Variable cross-section twisting and molding device and method for metal material

A metal material and variable cross-section technology, applied in the direction of metal extrusion dies, metal extrusion mandrels, etc., can solve the problems of low production efficiency and achieve the effect of improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

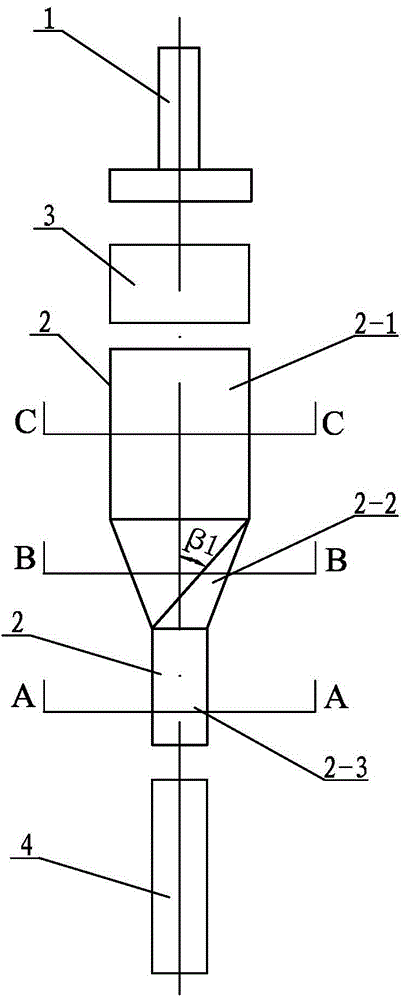

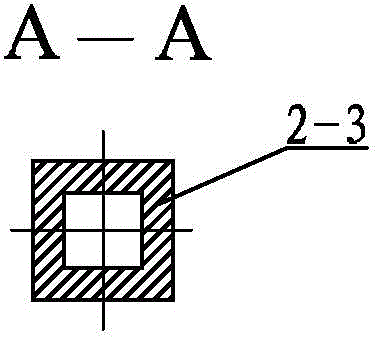

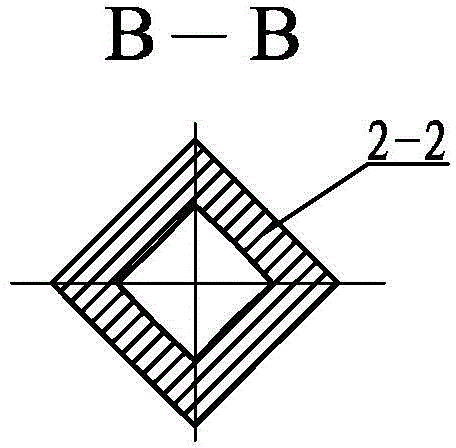

[0033] Specific implementation mode one: combine figure 1 , figure 2 , image 3 , Figure 4 and Figure 15 Describe this embodiment. This embodiment includes a first punch 1 and a first extrusion die 2. The first extrusion die 2 is the first large-section rectangular channel 2-1 and the first pyramidal spiral channel 2 from top to bottom. -2 and the first small-section rectangular passage 2-3, the cross-sectional area of the first pyramid spiral passage 2-2 gradually decreases from top to bottom, the cross section of the first pyramid spiral passage 2-2 is rectangular, and the first punch 1 It is coaxially arranged above the first extrusion torsion die 2 . The extrusion ratio is the ratio of the cross-sectional areas of the two channels.

specific Embodiment approach 2

[0034] Specific implementation mode two: combination figure 1 and Figure 15 This embodiment is described. This embodiment is a method for realizing variable cross-section extrusion and twisting of metal materials using the device of Embodiment 1. The steps are as follows:

[0035] Step 1. Setting the forming parameters: the first helix angle β1 of the first pyramidal helical channel 2-2 is 10°-60°, the length of the first pyramidal helical channel 2-2 is 0.5d-3d, where d is the first The diameter of the circumscribed circle of the rectangular section at the entrance of the pyramid spiral channel 2-2, the diameter d of the circumscribed circle is 30 mm to 100 mm, and the extrusion ratio of the first large-section rectangular channel 2-1 to the first small-section rectangular channel 2-3 4 to 100;

[0036] Step 2, the first punch 1 goes down to apply the load, and the blank 3 enters the first large-section rectangular channel 2-1 under the action of the first punch 1;

[003...

specific Embodiment approach 3

[0040] Specific implementation mode three: combination figure 1 , figure 2 and Figure 4 Describe this embodiment, this embodiment is that the first helix angle β1 of the first pyramid spiral passage 2-2 is set to be 30 ° in the step 1, the first large cross-section rectangular passage 2-1 and the first small cross-section rectangular passage 2- 3 has an extrusion ratio of 25. The extruded torsion angle of forming part 4 is 90 ° like this. Other steps are the same as in the second embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com