Multi-barrel rotary black tea fermentation device

A fermentation device and rotary technology, applied in the field of tea processing equipment, can solve the problems of difficult cleaning, low degree of automation, and difficult operation, and achieve the effects of high level of automation, convenient cleaning, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

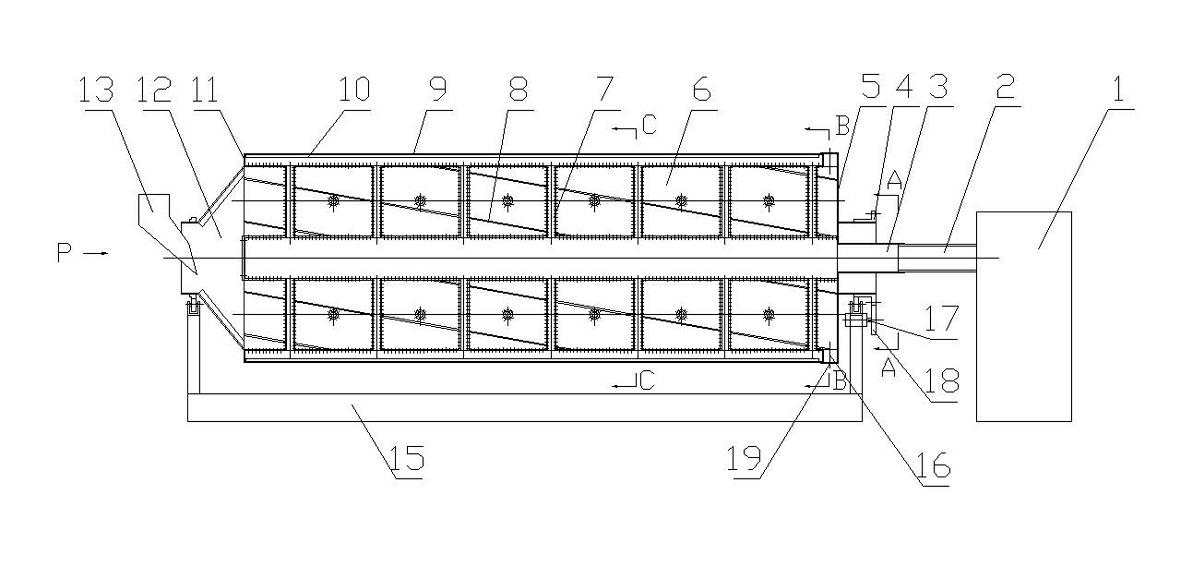

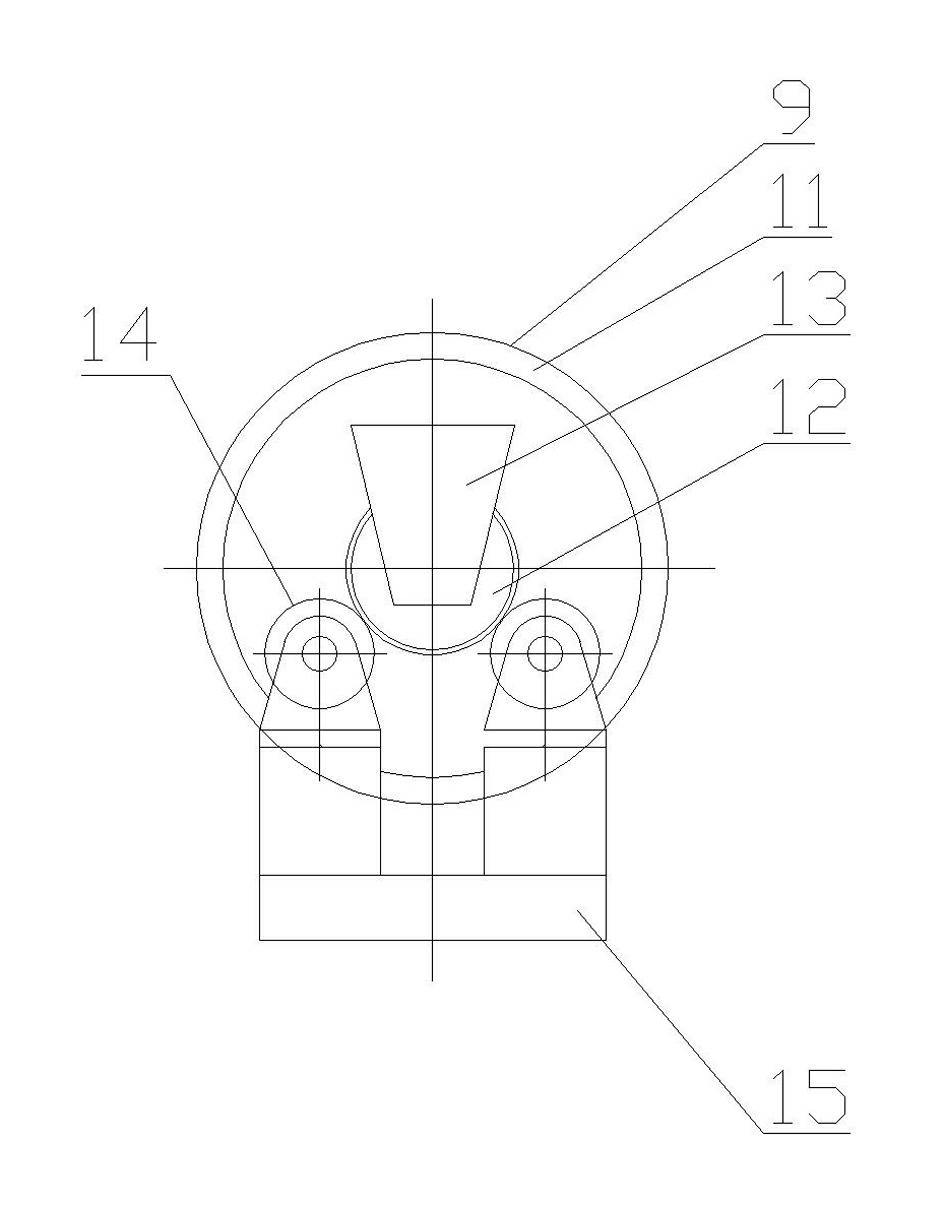

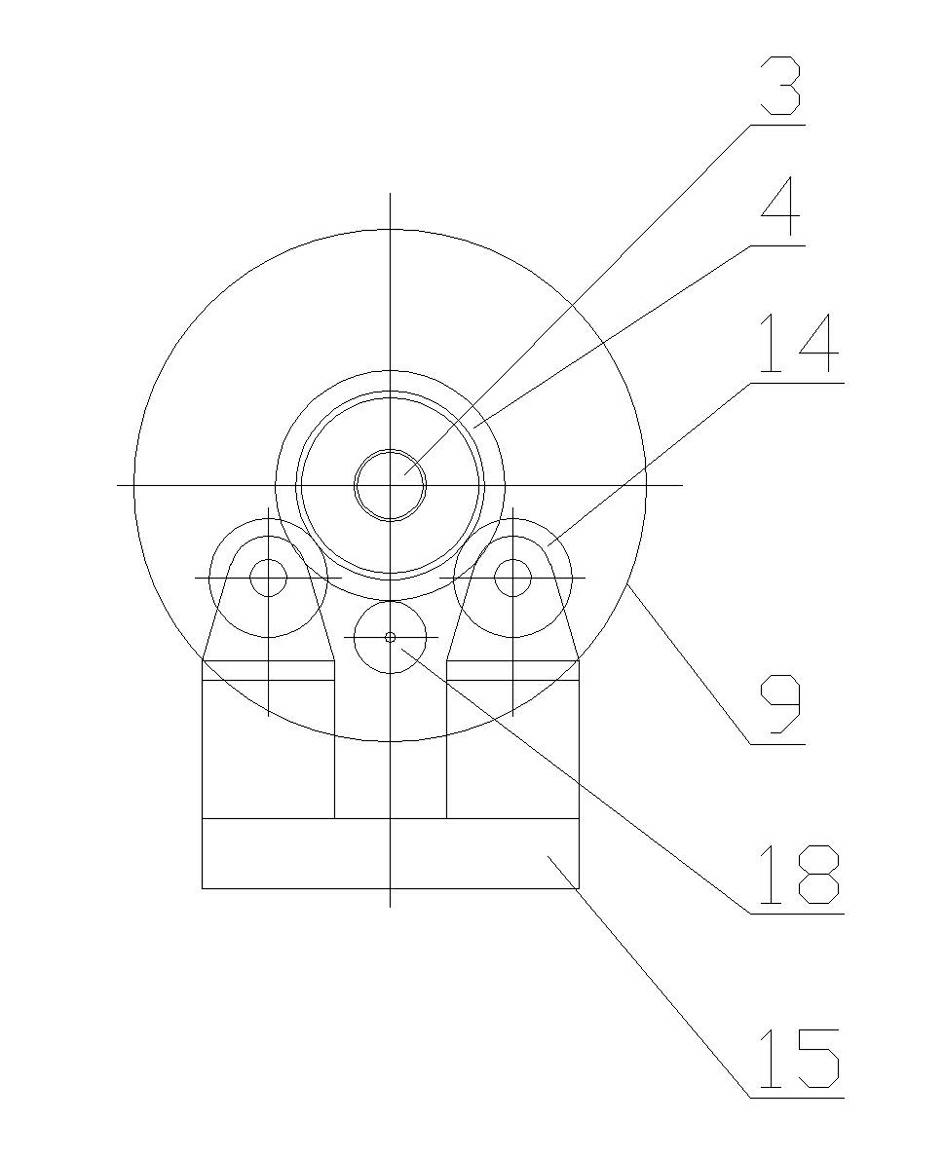

[0024] figure 1 Among them, a multi-cylinder rotary black tea fermentation device includes a power unit, a heat supply, humidity supply and oxygen supply system 1, a frame 15, a feed hopper 13 and a discharge port 19, and the outer cylinder 9 is provided with four cylinders on the same circumference. A fermentation cylinder 6, the fermentation cylinder 6 is a circular or polygonal long cylinder, the fermentation cylinder 6 and the outer cylinder 9 are fixedly connected, the cylinder wall surface of the fermentation cylinder 6 is arranged with uniform small holes, and the cylinder wall of the fermentation cylinder 6 is penetrated with a A number of small round tubes 7 with small holes, the small round tubes 7 are arranged in a staggered manner in the fermentation cylinder, a number of evenly distributed spiral material guide ribs 8 are arranged on the inner wall of the fermentation cylinder, and the feed hopper 13 and the front end of the outer cylinder 9 are provided with frust...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com