Patents

Literature

82 results about "Extremely hard" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

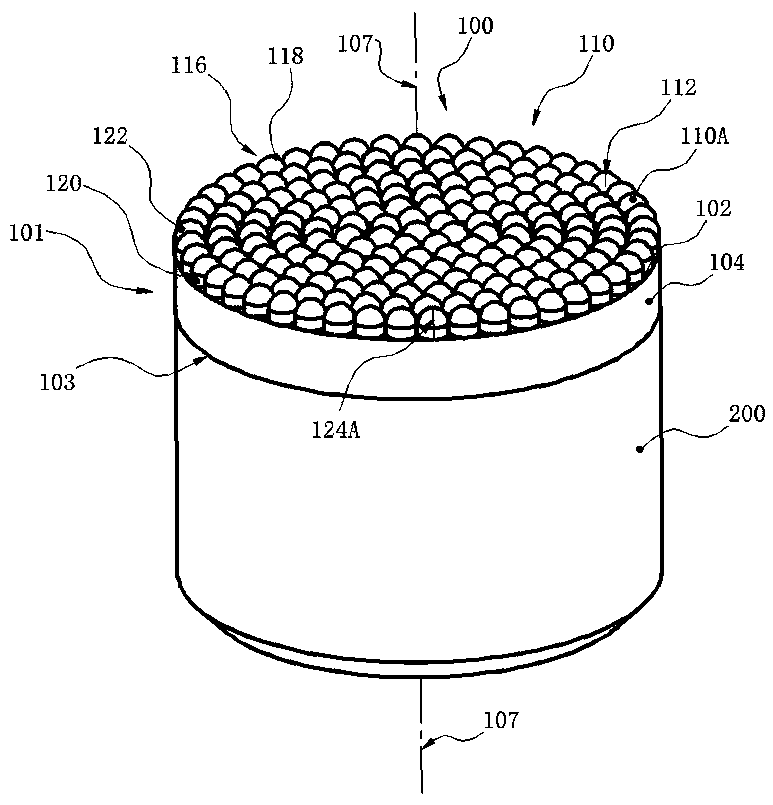

Preparation method for hydro-treating protecting agent

InactiveCN102310002ANo pollution in the processHigh strengthCatalyst protectionMetal/metal-oxides/metal-hydroxide catalystsMicron scaleVolumetric Mass Density

The invention discloses a preparation method for a hydro-treating protecting agent. An alumina carrier in the method is prepared by kneading two kinds of different pseudo-boehmite dry colloid powder and loading an active metal, wherein the first pseudo-boehmite has relatively low crystallization degree and large pore volume and can provide pores with diameter of 30 to 100 nanometers; and the second pseudo-boehmite has relatively high crystallization degree and can provide pores of micron scale, the second pseudo-boehmite represents extremely hard blocks after drying due to high acidic index, and the crushed second pseudo-boehmite can completely pass through a 50-mesh sieve, so that the number of micro-scale pores can be increased, and the strength of the catalyst carrier can be improved. By adjusting the mixing proportion of the two kinds of pseudo-boehmite, the hydro-treating protecting agent with high strength, high stacking density, large pore volume and low abrasion rate can be prepared. The hydro-treating protecting agent is particularly suitable to be used as a heavy oil or residuum hydro-treating protecting agent.

Owner:CHINA PETROLEUM & CHEM CORP +1

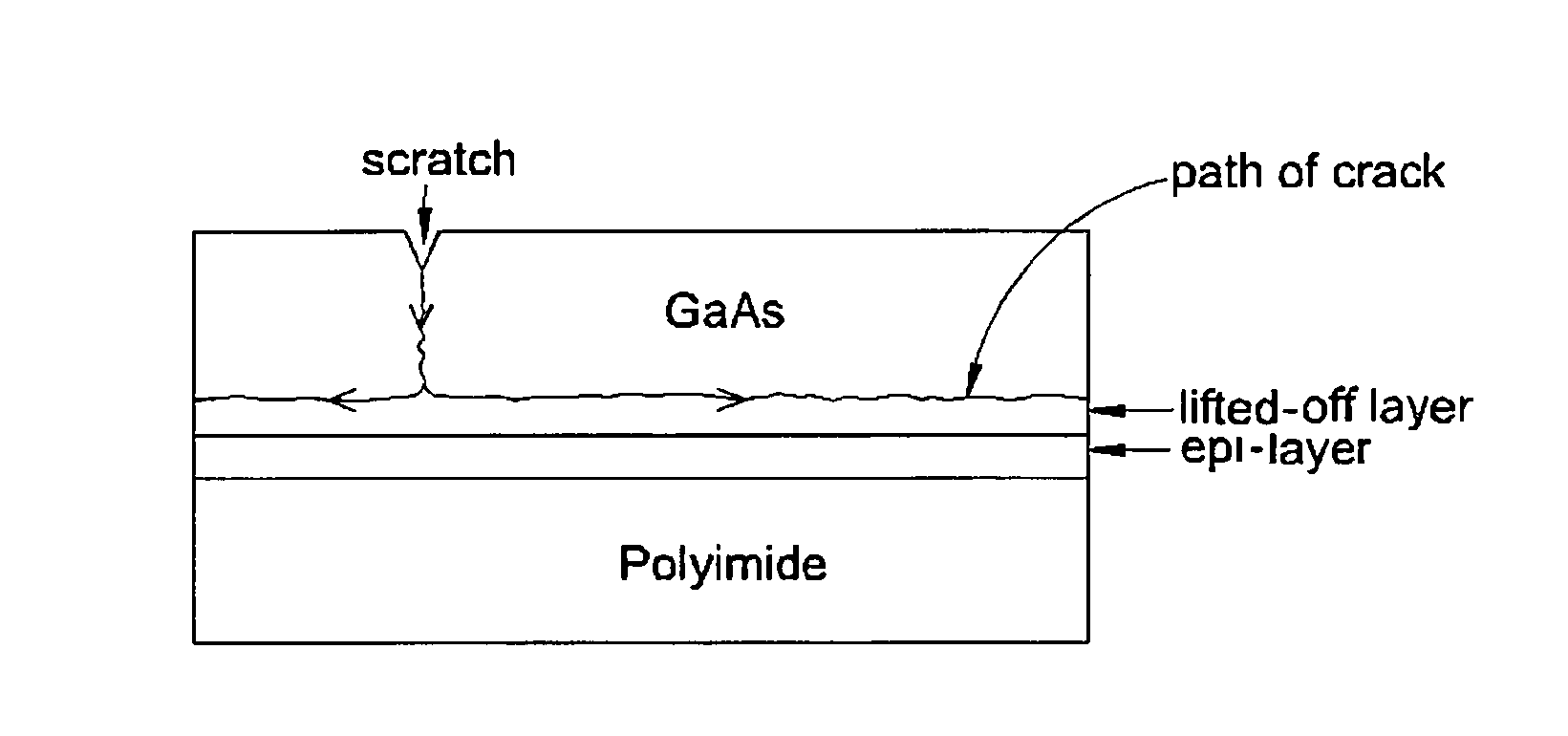

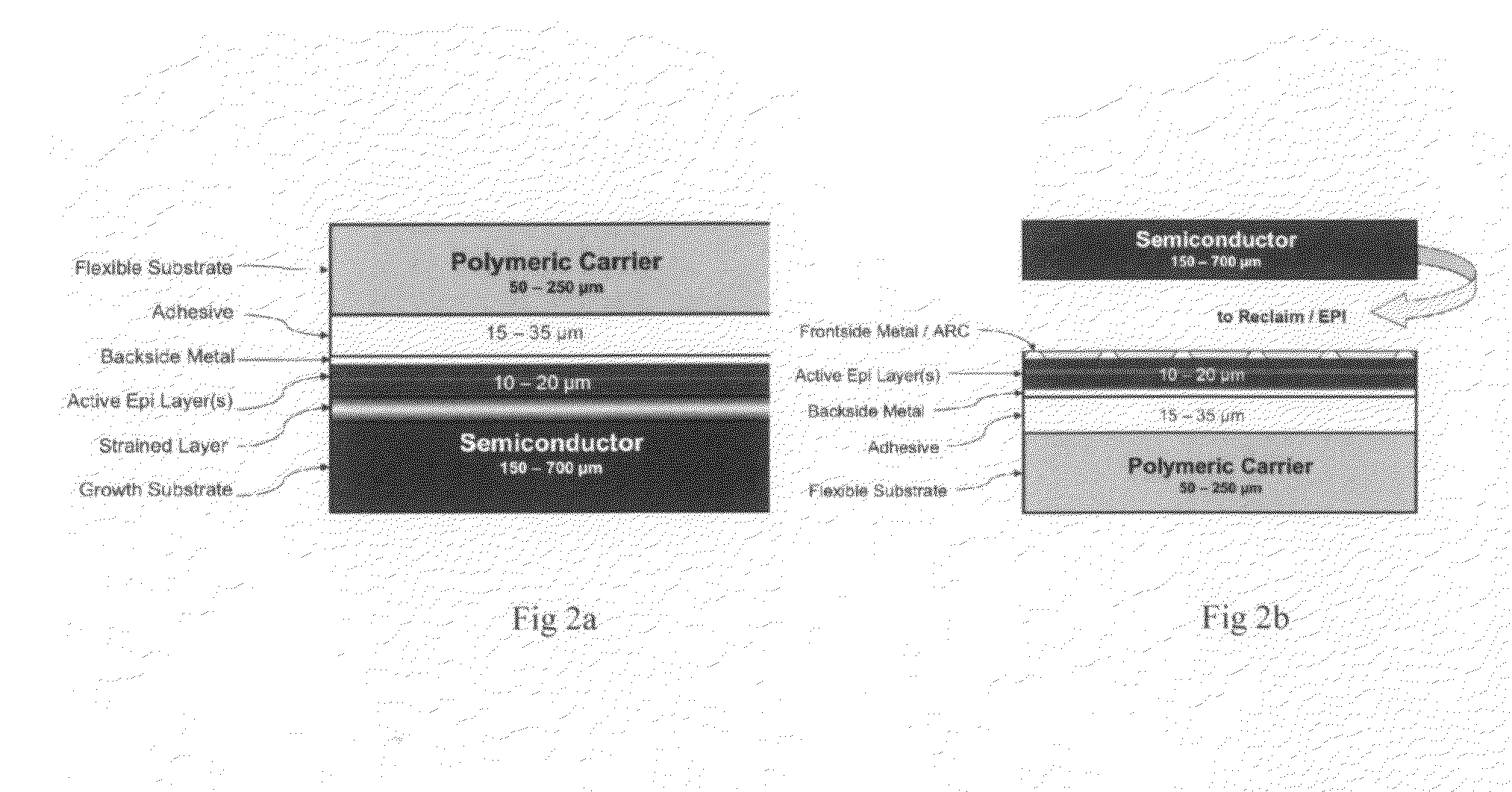

Rapid Thinning of GaN and SiC Substrates and Dry Epitaxial Lift-off

InactiveUS20150258769A1Minimize post lift-off polishingAvoid wasting substrate materialPolycrystalline material growthAfter-treatment detailsEtchingCopper plating

An epitaxially grown layer III-V solar cell is separated from the growth substrate by propagating a crack close to the epi / wafer interface. The crack is driven by the elastic strain energy built up due to thermal stresses between GaAs and polyimide by cooling below room temperature. A GaAs wafer is bonded to a polyimide substrate on the epi-side and scribed on the opposite side. The crack is initiated from the scratch and guided along the interface using an epitaxially grown sacrificial layer with lower fracture toughness under the solar cell. No expensive ion implantation or lateral chemical etching of a sacrificial layer is needed. The active layer is transferred wafer-scale to inexpensive, flexible, organic substrate. The process allows re-using of the wafer to grow new cells, resulting in savings in raw materials and grinding and etching costs amounting to up to 30% of the cost of the cell. Several cells are integrated on a common blanket polyimide sheet and interconnected by copper plating. The blanket is covered with a transparent spray-on polyimide that replaces the cover glass. The solar cell is stress-balanced to remain flat on orbit.Wide bandgap materials, such as Gallium Nitride (GaN) and Silicon Carbide (SiC) are very promising for light-emitting diodes (LEDs) and power electronics. These materials are extremely hard and difficult to machine and very expensive. The lack of good quality bulk GaN substrates with a smooth surface at a reasonable price is hampering the development of vertical devices.A rapid thinning technique is presented by lifting-off a 20-70 μm thick layer from the surface within a fraction of a second, which leaves the surface shiny and smooth. The savings in lapping and polishing add up to 60%, when this technique is incorporated in the crystal manufacturing process. This technology also has application for backside thinning where the savings are even larger.

Owner:FARAH JOHN

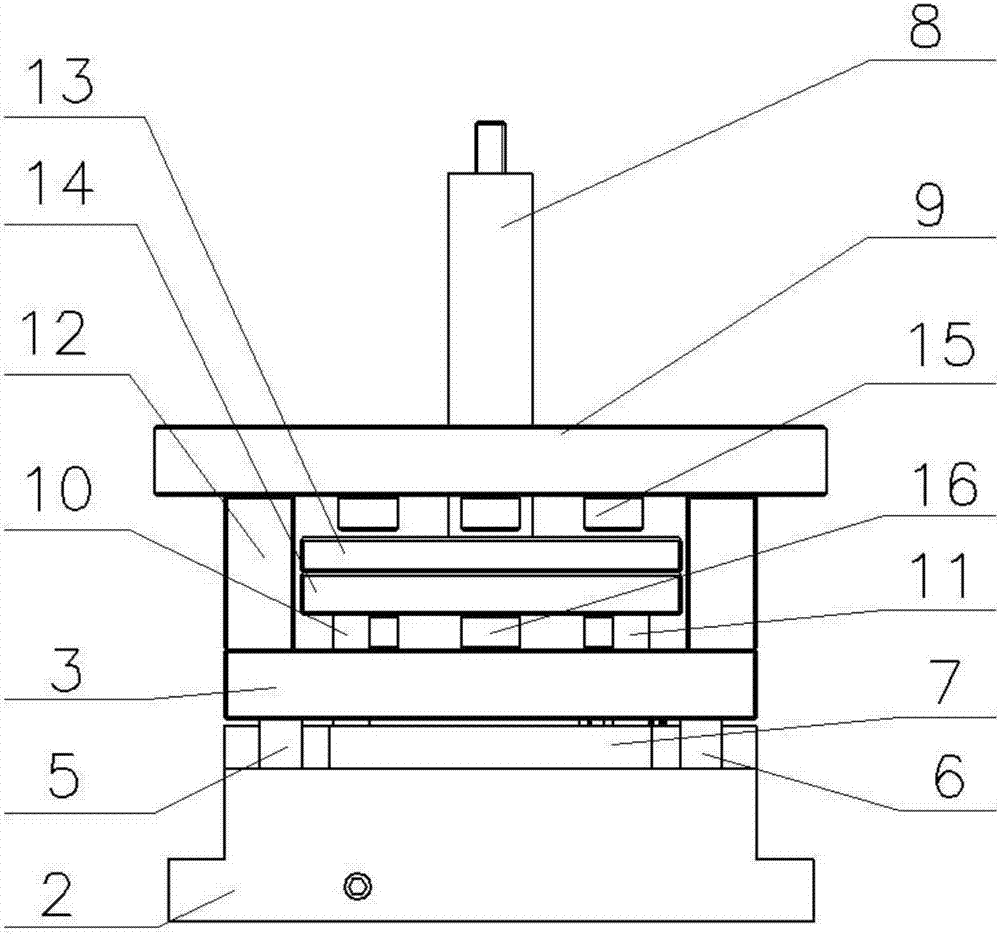

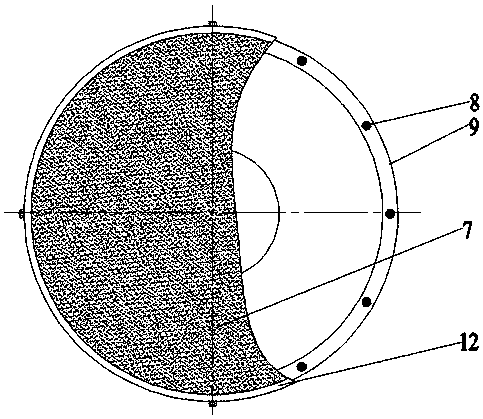

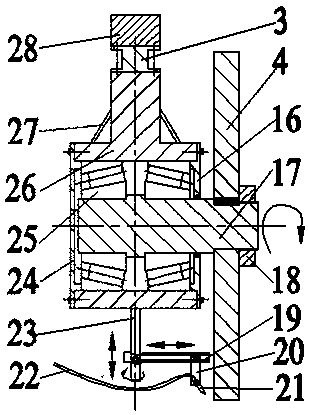

Aluminum alloy semisolid secondary combined extrusion casting method

The invention relates to an aluminum alloy semisolid secondary combined extrusion casting method to overcome the defects that in the current aluminum alloy semisolid extrusion casting technology, the quality of a sizing agent is extremely hard to control, meanwhile, close connection between sizing agent preparing and forming is very difficult to achieve, and the stability is poor. By adopting the aluminum alloy semisolid secondary combined extrusion casting method, semisolid sizing agent preparing and extrusion casting forming integration is achieved through the secondary combined extrusion casting technology. The preparation method is advanced, data is accurate and detailed, formed parts cast in a secondary combined extrusion manner are precise in shape, the metallographic structure compactness is good, primary alpha-Al is composed of spherical grains and nearly-spherical grains, the number of rose grains is small, the grain size is obviously reduced, the extension strength reaches 235 Mpa, the ductility reaches 8.5 %, and the aluminum alloy semisolid secondary combined extrusion casting method is advanced.

Owner:ZHONGBEI UNIV

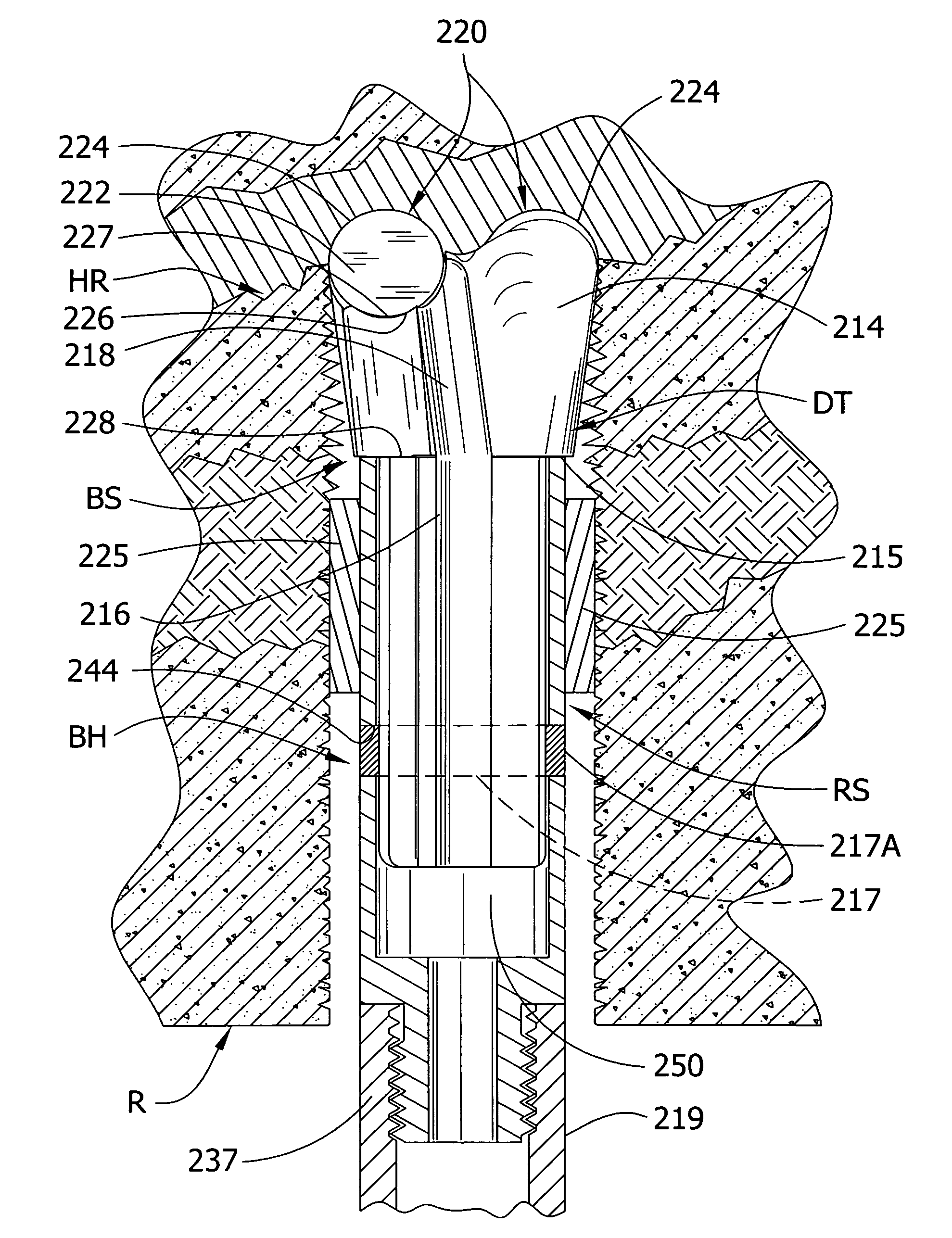

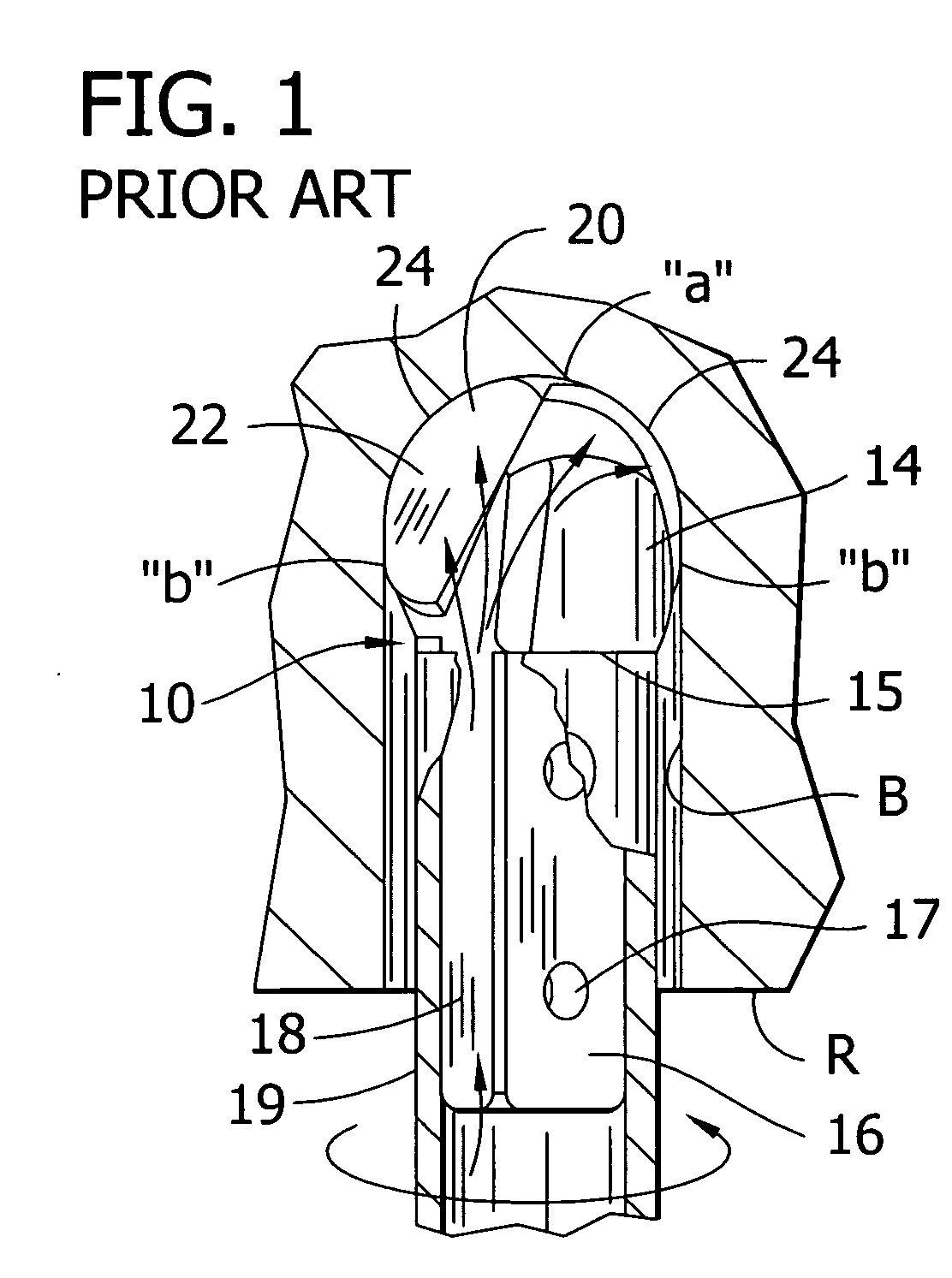

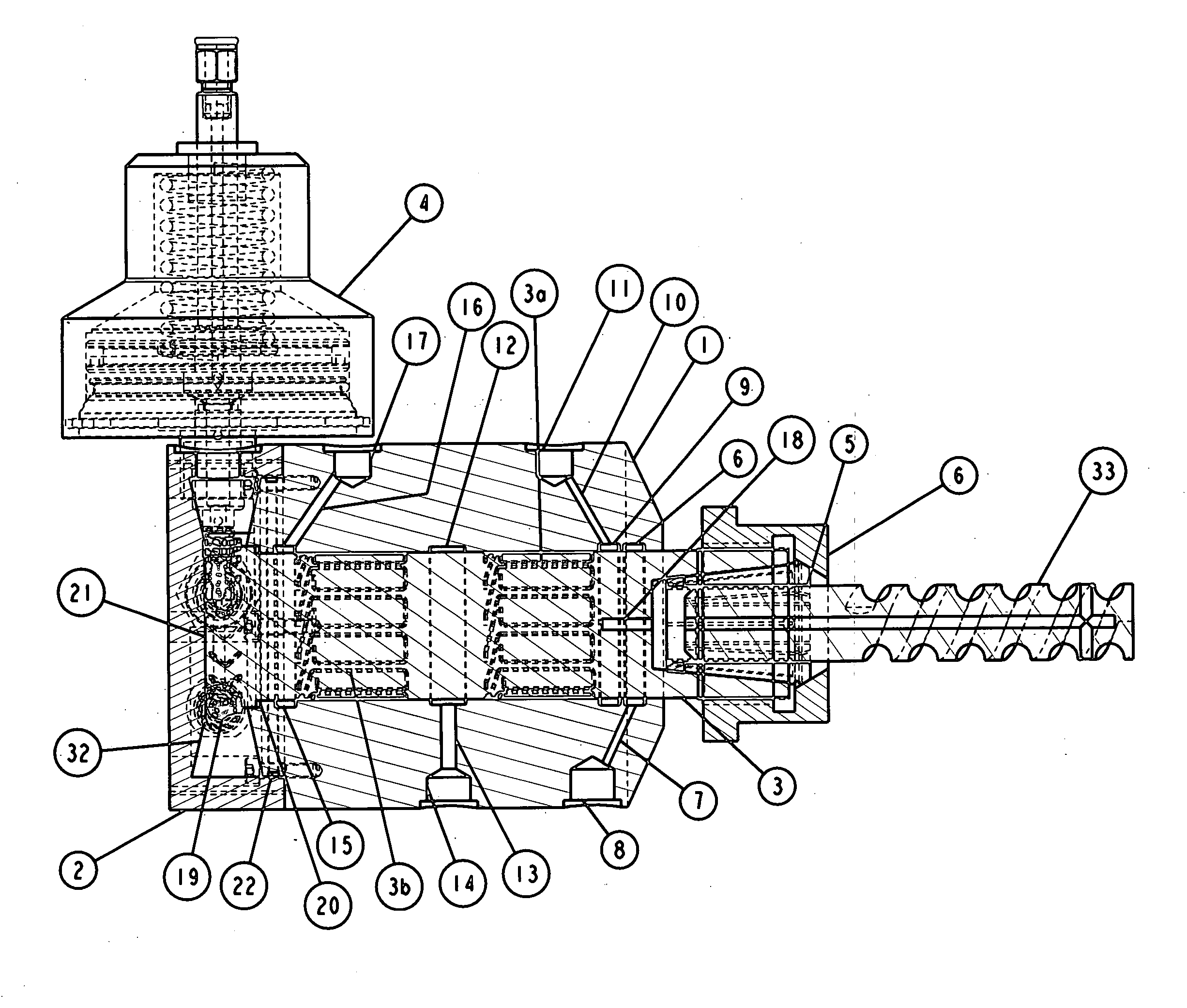

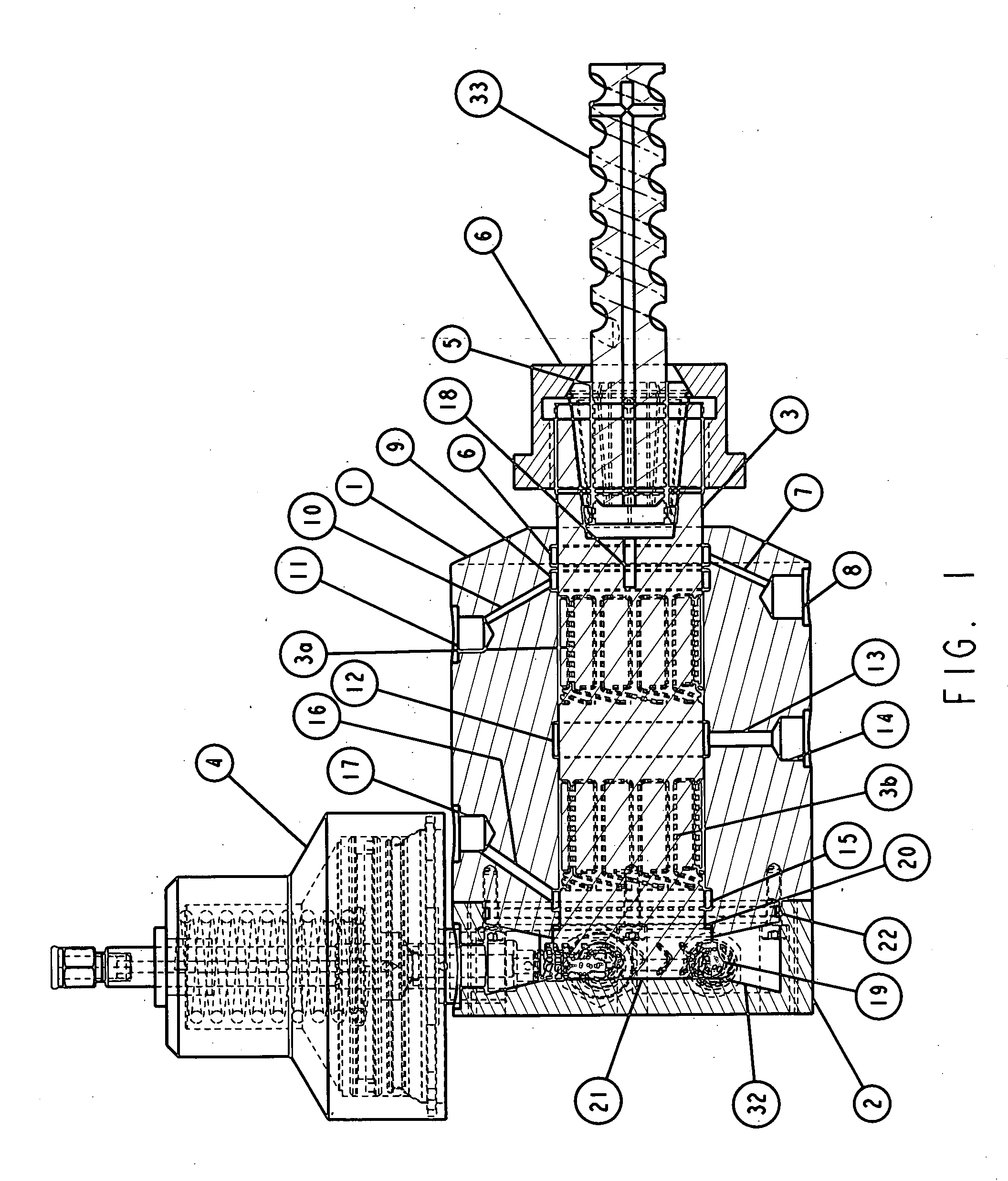

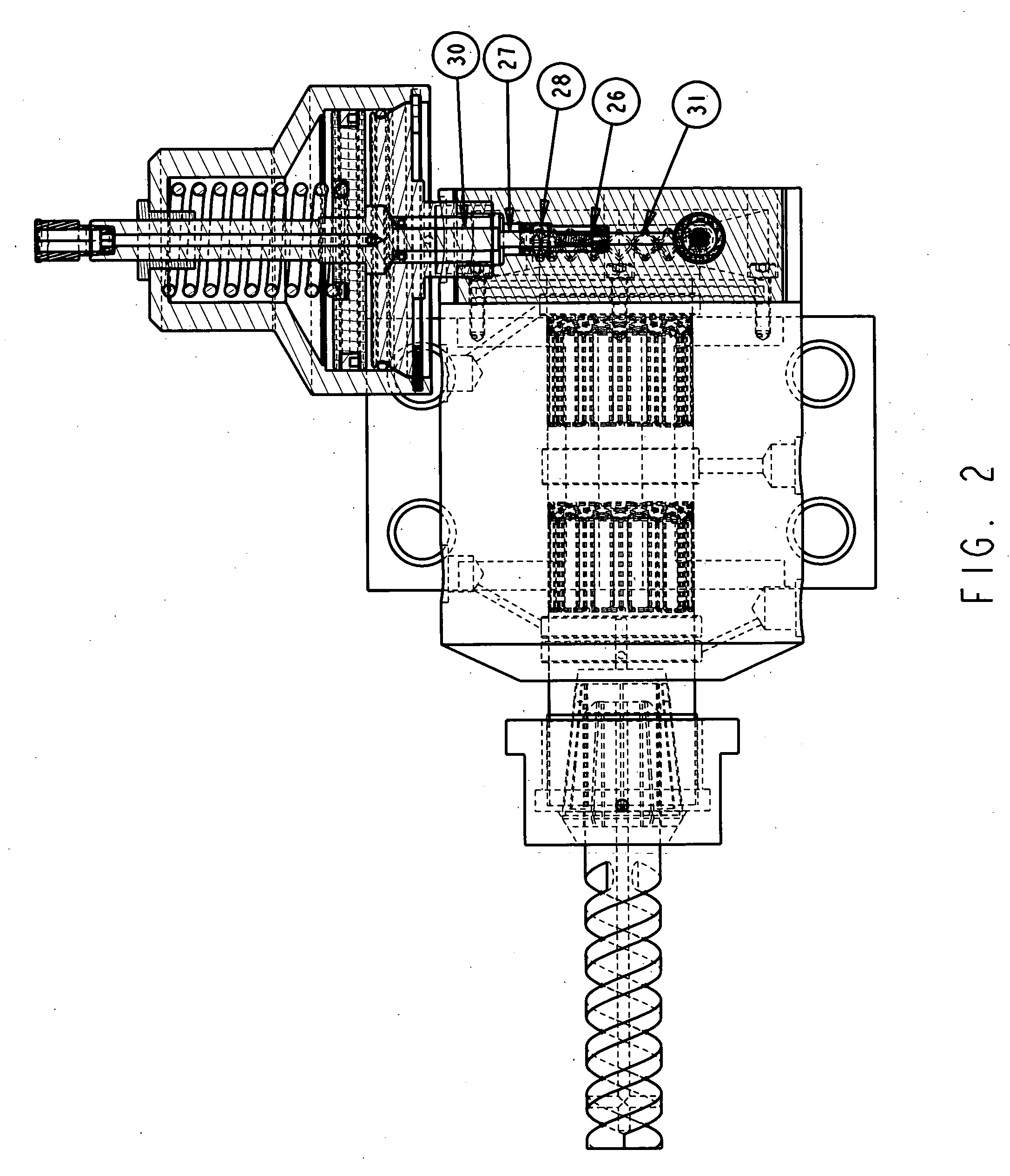

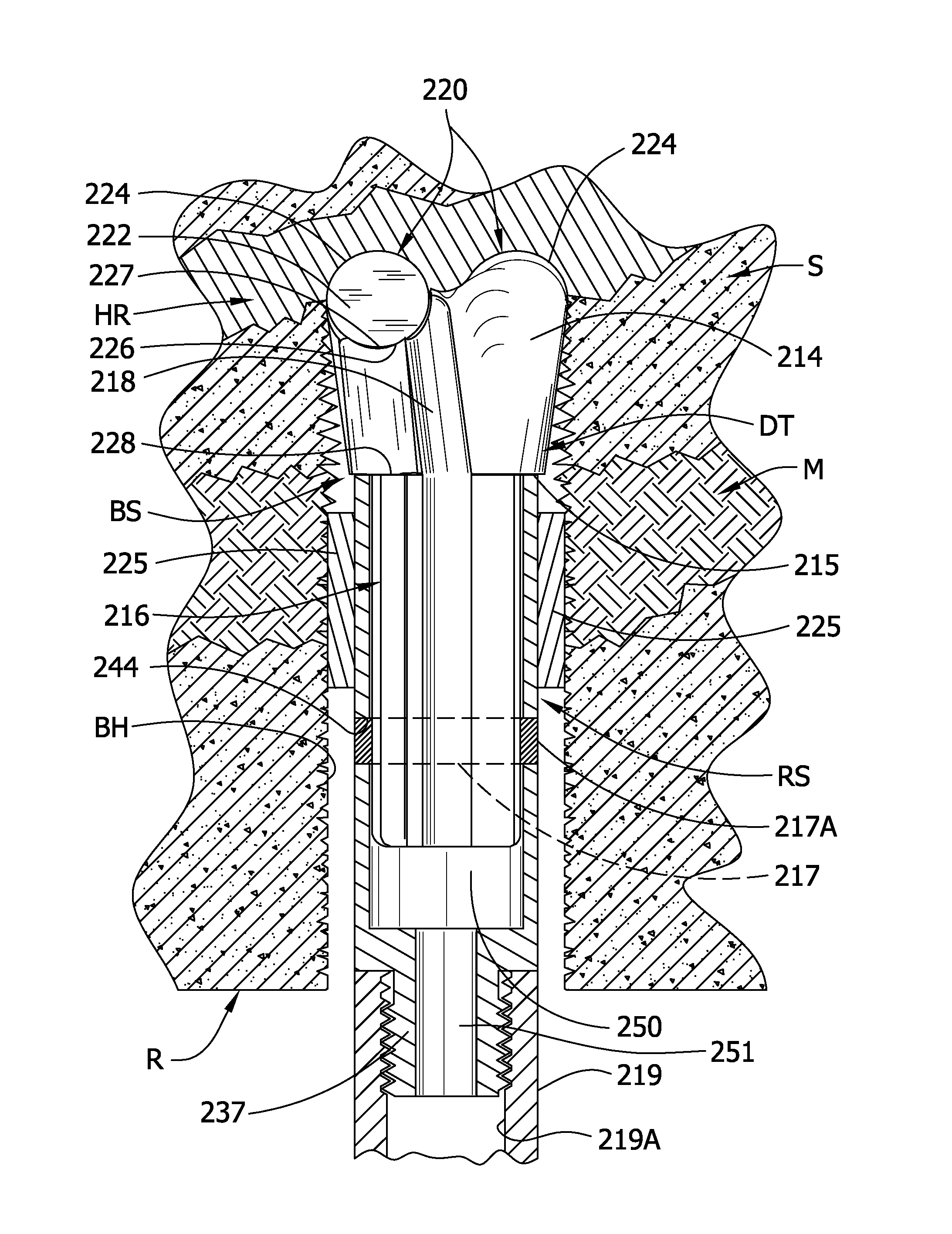

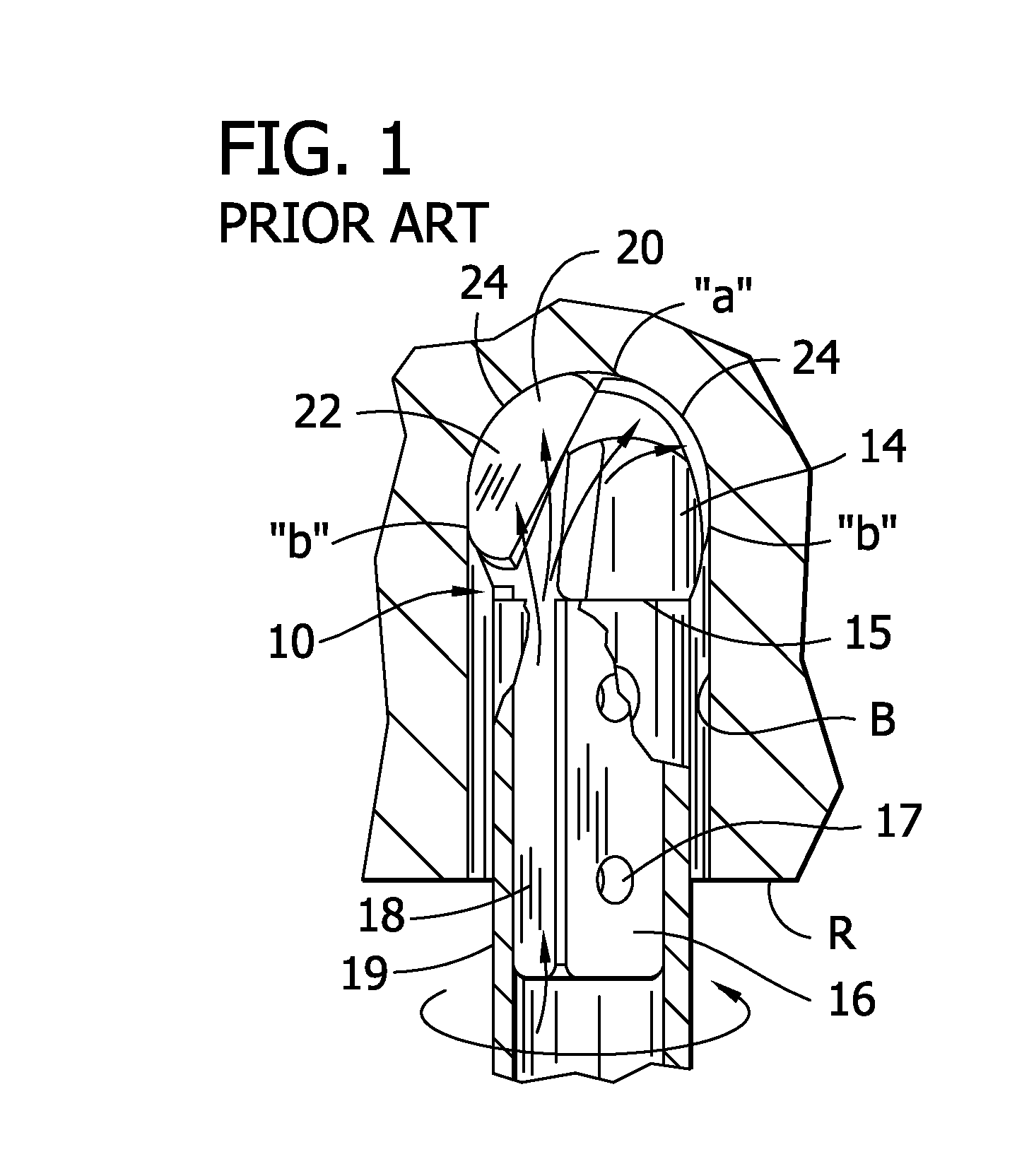

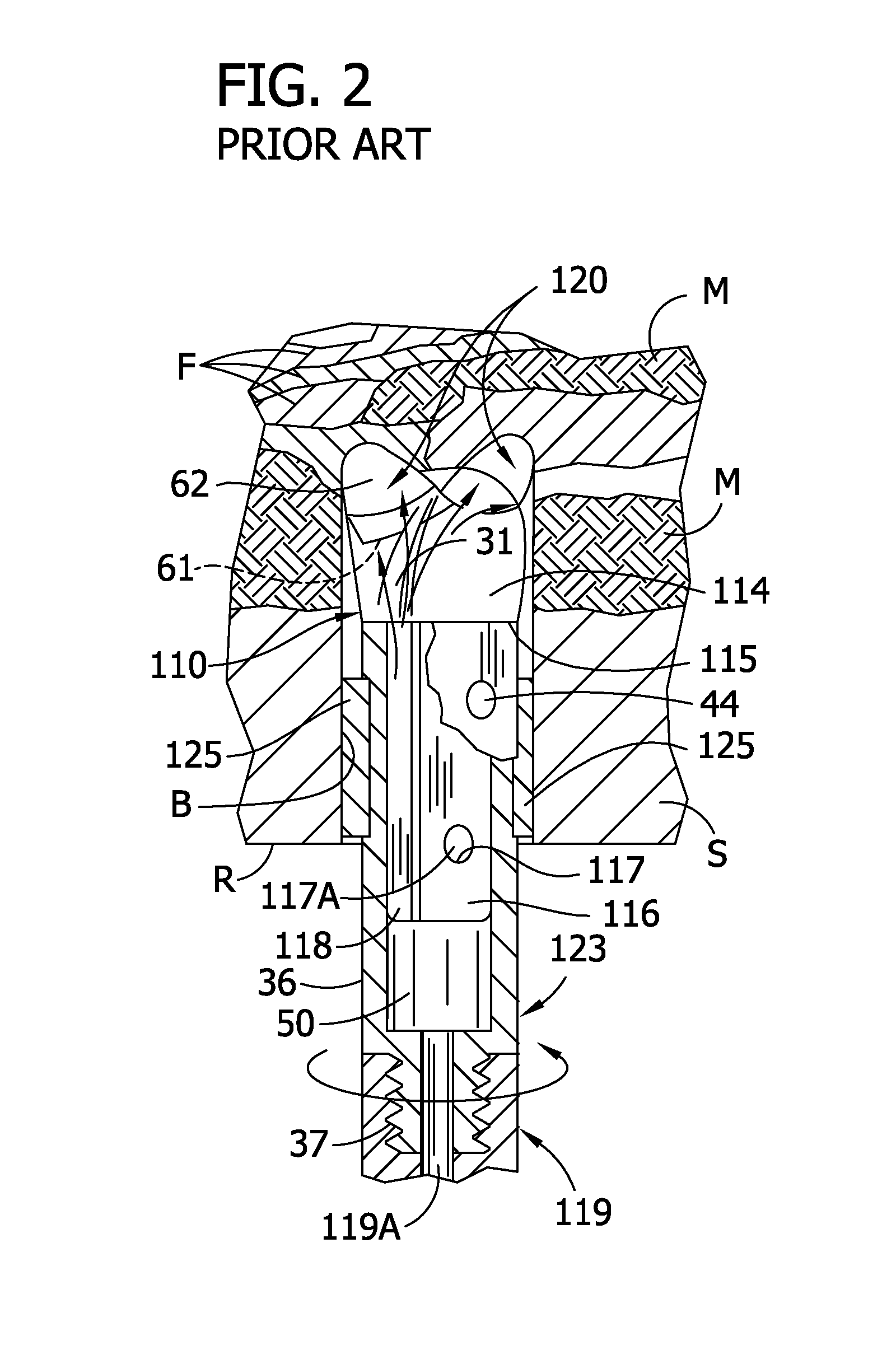

Roof drilling improvements

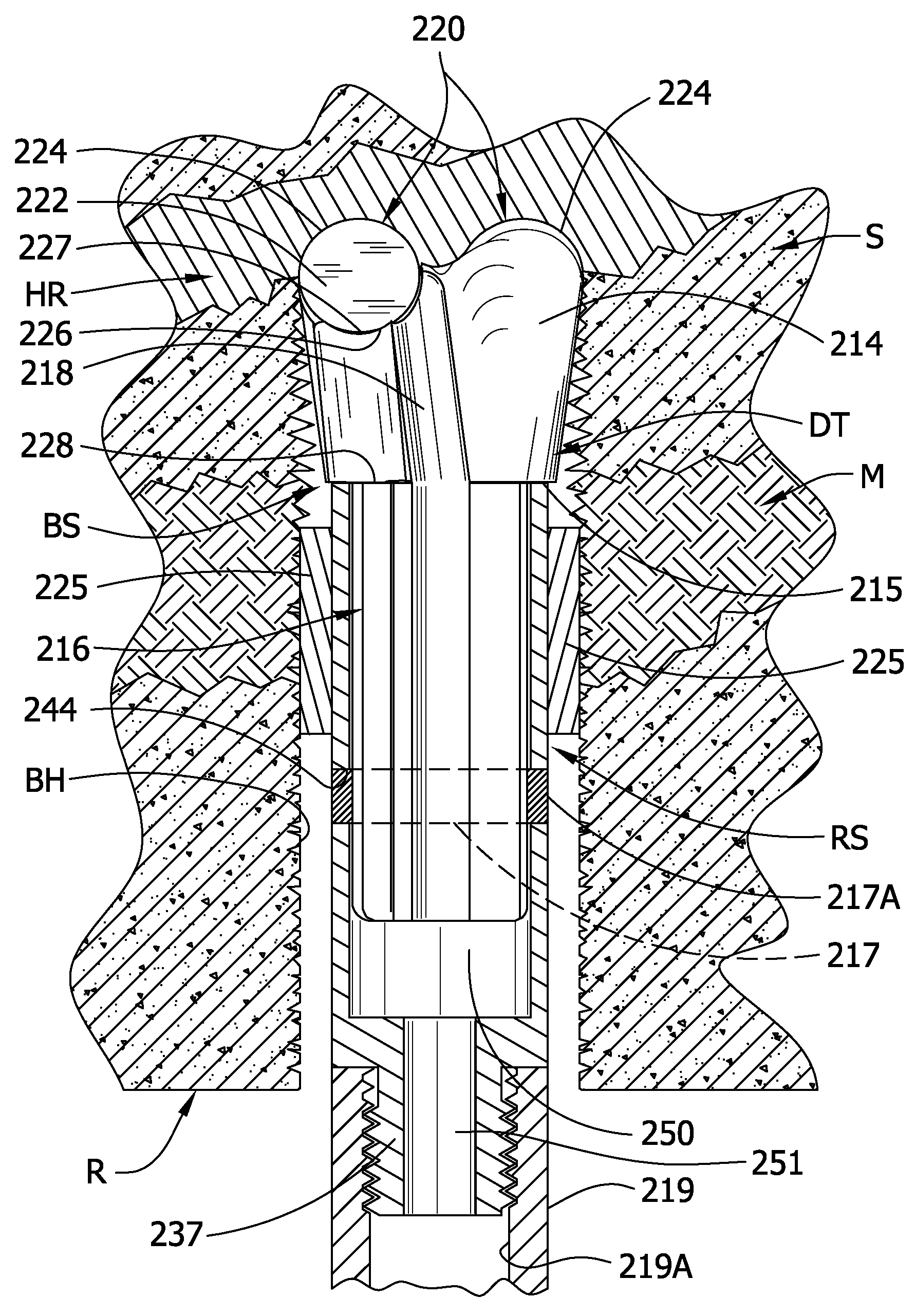

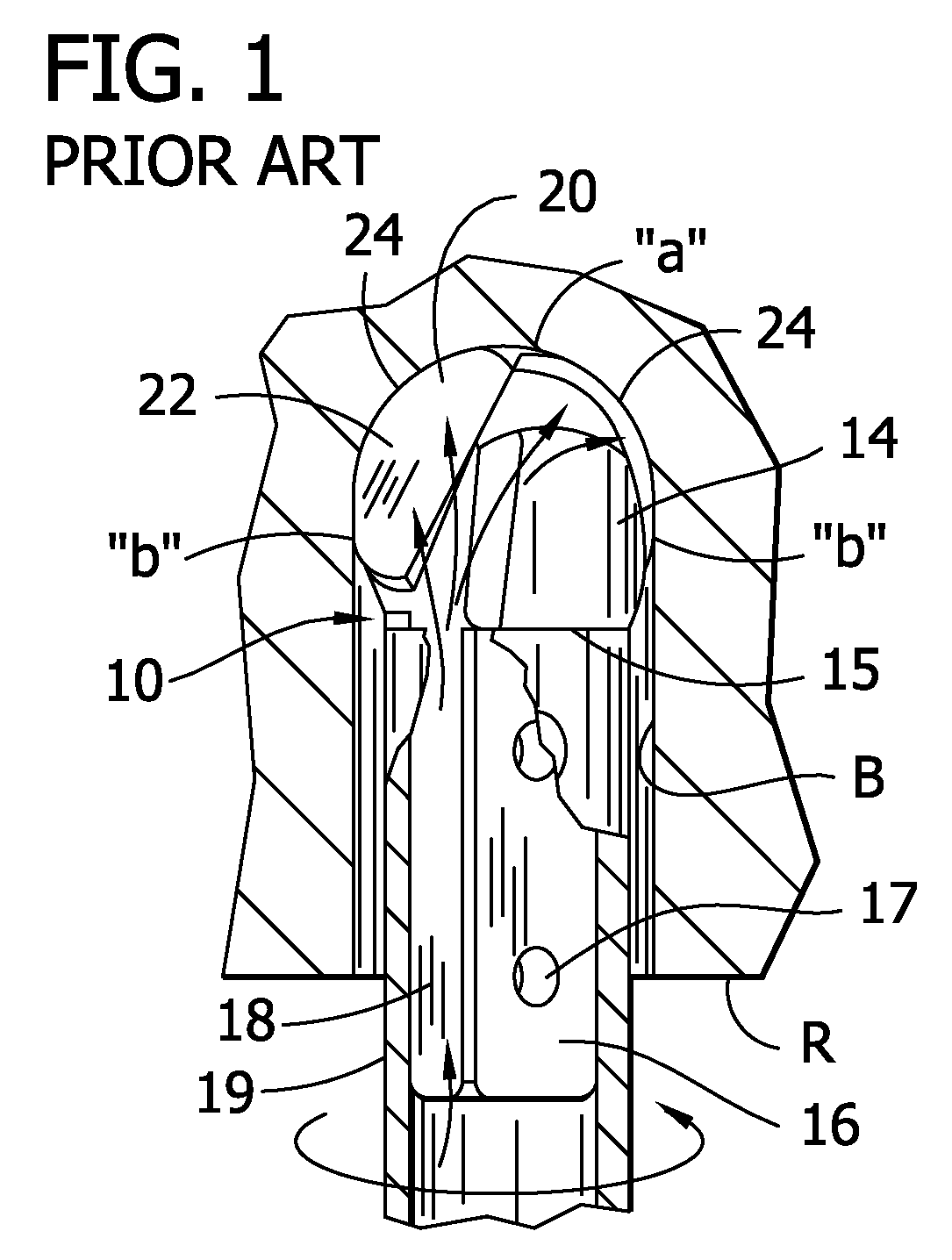

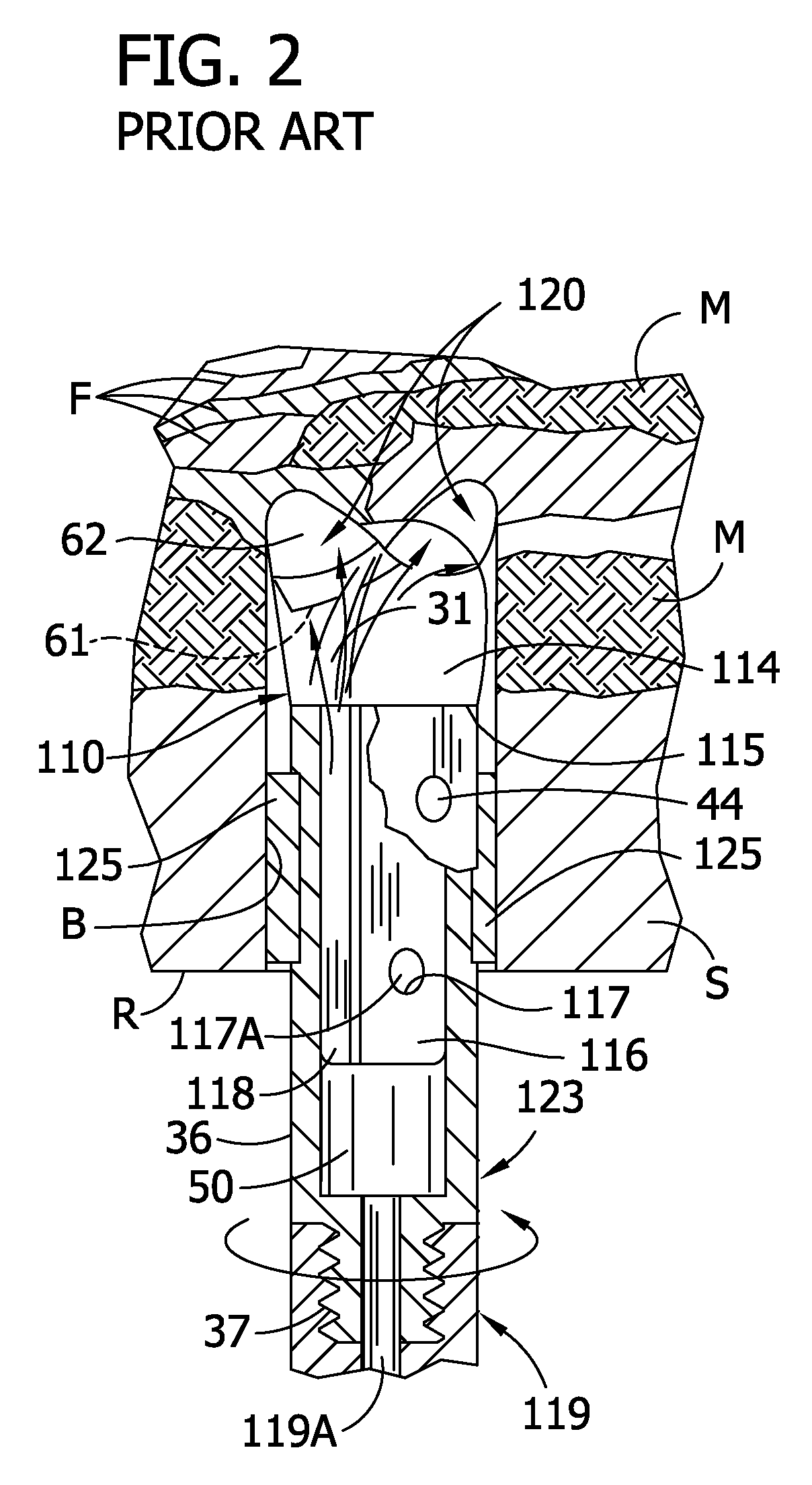

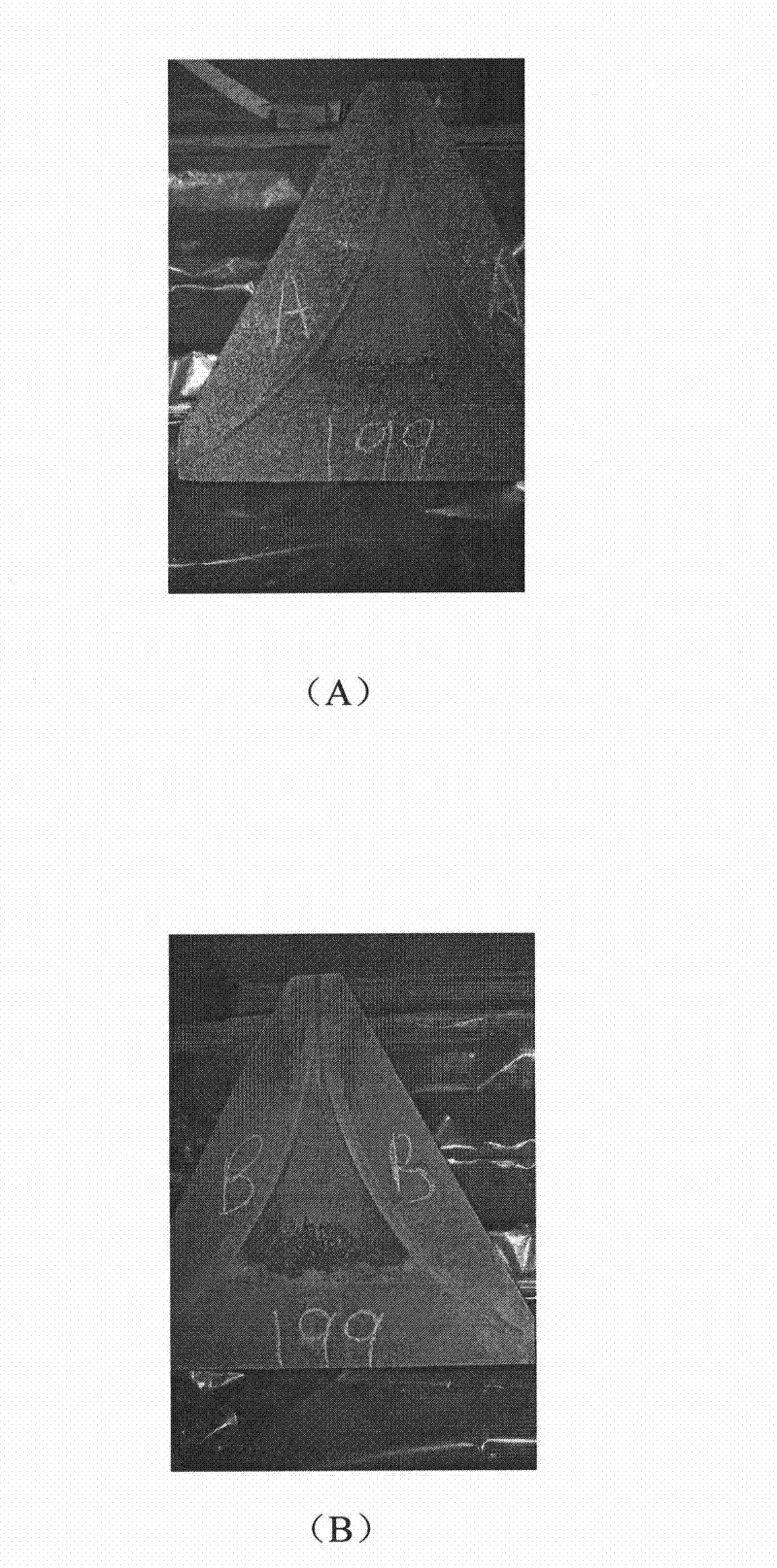

InactiveUS20070119624A1Extended service lifeFast drillingDrill bitsAnchoring boltsSuperhard materialHardness

The invention is embodied in a heavy duty drill bit for hard / soft rock drilling comprising a high fatigue resistant, high alloy steel bit body having a PCD cutter element of super hard material and an enlarged shank portion constructed to accommodate torsional forces at high thrust pressures, and reamer means for compensating the effect of bore hole rifling. The invention further involves the method of forming a roof bolting matrix in extremely hard rock formations having a compression strength up to about 50,000 psi using PCD wafers on a high tensile strength steel body coupled by a heavy duty shank through high fatigue resistant reamer means to a high strength drive steel member.

Owner:WILLIAM J BRADY LOVING TRUST THE

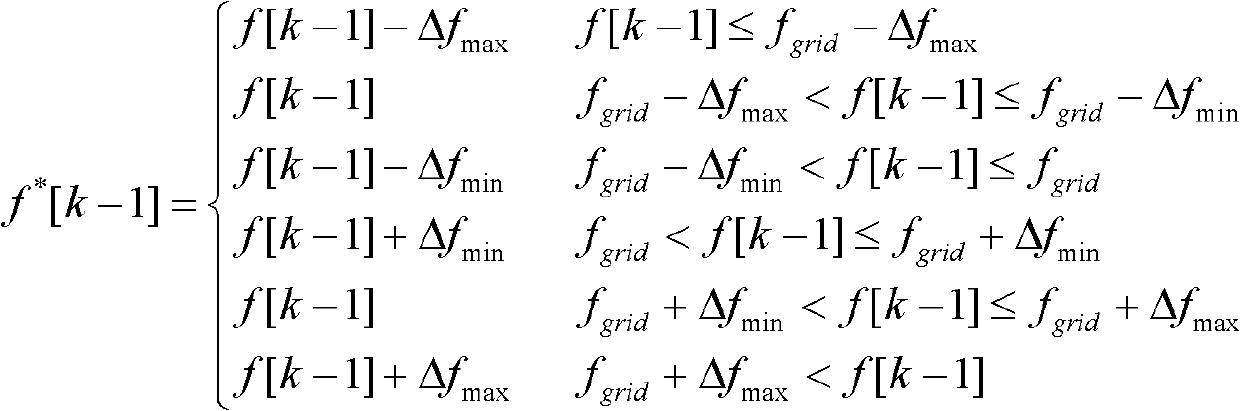

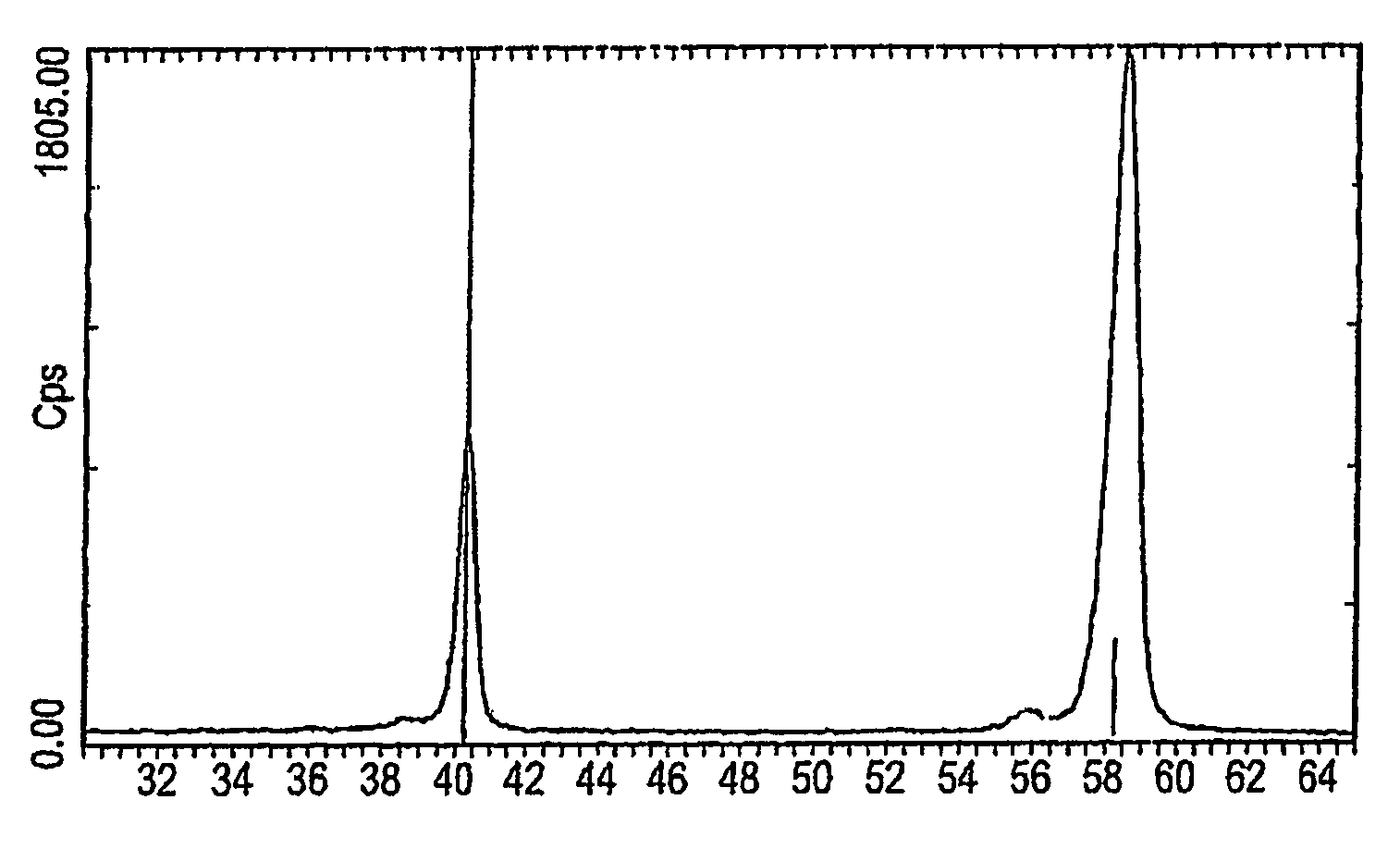

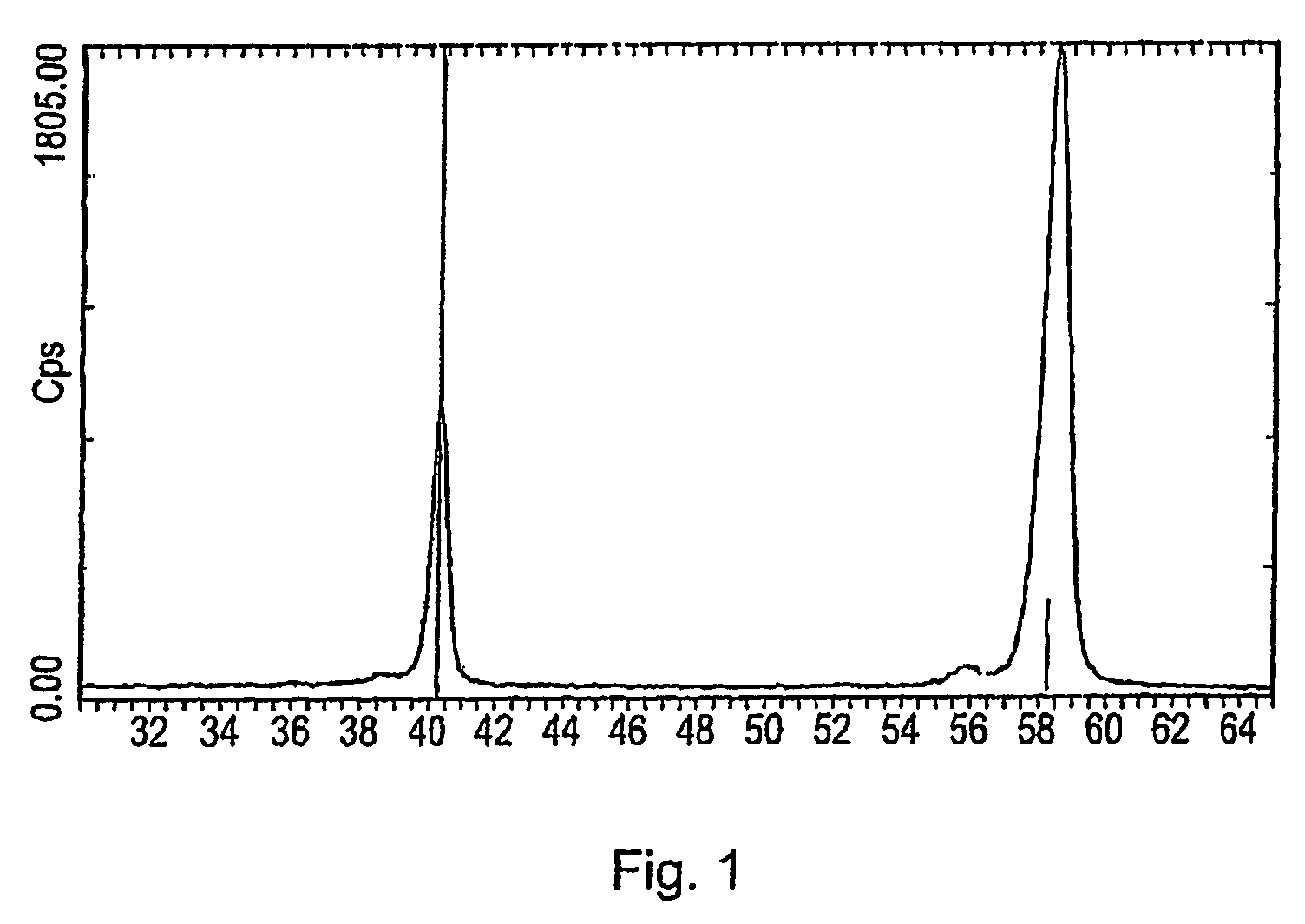

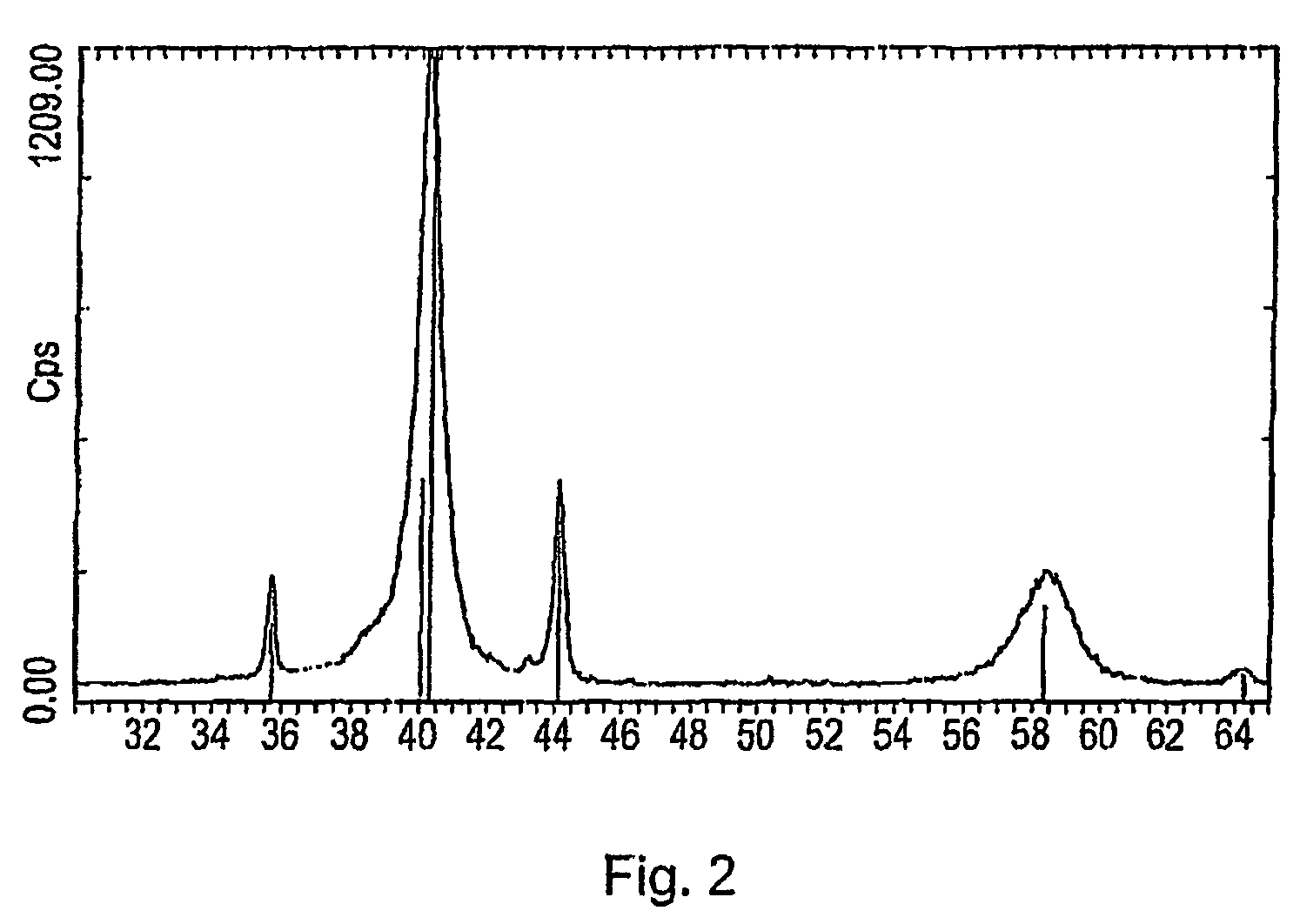

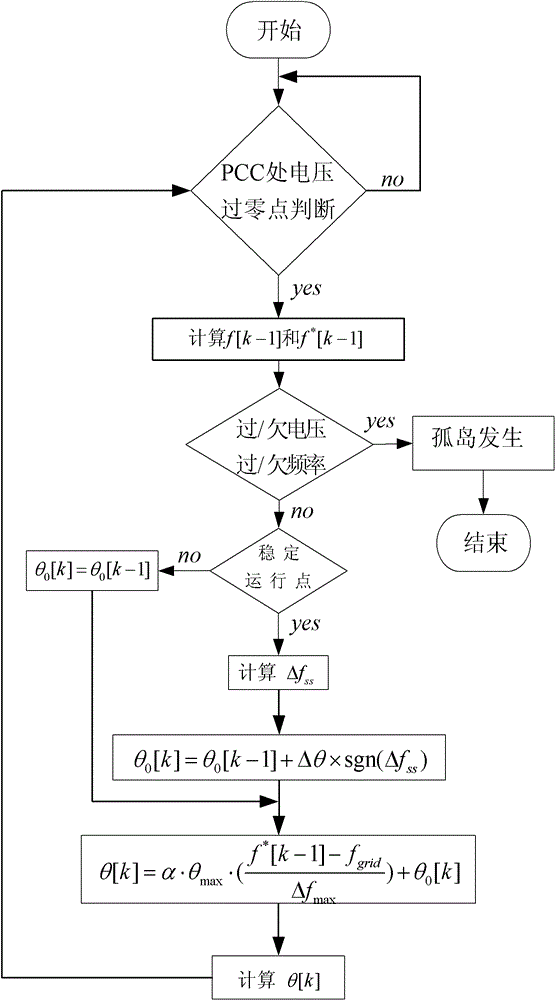

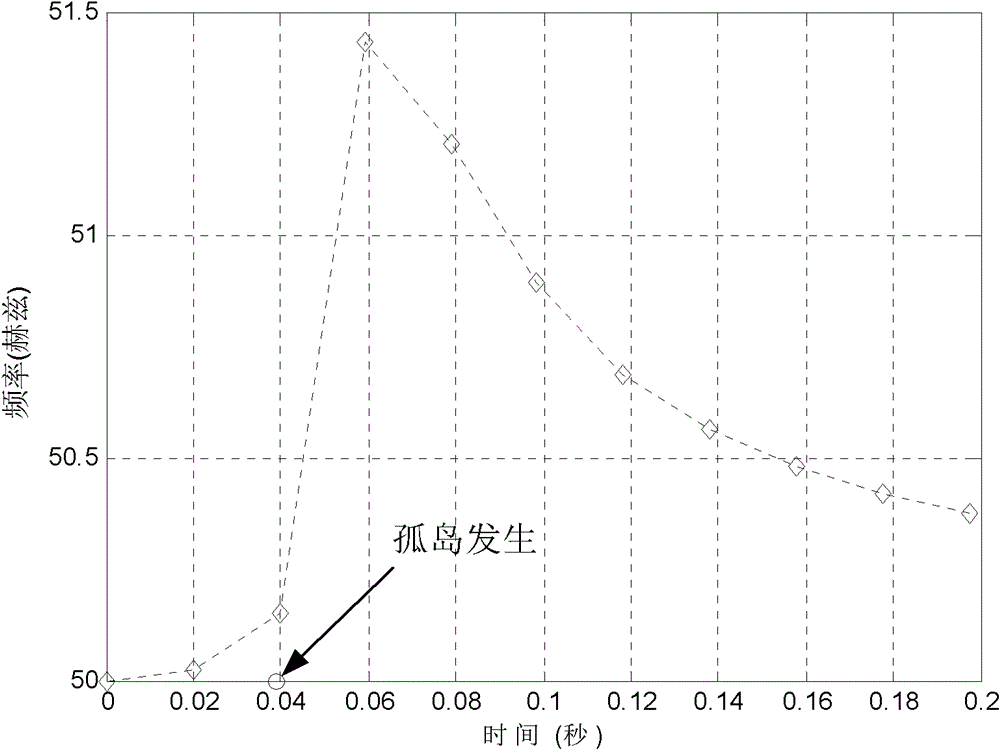

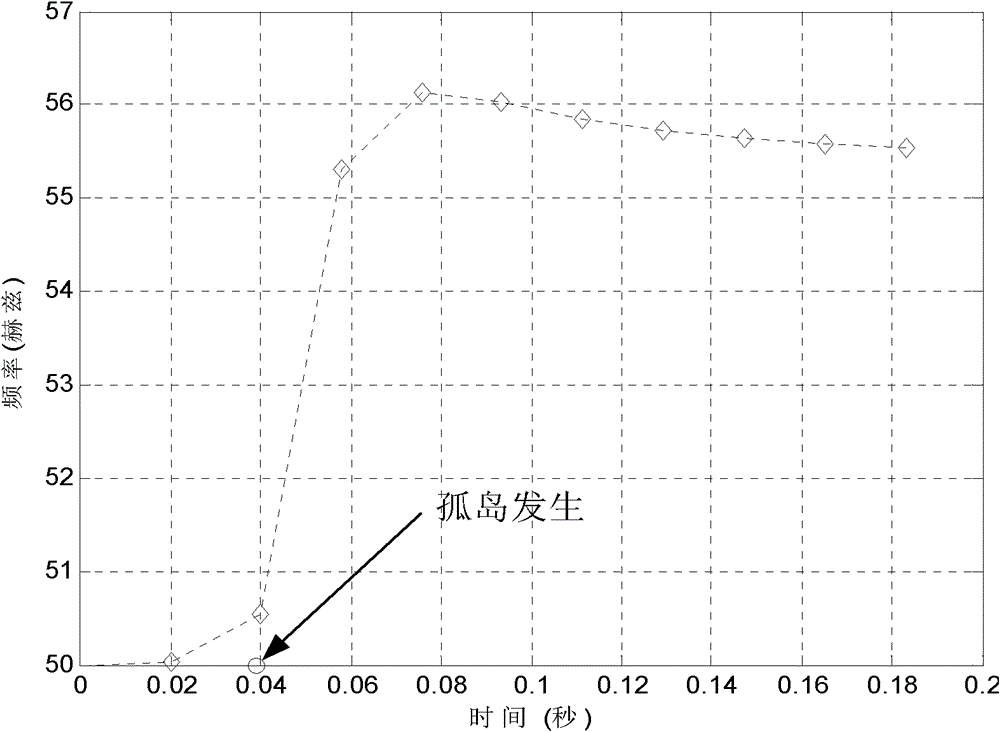

Phase deviation based auto-disturbance rejection isolated island detecting method

InactiveCN101931219AEffective destructionQuick checkEmergency protective circuit arrangementsVoltage-current phase angleIslandingPeriodic perturbation

The invention discloses a phase deviation based auto-disturbance rejection isolated island detecting method, which realizes periodic disturbance on the output current of an inverter by constructing an output current phase angle control function of the inverter so as to ensure that the voltage frequency of the position of a point of common coupling (PCC) deviates after the isolated island happens,and the occurrence of an isolated island phenomenon can be ensured to be effectively detected in time. The phase angle control function of the output current of the inverter consists of two parts, wherein one part is a homeostatic control function theta 0[k] which mainly plays roles in destroying a stable running point possibly existing in the system and ensuring effectiveness of disturbance, while the other part is a main function of the phase angle of the output current of the inverter which plays roles in ensuring that the method can effectively detect the isolated island when a secondary isolated island happens, and avoiding misjudgment caused by transient disturbance influence of the system, so that the normal operation of the system can be ensured. Therefore, compared with the priorart, the isolated island detecting method not only can avoid misjudgment caused by the effect of transient disturbance, and ensure the operation security of the system, but also can ensure that the isolated island can be quickly and accurately detected when the isolated island happens in an extremely hard condition, and greatly reduce the dead zone of detection.

Owner:XI AN JIAOTONG UNIV

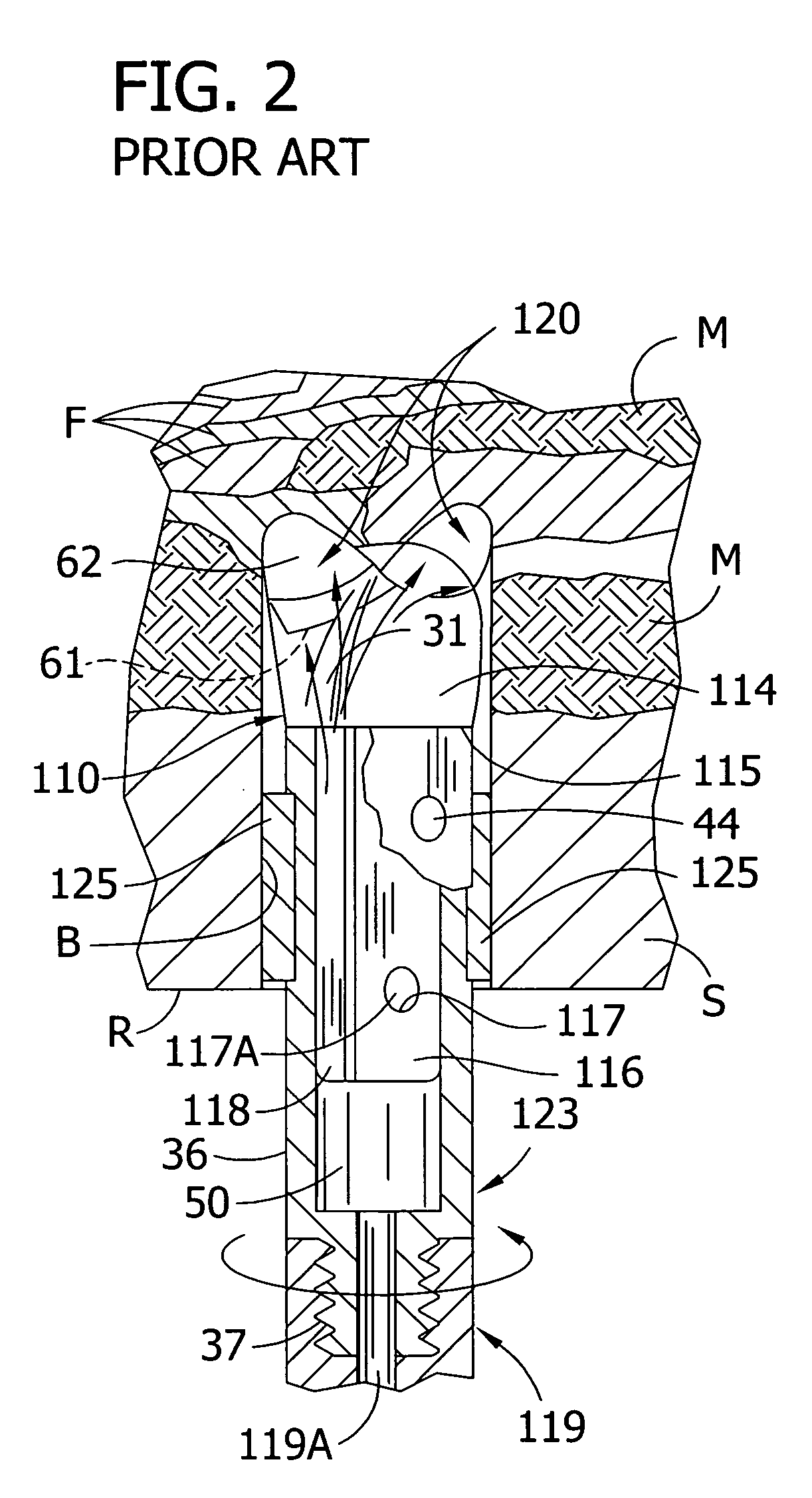

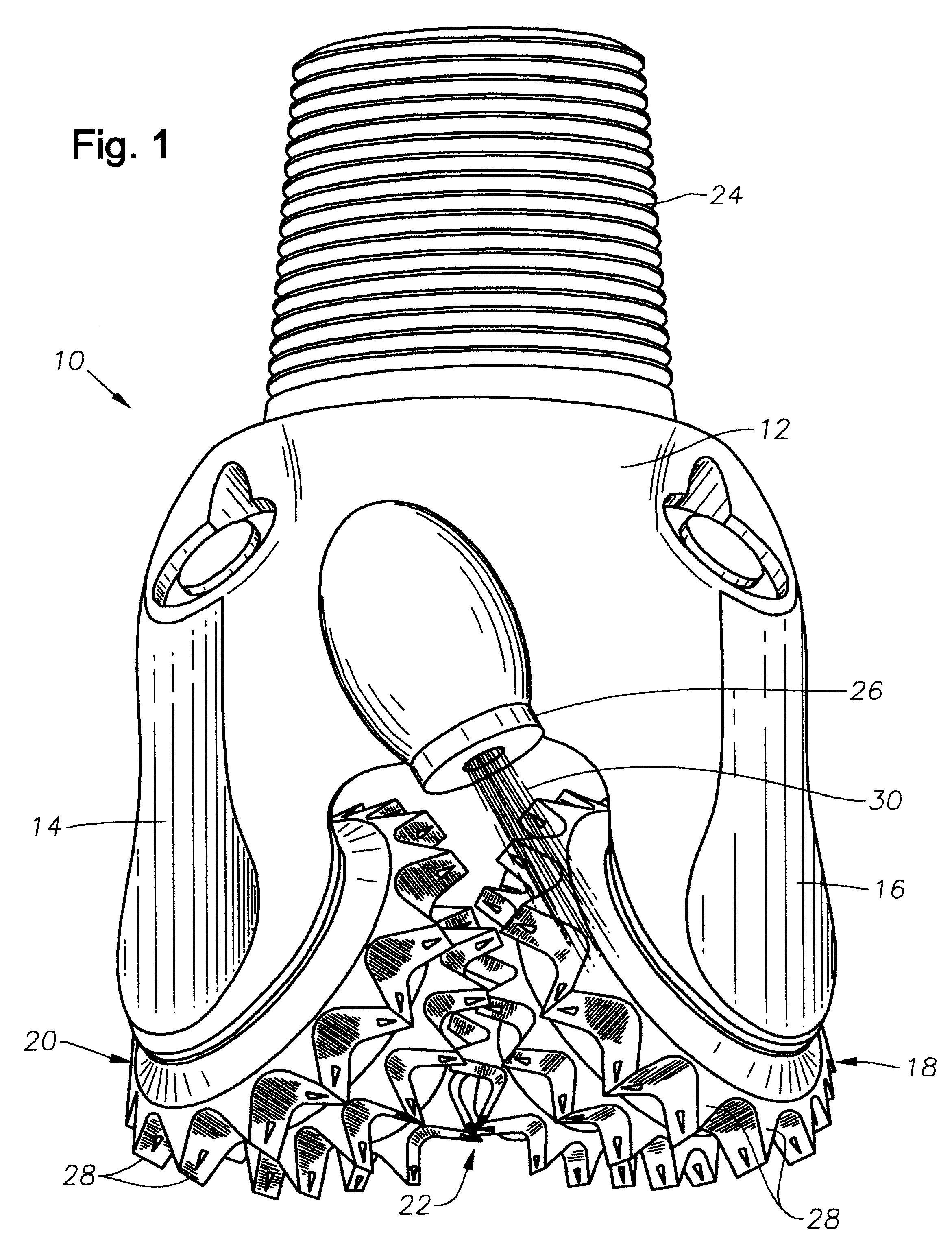

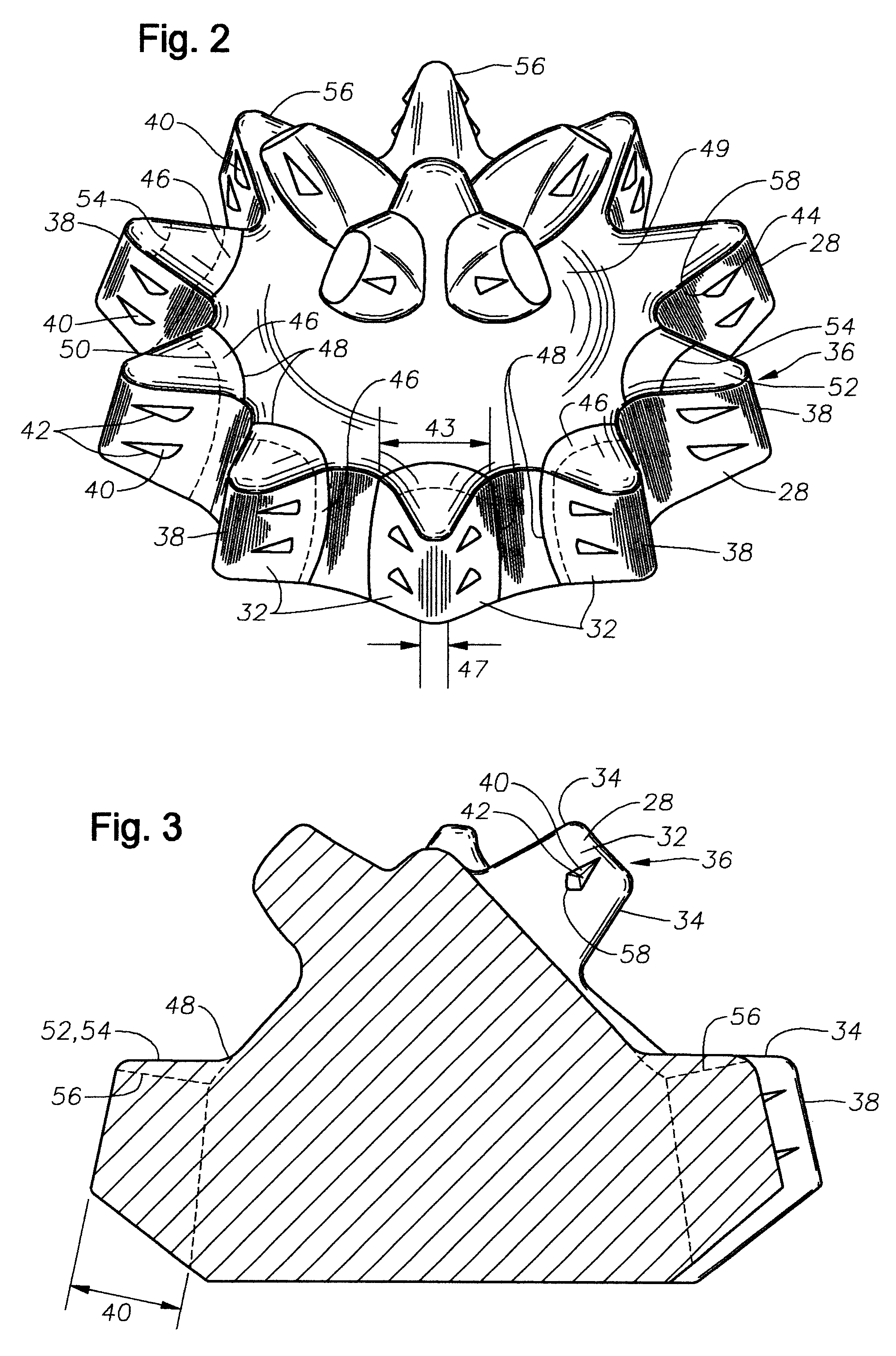

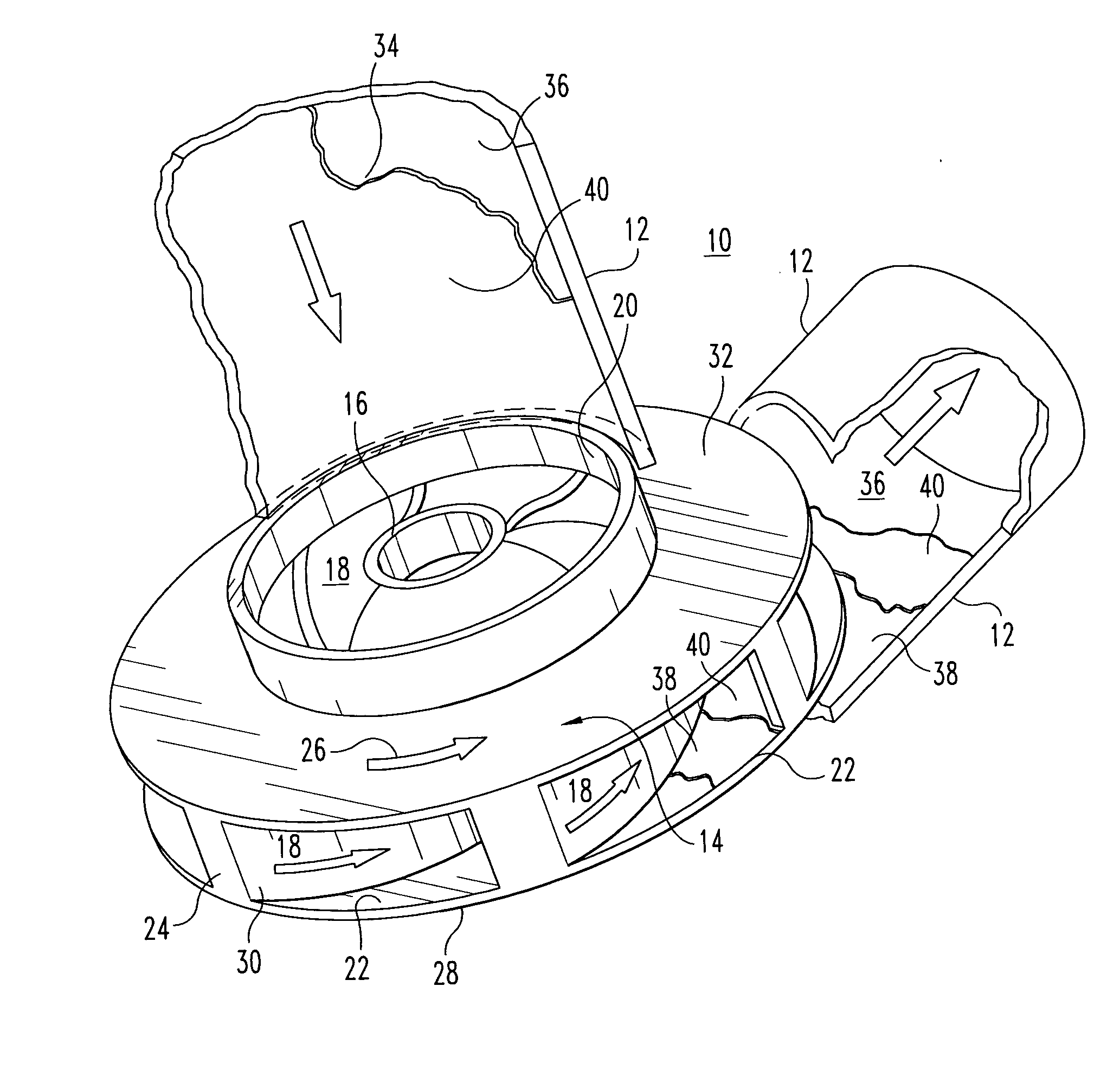

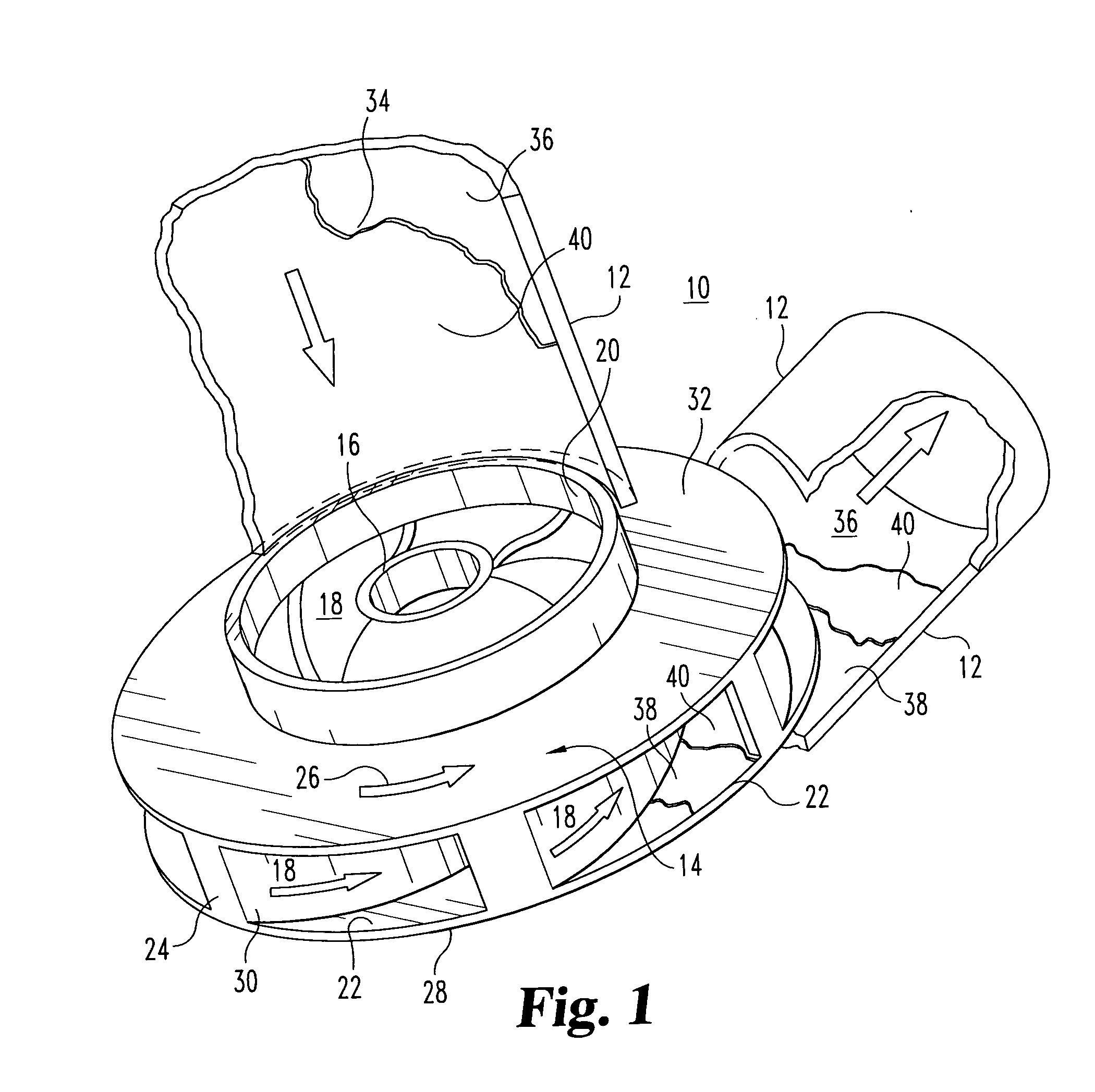

Roof drilling system improvements

ActiveUS20070119625A1Fast drillingExtended service lifeDrill bitsAnchoring boltsWell drillingHardness

The invention is embodied in a heavy duty drill bit for hard / soft rock drilling comprising a high fatigue-resistant, high alloy steel bit body having a PCD cutter member and an enlarged shank portion constructed to accommodate torsional forces at high thrust pressures, and reamer means for compensating the effect of bore hole rifling. The invention further involves the method of forming a roof bolting matrix in extremely hard rock formations having a compression strength up to about 50,000 psi using PCD wafers on a high tensile strength steel body coupled by a heavy duty shank through high fatigue-resistant reamer means to a high strength drive steel member.

Owner:WILLIAM J BRADY LOVING TRUST THE +1

Side sealing plate for thin-belt continuous casting and manufacturing method

The invention relates to a side sealing plate for a thin-belt continuous casting system. The side sealing plate is characterized by comprising the components in percentage by weight: 10-50% of boron nitride, 5-35% of zirconium boride, 5-25% of zirconium oxide, 1-15% of boron powder, 1-10% of graphite and 0.1-5% of carbon fiber. As the fabricate particles are firstly adopted in the side sealing plate, then the techniques such as high-temperature sintering and oil immersion and the like are adopted in the common sizing flame-resistant material technique, the porosity and the density of a product are obviously improved, and boron carbide (extremely hard substance) is formed in high-temperature sintering, so that the strength is further improved.

Owner:上海柯瑞冶金炉料有限公司

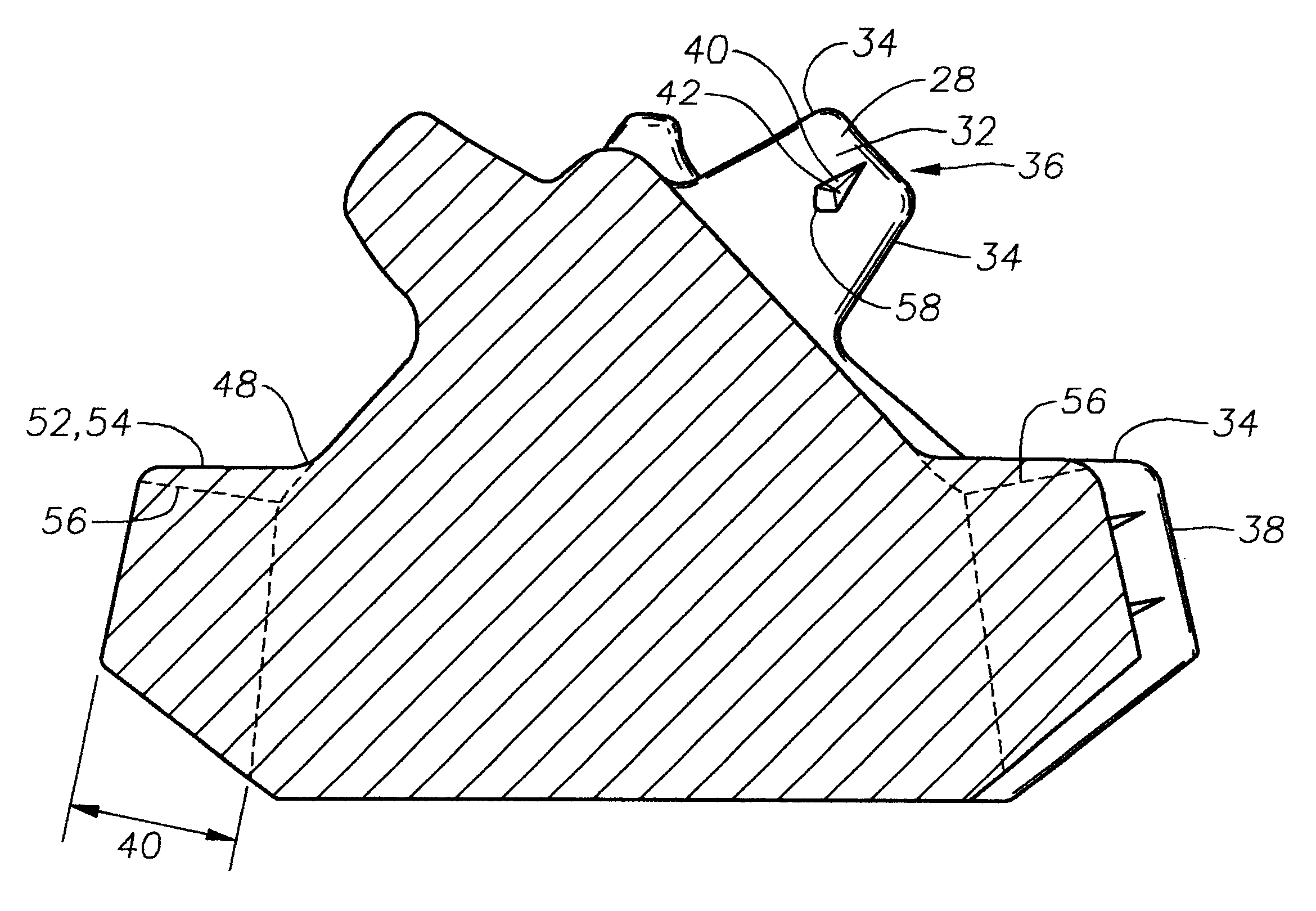

Tooth type drill bit with secondary cutting elements and stress reducing tooth geometry

Disclosed is a tooth type rolling cutter earth boring drill bit with secondary cutting elements on the tooth surfaces. The secondary cutting elements provide additional, relatively sharp edges that help cut hard rock. The teeth also have convex radiused buttresses at their bases to reduce the stresses the teeth experience when drilling through extremely hard rock. This allows the tooth bit to survive the high loads encountered when drilling hard, tough rock formations, without breaking the teeth. The combination of teeth with secondary cutting elements and convex radiused buttresses at their base provide a tooth type rotary drill bit that has superior resistance to wear and breakage when drilling through hard, tough rock without significantly reducing the drilling rate of penetration when drilling through soft rock.

Owner:REEDHYCALOG LP

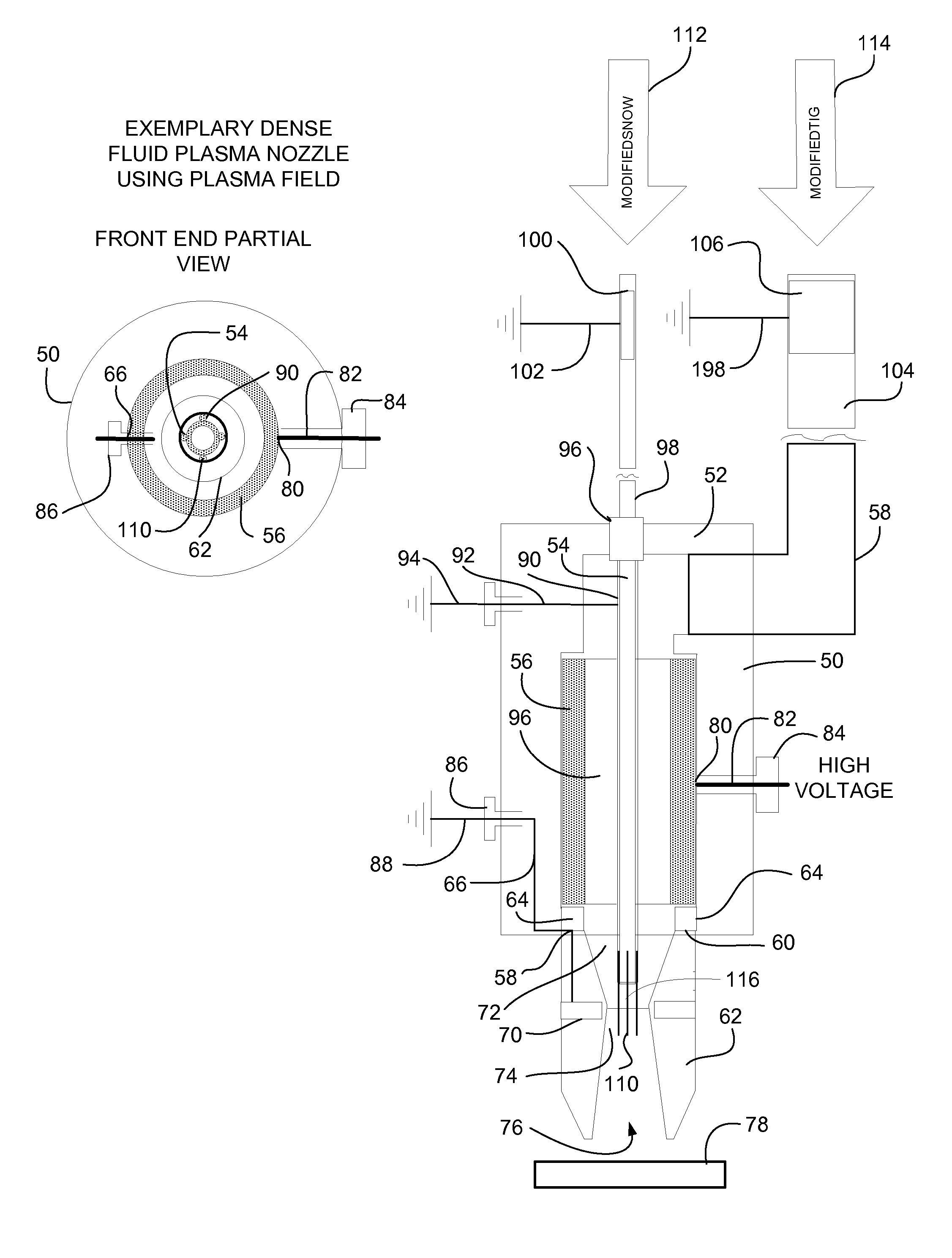

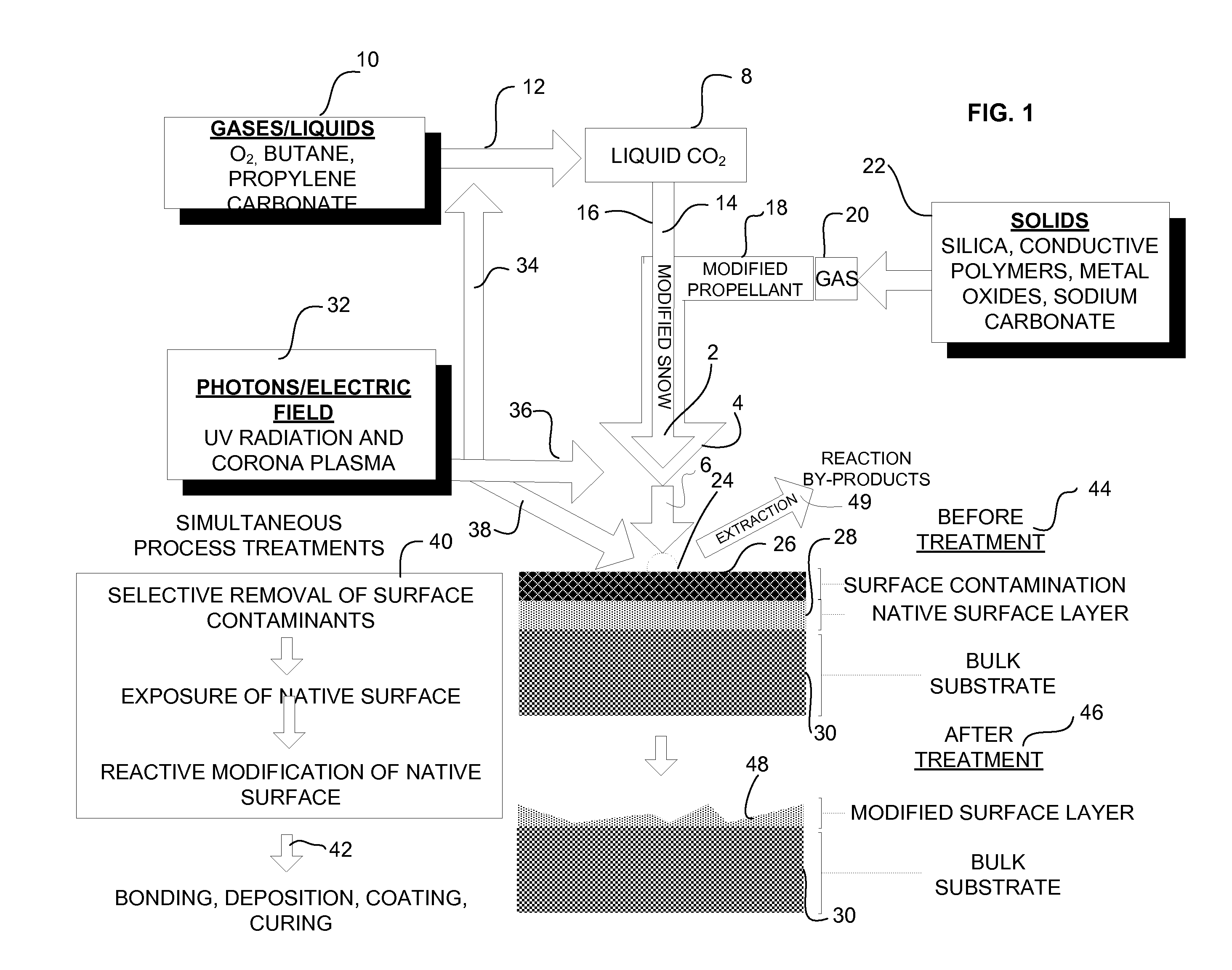

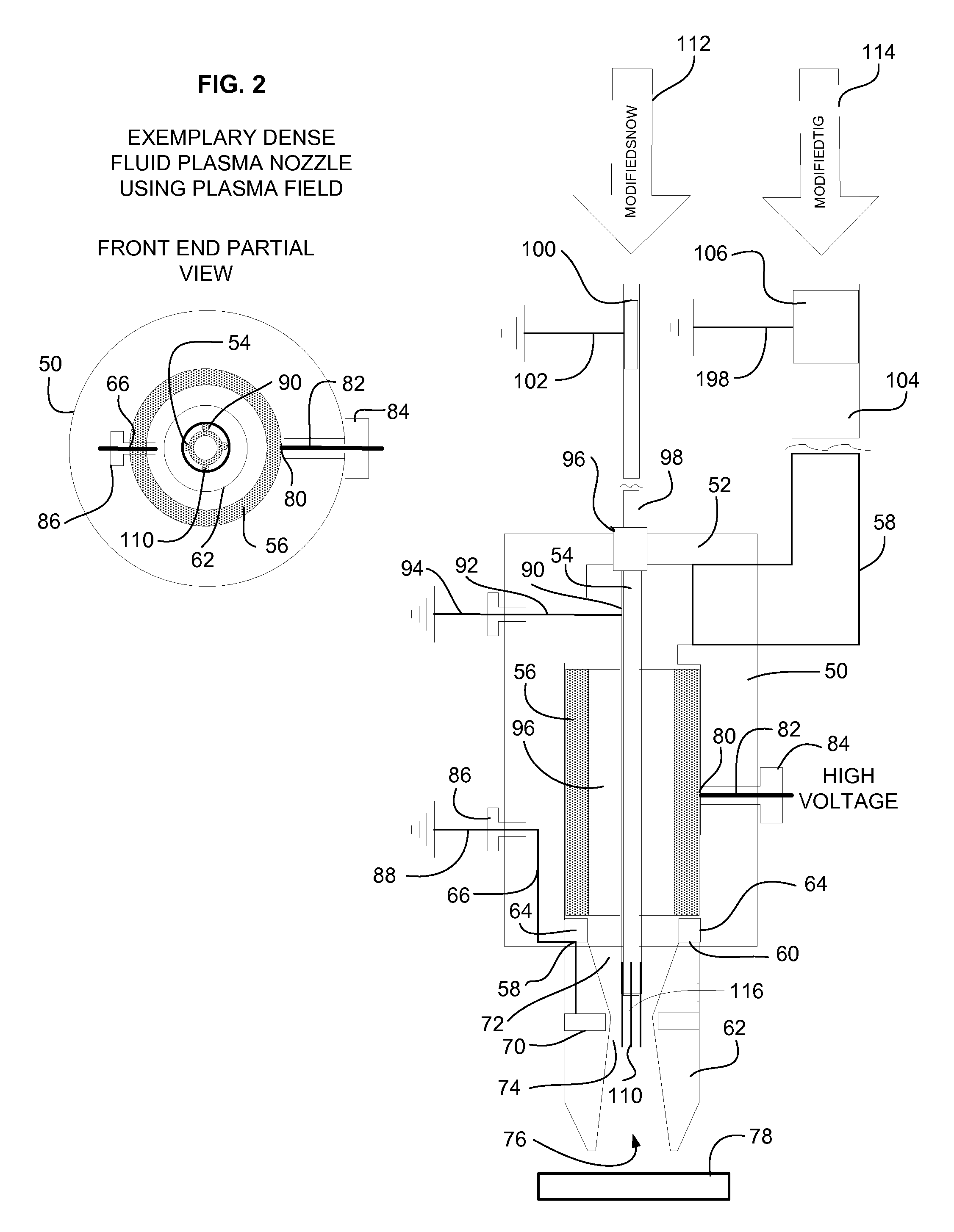

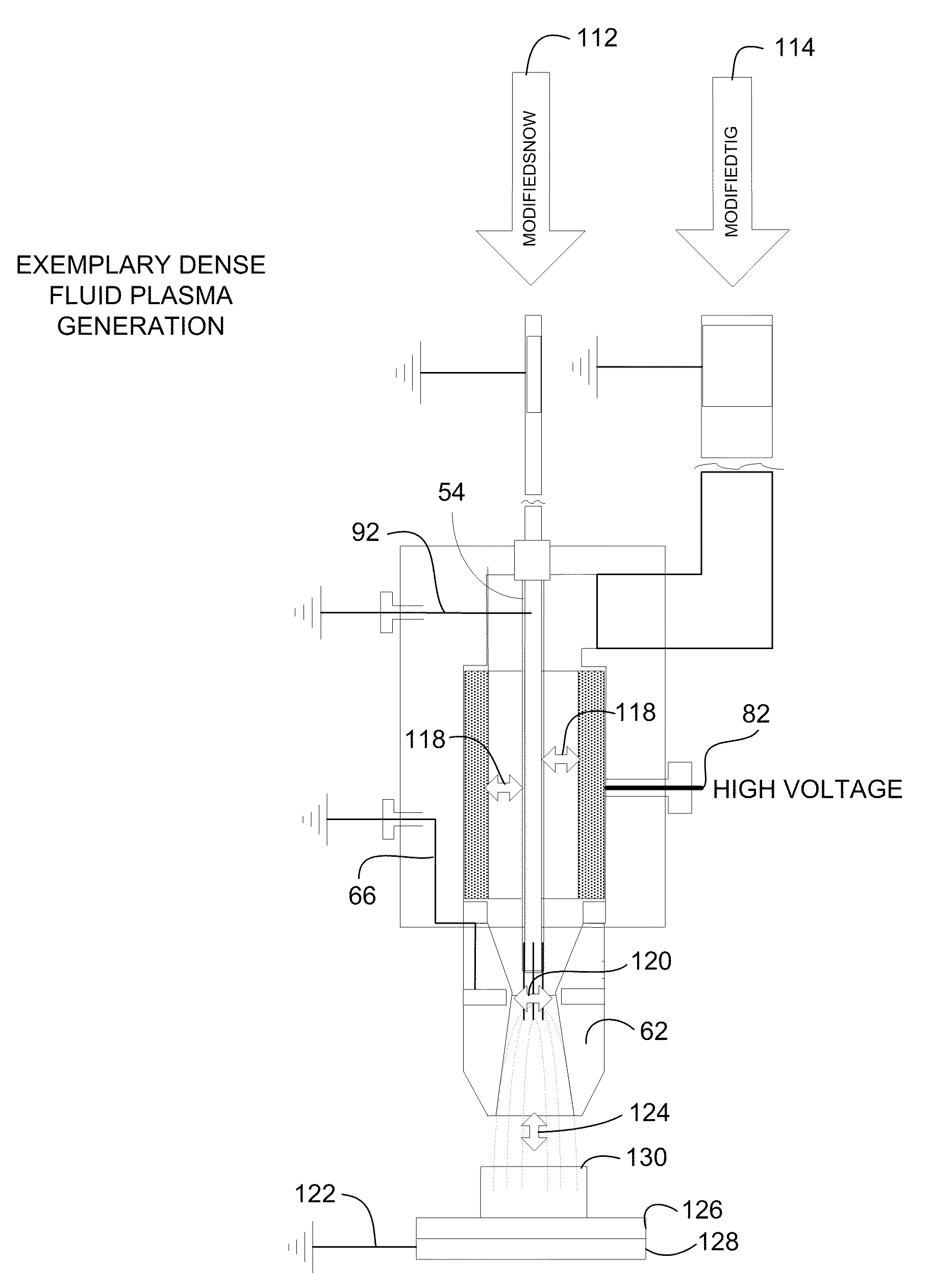

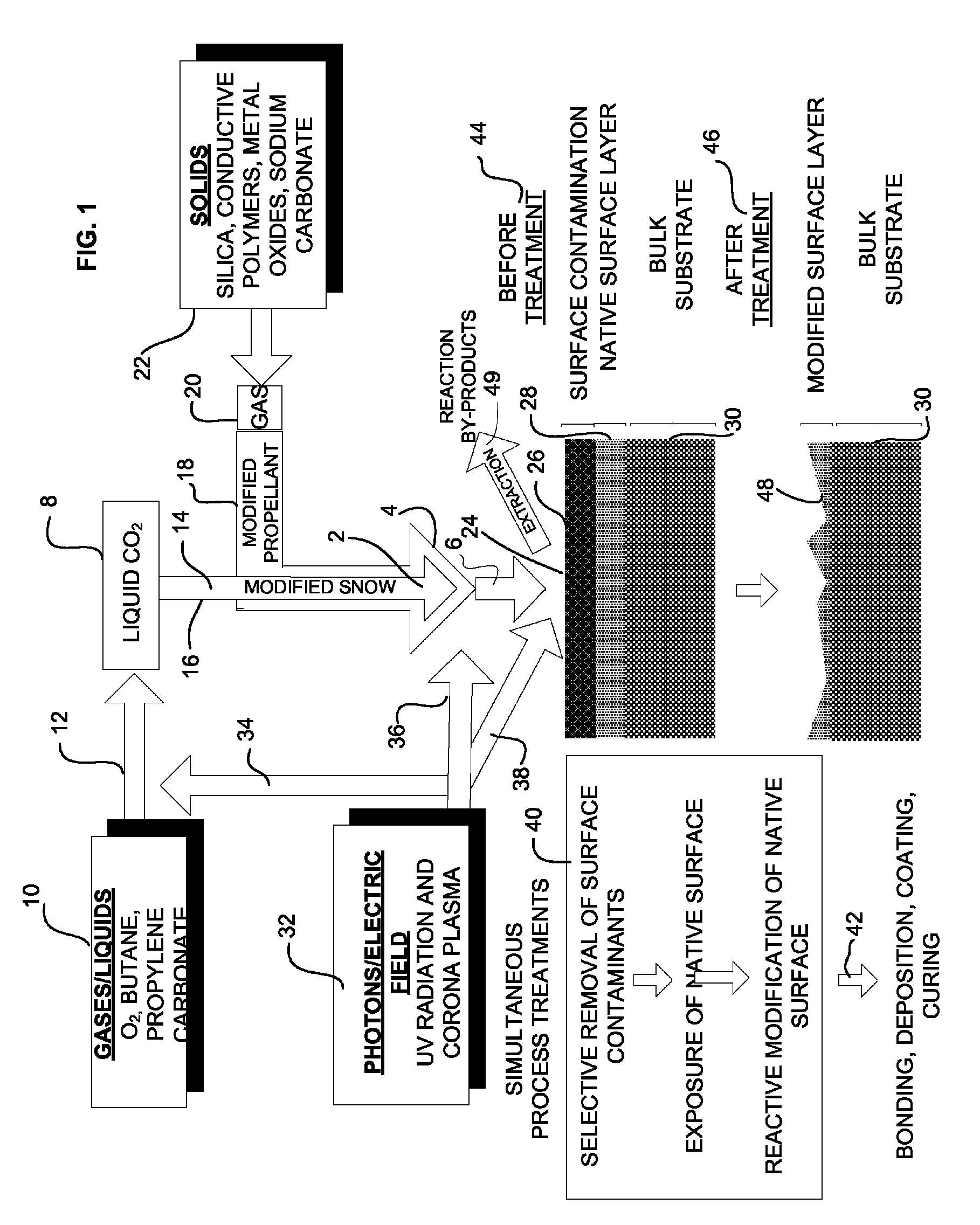

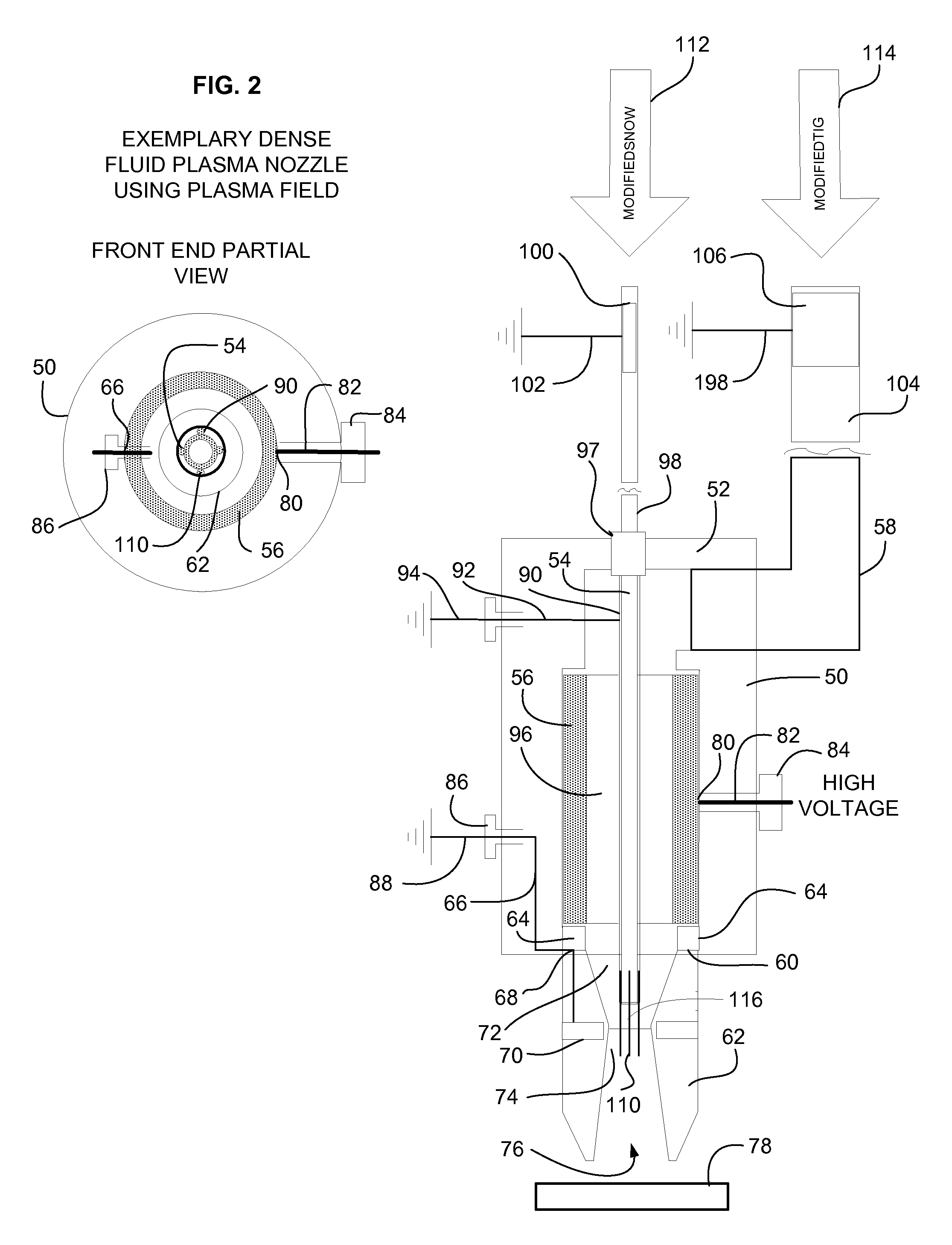

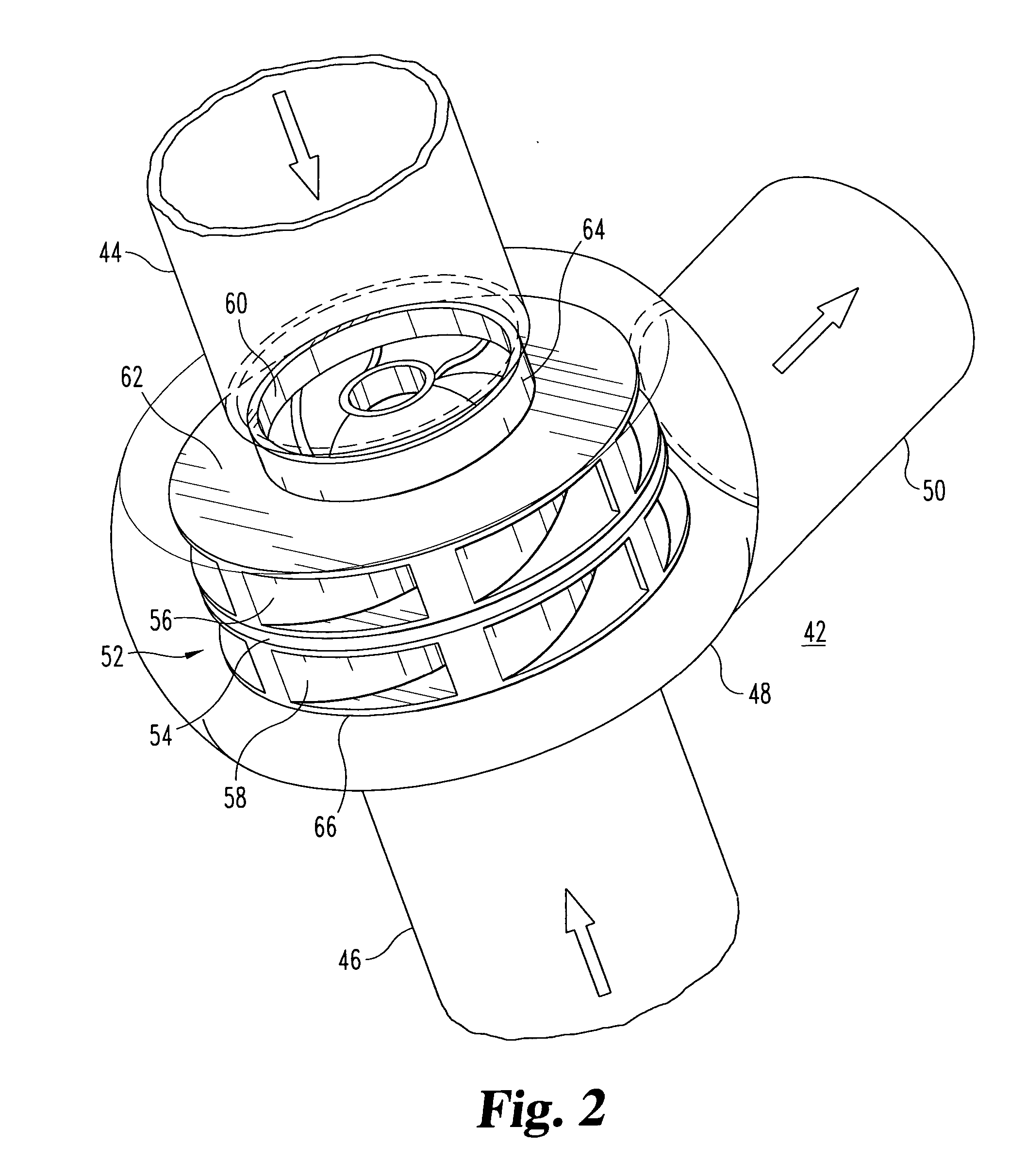

Dense fluid delivery apparatus

ActiveUS20060279222A1Improve adhesionImprove wettabilityElectric discharge tubesElectric arc lampsFree energiesSurface layer

The present invention generally relates to a method and apparatus to produce and apply a variety of surface cleaning and modification spray treatments. More specifically, the present invention provides the simultaneous steps of selectively removing one or more unwanted surface contaminants, including extremely hard coatings, exposing a native clean surface layer and modifying said exposed and cleaned native substrate surface layer to energetic radicals and radiation to improve adhesion, wettability or coatability. Reactive species in combination with non-reactive, but chemically or physically active, species provide a reaction control and surface treatment environment by which contaminants and surface interlayers are oxidatively, physically and / or chemically removed or modified to prepare an underlying substrate surface for subsequent bonding, deposition, coating and curing operations. Substrates treated in accordance with the present invention have cleaner and higher surface free energy surfaces.

Owner:HITACHI HIGH-TECH CORP

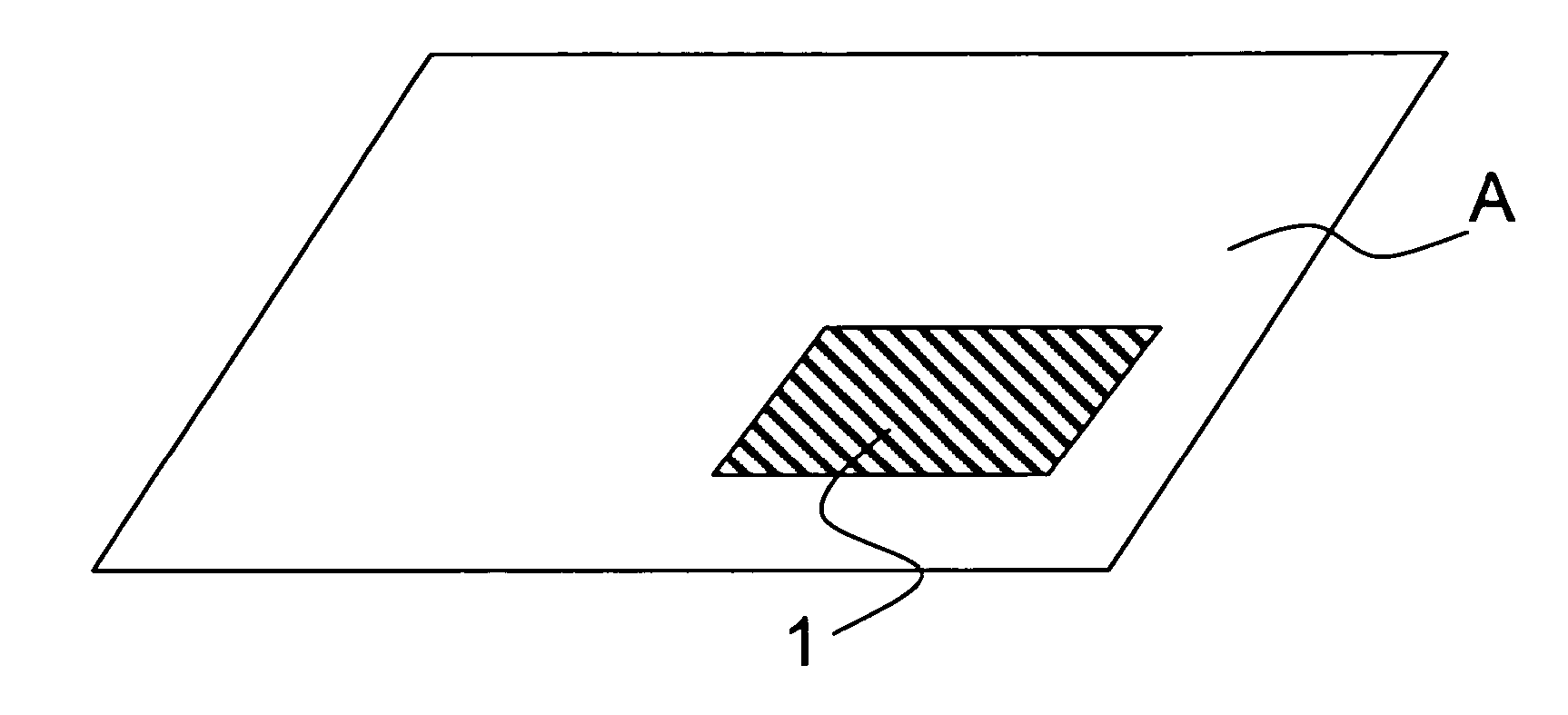

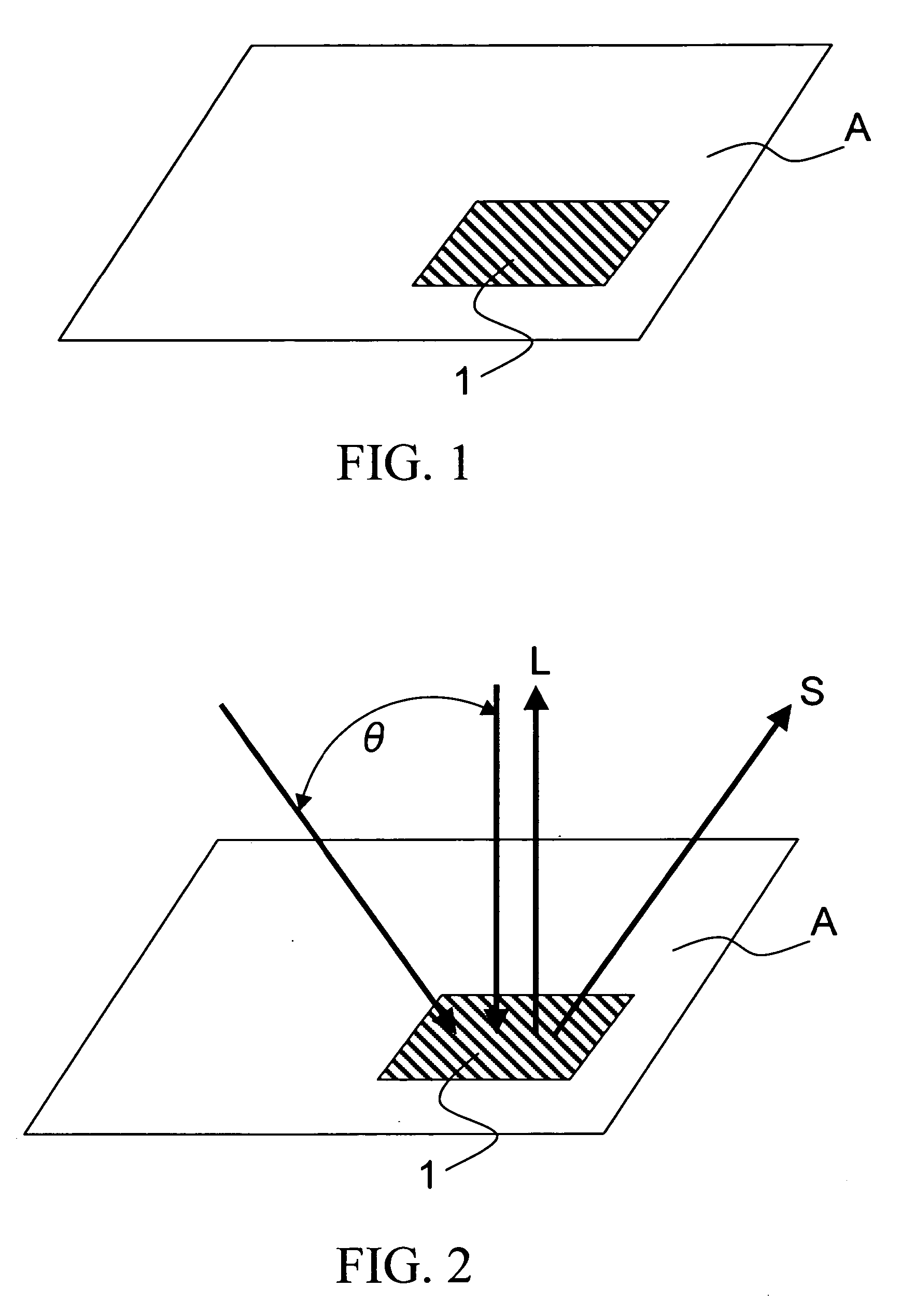

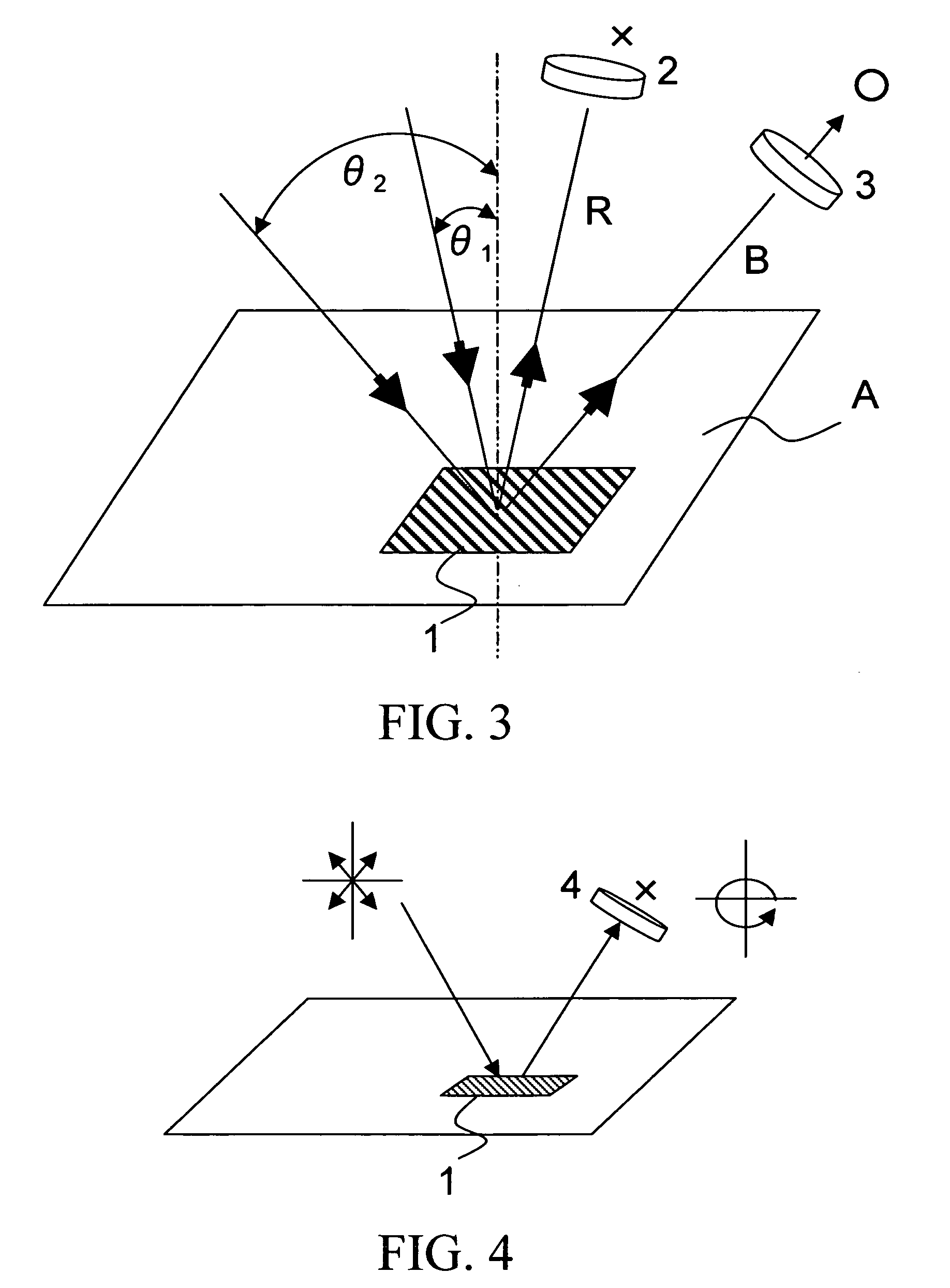

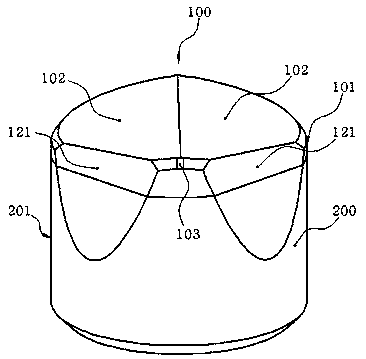

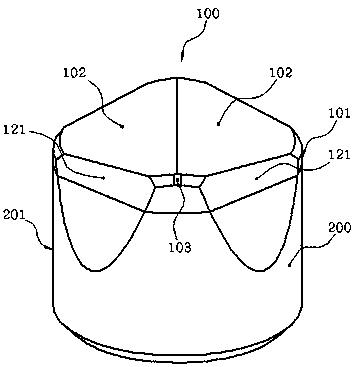

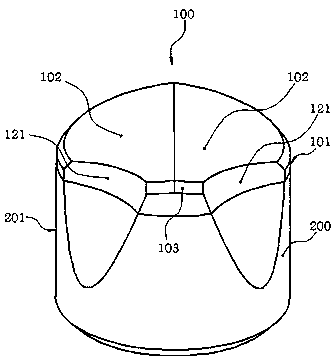

Object identification structure and object provided with the same

InactiveUS20060097514A1Improve heat resistanceOther printing matterPolarising elementsExtremely hardIdentifiability

An object identification structure for generally distributed products is provided which is extremely hard to forge, high in identifiability, and can be manufactured inexpensively. The object identification structure comprises a single layer cholesteric liquid crystal film which is substantially colorless and transparent when viewed from the front and appears colored when viewed from a predetermined oblique direction.

Owner:NIPPON OIL CORP

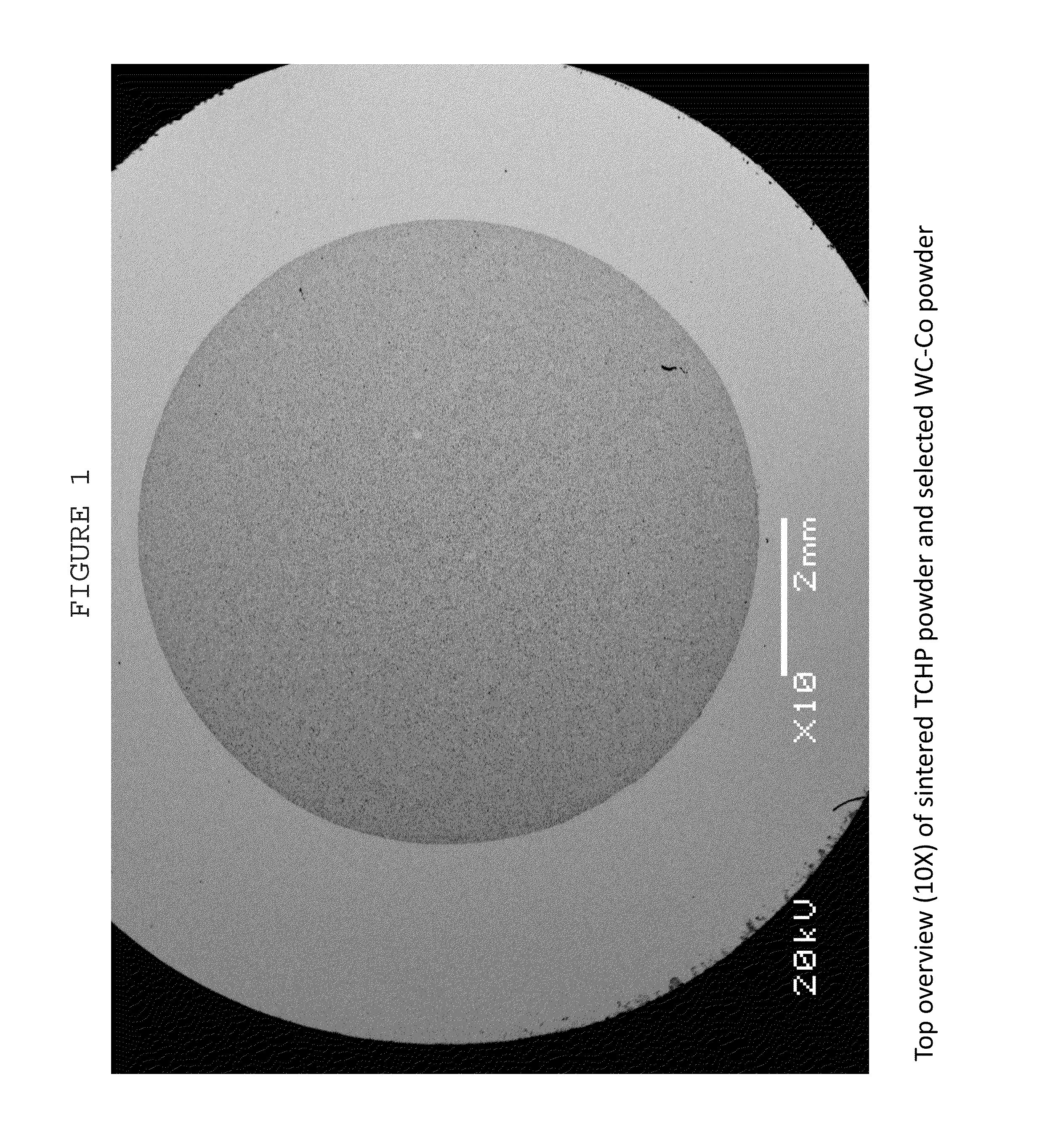

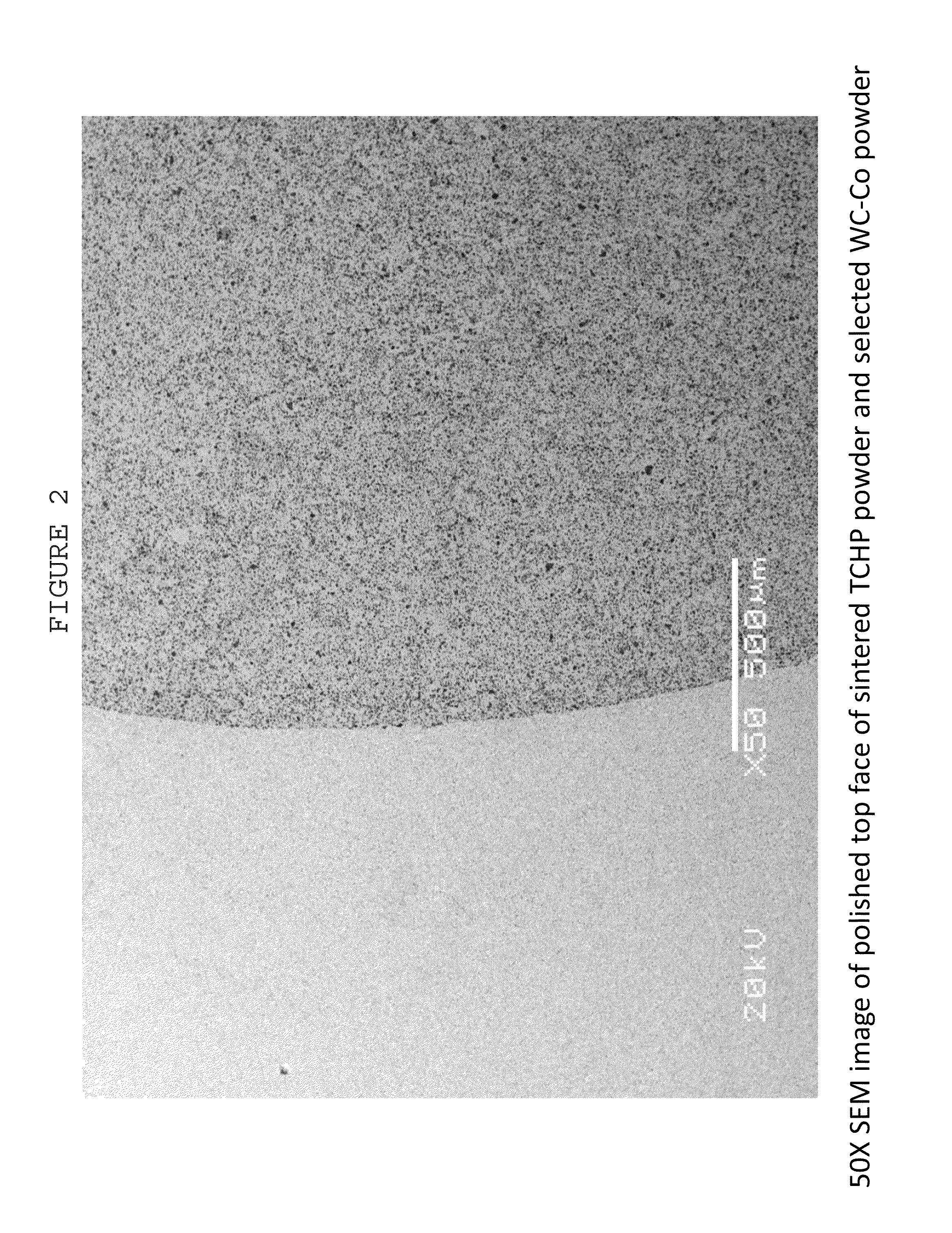

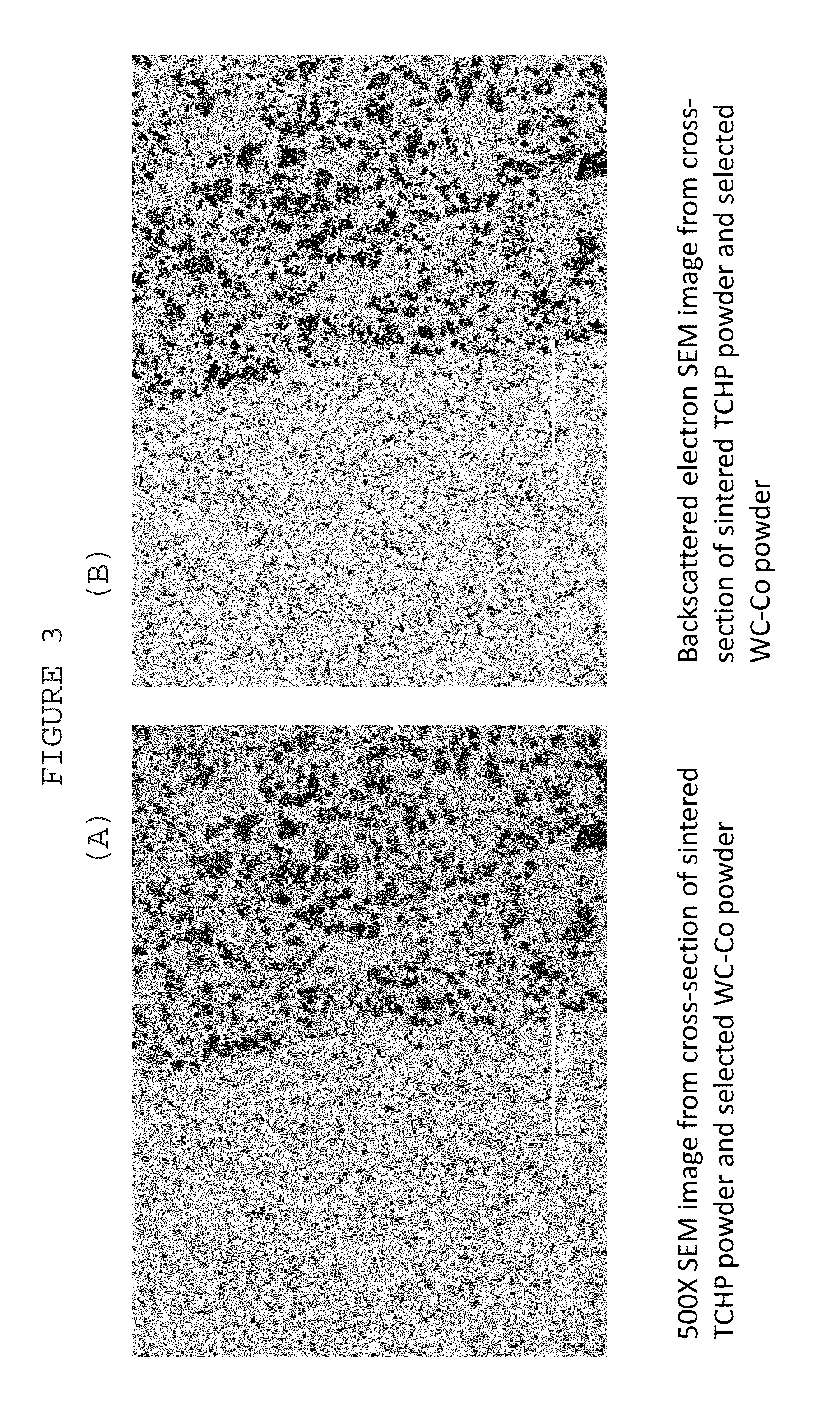

Methods of forming a metallic or ceramic article having a novel composition of functionally graded material and articles containing the same

ActiveUS9186726B2Improve fracture toughnessLow costAdditive manufacturing apparatusLayered productsMechanical componentsCarbide

There is disclosed a method of making a metallic or ceramic component, such as a cutting or forming tool, from at least two distinct powder precursors. In one embodiment, the method comprising forming a first mixture comprised of a plurality of coated particles, such as Tough-Coated Hard Powder (TCHP) composite particles created by encapsulating extremely hard core particles with very tough binder and structural materials, and at least one support powder, such as a carbide, typically WC—Co. The mixture is formed into a green body and sintered to form a functionally graded or multicomponent article. Non-limiting examples of the articles made from the disclosed methods are also disclosed and include drills, mills, cutting tools, forming tools, wires dies and mechanical components.

Owner:ETERNALOY HLDG GMBH

Dense fluid delivery apparatus

ActiveUS7901540B2Clearer and high surface free energy surfaceImprove adhesionElectric discharge tubesElectric arc lampsFree energiesSurface layer

The present invention generally relates to a method and apparatus to produce and apply a variety of surface cleaning and modification spray treatments. More specifically, the present invention provides the simultaneous steps of selectively removing one or more unwanted surface contaminants, including extremely hard coatings, exposing a native clean surface layer and modifying said exposed and cleaned native substrate surface layer to energetic radicals and radiation to improve adhesion, wettability or coatability. Reactive species in combination with non-reactive, but chemically or physically active, species provide a reaction control and surface treatment environment by which contaminants and surface interlayers are oxidatively, physically and / or chemically removed or modified to prepare an underlying substrate surface for subsequent bonding, deposition, coating and curing operations. Substrates treated in accordance with the present invention have cleaner and higher surface free energy surfaces.

Owner:HITACHI HIGH-TECH CORP

Alloyed tungsten produced by chemical vapour deposition

A wear-, erosion- and chemically-resistant material containing tungsten alloyed with carbon, the carbon being present in an amount of 0.01 wt % up to 0.97 wt % of the total weight, wherein the material preferably comprises a matrix of metallic tungsten with dispersed tungsten carbide nanoparticles having a particle size not greater than 50 nanometers, preferably not greater than 10 nanometers. The material is optionally also alloyed with fluorine, the fluorine being present in an amount of 0.01 wt % up to 0.4 wt % of the total weight. The material is extremely hard and tough.

Owner:ISLE HARDIDE LTD

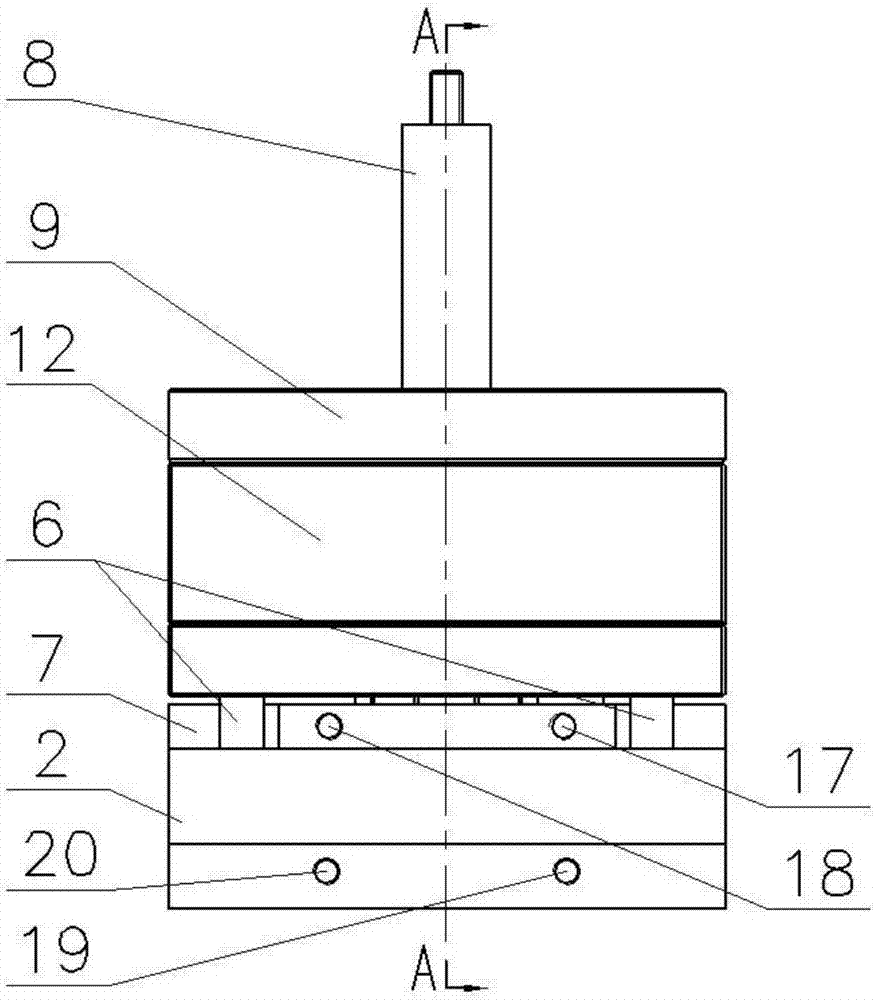

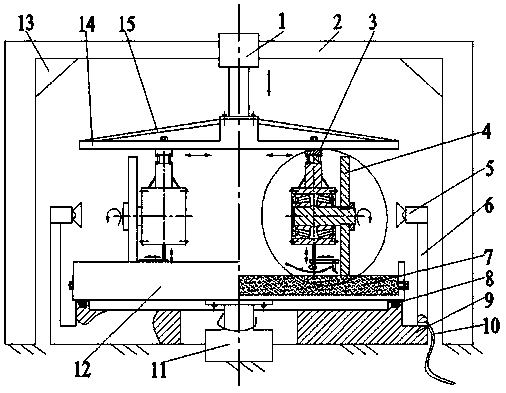

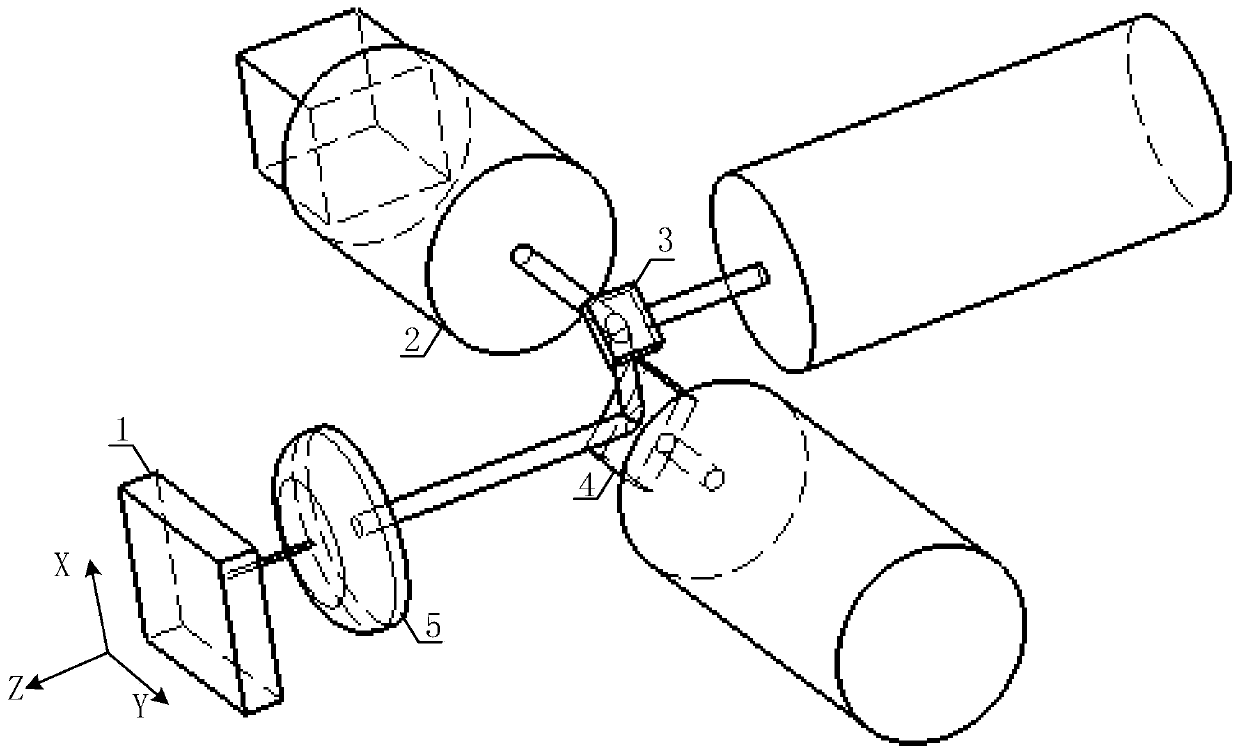

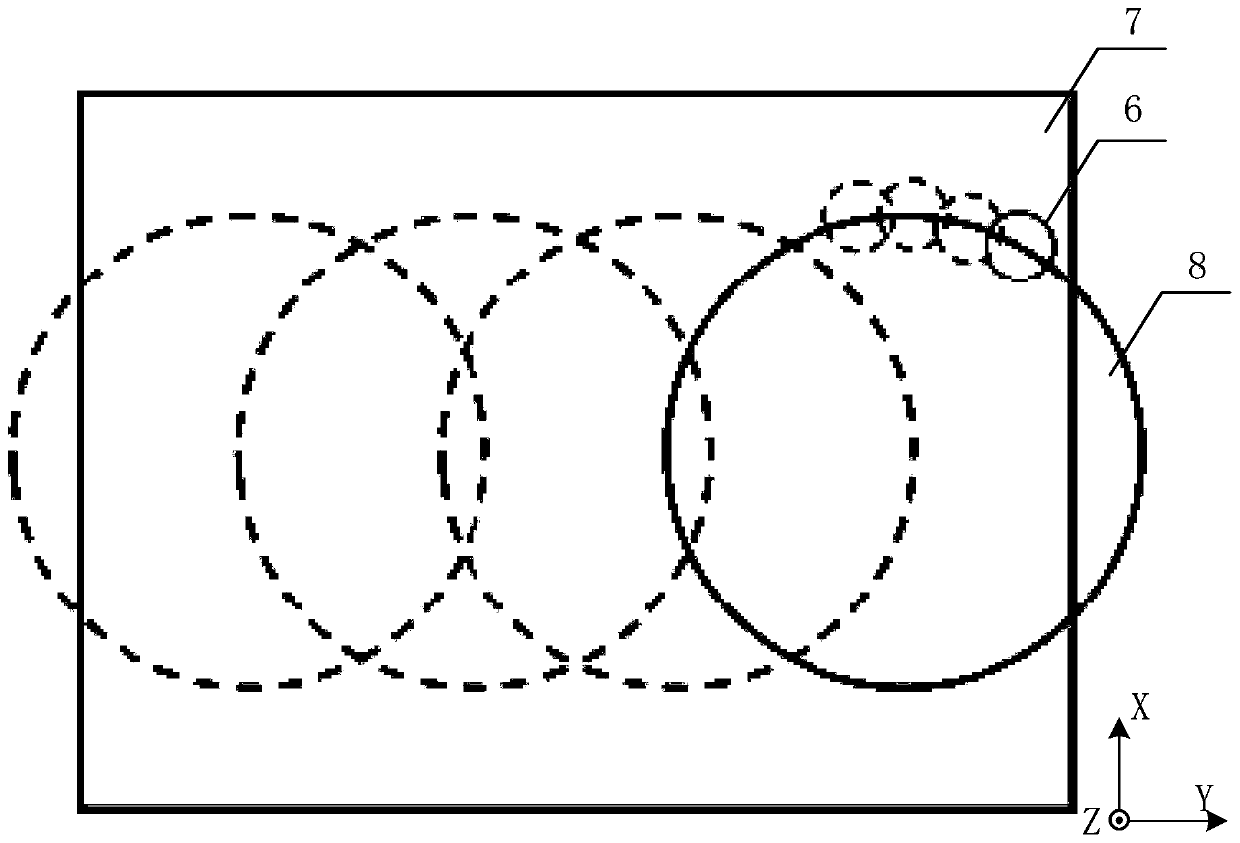

Water jet and corrosive liquid lower cutter ring wear test device and test method

PendingCN110057705AThe installation process is simple and convenientThe disassembly process is simple and convenientUsing mechanical meansInvestigating abrasion/wear resistanceHydraulic motorInfrared thermometry

The invention discloses a water jet and corrosive liquid lower cutter ring wear test device and a test method. In the testing device, a telescopic oil cylinder is connected to a three-dimensional rack, a cross beam, a connecting plate, a three-way force sensor and a tool rest are sequentially connected below the telescopic oil cylinder, a bearing, a cutter shaft and a reduced-size cutter ring areconnected in the tool rest, a vertical nozzle guide rail is connected below the tool rest, a transverse nozzle guide rail, a nozzle support and a nozzle are sequentially connected on the vertical nozzle guide rail, the cross beam is symmetrically provided with two sets of tool rests, the reduced-size cutter rings, the nozzles and other parts about the telescopic oil cylinder, an extremely hard rock sample is placed in a stock bin box, the bottom of the stock bin box is connected with a hydraulic motor through a bolt, and an infrared thermometer is fixedly connected to the outer ring of a supporting base. The test method can be matched with the test device to complete the whole cutting wear test process of the cutter ring under the conditions of water jet and corrosive liquid, and can provide basis for predicting the wear life of the cutter ring of a hob and designing the wear resistance of the cutter ring of the hob under the conditions of water jet and corrosive liquid.

Owner:HUNAN NORMAL UNIVERSITY

Protective coatings for pumps

The impellor, housing, flow channels, inlet and outlet flow passages of a pump used to pump a highly abrasive liquid at high volume. The flow surfaces are prepared, a primer is applied, and polyurea is applied on top of the primer to provide a protective coating rivaling extremely hard surfaces. The coating thus applied has at least the durability of expensive-to-apply hard coatings such as tungsten carbide, and siloxirane ceramic and ceramic metal filled epoxies. In addition, it minimizes the occurrence of cavitation within the pump housing, flow channels and passages.

Owner:ADIABATICS

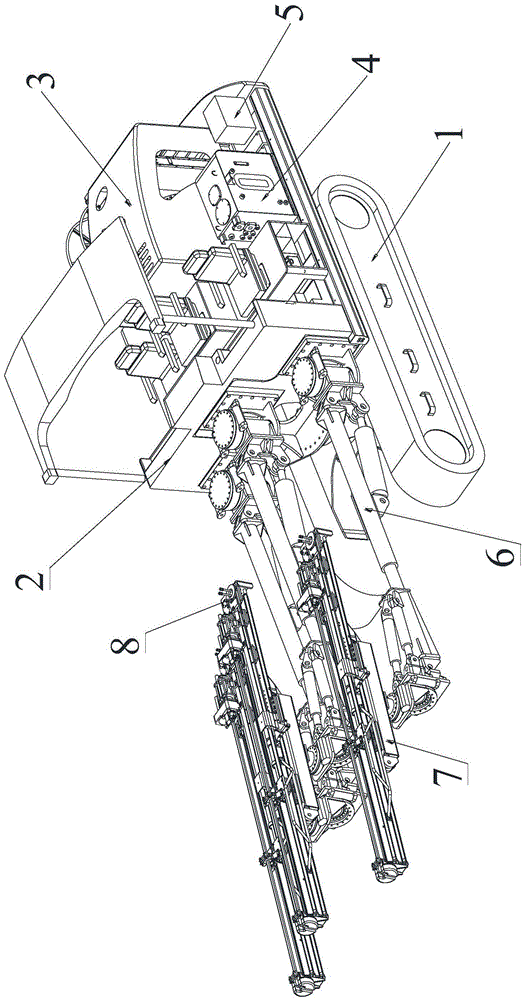

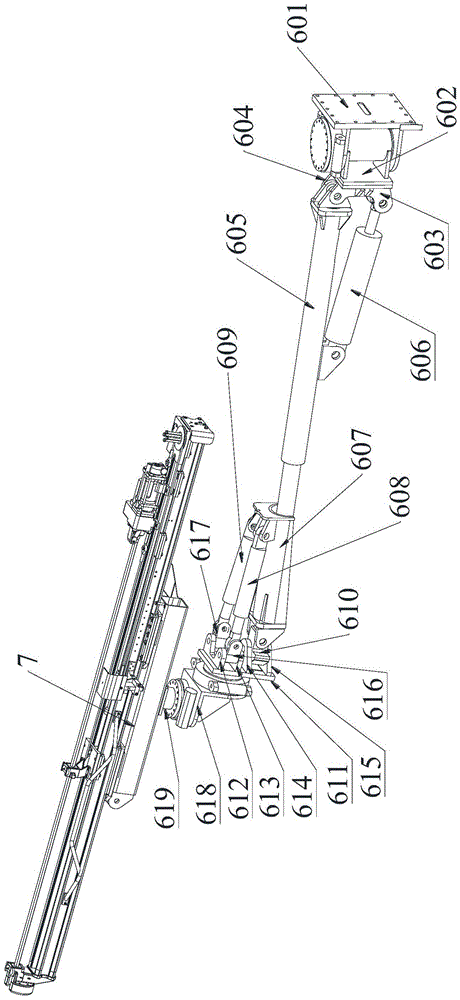

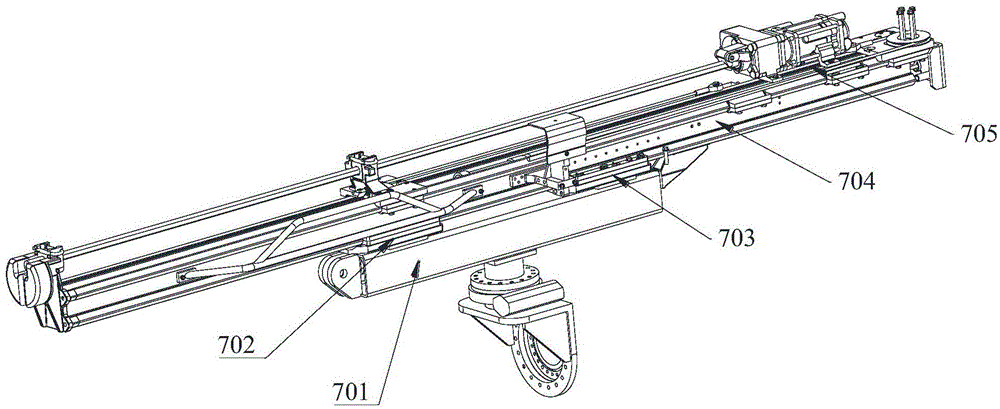

Drill jumbo

InactiveCN105525870AQuick Modular InstallationDerricks/mastsDrilling machines and methodsExtremely hardDrill

The invention discloses a drill jumbo comprising a travelling system, a rack, drill boom assemblies, propelling beam assemblies and replaceable drilling components. The rack is fixed to a chassis of the travelling system so as to move the rack through the travelling system; the drill boom assemblies are fixed to the frame; the propelling beam assemblies are fixed to the corresponding drill boom assemblies; the replaceable drilling components are fixed to the propelling beam assemblies correspondingly. The drill jumbo has the advantages that fast modular installation can be realized when the replaceable drilling components are replaced, parameter readjustment is not required, and the replaceable drilling component on one drill boom assembly is replaced within 10 minutes. The most rational drilling method can be selected according to requirements on the construction site, and the drill jumbo is highly adaptable to formations from soft formation to extremely hard formation as well as highly adaptable to non-blasting construction requirements and non-blasting and drilling blasting combined construction requirements.

Owner:王占军

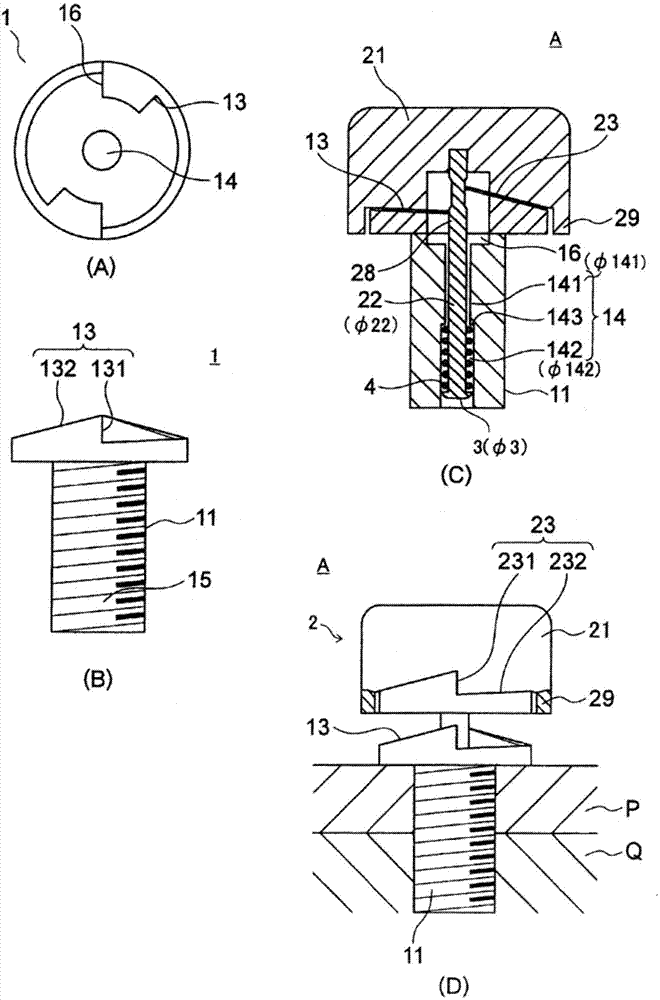

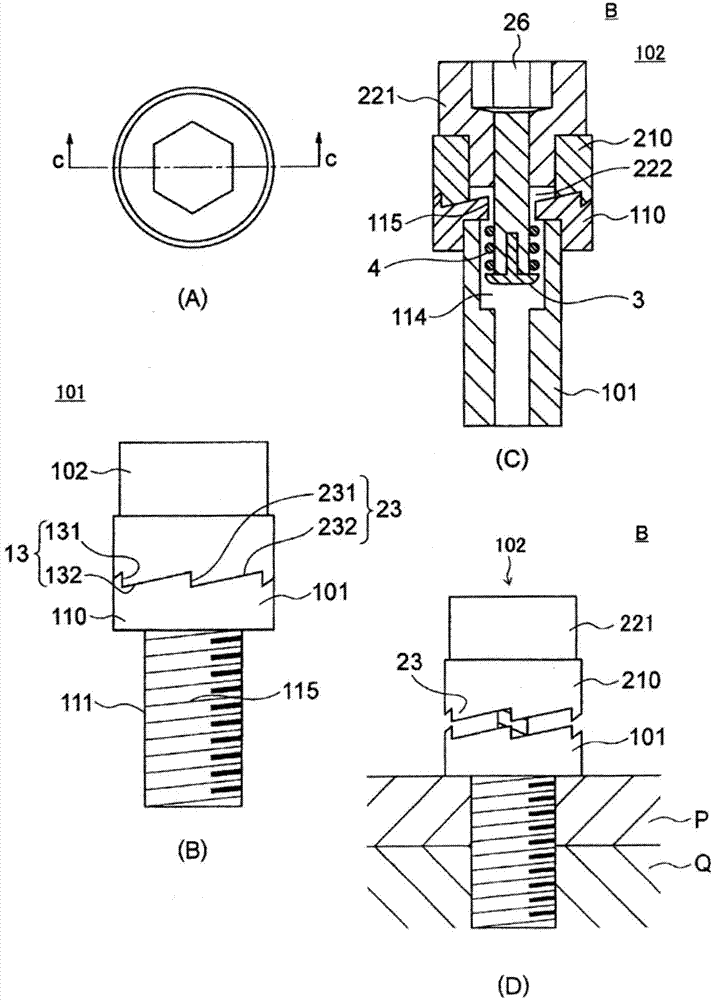

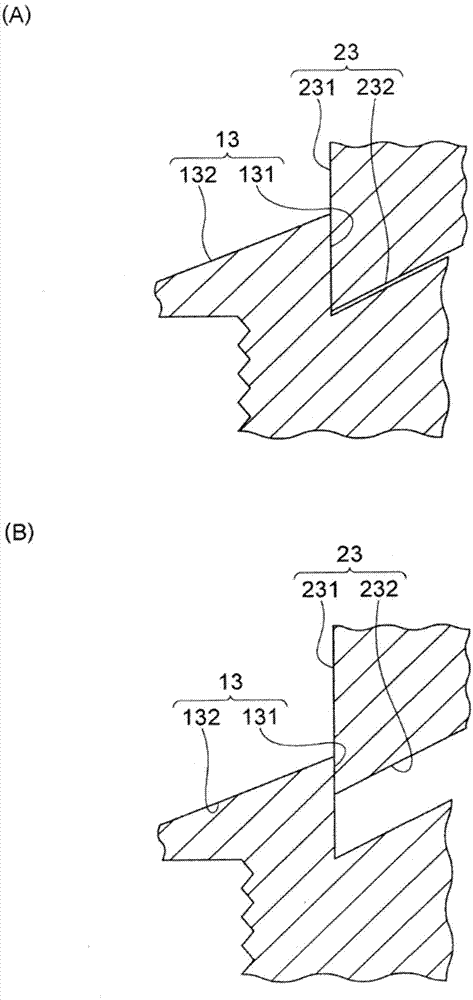

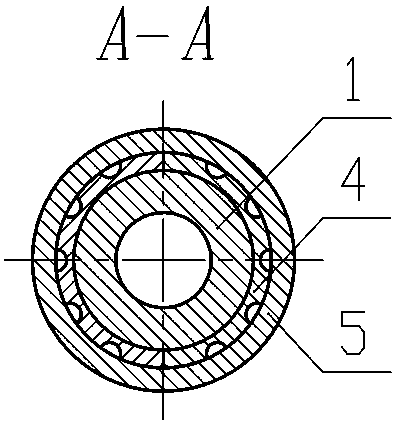

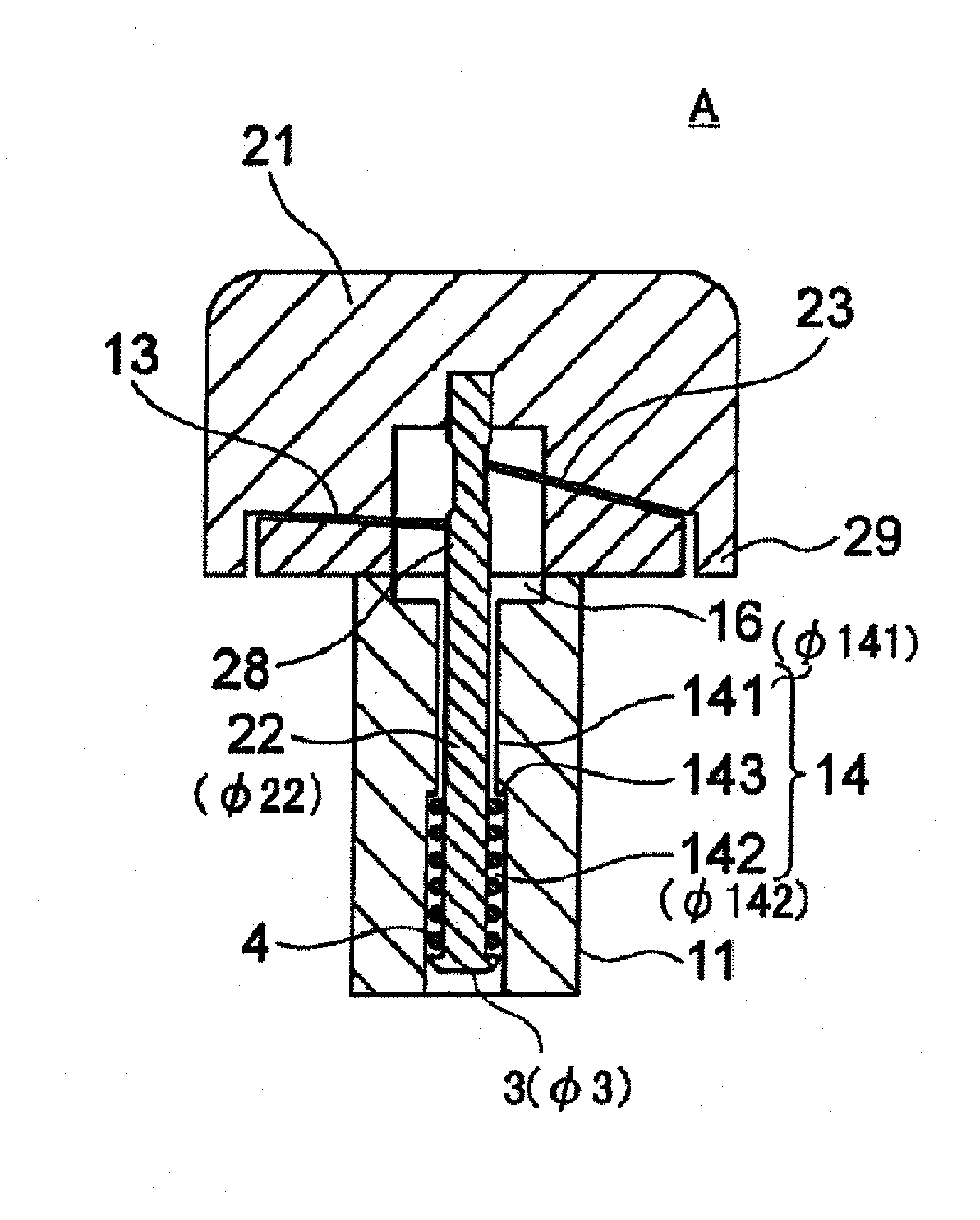

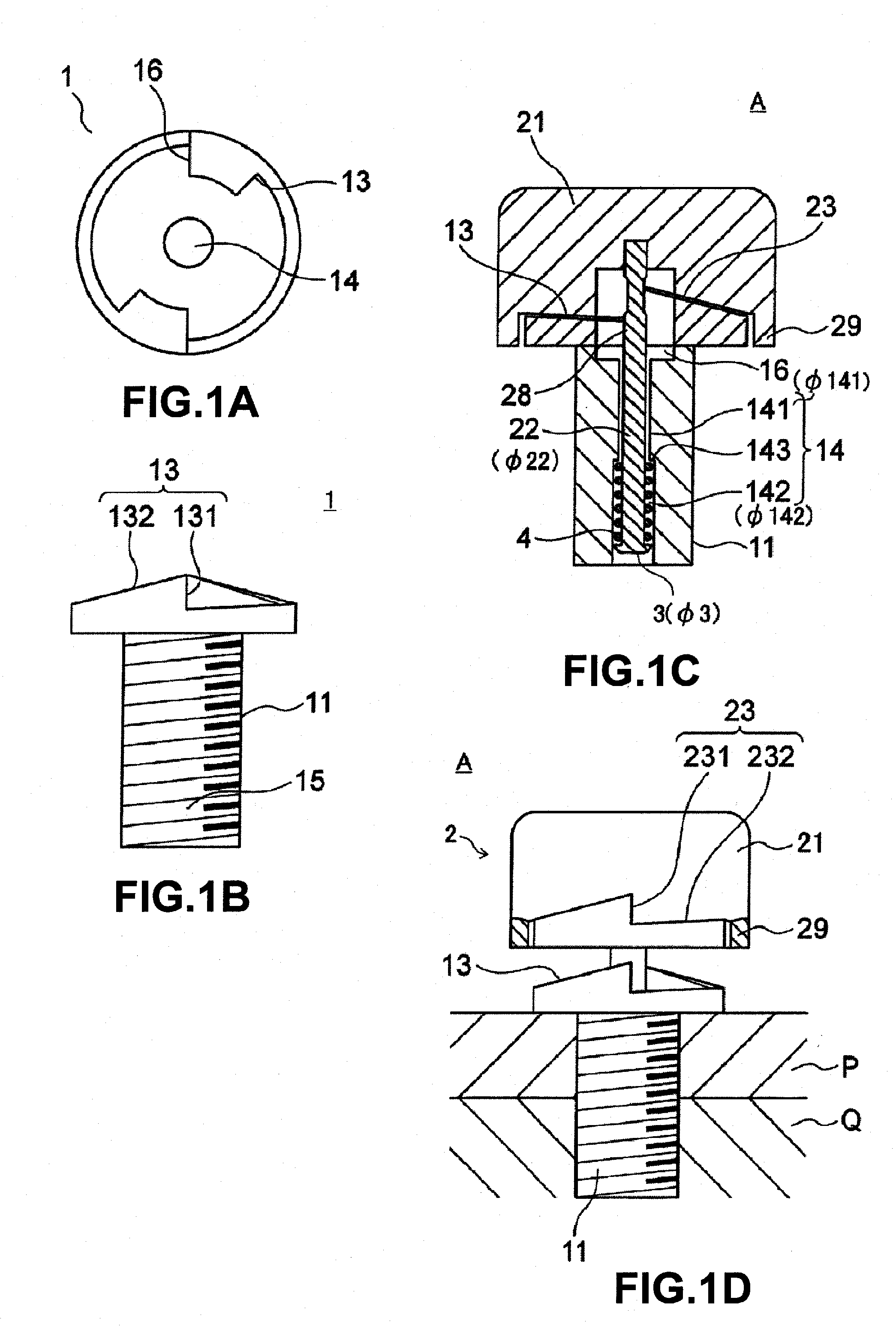

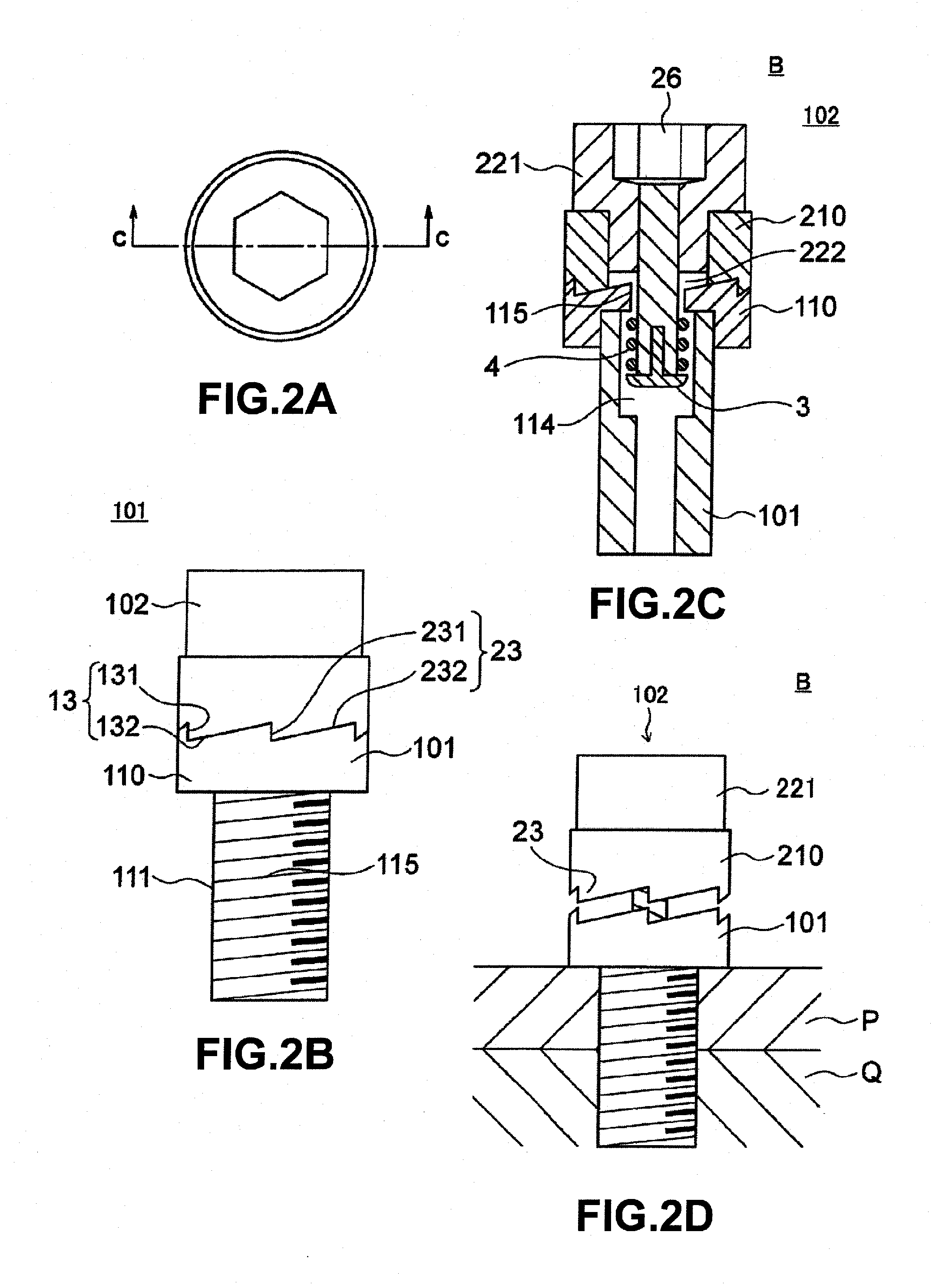

Bolt

InactiveCN104747570AImprove securityPinsLoad modified fastenersExtremely hardUltimate tensile strength

A bolt capable of fastening without use of a special tool and which is extremely hard to be loosened (detached) after fastening is provided. A bolt of the present invention is configured by a fastened bolt, a fastening bolt, and a lock portion. A first engagement portion is provided on one end of a fastened bolt shank, and a concave portion is provided in the center part of the bolt shank. The fastening bolt has a second engagement portion on the surface confronting the first engagement portion and a fastening shank which is slidably inserted into the concave portion. The bolt is configured so that when the fastening bolt is turned in only one direction, the first engagement portion and the second engagement portion are engaged to turn the fastened bolt, but when the clamp load rotating the fastened bolt in only one direction reaches a predetermined torque, the lower strength portion is damaged so that the clamp load of the fastening bolt is not transferred to the fastened bolt.

Owner:LOCKN BOLT

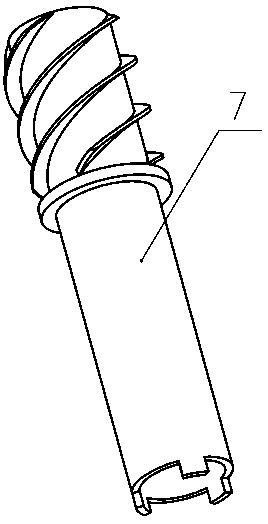

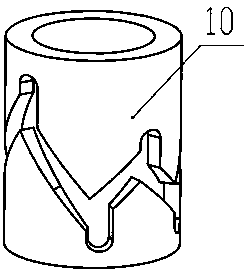

Grinding type anti-drop rock sampling device and use method thereof

The invention relates to a grinding type anti-drop rock sampling device for a coring operation and a use method thereof, and aims at solving the problem of low rock core cutting rate. The technical scheme of the grinding type anti-drop rock sampling device is that limit tubes are inserted into the inner cavity of an outer tube, one end of a sliding pin is fixed in a pinhole in the middle of the outer tube, and the other end of the sliding pin is capable of sliding in a sliding slot of the outer circle of the limit tube; the outer circle of an inner tube is sleeved with a rotor, and the rotor and the inner tube as a whole are inserted into the inner cavity of the outer tube; three claws are sequentially and respectively arranged in three oblique holes at the lower portion of the inner tube,and the claws are stuck in the oblique holes at the lower portion of the inner tube and slide in the oblique holes; the outer circle of the lower portion of the inner tube is sleeved with a sliding sleeve, the upper end surface of the sliding sleeve is in contact with the step surface of the outer side of the claw, and springs b are arranged in the lower end surface of the sliding sleeve; the lower end of a bearing seat is in threaded connection with the upper end of the inner tube, and guiding heads are in threaded connection with the lower end of the inner tube. According to the grinding type anti-drop rock sampling device, a rock core can be taken out after being ground and cut, and the breaking of the rock core is effectively prevented, and the grinding type anti-drop rock sampling device is especially applicable to cutting out extremely hard rock cores.

Owner:SOUTHWEST PETROLEUM UNIV

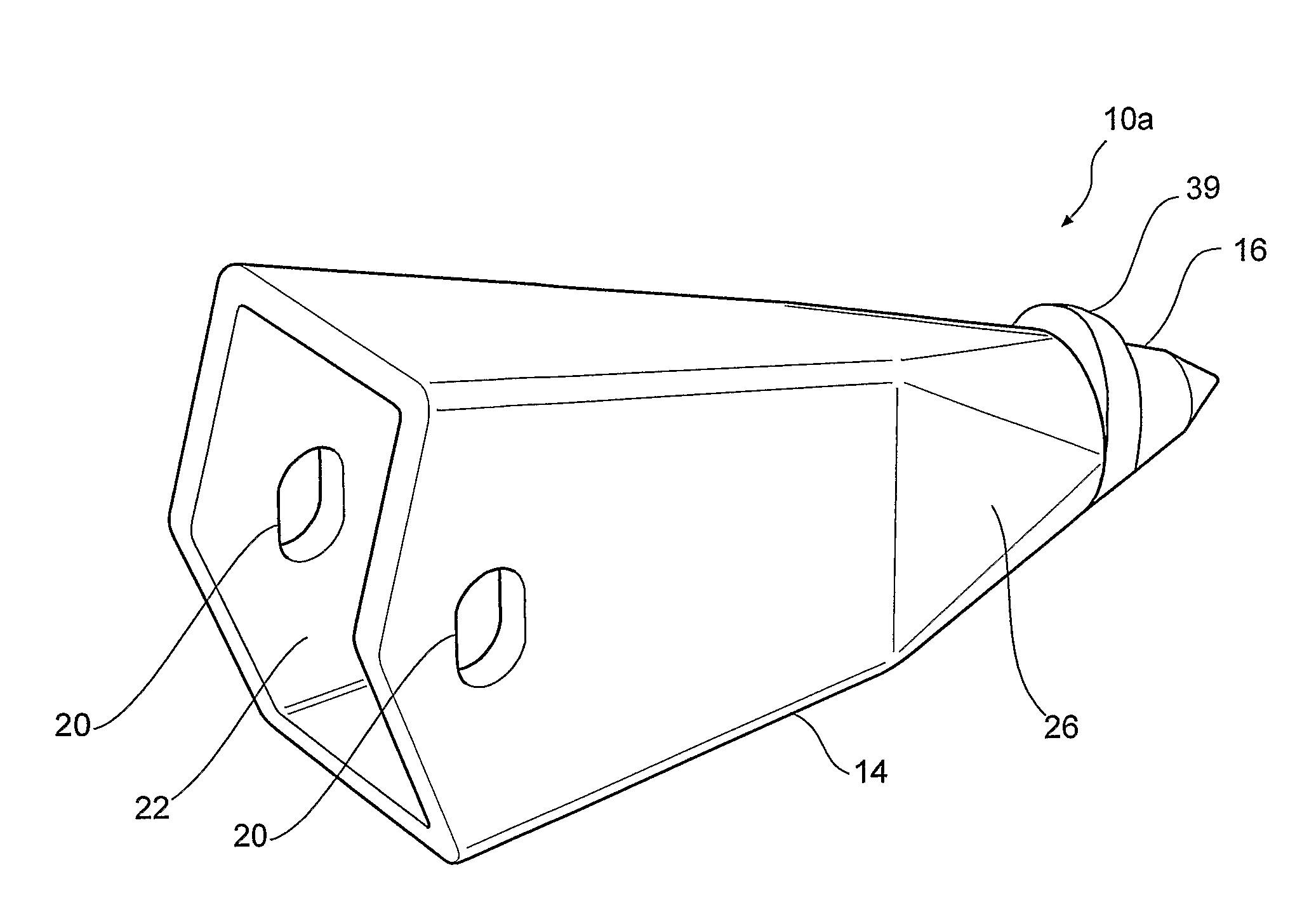

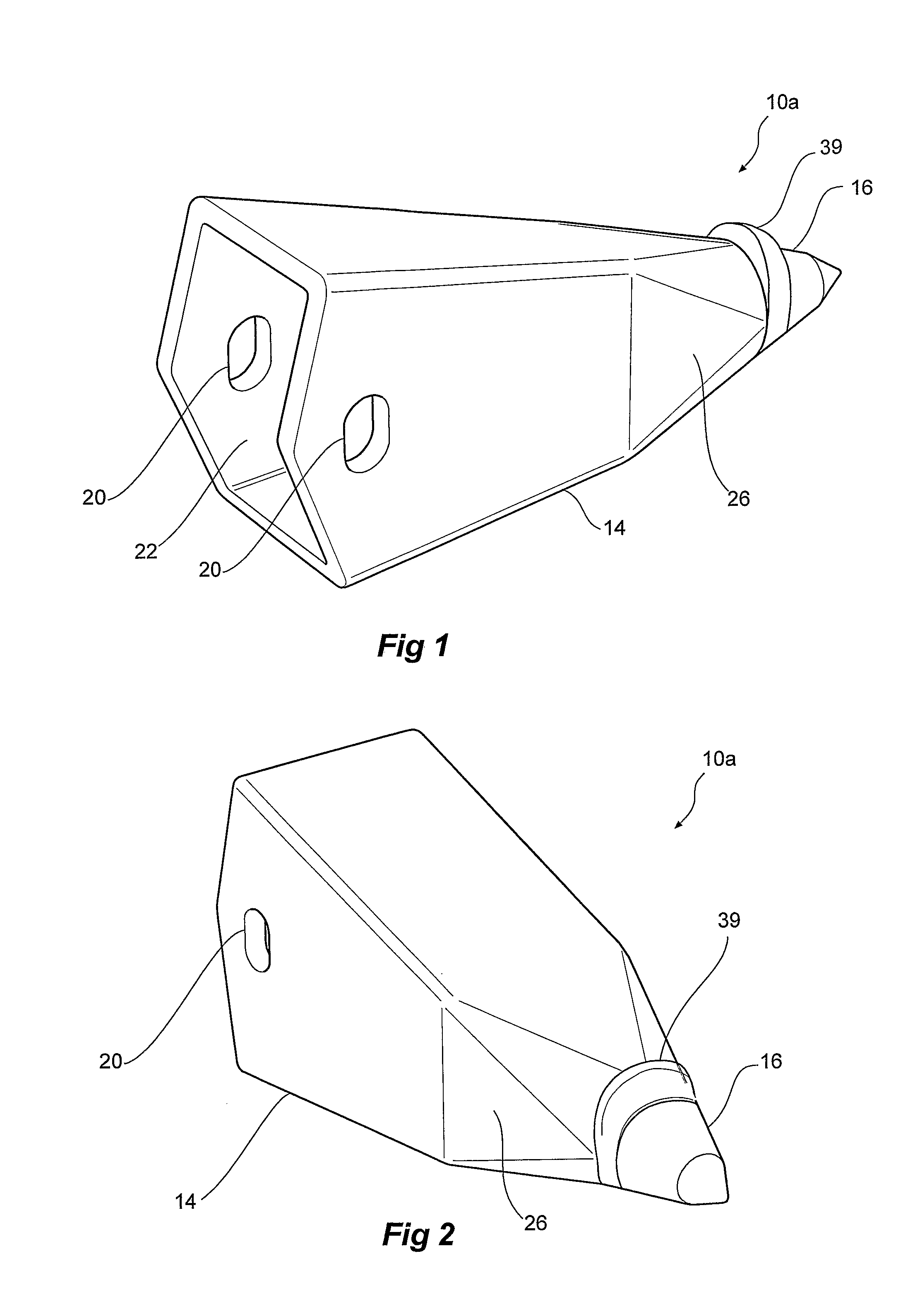

Ripper Boot

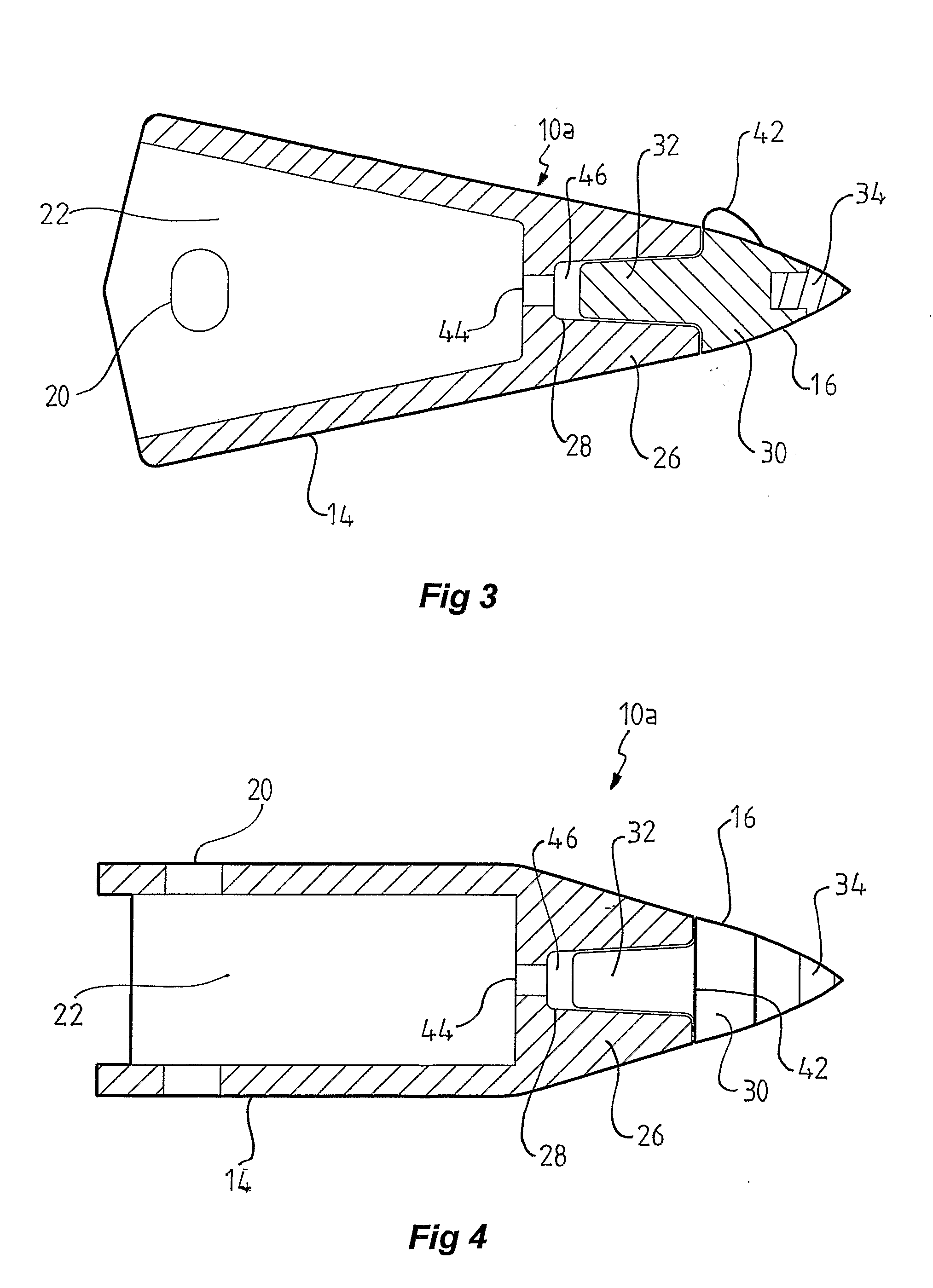

InactiveUS20080229627A1Avoid excessive wearReduce loadMechanical machines/dredgersPloughsInterference fitClassical mechanics

The present invention relates to improvements to ripper boots of the type adapted to be mounted to a bulldozer tyne for use in cleaving through hard ground. The ripper boot embodied in the present invention has particular application in opal mining where sometimes extremely hard ground is to be penetrated and ripped. The ripper boot includes a replaceable ripping tooth which is secured within the boot by way of an interference fit so that during use, it does not rotate. The interference fit prevents particular matter from entering between the walls of the tooth and the associated socket. In further forms of the invention, the replaceable ripping tooth is angled upwardly with respect to the carrier so that the angle of attack of the ripping tooth is raised so that it is almost parallel with the ground. The ripper boot provides a number of benefits including improved cleaving effect, reduced chatter and drag, reduced wear and tear, and reduced load on associated machinery.

Owner:CALDERWOOD JAMES A

Ultra high pressure machining spindle

A system and technique wherein an ultra high-pressure (UHP) stream of water passing through a calibrated orifice achieves high water velocity. The orifice would be made from an extremely hard material such as sapphire or diamond. This high velocity stream impacts on a driving fluid turbine impeller attached to a shaft forming an opposed high-speed tool, which results in very high rotational speed with very high available power to do work. Off / On Control of the system would be accomplished through an integrated ultra high-pressure valve system.

Owner:CLARK JOSEPH RICHARD

Non-planar polycrystalline diamond composite piece and drill bit for oil drilling

PendingCN110145243AReduce grinding heatImprove eating abilityDrill bitsConstructionsEdge surfacePolycrystalline diamond

The invention belongs to the technical field of super-hard composite materials, and mainly relates to the engineering equipment for oil drilling, mine tunnelling and the like, in particular to a non-planar polycrystalline diamond composite piece and a drill bit for the oil drilling. The non-planar polycrystalline diamond composite piece comprises a polycrystalline diamond layer and a hard alloy substrate which wraps the bottom of the polycrystalline diamond layer; the top surface which is exposed to the outside of the polycrystalline diamond layer at least consists of two surface structures; the surface structures and the circumferential outer edge surface of the polycrystalline diamond layer form a plurality of cutting edges which are distributed on the circumferential outer edge surfaceof the polycrystalline diamond layer in the circumferential direction; the cutting edges are arranged in the manner of extending in the radial direction of the polycrystalline diamond layer; and non-horizontal planar structures which extend integrally are distributed on the polycrystalline diamond layer on the two sides of at least one cutting edge and the hard alloy substrate. The non-planar polycrystalline diamond composite piece and the drill bit for oil drilling are unique in appearances; the service life of the drill bit can be effectively prolonged; the feeding capacity and the drillingefficiency of the drill bit in extremely hard and plastic formation with difficulty in drilling are improved; and the drilling cost is reduced.

Owner:SF DIAMOND CO LTD

Polycrystalline diamond composite sheet with extensions

InactiveCN110500039AIncrease contact areaReduce heat damageDrill bitsConstructionsEdge surfacePolycrystalline diamond

The invention discloses a polycrystalline diamond composite sheet with extensions. The polycrystalline diamond composite sheet with the extension comprises a polycrystalline diamond layer, the polycrystalline diamond extensions and a hard alloy matrix. The polycrystalline diamond layer comprises a first surface, a second surface and at least one side surface. The first surface is arranged on the polycrystalline diamond layer and is usually a supporting surface or a cutting surface; the second surface is spaced from the first surface; the first surface is connected with the second surface by the at least one side surface; at least one of the polycrystalline diamond extensions extends away from the first surface and the side surfaces; and the hard alloy matrix is coupled to the second surface. By changing the shape and structure of the upper surface and the outer edge surface of the polycrystalline diamond layer on the polycrystalline diamond composite sheet, the problems that the polycrystalline diamond composite sheet is difficult to enter and low in machine speed after being used in an extremely hard formation, a plastic formation and other difficult-to-drill formations are solved, the efficiency is improved, and the cost is reduced.

Owner:SF DIAMOND CO LTD

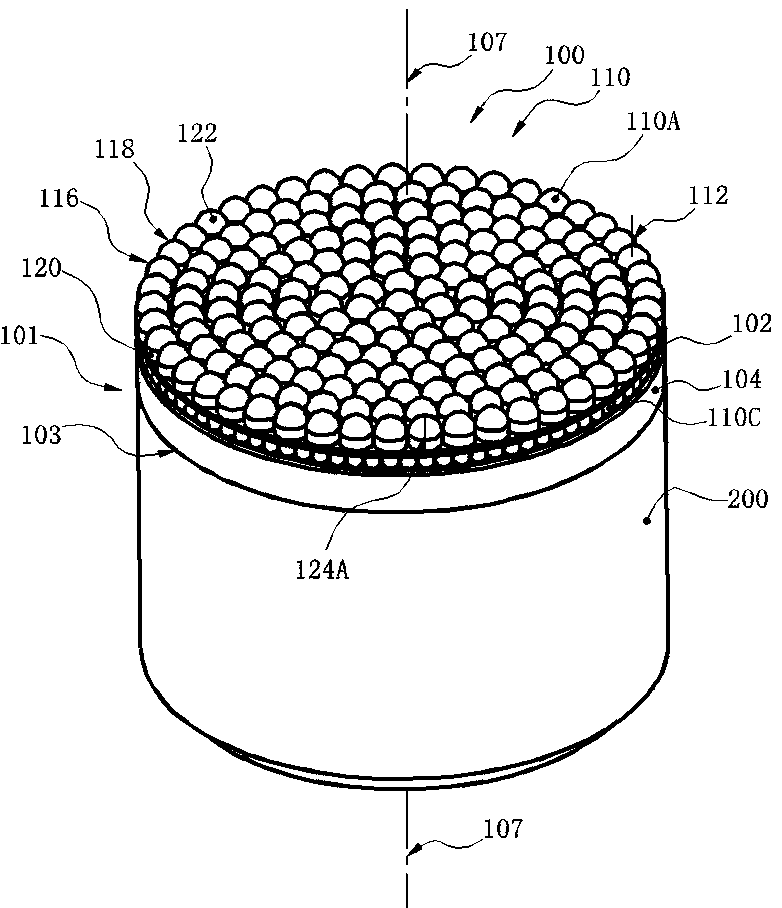

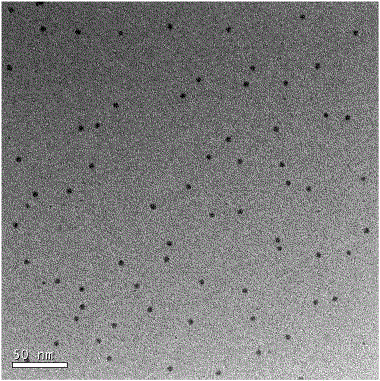

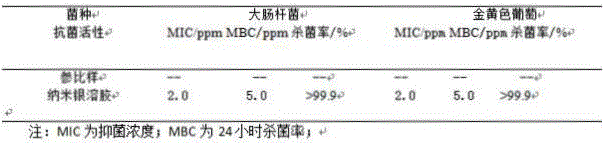

Preparation method for food-grade small-grain-size nano-silver sol

InactiveCN106735308AImprove stabilityImprove the bactericidal effectNanotechnologyUltraviolet lightsExtremely hard

The invention discloses a preparation method for good-grade small-grain-size nano-silver sol. According to the specific technical scheme, the method comprises the following steps that firstly, silver nitrate and water are blended according to the requirement that the silver content in a solution is 20-10000 pm, a surfactant is added into the silver nitrate solution to prepare a blended solution which is then stirred for 10-30 minutes, in the step, the surfactant is added for overcoming the defect that due to the small grain size and mutual attraction, a nano material is extremely prone to form a soft agglomerate which is extremely hard to disperse,; and secondly, the blended solution obtained in the first step is subjected to curing reaction, specifically, a light source containing ultraviolet light is utilized for irradiating the blended solution for 30 minutes to 24 hours, and then the small-grain-size nano-silver sol with the average grain size being 2 nm can be obtained.

Owner:苏州沐恩包装新材料有限公司

Phase deviation based auto-disturbance rejection isolated island detecting method

InactiveCN101931219BAvoid misjudgmentGuaranteed uptimeEmergency protective circuit arrangementsVoltage-current phase angleIslandingEngineering

The invention discloses a phase deviation based auto-disturbance rejection isolated island detecting method, which realizes periodic disturbance on the output current of an inverter by constructing an output current phase angle control function of the inverter so as to ensure that the voltage frequency of the position of a point of common coupling (PCC) deviates after the isolated island happens, and the occurrence of an isolated island phenomenon can be ensured to be effectively detected in time. The phase angle control function of the output current of the inverter consists of two parts, wherein one part is a homeostatic control function theta 0[k] which mainly plays roles in destroying a stable running point possibly existing in the system and ensuring effectiveness of disturbance, while the other part is a main function of the phase angle of the output current of the inverter which plays roles in ensuring that the method can effectively detect the isolated island when a secondary isolated island happens, and avoiding misjudgment caused by transient disturbance influence of the system, so that the normal operation of the system can be ensured. Therefore, compared with the prior art, the isolated island detecting method not only can avoid misjudgment caused by the effect of transient disturbance, and ensure the operation security of the system, but also can ensure that the isolated island can be quickly and accurately detected when the isolated island happens in an extremely hard condition, and greatly reduce the dead zone of detection.

Owner:XI AN JIAOTONG UNIV

Femtosecond laser machining system for nano-twin diamond tool, and machining method based on system

InactiveCN109954978ARealize processingImprove strong ablation damageLaser beam welding apparatusVibration amplitudeMaterial removal

The invention relates to the technical field of laser machining, in particular to a femtosecond laser machining system for a nano-twin diamond tool, and a machining method based on the system. The problem that the nano-twin diamond tool cannot be prepared through traditional machining means is solved. Machining is conducted through energy beams, and is not limited by material performance in the material removing process, and the novel extremely hard tool can be machined; meanwhile, the single-time scanning width is determined by the circular vibration amplitude, stable material removal withinthe maximum vibration amplitude can be achieved, and thus the machining efficiency of the nano-twin diamond tool is usually improved by 10 times or above; and in the single-time scanning area, incident laser energy is more evenly distributed on the machined surface, strong ablation damage caused by a thermal effect of femtosecond lasers to the material surface is improved, and the machining accuracy is greatly improved.

Owner:HARBIN INST OF TECH

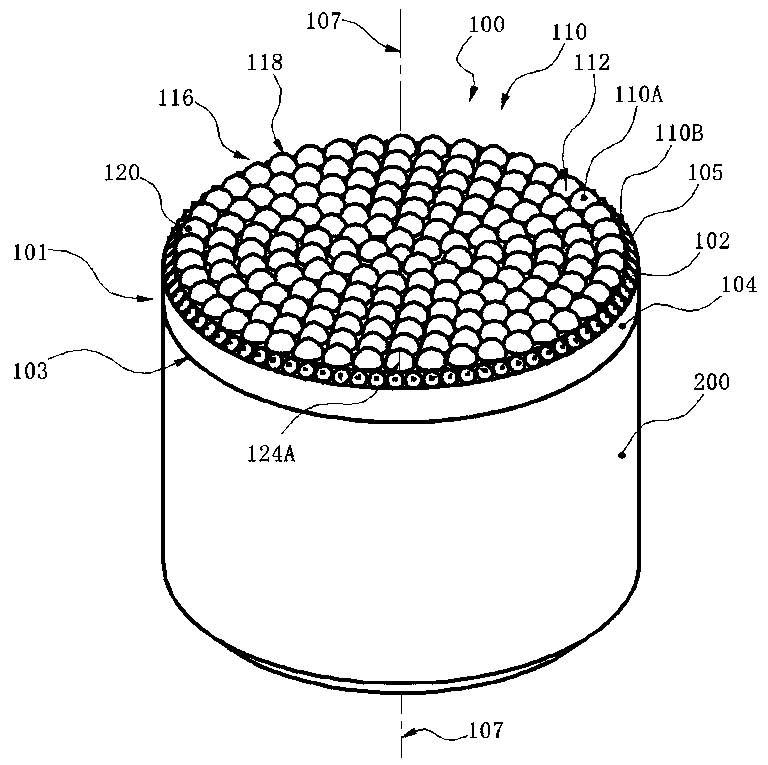

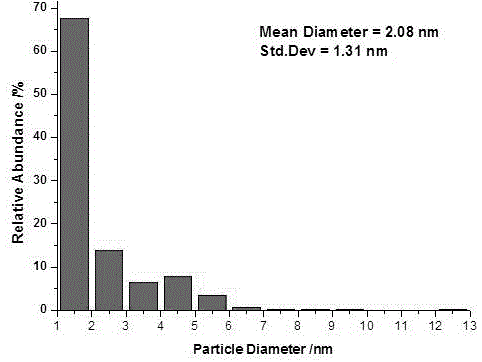

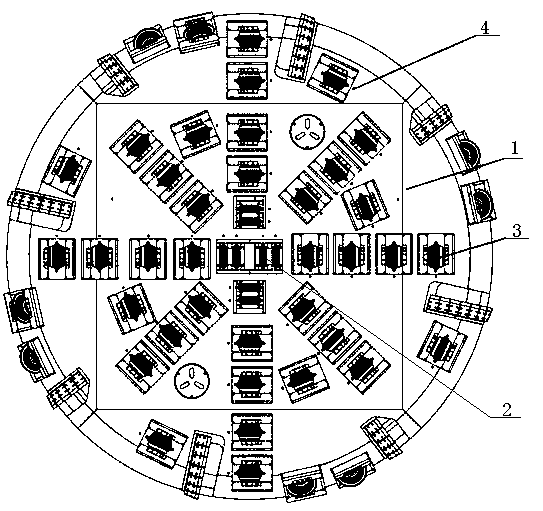

TBM cutter head with cavitation jet assisted rock breaking and rock breaking method

InactiveCN110924971AImprove rock breaking efficiencyReduce performanceTunnelsClassical mechanicsStructural engineering

The invention discloses a TBM cutter head with cavitation jet assisted rock breaking and a rock breaking method. The rock breaking efficiency of the TBM cutter head is improved. The cutter head comprises a cutter head body, wherein a central hob and positive hobs are arranged on the cutter head body, and the cutter head further comprises a cavitation jet mechanism, wherein a cavitation jet nozzleof the cavitation jet mechanism is arranged on the cutter head body and corresponds to the center hob and the positive hobs, the cavitation jet mechanism comprises the cavitation jet nozzle and a cavitation device, the cavitation jet nozzle is vertically arranged on the front face plate of the cutter head body, and the cavitation jet nozzle is connected with the cavitation device through a high-pressure water pipeline. According to the TBM cutter head, a cavitation jet rock breaking device for assisting cutting hard rock is additionally arranged on the conventional cutter head, through cooperation of the cavitation jet nozzle and the hobs, the cavitation jet is utilized to have strong damage to the extremely hard rock, various performances of the rock can be weakened, the rock is subjectedto double crushing, and the rock breaking efficiency of the cutter head is improved.

Owner:CHINA RAILWAY ENGINEERING EQUIPMENT GROUP CO LTD

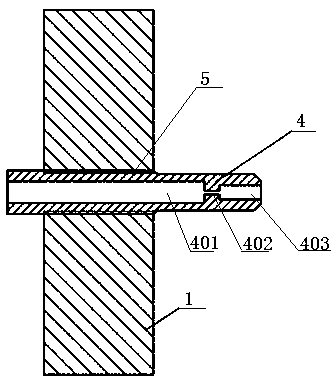

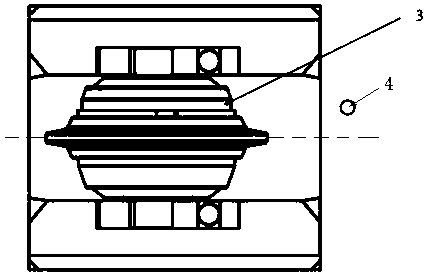

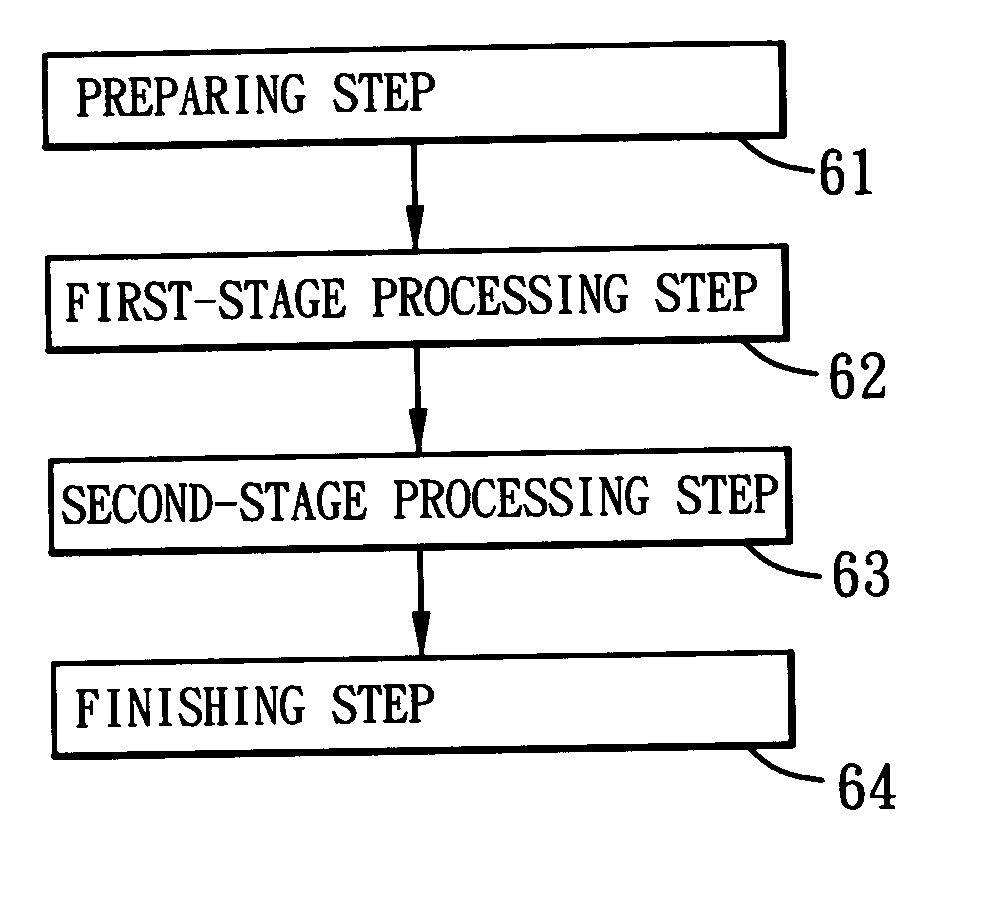

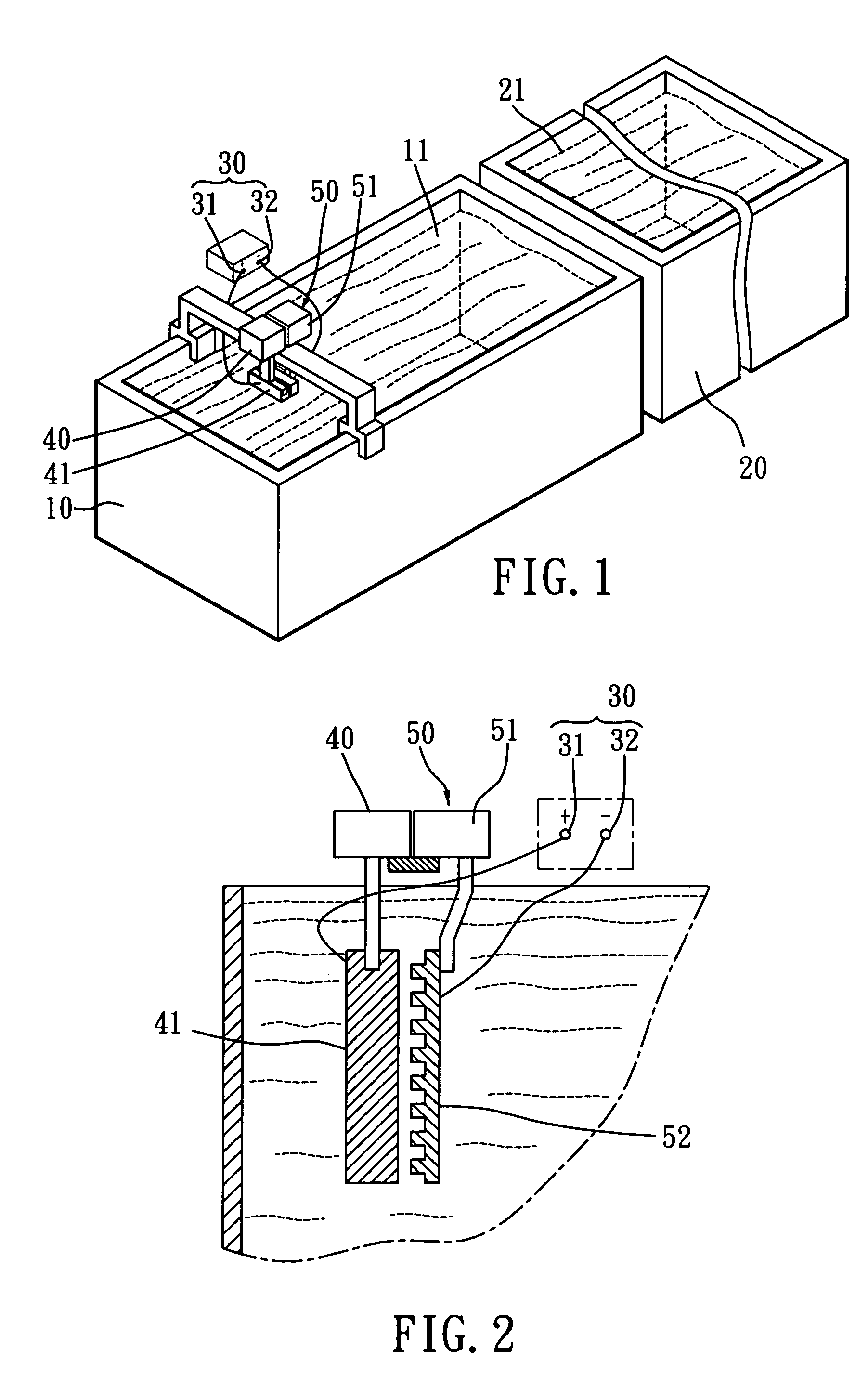

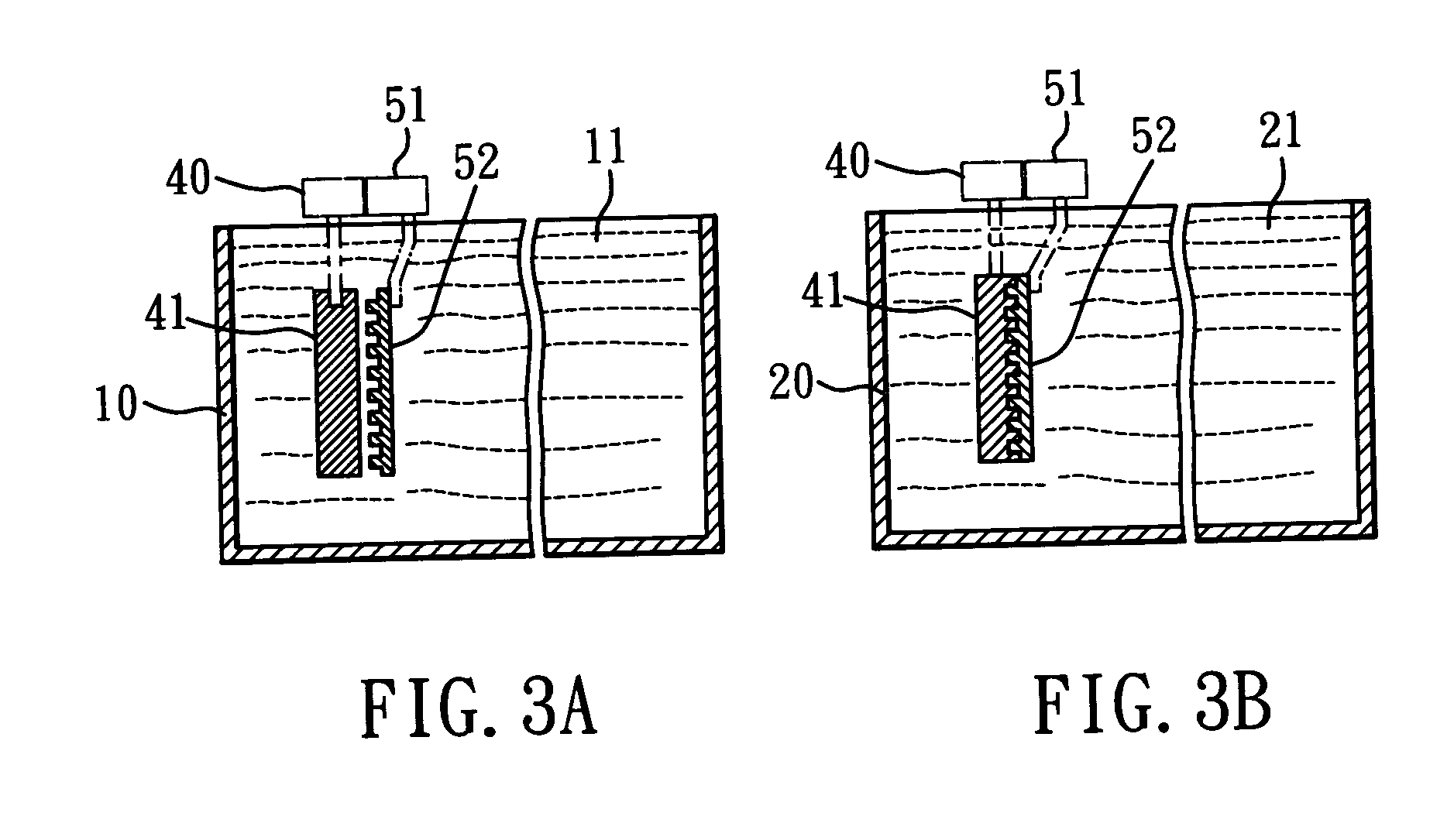

Combined electrochemical machining and electropolishing micro-machining apparatus and method

InactiveUS20070138023A1High speedImprove surface roughnessMachining working mediaElectrolysis componentsWorking fluidElectrolysis

A combined electrochemical machining and electropolishing micro-machining method includes the steps of (1) preparing step, (2) first-stage processing step, (3) second-stage processing step, and (4) finishing step. The apparatus includes an electrochemical machining solution container, an electropolishing solution container, a metal workpiece connecting with an anode, a mold-plate portion connecting with a cathode. Based on this arrangement, the metal workpiece is immersed in a first working fluid to conduct the electrochemical machining process and then to be immersed in a second working fluid to conduct the electropolishing process. So, the overall micro-machining speed is fast. It can improve the surface roughness significantly. It is suitable for extremely hard metal workpiece.

Owner:YUAN ZE UNIV

Bolt

InactiveUS20150184686A1Improve securityAvoid easy detachmentPinsLoad modified fastenersExtremely hardMechanical engineering

A bolt capable of fastening without use of a special tool and which is extremely hard to be loosened (detached) after fastening is provided. A bolt of the present invention is configured by a fastened bolt, a fastening bolt, and a lock portion. A first engagement portion is provided on one end of a fastened bolt shank, and a concave portion is provided in the center part of the bolt shank. The fastening bolt has a second engagement portion on the surface confronting the first engagement portion and a fastening shank which is slidably inserted into the concave portion. The bolt is configured so that when the fastening bolt is turned in only one direction, the first engagement portion and the second engagement portion are engaged to turn the fastened bolt, but when the clamp load rotating the fastened bolt in only one direction reaches a predetermined torque, the lower strength portion is damaged so that the clamp load of the fastening bolt is not transferred to the fastened bolt.

Owner:LOCKN BOLT

Roof drilling system improvements

The invention is embodied in a heavy duty drill bit for hard / soft rock drilling comprising a high fatigue-resistant, high alloy steel bit body having a PCD cutter member and an enlarged shank portion constructed to accommodate torsional forces at high thrust pressures, and reamer means for compensating the effect of bore hole rifling. The invention further involves the method of forming a roof bolting matrix in extremely hard rock formations having a compression strength up to about 50,000 psi using PCD wafers on a high tensile strength steel body coupled by a heavy duty shank through high fatigue-resistant reamer means to a high strength drive steel member.

Owner:WILLIAM J BRADY LOVING TRUST THE +1

High vacuum gas boronization

The invention provides a method for improving quality in boronizing industry, which is characterized in that boron element is infiltrated in the surface of the steel, thus forming an extremely hard boride layer on the surface, thereby improving the hardness of the die. Compared with other normal methods, the method has quick boronizing speed and good infiltration quality and improves the quality of the product.

Owner:SUZHOU WANTAI VACUUM FIRING FURNACE RES INST

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com