Method for finishing high-precision bearing-shaping abrasion wheel and feeding device thereof

A feeding device and forming grinding wheel technology, which is applied in the field of bearing precision machining, can solve the problems of low machining accuracy, achieve high cost performance, avoid step precision requirements, and reduce manufacturing requirements.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

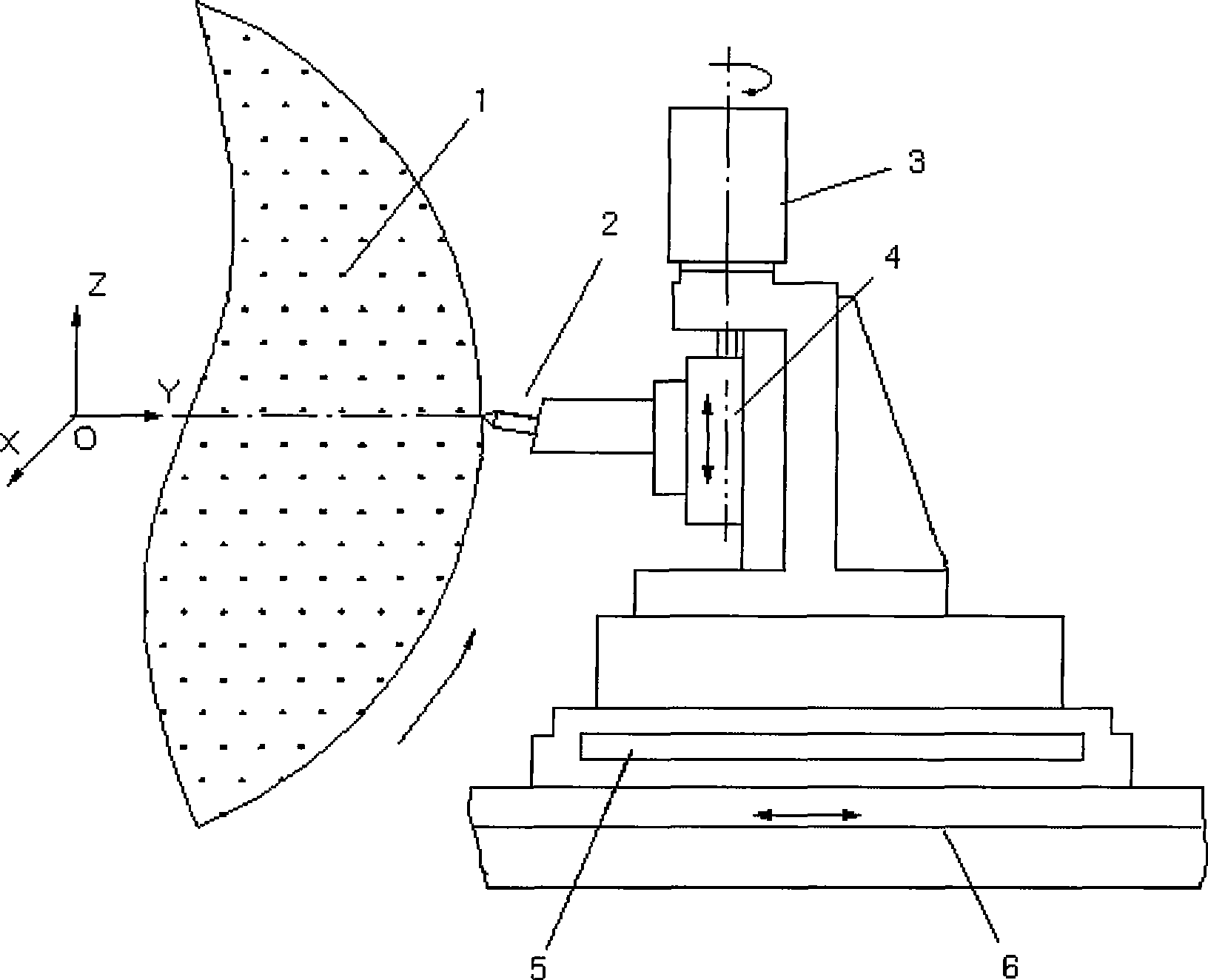

[0020] A feeding device for dressing high-precision bearing forming grinding wheels, which consists of three parts: gold pen 2, axial feeding device 5, tangential feeding device 4, and radial feeding device 6, and three independent servo motors 3 The above-mentioned three feeding devices are driven by the ball screw drive to drive the gold fountain pen 2 to move, and a programmable logic controller (PLC) is used to control the feeding motion of the above-mentioned three feeding devices.

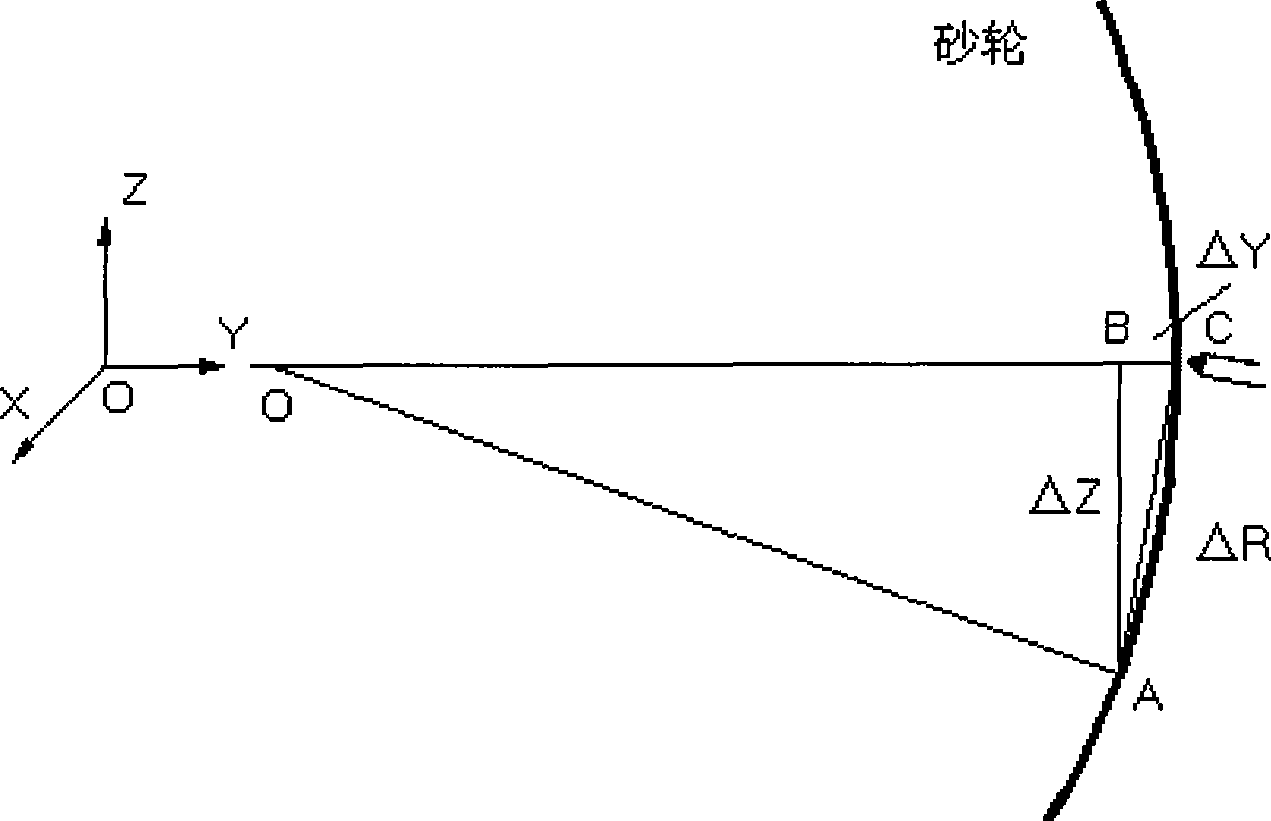

[0021] A method for dressing a high-precision bearing forming grinding wheel. The radial feed device 6 drives the gold pen 2 to move along the Y-axis in the radial direction of the grinding wheel, so as to realize the feeding of the gold pen 2 for a dressing amount and the compensation feeding of the wear amount. Through the tangential feeding device 4, the gold fountain pen 2 is directly driven along the tangential Z axis of the grinding wheel to indirectly complete its displacement relative ...

Embodiment 2

[0038]As described in Example 1, and the above method and device are used in the special grinding machine for the logarithmic curve inner raceway of the outer ring of the tapered roller bearing, the required logarithmic curve grinding wheel forming surface increment is 20 μm, and the logarithmic curve line profile The tolerance is 0.2 μm. The parameters of the selected grinding wheel are, diameter (D s ) 30mm, width (B) 20mm. Carry out adopting the accuracy analysis and benefit that the present invention can obtain below:

[0039] If according to the contour accuracy, the interpolation increment (ΔY) of the diamond pen on the Y axis is required to be 0.1 μm, then calculated by the formula (4): ΔZ=0.0547mm.

[0040] Obviously, according to the traditional grinding wheel dressing method, it is very expensive to require the Y-axis to directly feed 0.1 μm. Not only is the mechanism complex and huge, but it is also very difficult or even impossible to achieve stability and reliab...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com