Error compensation method of numerical control grinding contour of camshaft

A technology of contour error and compensation method, which is applied in the field of error compensation, can solve the problems of affecting application, imperfect compensation of cam contour error, and inability to comprehensively consider the comprehensive influence, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0057] (1) Trial cutting processing

[0058] Before performing trial cutting and measurement on the cam plate, clean the camshaft first, and place the workpiece for a short period of time as much as possible before measuring. During the measurement, multiple measurements are made on each cam piece to obtain multiple sets of measured lift data. The lift error values of several sets of data are calculated by formula (a), and the transformation trend of several sets of errors is observed. If the change trends of several groups of errors are basically consistent on the whole, it means that the detection state of the camshaft is relatively stable, and the actual contour detected at this time is also relatively accurate.

[0059] e=h S -h L (a)

[0060] In the formula: e-lift error

[0061] h S - measured lift

[0062] h L -Theoretical lift

[0063] After m times of trial cutting, each cam piece will produce m sets of measured lift and lift error. The arithmetic mean...

Embodiment 2

[0105] (1) Trial cutting process to obtain lift error

[0106] In this embodiment, the trial cutting process of a camshaft part is carried out on a fully numerically controlled camshaft grinder, and the maximum allowable lift error of the part is 0.020 mm. Because the grinding machine has been fully debugged and preheated before processing, and the running state is stable, it is enough to try cutting once. The obtained lift error is as Figure 4 As shown, the maximum lift error of the camshaft is at a rotation angle of 99°, and the error value is -0.021mm, which does not meet the accuracy requirements

[0107] (2) Analyze the law of lift error and obtain prediction error

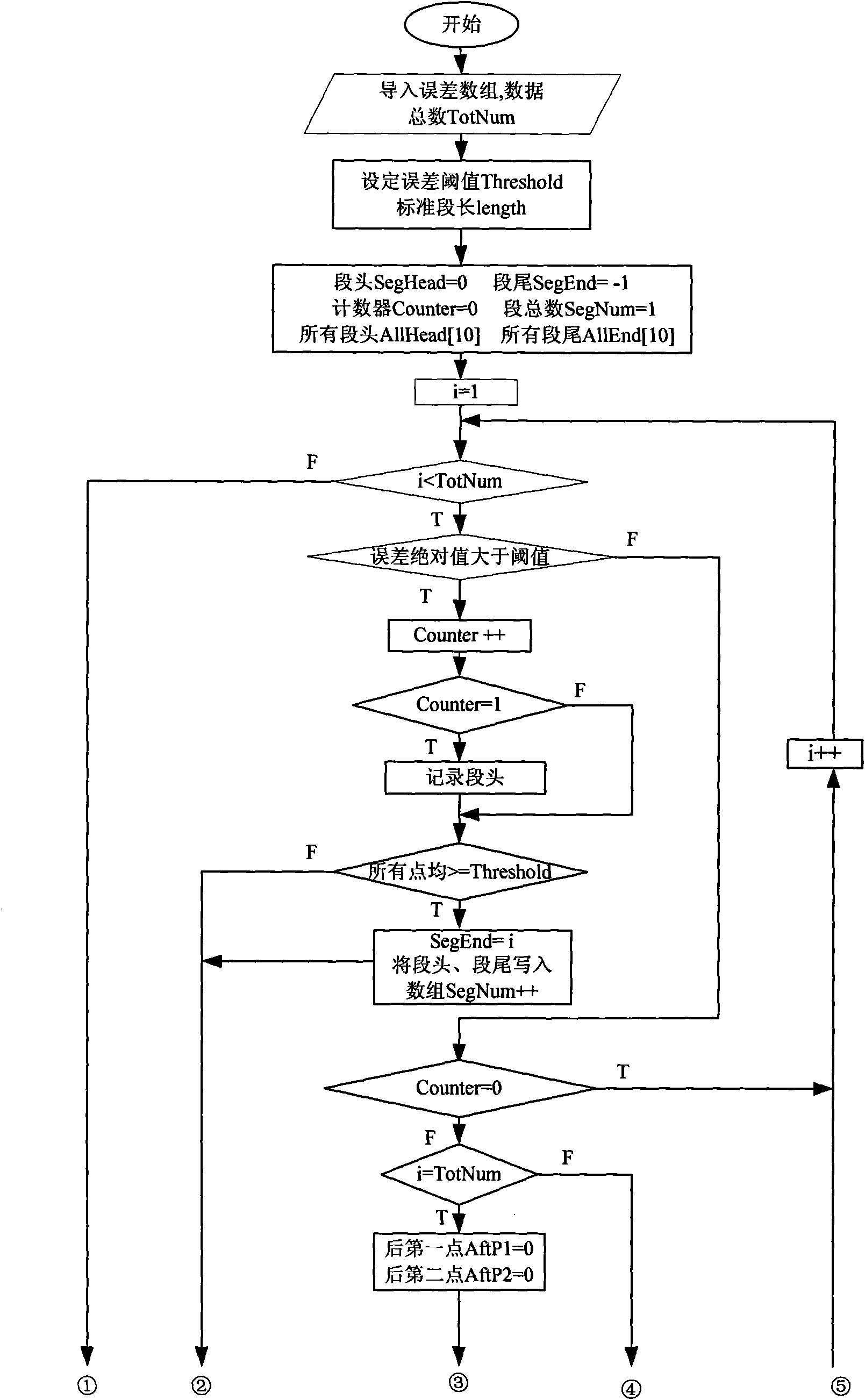

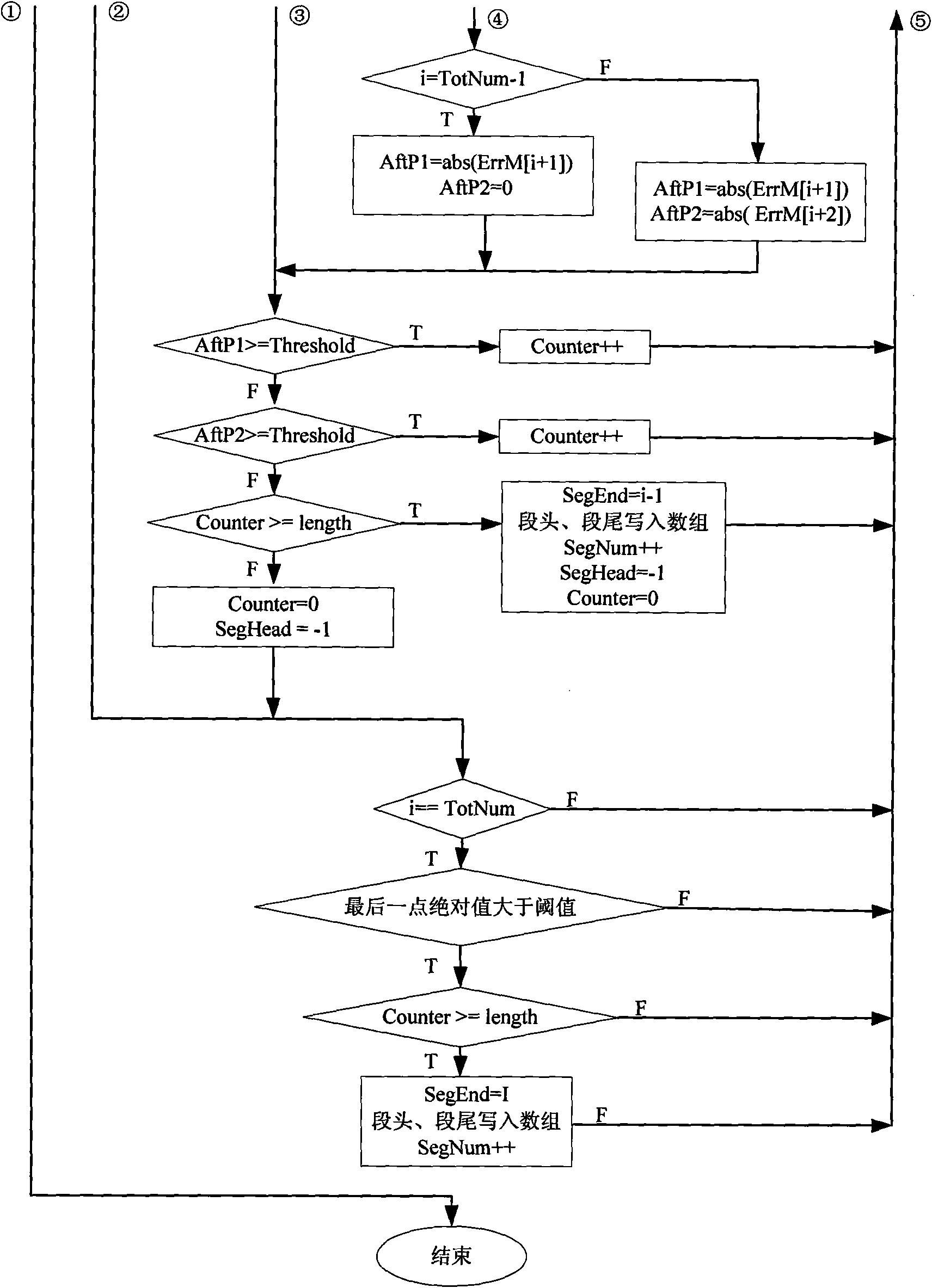

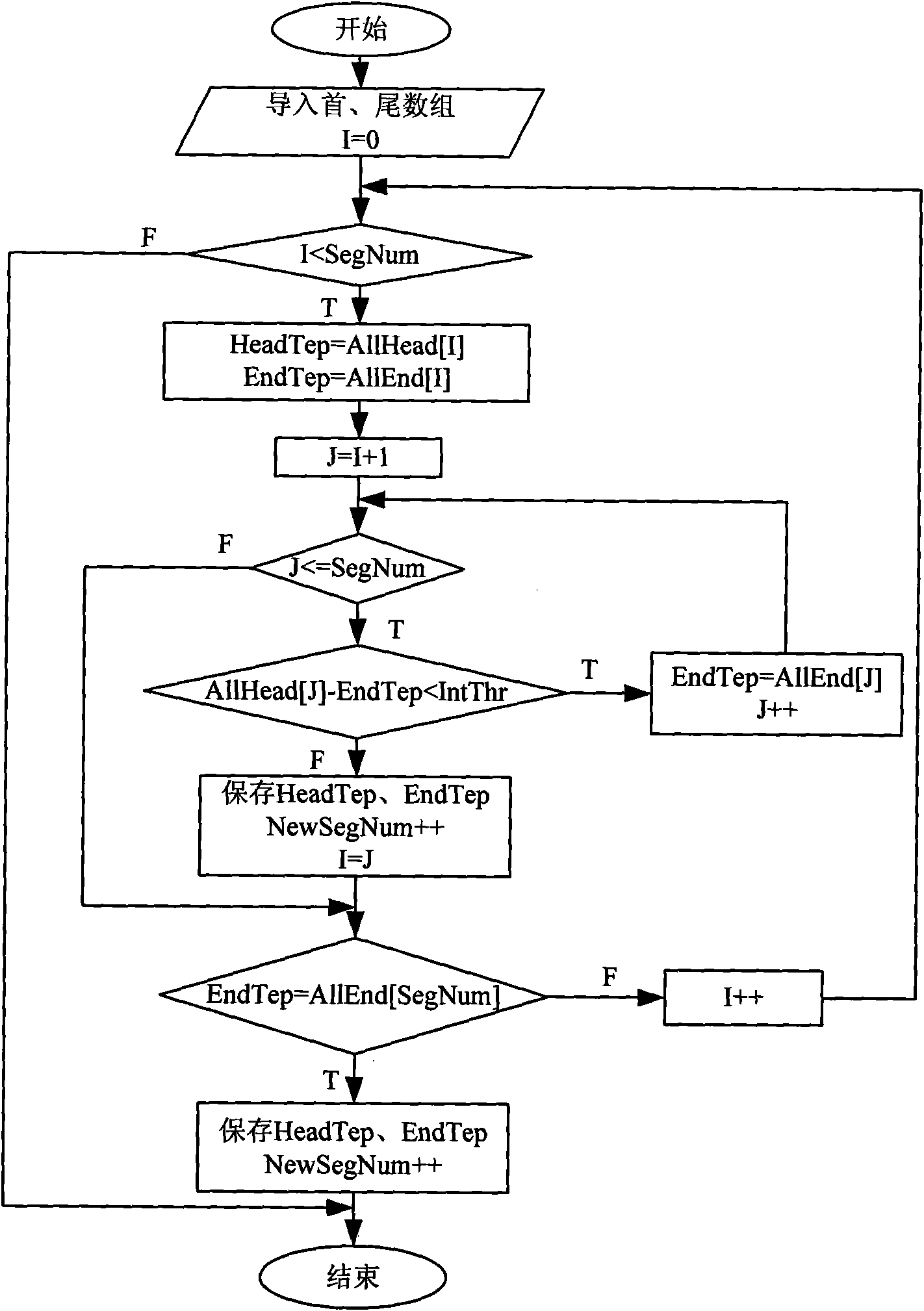

[0108] The lift error curve is analyzed by the error analysis software to realize the identification and merging of regular segments, and the least square method polynomial fitting is performed on the lift error curve. In this embodiment, the identification threshold of the error rule segment is set to 0....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com