Patents

Literature

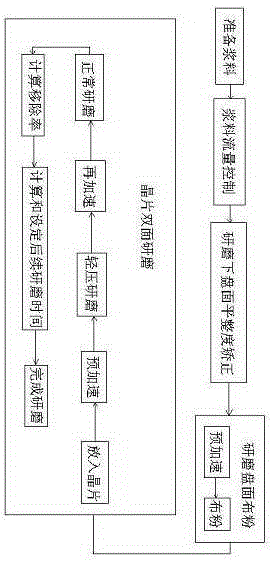

116results about How to "With uniformity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Manufacture method of ultra-low-temperature, high-strength and long-fatigue life automobile bridge seamless heterotype axle steel tube

The invention relates the method for producing seamless axle steel pipe. The method uses seamless steel pipe billet, and the billet adopts low-alloy high-strength steel, which comprises C 0.14-0.18%, Si 0.3-0.55%, Mn 1.4-1.8%, V 0.02-0.08%, Nb 0.02-0.08%, Ti 0.02-0.08%, and Al 0.015-0.03%. The method comprises the following steps: 1 normalization heat trematment; 2 acid cleaning and lubricating; 3 fluid pressure shaped cold-drawing, thickening four corners of the steel pipe, the rate of the wall thickness and the corner thickness being 1:1.15-1.2; 4 heat treating product. The hardening temperature is 880-950Deg.C, keeping temperature is 20-30min, the cooling temperature is 350-450Deg.C, drawing temperature is 500-600Deg.C, and keeping temperature is 40-60min. The invention has homogeneous integral structure property and strong combination mechanics property.

Owner:江苏界达特异新材料股份有限公司

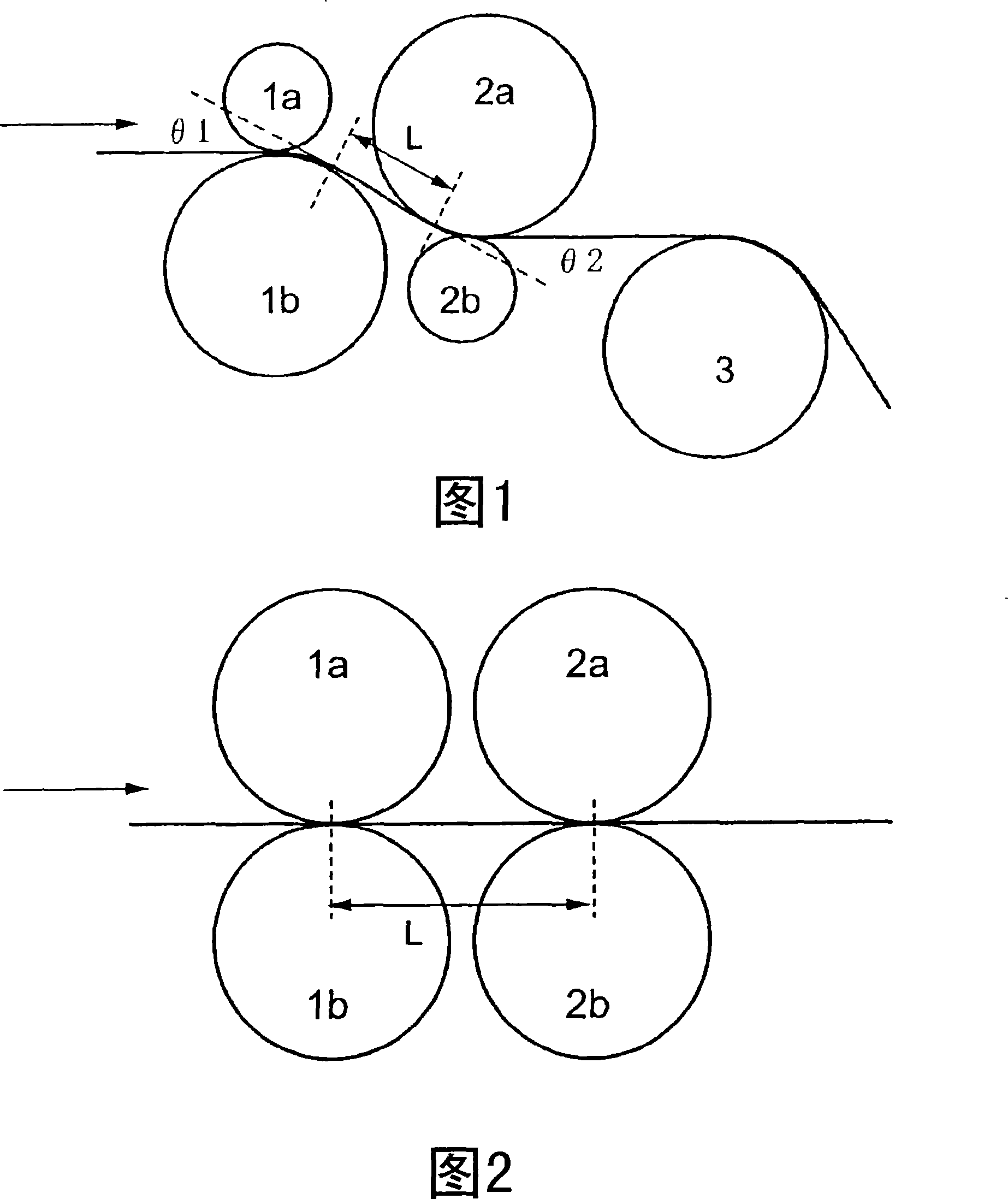

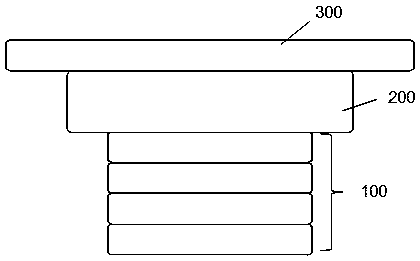

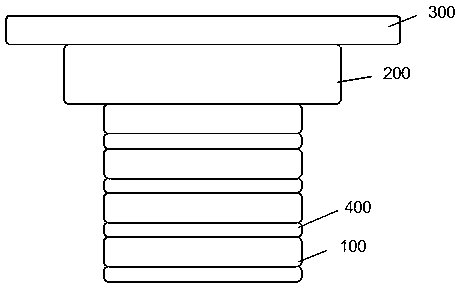

Method for preparing WC-Co gradient hard alloy material

A method for preparing WC-Co gradient hard alloy material includes ballmilling the WC powder, Co powder, adhesive and dissolvent made based on required ratio to mix into a moldable material; rolling the moldable material into monolithic film blanks with different Co content or different WC grain fineness number separately by a double-roller film machine, then laminating the monolithic film blank in sequence to roll again to obtain multilayer composite blank with different Co content or different WC grain fineness number; then the multilayer composite blank is feed to a sintering furnace to pre-sinter for 90 to 150 min at a temperature range from 750 to 800 DEG C with hydrogen gas, then to sinter for 40 to 80 min at a temperature range from 1350 to 1500 DEG C, last to cool to obtain the WC-Co gradient hard alloy material. The relative density of the material is all higher than 99%. The Rockwell hardness is all higher than 88HRA, and the flexural strength is improved obviously comparing with the hard alloy containing uniform component.

Owner:合肥庐阳科技创新集团有限公司

Method for profiling weaving thick top-to-thin wall capping fabric

The invention relates to a method for profiling weaving a thick top-to-thin wall capping fabric. The method comprises the following steps: 1, the capping fabric is woven from the center of a core model to form, the fabric is woven outside the weaving core model, and two pairs or four pairs of yarns which are crossed with each other are used to weave one or two weaving structures to circularly form a square top; 2, the interlaced yarns which form the square top are taken as warps, and wefts are gradually guided into each layer of yarns layer by layer; the square top is taken as a center, the wefts are woven in an intertwining manner to form a concentric circle, and a round top is formed after a plurality of circular weaving; and 3, after the round top is completely woven, the fabric is woven from a thick top capping fabric to a conical thin-wall fabric, the weaving diameter of the fabric is gradually increased during the conversion process and is increased through adding the weft arrays along the warp direction, and the weft density is kept consistent. By the method, a forming and producing technology of the complicated capping fabric is simplified, the internal fibers of the capping reinforcement fabric are distributed uniformly, a fabric forming effect is enhanced, and the clear dimension profiling weaving is realized.

Owner:NANJING FIBERGLASS RES & DESIGN INST CO LTD

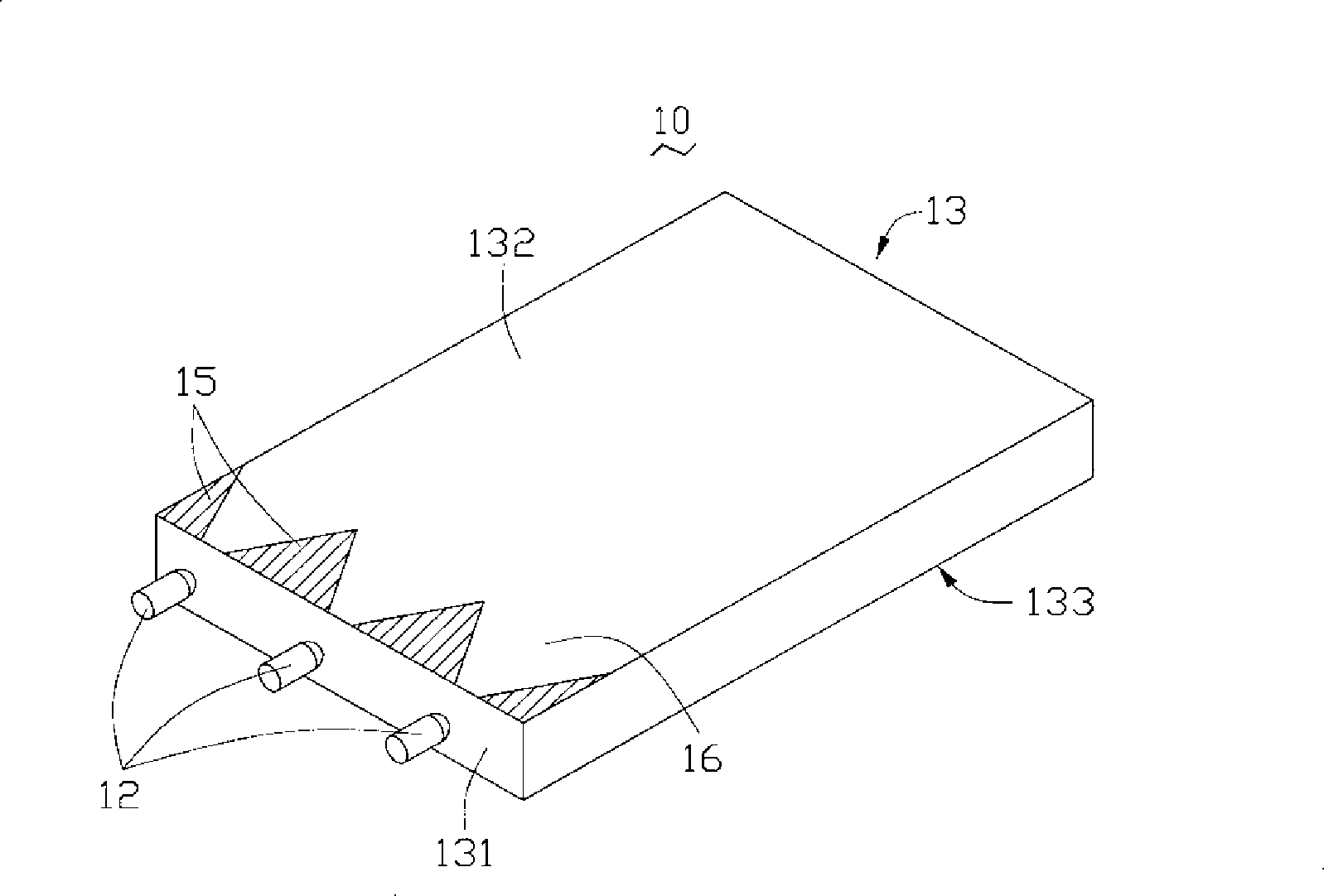

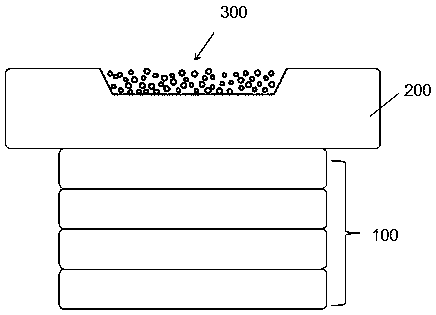

Light conducting plate and backlight module group

InactiveCN101210976ARealize multifunctional light guide effectWith brightnessOptical light guidesNon-linear opticsLight guideOptoelectronics

The invention relates to a light guide plate, comprising an incidence plane, an emergent plane crossed with the incidence plane and an undersurface opposite to the emergent plane. The incidence plane comprises at least a first groove passing through the emergent plane and the undersurface as a first light receiving region, and at least a second groove passing through the emergent plane and the undersurface as a second light receiving area. As the incidence plane forms at least two light receiving areas of different structures, different guides and adjustments of light from the same source can be realized so as to obtain different lights from the light guide plate, achieving the multi-functional light guide effect of the plate.

Owner:HONG FU JIN PRECISION IND (SHENZHEN) CO LTD +1

Grinding device for sapphire wafers and grinding method thereof

ActiveCN105215838AStir wellGood suspensionLapping machinesGrinding/polishing apparatusPeristaltic pumpPulp and paper industry

The invention discloses a grinding device for sapphire wafers. The grinding device for sapphire wafers comprises a pulp stock barrel, a peristaltic pump and a grinder, wherein a pulp stock trough is arranged on the grinder, and pulp stock enters into the grinder through the peristaltic pump and the pulp stock trough. The grinding method for the sapphire wafers comprises the following steps: 1, preparing the pulp stock: putting in raw materials by levels and layers; 2, controlling pulp stock flows: putting pulp stock accurately; 3, correcting the flatness of the surface of a grinding lower plate: repeatedly measuring by using a long gauge, a short gauge and a dial gauge, and correcting; 4, distributing powder on the surface of a grinding plate; and 5, grinding both sides of each wafer: firstly carrying out light pressing grinding. The grinding method provided by the invention is characterized in that raw material ratio of the pulp stock is optimized, the pulp stock supplying flow is more accurate, the conveying is more even, before normal grinding, light pressing grinding is performed firstly, the problem of wafer breakage during a grinding process can be prevented for the greatest possible, the wafer breakage rate is lowered, the merit factor of grinding is improved, the removing rate during grinding is stable, the problems of over grinding and low removing rate cannot be caused, and the efficiency is relatively high.

Owner:TUNGHSU GRP

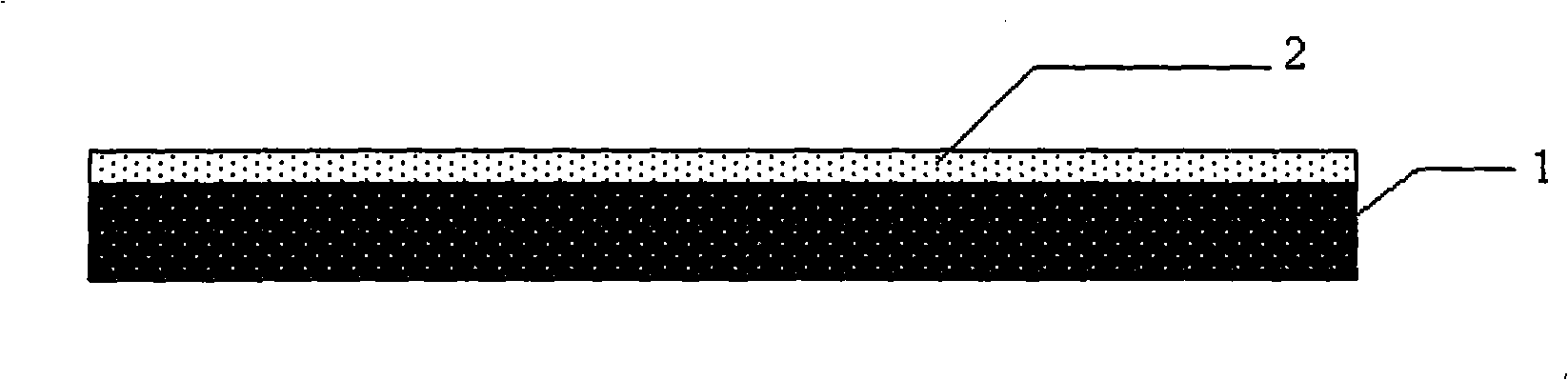

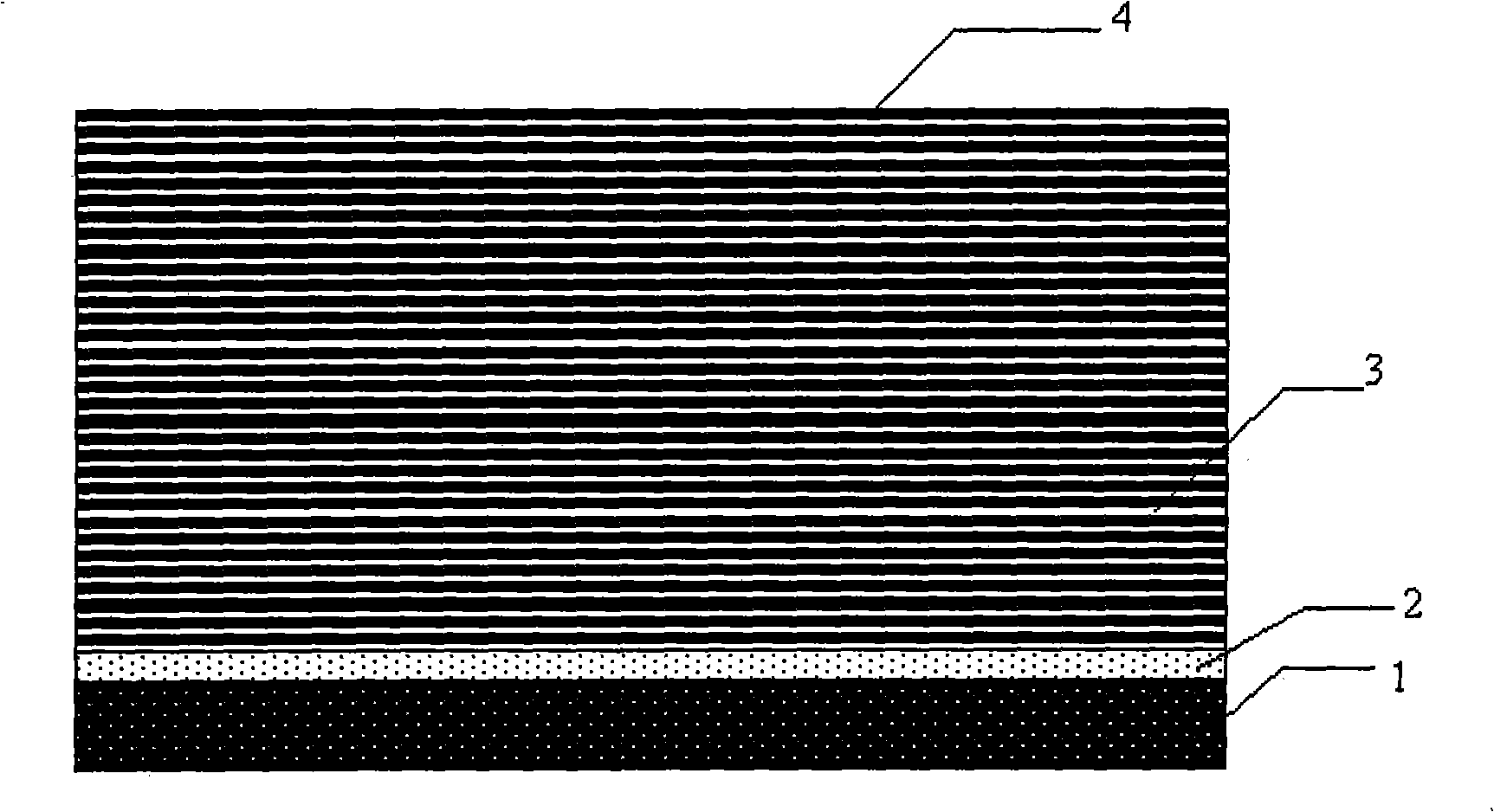

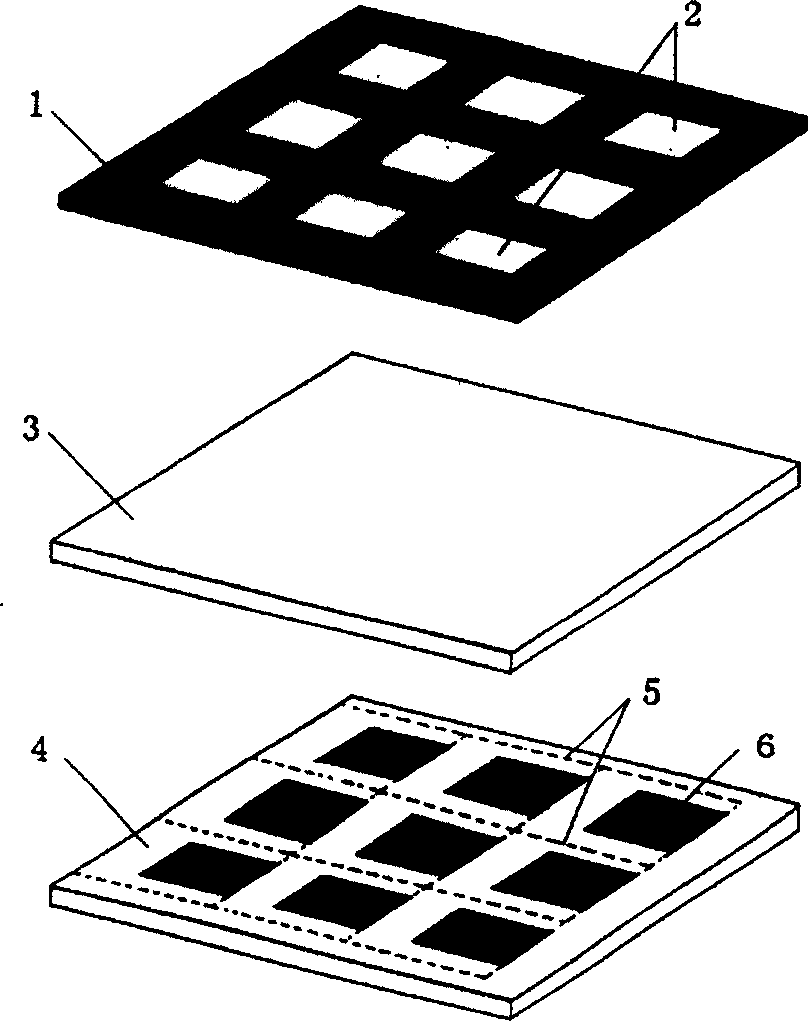

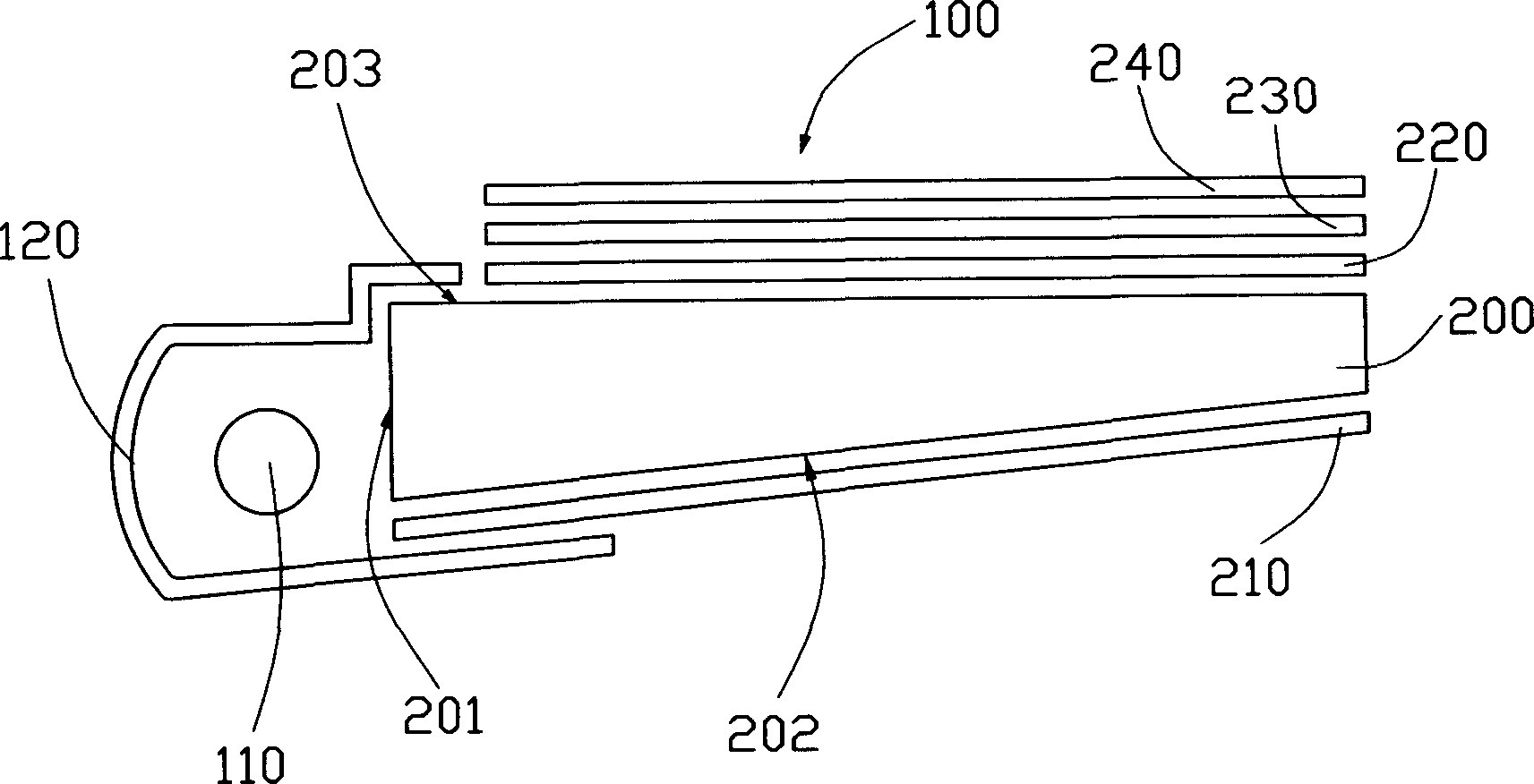

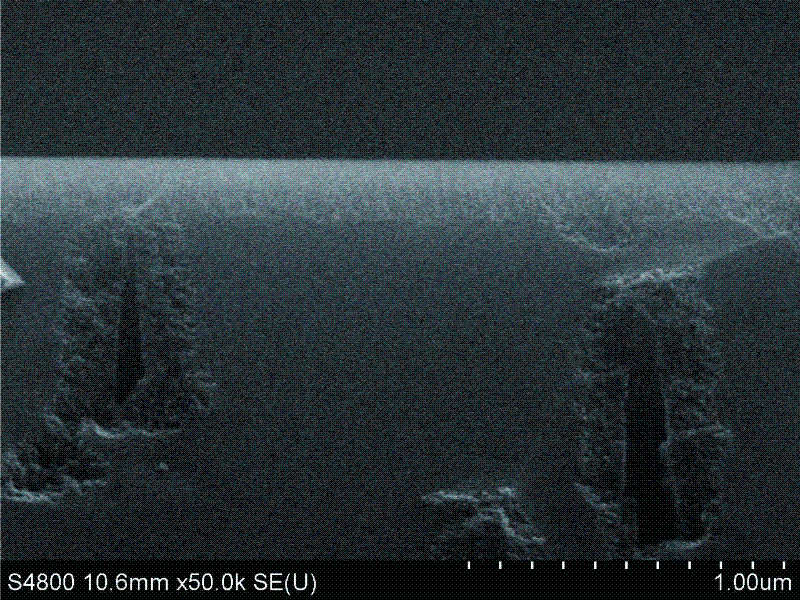

Method for accomplishing sub-wavelength interference photolithography utilizing multiple layer metal dielectric-coating structure

InactiveCN101261454AWith uniformitySolve the problem that sub-wavelength pattern lithography cannot be realizedSemiconductor/solid-state device manufacturingPhotomechanical exposure apparatusResistPhotolithography

A method for utilizing multilayer metal dielectric film structure to realize the sub-wavelength interference lithography is characterized by the following steps of selecting a substrate material; coating an anticorrosion agent on the surface of the substrate; carrying out the alternate vapor deposition of a metal material film and a dielectric material film on the surface of the anticorrosion agent to form a metal layer and a dielectric layer which are arranged alternately; designing and arranging a periodic structure pattern mask on the surface of the structure which is obtained by the above step; carrying out the exposure of the obtained structure; removing the mask structure after the finish of the exposure; further removing the material of the metal layer and the material of the dielectric layer; arranging the obtained structure in a developing liquid which is matched with the anticorrosion agent for carrying out the development; carrying out the dry etching of the structure after the development and transferring the structure on the substrate; removing the residual anticorrosion agent on the surface of the structure and obtaining a final sub-wavelength periodic structure pattern; the utilization of the method of the invention can realize the periodic structure pattern with a large area, evenness and the period of which is below the wavelength.

Owner:INST OF OPTICS & ELECTRONICS - CHINESE ACAD OF SCI

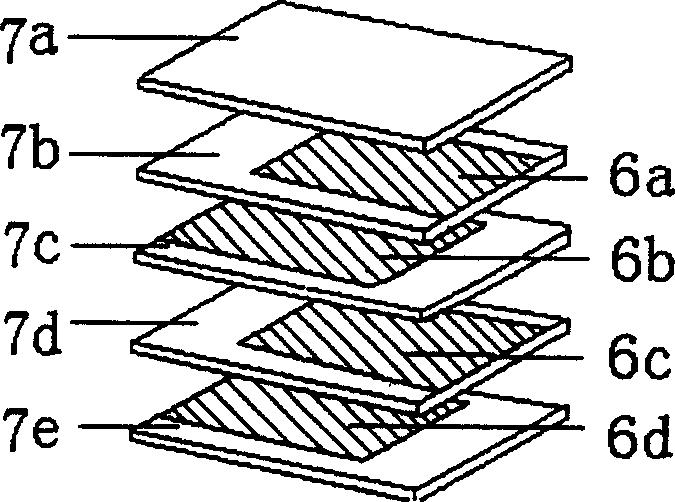

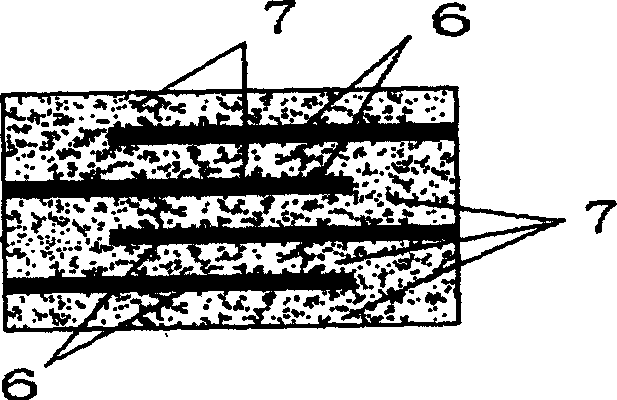

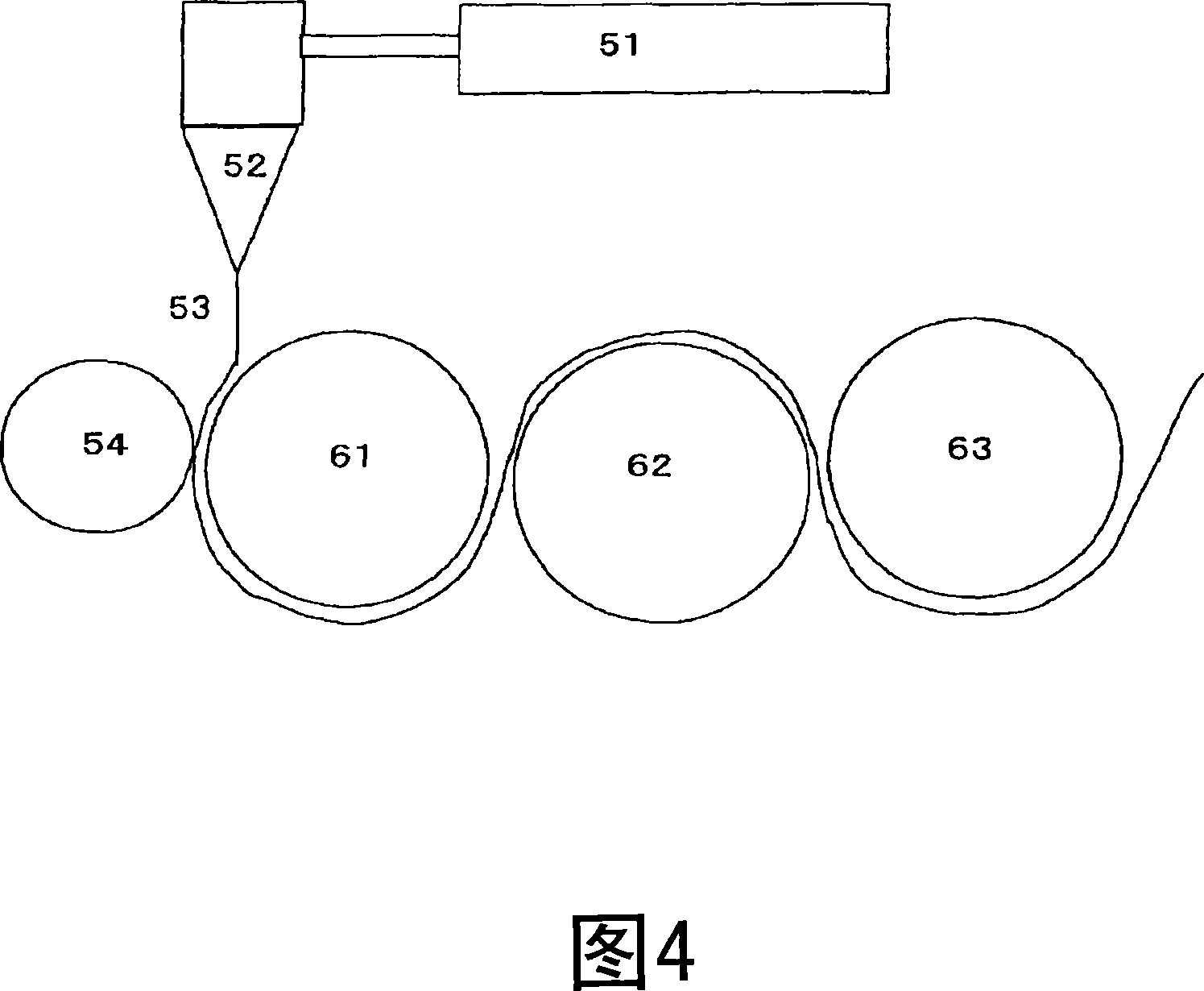

Process for preparing Ba TiO2 base laminated sheet type PTC thermosensitive resistor

InactiveCN1492451AReduce pollutionReduce labor intensityPositive temperature coefficient thermistorsMetallic electrodeOhmic contact

This invention discloses a preparation technology for BaTiO3 base laminated sheet PTC thermistors including 1. applying film grinding formation technology to prepare PTC sheet green compact, 2. sputtering internal electrodes, 3 co-sintering, 4 forming end-electrodes. Advantages: taking water as the solvent to prepare sheet PTC green compact with a film-grinding formation method results in little pollution, low cost and uniform, tight and smooth compact sheets. Good ohmic contact is formed during hot press sintering and oxidation problem of metallic electrodes is solved to form good PTC effect.

Owner:HUAZHONG UNIV OF SCI & TECH

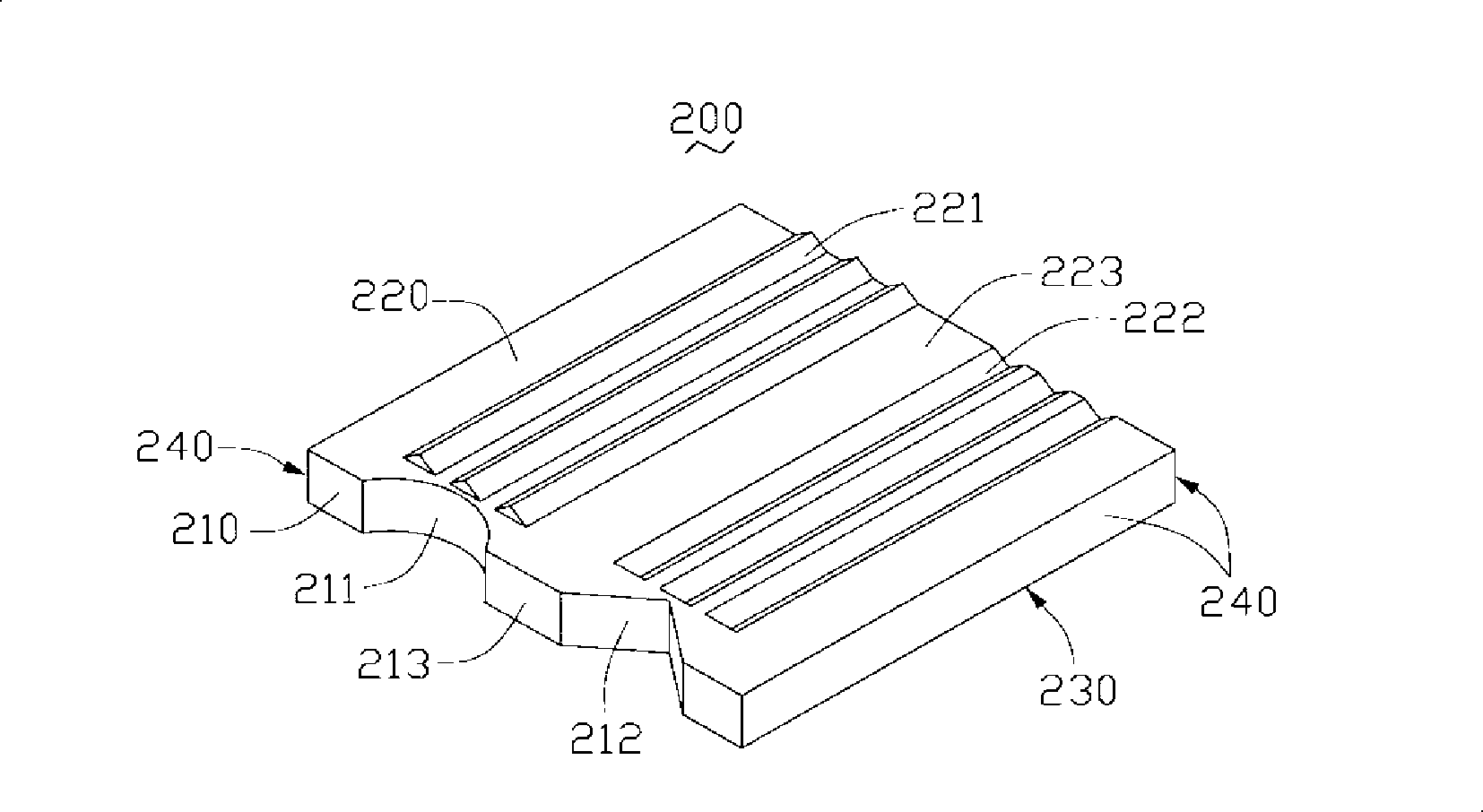

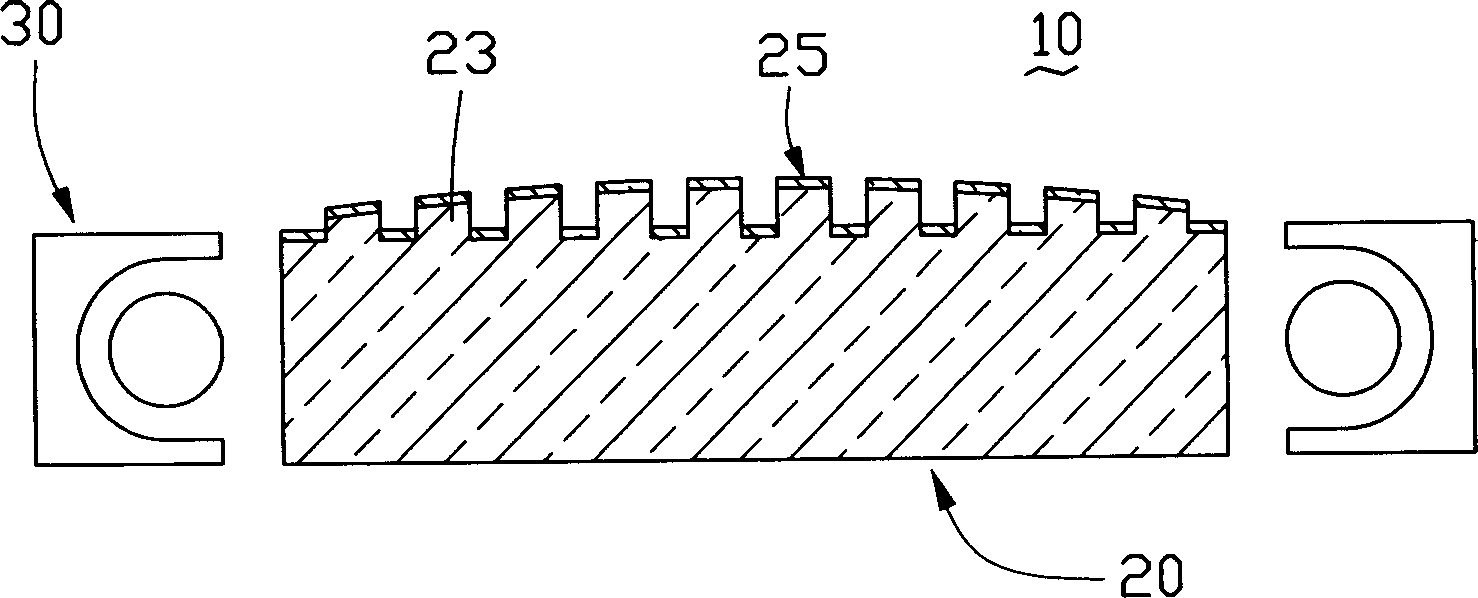

Light conducting plate and backlight module using the same

InactiveCN1504771AWith uniformityImprove luminosityMechanical apparatusDiffusing elementsLight guideLight beam

A backlight module comprising a light conducting board, a tube and a reflector encircling the tube, wherein the light conducting board is used for guiding the transmission direction of the light beams from the tube and the reflector and increasing the brilliance and uniformity for the outgoing light rays, the light conducting board includes an incident plane, an outgoing plane and a bottom plane arranged opposite the outgoing plane, the incident plane intersects the outgoing plane, a plurality of depressions are distributed on the bottom plane, the dissemination planes of the multiple depressions form a curved surface, the bottom plane and the projecting dissemination plane are coated by reflection films.

Owner:HONG FU JIN PRECISION IND (SHENZHEN) CO LTD +1

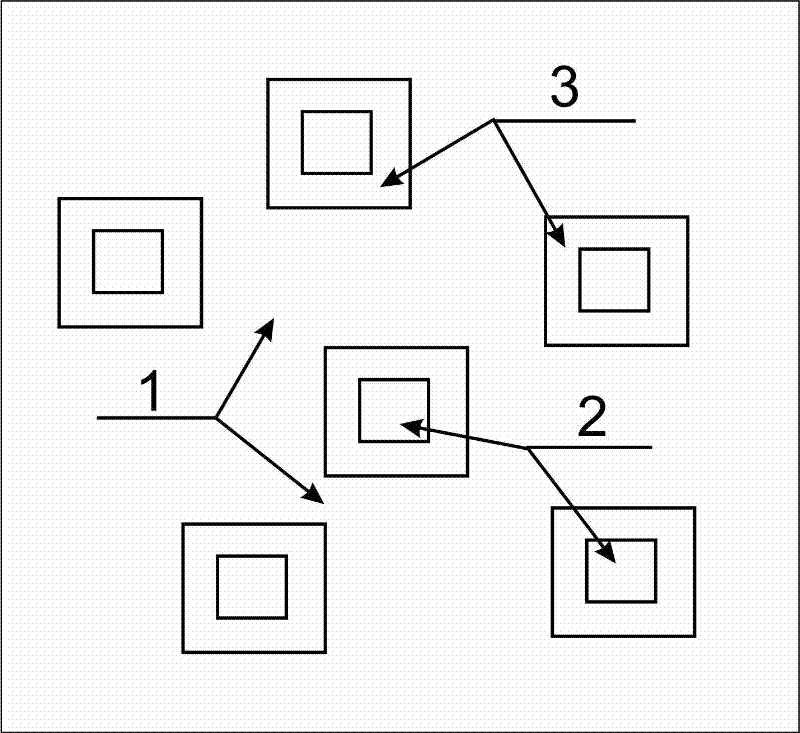

Novel porous silicon and a preparation method thereof

InactiveCN102400217ADoes not affect productionEasy to integratePolycrystalline material growthAfter-treatment detailsMicro nanoHydrofluoric acid

The invention discloses novel porous silicon and a preparation method thereof. The porous silicon has a structure that cylindrical nanometer porous silicon is formed in a low-doped and N-shape monocrystalline silicon film base, and closes straight hole cavities, and the surface is nanometer porous silicon. The invention employs an electrochemical corrosion method, where the structure of the novel porous silicon is made by controlling the mixture solution proportioning and the voltage and current of a dc source in a mixture solution of hydrofluoric acid and an organic solvent. The novel porous silicon structure and the preparation method provide a new technological approach and method for the integration of a silicon-based micro nano device with a sensor, a self-destructing chip, a luminescent device, etc.

Owner:SICHUAN UNIV

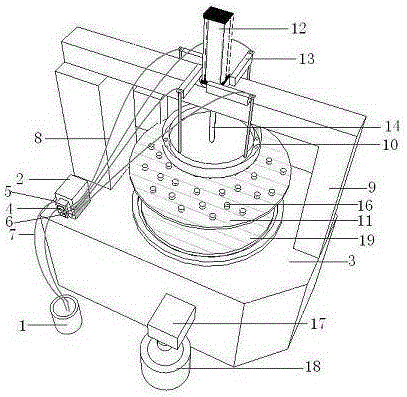

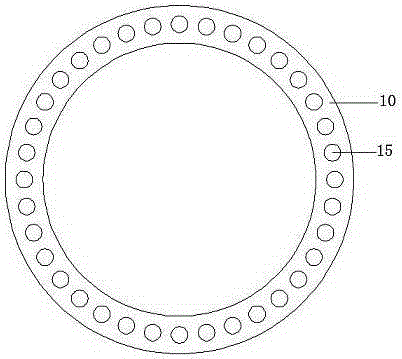

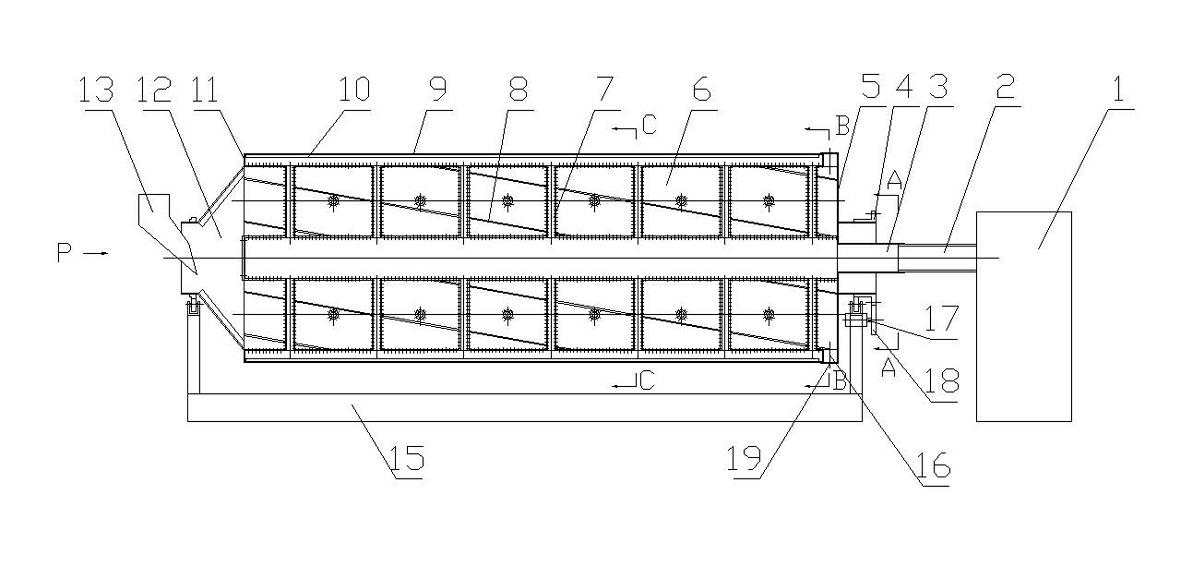

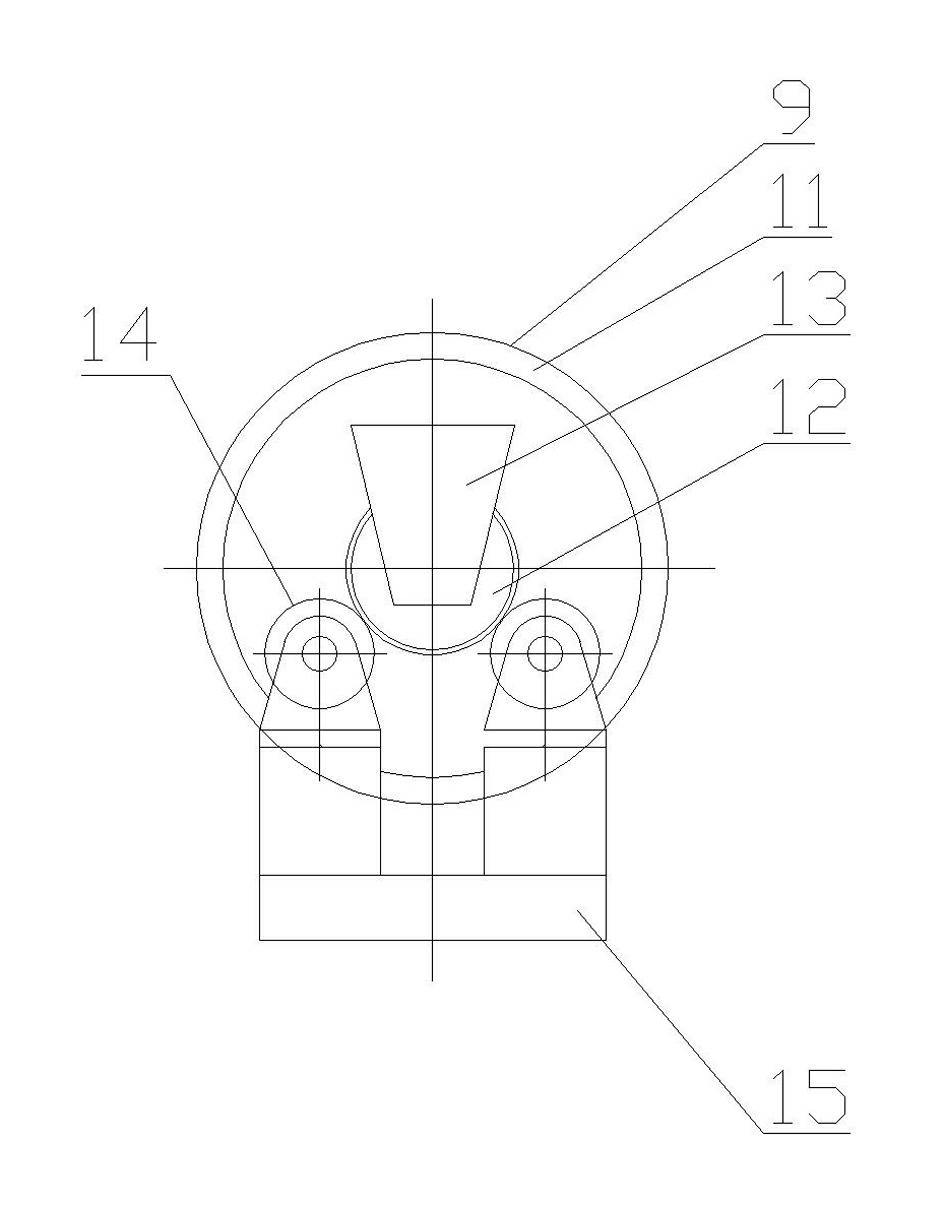

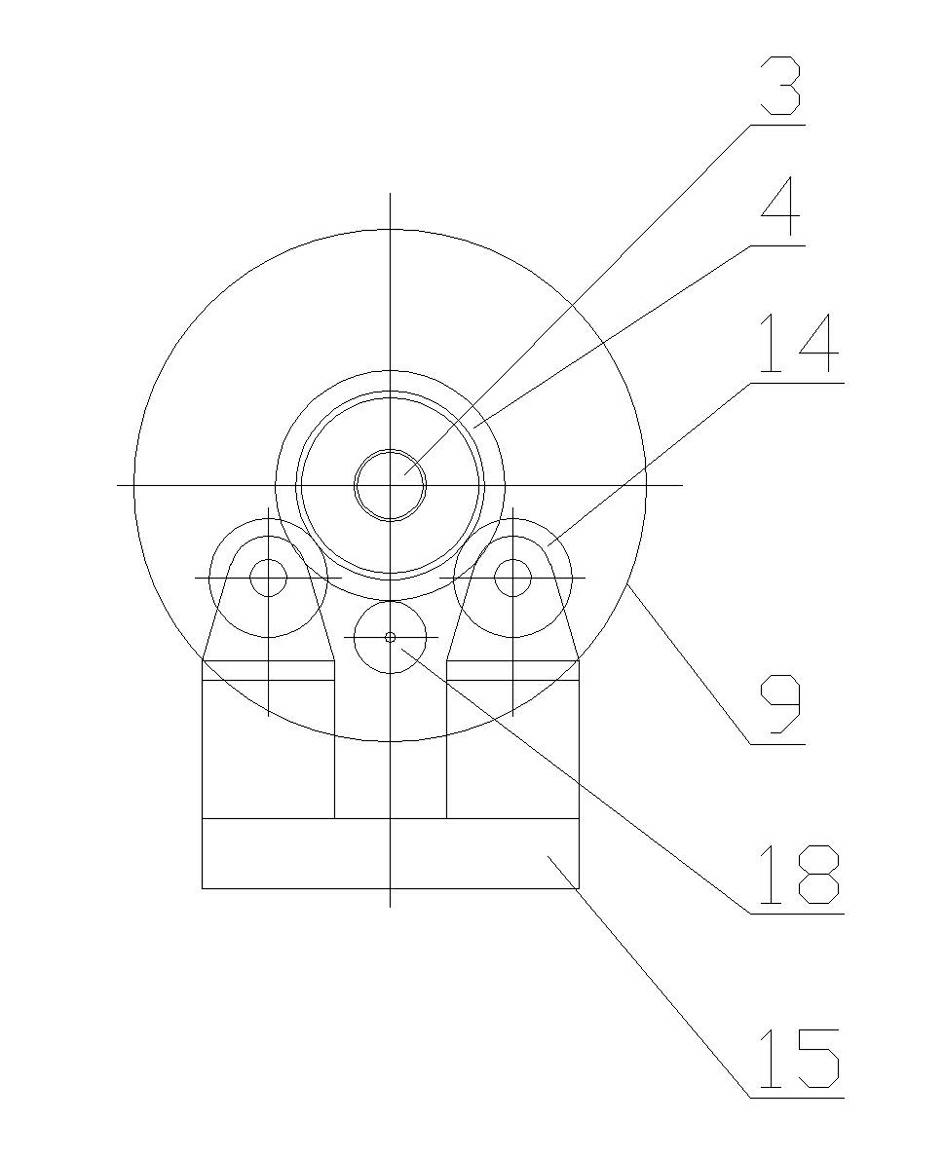

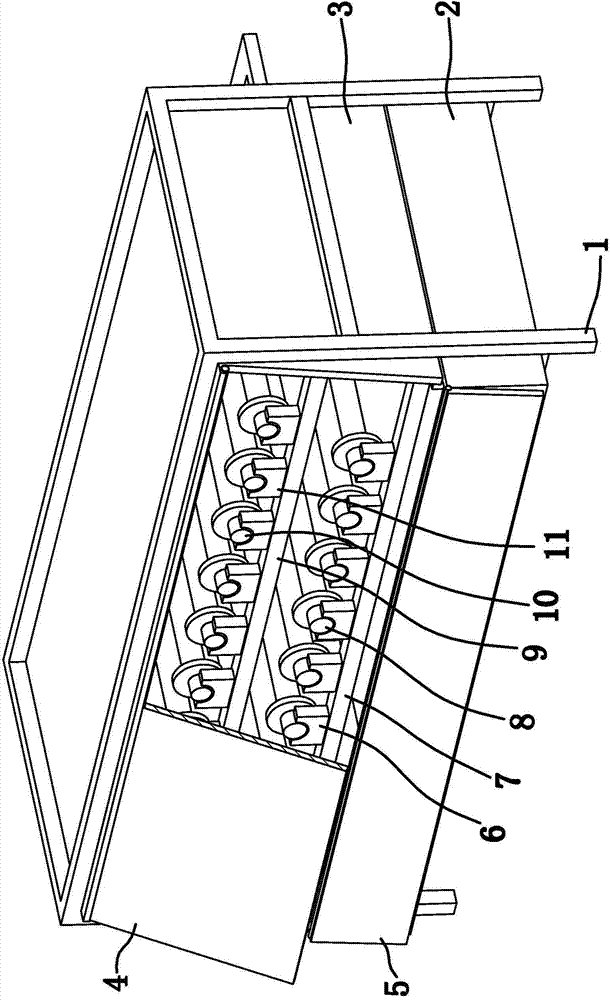

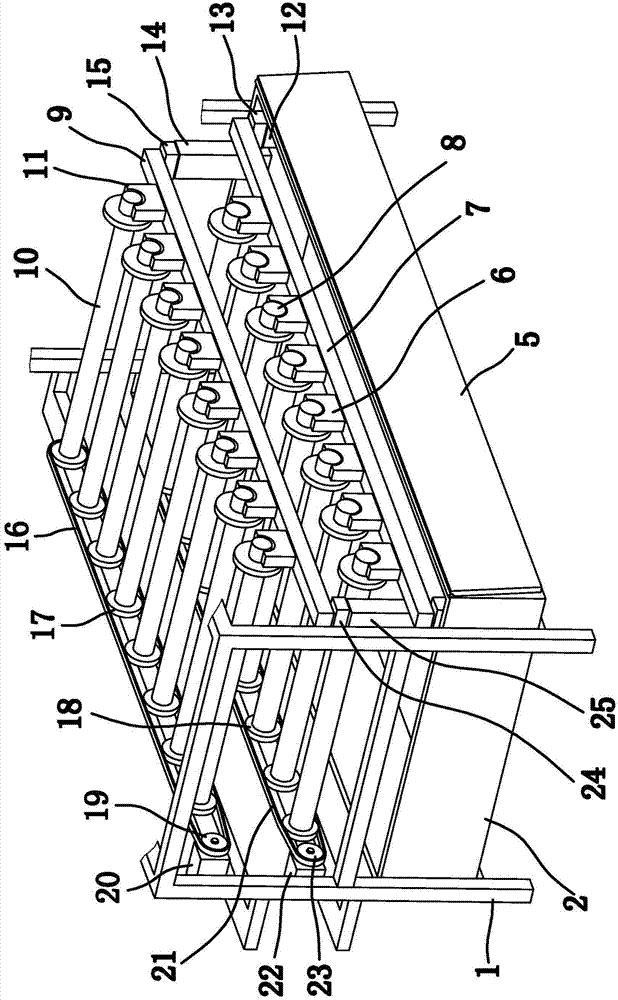

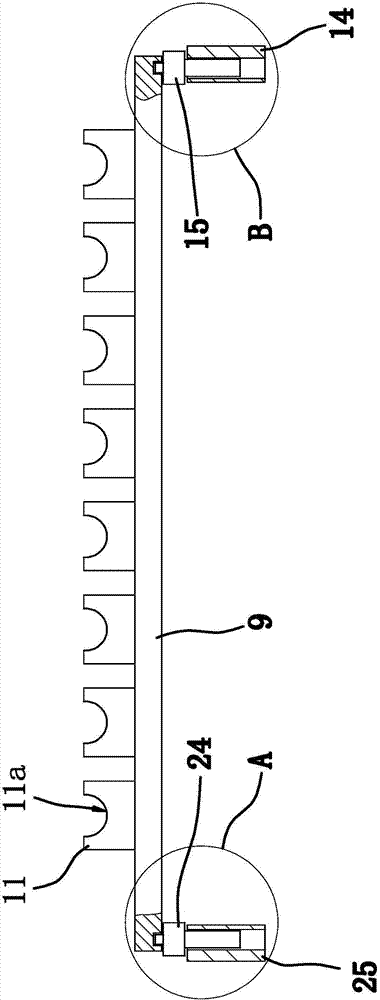

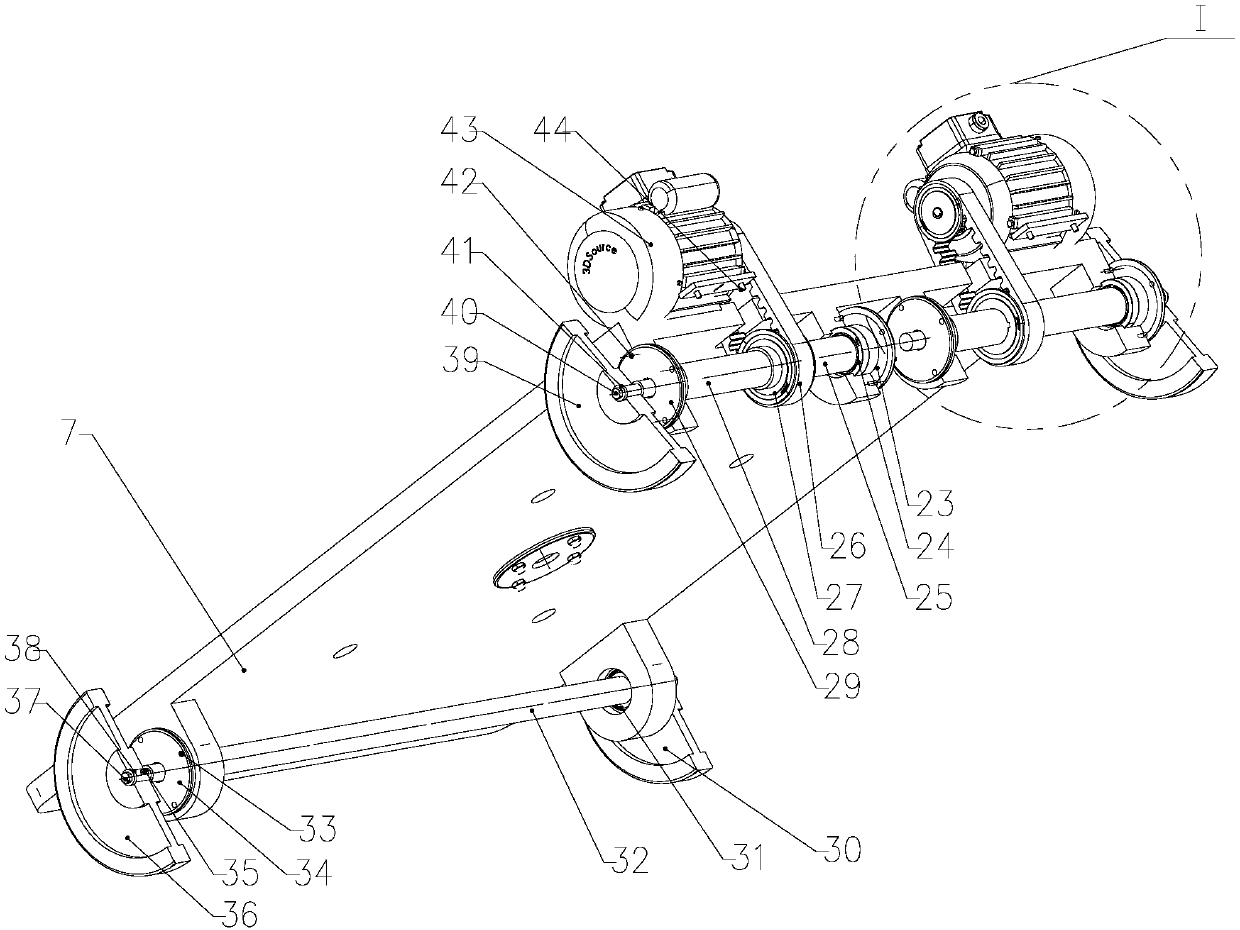

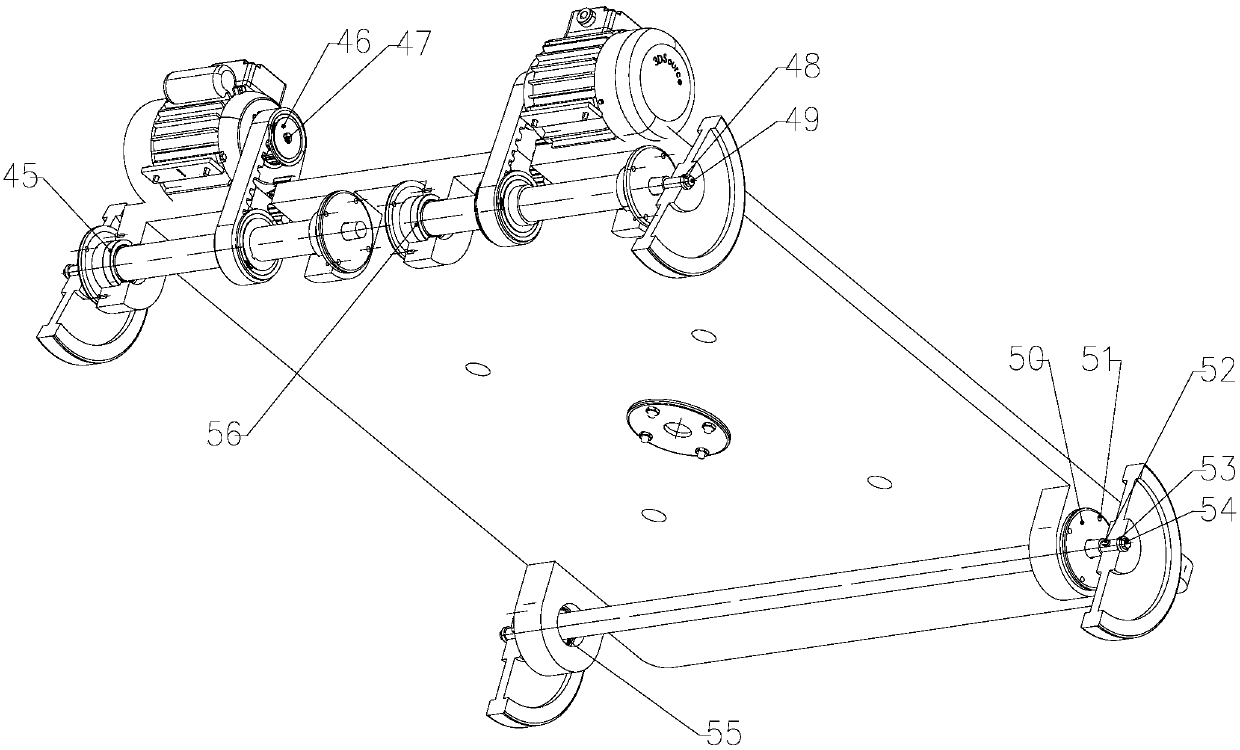

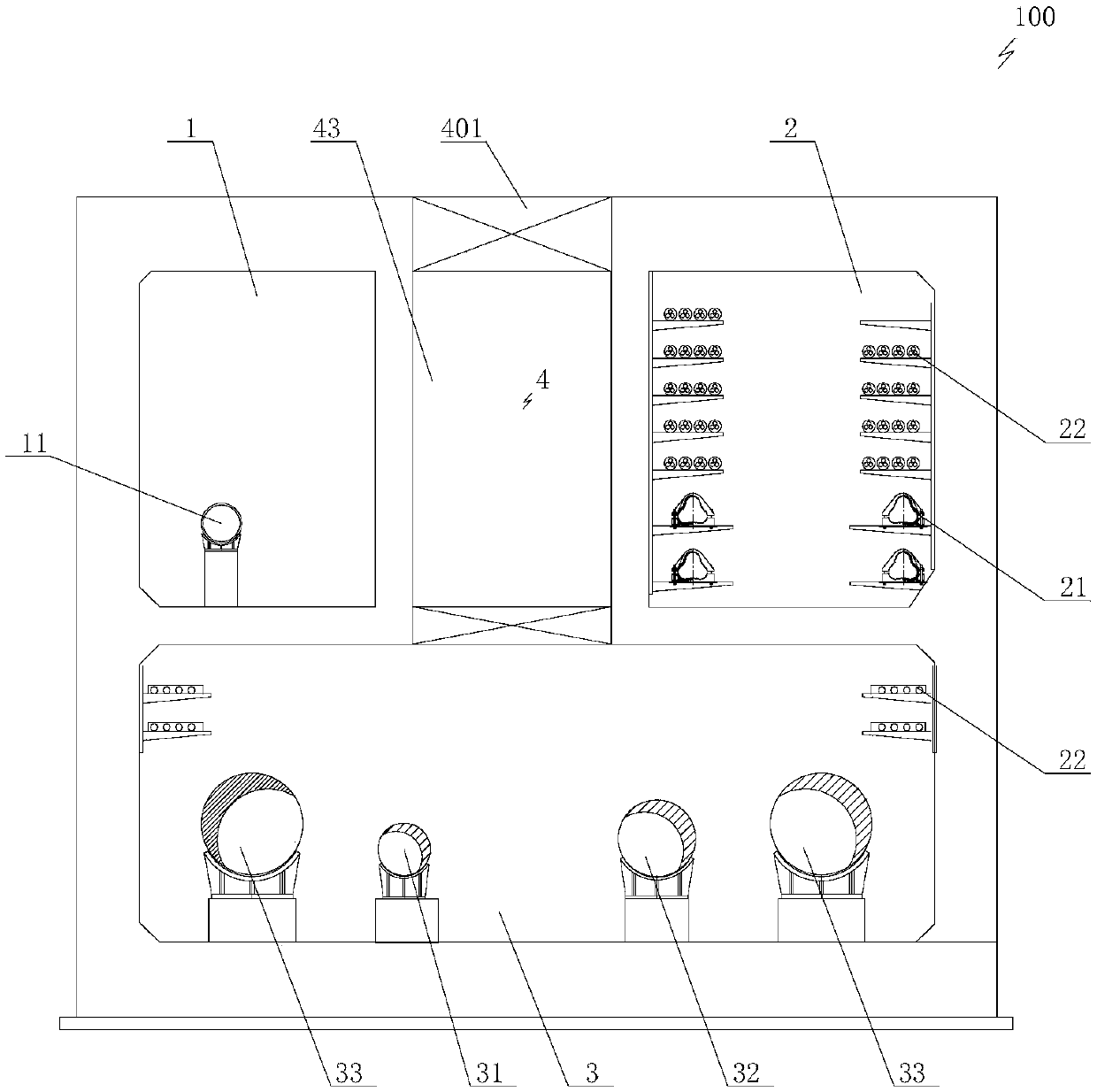

Multi-barrel rotary black tea fermentation device

ActiveCN102626149AImprove qualityWith uniformityPre-extraction tea treatmentAgricultural engineeringBlack tea

The invention discloses a multi-barrel rotary black tea fermentation device. The multi-barrel rotary black tea fermentation device comprises a power device, a heat, moisture and oxygen supplying system, a frame, a feeding port and a discharging port, wherein a long outer barrel is arranged; a plurality of fermentation barrel are arranged on the same circumference inside the outer barrel; the fermentation barrels are fixedly connected with the outer barrel; small holes are arranged uniformly on the surface of the barrel wall of each fermentation barrel; a plurality of small round pipes provided with small holes pass through the barrel wall of each fermentation barrel; the inner wall of each fermentation barrel is provided with a plurality of uniformly distributed spiral material guiding ribs; the feeding port is communicated with the fermentation barrels; the terminal end of each fermentation barrel is communicated with the discharging port; an air intake central pipe is arranged; one end of the air intake central pipe is communicated with the center of a cavity body of the outer barrel while the other end of the air intake central pipe is connected with the heat, moisture and oxygen supplying system; and the power device can drive the outer barrel to rotate. The multi-barrel rotary black tea fermentation device, disclosed by the invention, has the advantages of a simple structure, cleaning convenience, high automation level and capability of realizing clean production of tea leaves; the fermented black tea has uniformity and consistency; and the quality of the tea leaves is improved.

Owner:ZHEJIANG ZHUFENG MACHINERY

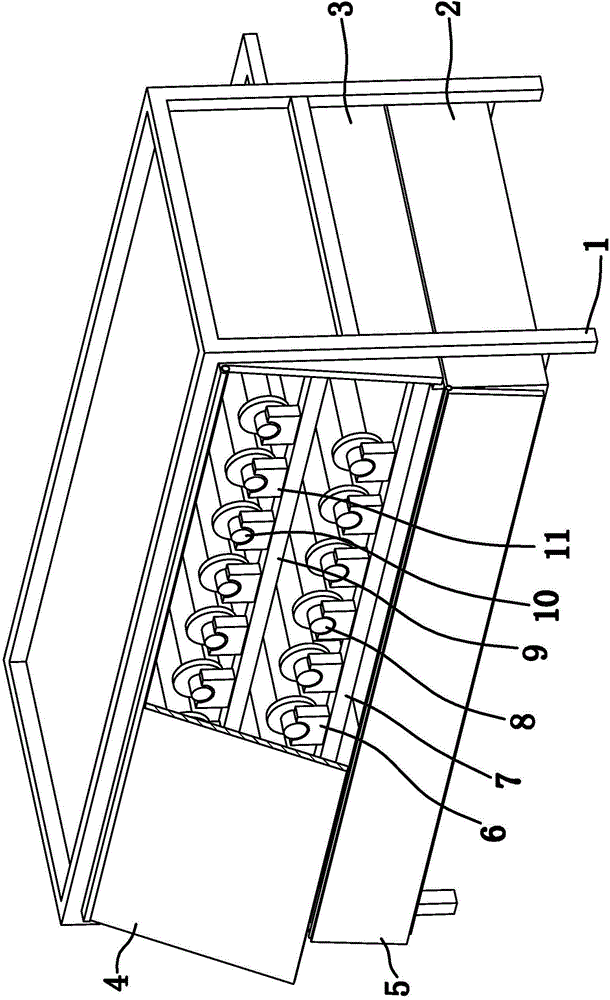

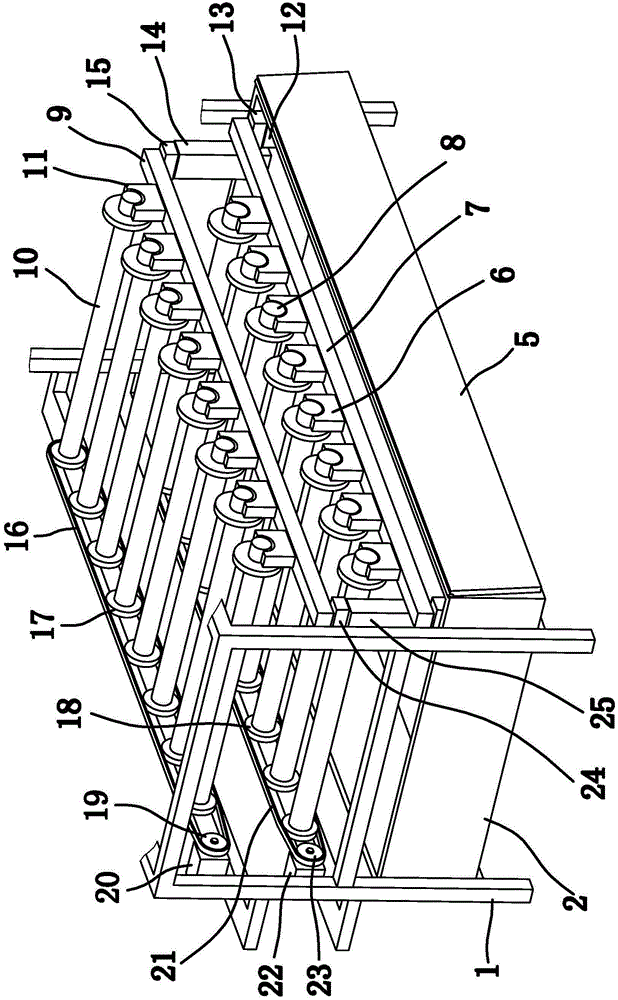

Cashmere-like yarn dyeing method and cashmere-like yarn dye vat

ActiveCN104499224APrevent splashEasy to assemble and disassembleSucessive textile treatmentsTextile treatment containersTextile technologyYarn

The invention provides a cashmere-like yarn dyeing method and a cashmere-like yarn dye vat, belongs to the technical field of textile and solves the technical problems that one end of a yarn hanger of an existing double-cylinder dyeing machine is a suspended end, bearing capacity is poor, the existing double-cylinder dyeing machine is not provided with a pedal device, an operator cannot conveniently take down upper yarns, operation is strenuous, a preparation method omits dye liquor and the like. The cashmere-like yarn dyeing method includes the steps: a, blank inspection; b, threading; c, dye liquor manufacture; d, feeding; e, dewatering; f, drying; g, warehousing. The dye vat is used for dyeing cashmere-like yarns and comprises a frame, a plurality of upper dyeing sticks and a plurality of lower dyeing sticks, and an upper vat body and a lower vat body are fixed on the frame. The dye vat has the advantages of high dyeing efficiency, fine supporting effect and fine working stability.

Owner:ZHEJIANG YINGSHANHONG TEXTILE TECH CO LTD

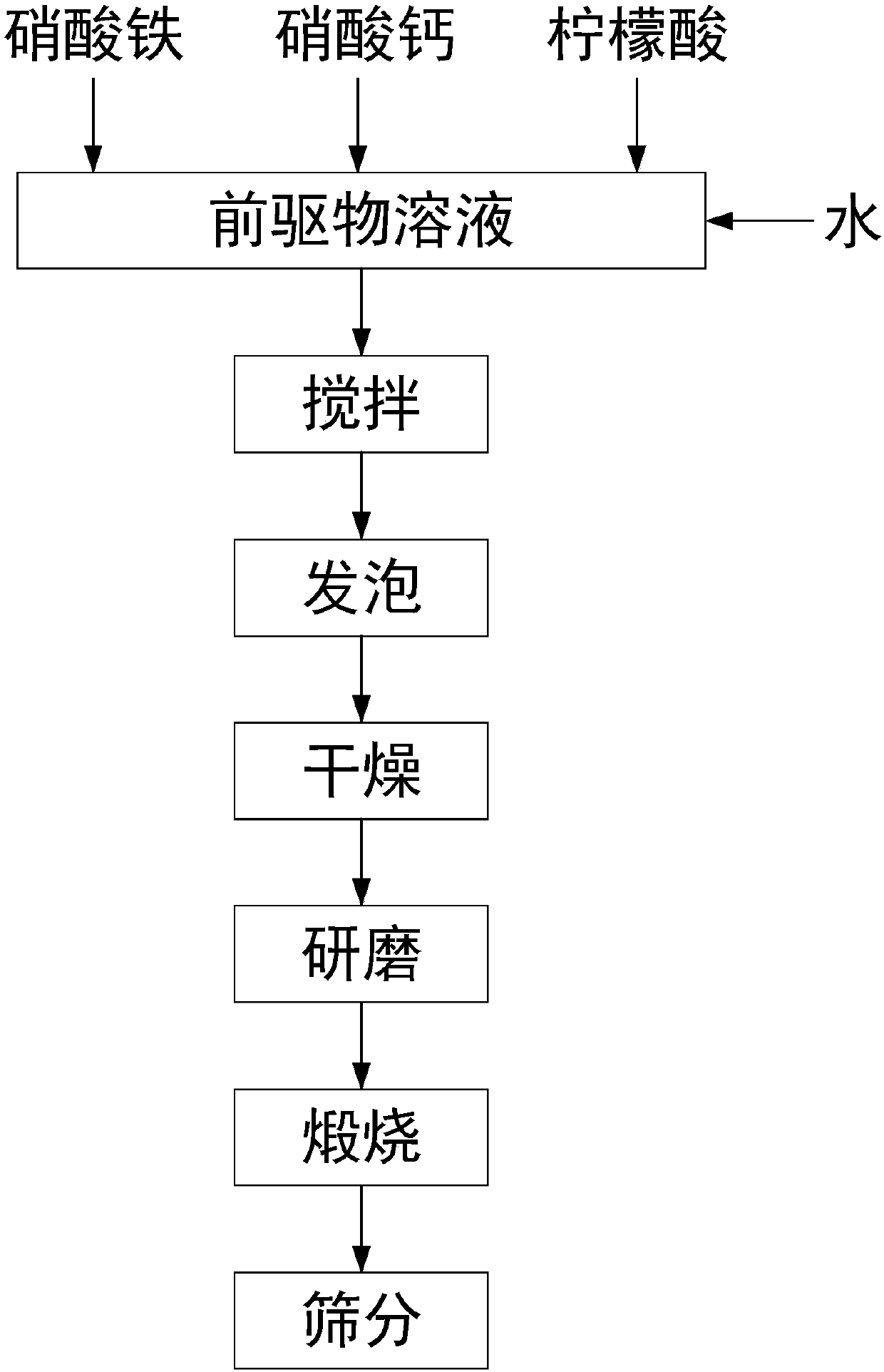

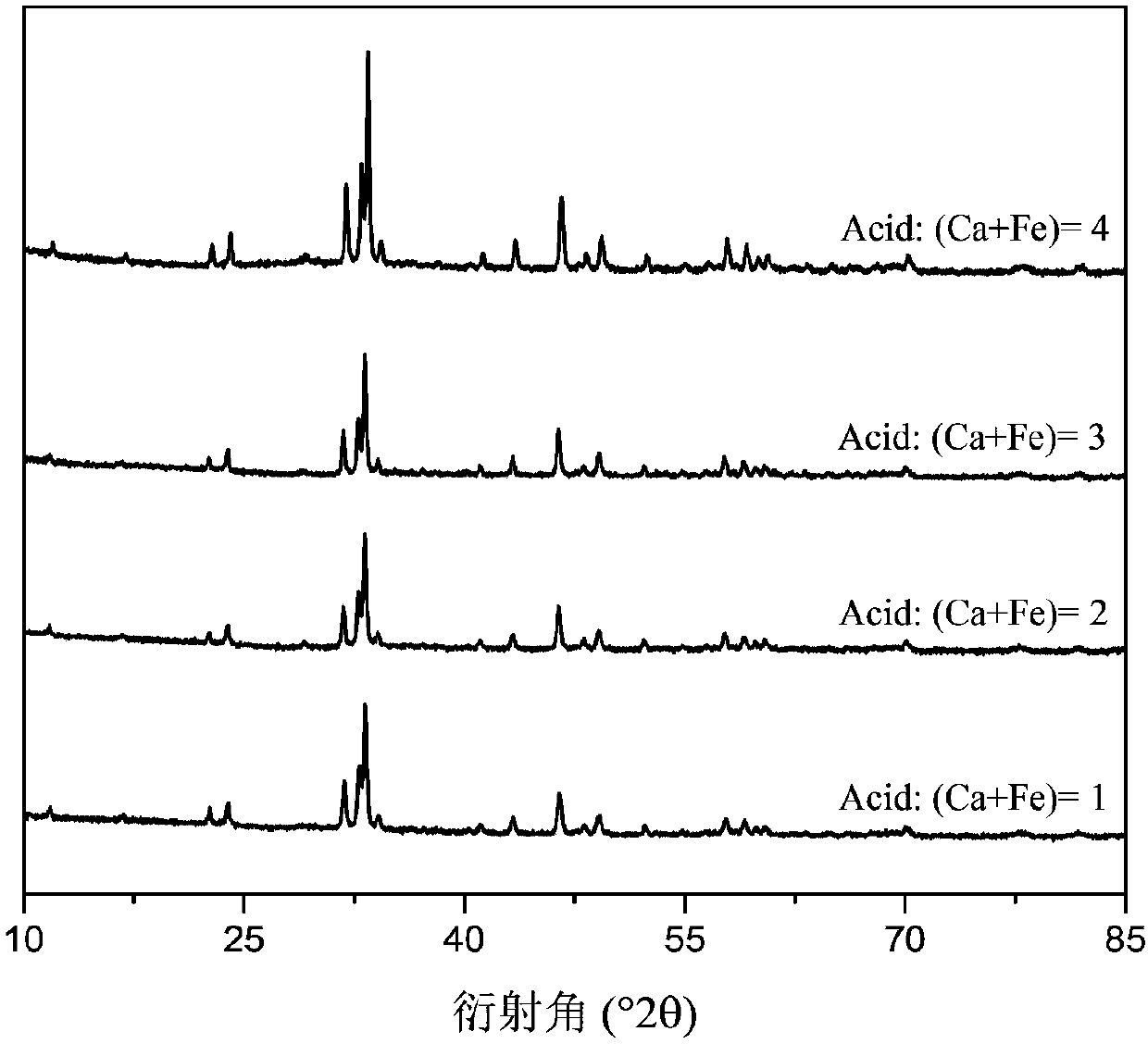

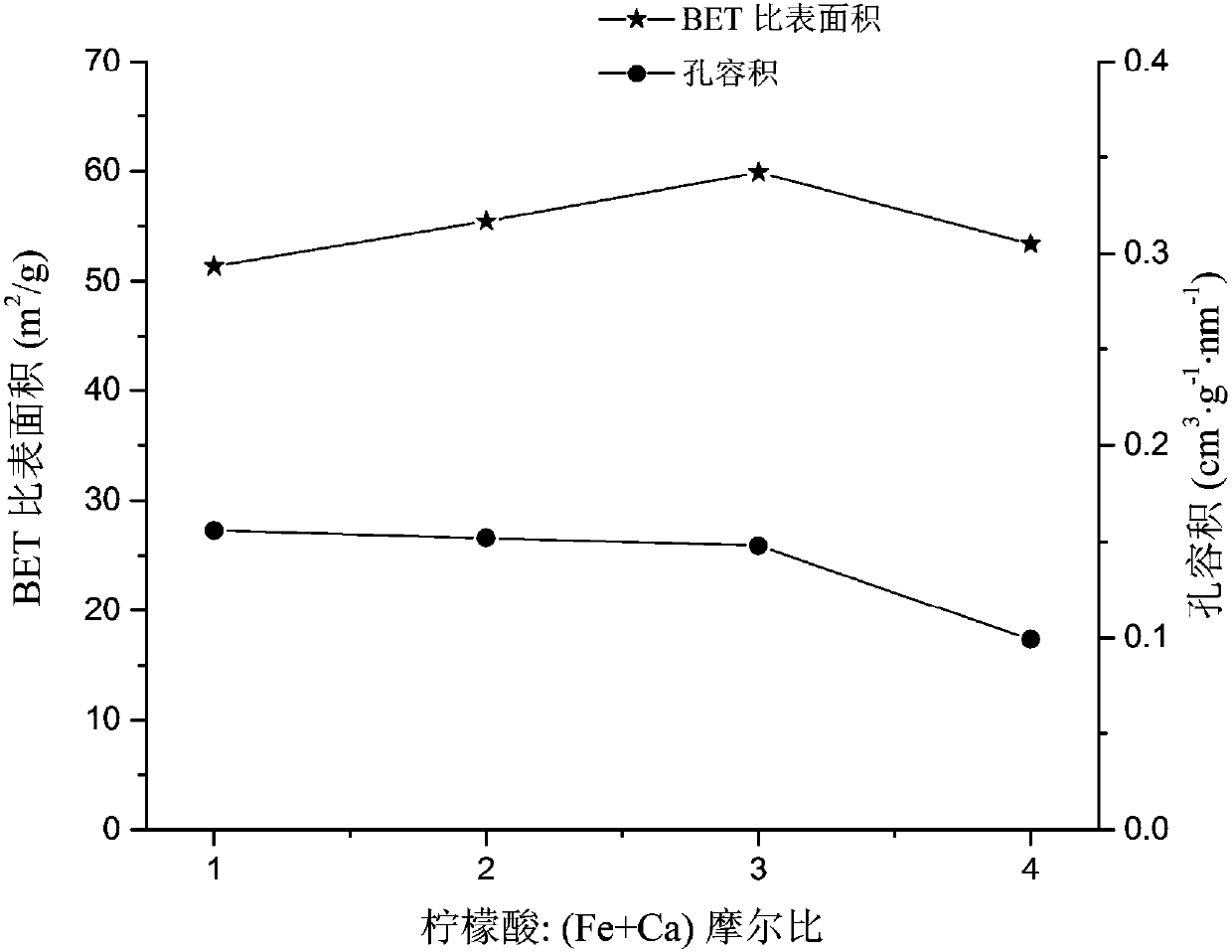

Preparation method of calcium-iron type Ca2Fe2O5 catalyst

InactiveCN107857301AGood dispersionLarge specific surface areaIron compoundsMetal/metal-oxides/metal-hydroxide catalystsCombustionFoaming agent

The invention discloses a preparation method of a calcium-iron type Ca2Fe2O5 catalyst. The method adopts ferric nitrate, calcium nitrate and citric acid as precursors which are added with a certain amount of water to prepare a solution, and the solution is stirred at 40 DEG C for 30 minutes to be evenly dispersed, wherein the citric acid is added as a foaming agent for foaming at 180 DEG C for 12h, an obtained foaming substance is ground, sieved, and then calcined at 650 DEG C in a muffle furnace for 4h to finally obtain a high-purity Ca2Fe2O5 catalyst. The Ca2Fe2O5 catalyst prepared by the method has a large specific surface area and a stable framework structure, can keep extremely strong stability after being oxidized and reduced by an oxidant and a reducing agent for a plurality of times, and can be used in the fields of chemical chain combustion, chemical chain hydrogen production, photocatalysis and the like.

Owner:SOUTHEAST UNIV

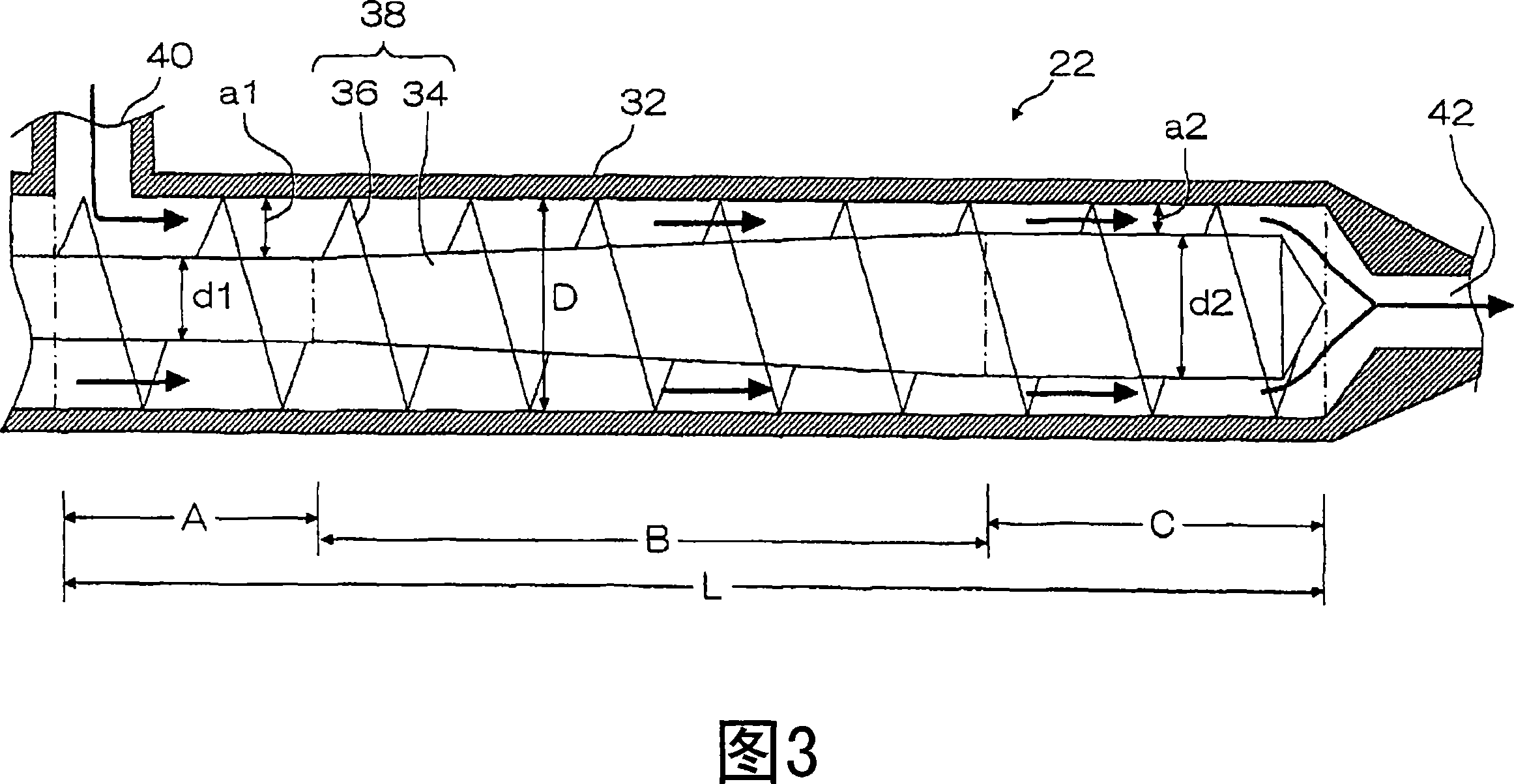

Cellulose acylate film, process for producing the same, polarizing plate, retardation film, optical compensating film, antireflection film, and liquid-crystal display

InactiveCN101208189AGood dimensional stabilityWith uniformityOptical articlesPolarising elementsCelluloseHigh humidity

By longitudinally stretching the cellulose acylate film under the condition that the aspect / lateral ratio (L / W) of the ratio of the width (W) of the film before stretching and the stretching interval (L) is more than 0.01 and less than 0.3 ~ 300%, and then relax 1 ~ 50% in the longitudinal direction to produce cellulose acylate film. When this film is incorporated in a liquid crystal display device, it is possible to suppress the occurrence of color unevenness even if it is placed under high temperature and high humidity.

Owner:FUJIFILM CORP

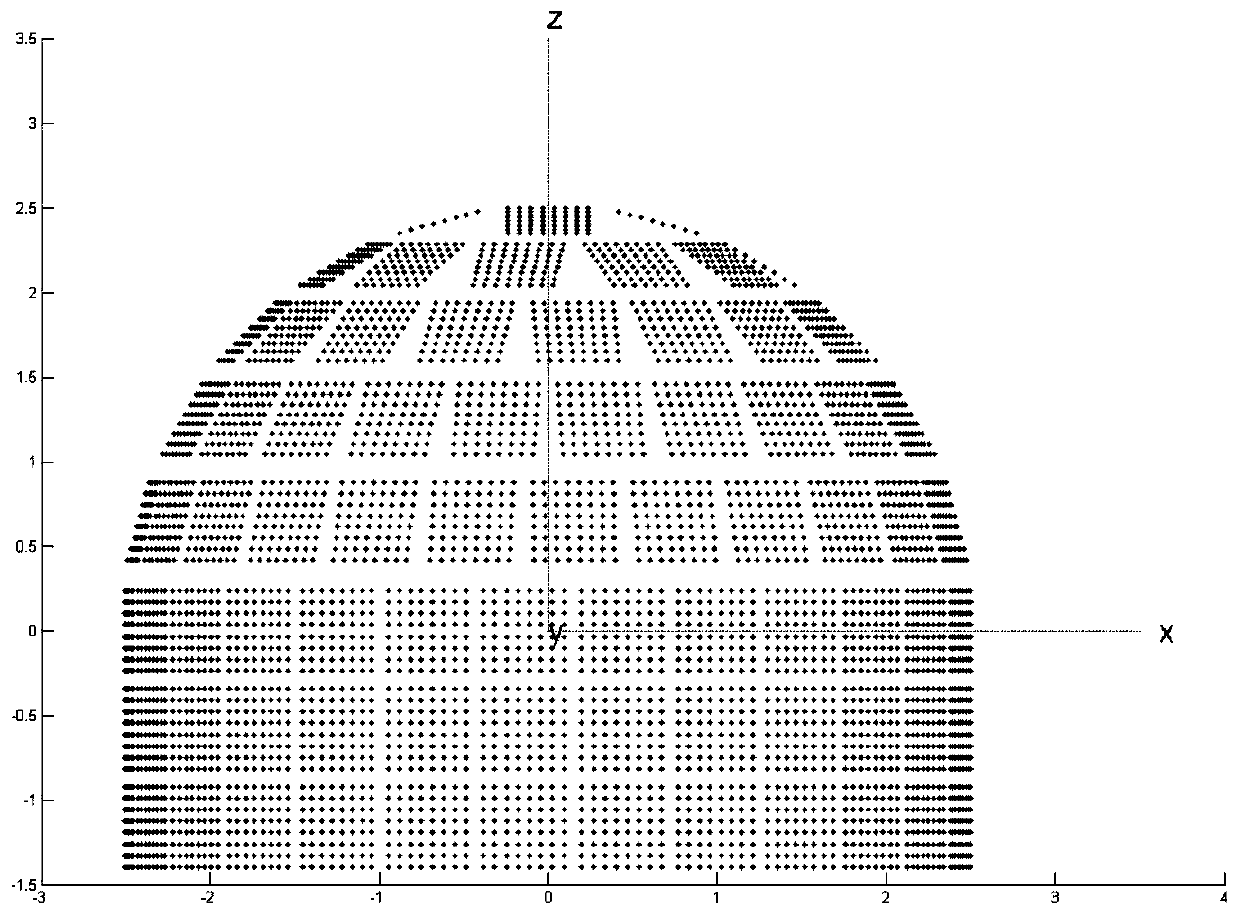

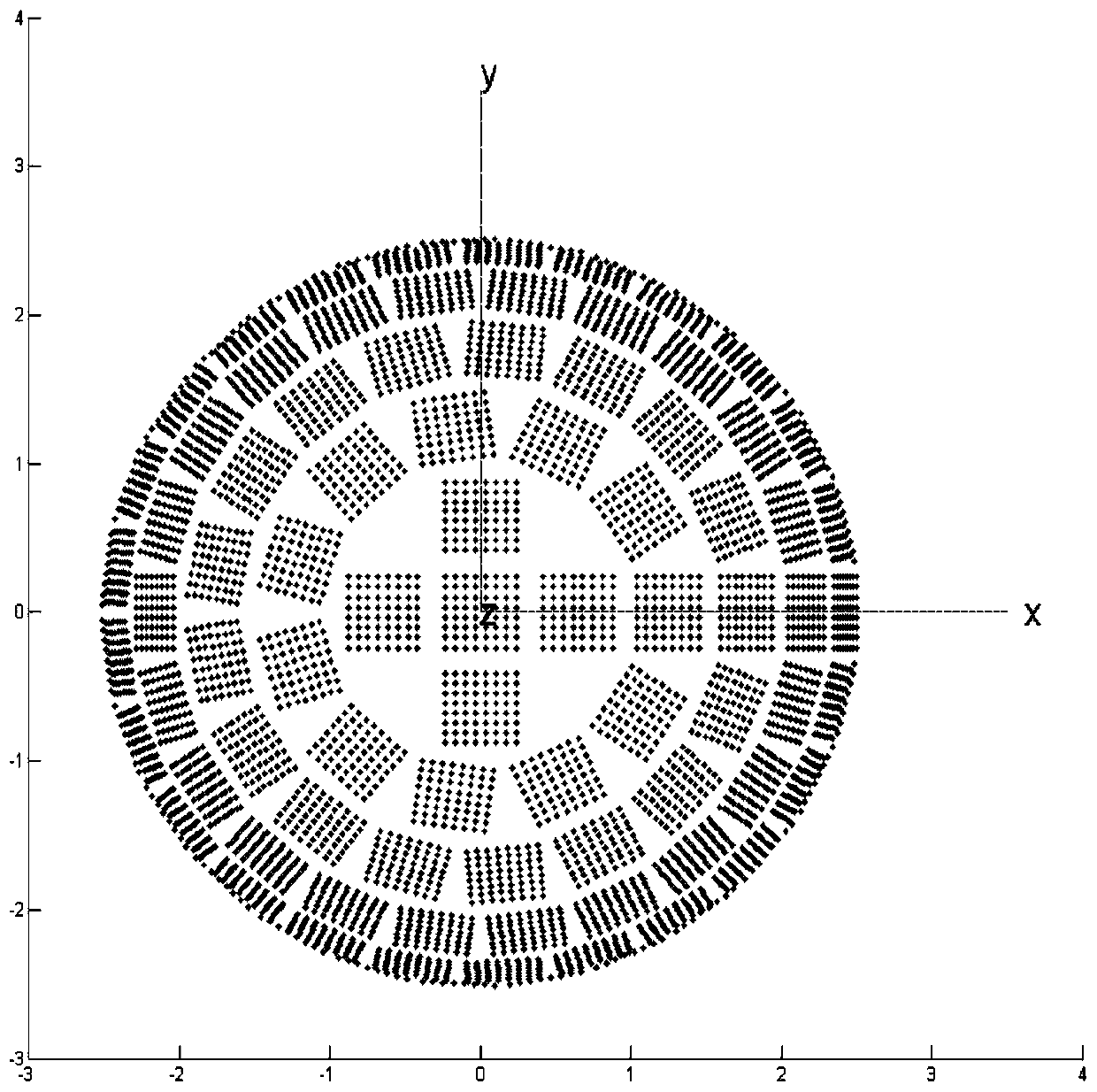

Method for reducing number of array elements of large-scale spherical surface array

ActiveCN111541049ALow costReduce the numberAntenna arrays manufactureAzimuth directionElectrical performance

The invention discloses a method for reducing the number of array elements of a large-scale spherical surface array, and aims to provide a method capable of obtaining electrical performance equivalentto that of a full array and remarkably reducing the total number of the array elements of a spherical surface antenna array. According to the technical scheme, the method comprises: establishing a coordinate system, and constructing an antenna subarray according to the rule of half-wavelength uniform arrangement of antenna units in the antenna subarray; dividing sub-arrays along the pitching direction and the azimuth direction of the coordinate system, and constructing an initial full array; establishing a spherical cylindrical array antenna array model based on large-spacing array element arrangement, and constructing a new antenna subarray with large-spacing array element arrangement; and then, setting an activation angle domain and different incoming wave directions according to the array element spacing, and calculating the synthetic gain of the antenna array under each array element interval. The total array synthetic gain of the antenna is compensated by reasonably reducing thecurvature of the spherical surface and increasing the diameter of the spherical surface to a proper value, and the gain value and the sidelobe characteristic similar to those of a full-array array areobtained while the number of the array elements is reduced.

Owner:10TH RES INST OF CETC

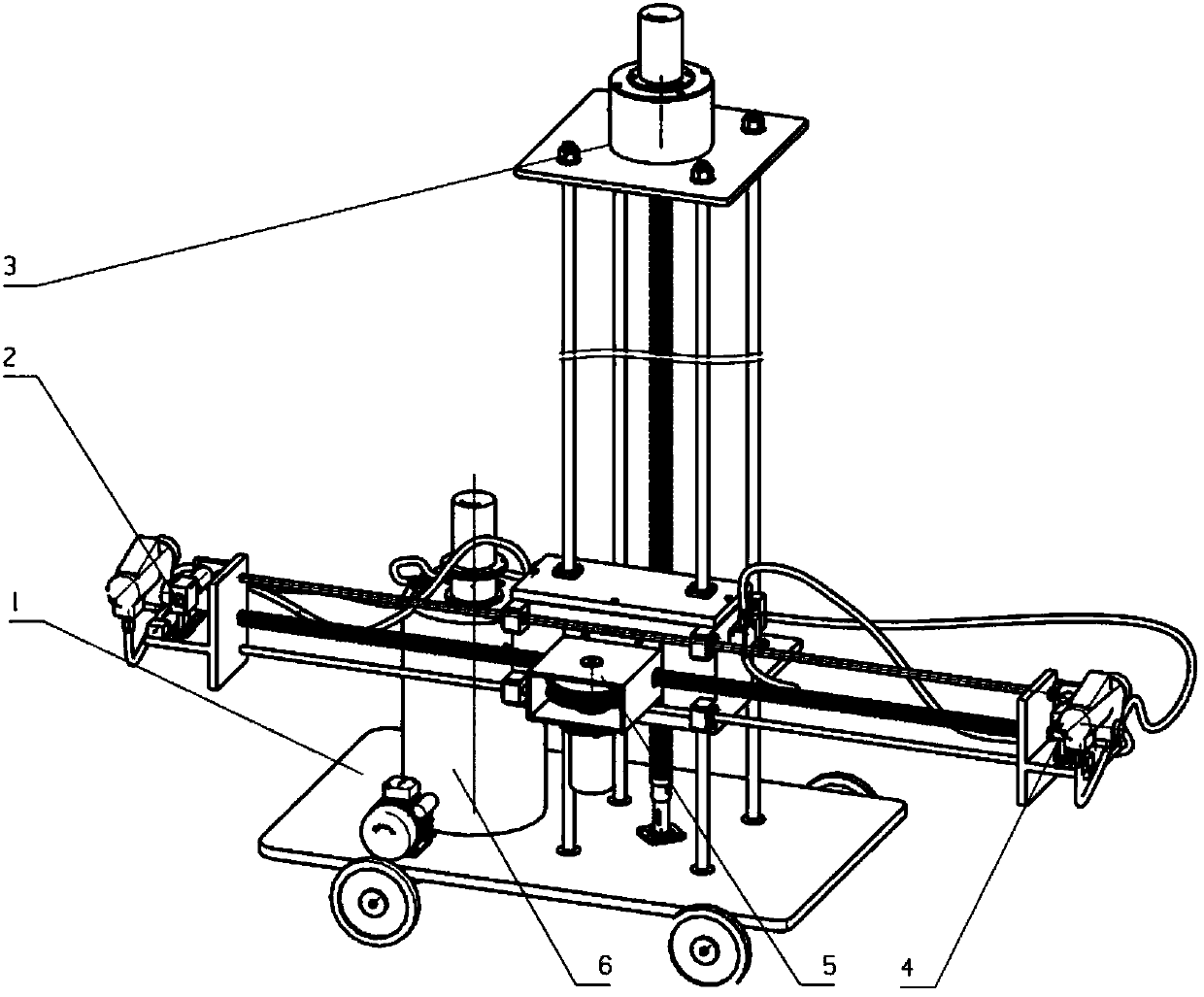

Wall spraying robot

PendingCN107724649AComprehensiveWith uniformityBuilding constructionsControl engineeringProcess engineering

The invention relates to the field of robots, in particular to a wall spraying robot. The wall spraying robot comprises a movable platform; the movable platform is provided with a moving mechanism; the movable platform is also provided with a Z-direction moving mechanism used for adjusting the up and down position; the Z-direction moving mechanism is provided with a Y-direction moving mechanism used for adjusting the horizontal position; the Y-direction moving mechanism is provided with an X-direction moving mechanism used for adjusting the front and back position; the movable platform is provided with a spraying system. Compared with a joint type spraying robot, the wall spraying robot provided by the invention is low in manufacturing cost as well as convenient to use and maintain; by adopting adjustment along the X direction, the Y direction and the Z direction, the wall spraying robot enables spraying to have comprehensiveness and uniformity, thus avoiding the phenomenon of inadequate spraying; after the robot is used for replacing manual painting, the efficiency and quality of automatic spraying are improved while the labor intensity of workers is lightened.

Owner:ANHUI UNIVERSITY OF TECHNOLOGY AND SCIENCE

Dyeing process of clothes fabric and dyeing vat thereof

ActiveCN104562501APrevent splashEasy to assemble and disassembleTextile treatment containersTextile treatment machine arrangementsTextile technologyEngineering

The invention provides a dyeing process of a clothes fabric and a dyeing vat thereof, belongs to the technical field of textile, and aims at solving the technical problems of low dyeing efficiency of the existing dyeing process of the clothes fabric and poor bearing capacity of the dyeing vat. The dyeing process of the jacquard fabric comprises the steps of a, inspecting a grey fabric; b, tailoring; c, drying by hanging; d preparing dyeing liquid; e, feeding into the vat; f, dewatering; g, drying; h, warehousing. The dyeing vat comprises a rack; an upper vat body and a lower vat body are fixed on the rack; the dyeing vat further comprises a plurality of upper dyeing bars and a plurality of lower dyeing bars. The dyeing process and the dyeing vat have the advantages of being high in dyeing efficiency, good in supporting effect and high in working stability.

Owner:HAINING TIANYI TEXTILE

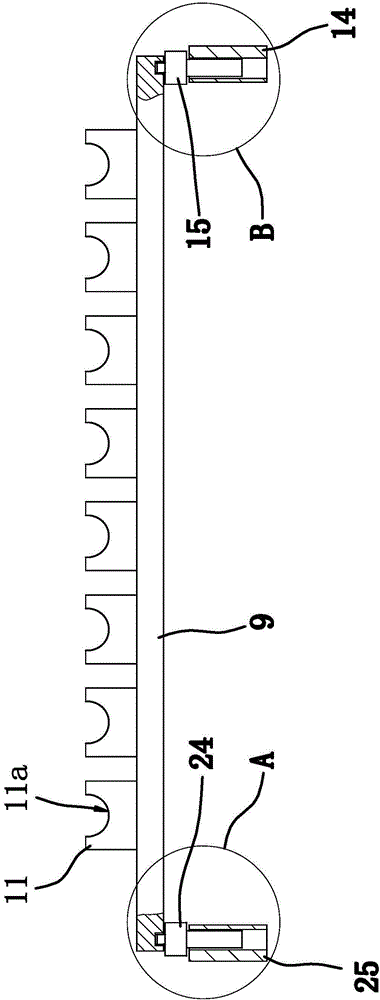

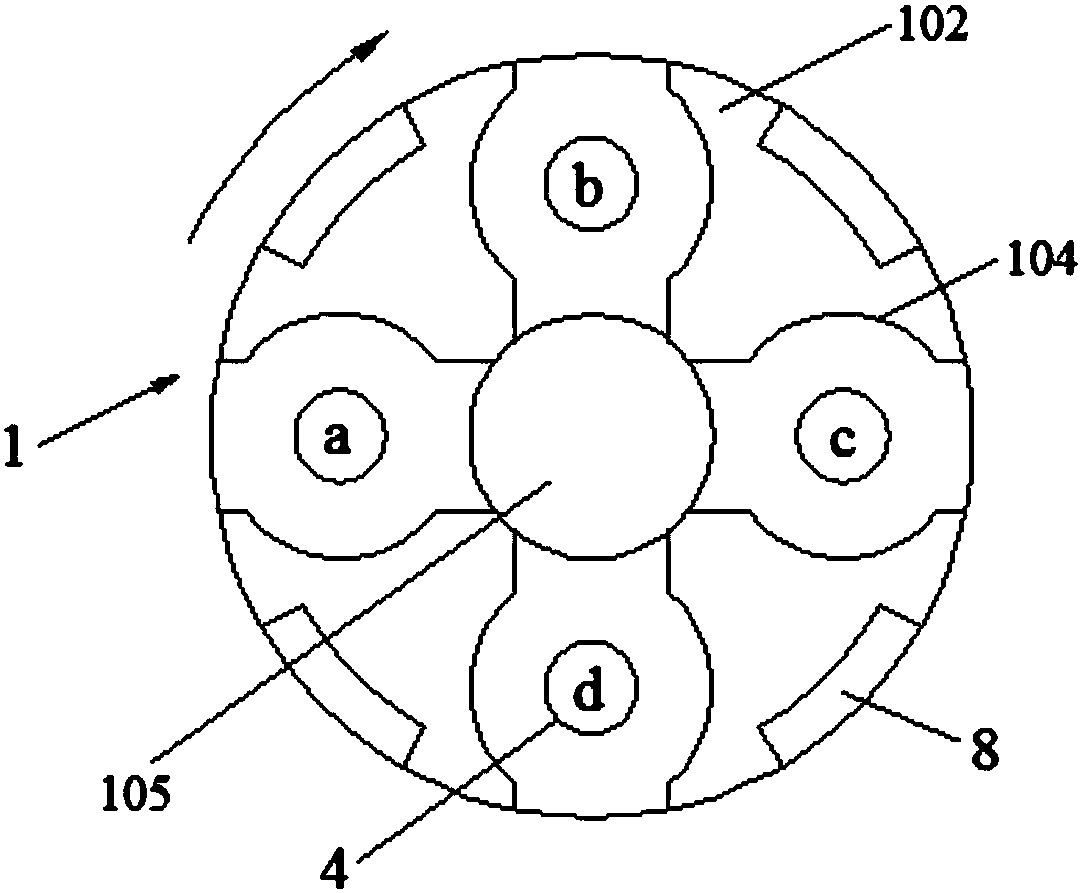

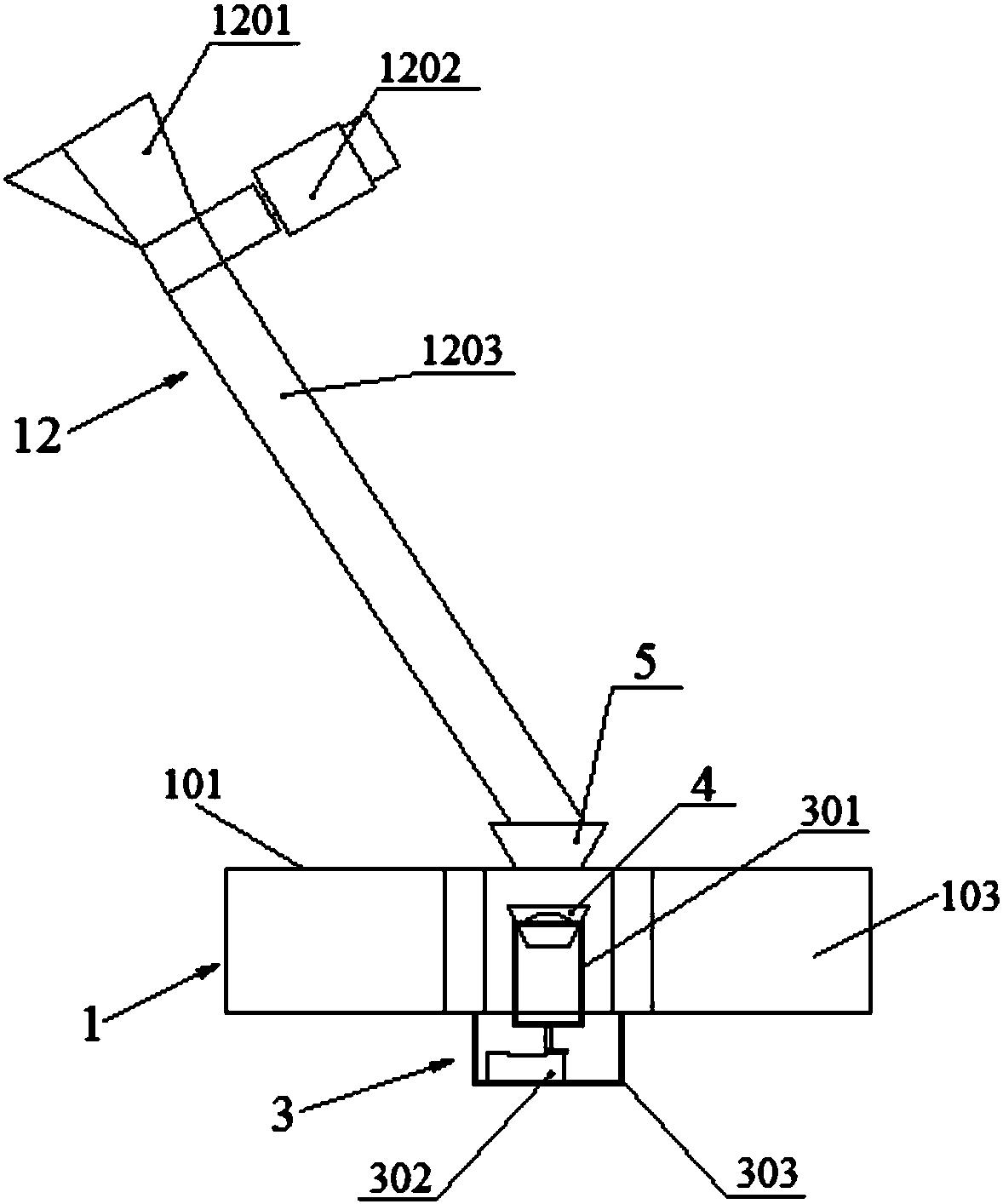

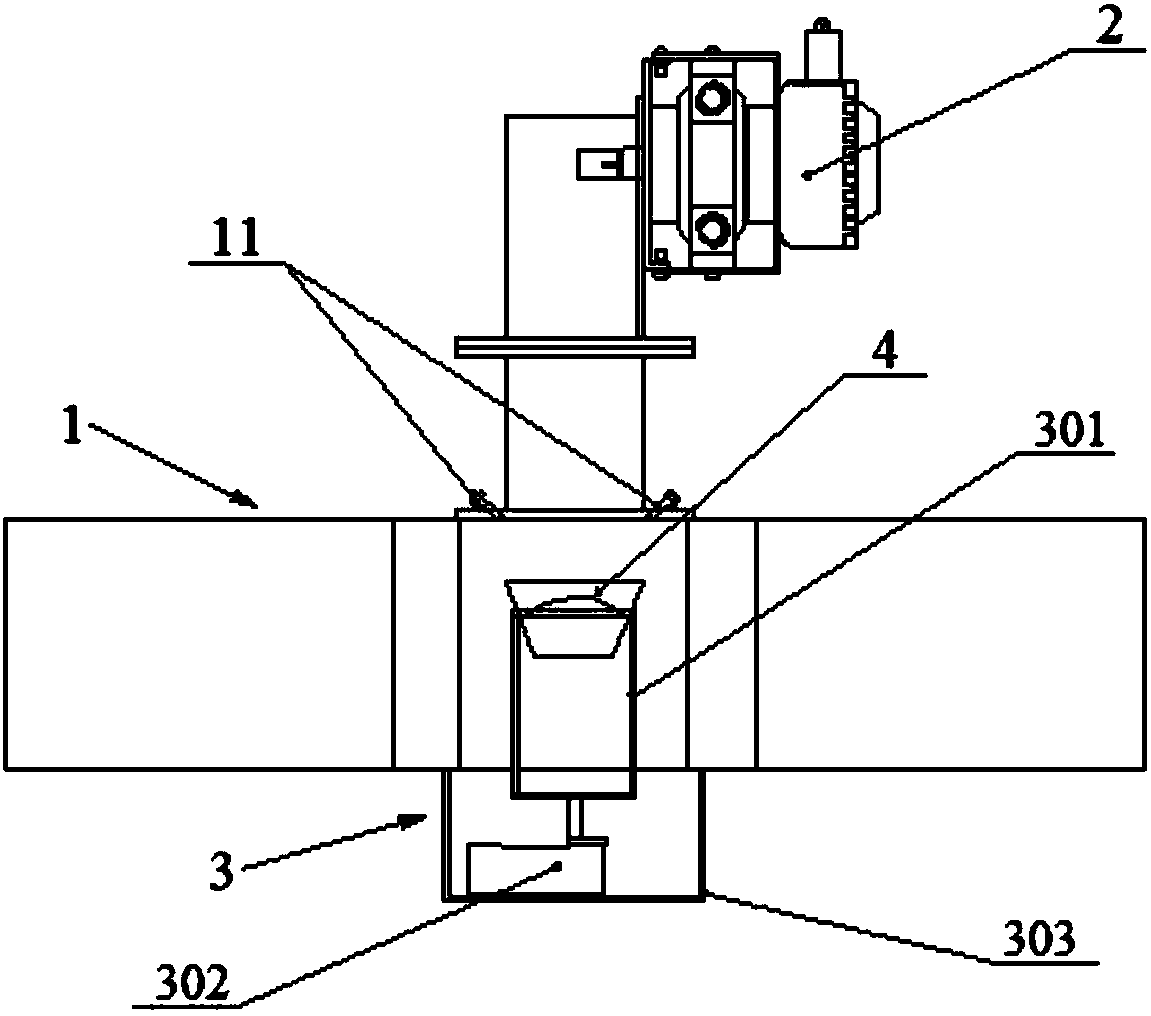

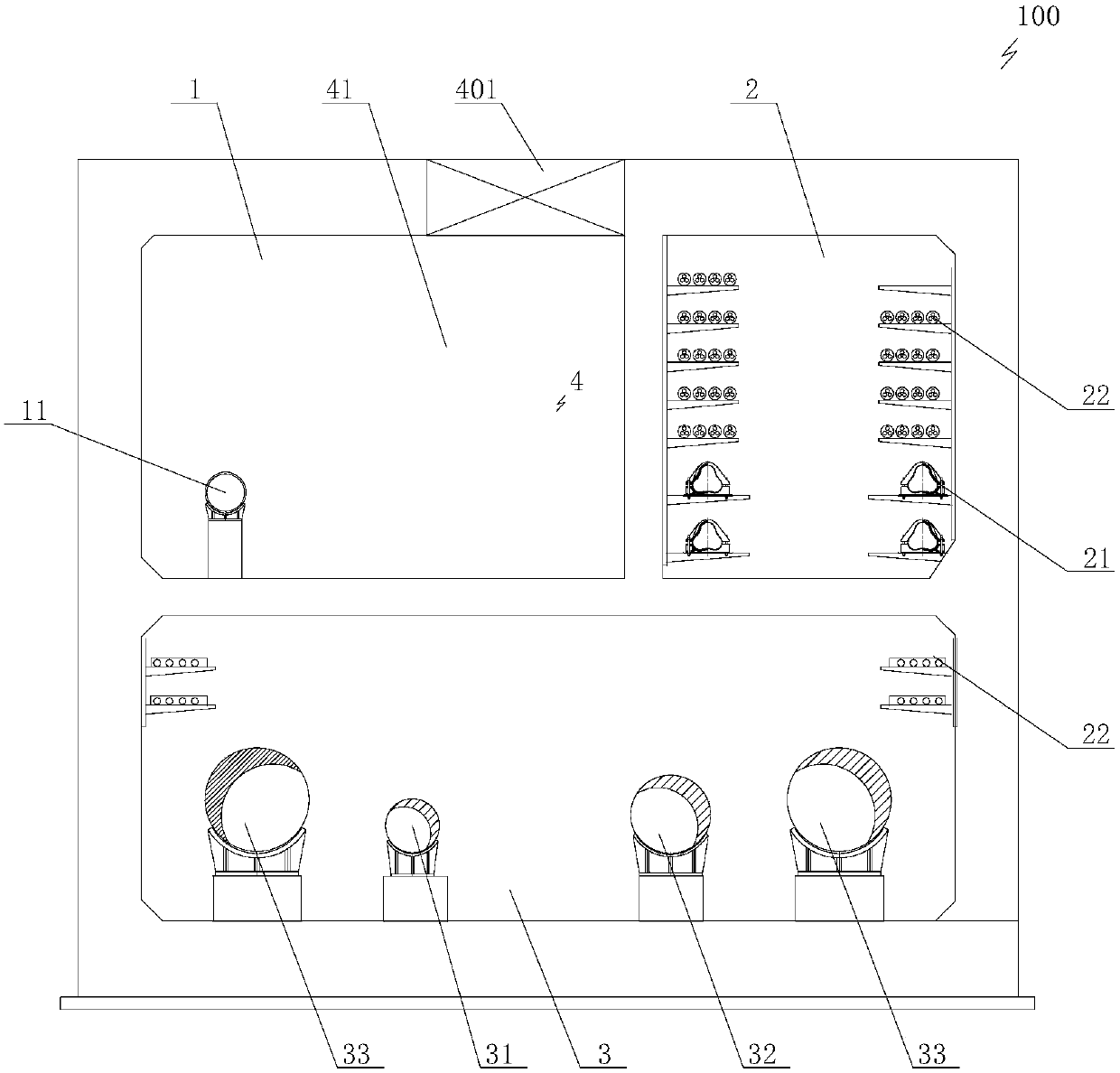

Material online moisture detection device and detection method thereof

PendingCN109470590AIonizing radiationImprove accuracyWeighing by removing componentBulk conveyorsMicrowaveEngineering

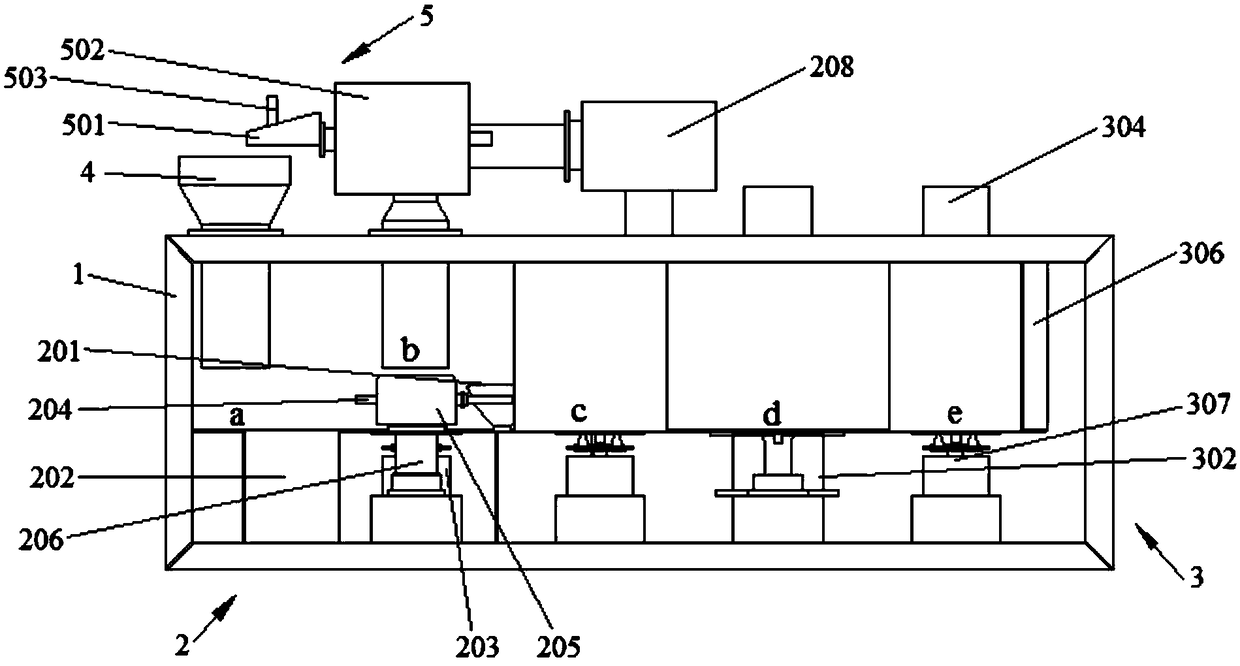

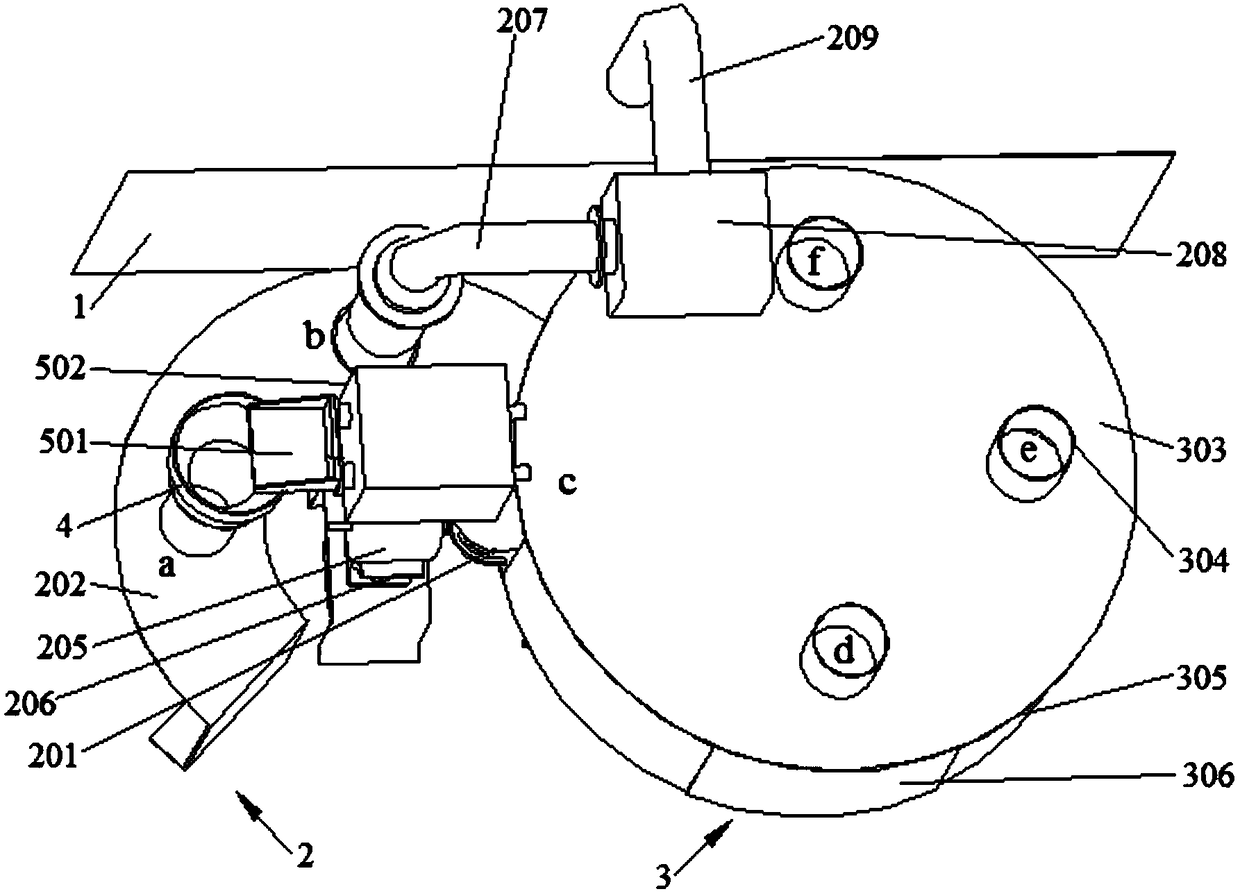

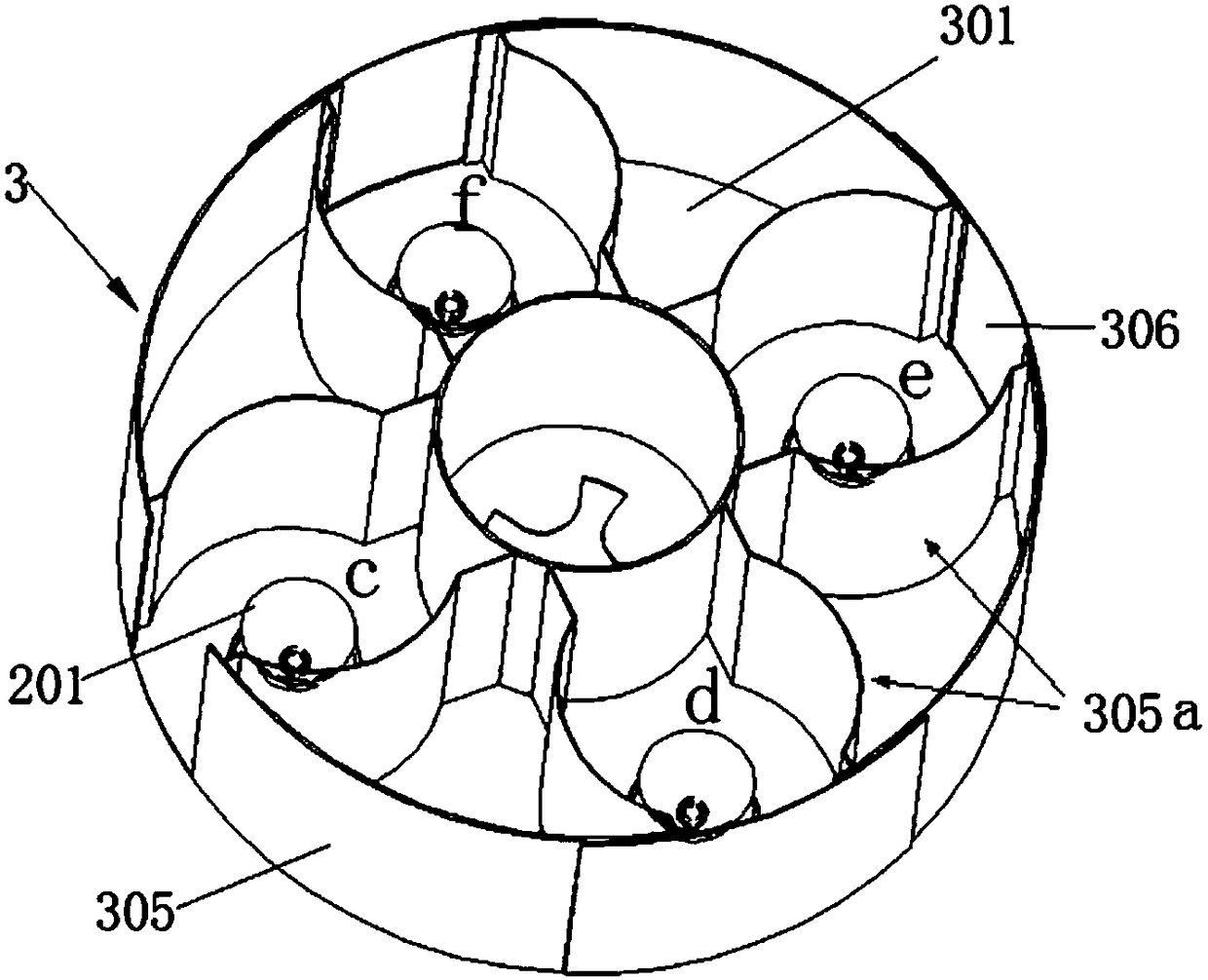

A material online moisture detection device comprises a (cylindrical) rotating bin (1), multiple microwave generation devices (2) arranged at the upper part of a rotating bin top cover (101) and multiple weighing devices (3) arranged at the lower part of a rotating bin chassis (102); four chambers are formed in the rotating bin chassis (102); the rotating bin (1) has four stations which are a material feeding station (a), a primary drying station (b), a secondary drying station (c) and a material discharging station (d) in sequence in a clockwise direction, wherein the four chambers are switched between the positions of the four stations in circulation. The material online moisture detection device provided by the invention has the advantages that the four chambers and the four stations work in sequence in circulation so as to guarantee that the moisture detection device can continuously detect the moisture content of materials on line in real time.

Owner:ZHONGYE-CHANGTIAN INT ENG CO LTD

Preparation method of high pressure slurry pump ceramic cylinder jacket for well drilling

InactiveCN1948756AWith uniformityDensePositive displacement pump componentsLiquid fuel engine componentsWell drillingSludge

The invention relates to a manufacture method of the ceramic cylinder jacket of high-pressure sludge pump for drilling, in which using zirconium oxide plasticized alumina (a-Al 203) as a matrix, leading in Zr 02 and Y 203-La 203 rare earth composite additive by using the modern plasticizing and reinforcing technology and adopting the isostatic compaction technology makes green bodies have uniformity and compactness. Because of using the atmospheric high-temp. drawer kiln once-through sintered, the temperature is distributed uniformly.

Owner:湖南泰鑫瓷业有限公司

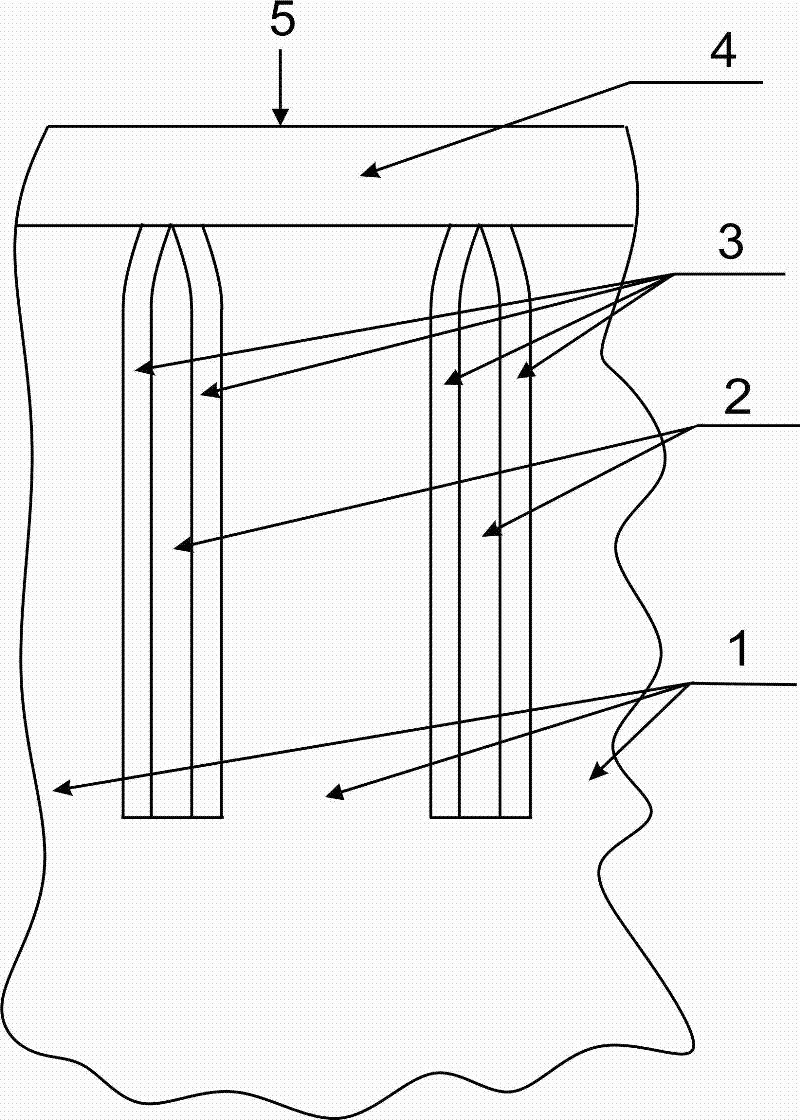

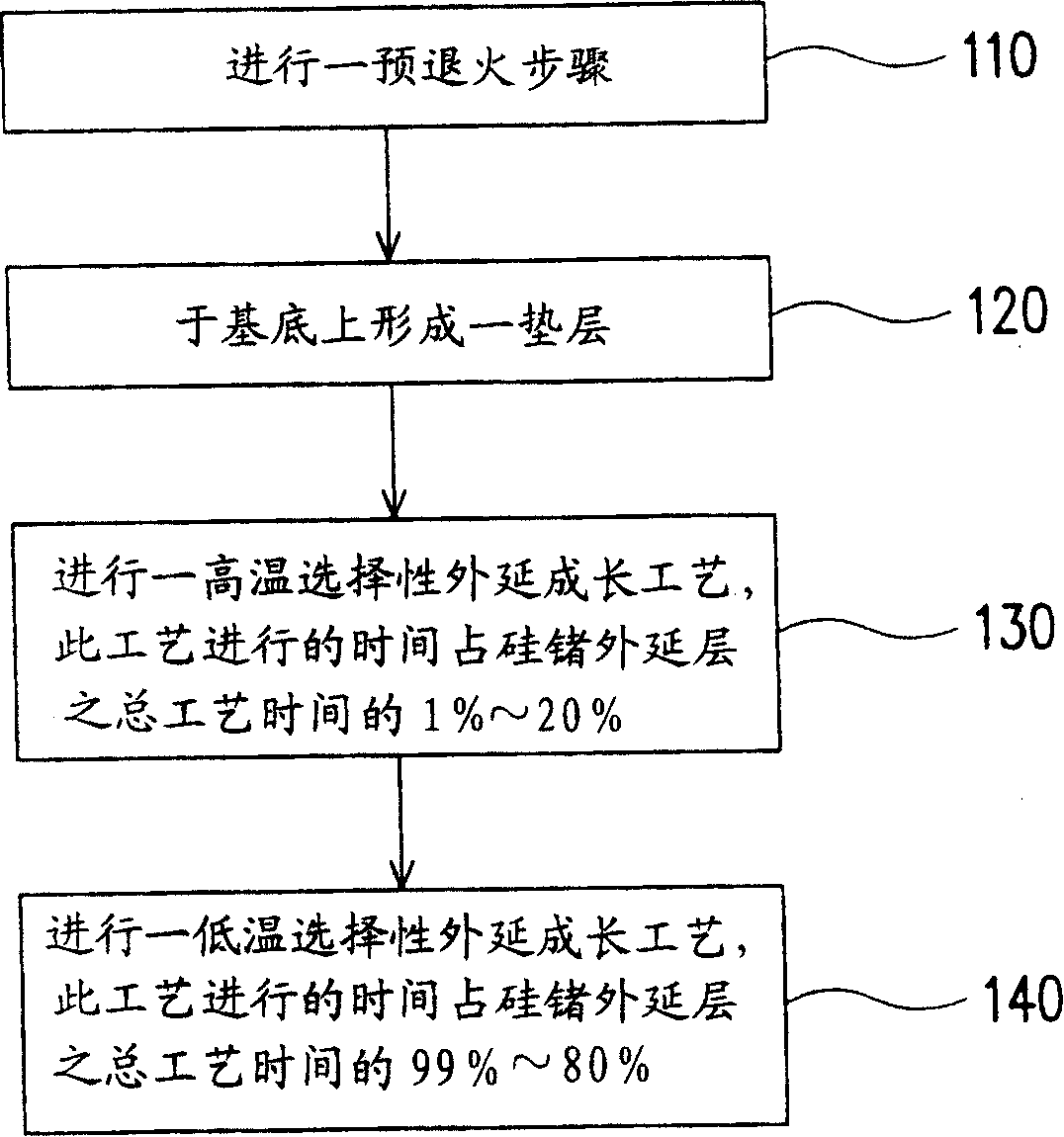

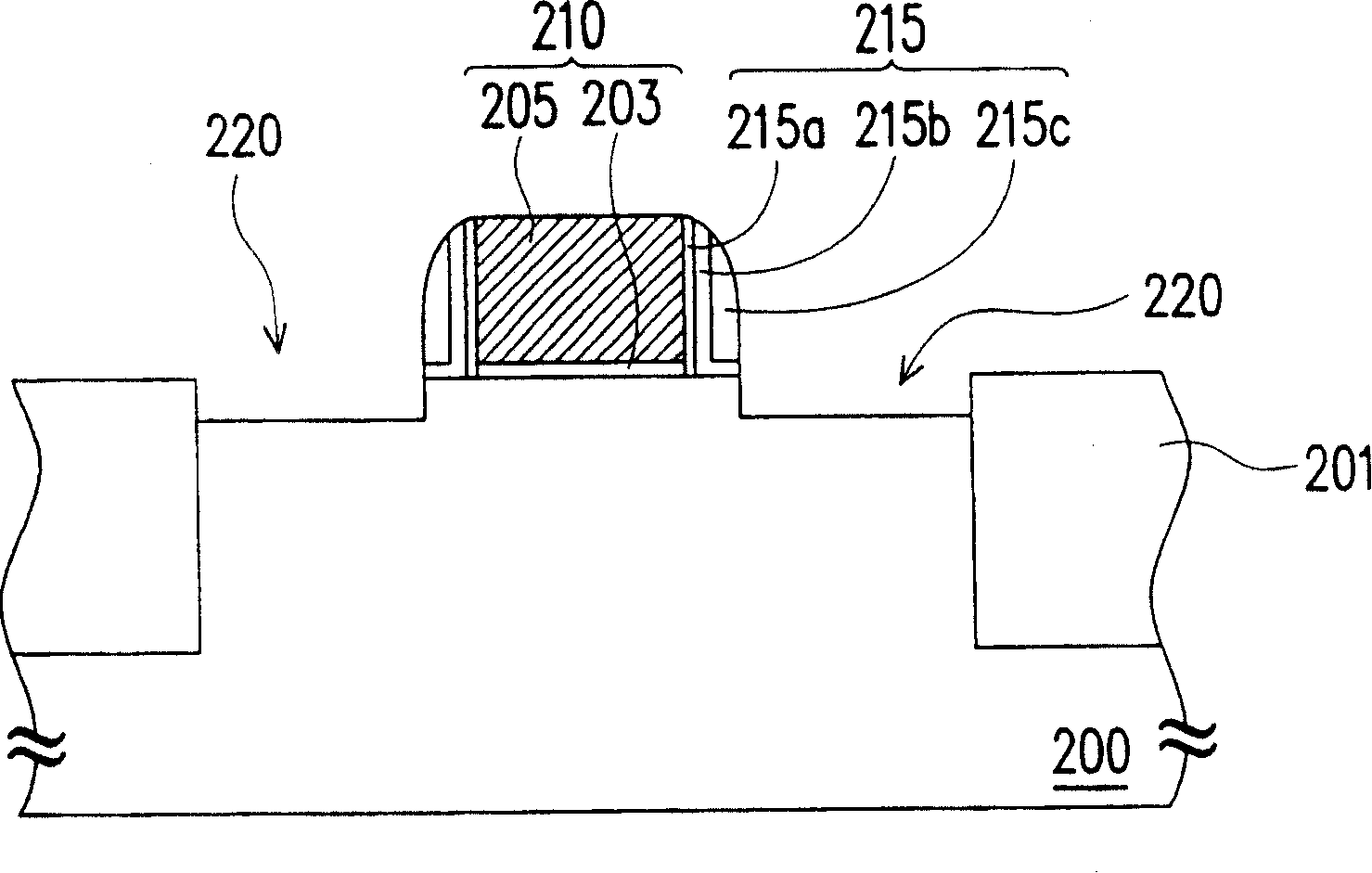

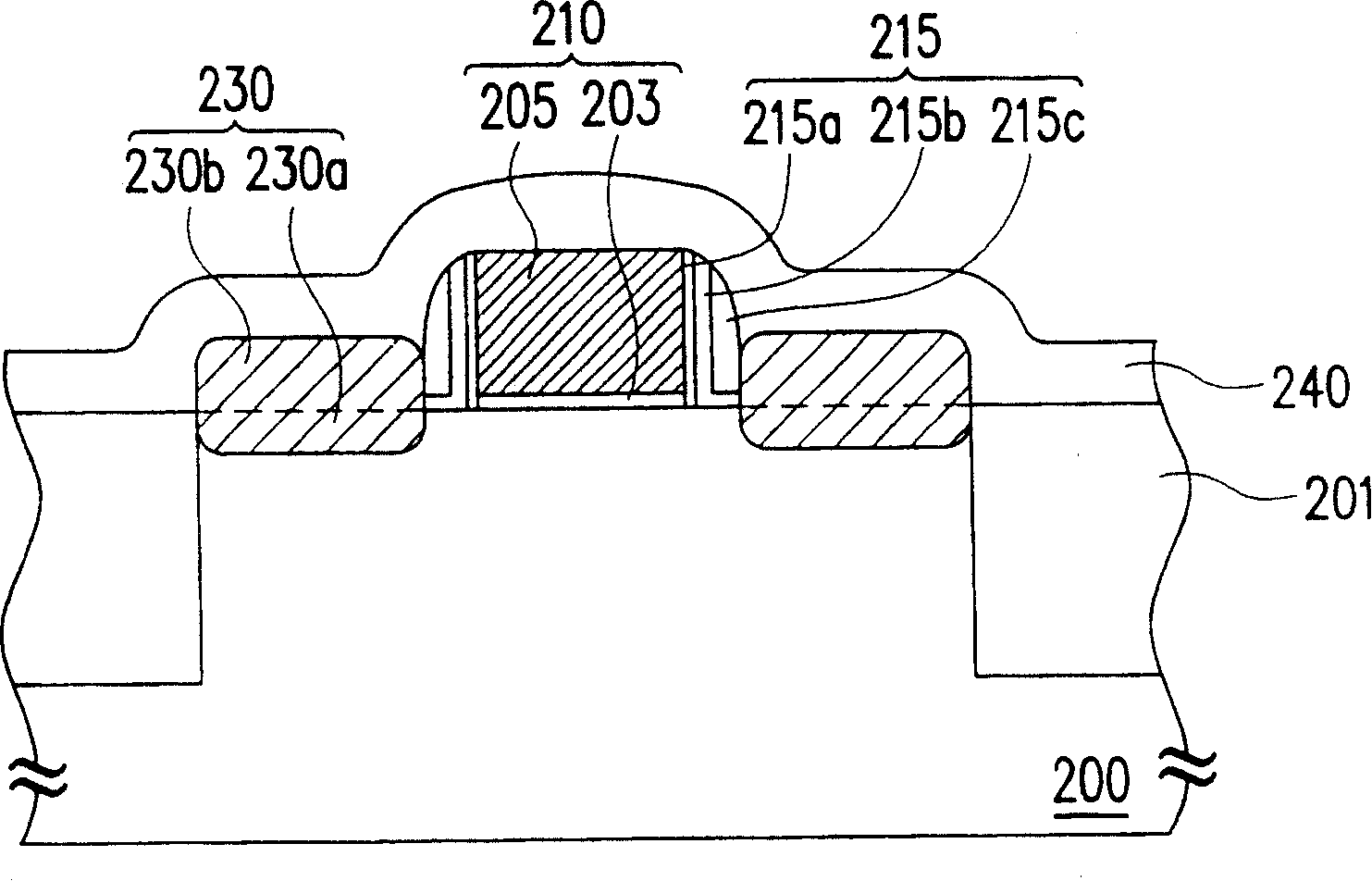

Making method for silicon germanium extension layer

InactiveCN101170060AWith uniformityIncrease productionSemiconductor/solid-state device manufacturingChemical vapor deposition coatingProduct gasProcess time

The invention provides a method for manufacturing a silicon germanium epitaxial layer. The method includes: carrying out the first selective epitaxial growth process under the first condition, and the processing time accounts for 1%-20% of the total process time of the silicon germanium epitaxial layer. Then, a second selective epitaxial growth process is carried out under the second condition, and its processing time accounts for 99%-80% of the total processing time of the SiGe epitaxial layer. Wherein, the first condition and the second condition include temperature condition or pressure condition, and the reaction gases used in the first selective epitaxial growth process and the second selective growth process include at least silicon-containing gas and germanium-containing gas.

Owner:UNITED MICROELECTRONICS CORP

Bread frozen dough containing maize germ meal and preparation method thereof

InactiveCN105580867AIncrease nutritionPromote respirationDough treatmentModified nutritive productsBalancing dietHigh activity

The invention discloses bread frozen dough containing maize germ meal. The bread frozen dough is prepared from, by weight, 16-20 parts of maize germ meal, 48-54 parts of high-gluten wheat meal, 0.5-1.5 parts of refined salt, 6.5-7.5 parts of powdered oil and fat, 8-10 parts of compound sugar, 1-1.2 parts of high-activity dried yeast, 4 parts of whole milk powder, 3-4 parts of a compound frozen dough improver, 0.2-0.6 part of baking powder and 4.4-4.8 parts of vital gluten. The invention further provides a preparation method of the bread frozen dough containing the maize germ meal. The survival rate and freezing resistance of the yeast can be effectively improved within the freezing shelf life of the prepared bread frozen dough, and the bread frozen dough has the nutrition function of balancing diet and meets the new demand of people for food nutrition at present.

Owner:SHANGHAI INST OF TECH

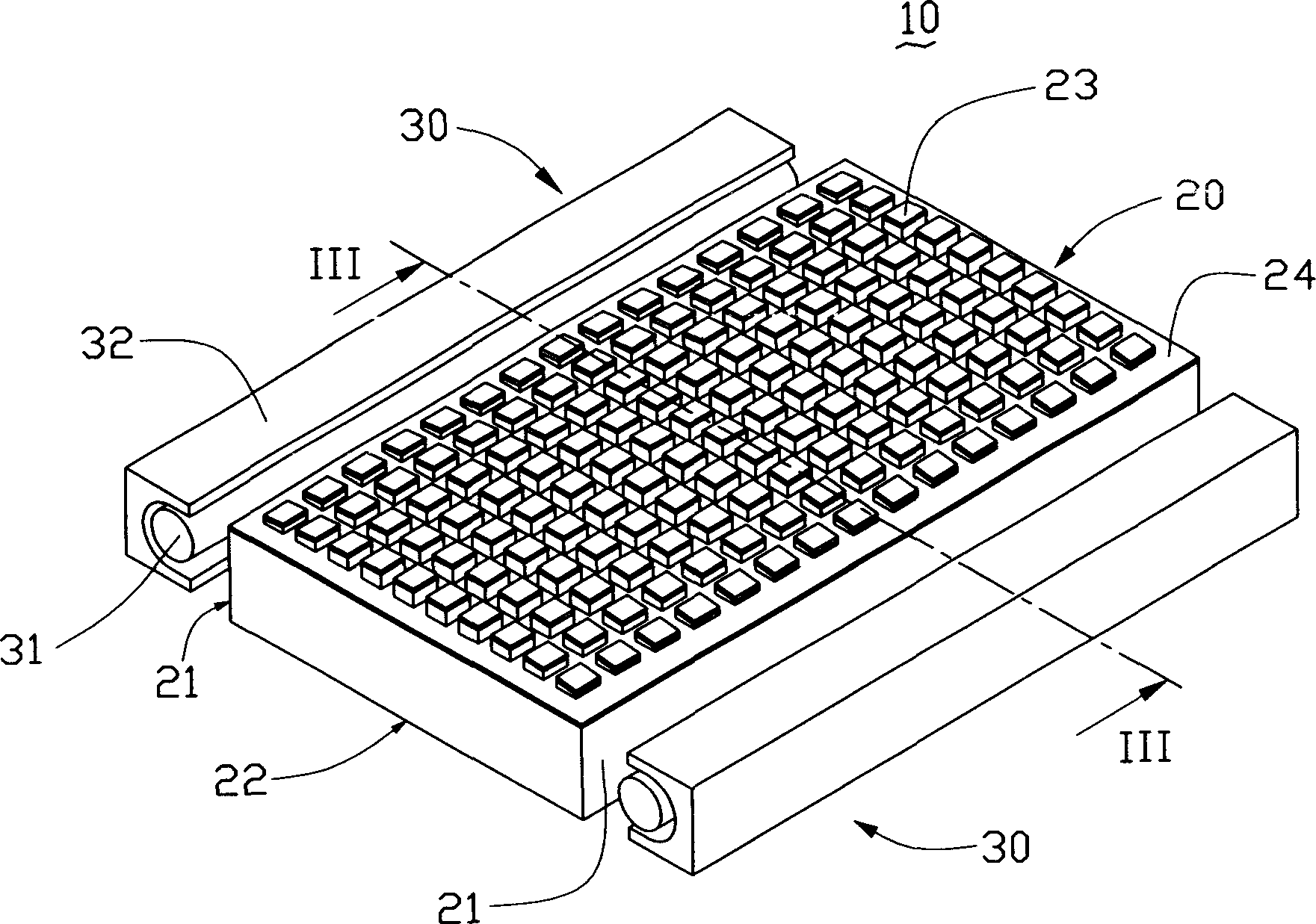

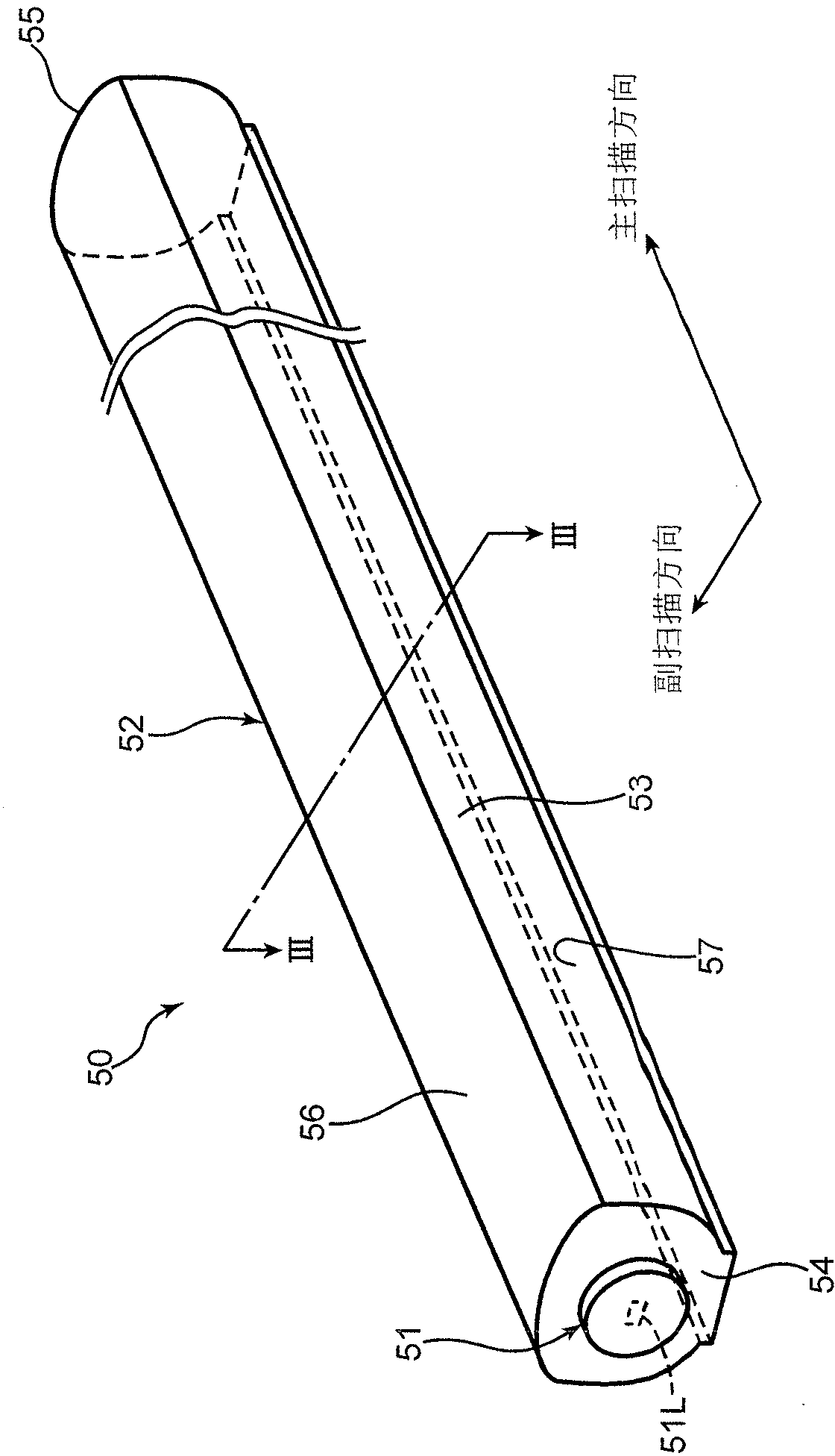

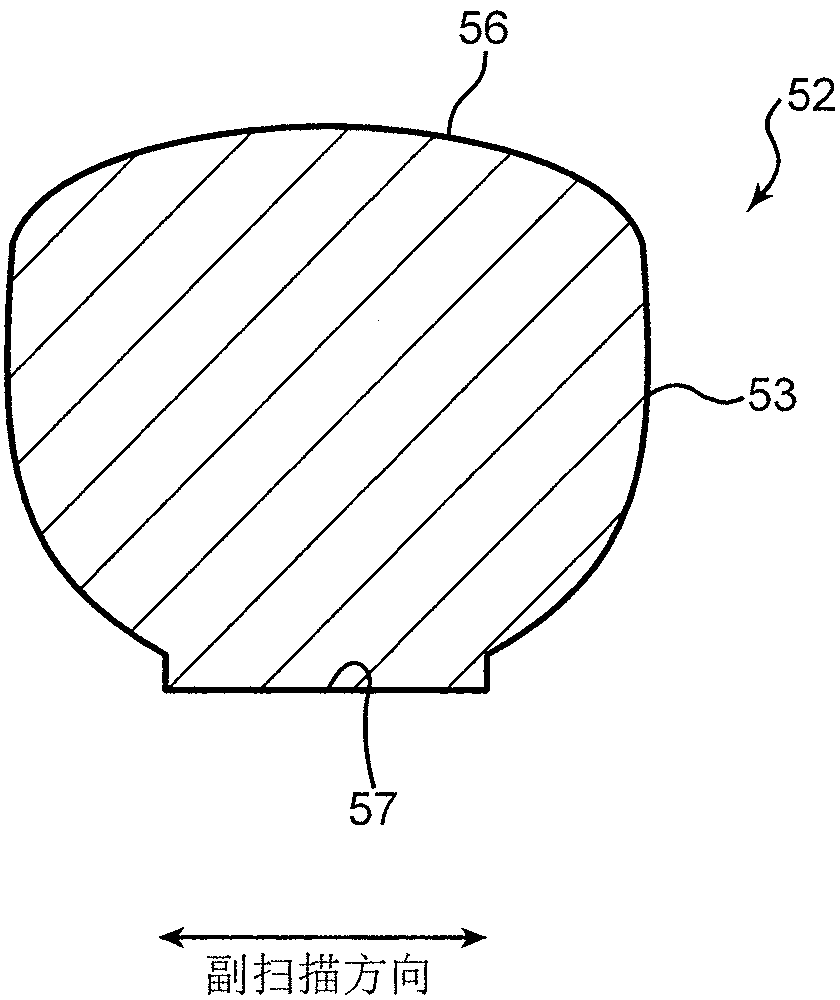

Light guide member, illuminating device, and image reading apparatus and image forming apparatus using same

ActiveCN103227884AWith uniformityFibre light guidesPictoral communicationLight guideComputer science

The present invention provides a light guide member, an illuminating device, and an image reading apparatus and an image forming apparatus using the same. The light guide member includes a main body part, and an entrance surface, a strip-shaped exit surface and a strip-shaped reflecting surface that are formed on the main body part. The illumination light is output from the exit surface. The reflecting surface extends in the first direction on a face placed opposite to the exit surface of the main body part and reflects the illumination light. The reflecting surface includes, on a flat face, a reflection pattern surface provided with a plurality of minute reflective concave parts having a function of reflecting the illumination light toward the exit surface. The reflective concave parts each include a deflection surface which deflects the illumination light in a direction in which a reflection angle widens in a cross sectional view in a second direction that is orthogonal to the first direction in a horizontal direction, and then reflects the illumination light. Accordingly, it is possible to output a uniform illumination light using a light guide member of a minimal size.

Owner:KYOCERA DOCUMENT SOLUTIONS INC

Double-layer comprehensive pipe gallery

ActiveCN107747320ASimple structureReduce construction costsArtificial islandsUnderwater structuresReclaimed waterProcess engineering

The invention relates to a double-layer comprehensive pipe gallery. A natural gas cabin, an electric cabin and a comprehensive cabin are arranged in the double-layer comprehensive pipe gallery, a natural gas pipeline can be contained in the natural gas cabin, an electric power pipeline and a communication pipeline can be contained in the electric cabin, a water supply pipeline, a reclaimed water pipeline, a heat power pipe and a communication pipeline are contained in the comprehensive cabin, and the natural gas cabin and the electric cabin are arranged above the comprehensive cabin to form adouble-layer distribution structure, and the natural gas cabin is independently arranged in a sealed manner; a function cabin is further arranged on the upper layer of the double-layer comprehensive pipe gallery, the function cabin can be communicated with the natural gas cabin, the electric cabin and the comprehensive cabin in the longitudinal direction of the double-layer comprehensive pipe gallery, and the top of the function cabin is provided with a function through opening which can be communicated with the exterior of the top of the double-layer comprehensive pipe gallery and can be sealed. The double-layer comprehensive pipe gallery is internally provided with the function cabin used for meeting the functions of hoisting, line leading and the like, the occupied space is effectivelyreduced, the structure is simple, the construction cost is low, and application and popularization are facilitated.

Owner:MCC CAPITAL ENGINEERING & RESEARCH

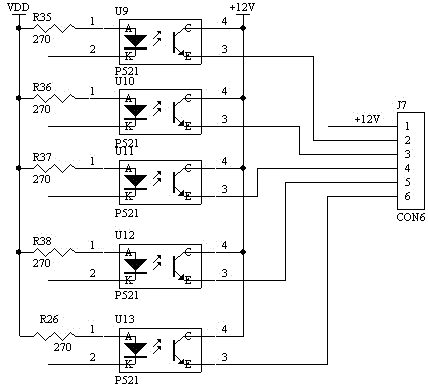

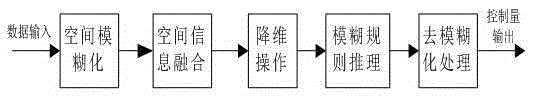

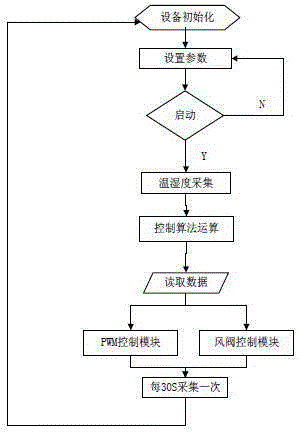

Baking oven temperature and humidity control system and method based on two-dimensional space 3-D fuzzy control

InactiveCN105334891AWith uniformityControl advantageTemperatue controlFuzzy control algorithmGood control

The invention relates to a baking oven temperature and humidity control system and method based on two-dimensional space 3-D fuzzy control. A baking oven system is composed of three parts including a two-dimensional space 3-D fuzzy controller on a PC, a control signal driving circuit, and a baking oven body. The innovation of the invention is that the temperature and humidity controller of the baking oven is designed by using a two-dimensional space 3-D fuzzy control method. Spatial positional information is integrated into a 3-D fuzzy control algorithm so that the 3-D fuzzy control algorithm has advantages in controlling a spatial distribution system. The two-dimensional space 3-D fuzzy control method expands the 3-D fuzzy control from a spot or a line previously to a surface, solves a problem that a conventional lumped control algorithm cannot well control the spatial distribution system, and achieves uniform baking oven temperature and humidity spatial distribution.

Owner:SHANGHAI UNIV

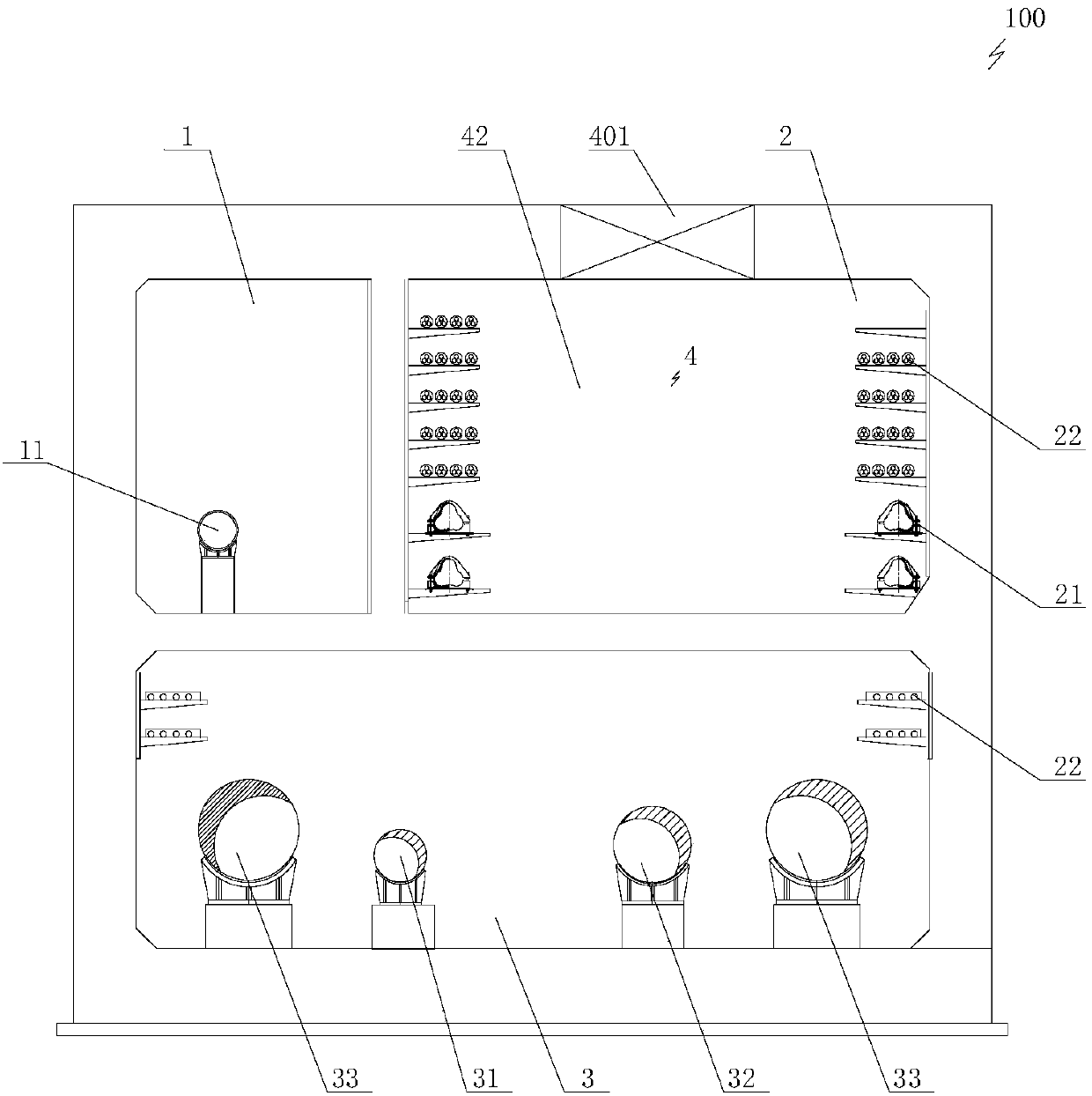

Online water detection system and detection method thereof

PendingCN109470592AIonizing radiationImprove accuracyWeighing by removing componentEngineeringWater content

The invention relates to an online water detection system by an absolute method. The system comprises a box body, an analyzing and discharging device located on one side in the box body and a transferring and drying device located on the other side in the box body, wherein the analyzing and discharging device is provided with a gripper which rotates along the center axis in the horizontal direction and is also provided with at least two stations: a receiving station and a weighing and discharging station; the transferring and drying device is provided with a rotary disc, four chambers arranged on the rotary disc, top covers located on the upper parts of the four chambers and micro generators arranged on the top covers as well as four stations: a first station, a second station, a third station and a fourth station. Openings are also formed in the upper parts, corresponding to the edge of the rotary disc, of the four chambers, and fixed sealing baffle plates are separately arranged onthe upper parts, corresponding to the edge of the rotary disc, of the second, third and fourth stations. The system can detect the true water content of a mixed material within a very short time, so that real-time online detection of water of the mixed material is achieved.

Owner:ZHONGYE-CHANGTIAN INT ENG CO LTD

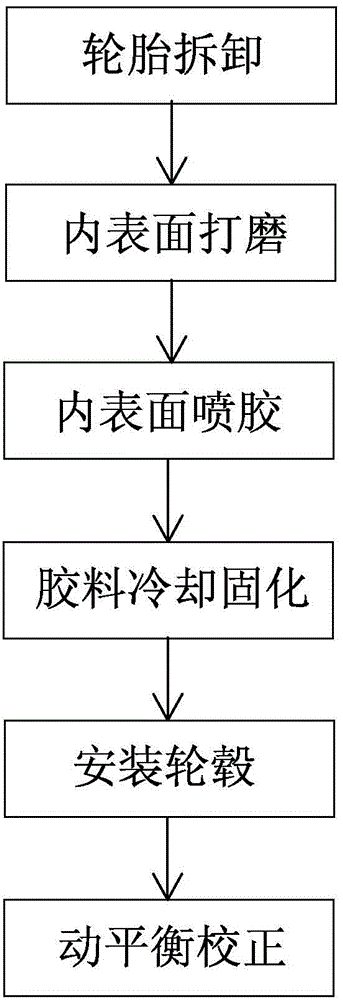

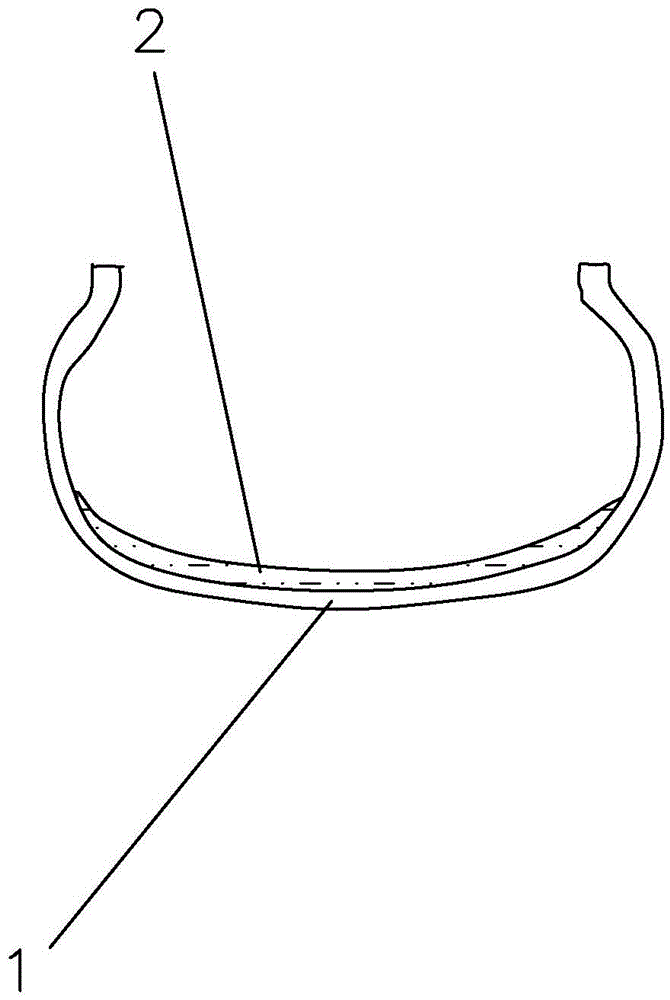

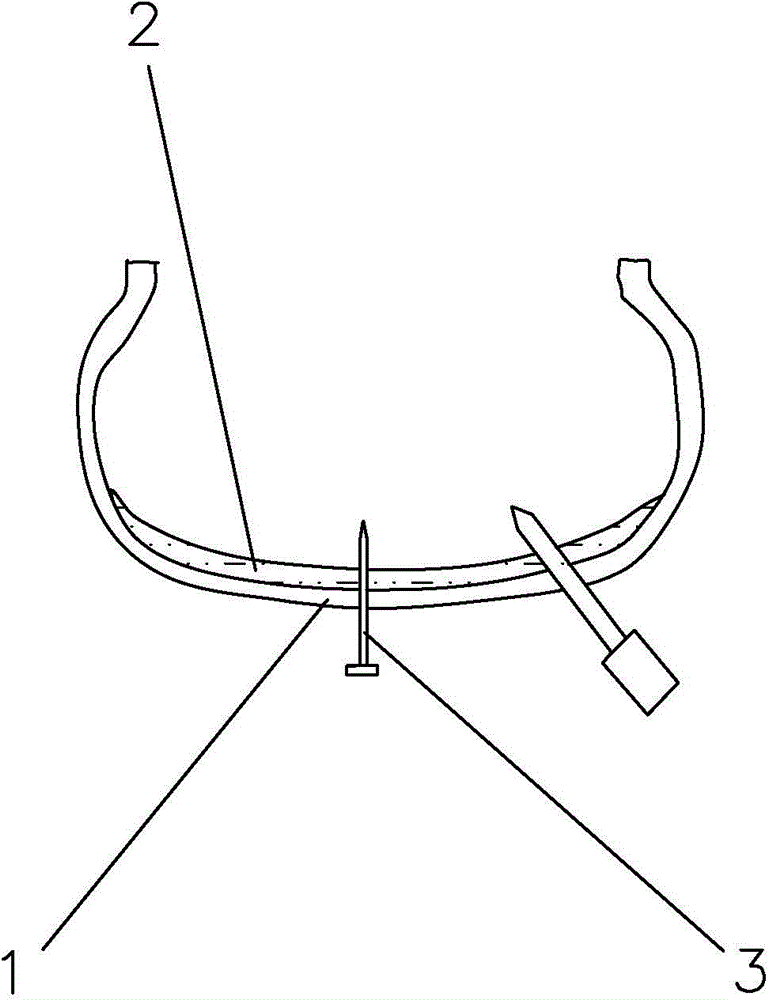

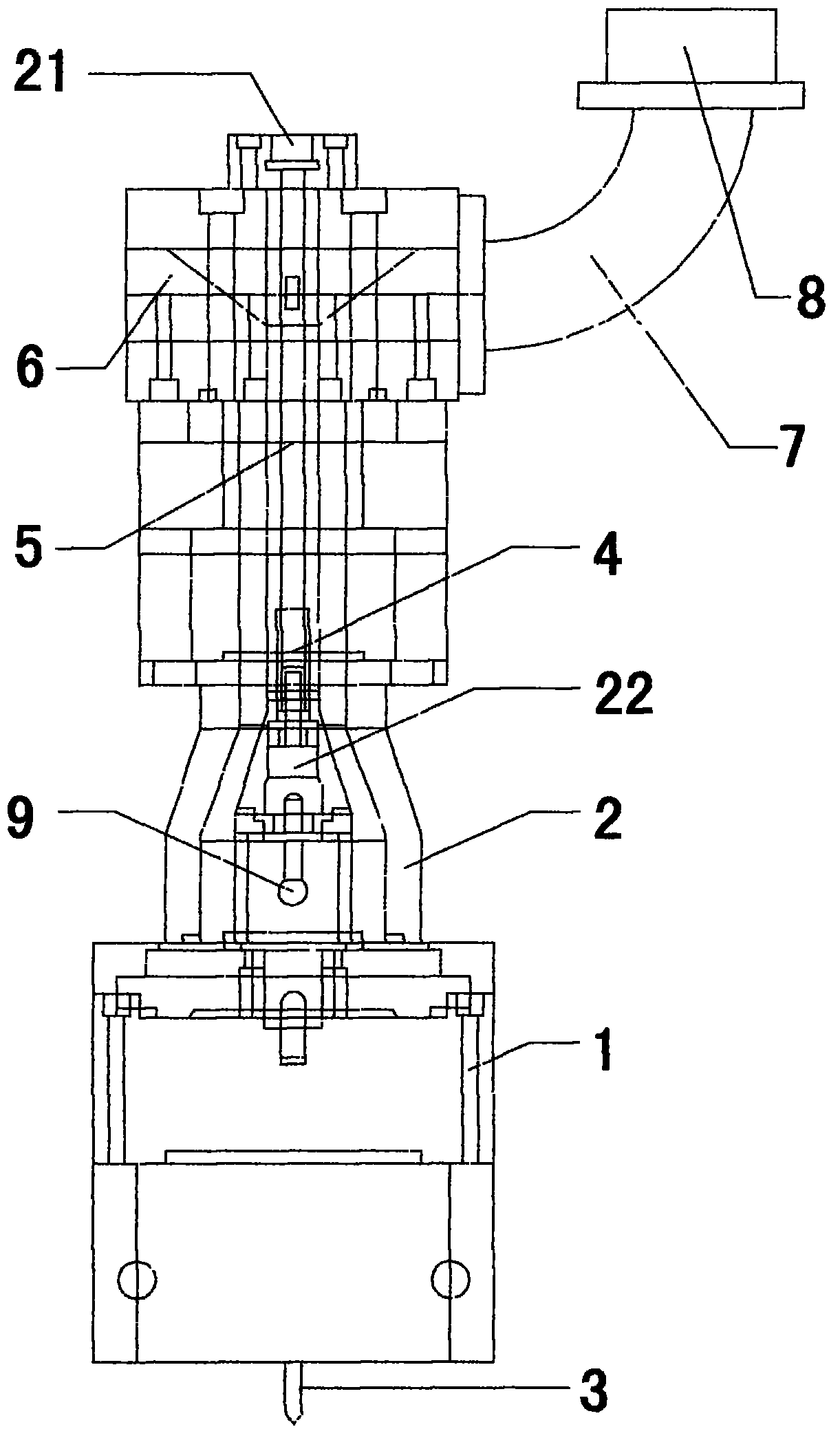

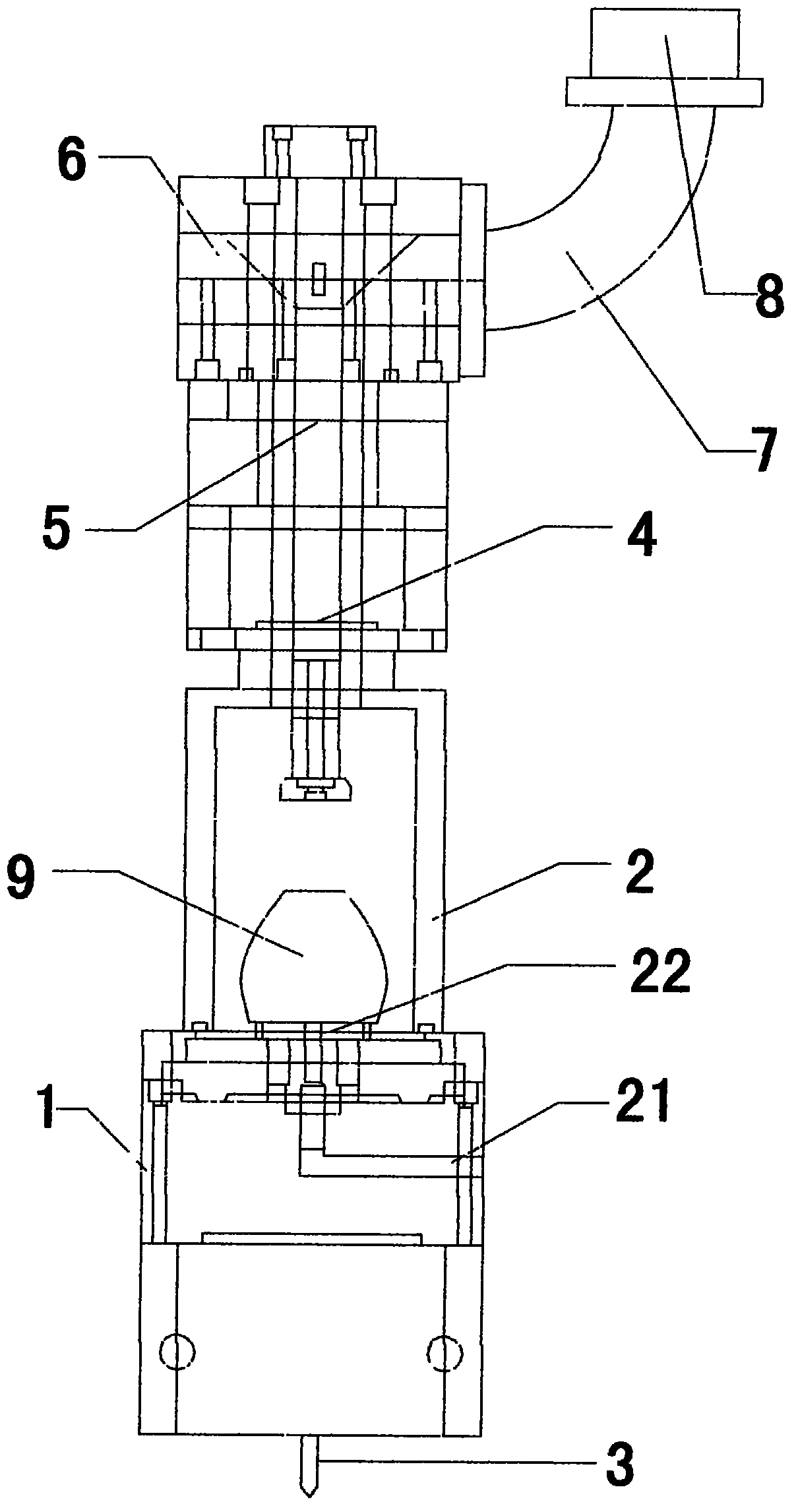

Method for upgrading common tyre to explosion-proof leakproof tyre and explosion-proof leakproof tyre

The invention discloses a method for upgrading a common tyre to an explosion-proof leakproof tyre. The method comprises the following steps: dismantling an old tyre and removing the tyre from a hub; polishing the internal surface of the tyre with a steel brush, clearing off impurities such as a release agent, wax and the like from the internal surface; melting a polymer synthesis memory rubber material block, and spraying the molten polymer synthesis memory rubber material onto the internal surface of the tyre; cooling the tyre with the internal surface sprayed with the rubber material to be solidified; remounting the dismantled hub onto the tyre sprayed with the memory rubber material; and carrying out dynamic balancing and calibration on the tyre equipped with the hub. The upgraded tyre comprises a tyre main-body, and the bottom of the internal surface of the tyre is coated with a layer of the polymer synthesis memory rubber material. As the polymer synthesis memory rubber material has high strength, high stretchability and high viscosity, it can be guaranteed that the tyre is leakproof and explosion-proof when pierced by a foreign matter and has a noise-reduction function.

Owner:WUXI I REACH TECH

Method and equipment for forming optical films on workpiece

ActiveCN104233235AProcess equipment is compactImprove deposition efficiencyChemical vapor deposition coatingPulse microwaveEngineering

The invention relates to a method and equipment for forming optical films with various functions on a workpiece. A pulse plasma chemical vapor deposition method is adopted as the method. The method comprises the following steps that a, the workpiece is fixedly arranged in a sealed microwave cover, and the sealed microwave cover is vacuumized; b, oxygen is led into the sealed microwave cover, pulse microwaves are guided into the sealed microwave cover, and reaction is carried out for a certain time; c, gas containing film-forming component elements is led into the sealed microwave cover, the oxygen is continued to be led into the sealed microwave cover, the pulse microwaves are continued to be guided into the sealed microwave cover, reaction is carried out for a certain time, then, the gas is stopped from being led into the sealed microwave cover, and the pulse microwaves are stopped from being guided into the sealed microwave cover. The pulse plasma chemical vapor deposition method has the high deposition efficiency, the whole process only needs few minutes, and therefore the production efficiency is quite high; plasmas of the oxygen perform plasma cleaning and surface activation treatment on the surface of the workpiece before film forming, and therefore film adhesion is greatly improved; therefore, the product quality is improved.

Owner:HUIZHOU OBOLAND OPTOELECTRONICS TECH

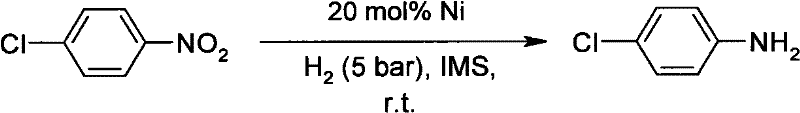

Microencapsulated catalyst

InactiveCN102316972AEasy to handleOvercome the problem of leachingCatalyst protectionOrganic compound preparationNasal cavityConvulsion

The present invention relates to a catalyst system. In particular the invention relates to a catalyst in the form of metal or an alloy that is encapsulated within a polymer shell or matrix. More specifically the invention is directed towards reactive catalytic metals that may be pyrophoric or otherwise reactive in air and / or susceptible to oxidation. In particular, the invention is concerned with catalysts based on nickel. Raney or sponge nickel is highly hazardous: a self-igniting solid; produces hazardous fumes when burning; causes irritation of the respiratory tract, nasal cavities; causes pulmonary fibrosis if inhaled; ingestion may lead to convulsions and intestinal disorders; causes eye and skin irritation; and chronic exposure may lead to pneumonitis and sensitization (''nickel itch''). The invention provides metal catalysts that avoid such problems and have a good shelf life and working life.

Owner:REAXA

Wafer blackening method and blackened wafer

PendingCN110129891ALow resistivityWeakened pyroelectric propertiesPolycrystalline material growthAfter-treatment detailsTransmittanceEngineering

The invention provides a wafer blackening method, wherein the wafer comprises a lithium tantalate wafer or a lithium niobate wafer. According to the present invention, with the method, the electric conductivity of the wafer can be increased, and the blackening degree is high and uniform; and by using the method, a blackening reaction is performed in a high temperature environment without the direct contact between a reducing material and a wafer, such that the technical problems of poor blackening effect and low blackening uniformity of the lithium tantalate wafer or lithium niobate wafer canbe solved, the low transmittance can be achieved, and the transmittance is uniformly distributed.

Owner:FUJIAN JING AN OPTOELECTRONICS CO LTD

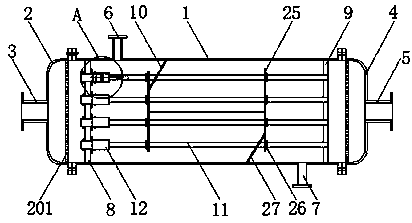

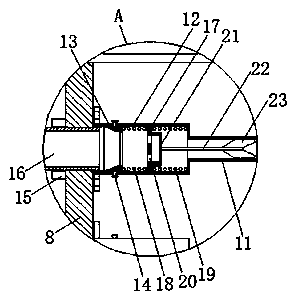

Diversion plate and anti-vortex device integration based condenser

PendingCN109780898AAvoid scourReduce vibration amplitudeHeat exchanger casingsStationary tubular conduit assembliesVibration amplitudeAxial distribution

The invention discloses a diversion plate and anti-vortex device integration based condenser which comprises a shell; the shell is a cylindrical shell with openings formed in the left end and the right end respectively; and a left end opening of the shell is provided with a left end cover. The diversion plate and anti-vortex device integration based condenser is simple in structure and convenientto mount and use; by performing progressive shunting through a shunting plate, an anti-flushing plate and a retaining cover, the axial distribution rate of a refrigerant is increased, the refrigeranthas uniformity in distribution of a section, and the refrigerant is prevented from washing a pipe wall when entering a condensation pipe; the anti-flushing plate has the self-adaptive moving capability, so that vibration of the anti-impact plate caused by pressure fluctuation is absorbed, transfer of the vibration is inhibited, the vibration amplitude of the condensation pipe is lowered, the structural strength of the anti-flushing plate is ensured at the same time, and the anti-flushing plate is difficult to damage; a diversion plate which moves along with the anti-flushing plate is provided,so that the radial blocking can be provided, and generation of vortices can be inhibited; and by fully utilizing a refrigerating fluid, the heat exchange efficiency and the flow discharge capacity are improved, and the energy consumption is low.

Owner:广东捷邦节能设备制造有限公司

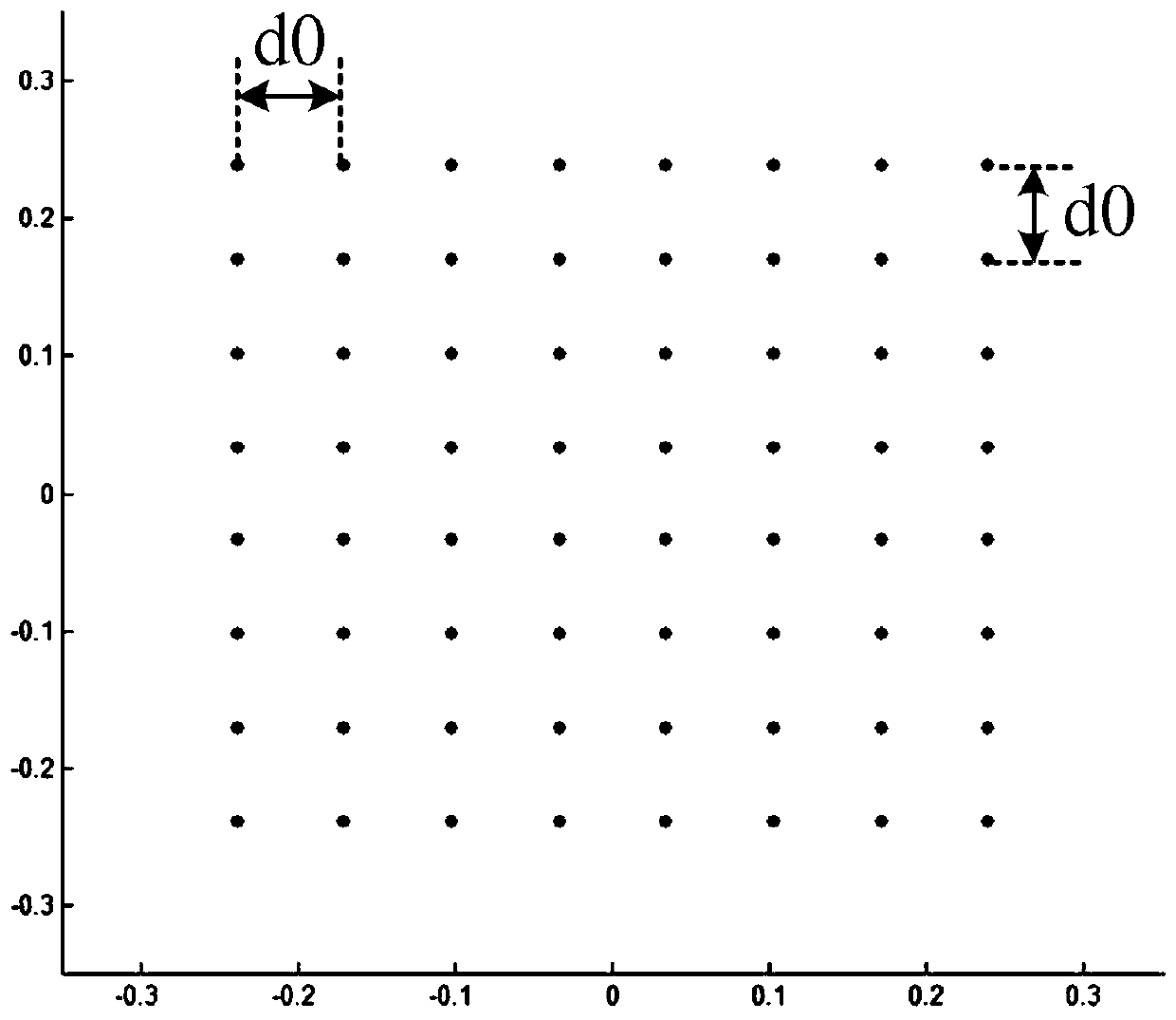

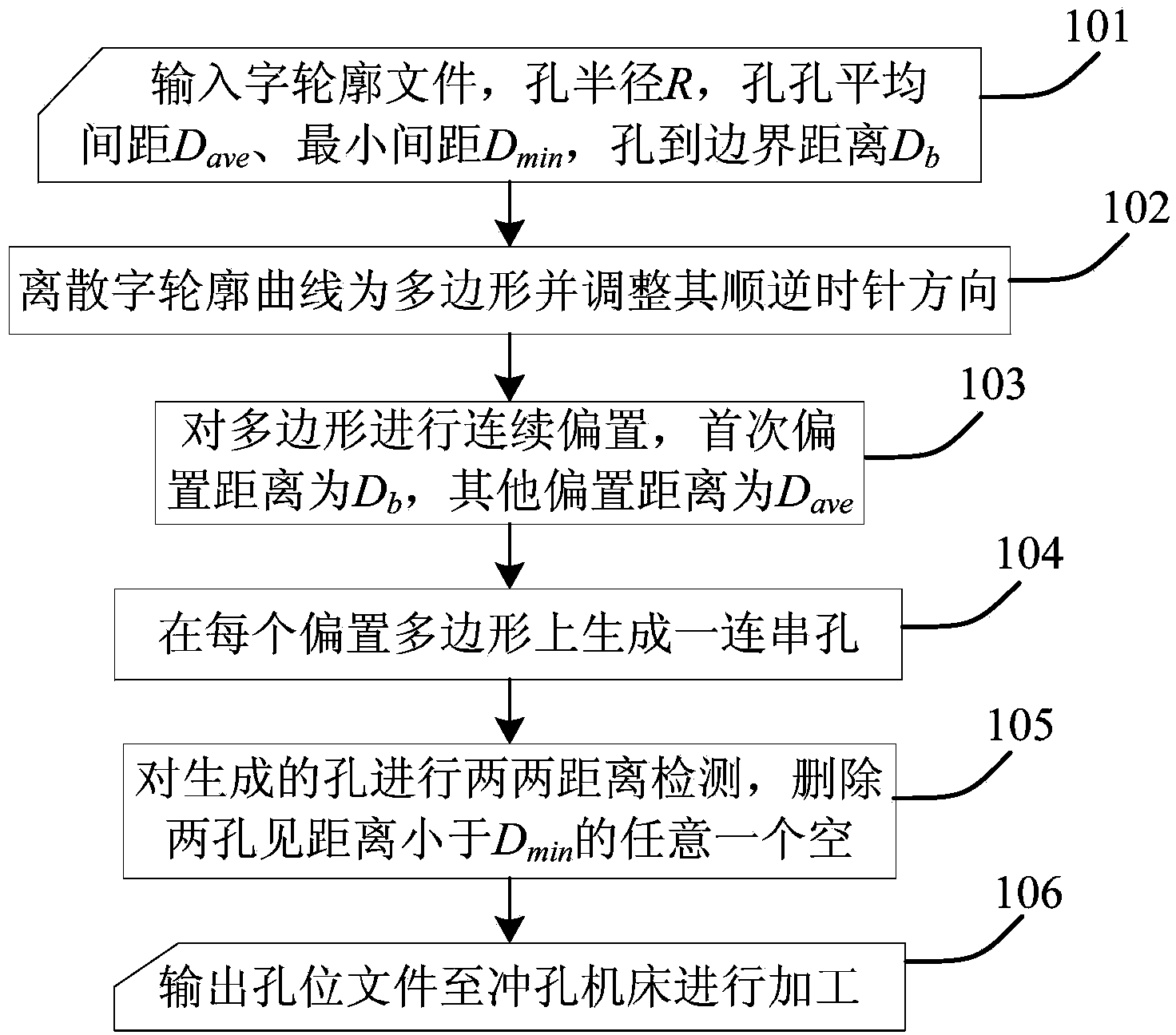

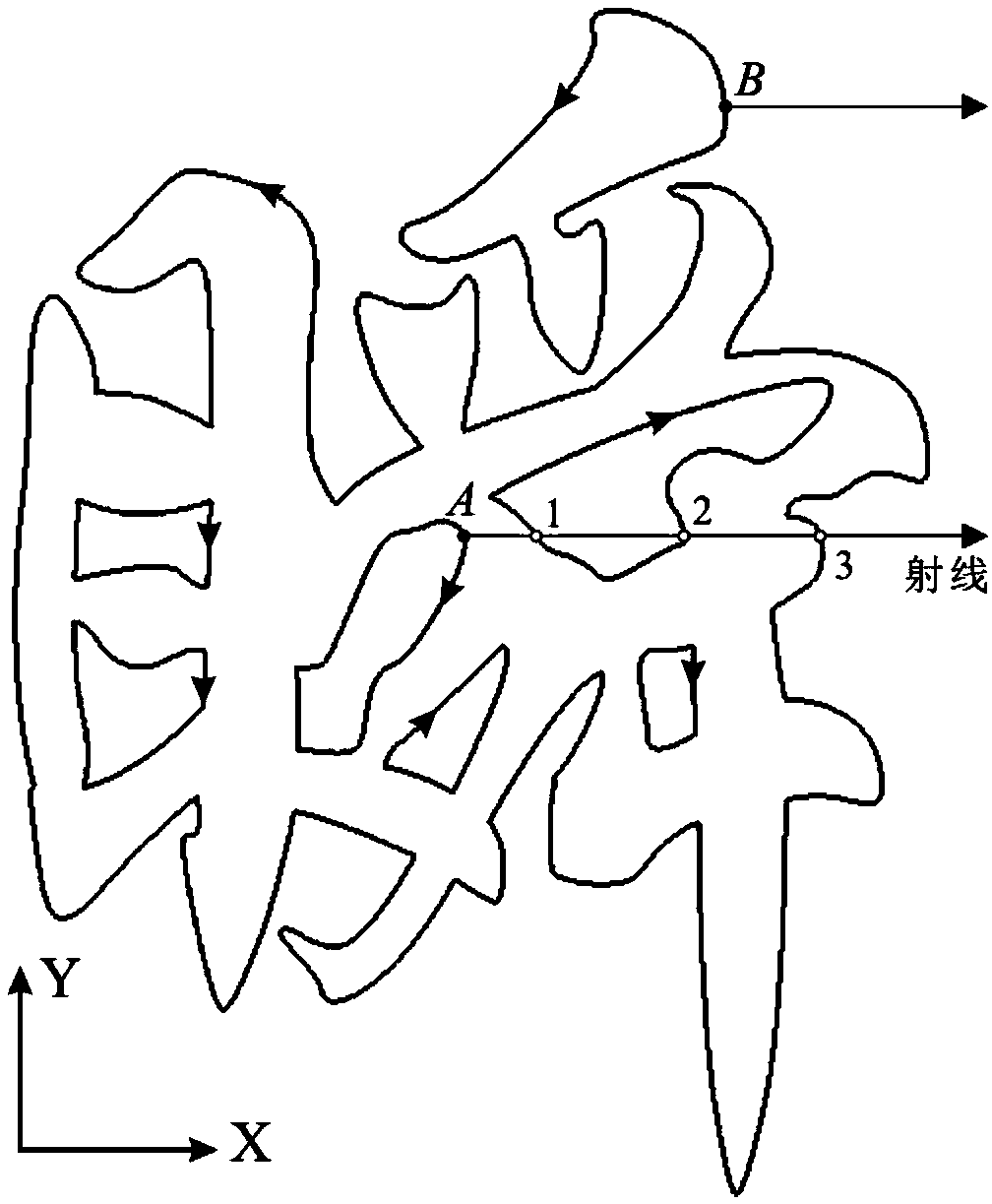

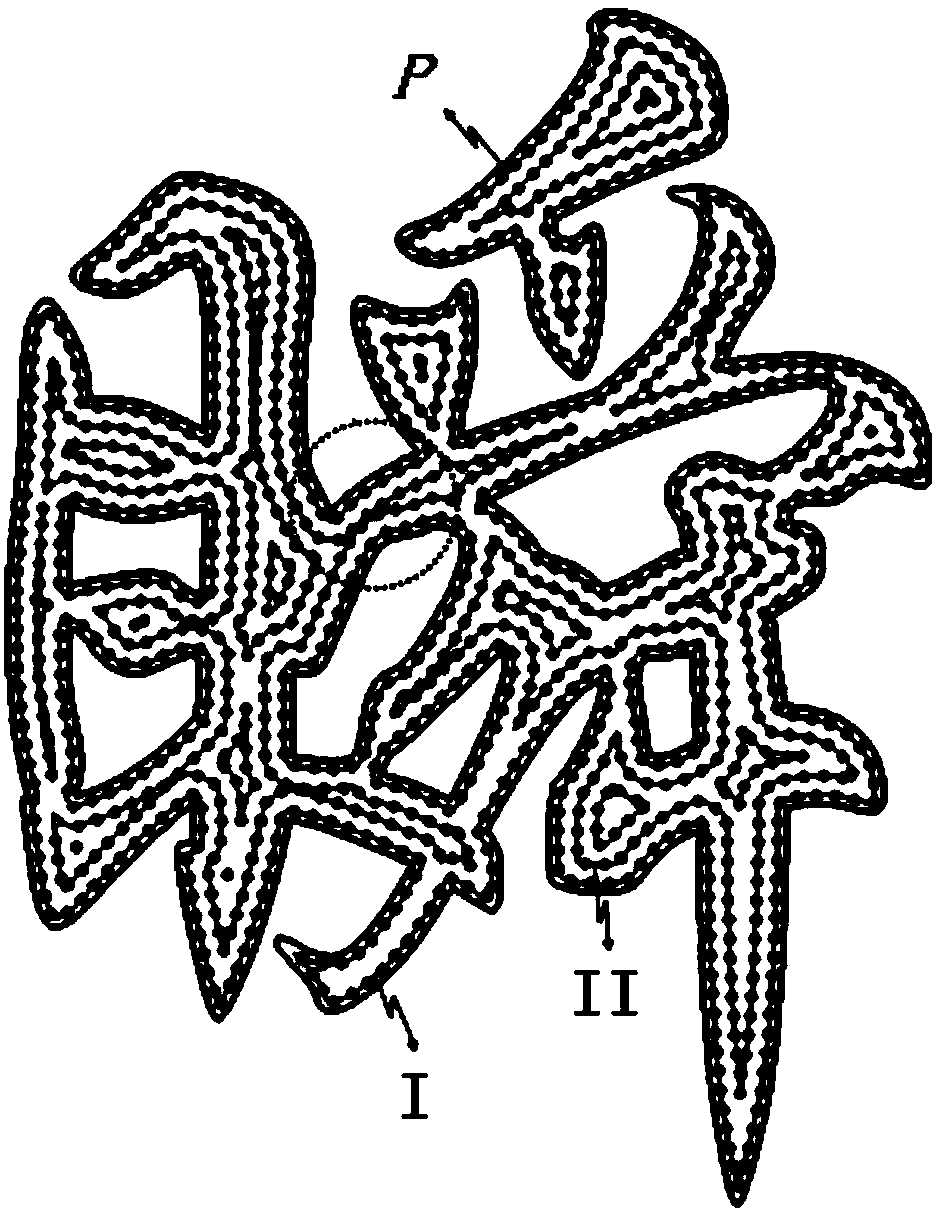

Method for uniformly distributing holes in light-emitting word based on contour offset

InactiveCN103956122AWith uniformityIncrease reflectionIlluminated signsOffset distanceComputer science

The invention discloses a method for uniformly distributing holes in a light-emitting word based on contour offset. The method comprises the following steps: inputting a contour file to be processed, wherein the hole radius is R, an average interval between every two holes is Dave, a minimum interval is Dmin, and a distance between each hole and a contour boundary is Db; dispersing a contour curve group into a polygon group and calibrating the direction of each polygon; continuously offsetting the polygon group, wherein a first-time offset distance is Db, and a subsequent offset distance is Dave; generating a series of holes on each offset polygon at intervals Dave, wherein the circle centers of the holes are arranged on the offset polygon, and the radius is R; detecting a distance between every two obtained adjacent holes and deleting one of the holes when an interval between any two practical holes is less than a given Dmin value. The method has the benefits that the holes are distributed at equal distances in an offsetting way, the positions of the obtained holes are uniformly distributed and clear in arrangement, and the situation that the holes are overlapped or the interval is undersize can be avoided.

Owner:ZHEJIANG UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com