Method for profiling weaving thick top-to-thin wall capping fabric

A technology for capping fabrics and forming methods, which is applied in the directions of fabrics, textiles, textiles and papermaking, can solve the problems of low profiling accuracy of fabric size and uneven density inside and outside the fabric, and achieves high profiling accuracy and uniform fabric density. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

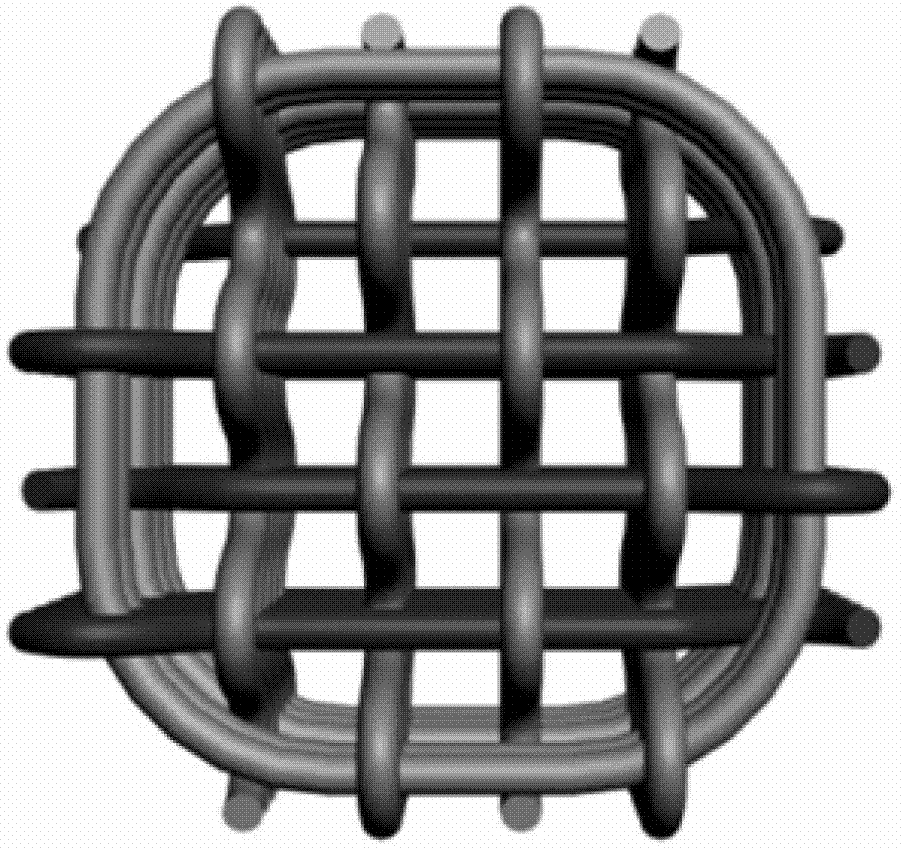

[0027] Embodiment 1: develop as Image 6 The glass fiber reinforced fabric with variable thickness on the top is shown, the thickness of the top of the fabric is 50mm, the diameter of the top is 30mm, and the gradual thickness of the top transitions to a cone, the thickness of the cone part is 5mm, and the diameter is 70mm. The technical parameters of the capping fabric are designed as shown in Table 1.

[0028] Table 1 Capping fabric process parameter table

[0029]

[0030] The specific weaving steps of the capping fabric are as follows:

[0031] ⑴Fix the fabric braiding mandrel on the operating platform; select glass fiber with a specification of 480Tex to carry out the square top weaving operation on the top of the mandrel, and interweave 4 pairs of yarns to form a square top. In order to achieve a top thickness of 50mm, the square top laying 4 pairs of yarns are interlaced, the number of warp yarn layers is 30 layers, and the fibers are radially introduced into the h...

Embodiment 2

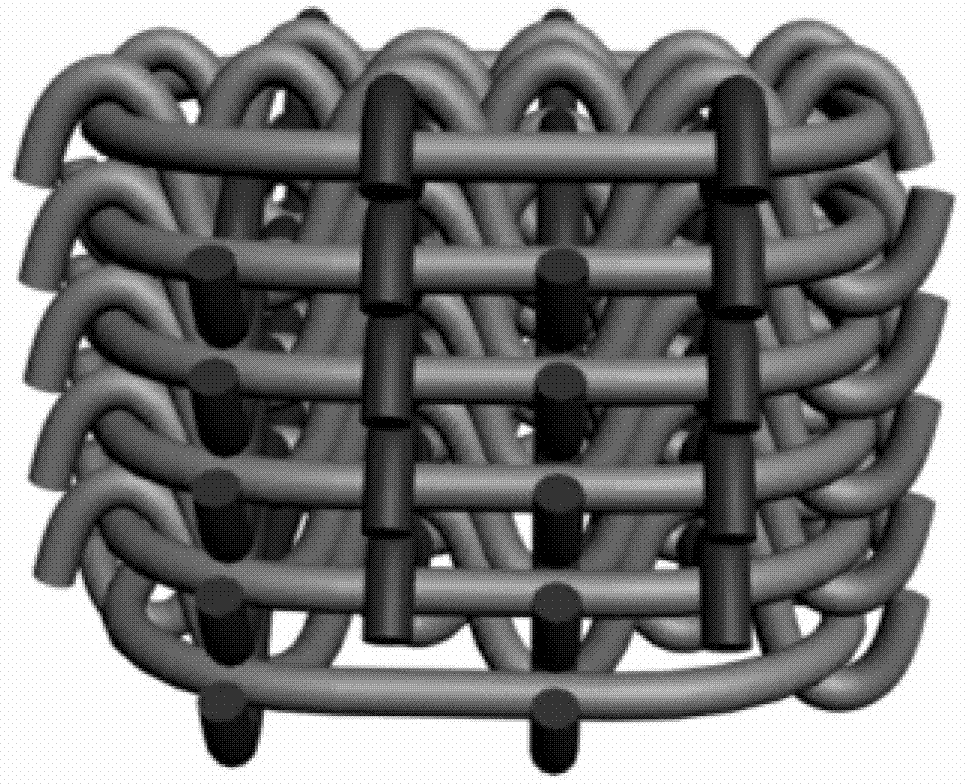

[0037] Example 2: Development of capped and variable thickness quartz fiber reinforced fabrics, the maximum thickness of the top of the fabric is 40mm (i.e. the thickness of the initial square roof), the capped diameter is 20mm, the transition from capped gradient thickness to cone, the thickness of the cone part is 20mm, the cone angle is 15°. The raw material of the fabric is quartz fiber 190Tex, the warp layer of the square top part is 30 layers, the outer 5 layers of warp yarn are quartz fiber 190Tex×4 ply yarn, the middle 9 layers are quartz fiber 190Tex×3 ply yarn, and the inner 9 layers are Quartz fiber 190Tex × 2 ply yarns; the warp of the cone part is 24 layers; the weft yarns are all quartz fiber 190Tex × 7 ply yarns.

[0038] (1) Fix the fabric braiding mandrel on the operating platform.

[0039] (2) The fabric adopts a 2.5D shallow cross-bending structure.

[0040] (3) Square top knitting operation, criss-crossing 4 pairs of yarns (each pair of warp yarns include...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com