Thermally stable polycrystalline diamond and methods of making the same

A polycrystalline diamond, diamond technology, applied in the direction of manufacturing tools, metal processing, earth-moving drilling and mining, etc., can solve problems such as failure of PCD cutting elements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

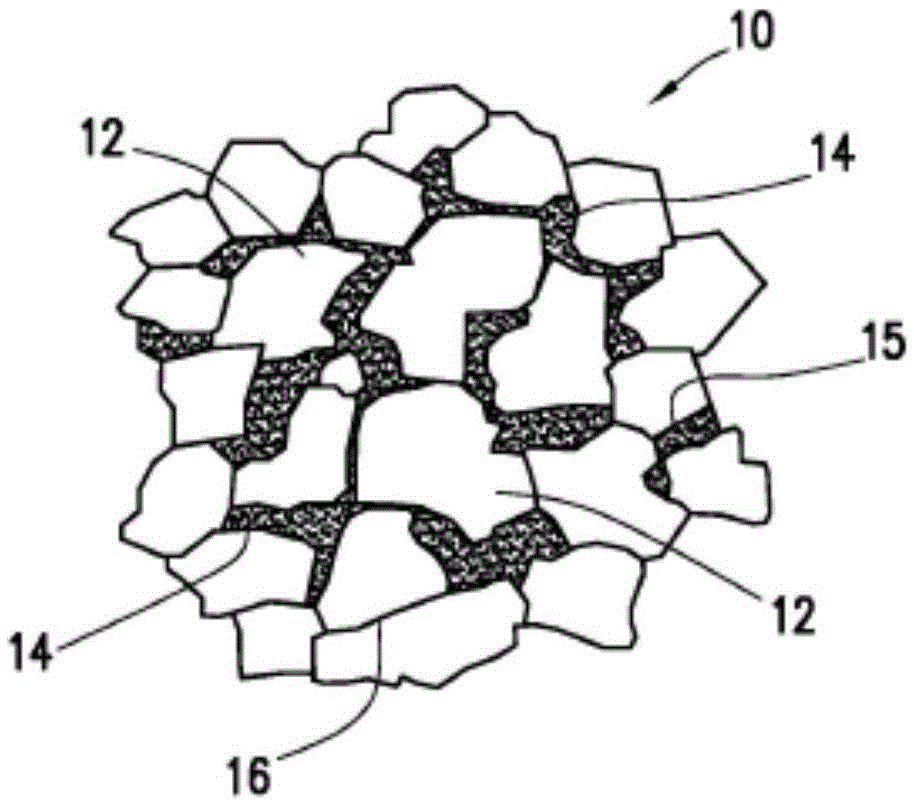

[0017] As used herein, the term "carbonate-based polycrystalline diamond" refers to a process obtained by exposing individual diamond grains in the presence of carbonate material to conditions of high pressure and high temperature (HPHT) sufficient so that adjacent Intergranular bonding occurs between the diamond crystals to form a diamond-to-diamond bond and a network or matrix phase of interstitial regions dispersed between the bonded diamond grains resulting in the final material. The carbonate-based polycrystalline diamond of the present invention may be referred to as polycrystalline diamond or PCD, but is distinct from conventionally formed polycrystalline diamond formed by transition metal solvent catalysts (described in the background section). Additionally, one or more embodiments relate to oxide-based polycrystalline diamond formed by decomposing a carbonate-based polycrystalline diamond body.

[0018] The carbonate-based polycrystalline diamond body may have a micro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com