High-flexibility fuse trimming circuit and use method thereof

A technology for trimming and adjusting circuits and flexibility, which is applied in the direction of logic circuits, electrical components, and electrical digital data processing, etc. It can solve problems such as low error tolerance, poor flexibility, and large size requirements, so as to improve flexibility and improve trimming The effect of precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

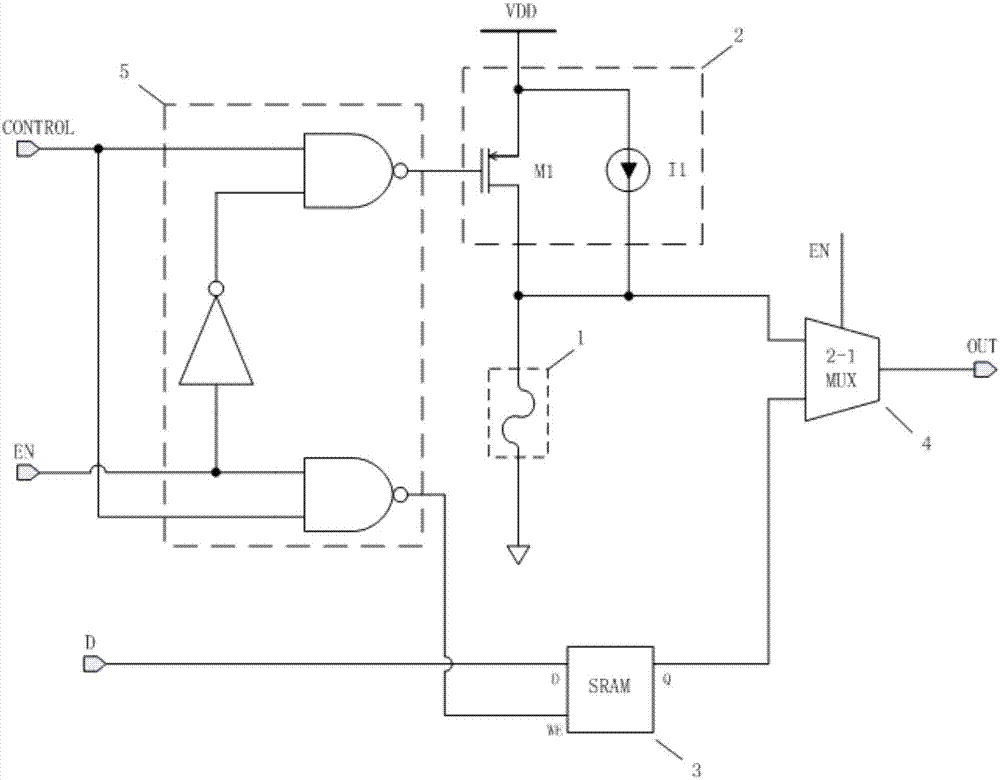

[0022] Such as figure 1 The shown fuse trimming circuit includes trimming control circuit 5 , fuse control circuit 2 , current blowing fuse 1 , SRAM static memory 3 and output driver 4 .

[0023] The trimming control circuit 5 is composed of a NAND gate and an inverter for controlling trimming steps and timing, and has two output terminals.

[0024] The fuse control circuit 2 is composed of a fuse current control tube M1 (using a PMOS tube) and a bias constant current source I1. The source of M1 is connected to the chip power supply, and its drain is connected to the current fuse fuse. Its substrate and its source are short The grid is connected to an output end of the trimming control circuit 5; the constant current source I1 is connected to the chip power supply and the current blown fuse 1.

[0025] The other output terminal of the trimming control circuit 5 is connected with the SRAM static storage unit 3 .

[0026] The output driver 4 is composed of a 2-1 multiplexer, w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com