Patents

Literature

110results about How to "Avoid easy detachment" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

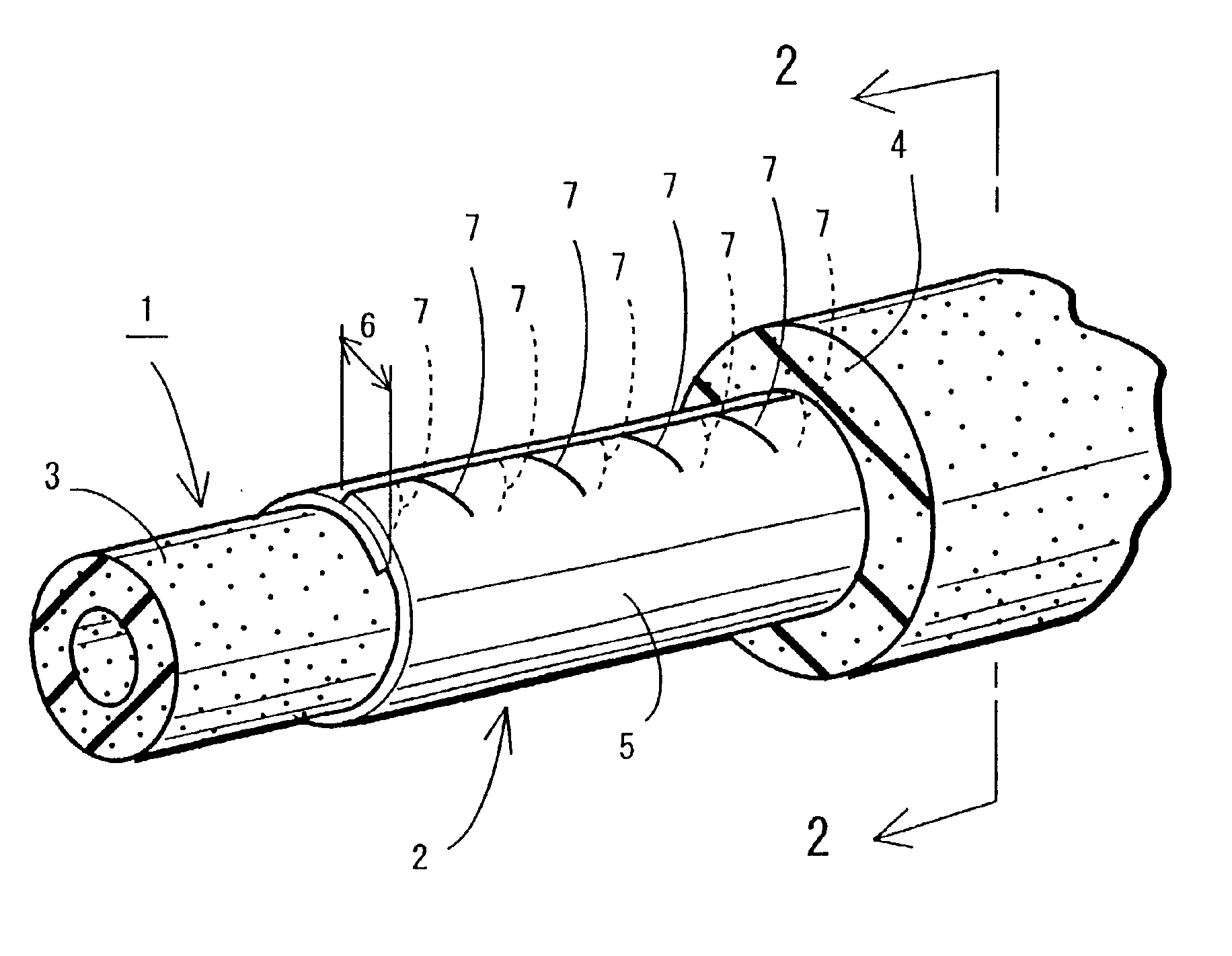

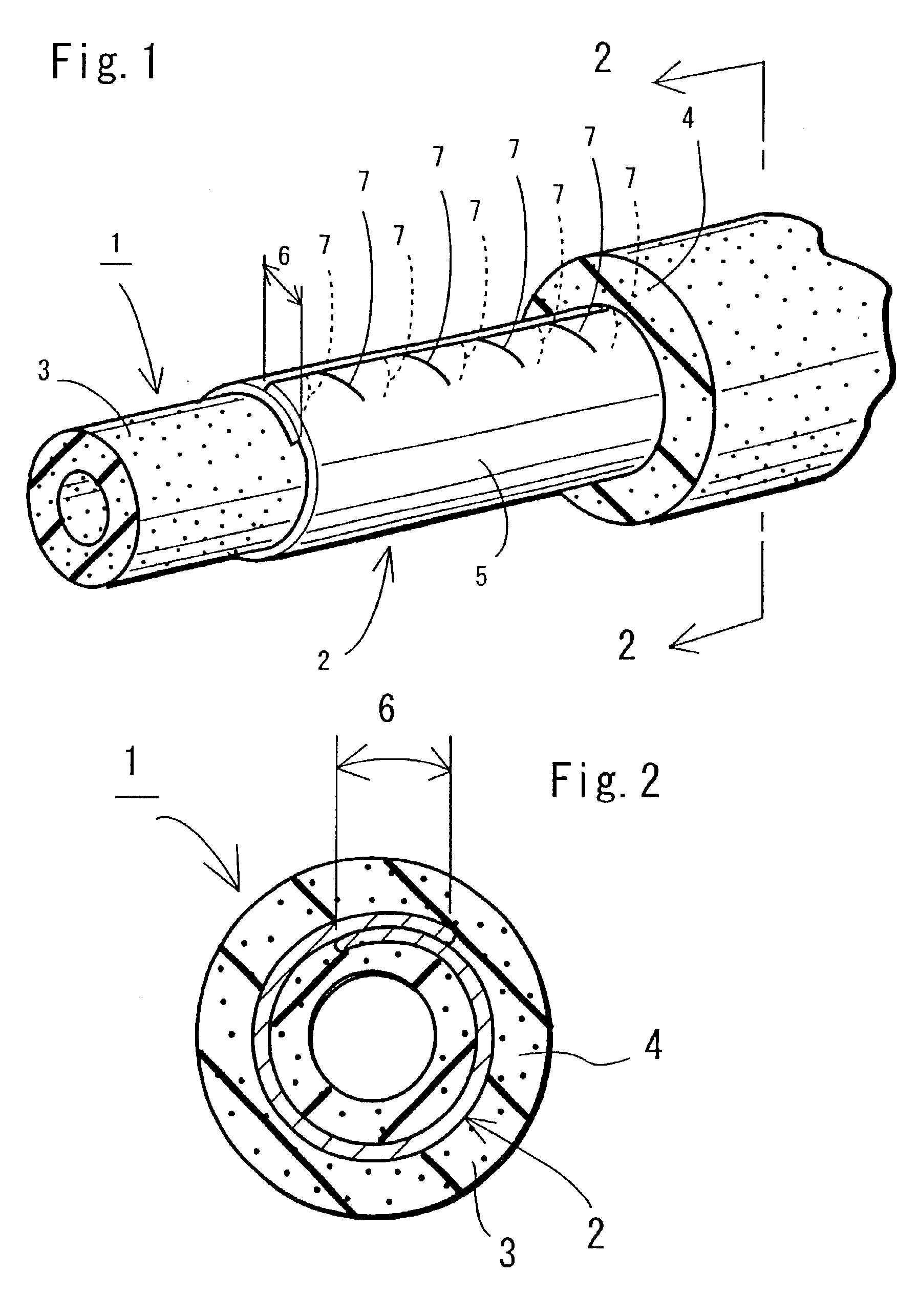

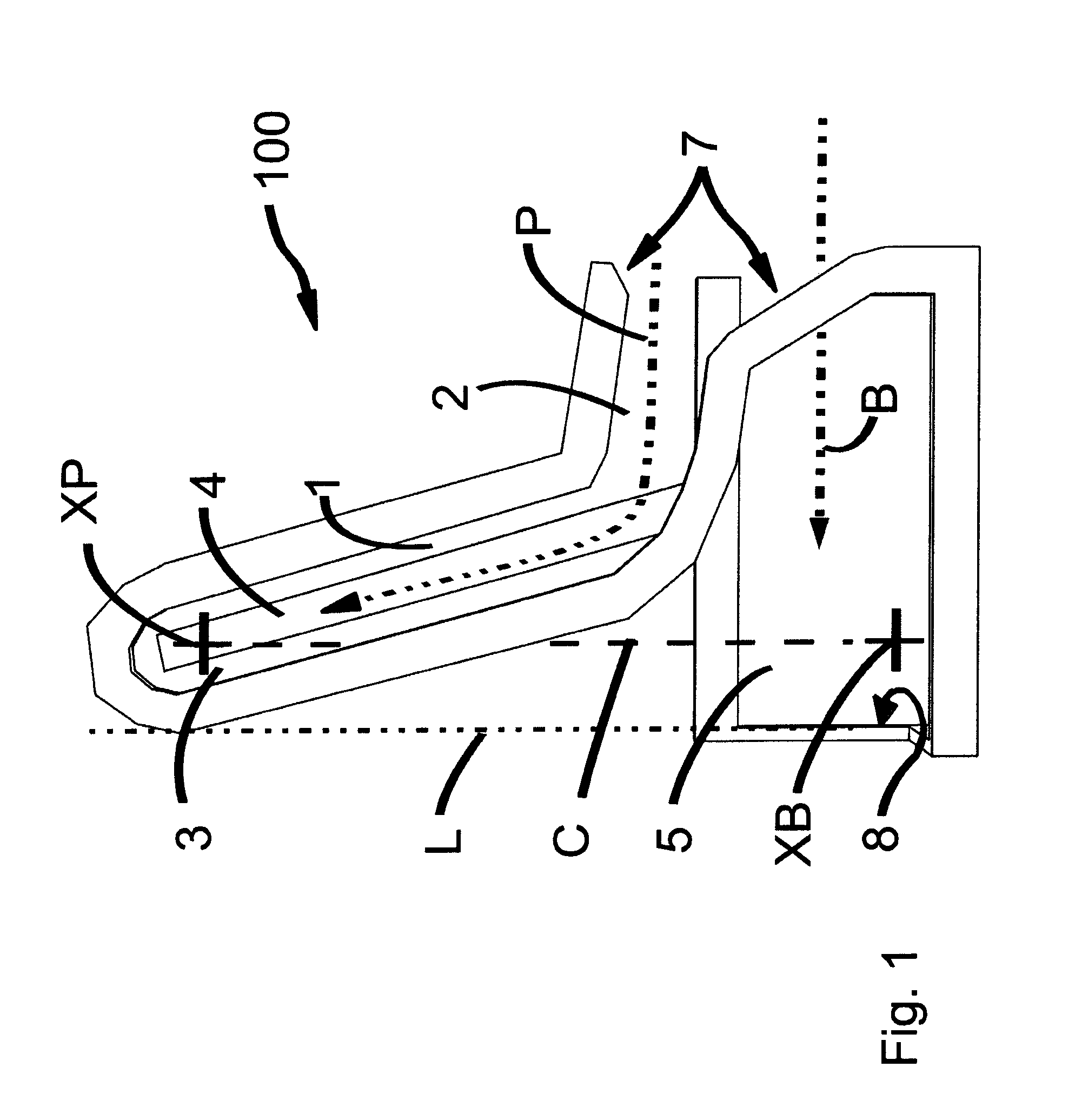

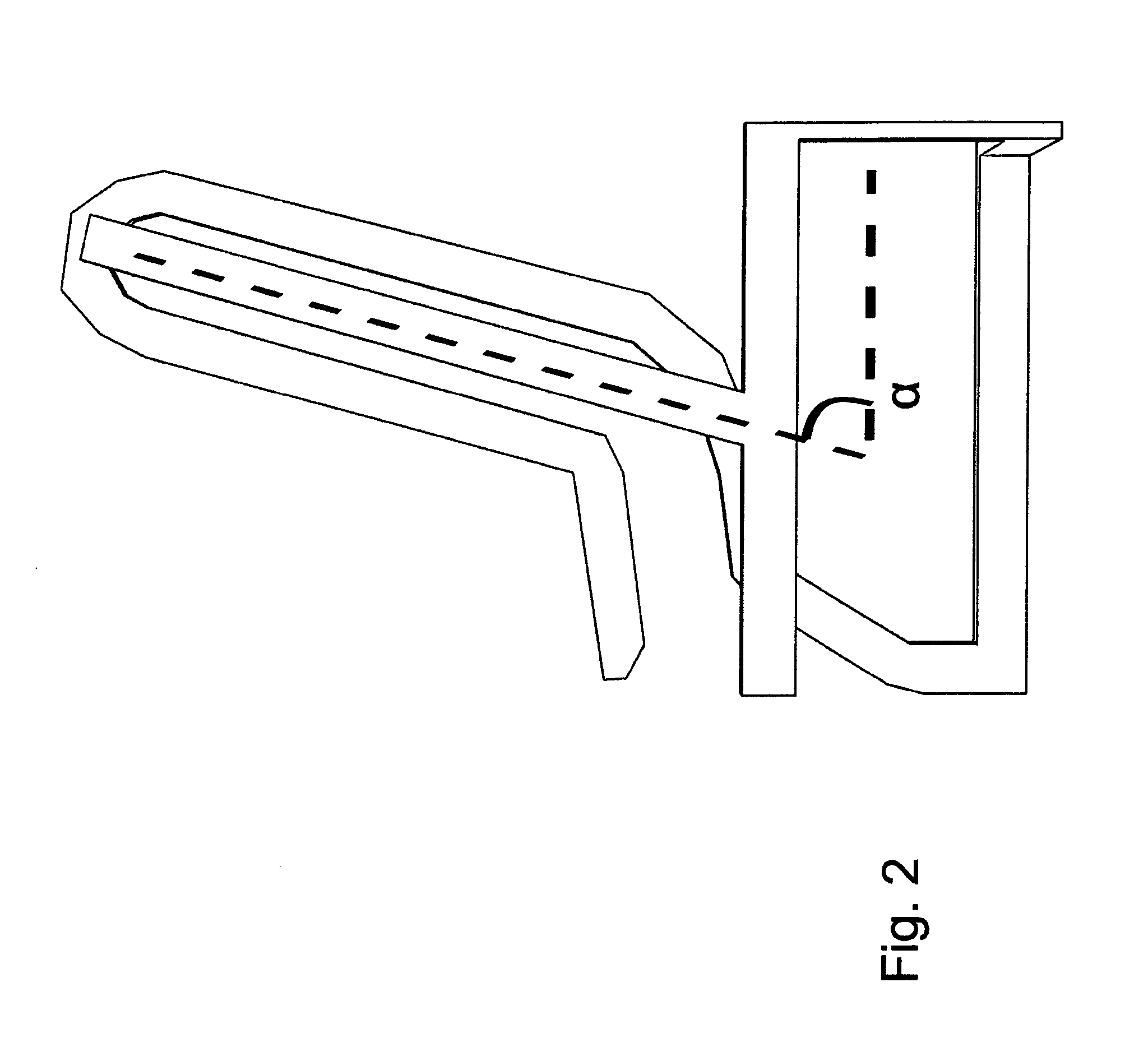

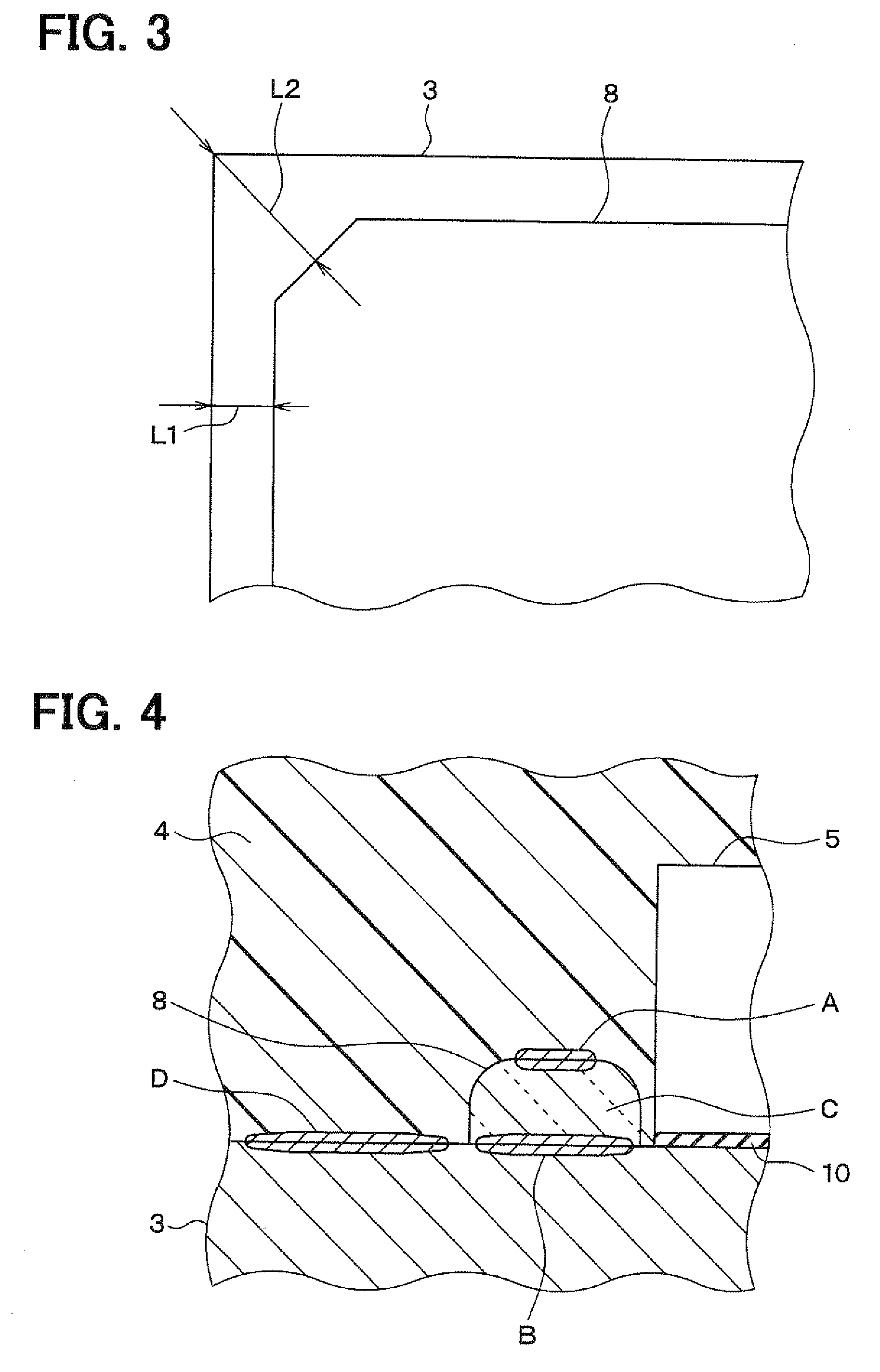

Thin-walled rubber hose and method of producing the same

InactiveUS6945279B2Increase production capacityImprove penetration resistanceHeat exhanger conduitsFlexible pipesEngineeringThin walled

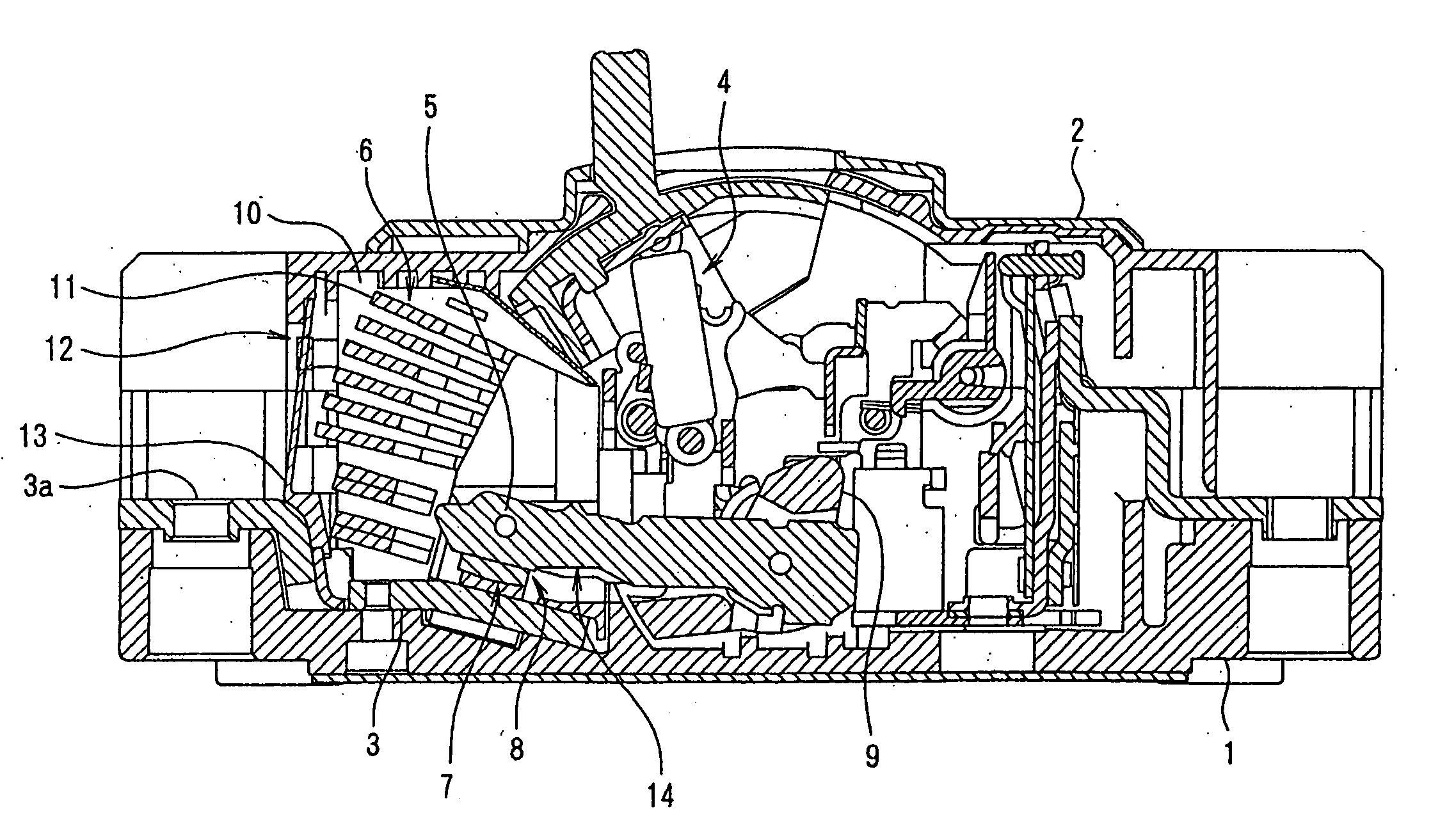

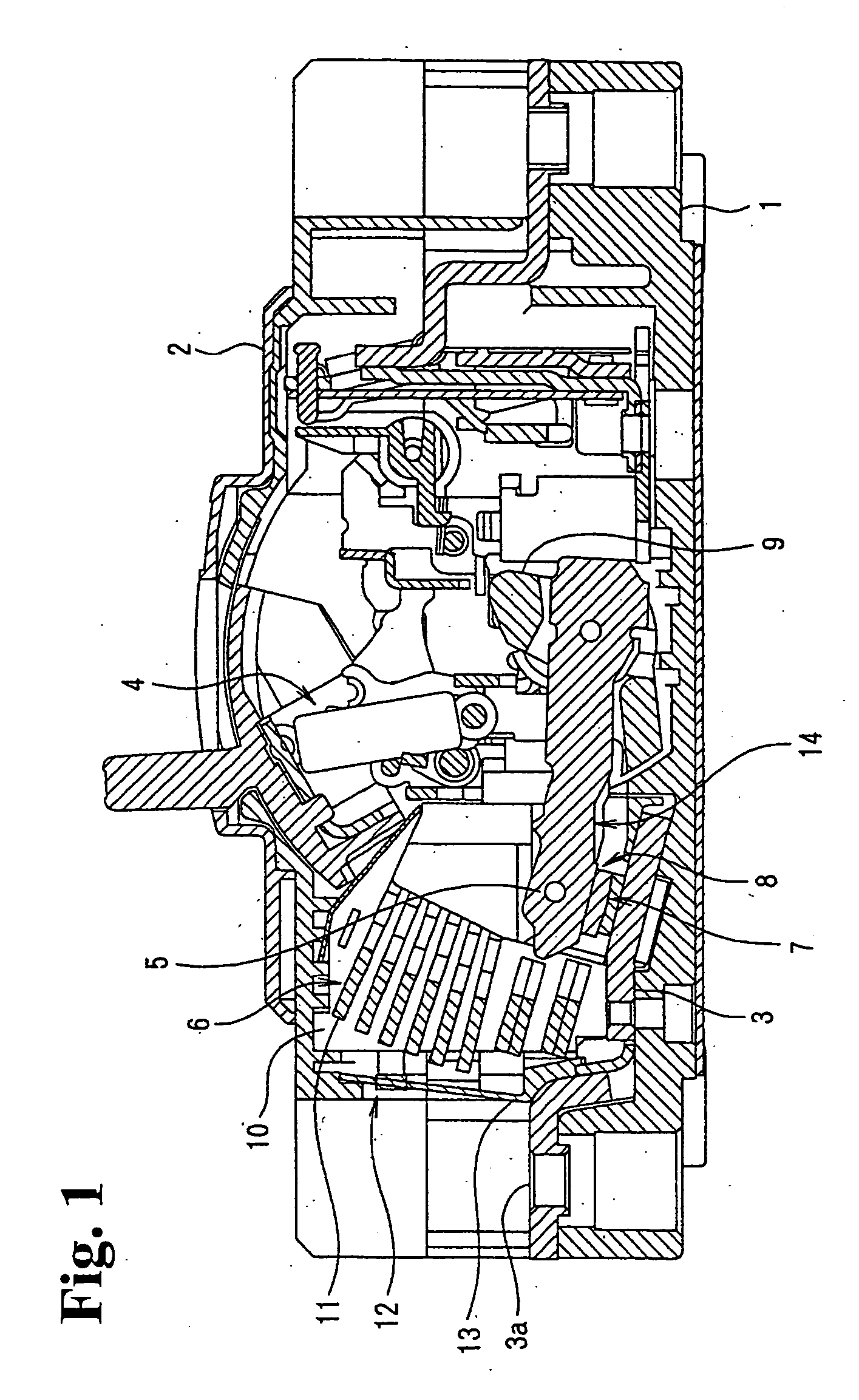

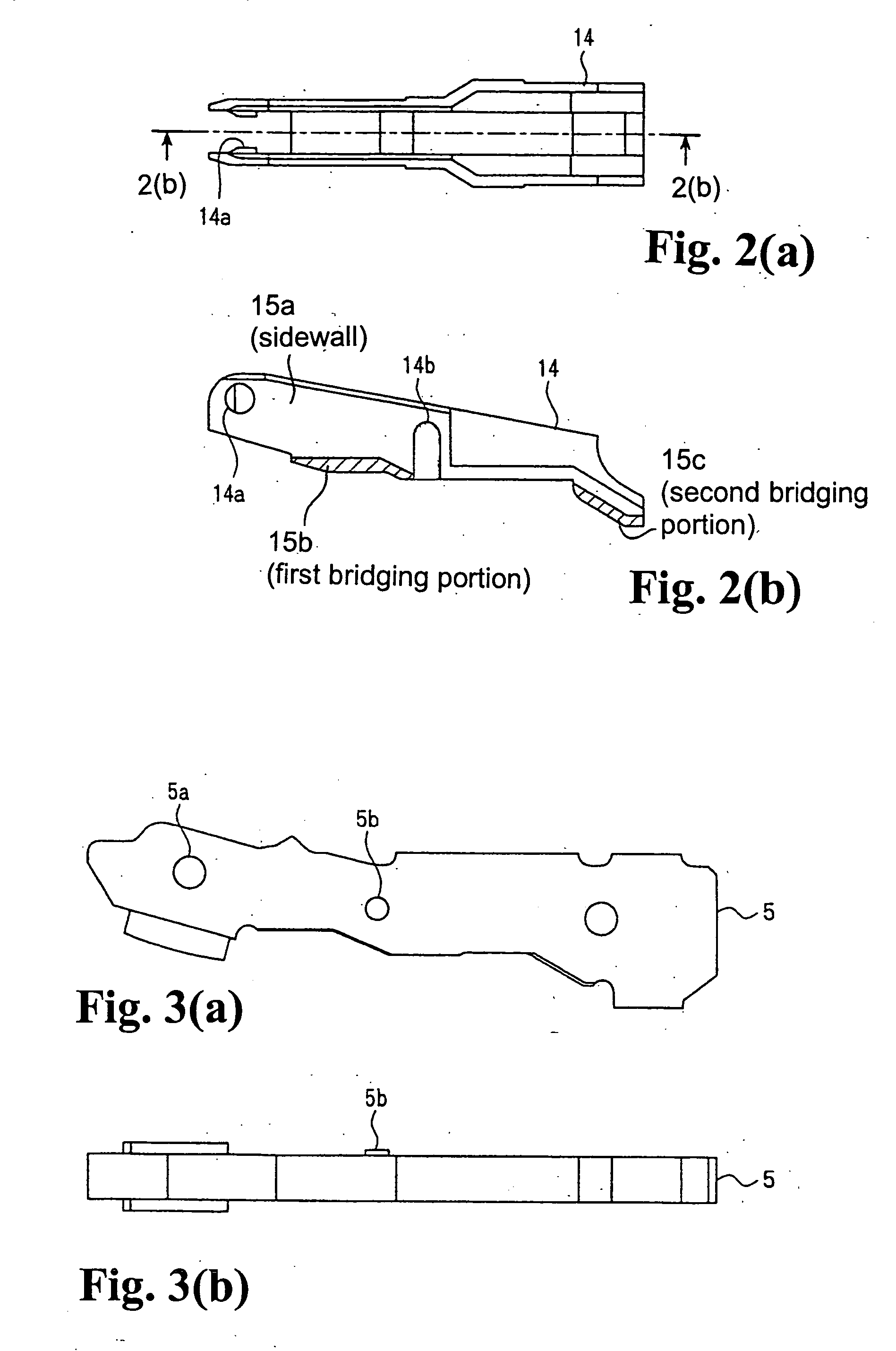

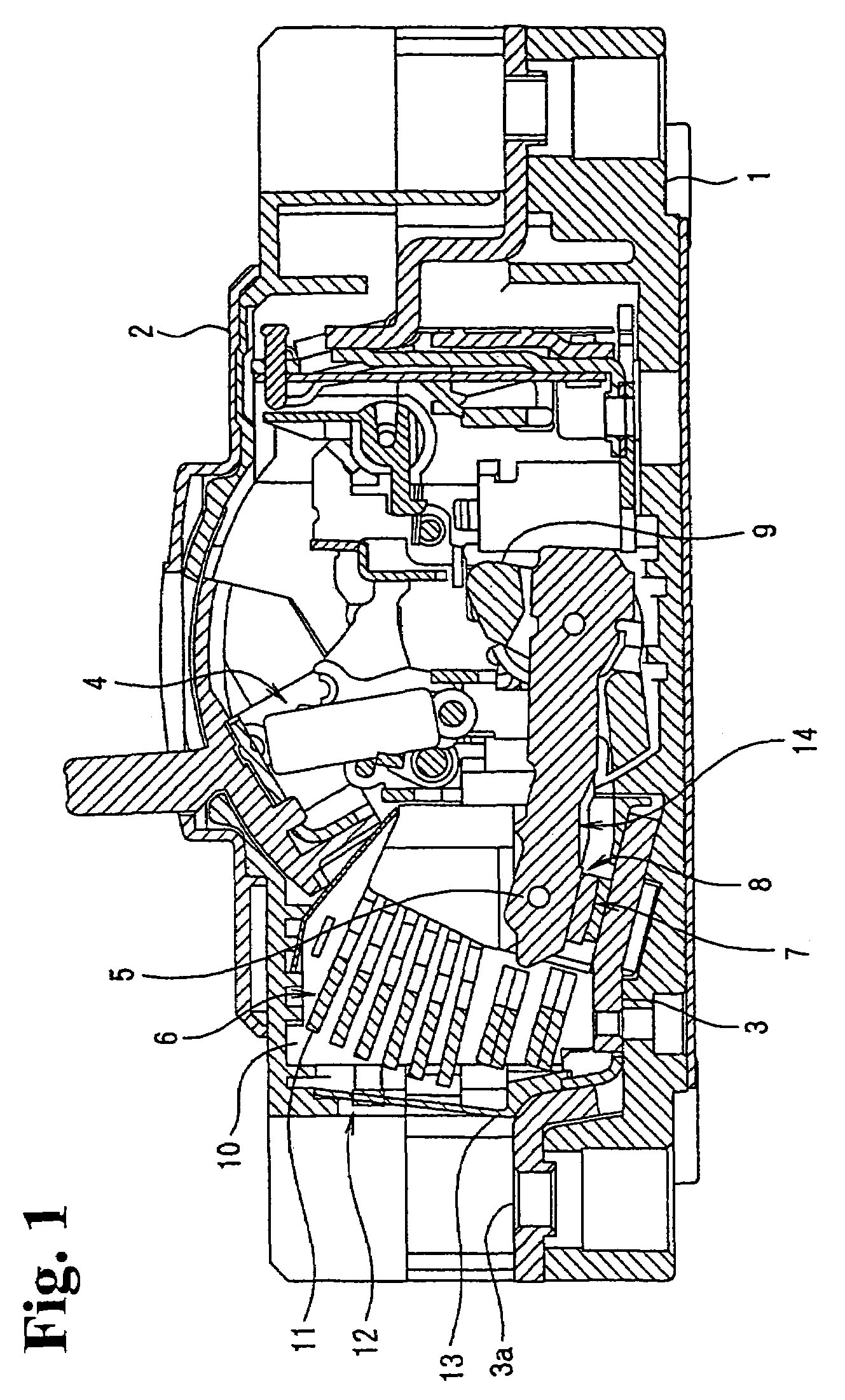

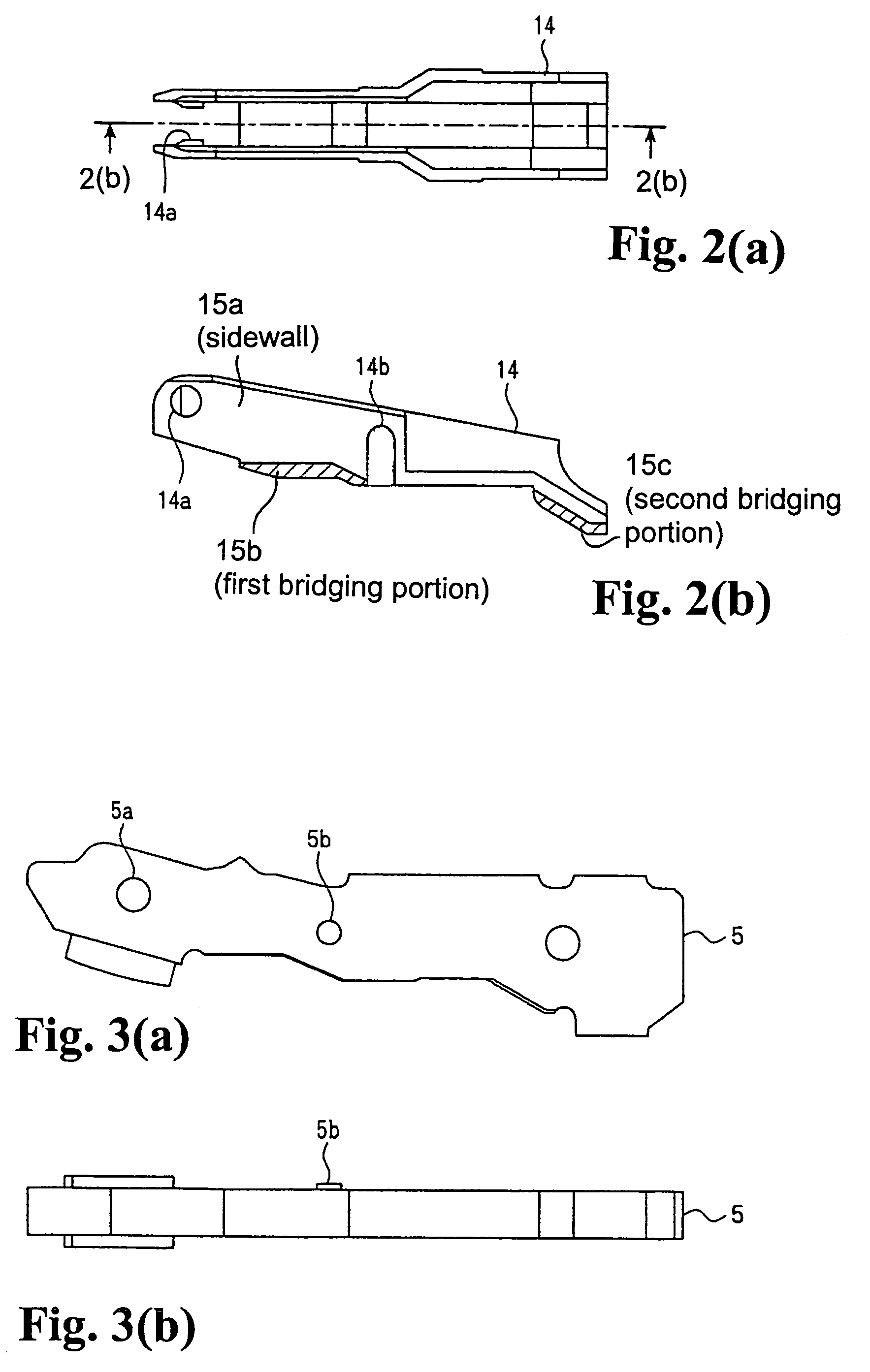

An impermeable rubber hose is thinned for the purpose of reducing weight and costs. A rigid resin film is used as an intermediate layer. When the resin film is gradually rolled up into a cylindrical shape from a planar shape and fed to an extrusion head and rubber is simultaneously extrusion-molded inside and outside the cylindrical film, the film produces a break or a twist to make extrusion molding difficult. It is an object of the present invention to make simultaneous extrusion molding possible even in such a condition.To attain the above object, a thermoplastic resin film (5) which forms an intermediate layer (2) and of which the melting point is lower than the vulcanizing temperature is formed in a long belt-shape. Slits (7) are provided at fixed intervals on the right and left long side sections (8, 8) of the film (5) in the longitudinal direction. When the resin film (5) is fed into an extrusion head (10) to be rolled up into a cylindrical shape, because both the long side sections (8, 8) of the film (5) are formed as weak sections by the slits (7), the film (5) adsorbs a strain when bent and is bent in a circle, thereby allowing the right and left long side sections (8, 8) to overlap at an overlapping section (6). In this condition, rubber is simultaneously extrusion-molded inside and outside the film and then, vulcanized to weld the overlapping section (6), thereby eliminating the slits (7).

Owner:YAMASHITA RUBBER CO LTD

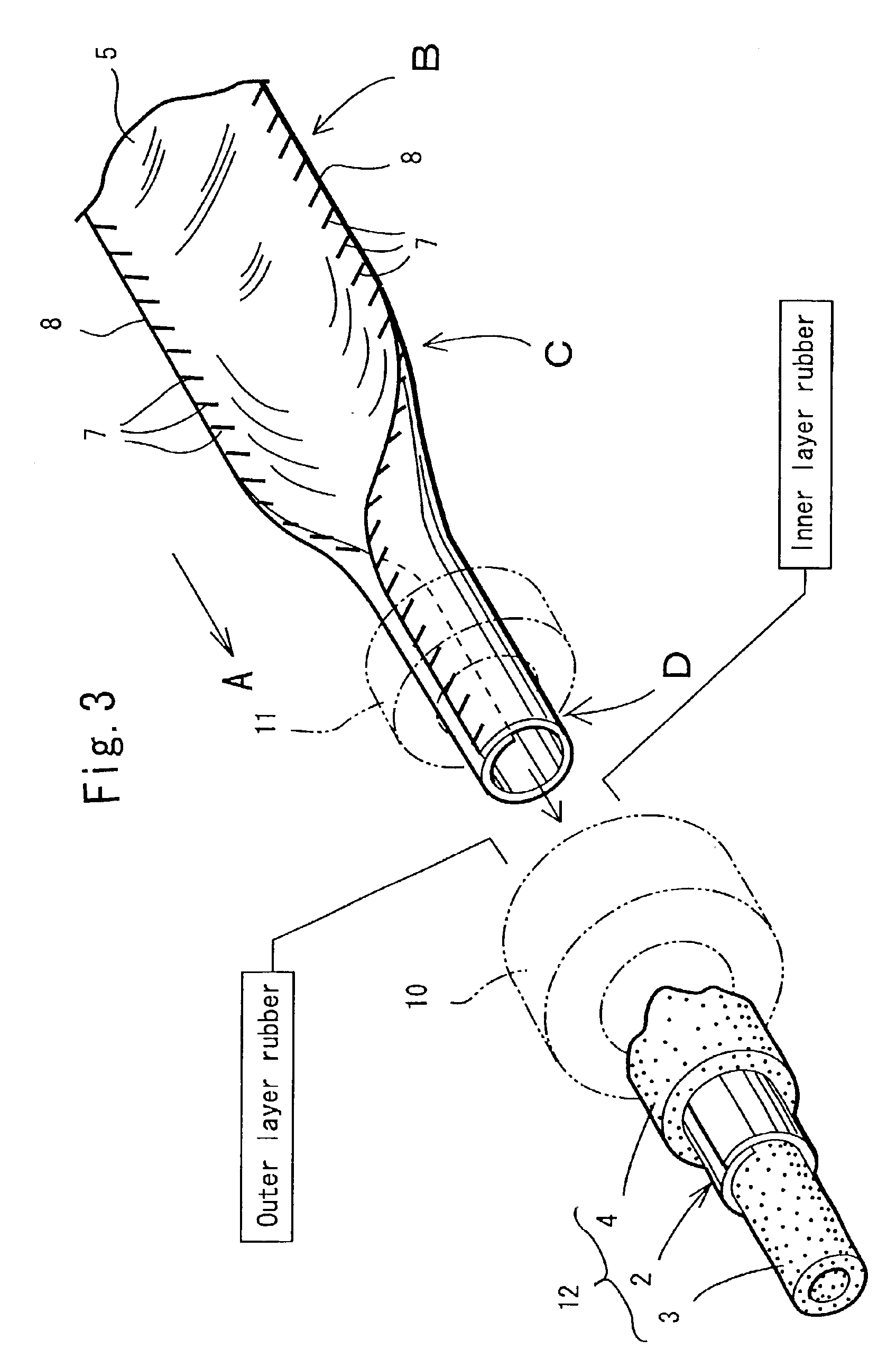

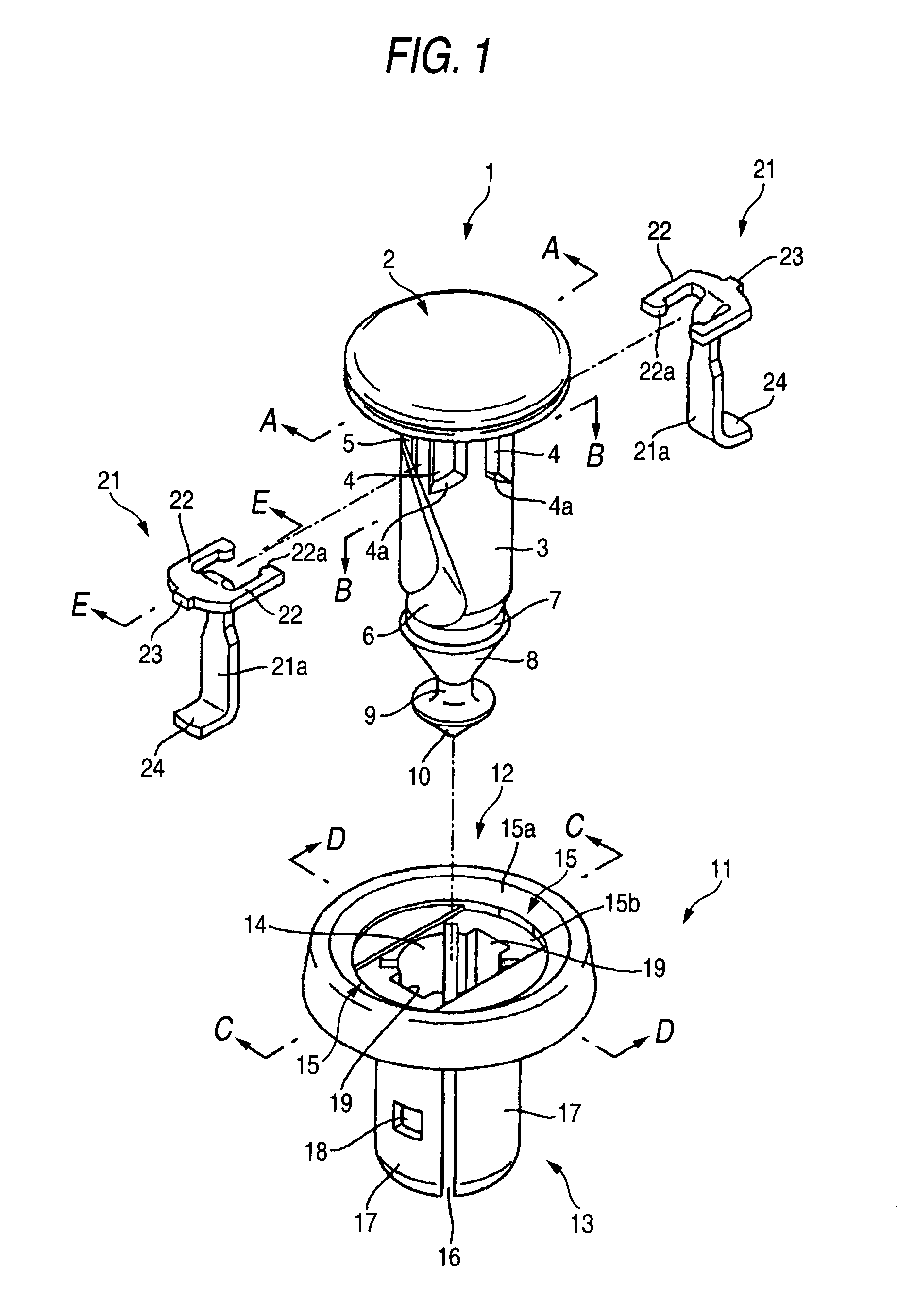

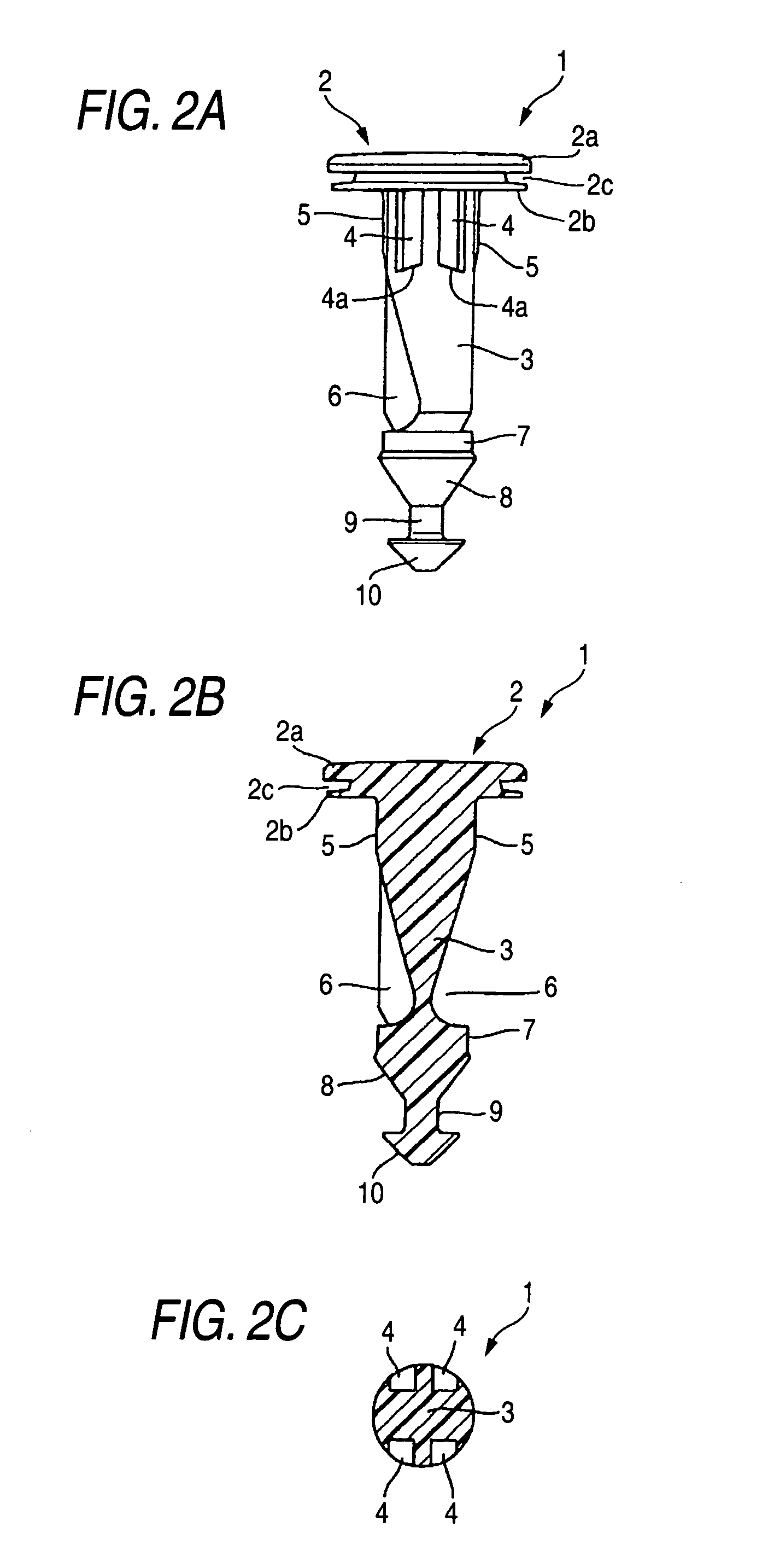

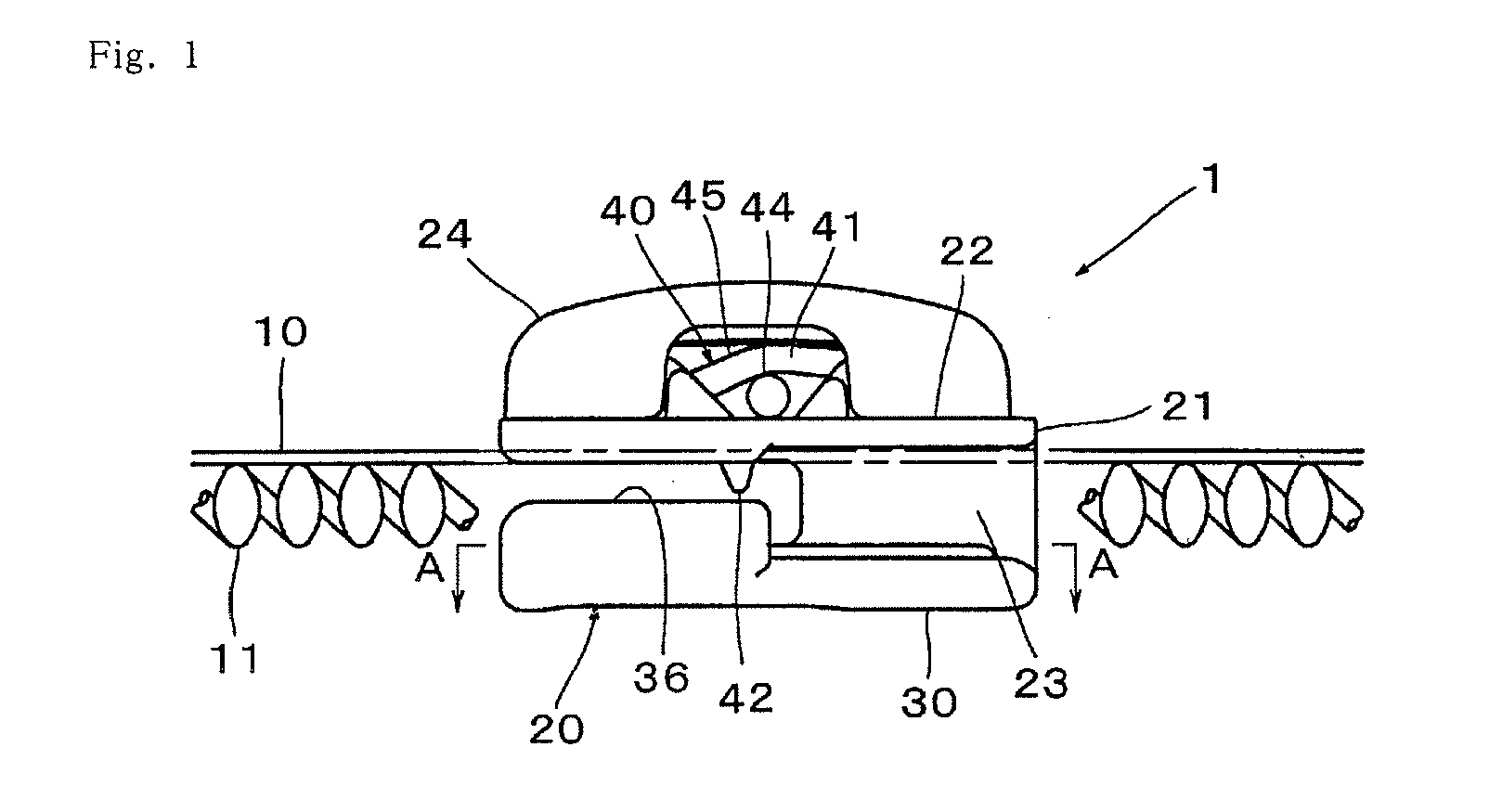

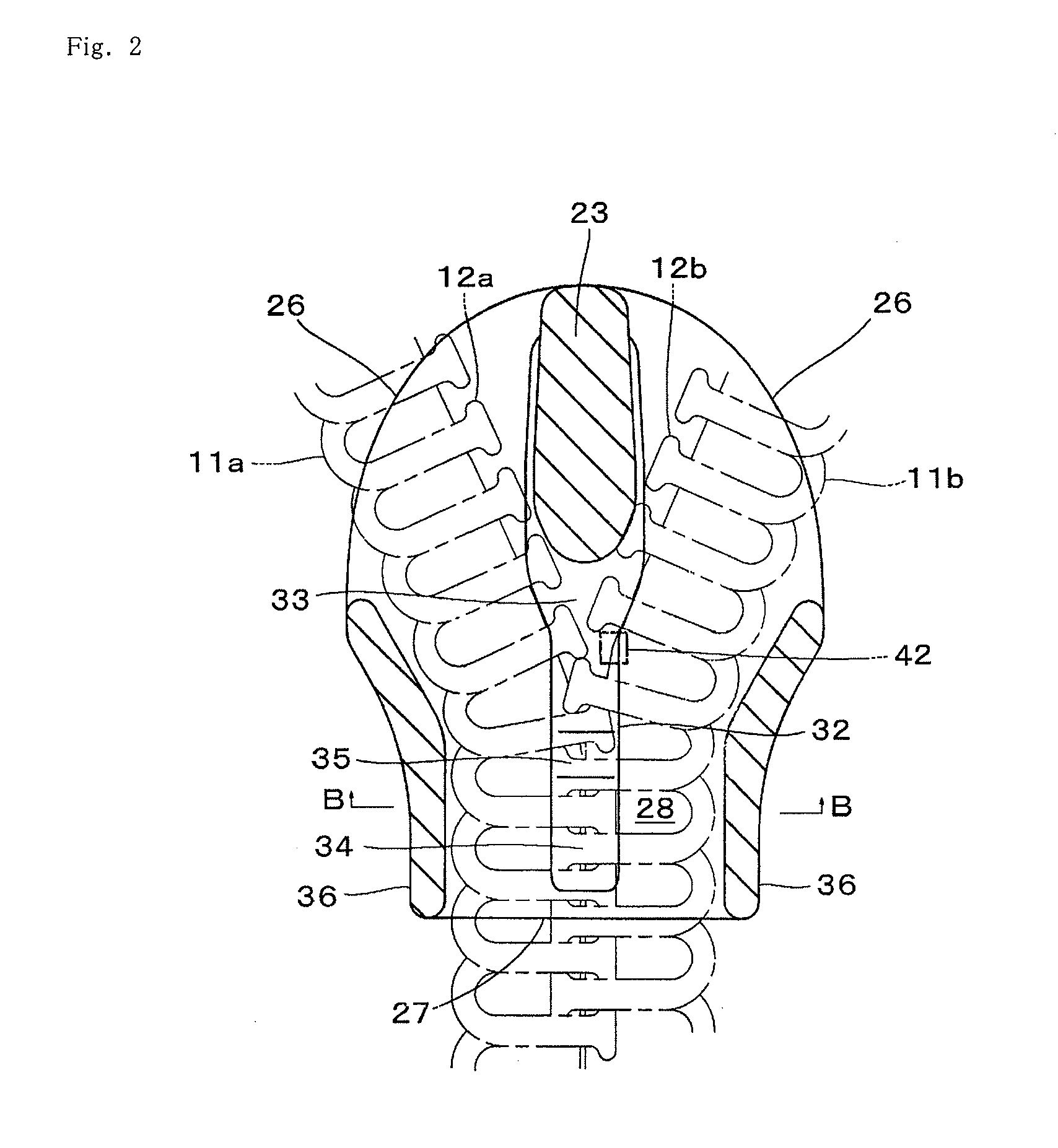

Fastener for fixing a part to a body panel

ActiveUS7607875B2Little strengthElastic bending of can easilySnap-action fastenersPicture framesGrommetFlange

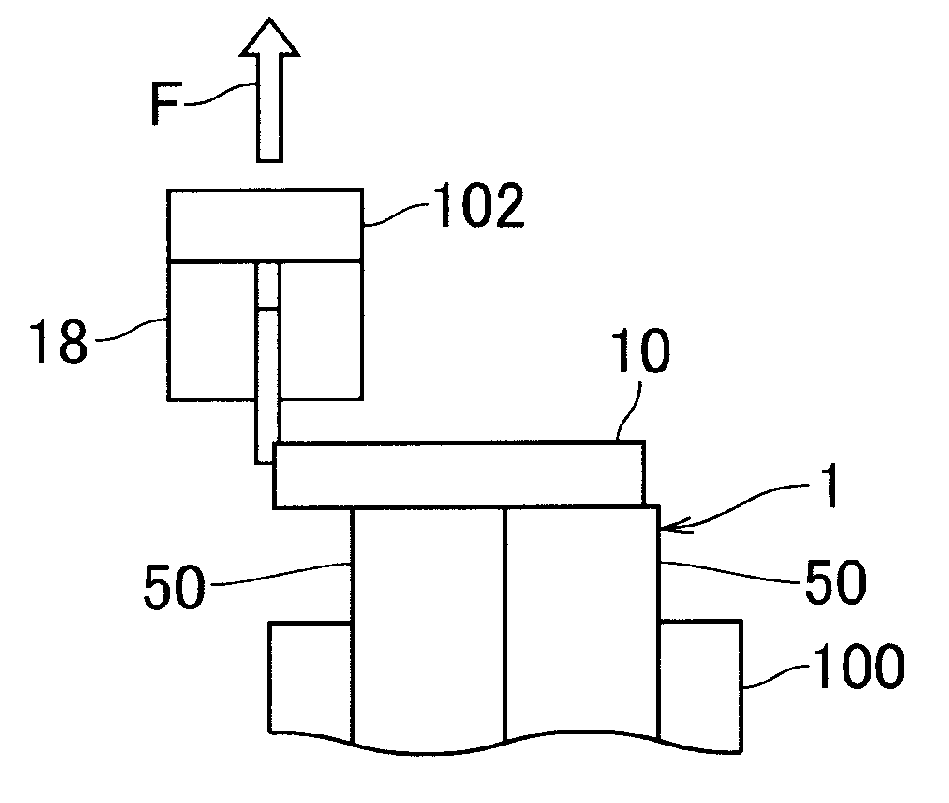

A fastener including a pin, a grommet and a pinching member, wherein the pin includes a head portion and a shaft portion, the grommet includes a flange portion and a barrel portion, and the pinching member includes an inward directed support arm and an outward directed pinching piece, the head portion includes a support portion for supporting the inward directed support arm of the pinching member, a containing chamber for containing a side of the outward directed pinching piece of the pinching member to direct in a direction of a center of the shaft portion and a press face for pressing outward the outward directed pinching piece of the pinching member at the shaft portion of the pin and forming an opening window for putting in and out the outward directed pinching piece of the pinching member at the barrel portion of the grommet.

Owner:PIOLAX CO LTD +1

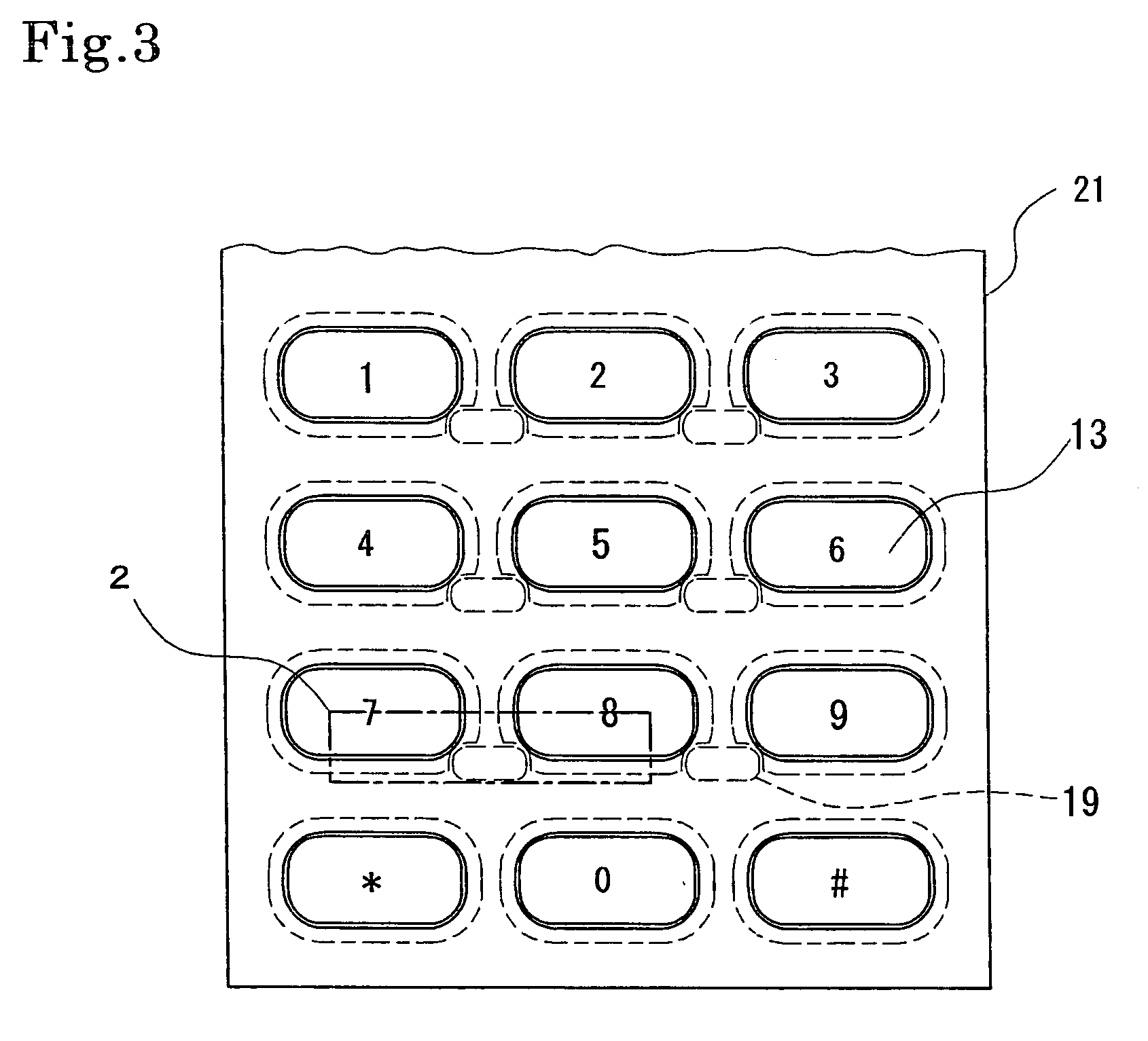

Key pad, resin key top injection mold, and resin key top manufacturing method

InactiveUS7014377B2Small sizeReduce thicknessMeasurement apparatus componentsLegendsEngineeringMechanical engineering

Owner:POLYMATECH CO LTD

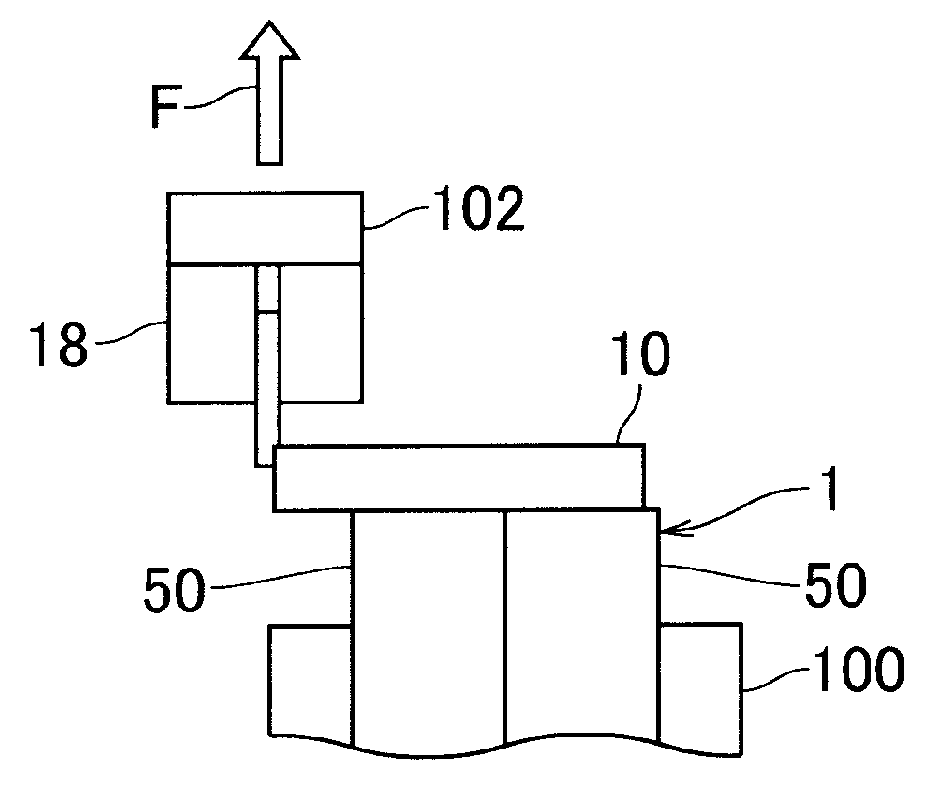

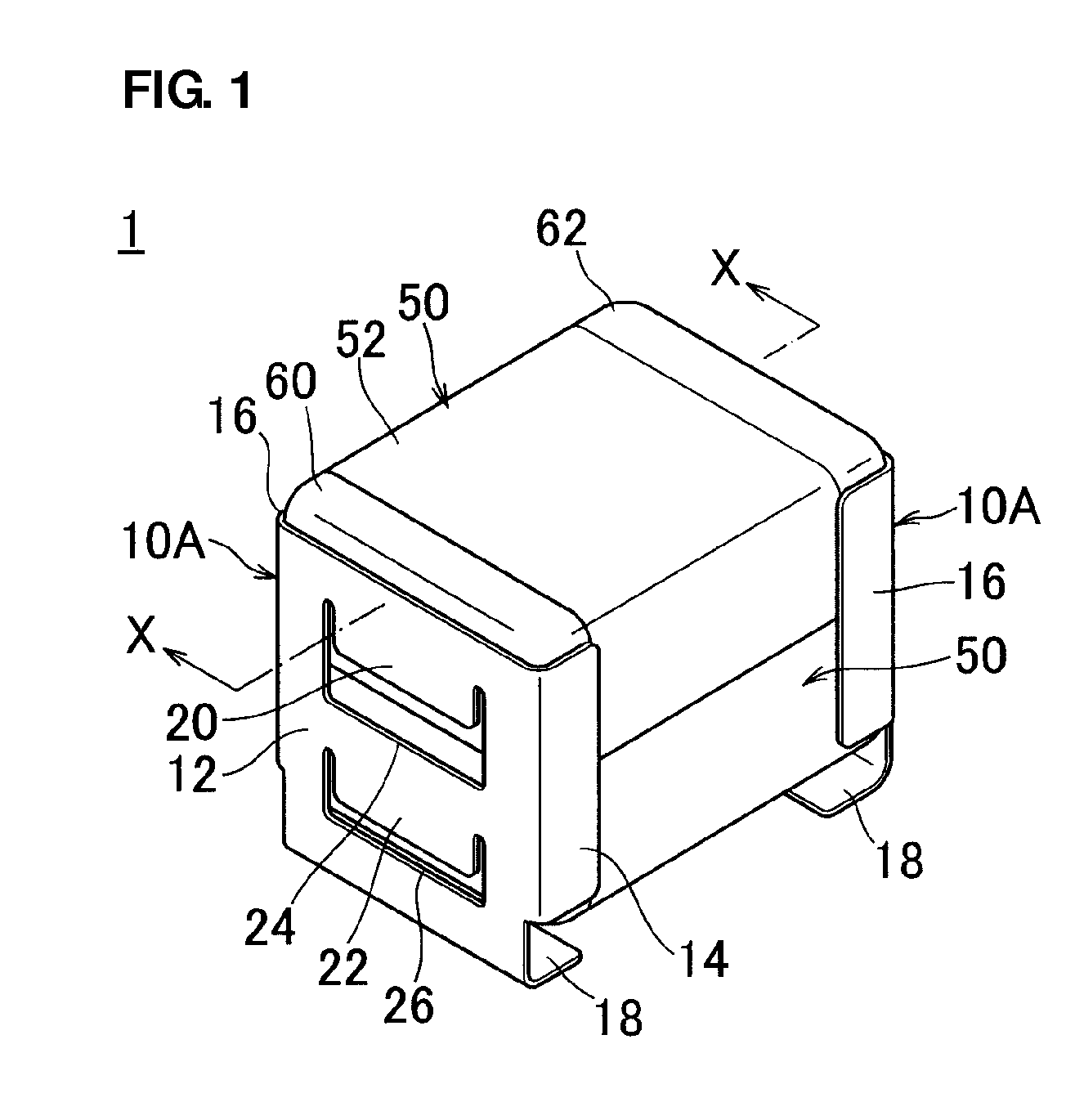

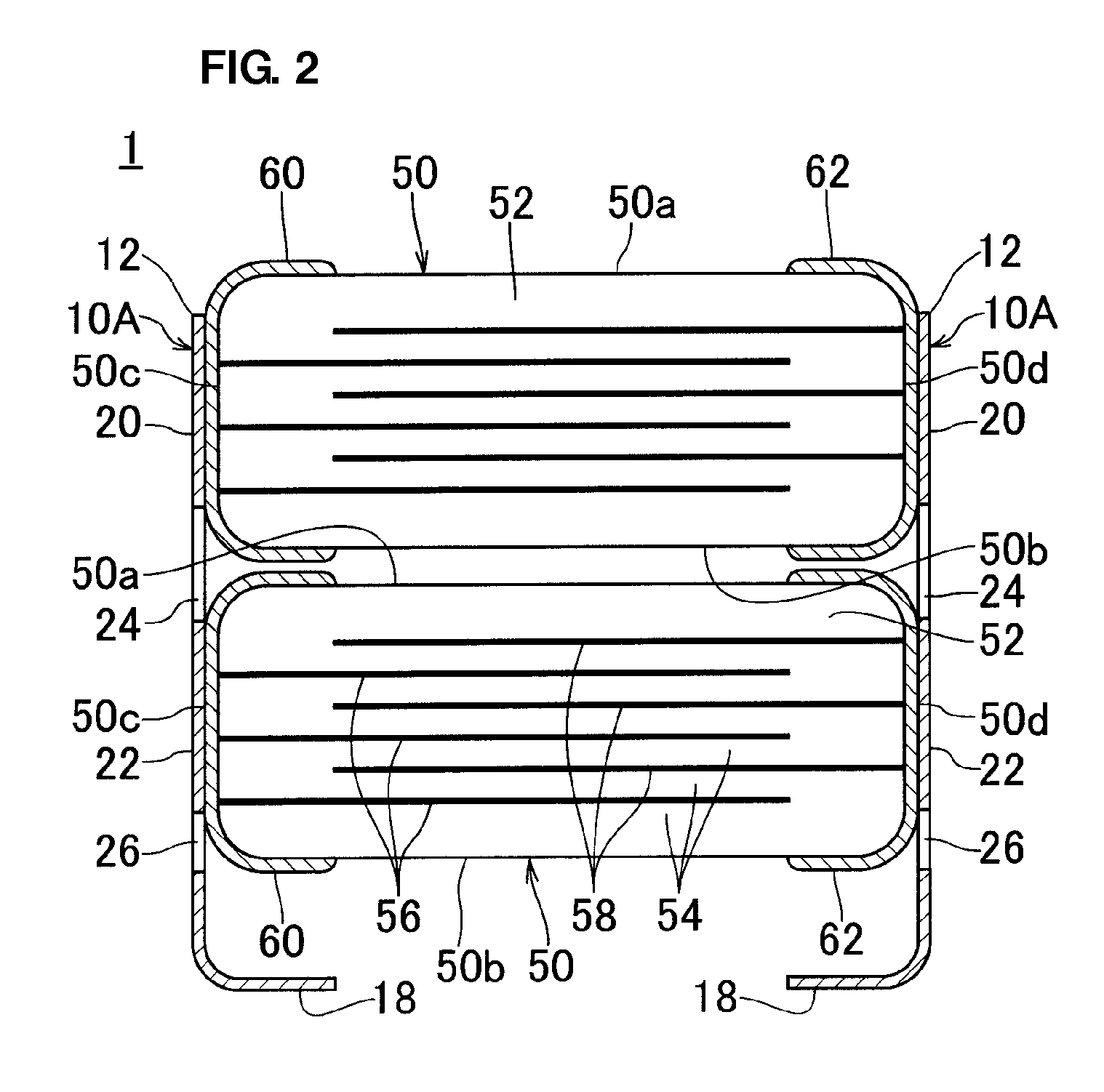

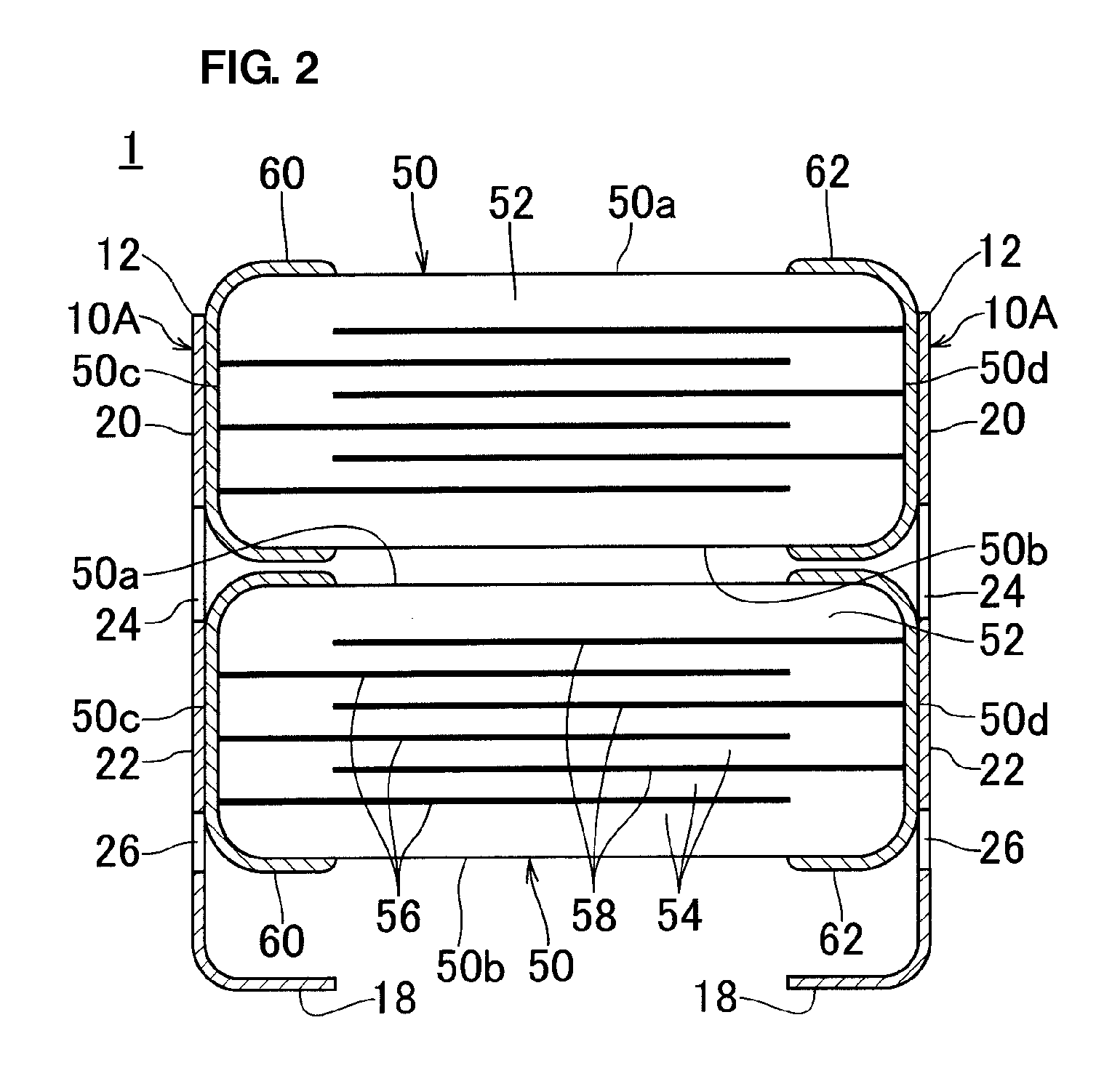

Ceramic electronic component

ActiveUS8570708B2Improve rigidityLow mechanical strengthMultiple fixed capacitorsFixed capacitor electrodesElectronic componentElectrode

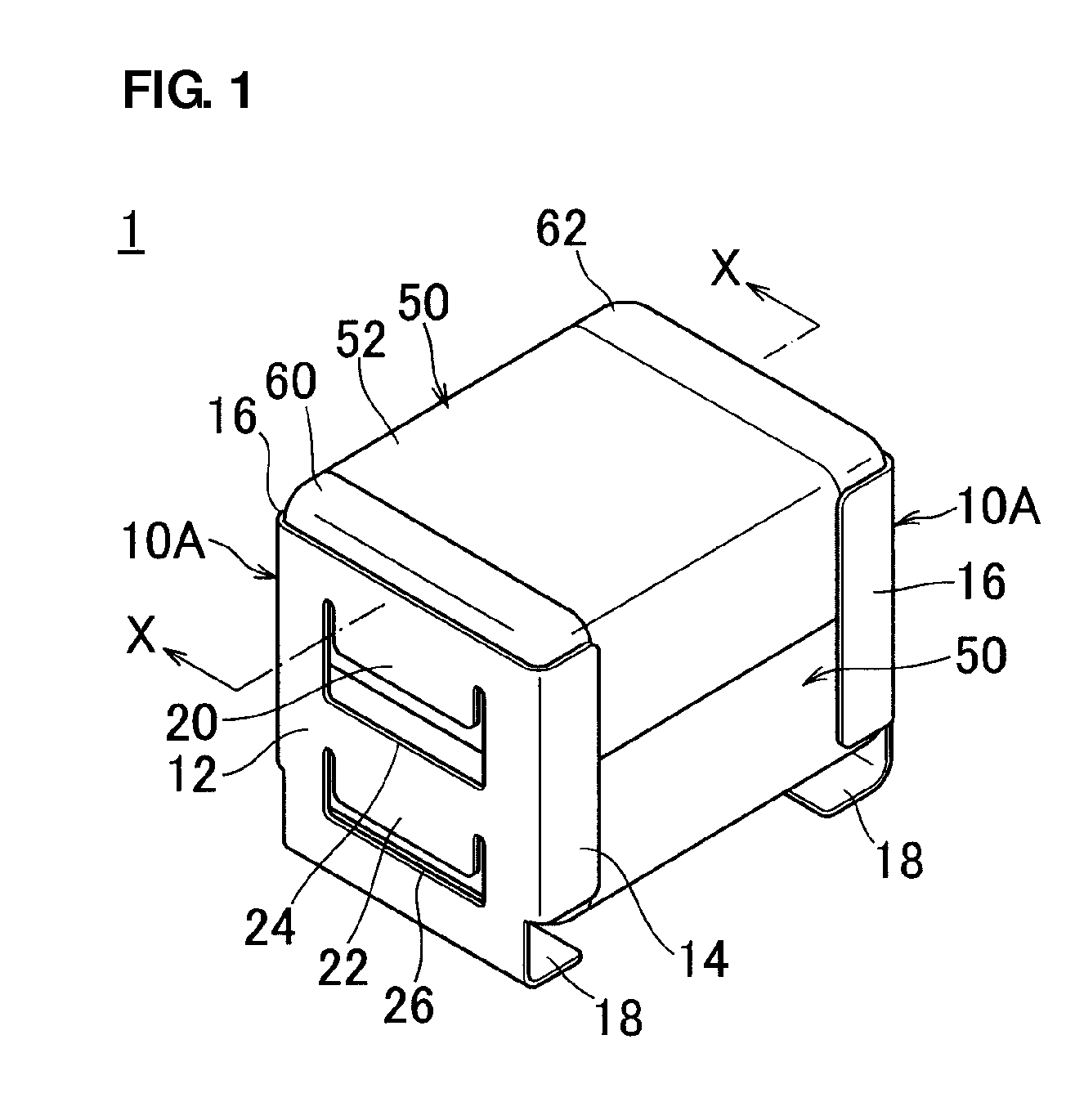

A ceramic electronic component includes two electronic-component main bodies and two metal terminals. Each of the metal terminals includes a base, ribs on left and right sides of the base, and a mounting portion below the base. The base includes two bonding portions to be bonded to respective external electrodes of the two electronic-component main bodies and cut-out portions each having a closed shape and being disposed below the respective bonding portions. The ribs are bent from the left and right sides of the base in the width direction toward the electronic-component main body. The ribs extend from the top of the base in the height direction to the vicinity of the mounting-side major surface of the mounting-side electronic-component main body and do not reach the mounting portion. The mounting portion is bent from the bottom of the base toward the electronic-component main body.

Owner:MURATA MFG CO LTD

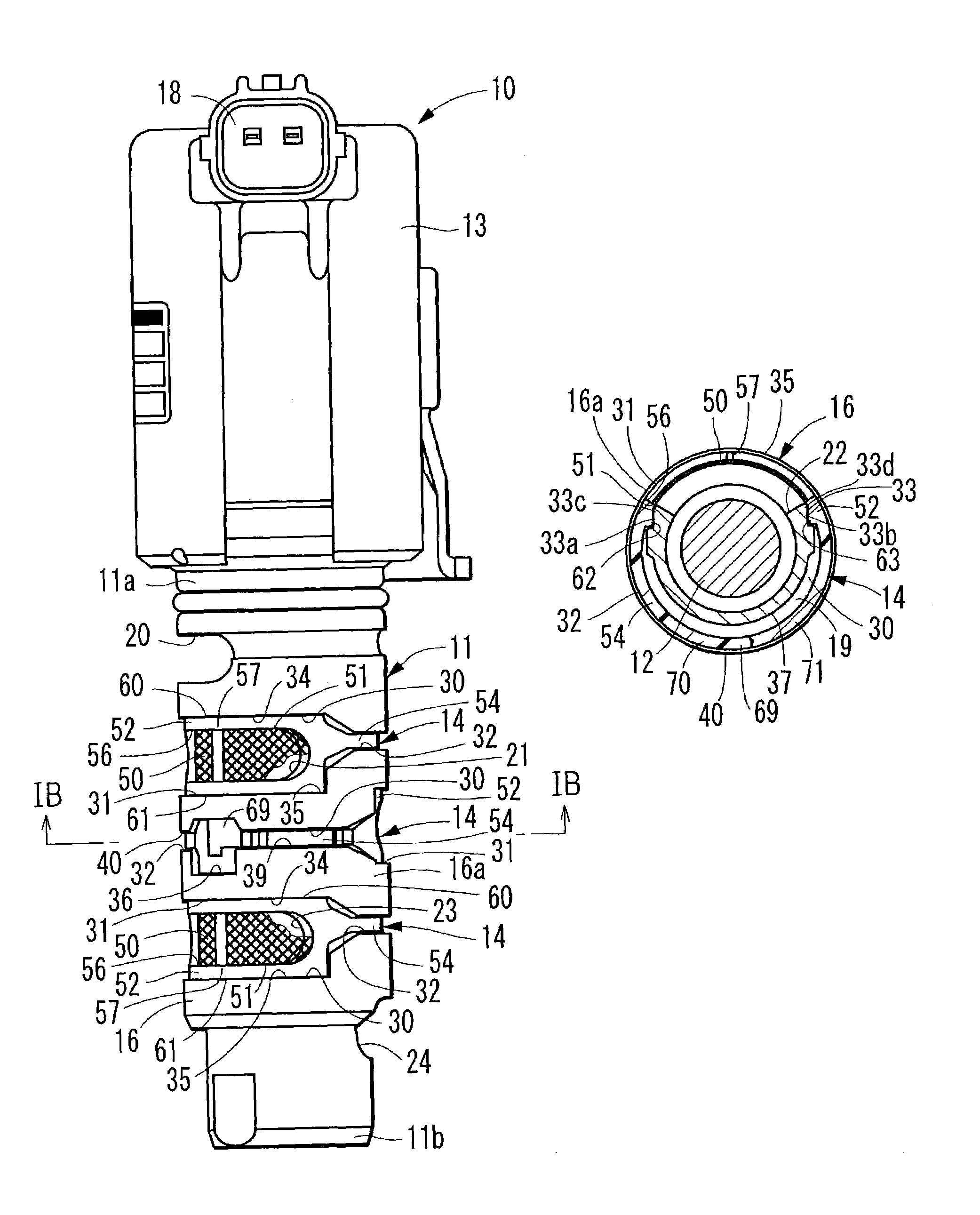

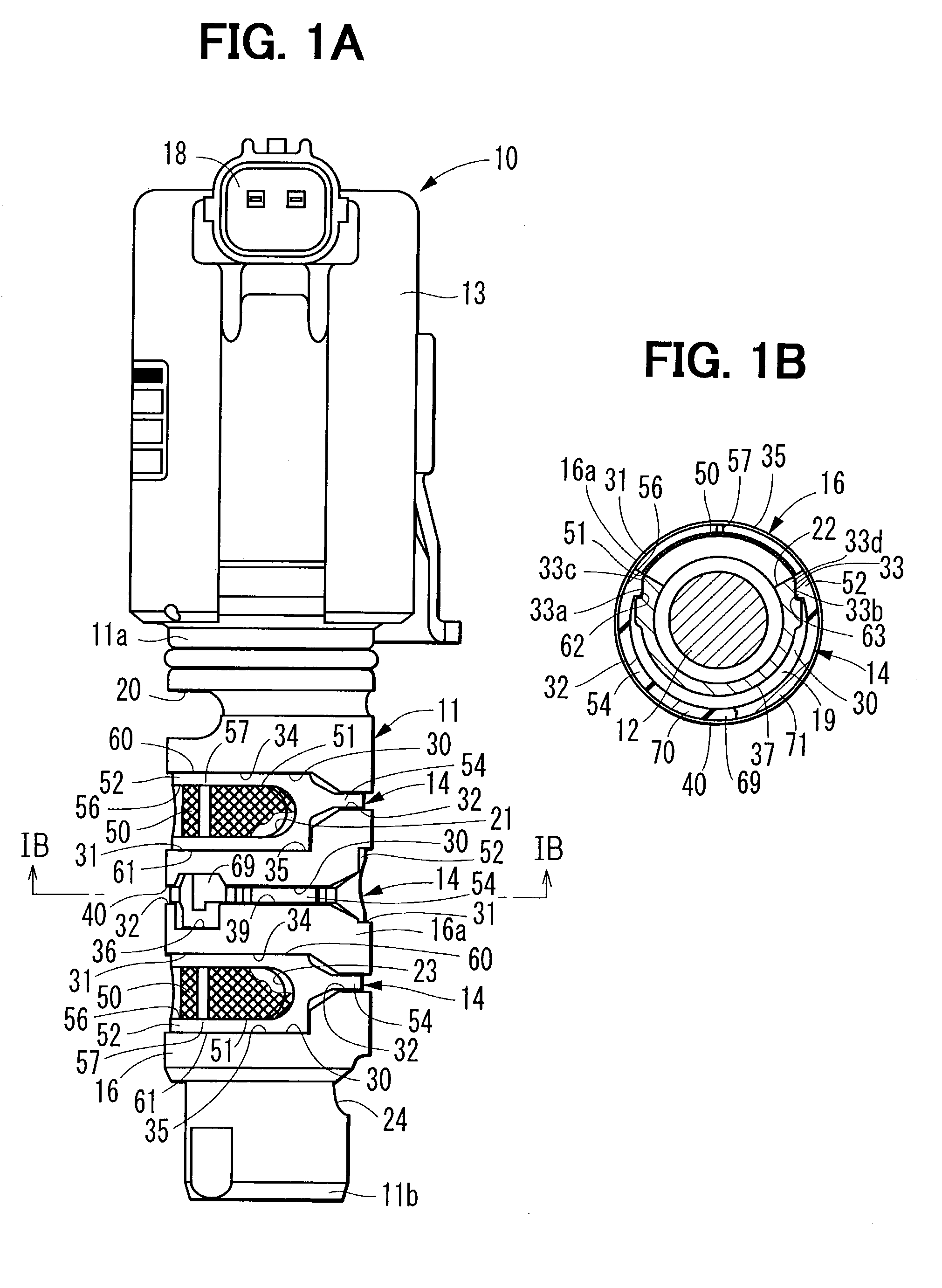

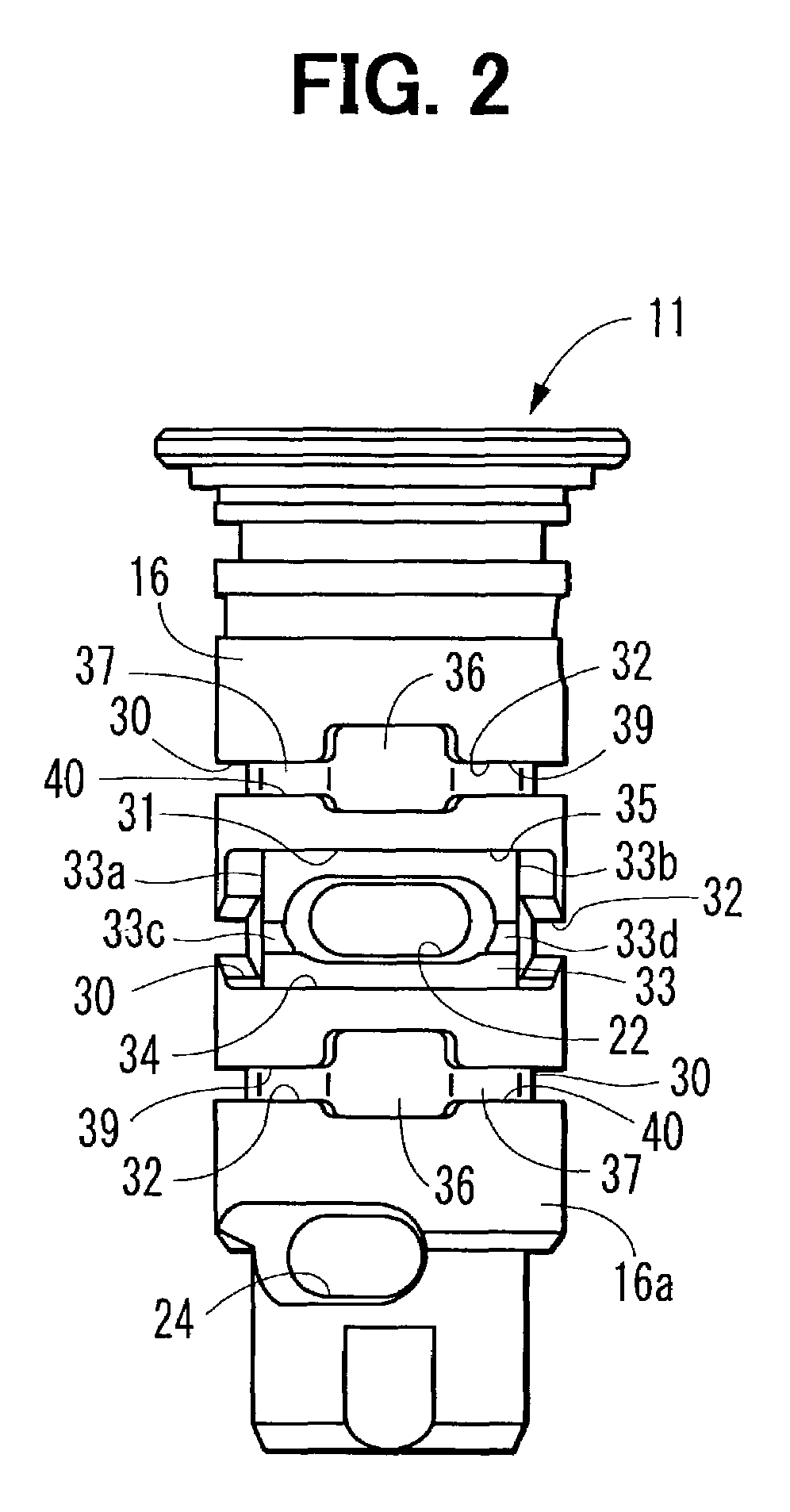

Flow amount control device

ActiveUS7000633B2Inhibit entryNarrow widthMachines/enginesService pipe systemsEngineeringMechanical engineering

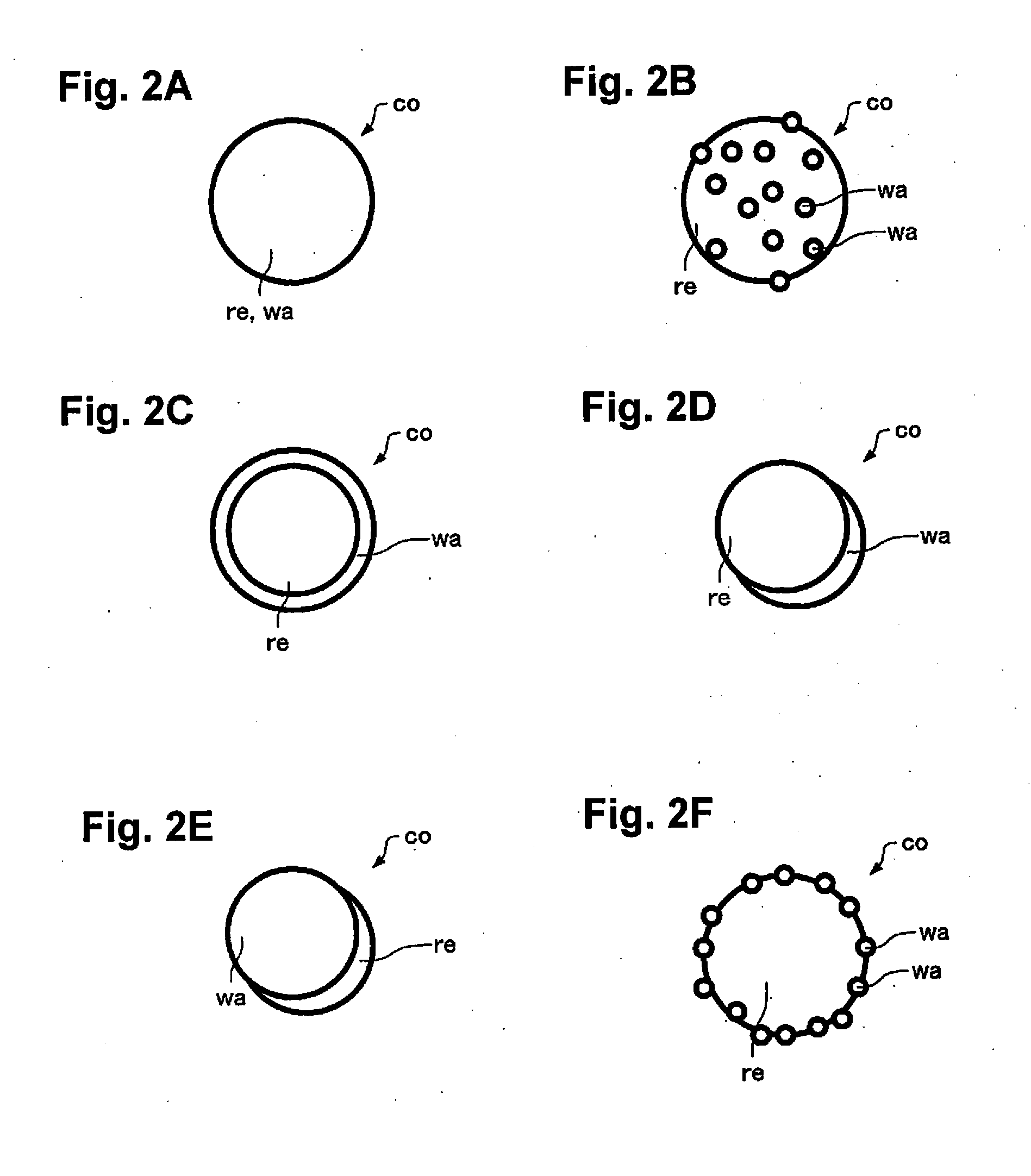

A filter is annularly attached around a peripheral wall of a housing. The filter is composed of a filtering element that covers a fluid passage for inhibiting foreign objects from entering, a supporting portion for supporting the filtering element, and a connecting portion for connecting between both ends of the supporting portion. The connecting portion is narrower than the supporting portion. The filter is movable radially in two directions according to a clearance between the filter and the housing. A contact portion is formed, with being able to be slid within a movable range of the filter, between an outer surface portion of the peripheral wall that surrounds an opening of the fluid passage and an inner surface portion of the filter that surrounds the filtering element.

Owner:DENSO CORP

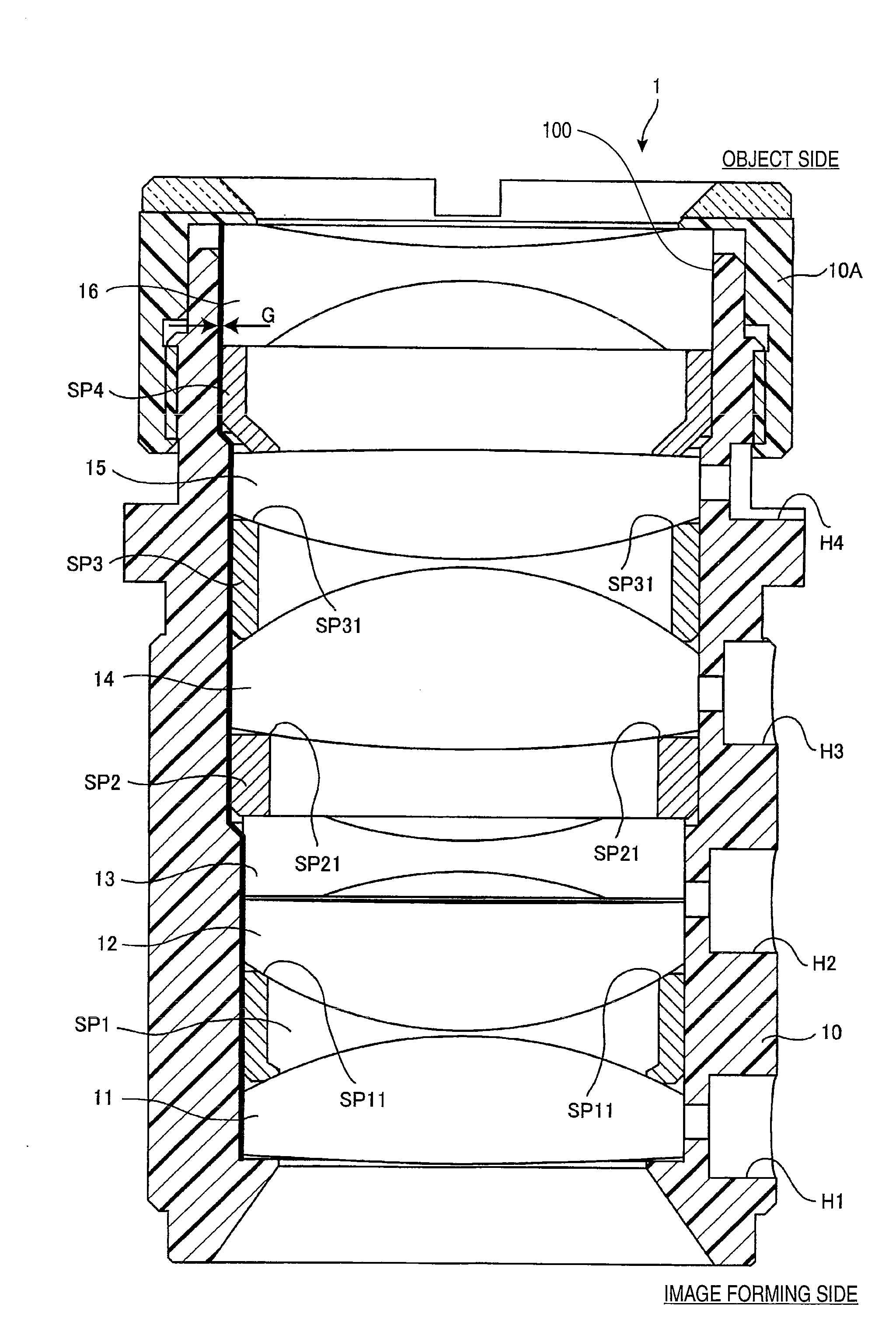

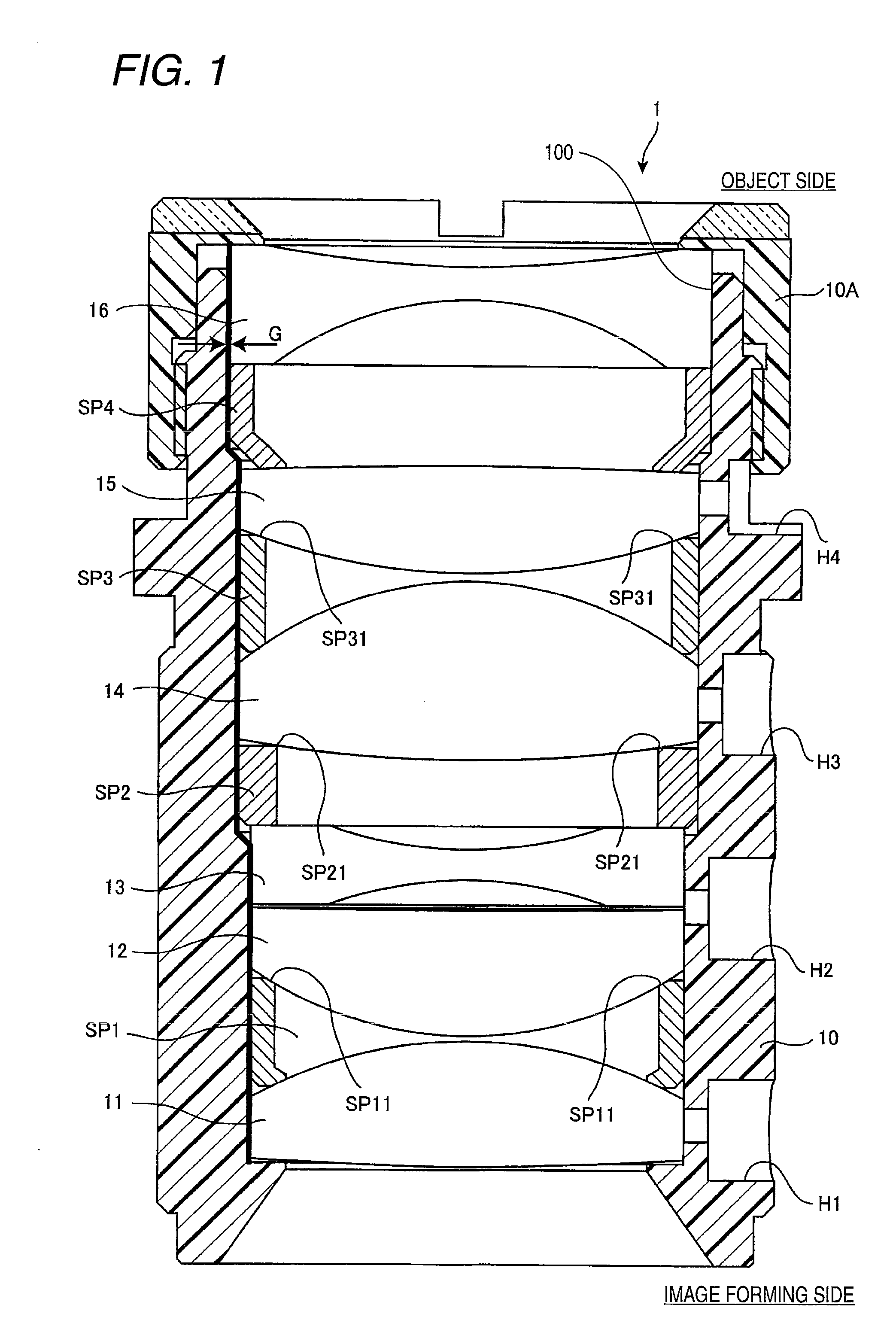

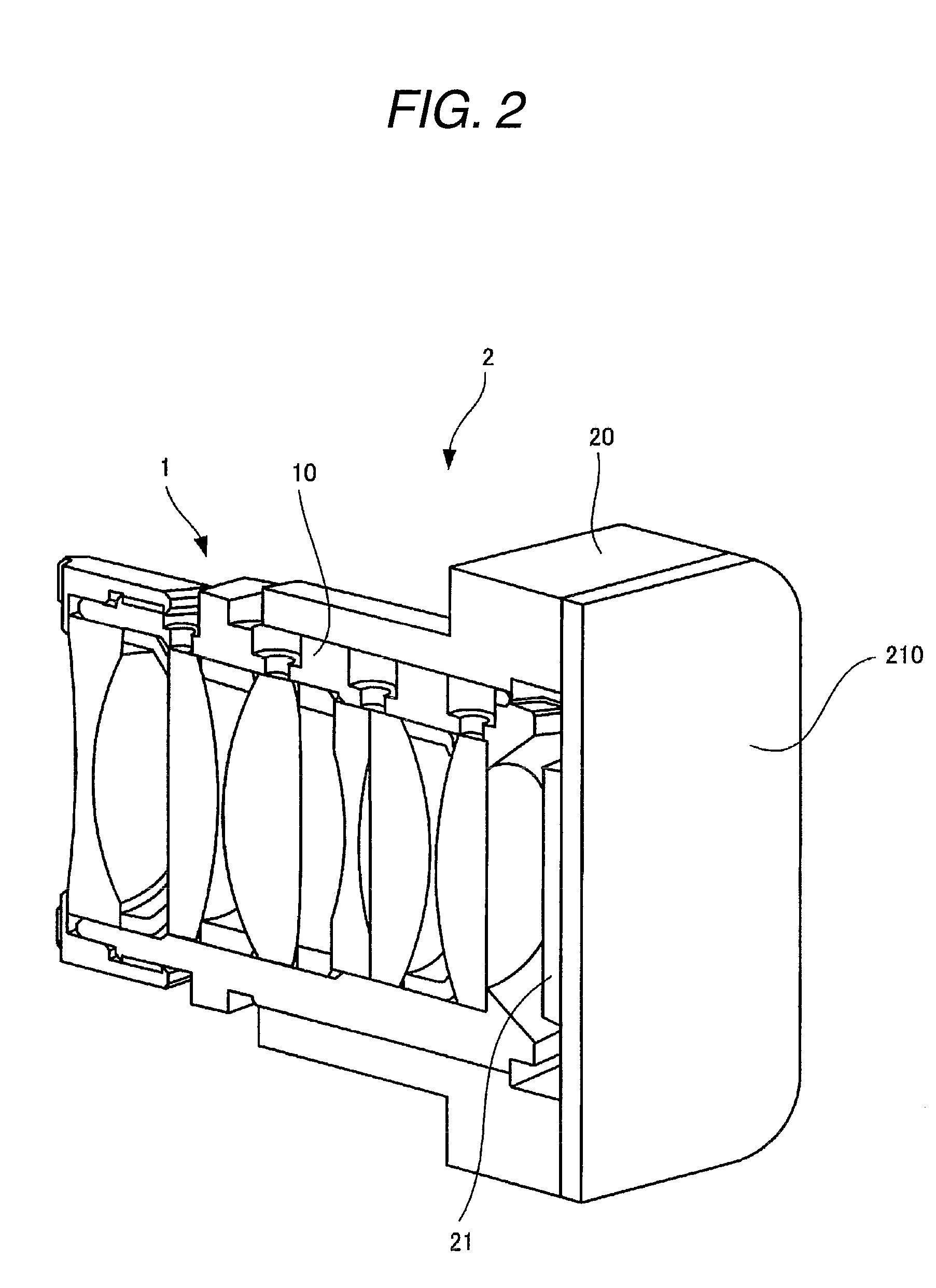

Lens assembly and imaging device

ActiveUS20090244726A1High bonding strengthAvoid easy detachmentMountingsCamera lensImaging equipment

A lens assembly is provided and includes: a lens frame; and a lens frame having a hollow part into which the lens is inserted. The lens frame has a bonding hole into which an adhesive agent is injected for bonding and fixing to the lens frame the lens inserted into the lens frame and which passes through an outer wall of the lens frame and an inner wall of the hollow part.

Owner:NANCHANG O FILM OPTICAL ELECTRONICS TECH CO LTD

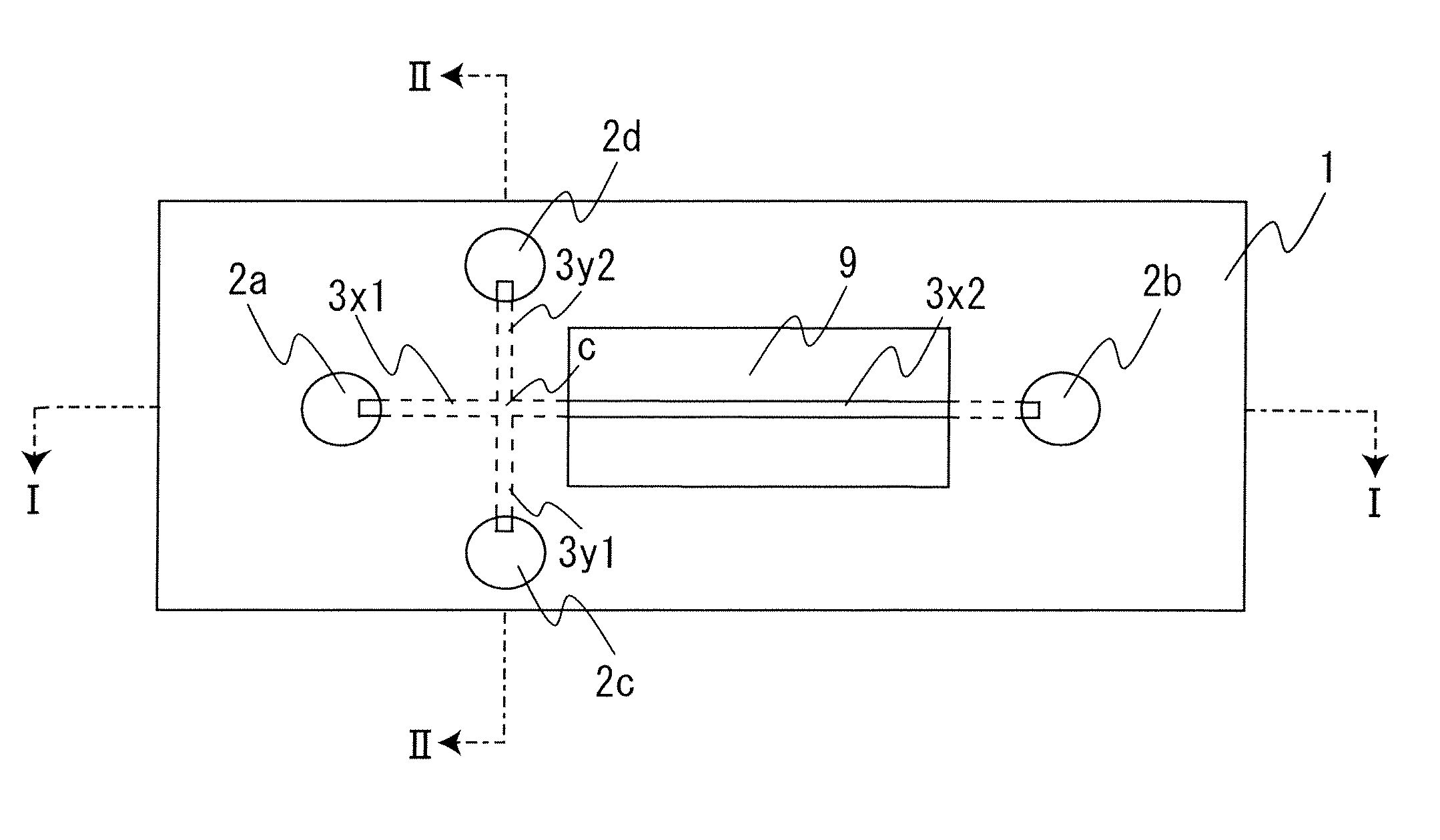

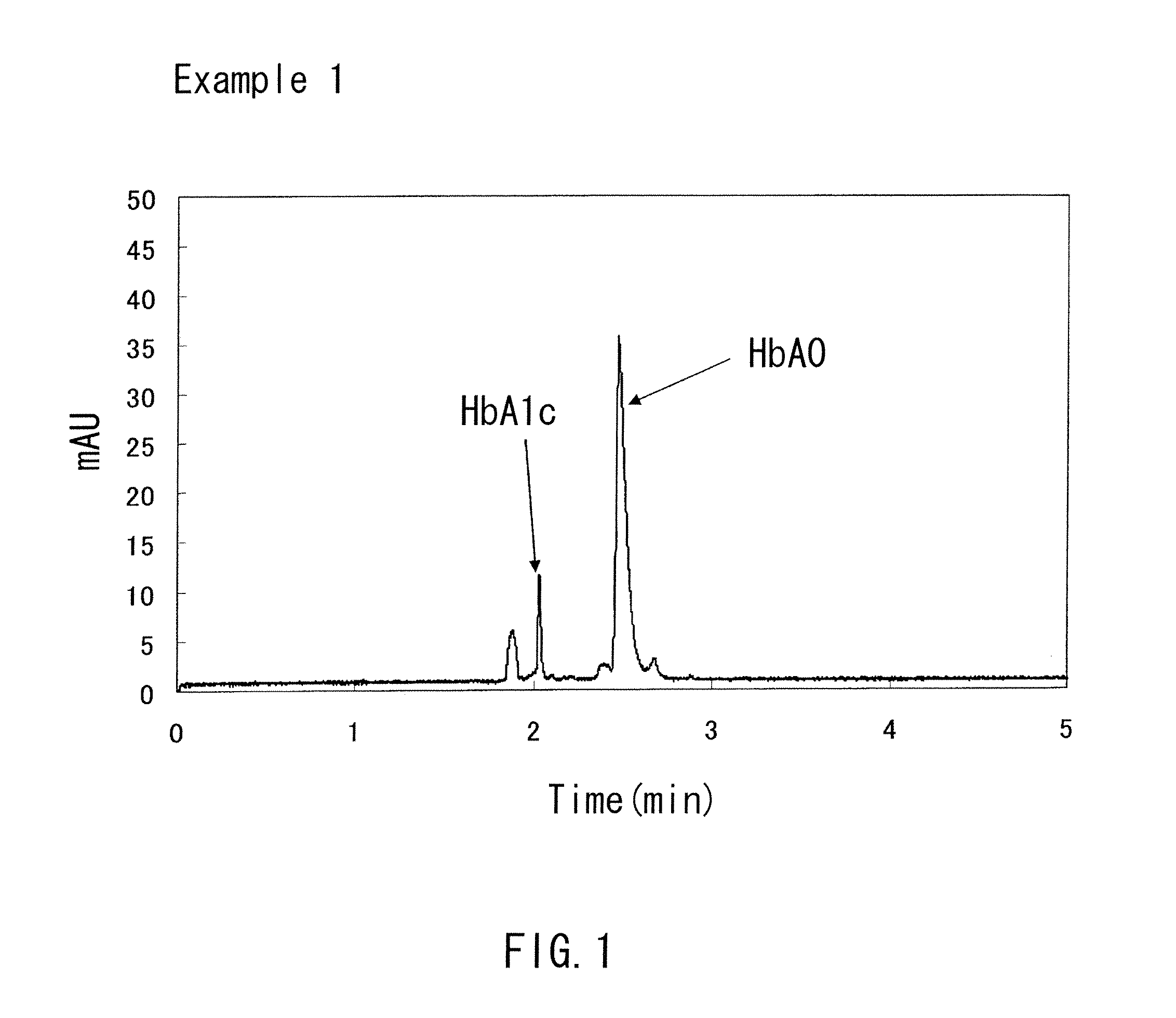

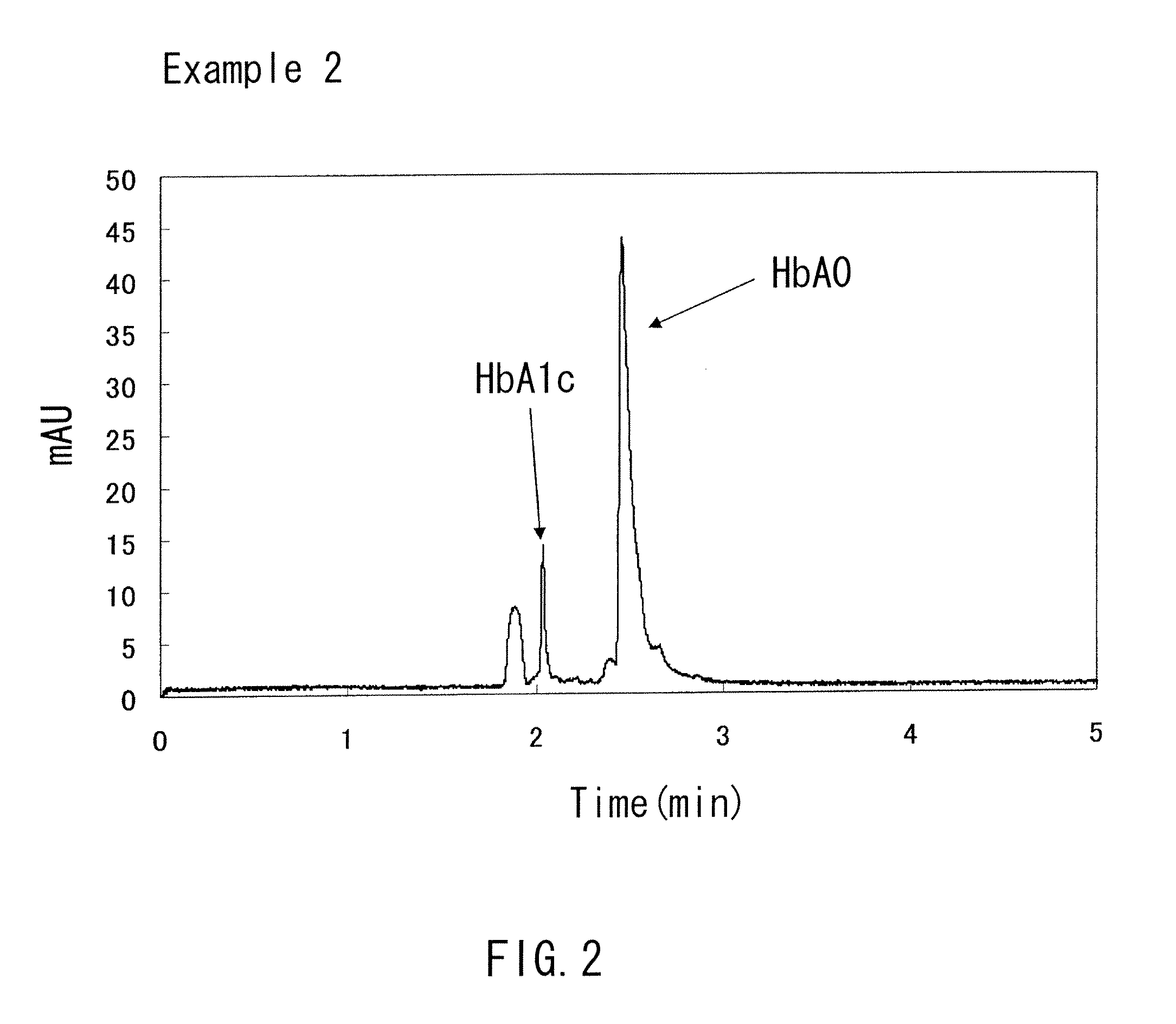

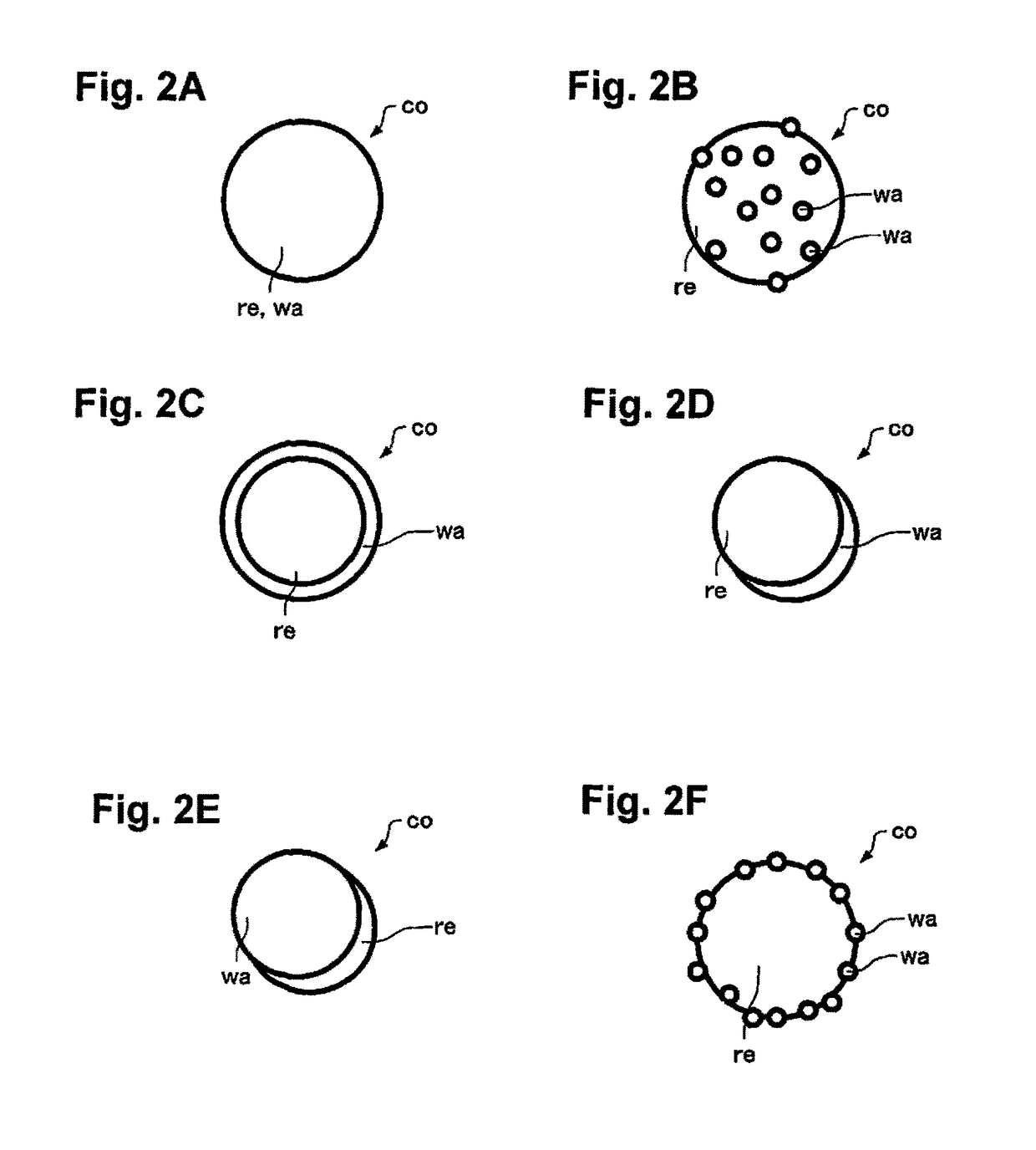

Process for analyzing sample by capillary electrophoresis method

ActiveUS20100175996A1Good electroosmotic flowHigh separationSludge treatmentVolume/mass flow measurementCompound (substance)Covalent bond

A process for analyzing a sample by a capillary electrophoresis method is provided that allows the apparatus to be reduced in size, allows a high analytical precision to be obtained, and can be carried out easily. The analytical process of the present invention is a process for analyzing a sample by a capillary electrophoresis method. The process includes a step of preparing a capillary channel to be used for the capillary electrophoresis method and a step of electrophoresing a complex of a sample and an anionic group-containing compound that are bonded together, in the capillary channel, wherein the capillary channel includes an A layer that is coated on an inner wall thereof and a B layer that is coated on the A layer.A layer: a spacer layer formed of at least one selected from the group consisting of polydiallyldimethylammoniumchloride, a nonpolar polymer, and a cationic group-containing compound, wherein the polydiallyldimethylammoniumchloride is coated on the inner wall of the capillary channel by physical adsorption when the layer includes the polydiallyldimethylammoniumchloride, and at least one of the nonpolar polymer and the cationic group-containing compound is coated on the inner wall of the capillary channel by covalent bond when the layer includes at least one of the nonpolar polymer and the cationic group-containing compoundB layer: an anionic layer formed of an anionic group-containing compound

Owner:NAT INST OF ADVANCED IND SCI & TECH +1

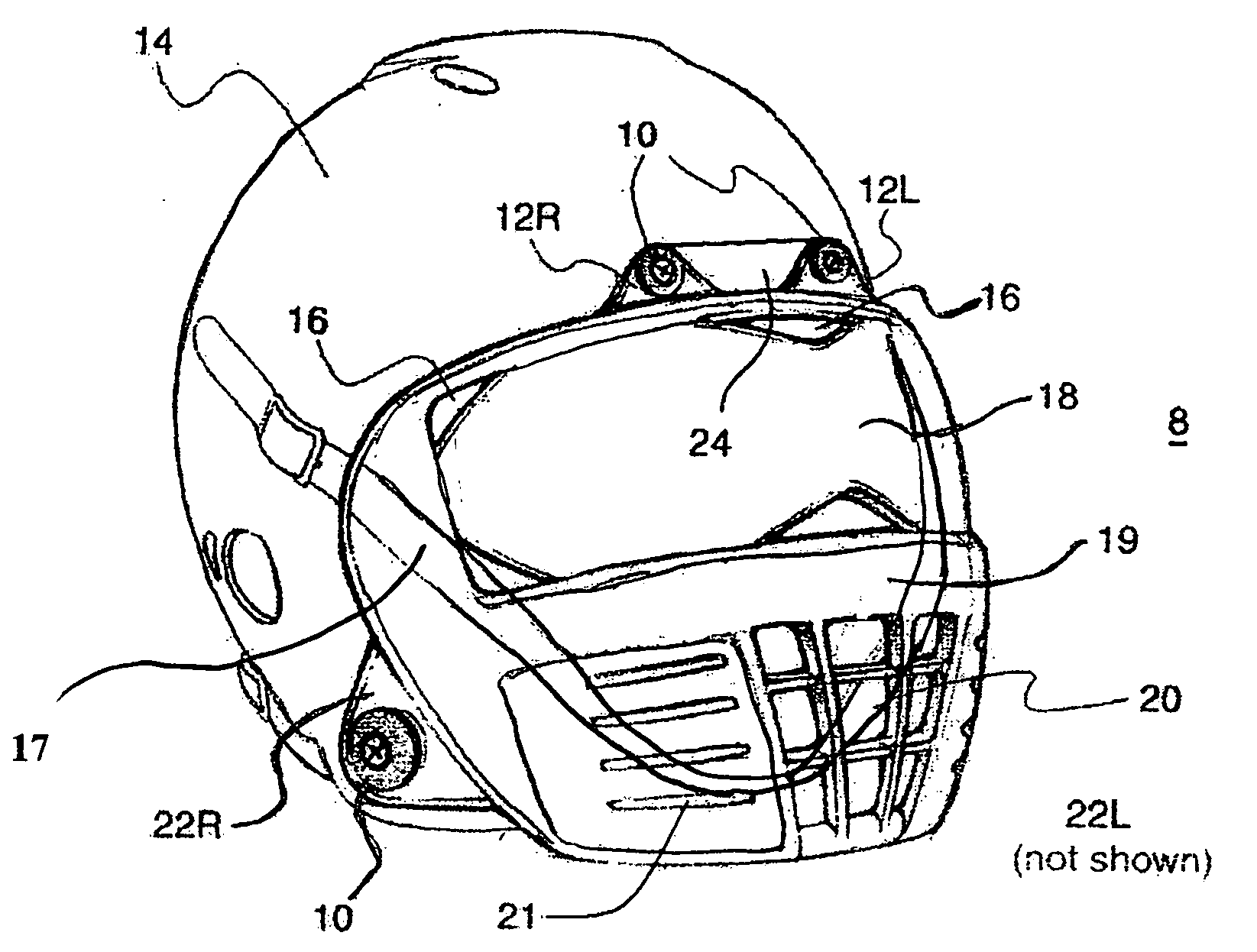

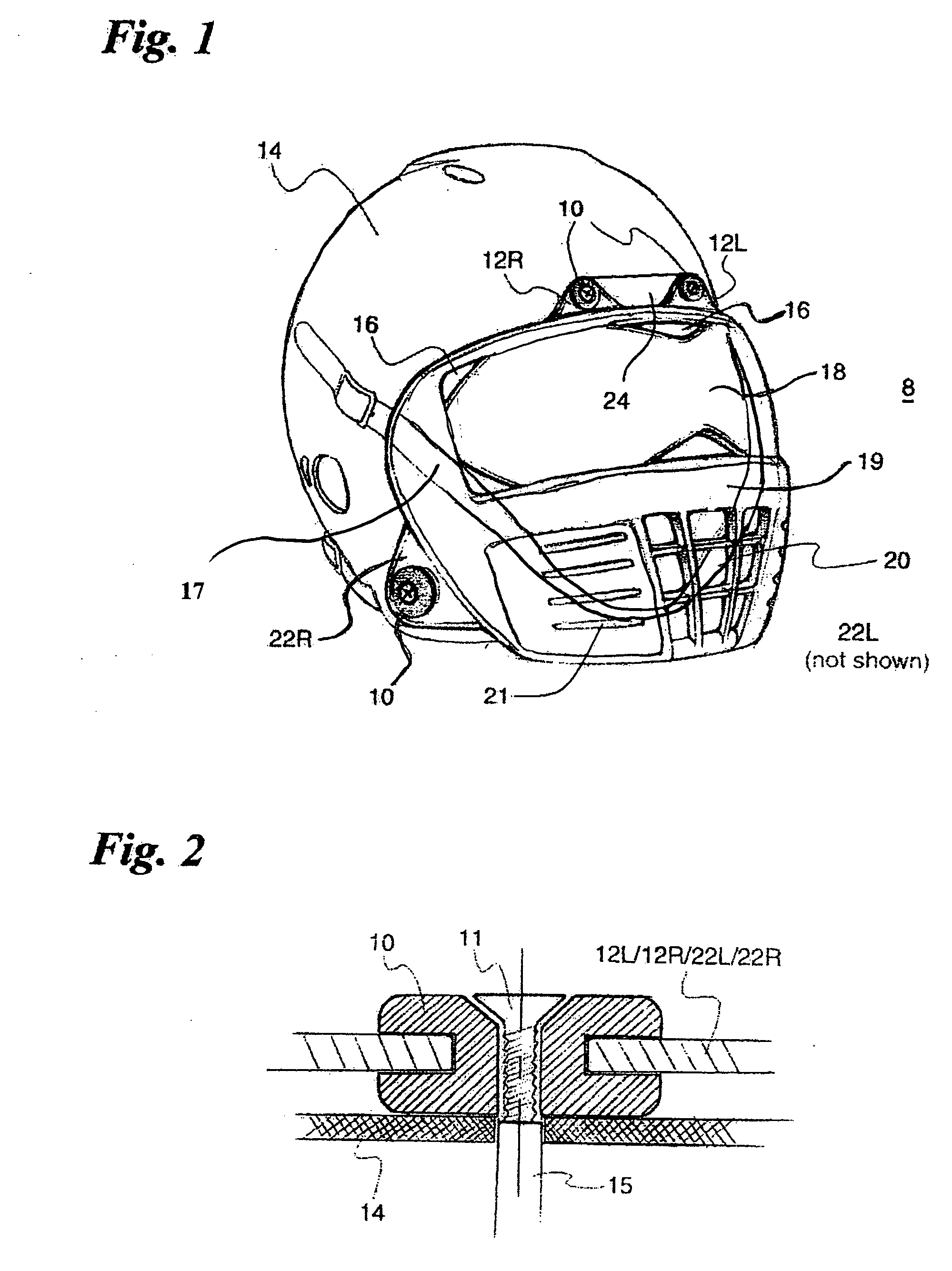

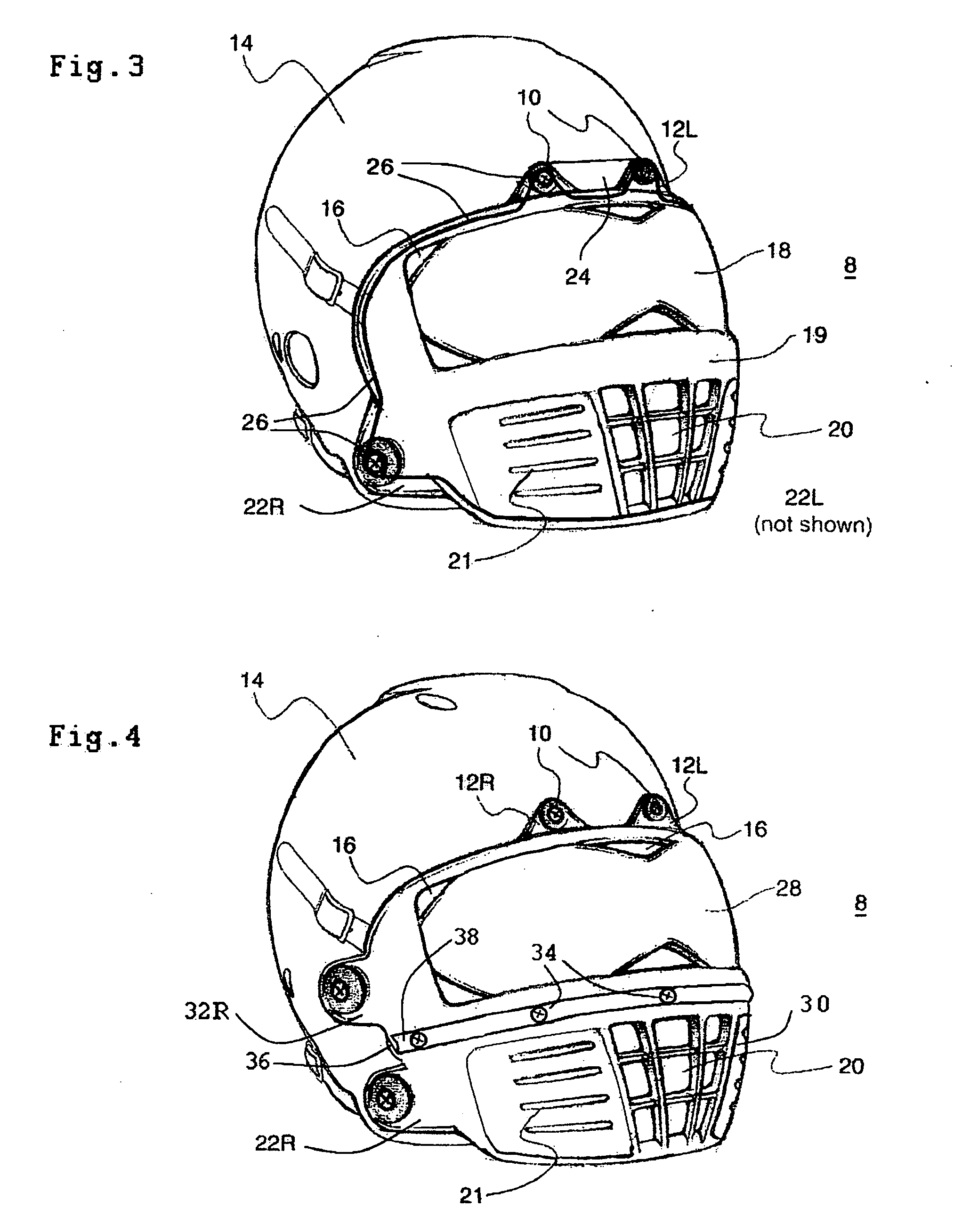

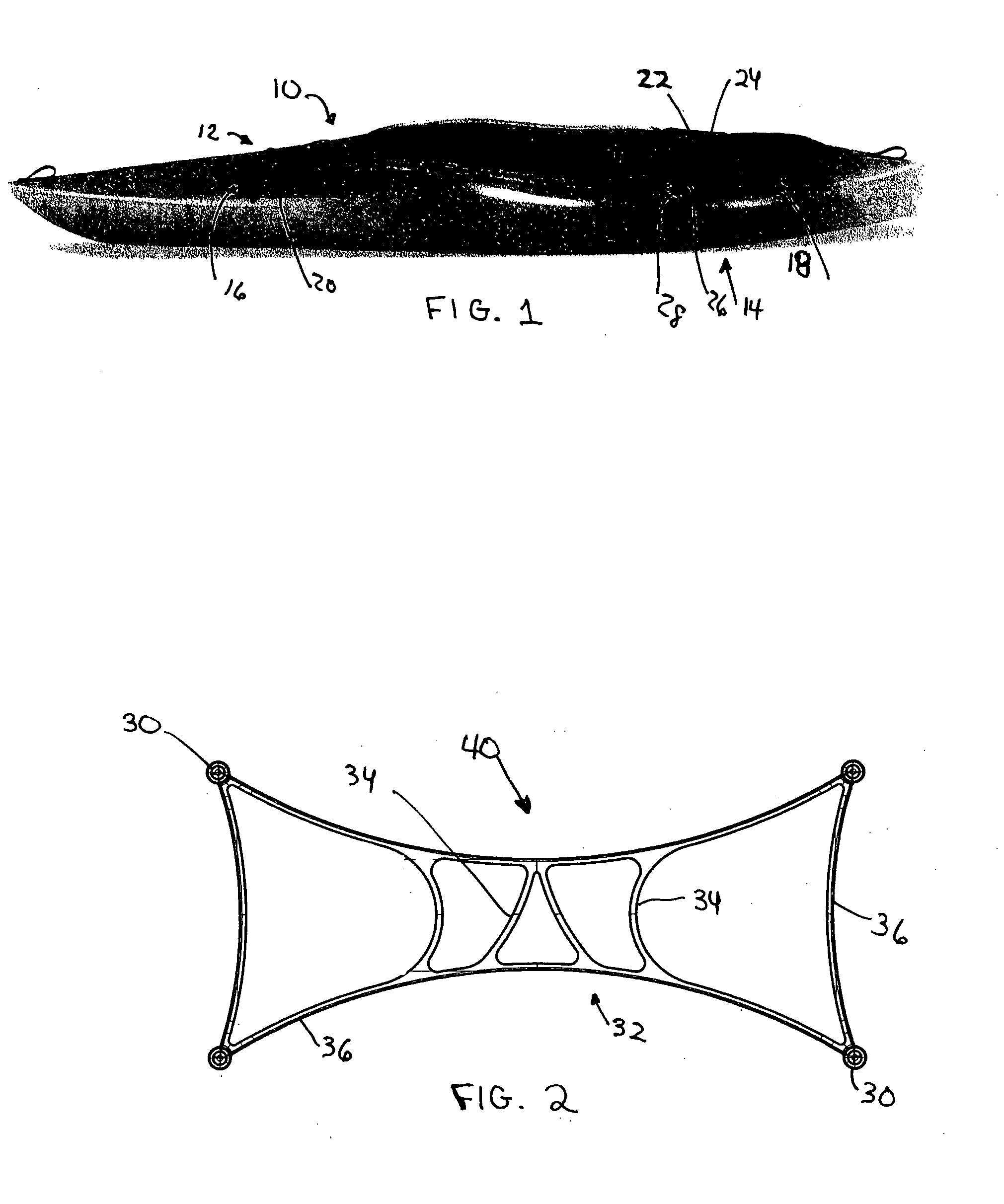

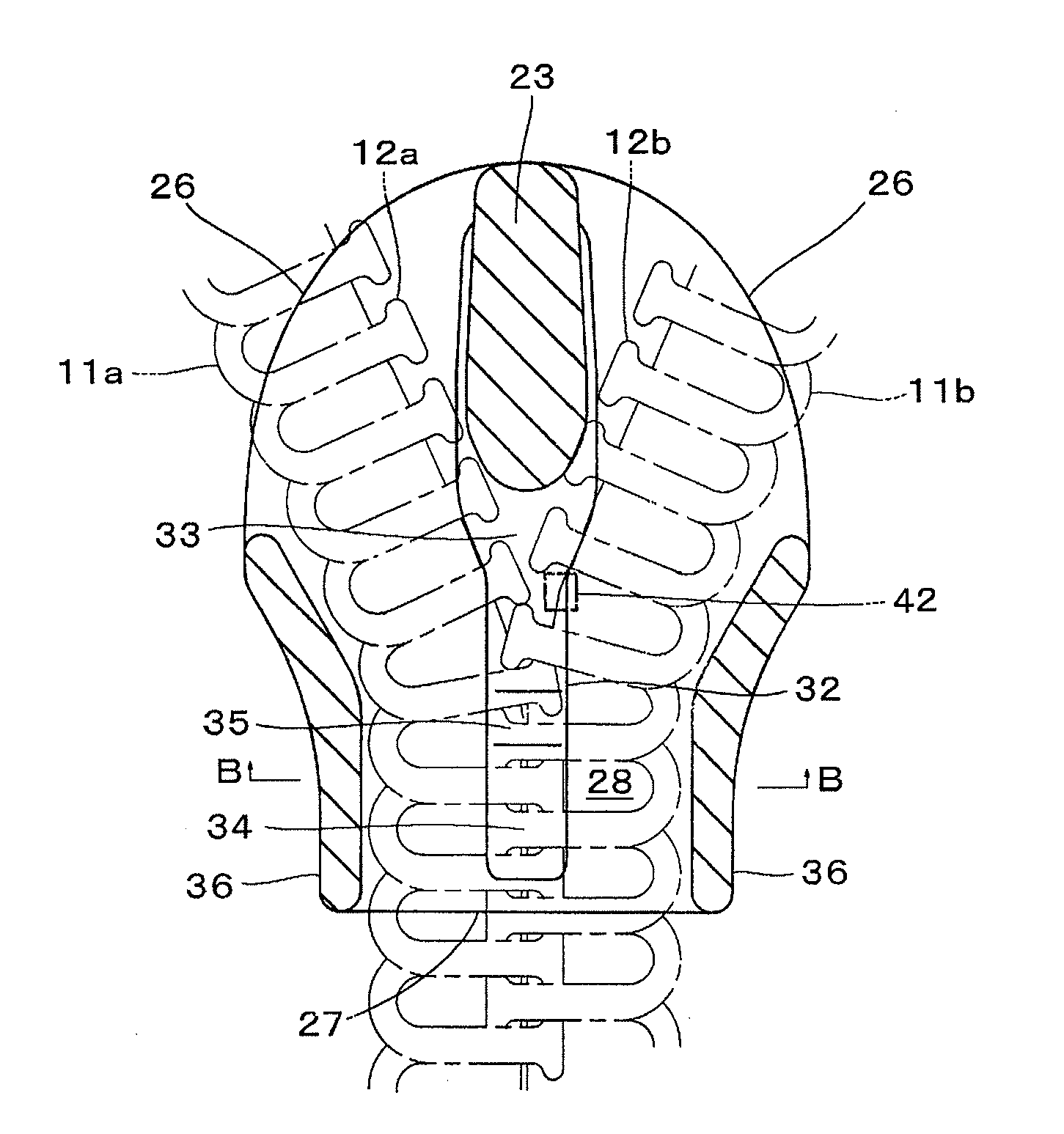

Faceguard

InactiveUS20110061152A1Increase awarenessEasy to manufactureEye treatmentHatsEngineeringCause injury

A faceguard to be mounted on a football helmet which greatly reduces the ability of an opposing player to penetrate the exterior surface of the faceguard and grasp, with his / her hands, the faceguard and rotate the wearer's head in such a way as to cause injury to the wearer's head, neck, or spine. Furthermore, the faceguard will accomplish the above stated while still providing appropriate ventilation for the wearer and allow the wearer to receive water from a standard squeeze type sports water bottle. The faceguard is provided with a flush elastomeric mounting bushing to make the faceguard simpler to manufacture and easier and less awkward to mount to a football helmet. The flush elastomeric mounting bushing provides shock absorption between the faceguard and the helmet at the mounting points. The flush feature of the mounting bushing provides an additional safety benefit of decreasing the likelihood that the mounting will be caught on a player's uniform or cause any puncture or scrape to the skin of another player. The flush feature also makes it difficult for an opposing player to grip or hold the facemask of the wearer. The faceguard is constructed of a single body of injection molded clear or tinted plastic which can withstand high-impact in order to sustain the abuse required of such a device in the game of football.

Owner:WISMANN JOSEPH B

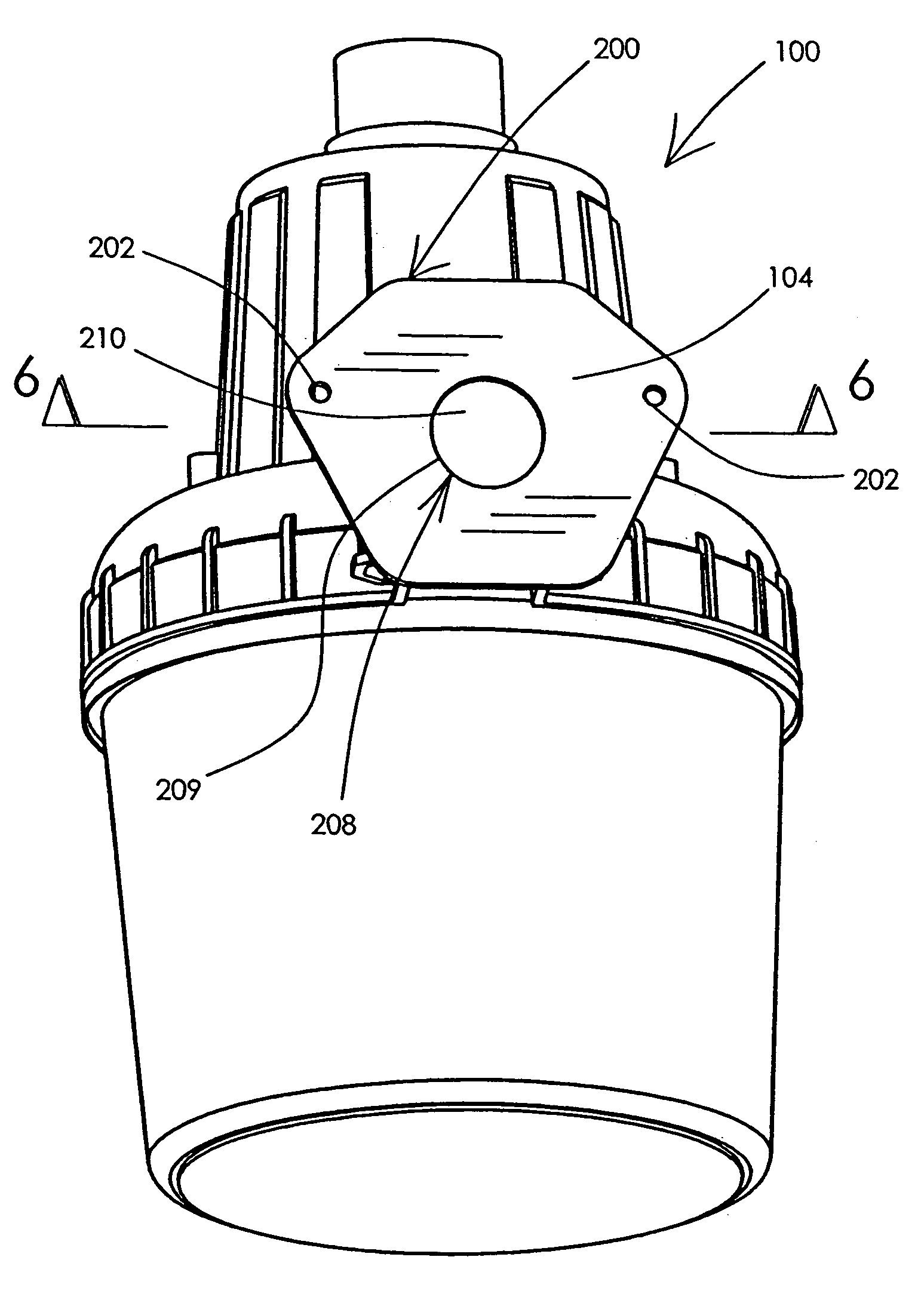

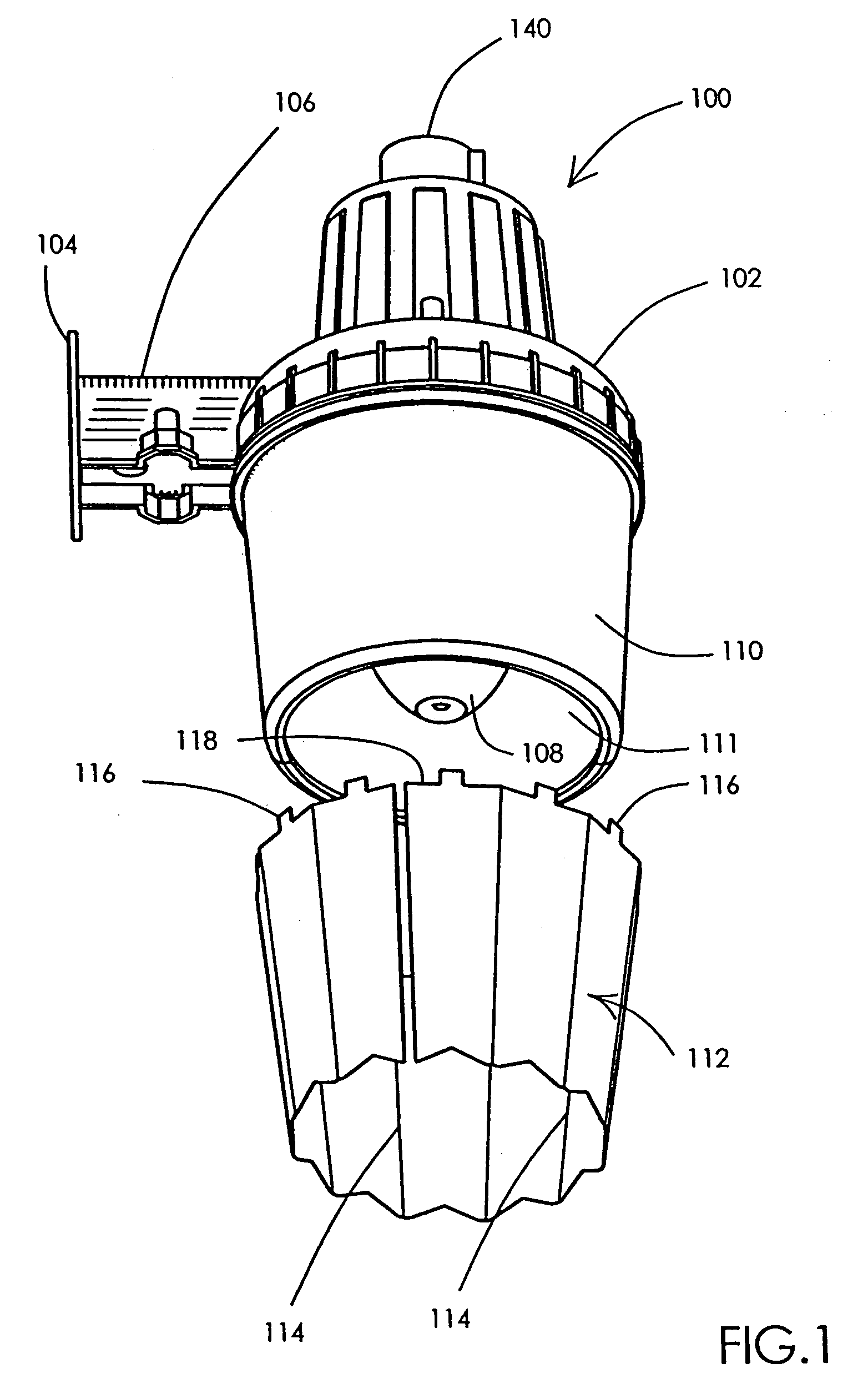

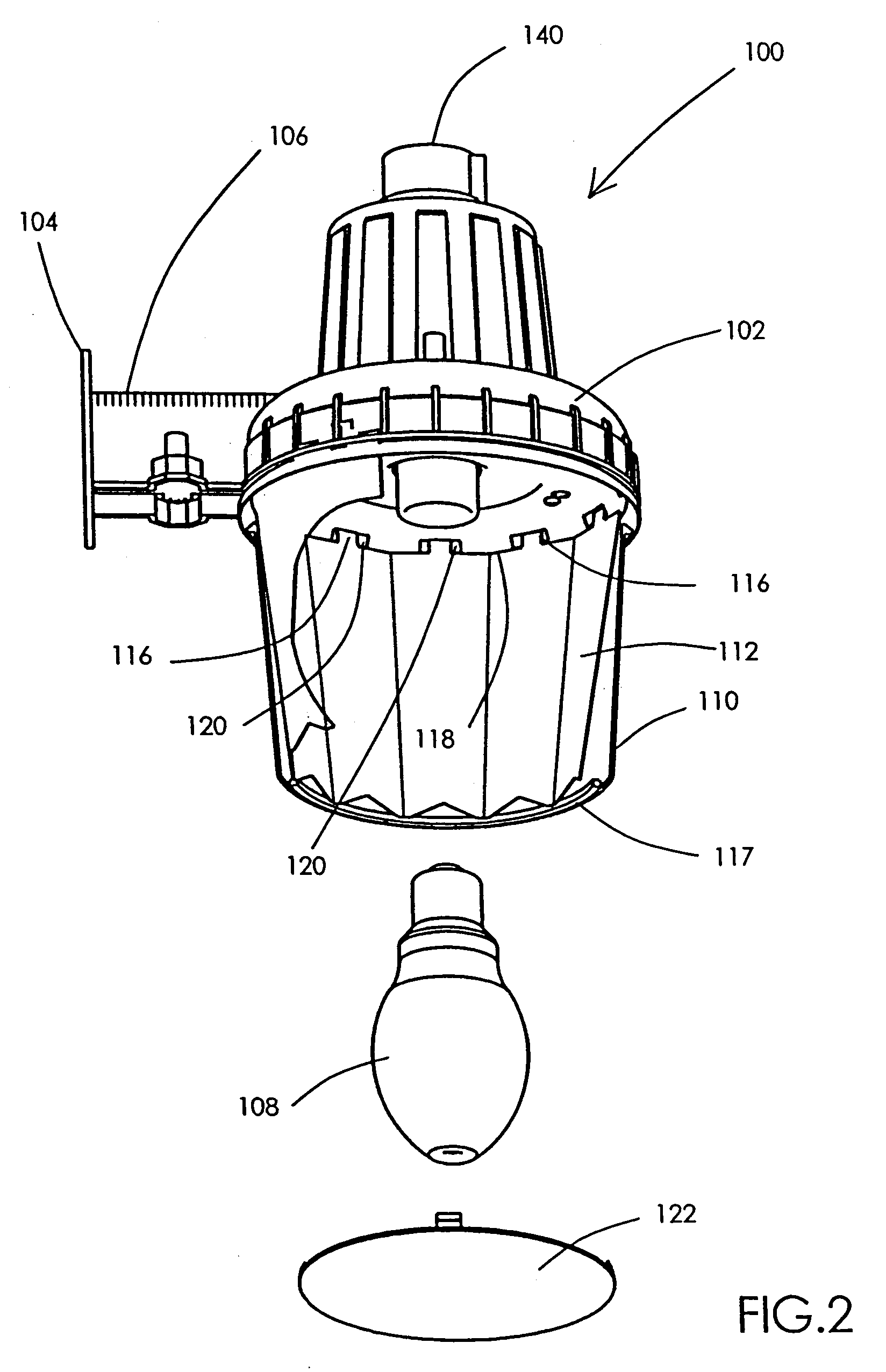

Light fixture mounting bracket

InactiveUS7152992B1Easy to installEasy to separateNon-electric lightingMechanical apparatusDrop and insertLighting system

A lighting system including a mount for one person installation to a support surface having a rigid conduit supplying electrical wires. The lighting system includes a housing containing a light source. A hollow suspension arm extends from the housing and a back plate is located on the arm opposite the housing. The suspension arm includes a removable bottom access plate with a knock-out blank to provide optional wiring access, and the back plate includes a frangible portion. An impact blow creates an opening in the frangible portion that leads into the hollow arm. Straight and curved extension sections are provided for optional attachment to the rigid conduit. The rigid conduit is inserted through the opening in the back plate and into the arm thus suspending the lighting system therefrom.

Owner:CORDELIA LIGHTING

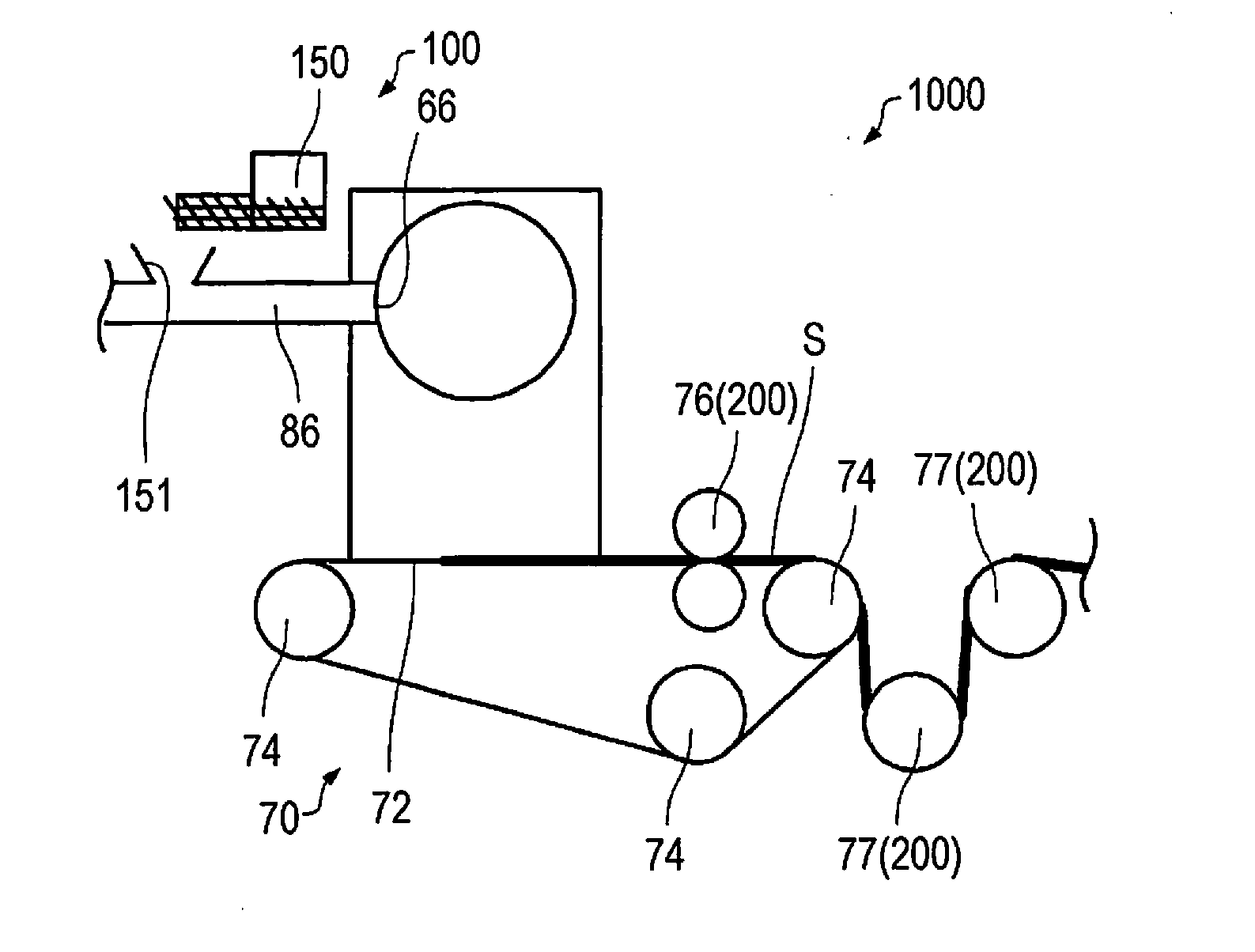

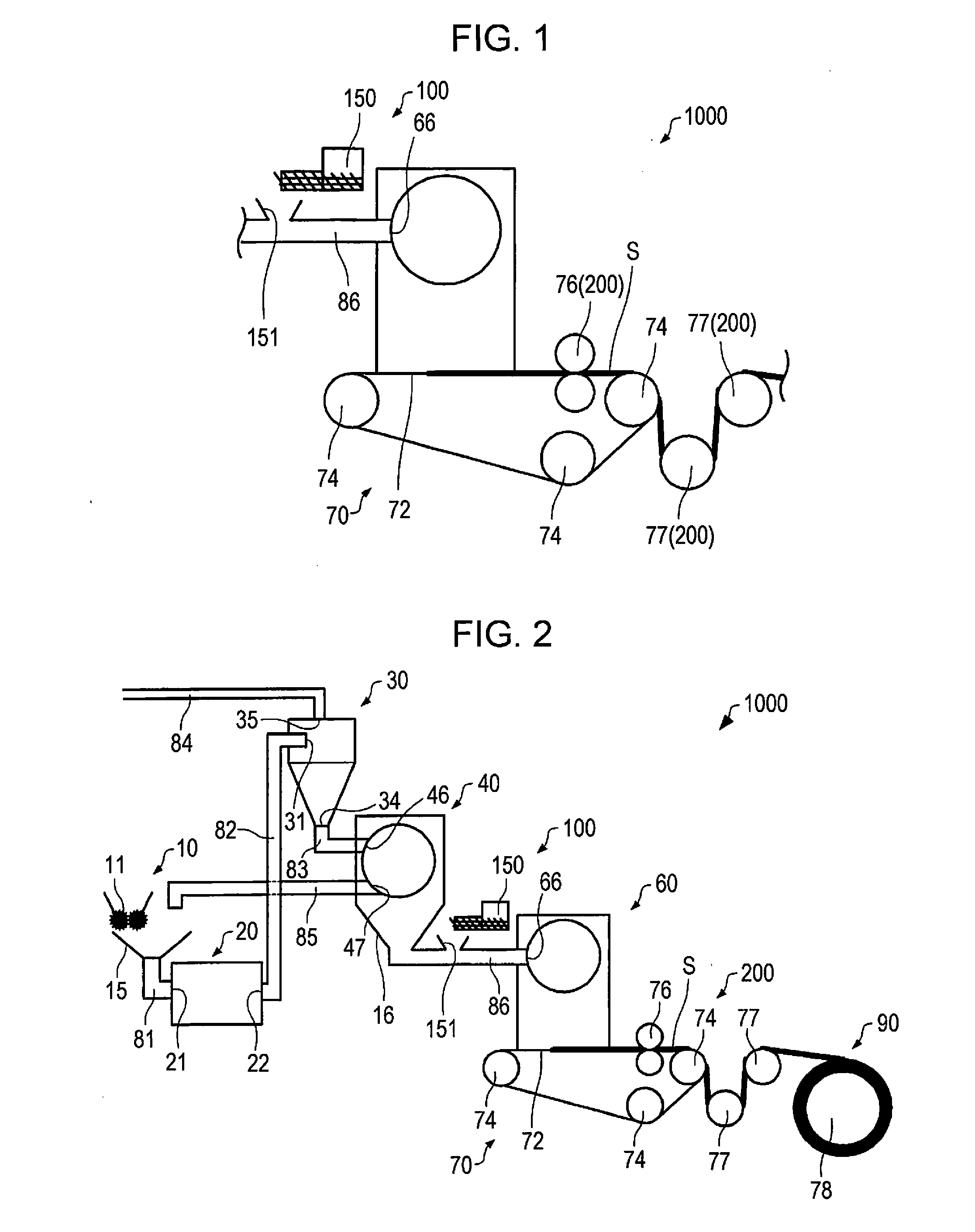

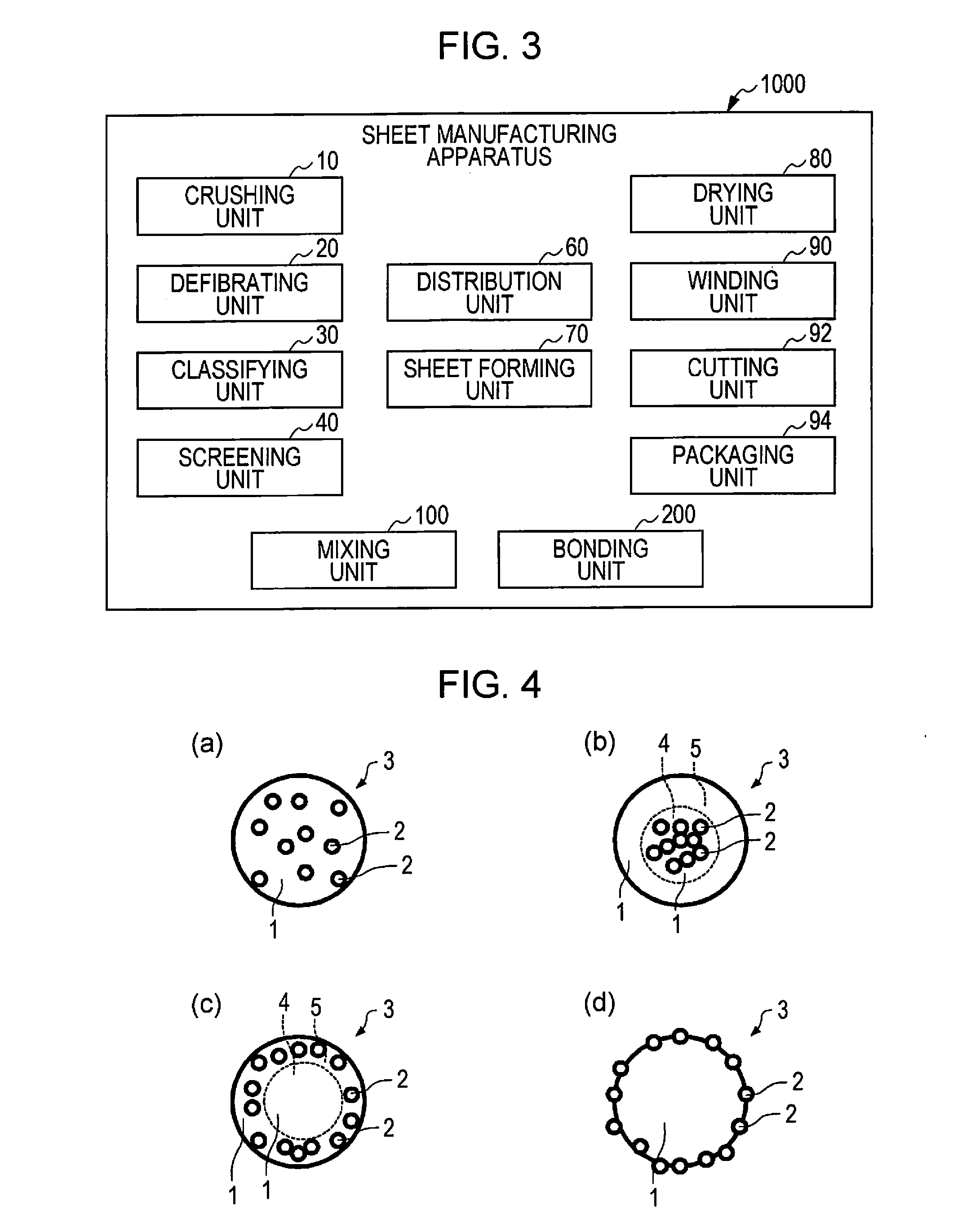

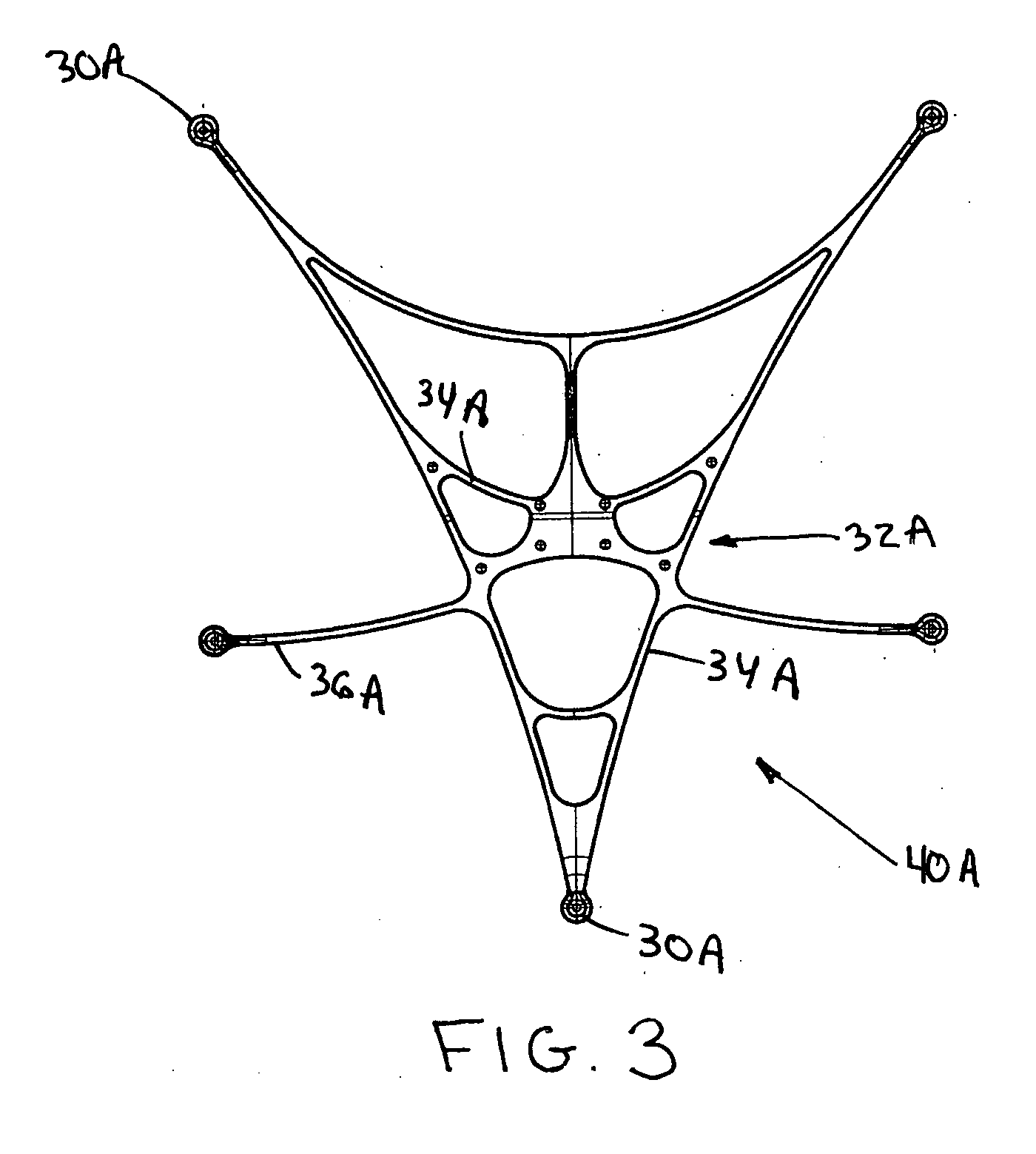

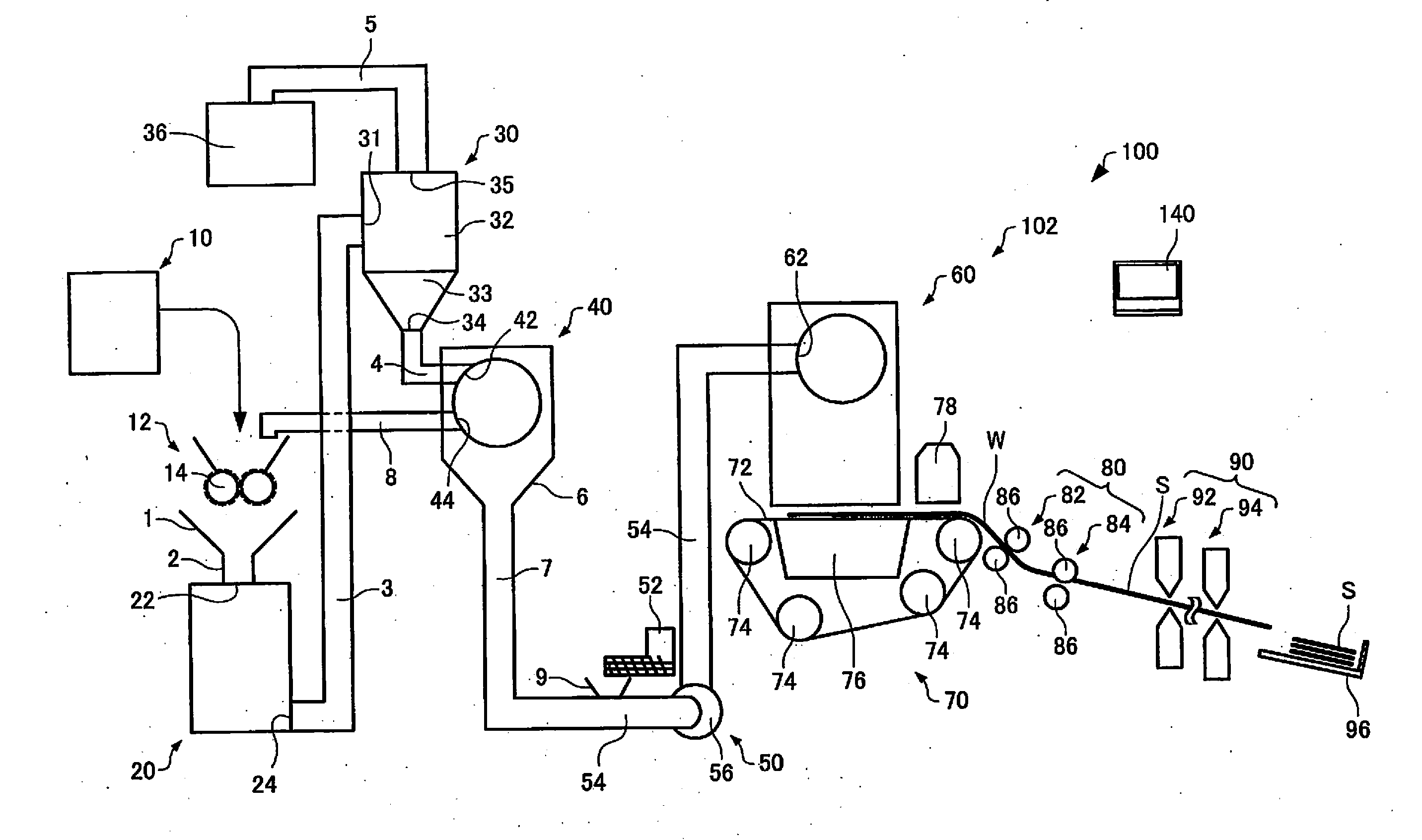

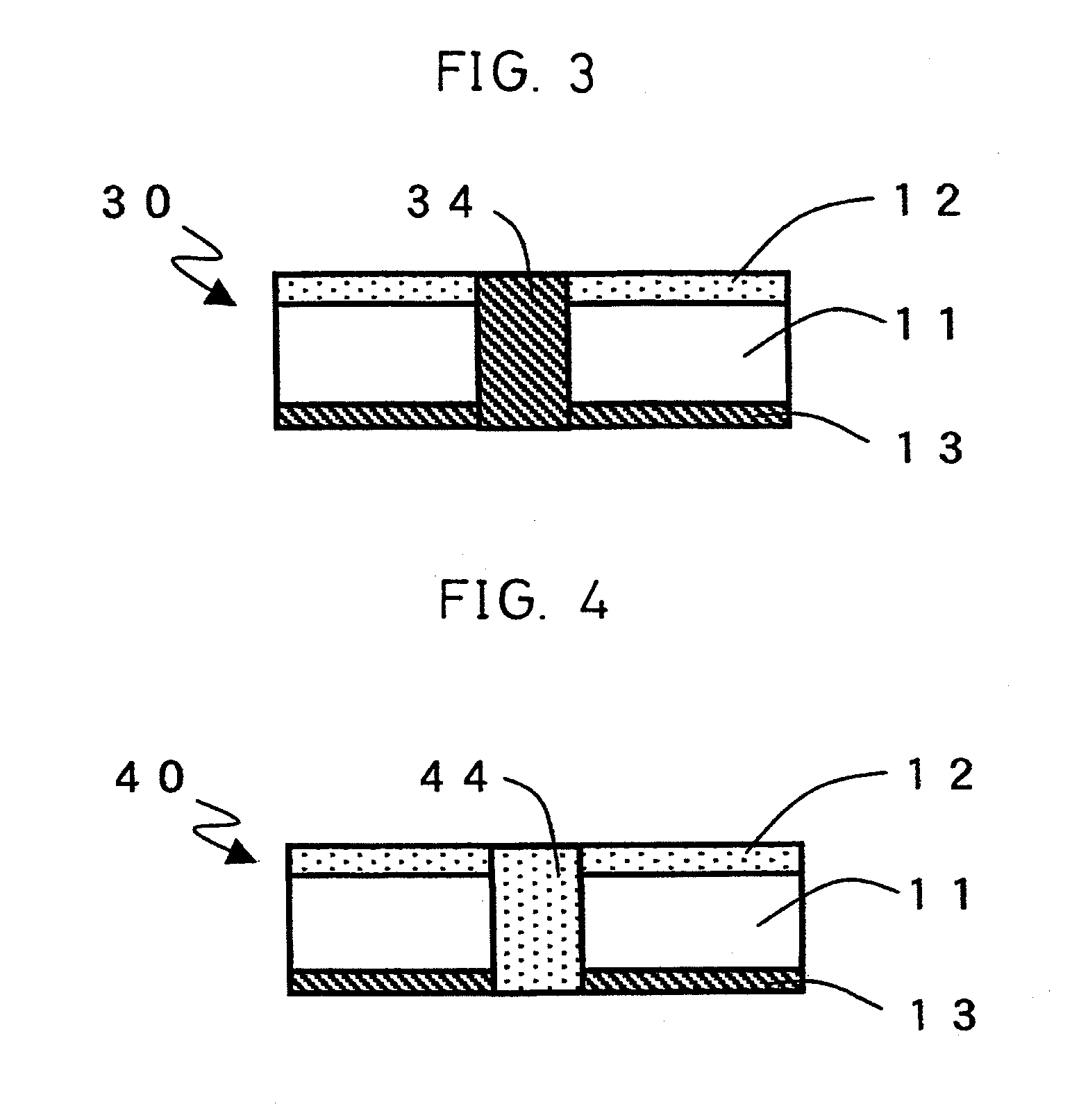

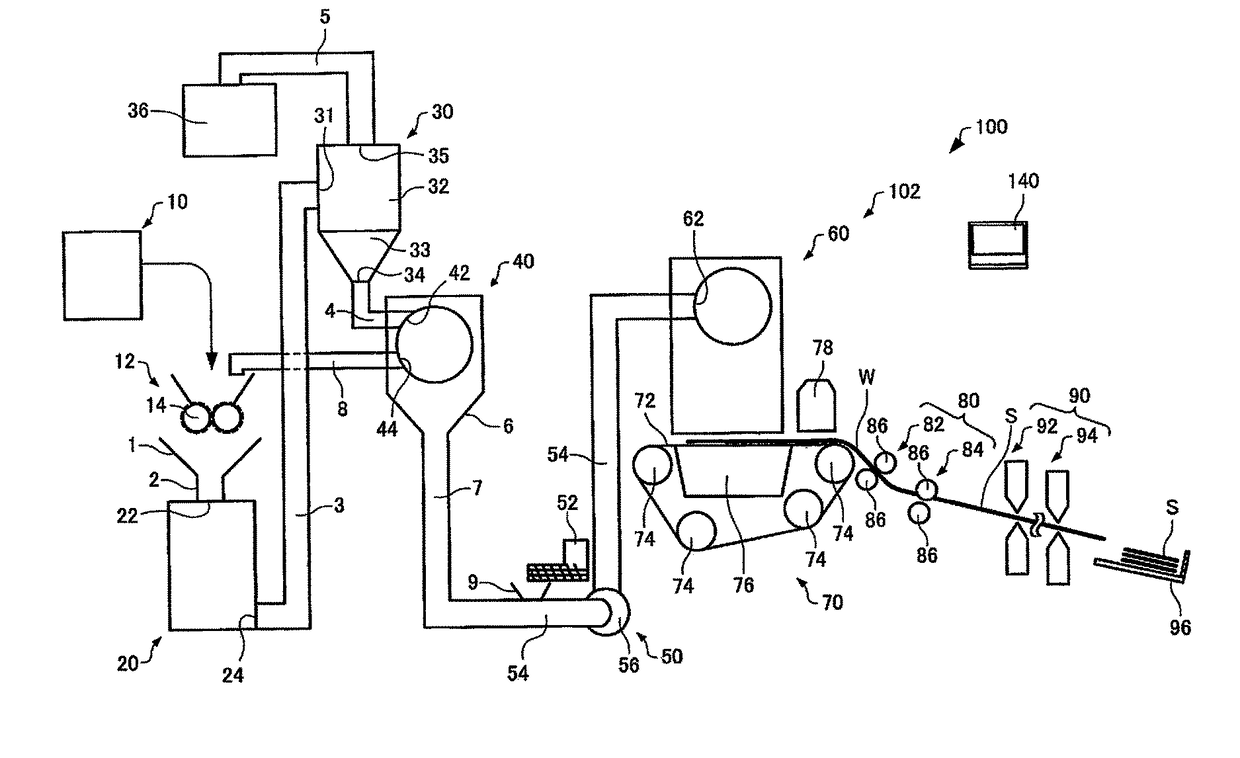

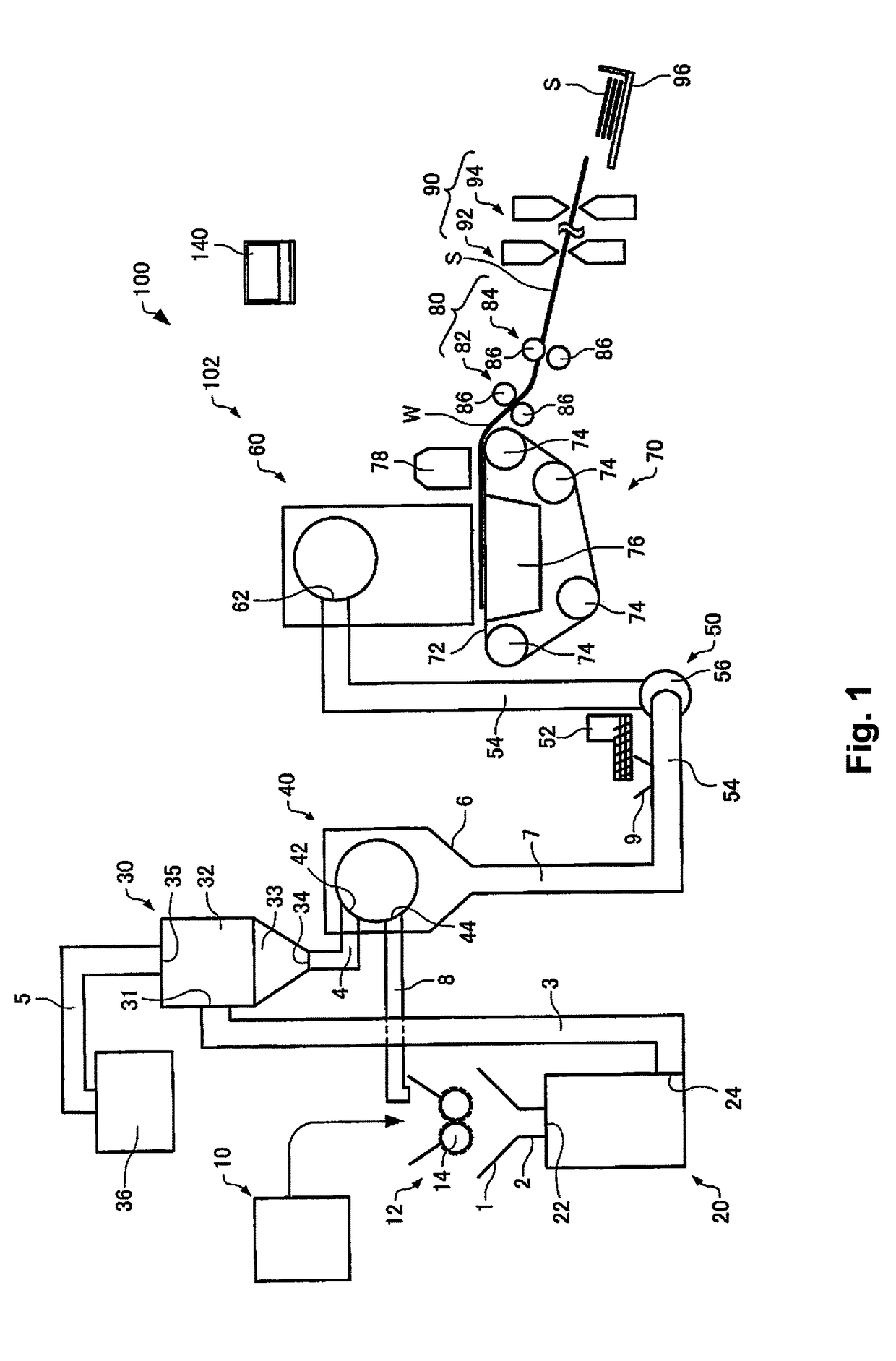

Sheet manufacturing apparatus, sheet manufacturing method, sheet manufactured with the same, composite used therewith and accommodation container therefor

InactiveUS20160230320A1Avoid easy detachmentSuppress color unevennessPaper recyclingNon-woven fabricsFiberManufactured apparatus

Owner:SEIKO EPSON CORP

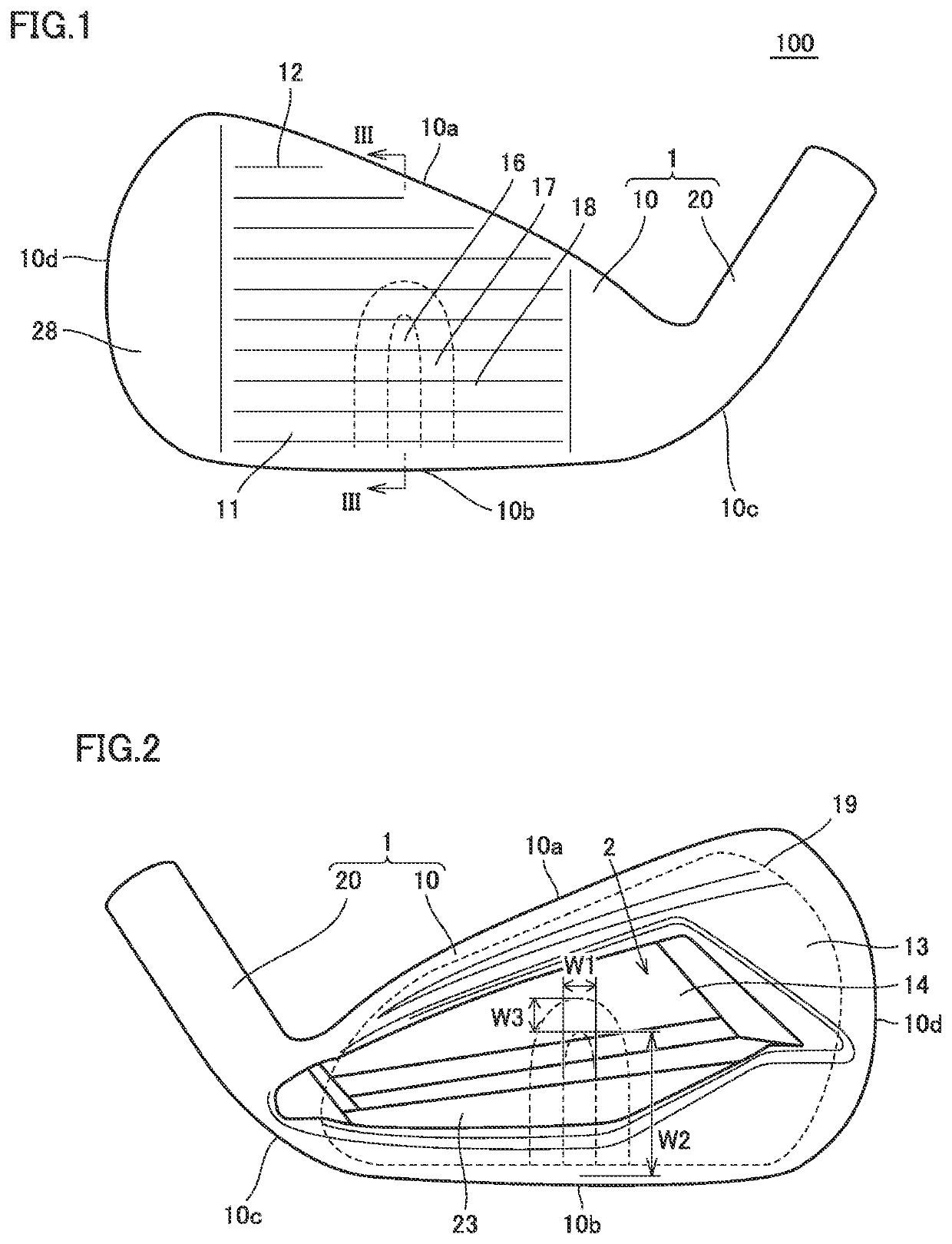

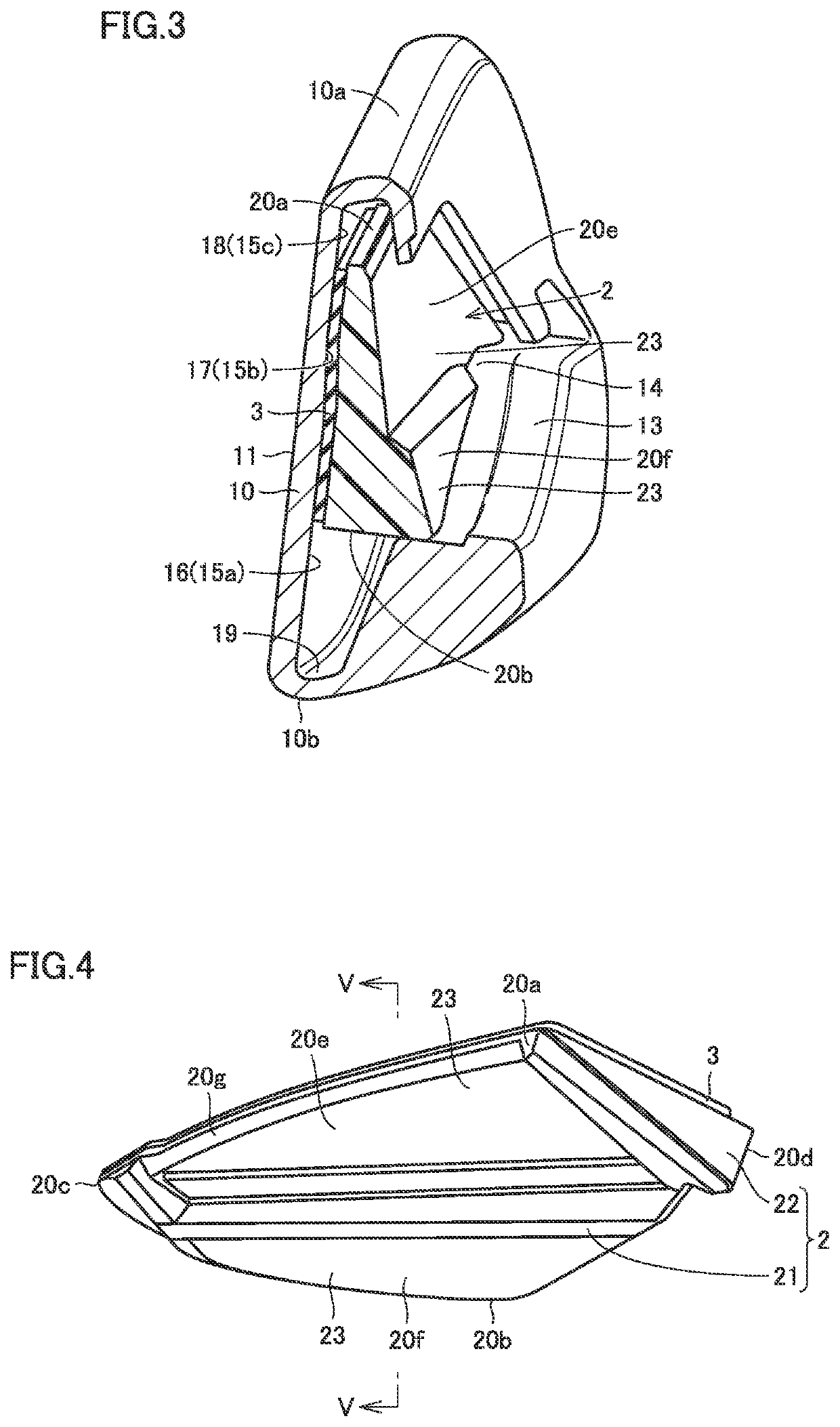

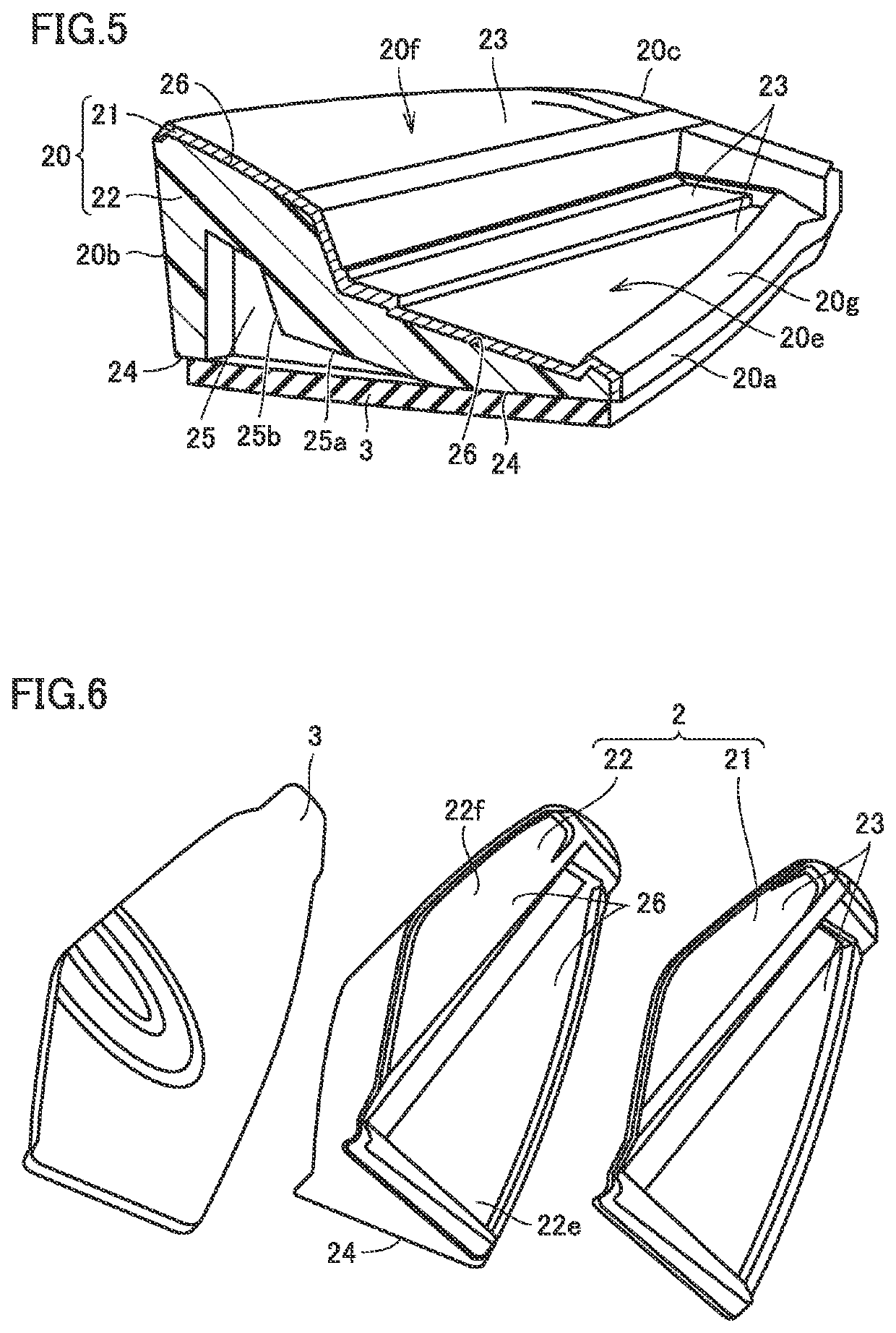

Iron golf club head

ActiveUS10716979B2Improve aesthetic appearanceAvoid easy detachmentGolf clubsPolymer scienceShoe laces

An iron golf club head includes a head member having a lace surface and a back surface located opposite to the face surface, and a badge member having an opposed surface facing the back surface and connected to the back surface and an exposed surface located opposite to the back surface the opposed surface and exposed to the outside. The badge member includes a resin plate having the opposed surface and made of a resin material, and a metal plate having the exposed surface and made of a metal material. The resin plate is provided with a plurality of recesses recessed toward the opposed surface. The plurality of recesses are arranged side by side in a toe-to-heel direction. The ratio V / S of a volume V (unit: mm3) of the badge member to an area S (unit: mm3) of the opposed surface is 4.0 or more and 10.0 or less.

Owner:MIZUNO CORPORATION

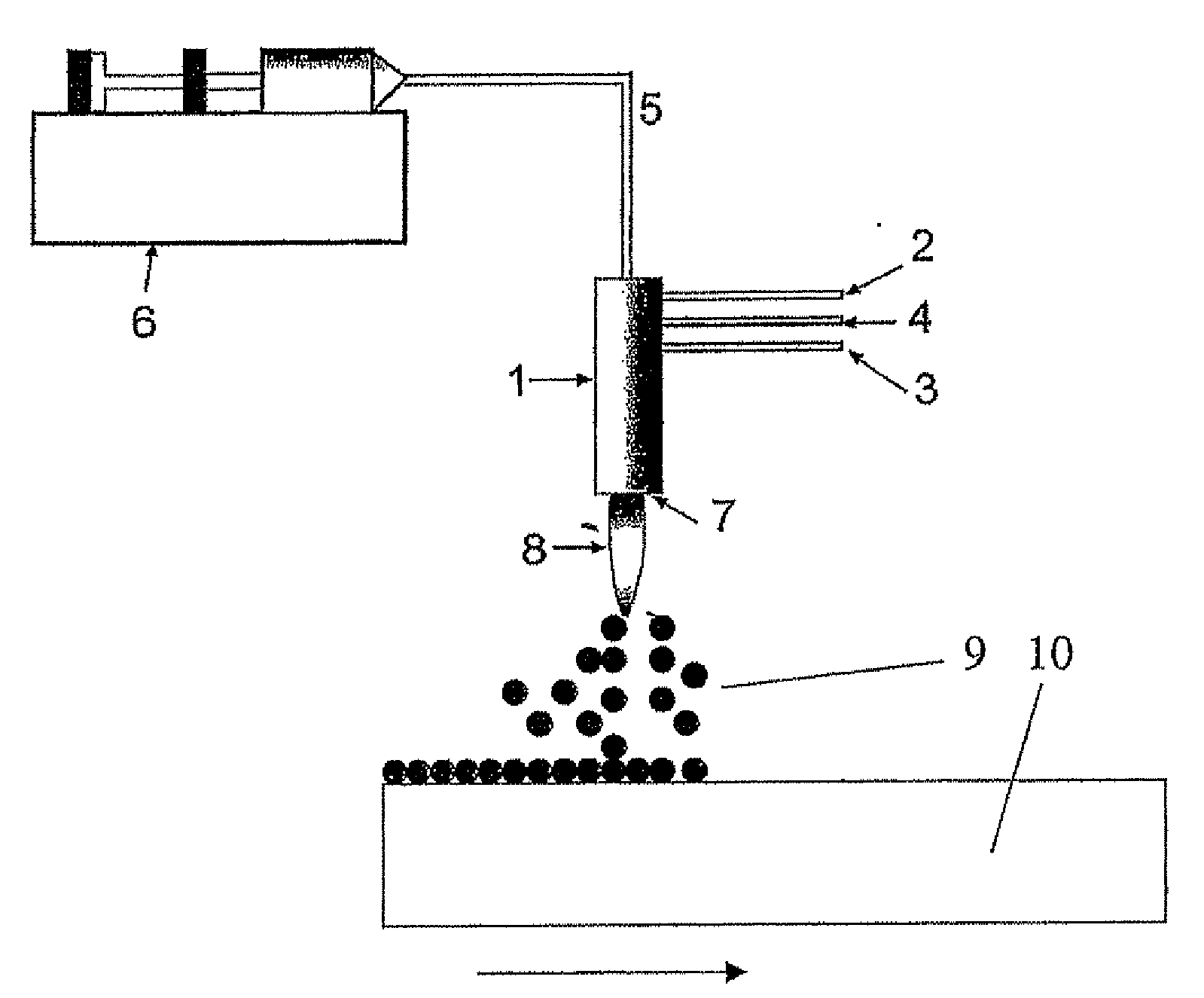

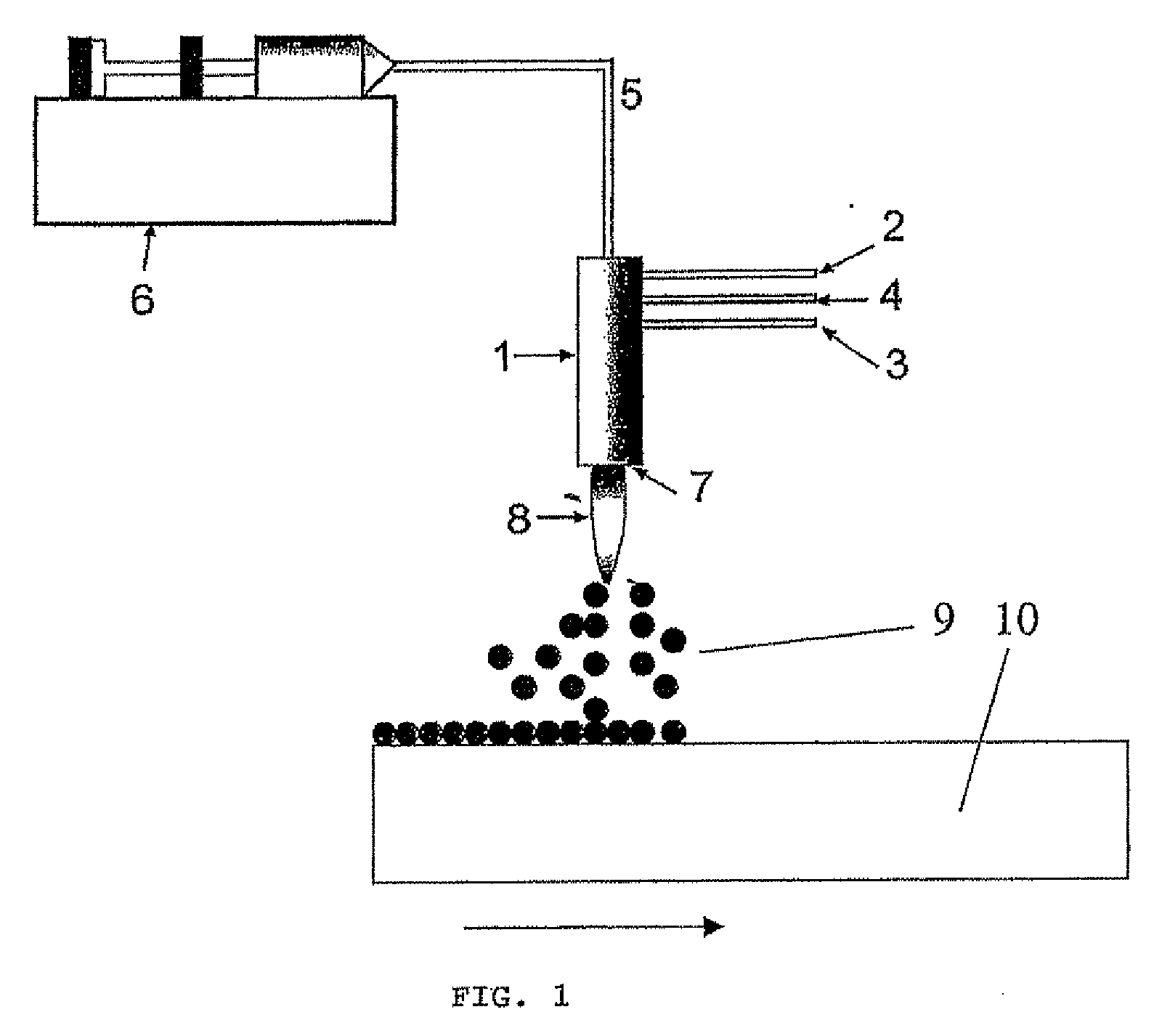

Hydrophobic glass surface

InactiveUS20090095021A1Effective dissolutionEffective diffusionLayered productsVacuum evaporation coatingMaterials scienceHydrophobic surfaces

The invention relates to a method of forming a hydrophobic surface for glass or glazing. The method comprises producing particles having an average aerodynamic particle size of less than 200 nm and guiding the particles further onto the glass surface. The particles to be produced according to the invention are hydrophobic particles and the particles are guided onto the glass surface so that they at least partly dissolve and / or diffuse into the glass surface.

Owner:BENEQ OY

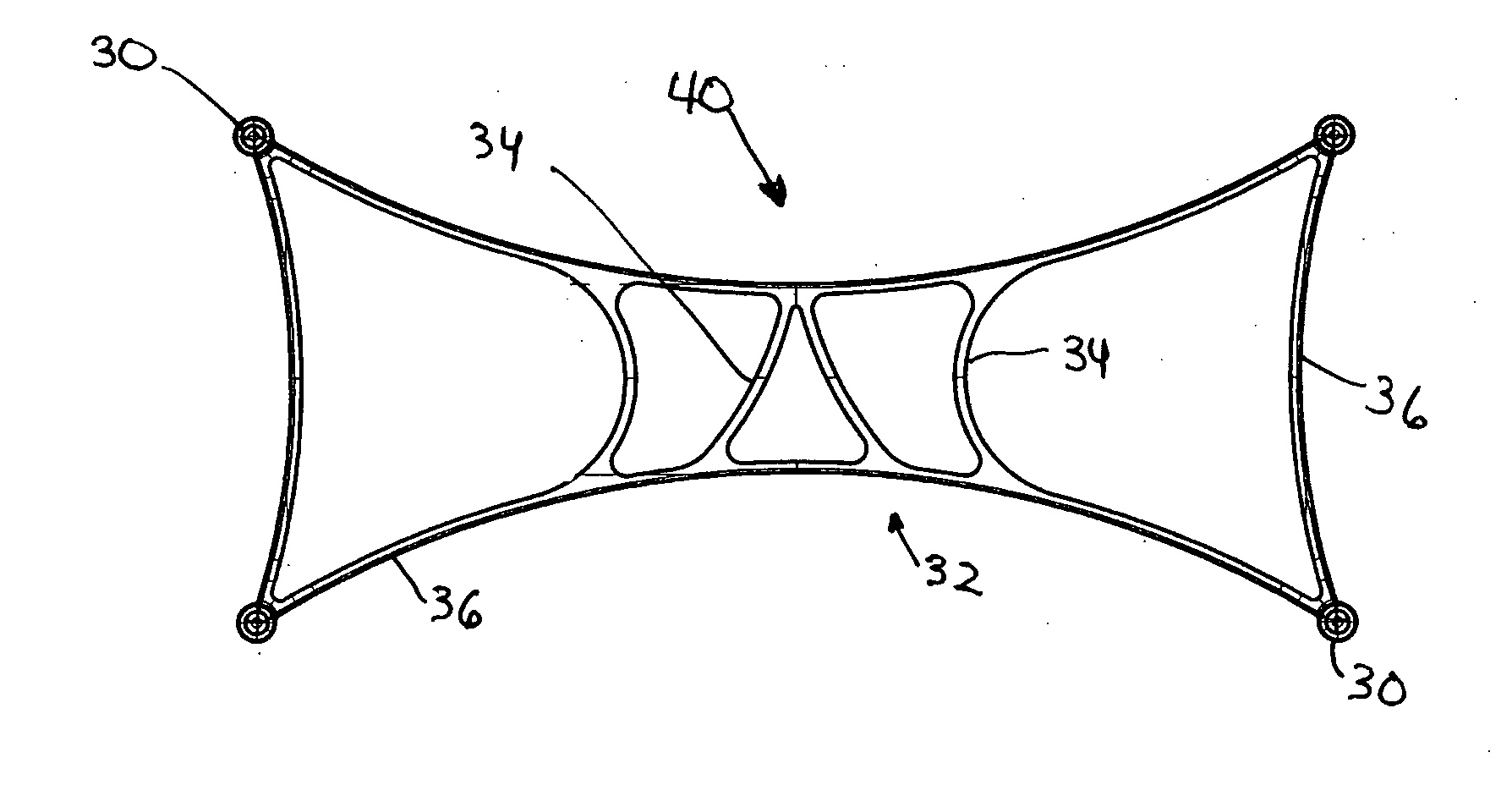

Elastic deck web

InactiveUS20050084359A1Easy to solveEasy to installLoad securingCargo supporting/securing componentsEngineeringFastener

Owner:LEGACY PADDLEPORTS

Sheet manufacturing apparatus, sheet manufacturing method, sheet manufactured using sheet manufacturing apparatus and sheet manufacturing method, and composite and container used in sheet manufacturing apparatus and sheet manufacturing method

A sheet manufacturing apparatus includes a mixing unit and a forming unit. The mixing unit is configured to mix fibers and a composite, where a resin and a wax are integrally combined, in air. The forming unit is configured to form a sheet by depositing and heating a mixed material where the fibers and the composite are mixed.

Owner:SEIKO EPSON CORP

Circuit breaker

ActiveUS20050275493A1Avoid damageAvoid easy detachmentEmergency casingsElectric switchesEngineeringCircuit breaker

Owner:FUJI ELECTRIC FA COMPONENTS & SYST CO LTD

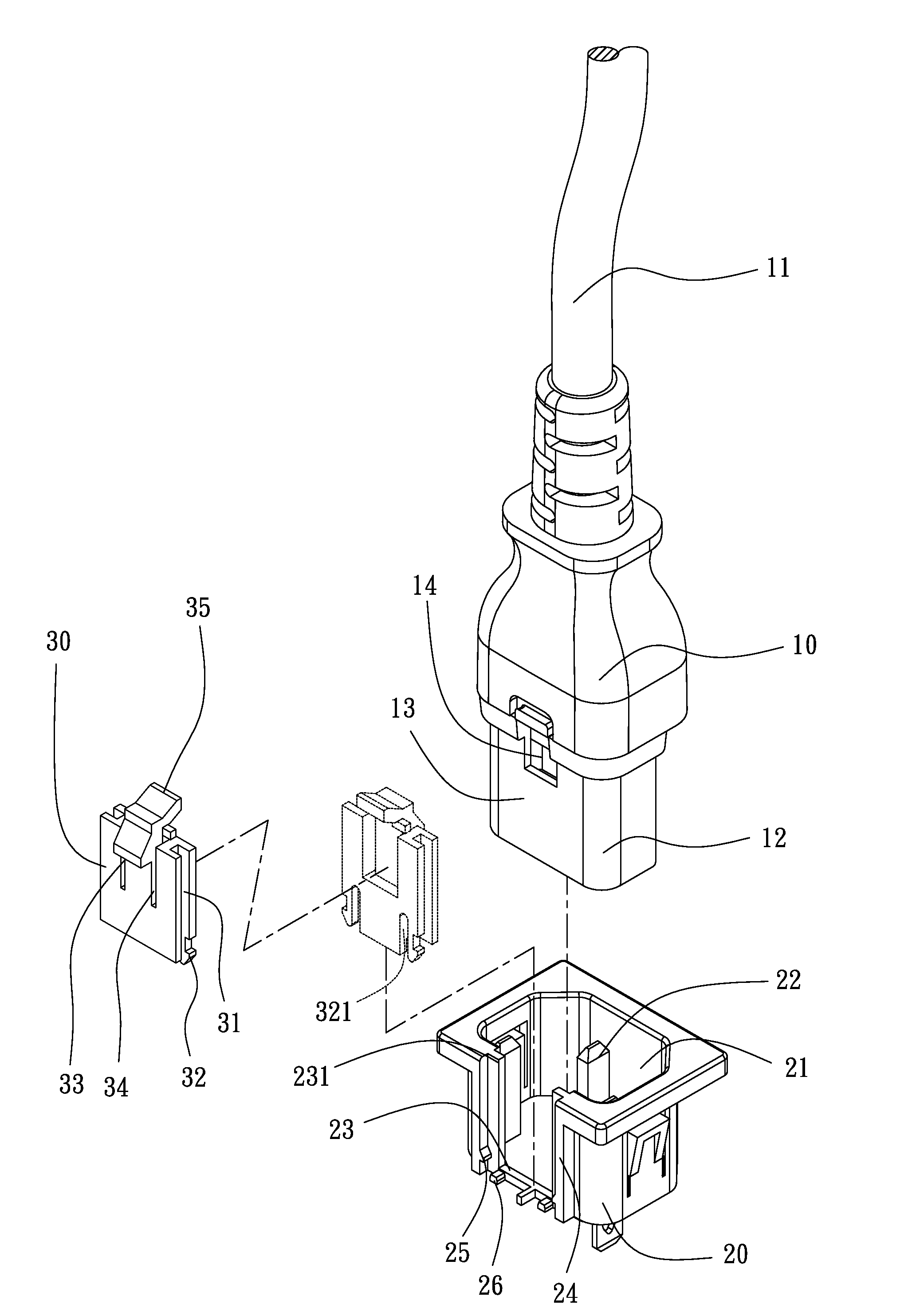

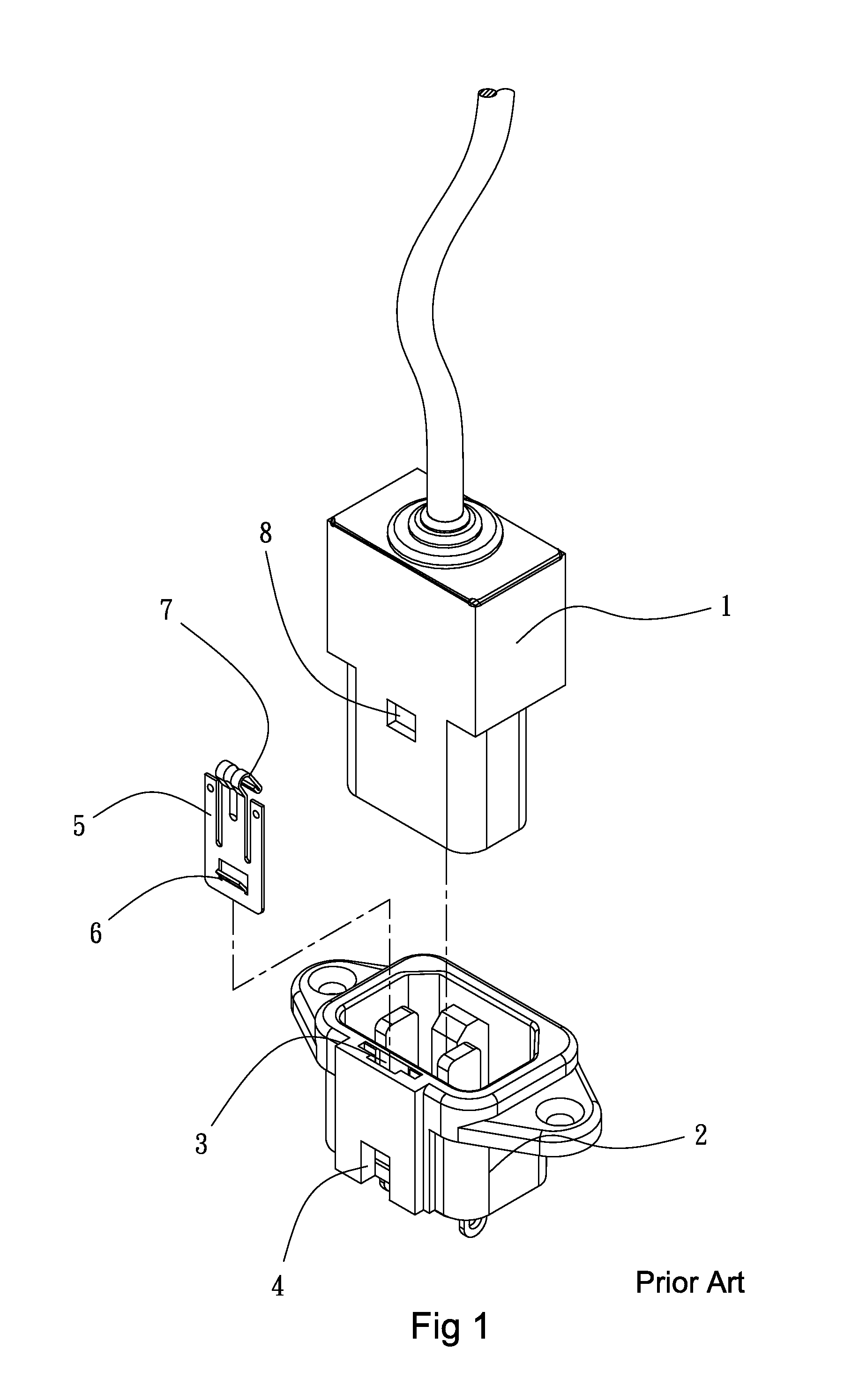

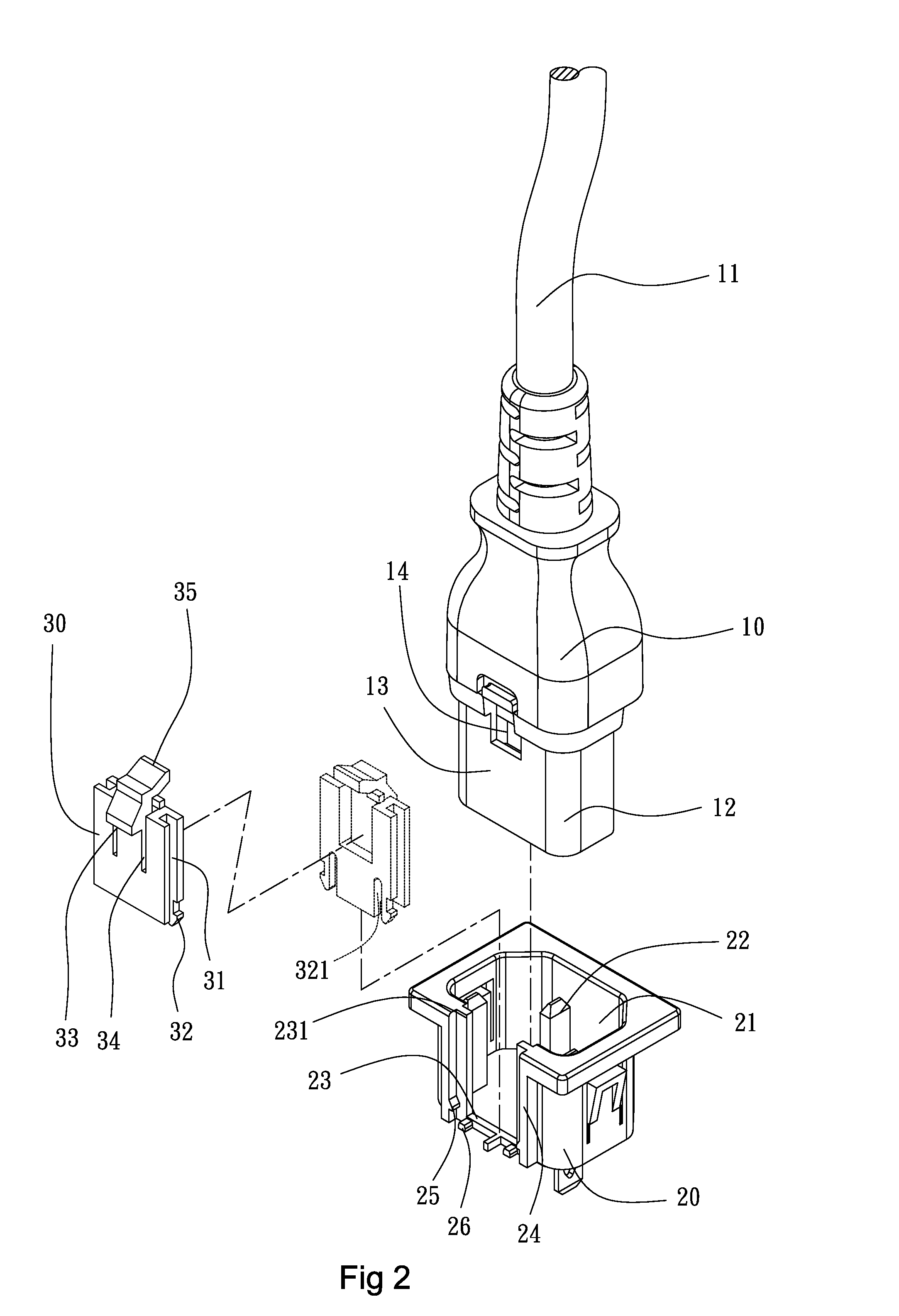

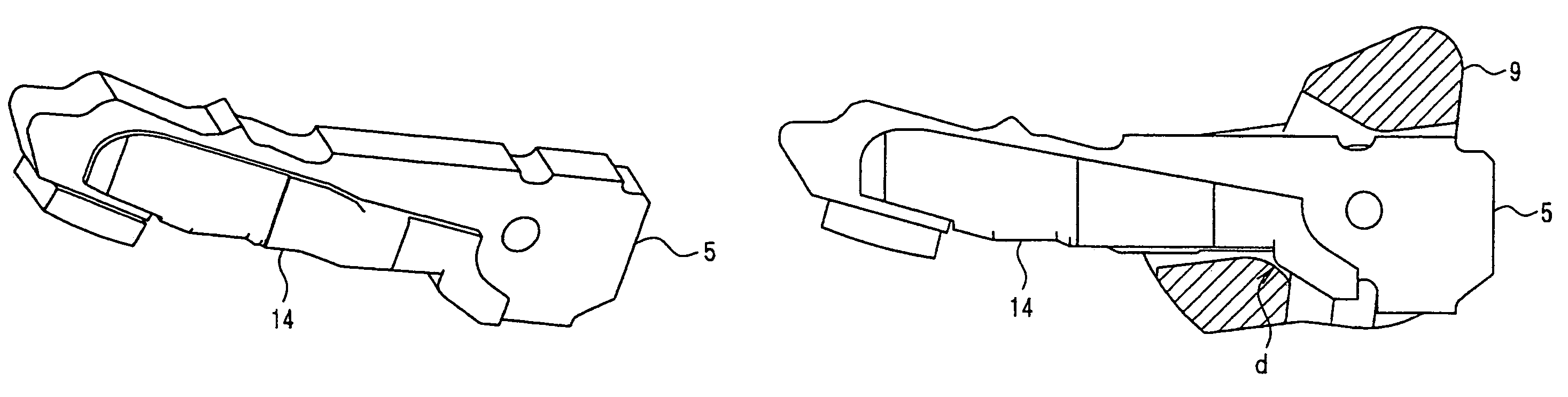

Fastening device of plug-socket combination

InactiveUS20150280362A1Avoid easy detachmentIncrease the areaTwo pole connectionsCoupling device detailsEngineeringMechanical engineering

A fastening device of a plug-socket combination includes a plug structure and a socket structure. The socket structure has a side wall in which an insertion slot is formed. A plastic fastening plate includes a slit-defined barb formed on each of two sides of a lower end thereof. When the plastic fastening plate is inserted into the insertion slot, the slit-defined barbs are allowed to elastically expand to respectively engage pawls formed at a lower end of the slot. The plastic fastening plate has a free end on which a plastic pawl is formed. The plug projection of the plug structure, when jointed, through insertion, to the insertion recess of the socket structure, smoothly passes over the plastic pawl to allow the plastic pawl to spring into and thus fix the positioning cavity at the time when the positioning cavity and the plastic pawl are in alignment with each other.

Owner:RONG FENG INDAL

Circuit breaker

ActiveUS7187258B2Exemption stepsReduce manufacturing costEmergency casingsElectric switchesEngineeringCircuit breaker

A circuit breaker includes an elongated movable contact having a contact at one end thereof for flowing a current therethrough and the other end rotatably supported with a holder, and a protection cover made of an insulating material for covering and protecting a movable contact from short circuit and discharge. The protection cover is made of only the insulating material, covers the movable contact, and has elasticity to tightly hold the movable contact.

Owner:FUJI ELECTRIC FA COMPONENTS & SYST CO LTD

Ceramic electronic component

ActiveUS20120326569A1Avoid easy detachmentLow profileMultiple fixed capacitorsPiezoelectric/electrostriction/magnetostriction machinesMetalElectronic component

A ceramic electronic component includes two electronic-component main bodies and two metal terminals. Each of the metal terminals includes a base, ribs on left and right sides of the base, and a mounting portion below the base. The base includes two bonding portions to be bonded to respective external electrodes of the two electronic-component main bodies and cut-out portions each having a closed shape and being disposed below the respective bonding portions. The ribs are bent from the left and right sides of the base in the width direction toward the electronic-component main body. The ribs extend from the top of the base in the height direction to the vicinity of the mounting-side major surface of the mounting-side electronic-component main body and do not reach the mounting portion. The mounting portion is bent from the bottom of the base toward the electronic-component main body.

Owner:MURATA MFG CO LTD

Slide Fastener and Slider for Slide Fastener

ActiveUS20130276270A1Avoid easy detachmentGuaranteed to workSnap fastenersSlide fastenersEngineeringFastener

A slider for a slide fastener includes a stopper mechanism formed for “forward use,” in which the surface where coiled fastener elements are attached on a fastener tape is the front surface, can be used for “reverse use,” in which the surface where the coiled fastener elements are attached on the fastener tape is the back surface. The inner surface of the lower blade of the slider body of a slider has a protrusion that extends in the forward-reverse direction from a guiding bar towards a posterior opening. The protrusion has a first horizontal upper surface on the guide bar end of the protrusion that is highest and a second upper surface on the posterior opening end that is lower than the first upper surface.

Owner:YKK CORP

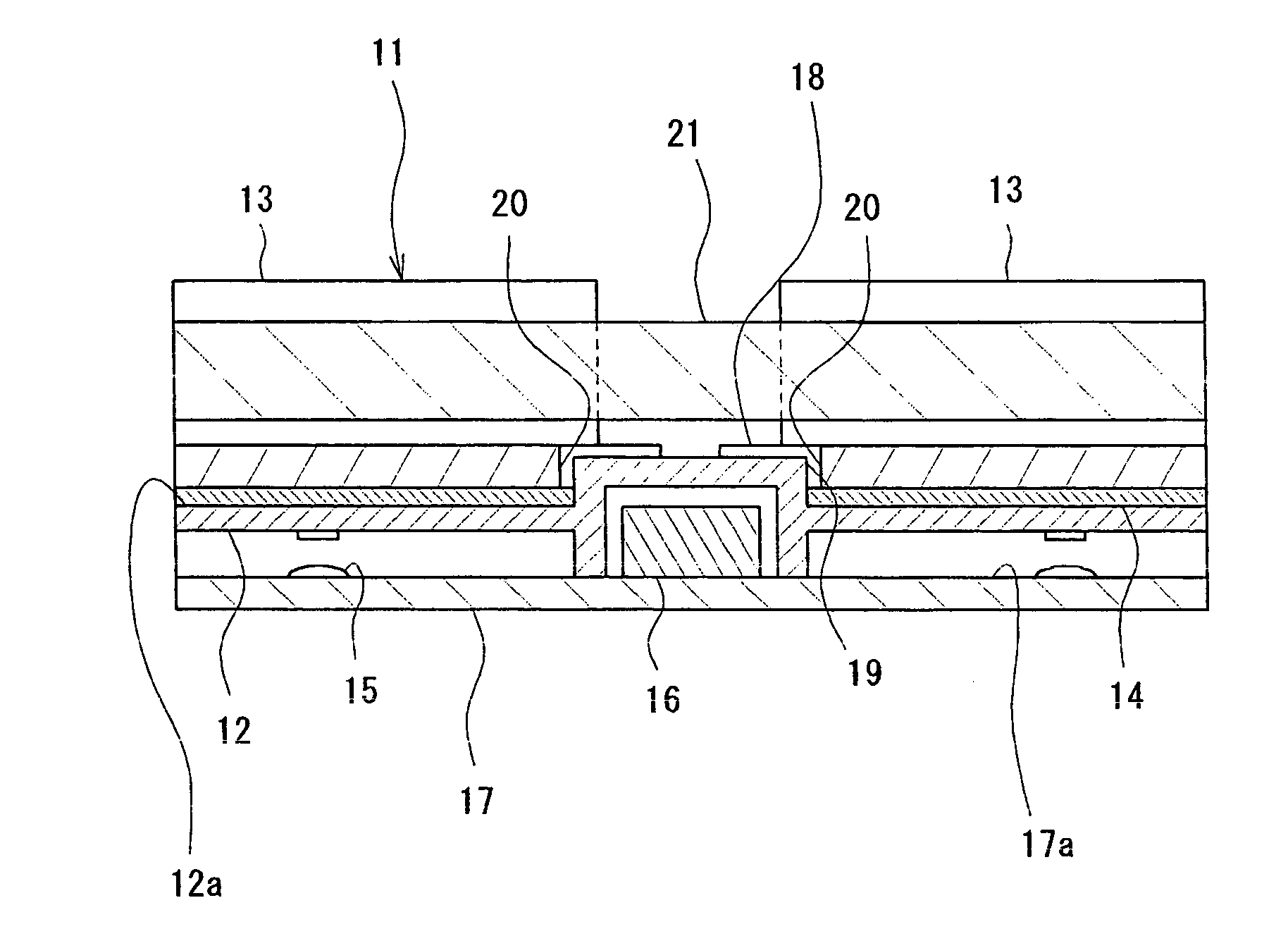

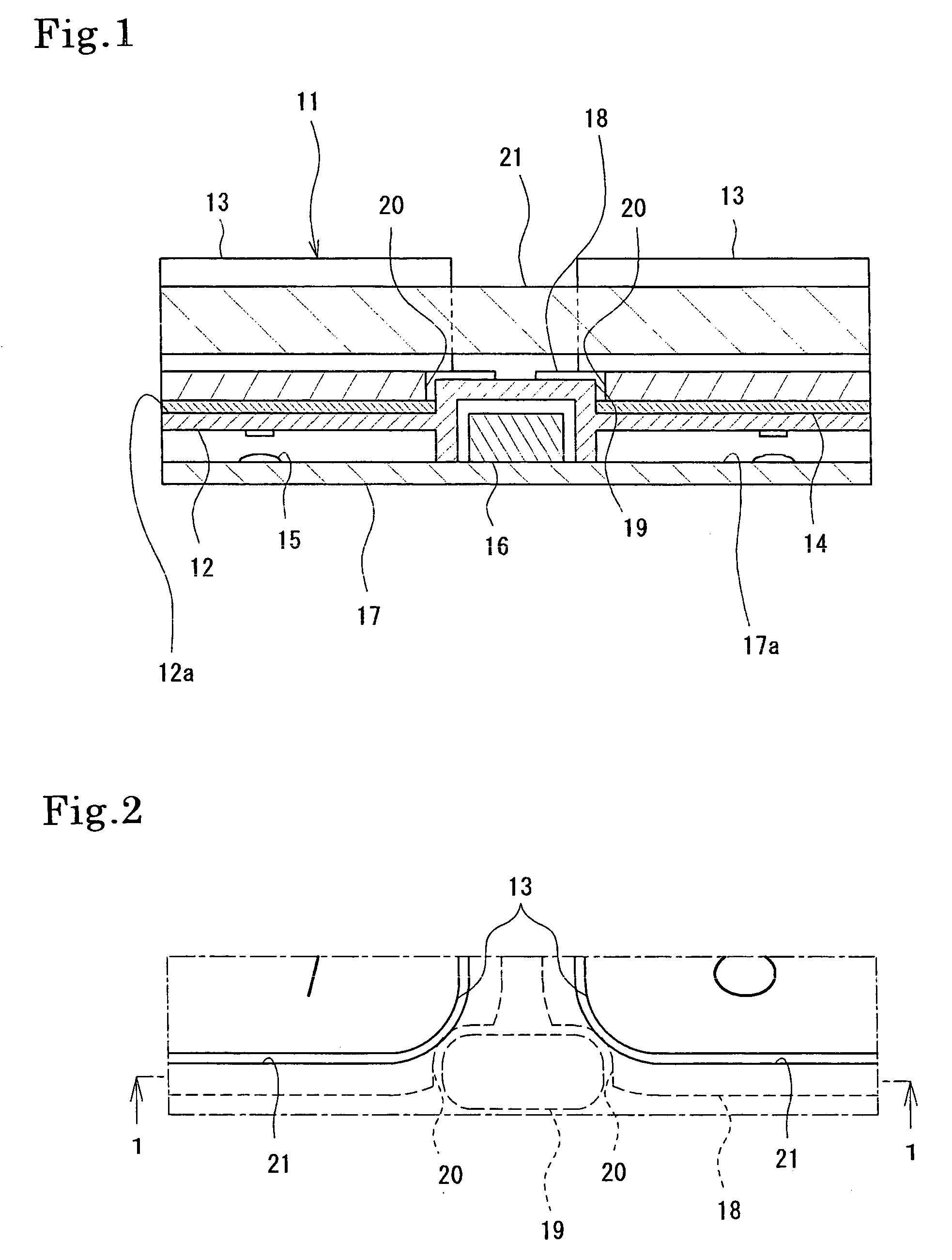

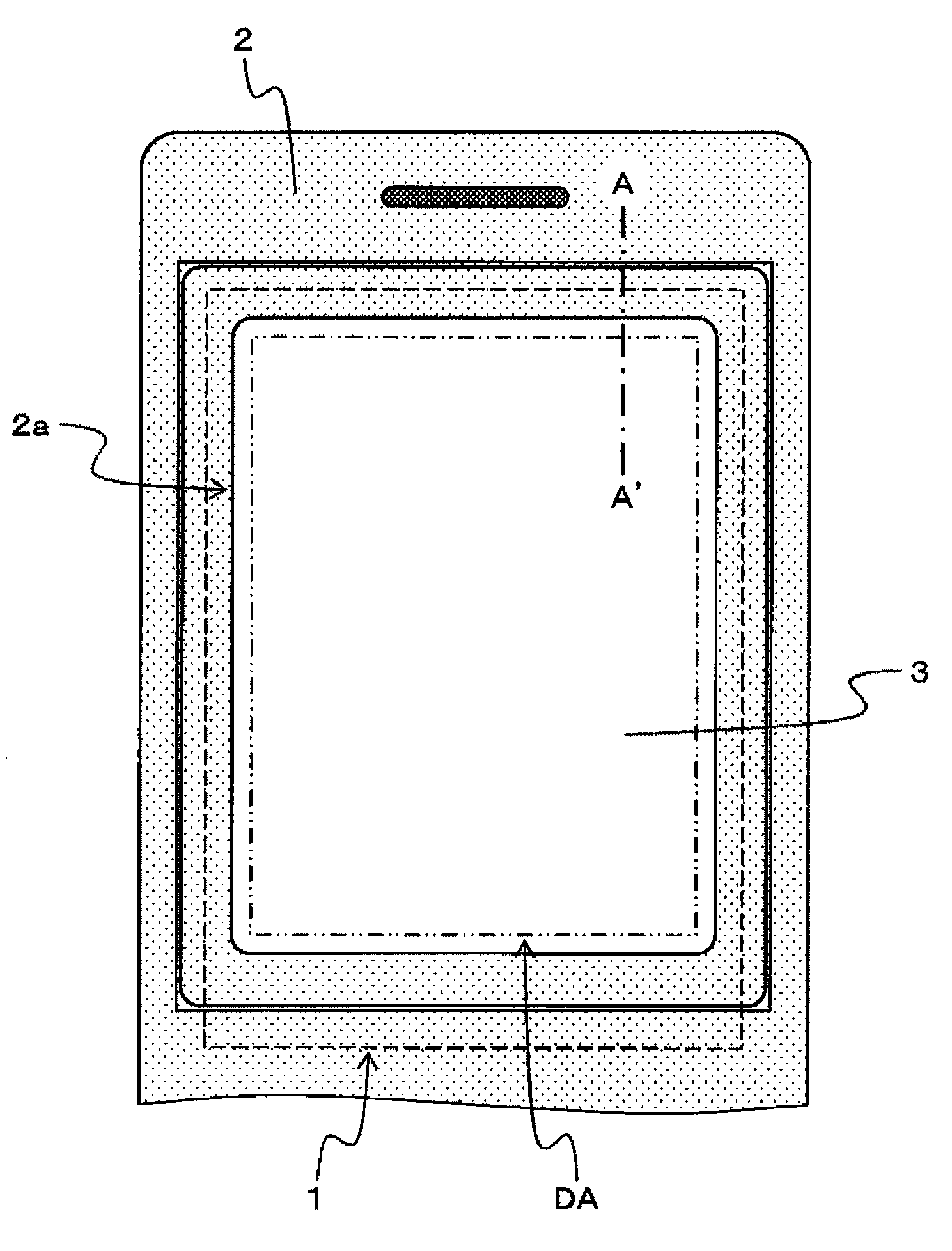

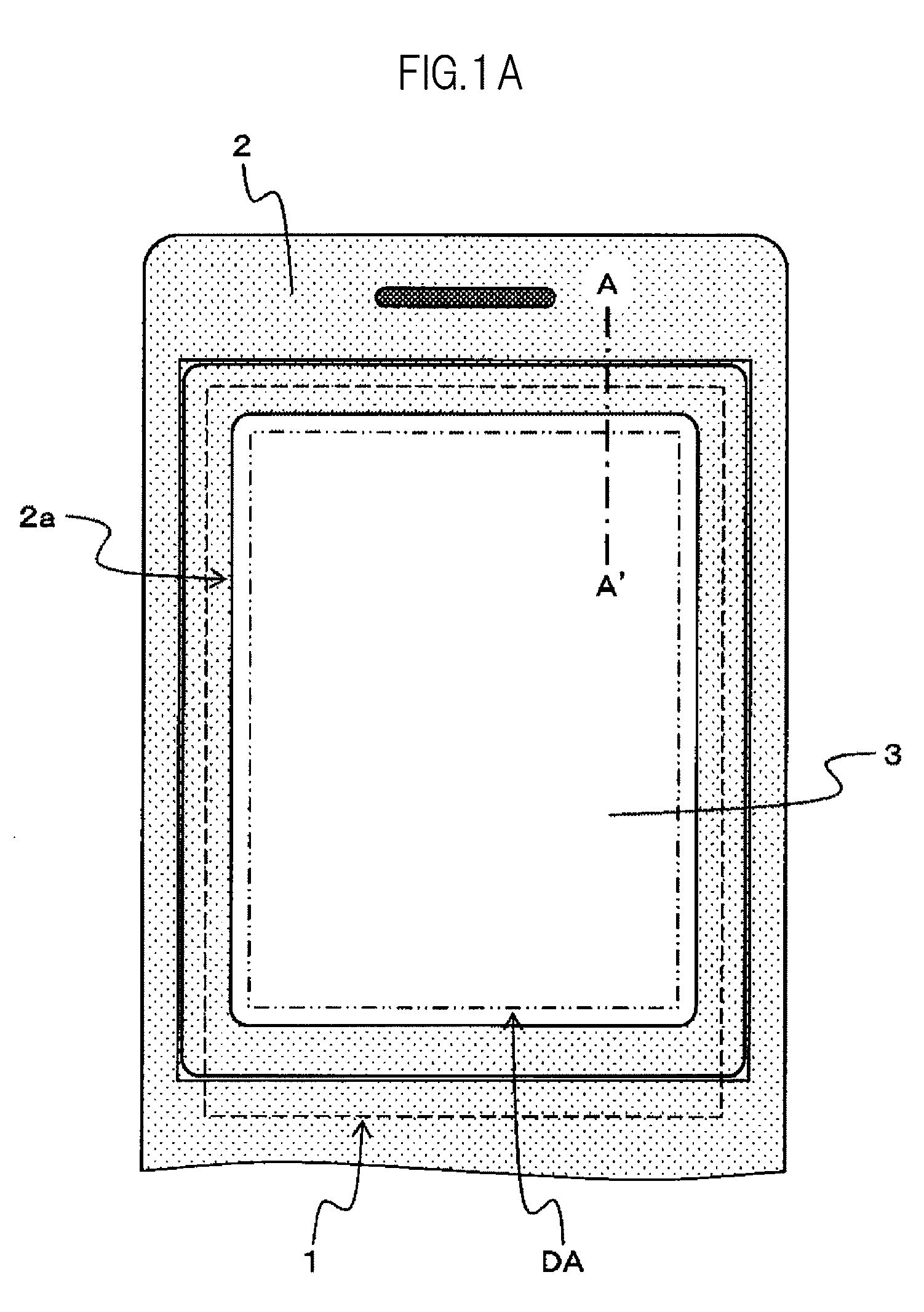

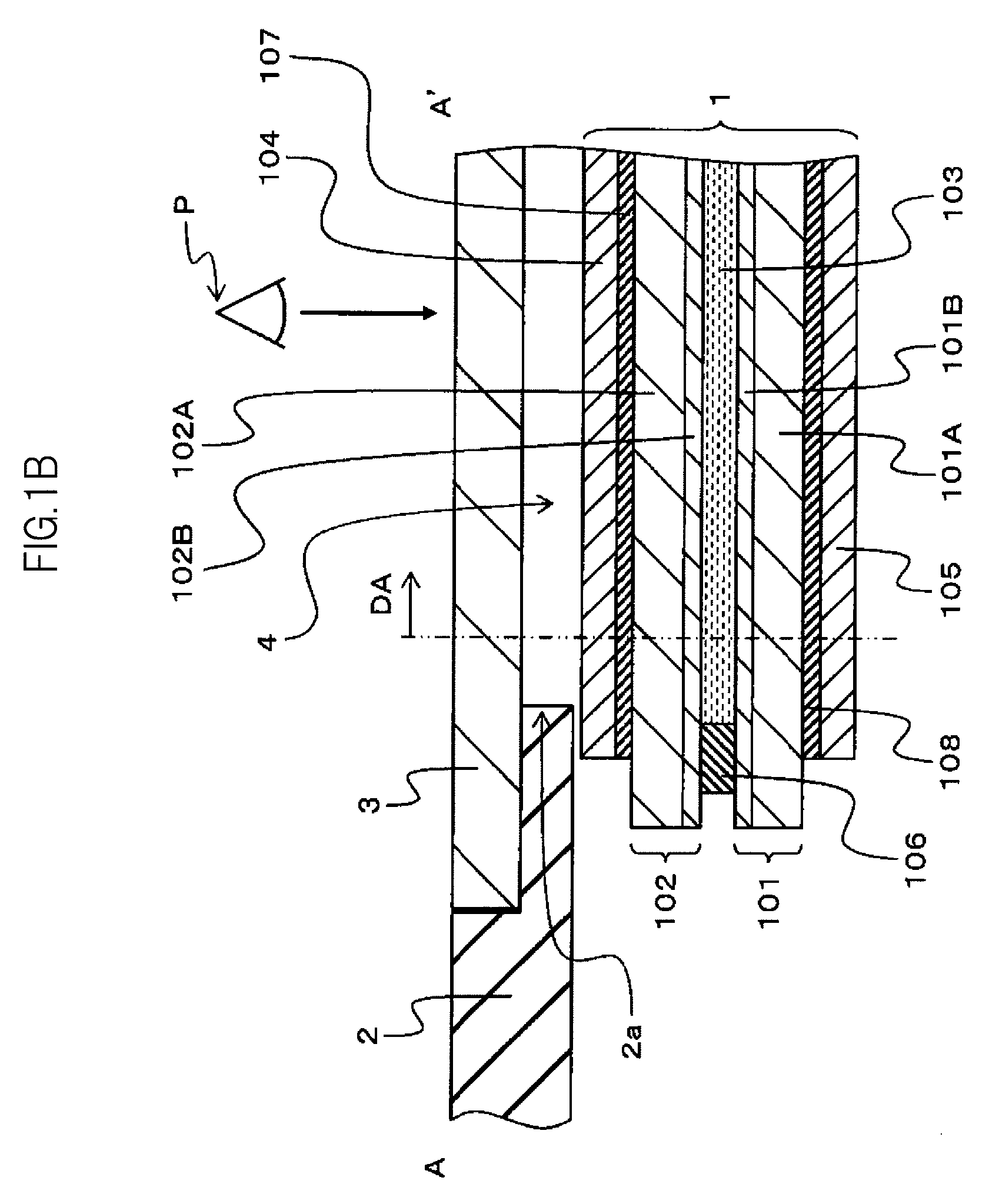

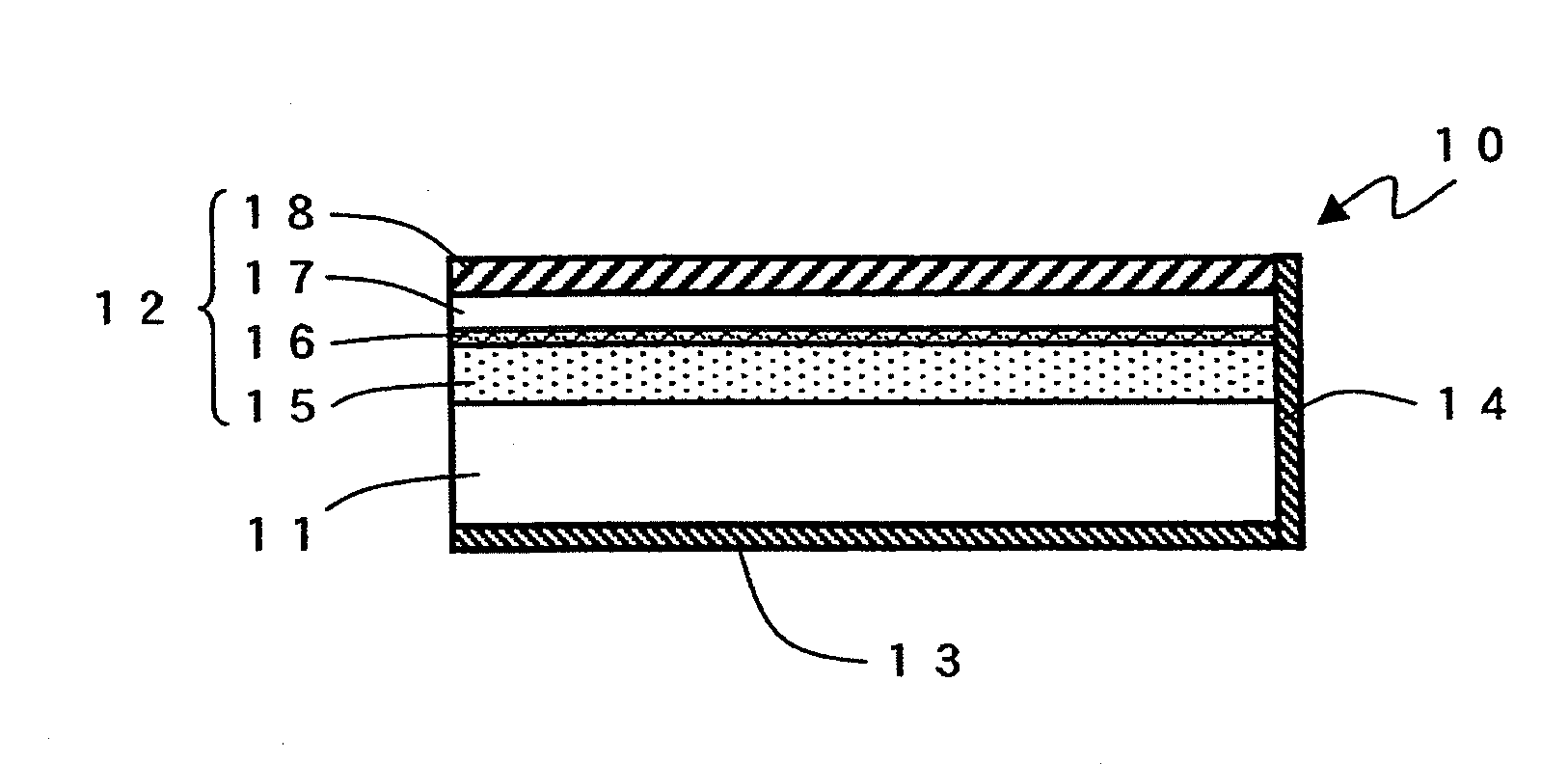

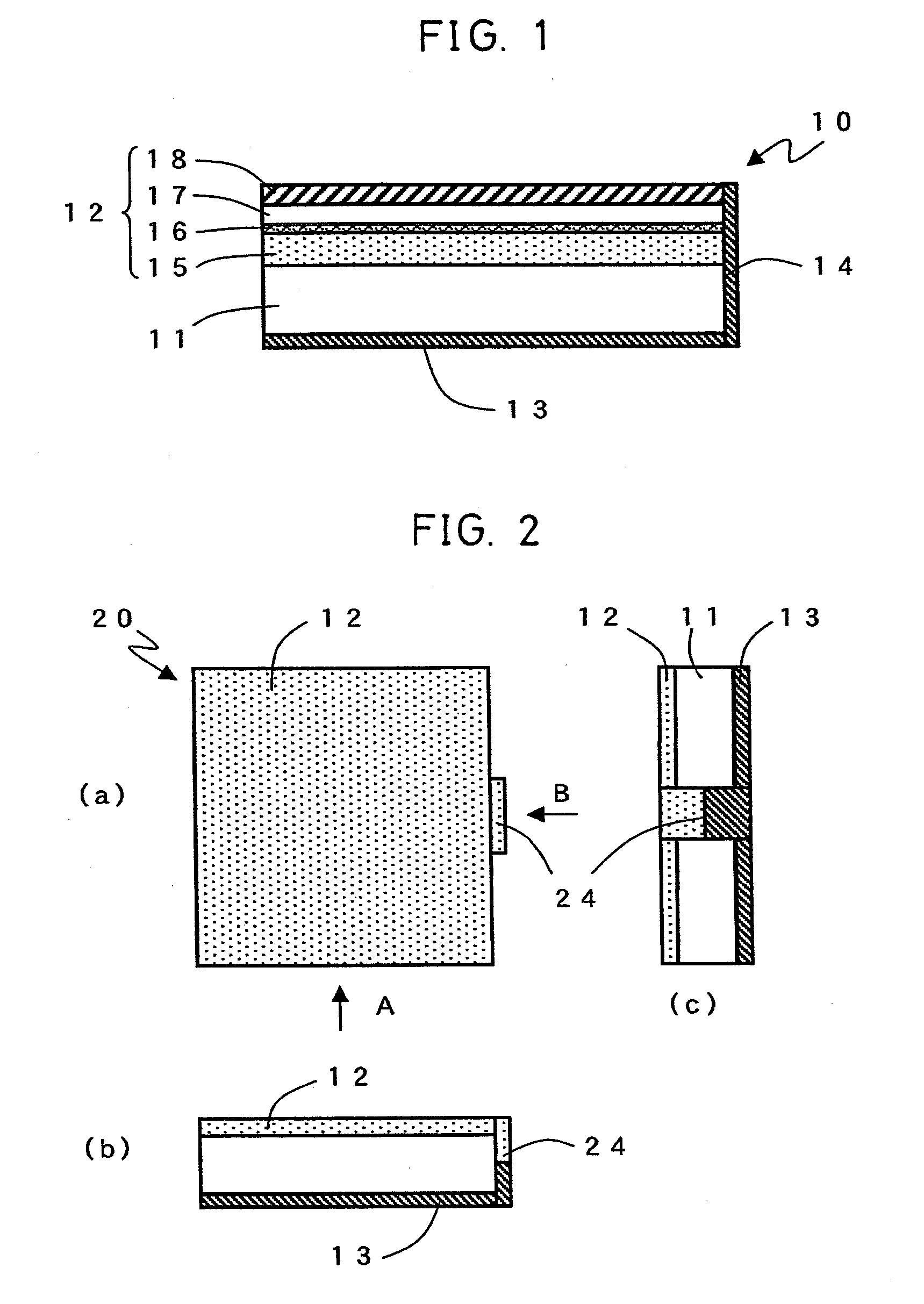

Liquid Crystal Display Device

A liquid crystal display device includes: a first substrate; a second substrate which is placed nearer to a viewer than the first substrate, and which faces a viewer side of the first substrate; a liquid crystal sandwiched between the first substrate and the second substrate; an upper polarization plate which is placed nearer to the viewer than the second substrate, and which faces a viewer side of the second substrate; and a transparent resin plate which is placed nearer to the viewer than the upper polarization plate, and which is attached to a viewer side of the upper polarization plate with one of an adhesive material and a bonding material, the transparent resin plate includes a transparent oxide film on a face that faces the upper polarization plate, and the transparent resin plate is in close contact with the adhesive material or the bonding material through the transparent oxide film.

Owner:PANASONIC LIQUID CRYSTAL DISPLAY CO LTD +1

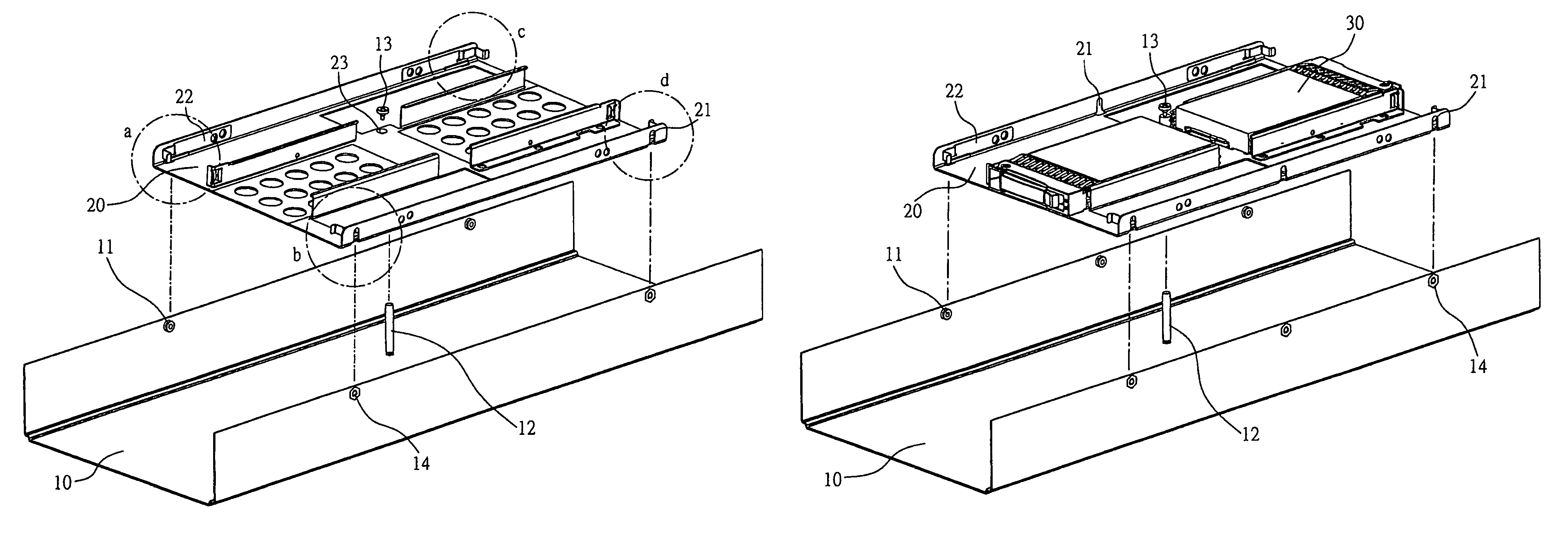

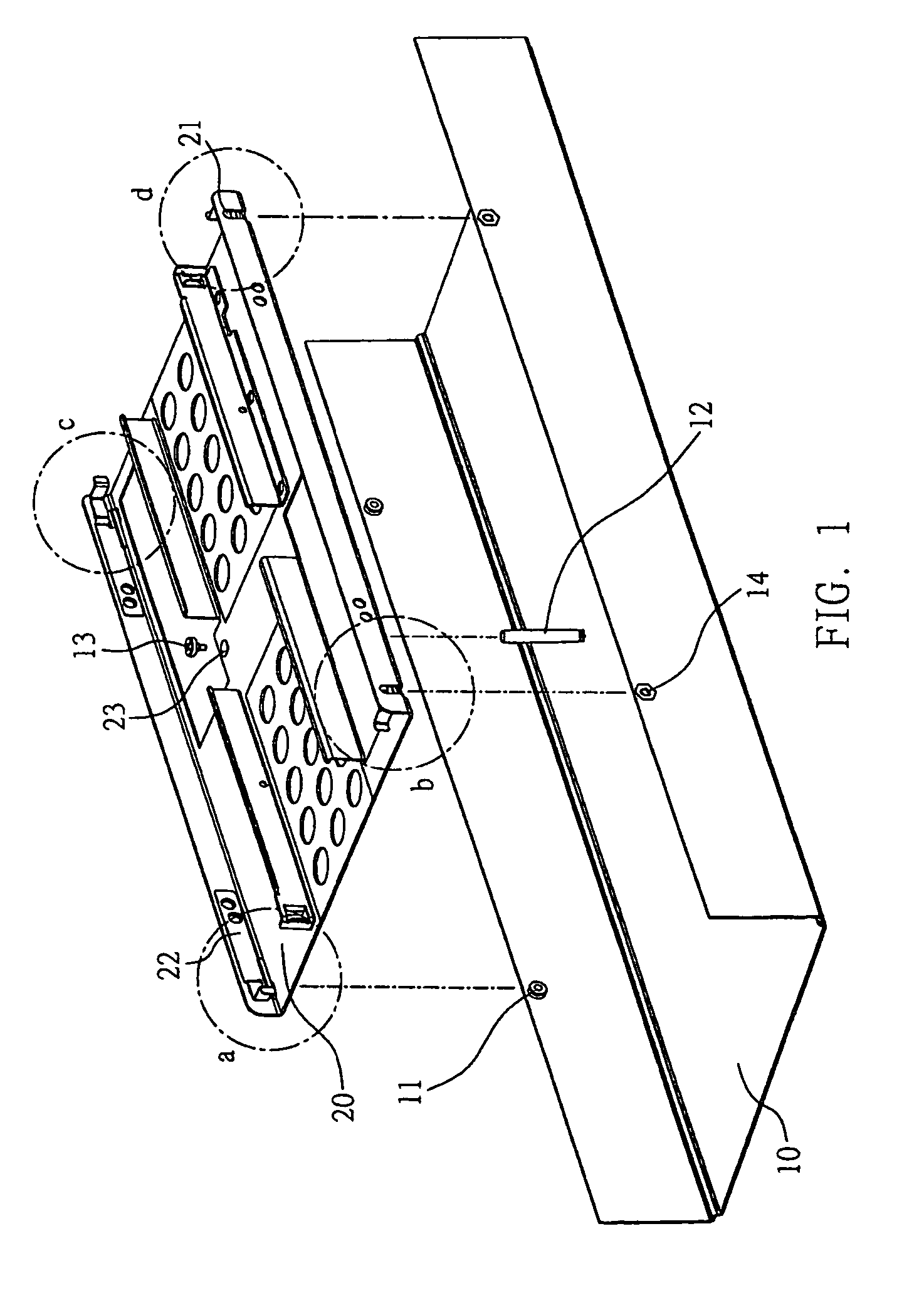

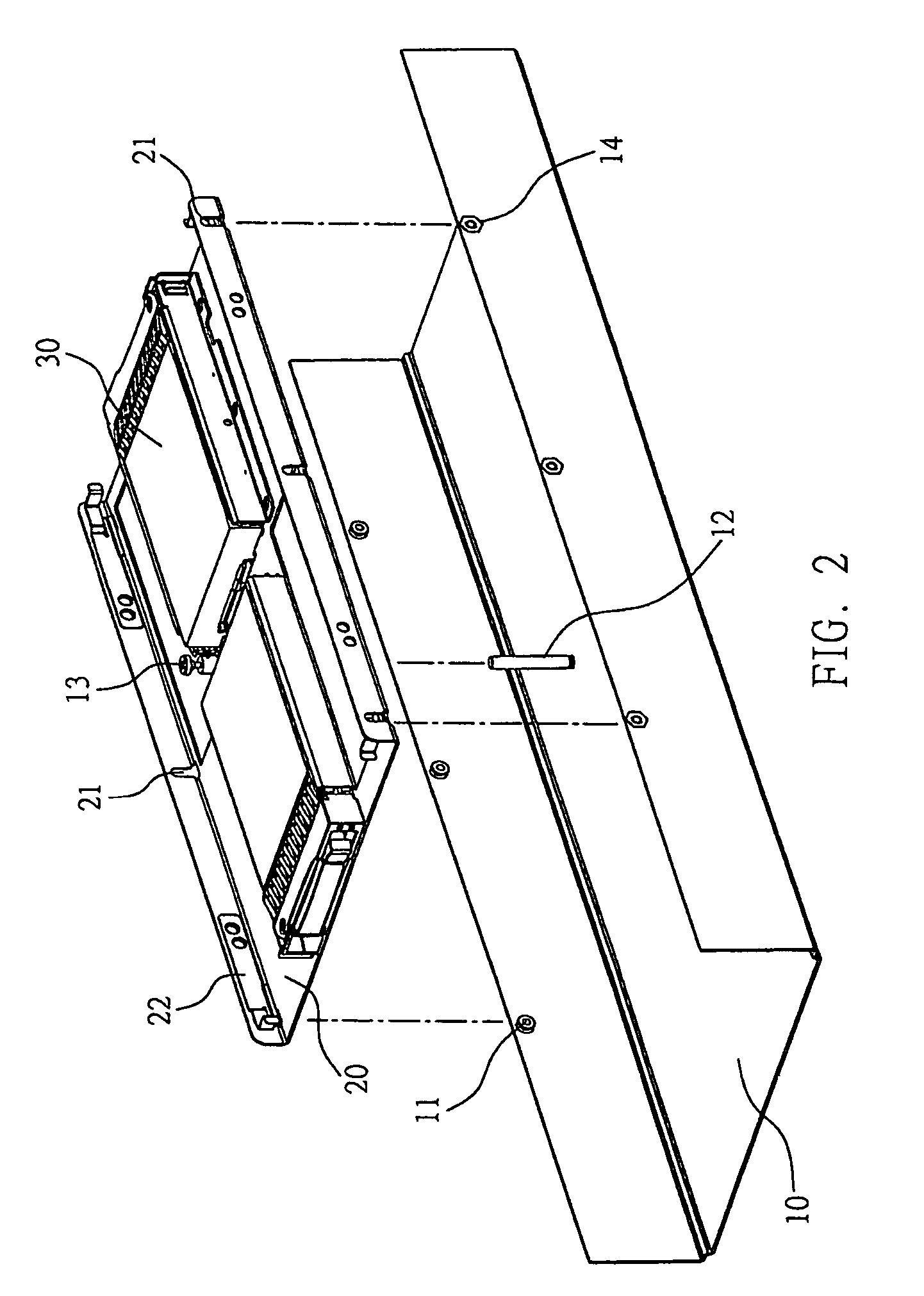

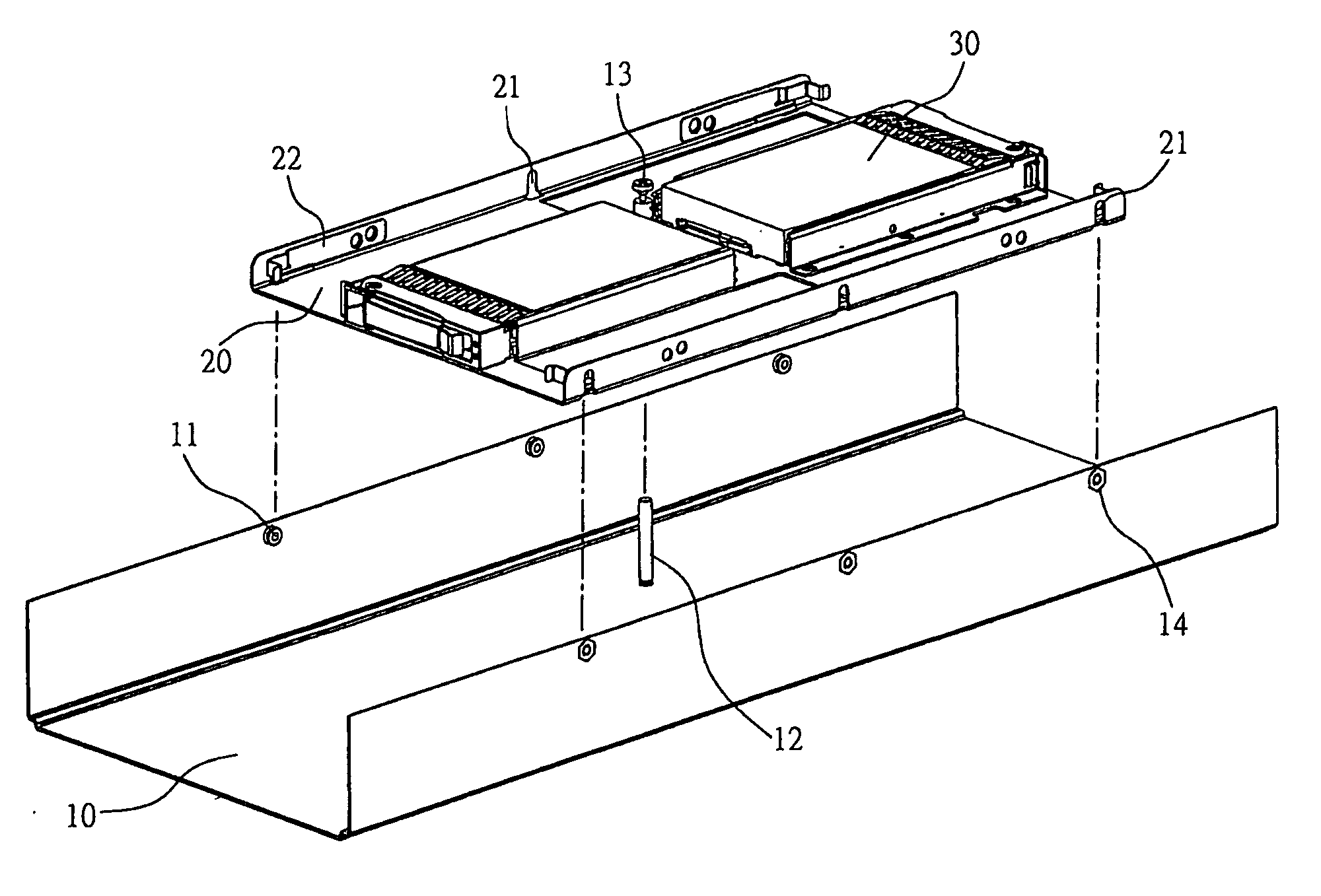

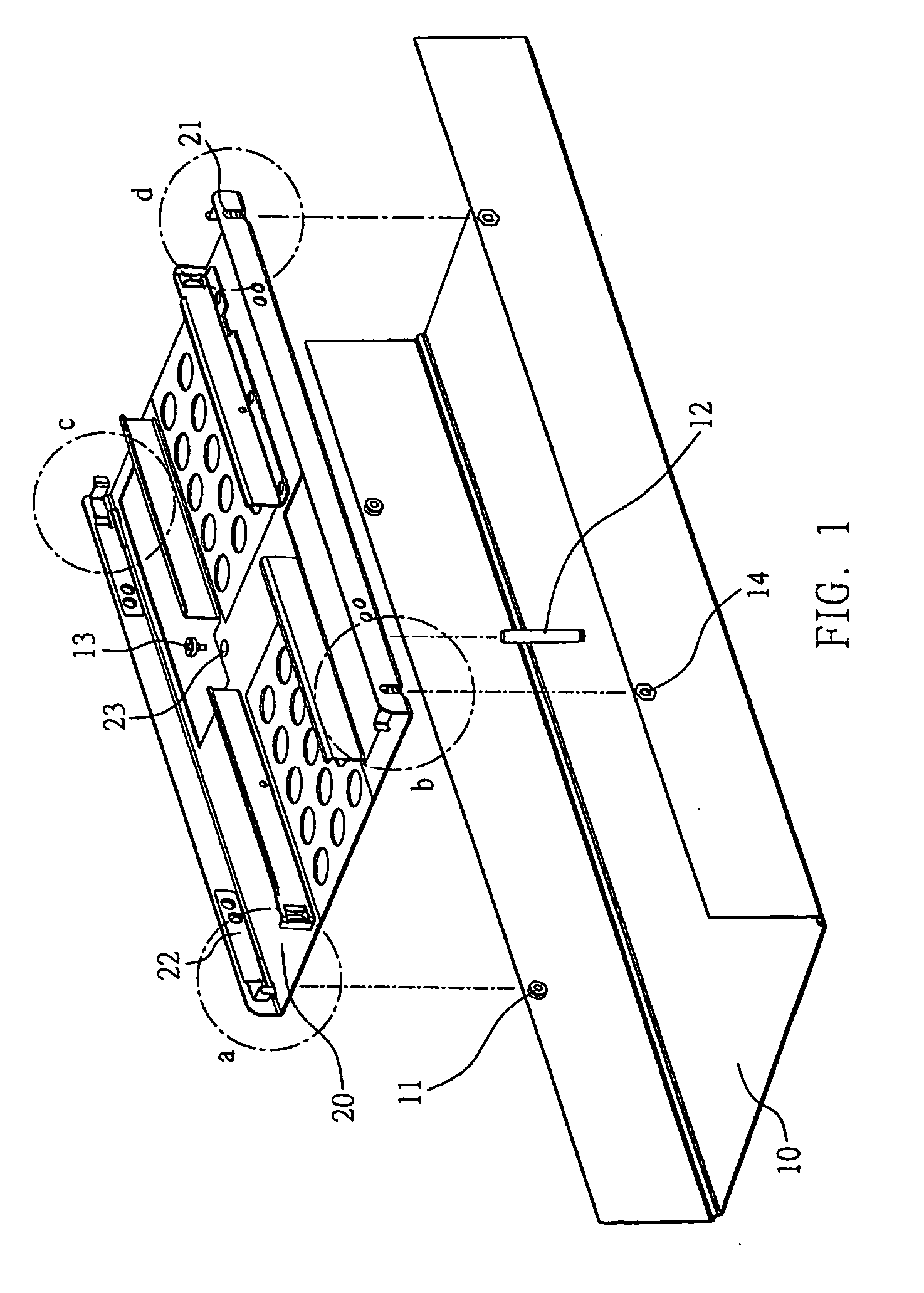

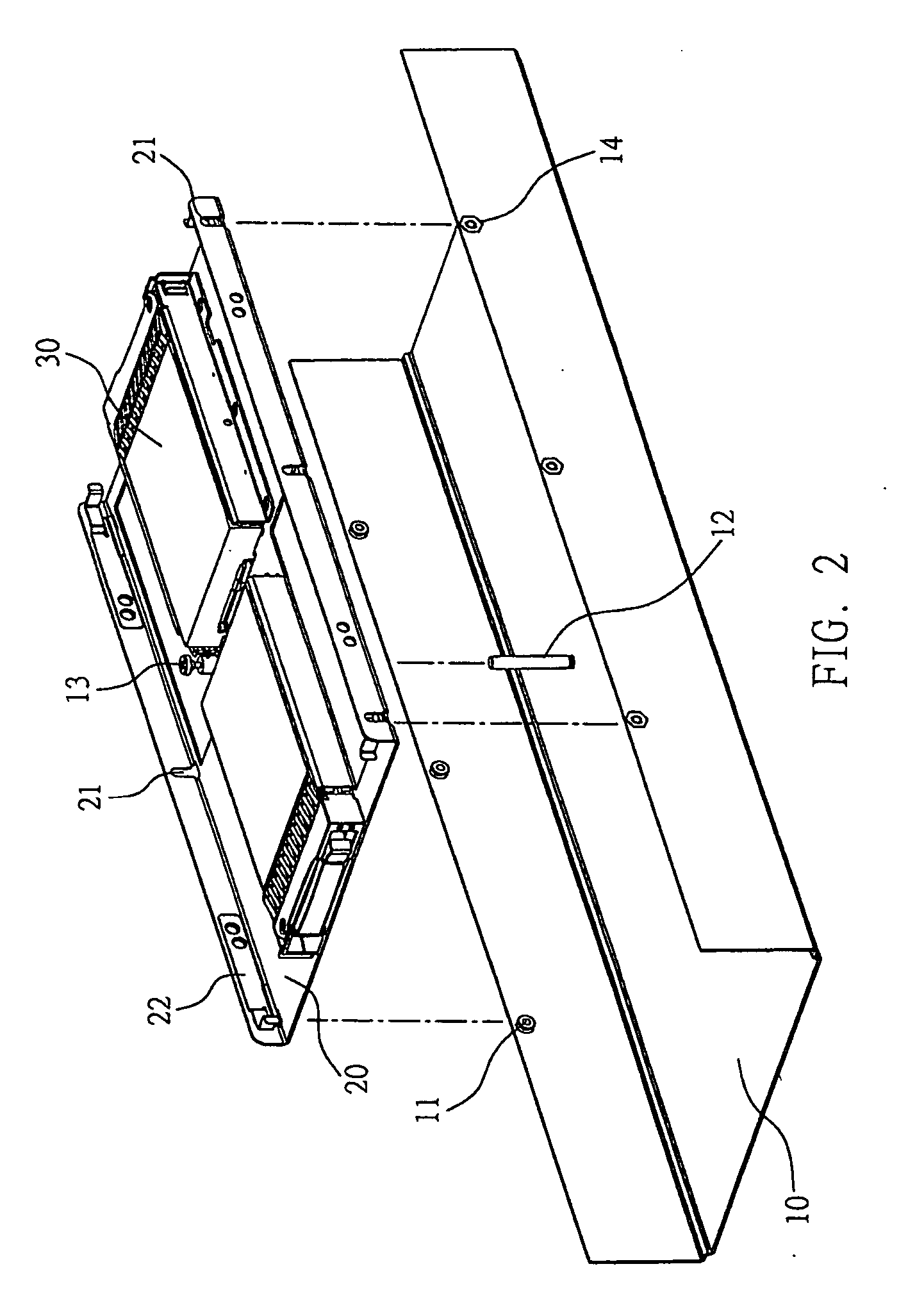

Supporting mechanism for storage drives

InactiveUS7447010B2Simple structureImprove stabilityDigital data processing detailsRecord information storageEngineeringElectronic equipment

Owner:INVENTEC CORP

Supporting mechanism for storage drives

InactiveUS20070025067A1Restrict space usageSimple structureDigital data processing detailsRecord information storageEngineeringCentral region

Owner:INVENTEC CORP

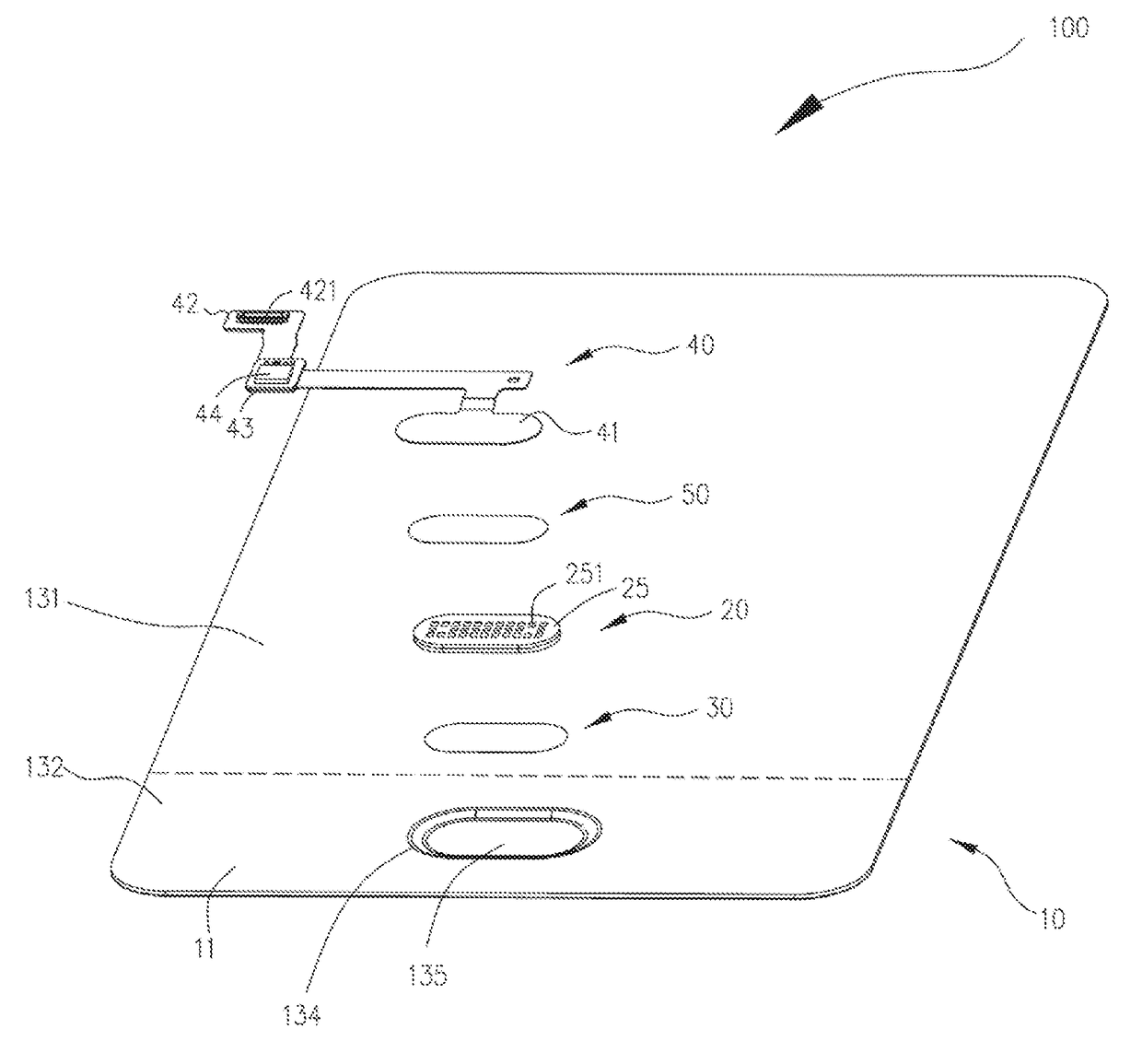

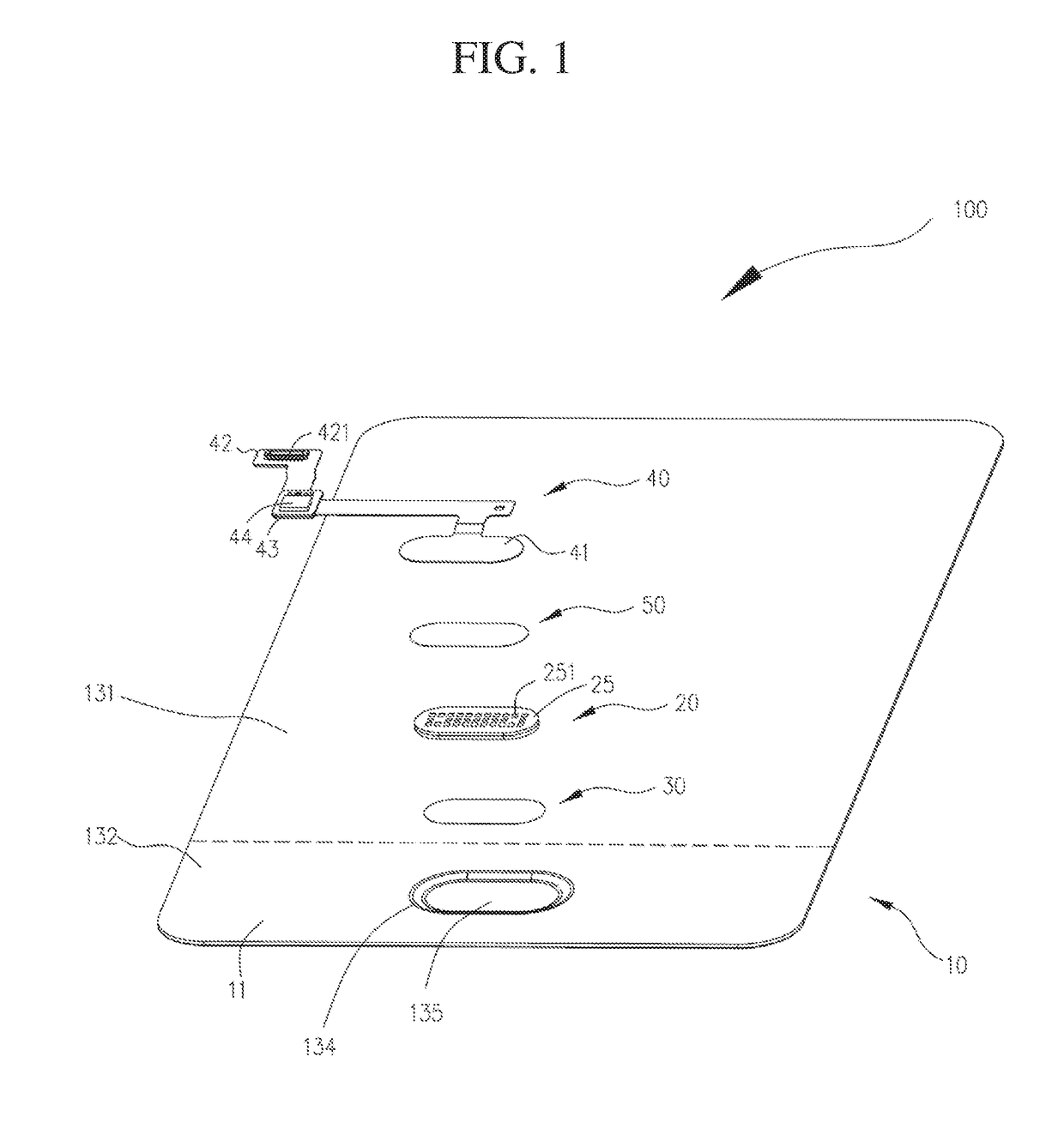

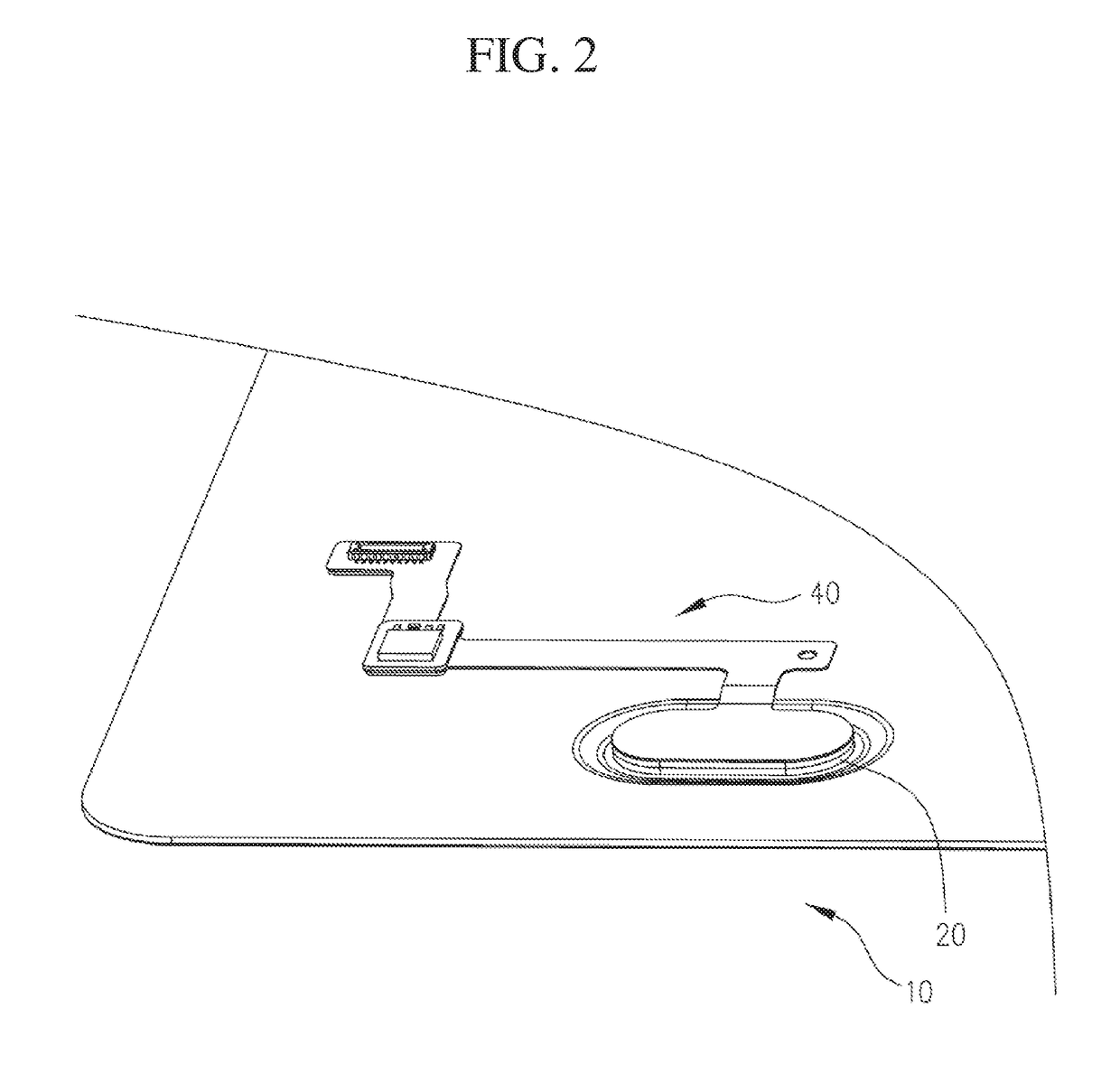

Fingerprint module, method for fabricating the same, and mobile terminal having the same

ActiveUS20180053030A1Quality improvementAvoid easy detachmentDigital data processing detailsDevices with sensorAdhesiveEngineering

A fingerprint module, a method for fabricating the same, and a mobile terminal having the same are provided. The fingerprint module has a cover plate and a fingerprint chip. The cover plate has an inner surface. The fingerprint chip is heat-pressed on the inner surface by adhesive, such that the adhesive fully contacts the cover plate and the fingerprint chip. The method includes after heating the adhesive which is coated on the inner surface of the cover plate, the fingerprint chip is laminated on the adhesive, such that the adhesive fully contacts the cover plate and the fingerprint chip.

Owner:GUANGDONG OPPO MOBILE TELECOMM CORP LTD

Packaging box and single-sheet packaging box prefabricating material and forming method and system thereof

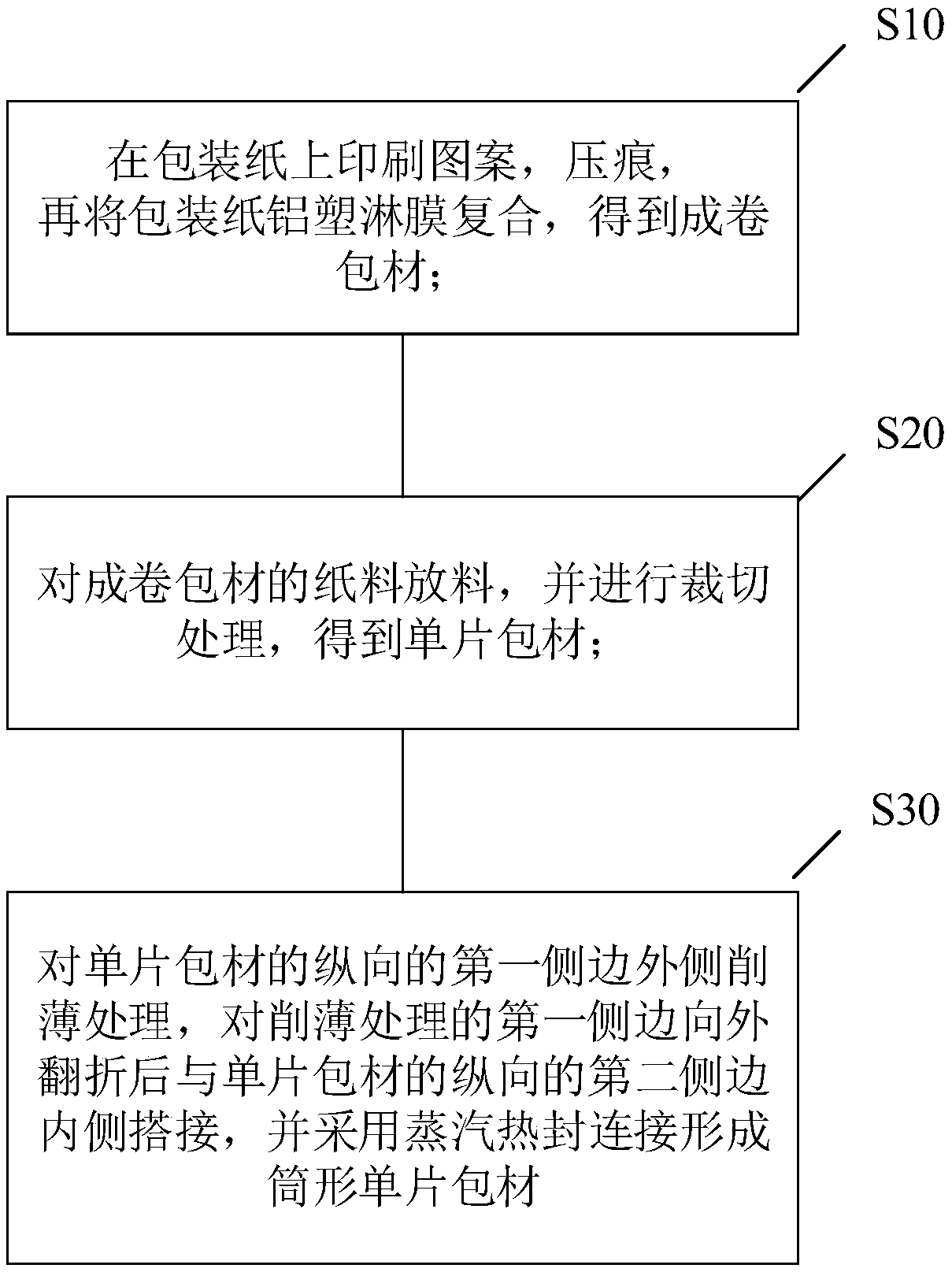

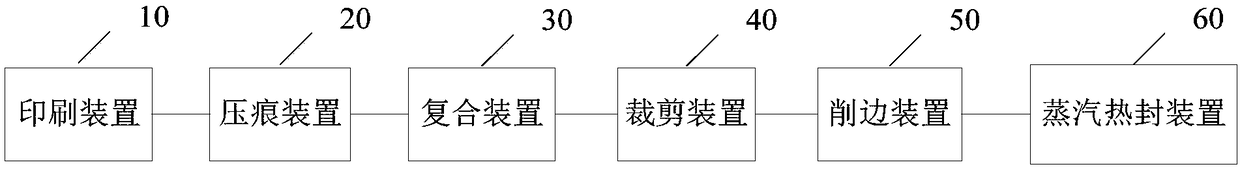

PendingCN109454924AImprove yieldImprove leakageSpecial paperBox making operationsLap jointEngineering

The invention discloses a packaging box, a single-sheet packaging box prefabricating material and a forming method and system thereof. The forming method of the single-sheet packaging box prefabricating material comprises the following steps that S10, patterns are printed on packaging paper, indenting is carried out, the packaging paper and an aluminum plastic laminating film are compounded, and arolled packaging material is obtained; and S20, paper of the rolled packaging material is discharged, cutting is carried out, and a single-sheet packaging material is obtained; S30, the outer side ofthe first longitudinal side of the single-sheet packaging material is thinned, the thinned first side is turned outwards to be in lap joint with the inner side of the longitudinal second side of thesingle-sheet packaging material, steam heat sealing connection is adopted, and a barrel-shaped single-sheet packaging material is formed. According to the packaging box, the single-sheet packaging boxprefabricating material and the forming method and system thereof, the packaging paper is printed and indented, and then combining, cutting, edge cutting and steam heat sealing are carried out; on one hand, the problem that printed content is likely to be separated is avoided; and on the other hand, the yield of the single-sheet packaging box is increased, and the problem of packaging box leakageis relieved.

Owner:GREATVIEW BEIJING TRADING CO LTD

EUV exposure mask blanks and their fabrication process, and EUV exposure mask

InactiveUS20070015065A1Readily attachable to and detachableDifficult to detachNanoinformaticsVacuum evaporation coatingElectrically conductiveOptoelectronics

The invention provides a mask blank for EUV exposure wherein a substrate is provided at its flank with an electrically conductive film unlikely to peel off in EUV exposure mask fabrication process steps, etc. and its fabrication process, and provide a mask for EUV exposure which is readily attachable to or detachable from an electrostatic chuck, thereby foreclosing the possibility of the mask remaining clinging firmly to the electrostatic chuck after EUV exposure and being hard to detach from it. A mask blank for EUV exposure is provided, in which on one major surface of a substrate, a reflective layer adapted to reflect EUV light and an absorptive layer located on said reflective layer for absorption of said EUV light are at least provided as a pattern-formation layer. An electrically conductive layer is formed on another major surface of the substrate, and the pattern-formation layer and the conductive layer on the opposite major surfaces of the substrate are in conduction with each other via one or more flank conductive films provided at the flank of the substrate.

Owner:DAI NIPPON PRINTING CO LTD

Sheet manufacturing apparatus, sheet manufacturing method, sheet manufactured using sheet manufacturing apparatus and sheet manufacturing method, and composite and container used in sheet manufacturing apparatus and sheet manufacturing method

A sheet manufacturing apparatus includes a mixing unit and a forming unit. The mixing unit is configured to mix fibers and a composite, where a resin and a wax are integrally combined, in air. The forming unit is configured to form a sheet by depositing and heating a mixed material where the fibers and the composite are mixed.

Owner:SEIKO EPSON CORP

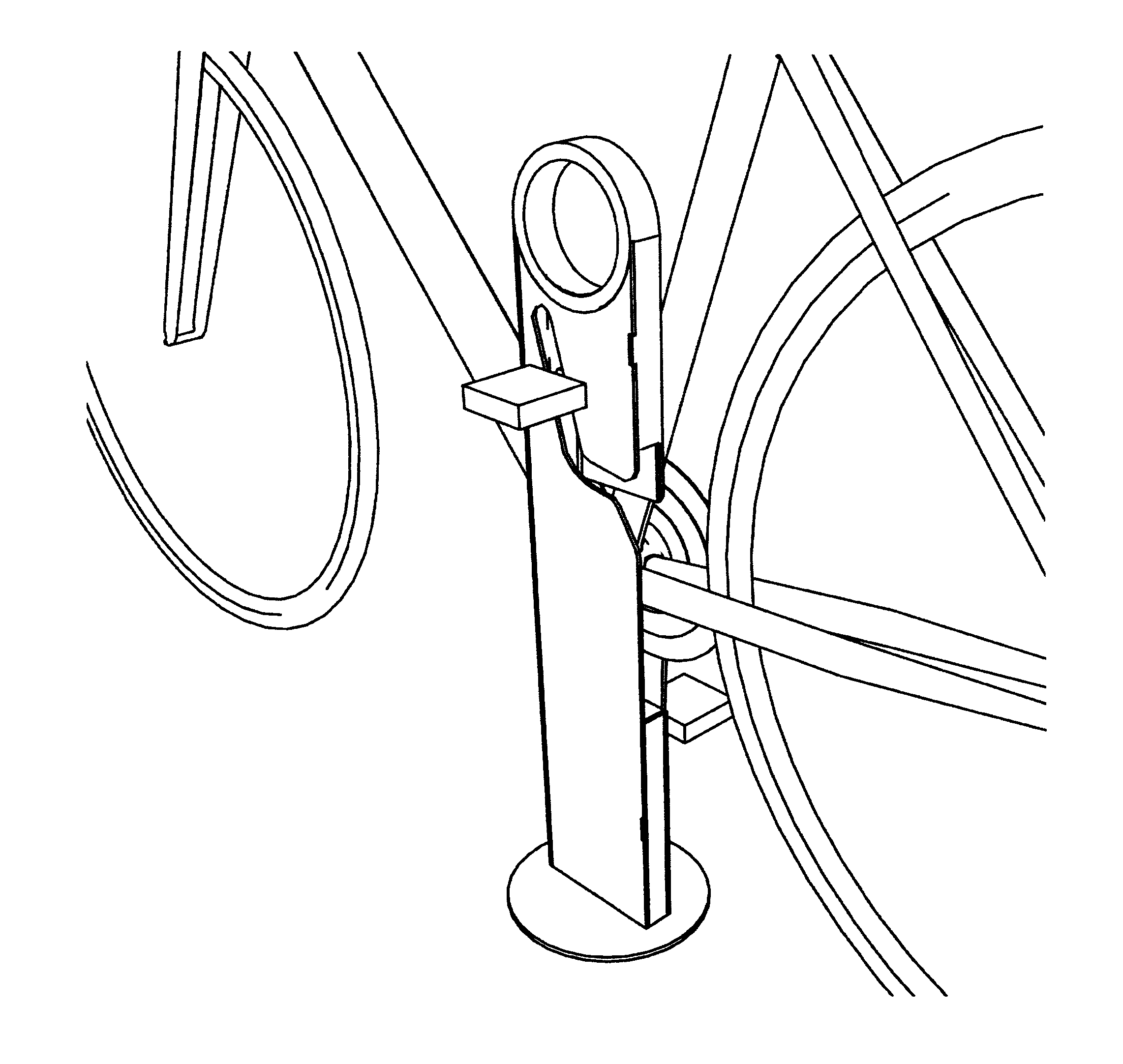

Bicycle rack

A bicycle rack including a first opening which is dimensioned to receive a pedal axle of a bicycle and which first opening is elongated in shape and arranged to be at least substantially on a vertical plane, and a first end of the first opening is arranged to open sideways on the plane and its second end is arranged to open upward of the first end; a mating surface that is arranged at a first distance from the first opening and at least partly at the first opening, the first distance being dimensioned to receive a top part of the pedal crank of the bicycle; a boss space that is arranged below the mating surface to open in the same direction as the first end of the first opening, the boss space being dimensioned to receive a bottom part of the pedal crank.

Owner:PEDALSLOT

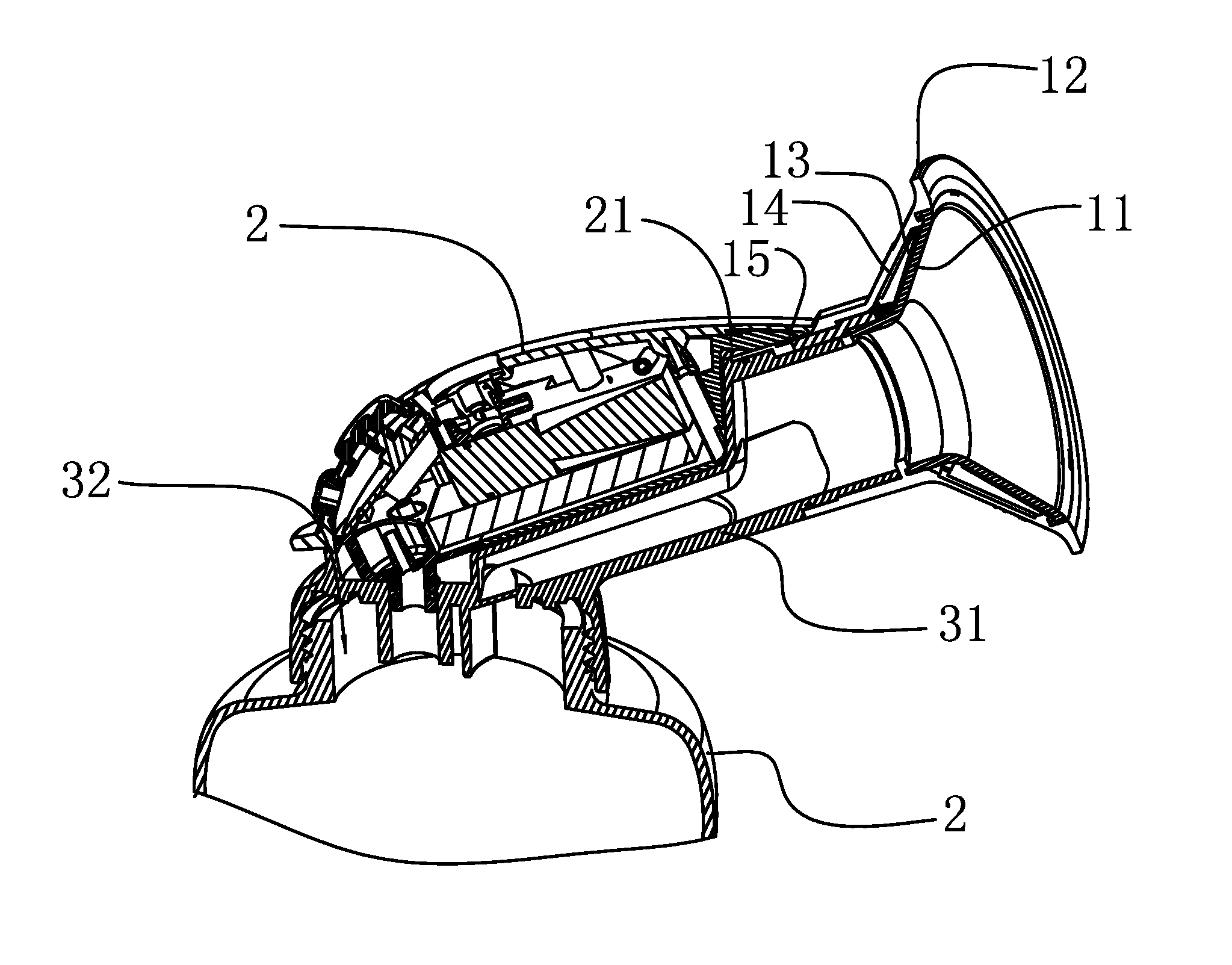

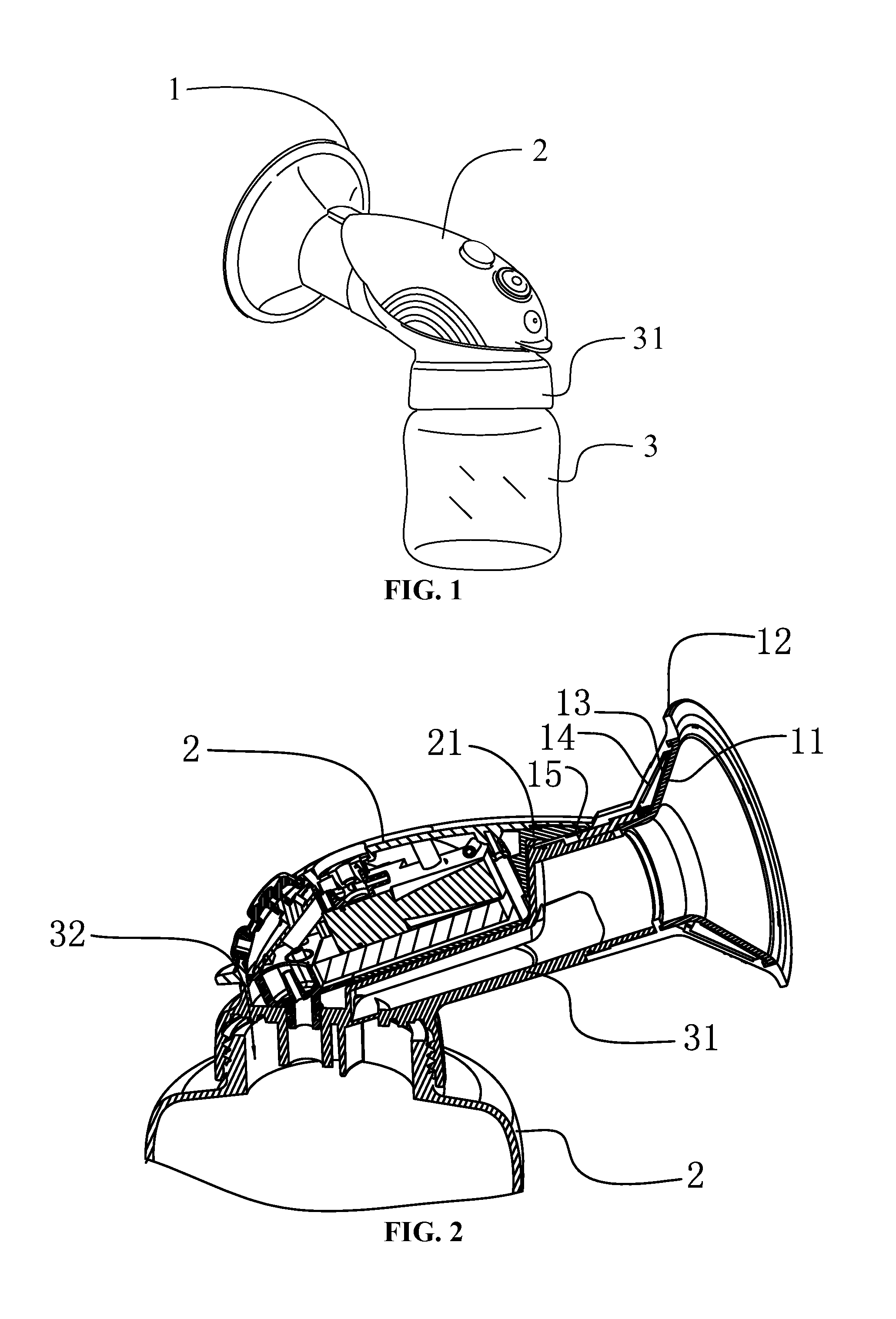

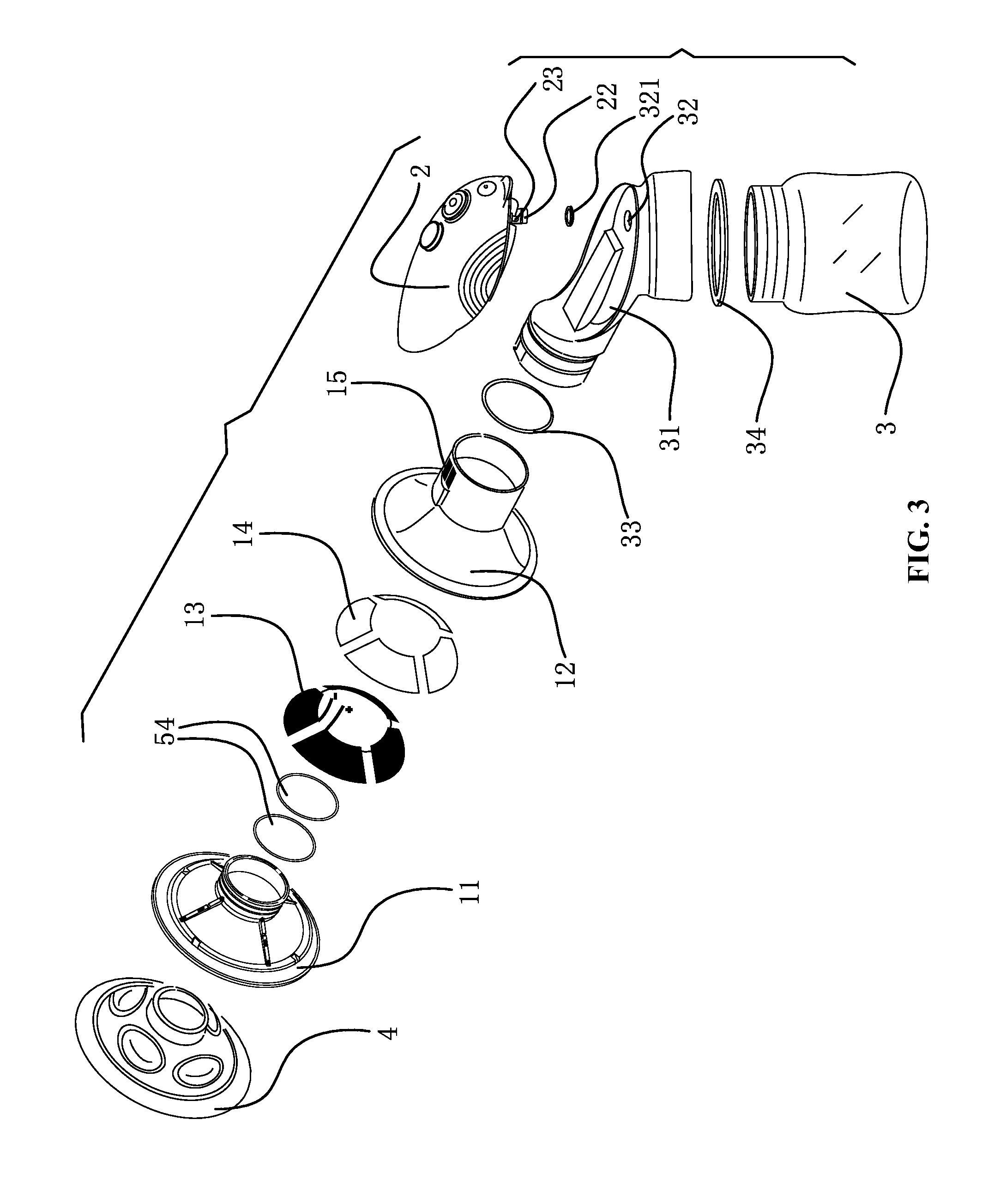

Breast pump comprising heating cup

InactiveUS20150157775A1Avoid easy detachmentEasy to cleanMilking pumpMedical devicesElectricityThermal insulation

A breast pump including a container, a host unit disposed above and communicating with the container, an electric heating cup disposed at the front end of the host unit and communicating with the container, an electric heating element, and heat insulation. The electric heating cup includes an inner cover and an outer cover which are integrated. The electric heating element and the heat insulation are disposed between the inner cover and the outer cover. The heat insulation is disposed between the electric heating element and the outer cover. Positive and negative electrodes of the electric heating element are connected to conducting plates disposed in the inner side of the outer cover via connection wires. The conducting plates extend to the outer side of the outer cover and are in electric connection to contact chips disposed at the lower front end of the host unit.

Owner:NINGBO LACTANS MEDICAL TECH

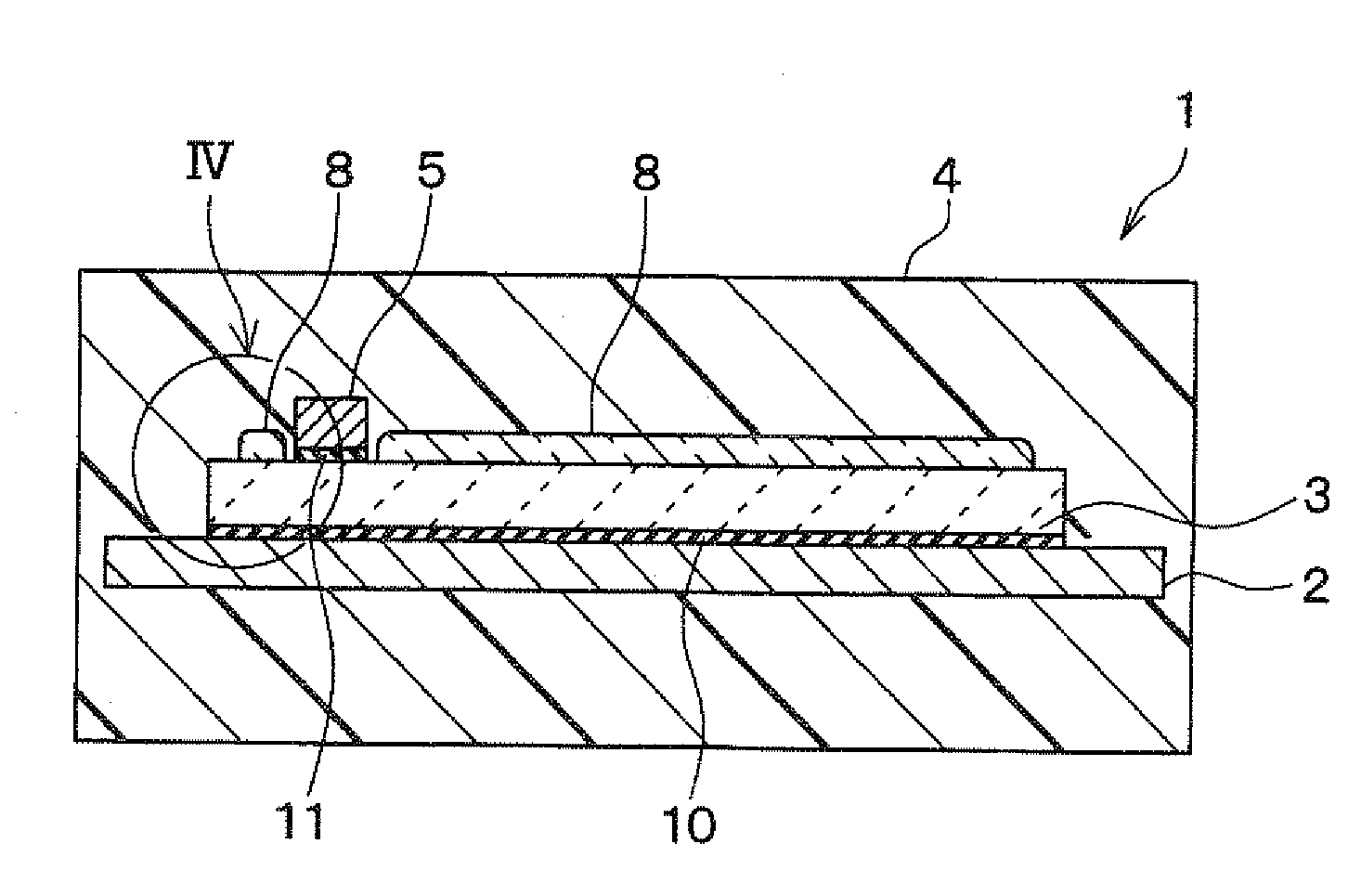

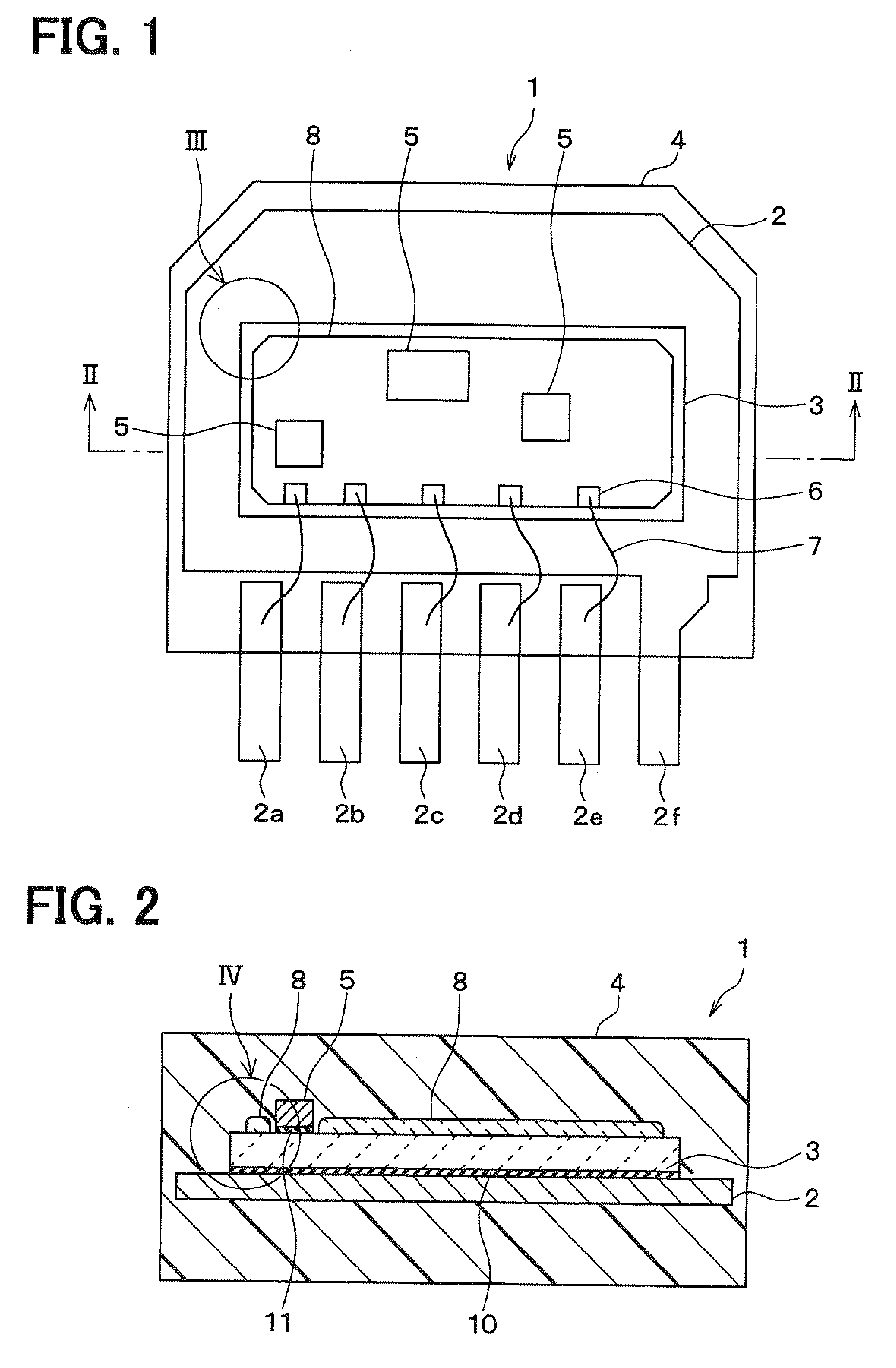

Resin molded semiconductor device

ActiveUS20080296783A1Avoid bondingAvoid crackingSemiconductor/solid-state device detailsSolid-state devicesDevice materialEngineering

A semiconductor device includes a circuit board, a wiring part, a protective coating glass, and a resin part. The circuit board has an approximately rectangular shape. The protective coating glass is disposed on the circuit board and is arranged on an inside of the circuit board in such a manner that an outer-peripheral end of the protective coating glass is away from each of four sides of the circuit board at a first distance and is away from each of four corners of the circuit board at a second distance that is larger than the first distance. The resin part seals the circuit board, the wiring part, and the protective coating glass in such a manner that an outer-peripheral end portion of the circuit board that is located on an outside of the protective coating glass directly contact with the resin part.

Owner:DENSO CORP

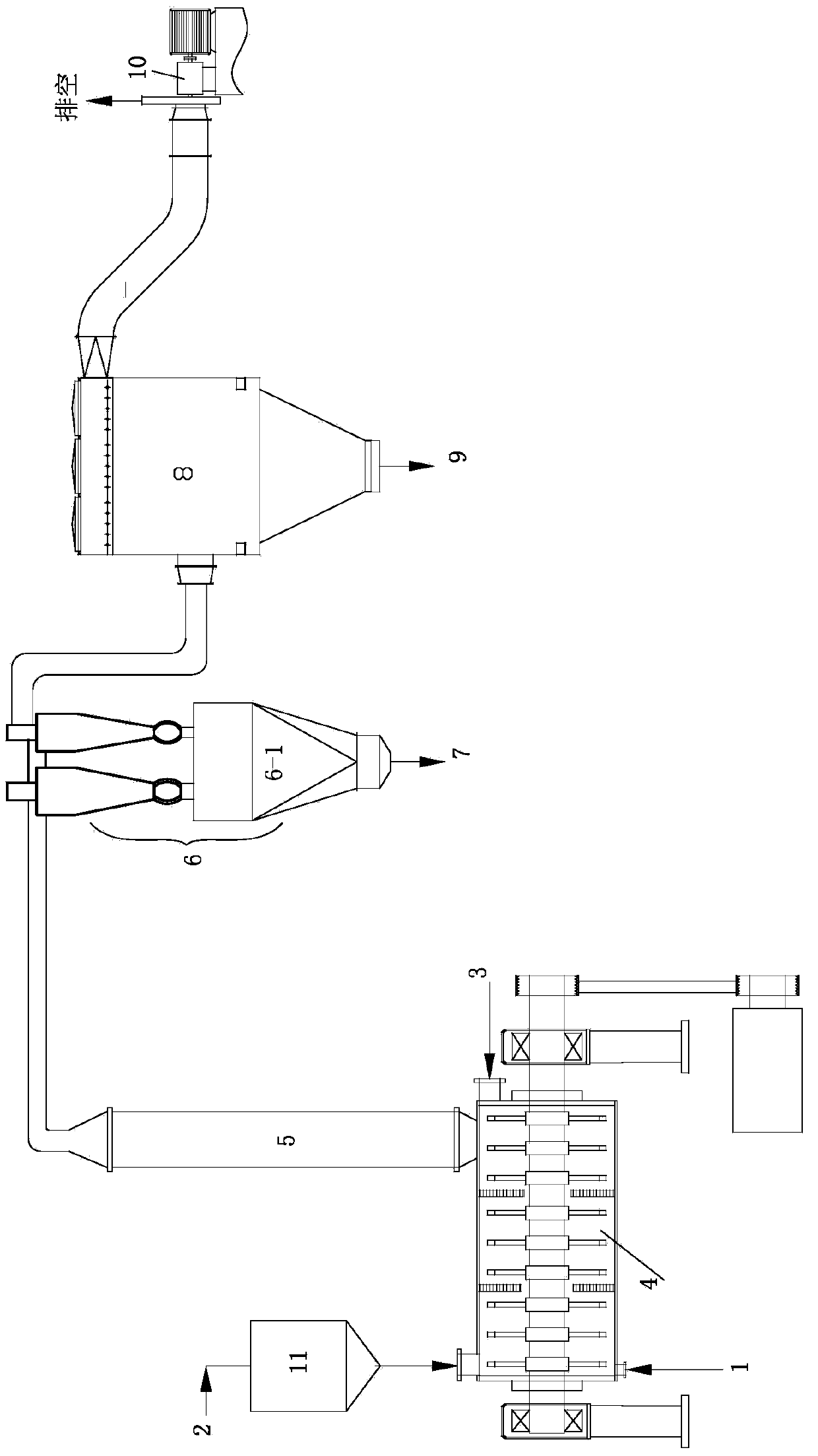

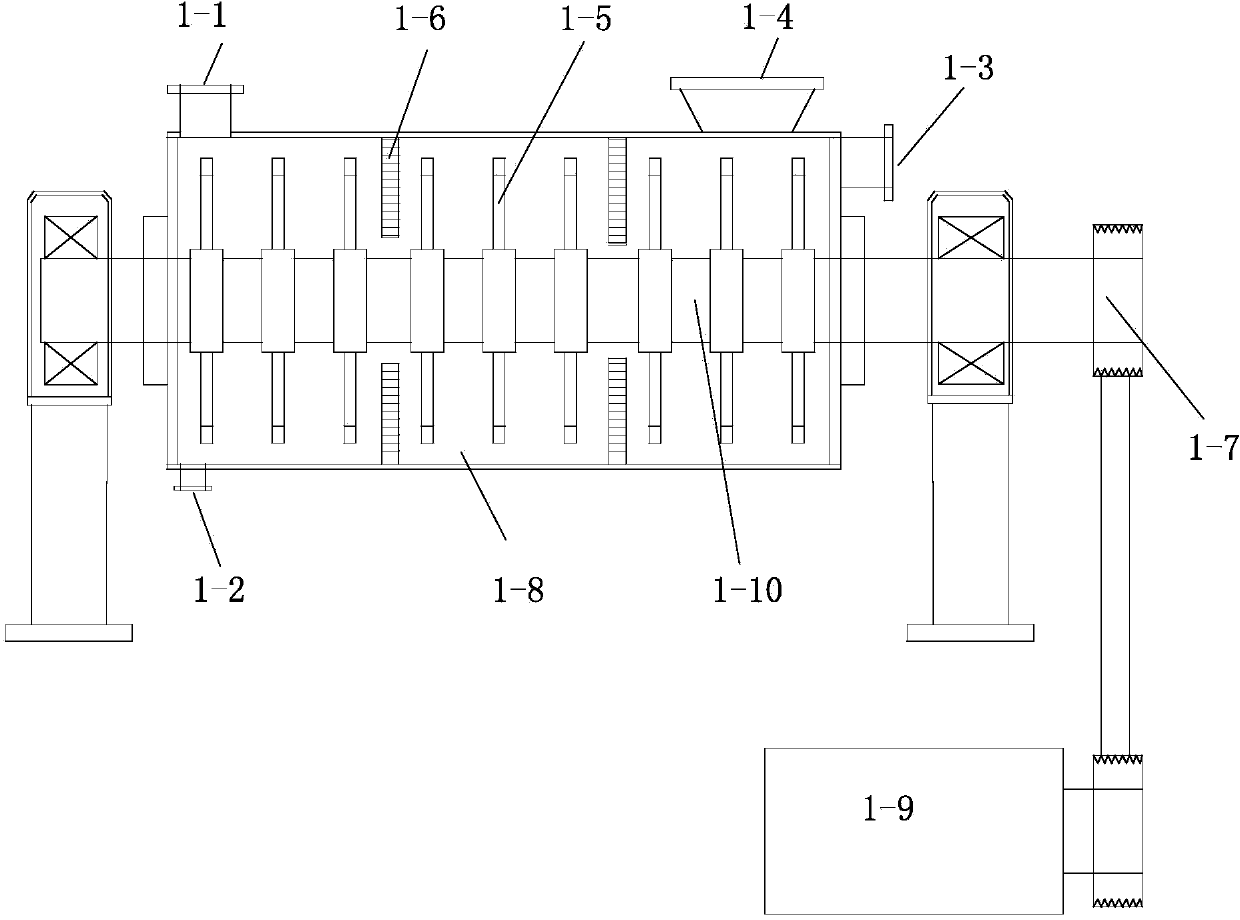

Process and device for continuously preparing powdery washing powder particles

ActiveCN103773618ASuitable for granulationReduce energy consumptionNon-ionic surface-active compoundsDetergent mixture composition preparationCyclonic separationBaghouse

The invention relates to a process and a device for continuously preparing powdery washing powder particles. The process provided by the invention is simple in adopted equipment and high in production efficiency. The provided preparation device is simple in structure. The technical scheme is as follows: the process comprises the following steps: (1) a powdery mixture of a neutralizing agent and a wrapping agent and organic-material acid ester enter a high-shearing reactor according to a certain proportion; (2) the formed washing powder particles are output and then enter a flashing dryer; (3) certain particle size is maintained for the obtained washing powder particles; (4) mixed gas flow from an outlet of the flashing dryer enters a cyclone separator for separation; and (5) a finished product is obtained. The device comprises the high-shearing reactor, the flashing dryer, the cyclone separator, a cloth-bag dust remover and an induced draft fan which are communicated in sequence; and the high-shearing reactor is provided with an acid-ester inlet, a powder inlet, an air inlet and a material outlet communicated with the flashing dryer.

Owner:ZANYU TECH GRP CO LTD +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com