Online water detection system and detection method thereof

A detection system, moisture technology, applied in the raw material preparation of pellet industry, metallurgical sintering field, can solve the problems such as it is difficult to realize automatic water measurement of different materials, the detection equipment and theoretical scheme are complicated, and it is difficult to realize the online detection of moisture.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

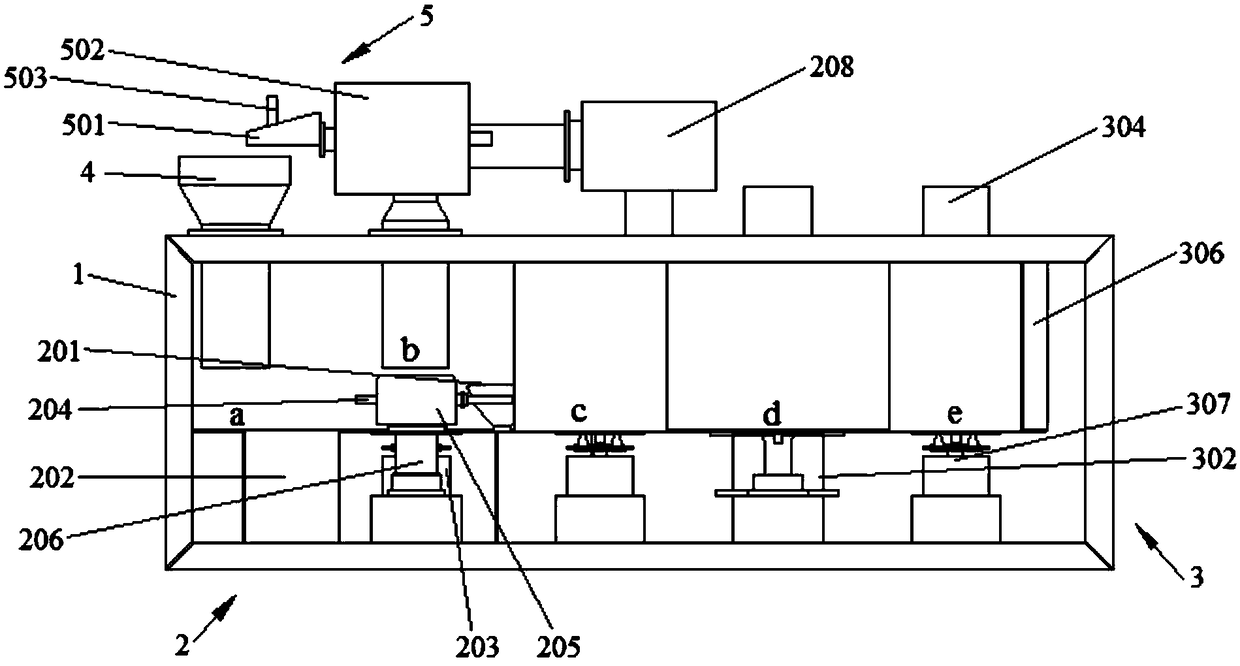

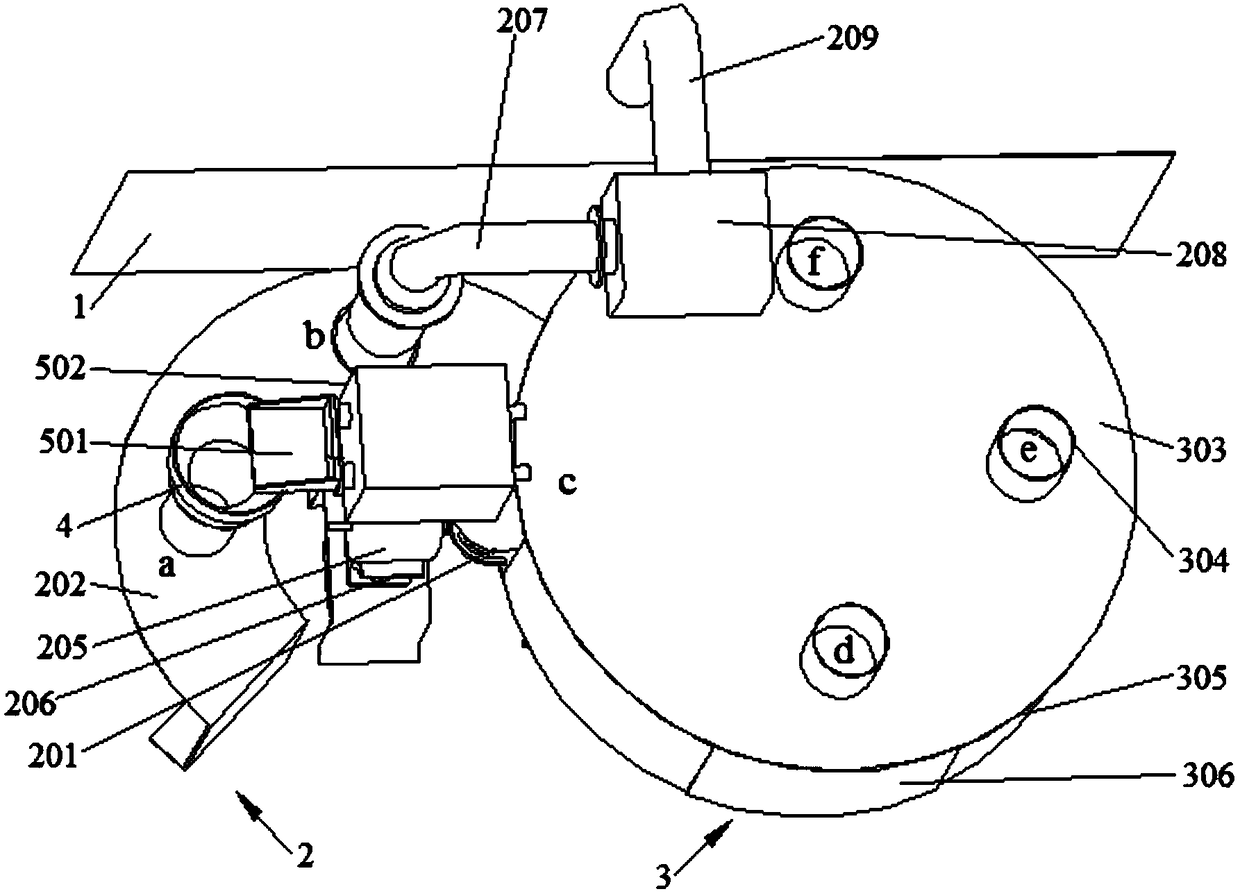

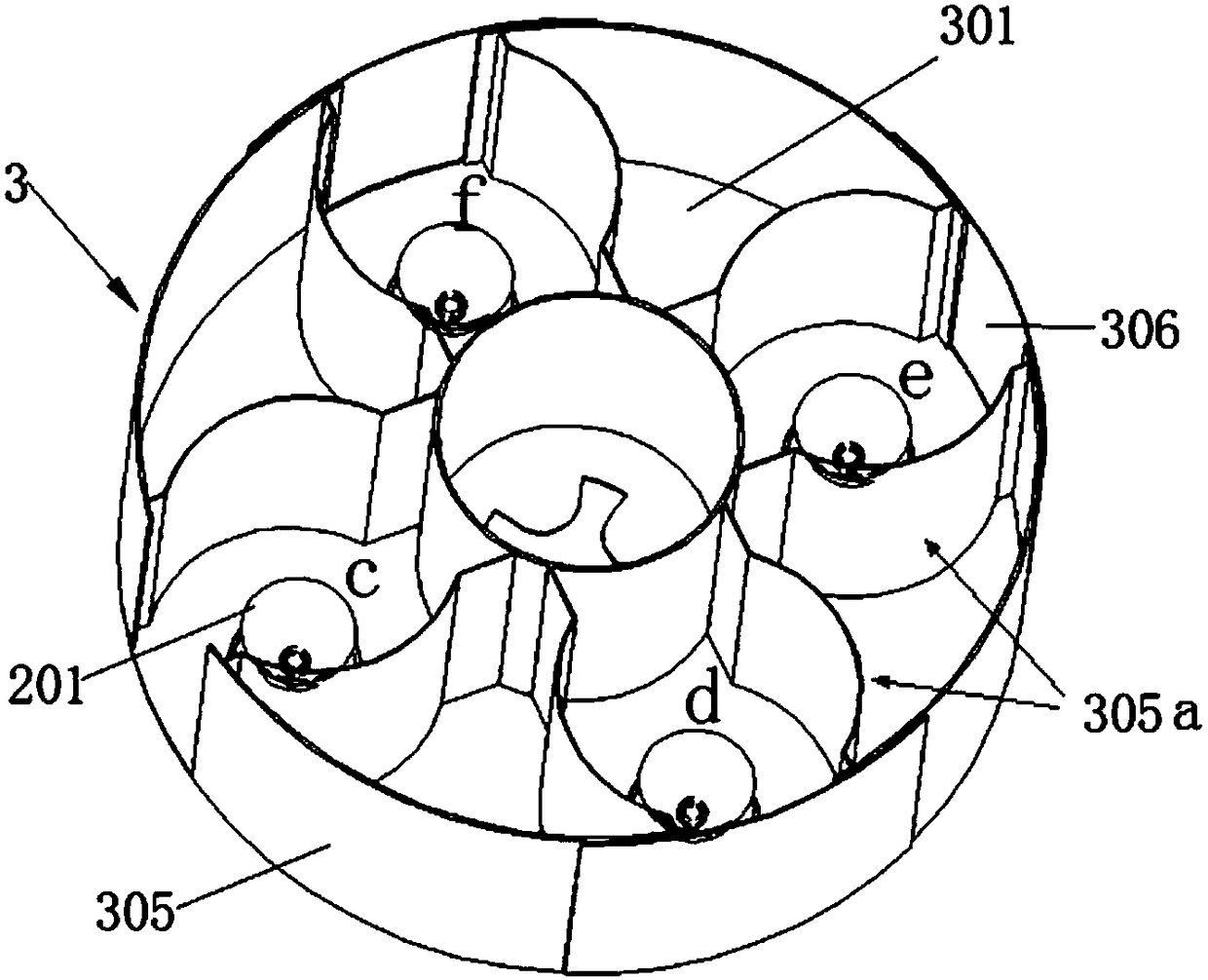

[0113] like Figure 1-3 , an absolute method on-line moisture detection system, which includes a box 1, an analysis and discharge device 2 located on the left side of the box 1, a running drying device 3 located on the right side of the box 1, and an analysis and discharge device 3. Sampling system 5 above device 2. The analyzing and discharging device 2 has a gripper 204 which is rotatable along the rotating mechanism 206 in the horizontal direction, and also has two workstations: a feeding position a and a weighing and discharging position b. The operation drying device 3 has a turntable 301, four chambers arranged on the turntable 301, a top cover 303 located on the upper part of the four chambers, and three microwave generators 304 arranged on the top cover 303, and also has four 1 station: the second station d, the third station e and the fourth station f are set in sequence in the counterclockwise direction close to the first station c of the analysis and discharge devi...

Embodiment 2

[0121] Example 1 is repeated, except that the operation drying device 3 further includes a second weighing device 307 disposed below the third station e and located at the lower part of the turntable 301 .

Embodiment 3

[0123] An absolute method on-line moisture detection method, using the moisture detection system in Embodiment 1, the method comprises the following steps:

[0124] 1) The first weighing device 203 located below the weighing and discharging level b weighs the weight of the sample container 201 after discharging (W 0 );

[0125] 2) The gripper 204 grasps the sample container 201 by lifting, and rotates the sample container 201 from the weighing and discharging position b to the feeding position a. Placed on the measuring platform 202, the feeding plate 501 receives the material from the belt blanking place of the belt conveyor and is driven by the moving shaft of the feeding plate driver 502 to recover, and the reclaiming baffle 503 scrapes off the material of the feeding plate 501, The sample material flows into the sample container 201 with the feeding funnel 4;

[0126] 3) The gripper 204 grasps the sample container 201 and rotates the sample container 201 from the feeding...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com