Grinding device for sapphire wafers and grinding method thereof

A sapphire wafer and grinding device technology, which is applied in the direction of grinding devices, grinding machine tools, grinding/polishing equipment, etc., can solve the problems of wafer cracking roughness, grinding quality rate decline, wafer loss, etc., to reduce cracking and roughness exceeding Poor, reduced scratches and chips, reduced abnormal loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

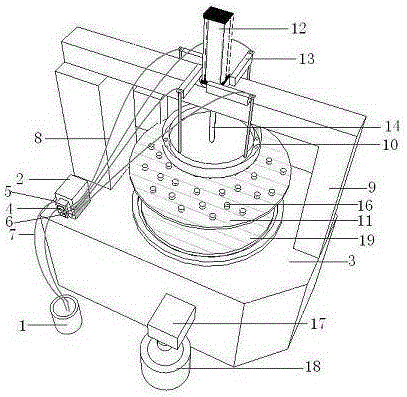

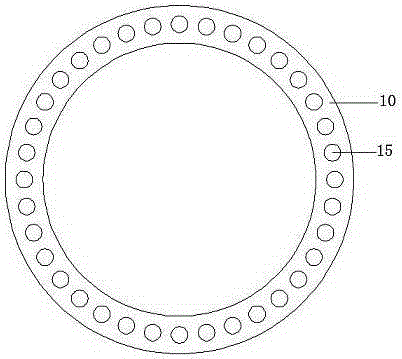

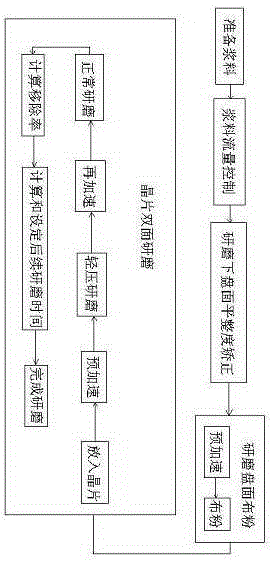

[0028] As shown in the figure, a sapphire wafer grinding device is characterized by comprising a slurry tank 1, a peristaltic pump 2 and a grinder 3. The peristaltic pump 2 includes two pump heads 4, a delivery tube 5 and a pump outlet tube 6. The pump head 4 controls the delivery of the delivery pipe 5. The delivery pipe 5 and the pump outlet pipe 6 are respectively sleeved with a delivery hose 7 and a pump outlet hose 8. The grinder 3 includes a beam 9, The slurry tank 10, the upper grinding plate 11 and the lower grinding plate 19 are provided with a control cylinder 12 and a hose support 13 on the beam 9. The control cylinder 12 is arranged vertically and includes a cylinder rod 14, the cylinder rod 14 It faces vertically downward and is rotatably connected with the upper grinding plate 11 through a bearing to realize the vertical movement and horizontal rotation of the upper grinding plate 11, and the slurry tank 10 is fixedly arranged above the upper grinding plate 11, Lo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com