Rotary online water detector and detection method thereof

A detection instrument and rotary technology, applied in the direction of instruments, furnace types, analysis materials, etc., can solve the problems of complex detection equipment and theoretical schemes, inability to accurately detect moisture content by microwave method, and difficulty in realizing online moisture detection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

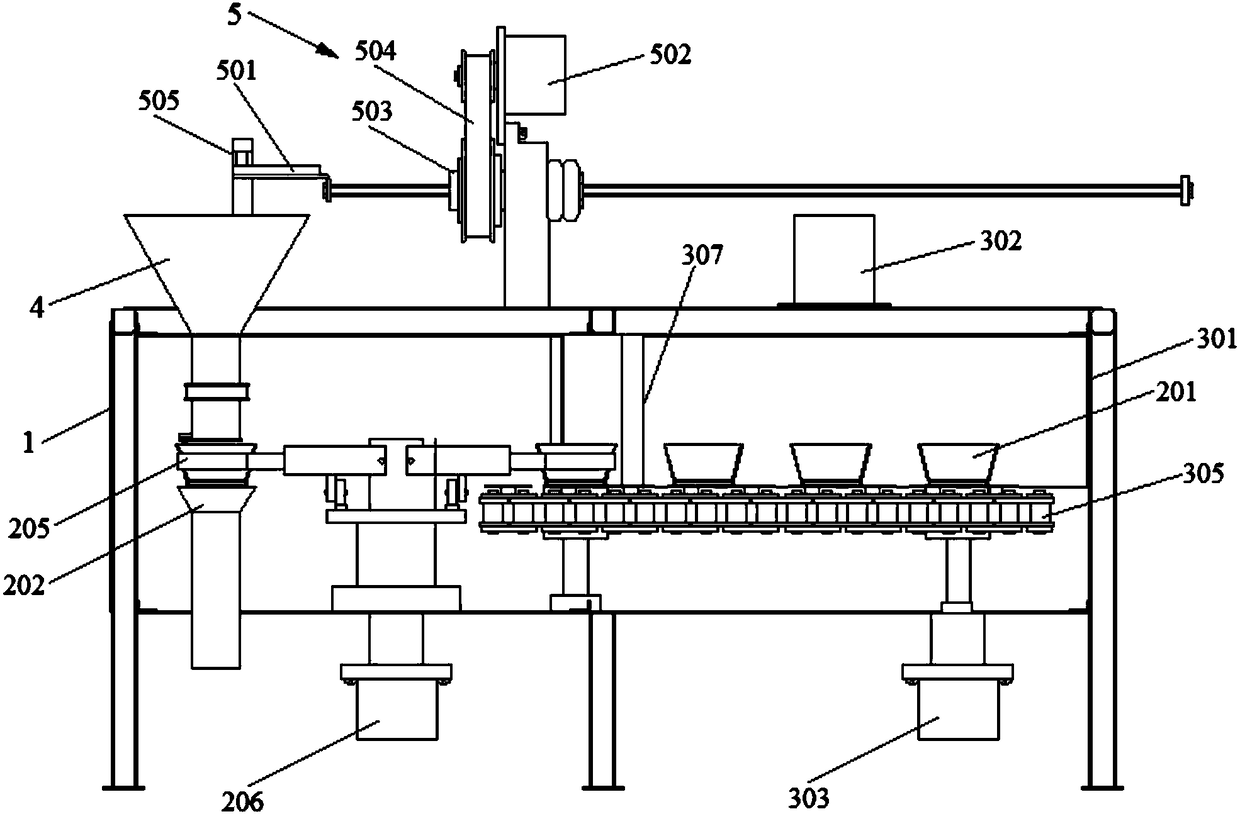

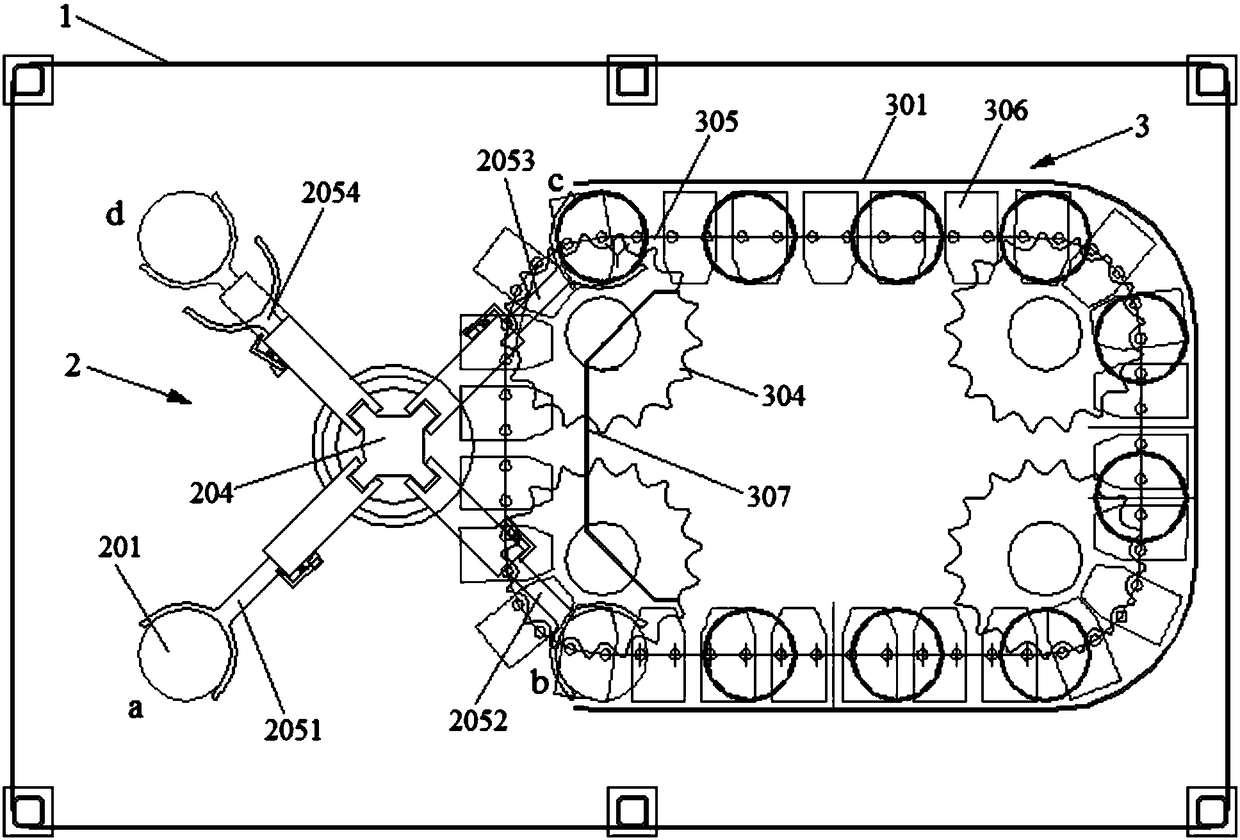

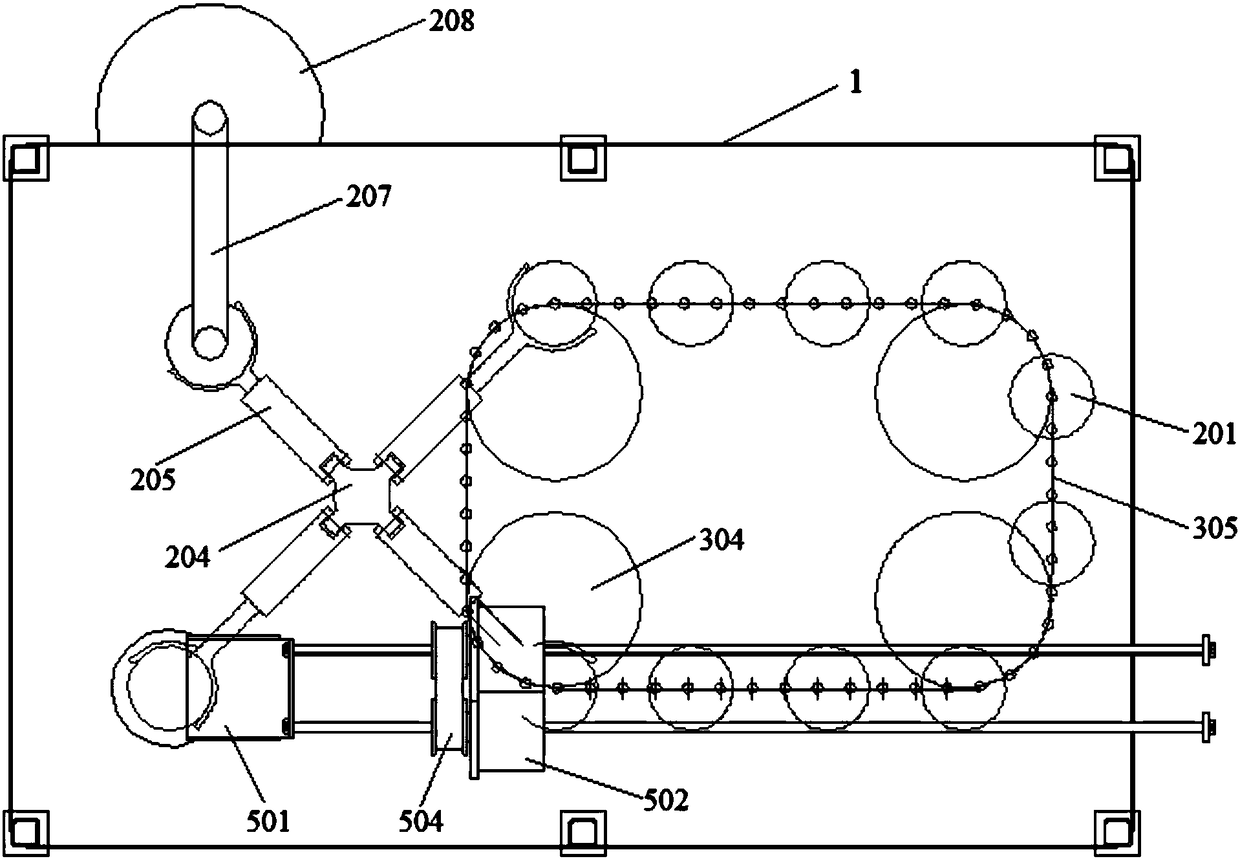

Embodiment 1

[0102] Such as Figure 1-4 , an absolute method online moisture detector, which includes a support frame 1, an analysis and discharge device 2 located on the left side of the support frame 1, a running drying device 3 located on the right side of the support frame 1, and an analysis and discharge device 2 located Upper sampling system 5. Wherein the analysis and discharge device 1 has four grippers 205 and these grippers 205 are rotatable along the vertical axis 204 in the horizontal direction; and also have four stations: feeding and weighing station a, rotary platform input Station b, rotary platform output station c and discharge and weighing station d. The operation drying device 3 has a microwave drying cover 301, a microwave generator 302 arranged on the top of the microwave drying cover 301, a rotary mechanism formed by a gear 304 driving a chain 305 in the microwave drying cover 301, and a chain 305 A rotary platform composed of a plurality of flat plates 306 install...

Embodiment 2

[0112] Embodiment 1 is repeated, except that the number of gears 304 is six. Each gear 304 is connected to a gear drive motor 303 .

Embodiment 3

[0114] An absolute method online moisture detection method, using the absolute method moisture online detector in embodiment 1, the method may further comprise the steps:

[0115] 1) weigh the weight (W 0 );

[0116] 2) The first gripper 2051 grasps the sample container 201 by lifting, and the feeding plate 501 receives the material from the belt blanking place of the belt conveyor, and is driven by the moving shaft of the feeding plate drive motor 502 to recover, and the material picking stopper 505 will The material on the feeding plate 501 is scraped off, and the sample material flows into the sample container 201 along with the feeding funnel 4;

[0117] 3) The first gripper 2051 loosens the sample container 201 by descending, and places the sample container 201 on the first weighing device 202, and the first weighing device 202 weighs the weight of the loaded sample container 201 ( W 1 );

[0118] 4) After weighing, the first gripper 2051 grasps the sample container 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com