Method for producing longitudinally-stretching film

A manufacturing method and technology of stretched film, applied in the field of manufacturing long stretched film, can solve the problems of axis deviation, uneven color, uneven axis, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0348] The obtained polycarbonate film (long film A: film thickness 90 μm) was obliquely stretched under the conditions of the production method according to the present embodiment. Thus, the elongated stretched film related to Example 1 was obtained. Then, the obtained elongated stretched film was wound up into a roll.

[0349] Specifically, oblique stretching was performed under the following conditions.

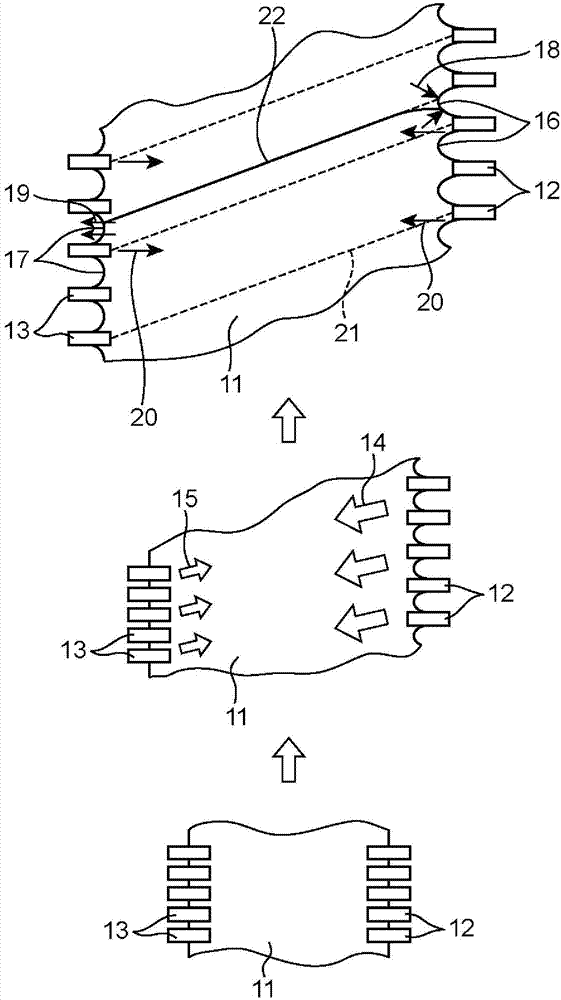

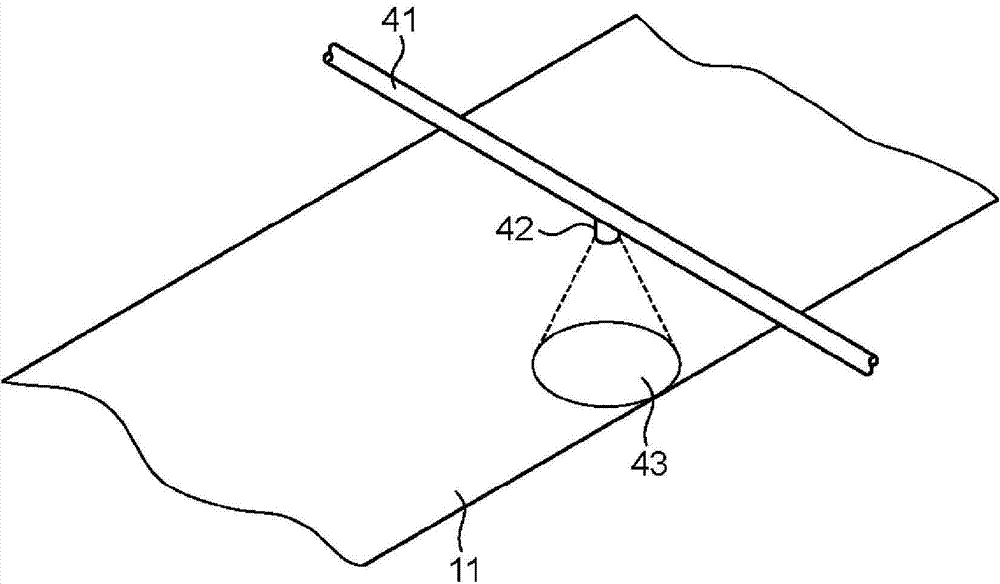

[0350] First, use Figure 4 The shown oblique stretching device T obliquely stretches the long film. The conveying speed of the long film was 5 m / min. The grip C1 (first grip) is accelerated from P1 to P2, whereby the grip C1 is made to precede the grip C2 (second grip). In addition, the gripper C2 is accelerated from P3 to P4, and the elongated stretched film is released when the gripper C1 and the gripper C2 are set at constant speeds. Thereafter, it was wound up into a roll with a pulling tension of 200 (N / m) by a winding device installed at the exit.

[0351] Usi...

Embodiment 2

[0355] In the stretching zone, the temperature of the hot air blown in the stretching zone, the air volume, etc. in the stretching zone are adjusted so that the end portion of the leading side of the elongated film behind the holding member C1 is 32°C higher than the film central portion. Heating conditions were the same as in Example 1 except for this.

Embodiment 3

[0357] In the stretching region, it is the same as in Example 1 except that intermittent heating such as hot air applied to the end portion on the front end side of the long film is applied only to the region between adjacent first grippers.

PUM

| Property | Measurement | Unit |

|---|---|---|

| photoelasticity | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com