Preparation method of calcium-iron type Ca2Fe2O5 catalyst

A ca2fe2o5, catalyst technology, applied in chemical instruments and methods, iron compounds, inorganic chemistry, etc., can solve the problems of long preparation and synthesis time, cumbersome process steps, long synthesis period, etc., and achieve good cycle stability and simple process flow. , stable performance and excellent effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

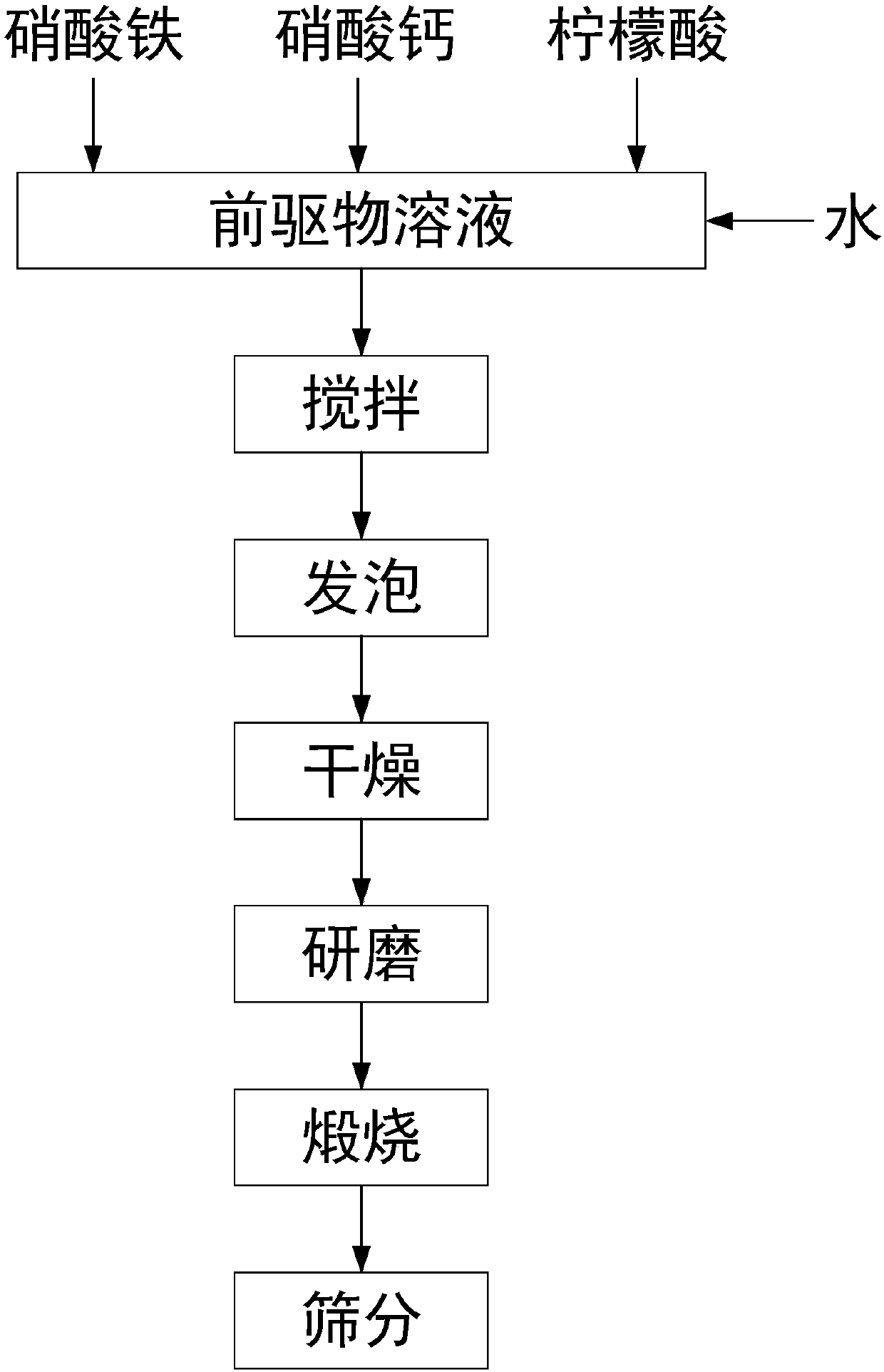

[0039] Include the following steps:

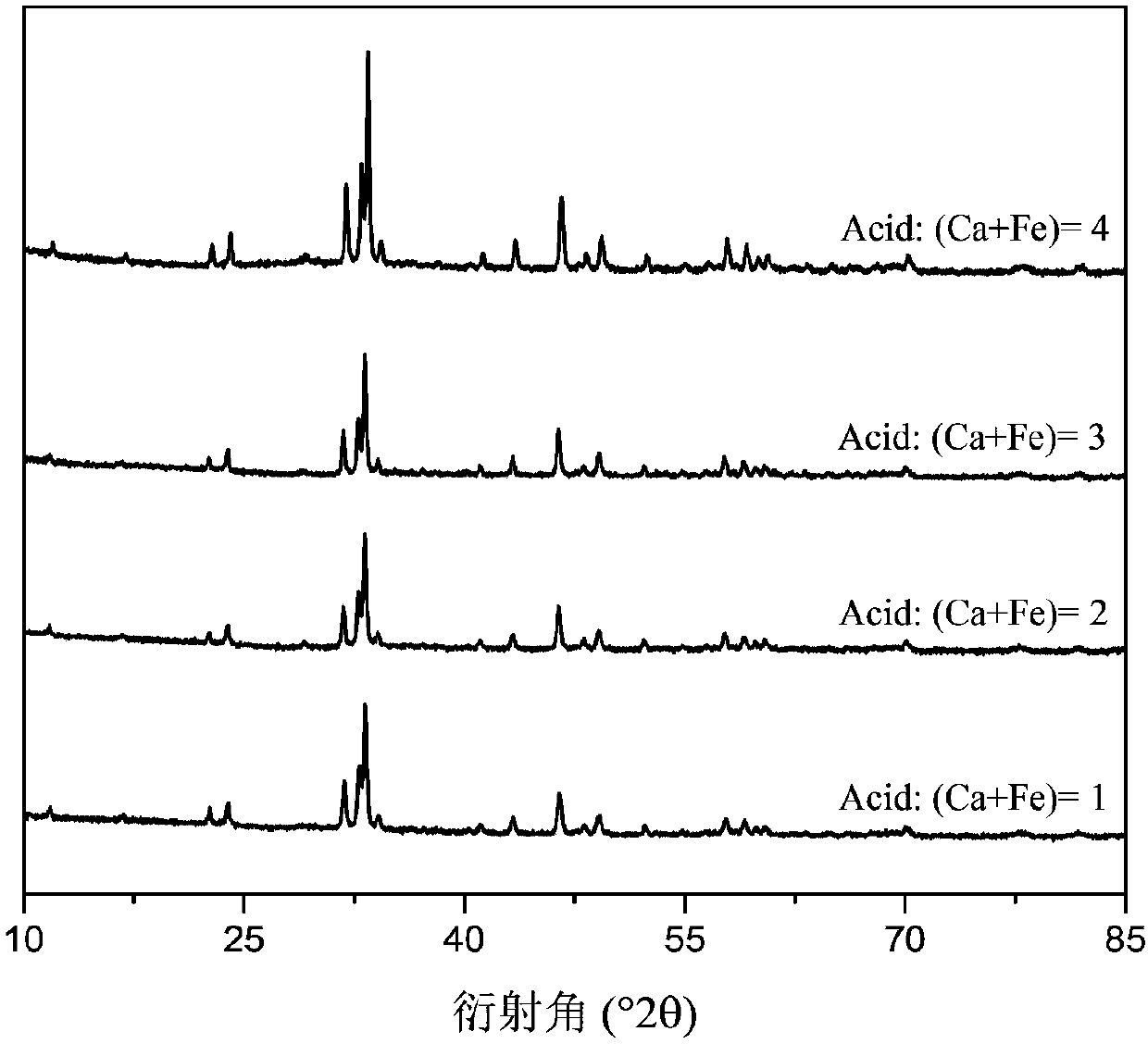

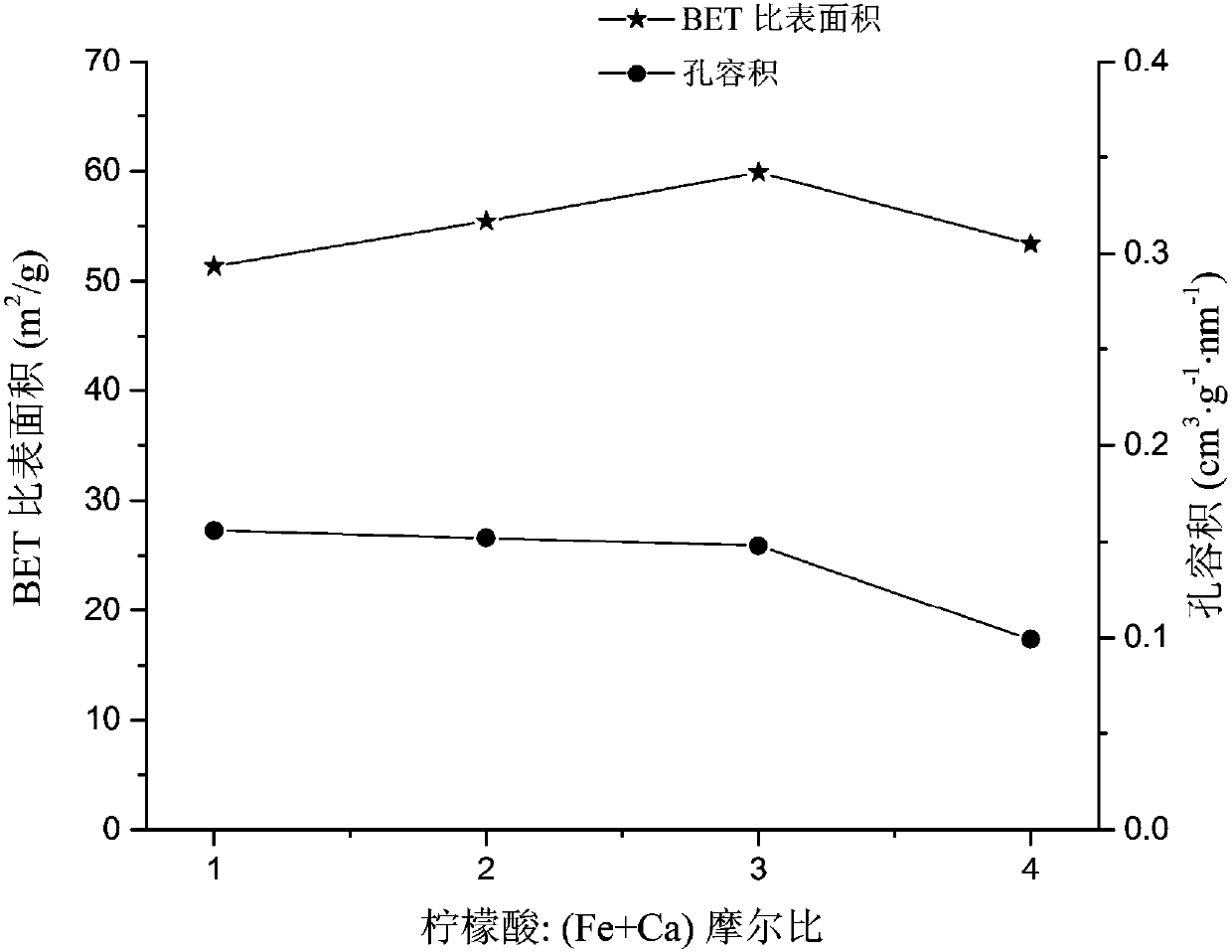

[0040] 1) Mix ferric nitrate, calcium nitrate and citric acid according to a certain ratio, and add according to the Ca:Fe molar ratio of 0.9:1, citric acid: (Fe+Ca)=3:1;

[0041] 2) Configure a mixed solution containing three precursors of ferric nitrate, calcium nitrate and citric acid, so that the concentration of the ferric nitrate solution is 0.08mol / L, and the concentration of the calcium nitrate solution is 0.072mol / L;

[0042] 3) Stir the prepared solution at 50°C for 20 minutes;

[0043] 4) Put the stirred solution in a drying oven, foam and dry at a temperature range of 180°C for 24 hours, then crush and sieve the obtained foam to a particle size of 0.25mm;

[0044] 5) Put the crushed and sieved solid powder into a muffle furnace, and calcinate at 650° C. in an air atmosphere for 4 hours, and keep the heating rate at 3° C. / min. The calcined samples were sieved according to different particle sizes, and finally the calcium-iron ...

Embodiment 2

[0046] 1) Ferric nitrate, calcium nitrate and citric acid are mixed according to a certain ratio, and added according to the Ca:Fe molar ratio of 1.1:1, citric acid: (Fe+Ca)=2:1;

[0047] 2) Configure a mixed solution containing three precursors of ferric nitrate, calcium nitrate and citric acid, so that the concentration of the ferric nitrate solution is 0.12mol / L, and the concentration of the calcium nitrate solution is 0.132mol / L;

[0048] 3) Stir the prepared solution at 40°C for 30 minutes;

[0049] 4) Put the stirred solution in a drying oven, foam and dry at a temperature range of 185°C for 15 hours, then crush and sieve the obtained foam to a particle size of 0.25 mm;

[0050] 5) Put the crushed and sieved solid powder into a muffle furnace, and calcinate at 750° C. in an air atmosphere for 3.5 hours, and keep the heating rate at 4° C. / min. The calcined samples were sieved according to different particle sizes, and finally the calcium-iron composite Ca 2 Fe 2 o 5 c...

Embodiment 3

[0052] 1) Mix ferric nitrate, calcium nitrate and citric acid according to a certain ratio, and add according to Ca:Fe molar ratio 1:1, citric acid: (Fe+Ca)=1:1;

[0053] 2) Configure a mixed solution containing three precursors of ferric nitrate, calcium nitrate and citric acid, so that the concentration of the ferric nitrate solution is 0.10mol / L, and the concentration of the calcium nitrate solution is 0.10mol / L;

[0054] 3) Stir the prepared solution at 30°C for 40 minutes;

[0055] 4) Put the stirred solution in a drying oven, foam and dry at a temperature range of 190°C for 12 hours, then crush and sieve the obtained foam to a particle size of 0.25 mm;

[0056] 5) Put the crushed and sieved solid powder into a muffle furnace, and calcinate at 850° C. in an air atmosphere for 3 hours, and keep the heating rate at 5° C. / min. The calcined samples were sieved according to different particle sizes, and finally the calcium-iron composite Ca 2 Fe 2 o 5 catalyst.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com