Patents

Literature

189results about How to "Improve trimming accuracy" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

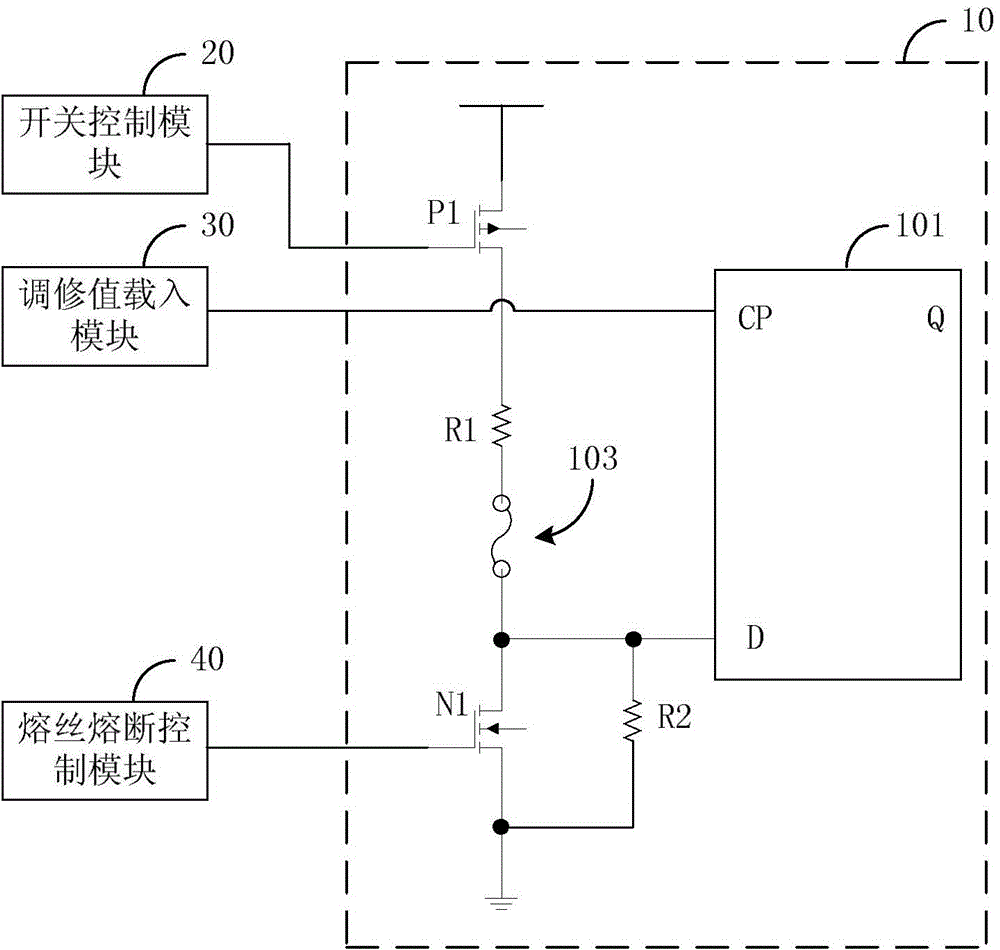

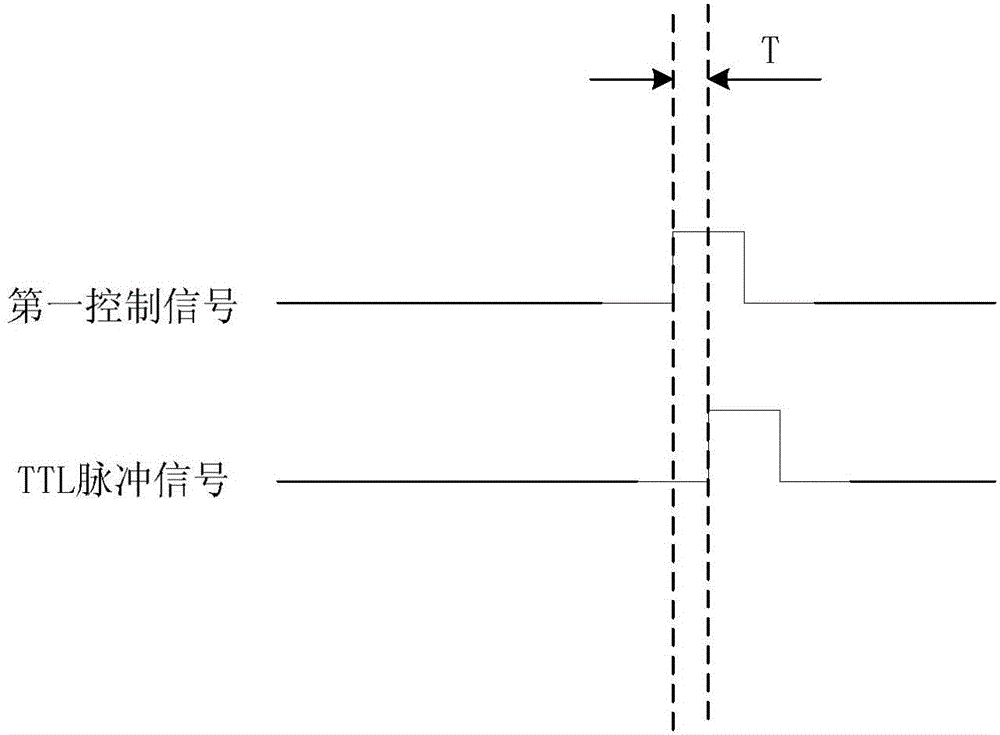

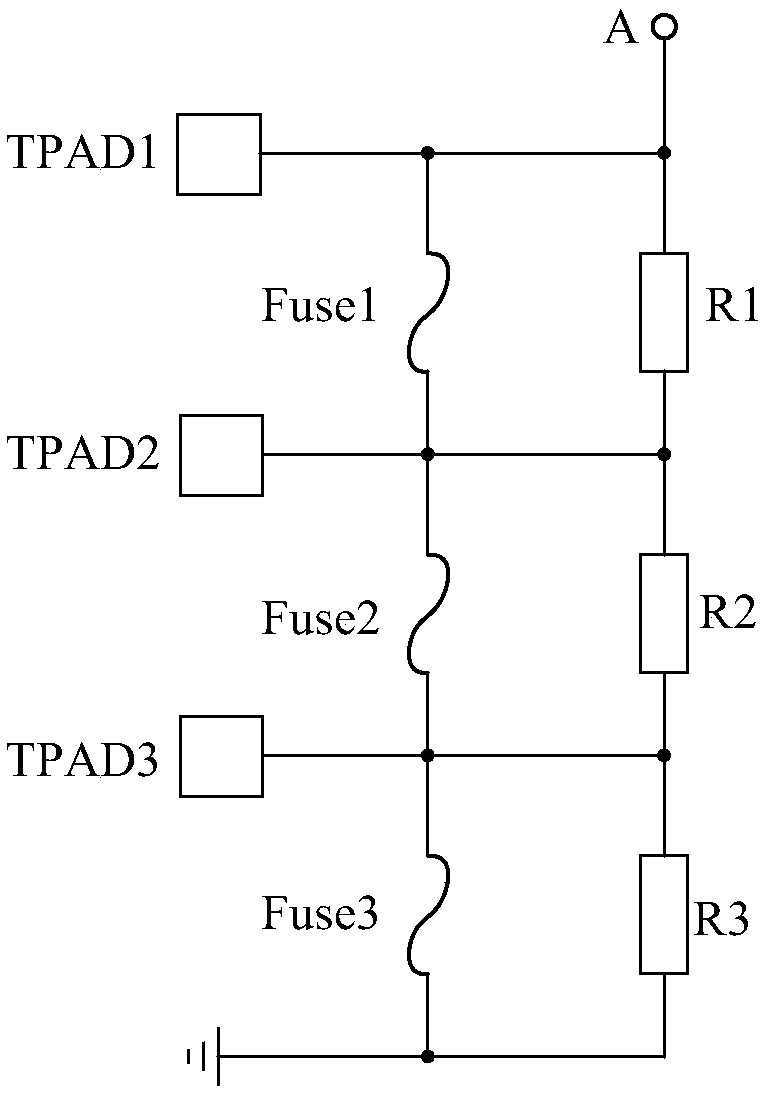

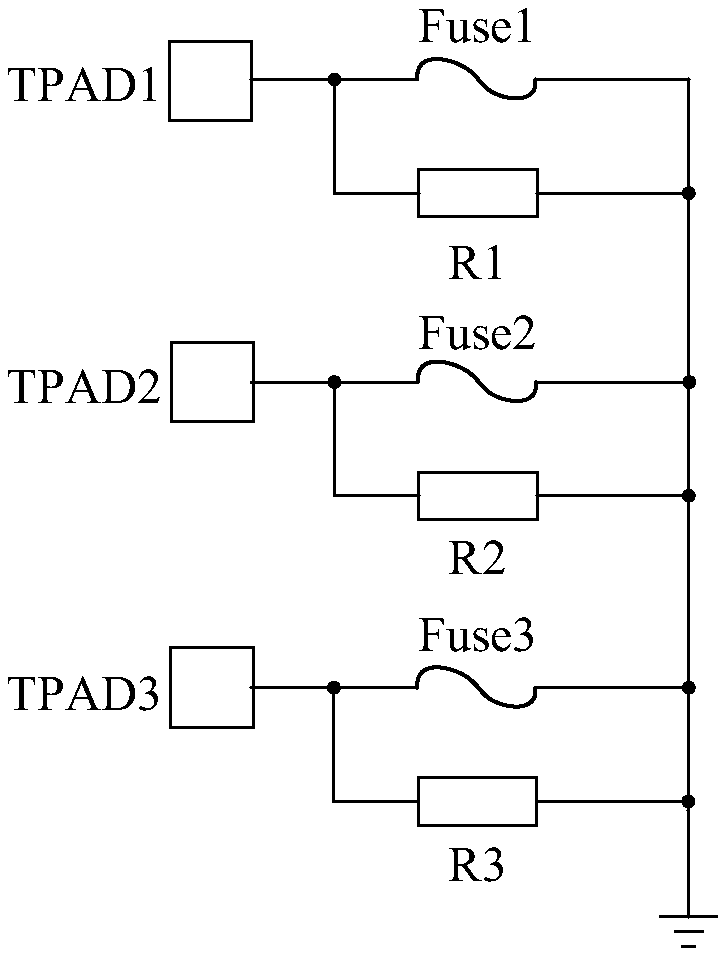

Fuse trimming and adjusting circuit

The invention discloses a fuse trimming and adjusting circuit comprising a switch control module, a trimming and adjusting value loading module, a fuse fusing control module and a trimming and adjusting module. The trimming and adjusting module comprises a PMOS transistor, a first resistor, a fuse, an NMOS transistor, a second resistor, and a D trigger. The source electrode of the PMOS transistor is connected with a voltage-stabilization power source; the grid electrode of the PMOS transistor is connected with the switch control module; the drain electrode of the PMOS transistor is connected with one end of the first resistor; the other end of the first resistor is connected with one end of the fuse; the other end of the fuse is connected with the source electrode of the NMOS transistor; the grid electrode of the NMOS transistor is connected with the fuse fusing control module; the drain electrode of the NMOS transistor is grounded; one end of the second resistor is connected with the source electrode of the NMOS transistor; the other end of the second resistor is grounded; the CP port of the D trigger is connected with the trimming and adjusting value loading module; and the D port of the D trigger is connected with the source electrode of the NMOS transistor. With the fuse trimming and adjusting circuit, a wafer can be trimmed and adjusted after being packaged, thereby reducing cost and improving trimming and adjusting precision.

Owner:CELLWISE MICROELECTRONICS CO LTD DONGGUAN

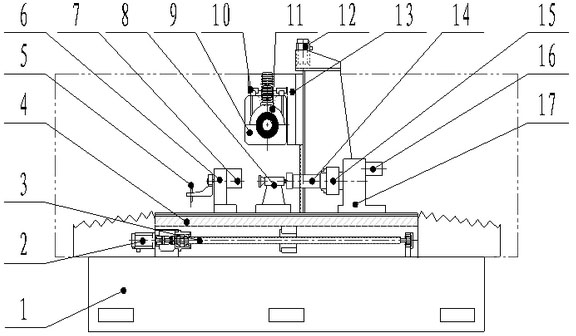

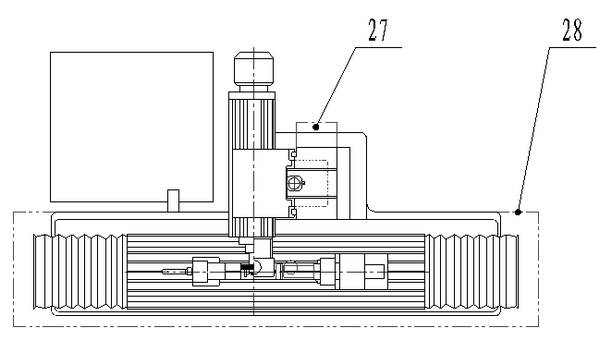

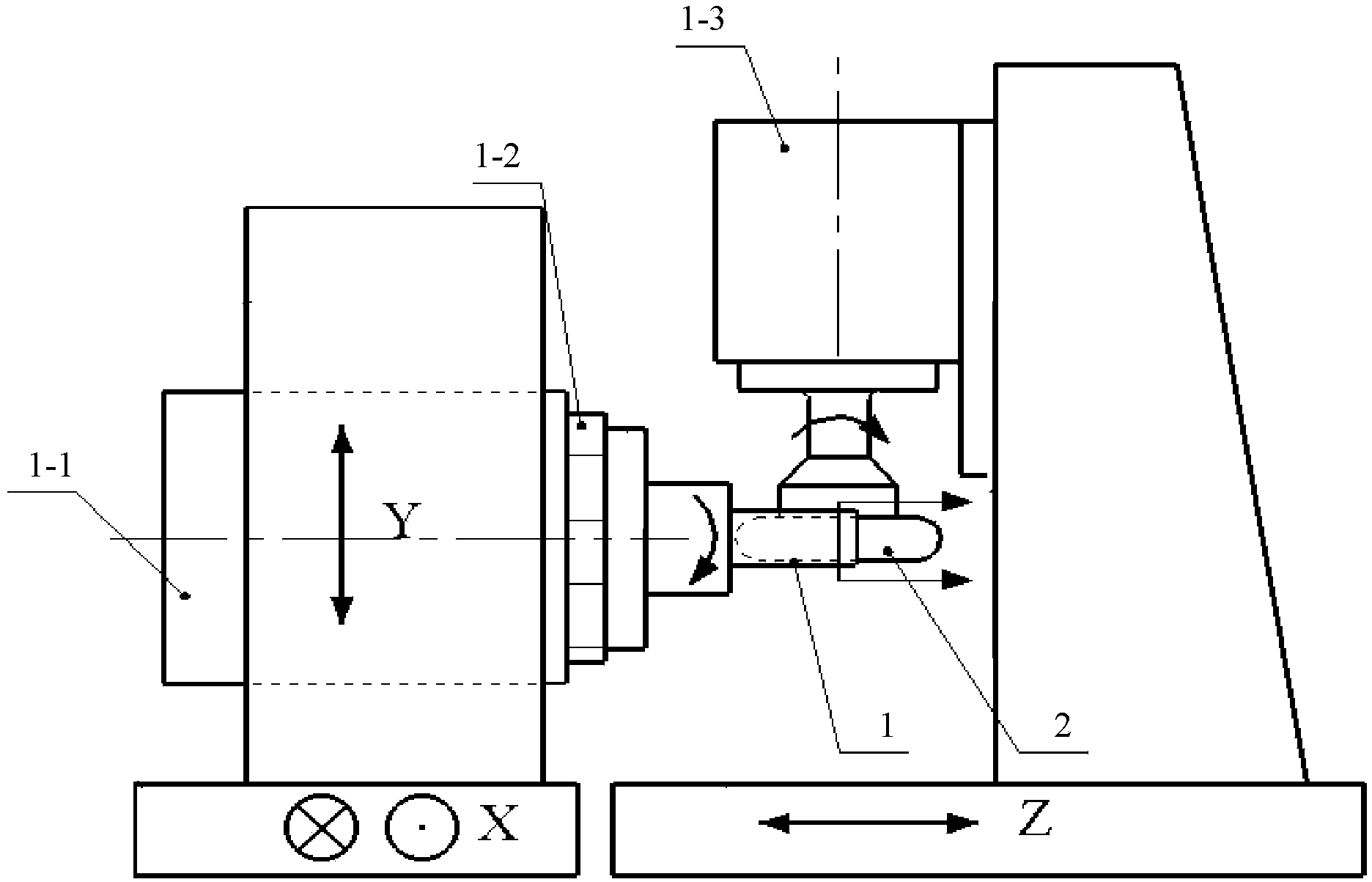

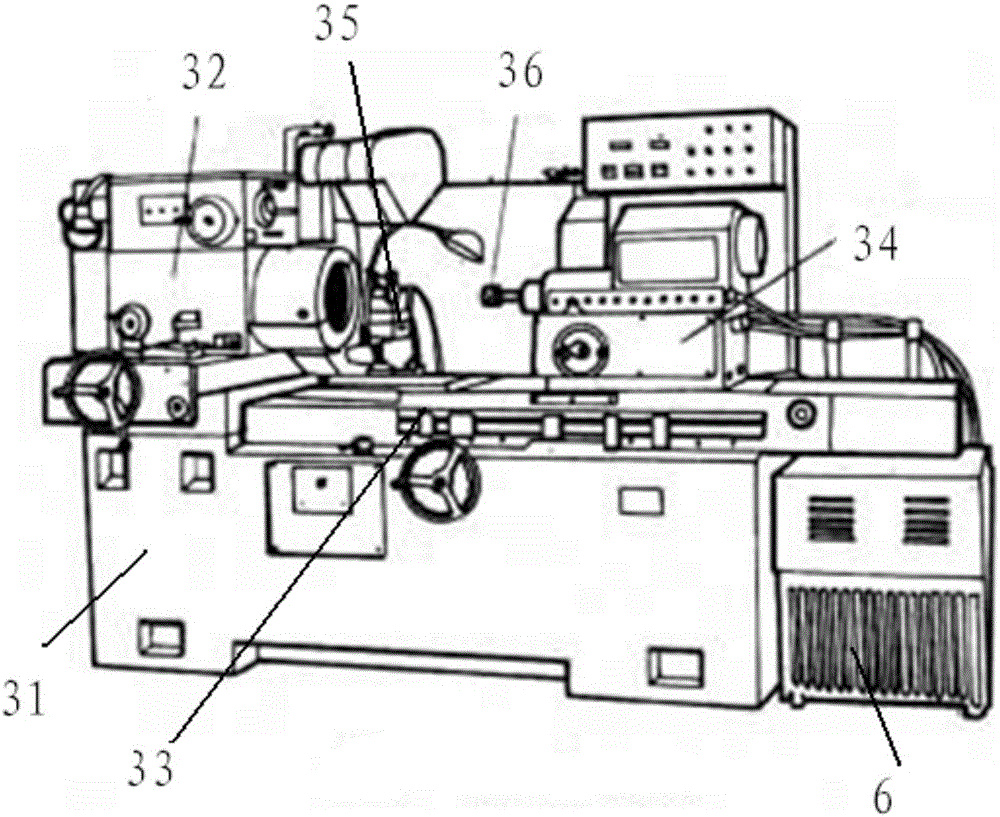

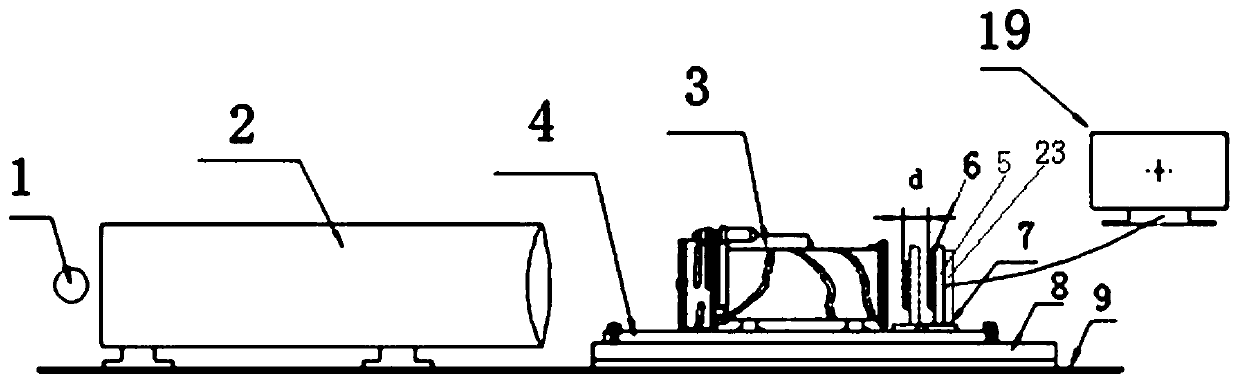

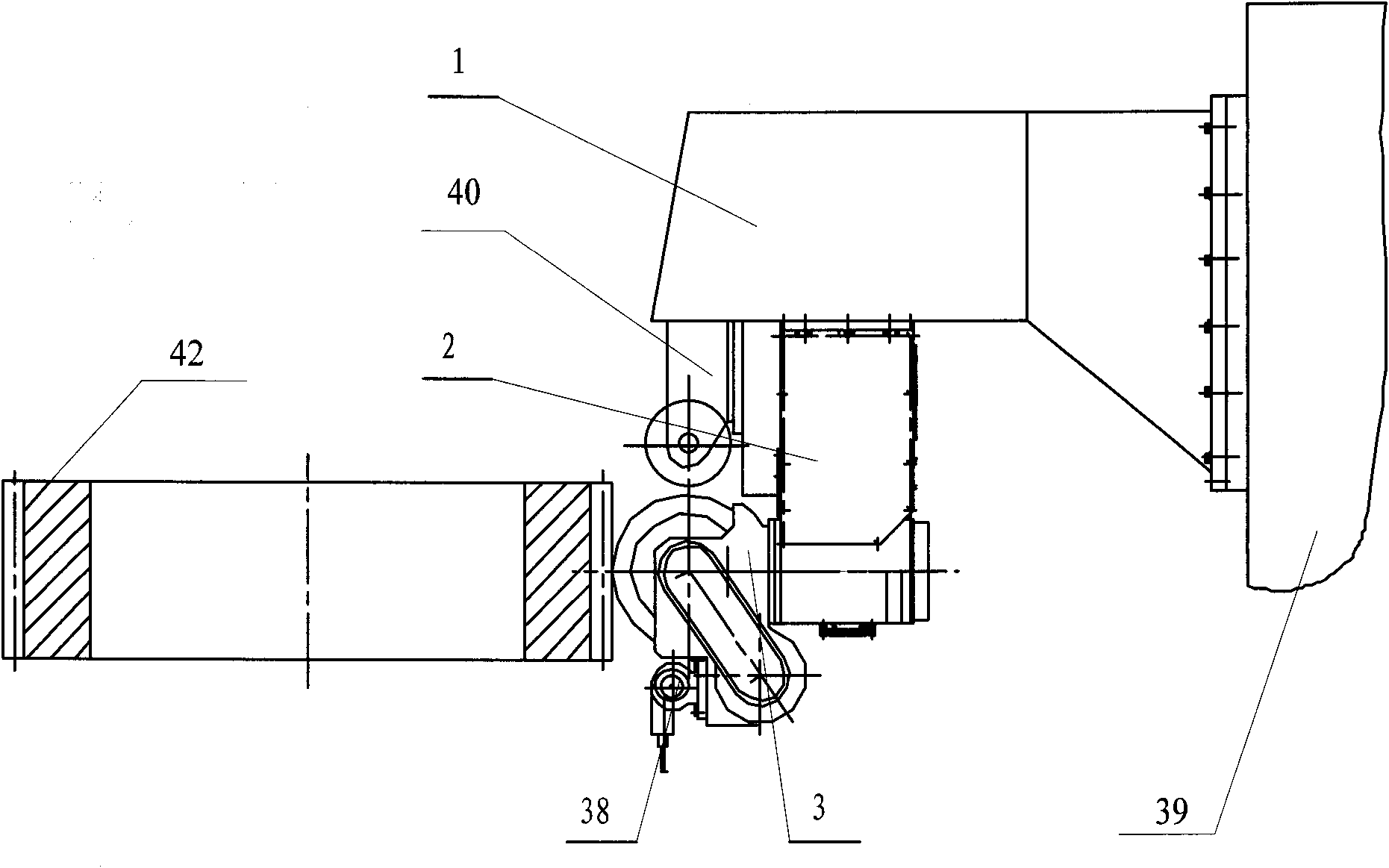

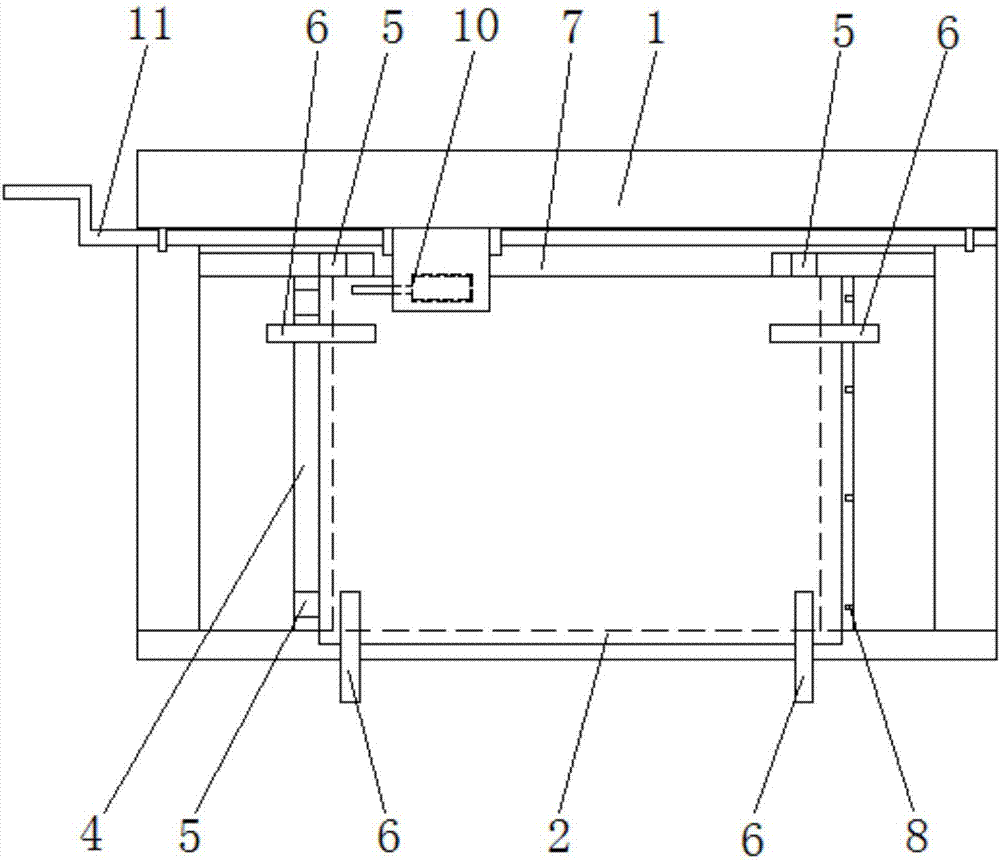

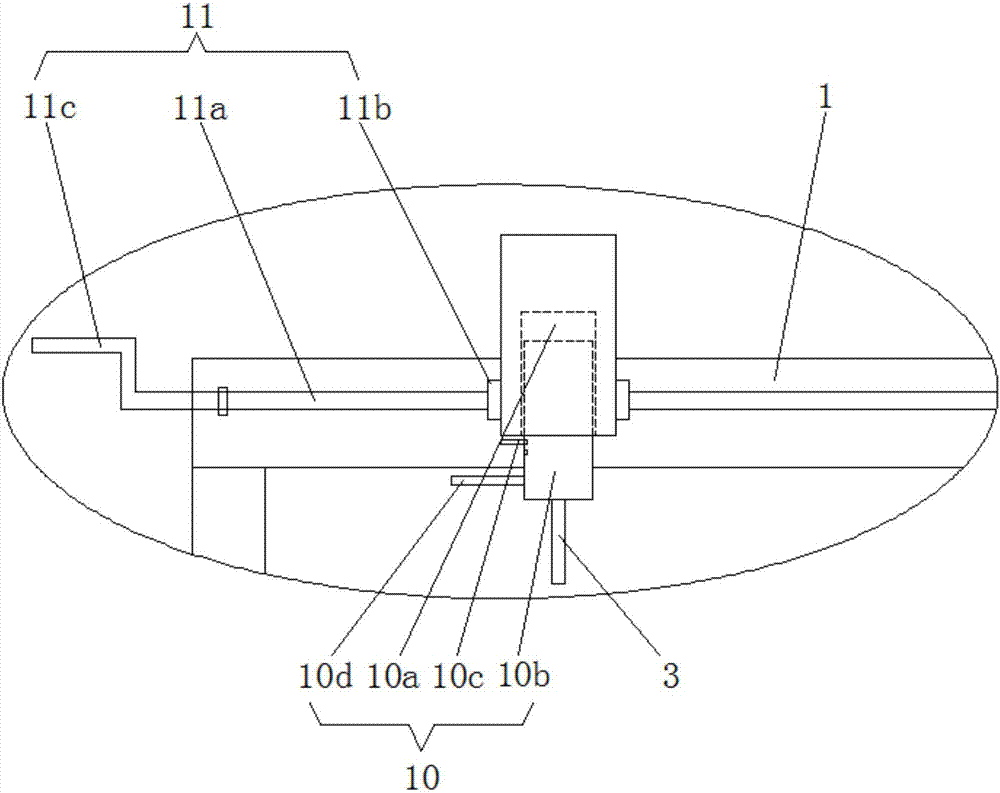

Numerically controlled grinder

InactiveCN101983839AHigh degree of automationImprove trimming accuracyGrinding machinesNumerical control systemMachine tool

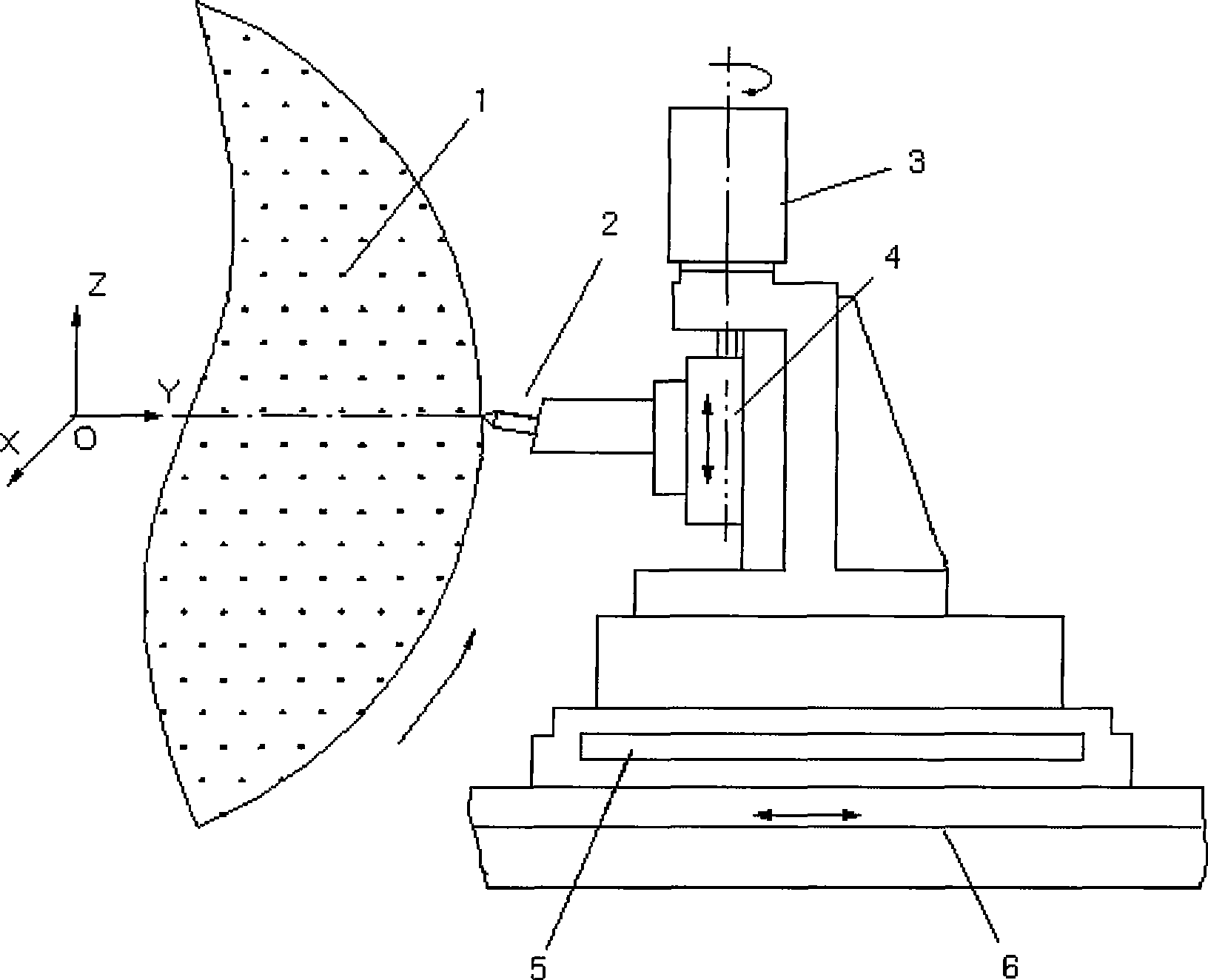

The invention relates to a numerically controlled grinder for forming and grinding an intermediate shaft channel of a rzeppa coupling. A numerical control system is respectively connected with servo motors and a stepping motor. A servo motor 1, a servo motor 2 and a servo motor 3 are respectively arranged on a grinding head frame, a stand column and a grinder body pedestal to respectively realize linear motion of the numerical control system in the Z direction, the X direction and the Y direction. A servo motor 4 is connected with a dividing mechanism to realize numerical control division or axial rotation of a workpiece; the stepping motor is connected with a trimmer to realize gyroscopic motion of a diamond pen; a grinding wheel spindle is driven by a grinding head motor to provide grinding main movement; the numerically controlled grinder is provided with a semi-closed shield, an air draft and dedusting system and a cooling and circulating system; and the servo motors are driven by a four-axis linkage numerical control system, and the stepping motor and the four-axis linkage numerical control system are controlled by a program controller. The invention is widely applied to carrying out ground finish on various curved surfaces of metal parts. In the invention, motion and positioning of the components can be numerically controlled and operated, the automation degree is high, the grinding wheel dressing precision is high, the working surface is smooth, the workpiece division accuracy is accurate, the labour environment can be improved and the labour intensity can be reduced.

Owner:XIANGYANG BOYA PRECISION IND EQUIP

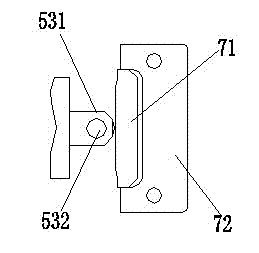

Angular trimmer for grinding wheel of grinding machine

InactiveCN102601737APrecise TrimmingImprove work efficiencyAbrasive surface conditioning devicesEngineeringGrinding wheel

The invention provides an angular trimmer for a grinding wheel of a grinding machine, which comprises a bottom plate, a diamond stylus, a sliding plate, a slider, a circular gear, a rotary rod and an adjusting supporting rod. The sliding plate is provided with a protrusion which is provided with a slot extending through the whole protrusion, the slider is provided with a groove, a strip toothed boss with a toothed opening is arranged at the bottom of the groove, the groove of the slider is slidably fixed with the protrusion of the sliding plate, and the groove is slidably fixed with the toothed boss. The diamond stylus is perpendicularly fixed to one face of the slider, one side of the sliding plate is movably and fixedly connected with the side of the bottom plate through the adjusting supporting rod, an adjusting gasket is arranged on a slide on one side of the sliding plate and fixed by a screw, and connecting blocks with symmetrical through holes are fixedly arranged on two sides of the sliding plate. The rotary rod penetrates through the through holes to be movably fixed with the connecting blocks, the circular gear is fixedly arranged on the rotary rod, the sliding plate is provided with an open slot, and the circular gear is meshed with the toothed boss through the open slot. The position of the slider and the height of the sliding plate are adjusted to fit angular adjustment of large-diameter grinding wheels.

Owner:MAANSHAN JINGHUA MACHINERY KNIFE & MOLD MFR

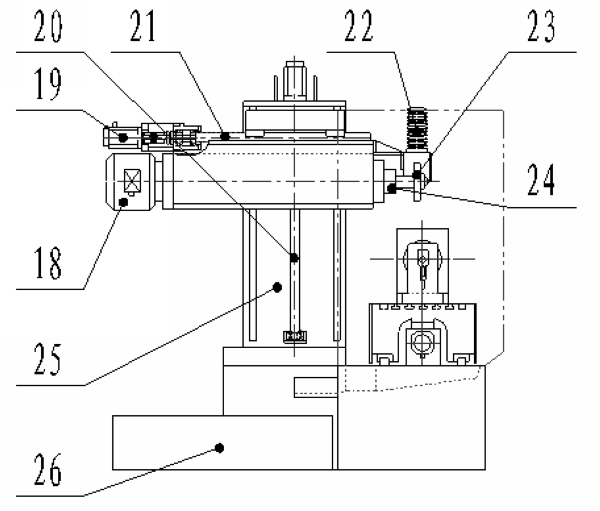

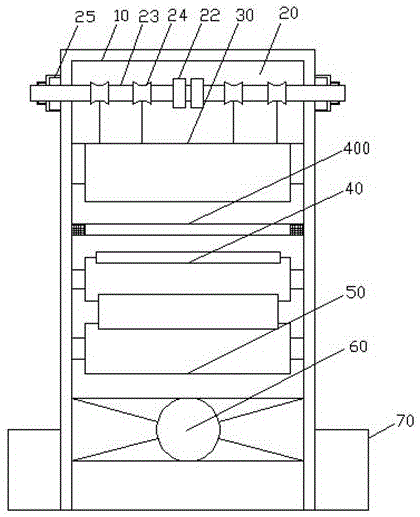

Cup type grinding wheel trimming device

InactiveCN101121250APrecise TrimmingTrim powerfulAbrasive surface conditioning devicesControl systemEngineering

A cup-shaped wheel dresser relates to a non-sphere processing grinding wheel; the wheel dresser provides a cup-shaped wheel dresser; the height and inclination of the wheel dresser are adjustable and the wheel dresser has the oscillating function. The wheel dresser is equipped with a base, an oscillating arm support saddle, an oscillating arm rotary shaft, a dressing grinding wheel, a grinding wheel panel, a main shaft, a main shaft band wheel box, servo motors, transmission mechanisms, a screw, a bolt, a supporting round stick, a triangle support saddle, runners and a numerically controlled system. The oscillating arm is equipped on the base and the oscillating arm base is connected with the oscillating arm rotary shaft. The grinding wheel is connected with the main shaft and the grinding wheel is installed on the main shaft; the main shaft is connected with the main shaft band wheel box; the first servo motor is connected with the main shaft by the first transmission mechanism and the second servo motor is connected with the oscillating arm rotary shaft by the second transmission mechanism. The bottom of the main shaft band wheel box is connected with the triangle support saddle and fixed on the triangle supported saddle; the bolt is equipped under the triangle support saddle and the triangle support saddle is connected with the oscillating arm; the screw is equipped on the oscillating arm and the triangle support saddle is linked with the lower end of the screw; the triangle support saddle and the oscillating arm are equipped with runners and the numerically controlled system is connected with the servo motors.

Owner:XIAMEN UNIV

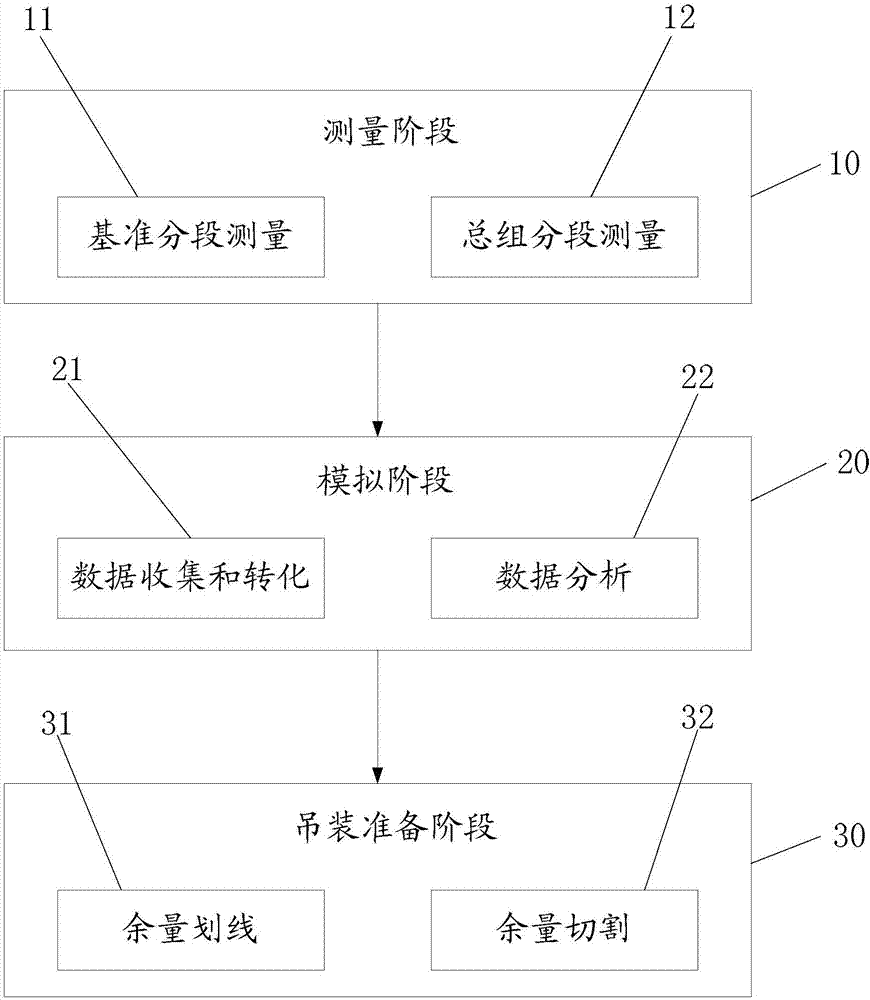

Control method for ship-body section carrying accuracy based on OTS

The invention discloses a control method for the ship-body section carrying accuracy based on OTS. The control method includes the steps of a measurement stage, a simulation stage and a lifting preparation stage, wherein the measurement stage includes the steps of data collection and conversion and data analysis; when the data collection and conversion step is carried out, actually-measured data is guided into a computer to generate a measurement file, and then a deviation value of the actually-measured data and theoretical data is calculated; when the data analysis step is carried out, a total-group section and a basic section are simulated and carried in the computer, a deviation value appears when the total-group section is in place to be in the best form, and margin data of the total-group section is obtained; the lifting preparation stage includes the steps of margin marking and margin cutting; when the margin marking step is carried out, margin lines are marked off on the total-group section according to the margin data; when the margin cutting step is carried out, margins on the total-group section are cut off along the margin lines, and the total-group section is margin-free carrying. According to the control method, sections are successfully lifted and carried one time, and resetting time is shortened.

Owner:SHANGHAI WAIGAOQIAO SHIP BUILDING CO LTD

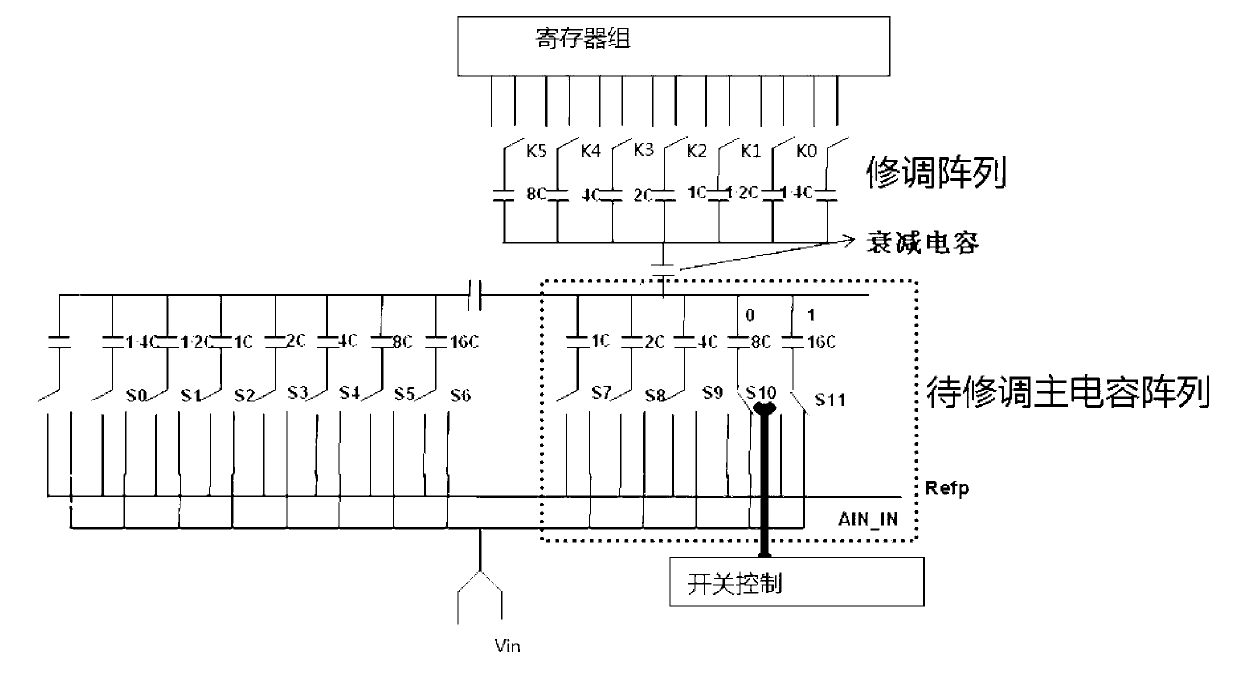

Successive approximation register (SAR) analog-to-digital converter (ADC) trimming method based on charge compensation and trimming circuit

InactiveCN103152046AEasy to mass produceReduce testing costsAnalogue-digital convertersCapacitanceRegister allocation

The invention provides a successive approximation register (SAR) analog-to-digital converter (ADC) trimming method based on charge compensation and a trimming circuit. The trimming circuit comprises a register block, an attenuation capacitor and a trimming array, wherein the register block comprises groups of registers, the trimming array includes multiple binary-weight capacitor networks, the trimming array is coupled to a to-be-trimmed main capacitor array through the attenuation capacitor, and the registers control the switching direction of corresponding capacitor switches in the trimming array. According to the trimming method and the trimming circuit, the charge compensation is carried out on the mismatched capacitors, the purpose that the capacitors are matched is achieved, compensation vector quantities can be configured through the registers, and the trimming method and the trimming circuit are suitable for being used in large-scale production and tests and can be carried out on most process platforms.

Owner:AVIC NO 631 RES INST

Method for trimming resin base circle arc diamond grinding wheel by adopting rotary green silicon carbide grinding bar

ActiveCN104044075AFix installation errorImprove shape errorAbrasive surface conditioning devicesMachine toolMachining

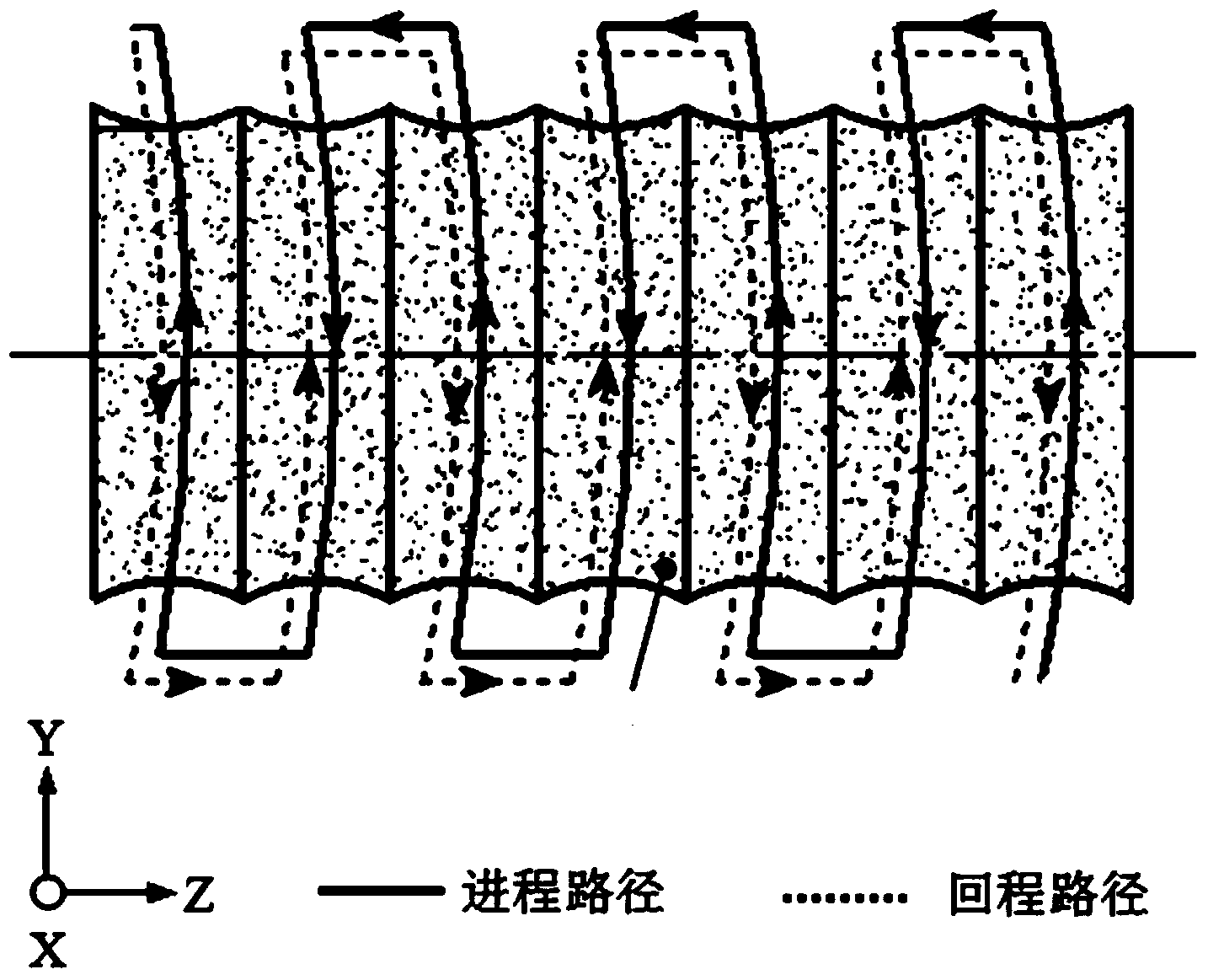

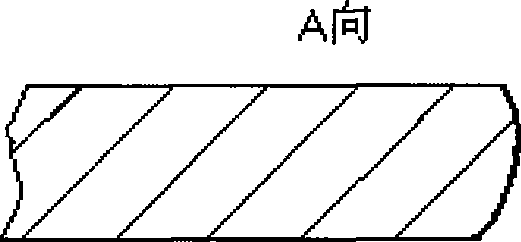

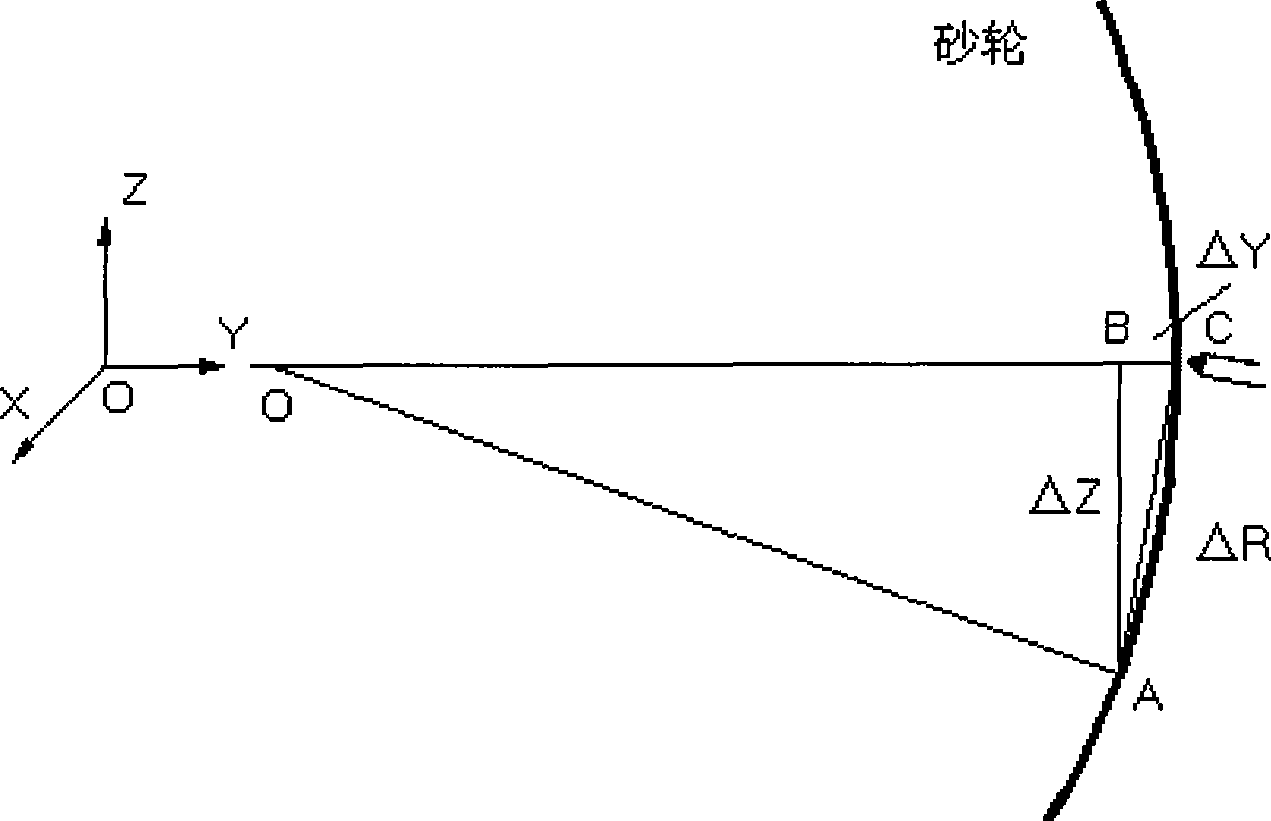

The invention provides a method for trimming a resin base circle arc diamond grinding wheel by adopting a rotary green silicon carbide grinding bar, and belongs to the technical field of machining of the resin base circle arc grinding wheel. The method aims to solve the problems that the installation position deviation, in the vertical direction, of the grinding wheel in a grinding process affects the shape accuracy of a machined workpiece, and machining accuracy is low. The method comprises the steps that firstly, the green silicon carbide grinding bar is arranged on a vacuum chuck of a workpiece main shaft of a three-linear-axis linkage machine tool, and the grinding wheel is arranged at the lower end of a grinding main shaft of the three-linear-axis linkage machine tool; then, a trimming path of the grinding wheel is planned, and the grinding wheel starts to be trimmed; every time the next adjacent interpolation period T starts, the radius R of the current green silicon carbide grinding bar is collected, the trimming path is corrected, and the grinding wheel continues to be trimmed by adopting the corrected trimming path until trimming is completed. The method is used for trimming the resin base circle arc diamond grinding wheel.

Owner:HARBIN INST OF TECH

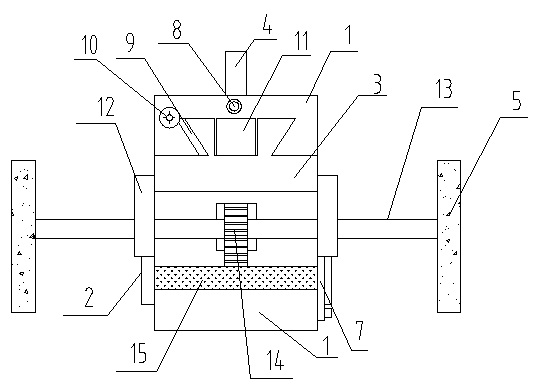

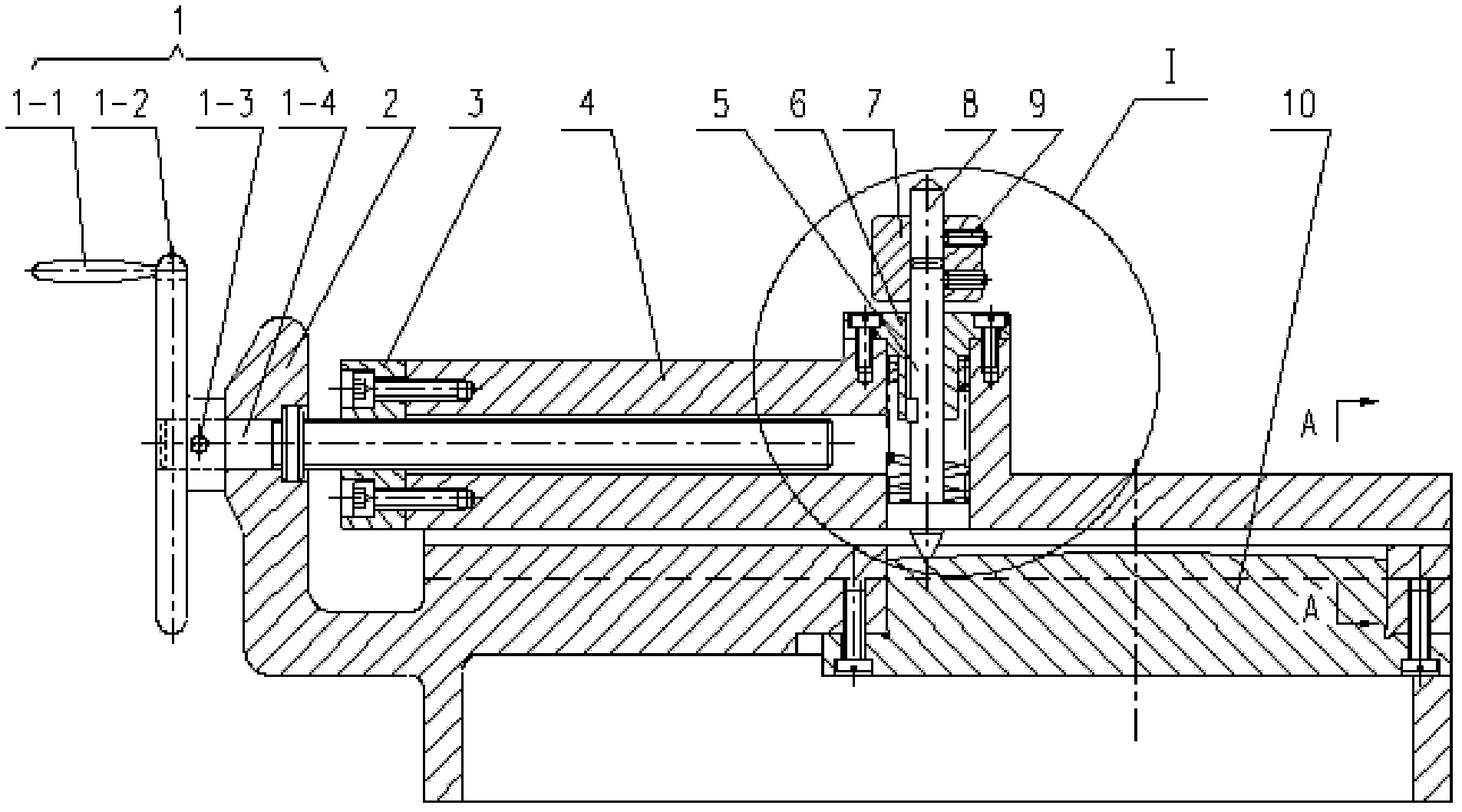

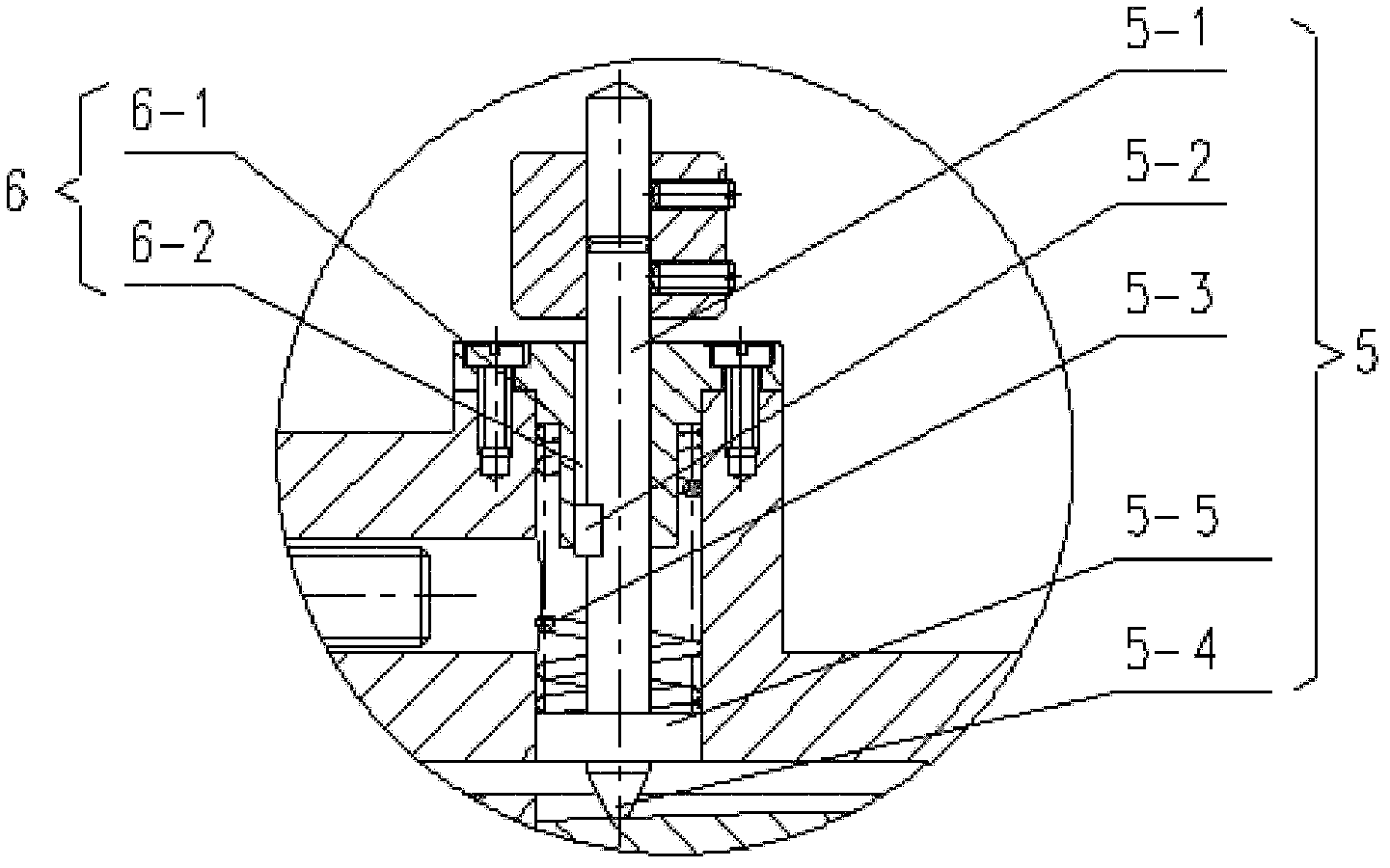

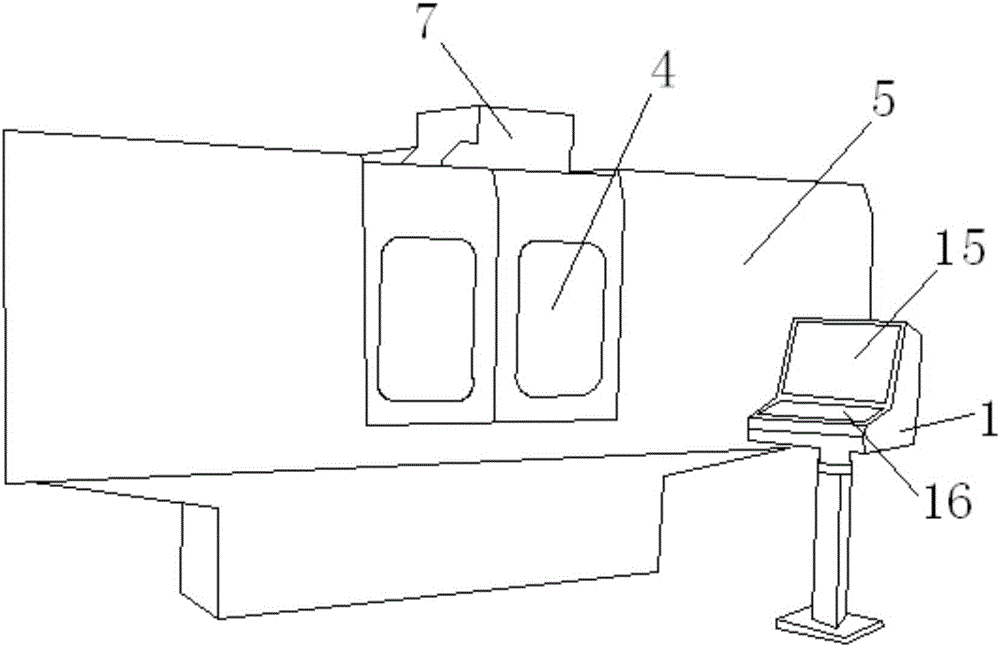

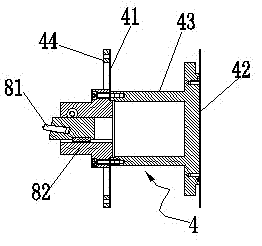

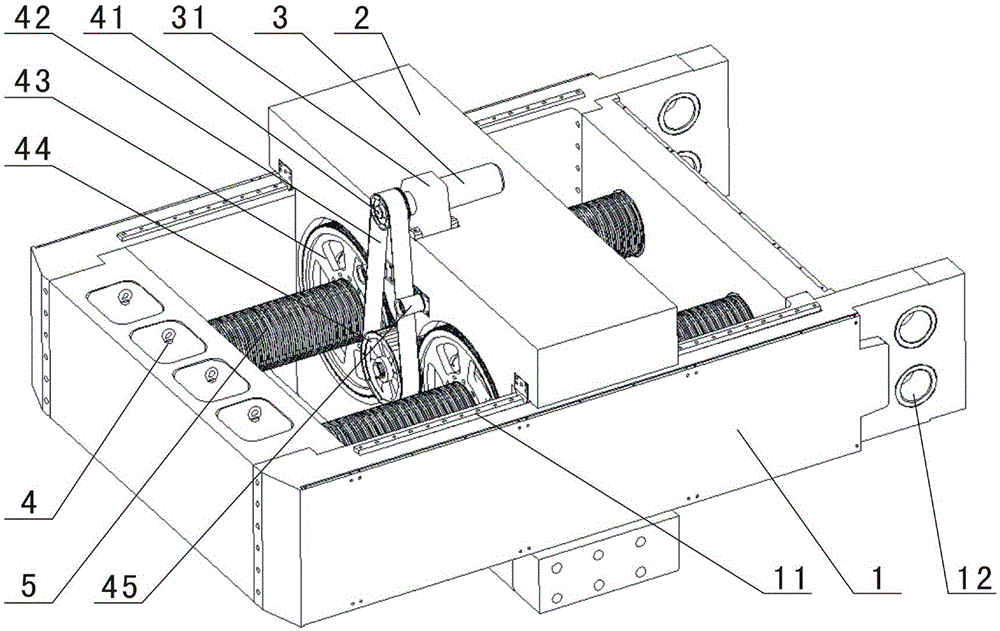

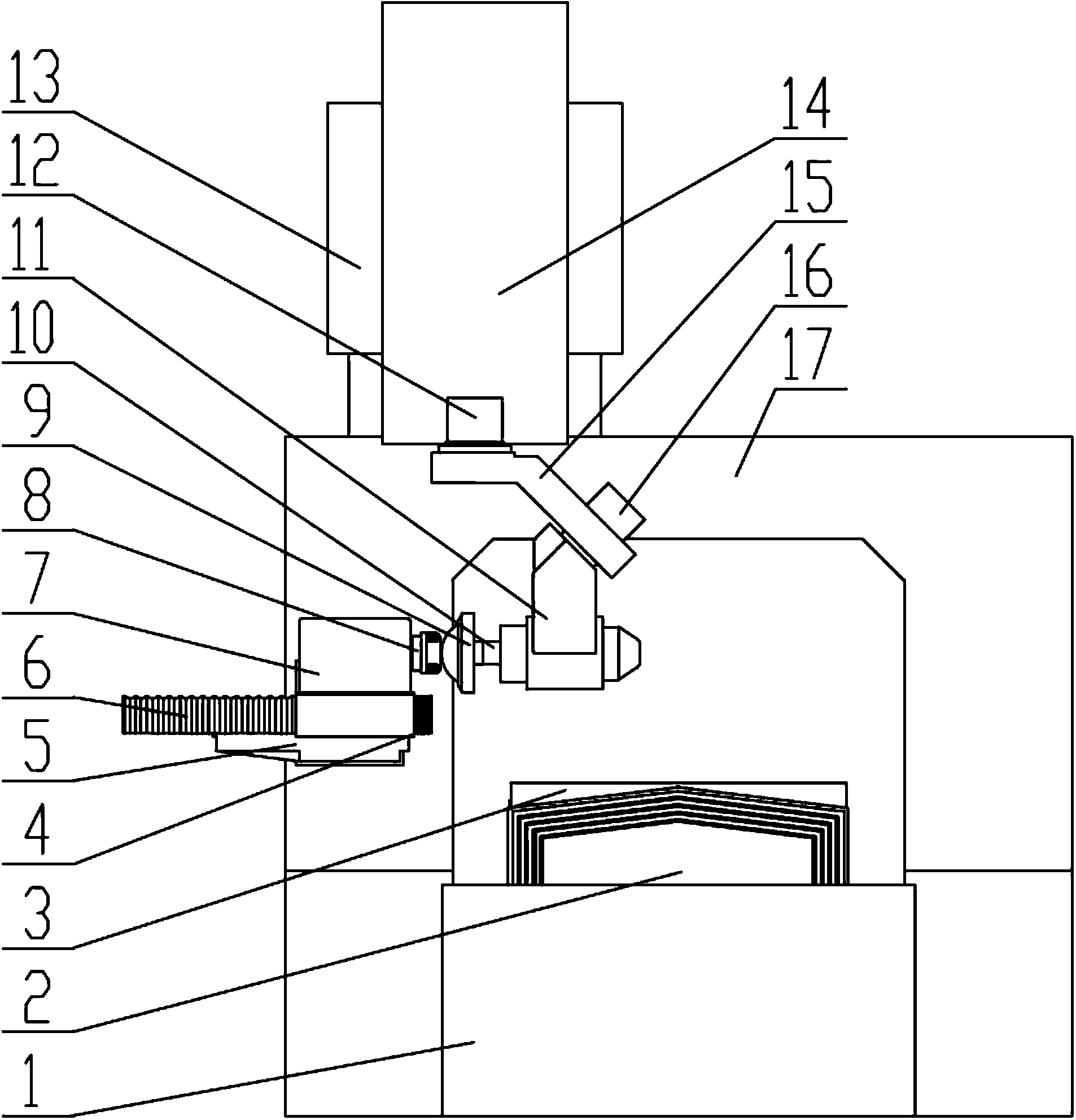

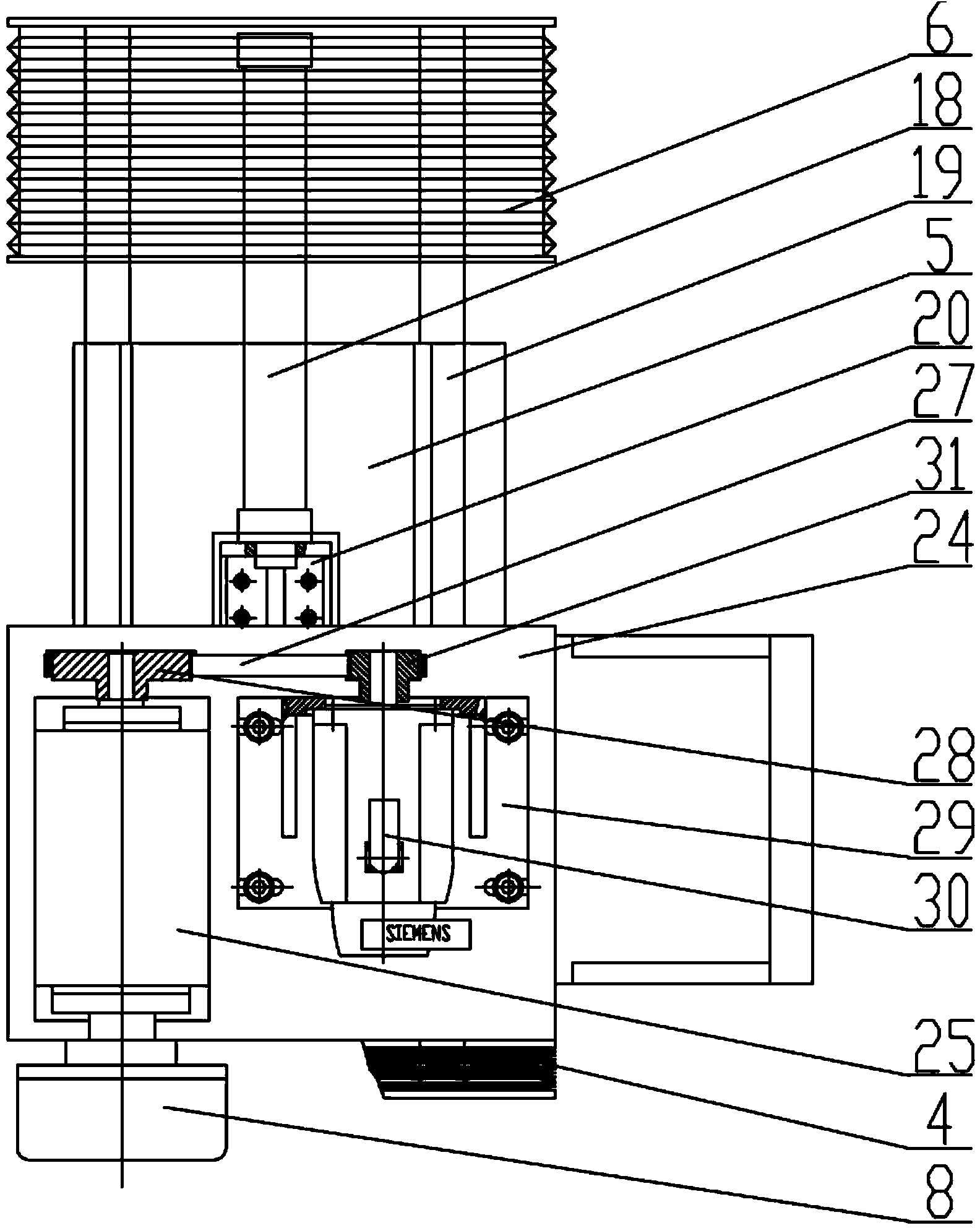

Method for finishing high-precision bearing-shaping abrasion wheel and feeding device thereof

InactiveCN101502948AGood value for moneyAvoid restrictionsAbrasive surface conditioning devicesEngineeringGrinding wheel

The invention relates to a feeding device of a forming grinding wheel for finishing high precision bearing which comprises three feeding devices for driving a pen-typed diamond to move in tangential, axial and radial directions. The three feeding devices are respectively driven by an independent servo motor through a transmission system and controlled by PLC. The feeding device adopts a method that the radial feeding device (4) indirectly finishes the radial direction motion of the grinding wheel along the tangential motion of the grinding wheel, avoids the limitation on the smallest step of a uniaxial coordinate and very high step precision requirement during the finishing of the grinding wheel and improves the finishing precision of the grinding wheel and the grinding bearing contour precision. With simple structure, the device of the invention can greatly lower the manufacturing requirement of the grinding wheel feeding device and has greatly high performance price ratio. Based on the method of the invention, developed tapered roller bearing log curve raceway grinder can greatly improve the processing precision and the stability of bearing raceway log curves, solve the industrial technical hard problem of bearing grinders and fill the gap of the field.

Owner:NINGBO ANJIESEN PRECISION MACHINE MFG +1

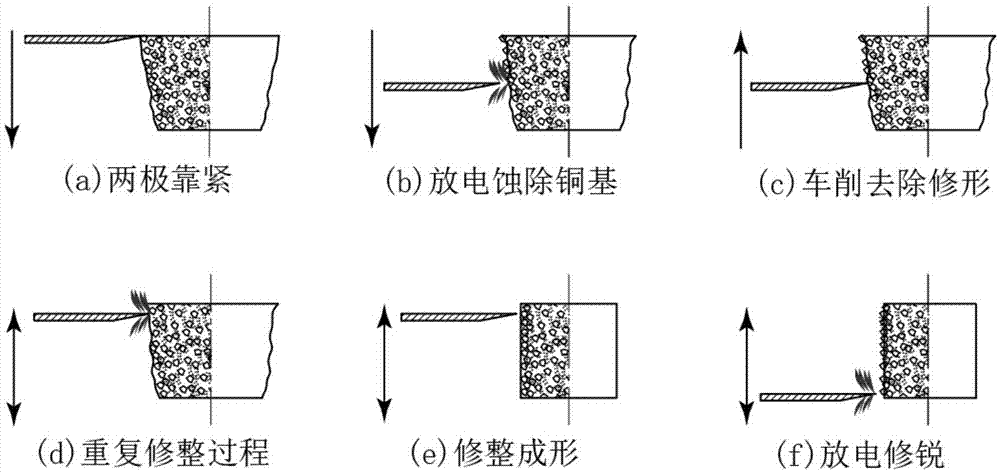

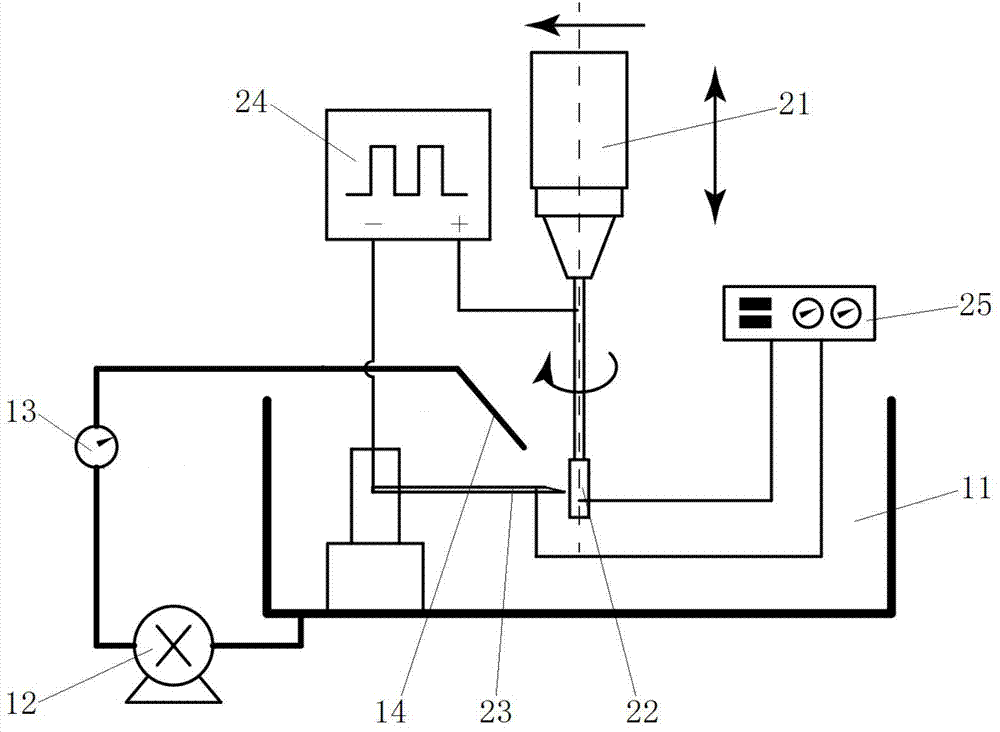

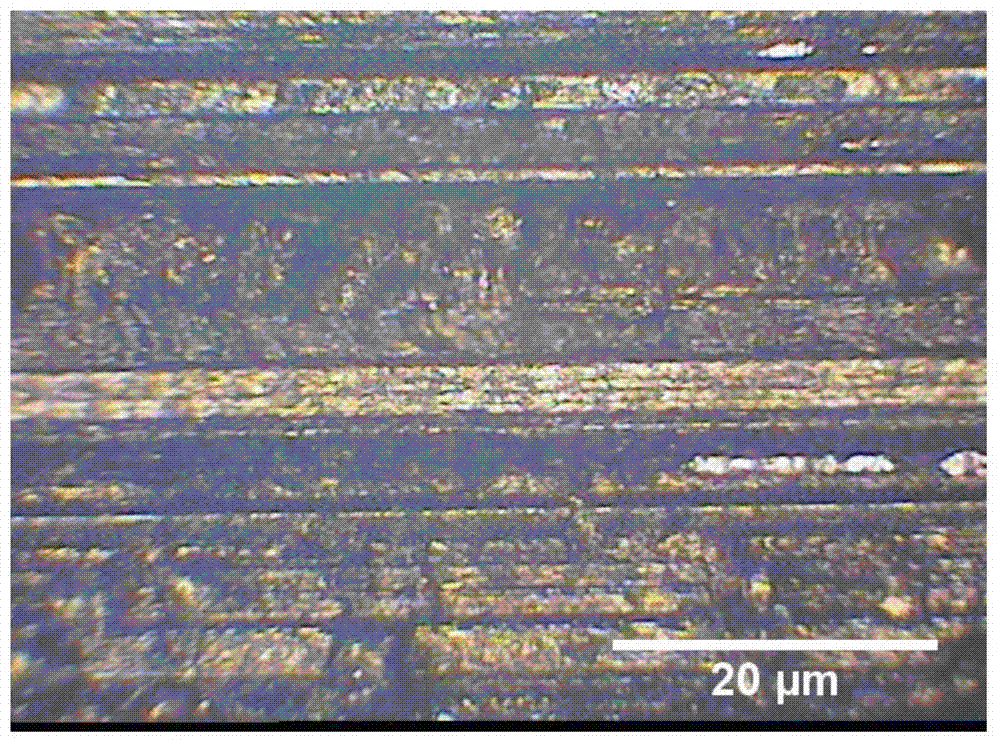

Diamond rotation body grinding wheel line electrode discharging and turning compound dressing method and device

ActiveCN104493719AGood removal effectFast preparationAbrasive surface conditioning devicesReciprocating motionEngineering

The invention discloses a diamond rotation body grinding wheel line electrode discharging and turning compound dressing method and device, and belongs to the field of machining. The dressing method includes the steps: S1, setting a tool, switching on a pulse power supply, controlling a diamond grinding wheel to rotate, reciprocating movement and feed movement of the diamond grinding wheel relative to a tool line electrode, and continuing feeding after a discharge current signal is monitored; S2, softening metal-based materials of a projection of the diamond grinding wheel and corroding parts of the metal-based materials under the discharge action; S3, turning and peeling exposed diamond particles by the aid of the relative reciprocating movement of the diamond grinding wheel and the tool line electrode; S4, repeating the steps S2 and S3; S5, judging shape modification conditions according to discharge waveforms; S6, stopping approaching movement of the diamond grinding wheel and the tool line electrode, and dressing the diamond grinding wheel under the discharge action. Line electrode discharge and turning are synchronously performed, the diamond grinding wheel with low circular run-out and a sharp surface is rapidly prepared, and machining efficiency and accuracy are high.

Owner:CHANGZHOU INST OF TECH

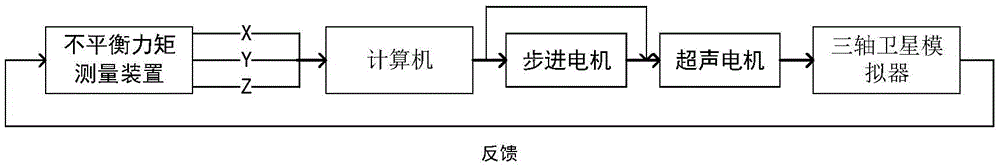

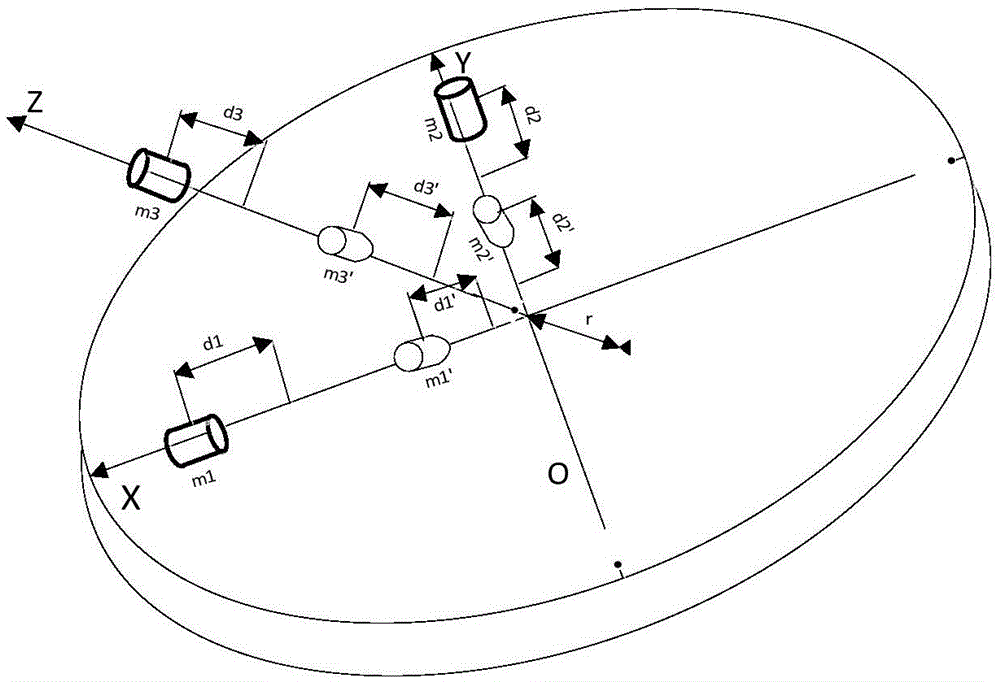

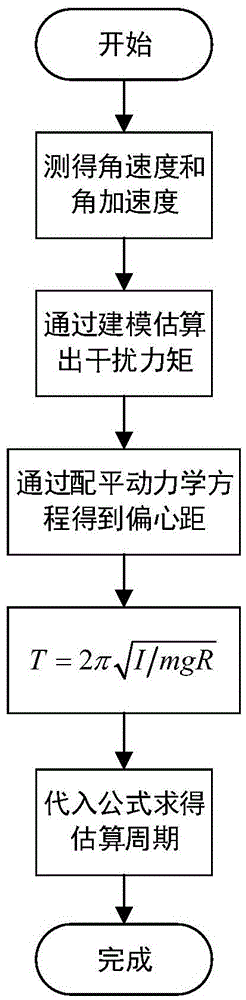

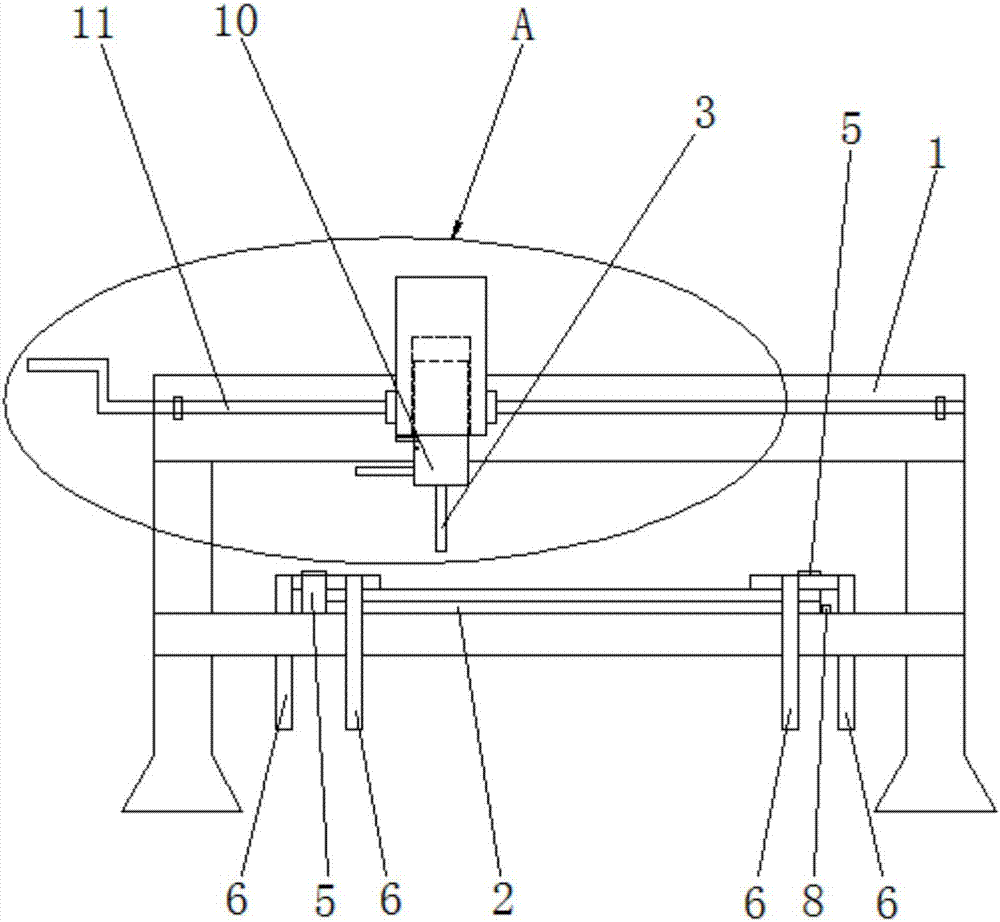

Double-motor automatic balancing method of triaxial satellite simulator

ActiveCN105589468AImprove trimming accuracyCosmonautic vehiclesCosmonautic partsSimulationSatellite attitude control

The invention discloses a double-motor automatic balancing method of a triaxial satellite simulator, wherein the double-motor automatic balancing method belongs to the technical field of satellite gesture control. According to the double-motor automatic balancing method, after artificial balancing is performed and stable airjet control gesture is realized, automatic balancing is performed by means of a stepping motor and an ultrasonic motor, wherein automatic balancing comprises the steps of firstly estimating a disturbance torque through establishing an air floating table kinetic model; then balancing an air floating table kinetic equation for determining the to-be-moved distance of a mass block in an actuating mechanism, then calculating the swinging period of the air floating table according to the vector of the mass center of the simulator which comprises a stepping motor mass block, estimating the disturbance torque according to the swinging period and determining an eccentric distance; and finally driving the stepping motor or the ultrasonic motor according to a comparison result between the eccentric distance precision and 0.01mm. According to the double-motor automatic balancing method, fine balancing is performed on the triaxial satellite simulator by means of the ultrasonic motor for compensating a defect of no enough precision in coarse balancing; furthermore balancing precision of the simulator is improved; and subsequent simulator tests are well ensured.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

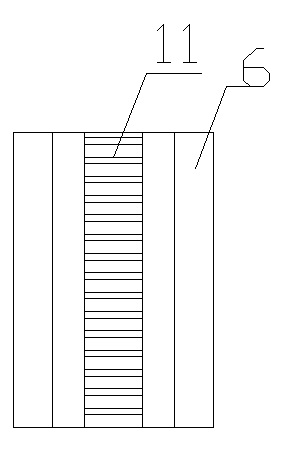

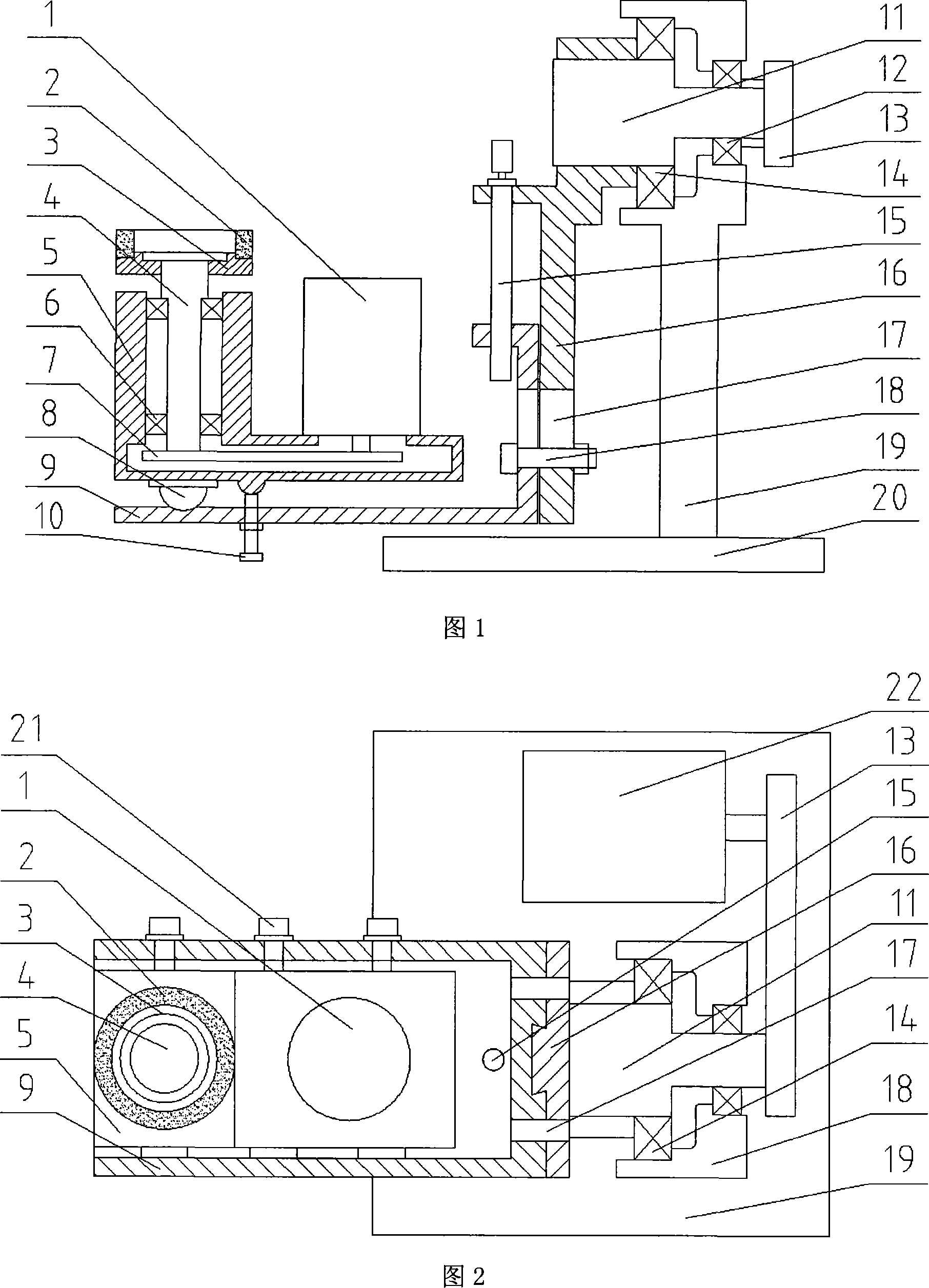

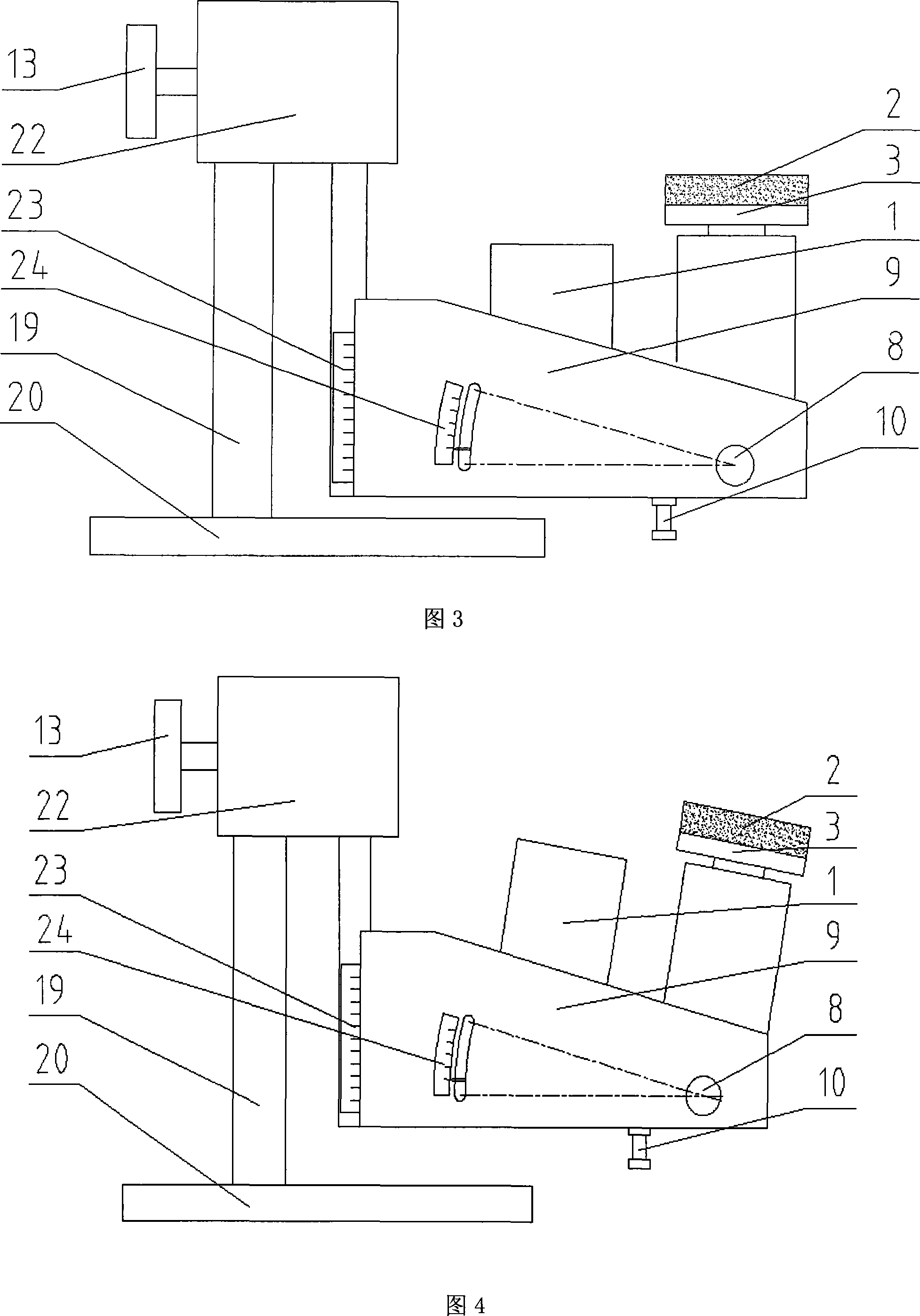

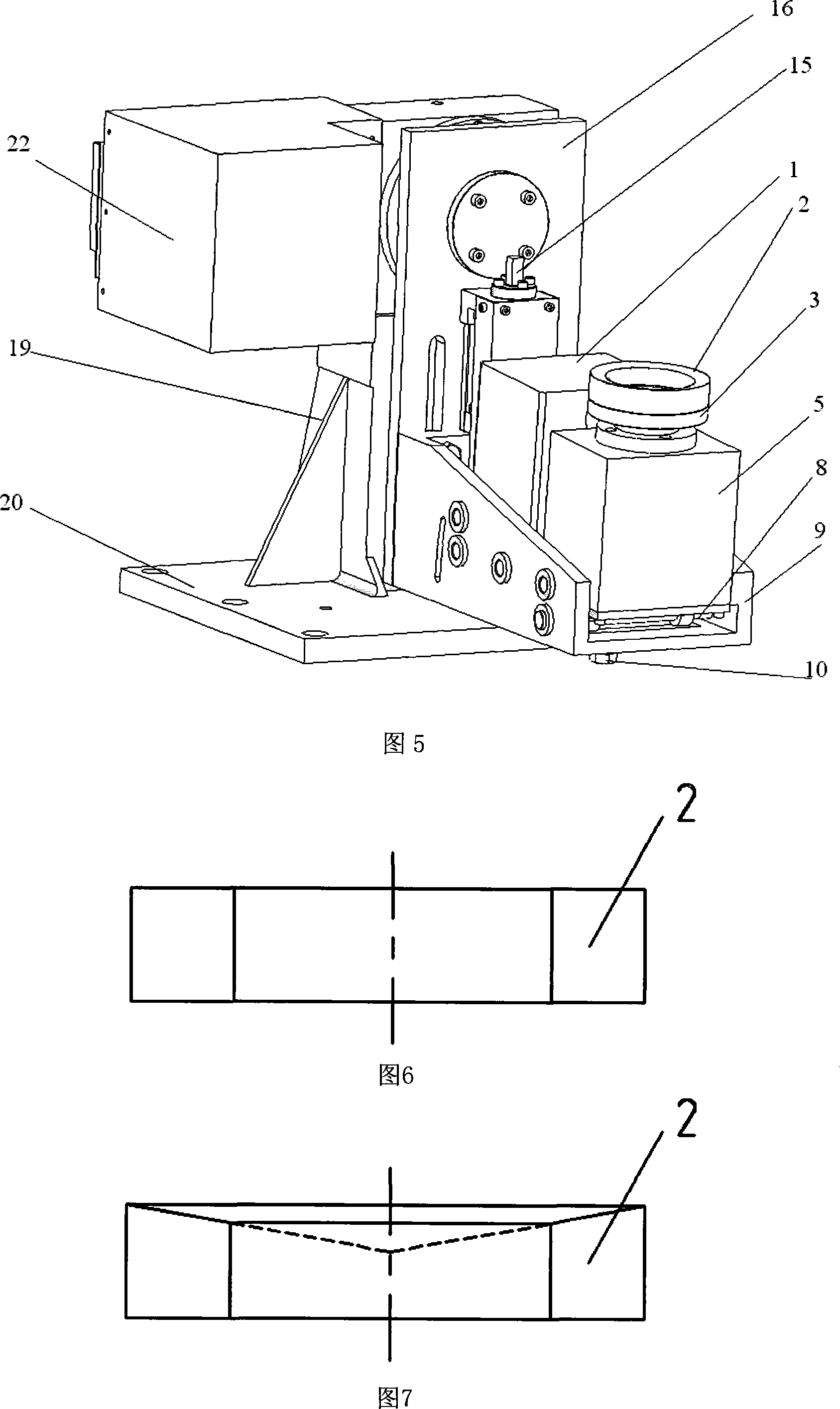

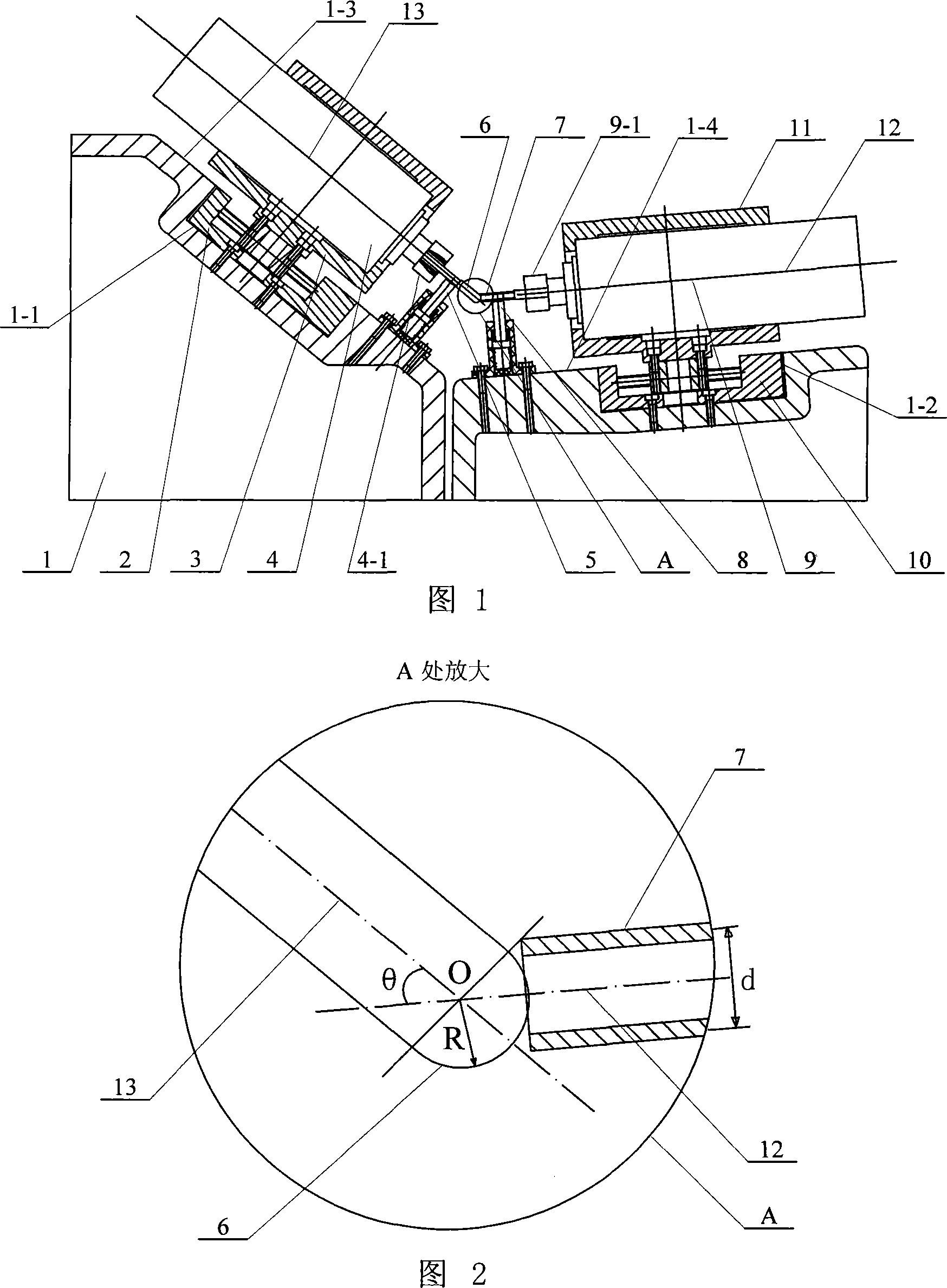

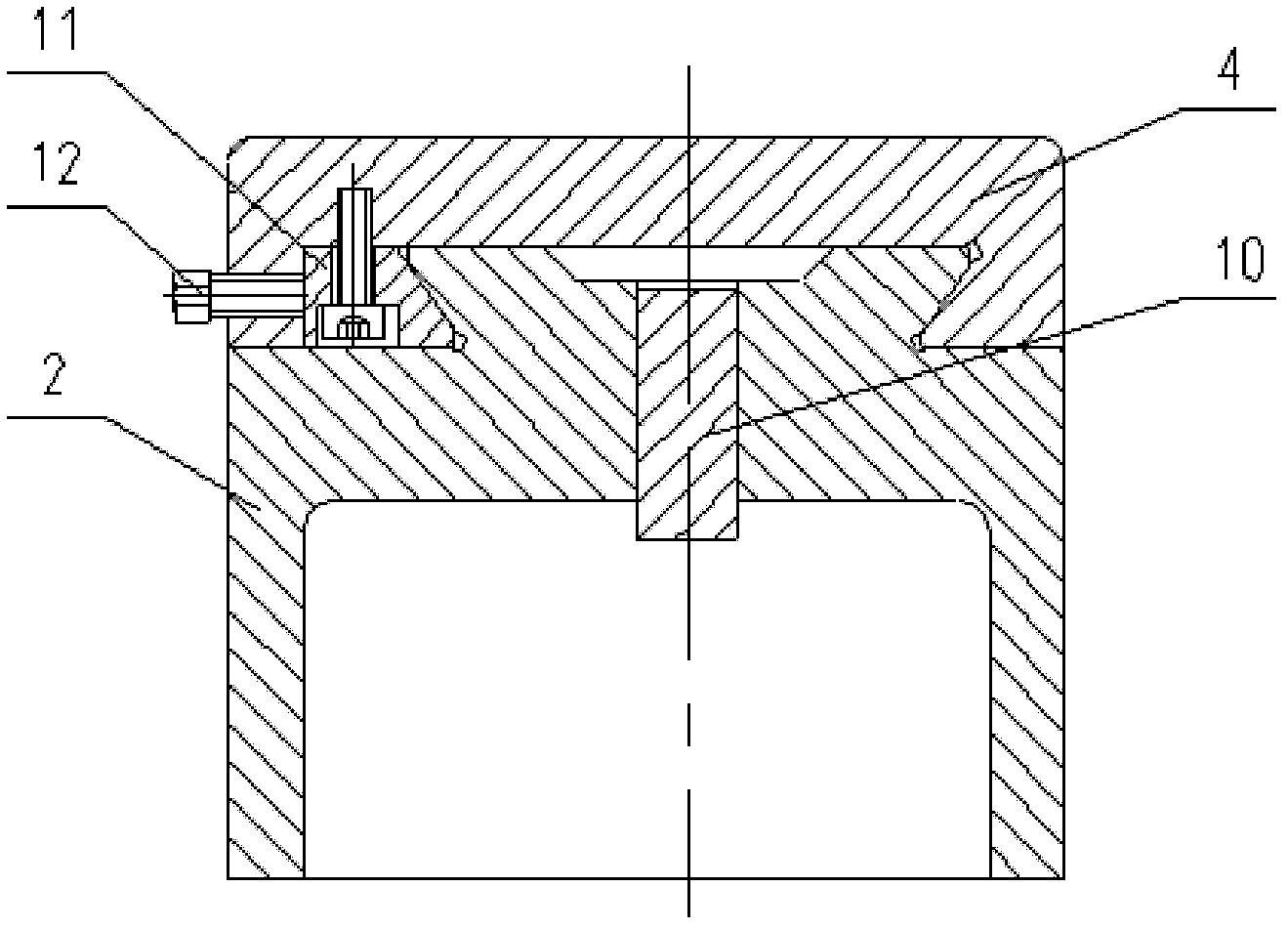

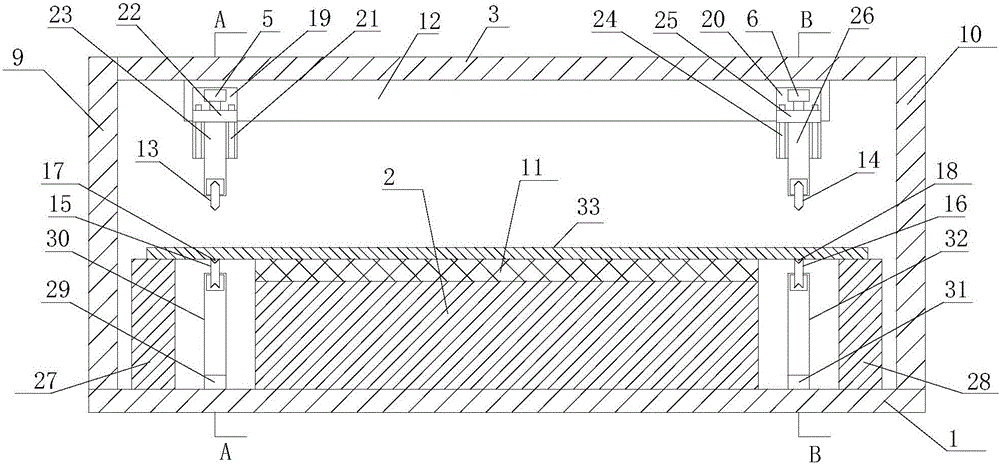

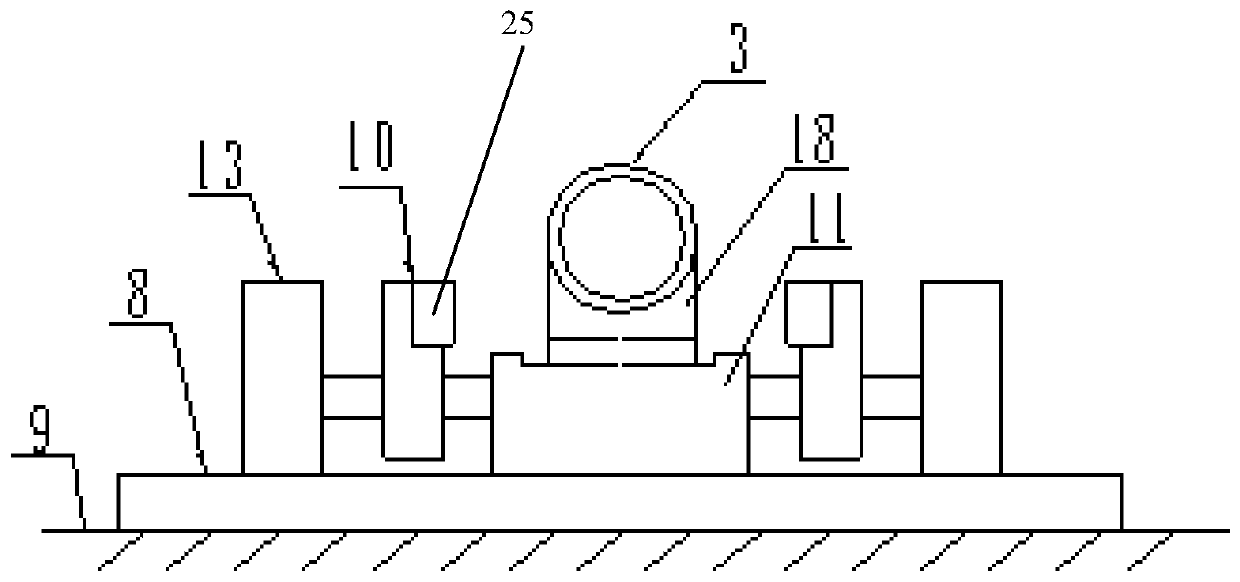

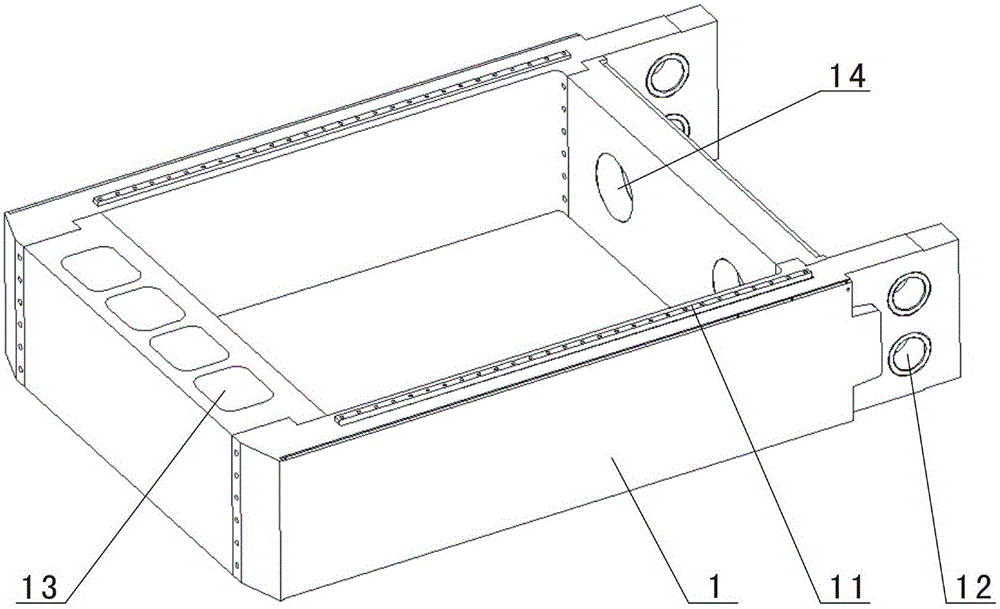

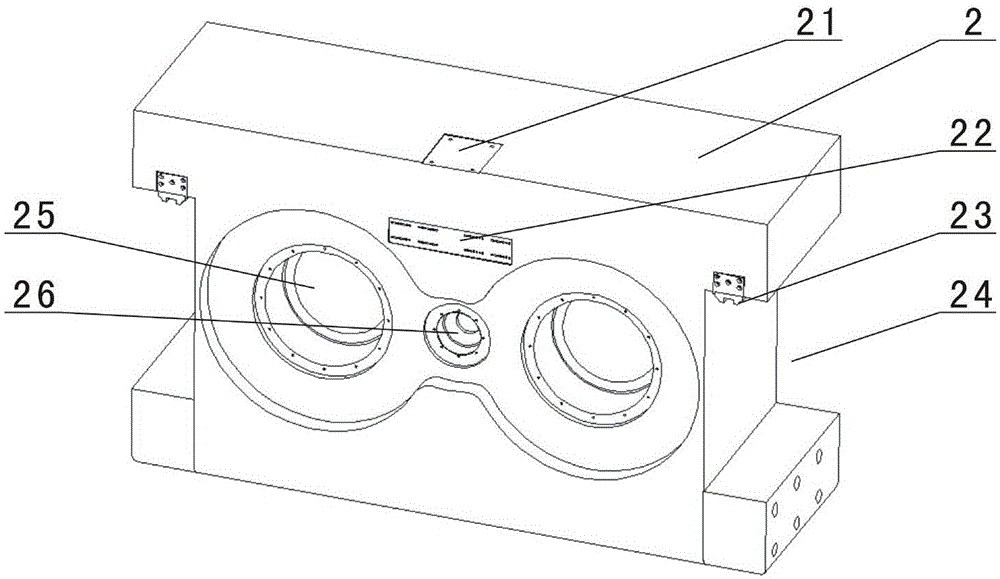

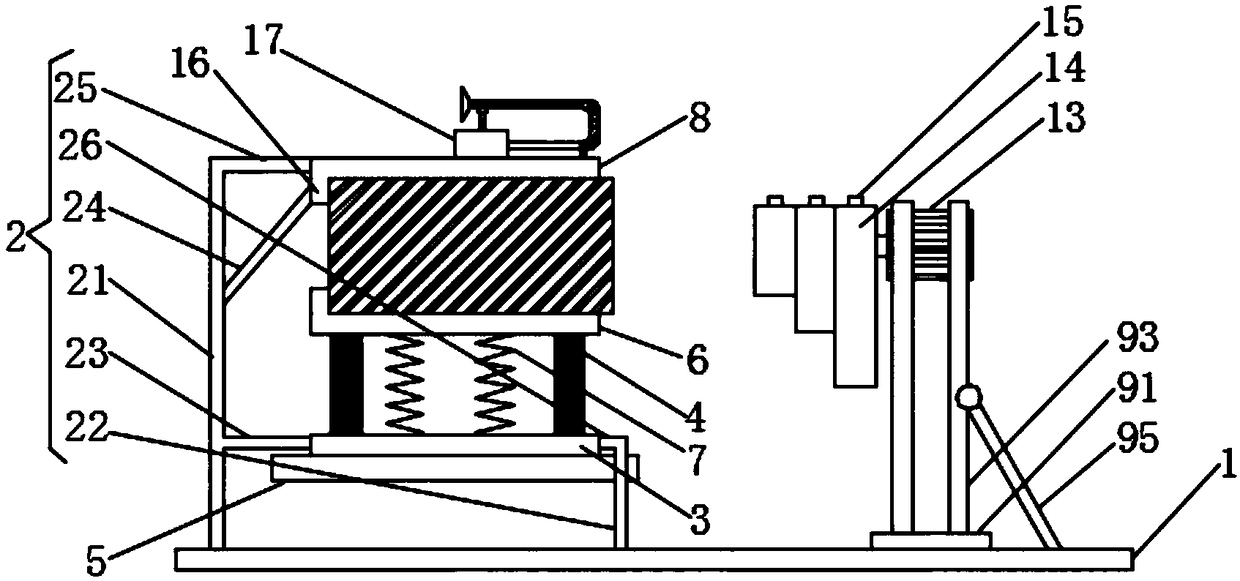

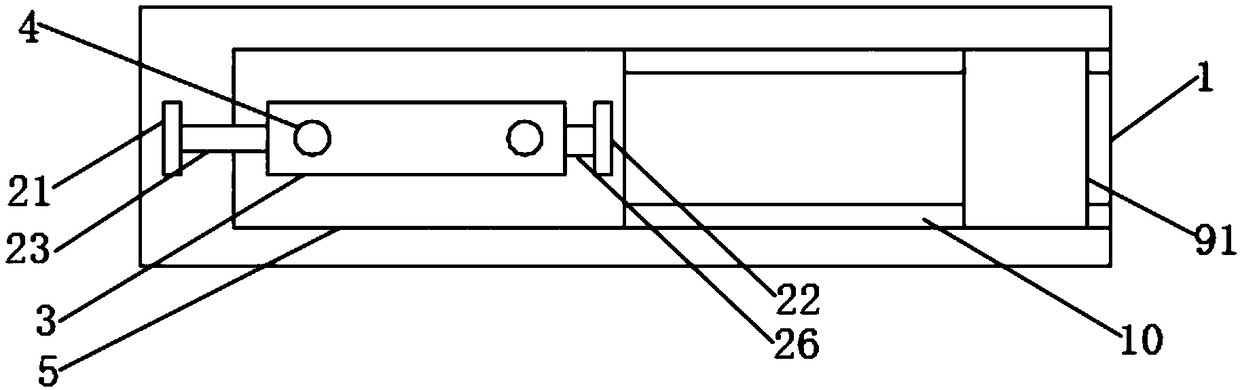

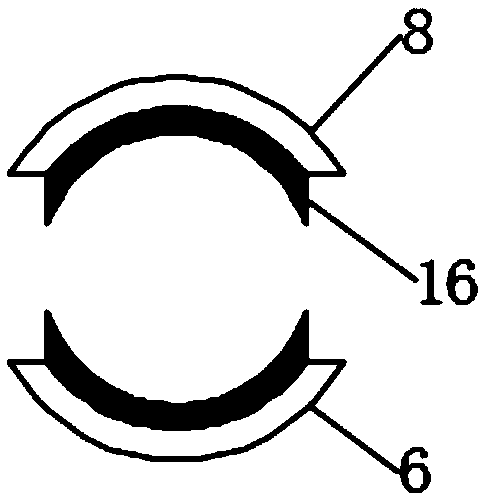

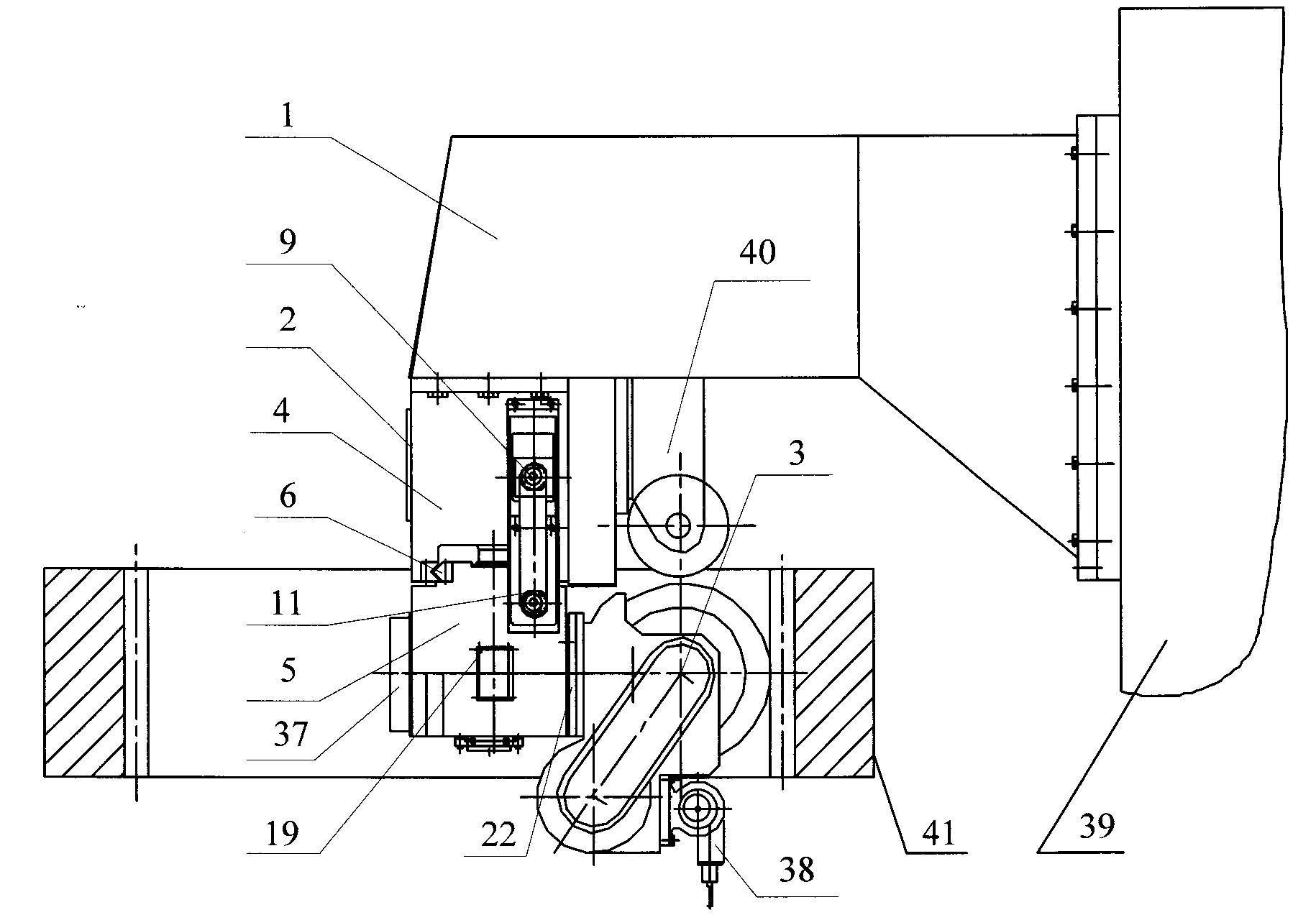

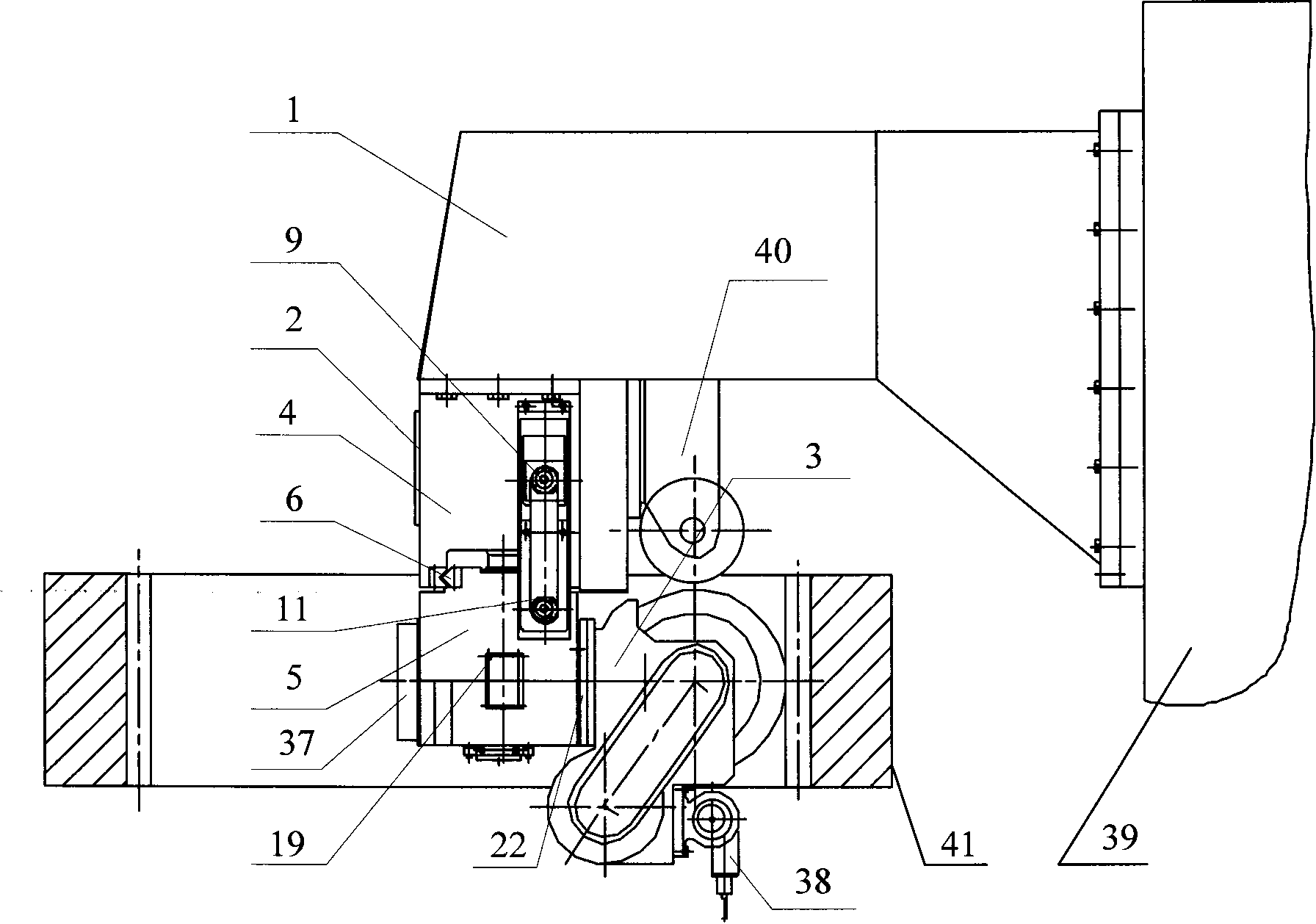

Metal base spherical diamond abrasive wheel dressing device

InactiveCN101234483AImprove trimming accuracyReduce repetitive clamping errorsAbrasive surface conditioning devicesDiamond grindingMachine tool

The invention discloses a metal-based spherical diamond grinding wheel dressing device, which relates to a grinding wheel dressing device, and the aim of which is to solve the problem that the existing spherical grinding wheel dressing device is low in dressing accuracy, in particular that the existing spherical grinding wheel dressing device can not dress a spherical grinding wheel with small size. The lower end of the wheel spindle gripper of the invention which is provided with a wheel spindle is connected with a grinding wheel location driving system, and one end of an electrode spindle is provided with an electrode locking device, which is correspondingly to the wheel locking device in the wheel spindle. The spherical wheel of the invention has a high dressing accuracy (the surface figure is less than or equal to 0.5Mum), and can dress the diamond grinding wheel into a shape of a hemisphere, which is the unique advantage of the invention. Meanwhile, the metal-based spherical diamond grinding wheel dressing device has the advantages of realizing the eutopic dressing of the grinding wheel, taking out the dressing part (electrode installation part) separately to assemble on the machining tool to realize the eutopic dressing, decreasing the repeated clamping error of grinding wheel, and realizing the dressing metal-based spherical diamond grinding wheel with small size (Phi 3 to 10mm).

Owner:HARBIN INST OF TECH

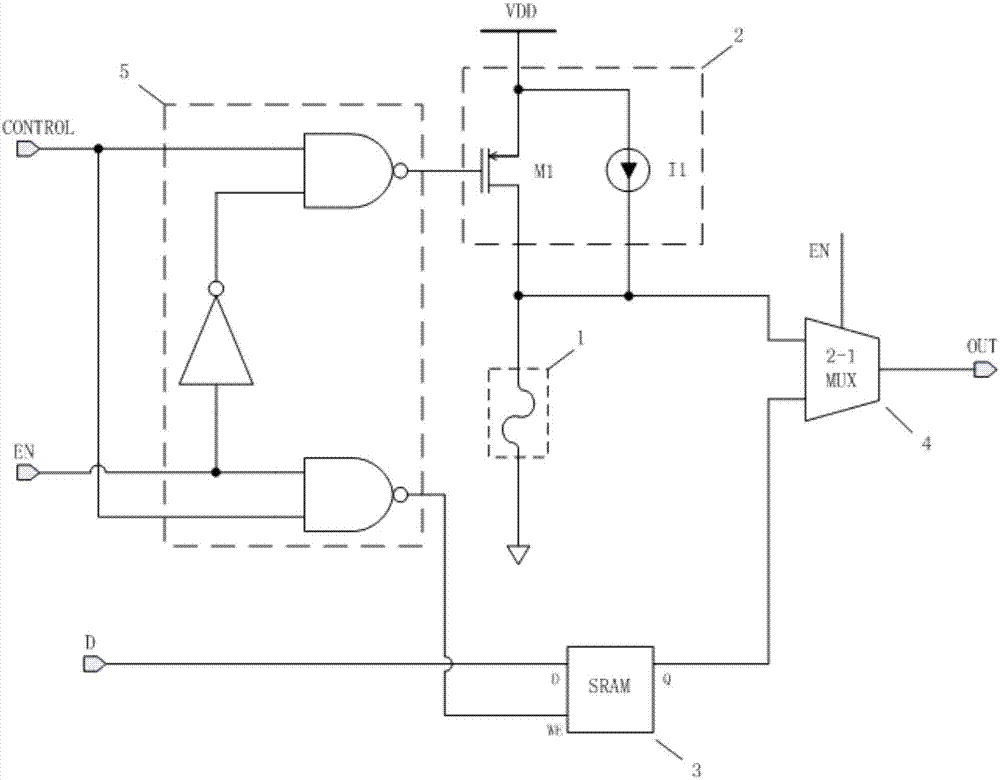

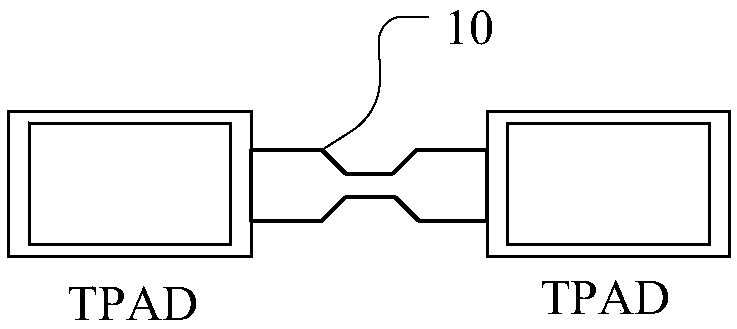

High-flexibility fuse trimming circuit and use method thereof

InactiveCN107169219AIncrease flexibilityImprove trimming accuracySpecial data processing applicationsLogic circuitsMultiplexerControl circuit

The invention provides a high-flexibility fuse trimming circuit. The fuse trimming circuit comprises a trimming control circuit, a fuse control circuit, a current melting fuse, an output driver, and a SRAM static storage cell. The fuse control circuit is formed by a fusing current control tube M1 and a constant current source I1. The constant current source I1 is connected with a chip power supply and the current melting fuse. The other output end of the trimming control circuit is connected with the SRAM static storage cell. The output driver is formed by a multiplexer, and an output end of the output driver is connected with the output end of the SRAM static storage cell and the current melting fuse. The fuse trimming circuit realizes to replace fuse operation by SRAM output in a simulation trimming stage through arrangement of the SRAM static storage cell, and repeated programming is realized, so as to effectively improve trimming circuit flexibility and trimming precision.

Owner:BEIJING GALLERIC ELECTRONICS CO LTD

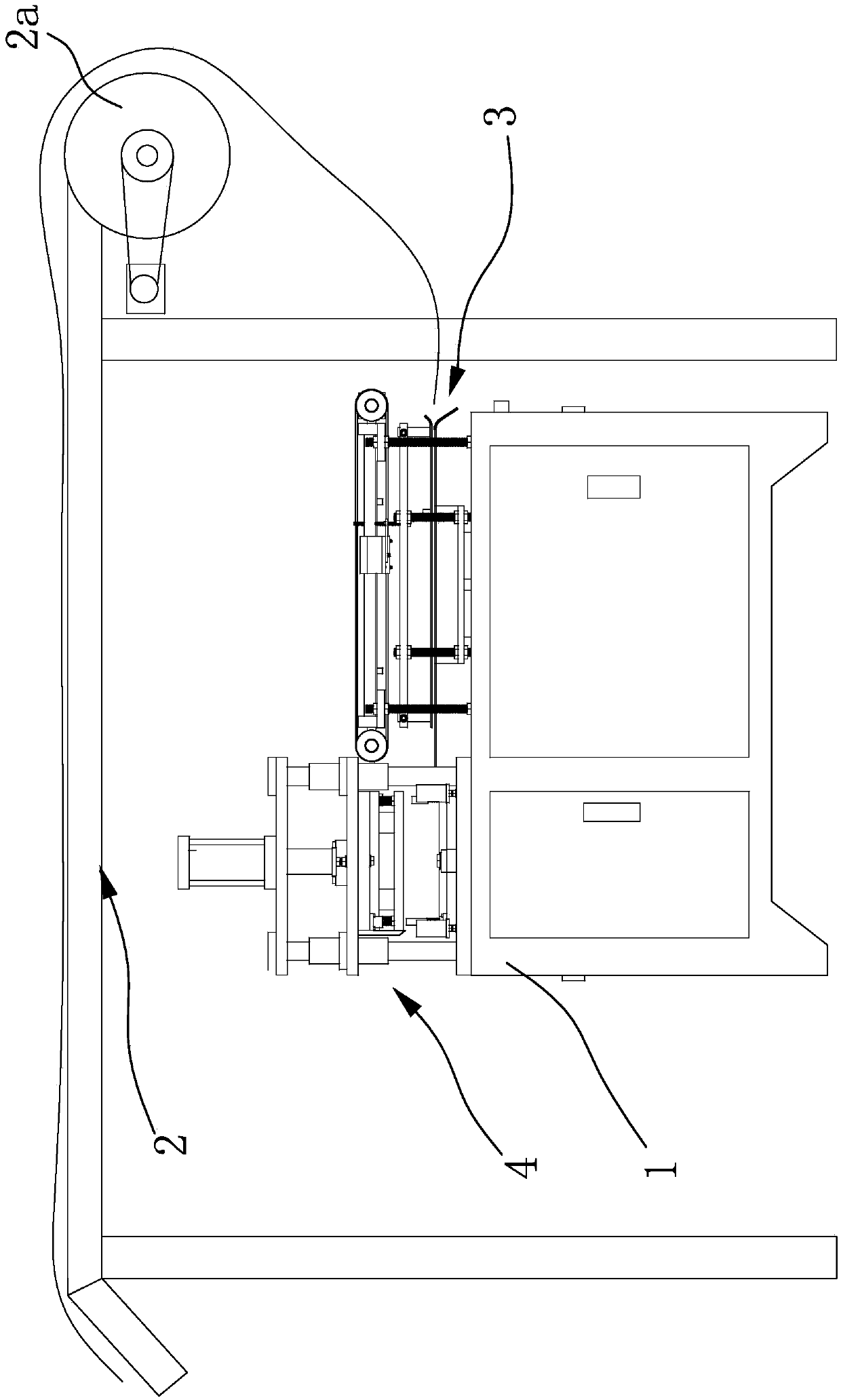

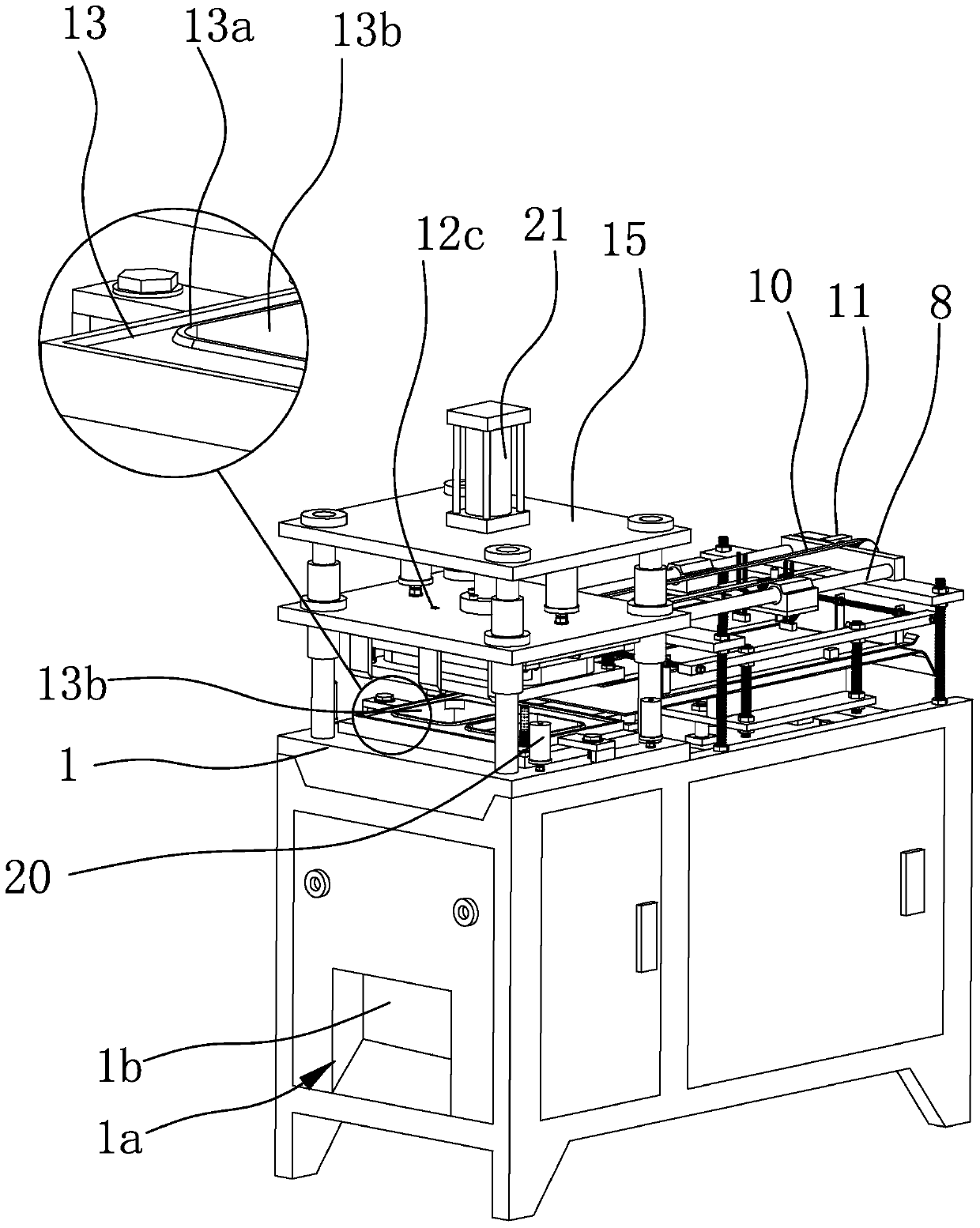

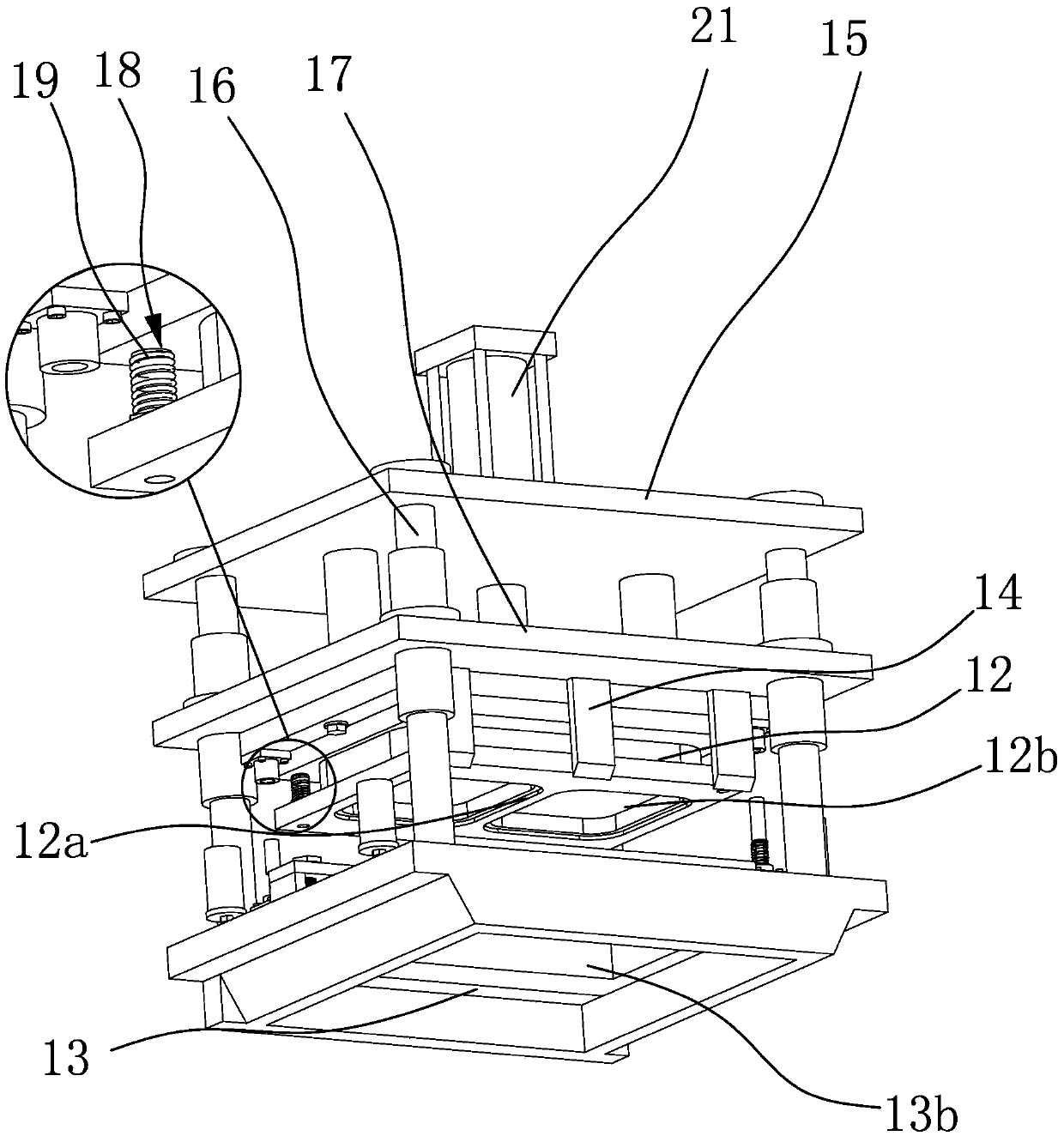

Blanking device for food box

ActiveCN105500455AImprove processing efficiencyLabor savingMetal working apparatusEngineeringMechanical equipment

The invention provides a blanking device for a food box and belongs to the technical field of mechanical equipment. The technical problem that an existing blanking device for the food box is low in efficiency is solved. The blanking device for the food box comprises a base, an upper die and a lower die, wherein the upper die and the lower die are arranged on the base. The lower surface of the upper die is provided with an inwards-concave containing groove for containing the bottom of the food box, the upper die can reciprocate towards the lower die, and an annular upper cutter is arranged on the groove side of the containing groove. The lower die is fixedly arranged on the base, the upper surface of the lower die is provided with an annular lower cutter opposite to the upper cutter, one side of the lower die is provided with a transfer platform capable of vertically moving, and a push block capable of pushing the food box to the space between the upper die and the lower die is arranged on the transfer platform. The blanking device has the advantages of being high in blanking efficiency and side cutting precision and the like.

Owner:沈正昌

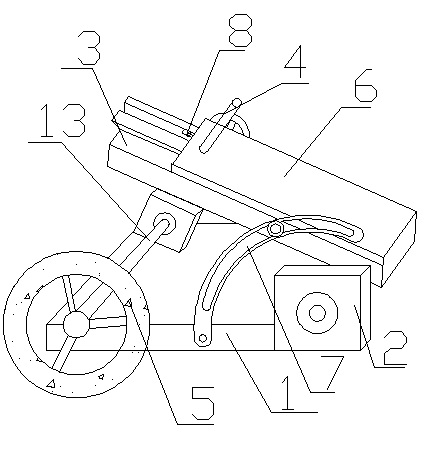

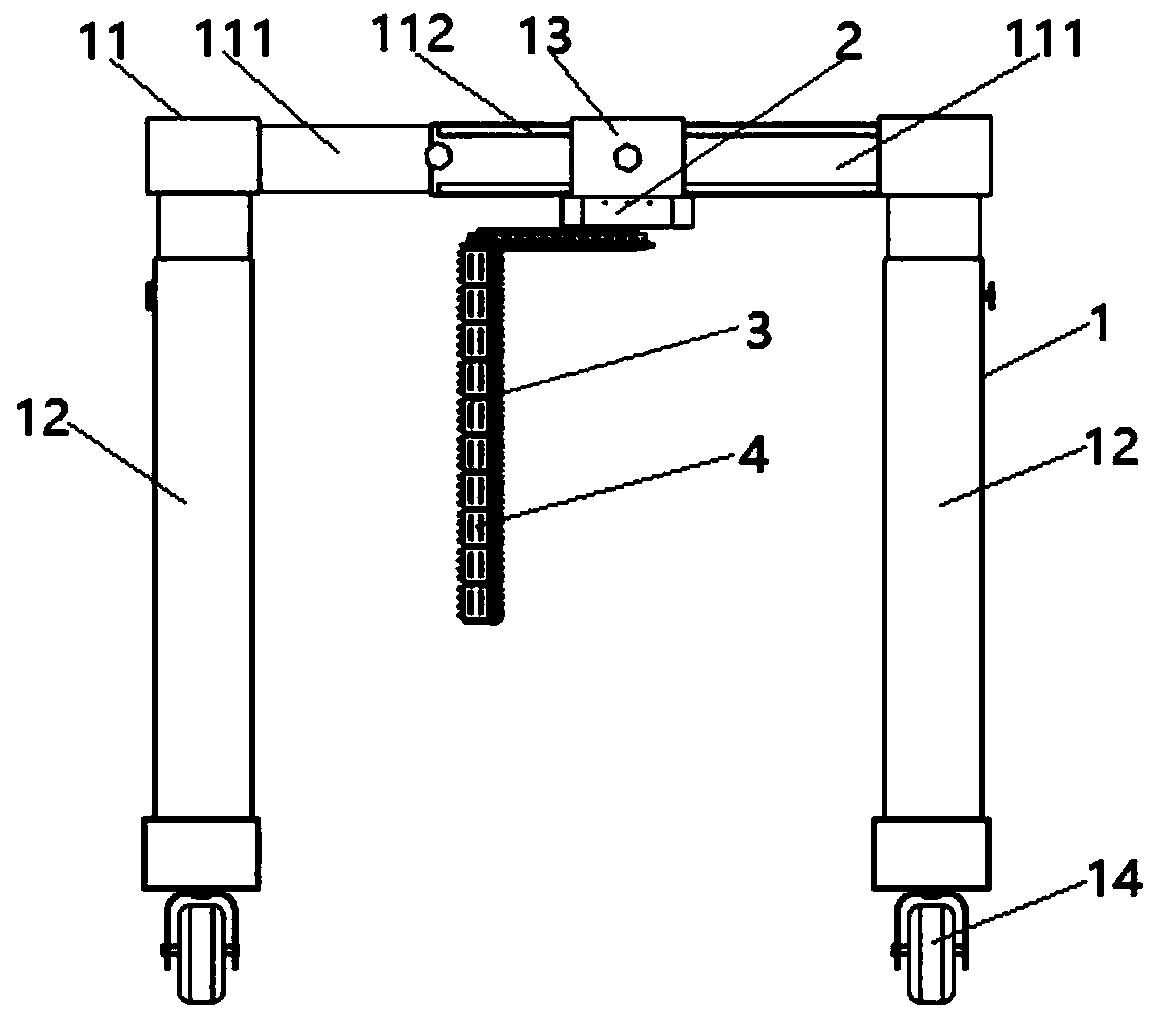

Hedge machine capable of adjusting seedling pruning shape

PendingCN110337934ALow costMeet the needs of greeningHedge trimming apparatusAgricultural engineeringGreening

The invention provides a hedge machine capable of adjusting the seedling pruning shape, and belongs to the technical field of garden pruning equipment. The hedge machine comprises an installation bracket, a rotating driving mechanism and a pruning mechanism. The installation frame is connected with the rotating driving mechanism, the rotating driving mechanism is connected with one end of the pruning mechanism and drives the pruning mechanism to rotate, the pruning mechanism is formed by series connection of several pruning power modules which can work independently, and angle adjustment unitsused for adjusting the connection angle between the pruning power modules are arranged on the pruning power modules. The hedge machine has the advantages that the overall structure of the hedge machine is reasonable in design, operation is convenient and flexible, the labor intensity of agriculture and horticulture workers is reduced, the machine can adapt to a variety of complex pruning environments, the diameter and shape of pruned seedlings can be adjusted according to the need, a variety of horticultural shapes can be configured, and the machine can meet the modern greening requirements and is suitable for application and popularization.

Owner:ANHUI UNIVERSITY OF TECHNOLOGY AND SCIENCE

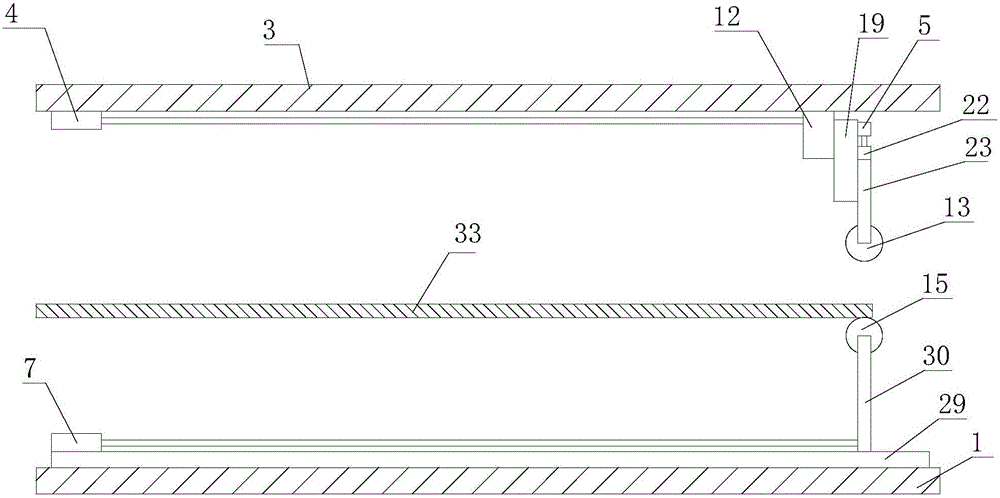

Profiling grinding wheel dressing device for surface grinder

ActiveCN102248487AImprove trimming accuracyLow costAbrasive surface conditioning devicesPlane surface grinding machinesEngineeringGrinding wheel

The invention discloses a profiling grinding wheel dressing device for a surface grinder. The profiling grinding wheel dressing device comprises a base, a mould plate and a movable tool carrier; one end of the base is provided with a hand-wheel assembly while the other end is fixedly connected with the mould plate; the base and the upper table-board of the mould plate are provided with the movable tool carrier; one end of the tool carrier is provided with a horizontal through hole, an end face of the through hole is fixed with a nut, the centre of the movable tool carrier is provided with a vertical positioning hole, an upper end face of the vertical positioning hole is fixedly equipped with a guiding sleeve, an elastic guide rod assembly is arranged in the vertical positioning hole, and a guide rod on the elastic guide rod assembly upwards extends out of the guide sleeve, the extending part of the guide rod is sleeved with a fixing sleeve in which a diamond cutter is arranged, the diamond cutter is coaxial with the guide rod, an upper end face of the diamond cutter extends out of the fixing sleeve, and a lower end face of the diamond cutter is propped against the upper end face of the guide rod. The profiling grinding wheel dressing device provided by the invention can enable the diamond cutter to finish the profiling action to dress the profile of the grinding wheel; and thestructure is simple and the operation is convenient.

Owner:中国冶金科工股份有限公司

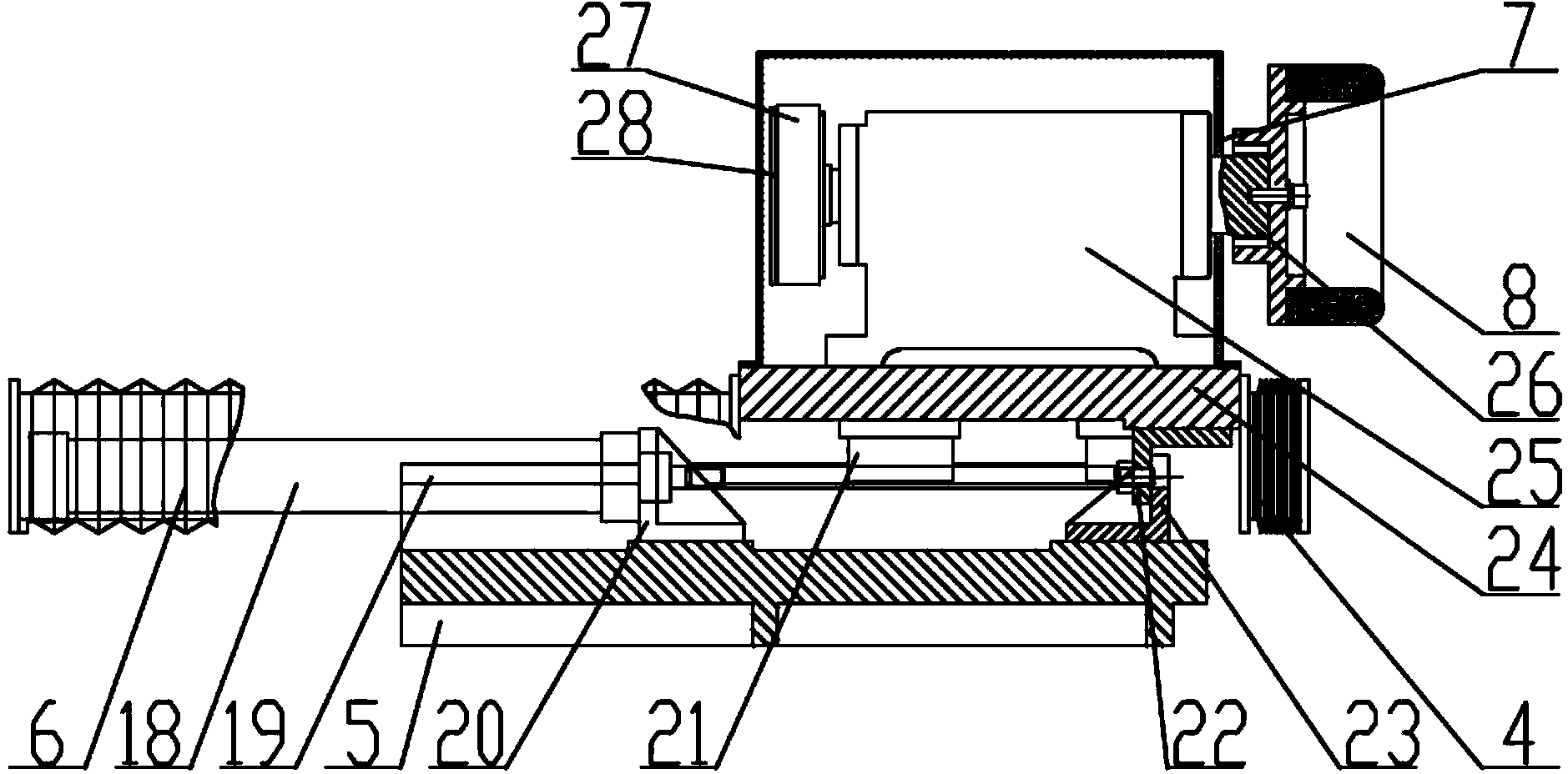

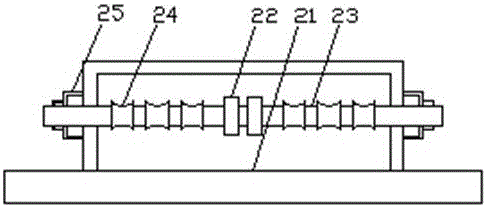

Numerical control extrusion screw tapping thread grinding machine

InactiveCN105798710AImprove trimming accuracySmooth working surfaceGrinding drivesOther manufacturing equipments/toolsNumerical controlMotor drive

The invention discloses a numerical control extrusion screw tapping thread grinding machine. The numerical control extrusion screw tapping thread grinding machine comprises a controller and a mechanical system; the controller is electrically connected with an A-axis servo motor, an X-axis servo motor, a Y-axis servo motor and a C-axis servo motor through drivers; the mechanical system comprises a lathe bed, a head support used for fixing a workpiece, a working table, a grinding carriage and a trimming wheel; and the A-axis servo motor is connected with a main shaft of the head support and drives the head support to drive the workpiece to rotate in the axial direction, the X-axis servo motor is installed on the lathe bed and drives the working table to move left and right through a second ball screw, the Y-axis servo motor drives the grinding carriage through a third ball screw so as to driven a grinding wheel to move front and back, and the C-axis servo motor drives the trimming wheel through a fourth ball screw to conduct automatic cutting supplementing on the trimming amount. The four-axis numerical control grinding machine is adopted, numerical control operation can be carried out on motion and positioning of all components, the automatic degree is high, the grinding wheel trimming accuracy is high, the working surface of the grinding wheel is smooth, and the machining accuracy and efficiency are greatly improved.

Owner:广东特普丝精密工具有限公司

Automatic edge cutting equipment for paperboard processing

ActiveCN105799214AGuaranteed flat and perfectImprove trimming accuracyBox making operationsPaper-makingPaperboardEngineering

The invention provides automatic edge cutting equipment for paperboard processing. The automatic edge cutting equipment comprises a base, a workbench, a mounting plate, an edge cutting mechanism, a first driving mechanism, a second driving mechanism, a third driving mechanism, a fourth driving mechanism, a fifth driving mechanism, a sixth driving mechanism, a monitor and a control mechanism, wherein a conveying roller group for conveying a paperboard is arranged between the material feeding end and the material discharging end of the workbench; the edge cutting mechanism comprises a mobile plate, a first edge cutter, a second edge cutter, a first supporting wheel and a second supporting wheel; the projection, on the base, of the first edge cutter is overlapped with the first supporting wheel; the projection, on the base, of the second edge cutter is overlapped with the second supporting wheel; the control mechanism is connected with and controls the actions of the first driving mechanism, the second driving mechanism, the third driving mechanism, the fourth driving mechanism, the fifth driving mechanism, the sixth driving mechanism and the monitor. The automatic edge cutting equipment is high in edge cutting precision and high in cutting speed; during processing, the automatic edge cutting equipment is high in processing efficiency.

Owner:安徽中天电器有限公司

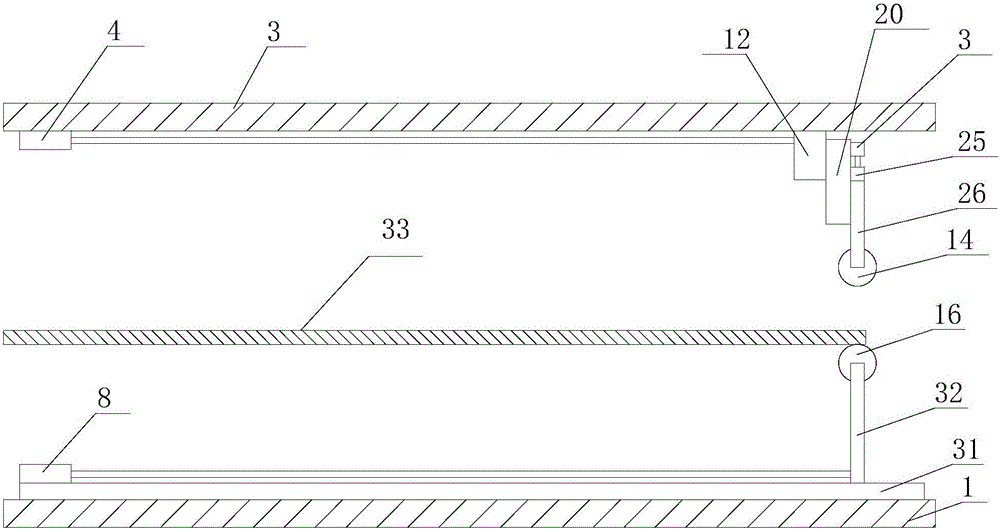

Roller bearing raceway crown grinding machine grinding wheel dresser

ActiveCN102267096ASimple structureEasy to manufactureAbrasive surface conditioning devicesGrinding machinesEngineeringGrinding wheel

The invention discloses a grinding machine abrasive wheel dresser for the convexity of a roller bearing raceway. The dresser comprises a base fixed on a dressing feeding carriage and a diamond pen dressing an abrasive wheel to have an inward concave profile curve, wherein the base is provided with a dressing reciprocating mechanism, an axial elastic moving element and a small plunger pump valve combination element are driven by the reciprocation of the dressing reciprocating mechanism, the axial elastic moving element and the diamond pen are fixed and assembled, the small plunger pump valve combination element is arranged at one side of the dressing reciprocating mechanism and can generate displacement change through a template which leans against and is fixed on the dressing feeding carriage and has a curve profile, hydraulic transfer drives the axial elastic moving element to drive the diamond pen to move, so that the diamond pen obtains a template profile curve moving track reducedin proportion and the abrasive wheel can be dressed to have an inward concave profile curve. The grinding machine abrasive wheel dresser has advantages of simple structure, low cost and convenience in regulation, and the convexity parameters of different specifications can be obtained by replacement of templates.

Owner:NINGBO NAITEJIA MACHINERY MFG

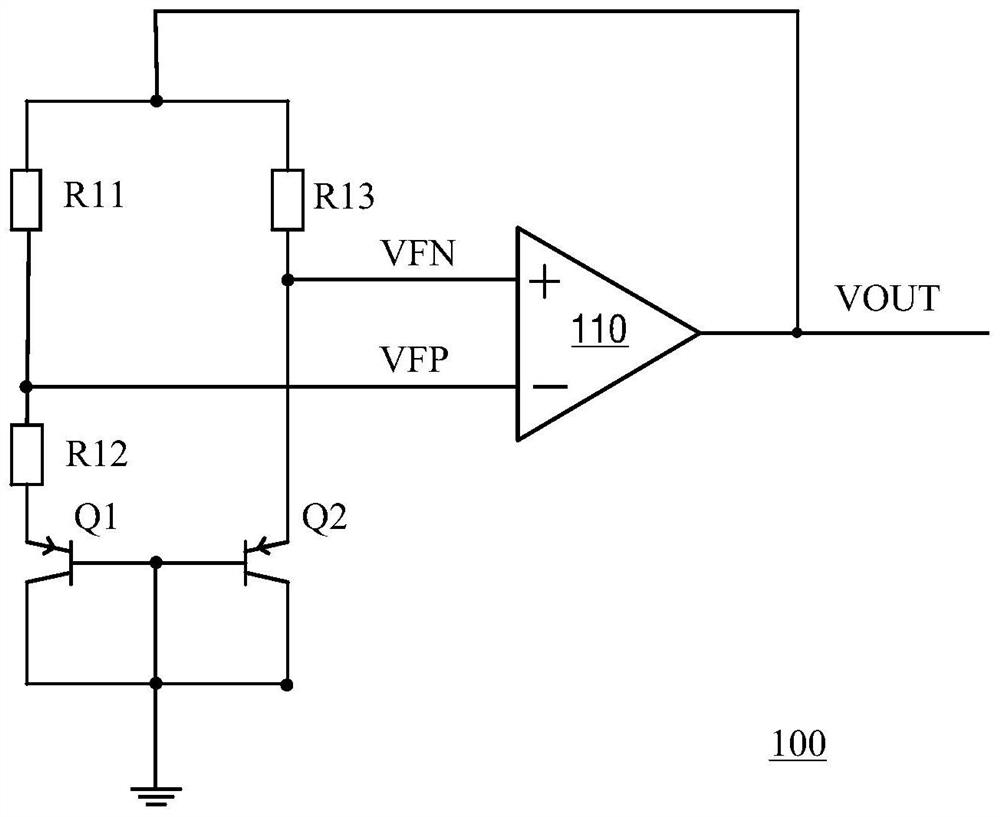

Trimming circuit and chip

ActiveCN110830022AAchieve the purpose of adjustmentIncrease productivityLogic circuit interface arrangementsComputer hardwareHemt circuits

The invention discloses a trimming circuit and a chip. The trimming circuit comprises a control module which is used for generating a fuse selection signal and a fuse signal according to a trimming signal and a reference voltage signal, a fuse unit which comprises a plurality of fuse structures, each of which comprises a fuse and a switching tube which are connected between the fuse signal input end and the ground, arranged in an array, a selection module which is used for scanning the switching tubes of the plurality of fuse structures according to a preset sequence and gating at least one switching tube according to the fuse selection signal, wherein the trimming signal at least comprises a first level and a second level, and when the trimming signal is the first level, the control module generates the fuse selection signal; and when the trimming signal is a second level, the control module generates the fuse wire signal and is used for applying the fuse wire signal to the fuse wirewhen the switching tube is switched on. The trimming precision can be improved, and a specific trimming pin does not need to be arranged on the chip.

Owner:SG MICRO

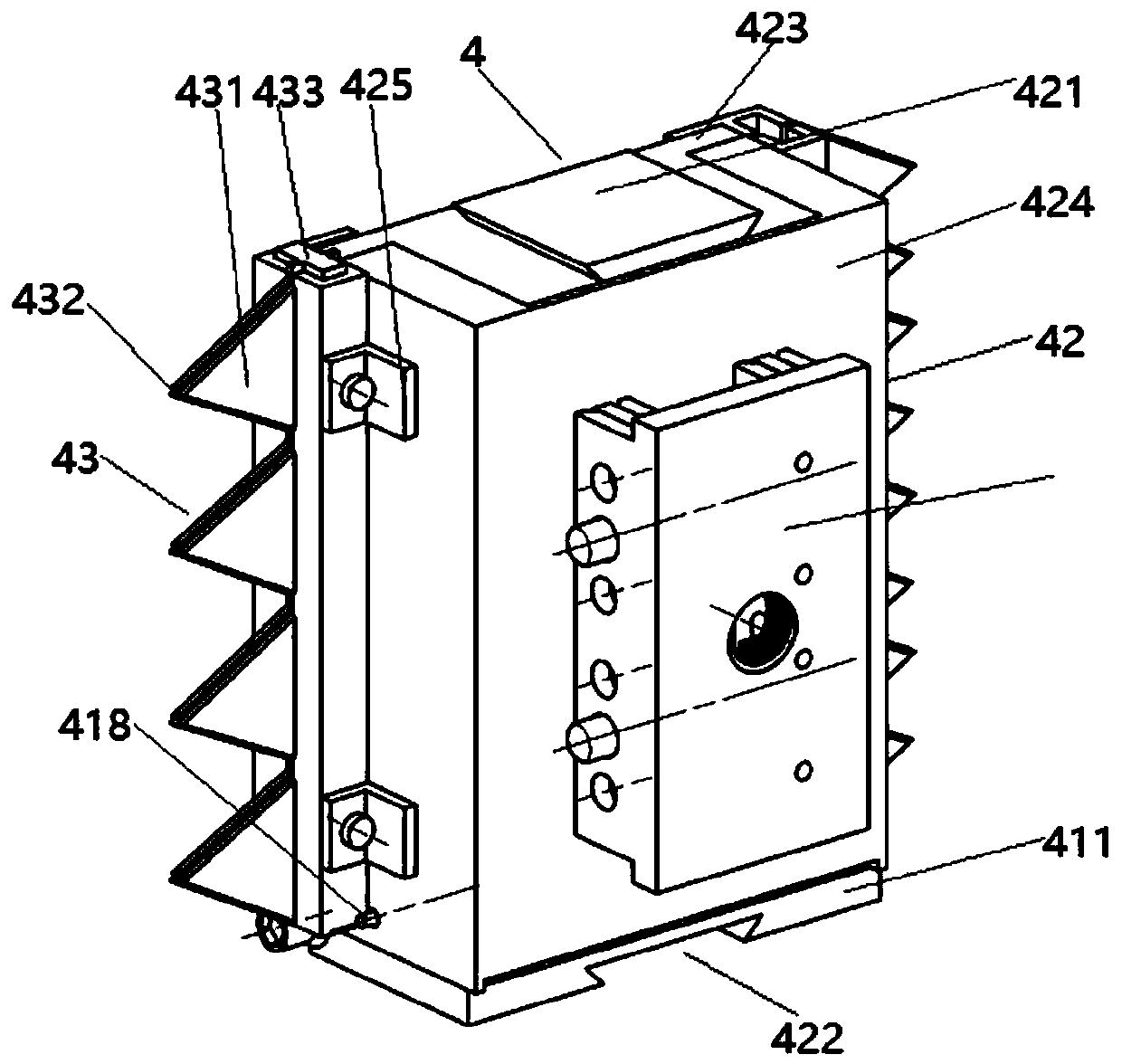

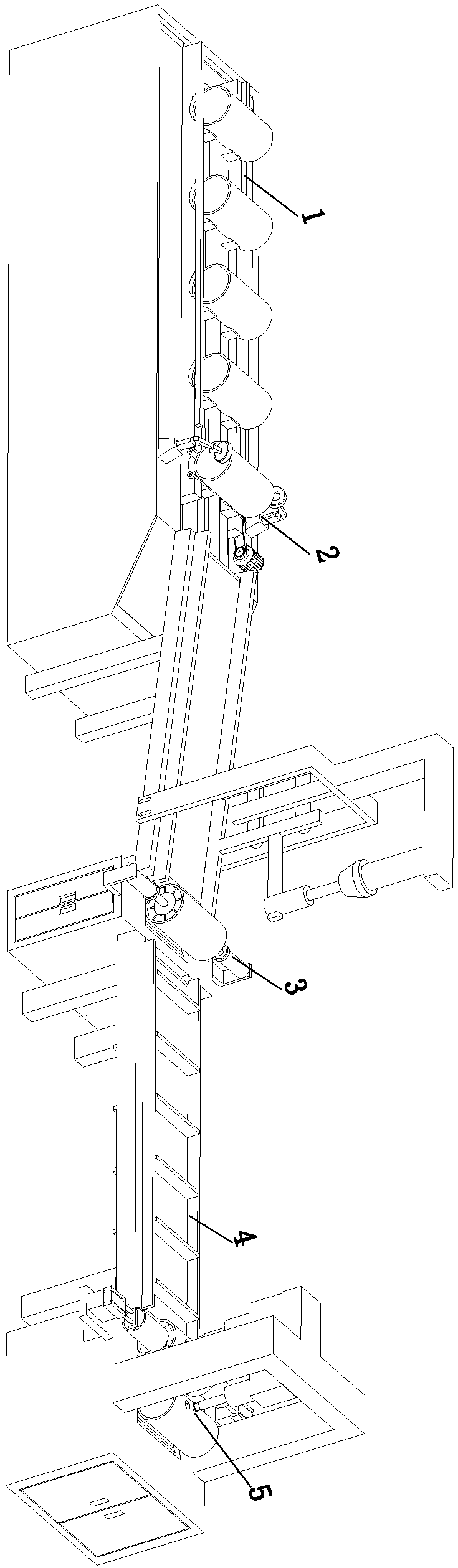

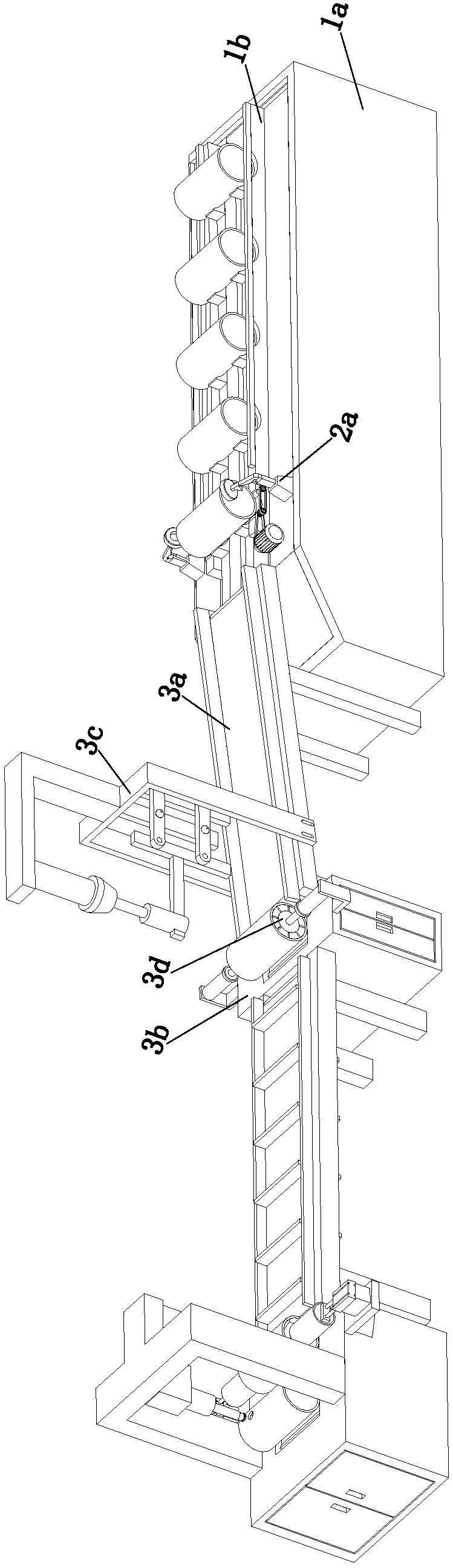

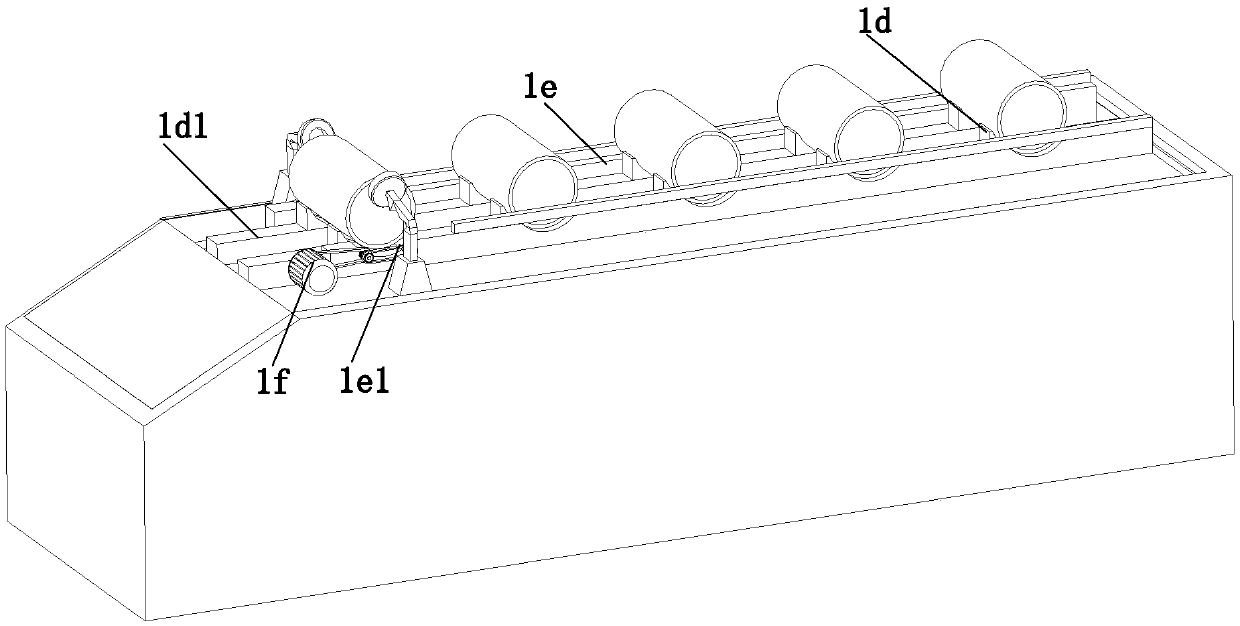

Device for rectifying inner diameter of main shell of air conditioner compressor

ActiveCN107597891AImprove trimming accuracyImprove work efficiencyMetal-working feeding devicesPositioning devicesEngineeringAir conditioning

The invention relates to the field of air conditioning equipment, in particular to a device for rectifying the inner diameter of a main shell of an air conditioner compressor. The device for rectifying the inner diameter of the main shell of the air conditioner compressor comprises an inner diameter rectifying mechanism, and the inner diameter rectifying mechanism comprises a first conveying table, a second working cabinet, a feeding blocking part and an inner diameter rectifying part. The first conveying table is arranged to tilt downwards, the feeding blocking part is fixedly mounted on thefirst conveying table, the second working cabinet is arranged to tightly abut against the output end of the first conveying table, and the inner diameter rectifying part is mounted on the second working cabinet. The first conveying table comprises two sets of first supporting supports symmetrically arranged at the bottom of the first conveying table and two first limiting plates arranged on the two sides of the first conveying table correspondingly, and the distance between the two first limiting plates is equal to the length of the inner-diameter-to-be-rectified main shell. According to the device for rectifying the inner diameter of the main shell of the air conditioner compressor, the repair precision can be improved when pipelines at the two ends of the main shell are repaired simultaneously, and accordingly the working efficiency of repair can be improved further.

Owner:芜湖美奥机械科技有限公司

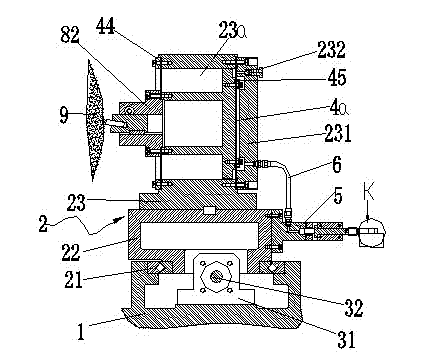

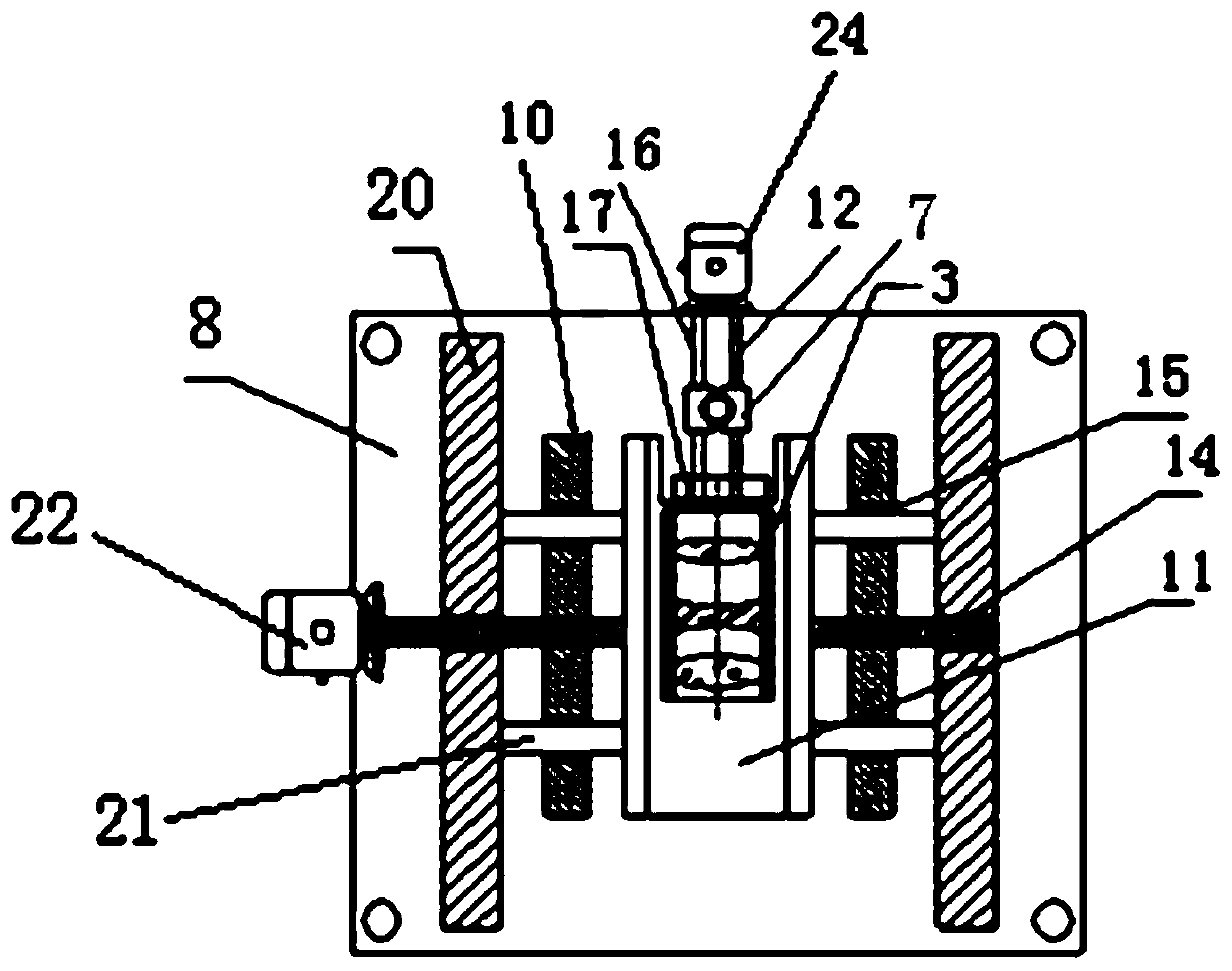

Full-wave-band high-precision zoom optical system image surface butt joint and coaxial adjustment device and method

ActiveCN111458896AConsistent clarityImprove trimming accuracyNuclear energy generationOptical elementsGratingDisplay device

The invention provides a full-wave-band high-precision zoom optical system image surface butt joint and coaxial adjustment device and method, and solves the problems that an existing zoom optical lensimage surface adjustment method is low in efficiency, an imaging assembly is easy to damage, and the image surface adjustment precision is relatively low. The device comprises an optical platform, agrating ruler, a display, a light source, a full-waveband collimator, a zoom lens fixing mechanism and an image plane adjusting assembly, the full-waveband collimator is arranged on the optical platform; the zoom lens fixing mechanism is arranged on the optical platform through the four-dimensional adjusting platform, and the four-dimensional adjusting platform adjusts the position of a zoom optical lens on the zoom lens fixing mechanism; the image plane adjusting assembly comprises a CCD mounting frame, a four-dimensional adjustable base, a sliding block and a guide rail control assembly fordriving the sliding block to move; the CCD mounting frame is arranged on the four-dimensional adjustable base; the four-dimensional adjustable base is arranged on the sliding block; the grating ruleris used for recording the position of the CCD imaging assembly; and the display is connected with the CCD imaging assembly.

Owner:西安中科西光光电科技有限公司

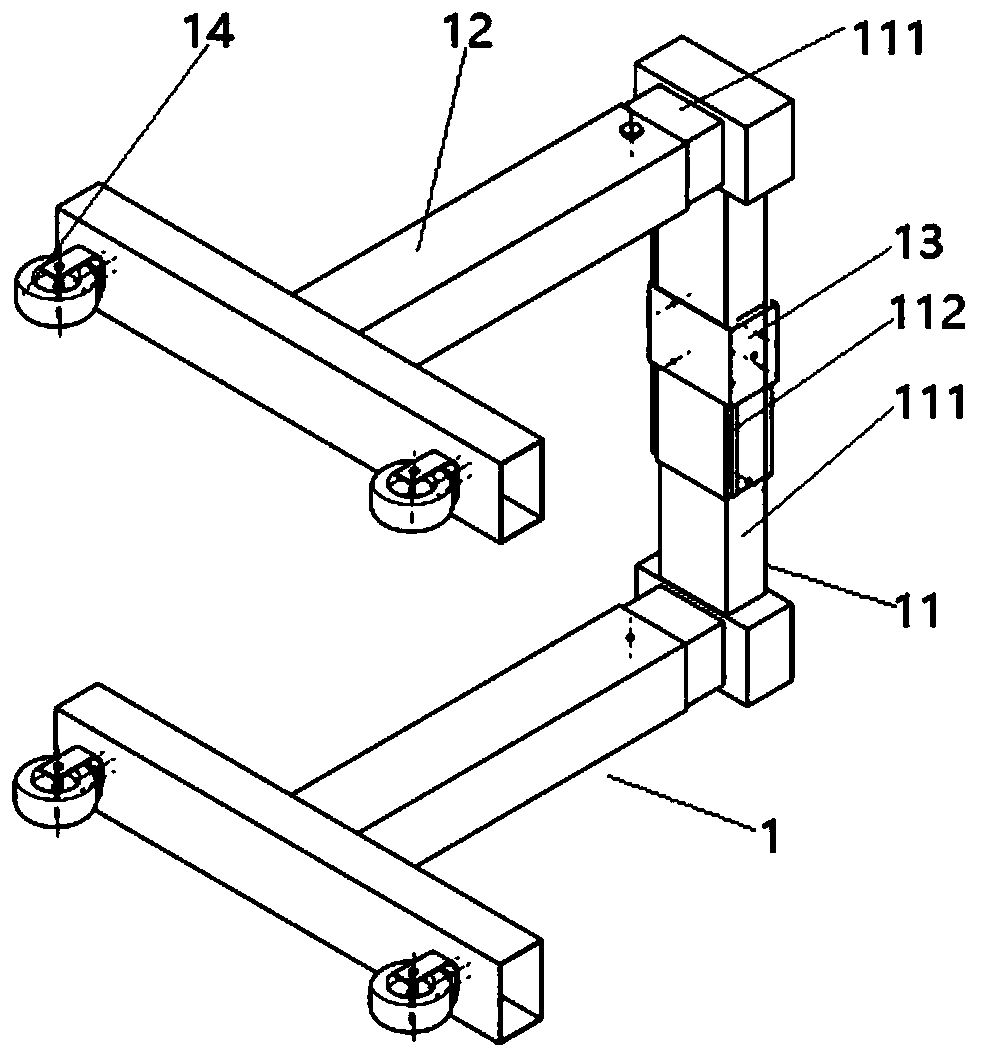

Novel centrifugal machine static balancing device

The invention discloses a novel centrifugal machine static balancing device. The novel centrifugal machine static balancing device comprises a balancing frame, a lead screw, a movable balancing weight, a motor, a rotary transmission device and a traveling nut. A connecting hole is formed in the first end of the balancing frame, and a fixed balancing weight is installed at the second end of the balancing frame. Two guide rails are arranged on the upper surfaces of the two sides of the balancing frame in parallel respectively. The two ends of the movable balancing weight are installed on the two guide rails respectively and can be moved. The motor is installed on the movable balancing weight. A rotary shaft of the motor is connected with the input end of the rotary transmission device. The output end of the rotary transmission device is connected with the traveling nut. The lead screw is sleeved with the traveling nut. The two ends of the lead screw are fixedly installed at the two ends of the balancing frame respectively. Through the combination of the movable balancing weight and the fixed balancing weight, the novel centrifugal machine static balancing device has the advantages that machining is easy due to modular design, the balancing range is wide, the application range is wide, and operation is easy.

Owner:GENERAL ENG RES INST CHINA ACAD OF ENG PHYSICS

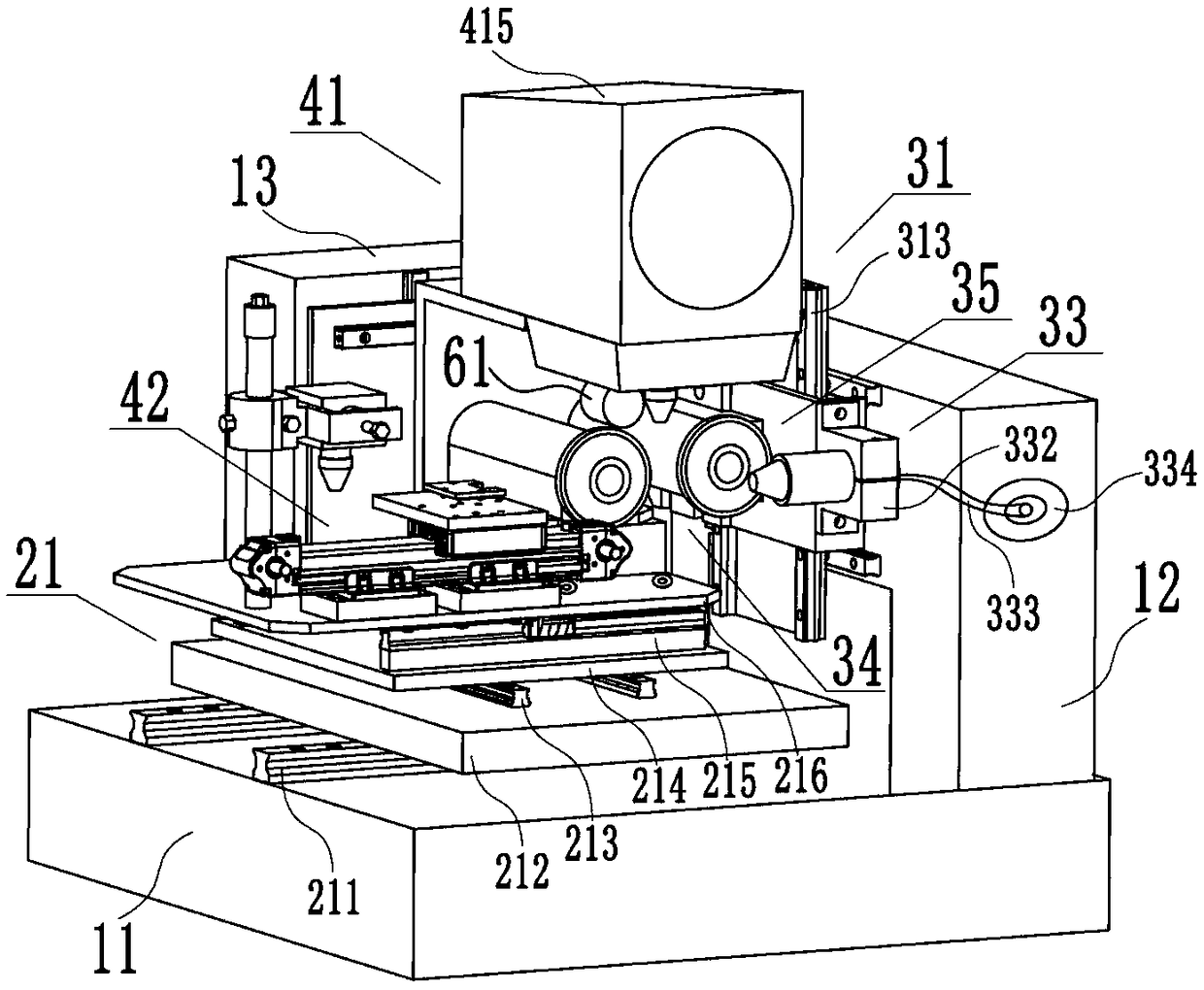

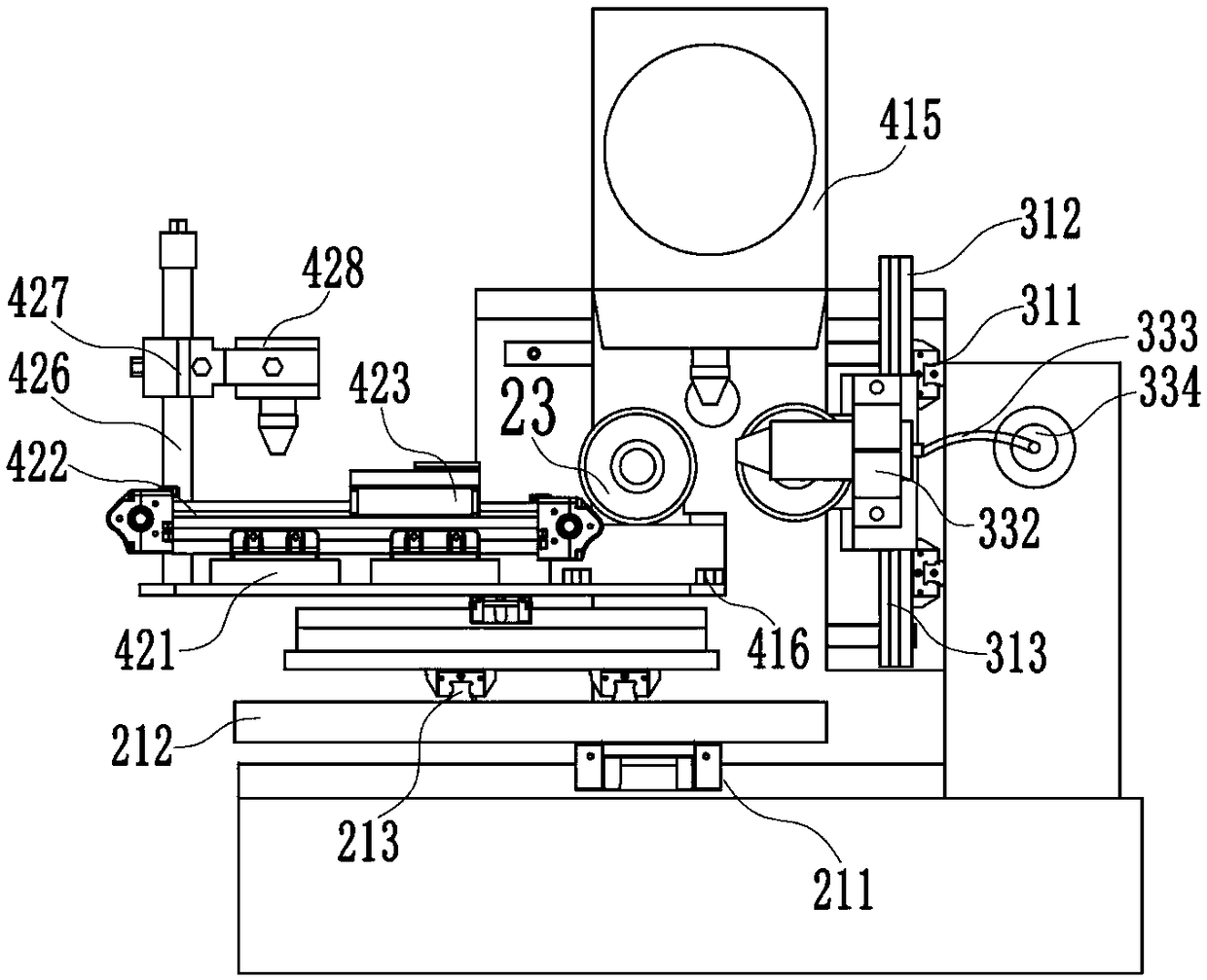

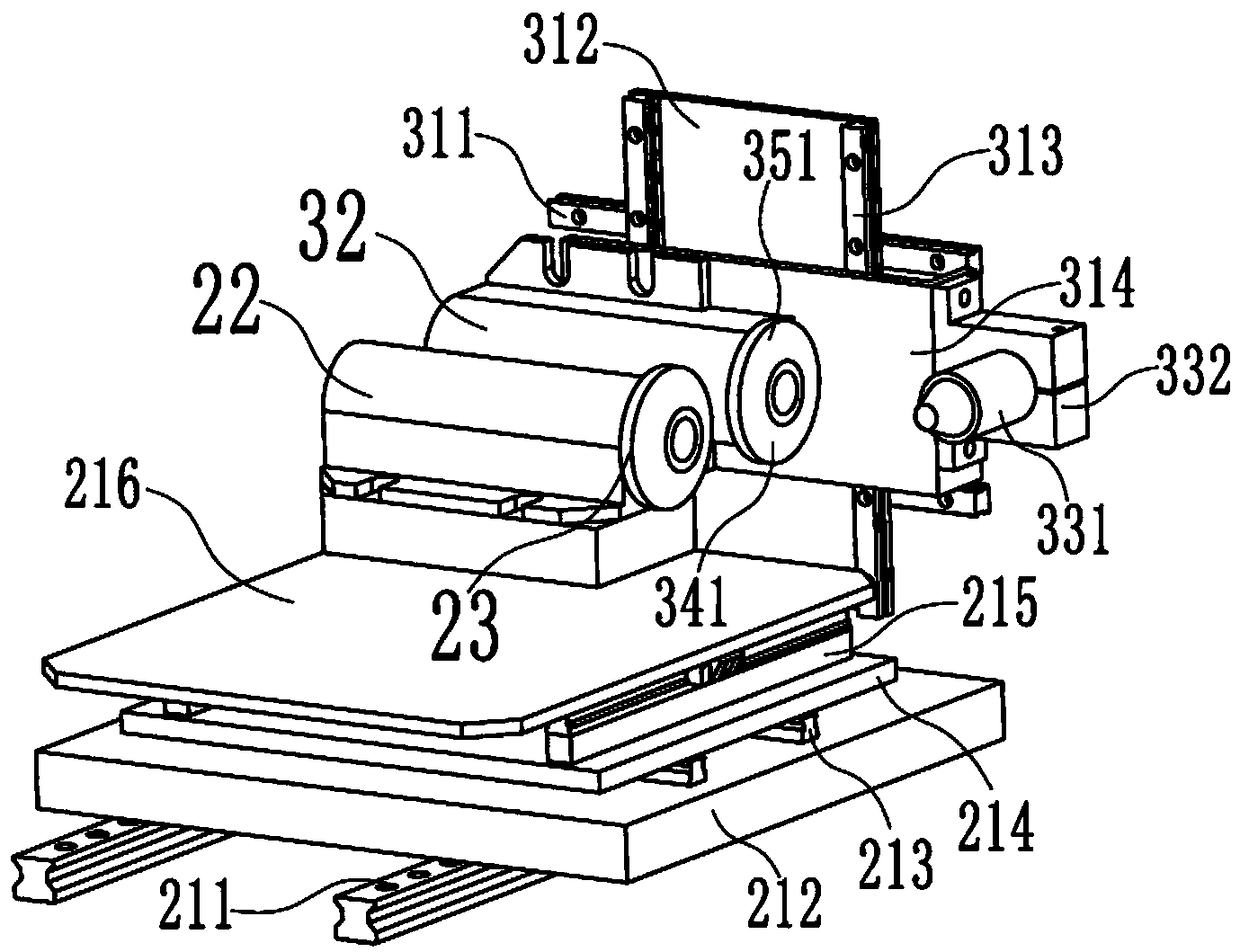

Universal automatic composite abrasive wheel trimming machine

ActiveCN108747823ALow costLow efficiencyGrinding feed controlAbrasive surface conditioning devicesDevice MonitorEngineering

The invention relates to a universal automatic composite abrasive wheel trimming machine. The trimming machine comprises a workpiece work mechanism, a trimming mechanism, a detection mechanism and a motion control mechanism. The workpiece work mechanism adjusts an abrasive wheel to the position needed for trimming. The trimming mechanism comprises a trimming feeding device, a main shaft S2, a laser trimming device, an electric spark trimming device and a mechanical trimming device. The laser trimming device, the electric spark trimming device or the mechanical trimming device moves to the position needed for trimming to trim an abrasive wheel. The detection mechanism comprises a projection monitoring device and a repeated reflection detection device. The projection monitoring device monitors trimming of the abrasive wheel in real time. The repeated reflection detection device conducts online repeated reflection method detection on trimming of the abrasive wheel, and the detection result is transmitted to the motion control mechanism. The motion control mechanism controls the actions of the workpiece work mechanism, the trimming mechanism and the detection mechanism according to thejudgment result. The universal automatic composite abrasive wheel trimming machine is low in cost, high in efficiency and precision, wide in adaptability, high in automation degree and simple in operation.

Owner:湖南镭盛机电科技有限公司

Diamond grinding wheel dressing method

InactiveCN108838890AGood shape retentionImprove trimming accuracyAbrasive surface conditioning devicesDiamond grindingDressing method

The invention relates to a diamond grinding wheel dressing method, and belongs to the technical field of grinding apparatuses. The diamond grinding wheel dressing method comprises the following stepsthat an electroplating diamond grinding wheel and a diamond grinding wheel to be dressed are relatively ground, then the relatively ground grinding wheel to be dressed is subjected to surface cleaning, and the diamond grinding wheel is obtained. According to the diamond grinding wheel dressing method, the diamond grinding wheel and the diamond grinding wheel are relatively ground, the diamond grinding wheel is dressed, and the problem that when a silicon carbide grinding wheel is used for dressing the diamond grinding wheel in the prior art, the silicon carbide grinding wheel is consumed too fast is avoided. Meanwhile, the diamond grinding wheel is adopted as the dressing grinding wheel, the shape retention performance is good, profile modeling dressing can be adopted for the diamond grinding wheel as the grinding wheel to be dressed, and the dressing precision of the diamond grinding wheel is improved.

Owner:ZHENGZHOU RES INST FOR ABRASIVES & GRINDING CO LTD

Oddment cutting table for plastic products

The invention discloses an oddment cutting table for plastic products, and belongs to the technical field of oddment cutting equipment for plastic products. The oddment cutting table comprises a cutting table board, a support, a fixing plate and the like. The plastic products are clamped and limited through an upper limiting plate and a lower limiting plate, and the positions of the plastic products are stable, so that the opening trimming precision is improved, the inner walls of openings of the plastic products are consistent and uniform, the quality consistency of final products is effectively ensured, and operation is convenient; and the diameters of a plurality of rotary rings are different, so that the oddment cutting table is suitable for plastic products with different opening diameters, and the application range of the oddment cutting table for the plastic products is widened; the position of a supporting plate is fixed, so that the opening trimming precision of the plastic products is further ensured; and a motor works to drive the rotary rings to rotate, a cutting knife rotates accordingly to completely scrap oddments on the inner walls of the openings of the plastic products. The oddment cutting table for the plastic products can replace manual operation to complete opening trimming work; and meanwhile, the opening trimming precision is high, and the quality consistency of the products is effectively ensured.

Owner:嘉善中佳电路板有限公司

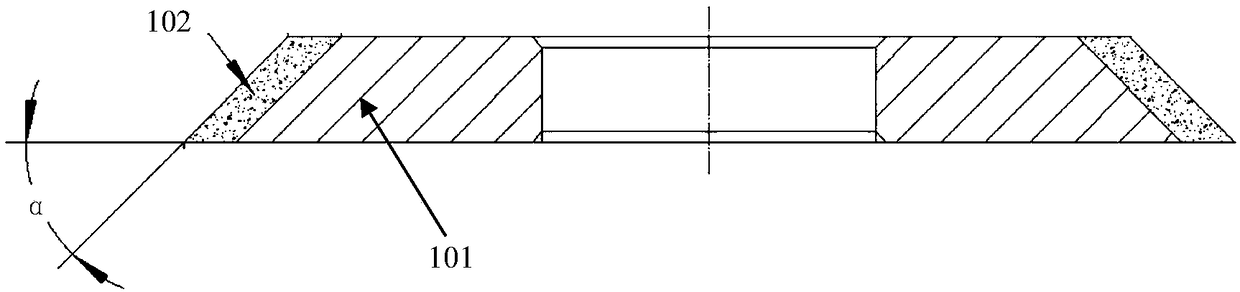

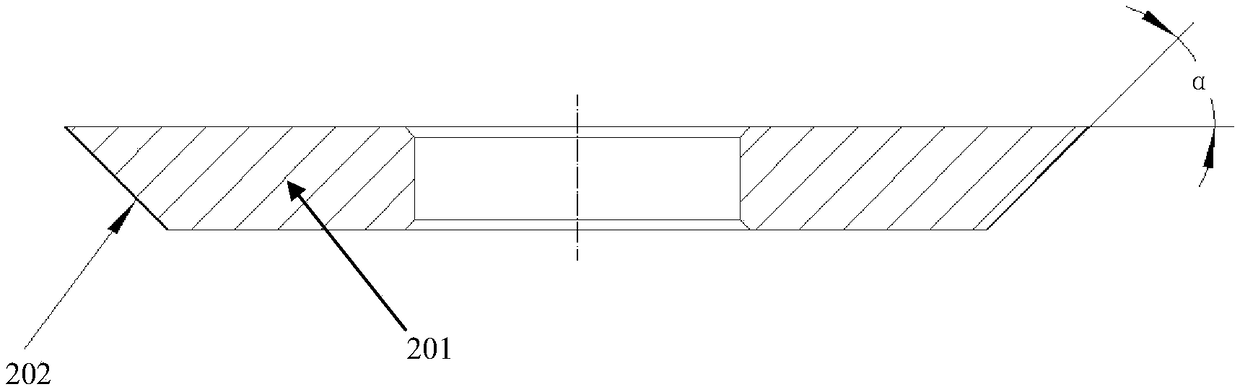

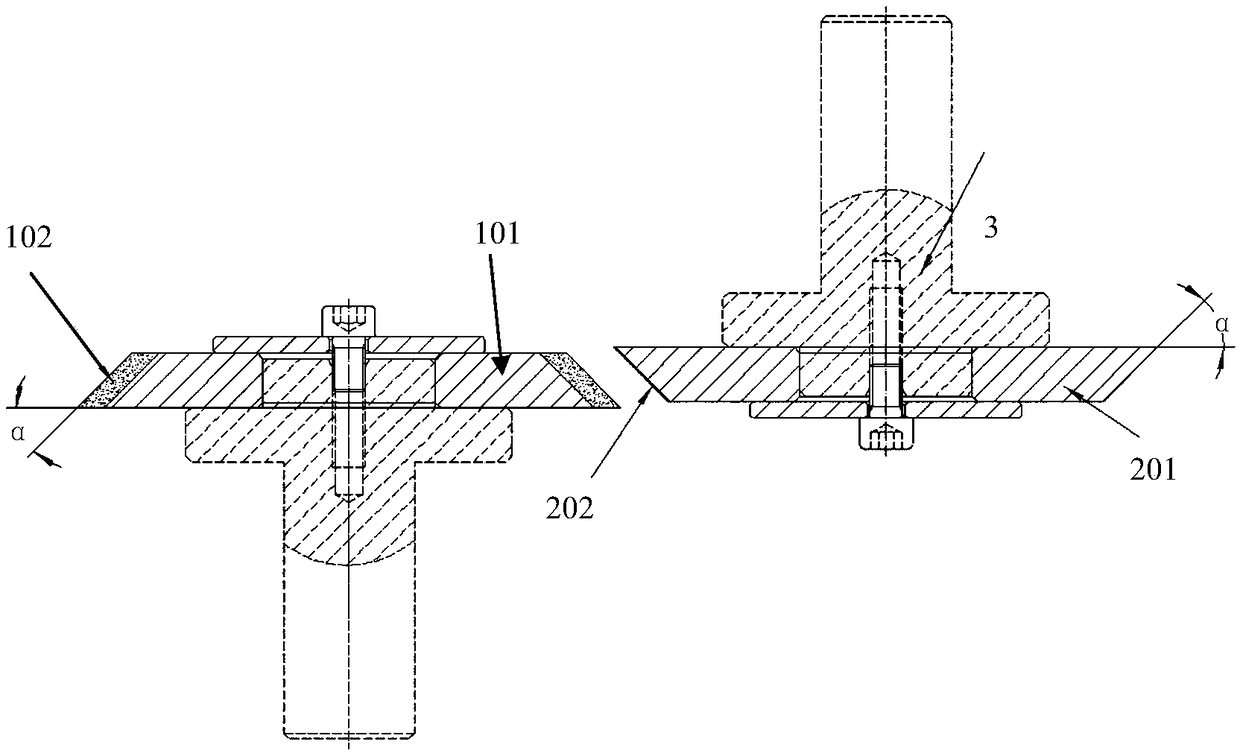

In-place finishing device and method for air bag polishing head

InactiveCN103624685ASimple structureLow costAbrasive surface conditioning devicesCushionMoving parts

The invention discloses an in-place finishing device and an in-place finishing method for an air bag polishing head. The in-place finishing device comprises an in-place sharpening device and an optimal machine tool body moving part, wherein the air bag polishing head is spherical-crown-shaped; the whole sharpening device is connected with a vertical column of a machine tool through a sharpening base; two parallel guide rails are arranged on the sharpening base; a grinding wheel spindle is arranged in a grinding wheel spindle box; the grinding wheel spindle box is erected on a bottom plate; the bottom plate is movably connected with the guide rails through sliding blocks; an air cylinder is arranged between the two guide rails; the tail end of a piston rod of the air cylinder is in transmission connection with the sliding blocks; a grinding wheel with circular-arc-shaped section is arranged at the output end of the grinding wheel spindle; a sharpening motor is in transmission connection with the other end of the grinding wheel spindle; the machining surface of the grinding wheel movably abuts against the surface of a polishing cushion of the air bag polishing head. By virtue of the self-movement of the polishing machine tool, in-place finishing can be realized. The in-place finishing device is simple in structure, low in cost, easy to operate and ideal in using effect; influence on finishing accuracy and polishing accuracy caused by repeated disassembly of the air bag polishing head can be avoided.

Owner:FUJIAN SANMING MACHINE TOOL

Universal grinding carriage for internal gears and external gears of formed grinding wheel gear grinding machine

ActiveCN101811285AReduce workloadImprove structural rigidityGrinding machine componentsGear grindingGear wheel

The invention provides a universal grinding carriage for internal gears and external gears of a formed grinding wheel gear grinding machine, comprising a horizontal cantilever; the lower end surface of the horizontal cantilever is connected and fixed with a vertical grinding arm by a bolt; and the side surface of the lower end of the vertical grinding arm is fixed with a grinding head component. The grinding carriage is directly arranged on the formed grinding wheel gear grinding machine and not only can process external gears, but also can process internal gears; when the external gears are ground, the whole grinding carriage is rotated by 180 degrees only, and the grinding carriage has good rigidity; when helical gears are ground, a grinding wheel can not generate interference with workpieces; the grinding wheel has convenient repair and maintenance, low cost and high cost performance.

Owner:秦川机床工具集团股份公司

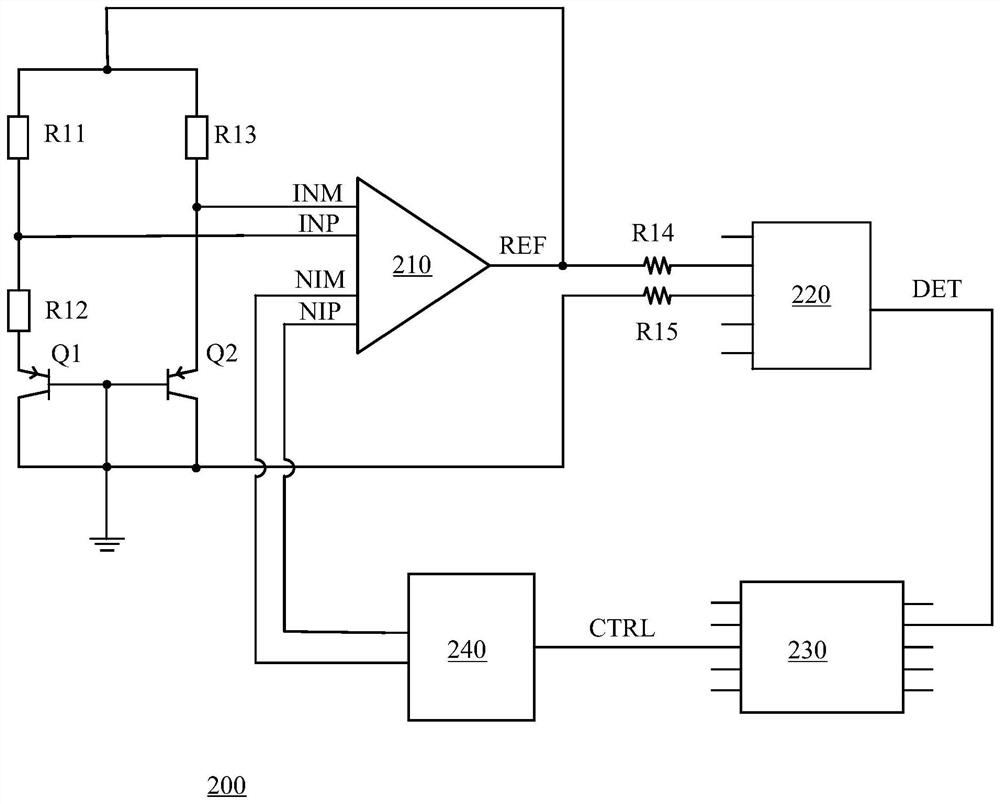

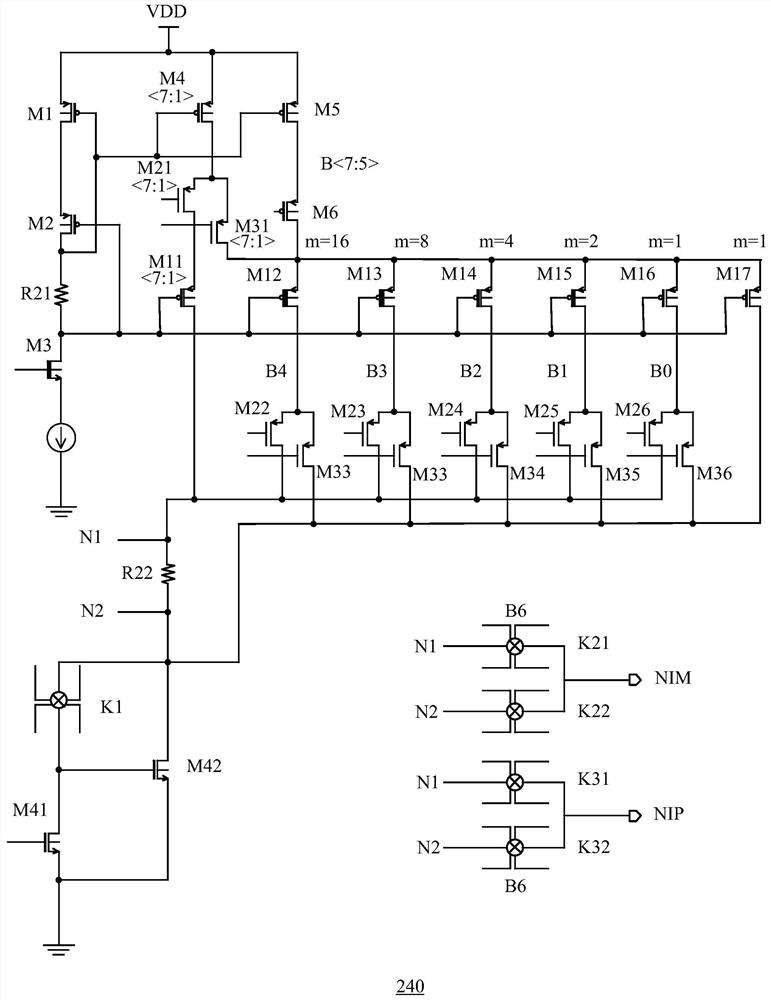

Direct-current trimming module and band-gap reference circuit adopting direct-current trimming

ActiveCN113126689AReduce difficultyControl complexityElectric variable regulationElectrical polarityHemt circuits

The invention discloses a direct current trimming module and a band-gap reference circuit adopting direct current trimming. The direct current trimming module comprises a first decoding module which generates a first current with a corresponding magnitude according to the weight and the numerical value of a first group of data bits of a control word, a second decoding module which is used for generating a second current with a corresponding magnitude according to the weight and the numerical value of a second group of data bits of the control word, a current sampling module which is used for superposing the first current and the second current to obtain a trimming current and converting the trimming current into a trimming voltage, and a polarity selection module which is used for providing the trimming voltage at the first output end as a first trimming signal or providing the trimming voltage at the second output end as a second trimming signal according to the numerical values of the third group of data bits of the control word. The direct current trimming module is adopted to perform feedback trimming on the output signal of the amplifier so as to reduce the offset voltage of the amplifier so that the precision and the temperature stability of the reference voltage generated by the band-gap reference circuit are improved.

Owner:SG MICRO

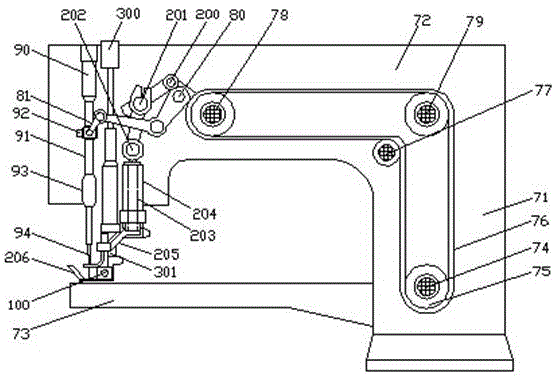

Sewing machine for weaving end products of Chinese knots from woolen yarn clews

InactiveCN106149211AImprove work efficiencyQuality improvementWorkpiece carriersSewing-machine control devicesYarnDrive shaft

The invention discloses a Chinese knot sewing machine from a ball of wool to a finished product, which includes a frame, and the frame is sequentially provided with a thread feeding mechanism, a pulling thread mechanism, a weaving mechanism, a trimming mechanism and a coiling mechanism from top to bottom. The bottom of the frame is also provided with a sewing mechanism parallel to the winding mechanism; the sewing mechanism includes a sewing machine base, and a cylindrical cylinder is arranged on the sewing machine base, and the front end of the cylindrical cylinder is backward. cloth feeding direction; the sewing machine base is provided with a main drive shaft, a driven shaft and a transmission chain used in conjunction with it, and a compression pulley is provided on the slack side of the transmission chain; the driven shaft is provided with Needle bar driving mechanism and yarn splitting driving mechanism. The invention changes the traditional single-row design concept, realizes the technical solution of integrating woolen yarn to finished products, greatly improves the working efficiency of the sewing machine and the quality of finished products, has better safety performance, and meets the actual use requirements.

Owner:孙丽君

Formed plate edge cutting machine

ActiveCN107160442AImprove trimming accuracySimple structureProfiling/shaping machinesMetal working apparatusReciprocating motionWorkbench

The invention discloses a formed plate edge cutting machine which comprises a workbench; a cutting tool which can carry out left and right as well as up and down reciprocation movement and can simultaneously cut multiple formed plates is arranged on the workbench; the workbench is provided with a supporting frame for supporting the formed plates; a plurality of positioning blocks for positioning the formed plates are arranged on two adjacent sides of the supporting frame; and the supporting frame is also provided with a plurality of adjustable clamping devices which can clamp the overlaid formed plates on the supporting frame. The formed plate edge cutting machine has a simple structure, is convenient to manufacture and can cut edges of multiple layers of formed plates at the same time by positioning the formed plates by the supporting frame and clamping the multiple layers of formed plates by the clamping device, so that the edge cutting efficiency and the edge cutting accuracy are improved, the labor intensity is greatly weakened, and the production cost is greatly lowered.

Owner:容县润达家具有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com