of equipment, reduces resource waste during clinker calcination, and meanwhile ensures the quality of cement calcination and is more safe and reliable.

Owner:WUXI JIANGDA ENERGY SAVING TECH CO LTD

Method for preparing a substrate by implantation and irradiation

The present invention relates to a method for preparing a substrate (1) with the purpose of detaching a layer, called the detachment layer, from said substrate by irradiation of the substrate with a light flux (F) for heating a buried region of the substrate and bringing about decomposition of the material of that region to detach said detachment layer, characterized by the fact that it comprises the steps consisting of: a) fabricating an intermediate substrate including a first layer (2) called the buried layer, and a second layer (4) called the covering layer, wherein the second layer (4) covers all or part of the first layer (2), the covering layer (4) is substantially transparent to said light flux (F), and the buried layer (2) which is formed by implantation of particles into the substrate can absorb said flux (F) for its part, and b) selectively and adiabatically irradiating a region called the treated region of the buried layer (2) until at least partial decomposition of the material constituting it ensues.

Owner:SOITEC SA

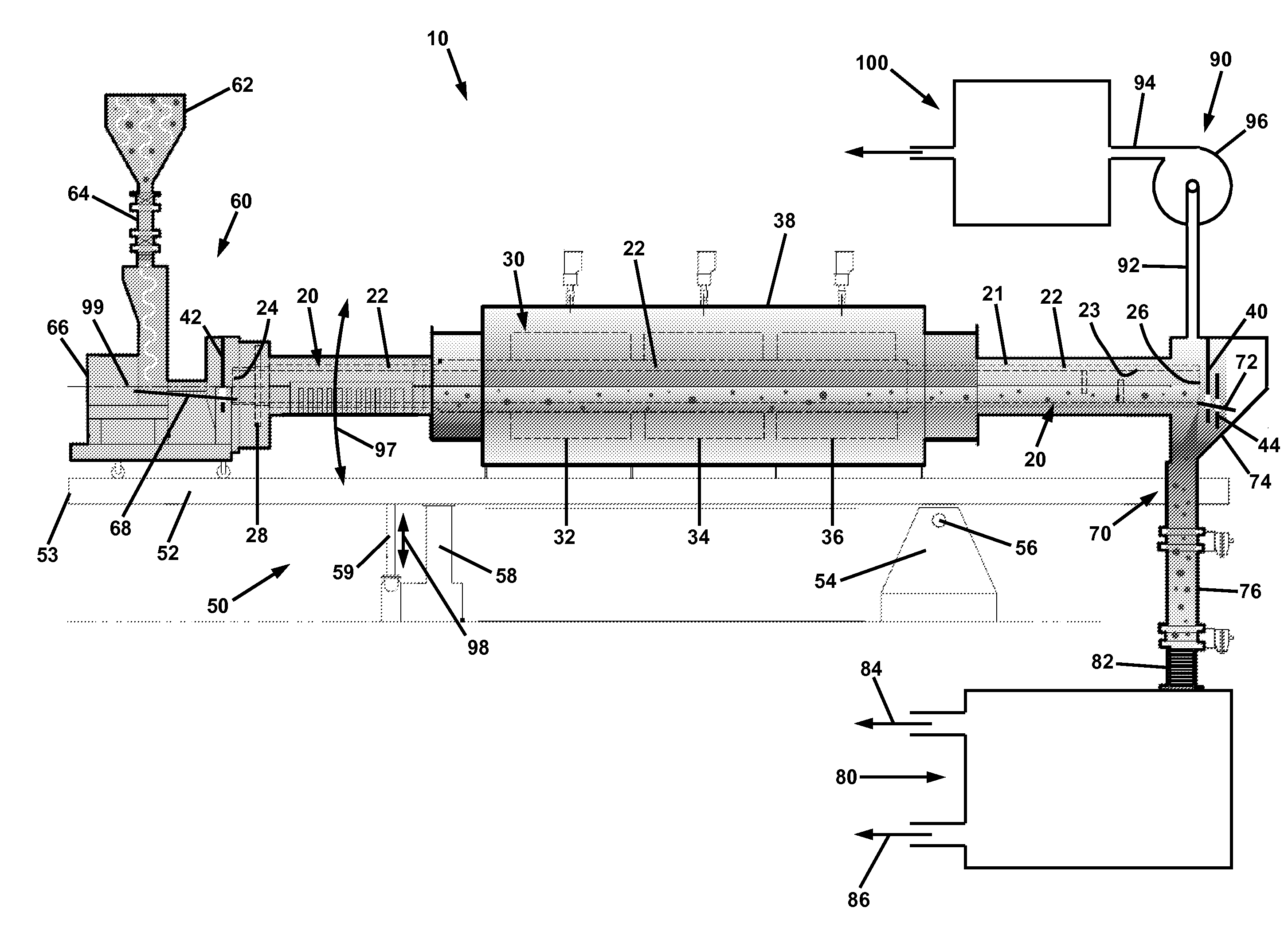

Method and apparatus to demilitarize munition energetics

ActiveUS9366517B2Maximized recovery/recycling or responsible disposalAmmunitionBlastingCombustionEnergetics

A method of demilitarizing an energetic is disclosed. The method comprises indirectly heating the energetic in a chamber to a temperature below a combustion temperature of the energetic to at least partially decompose the energetic and substantially preclude combustion of the energetic such that the indirect heating produces a decomposition gas, and separating at least a portion of the decomposition gas from the chamber. The method may further comprise monitoring the decomposition gas and / or passing the separated decomposition gas through an air abatement system. The method may further comprise adjusting at least one of the following: the indirect heating of the energetic, the separating of the decomposition gas, the air abatement system, and a residence time of the energetic in the chamber. The energetic may be a bulk energetic.

Owner:U S DEMIL

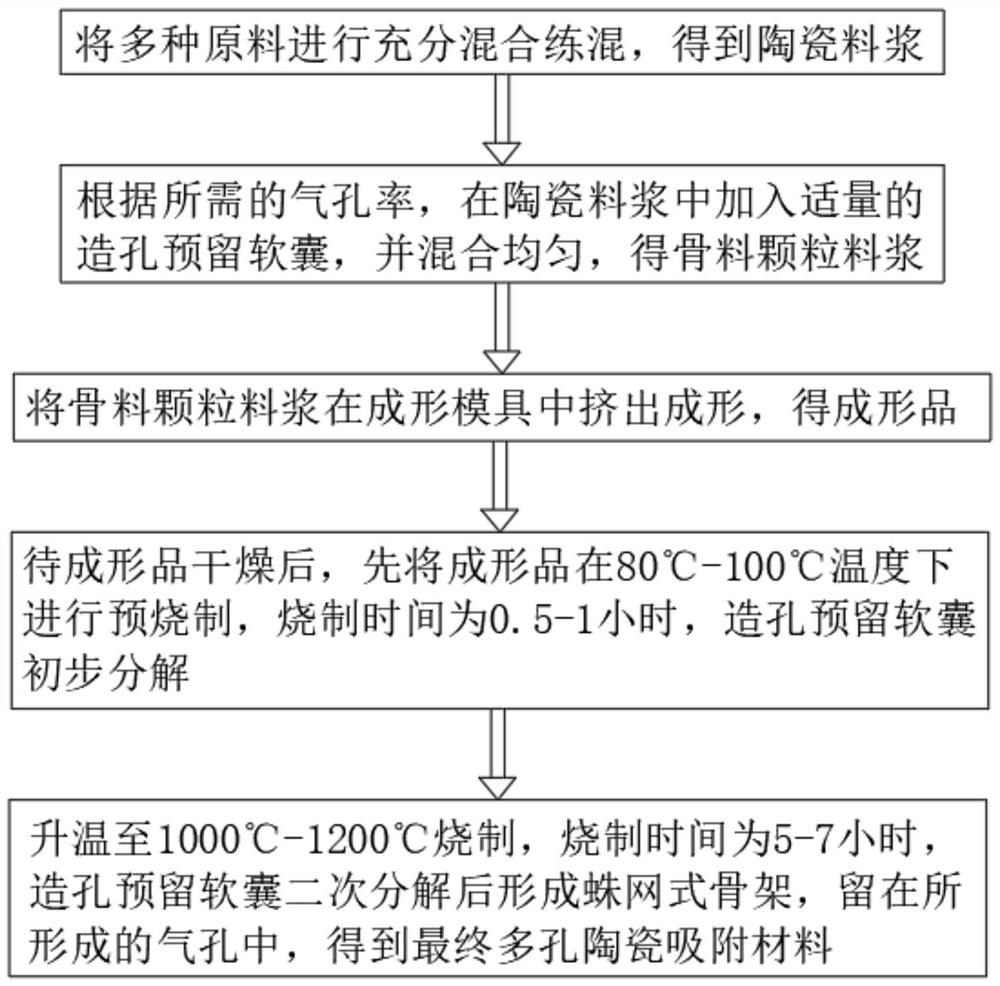

Preparation process of porous ceramic adsorption material high in adhesion rate and easy to desorb

InactiveCN112316930AImprove filter adsorption effectSolve Difficult-to-Rinse ProblemsOther chemical processesAlkali metal oxides/hydroxidesCeramic sinteringPore diameter

The invention discloses a preparation process of a porous ceramic adsorption material high in adhesion rate and easy to desorb, belonging to the field of ceramic materials. According to the invention,a mode of adding pore-forming reserved soft capsules into ceramic slurry is adopted, so on one hand, the ceramic slurry is partially decomposed to generate gas in a ceramic sintering process to obtain the porous ceramic adsorption material with uniform pore diameter, and on the other hand, along with the generation of pores, the pore-forming reserved soft capsules partially go deep into pore walls, and after the decomposition of the soft capsulesis completed, a residual skeleton is dispersed and fixed on the inner walls of the pores in the form of cobweb; compared with an existing porous ceramic material with the same pore diameter and the same porosity, the cobweb type skeleton left by decomposition of the pore-forming reserved soft capsules can improve the adsorption rate of the pores to impurities and enhance the filtration and adsorption effects of the material; and when the material is backwashed, the cobweb type skeleton moves actively in the pores and collides and rubs with theinner walls of the pores continuously, so the impurities on the cobweb-type skeleton and the inner walls of the pores can be backwashed quickly.

Owner:陈钲仁

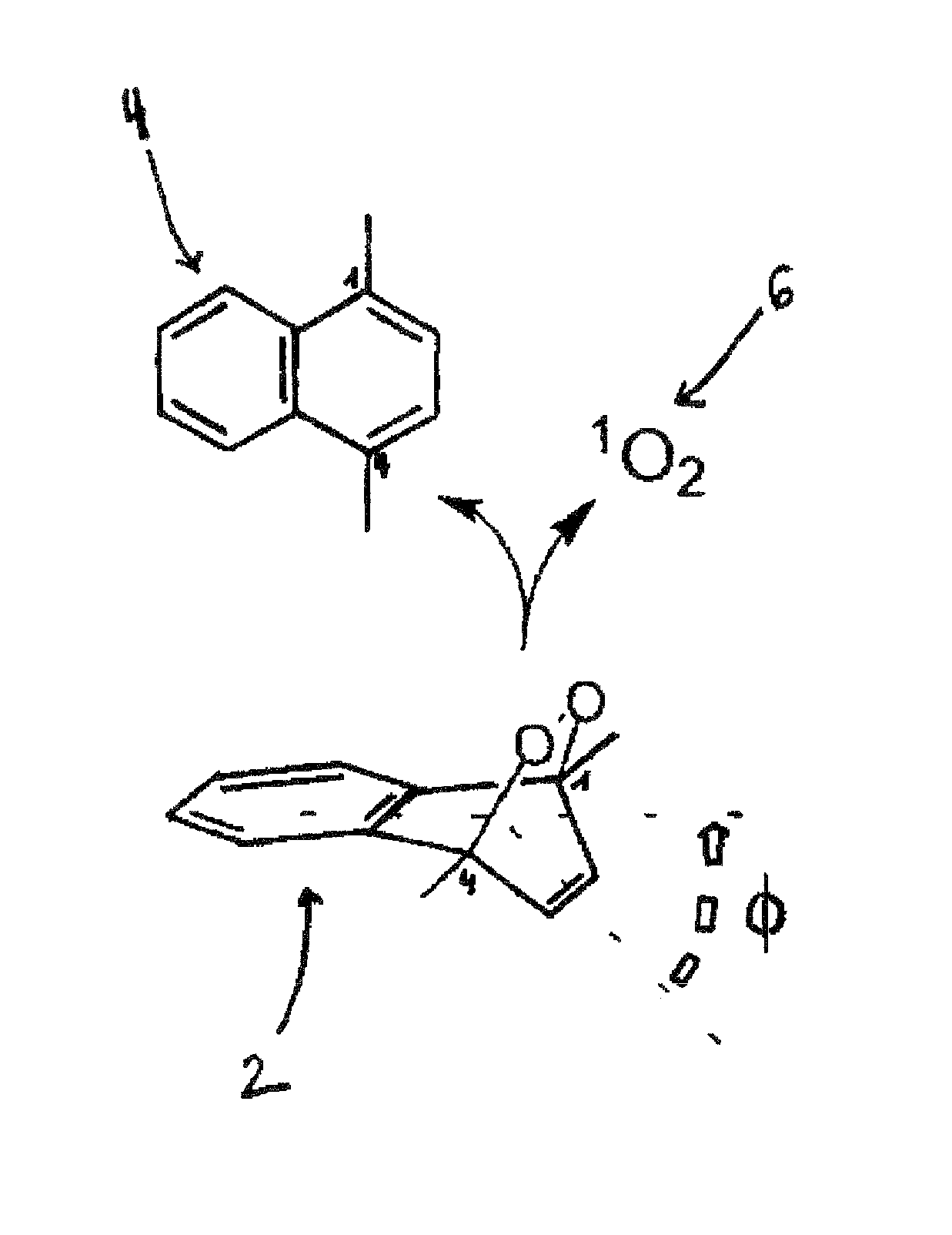

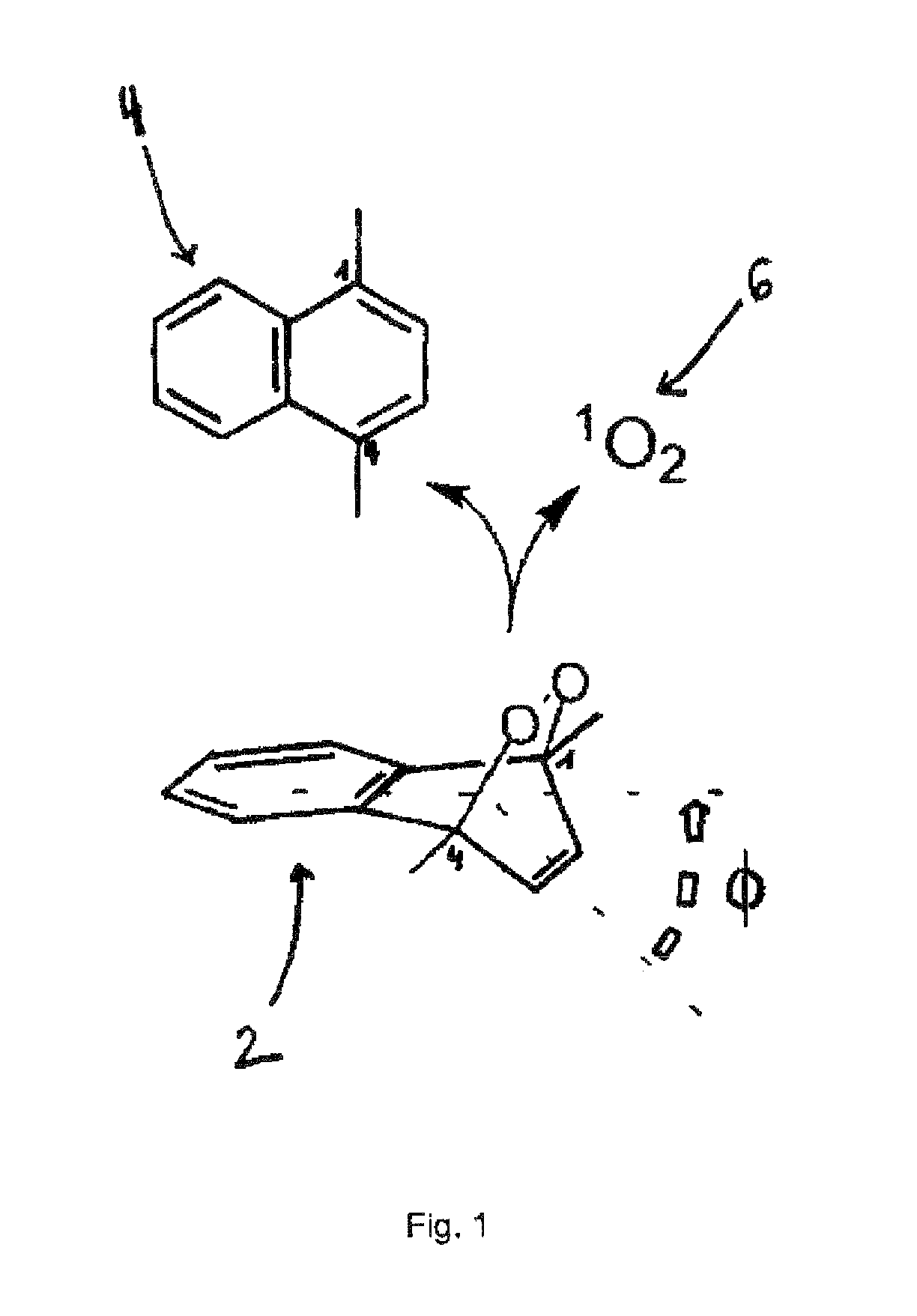

Material system containing endoperoxide with adaption of decomposition, and applications

This disclosure relates to the release of singlet oxygen by thermally activated decomposition of aromatic endoperoxide molecules in material systems [e.g. polymer (nano)particles or polymer films]. Due to the short lifespan and diffusion length of singlet oxygen, the technical problem is that the majority of the decomposition may only take place if the singlet oxygen molecules can reach the target region. For example, either the penetration of the polymer particles into the cancer cells to be killed, or the settlement of bacteria on an implant coated with the polymer film, must be accomplished. It is necessary to allow adaptation of the time progression of the decomposition for the application. The adaptation is performed by chemically and / or physically modifying the functional structures present in the material system, each made of the molecule forming the endoperoxide and at least one adjacent molecule or the cage formed by all adjacent molecules. Potential applications are in pharmacy and medicine, as well as in production technology.

Owner:BOGNER UDO +2

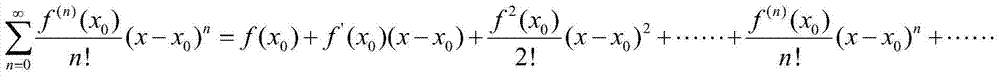

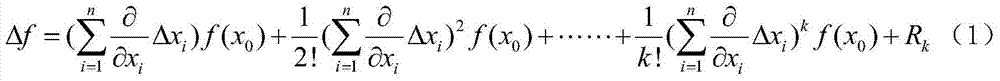

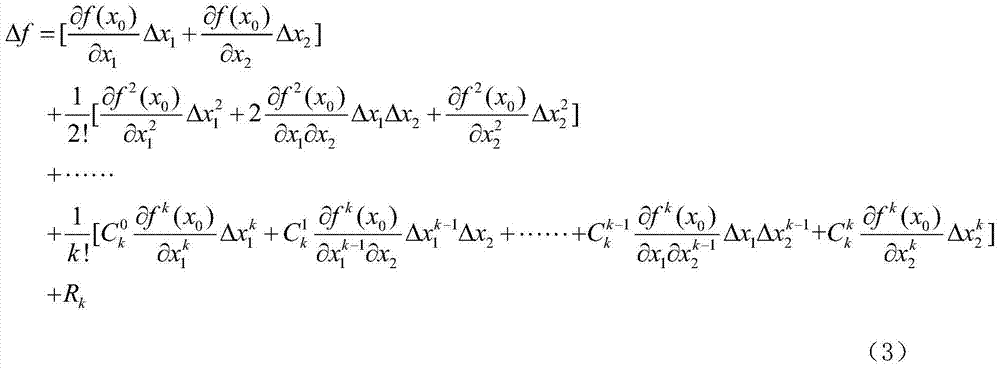

A Boiler Performance Index Analysis Method Based on Partial Incremental Factor Decomposition

ActiveCN104392095BGuaranteed uptimeEasy to adjustSpecial data processing applicationsAlgorithmWeakness

The invention discloses a boiler performance index analysis method based on partial incremental factor decomposition, which includes the following steps: (1) determining the small operation index that affects the boiler thermal efficiency according to the reverse equilibrium thermal efficiency calculation method. (2) Use the analytical theory of full increment and partial increment of functions in mathematical analysis, and use the method of factor decomposition to deduce the degree of influence of each factor on the full increment. (3) Establish a calculation model of boiler performance index inverse balance and partial increment, and use this model to analyze the influence degree of each small operating index on the boiler performance index. The method of the present invention is simple and easy to implement, easy to program, can know the process parameters when the boiler deviates from the optimal working condition in real time, quantitatively understand and grasp the influence direction and degree of influence of the change of each small index on the boiler performance index, and help the operating personnel to target the target It can deal with the weak link of boiler operation accurately, so that the boiler can always operate in the best condition.

Owner:STATE GRID HEBEI ENERGY TECH SERVICE CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com