Patents

Literature

134results about How to "Improve profile accuracy" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

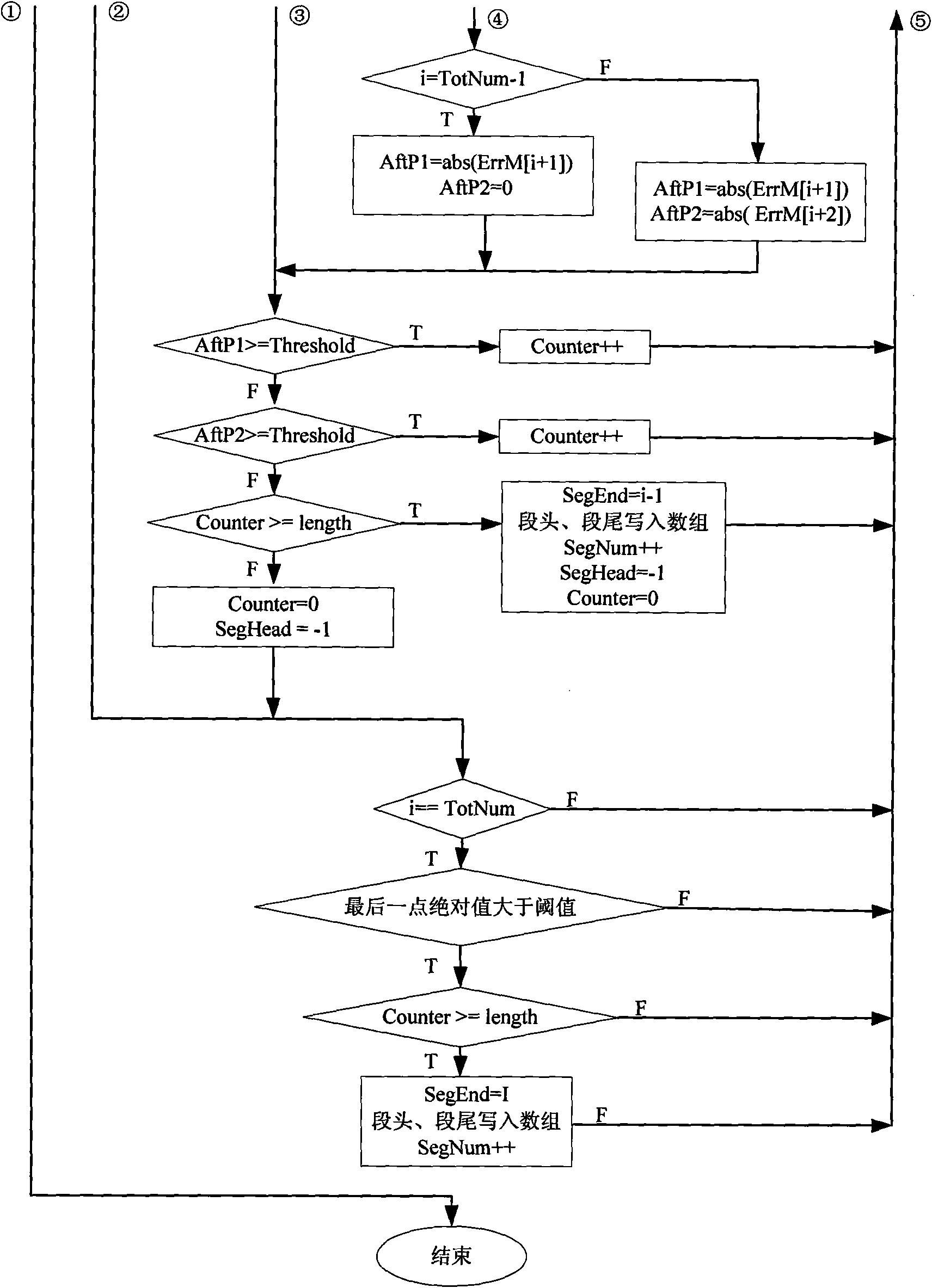

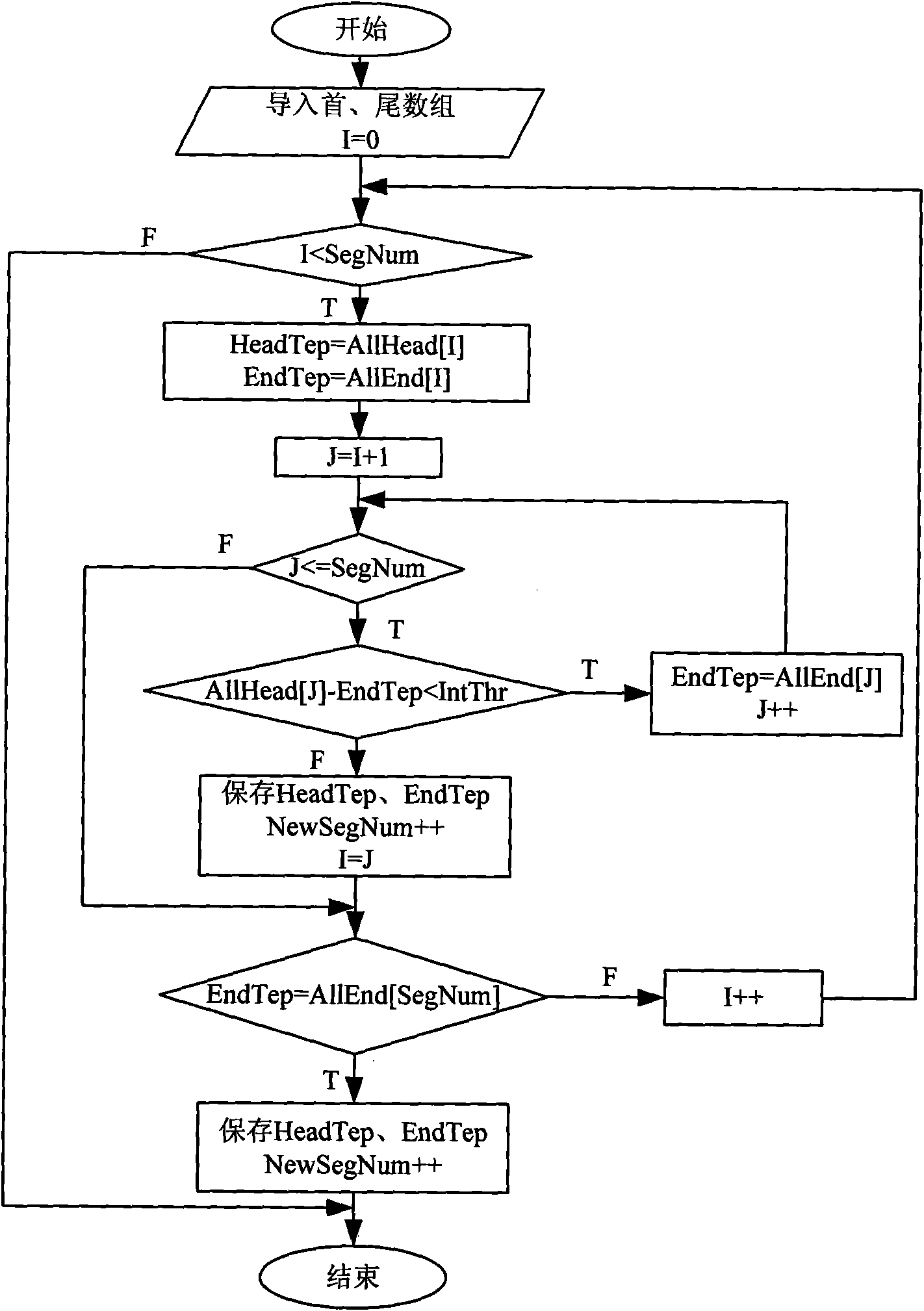

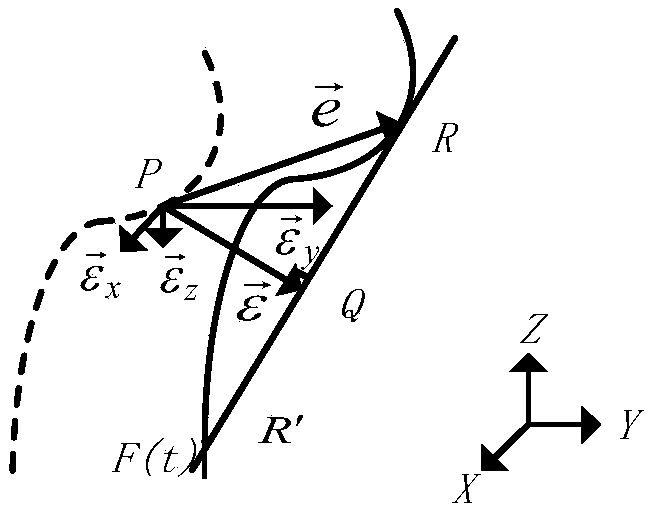

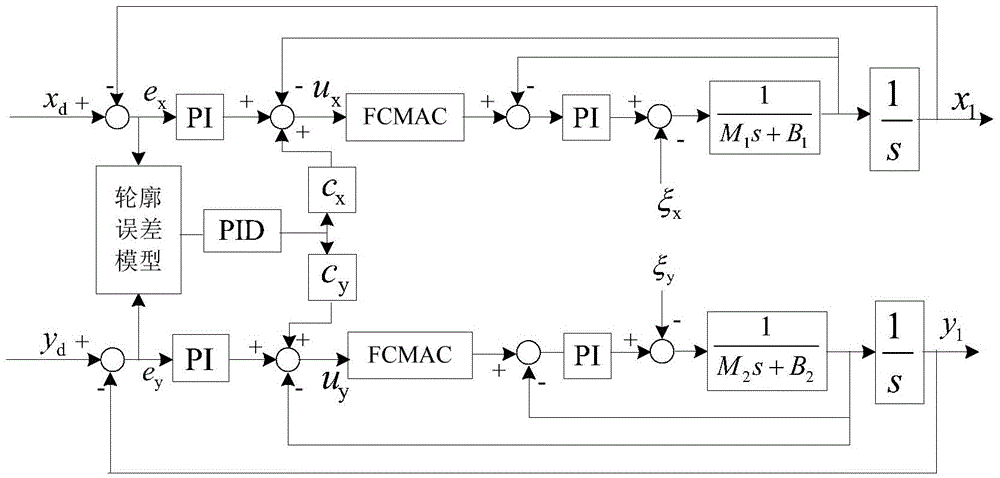

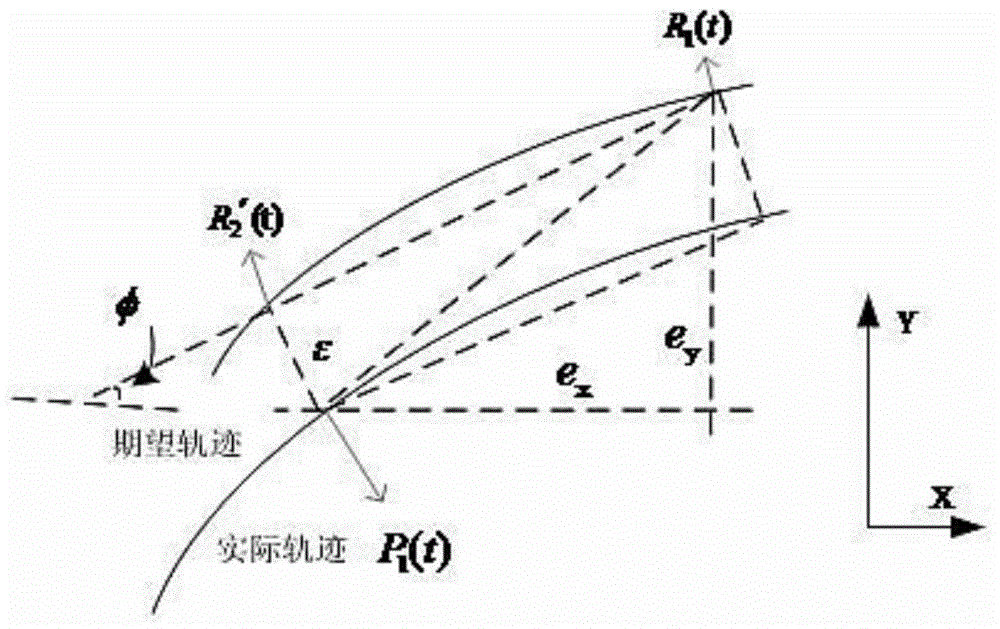

Control method for motion stability and outline machining precision of multi-shaft linkage numerical control system

ActiveCN102681489AAchieve smooth motionRealization errorNumerical controlFuzzy pid controlControl system

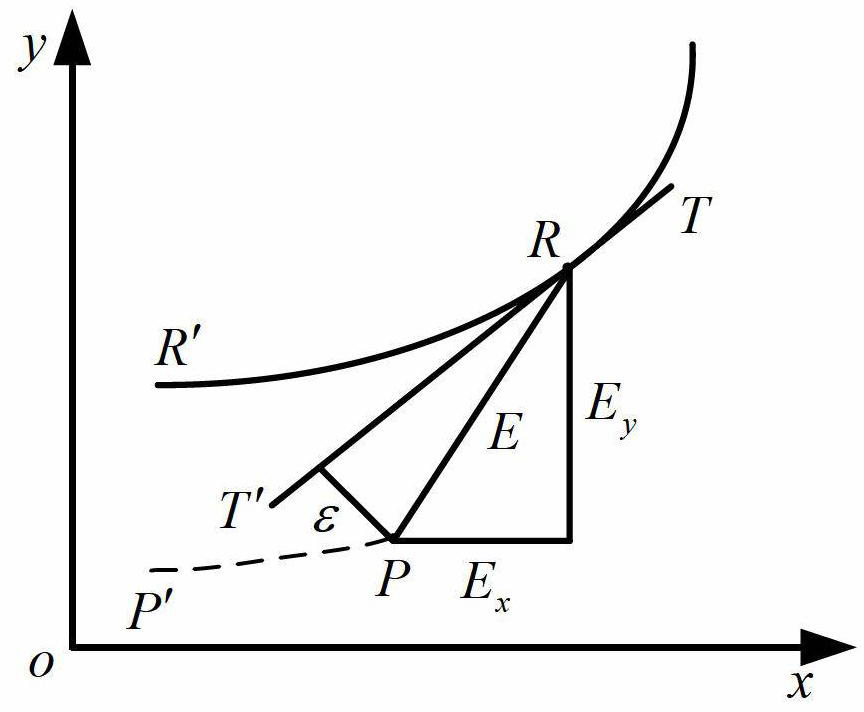

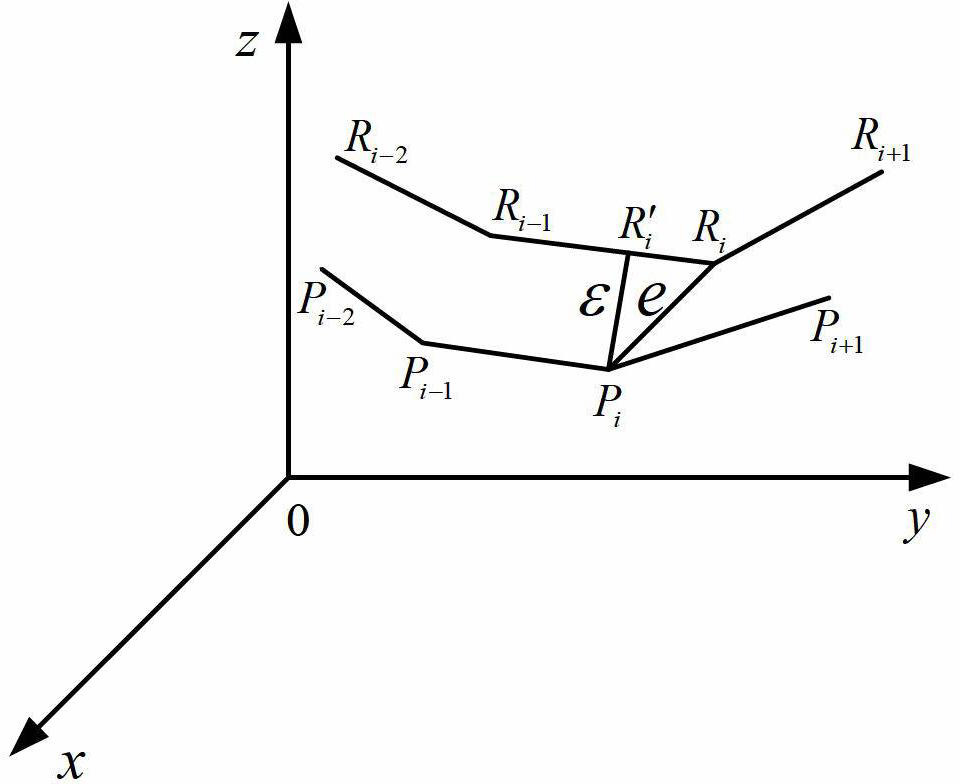

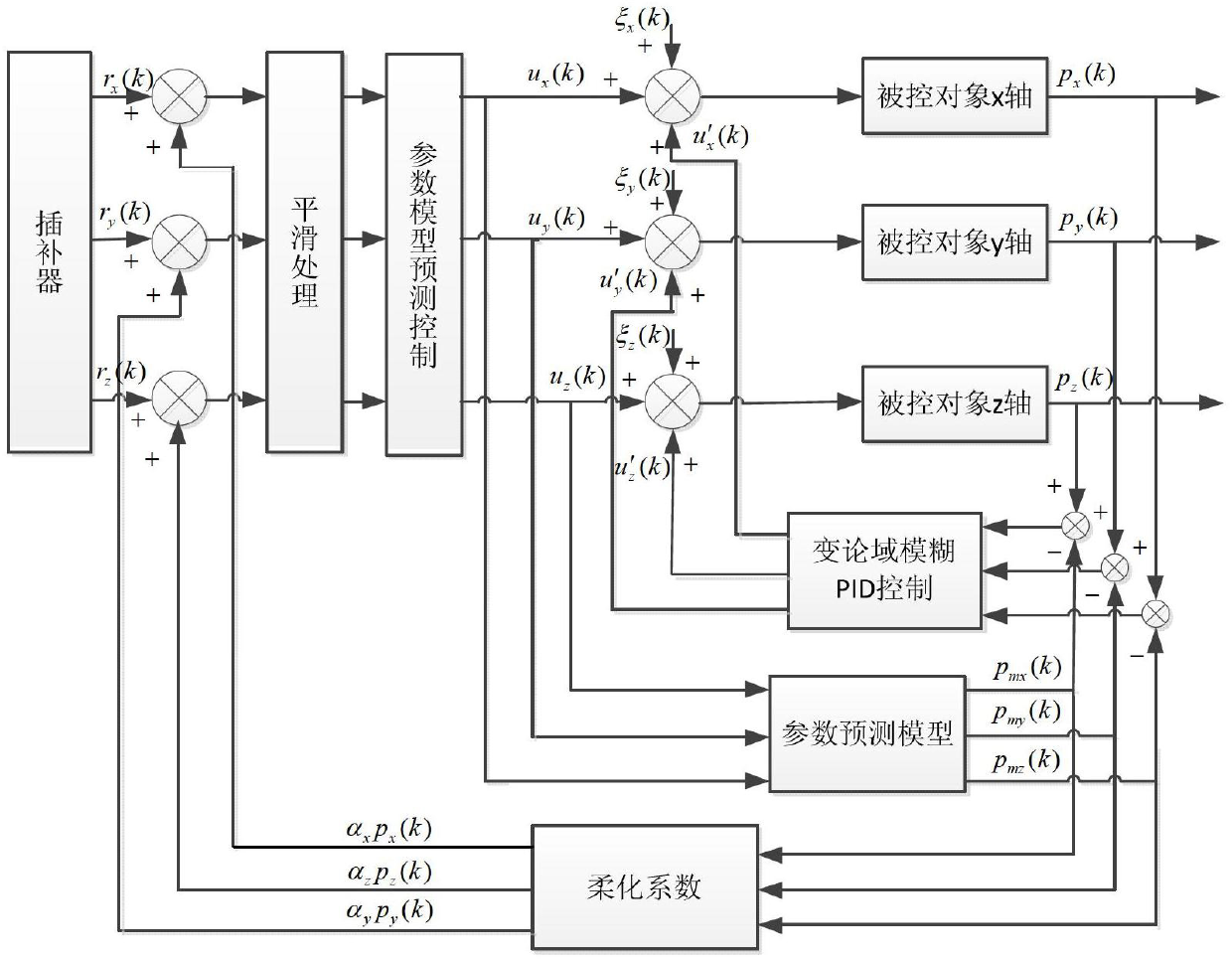

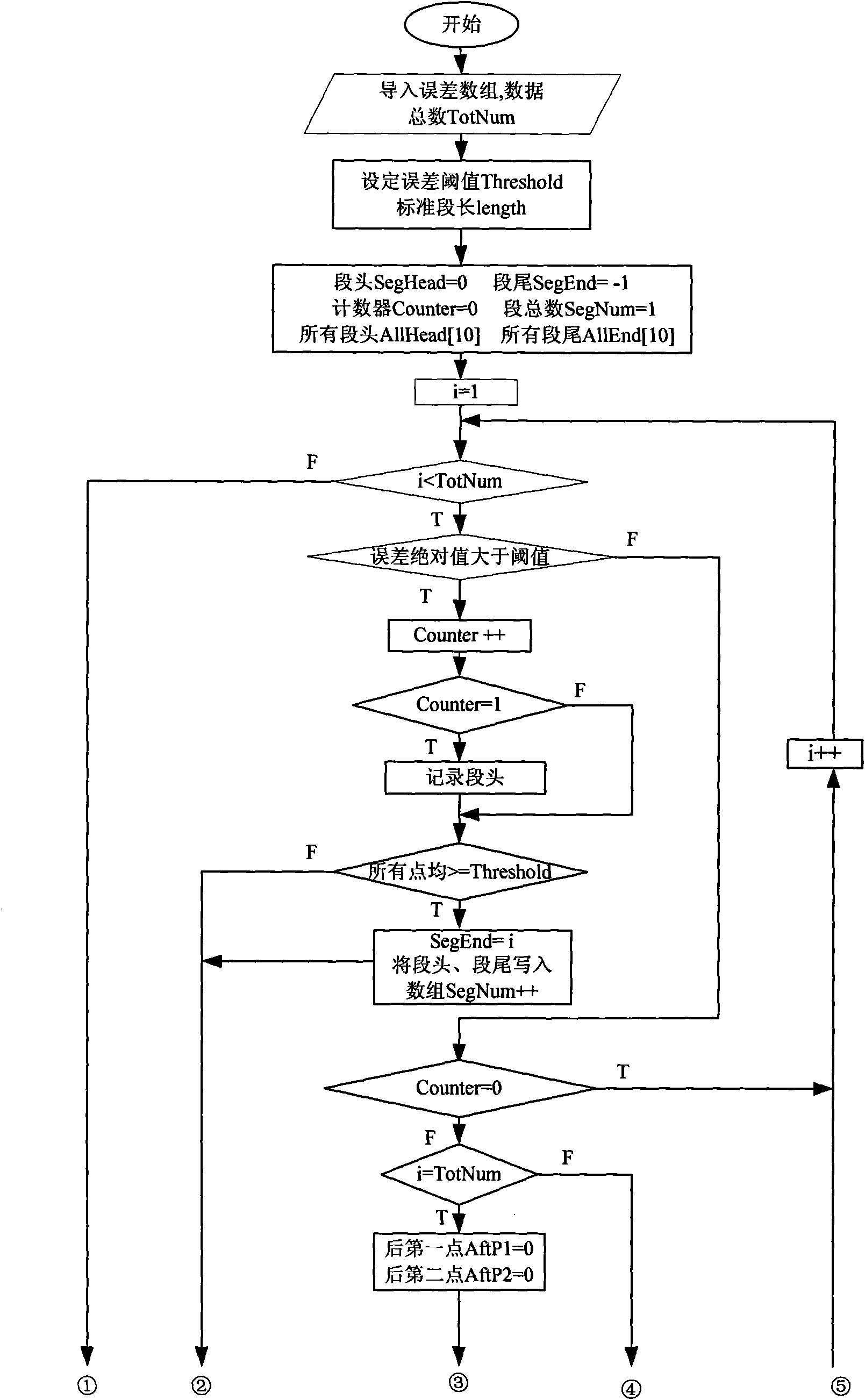

The invention discloses a control method for motion stability and outline machining precision of a multi-shaft linkage numerical control system. The control method achieves control on the motion stability and outline machining errors of the multi-shaft linkage numerical control system by using a compound control mode of multi-shaft parameter module predictive control and non-linear self-adaptive fuzzy proportional-integral-derivative (PID) control. Simultaneously, error module calculating efficiency is improved by building an outline error module, a speed error module and an acceleration error module. By means of performance optimization indexes, tracking errors, outline errors, speed errors and acceleration errors of the system are minimum, and control performance of a multi-shaft servo control system is improved. Multi-shaft parameter module predicative control increment is solved through a simplified calculating module so as to meet real-time requirements of the control system. Robust property of the multi-shaft linkage numerical control system is improved by adopting the non-linear self-adaptive fuzzy PID control method. The control method effectively improves the motion stability and outline machining precision of the multi-shaft linkage numerical control system.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

Error compensation method of numerical control grinding contour of camshaft

InactiveCN101653921AReduce lift error valueImprove profile accuracyBelt grinding machinesCompensation effectEngineering

The invention discloses an error compensation method of numerical control grinding contour of a camshaft, comprising the following steps: a. performing offline measurement on the contour line of a processed cam sheet by multiple trail cut processing to obtain practical contour line data for respectively lifting; b. calculating the lifting error value of one circle of the whole cam sheet by comparing theory lift and actual measurement lift data, analyzing the lift error, and predicting the error; c. building a virtual lift table, and performing secondary fairing processing to the virtual lift;d. adopting a post-processed virtual lift table to replace an original lift table, and performing numerical control processing of the camshaft which has the same type with a trail cut camshaft under the same technological condition. Based on the above steps, the invention programs and develops the error analysis and compensation processing software of numerical control grinding contour error of acamshaft and realizes the intelligent and automatic application of a technical method; the lift error value of the whole contour line of the processed cam sheet is integrally reduced, molded line precision is obviously improved, no burn or waveness exists on the surface of the contour, surface quality is favorable, and error compensation effect is obvious.

Owner:HUNAN UNIV

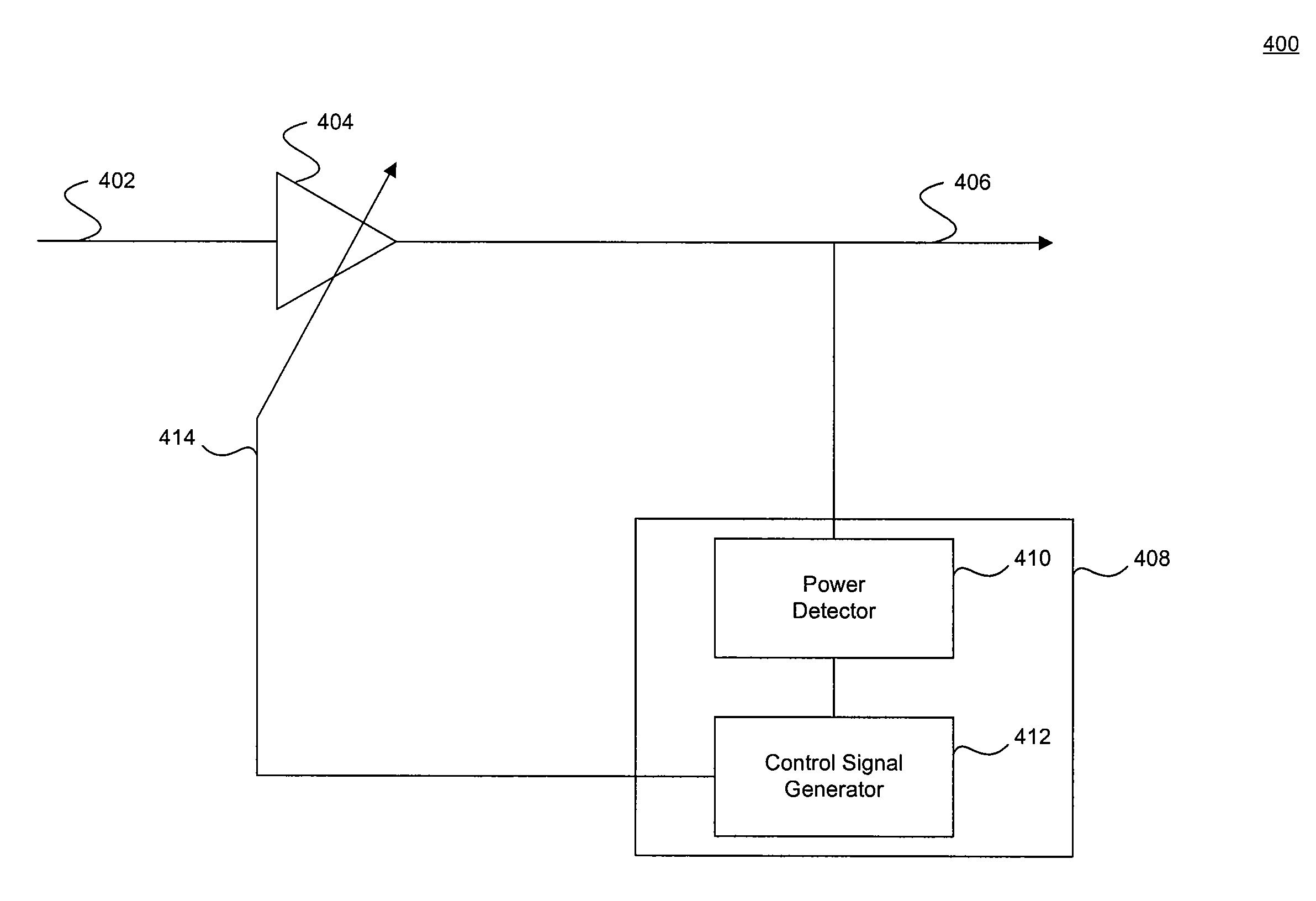

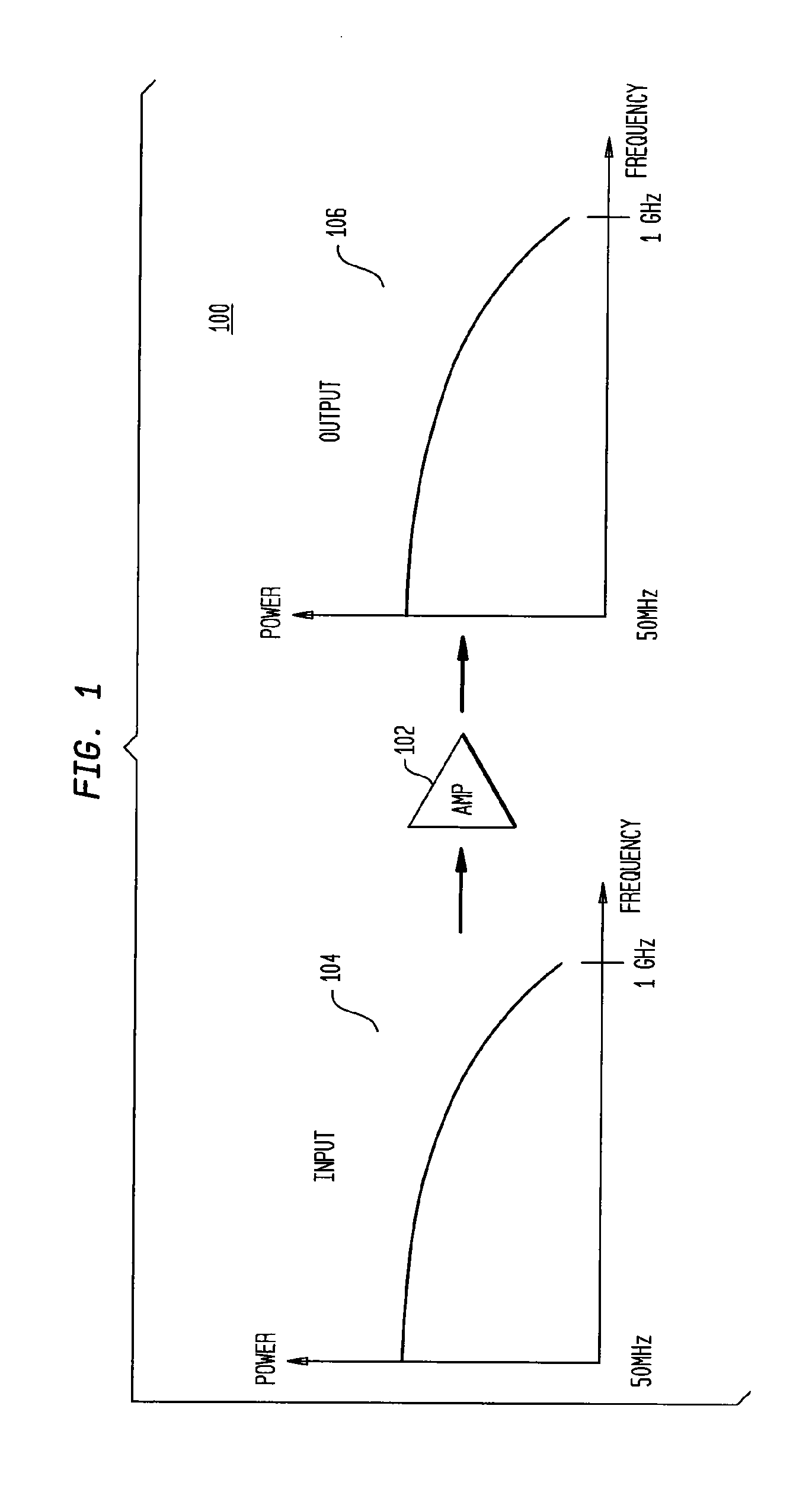

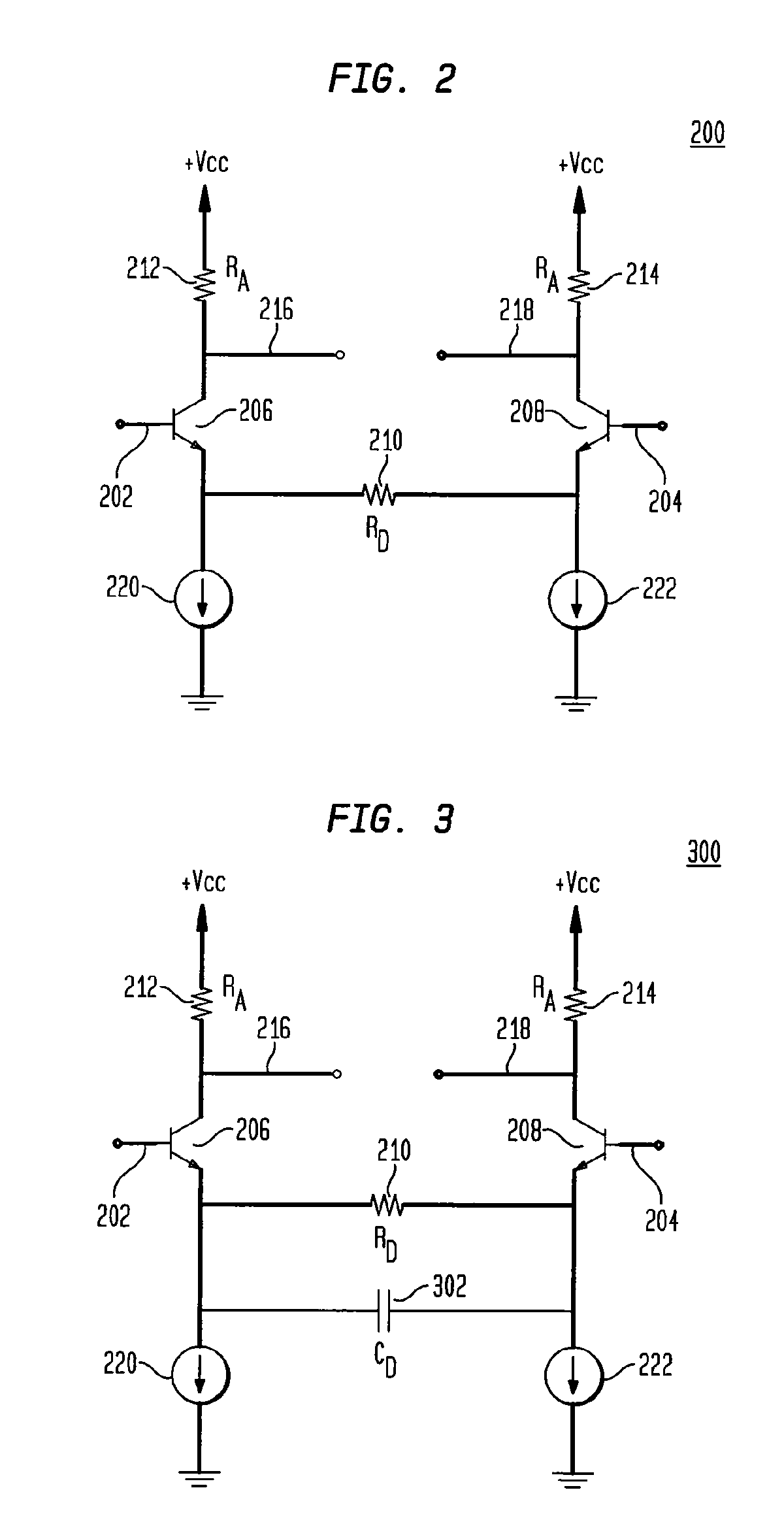

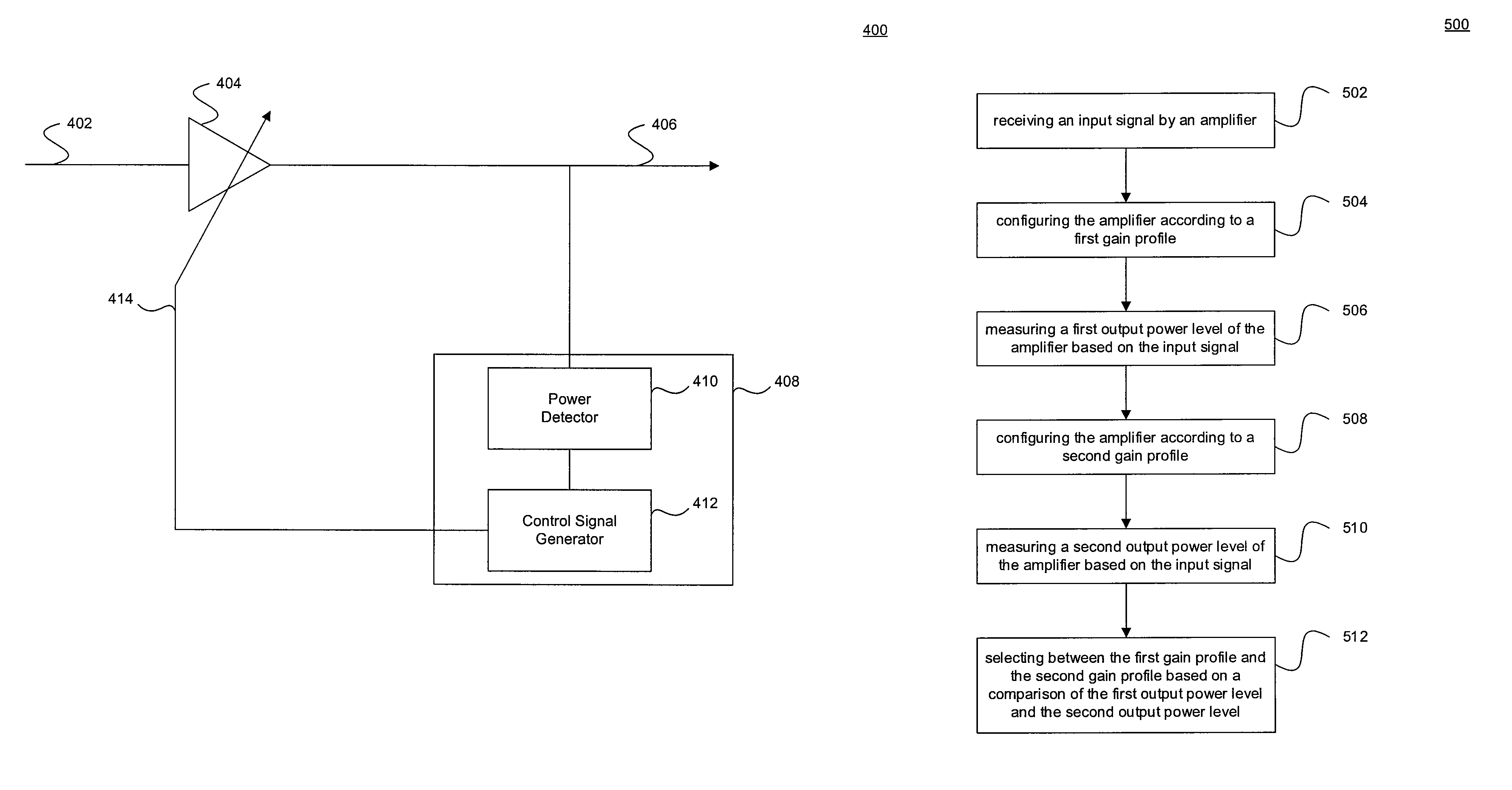

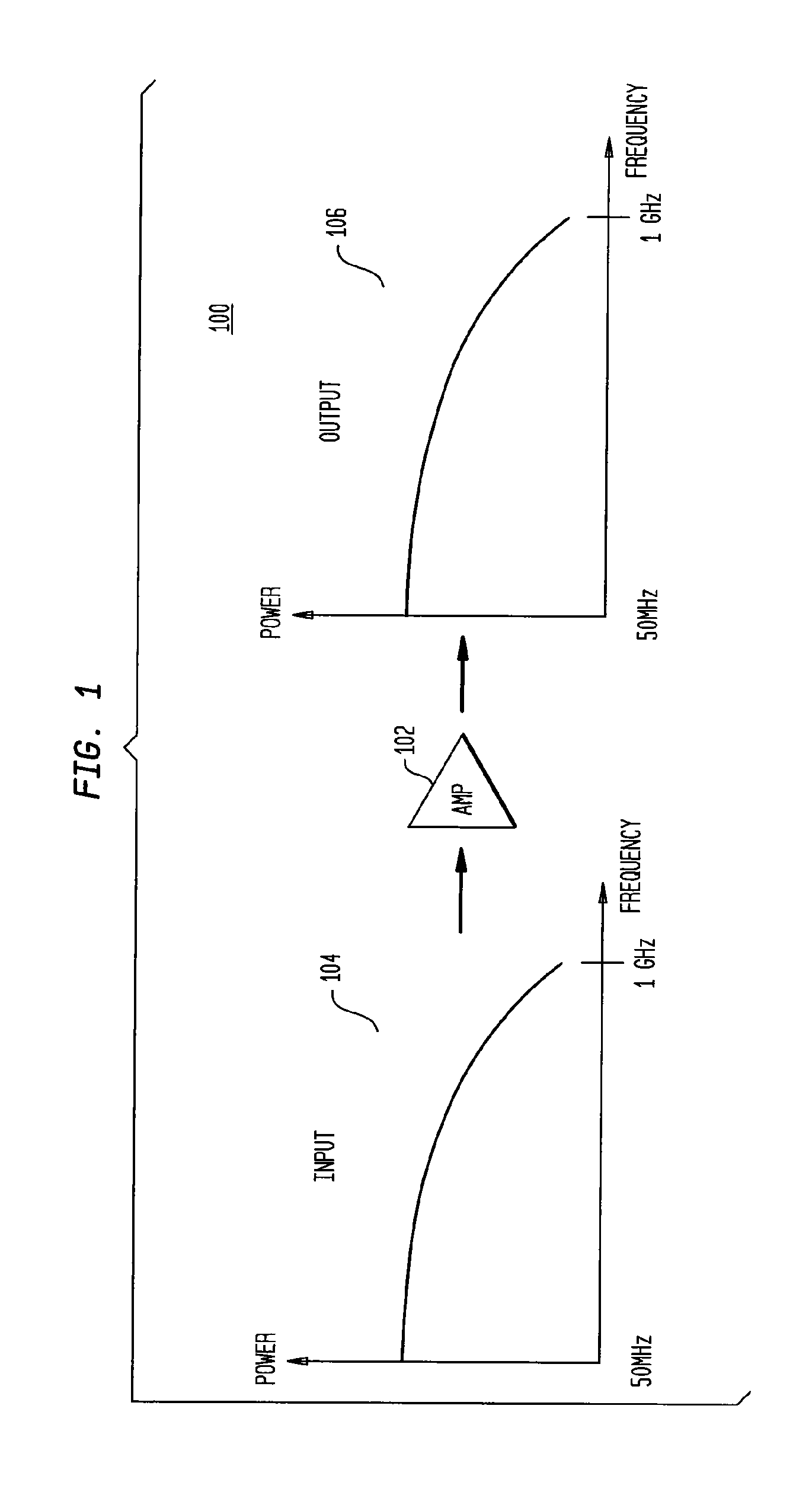

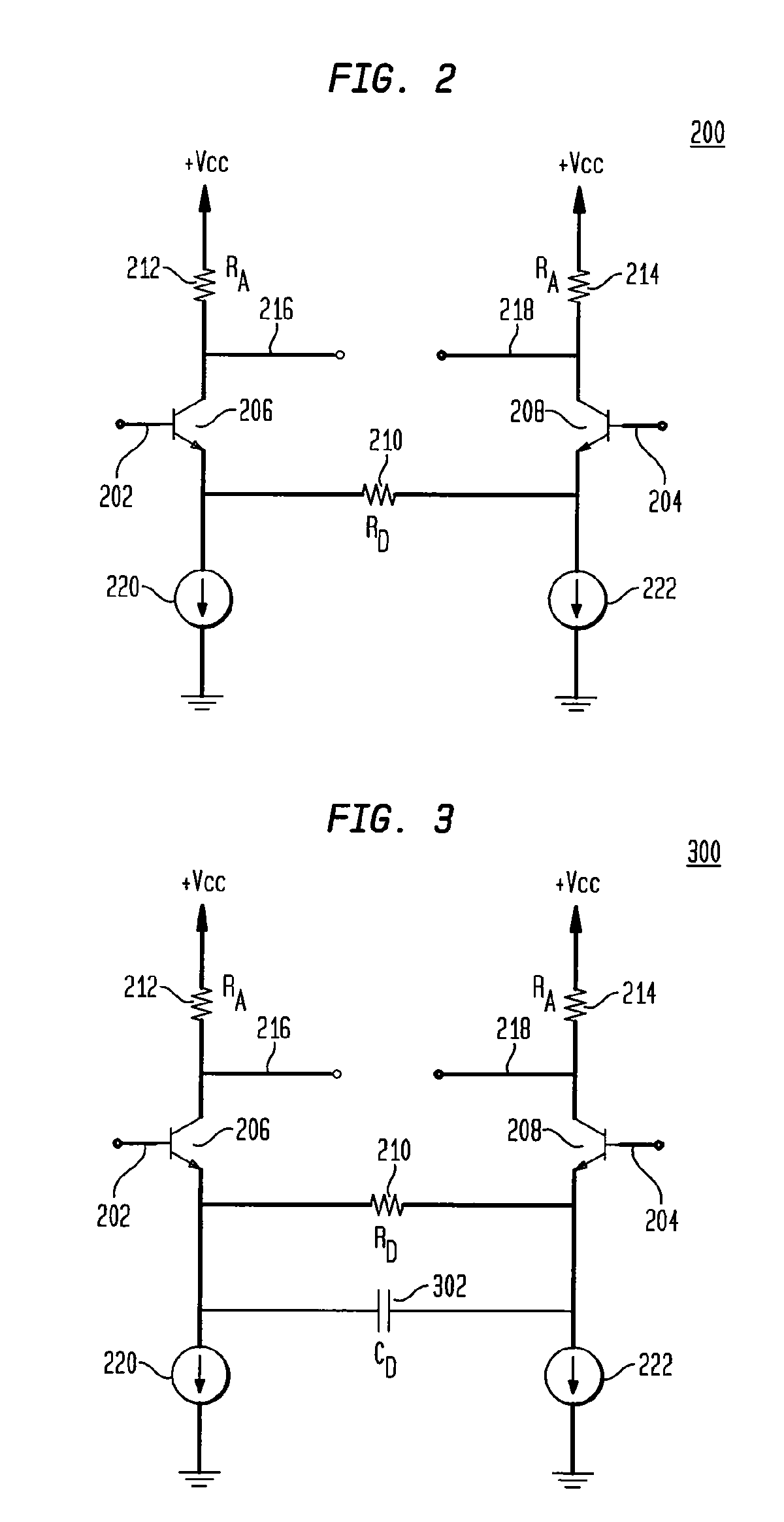

Amplifier with Automatic Gain Profile Control and Calibration

InactiveUS20090261899A1Increased gain profile accuracyReduce the impactElectric devicesCurrent/voltage measurementAudio power amplifierEngineering

Embodiments of the present invention provide systems and methods for automatic amplifier gain profile control, including a method for automatically configuring a variable gain profile amplifier according to received input and a variable gain profile amplification system. Further, embodiments of the present invention provide systems and methods for increased gain profile accuracy, including methods and systems to reduce the effects of temperature and / or process variations on the gain profile of an amplifier.

Owner:AVAGO TECH INT SALES PTE LTD

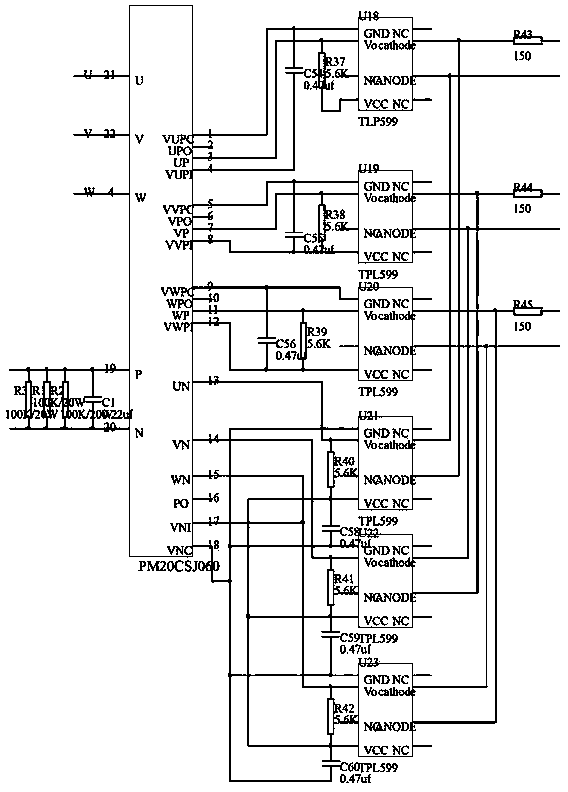

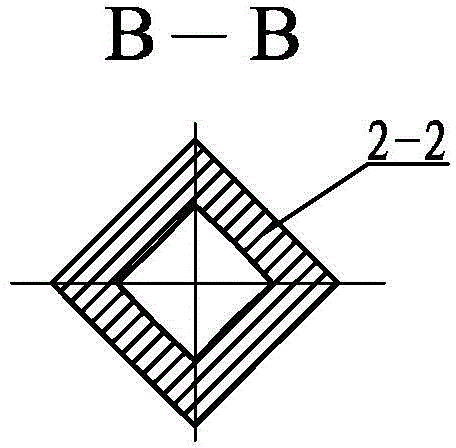

Double-linear-motor contour compensation device and method based on fuzzy RBF network sliding mode

InactiveCN103414419AEliminate chatterImprove profile accuracyElectronic commutation motor controlVector control systemsDigital signal processingGrating

The invention provides a double-linear-motor contour compensation device and method based on a fuzzy RBF network integral sliding mode with respect to a double-linear-motor numerical control feeding system with the axial direction being in mutual vertical movement. A real-time contour error is used as the input of a controller, the powerful self-learning ability of the controller enables the contour error to tend to zero within limited time, and thus contour machining precision is improved. The double-linear-motor contour compensation device comprises a commutating and voltage-stabilizing unit, an IPM inverter, a DSP, a Hall sensor, a grating ruler, a current detection unit, a position and speed detection unit, an optical coupling isolation circuit, a driving protection circuit and a fault detection and protection circuit. The DSP comprises a QEP circuit of an event manager EVA, an ADC module, a PWM unit, a Flash storage module, a program storage, a timer and a PDPINT pin. A PI controller of a position signal setter, a linear motor position loop, a speed loop and an electric current loop, a contour error calculator, a fuzzy RBF network integral sliding mode contour compensator and a driver device are further arranged inside the DSP. The double-linear-motor contour compensation device is good in robustness, suitable for contour machining tasks of any track and capable of achieving high-precision contour control.

Owner:SHENYANG POLYTECHNIC UNIV

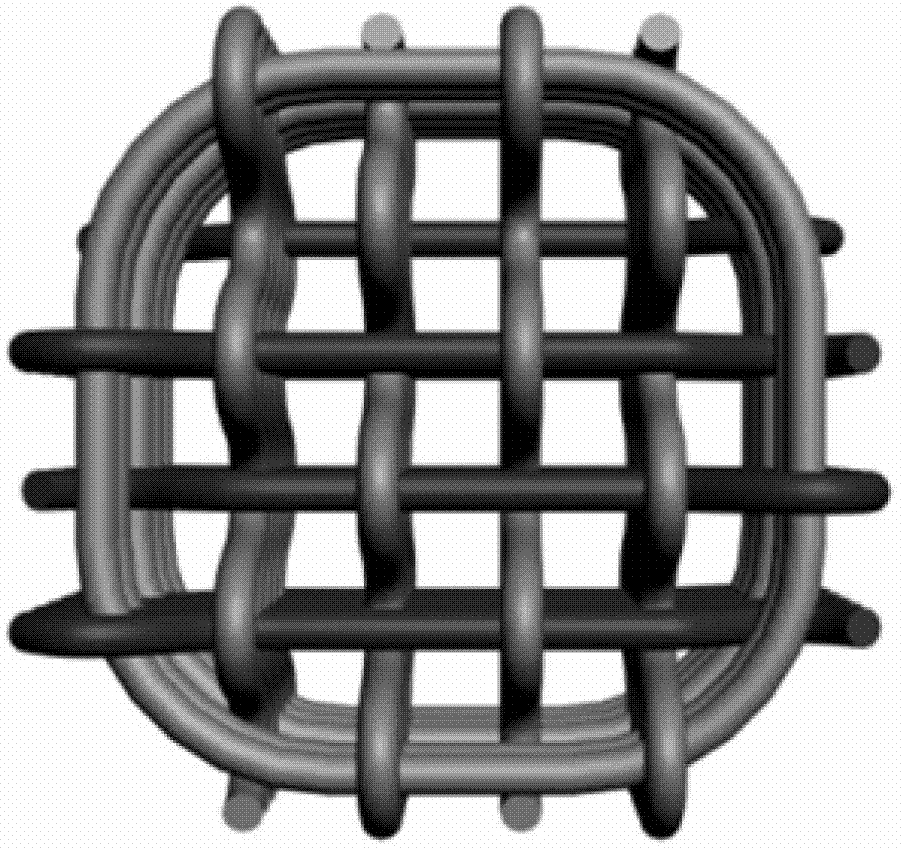

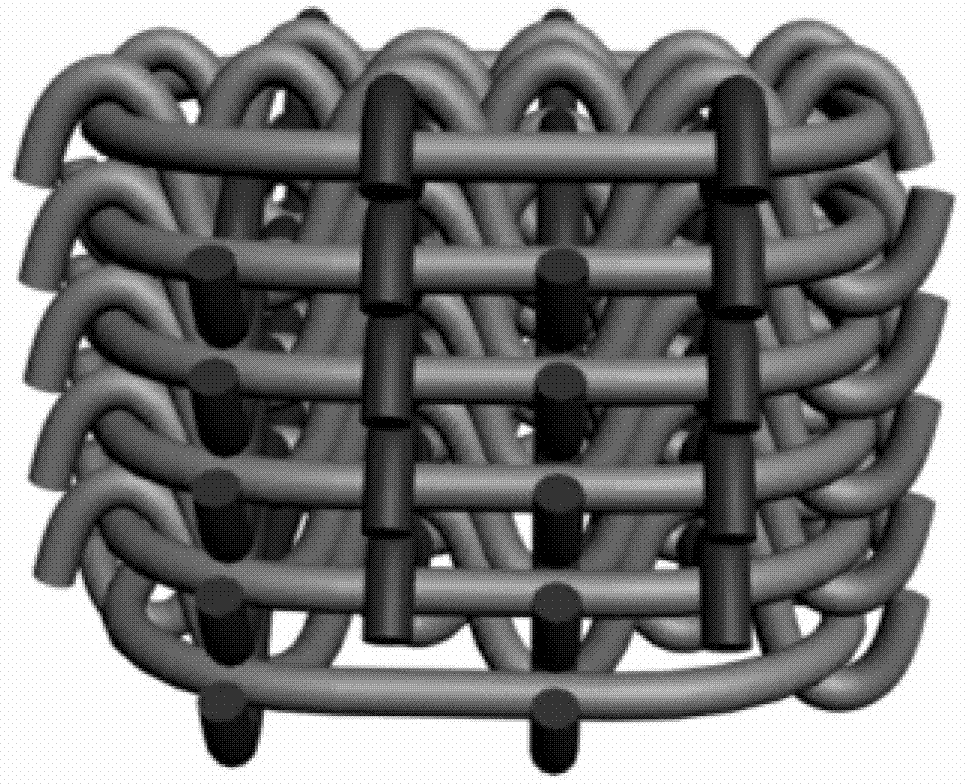

Method for profiling weaving thick top-to-thin wall capping fabric

The invention relates to a method for profiling weaving a thick top-to-thin wall capping fabric. The method comprises the following steps: 1, the capping fabric is woven from the center of a core model to form, the fabric is woven outside the weaving core model, and two pairs or four pairs of yarns which are crossed with each other are used to weave one or two weaving structures to circularly form a square top; 2, the interlaced yarns which form the square top are taken as warps, and wefts are gradually guided into each layer of yarns layer by layer; the square top is taken as a center, the wefts are woven in an intertwining manner to form a concentric circle, and a round top is formed after a plurality of circular weaving; and 3, after the round top is completely woven, the fabric is woven from a thick top capping fabric to a conical thin-wall fabric, the weaving diameter of the fabric is gradually increased during the conversion process and is increased through adding the weft arrays along the warp direction, and the weft density is kept consistent. By the method, a forming and producing technology of the complicated capping fabric is simplified, the internal fibers of the capping reinforcement fabric are distributed uniformly, a fabric forming effect is enhanced, and the clear dimension profiling weaving is realized.

Owner:NANJING FIBERGLASS RES & DESIGN INST CO LTD

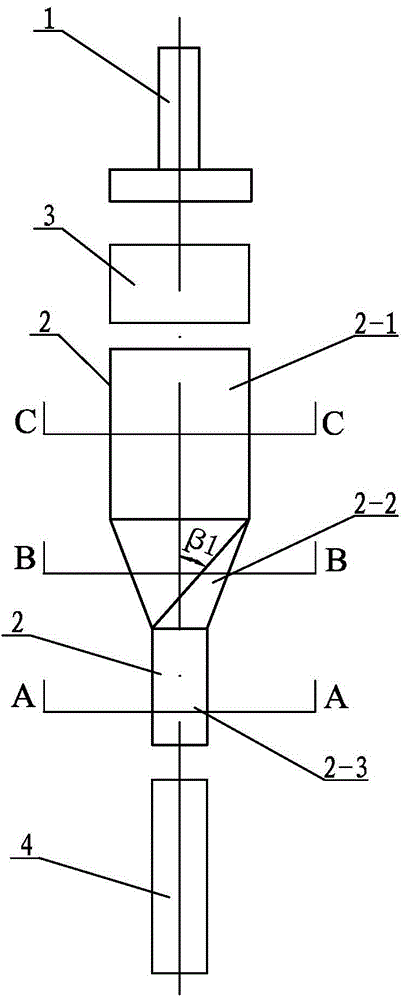

Variable cross-section twisting and molding device and method for metal material

ActiveCN103551415AImprove efficiencyTo achieve the effect of deep refinementExtrusion diesExtrusion mandrelsCrystalliteMetallic materials

The invention provides a variable cross-section twisting and molding device and method for a metal material, relates to a device and a method of a large plastic deformation technology, and aims to solve the problems of an existing twisting process that grain crystal refining can be realized only after a plurality of times of loading are carried out back and forth on the two sides and the production efficiency is low. The device is characterized in that a first twisting mould is composed of a first large cross-section rectangular channel, a first pyramid spiral channel and a first small cross-section rectangular channel in sequence from top to bottom; the cross section of the first pyramid spiral channel is reduced gradually from top to bottom; the cross section of the first pyramid spiral channel is rectangular; a first puncher pin is coaxially arranged above the first twisting mould. The method comprises the following steps: 1. the spiral angle is 10-60 degrees, the length of the spiral channel is 0.5d-3d and the extrusion ratio is 4-100; 2. a blank enters the first large cross-section rectangular channel under the effect of the first puncher pin; 3. the twisting angle of the blank is 90-180 degrees; 4. the variable cross-section twisting of the material is finished to form a part. The variable cross-section twisting and molding device and method for the metal material are used for preparing or machining and molding the high-performance metal material.

Owner:福建祥鑫股份有限公司

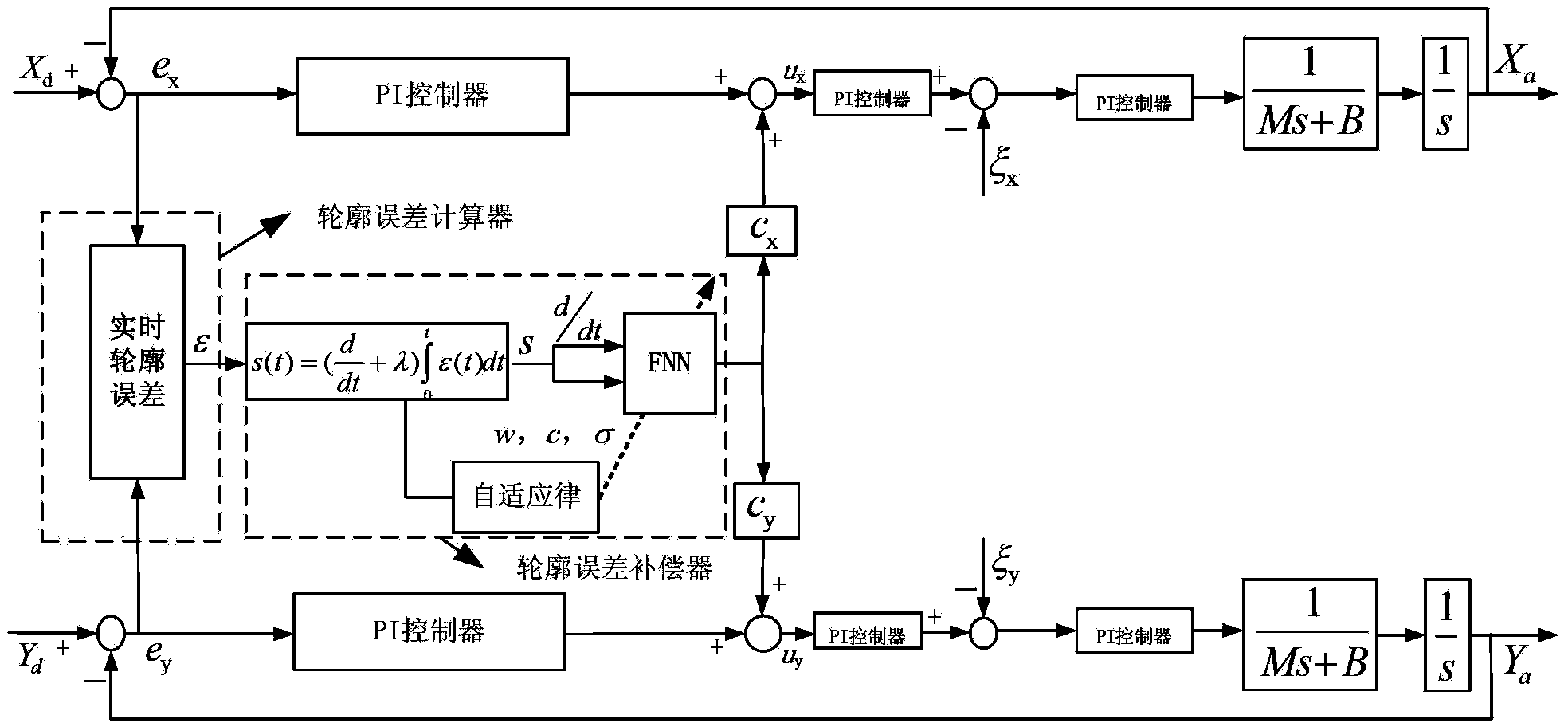

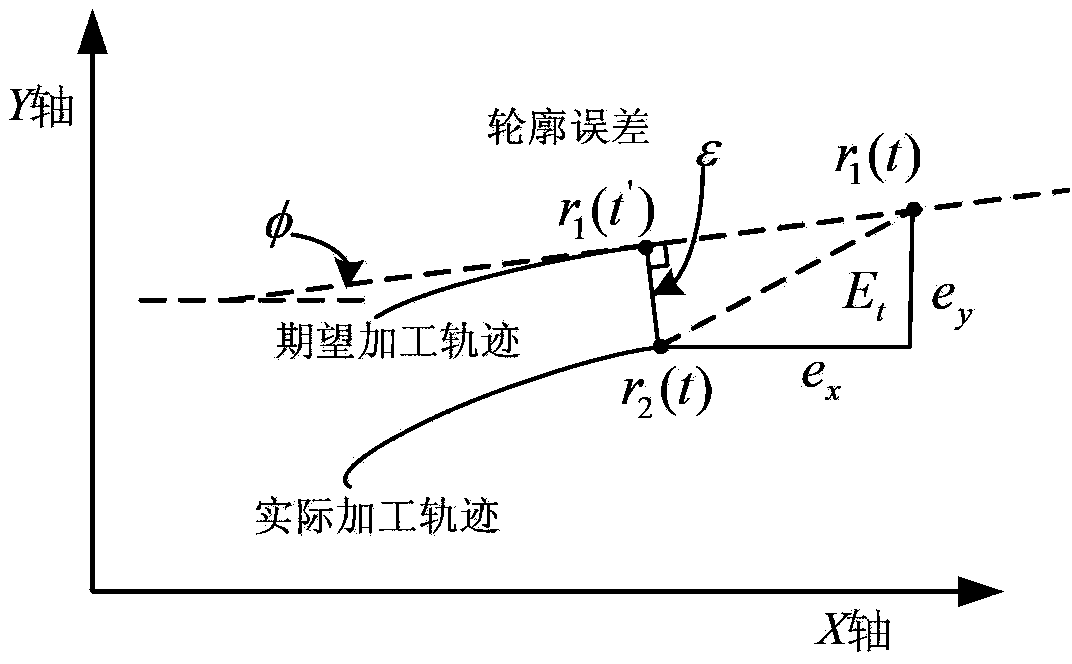

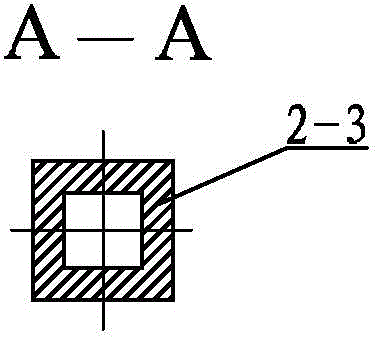

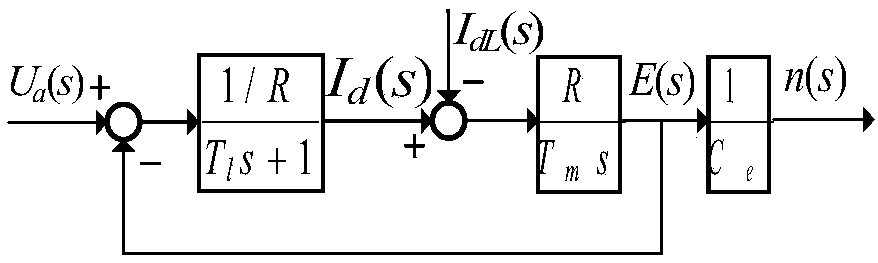

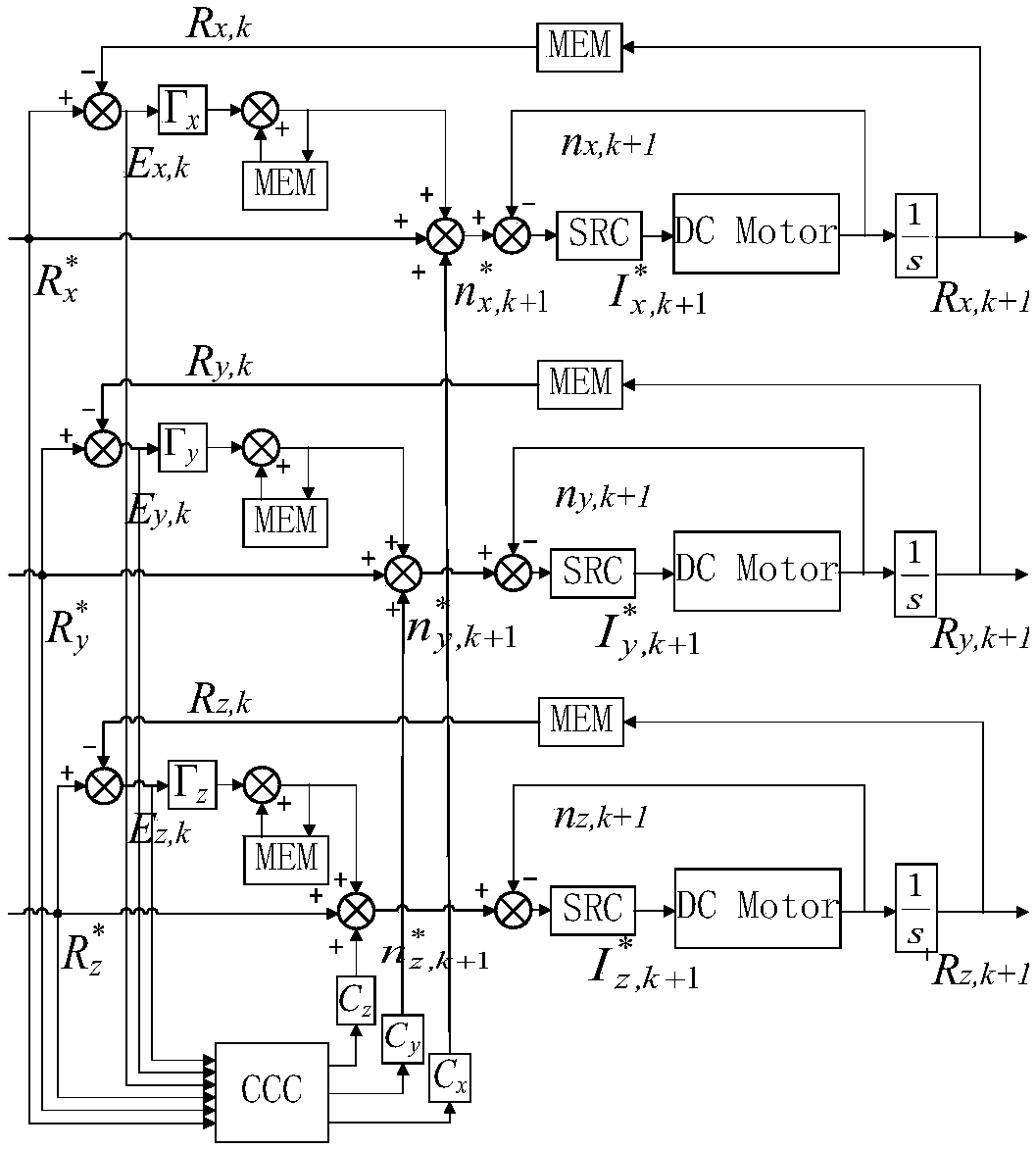

Rectangular coordinate robot iteration sliding mode cross coupling control method

ActiveCN107479385AImprove profile accuracyImprove robustnessAdaptive controlVelocity controllerTracking error

The present invention discloses a rectangular coordinate robot iteration sliding mode cross coupling control method. The method comprises the following steps: establishing a rectangular coordinate robot contour error model and a direct current motor model, establishing a sliding mode speed controller, an iteration learning position controller and an interaxial variable gain cross coupling controller, and performing iteration sliding mode cross coupling control, wherein the sliding mode speed controller is configured to inhibit aperiodic interference, the iteration learning position controller is configured to reduce tracking errors, and the interaxial variable gain cross coupling controller is configured to reduce contour errors. The constructed iteration sliding mode cross coupling controller has high contour precision and high robustness.

Owner:NANJING UNIV OF SCI & TECH

Amplifier with automatic gain profile control and calibration

InactiveUS7804356B2Reduce impactImprove profile accuracyElectric devicesCurrent/voltage measurementAudio power amplifierEngineering

Embodiments of the present invention provide systems and methods for automatic amplifier gain profile control, including a method for automatically configuring a variable gain profile amplifier according to received input and a variable gain profile amplification system. Further, embodiments of the present invention provide systems and methods for increased gain profile accuracy, including methods and systems to reduce the effects of temperature and / or process variations on the gain profile of an amplifier.

Owner:AVAGO TECH INT SALES PTE LTD

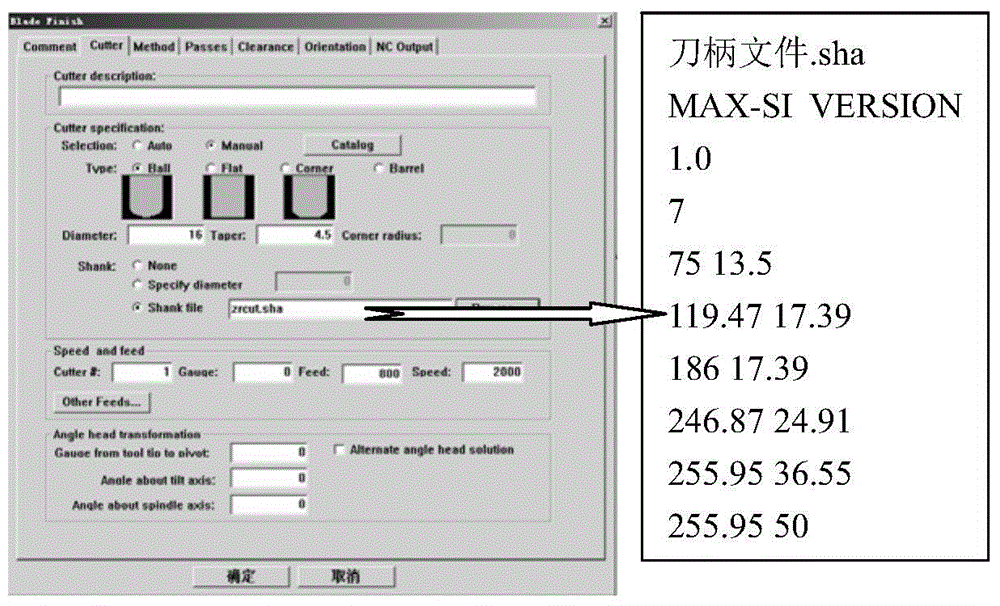

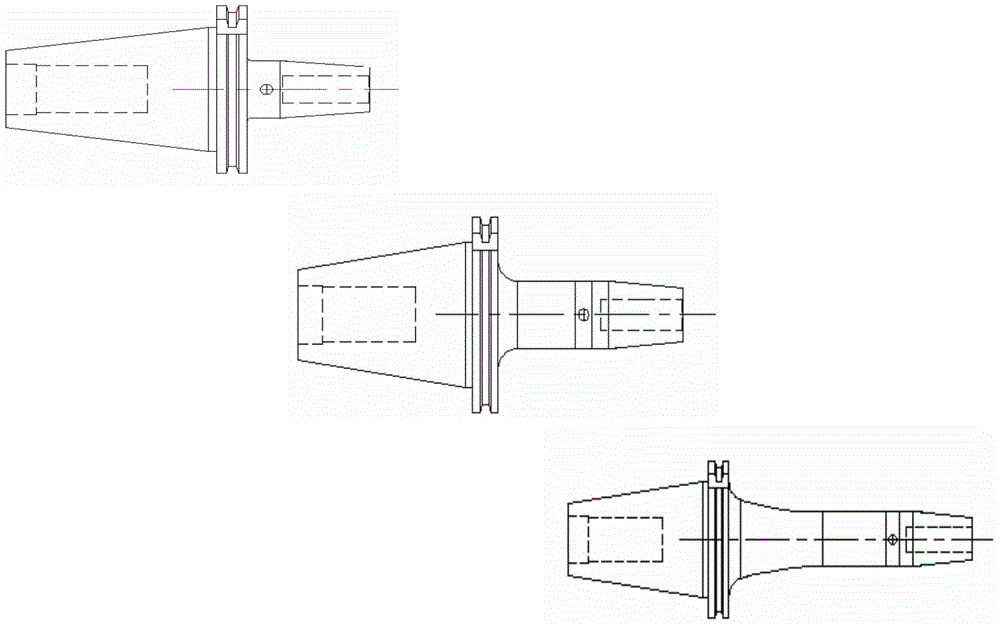

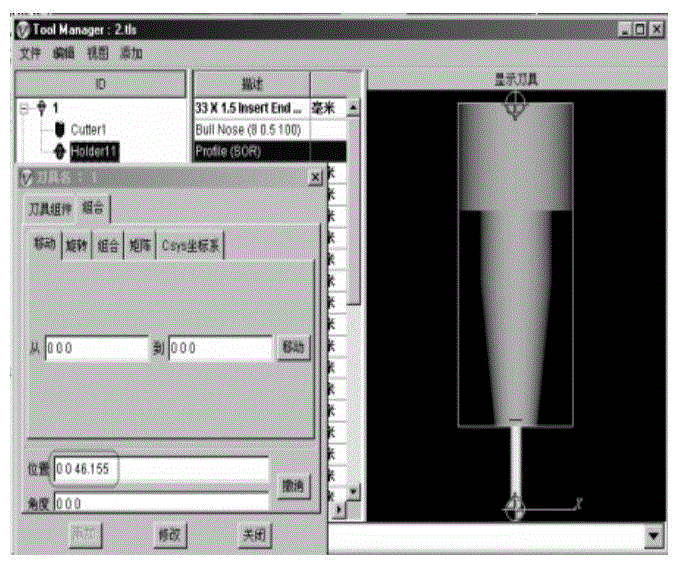

Long-cantilever large-scale integral blade-disc blade one-step milling method

ActiveCN104475841ASolve the long hanging problemIncrease overhangWorkpiecesMilling equipment detailsMachining vibrationsMilling cutter

The invention provides a long-cantilever large-scale integral blade-disc blade one-step milling method and belongs to the technical field of aeroengines. The long-cantilever large-scale integral blade-disc blade one-step milling method comprises the following steps of 1, cutter selection, 2, five-axis processing anti-interference calculation, 3, five-axis processing cutter locus design: 1), integral spiral cutter locus design and 2), blade root and channel cutter locus design, and 4, milling. The long-cantilever large-scale integral blade-disc blade one-step milling method adopts an integral spiral milling cutter locus mode, realizes precise milling of blades by one-step clamping, eliminates secondary clamping errors, prevents butt joint milling gear marks and effectively control processing deformation. A gradient cutter handle is used, stretches into a cavity groove and carries out milling so that the overhanging length of the cutter is at most shortened by 4 times than that of the cutter with the same size, processing vibration is effectively controlled, blade surface vibratory lines are eliminated and part surface quality is improved by one grade. Through the long-cantilever large-scale integral blade-disc blade one-step milling method, the non-standard cutter is changed to form a standard cutter so that all milling cutter standardization is realized, milling efficiency is greatly improved and machining efficiency is improved by 33%.

Owner:SHENYANG LIMING AERO-ENGINE GROUP CORPORATION

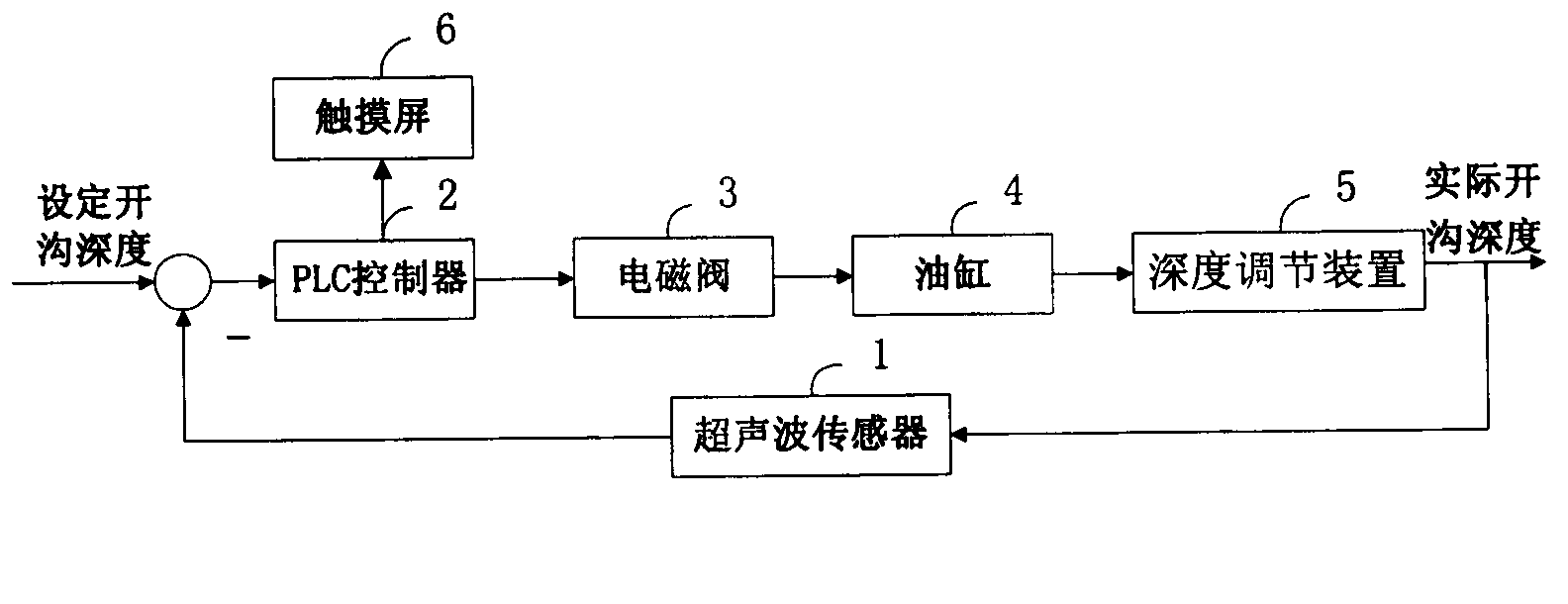

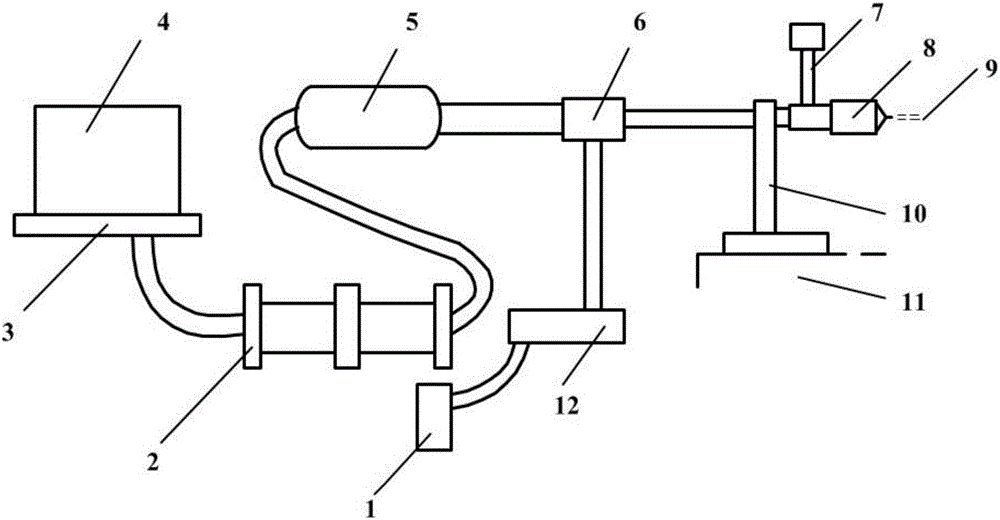

Seeder depth control system

InactiveCN103543755AControl depthDepth adjustmentControl using feedbackProgramme control in sequence/logic controllersSeederElectricity

The invention discloses a seeder depth control system. Land unevenness is collected by an ultrasonic sensor and converted into an electrical signal; the electrical signal is transmitted to a PLC to process; processing results are output an analog output module; action of an electromagnetic valve is controlled; an oil cylinder is driven to descend or ascend; a ditcher depth regulator is controlled in real time. Seeding depth can be regulated quickly and accurately. Seeding depth of a seeder can be precisely controlled effectively. Related parameters can be set in real time through an embedded integrated touch screen. The touch screen is communicated with the PLC through a communication port. Related information acquired is centrally displayed in real time. The seeder depth control system has the advantages that the quality of crop planting is guaranteed, the copying form of each component of a seeding unit of the precision seeder can be designed into independent copying, and seeding depth can be independently controlled according to surface fluctuation.

Owner:INNER MONGOLIA AGRICULTURAL UNIVERSITY

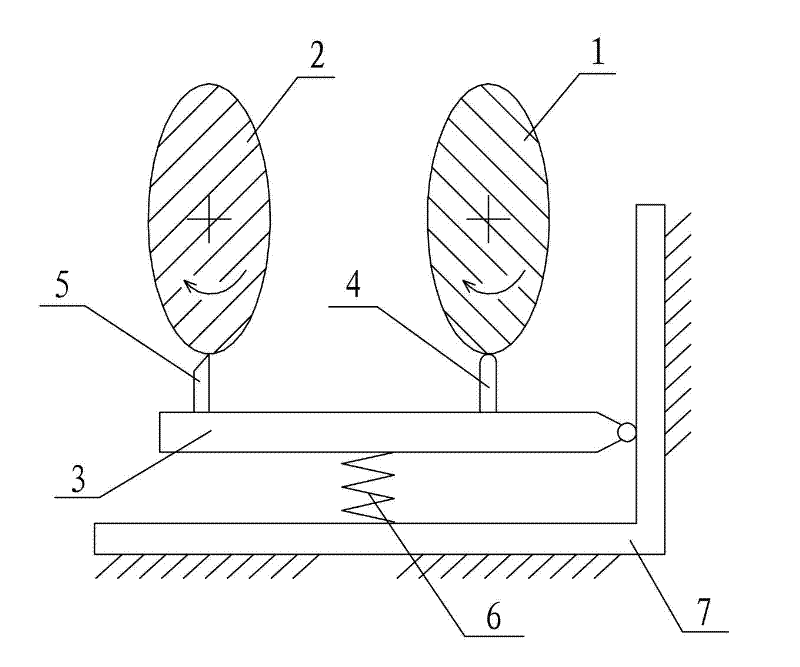

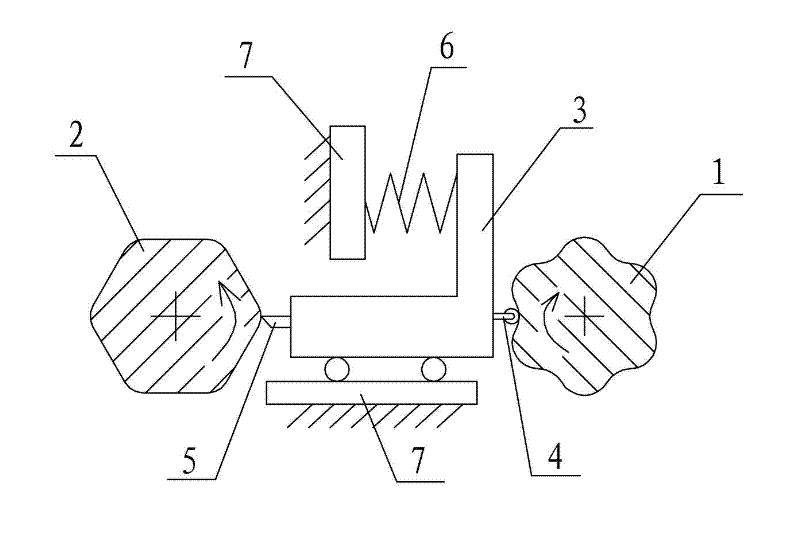

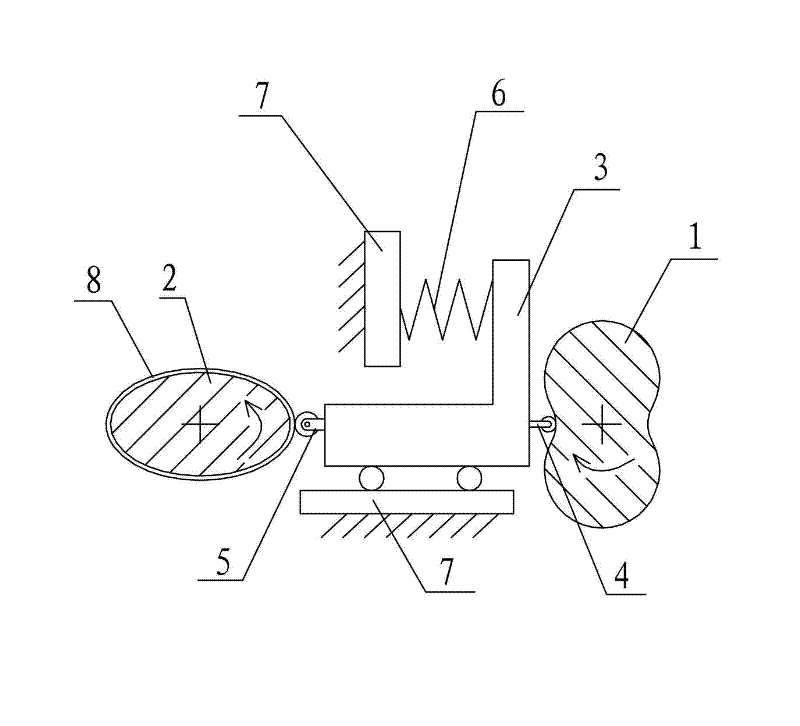

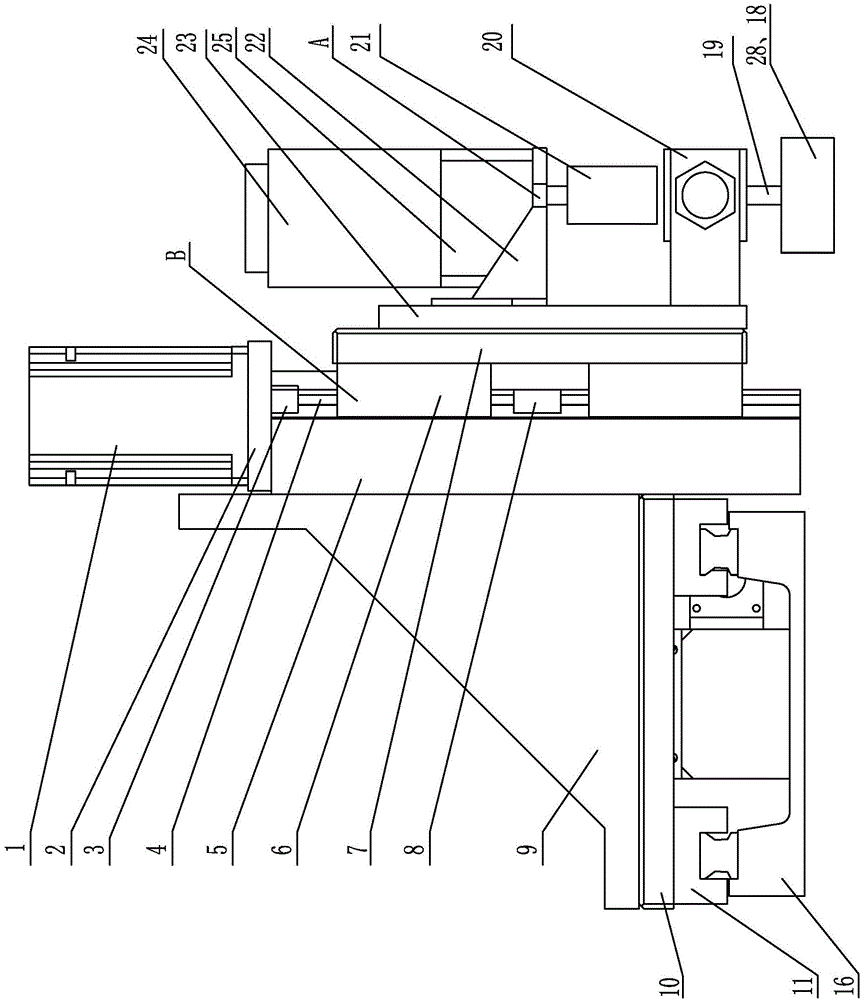

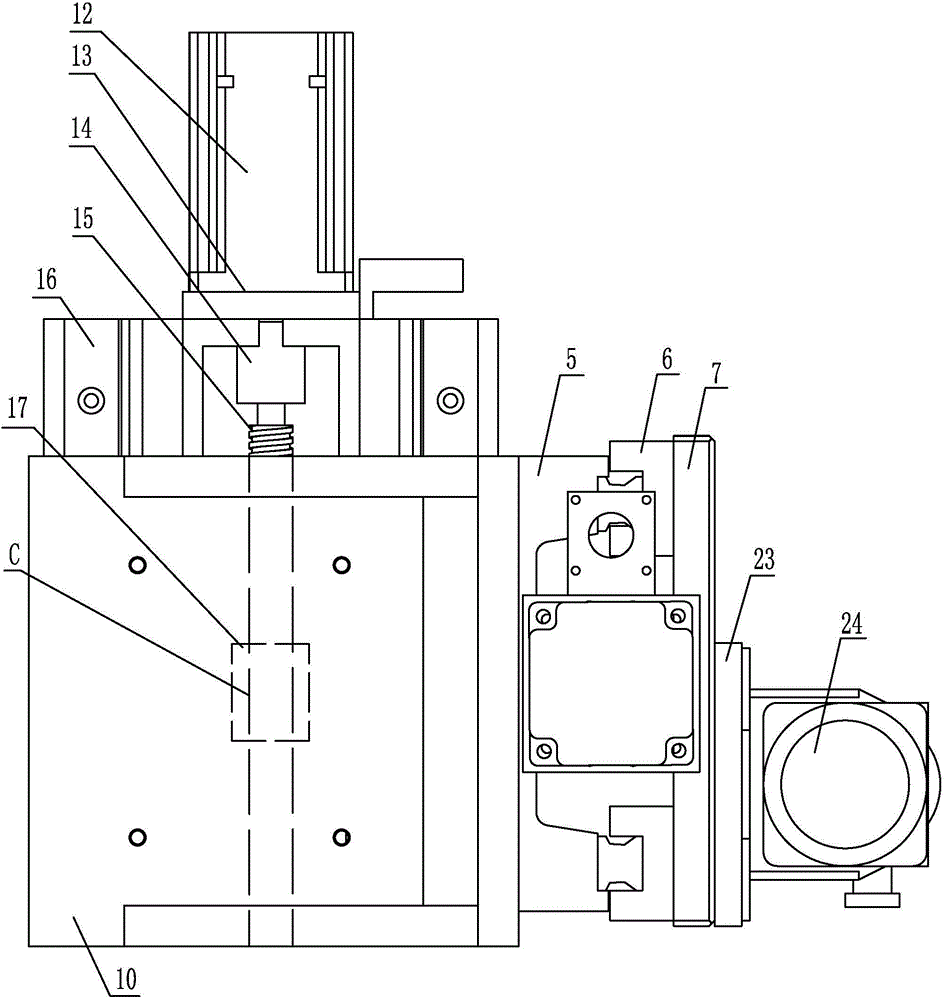

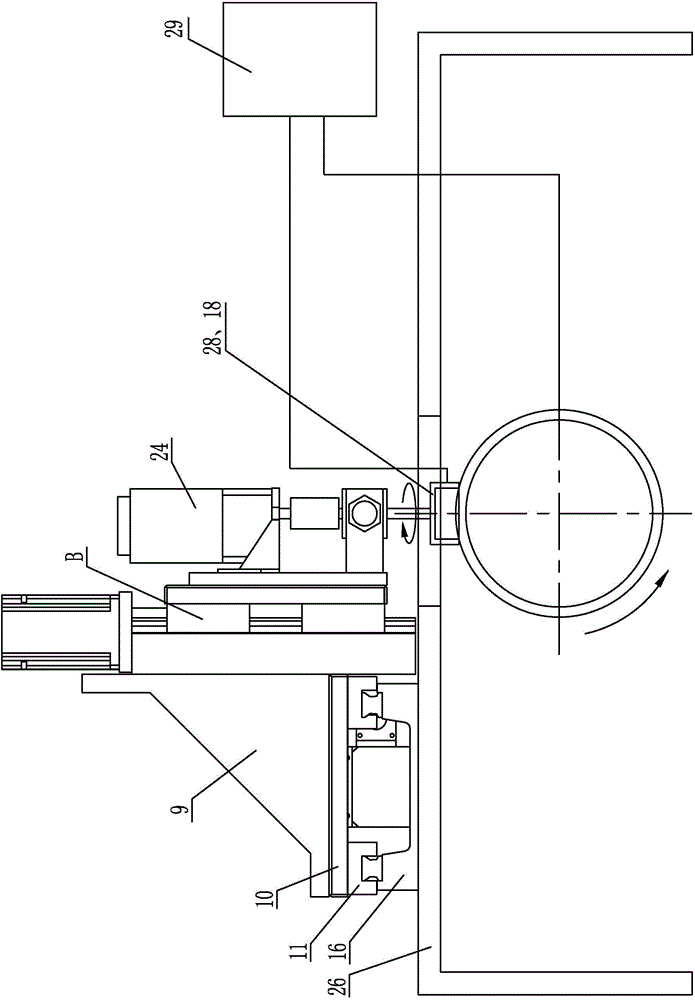

Transversely self-driven three-dimensional copying machining method and three-dimensional copying machine

InactiveCN102363274ASimple structureSimplified processing methodCopying process control systemsTurning machinesEngineeringSelf driven

The invention discloses a transversely self-driven three-dimensional copying machining method, which comprises the steps of: 1) leading a copying bracket to be positioned between a main shaft and a shaft of a profiling mould, leading a contact head to be faced to the shaft of the profiling mould, and leading a machining head to be faced to the main shaft; 2) transversely machining a retrofitted profiling mould and a workpiece to be machined; and 3) lengthways feeding. The invention further discloses a transversely self-driven three-dimensional copying machine which corresponds to the method. In the transversely self-driven three-dimensional copying machining method, the profiling mould can press the machining head to transversely move when the profiling mould rotates, so that a transverse power is provided and transmitted to the workpiece to be machined, the step of arranging a transversely driving device on the copying machine during conventional three-dimensional copying machining is eliminated, the structure and the machining method of the copying machine are simplified, and the invention is high in copying precision since the transverse power is directly provided by the profiling mould. The invention can be widely applicable to a three-dimensional copying technology.

Owner:GUANGZHOU CIVIL AVIATION COLLEGE

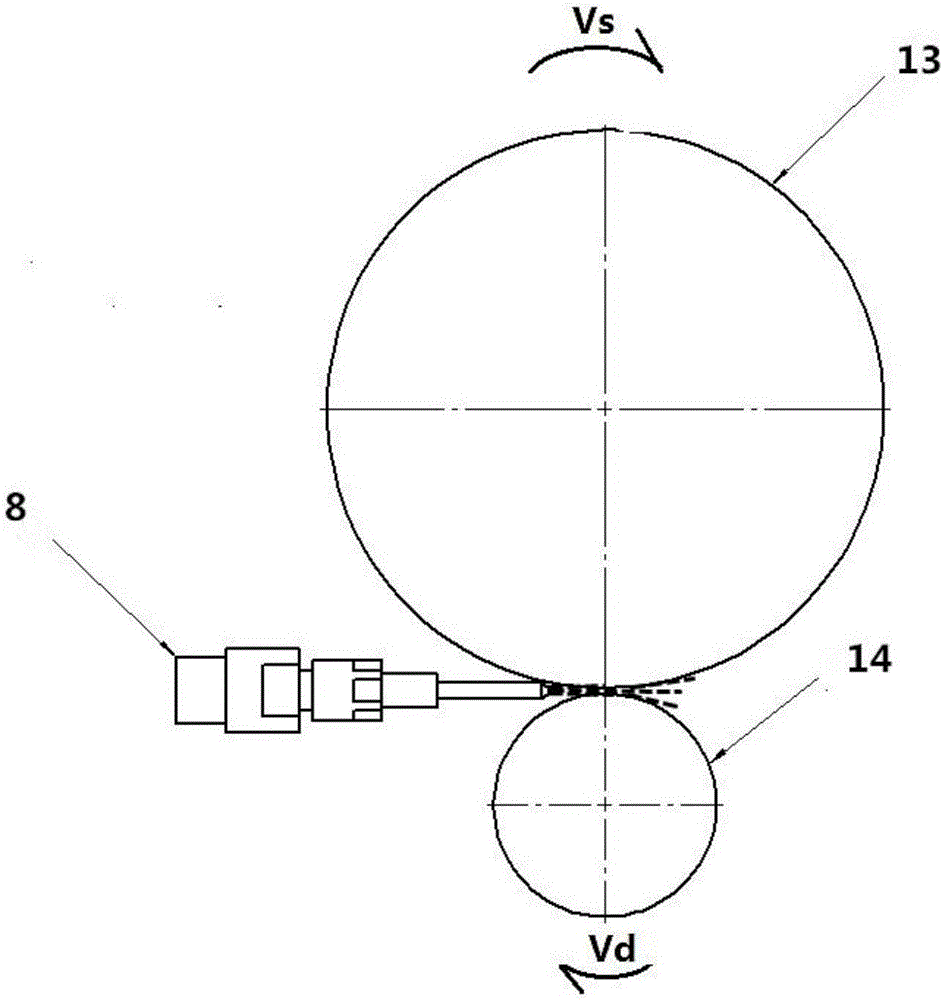

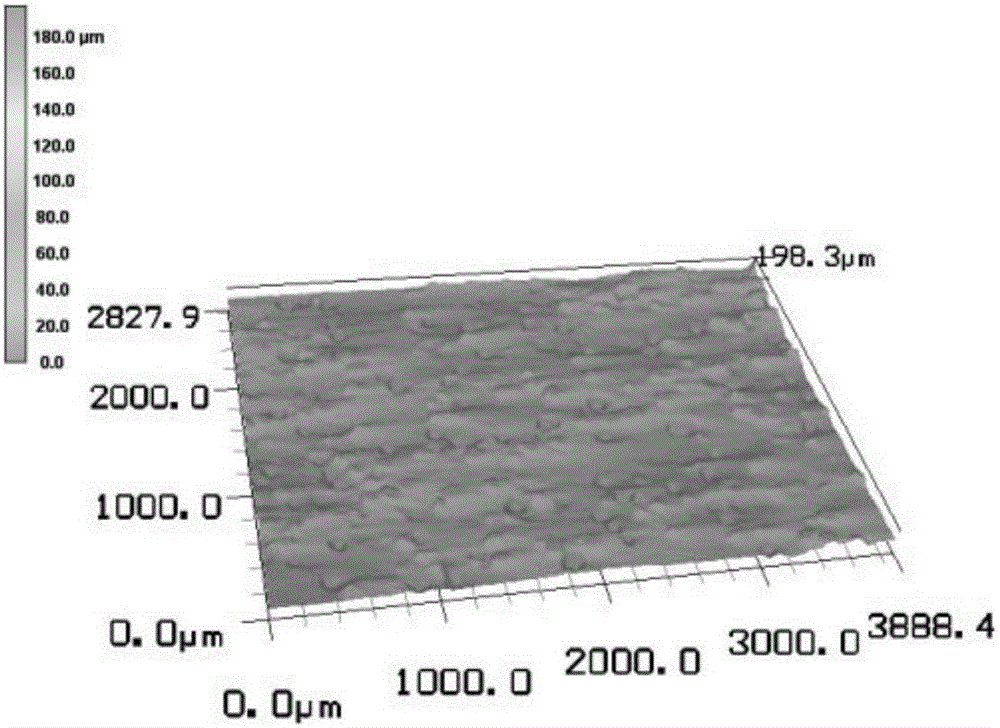

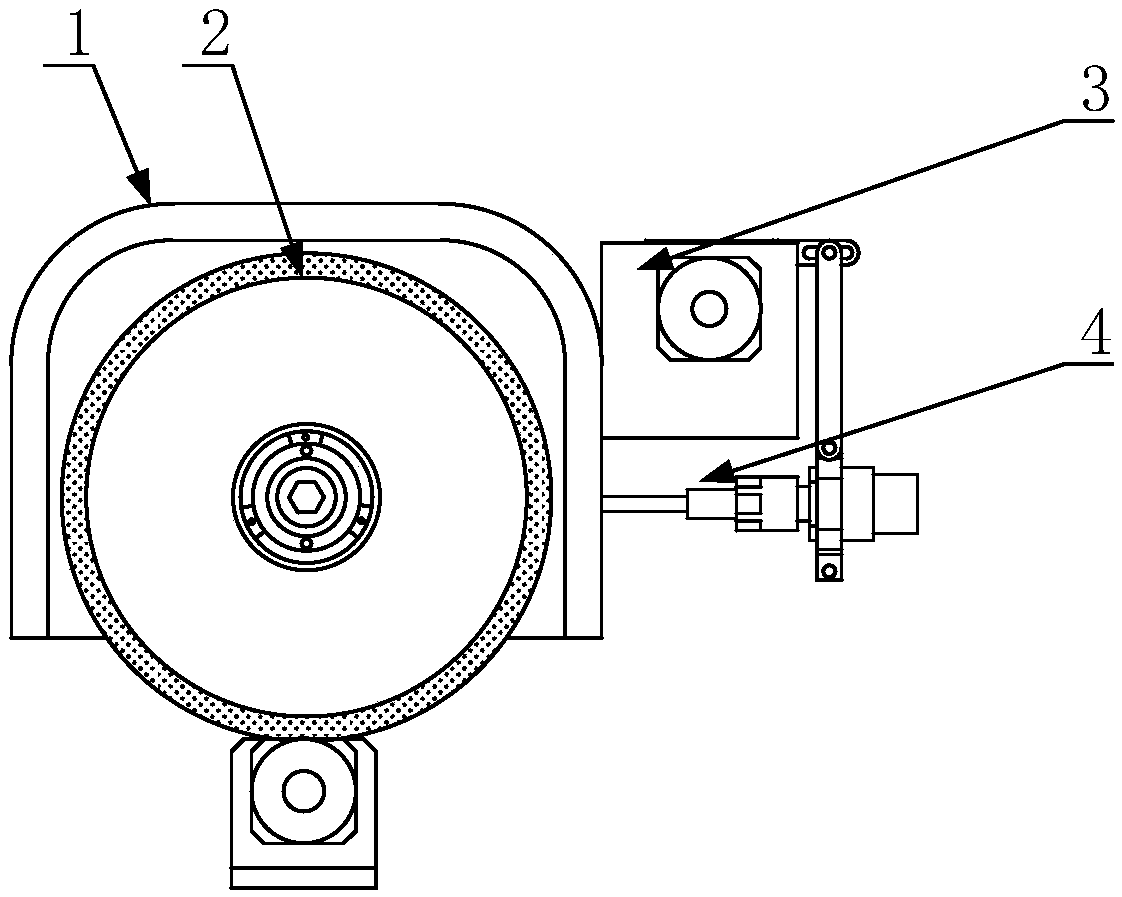

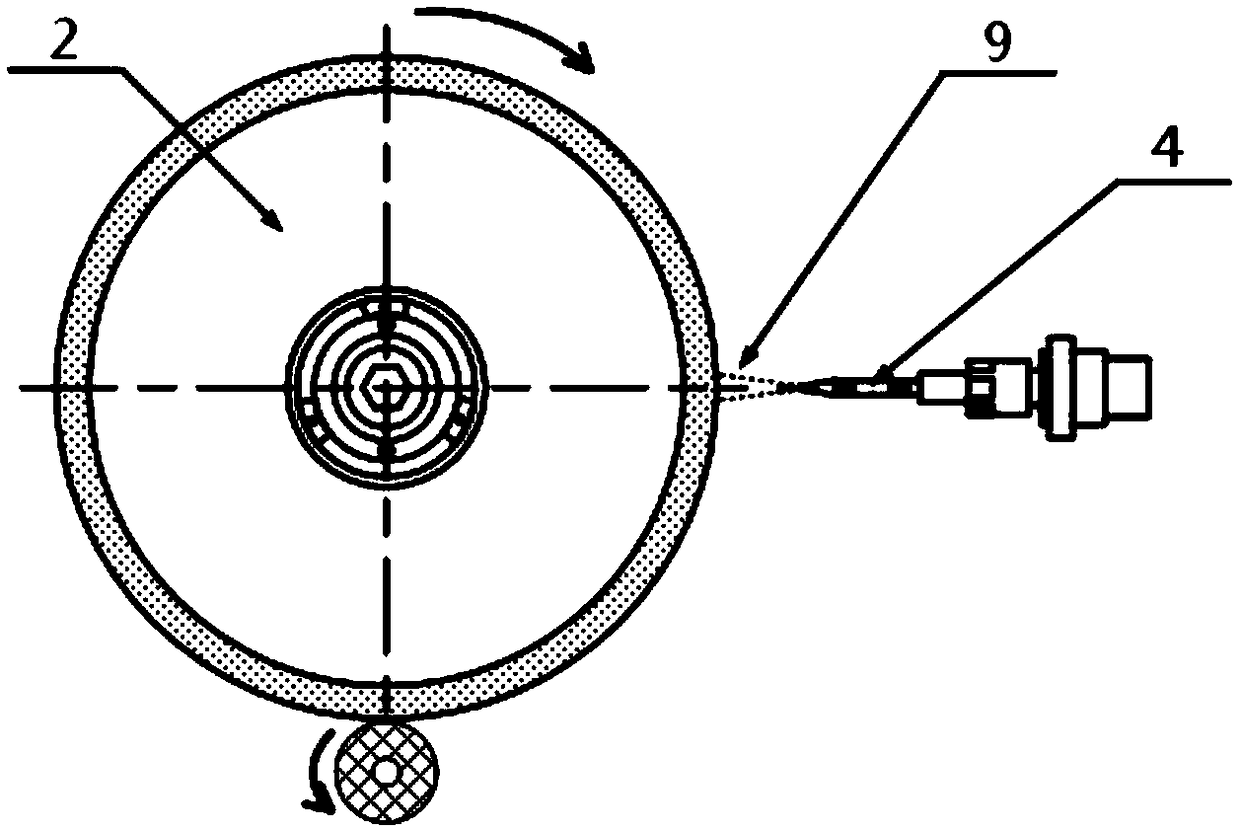

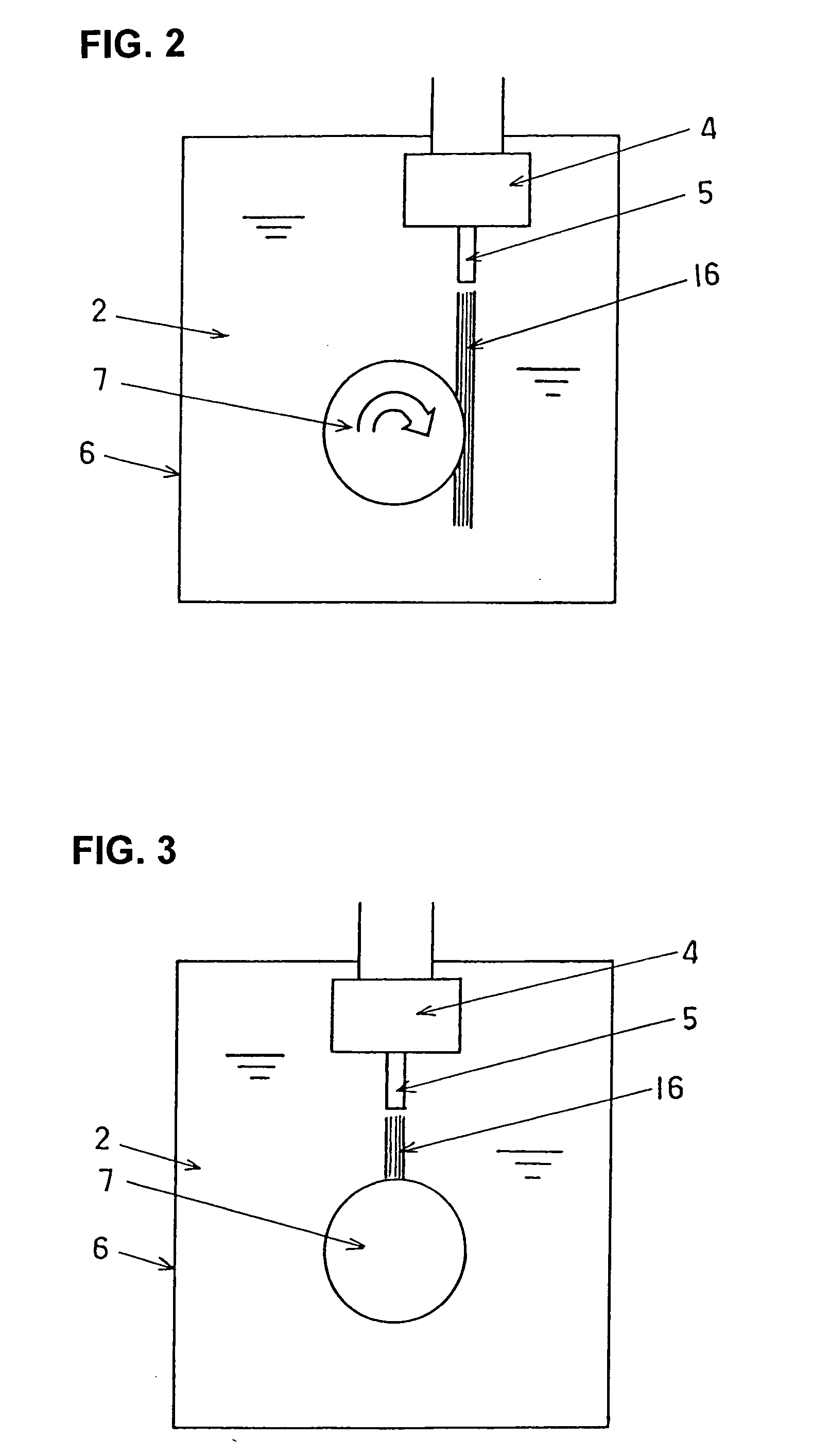

Combined precise trimming device and trimming method for ultrahard grinding sand wheel

ActiveCN106392885AImprove profile accuracySmall grinding forceAbrasive surface conditioning devicesEngineeringContact type

The invention discloses a combined precise trimming device and trimming method for an ultrahard grinding sand wheel. The method comprises a first step: grinding water jet rough trimming, specifically, an ultrahard grinding sand wheel and a trimming wheel are enabled to rotate at a certain speed, and the grinding sand wheel is enabled to feed in a reciprocation manner at a constant speed along an axial direction, meanwhile, the grinding water jet trimming device jets a grinding water jet into a gap formed by the ultrahard grinding sand wheel and the trimming wheel along a direction vertical to an axis of the grinding sand wheel, and the grinding water jet impacts the surface of the ultrahard grinding sand wheel, such that a finished sand wheel bonding agent is crushed and abrasive particles fall off; a second step: contact type fine trimming, specifically, when circle run-out of the sand wheel is reduced to certain extent, the circle run-out cannot be continuously reduced effectively by using the grinding water jet purely, and the trimmed ultrahard grinding sand wheel is used to perform fine trimming on stainless steel or cast iron. The abrasive particles with inconsistent heights are removed or ground off, such that the abrasive particles on the surface of the sand wheel tend to be consistent; and a third step: grinding water jet sharpening, specifically, performing final sharpening on the sand wheel by adopting low-pressure large-jet target distance grinding water jet.

Owner:SHANDONG UNIV

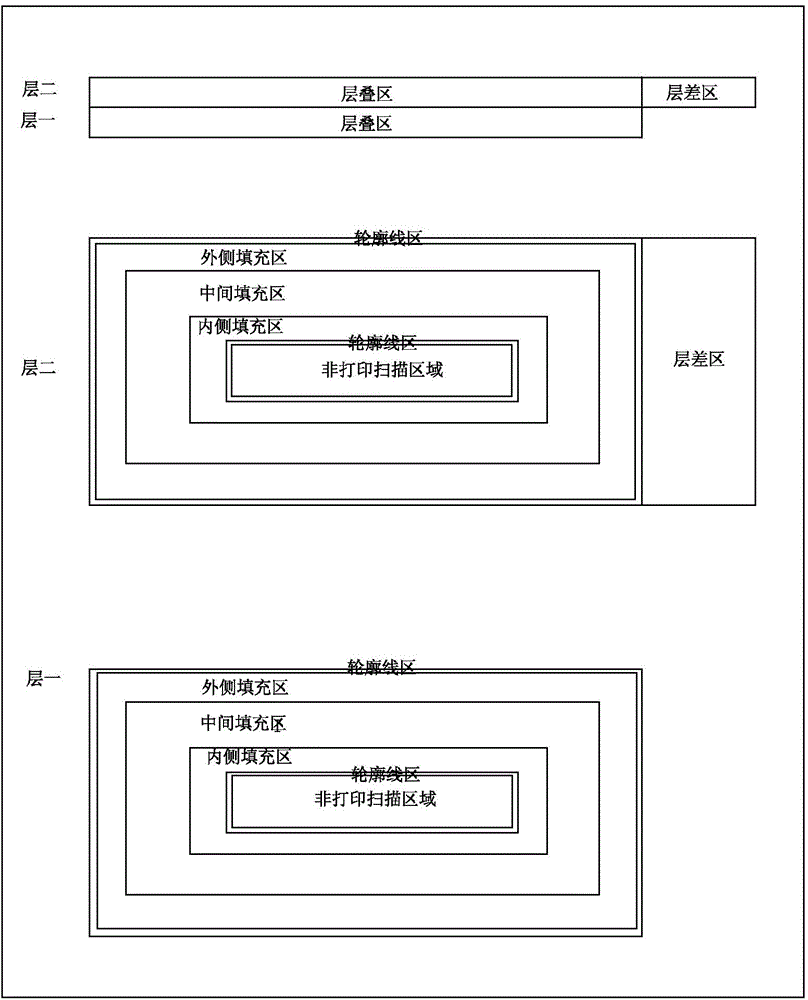

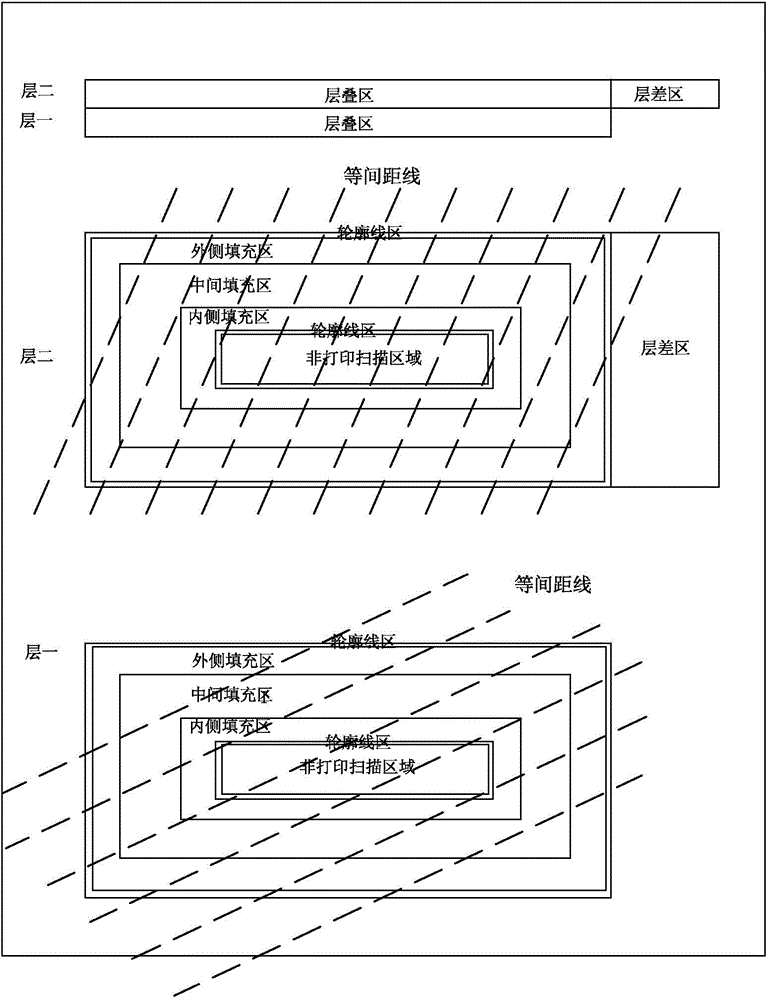

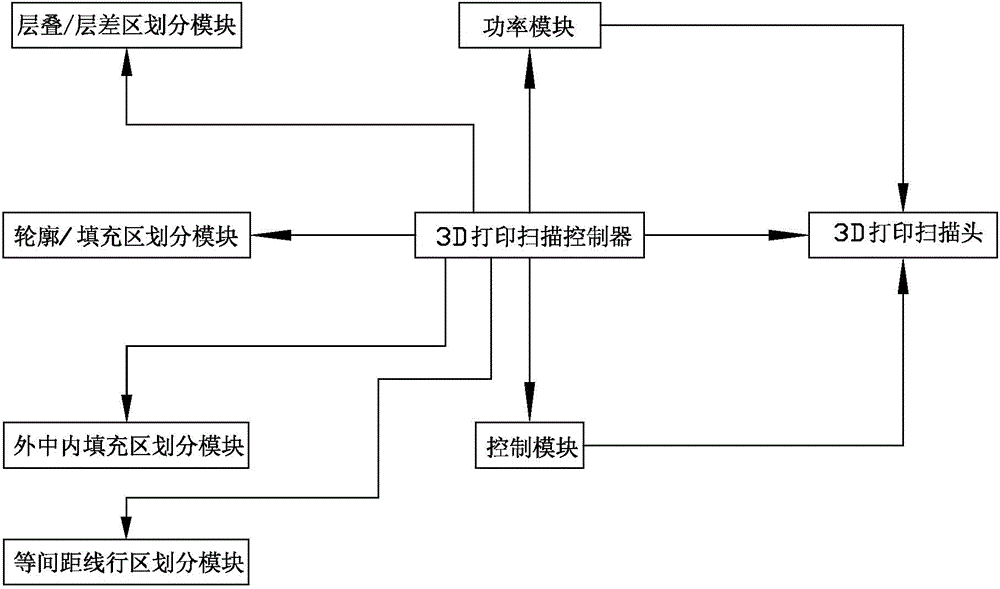

Control method and controller for 3D (three-dimension) printing and scanning

Owner:GUANGDONG HANBANG 3D TECH CO LTD

Method for finishing high-precision bearing-shaping abrasion wheel and feeding device thereof

InactiveCN101502948AGood value for moneyAvoid restrictionsAbrasive surface conditioning devicesEngineeringGrinding wheel

The invention relates to a feeding device of a forming grinding wheel for finishing high precision bearing which comprises three feeding devices for driving a pen-typed diamond to move in tangential, axial and radial directions. The three feeding devices are respectively driven by an independent servo motor through a transmission system and controlled by PLC. The feeding device adopts a method that the radial feeding device (4) indirectly finishes the radial direction motion of the grinding wheel along the tangential motion of the grinding wheel, avoids the limitation on the smallest step of a uniaxial coordinate and very high step precision requirement during the finishing of the grinding wheel and improves the finishing precision of the grinding wheel and the grinding bearing contour precision. With simple structure, the device of the invention can greatly lower the manufacturing requirement of the grinding wheel feeding device and has greatly high performance price ratio. Based on the method of the invention, developed tapered roller bearing log curve raceway grinder can greatly improve the processing precision and the stability of bearing raceway log curves, solve the industrial technical hard problem of bearing grinders and fill the gap of the field.

Owner:NINGBO ANJIESEN PRECISION MACHINE MFG +1

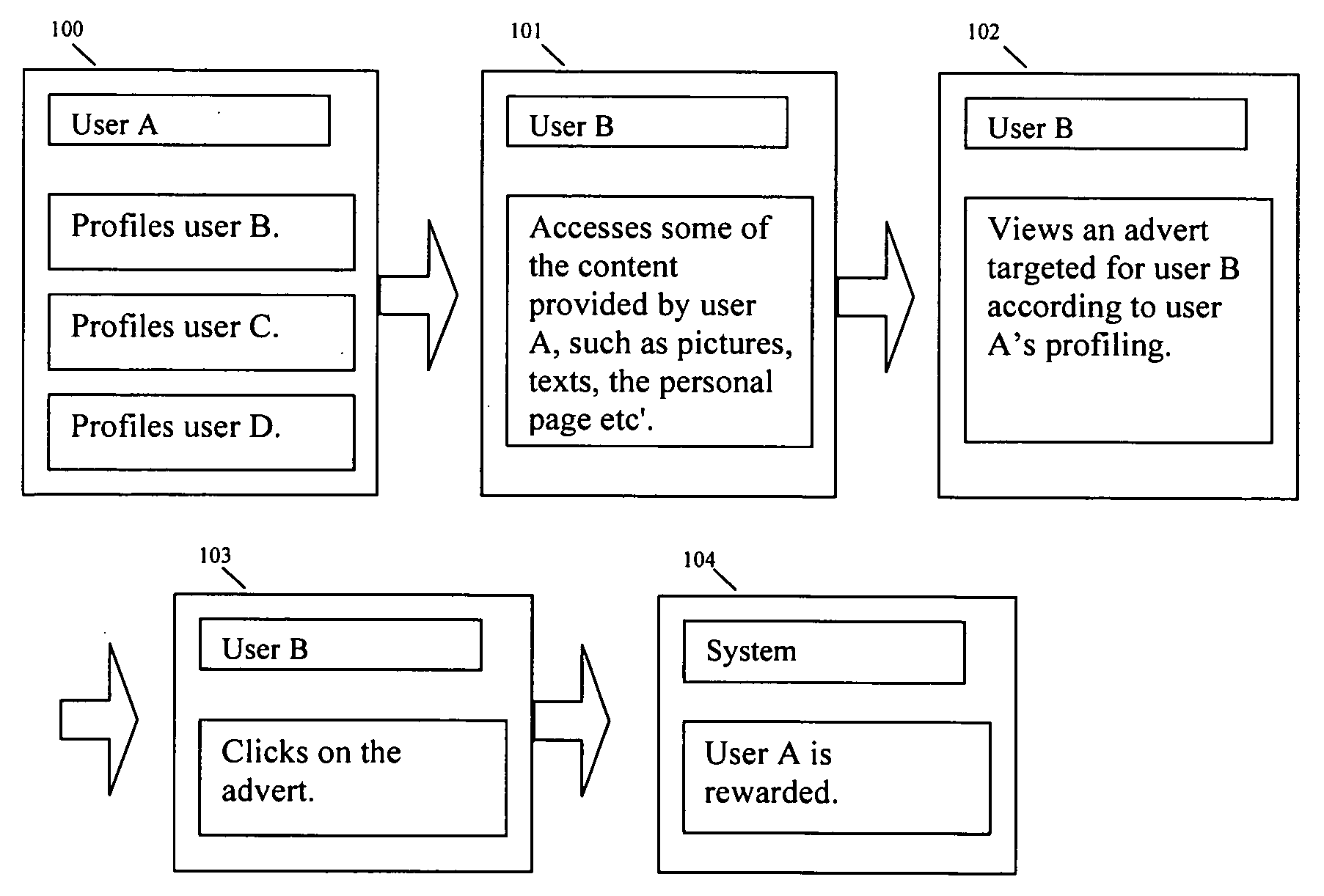

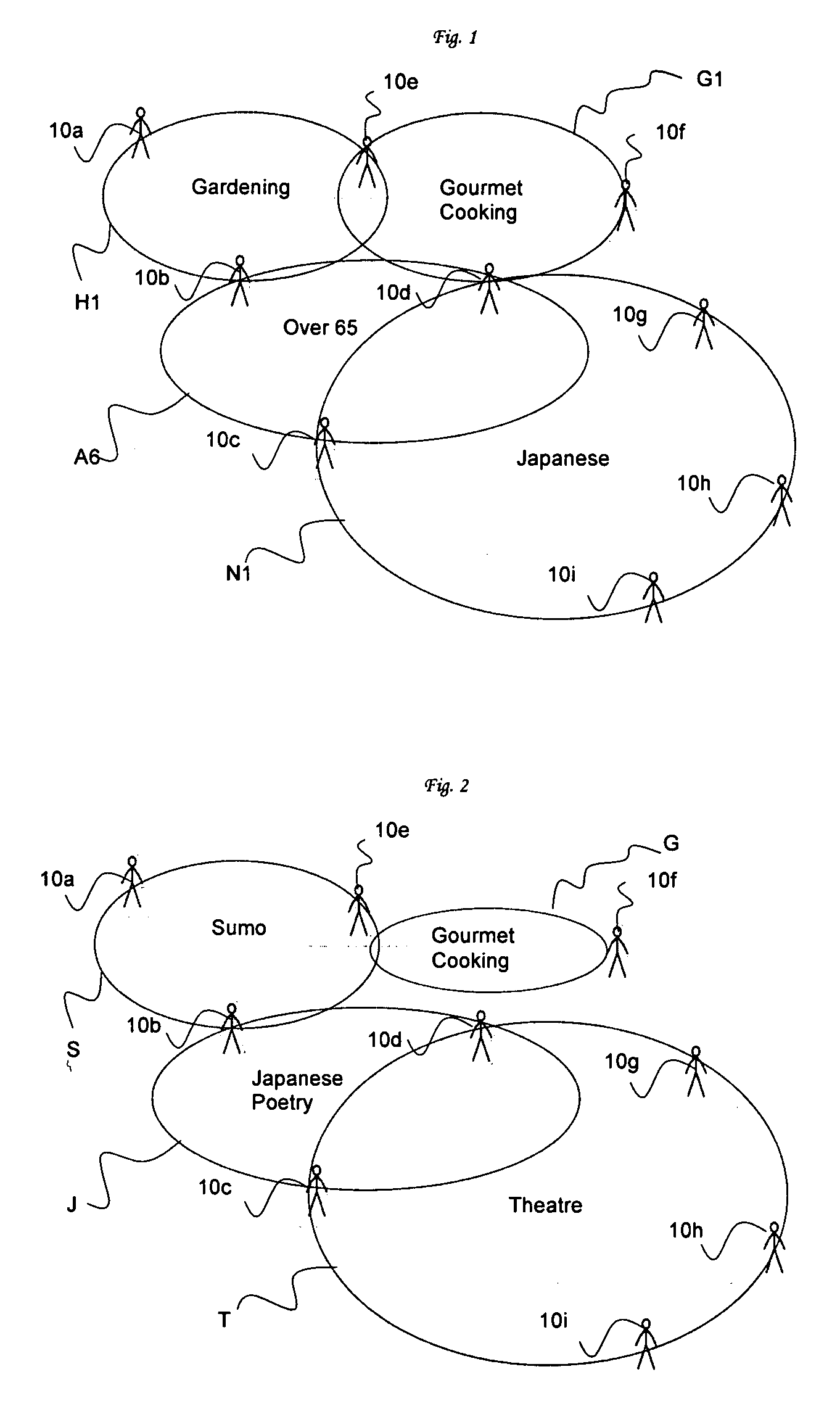

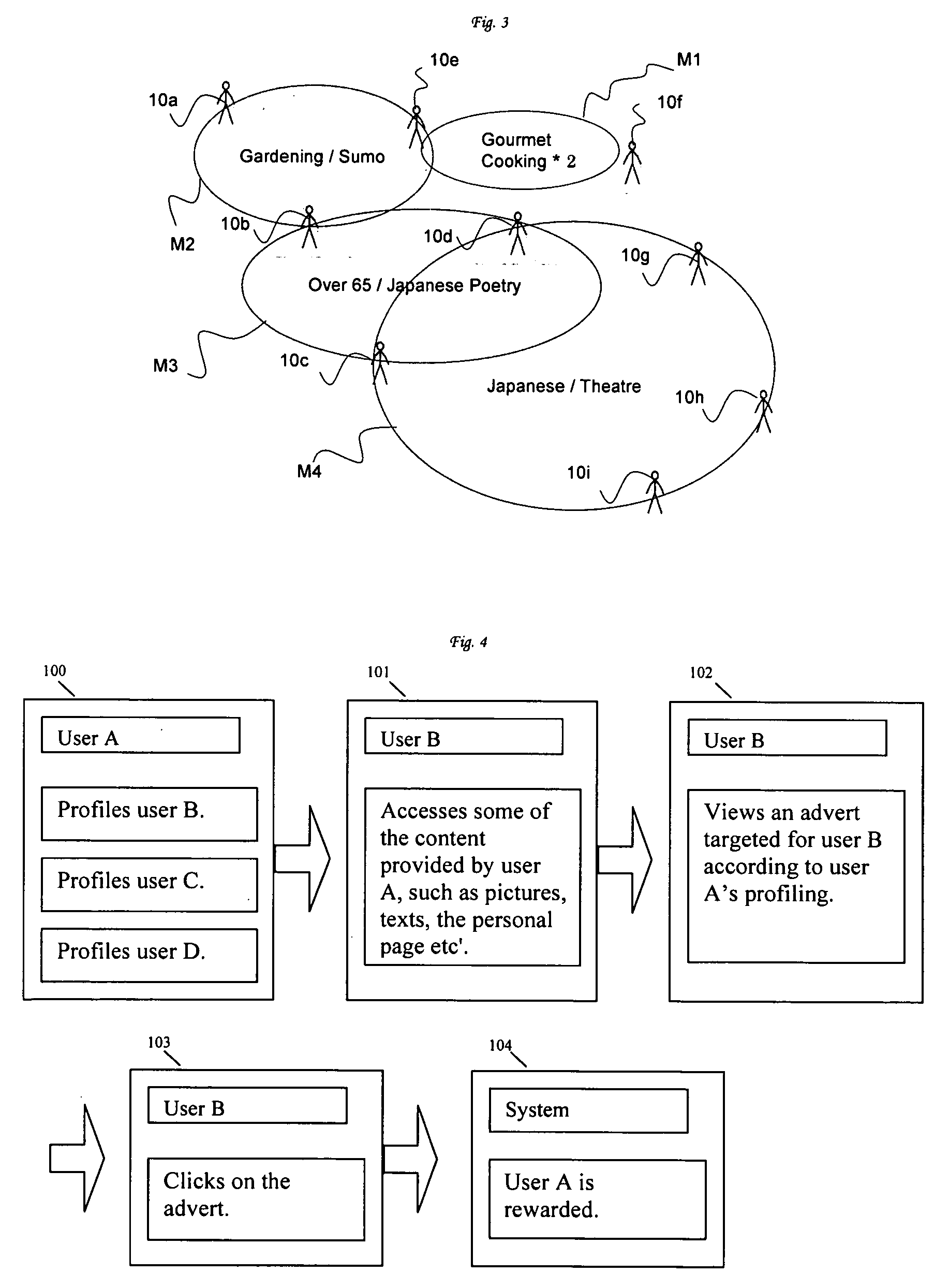

Method for increasing the accuracy of social network profiles

Owner:POLONSKY ALEXANDER

Large ship propeller casting technology

InactiveCN105195681AImprove profile accuracyQuality improvementFoundry mouldsFoundry coresWrinkle skinMedium frequency

The invention discloses a large ship propeller casting technology. The technology includes the first step of sand mold manufacturing, the second step of riser and chilling block arrangement, the third step of melting and pouring, the fourth step of cast drying and cooling and the fifth step of cleaning and riser gas cutting. In the step of riser and chilling block arrangement, two round open risers are arranged at the upper end of a sand mold, and an outer chilling block is placed on the portion, close to the thick and large part of a propeller hub, at the lower end of the sand mold. In the step of melting and pouring, a large double-furnace-body medium-frequency electric furnace is adopted so that a cast alloy ingot can be melted into cast alloy melt, then the cast alloy melt is poured in a bottom injection type pouring mode, and a large ship propeller casting is manufactured after pouring is completed. In the step of cast drying and cooling, after pouring is completed, the large ship propeller casting is dried through an electric hot air furnace, and then heat preservation, cooling and demolding are carried out. In the way, the technology is simple and easy to control, the blade outline precision and the surface quality of a propeller can be improved, the defect that pores, wrinkles and the like occur in the surface of the propeller is avoided, and accordingly the finished product yield of the large ship propeller is effectively increased.

Owner:SUZHOU JINYE MARINE MACHINERY PLANT

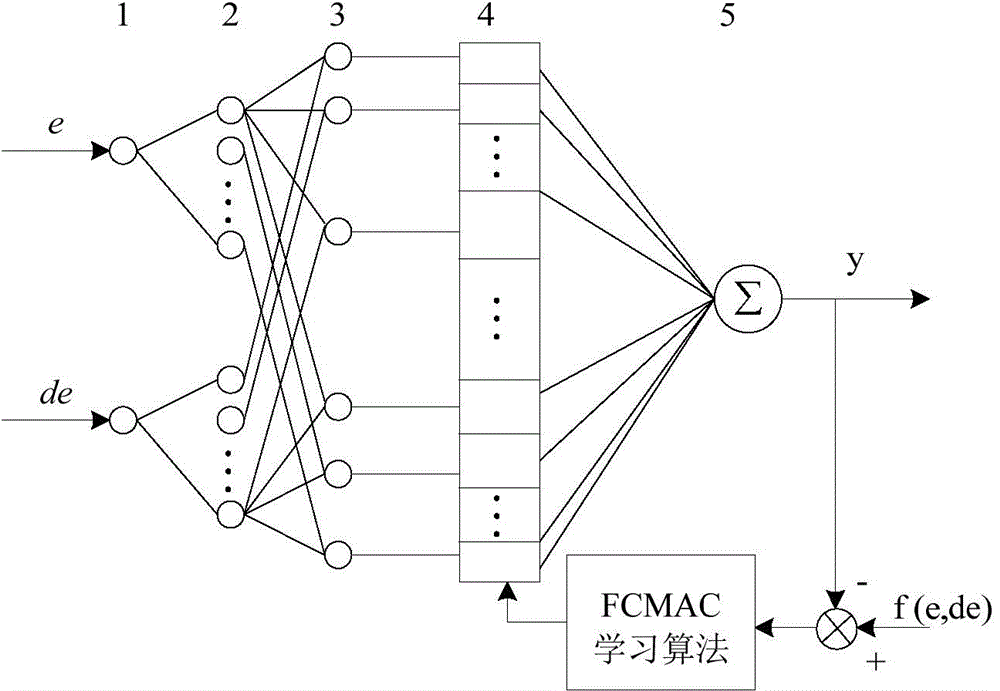

XY motion platform contour control method and device on the basis of fuzzy cerebellum model joint controller

InactiveCN105676780AStrong approach abilityImprove adaptabilityProgramme controlComputer controlDigital signal processingGrating

The present invention provides an XY motion platform contour control method and device on the basis of a fuzzy cerebellum model joint controller. The device comprises a voltage regulation circuit, a rectification filtering unit, an IPM inversion unit, an event manager of a digital signal processor DSP, a Hall sensor, a grating scale, a current sampling circuit, a position sampling circuit and an IPM isolation driving protective circuit. The DSP includes a position signal setter, a linear motor signal collector, a PI controller, an FCMAC controller and a driver. The XY motion platform contour control method adopts FCMAC to design a speed controller to reduce the tracking error so as to indirectly improve the contour processing precision of directly driving the XY motion platform. The XY motion platform contour control method and device on the basis of a fuzzy cerebellum model joint controller are applicable to the contour processing task of any locus and are able to realize the high-precision contour control and have good robustness.

Owner:SHENYANG POLYTECHNIC UNIV

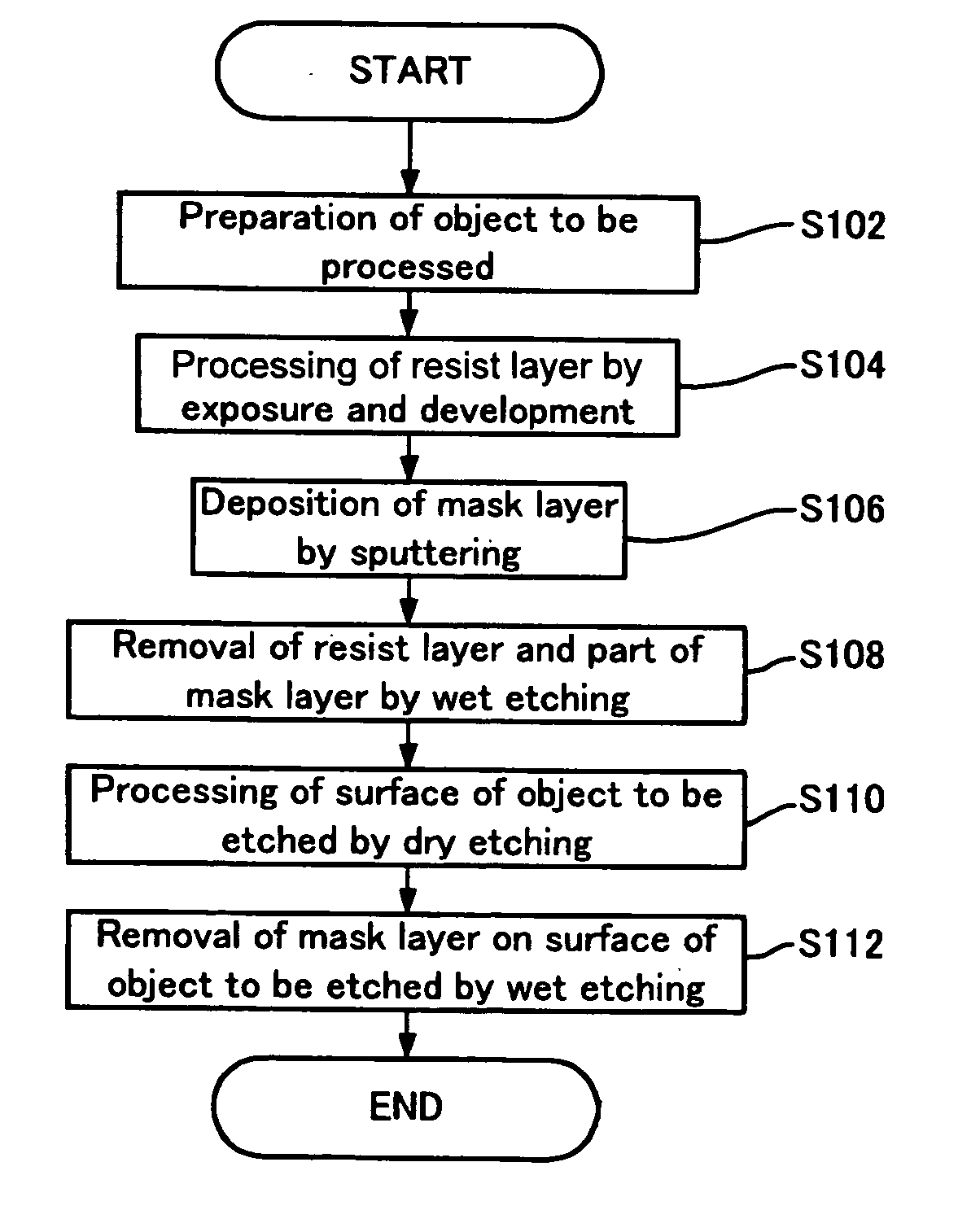

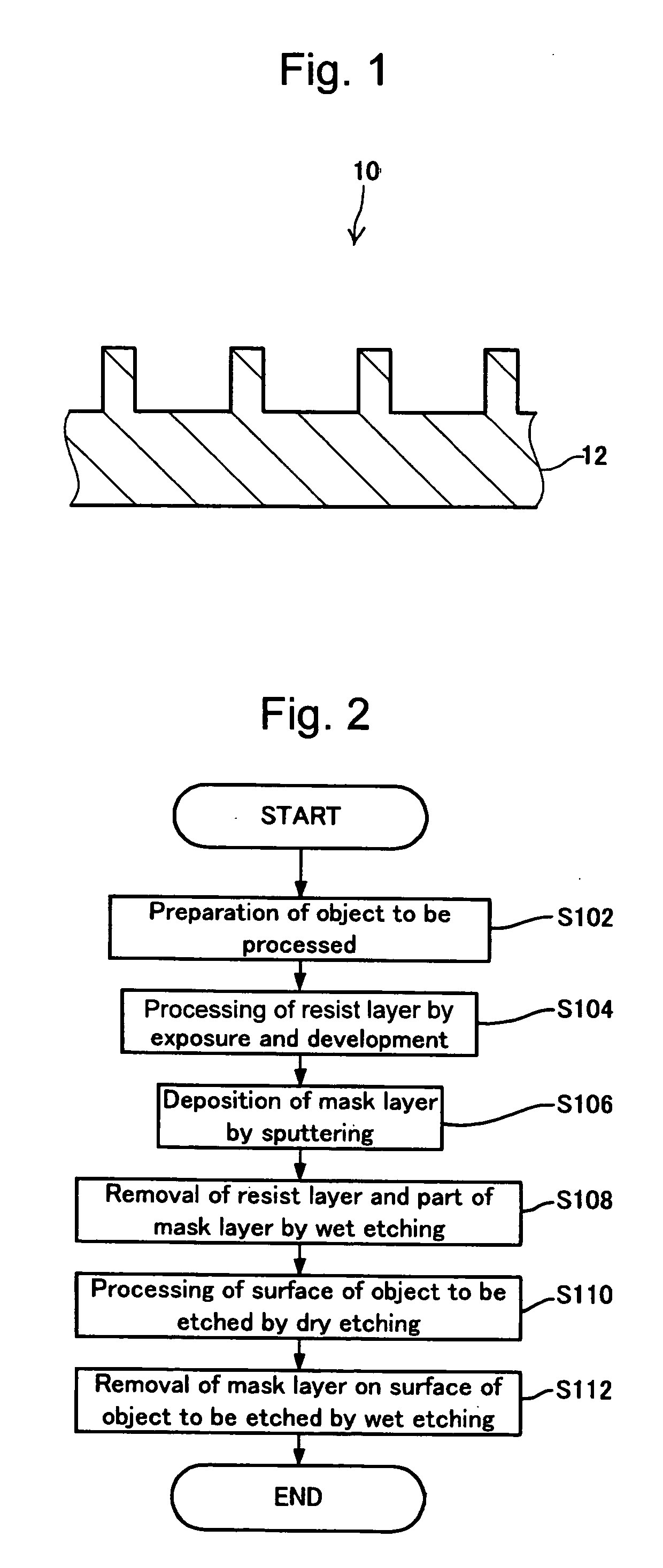

Master for concavo-convex pattern transfer and method for manufacturing stamp for manufacturing information recording medium

InactiveUS20050127032A1Efficient preparationImprove accuracyDecorative surface effectsNanoinformaticsResistEngineering

A method for manufacturing a master for concavo-convex pattern transfer, which enables highly accurate manufacture of a master carrying a concavo-convex pattern including a convex portion at a large aspect ratio, and a method for manufacturing a stamp using the master are provided. A mask layer is formed in a predetermined pattern on an object to be etched having a higher rigidity than that of a resist material. The object to be etched is then etched so as to form a concavo-convex pattern on the surface thereof to obtain a master for concavo-convex pattern transfer. A material having a lower etching rate than that of the resist material and that of the object to be etched is used as a material of the mask layer.

Owner:TDK CORPARATION

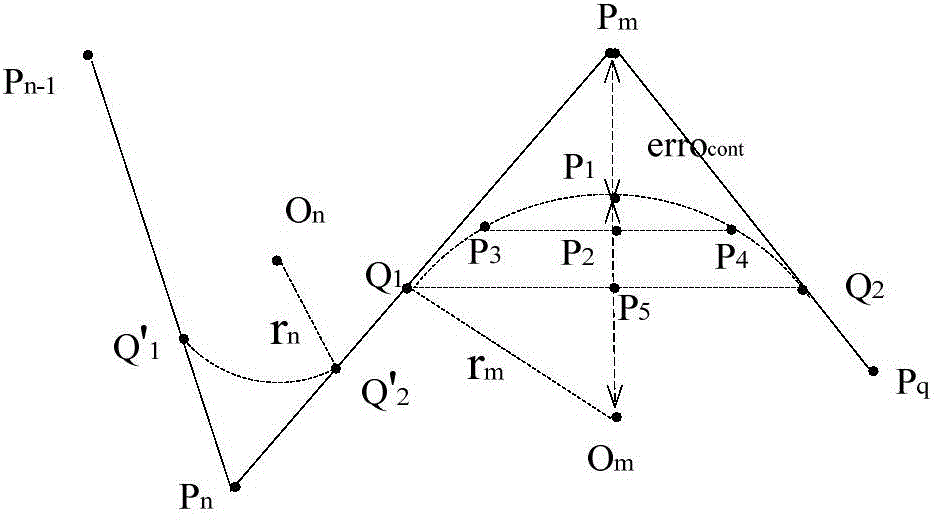

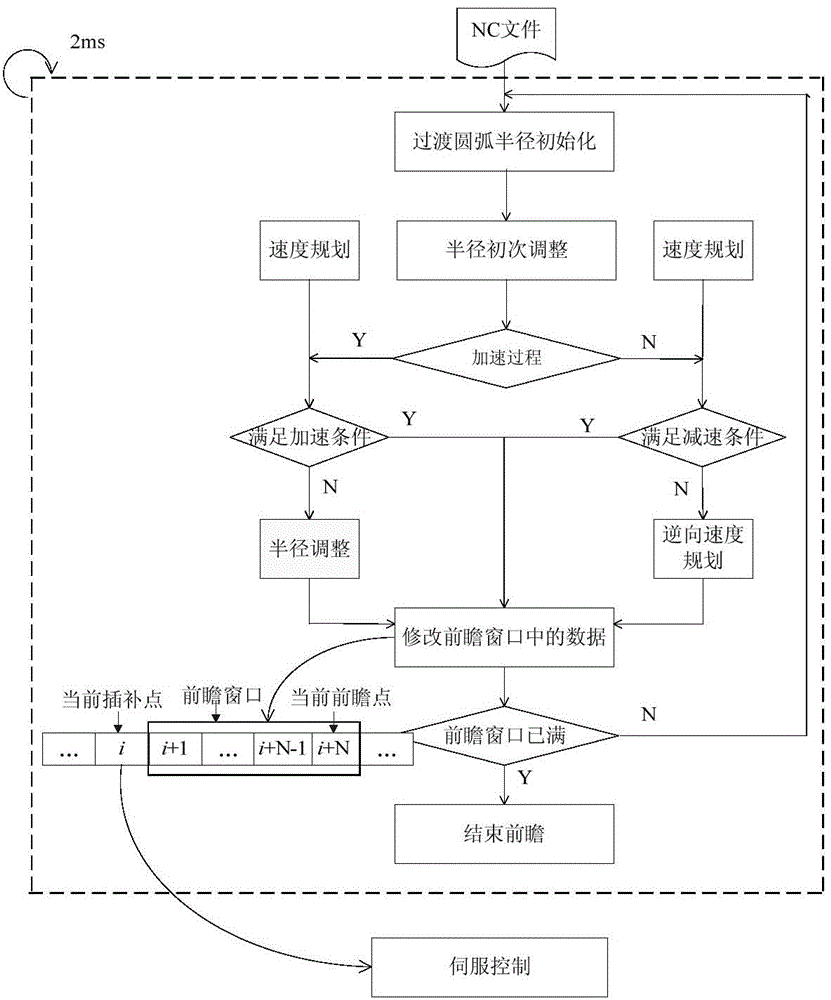

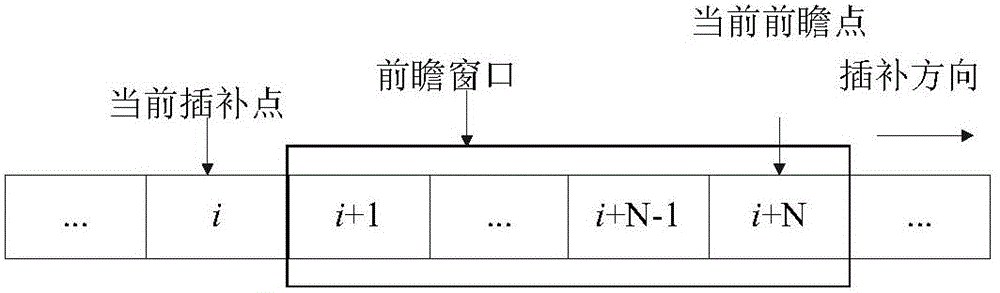

High-speed high-precision path dynamic forward-looking planning method

ActiveCN105785909AImprove profile accuracyReduce processing timeNumerical controlComputational physicsControl theory

The invention relates to a high-speed high-precision path dynamic forward-looking planning method. A radius of a transition arc can be initialized, and radius preliminary adjustment can be carried out. According to the maximum permission speed of the transition arc, whether the process from the previous transition arc to the current arc is the acceleration process or the deceleration speed can be determined. When the process is the acceleration process, whether the speed of the acceleration process arriving at the current arc can reach the maximum permission speed of the current arc can be determined by combining with the speed planning, when the answer is yes, the data of the forward-looking window can be corrected, otherwise the radius of the current transition arc can be adjusted. When the process is the deceleration process, and the speed decelerated from the previous transition arc to the current transition arc is greater than the maximum permission speed of the current transition arc, the reverse speed planning can be carried out by starting from the current arc, and then the given data of the forward-looking window can be corrected and stored, and at last, the data of the forward-looking window can be transmitted to the servo system for the processing. By combining the speed planning with the path planning, the processing speed can be accelerated.

Owner:SHENYANG GOLDING NC & INTELLIGENCE TECH CO LTD

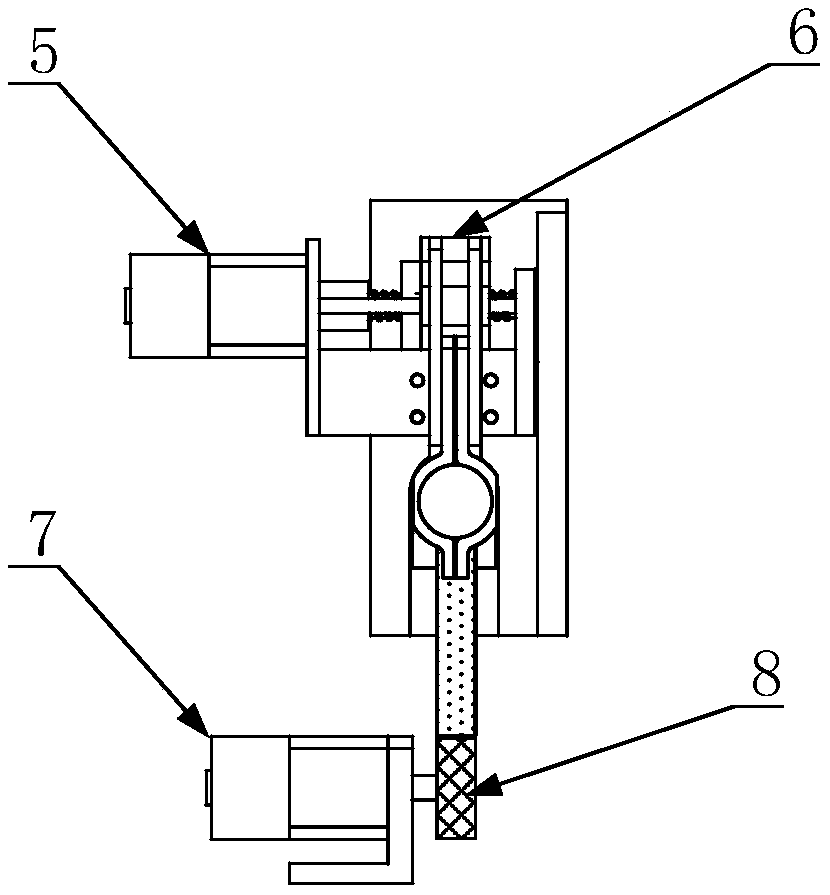

Online arc-shaped abrasive wheel trimming device based on cup-shaped tool spherical surface envelope

ActiveCN104802089ARealize online trimming functionImprove profile accuracyAbrasive surface conditioning devicesCopper electrodeGrinding wheel

The invention provides an online arc-shaped abrasive wheel trimming device based on cup-shaped tool spherical surface envelope and relates to online trimming devices for arc-shaped abrasive wheels. The online arc-shaped abrasive wheel trimming device is used for solving the problems of the existing arc-shaped abrasive wheel trimming methods that the adaptable range is small, the device function is single, the accuracy of trimming is low and online trimming cannot be provided for arc-shaped abrasive wheel trimming. The online arc-shaped abrasive wheel trimming device comprises a first stepping motor, a second stepping motor, a connecting rack, a horizontal connecting plate, a rotating mechanism, a vertical moving mechanism and a horizontal moving mechanism, wherein the rotating mechanism comprises a speed reduction motor and a connecting assembly, the first stepping motor and the horizontal moving mechanism are mounted on the connecting rack, the vertical moving mechanism is connected with the connecting assembly, the speed reduction motor is mounted on the connecting assembly, and a cup-shaped copper electrode or cup-shaped abrasive wheel is mounted at an output terminal of the speed reduction motor ; the second stepping motor is mounted on the horizontal connecting plate, and the horizontal connecting plate is mounted on an abrasive wheel cover. The online arc-shaped abrasive wheel trimming device is applied to the online trimming of the arc-shaped abrasive wheels.

Owner:HARBIN INST OF TECH

Non-rotation optical array coarse-fine integrated progressive grinding method

ActiveCN108747603ANo wearImprove profile accuracyOptical surface grinding machinesAbrasive surface conditioning devicesUltra fineMachine tool

The invention discloses a non-rotation optical array coarse-fine integrated progressive grinding method. The method comprises the steps that 1, structure outlines of a precision structuring coarse grinding diamond grinding wheel and a precision structuring superfine diamond grinding wheel and the structure of a separating plate are designed and manufactured; 2, the precision structuring coarse grinding diamond grinding wheel, the separating plate and the precision structuring superfine diamond grinding wheel in the step 1 are sequentially installed on a machine tool main shaft, and a machinedworkpiece is fixed to a machine tool working table; 3, grinding wheel in-place correction is carried out; 4, profile modeling coarse grinding is carried out, wherein a profile modeling grinding methodis adopted, and the precision structuring coarse grinding diamond grinding wheel is used for coarse grinding; and 5, tangent track progressive precision operation is carried out, wherein along the progressive grinding track, a precision structuring fine-grit or ultra-fine-grit diamond grinding wheel is used for conducting progressive grinding on the workpiece surface, and semifinishing and finishing of the overall microstructural array surface profile are efficiently completed through one grinding circulation.

Owner:SHANDONG UNIV

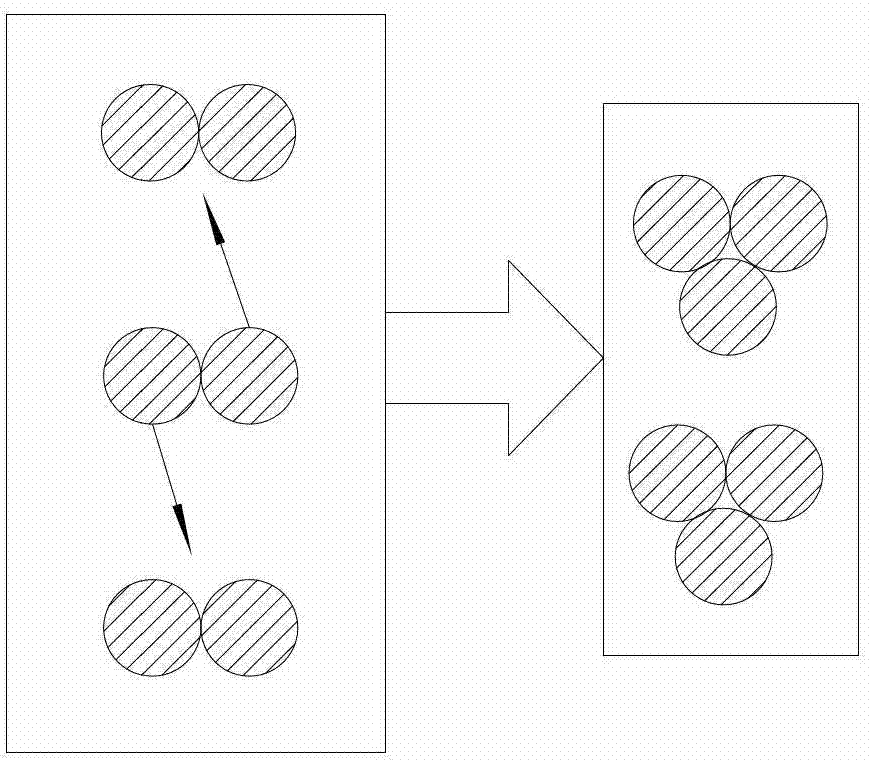

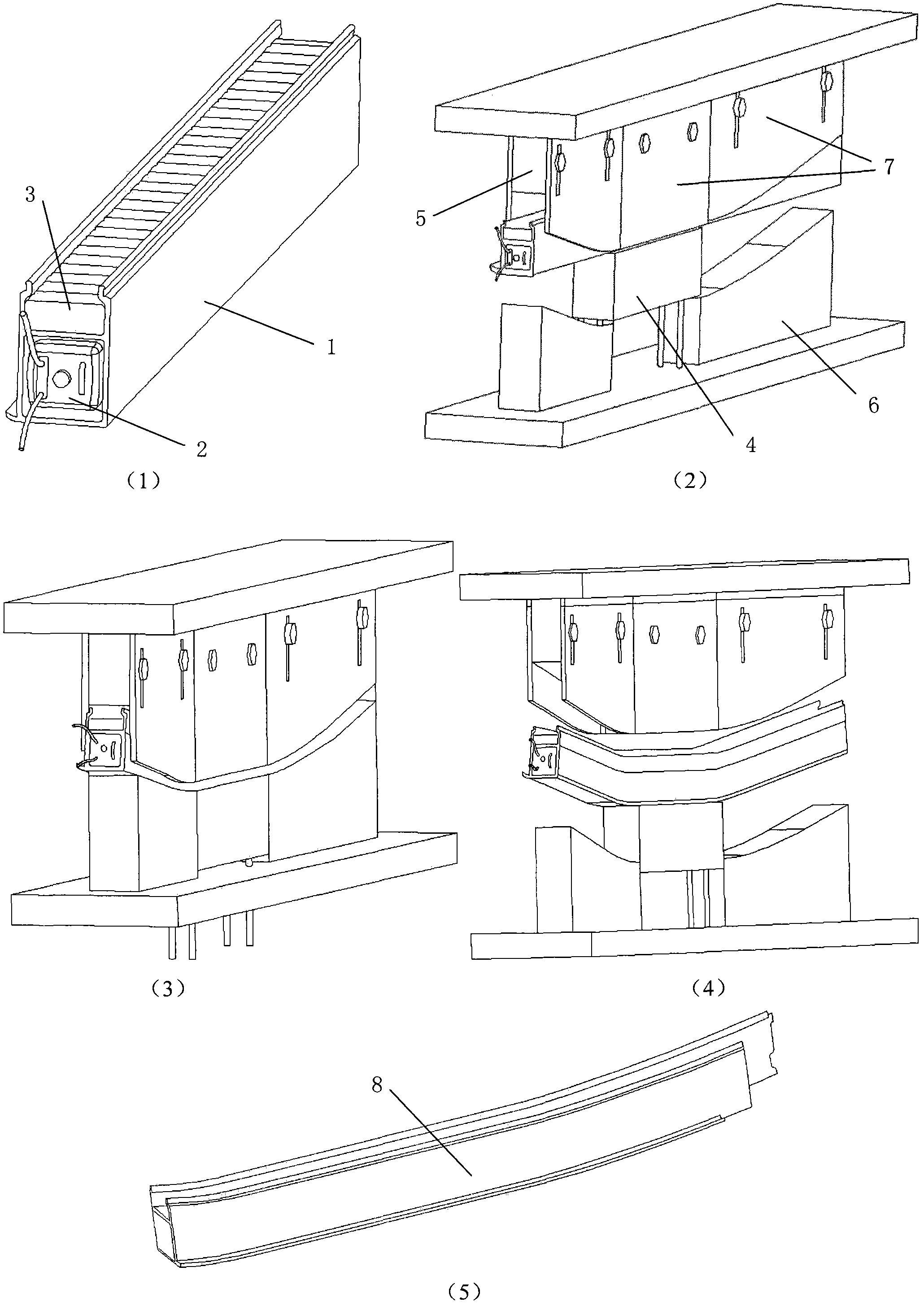

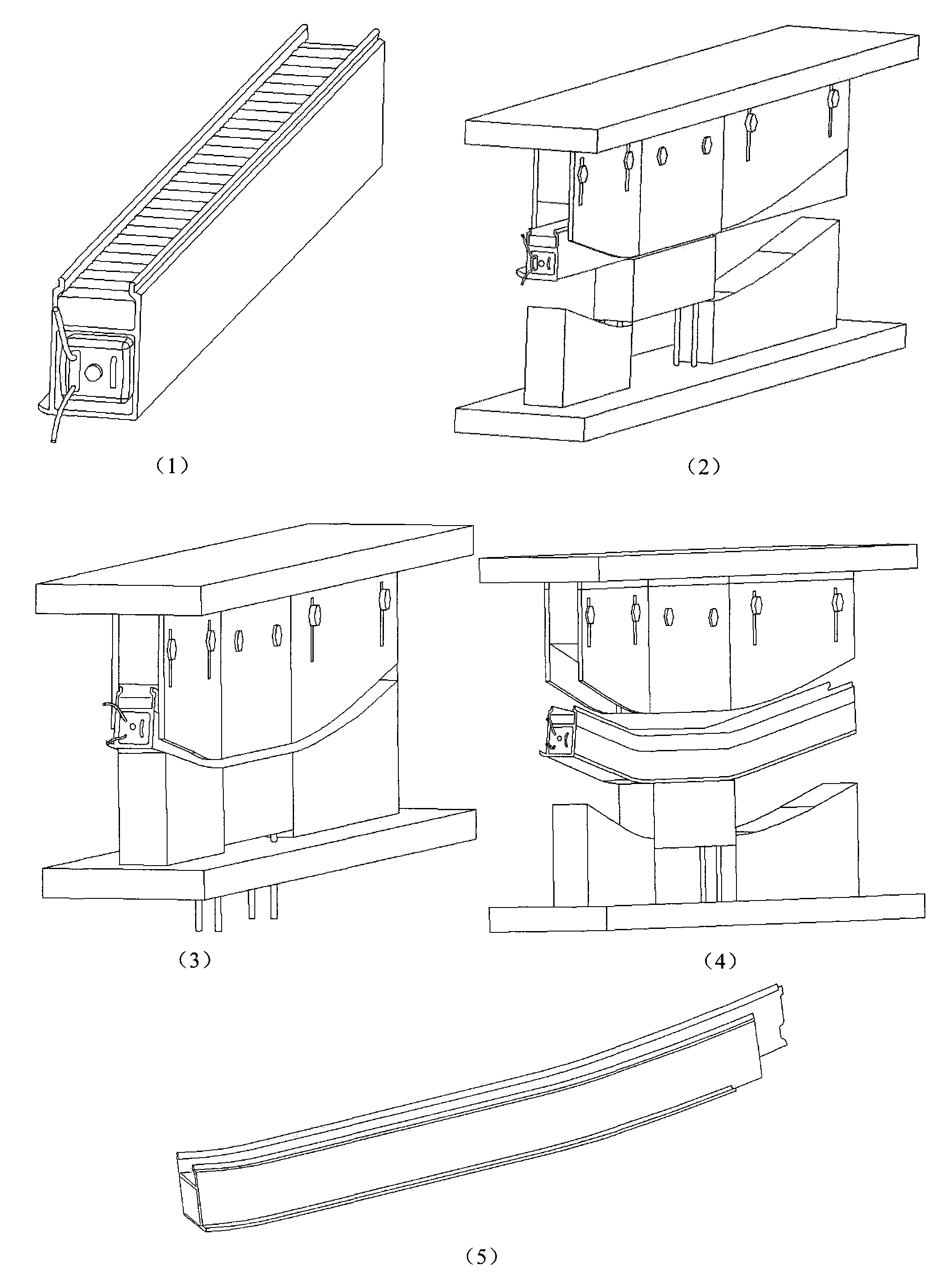

Method for bending and forming aluminum section side column member of railway vehicle body

InactiveCN102319778ASolving Bending Forming ProblemsImprove profile accuracySocial benefitsEngineering

The invention discloses a method for bending and forming an aluminum section side column member of a railway vehicle body, which belongs to the technical field of metal plastic working. The forming method is mainly characterized in that the aluminum section side column member is bent and formed on a hydraulic press by adopting a bending and forming manner of a die. The method comprises the following steps of: firstly, filling discrete type filler in a semi-closed die cavity of the section and filling a continuous mandrel in the closed die cavity; secondly, horizontally placing the section on a raised lower ejector plate and enabling a spigot of the section to be placed upwards; thirdly, enabling an upper die to downwards move to press the blocky filler; enabling the upper die to lock a straight line segment part of the member together with the lower ejector plate to continuously move downwards and bend the section, completely laminating and finishing bending and forming; and finally, returning the upper die, ejecting the bent section by using the lower ejector plate, taking out the filler and processing geometrical characteristics to obtain a qualified side column member. The quality of products produced by the forming process disclosed by the invention is favorable, thus the rework is avoided; the production efficiency can be multiply improved; and the method can be used for bringing huge economic and social benefits to enterprises.

Owner:吉林诺亚机电科技有限公司

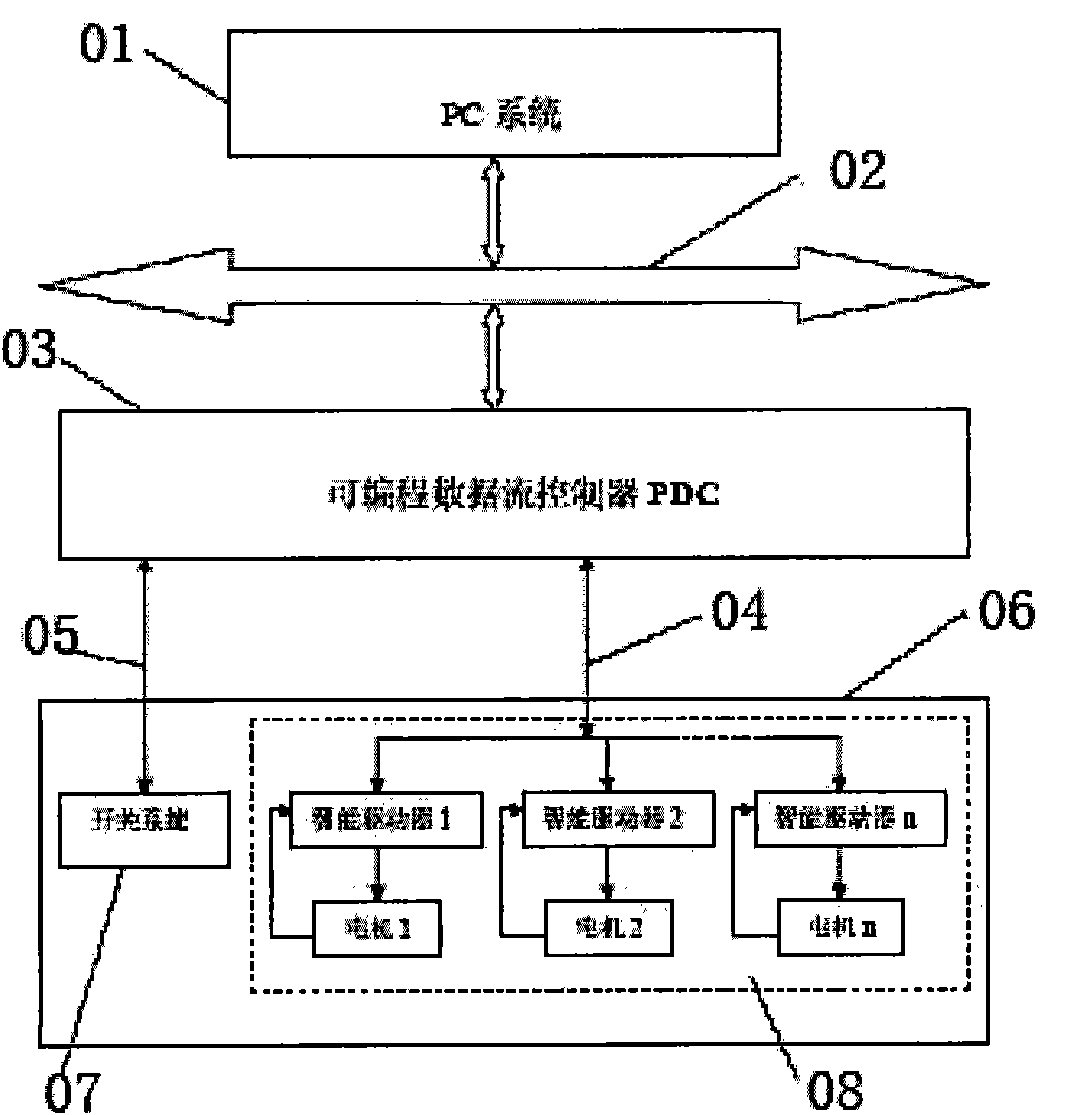

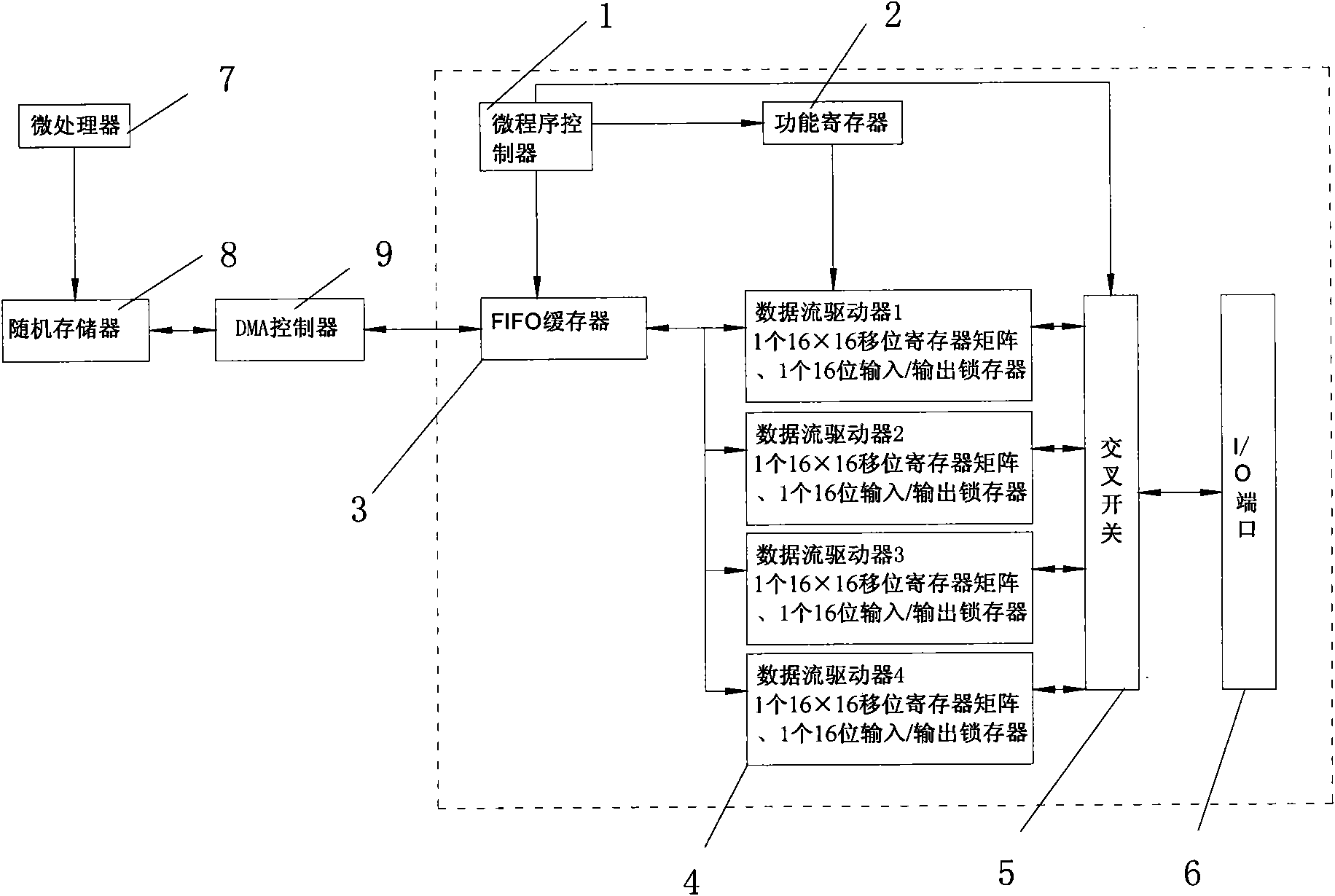

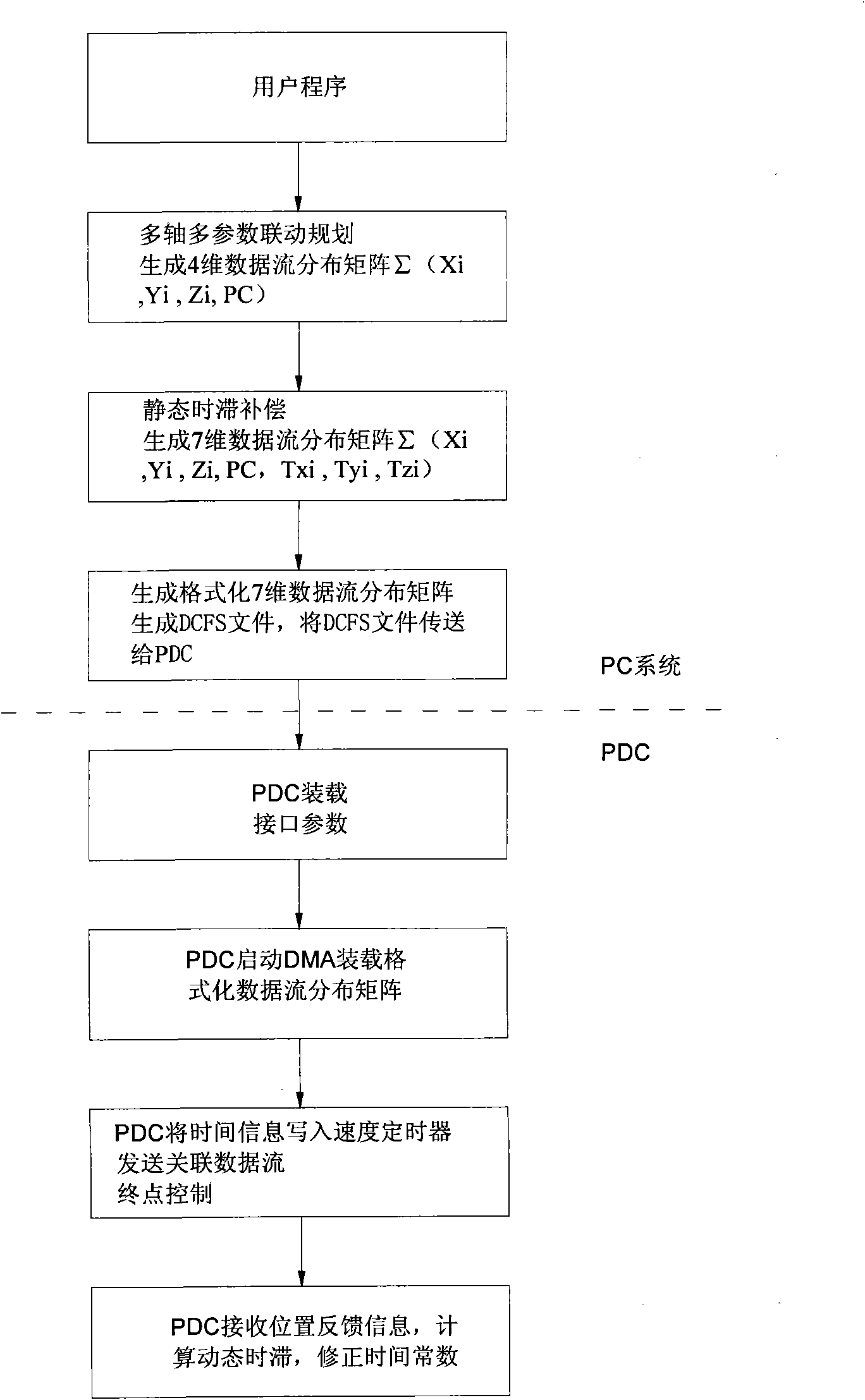

Method for controlling process parameter and related data stream in real time

InactiveCN101846993AEasy to control in real timeSimplified acceleration and deceleration controlNumerical controlAcceleration decelerationReal-time computing

The invention discloses a method for controlling the process parameter and the related data stream in real time, comprising the following steps: (1) establishing a distribution matrix for the multi-dimensional related data stream which comprises a multi-axis data stream and a parameter data stream by a PC system; (2) calculating a time value according to the multi-axis data stream and the feed speed by the PC system, adding the time value to the distribution matrix for the multi-dimensional related data stream, and formatting the distribution matrix for the multi-dimensional related data stream; (3) sending the formatted distribution matrix for the multi-dimensional related data stream to a programmable data stream controller by the PC system; (4) writing the time value into a speed timerand the multi-axis data stream and the parameter data stream into a data stream driver by the programmable data stream controller; and (5) controlling the data stream driver to send the multi-axis data stream and the parameter data stream to an executing mechanism by the programmable data stream controller at the given operation speed according to the set of the speed timer. The invention simplifies the real-time control of the related data stream as well as the real-time control and the acceleration-deceleration control of the process parameter.

Owner:JIANGXI FUTURE BIOMASS ENERGY CO LTD

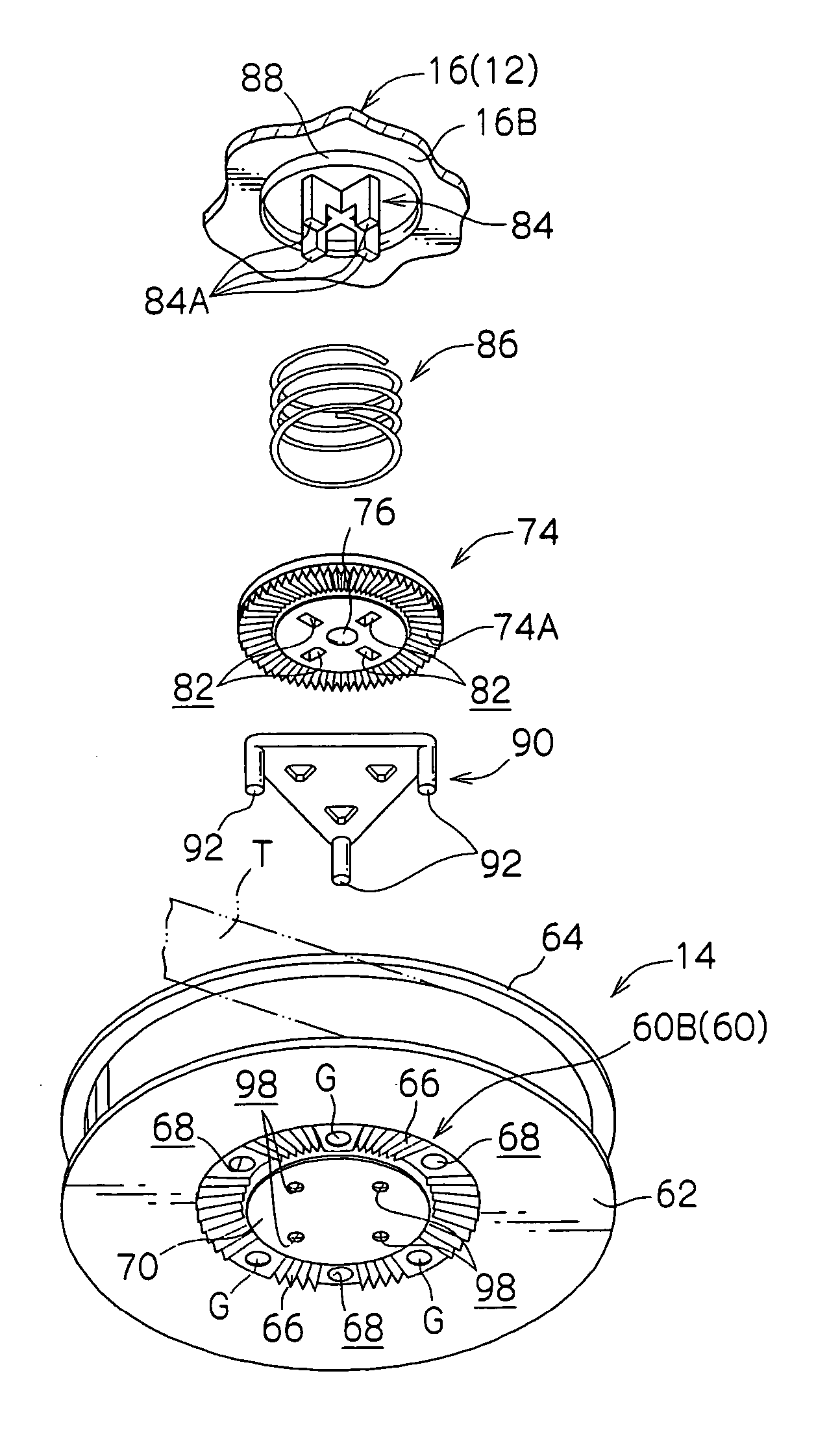

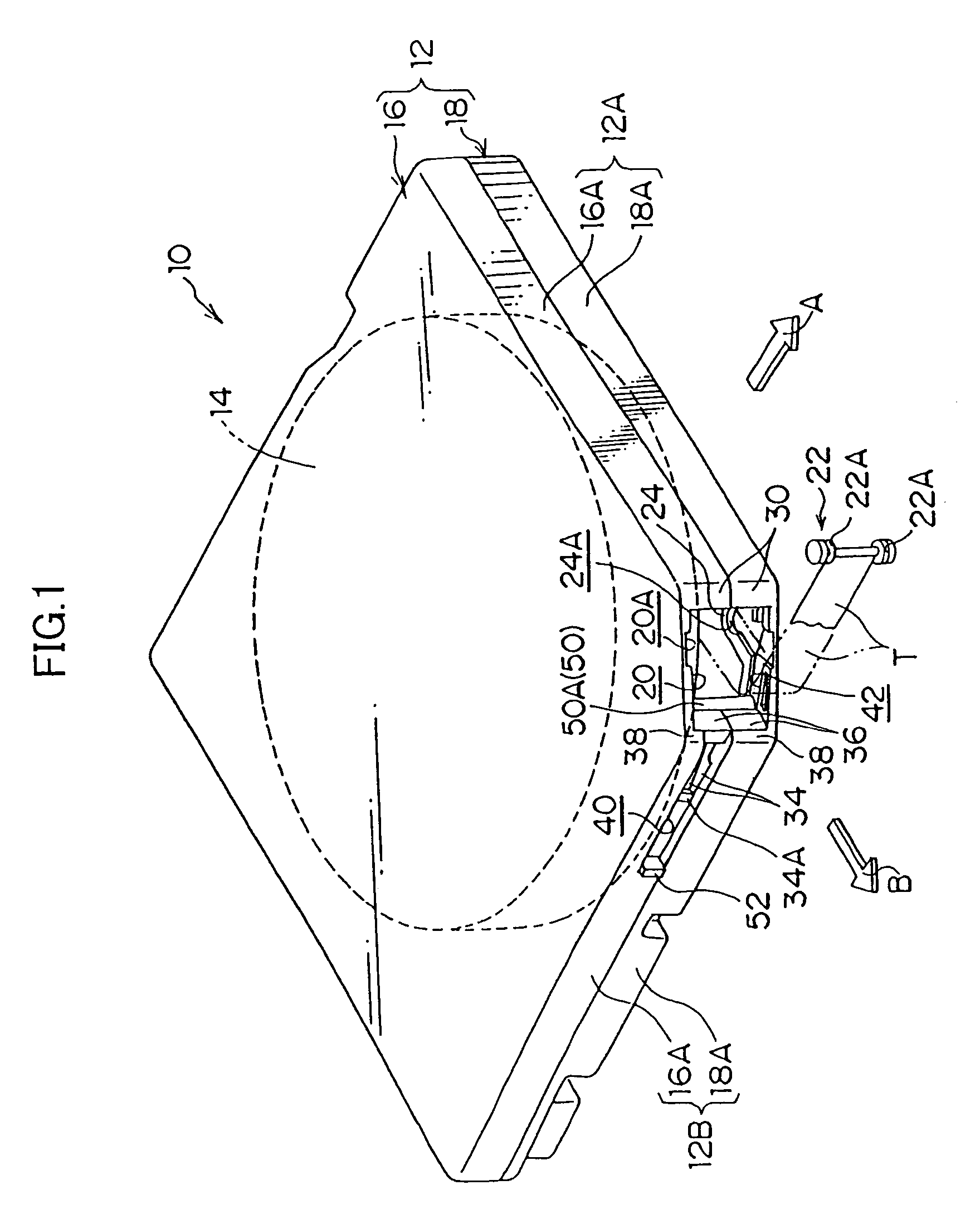

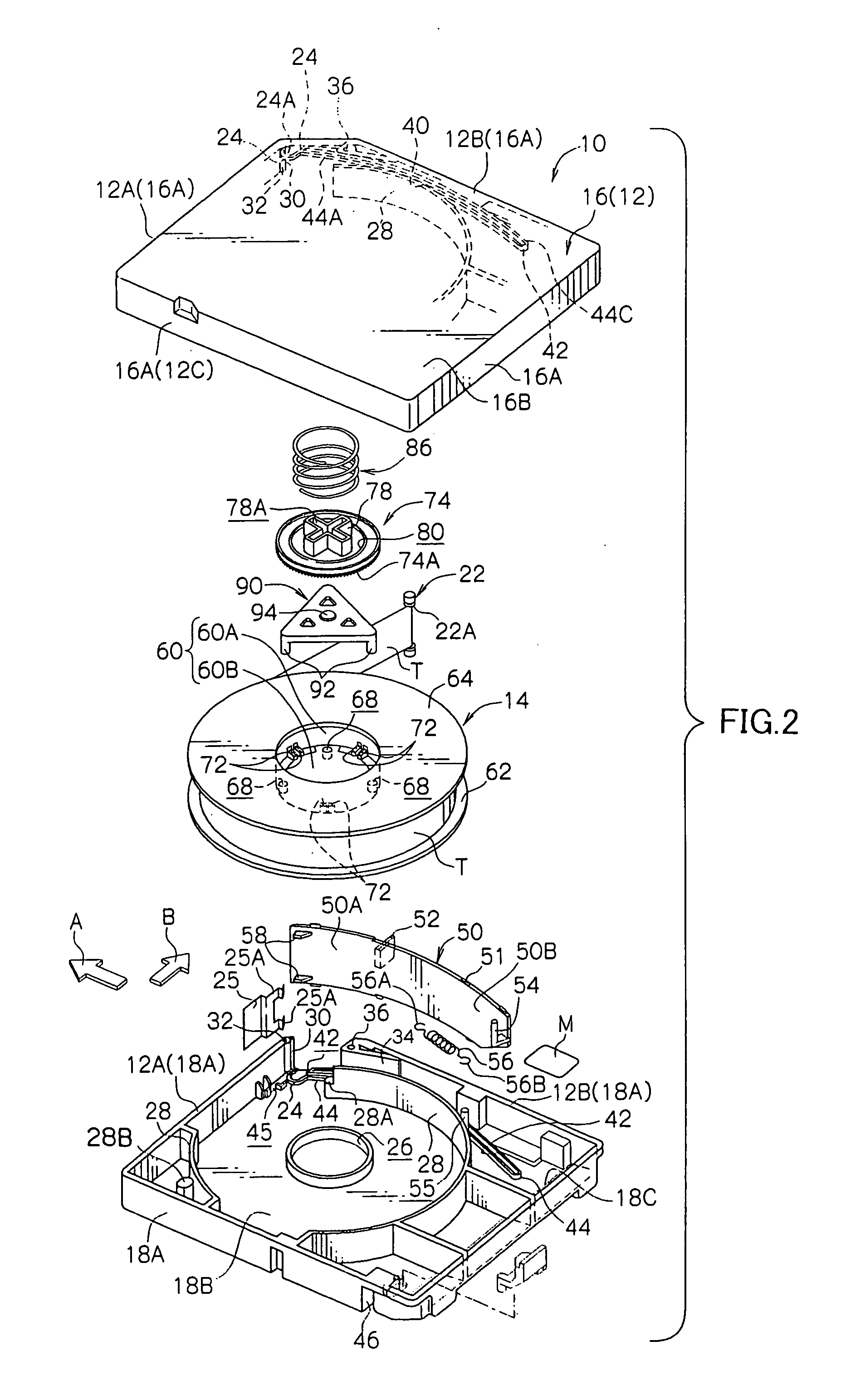

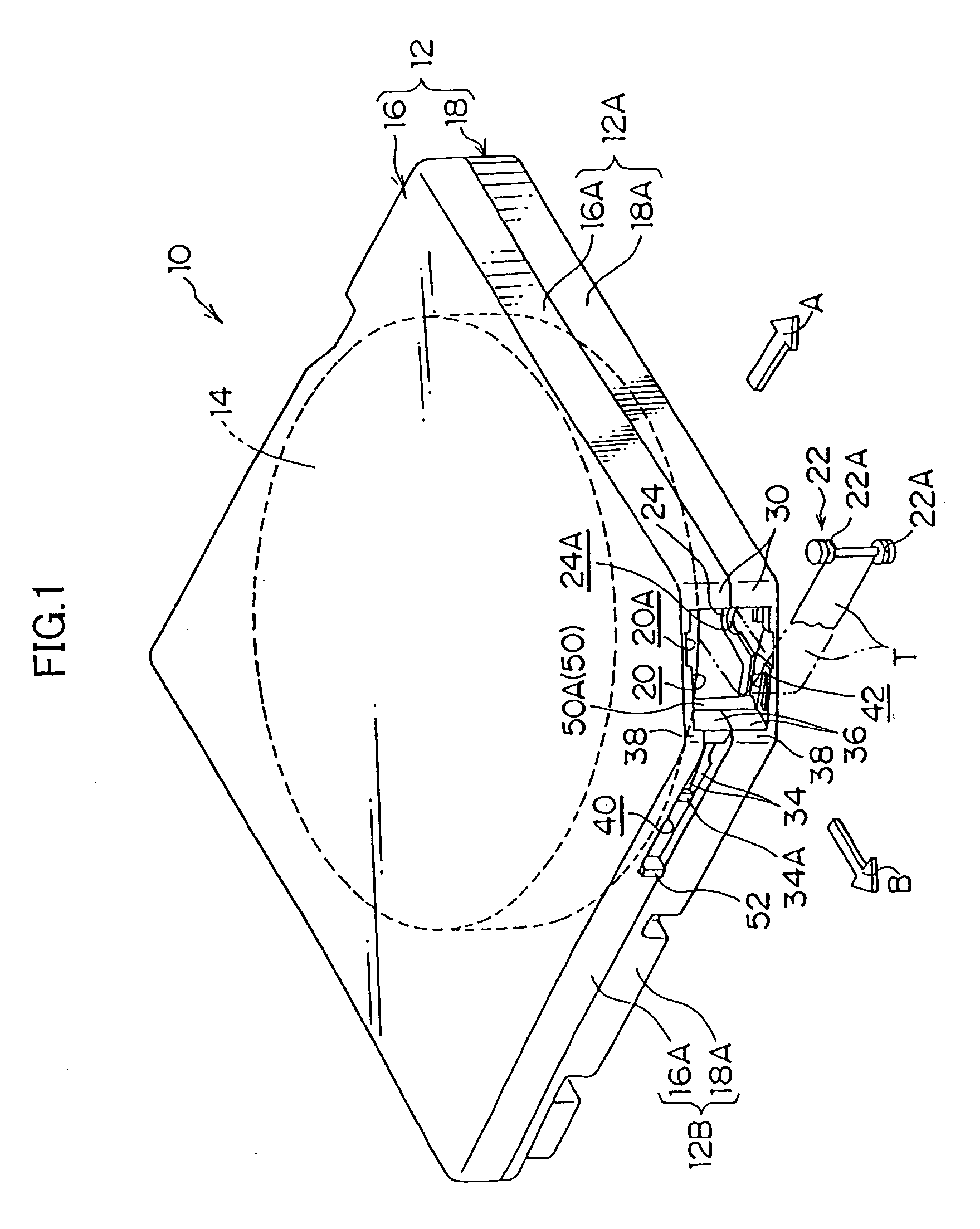

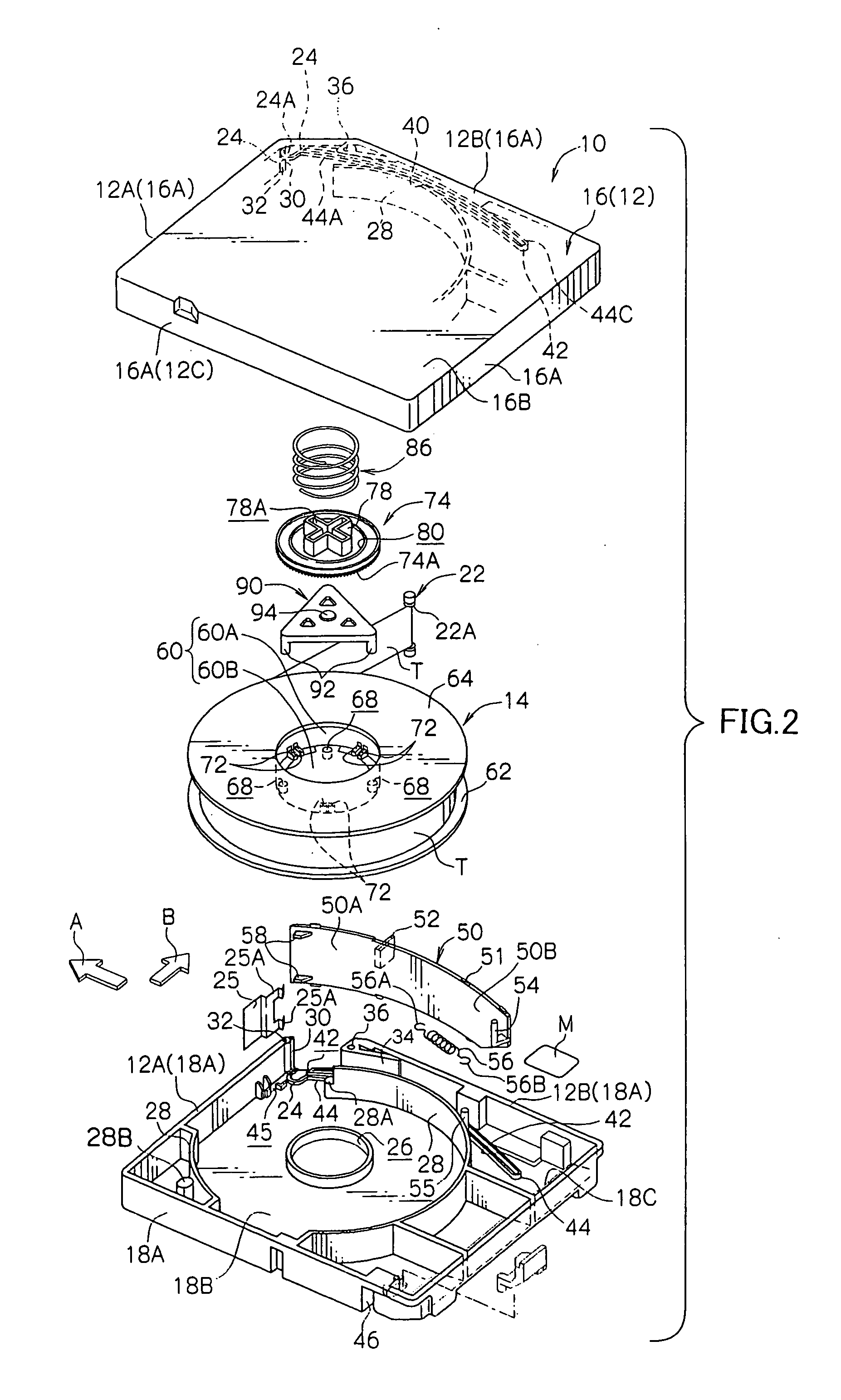

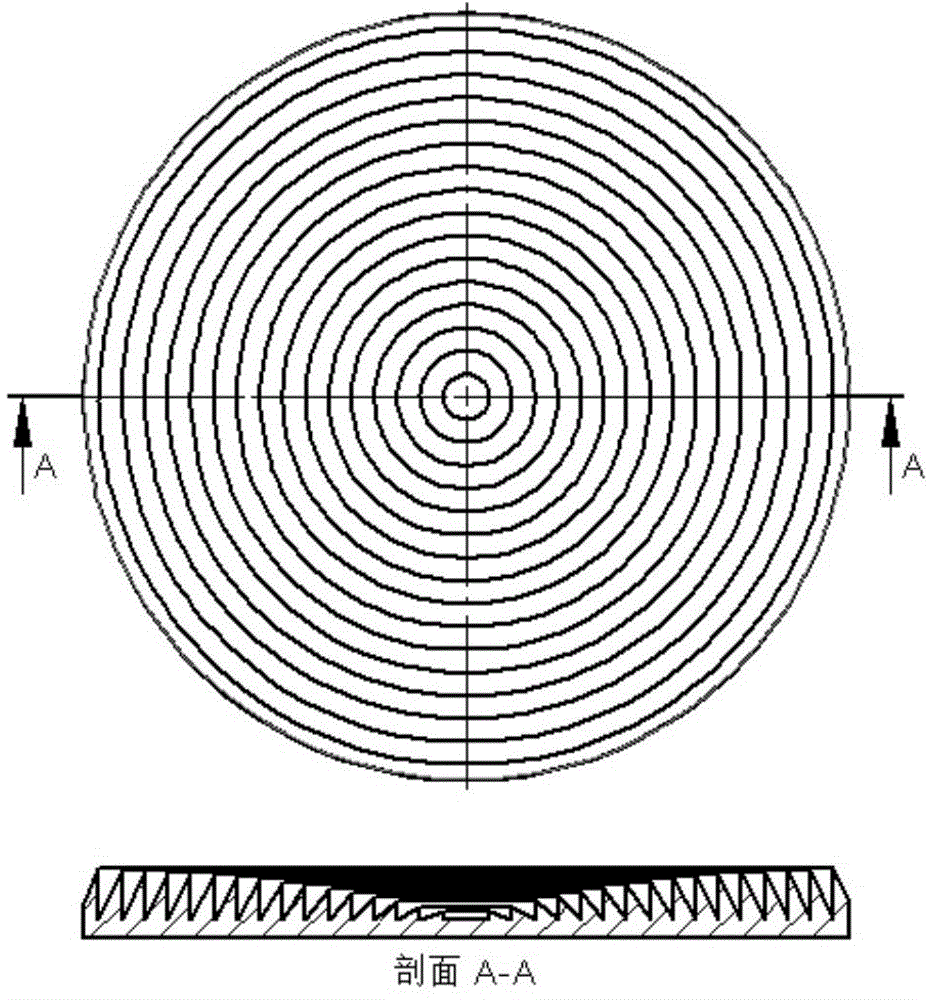

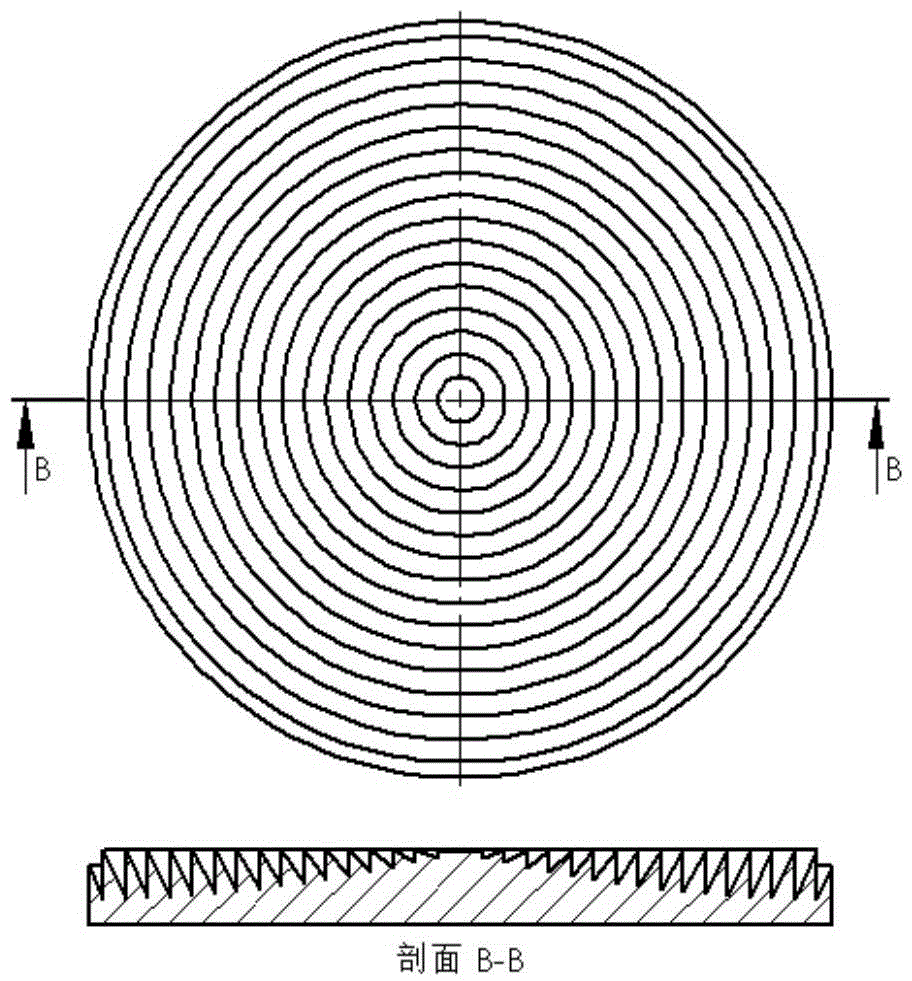

Recording tape cartridge

ActiveUS7252258B2Reduce areaImpairing mounting accuracyPicture changing apparatusRecord information storageEngineeringMechanical engineering

A recording tape cartridge which can be loaded into a drive device having a reel on which a recording tape is wound and which is rotatably accommodated in a case, the reel including: a resin-formed main portion which includes a reel hub formed in a tubular shape having a floor, the recording tape being wound around an outer peripheral surface of the reel hub; and a substantially disc-shaped metal plate attached firmly to an outer surface of a floor portion of the reel hub, wherein a gate portion, through which a resin material is introduced at the time of molding the main portion, is provided at a radial direction outer side of the metal plate.

Owner:FUJIFILM HLDG CORP +1

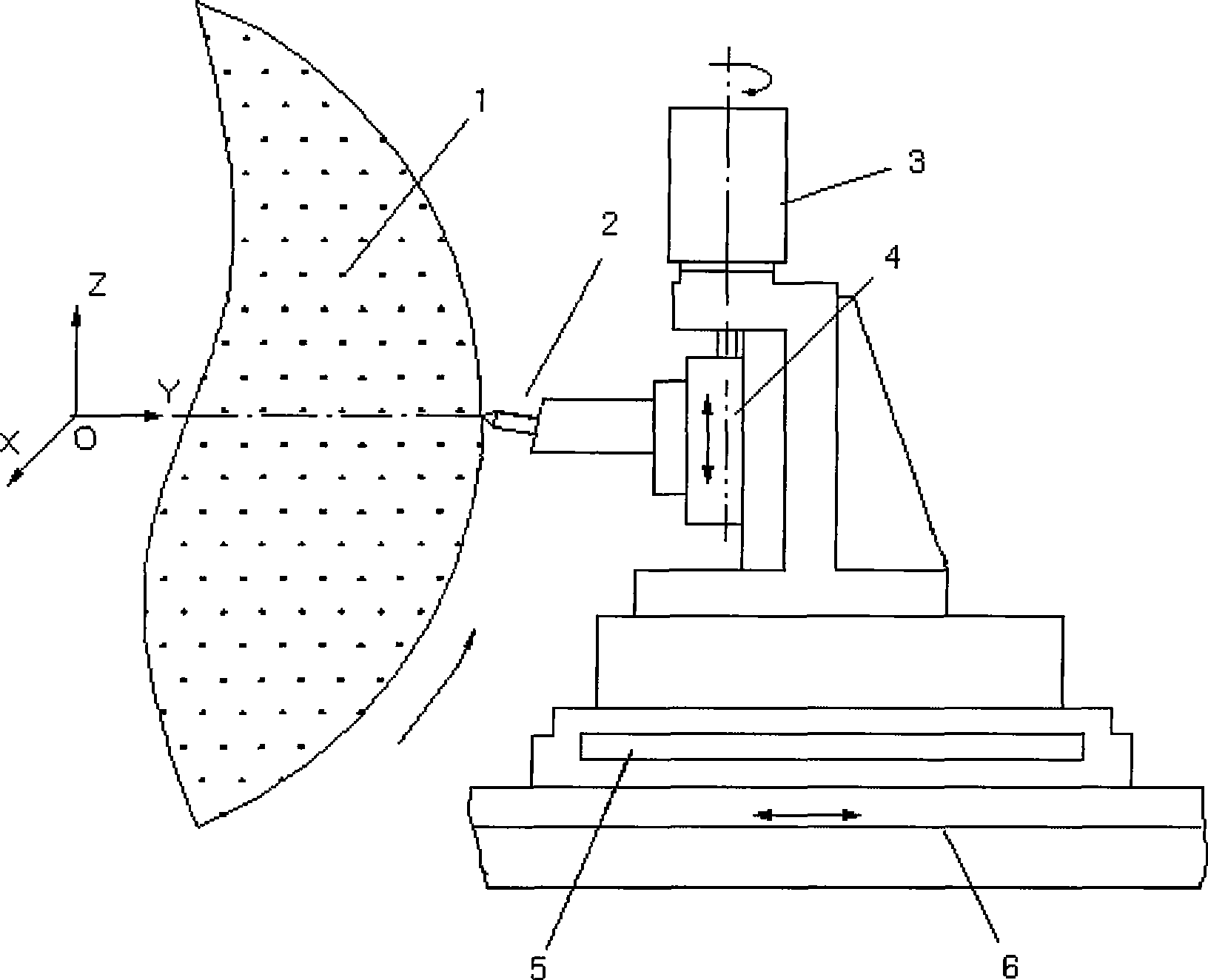

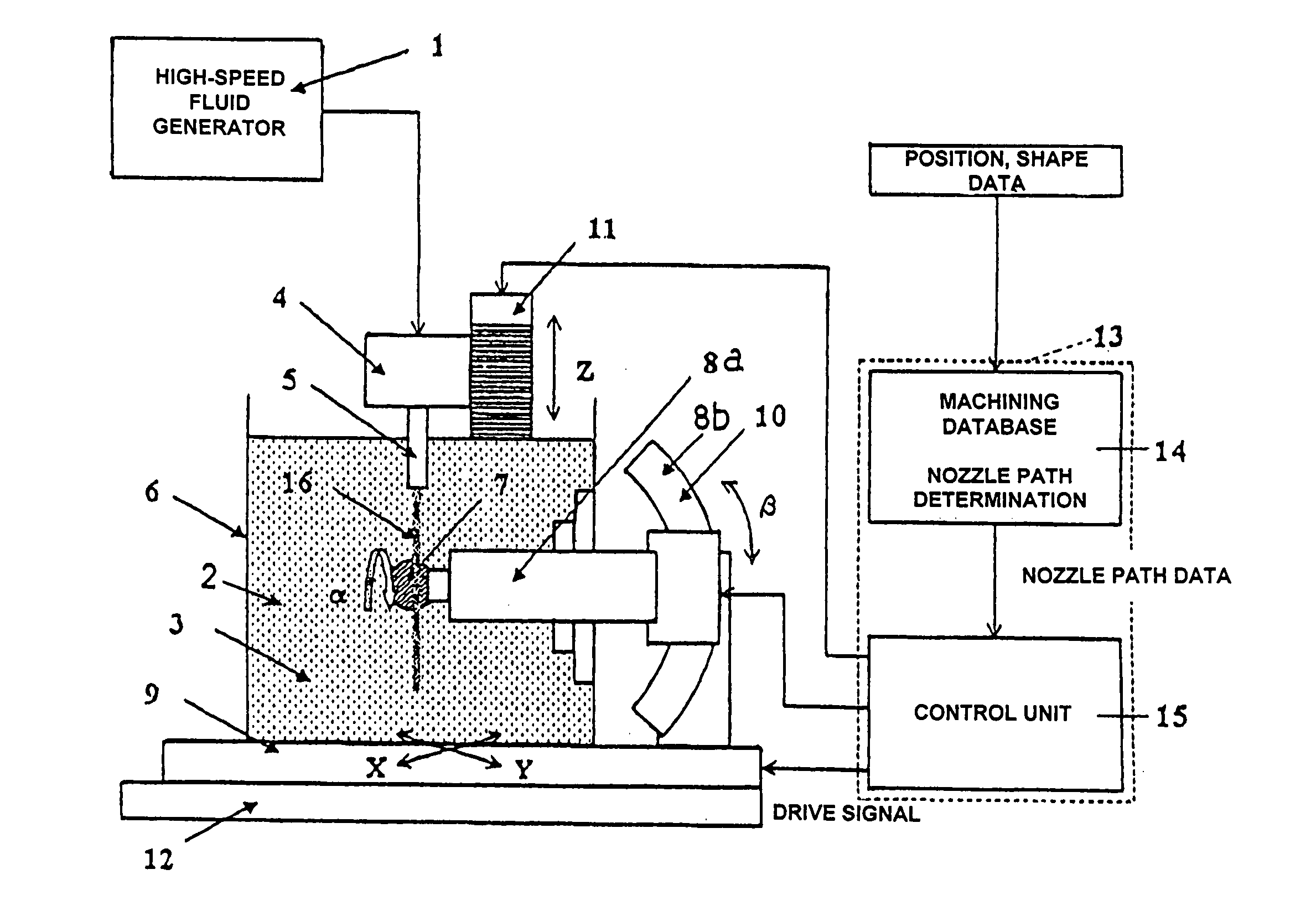

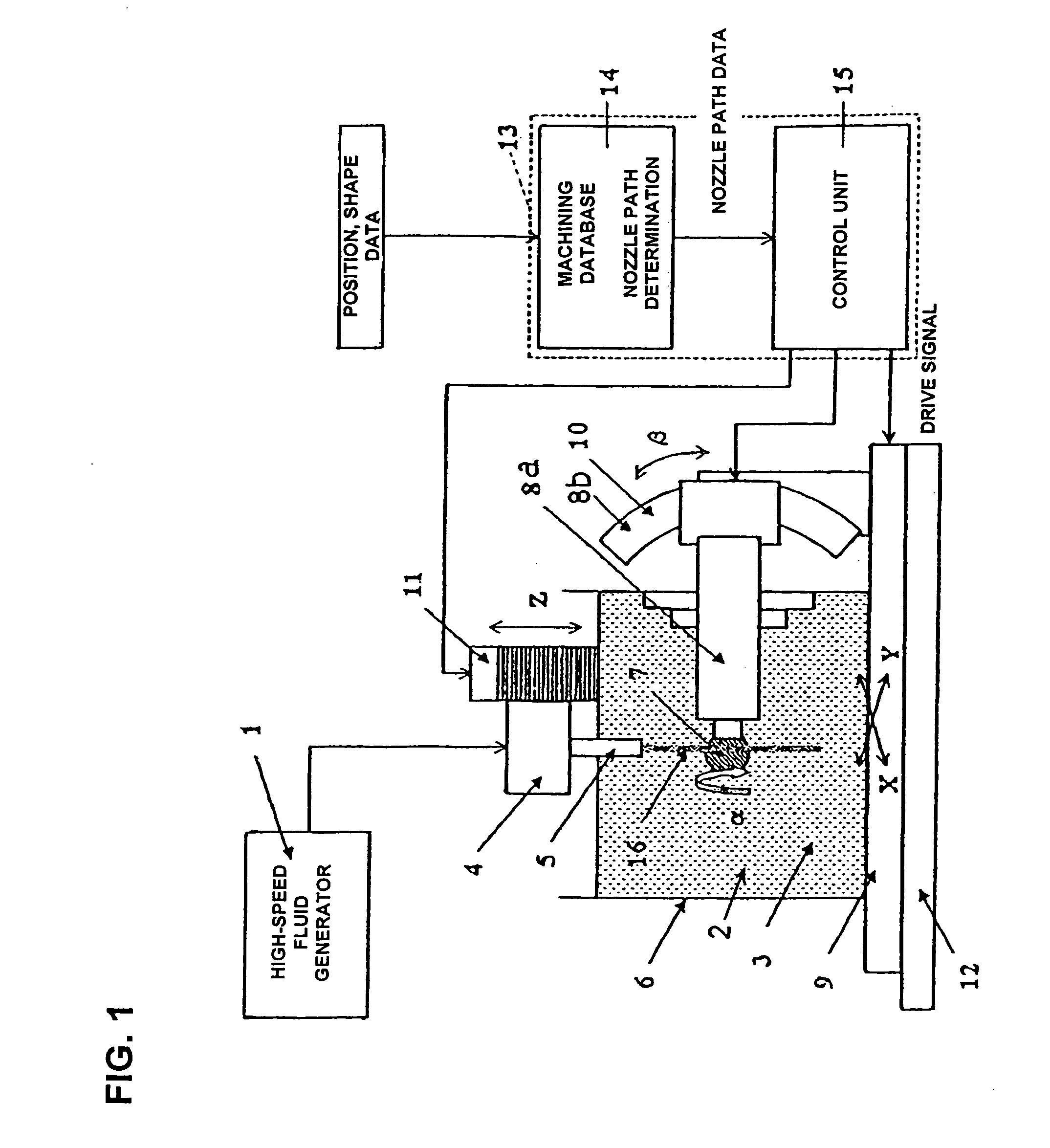

Curved surface machining method and an apparatus thereof

InactiveUS20050095955A1Easy to GrindImprove surface roughnessBlast gunsGrinding feed controlSurface roughnessEngineering

A curved surface machining method that performs finishing of the surface of a workpiece into a curved surface. The method includes the steps of: setting a workpiece in a rotating or stationary state in a water tank filled with an abrasive-containing solution into which an abrasive with a grain size of less than 1 μm has been admixed; and spraying a high-speed fluid in the abrasive-containing solution while a position, direction, and angle thereof is controlled relative to the workpiece, thus grinding and finishing the surface of the workpiece to an intended surface roughness and profile accuracy.

Owner:NAKASHIMA PROPELLER +2

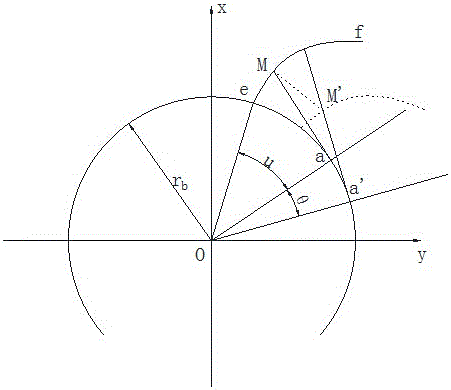

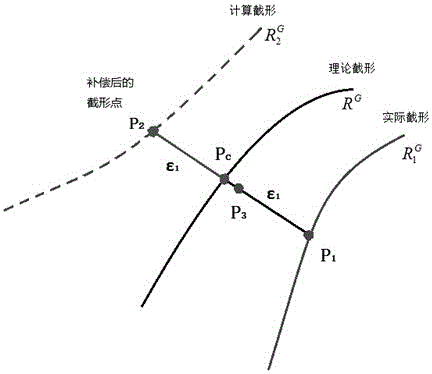

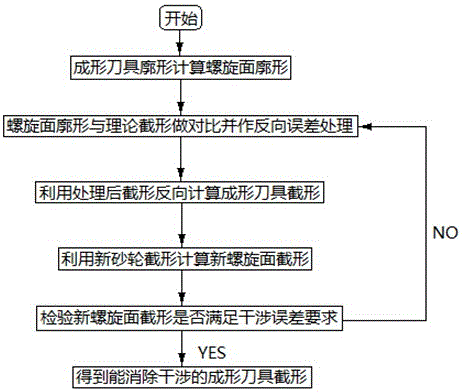

Spiral surface forming machining method

ActiveCN106020112AImprove profile accuracyLess interferenceNumerical controlMaximum errorEngineering

The invention discloses a spiral surface forming machining method. The method comprises a step according to which a forming cutter matched with the spiral surface of a workpiece to be machined is selected to carry out forming machining on the workpiece to be machined. According to the method, before machining, the theoretical cross-sectional shape of the spiral surface of the workpiece to be machined is determined; the theoretical cross-sectional shape of the forming cutter is determined according to the theoretical cross-sectional shape of the spiral surface of the workpiece to be machined; the actual cross-sectional shape of the spiral surface is obtained according to the theoretical cross-sectional shape of the forming cutter; the actual cross-sectional shape of the spiral surface is compared with the theoretical cross-sectional shape of the spiral surface; if the maximum error of the actual cross-sectional shape of the spiral surface and the theoretical cross-sectional shape of the spiral surface is smaller than the accuracy of the workpiece to be machined, it can be determined that the obtained cross-sectional shape of the forming cutter satisfies requirements, otherwise, the actual cross-sectional shape of the spiral surface is made into a symmetric spiral surface cross-sectional shape relative to the theoretical cross-sectional shape of the spiral surface, and the symmetric spiral surface cross-sectional shape is adopted as a new theoretical cross-sectional shape of the spiral surface; and iterative computation is carried out until the error satisfies the requirements. With the spiral surface forming machining method of the invention adopted, the improvement of the profile accuracy of the forming cutter can be benefitted, the interference of the forming cutter and the workpiece to be machined can be decreased, and the machining accuracy of a gear can be improved.

Owner:CHONGQING UNIV

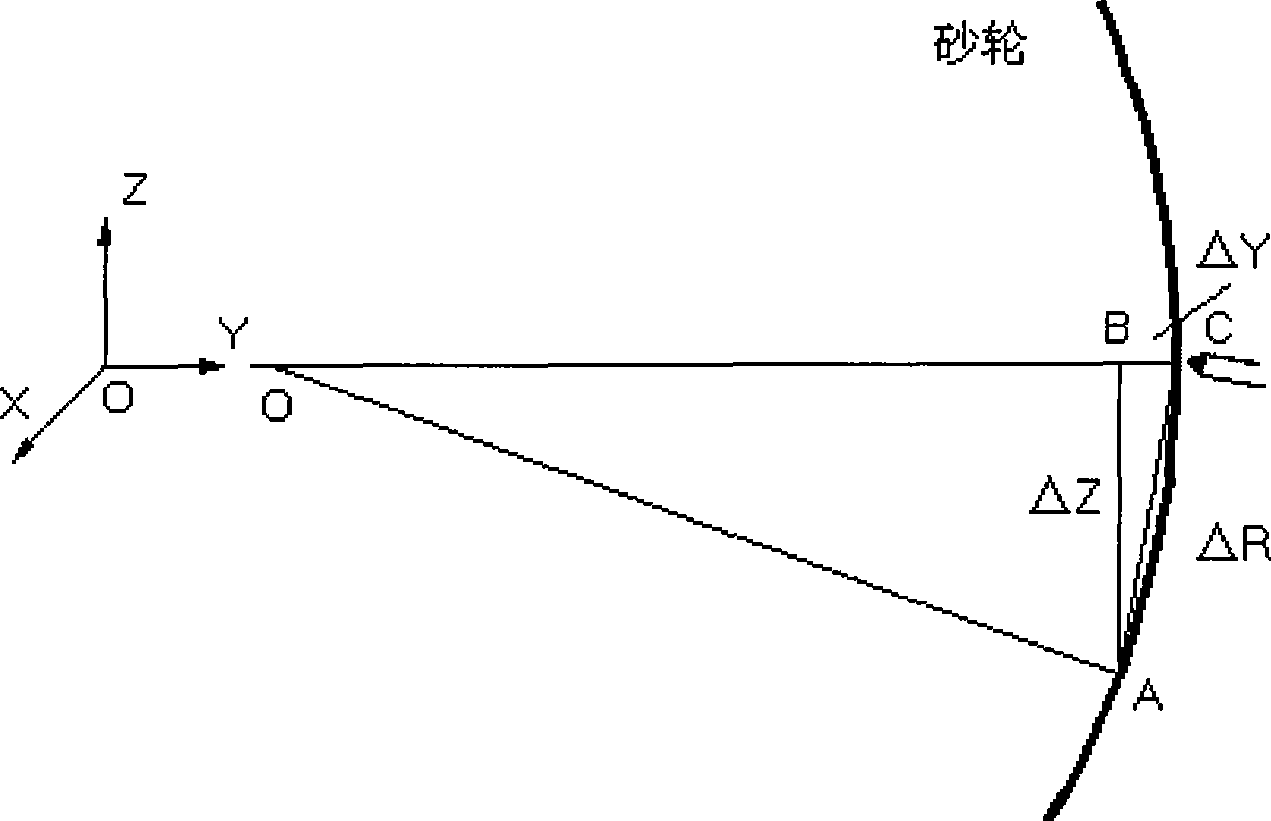

Circular-arc-shaped diamond grinding wheel dressing method

ActiveCN110202478AImprove dressing efficiencyImprove surface conditionAbrasive surface conditioning devicesLaser beam welding apparatusDiamond grindingHigh energy

A circular-arc-shaped diamond grinding wheel dressing method comprises the steps that 1, micro water guide laser parameters are set, and tool setting is conducted; 2, radial rough modification is conducted, specifically, the working surface of a grinding wheel is equally divided into a plurality of cross sections which are L wide in the axial direction of a parallel grinding wheel, according to the different depths of feeding, in the axial direction of the grinding wheel, of the laser water beam, different depths H of abrasive layers are removed from the cross sections in sequence, and finally, the parallel grinding wheel is formed into a circular-arc-shaped grinding wheel through rough modification; 3, the surface profile precision of the grinding wheel is detected, height information ofall points on the surface is obtained, and tool setting is conducted; 4, cutting direction precise shaping is conducted; 5, micro water guide laser technology parameters are set, and tool setting is conducted; and 6, radial sharpening is conducted. According to the method, the high-energy high-density laser beam is guided through the water beam to remove the grinding wheel material in the fusion and gasification modes, a laser water beam variable rate scanning mathematic model is disclosed, the abrasive particle exposure height consistency is ensured, the dressed grinding wheel is good in surface appearance, the dressing precision is high, in addition, the dressing quality is ensured through water beam cooling, and energy saving and environmental protection are achieved.

Owner:HUNAN UNIV OF SCI & TECH

Recording tape cartridge

ActiveUS20050145737A1Inhibition effectReduce areaPicture changing apparatusRecord information storageEngineeringMechanical engineering

A recording tape cartridge which can be loaded into a drive device having a reel on which a recording tape is wound and which is rotatably accommodated in a case, the reel including: a resin-formed main portion which includes a reel hub formed in a tubular shape having a floor, the recording tape being wound around an outer peripheral surface of the reel hub; and a substantially disc-shaped metal plate attached firmly to an outer surface of a floor portion of the reel hub, wherein a gate portion, through which a resin material is introduced at the time of molding the main portion, is provided at a radial direction outer side of the metal plate.

Owner:FUJIFILM HLDG CORP +1

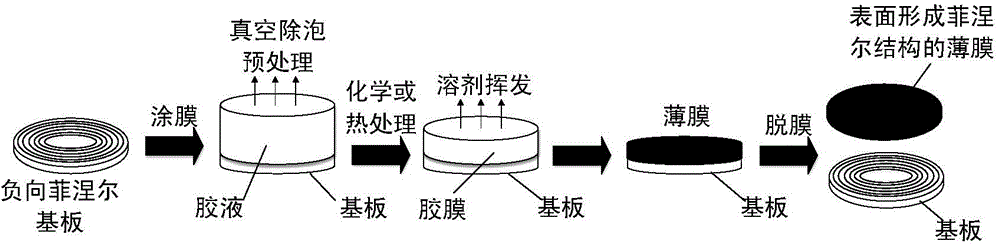

Fresnel lens manufacturing method taking high temperature resisting polymer film as substrate

InactiveCN104650376ASimplify surface processingImprove profile accuracyCoatingsLensFresnel lensGlass transition

The invention relates to a Fresnel lens manufacturing method taking a high temperature resisting polymer film as a substrate. As a negative complementary Fresnel structure is etched in the surface of a filming substrate used in an optical film preparation process, when a high glass-transition temperature (Tg) optical film is prepared, the Fresnel pattern structure can be transferred to the surface of the film, then the Fresnel lens manufacturing method taking the high temperature resisting polymer film as the substrate can be achieved, the machining process of the Fresnel structure on the surface of the film is greatly simplified, a great amount of labor and materials can be saved, the manufacturing cost can be lowered, the outline precision is high, and the Fresnel lens manufacturing method is particularly applicable to high temperature resisting high Tg polymer optical film materials, and is a gentle Fresnel structure forming method.

Owner:INST OF OPTICS & ELECTRONICS - CHINESE ACAD OF SCI

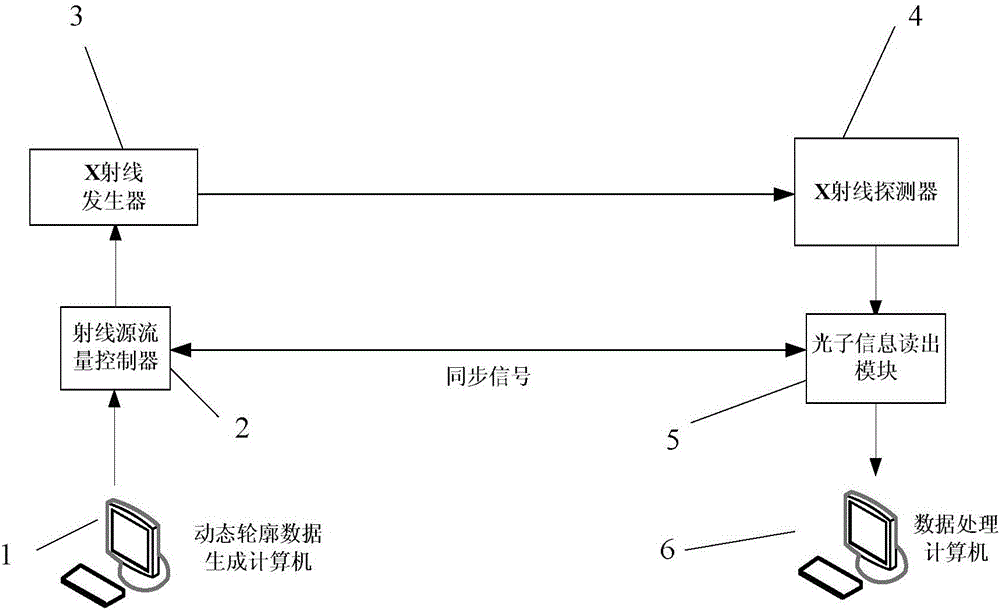

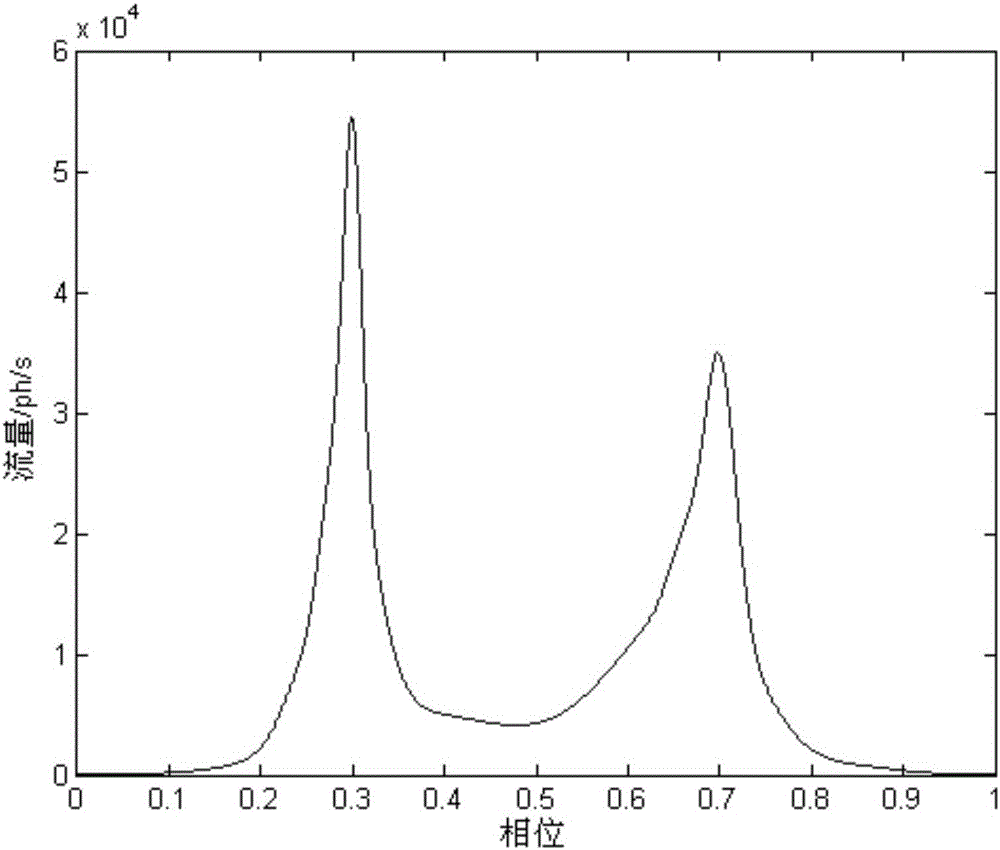

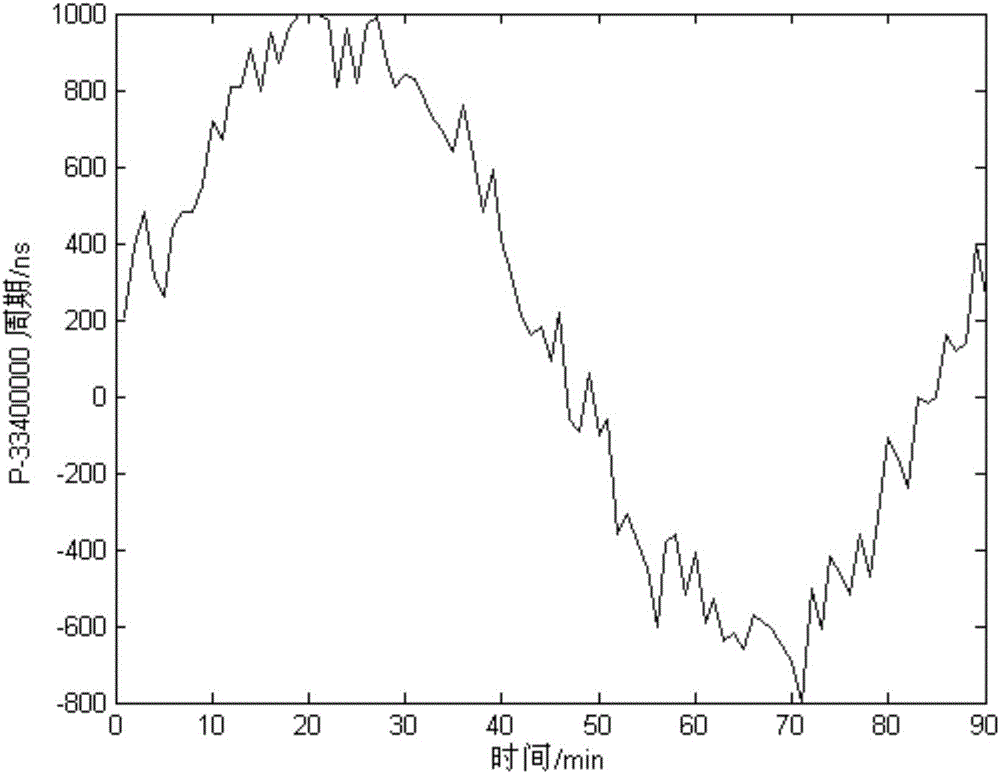

Semi-physical simulation method and system for X-ray pulsar dynamic signals

ActiveCN106052712AImprove profile accuracySimple and fast operationInstruments for comonautical navigationNavigation by astronomical meansTheoretical methodsNavigation system

The invention relates to a semi-physical simulation method for X-ray pulsar dynamic signals. The method includes 1) a step of setting spacecraft motional orbit parameters, observation pulsar parameters and observation time parameters, and generating pulsar signal dynamic contour data by a dynamic contour data generating server according to the set parameters, 2) a step of sending in real time the dynamic contour data by the dynamic contour data generating server to a radiation source flow controller every certain time, 3) a step of driving an X-ray generator, by the radiation source flow controller, to generate pulsar dynamic X-ray photon signals, and 4) a step of measuring an X-ray photon arrival event by an X-ray detector. The method achieves semi-physical simulation of the X-ray pulsar dynamic signals, and is suitable for verification and engineering technique research of a pulsar navigation system theoretical method.

Owner:NAT UNIV OF DEFENSE TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com