Patents

Literature

145results about How to "Suppress color unevenness" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

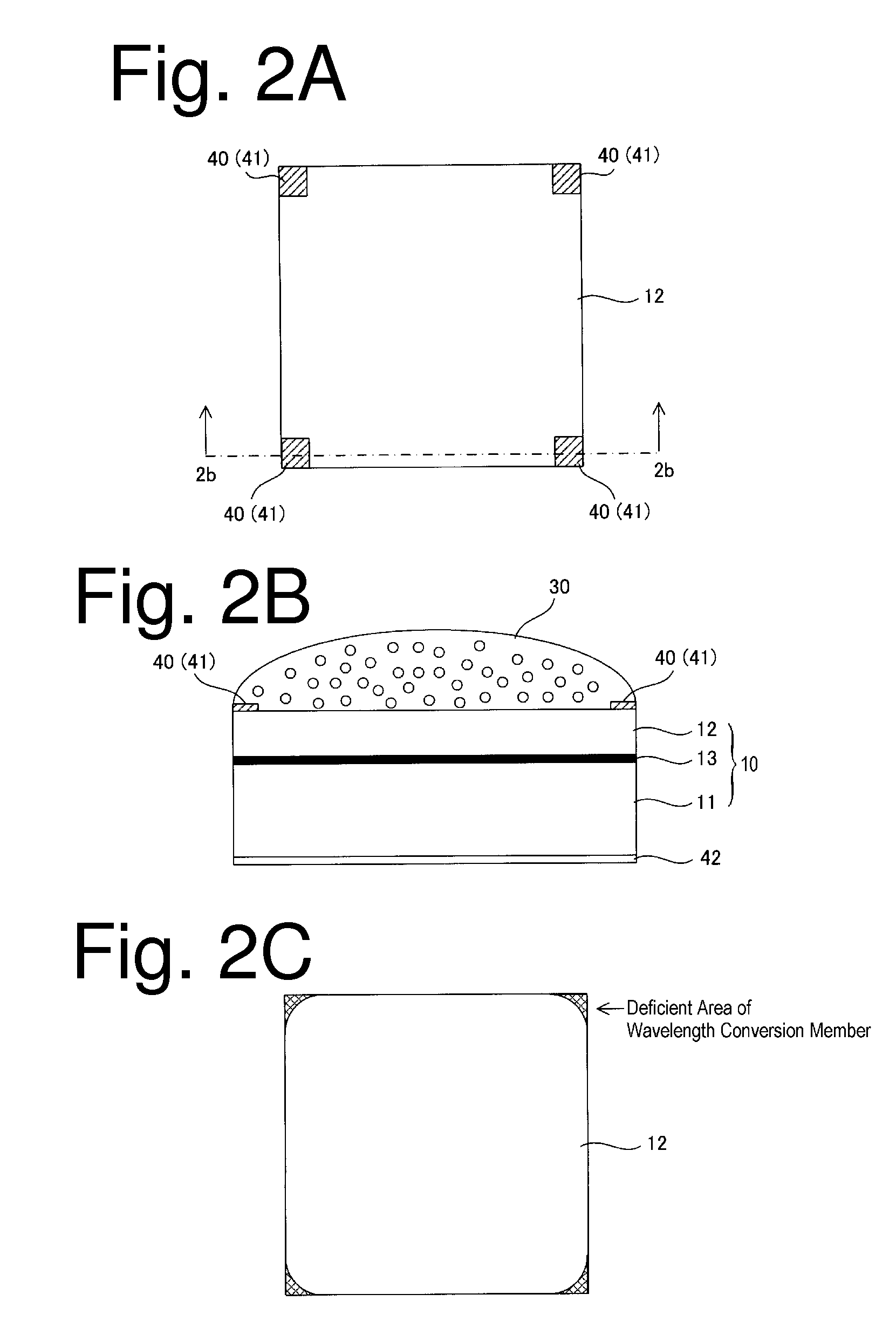

Light-emitting semiconductor device, light-emitting system and method for fabricating light-emitting semiconductor device

InactiveUS7023019B2Suppress color unevennessLittle color unevennessDischarge tube luminescnet screensPoint-like light sourceFluorescenceDevice material

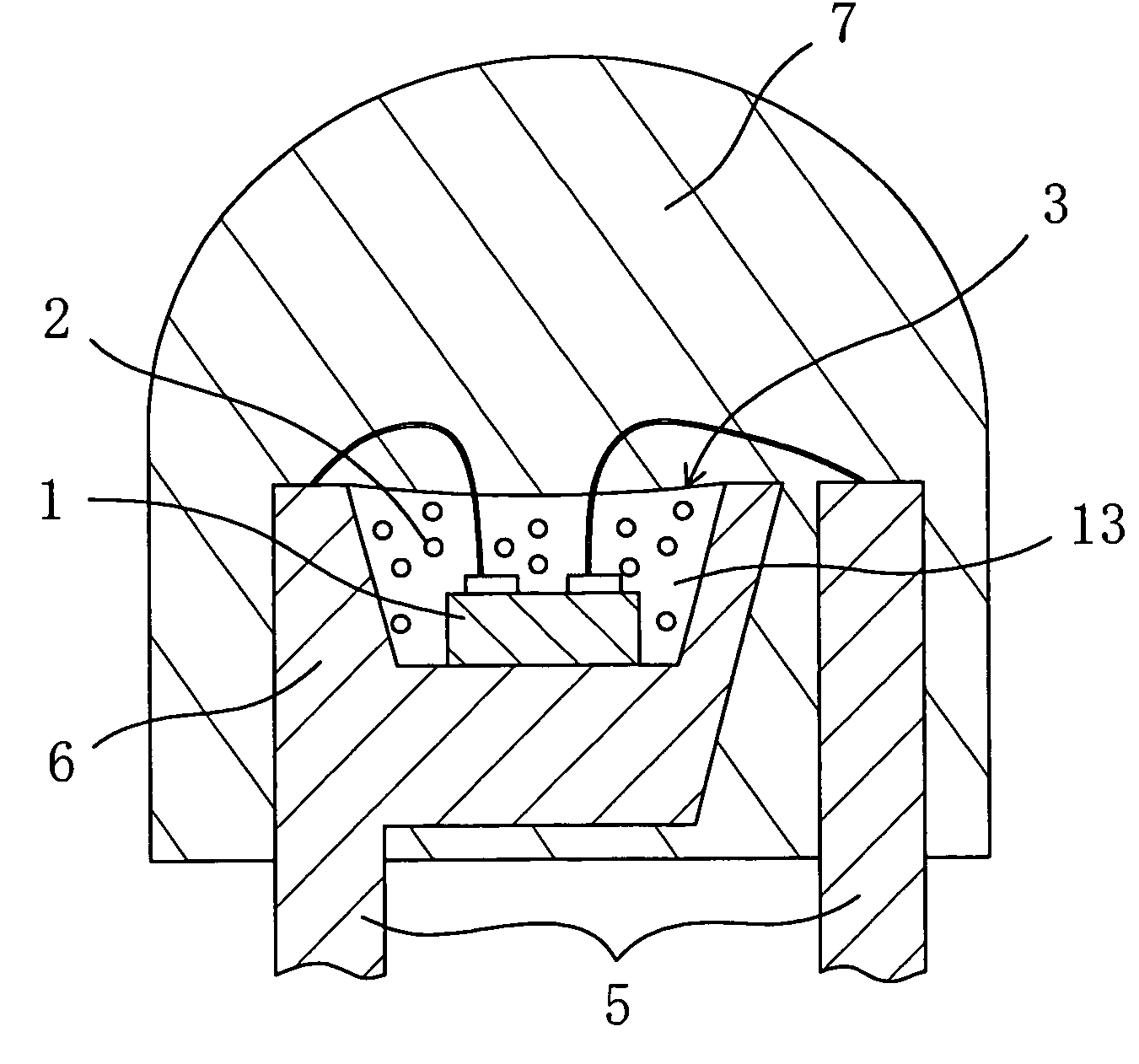

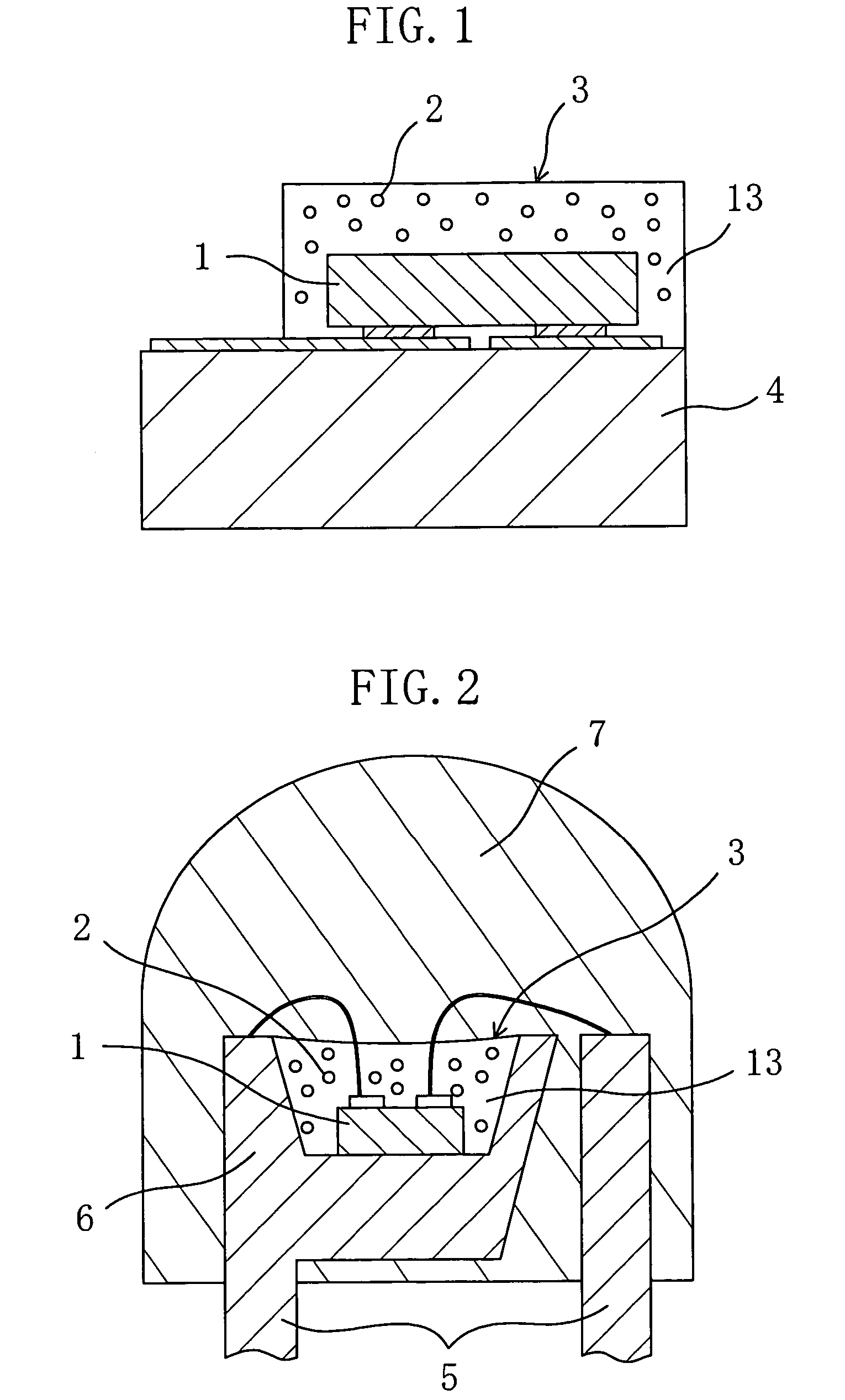

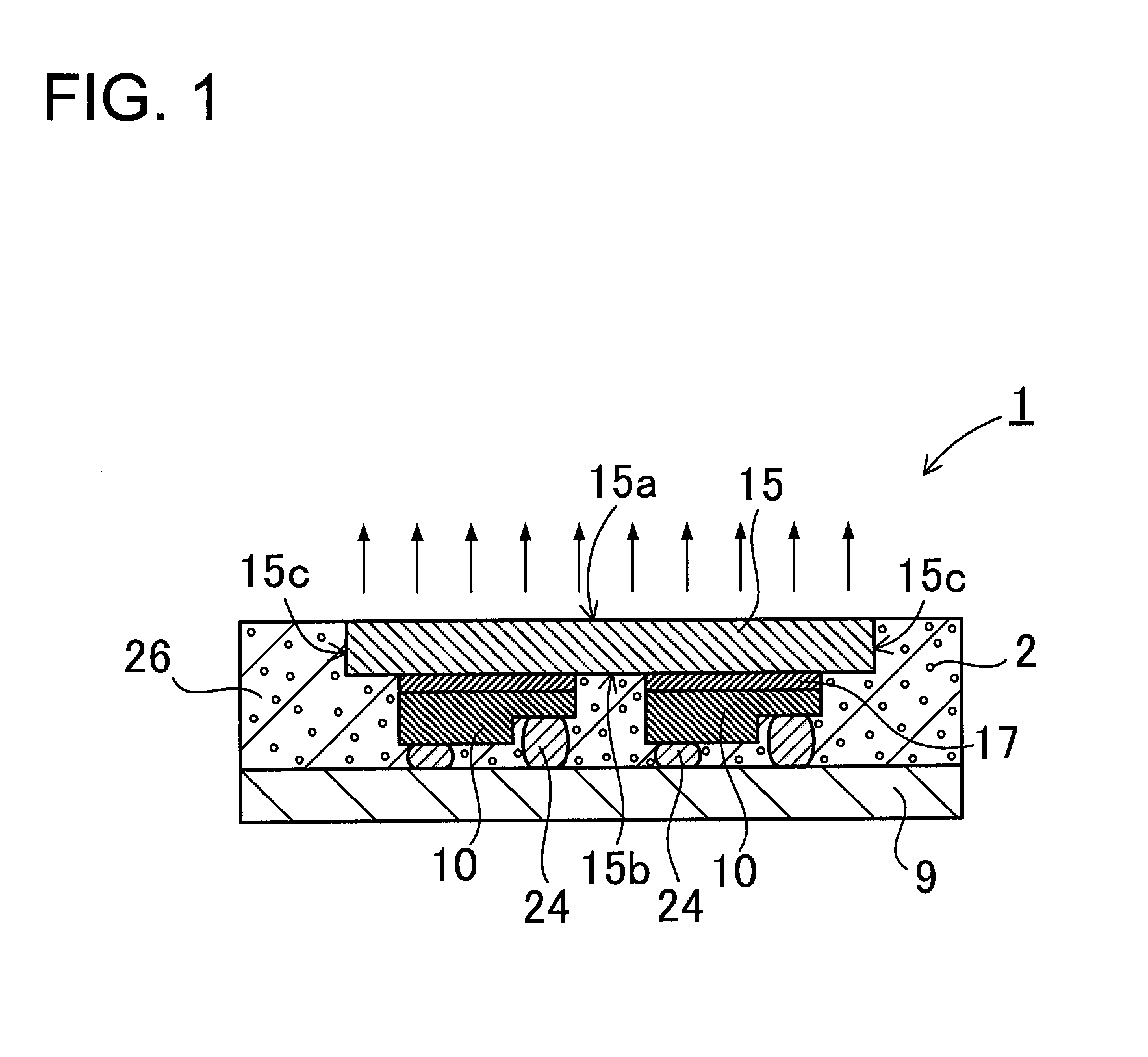

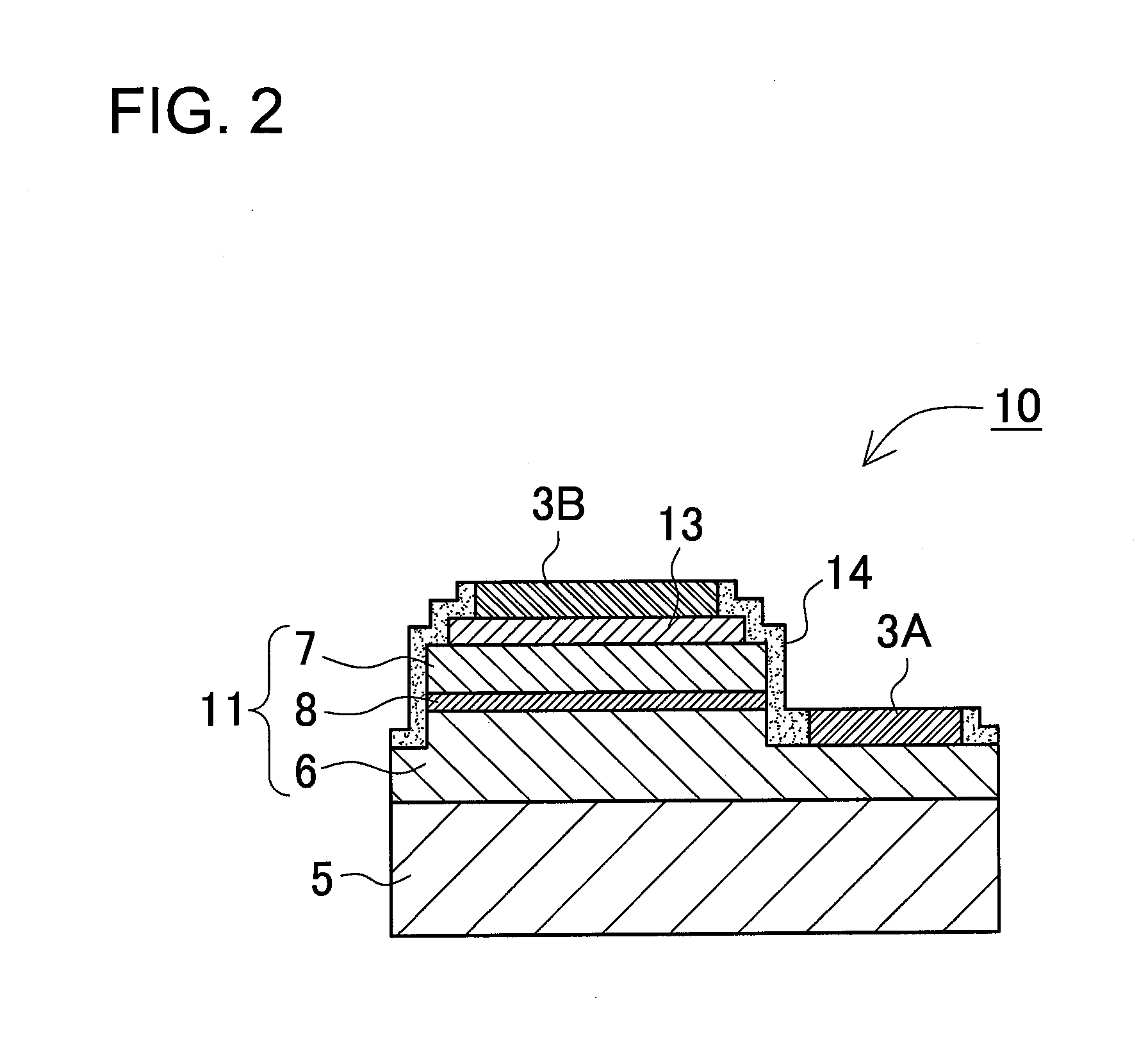

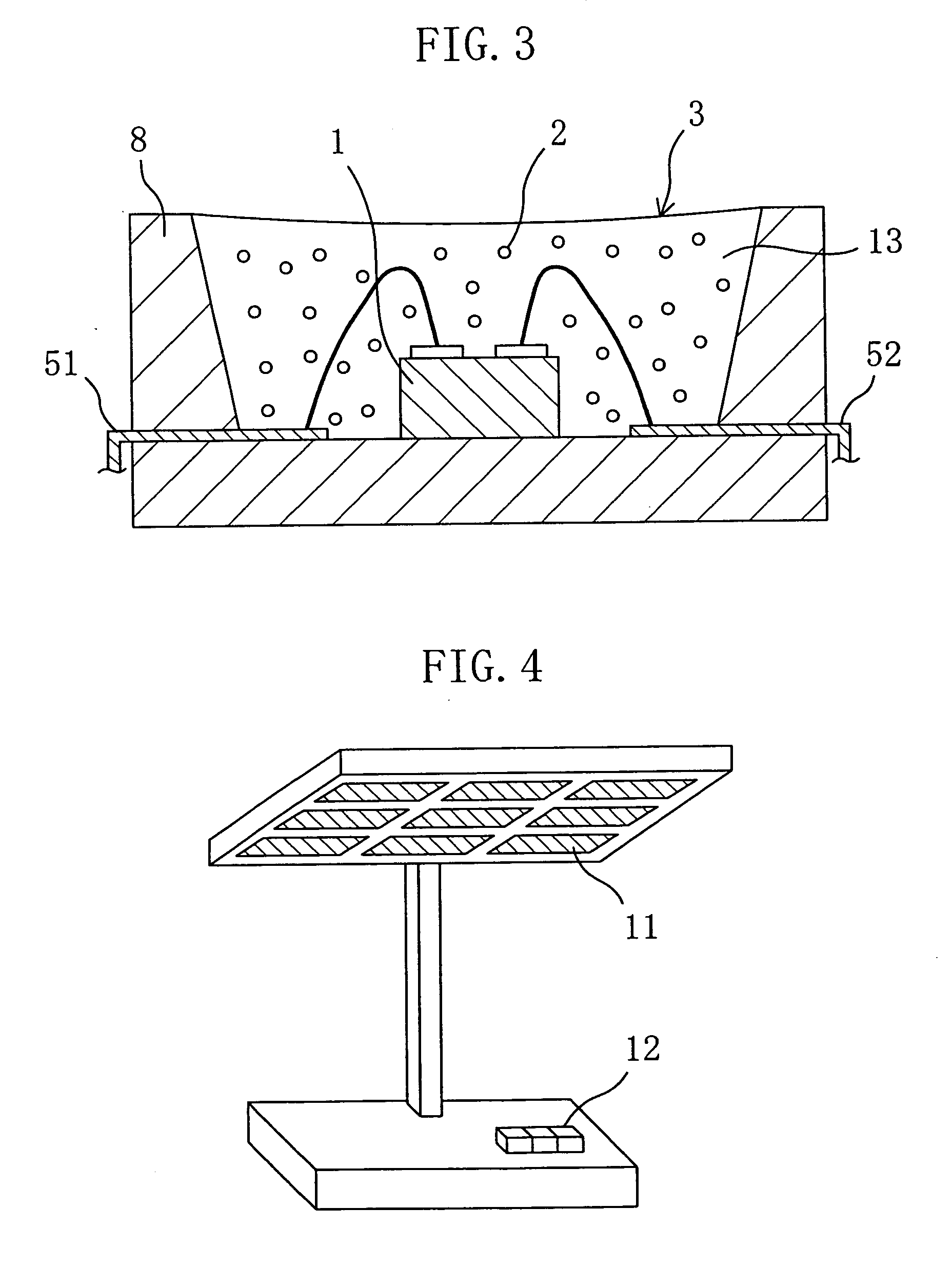

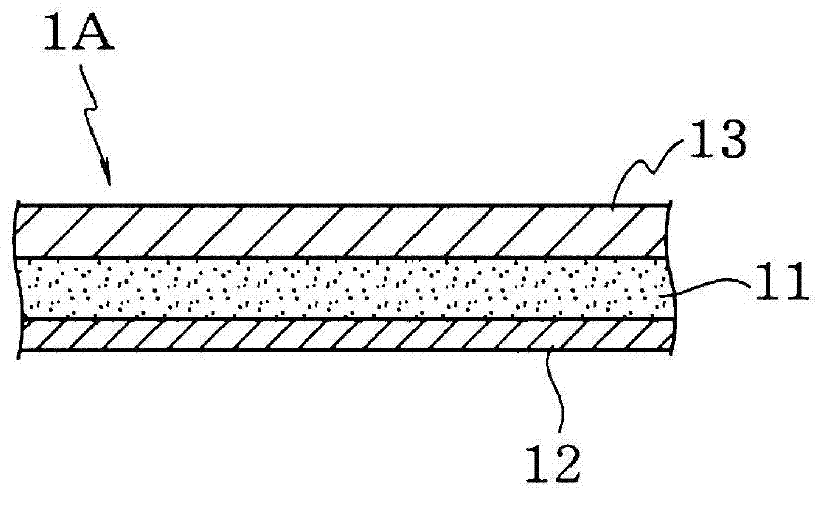

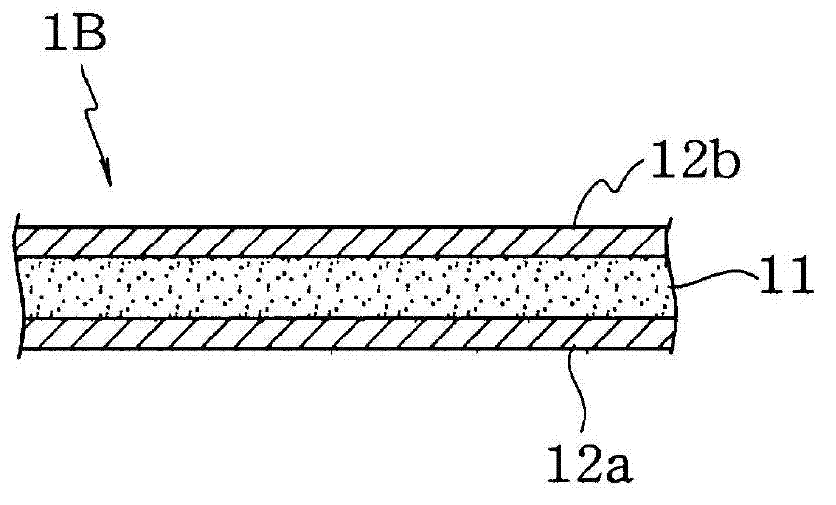

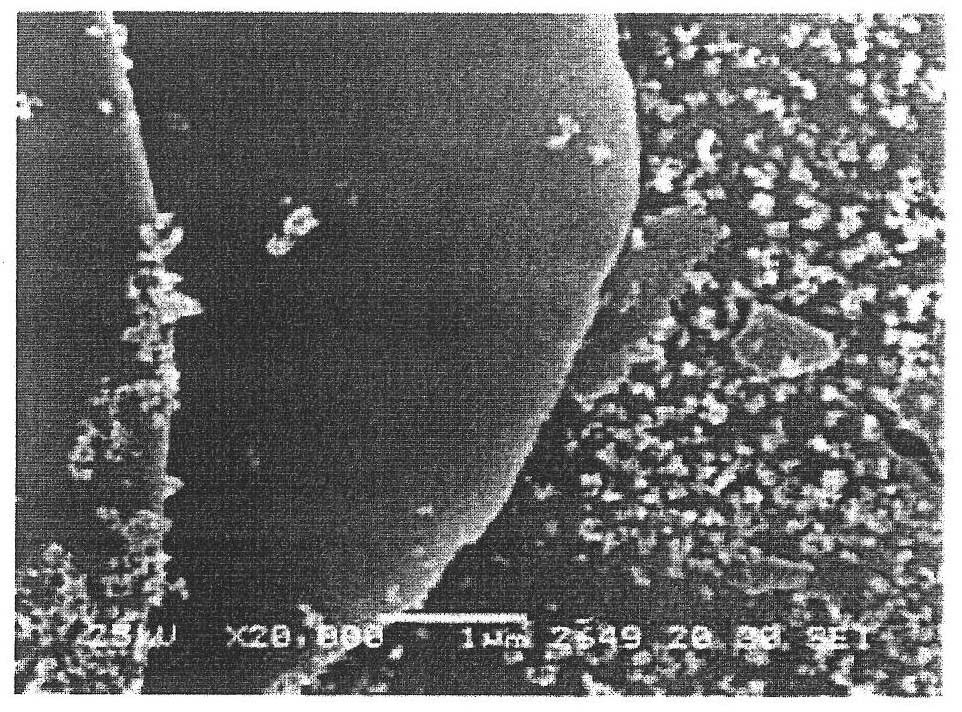

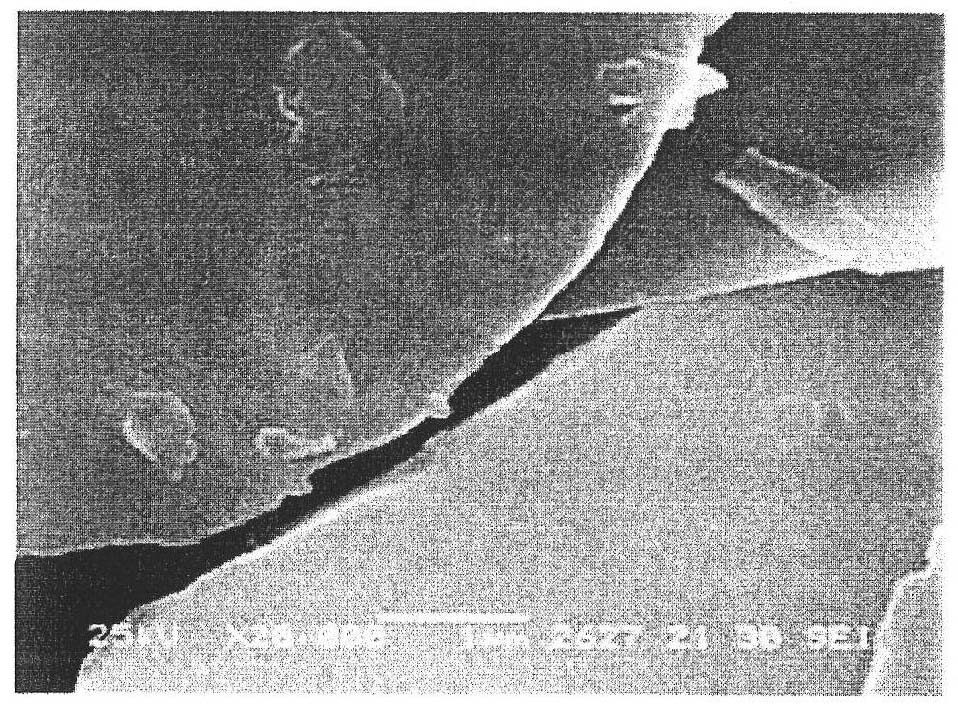

A chip-type light-emitting semiconductor device includes: a substrate 4 ; a blue LED 1 mounted on the substrate 4 ; and a luminescent layer 3 made of a mixture of yellow / yellowish phosphor particles 2 and a base material 13 (translucent resin). The yellow / yellowish phosphor particles 2 is a silicate phosphor which absorbs blue light emitted by the blue LED 1 to emit a fluorescence having a main emission peak in the wavelength range from 550 nm to 600 nm, inclusive, and which contains, as a main component, a compound expressed by the chemical formula: (Sr1-a1-b1-xBaa1Cab1Eux)2SiO4 (0<=a1<=0.3, 0<=b1<=0.8 and 0<x<1). The silicate phosphor particles disperse substantially evenly in the resin easily. As a result, excellent white light is obtained.

Owner:PANASONIC CORP

Light emitting apparatus and method for producing the same

ActiveUS20100320479A1Inhibition lossIncrease brightnessSolid-state devicesSemiconductor/solid-state device manufacturingOptical controlInorganic materials

A light emitting apparatus and a production method of the apparatus are provided that can emit light with less color unevenness at high luminance. The apparatus includes a light emitting device, a transparent member receiving incident light emitted from the device, and a covering member. The transparent member is formed of an inorganic material light conversion member including an externally exposed emission surface, and a side surface contiguous to the emission surface. The covering member contains a reflective material, and covers at least the side surfaces of the transparent member. Substantially only the emission surface serves as the emission area of the apparatus. It is possible to provide emitted light having excellent directivity and luminance. Emitted light can be easily optically controlled. In the case where each light emitting apparatus is used as a unit light source, the apparatus has high secondary usability.

Owner:NICHIA CORP

Light-emitting semiconductor device, light-emitting system and method for fabricating light-emitting semiconductor device

InactiveUS20050227569A1Excellent toneSuppresses reduction in luminous intensityDischarge tube luminescnet screensPoint-like light sourceFluorescenceDevice material

A chip-type light-emitting semiconductor device includes: a substrate 4; a blue LED 1 mounted on the substrate 4; and a luminescent layer 3 made of a mixture of yellow / yellowish phosphor particles 2 and a base material 13 (translucent resin). The yellow / yellowish phosphor particles 2 is a silicate phosphor which absorbs blue light emitted by the blue LED 1 to emit a fluorescence having a main emission peak in the wavelength range from 550 nm to 600 nm, inclusive, and which contains, as a main component, a compound expressed by the chemical formula: (Sr1-a1-b1-xBaa1Cab1Eux)2SiO4 (0≦a1≦0.3, 0≦b1≦0.8 and 0<x<1). The silicate phosphor particles disperse substantially evenly in the resin easily. As a result, excellent white light is obtained.

Owner:PANASONIC CORP

Light-emitting element reception package, light-emitting device and lighting device

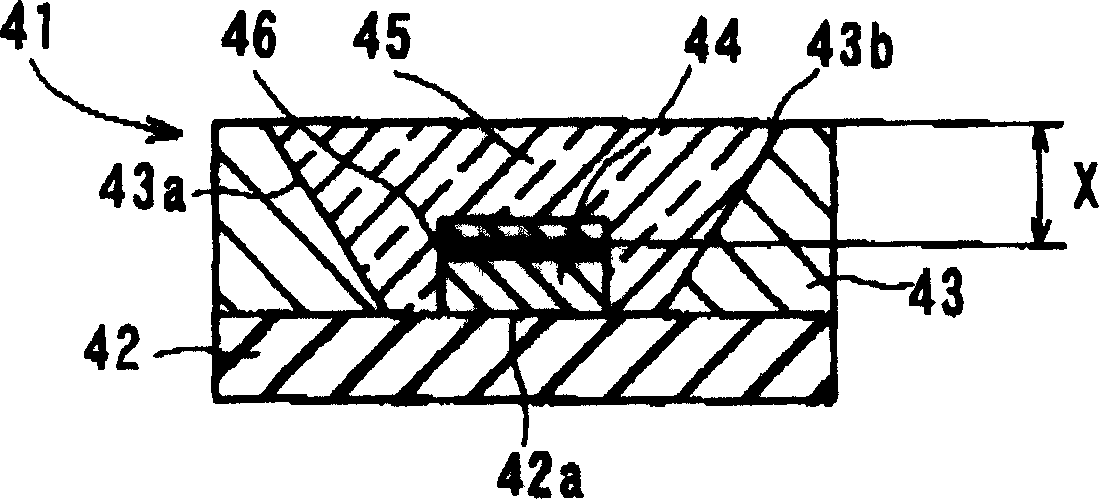

InactiveCN1612369ARaise the ratioImprove light outputSolid-state devicesSemiconductor/solid-state device manufacturingElectrical conductorEffect light

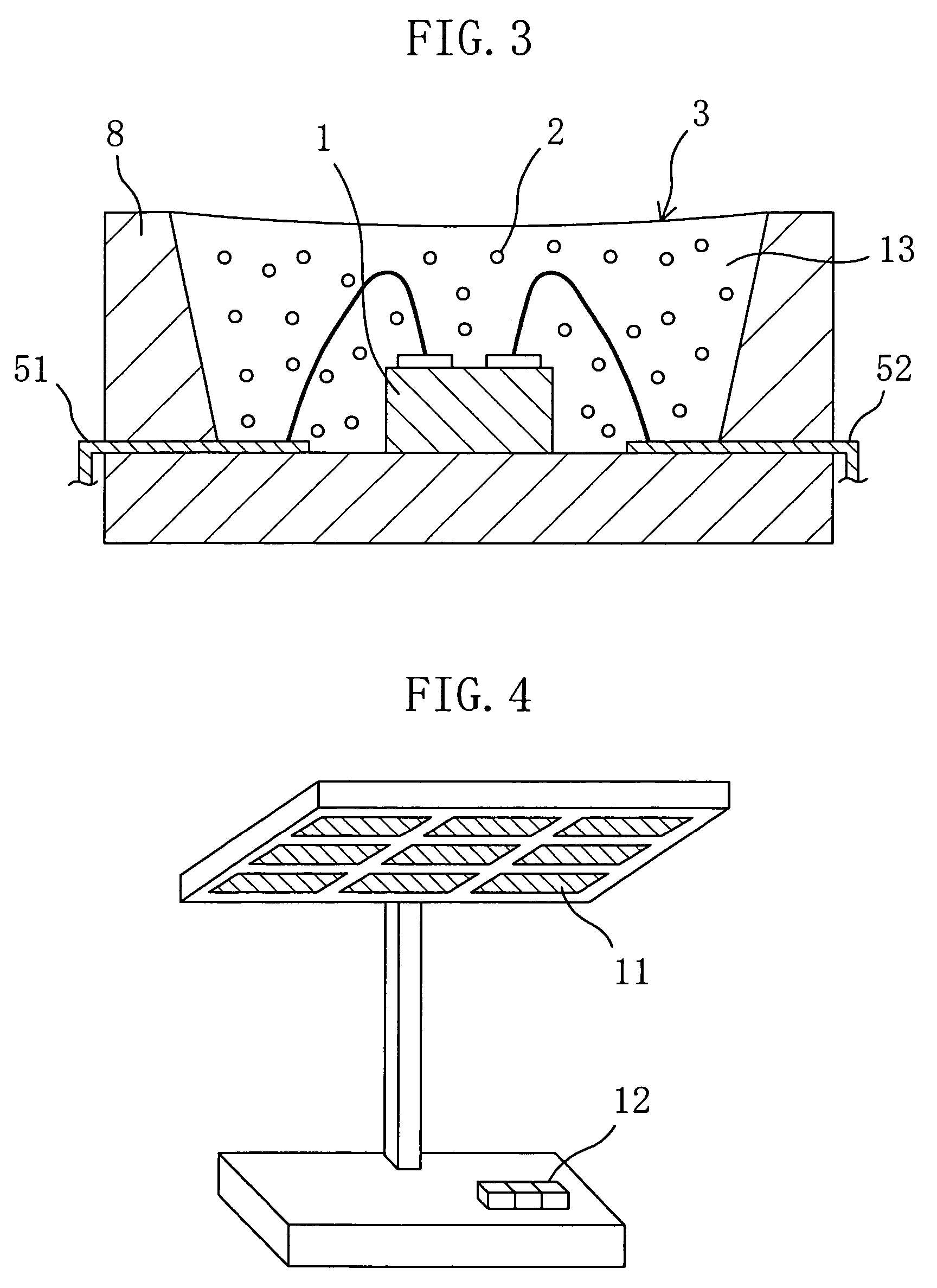

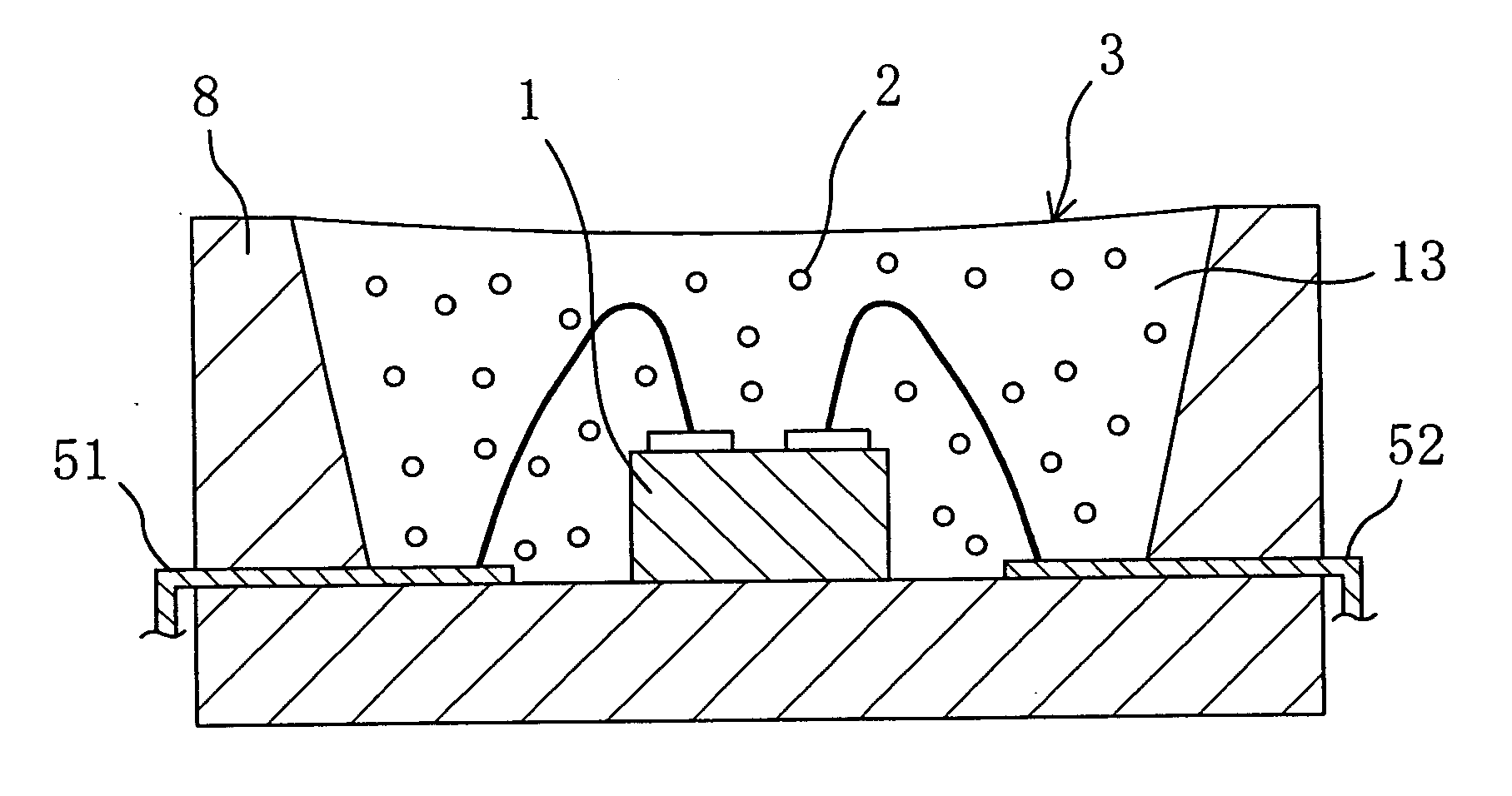

The package has a base body (51) with a mounting portion for mounting a light-emitting unit. A frame body is joined to an outer edge of the body (51) to surround the portion. A wiring conductor has its one end formed on an upper surface of the base body, to electrically connect an electrode of the light emitting unit. The light transmitting unit (53) is inside the frame body to cover the light emitting unit. - Independent claims are also included for the following: - (A) a light-emitting apparatus comprising a package for housing a light emitting unit - (B) an illumination apparatus constructed by setting up a light-emitting apparatus in a predetermined arrangement.

Owner:KYOCERA CORP

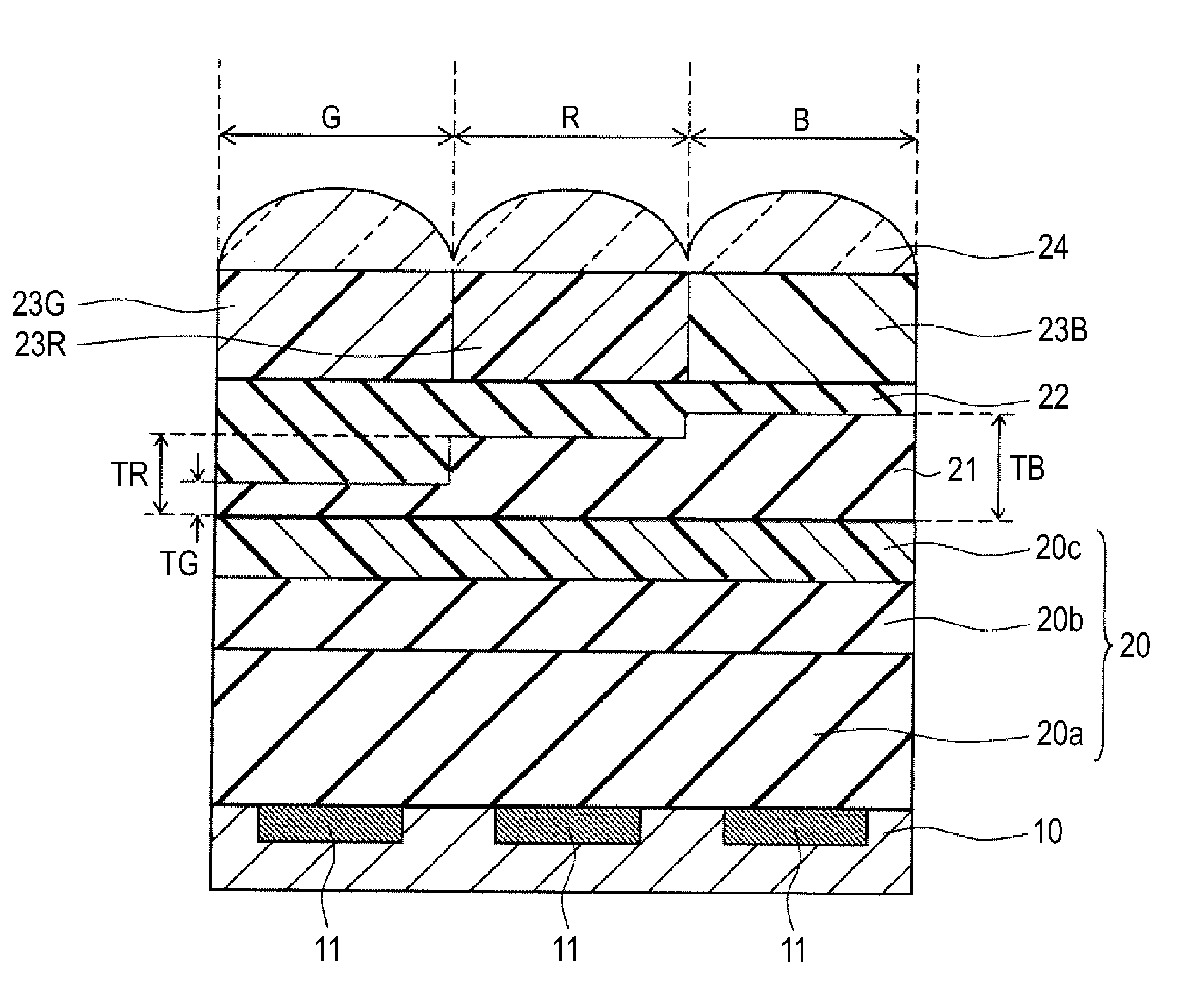

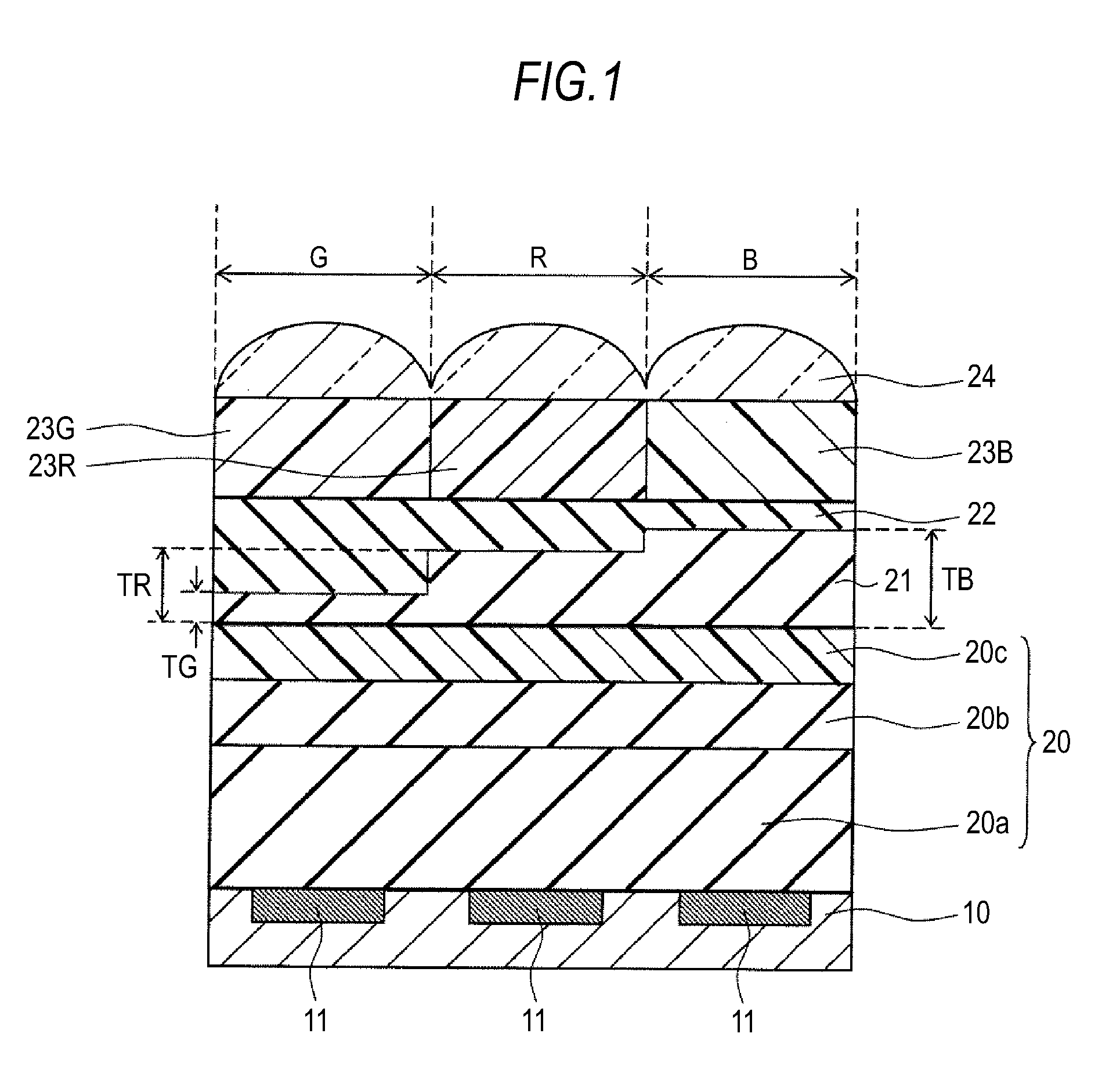

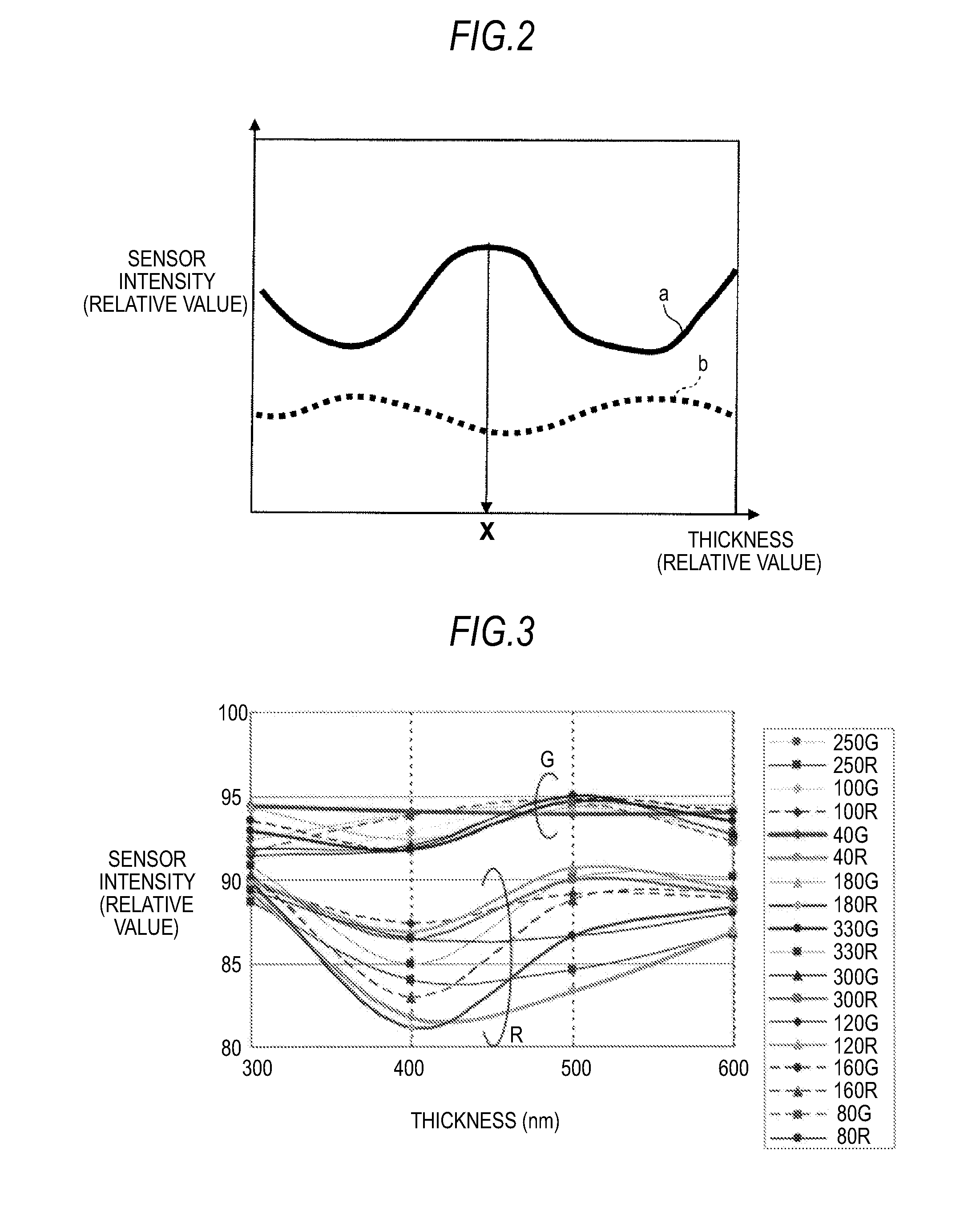

Solid-state imaging device, manufacturing method and designing method thereof, and electronic device

ActiveUS20110108705A1Reduce variationSuppress color unevennessRadiation pyrometrySolid-state devicesRefractive indexEngineering

A solid-state imaging device includes: a semiconductor substrate that includes a photodiode separately provided for each of pixels disposed in a matrix on a light-receiving surface; a first insulating film formed on the semiconductor substrate so as to cover multilayer wiring formed on and in contact with the semiconductor substrate, wherein the first insulating film is formed using material of a first refractive index lower than a refractive index of the semiconductor substrate for at least bottom surface and top surface portions of the first insulating film; a second insulating film of a second refractive index higher than the first refractive index formed on the first insulating film; a third insulating film of a third refractive index higher than the second refractive index formed on the second insulating film; and a color filter formed on the third insulating film in a corresponding manner with each pixel so as to transmit light in a wavelength region of red, green, or blue.

Owner:SONY SEMICON SOLUTIONS CORP

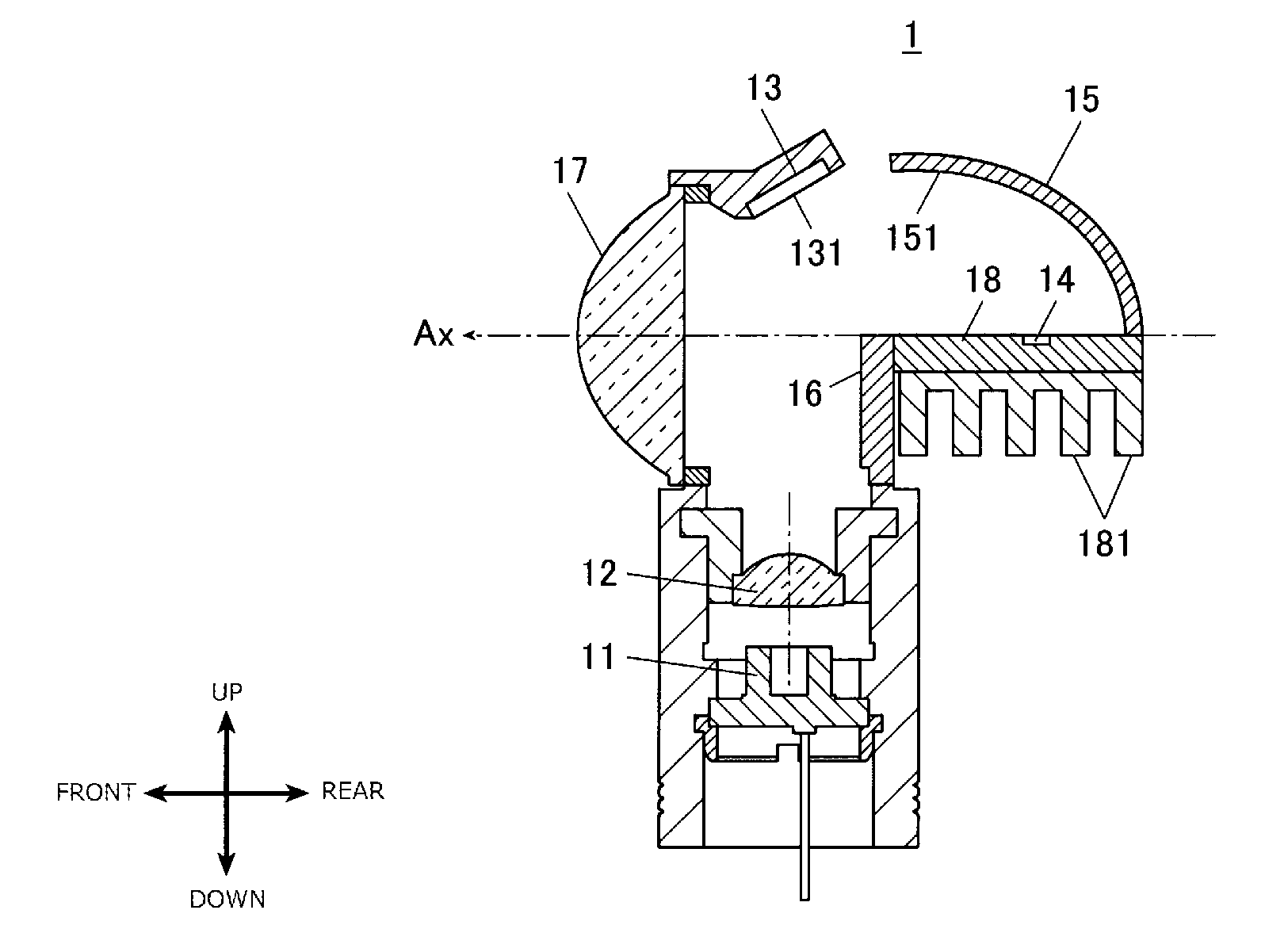

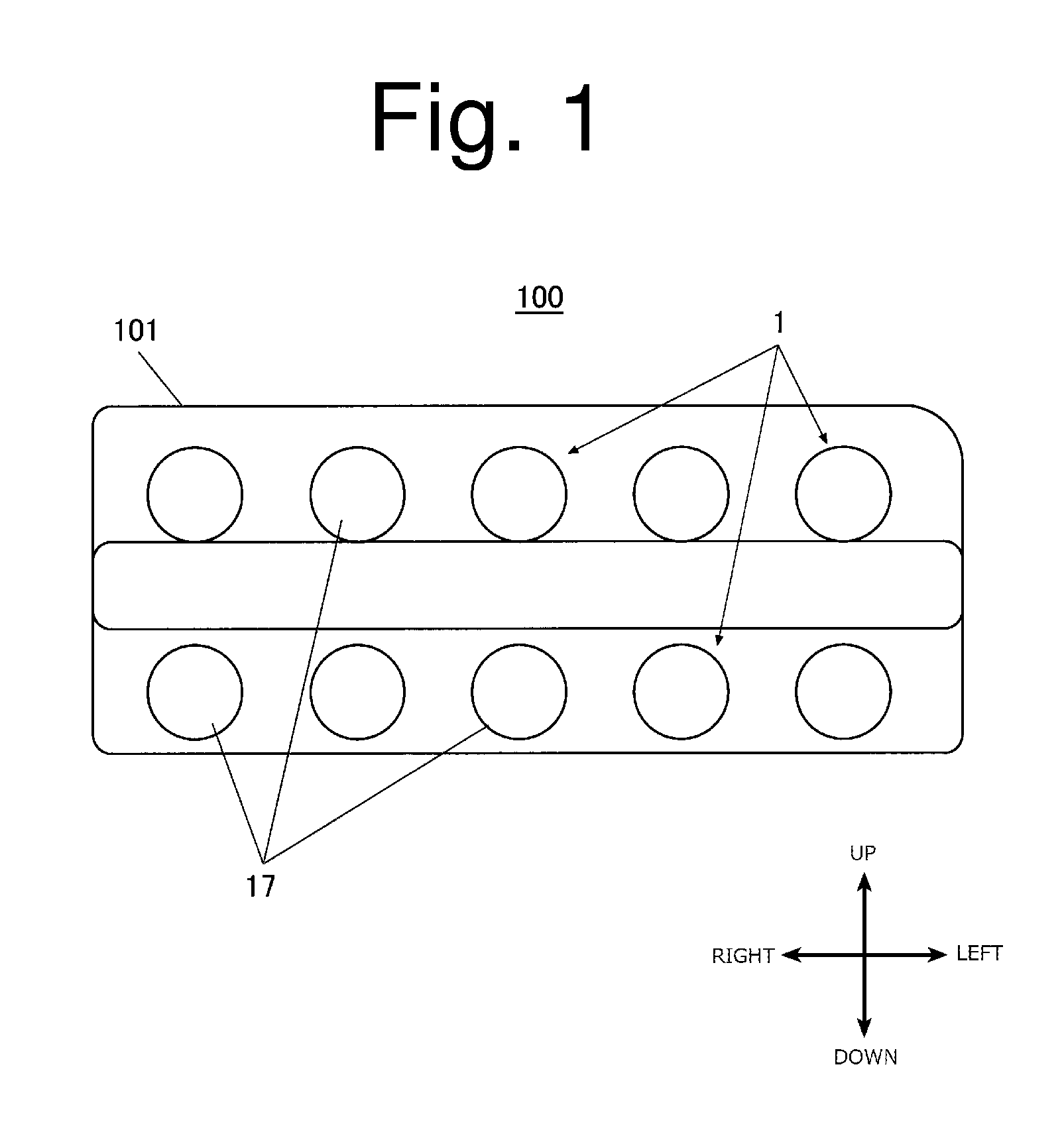

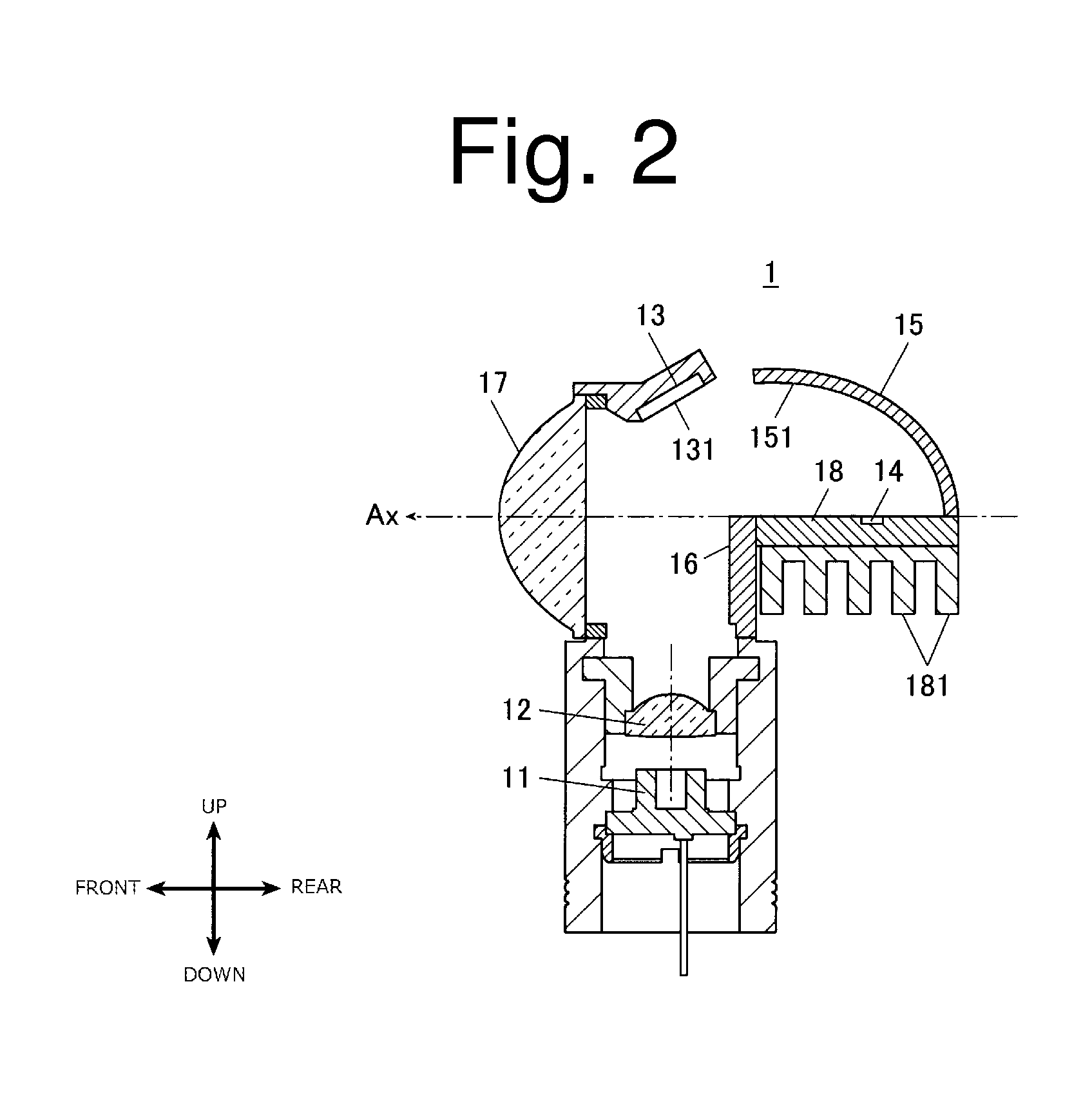

Vehicle lighting unit

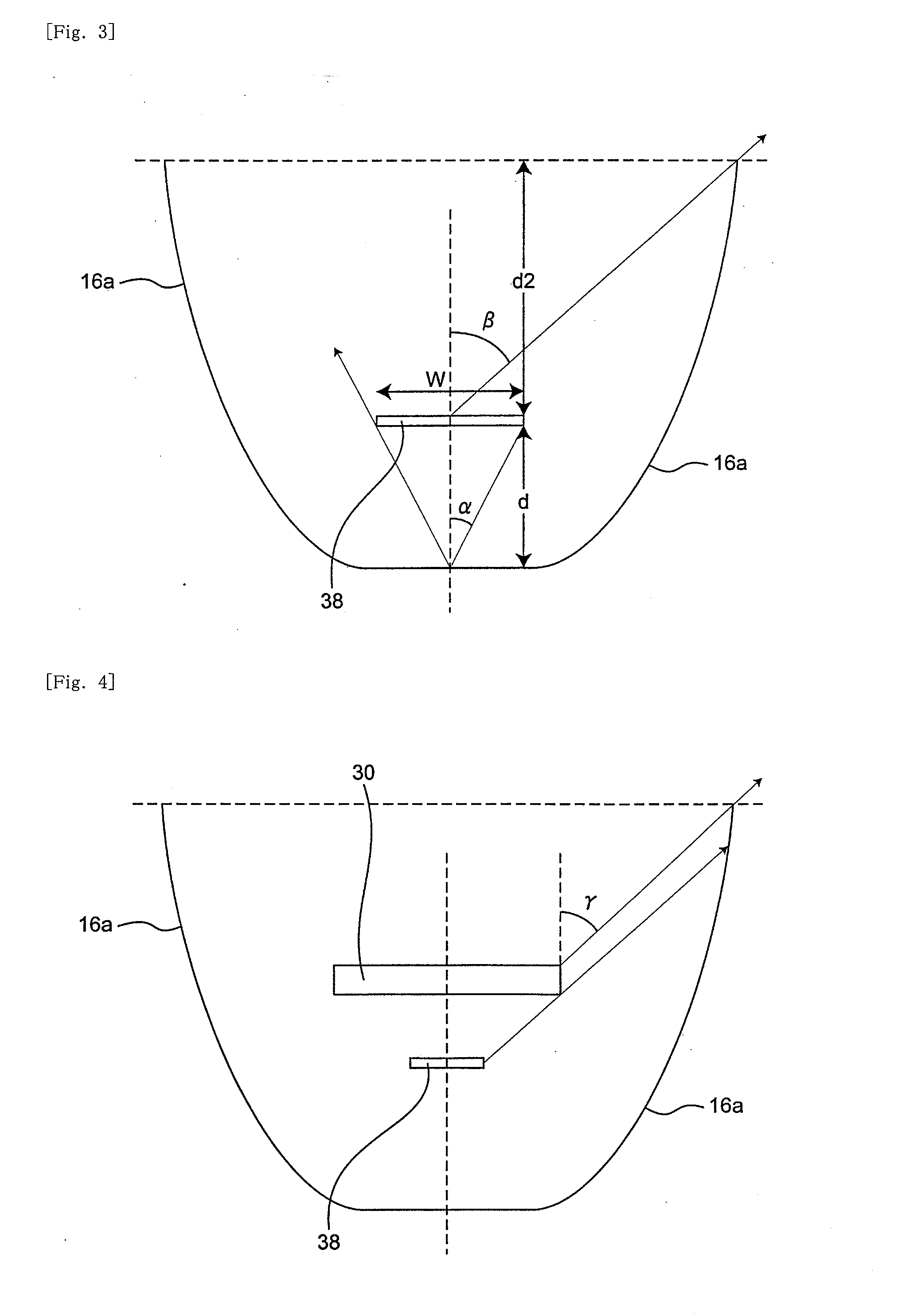

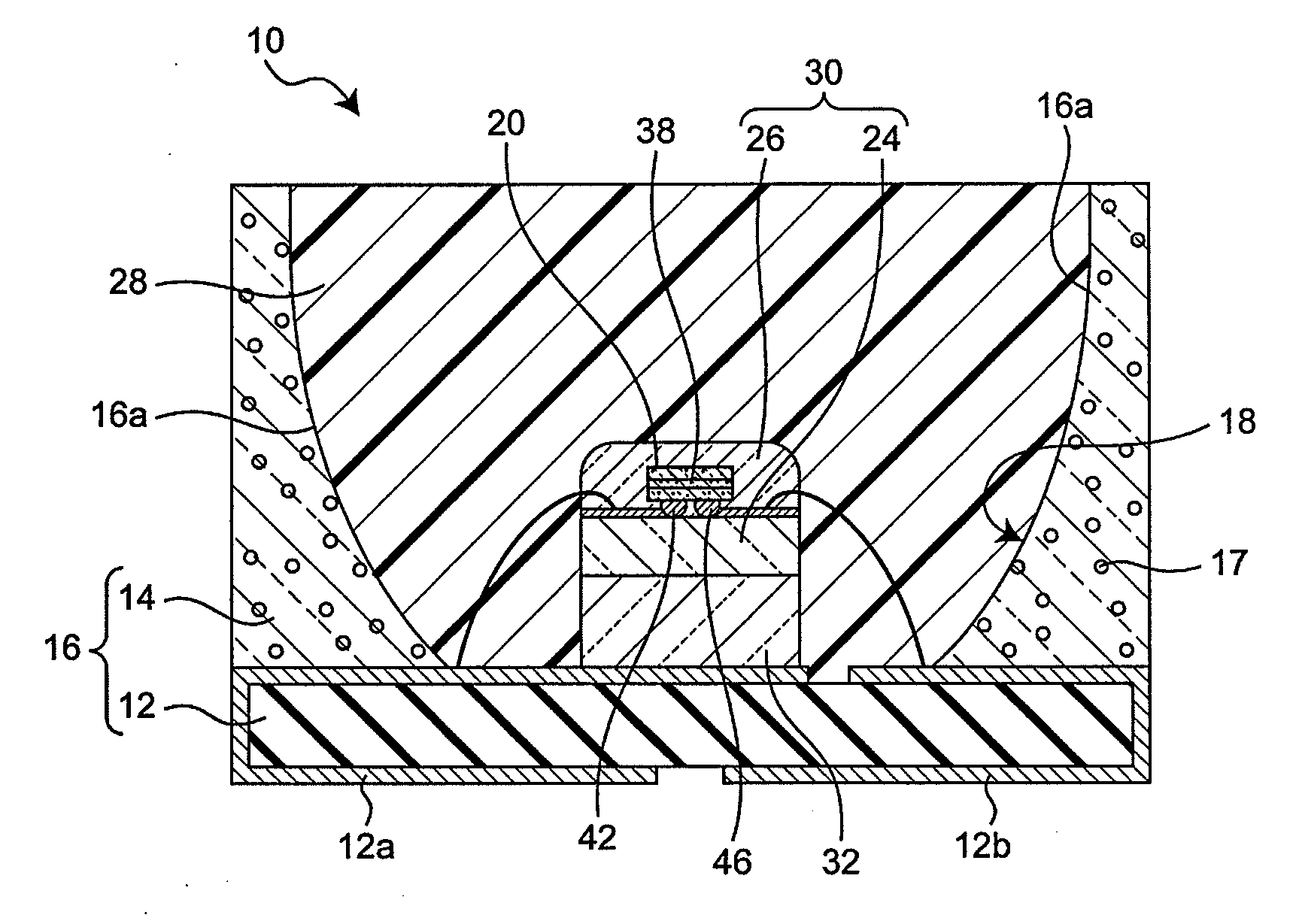

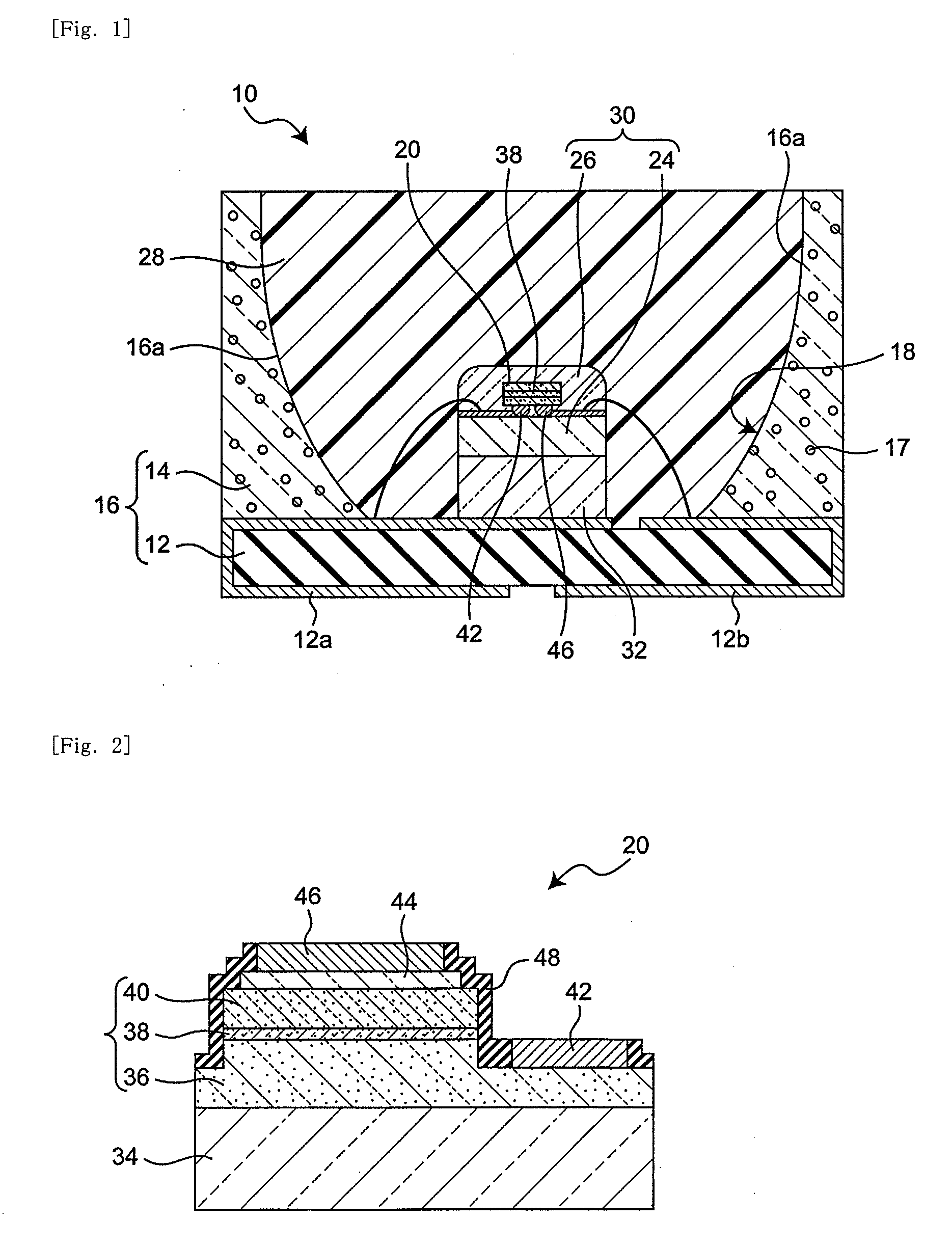

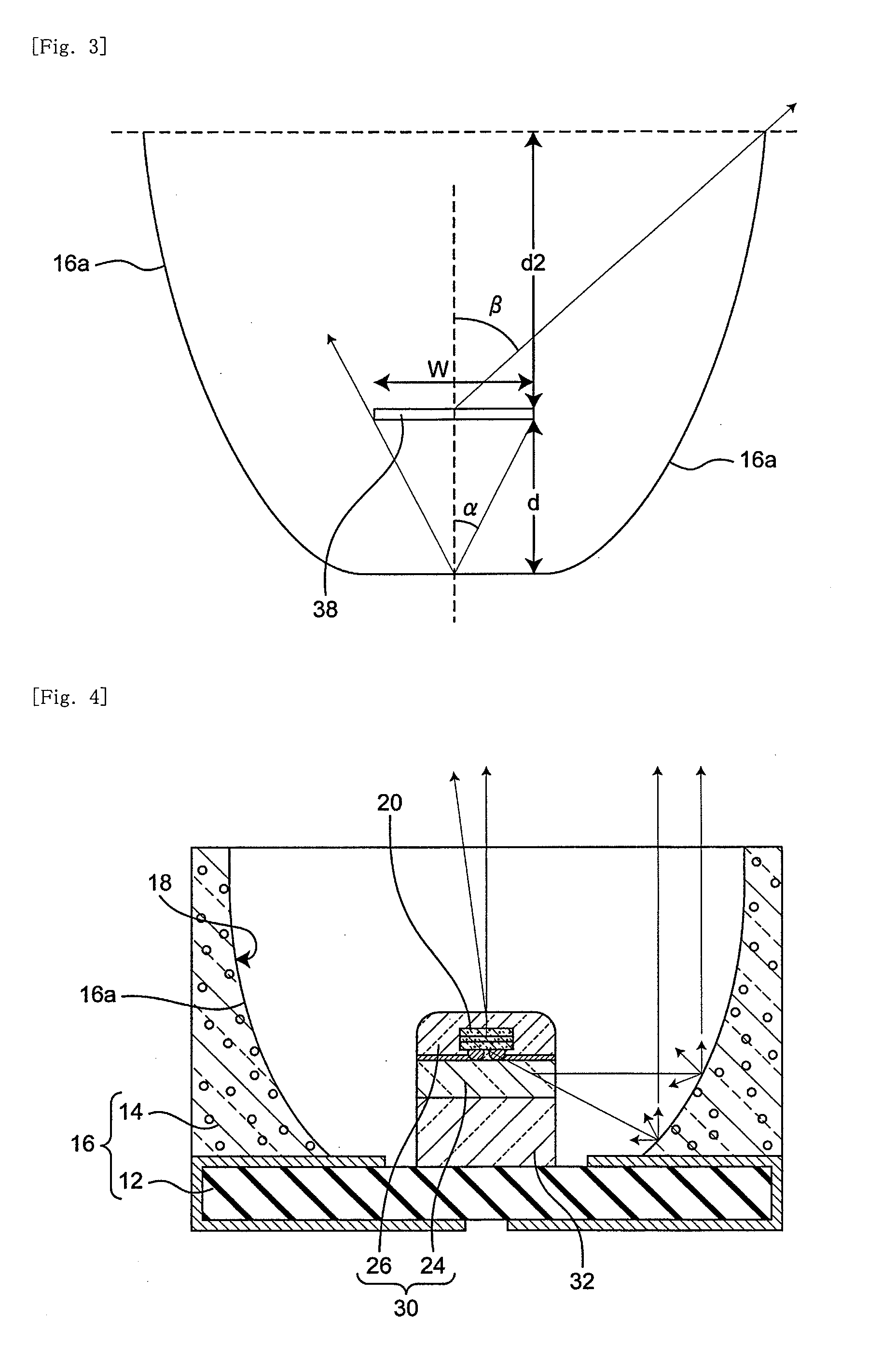

ActiveUS20120294023A1Reduce coherencySuppress color unevennessVehicle headlampsVehicle lighting systemsPhosphorEffect light

A vehicle lighting unit that utilizes a semiconductor laser light source can suppress color unevenness of a light distribution pattern while ensuring the usefulness of the semiconductor laser light source. The vehicle lighting unit can include a semiconductor laser light source, a phosphor configured to receive blue light emitted from the semiconductor laser light source and emit white light by excitation, and a reflector configured to reflect the light emitted from the phosphor so that the light can be diffused wider in a right-to-left direction than in a vertical direction on the basis of a posture when the lighting unit is mounted on a vehicle body. Part of the blue light that is emitted from the semiconductor laser light source and reflected off a surface of the phosphor can be incident on the reflector with an elongated area in the right-to-left direction.

Owner:STANLEY ELECTRIC CO LTD

Light emitting device

ActiveUS20110248623A1Reduce probabilityReduce absorptionIncadescent screens/filtersDischarge tube luminescnet screensLength waveLight emitting device

A light emitting device includes a housing member having a recess open upward, a light emitting element arranged in the recess and having a light emitting layer of a semiconductor, and a wavelength converting member arranged in the recess and capable of absorbing a part of light emission from the light emitting element and emitting light of different wavelength. The light emitting device is capable of mixing the light emission from the light emitting element and the light emission from the wavelength converting member to emit light from the opening of the recess. A light scattering surface for scattering light emission from the light emitting element and wavelength converting member is formed on at least part of the side surface of the recess. The light emitting element and the wavelength converting member are spaced apart from the side and bottom surfaces of the recess, and the side surfaces of the light emitting element are exposed without being covered with the wavelength converting member.

Owner:NICHIA CORP

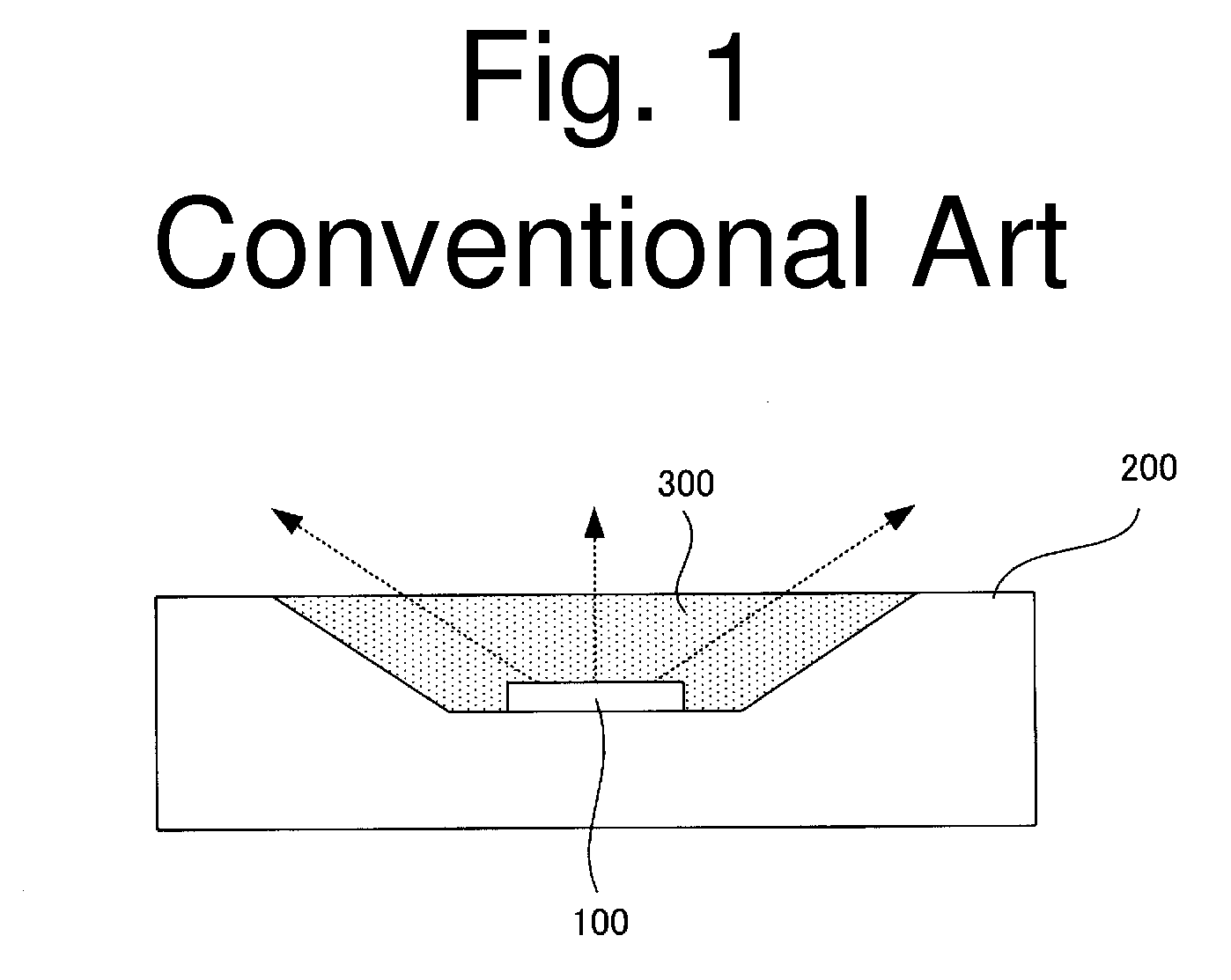

Semiconductor light emitting apparatus

InactiveUS20100084675A1Suppress color unevennessPrevent uneven colorSolid-state devicesSemiconductor devicesCurrent limitingColored light

A semiconductor light emitting apparatus for emitting a desired colored light by coating the top surface thereof with a wavelength conversion member prevents the color unevenness from occurring due to the unevenness of the coating thickness of the wavelength conversion member. The semiconductor light emitting apparatus can include a semiconductor layer having a light emitting layer with a light emitting surface having at least one corner area, a supporting substrate configured to support the semiconductor layer, and a wavelength conversion material layer formed on top of the semiconductor layer, the wavelength conversion layer having a thickness thinner from a center portion of the semiconductor layer to an outer peripheral portion. The at least one corner area can include a non-emitting portion where light cannot be projected. The non-emitting portion can be a light shielding portion, a non-light emission portion or a current confined portion.

Owner:STANLEY ELECTRIC CO LTD

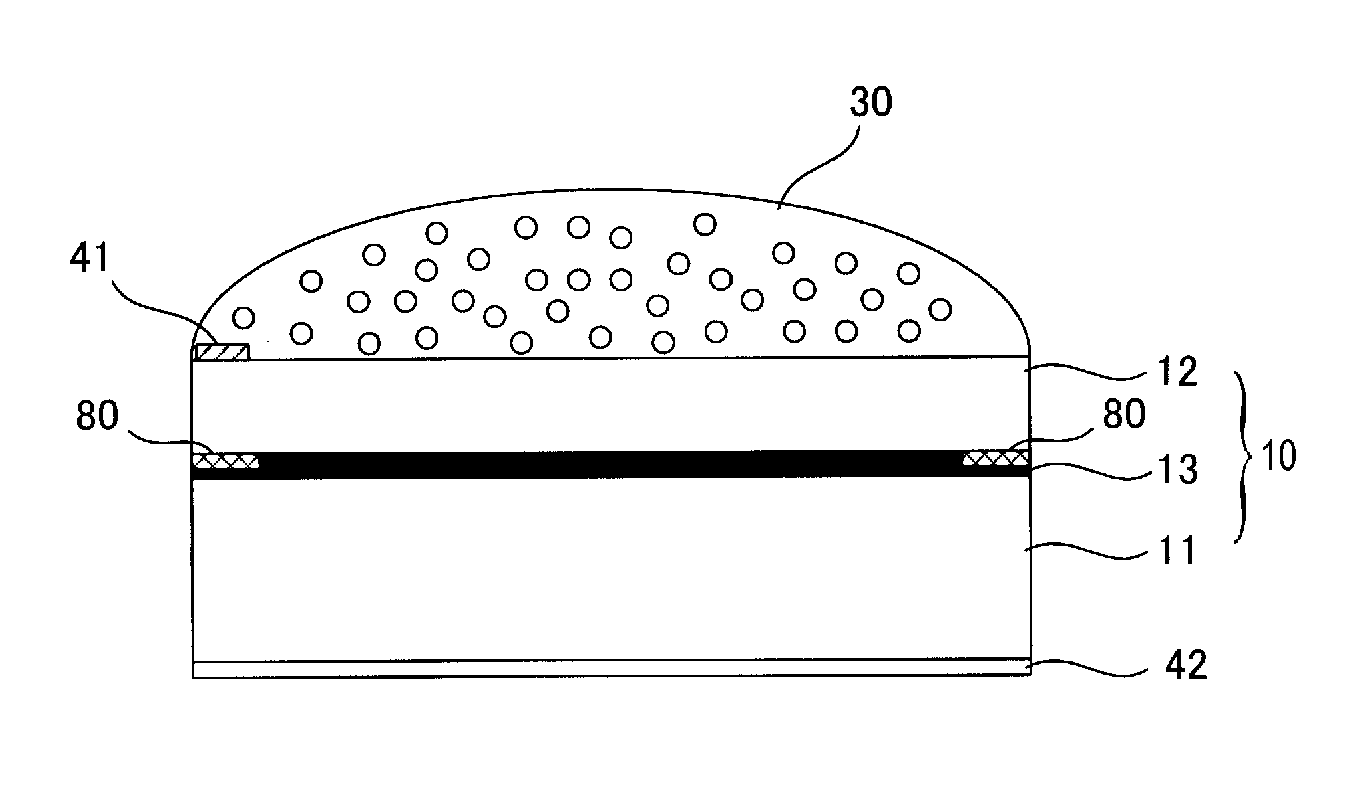

Light emitting device

ActiveUS20110248304A1InhibitionImprove light extraction efficiencySolid-state devicesSemiconductor devicesLength waveInorganic materials

The first wavelength converting member, the light emitting element, and the second wavelength converting member are disposed in this order toward the opening of the recess portion on the bottom surface of the housing member through a light transmissive supporting member, and spaced away from the side surface of the recess portion. The first wavelength converting member is a plate shape member made of a composite of an inorganic binder made of an inorganic material and a fluorescent material. A light scattering surface is formed on at least a portion of the side surface of the recess portion, which is irradiated with the light emitted from the side surfaces of the wavelength converting member in parallel with the principal surface of the first wavelength converting member.

Owner:NICHIA CORP

Acrylic resin composition

InactiveUS20050065252A1Suppress color unevennessReduce local stress concentrationSynthetic resin layered productsSpecial tyresMethacrylateHydrogen atom

An acrylic resin composition comprising the following acrylic resins (1) and (2): acrylic resin (1): an acrylic resin containing a structural unit derived from a monomer (a) (structural unit (a)), a structural unit derived from a monomer (b) (structural unit (b)) and a structural unit derived from a monomer (c) (structural unit (c)) and containing the structural unit (c) in an amount of 0.05 to 5 parts by weight based on 100 parts by weight of the acrylic resin (1); acrylic resin (2): a straight chain acrylic resin containing the structural unit (a) as the main component; (a): a (meth)acrylate of the formula (A) (wherein, R1 represents a hydrogen atom or methyl group, R2 represents an alkyl group having 1 to 14 carbon atoms or an aralkyl group having 1 to 14 carbon atoms, and a hydrogen atom in the alkyl group R2 or a hydrogen atom in the aralkyl group R2 may be substituted with an alkoxy group having 1 to 10 carbon atoms.), (b): a monomer containing an olefinic double bond in the molecule and at least one 5- or more-membered heterocyclic group in the molecule, (c): a monomer containing at least two olefinic double bonds in the molecule.

Owner:SUMITOMO CHEM CO LTD

Light emitting device and lighting device

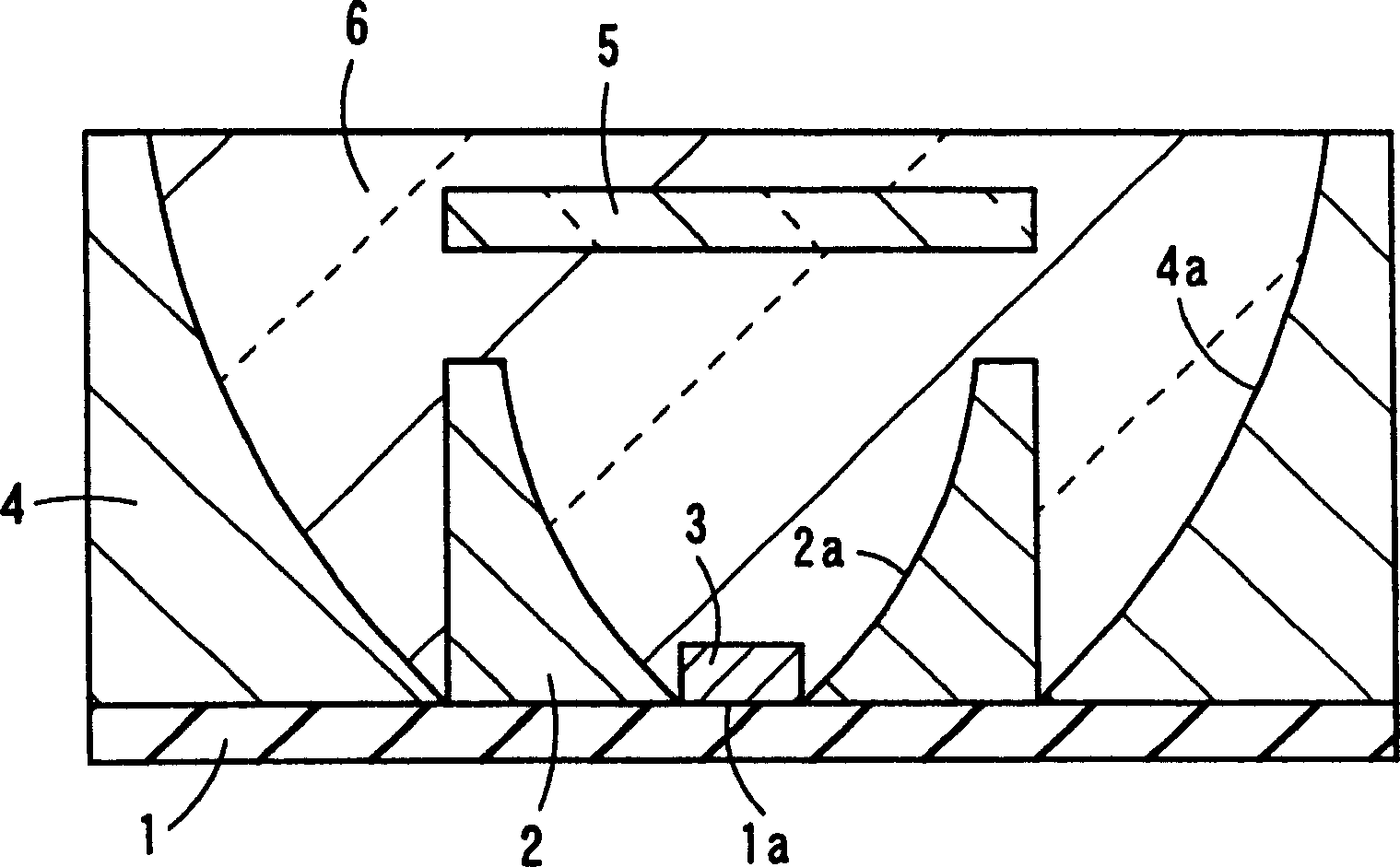

InactiveCN1716654AReduce ejectionIncreased wavelength conversion powerPlanar light sourcesSolid-state devicesEffect lightTransmittance

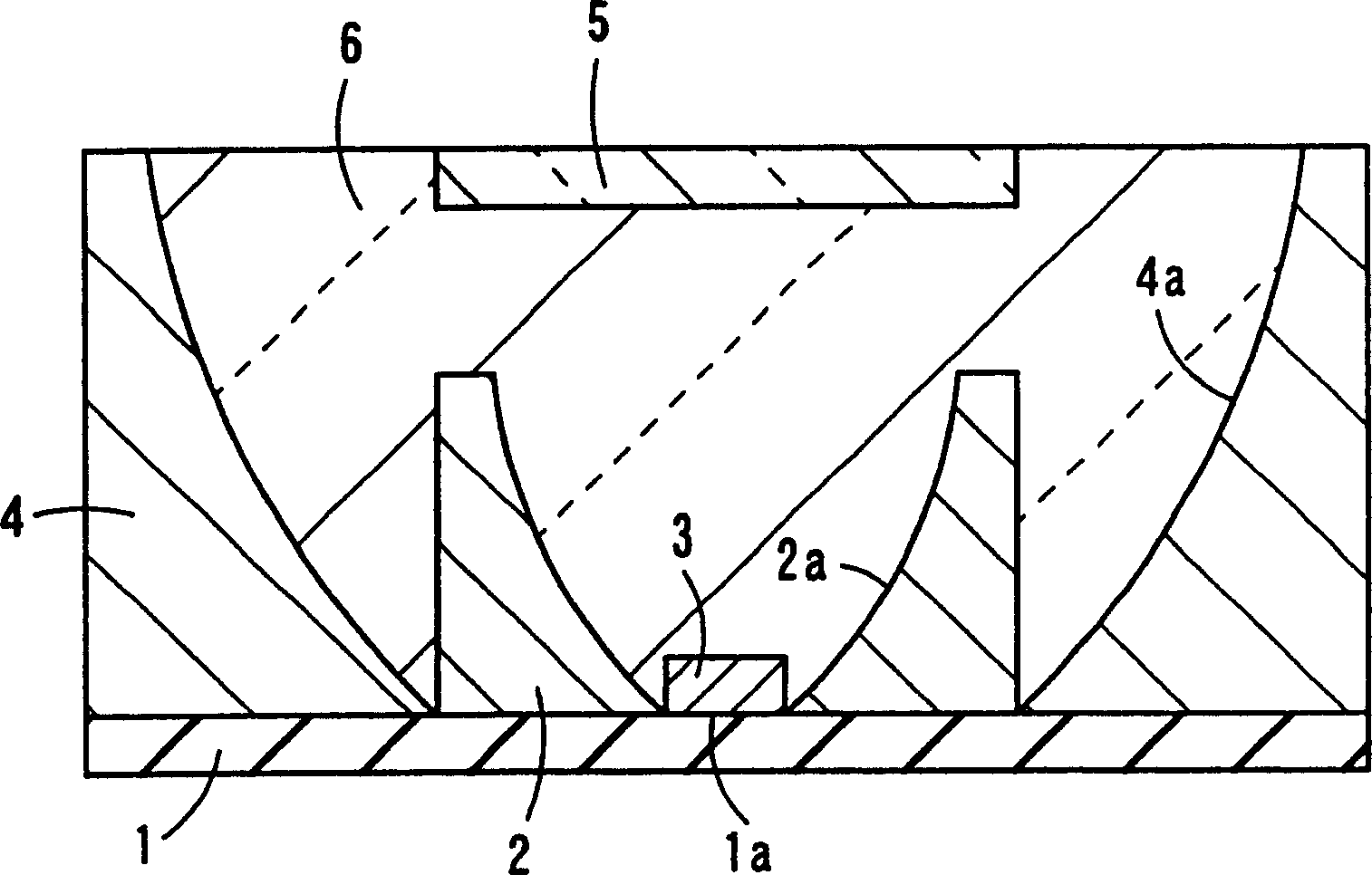

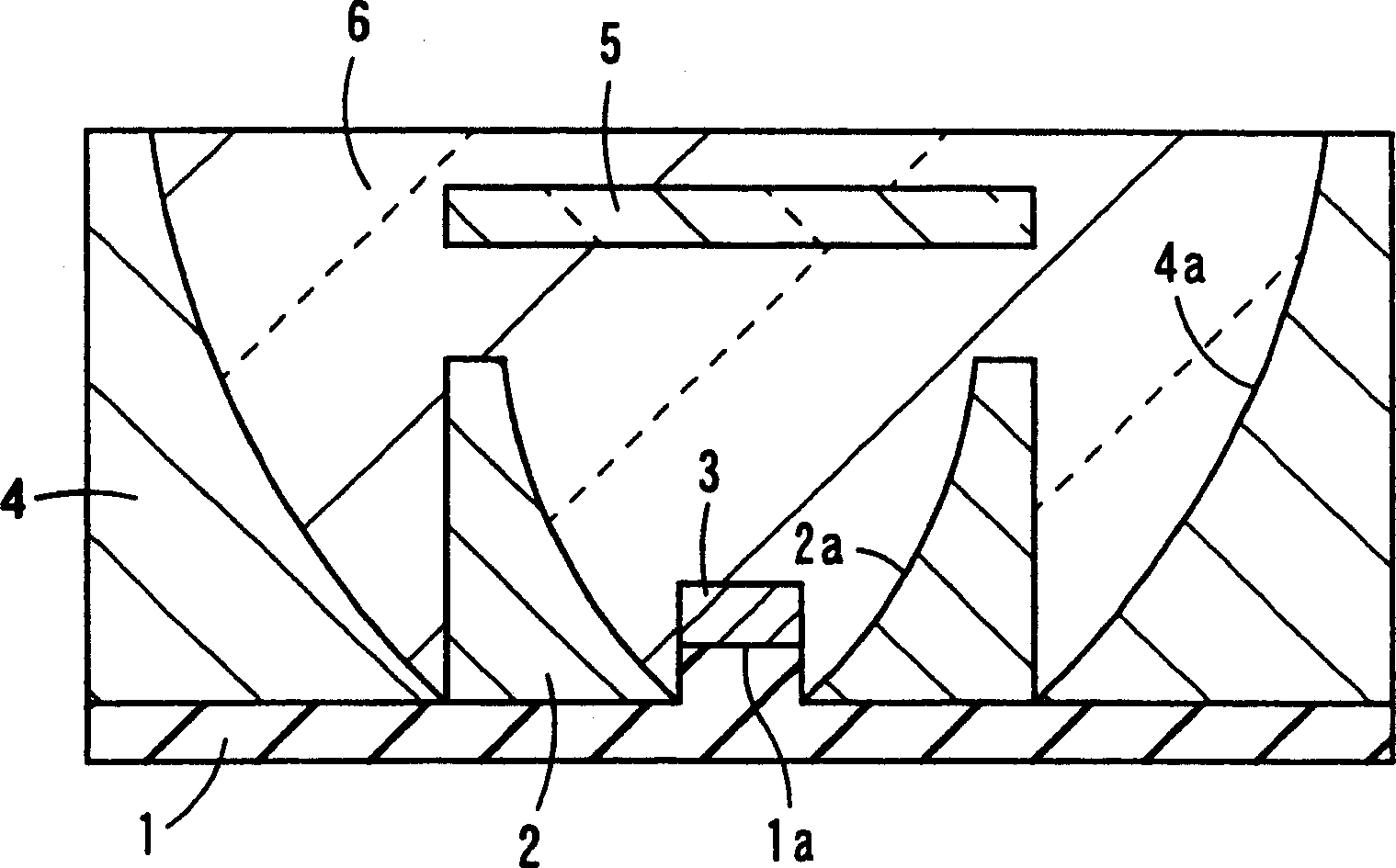

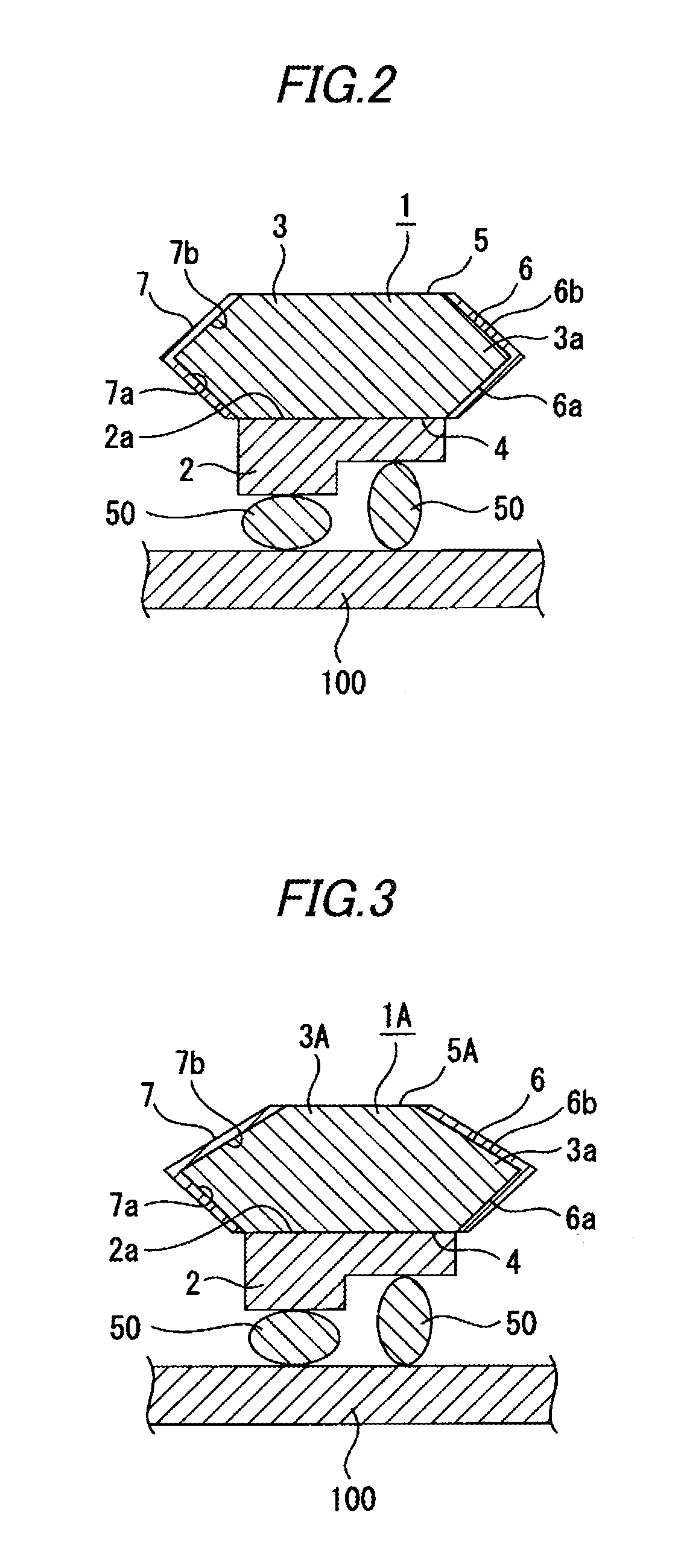

The invention provides a light-emitting device which is equipped with: a light-emitting element (3); a matrix (1) which is equipped with a placement part (1a) for placing the light-emitting element (3) on the upper main surface; a first frame-shaped reflective component (2) which is formed on the upper main surface of the matrix (1) according to a way of surrounding the placement part (1a); a second frame-shaped reflective component (4) which is formed on the upper main surface of the matrix (1) according to a way of surrounding the first reflective component (2); a light transmittance component (6) which is arranged on the inner lateral of the second reflective component (4) according to a way of covering the light-emitting element (3) and the first reflective component (2); a first wavelength conversion layer (5) which is arranged in the inside of the light transmittance component (6) on the upper part of the light-emitting element (3) with intervals to the first and the second reflective components (2, 4) and converts the wavelength of lights that are sent out from the light-emitting element (3).

Owner:KYOCERA CORP

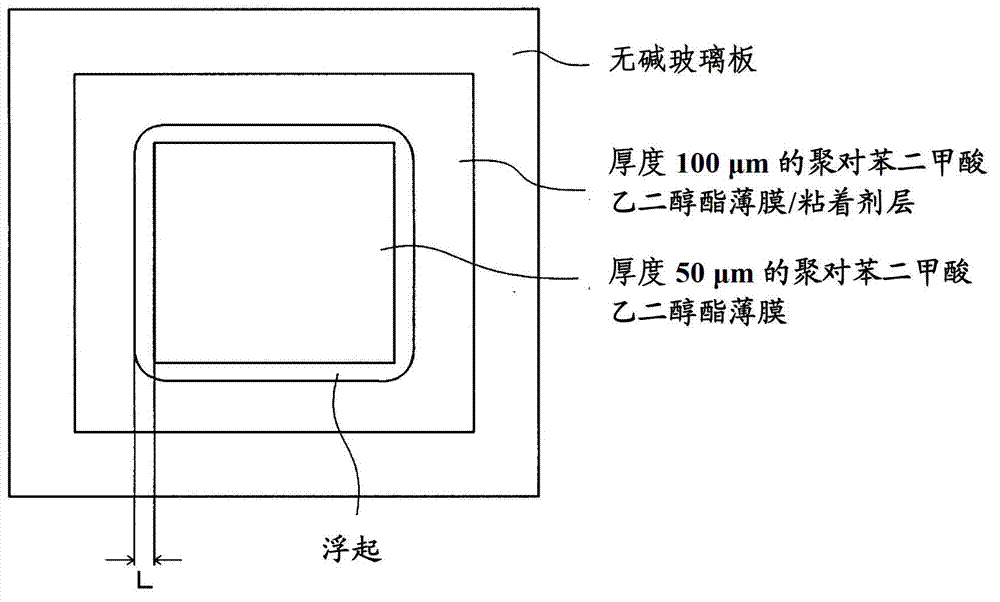

Adhesive composition, adhesive and adhesive sheet

ActiveCN102888201AExcellent stress relaxation rateExcellent unevenness followabilityNon-macromolecular adhesive additivesPolyureas/polyurethane adhesivesChemistryAdhesive

The invention provides an adhesive composition, an adhesive and an adhesive sheet which are suitable for optical components, such as polarization light panel, etc., and have light diffusivity, good stress relaxation rate, uneveness follow-up property and durability. The composition contains first (methyl) acrylic ester polymers (A) having a Mw of 500-3000 thousands, second (methyl) acrylic ester polymers (B) having a Mw of 80000-300 thousands, a cross-linking agent (C) and light diffusion micro-particles(D). The ratio of the polymers (B) with respect to 100 parts by mass of the polymers (A) is 5 to 50 parts by mass. The polymers (B) contain monomers having functional groups (b1) reacting with the cross-linking agent (C), and the ratio of the monomers in the polymers (B) is more than 1 mass% and less than 50 mass%. The polymers (A) do not contain monomers having functional groups reacting with the cross-linking agent (C) or contain monomers having functional groups (a1) having reactiveness with the cross-linking agent (C) lower than that of the functional groups (b1). The ratio of the light diffusion micro-particles(D) with respect to 100 parts by mass of the polymers (A) and the polymers (B) is 5.0 to 50.0 parts by mass.

Owner:LINTEC CORP

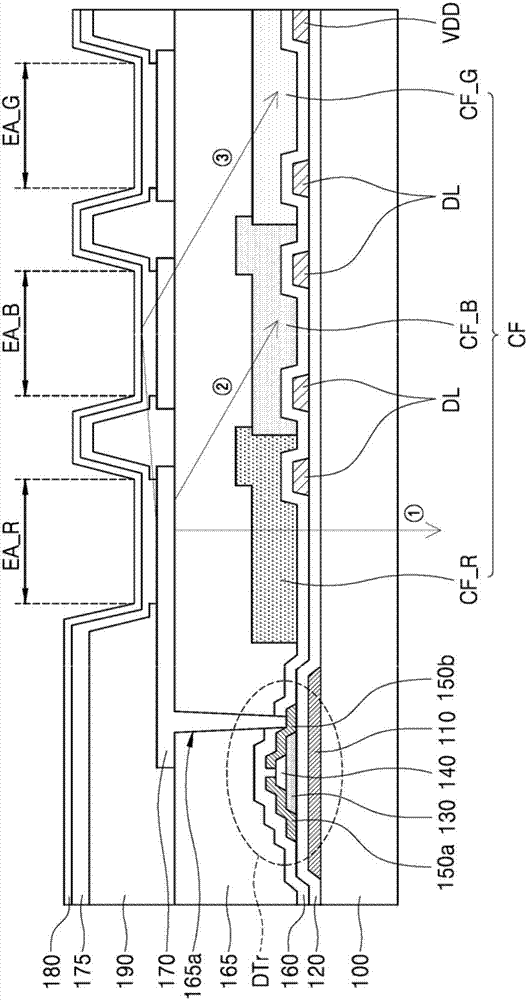

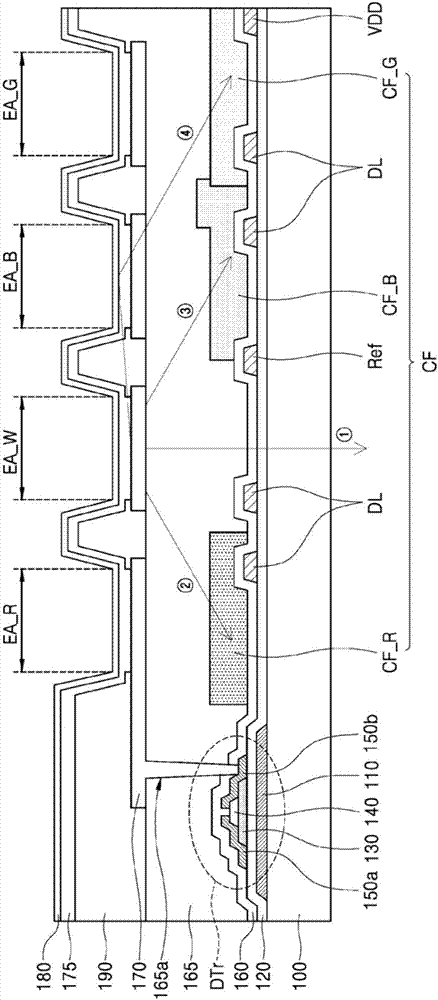

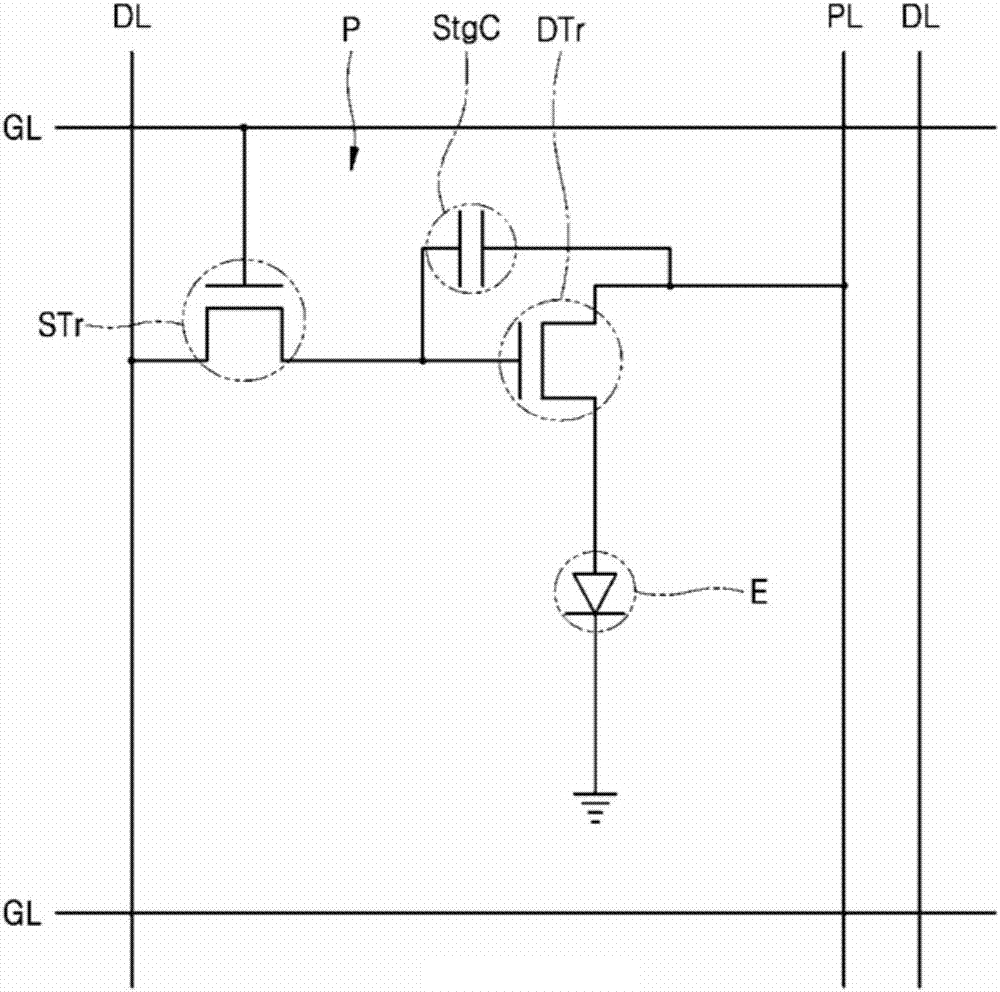

Organic Light Emitting Display Panel And Organic Light Emitting Display Device Comprising The Same

ActiveCN106920891AContainment leakAvoid scatterSolid-state devicesSemiconductor/solid-state device manufacturingGamutImaging quality

The present invention discloses an organic light emitting display panel and an organic light emitting display device comprising the same. The organic light-emitting display panel can improve the color purity and color gamut by reducing optical interference between adjacent pixel areas. A black bank layer is disposed on a planarization layer, such that it is possible to suppress light emitted from an organic emission layer from being reflected via various paths to be scattered to adjacent pixel areas. In addition, the black bank layer comes in contact with a color filter layer via holes formed in the planarization layer to thereby reduce optical interference between adjacent pixel areas. In this manner, the color purity and color gamut of displayed images can be improved, and a display device with excellent image quality can be implemented.

Owner:LG DISPLAY CO LTD

Flake pigment, powder coating material containing the flake pigment, powder coated film obtained by coating with frictional electrification-type electrostatic coating apparatus using the powder coating material, coated product with the powder coated film, and process for producing flake pigment

InactiveCN101965384AStable triboelectric characteristicsSuppress color unevennessChemical recyclingPowdery paintsPhosphateElectrostatic coating

Disclosed is a flake pigment characterized in that the flake pigment comprises flake particles, a film having a single-layer or multilayer structure and covering the surfaces of the flake particles, and fine particles, the outermost layer of the film contains a copolymer comprising one or more kinds of first bonding units derived from a fluorine-containing fluorine-type polymerizable monomer and one or more kinds of second bonding units derived from a phosphate group-containing polymerizable monomer, and the fine particles are fixed through the outermost layer and have such properties that impart frictional electrification properties to the flake pigment.

Owner:TOYO ALUMINIUM KK

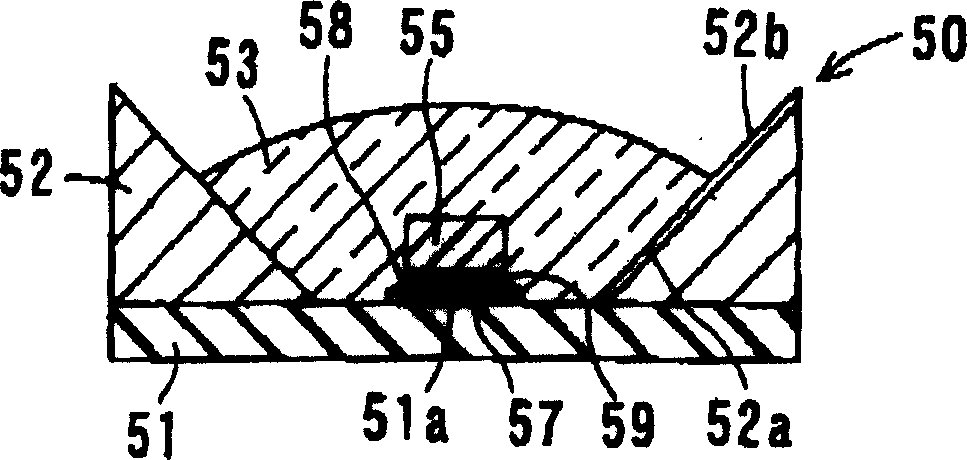

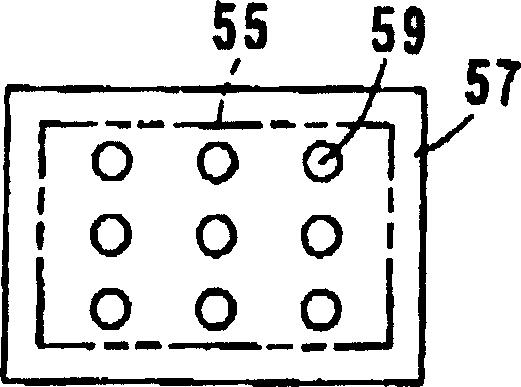

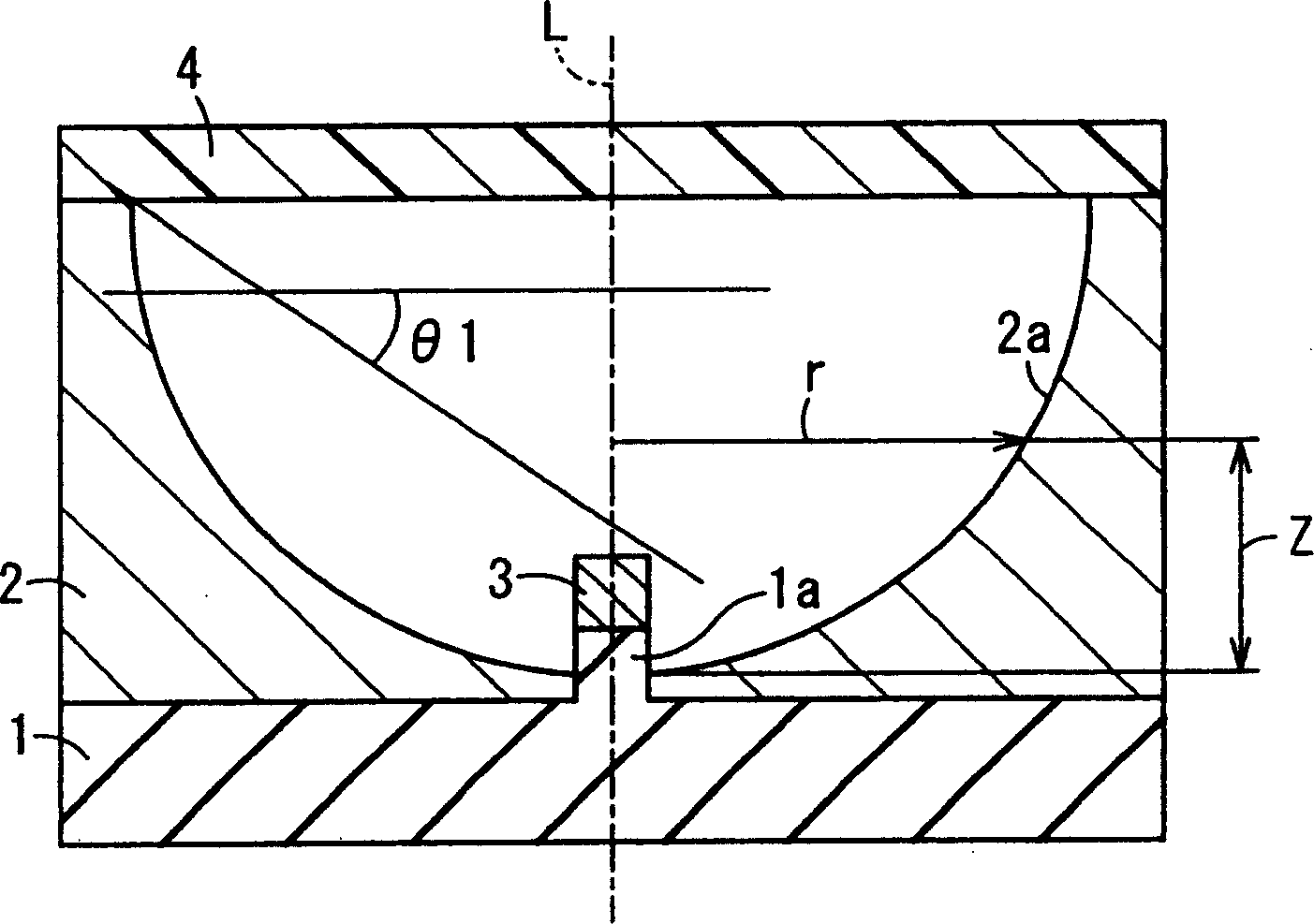

Luminous device and illuminator

InactiveCN1661825AIncrease reflectionReduce the refractive index differencePoint-like light sourceSolid-state devicesCurve lineLight emitting device

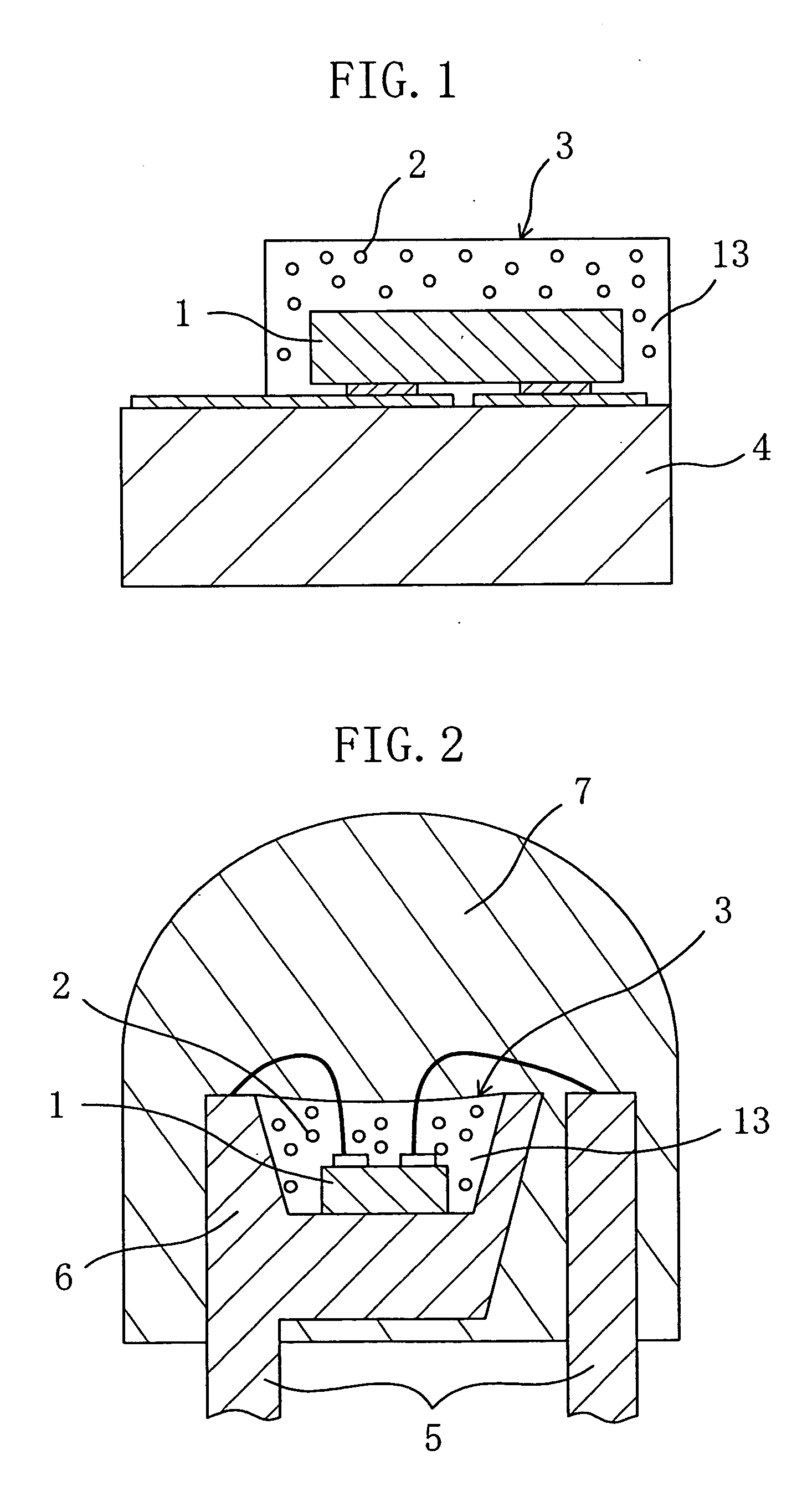

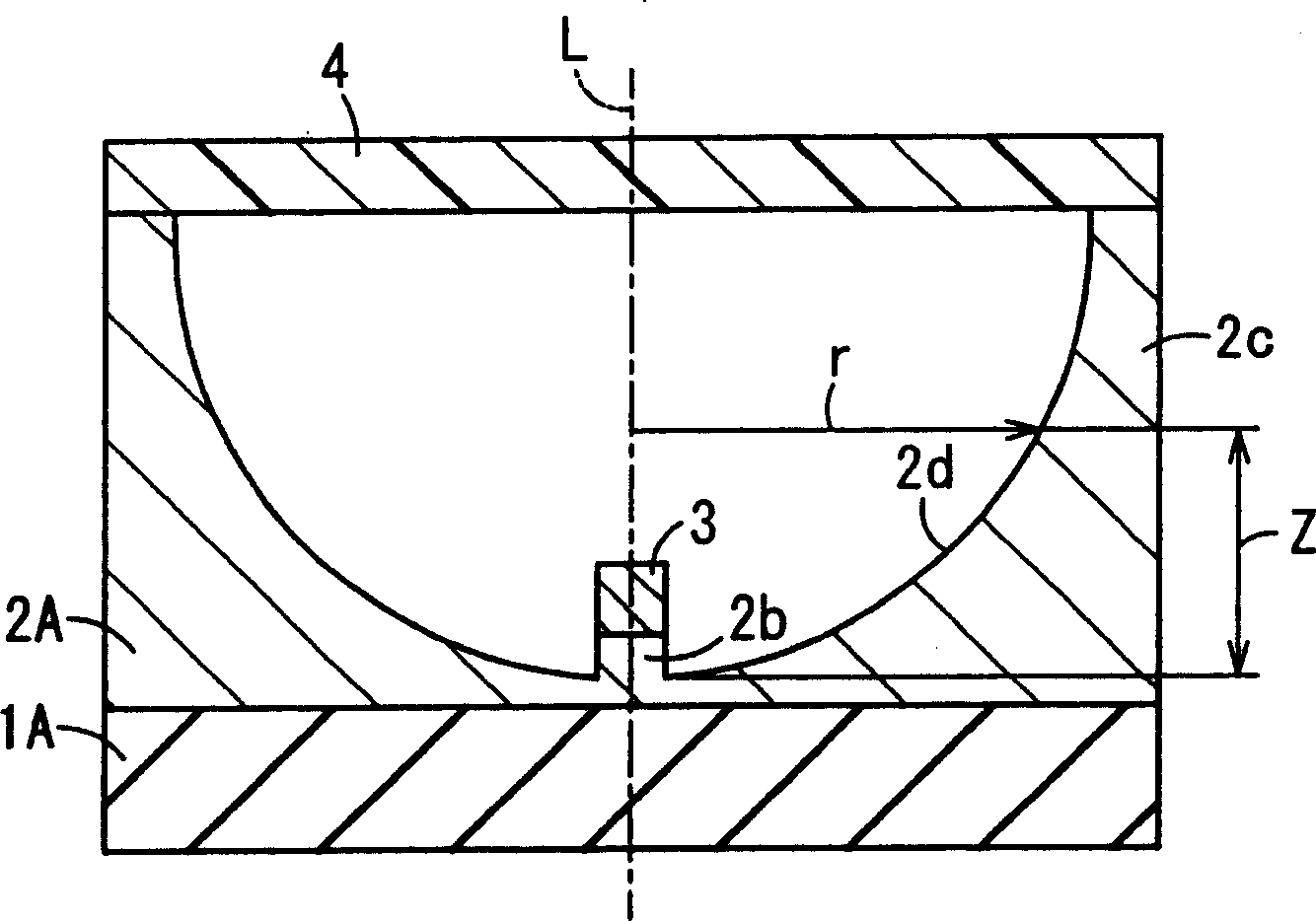

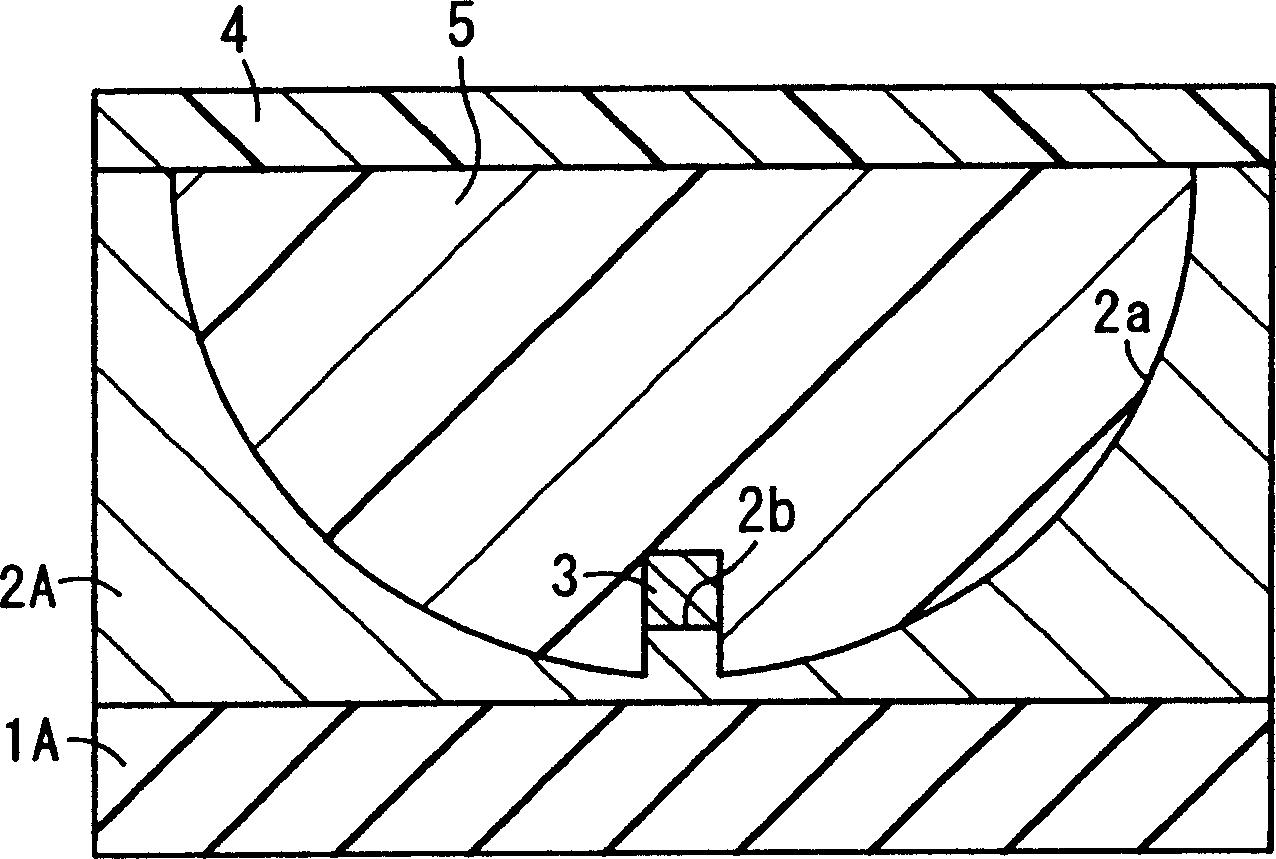

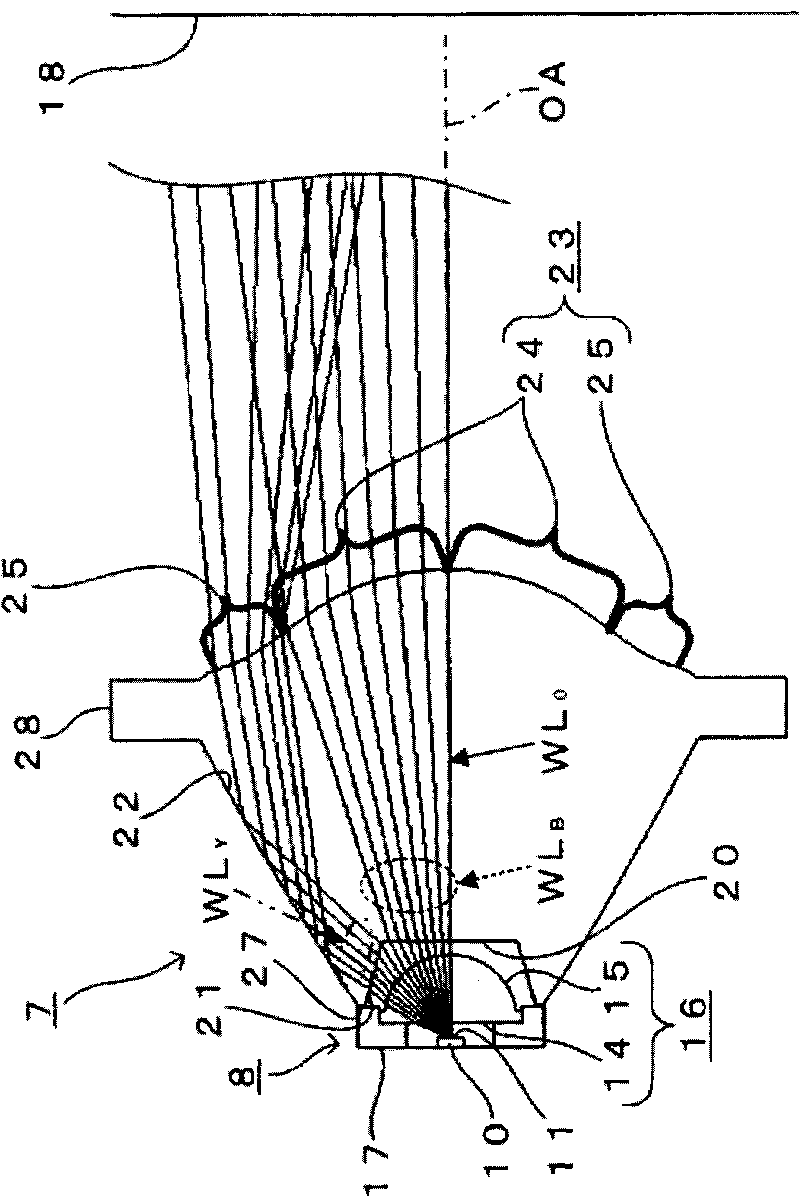

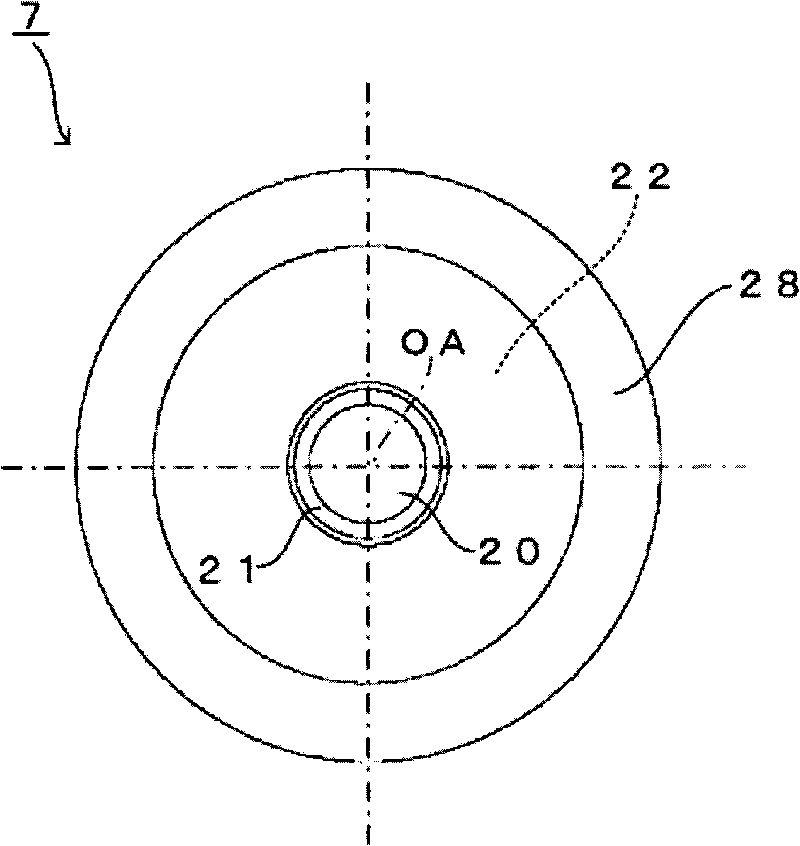

A light-emitting device has a light-emitting device (3), a base body (1) protruding section mounted the light-emitting device (3), a reflection member (2) and a fluorescent material layer (4) disposed with gap to the light-emitting device (3). A cross section of the inner circumferential surface (2a) of the reflection member (2) cut by a virtual plane including a virtual axis (L) penetrating a center of the inner surface and perpendicular to the upper principal surface of the base body (1) has a sectional profile defined by a curved line expressed by the following formula, and the inner surface of the reflection member is a curved surface obtained by rotating the curved line about the virtual axis: Z=(cr<2>) / [1+{1-(1+k)c<2>r<2>] ] <1 / 2>]} (wherein -1<=k<=-0.001, 0.001<=c<=10), r is the radius between the virtual axis and the surface of the inner circumferential surface, Z is the height from the lower end of the inner circumferential surface to the surface of the inner circumferential surface at the radius.

Owner:KYOCERA CORP

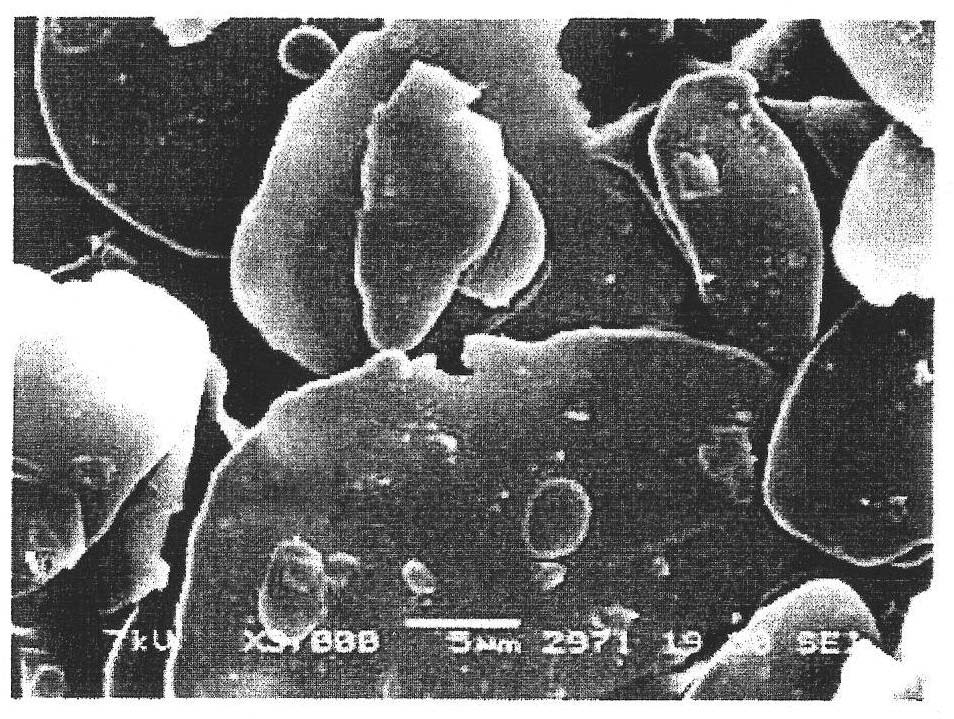

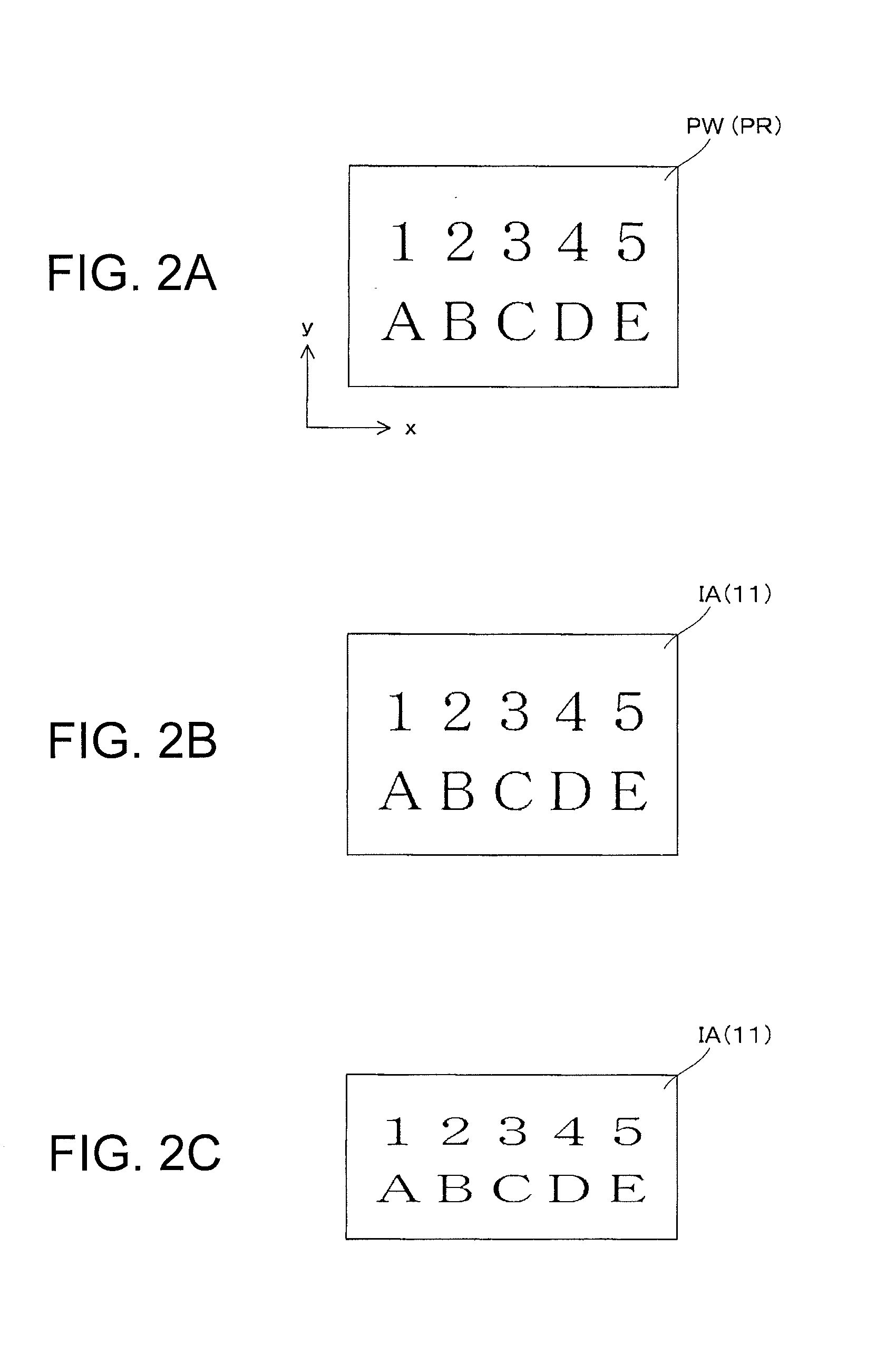

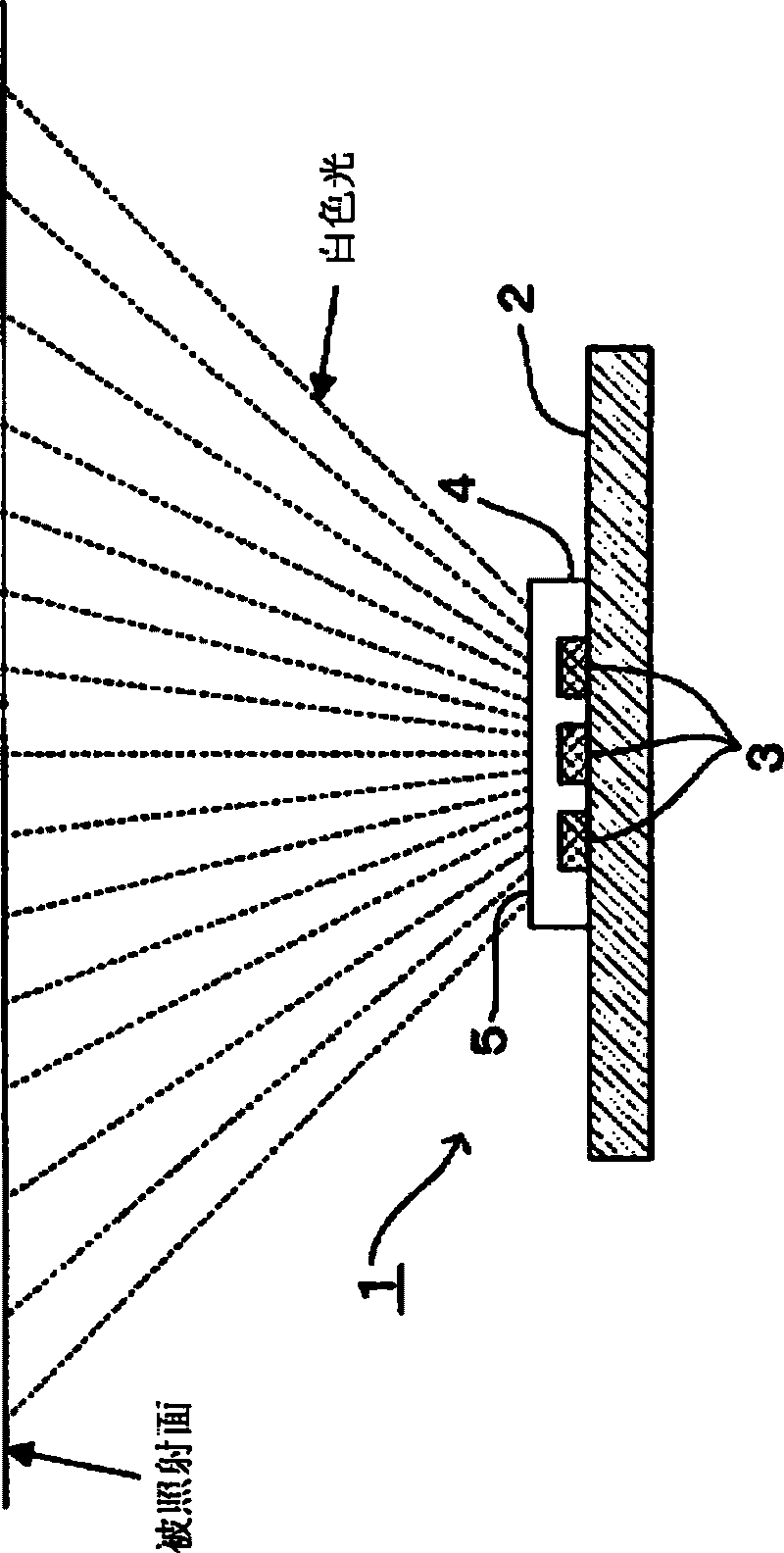

Composite wavelength conversion powder, resin composition containing composite wavelength conversion powder, and light emitting device

ActiveCN104471729AImprove utilization efficiencyImprove light utilization efficiencyMagnesium fluoridesCalcium/strontium/barium fluoridesInorganic particlePhosphor

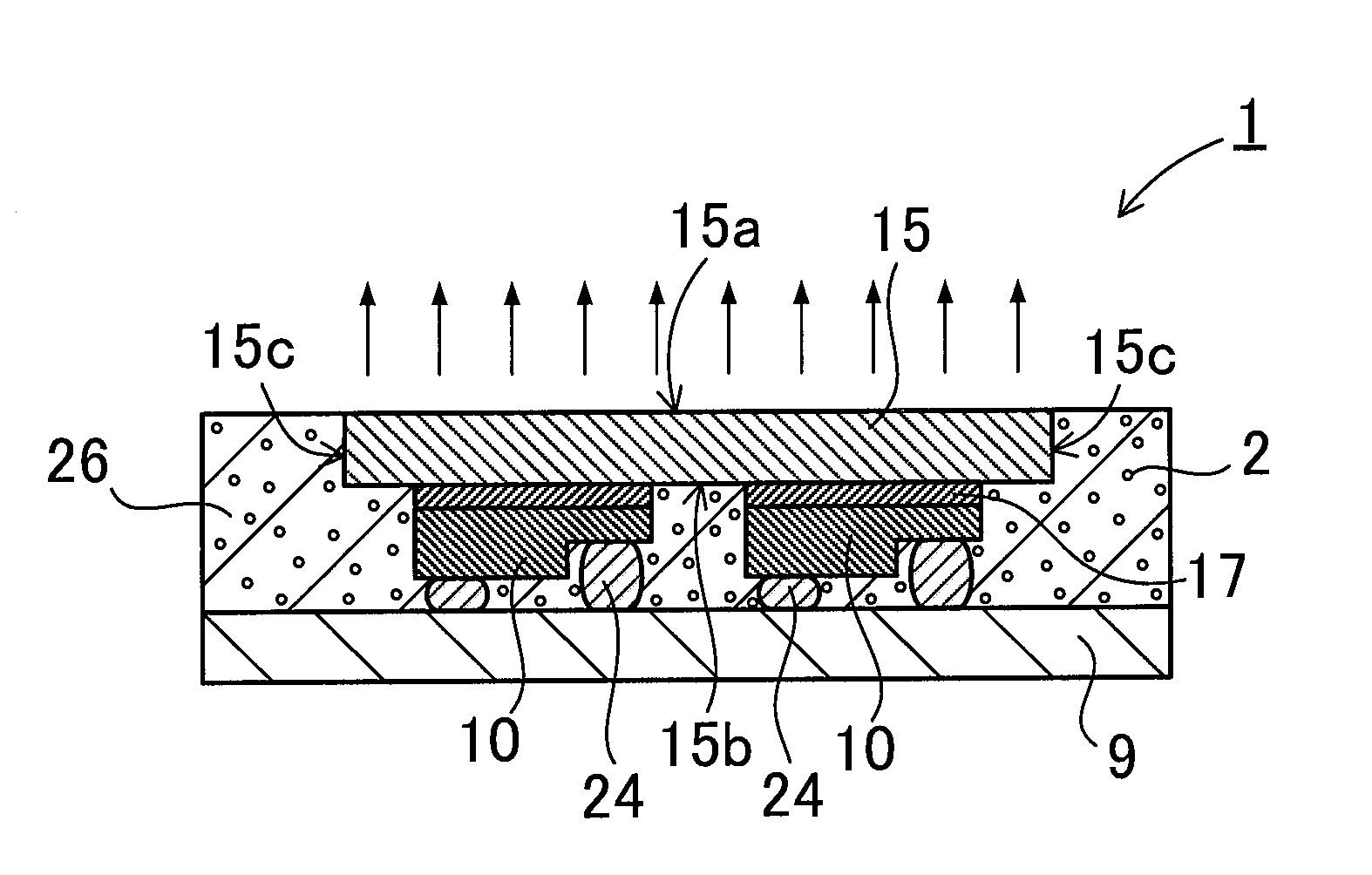

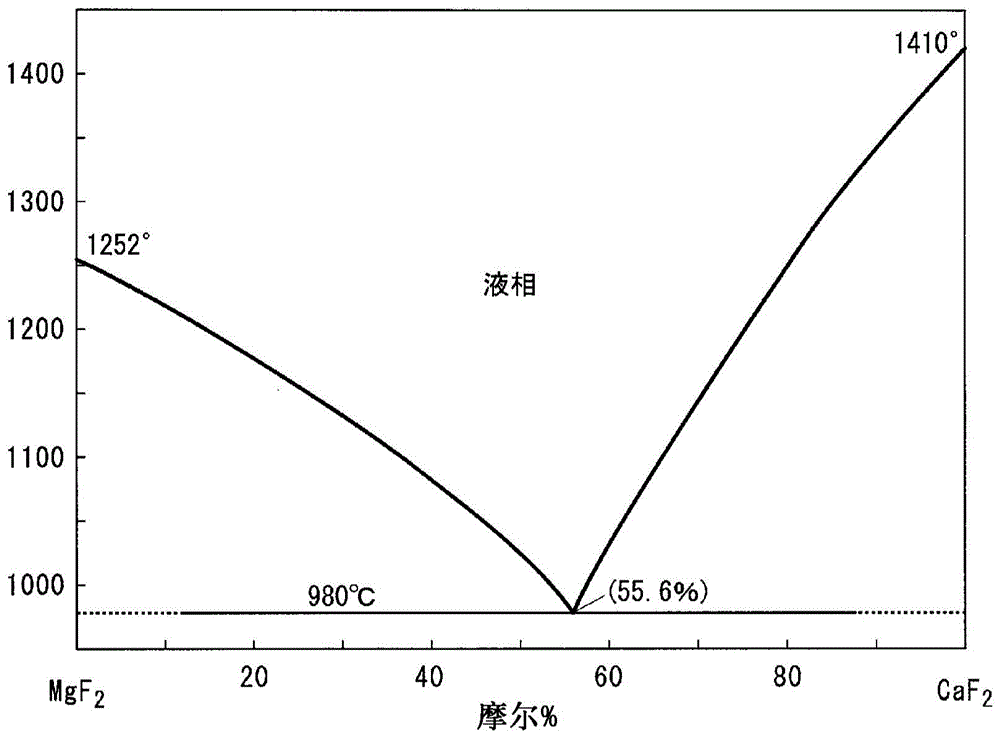

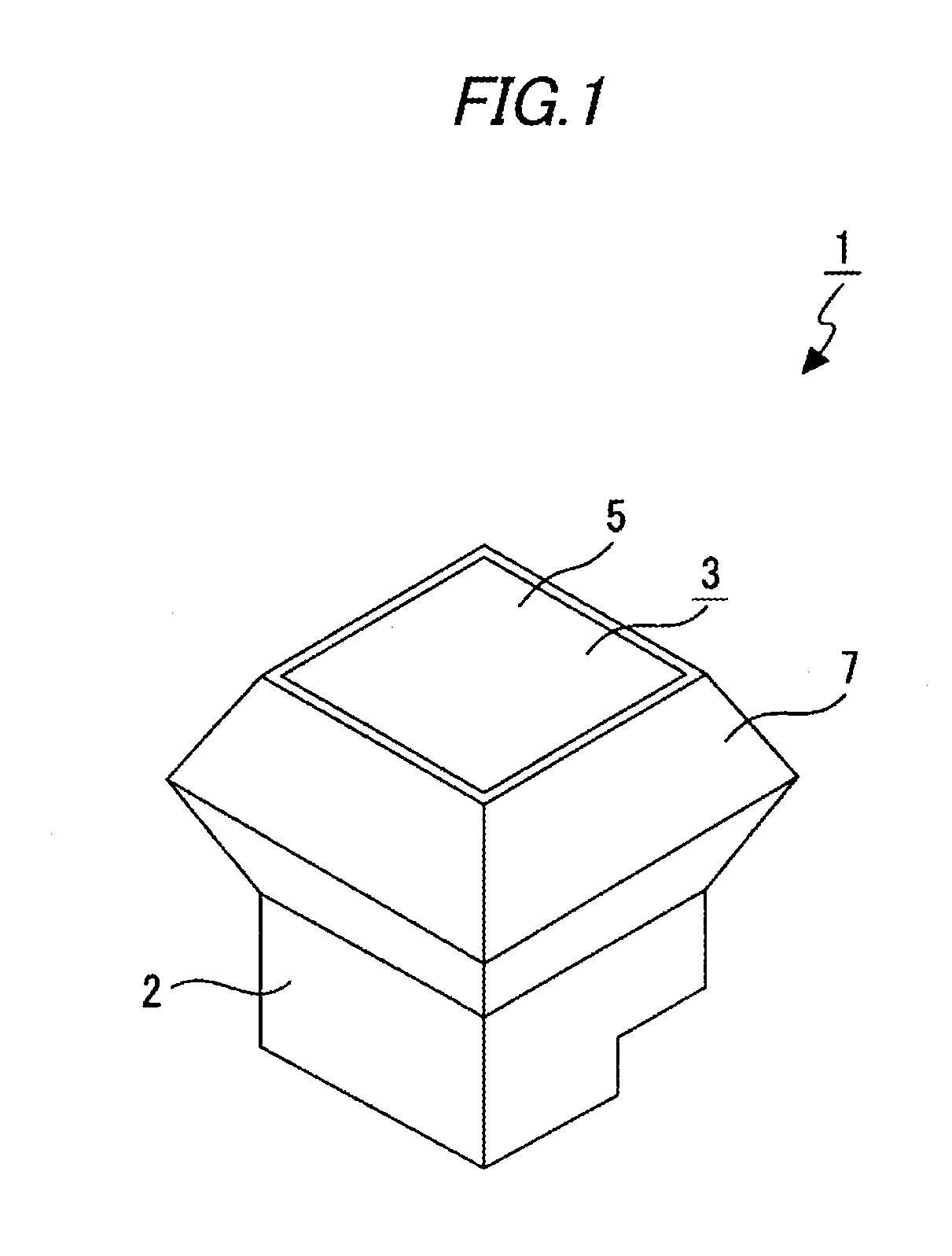

Provided are: a composite wavelength conversion powder which has high utilization efficiency of light and high utilization efficiency of a constituent material, and which is capable of achieving a good balance between highly efficient light emission and high reliability; and a resin composition which contains this composite wavelength conversion powder. This composite wavelength conversion powder is obtained by dispersing phosphor particles having a refractive index of 1.6 or more in a matrix particle which contains fine magnesium fluoride particles or fine calcium fluoride particles. Also provided is a light emitting device which is capable of improving the utilization efficiency of light produced by phosphor particles that are excited by primary irradiation light irradiated from a light emitting element, and which is capable of improving the optical output of light emission by increasing the amount of secondary irradiation light produced by the phosphor particles, while suppressing the occurrence of color unevenness or color variation of the light discharged to the outside of the device. A light emitting device (1) of the present invention is provided with a substrate (2), a light emitting element (3) that is mounted on the surface of the substrate (2), and a light transmitting member (4) that covers the light emitting element (3). This light transmitting member (4) contains composite wavelength conversion particles (12) which are composed of phosphor particles that have an average particle diameter of 500 nm or less and inorganic particles that are transparent to visible light and have an average particle diameter of 500 nm or less.

Owner:SUMITOMO OSAKA CEMENT CO LTD

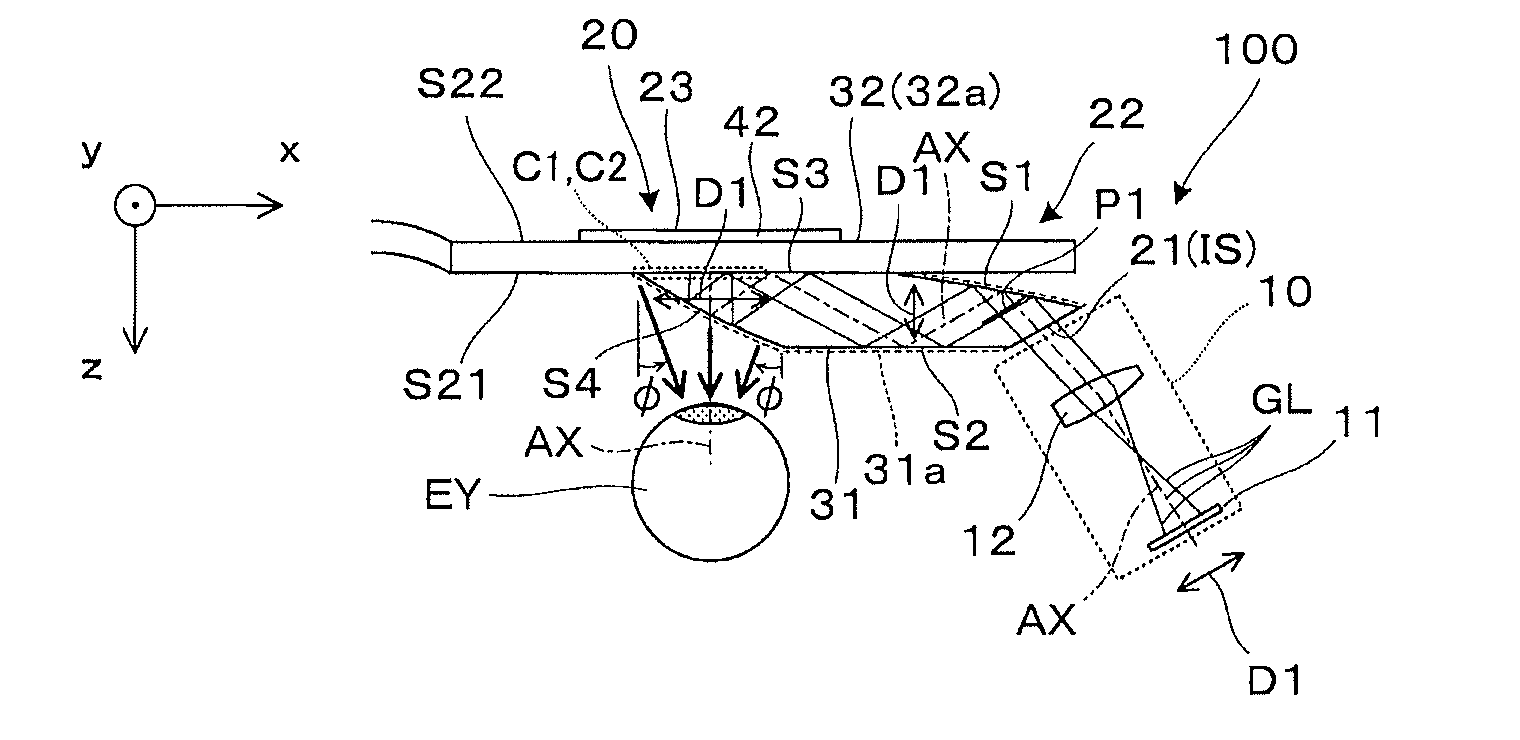

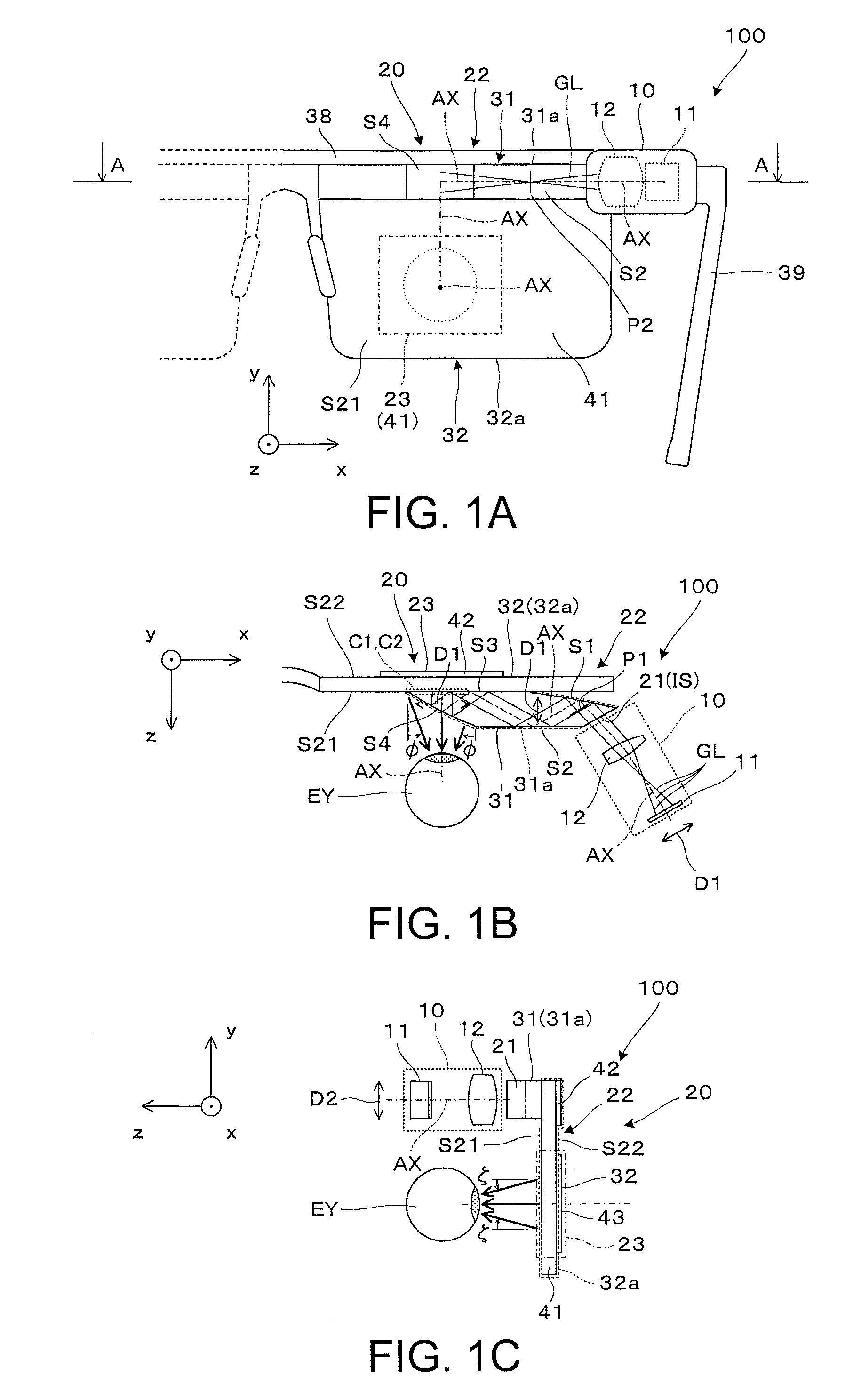

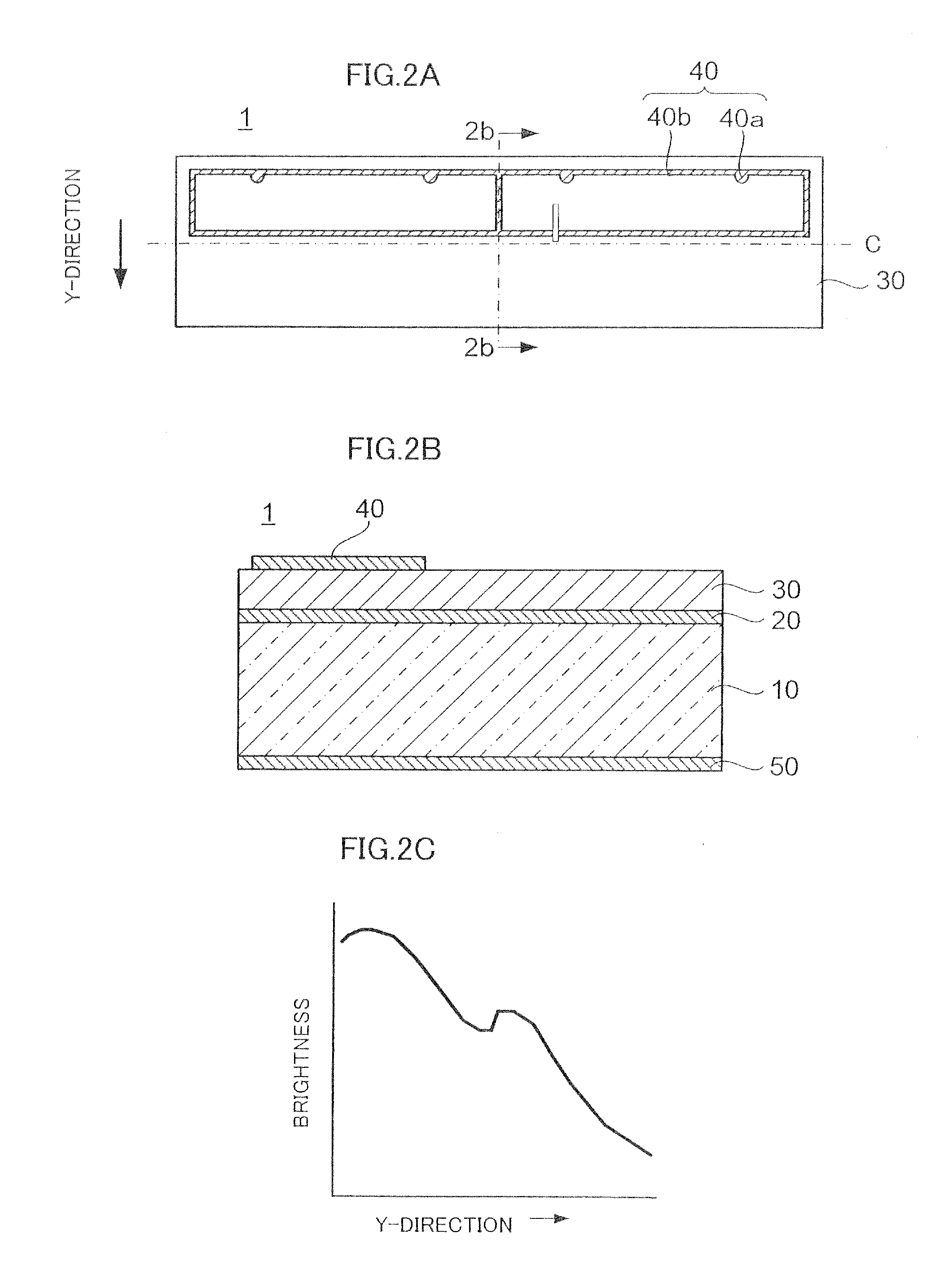

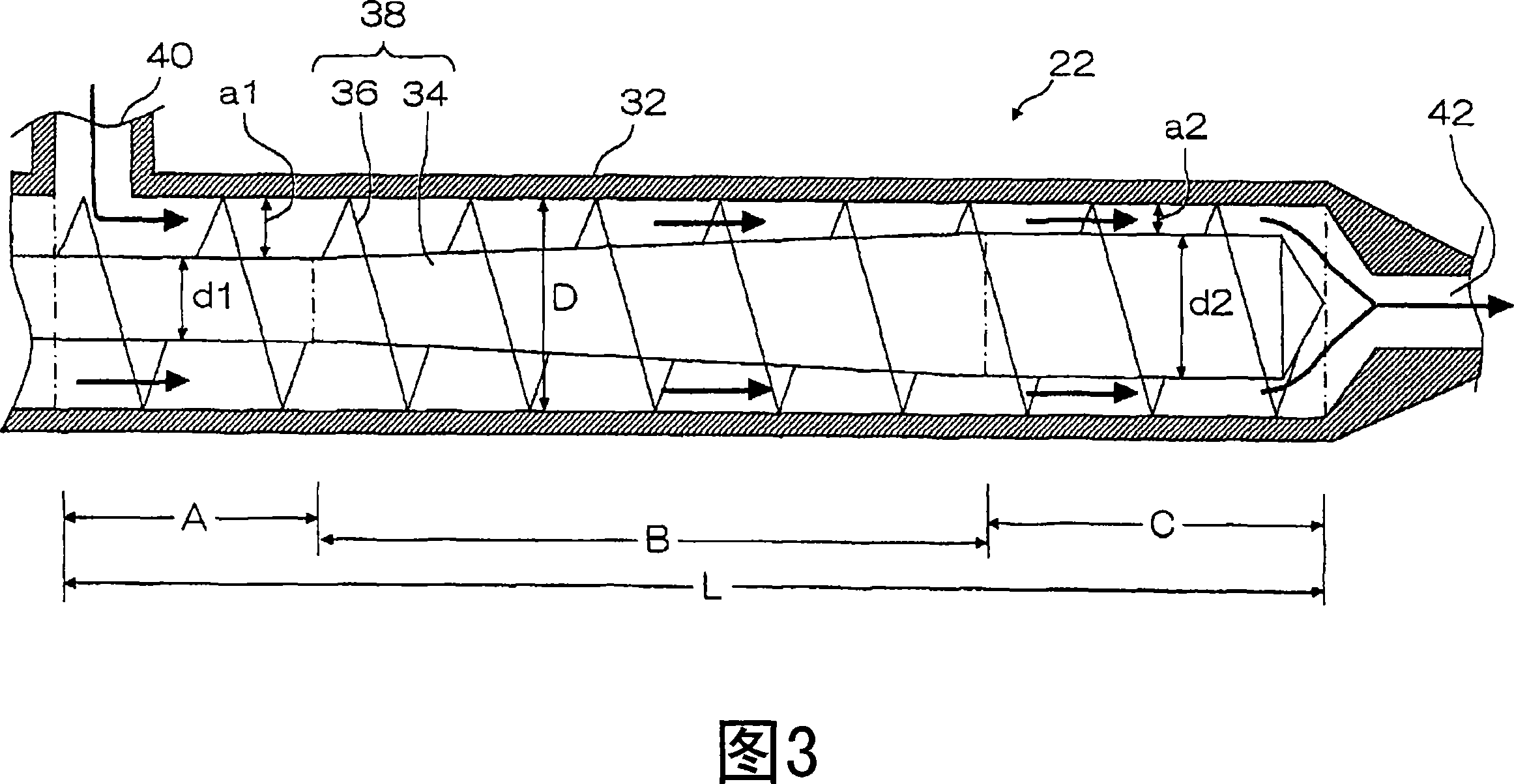

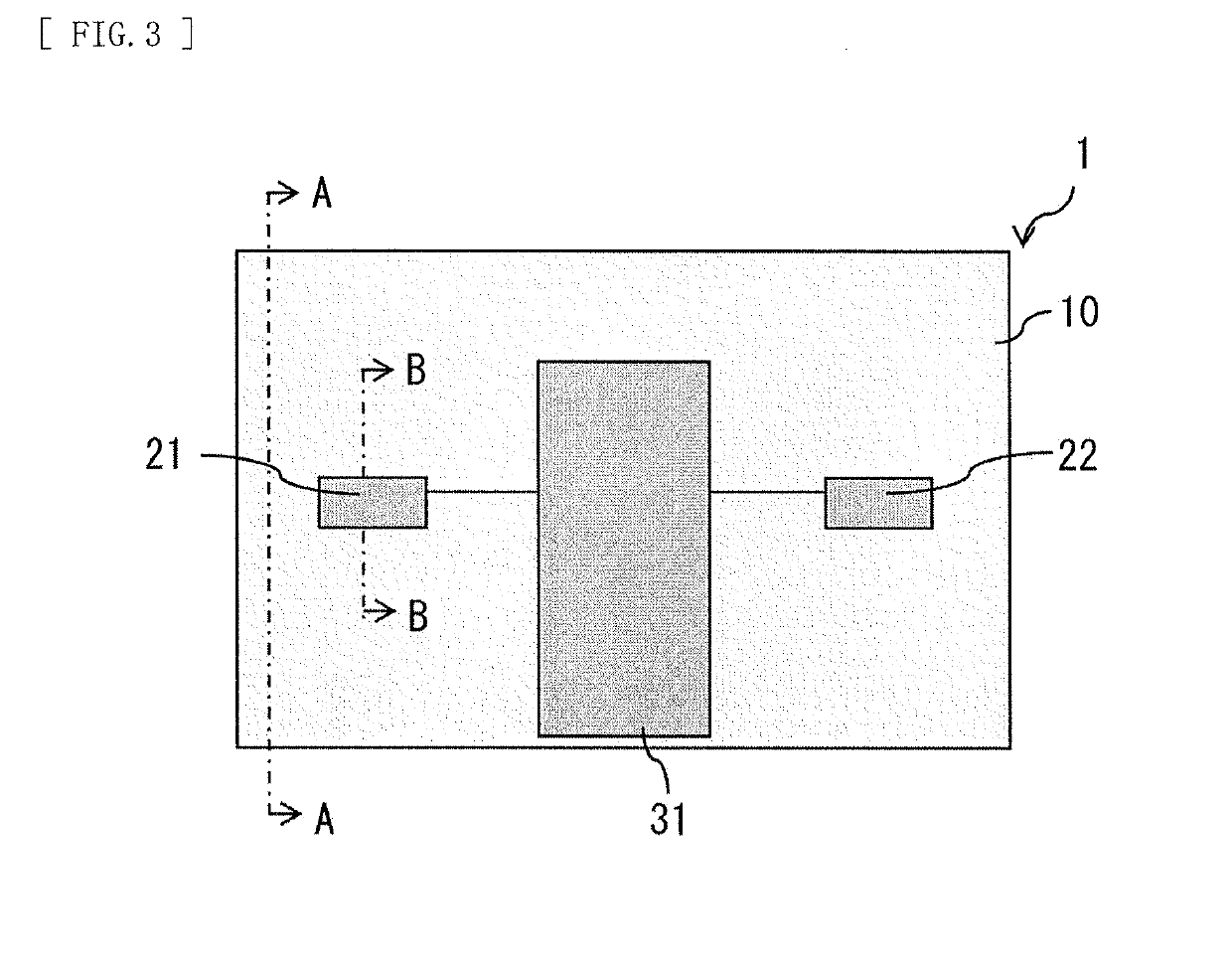

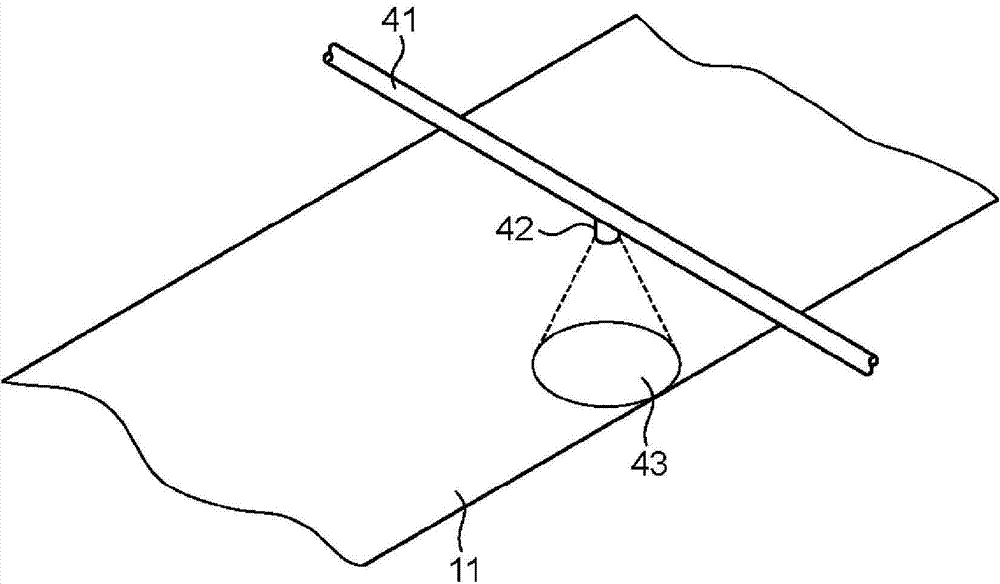

Light guide device and virtual image display apparatus

ActiveUS20170059868A1Suppress color unevennessReduce color unevennessMechanical apparatusPlanar/plate-like light guidesLight guidePupils size

A light guide device may be incorporated into a virtual image display apparatus, and functionally includes a light-incident part for entrance of picture lights, a light guide part that guides the picture lights via the light-incident part, and a light-exiting part that outputs the picture lights from the light guide part to a position of an eye. In the light guide device, light guide that enables non-diffraction virtual image formation is performed with respect to lateral first directions and a pupil size is enlarged by first and second diffraction optical elements with respect to longitudinal second directions.

Owner:SEIKO EPSON CORP

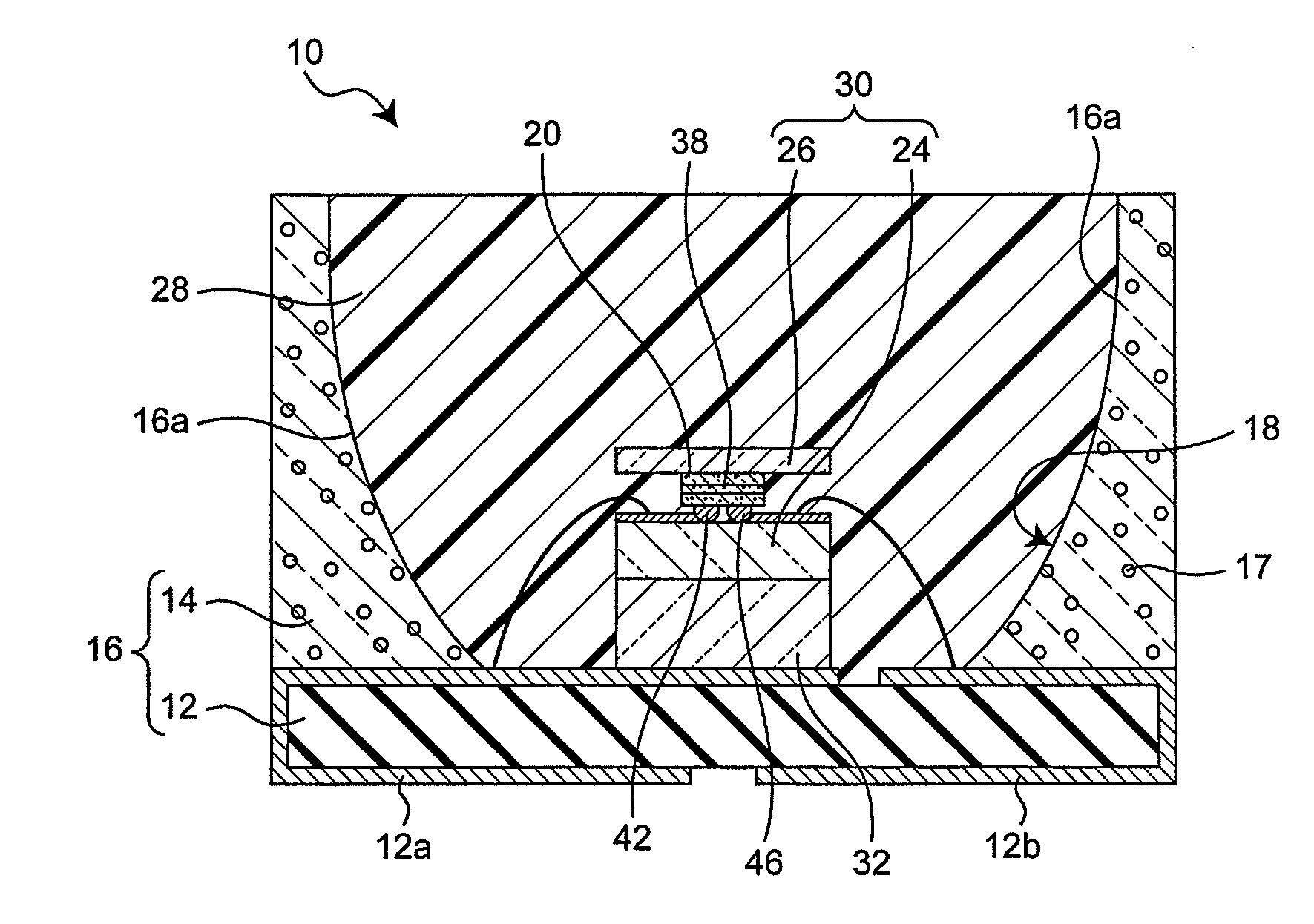

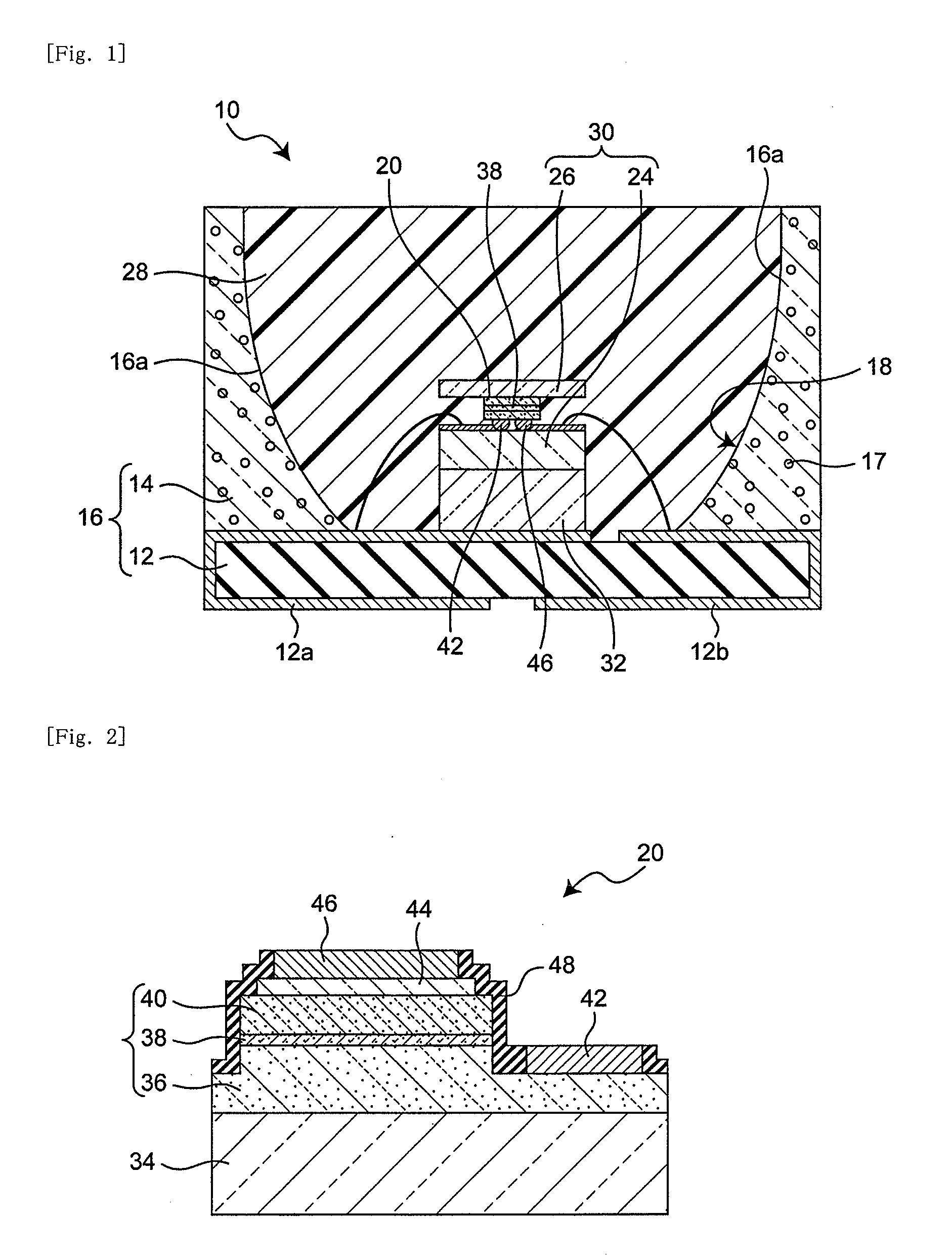

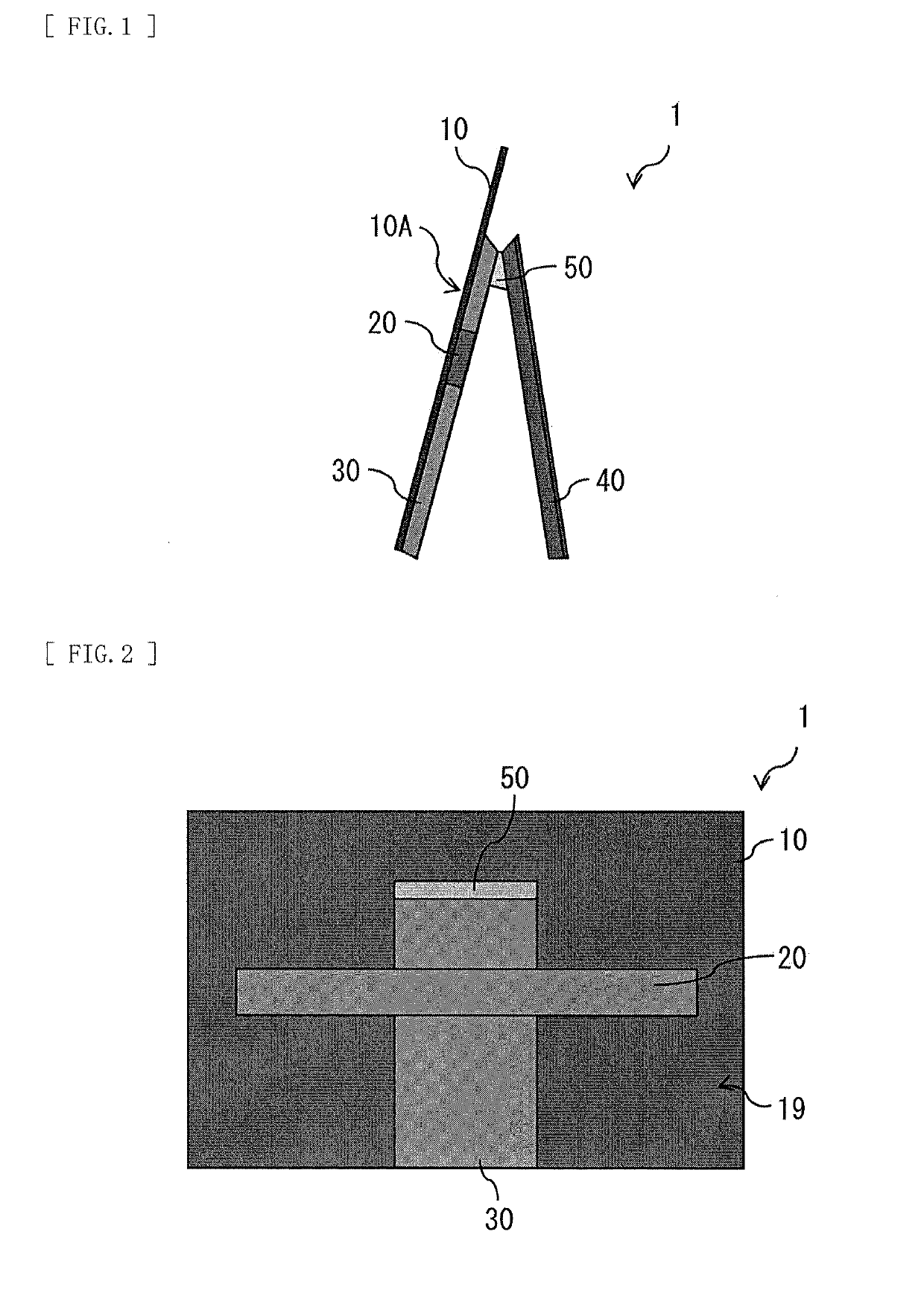

Light Emitting Device

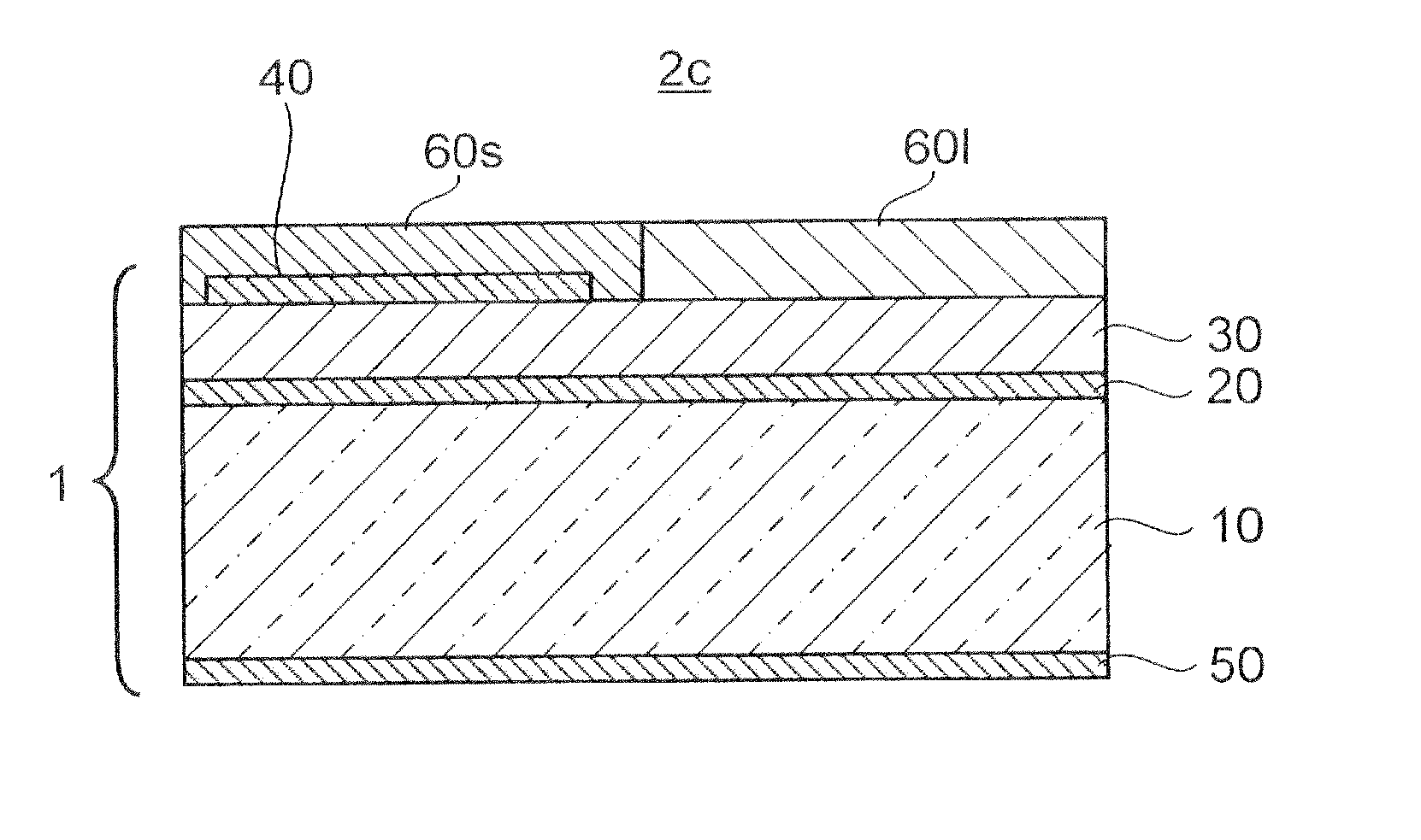

ActiveUS20130121009A1Improved light emitting efficiencySuppress color non-uniformitySolid-state devicesSemiconductor devicesSemiconductorWavelength conversion

A light emitting device is provided with a semiconductor light emitting element and a wavelength conversion portion. The wavelength conversion portion includes an outer peripheral portion between an input surface and an output surface. The outer peripheral portion includes a first inclined part at a side of the input surface and a second inclined part at a side of the output surface. The first inclined part and the second inclined part define a projecting portion that is projected on the outer peripheral portion.

Owner:KOITO MFG CO LTD +1

Semiconductor light emitting device and vehicle lamp

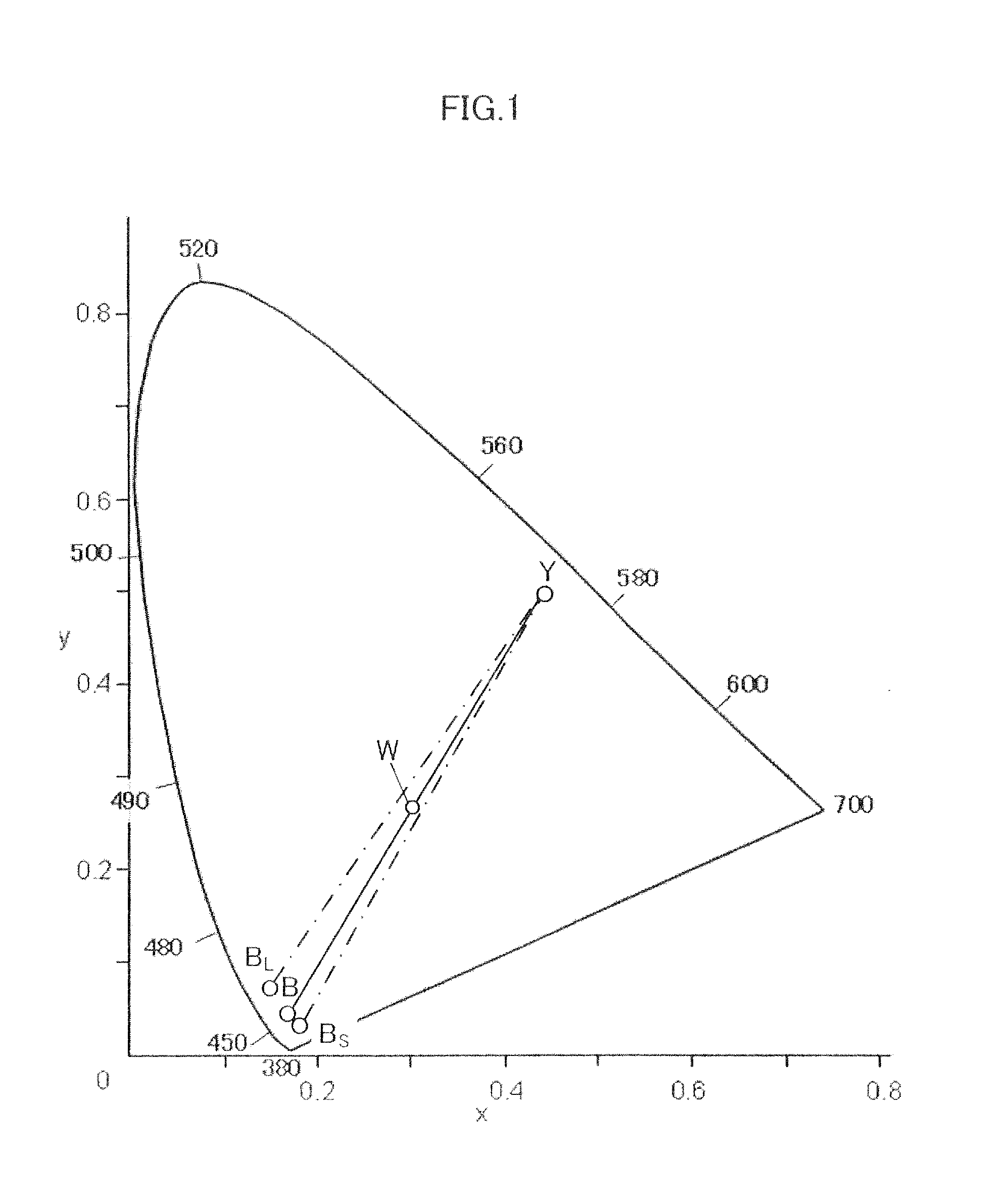

ActiveUS20130100692A1High densityReduce chroma differenceNon-electric lightingVehicle headlampsHigh current densityFluorescence

A semiconductor light emitting device which produces mixed light of a desired emission color by a combination of a semiconductor light emitting element and a wavelength converting layer containing a fluorescent substance, and a vehicle lamp including the semiconductor light emitting device. The wavelength converting layer has different wavelength conversion characteristics respectively at its portion covering an area of relatively high current density at light emission operation of the semiconductor light emitting element and at its portion covering an area of relatively low current density so as to reduce chromaticity difference over the light extraction surface of the mixed light due to non-uniformity of current density in the light emitting layer at light emission operation.

Owner:STANLEY ELECTRIC CO LTD

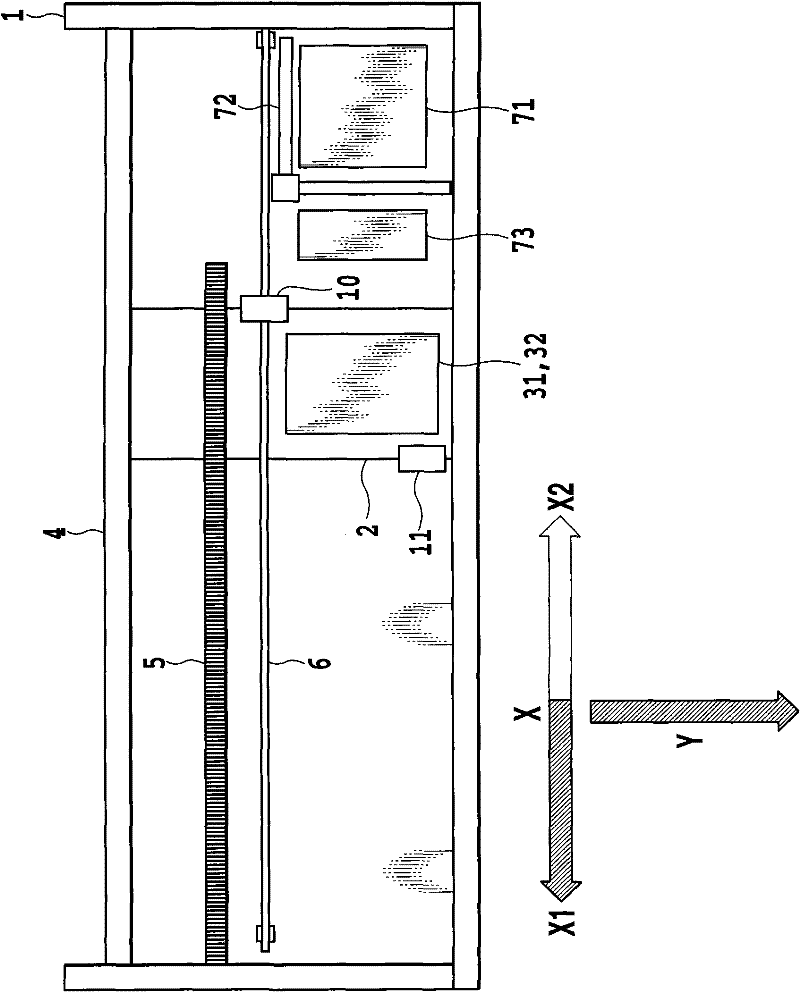

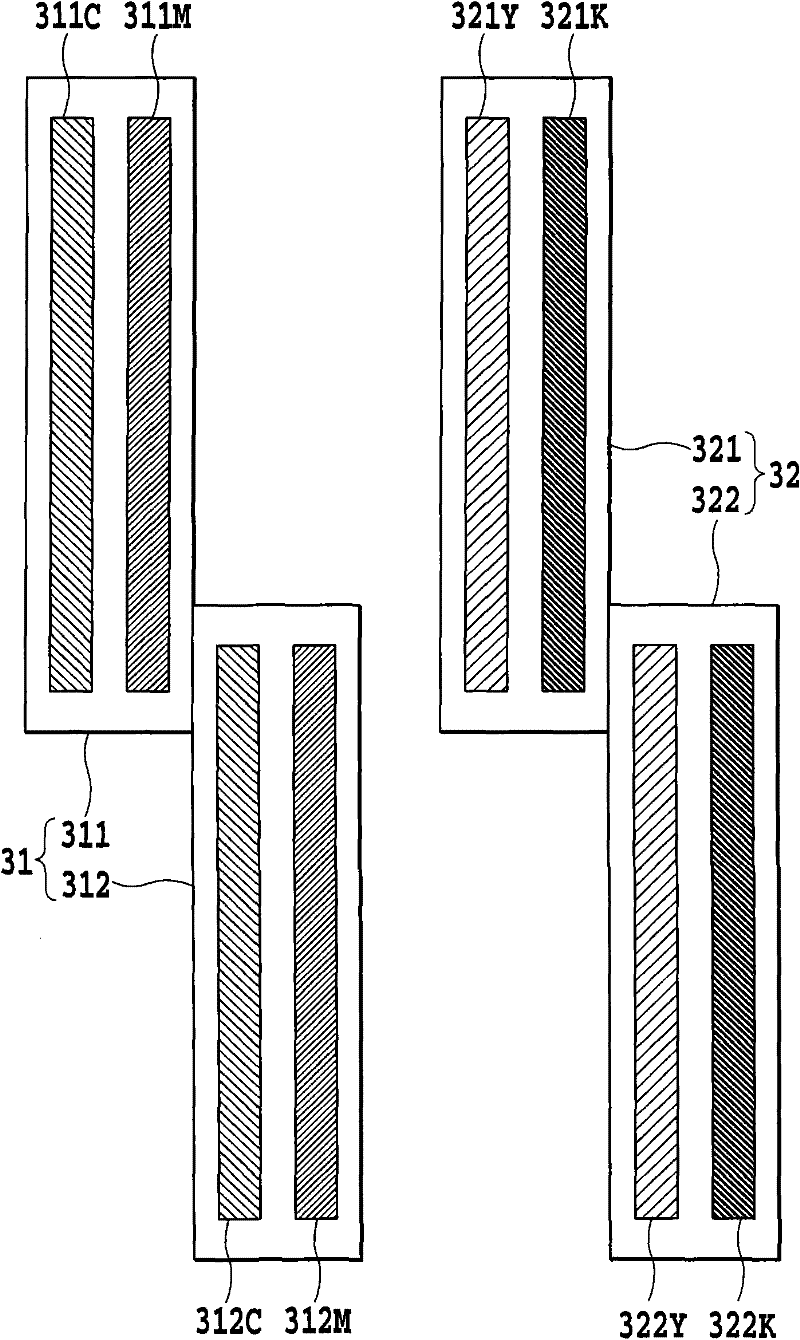

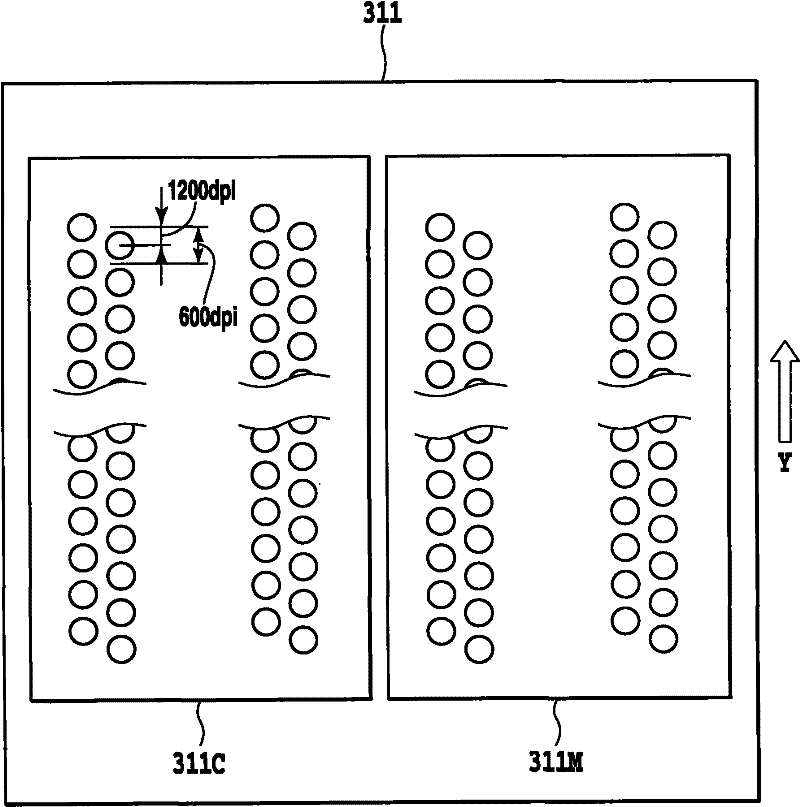

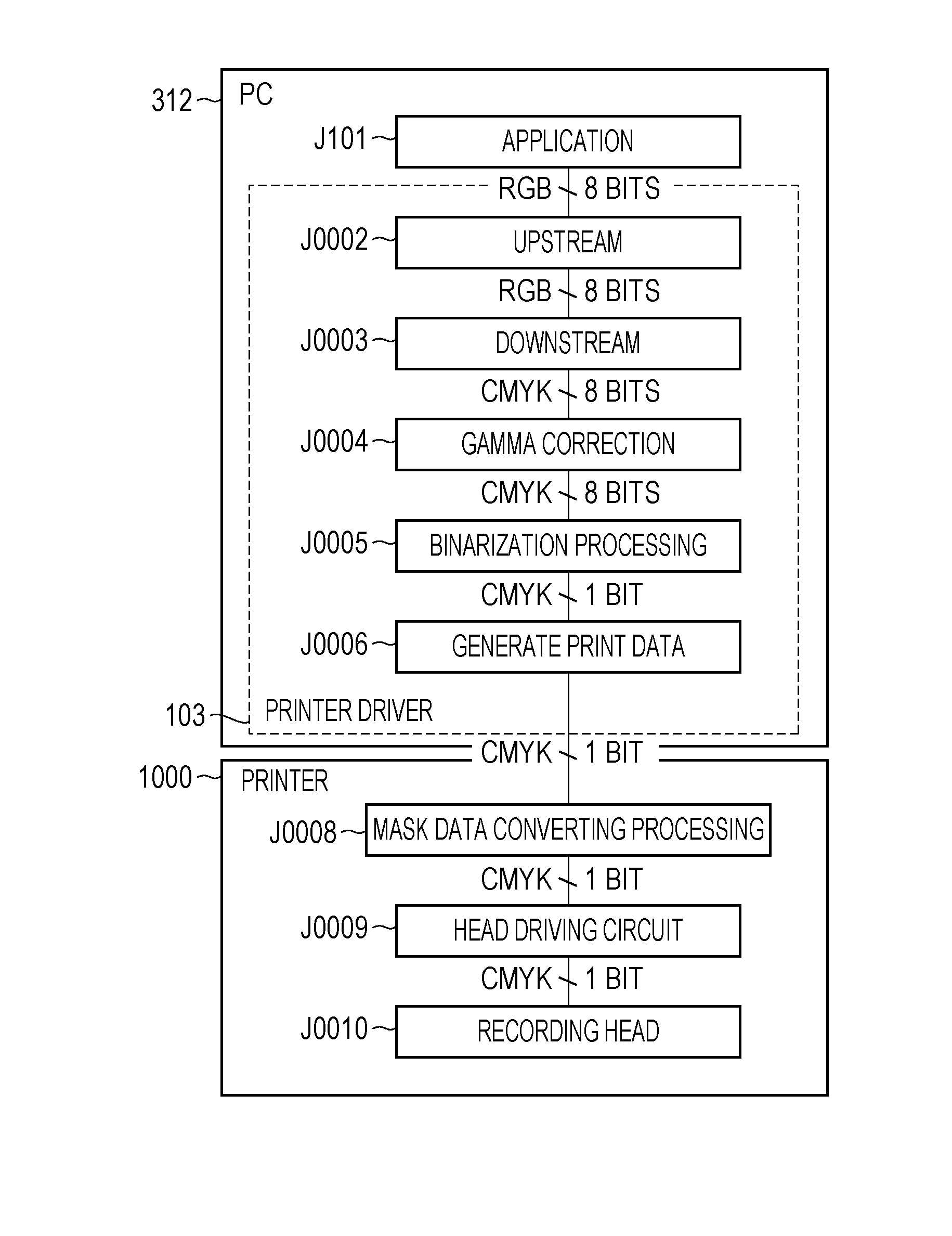

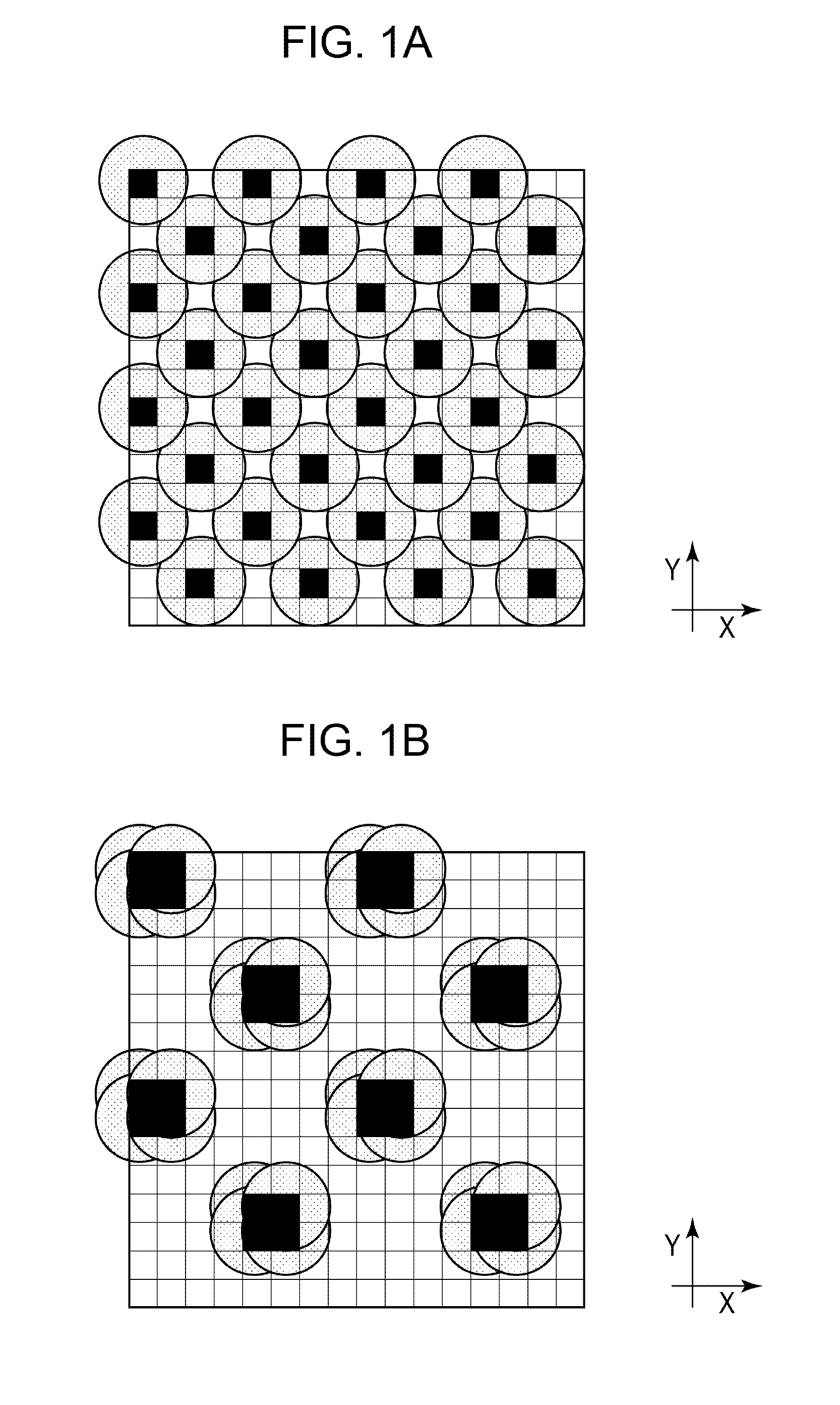

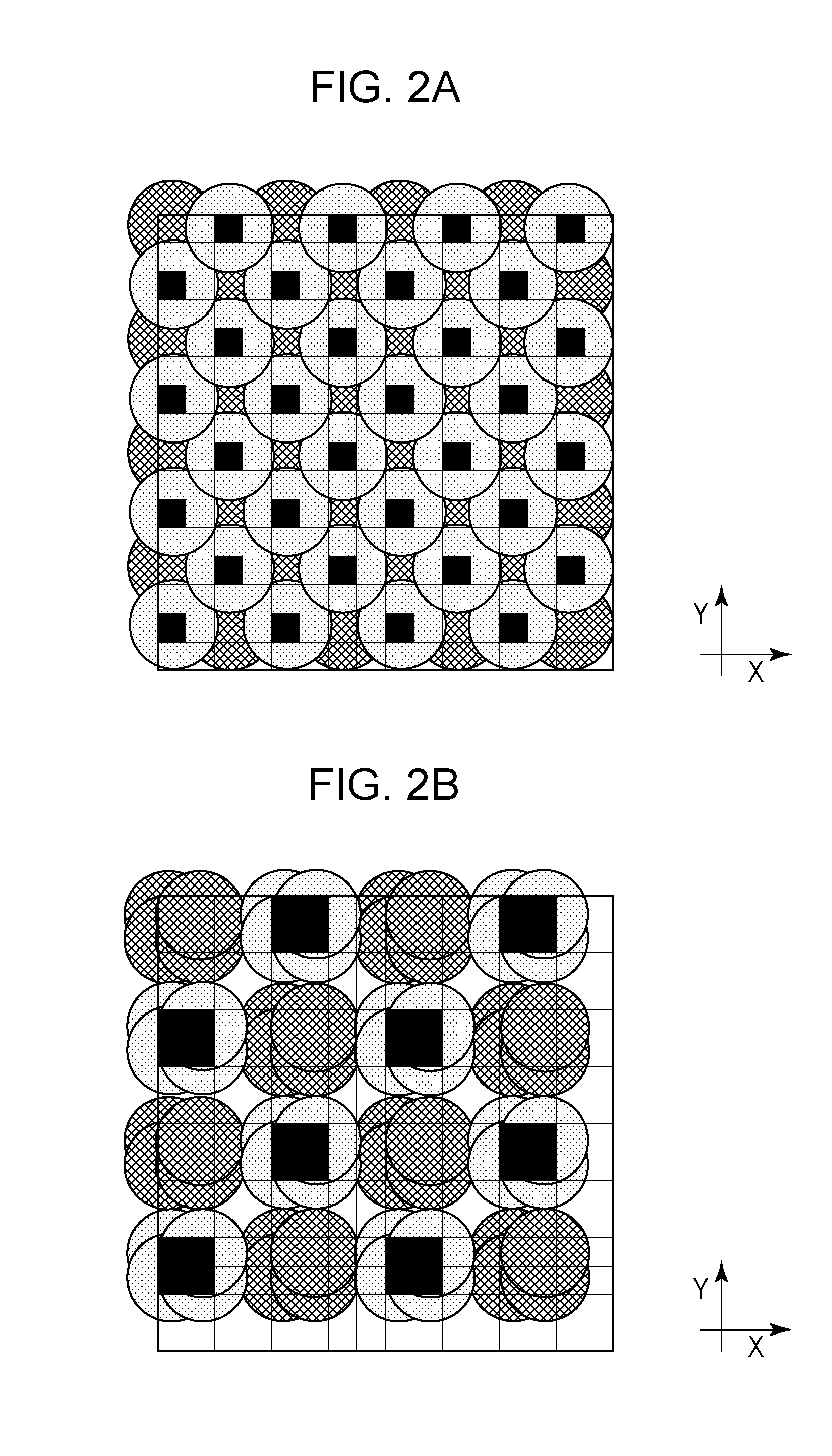

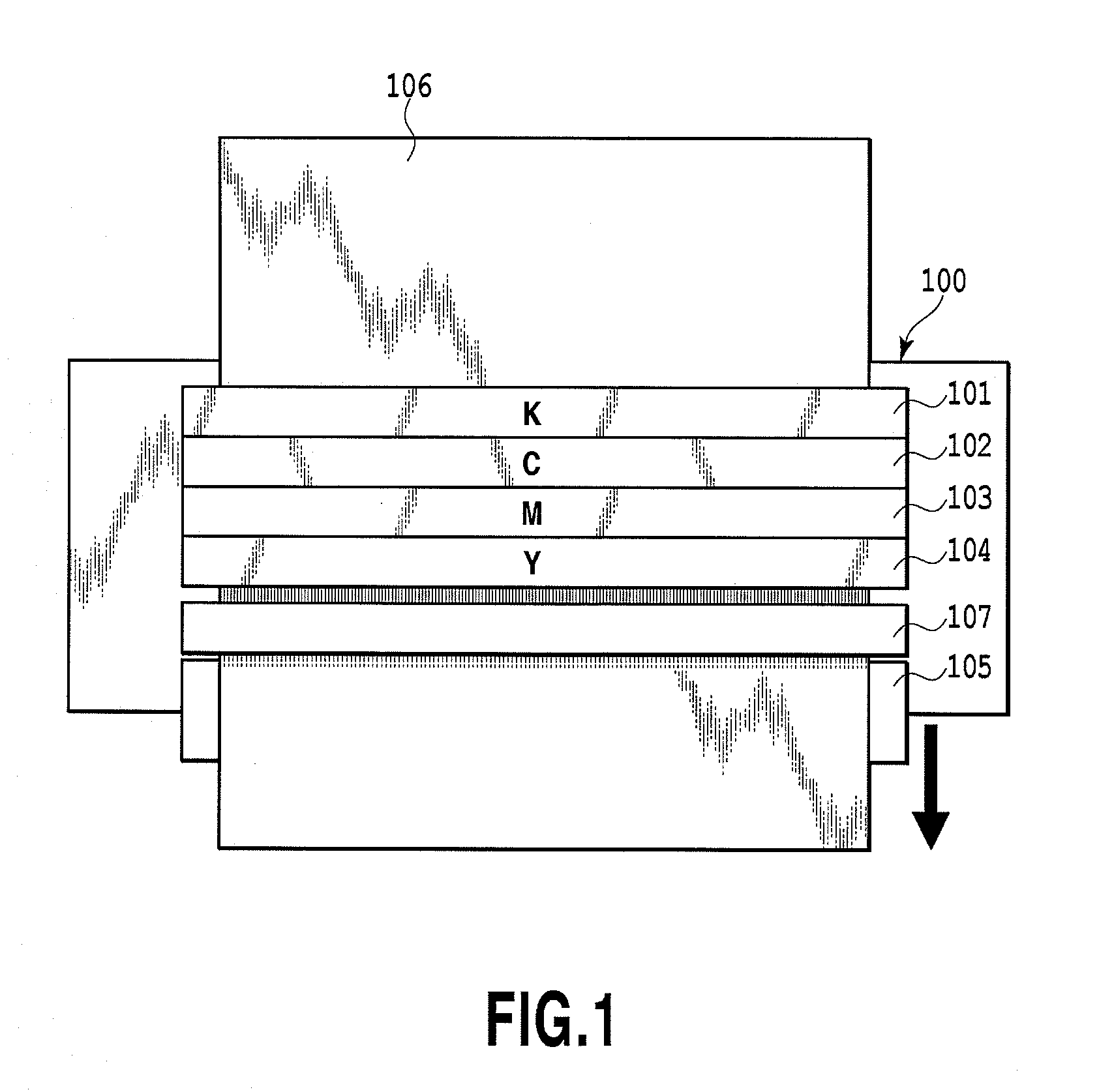

Ink jet printing apparatus and ink jet printing method

InactiveCN102161260ASuppress color unevennessHigh quality imagingOther printing apparatusEngineeringElectrical and Electronics engineering

The invention provides an ink jet printing apparatus and an ink jet printing method. This invention has a plurality of print heads, each including a first and second nozzle arrays. The different print heads are arranged so as to include an overlap area. The difference in distribution rate between the plurality of nozzle arrays for the same color is set to be larger when the number of ejections in the overlap portion is equal to or larger than the threshold than when the number of ejections in the overlap portion is smaller than the threshold. The print data for the same color is distributed among the plurality of nozzle arrays for the same color so that the number of pixels with the same ink overlap sequence as that in the non-overlap areas is larger than the number of pixels with an overlap sequence different from that in the non-overlap areas when the number of ejections is equal to or larger than the predetermined threshold.

Owner:CANON KK

Image display device, presentation box employing same, and method of driving image display device

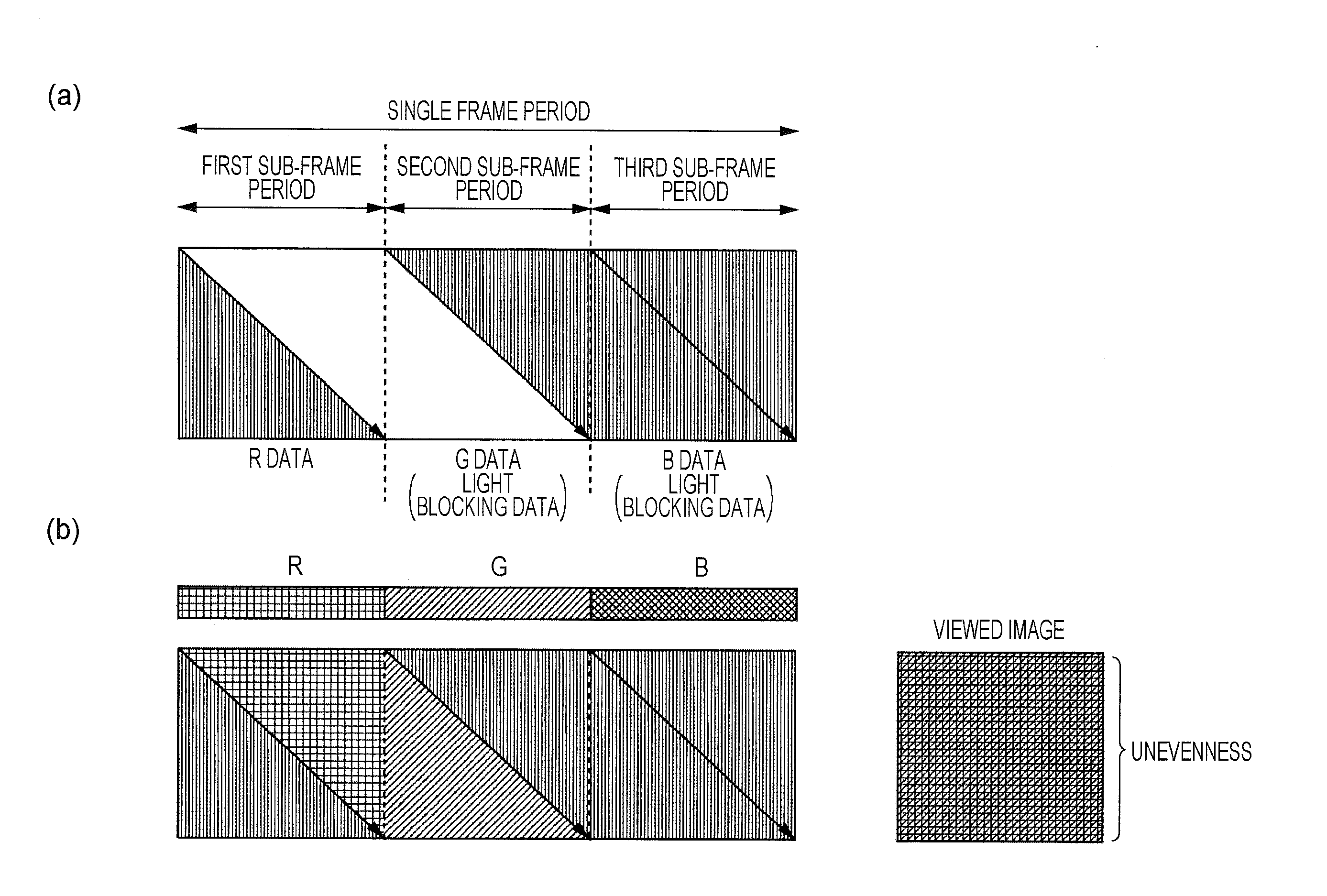

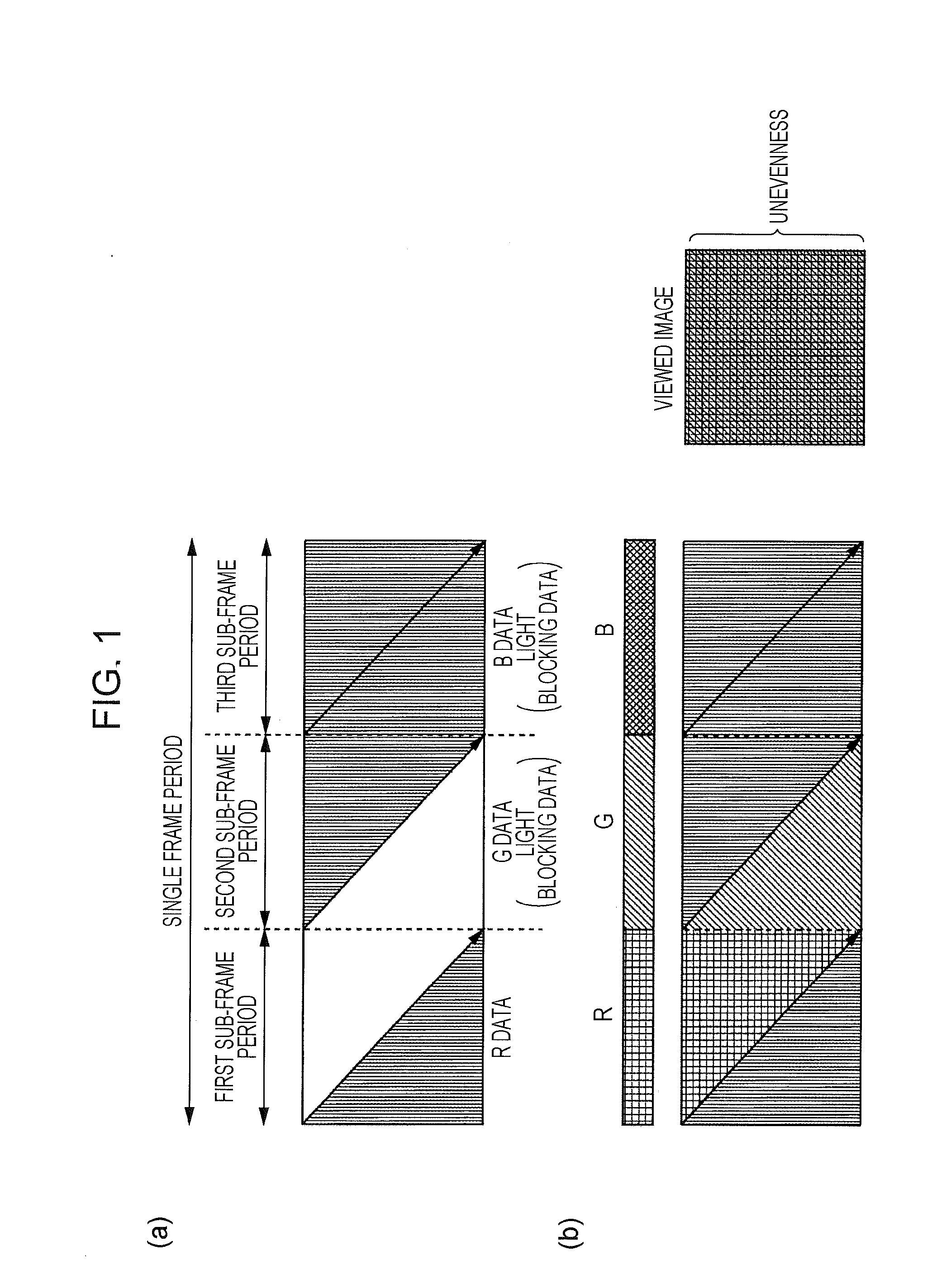

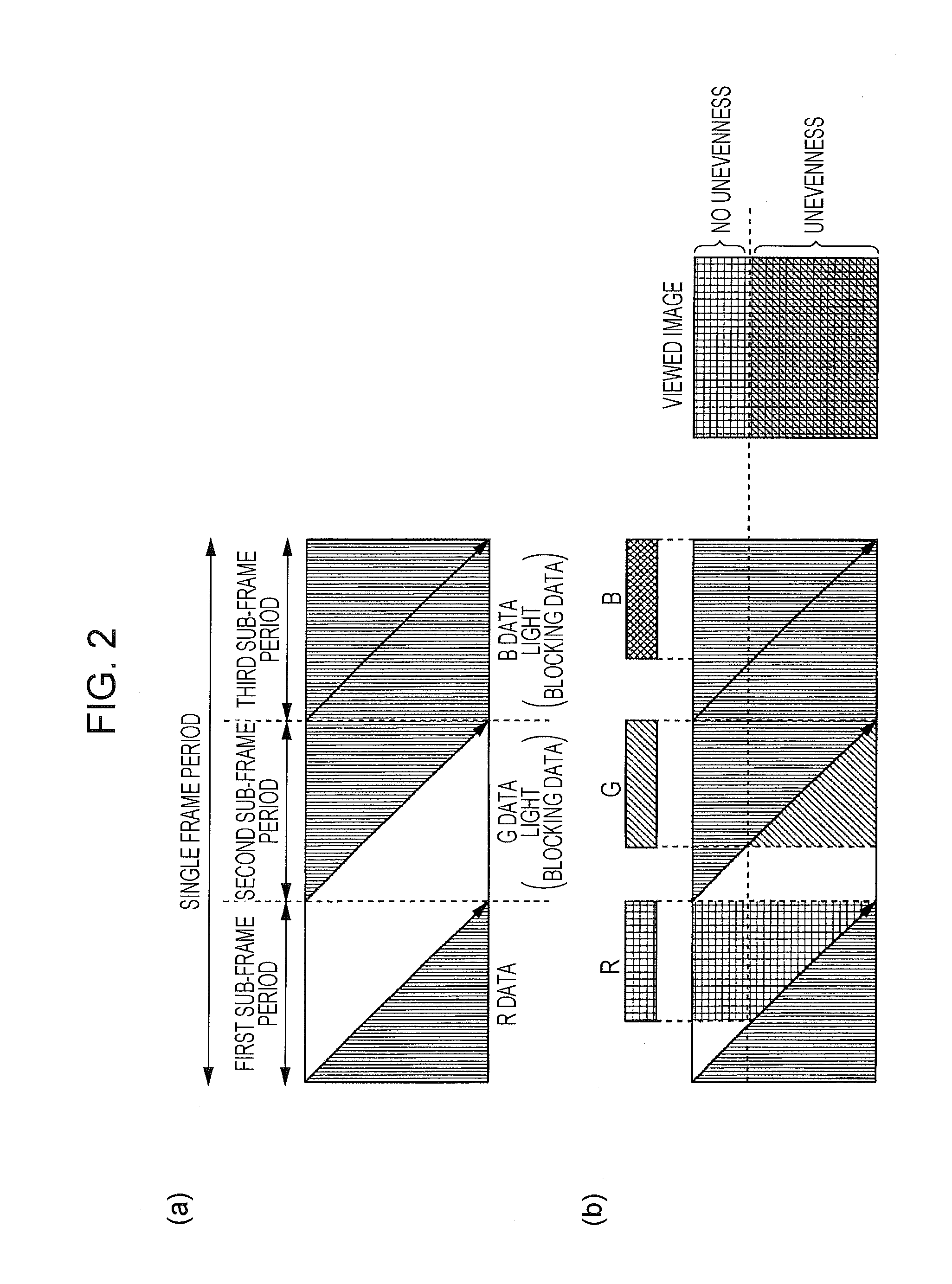

ActiveUS20150103107A1Reduce loadSuppress color unevennessCathode-ray tube indicatorsInput/output processes for data processingPhysicsComputer graphics (images)

An image display device is capable of displaying an image, in which occurrence of color unevenness is suppressed. A method of driving the image display device is also disclosed. In an area above the dotted line, red light is transmitted in a first sub-frame period. In second and third sub-frame periods, light blocking data are respectively supplied as green data and blue data. Therefore, green light and blue light cannot be transmitted through the area. Hence, a red image with no color unevenness is displayed in the area. In contrast, in an area under the dotted line, the red light is transmitted in the first sub-frame period, and the green light is transmitted in the second sub-frame period. As a result, in a viewed image of the area, there is color unevenness where green is mixed to red.

Owner:SHARP KK

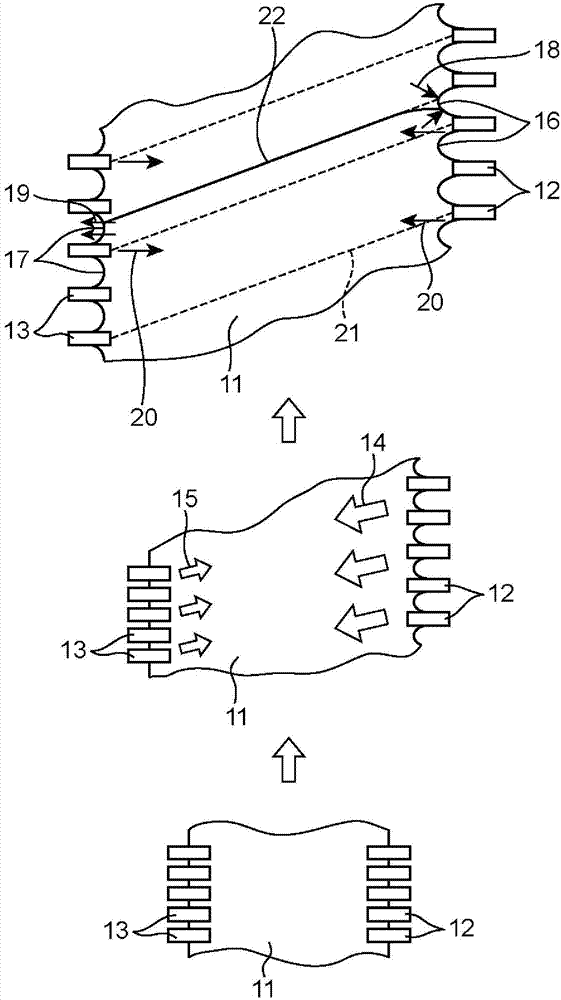

Lighting lens and lighting device equipped with the same

ActiveCN101725896ASuppression of color separationSuppress color unevennessPoint-like light sourceCondensersOptical axisEffect light

A lighting lens can sufficiently suppress unevenness color and improve light use efficiency. This light lens has: first incidence surface 20 that is orthogonal to the optical axis; second incidence surface 21 that expands the radius toward the light emitting element 8 side; total reflection surface 22 that expands the radius toward the emitting side; first emission surface 24 that mainly emits light incident on first incidence surface 21, toward illuminated surface 18; and second emission surface 25 that emits light incident on a second incidence surface, toward illuminated surface 18, and forms second emission surface 25 such that positive power in second emission surface 25 is weaker than positive power of first emission surface 24.

Owner:ENPLAS CORP

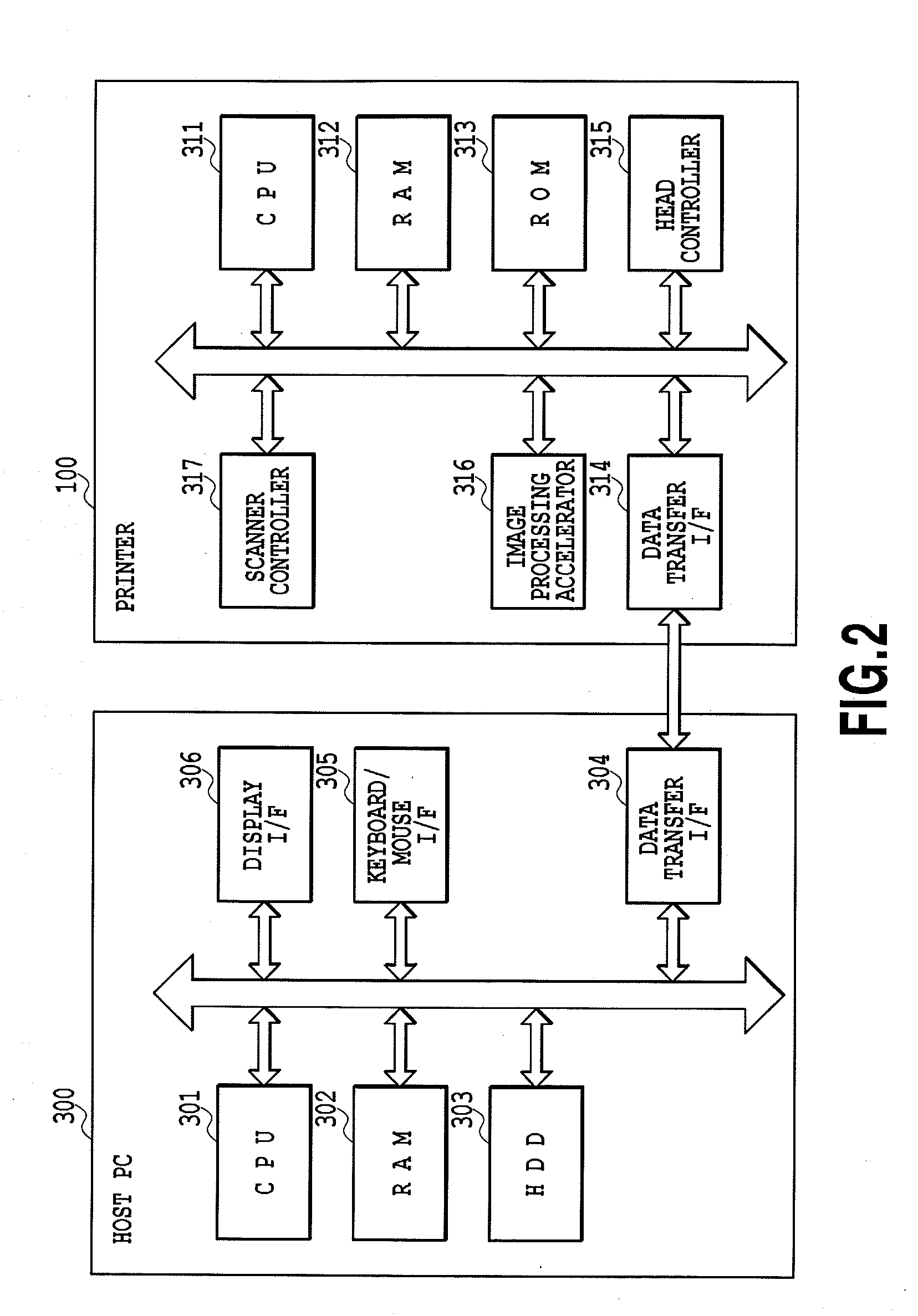

Image recording apparatus, image recording method, and storage medium

The number of recording-permitted pixels in an increment in each of multiple mask patterns is a relatively small number, and the number of recording-permitted pixels in an increment in each of multiple logical sum patterns is a relatively large number.

Owner:CANON KK

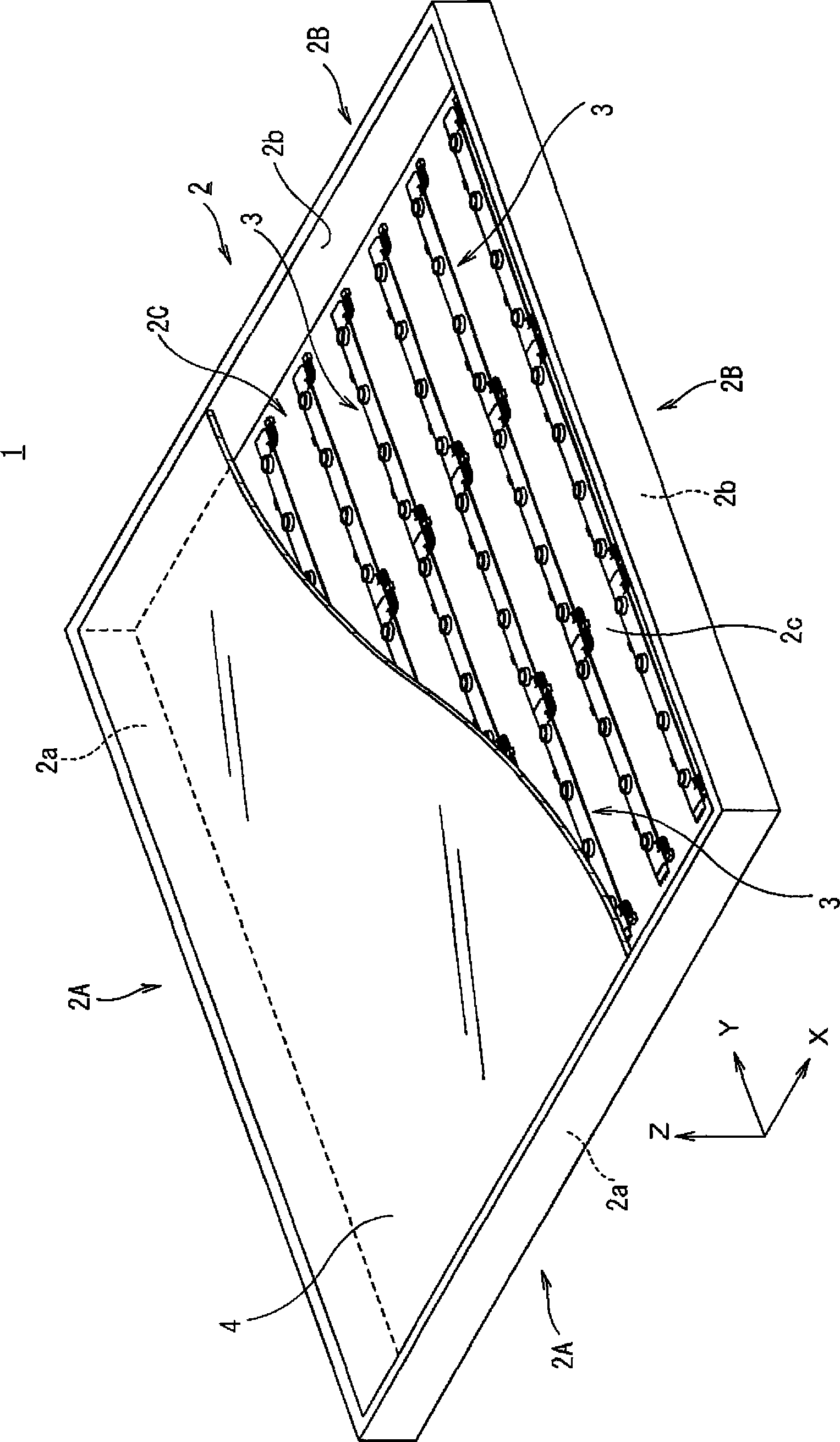

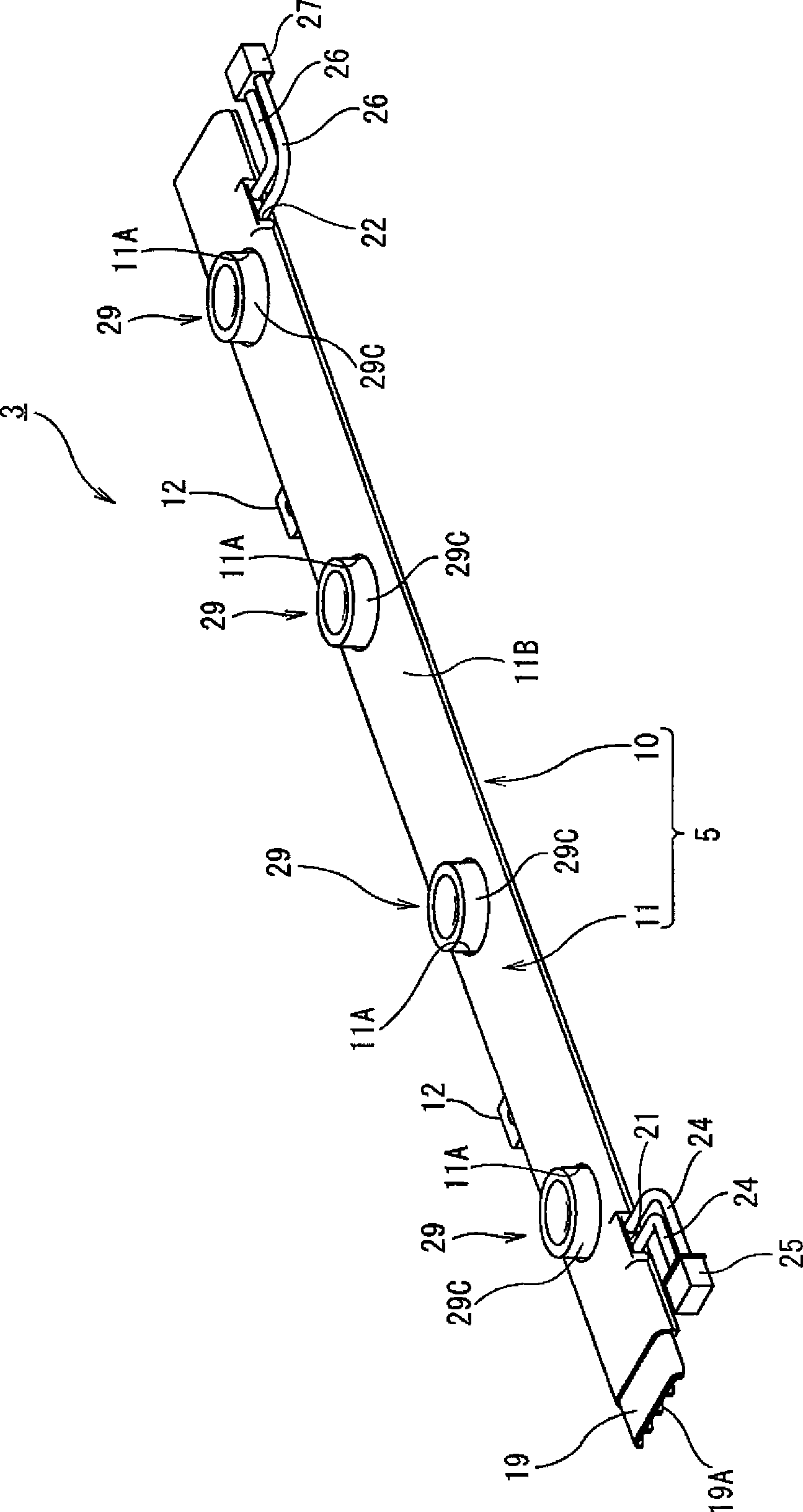

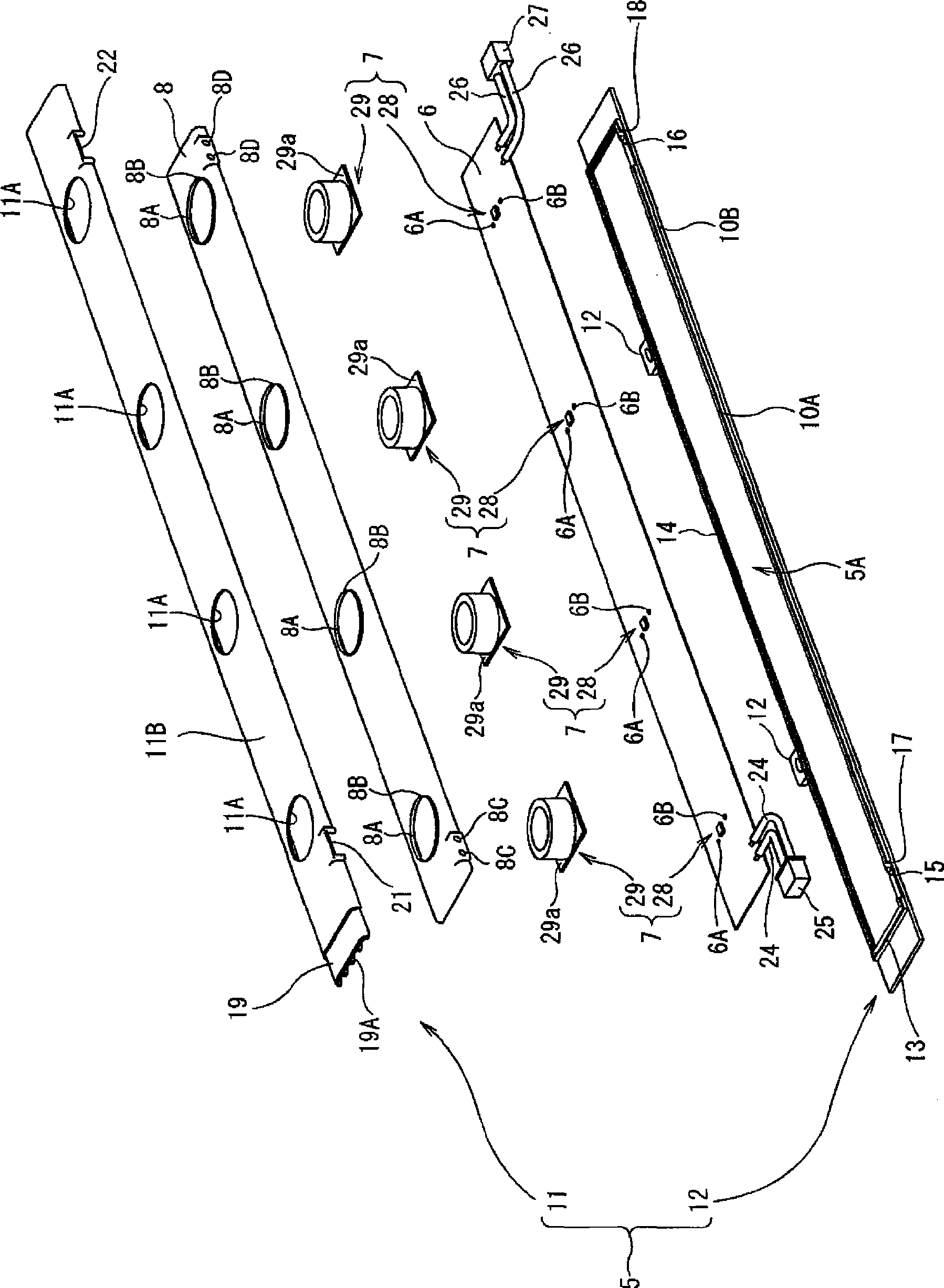

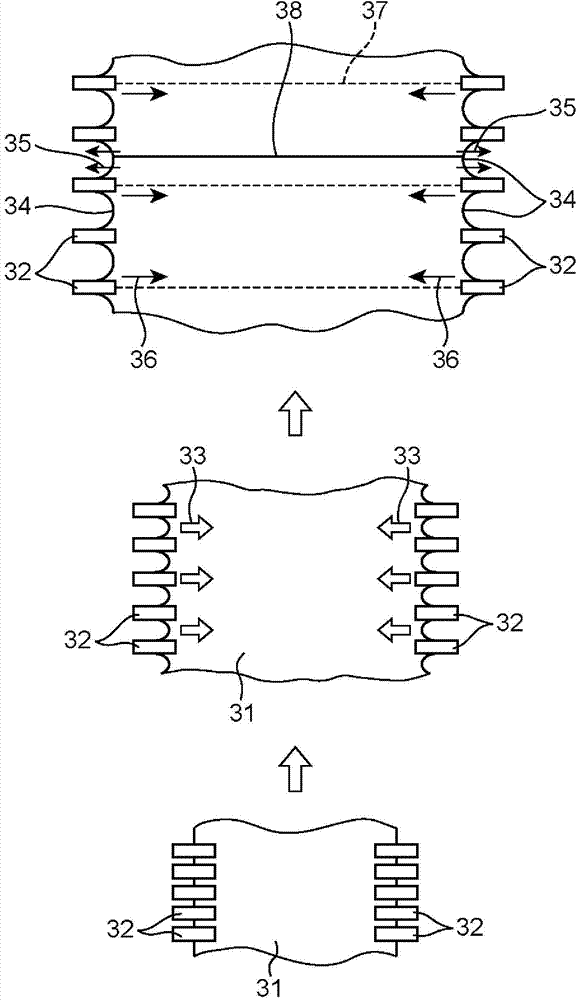

Light source module, surface area light-emitting unit, and surface area light-emitting device

InactiveCN101490465AEasy installationLow manufacturing costPoint-like light sourceElongate light sourcesLight sourceLight emission

The invention provides a light source module, surface area light-emitting unit, and surface area light-emitting device that have versatility, where installation work is simplified and production costs are reduced, and where irregularity of light emission and color is sufficiently suppressed. The light source module has a light direction-converting optical element (29) and an LED (28). The light direction-converting optical element (29) has a recess (290) with a light incident surface (29A) into which light enters, a light reflecting surface (29B) for reflecting light entered from the light incident surface (29A), and a light emitting surface (29C) for emitting to a side the light reflected by the light reflecting surface (29B). The LED (28) is placed in a recess (290) of the light direction-converting optical element (29) with a gap provided in between them and applies light to the light incident surface (29A).

Owner:KOHA

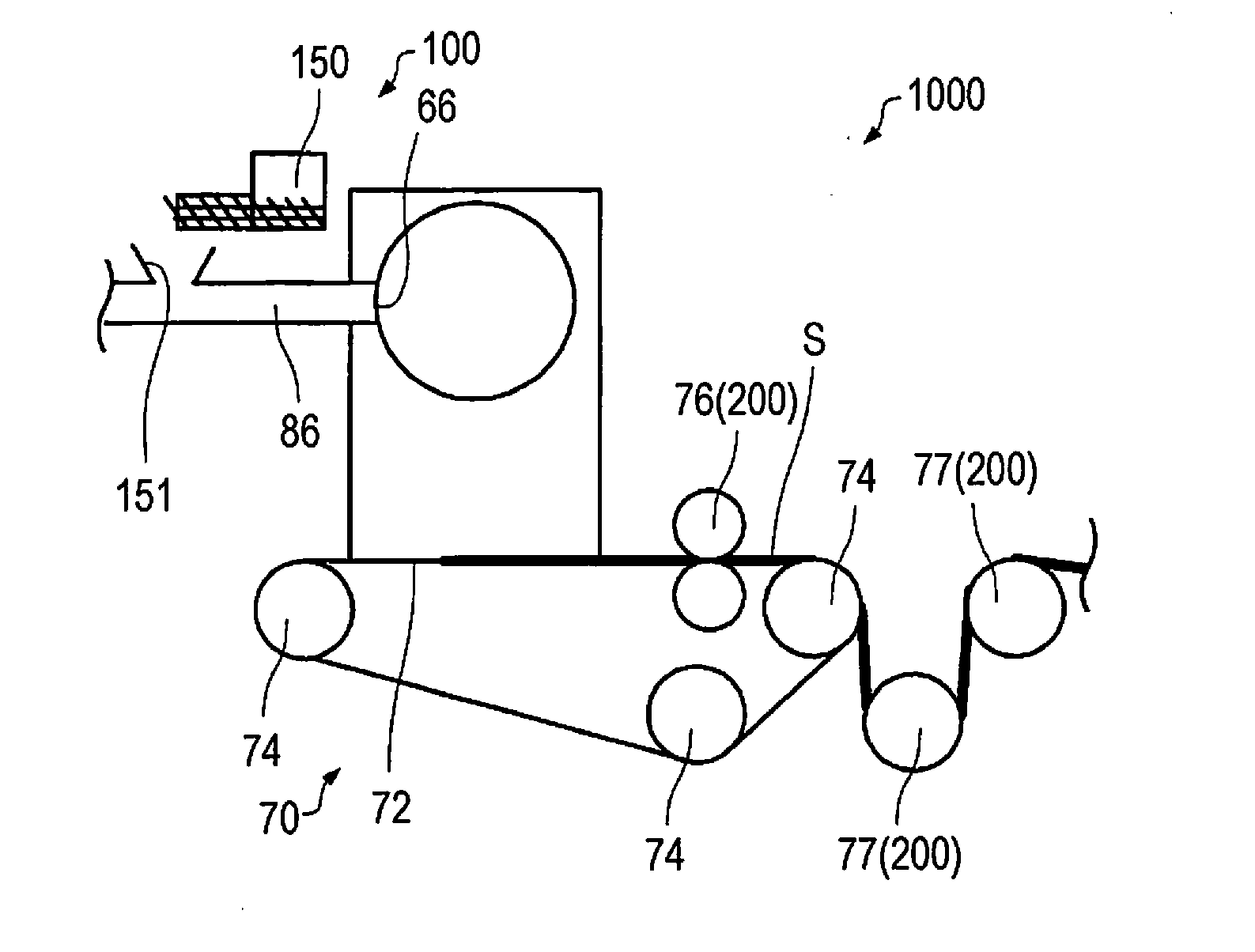

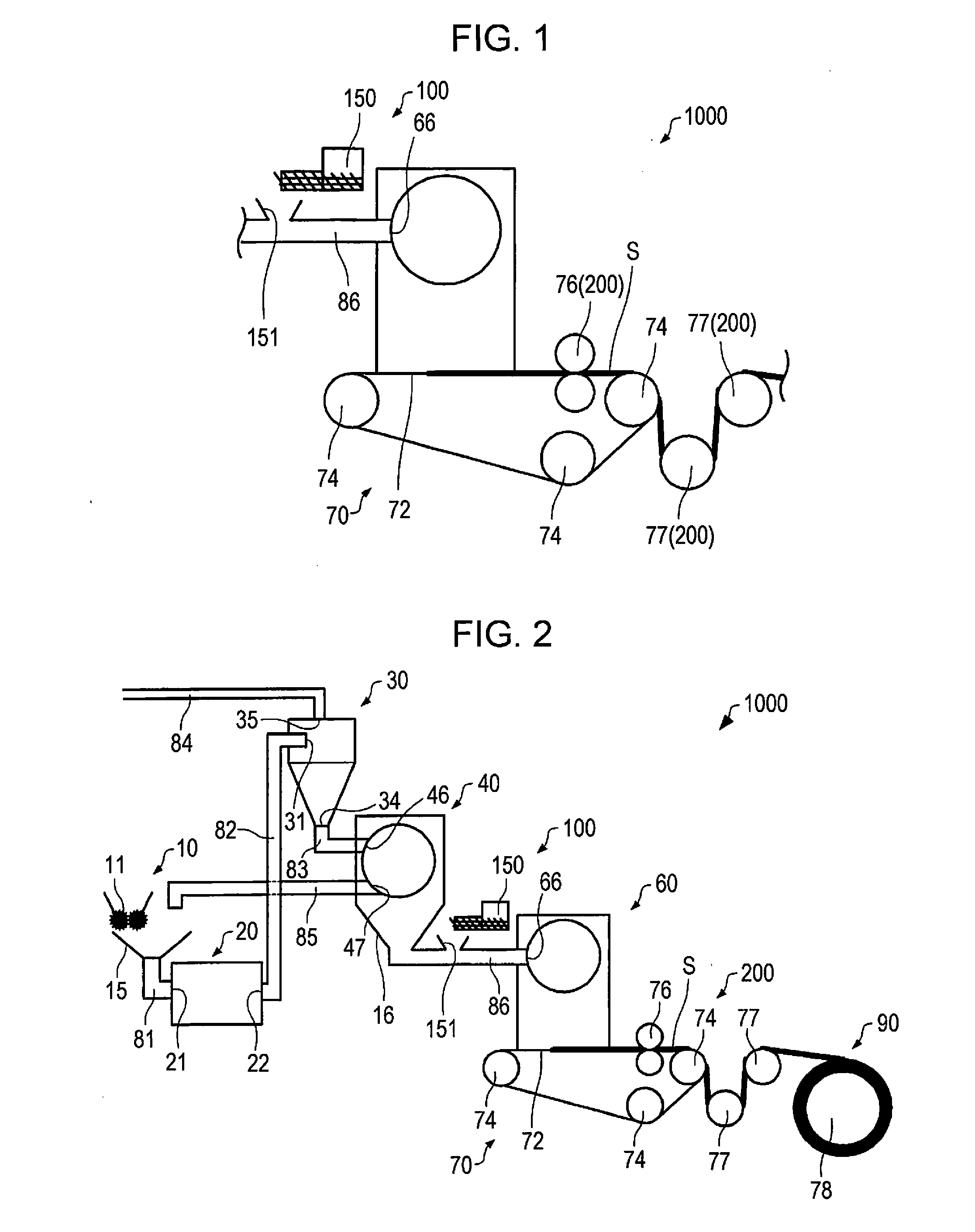

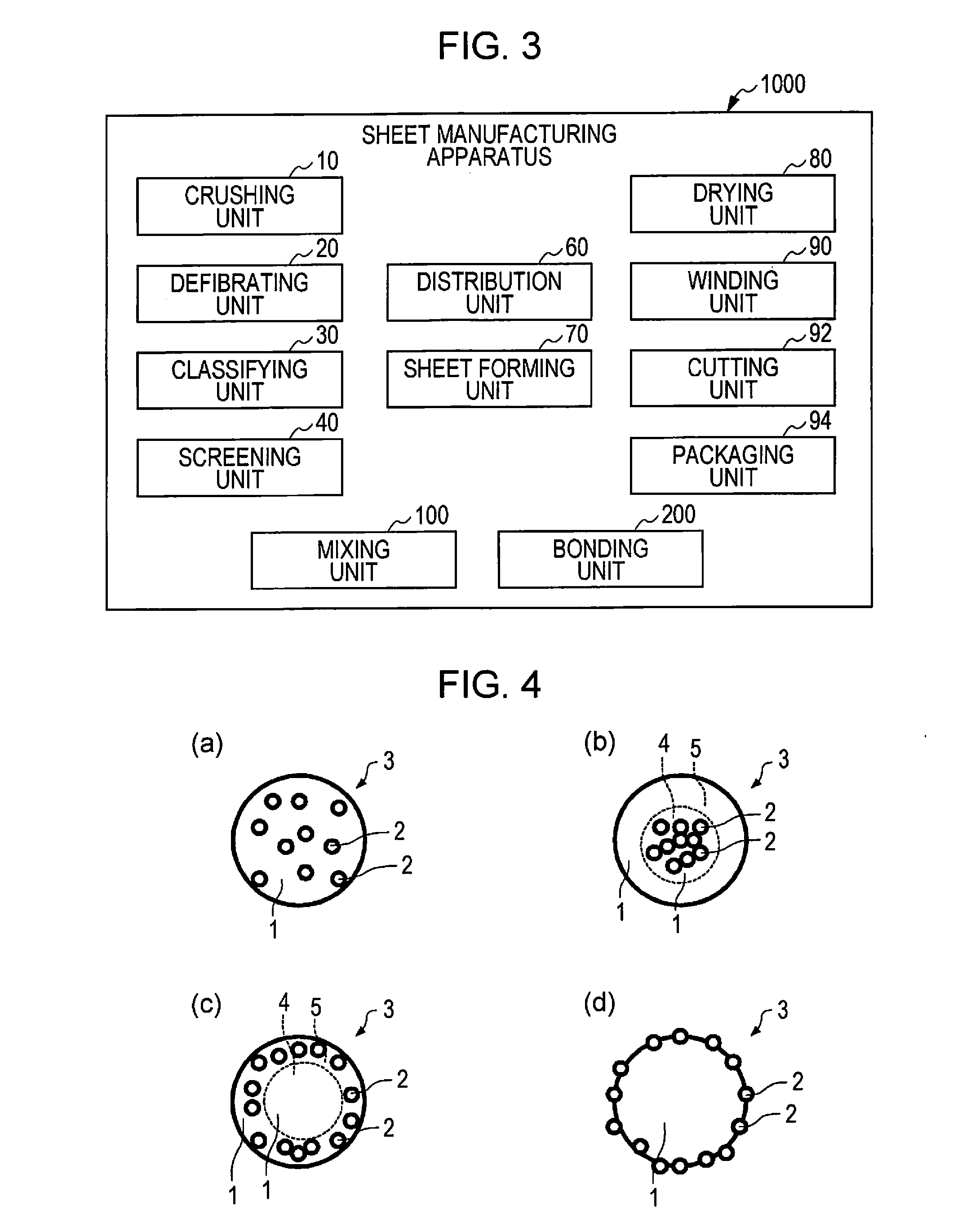

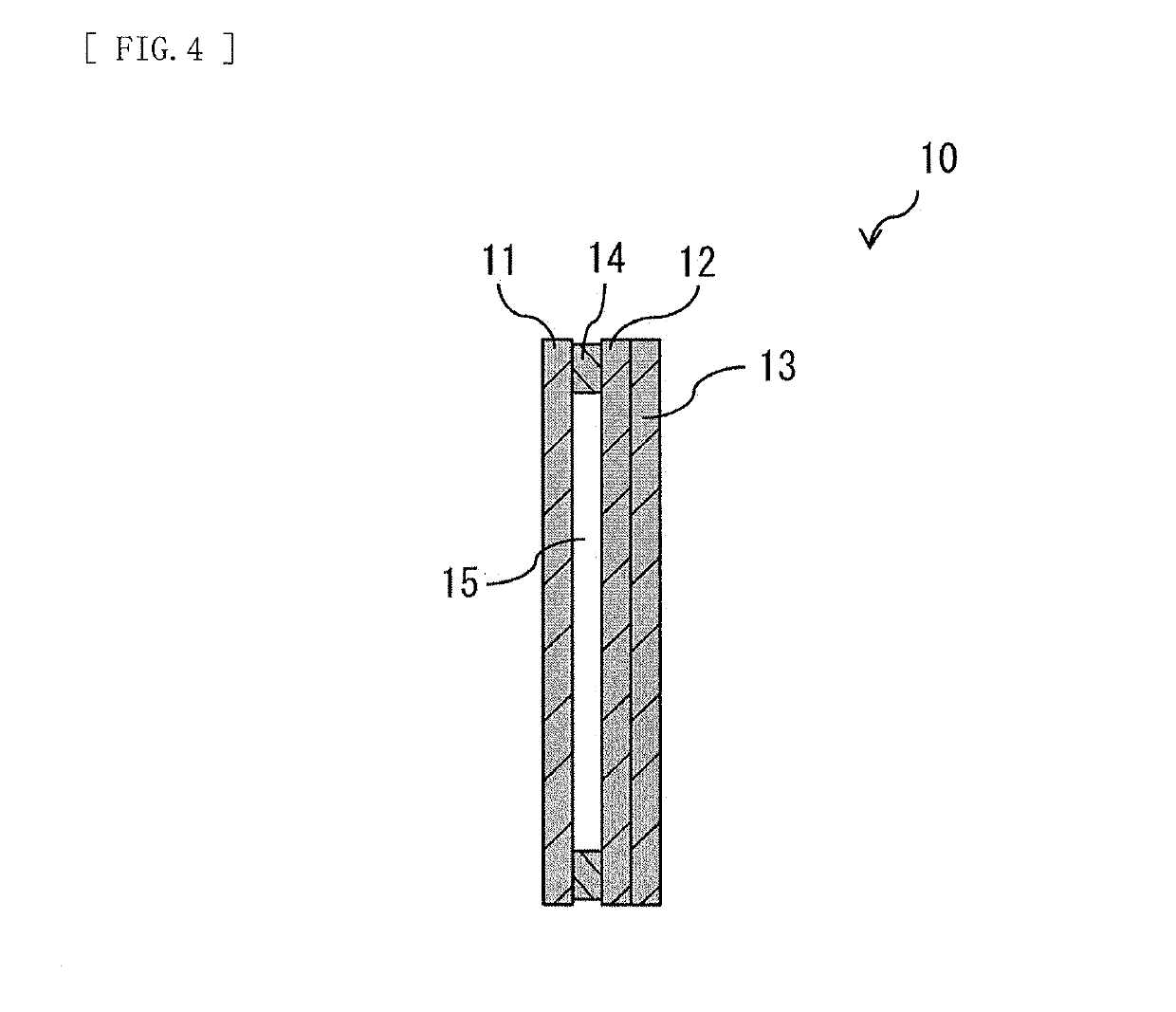

Sheet manufacturing apparatus, sheet manufacturing method, sheet manufactured with the same, composite used therewith and accommodation container therefor

InactiveUS20160230320A1Avoid easy detachmentSuppress color unevennessPaper recyclingNon-woven fabricsFiberManufactured apparatus

Owner:SEIKO EPSON CORP

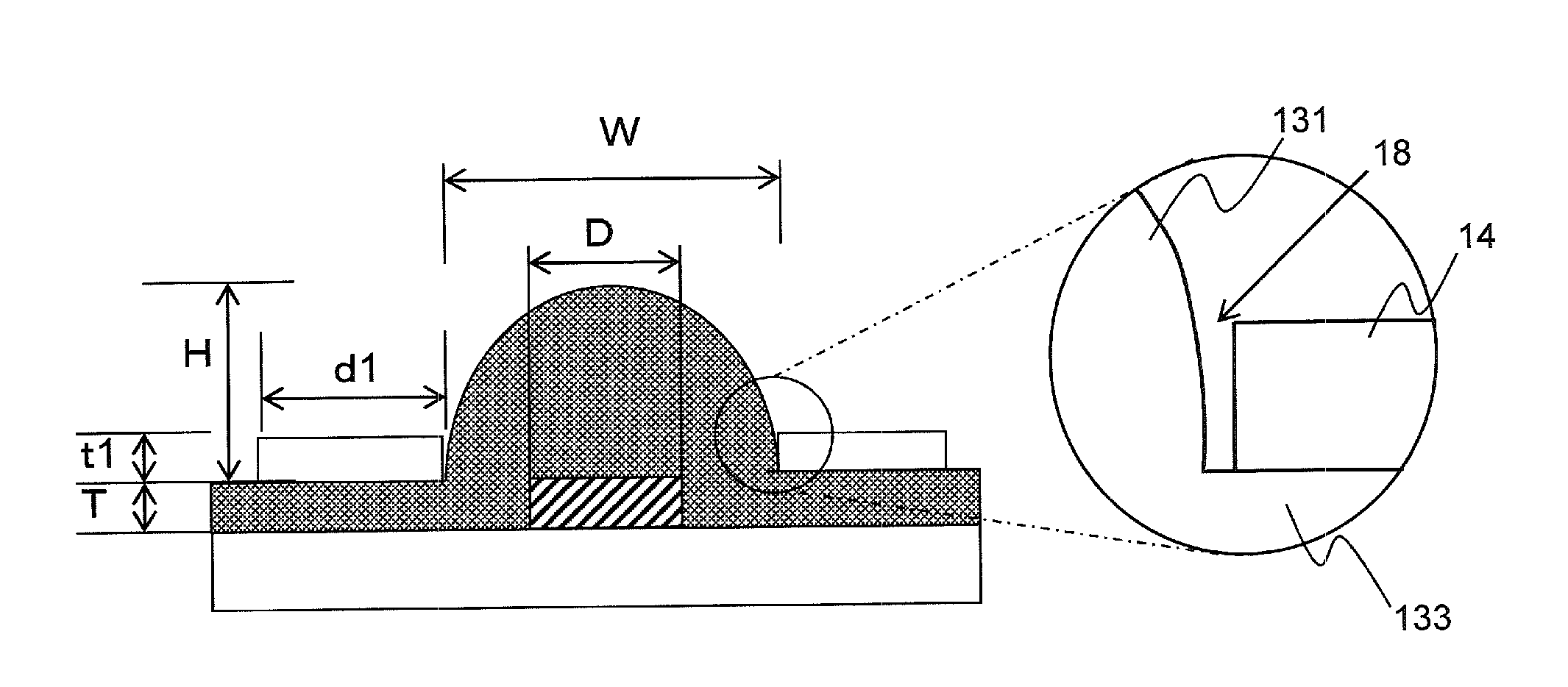

Light-emitting device, method for producing the same, and illuminating device

ActiveUS20120188772A1Easy to produceEfficient mixingDischarge tube luminescnet screensLamp detailsEngineeringLight emission

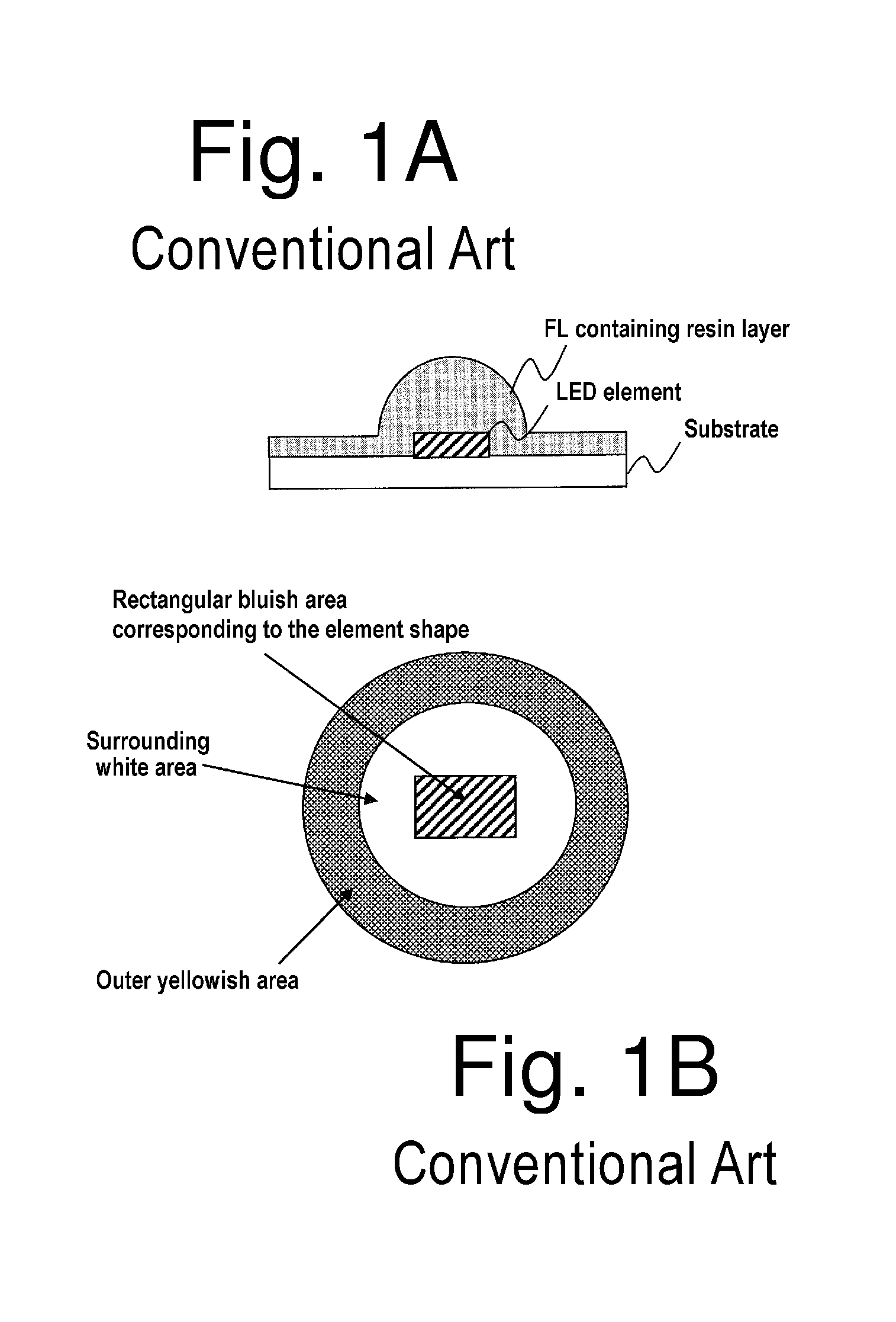

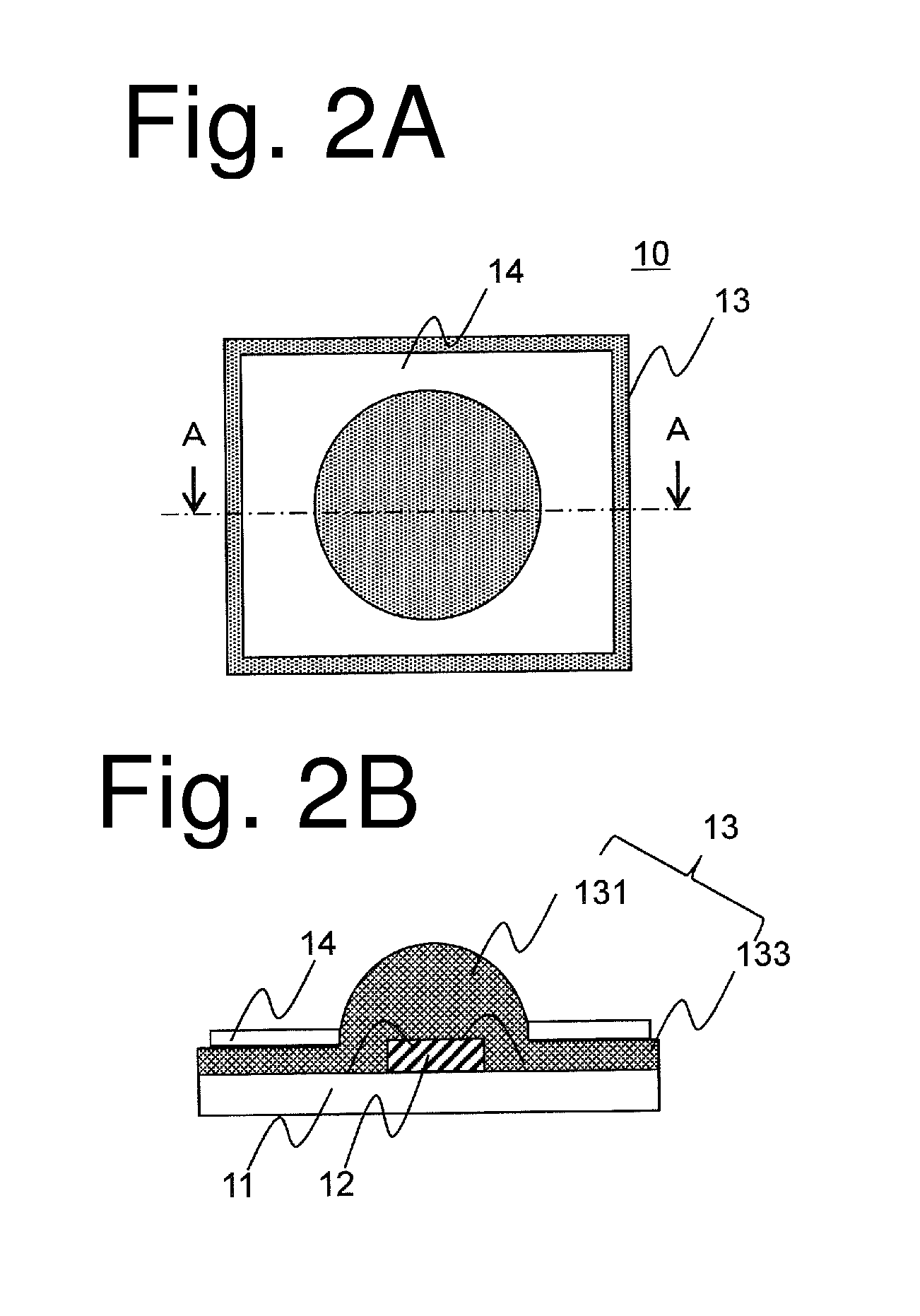

A light-emitting device having an LED element and a resin layer including a convex portion covering the LED element can suppress color unevenness to achieve light emission with uniform color distribution. The light-emitting device can include a substrate, an LED element mounted on the substrate, a resin layer which contains a wavelength conversion material and is formed on the substrate to cover the LED element, the resin layer including a convex portion directly covering the LED element and a flat thin film portion extending around the convex portion, and a reflective portion which is formed over the thin film portion around the convex portion. A diffusion portion can be formed to cover the convex portion of the resin layer.

Owner:STANLEY ELECTRIC CO LTD

Cellulose acylate film, process for producing the same, polarizing plate, retardation film, optical compensating film, antireflection film, and liquid-crystal display

InactiveCN101208189AGood dimensional stabilityWith uniformityOptical articlesPolarising elementsCelluloseHigh humidity

By longitudinally stretching the cellulose acylate film under the condition that the aspect / lateral ratio (L / W) of the ratio of the width (W) of the film before stretching and the stretching interval (L) is more than 0.01 and less than 0.3 ~ 300%, and then relax 1 ~ 50% in the longitudinal direction to produce cellulose acylate film. When this film is incorporated in a liquid crystal display device, it is possible to suppress the occurrence of color unevenness even if it is placed under high temperature and high humidity.

Owner:FUJIFILM CORP

Display Apparatus

A display apparatus according to an embodiment of the present disclosure includes a thin plate-shaped display cell that displays image and a plurality of exciters disposed on a back surface of the display cell and causing the display cell to vibrate. The plurality of exciters is such configured that the plurality of exciters is regarded as one exciter when the plurality of exciters generates vibration in the display cell.

Owner:SONY CORP

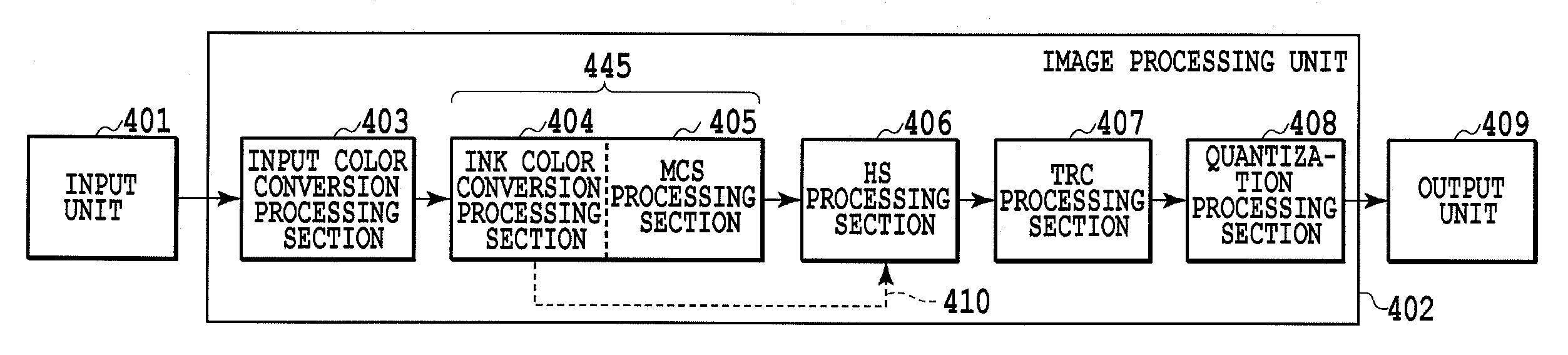

Image processor and image processing method

ActiveUS20110286020A1Reduce color unevennessShorten speedDigitally marking record carriersDigital computer detailsColor imageImaging processing

The present invention is intended to provide an image processor that can reduce color unevenness occurring in a composite color image formed by overlapping different types of inks due to a variation in printing characteristic among a plurality of nozzles while suppressing a reduction in processing speed in generation of printing data. The image processor converts a color signal indicating the image represented by a plurality of elements to a color signal corresponding to the plurality of inks with use of a conversion table determined on the basis of ejection characteristics of nozzle groups corresponding to the plurality of inks so as to suppress color unevenness occurring in a composite color image due to a variation in ejection characteristic among the plurality of nozzles.

Owner:CANON KK

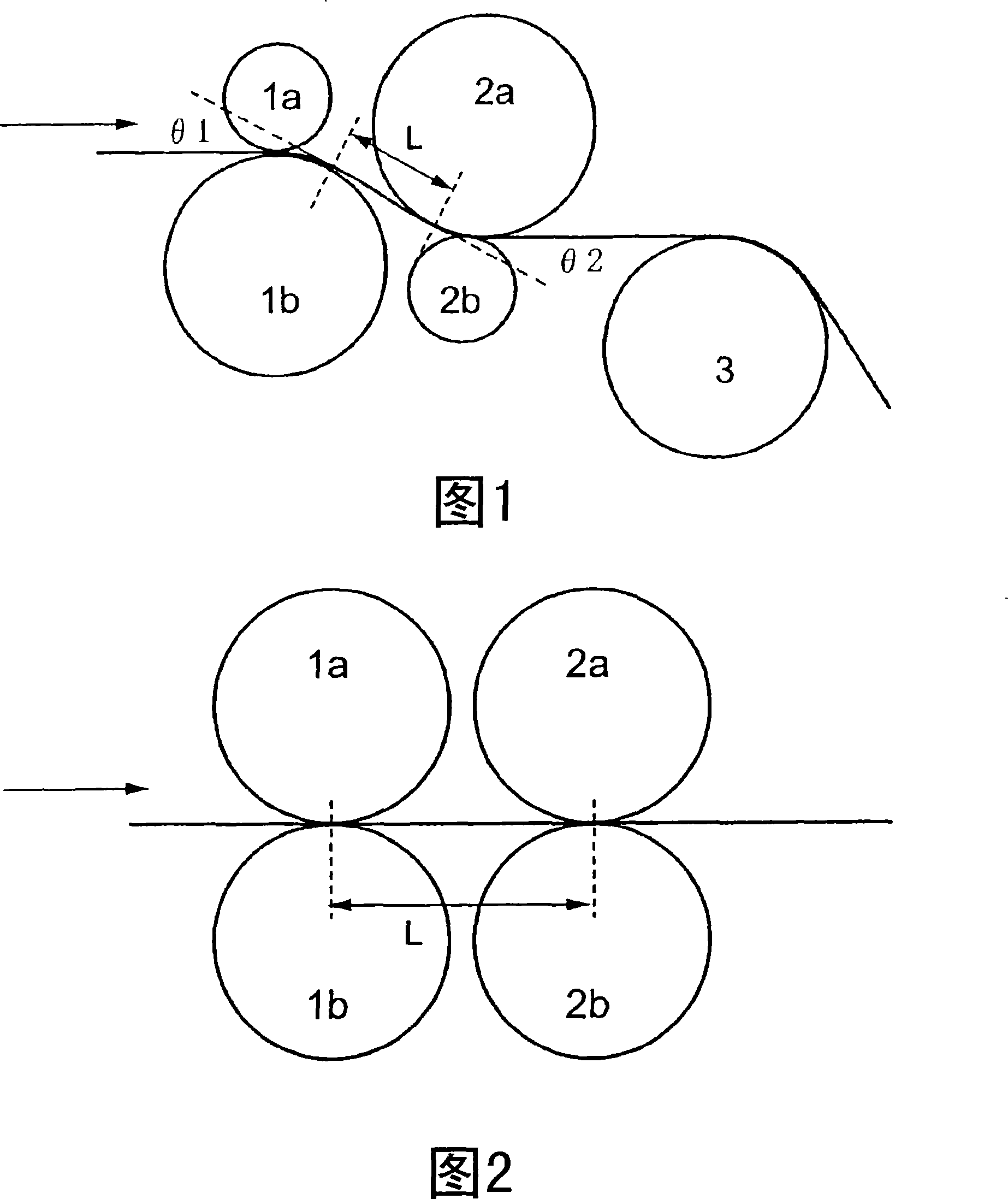

Method for producing longitudinally-stretching film

ActiveCN104768729ASuppress deviation of orientation angleSuppress color unevennessOptical axisMechanical engineering

One aspect of the present invention is a method for producing a longitudinally-stretching film equipped at least with a diagonal-stretching step for angling the optical axis of the longitudinal film by gripping both ends of a thermoplastic longitudinal film using a plurality of gripping tools, and conveying the gripping tools gripping both ends at a constant speed, then accelerating first gripping tools gripping one end faster than second gripping tool gripping the other end, and advancing the first gripping tools farther than the second gripping tools, the method for producing the longitudinally-stretching film being characterized in that after advancing the first gripping tools in the diagonal-stretching step, a relaxing treatment is performed for relaxing the distortional stress applied to the longitudinal film in the regions between adjacent first gripping tools.

Owner:KONICA MINOLTA INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com