Material online moisture detection device and detection method thereof

A detection device and material technology, which is applied in the direction of measuring device, conveying bulk materials, and weighing by removing certain components, can solve the problem of automatic water measurement of different materials, inaccurate detection of moisture content, detection equipment and Complicated theoretical schemes and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

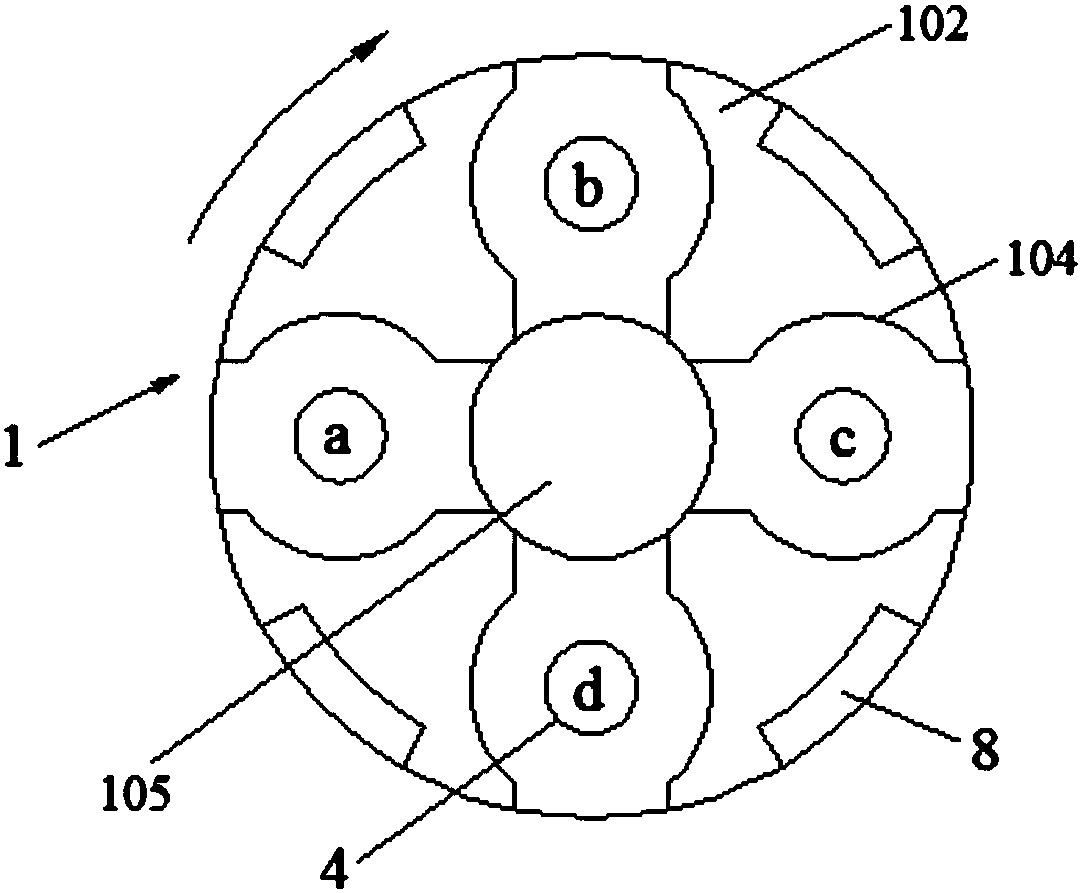

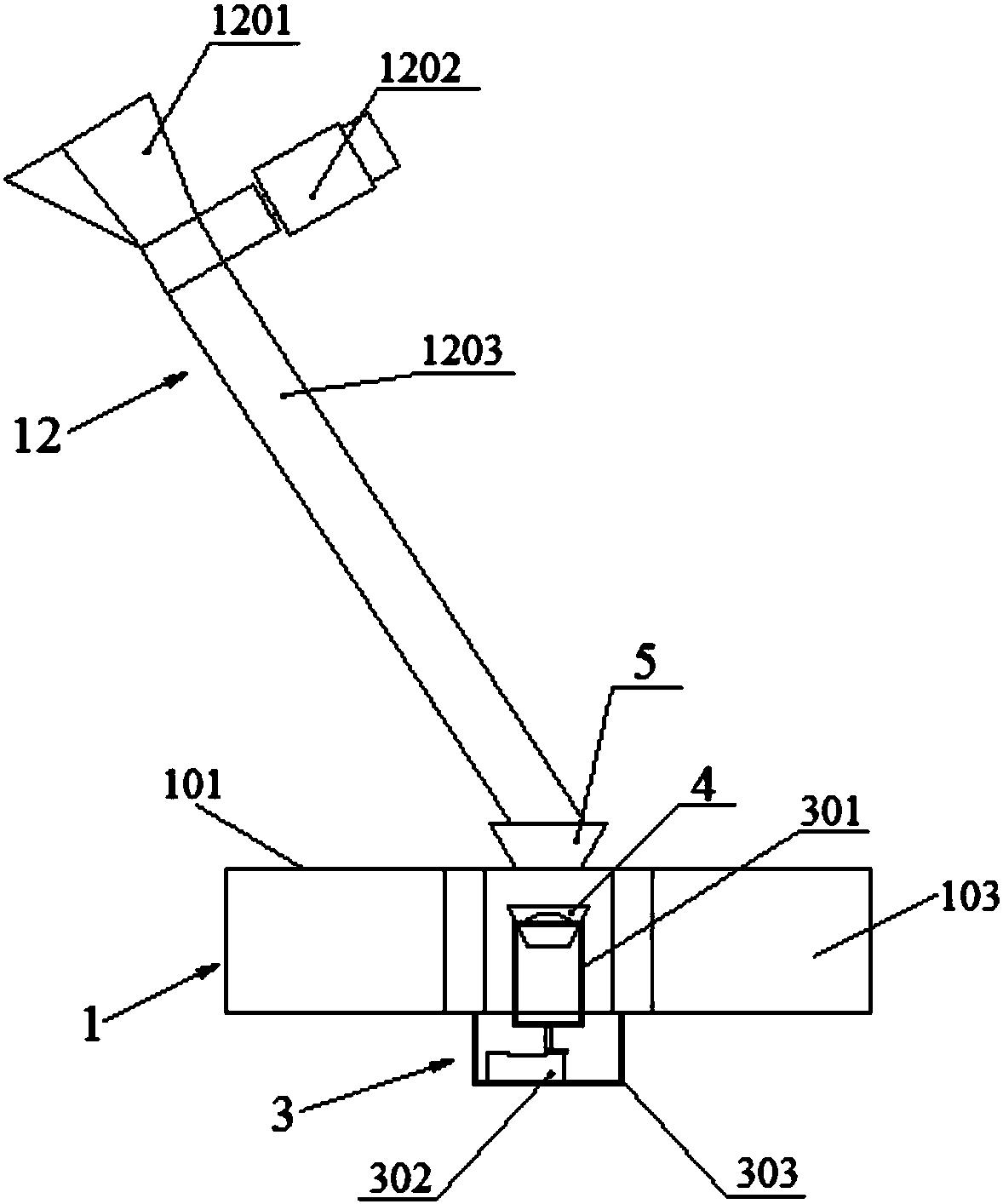

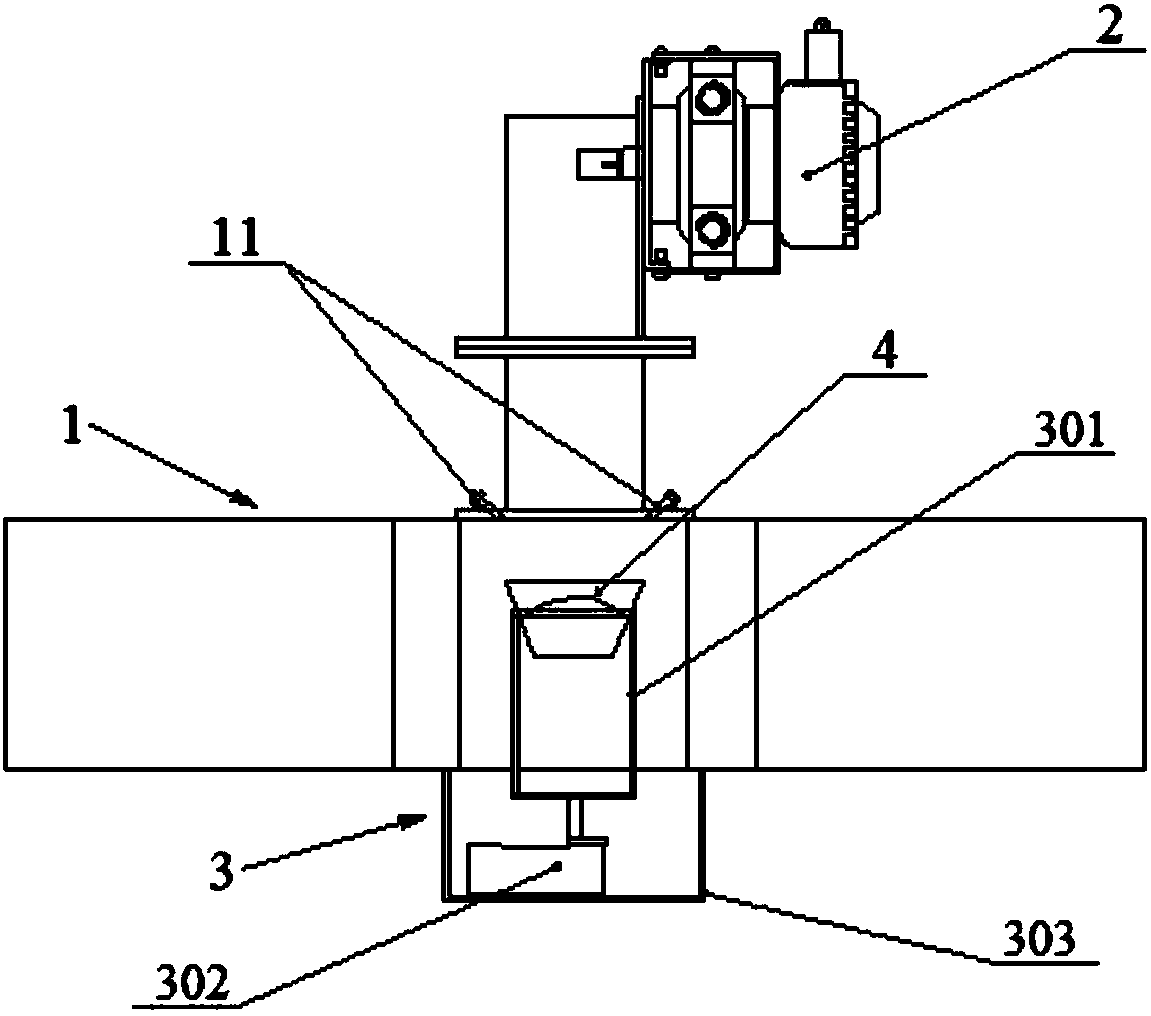

[0094] like figure 1 , an online moisture detection device for materials, which includes a cylindrical revolving bin 1, two microwave generators 2 arranged on the upper part of the revolving bin top cover 101 and four weighing devices 3 arranged on the lower part of the revolving bin chassis 102. Four chambers are arranged on the slewing bin chassis 102 . And the rotary bin 1 has four stations: in a clockwise direction, they are the feeding station a, the primary drying station b, the secondary drying station c and the discharging station d. Four of the chambers cycle through the positions of the four stations. The four chambers and the four stations of the carousel 1 take the axis center of the carousel chassis 102 as the apex of the angle, and all have equal included angles of 90° among each other.

[0095] The revolving bin 1 includes an upper top cover 101 , a lower chassis 102 , a side wall 103 and a partition 104 inside the revolving bin 1 . The partition 104 divides ...

Embodiment 2

[0102] Example 1 was repeated, except that the diameter of the opening on the partition 104 at the junction of each of the four chambers of the revolving bin 1 and the dehumidification space 105 was 6 mm.

Embodiment 3

[0104] Repeat Example 1, except that the device also includes a temperature measuring device 11 arranged on the upper part of the revolving bin top cover 101 above the primary drying station b and the secondary drying station c.

PUM

| Property | Measurement | Unit |

|---|---|---|

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com